Patents

Literature

1063results about How to "Improve creativity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

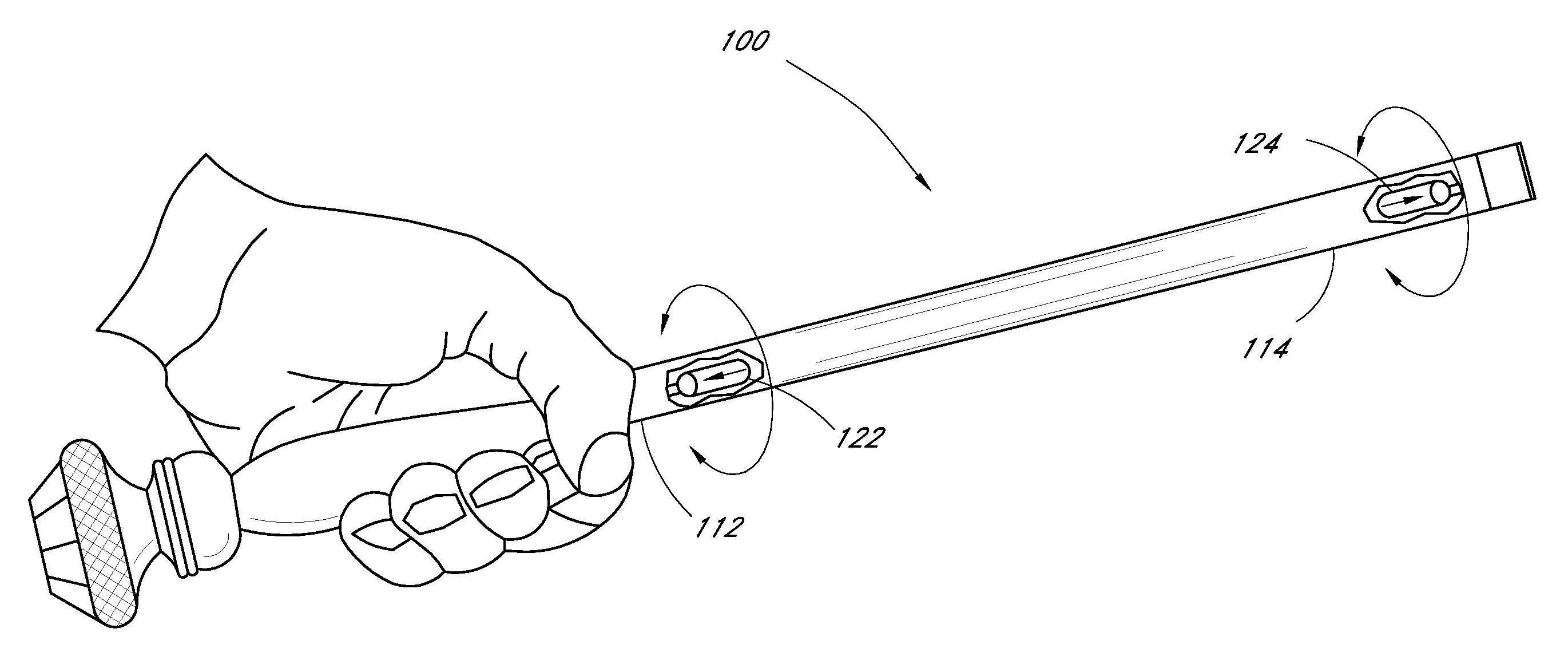

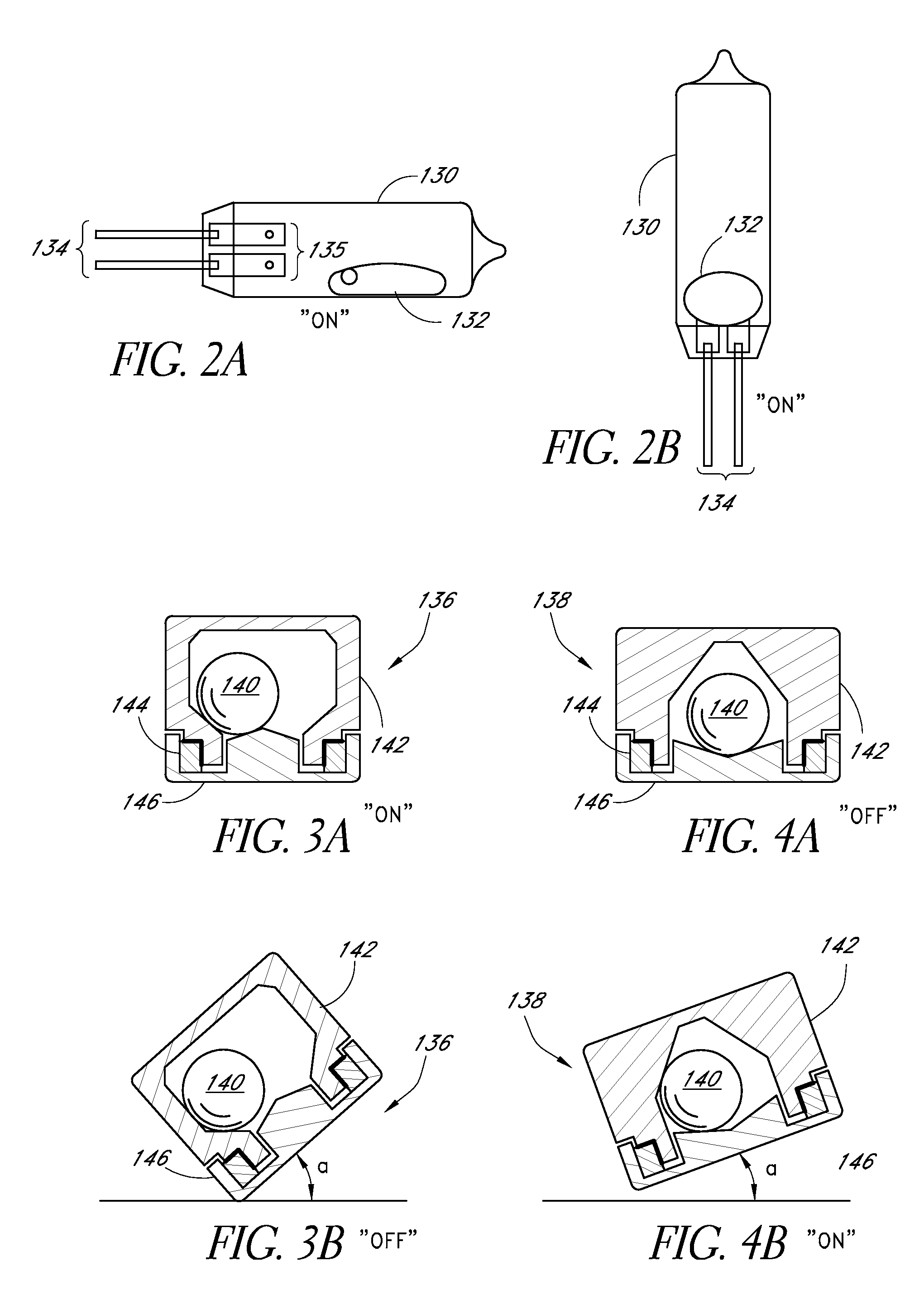

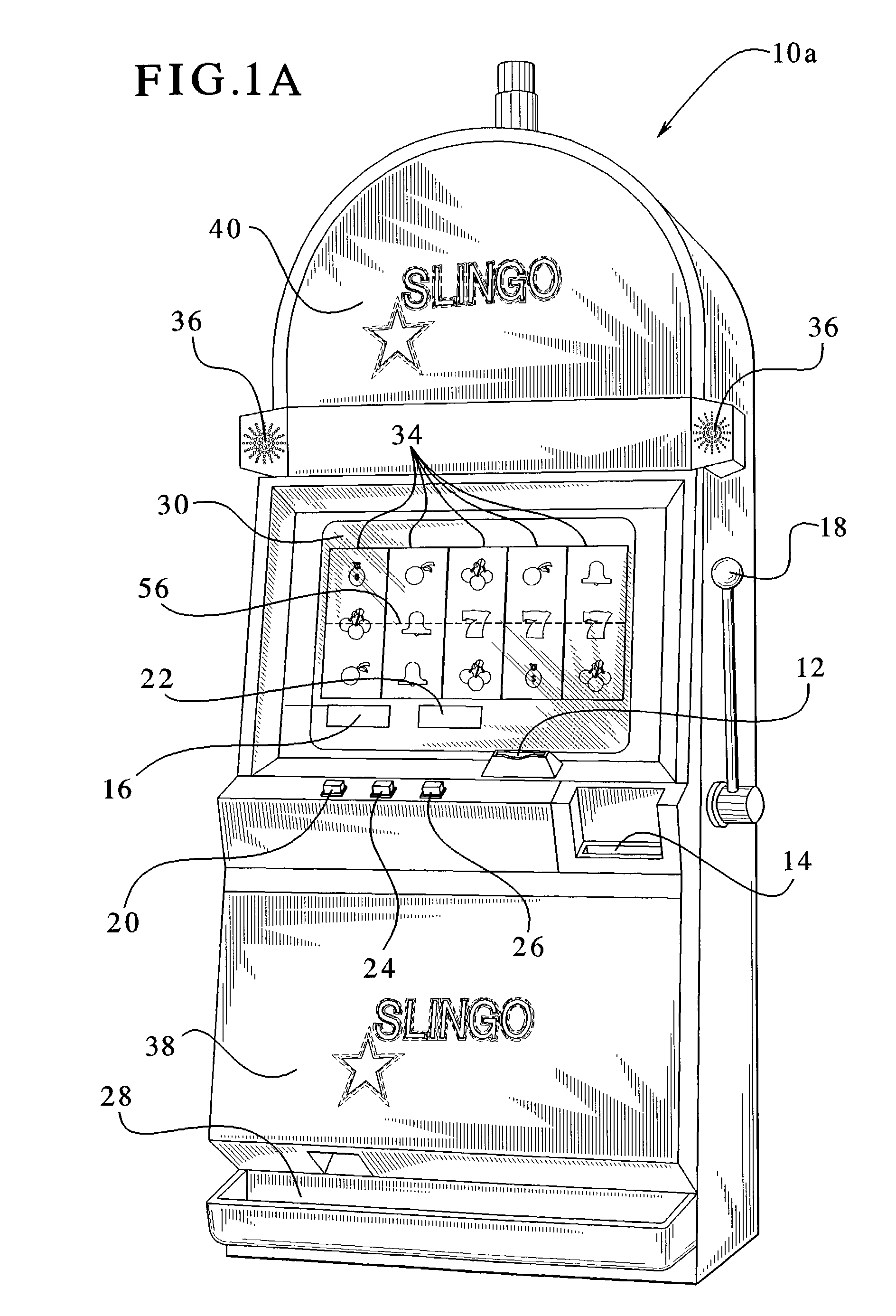

Apparatus and methods for providing interactive entertainment

InactiveUS20080014835A1Increase learning and entertainment opportunityImprove creativityComputerized toysVideo gamesReady to useSpecial effects

Embodiments of the invention provide a unique interactive game that includes multiple dynamic layers in which a participant may complete a variety of challenges and / or tasks. For example, the participant may obtain a toy “wand” from a retail phase that is usable in an interactive entertainment phase. The interactive entertainment phase may include multiple interrelated layers such that progress in one or more layers may affect the participant's experience in one or more other layers. The participant may also receive training on how to use the wand and / or complete one or more special effects, adventures and / or quests. During or following the interactive entertainment phase, the participant may use accumulated points and / or powers to redeem prizes and / or compete against other participants, such as in a duel.

