Patents

Literature

71 results about "Tolerance design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Measuring and adjusting process-considered tolerance design method of precise machine tool

ActiveCN104850698AAccurate analysisReliable analysisSpecial data processing applicationsEngineeringState space equation

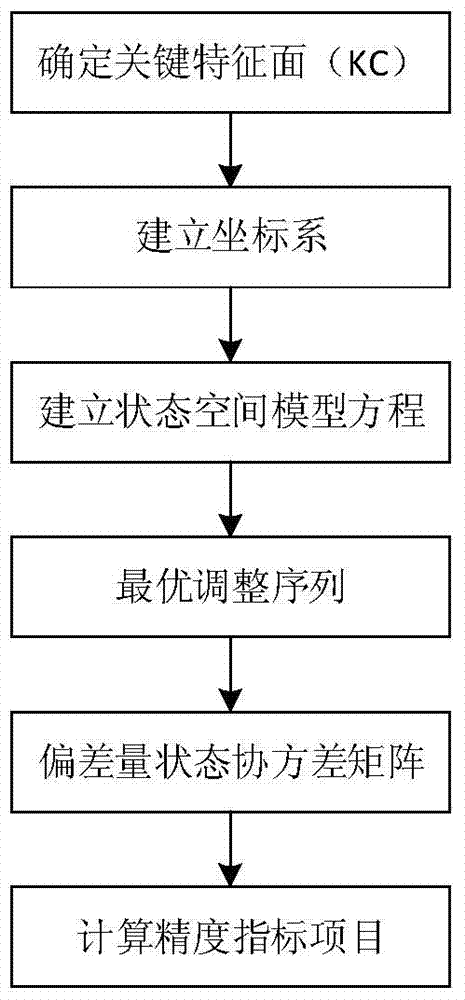

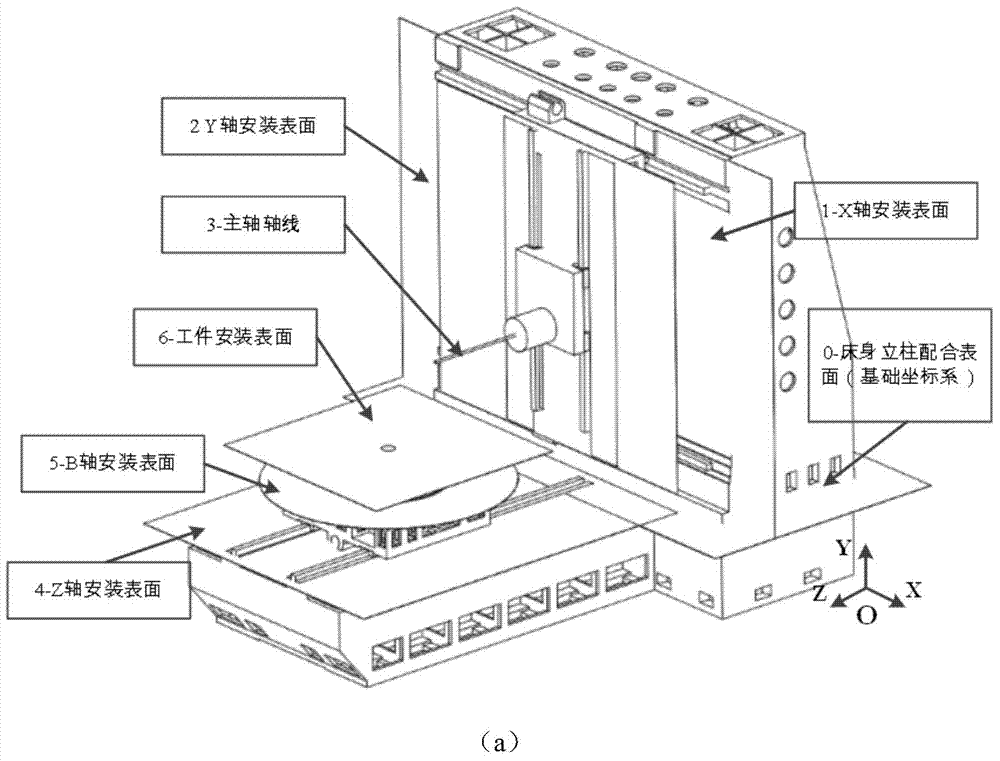

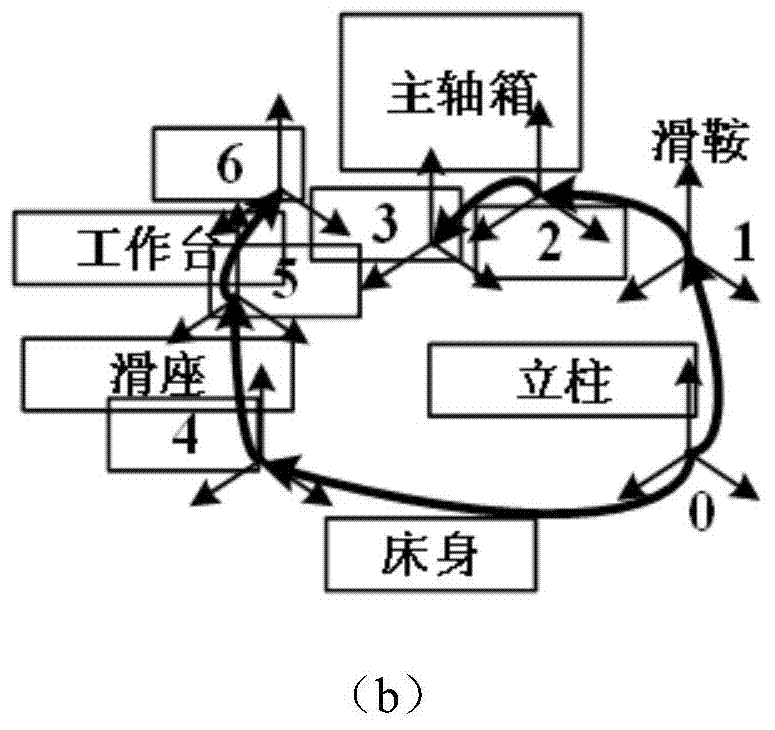

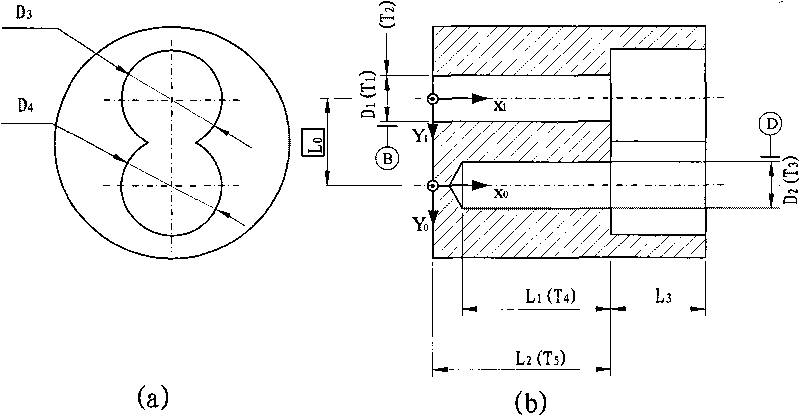

The invention discloses a measuring and adjusting process-considered tolerance design method of a precise machine tool, which comprises the steps of: firstly defining a related coordination system according to a key feature plane; then determining a state space equation and a basic coefficient matrix thereof of a machine tool assembly; next, establishing a cost target function, obtaining an optimal adjustment sequence by a discrete system output regulator so as to convert the state space equation into a Gauss-Markov random process equation; then obtaining a covariance matrix, and performing iteration computation to obtain the covariance matrix after integral assembly is finished; computing a corresponding function relationship between a total precision index and a part precision index of the machine tool according to the covariance matrix after the integral assembly is finished; finally, establishing a function relation between a precision total cost and a part precision and solving to obtain an optimal part tolerance allocation result. The method can be used for accurately and reliably analyzing the tolerance of the machine tool, thus ensuring the precision performance of the machine tool.

Owner:XI AN JIAOTONG UNIV

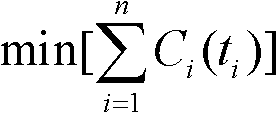

Tolerance optimization allocation method based on tolerance grade and genetic algorithm

ActiveCN102622495AImprove execution efficiencyImprove efficiencyBiological neural network modelsSpecial data processing applicationsMathematical modelComputer-aided

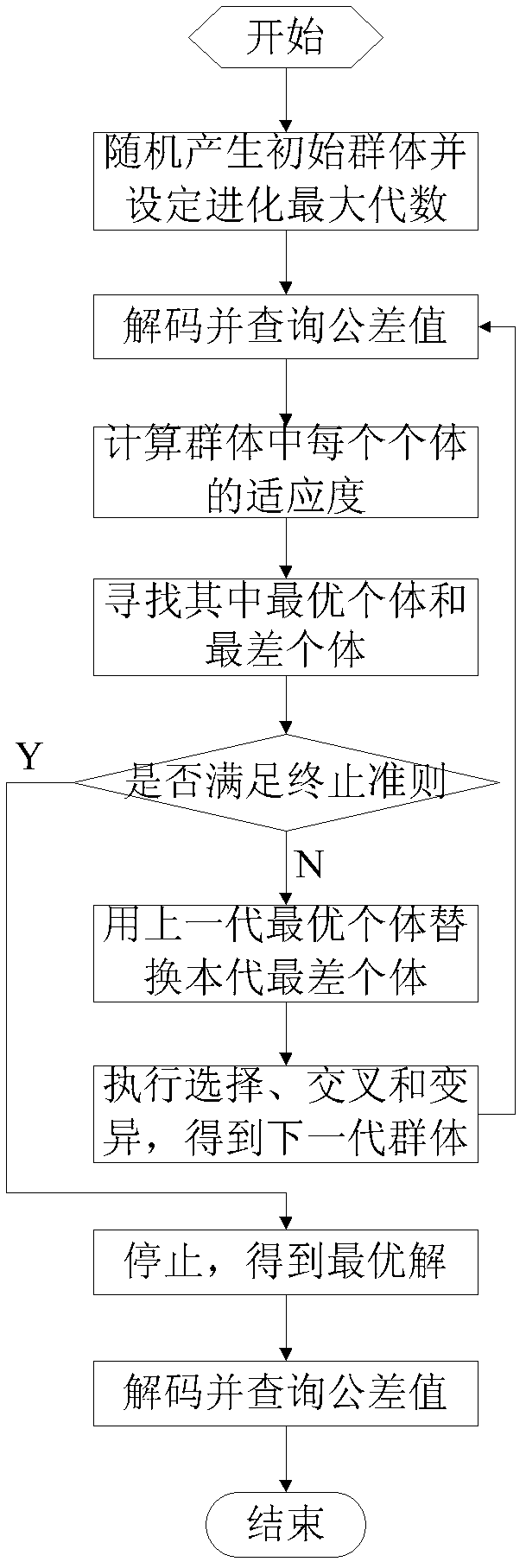

The invention discloses a tolerance optimization allocation method based on a tolerance grade and a genetic algorithm, comprising the following steps: (1) creating a tolerance optimization mathematical model; (2) creating a standard tolerance database; (3) encoding based on the tolerance grade; (4) determining an adaptability function of the genetic algorithm; (5) setting a genetic operator; (6) performing genetic evolution; and (7) decoding to obtain a corresponding tolerance grade and inquiring a corresponding tolerance value. The method disclosed by the invention realizes the tolerance optimization allocation in the product design by using a computer, thereby replacing the manual distribution, improving the efficiency and saving the time; meanwhile, the method performs the optimization allocation through the genetic algorithm, serves the minimum processing cost as an optimization target and reduces the processing cost of products. Therefore, the method has good practical value and extensive application prospect in the technical field of computer aided tolerance design.

Owner:BEIHANG UNIV

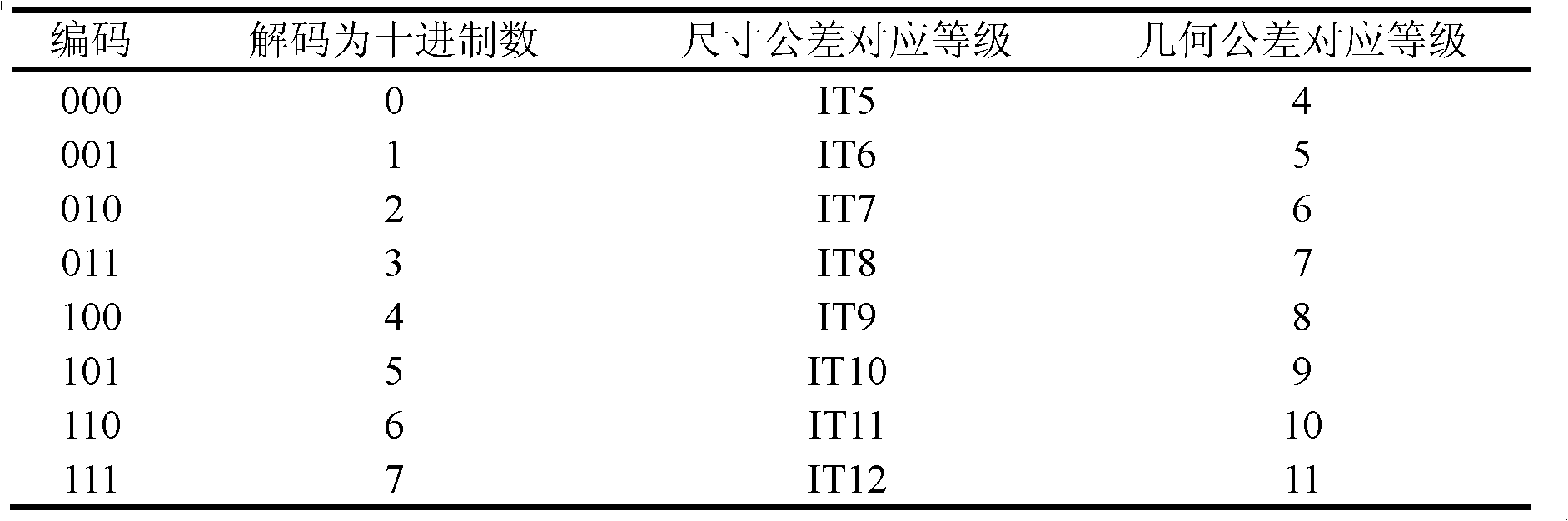

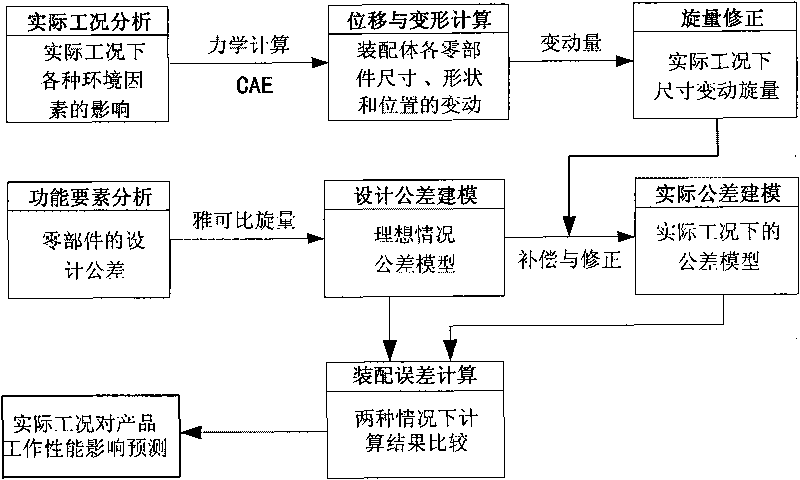

Actual-condition tolerance modeling method based on Jacobian spinors

InactiveCN101710355AMathematical brevityQuantifiable computingSpecial data processing applicationsMathematical modelSimulation

The invention relates to an actual-condition tolerance modeling method based on Jacobian spinors, belonging to the technical field of mechanical tolerance digitization. By calculating the deformation of a working part during loading, changing to the correction quantity of Jacobian spinors and compensating and correcting a Jacobian spinor tolerance model in an ideal condition, the invention establishes an assembly tolerance mathematical model based on Jacobian spinors and actual conditions. The actual-condition tolerance modeling method is technically characterized by comprising the steps of: firstly establishing an assembly tolerance model in the ideal condition; then considering the influences of environmental factors in the actual conditions, and calculating the changes of the size, the shape and the position of a component caused by the influences; mathematically expressing the changes in a spinor matrix mode as compensation, and combining the compensation with the tolerance model in the ideal conditions; and finally obtaining the assembly tolerance model in the actual conditions accordingly. The invention has the advantages that calculation results can be used for judging the assembling properties in the actual conditions and verifying and checking the tolerance design results, thereby predicting and judging the changes of product performances under different assembling design tolerances.

Owner:TONGJI UNIV

Refinement of spindle motor bearing gap

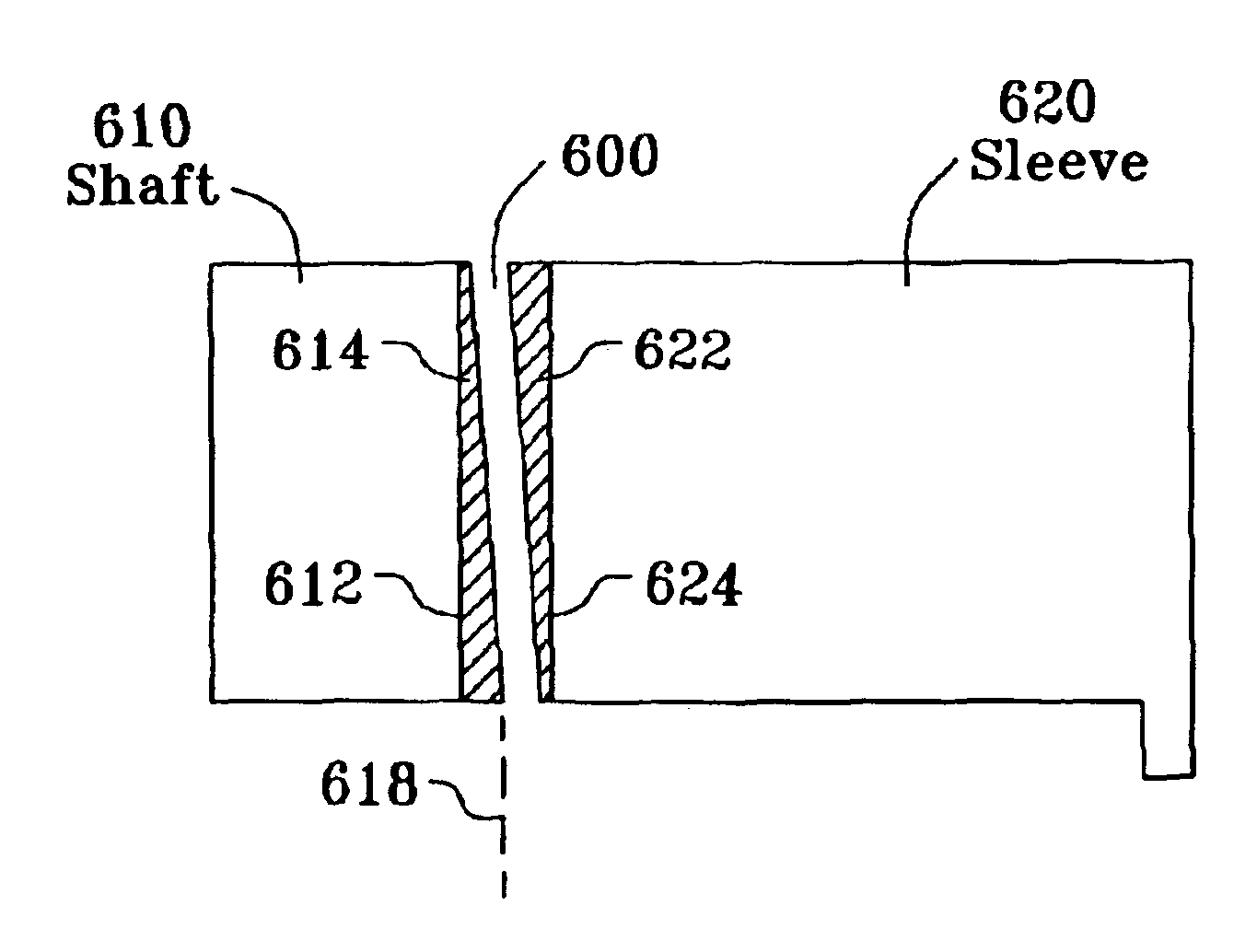

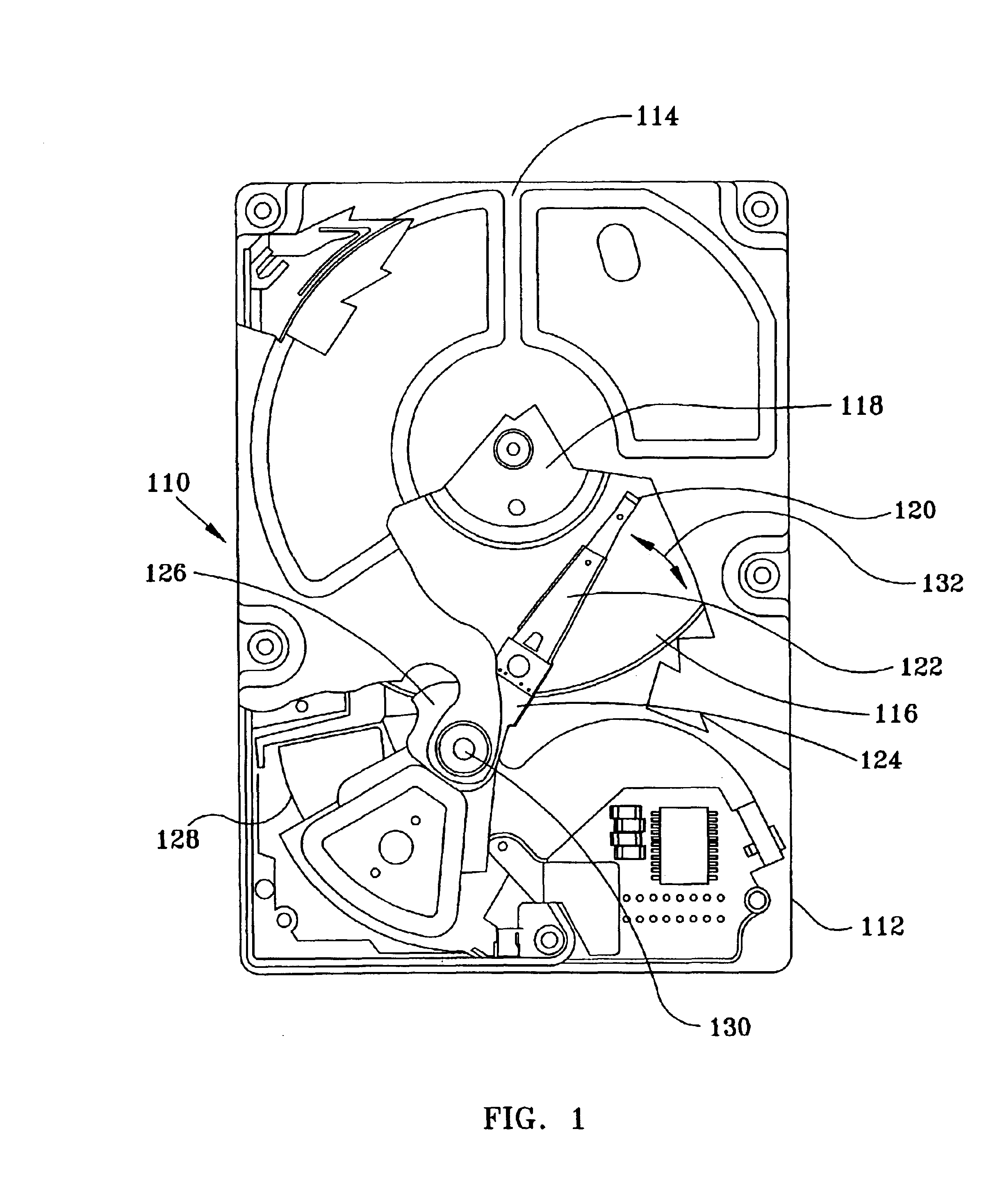

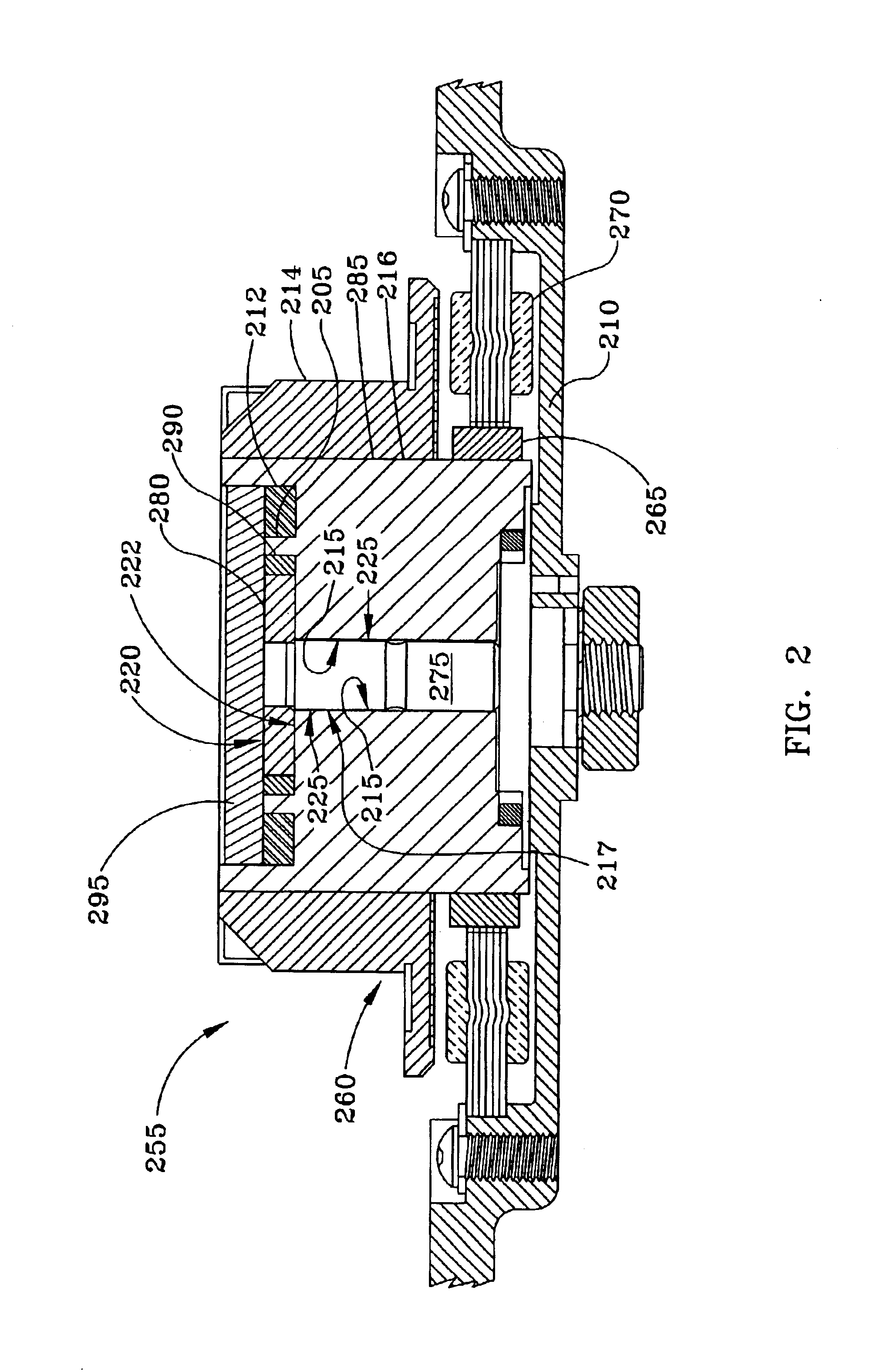

InactiveUS6961214B2Improve dynamic performanceNegligible wearApparatus for flat record carriersRecord information storageDiamond-like carbonGas phase

A method and system is provided for achieving good dynamic performance and negligible wear to spindle motor components. In an aspect, a disc drive storage system is provided having a hydro bearing surface coating for meeting bearing gap tolerance design specifications. In an aspect, the surface coating is a non-reactive coating of diamond like carbon (DLC), applied with physical vapor deposition (PVD). In an aspect, the surface coating nullifies any taper of an opposing surface coating. In an aspect, the hydro bearing, with an applied coating, defines a uniform gap between 0.5 microns and 6 microns.

