Patents

Literature

120 results about "Virtual entity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

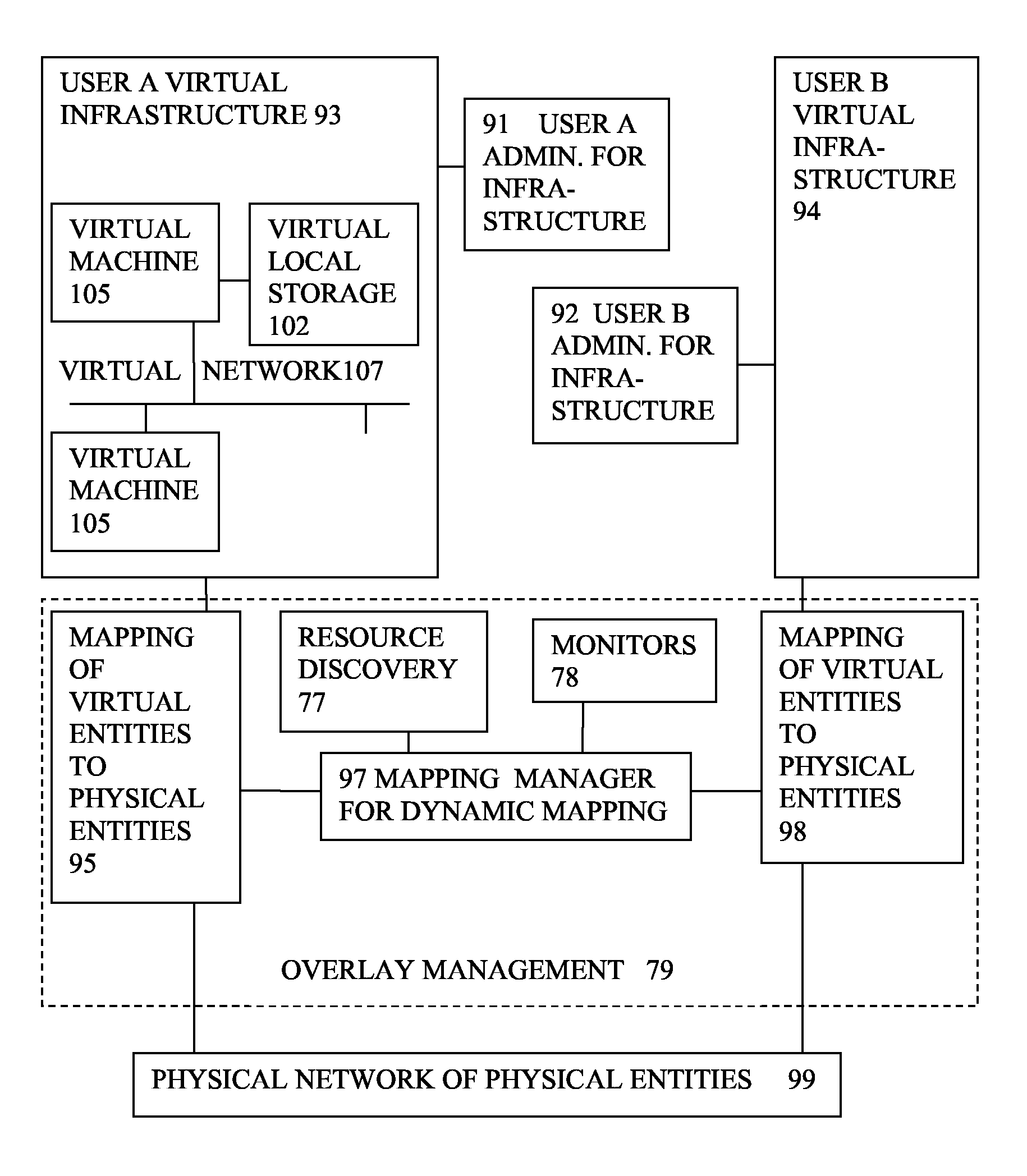

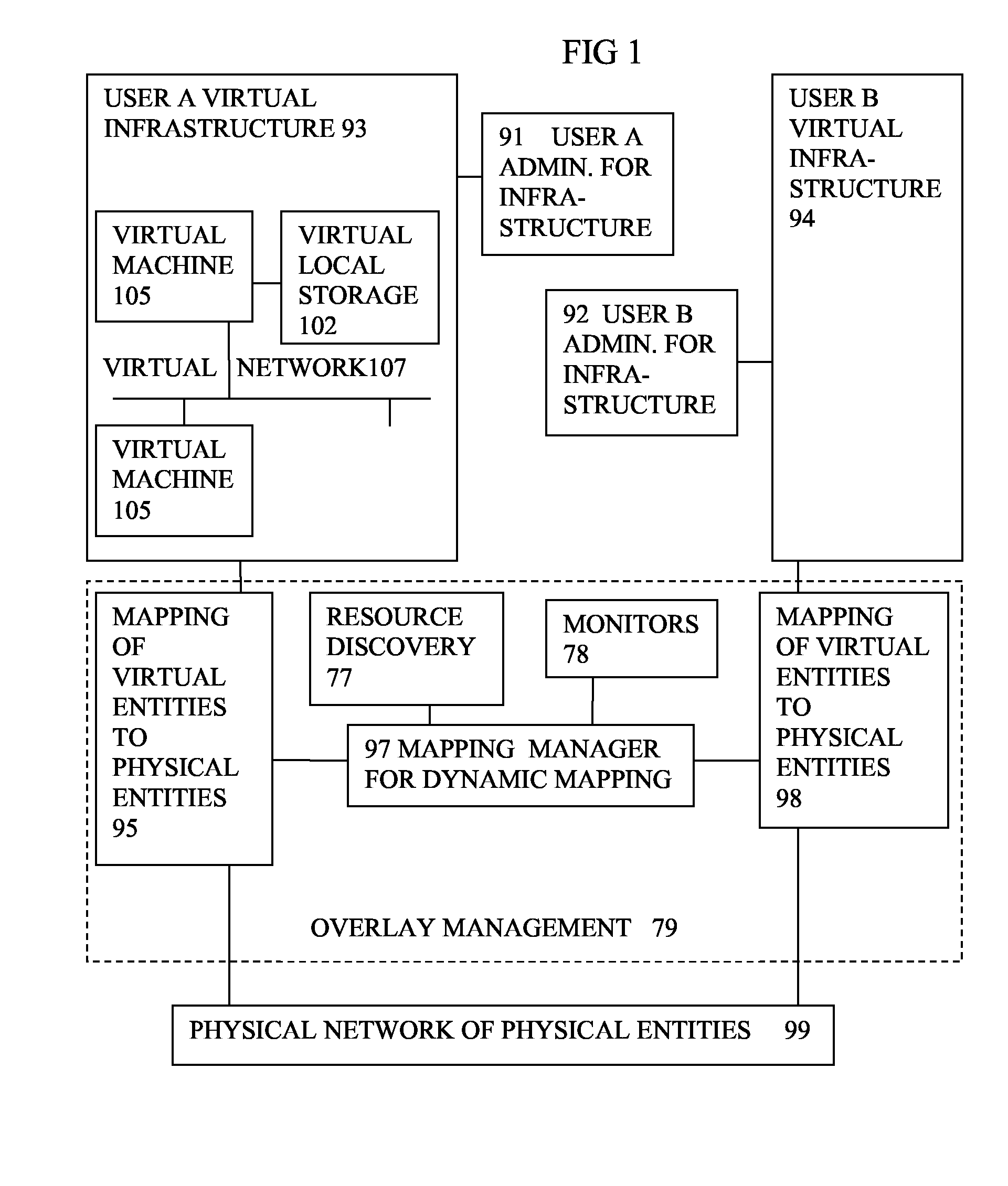

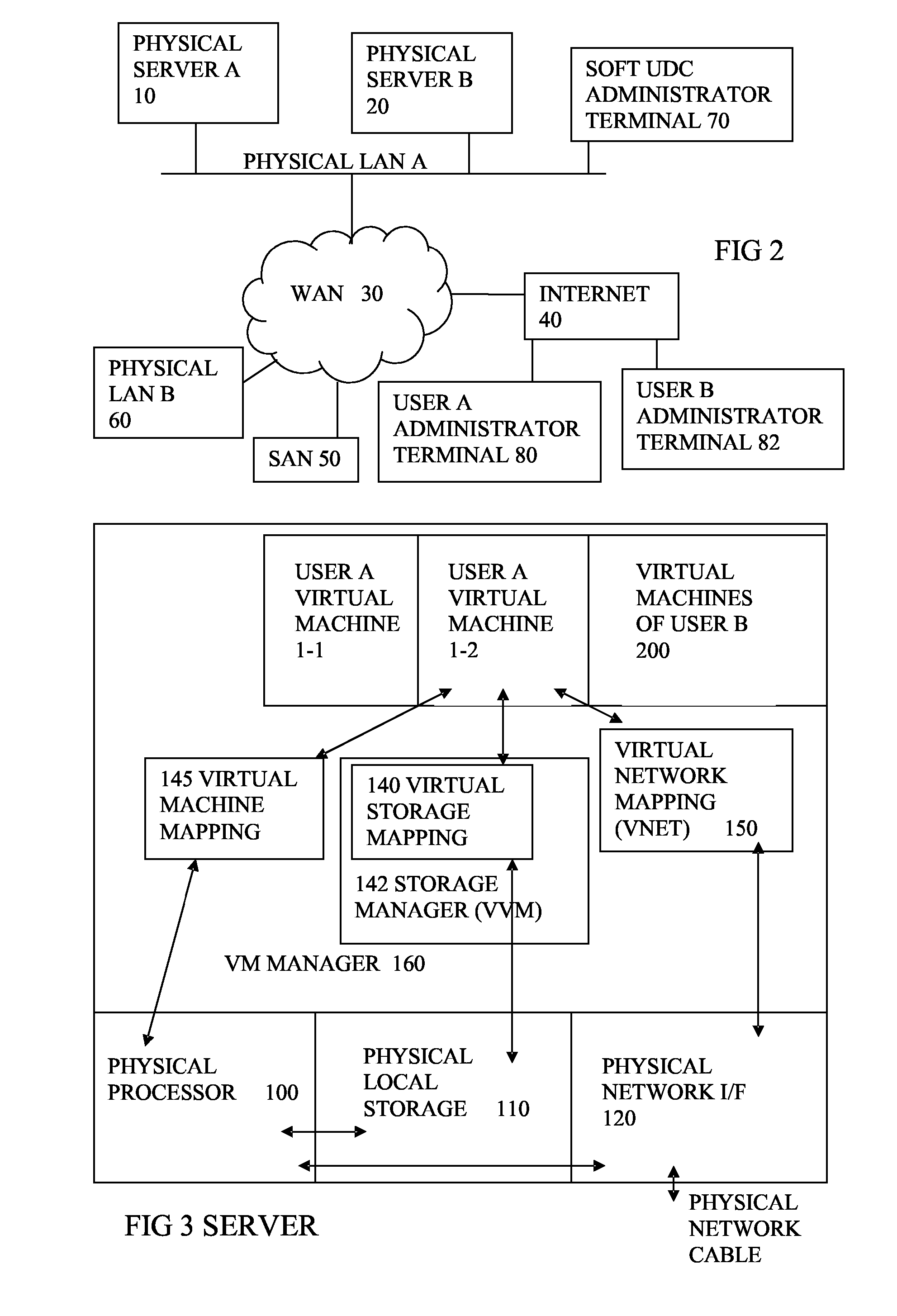

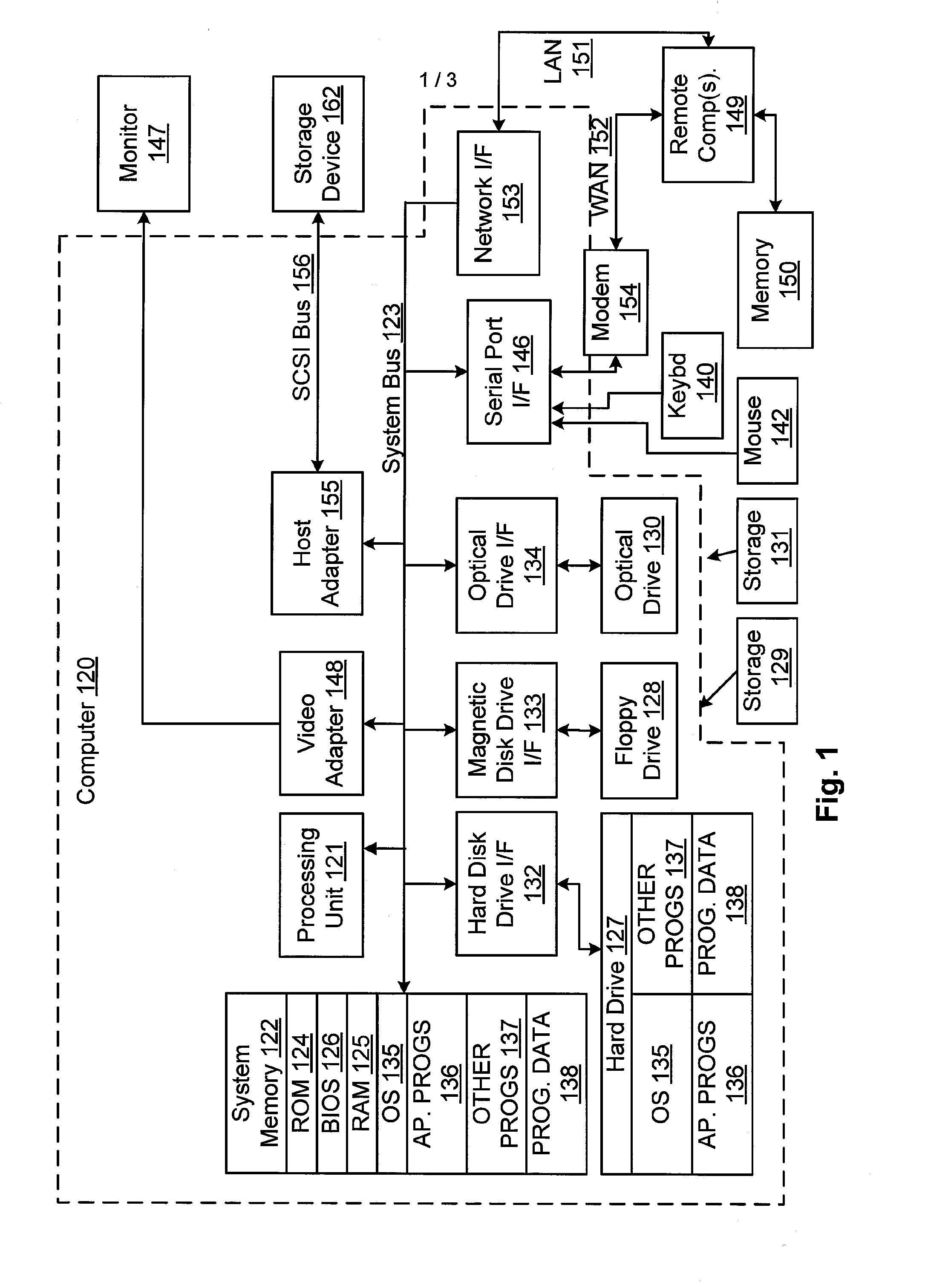

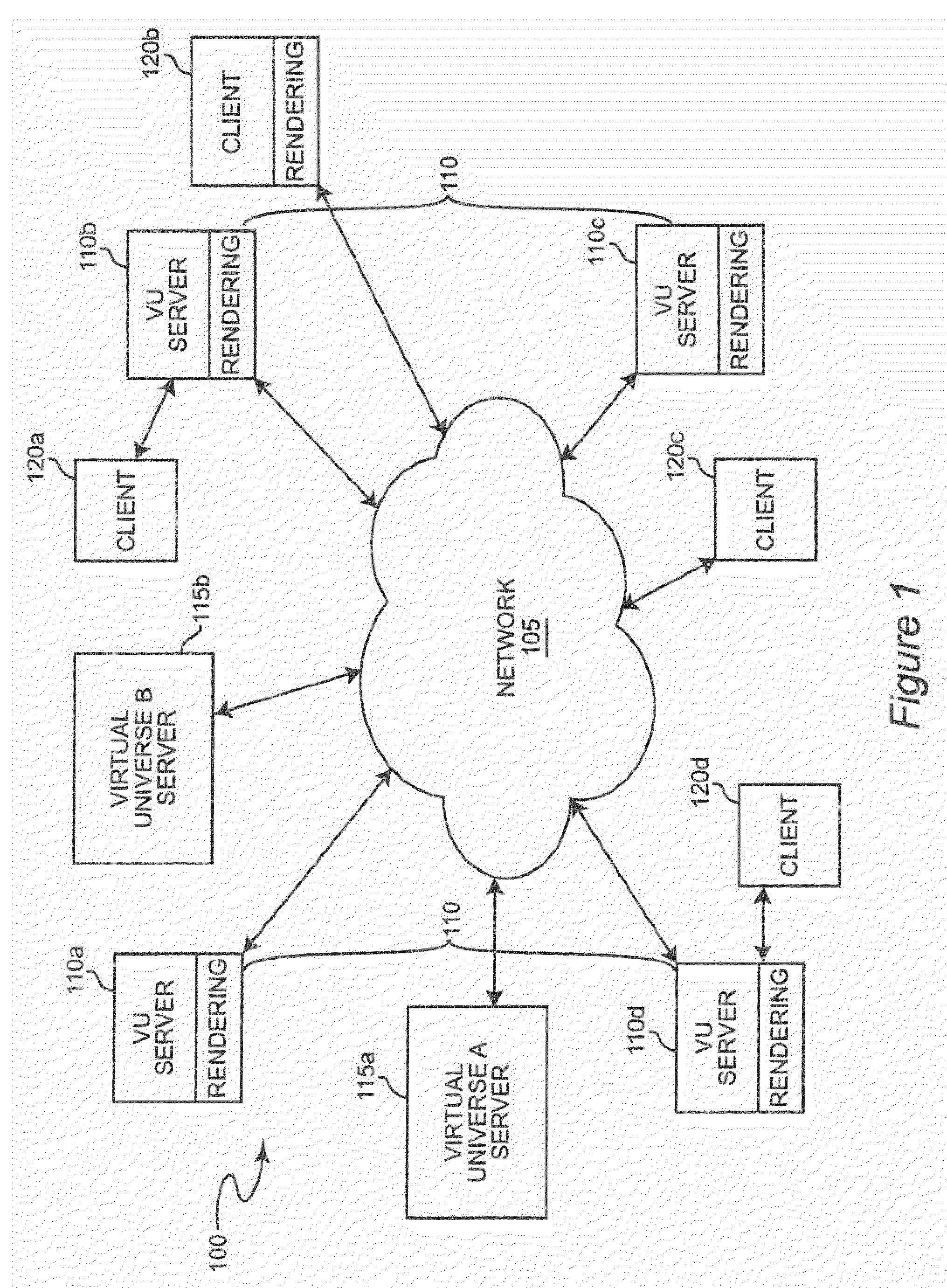

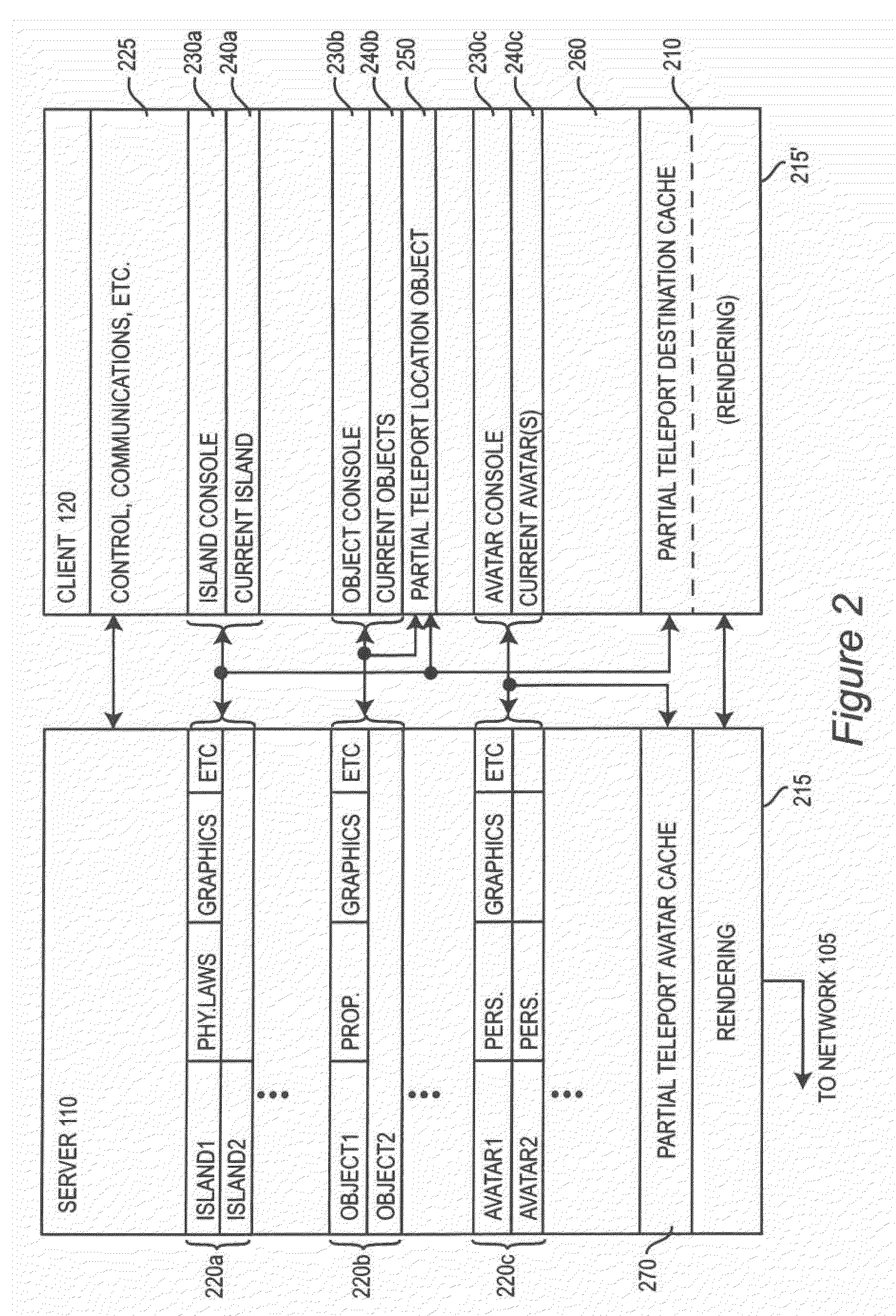

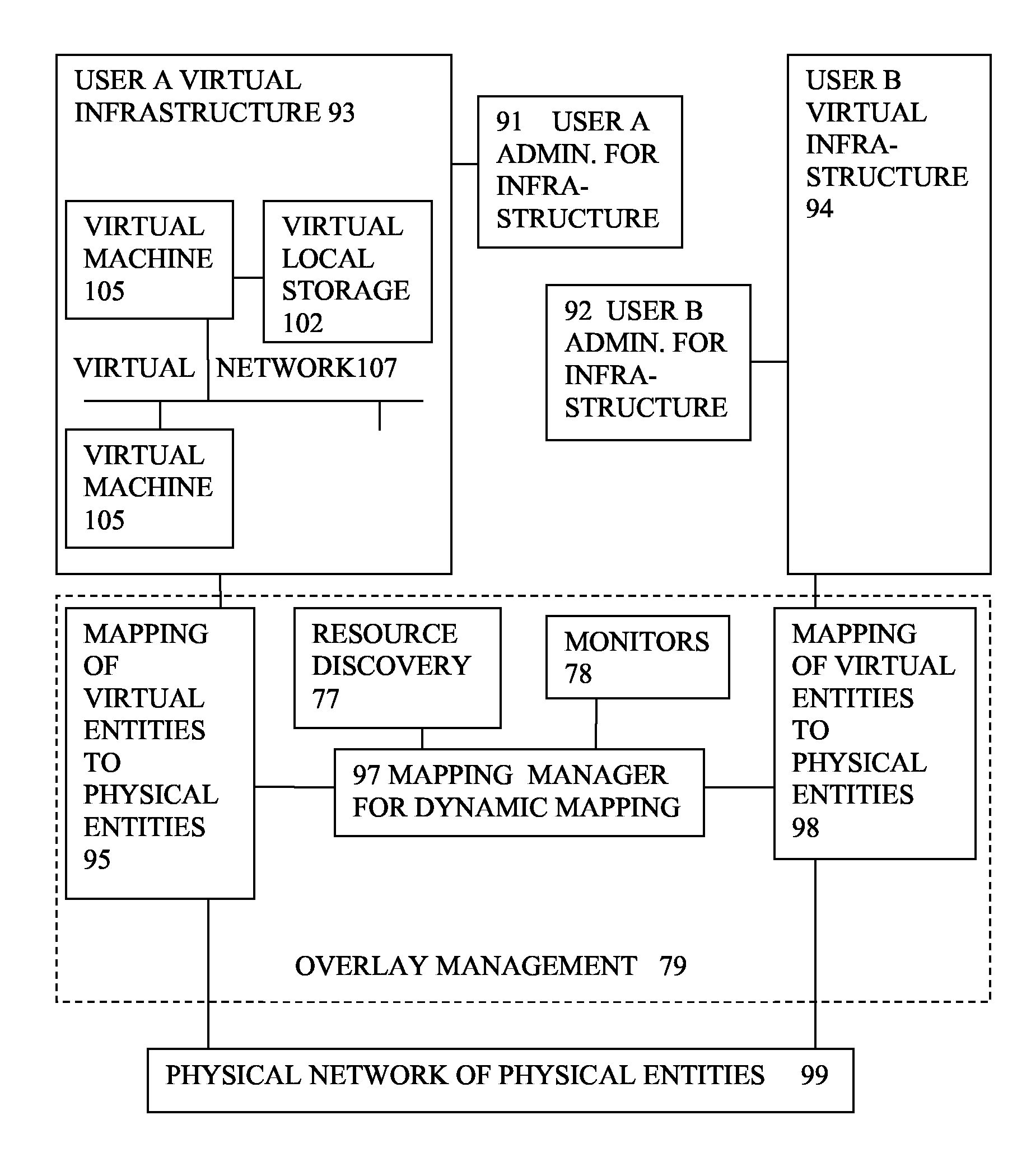

Virtual computing infrastructure

InactiveUS20090199177A1Overcome disadvantagesCritical applicationResource allocationTransmissionVirtualizationNetwork communication

