Patents

Literature

96results about How to "Improve acidification effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

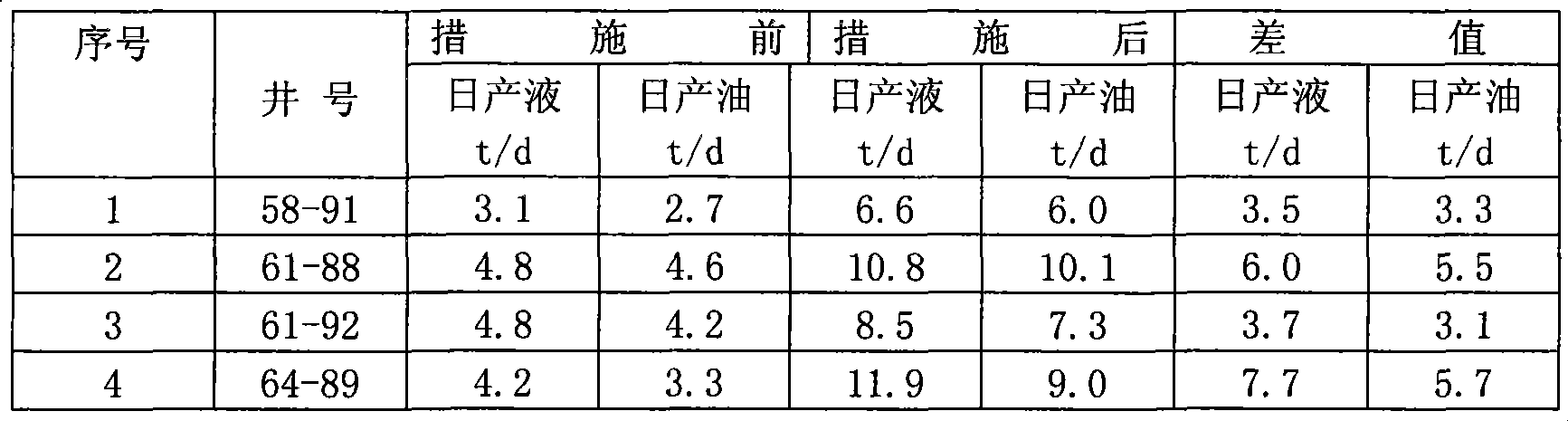

Viscosity-variable diverting acid for improving stratigraphic acidified section

InactiveCN102020983AViscosity auto-increasingConing reductionDrilling compositionBetaineActive agent

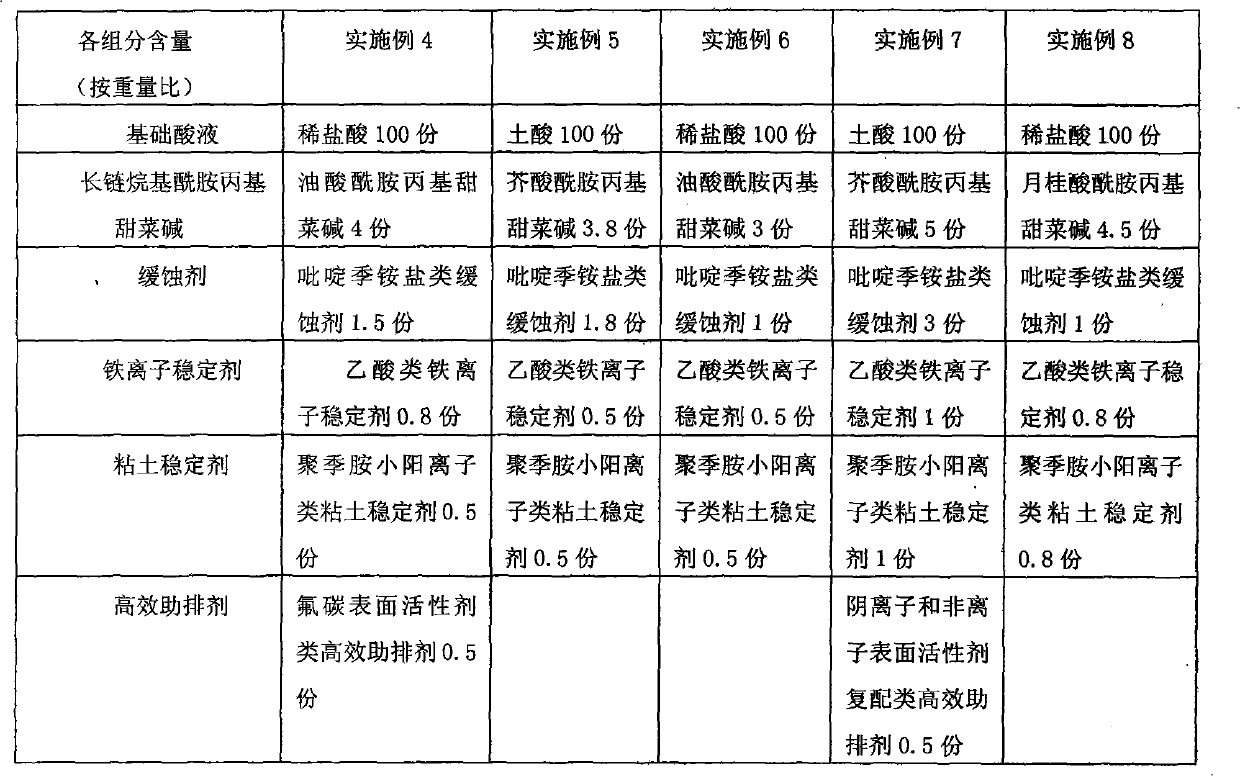

The invention discloses viscosity-variable diverting acid for improving a stratigraphic acidified section. An oil layer is uniformly acidified, and the coning of acid liquor in a high permeable stratum is reduced to ensure that part of acid liquor enters middle and low permeable target stratums so as to improve and expand an acidified sweep section. In the viscosity-variable diverting acid, each component is controlled by a pH value, and the viscosity-variable diverting acid mainly comprises the following components in part by weight: 100 parts of basic acid liquor, 3 to 5 parts of long chain alkylamide propyl betaine, 1 to 3 parts of corrosion inhibitors, 0.5 to 1 part of ferrous stabilizer and 0.5 to 1 part of clay stabilizer. The viscosity-variable diverting acid consisting of the components is injected into a target oil layer. In the acidification process, the initial viscosity of the acid liquor is lower, and the initial viscosity at the temperature of 20 DEG C is 10 to 15mPa.s, the acid liquor is easy to enter the high permeable stratum, and subsequent unreacted low-viscosity acid liquor automatically diverts to enter the middle and low permeable stratums. The long chain alkylamide propyl betaine serving as a diverter is an ampholytic surfactant, does not have any macromolecular residues after a gel is broken and does not have any secondary damage to a reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

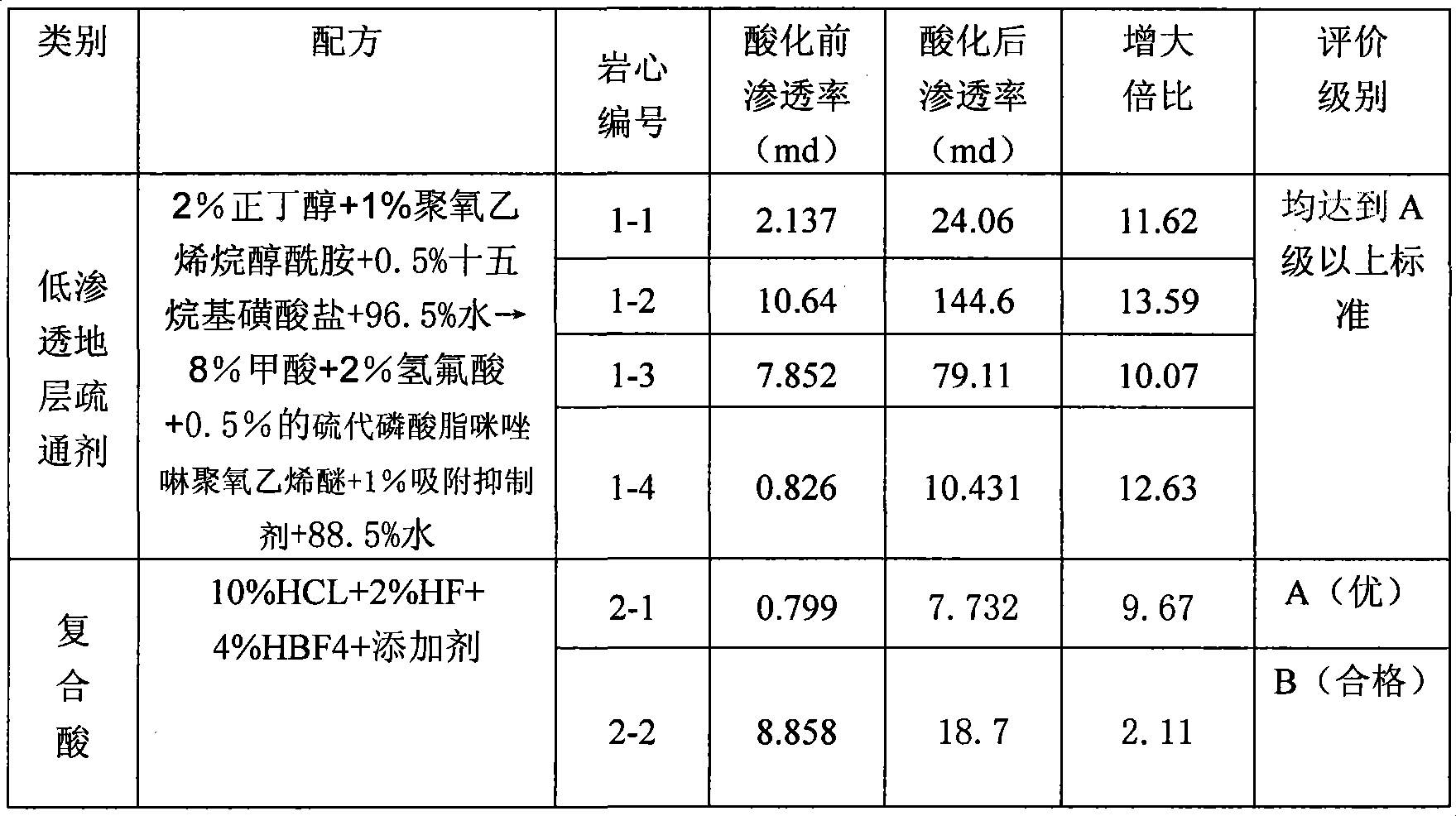

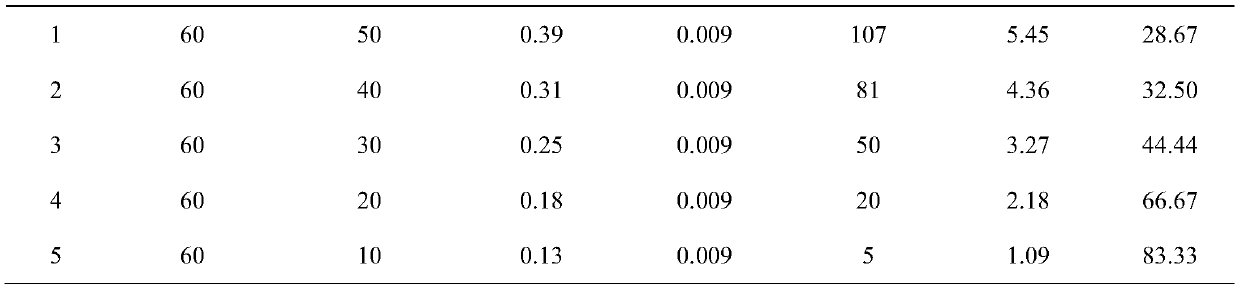

Formation opener agent for low permeable reservoir of oilfield

The invention relates to a stratum opener agent which is applied to oilfield low permeability reservoir. The stratum opener agent comprises two parts: pre-disposal liquid and acid inhibitor system; according to the weight percentage, the pre-disposal liquid consists of solvent and surfactant as follows: 1-3% of organic solvent such as higher alcohol, 0.2-1% of non-ionized surfactant polyoxyethylene alkylolamide, 0.3-0.5% of tenthfive alkyl sulfonate, and the residual quantity of stratum water; according to the weight percentage, the acid inhibitor system comprises 5-10% of low-carbon organic acid, 1-3% of hydrofluoric acid, 0.5% of inhibitor thio-phosphate imidazoline polyoxyethylene ether, 1% of adsorption inhibitor and the residual quantity of water; the adsorption inhibitor comprises 0.5-2% of ethyl dimethylene-bi-cetyltrimethylammonium ammonium bromide, 0.2-1% of quaternary ammonium salt small kation, 2-5% of inorganic salt, 0.2% of 1,3-amine group propyl alcohol N-methyl sodium phosphate or potassium dihydrogen phosphate or sodium hexametaphosphate. The opener agent can effectively improve the seepage capability of reservoir and achieve the objects of decompression and augmented injection and improving the yielding.

