Patents

Literature

168results about How to "High yield and purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

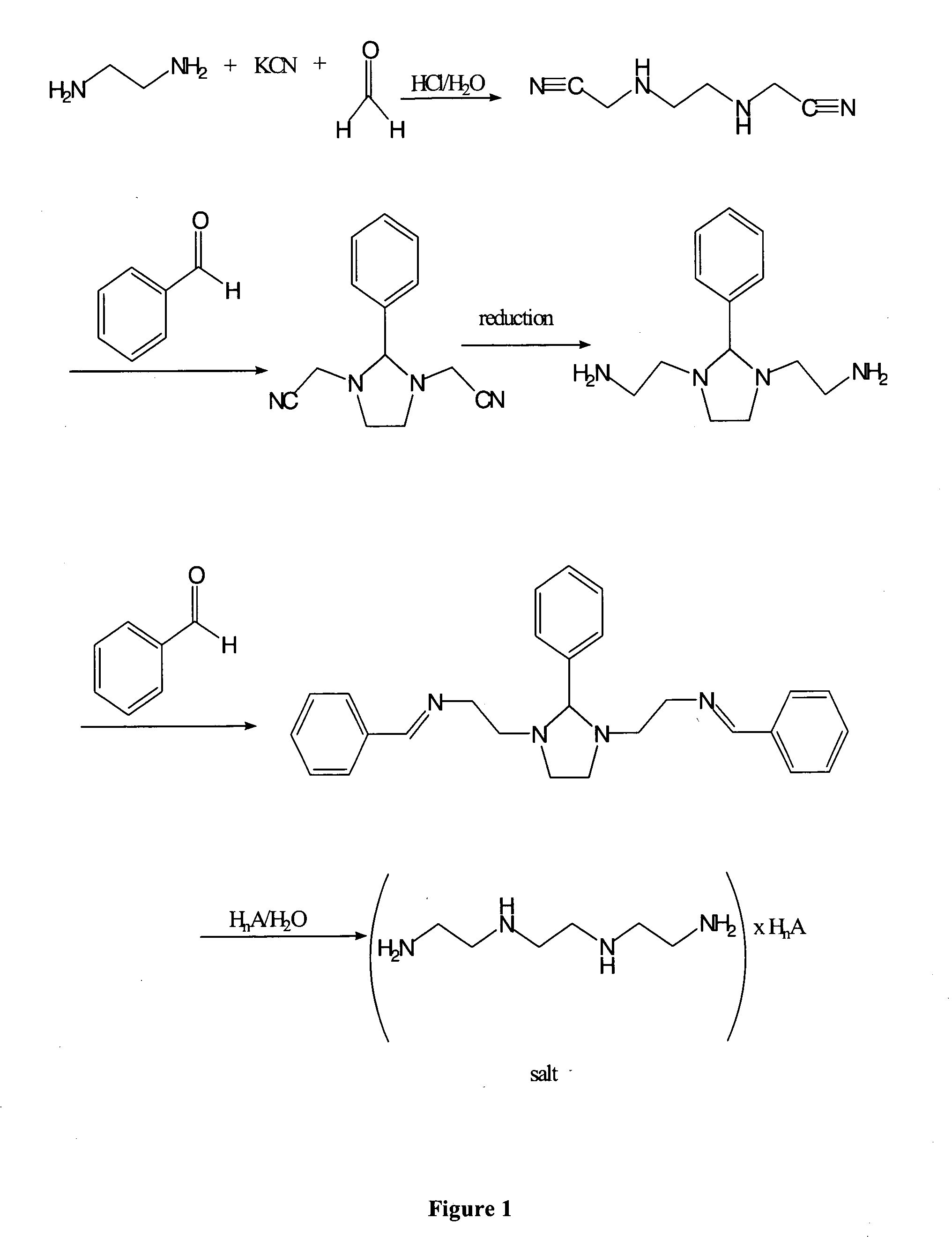

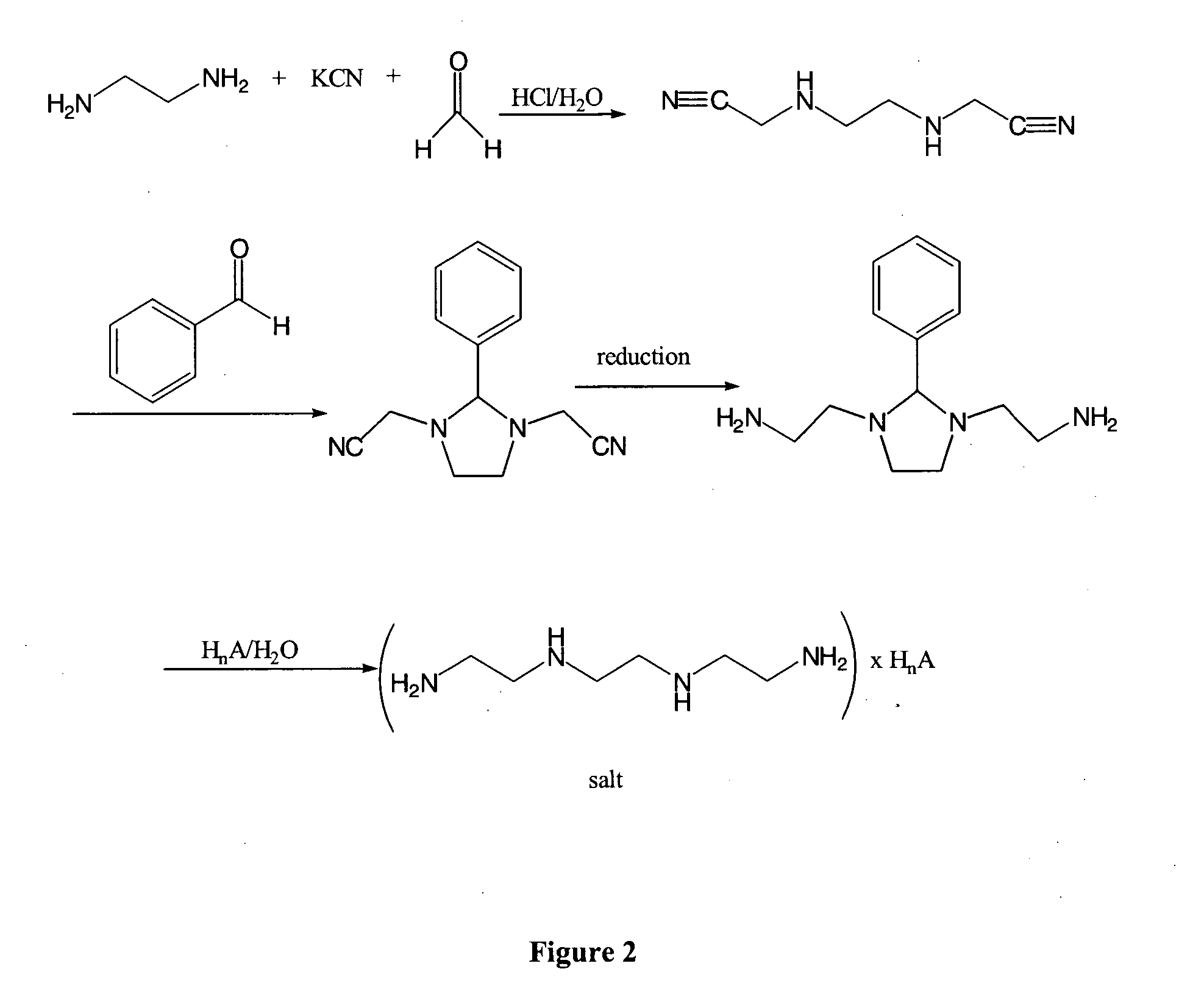

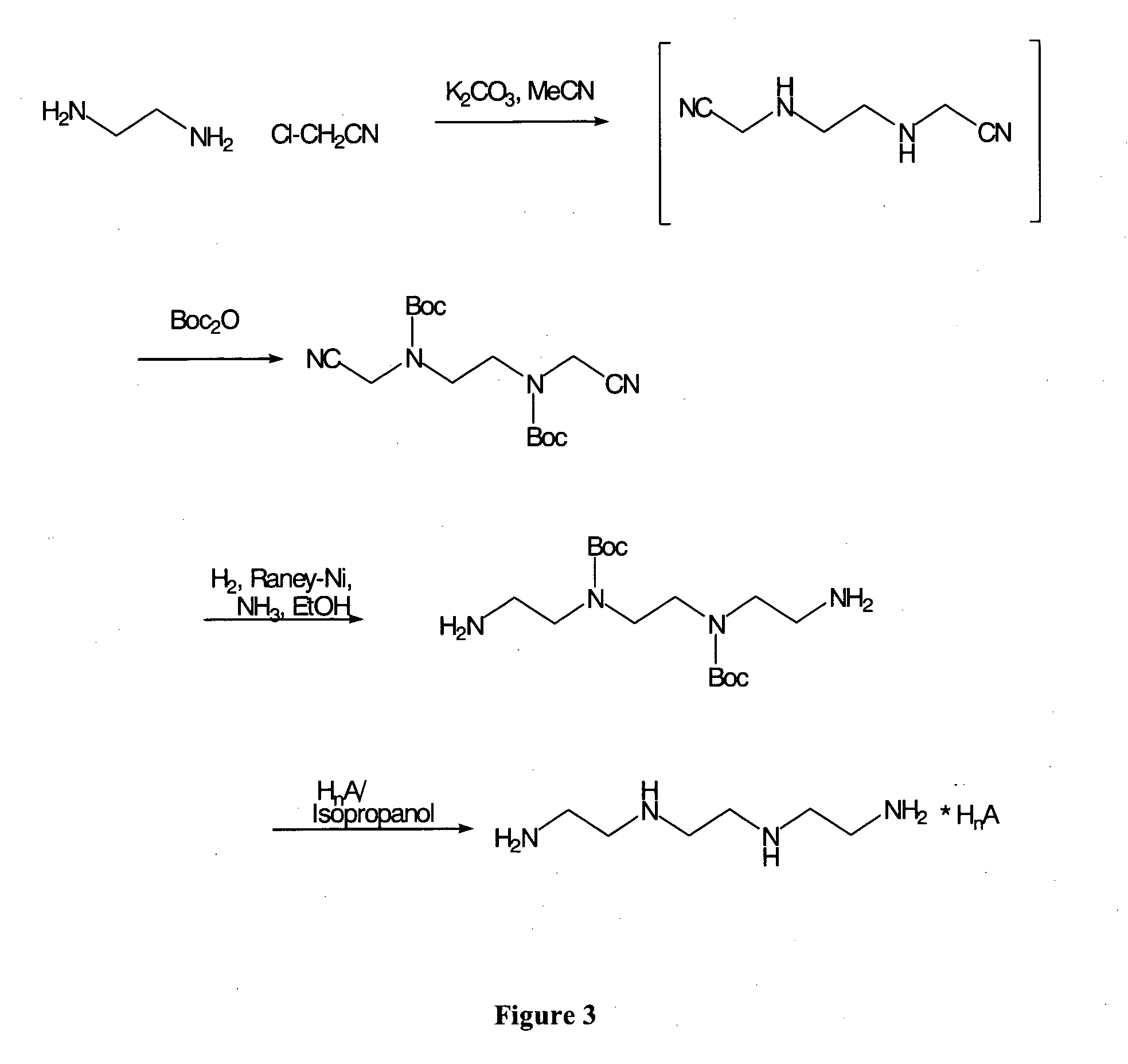

Synthesis of triethylenetetramines

ActiveUS20060041170A1High yield and purityHigh purityOrganic compound preparationMetabolism disorderTriethylenetetramineMedicinal chemistry

Methods and intermediates for synthesizing triethylenetetramine and salts thereof, as well as novel triethylenetetramine salts and their crystal structure, and triethylenetetramine salts of high purity.

Owner:PHILERA NEW ZEALAND

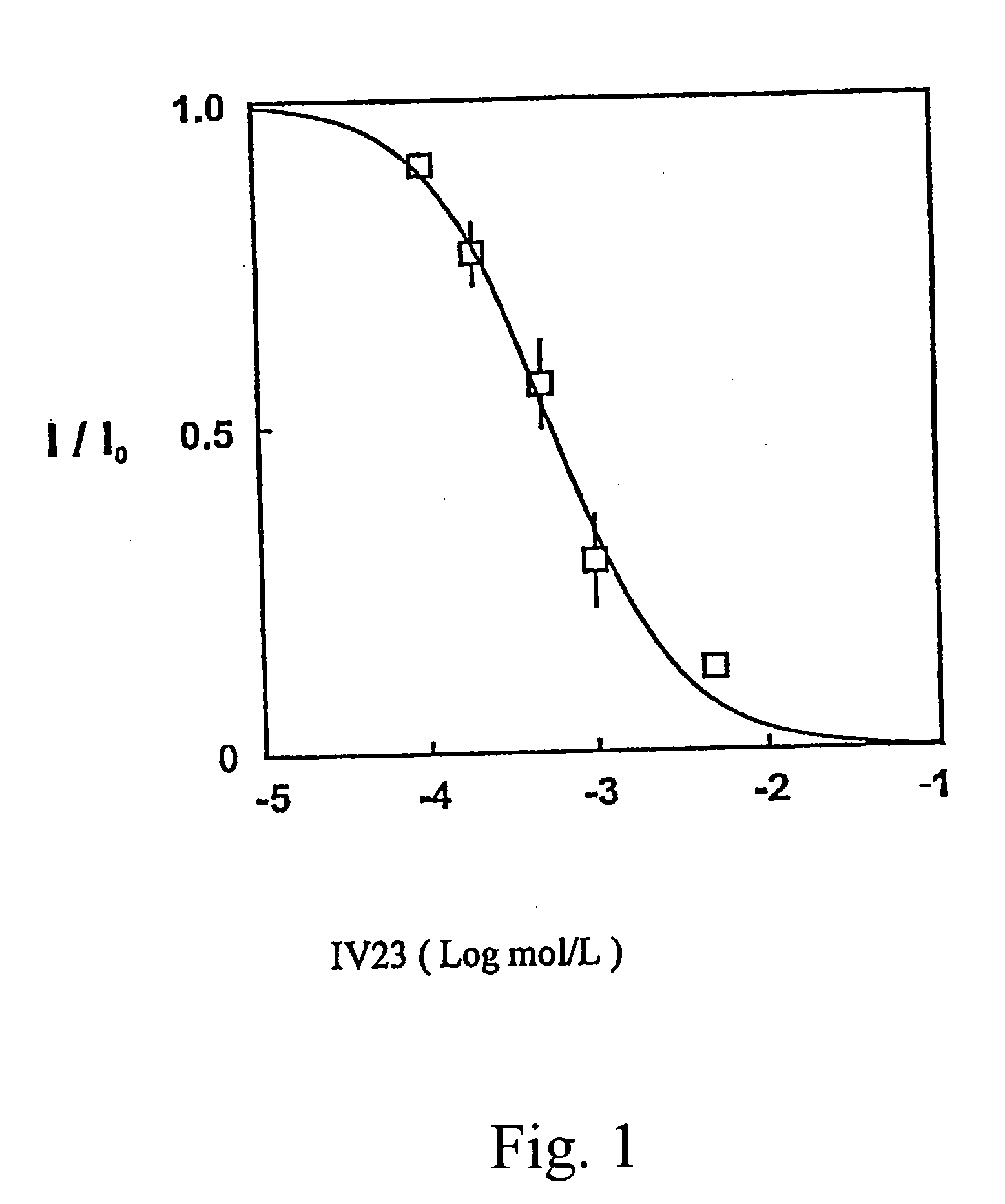

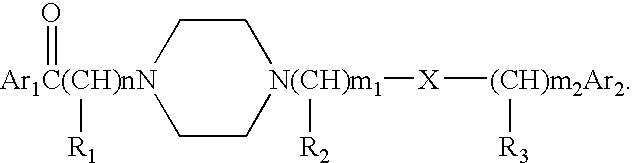

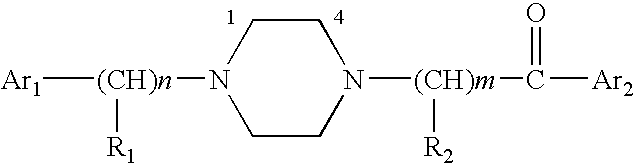

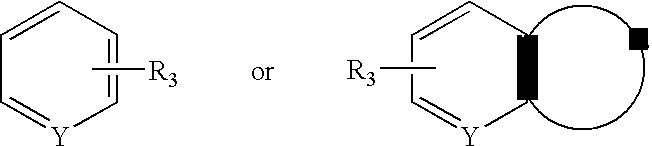

Aralkyl formly-alkyl piperazine derivatives and their uses as a cerebral nerve protective agent

InactiveUS20050153981A1Transmission very difficultReduced bioavailabilityOrganic active ingredientsNervous disorderSide effectMedicine

Aralkyl formyl alkyl piperazine derivatives Pharmaceutical compositions comprising the same, and methods of using them as a neuroprotective agent. Pharmaceutical results indicate that these compounds have excellent neuroprotective activities and fewer side effects.

Owner:SHANGHAI INST OF PHARMA IND

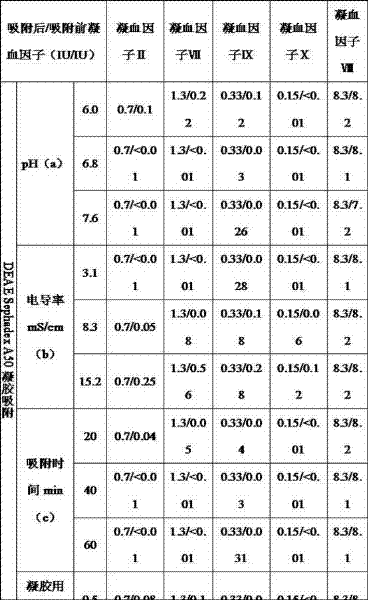

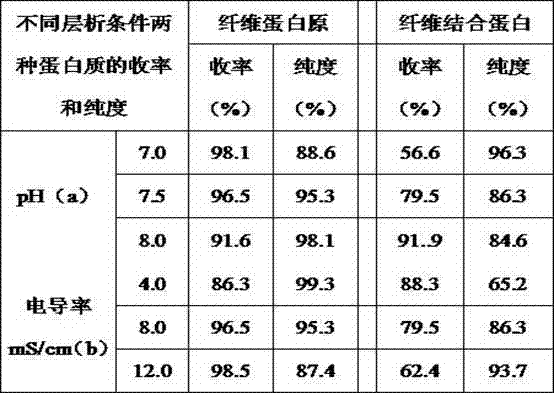

Method for preparing blood coagulation factor ⅷ, fibrinogen and fibronectin by cryoprecipitation

ActiveCN102295696AIncrease profitHigh yield and purityFactor VIIConnective tissue peptidesFibrinBlood plasma

The invention relates to the field of blood products, in particular to a process method for preparing three kinds of blood products from cryoprecitation, and aims to provide a complete separation and purification process for respectively and sequentially preparing the three kinds of blood products, i.e. a coagulation factor VIII, fibrinogen and fibronectin, from the cryoprecitation. The process method is implemented by the following technical scheme that the process method comprises the preparation steps of cryoprecitation dissolution, gel adsorption, precipitation of the fibrinogen and the fibronectin, two-step ion exchange chromatography and glycin / sodium chloride precipitation and inactivation of virus. The process method has the beneficial effects that the three kinds of useful blood products, i.e. the coagulation factor VIII, the fibrinogen and the fibronectin, can be separated and extracted from the cryoprecitation sequentially; and the utilization rate of blood plasma is greatly improved.