Owner:MQ GAMING

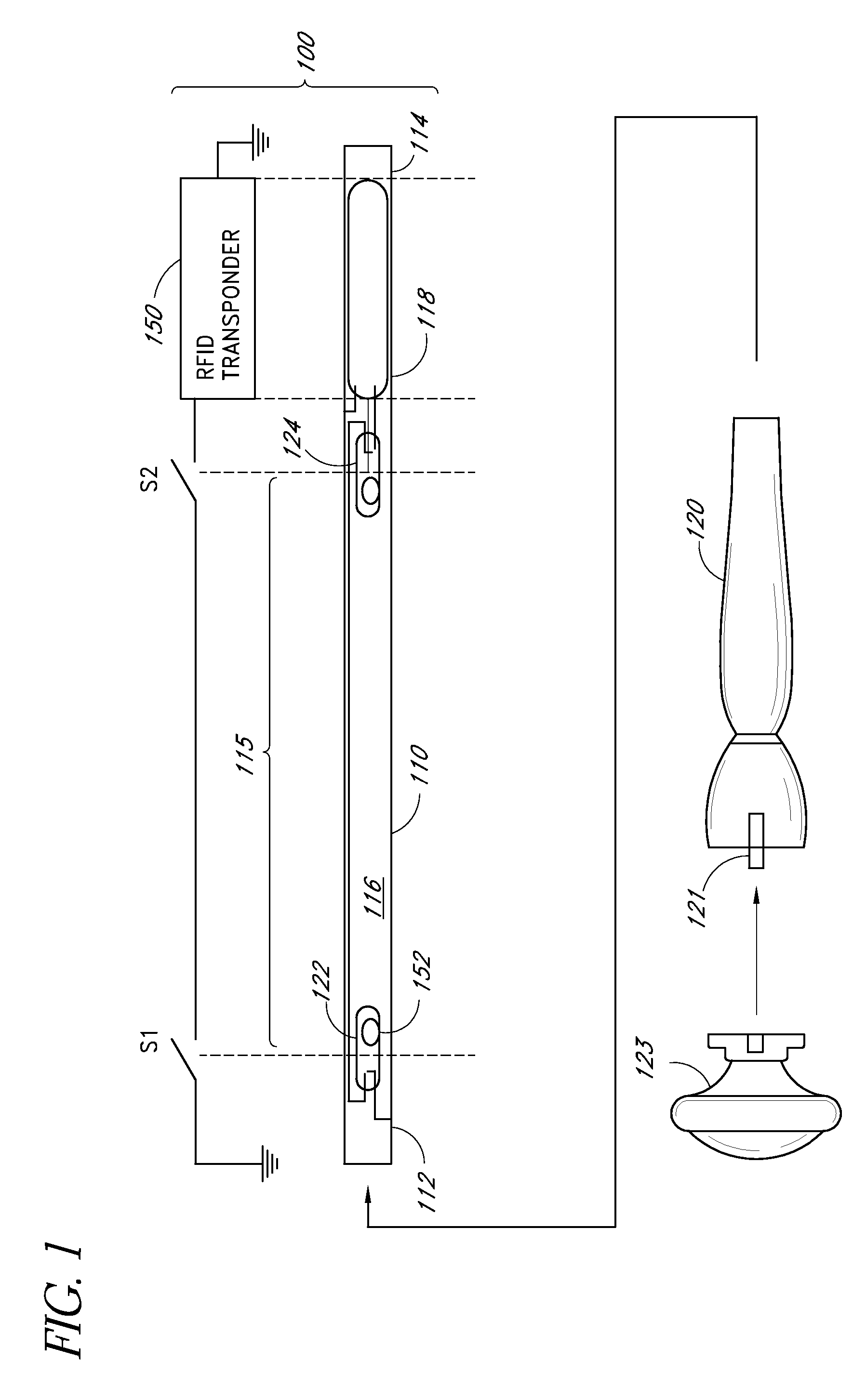

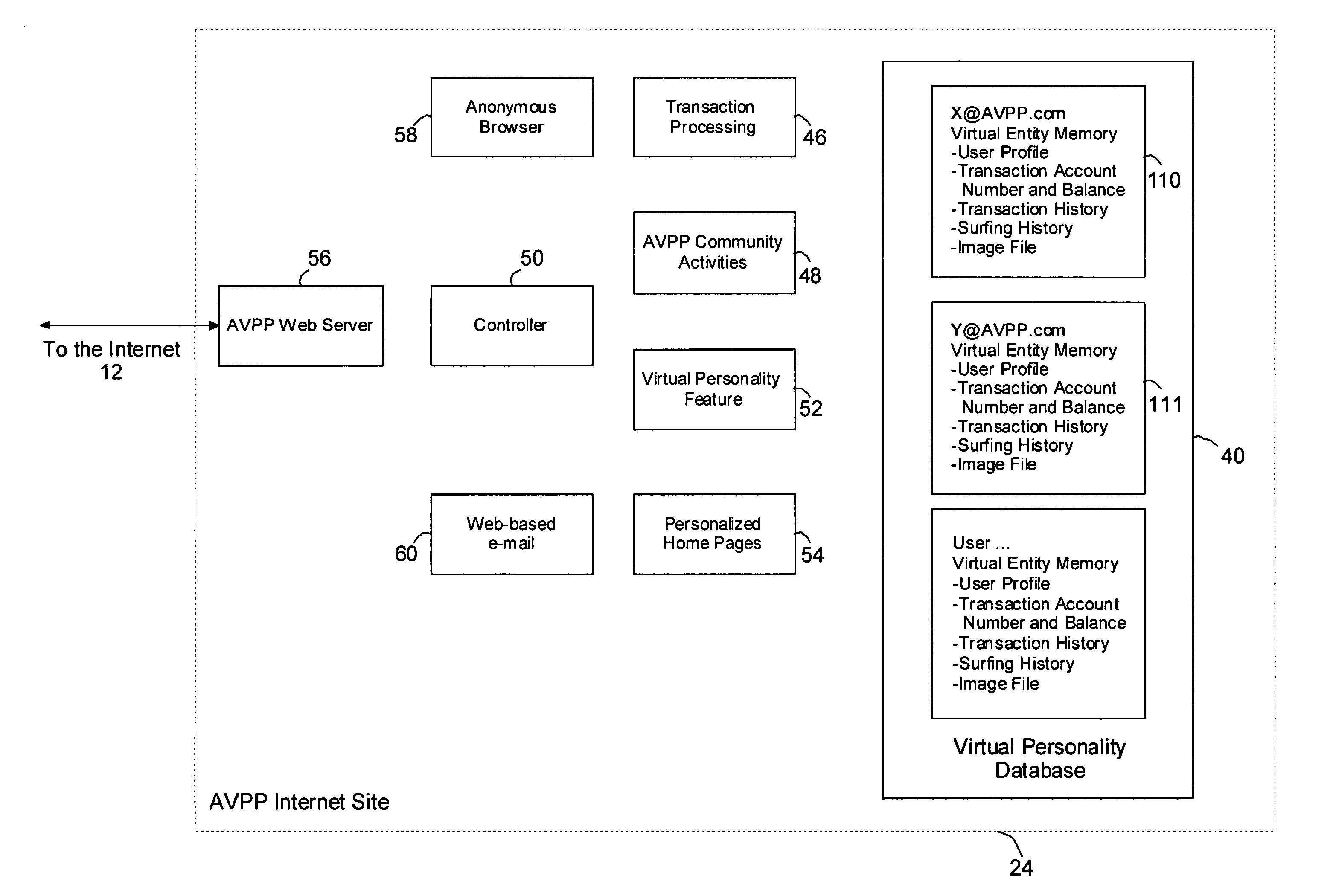

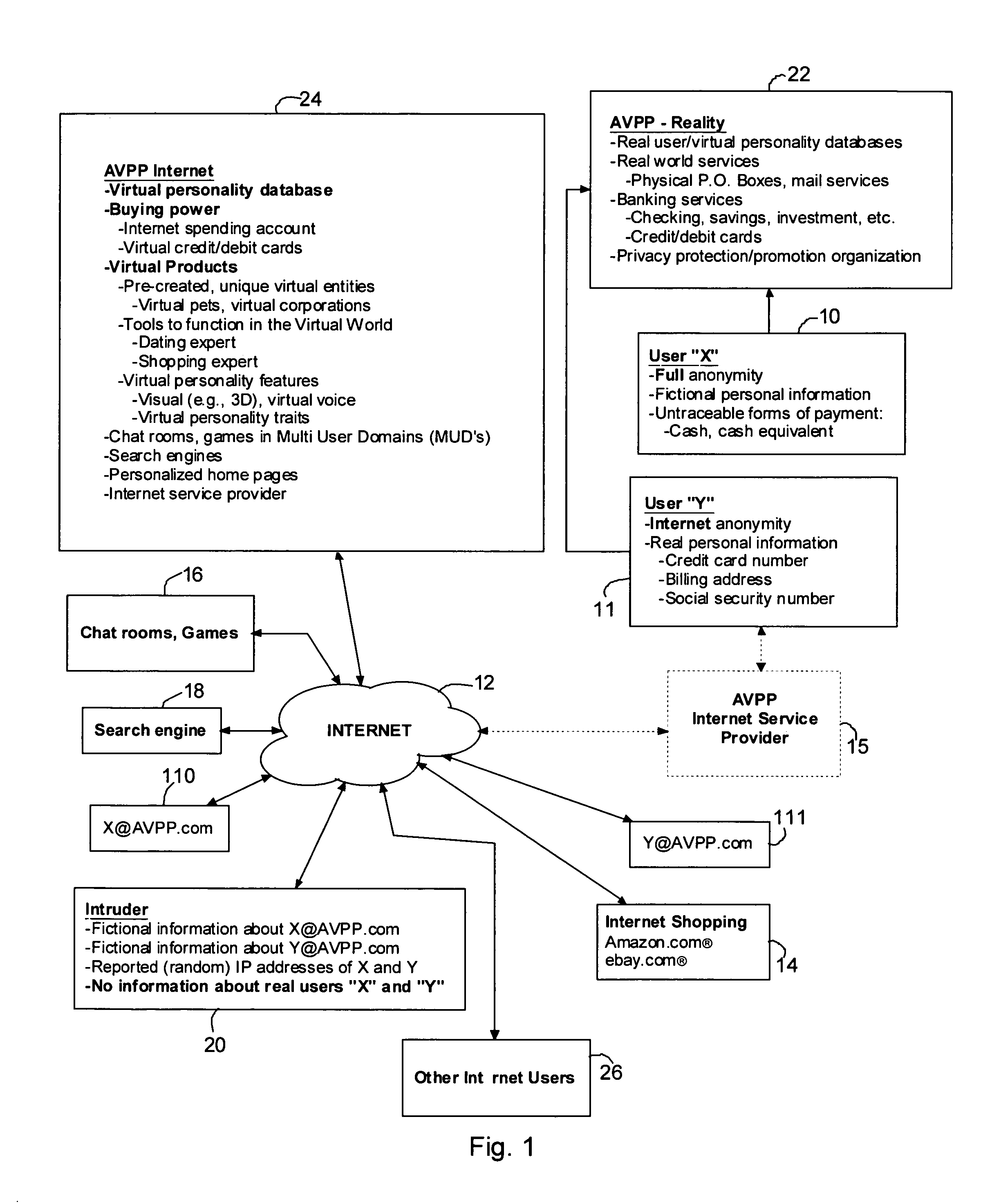

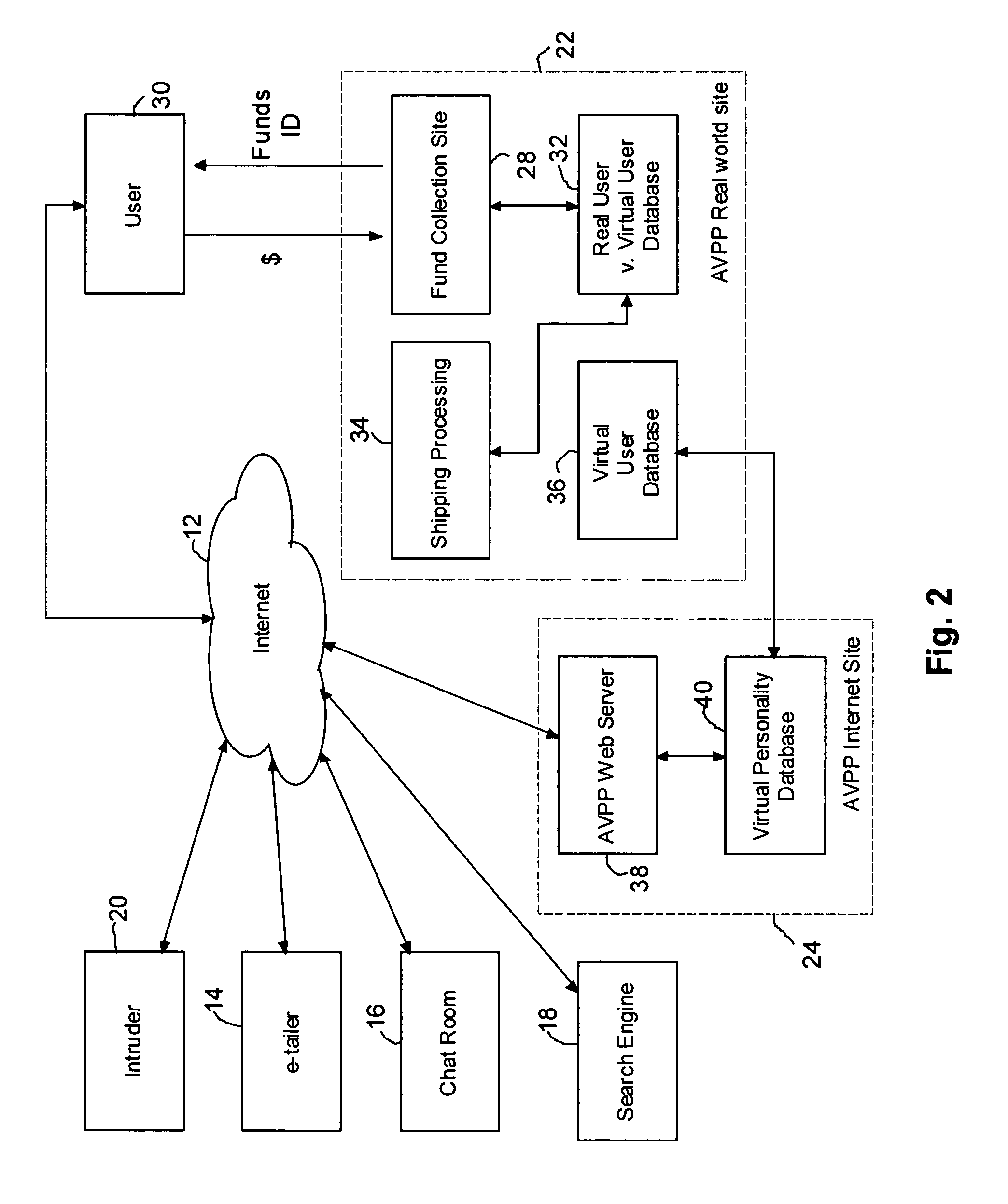

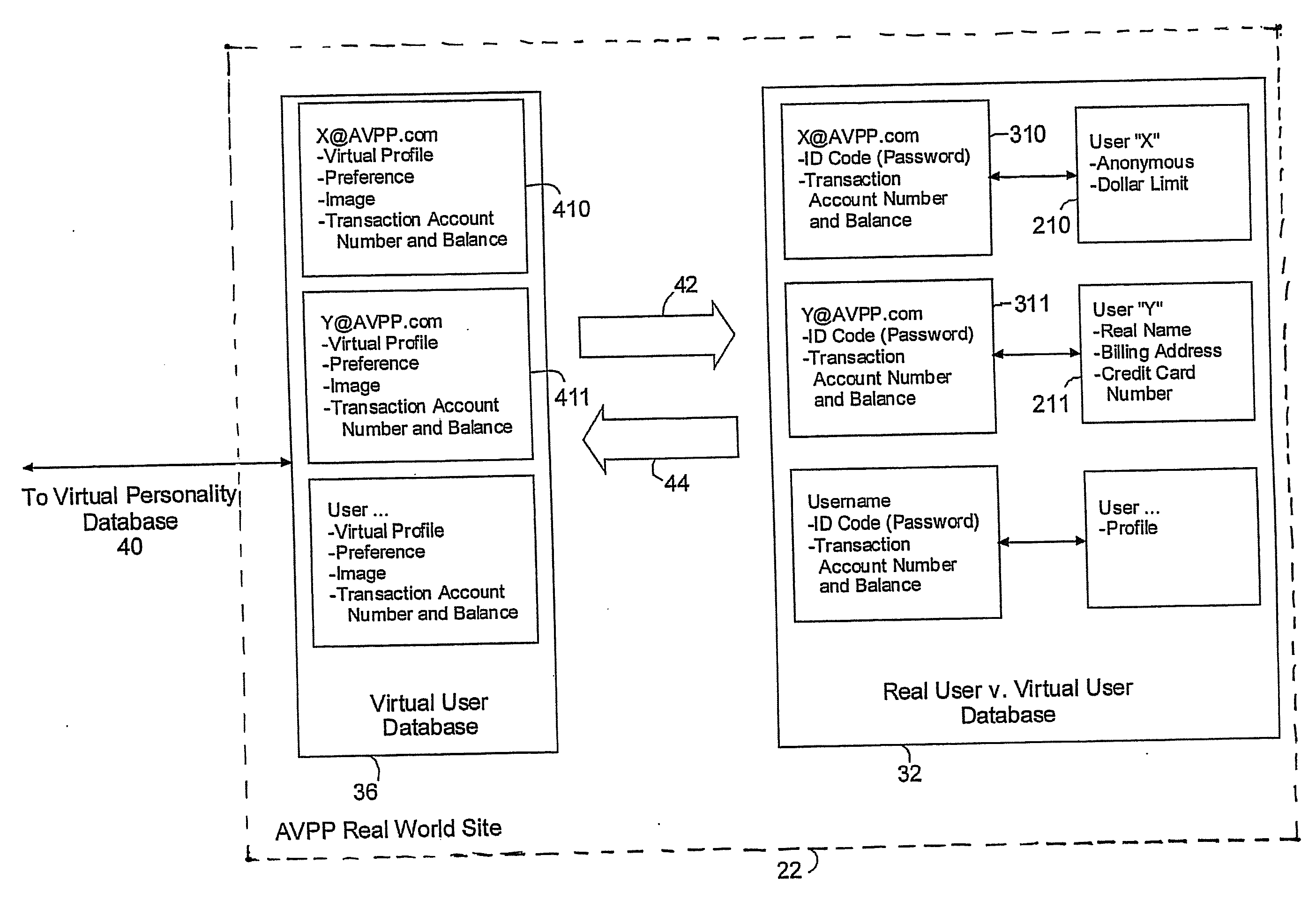

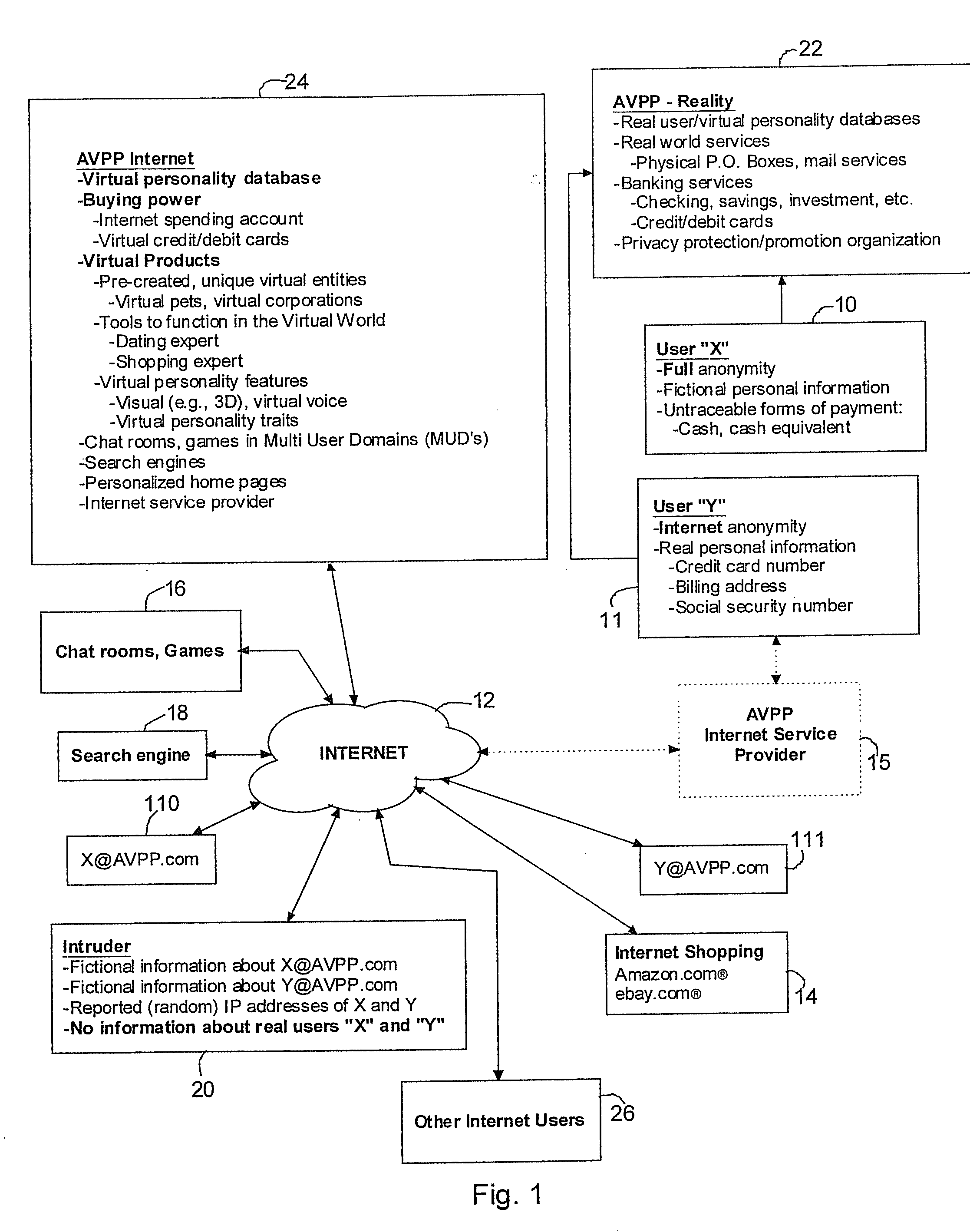

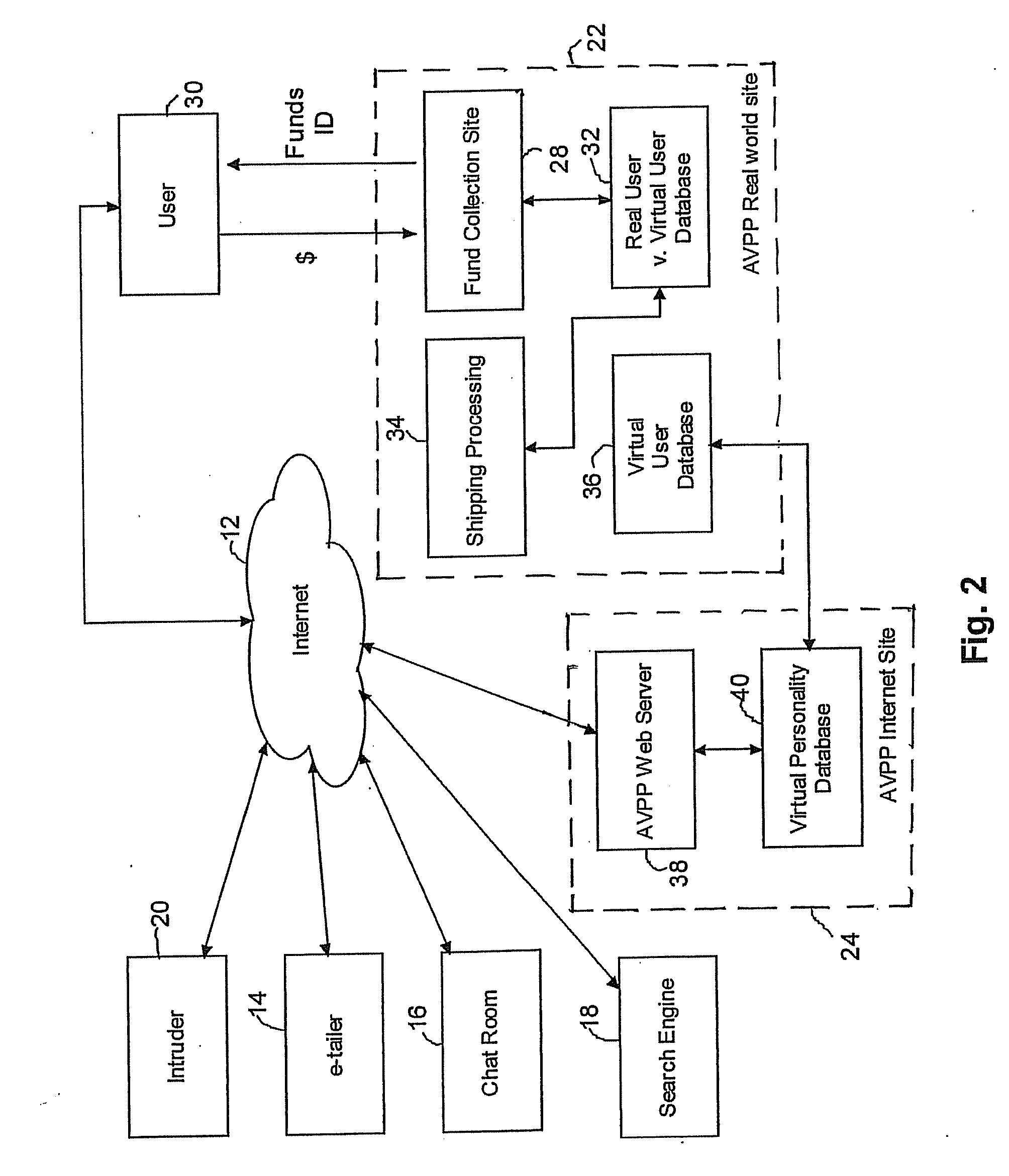

Method and system for securing user identities and creating virtual users to enhance privacy on a communication network

InactiveUS7412422B2Effective distributionMinimize shipping timeComplete banking machinesFinanceVirtual userVirtual entity

A method of enabling a real entity to access a service on a communication network using a virtual entity, the method including the steps of establishing a user account including at least first data corresponding to the identity of the real entity and second data corresponding to the virtual entity and not identifying the real entity, storing the first and second data in a first database, linking between the first and second data in the first database, storing the second data at a second database, associating the second database with a communication network site, connecting the communication network site to the communication network, receiving the second data from an unidentified user on the communication network site, identifying the unidentified user as the virtual entity based on receiving the second data, and allowing the virtual entity to access the service.

Owner:SHILOH DEKEL

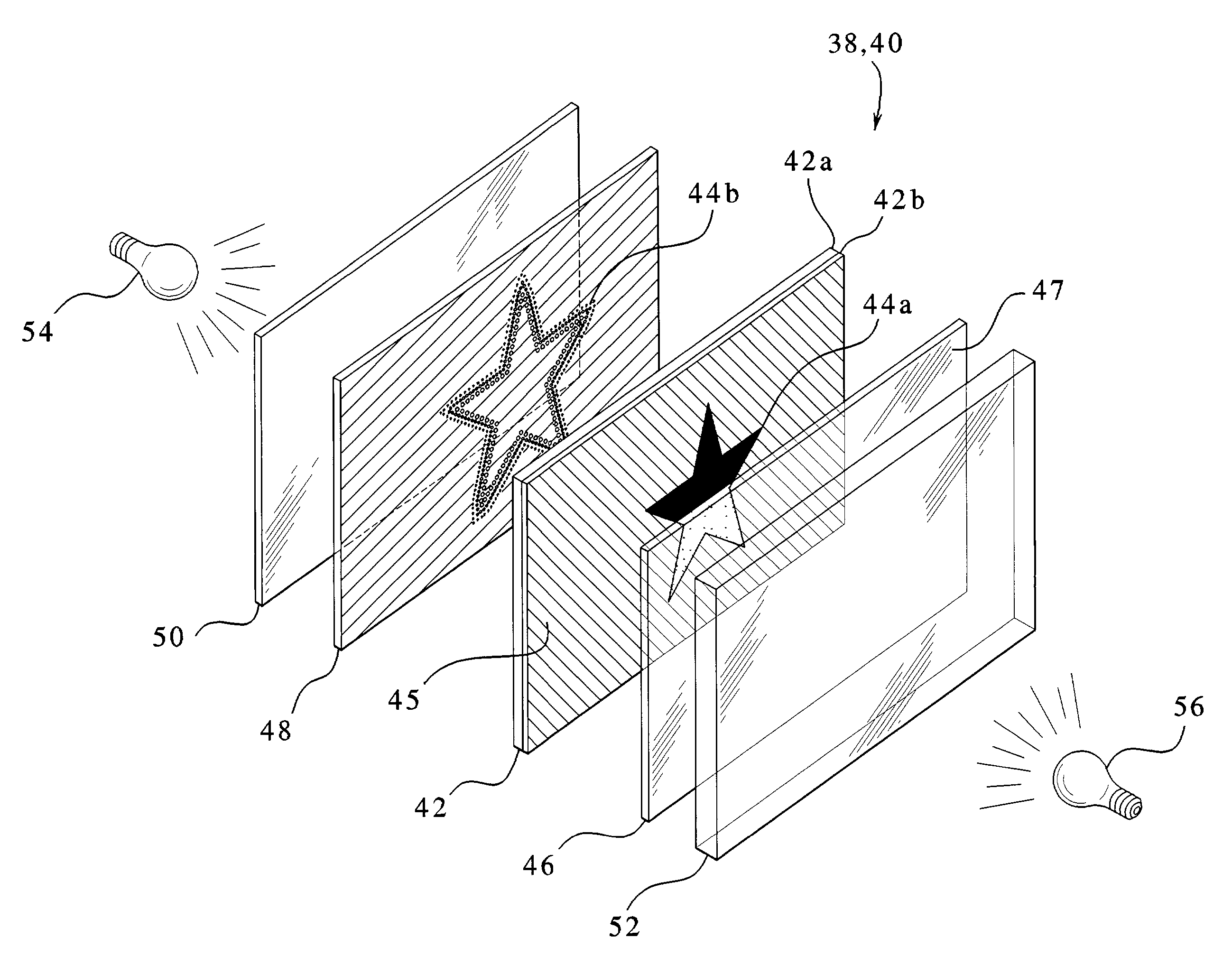

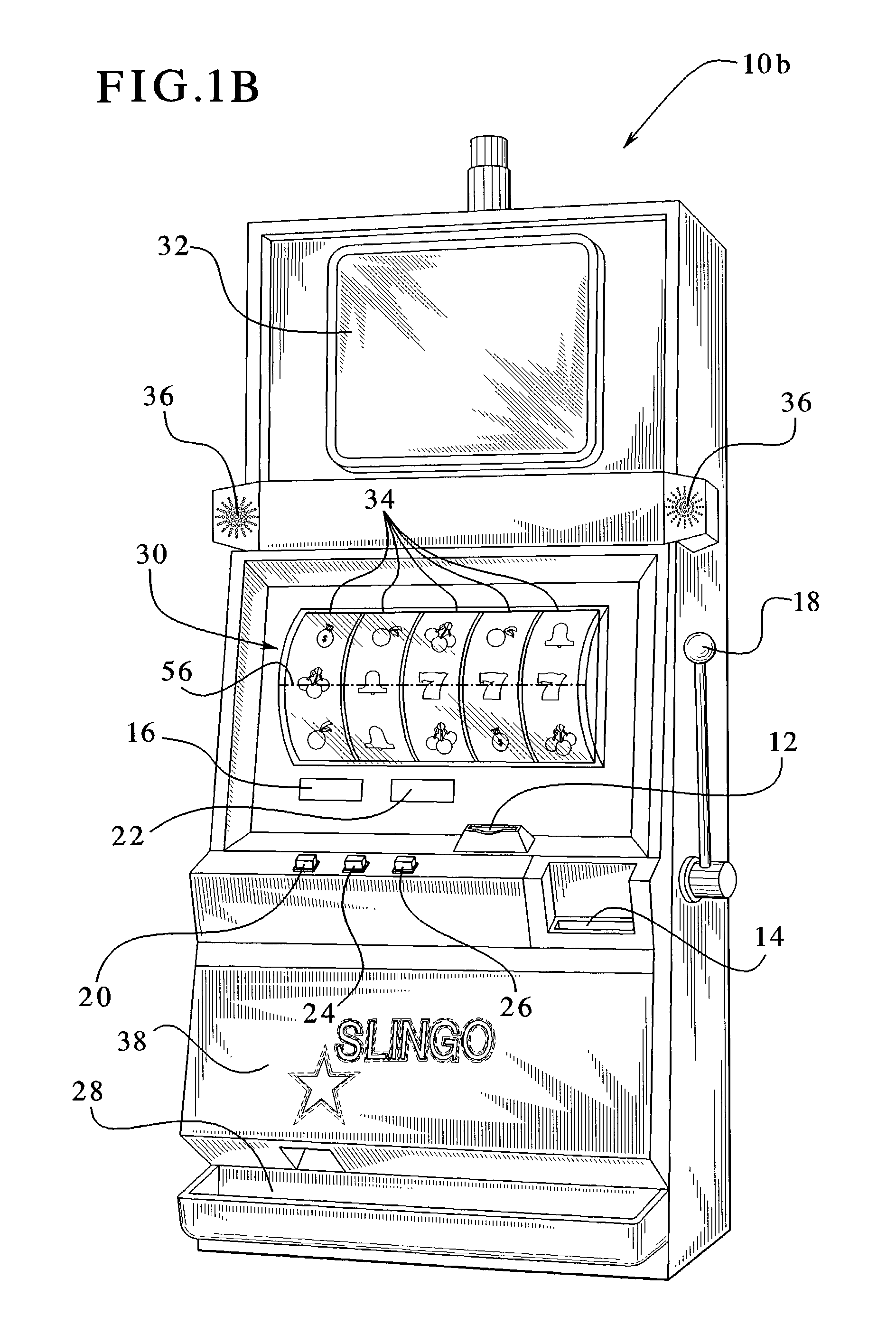

Gaming device display with simulated halftones

InactiveUS6976915B2Cost-effectiveEnhance creativityTypewritersApparatus for meter-controlled dispensingColor toneEngineering

A panel or reel strip of a gaming device that includes halftones. The panel or reel strip includes a medium and a photographically created multicolor image on one side of the medium. A silkscreen ink layer is provided on the other side of the medium. The ink defining at least one halftone producing hole array. The multicolor image and the hole array are both computer created and downloaded to a photo imager. The photo image of the hole array is used to create a screen that produces a wash layer of ink on the back of the colored image. The wash layer defines selectively made hole arrays that enable a desired amount of light to shine through the colored image, providing a glow effect.

Owner:IGT

Method and system for securing user identities and creating virtual users to enhance privacy on a communication network

InactiveUS20090024636A1High activityEffective interactionDigital data processing detailsAnalogue secracy/subscription systemsVirtual userVirtual entity

A method of enabling a real entity to access a service on a communication network using a virtual entity, the method including the steps of establishing a user account including at least first data corresponding to the identity of the real entity and second data corresponding to the virtual entity and not identifying the real entity, storing the first and second data in a first database, linking between the first and second data in the first database, storing the second data at a second database, associating the second database with a communication network site, connecting the communication network site to the communication network, receiving the second data from an unidentified user on the communication network site, identifying the unidentified user as the virtual entity based on receiving the second data, and allowing the virtual entity to access the service.

Owner:SHILOH DEKEL

Technology for recovering water resources and salt from coking wastewater in coal chemical industry

ActiveCN105502782ANo secondary hazardous waste generatedLow running costMultistage water/sewage treatmentAlkali metal chloridesChemical treatmentAdvanced oxidation process

A technology for recovering water resources and salt from coking wastewater in the coal chemical industry comprises the following steps: the wastewater is subjected to defluorination chemical treatment and subjected to sodium carbonate softening and precipitating treatment simultaneously, an advanced oxidation process is used for TOC (total organic carbon) degradation, a multi-medium and activated carbon filter is used for filtering separation, ultrafiltration is performed, nanofiltration membrane separation is performed, calcium and magnesium ions are separated, the calcium and magnesium ions in water produced through nanofiltration are lower than 2 mg / L, CaF2 crystallization scaling is hard to form, and nanofiltration passing liquid and nanofiltration strong brine are obtained; the nanofiltration passing liquid and the nanofiltration strong brine are treated respectively. Fluoride ions, hardness and organic carbon in the wastewater are removed, separation of multivalent salt and monovalent salt as well as concentration and evaporative crystallization of the salt is realized, more than 98% of the water resources is recovered, more than 95% of the salt resources are recovered, secondary hazardous waste is not produced, the system operation cost is reduced, and the problem about resource recovery and the environmental problem are solved finally.

Owner:湖南湘牛环保实业有限公司

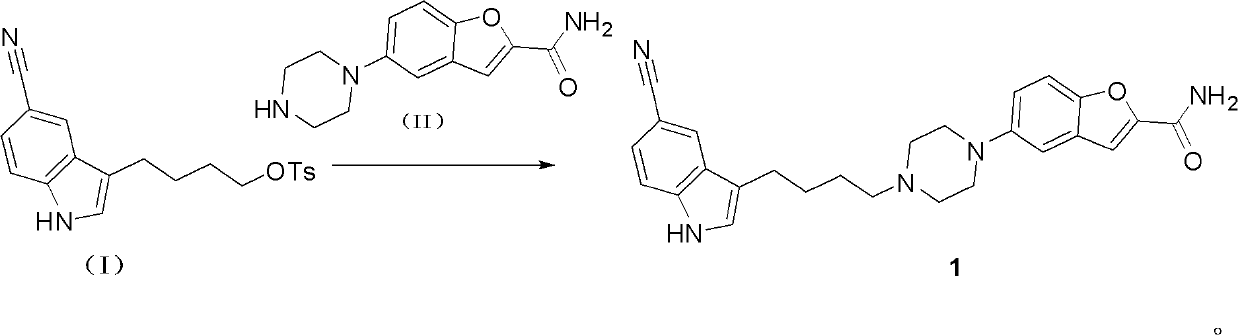

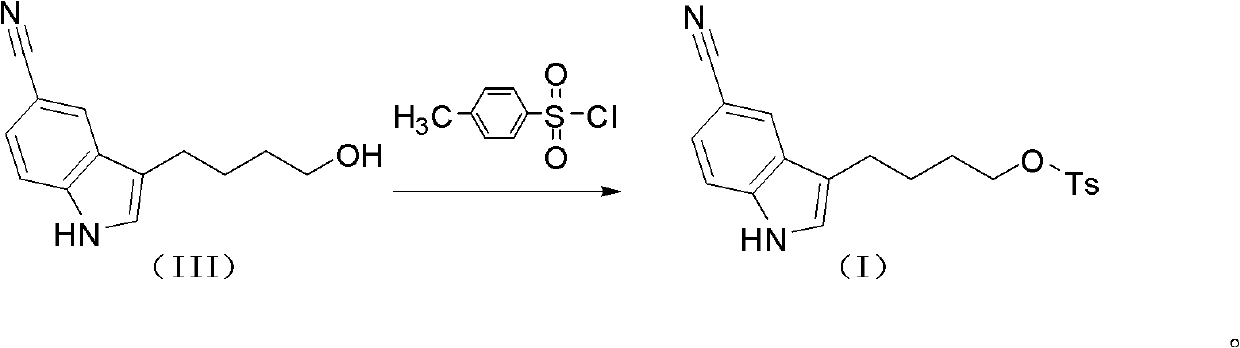

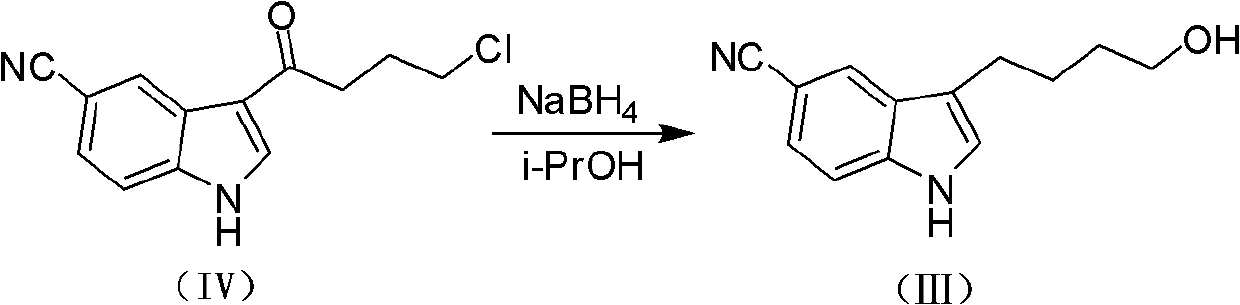

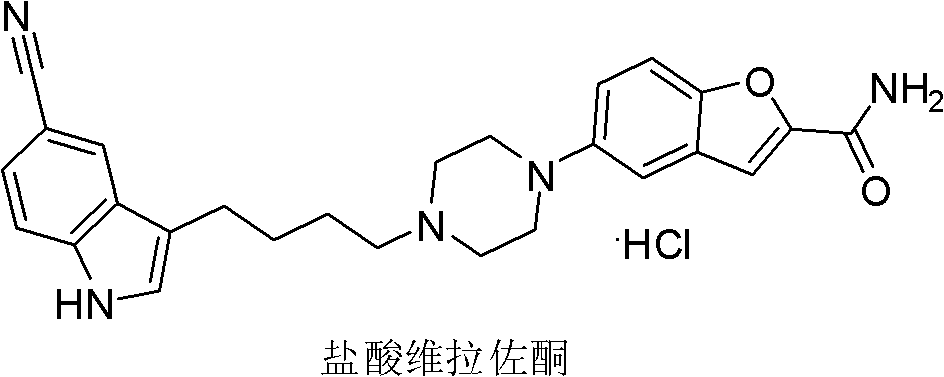

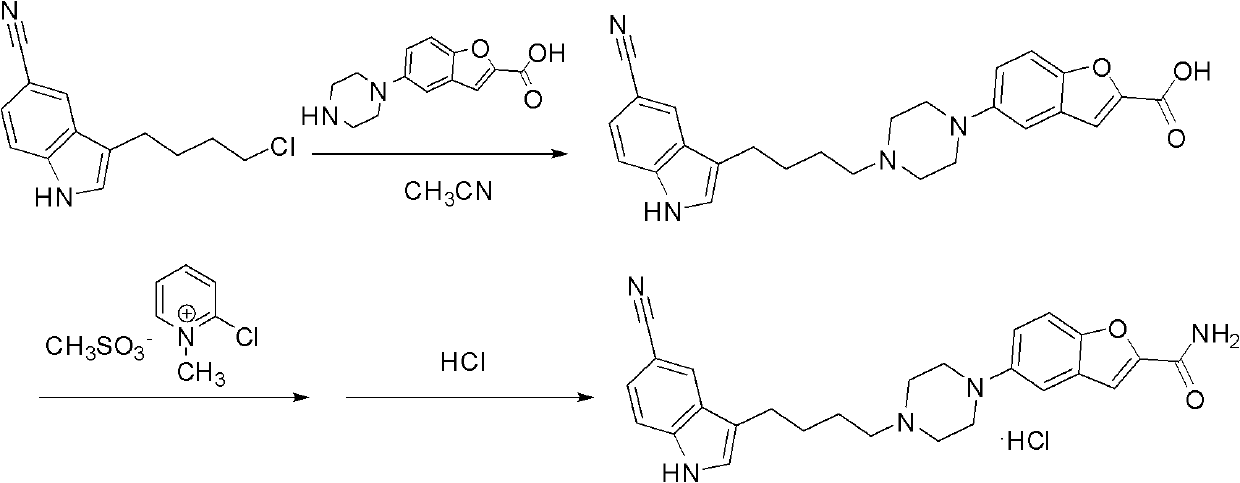

Preparation method of vilazodone or its hydrochloride

The invention discloses a preparation method of vilazodone or its hydrochloride, which comprises the following steps: the compound of formula (I) is mixed with the compound of formula (II) 5-(1 -piperazinyl)-benzofuran-2-formamide reaction, then collect vilazodone shown in formula 1 from the reaction product; Gained vilazodone 1 is in a solvent, and hydrochloric acid is salified to prepare formula (A ) shown vilazodone hydrochloride. The present invention overcomes the defects and deficiencies in the existing preparation methods of vilazodone and its intermediates, is more suitable for the large-scale industrial preparation of vilazodone hydrochloride, has obvious creativity, and has a relatively large positive progress effect and practical application value. The reaction formula is as follows:

