Patents

Literature

605results about How to "White color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stevioside glycoside refining process

InactiveCN1349997AHigh yieldNo smellSugar derivativesSugar derivatives preparationAlcoholGlycoside formation

The present invention adopts ethyl alcohol as reinfing solvent, and adopts the following steps: mixing stevioside and ethyl alcohol according to a certain proportion, stirring in dissolving process, solid-liquid separation of dissolved mixture, respectively decolouring obtained solid and liquid, drying to obtain refined stevoiside, in which the refined solid content is up to 88%, and its total recorery rate is high, and the refined stevioside is colourless, and has no abrormal taste.

Owner:青岛创升生物科技有限公司

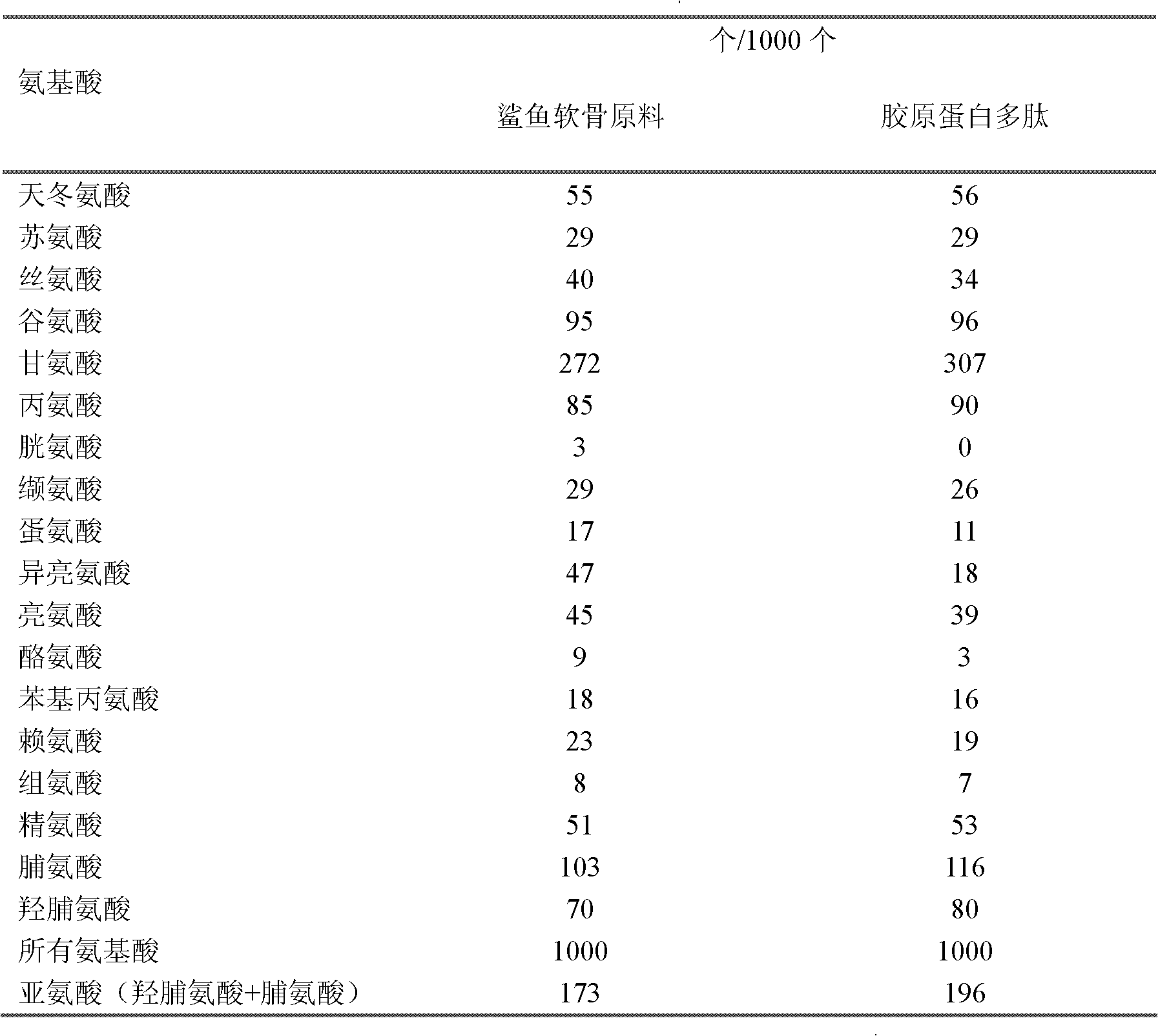

Method for preparing collagen oligopeptide

InactiveCN102559826AWhite colorGreat tastePeptide preparation methodsFermentationFood industryProcollagen type i n-terminal peptide

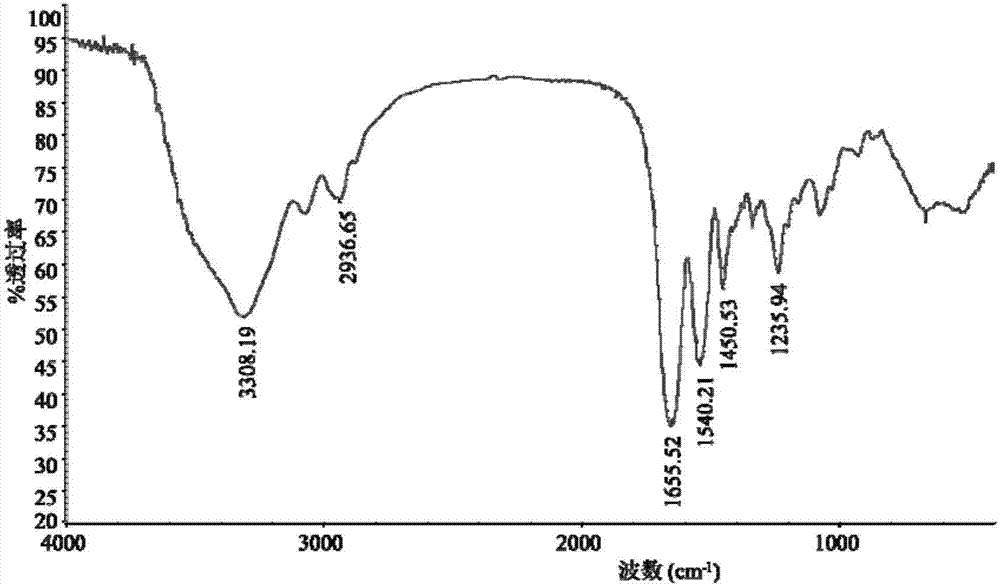

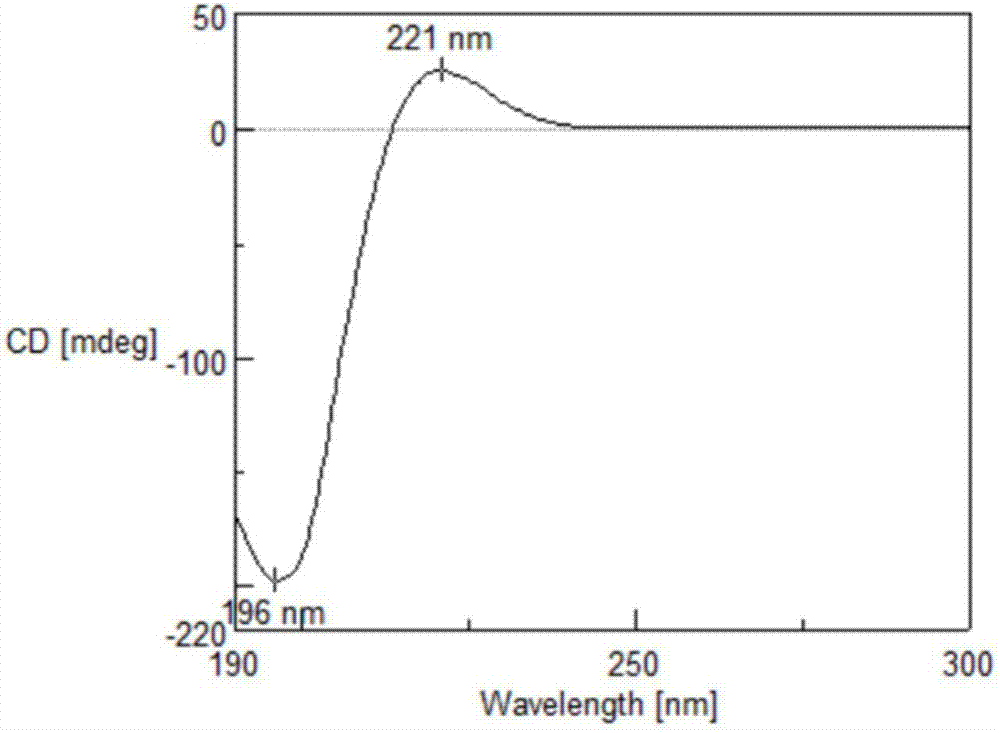

The invention discloses a method for preparing collagen oligopeptide. Animal skins are taken as raw materials, and are subjected to acid and surfactant pretreatment, enzymolysis, decoloration, membrane separation and drying to form the collagen oligopeptide. The relative molecular weight of the prepared collagen oligopeptide is mainly distributed below 1,000Dalton, and preferably, the Gaussian distribution peak area percentage of oligopeptide with the relative molecular weight of less than 1,000Dalton is over 85 percent and preferably over 90 percent. The method solves the general problems that the conventional collagen products have odor, are dark yellow and the like; and the obtained collagen oligopeptide powder is white, free of odor and good in mouthfeel, has high absorptivity and penetrability and can be widely applied to the cosmetics industry, the food industry and the like.

Owner:胡如桂

Hemp seed beverage and preparation method thereof

InactiveCN101313770AReduce cholesterolIncrease milk flavorMilk preparationFood preparationCannabisSlurry

The invention relates to a fructus cannabis beverage, which is mainly made from fructus cannabis and condensed milk, to which an appropriate amount of white sugar, emulsifier and stabilizer are added. A method for preparing the fructus cannabis beverage adopts a disc-type vegetable stuffing machine to grind the fructus cannabis, which can prevent fructus cannabis shells from being ground excessively and becoming nigrescent in color, so as to ensure that fructus cannabis slurry is pure white and closer to the primary color of milk slurry. The fructus cannabis beverage is simple in formula, convenient in making process, low in production cost and suitable for industrial production.

Owner:刘国铨

Cu-Sn-Zn plating solution containing organic addition agent and electroplating technique utilizing same

The invention provides a Cu-Sn-Zn plating solution containing organic addition agent and an electroplating technique utilizing same; the plating solution has the parameters and the content of all components: 4-15g / L of Cu<2+>, 6-42g / L of Sn<4+>, 0.15-1g / L of Zn<2+>, 6-35g / L of KOH or NaOH, 20-60g / L of free NaCN or KCN, 0.05-2.5g / L of surface active agent, 1-30g / L of organic complexing agent and 0.5-35g / L of organic depolarizing agent; the pH value is more than 12, and the temperature is 30-65 DEG C. The practicability examination is carried out on the plating solution and the technical finished product, and the examination proves that plating layer under the technique of the addition agent has bright white color and achieves the effect of replacing nickel; the discoloration preventing capability is better, experimental effect of neutral salt spray resistance is good, and the solderability is excellent; furthermore, the plating layer contains no harmful substances such as heavy metal, cyanide, etc.

Owner:佛山市光远科技有限公司

Method for planting organic arabian jasmine flowers

The invention discloses a method for planting organic arabian jasmine flowers. The method comprises the steps of seed selection of the arabian jasmine flowers, soil ph adjustment, seedling growing, soil preparation, planting, pruning and cutting, weeding, fertilization and plant disease and insect pest prevention, the method mainly aims to produce the high-quality organic arabian jasmine flowers free of pesticides, hormones and chemical pollution and meet the needs of providing and producing various high-end organic jasmine tea and producing edible fresh and dry arabian jasmine flowers or arabian jasmine flower spices, and the arabian jasmine flowers obtained through the full-ecological technology planting method are purely natural, have fragrance, are free of peculiar smells, and are pure white in color.

