Retarding acidification system

A retarded acid and system technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of short acid penetration distance, fast reaction rate of acid rock, etc., and achieve deep penetration distance, low viscosity, The effect of good dissolution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Add an appropriate amount of water into the three-necked flask, add diethylenetriamine, formaldehyde solution, and phosphorous acid into a 250mL three-necked flask at a molar ratio of 1:3:3, so that the total monomer concentration is 15%, and add hydrochloric acid to adjust the pH value to 1. Stir, react at a temperature of 110°C for 6h, cool to room temperature, and remove the solvent from the reaction solution with a rotary evaporator, set the temperature at 60°C and vacuum at 0.098MPa during evaporation to obtain a reddish-brown viscous liquid.

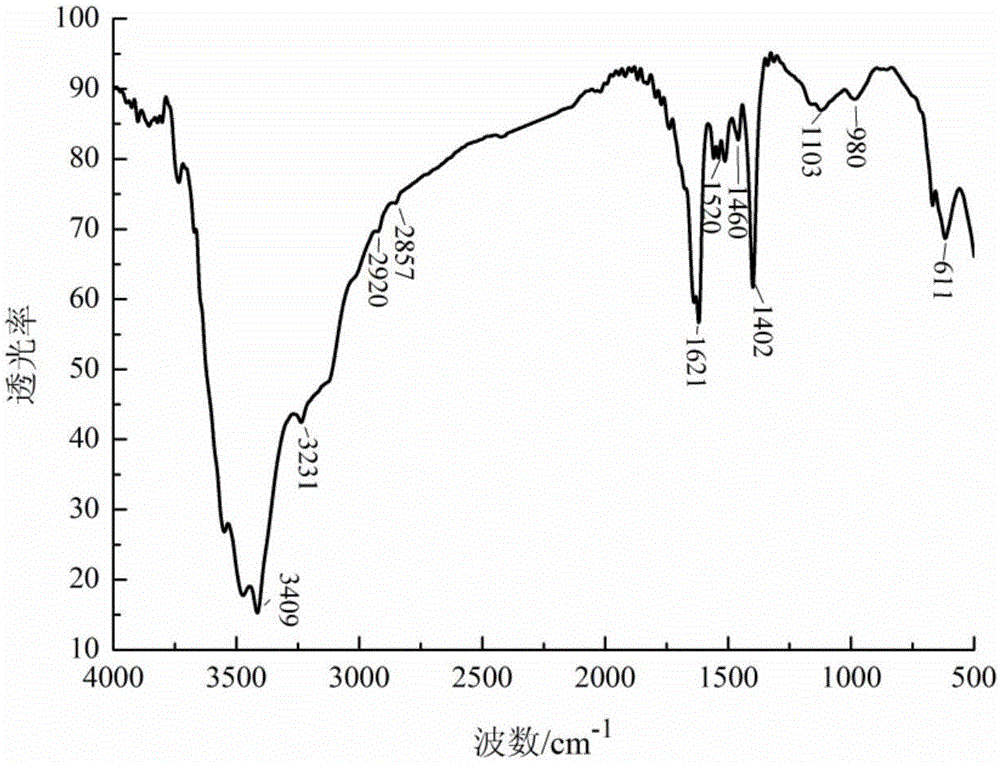

[0062] The molecular structure of the synthesized product was identified by infrared spectroscopy, and the infrared spectrum of the product was as follows figure 1 shown.

[0063] Depend on figure 1 It can be seen that v=3409cm -1 It is O-H in phosphorous acid, v=2920cm -1 and v = 2857cm -1 Symmetric and asymmetric stretching vibration peaks of methyl and methylene, v=1103cm -1 It is P=O stretching vibration, v=1621cm ...

Embodiment 2

[0065] Add an appropriate amount of water into the three-necked flask, add diethylenetriamine, formaldehyde solution, and phosphorous acid into a 250mL three-necked flask at a molar ratio of 1:5:5, so that the total monomer concentration is 20%, and add hydrochloric acid to adjust the pH value to 3. Stir, react at a temperature of 100°C for 7 hours, cool to room temperature, and remove the solvent from the reaction solution with a rotary evaporator, set the temperature at 60°C and vacuum at 0.098MPa during evaporation to obtain a reddish-brown viscous liquid.

Embodiment 3

[0067] Add an appropriate amount of water into the three-necked flask, add triethylenetetramine, formaldehyde solution, and phosphorous acid into a 250mL three-necked flask at a molar ratio of 1:7:7, so that the total monomer concentration is 20%, and add hydrochloric acid to adjust the pH value to 3. Stir, react at a temperature of 100°C for 7 hours, cool to room temperature, and remove the solvent from the reaction solution with a rotary evaporator, set the temperature at 60°C and vacuum at 0.098MPa during evaporation to obtain a reddish-brown viscous liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com