Patents

Literature

179results about How to "Good environmental stress cracking resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of high density polyethylene pipe material

ActiveCN1903896AHigh mechanical strengthGood environmental stress cracking resistanceHydrogenPolymer science

The present invention relates to a preparation method of high-density polyethylene pipe material. It is characterized by that two reactors are series-connected, under the condition of polymerization the ethylene is contacted with alpha-olefin copolymer monomer containing at least 3-6 carbon atoms and catalyst. In first reactor the added quantity of ethylene is 40%-60% of total added quantity of ethylene of two reactors, and the volume ratio of hydrogen gas and ethylene is 3.0-15.0; in second reactor the added quantity of ethylene is 40%-60% of total added quantity of ethylene of two reactors, and the volume ratio of hydrogen gas and ethylene is 0.02-0.20, and the added quantity of copolymer monomer is 0.5%-2.5% of total added quantity of ethylene of two reactors.

Owner:SINOPEC YANGZI PETROCHEM

Large hollow container blow molding material and preparation method thereof

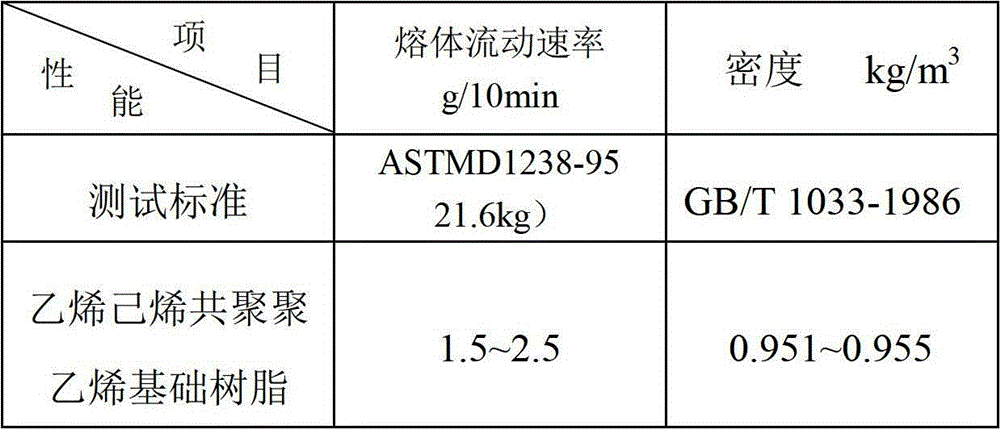

The present invention discloses a large hollow container blow molding material, which comprises the following raw materials, by weight, 99.9-100.0 parts of an ethylene hexene copolymerization polyethylene base resin, 0.05-0.10 part of an antioxidant, 0.07-0.12 part of a co-antioxidant, and 0.03-0.05 part of a slip agent. The present invention further discloses a preparation method for the large hollow container blow molding material. The large hollow container blow molding material has characteristics of low fusion index, large molecule weight, high strength, and the like, and is suitable for blowing of large size containers, wherein the product has prominent rigidity and toughness balancing capacity, creep resistance, excellent ESCR and good chemical resistance.

Owner:CHINA PETROLEUM & CHEM CORP

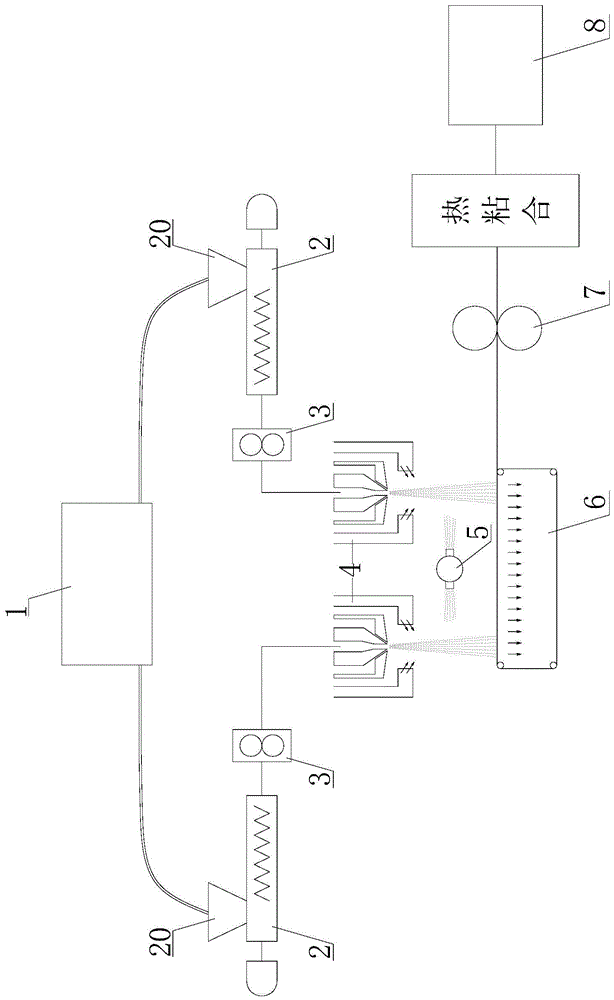

Super-soft skin-close mask specific non-woven fabric and manufacturing method for same

ActiveCN105463699ANon-toxic, tasteless and odorlessLow densityCosmetic preparationsToilet preparationsElastomerFiber

The invention discloses a super-soft skin-close mask specific non-woven fabric comprising the following components by parts: 35 to 105 parts of propylene based elastomer, 12 to 36 parts of polypropylene resin, 2.5 to 7.5 parts of hydrophilic master batches and 0.5 to 1.5 parts of soft master batches. The invention further provides a manufacturing method for the super-soft skin-close mask specific non-woven fabric. The manufacturing method comprises the following steps of preparing raw material, mixing and stirring raw material, conveying raw material, fusing and extruding, extruding spinning filaments, forming a net via air flows, conducting a heat bonding technology and cutting and packing. The manufacturing method for the super-soft skin-close mask specific non-woven fabric has simple steps; Vistamaxx 7050 type propylene based elastomer and S2040 type polypropylene resin are raw material for the non-woven fabric fibers and have great softness, small density and great skin-close property; a technical problem of decreased skin-close property of mask base cloth due to low density of the mask base cloth in the prior art can be solved; and mask base cloth quality and practicality can be enhanced.

Owner:ZHEJIANG KEDEBANG NONWOVEN CLOTH

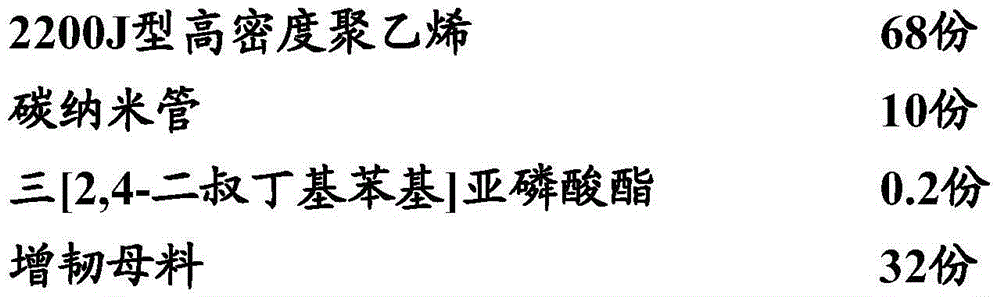

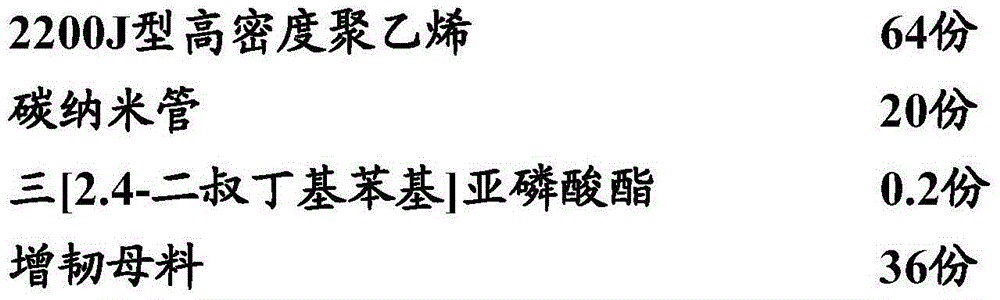

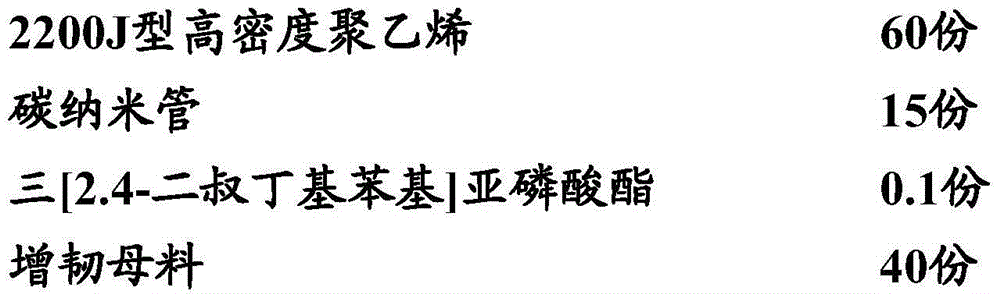

Toughened high density polyethylene 3D printing moulding material and preparation method thereof

The invention relates to a toughened high density polyethylene which includes high density polyethylene and a toughening master batch. The toughening master batch is prepared from an ethylene-propylene elastomer, butylbenzene elastomer, a diluent, an anti-crosslinking agent and a free radical polymerization initiator. The invention also relates to a preparation method of the toughened high density polyethylene, the toughening master batch, a preparation method of the toughening master batch, an application of the toughening master batch in the toughened high density polyethylene, an application of the toughened high density polyethylene in 3D printing and a 3D printing method. High density polyethylene is toughened with the self-made synthesized toughening master batch. The toughened high density polyethylene is good in heat resistance, has high rigidity and toughness, and is also good in environment stress cracking resistance. An obtained blend, which is formed by blending the toughened high density polyethylene with elastomers, has not only original characteristics but also a relative high rigidity conservation rate when toughness of the obtained blend is significantly increased, so that the blend is suitable for 3D printing.