Owner:SHANGHAI INST OF PHARMA IND

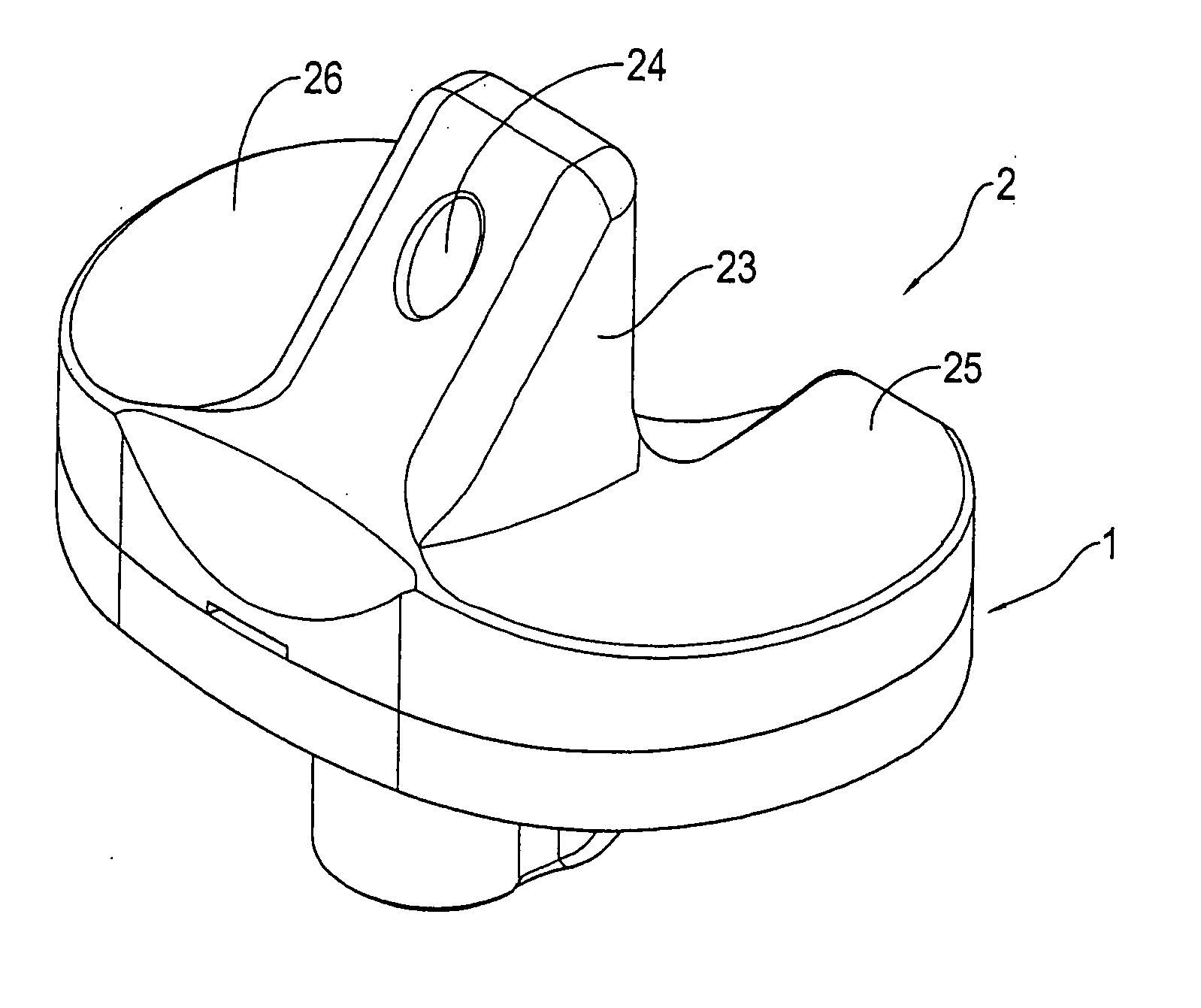

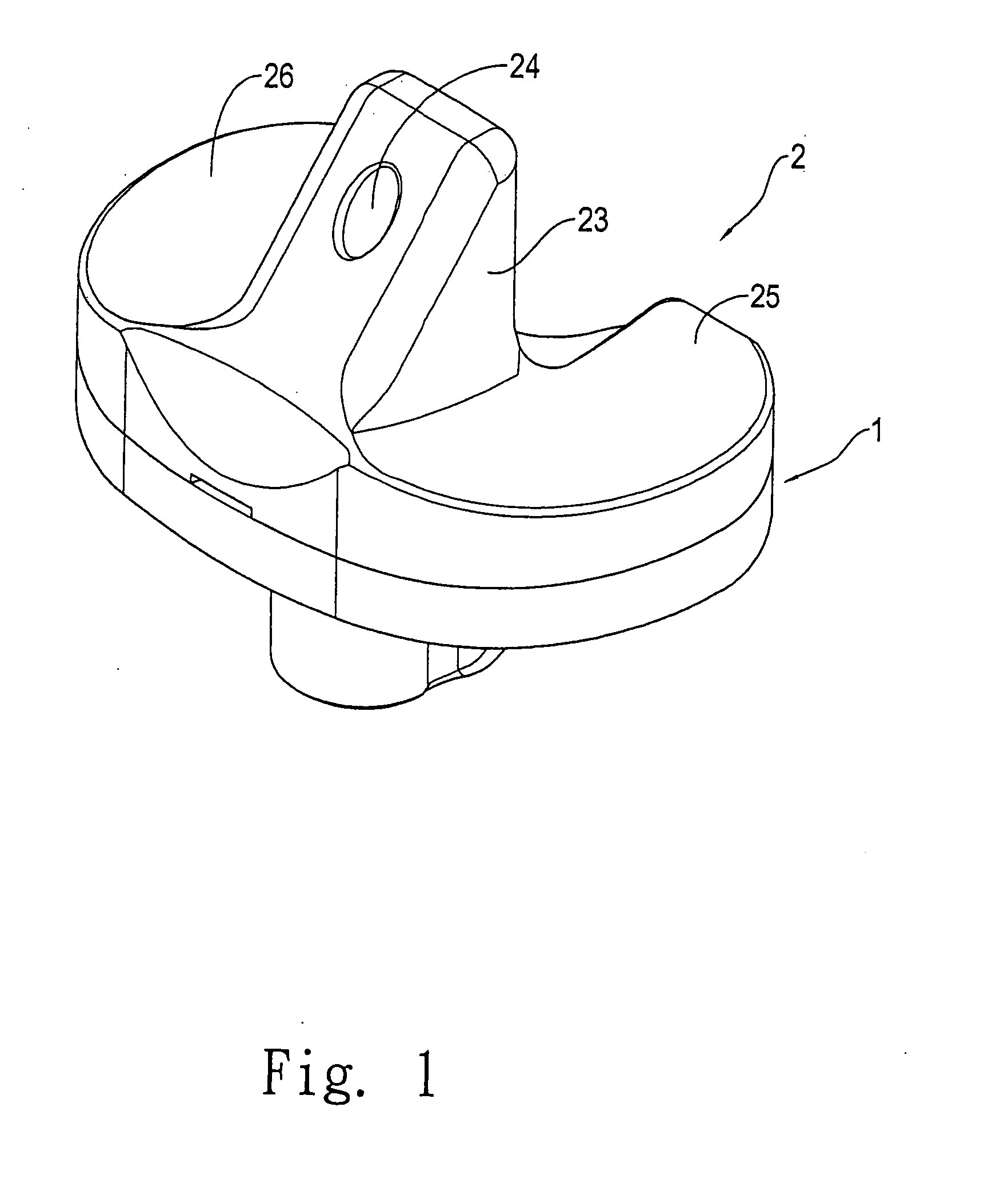

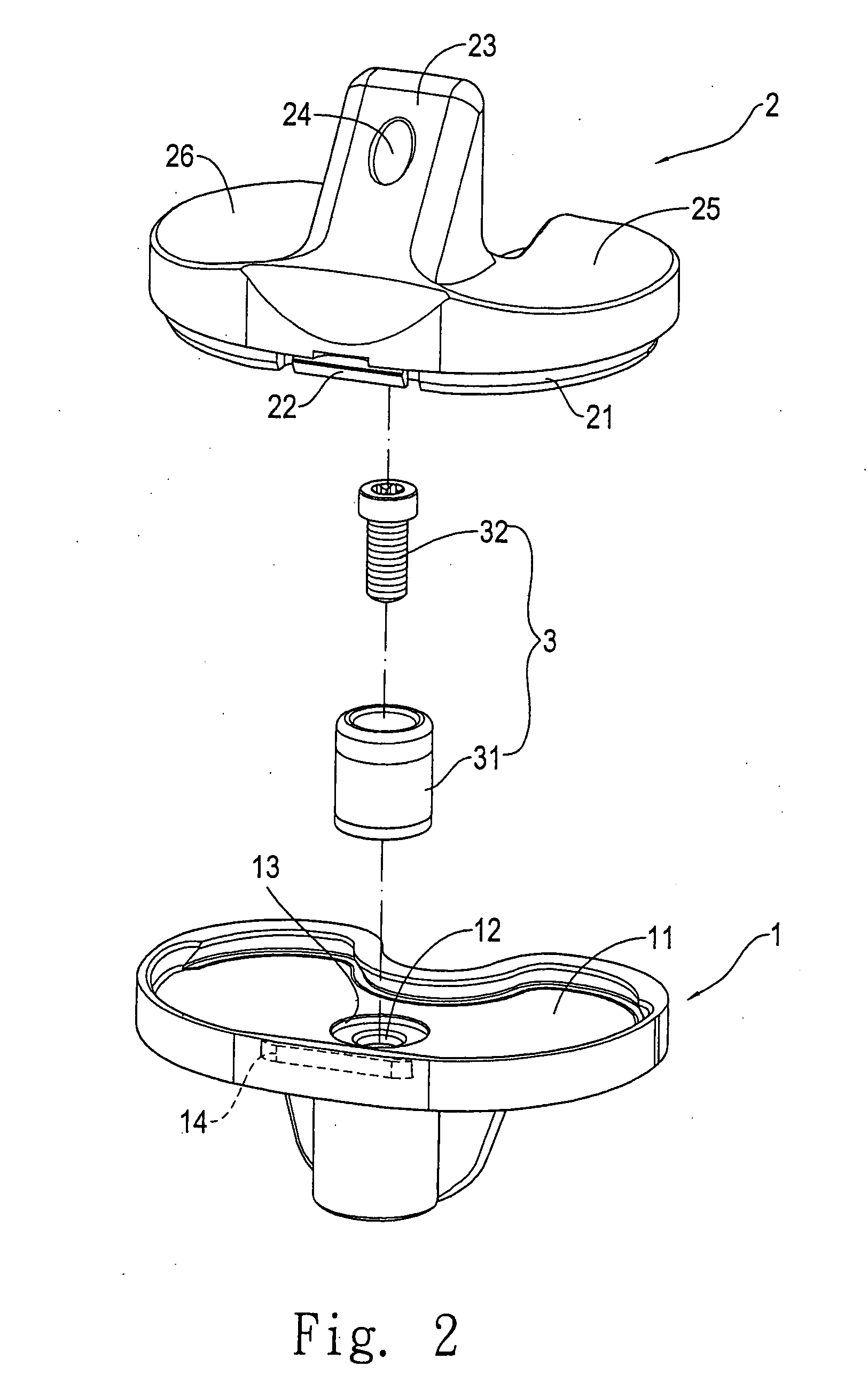

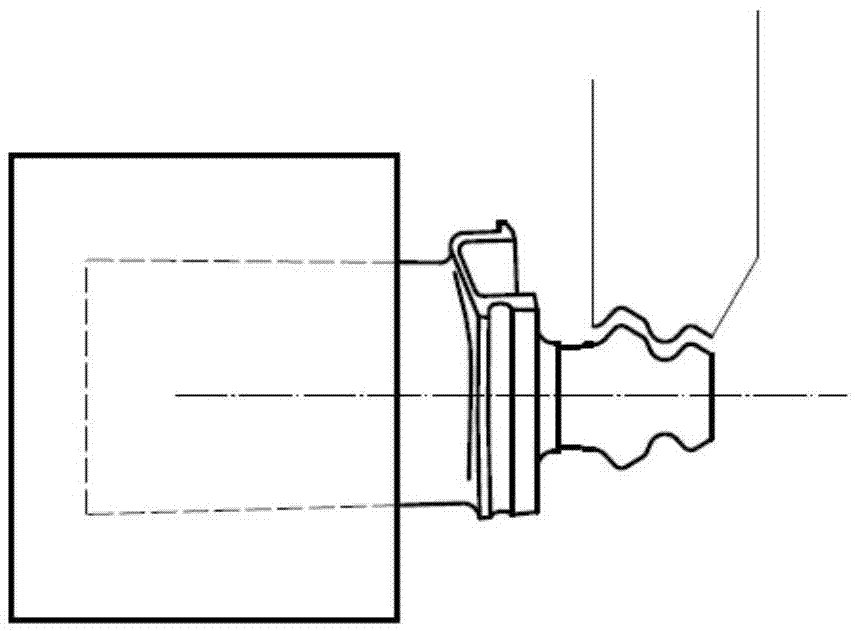

Structure improvement of orthopaedic implant

InactiveUS20100152858A1Enhance practicability and inventivenessStable couplingJoint implantsKnee jointsOrthopaedic implantPlastic surgery

A structure improvement of orthopaedic implant includes a tibial baseplate, a tibial insert, and a reinforcement. The tibial baseplate forms a recess having a bottom that has a central portion defining a through hole extending through the tibial baseplate. The through hole has a top circumference that defines a circumferential groove extending outward. The tibial insert has a bottom forming a projection corresponding to the recess of the tibial baseplate for press-fitting to the tibial baseplate. A support is formed on at a central portion of a top of the tibial insert and defines a bore that extends through the tibial insert. The tibial insert forms two curved surfaces on opposite sides of the support to support contact and rolling. The reinforcement is inset in the tibial insert and includes a sleeve and a bolt.

Owner:UNITED ORTHOPEDIC CORP

Zr-Al-Si composite ceramic beads with high wear resistance and high strength and processing technique thereof

InactiveCN101723666AAdapt to a wide rangeDensity can be adjusted flexiblyMischmetalComposite ceramic

The invention provides a Zr-Al-Si composite ceramic bead with high wear resistance and high strength and a processing technique thereof. The Zr-Al-Si composite ceramic bead comprises the following components by weight percent: 2-65% of ZrO2, 2-60% of Al2O3, 10-50% of SiO2 and 5% of MgO and mischmetal. The production method comprises the following steps: firstly, evenly mixing zircon sand, zirconia, aluminia, magnesia, kaoline and mischmetal, then carrying out ball milling with a wet method, drying to prepare superfine pulverulent body, rolling and molding, sintering at high temperature, and polishing to obtain the Zr-Al-Si composite ceramic beads with high wear resistance and high strength with the diameter being Phi 0.2mm to Phi 15mm. The prepared ceramic bead has flexibly adjusted density, wide application, wear resistance, stable chemical property and simple process and is easy for scale production.

Owner:许兴康

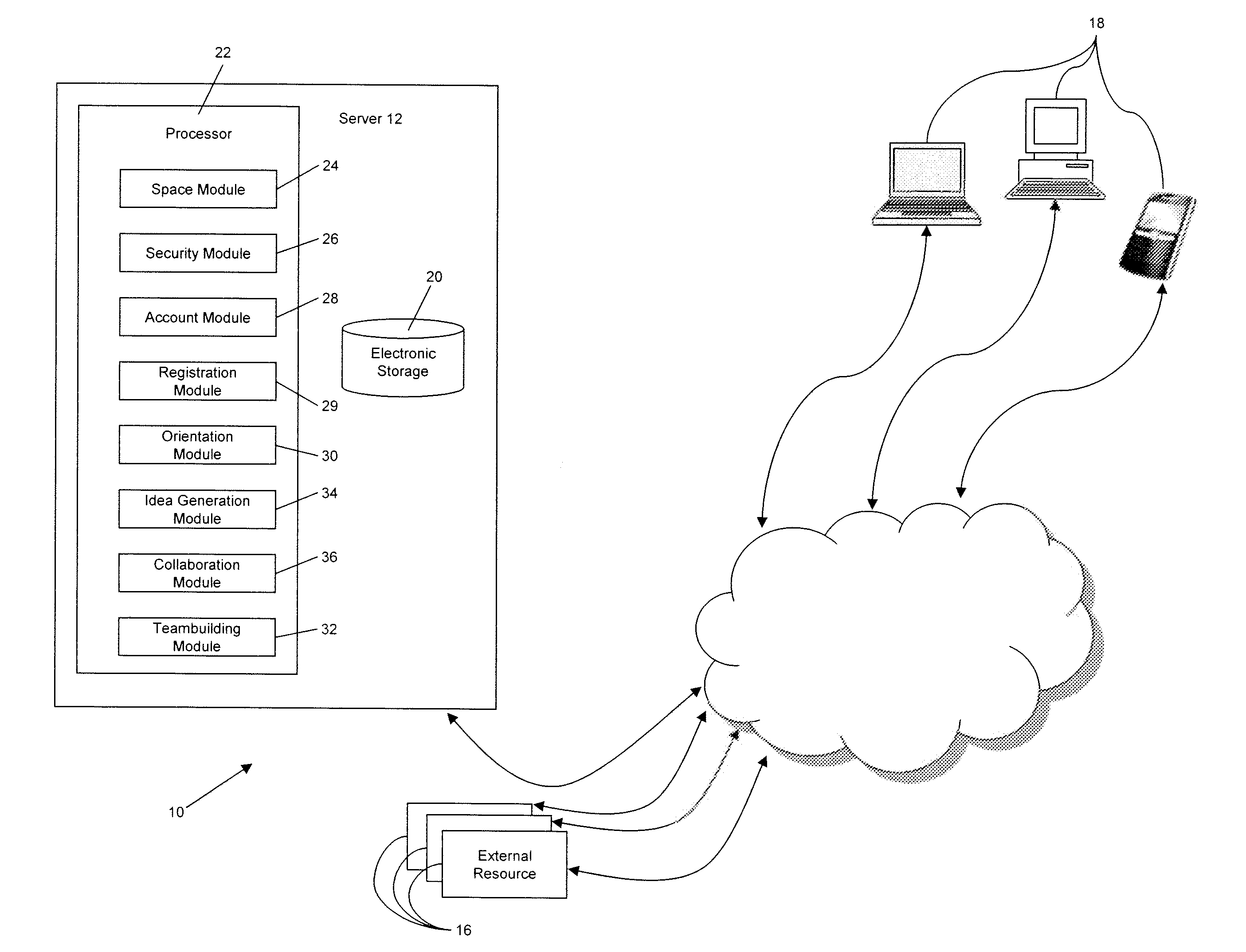

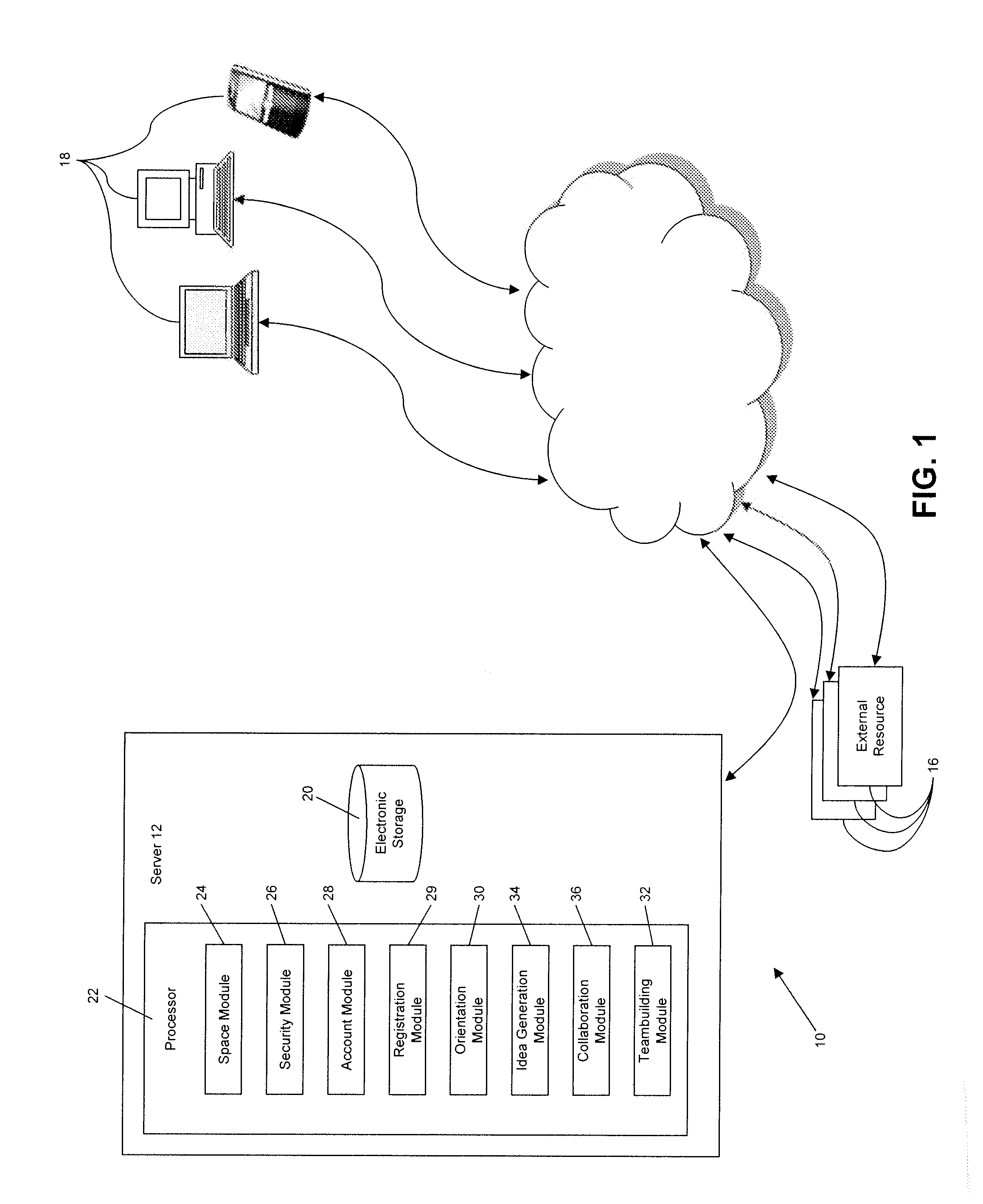

System And Method For Enhancing Group Innovation Through Teambuilding, Idea Generation, And Collaboration In An Entity Via A Virtual Space

InactiveUS20120054281A1Accelerate innovationPromote coherenceMultiple digital computer combinationsArtificial lifeThird partyVirtual space

A virtual space and / or instances thereof may be designed to facilitate enhanced performance of users associated with an entity in fulfilling roles and / or performing tasks for the entity. The virtual space may be designed to provide users with experiences that promote teamwork, coherence, and / or cohesiveness amongst a group of users; experiences that promote idea generation and / or creativity amongst a group of users; and / or, experiences that facilitate collaboration with internal and / or third party users that are external to the entity. The virtual space may be designed with separate areas to be used for different activities related to user interaction with people, ideas, data, documents, and / or objects separately. The activities to which the separate areas are dedicated may enhance innovation through teambuilding, idea generation, collaboration, and / or activities that provide other group benefits as compared to conventional techniques and systems.

Owner:INTERCENTERS INC

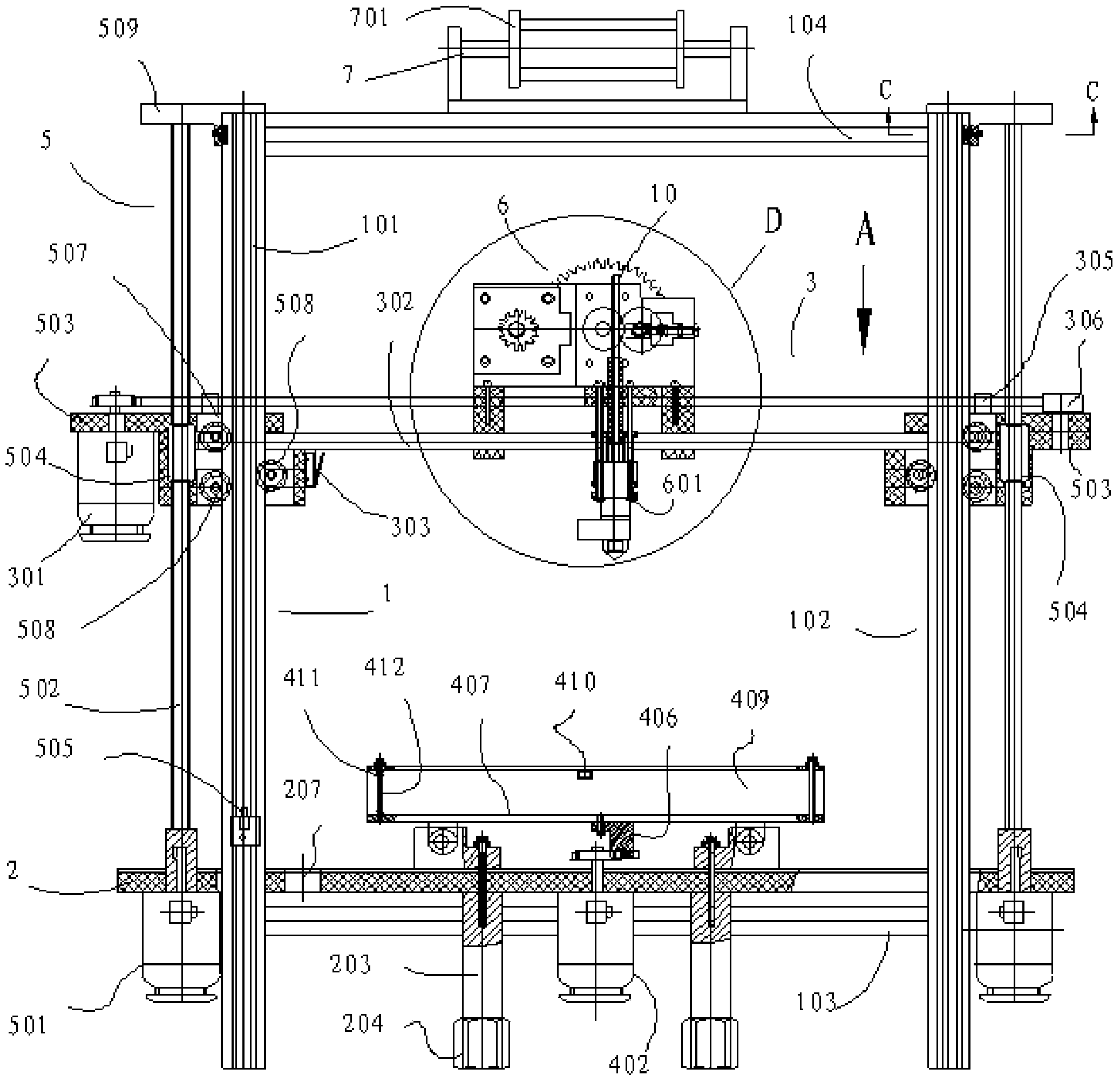

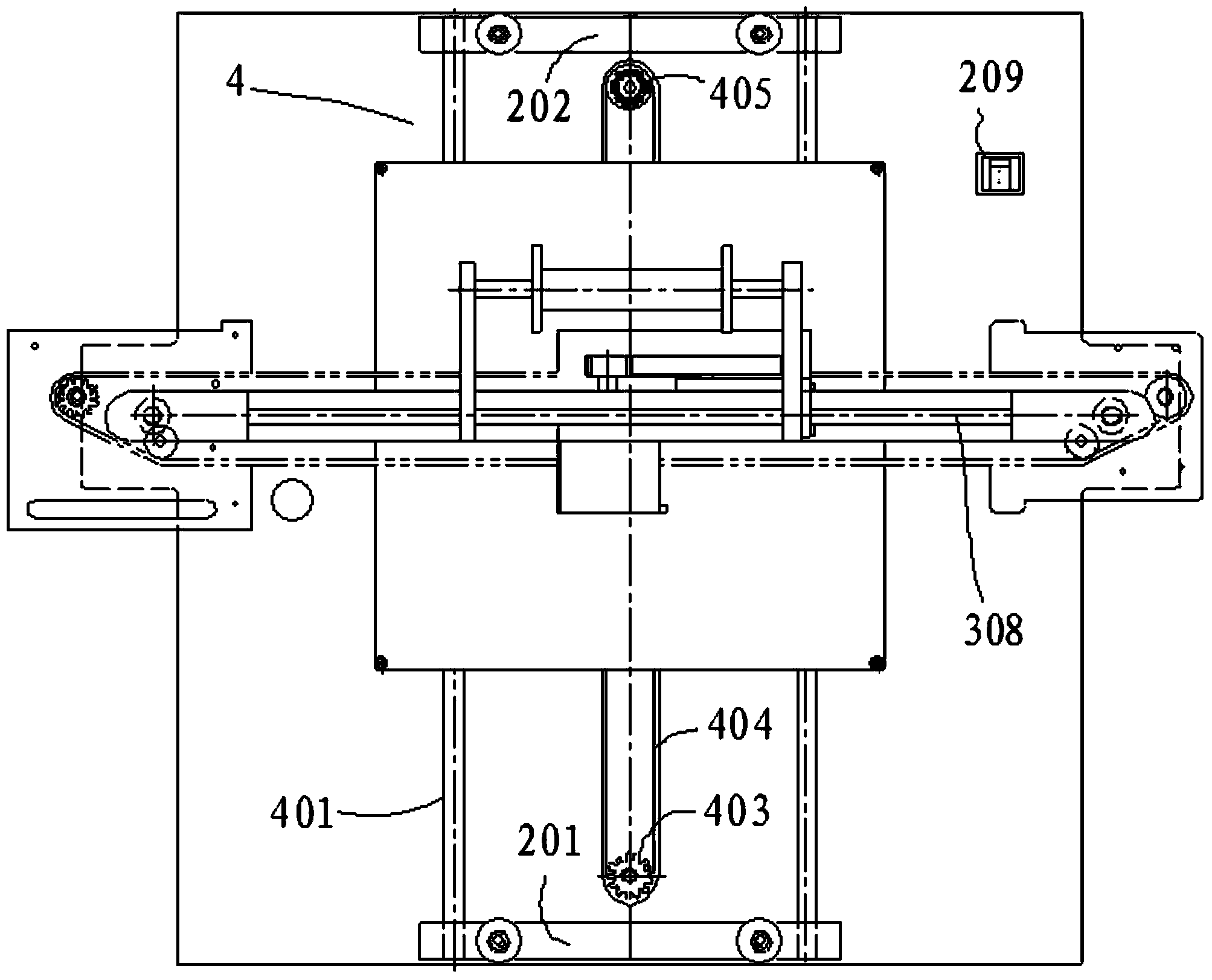

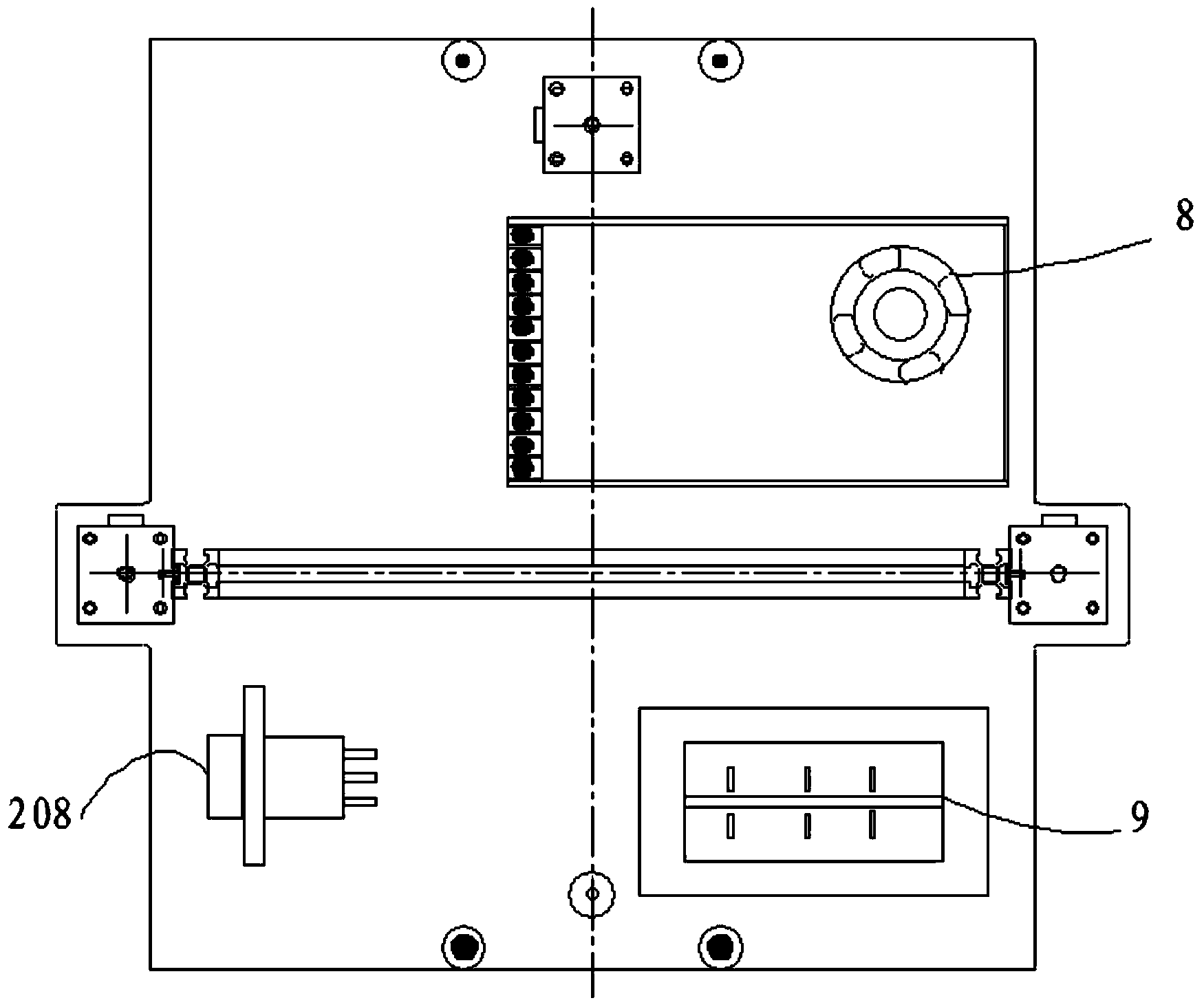

Three-dimensional (3D) printer

The invention discloses a three-dimensional (3D) printer which comprises a rack, a base, an X-axis movement system, a Y-axis movement system, a Z-axis movement system and a printing device, wherein the rack comprises a left upright post, a right upright post, an upper connecting plate and a lower connecting plate; the upper connecting plate and the lower connecting plate are connected with the left upright post and the right upright post, respectively; the base is connected with the lower connecting plate; the upper connecting plate is connected with a printing supplies connecting rack; the printing supplies connecting rack is connected with a printing supplies fixing disc; the printing device is connected with the X-axis movement system; the X-axis movement system is connected with the Z-axis movement system; the Z-axis movement system is connected with a guide rail of the left upright post and the right upright post; the Y-axis movement system is connected with the base; the X-axis movement system is provided with an X-axis movement guide rail through which the printing device moves; a power supply and a controller which are connected with each other are arranged at the bottom of the base; the controller is connected with the X-axis movement system, the Y-axis movement system, the Z-axis movement system and the printing device. The 3D printer is simple and compact in structure, small in size and low in manufacturing cost.