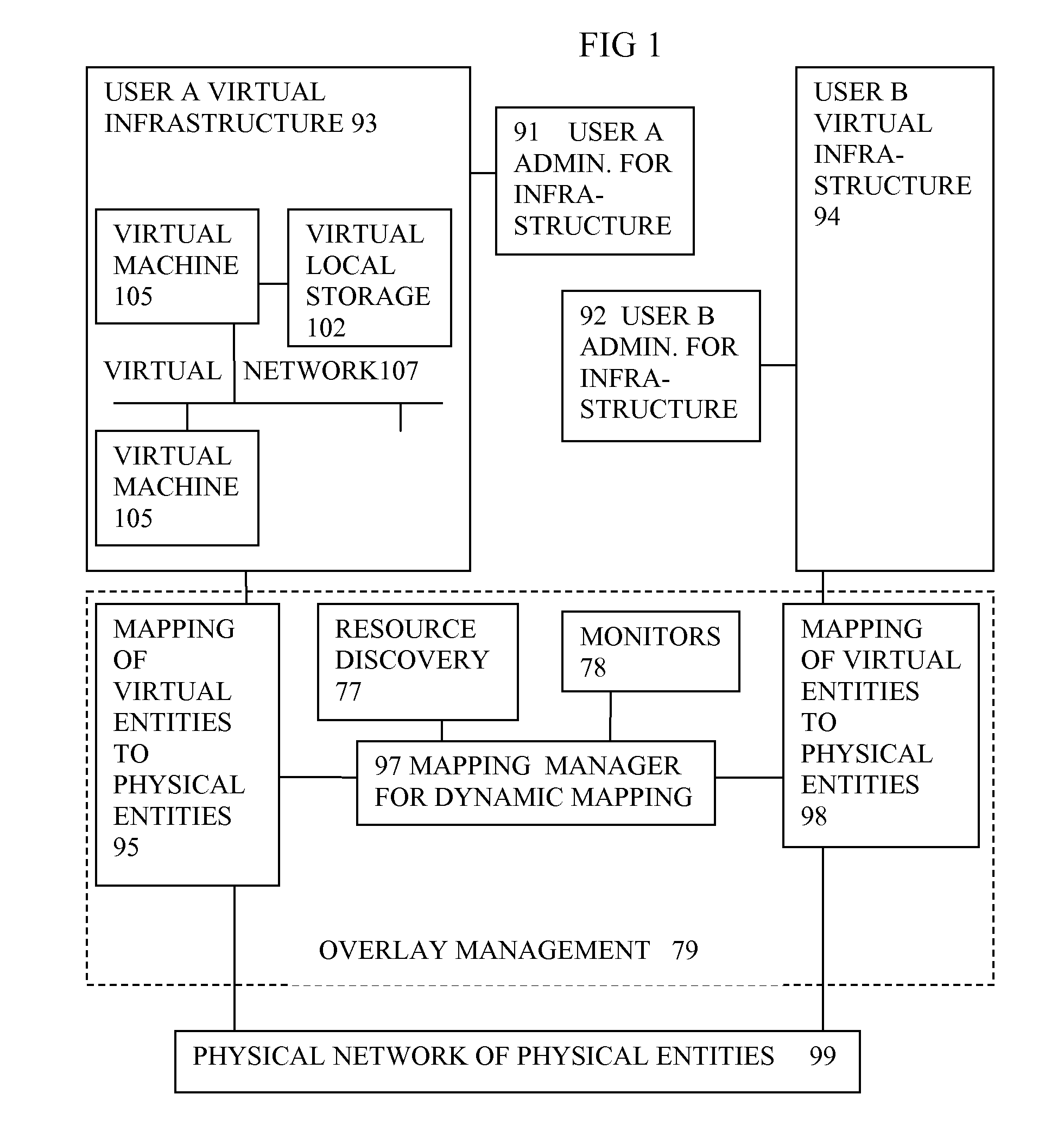

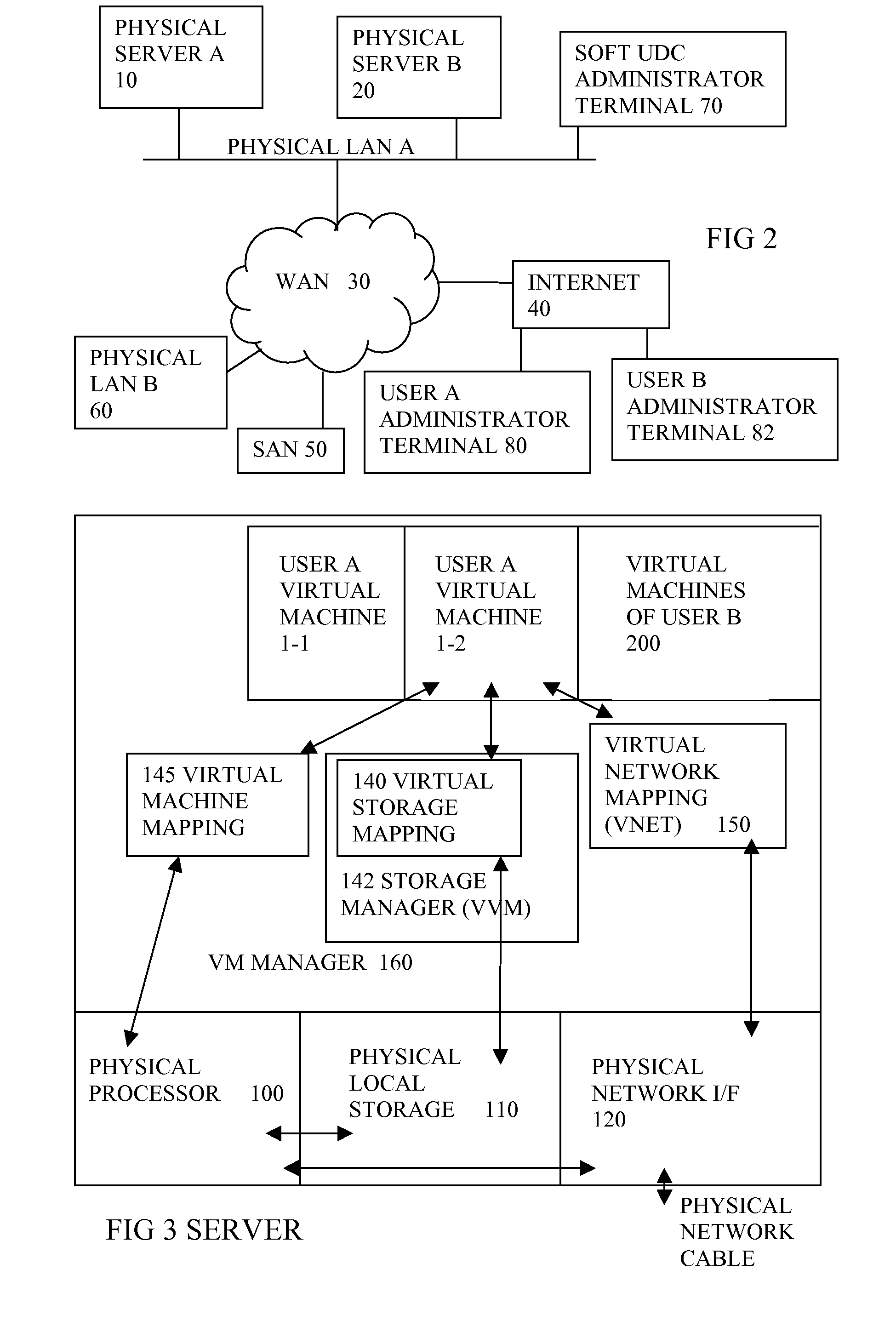

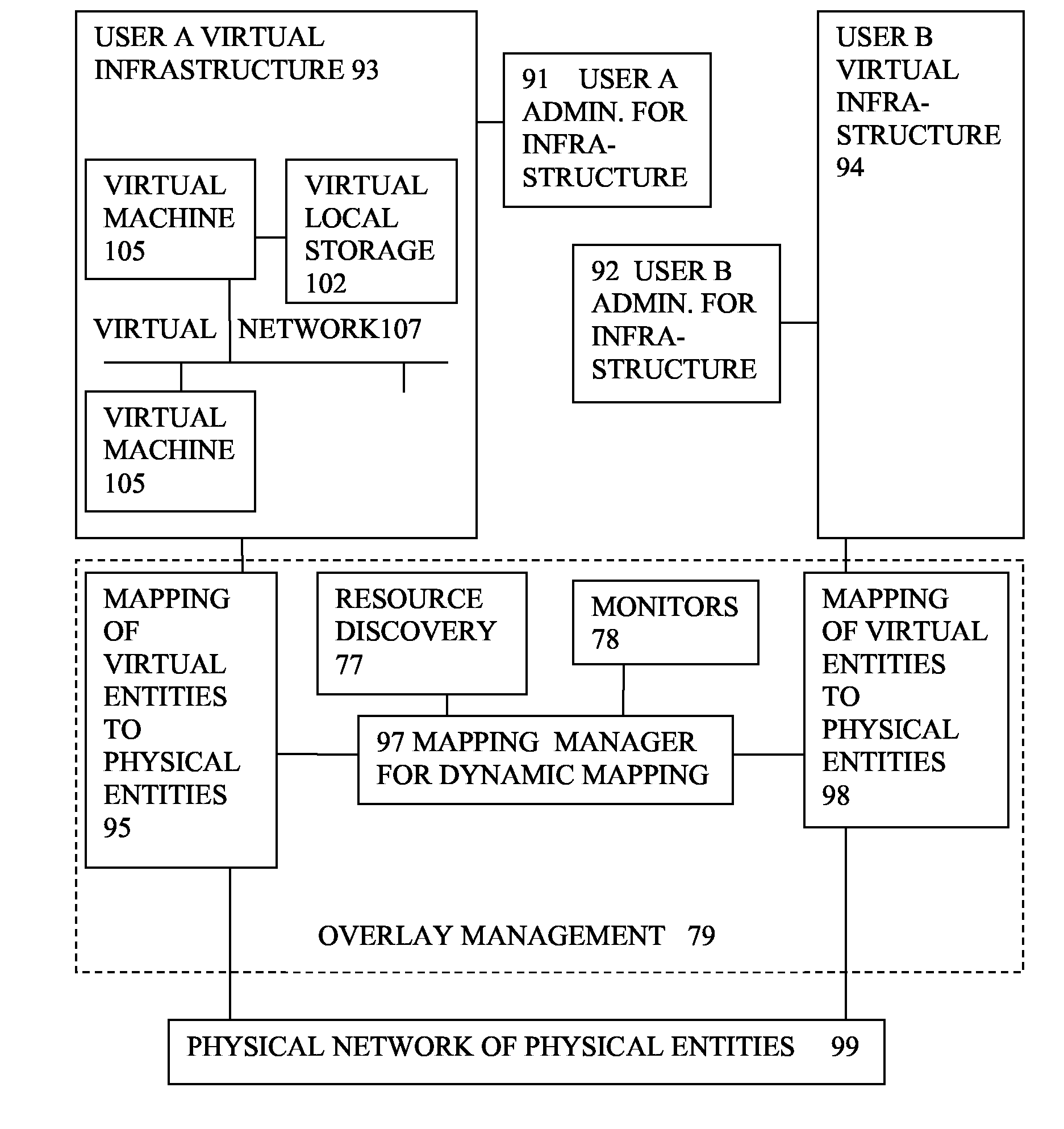

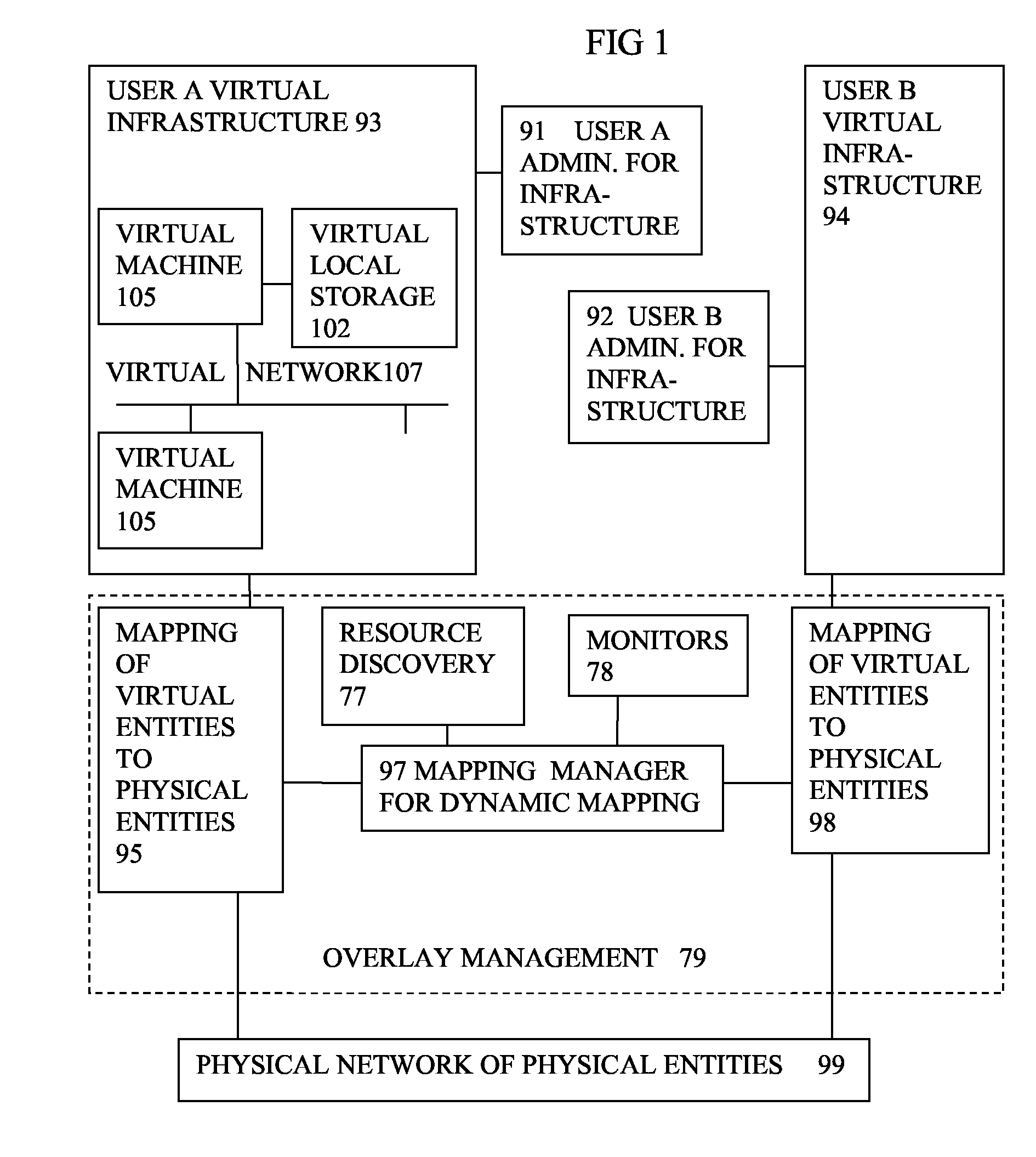

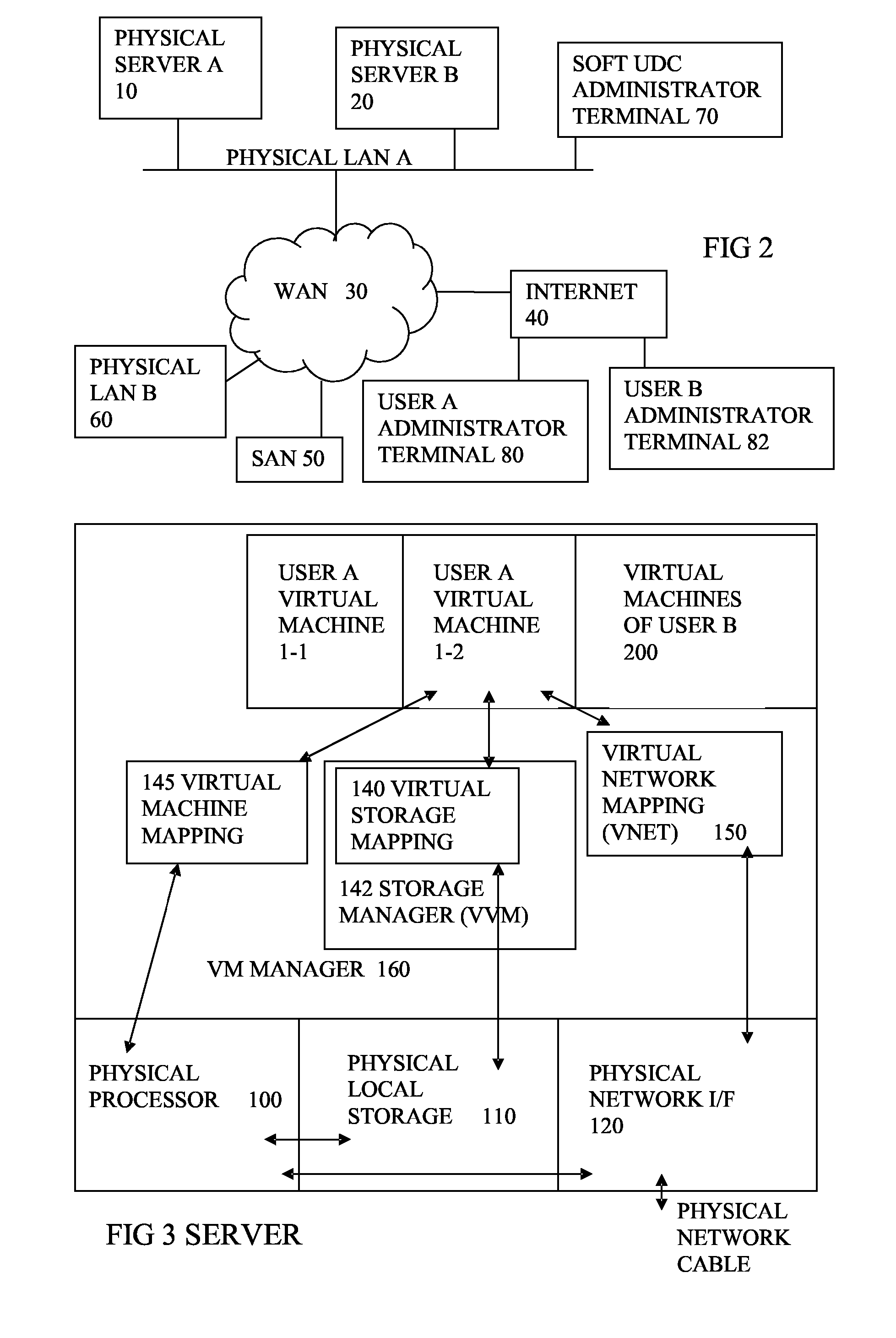

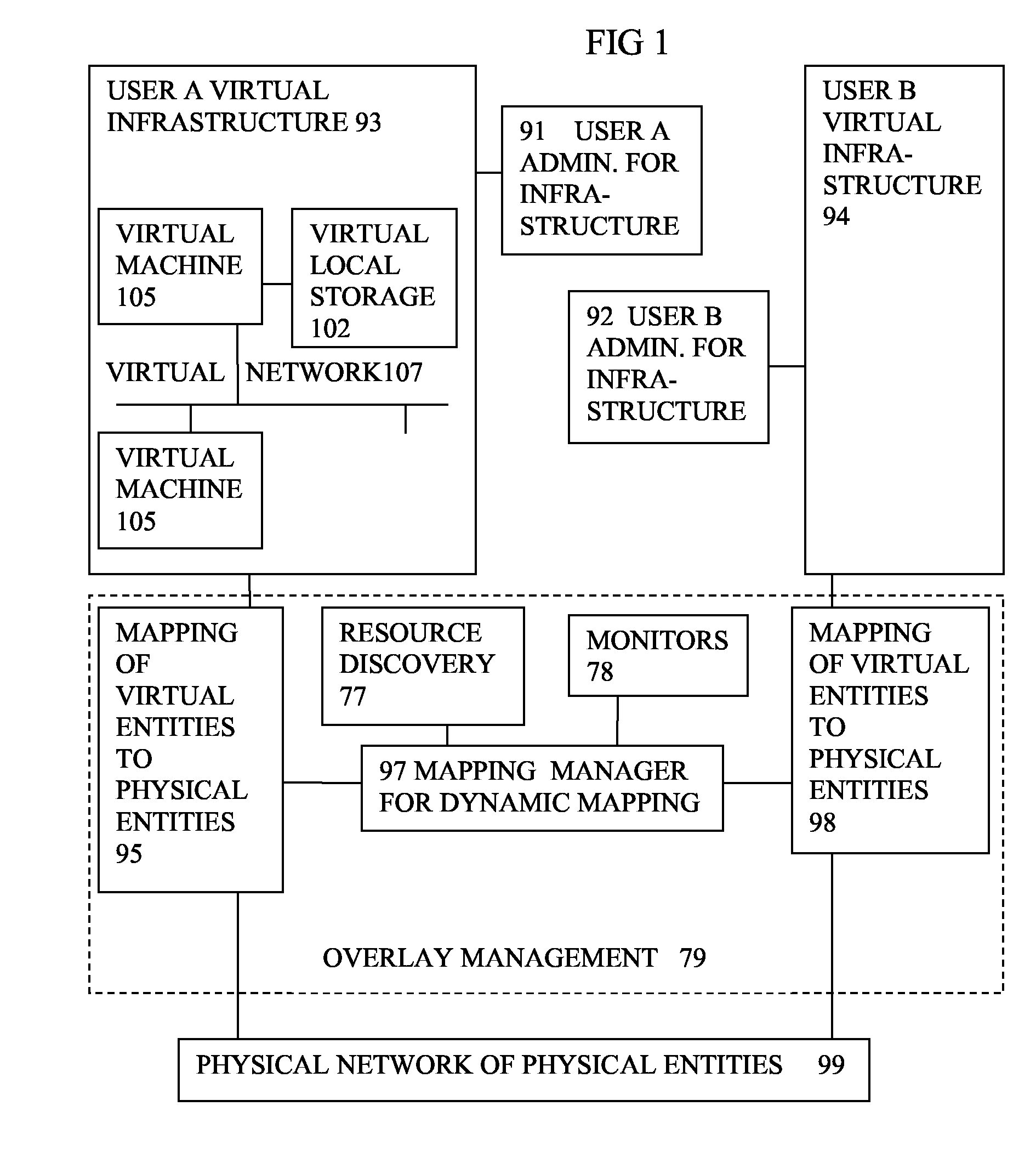

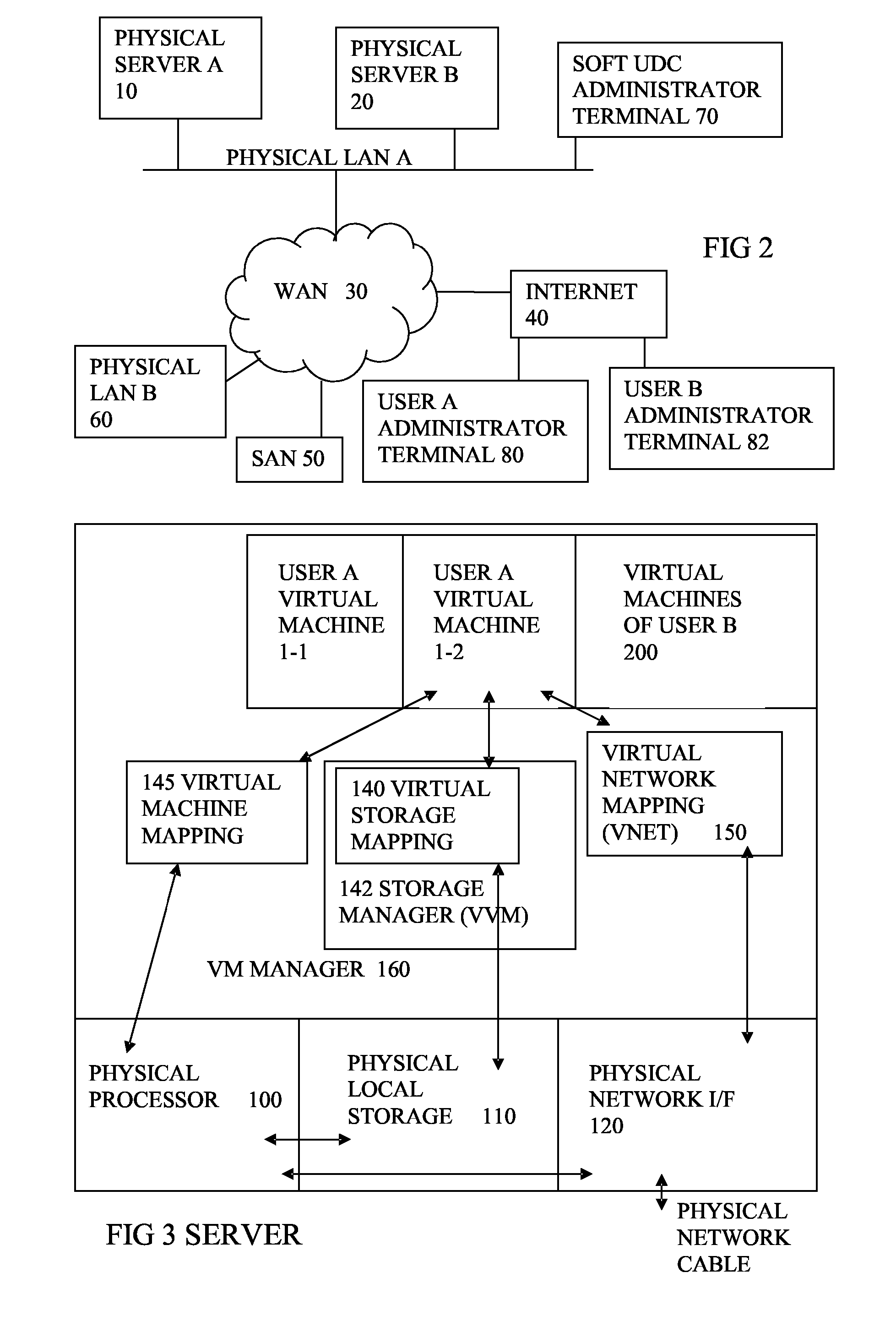

A system has a virtual overlay infrastructure mapped onto physical resources for processing, storage and network communications, the virtual infrastructure having virtual entities for processing, storage and network communications. The system has a mapping manager to dynamically alter the mapping for balancing, performance, and redundancy. There can be more independence from the underlying physical configuration, compared to known methods of virtualizing only some of the entities. The mapping manager can be distributed across a number of entities on different physical servers arranged to cooperate with each other.

Owner:HEWLETT PACKARD DEV CO LP

Virtual computing infrastructure

ActiveUS20110119748A1More separatedReduce hardware costsResource allocationComputer security arrangementsNetwork communicationApplication software

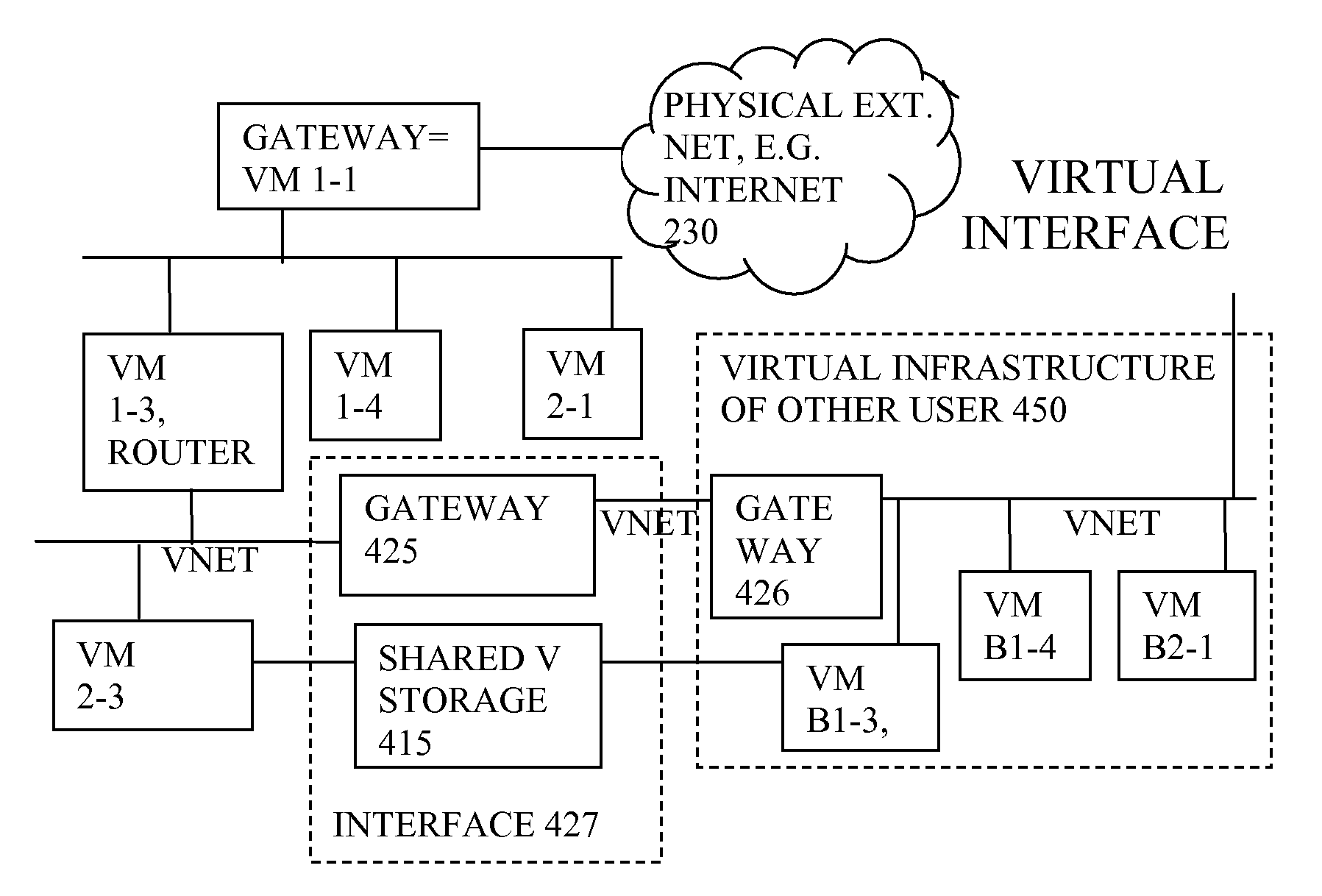

A system has a virtual overlay infrastructure mapped onto physical resources for processing, storage and network communications, the virtual infrastructure having virtual entities for processing, storage and network communications. Virtual infrastructures of different users share physical resources but are isolated and have their own management entities. An interface between infrastructures allows controlled relaxation of the isolation, using a gateway between virtual nets, or shared virtual storage devices. This can allow businesses to share data or applications, while maintaining control of security.

Owner:RED HAT +1

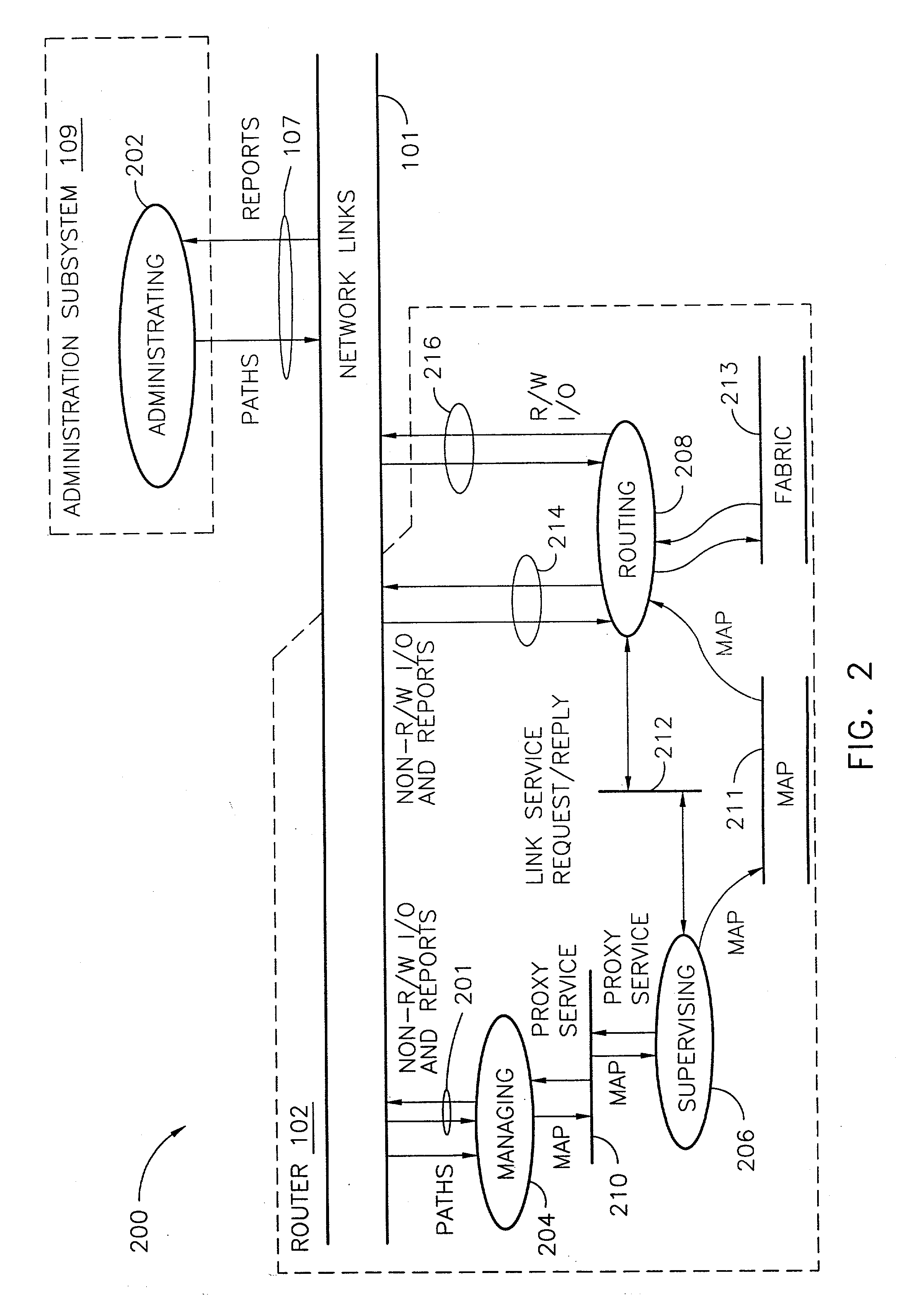

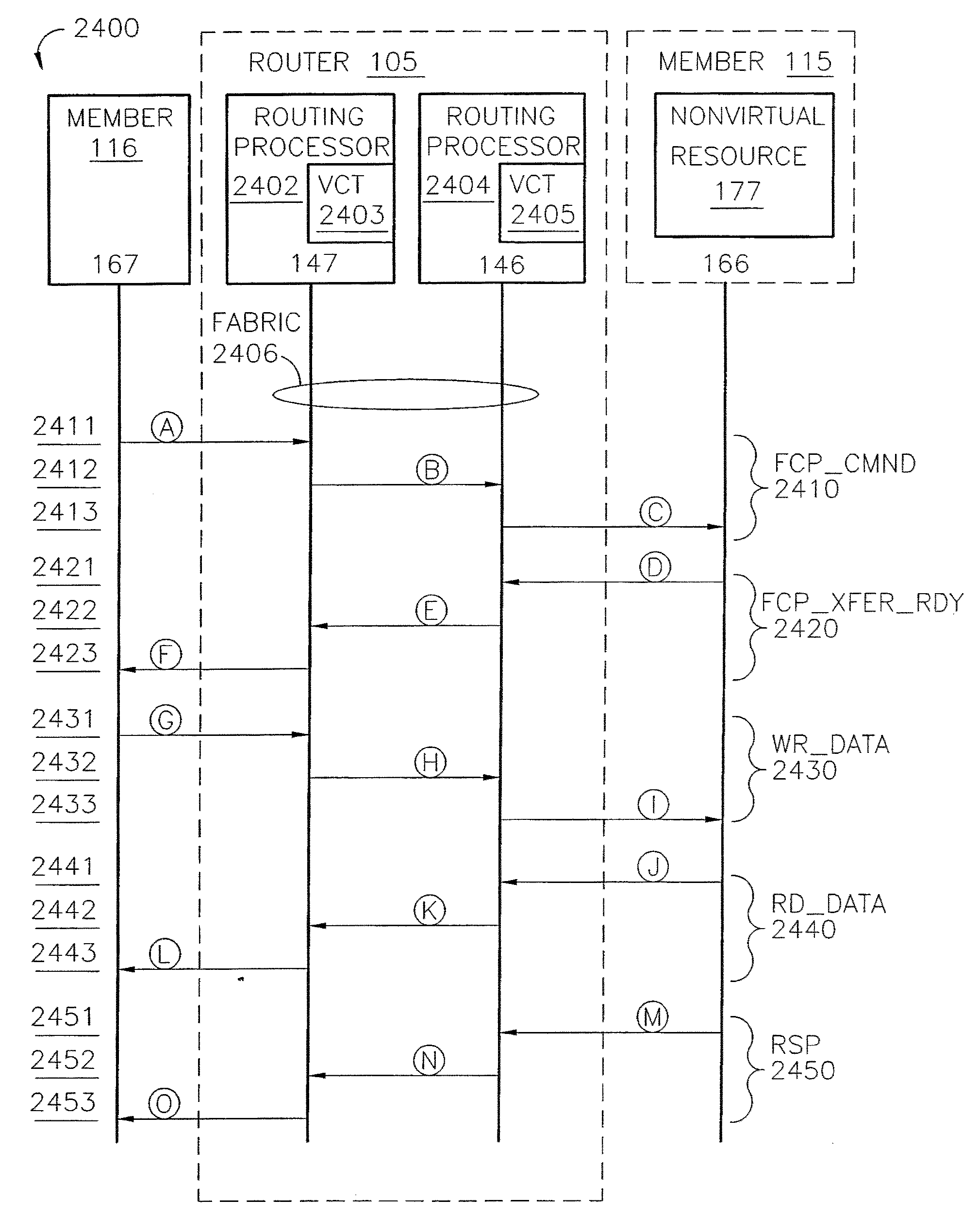

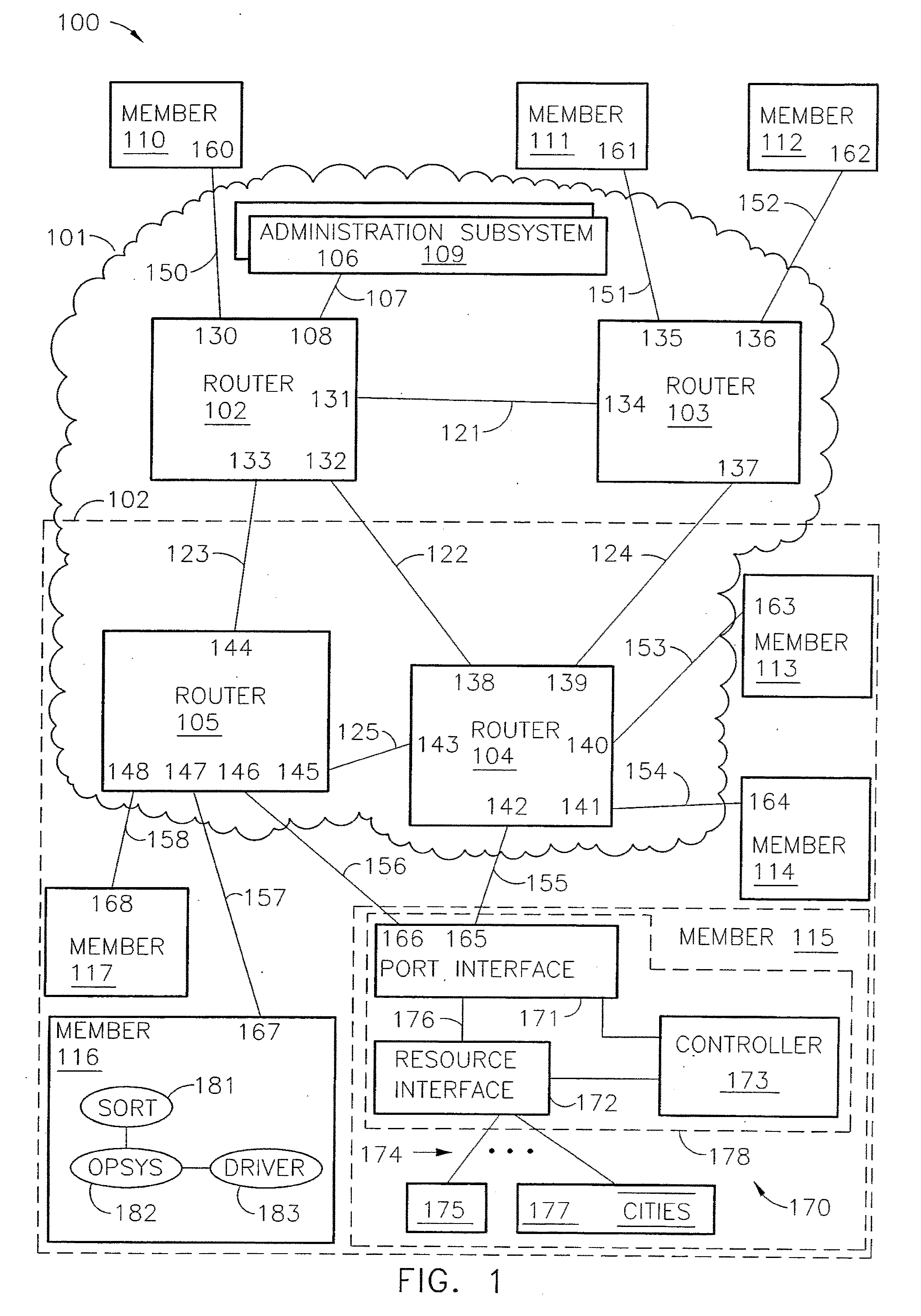

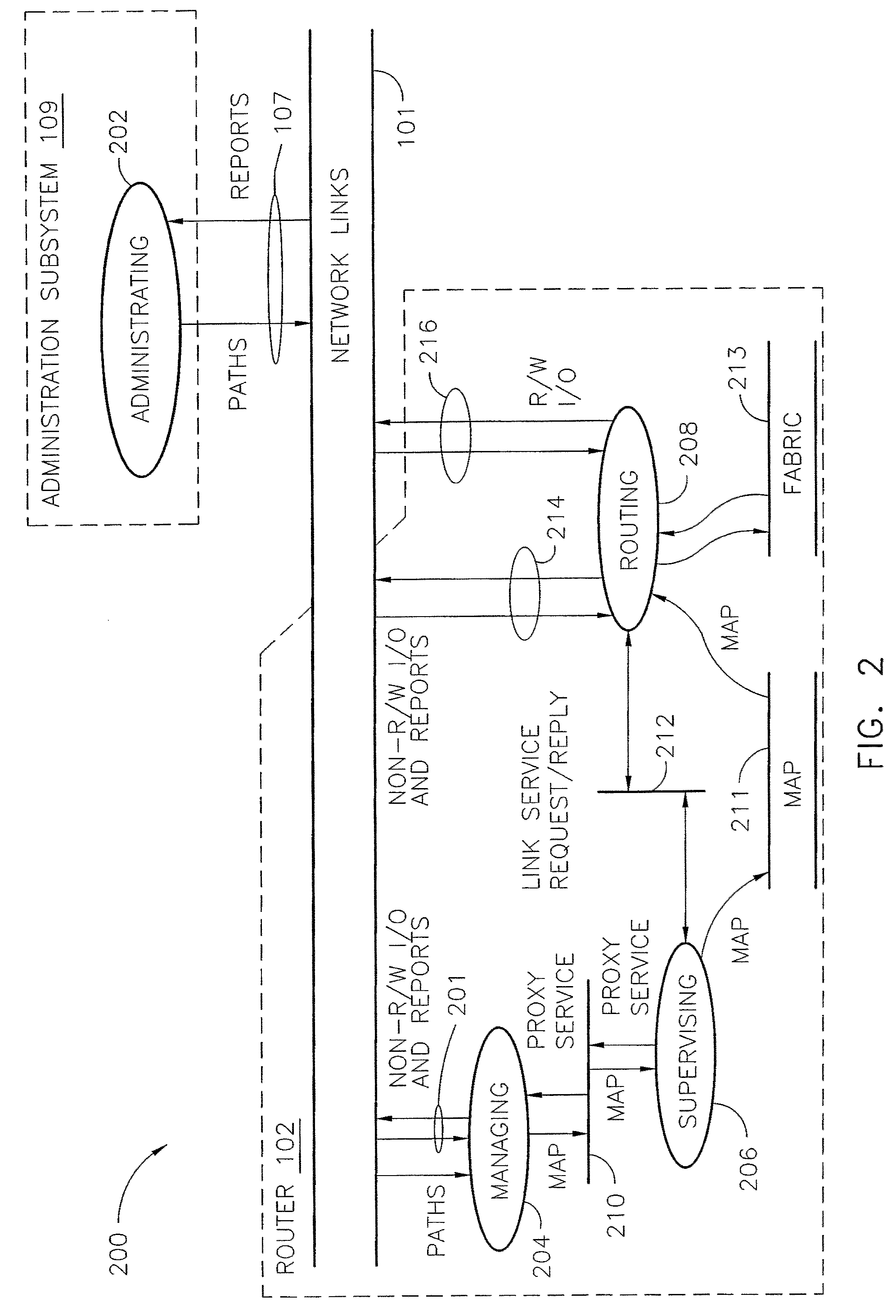

Router and methods using network addresses for virtualization

ActiveUS7200144B2Easy to operateImprove efficiency and reliabilityData switching by path configurationQuality of serviceDeficit round robin

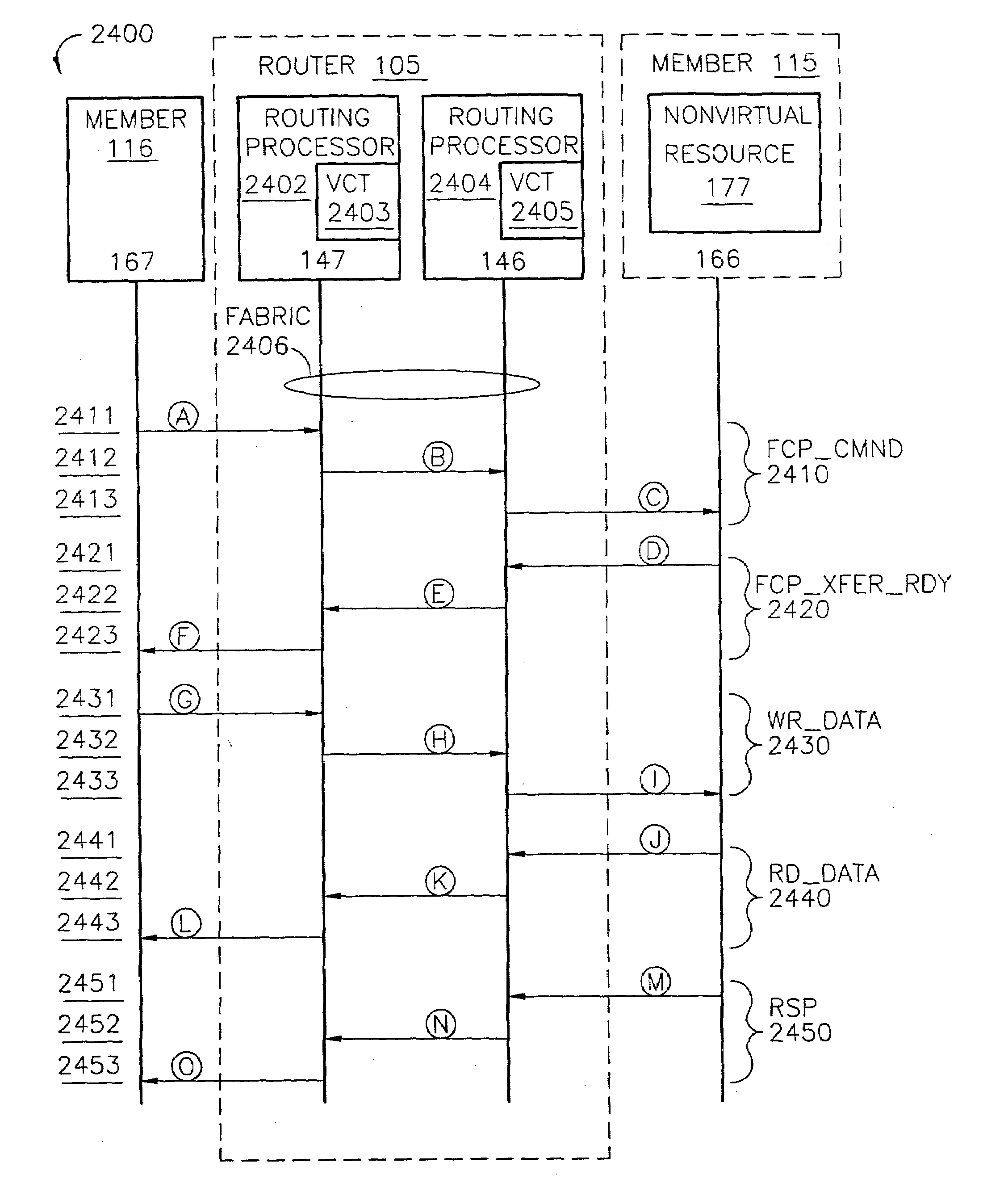

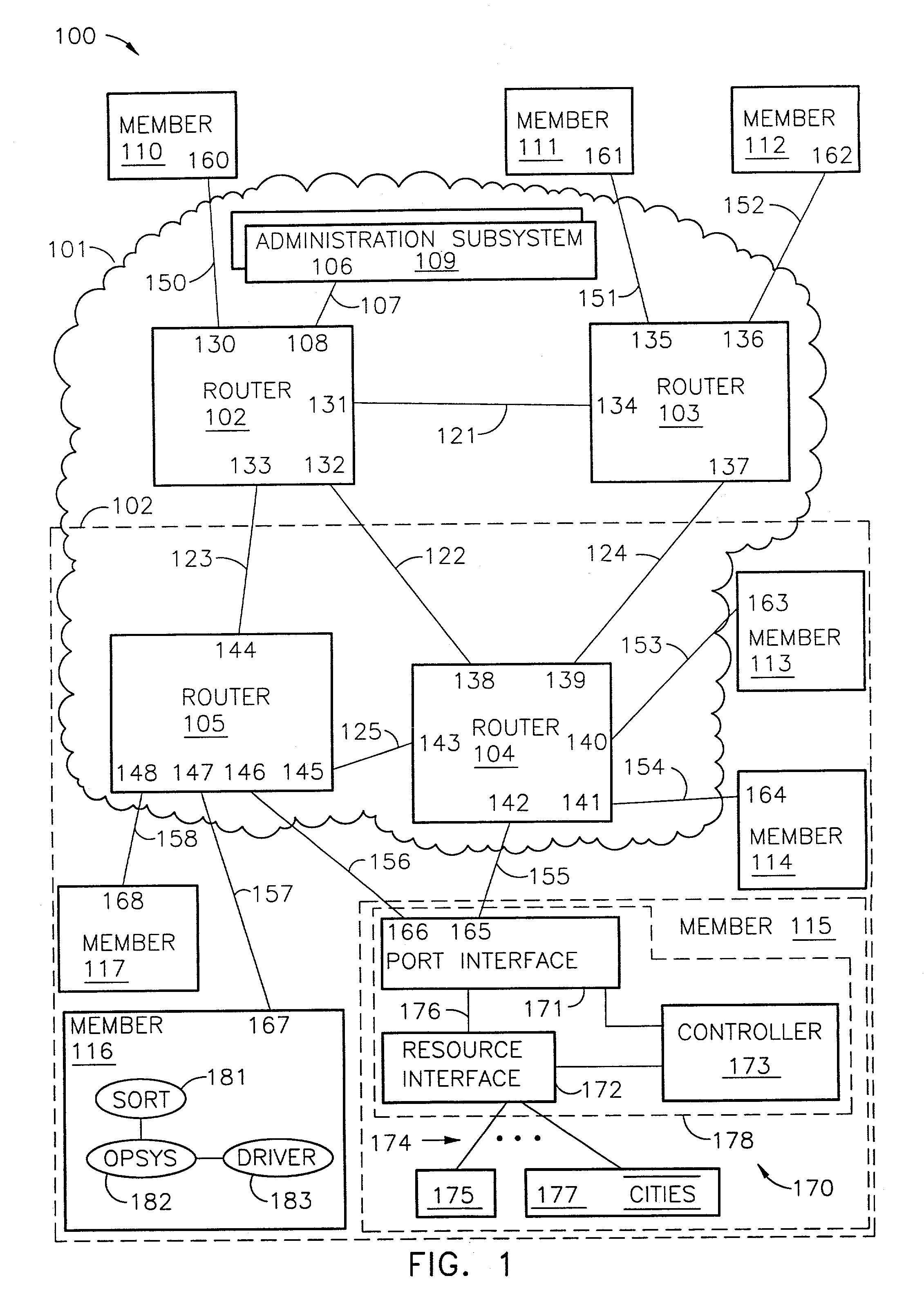

A router for use in a network includes a scalable architecture and performs methods for implementing quality of service on a logical unit behind a network port; and for implementing storage virtualization. The architecture includes a managing processor, a supervising processor; and a plurality of routing processors coupled to a fabric. The managing processor has an in-band link to a routing processor. A routing processor receives a frame from the network, determines by parsing the frame, the protocol and logical unit number, and routes the frame to a queue according to a traffic class associated with the logical unit number in routing information prepared for the processors. An arbitration scheme empties the queue in accordance with a deficit round robin technique. If a routing processor detects the frame's destination is a virtual entity, and so is part of a virtual transaction, the router conducts a nonvirtual transaction in concert with the virtual transaction. The nonvirtual transaction accomplishes the intent of the virtual transaction but operates on an actual network port, for example, a storage device.