Owner:SEAGATE TECH LLC

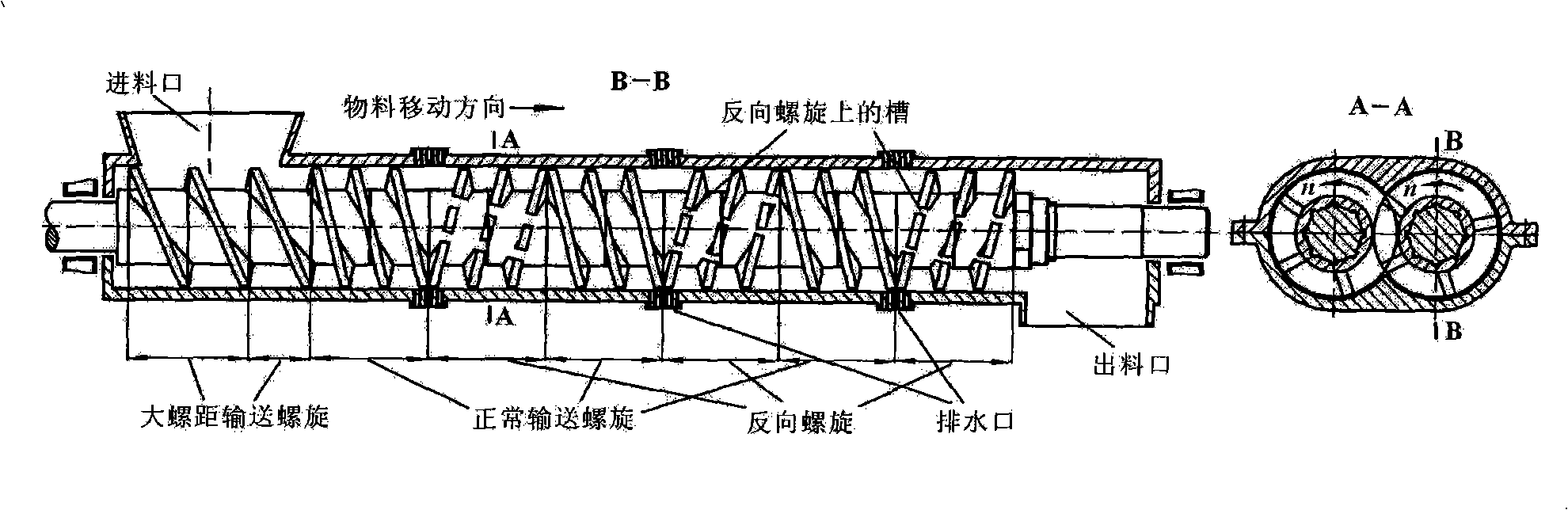

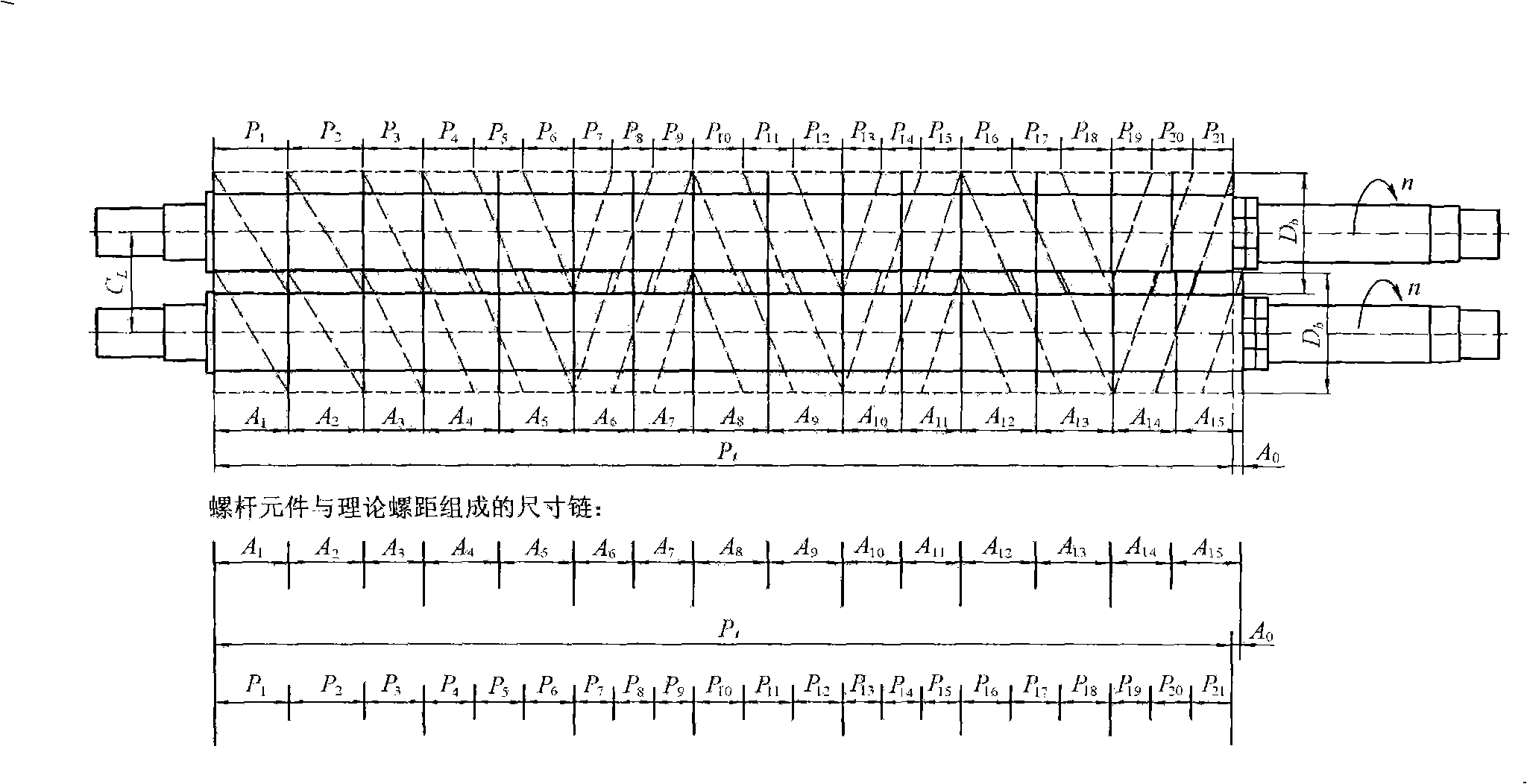

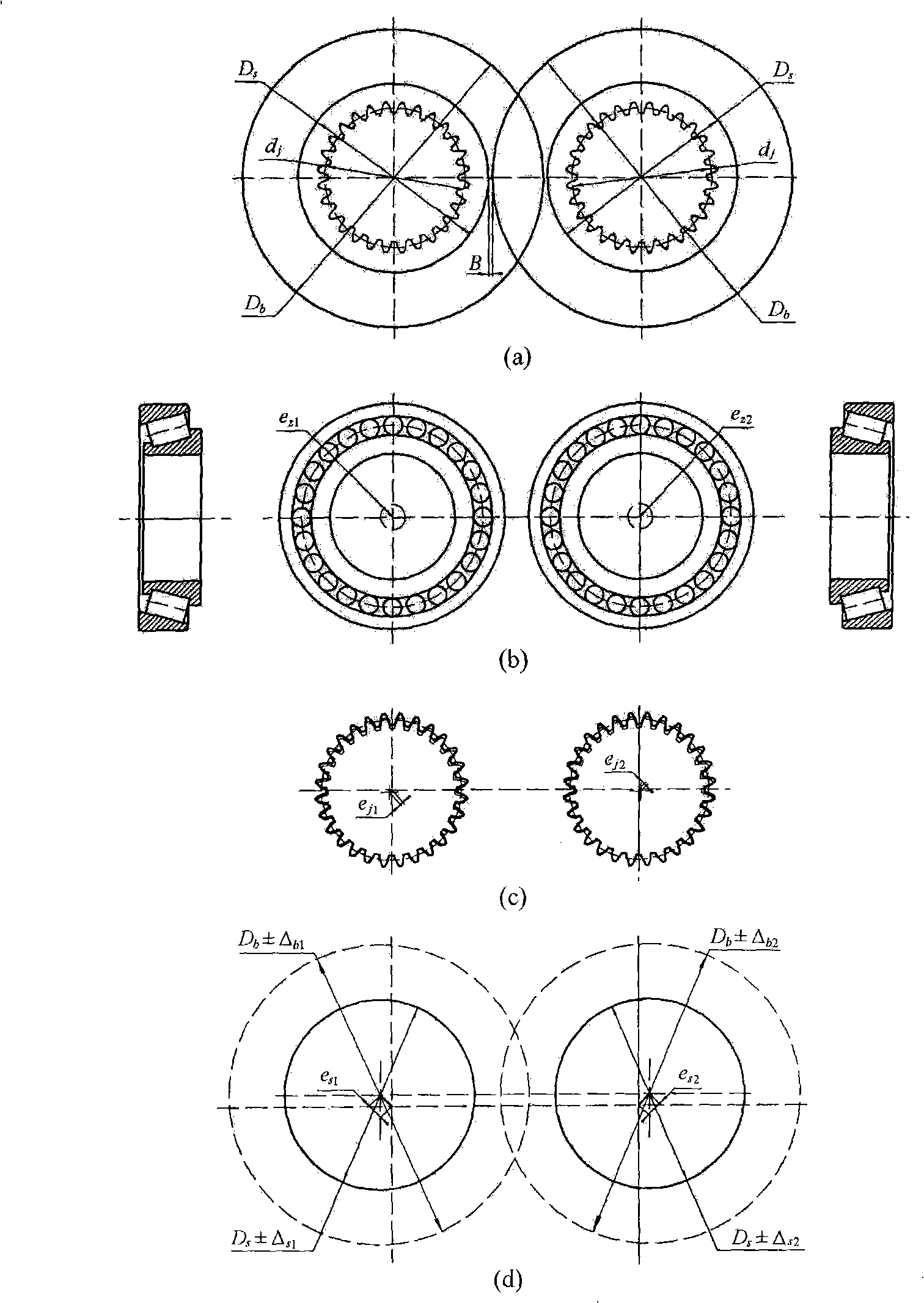

Double-screw pulp-milling mechanism statistical tolerance design method

InactiveCN101493860AQuality assuranceGuaranteed processing costSpecial data processing applicationsManufacturing cost reductionPosition tolerance

The invention relates to a design method of twin-screw pulping mechanism statistical tolerance. The requirements for side clearance and diametral clearance of the twin-screw pulping machine are transformed to the requirements for dimension tolerance and form and position tolerances of such parts of the twin-screw pulping machine as a screw element, a mandrel and the like, thus laying a solid foundation for the precision design, tolerance design, assurance of assembly quality and reduction of manufacturing cost. Especially, the design method of computer assistant statistical tolerance based on mixed convolution algorithm, on the premise of guaranteeing the assembly quality of a complex dimension chain, provides more favorable tools and methods for the further reduction of the processing cost of the parts. The design method has important meaning for the design and manufacturing of the twin-screw pulping machine and assurance of the quality of the twin-screw pulping machine.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

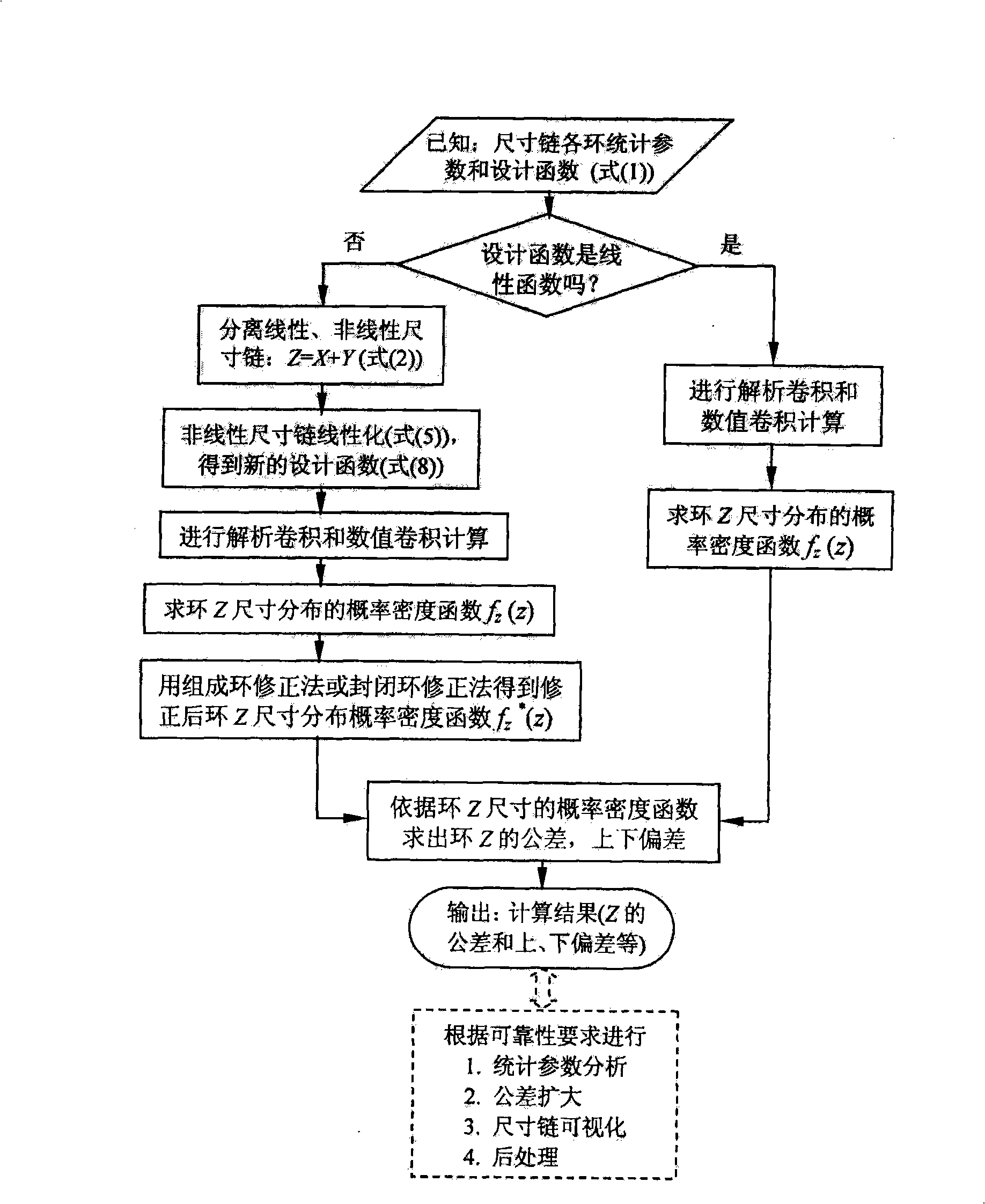

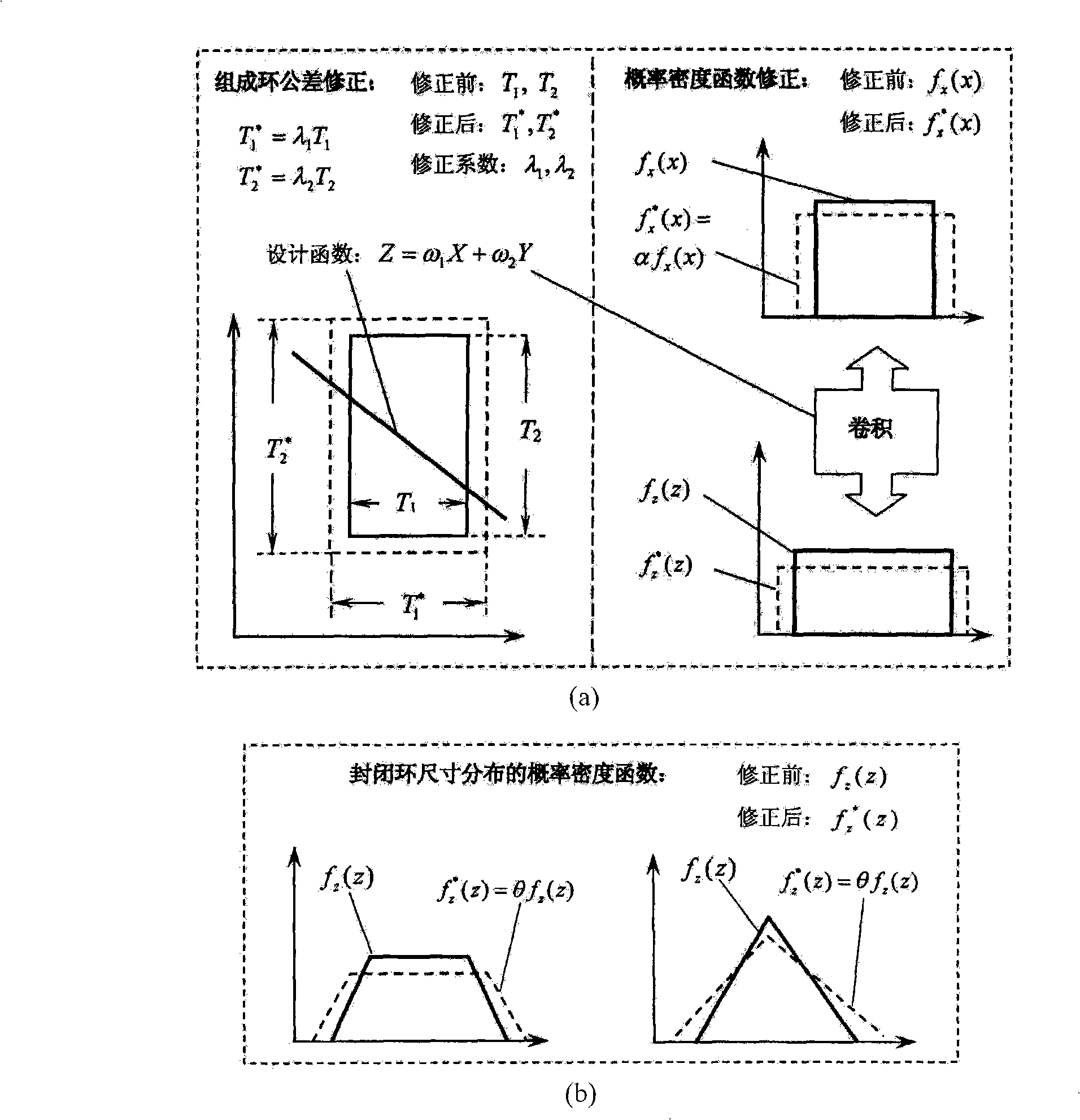

Computer auxiliary statistical tolerance design method based on mixing convolution algorithm

InactiveCN101493859AReduce calculation errorsGuaranteed reliabilitySpecial data processing applicationsAlgorithmComputer-aided

The invention relates to a design method of computer assistant tolerance statistics based on mixed convolution algorithm. A dimension chain is provided with n composition rings, the function relation between the dimension Z of a closed ring and the dimension Xi of the composition ring is set as a design function which is analyzed into a linear part and a nonlinear part, the nonlinear part is linearized and a high-level remainder is omitted to transform the design function into a linear function, i.e., a mixed convolution method comprising a resolution convolution and a numerical convolution can be used for determining the distribution of the dimension Z of the closed ring, and the calculation results can be corrected by the adoption of a closed ring correction method or a composition ring correction method. The design method promotes the existing tolerance statistics method to the calculation of the dimension chain of the composition ring and the closed ring with different distributions, is applicable to the mixed convolution algorithm that is effective for various linear and nonlinear problems, and has relatively rapid calculation speed and relatively high calculation precision.

Owner:TIANJIN UNIV OF SCI & TECH

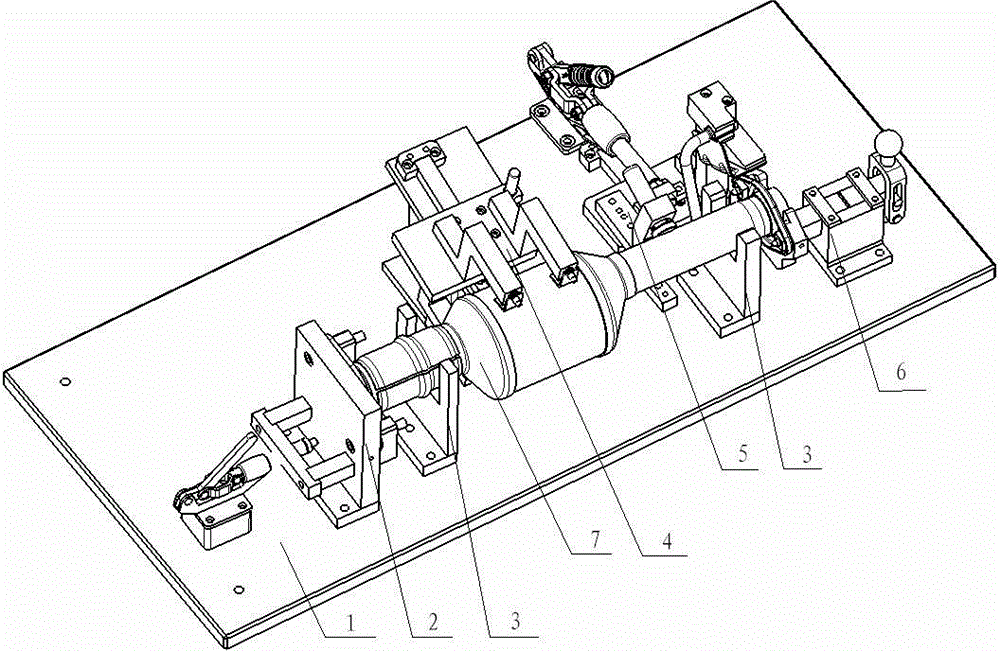

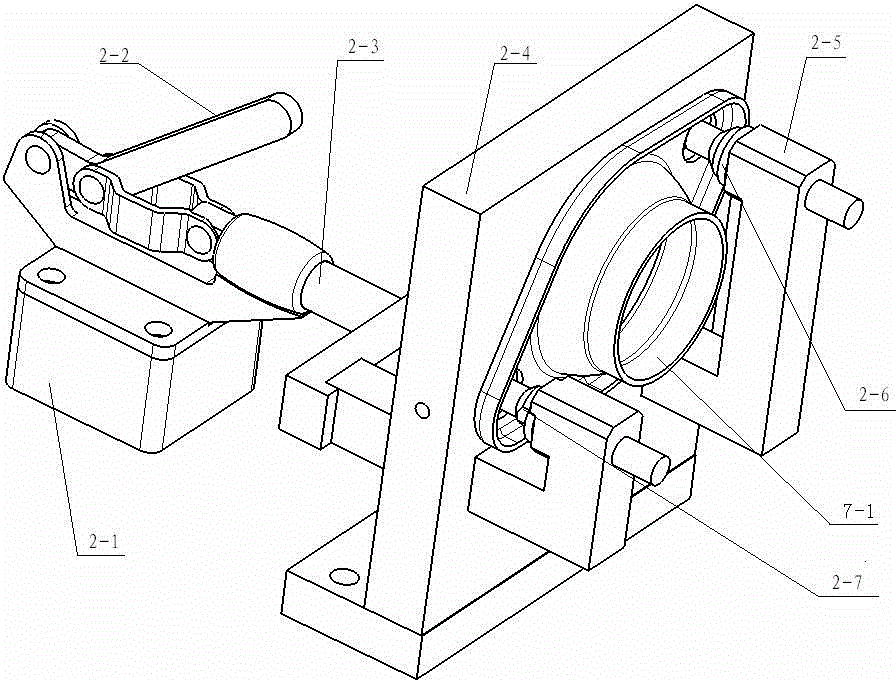

Inspection device for three-way catalyst assembly of automobile

ActiveCN103604335ASimple and fast operationImprove detection accuracyMechanical measuring arrangementsOxygen sensorEngineering

The invention discloses an inspection device for a three-way catalyst assembly of an automobile. The inspection device comprises a base, a benchmark positioning mechanism, a guide supporting mechanism, a support location detecting mechanism, an oxygen sensor base and hanging hook location detecting mechanism and a discharge flange detecting mechanism, wherein the benchmark positioning mechanism, the guide supporting mechanism, the support location detecting mechanism, the oxygen sensor base and hanging hook location detecting mechanism and the discharge flange detecting mechanism are respectively fixed on the base according to the mutual corresponding relations with the three-way catalyst assembly. The inspection device is easy and convenient to operate, high in detecting accuracy and capable of detecting whether a key assembly location satisfies the assembly requirements and tolerance design requirements, improving detecting tact and enhancing production efficiency.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

tolerance modeling method based on a peripheral Bezier parameter space

The invention discloses a tolerance modeling method based on a peripheral Bezier parameter space. An ideal workpiece is embedded into a peripheral Bezier parameter space, the workpiece is expressed through control points of the peripheral parameter space, the positions of the control points are changed, the peripheral parameter space is changed, and therefore the size, the shape and the position of the embedded workpiece are indirectly changed. By establishing a mathematical model between the offset of the peripheral space control point and the workpiece tolerance range, the offset of the peripheral control point can be solved within a given tolerance range, and finally a tolerance representation and statistical tolerance model under the worst condition is obtained. According to the method, the assembly property under the actual working condition can be judged according to the calculation result, the tolerance design result is verified and checked, and then product performance changesunder different assembly design tolerances can be predicted and judged; The modeling mode is not only suitable for dimensional tolerance modeling, but also suitable for form and location tolerance modeling; And meanwhile, the method is suitable for tolerance analysis and integration under the worst condition, and is also suitable for tolerance analysis and design under statistical significance.

