Patents

Literature

147results about How to "Weak acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

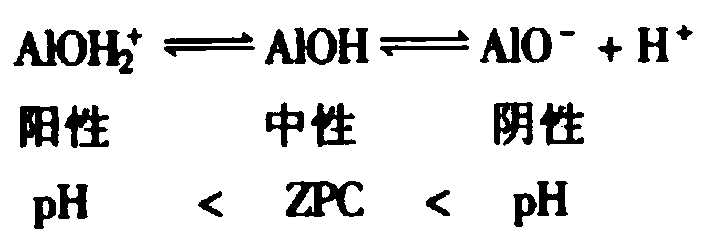

Aluminium oxide carrier containing magnesium and phosphor and preparing method

InactiveCN101069853AStrong anti-coking abilityHigh activityMetal/metal-oxides/metal-hydroxide catalystsLarge poreChemistry

The present invention discloses an aluminium oxide carrier which contains magnesium and phosphorus, also can contain potassium and its preparation method. The magnesium, phosphorus and potassium can be added in the process of preparation. Said carrier is low in acidity and has large pore volume and large specific surface area. The catalyst prepared by using said carrier has the features of strong anti-coking property and good stability.

Owner:林方 +3

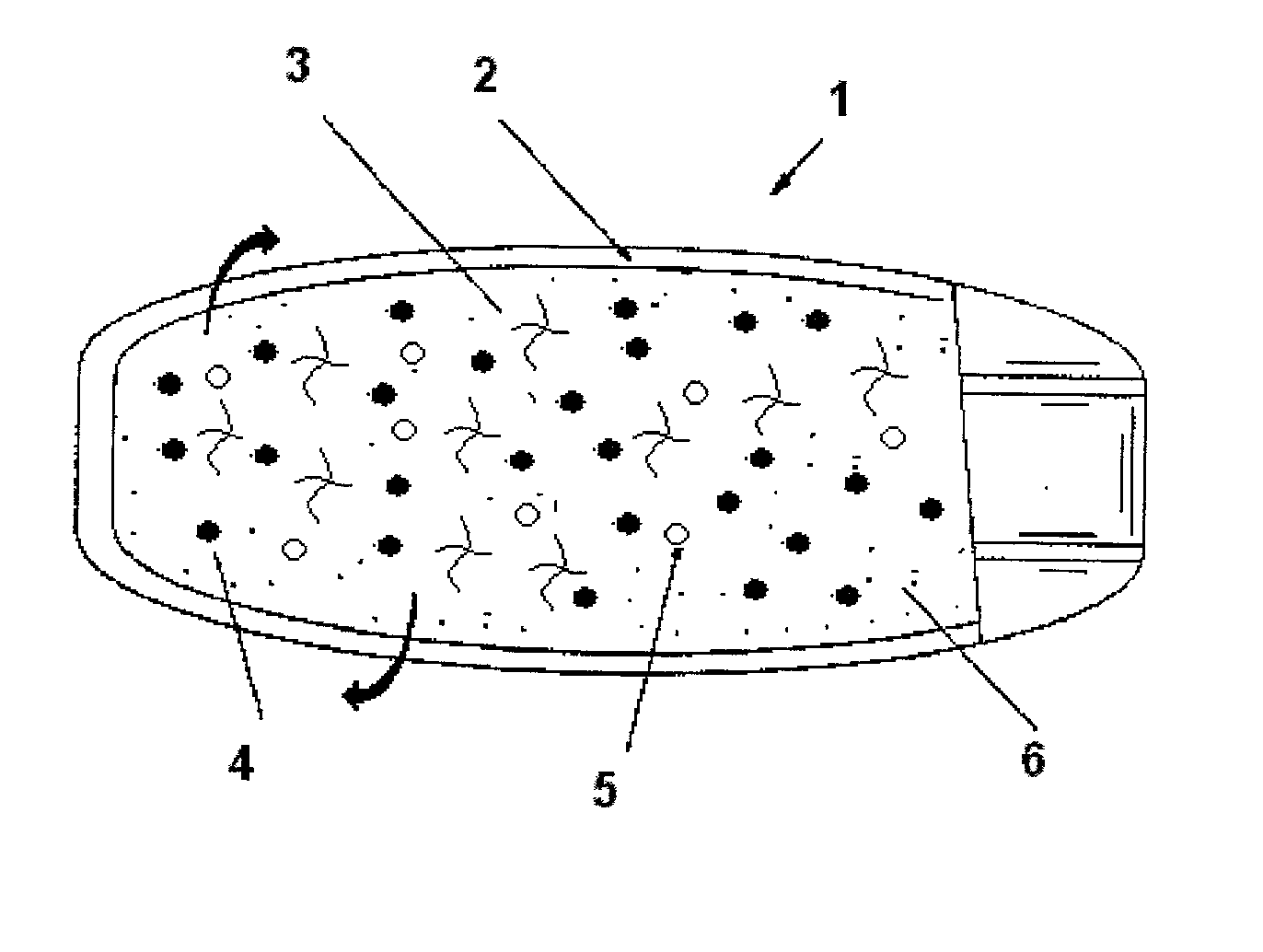

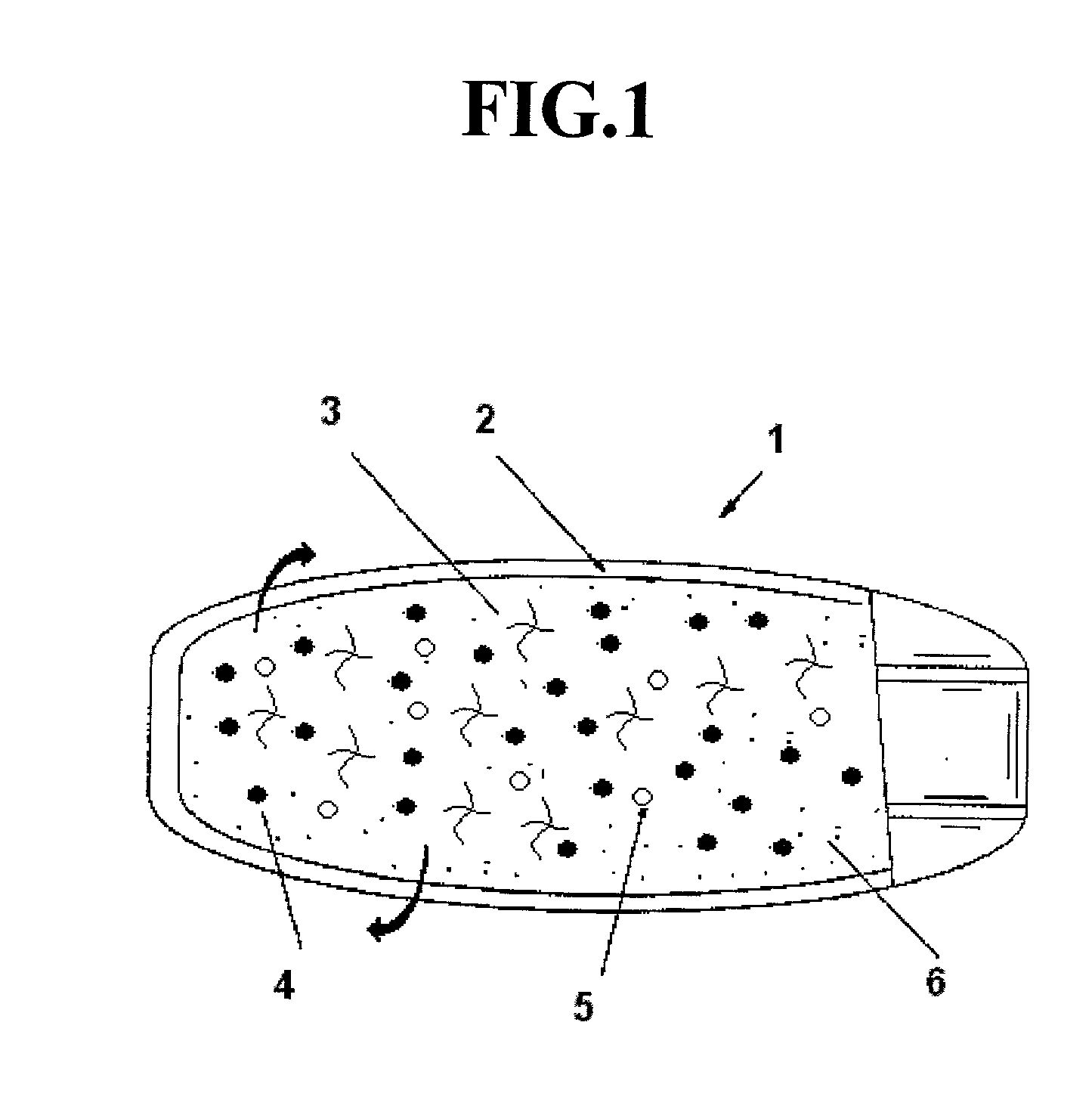

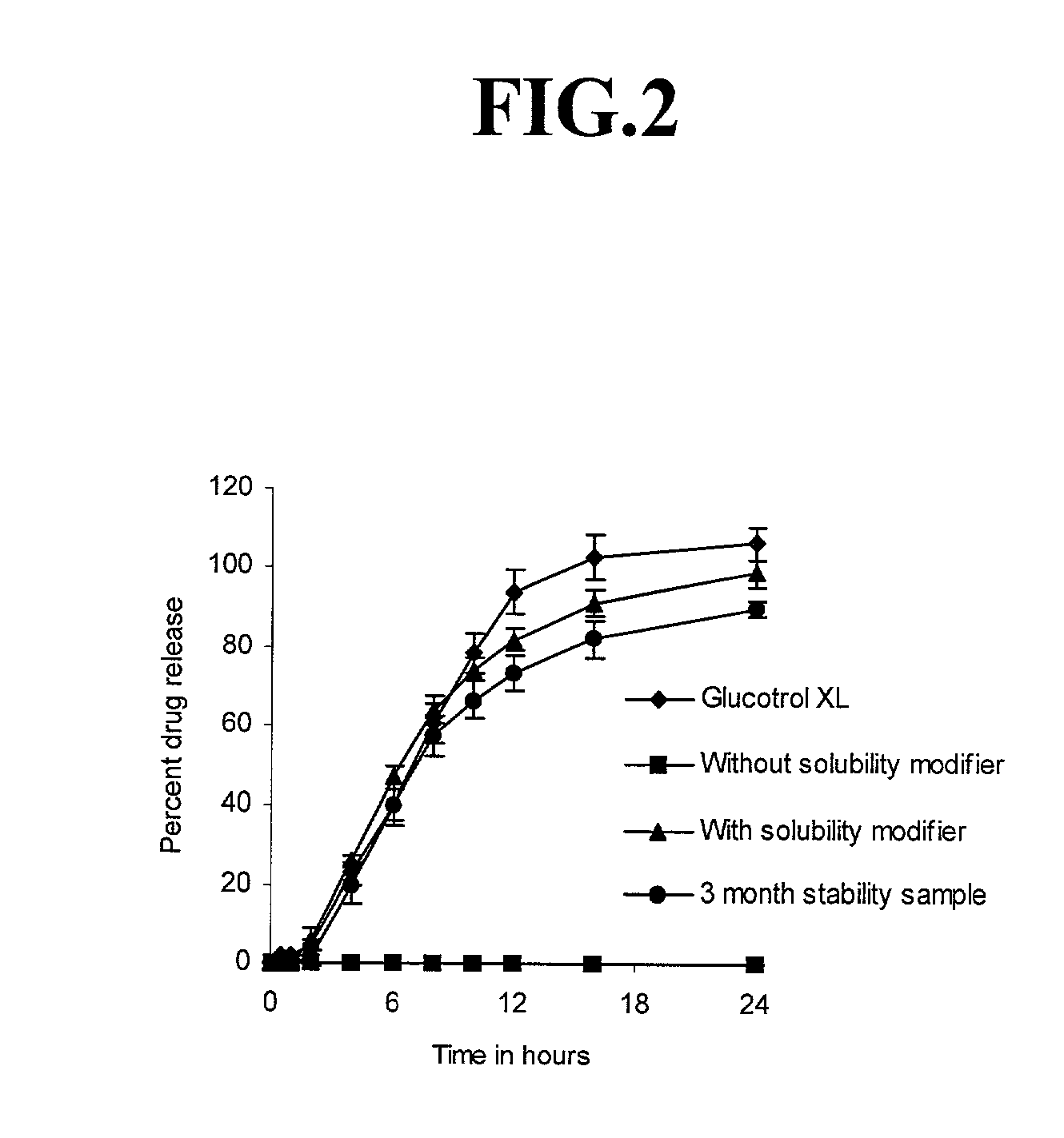

Pharmaceutical compostion for extended/sustained release of a therapeutically active ingredient

InactiveUS20030175349A1Limited solubilityImprove solubilityAntibacterial agentsMetabolism disorderSolubilityPlasticizer

A pharmaceutical composition useful for sustained / extended release of a therapeutically active ingredient to an environment of use, said composition comprises a tablet core composition consists of a therapeutically active ingredient that is weakly acidic in nature and has a limited solubility in the aqueous environment, said the therapeutically active ingredient is in immediate contact with the agents that are capable of improving the solubility of the agent within the core, for e.g., by changing the micro environmental pH of the core and the tablet core is surrounded by a release rate controlling membrane consisting of a semi-permeable membrane forming polymer, permeable membrane forming polymer, and at least one plasticizer capable of modulating the film formation properties of the polymers.