Owner:MARVELL ASIA PTE LTD

Virtual computing infrastructure

ActiveUS20090300605A1More separatedReduce hardware costsResource allocationSoftware simulation/interpretation/emulationOperational systemNetwork communication

A system has a virtual overlay infrastructure mapped onto physical resources for processing, storage and network communications, the virtual infrastructure having virtual entities for processing, storage and network communications. Each virtual infrastructure can be passivated by suspending applications, stopping operating systems, and storing state, to enable later reactivation. This is simpler for a complete virtual infrastructure than for groups of virtual entities and physical entities. It enables cloned virtual infrastructure to be created for testing, upgrading or sharing without risk to the parent. On failure, reversion to a previous working clone is feasible.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

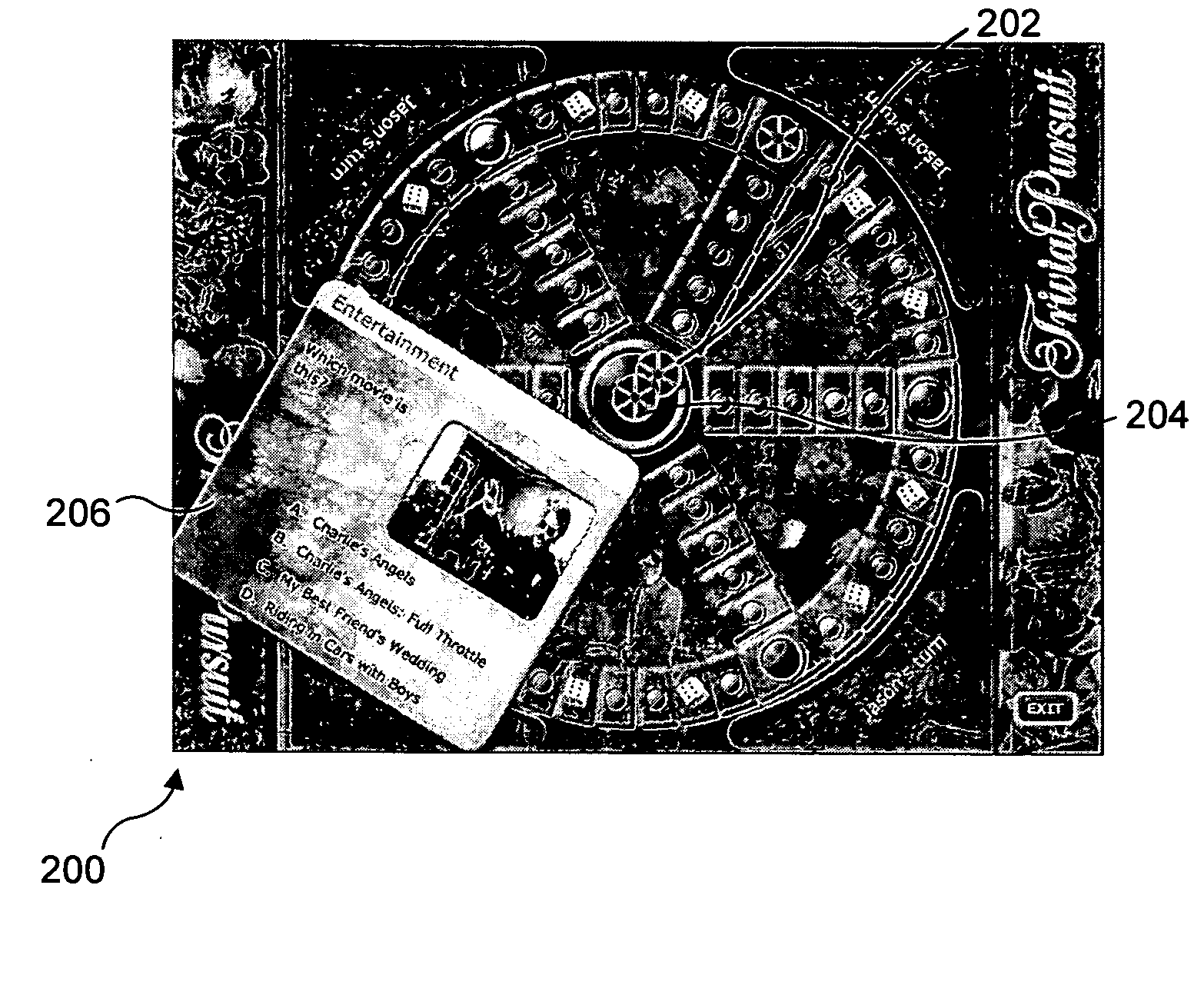

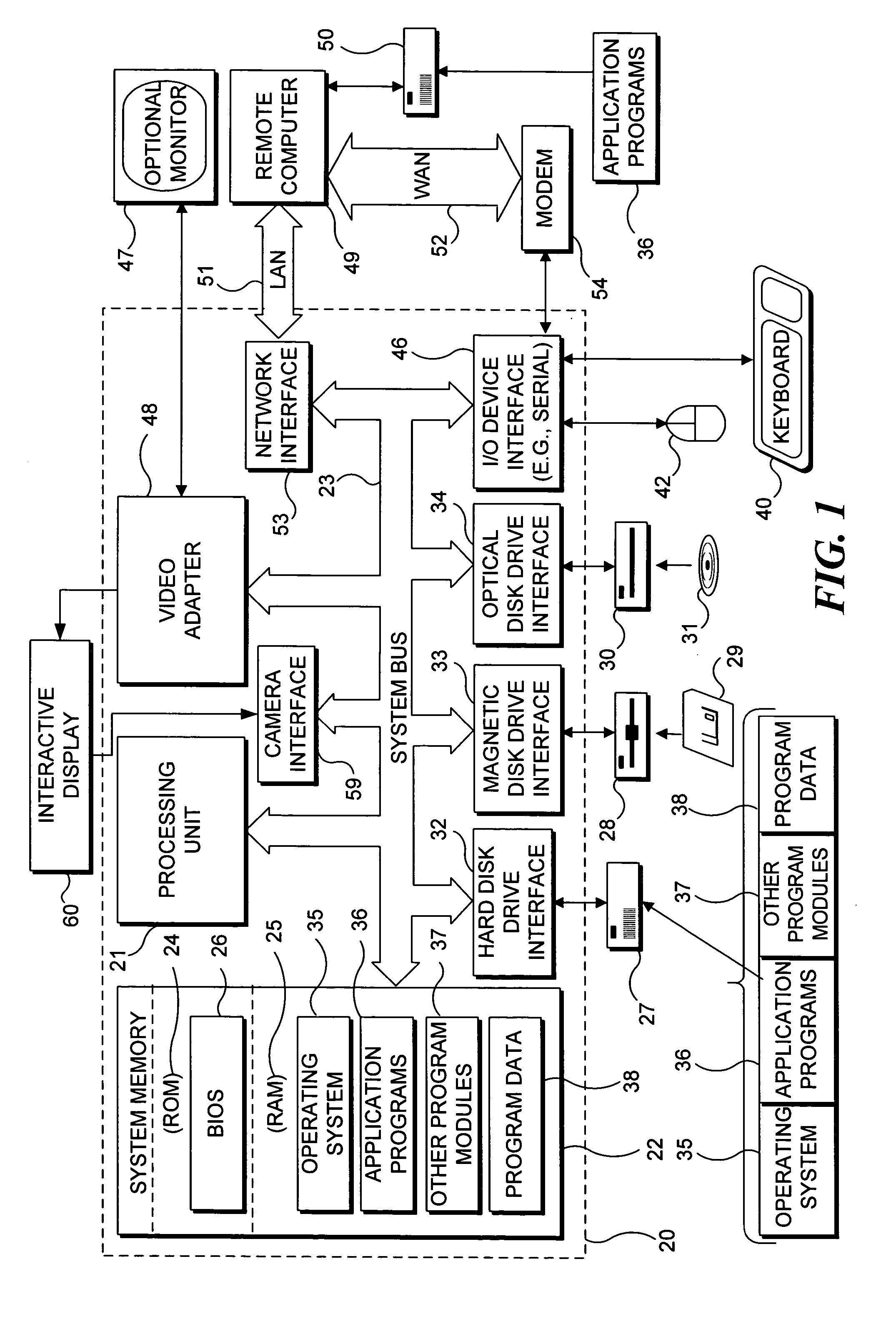

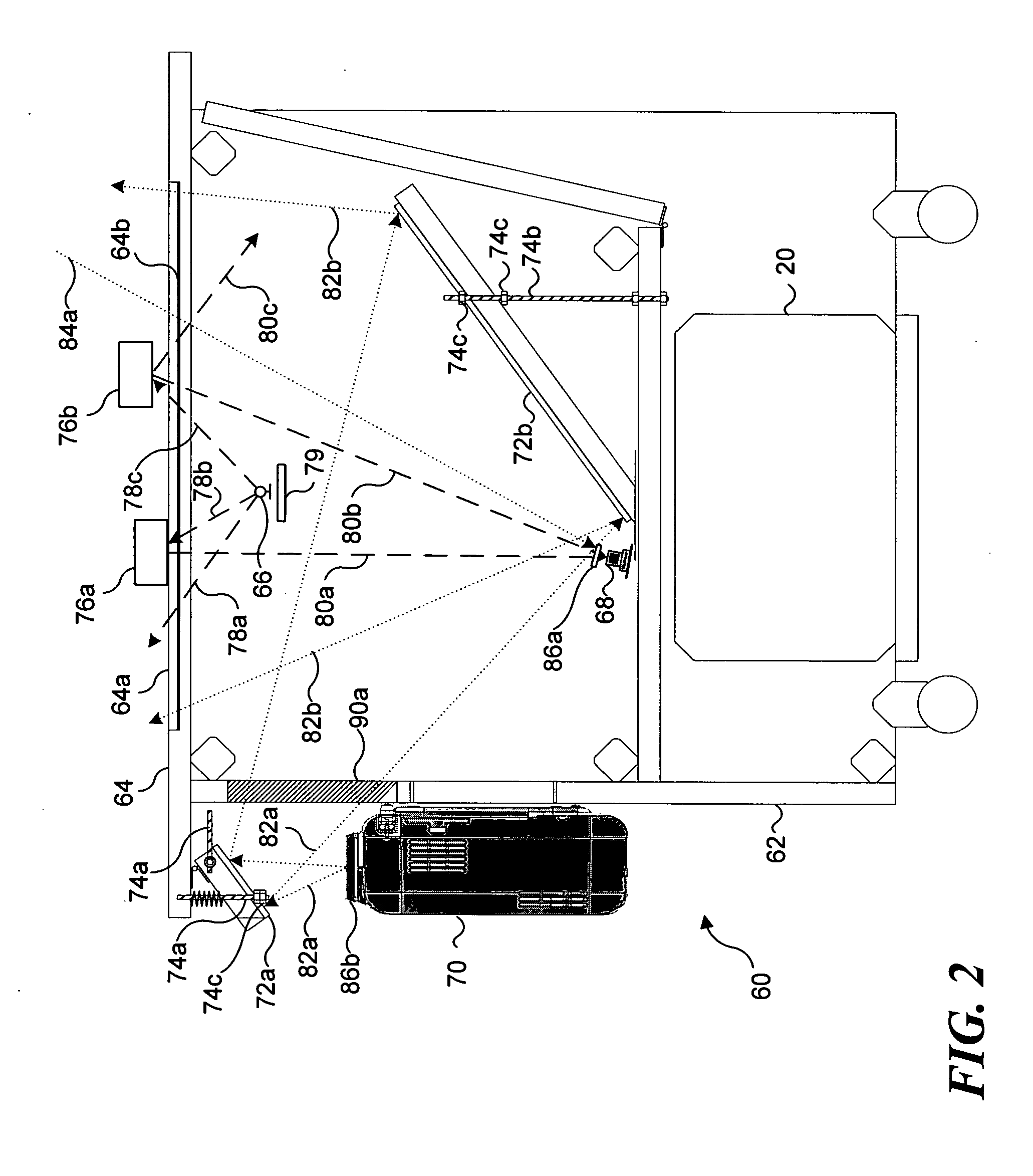

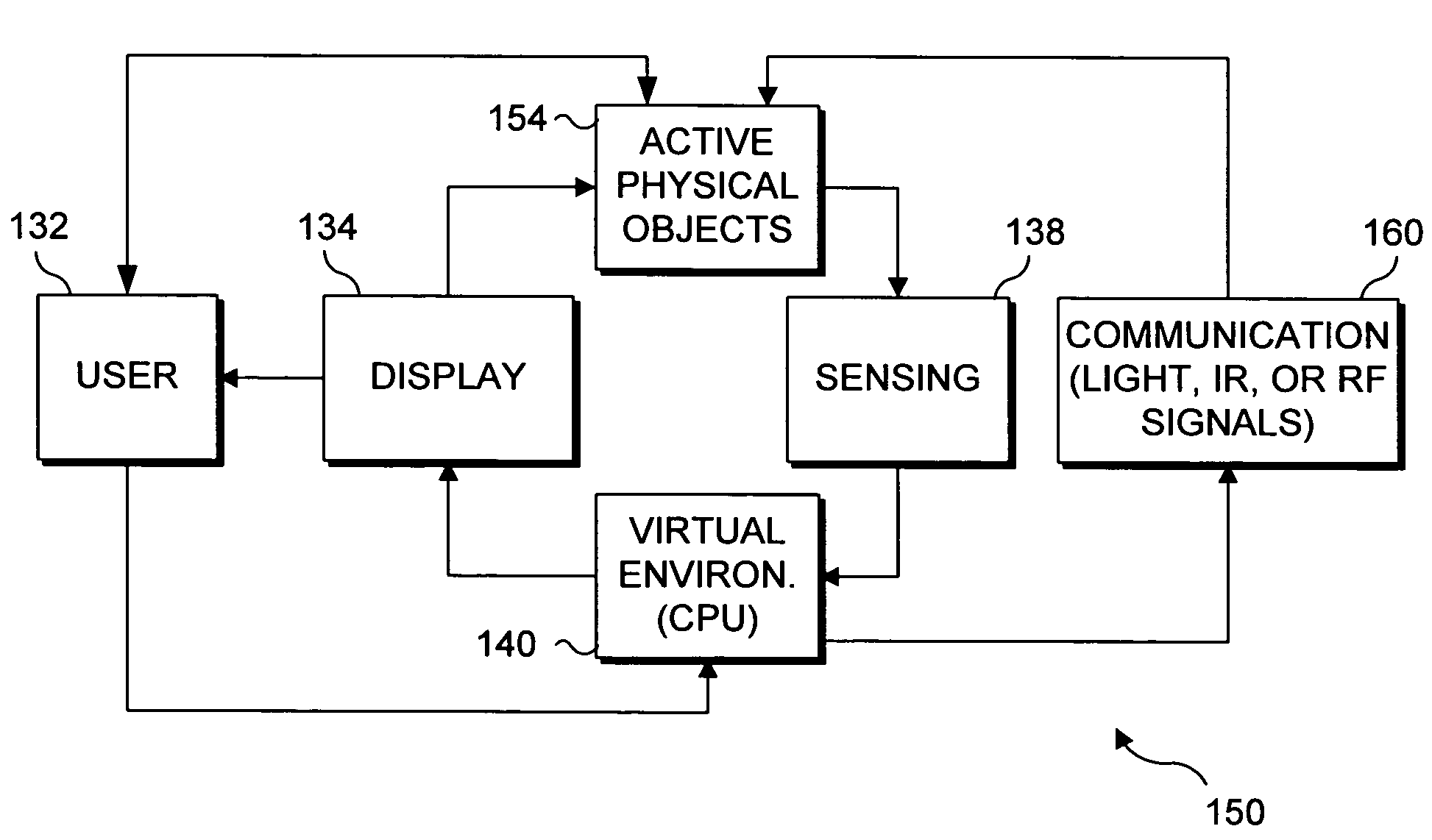

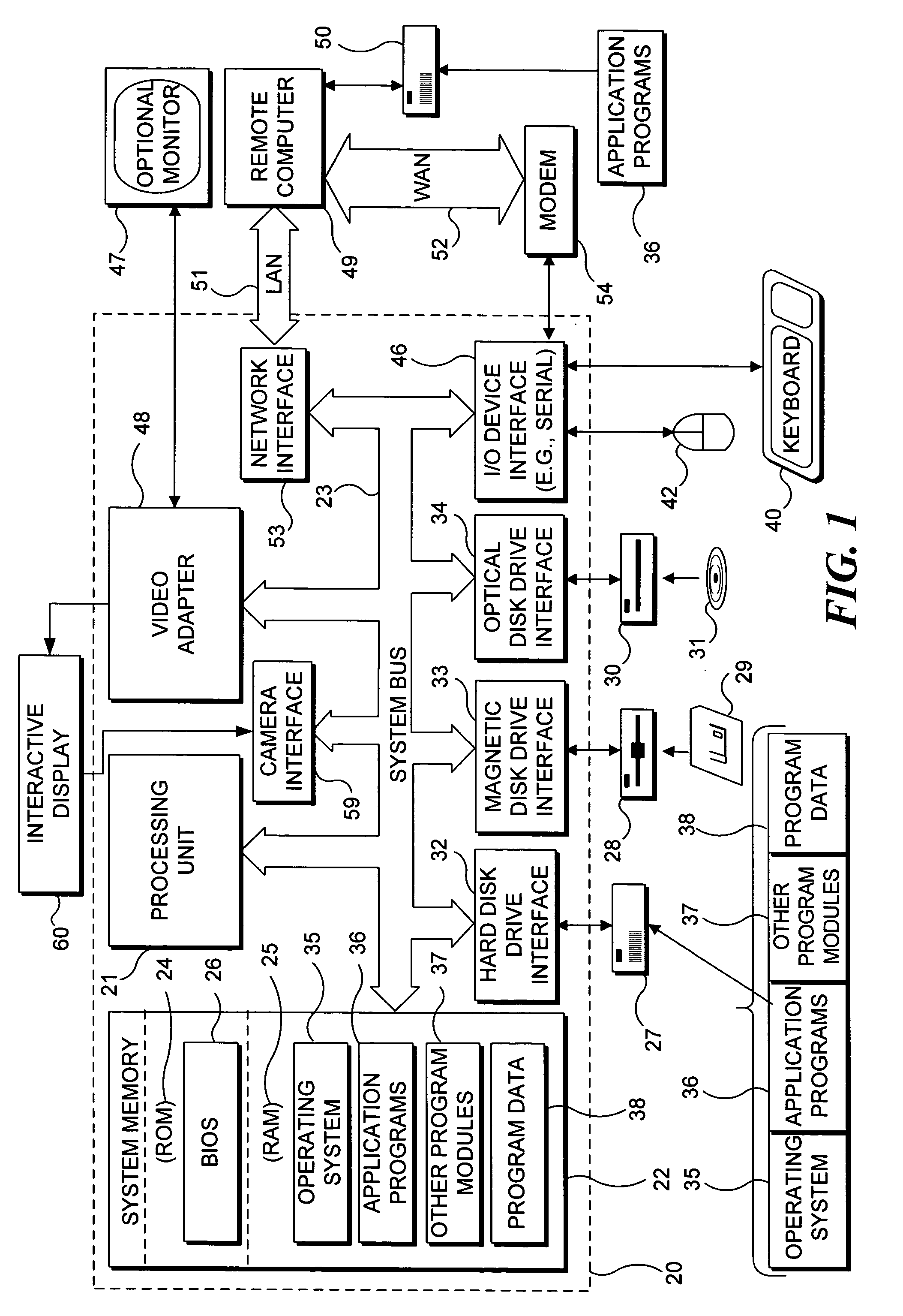

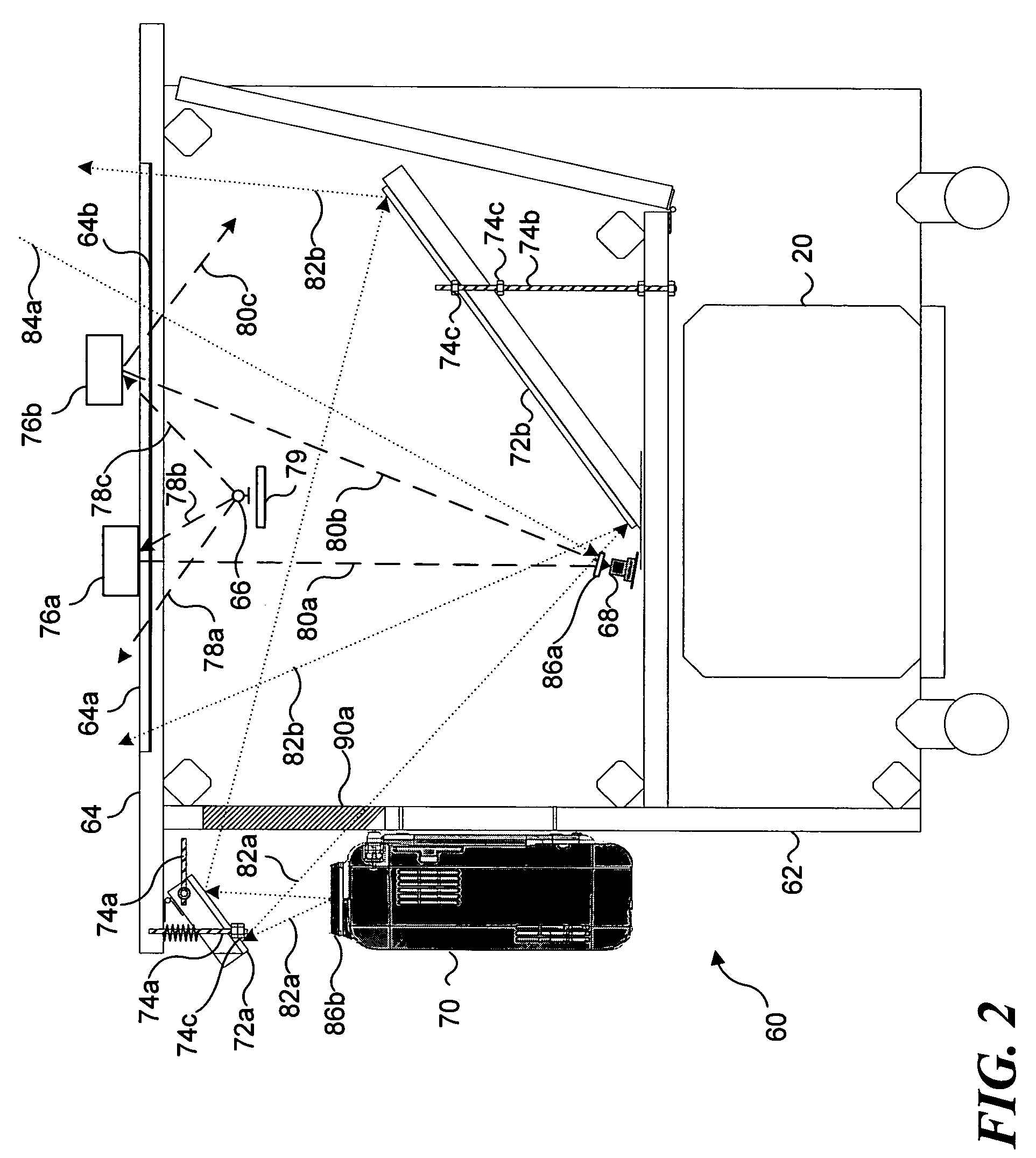

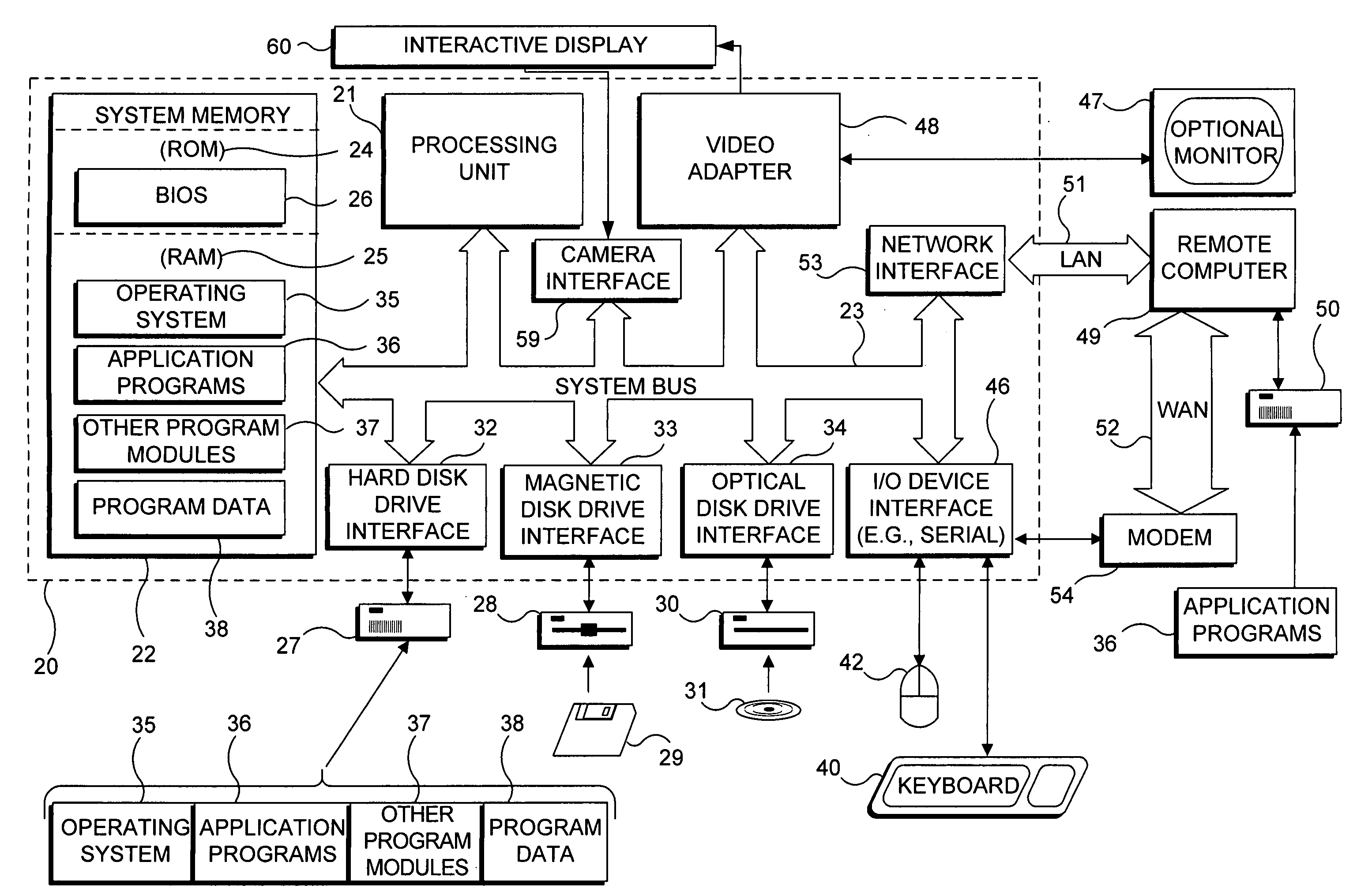

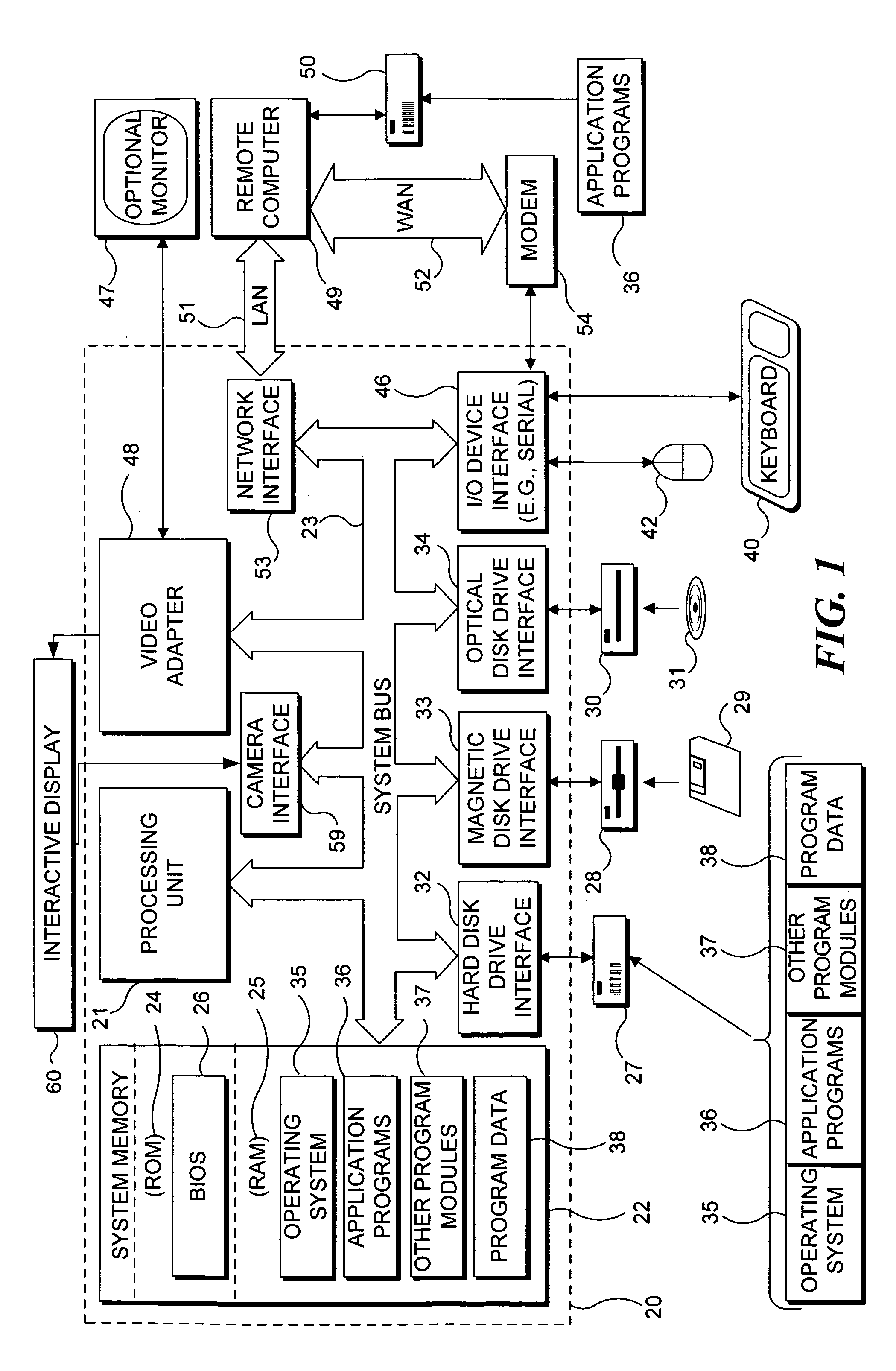

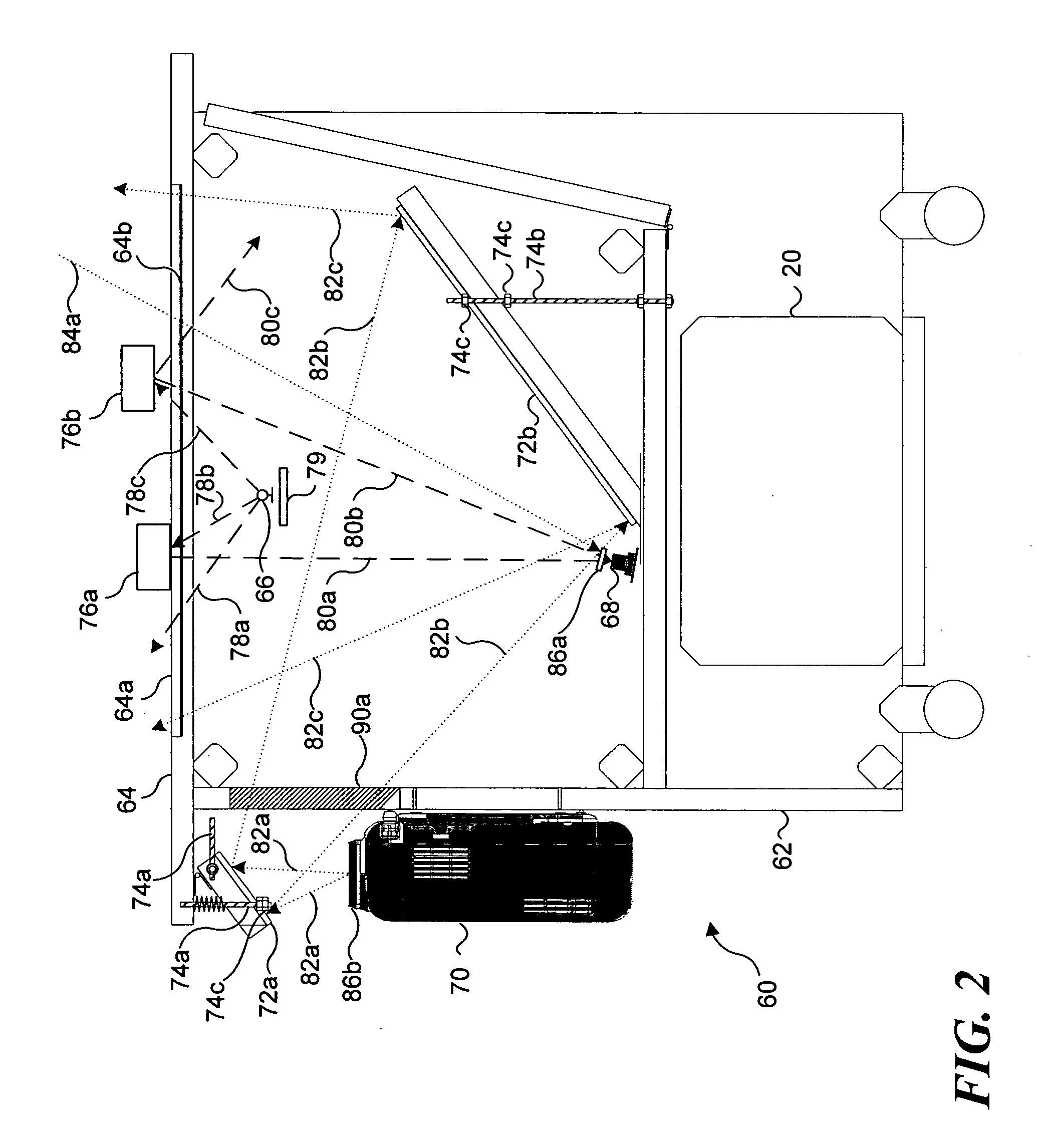

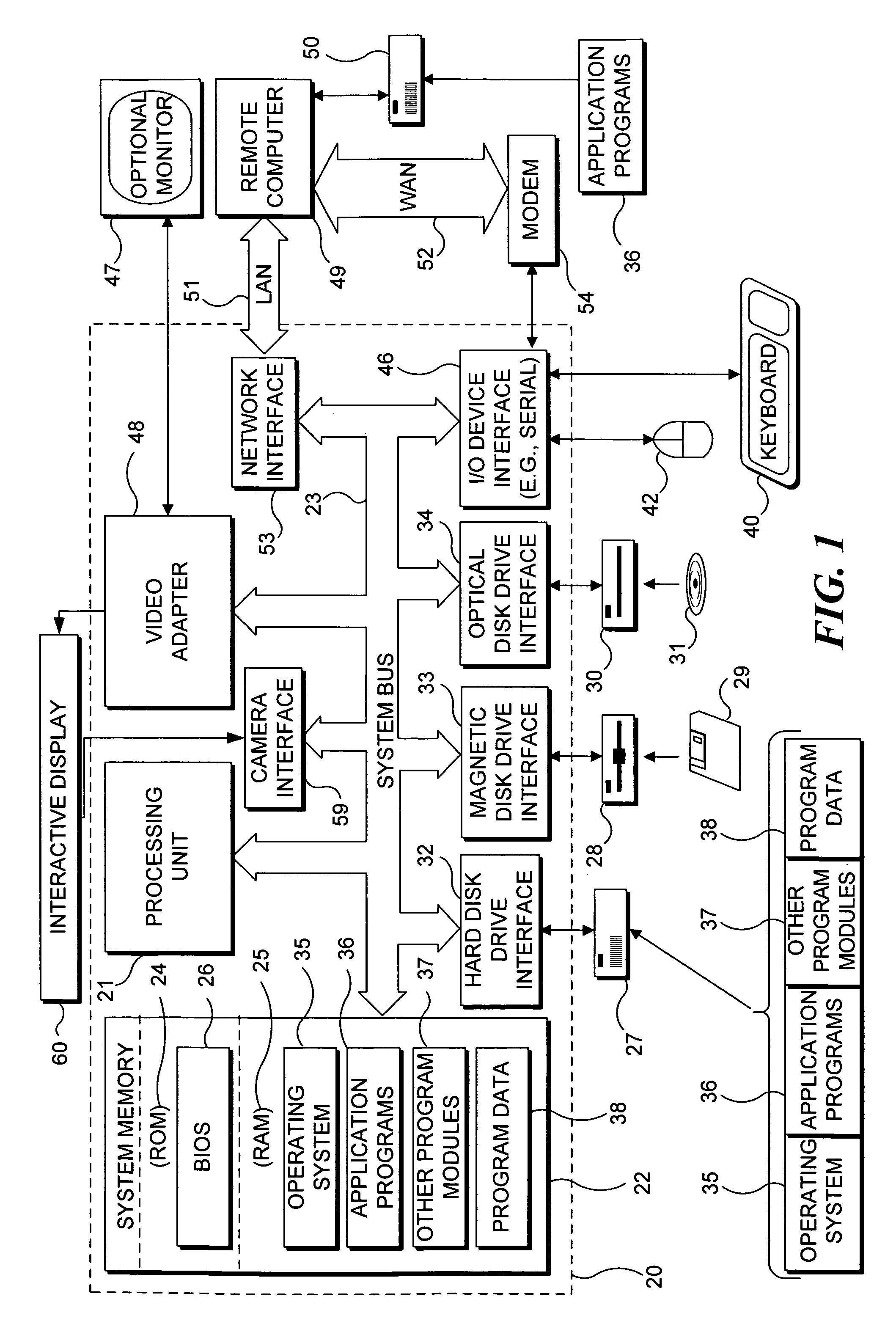

Interaction between objects and a virtual environment display

InactiveUS20050245302A1Enhanced interactionBlurring distinctionInput/output for user-computer interactionDigital data processing detailsProjection imageHuman–computer interaction

