Polyethylene resin composition for pipe

A technology of polyethylene resin and resin composition, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of difficult control of the processing process, large amount of cross-linking agent added, and difficulty in recycling, and achieves good resistance. Environmental stress cracking performance, good workability, improved effect of environmental stress cracking resistance

Active Publication Date: 2011-12-28

PETROCHINA CO LTD

View PDF16 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above-mentioned traditional chemical cross-linking methods generally have the problem of complicated process, and the addition of a large amount of cross-linking agent makes the original linear molecular structure of polyethylene into an interpenetrating network structure, which makes the processing process difficult to control and difficult to recycle.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

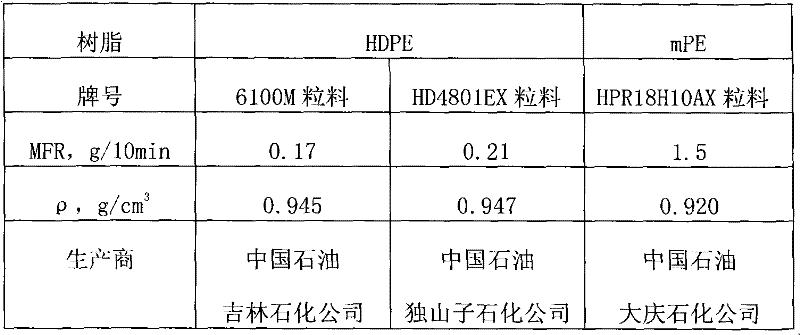

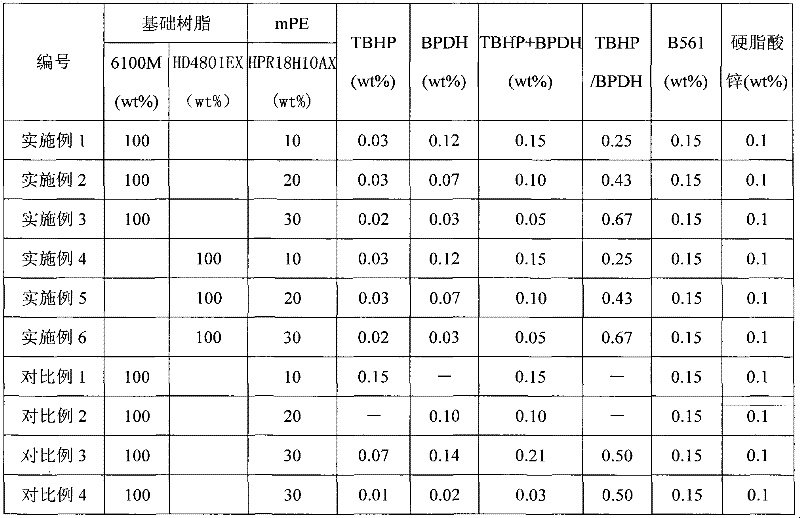

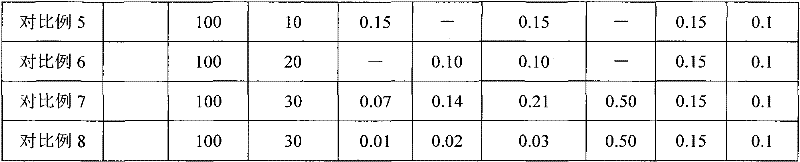

[0052] Take base resin HDPE as 100 parts, and the parts added by other additives are parts by mass.

[0053] Table 1 Raw material formula

[0054]

[0055]

[0056] Table 2 Preparation process conditions

[0057]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a polyethylene resin composition for a pipe. Based on 100wt% of high density polyethylene, the polyethylene resin composition comprises the following components in percentage by weight: 100% of high density polyethylene, 10%-30% of metallocene polyethylene, 0.05%-0.15% of complex crosslinking auxiliary, 0.1%-0.15% of lubricant and 0.1%-0.2% of antioxidant. The resin composition for the pipe has good environment stress cracking resistant property (large than 1000 hours). By using the polyethylene resin composition in the invention, the problem of poor environment stress cracking resistant property of the common high density polyethylene (HDPE) resin is solved.

Description

technical field [0001] The invention relates to a polyethylene resin composition, in particular to a pipe resin composition with high-density polyethylene and metallocene polyethylene as base materials. Background technique [0002] In recent years, with the development of the plastics industry, polyethylene pipes have attracted more and more attention due to their light weight, corrosion resistance, low thermal conductivity, good insulation performance, convenient construction, installation and maintenance, and have become the next PVC pipe. , the world's largest consumption of plastic pipe varieties, the application areas throughout the water supply, agricultural irrigation, gas transmission, sewage, mine mortar transportation and other engineering and oil fields, chemical industry, post and telecommunications and other fields. [0003] Among polyethylene pipes, high-density polyethylene (HDPE) pipes have the characteristics of light weight, excellent mechanical properties...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/08C08L23/06C08K5/14C08K5/098C08J3/24B29C47/92F16L9/12B29C48/92

CPCB29C48/04B29C48/92B29C2948/92561B29C2948/92704B29C2948/92895

Inventor 徐典宏张宇牛承祥白竞冰朱博耿占杰陈红薛旭辉梁滔赵燕谈敦礼何连成

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com