Owner:INST OF CHEM CHINESE ACAD OF SCI

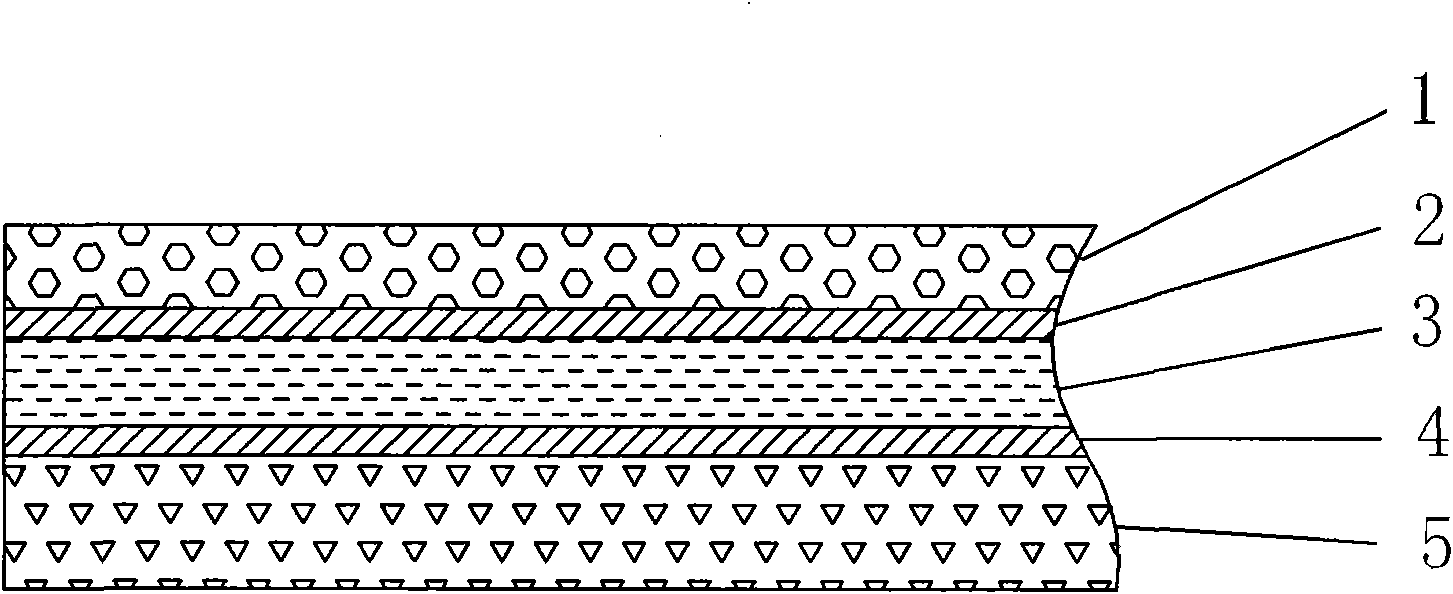

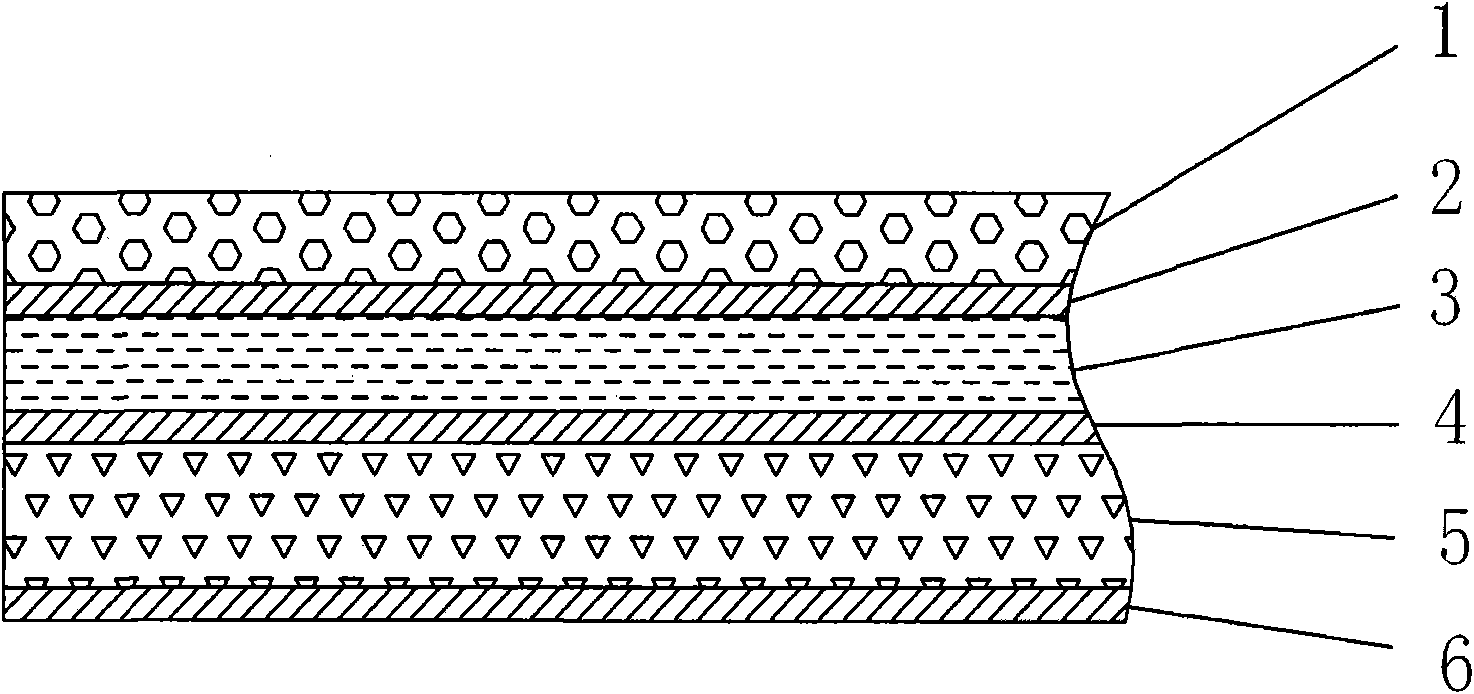

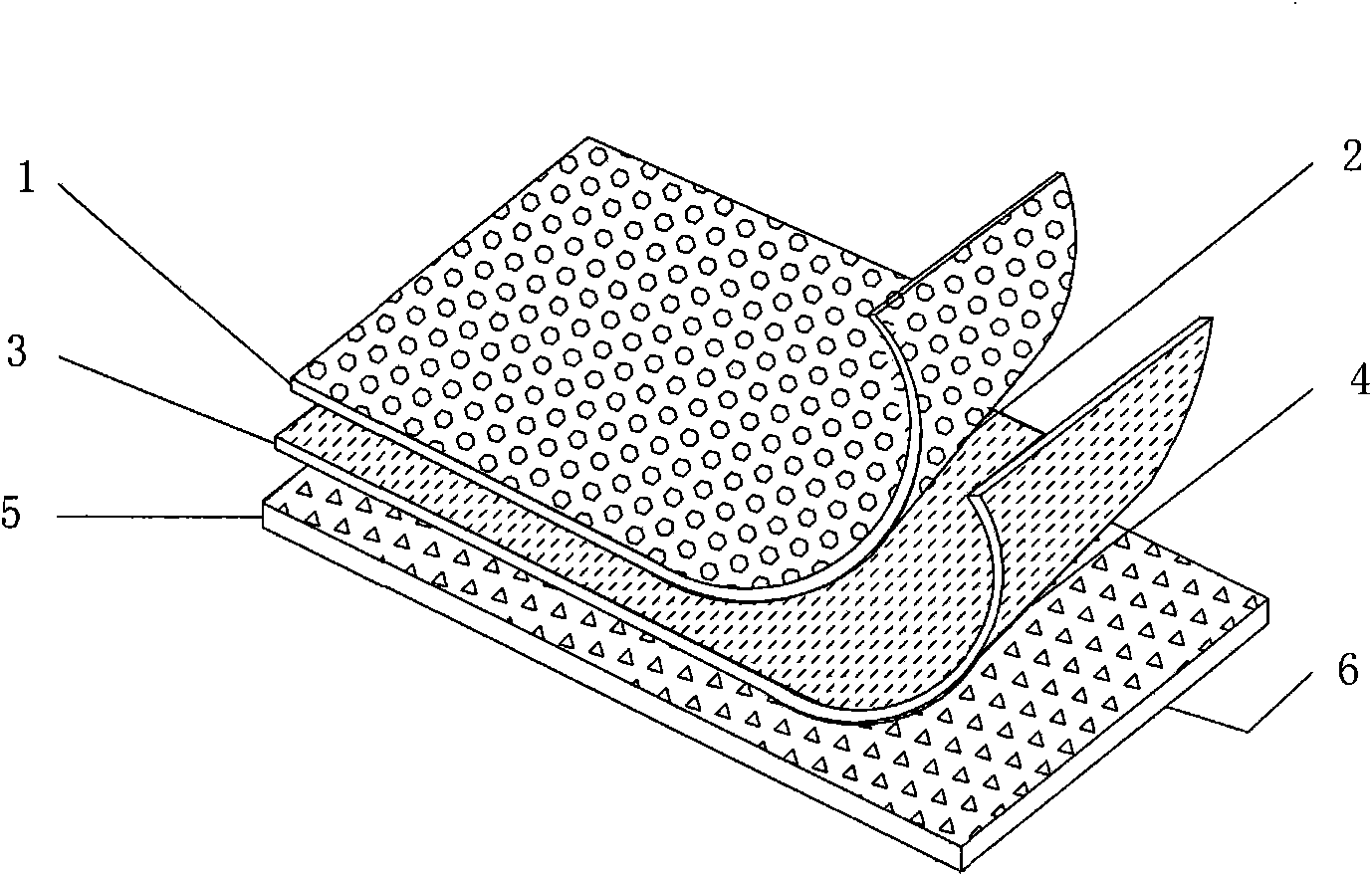

Composite material with high obstruction and high performance and preparation method thereof

InactiveCN101554789AGood weather resistanceImproves resistance to gas permeationLamination ancillary operationsSynthetic resin layered productsPolyurethane adhesiveSolvent free

The invention relates to a composite material with high obstruction and high performance and a preparation method thereof. The composite material with high obstruction and high performance is a laminated body sequentially compounded by a polyfluoroethylene thin film layer, a polyurethane adhesive layer, an AL / PET film layer, a polyurethane adhesive layer, a Kevlar fabric layer and a polyurethane coating. The composite material can ensure lower gas permeability and good mechanical properties and fatigue resistivity under the condition of lighter quality and can be really adapted to the application requirement on the material with high obstruction in the aerospace field. The preparation method is a dry method solvent-free composite technology, the solid content of adhesive used for the method is 100 percent, and no solvent is contained. The method has the great characteristics of environment protection, high product hygiene index and product quality guarantee.

Owner:CHINESE TEXTILE ACAD +1

Preparation method and applications of polyethylene foaming calcic-plastic composite material

ActiveCN103122089ALightweight and high strengthGood environmental stress cracking resistanceLow-density polyethyleneLinear low-density polyethylene

The invention belongs to the technical fields of polymer modification and processing, and relates to a preparation method and applications of a polyethylene foaming calcic-plastic composite material. The polyethylene foaming calcic-plastic composite material is prepared from the following components in parts by weight: 100 parts of low-density polyethylene resin, 10-30 parts of linear low-density polyethylene resin, 80-130 parts of calcic-plastic stuffing, 5-20 parts of foaming agent, 0.8-11 parts of cross-linking agent, 2-4.5 parts of accelerant, 40-60 parts of elastic toughening material and 9-15 parts of composite fire retardant. The polyethylene foaming calcic-plastic composite material has the advantages of light weight, high strength, goog heat insulation property, environmental stress resistance, good impact resilience, fire retardant property, corrosion resistance and the like, and can be used for manufacturing ceilings, vehicle door sheets, float products, decorative plates of acid-alkali corrosion resistant material producing workshops in chemical enterprises, and the like.