Owner:SOUTHEAST UNIV

Tolerance analysis method for space dimension chain

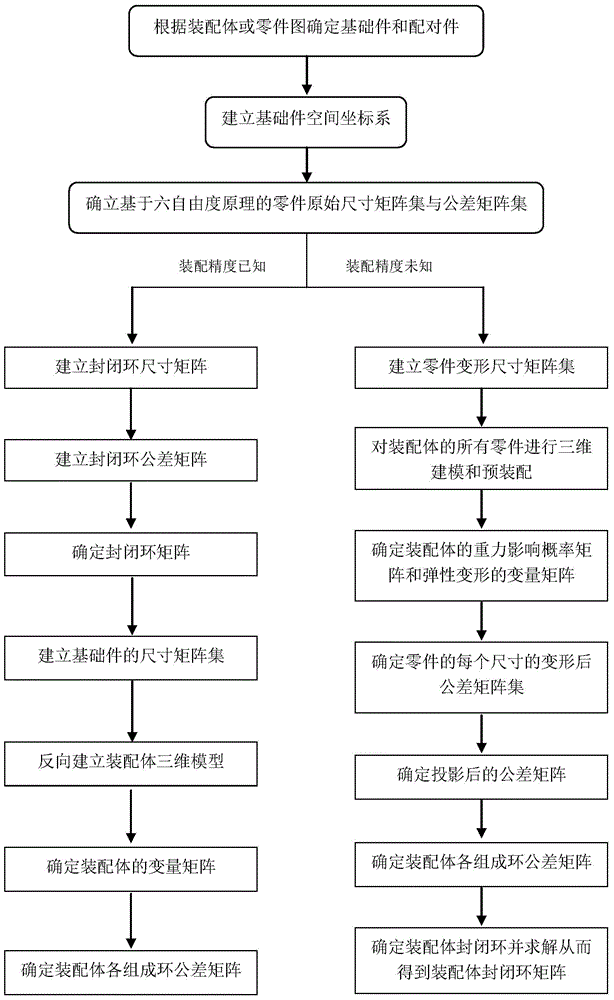

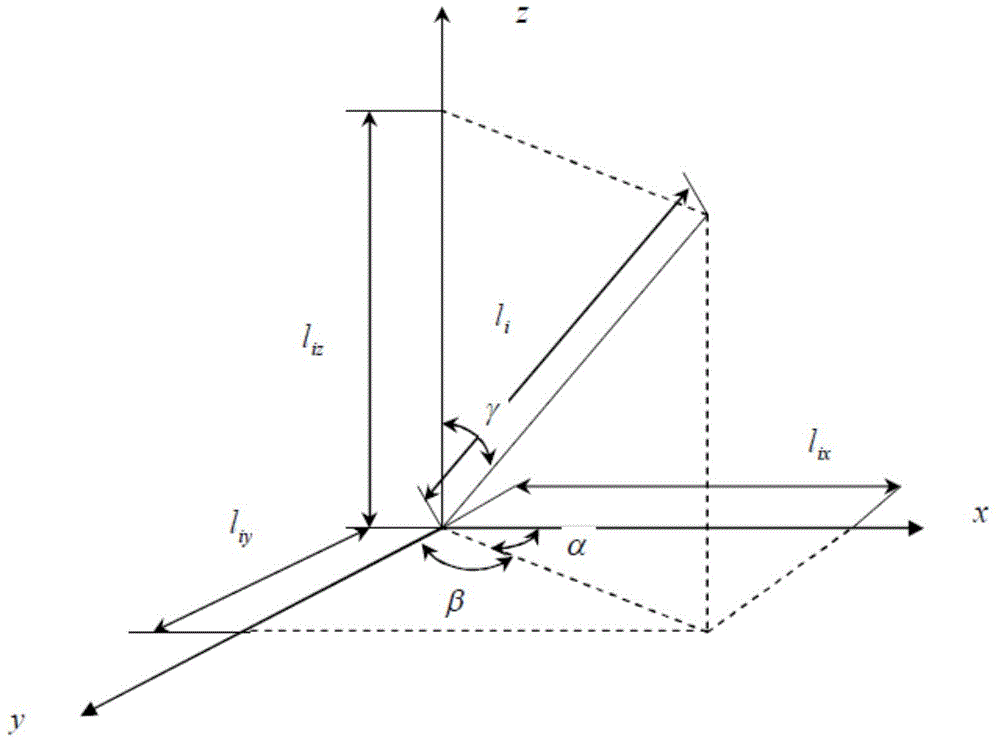

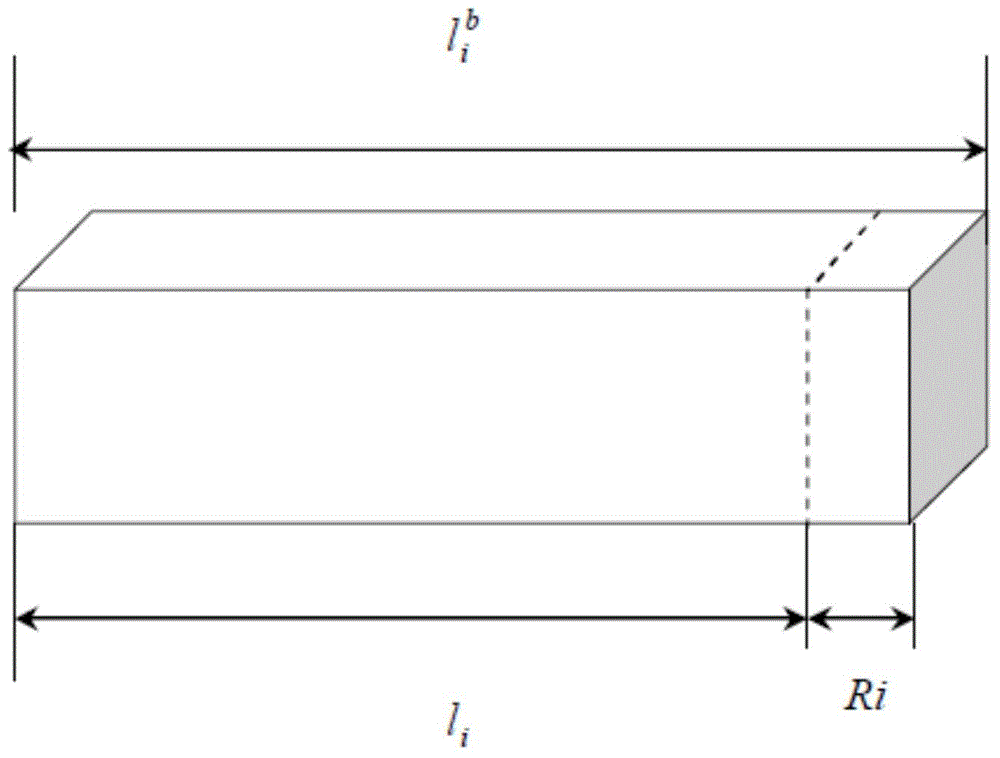

ActiveCN104834790ASolving Dimensional Chain ModelingEasy to calculateSpecial data processing applicationsElement analysisSimulation

The invention provides a tolerance analysis method for a space dimension chain. The method supports large-weight and large-size assembling. The method takes the self-weight and elasticity of a large-weight and large-size assembling body into account, utilizes matrix and three-dimension modeling and finite element analysis to construct a three-dimension space dimension chain, and fully takes the space change of the dimensions and dynamic compensation of assembling accuracy into account. The method utilizes the six degrees of freedom principle of space to construct the matrix and conducts optimized classification and balancing calculation on the space dimension chain, so the size and tolerance design of large-weight and large-size engineering equipment tends to be reasonable, the machining and installing difficulty is reduced, and manual costs are saved.

Owner:COSCO SHIPPING SHIPYARD (NANGTONG) CO LTD +1

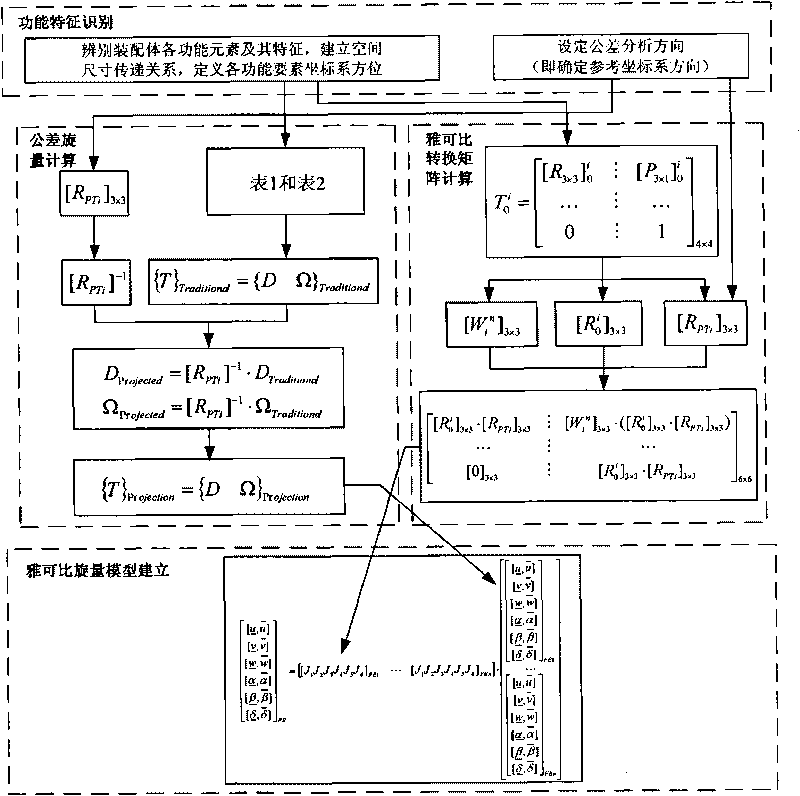

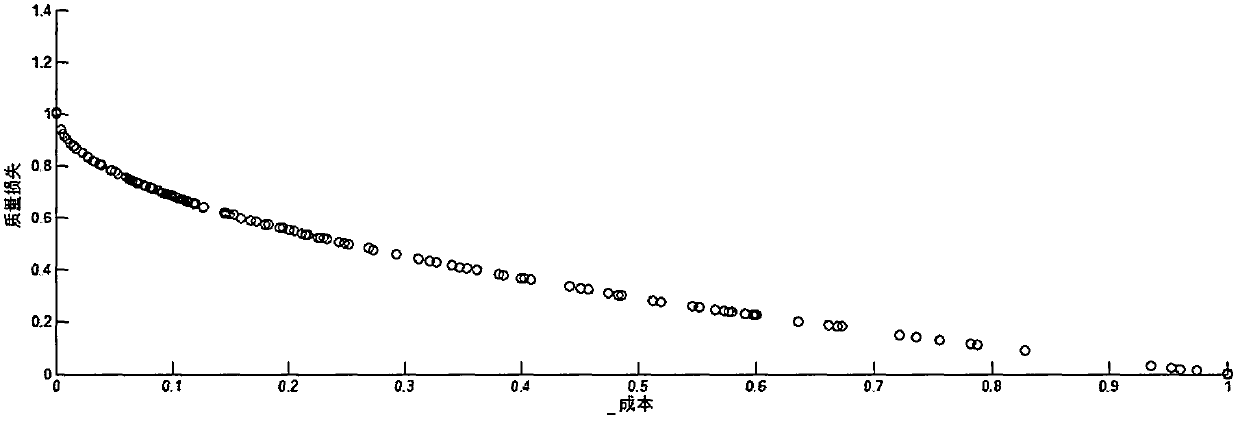

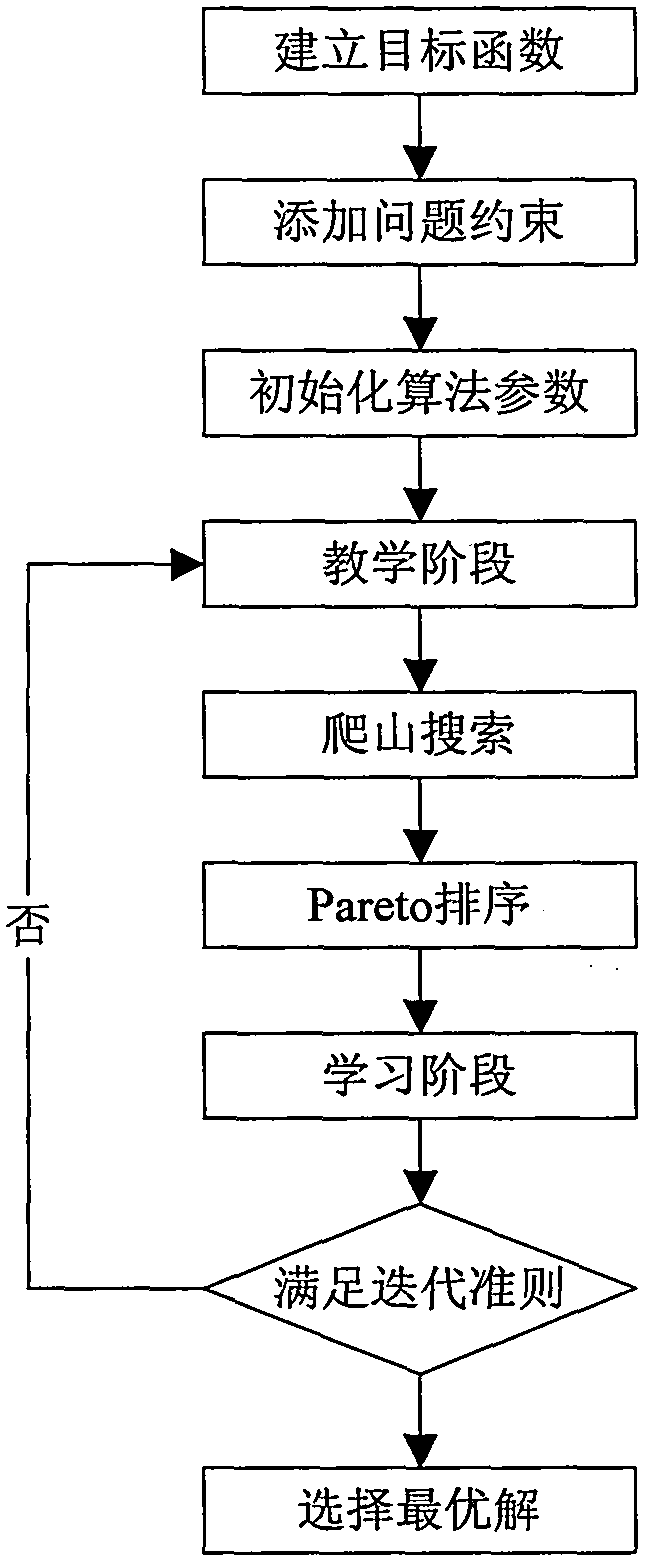

Assembly tolerance optimization method based on quality loss and cost minimization

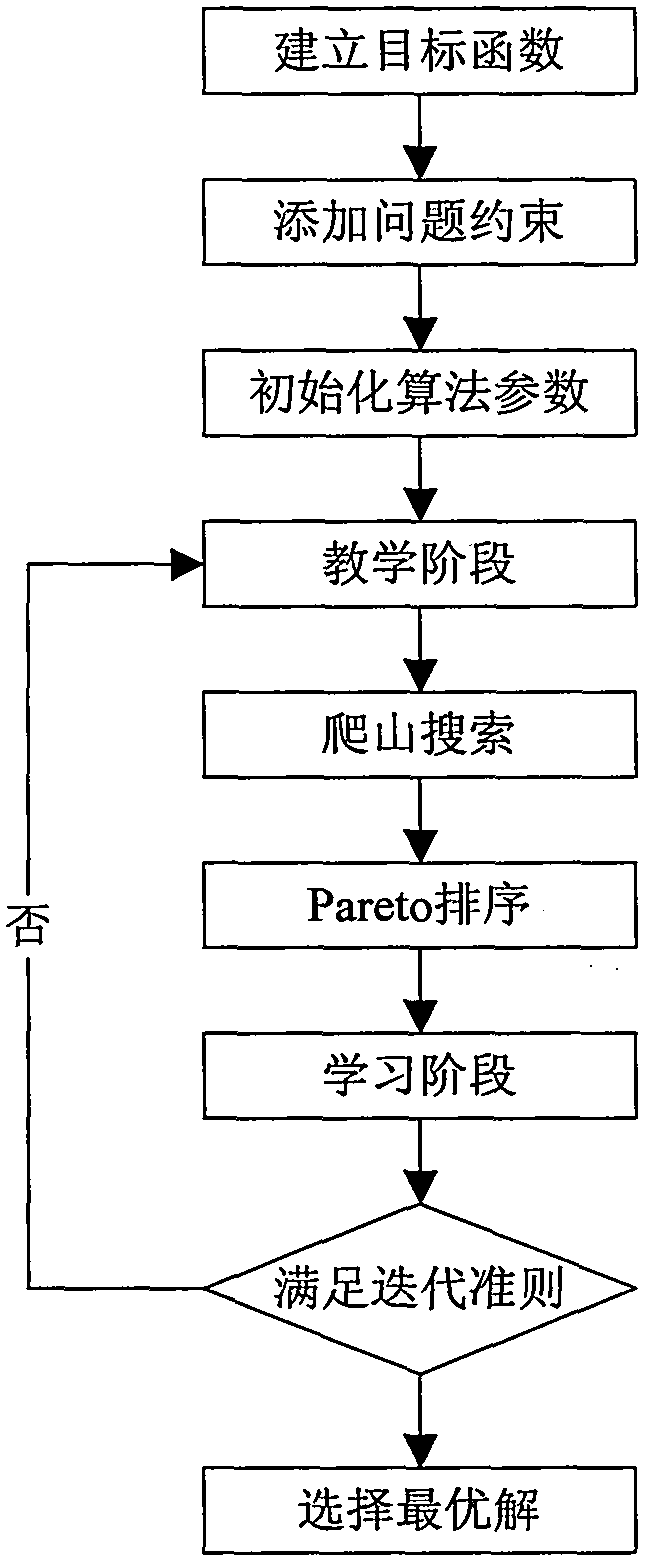

InactiveCN106960101AFew basic parametersCalculation results are stableGeometric CADDesign optimisation/simulationPareto rankingMathematical model

The invention relates to an assembly tolerance optimization method based on quality loss and cost minimization. The method mainly comprises the following steps: establishing a mathematical model of quality loss and processing cost; adding actual processing capability constraints; performing parameter initialization on a multi-objective teaching and learning algorithm; performing iteration in a teaching phase on an initial solution of the algorithm; adopting a hill-climbing search strategy to further develop the solution; performing Pareto ranking on a population; further studying the solution, and further increasing the accuracy of the solution; and completing the iterative process and finding the optimal solution. The assembly tolerance optimization method based on the quality loss and cost minimization provided by the invention is based on the computer technology, and combines the swarm intelligent optimization algorithm in the field of artificial intelligence, which further improves the calculation efficiency and calculation accuracy of assembly tolerance design, and aims to satisfy the design accuracy under precision manufacturing, improve the production efficiency, and improve the parts quality, so as to further reduce the production cost.

Owner:SHANGHAI UNIV

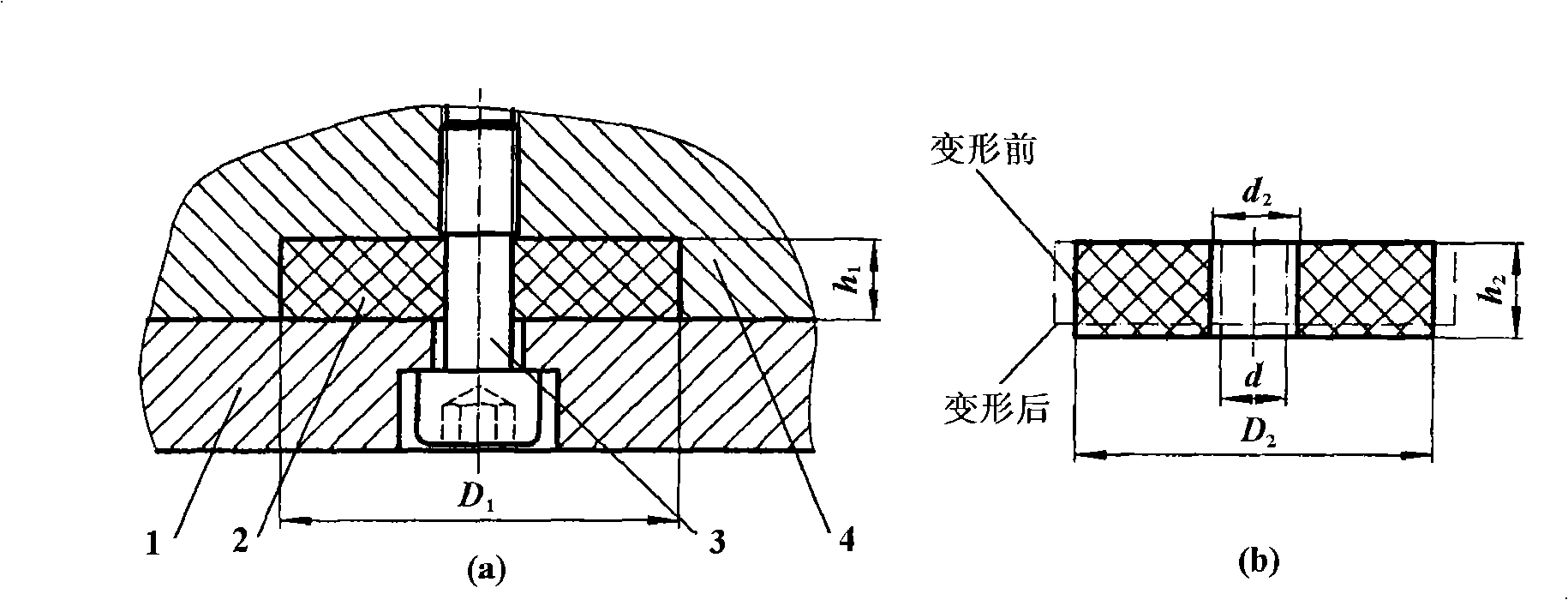

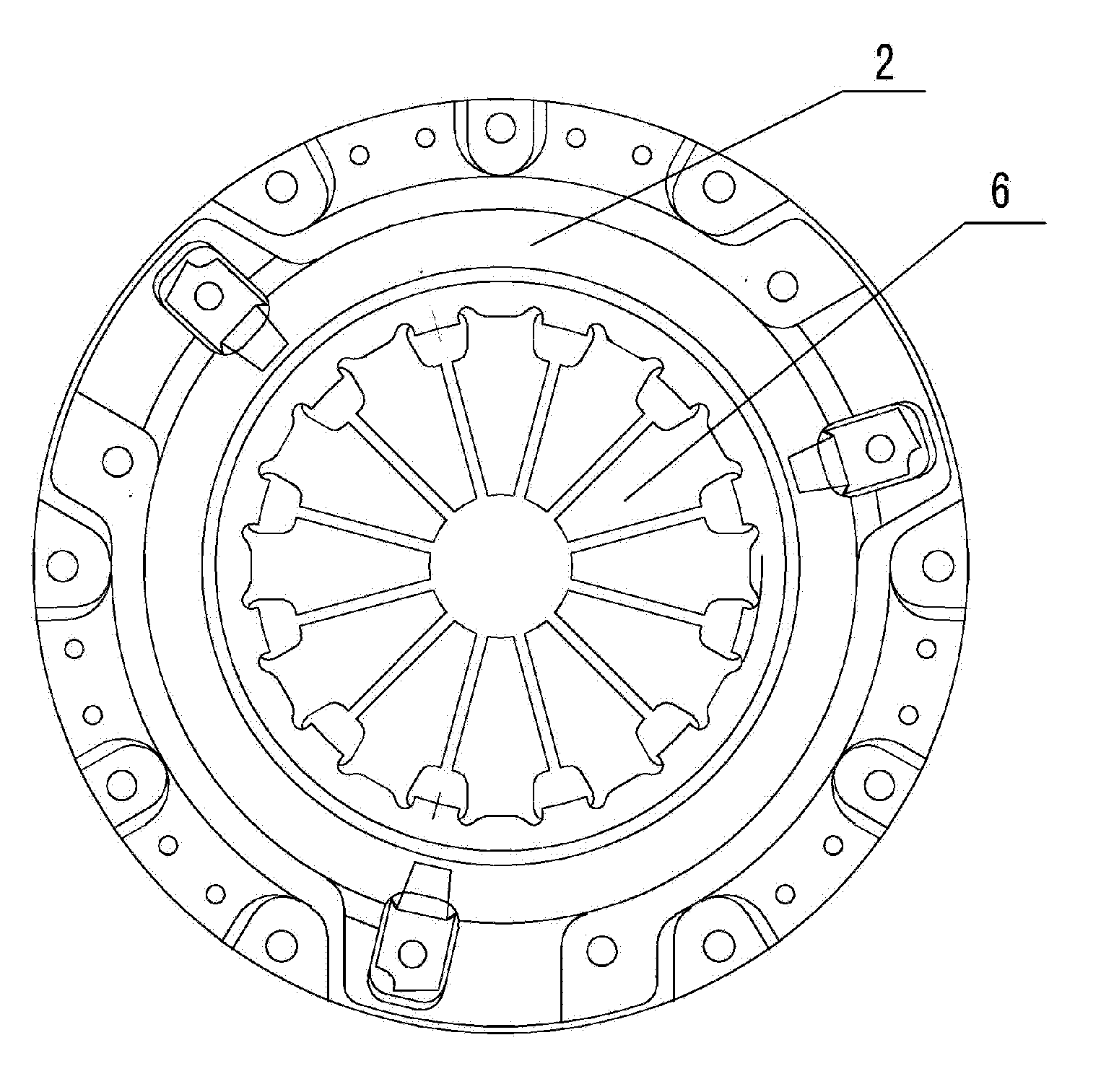

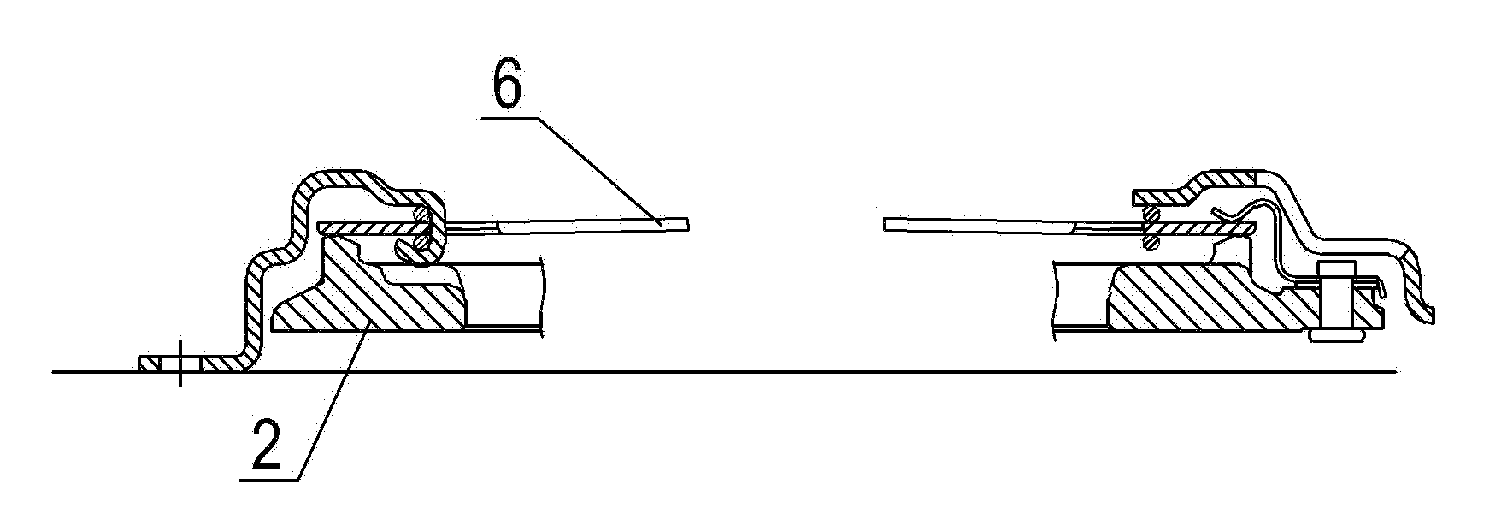

Separation finger jumping correction and detection device for automobile diaphragm spring clutch

ActiveCN102626858AGuaranteed runoutReliable methodMeasurement devicesMetal working apparatusEngineeringControl theory

The invention discloses a separation finger jumping correction and detection device for an automobile diaphragm spring clutch, which is characterized in that the separation finger jumping correction and detection device is provided with a working platform, a limit mechanism, a correction mechanism and a detection mechanism; and when the separation finger jumping correction and detection device is in use, firstly, the connection height of a separation finger of the diaphragm spring clutch is controlled in the range of (L-1)+ / -1 by the product and tolerance design and then correction and detection are carried out, wherein in the correcting and detecting process, a jack screw is driven by a servo motor, the separation finger of the diaphragm spring clutch is jacked upward to be deformed, the connection height of the separation finger reaches the specified size range by the deformation, the separation finger is ensured to jump in the specified tolerance range and L represents a separation finger connection height standard value. According to the invention, the requirement on the jumping of the separation finger of the diaphragm spring clutch can be met and reliable data of each separation finger connection height is provided.