Owner:横县生产力促进中心

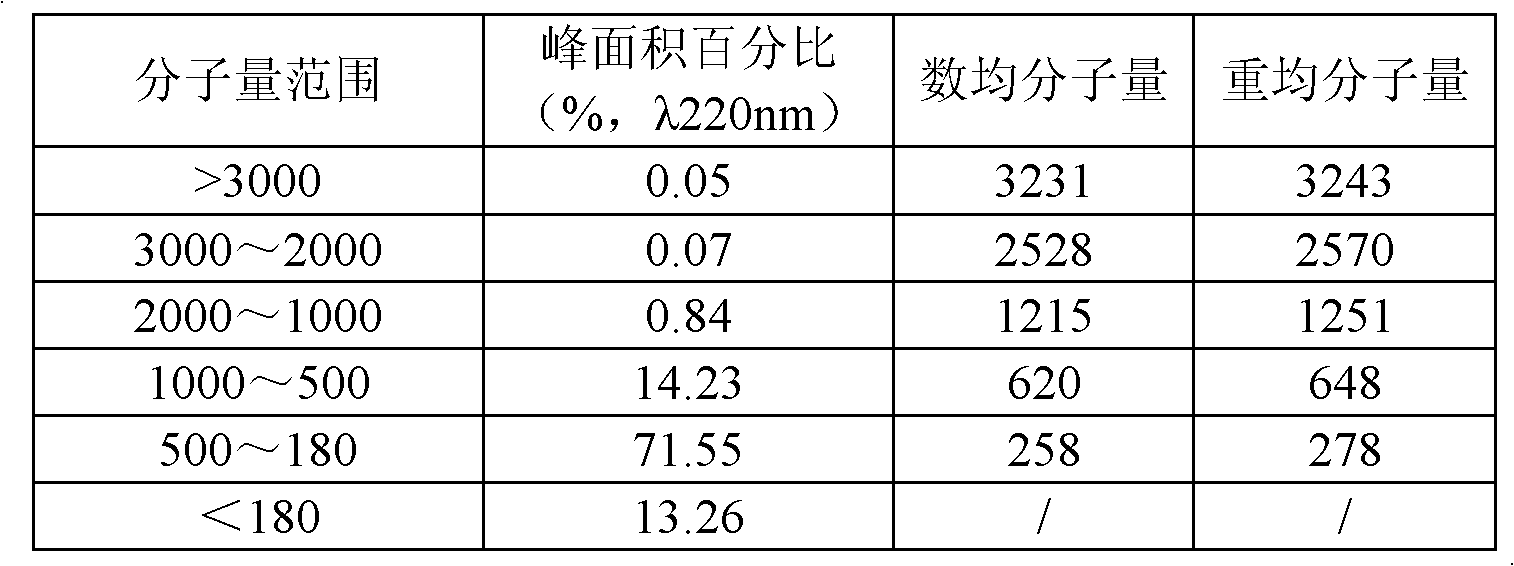

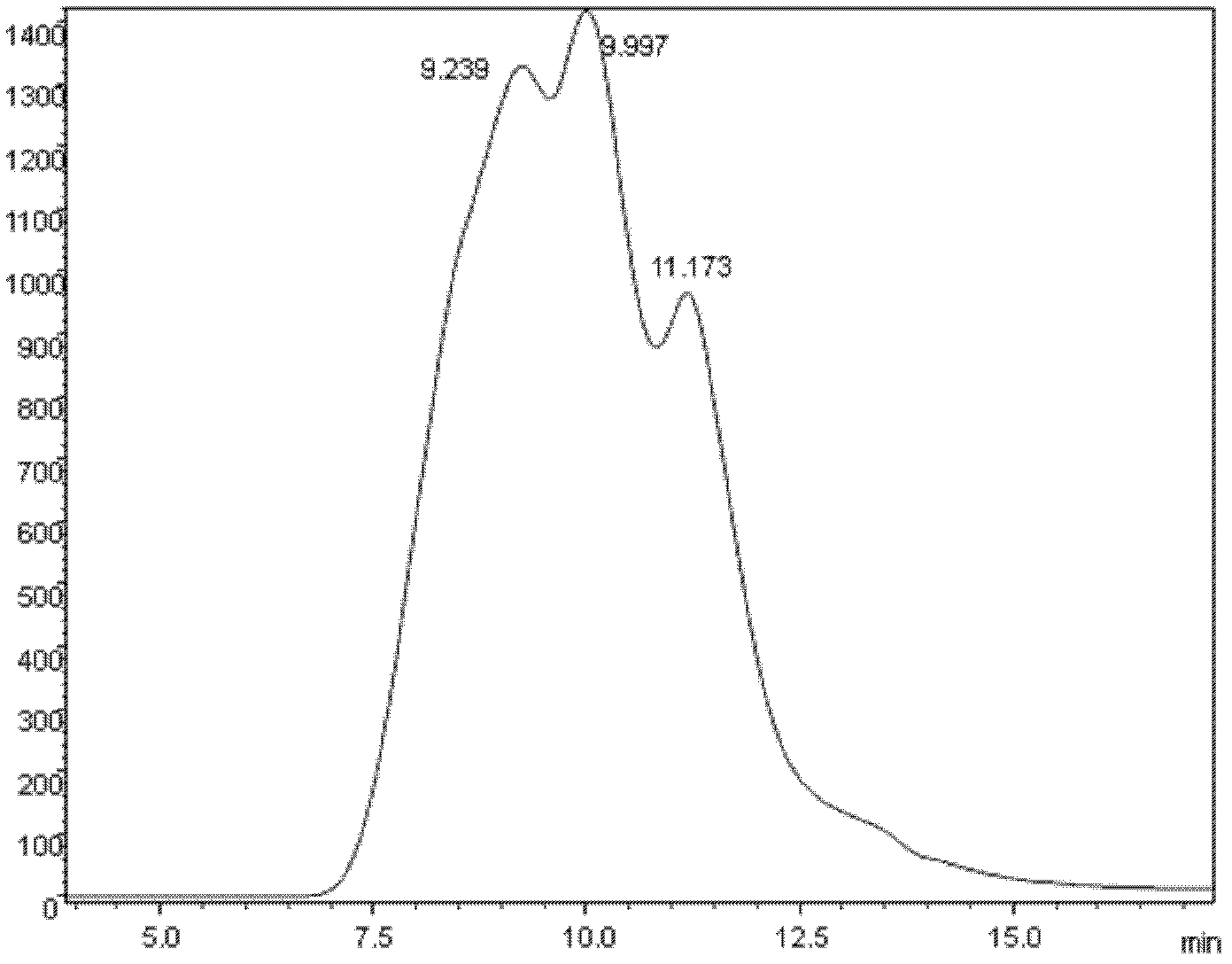

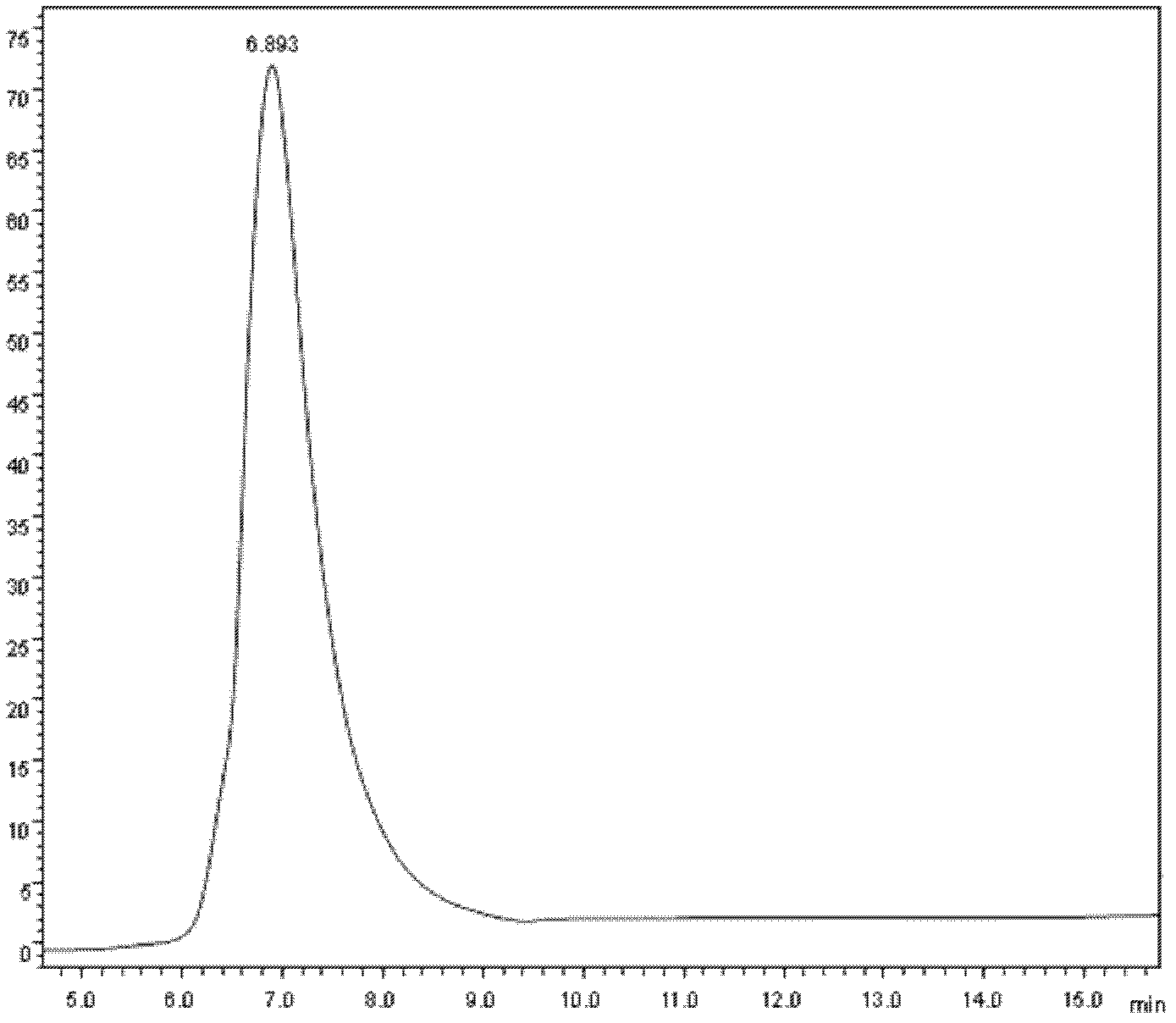

Method for preparing chondroitin sulfate and collagen polypeptide from animal cartilages

ActiveCN102533915ARealize high-value utilizationEfficient separation and extractionPeptide preparation methodsFermentationAlcoholUltrafiltration

The invention discloses a method for preparing chondroitin sulfate and collagen polypeptide from animal cartilages, which comprises the following steps: crushing animal cartilage materials to obtain cartilage powder; hydrolyzing the cartilage powder with protease, and then carrying out ultrafiltration and concentration to obtain a concentrated solution; passing the concentrated solution through an anion exchange resin column, and collecting an effluent solution A; eluting with pure water, and collecting a water washing solution B; merging the effluent solution A and the water washing solution B, carrying out ultrafiltration and concentration, and carrying out spray drying to obtain the collagen polypeptide; and eluting the anion exchange resin column with an NaCl solution, carrying out ultrafiltration and concentration on the eluent solution, carrying out alcohol precipitation, dehydrolyzing, and drying to obtain the chondroitin sulfate. The invention realizes the high-valued utilization of cartilage resources, can simultaneously and efficiently extract and separate the chondroitin sulfate and the collagen polypeptide, increases the added values of the products and reduces the environment pollution.