Owner:滁州格美特科技有限公司

Solar cell encapsulating EVA (ethylene vinyl acetate copolymer) adhesive film with high light transmittance and preparation method of adhesive film

ActiveCN107502232AHigh transparencyGood flexibilityNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkMechanical property

The invention relates to a solar cell encapsulating EVA (ethylene vinyl acetate copolymer) adhesive film with high light transmittance. The solar cell encapsulating EVA adhesive film is characterized in that the thickness of the EVA adhesive film is 0.8 mm-1.1 mm, and the EVA adhesive film is prepared from raw materials in parts by weight as follows: 100 parts of EVA resin, 0.5-2.5 parts of a plasticizer, 0.1-0.3 parts of a photoelectric conversion rate enhancer, 1-4 parts of an anti-aging agent, 1.5-2.5 parts of a blocking agent, 1-2 parts of a dispersing agent, 1-3 parts of a coupling agent and 1-3 parts of a cross-linking agent. Firstly, the raw materials are added to a mixer proportionally and mixed into uniform components, the components are subjected to melt mixing by a banbury mixer and then subjected to extrusion and pelletizing, and the EVA adhesive film is obtained. According to the prepared EVA adhesive film, the light transmittance of the adhesive film is not influenced and the mechanical properties are greatly improved while properties and photoelectric conversion efficiency of the adhesive film are improved with addition of multiple additives.

Owner:NINGBO HUASHUN SOLAR ENERGY TECH

Regeneration polyethylene resin combination for sheath production and preparation method thereof

InactiveCN102643468ALow costGood physical and mechanical propertiesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a regeneration polyethylene resin combination for sheath production and a preparation method thereof. The regeneration polyethylene resin combination for sheath production is prepared by the following raw materials, by weight: 70-80 parts of polyethylene pipe reworked materials, 8-10 parts of polyethylene bottle cover reworked materials, 10-15 parts of linear low density polyethylene (LLDPE) film reworked materials, 2-5 parts of ethylene-vinyl acetate ester copolymers, 0.2-0.4 parts of antioxidants, 5-7 parts of carbon black master batches and 0.01-0.03 parts of processing agents. The raw materials are put into a high-speed mixer to perform stirring and mixing, and evenly-mixed materials are fed into a double-screw extruder to perform melting, plasticization, extrusion and pelleting. The combination has excellent physical and mechanical properties, environmental stress crack resistance (ESCR), thermal aging resistance and processability, wherein the ESCR (10%, F0) is larger than or equal to 500 hours, thermal aging elongation at break at the temperature of 110 DEG C for 1500 hours is larger than or equal to 650%, tensile strength is larger than or equal to 28MPa, and the processing traction speed is larger than or equal to 30m / min.

Owner:QINGZHOU LUCHUANG RENEWABLE RESOURCE

Insulating heat conducting cable material and preparation method thereof

InactiveCN105837911AImprove heat resistanceImprove cold resistancePlastic/resin/waxes insulatorsElastomerPolyolefin

The invention discloses an insulating heat conducting cable material. The insulating heat conducting cable material comprises the following raw materials in parts by weight: 60 to 70 parts of high-density polyethylene, 20 to 30 parts of modified polypropylene, 15 to 25 parts of heat conducting filler, 6 to 10 parts of polyolefin elastomers, 5 to 8 parts of glass fibres, 3 to 5 parts of a compatilizer, 3 to 8 parts of modified zinc borate, and 10 to 15 parts of ethylene-vinyl acetate copolymer. The insulating cable material is high in heat conductivity, high in insulating property, high in tensile strength, high in toughness, and convenient to process.

Owner:STATE GRID HENAN SHEQI POWER SUPPLY CO

Polyolefin resin composition for pipe

InactiveCN102276891AReasonable dosageGood physical propertiesLow-density polyethylenePolymer science

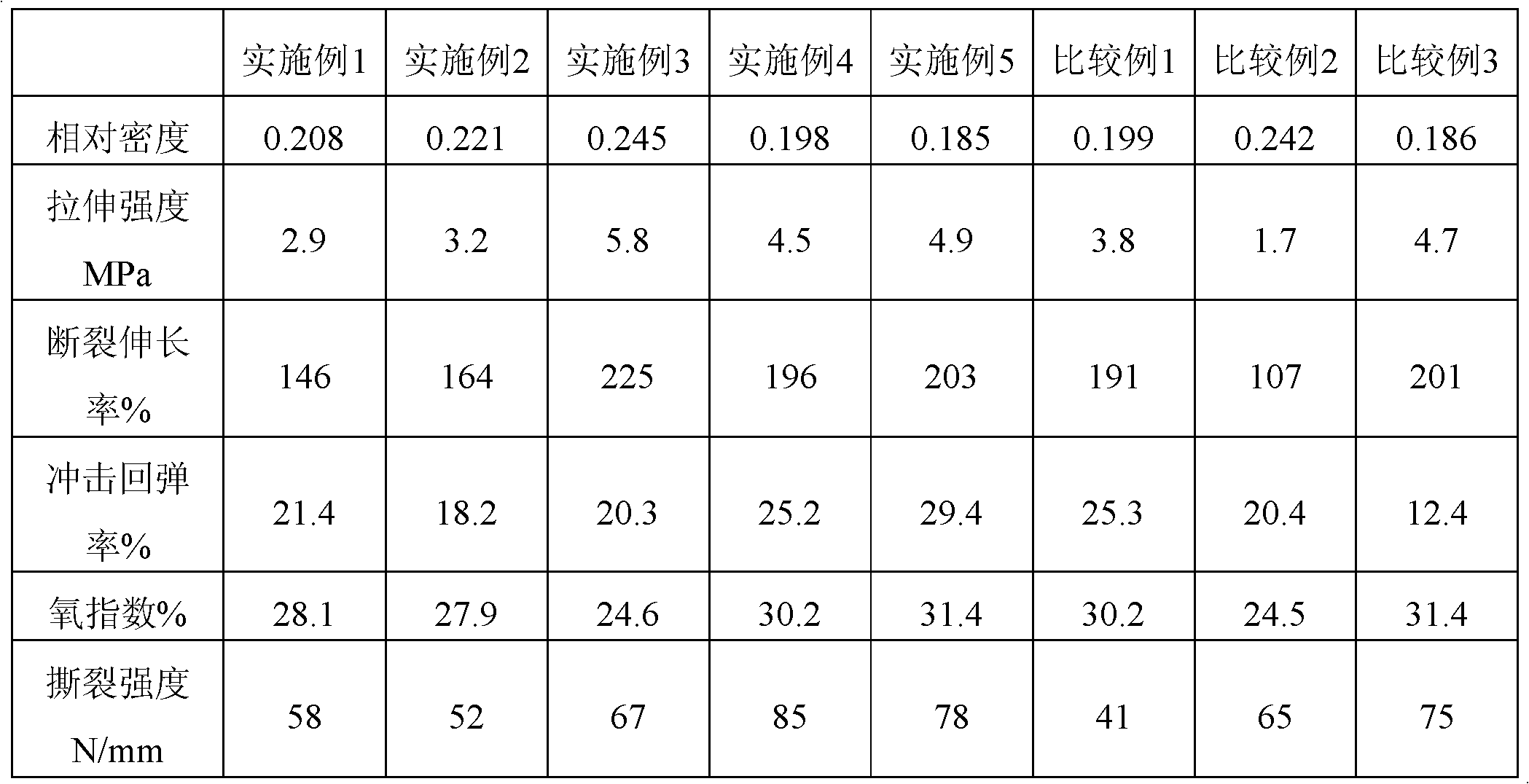

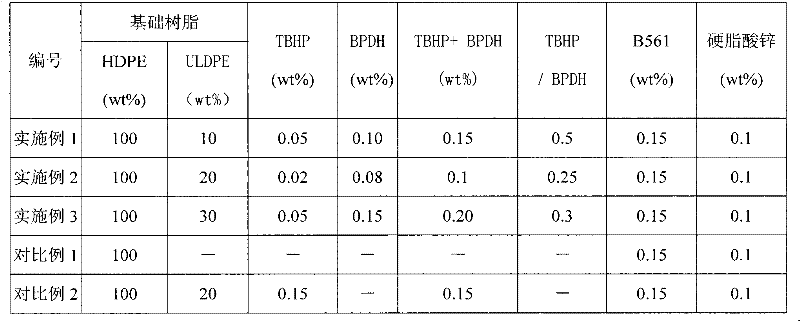

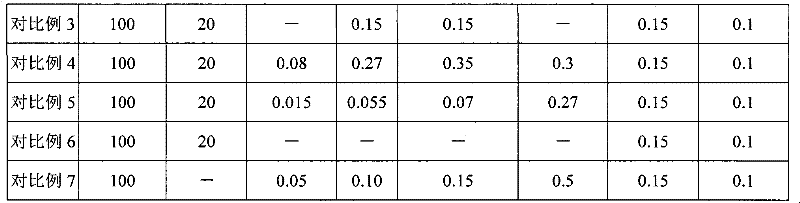

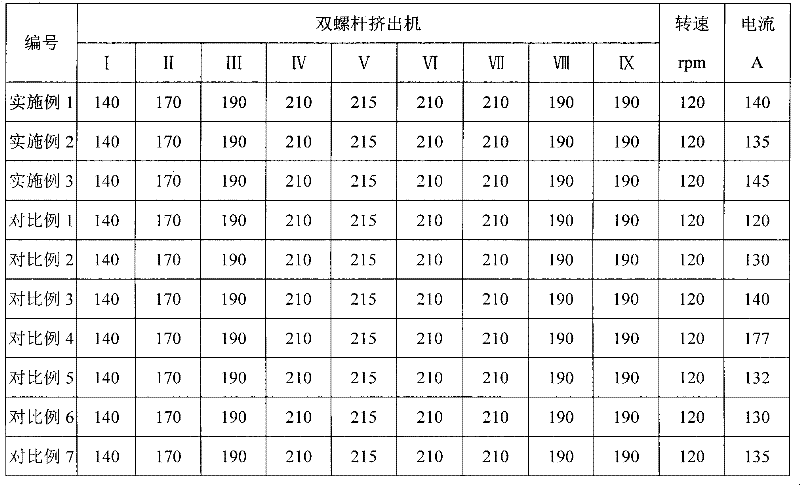

A polyolefin resin composition for pipes, comprising: 100% high-density polyethylene, melt flow rate 0.1-0.5g / 10min, density 0.945-0.957g / cm3; 2) 10%-30% ultra-low density polyethylene, melt flow rate 0.1-20g / 10min, density 0.860-0.900g / cm3; 3) 0.1%-0.30% peroxide modifier. The composition undergoes a micro-crosslinking reaction through a reactive extrusion process, which improves the environmental stress cracking resistance (>2000 hours) of the high-density polyethylene, and expands the application of the high-density polyethylene in pipes or other fields. The invention further discloses a preparation method of the resin composition.