Owner:UNIV OF JINAN

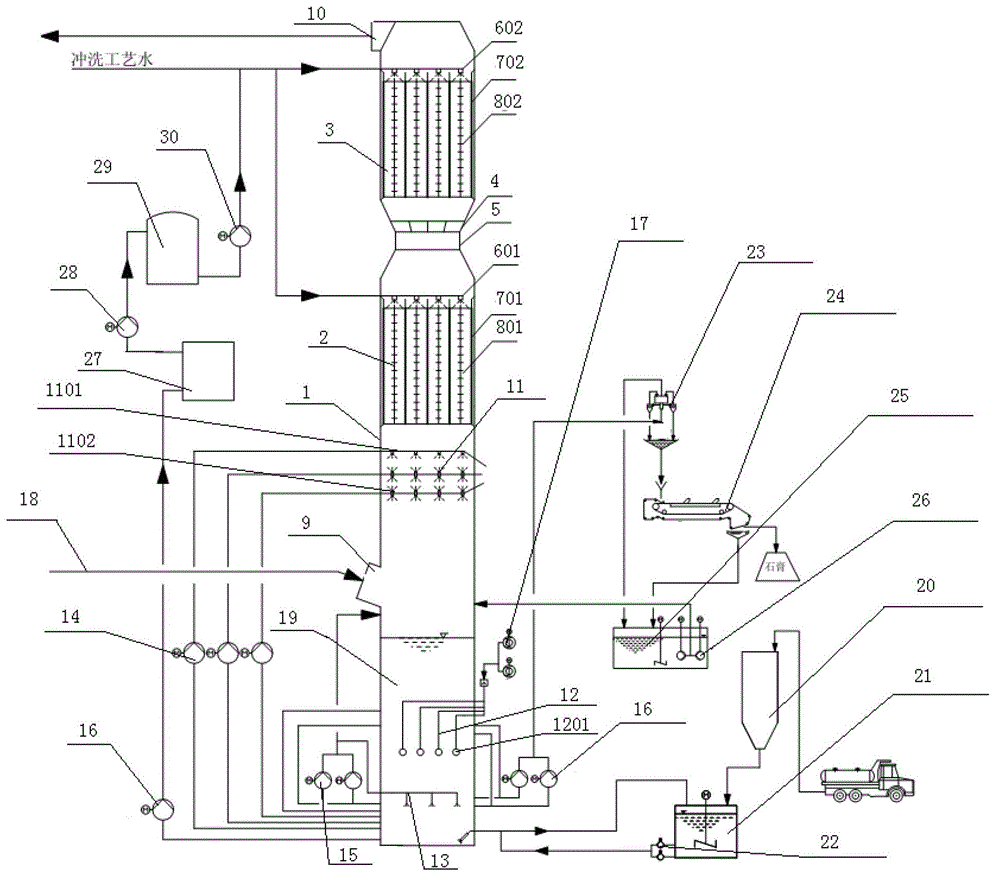

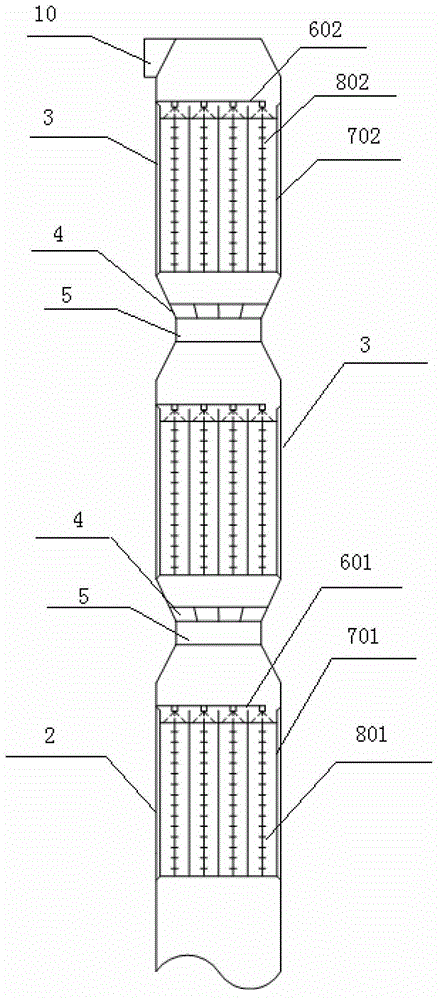

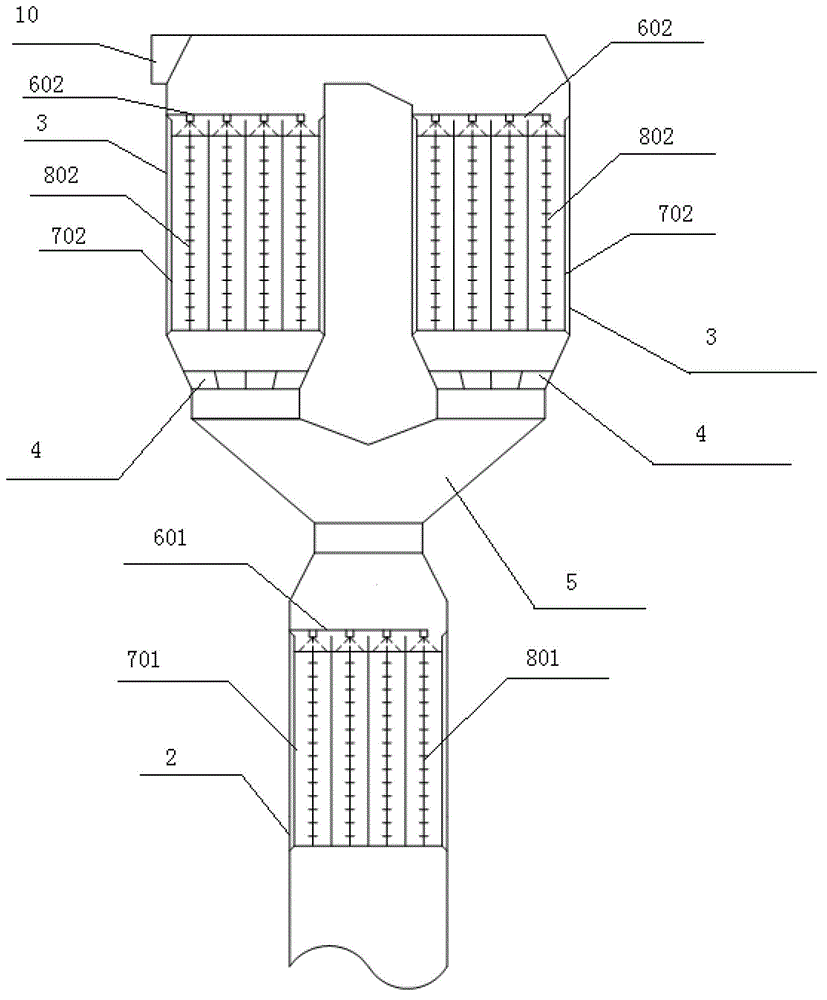

Modularized integrated smoke purification system and method for removing plurality of pollutants

ActiveCN102974185ALow running costLower stoichiometric ratioCombination devicesElectricityMulti pollutant

The invention discloses a modularized integrated smoke purification system and method for removing a plurality of pollutants. The system comprises an absorption tower, wherein a smoke inlet is arranged in the lower end of the absorption tower; the absorption tower is internally provided with a spraying device which is located above the smoke inlet and is used for spraying an absorbent, a first wet-type electric precipitation device located above the spraying device, and a second wet-type electric precipitation device located above the outer side of the absorption tower; and a smoke uniform distributor is arranged between the first wet-type electric precipitation device and the second wet-type electric precipitation device. The invention further discloses a method for carrying out smoke purification by using the system; the pollutants existing in an aerosol form, including SO2, NOX, superfine smoke dust, SO3 acid fog, mercury and the like in the smoke, can be intensively removed; gypsum rain is prevented and an environment is protected; and the smoke purification efficiency is improved.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

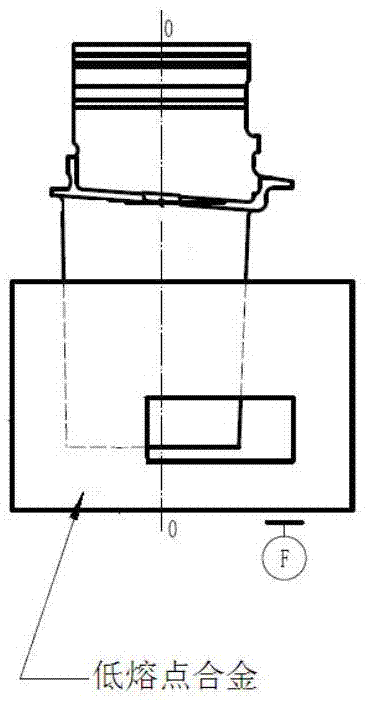

Machining method for turbine work blade

The invention discloses a machining method for a turbine work blade. The machining method for the turbine work blade aims to improve the production quality and production efficiency of the turbine blade and meet the machining and use requirements for the turbine work blade of an aero-engine. According to the technical scheme, the machining process comprises the steps of oil removing, precision positioning of the blade, wax filling, grinding of tenon teeth and the tooth exhaust side, wax removing, melting of low-melting-point alloy, pollutant removing, grinding of the bottoms of the tenon teeth, grinding of a marginal plate and the tooth air inlet lateral face, fluorescent inspection, comprehensive detection, machining of film holes, cleaning and storage. A five-axis numerical control creep feed grinder is adopted, the turbine work blade machining process with the advanced manufacturing technology is achieved, novelty, creativity and practicability are high, the process route is arranged reasonably, the production efficiency is high, the blade machining quality is high, the requirement for production of a large batch of turbine blades can be met, and the machining method can be widely used for machining turbine work blades of aero-engines.

Owner:AECC AVIATION POWER CO LTD

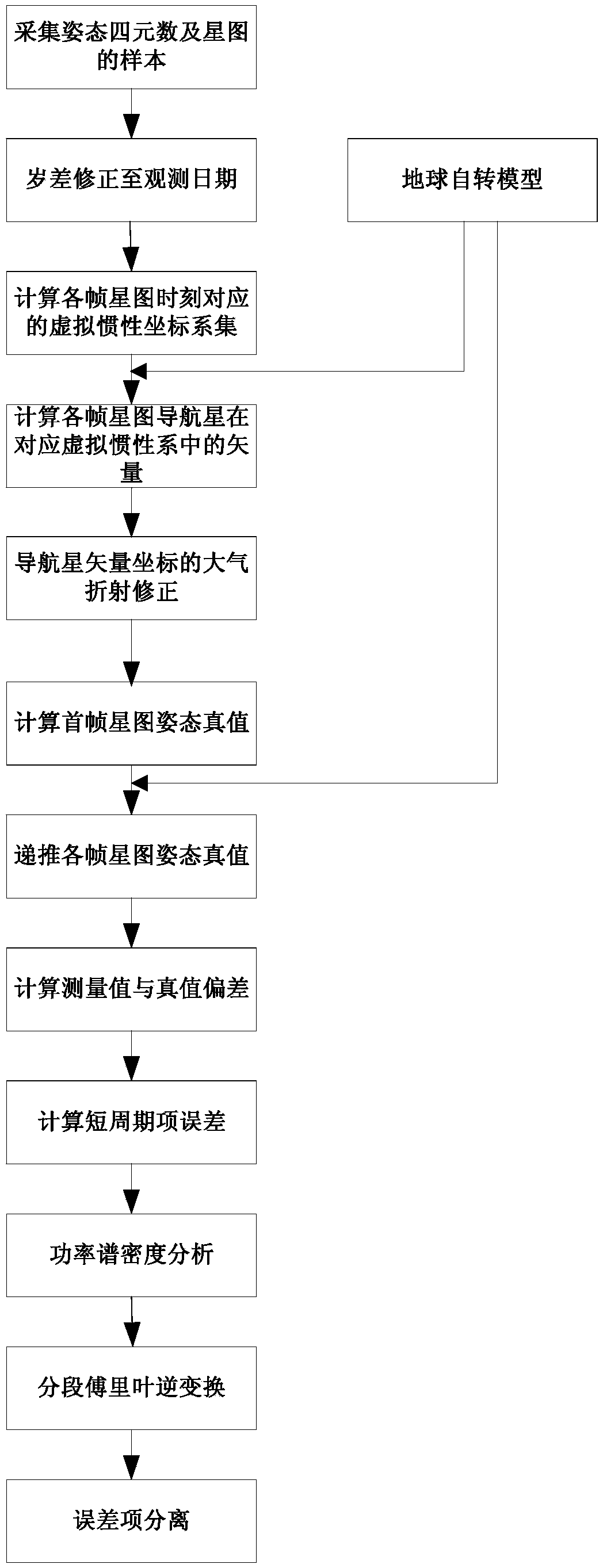

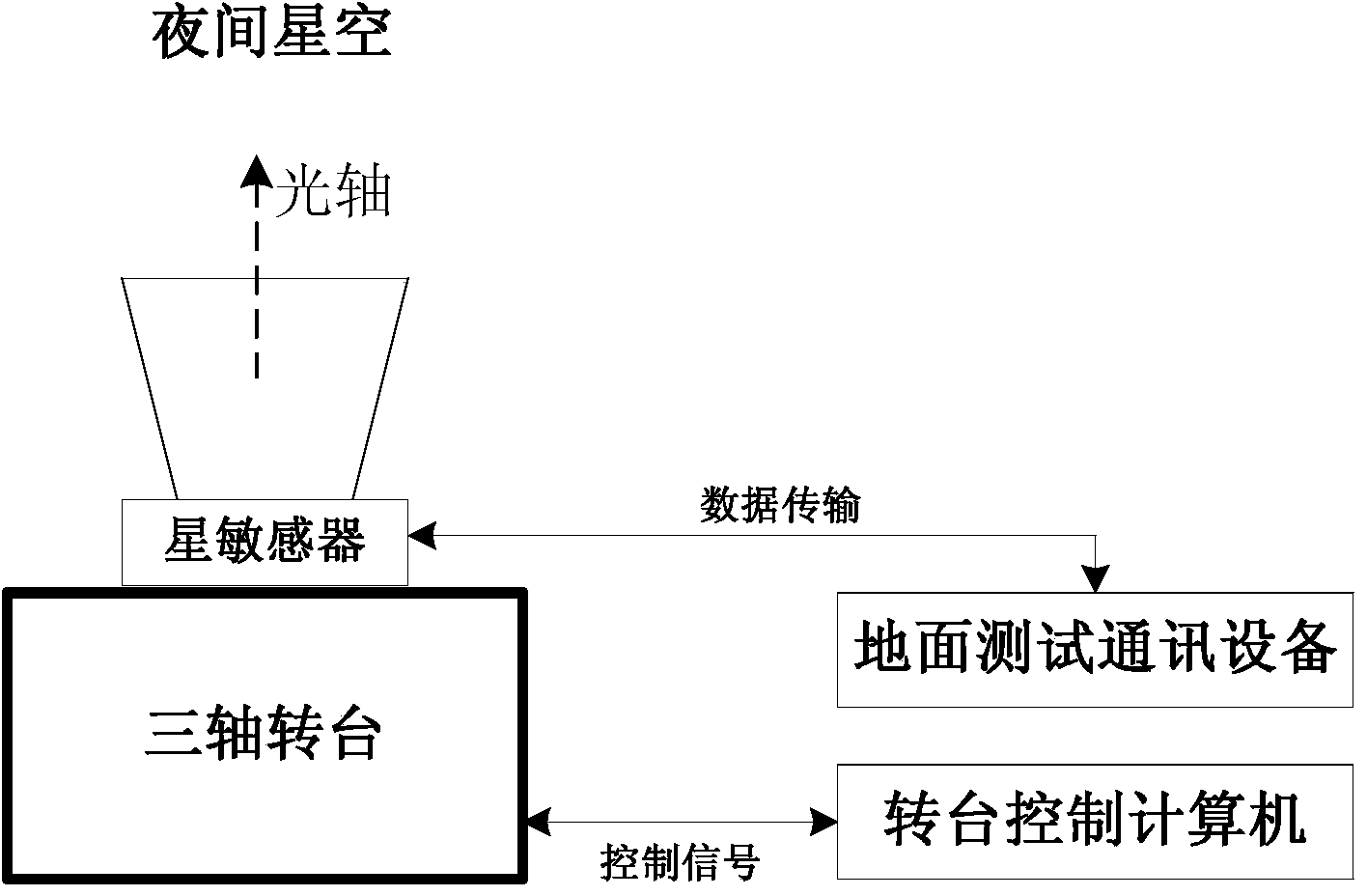

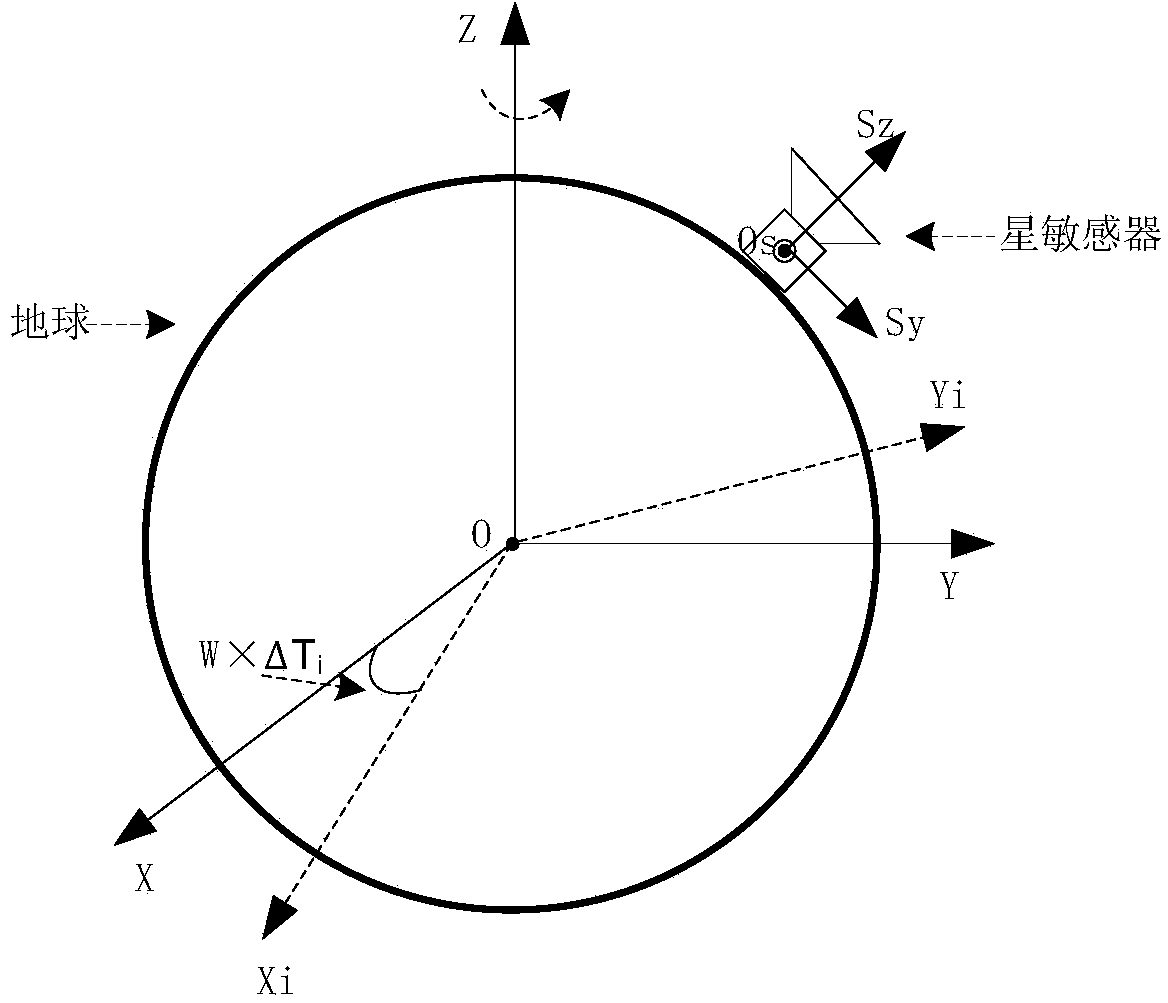

Outfield precision testing method for high-precision star sensor

ActiveCN104280049AAchieving Frequency Domain StrippingAccurate calculationNavigation by astronomical meansStar patternObservational error

The invention discloses an outfield precision testing method for a high-precision star sensor. Accuracy in calculation of a star pattern posture of the star sensor and frequency domain stripping of short-period error terms of the posture are realized by utilizing a procession correction formula, an earth rotation model, an atmosphere correction model and a power spectral density formula, and the posture measuring error of the star sensor can be rapidly and effectively analyzed and evaluated. According to the method, the hardware resource is not occupied, the method is realized by utilizing software and does not need the ground intervention. According to the method, by combining the posture identification principle of the star sensor and adopting a data smoothing method, the posture truth value of each frame star pattern moment is calculated, so that a foundation is established for the subsequent analysis on the posture measuring error; by adopting the method for combining the time domain and the frequency domain, the short-period error term is decomposed into an airspace low-frequency error, a high-frequency error and a time-domain error by virtue of the power spectral density analysis, so that reasonable data support is provided for further evaluation of the precision indexes of the star sensor, and the index performance of the star sensor can be improved.

Owner:BEIJING INST OF CONTROL ENG

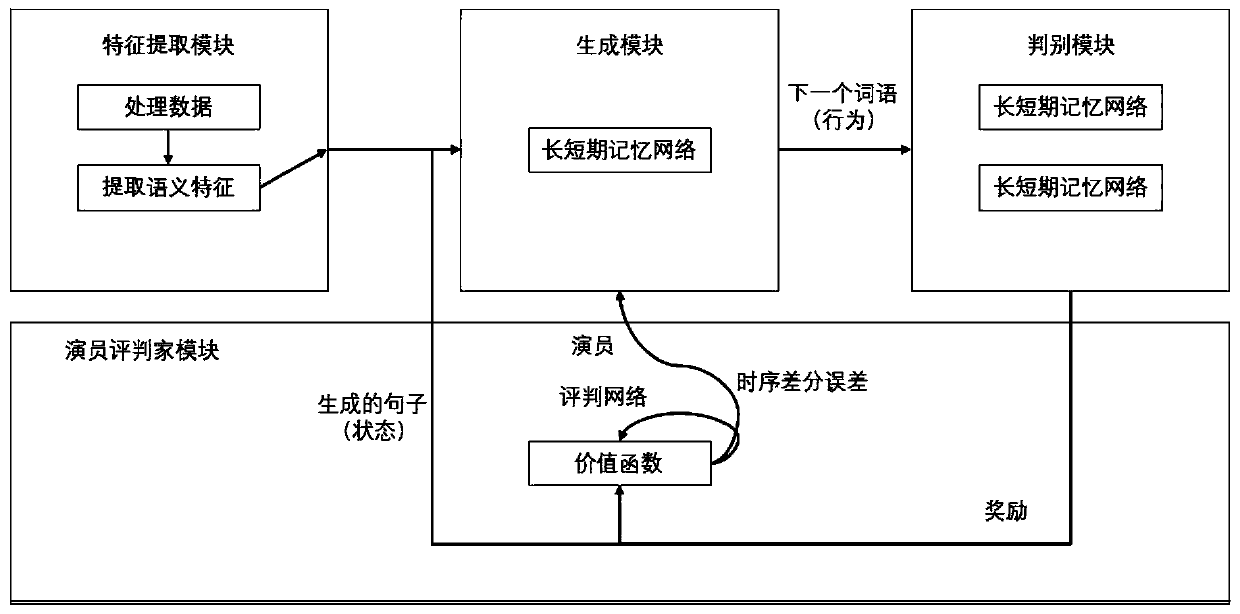

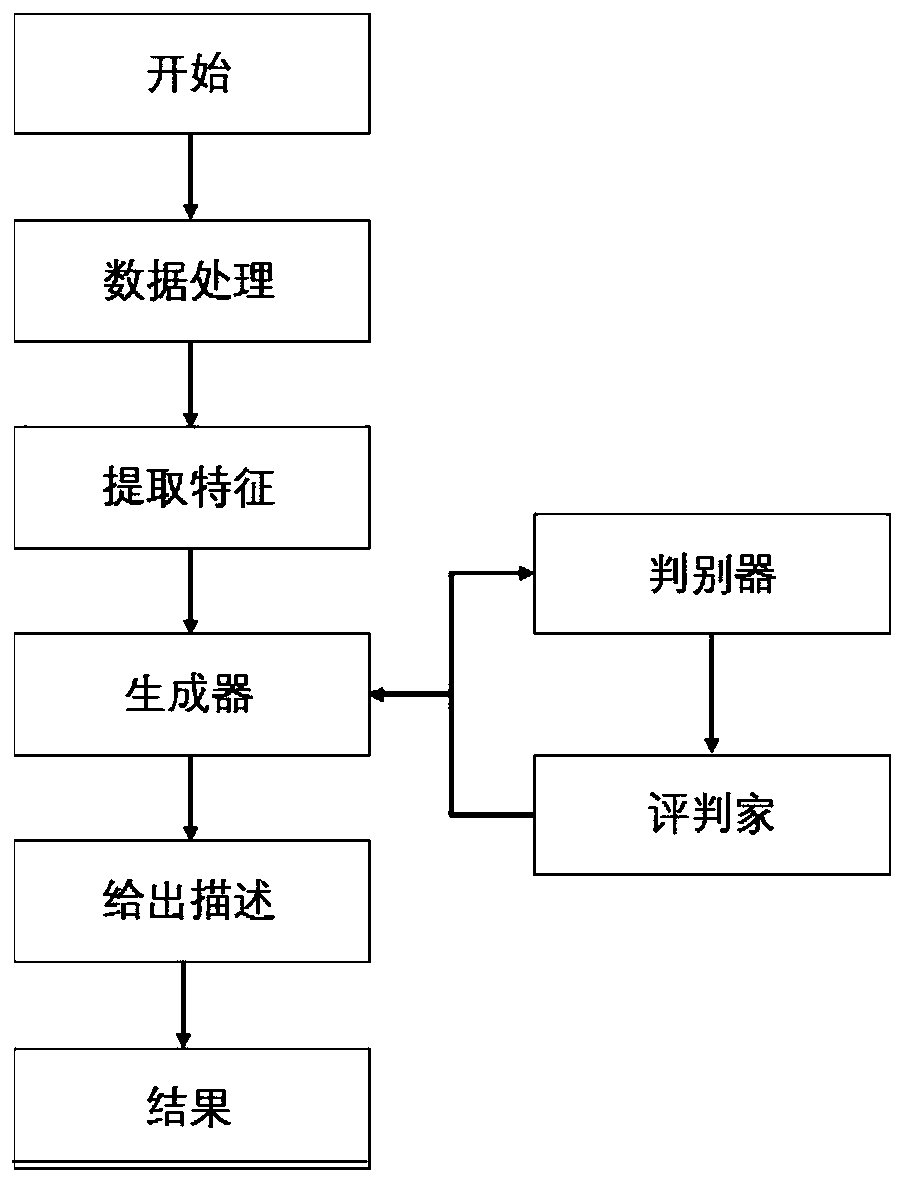

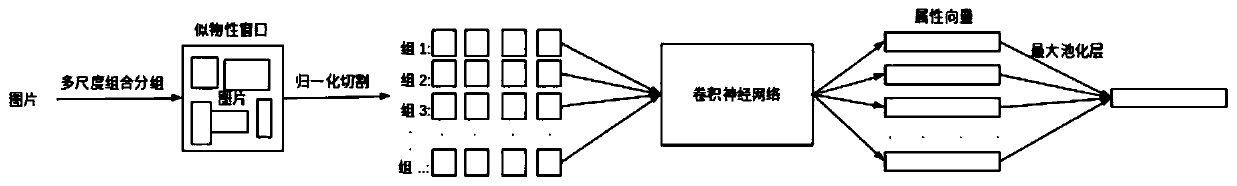

Picture description generation method and system based on Actor-Critic generative adversarial network

PendingCN111159454AIncrease diversityImprove creativityCharacter and pattern recognitionNeural architecturesAlgorithmGenerative adversarial network

The invention discloses a picture description generation method and system based on an Actor-Critic generative adversarial network, and the method comprises the following steps: (1) obtaining a picture described by a known text, carrying out the preprocessing, and constructing a training set, (2) establishing a target network based on a generative adversarial network and an Actor-Critic algorithm,wherein the target network comprises a generator network, a discriminator network and a Critic network, (3) inputting the pictures in the training set and the text description of the pictures into the target network, performing pre-training and adversarial training on the generator and the discriminator, and performing single-step updating on the parameters of the generator by adopting an Actor-Critic algorithm, and (4) inputting the target picture needing to generate the text description into the trained generator to obtain the text description of the target picture. According to the method,based on the Actor-Critic algorithm, an adversarial network technology is adopted, and diversified text description can be generated on a given image.

Owner:ZHEJIANG UNIV

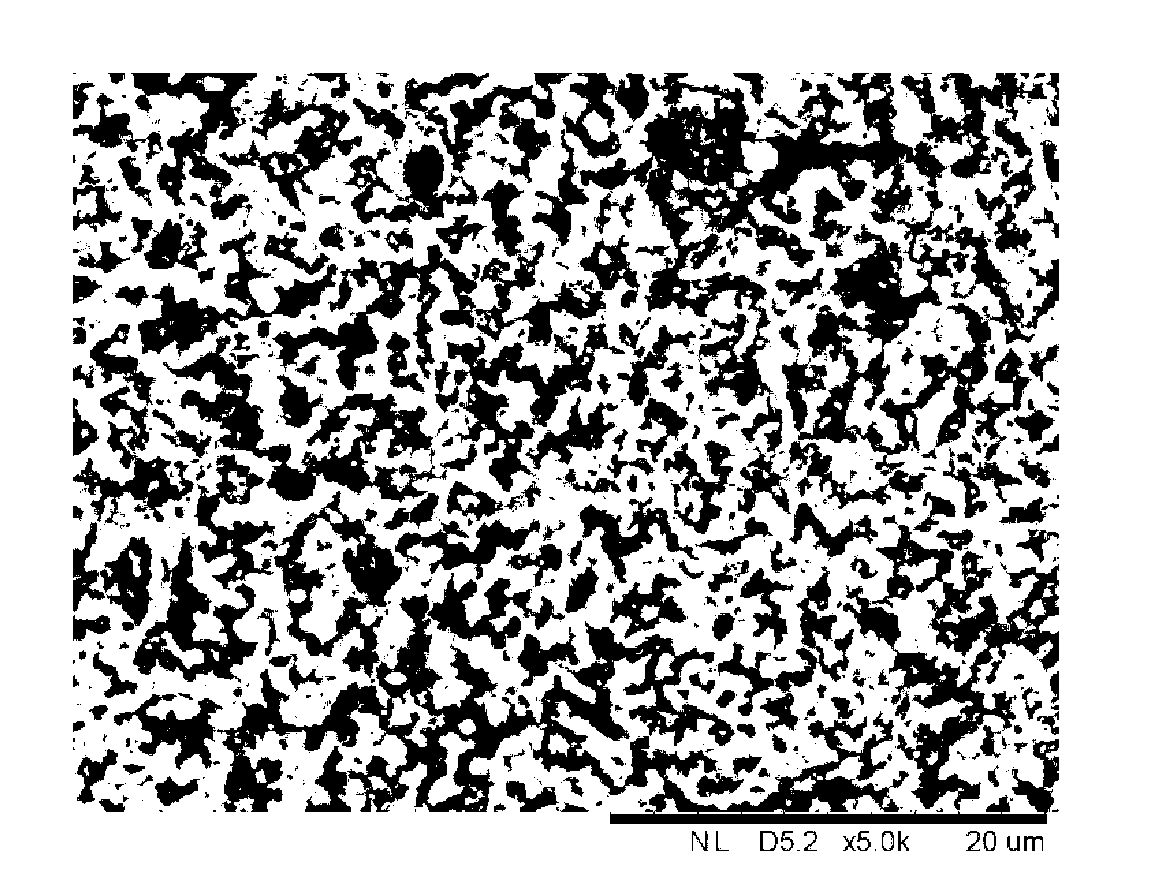

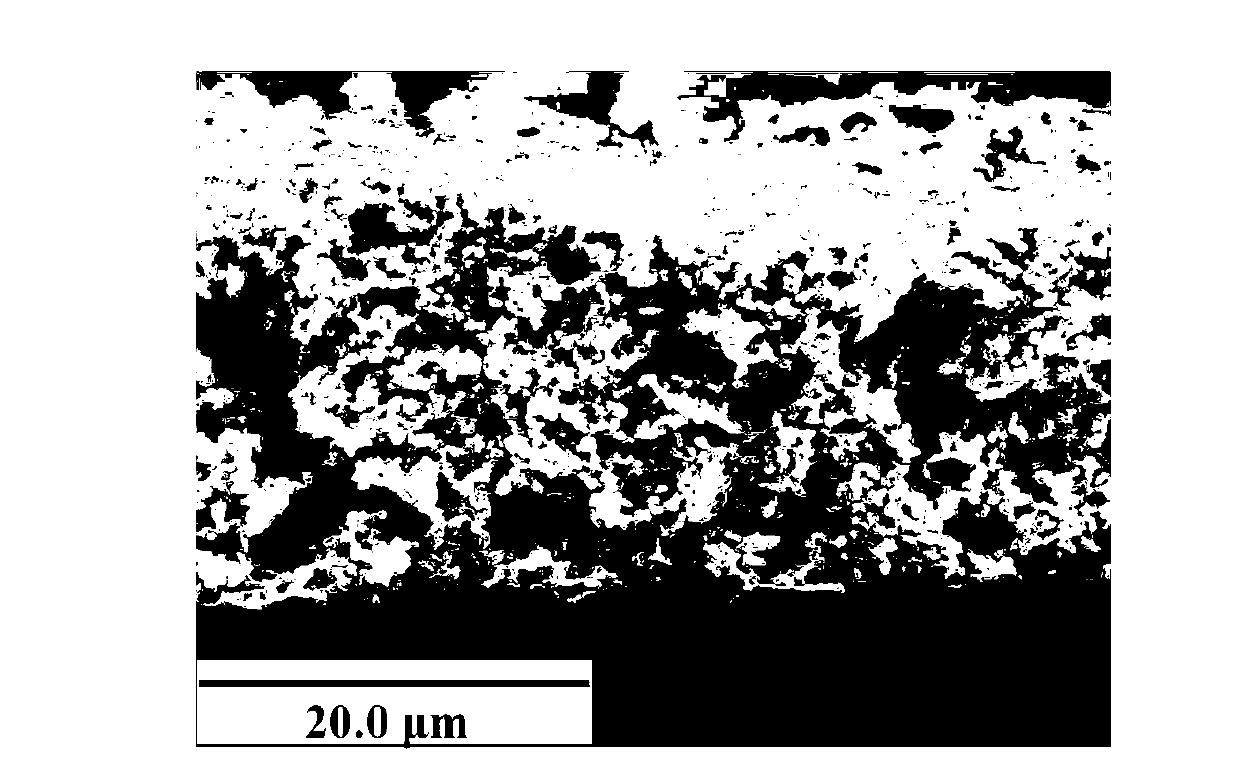

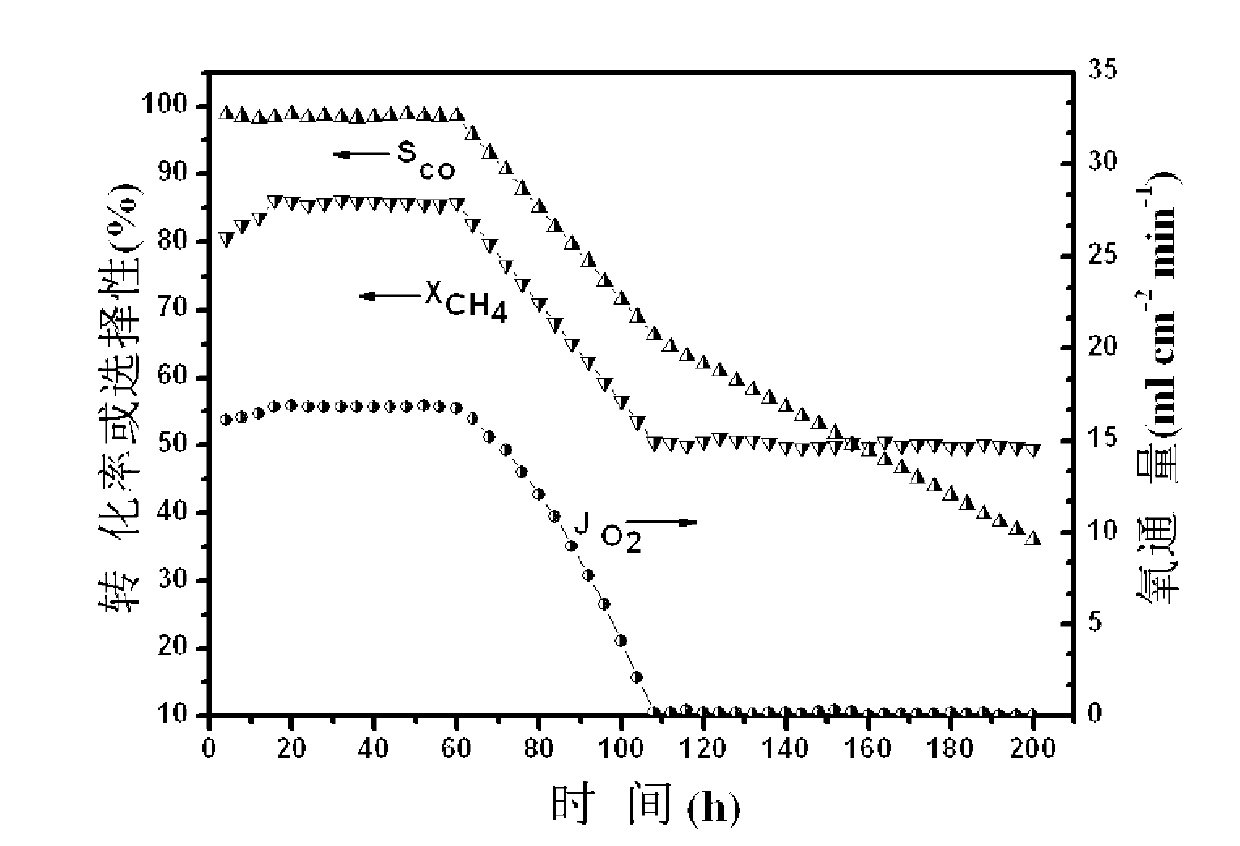

Multi-layer composite ceramic oxygen permeation film as well as preparation and application thereof

ActiveCN103272488AReasonable designHigh Oxygen Osmotic FluxSemi-permeable membranesDispersed particle separationComposite filmComposite ceramic

The invention relates to a multi-layer composite ceramic oxygen permeation film as well as preparation and an application thereof. The composite film is composed of a porous layer which is resistant to a reaction atmosphere and has a protective function, and a compact layer which has high oxygen permeation performance. Methods such as a spraying method are adopted for combining the porous layer with the compact layer, and the multi-layer composite ceramic oxygen permeation film is prepared through certain degree of thermal treatment. According to the invention, the design is reasonable, the structure is compact, the traditional design concept is broken through, and the practicability of an oxygen permeation film reactor can be effectively enhanced. The invention is applicable to a film reaction process, particularly the multiple-reaction coupling, and solves the problem that a traditional single-layer reactor is hardly balanced between the high oxygen permeation performance and excellent chemical stability.