Owner:DAQING PETROLEUM ADMINISTRATION +1

High-temperature acidic corrosion inhibitor and preparation method thereof

InactiveCN102226081AImprove high temperature resistanceGood corrosion inhibitionDrilling compositionAlkylphenolKetone

The invention relates to a high-temperature acidic corrosion inhibitor, which is characterized in that the high-temperature acidic corrosion inhibitor comprises the following components in parts by weight: 100 parts of solution containing 40-50 wt% ketone-aldehyde-amine condensate, 3-15 parts of propiolic alcohol, and at least one component selected from potassium iodide, formamide, antimonous oxide and antimonous chloride (wherein potassium iodide is 3-12 parts, formamide is 8-15 parts, antimonous oxide is 3-12 parts, antimonous chloride is 3-12 parts), wherein the solution containing 40-50 wt% ketone-aldehyde-amine condensate is prepared by mixing a ketone-aldehyde-amine and an alcohol solvent of alkylphenol polyoxyethylene based on a ratio of 1: (10-15). The invention also relates to a method for preparing the high-temperature acidic corrosion inhibitor.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for acidification to dispel block

The present invention discloses an acidizing plugging removal method which comprises steps of: injecting liquid gas as energy increased slug into target layer before traditional acidification process, the liquid gas is liquid nitrogen or liquid carbon dioxide, the injection rate is 1-1.5 stere each meter oil layer, optimal selection is 1.2 stere, the injection speed is 100-250L / min, optimal selection is 200L / min. The method of present invention can relieve zone blocking, improve yield of oil well, successful rate of plugging removal is above 98%, the average base increase production of single well is above 1.5ton / day.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Anti-scaling multi-hydrogen retarded acid for highly argillaceous sandstone reservoir

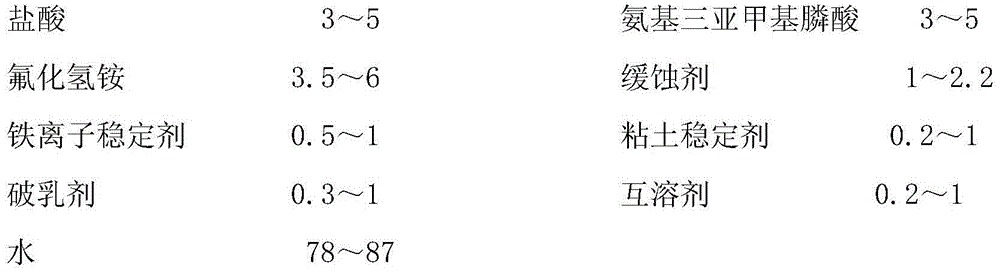

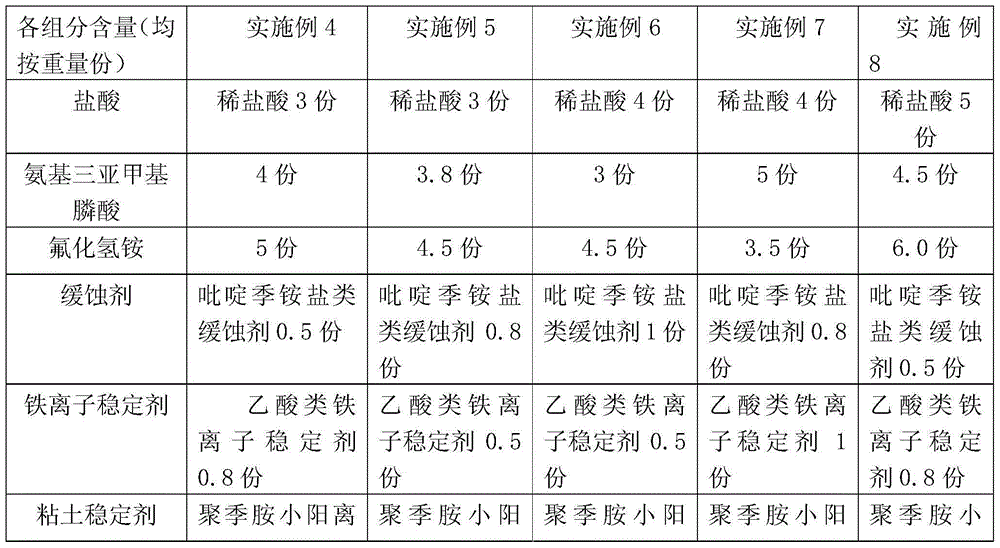

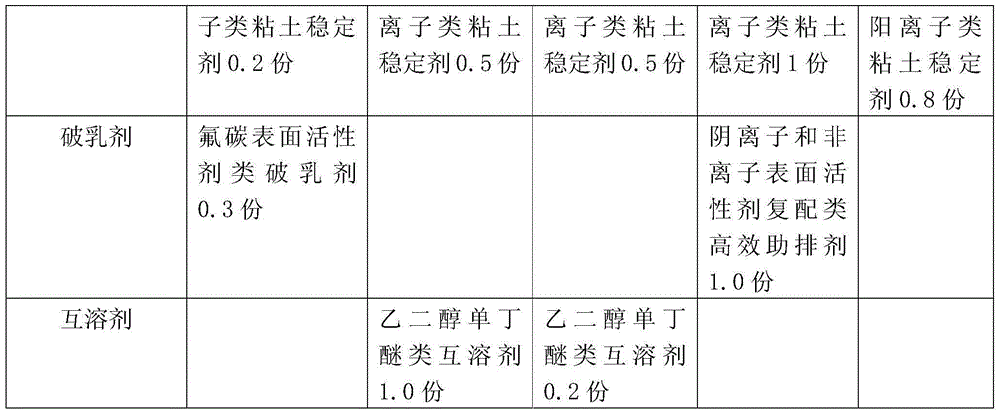

The invention provides an anti-scaling multi-hydrogen retarded acid for a highly argillaceous sandstone reservoir. The retarded acid is prepared from the following raw materials by weight: 3 to 5 parts of hydrochloric acid, 3 to 5 parts of amino trimethylene phosphonic acid, 3.5 to 6 parts of ammonium bifluoride, 1 to 2.2 parts of a corrosion inhibitor, 0.5 to 1 part of a ferric ion stabilizing agent, 0.2 to 1 part of a clay stabilizing agent, 0.3 to 1 part of a de-emulsifier, 0.2 to 1 part of a mutual solvent and 78 to 87 parts of water. The anti-scaling multi-hydrogen retarded acid is used in the petroleum industry to control a reaction speed of hydrofluoric acid and clay so as to realize deep acidization of the highly argillaceous reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

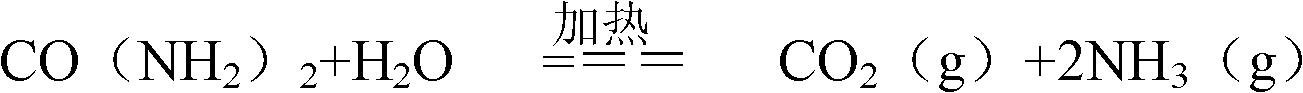

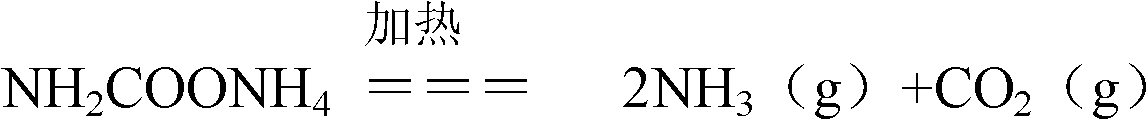

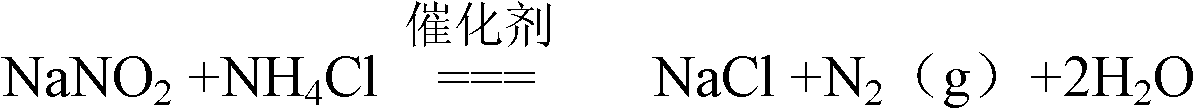

Gas self-production agent, use of the gas self-production agent, and self-produced gas foam acidizing method for oil wells and water wells

InactiveCN102373036ASimplify construction proceduresReduce construction costsCleaning apparatusFluid removalProduct gasAmmonium carbamate

The invention discloses a gas self-production agent, a use of the gas self-production agent, and a self-produced gas foam acidizing method for oil wells and water wells. The gas self-production agent can produce gas in an acid environment or at an oil well bottom temperature. An active ingredient of the gas self-production agent is ammonium carbamate. The gas self-production agent has the advantages of low requirement on gas production conditions, large gas yield, simplification of foam acidizing processes for oil wells and water wells, reduction of a foam acidizing cost, and improvement of acidizing effects.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

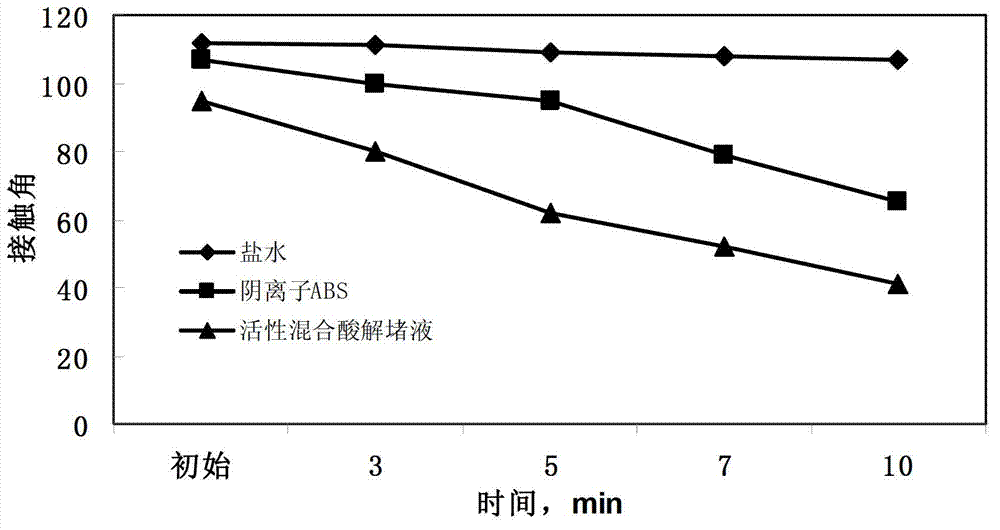

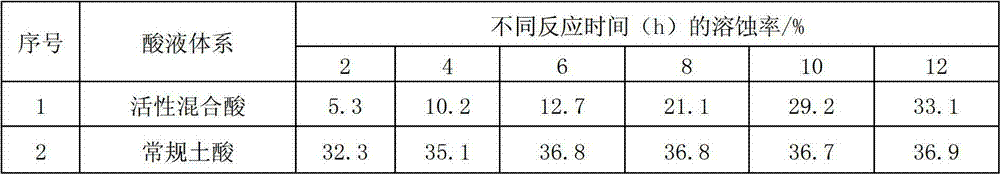

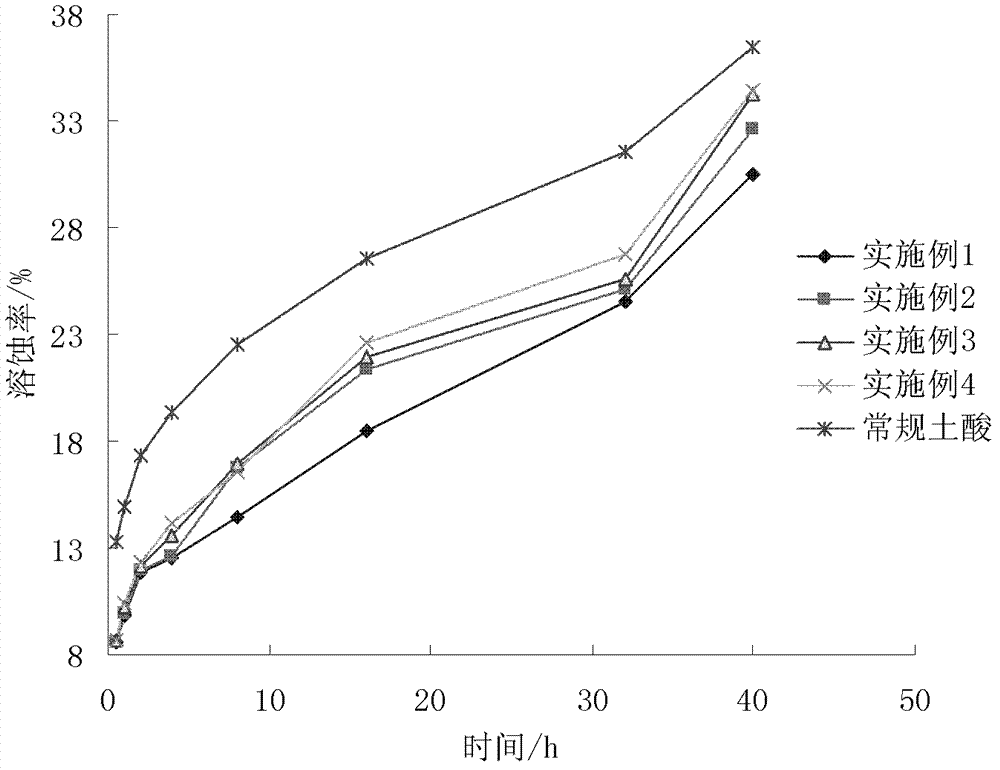

Active mixed acid plugging removal solution applicable to low permeability reservoir

ActiveCN102775974AChange wettabilityProlong the action timeDrilling compositionReaction rateEffective action

The invention relates to active mixed acid plugging removal solution applicable to a low permeability reservoir and mainly solves the problems of short period of validity and poor plugging removal and augmented injection effects when conventional mud acid and composite acid methods are adopted for plugging removal treatment on low permeability formation. The active mixed acid plugging removal solution consists of the following components in proportions according to weight percent: 9-10% of acetic acid, 5-7% of formic acid, 2%-3% of bifluorid acid ammonium, 2%-4% of boric acid, 1.0-2.0% of corrosion inhibitor, 2.0-4.0% of mutual solvent, 2.0% of clay stabilizer, 0.5-1.0% of dewetting active agent and 67.0-76.5% of water. The active mixed acid plugging removal solution applicable to the low permeability reservoir can delay the reaction rate of acid rock, increase the effective operating distance of acid solution, and realize the acidification of deep formation, and simultaneously can improve the oil and water seepage characteristics and increase the water phase permeability.

Owner:DAQING JINGSHENG WEIYE OILFIELD TECH SERVICE +1

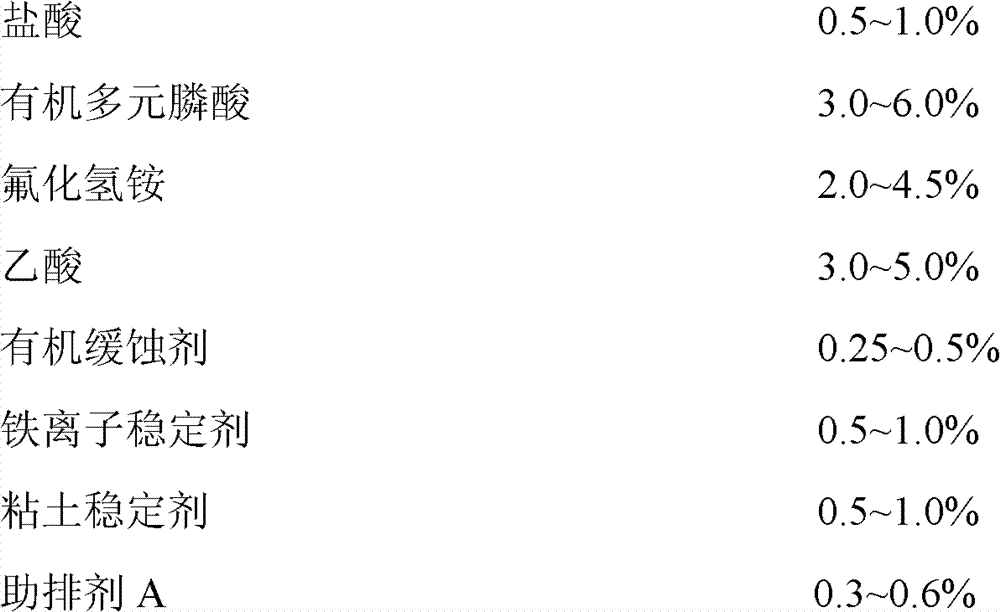

Clastic sandstone gas reservoir acidizing fluid

InactiveCN102899013AEnsure safetyIncrease test throughputDrilling compositionAcetic acidFluorocarbon

The invention relates to a clastic sandstone reservoir acidizing fluid, which comprises, by weight, 0.5-1.0% of hydrochloric acid, 3.0-6.0% of HEDP, 2.0-4.5% of ammonium bifluoride, 3.0-5.0% of acetic acid, 0.25-0.5% of an organic acid corrosion inhibitor Lan-926, 0.5-1.0% of nitilotriacetic acid or iso ascorbic acid, 0.5-1.0% of a polyquaternary anti-swelling agent, 0.3-0.6% of a hydrocarbon chain surfactant peregal O-15 or O-20, 0.3-0.6% of a fluorocarbon chain surfactant FSO-100 or FSN-100 and the balance of water. The acidizing fluid has little corrosion and good cleanup effect, hardly produces secondary precipitation, and has little damage to reservoir.