Owner:SHANDONG TAIBANG BIOLOGICAL PROD CO LTD

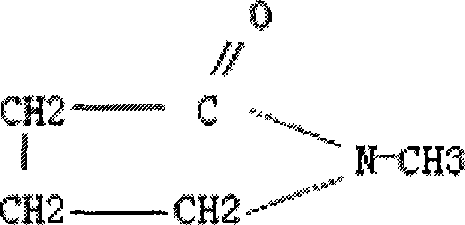

Purification method of N-methyl pyrrolidone

InactiveCN101508667AHigh yield and purityAdvanced and reasonable technologyOrganic chemistryVacuum distillation separationIonChemistry

The invention relates to a method for purifying N-methylpyrrolidone, which is a method for producing a heterocyclic compound. The method comprises the following steps: adding a water repellent agent accounting for 0.1 to 2 percent of a crude product into crude product solution, and then continuously throwing the mixture into a three-tower combined rectifying system. By adopting good-quality stuffing and three-tower continuous pressure reduced rectification, adopting an advanced rectifying operation method according to the optimal principle of reflux separation effect, and adopting a reflux ratio of 1.5 to 3 to extract a product, the method effectively controls the contents of impurities such as metal ions and the like.

Owner:MAIQI CHEM CO LTD

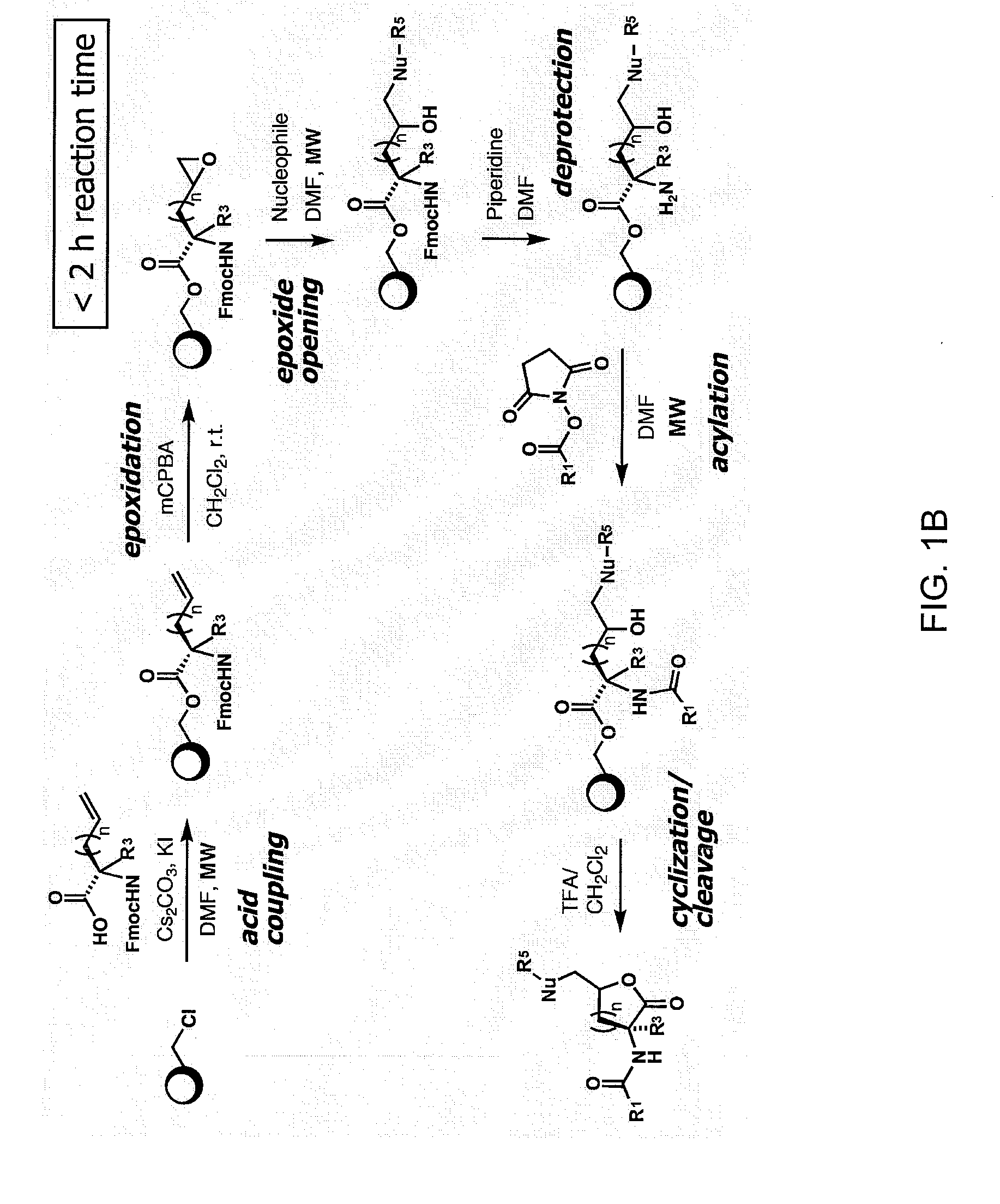

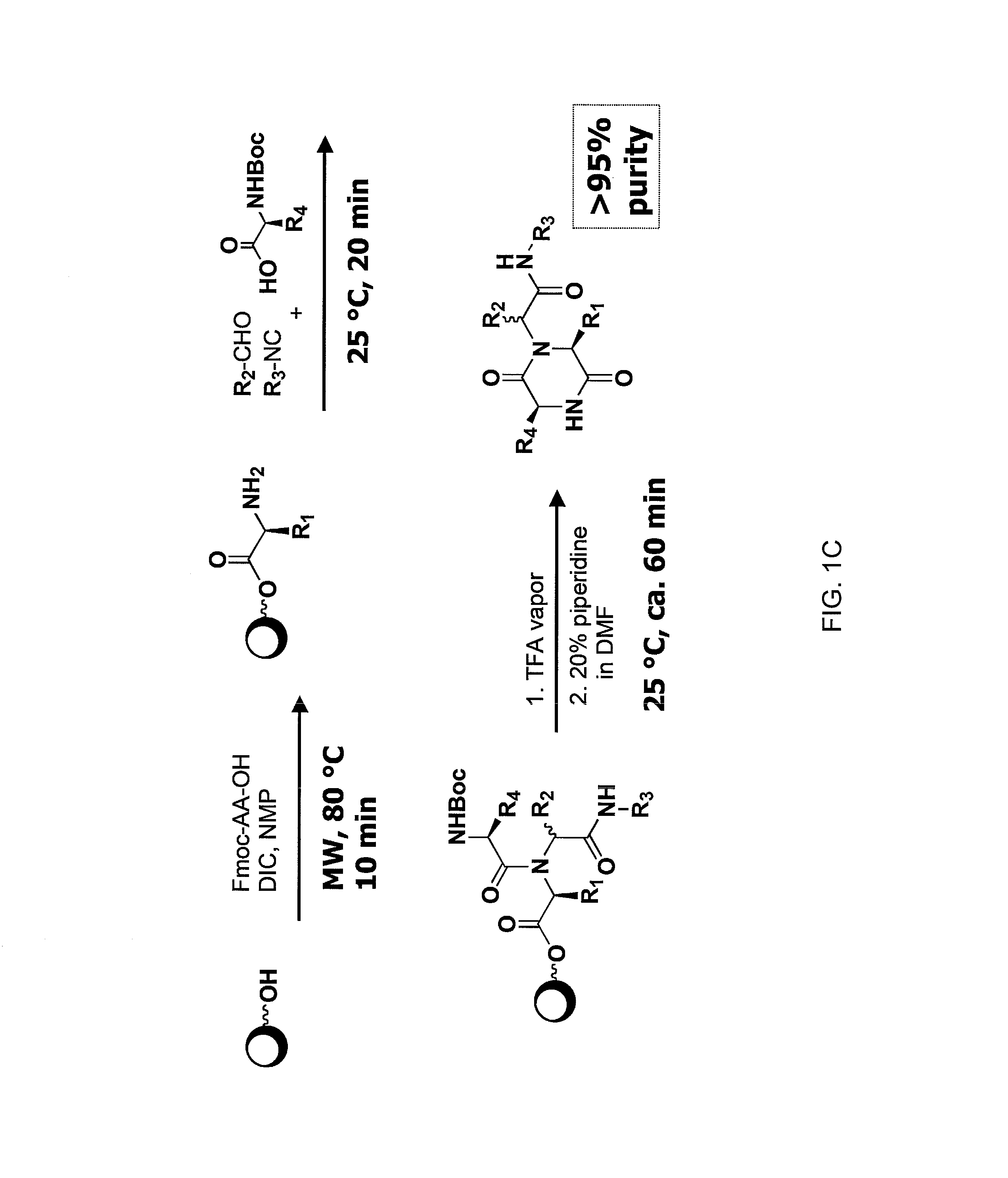

Compounds and methods for modulating communication and virulence in quorum sensing bacteria

InactiveUS20060178430A1High yield and purityEfficient synthesisAntibacterial agentsBiocideBiologyAcyl-Homoserine Lactones

The present invention provides compositions and methods for modulating the communication and virulence of quorum sensing bacteria. In various exemplary embodiments, the invention provides a combinatorial library of quorum sensing compounds including synthetic analogs of naturally occurring and non-naturally occurring acyl-homoserine lactone (AHL) analogs, and methods of synthesizing and using these compounds.

Owner:WISCONSIN ALUMNI RES FOUND

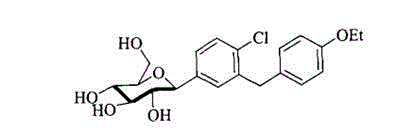

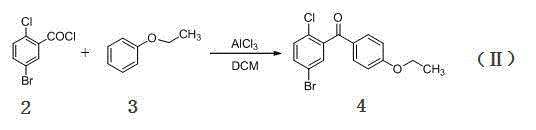

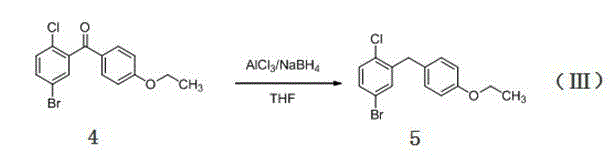

Method for synthesizing forxiga intermediate

ActiveCN104086379ALow impurity contentHigh yield and purityOrganic compound preparationCarbonyl compound preparation by condensationAluminum trichlorideDichloromethane

The invention relates to a method for synthesizing a forxiga intermediate. The method comprises the following steps: step 1, by taking dichloromethane as a solvent, reacting a compound (1) and oxalyl chloride under stirring conditions, performing reduced pressure distillation to remove the dichloromethane, and obtaining a concentrated solution of a compound (2); step 2, by taking the dichloromethane as a solvent, reacting the compound (2) and a compound (3) under the condition that aluminum trichloride serves as a catalyst, wherein the reaction temperature is 20 DEG C below zero to 10 DEG C below zero, the reaction time is 2-4 hours, and obtaining a compound (4); and step (3) by taking THF as a solvent, carrying out a reduction reaction on the compound (4), sodium borohydride and aluminum chloride anhydrous, thereof obtaining a compound (5), namely 5-bromine-2-chloro-4'-ethyoxydiphenylmethane. According to the method, the content of impurities can be reduced, the purity is improved, the yield is improved, and the method is suitable for synthesizing the forxiga intermediate in a large scale.

Owner:安徽联创生物医药股份有限公司

Aralkyl-ketone piperazine derivatives and their uses as new antalgic or ataractic agent

ActiveUS7332495B2High yield and purityQuality improvementOrganic active ingredientsNervous disorderSide effectMedicine

Owner:NHWA PHARMA CORPORATION

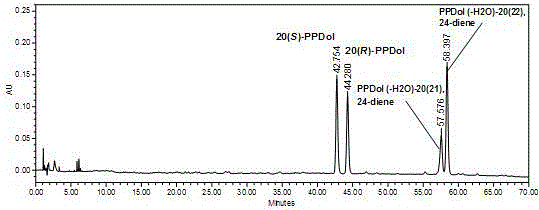

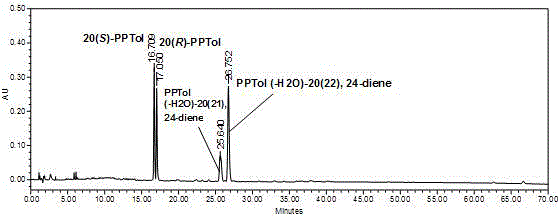

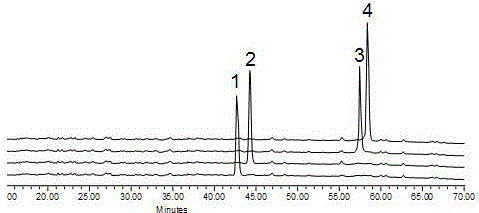

Preparation method for rare ginsenoside C-K and F1 and four kinds of isomer ginsengenin

The invention discloses a preparation method for rare ginsenoside C-K and F1 and four kinds of isomer panoxadiol saponin and panaxatriol sapogenin. Ginseng is used as a raw material, panoxadiol saponin (mixture), panaxatriol sapogenin (mixture) and a ginseng saponin enzyme compound are extracted. Panoxadiol saponin and an organic solvent are prepared into a substrate solution, panaxatriol sapogenin and a buffer solution are prepared into a substrate solution, the two substrate solutions are fermented with aspergillus microorganisms to obtain crude enzyme liquid for a reaction, there is almost no other byproduct saponin, and rare ginsenoside C-K or rare ginsenoside F1is obtained; after the reaction, the enzyme can be recovered and used repeatedly. The obtained C-K or F1 saponin reacts with the ginseng saponin enzyme compound (a proper amount of organic acid is added), and then four kinds of isomer panoxadiol saponin and panaxatriol sapogenin are obtained. Operation is easy, yield is high, cost is low, and the method is suitable for mass production; the obtained products can be used for medicine development, ginseng products, health care products and cosmetics.

Owner:金凤燮

Method for extracting tea saponin from Camellia oleiera Aberl. cake

The invention discloses a method for extracting tea saponin from Camellia oleiera Aberl. cake. The extraction method comprises the following steps: putting Camellia oleiera Aberl. cake powder together with a solid reagent in a ball mill, carrying out ball milling, taking out ball milled powder, adding water to the ball milled powder, stirring, filtering, taking the filtrate to a macroporous resin column, eluting with an aqueous solution containing 80 wt% of ethanol, collecting an eluate, concentrating to evaporate a solvent, and drying to obtain the tea saponin. The method of the invention, which has the advantages of cheap raw material, high yield and high purity of the tea saponin, simple process, convenient operation, low cost, environment protection and the like, is a tea saponin preparation method with good popularization and application prospects.

Owner:ZHEJIANG UNIV OF TECH

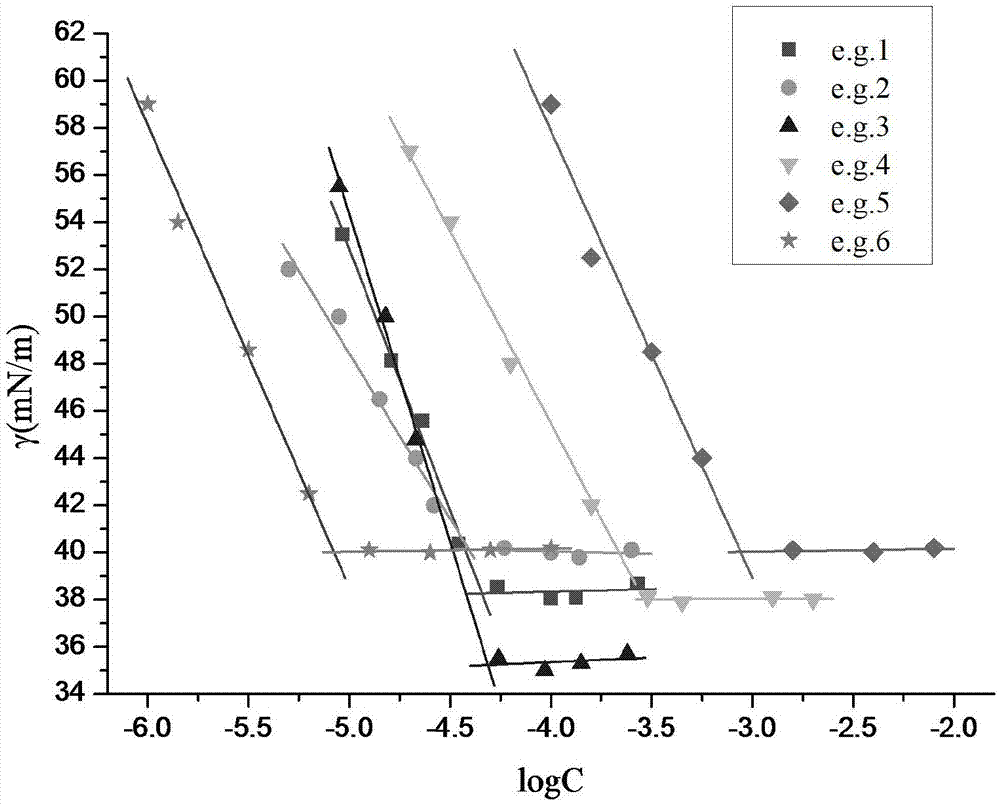

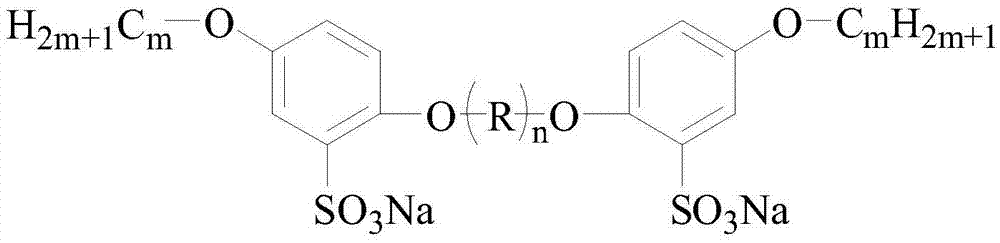

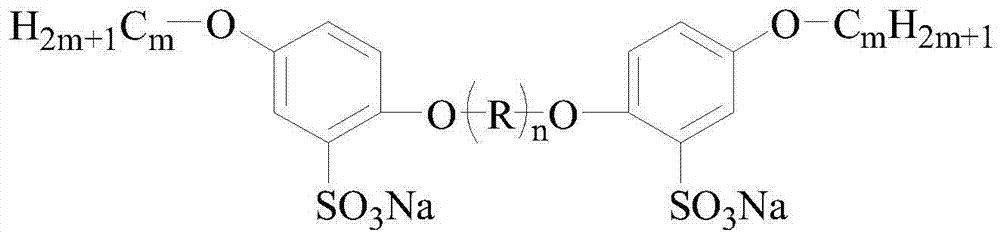

Sulfonate-type anion dimeric surfactant and preparation method thereof

ActiveCN105435706ASimple preparation processHigh yield and purityTransportation and packagingMixingBromineHydroquinone Compound