Owner:ZHEJIANG UNIV OF TECH

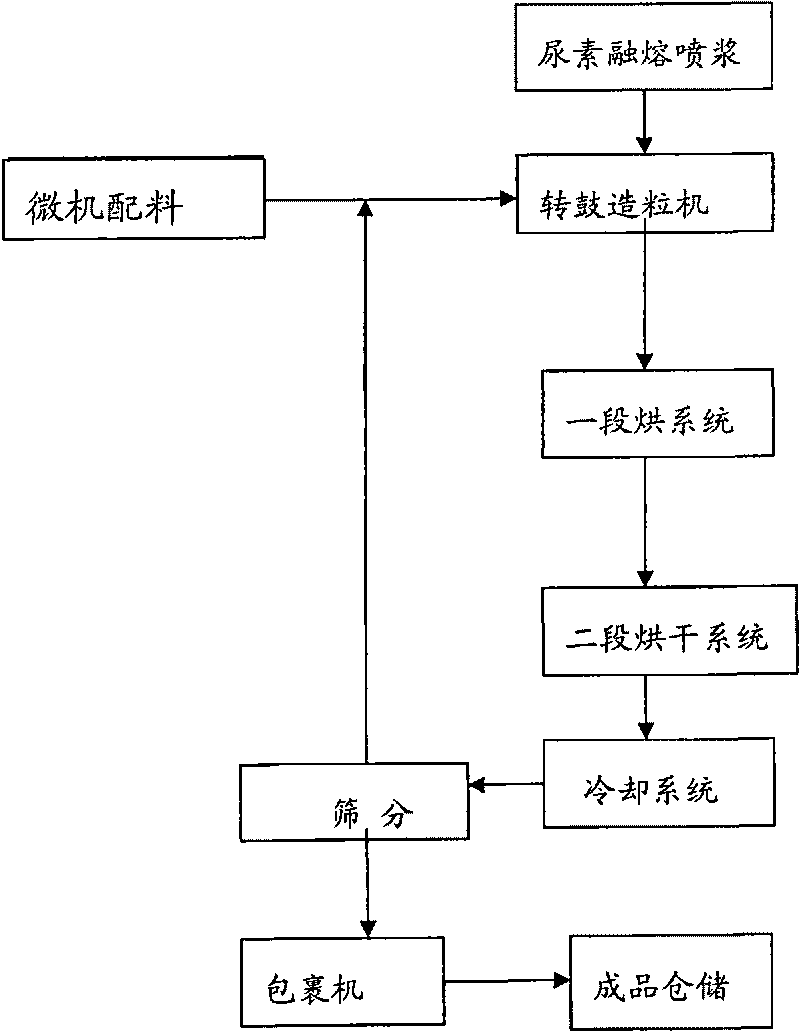

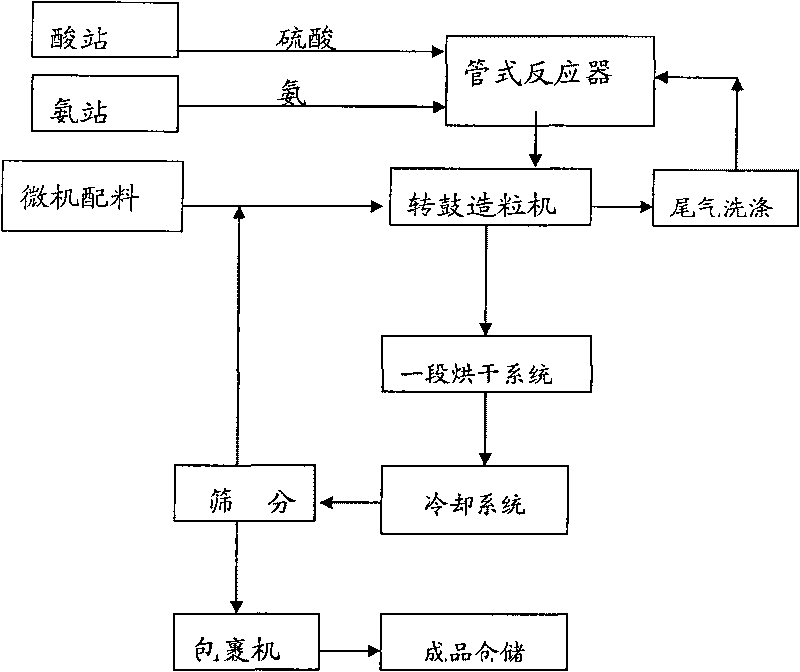

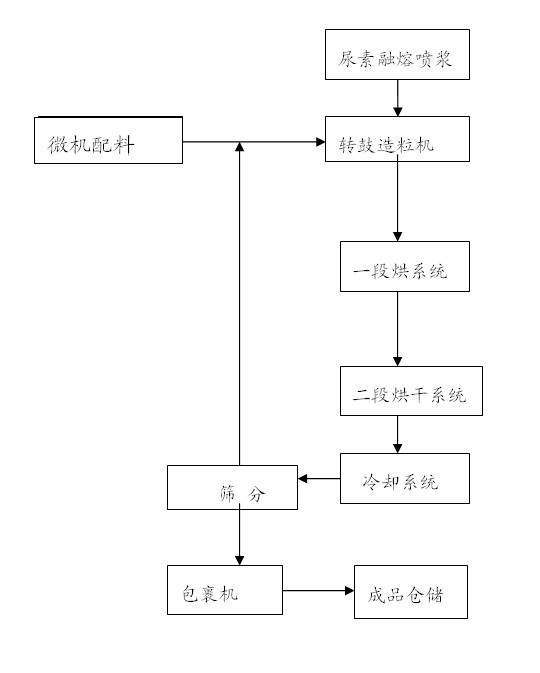

Method for producing Nitrogen-Phosphorus-Potassium compound fertilizer by ammonia and acid tubular reactor

The invention discloses a method for producing a Nitrogen-Phosphorus-Potassium compound fertilizer by using an ammonia and acid tubular reactor. The method comprises the following steps of: preparing an ammonium sulfate solution at 180-220 DEG C by concentrated sulfuric acid, ammonia and water; controlling the reaction heat of ammonia and acid by the addition amount of the water; spraying in a granulator to granulate with other base fertilizers containing nitrogen, phosphorus and potassium; drying; cooling; screening; and filming to obtain a nitrogen-phosphorus-potassium compound fertilizer. The reaction heat of the ammonia and the acid is fully utilized, the ammonium sulfate solution generated by the reaction is in liquid phase and viscosity, the balling rate is high, the moisture of granulation materials is obviously reduced, the drying load is lowered, the production need can be satisfied by changing two-section drying into one-section drying, and the equipment investment and great energy consumption are saved.

Owner:天津达汇丰生物科技有限公司

Technique for producing fine barium sulfate by barite sulfuric acid process

The present invention discloses sulfuric acid process of producing refined barium sulfate with barite, and belongs to the field of chemical technology. The process includes the following main technological steps: producing black ash containing barium sulfate with coal calcining barite; soaking black ash containing barium sulfate in water to obtain barium sulfate solution; adding sulfuric acid into the barium sulfate solution to obtain slurry with barium sulfate precipitant; and dewatering the slurry, stoving and crushing to obtain refined barium sulfate product. The refined barium sulfate product has low cost, and may be applied widely in high grade paint, etc. and the production process is harmless and has environment friendship and high marketability.

Owner:HONGXING XINHUANG EXACT CHEM

Instant balls and preparation method thereof

The invention relates to instant balls and a preparation method thereof. According to the formula, the install balls comprise the following raw materials by weight: 30 to 45 percent of minced fillet, 5.25 to 9 percent of chicken, 11 to 22.25 percent of fat pork, 6.25 to 10 percent of pork ham, 6 to 11.25 percent of potato starch, 8.25 to 17 percent of water, 1.35 to 1.90 percent of salt, 1.45 to 2.15 percent of sugar, 0.11 to 0.19 percent of polyphosphate, 0.31 to 0.44 percent of monosodium glutamate, 0.23 to 0.60 percent of seasoning fish meal, 1.5 to 2.5 percent of scallion, 0.75 to 2 percent of soy sauce, 0.08 to 0.18 percent of sesame oil, 0.08 to 0.20 percent of pork cream, 0.08 to 0.2 percent of meat fine powder, 0.25 to 0.75 percent of yellow wine and 1.25 to 5 percent of pigskin jelly. The skin of the instant balls has elasticity, white luster and crisp mouthfeel; and the stuffing has much soup, is oily but not greasy, and has pure taste.

Owner:PENGLAI JINGLU FISHERY

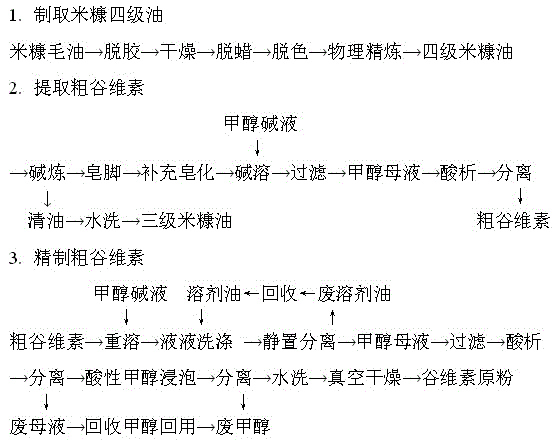

Method for extracting oryzanol from rice bran crude oil

InactiveCN103145789AReduce lossesIncrease contentFatty-oils/fats refiningSteroidsRice Bran ExtractDissolution

The invention discloses a method for extracting oryzanol from rice bran crude oil. The method comprises the following steps: (1) preparing four-stage rice bran oil: (a) performing hydration, degumming and dewaxing on the rice bran crude oil, (b) decolorizing the dewaxed rice bran oil and (c) performing physical refining on the decolorized rice bran oil; (2) extracting crude oryzanol, namely (a) preparing a soap base, (b) performing alkali dissolution operation and (c) performing acidification operation; and (3) refining the crude oryzanol, namely (a) re-dissolving the crude oryzanol and performing solvent oil liquid-liquid washing, (b) performing acidification and acid soaking and (c) drying and crushing the oryzanol. According to the method disclosed by the invention, a physical refining and deacidification process is applied to an alkali dissolution and acidification oryzanol production process, the first alkali refining operation in the existing process is reduced, the yield of the rice bran refined oil is improved, and the loss of 20% of the oryzanol produced by soapstock due to the alkali refining is also reduced. As the physical refining and deacidification process is adopted, the yield of the refined rice bran oil is greatly improved in comparison with the existing alkali dissolution and acidification process, and the yield of essential oil is improved from the original 50-55% to 60-65%.

Owner:郑州良远科技有限公司

Use of stannous benzoate as catalyst

ActiveCN1806919AReduce dosageLow cracking temperatureOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidPolymer science

The invention provides the usage of using the benzoic acid stannous as catalyst. The invention solves the problem that polymerization rate of current catalyst in lactic acid and glycolic acid is slow. The benzoic acid stannous is the catalyst used for preparing low-molecular polymer lactic acid with lactic acid dewatering; benzoic acid stannous is the catalyst used for preparing lactide with low-molecular polymer lactic acid cracking; benzoic acid stannous is the catalyst used for preparing polylactic acid with lactide polymerizing; benzoic acid stannous is the catalyst used for preparing low-molecular polymer glycolic acid with glycolic acid dewatering; benzoic acid stannous is the catalyst used for preparing glycolide with low-molecular polymer glycolic acid cracking; benzoic acid stannous is the catalyst used for preparing poly-glycollide with glycolide polymerizing. The benzoic acid stannous is the catalyst used for polymerizing glycolide, lactide and epsilon-caprolactone. Using the benzoic acid stannous is low content, high productivity, high product purity, low temperature and good repeatability.

