Extraction method of L-malic acid

An extraction method and malic acid technology, applied in the field of L-malic acid extraction, can solve the problems of low extraction purity, complex process, low yield and the like, and achieve high yield and purity, simplified operation process and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

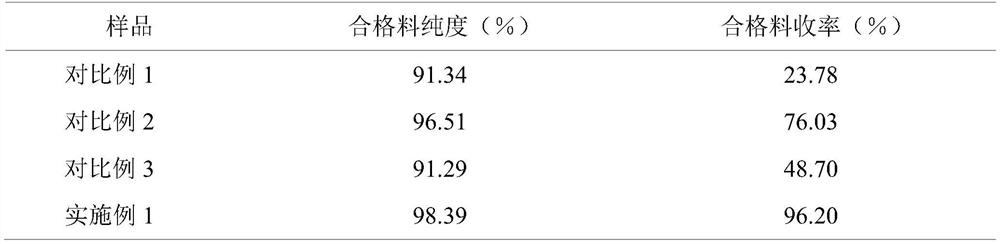

Examples

Embodiment 1

[0027] The extraction method of the L-malic acid of the present embodiment, comprises the following steps:

[0028] 1) Acidification: acidify the L-malic acid fermentation broth with oxalic acid until the pH is 2.0, remove calcium salts, mycelia and fermentation residues by vacuum filtration, and wash the filtered filter cake with deionized water until the pH is 5.0 to ensure that no Malic acid is lost to obtain L-malic acid acidification solution.

[0029] 2) Impurity removal: under the condition of 35°C, put the L-malic acid acidification solution into the TY019 separation resin column, the column flow rate is 50mL / min, and the feed amount is 150g, and the separation solution is collected in sections, and the first section is collected as chromatographic resin The water in the gap is collected and reused; the second section collects the impurity solution and discards it; the third section collects the low-purity L-malic acid solution, which is stored for the next separation;...

Embodiment 2

[0033] The extraction method of the L-malic acid of the present embodiment, comprises the following steps:

[0034] 1) Acidification: acidify the L-malic acid fermentation broth with oxalic acid until the pH is 1.8, vacuum filter to remove calcium salts, mycelia and fermentation residues, and wash the filtered filter cake with deionized water until the pH is 5.0 to ensure that no Malic acid is lost to obtain L-malic acid acidification solution.

[0035]2) Impurity removal: under the condition of 35°C, put the L-malic acid acidification solution into the TY019 separation resin column, the column flow rate is 80mL / min, the feed amount is 100g, and the separation solution is collected in sections, and the first section is collected as chromatographic resin The water in the gap is collected and reused; the second section collects the impurity solution and discards it; the third section collects the low-purity L-malic acid solution, which is stored for the next separation; the four...

Embodiment 3

[0039] The extraction method of the L-malic acid of the present embodiment, comprises the following steps:

[0040] 1) Acidification: acidify the L-malic acid fermentation broth with oxalic acid until the pH is 2.5, remove calcium salts, mycelia and fermentation residues by vacuum filtration, and wash the filtered filter cake with deionized water until the pH is 5.0 to ensure that no Malic acid is lost to obtain L-malic acid acidification solution.

[0041] 2) Impurity removal: under the condition of 45°C, put L-malic acid acidified liquid into TY019 separation resin column, the flow rate of the column is 25mL / min, the feeding amount is 200g, and the separation liquid is collected in sections, and the first section is collected as chromatographic resin The water in the gap is collected and reused; the second section collects the impurity solution and discards it; the third section collects the low-purity L-malic acid solution, which is stored for the next separation; the fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com