Method for preparing salvianolic acid A from a plurality of salvia plants

A technology of Salvia genus and salvianolic acid, applied in the separation/purification of carboxylic acid esters, organic chemistry, etc., to achieve the effect of high yield and purity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Extraction: Weigh 100g of herbal decoction pieces of Salvia miltiorrhiza, add 1000ml of water, heat and extract at 70°C under nitrogen protection for 2 hours, extract twice, add 800ml of water for the second time, combine and filter to obtain the extract.

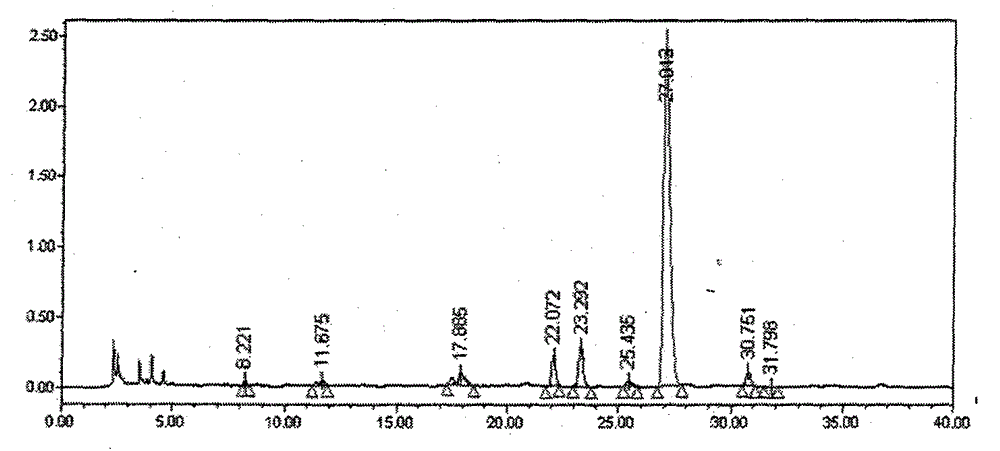

[0048] 2. Transformation: Concentrate the extract to 200ml, reflux under normal pressure for 15hr under the protection of argon, and stop the reaction. The content of salvianolic acid B in the extraction liquid was determined to be 1.36%, the content of salvianolic acid A in the conversion liquid was 0.53%, and the conversion rate was 56.6%.

[0049] 3. Column chromatography separation: Weigh 200g of DM301 macroporous resin, pretreat and pack into a column. Add the conversion liquid to the top of the chromatography column, and after it completely enters the column bed, it is eluted with water for 3 column volumes, and this part of the eluate is discarded; then, it is eluted with 70% ethanol for 3 column volumes, a...

Embodiment 2

[0052] 1. Extraction: Weigh 100g of decoction pieces of pseudo-danshen medicinal material, add 1000ml of water, heat and extract at 60°C under the protection of argon for 2 hours, extract twice, add 800ml of water for the second time, combine and filter to obtain the extract.

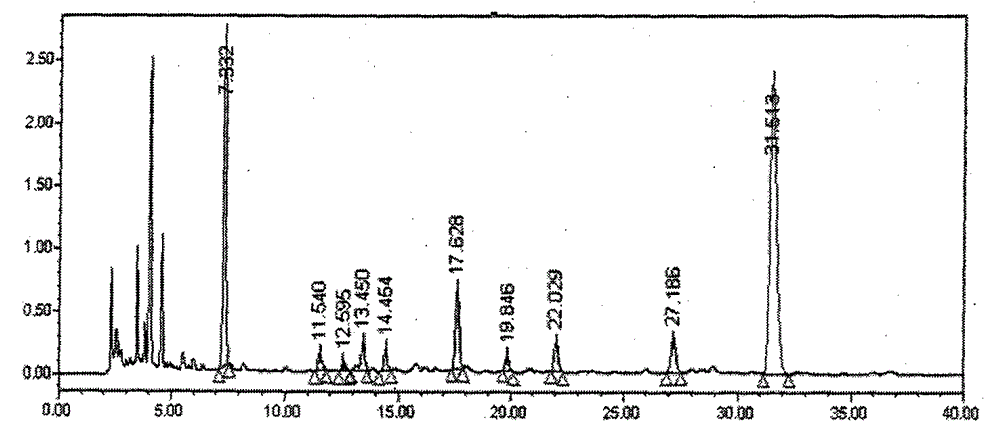

[0053] 2. Transformation: Concentrate the extract to 200ml, reflux for 8hr under the protection of nitrogen, and stop the reaction. The content of salvianolic acid B in the extraction liquid was determined to be 1.12%, the content of salvianolic acid A in the conversion liquid was 0.41%, and the conversion rate was 53.2%.

[0054] 3. Column chromatography separation: Weigh 200g of 330 type macroporous resin, pretreat and pack into a column. Add the conversion solution to the top of the chromatography column, and after it completely enters the column bed, it is eluted with water for 3 column volumes, and this part of the eluate is discarded; then, it is eluted with 60% methanol for 3 column volumes, and ...

Embodiment 3

[0057] 1. Extraction: Weigh 100g of herbal decoction pieces of Zihua, Zhejiang and Anhui Danshen, add 1000ml of water, heat and extract at 50°C under nitrogen protection for 2 hours, extract twice, add 800ml of water for the second time, combine and filter to obtain the extract.

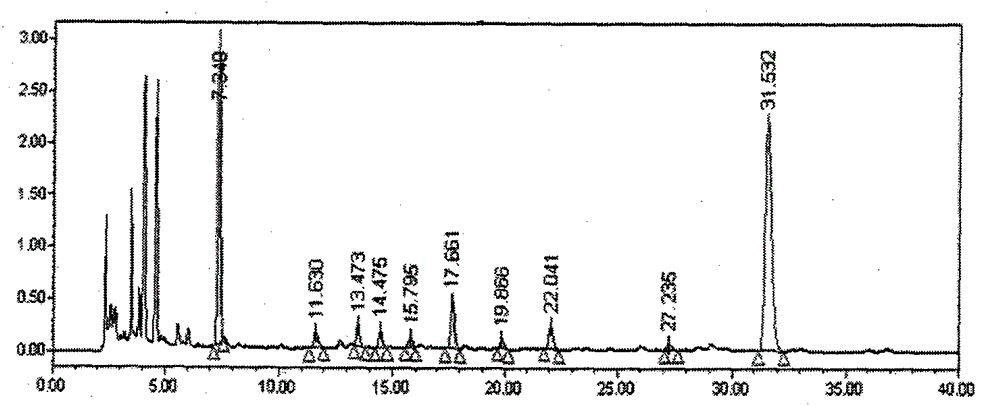

[0058] 2. Transformation: Concentrate the extract to 200ml, reflux for 24hr under the protection of argon, and stop the reaction. The content of salvianolic acid B in the extraction liquid was determined to be 1.41%, the content of salvianolic acid A in the conversion liquid was 0.53%, and the conversion rate was 54.6%.

[0059] 3. Column chromatography separation: Weigh 200g of CAD45 macroporous resin, pretreat and pack into a column. Add the transformation liquid to the top of the chromatography column, and after it completely enters the column bed, it is eluted with water for 3 column volumes, and this part of the eluate is discarded; then, it is eluted with 50% ethanol for 3 column volumes, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com