The invention provides a sulfonate-type anion dimeric surfactant and a preparation method thereof. The preparation method comprises the following steps: performing a substitution reaction on hydroquinone and brominated alkanes so as to obtain 4-alkoxy phenol; performing a substitution reaction on 4-alkoxy phenol and dibromo alkane or dibromo-poly-dihydric alcohol to obtain 4-alkoxy phenol glycidyl ether; and performing a sulfonation reaction on 4-alkoxy phenol glycidyl ether and chlorosulfonic acid to obtain the dimeric surfactant. Raw materials adopted in the method are easily available; the preparation process is simple, the reaction product yield and the reaction product purity are relatively high, and the sulfonate-type anion dimeric surfactant has favorable surface activity.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

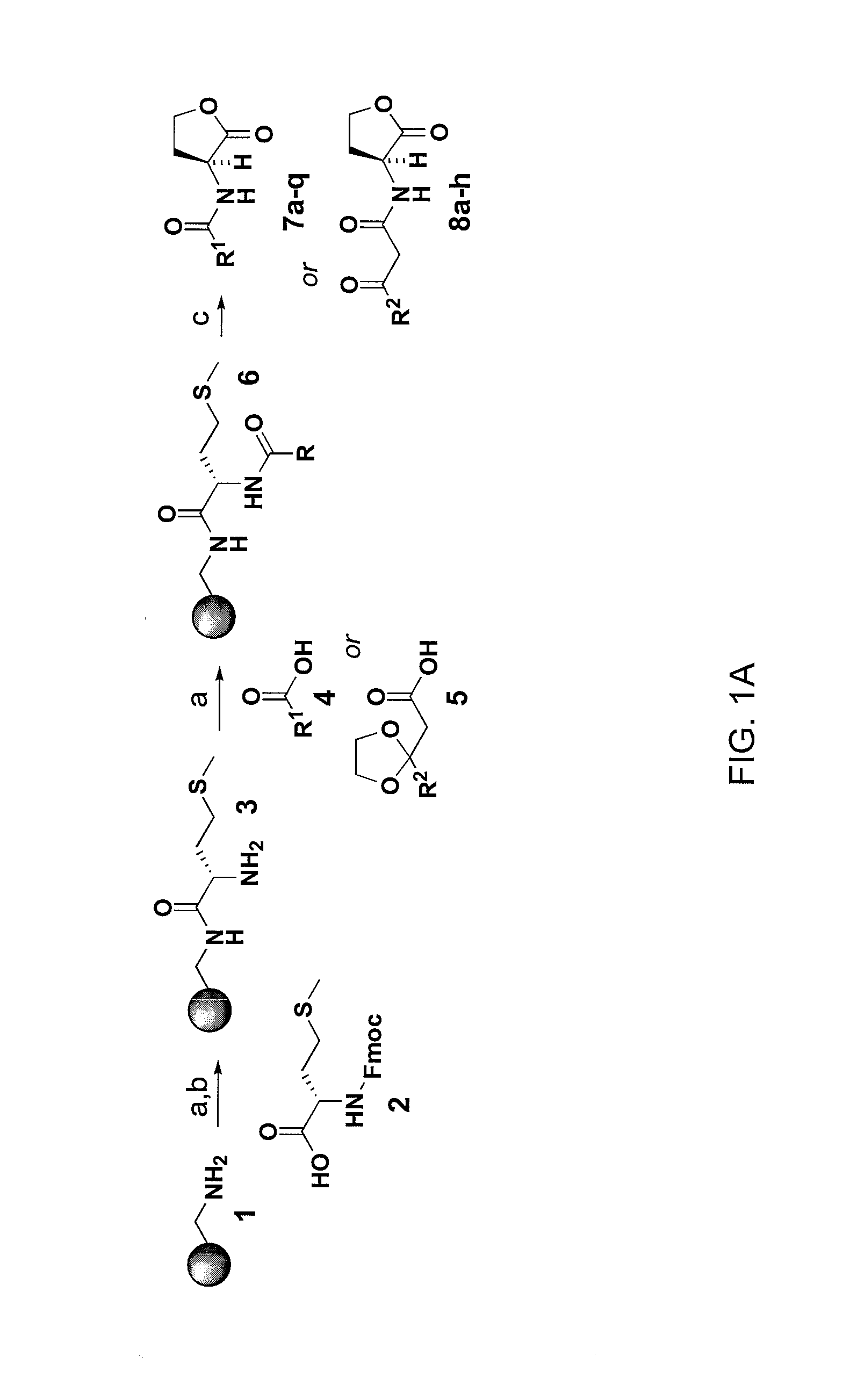

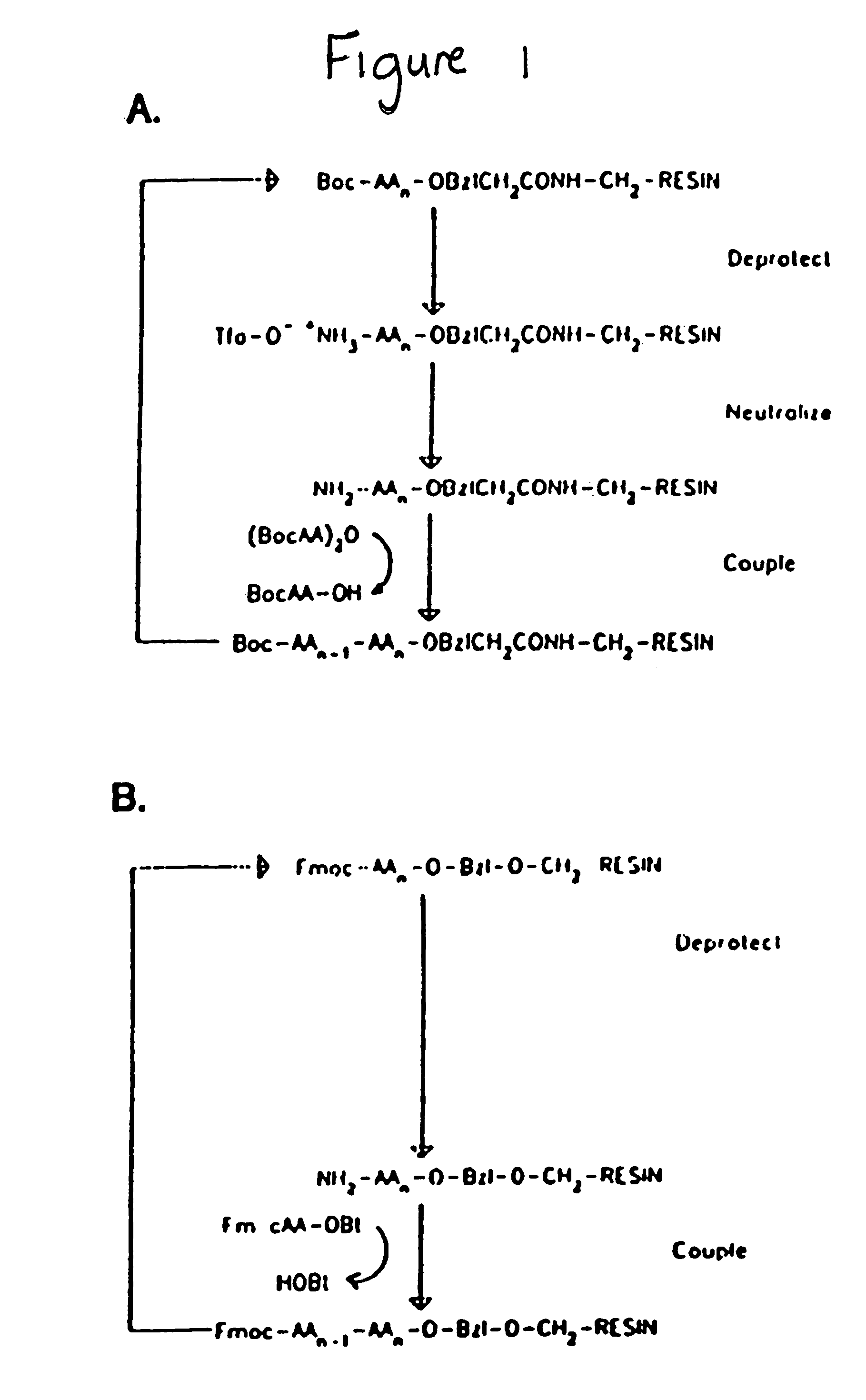

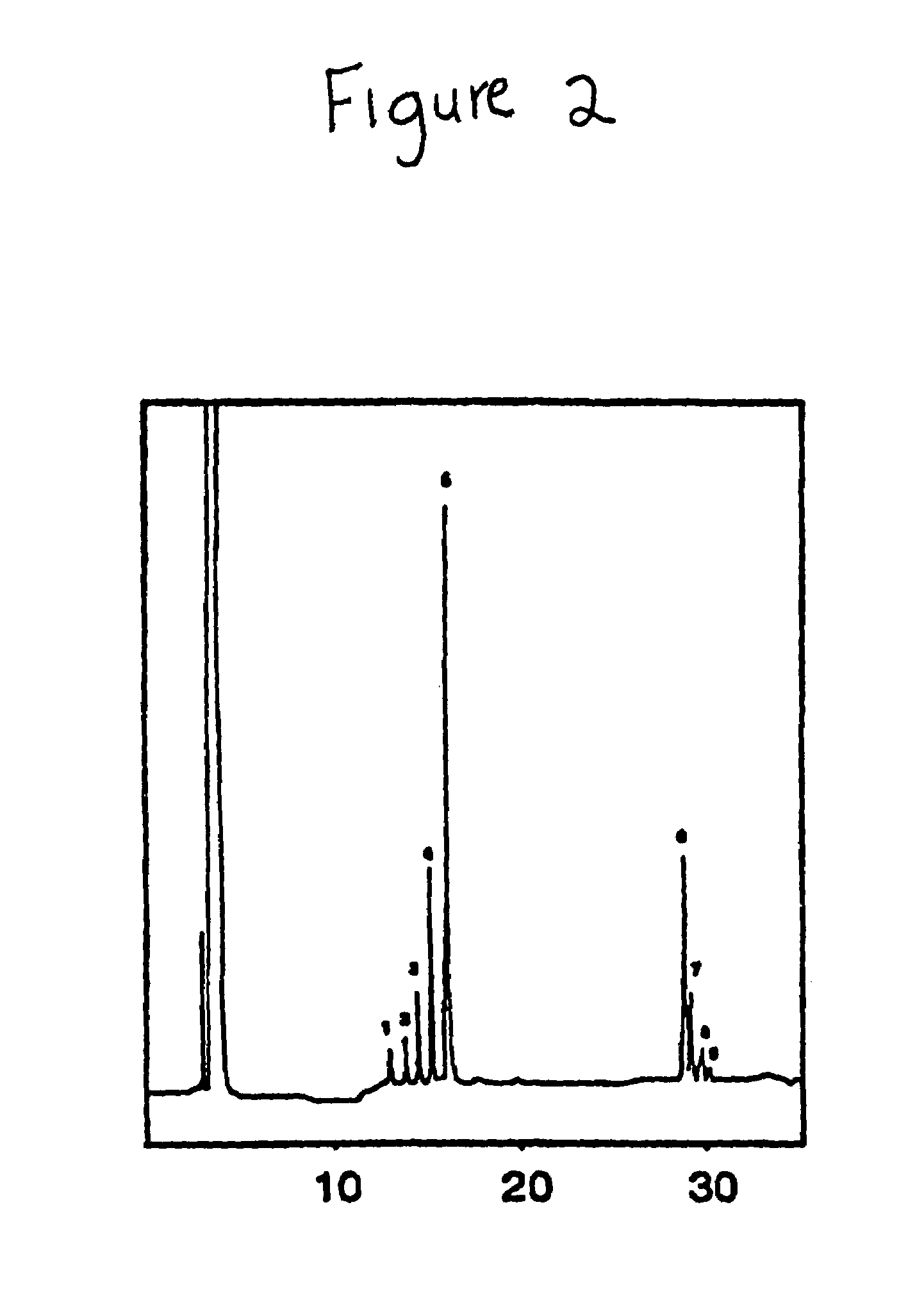

Solid-phase peptide synthesis and agent for use in such synthesis

InactiveUS7176282B1High yield and purityCouple time be reducePeptide/protein ingredientsPeptide preparation methodsSolid phasesCombinatorial chemistry

The present invention relates to an improved process for the production of peptides by solid-phase synthesis. The invention also relates to agents, which are useful in solid-phase peptide synthesis.