Owner:PETROCHINA CO LTD

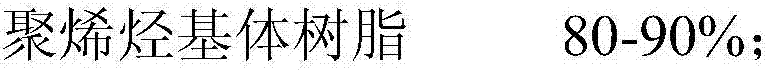

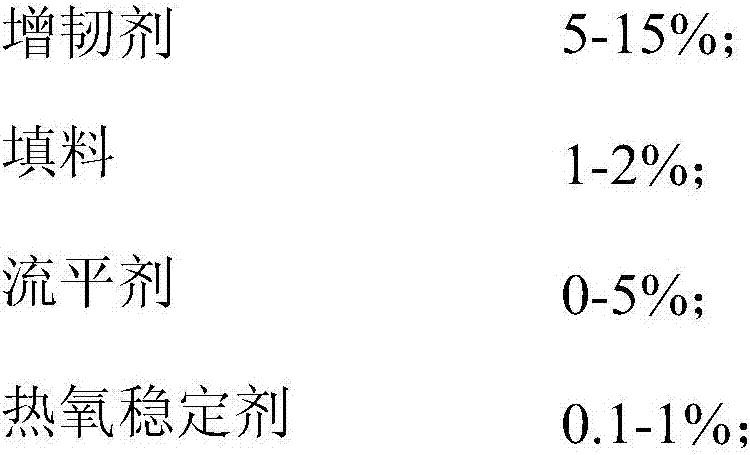

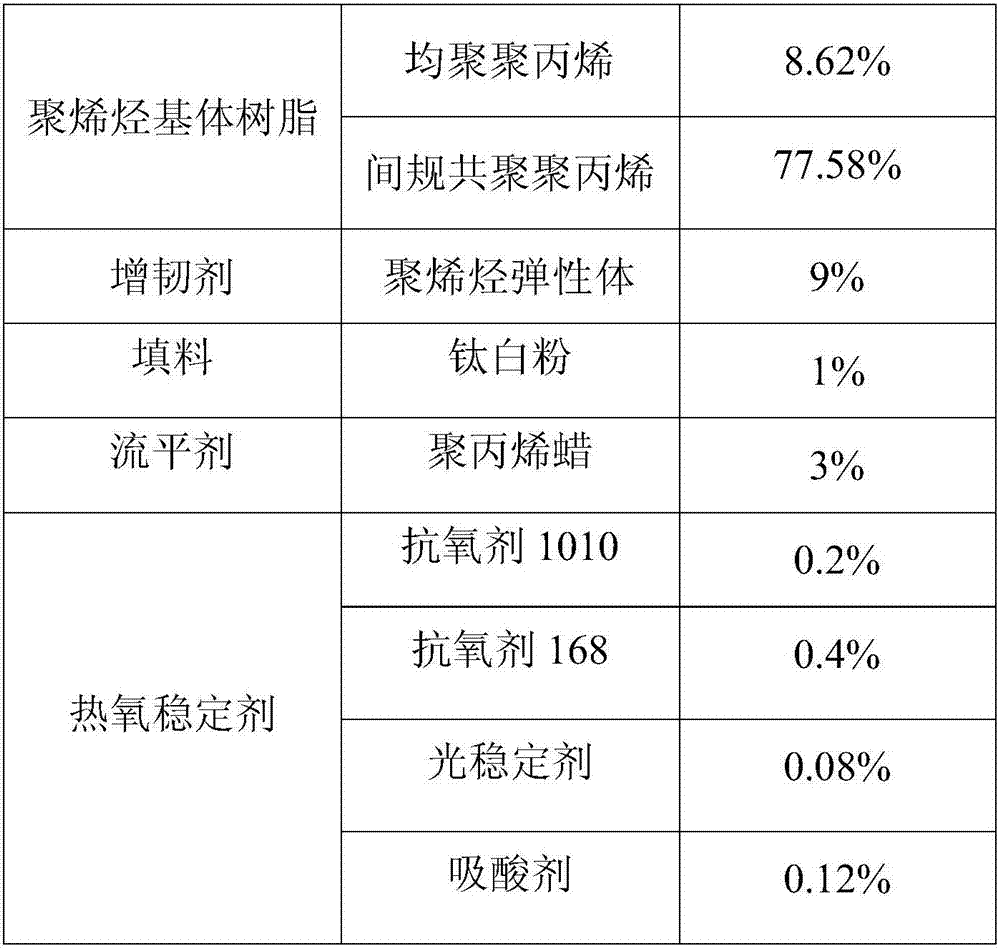

Polypropylene powder for 3PP anticorrosion pipeline coating external layers, and preparation method thereof

ActiveCN106854311AGood dry powder fluidityImprove the level ofAnti-corrosive paintsPowdery paintsPolymer sciencePolyolefin

The invention discloses a polypropylene powder for 3PP anticorrosion pipeline coating external layers, and a preparation method thereof. The polypropylene powder comprises, by weight, 80-90% of polyolefin matrix resin, 5-15% of a flexibilizer, 1-2% of a filler, 0-5% of a leveling agent and 0.1-1% of a heat and oxygen stabilizer, and the sum of weight percentages of all above raw materials is 100%. The preparation method comprises the following steps: 1, mixing the raw materials in proportion, and carrying out extrusion granulation on the mixed raw materials at 190-220 DEG C through a double screw extruder to obtain polypropylene granules; and 2, grinding the polypropylene granules obtained in step 1 to obtain the polypropylene powder. The polypropylene powder can be mainly used in petroleum natural gas anticorrosion pipelines as an anticorrosion layer material, is suitable for a powder sprinkling technology and a flame spraying technology, naturally levels in the construction process, has very good bonding strength with adhesives, and is suitable for anticorrosion of pipeline interfaces and bent tubes.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Graphene reinforced heat-resistant polyethylene composite pipe and preparation method thereof

The invention provides a graphene reinforced heat-resistant polyethylene composite pipe and a preparation method thereof and belongs to the technical field of pipeline materials. The invention mainly aims to solve the technical problem that a general polyethylene pipe is not high-temperature-resistant and is easy to damage. The graphene reinforced heat-resistant polyethylene composite pipe provided by the invention comprises the following components in parts by weight: 80-90 parts of hexane copolymerizing high-density heat-resistant polyethylene, 0.1-3 parts of graphene, 2-4 parts of fluorine-containing styrene, 2-4 parts of a coupling agent, 6-8 parts of a plasticizer, 1-3 parts of an antioxidant, 2-4 parts of a lubricating agent, 10-30 parts of a dissolution agent and 0.1-0.3 part of a surfactant. The invention further provides a preparation method of the graphene reinforced heat-resistant polyethylene composite pipe. The method comprises the following steps: dissolving, stirring, performing ultrasonic treatment, mixing, heating, performing single-screw extrusion and the like. The various raw materials are high in compatibility, the characteristics of the raw materials are effectively achieved, and the prepared pipe has high strength and heat resistance.

Owner:吉林省慧燊节能科技有限公司

Halogen-free combustion-proof polypropylene high-speed abrasion-proof insulating material for auto initial line

ActiveCN1807499AHigh strengthImprove wear resistancePlastic/resin/waxes insulators1-OctenePolypropylene

The invention relates to a halogen-free combustion-proof polypropylene high-speed abrasion-proof insulating material for auto initial line, wherein the invention is characterized in that the constituents include base resin a and b comprising ethene-propene copolymer, modified resin c including ethane-1-octene copolymer, capacity-adding resin d including the polar monomer grafts of ethane-1-octene copolymer, combustion inhibitor e, expansion combustion inhibitor, composite anti-oxidant f, metal deactivator g, outer lubricating agent h, outer lubricating agent i, lubricating agent j, brightening lubricant k. The process for preparation comprises blending and squeezing with a double screw rod extrusion machine, then squeezing and coating the obtained composition into isolated wires.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

High-flame retardation solar energy cell organosilicon pouring sealant and preparation method thereof

InactiveCN107384305AHigh transparencyGood flexibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkAcrylic resin

The invention relates to a high-flame retardation solar energy cell organosilicon pouring sealant and a preparation method thereof. The high-flame retardation solar energy cell organosilicon pouring sealant comprises the following raw materials in parts by weight: 40 parts of methyl phenyl vinyl silicone rubber, 20 parts of room-temperature sulfured phenylene silicone rubber, 20 parts of addition-type heat vulcanized nitrile silicone rubber, 20 parts of phosphate silicone oil, 20 parts of polyoxypropylene glycerol ether silicone oil, 10 parts of mercapto silicone oil, 5 parts of low-molecular hydroxy silicone oil, 5 parts of hydrogen-containing silicone oil with hydrogen containing amount accounting for 0.5% of mass content, 10 parts of an ethene-vinyl acetate copolymer, 10 parts of otcamethylcyclotetrasiloxane-modified acrylic resin, 7 parts of hydrogenated castor oil, 1-3 parts of an adhesion agent, 1-3 parts of a strengthening agent, 0.1-0.4 parts of a catalyst, 1-3 parts of a silicon nitrogen cross-linking agent, 0.5-2.5 parts of an inhibitor, and 1-2 parts of a flame-retardation filling material.

Owner:NINGBO HUASHUN SOLAR ENERGY TECH

Long-chain branched high-density polyethylene material resisting environmental stress cracking and preparation method thereof

The invention discloses a long-chain branched high-density polyethylene material resisting environmental stress cracking and a preparation method thereof. According to the preparation method, long-chain branched modification is conducted on high-density polyethylene by selecting a melting reaction processing method to improve the environmental stress cracking resisting property of the material, branching generation is promoted by adding two-functionality-degree graft monomers, acrylic ester double bonds are adopted to stabilize the macromolecular free radicals and improve the branching efficiency, and meanwhile an efficient free radical regulating agent is added to regulate and control the activity of the macromolecular free radicals to inhibit crosslinking side reaction; the prepared long-chain branched high-density polyethylene has the low gel fraction, and long-branch-chain high-density polyethylene of which the branch chain length meets the stress cracking resisting requirement is obtained. The long-chain branched high-density polyethylene prepared through the preparation method has the excellent environmental stress cracking resisting property and the good comprehensive mechanical property.

Owner:KANGMINGYUAN GUIZHOU SCI & TECH DEV CO LTD

Composite auxiliary agent for high density polyethylene overpressure resistant tubing, preparation method thereof, and resin raw material containing the composite auxiliary agent

ActiveCN105733023AGood environmental stress cracking resistanceImprove pressure resistanceProcedure AgentsAntioxidant

The invention provides a composite auxiliary agent for a high density polyethylene overpressure resistant tubing. The composite auxiliary agent comprises 30-50 parts by weight of a long-term ageing resistant auxiliary agent , 10-30 parts by weight of a thermal stable auxiliary agent, and 10-30 parts by weight of a processing auxiliary agent, wherein the long-term ageing resistant auxiliary agent is at least one selected from a group consisting of hindered phenols antioxidants, amines antioxidants, and phosphorus antioxidants; the thermal stable auxiliary agent is at least one selected from metal soap stabilizers; and the processing auxiliary agent comprises at least a fluoroelastomer. The invention also provides a preparation method of the composite auxiliary agent, and a high density polyethylene overpressure resistant tubing resin raw material containing the composite auxiliary agent. The high density polyethylene overpressure resistant tubing resin raw material containing the composite auxiliary agent has excellent processing performance. The formed tubing has excellent environmental stress crack resistance, ageing resistance, and rigidity-toughness balance.