Owner:COUNCIL OF SCI & IND RES

Method for producing chitin, calcium citrate and protein powder

The invention relates to a method for producing chitin, calcium citrate and albumen powder by using the shells of crustaceans like shrimps and crabs as the materials; the shells of shrimps and crabs are selected and arranged into an oven, and dried and then water with weight of 6 times of the shells are added; then the mixture is heated to be between 50 and 55 DEG C; then a neutral papain with a mass ratio of 1: 0.001 to 0.003 with the shells of shrimps and crabs, is added for carrying out zymohydrolysis and obtaining zymohydrolysis liquid; the zymohydrolysis liquid is filtered for obtaining the shells of shrimps and crabs; 15% to 20% citric acid solution is added for dipping for 24 to 36 hours; then the chitin is obtained through filtering, acid rinsing and drying; cold separation is carried out on the filtered liquid and a cold separation matter which can be named the calcium citrate is obtained through centrifugalizing; vacuum condensing and drying are carried out on the rest liquid obtained through centrifugalizing, thus obtaining the albumen powder. In the invention, the technical method adopts enzymes for removing proteins and citric acid decalcification for leading the separation of the protein and the calcium with the chitin to be more complete; the yield rate of the chitin is high; and the prepared chitin product has the advantages of white color, high purity and good quality.