Owner:ZEALAND PHARM AS

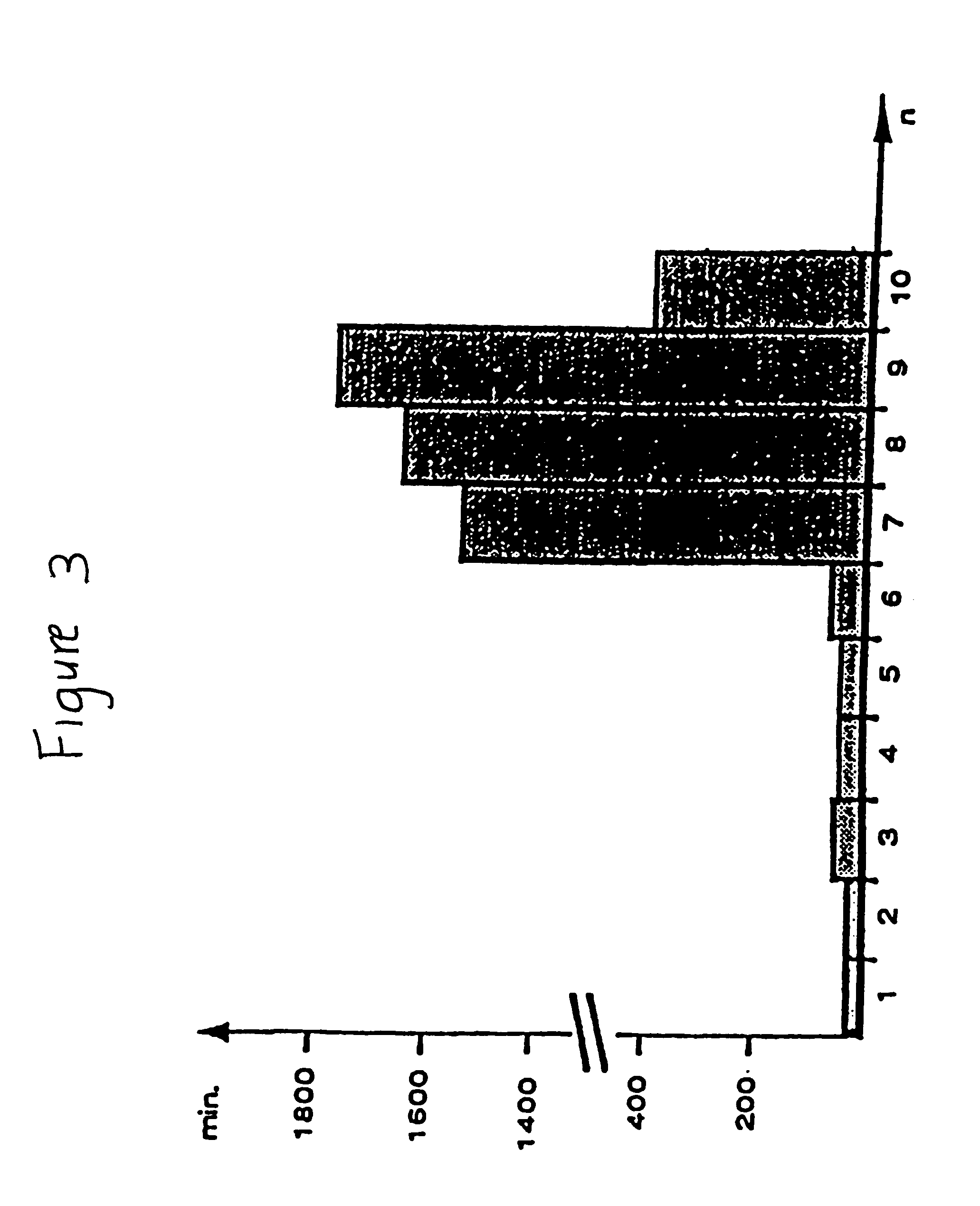

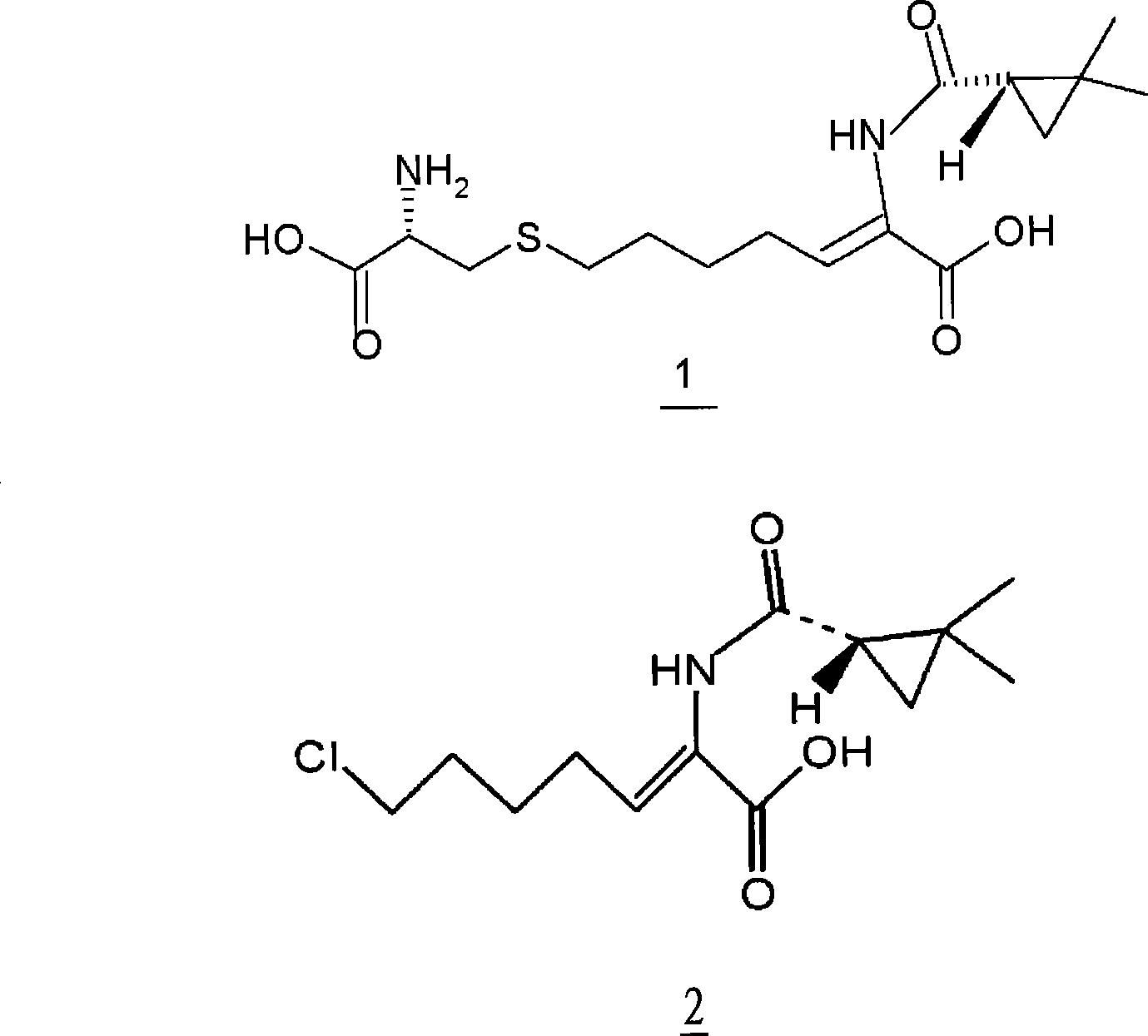

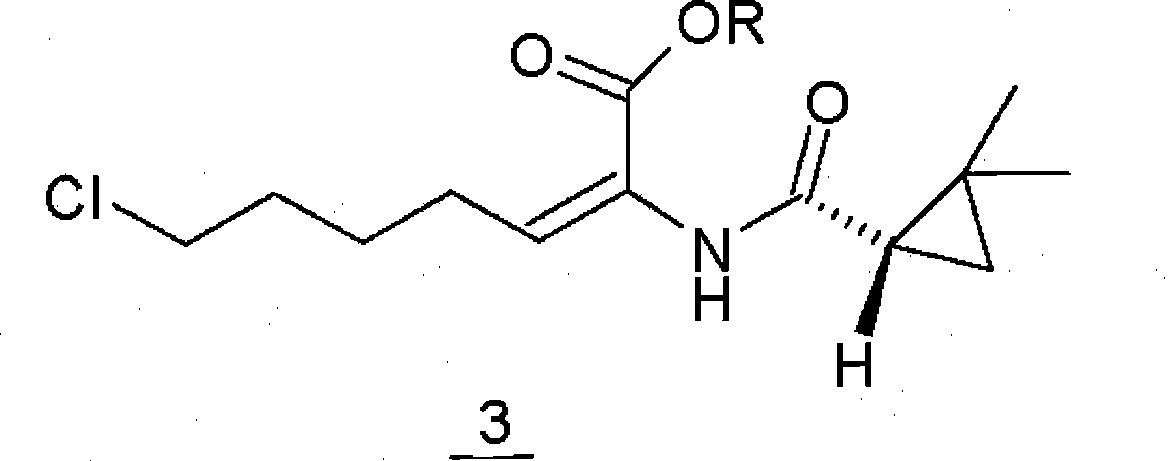

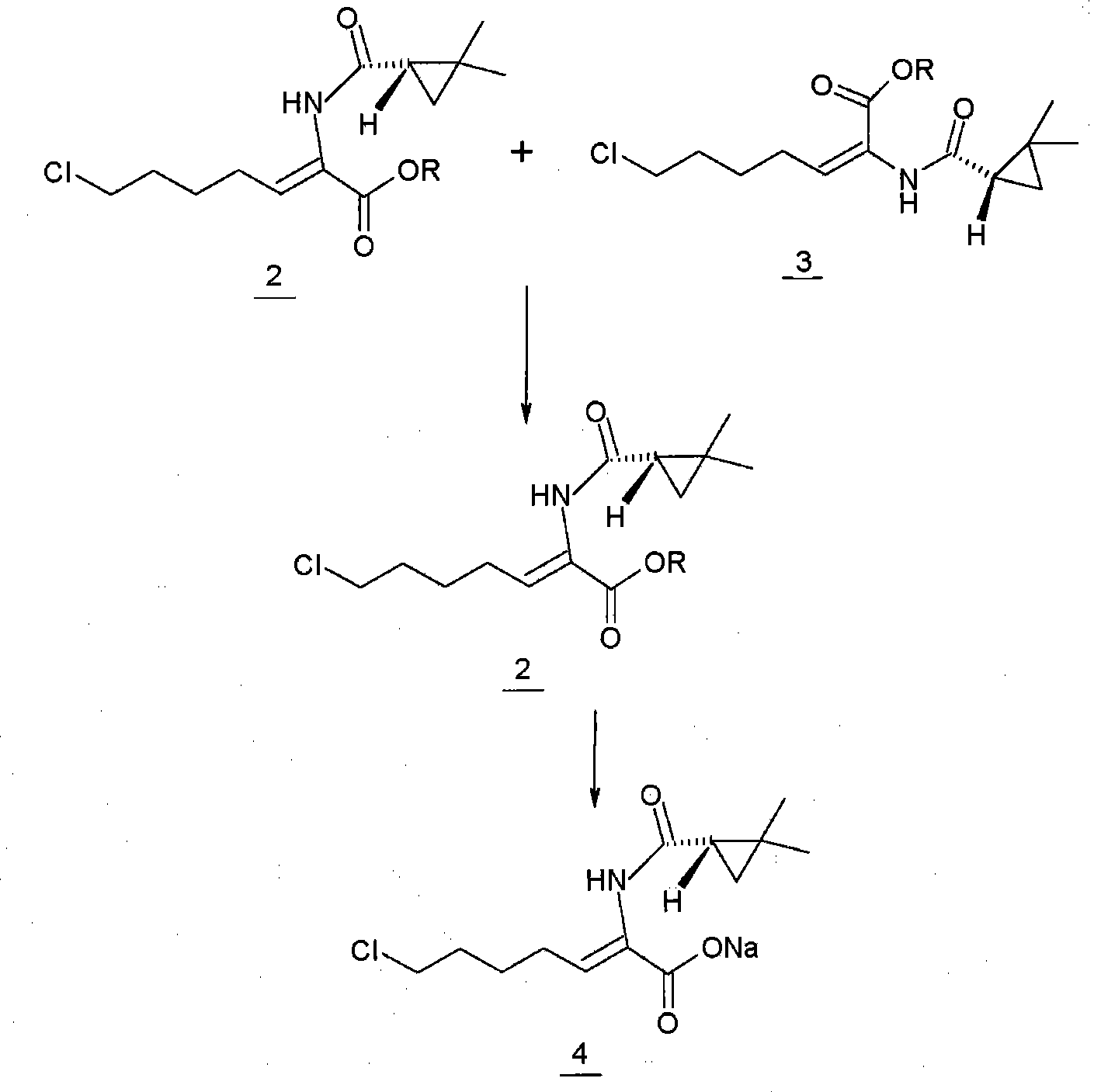

Method for preparing cilastatin acid

ActiveCN101386588AHigh yield and puritySimplify operation stepsSulfide preparationMethylcyclopropaneEthyl ester

The present invention discloses a novel method for preparing cilastatin acid. Under a strongly acidic condition, (E)-7-chlorine-((S)-2,2-dimethyl cyclopropane amido)-2-heptenoic ethyl ester in a mixed liquid which contains (Z)-7-chlorine-((S)-2,2-dimethyl cyclopropane amido)-2-heptenoic ethyl ester and (E)-7-chlorine-((S)-2,2-dimethyl cyclopropane amido)-2-heptenoic ethyl ester is directly isomerized to form a reaction liquid that contains pure (Z)-7-chlorine-((S)-2,2- dimethyl cyclopropane amido)-2-heptenoic ethyl ester, and then pure (Z)-7-chlorine-((S)-2,2- dimethyl cyclopropane amido)-2-heptenoic ethyl sodium is obtained to prepare cilastatin acid. The method has the advantages that the product is high in yield and good in purity; the preparation process consumes less energy, and the like.

Owner:ZHUHAI UNITED LAB

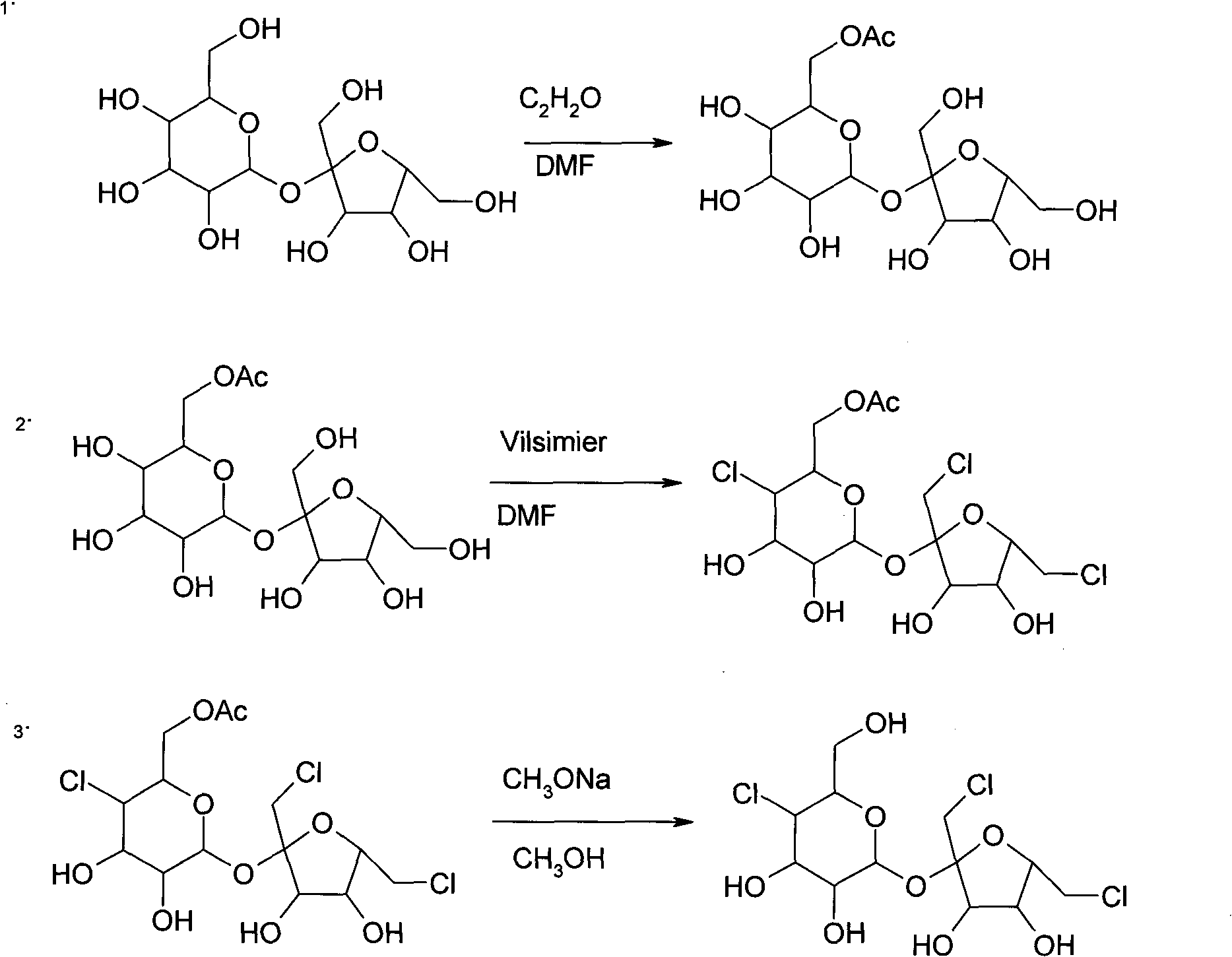

Preparation method of sucralose

ActiveCN101812095AHigh yield and purityReduce the temperatureSugar derivativesSugar derivatives preparationSucrose-6-acetateAcylation

The invention discloses a method for preparing sucralose by using a new acetylation reagent, which comprises the following steps: (1) acylation reaction: reacting sucrose with acetylation reagent to produce sucrose-6-acetate; (2) chlorination reaction: carrying out chlorination reaction on the sucrose-6-acetate obtained in the step (1) to obtain sucralose-6-acetate; (3) and deacetylation reaction: carrying out deacetylation reaction on the sucralose-6-acetate obtained in the step (2) to obtain sucralose. The ketene gas used in the acylation reaction is used as the acetylation reagent. The method can effectively increase the sucralose yield, and has the advantages of short reaction time, easy control of reaction temperature, and easy realization of industrial production.

Owner:南通宏信化工有限公司

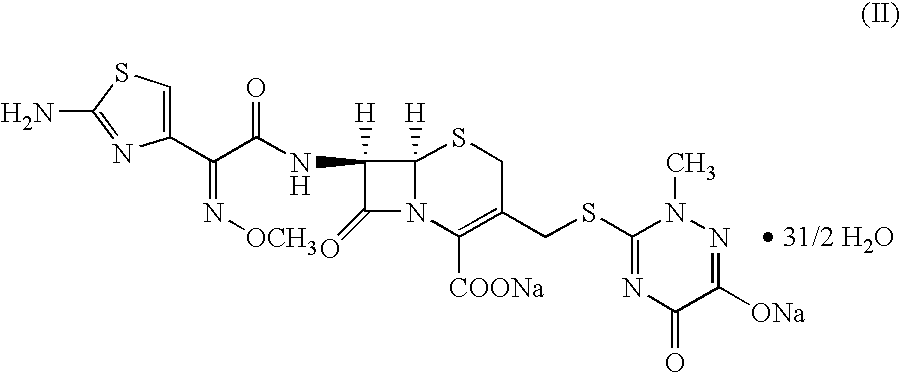

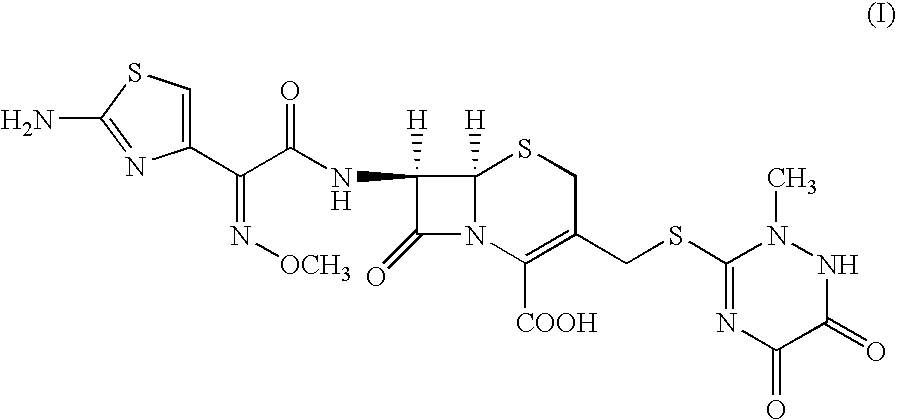

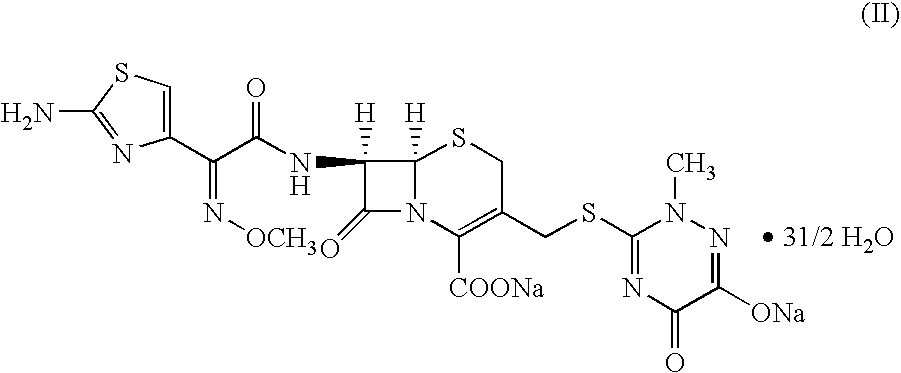

Method for manufacture of ceftriaxone sodium

InactiveUS20050059821A1High yield and purityHigh yieldOrganic chemistryPhotochemistryCeftriaxone Sodium

Owner:DATTA DEBASHISH +3

Method for continuously catalytically synthesizing triethyl citrate plasticizer

InactiveCN102659591ANo wasteHigh yield and purityOrganic compound preparationCarboxylic acid esters preparationCationic exchangeCitric acid

The invention relates to a method for continuously catalytically synthesizing triethyl citrate. The method comprises the following steps: taking citric acid and alcohol as raw materials; performing continuous catalytic esterification reaction on a fixed bed; taking a styrene cation exchange resin catalyst loaded with lewis acid as catalyst; filling the catalyst in the serially connected fixed bed; discharging materials after reacting from the bottom of a reactor and pouring into a gas-liquid separator for separating; discharging the unreacted alcohol from the upper part of the gas-liquid separator; discharging a triethyl citrate crude product from the bottom of the gas-liquid separator; and refining the triethyl citrate crude product, thereby obtaining the qualified product. According to the method provided by the invention, the esterification reaction yield is high, the reaction is free from corrosiveness and three wastes, the yield and the purity are high, and the comprehensive cost is low. The method is the most ideal and energy-saving production method for synthesizing the triethyl citrate at present and is worthy of quick popularization and application in industry.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