Owner:ZHEJIANG HISUN BIOMATERIALS +1

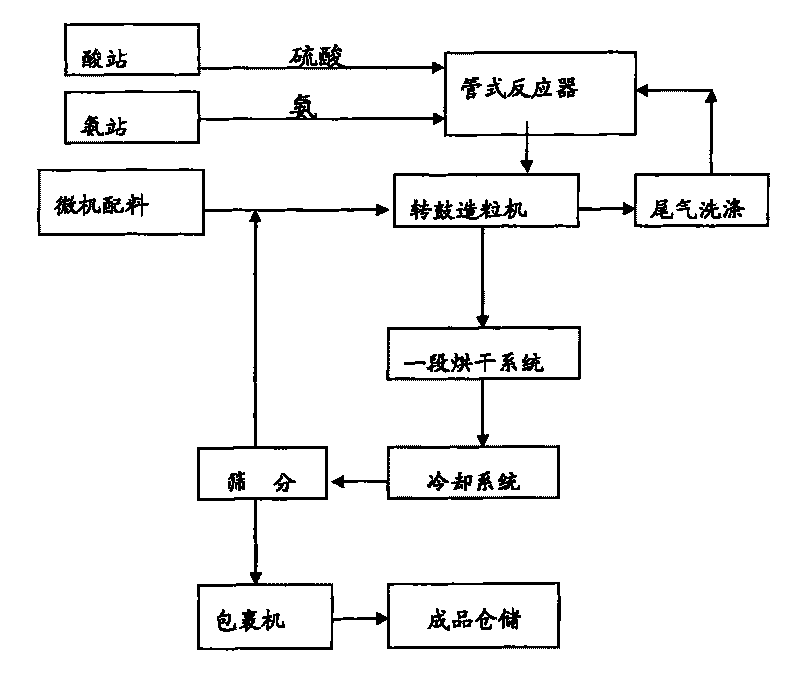

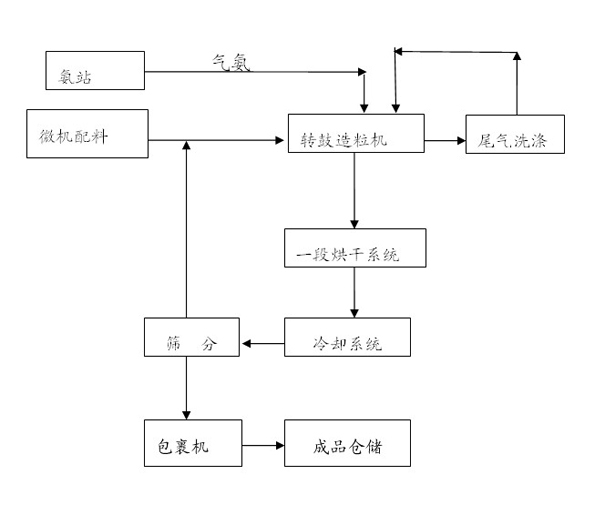

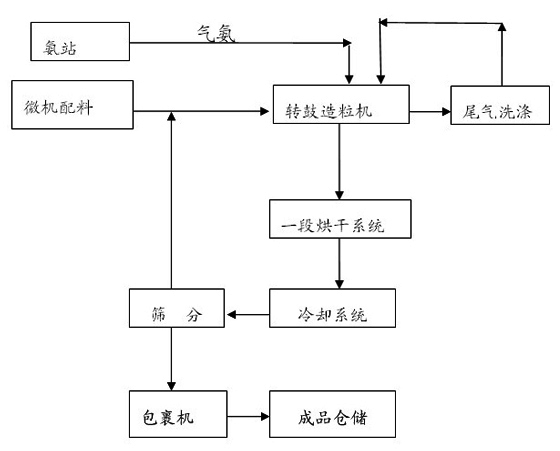

Method for producing chlorine-based high phosphorus compound fertilizer by ammoniation method

The invention discloses a method for producing a chlorine-based high phosphorus compound fertilizer by an ammoniation method. The method is characterized by directly introducing gas ammonia to a material layer of a rotary drum granulator to increase the neutralization degree of monoammonium phosphate, granulating gas ammonia with other powdered fundamental fertilizers containing nitrogen, phosphorus and potassium and obtaining the compound fertilizer containing nitrogen, phosphorus and potassium through drying, cooling, screening and enveloping after granulation. The method has the following advantages: the heat producing reaction between the gas ammonia and double superphosphate and heat of neutralization generated by the reaction between the gas ammonia and the monoammonium phosphate are fully used of to maintain the temperature of the materials, and the solubility of ammonium phosphate salt is improved to satisfy the liquid phase quantity needed by granulation; the higher granulation rate can be ensured without adding other adhesives, thus lowering the input cost of the materials; and the moisture of the materials to be granulated is obviously reduced, thus reducing the drying load and saving plenty of energy.

Owner:天津芦阳肥业股份有限公司

Ultrawhite ultrahigh-molecular weight ultrahigh-modulus polyethylene fibers and preparation process thereof

ActiveCN101962819AIntensity is not affectedModulus is not affectedArtificial filament heat treatmentWet spinning methodsFiberPolymer science

The invention relates to ultrahigh-molecular weight ultrahigh-modulus polyethylene fibers and a manufacturing method thereof, in particular to ultrawhite ultrahigh-molecular weight ultrahigh-modulus polyethylene fibers and a preparation process thereof, which are applicable in fields of various protective textiles with an ultrawhite color requirement. In the invention, ultrahigh-molecular weight polyethylene is used as a raw material and is mixed with white oil to form a mixture, a diphenylethyl dibenzimidazole compound is added into the mixture as an additive to form spinning solution, and the ultrahigh-molecular weight ultrahigh-modulus polyethylene fibers are obtained by a spinning process, wherein the amount of the additive is 0.01 to 0.05 percent based on the weight of the ultrahigh-molecular weight polyethylene. The preparation process comprises the following steps: preparing the spinning solution; performing gel spinning; balancing semi-finished product gel spinning; extracting; displacing; drying; and hot high drafting. The fibers are ultrawhite and brighter and can meet requirement for differentiation; meanwhile, the biological indexes such as strength and modulus of the finished fibers are not affected, the manufacturing method is simple, and the production cost is low.

Owner:长青藤高性能纤维材料有限公司

Method for preparing konjac glucomannan and oligo-glucomannan with different molecular weights

The invention relates to a method for preparing konjac glucomannan and oligo-glucomannan with different molecular weights. The method comprises the following steps of: rapidly adding0.1-30 parts of purified konjac glucomannan into a solution prepared by 0.001-0.01 part of glycoside hydrolase and 10-100 parts of distilled waterunder the stirring condition; reacting for 0.5-72 hours under the condition of the temperature of 30-60 DEG C and the pH of 2.0-10.0; and deactivating enzyme for 15 minutes in a boiling water bath to obtain konjac glucomannan and oligo-glucomannan aqueous solutions with different molecular weights; adding 1-30 parts of peptizing agent for stirring for 0.5-5 hours; depositing konjac glucomannan and oligo-glucomannan molecules with different molecular weights with 10-100 parts of anhydrous ethanol; after centrifugally separating sediments, adding 10-100 parts of anhydrous ethanol for strongly stirring for 0.5-5 hours; repeatedly depositing, centrifuging and stirring for 3-5 times, drying the sediment obtained by last centrifugation in a double-conic vacuum rotary drier; and grinding and screening the sediment to obtain the konjac glucomannan and the oligo-glucomannan. The method disclosed by the invention has the advantages of simplicity, low cost and wide product application.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for producing chitin, calcium citrate and protein powder

The invention relates to a method for producing chitin, calcium citrate and albumen powder by using the shells of crustaceans like shrimps and crabs as the materials; the shells of shrimps and crabs are selected and arranged into an oven, and dried and then water with weight of 6 times of the shells are added; then the mixture is heated to be between 50 and 55 DEG C; then a neutral papain with a mass ratio of 1: 0.001 to 0.003 with the shells of shrimps and crabs, is added for carrying out zymohydrolysis and obtaining zymohydrolysis liquid; the zymohydrolysis liquid is filtered for obtaining the shells of shrimps and crabs; 15% to 20% citric acid solution is added for dipping for 24 to 36 hours; then the chitin is obtained through filtering, acid rinsing and drying; cold separation is carried out on the filtered liquid and a cold separation matter which can be named the calcium citrate is obtained through centrifugalizing; vacuum condensing and drying are carried out on the rest liquid obtained through centrifugalizing, thus obtaining the albumen powder. In the invention, the technical method adopts enzymes for removing proteins and citric acid decalcification for leading the separation of the protein and the calcium with the chitin to be more complete; the yield rate of the chitin is high; and the prepared chitin product has the advantages of white color, high purity and good quality.

Owner:RONGCHENG TAIXIANG FOOD

Preparation method of peanut wire-drawing protein

ActiveCN101999512AReasonable compositionMeet nutritional intake needsProtein composition from vegetable seedsFiberBiotechnology

The invention relates to a preparation method of peanut wire-drawing protein. The preparation method comprises the following steps: 1) preparing low-denaturalization peanut protein powder; 2) mixing uniformly; 3) hardening and tempering; 4) extruding and swelling; and 5) discharging. The product of the invention is pure white and has specific peanut aroma and rapid rehydration; when the product is torn, a structure as thin as hair can be formed; and moreover, the product has an obvious fibrous tissue, high fiber toughness, tensile force and elasticity, forms a ball without breakage when kneaded by hands, and disperses like fiber immediately after rehydration. The peanut wire-drawing protein ensures that the nutrition level of people is improved without increasing cholesterol, has a uniqueflavor without beany flavor or flatulence factor of soy protein, and is a high-quality resource of vegetable protein. Meanwhile, a proper amount of soy protein and wheat protein is added, and the three high-quality vegetable proteins are combined so that the allocation of essential amino acids for human contained in the peanut wire-drawing protein is more reasonable and better conforms to the nutrition requirements of the human.

Owner:QINGDAO CHANGSHOU FOOD

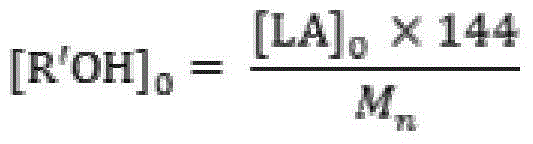

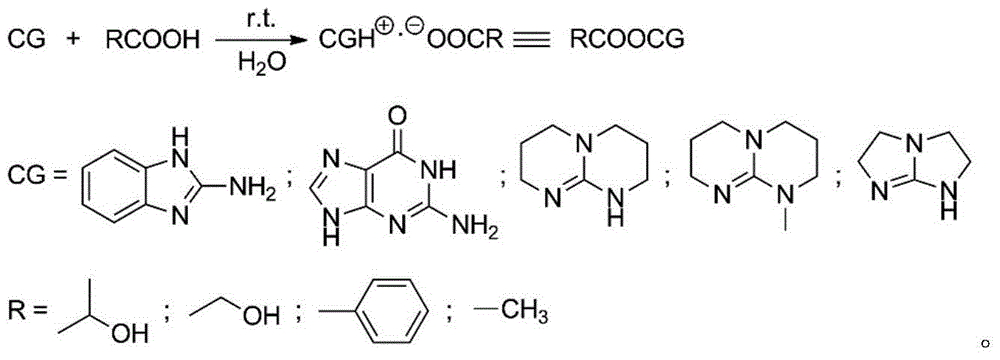

Technology for controlled synthesis of polylactic acid through lactide activity ring-opening polymerization under catalytic action of organic guanidine-nontoxic alcohol

The invention discloses a technology for controlled synthesis of polylactic acid through a lactide active ring-opening polymerization reaction under the catalytic action of organic guanidine-nontoxic alcohol serving as a catalyst. According to the technology, nontoxic organic RCOOCG is adopted as the catalyst, nontoxic organic alcohol is adopted as an initiating agent, and the lactide active ring-opening polymerization reaction is performed according to a noumenon fusion and polymerization method. The technology is characterized in that the catalyst activity is high; the temperature of the polymerization reaction is low; the reaction time is short; a polymer product, namely polylactic acid, can be subjected to controlled synthesis within a range (Mn: 0.5*10<4>-5.0*10<4>) of the actual application requirement for the number-average molecular weight; the molecular weight distribution of the polymer product is narrow (PDI: 1.10-1.25); no monomer is remained in the polymer product (monomer conversion rate: 100%); the polymer product is snow-white in color and high in biological safety.

Owner:NANJING UNIV

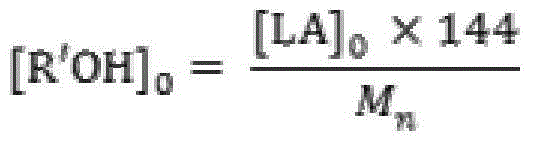

Method for manufacturing anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials

InactiveCN106346589AWhite colorGood film formingFlat articlesDomestic articlesOptoelectronicsImpurity

The invention discloses a method for manufacturing an anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials. The manufacturing method comprises the following steps of: preparing materials, drying, peeling and removing impurities, sorting and storing, respectively gluing on a surface core layer, hierarchically paving, in advance hot press molding, and sanding wood finishes; an isocyanate sawdust powder hybrid adhesive is coated on the surface, and an anti-insect and anti-mold composite urea-formaldehyde resin adhesive is coated on the core layer; wood shavings on the core layer are divided into three-layer structures, comprising intermediate layer of core layer, upper surface layer of core layer and lower surface layer of core layer; the intermediate layer of the core layer is paved longitudinally, and the upper surface layer of the core layer and the lower surface layer and surface layer of the core layer are paved horizontally. For the oriented strand board prepared by the method, the static bending intensity in a parallel direction is in a scope of 33-39 MPA, the parallel elasticity modulus is in the scope of 4614-4779 MPA, the vertical elasticity modulus is in the scope of 1504-1771 MPA, the thickness swelling rate of water absorption in 24 h is in the scope of 10%-17%, and the vertical nail-holding power reaches up to 89000N. In the manufacturing method, a problem that the board is easy to suffer from erosion of white ants and moths is thoroughly solved by adding an anti-insect and anti-mold additive, and the service life of the board is prolonged.

