Light-weight high-strength PBT material and preparation method thereof

A high-strength, light-weight technology, applied in the field of polymer materials, can solve the problems of large cells, unevenness, and decreased mechanical properties, and achieve the effects of reducing density, increasing the specific strength of bending and stretching, and realizing light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

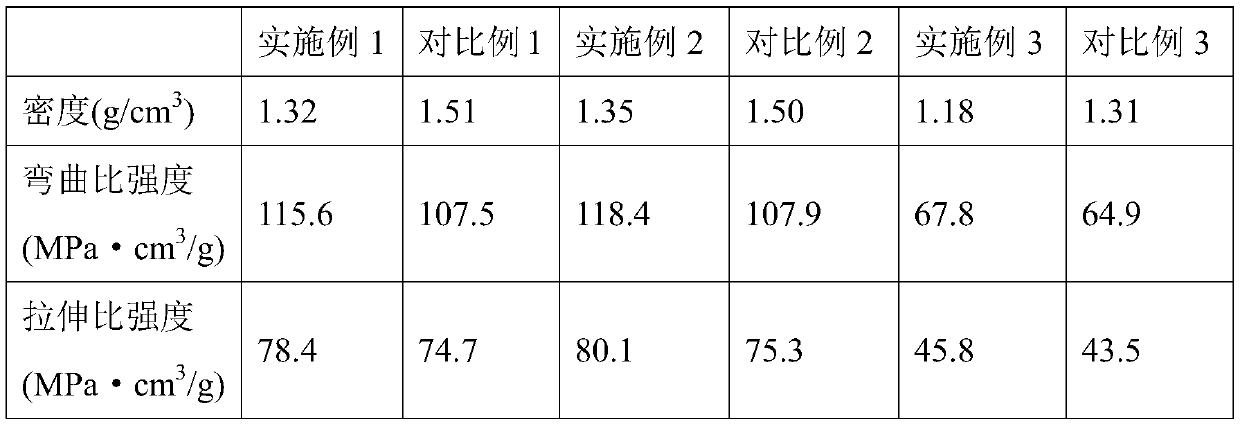

Embodiment 1

[0029] Put 500 parts by weight of polybutylene terephthalate (PBT) in an oven, and dry at 130° C. for 2-3 hours. The form of microspheres is masterbatch, and the amount of microspheres added is 10 parts, 5 parts of DOP (dioctyl phthalate), 10 parts of maleic anhydride graft, and mixed in a mixer for 5 minutes. Enter the single-screw injection molding machine through the feeding port for injection, set the temperature of the multi-stage screw at 220-250°C, the injection pressure at 1.0MPa, the back pressure at 0.04MPa, the screw speed at 35rpm, the holding time at 5s, and control the mold temperature at 12°C, the mold is a standard dumbbell-shaped mold.

Embodiment 2

[0033] Put 500 parts by weight of polybutylene terephthalate (PBT) in an oven, and dry at 110° C. for 2-3 hours. The form of microspheres is dry powder, the amount of microspheres added is 10 parts, add 5 parts of DOP (dioctyl phthalate), 5 parts of white oil (lubricant), 5 parts of antioxidant 1010, and mix in the mixer for 5 minutes Even after. Add the injection molding into the single-screw injection molding machine through the feeding port, set the temperature of the multi-stage screw at 230-260°C, the injection pressure at 1.5MPa, the back pressure at 0.04MPa, the screw speed at 25rpm, the holding time at 5s, and control the mold temperature at 15°C, the mold is a standard dumbbell-shaped mold.

Embodiment 3

[0037] Put 500 parts by weight of polybutylene terephthalate (PBT) in an oven and dry at 110-150°C for 2-3 hours. The form of microspheres is dry powder, the amount of microspheres added is 5 parts, 5 parts of white oil lubricant and 10 parts of maleic anhydride graft are added, and mixed in a mixer for 5 minutes. Add the injection molding into the single-screw injection molding machine through the feeding port, set the temperature of the multi-stage screw at 220-240°C, the injection pressure at 1.6MPa, the back pressure at 0.02MPa, the screw speed at 35rpm, the holding time at 5s, and control the mold temperature at 20°C, the mold is a standard dumbbell-shaped mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com