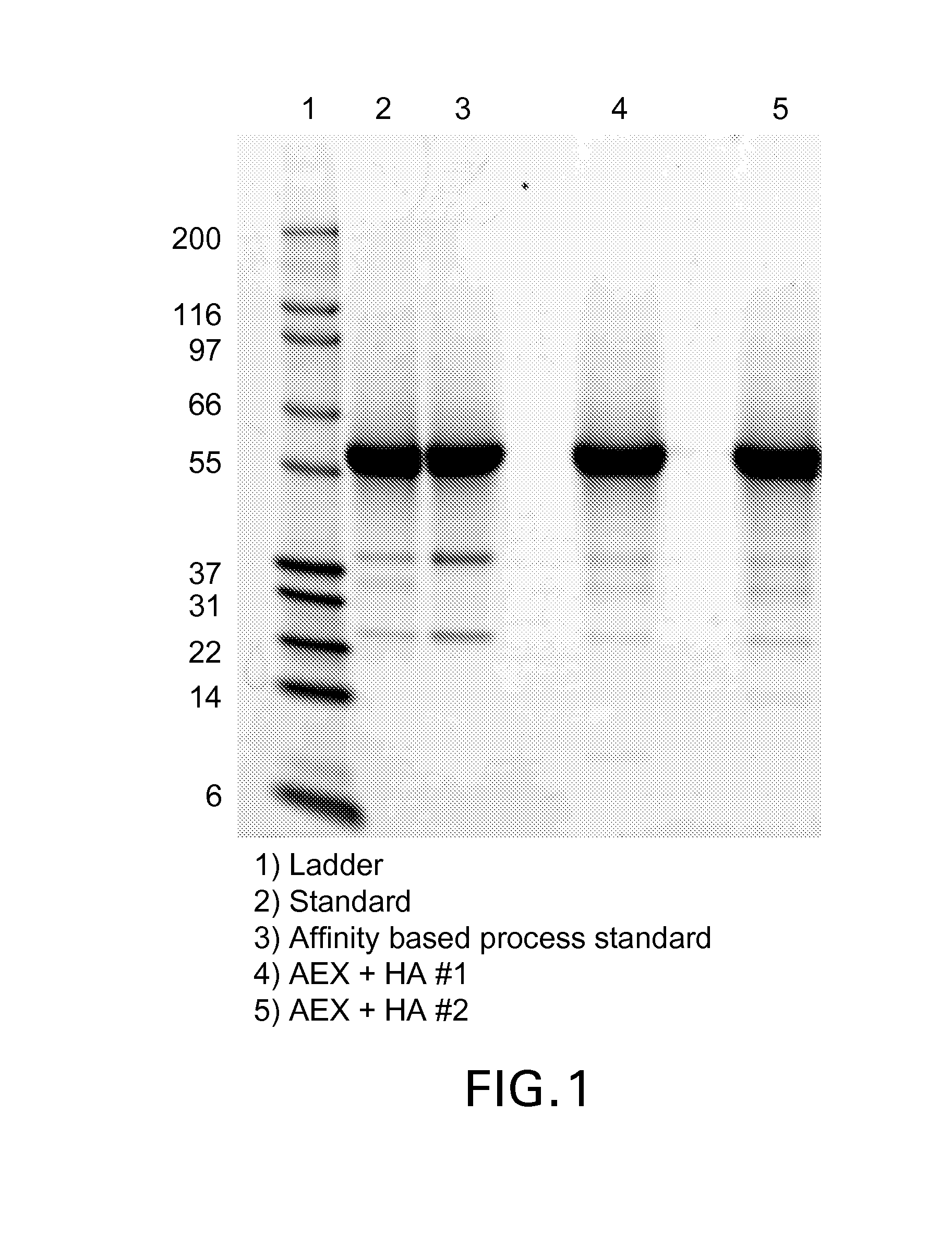

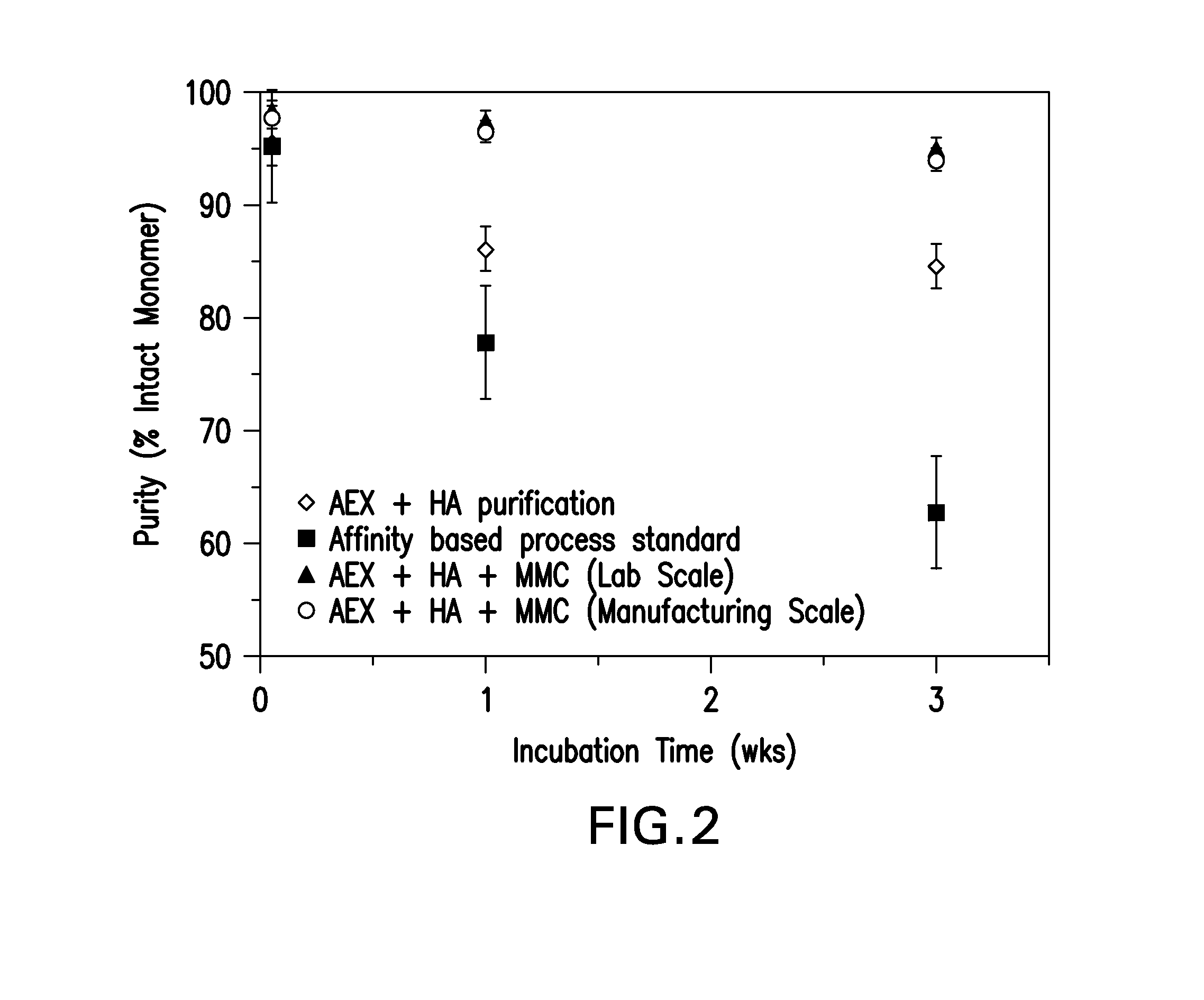

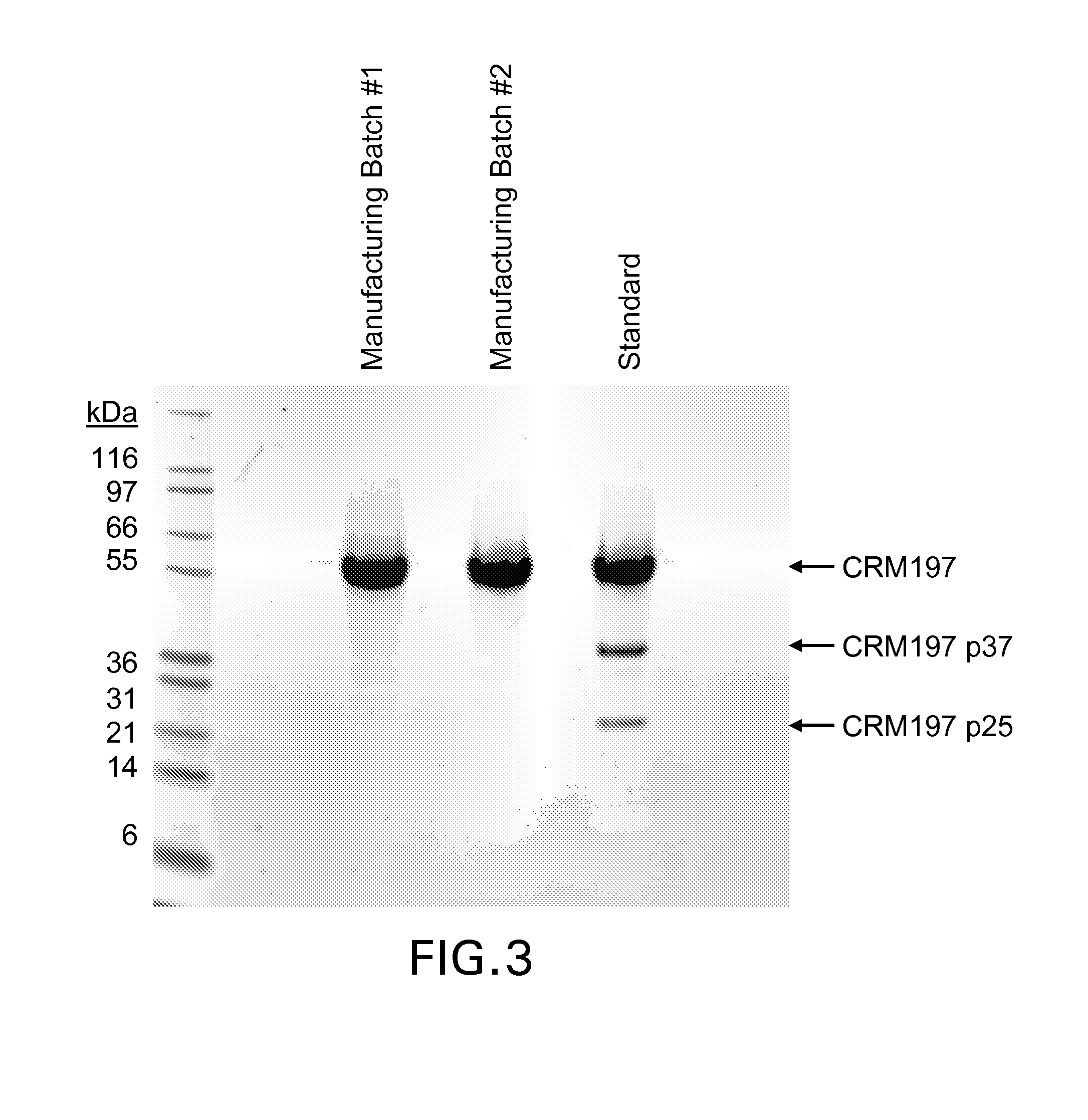

Methods of purification of native or mutant forms of diphtheria toxin

InactiveUS20140193876A1High yield and puritySugar derivativesTransferasesProtein formationHydroxyapatites

The present invention relates to the use of hydroxyapatite chromatography and multimodal chromatography, for punfication of diphtheria toxin, or a mutant form thereof, from a mixture, for example, a host cell fermentation mixture containing impurities such as host cell proteins and DNA. This invention further relates to the integration of such a method into a multi-step procedure with other fractionation methods for purification of diphtheria toxin suitable for in vitro and in vivo applications.

Owner:GOERKE AARON R +3

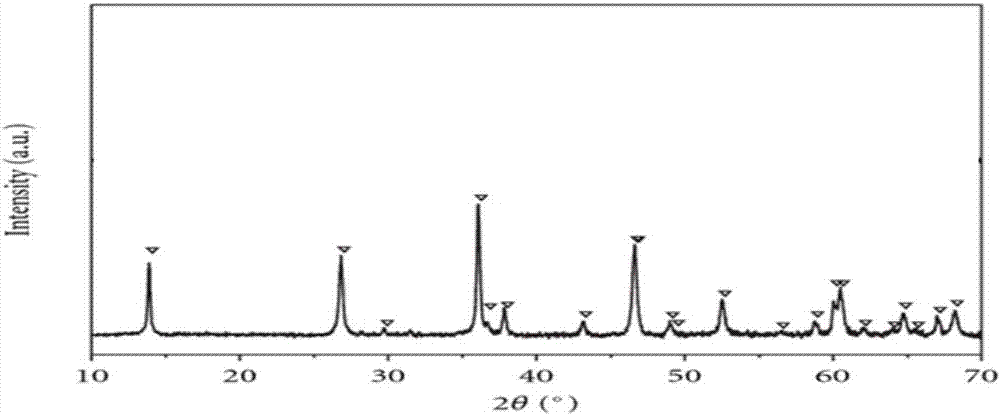

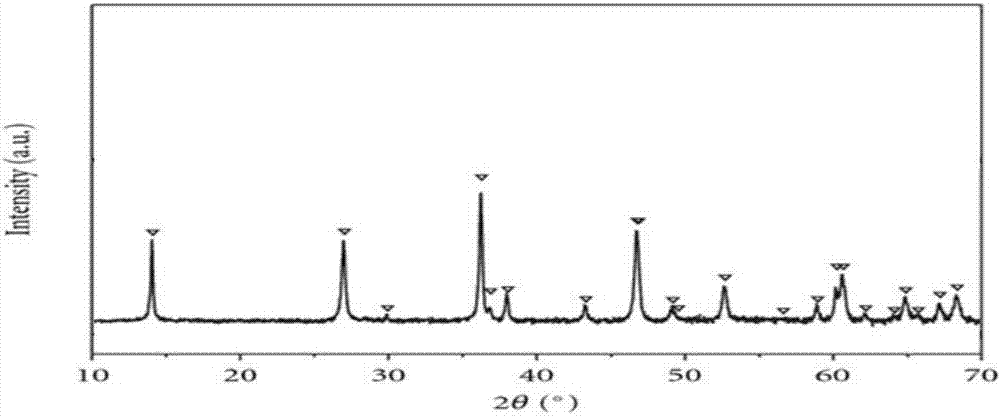

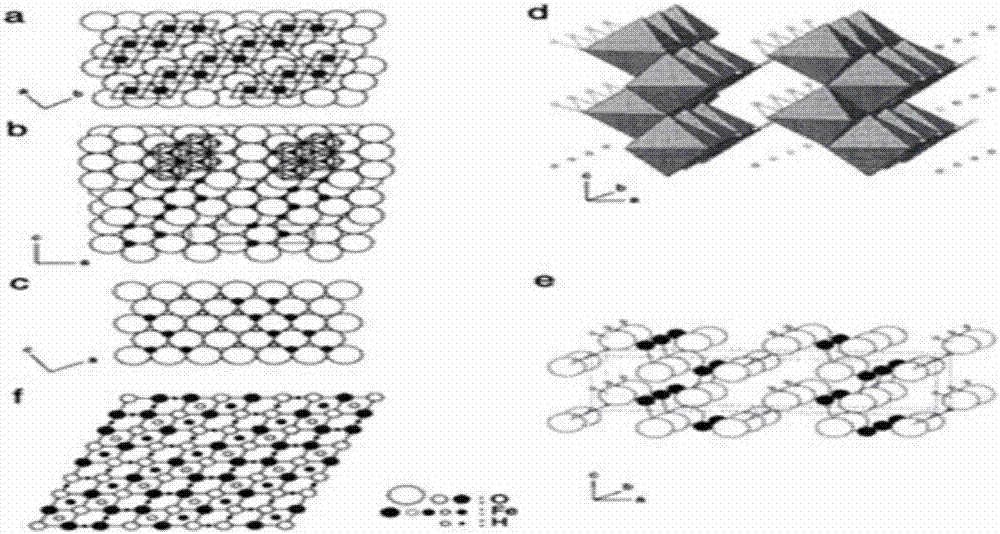

Preparation method of gamma-FeOOH

InactiveCN107572593AHigh yield and purityLarge specific surface areaIron oxides/hydroxidesAmmonium salt fertilisersExothermic reactionOxide

The invention belongs to the technical field of sulfur removal and discloses a preparation method of gamma-FeOOH. The method comprises the following steps: enabling green rust to react with an oxidizing agent at 0-10 DEG C, wherein gamma-FeOOH is obtained after the reaction is over. According to the preparation method disclosed by the invention, the gamma-FeOOH having purity of 98% or more can beprepared by oxidizing the green rust at low temperature (0-10 DEG C); this is because the oxidizing reaction is an exothermic reaction, the low-temperature condition is helpful to dissipate heat in time, thus the generation of FeOOH of other crystal phases or other oxide crystal phases of iron is effectively avoided, and the purity and yield of the gamma-FeOOH are remarkably improved. Moreover, hydrogen peroxide is adopted as the oxidizing agent, and the prepared gamma-FeOOH has relatively large specific surface area and relatively strong absorbability and can be widely applied to the field ofsulfur removal.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

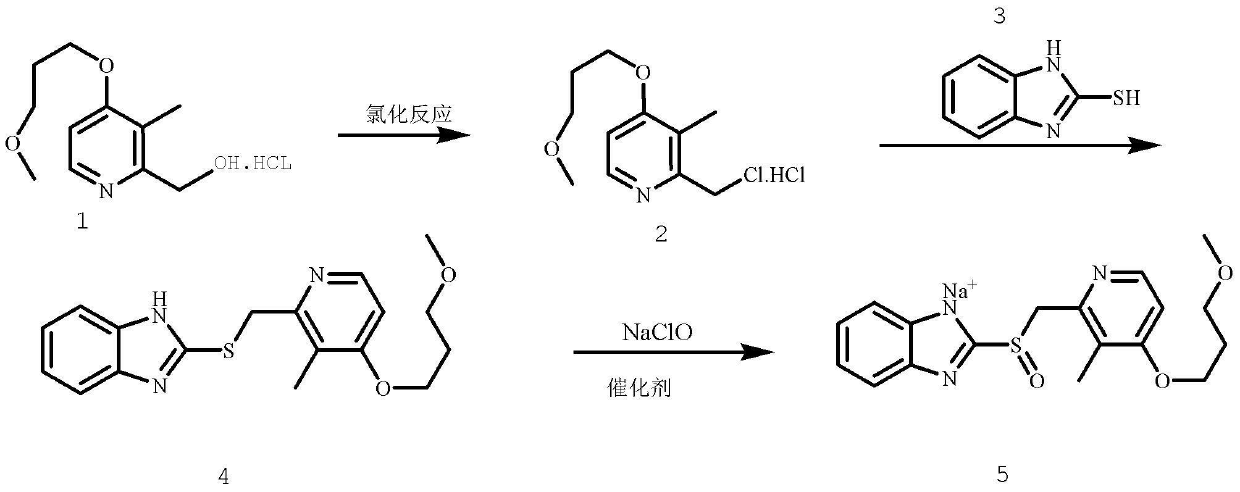

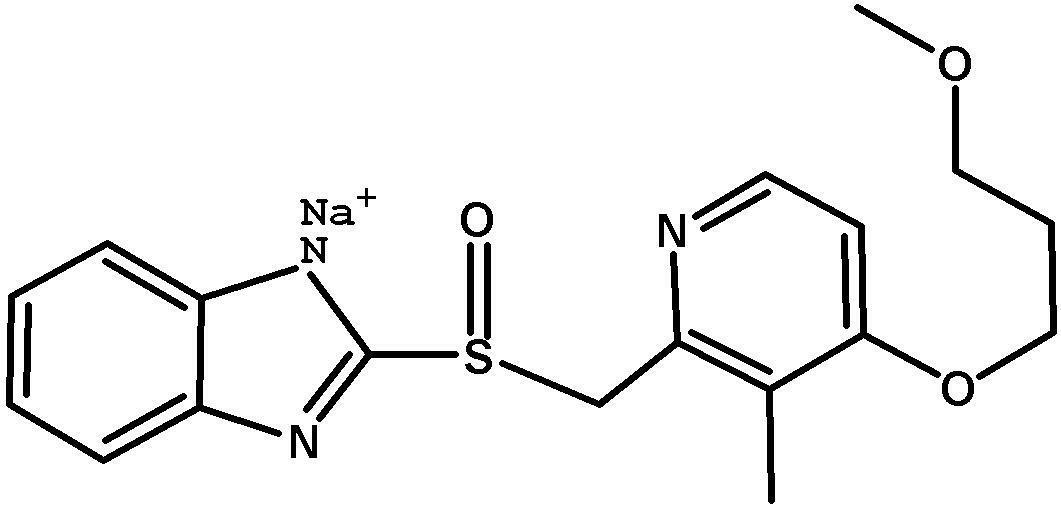

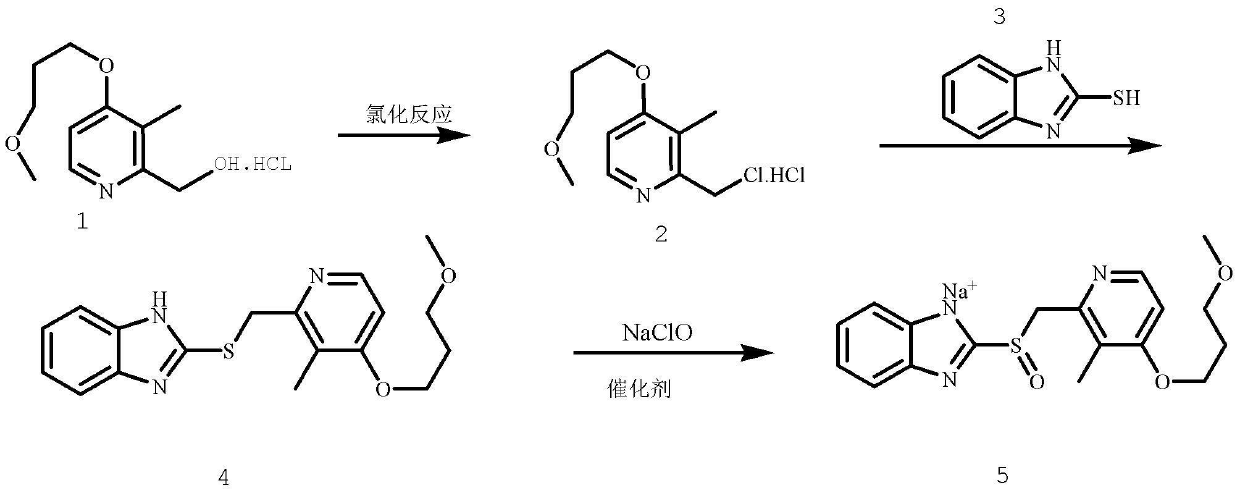

Method for pure water phase preparation of rabeprazole sodium

The invention provides a method for pure water phase preparation of rabeprazole sodium and belongs to the technical field of medicines. The method is characterized in that an intermediate, 2-hydroxymethyl-3-methyl-4-(3-methoxyl propoxy) pyridine hydrochloride, of the rabeprazole sodium is adopted as a raw material to be subjected to chlorination reaction, condensation reaction and oxidation reaction, so as to synthesize the rabeprazole sodium through three steps. The method adopts a novel chlorination reaction system and a novel sodium hypochlorite oxidation system, and can achieve a higher chloridization rate and excellently control a sulfur ether intermediate to be oxidized into sulfoxide; the reaction conditions are wild; both the reaction conversion rate and the reaction selectivity are very high; few reaction by-products are produced; the whole process can be carried out under the condition of no solvent; the content of residual solvent is lowered; time-consuming and toilsome vacuum rectification is not needed; the operation is simplified to a great extent; the process flow is short; and suitability for industrial application is achieved.