Owner:广西横县新威林板业有限公司

Primary walnut pulp and production method thereof

ActiveCN102150916ASolve high fatSolve the real problem of low protein and serious disproportionFood preparationCholesterolImpurity

The invention provides primary walnut pulp and a production method thereof. The primary walnut pulp is prepared from raw materials of walnut kernels and pure water through pulping, enzymolysis, oil taking and standardization; and through detection, the product has the protein content of more than or equal to 2.5 percent, the fat content of more than or equal to 2.6 percent and the polypeptide content of more than or equal to 18mg / ml. The production method comprises the following steps of: preparing walnut pulp, performing enzymolysis, centrifuging to take oil, and performing secondary enzymolysis; adding pure water for standardization; and homogenizing feed liquid, separating impurities by using a self-discharging disc centrifuge, performing ultra high temperature short-time sterilizationtreatment, cooling to the temperature below 35DEG C, and performing sterile filling to obtain the final product. The obtained product is white in color and thick in walnut flavor, contains nutrient components such as walnut protein, linoleic acid, linolenic acid and walnut phosphatide, and is rich in walnut polypeptide with high bioactivity, does not contain cholesterol or lactose; the bioavailability of walnut protein is greatly improved; and the product has high stability and meets the consumption requirements of people on nature, health and nutrition.

Owner:SHANXI FENZHOU YUYUAN FOOD CO LTD

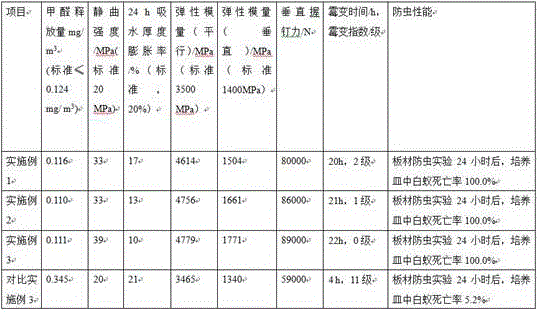

Compound multilayer medical dressing of aquatic biological source crosslinking collagen

ActiveCN107233613AWide variety of sourcesIncrease profitConnective tissue peptidesSurgical adhesivesFreeze-dryingCollagen sponge

The invention discloses an aquatic biological source medical collagen with high purity and activity, and is capable of solving the problems of a natural collagen dressing that the mechanical strength is bad, the degradation resistance ability is weak and the wound is easily infected by microorganisms. An acid extraction method and a method of removing telopeptide by pepsase are used for extracting the collagen, the extraction ratio is improved by the ultrahigh pressure treatment and a tissue mashing method, and through a series of purification operations, such as decellularization, protein elimination, degreasing, repeated salting out, dialysis, degerming, decoloration and heat source removal, the medical collagen with the high purity and activity is prepared. A netlike collagen sponge with uniform pores is prepared by a vacuum freeze-drying technology, and the collagen sponge is modified by a physical crosslinking and chemical crosslinking mode so as to prepare the inner layer, and is compounded with a chitosan outer layer film and a medical non-woven fabric base cloth layer, finally a compound multilayer medical dressing finished product is obtained by Co-60 sterilization.

Owner:OCEAN UNIV OF CHINA

Method for processing purified konjac flour

A method for processing purified konjac flour comprises twelve steps of material selection, swelling, extraction, material placing in a low temperature oxygen-free room, grinding, dehydration, dehumidification drying, dry grinding, winnowing, sieving, checkout and homogeneous warehousing. The method for processing the purified konjac flour has the advantages that the swelling and the extraction can enable impurities in the konjac flour to be soluble in impregnation liquid and accordingly separated out, the activity of polyphenol oxidase can be restrained and brown stain can be prevented through processing in the low temperature oxygen-free room. Starch and the impurities attached to glucomannan particles can be further peeled off through the grinding, and then the impurities are removed through the dehydration. Heating can be avoided and brown stain, gelatinization and adhesion can be prevented through the dehumidification drying. By means of the grinding in the low temperature environment, the ragility of konjac particles can be improved, the impurities can be easily separated, and small particles can be obtained. Various levels of purified konjac flour meeting the national requirements is obtained after the sieving. Therefore, produced purified konjac flour does not contain sulfur, is free of brown stain, gelatinization and adhesion and is pure white, and the product quality is improved.

Owner:重庆天娇农业开发有限公司

Method for preparing chitin and process for preparing chitosan by using chitin

The invention discloses a method for making crust element which comprises the following steps that: a crab shell which is cleaned and soaked for the first time is put into a sodium hydrate solution for heat preservation; the crab shell which is washed by tap water to the neutral is soaked for the second time, the acid liquor is scoured off by the tap water; the curst element soaked by hydrochloric acid is put into the sodium hydrate solution for heat preservation and then is fished out as well as is washed by the tap water to the neutral, and the crust element is obtained. The method for making chitosan by the crust element comprises the following steps that: the crust element is put into the sodium hydrate solution and is sealed, after temperature preservation and the reaction, the mixture is soaked by the tap water and is washed by the tap water; the processed chitosan is taken out to be dried and put into the sodium hydrate solution as well as be sealed while preserving the temperature, after the reaction, the chitosan is taken out and is soaked in the tap water as well as is taken out and dried, thereby obtaining the chitosan. By processing by the method, the reaction speed is increased by 30 times, the alkali liquor dosage is reduced by 50 percent; the made crust element has white color, the crust element is washed by water and soaked to produce the chitosan, the molecular weight is great, the deacetylation is more than or equal to 95 percent, and the viscosity coefficient is more than or equal to 2000MPa.S.

Owner:石勇

Viable type lactobacillus fermented litchi juice beverage and preparation method thereof

InactiveCN103815483AShort half-lifeAvoid destructionFood ingredient functionsFood preparationBiotechnologyLychee fruit

The invention discloses a viable type lactobacillus fermented litchi juice beverage and a preparation method thereof, and the prepared litchi juice beverage is rich in active lactobacilli. The preparation method comprises the following steps: preparing litchi juice, adding DMDC into the litchi juice, allowing the litchi juice to stand still for 2 to 3 hours at a room temperature, adjusting the pH value to a range of 6 to 7, and adding lactobacilli to carry out fermentation so as to obtain the fermented litchi juice beverage. The preparation method utilizes DMDC to carry out a sterilization treatment on litchi juice at a room temperature, thus the flavor and nutrient destruction caused by the conventional pasteurization is avoided, and the fermentation effect of lactobacilli is not influenced either. The fermented litchi juice beverage is rich in active lactobacilli; the thickening effect can be achieved and the pulp precipitation phenomenon can be avoided without any thickening agent and stabilizing agent, because lactobacilli can generate a large amount of extracellular polysaccharide; and at the same time the beverage has a proper sweet and sour taste, a smooth and sticky mouth feel, and a rich litchi flavor, is accord with the food safety and sanitation standards, is also accord with the natural and healthy food theory, and has a very good market prospect.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

