Patents

Literature

48results about How to "Achieving Lightweight Goals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dynamic lightweight class trust evaluation method based on Bayesian theory and entropy theory

InactiveCN103297956AEfficient identificationResistance to insider attacksSecurity arrangementLimited resourcesUltrasound attenuation

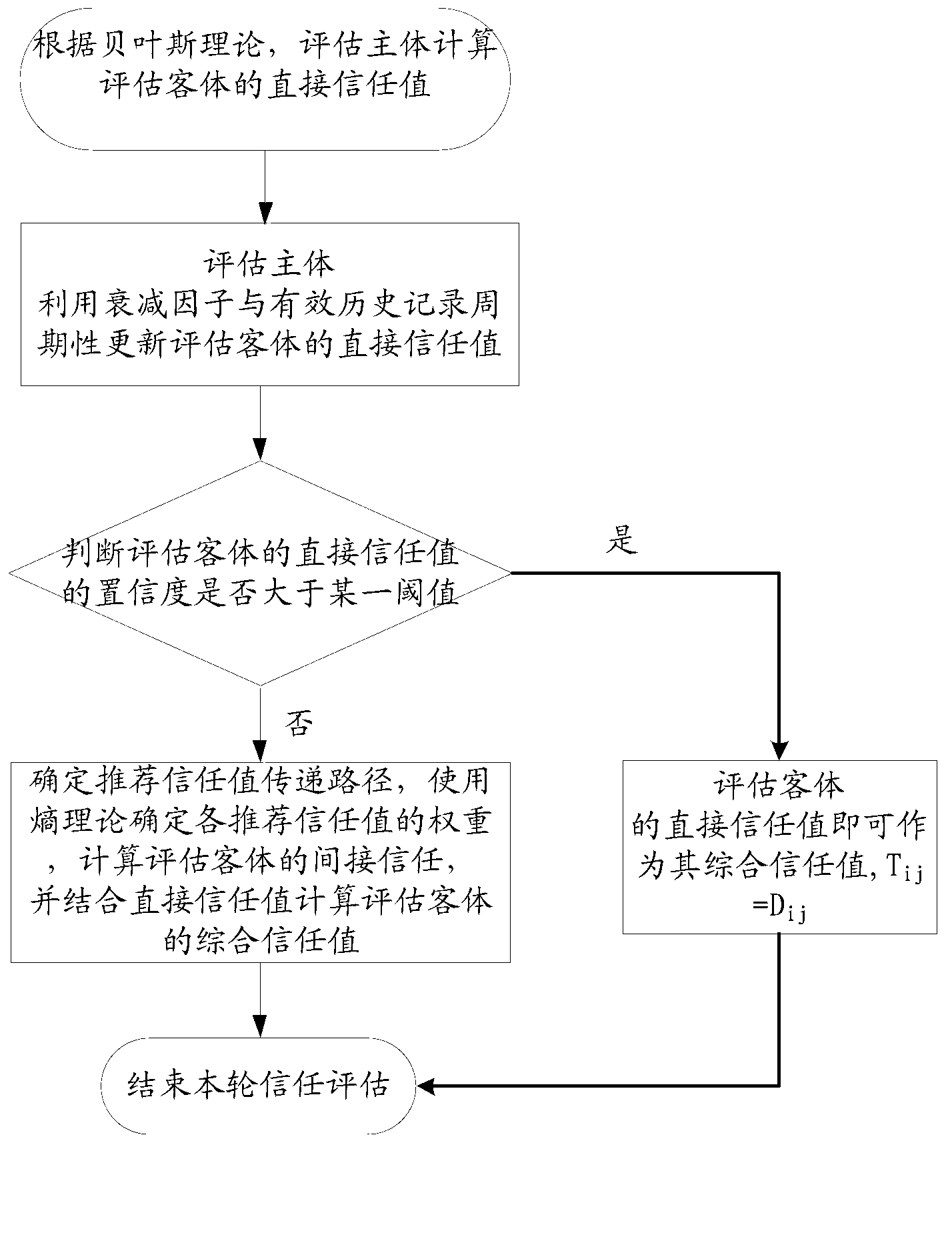

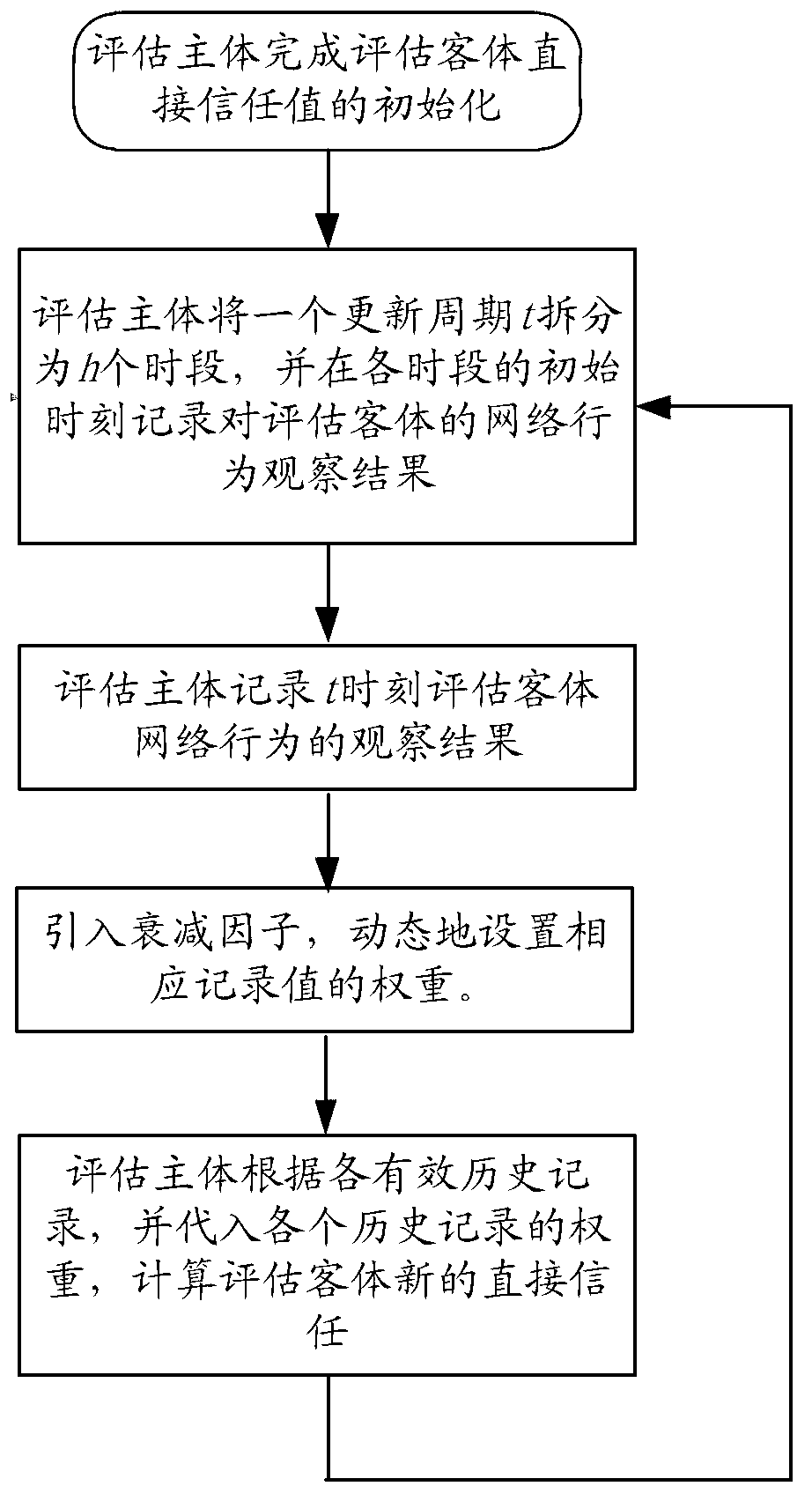

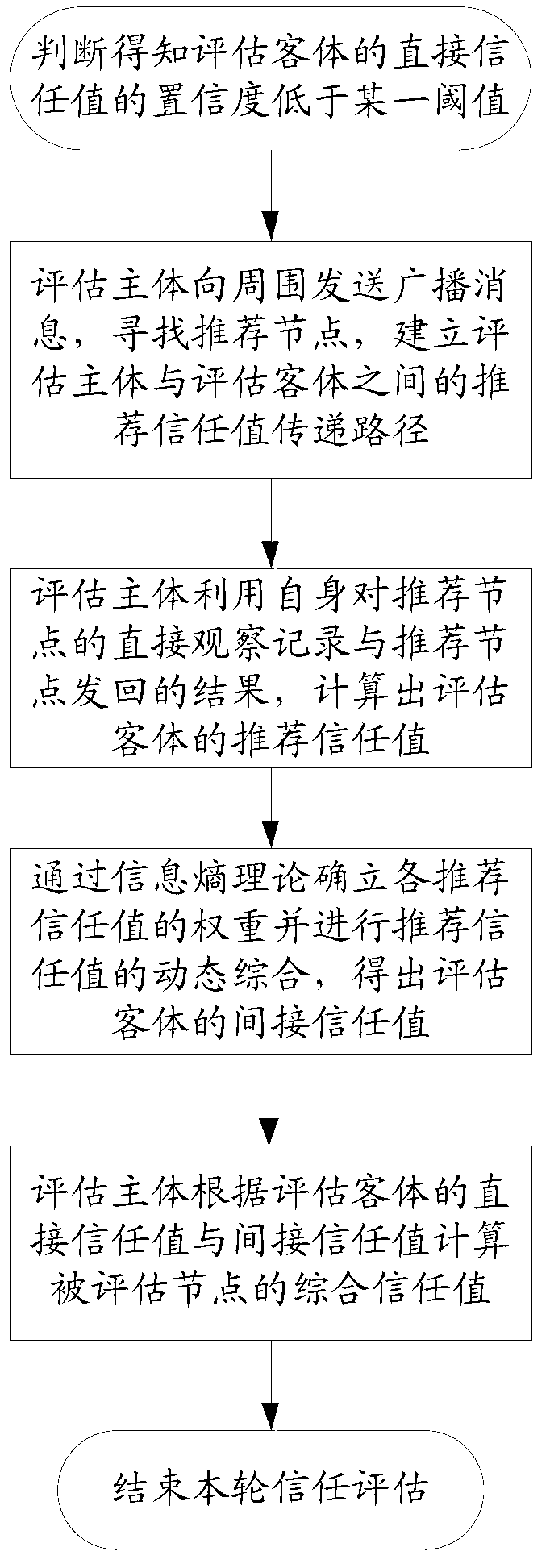

The invention provides a dynamic lightweight class trust evaluation method based on the Bayesian theory and the entropy theory, and belongs to the technical field of wireless sensor network security. The dynamic lightweight class trust evaluation method based on the Bayesian theory and the entropy theory includes the following steps: S1, an evaluation subject calculates the direct trust value of an evaluation object according to the Bayesian theory; S2, the evaluation subject updates the direct trust value of the evaluation object by means of attenuation factors and valid history memory periodically; S3, the evaluation subject calculates the confidence coefficient of the direct trust value of the evaluation object, and judges whether the confidence coefficient is larger than a certain threshold value to determine whether the indirect trust value of the evaluation object needs to be calculated or not; S4, the evaluation subject confirms the bang path of the recommendation trust values, confirms the weight of the recommendation trust values by means of the entropy theory, calculates the indirect trust value of the evaluation object, and calculates the comprehensive trust value of the evaluation object through the combination of the direct trust value and the indirect trust value of the evaluation object. The dynamic lightweight class trust evaluation method based on the Bayesian theory and the entropy theory is in accordance with the characteristics that sources such as capacity, calculation, and storage of network nodes are limited and has the advantages of being dynamic, adaptive, lightweight and the like.