Owner:PETROCHINA CO LTD

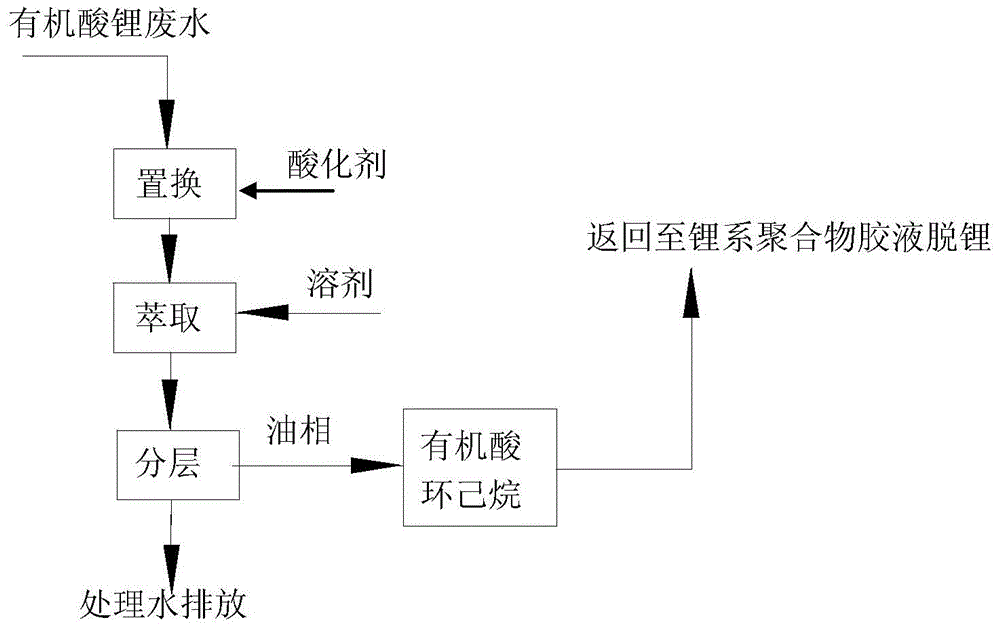

Circulation method for recovering organic acid from organic acid lithium waste water

ActiveCN105016415AHigh transparencyHigh whitenessWater/sewage treatment by extractionOrganic acidLithium

The invention discloses a circulation method for recovering organic acid from organic acid lithium waste water. The circulation method is characterized in that the waste water is generated by lithium deintercalation in a lithium system polymer glue solution through organic acid; solvent and acidifying agents used for polymerization reaction of generated lithium system polymers are added into the waste water for acidifying reaction with organic acid lithium in the waste water, and the pH value of an acidifying reaction endpoint is controlled to be within 3.0-6.9; the organic acid is extracted to be recovered through the solvent, and oil phases obtained after layering are returned into the process of lithium deintercalation of the organic acid. The method can be used for using the original organic acid in a lithium system polymer glue solution lithium deintercalation unit in a circulating mode after the organic acid lithium waste water is treated and restored, meanwhile, COD in the waste water can be effectively reduced, and corrosion to equipment in the treatment process is greatly reduced; the lithium deintercalation cost in the lithium system polymer technology is effectively lowered.

Owner:CHINA PETROLEUM & CHEM CORP

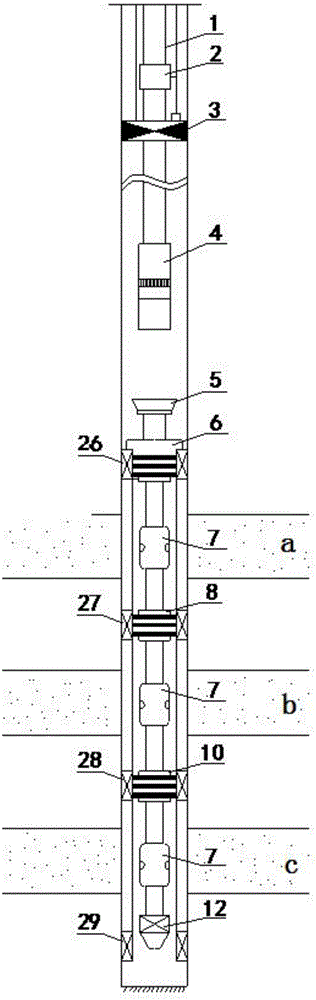

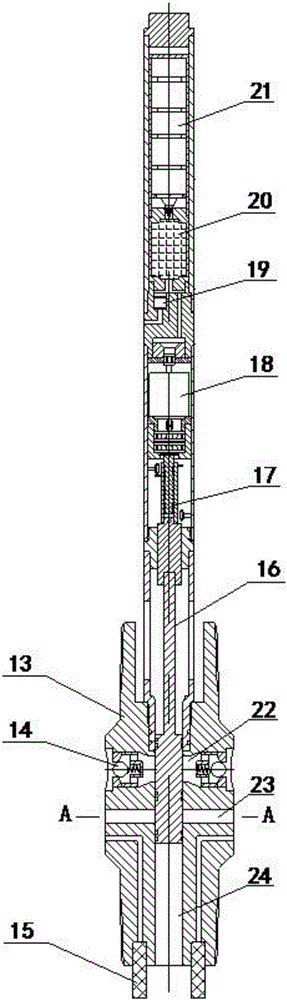

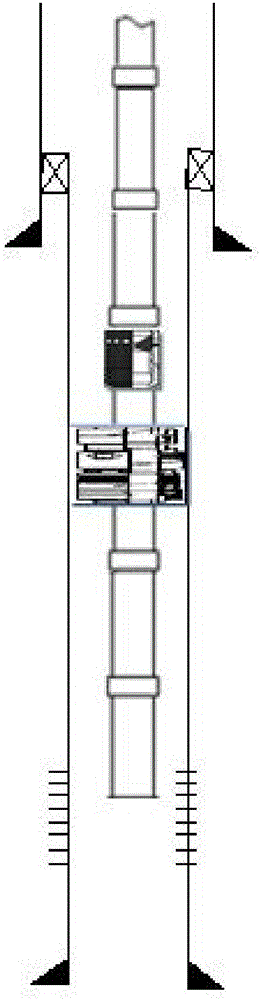

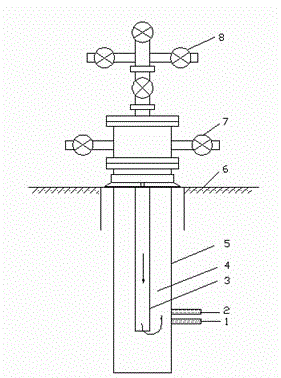

Pressure control type intelligent production pipe column capable of injecting acid by layer selection and production method

ActiveCN106640026ASimple structureEasy to operateDrilling rodsFlexible member pumpsProduction stringMethods of production

The invention discloses a pressure control type intelligent production pipe column capable of injecting acid by layer selection and a production method. The production pipe column comprises an upper-section pipe column provided with an underground safety valve, a passing cable packer and an electric submersible pump, and a lower-section releasing layered pipe column provided with a releasing tool, a positioning seal, a first inserting seal, a second inserting seal and a guide screw plug; pressure control switches are arranged at a plurality of positions of the production pipe column respectively; and the production method comprises the steps of manufacturing the production pipe column, mounting the pressure control switches, putting in the releasing layered pipe column and the upper-section pipe column, remotely controlling and pressurizing, digging in turn and exploring water, acidifying at a fixed point and the like. The pressure control type intelligent production pipe column and the production method, disclosed by the invention, have the advantages that the production pipe column can work only if the releasing layered pipe column is put for one time, and an instrument or the pipe column does not need to be detached; the technical difficulty of large-inclination well layered water control and oil extracting can be effectively solved; water finding, water control, layer-adjusting production and fixed-point acidifying of different oil layers are realized through remotely controlling the pressure control switches on the ground; and the acid can effectively enter a target reservoir stratum in an acidifying process.

Owner:CHINA NAT OFFSHORE OIL CORP +2

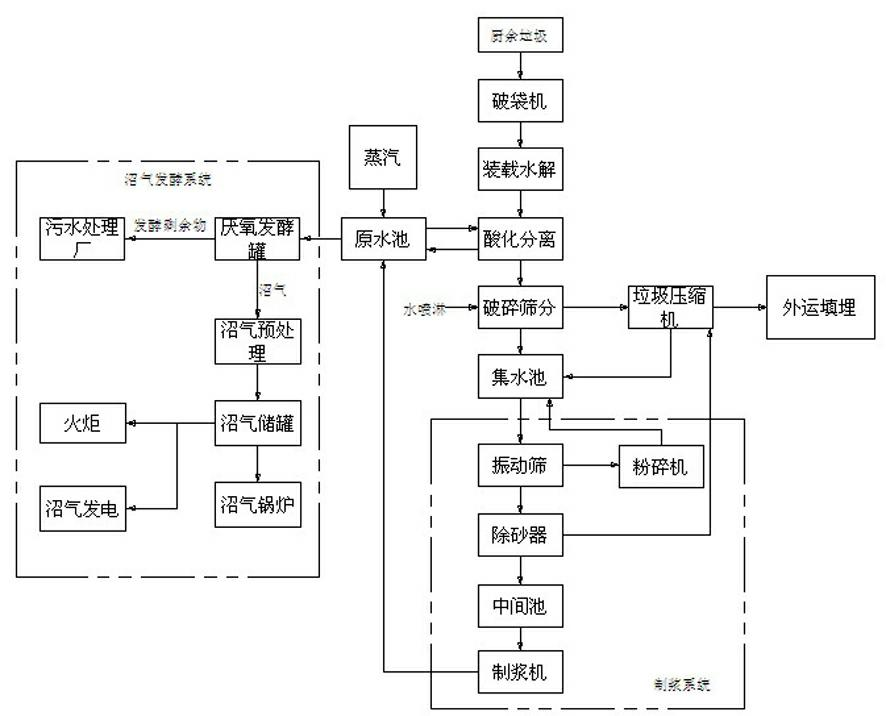

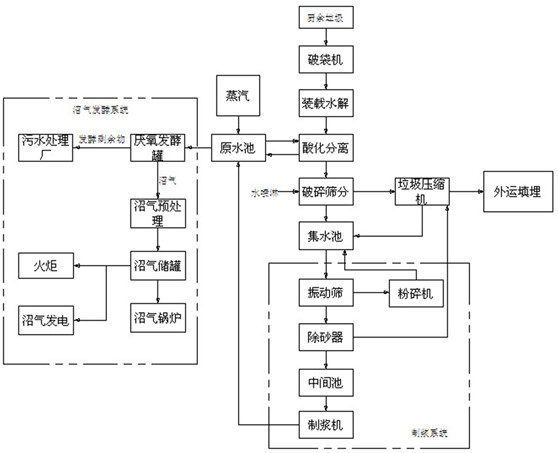

Biochemical treating system for kitchen garbage

ActiveCN102671918AIncrease digestion rateCompletely producedBiological substance pretreatmentsSolid waste disposalBiochemical engineeringClean energy

The invention discloses a biochemical treating system for kitchen garbage. The biochemical treating system comprises an acidizing loading machine, an acidizing basin, a crushing sieving machine, a raw water basin and a water collecting basin. The biochemical treatment for kitchen garbage comprises a bag-breaking step, a loading hydrolysis step, an acidizing separating step and a crushing sieving step. The bag-breaking and loading hydrolysis steps are arranged, so that the process is simple and the technical design is reasonable; the sieving mode of crushing adding water-cleaning is adopted, so that the sieving efficiency is high, the whole process is designed on the basis of streamline operation, the whole operating efficiency is high, the treating speed is high and the effect is obvious; according to the high-level liquid soaking design of the acidizing basin, the acidizing effect for embedded garbage is excellent and the garbage is thoroughly acidized; the pulping fine particle treating mode is adopted, so that during the anaerobic treatment process, the digestion speed of an anaerobic fermentation system is effectively improved, the generation of biogas residues is greatly reduced and the methane volume is increased; and the anaerobic fermentation mode is adopted, so that the traditional compost or feed treating mode is changed, the garbage is effectively converted into the clean energy, and the surrounding environment is protected.