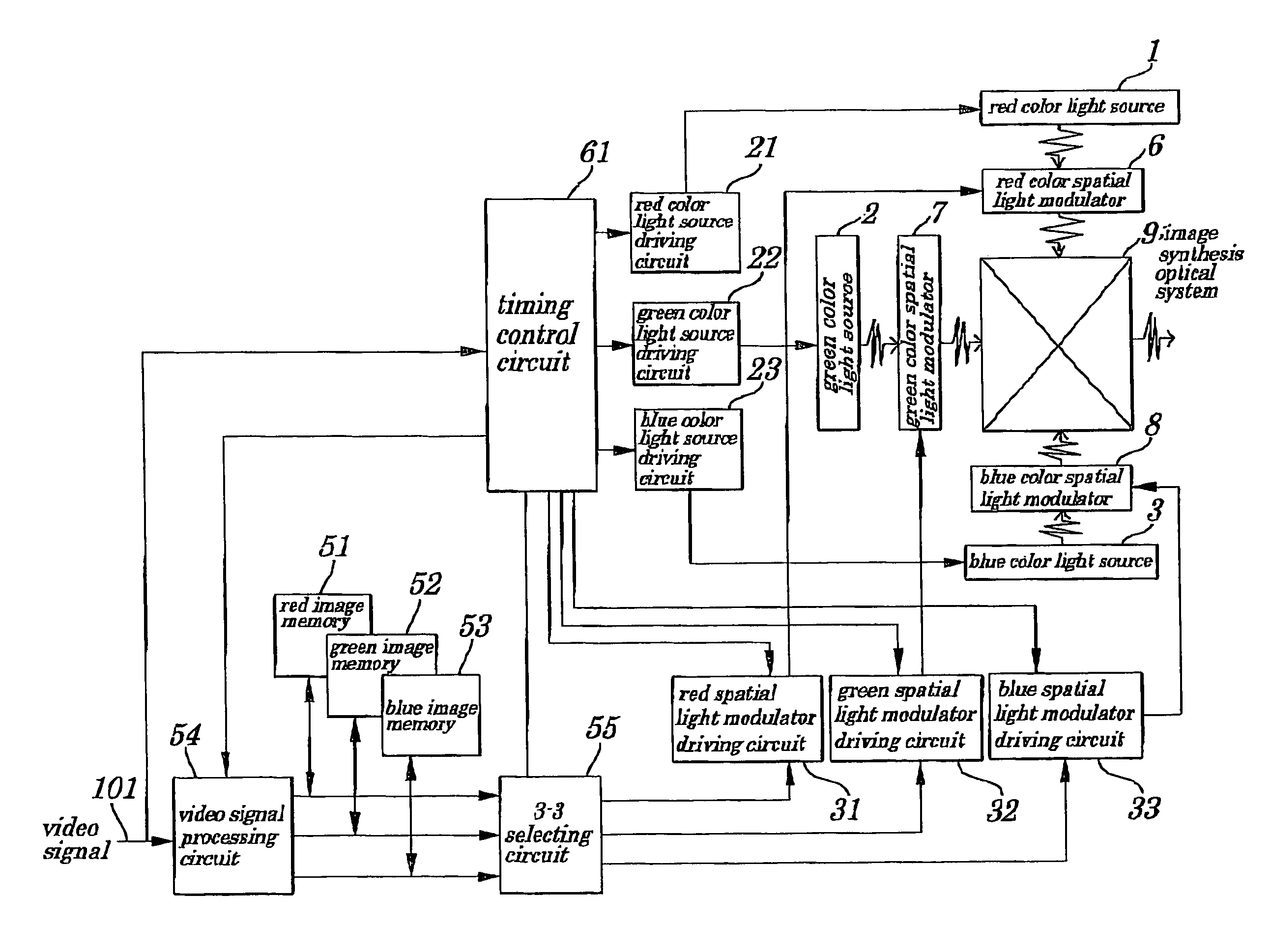

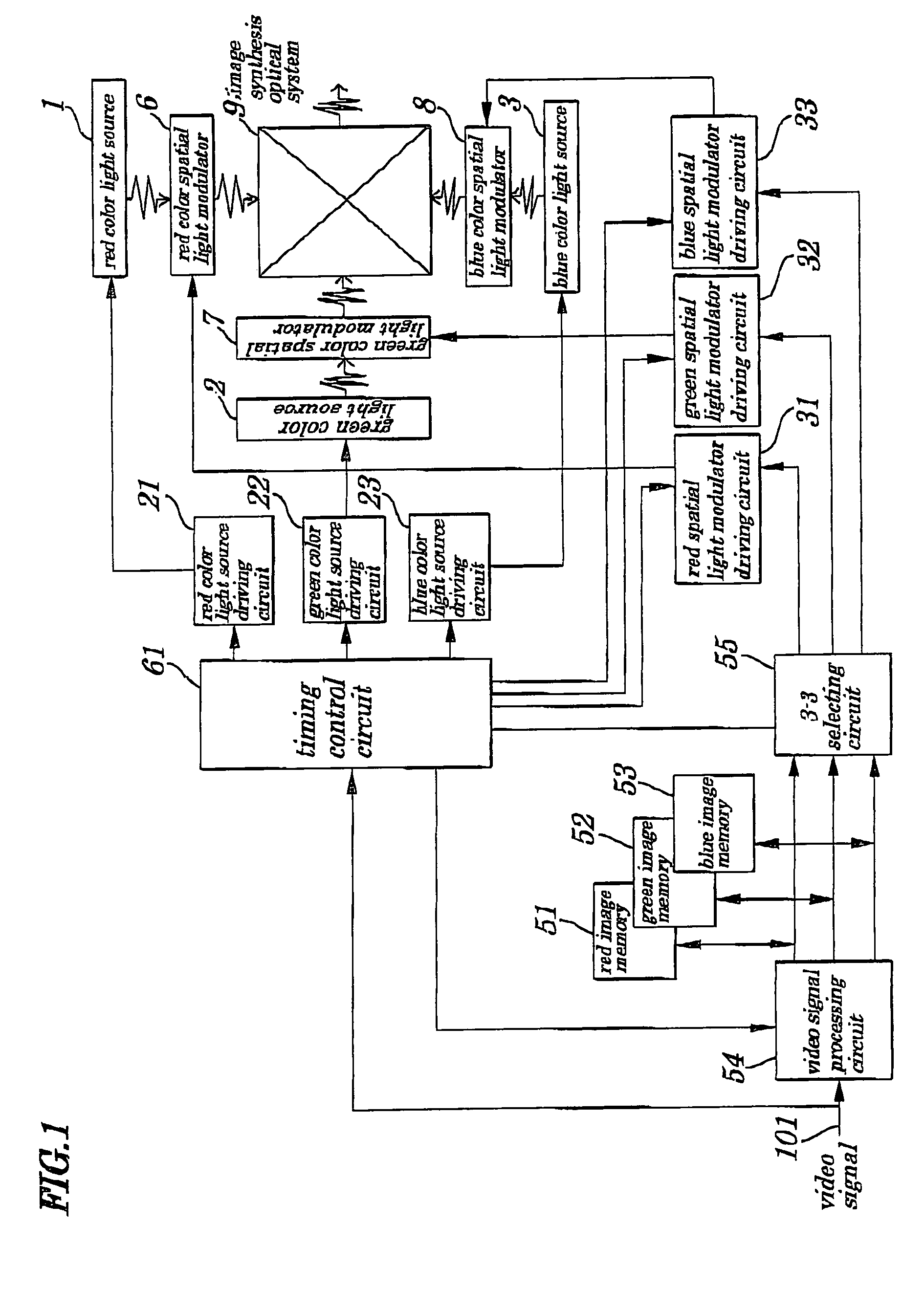

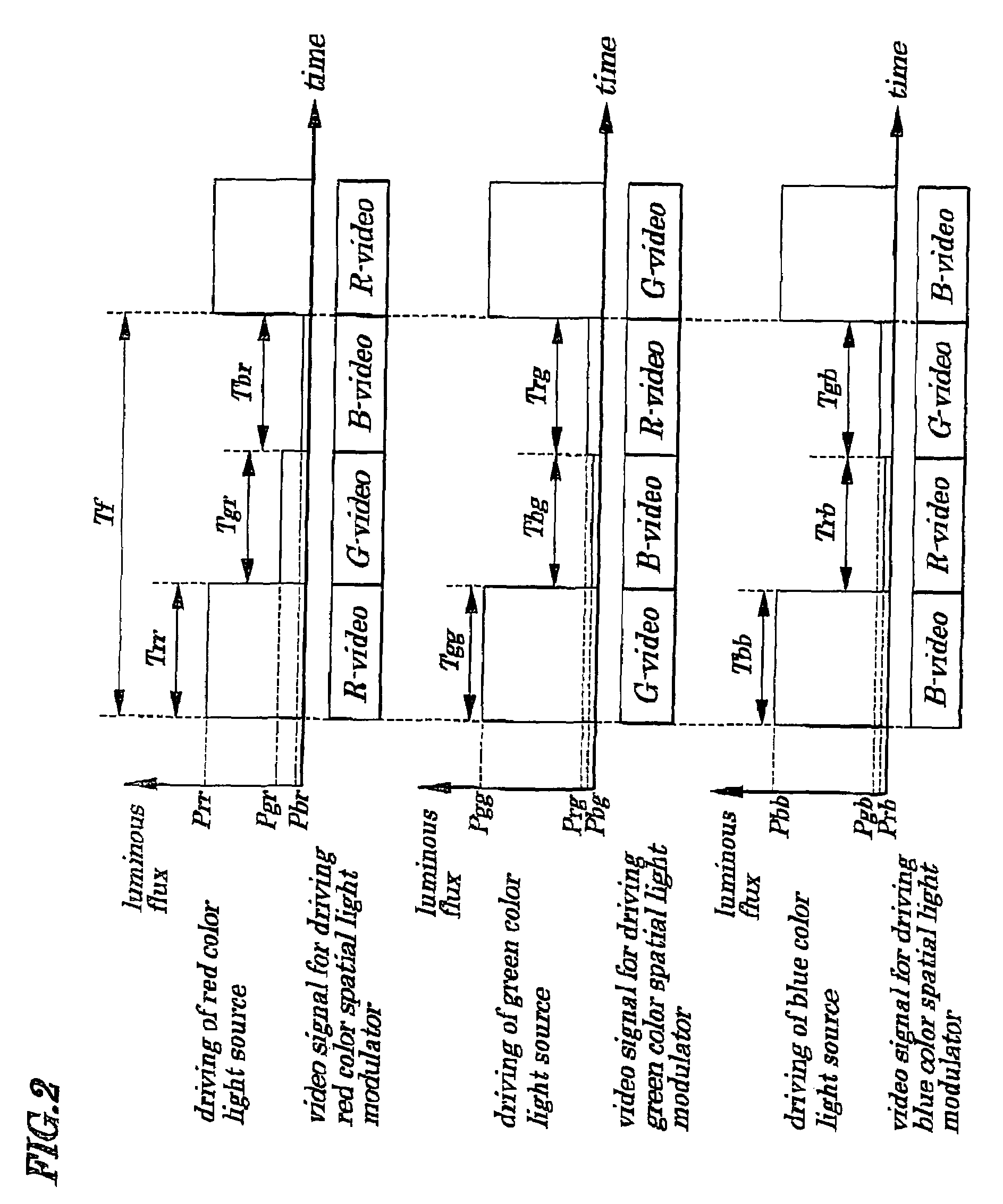

Video display device with spatial light modulator

ActiveUS7154458B2High color reproductionIncrease image brightnessPicture reproducers using projection devicesCathode-ray tube indicatorsDisplay deviceImage synthesis

A spatial light modulating-type video display device is provided which has excellent color reproductivity of a video even when a light source is used which emits light having chromaticity coordinates of each of three primary colors (R, G, and B) being different from those designated by specifications of colorimetry. The video display device has a red color light source being driven by the red color light source driving circuit and emitting red color light being, a green color light source being driven by the green color light source driving circuit and emitting green color light, and a blue color light source being driven by the blue color light source driving circuit and emitting blue color light, spatial light modulators each performing spatial modulation on red color light, green color light, and blue color light, an image synthesis optical system to synthesize spatially modulated light, a selecting circuit to select orders of video signals to modulate incident light in each spatial light modulator, and a control circuit to control driving timing and / or driving current of the light sources in each of the spatial light modulators and timing of selection in the selecting circuit.

Owner:SHARP NEC DISPLAY SOLUTIONS LTD

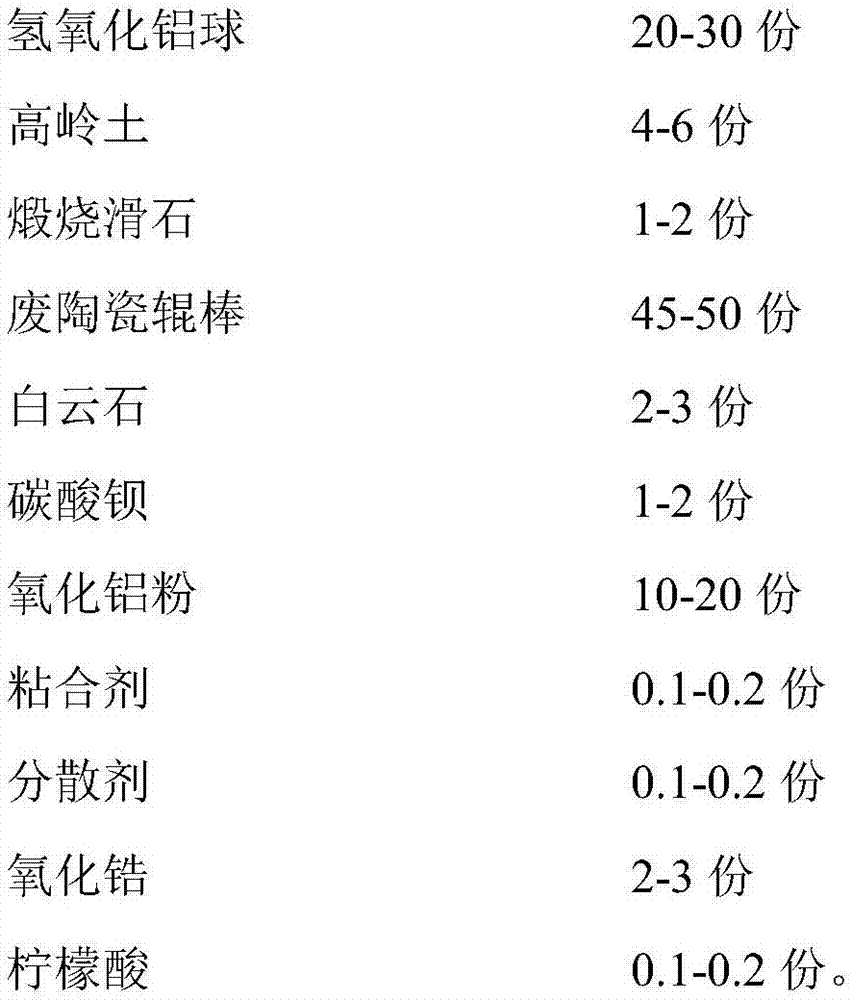

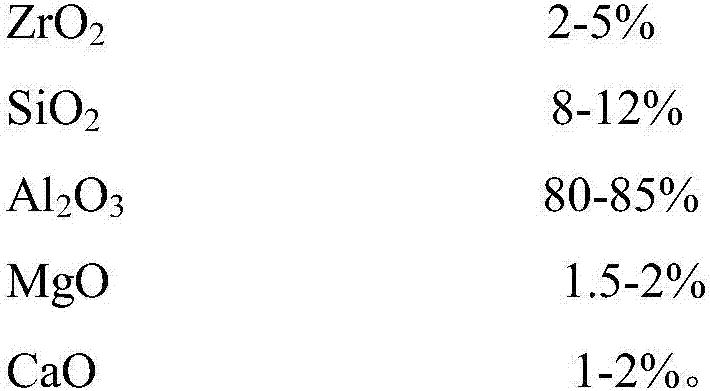

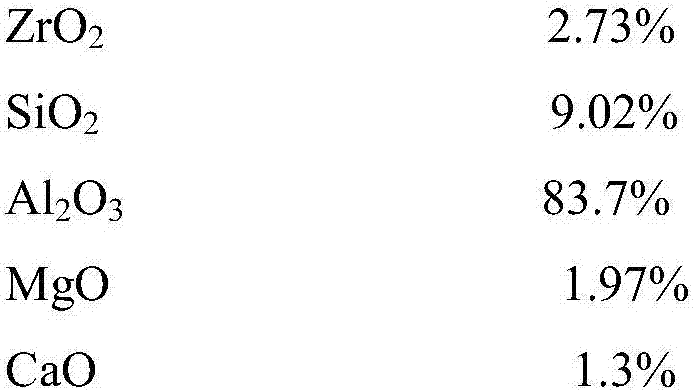

Wear-resistant zirconium-aluminum composite ball and preparation method thereof

InactiveCN107226684AHigh densityChemically stableCeramic materials productionClaywaresWear resistantAdhesive

The invention belongs to the technical field of grinding media, and particularly provides a wear-resistant zirconium-aluminum composite ball and a preparation method thereof. The wear-resistant zirconium-aluminum composite ball is composed of the following components in parts by weight: 20-30 parts of aluminum hydroxide ball, 4-6 parts of kaolin, 1-2 parts of calcined talcum, 45-50 parts of waste ceramic roller, 2-3 parts of dolomite, 1-2 parts of barium carbonate, 10-20 parts of aluminum oxide powder, 0.1-0.2 part of adhesive, 0.1-0.2 part of dispersant, 2-3 parts of zirconium oxide and 0.1-0.2 part of citric acid. The invention also provides a preparation technique of the wear-resistant zirconium-aluminum composite ball. The prepared wear-resistant zirconium-aluminum composite ball has the advantages of high density, high wear resistance and stable chemical properties.