Owner:NANJING TECH UNIV

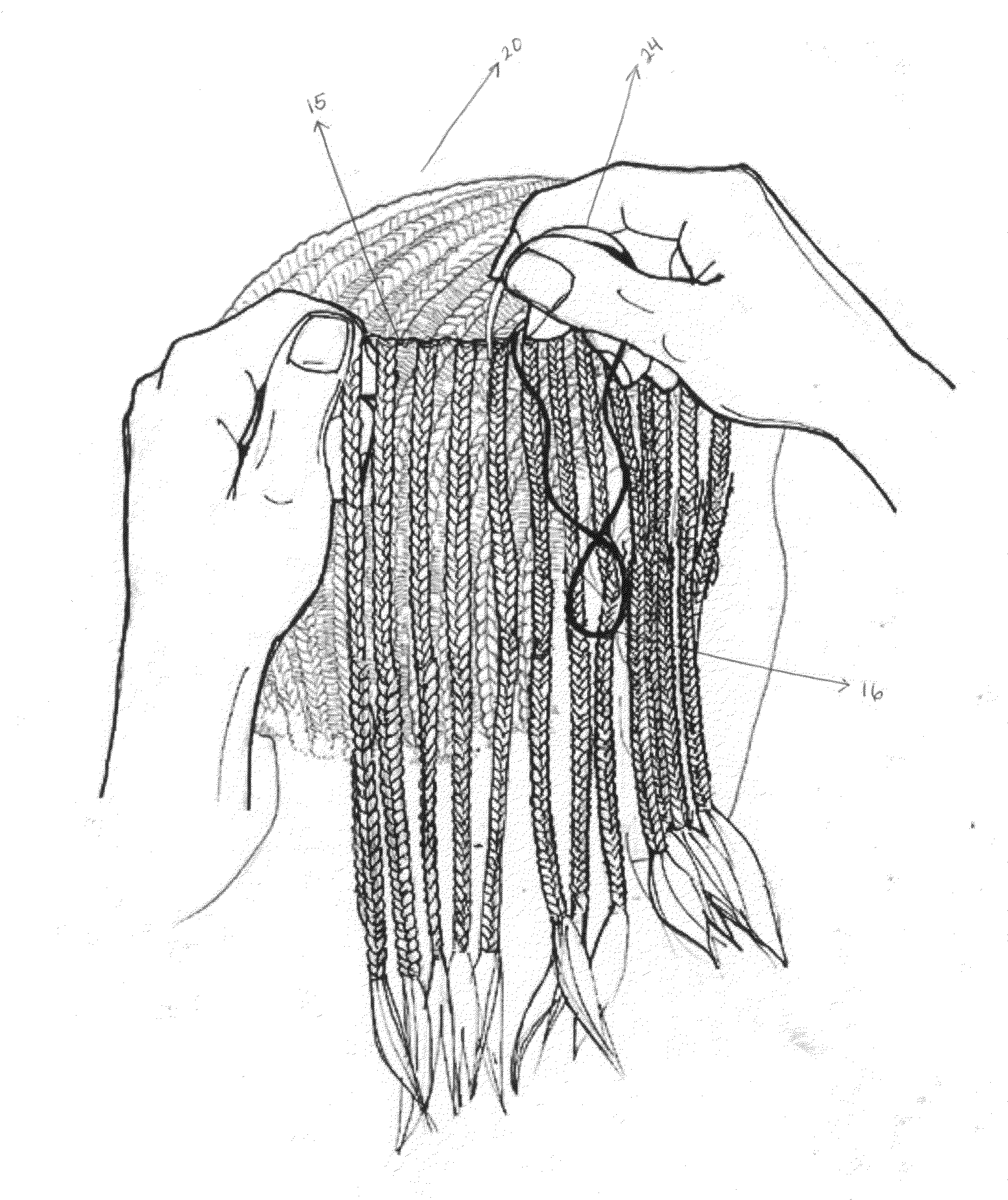

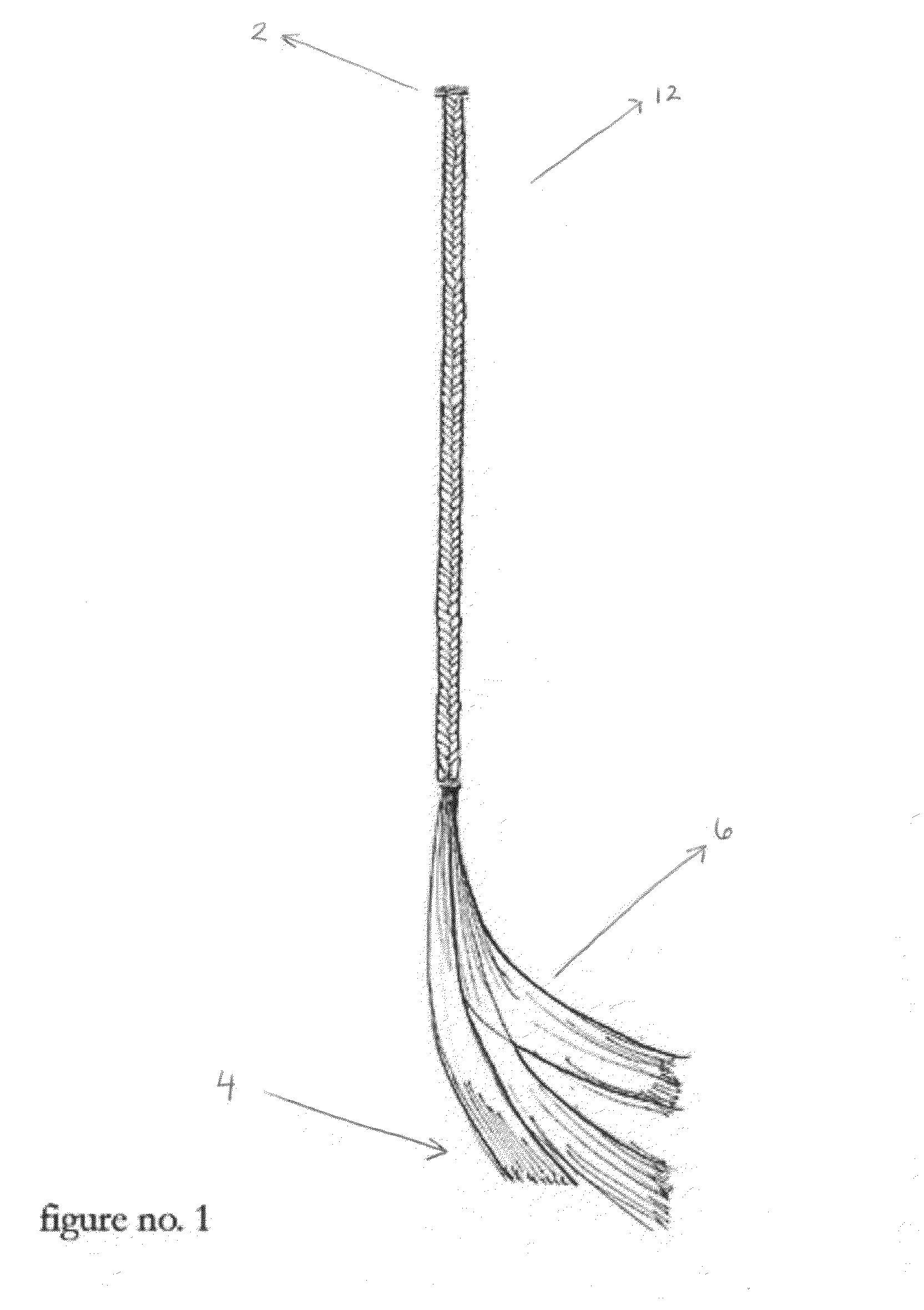

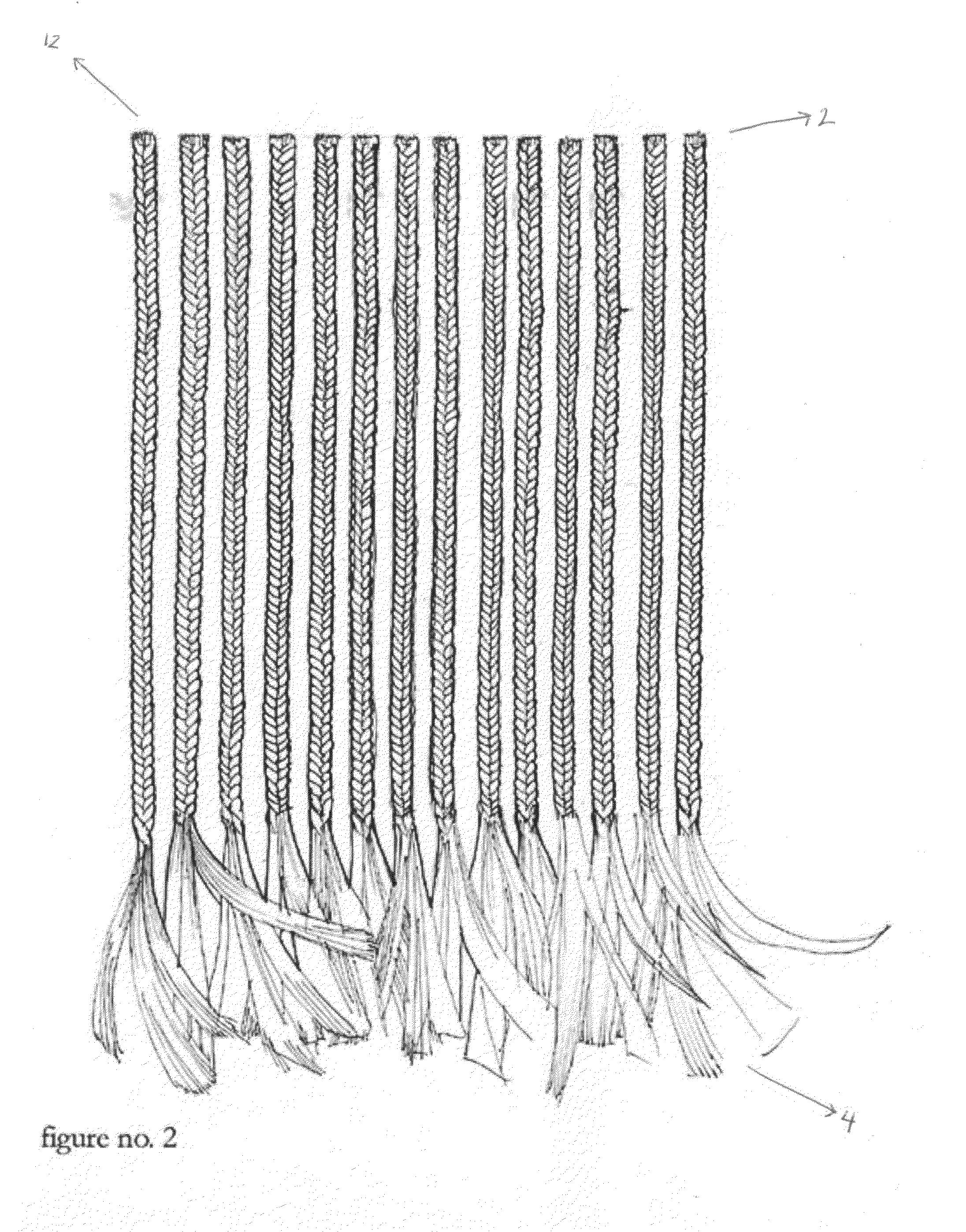

Braided hair weft

The present invention is an apparatus designed to reduce the length of time it takes to add hair extensions and braid individual braids to a person's head. The present invention requires anchoring hair fibers to a weft creating an apparatus for quickly adding the look of individual braids without requiring one to individually braid strands of a person's hair. Creating this apparatus requires: (1) Braiding individual braids from hair fibers; (2) Using thread to stitch the individual braids together creating a horizontal anchor of Singles stitched together forming an apparatus we'll call a Braided Hair Weft. The present invention is a single apparatus that does not have multiple parts. It requires no preparatory work to make ready to apply to one's head because the individual braids come pre-braided and application is simple requiring a single step which is to sew it onto the cornrows on the client's head.

Owner:OWENS SHERRELLE +1

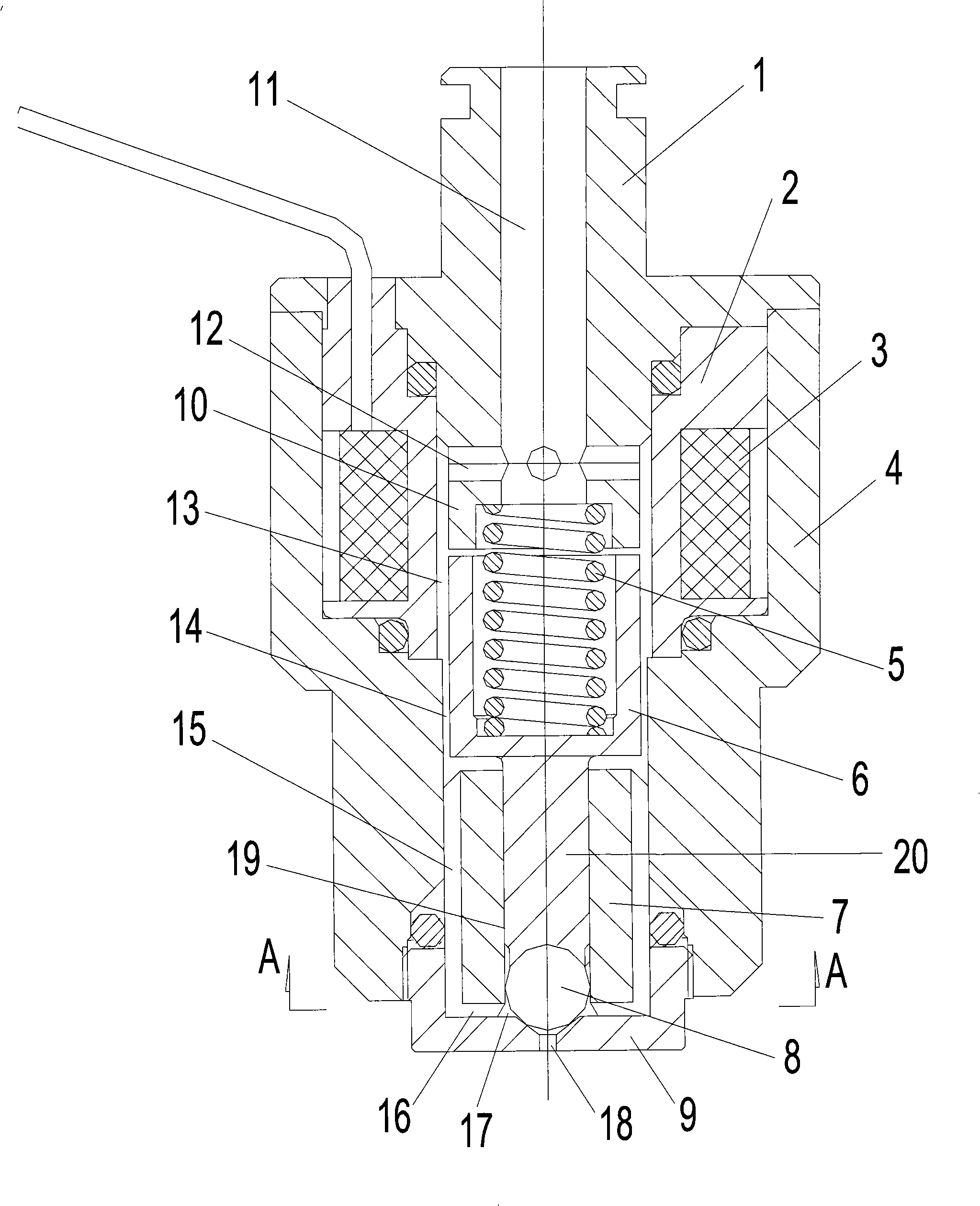

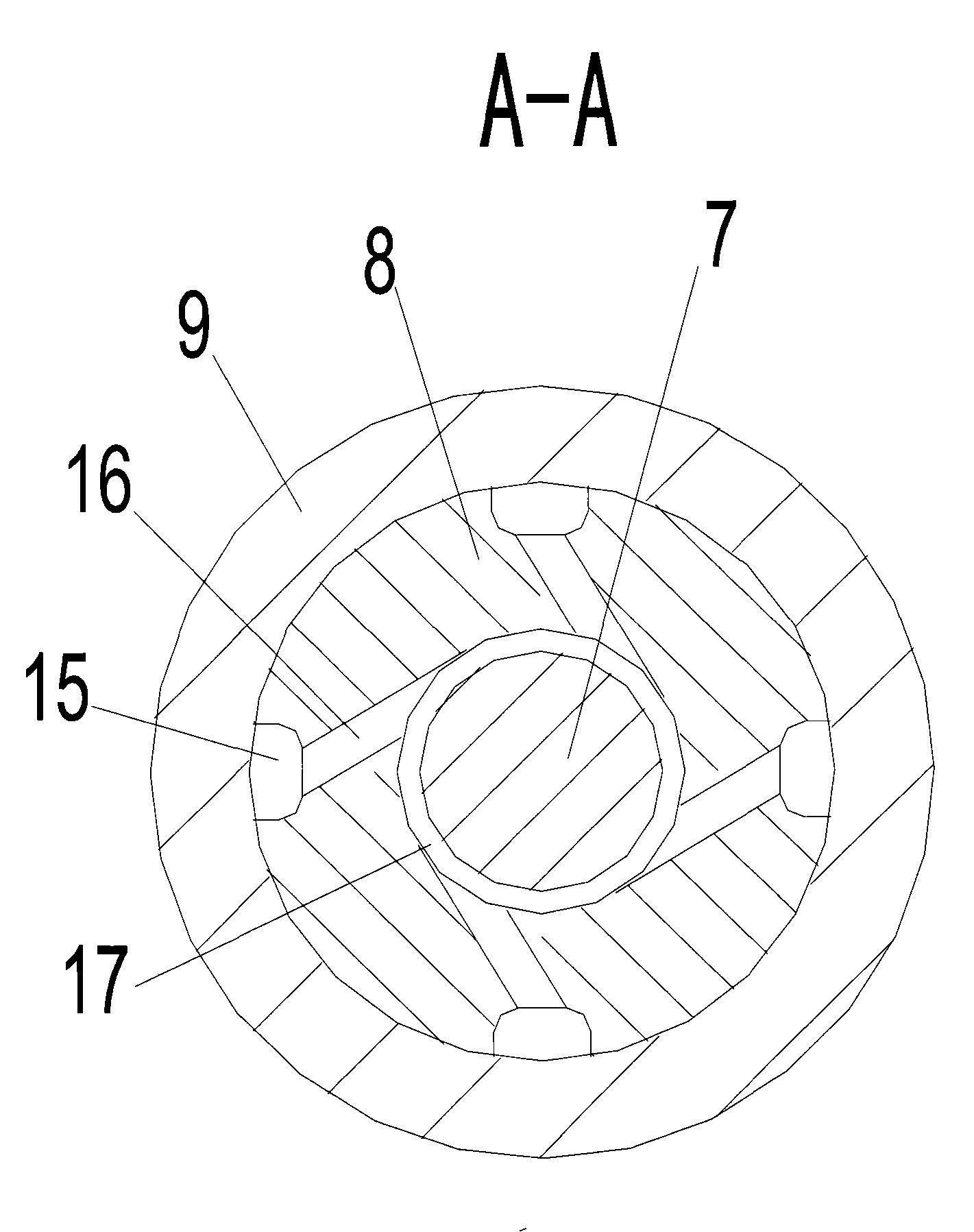

Swirling electronic-controlled fuel injector of gasoline engine

InactiveCN101806265ASolve the problem of poor atomization effectPromote atomizationFuel injection apparatusMachines/enginesGasolineEngineering

The invention discloses a swirling electronic-controlled fuel injector of a gasoline engine. The swirling electronic-controlled fuel injector of the gasoline engine consists of an end cover, an iron core, a reset spring, an armature, a valve rod, a valve core and a valve seat which are connected axially in turn, and also comprises a coil frame and a coil arranged at the periphery of the iron core, a casing at the periphery of the coil, a guide sleeve movably matched with the valve core and an injection hole, wherein a flow guide slot is formed between the guide sleeve and the valve seat and communicated with an oil through hole 1 indirectly; a swirling chamber of a ring structure is arranged at the periphery of a sealed ring belt formed by the matching of the valve core and the valve seat in sealed way; the flow guide slot is tangent to the swirling chamber or communicated with the swirling chamber in a proximately tangent direction; the swirling chamber is communicated with the injection hole when the valve core moves upward; and the number of the injection hole is only one. The electronic-controlled fuel injector of the invention enables fuel oil to form high speed revolution in the swirling chamber to form umbrella-like spraying, thereby achieving good atomization effect, overcoming a conflict between the atomization and anti-clogging performance of the conventional electronic-controlled fuel injectors of the gasoline engines, and fulfilling the purpose of having good atomization effect and high anti-clogging performance.