Owner:NINGBO KASEEN ECOLOGY TECHNOLOGY CO LTD

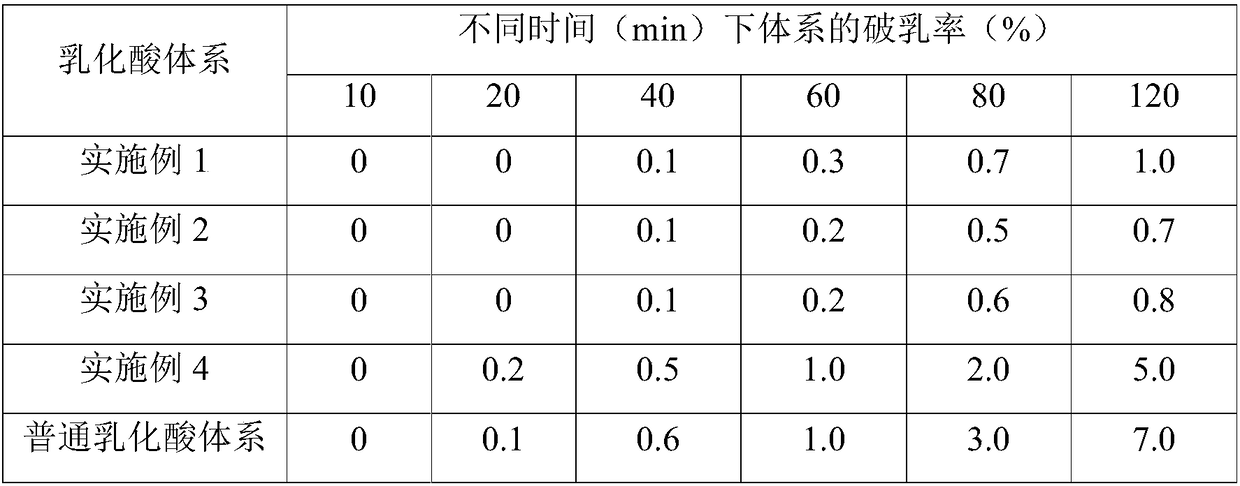

Gelatinizing emulsified acid and preparation method thereof

ActiveCN108285784AImprove stabilityImprove acidification effectDrilling compositionAcid fracturingOil phase

The invention relates to gelatinizing emulsified acid and a preparation method thereof in the field of carbonate reservoir acid fracturing and production increment. The gelatinizing emulsified acid comprises the following components in parts by volume: low-viscosity gelatinizing acid: 60 to 80 parts, preferably 65 to 75 parts; oil phase: 40 to 20 parts, preferably 35 to 25 parts, wherein based on100 parts by weight of the use amount of the oil phase, the oil phase further comprises 3 to 5 parts by weight of efficient emulsifier, preferably 3.5 to 4.5 parts. The low-viscosity gelatinizing acidcomprises the following components in parts by weight: 96 to 97.2 parts of hydrochloric acid solution, 1.5 to 2 parts of corrosion inhibitor, 1 to 1.5 parts of iron ion stabilizer and 0.3 to 0.6 partof thickening agent for acid, wherein the hydrochloric acid concentration of the hydrochloric acid solution is 15 to 30 percent by weight. The gelatinizing emulsified acid provided by the invention is a novel acid liquid system which integrates the gelatinizing acid and emulsified acid into one; the preparation method is simple; high temperature resistance and viscosity stability are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

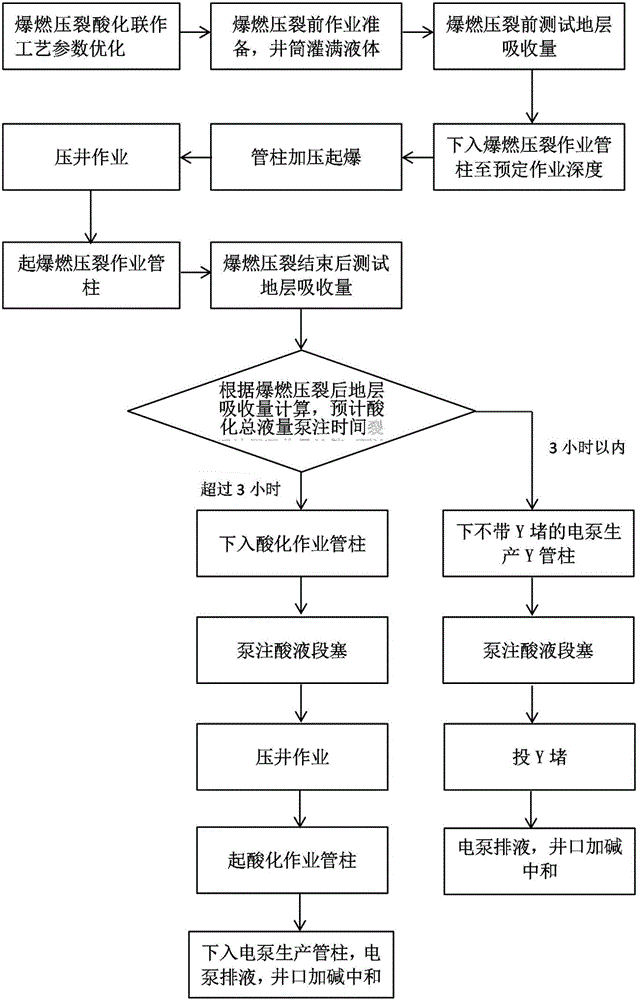

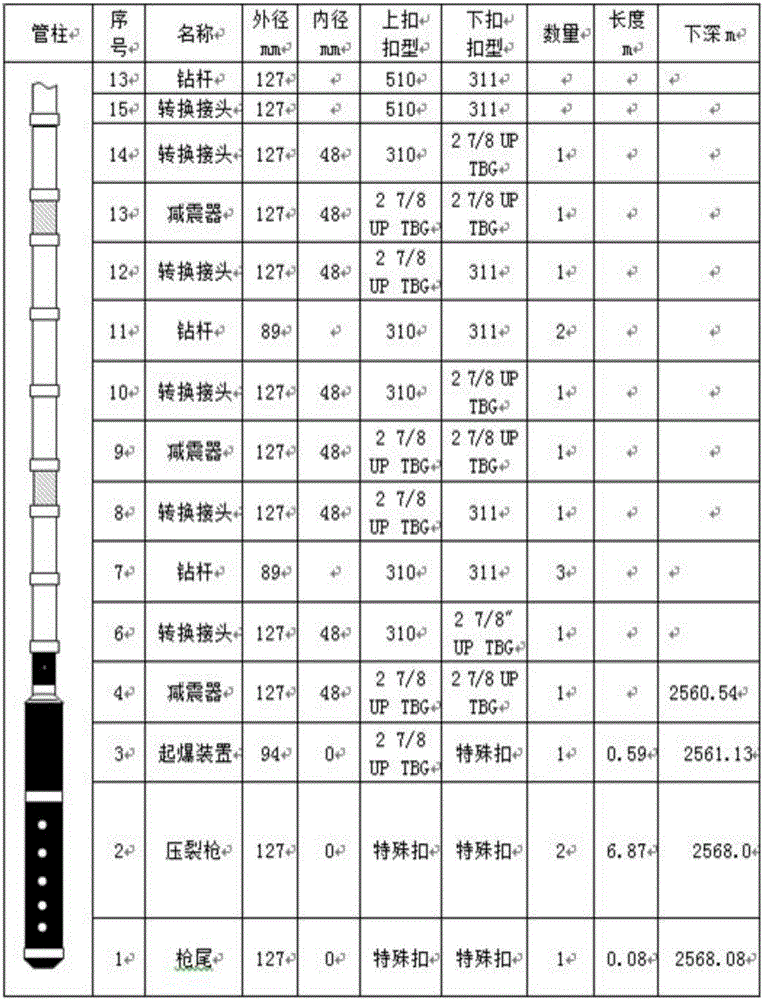

Method for detonation fracture acidizing combined operation

ActiveCN106246156AEnhancing the effectiveness of deflagration fracturingGuaranteed work effectFluid removalDrilling compositionWell killDetonation

The invention discloses a method for detonation fracture acidizing combined operation. The method comprises the steps of optimizing detonation fracture acidizing combined operation process parameters, performing operation preparation before detonation fracture and filling a pitshaft with liquid, testing stratum absorption amount before the detonation fracture, placing a detonation fracture operation tubular column to a predetermined operation depth, performing pressurization detonation of the tubular column, performing well killing operation, detonating the fracture operation tubular column, testing the stratum absorption amount after the detonation fracture, placing an acidizing operation tubular column, performing pumping injection acid liquid slug, lifting the acidizing operation tubular column, placing an electric pump production tubular column and performing electric pump liquid drainage and well opening alkalifying neutralization, placing an electric pump production Y tubular column without a Y tubular column, performing pumping injection of acid liquid slug, placing the Y tubular column, performing electric pump liquid drainage and well opening alkalifying neutralization and the like. The method has the advantages that detonation fracture and acidizing effects can be further enhanced, the acid liquid injection capability is enhanced, the acidizing radius is expanded, crack closure is further avoided, and a physical effect is enhanced; a detonation fracture effect can be enhanced, a follow-up acidizing step is selected flexibly, and the operation step is omitted while an operation effect can be guaranteed.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Composite retarded acid

The invention relates to a composite retarded acid for carrying out acidification on an oil-water well in the oil-field development, which comprises the following raw material components in part by mass: 10 to 40 parts of hydrochloric acid, 2 to 10 parts of hydrofluoric acid, 2 to 10 parts of phosphoric acid, 2 to 6 parts of citric acid, 0 to 10 parts of methyl alcohol, 0 to 5 parts of mutual solvent, 0.5 to 5 parts of demulsifying agent, 5 to 15 parts of acidizing corrosion inhibitor and 30 to 70 parts of water. The composite retarded acid of the invention realizes low damage or no damage inthe acidification process and improves the intrinsic permeability of an acidification band furthest.

Owner:SUNCOO PETROLEUM TECH

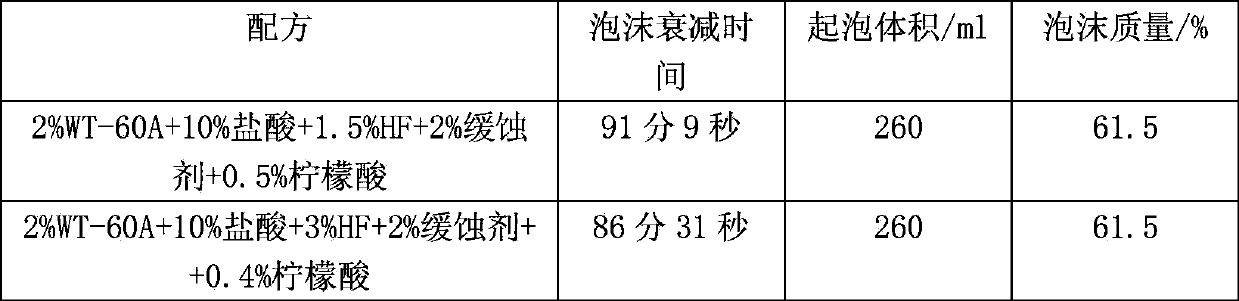

Turning foamed acid for heterogeneous reservoir acidification

InactiveCN103865515AImprove acidification effectAvoid secondary pollutionDrilling compositionCross-linkHydrofluoric acid

The invention relates to a turning foamed acid for heterogeneous reservoir acidification. The turning foamed acid comprises, by volume, a nitrogen gas phase, 10% of hydrochloric acid, 1.5-3% of hydrofluoric acid, 2WT-60A, 2% of a corrosion inhibitor and 0.5% of citric acid. The 2WT-60A is cocoalkanoylamido propyl betaine or dodecyl dimethyl betaine. After the turning foamed acid is stirred at a stirring rate of 1000r / min for 1min, a foam half-life period is about 91min and form mass is 61.5% of the original mass. The turning foamed acid has the characteristic of self-tackifying, is free of a cross-linking agent and a gel breaker, controls a self-turning function based on a pH value, and has good diffluence performances, good retardance and high flowback performances.