An interactive table has a display surface on which a physical object is disposed. A camera within the interactive table responds to infrared (IR) light reflected from the physical object enabling a location of the physical object on the display surface to be determined, so that the physical object appear part of a virtual environment displayed thereon. The physical object can be passive or active. An active object performs an active function, e.g., it can be self-propelled to move about on the display surface, or emit light or sound, or vibrate. The active object can be controlled by a user or the processor. The interactive table can project an image through a physical object on the display surface so the image appears part of the object. A virtual entity is preferably displayed at a position (and a size) to avoid visually interference with any physical object on the display surface.

Owner:MICROSOFT TECH LICENSING LLC

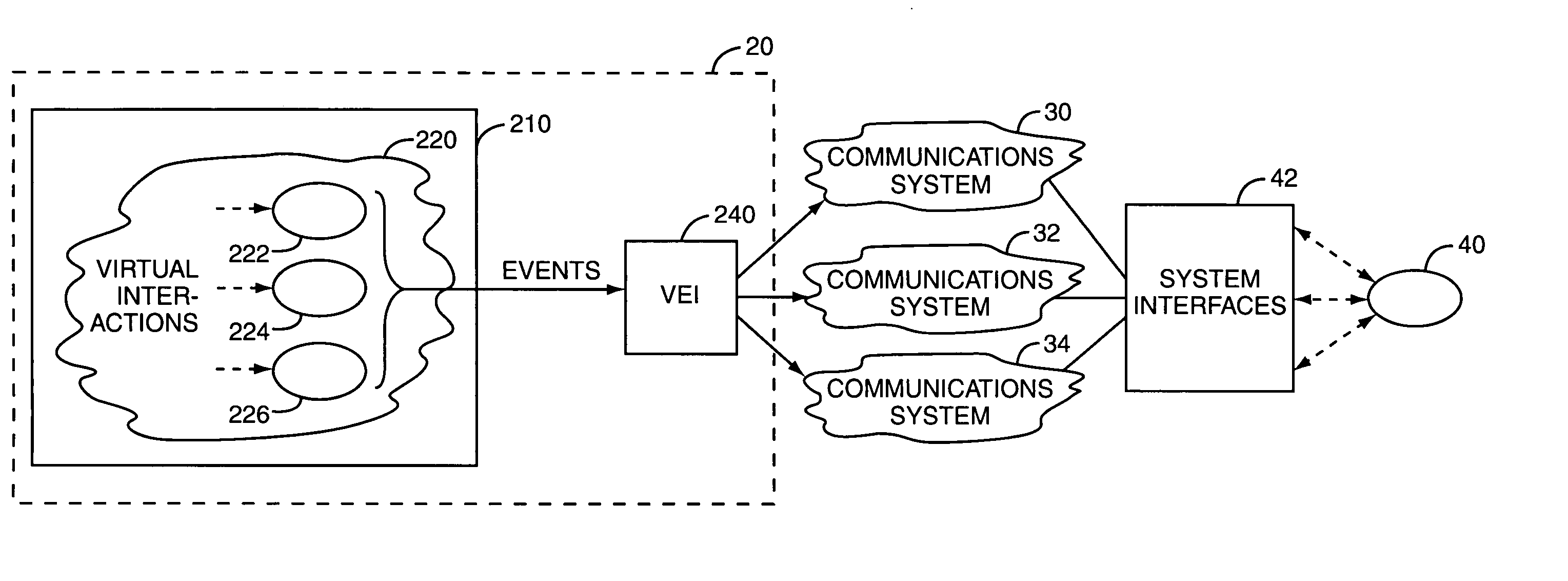

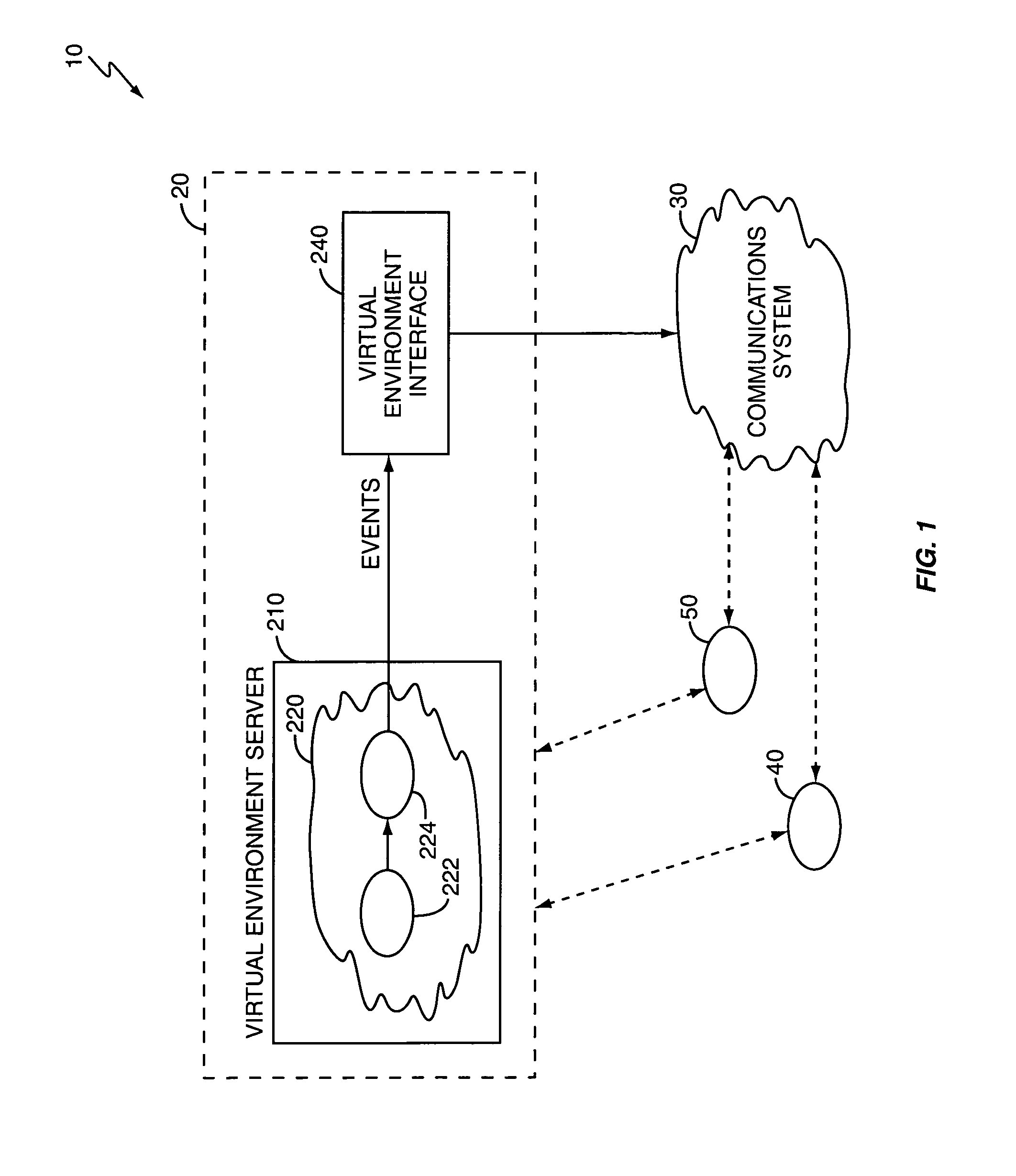

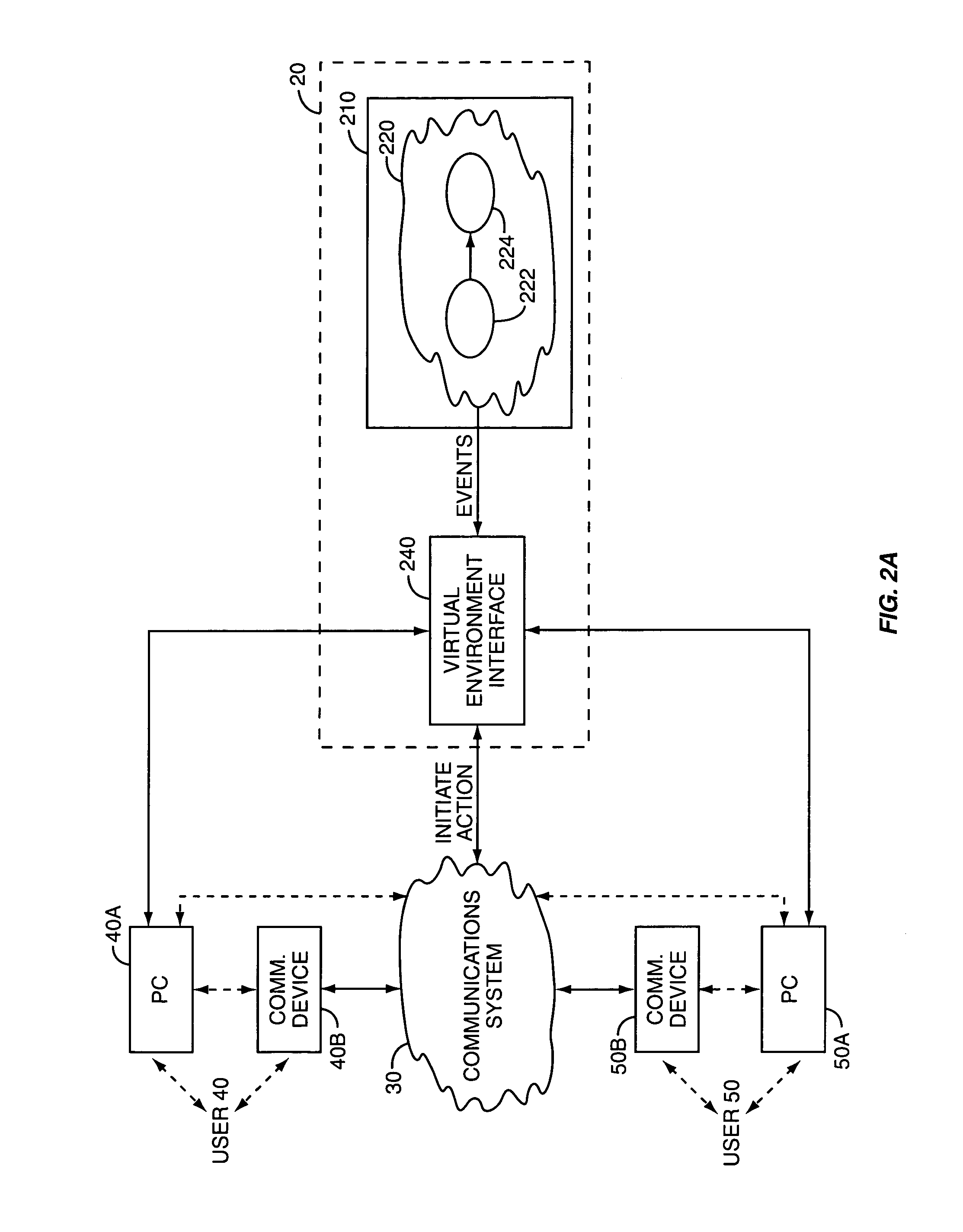

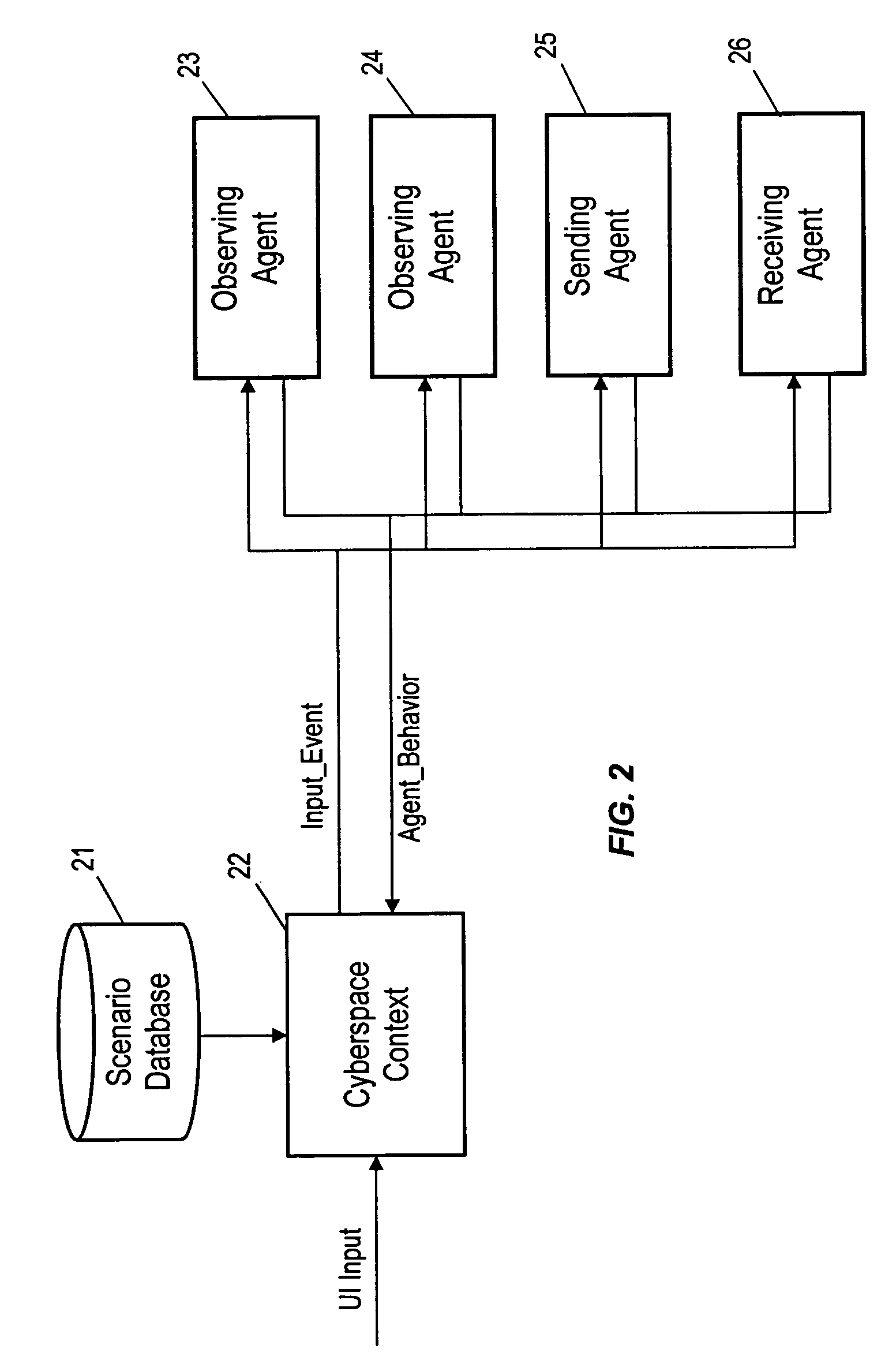

Controlling communications through a virtual reality environment

InactiveUS7036082B1Maximum flexibilitySuitable for communicationProgram controlNetwork connectionsTelecommunications linkCommunications system

A virtual reality system initiates desired real world actions in response to defined events occurring within a virtual environment. A variety of systems, such as communications devices, computer networks, and software applications, may be interfaced with the virtual reality system and made responsive to virtual events. For example, the virtual reality system may trigger a communications system to establish a communications link between people in response to a virtual event. Users, represented as avatars within the virtual environment, generate events by interacting with virtual entities, such as other avatars, virtual objects, and virtual locations. Virtual entities can be associated with specific users, and users can define desired behaviors for associated entities. Behaviors control the real world actions triggered by virtual events. Users can modify these behaviors, and the virtual reality system may change behaviors based on changing conditions, such as time of day or the whereabouts of a particular user.

Owner:AVAYA INC

Interaction between objects and a virtual environment display

InactiveUS7394459B2Enhanced interactionBlurring distinctionInput/output for user-computer interactionDigital data processing detailsHuman–computer interactionVisual perception

An interactive table has a display surface on which a physical object is disposed. A camera within the interactive table responds to infrared (IR) light reflected from the physical object enabling a location of the physical object on the display surface to be determined, so that the physical object appear part of a virtual environment displayed thereon. The physical object can be passive or active. An active object performs an active function, e.g., it can be self-propelled to move about on the display surface, or emit light or sound, or vibrate. The active object can be controlled by a user or the processor. The interactive table can project an image through a physical object on the display surface so the image appears part of the object. A virtual entity is preferably displayed at a position (and a size) to avoid visually interference with any physical object on the display surface.

Owner:MICROSOFT TECH LICENSING LLC

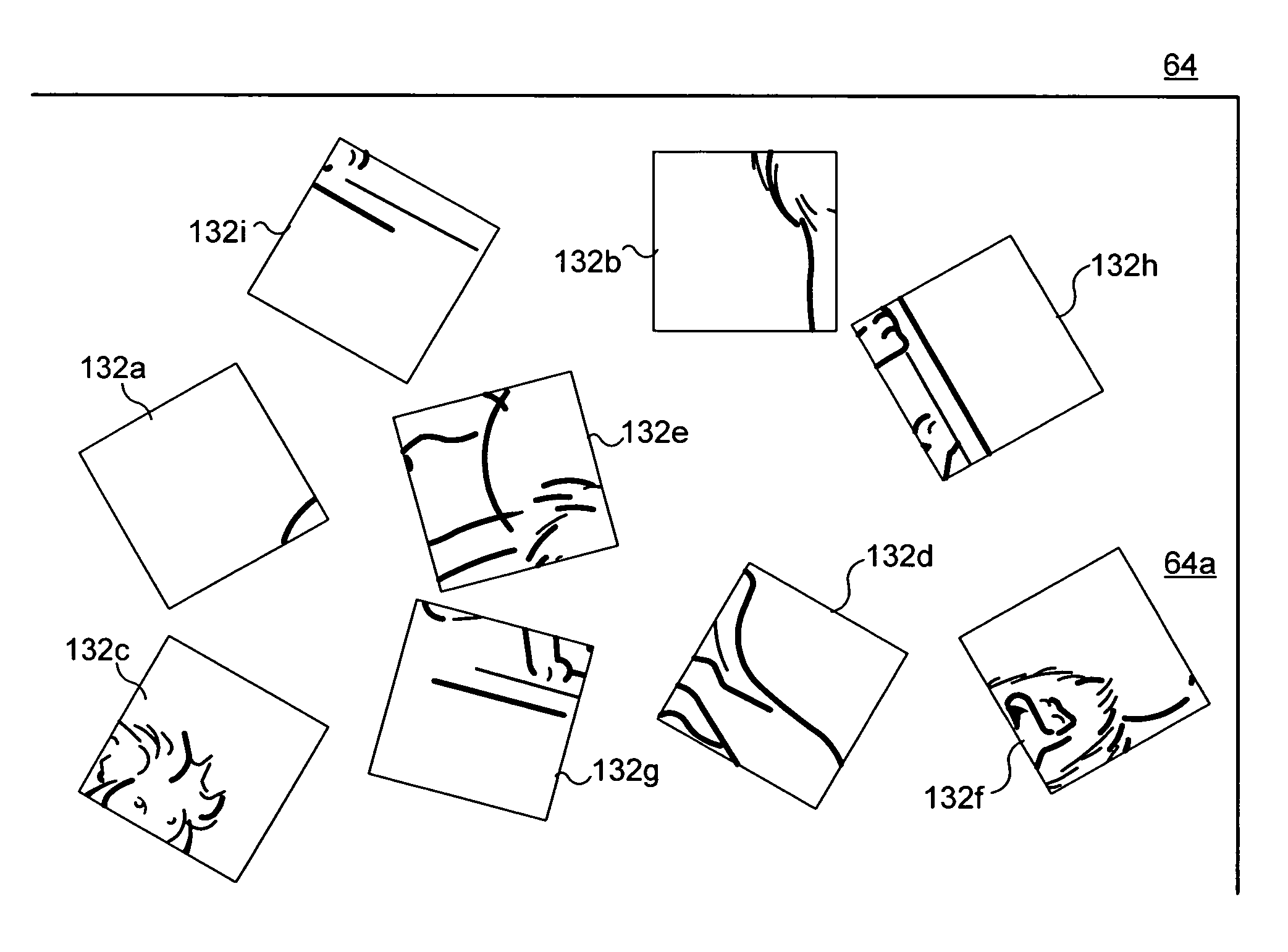

Using clear-coded, see-through objects to manipulate virtual objects

ActiveUS20060092170A1Improve usabilityCathode-ray tube indicatorsVideo gamesComputer visionInteractive displays

An object placed on an interactive display surface is detected and its position and orientation are determined in response to IR light that is reflected from an encoded marking on the object. Upon detecting the object on an interactive display surface, a software program produces a virtual entity or image visible through the object to perform a predefined function. For example, the object may appear to magnify text visible through the object, or to translate a word or phrase from one language to another, so that the translated word or phrase is visible through the object. When the object is moved, the virtual entity or image that is visible through the object may move with it, or can control the function being performed. A plurality of such objects can each display a portion of an image, and when correctly positioned, together will display the entire image, like a jigsaw puzzle.