Owner:山东中和金石科技集团股份有限公司

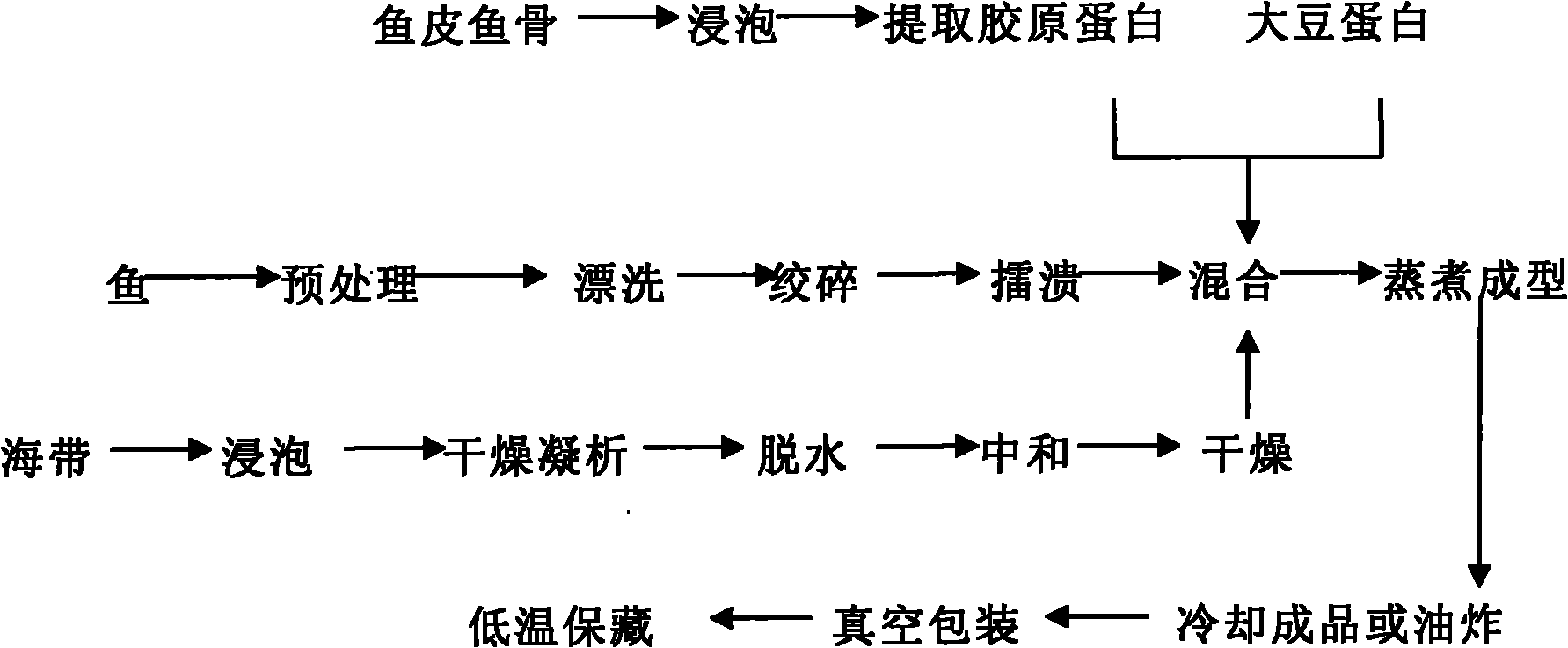

Processing method of recombined braised tofu with seafood

The invention relates to a recombined braised tofu with seafood and a processing method thereof, belonging to the food science and technology field. The method comprises the following steps of: adding accessories, such as soy protein, collagen of fish skin and fish bone, kelp extractives, and the like by using fresh-water minced fillet as a main raw material; and recombining, mixing (chopping in vacuum for 30 min), stewing and forming at a high temperature (for 30 min), frying with oil in vacuum, quickly cooling and packaging in vacuum to make a polymer of protein and amylase and form a tofu-shaped, fresh, tender and smooth product with seafood taste, i.e. the recombined braised tofu with seafood, and storing the finished product in the environment at 0-4 DEG C. The recombined braised tofu with seafood, which is produced by applying the technology, is rich in nutrition, has excellent consistency, white color and luster, great and strong seafood taste and long product shell life, and is widely suitable for Chinese and western foods.