Owner:HUBEI TRI RING CLUTCH

Machine tool assembling joint surface design method capable of taking deformation error compensation as target

ActiveCN105956303ASimple structureScientific and quantitative anti-deformation designGeometric CADDesign optimisation/simulationEngineeringEntity model

The invention discloses a machine tool assembling joint surface design method capable of taking deformation error compensation as a target. The method comprises the following steps: in CAD (Computer Aided Design) software, according to statics analysis requirements and the structural characteristics of a machine tool, carrying out structure simplification; then, carrying out parameterized assembling on a machine tool entity model; importing the entity model subjected to the simplification and the parameterized assembling into finite element analysis software Ansys Workbench; creating a container capable of carrying out automatic analysis and extraction deformation by utilizing the software, carrying out orthogonalization of a processing spatial position and mesh generation, and meanwhile, finishing statics analysis and result storage; then, through data learning, obtaining the practical deformation amount of a machine tool assembling nominal joint surface under a situation that whole processing space deformation is considered; flipping the obtained practical deformation amount, adding the flipped amount and the nominal joint surface to serve as an actively designed machine tool assembling joint surface; and on the basis of a Monte Carlo method and a least square method, finishing profile tolerance design of the assembling joint surface with the combination of a data regression technology.

Owner:XI AN JIAOTONG UNIV

Robust design method for a textile-manufacturing-dedicated, high-efficient, energy-saving, multiphase asynchronous motor

ActiveUS20150127303A1Improve efficiencyIncrease powerAerodynamics improvementComputer aided designMathematical modelWire cutting

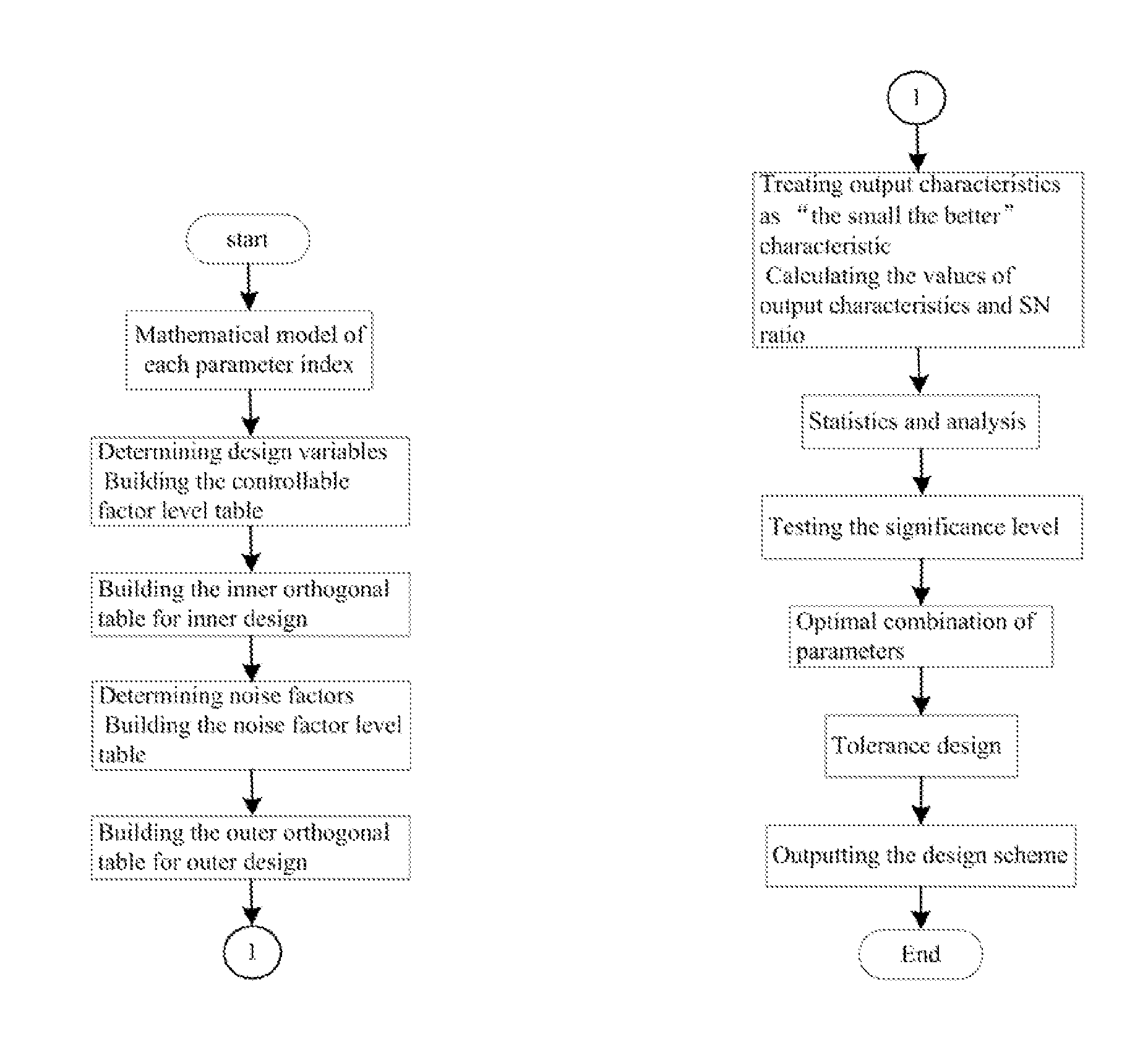

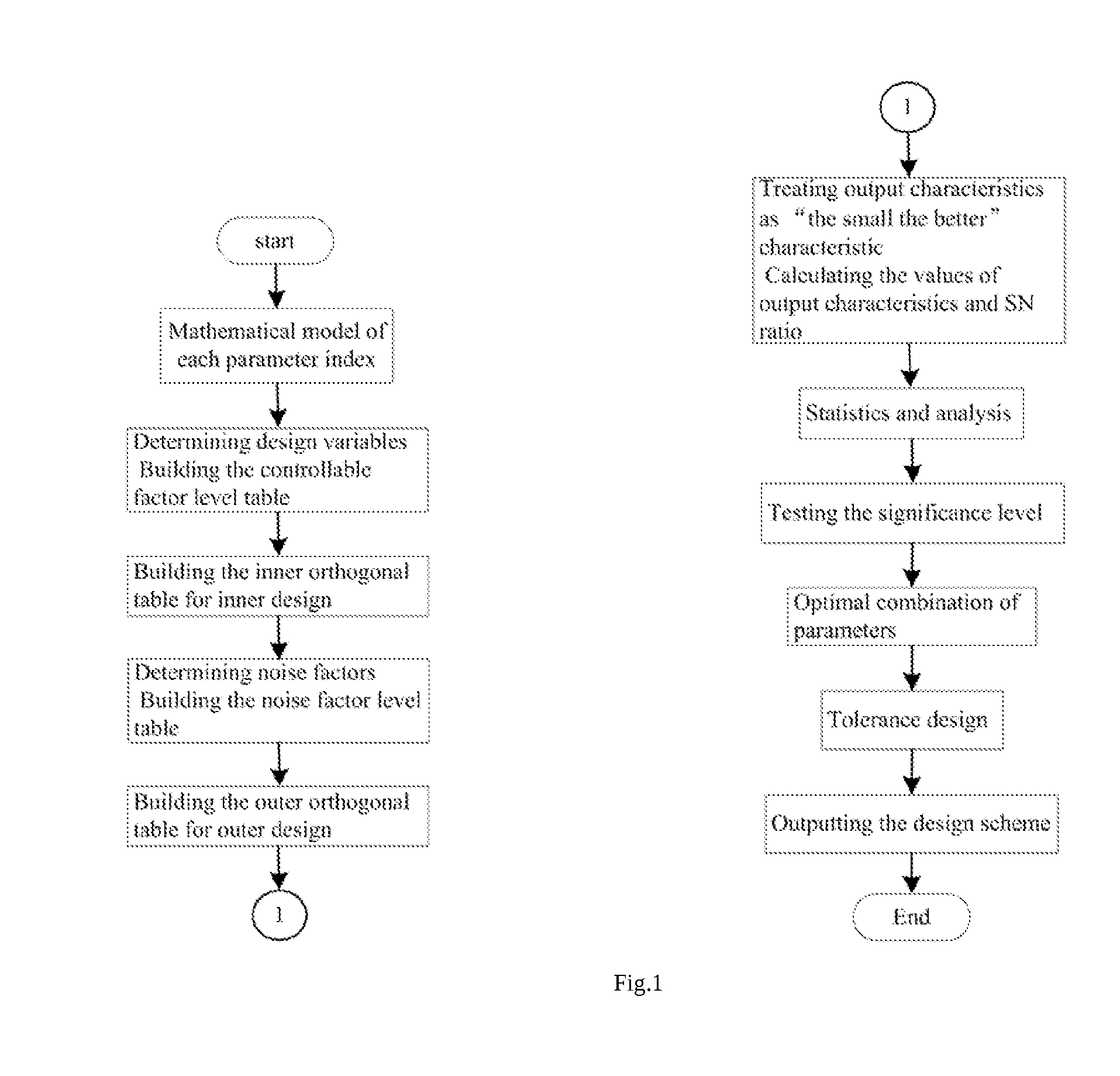

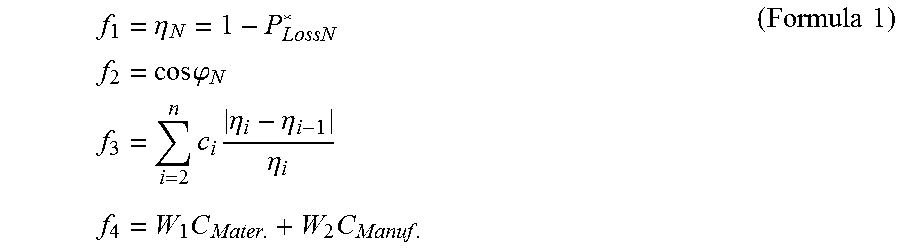

A robust design method for a textile-manufacturing-dedicated, high-efficient, energy-saving, multiphase asynchronous motor, includes the following steps: designating a motor; designating design method; designating design variables of the high-efficient, energy-saving, multiphase asynchronous motor; building mathematical models of each index respectively to constitute a robust design model with multiple indexes; building the controllable factor level table; selecting appropriate orthogonal table according to the number of the optimizing variables and the level number of each variable; building an inner orthogonal table for inner design; building an outer orthogonal table for outer design; computing the values of the output characteristics and signal to noise ratio of the experimental schemes determined by the inner and outer orthogonal tables; determining the optimal combination of parameters; going through tolerance design; drawing the parts of the textile-manufacturing-dedicated, high-efficient, energy-saving, multiphase asynchronous motor according to the optimal design scheme, wire-cutting the mold, dieing, laminating, coiling, inserting windings, dipping paint and assembling. Combining the actual operating characteristics of textile-manufacturing-dedicated motor, a high-efficient, energy-saving, multiphase asynchronous motor with stable performance, reliable operation and low cost is achieved. The motor achieves the optimal balance between the quality and cost, and enhances the market competitiveness.

Owner:TIANJIN POLYTECHNIC UNIV

Tolerance management system and management method

PendingCN111931340ASimple designImprove management abilityGeometric CADSustainable transportationData streamBusiness enterprise

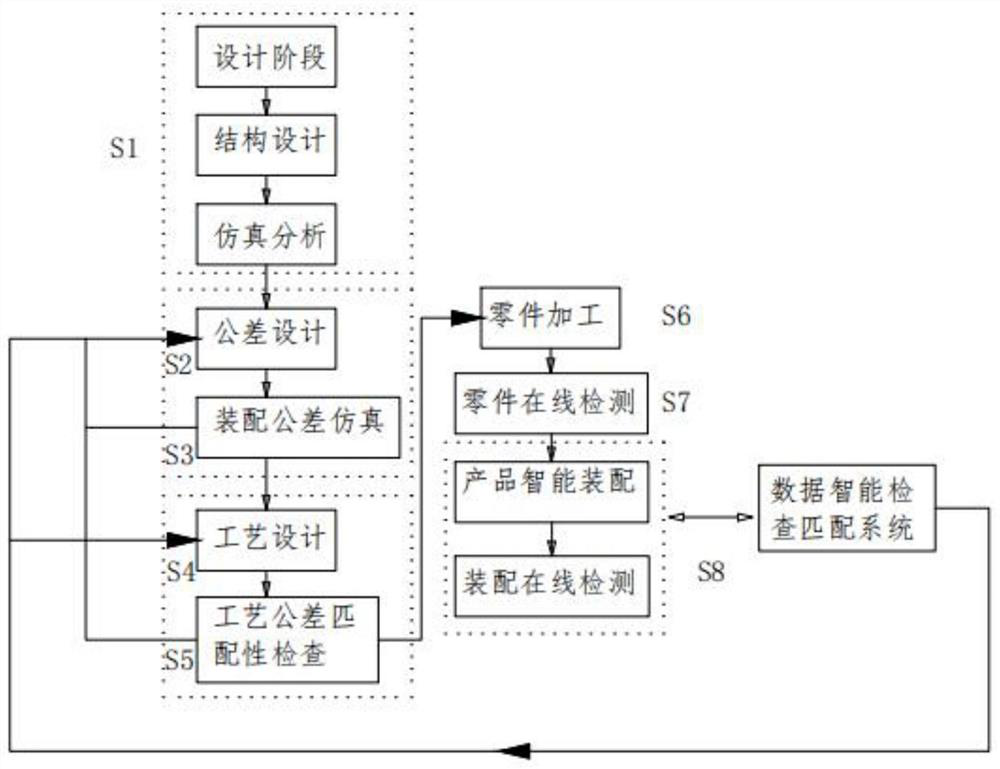

The invention discloses a tolerance management system and a tolerance management method. The method is used for enterprises to manage product appearance (gap and surface difference), noise, vibration,assembly interference, poor product interchangeability, long manufacturing period and low product qualification rate caused by tolerance in product design and manufacturing stages. According to the solution, tolerance is taken as an entry point, and analysis and feedback are established for detection data of a product in a design stage and a manufacturing stage of the product, so that closed-loopcyclic feedback of a size data flow from design to manufacturing to design is realized; whole-process tracking and management of product part dimensional tolerance from design to process, to manufacturing and then to detection are realized; the capacity of dimensional tolerance design and management of enterprises is continuously improved, and the iterative efficiency of product structure designoptimization is improved. Therefore, the consistency of products is improved, the assembly quality and the assembly efficiency are improved, the design robustness and the product quality stability areimproved, and finally the purposes of improving the quality, reducing the cost, increasing the batch and shortening the period are achieved.

Owner:重庆诚智鹏科技有限责任公司

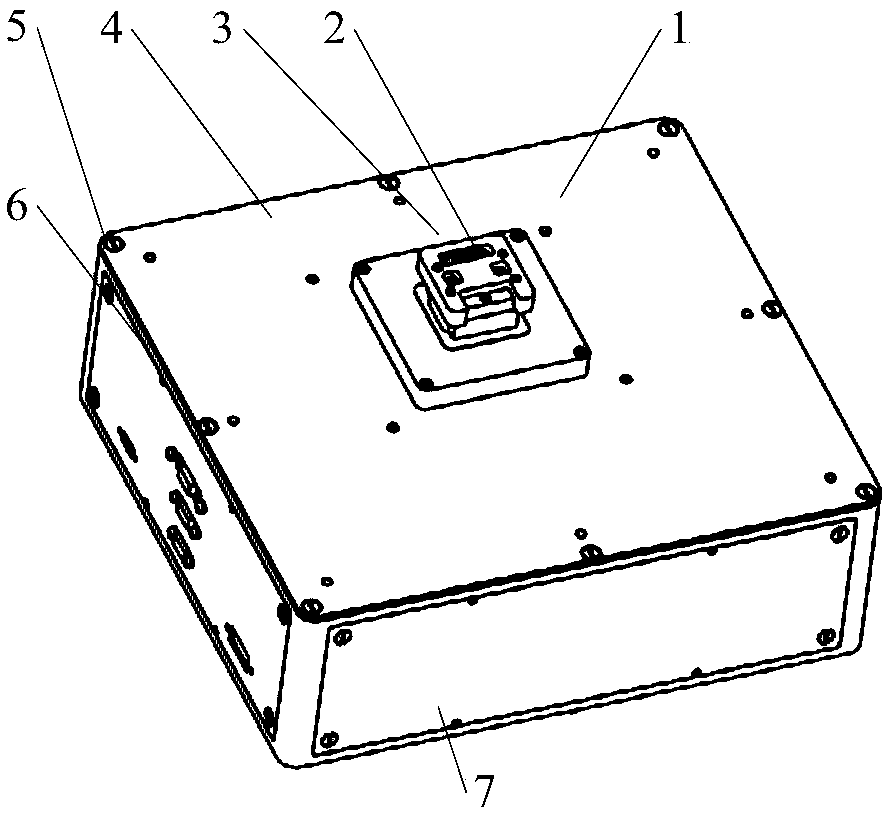

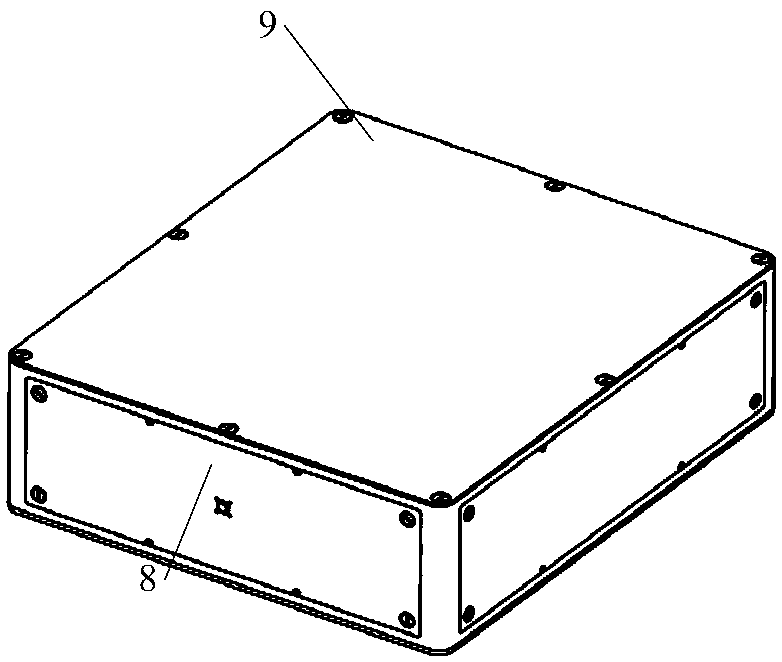

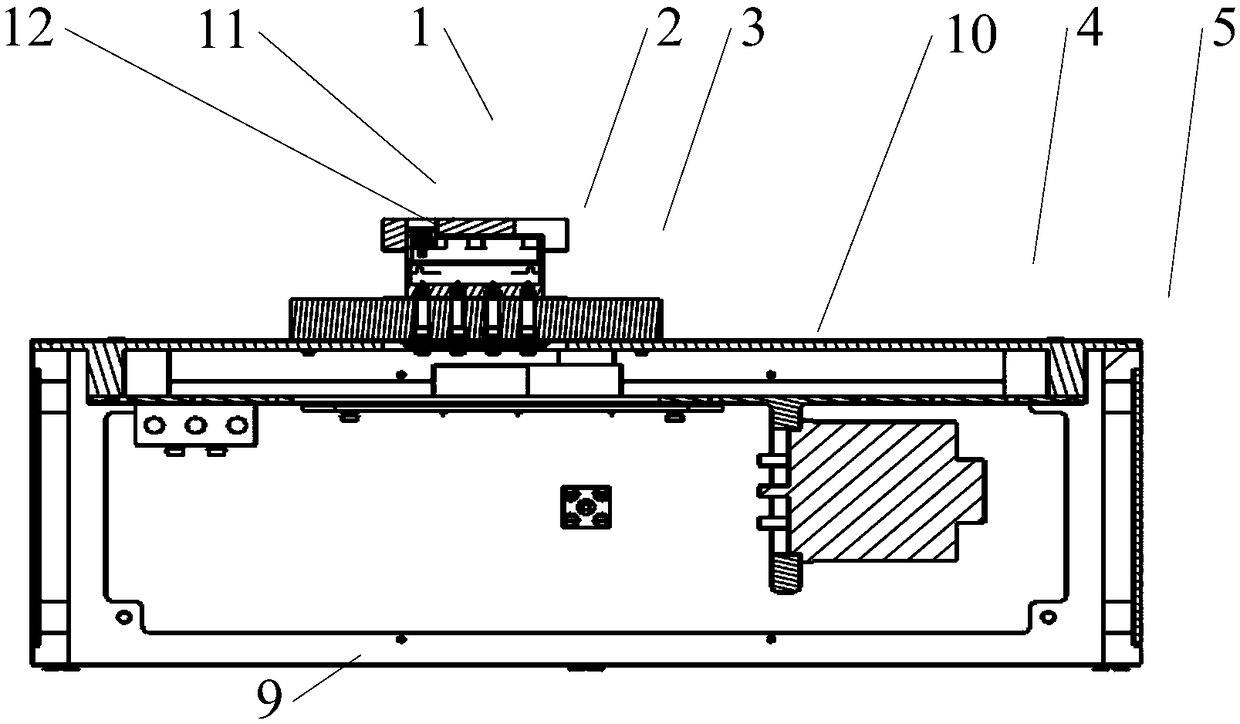

T/R module automatic test system structure

ActiveCN109407063ACompact structureWave based measurement systemsTest efficiencyElectrical performance

The present invention discloses a T / R module automatic test system structure. The structure comprises a pressing plate, a heat conduction pad, a cold plate, an upper cover plate, a frame, an A panel,a side cover plate, a B panel, a bottom plate and a device installation plate. A standard piece is employed to connect with the cold plate, the heat conduction pad, a T / R module, the pressing plate and the upper cover plate, an upper end of a KK joint is inserted into the T / R module through circular holes of the upper cover plate and the cold plate, and the test system is inserted into the lowerend of the KK joint to form an access. Through the dimensional tolerance design of the cold plate, the KK joint and the T / R module, the high-precision mutual insertion is achieved to ensure the electrical performances. The test system is installed on the installation plate. The A panel, the B panel, the side cover plate and the bottom plate are connected with an assembling structure on the frame to achieve the automatic test function of the T / R module. The system is compact in structure, convenient to implement and low in cost, simulates the T / R module working scene in high precision, improvesthe test efficiency of the T / R module and ensures the test reliability.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

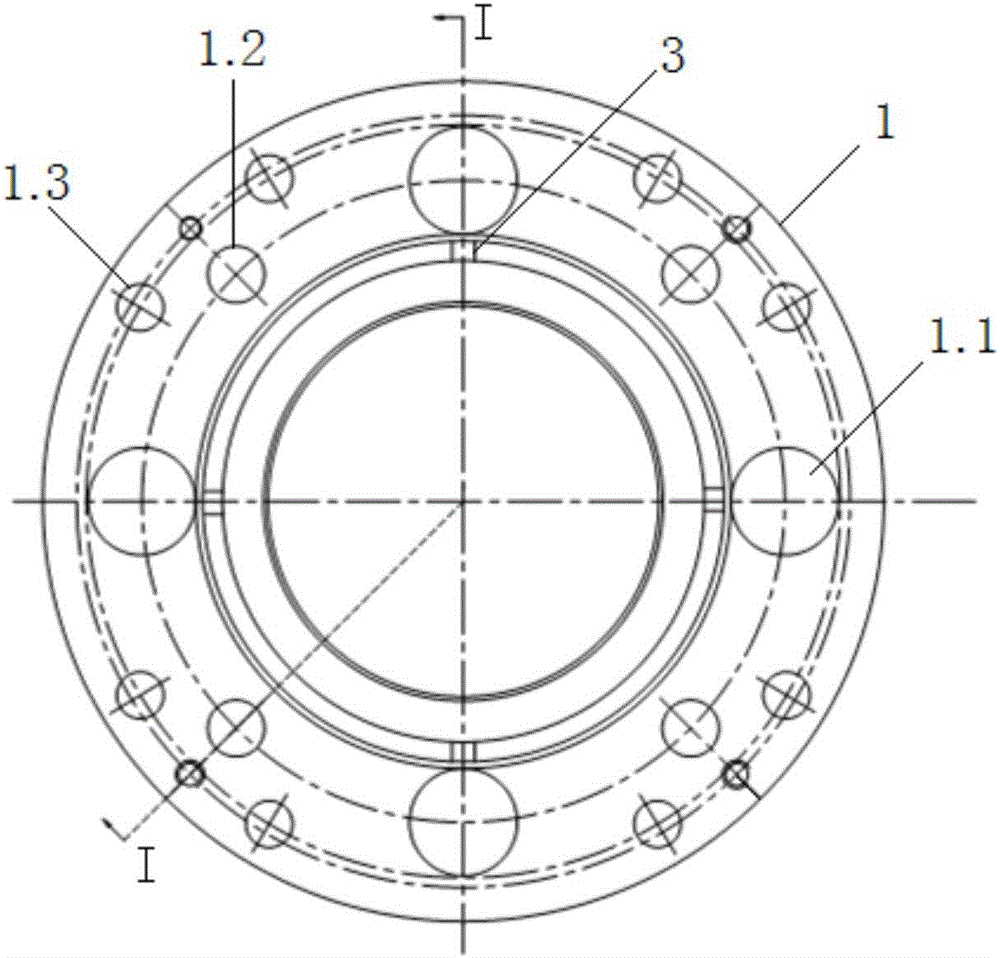

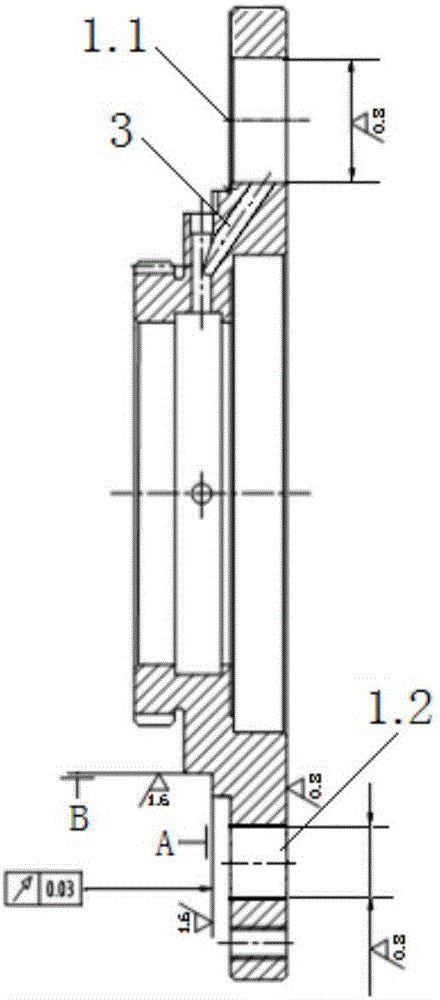

Split type high-precision planet carrier and manufacturing method thereof

ActiveCN107178607AGuaranteed machining accuracyPositioning accuracy unchangedGearing detailsEngineeringTolerance design

The invention provides a split type high-precision planet carrier and a manufacturing method of the split type high-precision planet carrier. The split type high-precision planet carrier comprises a primary planet carrier and a secondary planet carrier. The primary planet carrier comprises a circular main disk with a center hole, the secondary planet carrier comprises a circular main disk with a center hole, and planet gear shaft holes, planet carrier locating pin holes and planet carrier bolt holes are formed in each main disk and located in a one-to-one correspondence mode. Three concentric stepped convex circles are arranged on one side of the secondary planet carrier in a protruding mode, and the middle convex circle can be used for supporting the planet carrier. The primary planet carrier and the secondary planet carrier are fastened together. When the split type high-precision planet carrier is manufactured, the independent part size element, roughness element and geometric tolerance element machining of the primary planet carrier, the secondary planet carrier and locating pins is conducted according to the standards of the parts; the locating pin holes are formed in the state that the primary planet carrier and the secondary planet carrier are combined after exquisite alignment of the standards is accomplished; and finally centering alignment, machining and locating are conducted to accomplish the size and geometric tolerance design of the planet gear shaft holes. The split type high-precision planet carrier and the manufacturing method of the split type high-precision planet carrier solve the problem that disassembling, assembling, adjustment and machining of a split type high-precision planet carrier assembly cannot be conducted, and can guarantee that the supporting and locating accuracy of the primary planet carrier and the secondary planet carrier is unchanged after the planet carrier is disassembled and assembled repeatedly.