Owner:临海弘征汽车电喷技术有限公司

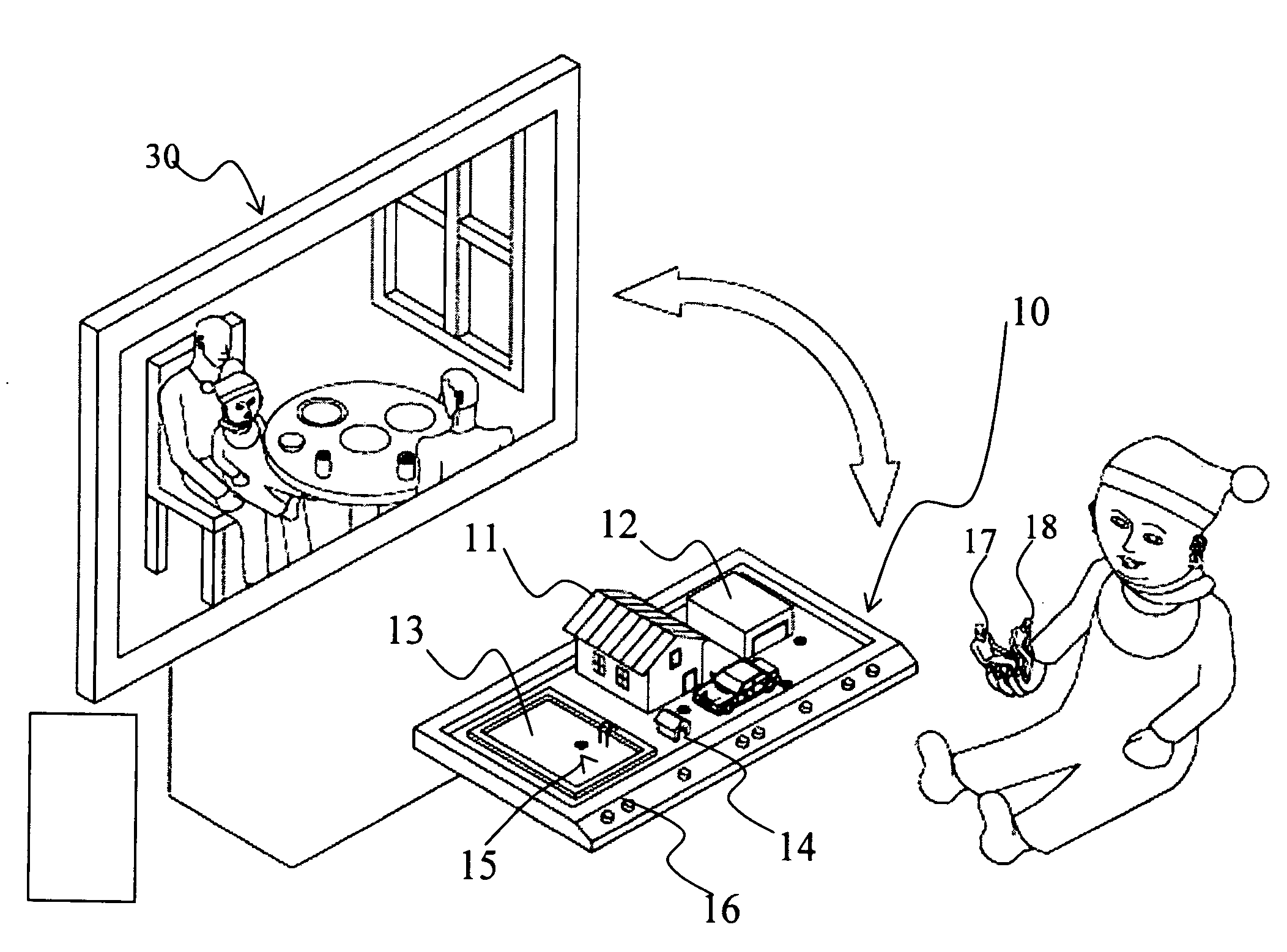

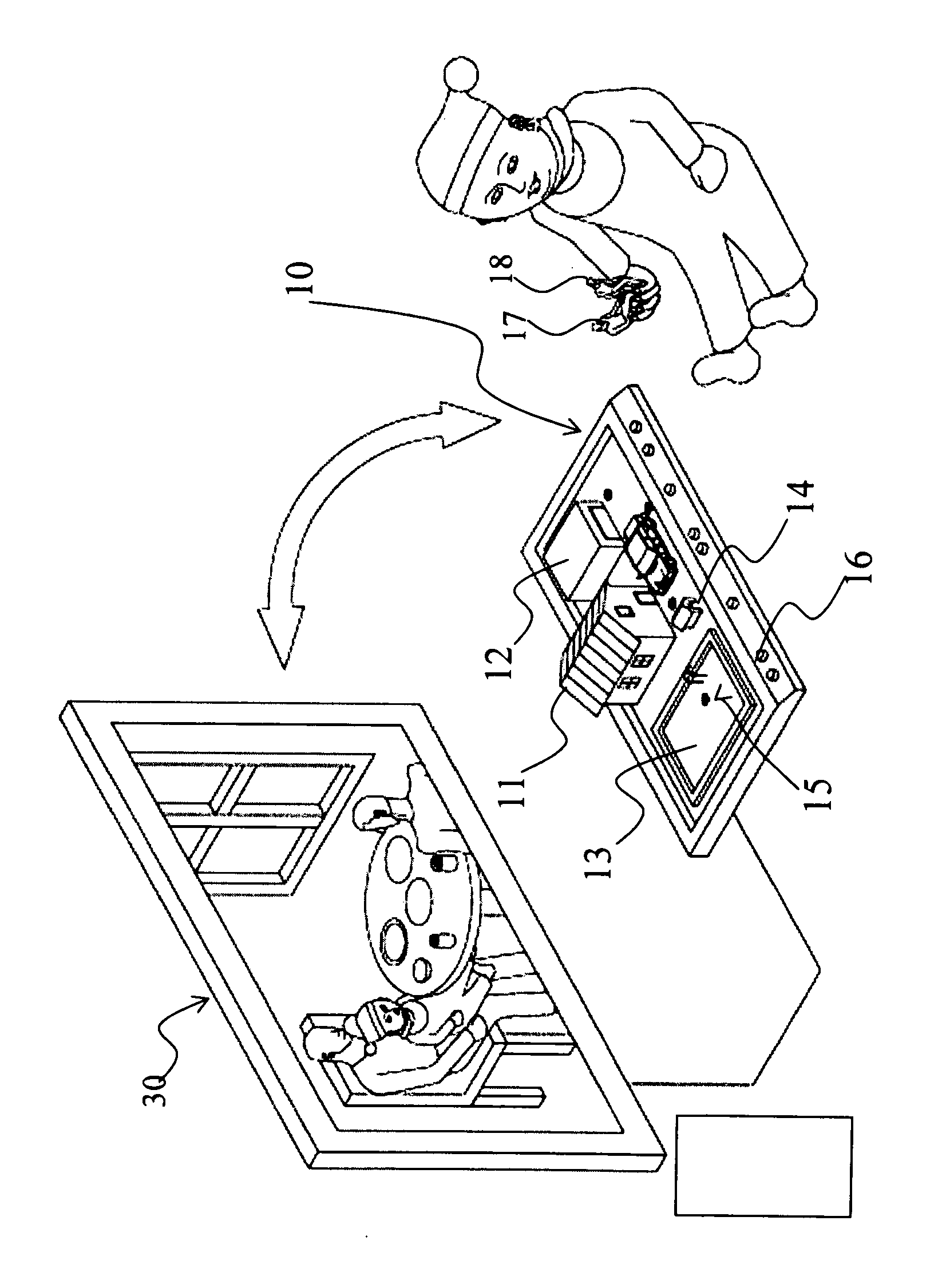

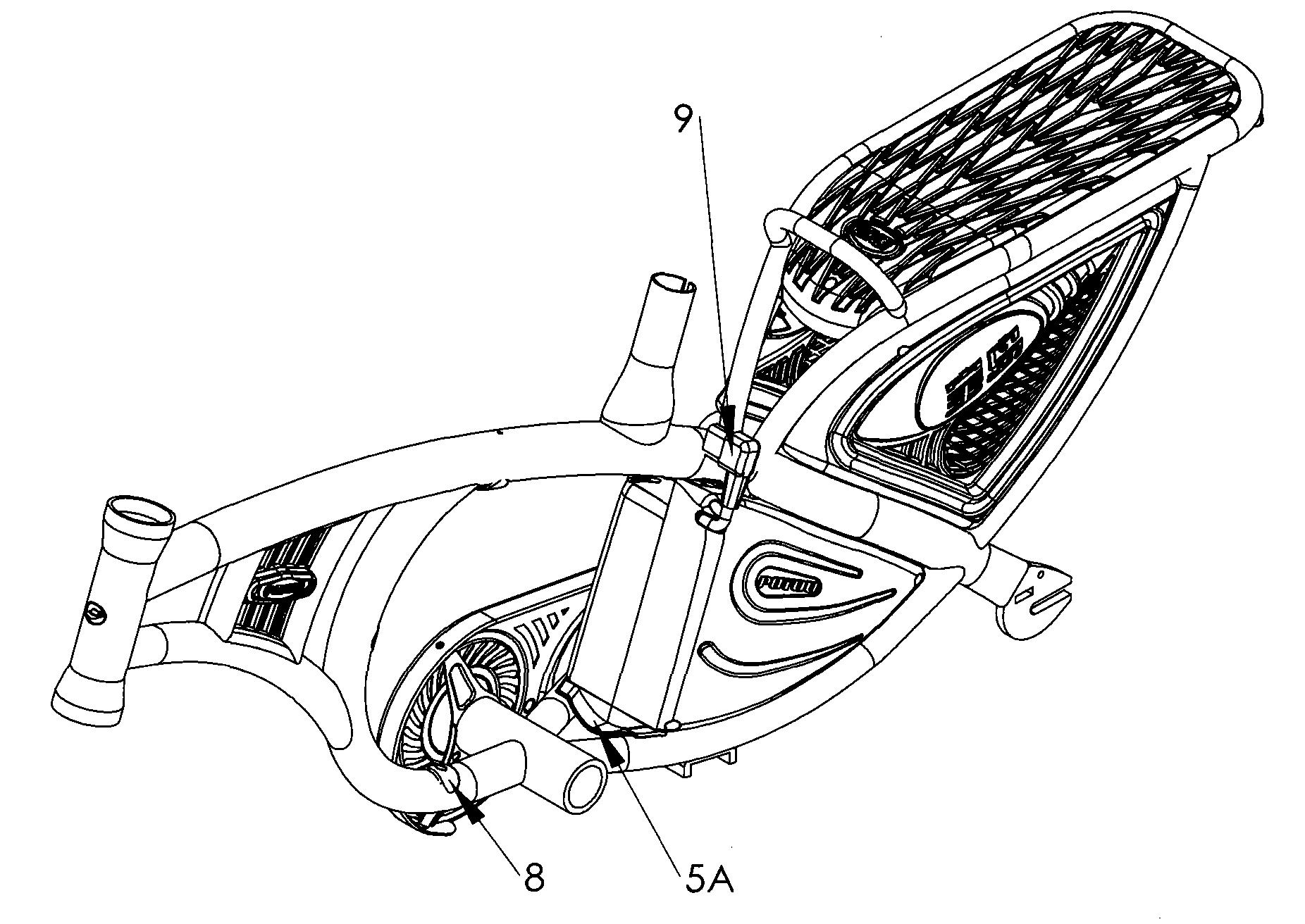

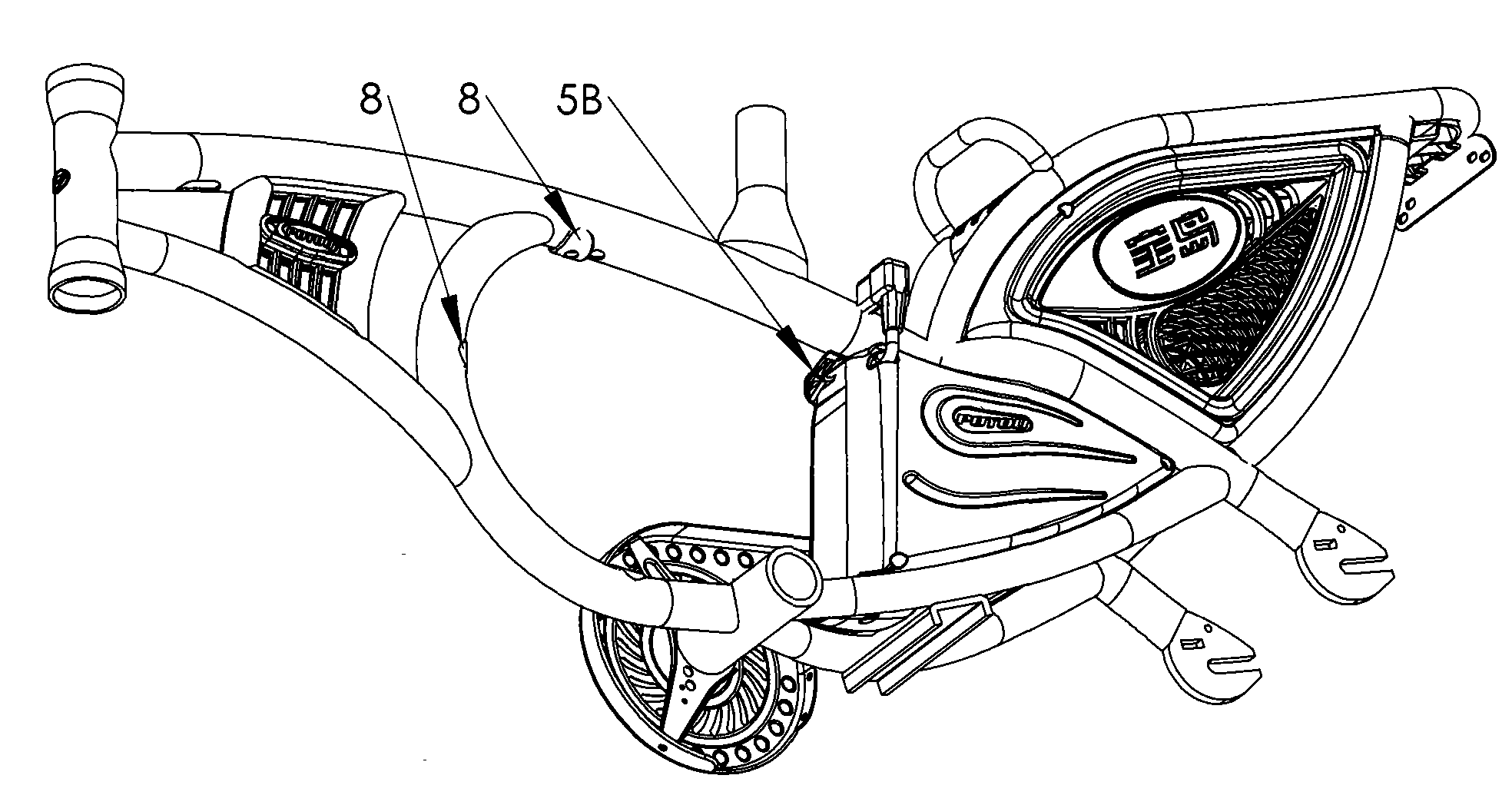

Pretend play toy with reality and virtual interaction

InactiveUS20090197678A1Improve creativityStimulate imaginationComputerized toysVideo gamesVirtual interactionVirtual reality

A pretend play toy with virtual reality interaction is disclosed. Children play toys on a platform in pretend play, and a circuit board underneath unseen by the children can sensor toys' characters and positions for playing virtual scene on the display where the children have interaction with the virtual playground. The present invention combines the physical toys and children's imagination on the display like TV, and let the children unconsciously learn and enhance their creativity and imagination.

Owner:TIRID TECH

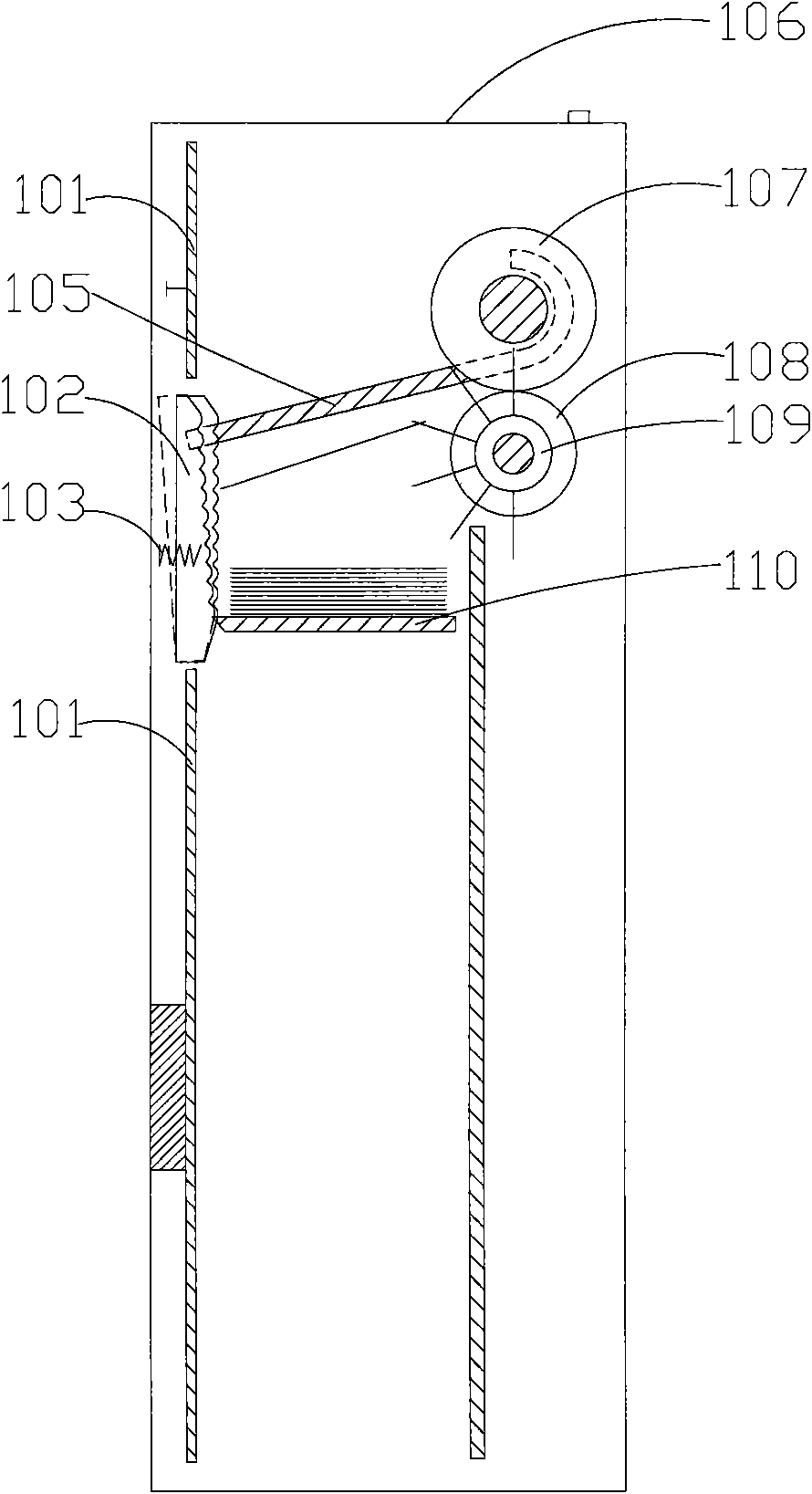

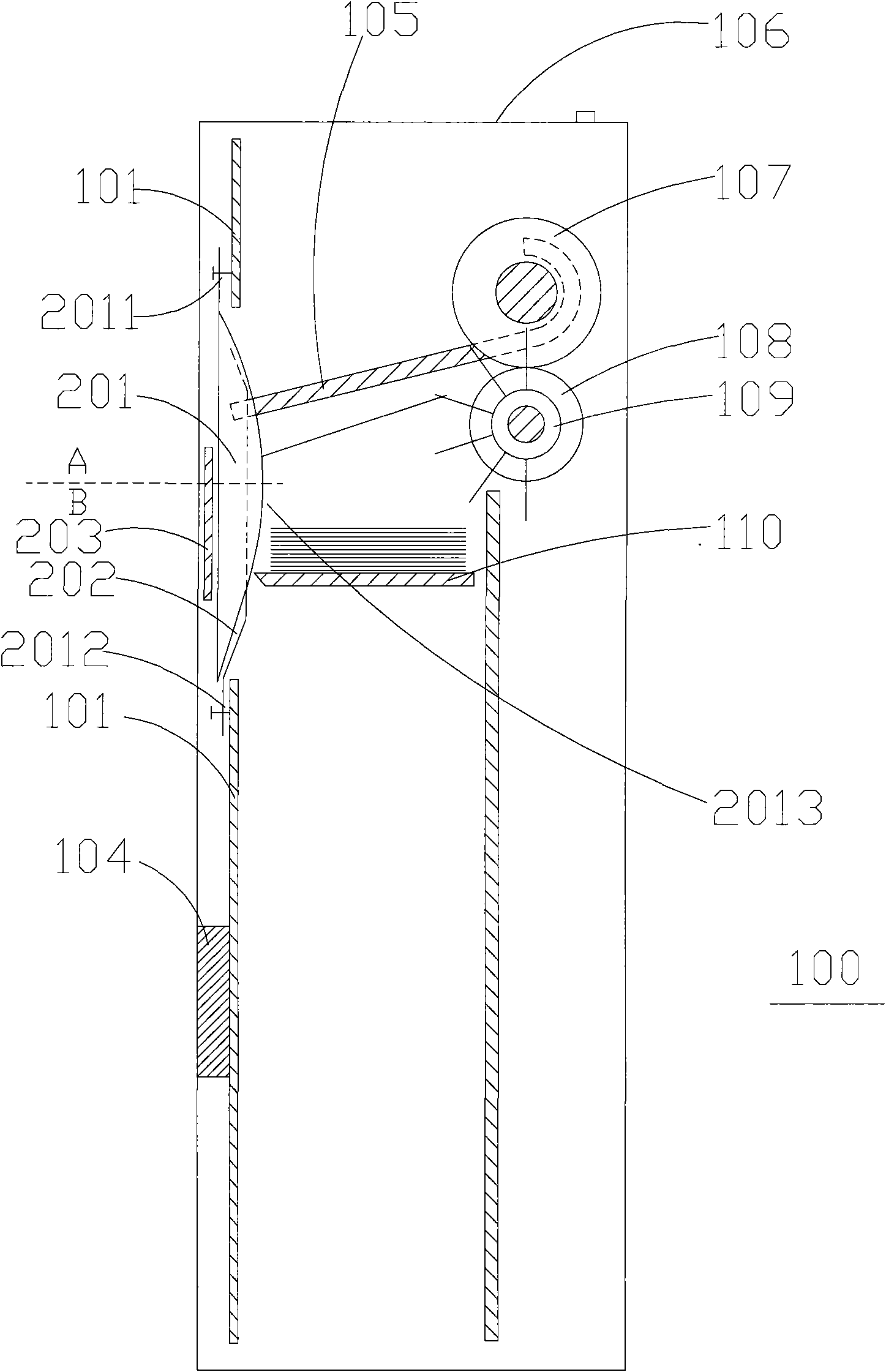

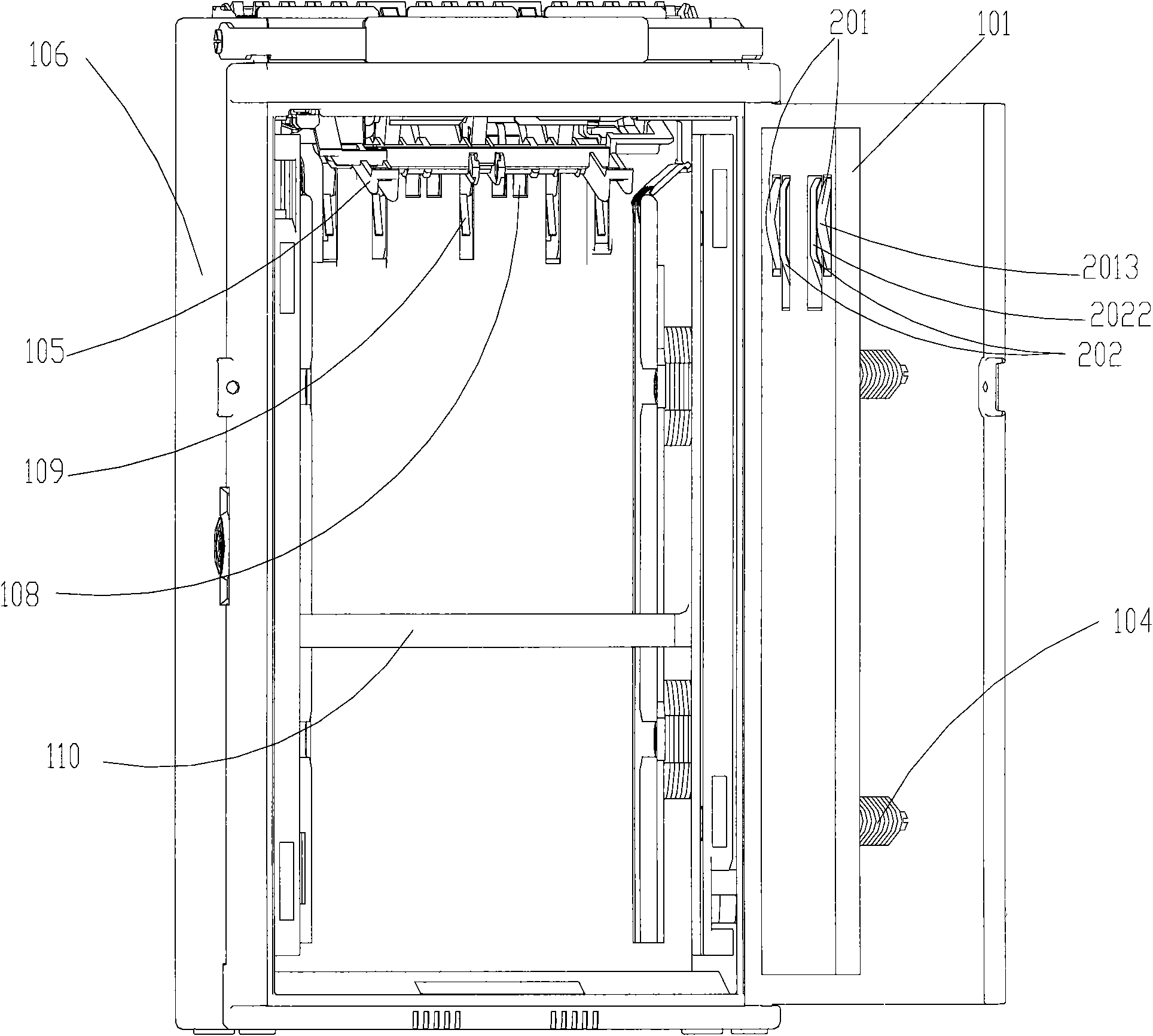

Deposit/withdrawal machine and cashbox thereof

ActiveCN101685557ASlow downImprove creativityCoin/currency accepting devicesPulp and paper industrySelf-service

The invention relates to financial automatic service equipment, in particular to an automatic deposit / withdrawal machine and a cashbox thereof. The cashbox is applied to a financial self-service system and comprises a container containing paper currency and a supporting plate for supporting the paper currency, wherein the container is provided with an outlet / inlet for the paper currency; the outlet / inlet for the paper currency is provided with a pair of pinch wheels for pinching the paper currency into the container; the supporting plate is positioned in the container and can move up and down in the container; the outlet / inlet for the paper currency of the container is provided with a paper currency buffering device corresponding to one side of the pair of pinch wheels; the paper currency buffering device comprises a pedestal and at lease one buffering strip; the pedestal is arranged on the inner wall of the container; the at least one end of the buffering strip is fixed on the pedestal; and the buffering strip is made of a material with certain elasticity and rigidity.

Owner:GRG BAKING EQUIP CO LTD

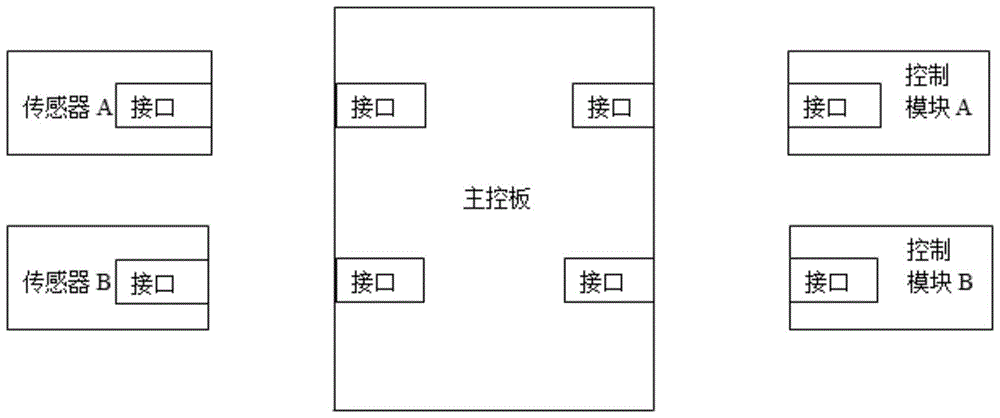

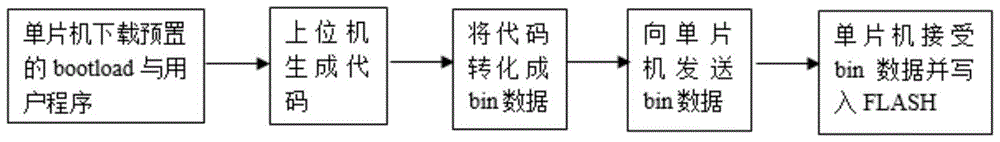

Method for controlling electronic building blocks by graphical programming

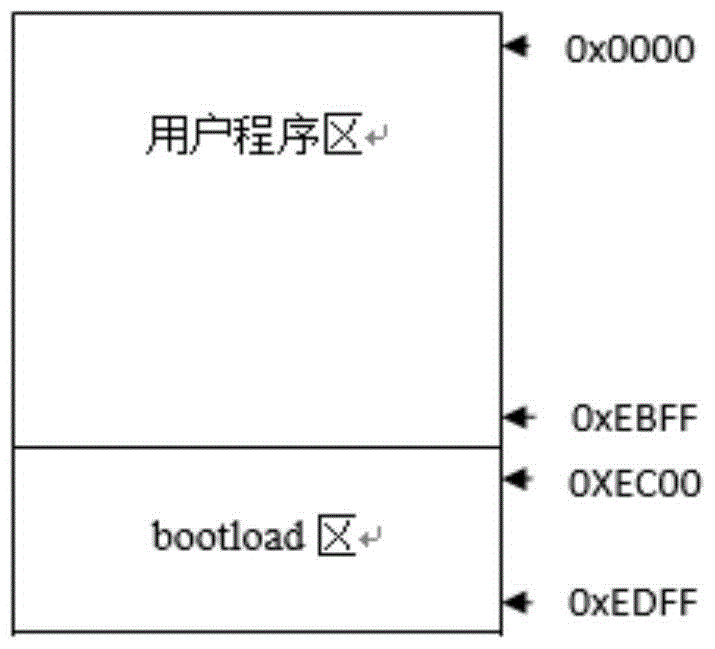

InactiveCN105739974AGood for thinkingImprove creativityToysVisual/graphical programmingMicrocontrollerMicrocomputer

The invention discloses a method for graphically programming and controlling electronic building blocks. At present, the lack of educational toys has a single function and is easy to be boring. The steps of the present invention: divide the FLASH of the single-chip microcomputer of the main control board into the user program area and the bootload area; build electronic building blocks; drag the modules on the host computer interface to the program writing box, each icon has a node, and the upper After traversing each node, the code stored in each node is combined into a complete program in order to save; the saved code is compiled into data in bin format; the MCU receives the character a sent by the host computer, jumps to the bootload area, and erases After removing the user program area, it receives the bin data sent by the host computer, writes the data into the user program area through the bootload program, and then jumps to the user program area. The invention solves the problem that children cannot program, and enables children to open their brains, diverge their thinking, and entertain and educate.

Owner:HANGZHOU DIANZI UNIV

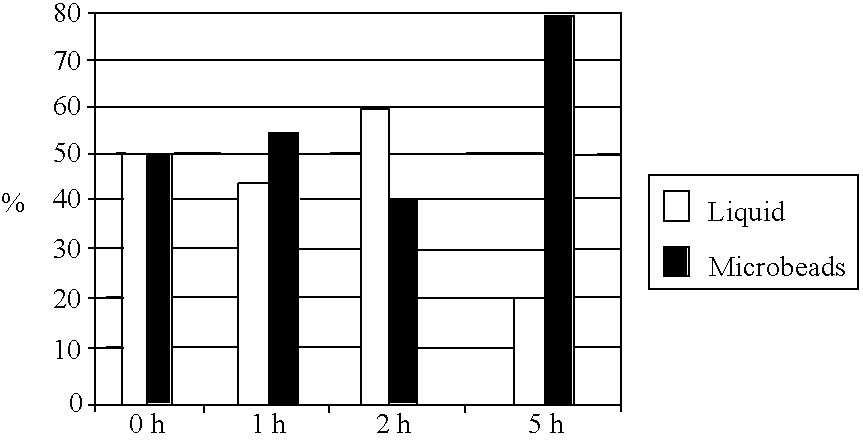

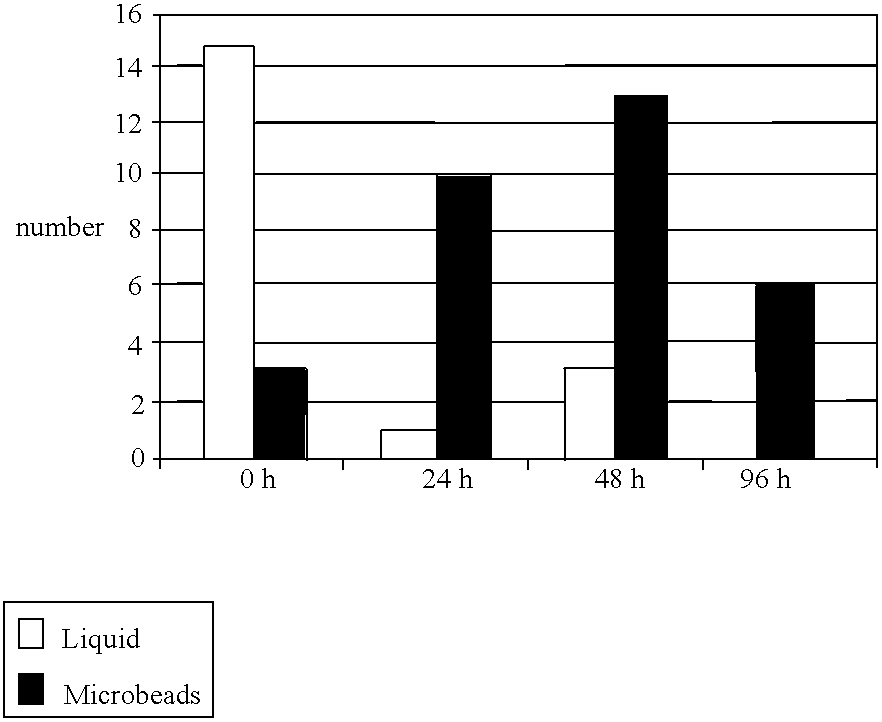

Solid perfumed preparation in the form of microbeads and the use thereof

InactiveUS7723284B2Improve durabilityAllow useCosmetic preparationsToilet preparationsAntioxidantExcipient

The invention concerns a solid perfumed preparation with high persistency in the form of microbeads and comprising a volatile aromatic raw material, or a mixture of volatile aromatic raw materials, and one or several fusible excipients. Said preparation can further comprise one of the following constituents: one or more polymers dispersible in the melted mass formed by the constituents of the preparation, one or more mineral additives, one or more surfactants, one or more antioxidants, one or more colouring agents. The invention can be used in cosmetics and in household product industries.

Owner:V MANE FILS

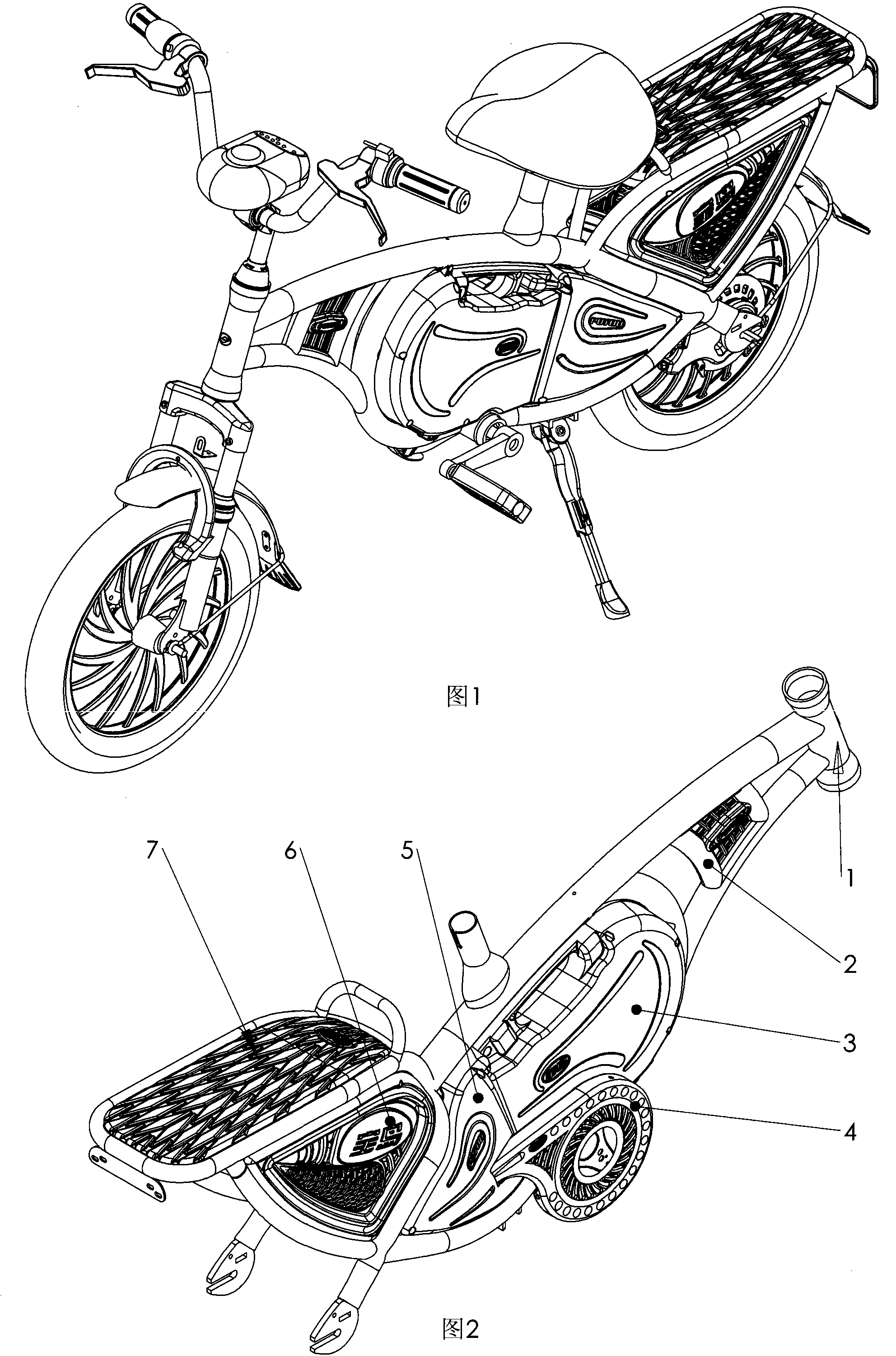

Electric bicycle

ActiveCN102120480AEasy to spin (put) inEasy to spin (take) outRider propulsionVertical tubeVehicle frame

The invention discloses a two-wheel electric bicycle which mainly comprises a bicycle body and standardized parts, wherein the bicycle body mainly comprises a frame, a battery case, a controller case, a chain cover, a front decorating plate, a rear decorating plate, a hanger panel, a protective pad and the like. The frame mainly comprises a head tube, an upper tube, a lower tube, a vertical tube, a loop lug, a bottom fork, a bottom fork axle tube, a vertical fork, a fork joint strip, a fork branch tube, a hanger branch tube, a hanger main tube and the like, wherein the lower tube includes a front lower tube and a rear lower tube, the frame and hangers are assembled and welded into a whole, the upper tube and the vertical fork are integrated into a coherent arc arch, the vertical tube spans over the middle upper part of the upper tube, and the rear lower tube, the bottom fork and the hanger branch tube are connected into a whole by an axis which is a tangent. The controller case is arranged behind the battery case, the battery case and the controller case are arranged in a space defined by the upper tube, the rear lower tube, the loop lug, the bottom fork and the vertical fork, the battery case is arranged at the middle part of the bicycle, and the battery case can be conveniently screwed (put) in or screwed (taken) out from the side of the frame just by rotating the battery case around a positioning arc surface at the lower part of the bicycle. All plastic parts are wrapped in a frame metal piece with a frame structure.