Owner:TIANJIN UNIV OF SCI & TECH

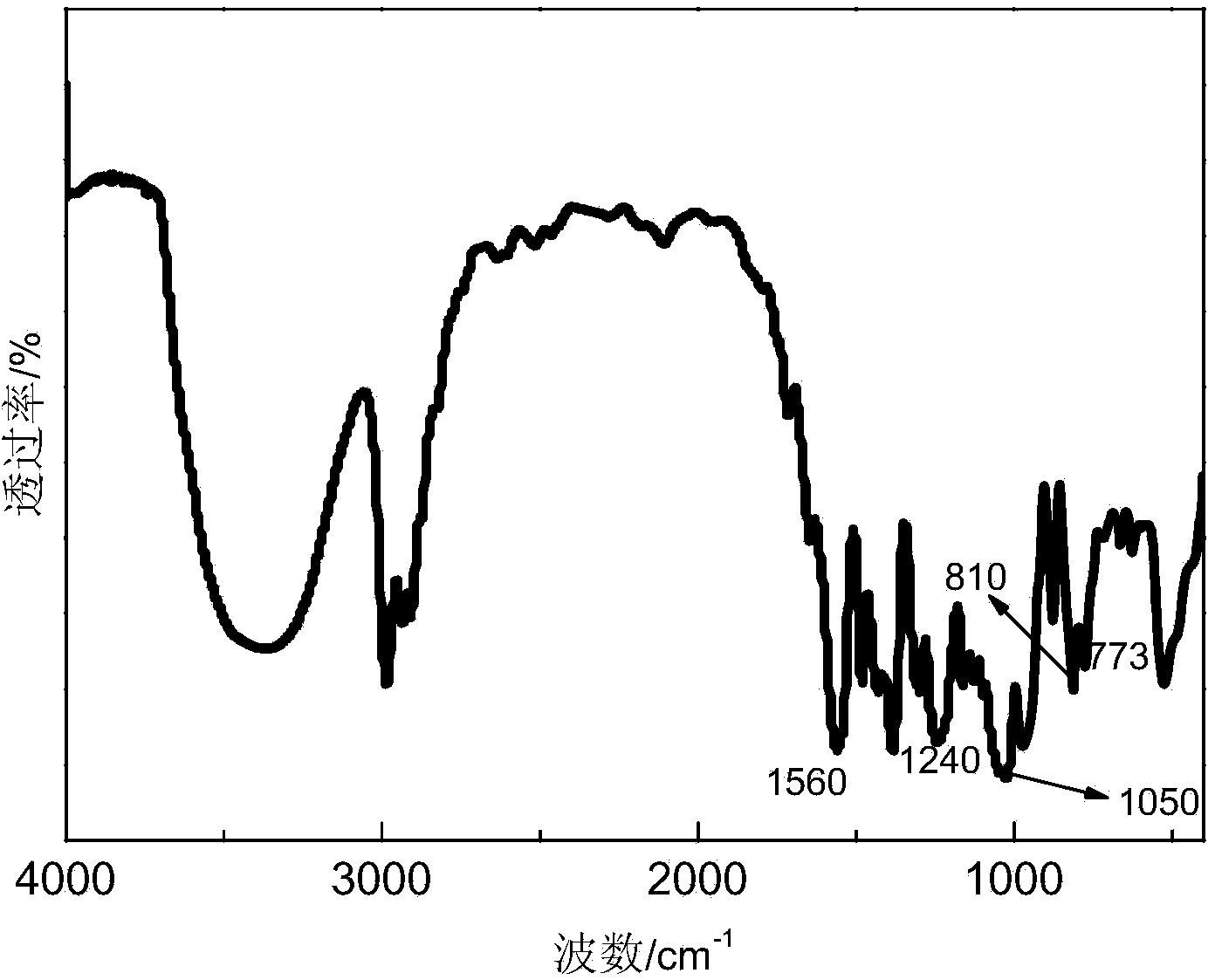

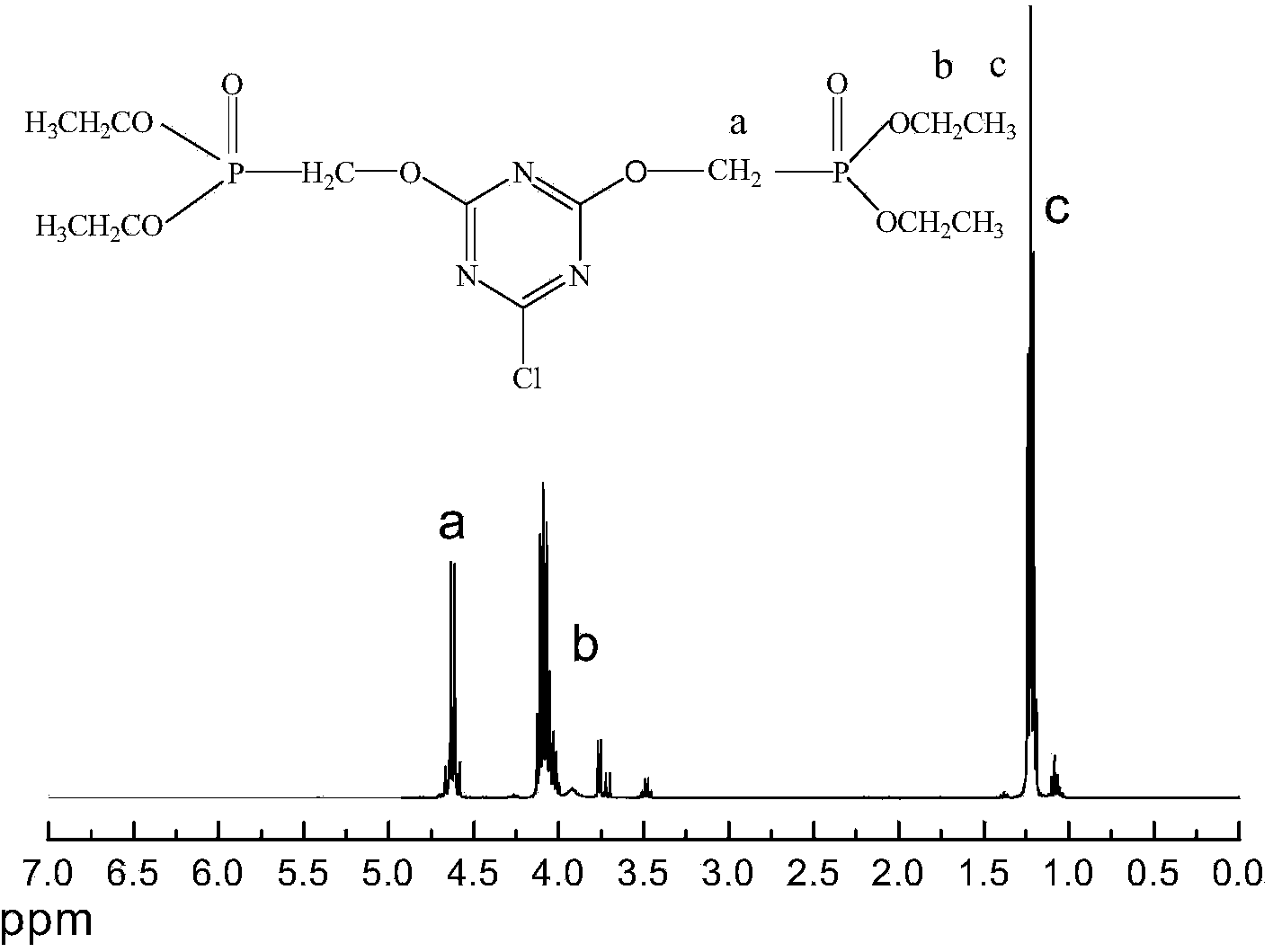

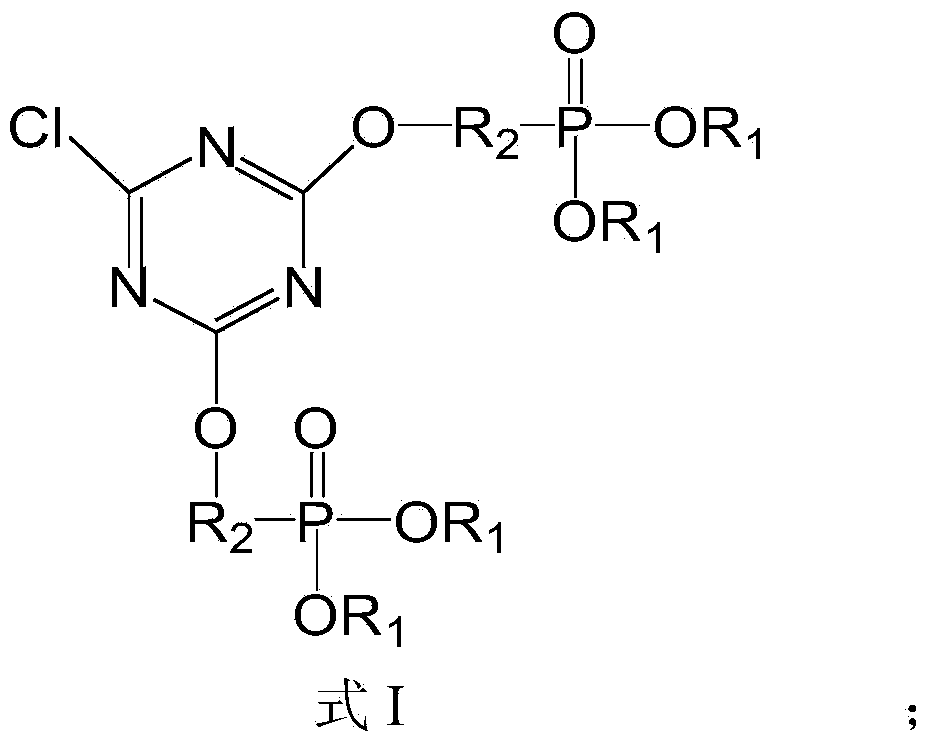

Symtriazine-type flame retardant, preparation method and application of symtriazine-type flame retardant

ActiveCN103882698AWhite colorImprove thermal stabilityGroup 5/15 element organic compoundsVegetal fibresCombustionHeat stability

The invention discloses a smtriazine-type flame retardant, a preparation method and application of the smtriazine-type flame retardant. The structure of the smtriazine-type flame retardant is shown as a formula I, the method is easy in preparation and easy to implement, and the prepared smtriazine-type flame retardant is high in heat stability and excellent in physical and mechanical properties. The method comprises the following steps: mixing and dissolving cyanuric chloride and acetone, reducing the temperature, continuously dripping an aqueous solution of potassium carbonate to regulate the pH to be 5-7, reacting at the temperature of 15-45 DEG C for 15-60 minutes after dripping, and performing aftertreatment to obtain the smtriazine-type flame retardant. In the used method for preparing the smtriazine-type flame retardant, the raw materials are readily available; the obtained smtriazine-type flame retardant is white in color, excellent in heat stability and physical and mechanical properties and high in yield; a fabric finished by the flame retardant is small in combustion smoke amount, high in char yield and environmentally friendly and can obtain long-lasting flame retardant property. The product is high in washing resistance after being applied to the fabric and is ecological, environmentally friendly and convenient to use, and the colored light and handfeel of the fabric are hardly influenced.

Owner:ZHEJIANG SCI-TECH UNIV

White asparagus ridging-free cultivation method

InactiveCN103718825AIncrease productionIncrease productivityAspharagus cultivationPlant protective coveringsAsparagus adscendensAsparagus

The invention relates to a white asparagus ridging-free cultivation method and belongs to field of asparagus cultivation. White asparagus is produced by using a high-density sunshade net to make a frame so as to cover the white asparagus, ridging-free cultivation is achieved, a planar support is 40cm away from a bed surface, the sunshade net covers the periphery of the support, a layer of straws is laid on the sunshade net to enhance sunshade effect during the asparagus harvesting season, the sunshade net is 6-stitch high-density black sunshade net with sunshade rate as high as 95%, sunshade processing can be performed effectively, matched farm operations such as water and fertilizer management and asparagus harvesting are provided, the produced white asparagus is pure white in color, and the average yield per mu can reach more than 1200kg in the second year of planting. Compared with traditional earthing blanching cultivation methods, the cultivation method has the advantages that steps such as ridging and ridge removing are omitted, asparagus can be harvested without push aside soil layers, labor is saved, white asparagus production efficiency is increased, large planting density and high yield are achieved, and the cultivation method is suitable for being popularized and applied, especially suitable for white asparagus production in the southern areas, and is promising in application prospect.

Owner:JIANGXI ACAD OF AGRI SCI

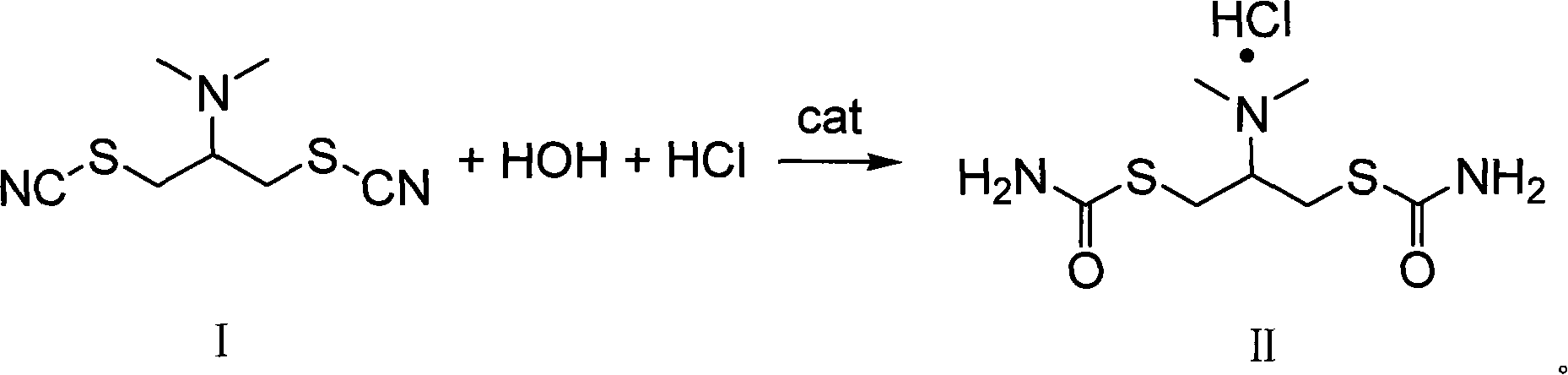

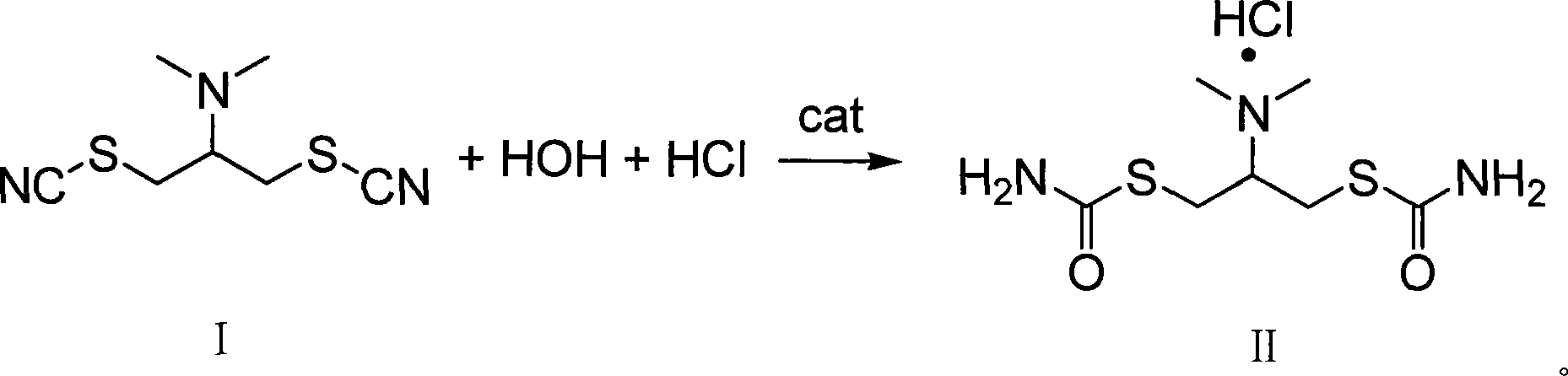

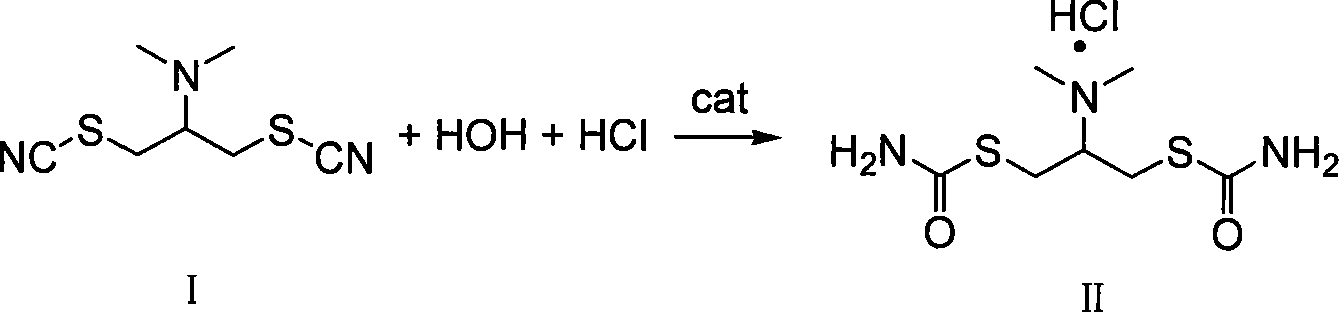

Cartap environment-friendly type preparing method

InactiveCN101103725ATaking into account the costTaking toxicity into accountBiocideOrganic chemistryAlcoholWastewater

The invention discloses an environmental protection preparation method for cartap hydrochloride; rhodanide solution, water and catalyst are arranged inside a reactor, and chlorine hydride gas is input in the reactor for hydrolysis reaction for 15 to 24 hours under -18 to 25 DEG C, so that the cartap hydrochloride can be produced. The hydrolysis processing technique of the invention firstly adopts a hydrolyst method instead of a methyl alcohol alcoholysis for solving the problems of the exhaust gas and waste water from the prior processing technique, furthermore, the hydrolysis rate can reach 95 percent, the quality stability of the cartap hydrochloride product is good, and the processing to the recovery solvent and the mother liquor has unparalleled advantages than the prior art, which fully embodies the call of nation on energy saving and pollutants discharge reduction, thereby the invention has a great social and economic efficiency.

Owner:JIANGSU TIANRONG GROUP

Preparation method of soybean milk

ActiveCN102524410AAvoid emissionsEliminate sources of pollution emissionsMilk substitutesFood scienceBoiling processRoom temperature

The invention provides a preparation method of soybean milk. The preparation method includes 1) adopting soybean cotyledon particles subjected to breaking, embryo removal, fine powder removal and soybean skin removal to serve as a raw material; 2) soaking the soybean cotyledon particles in water for 30-60 minutes, milling the soybean cotyledon particles to obtain raw soybean milk after removing bean dregs; 3) boiling the raw soybean milk, and maintaining temperature at over 85 DEG C for 30-45 minutes to obtain the soybean milk. Hardness of the water for soaking the cotyledon particles is 2-4.5 mmol / l, and water temperature is at room temperature. The pH value of the raw soybean milk is adjusted to 6.6-7.2 prior to boiling or in the boiling process; and preferably, the pH value of the raw soybean milk is adjusted to 6.8-7.0, and the pH value is adjusted through NaOH or KOH. The preparation method of soybean milk shortens soaking time of soybean, and obtains the soybean milk which is white in color and good in creaming state while saving investment and reducing energy consumption. When the soybean milk produced through the preparation method is used for production of bean curd, the yield rate, water-retaining property and hardness of the bean curd are greatly improved.

Owner:FOODSTUFF INST BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com