Owner:BEIHANG UNIV

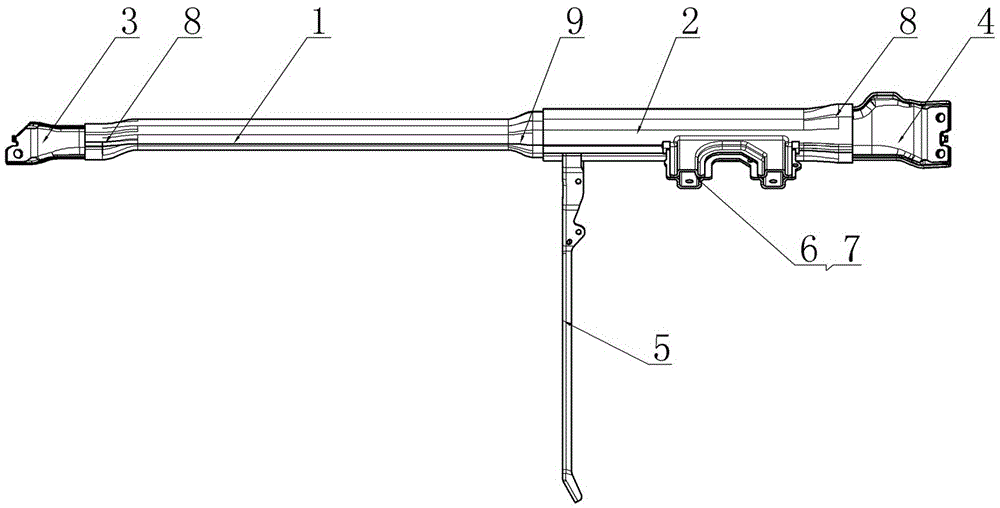

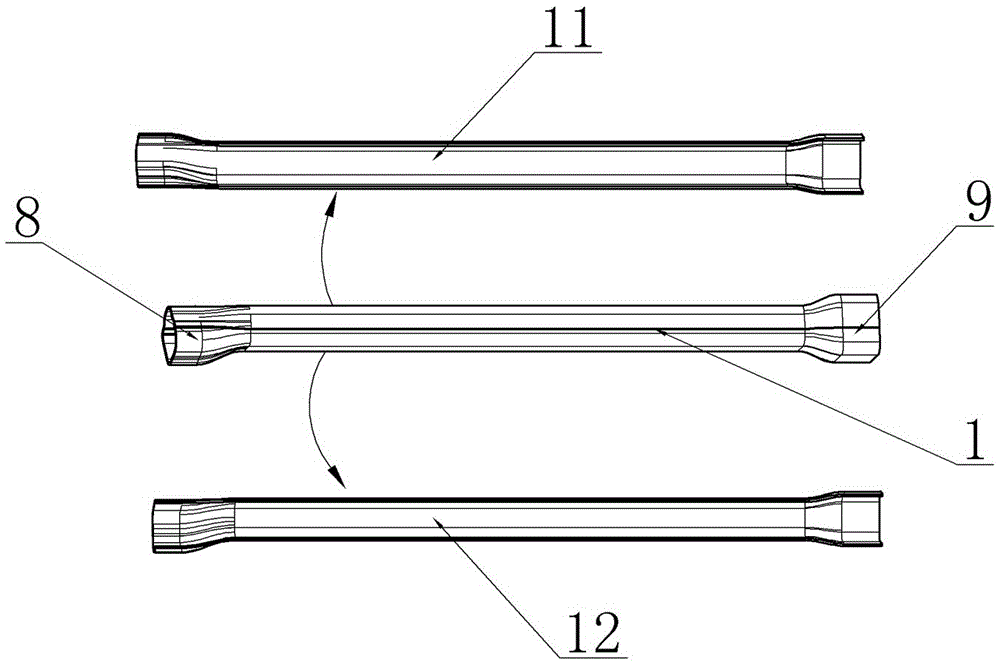

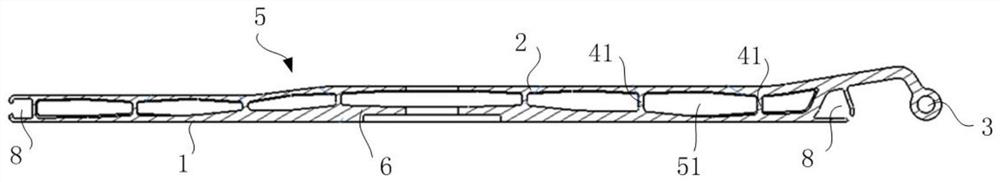

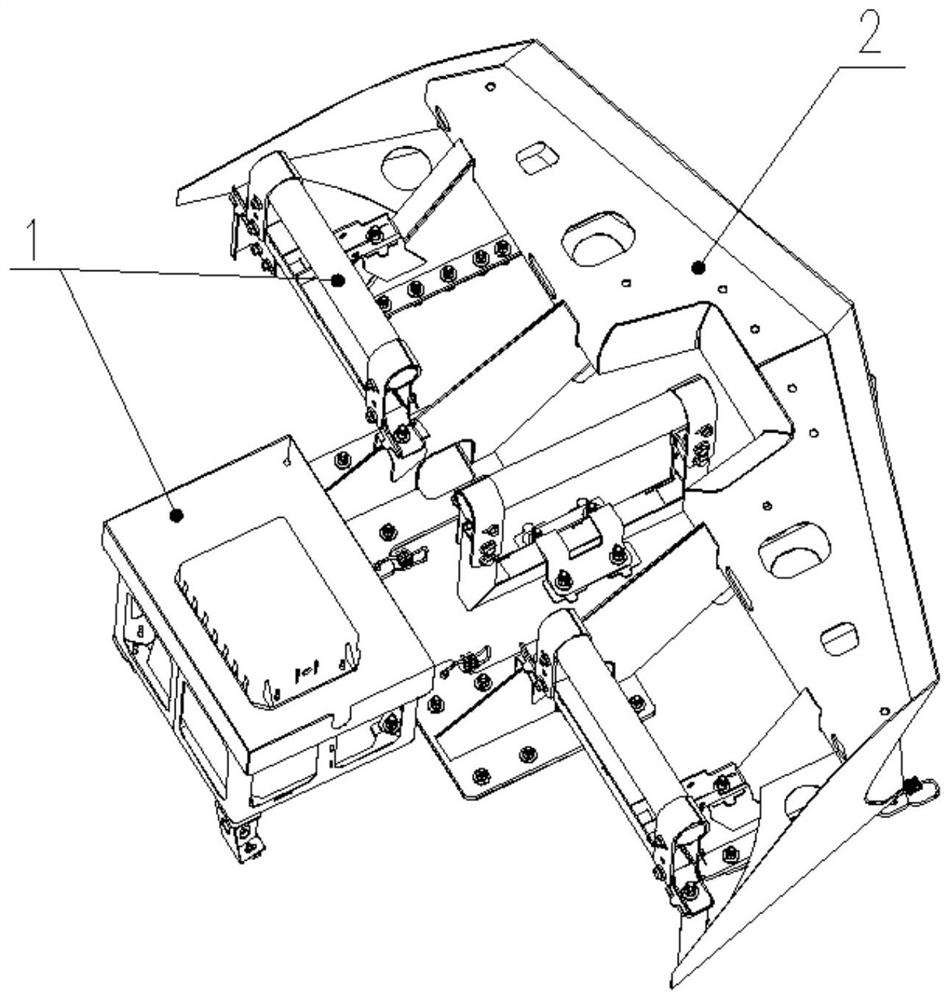

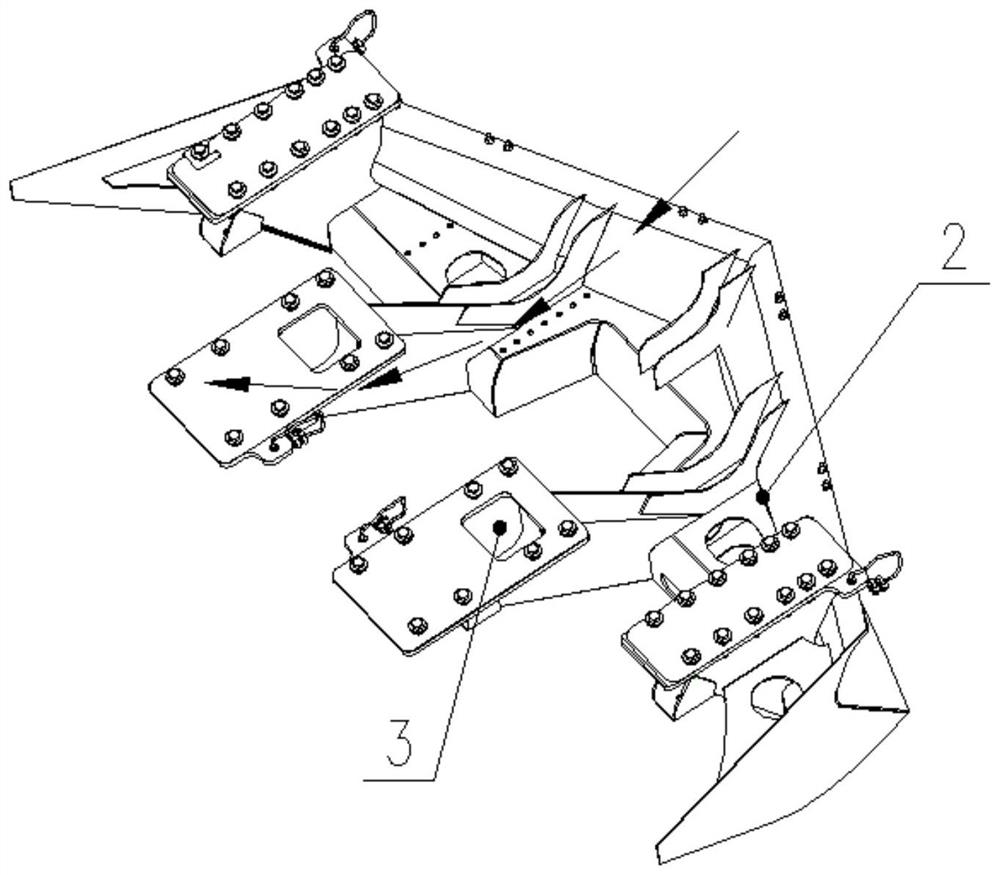

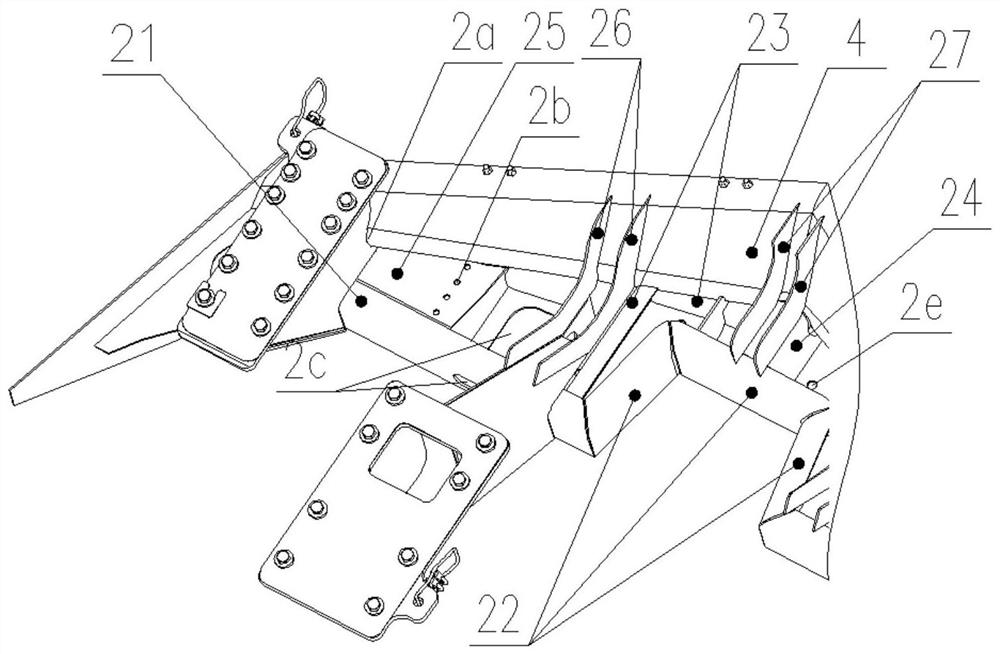

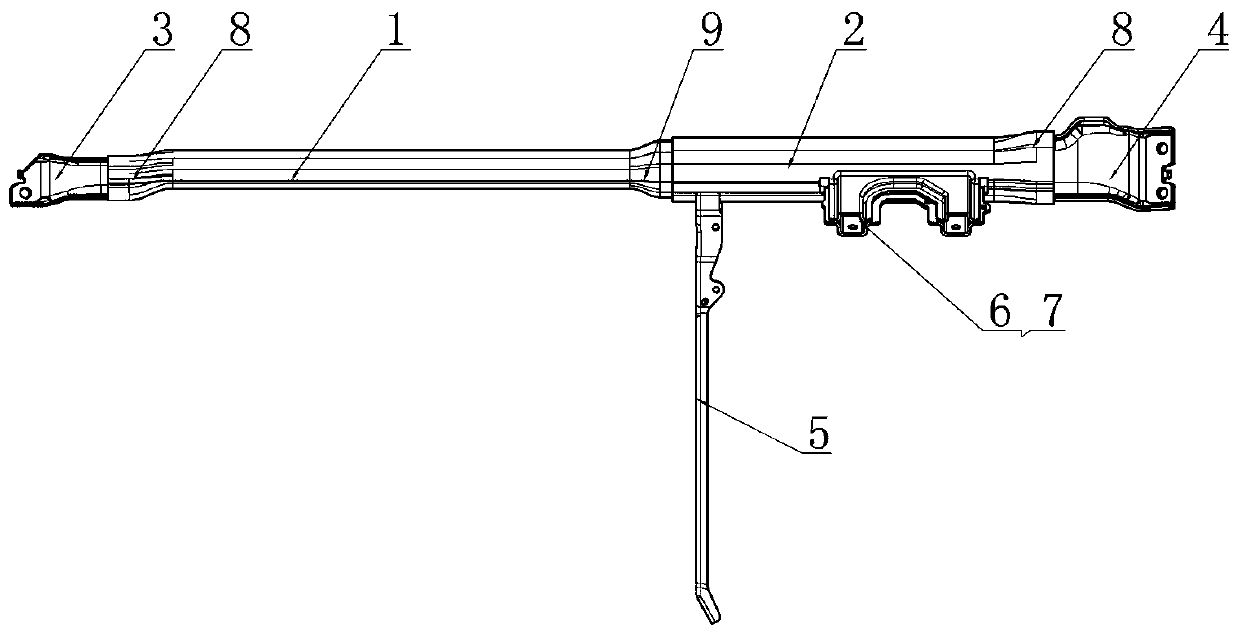

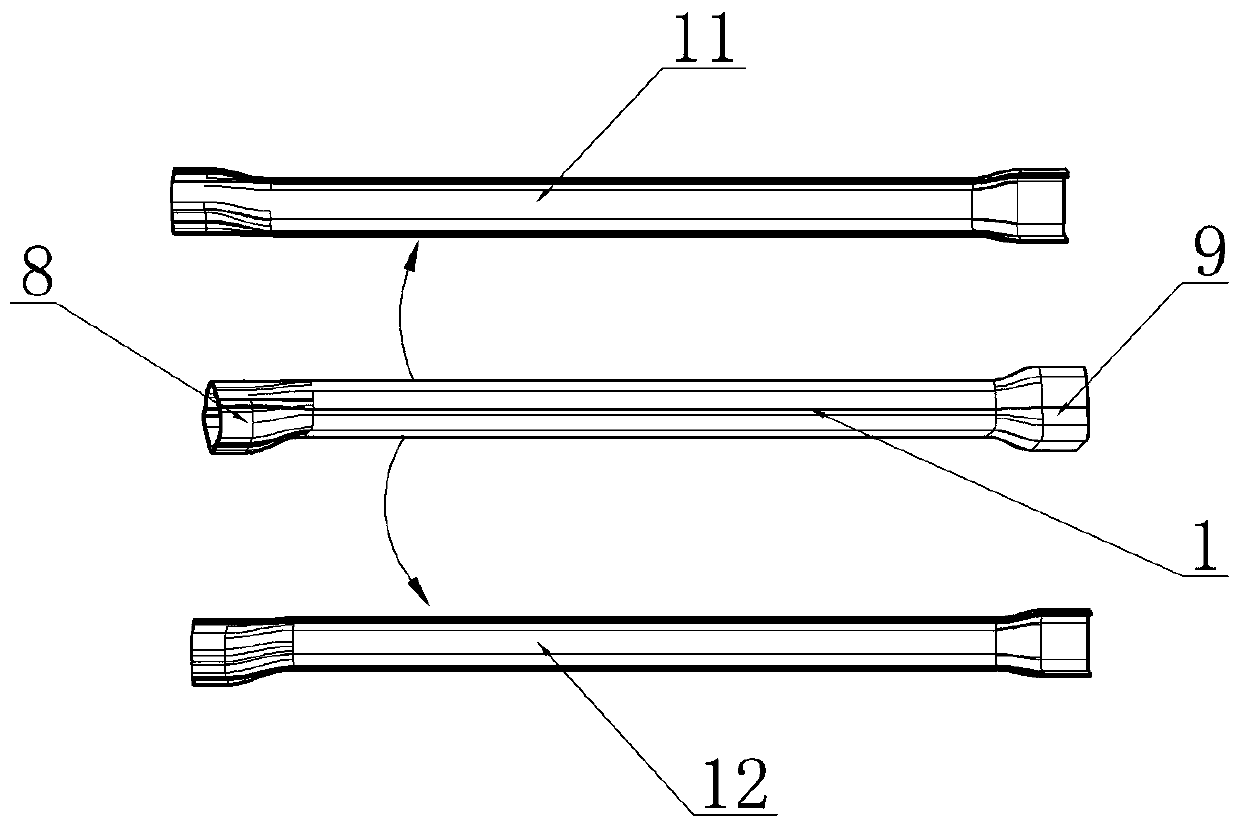

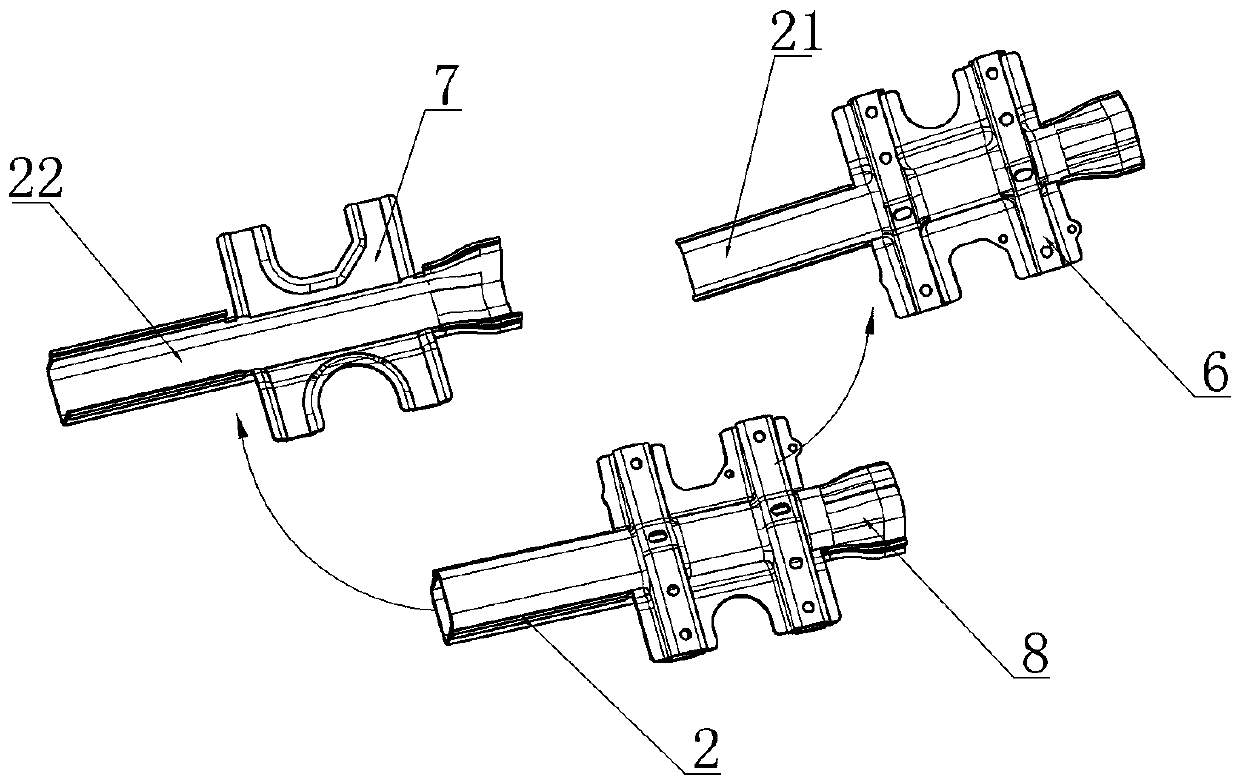

Novel instrument board beam assembly of blade electric vehicles

ActiveCN105539601AAvoid wastingReduce weightSuperstructure subunitsElectric vehicleCar manufacturing

The invention belongs to the technical field of car manufacturing. A novel instrument board beam assembly of blade electric vehicles comprises a beam body, a left instrument board beam connecting plate, a right instrument board beam connecting plate and a longitudinal arm beam; the beam body comprises a left tube beam and a right tube beam which are fixed in a matched and sleeved manner, the left tube beam comprises an upper left tube beam and a lower left tube beam, the upper left tube beam and the lower left tube beam are in U-shaped groove shapes, and openings of the upper left tube beam and the lower left tube beam are opposite; the right tube beam comprises an upper right tube beam and a lower right tube beam, and the upper right tube beam and the lower right tube beam are provided with an upper steering wheel support and a lower steering wheel support; and the upper steering wheel support and the upper right tube beam are of an integrated molding structure, and the lower steering wheel support and the lower right tube beam are of an integrated molding structure. According to the novel instrument board beam assembly, the left tube beam and the right tube beam are welded together in a sleeved manner, by means of the structural design, the material using amount of parts is reasonably distributed, and material waste is avoided; and meanwhile, aluminum alloy die-cast formation is adopted in the tube beams, and the overall weight is reduced while the performance requirement is met.

Owner:ZHENGZHOU BIKE NEW ENERGY AUTOMOBILE

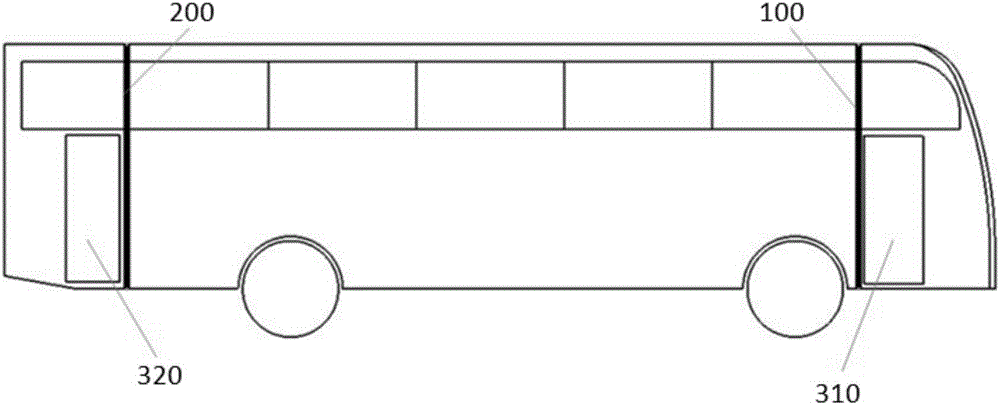

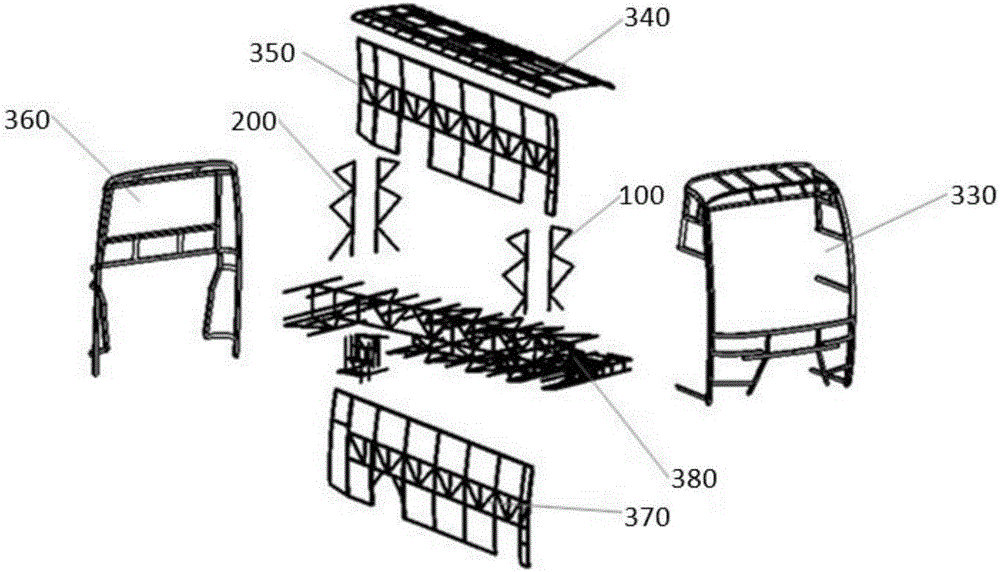

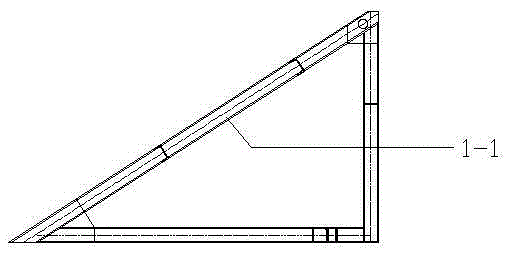

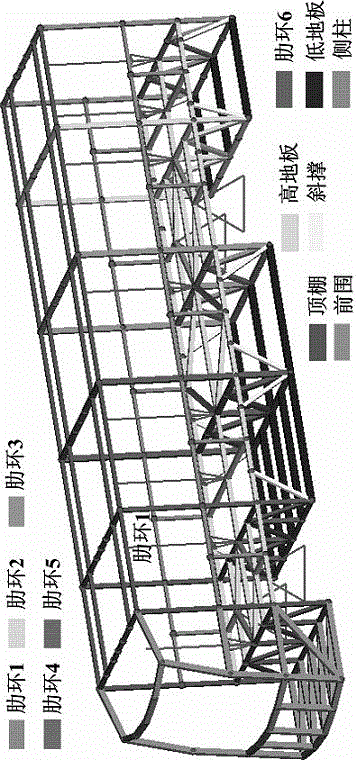

Integral body structure of large highway bus with safety partition

ActiveCN106428240AImproved rollover safetyStrong resistance to axial loadPassenger vehicle superstructuresEngineeringTop cap

The invention discloses an integral body structure of a large highway bus with a safety partition. The body structure comprises a first safety partition in front of the body structure, wherein the upper portion of the inside upright post of the first safety partition is fixed on the front beam of the top cap of the body structure, the lower portion is fixed on the front lower beam of the chassis of the body structure. Multiple first inclined struts are arranged between the inner side upright post and the front side periphery of the body structure, and the first inclined struts and the inner side upright post form multiple triangular structures; a second safety partition is positioned at the rear part of the body structure, wherein the upper portion of the inner side upright post of the first safety partition is fixed on the rear beam of the top cap of the body structure, the lower portion is fixed on the rear lower beam of the chassis of the body structure. Multiple second inclined struts are arranged between the inner side upright post and the rear periphery of the body structure, and the second inclined struts and the inner side upright post form multiple triangular structures.