Owner:RONGCHENG TAIXIANG FOOD

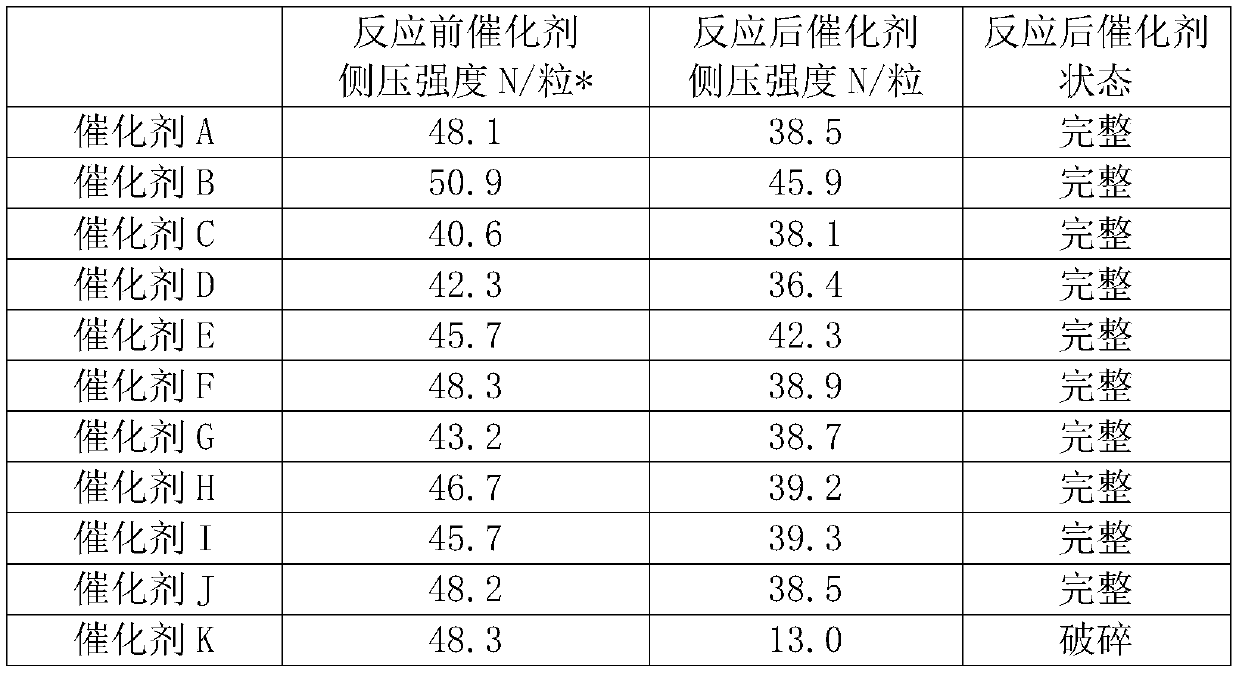

Dimethyl benzyl alcohol hydrogenolysis catalyst and preparation method thereof

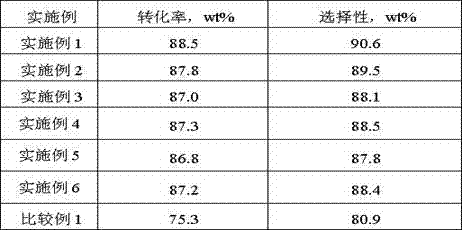

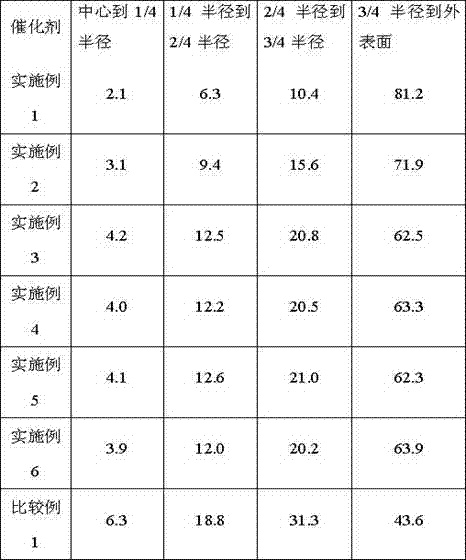

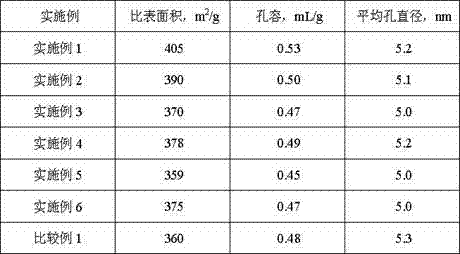

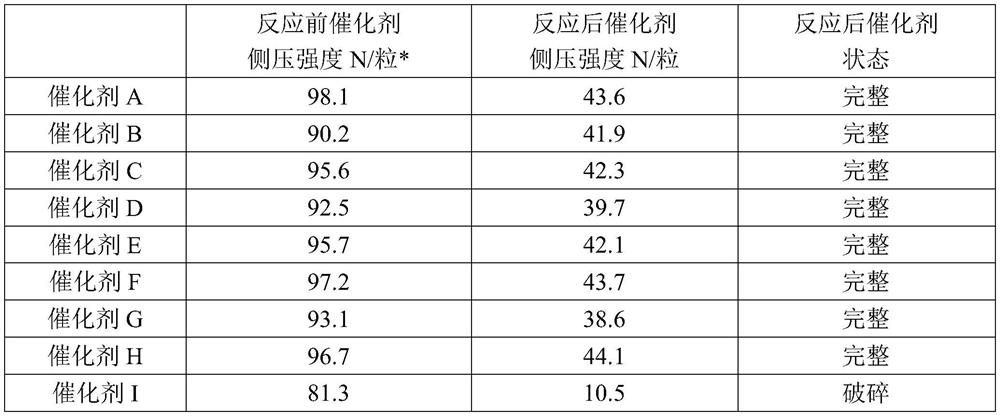

ActiveCN110075857AImprove mechanical stabilityEvenly distributedHeterogenous catalyst chemical elementsCatalyst activation/preparationCopper oxideSlurry

The invention discloses a dimethyl benzyl alcohol hydrogenolysis catalyst and a preparation method thereof. The catalyst comprises 35-70wt% of copper oxide, 5-25wt% of zinc oxide, 15-40wt% of silicondioxide, 0.5-15wt% of alkaline earth metal oxide and 0.1-5wt% of bismuth oxide and lead oxide. The preparation method comprises the following steps: (a) adding a mixed solution containing a Cu compound, a Zn compound, an alkaline earth metal compound, a Bi compound and a Pb compound and an alkaline precipitant solution into a silica sol aqueous solution for precipitation reaction and heating aging; (b) filtering, washing, drying and roasting the aged slurry to obtain complex compound powder; and (c) adding a binder, a forming assistant and the like into the complex compound powder, fully mixing, extruding and forming, drying and roasting to obtain the catalyst. When used for preparing cumene by hydrogenolysis of dimethylbenzyl alcohol, the method not only has good activity and selectivity,but also has good liquid resistance and high mechanical stability.

Owner:WANHUA CHEM GRP CO LTD

Technology method for deblock of oil field oil-water well using biological acid

The invention is a process method for unblocking water and oil wells in an oil field by biological acid, characterized by mixing biological acid and water as well as assistant into unblocking agent, squeezing the unblocking agent into oil or water well at normal temperature, so that the unblocking agent gradually seeps into strata, the biological acid seeps into throats to enter in micro-scopical holes and are absorbed on the surface layers of cores, where the squeezing radius is 1-15 m, pressure is stabilized for 0-1.5 h, and 4-18 h later, opening the well,and not discharging fluid, thus improving core property, recovering stratum permeability, stopping stains redeposition, reducing oil and water interface tension and raising crude oil recovery.