Owner:TIANJIN XINHE TECH +1

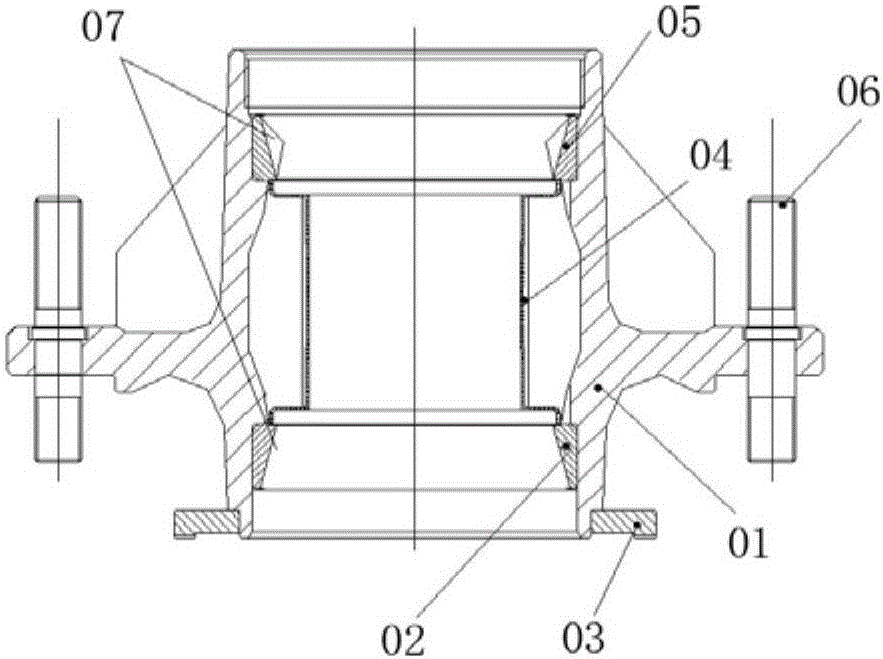

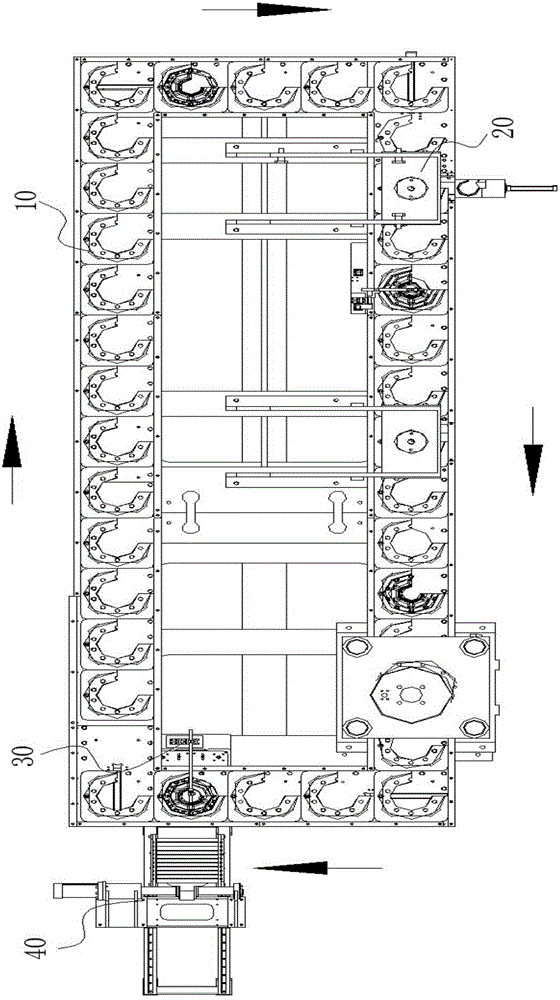

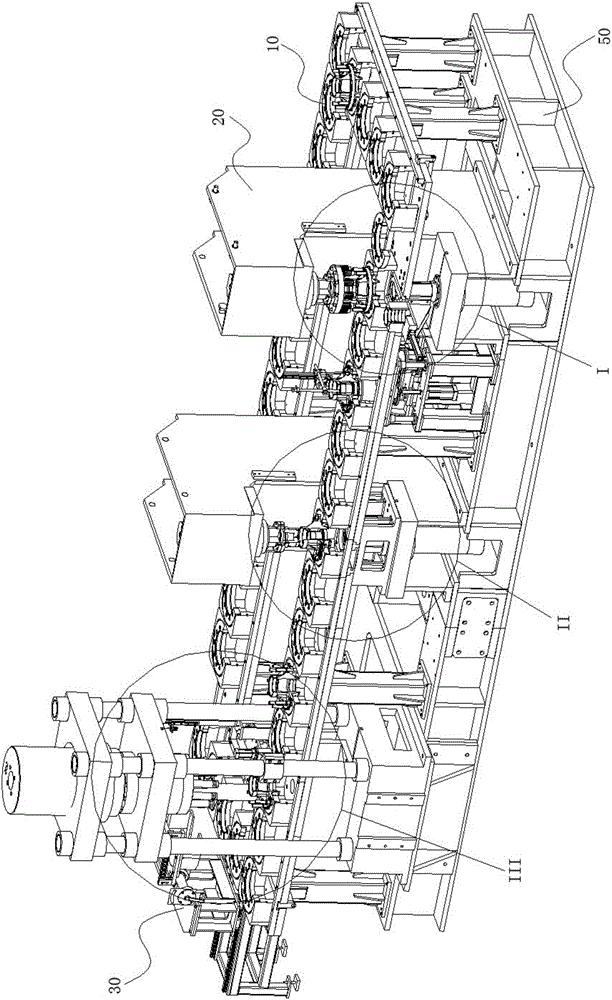

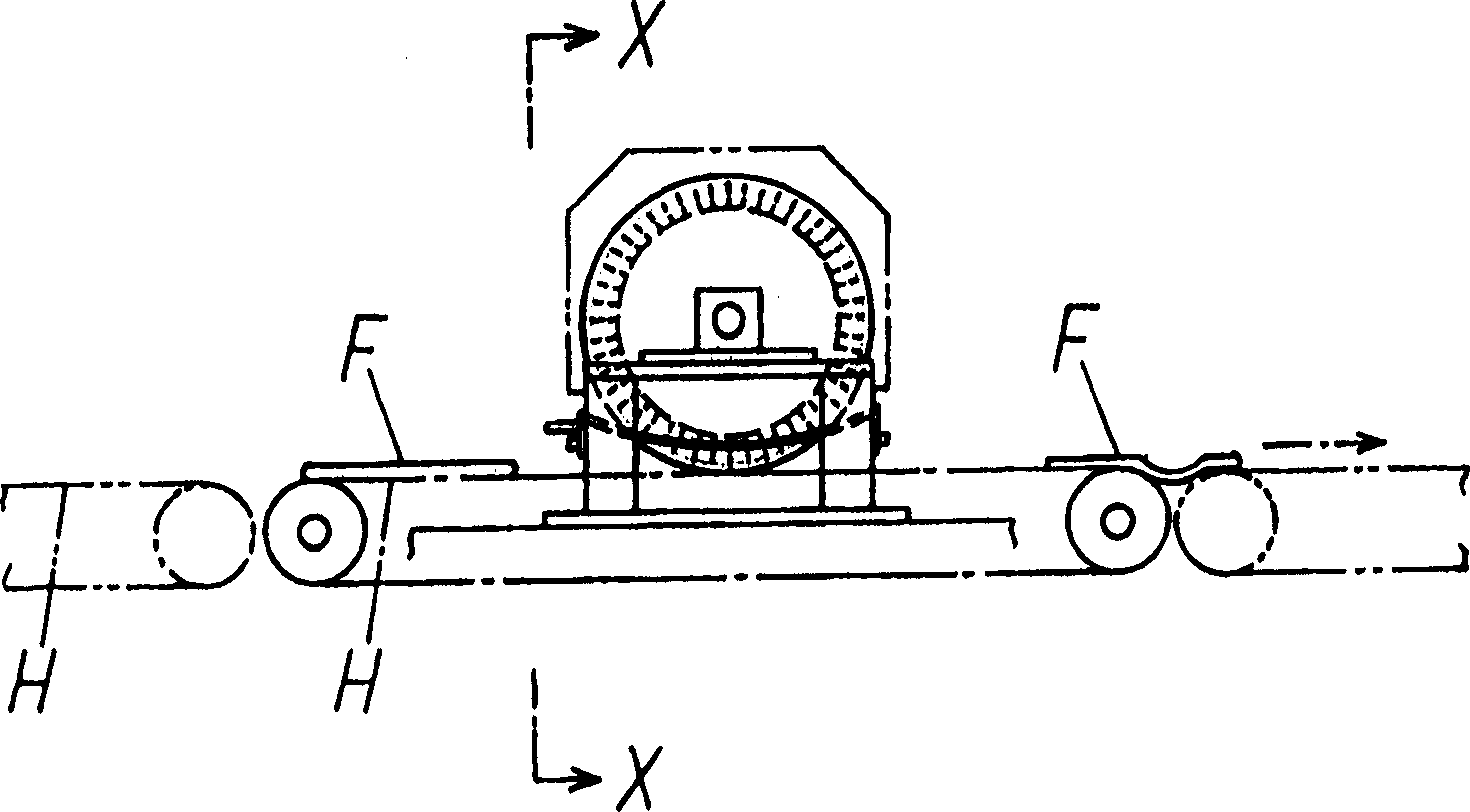

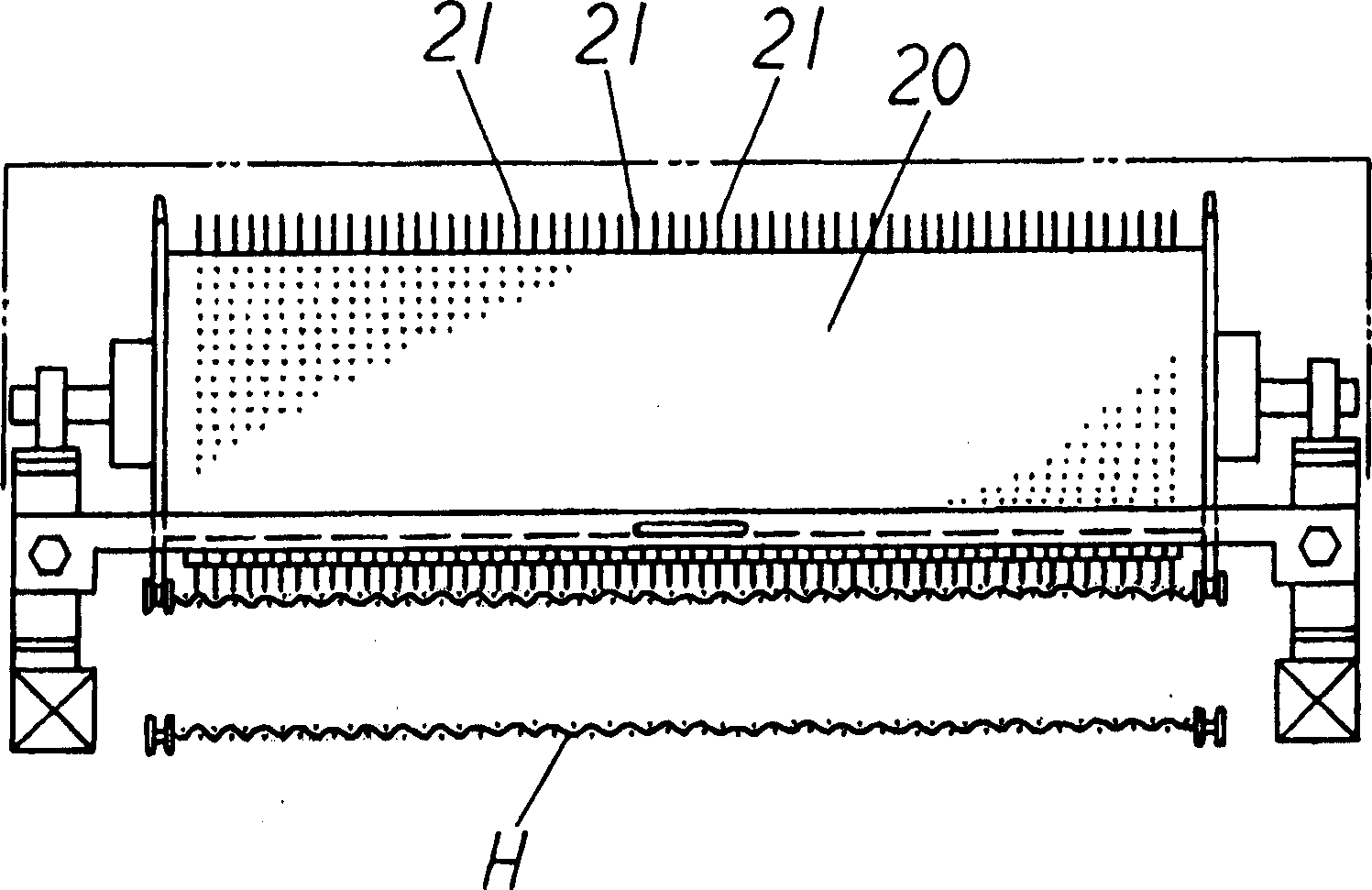

Press-fitting production line for hub assemblies

ActiveCN106112511AHigh degree of automationIncrease productivityAssembly machinesVehicle componentsAutomationProduction line

The invention discloses a press-fitting production line for hub assemblies. The press-fitting production line comprises a circulatory conveying assembly and a part press-fitting mechanism; the circulatory conveying assembly comprises a support and a plurality of supporting brackets arranged on the support, and the multiple supporting brackets are used for conveying hubs on the support in a circulation mode so that the hubs can undergo the press-fitting work of each process; and the part press-fitting mechanism comprises a lower bearing outer ring pressing machine, an upper bearing outer ring pressing machine, an ABS gear ring pressing machine and a bolt pressing machine, wherein the lower bearing outer ring pressing machine, the upper bearing outer ring pressing machine, the ABS gear ring pressing machine and the bolt pressing machine are arranged along the support, the lower bearing outer ring pressing machine is used for carrying out press-fitting on lower bearing outer rings of the hubs, the upper bearing outer ring pressing machine is used for carrying out press-fitting on upper bearing outer rings of the hubs, the ABS gear ring pressing machine is used for pressing ABS gear rings on the hubs, and the bolt pressing machine is used for pressing bolts on the hubs. The press-fitting production line for the hub assemblies has the advantages of being high in automation level and safe and saving energy and is suitable for being widely popularized and used.

Owner:GUANGDONG FUWA HEAVY IND

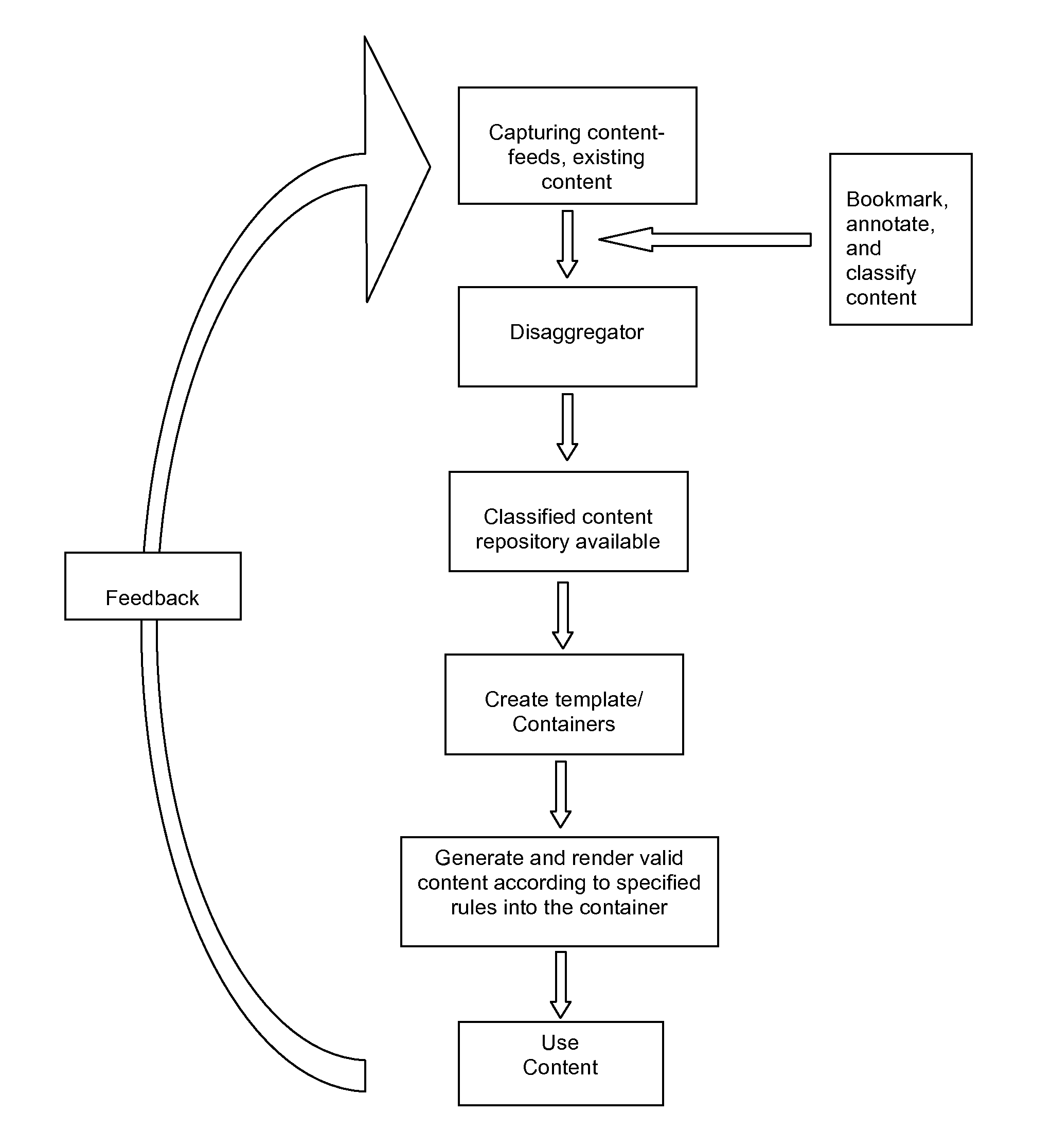

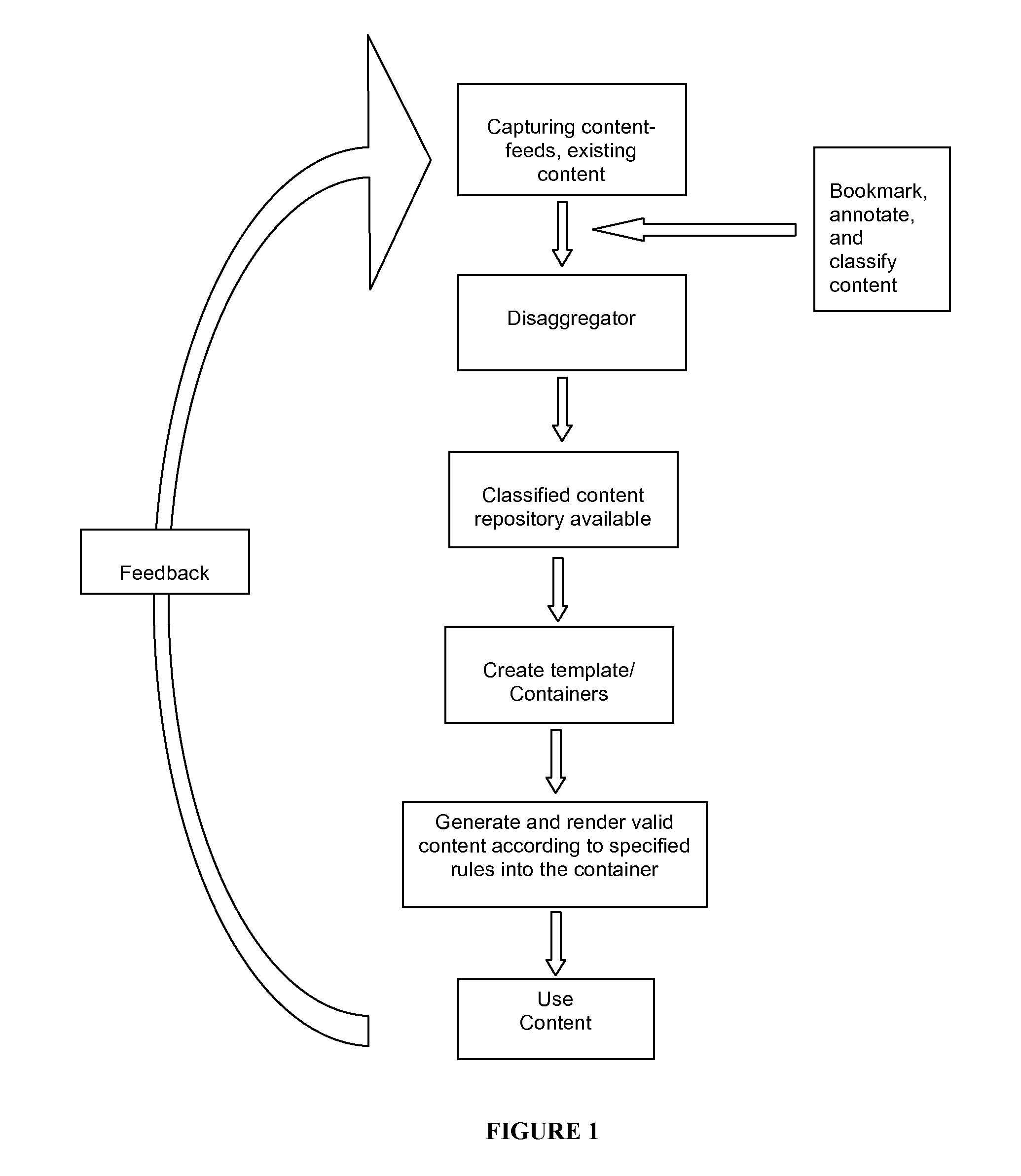

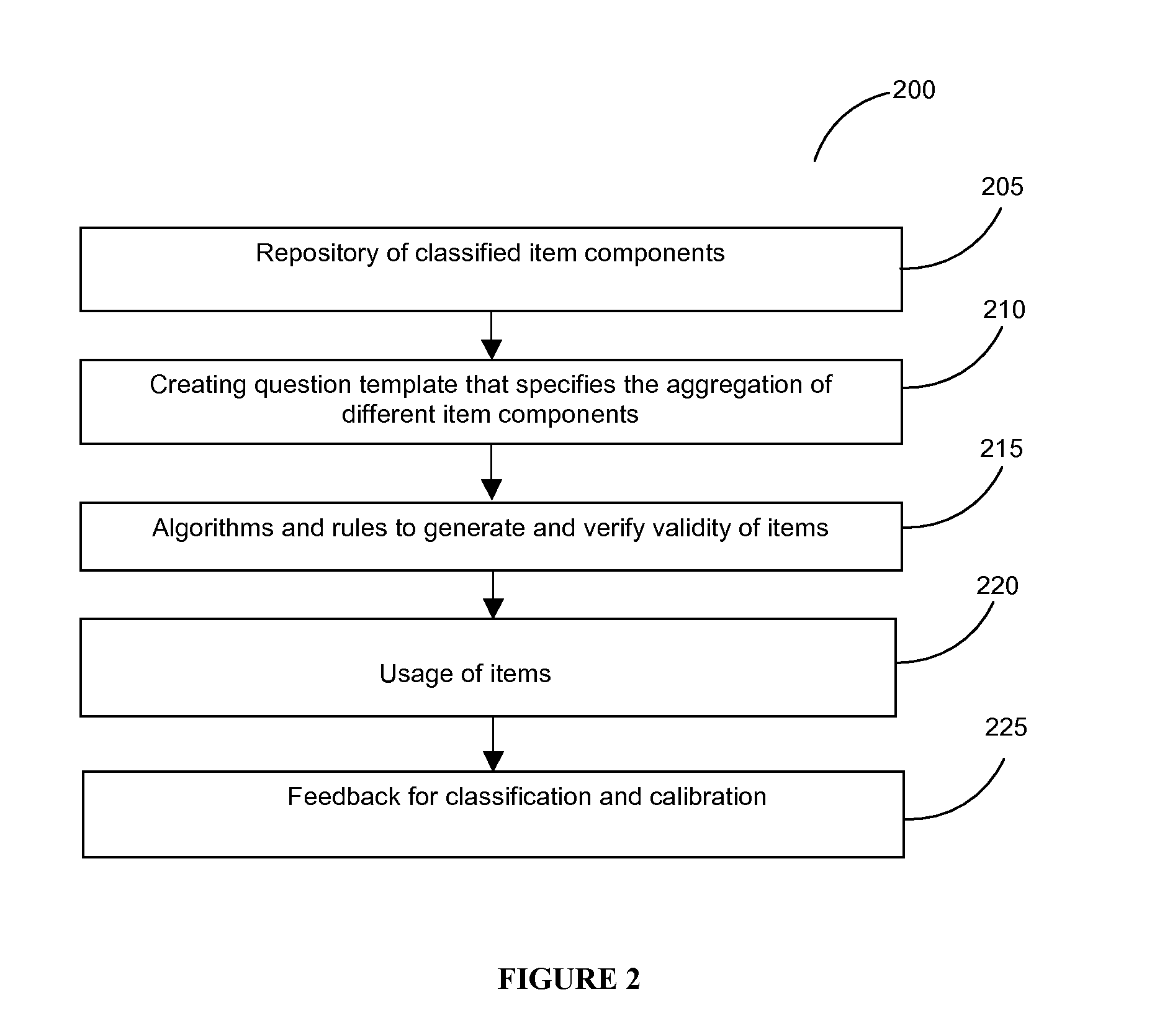

System and method for automated content generation for enhancing learning, creativity, insights, and assessments

ActiveUS20110217685A1Improve content qualityImprove creativityNatural language data processingElectrical appliancesKnowledge contentData science

The present invention provides an automated system for multiple types of knowledge content generation for enhancing learning, creativity, insights and assessments comprising the means of: Capturing one or more contents; Storing the captured contents in raw content database; Classifying the captured content by one or more means of selected from Bookmarking or annotating, Using meta information from the content source files, Using algorithms to classify information and Receiving feedback from users and user interaction with content; Defining content template; Specifying rules and algorithms for automatic generation of knowledge content; Finally, Using the generated knowledge content by means of a display to candidate. Invention reduces the manual effort and time taken to create the multiple types of knowledge contents as well as reduce the cost for creation of the multiple types of knowledge contents.

Owner:TATA CONSULTANCY SERVICES LTD

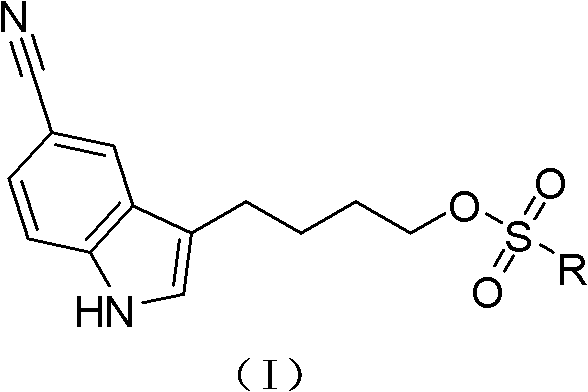

4-(5-cyano-1h-indol-3-yl) butyl substituted sulfonate compounds and their applications

The invention discloses a 4-(5-cyano-1H-indol-3-yl) butyl substituted sulfonate compound and its application. The 4-( 5-cyano-1H-indol-3-yl) butyl substituted sulfonate compounds, as new intermediates, in the preparation of vilazodone and its pharmaceutically acceptable salts, overcome the existing The defects and deficiencies in the preparation method reported in the literature are more suitable for the large-scale industrial preparation of vilazodone hydrochloride, which has obvious creativity, great positive progress effect and practical application value. The general structural formula of the compound shown in formula (I) is as follows:

Owner:SHANGHAI INST OF PHARMA IND CO LTD

Lava

The invention relates to Lava, in particular to Lava which has good stretching effect and cannot be stuck to hands. The Lava contains polyvinyl alcohol solution which accounts for 20-60 portions of 100 portions of the total weight of the Lava; the Lava also comprises 30-60 portions of demineralized water, 0.5-2 portions of xanthan gum, 6-20 portions of propanetriol and 0.1-0.3 portion of borax, and the Lava is manufactured by stirring the composition. The invention has the advantages that: (1) the Lava enables children to practice the operation skill, promote the development of small muscle of hands and enhance the coordination ability of hands and eyes; (2) the capability of bravely expressing individual points of view and communicating and cooperating with other people of children is fostered; (3) membrane with the thickness smaller than 0.01 mm can be stretched, cannot break after being wound for 360 degrees, cannot be stuck to hands and can be used for blowing bubbles; (4) the Lava has better tenacity, enhanced stretching performance and very good elasticity and is not easy to stick to hands; and (5) shimmering powder in the shimmering powder Lava is not easy to sink.

