Polymer waterproof roll and production process thereof

A polymer waterproof and waterproof membrane technology, applied in the direction of non-polymer organic compound adhesives, layered products, synthetic resin layered products, etc., can solve problems such as performance degradation, ductile fracture, and harm to human health. Achieve good waterproof and moisture resistance, improved stability and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

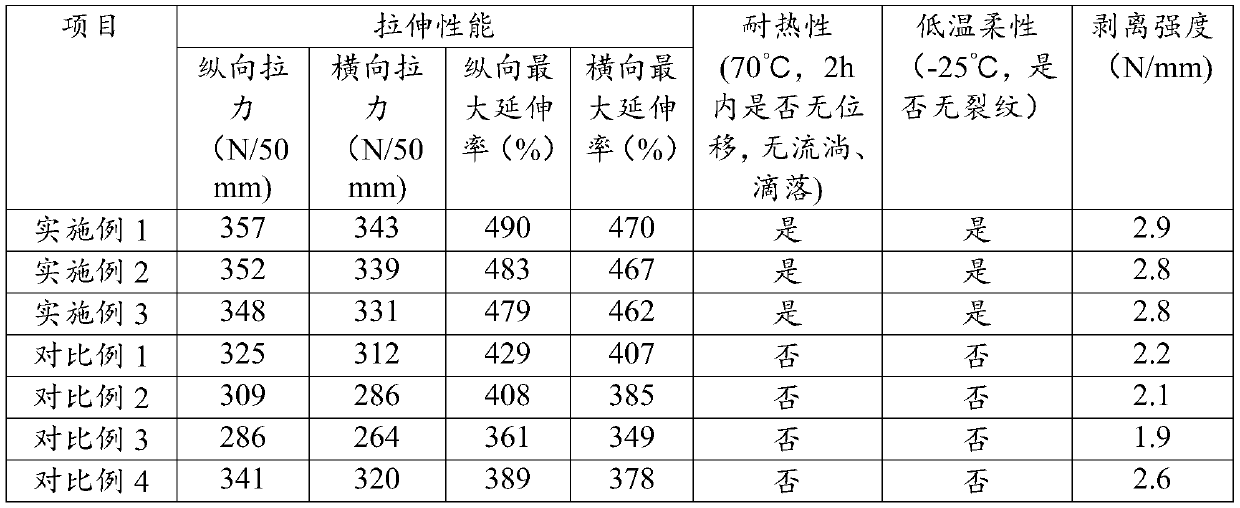

Embodiment 1

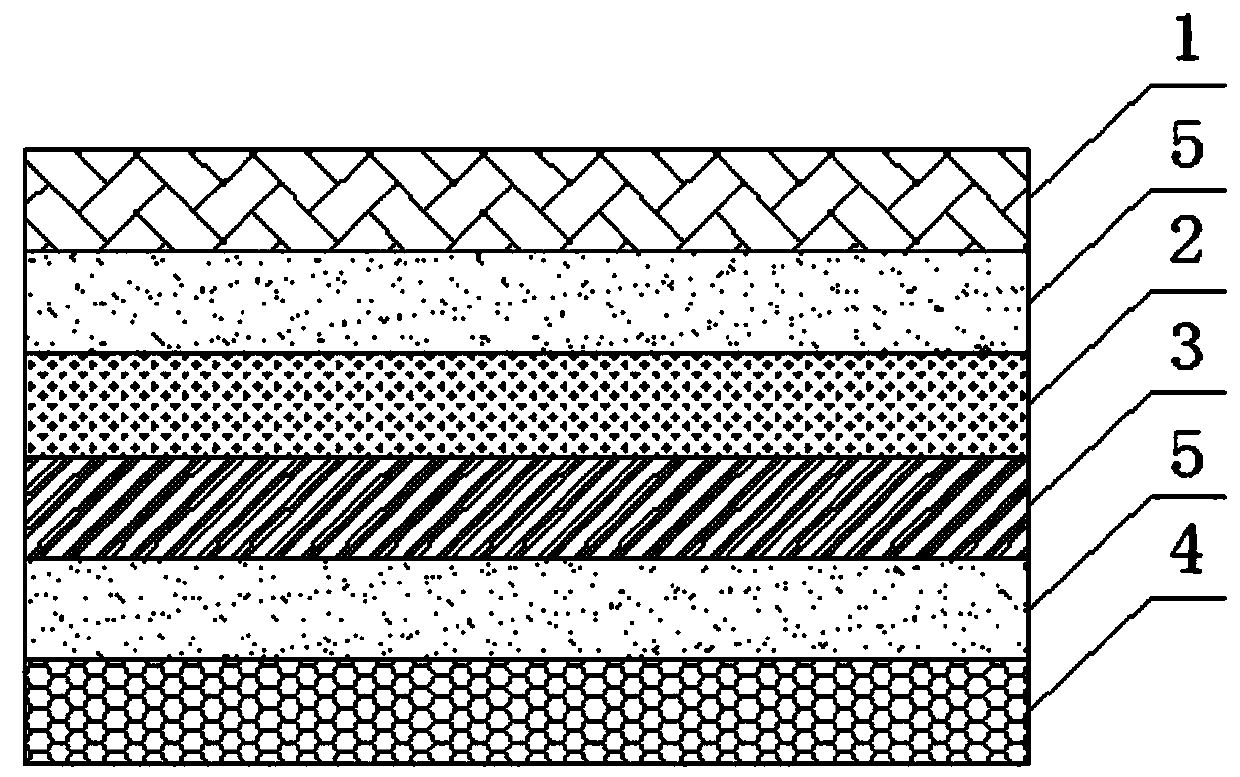

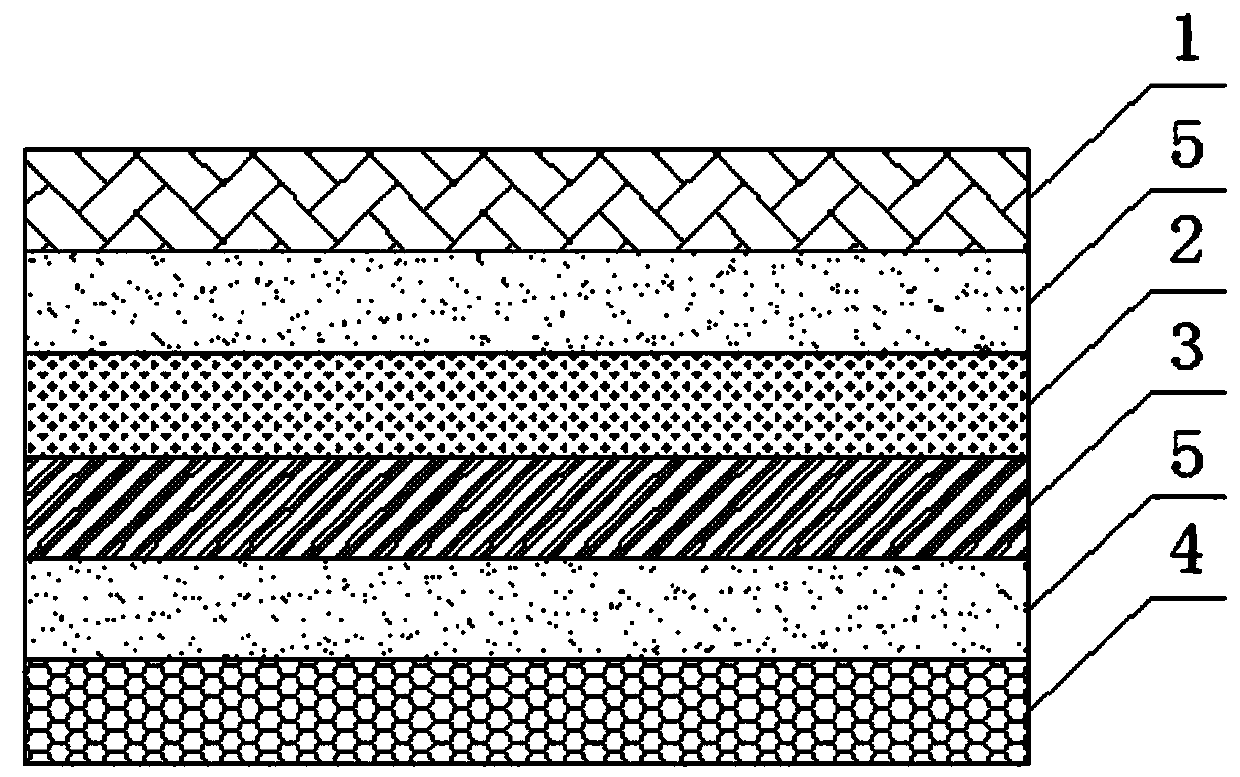

[0043] refer to figure 1 As shown, a polymer waterproof membrane in this embodiment includes an outer waterproof layer 1, a base material layer 2, an isolation film layer 3, a polymer polyester inner layer 4, and an outer waterproof layer 1 laminated from outside to inside. It is combined with the base material layer 2 through a pressure-sensitive adhesive 5 , and between the isolation film layer 3 and the high molecular polyester inner layer 4 is combined through a pressure-sensitive adhesive 5 .