Owner:XIAMEN KING LONG UNITED AUTOMOTIVE IND CO LTD

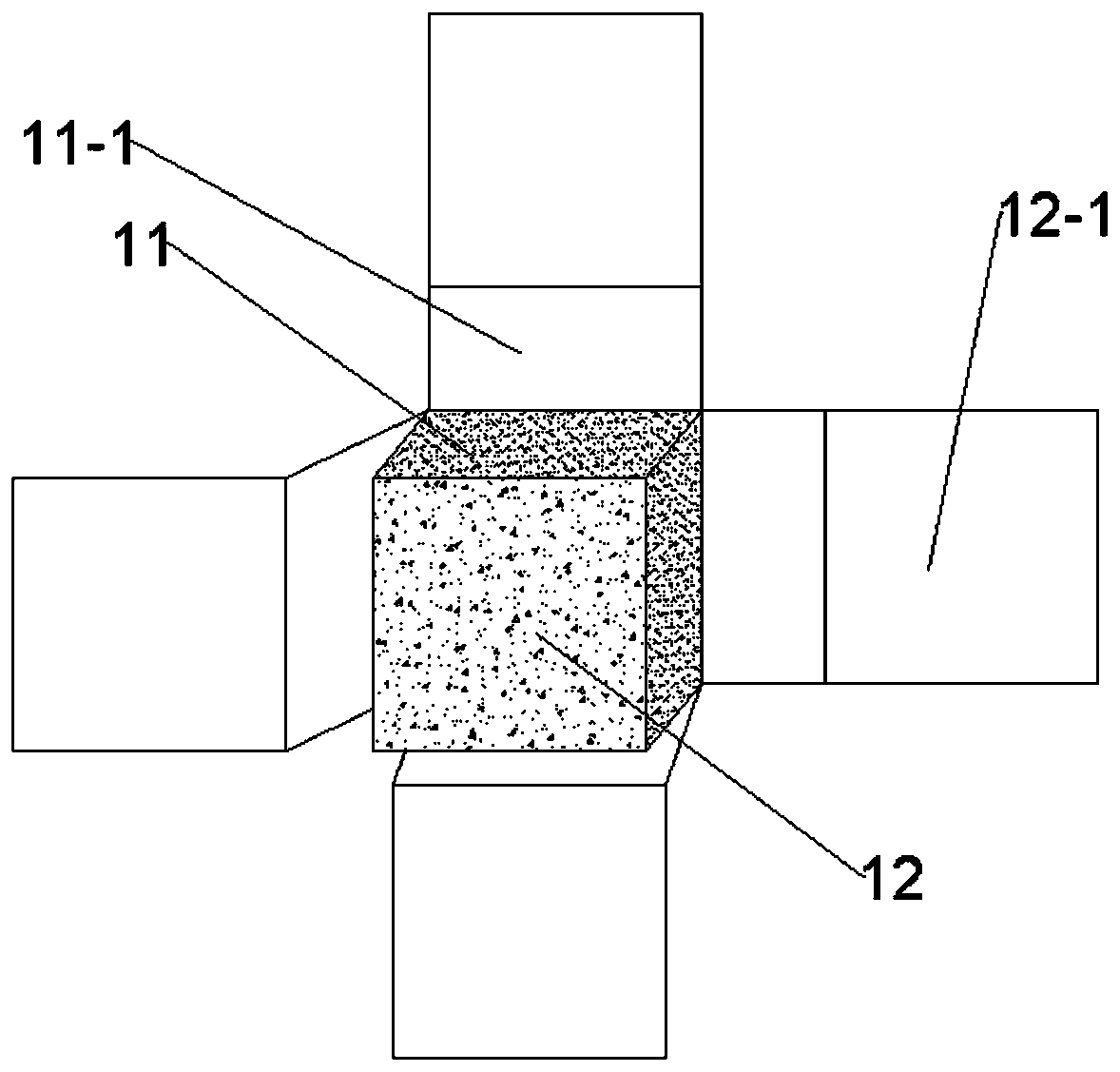

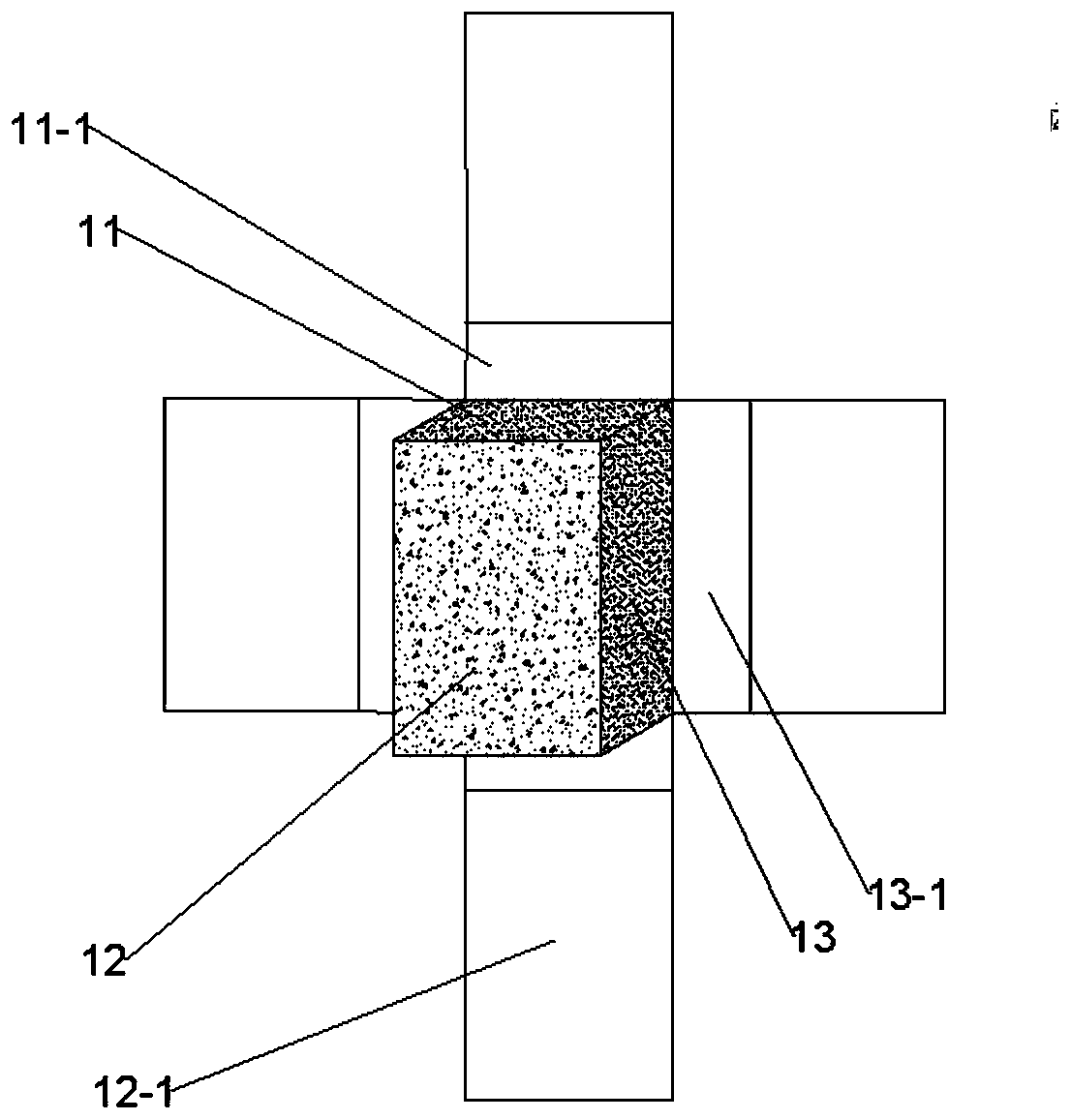

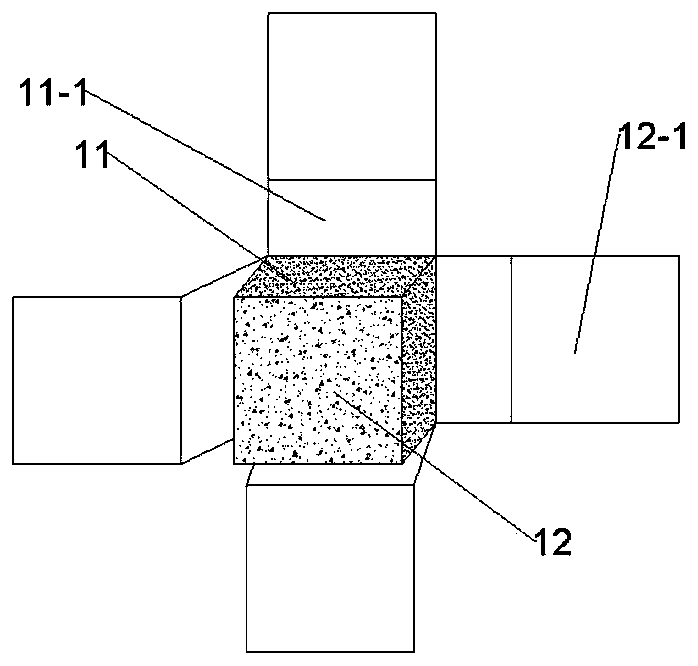

Preparation method of composite ceramic

The invention provides a preparation method of a composite ceramic. The preparation method of the composite ceramic comprises the following steps that fiber cloth is bonded on the surface of a bulletproof back plate; a plurality of packaged ceramic small blocks are bonded on the surface of the fiber cloth; the fiber cloth is bonded on the surface of the plurality of packaged ceramic small blocks to form a ceramic plate; and the ceramic plate is cured to obtain the composite ceramic. The composite ceramic prepared by the method provided by the invention forms a new integral ceramic plate, and has the shock wave isolation effect, so that the anti-multiple attack ability is remarkably enhanced; the ceramic small blocks are bonded to one another, so that the overall bending strength is remarkably improved, the structural integrity and the bulletproof performance of the ceramic small blocks are not reduced under a long-term static load or dynamic load; and after impact, the damaged ceramicsmall blocks can be removed and replaced with the new ceramic small blocks in order to be used for multiple times and improve the use efficiency of the ceramic plate, and even in an emergency situation, the ceramic plate can be repaired. The invention further provides a composite ceramic.

Owner:BEIJING TONGYIZHONG NEW MATERIAL TECH CORP

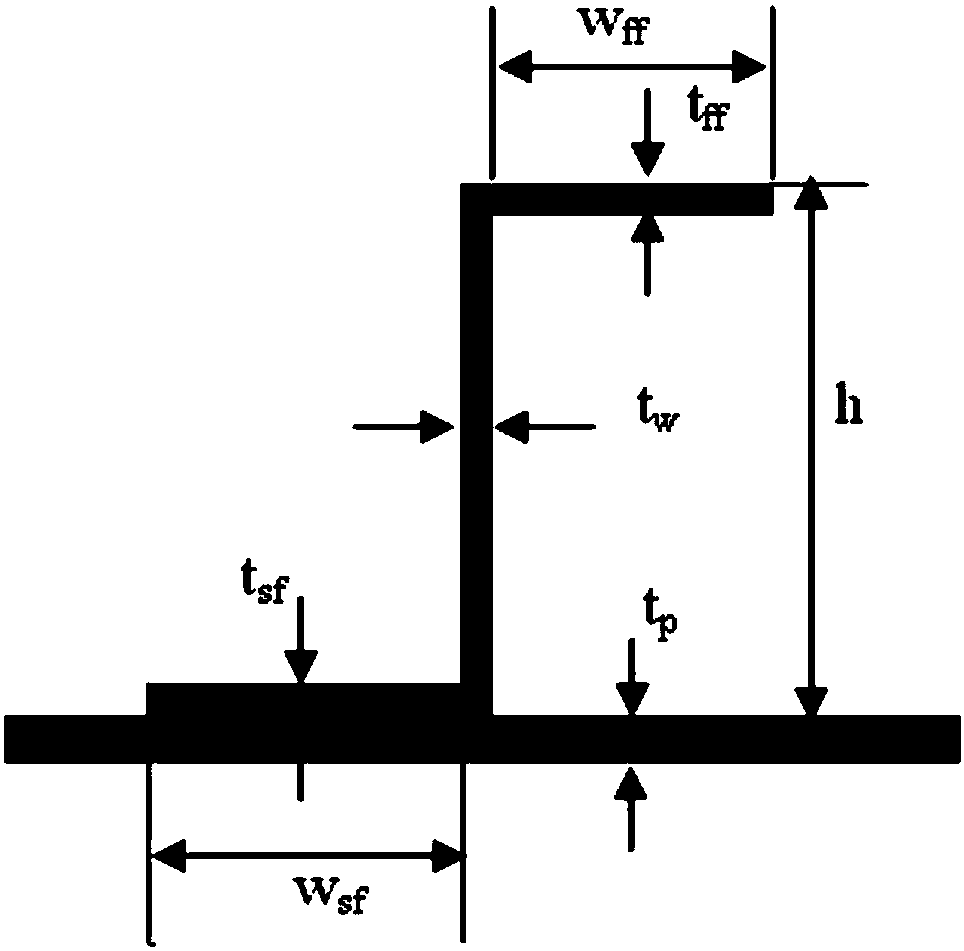

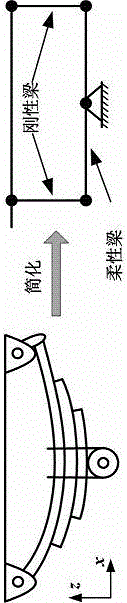

Optimized design method for initial size of thin-wall structure for wings and body of aircraft

ActiveCN108563916AAchieving Lightweight GoalsGeometric CADSpecial data processing applicationsFatigue damageDirect effects

The invention relates to an optimized design method for the initial size of a thin-wall structure for wings and a body of an aircraft. According to the method, the scheme of a thin-wall stiffened plate for the wings and a body of the aircraft in the early stage of the project is determined based on a thin-wall project beam theory. The design of the initial size of the thin-wall stiffened plate isa work with challenge and judgment property, and the subsequent design work is directly influenced when the initial size designed and defined by the scheme is reasonable or not. The ideal thin-wall structure needs to adequately meet the design requirements of static strength design, fatigue damage tolerance design, manufacturing, maintaining and the like. By simplifying any one of an analytical method or a to-be-analyzed structure in the design process of the initial size, the cost benefit of the project can be increased. By further introducing manufacturing and maintaining requirements in thepremise that the static strength requirement is satisfied under the condition that the strength requirement is satisfied, the relatively optimized initial size can be acquired. By defining the initial size of the structure according to the design requirements of manufacturing, maintaining and the like under the condition that the strength requirement is satisfied, the optimized design method canmeet the lightweight design requirement of the structure, and the design efficiency is improved.

Owner:AVIC SAC COMML AIRCRAFT

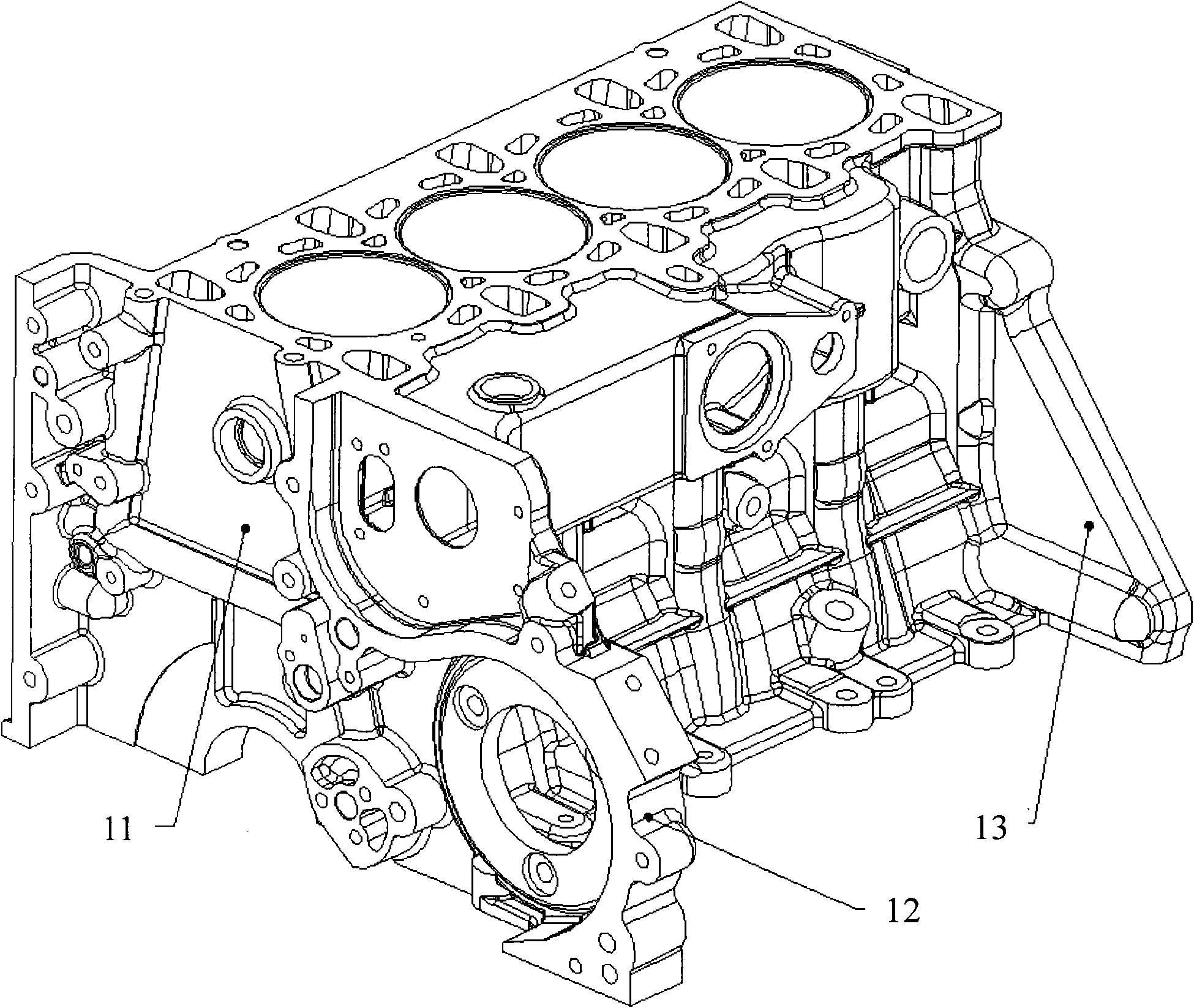

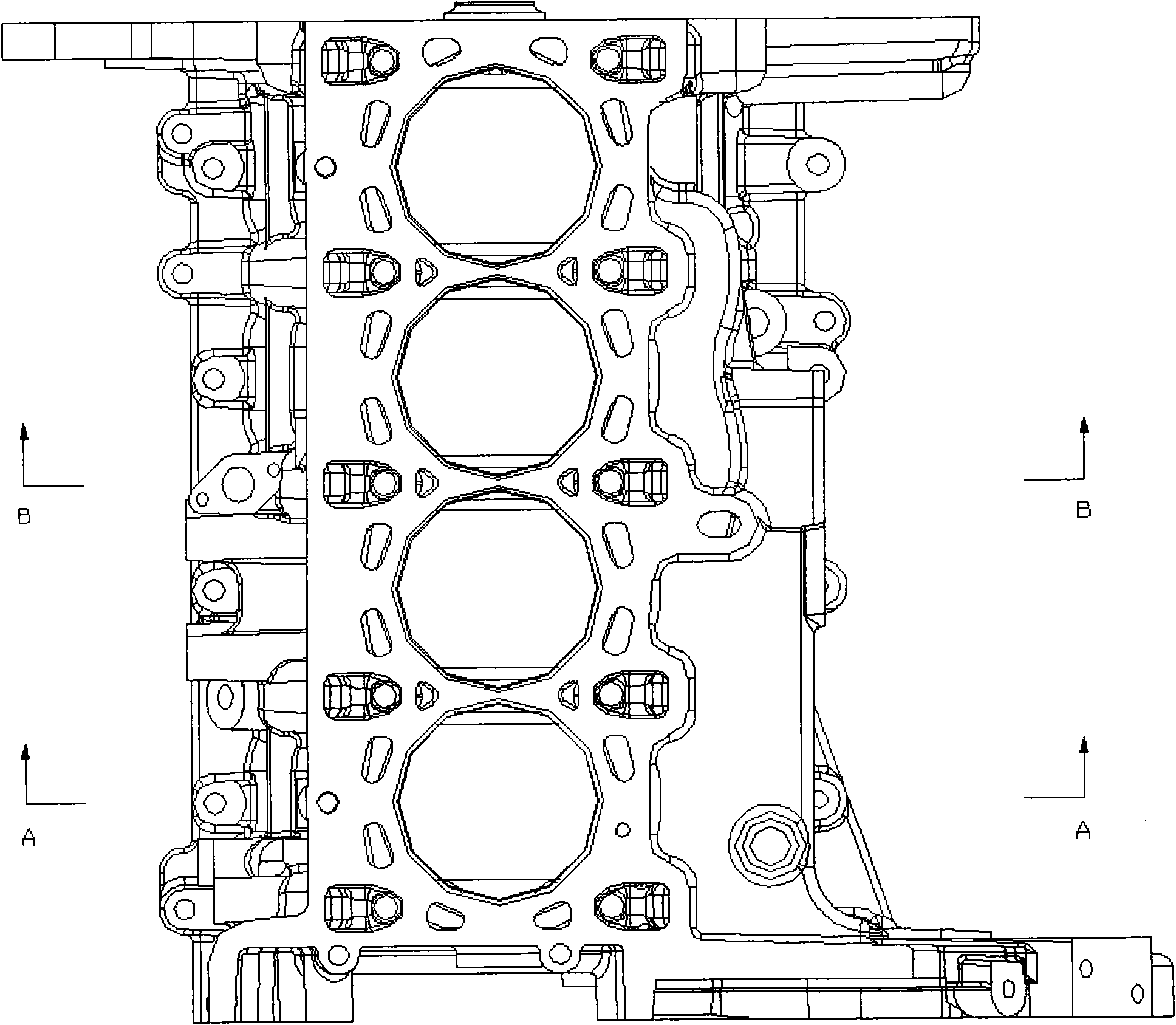

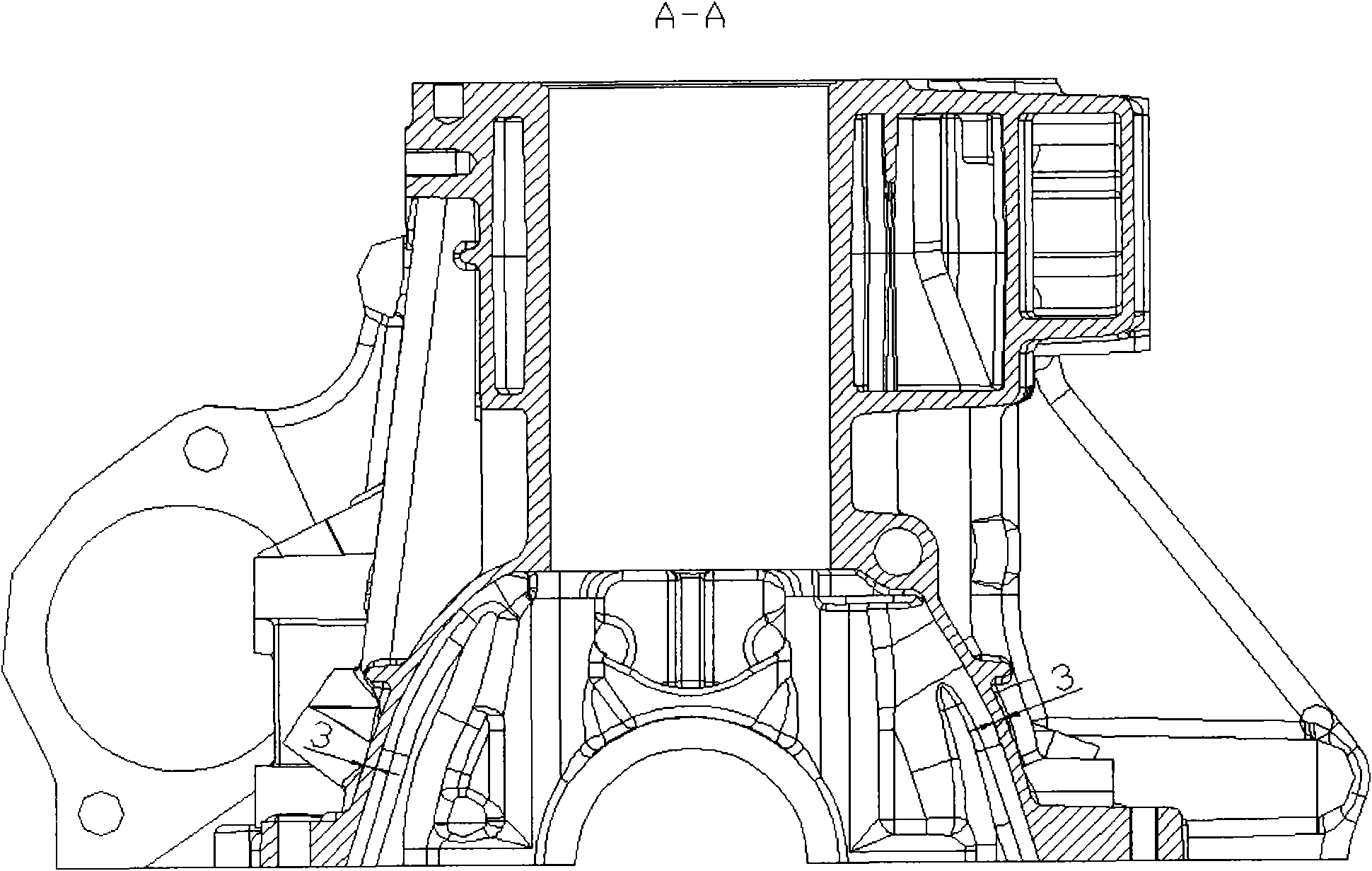

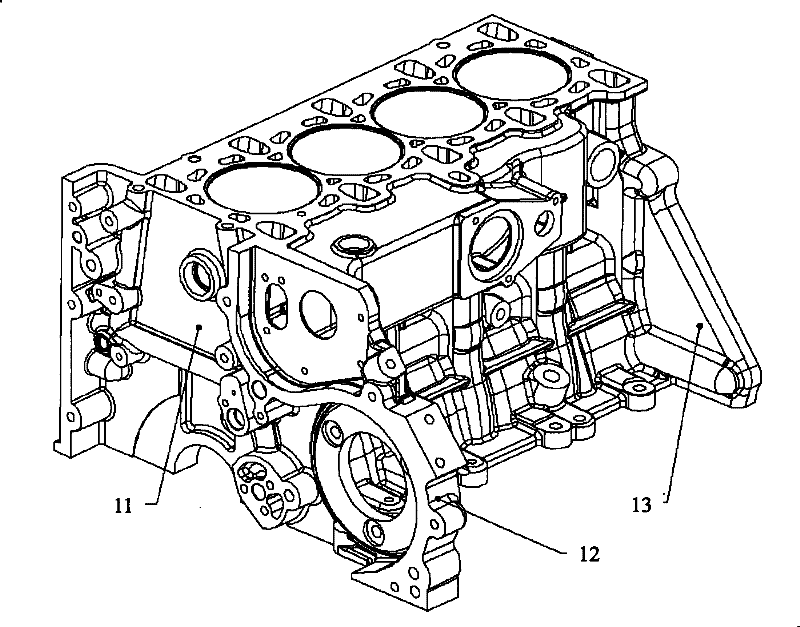

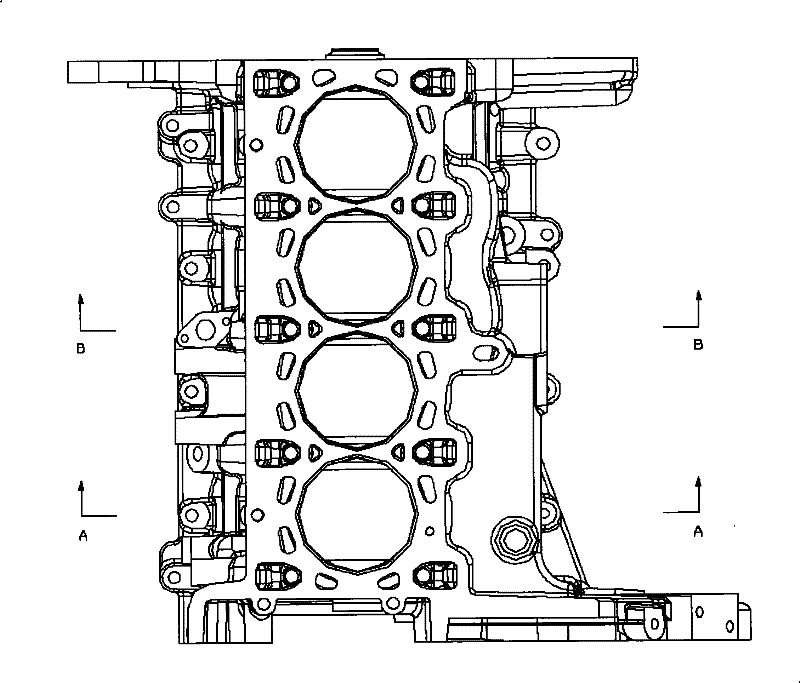

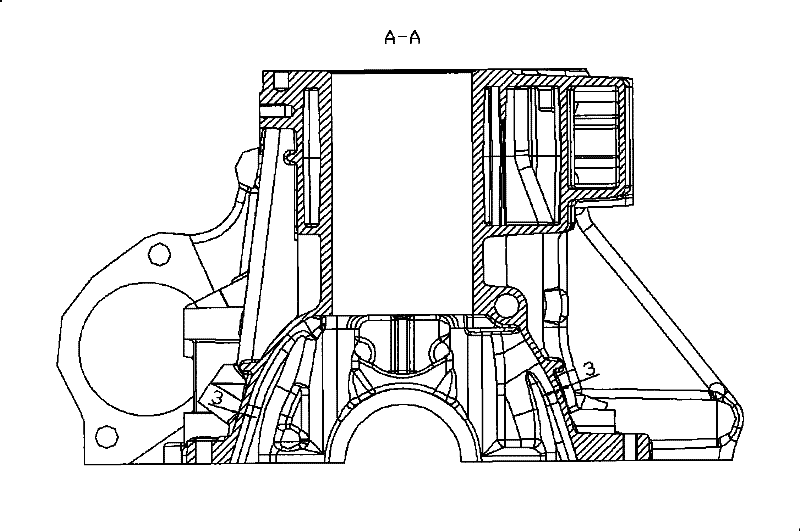

Diesel engine cylinder block of sedan and casting method thereof

The invention discloses a diesel engine cylinder block of a sedan and a casting method thereof. The diesel engine cylinder block of the sedan adopts vermicular cast iron materials; the thickness of the wall is 3mm, and the cylinder core distance is 86mm; the front end of the cylinder block is provided with an injection pump mounting flange and a gear chamber or a chain wheel chamber in the manner of directly casting; the rear end of the cylinder block is provided with a gear box connecting flange and a cranking motor mounting flange in the manner of directly casting. The targets of light-weight design and high strength of the thin-wall are realized by adjusting the formula of a vermiculizer and controlling the smelting and pouring techniques; a water jacket sand core adopts an integral structure; the pouring manufacturability is favorable; the casting mode with a gadarene cylinder top is adopted to ensure the precision of water jacket casting; the casting mould of a full-cold core is adopted; the casting mould can be painted with high-temperature resistant coatings; a sand mould has high strength and rigidity and high precision; and the casting mould has little gas evolution, thus ensuring the precision of thin-walled cylinder block castings and effectively reducing casting defects.