Owner:DALIAN UNIV OF TECH

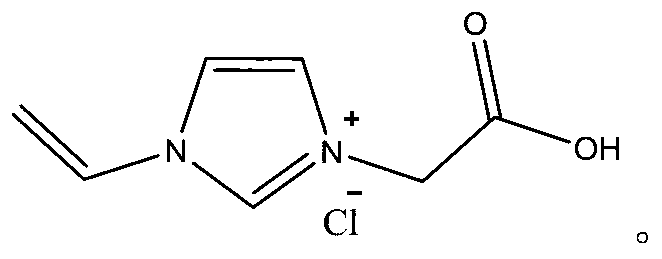

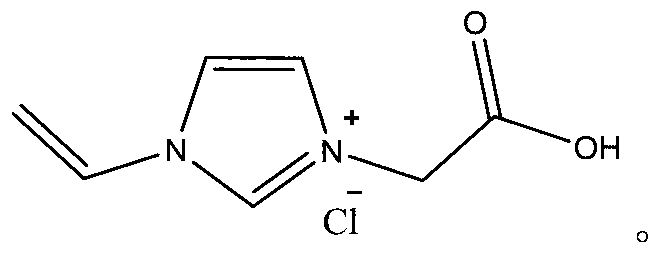

Chlorinated 1-vinyl-3-carboxymethyl imidazole polymerizable acidic ionic liquid and synthetic method thereof

The invention proposes a chlorinated 1-vinyl-3-carboxymethyl imidazole polymerizable acidic ionic liquid and a synthetic method thereof. The synthetic method taking 1-vinyl imidazole and 2-chloroacetic acid as materials, ethyl acetate as a solvent, and phenol as a polymerization inhibitor comprises the steps of reacting at the temperature of 45-50 DEG C so as to synthesize the chlorinated 1-vinyl-3-carboxymethyl imidazole polymerizable acidic ionic liquid, wherein the ionic liquid has Bronsted acidity; and the ionic liquid can participate in the polymerization reaction in the presence of double bonds and is immobilized. The ionic liquid has the acidity and the polymerizable characteristic, so that the ionic liquid is named as the polymerizable acidic ionic liquid. The synthetic method is simple, high in product purity, and easy to industrialize. The chlorinated 1-vinyl-3-carboxymethyl imidazole polymerizable acidic ionic liquid synthesized by the method enriches the variety of the functional ionic liquid, and can be widely applied to the fields such as separation, catalysis, material science and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

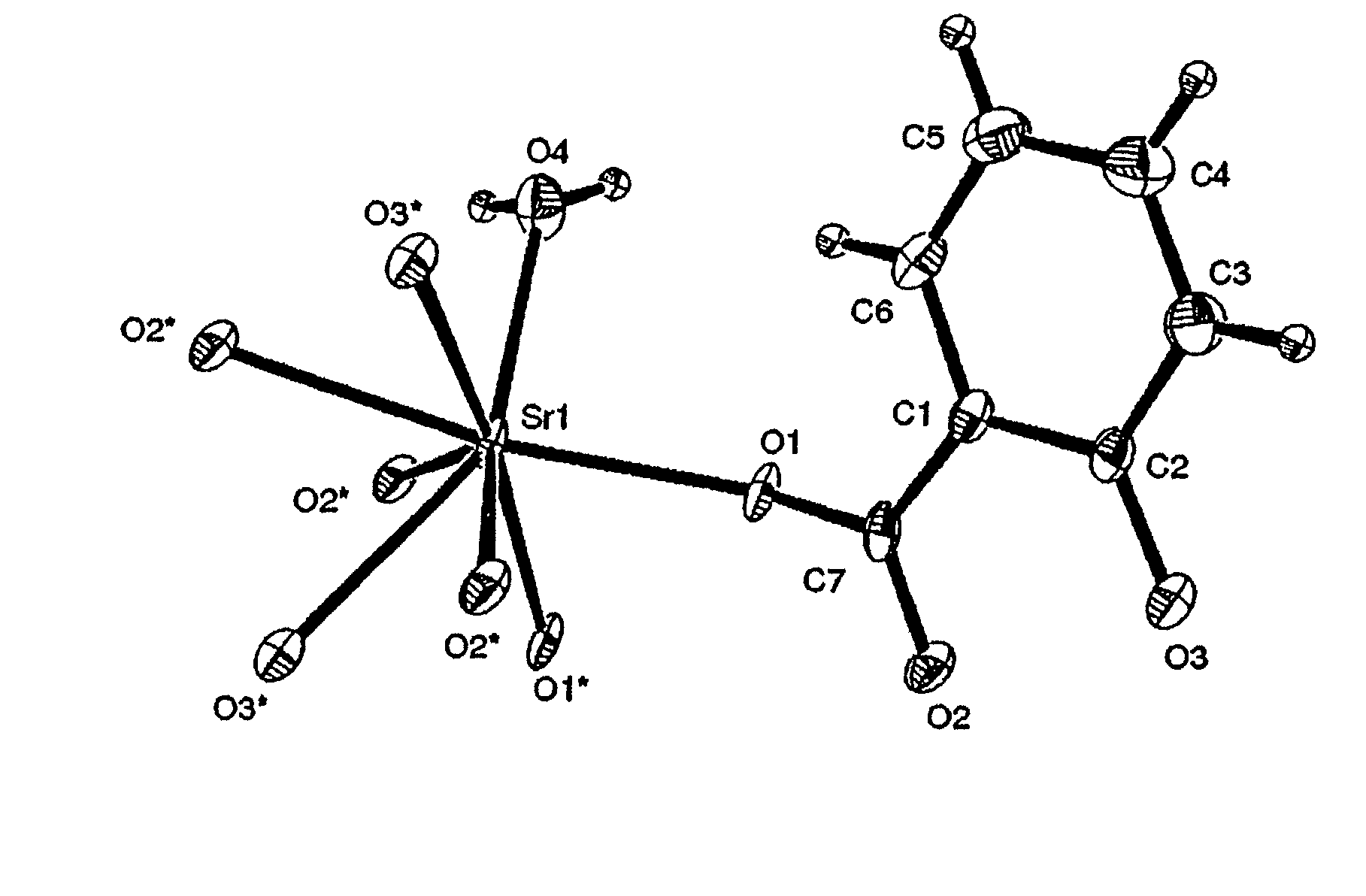

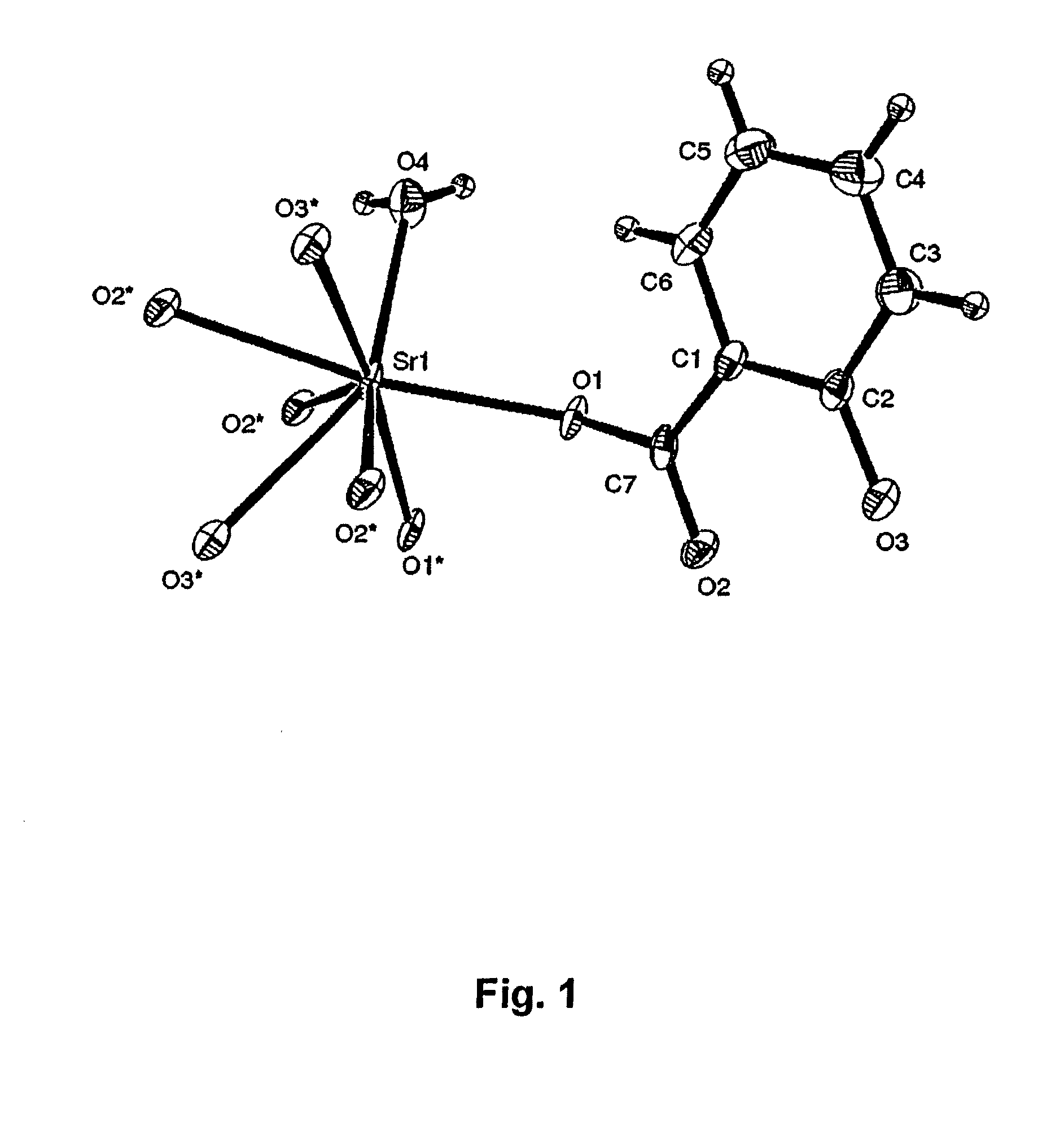

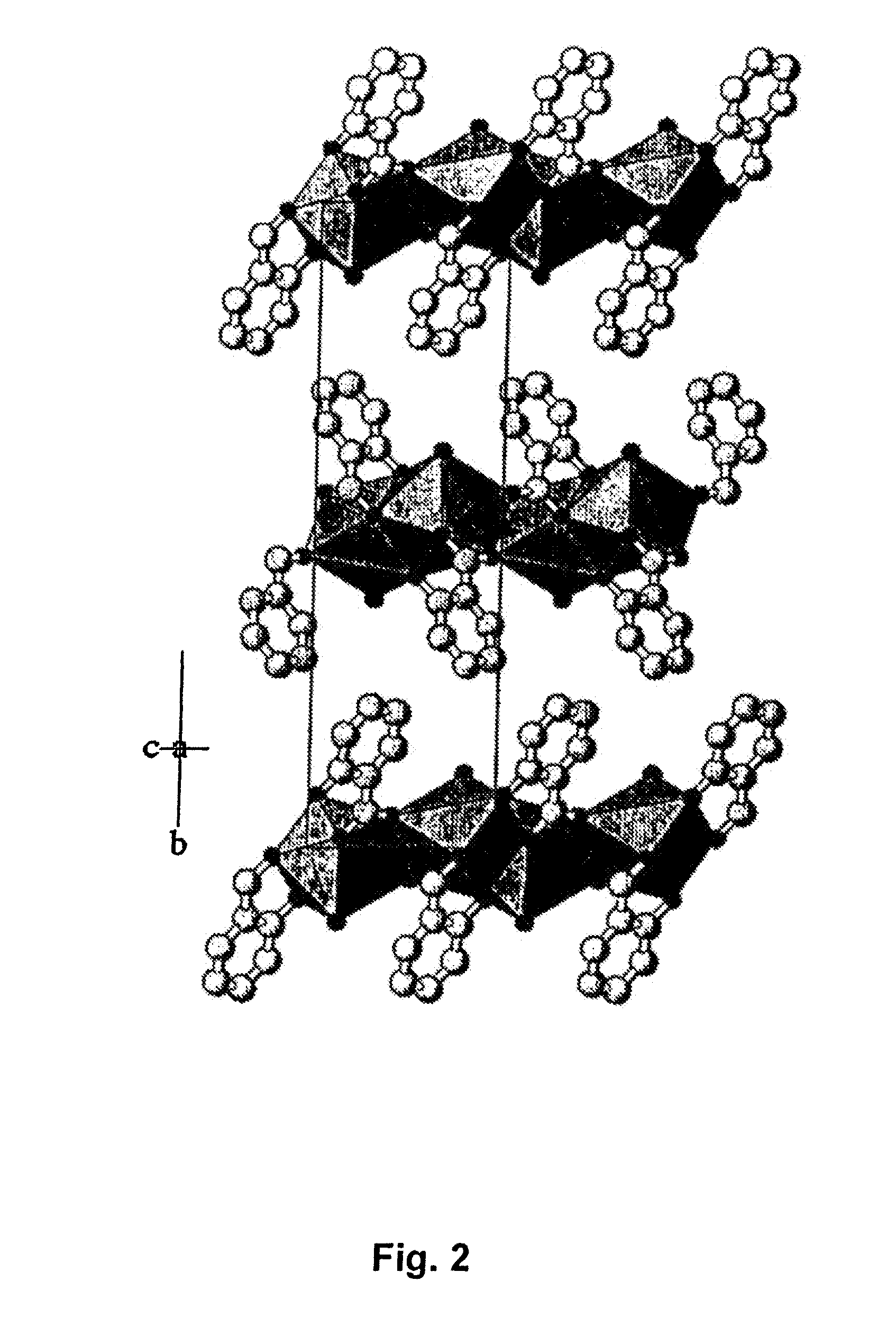

High yield synthesis methods for producing organic salts of strontium

New organic salts of strontium and methods of synthesizing such salts with high purity, high yields and with short processing times, at neutral conditions and at low reaction temperature, such as a temperature at or below 50° C.

Owner:OSTEOLOGIX AS

Method for preparing artemisinin

ActiveCN102718774AAvoid destructionHigh yield and purityOrganic chemistrySolventChromatographic column

The invention provides a method for preparing artemisinin. The method comprises the following steps of: (1) extracting: extracting the plant material containing artemisinin under refluxing for two to four times with organic solvent, and combining the extracting solutions; (2) chromatography: passing the extracting solution obtained in step (1) through a chromatographic column filled with resin, wherein the resin is 1 / 2 to 1 / 5 the weight of the raw material; recovering the liquid flowing out of the column so as to be used as the solvent for extracting, and eluting with the eluant until artemisinin does not flow out of the chromatographic column, and then collecting the eluate; (3) membrane separation: treating the eluate obtained in step (2) through membrane separation equipment, wherein the membrane separation equipment adopts a nanofiltration membrane with molecular weight cut off of 200 to 800; and recovering the penetrating fluid so as to be used as the eluant, and transferring thefluid into the next process; and (4) crystallizing: freezing and crystallizing the fluid obtained in step (3), and filtering to obtain the pure product of artemisinin. By adopting the method providedby the invention to prepare artemisinin, the cost of production can be reduced, and the yield and quality of the product are improved.

