Polypropylene composite material and preparation method thereof

A composite material and polypropylene technology, applied in the field of polypropylene composite materials and its preparation, can solve problems such as unstable product quality and high material performance requirements, and achieve good balance of rigidity and toughness, simple process operation, and expanded application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

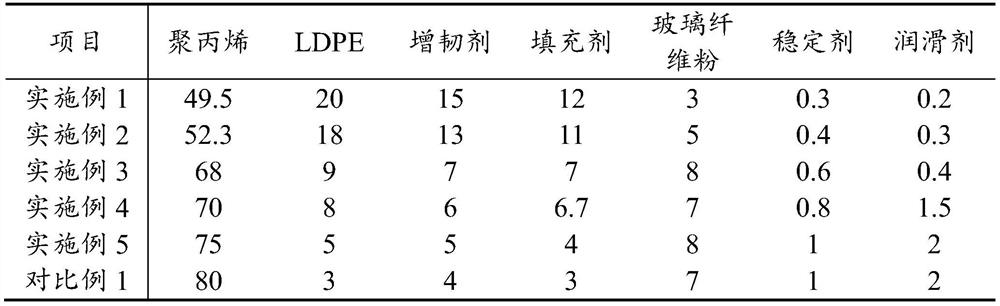

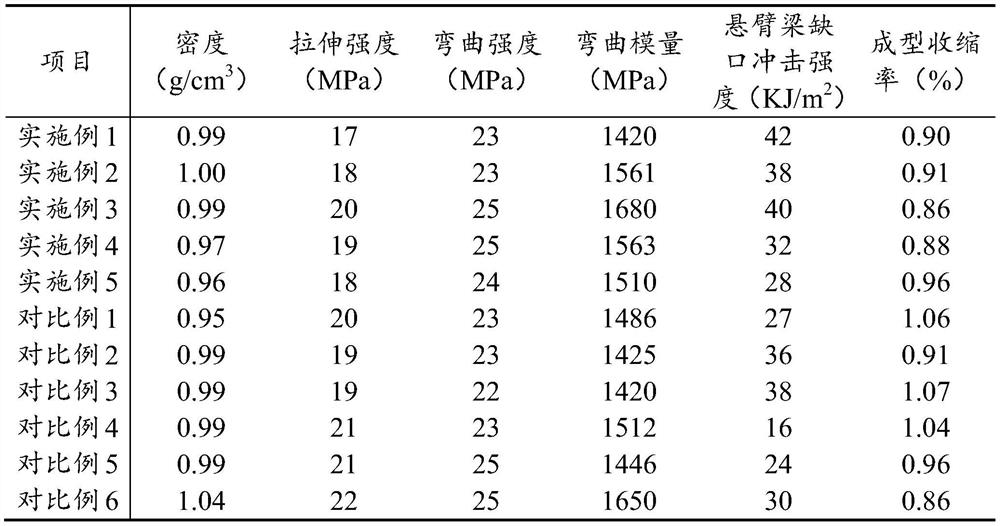

[0025] The embodiment of the polypropylene composite material of the present invention, the formula of the polypropylene composite material described in Examples 1 to 5 is shown in Table 1, and the preparation method comprises the following steps:

[0026] (1) Mix polypropylene, low-density polyethylene (LDPE), and toughening agent, and stir for 5 minutes at 1000 rpm to obtain mixture A;

[0027] (2) Add stabilizer and lubricant to mixture A, and stir for 5 minutes at 1000 rpm to obtain mixture B;

[0028] (3) Mix the glass fiber powder and filler, stir at 800rpm for 3min to obtain mixture C;

[0029] (4) Mixture B is added to the main feed port of the twin-screw extruder, and mixture C is added to the side feed port of the twin-screw extruder. The aspect ratio of the twin-screw extruder is 44:1, and the screw The rotational speed is 300 rpm, melt blending is carried out under the protection of inert gas or nitrogen at a temperature of 200°C, and finally extruded and granulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com