Owner:GUANGXI YUCHAI MASCH CO LTD

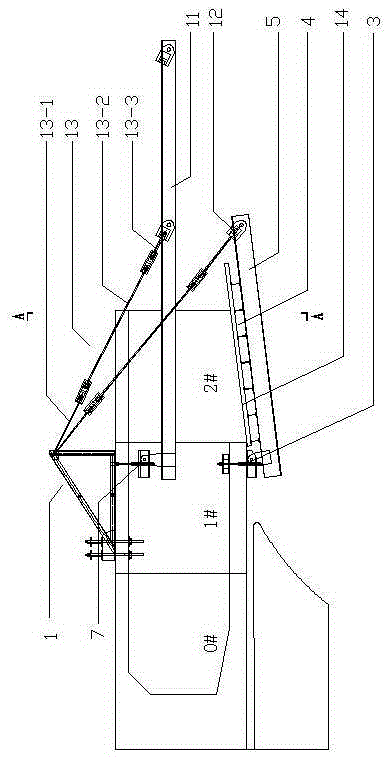

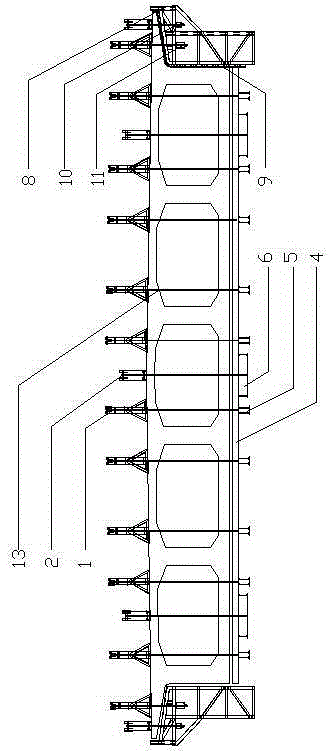

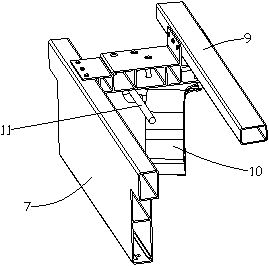

Lower-guide type main-truss-free hanging basket

ActiveCN105386414AReduce volumeAchieving Lightweight GoalsBridge erection/assemblyEngineeringHanging basket

The invention discloses a lower-guide type main-truss-free hanging basket. The lower-guide type main-truss-free hanging basket is characterized by comprising a triangular support supporting mechanism, a bottom basket mechanism, side mould mechanisms and a connecting mechanism, wherein the triangular support supporting mechanism is arranged on the upper part of a top plate of a completed box beam; the bottom basket mechanism is arranged on the lower part of the bottom plate of the completed box beam; the side mould mechanisms are arranged at left and right sides of the completed box beam; and the connecting mechanism is used for connecting and suspending the bottom basket mechanism and the side mould mechanisms below the triangular support supporting mechanism. The lower-guide type main-truss-free hanging basket disclosed by the invention has the advantages of being free of a main truss and small in size, realizing a light-weight goal (by improving the form of the hanging basket) of an integral design of the hanging basket by virtue of a miniature design of a stress unit, so that the structures, above bridge floor, of the hanging basket are greatly reduced, thereby greatly reducing weight of the hanging basket and saving a great deal of material (steel) investment.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

Method for preparing forging piece of aluminum-steel composite structure track plate

ActiveCN106514141AGuaranteed wear resistanceGuaranteed StrengthMetal-working apparatusIngot castingMetallic materials

The invention belongs to the field of metal material processing, and relates to a track plate preparation method, in particular to a method for preparing a forging piece of an aluminum-steel composite structure track plate. The method includes the steps that an ingot casting is prepared by means of semi-continuous casting at first; then the aluminum alloy ingot casting is prepared into an extrusion material by the adoption of forward or backward extrusion; the extrusion material is blanked according to the dimension, and an aluminum alloy track plate pre-forging piece is pre-forged through constant temperature die forging; and afterwards, a cast steel block and a pre-forged aluminum alloy track plate are forged into a whole by means of finish forging, so that the aluminum-steel composite structure is formed. The weight of the aluminum-steel composite structure track plate prepared through the method is lowered by 30% compared with a steel track plate; and meanwhile the abrasion resistance and overall strength of the track plate can be guaranteed, and the structural performance is reliable.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

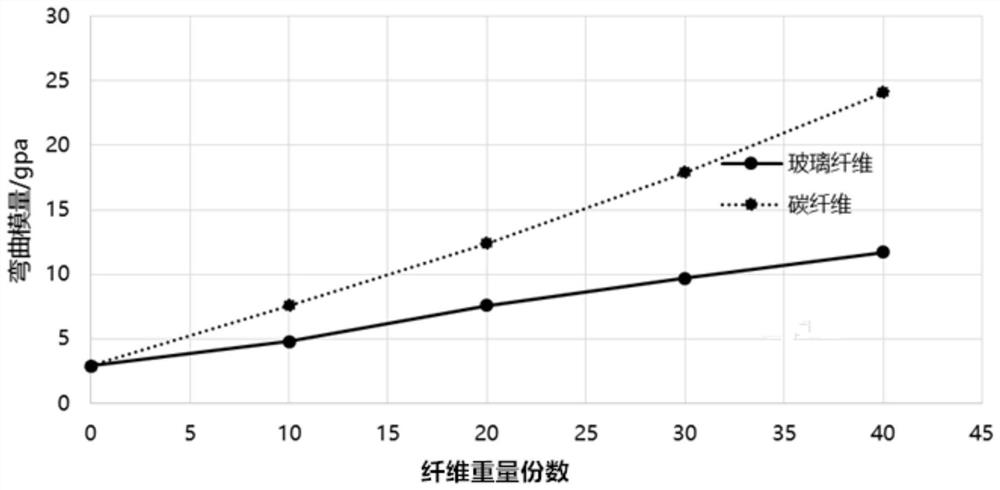

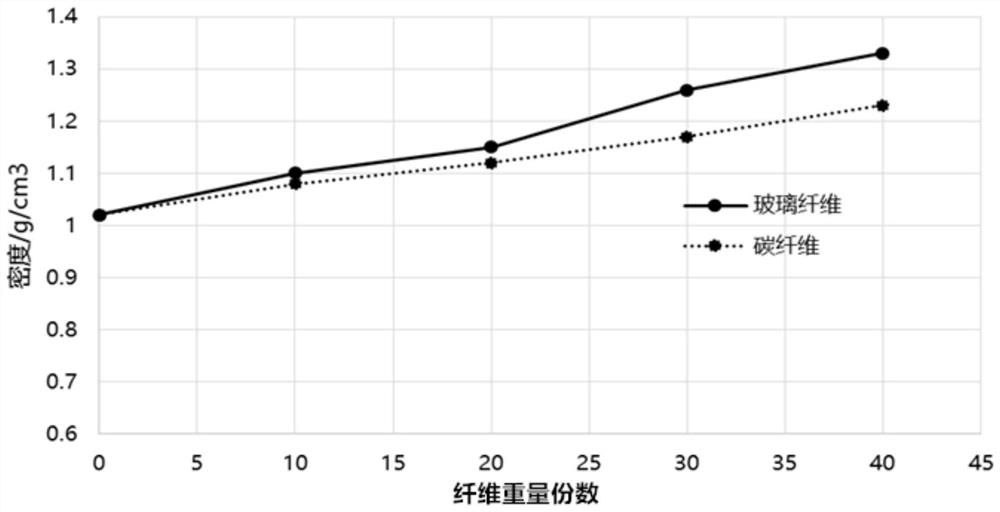

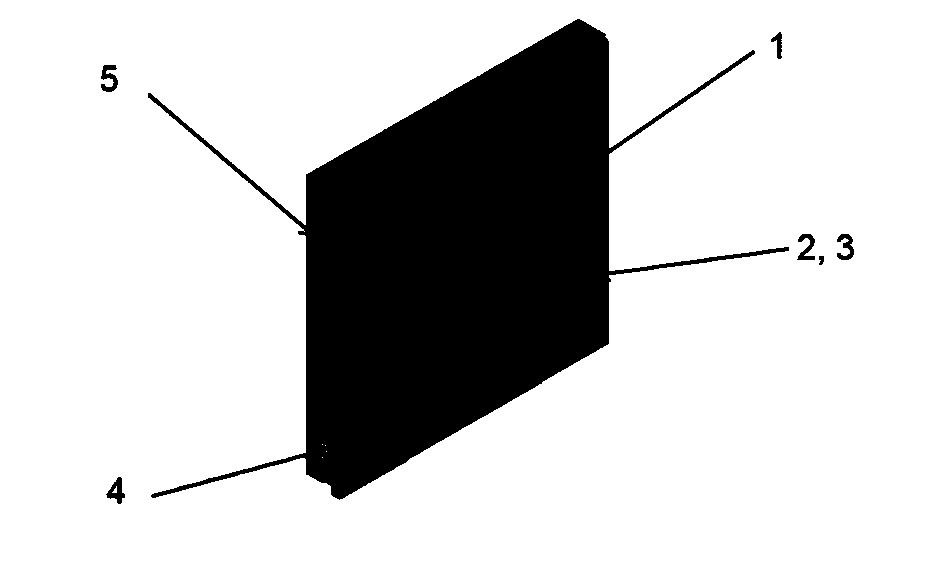

Shell for sound production device and sound production device

PendingCN114806034AHigh strengthLow densityTransducer casings/cabinets/supportsPolymer chemistryPolystyrene

The embodiment of the invention provides a shell for a sound production device and the sound production device, the shell comprises a plastic component and a reinforcing component, the plastic component comprises syndiotactic polystyrene, the range of the mass fraction of the syndiotactic polystyrene is 40-90, and the range of the mass fraction of the reinforcing component is 5-50. The shell comprises a plastic component and a reinforcing component, the plastic component comprises syndiotactic polystyrene, the range of the mass fraction of the syndiotactic polystyrene is 40 to 90 parts, and the range of the mass fraction of the reinforcing component is 5 to 50 parts. Through the cooperation of the low density of the syndiotactic polystyrene and the high strength of the reinforcing component, the shell has the characteristics of high strength, low density, small deformability and high assembly precision, and the aim of light weight of the shell is achieved.

Owner:GOERTEK INC

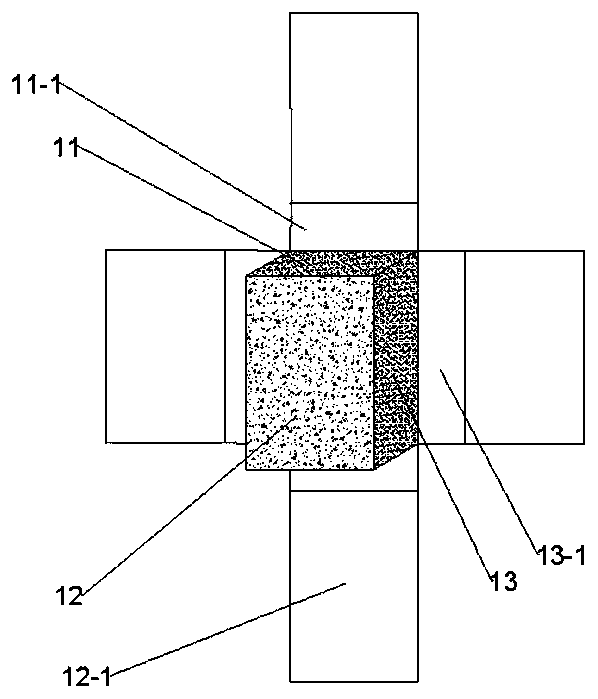

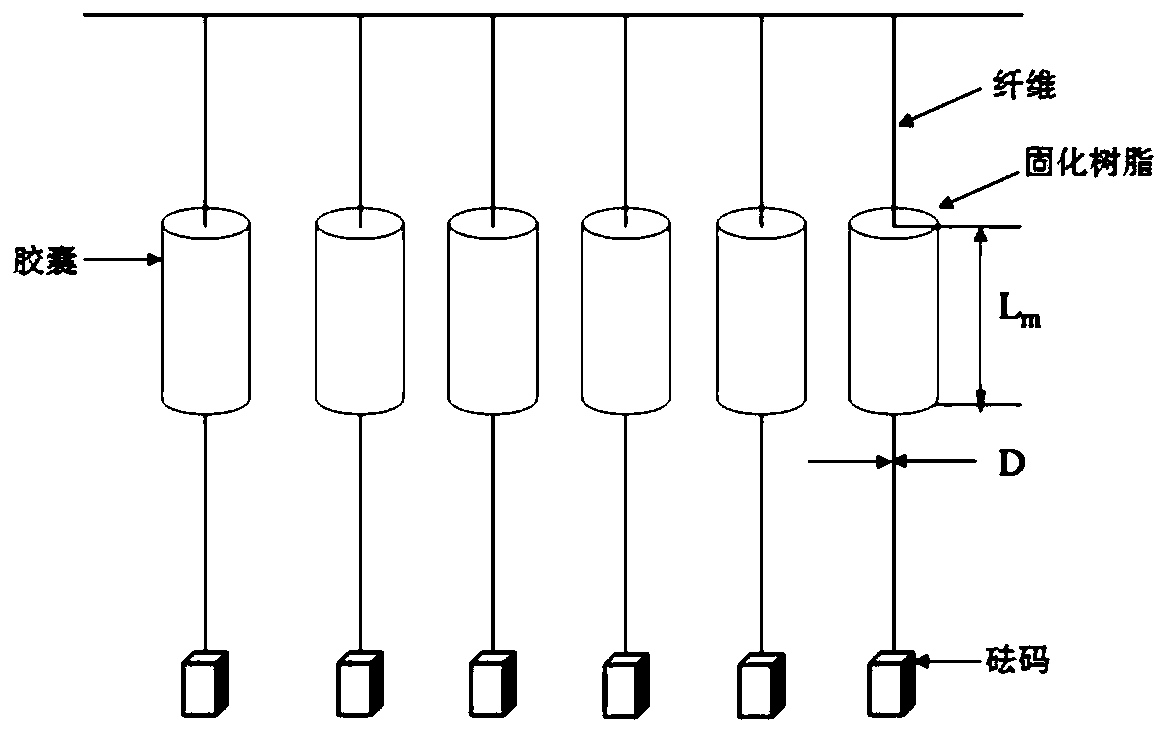

Ultralight armored product and preparation method thereof

PendingCN110749235AGuaranteed protective effectIncrease incidenceProtective equipmentLaminationFiberMaterials science

The invention provides an ultralight armored product. The ultralight armored product comprises a fiber layer press plate, a metal plate bonded onto the surface of the fiber layer press plate, a fibercloth bonded onto the surface of the metal plate, a plurality of packaged small ceramic blocks bonded onto the surface of the fiber cloth, and a fiber cloth bonded onto the surfaces of the plurality of packaged small ceramic blocks, wherein the interiors of the packaged small ceramic blocks are small ceramic blocks, and the exteriors of the packaged small ceramic blocks are packaged by the fiber cloth. The ultralight armored product prevents multiple attacks; through three-dimensional wrapping packaging, the independent small ceramic blocks re-compose an integer, and the integer is high in structural strength, great in mechanical property such as bending property, anti-seismic, and resistant to collision damage; the bullet-proof capability is improved; and the ultralight armored product can be secondarily repaired and used, so that the use efficiency for a ceramic plate is increased. The invention further provides a preparation method for the ultralight armored product.