Owner:CHINA NORTH VEHICLE RES INST

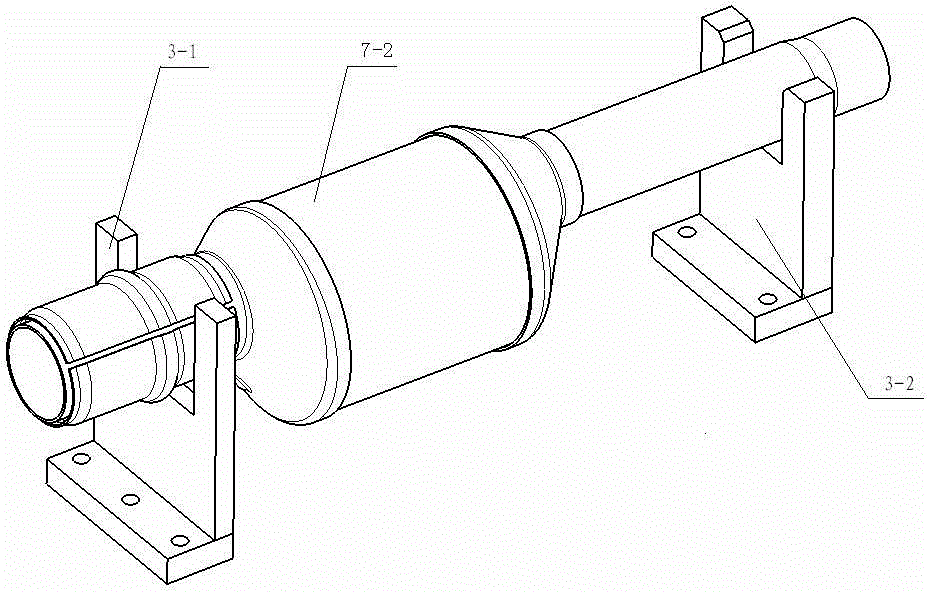

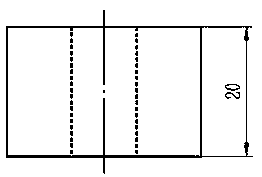

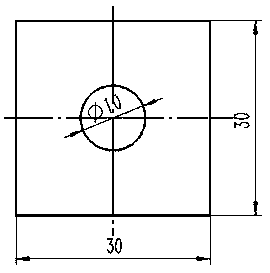

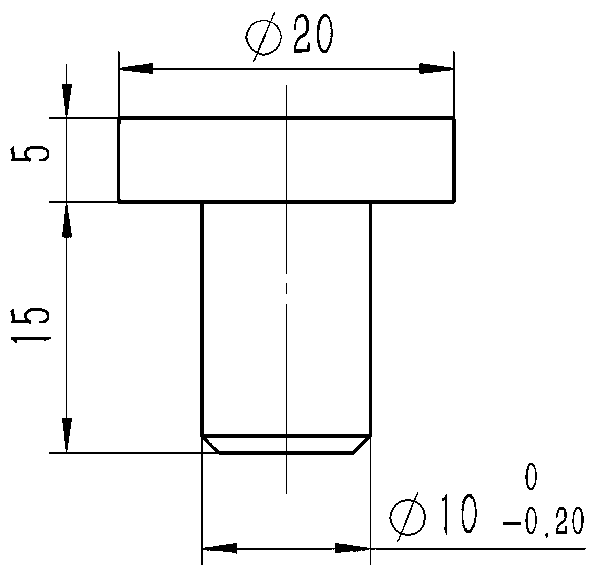

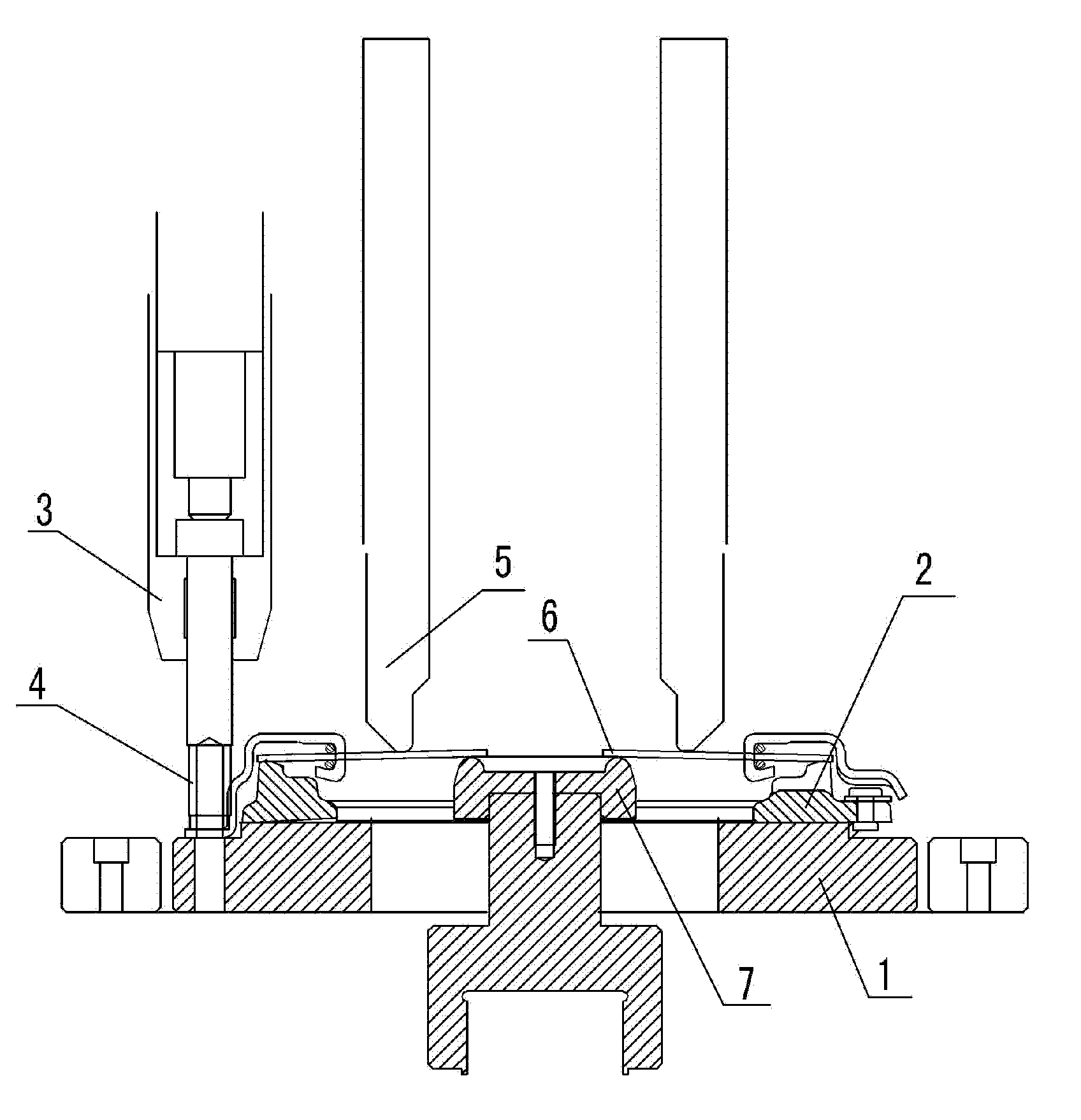

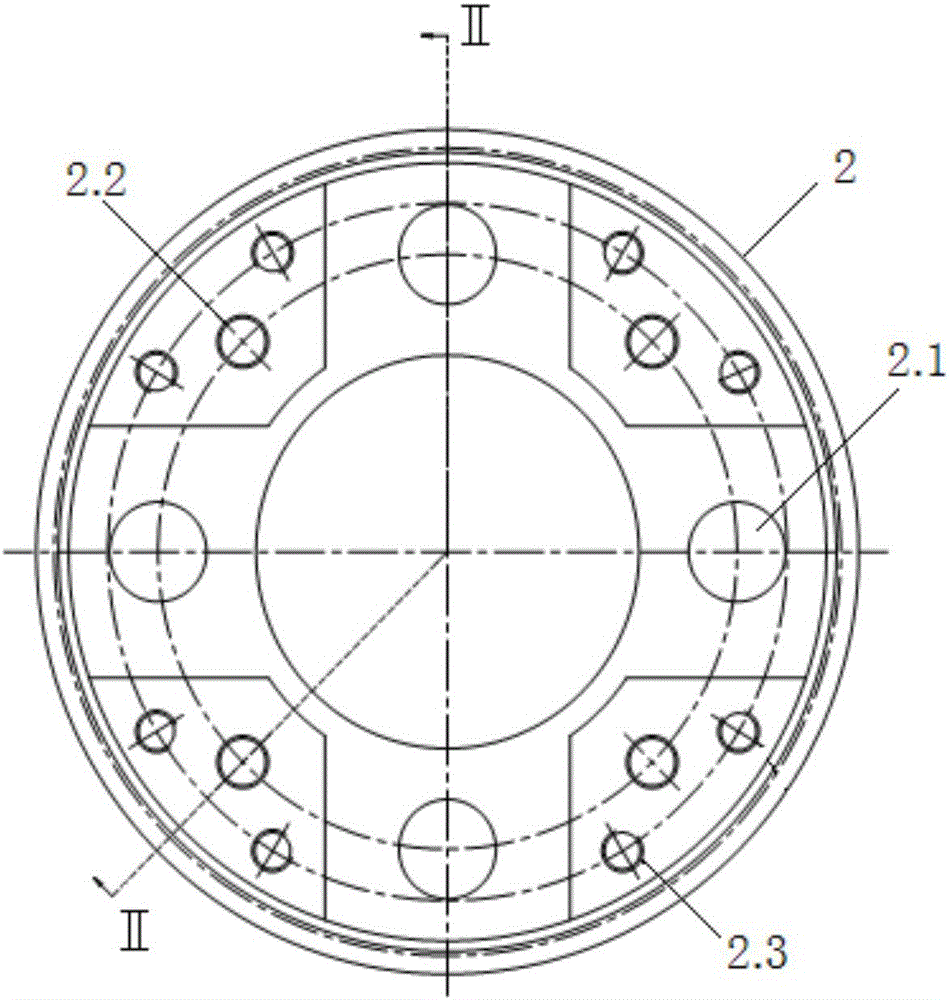

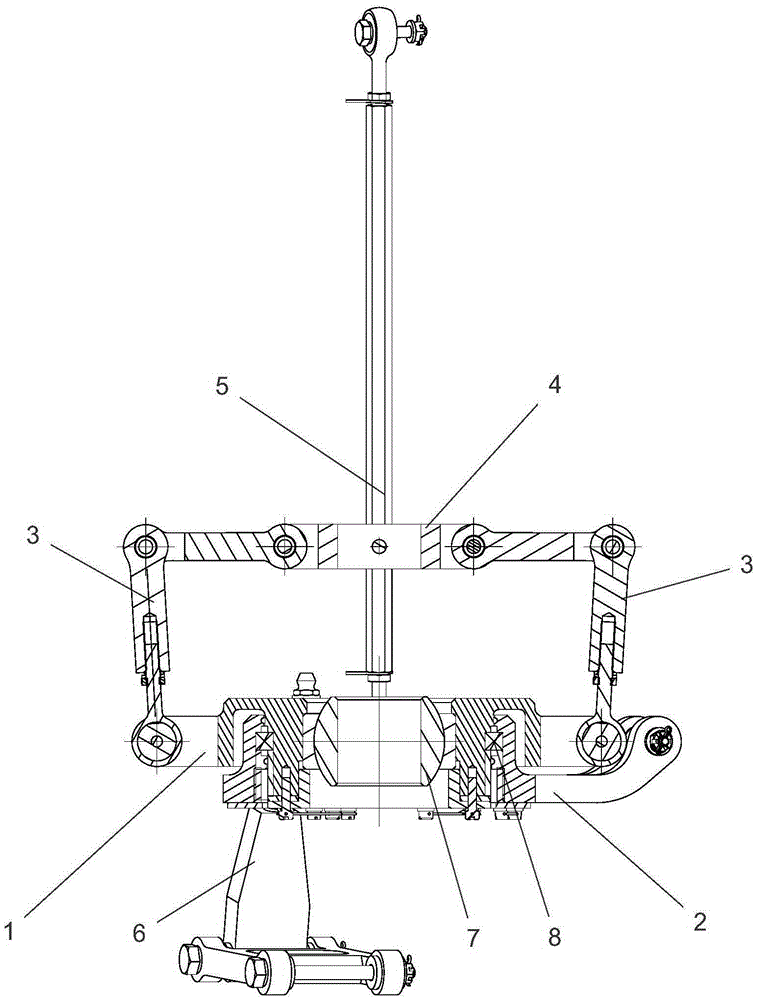

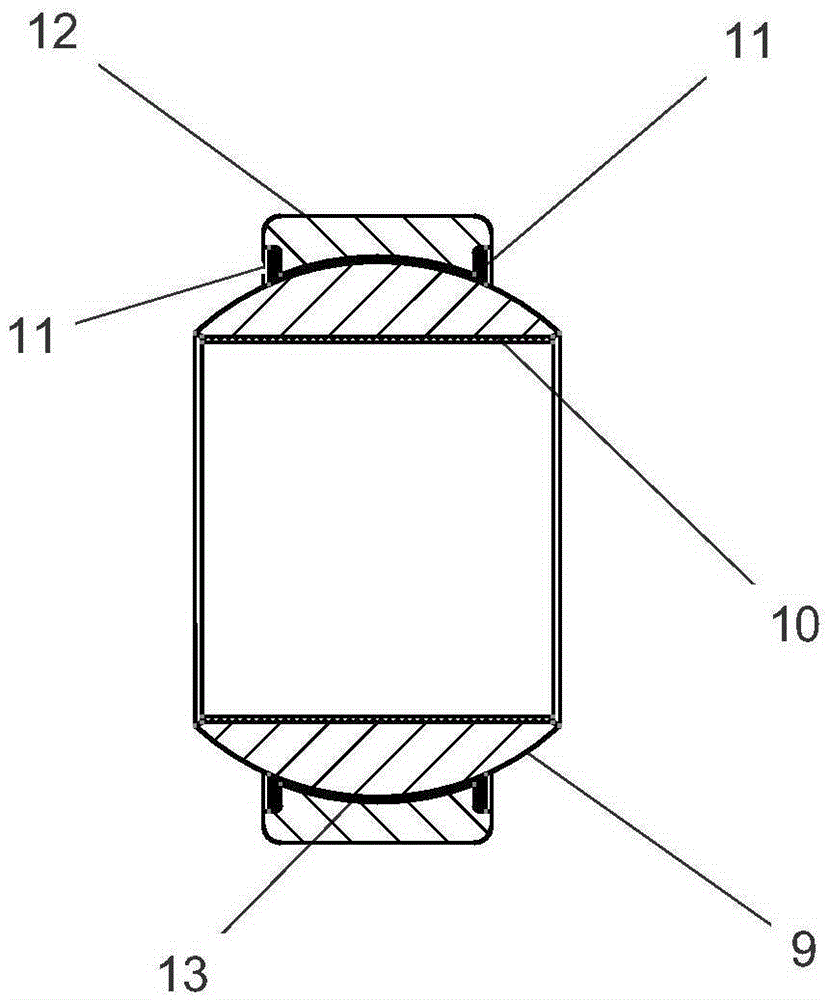

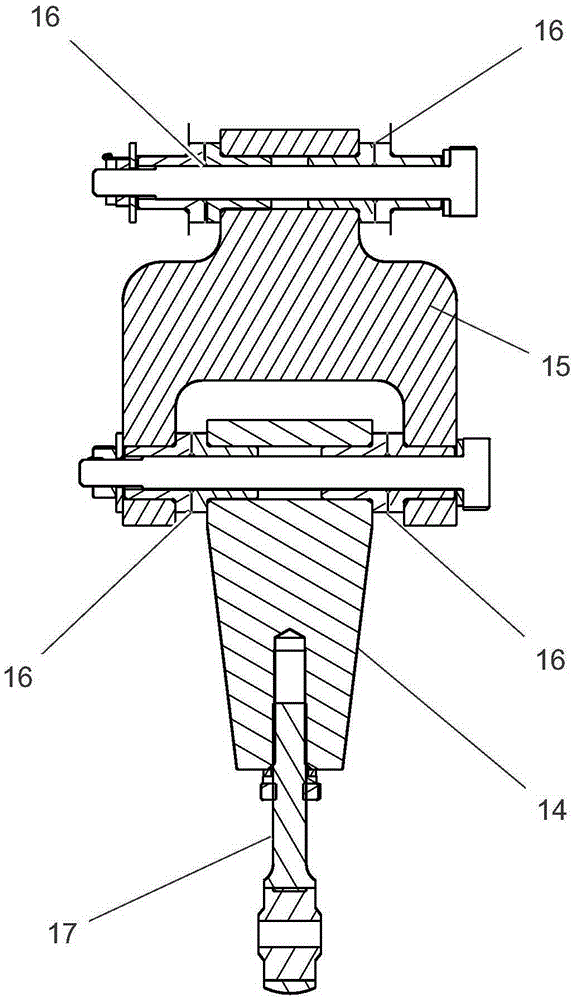

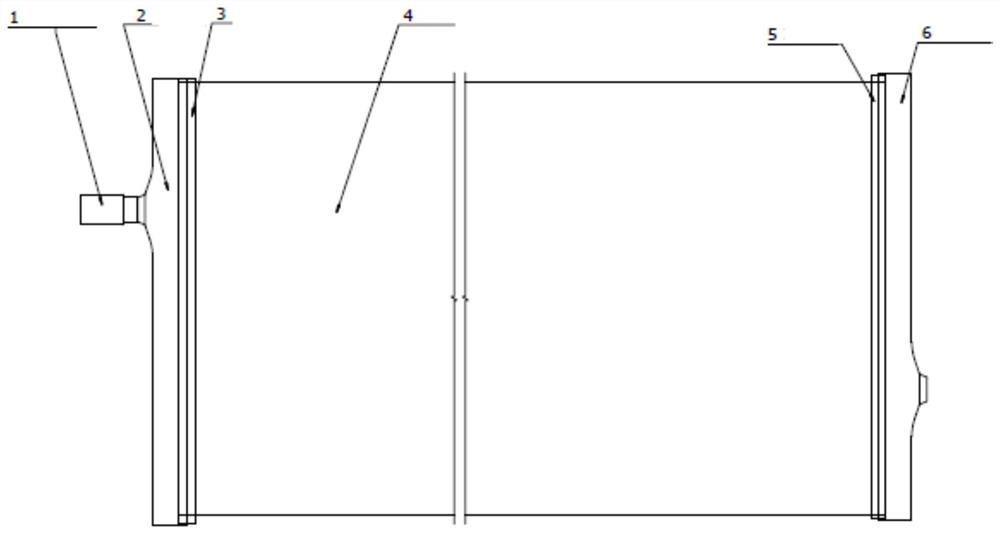

Guide cylinder-free automatic inclinator of unmanned helicopter

The invention belongs to the design of a helicopter automatic inclinator, and in particular relates to a guide cylinder-free automatic inclinator which is an important part of a light unmanned helicopter rotor system. The guide cylinder-free automatic inclinator of the unmanned helicopter is characterized by comprising moving rings (1), a fixed ring (2), variable pitch pull rod components (3), torque arm components (4), a snap ring (5), an anti-torque arm component (6) and spherical hinge components (8). According to a set of the guide cylinder-free automatic inclinator provided by the invention, the spherical hinge components and self-lubricating bushings of special structures are selected to reduce the design of high-cost parts of guide cylinders, wear-resistant bushings and the like, and the guide cylinder-free automatic inclinator has the advantages of simple structure, light weight, convenience in use and maintenance and the like. Clever part tolerance design is adopted, so that the use of wear-resistant washers at part assembling interfaces is canceled to control transverse gaps of the assembling interfaces between the torque arm parts and the anti-torque arm parts to effectively improve the reliability and prolong the fatigue life of the whole automatic inclinator and lower the design and manufacture costs.

Owner:CHINA HELICOPTER RES & DEV INST

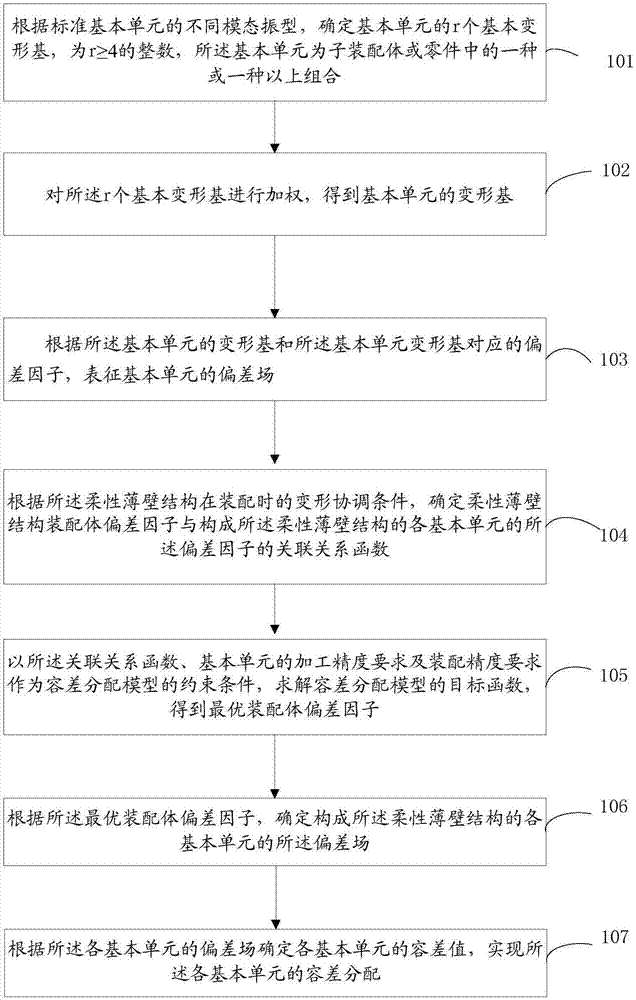

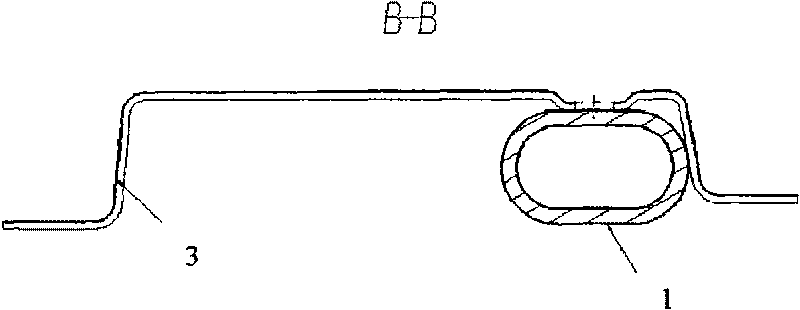

Tolerance distribution method and device for flexible thin-wall structure based on deformed base

ActiveCN107153727ASolving Tolerance Design IssuesAchieve forecastGeometric CADDesign optimisation/simulationDistribution methodBias field

The invention discloses a tolerance distribution method and device for a flexible thin-wall structure based on a deformed base, and belongs to the technical field of machine manufacturing. According to the tolerance distribution method for the flexible thin-wall structure based on the deformed base provided by the invention, a modal shape forming a basic unit of an assembly is selected as a basic deformed base, a bias field is represented by using the deformed base and a corresponding bias factor, the relevance of the bias factor of the assembly and the bias factor of the basic unit is used as one item in constraint conditions, an objective function for a tolerance allocation model is solved, and an optimal bias factor of the assembly is solved, so that prediction and control for the bias factor of each basic unit of the assembly are realized, and the tolerance design problem of the flexible large thin-film structure can be solved. Tolerance values are allocated for each basic unit, so that the measuring efficiency and the assembling quality of the product are effectively improved.

Owner:CAPITAL AEROSPACE MACHINERY +1

Method for welding automotive anti-rolling steel tube and A column reinforcement plate

ActiveCN101758318AGuaranteed manufacturing tolerancesGuaranteed clamping errorArc welding apparatusWorkpiece edge portionsArchitectural engineeringEngineering

The invention discloses a method for welding an automotive anti-rolling steel tube and an A column reinforcement plate. The A column reinforcement plate comprises an upper reinforcement plate and a lower reinforcement plate. The A column reinforcement plate and the steel tube are positioned by molding surfaces. A certain welding manufacture gap is formed between the steel tube and two sides of the upper reinforcement plate. One side of the lower reinforcement plate contacts the steel tube, and the steel tube is welded on the A column reinforcement plate under the condition that the other side of the lower reinforcement plate is not contacted with the steel tube. The welding method has the following advantages: a tolerance design is adopted for the welding between the A column reinforcement plate and the steel tube, so that a design gap is formed between the A column reinforcement plate and the steel tube, and a manufacturing error and a clamping error of the steel tube (with a curvature) are guaranteed; the A column steel tube and the A column reinforcement plate are positioned by the molding surfaces, the welding is more firm and the requirement on complete automobile performance is met due to a plug welding mode; the welding method can guarantee welding precision and assembly, realizes the welding technology, also can improve the welding strength of the steel tube and has more firm welding.