Owner:稂武忠

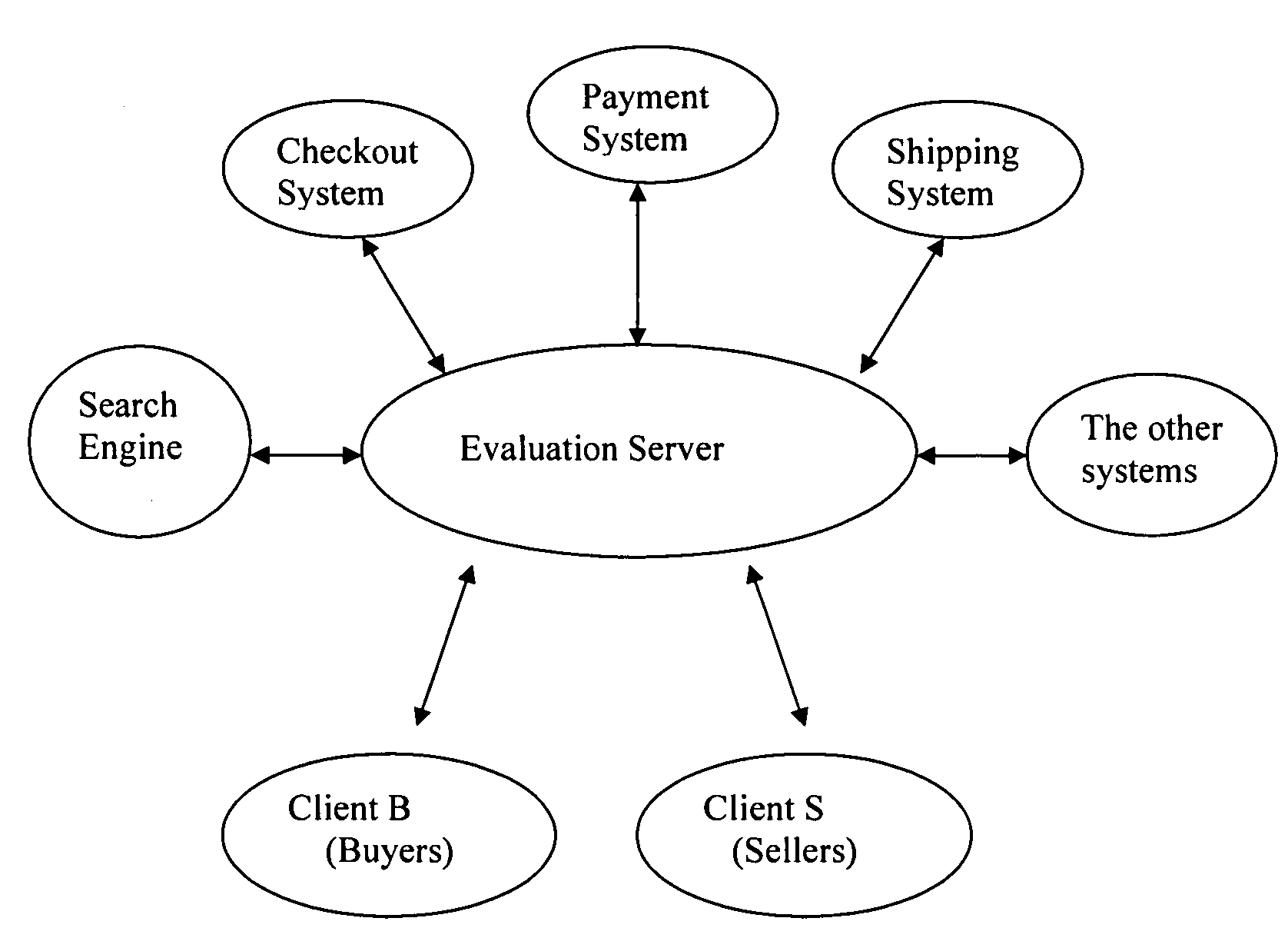

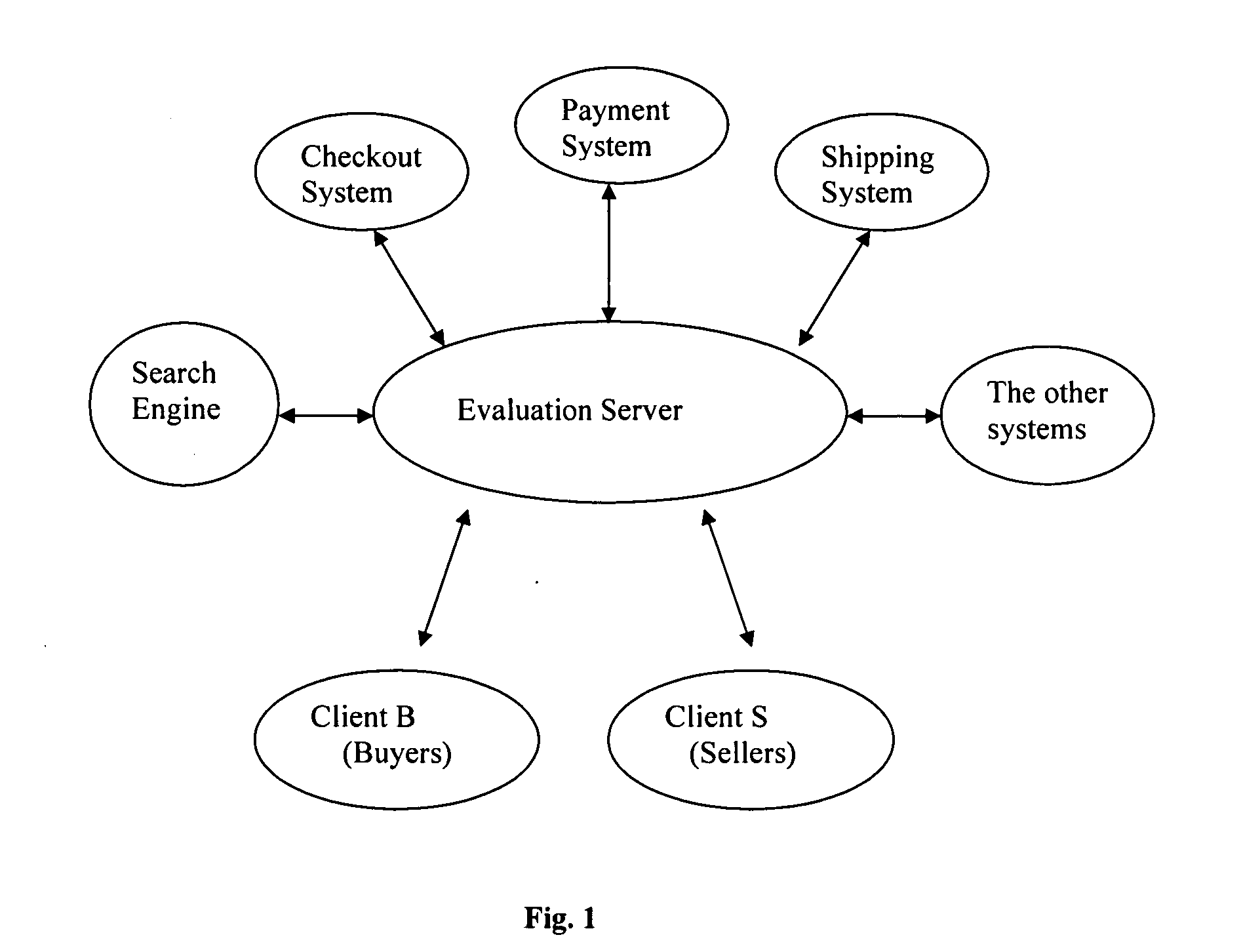

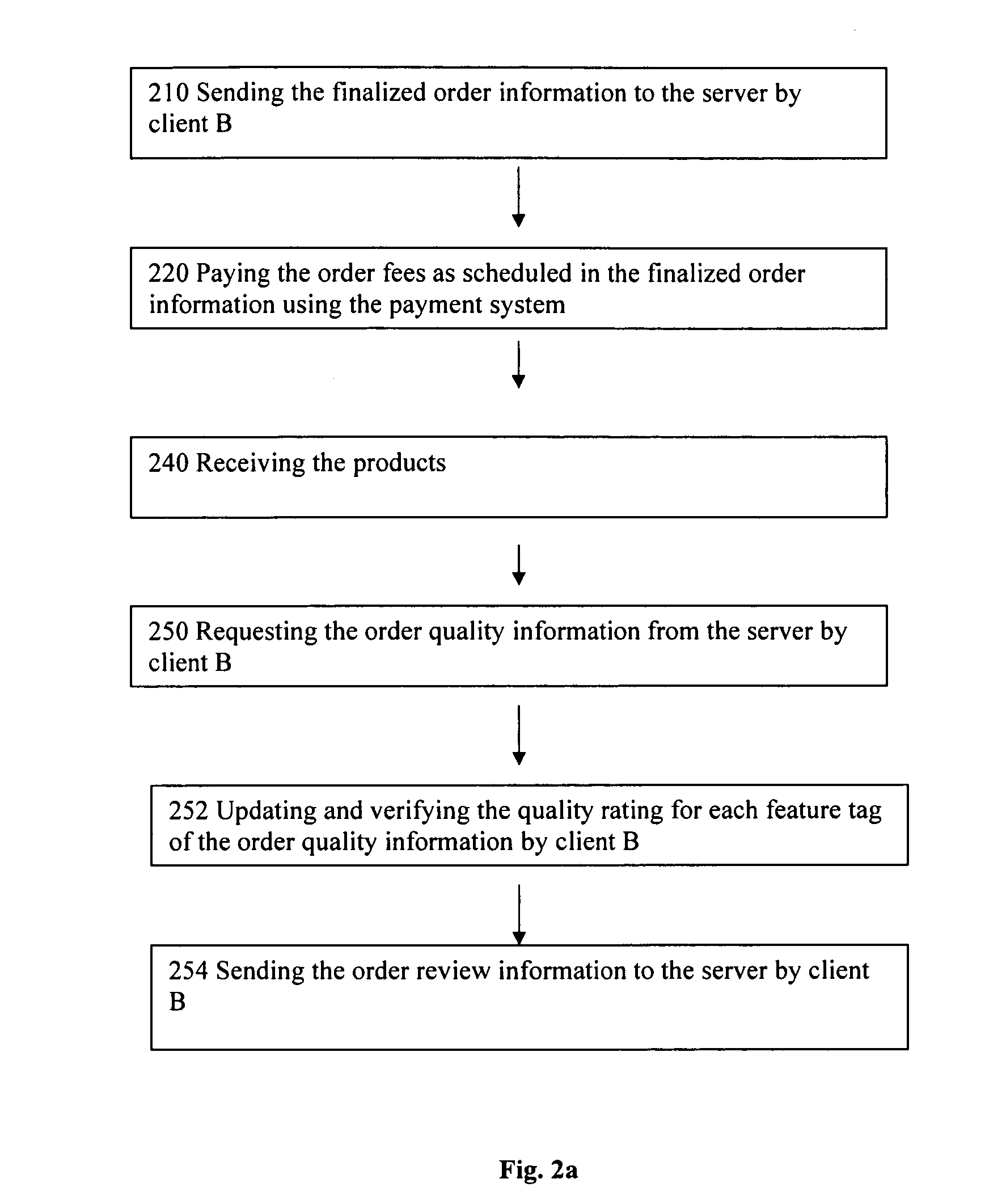

Online Dynamic Evaluation and Search for Products and Services

InactiveUS20080235148A1Improve performanceImprove search engine performanceDigital data information retrievalDigital data processing detailsRating systemWorld Wide Web

In one aspect, computer implemented dynamic evaluation is based on feature tags. As will be described in more detail below, a buyer may be interested in certain features of a product (e.g., color, material, design, lining, warranty, delivery terms, etc.) and the different features are described using feature tags. For custom products, the buyer's specification may be described at least in part by feature tags. Each feature tag may include one or more standardized keywords. The computer-based system can use the feature tag representation of a buyer's order to both search for appropriate products (i.e., appropriate sellers of the product requested by the buyer), and then subsequently to allow the seller to review the performance of the selected buyer. Over time, each seller will receive different reviews from different buyers. These reviews can be stored and the data used to better predict which sellers will be appropriate for a future buyer request. Buyers can also be evaluated and reviewed to allow similar screening by the sellers. The use of standardized keywords establishes a common vocabulary and rating system among the community of buyers and sellers.

Owner:LIU JIEZHOU

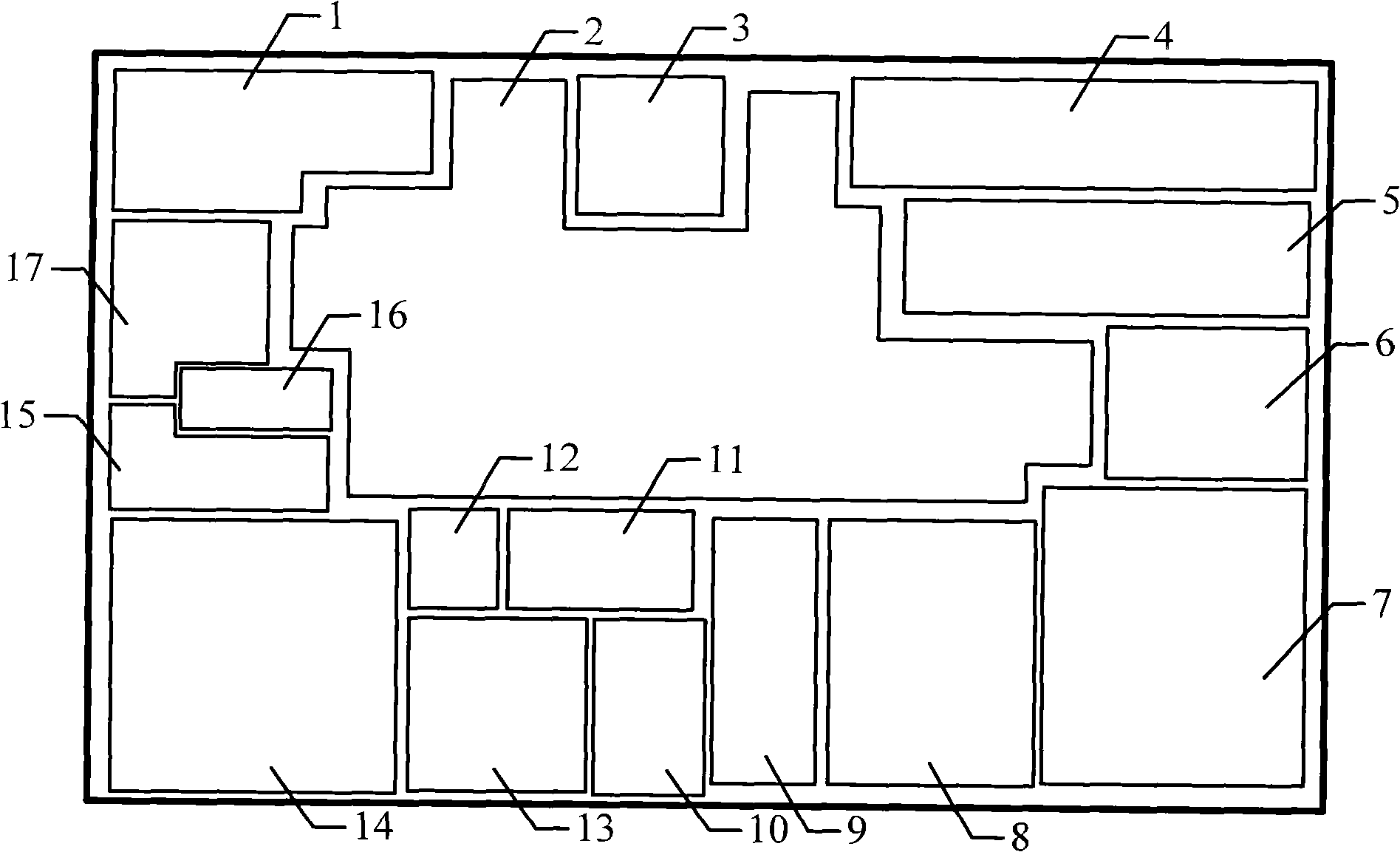

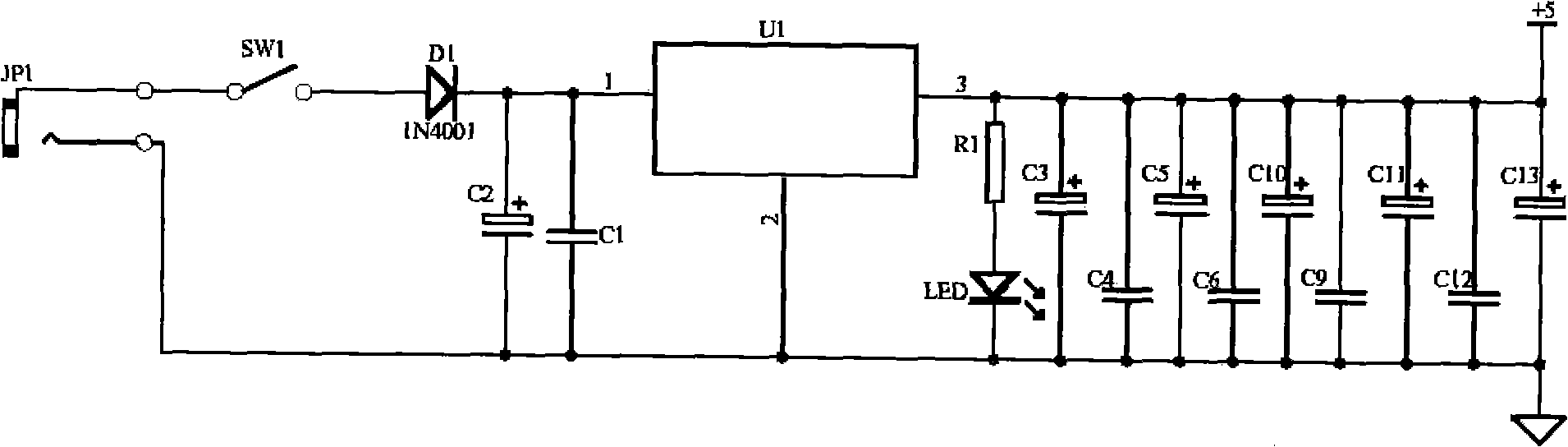

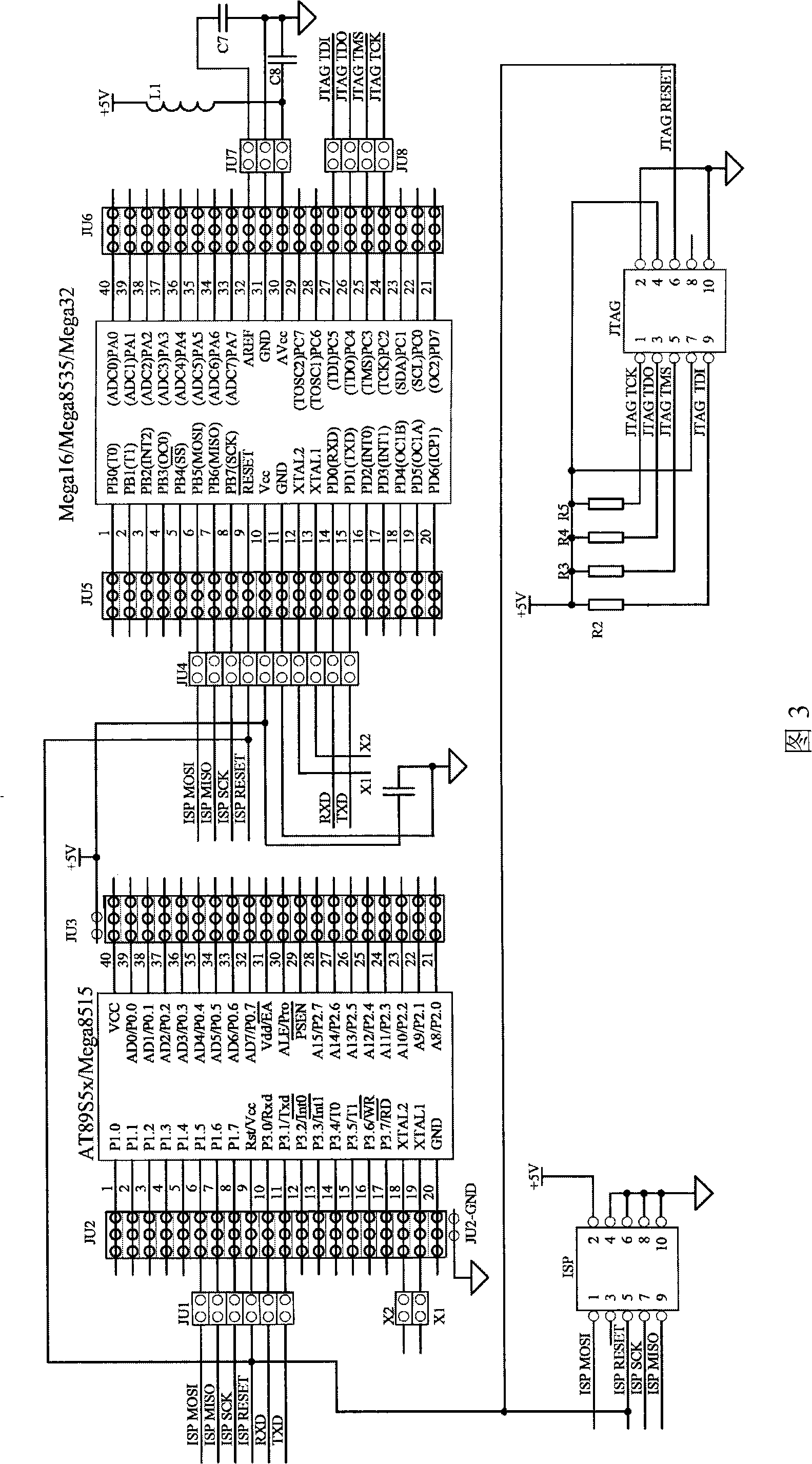

Multifunctional single-chip experimental development plate

InactiveCN101281697AAccelerated trainingImprove creativityEducational modelsKey pressingLiquid-crystal display

The invention discloses a multifunction SCM experiment development plate applied in the fields of SCM experiment teaching and SCM product development and the like, characterized in that, a system power, a MCU seat and a plurality of periphery function modules namely an LED, an LCD interface, a 8-section nixietube display circuit, an adjustable DC voltage source, an LED lattice display module, a matrix keyboard, an independent key-press, a power drive, a system clock circuit, an RC filter circuit, a square wave pulse generator, an expanding socket, a passive buzzer, an external reset circuit, an RSS serial interface unit are arranged on the plate body, wherein each periphery function modules are independent each other and combined flexibly according to the design requirement; a locking jack with 40 pins is arranged on the plate body compatible with a plurality of series of SCMs, which can be widely applied in the SCM experiment teaching and product development.

Owner:EAST CHINA NORMAL UNIV

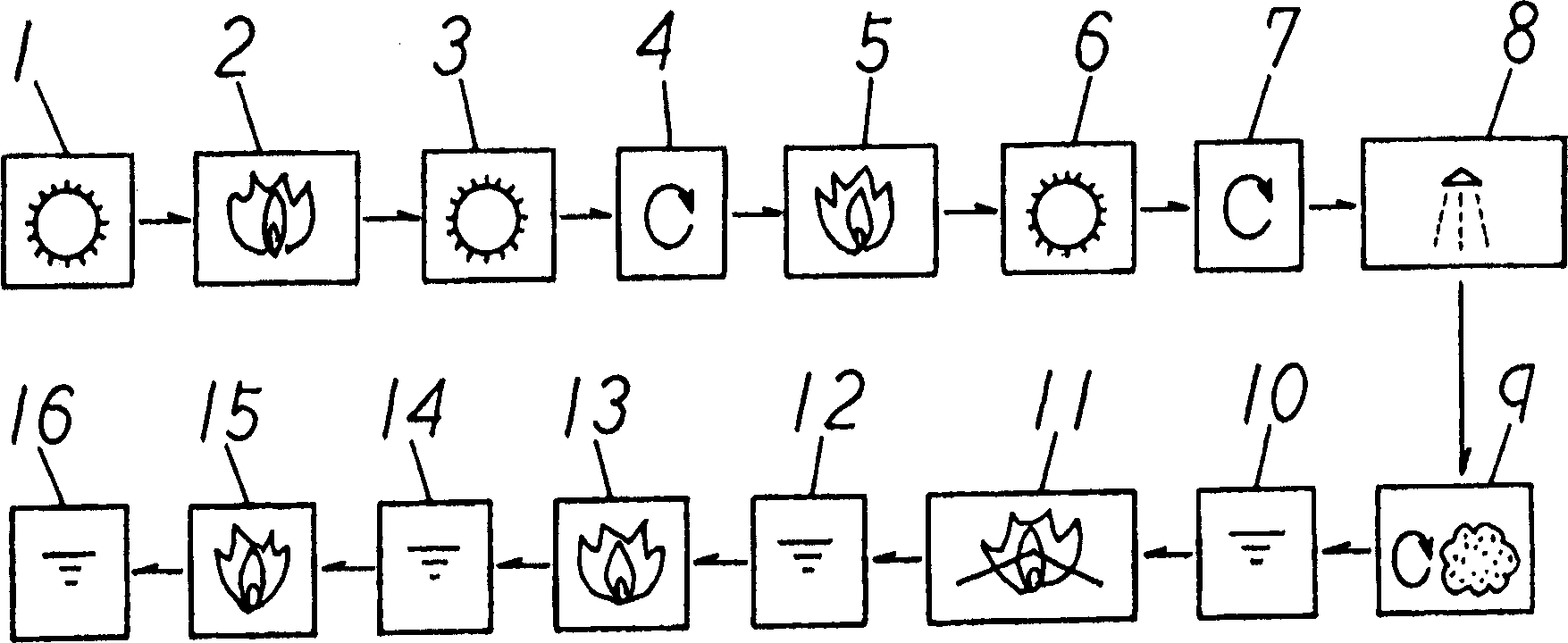

Grilled fish processing method and grilled fish processing device

ActiveCN1903076AAvoid partial sheddingInhibition of local expansionFood preparationAnguilliformesConger

The invention provides a processing method and apparatus for split and broiled fish which makes piercing holes in a food material for broiling. This processing method for the split and broiled fish comprises applying seasoned sauce to a food material of either one of eel, conger eel or loach followed by broiling the food material. The method has a process of making piercing holes in the skin surface of the food material before applying seasoned sauce and broiling, and then broiling the skin surface.

Owner:KYOMARU +2

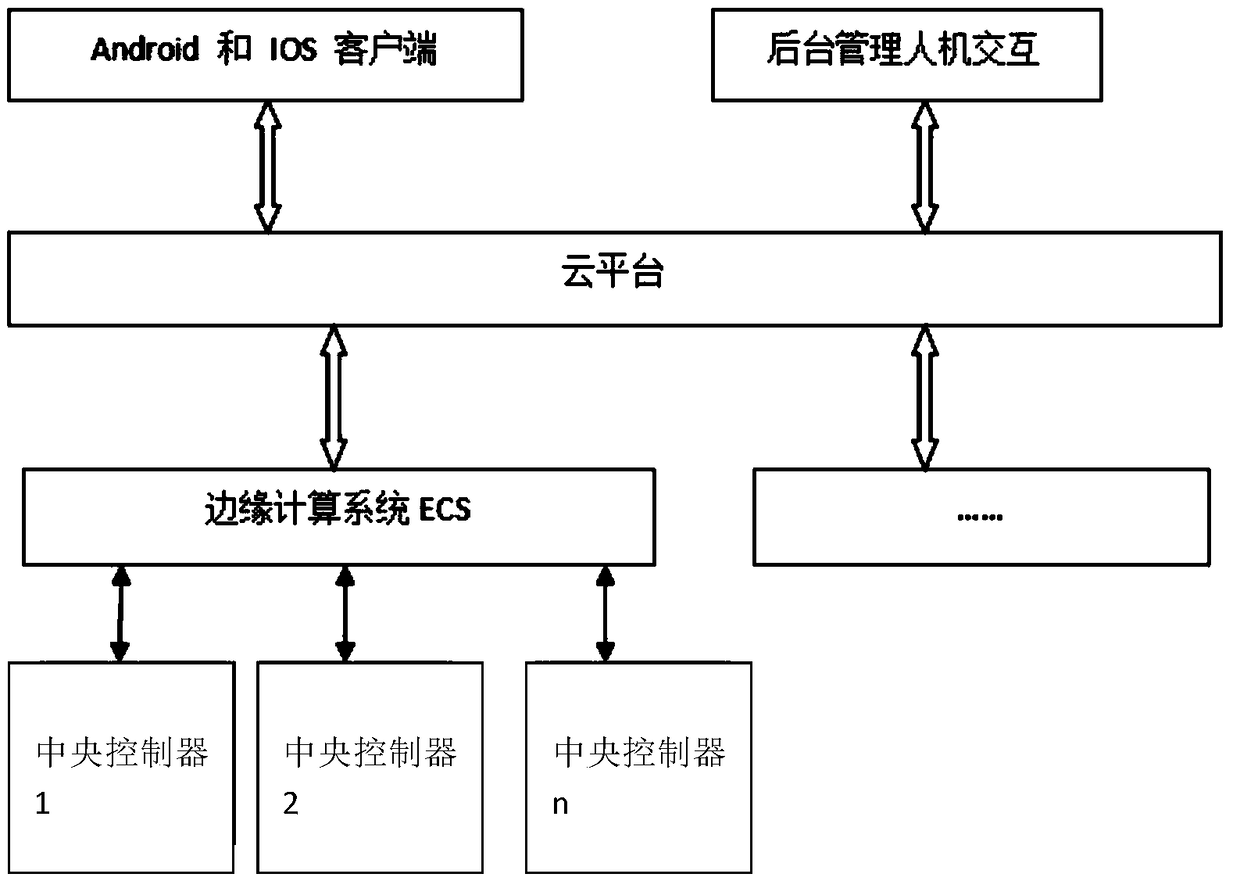

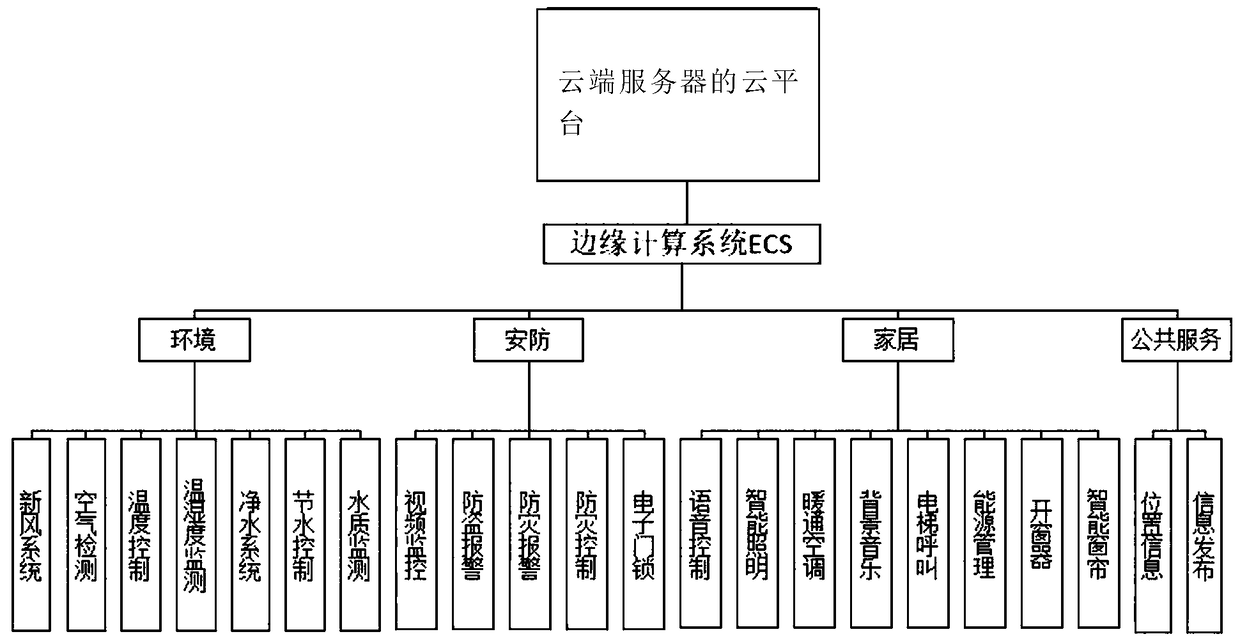

Edge computing system (ECS)

InactiveCN108873712ASave time on transfersFix security issuesComputer controlTotal factory controlMass storageEdge computing

The present invention provides an edge computing system (ECS). Processor structures are employed to connect with a server, the edge computing system is connected with all the sensors and devices in ahouse through a sensor and is connected with an external computer and / or a cloud system of a mobile communication device, and users monitor the operation states of all the devices through the cloud system; at ordinary times, one processor is responsible for an IOT end control task, the other processor is responsible for mass storage access control, when one processor has faults, the other processor takes over the work to process the storage access, the end IOT and transmission time at the same time so as to solve the safety of family or office IOT data, users perform maintenance and managementby themselves to perform sharing of the data stored by the users so as to reduce the storage of the server, improve the transferring response speed, improve the user experience effect and have a highcreativity.

Owner:北京王府科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com