High-impact flame-retardant polypropylene composite material for passenger car interior decoration and preparation method of high-impact flame-retardant polypropylene composite material

A technology of flame-retardant polypropylene and composite materials, which is applied in the field of high-impact flame-retardant polypropylene composite materials for passenger car interiors and its preparation, and can solve the problems of failing to meet the smoke density index of passenger car interior materials, difficult to self-extinguish, and a large number of black smoke and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

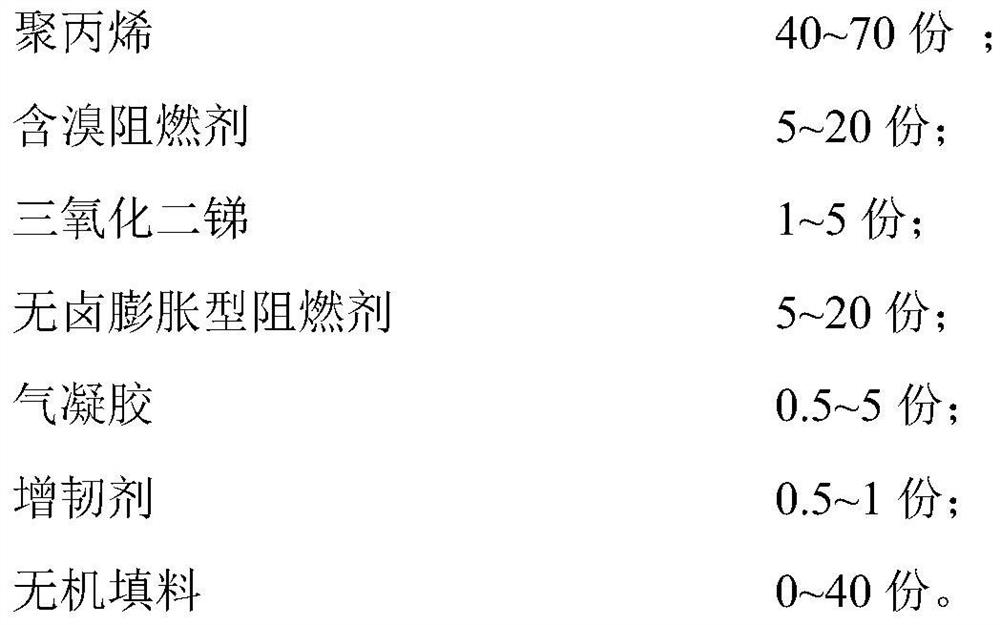

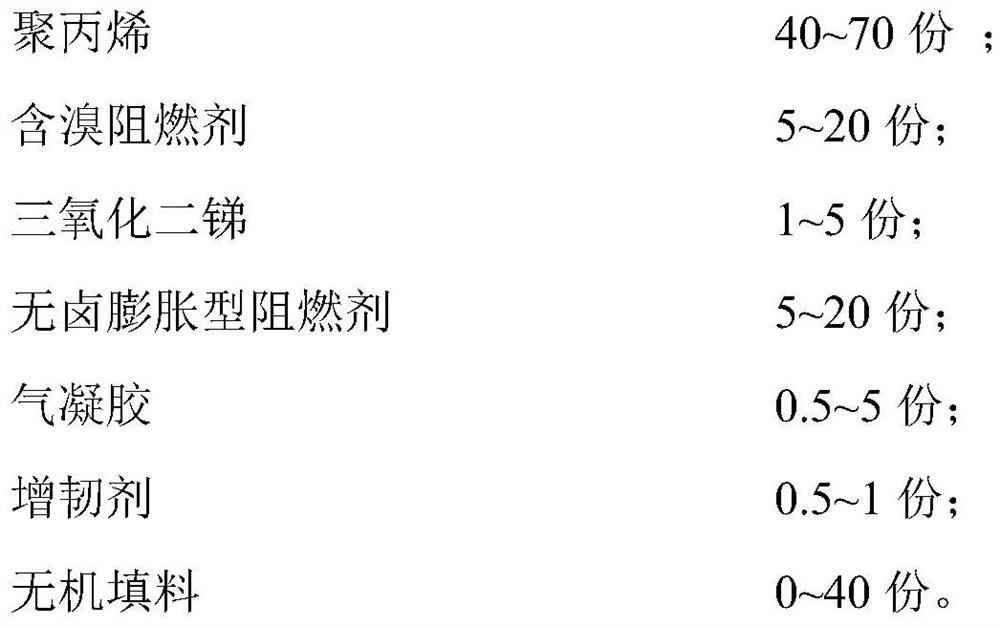

Method used

Image

Examples

Embodiment 1

[0040] Each raw material was weighed according to the weight percentage of Example 1 described in Table 1, stirred in a high-speed mixer for 3-5 minutes, and dried in an oven to obtain a mixed raw material.