Owner:CHERY AUTOMOBILE CO LTD

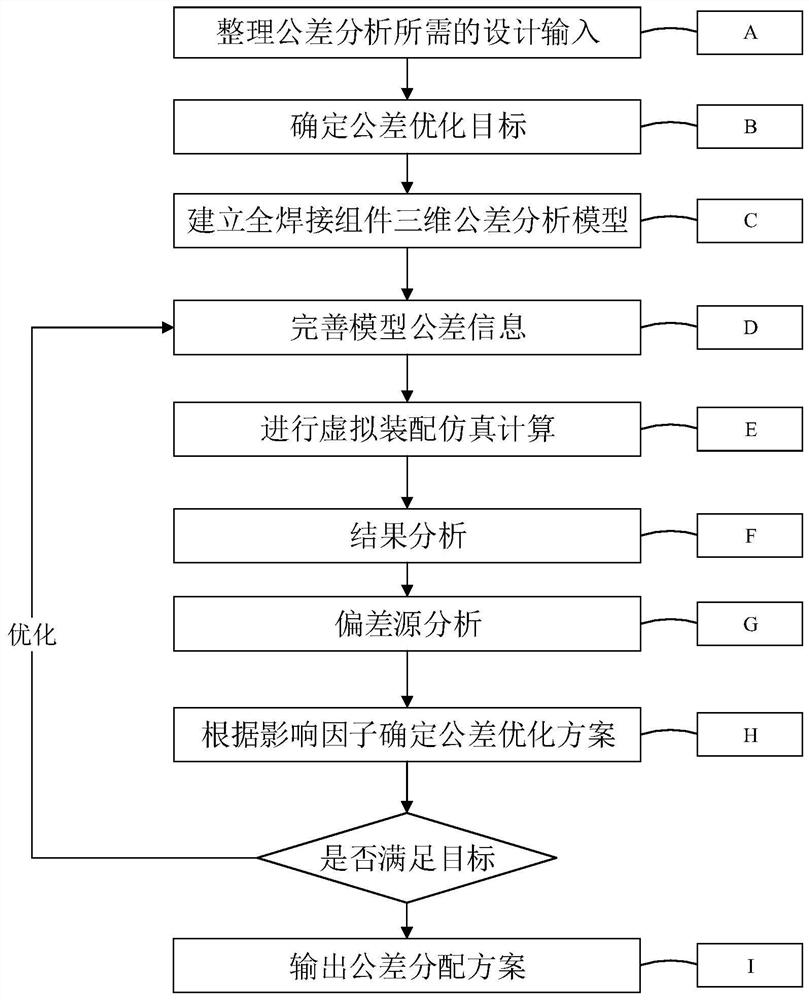

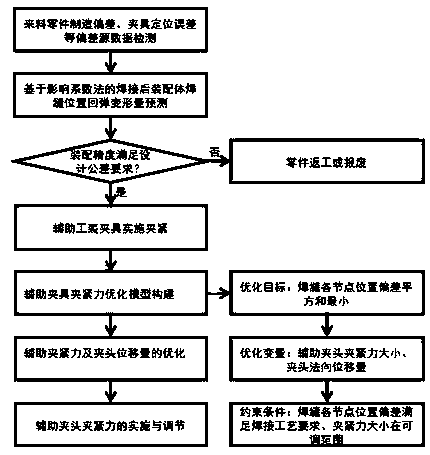

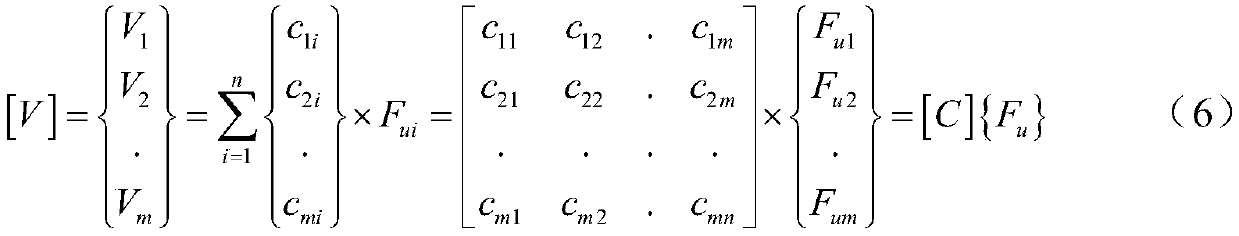

Tolerance optimization method for all-welded assembly

ActiveCN113204851AEffective predictionAchieve Tolerance OptimizationGeometric CADDesign optimisation/simulationStructural engineeringDesign information

Owner:NUCLEAR POWER INSTITUTE OF CHINA

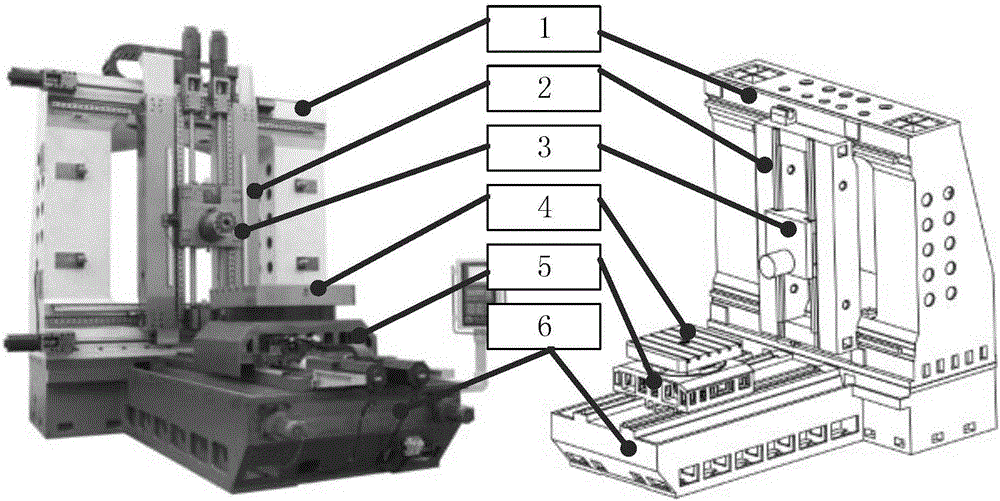

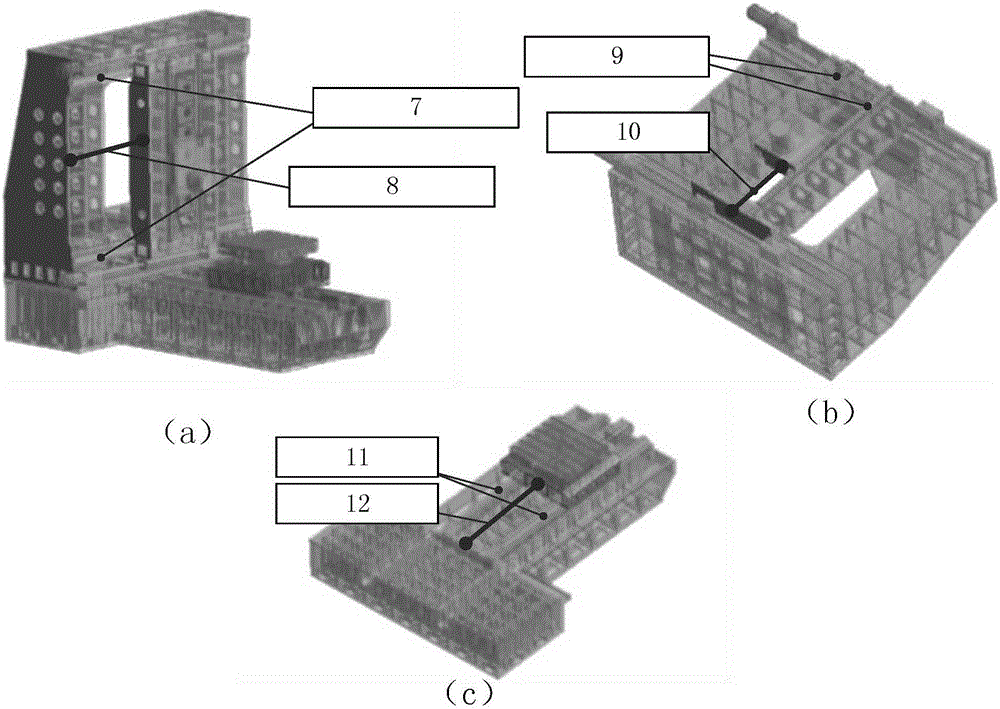

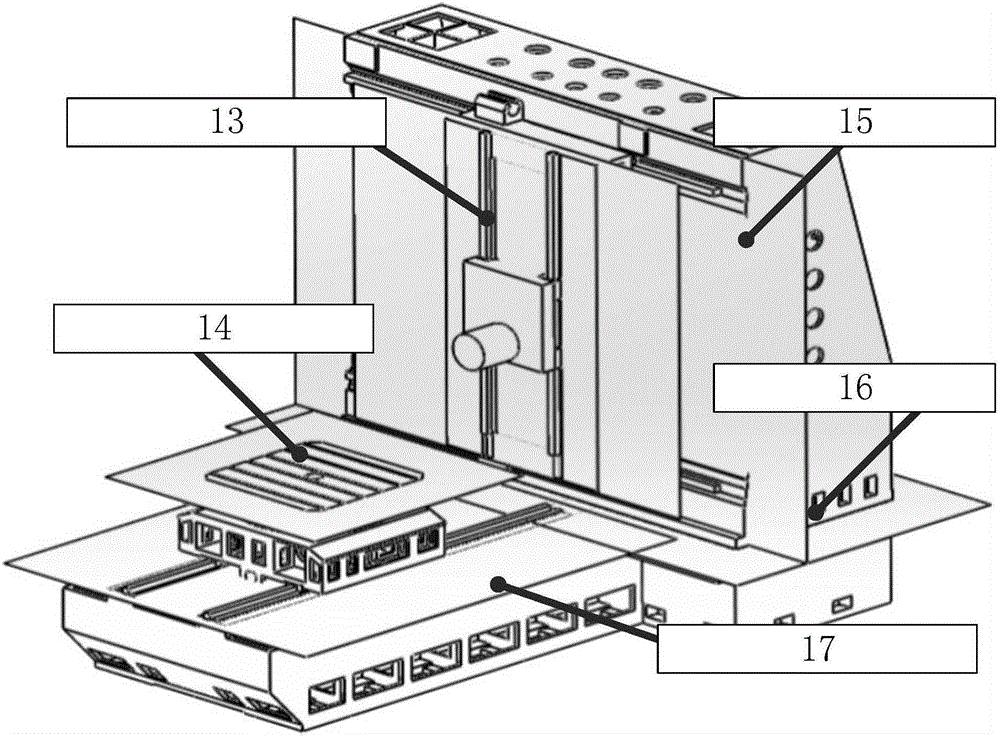

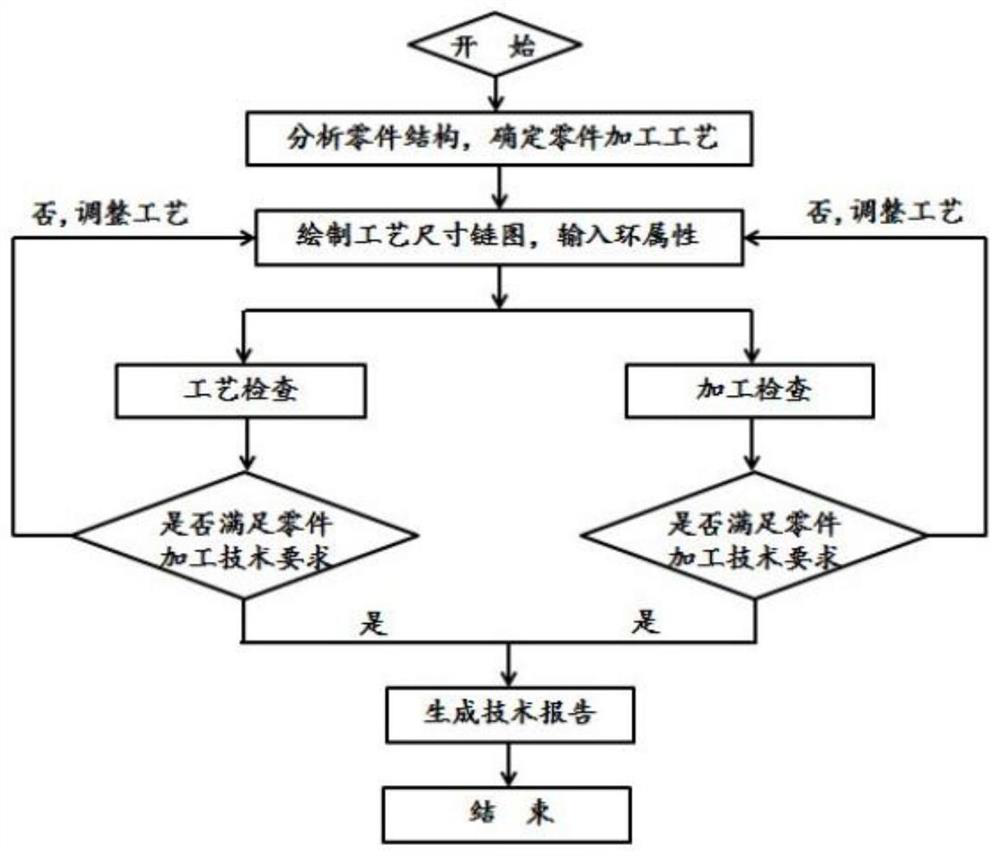

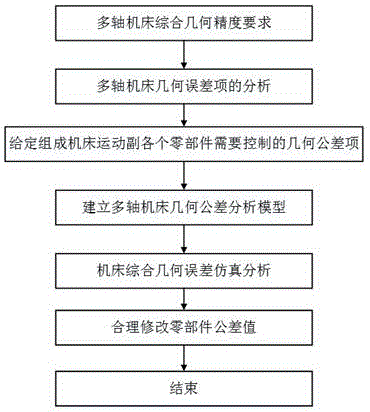

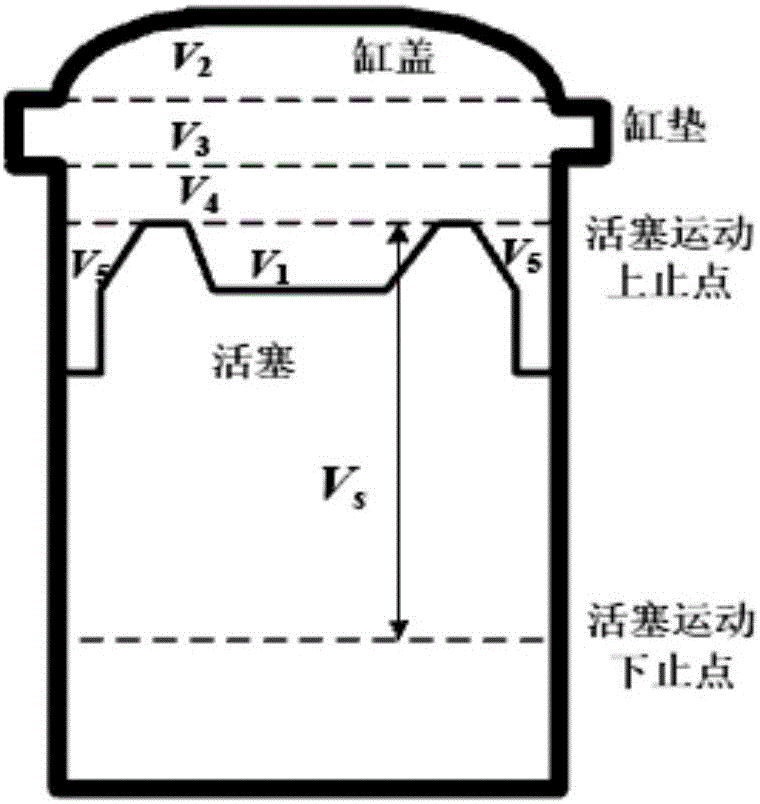

Tolerance design method of multi-axis machine tool parts based on comprehensive geometric precision

InactiveCN106250662AStrong reliabilityExcellent design flexibilityDesign optimisation/simulationConstraint-based CADGeometric errorKinematic pair

The invention relates to a tolerance design method of multi-axis machine tool parts based on comprehensive geometric precision, in particular to a tolerance design method of multi-axis machine tool parts to solve the problems that an existing comprehensive geometric precision design of a multi-axis machine tool is not implemented into a specific tolerance design of each part forming a kinematic pair, and the comprehensive geometric precision design has a long period and a poor feasibility, and does little help to subsequent comprehensive error compensation direction of the machine tool. The design method mainly comprises the following steps: step 1, analyzing geometric error items of the multi-axis machine tool; step 2, giving geometric tolerance items required to be controlled for each part forming the kinematic pair of the machine tool; step 3, establishing a geometric tolerance analysis model of the multi-axis machine tool; and step 4, giving an emulation analysis report of comprehensive geometric errors of the machine tool, and modifying corresponding part tolerance values. The tolerance design method provided by the invention is used for tolerance design of the multi-axis machine tool parts.

Owner:SHANGHAI UNIV

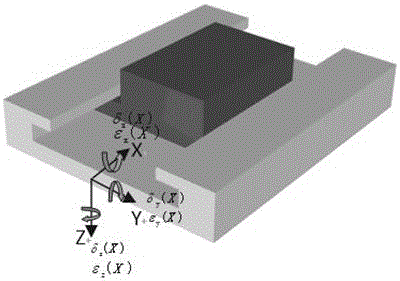

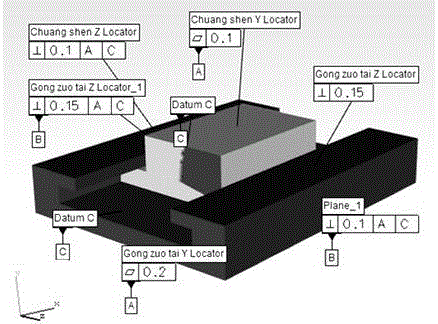

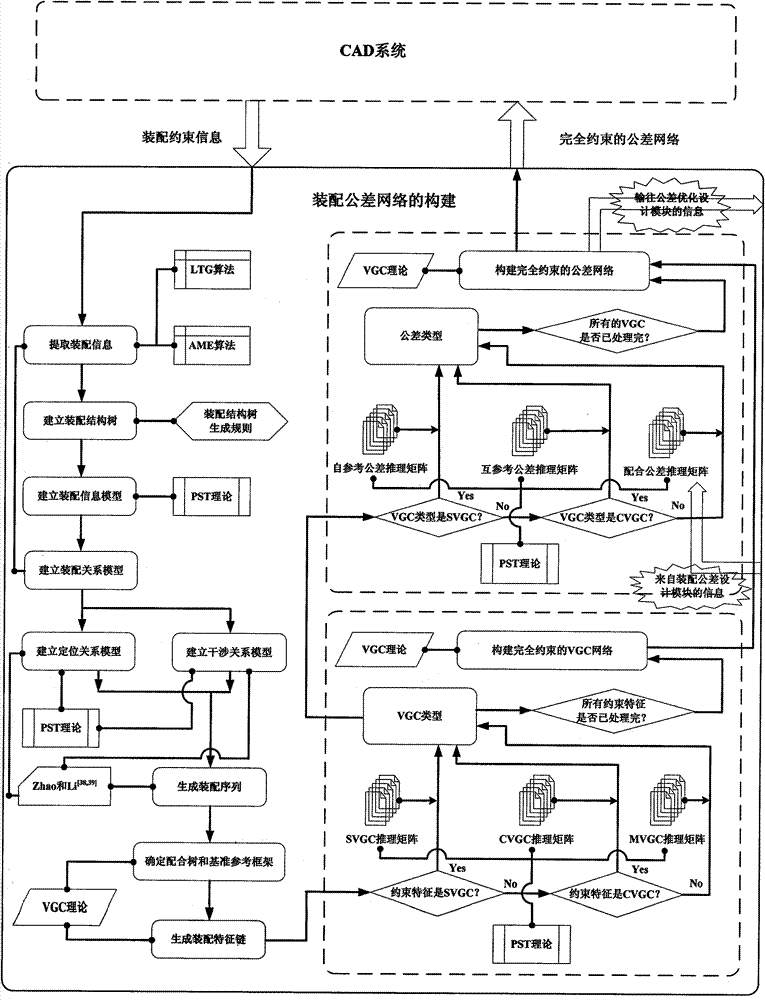

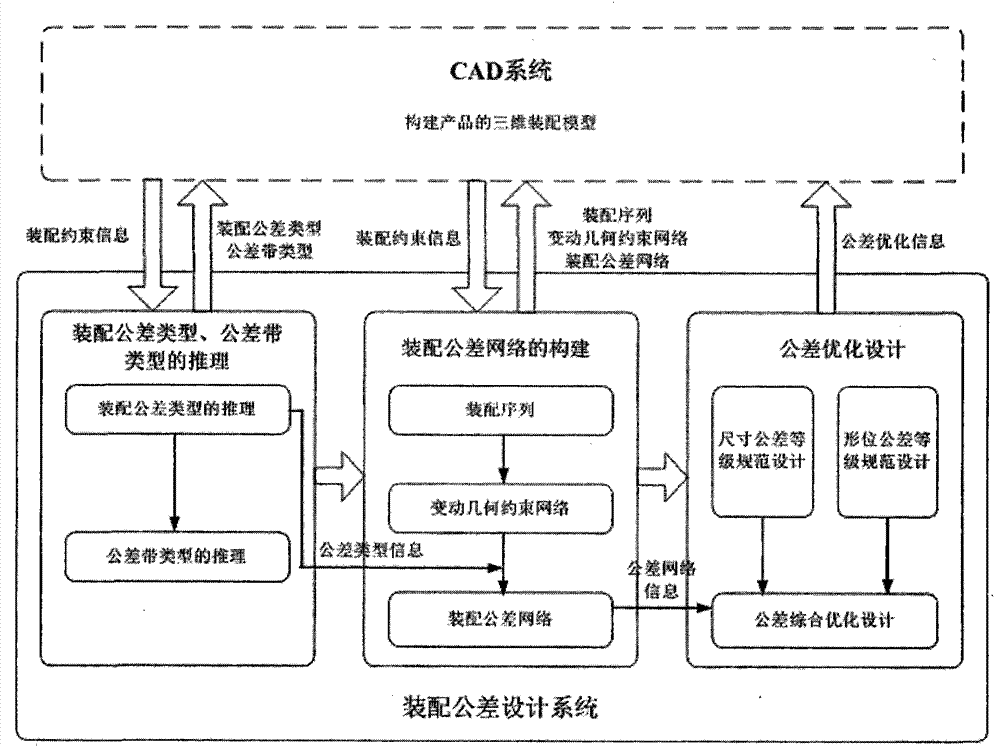

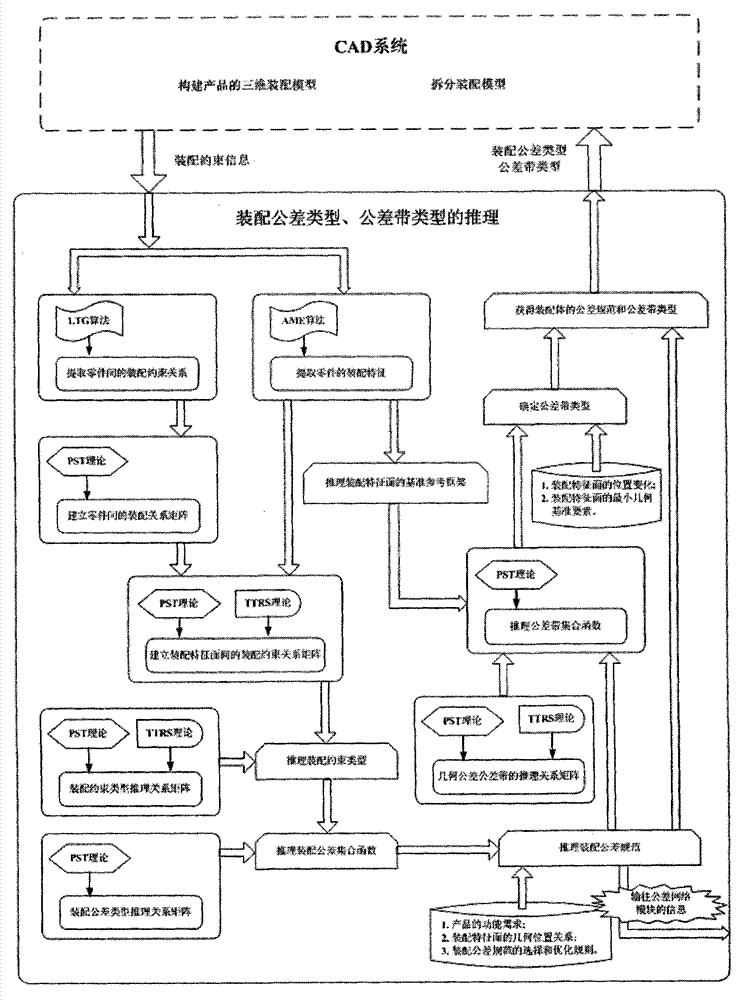

Fitting tolerance network establishing method

The invention relates to a fitting tolerance network establishing method. The fitting tolerance network establishing method includes extracting fitting information of products from a three-dimensional model of the CAD (computer-aided design) system, generating fitting sequences of the product, and establishing a VGC (viscosity gravity constant) network on the basis of the VGC theory; reasoning to generate three fitting tolerance types via the corresponding relation of the VGC and the tolerance types and tolerance type information input from the step a, adding the fitting tolerance types to the VGC network and establishing a fitting tolerance network; displaying fitting sequence generated in the step b, the VGC network and the fitting tolerance network on the CAD system, and outputting the tolerance network information for tolerance optimization and design. The fitting tolerance design system is established on the CAD system platform, and comprehensive design of fitting dimensional tolerance and geometric tolerance is realized by means of information acquired from a product entity model.