Owner:BEIJING TONGYIZHONG NEW MATERIAL TECH CORP

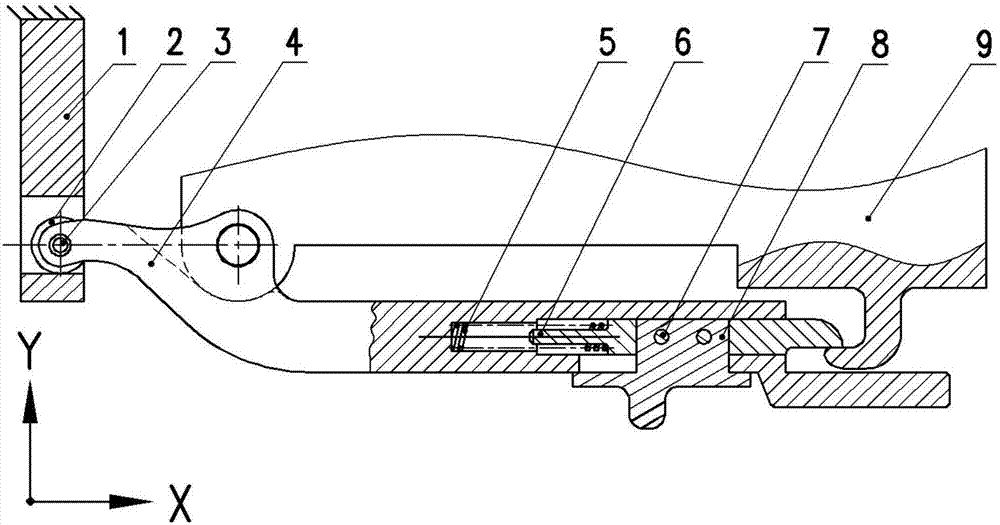

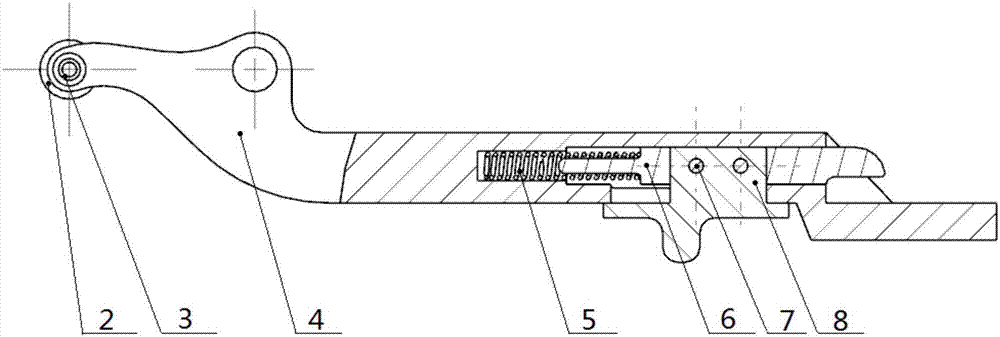

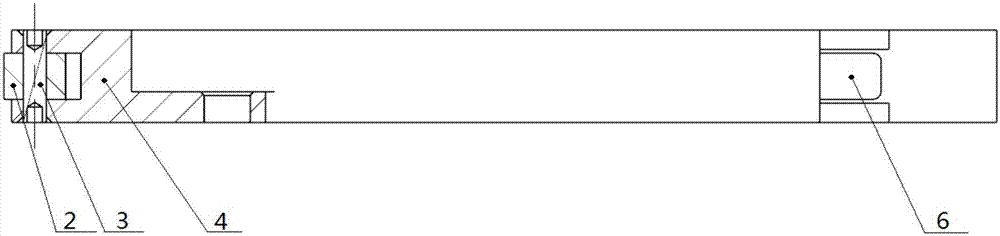

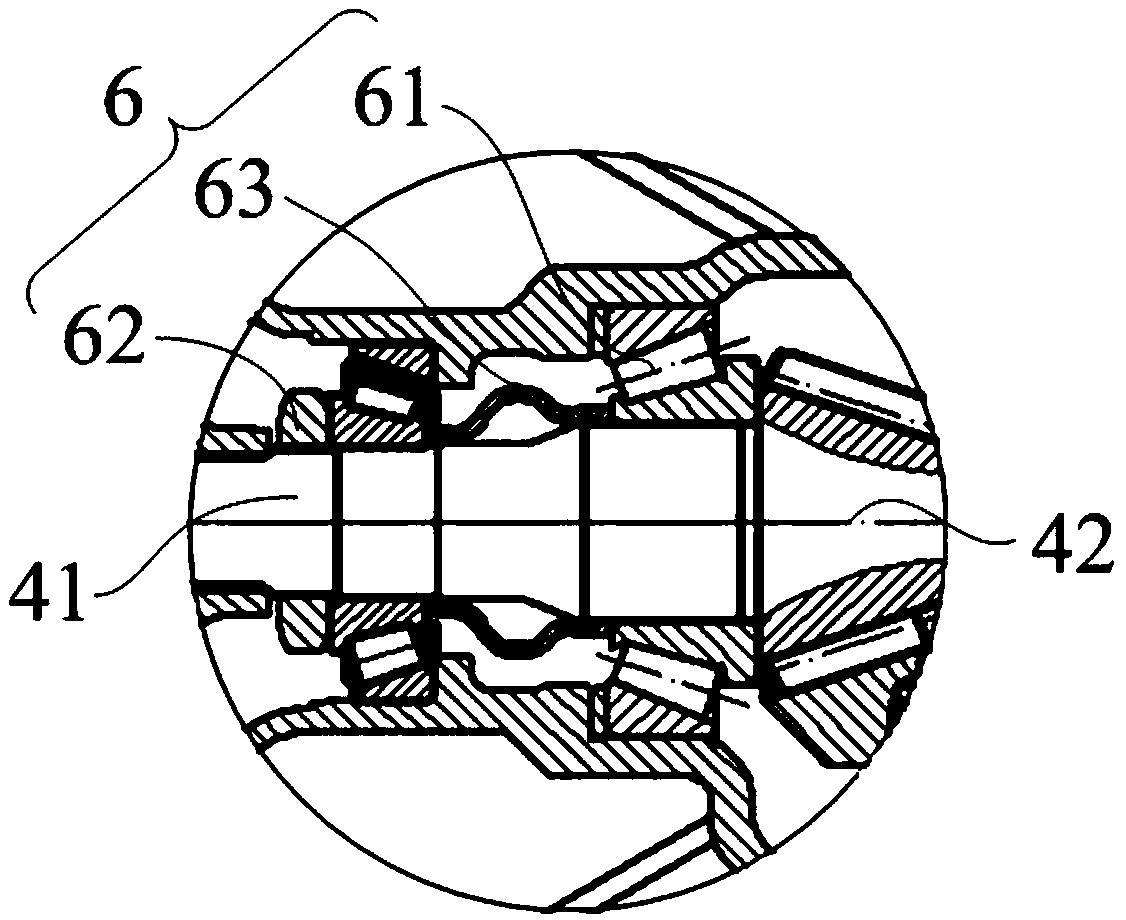

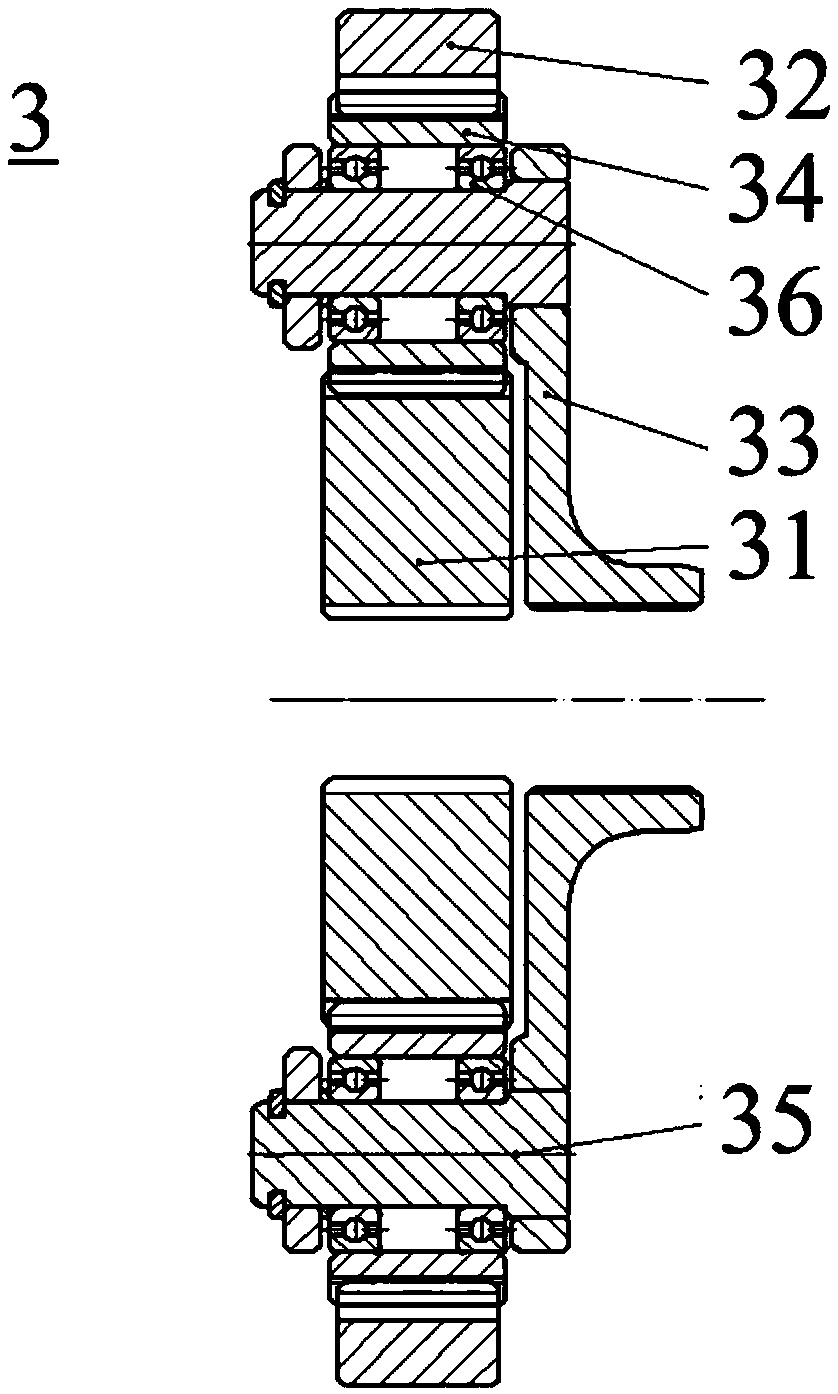

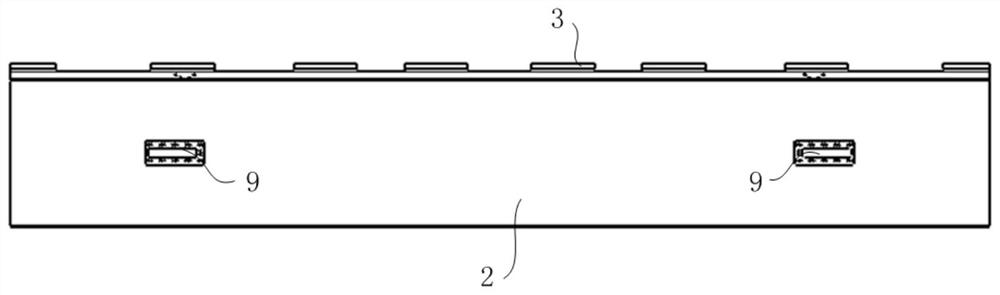

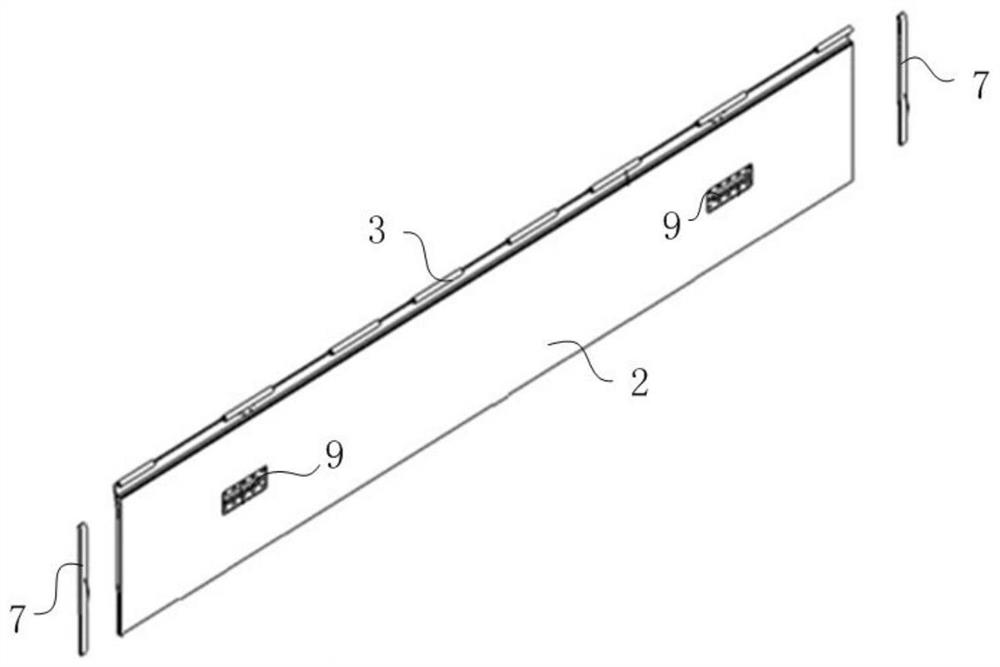

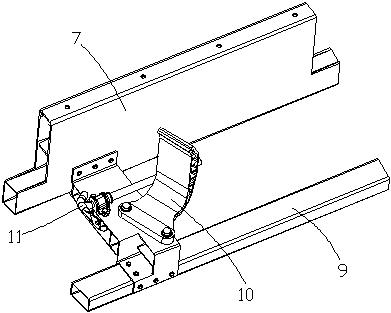

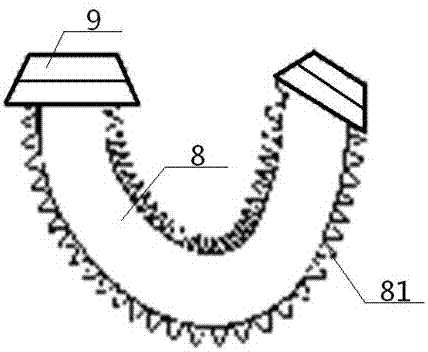

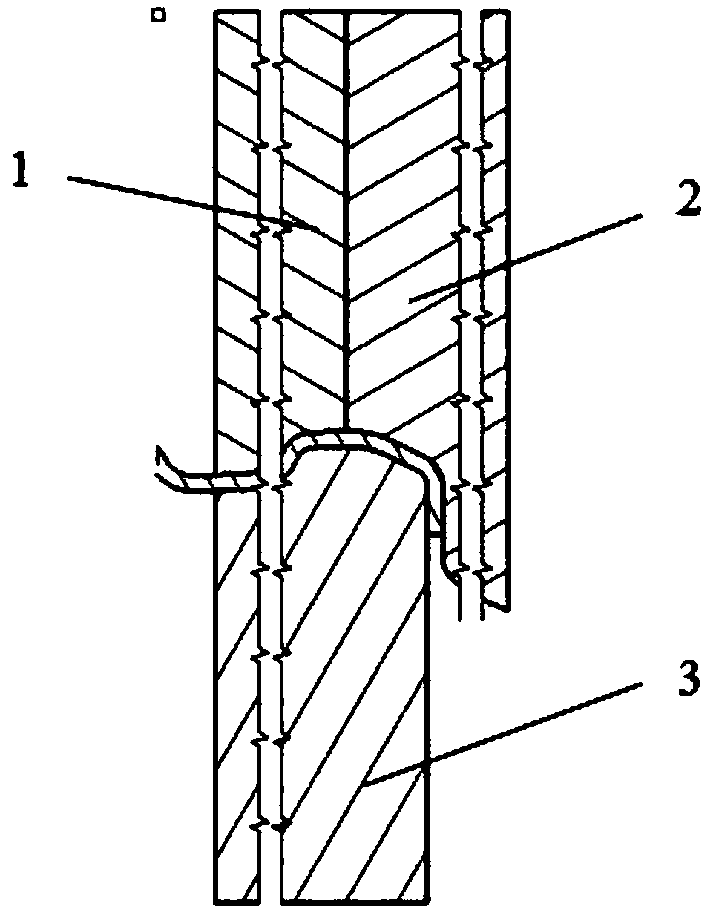

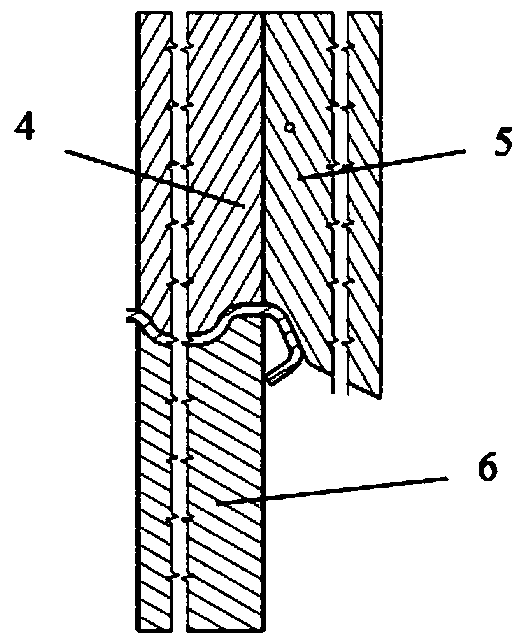

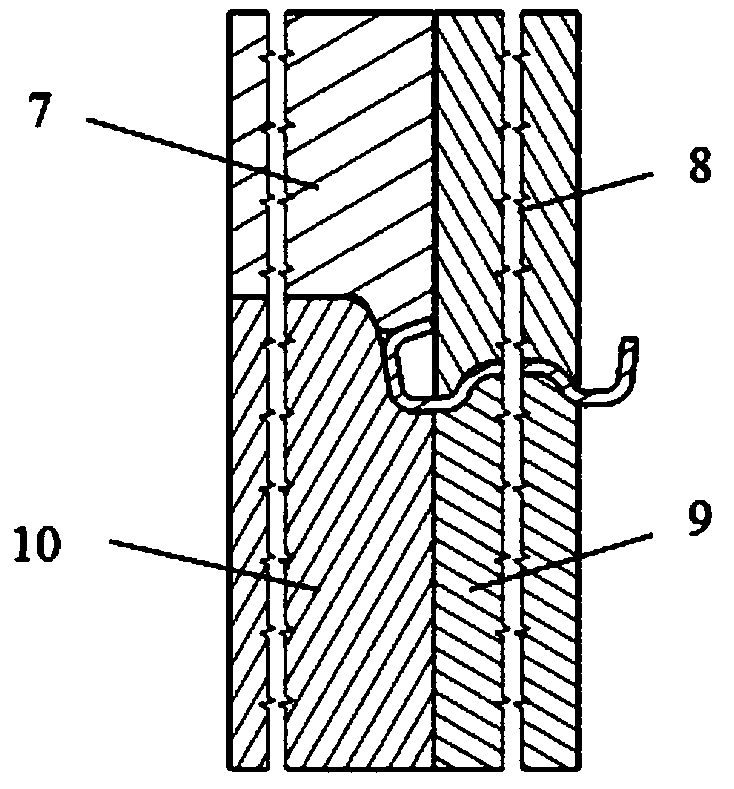

Dismountable assembly push-assisting and pull-assisting device

InactiveCN107511790ARealize the function of boosting and pulling outAchieving Lightweight GoalsMetal-working hand toolsEngineeringRivet

The invention discloses a dismountable assembly push-assisting and pull-assisting device. The dismountable assembly push-assisting and pull-assisting device comprises a fixed base 1, a handle 4 and an assembly 9 with a hook-shaped structure. A roller 2, a clamping needle 6 and a pusher 8 are connected to the handle 4, the handle 4 is in rivet connection with the roller 2 through a plug pin 3 to form a rotation pair, the clamping needle 6 is in rivet connection with the pusher 8 through a plug pin 7, a guide groove used for storing a spring 5 and the clamping needle 6 is formed in the handle 4, and the clamping needle 6 and the handle 4 build a sliding pair connection relation through the spring 5. A hook-shaped structure matched with the clamping needle 6 for locking is arranged on the position, on the right side of a picture, of the assembly 9, and a cylindrical boss matched with a through hole formed in the handle 4 is arranged on the left side of the picture of the assembly 9. The base 1 is fixed, and a groove interacting with the roller 2 is formed in the base 1. According to the dismountable assembly push-assisting and pull-assisting device, the structure is relatively simple, operation is convenient, and the dismountable, push-assisting and pull-assisting functions can be effectively achieved.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

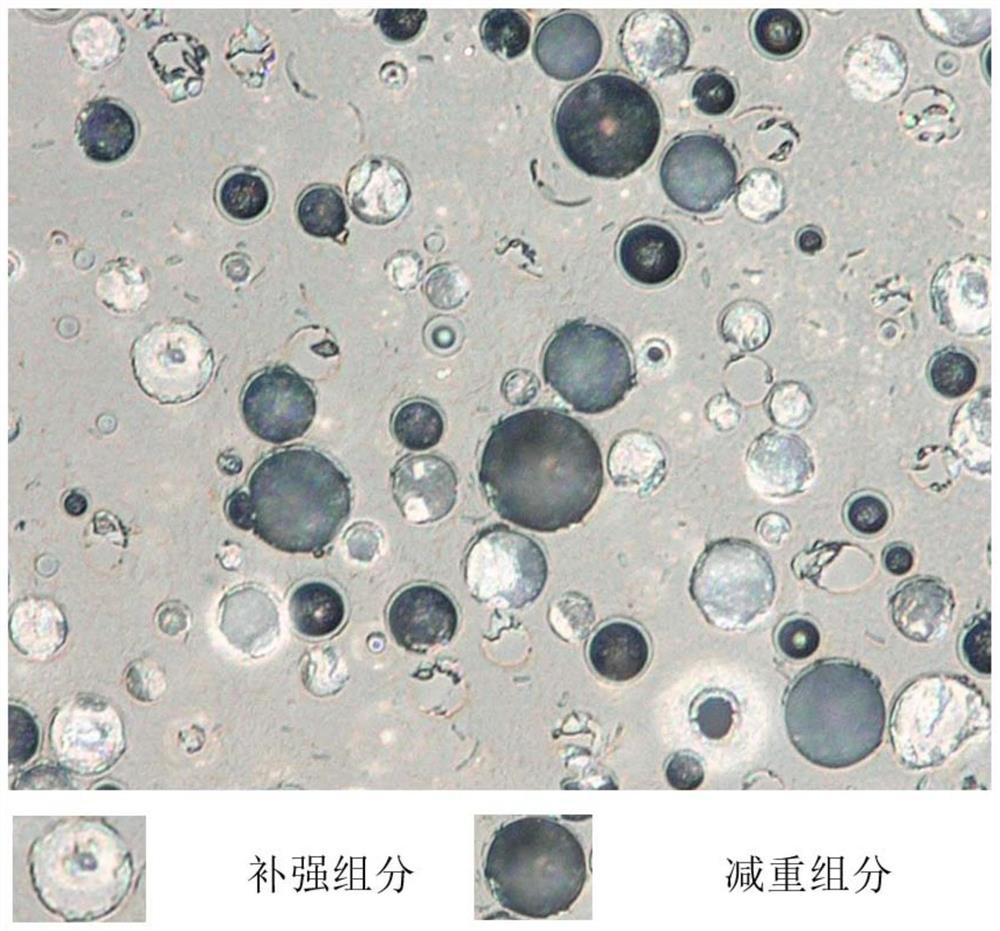

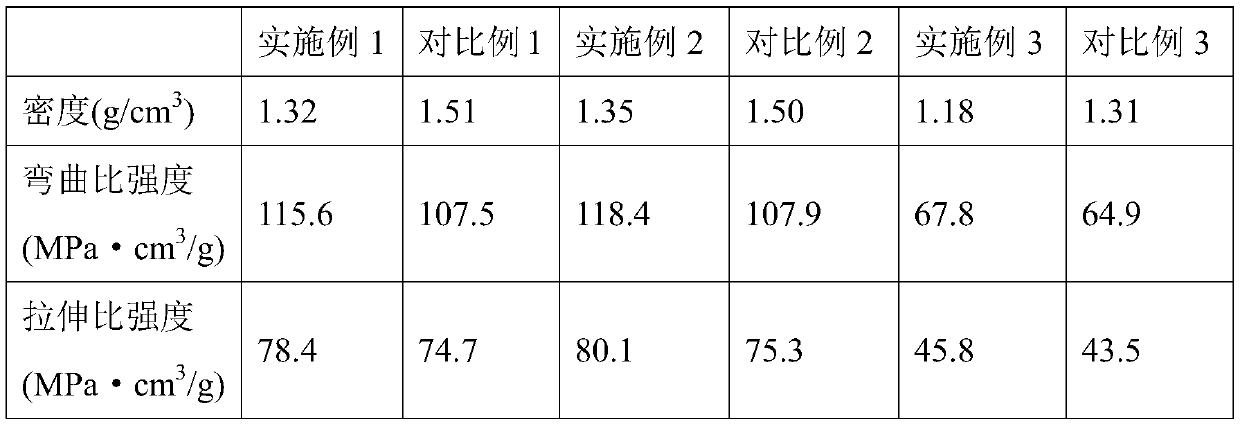

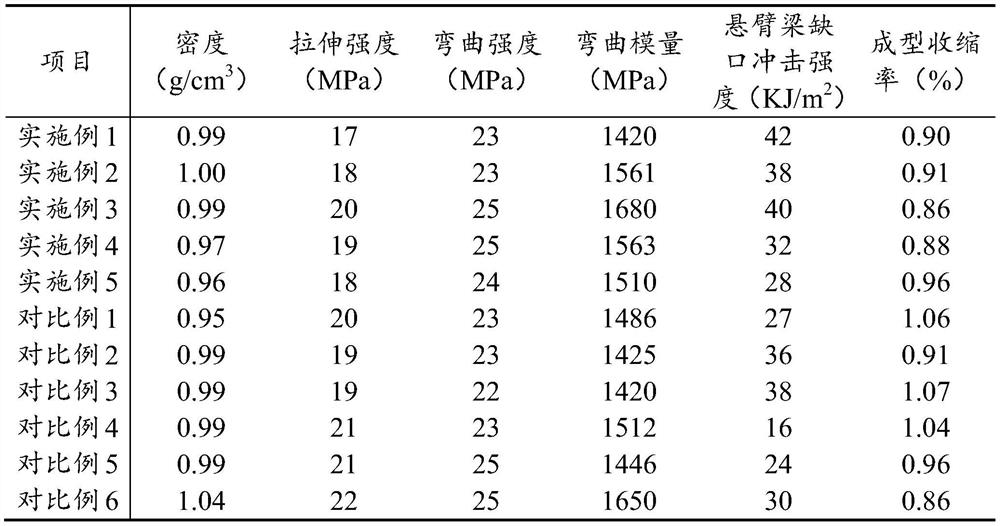

Light-weight high-strength PBT material and preparation method thereof

The invention discloses a light-weight high-strength PBT material and a preparation method thereof. The PBT material comprises PBT plastic particles, an auxiliary agent and expandable microspheres. The expandable microsphere is of a shell-core structure, wherein a shell material is a thermoplastic polymer, and a core material is a foaming agent with the boiling point not higher than boiling pointof the shell material. The preparation method comprises the following steps: adding the auxiliary agent and the color master batch into the PBT plastic particles as required, then adding the expandable microspheres, and uniformly mixing; injecting the mixture into an injection molding machine through a feeding port, and melting the mixture through heating of a charging barrel; and injecting the molten mixture into a mold, and carrying out injection molding. In the injection molding process, the microsphere shell is heated to be softened and expanded in size to form stable foam holes with similar sizes. After the microspheres are expanded, gas is mainly contained in the spheres, the density of an injection molding part can be well reduced, and light weight is achieved; after the proper temperature and pressure are adjusted, the weight of the PBT material can be reduced by 10%-30%, and the bending strength and the tensile strength are both improved.