Owner:PETROCHINA CO LTD

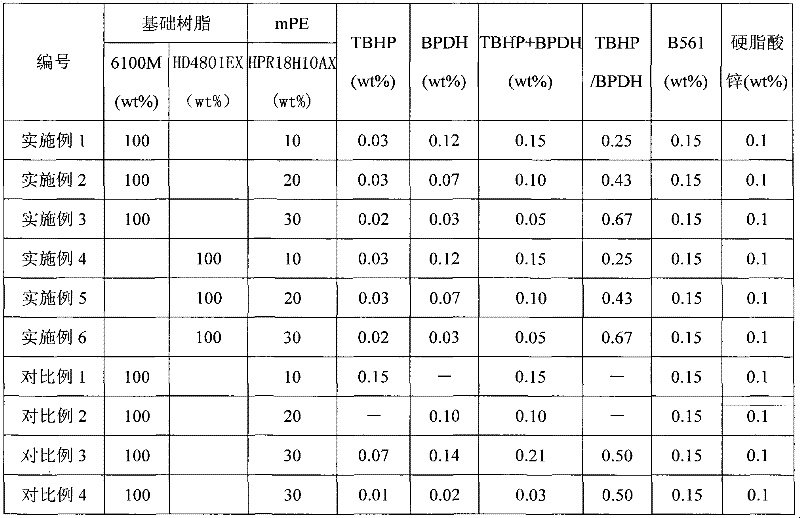

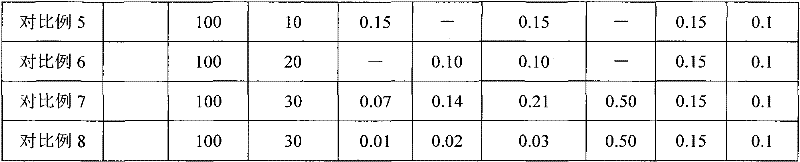

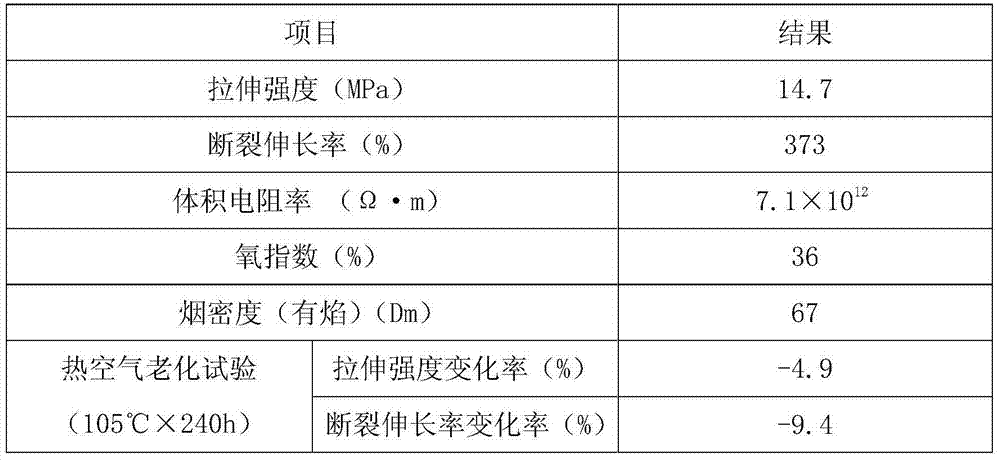

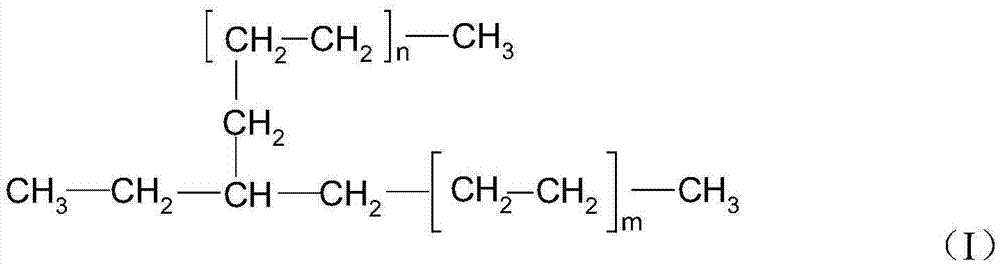

Polyethylene resin composition for pipe

ActiveCN102295799AImprove physical properties such as resistance to environmental stress crackingGood environmental stress cracking resistanceRigid pipesAntioxidantEnvironmental stress cracking

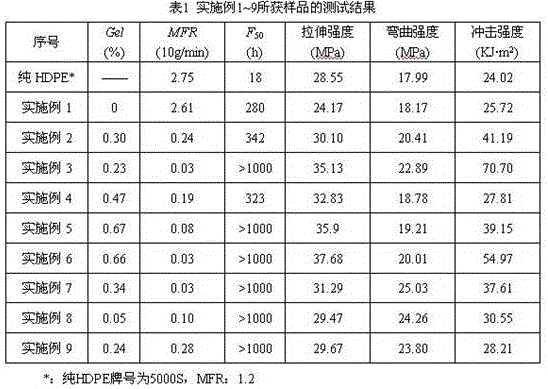

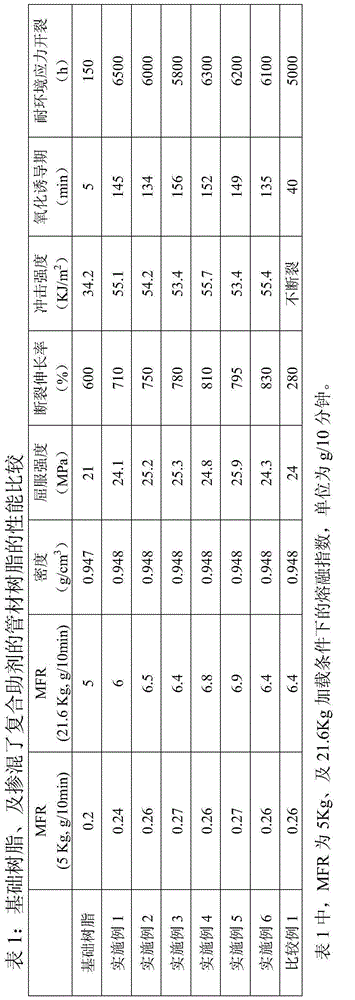

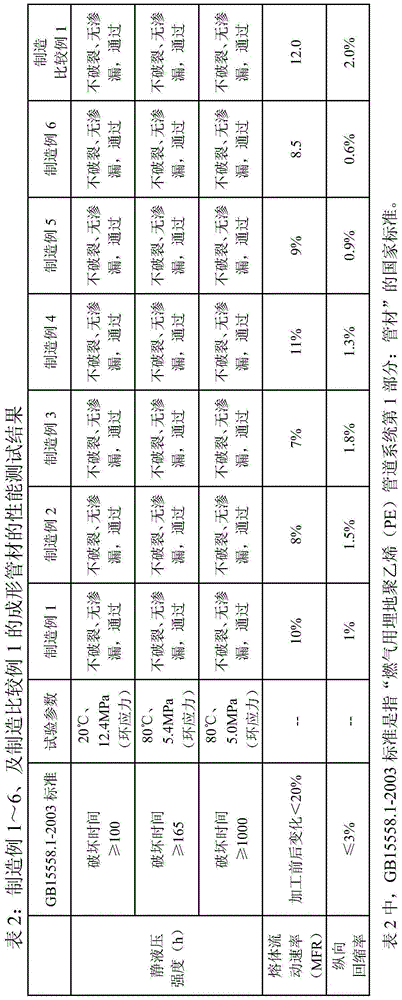

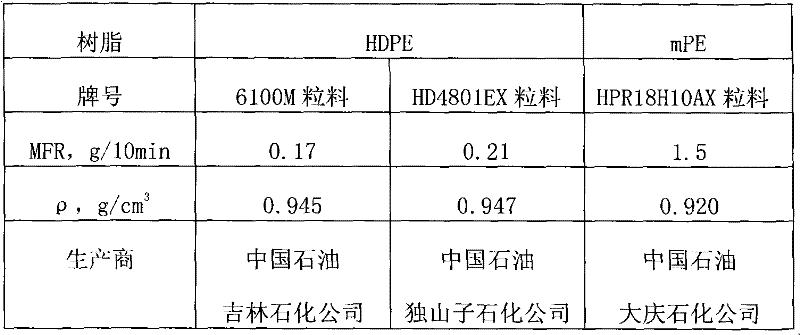

The invention provides a polyethylene resin composition for a pipe. Based on 100wt% of high density polyethylene, the polyethylene resin composition comprises the following components in percentage by weight: 100% of high density polyethylene, 10%-30% of metallocene polyethylene, 0.05%-0.15% of complex crosslinking auxiliary, 0.1%-0.15% of lubricant and 0.1%-0.2% of antioxidant. The resin composition for the pipe has good environment stress cracking resistant property (large than 1000 hours). By using the polyethylene resin composition in the invention, the problem of poor environment stress cracking resistant property of the common high density polyethylene (HDPE) resin is solved.

Owner:PETROCHINA CO LTD

Tracking-resistant polyethylene sheath material for power wire and preparation method thereof

InactiveCN103540000AExcellent tracking resistanceGood physical and mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesGas releaseMechanical property

The invention discloses a tracking-resistant polyethylene sheath material for a power wire and a preparation method thereof. The tracking-resistant polyethylene sheath material for the power wire is prepared from the following substances in parts by weight: 50-70 parts of high-density polyethylene, 30-40 parts of linear low-density polyethylene, 15-25 parts of ethylene-propylene-diene monomer, 3-6 parts of polytrifluoropropyl methylsiloxane, 10-15 parts of nano wollastonite, 20-25 parts of sediment white carbon black, 5-10 parts of nano-montmorillonite, 4-6 parts of ferrocene, 10-15 parts of magnesium hydroxide, 8-12 parts of methyl phenyl silicone oil, 2-3 parts of dibutyltin dilaurate, 3-5 parts of phosphoguanidine and 5-10 parts of borax. The sheath material is excellent in tracking resistance, so that the electric erosion phenomenon on the surface of the power wire in extra-high voltage can be solved; meanwhile, the sheath material is good in physical and mechanical properties, electrical insulation property, environmental stress crack resistance, ageing resistance and heat resistance, durable in use, long-term in operation in outdoor severe environment without failure, good in flame retardant effect, low in smoke during combusting without harmful gas release, free of environmental pollution, safe and environment-friendly.

Owner:天长市富达电子科技股份有限公司

Polyethylene base resin powder and preparation method thereof

The invention relates to a polyethylene base resin powder for preparing an IBC barrel special material and a preparation method thereof. Polyethylene base resin is produced by a gas phase polyethylene process, the polymerization temperature is 96 DEG C-120 DEG C, and the polymerization pressure is 0.85-2.5 MPa. The prepared base resin powder is generated by copolymerization of ethylene and long-chain alpha-olefin, the weight-average molecular weight is 200-350 thousand, the molecular weight distribution index is 7-15, the alpha-olefin content is 0.5-1.5%, the melt flow rate is 5-8 g / 10 min, the density is 0.942-0.952 g / cm<3>, the low temperature impact strength (-30 DEG C) is more than 30 kJ / m<2>, and the melt strength is more than 15 cN. The special material is guaranteed to have high mechanical strength, good processing performance and high melt strength, can be guaranteed to have good antisagging property, and can meet various properties of the IBC barrel special material.