Owner:XIJING UNIV

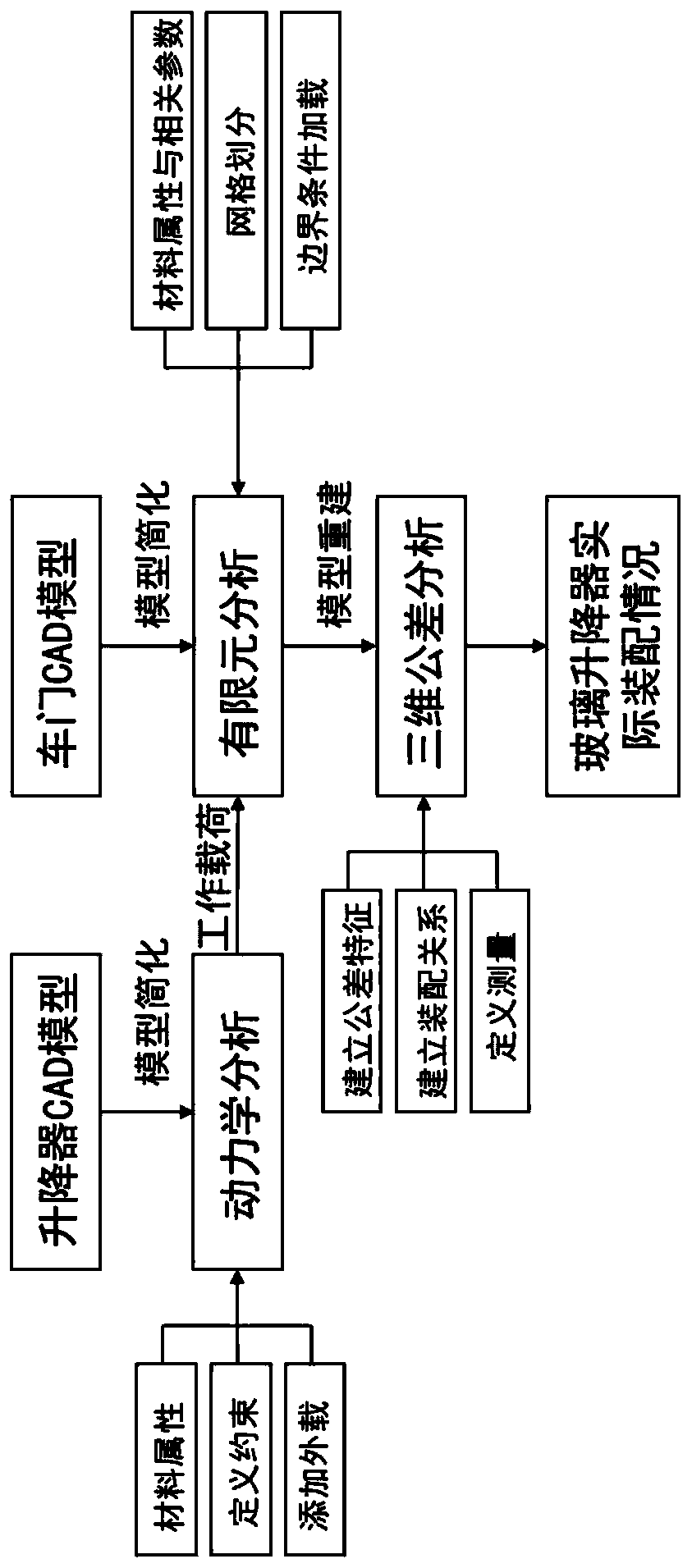

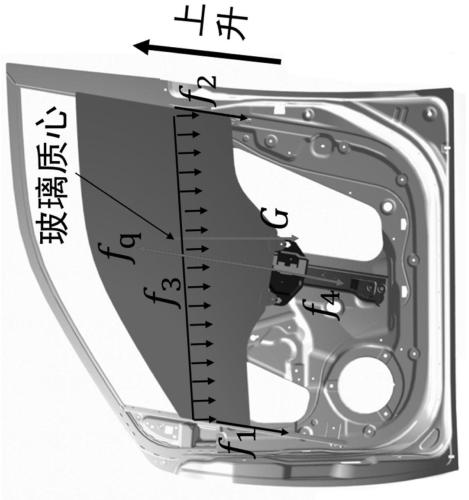

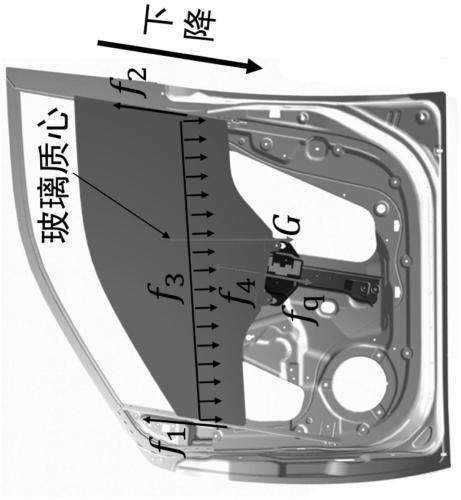

Glass lifter three-dimensional flexible assembly tolerance prediction method based on finite element

PendingCN111209705AImprove ride comfort design levelImprove lifting smoothnessDesign optimisation/simulationPredictive methodsClassical mechanics

The invention relates to a glass lifter three-dimensional flexible assembly tolerance prediction method based on a finite element, and the method comprises the steps: 1, building a glass lifter dynamic simulation analysis model, and obtaining a lifting load; 2, based on the extracted lifting load, calculating the rigidity expression of the vehicle door inner plate under the action of the load, andobtaining the deformation of the upper and lower mounting surfaces of the glass lifter; 3, reconstructing lifter mounting surface characteristics according to an obtained deformation result, and establishing a three-dimensional flexible assembly tolerance model of the glass lifter; and 4, defining the ratio of the out-of-tolerance rate reduction amplitude to the tolerance reduction as the yield ratio of the tolerance reduction, and taking the yield ratio as an evaluation index to realize the tolerance optimization design of the vehicle window lifting system. According to the method, the finite element and three-dimensional tolerance design combined method is adopted, the influence of lifting loads on the assembly relation is considered, the influence of sealing resistance and the rigidityof the vehicle door inner plate on the assembly state of the lifter is revealed, the assembly relation of the glass and the sealing strip is guaranteed by optimizing tolerance design, and the liftingsmoothness is improved.

Owner:TONGJI UNIV

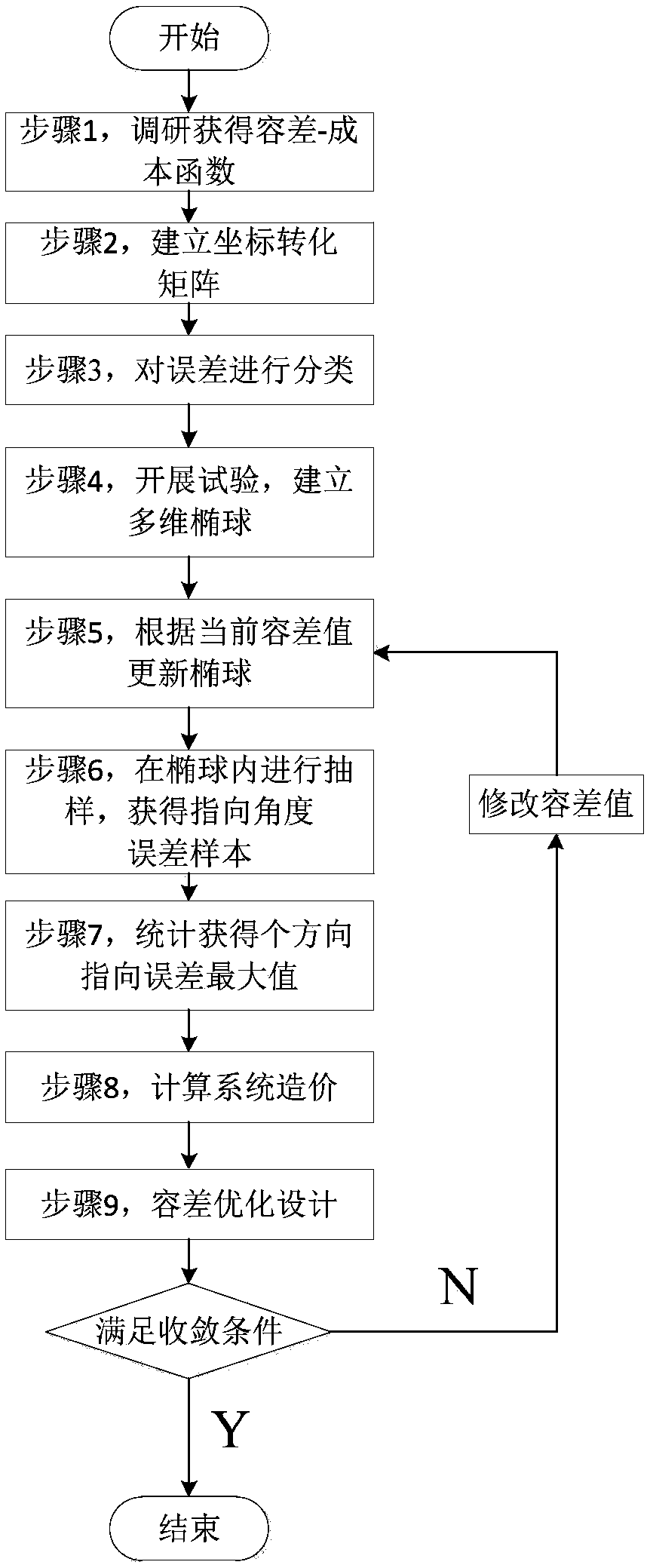

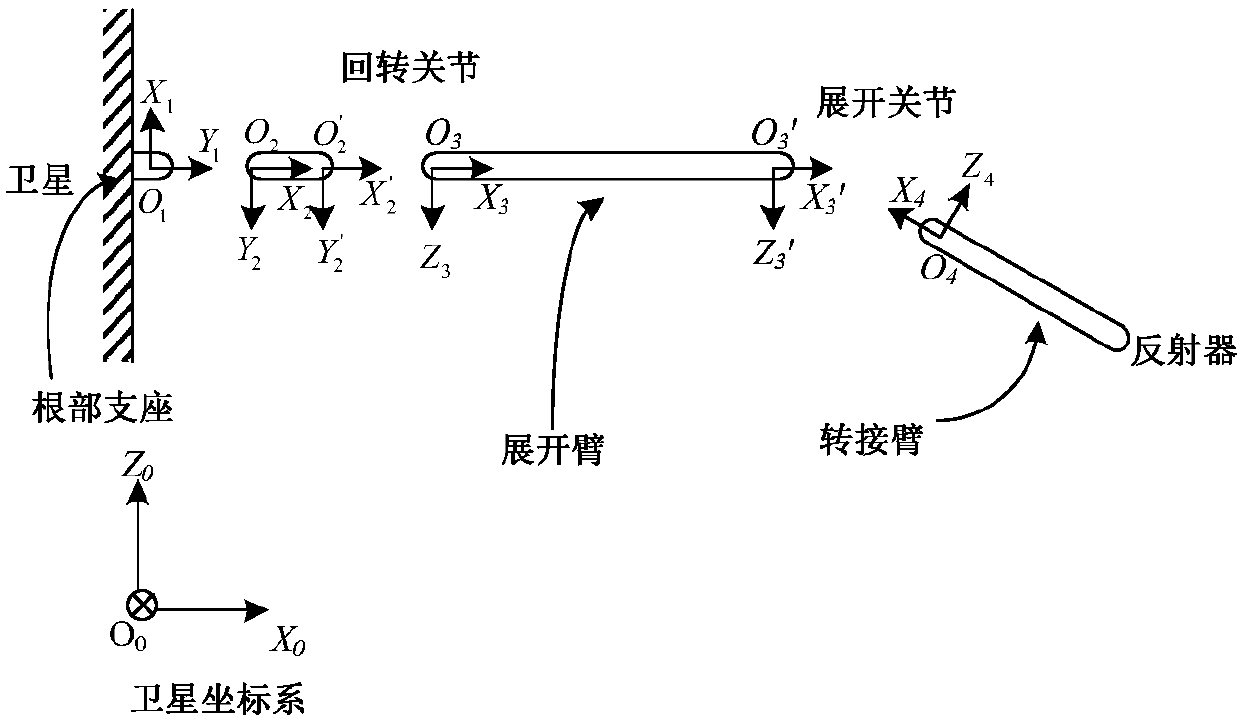

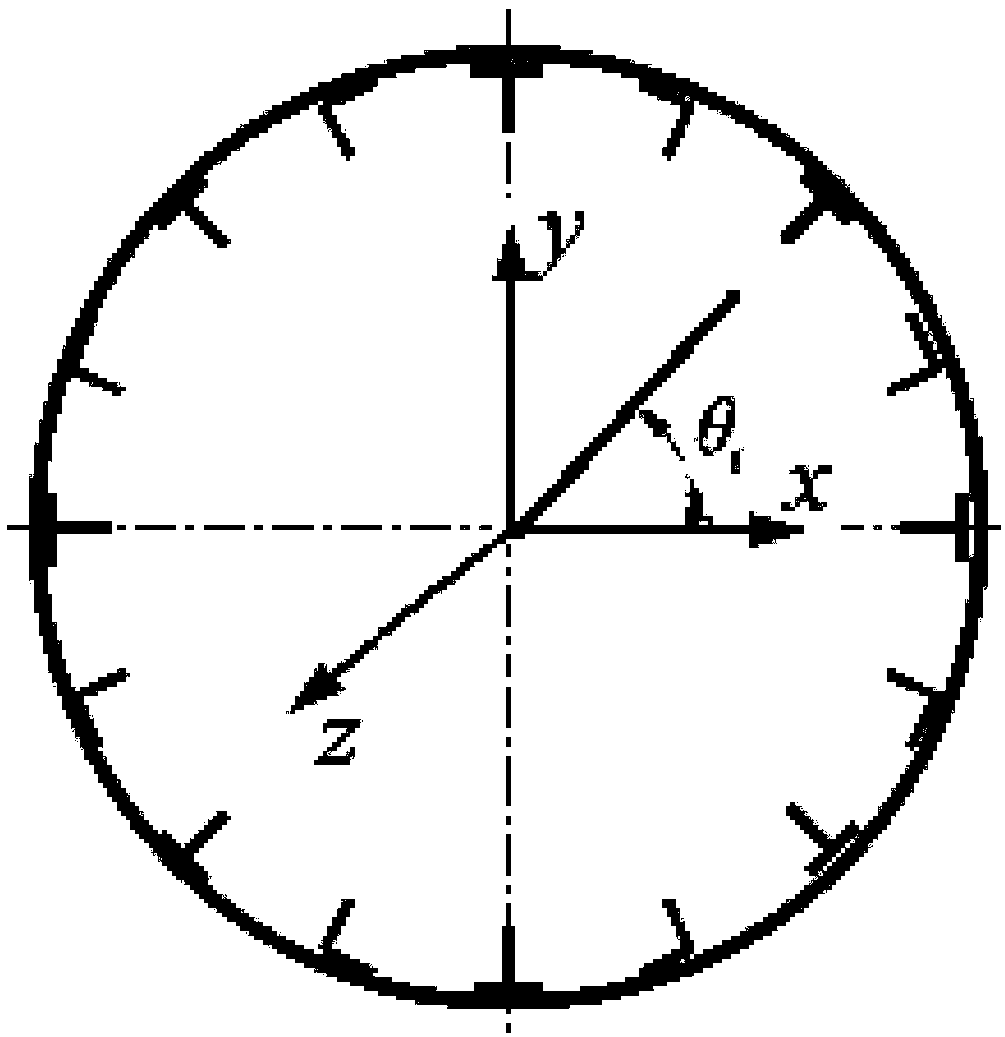

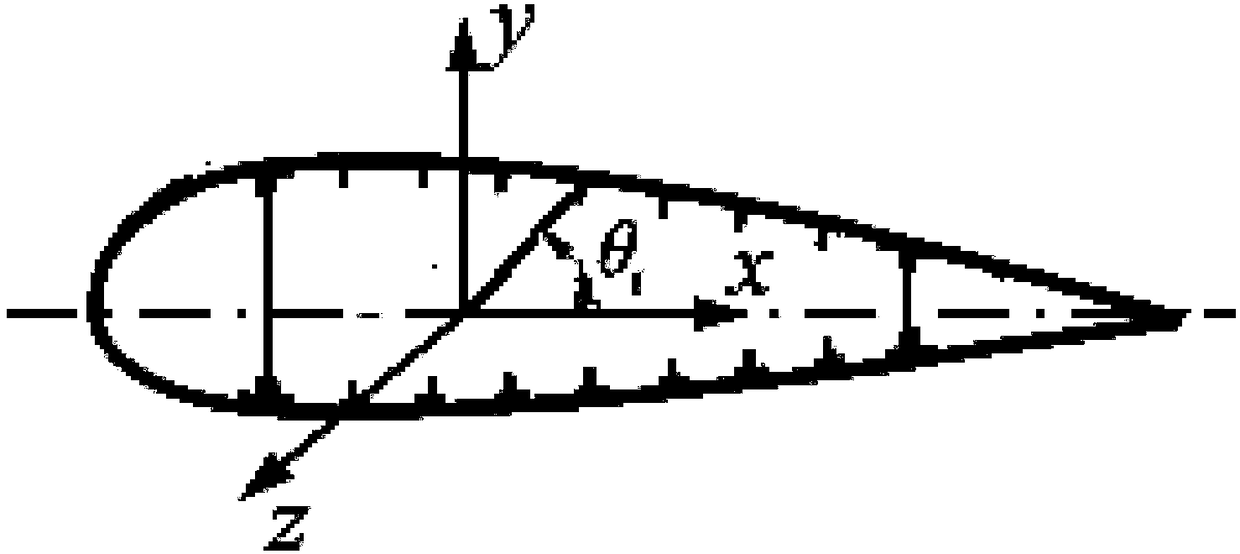

Ellipsoidal model-based expandable antenna unfolding arm tolerance design method

ActiveCN107863599ACorrelation representationFit the actual engineeringPivotable antennasDesign optimisation/simulationMathematical modelEngineering

The invention relates to a related ellipsoidal model-based expandable antenna unfolding arm joint tolerance design method. According to the method, a coordinate conversion matrix from a reflector on the end part of an unfolding arm to a satellite coordinate system is established firstly; and meanwhile, a tolerance-cost relation is obtained through research analysis. Specific to the overall structural form of the unfolding arm, various errors in the multi-stage unfolding arms are classified based on correlation; meanwhile, specific to each type of errors with internal correlation, an ellipsoidal mathematical model which represents the correlation is obtained through tests; next, Monte Carlo random sampling is performed in the ellipsoidal sphere, and a final angle error of the reflector is obtained based on the coordinate conversion matrix; and finally, by taking the total cost minimization as the object, by taking tolerance as a design variable, and by taking pointed error for satisfying design requirement as the constraint, tolerance optimization design is performed. A simulation structure shows that effective unfolding arm joint tolerance design can be realized by the method, andmeanwhile, design difficulty of the conventional method caused by no consideration of the correlation is avoided.

Owner:XIDIAN UNIV

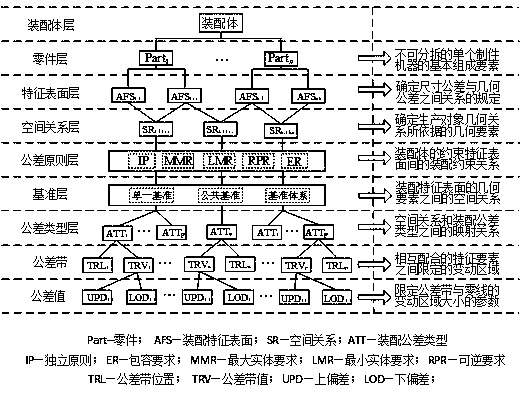

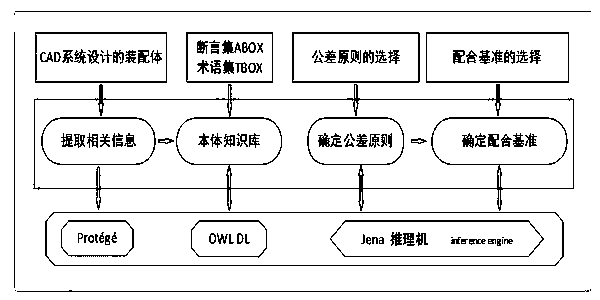

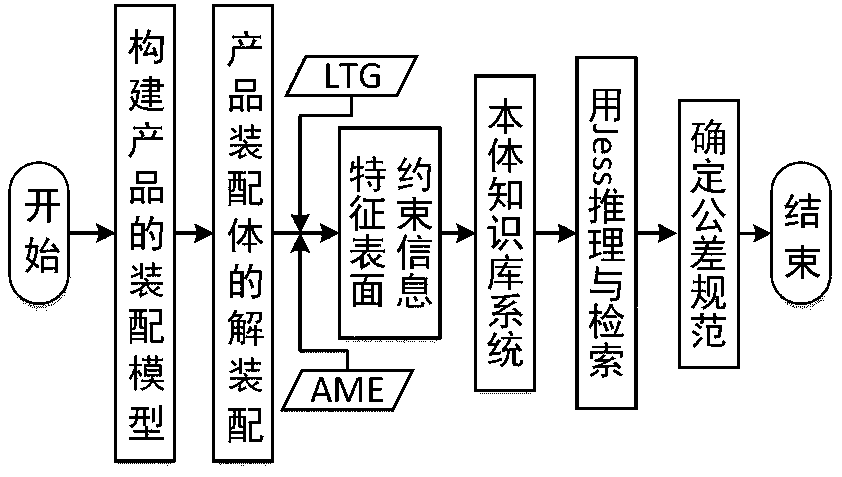

Assembly tolerance specification intelligent design method based on Ontology

InactiveCN110348119AScalableGuaranteed portabilityGeometric CADKnowledge representationIntelligent designComputer aid

The invention belongs to the technical field of assembly tolerance specification design and computer-aided tolerance design (CAT), and particularly relates to an assembly tolerance specification intelligent design method based on Ontology. The method specifically comprises the following steps: (1) constructing a body of an assembly tolerance specification; (2) establishing an SWRL reasoning rule of an assembly tolerance specification; (3) extracting related tolerance information of the assembly tolerance specification; (4) constructing an assembly tolerance specification instantiation ontologymodel; and (5) combining the Jess inference machine with the SWRL rule, inferring the assembly tolerance specification, and outputting a result inference result. An ontology reasoning knowledge framework for the assembly tolerance specification domain knowledge is constructed by utilizing an ontology, and an assembly tolerance specification knowledge base is expanded according to dominant domainknowledge reasoning implicit knowledge. In combination with a semantic network rule language rule base, reasoning design parameters of assembly tolerance specifications for specific design of geometric products and using environmental conditions. The consistency knowledge description framework of the assembly tolerance specification can be provided, so that a computer can automatically select appropriate tolerance principles, tolerance types, size parameters and the like according to shape and size parameters of geometric products, and a quick and effective method is provided for intelligent design of the assembly tolerance specification.

Owner:GUILIN UNIV OF ELECTRONIC TECH

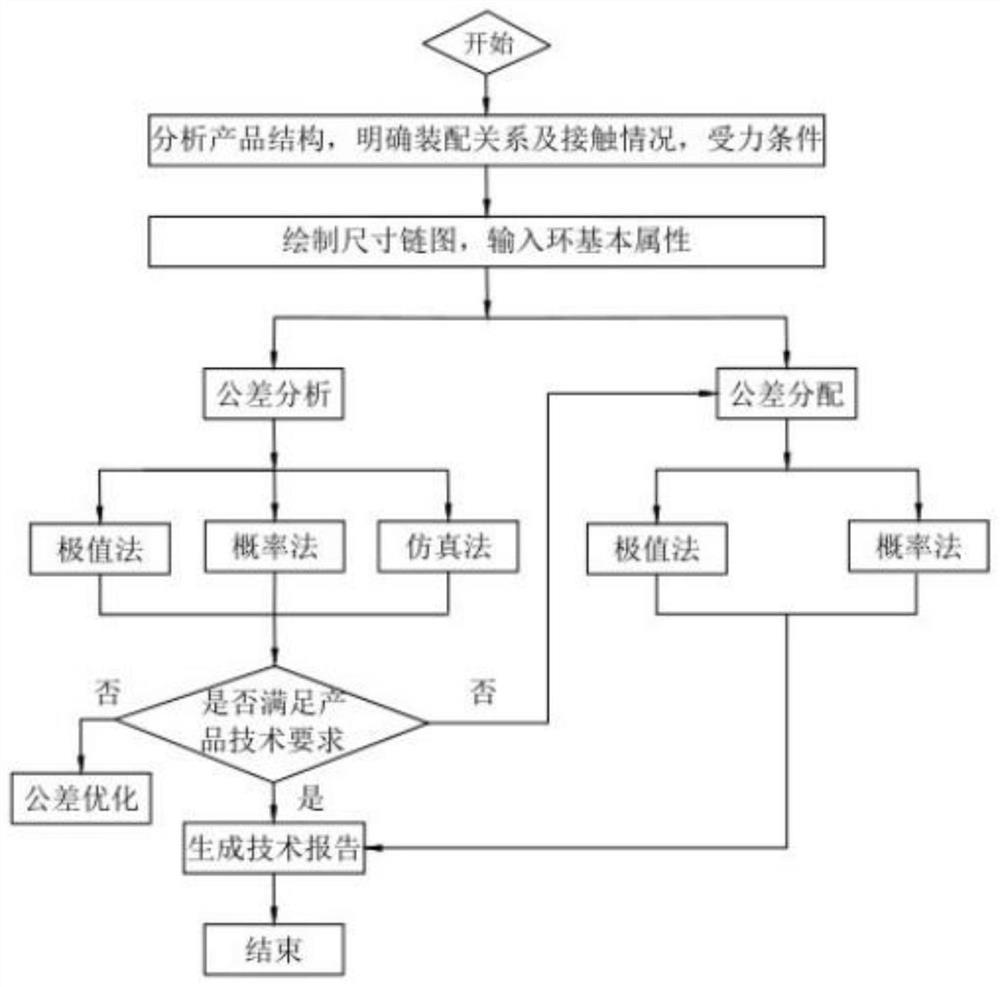

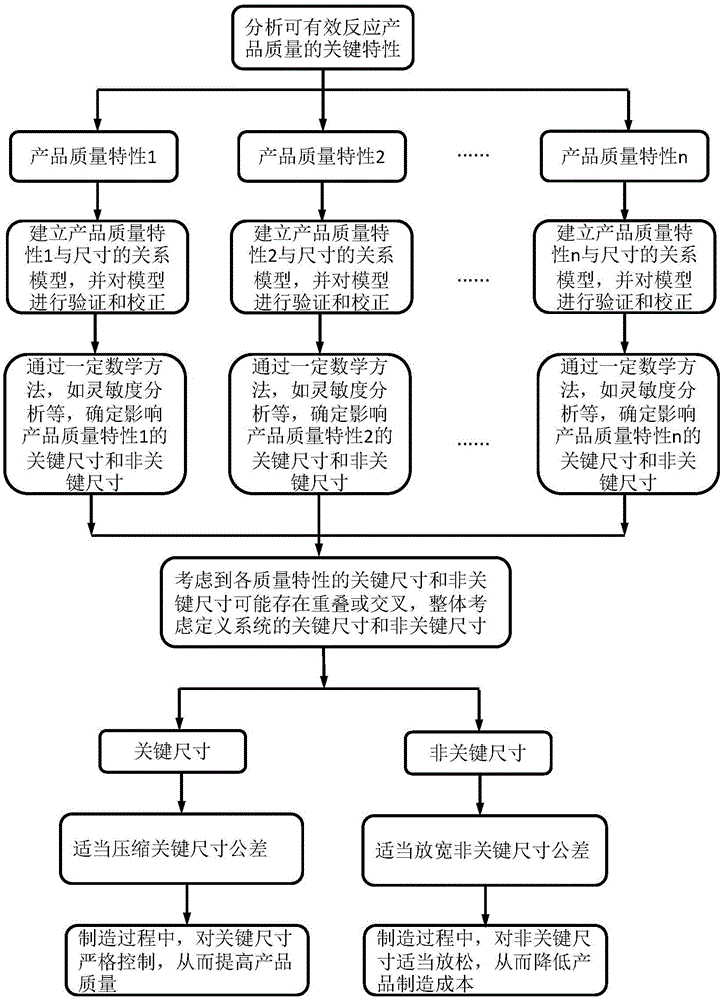

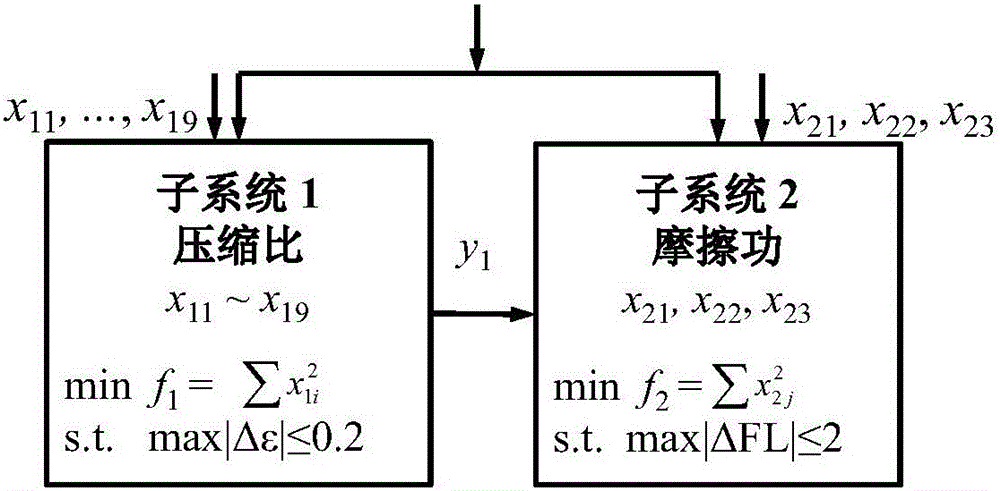

Intelligent manufacturing method driven by rational tolerance design

ActiveCN105912778AQuality improvementCost controlGeometric CADSpecial data processing applicationsRelational modelEngineering

The present invention provides an intelligent manufacturing method driven by rational tolerance design. The intelligent manufacturing method comprises the steps of determining key physical parameters capable of effectively reflecting corresponding product quality for a manufactured target product, and establishing a corresponding optimization model; verifying the optimization model; determining critical dimensions and non-critical dimensions which influence the product quality; establishing a multiple discipline optimization problem, respectively optimizing the critical dimensions and the non-critical dimensions, and generating an optimization result; and adjusting manufacturing processes of the critical dimensions and the non-critical dimensions according to the optimization result. According to the intelligent manufacturing method, first, the relation model of the product quality and the dimensions is established, critical factors and non-critical factors which influence the product quality can be effectively determined through determining the critical dimensions and the non-critical dimensions which influence the product quality, so that the product quality and cost can be targetedly controlled.