Owner:HUNAN KEYUAN BIO PRODS

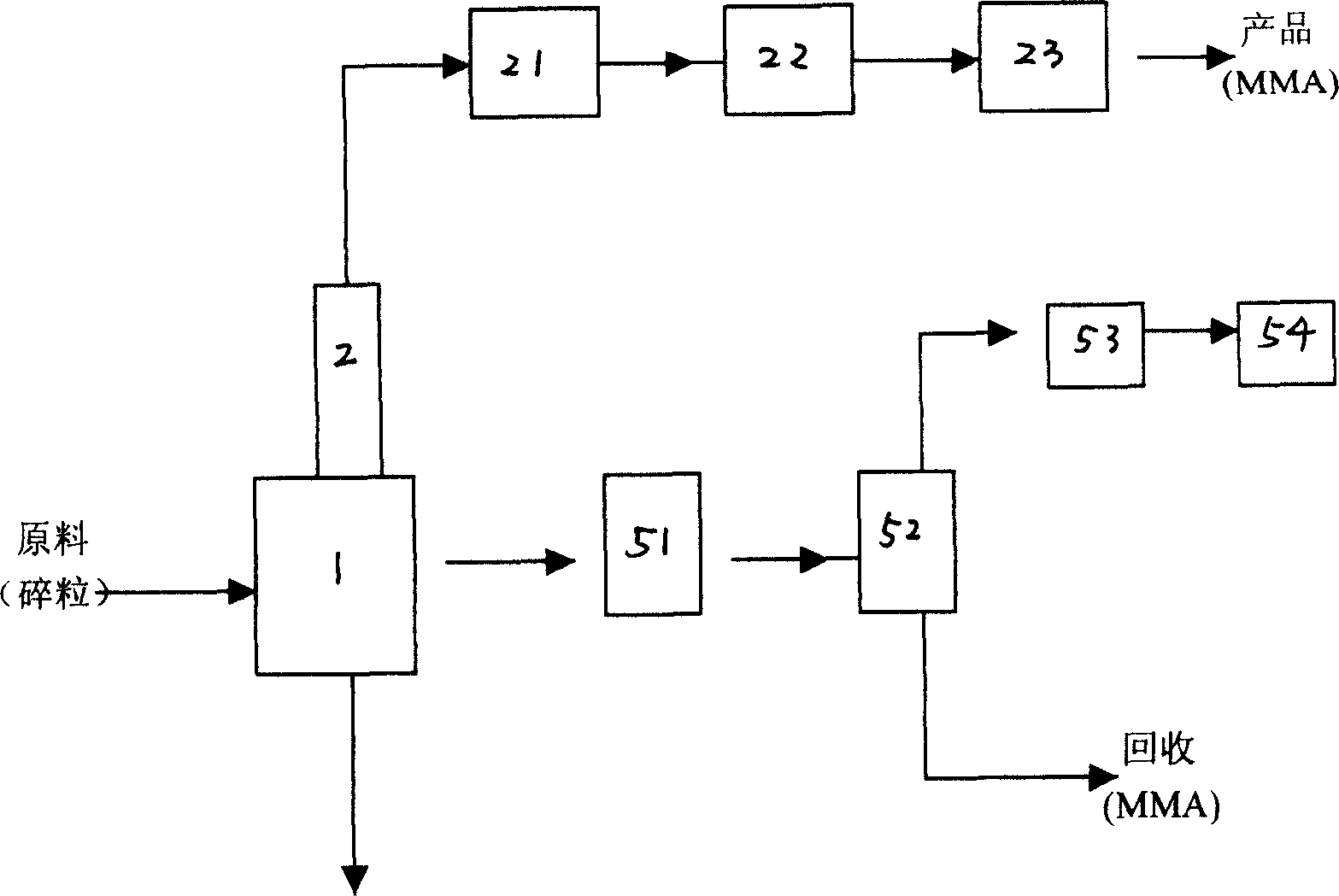

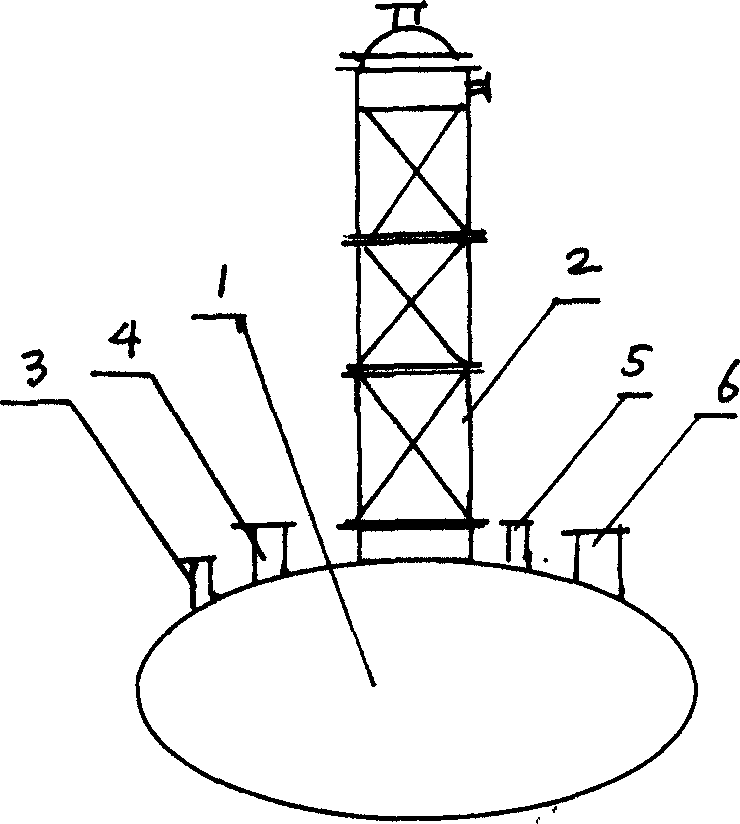

Process of preparaing methyl acrylate by waste organic glass and apparatus thereof

InactiveCN1560021AAdvanced equipment and process parametersHigh yield and purityOrganic compound preparationCarboxylic acid esters preparationMethyl methacrylateEngineering

The invention relates to a technique of preparing methyl methacrylate (MMA) by waste organic glass and its device, disclosing a semicontinuous cracking method and an integrated cracking and distilling device. It implements a technique of combining cracking and distilling and the technical courses: crushing the waste organic glass, adding the made glass particles in cracking kettles continuously, orderly and properly, temperature range 140-380 deg.C, as the glass particles reaches a certain quantity, stopping feeding and making final-period cracking and processing, where the average time of cracking and distilling in each a kettle in a cycle (by 1000 kg raw material) is 5-7 hours. On at 140 deg.C can it generate cracked MMA; the MMA product at 140-280 deg.C is dehydrated and becomes a transparent and clear liquid; the MMA purity is 97-99% and the MMA yield is 85-92%.

Owner:廖活强

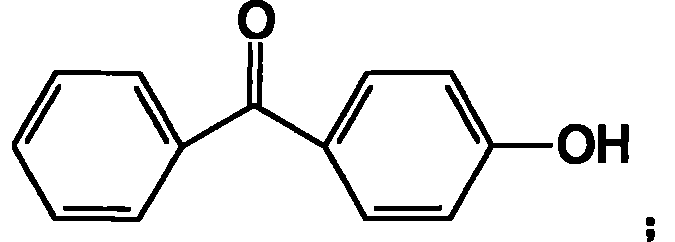

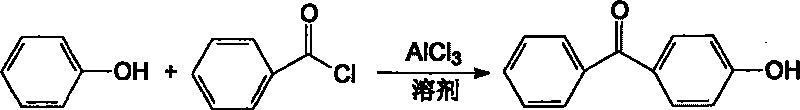

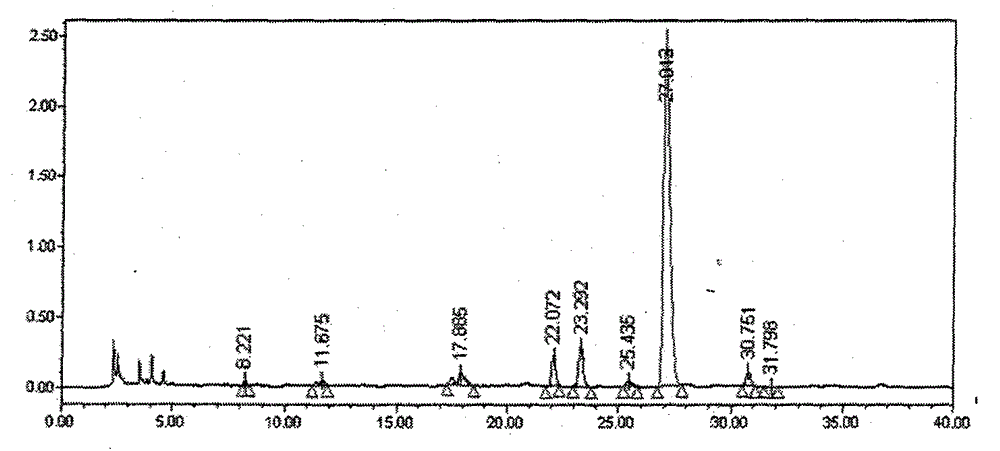

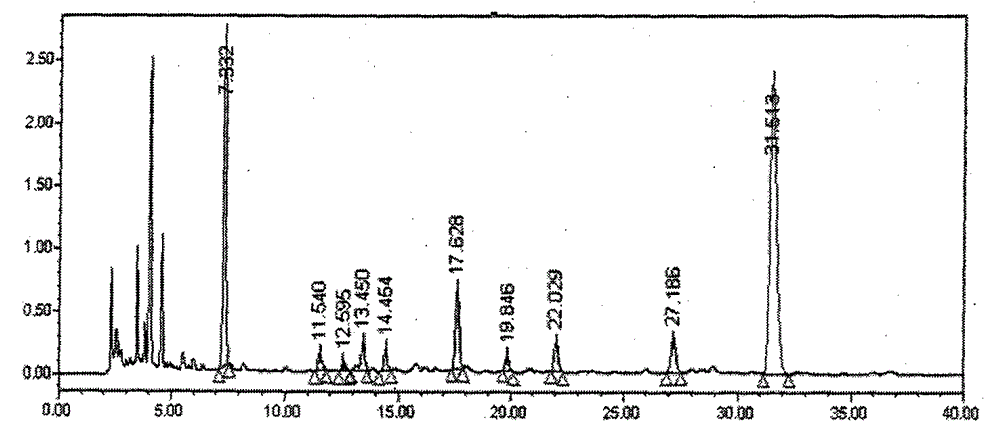

Process for preparing high-pure 4-hydroxybenzophenone

InactiveCN101693652AHigh yield and purityReduce usageCarbonyl compound preparation by condensationSolventChemistry

The invention relates to a process for preparing high-pure 4-hydroxybenzophenone, which belongs to the field of organic chemical synthesis. The process includes steps of adding and stirring chlorobenzene and aluminium choride in a reactor, dripping mixing fluid of phenol and chlorobenzene when at a temperature of 10DEG C-50 DEG C, stirring for 30 min again after dripping, dripping benzoyl, raising temperature slowly, reacting for 2h when at a temperature of 40DEG C-45DEG C, reacting for 1h when at a temperature of 60DEG C-70DEG C, slowing adding reaction fluid into cold water, stirring for 2hwhen at the temperature of 20-30DEG C, centrifuging, washing solid via water until being neutral, drying to obtain crude 4-hydroxybenzophenone, utilizing toluene with quantity double of that of the crude 4-hydroxybenzophenone to recrystallize to obtain white 4-hydroxybenzophenone, washing an oil layer via water until being neutral, distilling anhydrous calcium chloride after drying and then recycling chlorobenzene. Mole ratio of phenol and benzoyl chloride is 1: (1-1.5), mole ratio of phenol and aluminium choride is 1: (1-2), and mass ratio of phenol and chlorobenzene is 1: (1-5). The processutilizes the chlorobenzene as a reaction solvent, greatly increases purity and yield of products, and greatly reduces usage of the solvent.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

PBMC separation method

InactiveCN105255829AHigh yield and purityShorten separation timeBlood/immune system cellsChemistryFicoll

The invention relates to a PBMC separation method. The method includes the following steps that after whole blood centrifugation blood cells are taken for being made into blood cell diluent, a Ficoll separating medium is utilized for conducting centrifugation for 20-30 minutes for separating PBMC in the blood cell diluents, wherein the temperature is 15-18 DEG C, the weight is 500-1000 g, and the centrifugal force ascending and descending speed is zero. According to the PBMC separation method, when the PBMC is separated, the centrifugal force ascending and descending speed is zero so that PBMC layers can be layered more obviously, and it is beneficial to improve the yield and purity of PBMC. By means of the method, plasma can be recycled, and the plasma contains a great number of protein factors which provide rich nutrition for subsequent culture.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

Method for preparing salvianolic acid A from a plurality of salvia plants

InactiveCN105085266AThe process is simpleHigh yield and purityCarboxylic acid esters separation/purificationChemistrySavia

The present invention relates to a method for preparing salvianolic acid A from a plurality of salvia plants, major steps include: (1) plant roots and rhizomes are sliced, water is poured into a closed container and the decoction pieces are heated for extraction under oxygen free conditions; and (2) the extract is concentrated under reduced pressure to an appropriate volume, refluxed for reaction at 100 DEG C under oxygen free conditions at atmospheric pressure, or placed in an autoclave or a microwave reactor for heating for reaction to obtain a salvianolic acid A conversion solution. The salvianolic acid A conversion solution is further purified by conventional separation techniques such as macroporous resin, reversed phase chromatography on silica gel, Sephadex LH-20, droplet countercurrent chromatography, and the like to obtain a salvianolic acid A product with the content of more than 90%, and the salvianolic acid A product is used for clinical treatment and research. The method is simple in process, higher in salvianolic acid A conversion rate, and suitable for industrial production.

Owner:南京虹桥医药技术研究所有限公司

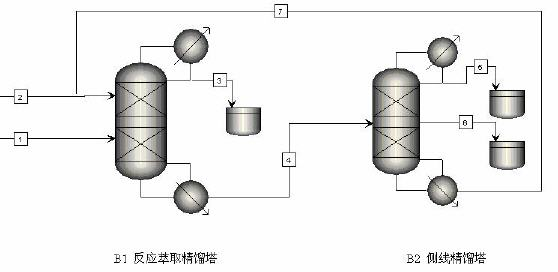

Method for preparing electronic grade dimethoxymethane through lateral-line reactive extraction rectifying

InactiveCN102167660AHigh yield and purityThe process is simpleOrganic chemistryOrganic compound preparationChemistryProduced water

The invention provides a method for preparing electronic grade dimethoxymethane through lateral-line reactive extraction rectifying. The method comprises the following steps: adding acid catalyst in a reactive extraction rectifying tower for the tower bottom at one time, adding mixed liquid of formaldehyde and methanol from the lower middle part of the tower continuously, adding glycerin from theupper middle part of the tower continuously, wherein the temperature of the tower bottom is 81.0-83.0 DEG C, the temperature of the tower top is 39.0-42.0 DEG C; obtaining more than 99.70% of dimethoxymethane from the top of the reactive extraction rectifying tower, rectifying distillate from the tower bottom by a lateral-line rectifying tower, wherein the temperature of the top of the lateral-line rectifying tower is 61.0-64.5 DEG C, the temperature of the tower bottom of the lateral-line rectifying tower is 165.0-169.0 DEG C; obtaining methanol and glycerin separately from the top and bottom of the lateral-line rectifying tower and recycling so that produced water at a lateral line reaches discharge standard. By the method, more than 99.70% of electronic grade dimethoxymethane can be prepared, the purity and yield of dimethoxymethane can be further increased; and the technical process is simple, the energy consumption is obviously reduced and no wastewater is discharged.

Owner:江苏沿江化工资源开发研究院有限公司

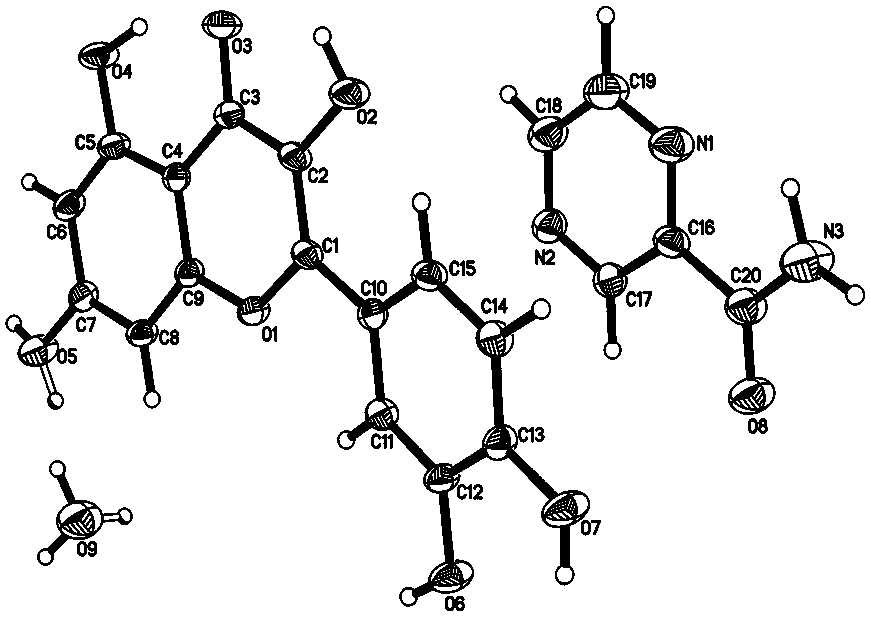

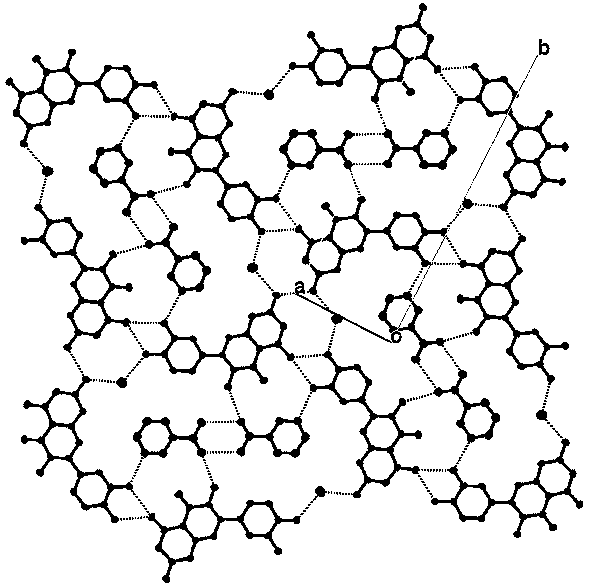

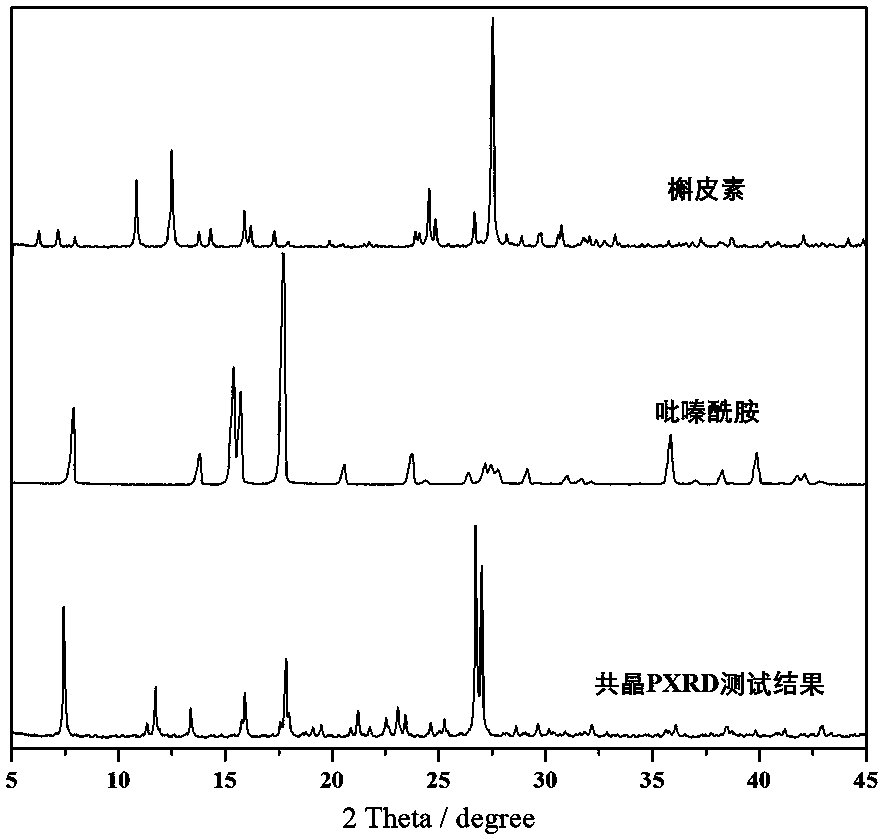

Co-crystal of pyrazinamide and quercetin and preparation method of co-crystal

The invention discloses a co-crystal of pyrazinamide and quercetin and a preparation method of the co-crystal. The invention relates to the field of pharmaceutical co-crystal. The composition of the pharmaceutical co-crystal is [C5H5N30.C15H10O7.H2O]; a basic construction unit is formed by a pyrazinamide molecule, a quercetin molecule and a water molecule. The pharmaceutical co-crystal is a monoclinic system with a space group of P21 / n. The pharmaceutical co-crystal is prepared by using a pyrazinamide crude drug and the quercetin as raw materials and respectively adopting a cooling method anda solvent evaporation method. The pharmaceutical co-crystal disclosed by the invention has the advantages that the solubility of the quercetin is improved, so that the inhibiting effect of the quercetin on the hepatotoxicity of the pyrazinamide is facilitated; in addition, after being putted under the condition of room temperature for a long time, the pharmaceutical co-crystal can be still keep the skeleton structure without deterioration.