Owner:PETROCHINA CO LTD

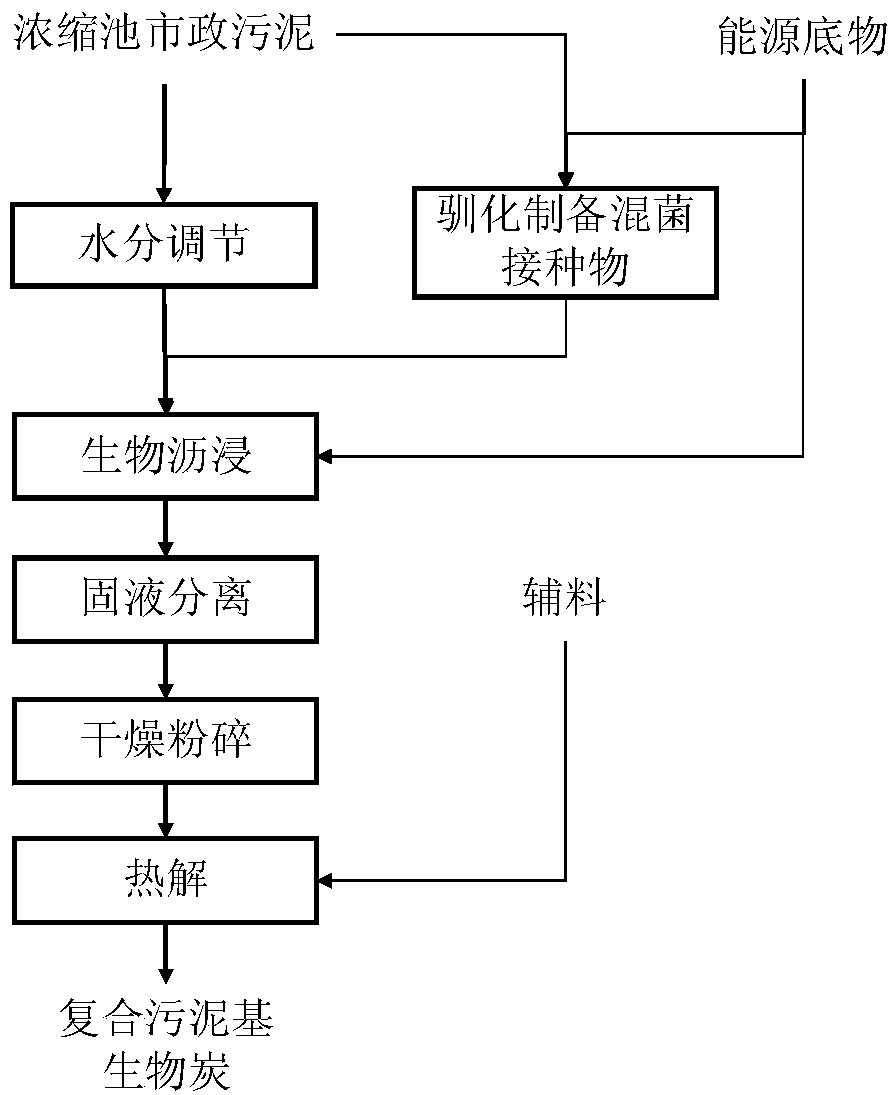

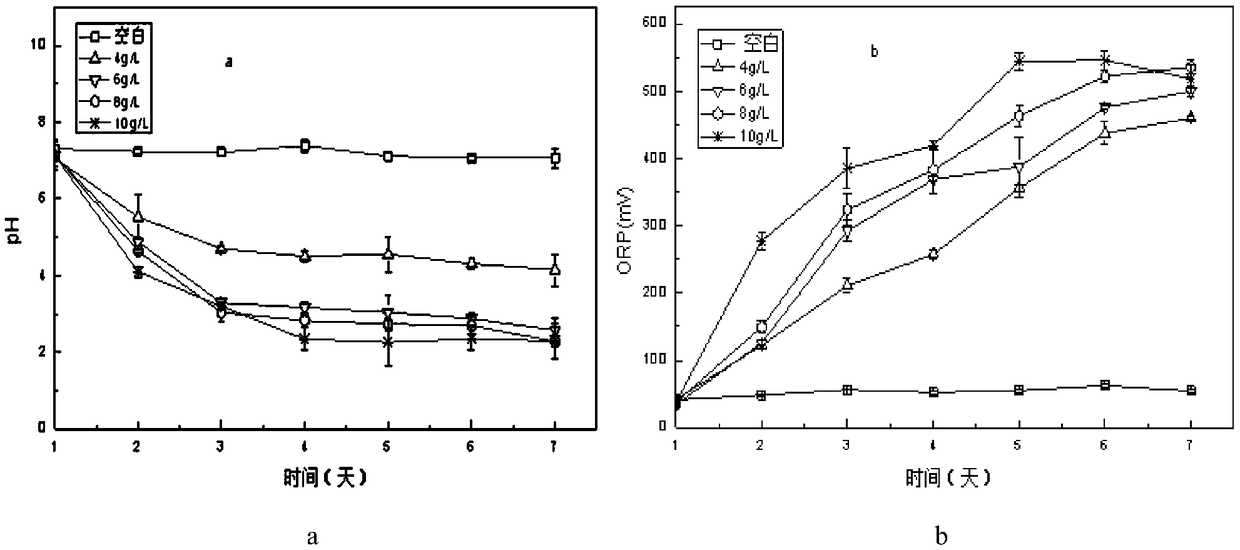

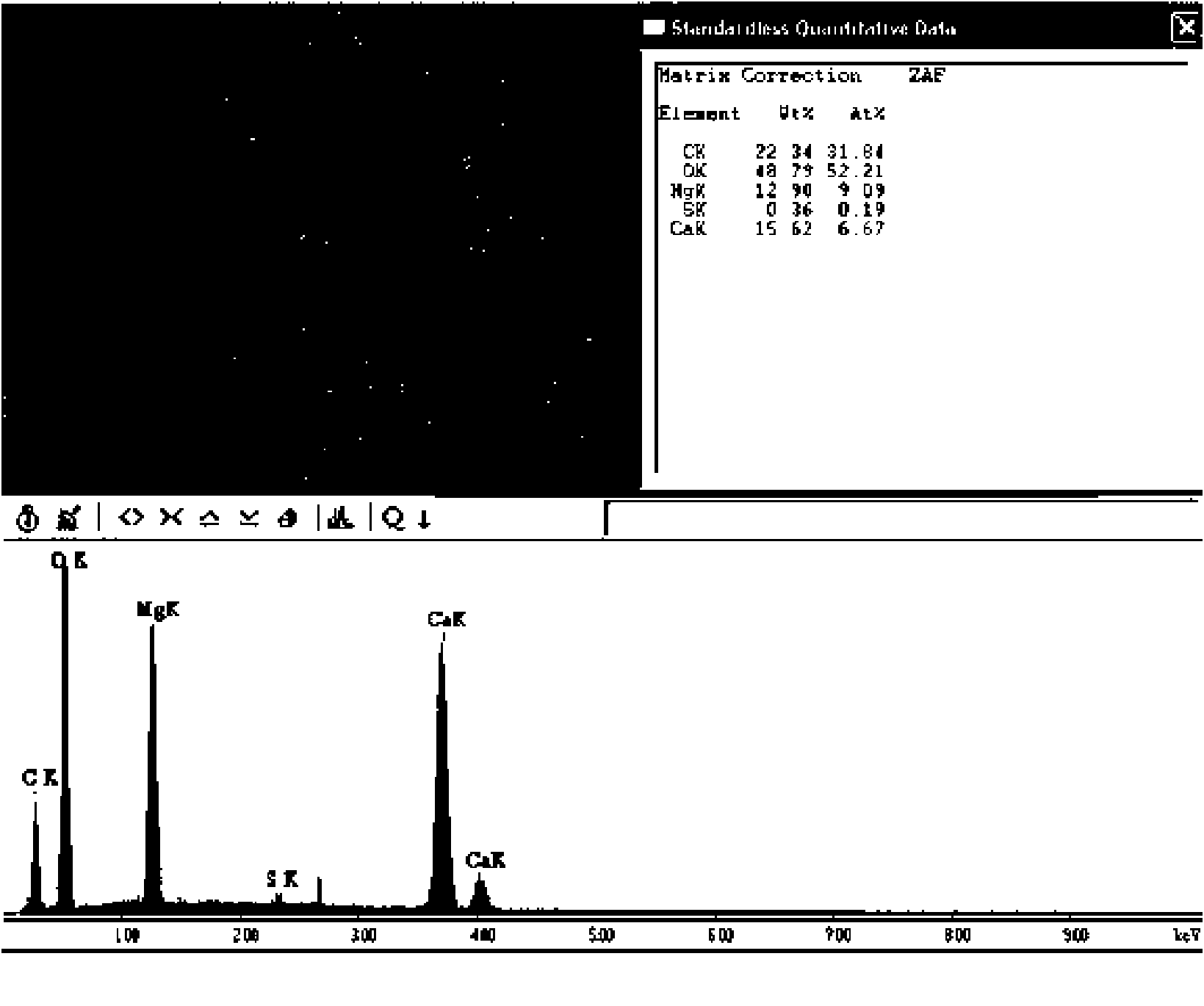

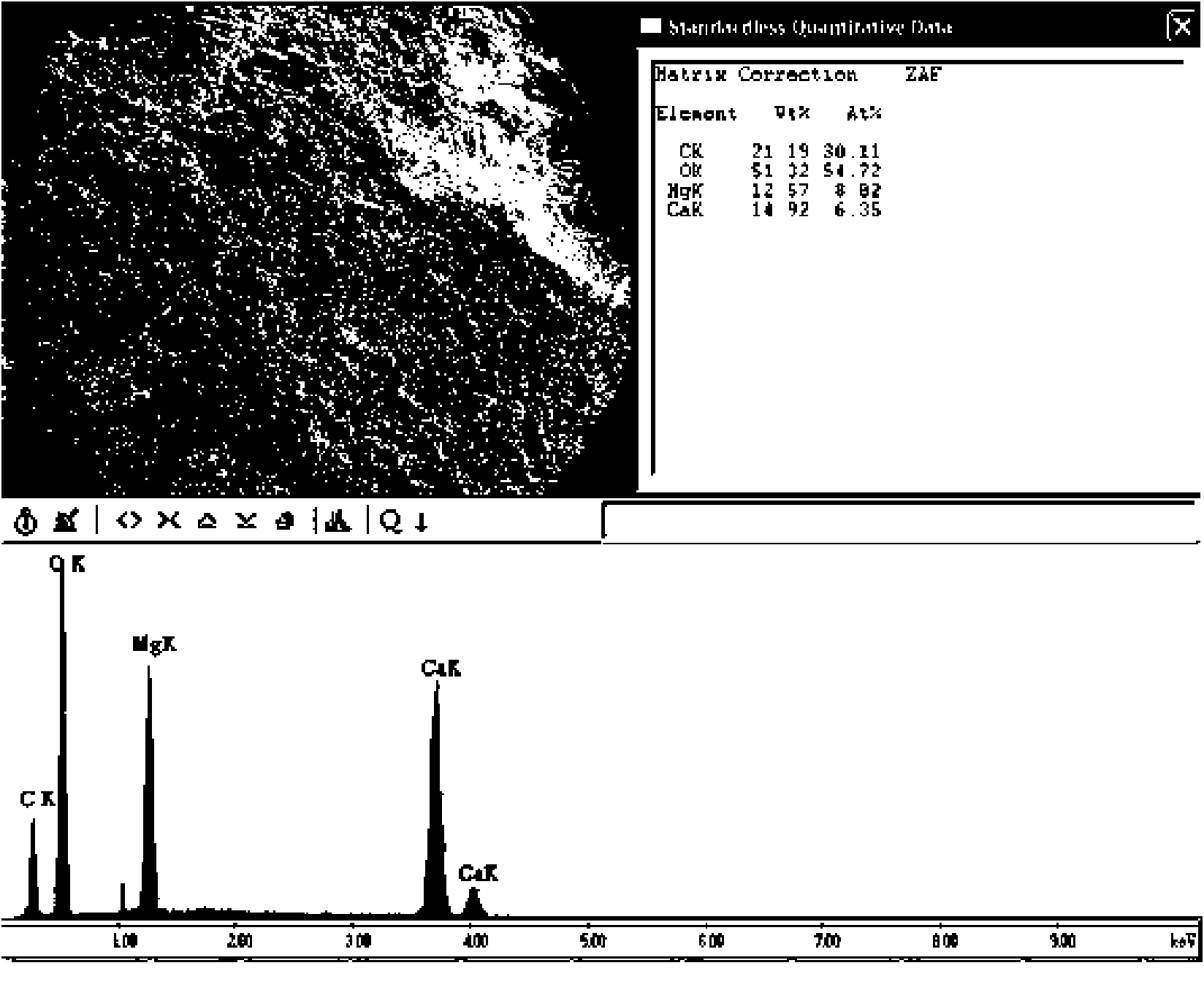

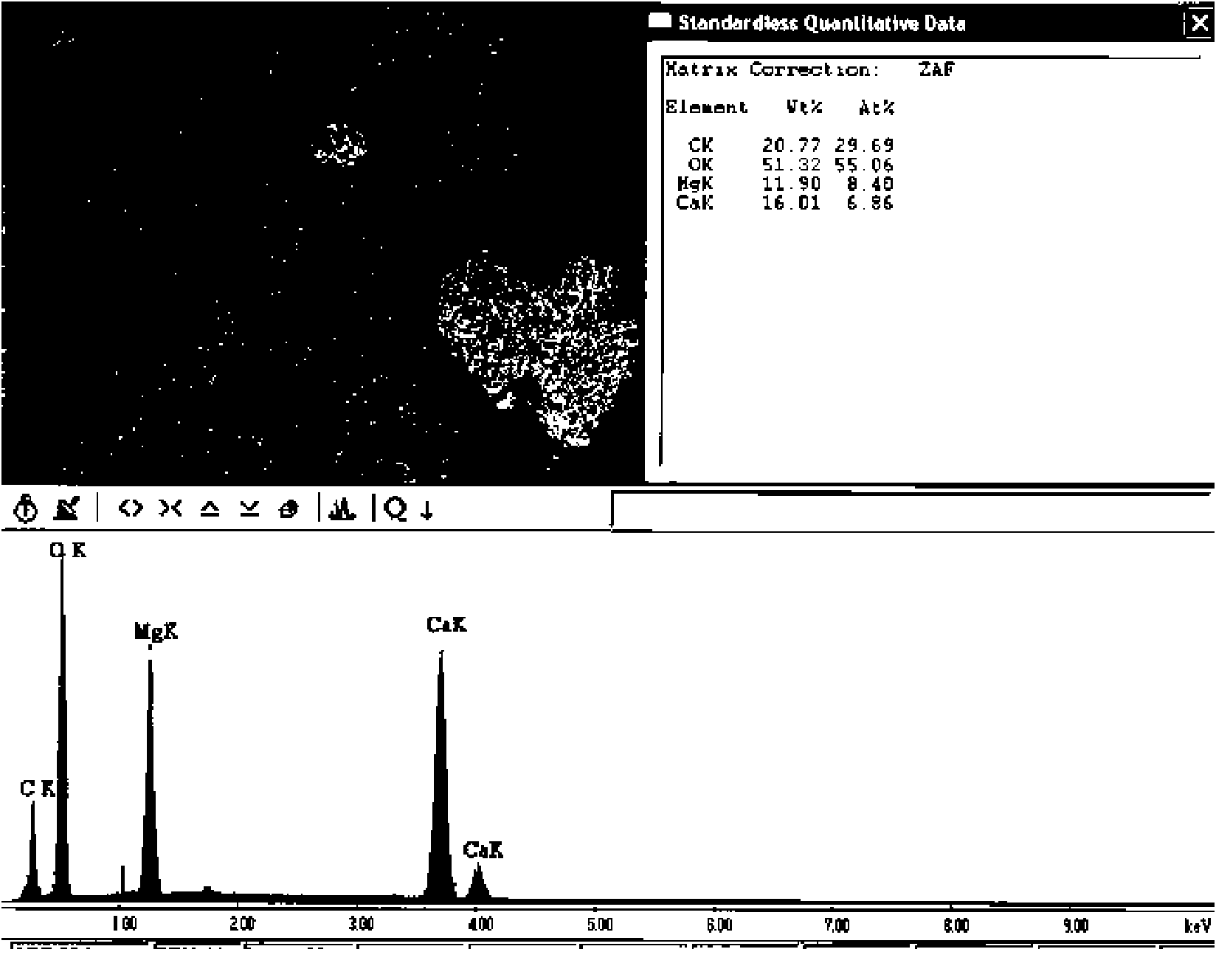

Method for preparing heavy metal adsorbent by sludge bioleaching-pyrolysis combined treatment

InactiveCN108905965ASolve the problem of disposing of two aspectsImprove acidification effectSludge treatment by de-watering/drying/thickeningOther chemical processesSludgeSorbent

The invention discloses a method for preparing a heavy metal adsorbent by sludge bioleaching-pyrolysis combined treatment. The method comprises the following steps: (1) taking concentrated sludge as abacterial source, adding FeSO4.7H2O as an energy substrate, culturing until the pH value is 2.0-3.0, taking a bacterial solution as inoculum, and adding the inoculum to the concentrated sludge to culture for 3-5 times as bioleaching inoculation fluid; (2) regulating the solid content of the concentrated sludge to 2%-6%, adding the inoculum, adding FeSO4.7H2O to treat for 3-7 days, performing solid-liquid separation and drying until moisture content is 10% or lower, thereby obtaining leached dried sludge; and (3) crushing the obtained sludge to be 0.3 mm, adding crushed organic waste, heatingto 300-700 DEG C, and performing constant-temperature pyrolysis for 0.5-3 hours. The method is low in cost, and is wide in material source; and the obtained composite sludge-based biochar is low in heavy metal residue, is high in iodine adsorption value and is high in heavy metal ion adsorption capacity.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Enzymatic on-site deep acidizing fluid for oil and gas fields and application thereof

InactiveCN101838529AAvoid corrosionImprove formation permeabilityDrilling compositionOrganic acidChemistry

The invention relates to biological acidification technology of carbonate rock oil and gas well matrix acidification and acid-fracturing reformation, and oil-water well inorganic carbonate scaling comprehensive de-plugging, in particular to enzymatic on-site deep acidizing fluid for oil and gas fields and application thereof. According to weight concentration, the enzymatic on-site deep acidizingfluid comprises 15 to 25 percent of organic acid ester which serves as a neutral precursor and has good water solubility, 0.005 to 0.1 percent of hydrolytic enzyme of the organic acid ester, and the balance of water. The rock core acid-etching reaction is completed in 4 to 48 hours; and results show that 5 to 20 grooves are formed on the surface of the rock core, the permeability of earth seams is improved in a large area, the acidification or acid-fracturing effect can be improved, and the enzymatic on-site deep acidizing fluid can be used for oil field carbonate rock matrix acidification oracid-fracturing and oil-water well de-plugging projects.