Owner:ZHIGU HLDG

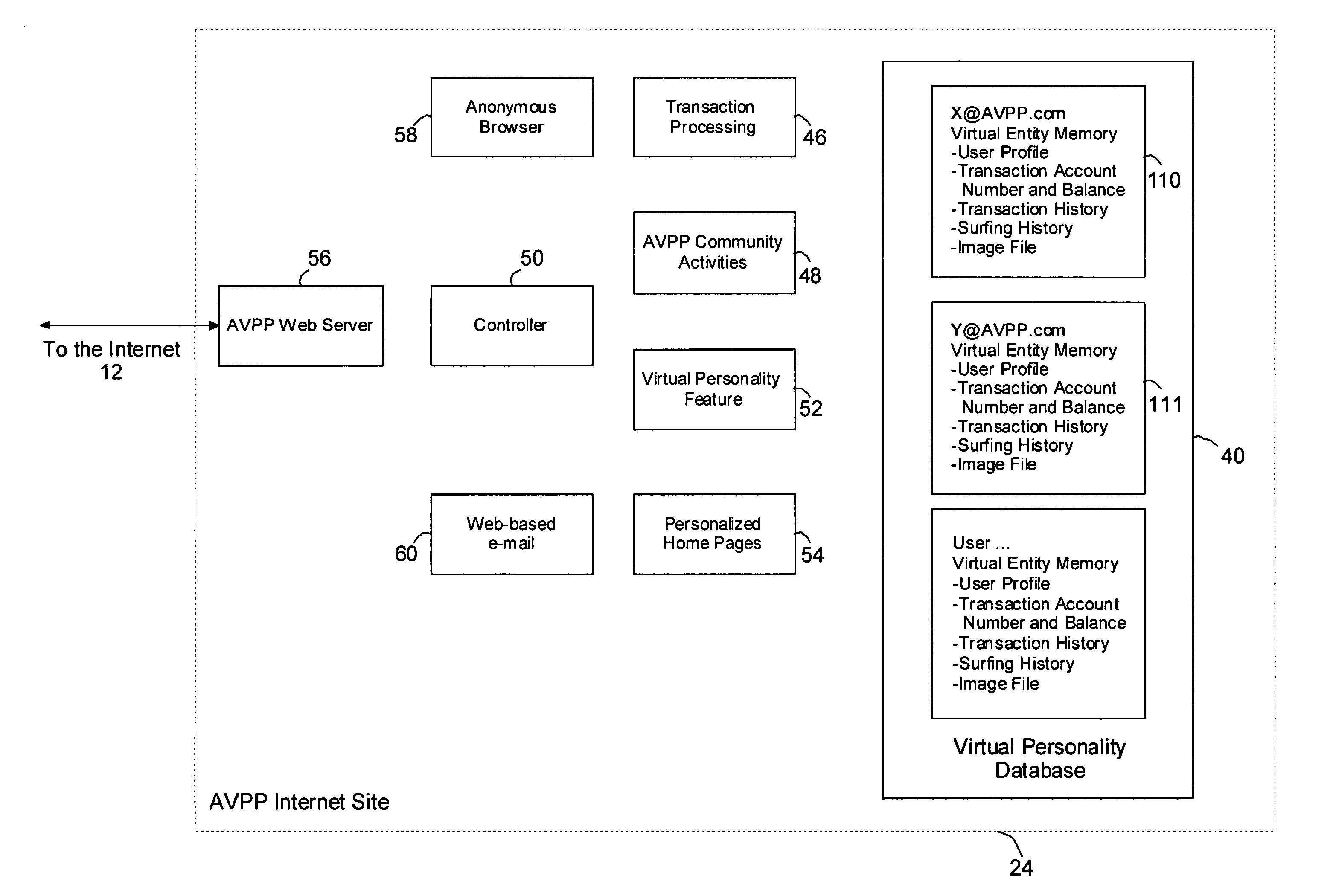

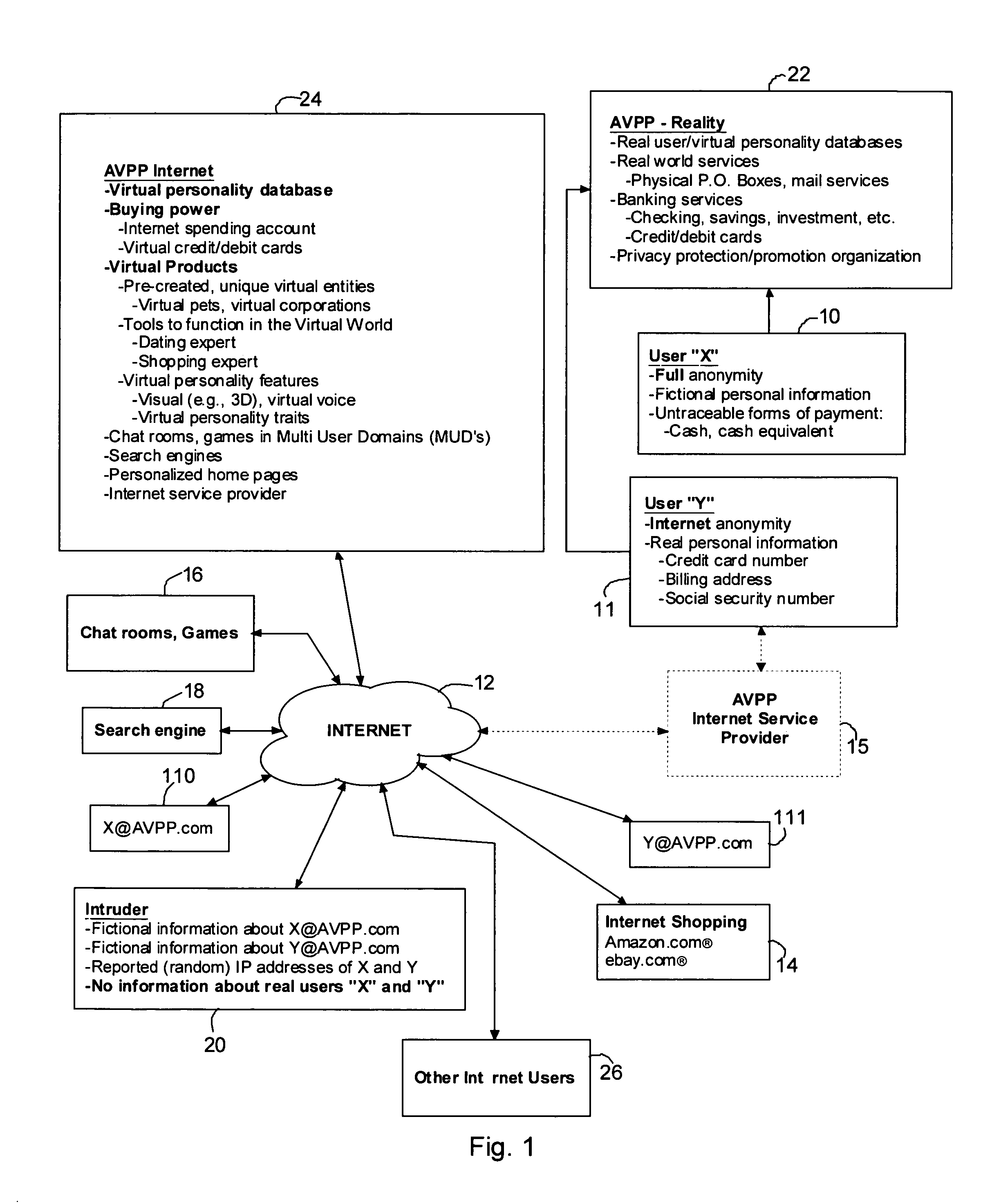

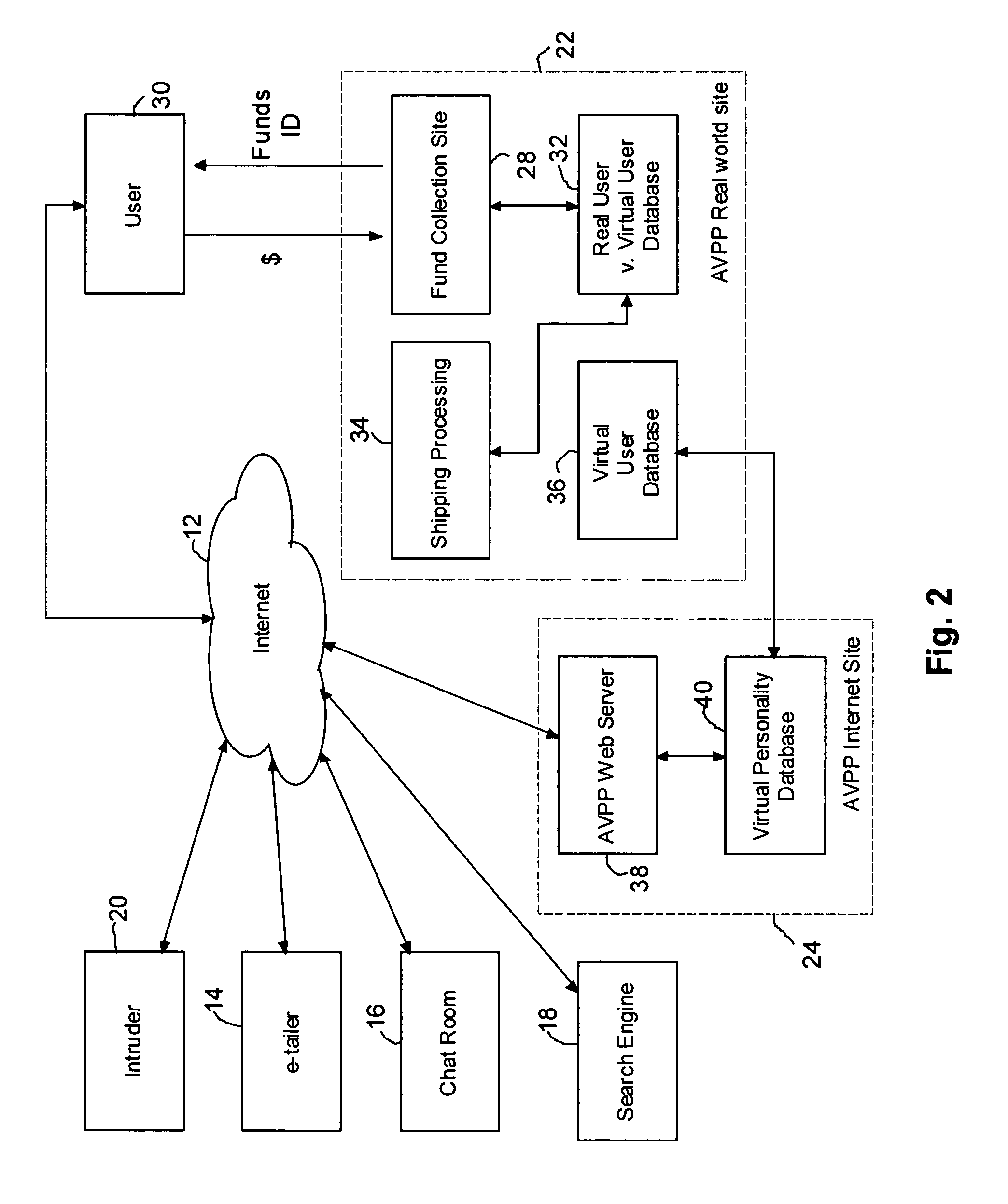

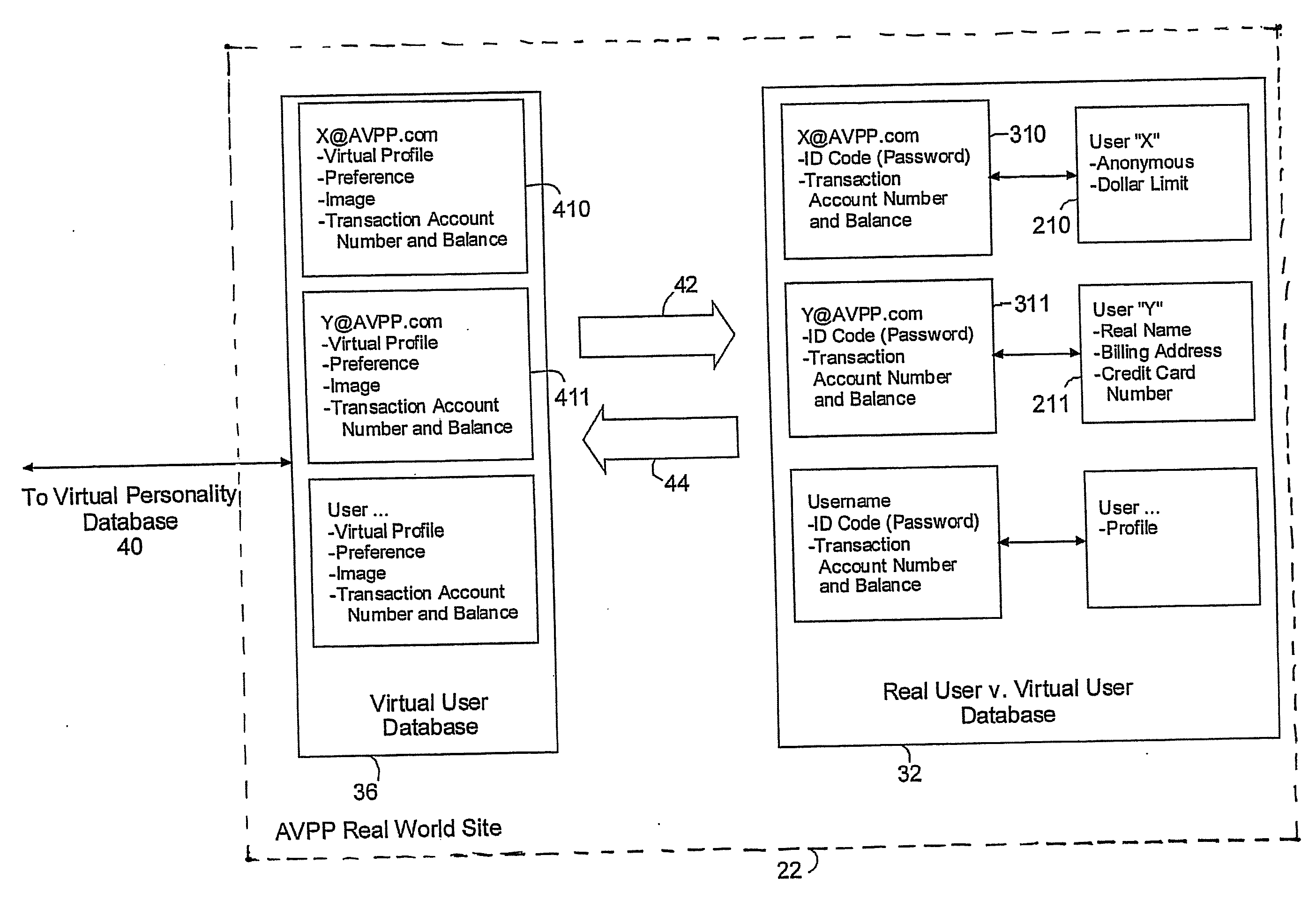

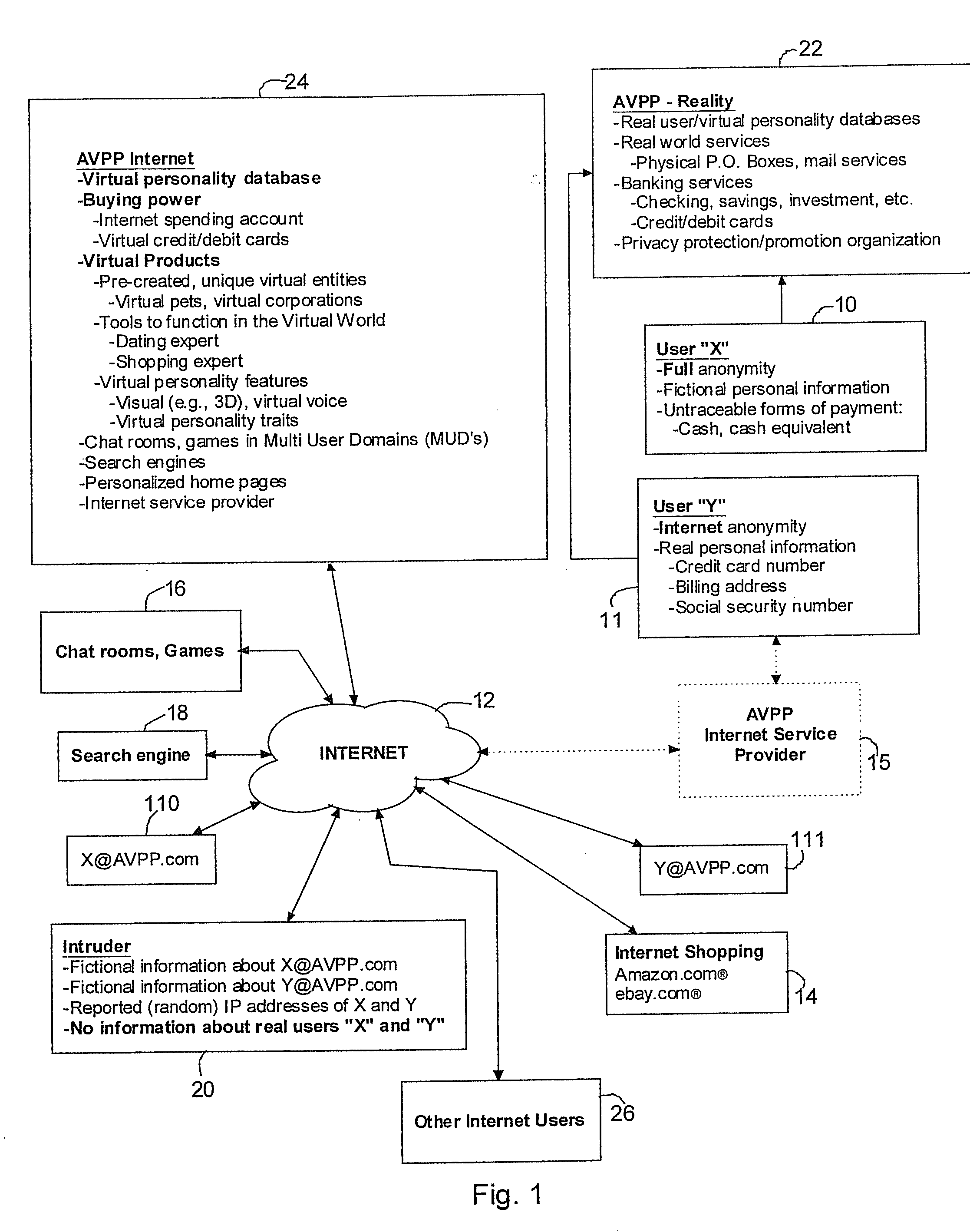

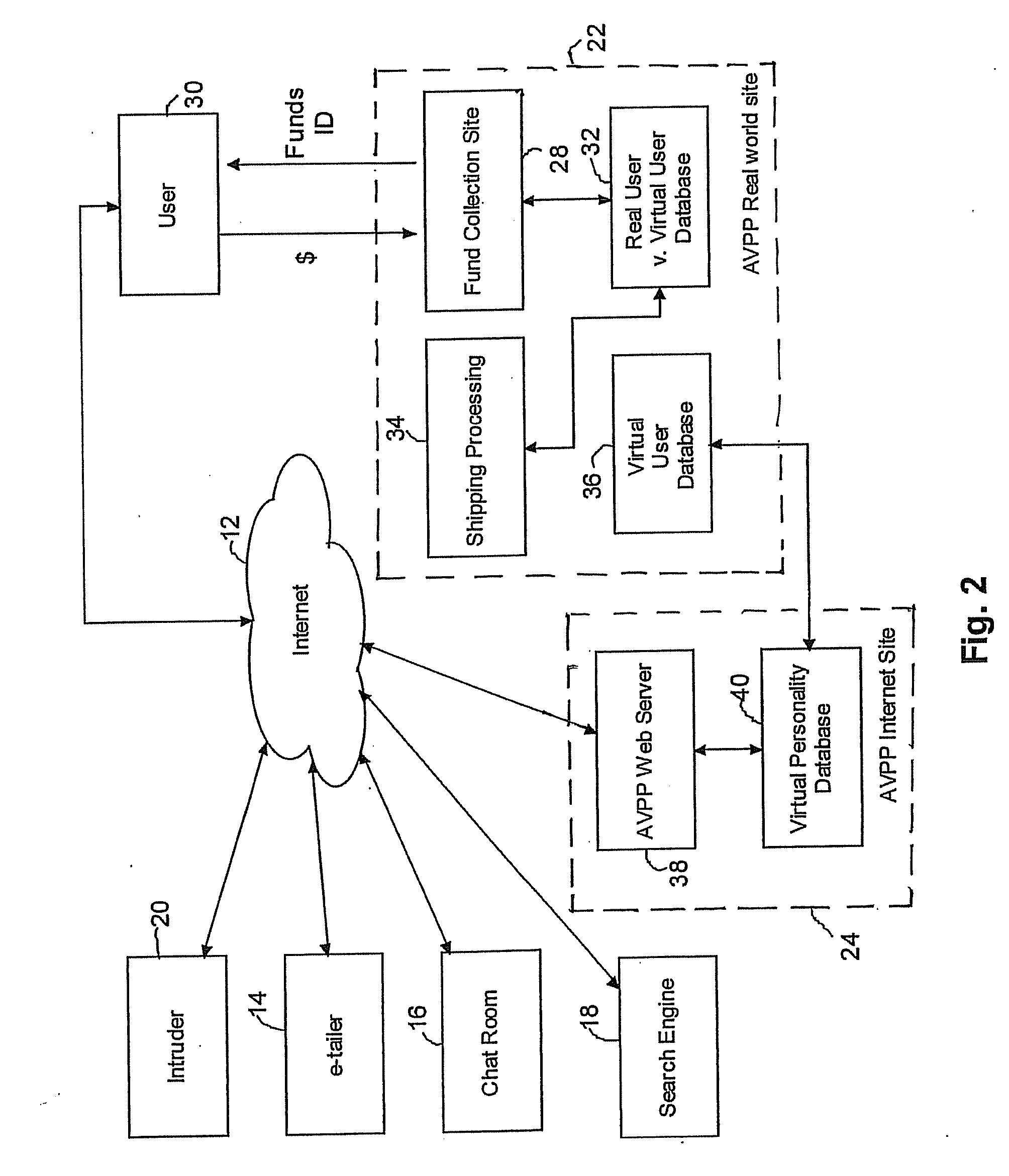

Method and system for securing user identities and creating virtual users to enhance privacy on a communication network

InactiveUS7412422B2Effective distributionMinimize shipping timeComplete banking machinesFinanceVirtual userVirtual entity

A method of enabling a real entity to access a service on a communication network using a virtual entity, the method including the steps of establishing a user account including at least first data corresponding to the identity of the real entity and second data corresponding to the virtual entity and not identifying the real entity, storing the first and second data in a first database, linking between the first and second data in the first database, storing the second data at a second database, associating the second database with a communication network site, connecting the communication network site to the communication network, receiving the second data from an unidentified user on the communication network site, identifying the unidentified user as the virtual entity based on receiving the second data, and allowing the virtual entity to access the service.

Owner:SHILOH DEKEL

Router and methods using network addresses for virtualization

InactiveUS20070183421A1Improve efficiency and reliabilityEasy resource managementData switching by path configurationQuality of serviceDeficit round robin

A router for use in a network includes a scalable architecture and performs methods for implementing quality of service on a logical unit behind a network port; and for implementing storage virtualization. The architecture includes a managing processor, a supervising processor; and a plurality of routing processors coupled to a fabric. The managing processor has an in-band link to a routing processor. A routing processor receives a frame from the network, determines by parsing the frame, the protocol and logical unit number, and routes the frame to a queue according to a traffic class associated with the logical unit number in routing information prepared for the processors. An arbitration scheme empties the queue in accordance with a deficit round robin technique. If a routing processor detects the frame's destination is a virtual entity, and so is part of a virtual transaction, the router conducts a nonvirtual transaction in concert with the virtual transaction. The nonvirtual transaction accomplishes the intent of the virtual transaction but operates on an actual network port, for example, a storage device.

Owner:TERRELL WILLIAM C +9

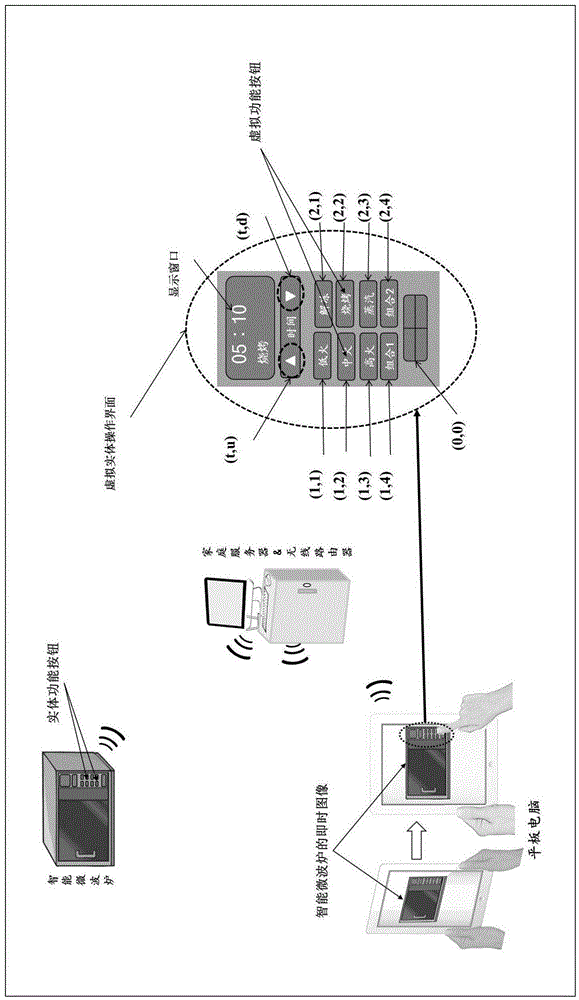

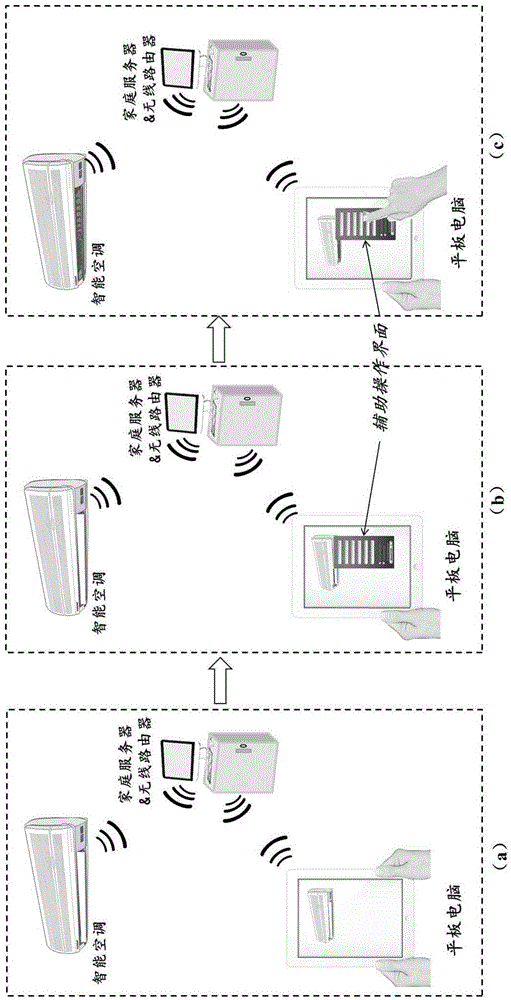

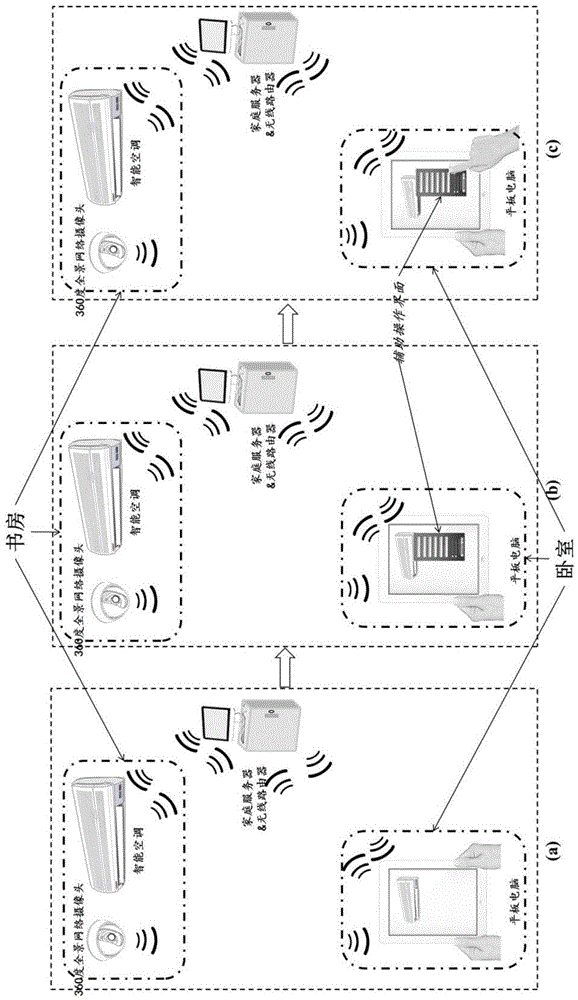

Visible and controllable intelligent household control system and control method thereof

ActiveCN104977904AImprove experienceImprove visibilityComputer controlProgramme total factory controlVisibilityControl system

The present invention provides a visible and controllable intelligent household control system and a control method thereof. The control system utilizes an instant image of the intelligent household electrical appliances which is caught on the spot to identify the intelligent household electrical appliances, then generates a virtual entity operation interface and / or auxiliary operation interface based on the intelligent household electrical appliance instant image or a preset image, and then users can operate and control the intelligent household electrical appliances. The control system of the present invention utilizes the instant image of the intelligent household electrical appliances to identify the to-be-controlled intelligent household electrical appliances of users, so that users do not need to select the intelligent household electrical appliances needing to be controlled from a household electrical appliance list any more, and can control the intelligent household electrical appliances as long as seeing the intelligent household electrical appliances. The virtual entity operation interface provided by the control system of the present invention is completely same with an entity operation interface, so that users have the feelings of operating the intelligent household electrical appliance entities directly. The control system is strong in visibility and good in user experience, is convenient to operate and easy to use, even can be used by the illiteracy. In addition, the control system of the present invention can be realized by a portable intelligent terminal, is simple and easy in equipment, good in universality and low in cost.

Owner:ZHEJIANG UNIV

Method and system for securing user identities and creating virtual users to enhance privacy on a communication network

InactiveUS20090024636A1High activityEffective interactionDigital data processing detailsAnalogue secracy/subscription systemsVirtual userVirtual entity

A method of enabling a real entity to access a service on a communication network using a virtual entity, the method including the steps of establishing a user account including at least first data corresponding to the identity of the real entity and second data corresponding to the virtual entity and not identifying the real entity, storing the first and second data in a first database, linking between the first and second data in the first database, storing the second data at a second database, associating the second database with a communication network site, connecting the communication network site to the communication network, receiving the second data from an unidentified user on the communication network site, identifying the unidentified user as the virtual entity based on receiving the second data, and allowing the virtual entity to access the service.

Owner:SHILOH DEKEL

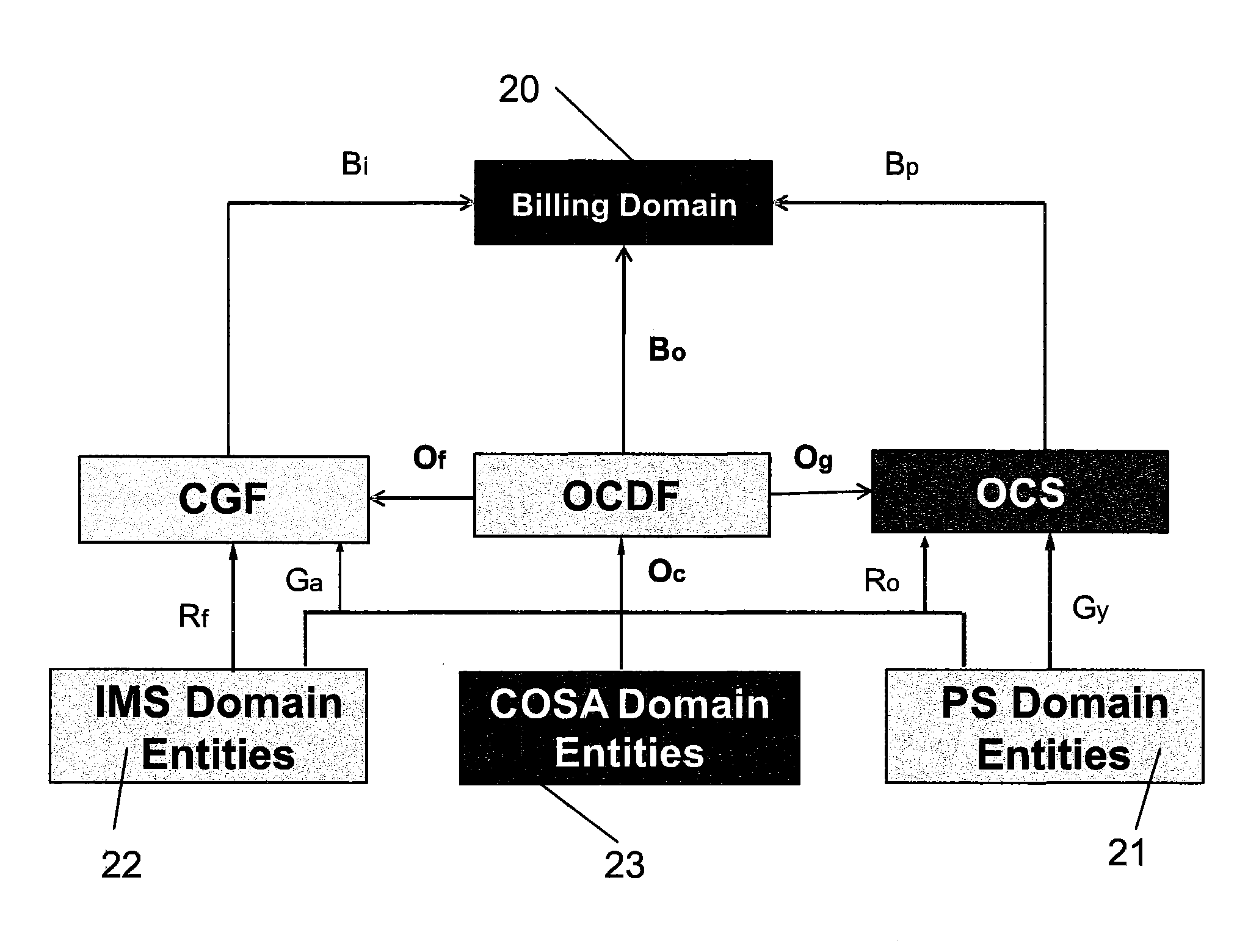

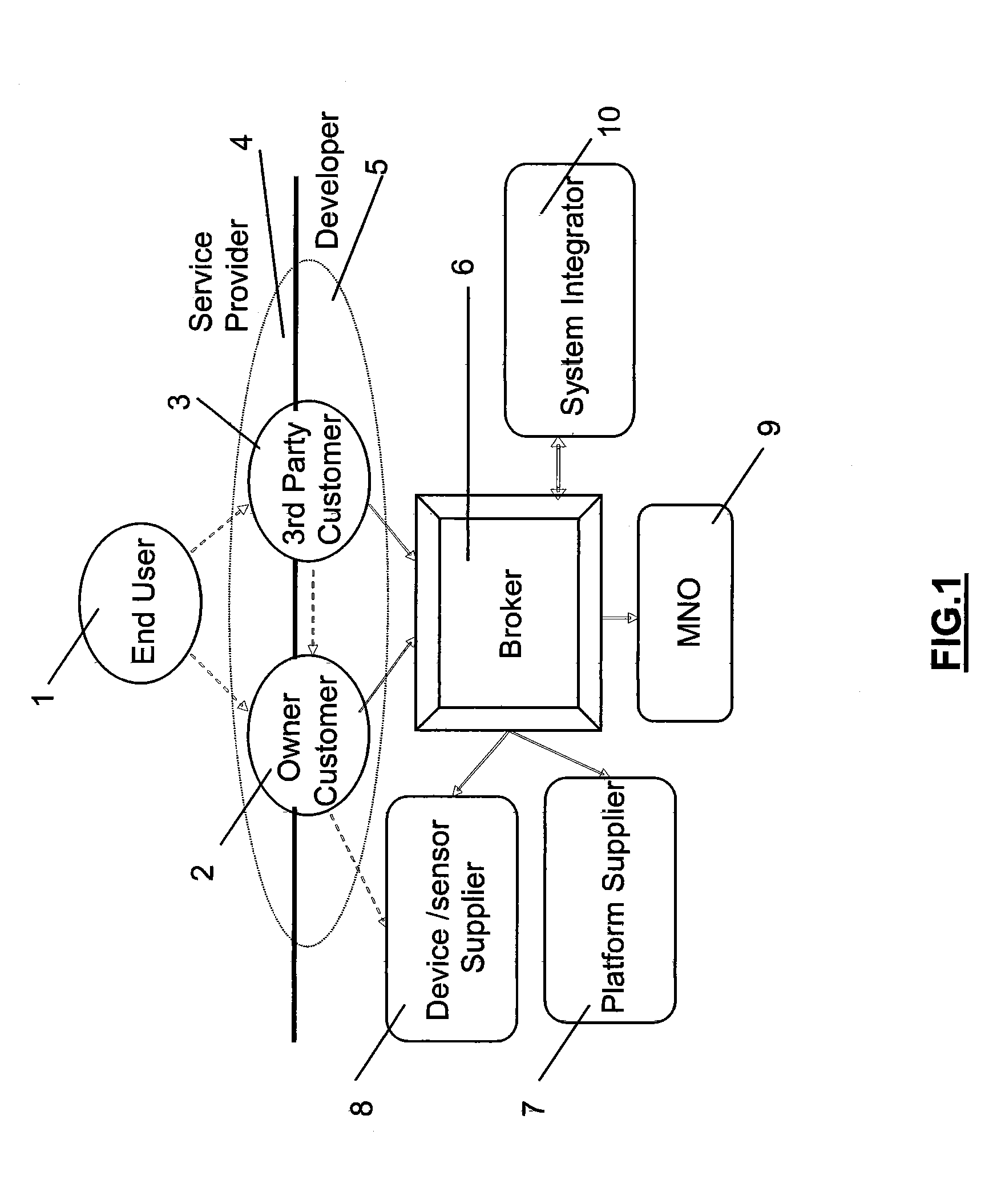

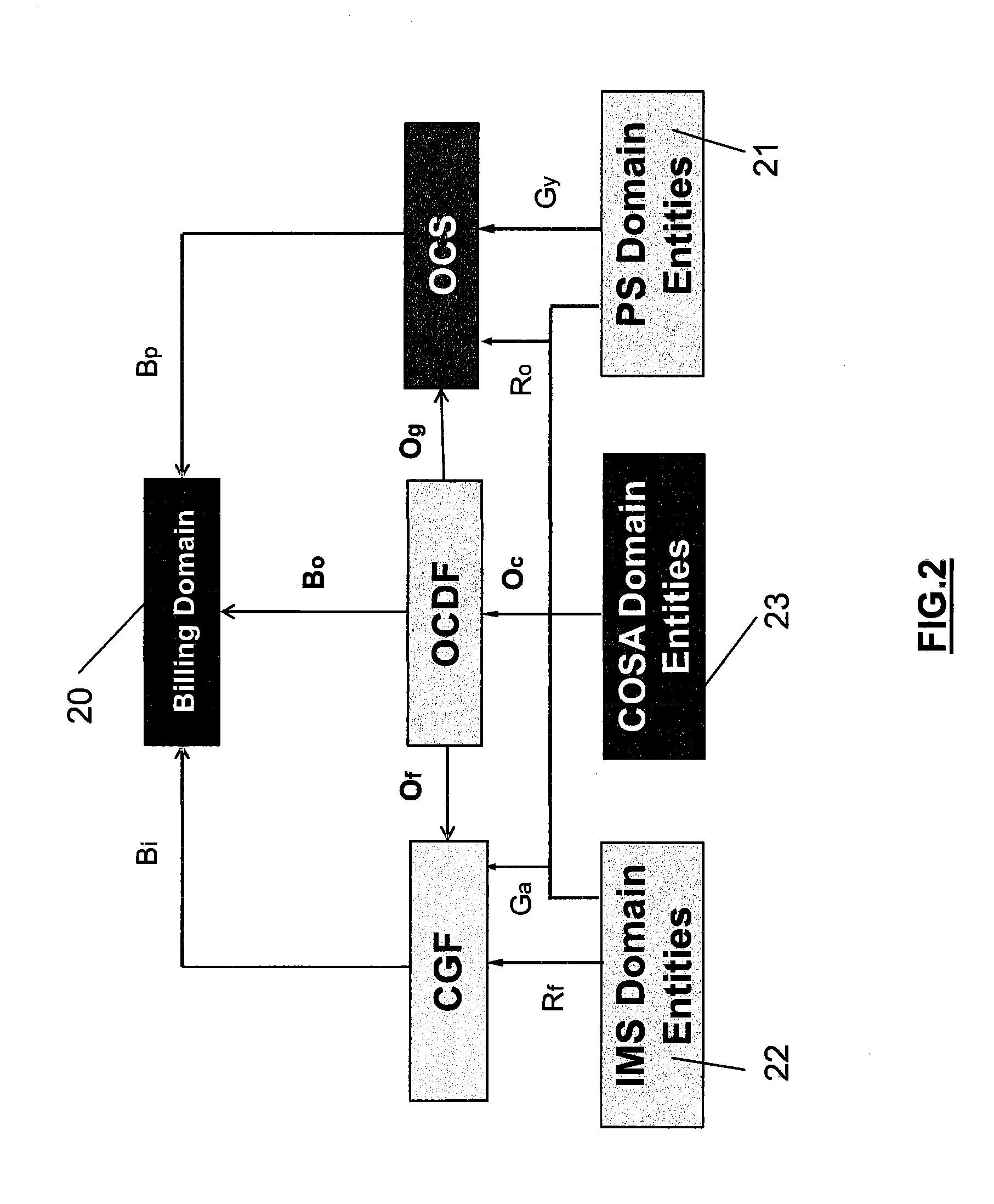

Method for managing data in m2m systems

InactiveUS20120284777A1Sufficient confidenceComplex taskService provisioningMetering/charging/biilling arrangementsThird partyData aggregator

A method enabling managing sensor devices data by aggregating them in virtual entities: Connected Objects (COs). Third Parties access those exposed data if and only if the Owner of those data grants the corresponding access rights. Since communication is bidirectional, Third Parties can also be granted to manage the device set belonging to those COs for which data access was granted. The method allows managing multiple remote devices, enabling systematic naming and addressing schemes to reach those devices. Eventually, the method enables charging procedures through an Object Charging Data Function entity, which finds out the right Object to be charged for and sends the bill to both Owner and Third parties for the provided services. Charging Objects (CHOs) are those COs exposed for the specific application of charging. A hierarchy is proposed (Organisational, Fundamental, Derived and Temporary CHO) enabling inheritance rules (Reverse and Direct) for access rights and / or charging policy.

Owner:VODAFONE IP LICENSING

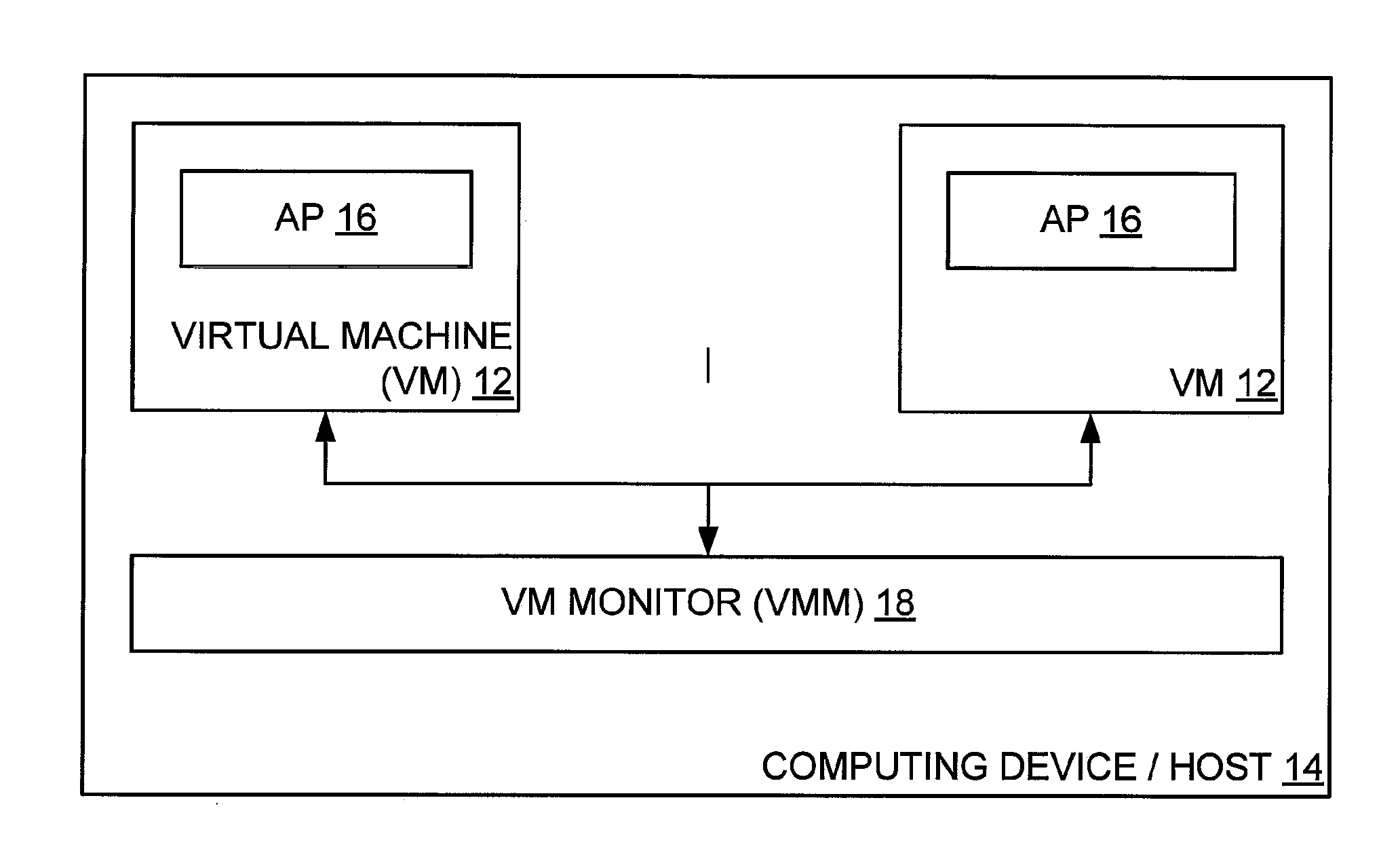

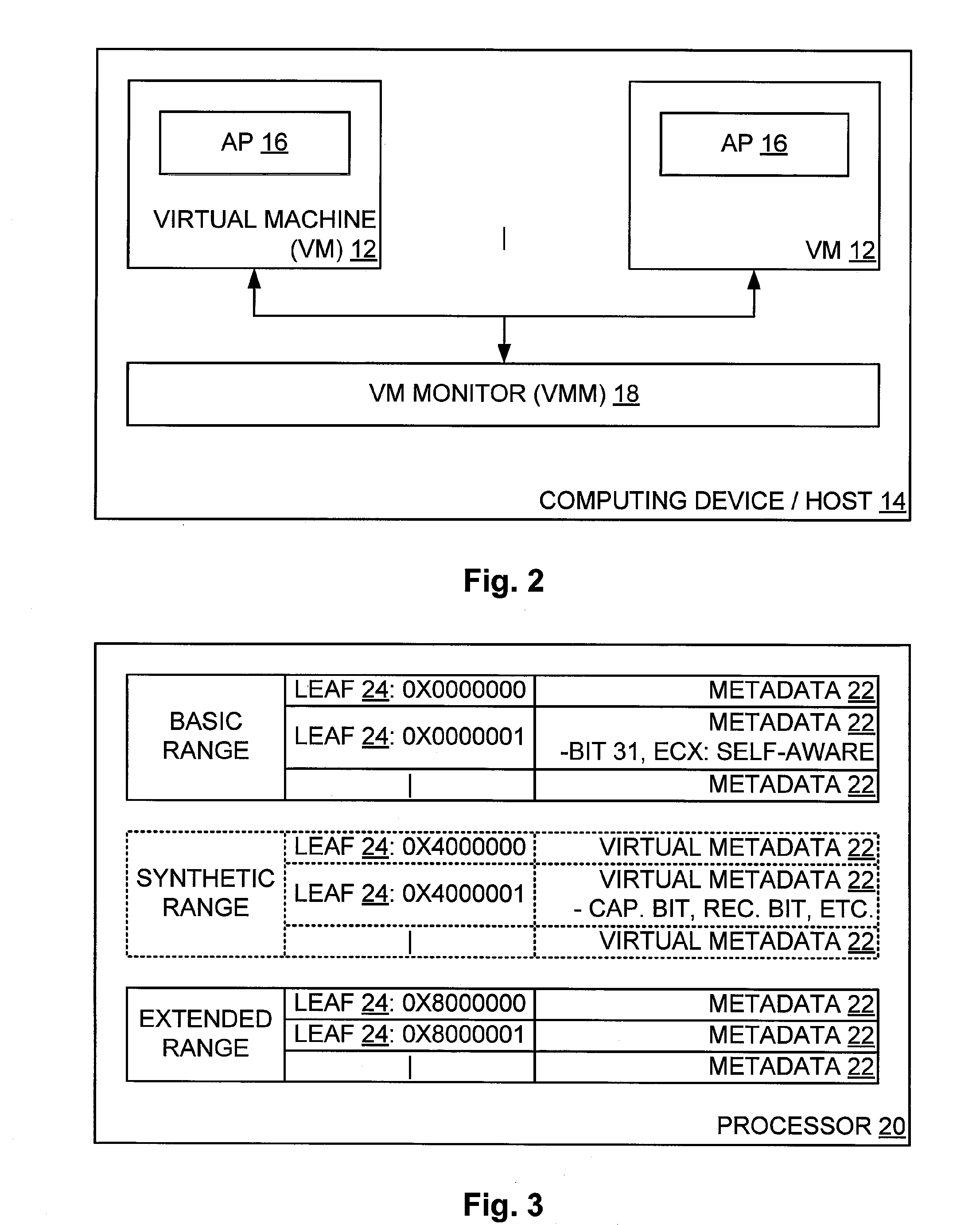

Allowing Virtual Machine to Discover Virtual Status Thereof

InactiveUS20080104586A1Easy to operateSoftware simulation/interpretation/emulationMemory systemsPhysics processing unitApplication software

A host computing device has a virtual machine (VM) instantiated thereon. The VM has a virtual application instantiated thereon and a virtual processor. The host also has a virtual machine monitor (VMM) instantiated thereon to oversee the VM and to intercept instructions from a virtual entity comprising one of the virtual application and the VM to the virtual processor of such VM. The virtual entity becomes self-aware of the virtual status thereof based on a self-aware flag as obtained from the VMM, and based thereon obtains particular virtual metadata from a Synthetic range of the virtual processor by way of the VMM to operate efficiently. The Synthetic range of the virtual processor is implemented by the VMM and does not correspond to any defined range of the physical processor corresponding to the virtual processor.