[0044] Wherein, the outer waterproof layer includes the following raw materials by weight: 106 parts of thermoplastic polyester elastomer, 48 parts of butyl acrylate, 25 parts of octyl acrylate, 12 parts of white sand, 9 parts of white carbon black, 6 parts of nano-magnesium oxide, 1.6 parts of decabromodiphenyl ether; the base layer is one of polyester non-woven fabric, glass fiber cloth or polyester woven fabric; the isolation film layer includes the following raw materials by we...

Embodiment 2

[0062] A polymer waterproof coiled material in this embodiment includes an outer waterproof layer, a base material layer, an isolation film layer, and a polymer polyester inner layer that are laminated from outside to inside, and the outer waterproof layer and the base material layer are pressed together. Sensitive adhesive compounding, the isolation film layer and the inner layer of polymer polyester are compounded by pressure-sensitive adhesive.

[0063] Wherein, the outer waterproof layer includes the following raw materials in parts by weight: 114 parts of thermoplastic polyester elastomer, 47 parts of butyl acrylate, 28 parts of octyl acrylate, 15 parts of white sand, 11 parts of white carbon black, 7 parts of nano-magnesium oxide, 1.7 parts of decabromodiphenyl ether; the base material layer is one of polyester non-woven fabric, glass fiber cloth or polyester woven fabric; the isolation film layer includes the following raw materials in parts by weight: 62 parts of bisphe...

Embodiment 3

[0078] A polymer waterproof coiled material in this embodiment includes an outer waterproof layer, a base material layer, an isolation film layer, and a polymer polyester inner layer that are laminated from outside to inside, and the outer waterproof layer and the base material layer are pressed together. Sensitive adhesive compounding, the isolation film layer and the inner layer of polymer polyester are compounded by pressure-sensitive adhesive.

[0079] Wherein, the outer waterproof layer includes the following raw materials in parts by weight: 115 parts of thermoplastic polyester elastomer, 57 parts of butyl acrylate, 30 parts of octyl acrylate, 14 parts of white sand, 11 parts of white carbon black, 8 parts of nano-magnesium oxide, 2.3 parts of decabromodiphenyl ether; the base material layer is one of polyester non-woven fabric, glass fiber cloth or polyester woven fabric; the isolation film layer includes the following raw materials by weight: bisphenol S type epoxy resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com