Owner:SUNCOO PETROLEUM TECH

Hydrocracking catalyst and preparation method thereof

ActiveCN103100392AWeak acidLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionAlkaneOrganic acid

The invention discloses a hydrocracking catalyst and a preparation method thereof. In the catalyst, the acidic component is a silicotungstate, the hydrogenation metal component is nickel, and the carrier is silicon oxide. The catalyst is prepared by: adding a nickel salt and an alkali metal salt respectively into an aqueous solution containing organic acid I to obtain a solution A, adding a silicon source into a solution containing organic acid II to obtain a solution B, then mixing the solution A with the solution B, adding a silicotungstic acid aqueous solution, conducting stirring to evaporate the solution, and carrying out drying and roasting, thus obtaining the catalyst. The heteropolyacid used by the method is silicotungstic acid, and two organic acids are used cooperatively to reach a mutual promotion effect, so that the metal components and the acidic component are dispersed more evenly, the hydrogenation activity and the acid function are matched better, and also the catalyst can have larger specific surface area, pore size and pore volume. Thus, the catalyst has better catalytic performance. The catalyst prepared by the invention is especially suitable for a hydrocracking reaction of long chain alkane.

Owner:CHINA PETROLEUM & CHEM CORP +1

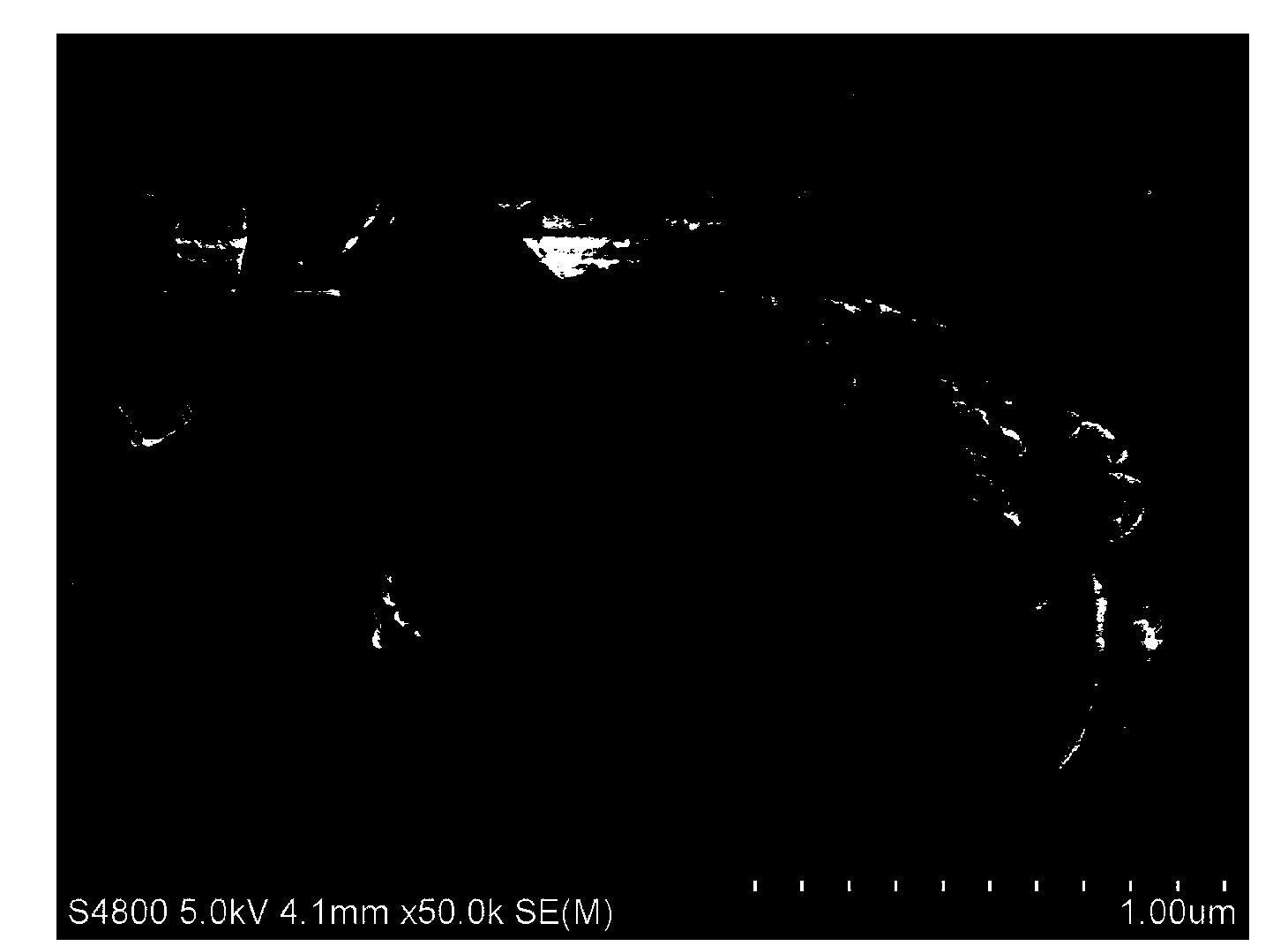

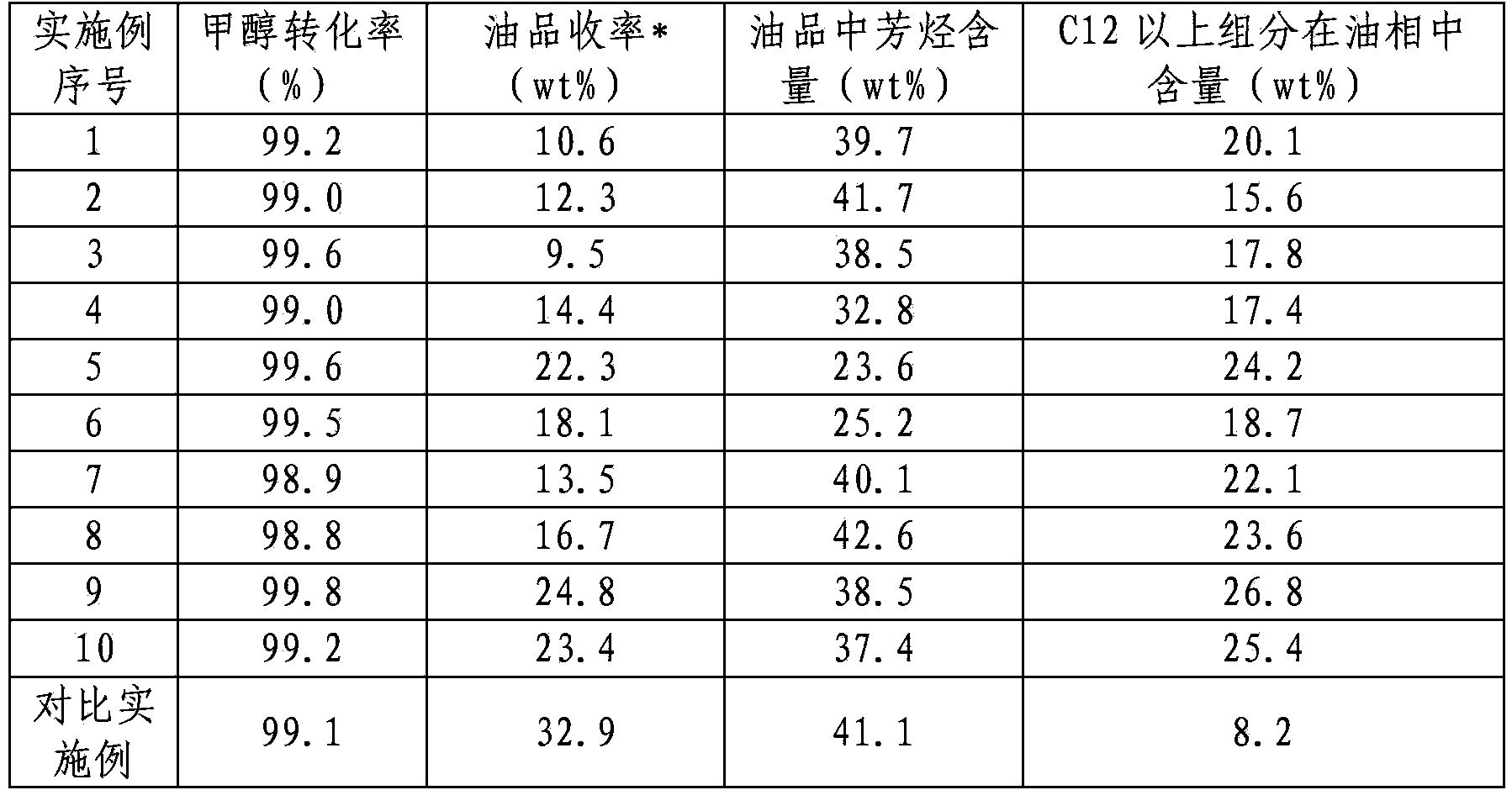

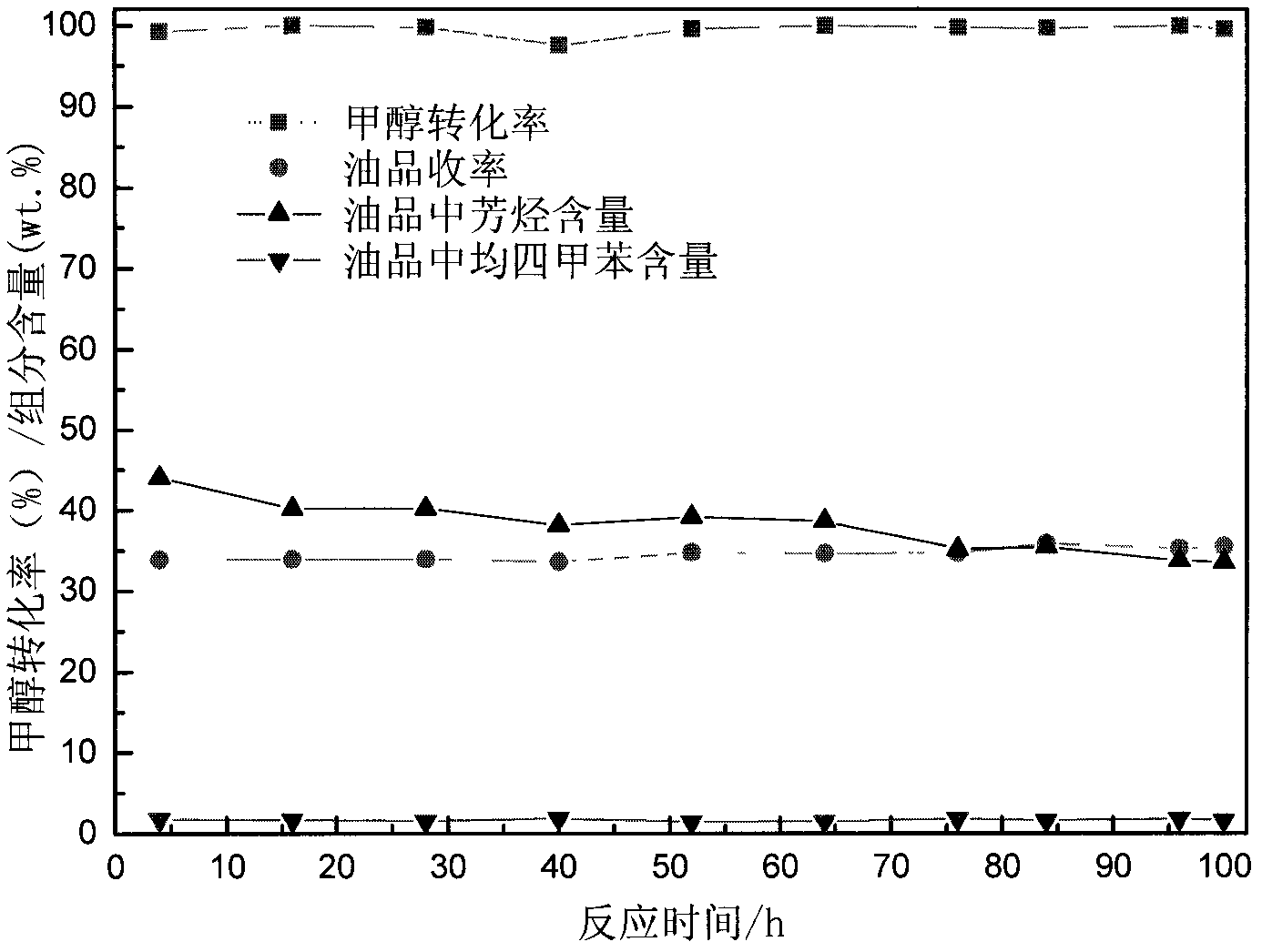

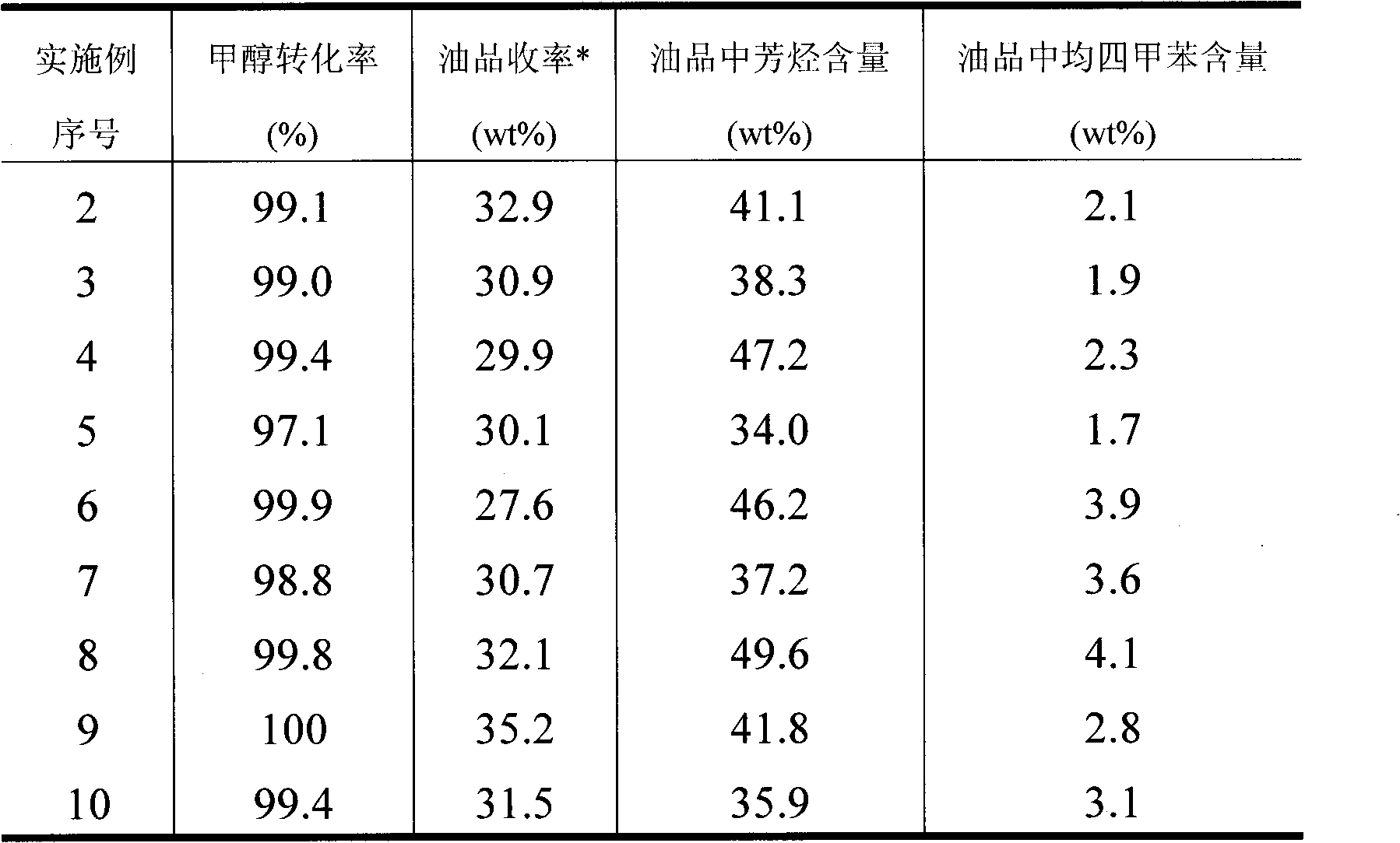

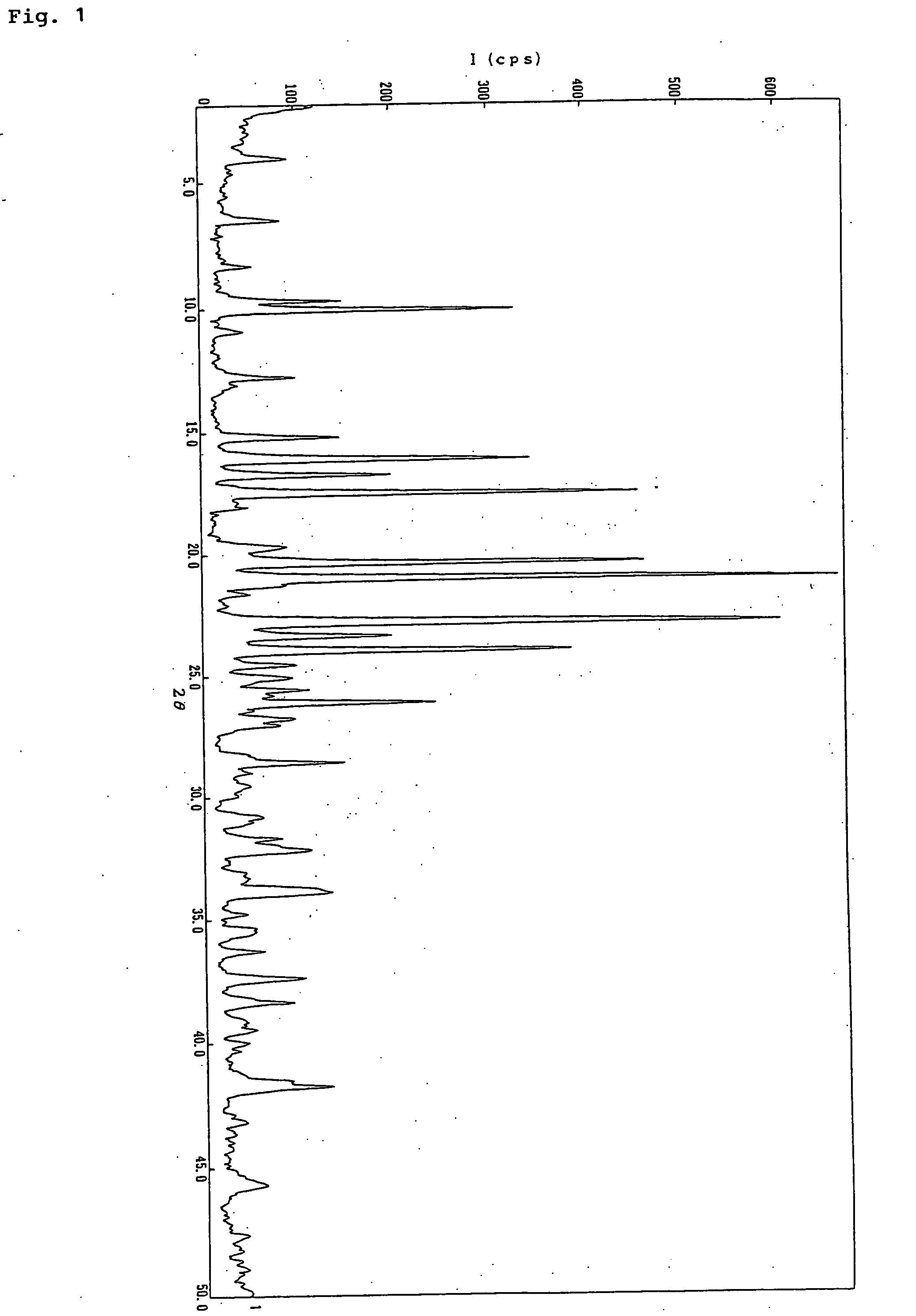

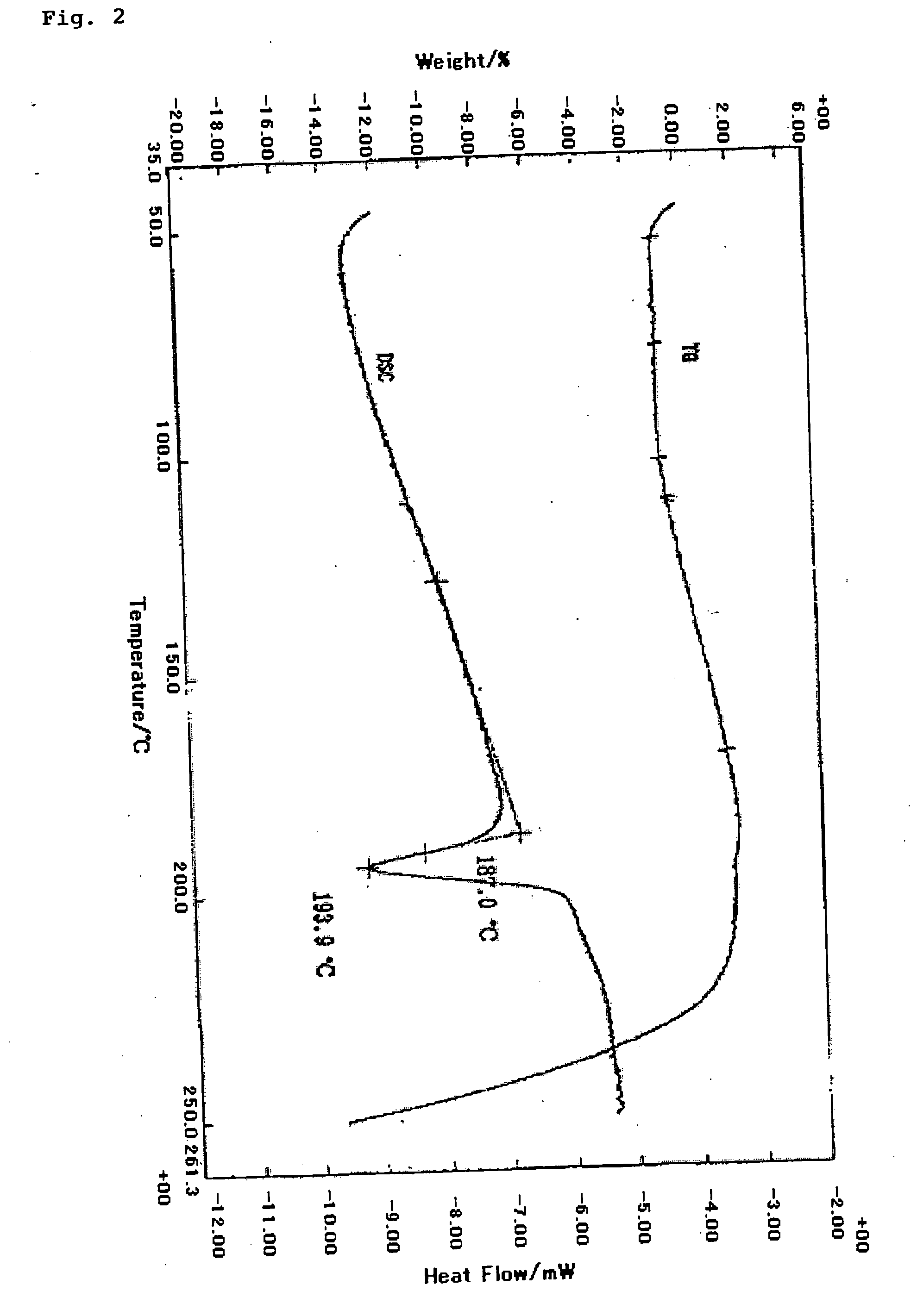

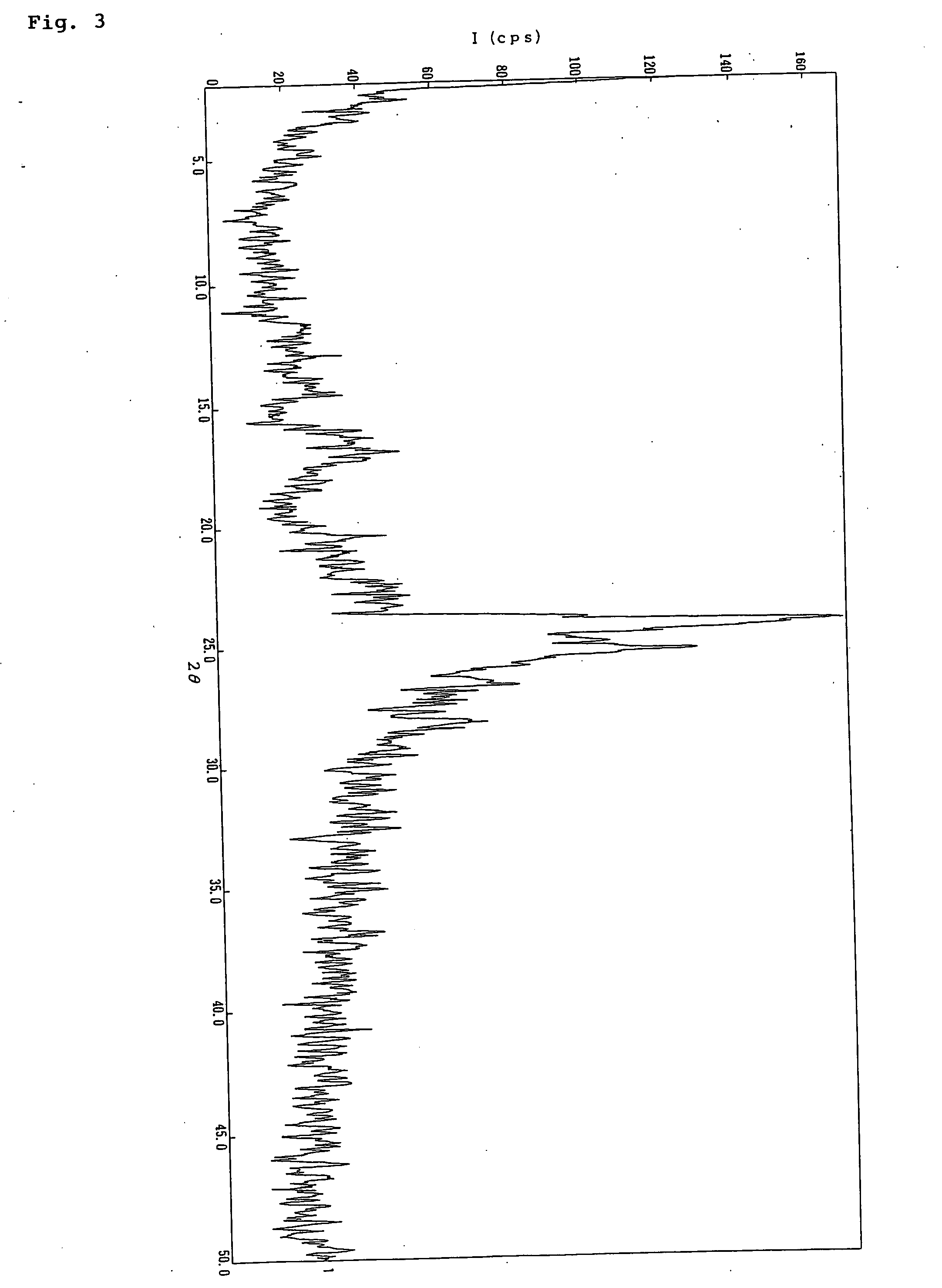

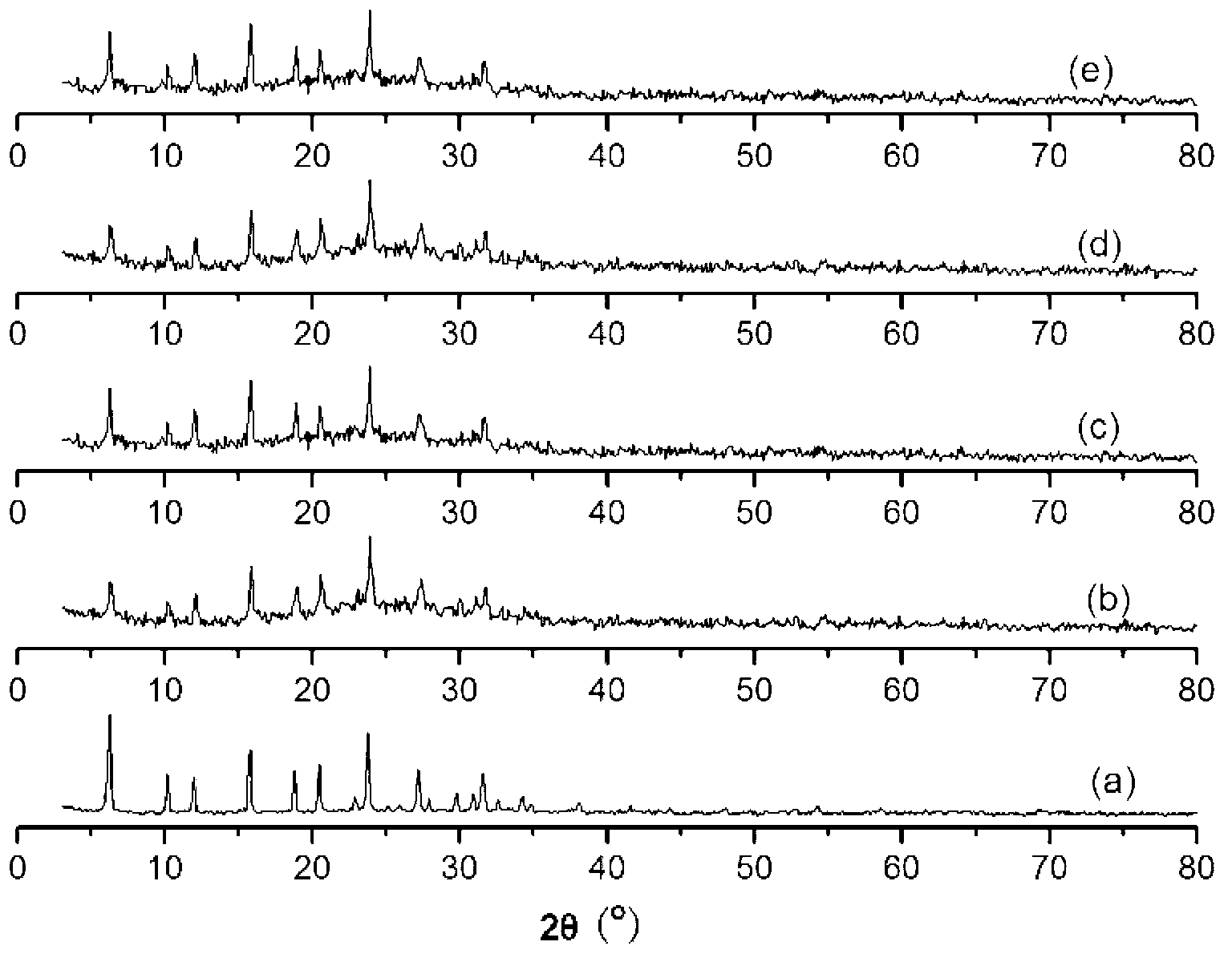

ZSM-5/MCM-48 composite molecular sieve, preparation method and application thereof

ActiveCN104043477AHigh selectivityLow aromatic contentMolecular sieve catalystsLiquid hydrocarbon mixture productionReaction temperatureGasoline

