Digital twinning-based product quasi-physical assembly model generation method and implementation framework

A technology for assembling models and physical models, which is applied in 3D modeling, image data processing, and details involving processing steps, etc. It can solve the problems of insufficient geometric accuracy and lack of high-fidelity expression means for product assembly, so as to improve assembly quality and The effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

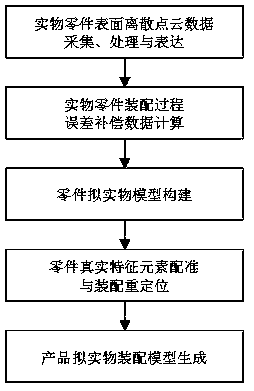

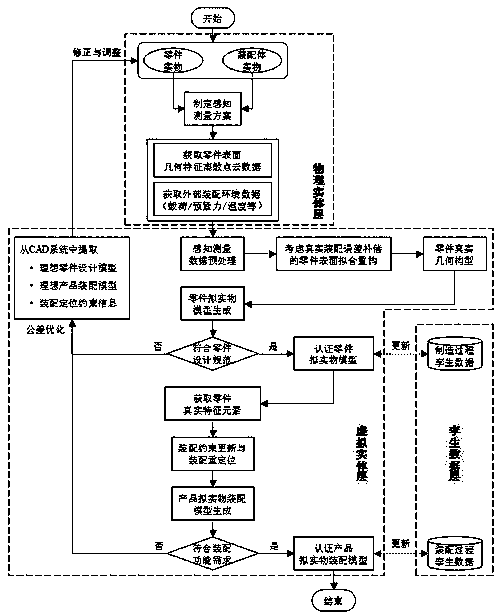

[0038] Such as figure 1 and 2 As shown, the digital twin-based product quasi-physical assembly model generation method of this embodiment includes the following steps:

[0039] (1) Acquisition, processing and expression of discrete point cloud data on the surface of physical parts

[0040] Use the perception measurement equipment at the physical entity layer to collect discrete point cloud data on the surface of physical parts in key assembly processes, and use the analysis process of multi-view point cloud alignment, error point elimination, point cloud filtering, and data reduction for the original point cloud data It is processed to obtain the preprocessed part surface measured point cloud data, and a part surface model based on the measured point cloud data is generated through a triangulated mesh algorithm.

[0041] The key assembly process in the product assembly process is the assembly process that contains key assembly features that significantly affect the assembly ...

Embodiment 2

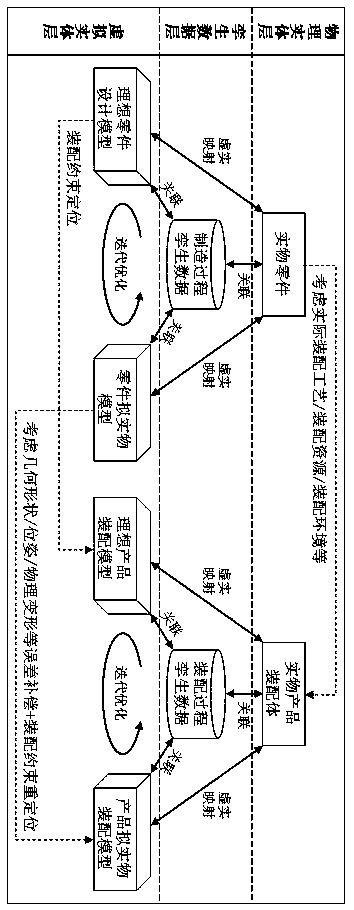

[0052] Such as image 3 and 4 As shown, this embodiment discloses a digital twin-based product quasi-physical assembly model generation method implementation framework, including a physical entity layer, a twin data layer and a virtual entity layer;

[0053] The physical entity layer refers to the collection of all physical entities objectively existing in the workshop, including raw materials, material consumables, processing equipment, assembly equipment, fixtures, operators, workshop environment, and equipment for sensing measurement data. Among them, deployed in the workshop Perceptual measurement equipment includes three coordinate measuring machines, laser scanners, laser trackers, total stations, photogrammetry equipment, force sensors, speed / acceleration sensors, temperature / humidity sensors and other sensory measurement equipment, which combine physical physical layer The manufacturing process and assembly process carry out data collection, processing and fusion upda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com