Owner:DALIAN BITEOMICS INC

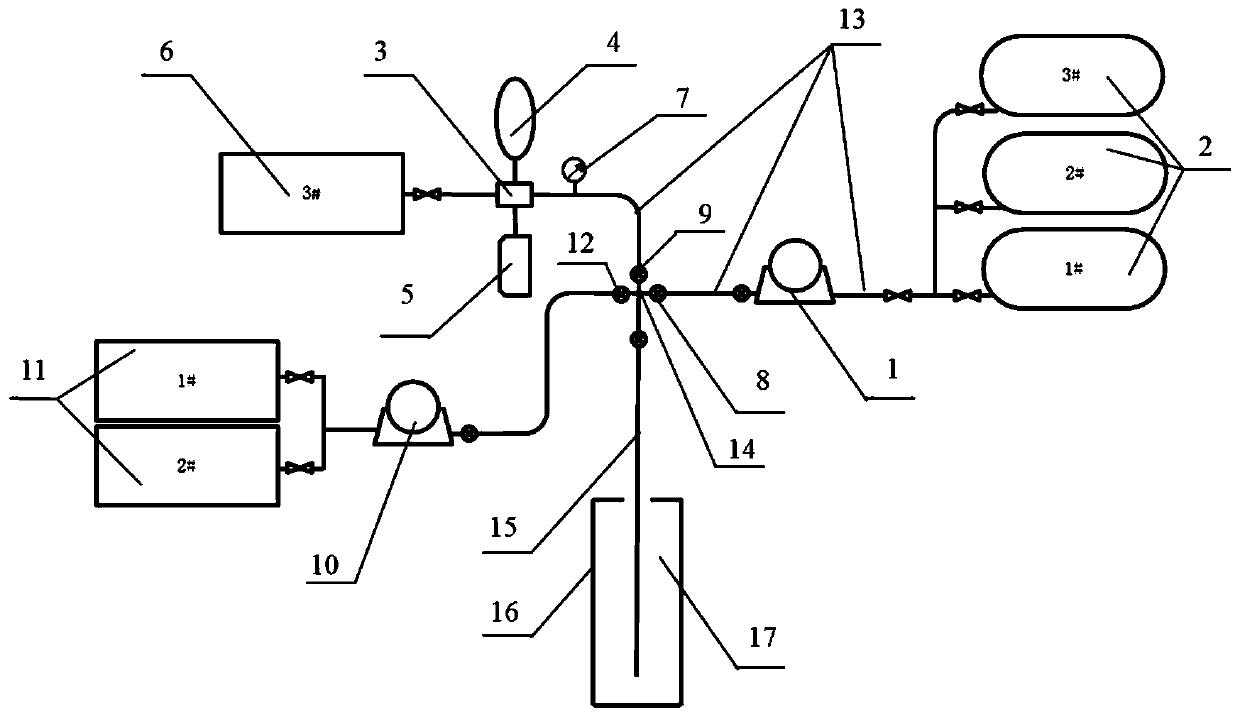

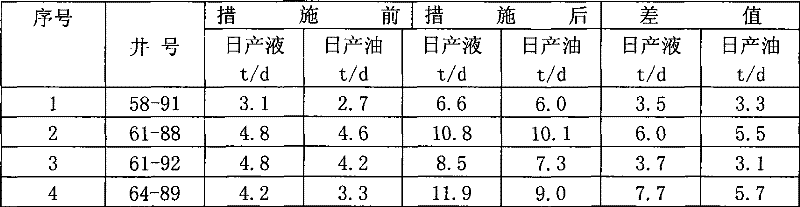

Method for enhancing acidification effect of oil well of offshore oil field

InactiveCN110219627AImprove acidification effectAvoid contamination riskFluid removalOil fieldPneumatic valve

The invention discloses a method for enhancing the acidification effect of oil well of offshore oil field. The method for enhancing the acidification effect of oil well of offshore oil field includesthe following steps that an oil well production pipe string is taken up; an acidification construction operation pipe string is lowered down; ground acidification equipment, a pressure pulse pluggingremoval device and a pipeline are connected, an acidification wellhead manifold valve is closed, and pressure tests of an acidification process pipeline are conducted; a displacing liquid is prepared,a mud pump wellhead manifold valve is opened, and pilot injection of the oil well is conducted; the mud pump wellhead manifold valve is closed, a wellhead manifold valve of the pressure pulse plugging removal device is opened, and an energy generator pneumatic valve is opened or closed; the mud pump wellhead manifold valve is opened, and the pumping and injection of a mud pump are conducted; circulating well cleaning operation is conducted; the mud pump wellhead manifold valve and the wellhead manifold valve of the pressure pulse plugging removal device are closed, the acidification wellheadmanifold valve is opened, and the pumping and injection of an acid liquor are conducted; the acidification wellhead manifold valve is closed, the mud pump wellhead manifold valve is opened, and the pumping and injection of the displacing liquid are conducted; the circulating well cleaning operation is conducted; and the ground acidification equipment, the pressure pulse plugging removal device andthe pipeline are disassembled.

Owner:CHINA NAT OFFSHORE OIL CORP +1

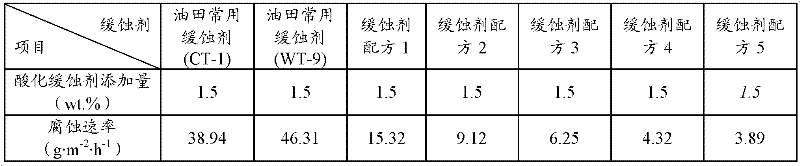

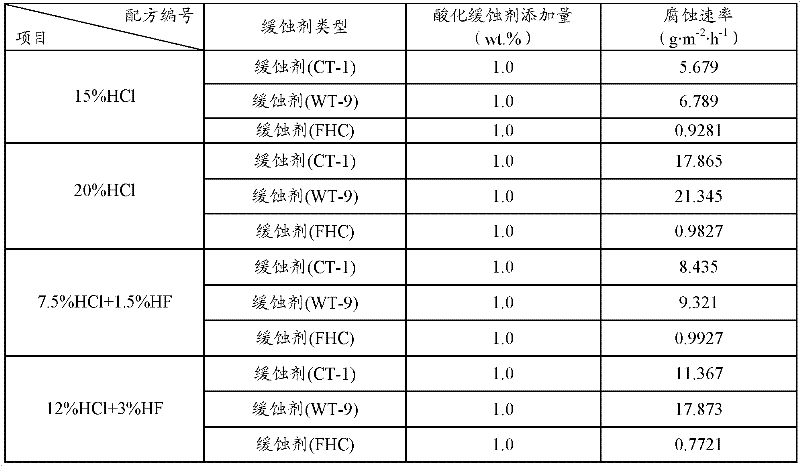

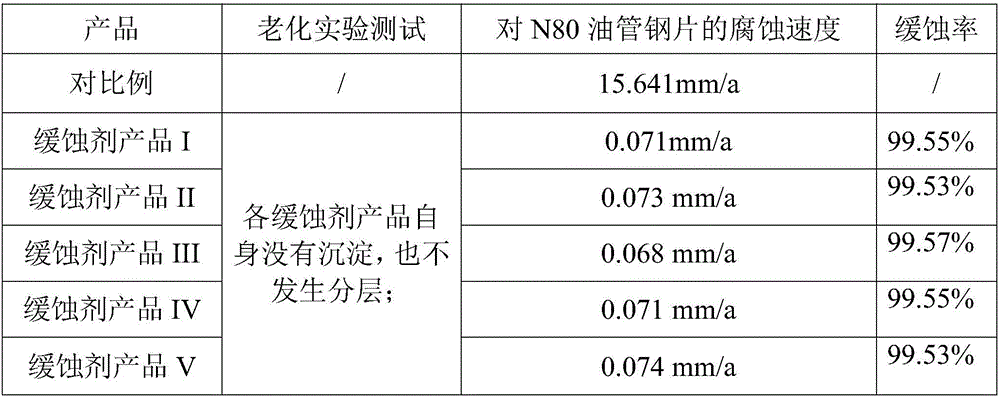

Acidification compound imidazoline corrosion inhibitor and method for preparing same

InactiveCN106085399AGood corrosion inhibitionImprove acidification effectDrilling compositionBorehole/well accessoriesPhysical chemistrySolvent

The invention discloses an acidification compound imidazoline corrosion inhibitor. The acidification compound imidazoline corrosion inhibitor comprises, by weight, 2-5% of cationic surfactants, 25-55% of imidazoline, 0.5-3% of non-ionic surfactants, 30-50% of mutual solvents and the balance water. The acidification compound imidazoline corrosion inhibitor has the advantages that the acidification compound imidazoline corrosion inhibitor is made of the imidazoline, the imidazoline, the cationic surfactants and the non-ionic surfactants are matched with one another to prepare the acidification compound imidazoline corrosion inhibitor, accordingly, raw materials for the acidification compound imidazoline corrosion inhibitor can come from wide sources, the prepared acidification compound imidazoline corrosion inhibitor is low in cost, excellent in corrosion inhibition performance, free of harm to natural environments and safe in use, metal corrosion can be effectively reduced, and acidification effects of the acidification compound imidazoline corrosion inhibitor can be improved; the acidification compound imidazoline corrosion inhibitor is prepared from the raw materials, a method for preparing the acidification compound imidazoline corrosion inhibitor is simple, conditions are easy to control, and accordingly requirements of industrial production can be met.

Owner:CNPC BOHAI DRILLING ENG

Even acid distribution method for acidification of heterogeneous storage layer

InactiveCN105401929AReduce leakageAvoid Big Leakage ProblemsFluid removalDistribution methodPump pressure

The invention provides an even acid distribution method for acidification of a heterogeneous storage layer. The method comprises the following steps that a, after an acidification tubular column is tripped into a an oil layer bottom boundary in a well hole, high-permeation layer acidification liquid containing flocculent temporary plug materials is circulated to the middle portion of an oil layer, then a casing pipe gate is closed, the high-permeation layer acidification liquid is continuously injected into the oil layer, and the high-permeation layer acidification liquid containing the flocculent temporary plug materials is obtained by taking 0.8-1.2 m<3> of acid liquid from every meter of oil layer, adding 0.3-0.5 ton of temporary plug agent in the acid liquid on every meter of plug layer and then carrying out even mixing; b, when the pump pressure rises by 3-5 MPa, the pump car displacement is controlled, and 1.8-2.2 m<3> of acid liquid needed by low-permeation layer acidification is injected into every meter of oil layer; c, a pump is shut down for a reaction for 30-60 min; d, an oil pipe gate is opened for spraying, and residual acid is removed; and e, the oil pipe gate is opened, well washing liquid is pumped from the casing pipe gate, and a well drum is cleaned up. The problem that losses of acid liquid in conventional acidification are large is solved, and the acidification effect is effectively improved. Meanwhile, no special device or equipment is needed, and the defects that layering acidification wastes time, the cost is high, the process is complex, and accidents are likely to happen are overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

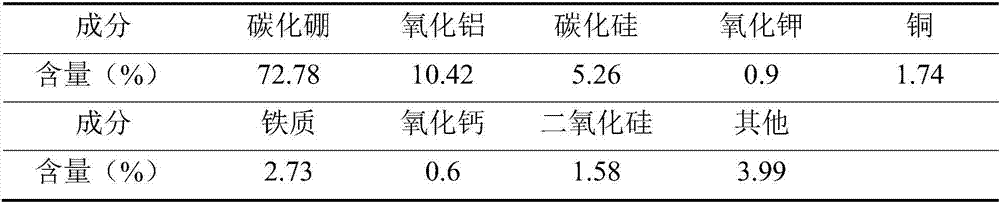

Method for recycling boron carbide from sapphire ground waste materials

InactiveCN107986284AAchieve recyclingRemove completelyCarbon compoundsOther chemical processesAcid dissolutionBoron carbide

The invention discloses a method for recycling boron carbide from sapphire ground waste materials. The method comprises the following steps: S1, sieving the sapphire ground waste materials through a 200-mesh sieve, so as to obtain a magnetic separation material; S2, performing magnetic separation on the magnetic separation material, so as to remove iron impurities and obtain an acid dissolution material; S3, putting the acid dissolution material into a acidification medium, so as to perform acid dissolution on the acid dissolution material, removing silicon impurity, and performing solid-liquid separation, so as to obtain a sintering material; S4, mixing and grinding the sintering material and an alkaline medium, and performing sintering for 4h to 48h at 300 DEG C to 800 DEG C, so as to obtain a sintered product; S5, performing water dissolution, solid-liquid separation and drying on the sintered product, so as to obtain boron carbide. According to the method, recycling of boron carbide ultrafine powder in the sapphire ground waste material is realized, resources and energy consumption are greatly saved, the recycled boron carbide meets the requirement on a grinding material and can be directly used, and the recycle rate of the boron carbide ultrafine powder reaches 93 percent or more.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Feed for laying hens and preparation method thereof

PendingCN109601754AReduce in quantityImprove MicroecologyAnimal feeding stuffAccessory food factorsSodium bicarbonateAnimal science

The invention discloses a feed for laying hens and a preparation method thereof. The feed for laying hens is composed of the following raw materials in parts by weight: 50-65 parts of corn, 15-20 parts of soybean meal, 3-5 parts of corn gluten meal, 4-6 parts of corn germ cakes, 2-5 parts of rice bran, 8-10 parts of stone powder, 1-2 parts of soybean oil, 0.1-0.3 part of compound trace element, 0.2-0.5 part of compound multi-vitamin, 0.6-0.9 part of sodium bicarbonate, 0.1-0.3 part of isomalto-oligosaccharide, 0.2-0.4 part of saccharomyces cerevisiae culture, 0.1-0.2 part of coated organic acid, and 0.05-0.1 part of lactobacillus lactis. Through reasonable feed nutrient regulation and compounding of functional additives, the feed can improve the health and disease resistance of laying hens, reduce the number of salmonella in the intestines of the laying hens, improve intestinal health and improve production performance.

