Method for extracting oryzanol from rice bran crude oil

A technology for crude rice bran oil and rice bran oil, which is applied in the direction of fat oil/fat refining, steroid compound, fat production, etc., can solve the problems of low yield of oryzanol and rice bran oil, unstable product quality of oryzanol, long production cycle, etc. The effect of reducing oryzanol loss, improving yield and white color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

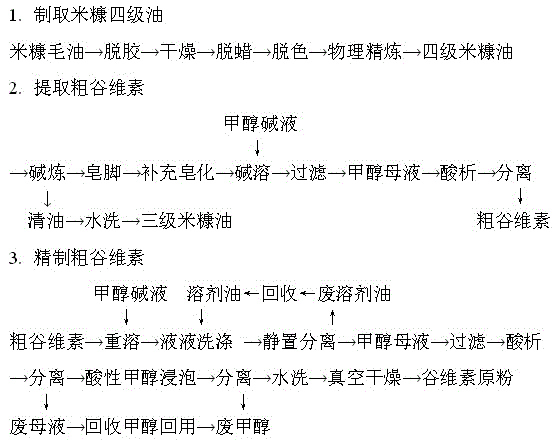

Image

Examples

Embodiment 1

[0024] The method for extracting oryzanol from crude rice bran oil, the steps are as follows:

[0025] (1) Preparation of grade 4 rice bran oil

[0026] ①Rice bran crude oil hydration degumming and dewaxing: at a temperature of 90°C, the rice bran crude oil is hydration degumming, the water mass is 8% of the rice bran crude oil mass, and the degumming time is 1 hour. The degumming operation is completed once, and the hydration removal Phospholipids to obtain degummed rice bran oil. The degummed rice bran oil is washed twice at a temperature of 85°C. The quality of water is 10% of the quality of the degummed rice bran oil. The washed degummed rice bran oil is vacuum-dried at a drying temperature of 120°C. , the dried degummed rice bran oil is subjected to freeze dewaxing, and the dewaxing temperature is 23° C. to obtain dewaxed rice bran oil;

[0027] ② Decolorization of dewaxed rice bran oil: Dewaxed rice bran oil plus activated clay for adsorption and decolorization, the mas...

Embodiment 2

[0038] The method for extracting oryzanol from crude rice bran oil, the steps are as follows:

[0039] (1) Preparation of grade 4 rice bran oil

[0040] ①Rice bran crude oil hydration degumming and dewaxing: at a temperature of 80°C, the rice bran crude oil is hydration degumming, the water mass is 5% of the rice bran crude oil mass, and the degumming time is 0.5 hours. The degumming operation is completed once, and the hydration removal Phospholipids to obtain degummed rice bran oil. The degummed rice bran oil was washed once at a temperature of 75°C. The quality of water was 5% of the mass of the degummed rice bran oil. The washed degummed rice bran oil was vacuum-dried at a drying temperature of 100°C. , the dried degummed rice bran oil is subjected to freeze dewaxing, and the dewaxing temperature is 20° C. to obtain dewaxed rice bran oil;

[0041] ② Decolorization of dewaxed rice bran oil: Dewaxed rice bran oil plus activated clay for adsorption decolorization, the qualit...

Embodiment 3

[0052] The method for extracting oryzanol from crude rice bran oil, the steps are as follows:

[0053] (1) Preparation of grade 4 rice bran oil

[0054] ①Rice bran crude oil hydration degumming and dewaxing: at a temperature of 85°C, the rice bran crude oil is hydration degumming, the water mass is 5% of the rice bran crude oil mass, and the degumming time is 0.5 hours. The degumming operation is completed once, and the hydration removes Phospholipids to obtain degummed rice bran oil. The degummed rice bran oil is washed once at a temperature of 80°C. The quality of water is 8% of the quality of the degummed rice bran oil. The degummed rice bran oil after washing is vacuum-dried at a drying temperature of 110°C. , the dried degummed rice bran oil is subjected to freeze dewaxing, and the dewaxing temperature is 22° C. to obtain dewaxed rice bran oil;

[0055] ②Decolorization of dewaxed rice bran oil: Dewaxed rice bran oil plus activated clay for adsorption and decolorization, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com