Owner:PETROCHINA CO LTD

Environmental stress crack-resistant polyethylene sheath material for power wire and preparation method thereof

InactiveCN103540008AGood environmental stress cracking resistanceGood high and low temperature resistancePlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethyleneLead phosphate

The invention discloses an environmental stress crack-resistant polyethylene sheath material for a power wire and a preparation method thereof. The environmental stress crack-resistant polyethylene sheath material is prepared from the following substances in parts by weight: 80-100 parts of linear low-density polyethylene, 15-20 parts of polystyrene resin, 10-15 parts of polyphthalamide, 4-8 parts of dimethyl silicon oil, 2-3 parts of dibasic lead phosphate, 1-2 parts of calcium stearate, 1-2 parts of zinc stearate, 0.5-1 part of antioxidant 1010, 1-2 parts of antioxidant 168, 2-4 parts of ethylene distearate amide, 4-6 parts of chlorinated paraffin and 3-5 parts of pine tar. The sheath material has the advantages of excellent environmental stress crack resistance, high-low temperature resistance, acid-base resistance, salt mist resistance, ozone aging resistance, ultraviolet radiation resistance, abrasive resistance and tensile strength, is capable of working normally in a working environment at a temperature ranging from 60 DEG C below zero to 105 DEG C, is non-deformable and non-cracking in long-time use, is safe and reliable and is applicable to internal and external sheathes of overhead power wires in the outdoor.

Owner:天长市富达电子科技股份有限公司

Anti-cracking flame-retardant cable sheath material and preparation method thereof

InactiveCN110294890AImprove flame retardant performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsCross-linkLinear low-density polyethylene

The invention discloses an anti-cracking flame-retardant cable sheath material. The material is prepared from, by weight, 40-55 parts of linear low-density polyethylene, 10-15 parts of high-density polyethylene, 25-40 parts of methyl vinyl silicone rubber, 20-30 parts of ethylene-octylene copolymer, 5-10 parts of hydrogen-containing silicone oil, 4-8 parts of talcum powder, 0.5-1.5 parts of aluminum nitride nano-particles, 10-20 parts of aluminum hydroxide, 6-10 parts of zinc borate, 1-3 parts of an antioxidant, 0.1-0.3 part of chloroplatinic acid and 1-5 parts of a cross-linking agent. The anti-cracking flame-retardant cable sheath material is excellent in mechanical property, flame retardancy and cracking resistance.

Owner:国网河南省电力公司桐柏县供电公司

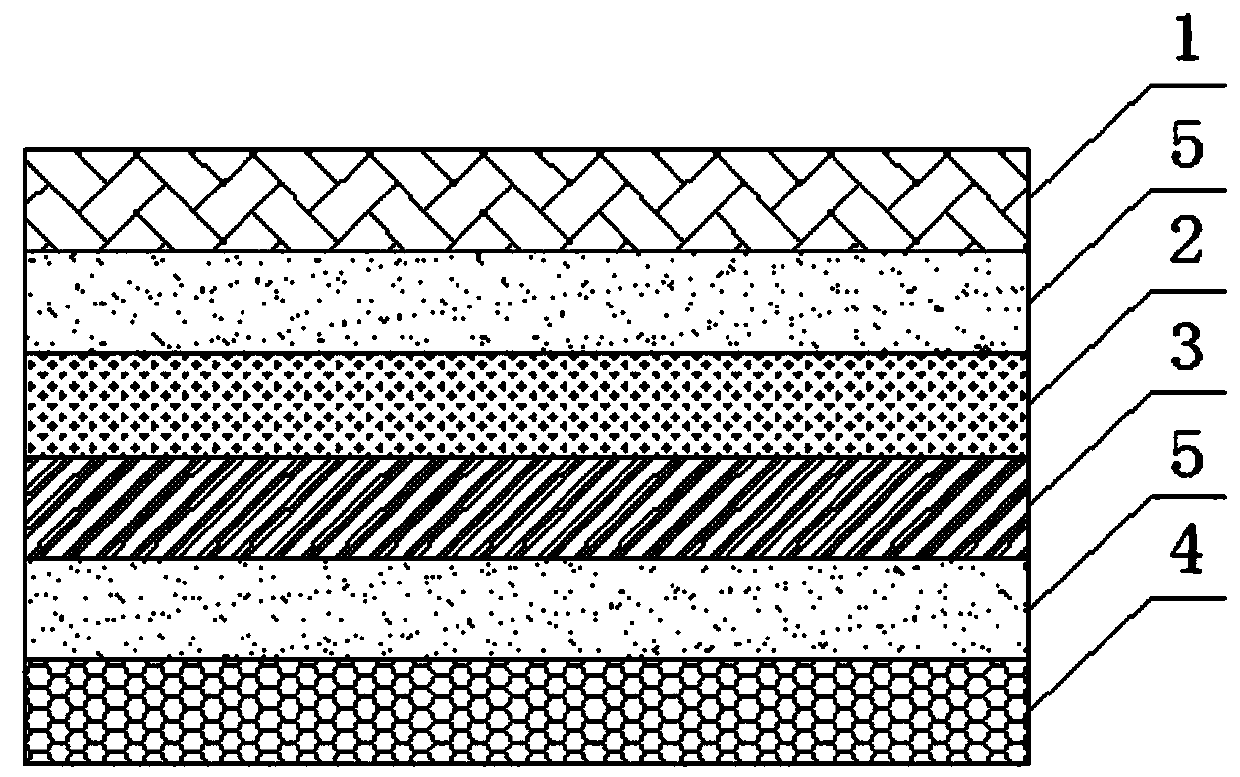

Two-layer composite pipe and preparation method thereof

InactiveCN108397608AGood miscibilityImprove mechanical propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesLow-density polyethyleneCrack resistance

The invention discloses a two-layer composite pipe which comprises an inner layer and an outer layer. A binding layer is arranged between the inner layer and the outer layer. The inner layer is prepared from, by mass, 43%-45% of ultra-high molecular weight polypropylene and 30%-32% of low-density polyethylene, the outer layer is prepared from, by mass, 2%-15% of modified nano calcium carbonate, 62%-70% of HDPE, 20%-28% of nano calcium carbonate and 0.5%-6% of lubricating agent, and the binding layer is formed by a coated binding agent prepared from raw rubber, butadiene styrene rubber, silicasolution, refractory mortar, pitch, rosin, silicon dioxide, zinc oxide, water and diethylenetriamine. The two-layer composite pipe has the beneficial effects that the good ultraviolet light resistanceand nuclear radiation resistance, flexibility and excellent wear resistance and durability are achieved, the binding agent is good in compatibility, capable of being dried by itself at normal temperature, nontoxic, odorless and high in adhesive force, the modified nano calcium carbonate and the nano calcium carbonate are added to enable the composite material to have the better mechanical property, and the pipe has the better toughness, better hardness and higher environment stress cracking resistance compared with an HDPE two-wall corrugated pipe.

Owner:贵州黔峰管业有限公司

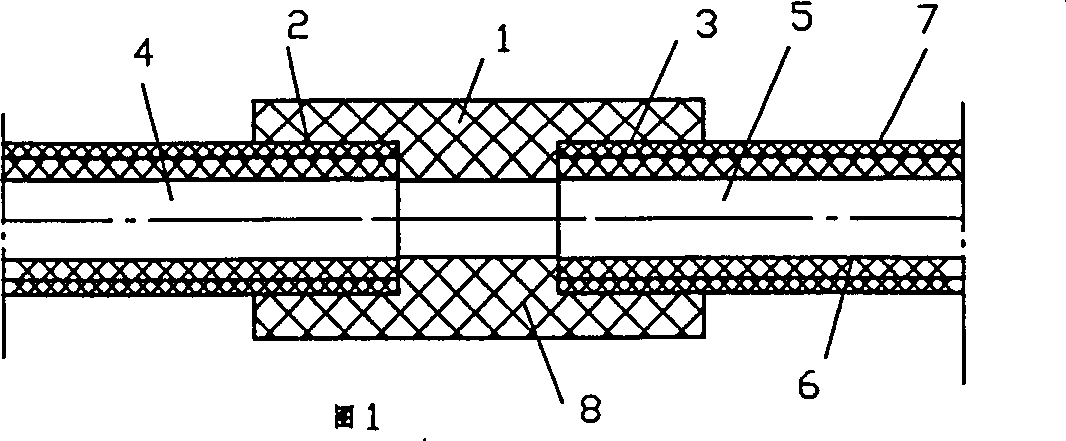

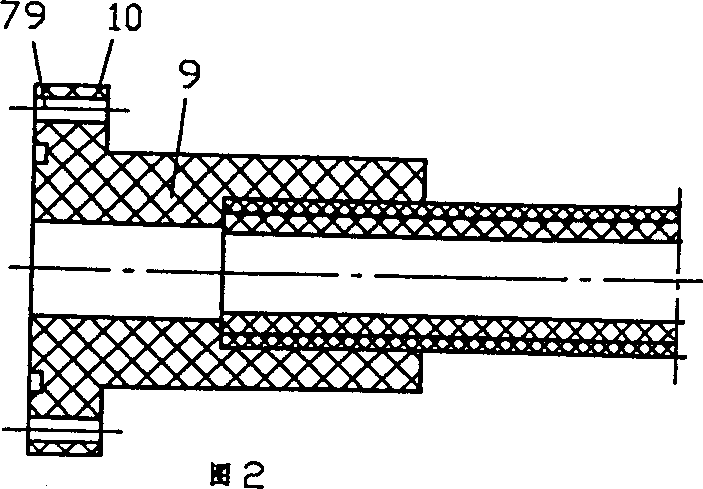

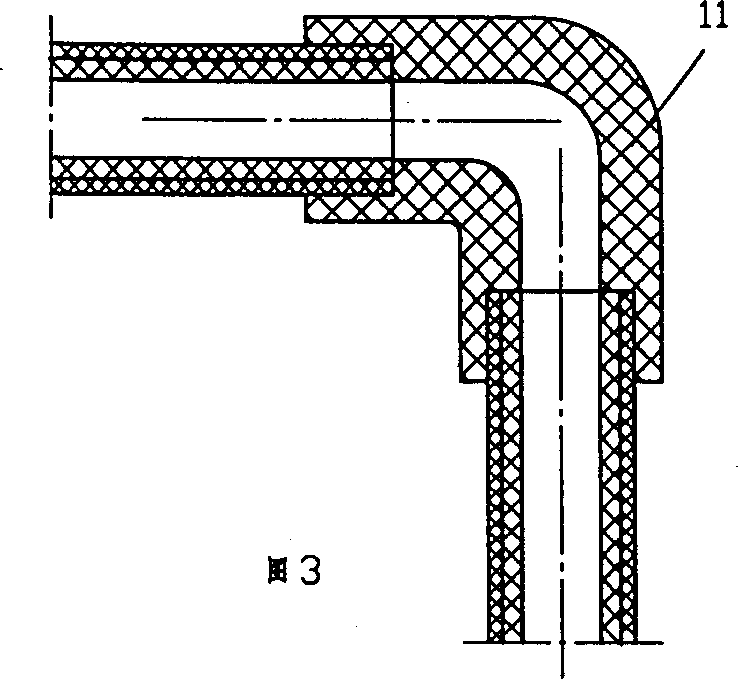

Plastic pipe network connected by pipe jointers made of refractory non-cross-linked poly ethylene

InactiveCN1391055ASmall percentage of total costSave raw materialsRigid pipesPipe connection arrangementsHigh resistanceCross-link

A composite plastic pipeline is composed of the pipe jointer made of non-cross-linked refractory polyethylene and the composite plastic pipe consisting of internal cross-linked polyethylene layer and external layer of refractory non-cross-linked polyethylene. The plastic pipes and the pipe jointer are connected by thermal fusion or electrothermal fusion. Its advantages are high thermal strength, good electric insulation, high resistance to ageing and cracking, and low cost.