Owner:四川圣迪乐村生态食品股份有限公司

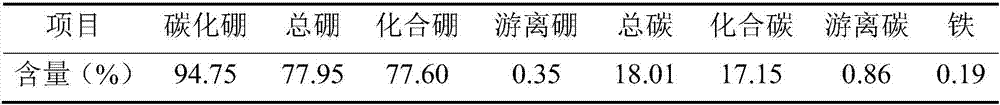

A kind of anti-scaling type multi-hydrogen retarded acid for high shale sandstone reservoir

The invention provides an anti-scaling multi-hydrogen retarded acid for a highly argillaceous sandstone reservoir. The retarded acid is prepared from the following raw materials by weight: 3 to 5 parts of hydrochloric acid, 3 to 5 parts of amino trimethylene phosphonic acid, 3.5 to 6 parts of ammonium bifluoride, 1 to 2.2 parts of a corrosion inhibitor, 0.5 to 1 part of a ferric ion stabilizing agent, 0.2 to 1 part of a clay stabilizing agent, 0.3 to 1 part of a de-emulsifier, 0.2 to 1 part of a mutual solvent and 78 to 87 parts of water. The anti-scaling multi-hydrogen retarded acid is used in the petroleum industry to control a reaction speed of hydrofluoric acid and clay so as to realize deep acidization of the highly argillaceous reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

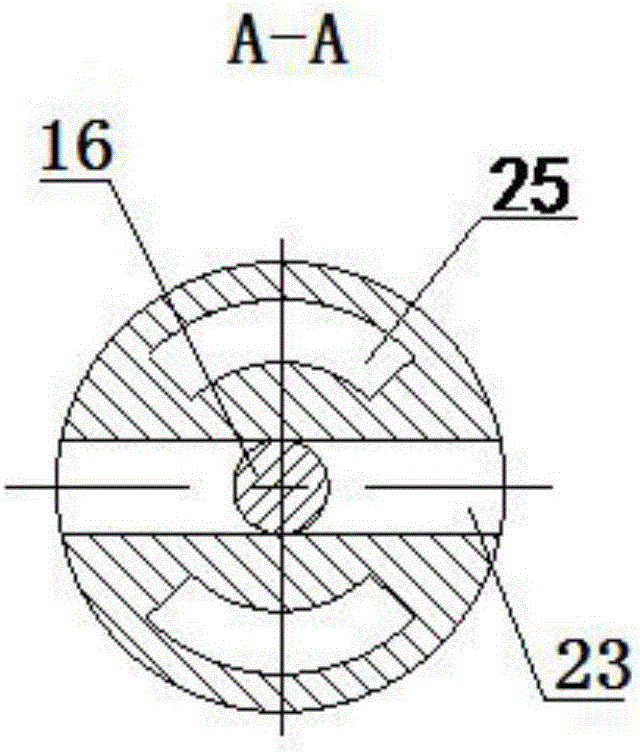

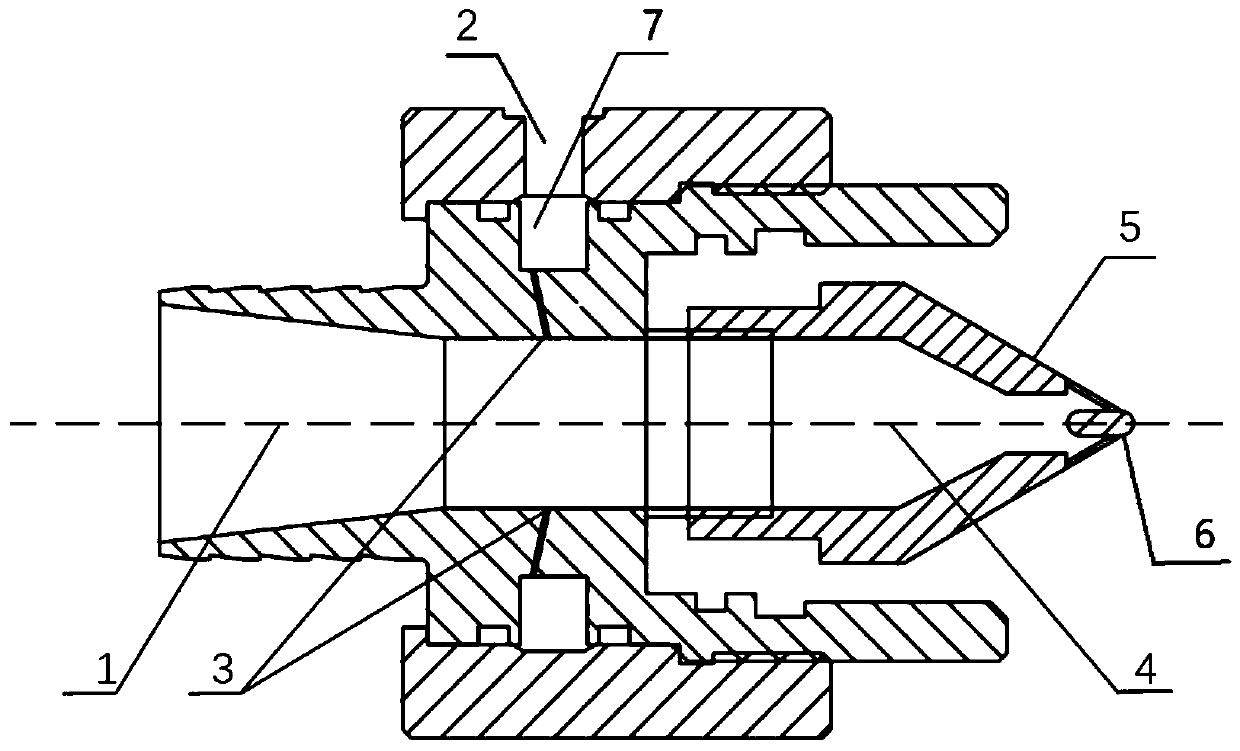

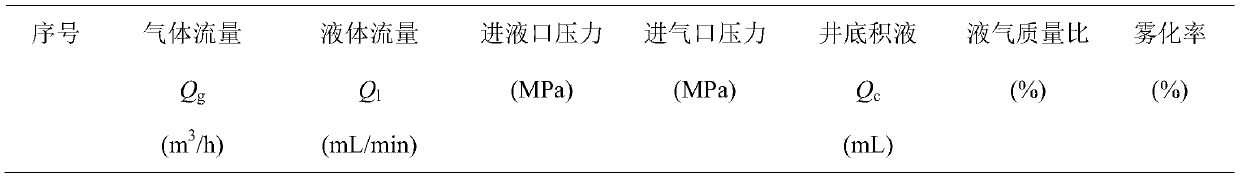

Acid liquid atomization device for deep acidification of fractured-vuggy reservoir and atomization method thereof

ActiveCN111085349AInto the uniformEasy to assembleFluid removalDrilling compositionAtomizer nozzleAir compressor

The invention discloses an acid liquid atomization device for deep acidification of a fractured-vuggy reservoir. The acid liquid atomization device for deep acidification of the fractured-vuggy reservoir comprises a gas path system, a liquid path system and an atomization nozzle; the gas path system comprises a gas inlet and an air compressor; the liquid path system comprises acid liquid inlets, ahigh-pressure acid-proof pump and a double-flow type Venturi tube; air is pressurized by the air compressor and then enters the gas inlet; and acid liquid is pressurized by the high-pressure acid-proof pump and then enters an annular cavity, the annular cavity is used for accumulating the acid liquid, the acid liquid in the annular cavity enters a cylindrical cavity through the acid liquid inletsformed in the wall, acid mist is formed in the cylindrical cavity as the hydrodynamic cavitation effect, the acid mist is constrained by the cylindrical cavity to form acid mist columnar fluid, the acid mist columnar fluid moves at high speed in an atomization generator and is finally sprayed out from the atomization nozzle of the atomization generator, and the atomization nozzle is directly connected with a shaft. The acid liquid atomization device for deep acidification of the fractured-vuggy reservoir has the good high temperature resistance, high pressure resistance and acid resistance, the injection displacement can be controlled through the gas path system and the liquid path system, the high acid liquid atomization rate is kept, and the acidification effect of the fractured-vuggy reservoir is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Formation opener agent for low permeable reservoir of oilfield

The present invention relates to a stratum opener agent which is applied to oilfield low permeability reservoir. The stratum opener agent comprises two parts: pre-disposal liquid and acid inhibitor system; according to the weight percentage, the pre-disposal liquid consists of solvent and surfactant as follows: 1-3% of organic solvent such as higher alcohol, 0.2-1% of non-ionized surfactant polyoxyethylene alkylolamide, 0.3-0.5% of pentadecane alkyl sulfonate, and the residual quantity of stratum water; according to the weight percentage, the acid inhibitor system comprises 5-10% of low-carbon organic acid, 1-3% of hydrofluoric acid, 0.5% of inhibitor thio-phosphate imidazoline polyoxyethylene ether, 1% of adsorption inhibitor and the residual quantity of water; the adsorption inhibitor comprises 0.5-2% of ethyl dimethylene-bi-cetyltrimethylammonium ammonium bromide, 0.2-1% of quaternary ammonium salt small kation, 2-5% of inorganic salt, 0.2% of 1,3-amine group propyl alcohol N-methyl sodium phosphate or potassium dihydrogen phosphate or sodium hexametaphosphate. The stratum opener agent can effectively improve the seepage capability of reservoir and achieve the objects of decompression and augmented injection and improving the yielding.

Owner:DAQING PETROLEUM ADMINISTRATION +1

Extraction method of L-malic acid

PendingCN111892498AGood protein adsorptionGood salt absorptionCarboxylic compound separation/purificationOXALIC ACID DIHYDRATEOrganic acid

The invention relates to an extraction method of L-malic acid, and belongs to the technical field of downstream extraction of organic acid biological fermentation. The extraction method of the L-malicacid comprises the following steps: 1) adding oxalic acid into an L-malic acid fermentation liquid, acidifying, and filtering to obtain a filtrate, namely an L-malic acid acidified liquid; 2) separating and removing impurities from the L-malic acid acidified liquid through a TY019 resin to obtain an L-malic acid separated liquid; 3) concentrating the L-malic acid separated liquid in the step 2),and crystallizing to obtain an L-malic acid wet product; and 4) placing the L-malic acid wet product in a vacuum drying oven, and performing vacuum gradient drying to obtain an L-malic acid finished product. According to the invention, the TY019 resin is used for separating the L-malic acid acidified liquid, so that the impurity removal effect is good, and the purity of the separated liquid is high; and compared with a conventional L-malic acid extraction method, the method of the invention has the advantages that the yield and purity of the L-malic acid product are high, the operation processis greatly simplified, and the production cost is greatly reduced.

Owner:新拓洋生物工程有限公司

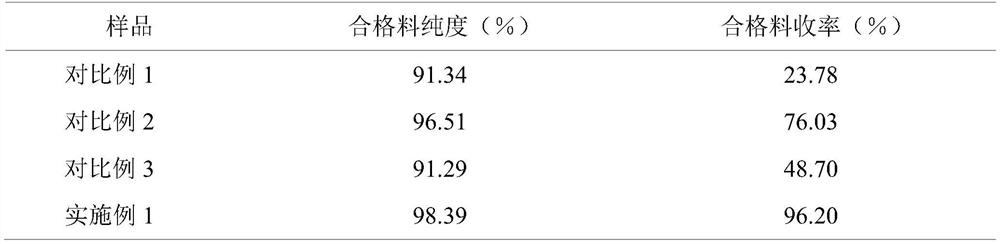

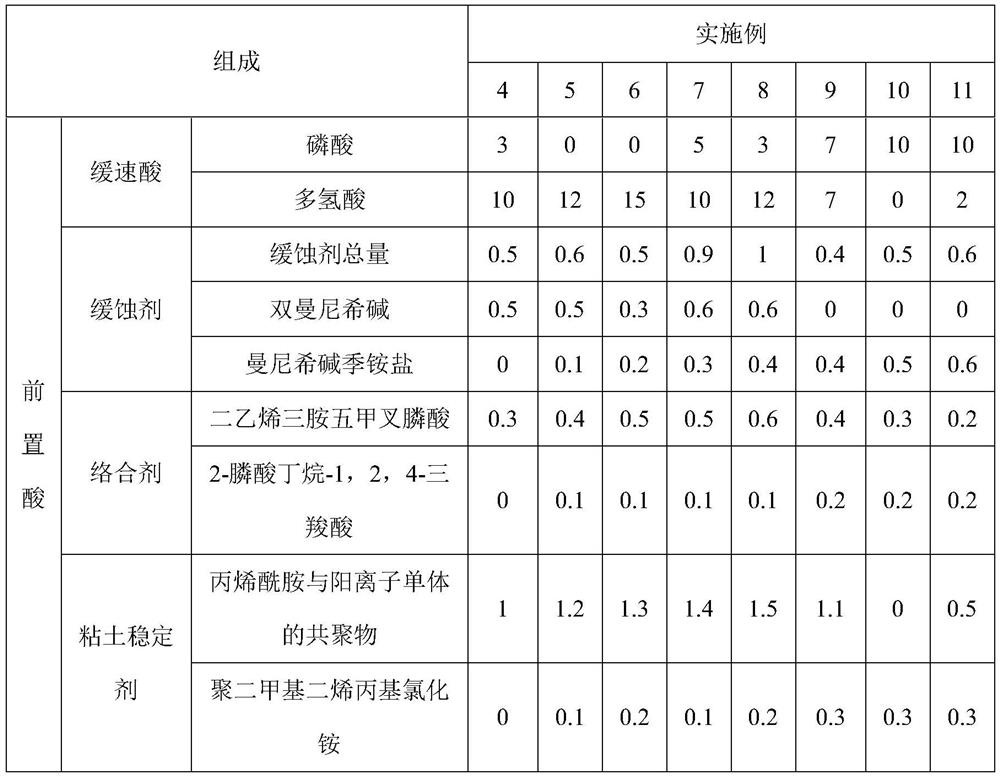

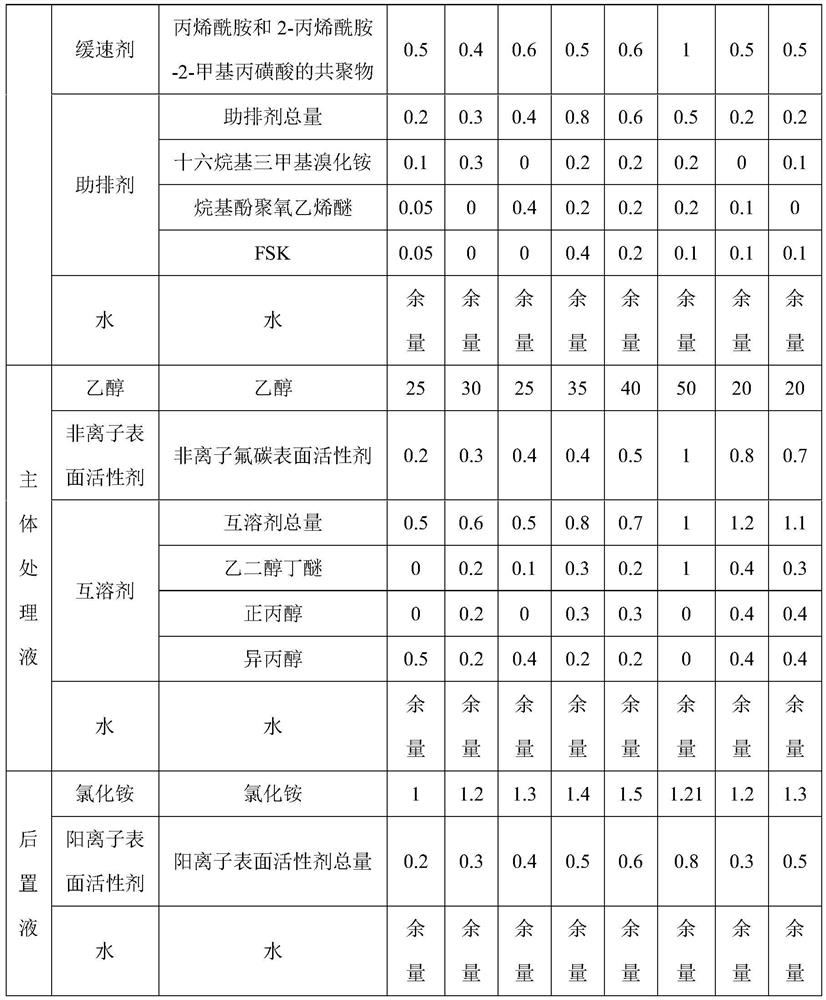

Water-blocking damage blocking remover, using method thereof and water-blocking damage acidizing fluid