Owner:OCEAN UNIV OF CHINA

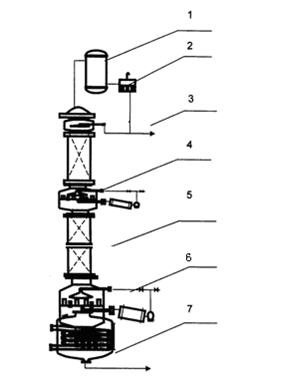

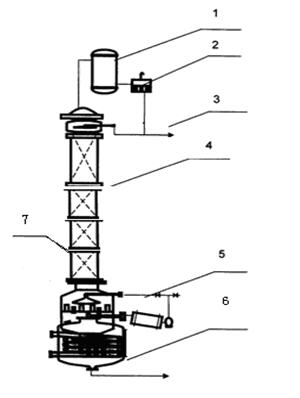

Method for preparing 2,2-dual [3-amido-4-(4-nitrophenoxy)phenyl group]-1,1,1,3,3,3-hexa-fluoropropane

InactiveCN101130502AHigh yield and purityEasy to operateOrganic compound preparationAmino-hyroxy compound preparationNitrobenzeneSolvent

The invention discloses a making method of 2,2-di [3-amino-4-(4-nitrobenzeneoxy) phenyl]-1,1,1,3,3,3-hexafluoropropane, which comprises the following steps: (1) heating 2, 2-di (3-amino-4-hydroxybenzene)-1,1,1,3,3,3-hexafluoropropane and 4-halogenated nitrobenzene with molar rate at 1. 00: 2. 00-3. 00 under inert gas to reflux and do diversion reaction for 4-18h; (2) condensing the reacting liquid; cooling the reactant system; adding water; evolving solid product; filtering; washing; drying; obtaining the product. The invention simplifies the operation with high receiving rate and purity, which is easy to recycle solvent to use reciprocally to reduce three wastes for industrialized manufacturing.

Owner:DONGHUA UNIV

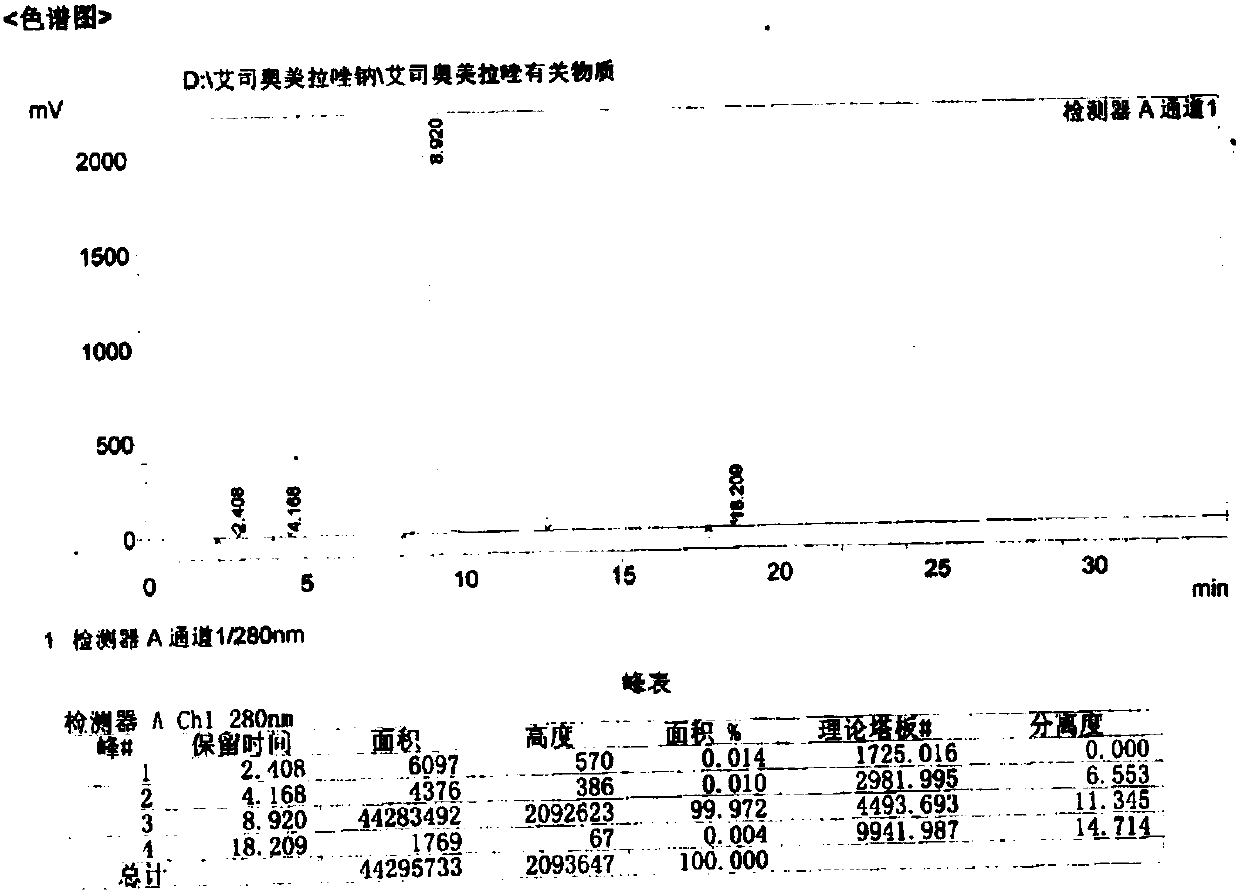

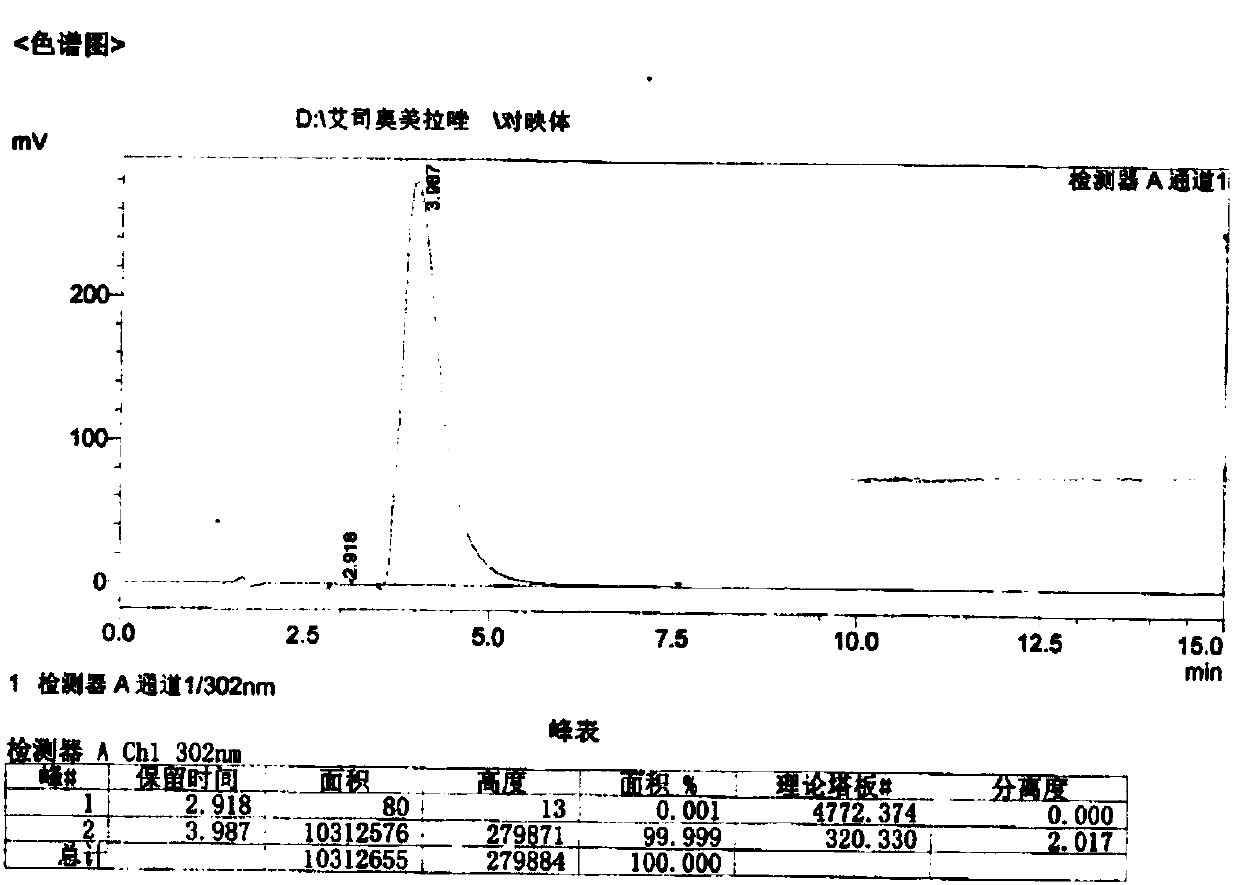

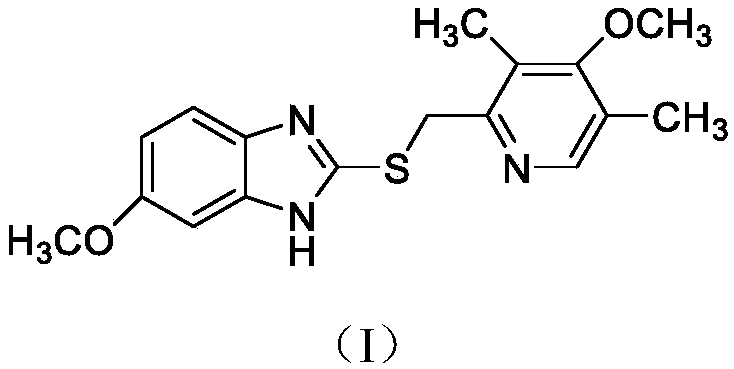

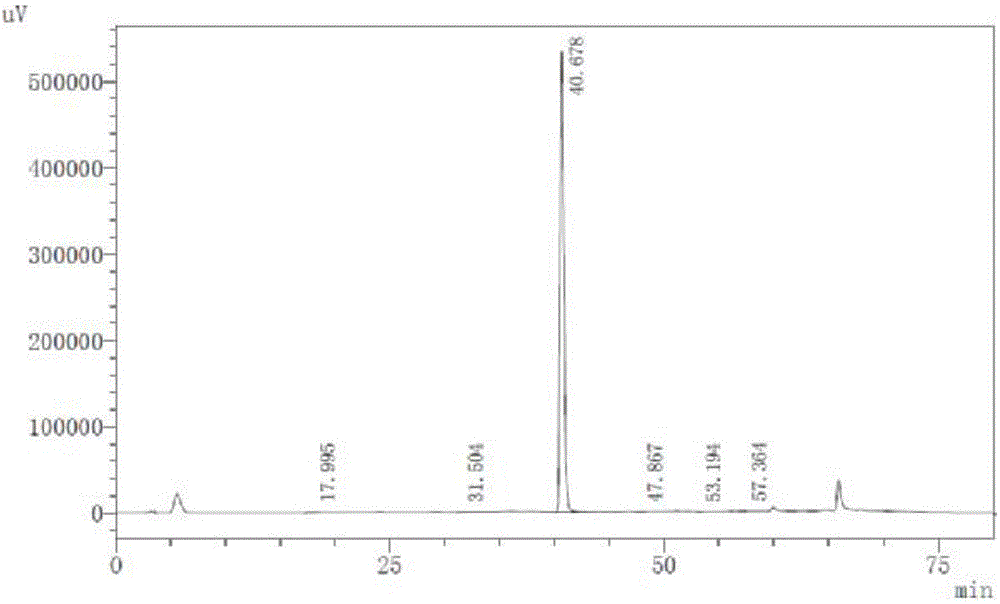

Preparation method for esomeprazole

InactiveCN107892683AHigh yield and purityReduce generationOrganic chemistry methodsNitrogen oxideSulfone

The invention discloses a method for preparing esomeprazole, belonging to the technical field of medicine. According to the invention, 2-chloromethyl-4-methoxy-3,5-dimethylpyridine hydrochloride and 2-mercapto-5-methoxybenzimidazole are used as starting materials and are subjected to condensation and oxidation so as to prepare an esomeprazole salt. The method has good reproducibility, and is simple to operate, easy for realizing industrial production and mild in preparation conditions; and the production of impurity nitrogen oxide and sulfone (peroxide) during the preparation is reduced, and the yield and purity of the esomeprazole salt are improved.

Owner:JIANGSU ZHONGBANG PHARMA

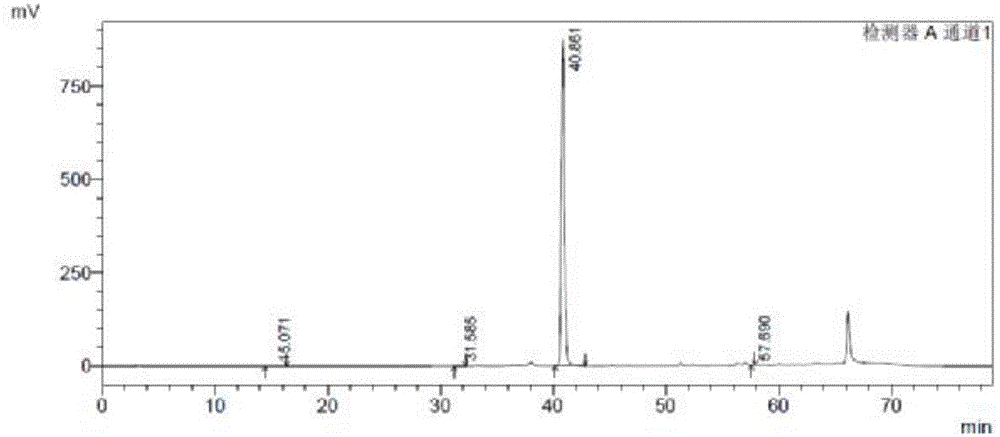

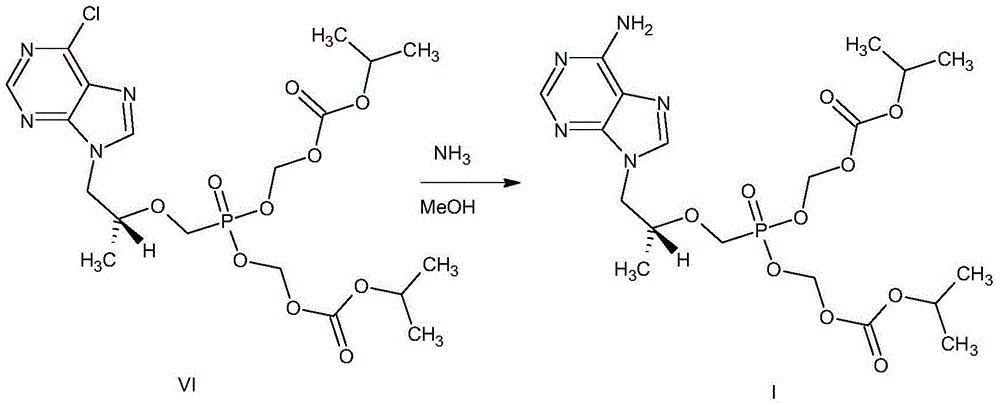

Tenofovir disoproxil salt preparation method

InactiveCN104130288AHigh yield and purityFast removalGroup 5/15 element organic compoundsDecompositionEvaporator

The invention relates to a tenofovir disoproxil salt preparation method; first tenofovir or tenofovir monohydrate is used as a starting material for condensation reaction with chloromethyl isopropyl carbonate in a strong polar organic solvent in the presence of a phase transfer catalyst to prepare tenofovir disoproxil, then the tenofovir disoproxil is salified with succinic acid and fumaric acid to prepare a tenofovir disoproxil salt; in the stage of esterification reaction for removing the organic solvent, a thin film evaporator is used for distillation for removing rapidly the solvent at low temperature, the material flows through the evaporator in a very short time about 10 seconds, the problems of reactant decomposition caused by too high distillation temperature and long heating time in the prior art can be avoided, and the product purity and yield are greatly improved. The final finished product HPLC (high performance liquid chromatography) is more than or equal to 99.85%, the single impurity content is less than 0.1%, and the yield is 62%-67%.

Owner:NINGBO MENOVO PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing 2,2-dual [3-amido-4-(4-nitrophenoxy)phenyl group]-1,1,1,3,3,3-hexa-fluoropropane Method for preparing 2,2-dual [3-amido-4-(4-nitrophenoxy)phenyl group]-1,1,1,3,3,3-hexa-fluoropropane](https://images-eureka.patsnap.com/patent_img/b565daec-498e-4ac0-847c-ac55e79f52eb/A20071004578600101.PNG)

![Method for preparing 2,2-dual [3-amido-4-(4-nitrophenoxy)phenyl group]-1,1,1,3,3,3-hexa-fluoropropane Method for preparing 2,2-dual [3-amido-4-(4-nitrophenoxy)phenyl group]-1,1,1,3,3,3-hexa-fluoropropane](https://images-eureka.patsnap.com/patent_img/b565daec-498e-4ac0-847c-ac55e79f52eb/A20071004578600061.PNG)

![Method for preparing 2,2-dual [3-amido-4-(4-nitrophenoxy)phenyl group]-1,1,1,3,3,3-hexa-fluoropropane Method for preparing 2,2-dual [3-amido-4-(4-nitrophenoxy)phenyl group]-1,1,1,3,3,3-hexa-fluoropropane](https://images-eureka.patsnap.com/patent_img/b565daec-498e-4ac0-847c-ac55e79f52eb/A20071004578600062.PNG)