Owner:MICROSOFT TECH LICENSING LLC

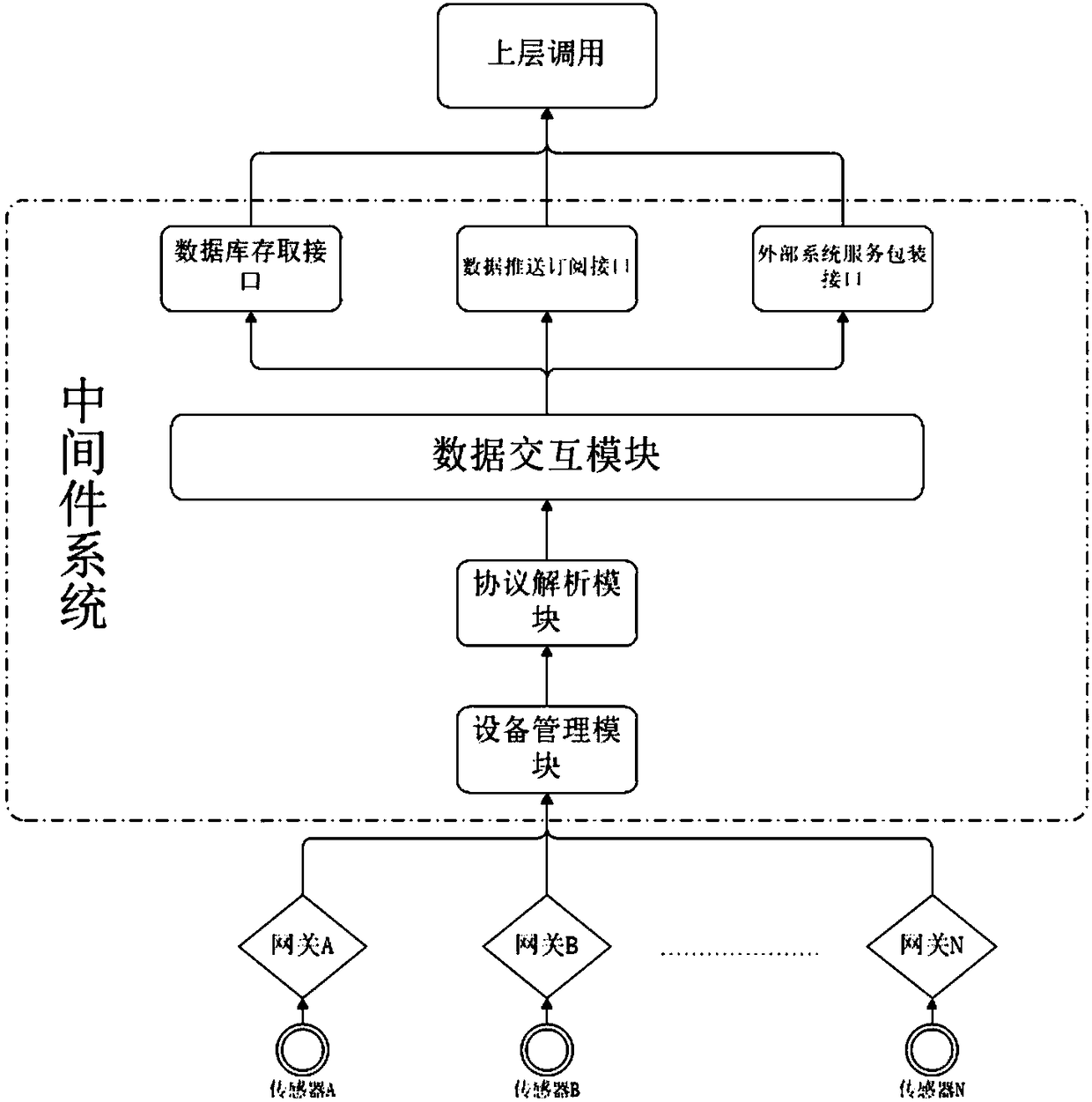

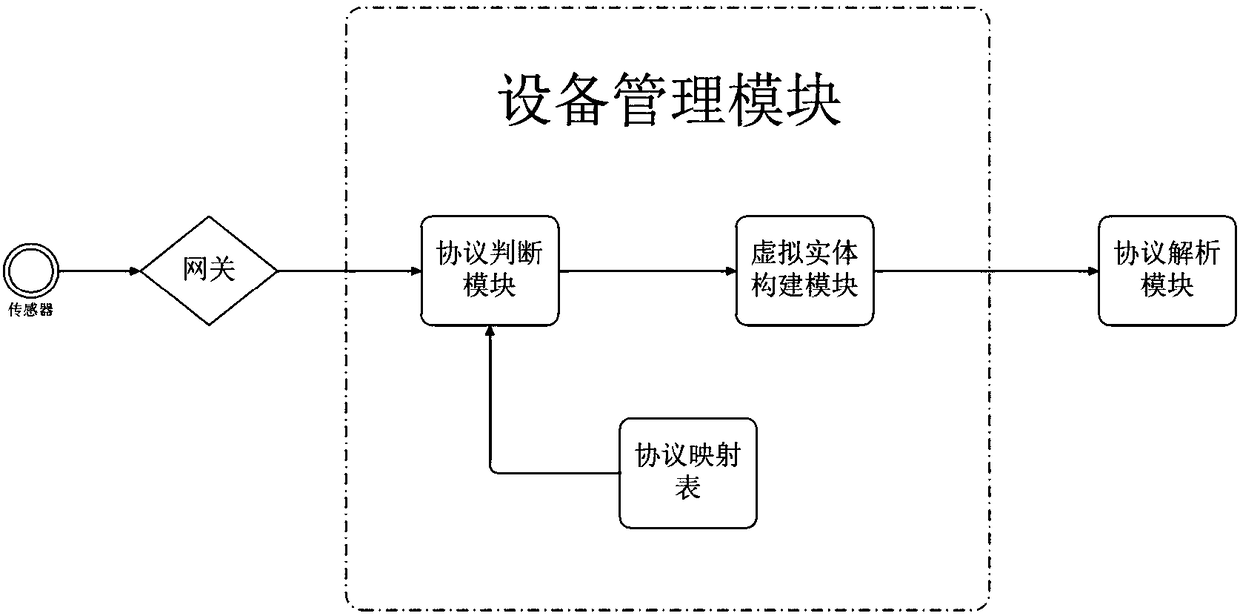

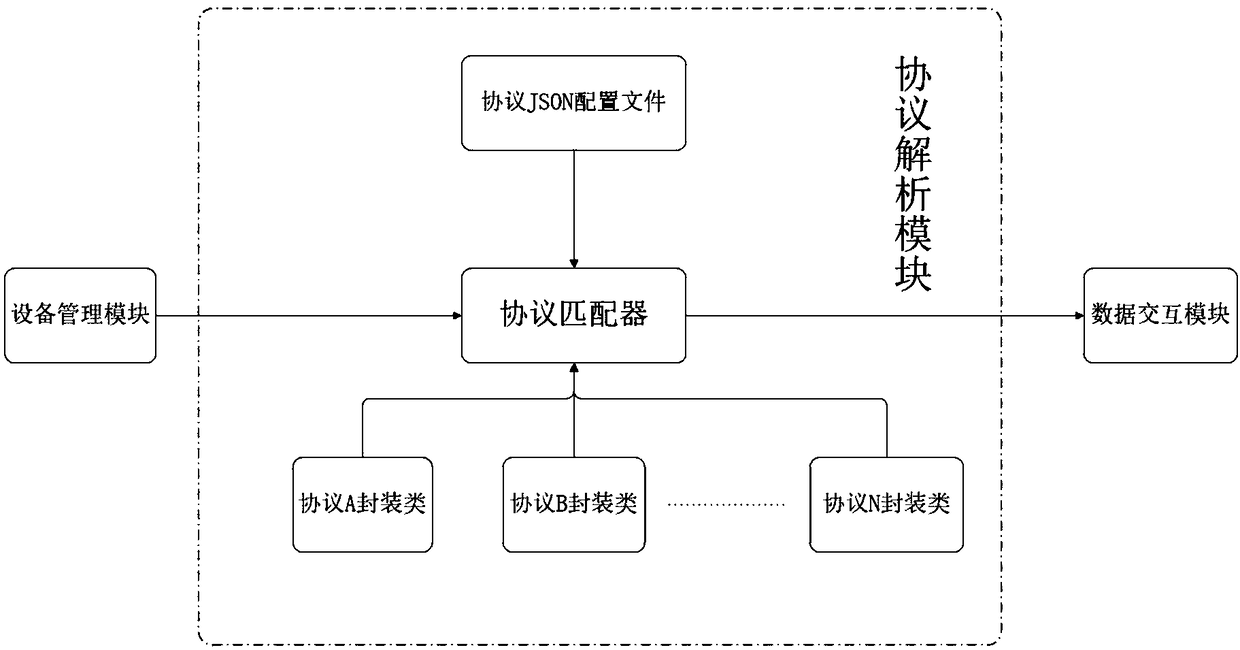

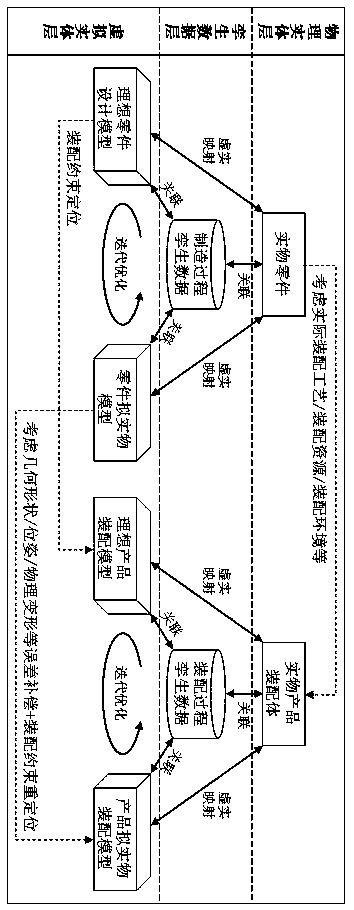

Internet of Things data service middleware system

ActiveCN108093070ARealize mutual conversionRealize plug and playTransmissionNetwork packetData interface

The invention belongs to the technical field of Internet of Things, and specifically relates to an Internet of Things data service middleware system. The system mainly comprises a device management module, a protocol analysis module, a data interaction module, a database access interface, a data push subscription interface and an external system service packaging interface. An external sensor device sends data to the middleware system through a gateway. The device management module determines whether the used protocol is configured in a configuration file in the protocol analysis module according to the data packet. If the protocol is configured, a corresponding virtual entity is established for the sensor, and the data packet is sent to the protocol analysis module. The data packet is unpacked according to the corresponding protocol encapsulation class. The unpacked data enter the data interaction module for unified format conversion and enter a data queue to wait for processing. Three data interfaces are used for providing a database access operation, pushing data to a subscribed user system for a push service system, and transmitting the data to an external service system, wherein the data are as used as the source data of the external service system.

Owner:FUDAN UNIV

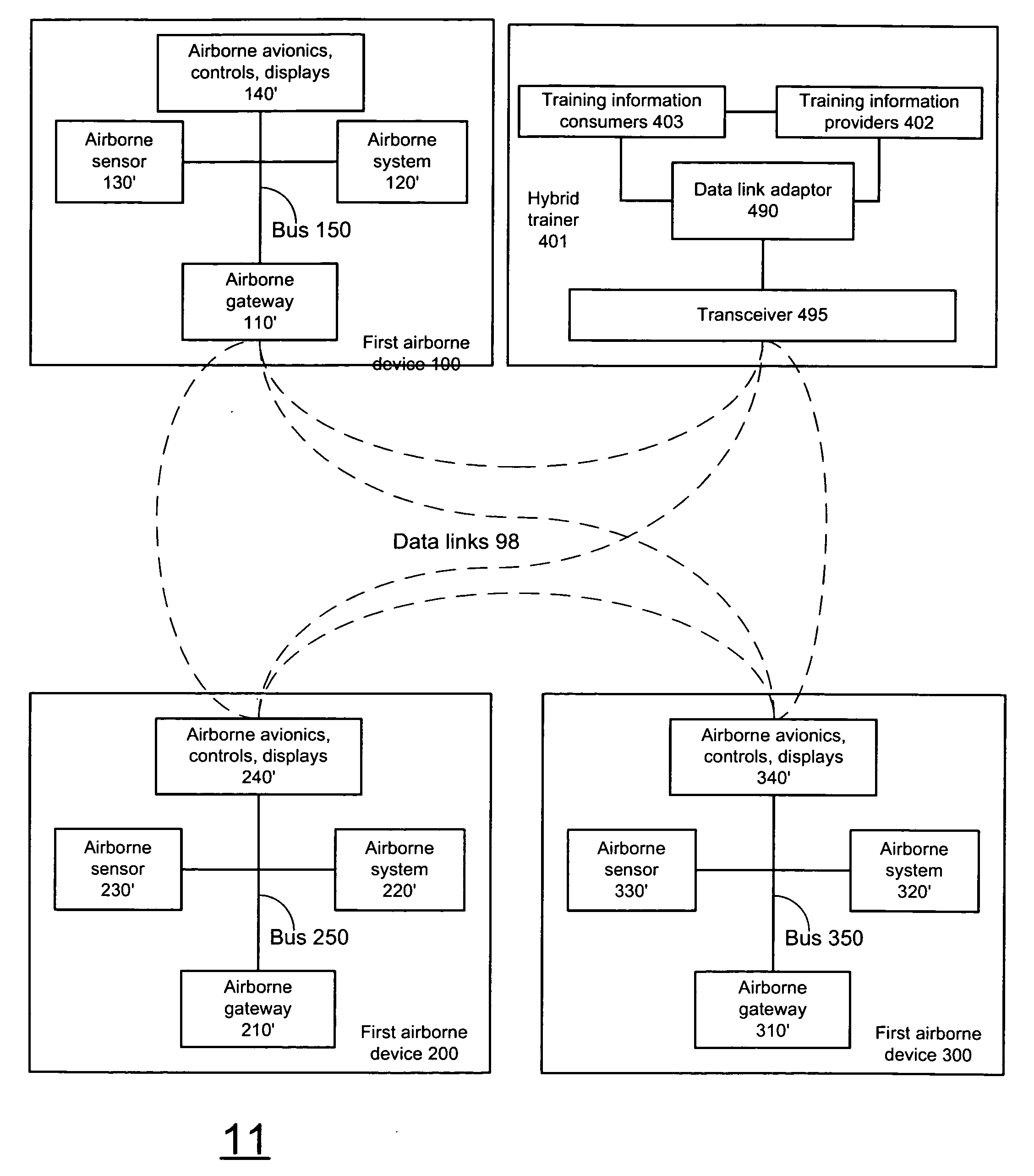

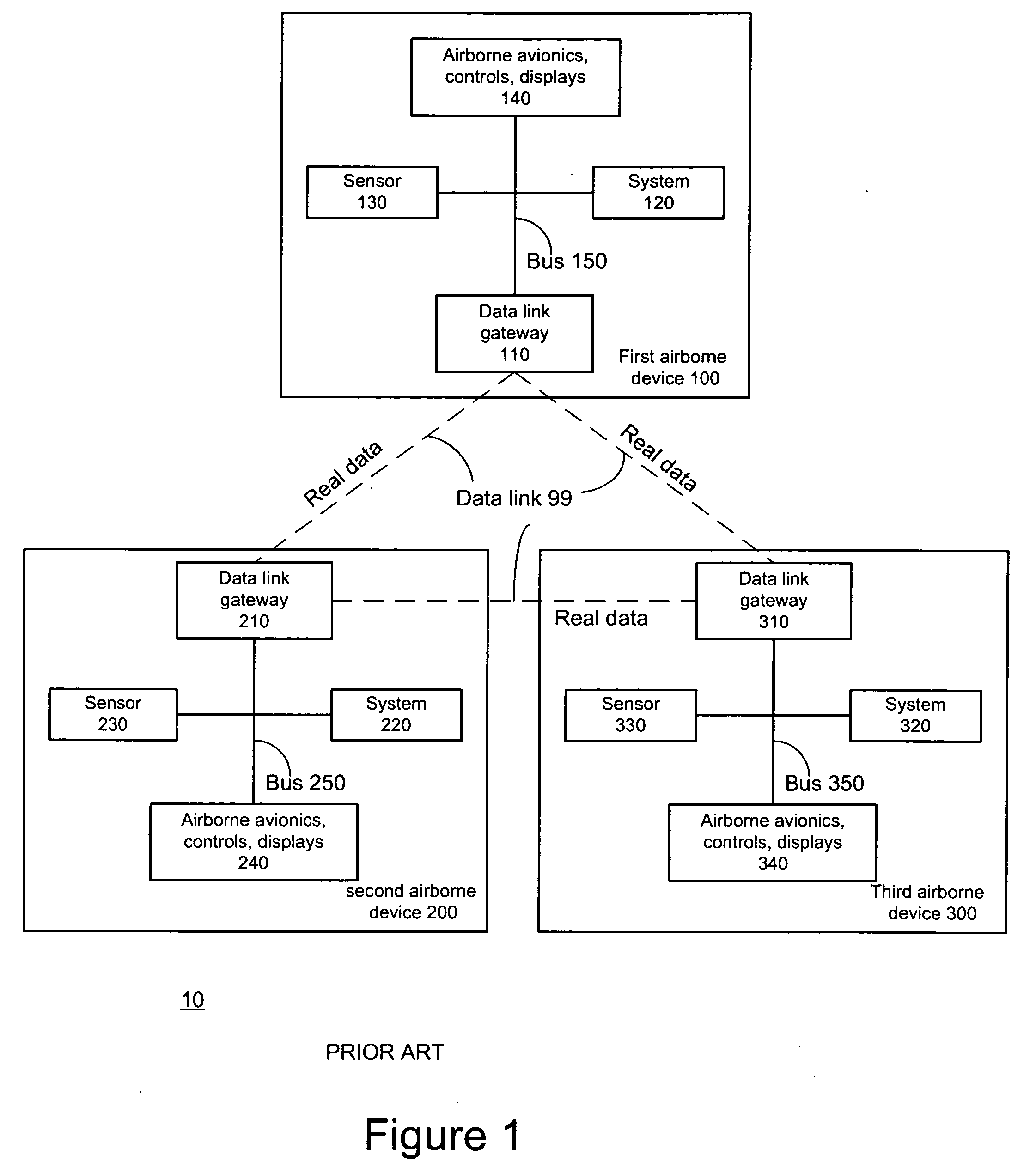

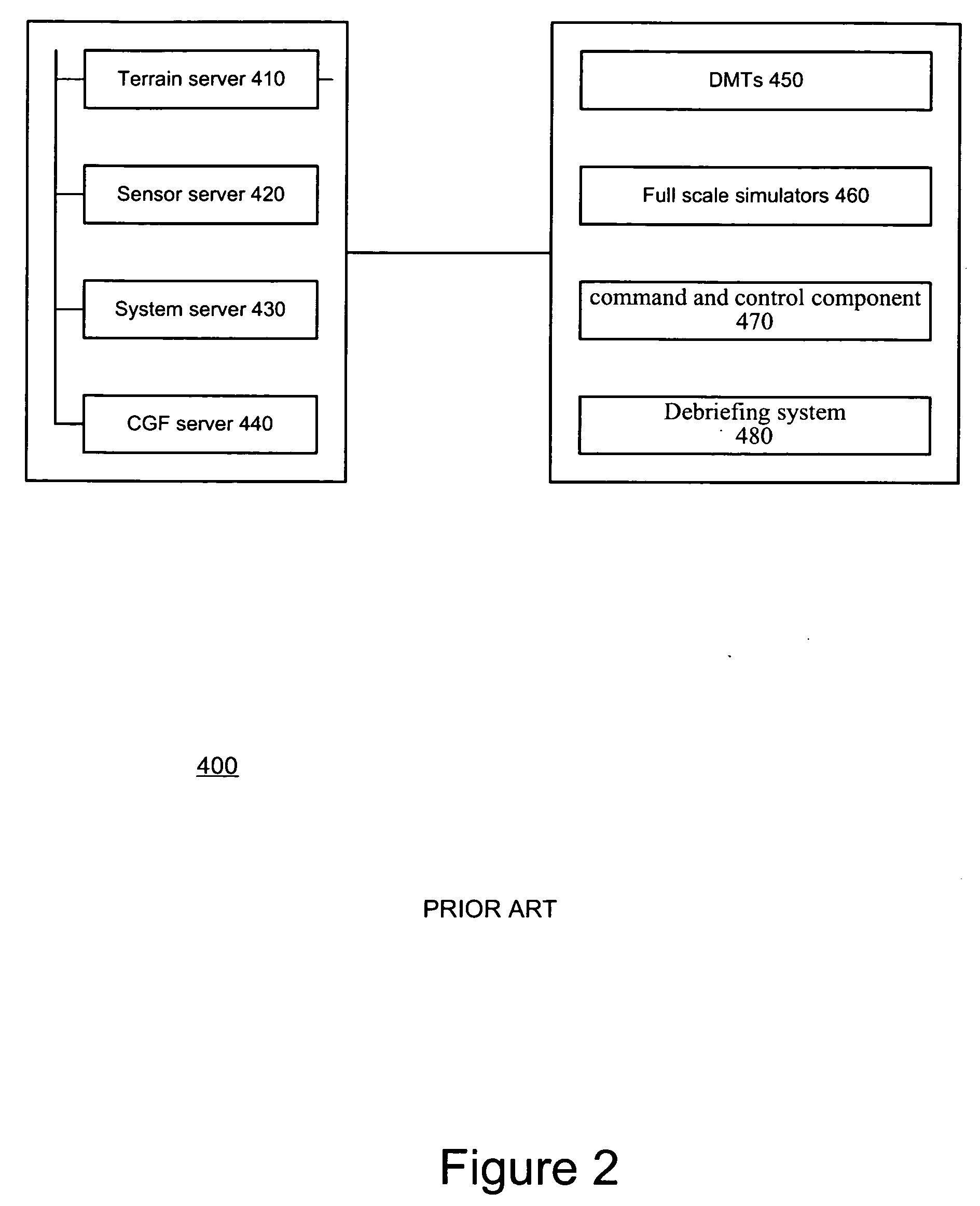

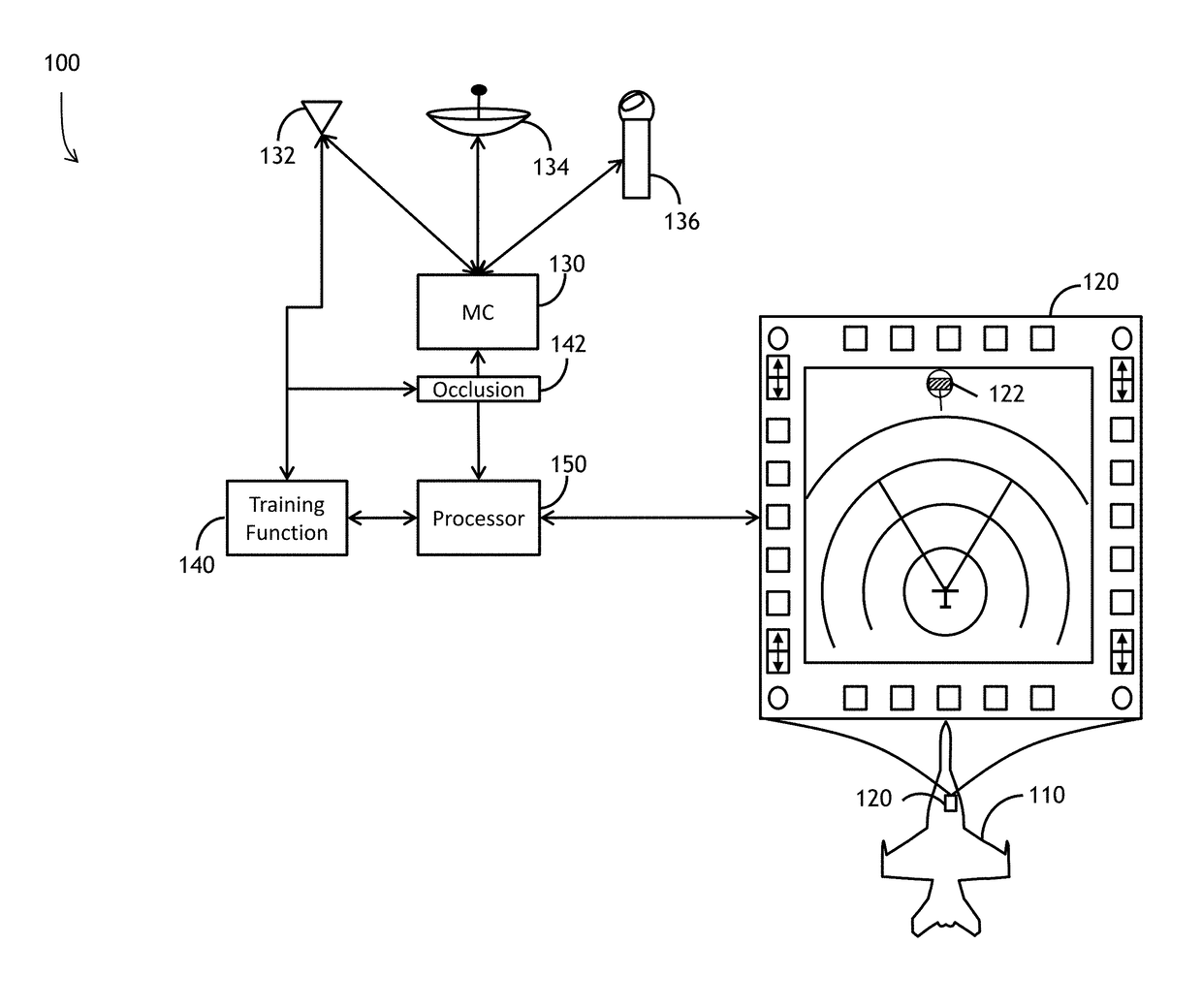

Training methods and systems

An airborne device, a hybrid trainer and methods are provided, The method includes providing, by an airborne gateway, data representative of at least one virtual entity; sensing, by an airborne sensor, signals representative of at least one real entity; and generating, by an airborne component, data representative of a virtual entity and of a real entity.

Owner:ISRAEL AEROSPACE IND

Internet of Things industrial production process monitoring method based on digital twin technology

InactiveCN110187686ARealize data interactionEfficient productionTotal factory controlProgramme total factory controlThe InternetOperational behavior

The invention discloses an Internet of Things industrial production process monitoring method based on a digital twin technology, and relates to the technical field of Internet of Things industrial workshops. On the basis of the Internet of Things industrial workshop, the method utilizes the virtual twin, the prediction twin and the twin projection of the digital twin technology; firstly, a digital space is created on an Internet of Things cloud platform, one set of virtual entities used for representing industrial production equipment in the Internet of Things industrial workshop in the processes of design, research, development, work and iteration is constructed in the digital space, and then, the predictive modeling and predictive twin operation behaviors of the virtual entity are carried out in the digital space; secondly, insight is provided for the operation of industrial production equipment, and is projected to the virtual entity through the Internet of Things cloud platform torealize data interaction between the virtual entity and the Internet of Things industrial workshop; and finally, through the analysis of data mining and machine learning technologies and an AI (Artificial Intelligence) algorithm, the intelligent monitoring of the production process of the Internet of Things industrial workshop is finished, according to monitoring information, the whole productionprocess of the Internet of Things industrial workshop is regulated for multiple times in order to obtain an optimal production process and an optimal yield output.

Owner:JINAN INSPUR HIGH TECH TECH DEV CO LTD

Interactive system and method

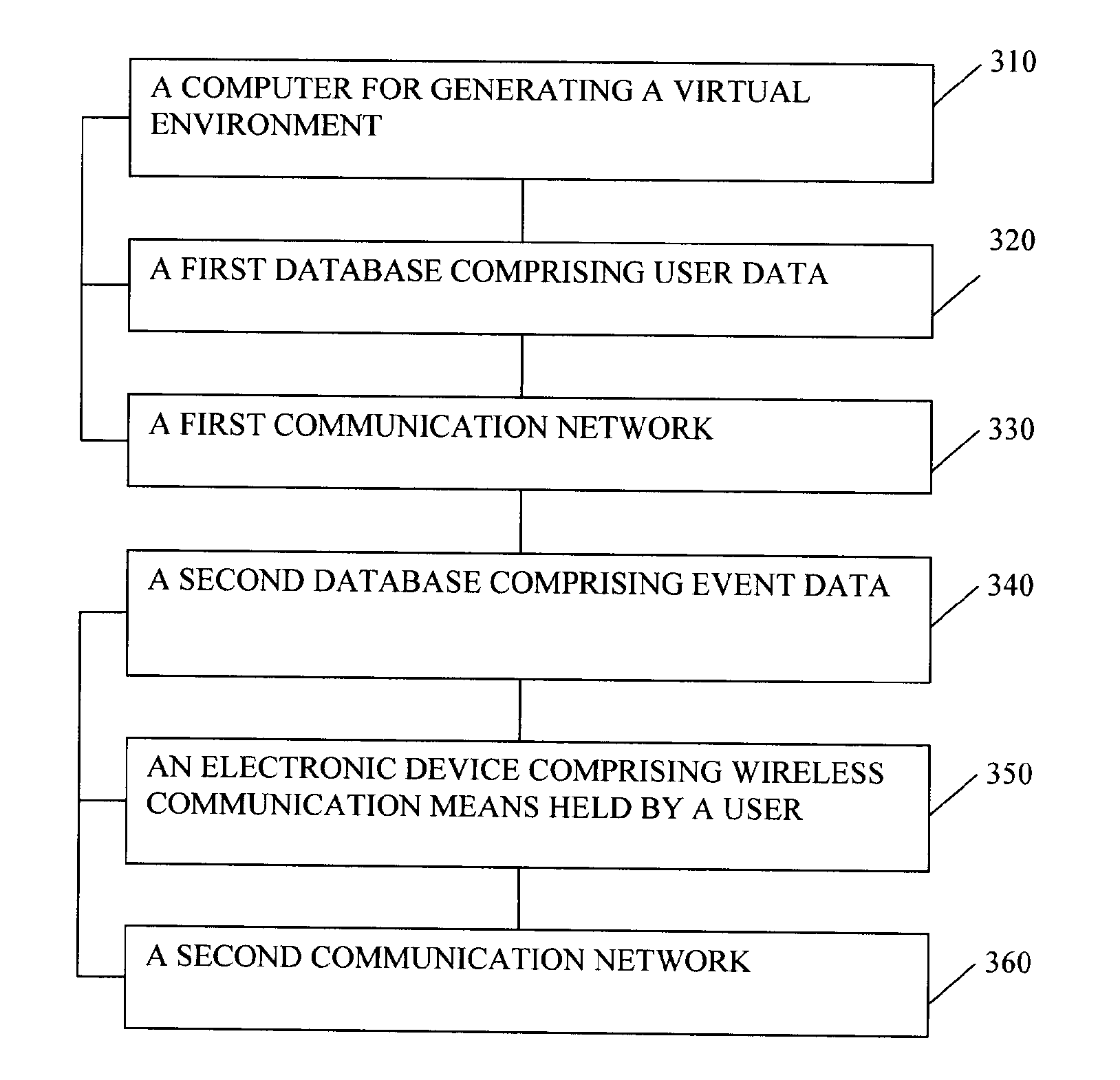

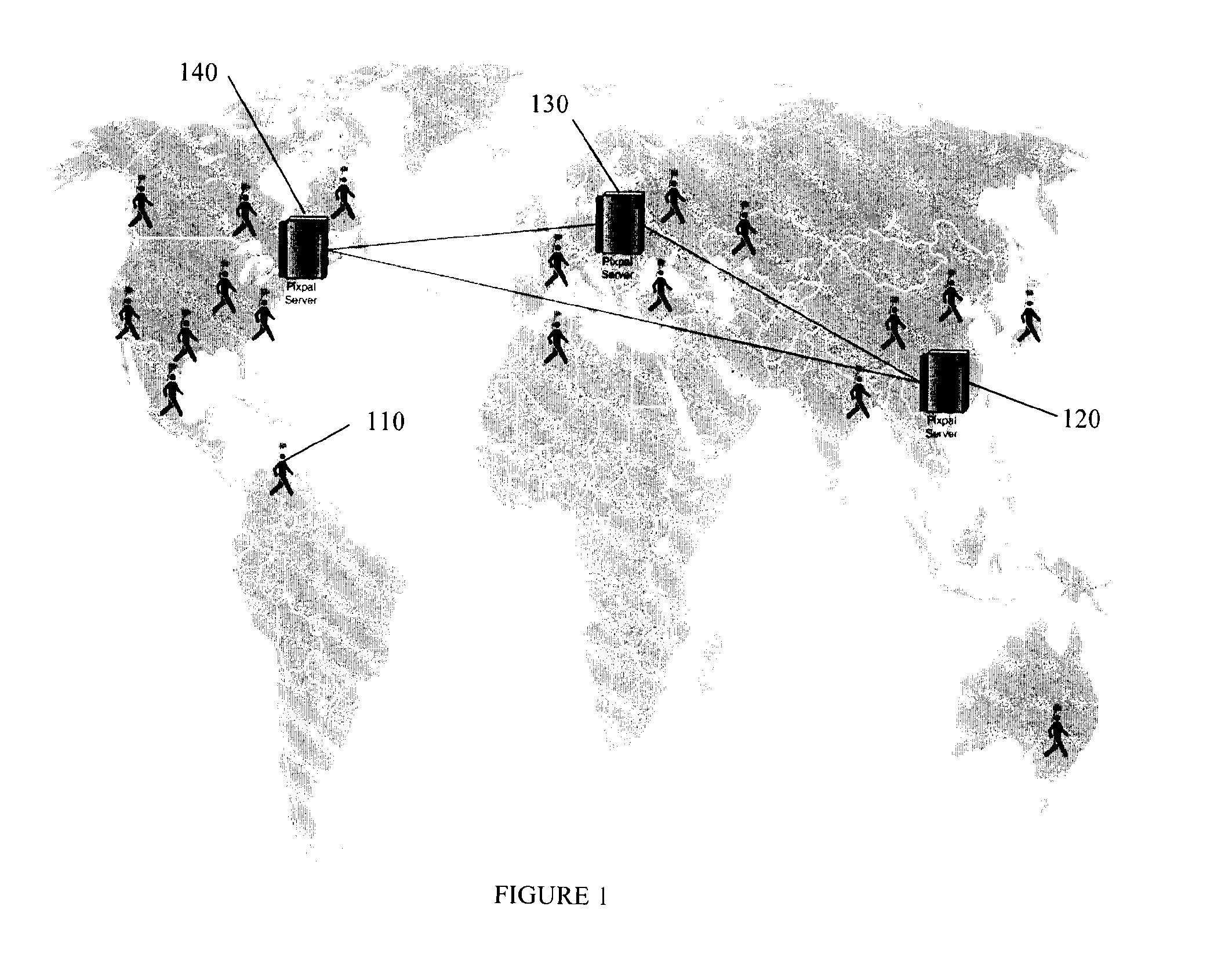

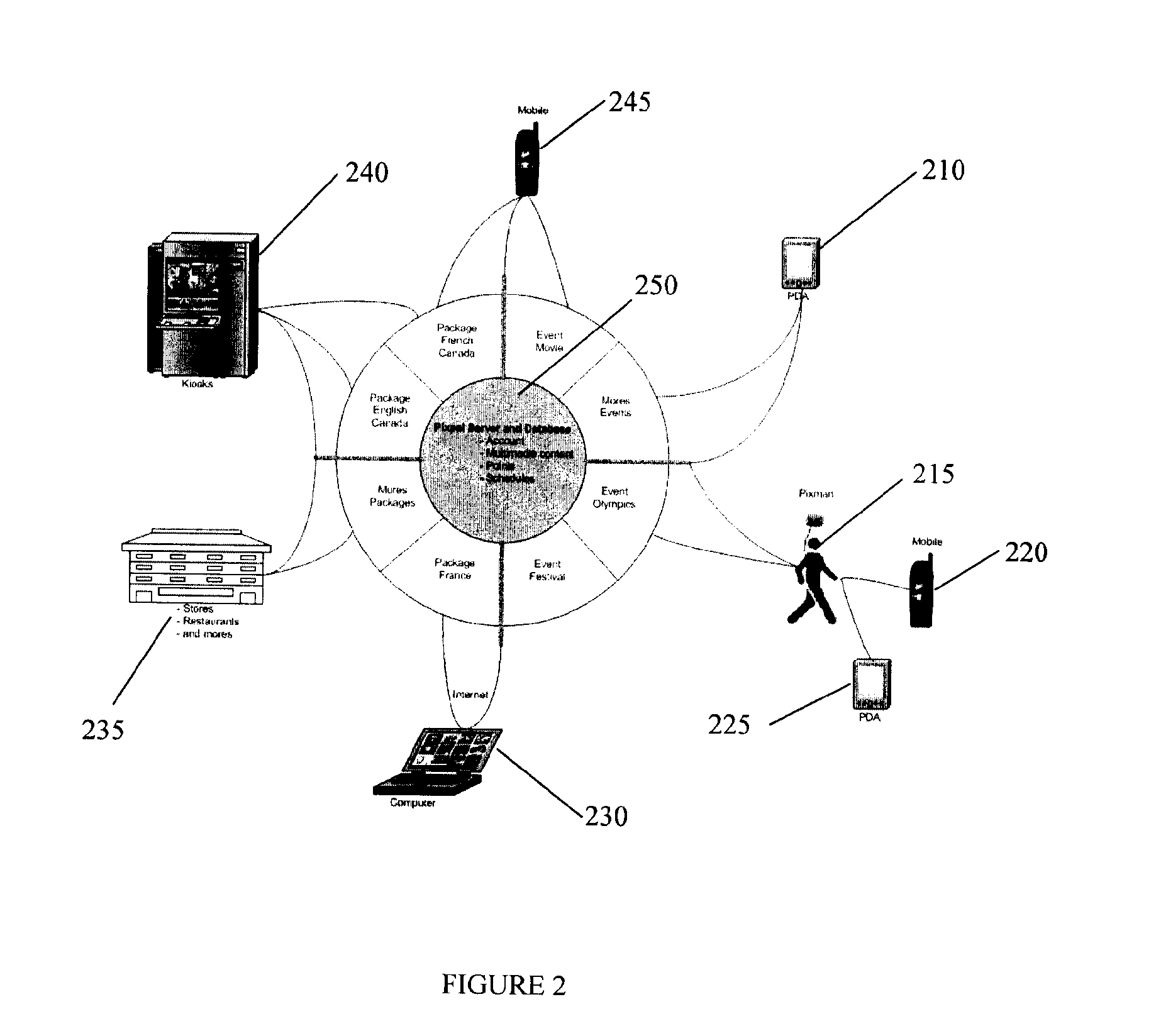

InactiveUS20100095225A1Better networkEasy accessArtificial lifeDatabase modelsVirtual entityWireless network

A system and method to interactively connect real entities (object or person) to virtual entities or representation thereof and share information therebetween is provided. Moreover, the virtual entities are linked, via a network and / or via a wireless network-enabled device to their real life counterparts. Hence, the system allows, via the network and / or wireless network-enable devices, the gathering of information related to the real entities and the virtual representations thereof. In another aspect of the invention, the system and method allow interactions between the operator and / or sponsor of a real life or virtual event and real life and / or virtual participants therein.