Owner:快思瑞科技(上海)有限公司

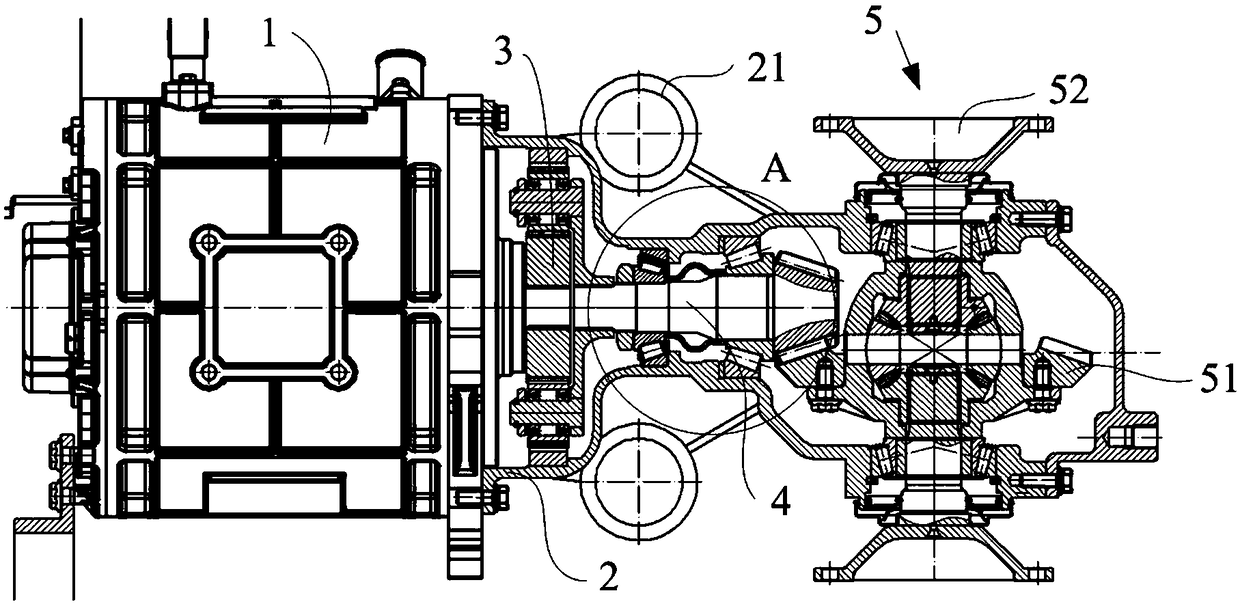

Electric drive axle assembly and vehicle

PendingCN108859706AIncrease load capacityExtended service lifeElectric propulsion mountingControl devicesGear driveGear wheel

The invention relates to an electric drive axle assembly and a vehicle, wherein the electric drive axle assembly comprises a motor, a shell and a planetary wheel speed reduction mechanism, hypoid gear and differential mechanism which are arranged in the shell, wherein the shell is fixedly connected with the motor; the driving shaft of the motor, the planet wheel speed reduction mechanism and theactive gear shaft of the hypoid gear are in transmission coaxially, and the passive gear of the hypoid gear is in transmission connection with the half shaft gear of the differential mechanism; an output half shaft of the differential mechanism extends out of the shell and is perpendicular to the active gear shaft. The electric drive axle assembly can improve the stability of the gear transmissionand the installation operability, and also can improve the adaptability of the shell to the speed ratios of different gears and reduce the cost.

Owner:LIUZHOU WULING MOTORS +1

Railway vehicle and vehicle body apron board thereof

PendingCN111661084AAchieving Lightweight GoalsEnsure connection stabilityAxle-box lubricationRailway bodiesAutomotive engineeringCarbon fiber composite

The invention relates to a railway vehicle and a vehicle body apron board of the railway vehicle. The vehicle body apron board of the railway vehicle comprises an apron board body, and the apron boardbody is an integrally formed carbon fiber composite material; and the apron board body comprises an outer skin, an inner skin, a shaft hole part and a vertical rib set, the shaft hole part and the vertical rib set are arranged between the outer skin and the inner skin, the vertical rib set can form a multi-cavity structure between the outer skin and the inner skin, and the shaft hole part is located at an end of one side of the multi-cavity structure. The vehicle body apron board can meet requirements for rigidity, strength and a service life, and meanwhile a light weight target can be achieved.

Owner:CRRC QINGDAO SIFANG CO LTD +1

Gray pig iron and preparing method and application thereof

The invention discloses gray pig iron and a preparing method and application thereof. The gray pig iron comprises, by mass percentage, 3.6-4.0 parts of carbon, 2.2-2.4 parts of silicon, 0.2-0.4 part of manganese, 0.1-0.3 part of phosphorus, 0.08-0.12 part of sulphur, 2-4 parts of boron, 1-3 parts of vanadium, 0.2-0.6 part of chromium, 0.8-1.0 part of copper, 0.8-1.0 part of tin, 1-2 parts of nickel, 1-3 parts of titanium and 76-80 parts of iron. The invention further provides a preparing method of the gray pig iron. In addition, an accessory for a car is further provided. The accessory is made of the above gray pig iron. According to the gray pig iron, the chromium, the tin, the titanium and the iron are used in cooperation, and the firmness of the gray pig iron is greatly improved; and meanwhile, the stability of the gray pig iron is improved, and the safety of the gray pig iron accessory is improved. In addition, the preparing method of the gray pig iron is provided, the performance of the gray pig iron can be greatly improved through the method, and the safety of the gray pig iron is further improved.

Owner:WUHU HEXU MACHINERY

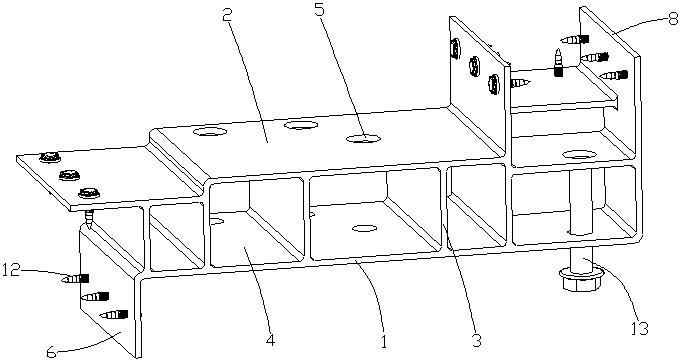

Aluminum extrusion profile bracket structure

PendingCN111907595AEasy to installLow costUnderstructuresInterconnection systemsVehicle frameEngineering

The invention relates to an aluminum extrusion profile bracket structure, and belongs to the technical field of automobile parts. The structure comprises a supporting bottom plate and a supporting upper plate which are parallel to each other, a plurality of middle supporting reinforcing plates are arranged between the supporting bottom plate and the supporting upper plate, a plurality of bolt connecting holes are formed in the supporting bottom plate and the supporting upper plate, a left side connecting plate is arranged on the left side of the supporting bottom plate, and the left side connecting plate is perpendicular to the supporting bottom plate; a front connecting cross beam is arranged on the left side connecting plate, a U-shaped connecting plate is arranged on the right side of the upper supporting plate, and a rear connecting cross beam is arranged on the U-shaped connecting plate. The aluminum extrusion profile bracket structure has the beneficial effects that a traditionalstamping support is replaced with the aluminum extrusion profile support, reliable installation of the auxiliary frame and the transverse stabilizer bar is achieved, the die cost and the weight of anautomobile body are reduced, the cost is saved, the purpose of light weight of an automobile is achieved, and the aluminum extrusion profile bracket structure is novel in structure and low in cost.

Owner:苏州同捷汽车工程技术股份有限公司

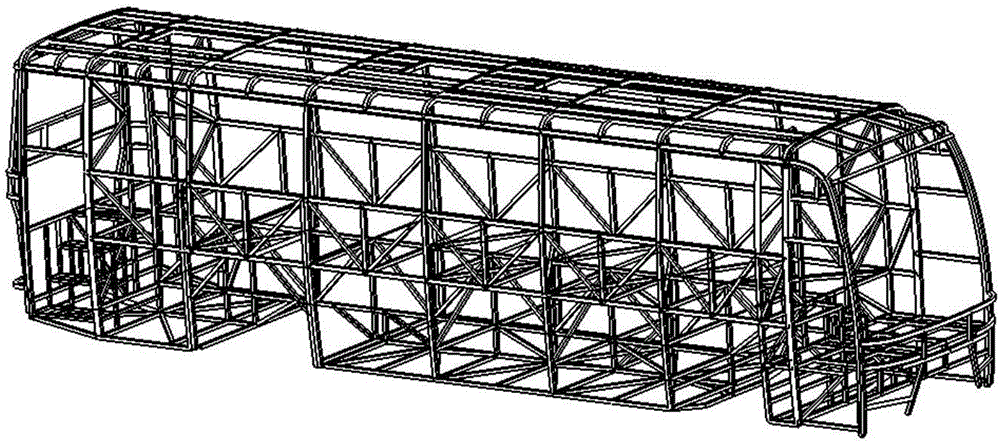

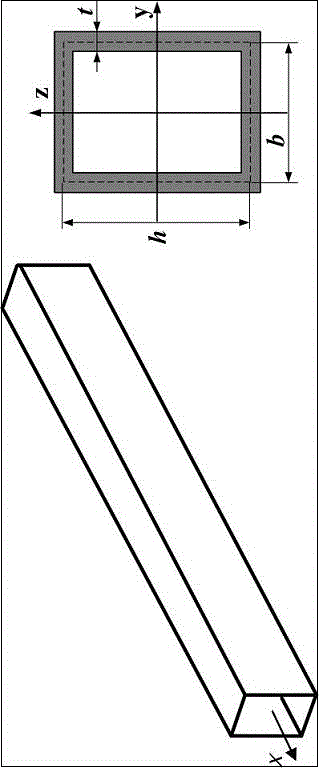

Sensitivity Analysis Method for High Stiffness and Light Weight of Bus Body Frame

ActiveCN103823944BSmall amount of calculationReduce quality problemsSpecial data processing applicationsHigh stiffnessBody weight

The invention relates to a high-rigidity and light-weight sensitivity analysis method for a passenger bus skeleton and belongs to the field of design of a passenger bus body. The method comprises the steps of parameterization assembly modeling of a passenger bus skeleton structure, static and dynamic rigidity defining and sensitivity analysis of the static and dynamic rigidity on the whole bus weight. The method is different from other rigidity and sensitivity analysis methods on the other bus body structures; the static and dynamic rigidity sensitivity of the method is the derivative of the whole bus weight, the bus body weight is reduced while the rigidity is increased and the light weight target is realized; in the traditional method, the static and dynamic rigidity is subjected to differentiation for the section size, and the bus body rigidity is improved while the bus body weight is not reduced. In addition, the invention adopts the adjoint variable sensitivity analysis method, and the calculated amount is greatly reduced, so a large-sized passenger bus body can be designed and the method has important guide action for the design technology of the passenger bus body.