ActiveCN112111258ARealize the purpose of increasing production and injectionExpand the scope of actionCleaning apparatusFluid removalActive agentEnvironmental engineering

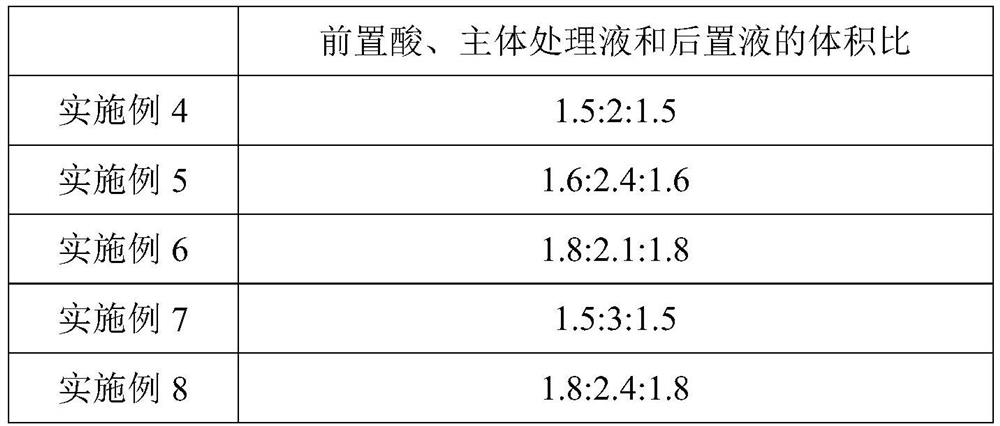

The invention relates to a water-blocking damage blocking remover, a using method thereof and a water-blocking damage acidizing fluid, and belongs to the field of oilfield chemistry application. The water-blocking damage blocking remover comprises prepad acid, main treatment fluid and postpad fluid, and the prepad acid is composed of the following components, by mass: 10-15% of retarded acid, 0.3-1% of a corrosion inhibitor, 0.3-0.7% of a complexing agent, 0.3-1.7% of a clay stabilizer, 0.4-1% of a retarder, 0.2-0.8% of a cleanup additive and the balance of water; the main treatment fluid is prepared from the following components, by mass: 20 to 50 percent of ethanol, 0.2 to 1 percent of nonionic surfactant, 0.5 to 1.5 percent of mutual solvent and the balance of water; and the postpad fluid is composed of a cationic surfactant, ammonium chloride and water. According to the blocking remover disclosed by the invention, blocking is removed through the combination of the prepad acid, themain treatment liquid and the postpad liquid, so that the action range of acidifying blocking removal is wider, and the action time is longer.

Owner:CHINA PETROLEUM & CHEM CORP +1

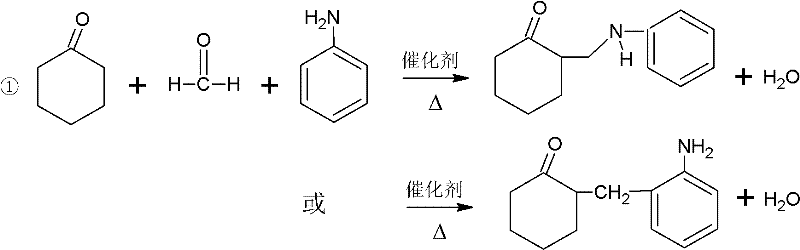

Retarding acidification system

InactiveCN105647510AImprove performanceGood retarding performanceDrilling compositionPhosphorous acidHydrogen

The invention provides a retarding acidification system. The retarding acidification system comprises a retarding admixture, wherein the retarding admixture is synthesized through a Mannich reaction of polyethylene polyamine, formaldehyde and phosphorous acid. A multi-hydrogen acid retarding acidification system is adopted, and the molecular structure of the retarding acidification system comprises multiple phosphate groups which can provide multiple H<+>. Compared with other acidic solutions, the retarding acidification system has more excellent performance including more excellent retarding performance, longer penetration distance, lower clay corrosion rate, higher quartz corrosion rate and capability of inhibiting secondary precipitation and has the advantages of being good in corrosion inhibition and chelating property, low in viscosity and the like. The retarding acidification system further has better corrosion capability when acid liquor reaches the deep stratum, and further, the acidification effect of the high-retardancy acidification system is improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

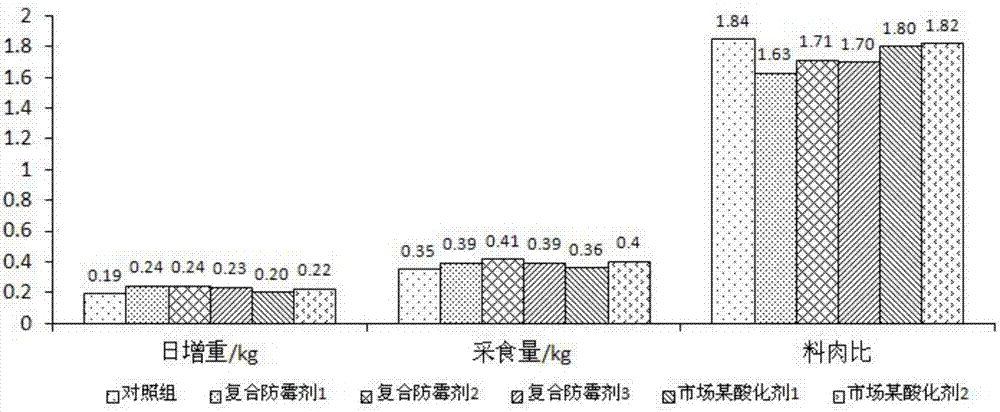

Organic compound acidifier added in domestic rabbit high-fiber feed and preparation method thereof

InactiveCN104982669AImprove acidification effectGood antibacterial effectAnimal feeding stuffFiberNutrients substances

The invention discloses an organic compound acidifier added in a domestic rabbit high-fiber feed and a preparation method thereof. The organic compound acidifier is composed of the following raw materials: lactic acid, formic acid, citric acid, fumaric acid and white carbon black. The organic compound acidifier is mainly used in the domestic rabbit high-fiber feed, and is strong in pertinency; all the components are organic acids, do not contain inorganic acid, and have good acidification effect on the high-fiber feed; with lactic acid as a main acid, the organic compound acidifier has a lactic taste and is good in palatability, and the small molecular acid formic acid has strong bacteriostasis and sterilization abilities; and the organic compound acidifier can lower pH values in stomach and intestinal tracts, improves the digestibility of nutrient substances, promotes the growth of beneficial bacteria, improves a intestinal tract flora structure, prevents diarrhoea, and promotes growth.

Owner:SICHUAN AGRI UNIV

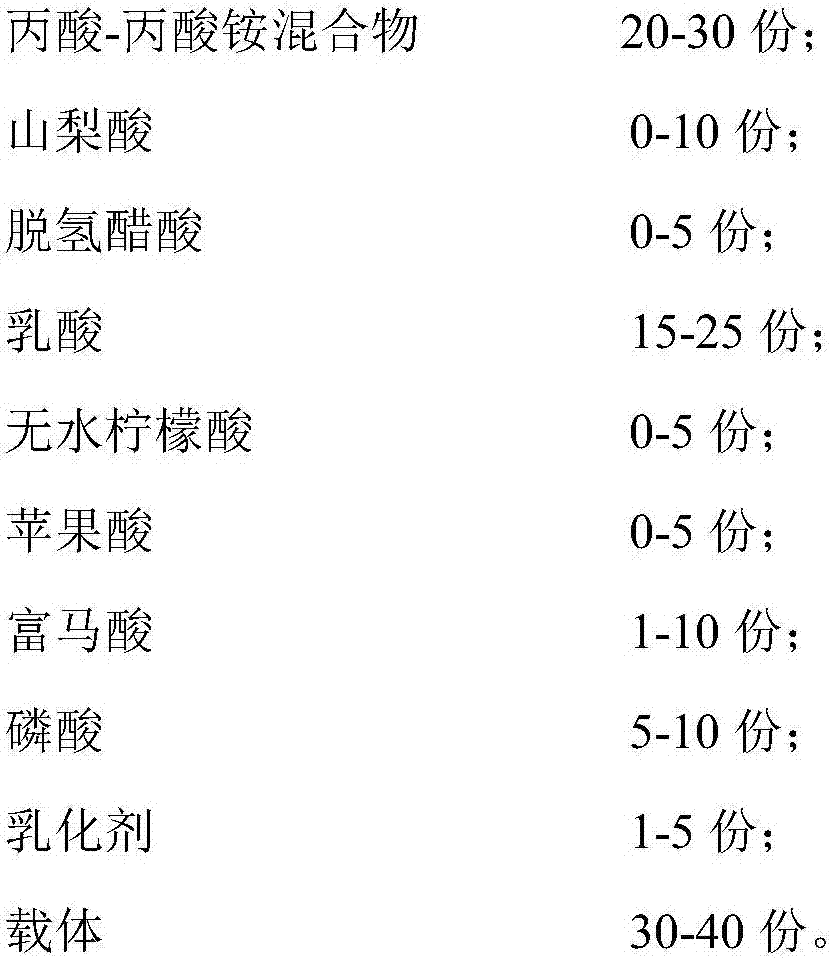

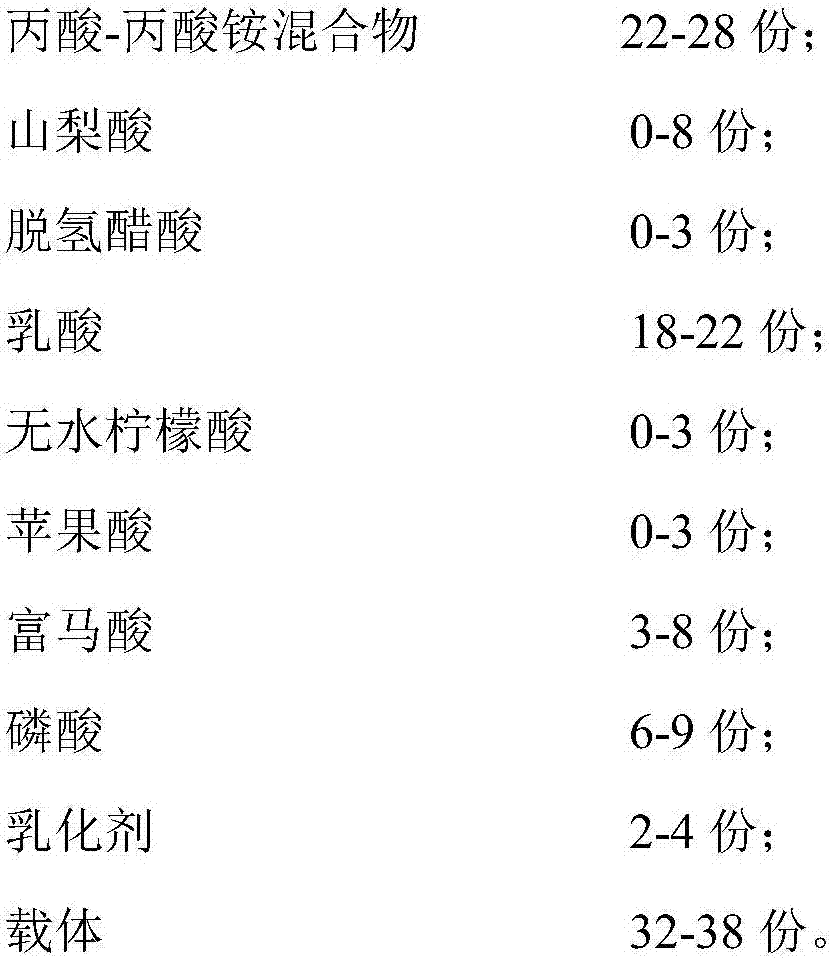

Combined antifungal agent with acidizing effect on feed, as well as preparation method and application thereof

InactiveCN106962655ASolve mildewAddress acidificationFodderFood preservationDehydroacetic acidPropanoic acid

The invention discloses a combined antifungal agent with acidizing effect on feed, as well as a preparation method and application thereof. The combined antifungal agent comprises the following components in parts by weight: 20 to 30 parts of propionic acid-ammonium propionate mixture; 0 to 10 parts of sorbic acid; 0 to 5 parts of dehydroacetic acid; 15 to 25 parts of lactic acid; 0 to 5 parts of anhydrous citric acid; 0 to 5 parts of malic acid; 1 to 10 parts of fumaric acid; 5 to 10 parts of phosphoric acid; 1 to 5 parts of an emulgator; 30 to 40 parts of a carrier. The combined antifungal agent with acidizing effect on feed can not only weaken the irritation to the antifungal agent, but also give full play to the synergistic interaction among all components, reduce the dosage of components of the antifungal agent, meanwhile solves the problems of mold prevention and acidification of the feed, and has positive significance for guaranteeing food safety; in addition, the preparation method is low in production cost, simple in technology, safe and high in operability, and does not cause any environmental pollution.

Owner:上海邦成生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com