Owner:SHANGHAI JIAO TONG UNIV

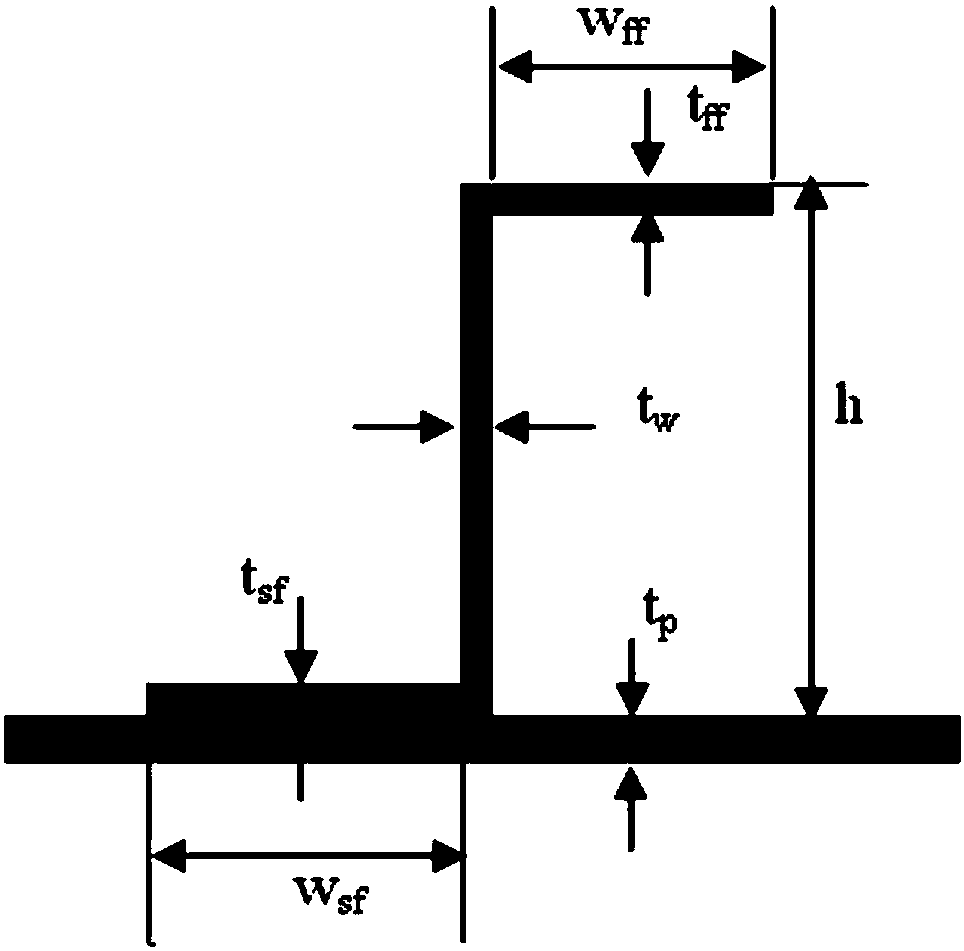

Optimized design method for initial size of thin-wall structure for wings and body of aircraft

ActiveCN108563916AAchieving Lightweight GoalsGeometric CADSpecial data processing applicationsFatigue damageDirect effects

The invention relates to an optimized design method for the initial size of a thin-wall structure for wings and a body of an aircraft. According to the method, the scheme of a thin-wall stiffened plate for the wings and a body of the aircraft in the early stage of the project is determined based on a thin-wall project beam theory. The design of the initial size of the thin-wall stiffened plate isa work with challenge and judgment property, and the subsequent design work is directly influenced when the initial size designed and defined by the scheme is reasonable or not. The ideal thin-wall structure needs to adequately meet the design requirements of static strength design, fatigue damage tolerance design, manufacturing, maintaining and the like. By simplifying any one of an analytical method or a to-be-analyzed structure in the design process of the initial size, the cost benefit of the project can be increased. By further introducing manufacturing and maintaining requirements in thepremise that the static strength requirement is satisfied under the condition that the strength requirement is satisfied, the relatively optimized initial size can be acquired. By defining the initial size of the structure according to the design requirements of manufacturing, maintaining and the like under the condition that the strength requirement is satisfied, the optimized design method canmeet the lightweight design requirement of the structure, and the design efficiency is improved.

Owner:AVIC SAC COMML AIRCRAFT

Vehicle body auxiliary clamping method for assisting robot in automatic arc welding

ActiveCN109759684AEnsure successful solderingPrecise automatic weldingWelding accessoriesManufacturing cost reductionWeld seam

The invention discloses a vehicle body auxiliary clamping method for assisting a robot in automatic arc welding. Aimed at separated supplied parts existing in welding of a vehicle body, the method comprises the following steps that the resilience deformation at a welding seam position of an assembled body after welding is firstly calculated according to the manufacturing deviation of the suppliedparts, and on the premise that the value meets the design requirements of tolerance, an auxiliary tool clamp is used for clamping the supplied parts; and through deviation source data input of the manufacturing deviation of the supplied parts, clamp positioning errors and the like, a welding seam position adjustment optimization model is constructed, the optimal clamp deviation compensation amountis obtained, the welding seam position is adjusted through the auxiliary tool clamp, and the arc welding robot is guaranteed to conduct welding successfully. According to the method, the arc weldingrobot can be used for accurately performing automatic welding on a target welding seam conveniently according to a preset program, the production efficiency is improved, the manufacturing cost is reduced, and the method has excellent engineering application value.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

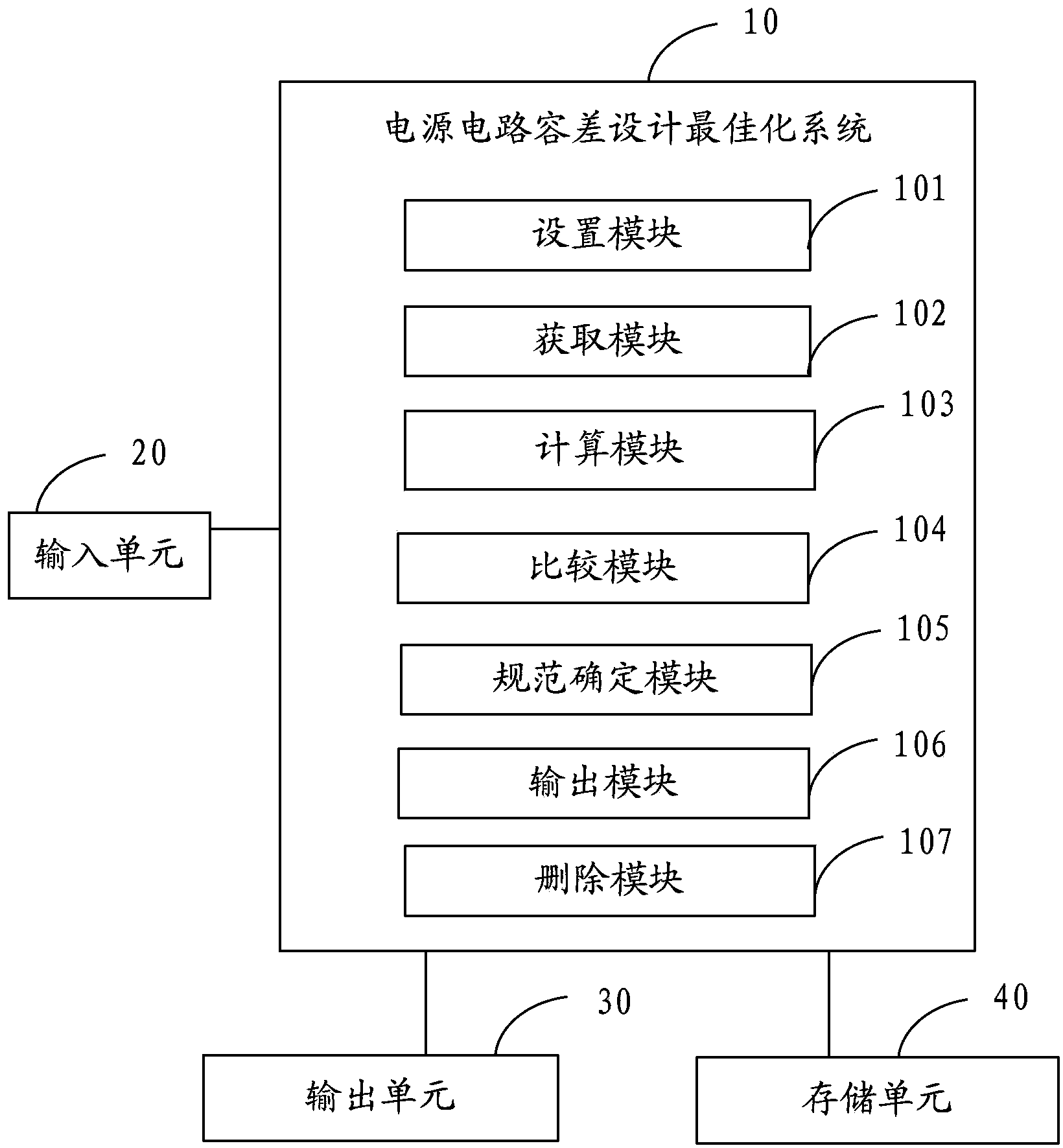

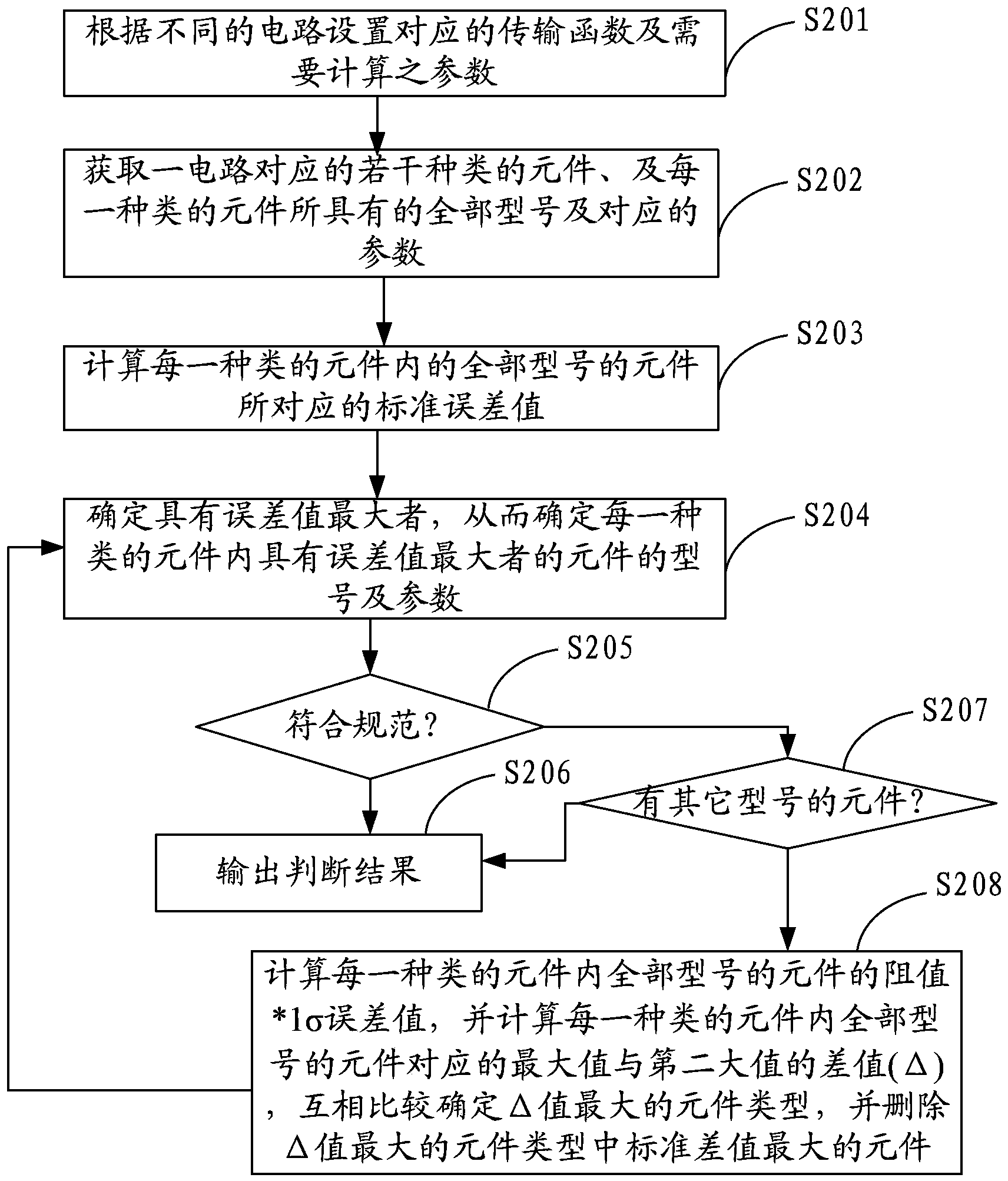

System and method for optimizing tolerance design of power circuit

InactiveCN104102754ASave human effortShorten the timeSpecial data processing applicationsMaximum errorPower circuits

The invention provides a system and a method for optimizing the tolerance design of a power circuit. The method comprises the following steps: setting corresponding transmission functions and parameters needing to be calculated according to different circuits; obtaining a plurality of types of elements corresponding to a circuit, all models of each type of elements and corresponding parameters; calculating standard error values corresponding to all models of elements in each type of elements according to a standard error value calculation formula; comparing the standard error values corresponding to all models of elements in each type of elements, and determining the model with a maximum error value; substituting the parameters corresponding to all types of elements of the model with the maximum error value into the transmission function for calculation, and judging whether the elements accord with the standard; outputting a judging result. According to the system and the method for optimizing the tolerance design of the power circuit disclosed by the invention, data search, input and calculation are completed by utilizing programmable software, so that the manpower and time are effectively saved, and the degree of accuracy is improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

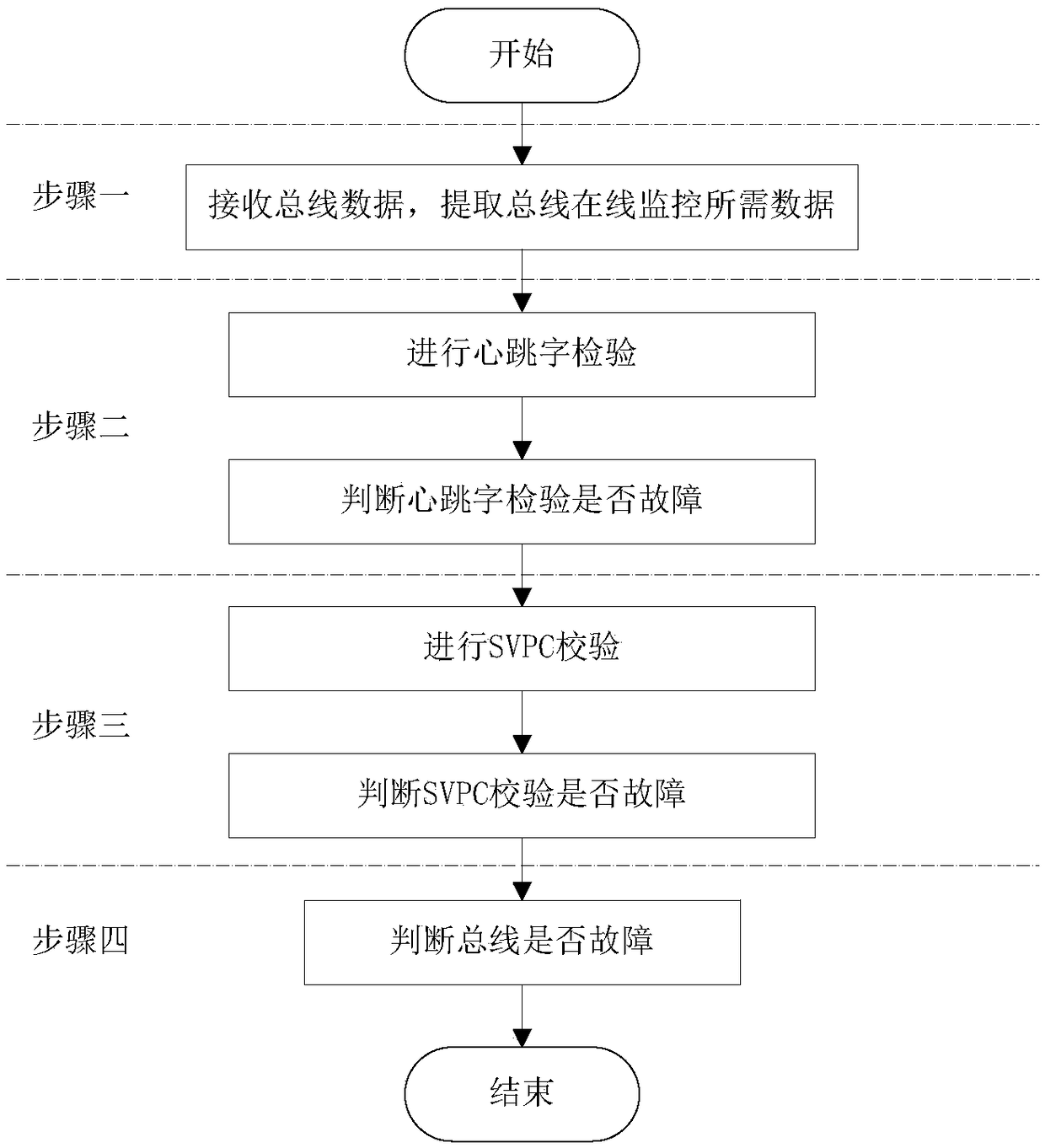

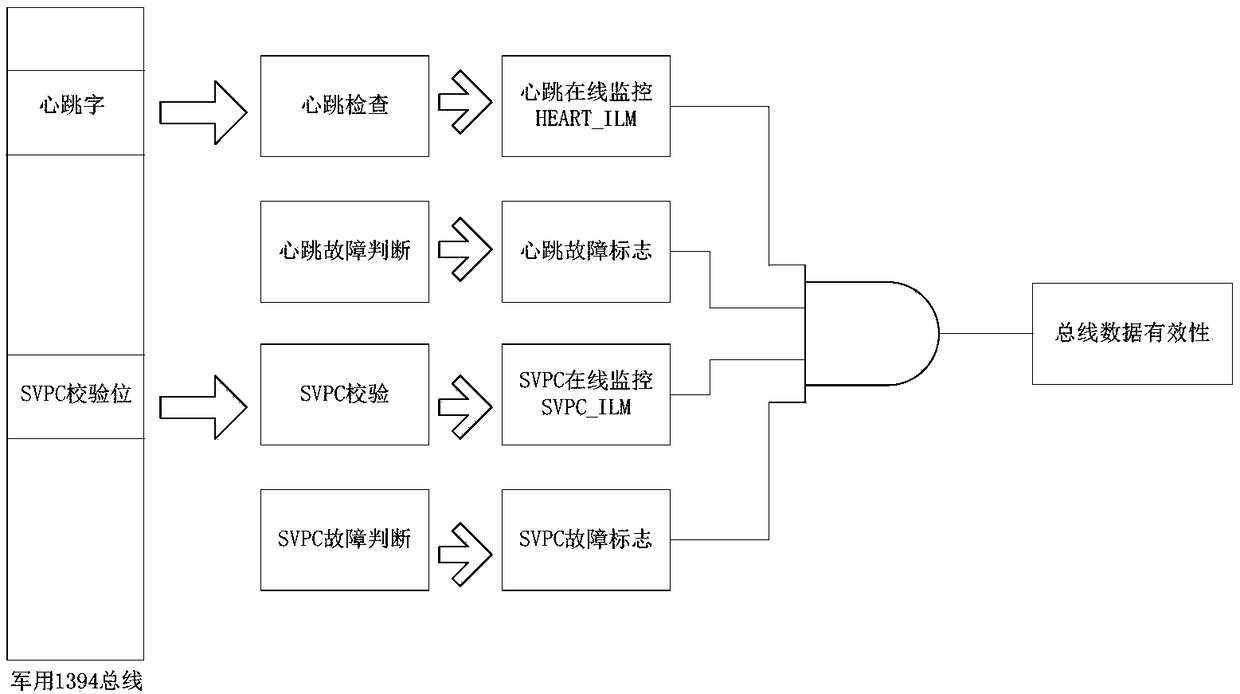

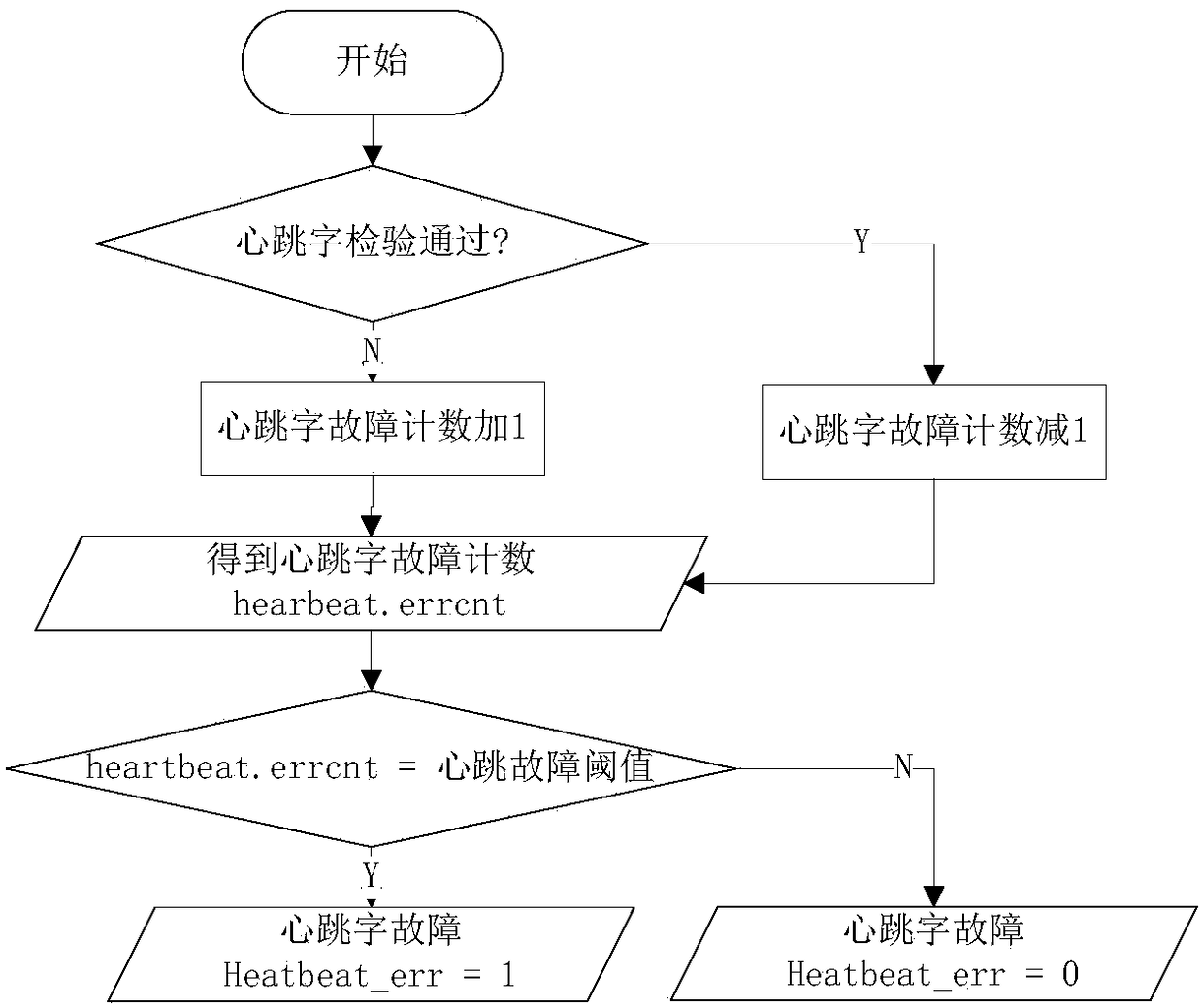

Method for monitoring data integrity of military 1394 bus of distributed system

ActiveCN108183835AStrict detection methodThe detection method is comprehensive and convenientError preventionData switching networksAviationData integrity

The invention belongs to an avionics system technology, and relates to a method for monitoring data integrity of a military 1394 bus of a distributed system. The method is a method for a military 1394bus detection method which combines two bus check methods of heartbeat word monitoring and SVPC monitoring. A bus ILM online monitor is designed on the basis of two check modes, and a fusion judgingalgorithm is designed according to the fault frequency of the ILM monitor of the two check methods in a continuous period, so that a bus transmission signal is monitored, and thus the effectiveness ofthe bus is judged. A heartbeat word tolerance design applied to the military 1394 bus detection method is provided for bus operation cycles of different systems in the actual distributed system. Meanwhile, an SVPC check method for generating a check bit by a way of sequentially carrying out XOR calculation on data one by one is provided for bus data check.

Owner:CHENGDU AIRCRAFT DESIGN INST OF AVIATION IND CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com