Owner:左文杰 +1

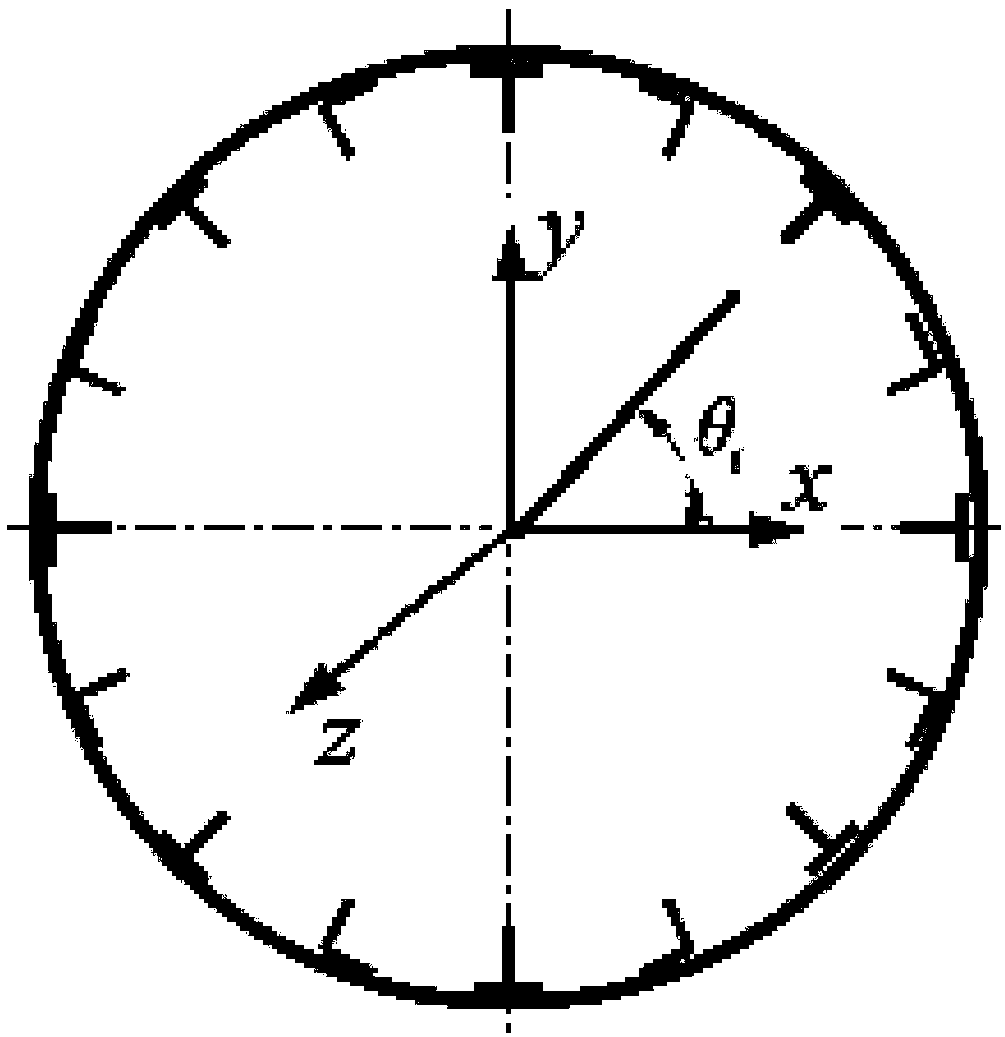

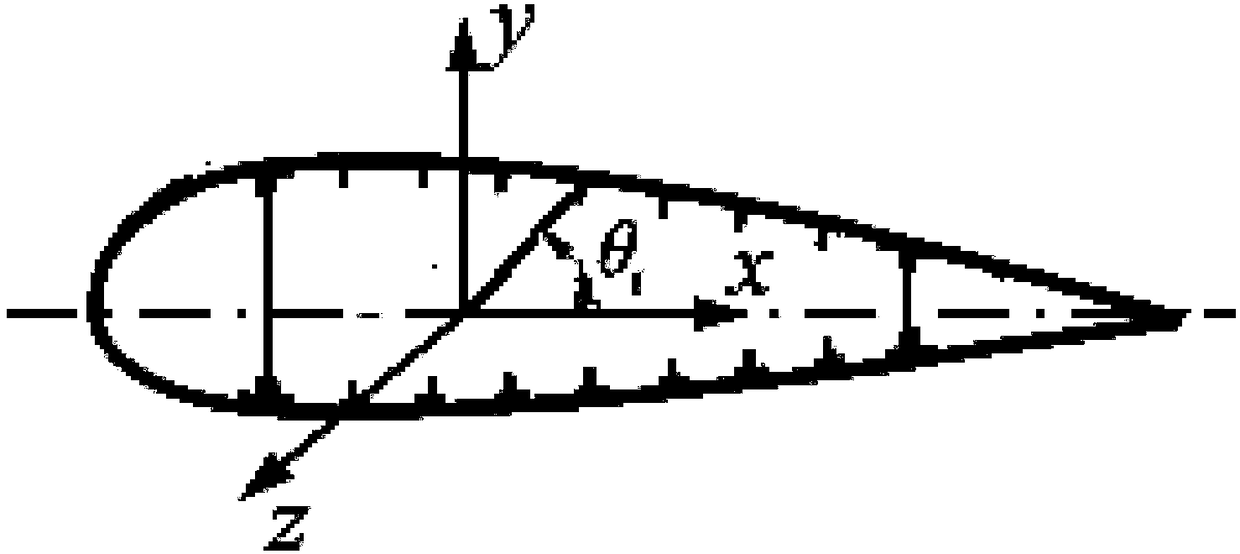

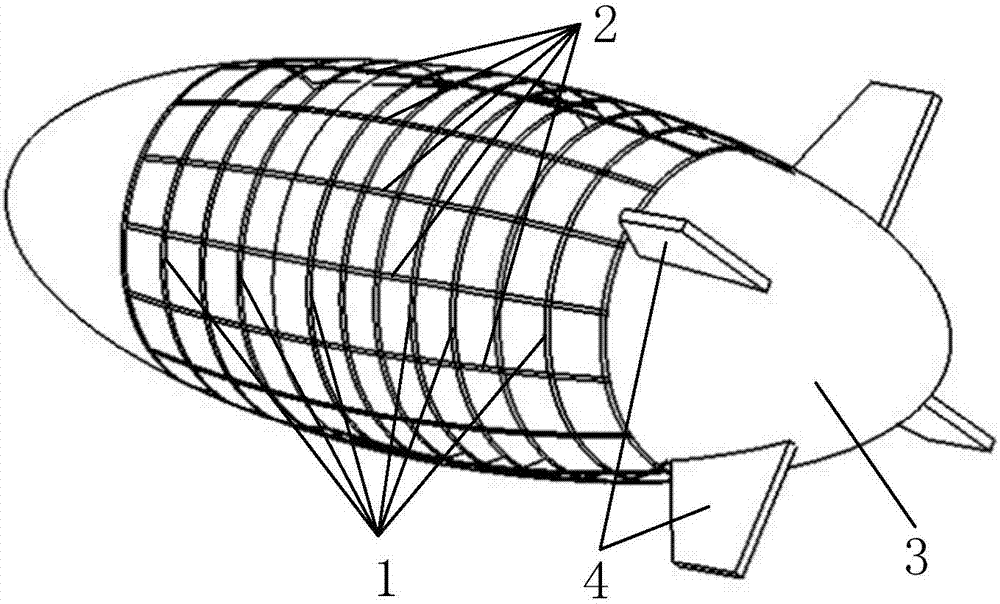

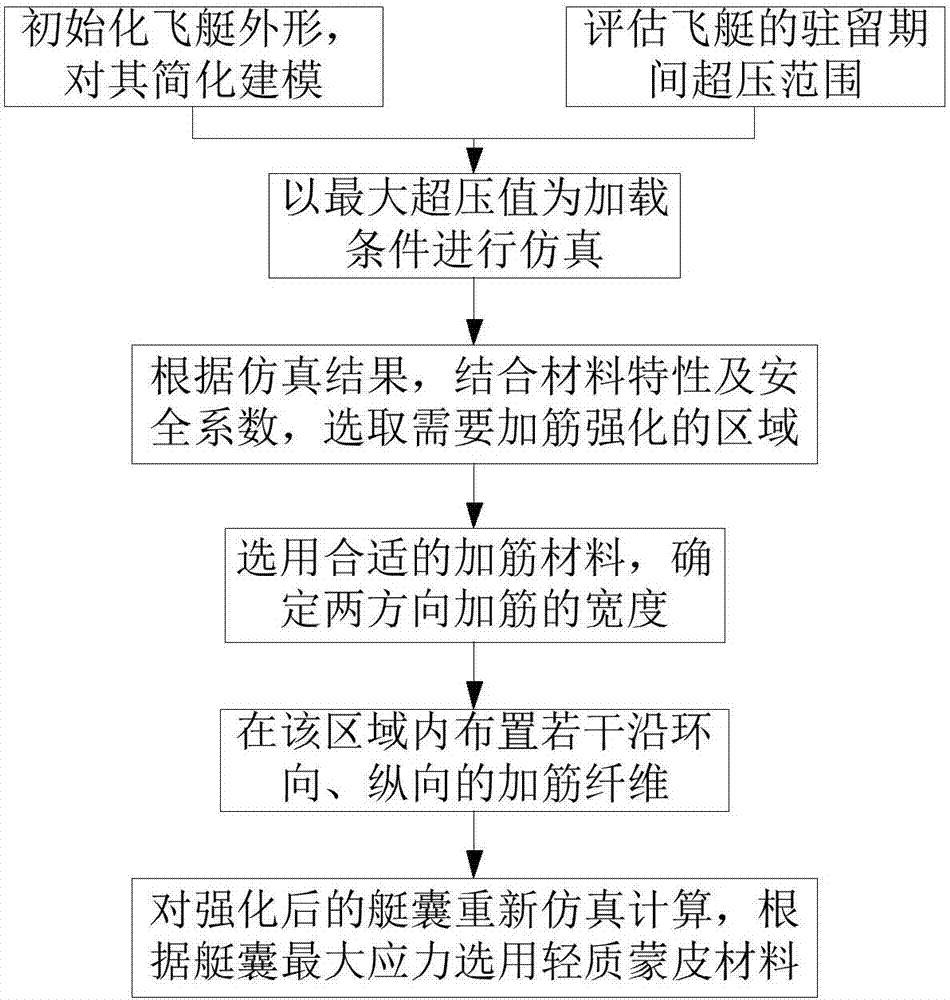

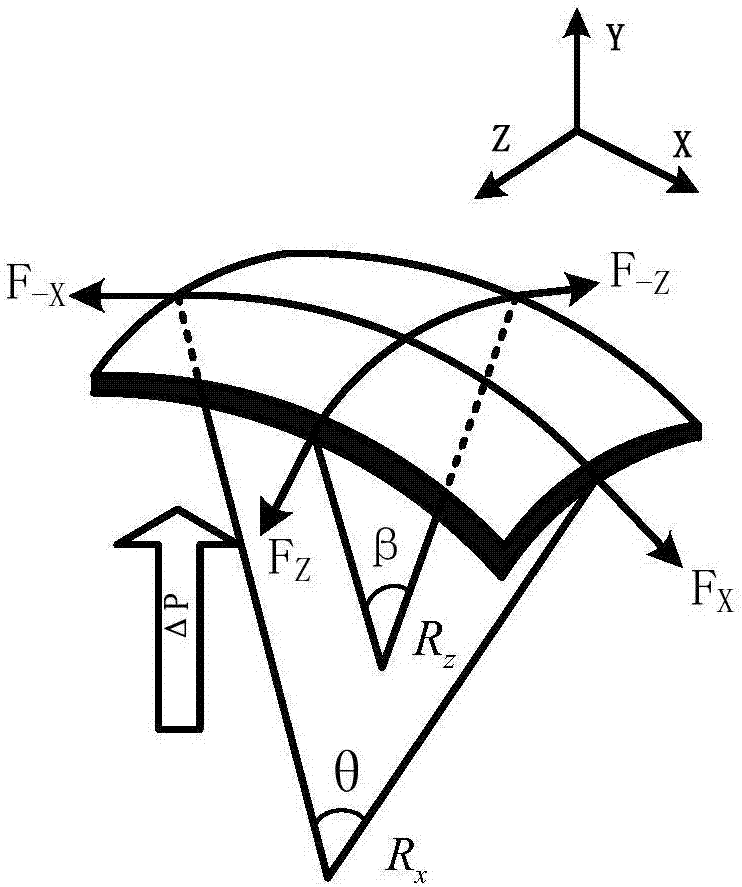

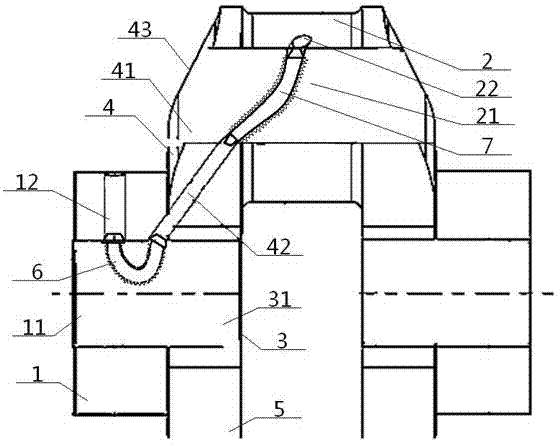

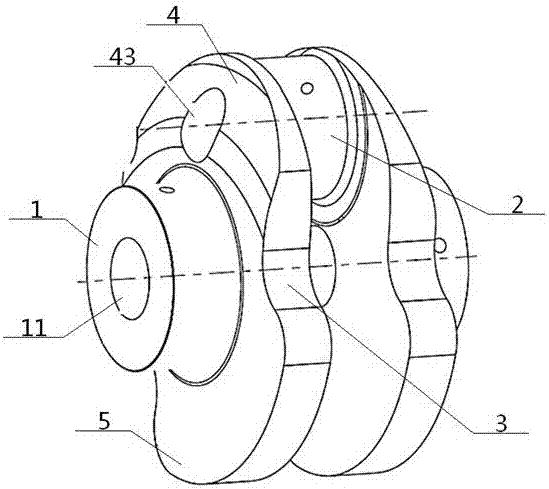

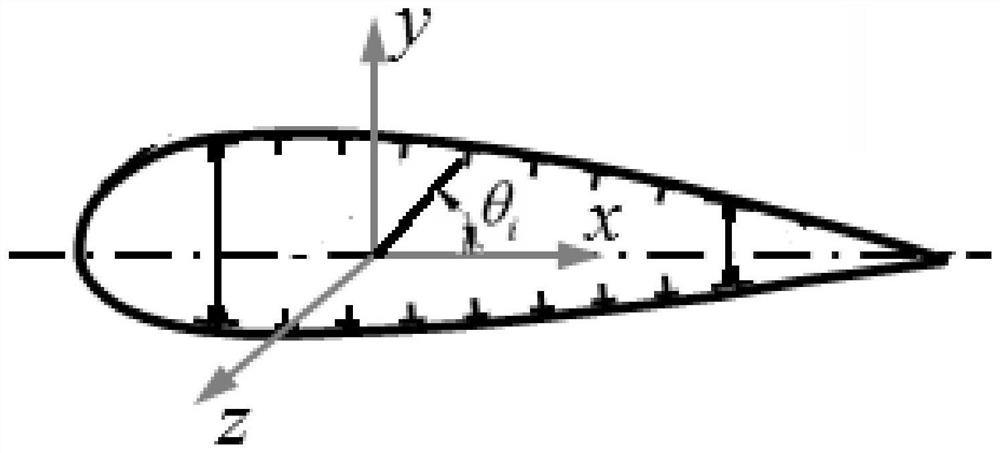

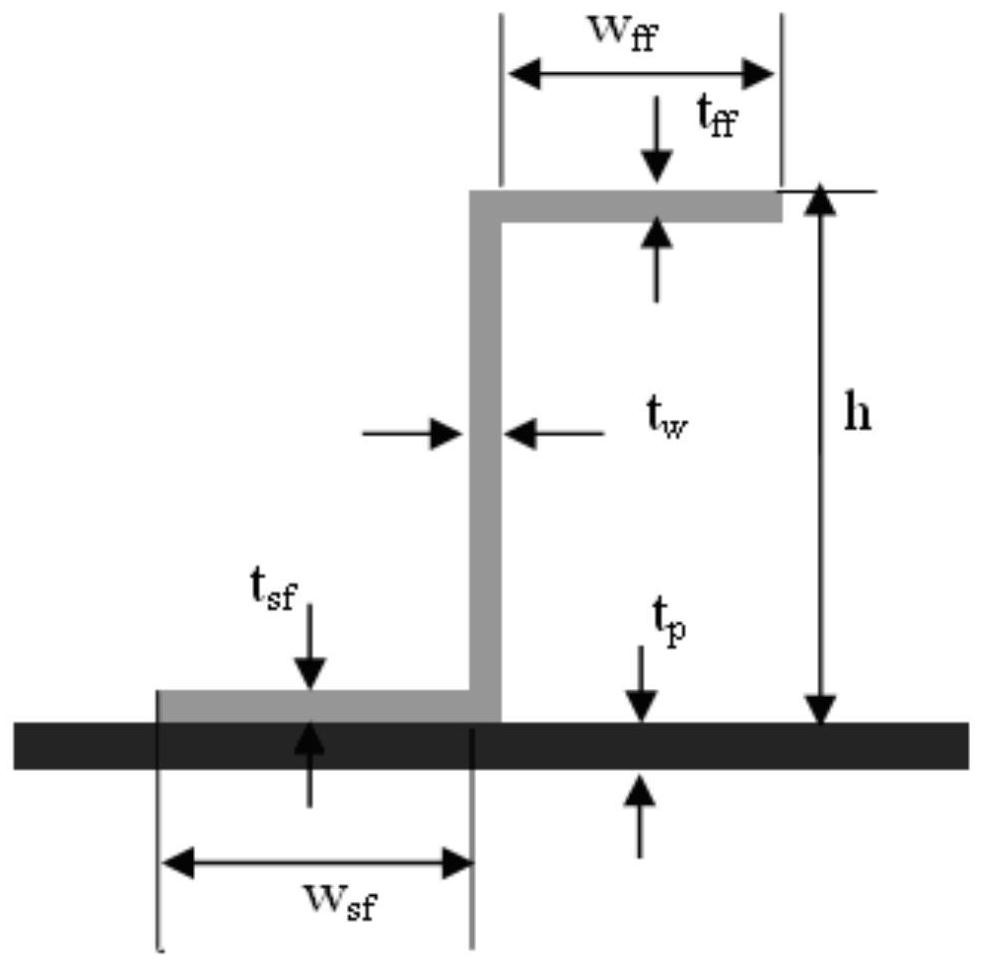

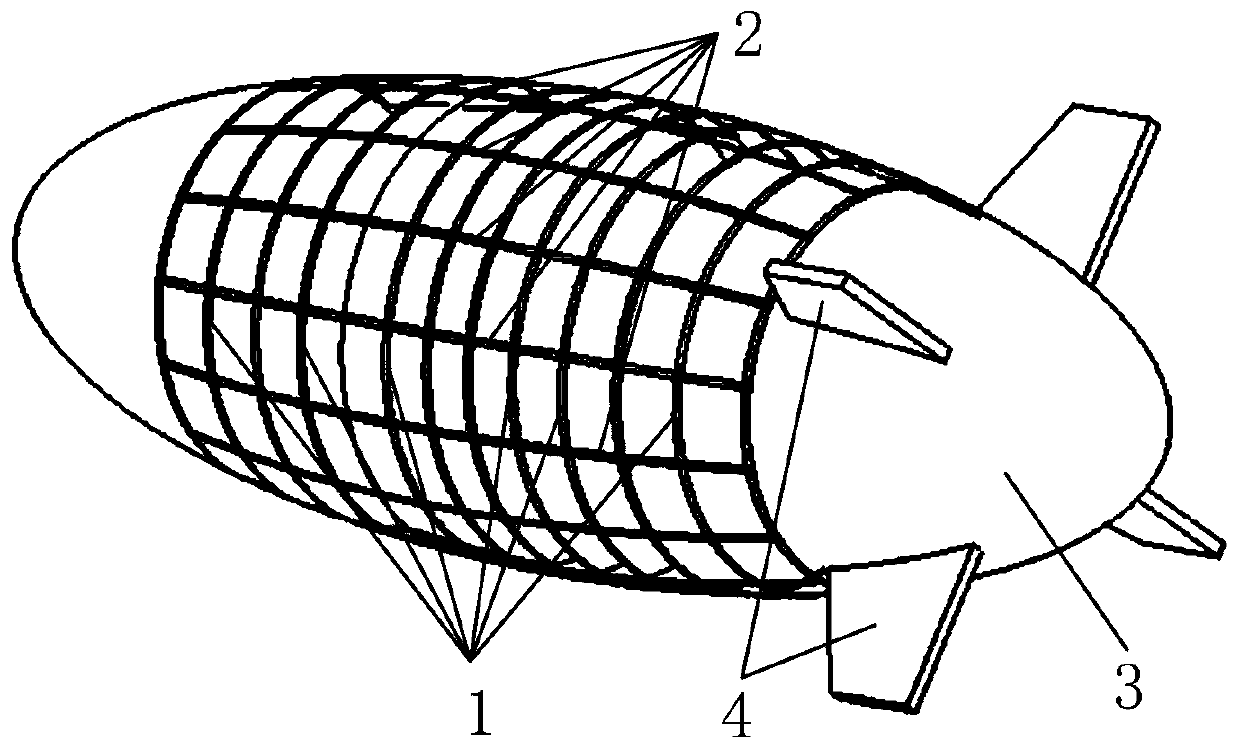

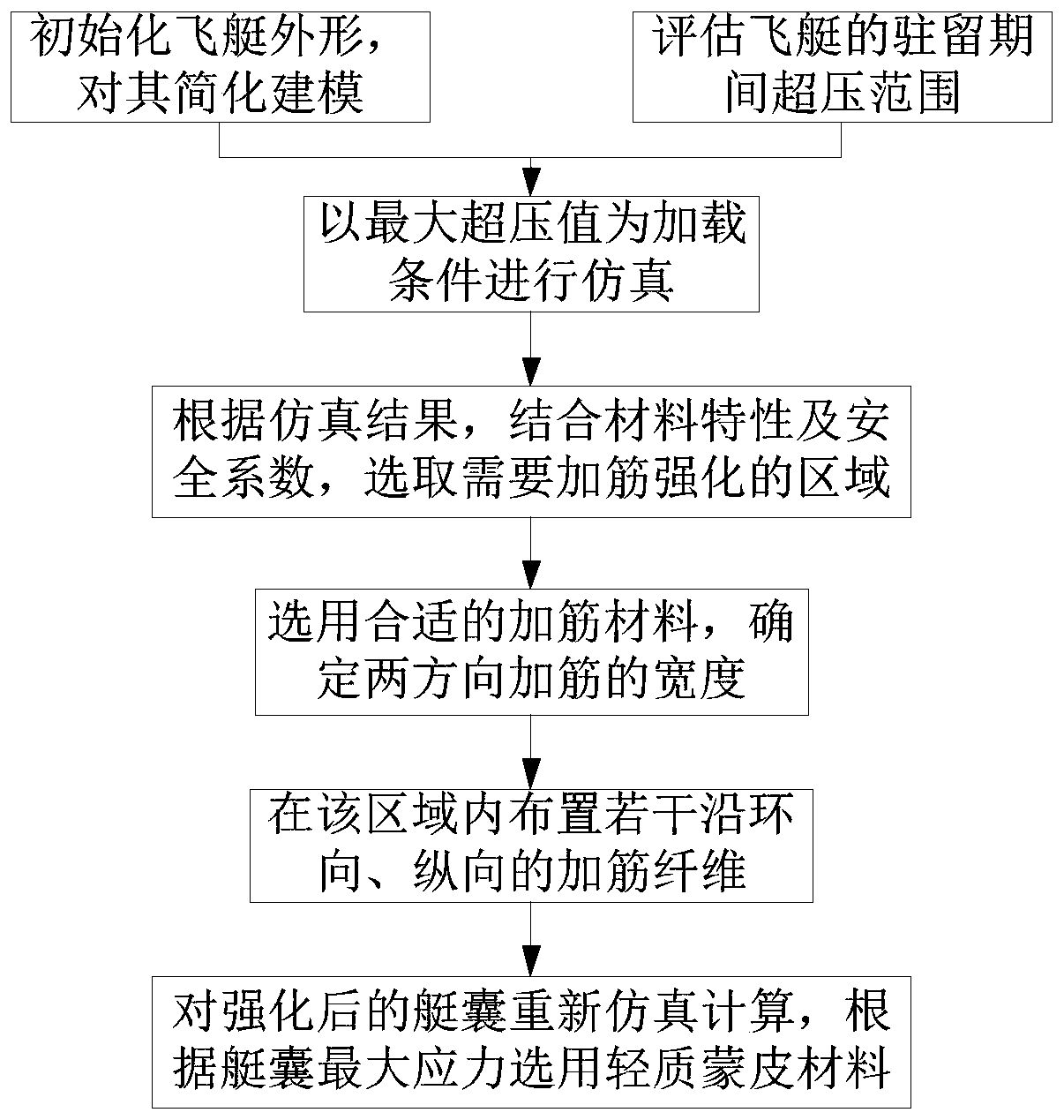

Simulation method for strengthening and lightening airship gasbag of stratospheric airship, and manufacturing method for stratospheric airship

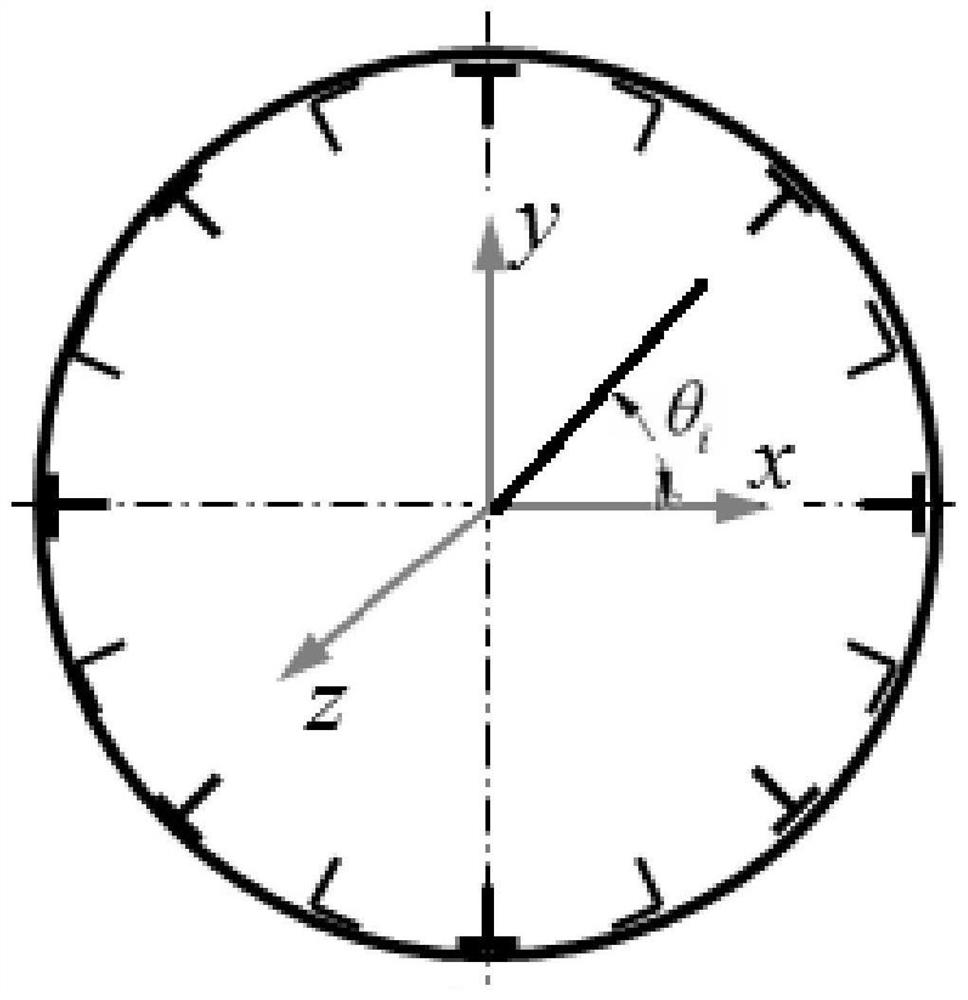

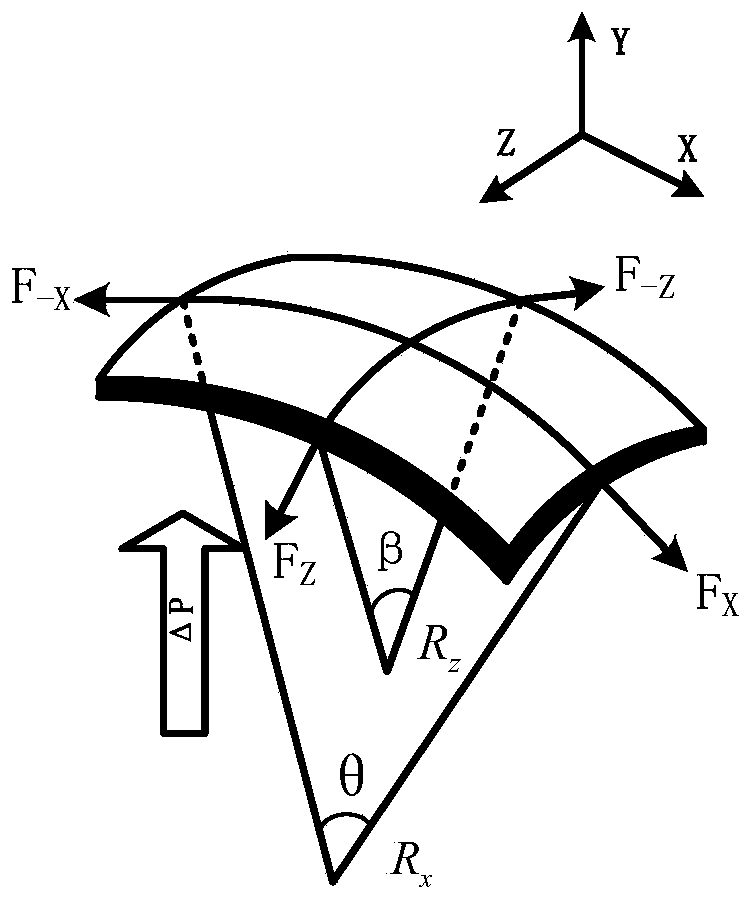

ActiveCN106934148AReduce stressIncrease stressGeometric CADDesign optimisation/simulationSurface stressFiber

The invention provides a simulation method for strengthening and lightening an airship gasbag of a stratospheric airship, the stratospheric airship and a manufacturing method for the stratospheric airship. The simulation method comprises the following steps of (1), determining a basic shape of the stratospheric airship needed to be researched, and performing modeling on the shape; (2) performing simulation calculation to obtain airship gasbag surface stress distribution of the airship under a maximum overpressure condition; (3) according to related characteristics and a safety coefficient of an airship gasbag material, defining that an airship gasbag surface stress of the airship under the maximum overpressure condition is greater than a maximum safety stress, and serving as a reinforcement rib strengthening region; (4) selecting and using a proper reinforcement rib material to meet a lightweight requirement; arranging a plurality of reinforcement fiber ribs in circumferential and longitudinal directions in a simulated manner in the reinforcement rib strengthening region to strengthen the airship gasbag; and (5) after the airship gasbag is strengthened, performing simulation calculation again to obtain the airship gasbag surface stress distribution, and according to the maximum stress, selecting a proper low-density material to be applied to the airship gasbag.

Owner:北京天恒长鹰科技股份有限公司

Single crank unit of light crankshaft of internal combustion engine

PendingCN107061476ALight in massAchieving Lightweight GoalsCrankshaftsEngine lubricationCrankInternal combustion engine

The invention discloses a single crank unit of a light crankshaft of an internal combustion engine. The single crank unit comprises a main shaft neck, a connecting rod neck and a crankshaft block; the upper and lower two ends of the joined place of the crankshaft block with the main shaft neck are respectively a crank arm and a balance block; through holes 1, 2, 3 and 4 for communicating in sequence are formed in the main shaft neck, the crankshaft block, the crank arm and the connecting rod neck; a main shaft neck oil way, a crank arm oil way and a connecting rod neck oil way formed in the main shaft neck, the crank arm and the connecting rod neck communicate through two internal oil pipes arranged in the four through holes; the internal oil pipe comprises an oil pipe body, a wedged joint and a spring; and a mounting groove is formed in the periphery of the wedged joint for embedding and matching with a sealing ring. The single crank unit is higher in lightweight degree and overall cooperativeness, better in lubrication effect, liable to operate and higher in stability.