Owner:PIXMAN CORP

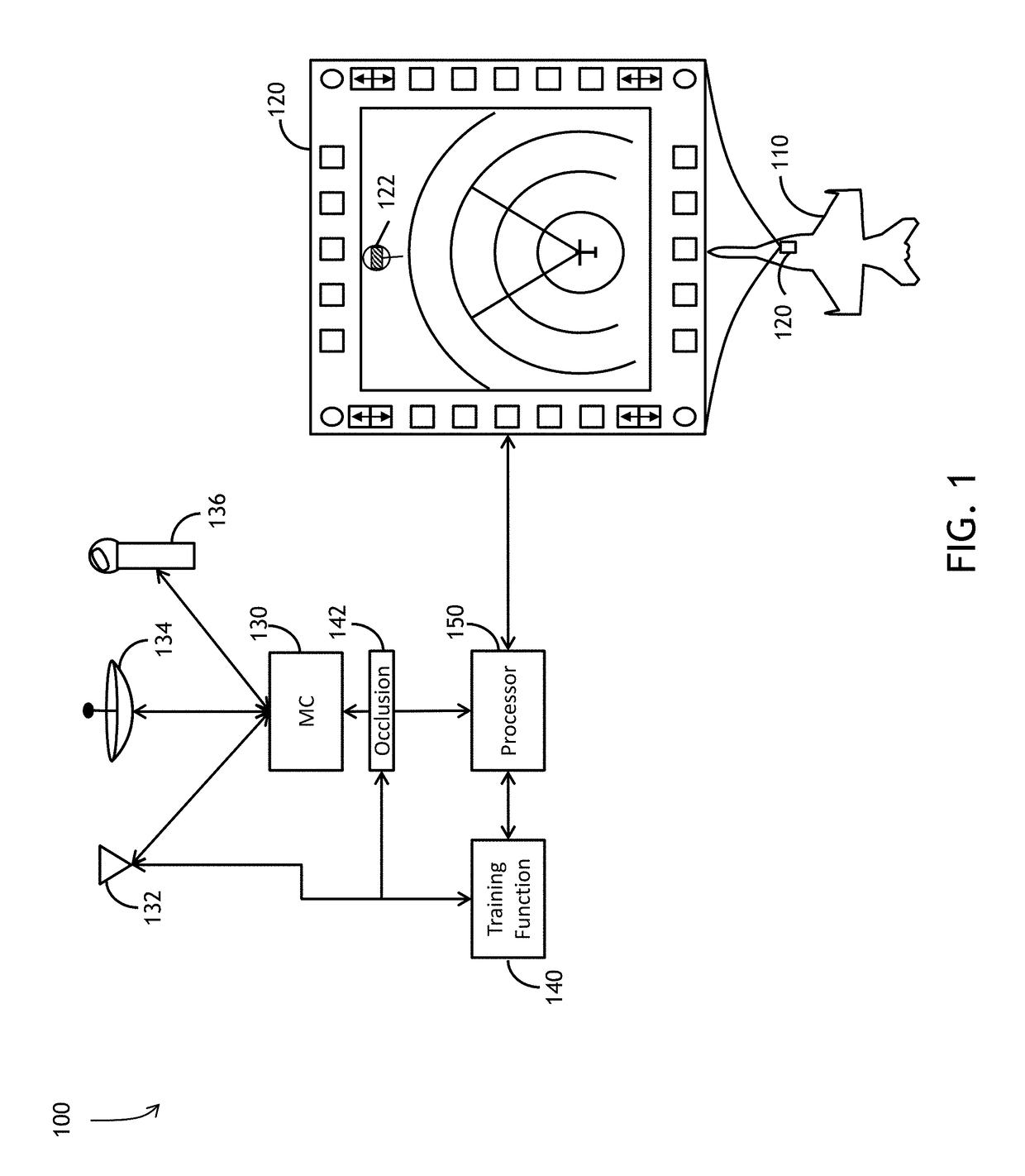

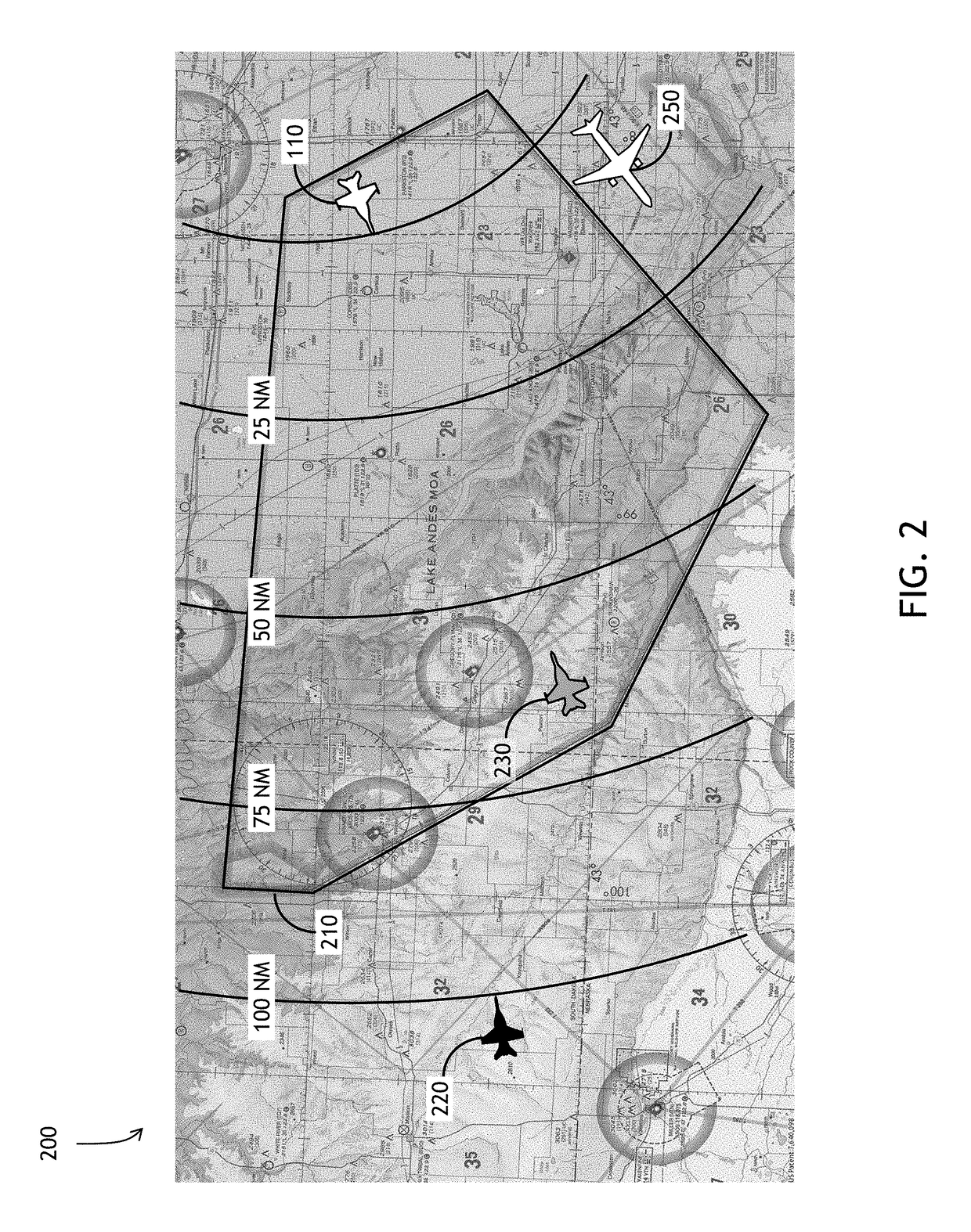

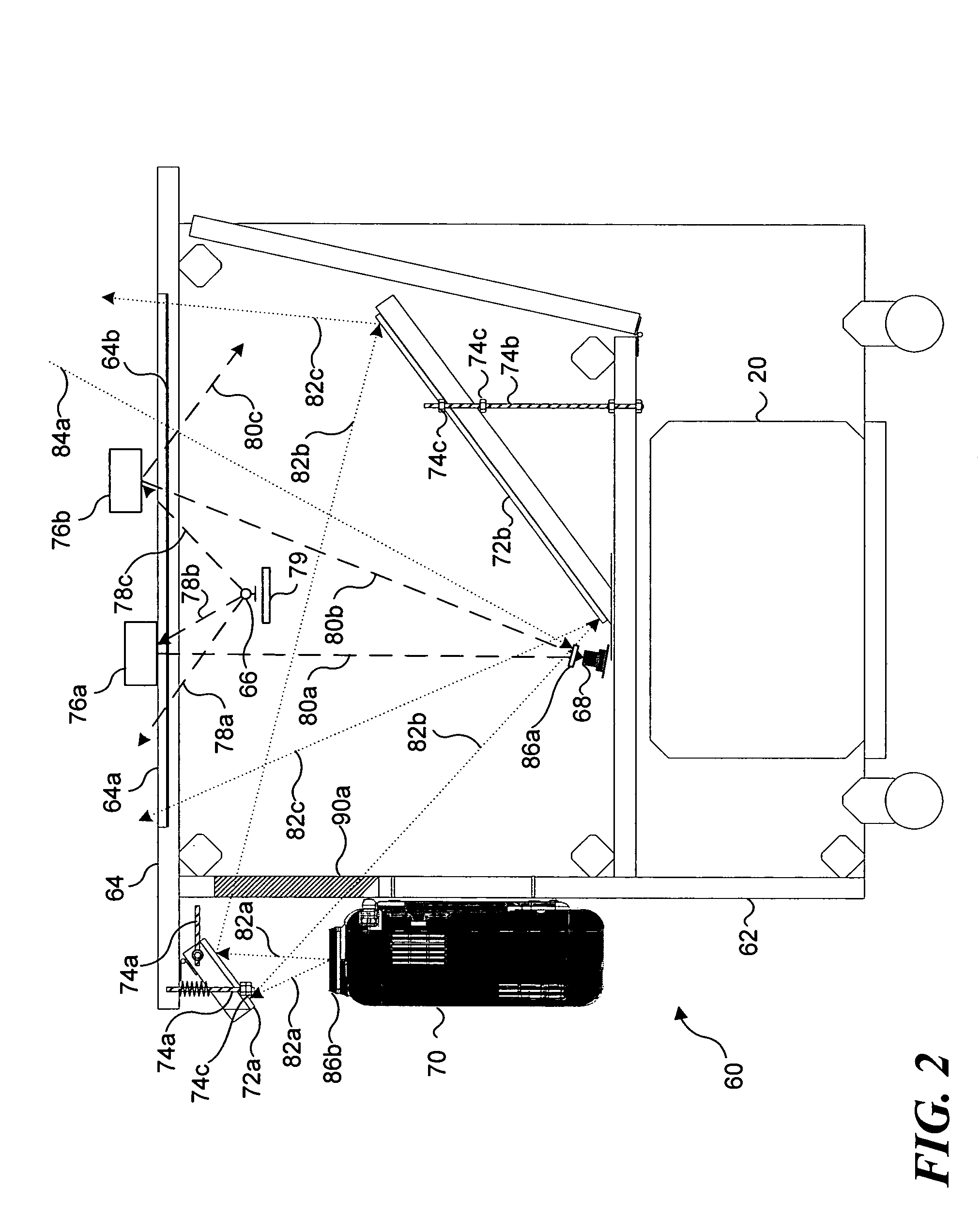

Virtual/live hybrid behavior to mitigate range and behavior constraints

ActiveUS9754507B1Input/output for user-computer interactionCosmonautic condition simulationsVirtual entityOperational performance

A system and method are disclosed for offering a trainee presentation blending live and virtual entities to create a training scenario unconstrained by live entity operational performance and geographical limitations. The system blends an instance of a virtual entity with an actual presentation of a live entity within a trainee presentation. Outside of trainee local sensor range, the system presents a virtual entity to the trainee while occluding local sensor presentation of the live entity. As the scenario progresses to a lessor range or higher criticality, the system offers the live entity emulation information concerning characteristics of the virtual entity so the live entity may anticipate and begin to emulate the virtual. At a crossover point, the system determines if the live entity has successfully emulated the virtual and if so, discontinues presentation of the virtual while removing the occlusion allowing presentation of the live entity.

Owner:ROCKWELL COLLINS INC

Using clear-coded, see-through objects to manipulate virtual objects

ActiveUS7576725B2Improve usabilityCathode-ray tube indicatorsVideo gamesComputer visionInteractive displays

An object placed on an interactive display surface is detected and its position and orientation are determined in response to IR light that is reflected from an encoded marking on the object. Upon detecting the object on an interactive display surface, a software program produces a virtual entity or image visible through the object to perform a predefined function. For example, the object may appear to magnify text visible through the object, or to translate a word or phrase from one language to another, so that the translated word or phrase is visible through the object. When the object is moved, the virtual entity or image that is visible through the object may move with it, or can control the function being performed. A plurality of such objects can each display a portion of an image, and when correctly positioned, together will display the entire image, like a jigsaw puzzle.

Owner:ZHIGU HLDG

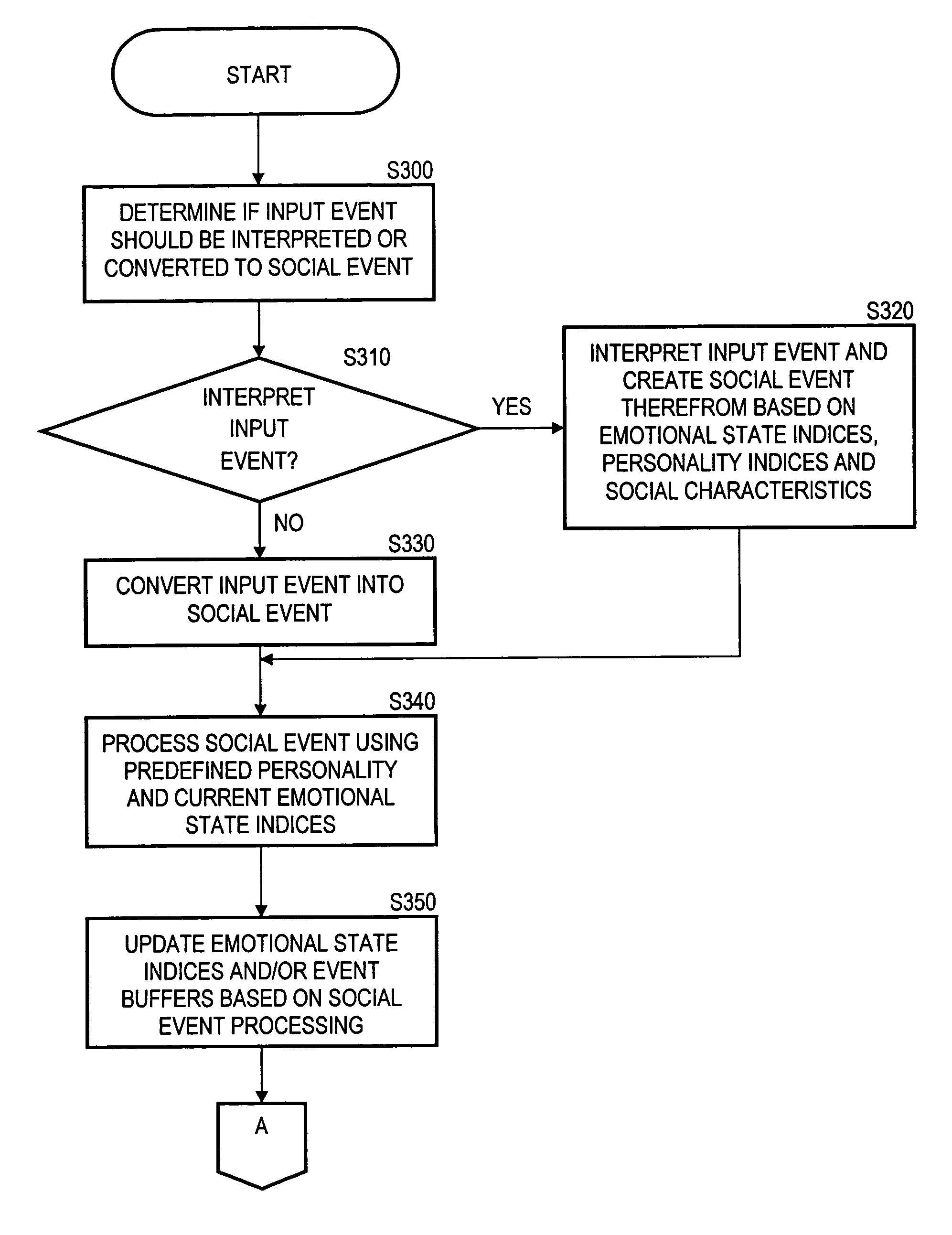

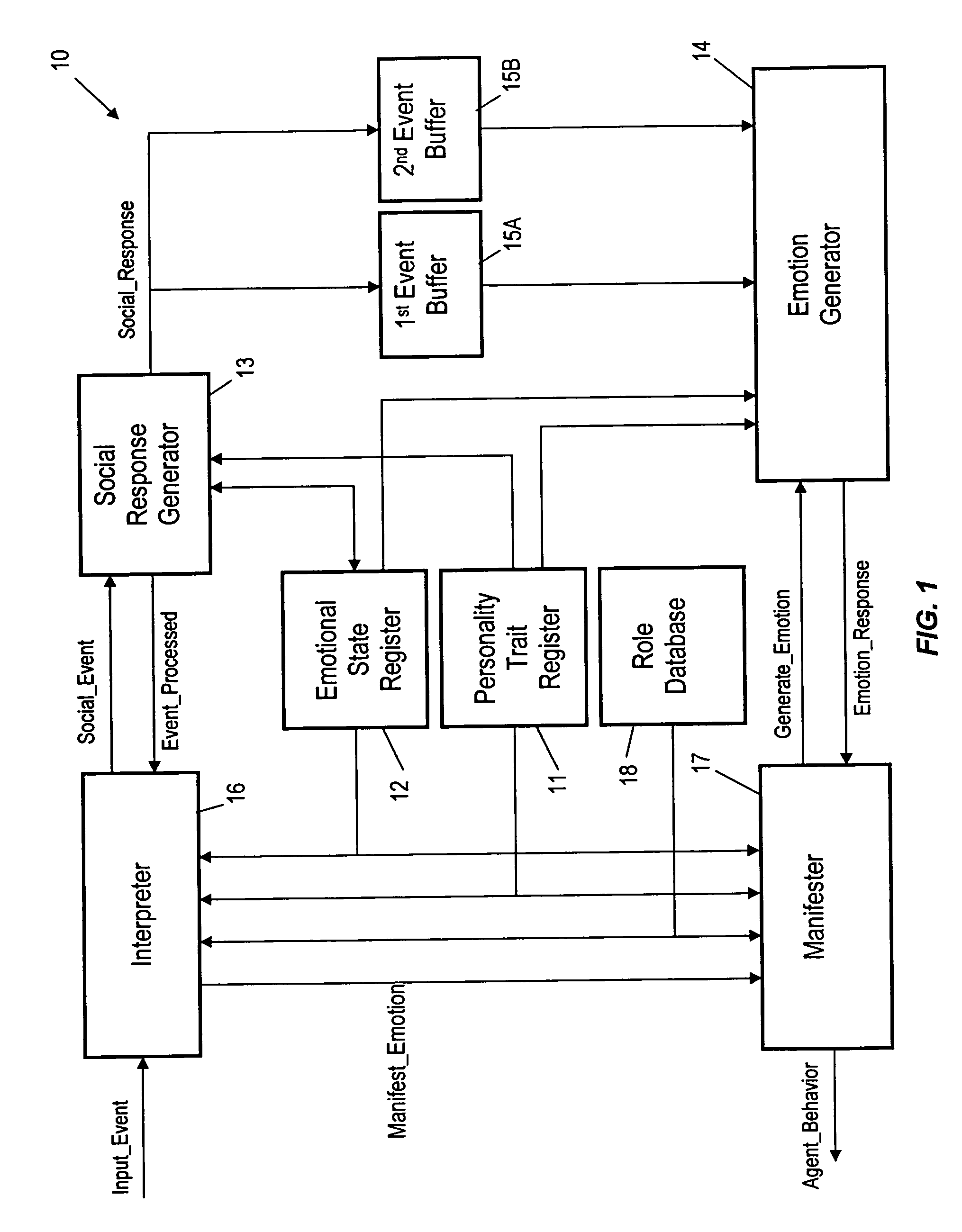

Apparatus and method for socially intelligent virtual entity

Owner:ORMON CORP +1

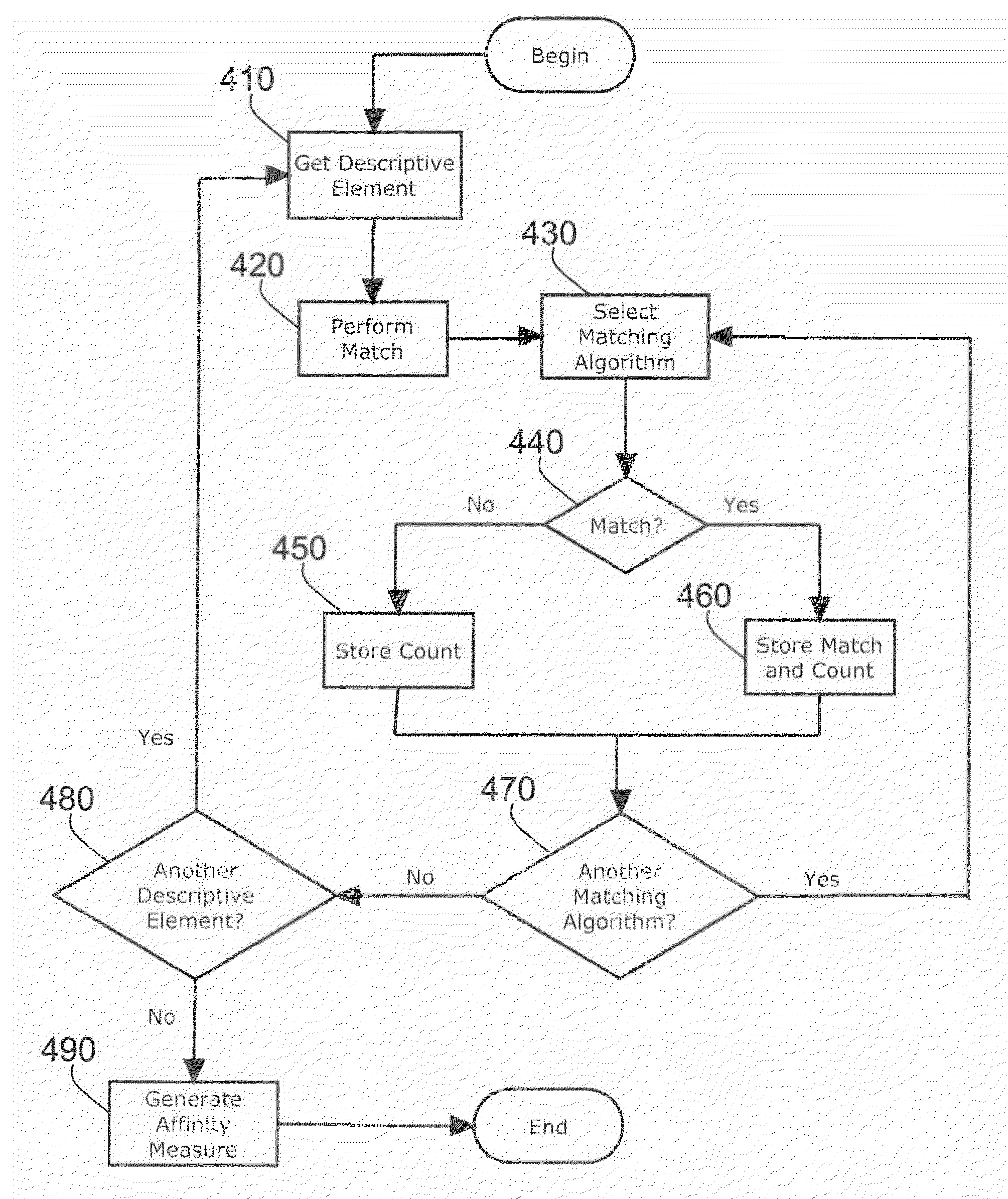

Method and System for Dynamic Detection of Affinity Between Virtual Entities

InactiveUS20110060744A1Facilitates dynamic matchingIncrease choiceDigital data processing detailsOffice automationVirtual universeVirtual entity

A method and system are disclosed for detecting affinity between entities in a virtual universe (VU) using real time access to descriptions prepared from information about objective entities available in VU databases as well as descriptive information made available by the objective entities. Objective entities may be aggregations of virtual entities. Activators for affinity determinations are provided. The information on an objective entity is compared with descriptive information on a VU subject to determine affinity, and corresponding action of the VU subject. In this manner also the comparative affinities of different objective entities may determine actions of the VU subject.

Owner:IBM CORP

Virtual computing infrastructure

ActiveUS8719914B2Overcome disadvantagesAssist in debugging and testingResource allocationMultiple digital computer combinationsNetwork communicationApplication software

Owner:RED HAT +1

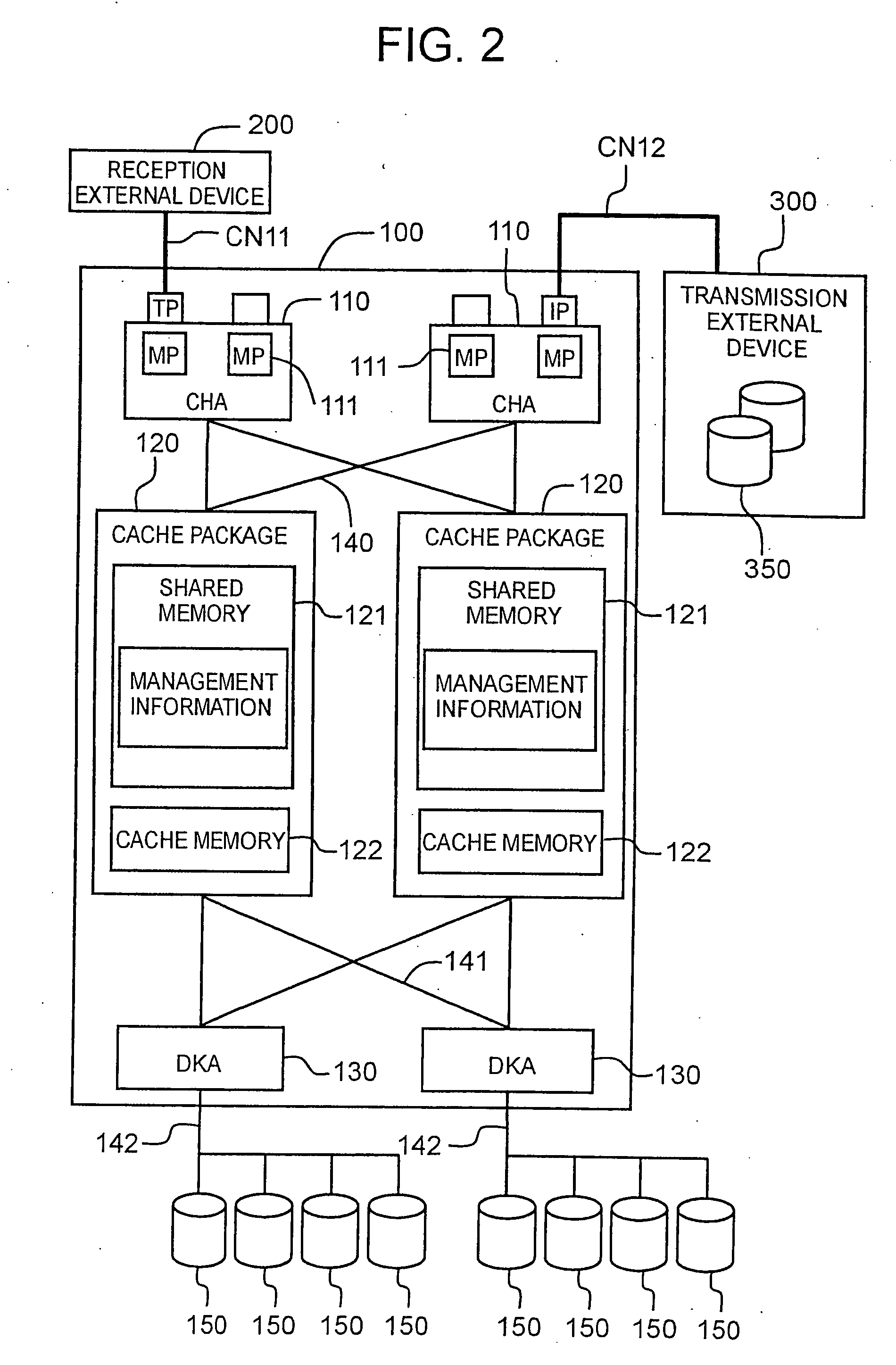

Storage system, storage control device, and data relay method using storage control device

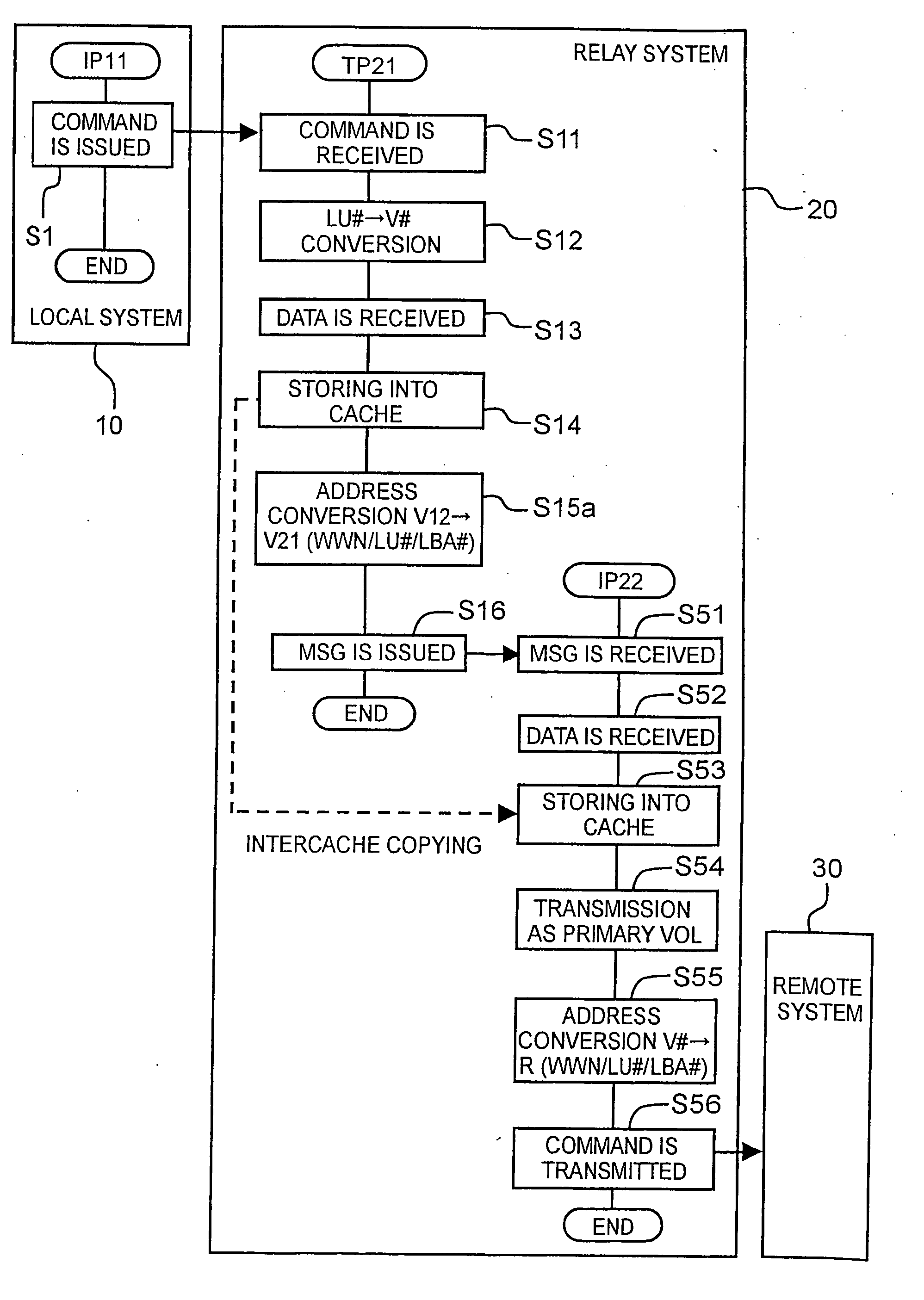

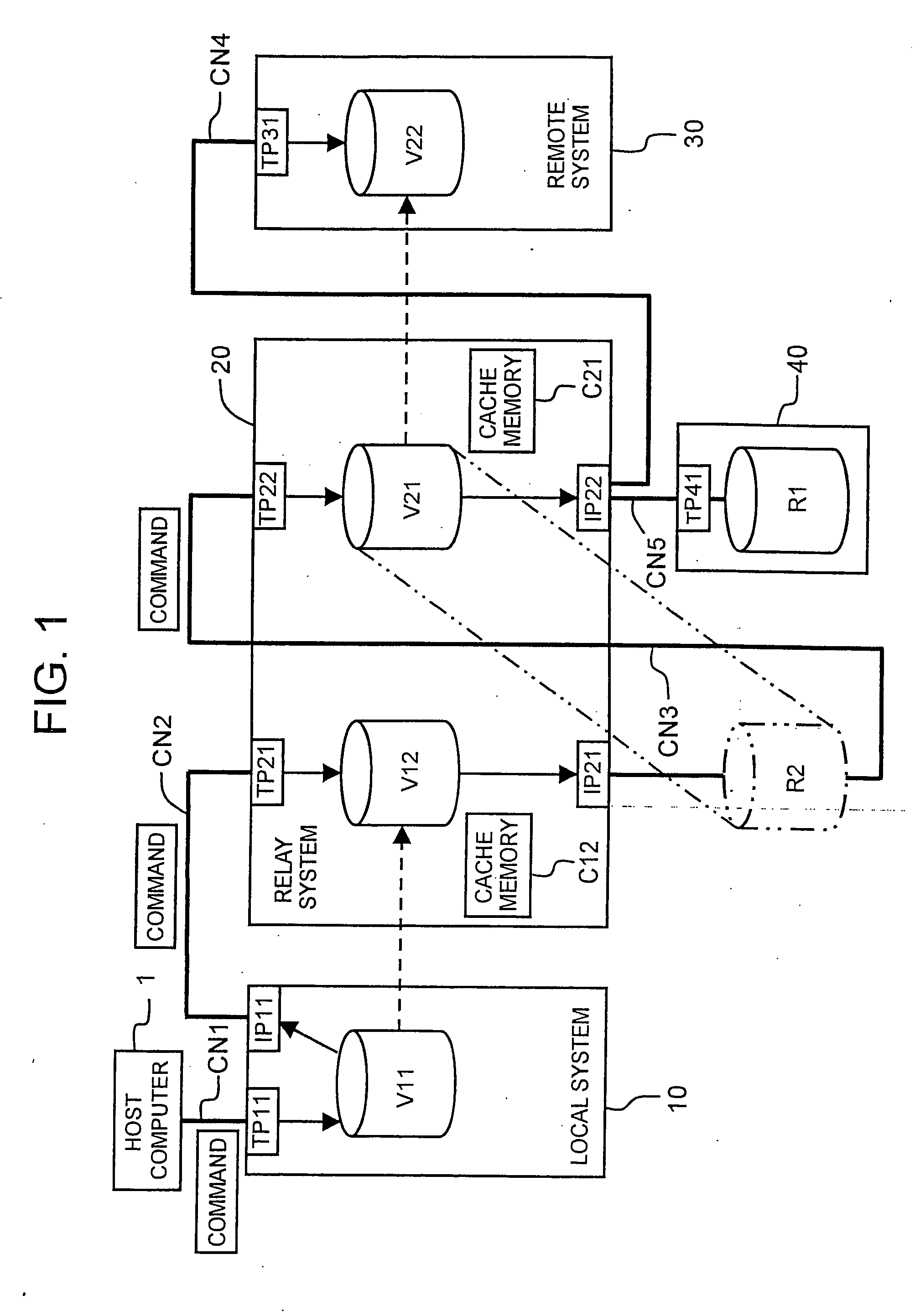

ActiveUS20050120172A1Improve storage reliabilityImprove reliabilityData processing applicationsInput/output to record carriersComputer graphics (images)Virtual entity

A plurality of virtual volumes with different control functions are associated with one real volume and remote copying is conducted. A relay system comprises a plurality of virtual volumes V12, V21 mapped to the same real volume R1. A virtual volume V21 for transmission control is mapped to a real volume R1, a real volume R2 is mapped to the virtual volume V21, and the virtual volume V12 for reception control is mapped to the real volume R2. If a command is received from a local system 10, the virtual volume V12 for reception control writes data into the virtual volume V21 via the real volume R2 (virtual entity). The virtual volume V21 transmits the data to a copy destination volume V22 and writes the data into the real volume R1.