[0041] The mixed raw materials are evenly added to the intermeshing co-rotating twin-screw extruder, and after a series of processes such as melt extrusion, granulation, and drying treatment, the high-impact flame-retardant polypropylene composite material for passenger car interiors is obtained, wherein , the extruder screw diameter is 35mm, the length-to-diameter ratio L / D is 40, the screw speed is 200-300rpm / min, and the temperature of each section of the extruder is between 180-210°C.

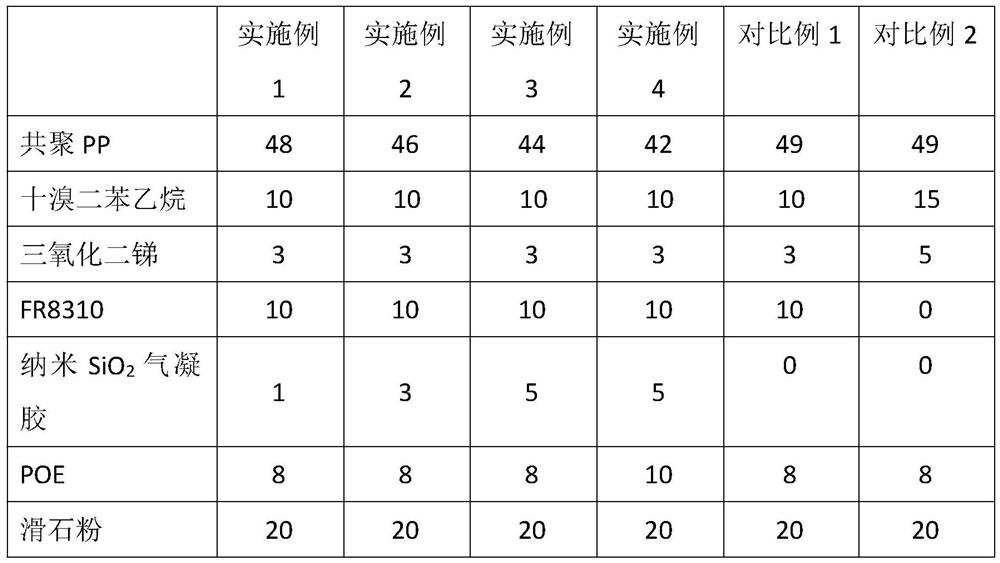

[0042] Table 1 Formula table of high-impact flame-retardant polypropylene composite materials for passenger car interior (unit: %)

[0043]

Embodiment 2

[0045] Each raw material was weighed according to the weight percentage of Example 2 described in Table 1, stirred in a high-speed mixer for 3-5 minutes, and dried in an oven to obtain a mixed raw material.

[0046] The mixed raw materials are evenly added to the intermeshing co-rotating twin-screw extruder, and after a series of processes such as melt extrusion, granulation, and drying treatment, the high-impact flame-retardant polypropylene composite material for passenger car interiors is obtained, wherein , the extruder screw diameter is 35mm, the length-to-diameter ratio L / D is 40, the screw speed is 200-300rpm / min, and the temperature of each section of the extruder is between 180-210°C.

Embodiment 3

[0048] Each raw material was weighed according to the weight percentage of Example 3 described in Table 1, stirred in a high-speed mixer for 3-5 minutes, and dried in an oven to obtain a mixed raw material.

[0049] The mixed raw materials are evenly added to the intermeshing co-rotating twin-screw extruder, and after a series of processes such as melt extrusion, granulation, and drying treatment, the high-impact flame-retardant polypropylene composite material for passenger car interiors is obtained, wherein , the extruder screw diameter is 35mm, the length-to-diameter ratio L / D is 40, the screw speed is 200-300rpm / min, and the temperature of each section of the extruder is between 180-210°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com