Owner:DONGTAI NEW MATERIAL SCI ANG TECH SICHUAN

Modified weather-resistant high-density polyethylene sheathing compound for bridge cables and method for preparing modified weather-resistant high-density polyethylene sheathing compound

ActiveCN105086079AGood resistance to environmental stress crackingUniform colorCarbon blackPOLYETHYLENE WAX

The invention discloses a modified weather-resistant high-density polyethylene sheathing compound for bridge cables. A method for preparing the modified weather-resistant high-density polyethylene sheathing compound includes mixing ultrahigh-molecular-weight polyethylene, high-density polyethylene, linear low-density polyethylene, low-density polyethylene, antioxidants and polyethylene wax with one another in high-speed mixers at normal temperatures to obtain mixtures, discharging the mixtures into parallel double-screw granulation units, melting and extruding the mixtures, granulating the mixtures under underwater conditions to obtain particles, dehydrating the particles, and then drying the particles to obtain modified high-density polyethylene particles; mixing the obtained modified high-density polyethylene particles, high-density polyethylene, carbon black parent materials, antioxidants and silicone parent materials with one another in the high-speed mixers at normal temperatures to obtain mixtures, discharging the mixtures into the parallel double-screw granulation units, melting and extruding the mixtures, granulating the mixtures under underwater conditions to obtain particles, dehydrating the particles, and drying the particles to obtain the modified weather-resistant high-density polyethylene black sheathing compound for the bridge cables. The modified weather-resistant high-density polyethylene sheathing compound and the method have the advantages that the sheathing compound is excellent in physical and mechanical properties, in particular, the ultraviolet resistance property and the environmental stress cracking resistance property, and various indexes of manufactured products conform to requirements of standards CJ / T297-2008 of housing construction departments.

Owner:HUBEI YANGTIAN PLASTIC PROD CO LTD

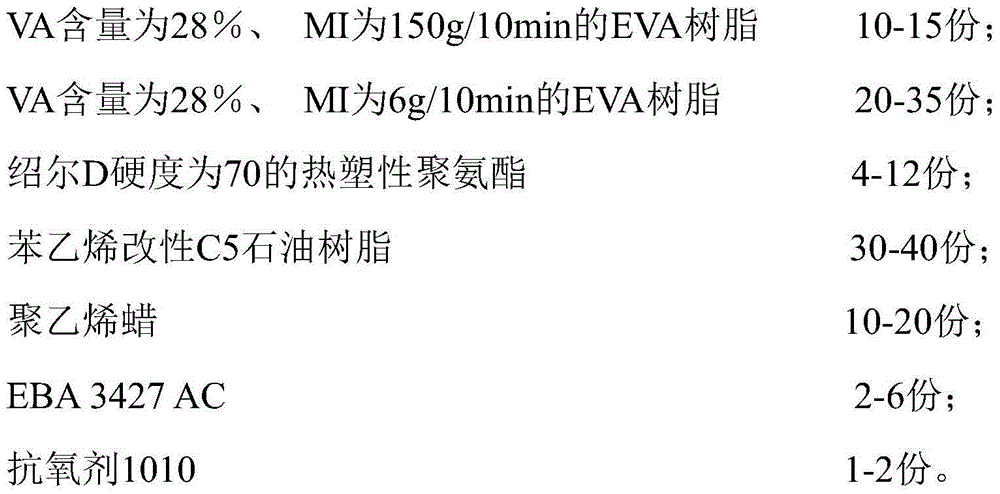

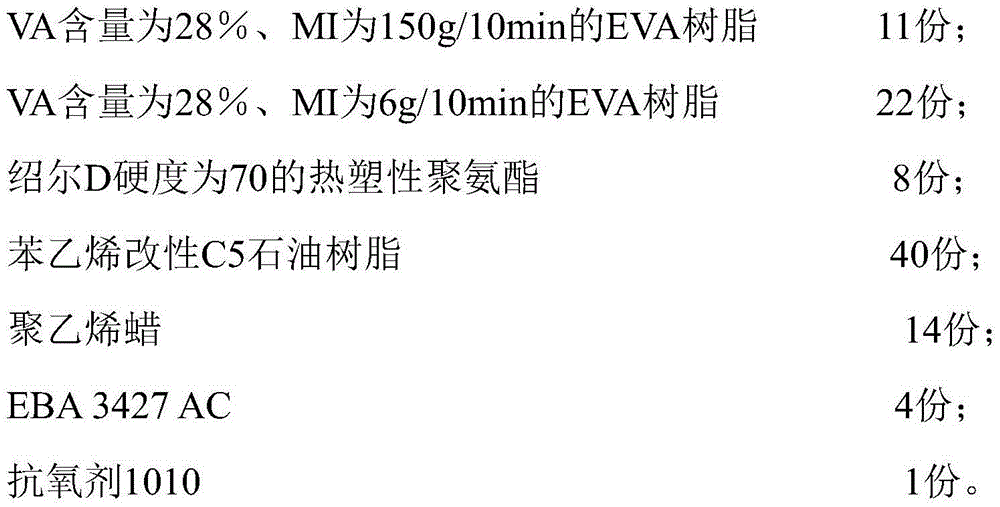

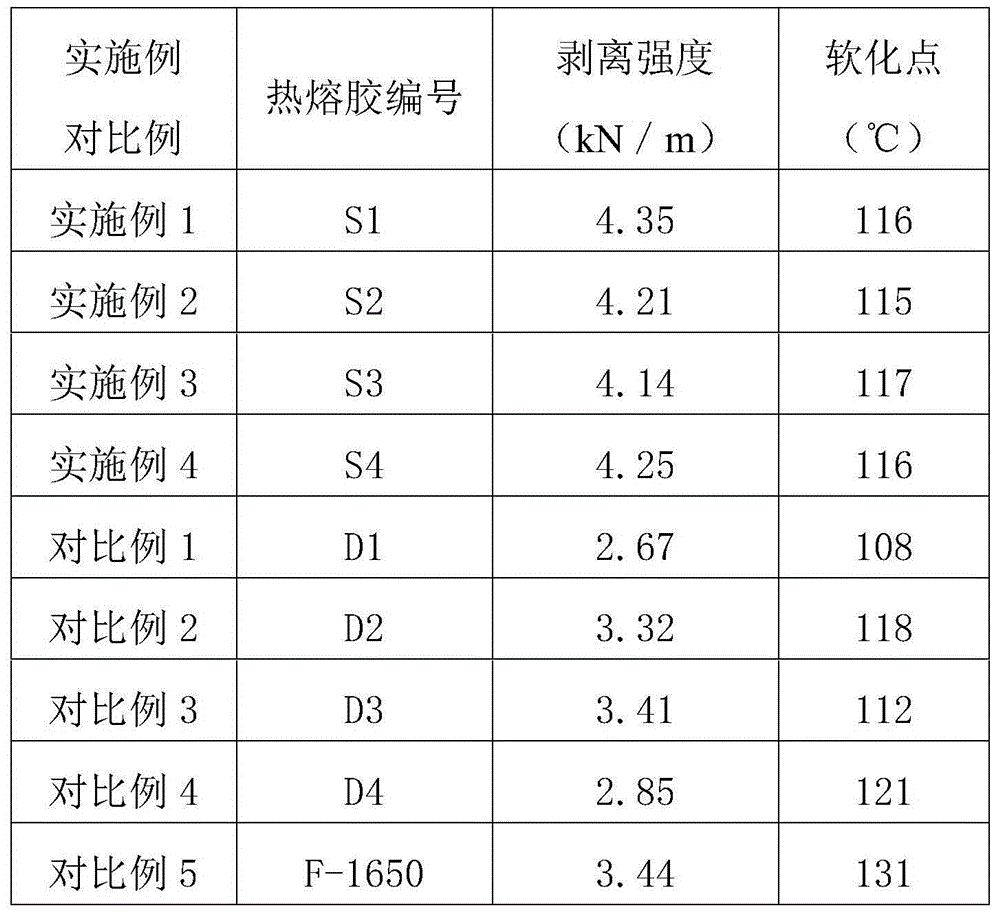

Hot melt adhesive for acrylic hot-fix rhinestone and preparation method thereof

ActiveCN105273669AAdjust melt viscosityReduce crystallinityMineral oil hydrocarbon copolymer adhesivesPolyureas/polyurethane adhesivesPetroleum resinThermoplastic polyurethane

The invention provides a hot melt adhesive for an acrylic hot-fix rhinestone. The hot melt adhesive comprises the following components by weight: 10 to 15 parts of EVA resin with the VA content of 28% and the MI of 150 g / 10min, 0 to 35 parts of EVA resin with the VA content of 28% and the MI of 6 g / 10min, 4 to 12 parts of thermoplastic polyurethane with Shore D hardness of 70, 30 to 40 parts of styrene modified C5 petroleum resin, 10 to 20 parts of polyethylene wax, 2 to 6 parts of EBA3427AC and 1 to 2 parts of an antioxidant 1010. The hot melt adhesive for the acrylic hot-fix rhinestone provided by the invention has a hot-press temperature of 115 to 120 DEG C, is not prone to scalding the acrylic hot-fix rhinestone and fabrics, and has peeling strength of no less than 4.0kN / m , thereby having high bonding strength at the same time; meanwhile, the hot melt adhesive has the advantage of good adhesive force with a variety of fabrics and acrylic hot-fix rhinestones, and is an ideal hot melt adhesive for the acrylic hot-fix rhinestone.