Owner:DONGFENG COMML VEHICLE CO LTD

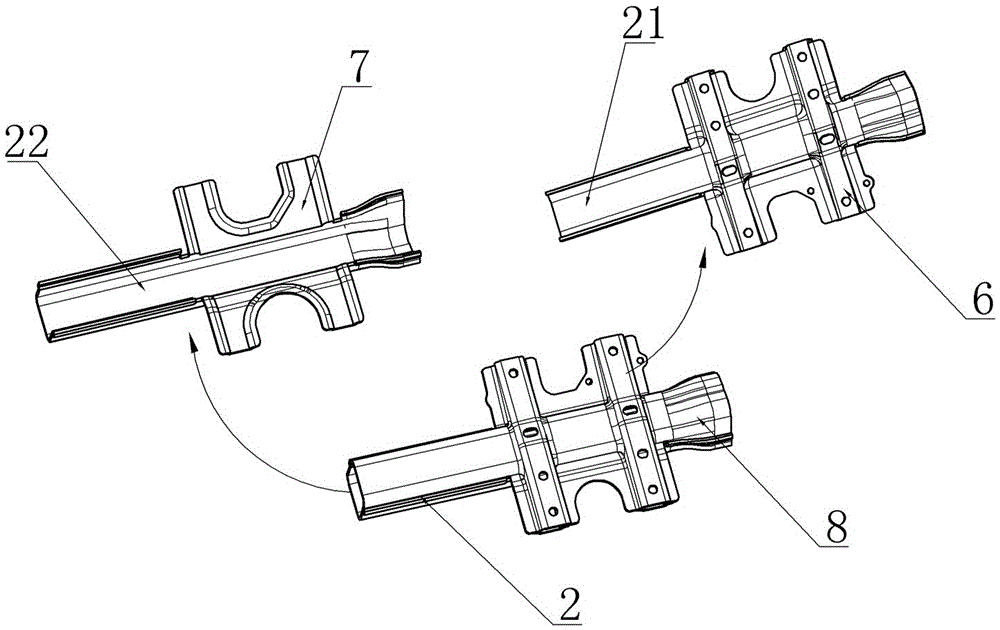

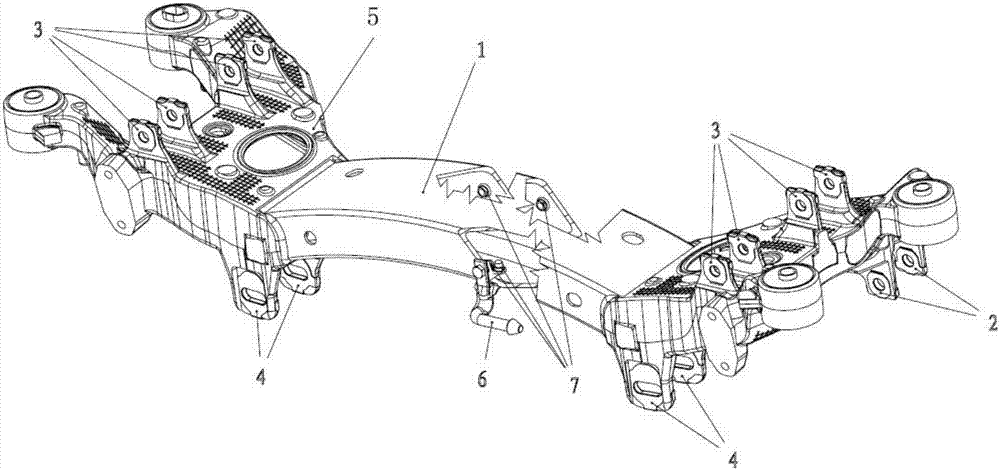

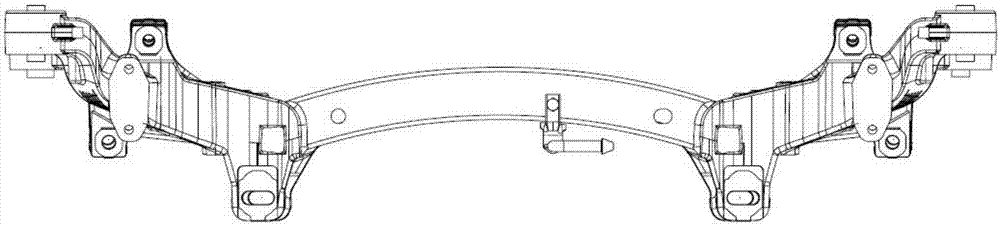

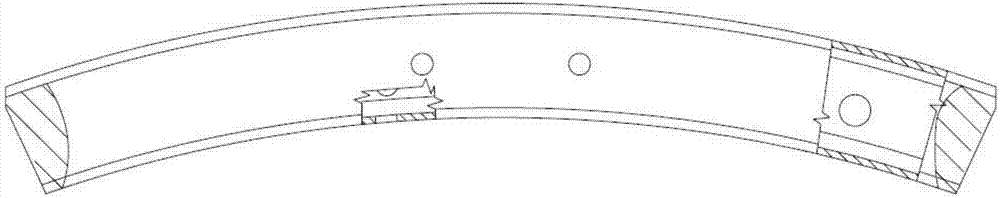

General type aluminum alloy automobile sub-frame structure

ActiveCN107097850AHigh strengthGuaranteed StrengthUnderstructuresVehicle frameUltimate tensile strength

The invention relates to a general type aluminum alloy automobile sub-frame structure. The general type aluminum alloy automobile sub-frame structure comprises an aluminum sub-frame crossbeam and end part aluminum castings, wherein the aluminum sub-frame crossbeam is in the shape of a bended arch; the end part aluminum castings are separately and symmetrically connected to two ends of the aluminum sub-frame crossbeam; upper swinging arm connecting seats are arranged on the upper end surface of each end part aluminum casting side by side; a lower swinging arm connecting seat and an oblique pull rod connecting seat are arranged at the lower end surface of each end part aluminum casting; each upper swinging arm connecting seat, each lower swinging arm connecting seat and each oblique pull rod connecting seat are separately formed by two punched vertical plates which are arranged side by side; a U-shaped clamping plate is in sleeving connection to each punched vertical plate to cover two side walls of the corresponding punched vertical plate; and an exhaust pipe lifting hook is also mounted on the aluminum sub-frame crossbeam. According to the general type aluminum alloy automobile sub-frame structure disclosed by the invention, the problem that under the premise that relevant surrounding pieces of a sub-frame are not changed, when a conventional iron sub-frame is switched into the aluminum sub-frame, the changes of the strength and the rigidity between iron materials and aluminum materials are great can be solved; the total weight of an automobile chassis system is reduced; and lightweighting is realized.

Owner:NINGBO TUOPU GROUP CO LTD

Railway vehicle and cowcatcher structure thereof

The invention discloses a railway vehicle and a cowcatcher structure thereof. The cowcatcher structure comprises a cowcatcher main structure with a concave area design, and the concave area of the cowcatcher main structure is used for installing a signal system; the cowcatcher main structure comprises an upper cover plate, a lower cover plate and a middle support. The concave area is of a trapezoidal structure which is formed by splicing a plurality of middle U-shaped beams and is large in outside and small in inside; a plough-shaped cowcatcher plate is arranged at the front end of the cowcatcher main structure; and a longitudinal strength reinforcing structure is arranged in the cowcatcher main structure, and a box-shaped body is formed between the longitudinal strength reinforcing structure and the lower cover plate. The cowcatcher structure has the characteristics of being light in weight and high in strength, and can meet the requirement for an ultra-large installation space needed by a vehicle signal system.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

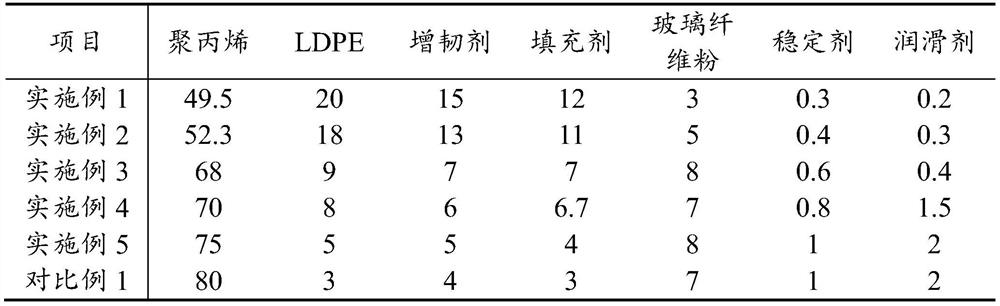

Polypropylene composite material and preparation method thereof

PendingCN112480552AGood rigidity balanceExpand the scope of useLow-density polyethylenePolypropylene composites

The invention discloses a polypropylene composite material, and relates to the technical field of composite materials. The polypropylene composite material is prepared from the following components inpercentage by mass: 50 to 75 percent of polypropylene, 5 to 20 percent of low-density polyethylene, 5 to 15 percent of a toughening agent, 4 to 12 percent of a filling agent, 3 to 8 percent of glassfiber powder, 0.3 to 1 percent of a stabilizing agent and 0.2 to 2 percent of a lubricating agent. According to the invention, the polypropylene is used as a base material, and the low-density polyethylene, the glass fiber powder and the filling agent are added, so that the prepared polypropylene composite material has the characteristics of low density and low shrinkage, and meets the requirementof light weight.

Owner:GUANGDONG JUSHI CHEM CO LTD

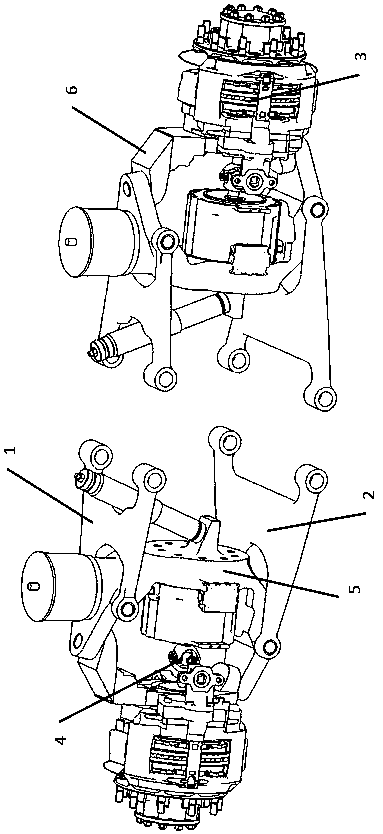

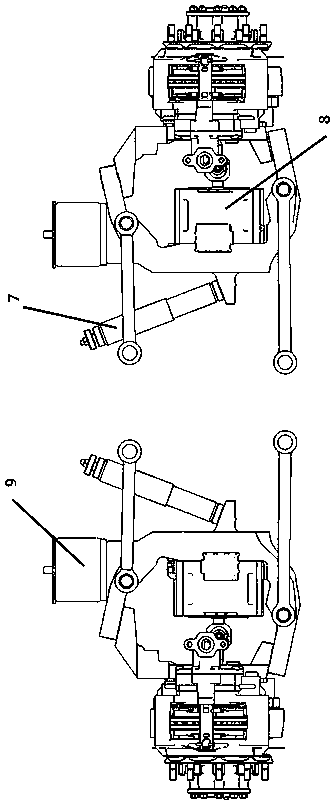

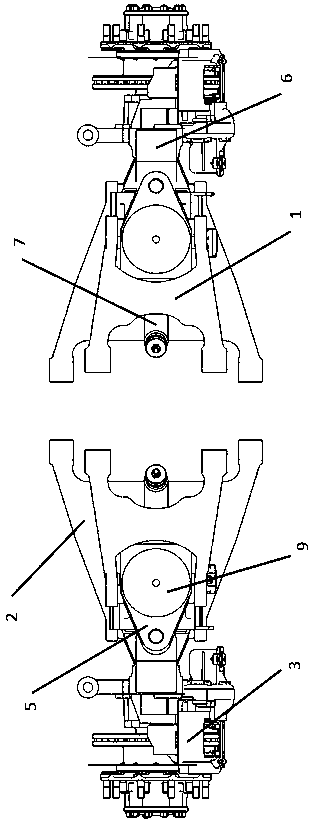

Independent suspension integrated wheel-side motor assembly

PendingCN111361409AReduce weightImprove handling stabilityMotor depositionVehicle frameReduction drive

An independent suspension integrated wheel-side motor assembly is mainly used for manufacturing pure electric vehicles. A disconnected suspension structure is adopted, and suspensions on the left sideand the right side are independently connected with a vehicle frame, so independence during vertical jumping of a left wheel end and a right wheel end is achieved; a motor is installed on a stand column and does not rotate along with a knuckle; a two-section type main pin and a coaxial speed reducer structure are adopted, so a space is provided for arrangement and power transmission of the motor.The motor, the wheel ends and the independent suspension structure are integrated, a traditional transmission shaft and variable box structure is omitted, and due to the fact that the suspension is of an independent suspension structure, the unsprung mass can be reduced to a large extent, so the system is simplified, the assembly weight is reduced, the light-weight target is achieved, and the whole vehicle control stability and smoothness are greatly improved.

Owner:DONGFENG DANA AXLE

A Forming Method of Negative Angle in Semicircle Area of Automobile Control Arm

ActiveCN107116142BAchieving Lightweight GoalsEasy to processShaping toolsVehicle componentsControl armEngineering

The invention relates to the field of automobiles and particularly provides a forming die and a forming method of an automobile control arm semicircle area negative corner. The forming die comprises a first die body, a second die body and a third die body; and the forming die is characterized in that the first die body is composed of a first die material-pressing plate, a first die flanging insert and a first die lower die body, the first die material-pressing plate is arranged above the first die lower die body, the position, located on the right side of the first die material-pressing plate, of the first die lower die body is provided with the first die flanging insert, and the bottom of the right side of the first die flanging insert is exposed out of the right side of the first die lower die body. Compared with the prior art, machining is convenient, and the light weight target of a control arm with a negative corner structure is achieved; and complex forming and flanging can be effectively avoided, and the production and manufacturing cost is lowered.

Owner:上海汇众汽车车桥系统有限公司

Optimal Design Method for Initial Dimensions of Aircraft Wing and Fuselage Thin-walled Structures

ActiveCN108563916BAchieving Lightweight GoalsGeometric CADSpecial data processing applicationsFatigue damageFlight vehicle

The initial size optimization design method of the aircraft wing and fuselage thin-walled structure is based on the theory of thin-walled engineering beams to determine the wing and fuselage thin-walled reinforced panel scheme at the initial stage of the aircraft project. The initial size design of thin-walled and reinforced panels is a challenging and judgmental task. Whether the initial size defined in the scheme design is reasonable will directly affect the subsequent design work. The ideal panel structure should fully meet the design requirements of static strength design, fatigue damage tolerance design, manufacturing and maintenance. During the initial dimensioning process, simplification of either the method of analysis or the structure to be analyzed will improve project cost-effectiveness. In the scheme design stage, on the premise of satisfying the static strength requirements, the manufacturing and maintenance requirements can be further introduced to obtain a more optimized initial size. Under the condition that the strength requirements are met, the initial size definition of the structure is carried out through the design requirements of manufacturing and maintenance, which not only meets the requirements of the lightweight design of the structure, but also improves the design efficiency.

Owner:AVIC SAC COMML AIRCRAFT

Raiders and lightweight simulation methods and preparation methods of the boat capsule of the flat straton airship

ActiveCN106934148BReduce stressIncrease stressGeometric CADDesign optimisation/simulationClassical mechanicsDirigible airship

The invention provides a simulation method for strengthening and lightening an airship gasbag of a stratospheric airship, the stratospheric airship and a manufacturing method for the stratospheric airship. The simulation method comprises the following steps of (1), determining a basic shape of the stratospheric airship needed to be researched, and performing modeling on the shape; (2) performing simulation calculation to obtain airship gasbag surface stress distribution of the airship under a maximum overpressure condition; (3) according to related characteristics and a safety coefficient of an airship gasbag material, defining that an airship gasbag surface stress of the airship under the maximum overpressure condition is greater than a maximum safety stress, and serving as a reinforcement rib strengthening region; (4) selecting and using a proper reinforcement rib material to meet a lightweight requirement; arranging a plurality of reinforcement fiber ribs in circumferential and longitudinal directions in a simulated manner in the reinforcement rib strengthening region to strengthen the airship gasbag; and (5) after the airship gasbag is strengthened, performing simulation calculation again to obtain the airship gasbag surface stress distribution, and according to the maximum stress, selecting a proper low-density material to be applied to the airship gasbag.

Owner:北京天恒长鹰科技股份有限公司

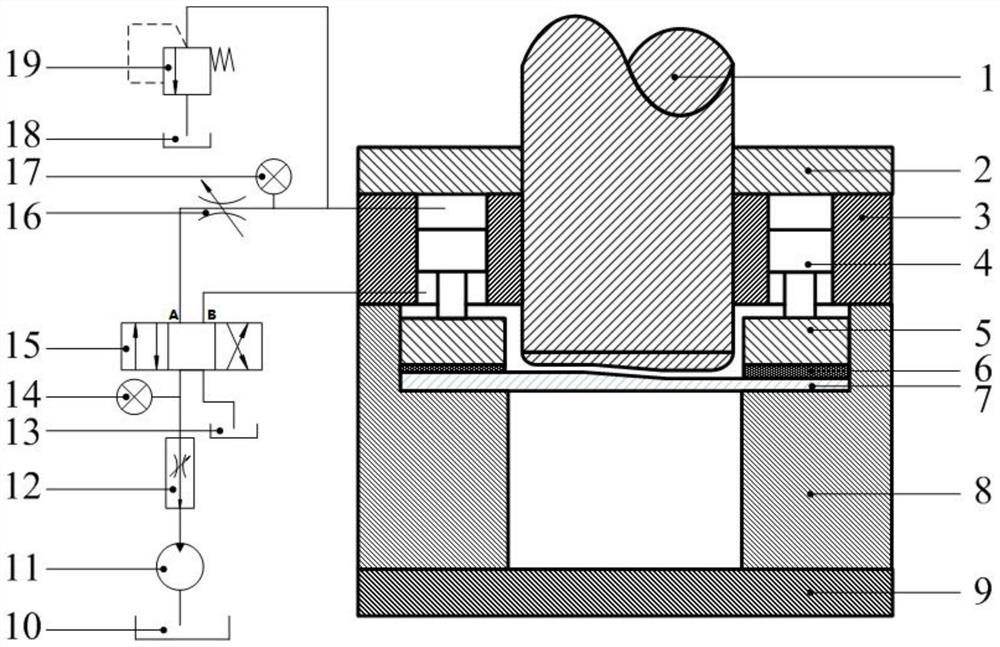

Die for drawing forming of tailor rolled blank box-shaped piece

The invention discloses a die suitable for drawing forming of a tailor rolled blank box-shaped piece, and is applied to the technical field of blank drawing dies. The die comprises a drawing die part and a hydraulic control part; a drawing die main body comprises a stepped male die, a female die, blocked blank holders, a die gap adjusting device and the like; and the hydraulic control part mainly comprises a pump, a valve, a measurement and control instrument and the like. According to the die, drawing of the rolling tailor rolled blank box-shaped piece can be achieved, and the high-quality rolling tailor rolled blank box-shaped piece can be obtained by controlling blank holder force applied to the thin side and the thick side of a tailor rolled blank to be reasonably matched. The die is simple in structure, low in production cost, high in stamping efficiency and good in part quality, the male die and the female die are convenient to replace, and the blank pressing gap can be flexibly adjusted.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

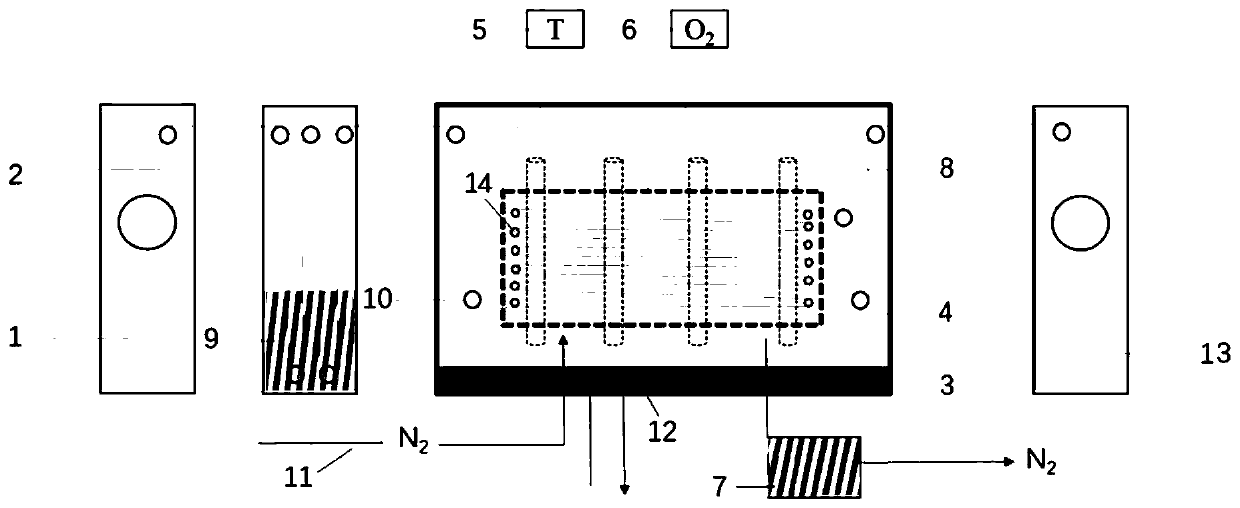

Ultra-high molecular weight polyethylene fiber surface continuous ultraviolet grafting treatment system

The invention relates to an ultra-high molecular weight polyethylene fiber surface continuous ultraviolet grafting treatment system that comprises an ultraviolet irradiation unit and a matching unit,wherein the ultraviolet irradiation unit consists of an ultraviolet control box and a quartz reactor positioned in the ultraviolet control box; the quartz reactor is provided with a fiber inlet and afiber outlet, a plurality of quartz rotating shafts for guiding fiber transmission are arranged in the quartz reactor, and an ultraviolet lamp for irradiating the quartz reactor and a transmission shaft for guiding fiber transmission are arranged in the ultraviolet control box; the matching unit is provided with a solution tank and a fiber winding and unwinding mechanism which are arranged outsidethe ultraviolet irradiation unit, and the fiber winding and unwinding mechanism is used for driving fibers to sequentially pass through the solution tank and the ultraviolet irradiation unit. Compared with the prior art, the invention has the advantages of simplicity, convenience, high efficiency, few side reactions, low cost and continuous and controllable process.

Owner:SHANGHAI RES INST OF CHEM IND

Dashboard beam assembly for pure electric vehicles

The invention belongs to the technical field of car manufacturing. A novel instrument board beam assembly of blade electric vehicles comprises a beam body, a left instrument board beam connecting plate, a right instrument board beam connecting plate and a longitudinal arm beam; the beam body comprises a left tube beam and a right tube beam which are fixed in a matched and sleeved manner, the left tube beam comprises an upper left tube beam and a lower left tube beam, the upper left tube beam and the lower left tube beam are in U-shaped groove shapes, and openings of the upper left tube beam and the lower left tube beam are opposite; the right tube beam comprises an upper right tube beam and a lower right tube beam, and the upper right tube beam and the lower right tube beam are provided with an upper steering wheel support and a lower steering wheel support; and the upper steering wheel support and the upper right tube beam are of an integrated molding structure, and the lower steering wheel support and the lower right tube beam are of an integrated molding structure. According to the novel instrument board beam assembly, the left tube beam and the right tube beam are welded together in a sleeved manner, by means of the structural design, the material using amount of parts is reasonably distributed, and material waste is avoided; and meanwhile, aluminum alloy die-cast formation is adopted in the tube beams, and the overall weight is reduced while the performance requirement is met.

Owner:ZHENGZHOU BIKE NEW ENERGY AUTOMOBILE

Diesel engine cylinder block of sedan and casting method thereof

The invention discloses a diesel engine cylinder block of a sedan and a casting method thereof. The diesel engine cylinder block of the sedan adopts vermicular cast iron materials; the thickness of the wall is 3mm, and the cylinder core distance is 86mm; the front end of the cylinder block is provided with an injection pump mounting flange and a gear chamber or a chain wheel chamber in the mannerof directly casting; the rear end of the cylinder block is provided with a gear box connecting flange and a cranking motor mounting flange in the manner of directly casting. The targets of light-weight design and high strength of the thin-wall are realized by adjusting the formula of a vermiculizer and controlling the smelting and pouring techniques; a water jacket sand core adopts an integral structure; the pouring manufacturability is favorable; the casting mode with a gadarene cylinder top is adopted to ensure the precision of water jacket casting; the casting mould of a full-cold core is adopted; the casting mould can be painted with high-temperature resistant coatings; a sand mould has high strength and rigidity and high precision; and the casting mould has little gas evolution, thusensuring the precision of thin-walled cylinder block castings and effectively reducing casting defects.

Owner:GUANGXI YUCHAI MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com