Owner:GOOGLE LLC

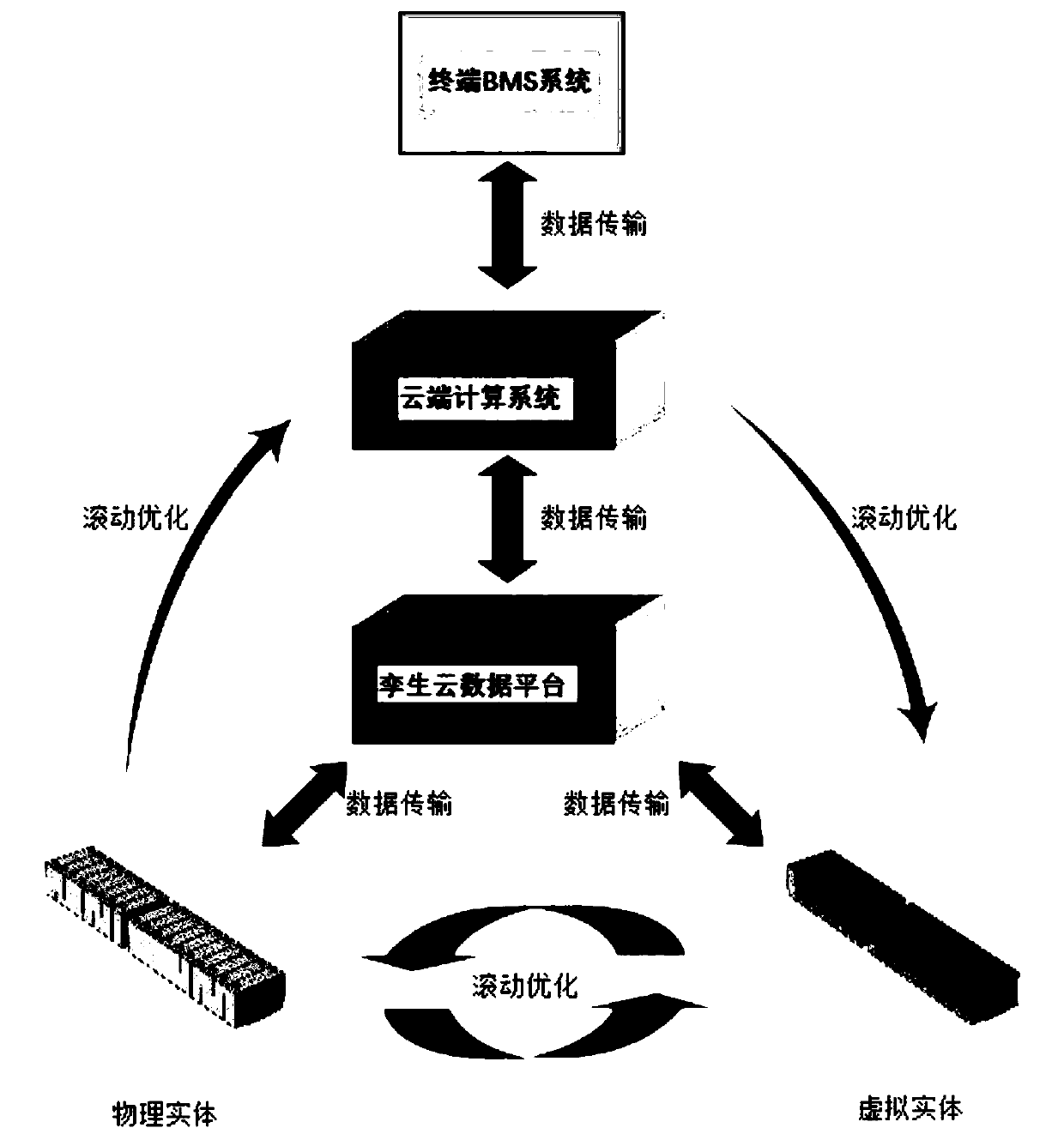

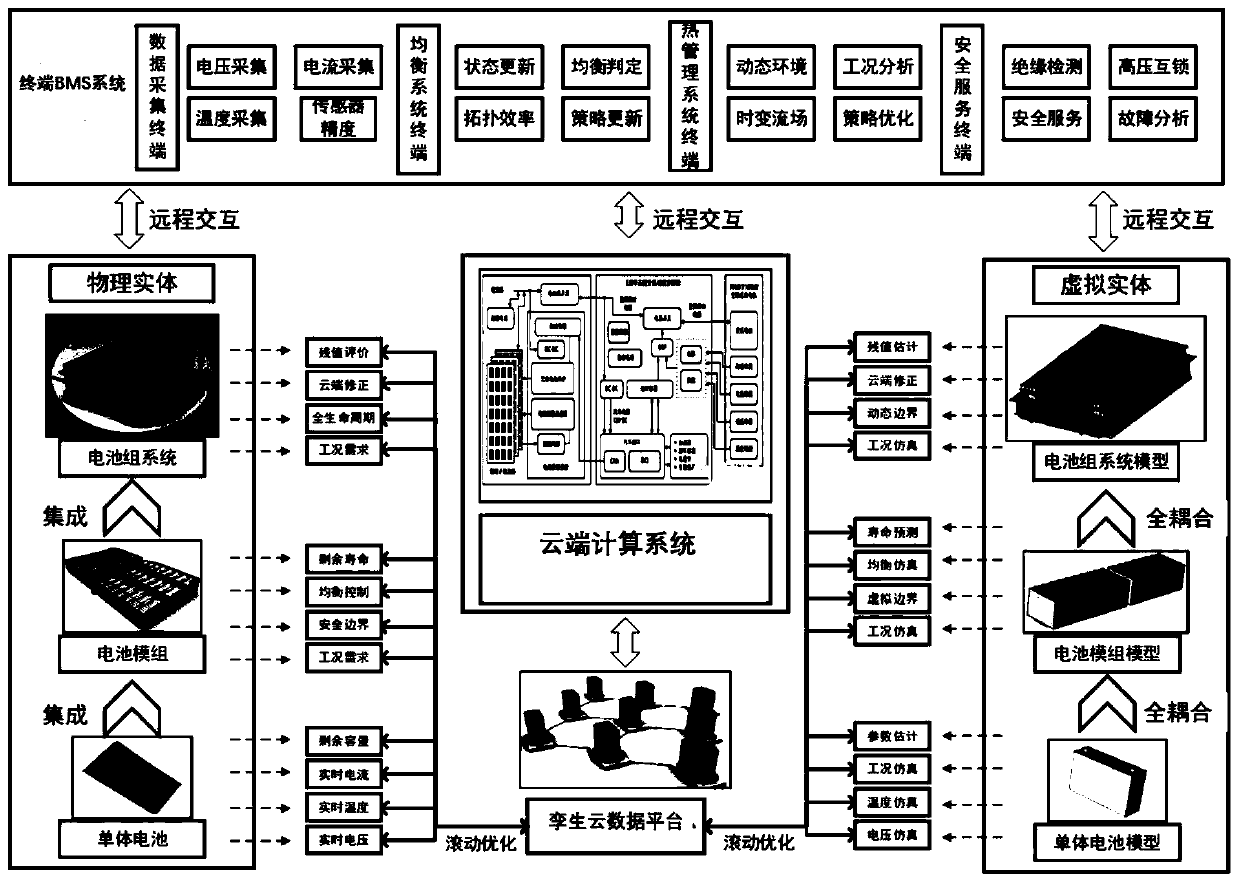

Power battery pack management system and method based on digital twinning

ActiveCN111027165ARealize full lifecycle managementImprove adaptabilityCells structural combinationDesign optimisation/simulationPower batteryFull life cycle

The invention relates to a power battery pack management system and method based on digital twinning. A digital twin system is established in a mode of coupling a physical entity and a virtual entity;a twinning cloud data platform is used for analyzing a physical entity and a virtual entity through a rolling optimization method; and the twinning cloud data is processed through the cloud computingsystem to obtain the power battery pack states of the entity battery pack and the twinning virtual battery pack in the full life cycle, and the cloud computing system interacts with the terminal BMSsystem to achieve full life cycle management of the power battery pack.

Owner:BEIHANG UNIV

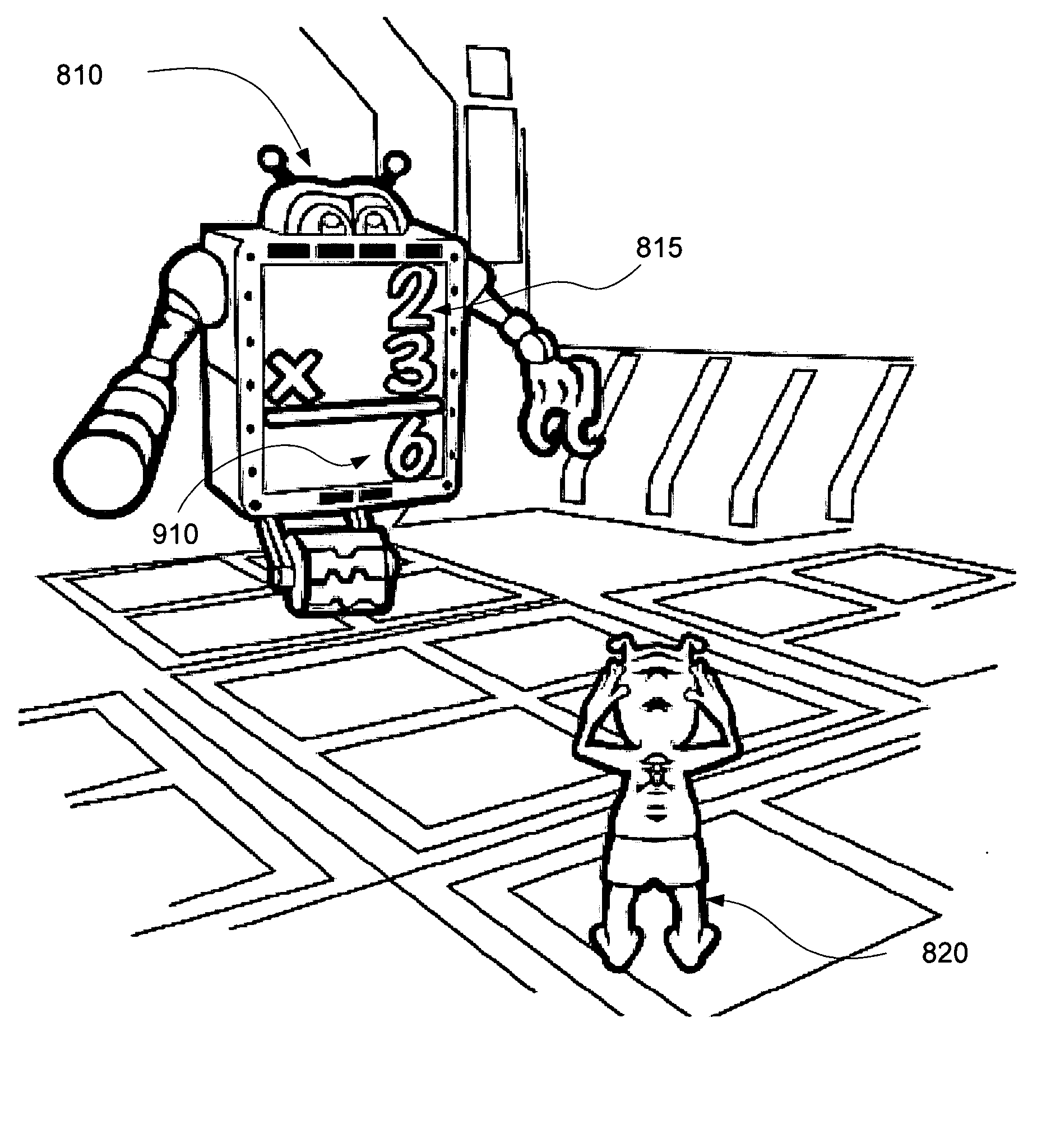

Strategic enforcement of long-term memory

Methods are disclosed for instructing a player in a video game in a more effective manner. In an embodiment, a first fact is provided to a player and then the player is asked questions about the first fact, solidly placing the first fact in the player's short-term memory. Then a player is provided a second fact, interrupting the short-term memory of the first fact. The player is then asked a question about the first fact, interrupting the short-term memory of the second fact. A question is then asked about the second fact, interrupting the player's short-term memory of the first fact. Additional facts may be similarly handled. By the use of the strategic interruptions, the facts are pushed into the player's long-term memory deeper and more quickly than with the use of pure repetition of facts while they are in the player's short-term memory. The questions may be incorporated into virtual entities that the player is required to interact with. To improve gameplay, the player's input may be automatically processed once the player enters the expected number of digits associated with the expected answer.

Owner:BIG BRAINZ

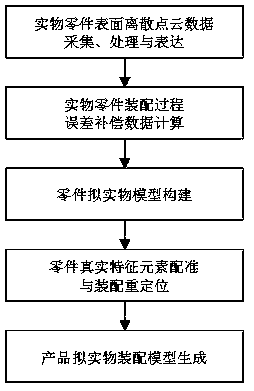

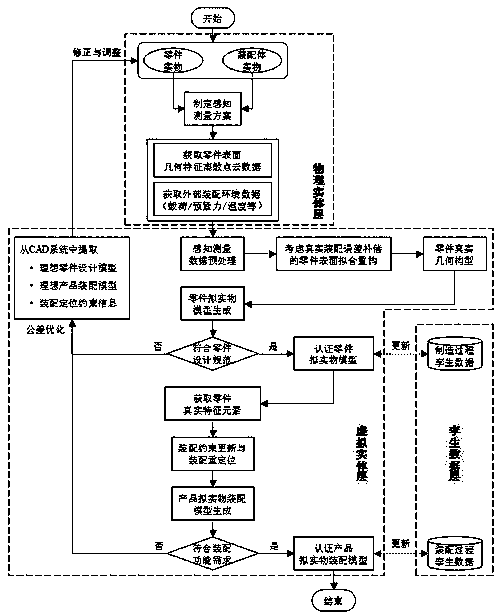

Digital twinning-based product quasi-physical assembly model generation method and implementation framework

ActiveCN111145236ARealize intelligent closed-loop controlImprove quality and efficiencyDetails involving processing stepsImage enhancementLoop controlPhysical model

The invention relates to a digital twinning-based product quasi-physical assembly model generation method and an implementation framework. The implementation framework comprises a physical entity layer, a twinning data layer and a virtual entity layer, a product physical object and a virtual digital model are deeply fused through an information physical fusion technology; discrete point cloud dataof the surface of the part are acquired by means of perception measurement equipment of a physical entity layer, and through measurement data preprocessing, assembly error compensation data of a twindata layer is introduced to reconstruct geometrical characteristics of the surface of the part, so that a part quasi-physical model is generated; and assembly positioning constraint information is extracted according to the virtual entity layer, and real feature element registration and assembly repositioning are performed on the part quasi-physical model, thereby obtaining a product quasi-physical assembly model. The method can be used for high fidelity expression of a product assembly model, the constructed product quasi-physical assembly model can also be used as the basis of three-dimensional assembly process design and assembly precision prediction, and support is provided for intelligent closed-loop control of the complex product assembly process.

Owner:SOUTHEAST UNIV

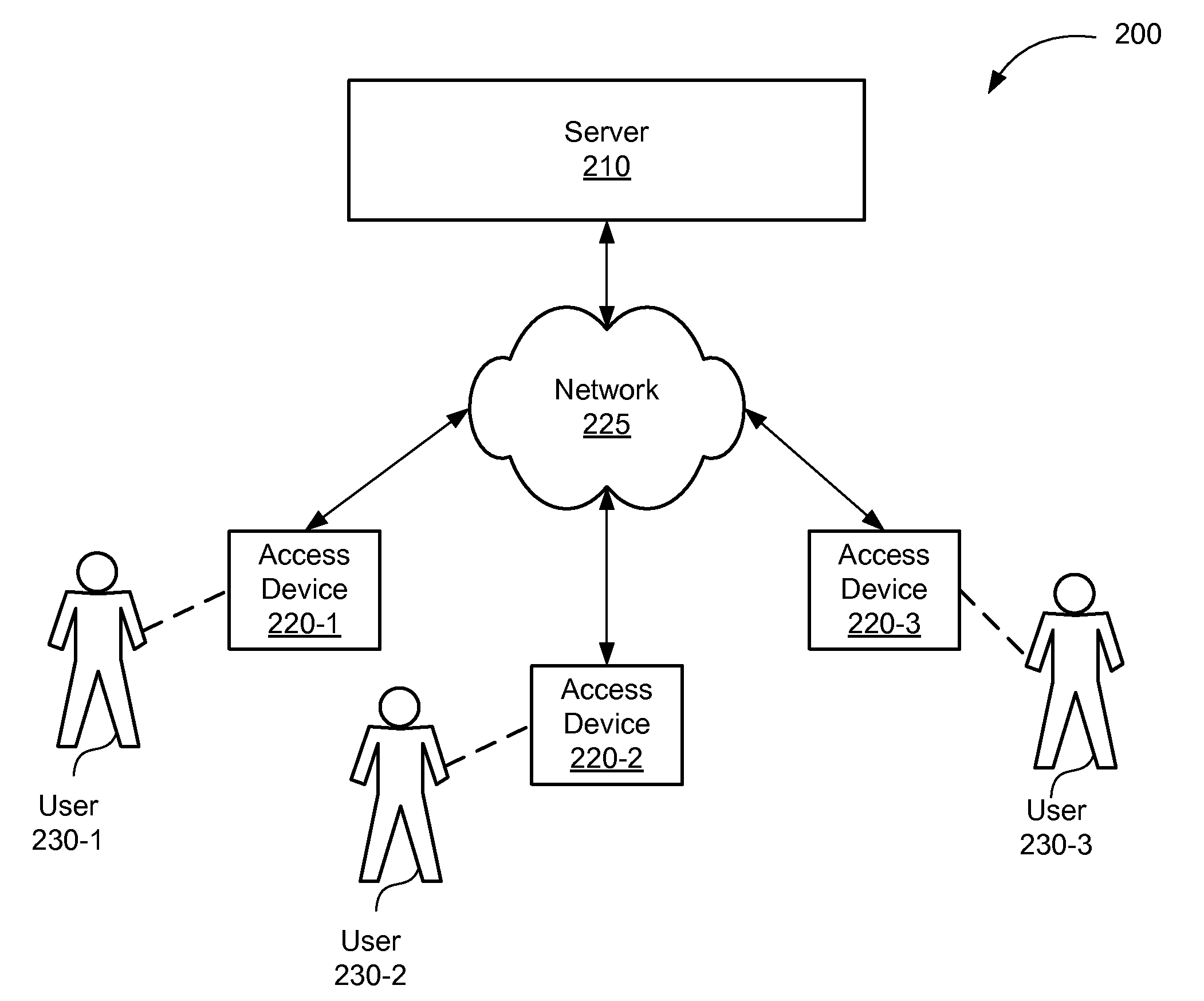

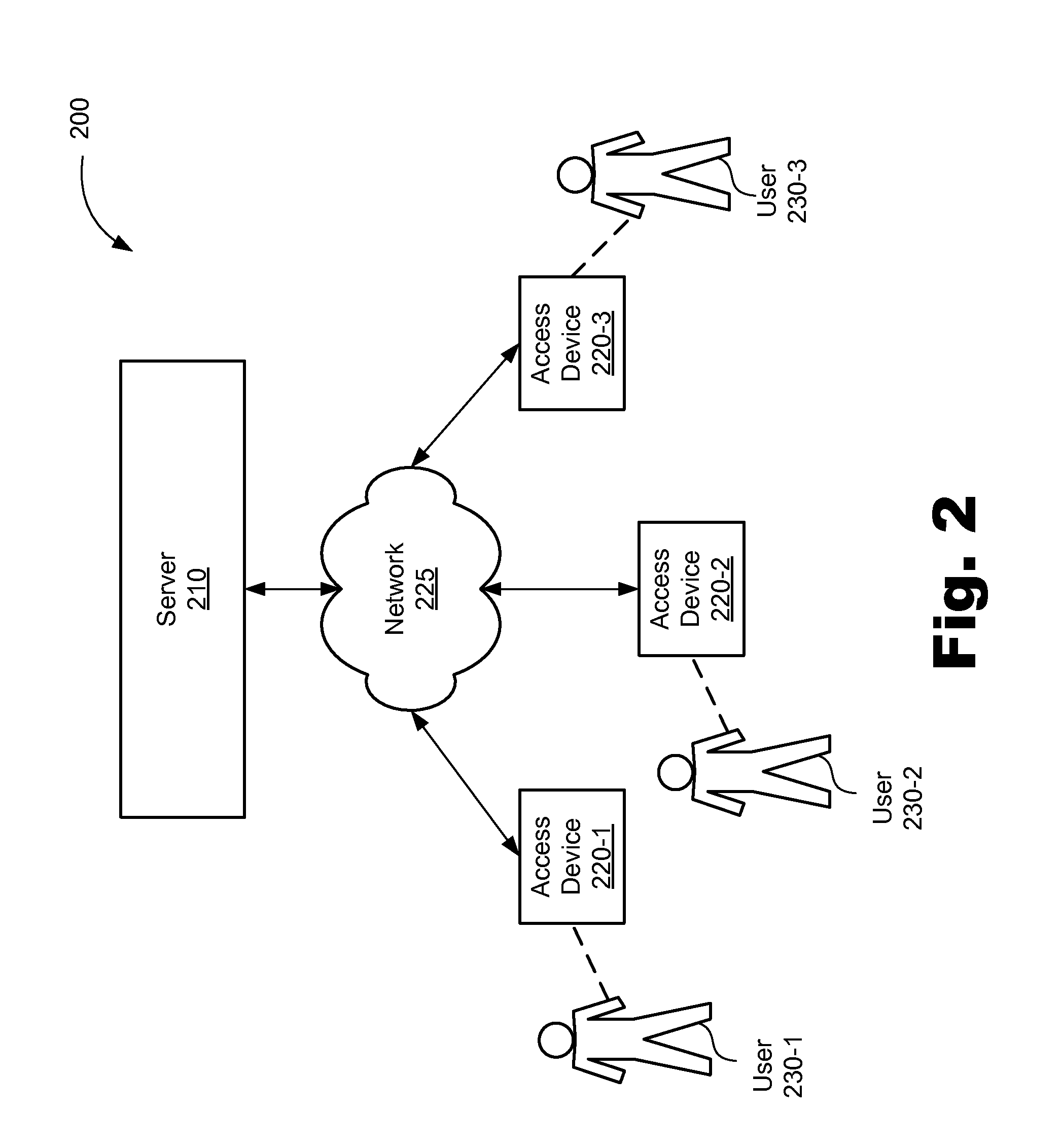

Environmental factor based virtual communication systems and methods

InactiveUS20100082515A1Artificial lifeKnowledge representationCommunications systemHuman–computer interaction

In an exemplary method, an agent facility associated with an access device and a user is maintained, data representative of one or more rules associated with the user is also maintained, at least one environmental factor of the user is detected, and a predefined action is performed with the agent facility in response to the detected environmental factor and in accordance with at least one of the rules. In another exemplary method, a virtual entity configured to electronically represent one or more traits is maintained, electronic interaction by the virtual entity with at least one user is facilitated, at least one environmental factor of the user is detected; and at least one parameter defining the virtual entity is adjusted in accordance with the at least one detected environmental factor.

Owner:VERIZON PATENT & LICENSING INC

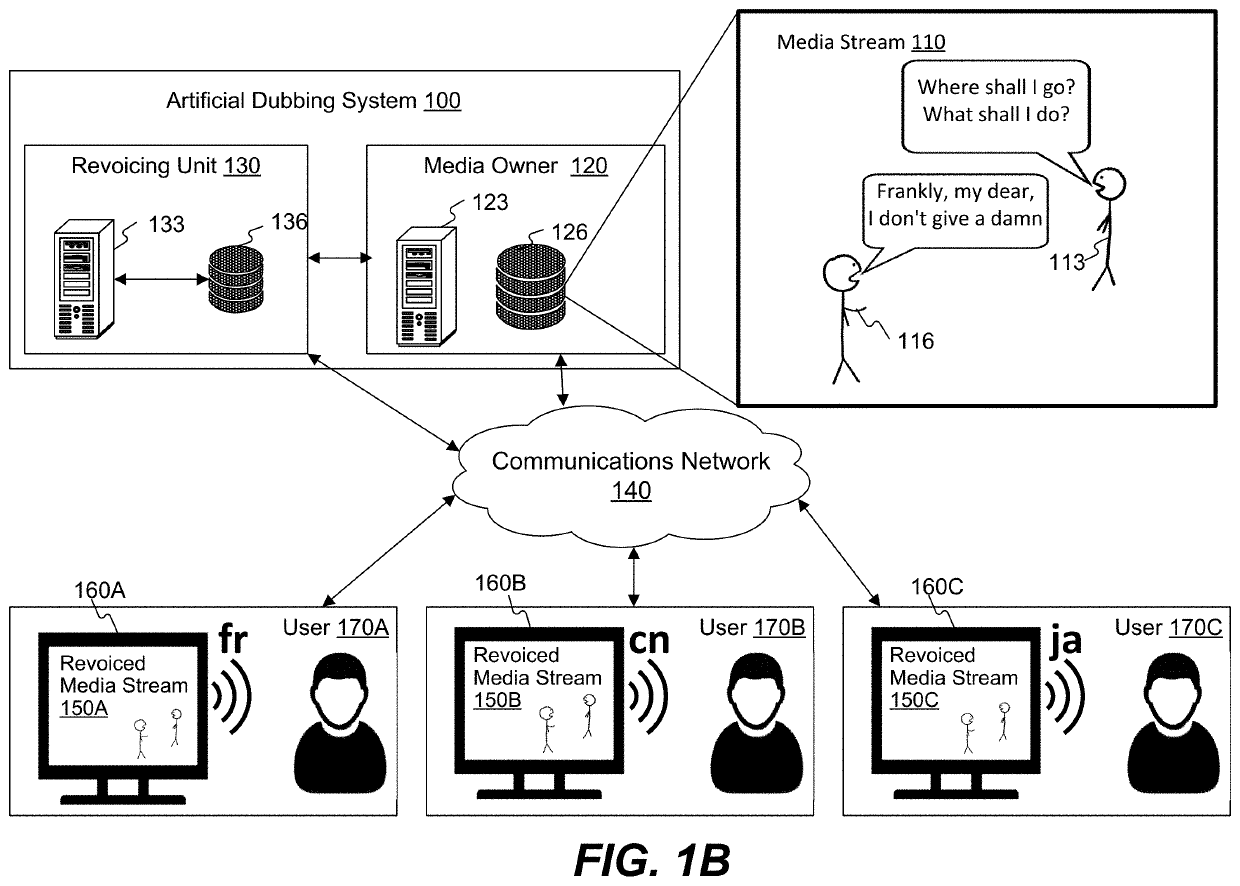

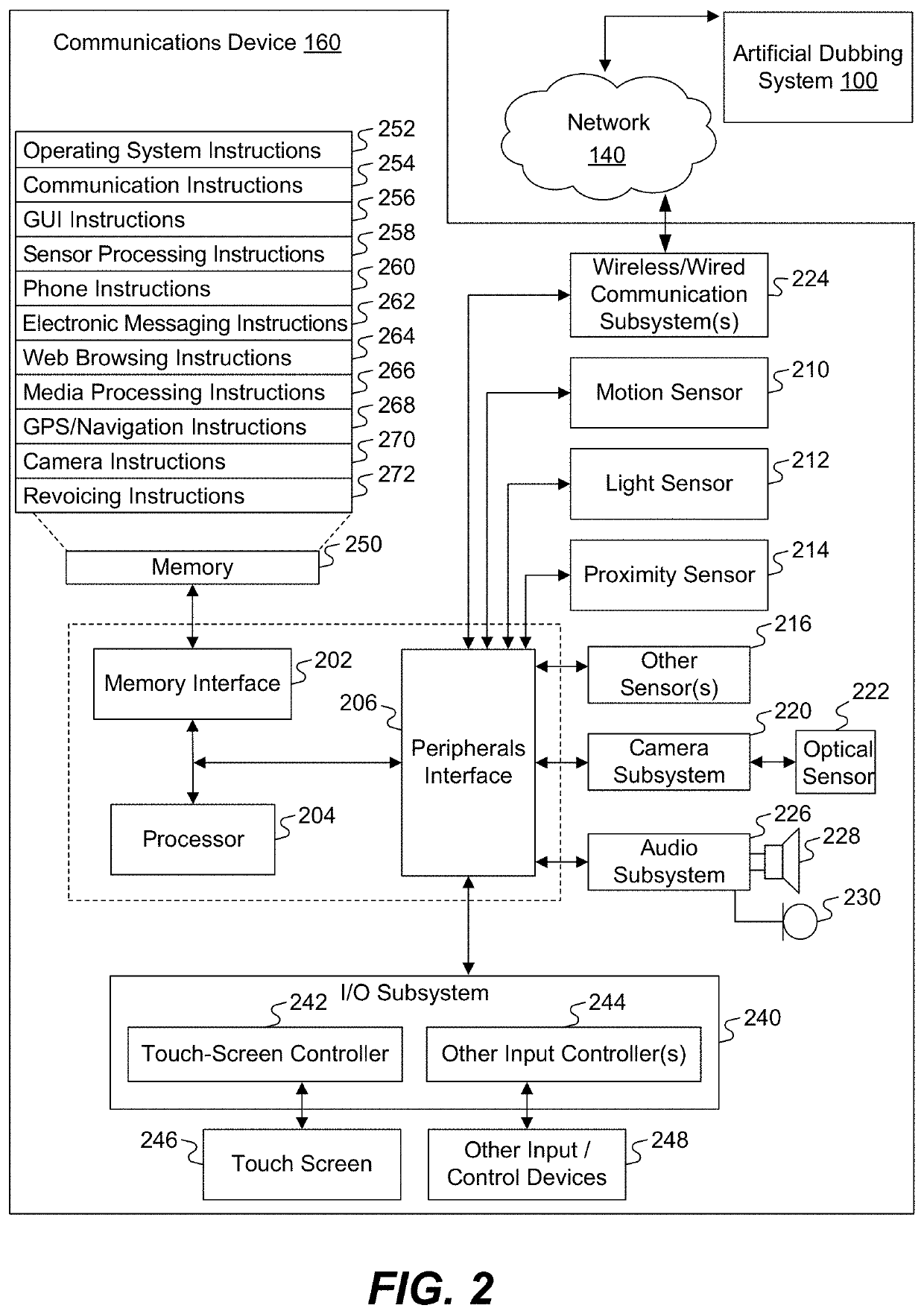

Systems and methods for artificial dubbing

Owner:VIDUBLY LTD

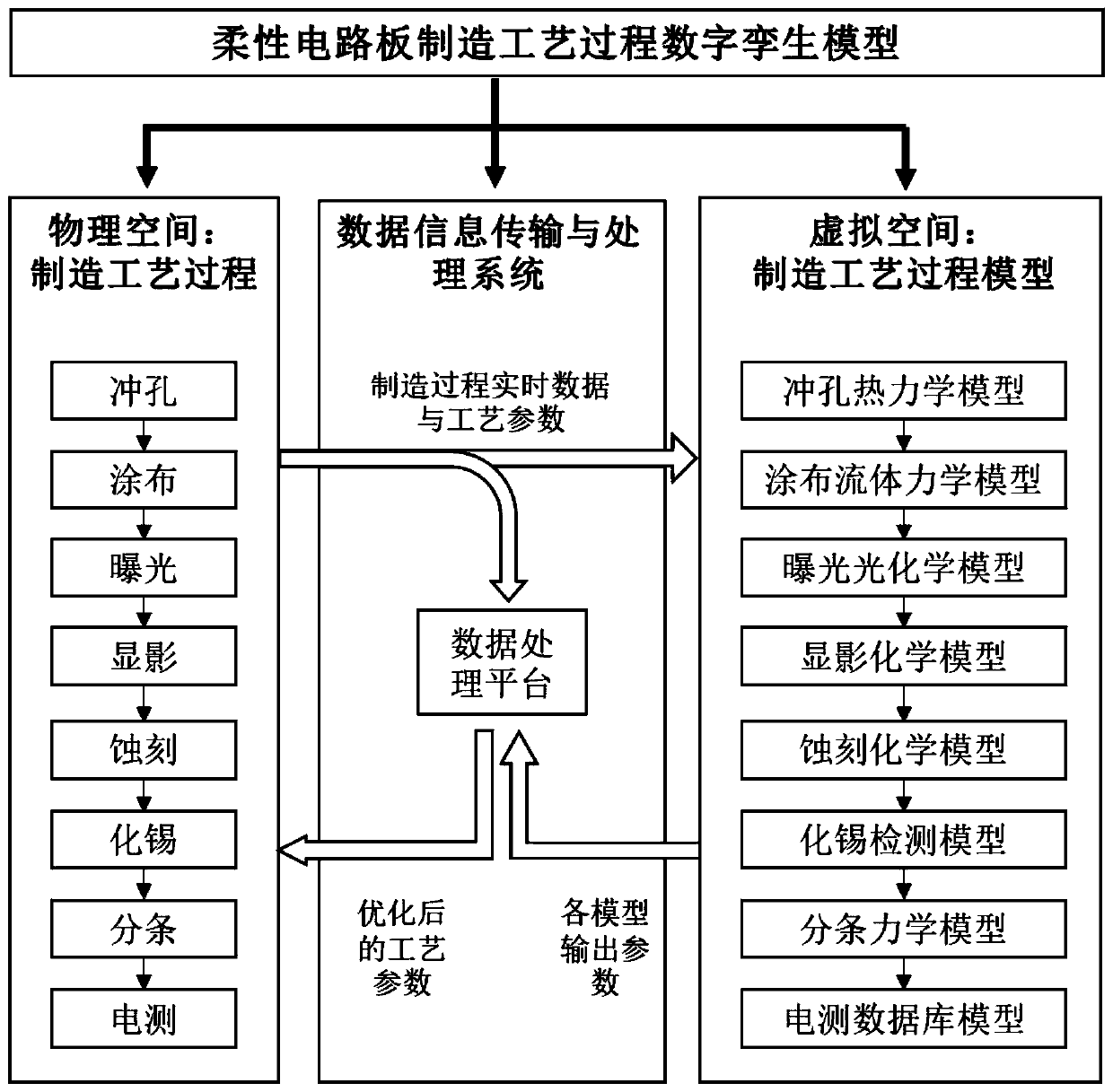

Digital twinning model for manufacturing process of flexible circuit board

InactiveCN110795874AImprove yieldOptimizing Failure PredictionDesign optimisation/simulationCAD circuit designInformation spaceInformation processing

The invention discloses a digital twinning model for a manufacturing process of a flexible circuit board. The digital twinning model of the flexible circuit board manufacturing process is composed ofthree parts, namely a physical space, a virtual space, a data information chain and a data processing system, wherein the physical space is the manufacturing process of the flexible circuit board, wherein the virtual space is a flexible circuit board manufacturing process model, and a virtual entity system model capable of representing the full life cycle of flexible circuit board manufacturing isconstructed in the virtual information space. The data information chain and the data processing system are information transmission chains connected with the physical space and the virtual space, and the transmitted information is subjected to artificial intelligence analysis through the information processing system. According to the digital twinning model for the manufacturing process of the flexible circuit board, real-time monitoring, fault prediction and process parameter optimization are carried out on the full-life-cycle production process, the yield of the flexible circuit board is improved, the production cost of products is reduced, and the production efficiency is improved.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com