Owner:HUANGSHAN XINDECHENG GLUE IND CO LTD

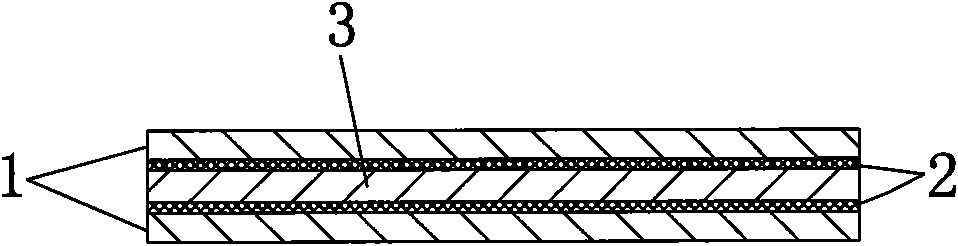

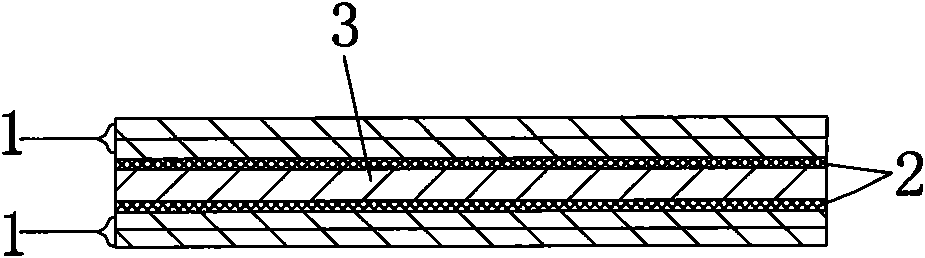

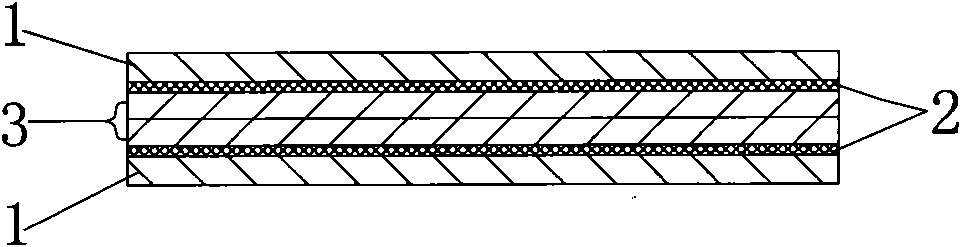

New composite film

InactiveCN101830086ASmall water absorptionGuaranteed softnessFlexible coversWrappersComposite filmPolyurethane adhesive

The invention discloses a novel composite film. The composite film consists of an upper outer layer, a lower outer layer and a middle core layer, wherein the core layer and the outer layers are compounded into a whole by adhesive. The outer layer can be in a single layer structure, a double-layer structure or a multi-layer structure which consists of more than two layers of single film. The core layer can be in a single layer structure, a double-layer structure or a multi-layer structure which consists of more than two layers of single film. The core layer is made of polyethylene glycol terephthalate PET has the density of 1.395g / cm<3>-1.405g / cm<3> and the thickness of 10 micrometers to 50 micrometers. The outer layer is made of one of low-density polythene (LDPE), high-density polythene (HDPE) and casting polypropylene (CPP), and also can be made by mixing two or more than two of low-density polythene (LDPE), high-density polythene (HDPE), casting polypropylene (CPP) and metallocene polythene (mPE). The adhesive is one of single-component polyurethane adhesive, bicomponent polyurethane adhesive, alcohol-soluble polyurethane adhesive and water-soluble polyurethane adhesive. The overall thickness of the composite film is 25 micrometers to 150 micrometers.

Owner:徐建学

Non-asphalt-based reaction type pre-paving macromolecular self-adhesion adhesive film waterproof coiled material

InactiveCN107267083AAvoid pollutionAvoid Fire HazardsFilm/foil adhesivesPolymer scienceCrack resistance

The invention discloses a non-asphalt-based reactive pre-paved polymer self-adhesive film waterproof coiled material, which includes a waterproof coiled material body, and the waterproof coiled material body includes a resin polymer sheet, a polymer waterproof base layer and a self-adhesive membrane. Adhesive outer layer, the outer surface of the polymer waterproof base layer is fixedly connected with the resinous polymer sheet, and the outer surface of the resinous polymer sheet is fixedly connected with the self-adhesive outer layer. The non-asphalt-based reactive pre-paved polymer self-adhesive film waterproof membrane has super bonding performance, the peel strength is 2-3 times that of ordinary self-adhesive membranes, high tear resistance, waterproof and impermeable It has strong performance and hydrolysis resistance, and has a skin-like waterproof effect, which is conducive to popularization and use. It has excellent toughness, strong elasticity, stress crack resistance, softness, and high toughness. Poor, low tear strength, poor waterproof and impermeable performance and hydrolysis resistance, which is not conducive to popularization and use.

Owner:淮安市大有塑纤有限公司

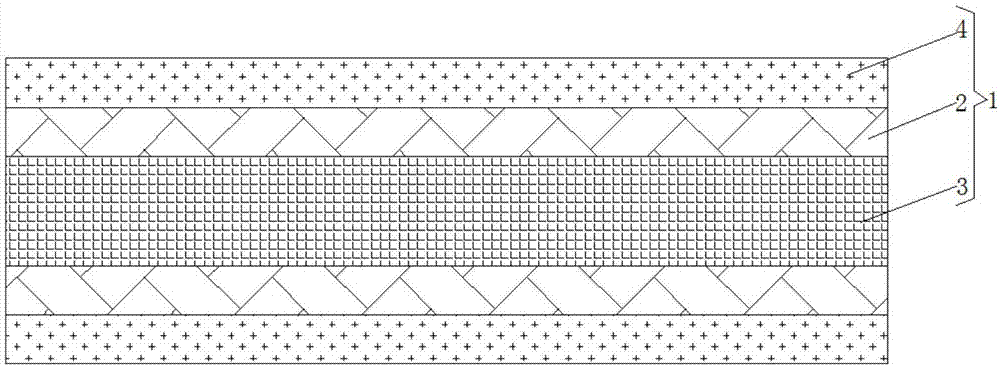

Smooth-surface geomembrane and preparation method thereof

InactiveCN103131077AGood flexibilityUniform mechanical propertiesGeomembraneHindered amine light stabilizers

The invention relates to a geomembrane and a preparation method thereof. The invention specifically relates to a smooth-surface geomembrane and a preparation method thereof. According to the invention, the geomembrane is composed of MDPE (medium density polyethylene), LLDPE (linear low density polyethylene), carbon (nano-leveled, with concentration of 45-48%), an antioxidant (hindered phenol), and a light stabilizer (hindered amine). Heating, shearing, and plasticizing are carried out, and three layers of membrane foam are formed by using a die head; the three layers of membrane foam are formed into one-layer membrane foam through seamless hot fusion; the formed membrane foam is subjected to transverse inflation orientation and longitudinal leading orientation, such that the smooth-surface geomembrane is prepared. The smooth-surface geomembrane provided by the invention has excellent environmental stress cracking capacity, outstanding flexibility, and balanced mechanical performance. The occurrence of geomembrane body loophole is avoided. The geomembrane has uniform thickness uniformity and smooth appearance.

Owner:JIANGSU JINBA ENVIRONMENT TECH

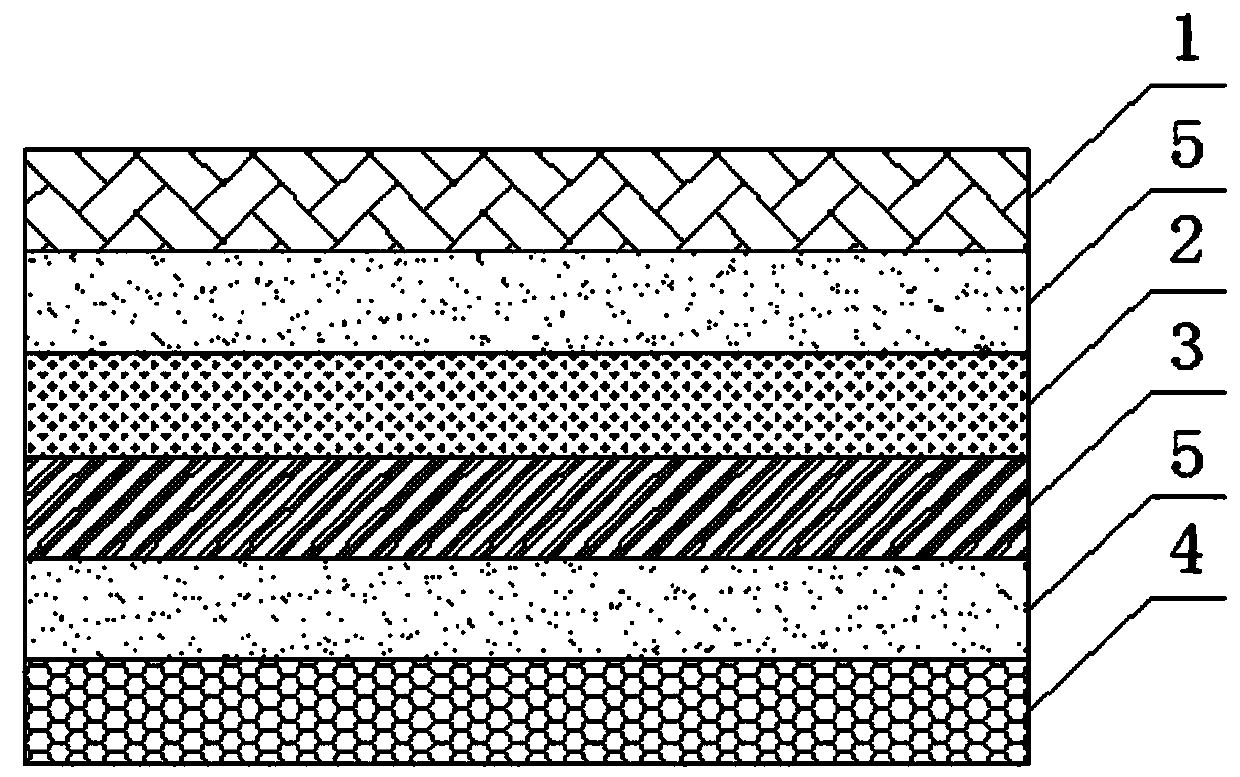

Polymer waterproof roll and production process thereof

ActiveCN109910414AImprove waterproof and moisture-proof performanceGood weather resistanceLamination ancillary operationsSynthetic resin layered productsPolyesterWeather resistance

The invention discloses a polymer waterproof roll and a production process thereof. The waterproof roll comprises an outer waterproof layer, a base material layer, an isolating membrane layer and an inner polymer polyester layer which are in press fit from outside to inside, wherein the outer waterproof layer and the base material layer are composited by a pressure-sensitive adhesive, and the isolating membrane layer and the inner polymer polyester layer are composited by the pressure-sensitive adhesive. The production process comprises five steps as follows: material blending and internal mixing; extrusion; three-roller calendering; cooling forming; cutting and rolling. The waterproof roll has good waterproof and dampproof performance, weather resistance, aging resistance, wear resistanceand tensile property and can meet the demand of most building fields for waterproof and dampproof performance.

Owner:陕西普石建筑材料科技有限公司

Novel high-strength composite material and preparation method thereof

InactiveCN104710681AImprove wear resistanceImprove rigidityLow-density polyethyleneLinear low-density polyethylene

A novel high-strength composite material and a preparation method thereof belong to a polyvinyl structural composite material and a preparation method thereof. The novel high-strength composite material is prepared by the following materials in parts by weight: 100 parts of linear LDPE ( low density polyethylene), 2 to 10 parts of HDPE (high density polyethylene), 1 to 5 parts of PA (polyamide) (nylon), 0.1 to 2 parts of a strong oxidant, 1 to 5 parts of PE starch, 1 to 8 parts of carbon black, and 1 to 5 parts of a fire retarding agent. The novel high-strength composite material provided by the invention is excellent in comprehensive service performance, can improve material rigidity, toughness and environmental stress crack resistance. The novel high-strength composite material is excellent in mechanical processing capability, runnability, thermal stability, and impact resistance, and also is relatively good in wearing resistance, environmental stress crack resistance, heat resistance, rigidity, antistatic performance, degradability, flame retardancy and the like.

Owner:JIANGXI LEFU IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com