The invention relates to methanol-to-gasoline catalysts, in particular to a ZSM-5 / MCM-48 composite molecular sieve, a preparation method and application thereof. The composite molecular sieve adopts a ZSM-5 microporous molecular sieve as the seed crystal, on the surface of which a MCM-48 mesoporous structure composite molecular sieve that is chemically interlinked at a mesoporous and micropore interface is obtained by overgrowth. The composite molecular sieve undergoes acidification, and then is mixed with a binder to undergo molding and roasting, and the product is used as a catalyst for methanol-to-gasoline (MTG) reaction. The catalyst provided by the invention is used for overgrowth of the mesoporous molecular sieve on the microporous molecular sieve surface, integrates the advantages of the microporous material and the mesoporous material so as to develop the strong points and avoid the weak points and reach a synergistic effect. The catalyst shows good catalytic properties to the methanol-to-gasoline (MTG) reaction, has high selectivity to gasoline products and a low aromatic hydrocarbon content, and extends the carbon chain length. More importantly, the problems of high reaction temperature, high aromatic hydrocarbon content in oil products, and limitation of hydrocarbon compounds only to less than C11 in traditional MTG technologies are solved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

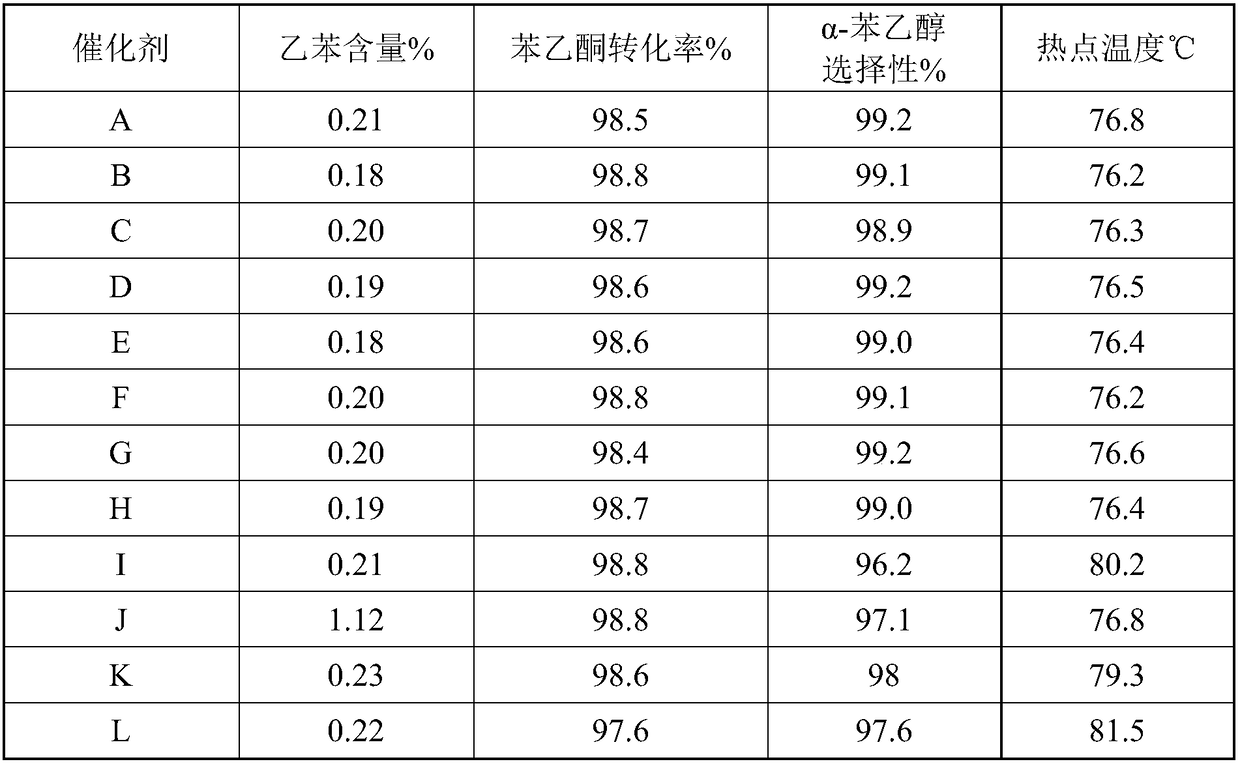

Method for preparing alpha-phenylethanol catalyst through hydrogenation of acetophenone and application

ActiveCN109482192AHigh activityAvoid filter effectsOrganic compound preparationHeterogenous catalyst chemical elementsPhenethyl alcoholSlurry

The invention relates to a method for preparing an alpha-phenylethanol catalyst through hydrogenation of acetophenone and application. The catalyst contains copper oxide, zinc oxide, silicon dioxide and bismuth oxide. The method of the catalyst is realized by virtue of a sub-step precipitation method and comprises the following steps: precipitating zinc salt and a precipitator at a certain temperature, and aging, so as to obtain slurry (1); adding a mixed solution of copper salt and bismuth salt as well as the precipitator into the slurry (1), carrying out coprecipitation, and aging, so as toobtain slurry (2); adding carrier silicon into the slurry (2), and uniformly stirring and mixing, so as to obtain slurry (3); filtering, washing, drying and roasting the slurry (3), so as to obtain catalyst powder; adding a certain amount of pore forming agents into the catalyst powder, and carrying out piece formation; and carrying out secondary roasting on the formed catalyst, so as to obtain the final catalyst. The catalyst prepared by virtue of the method is large in pore volume and aperture, good in mass transfer property and heat transfer property and high in activity and selectivity.

Owner:WANHUA CHEM GRP CO LTD

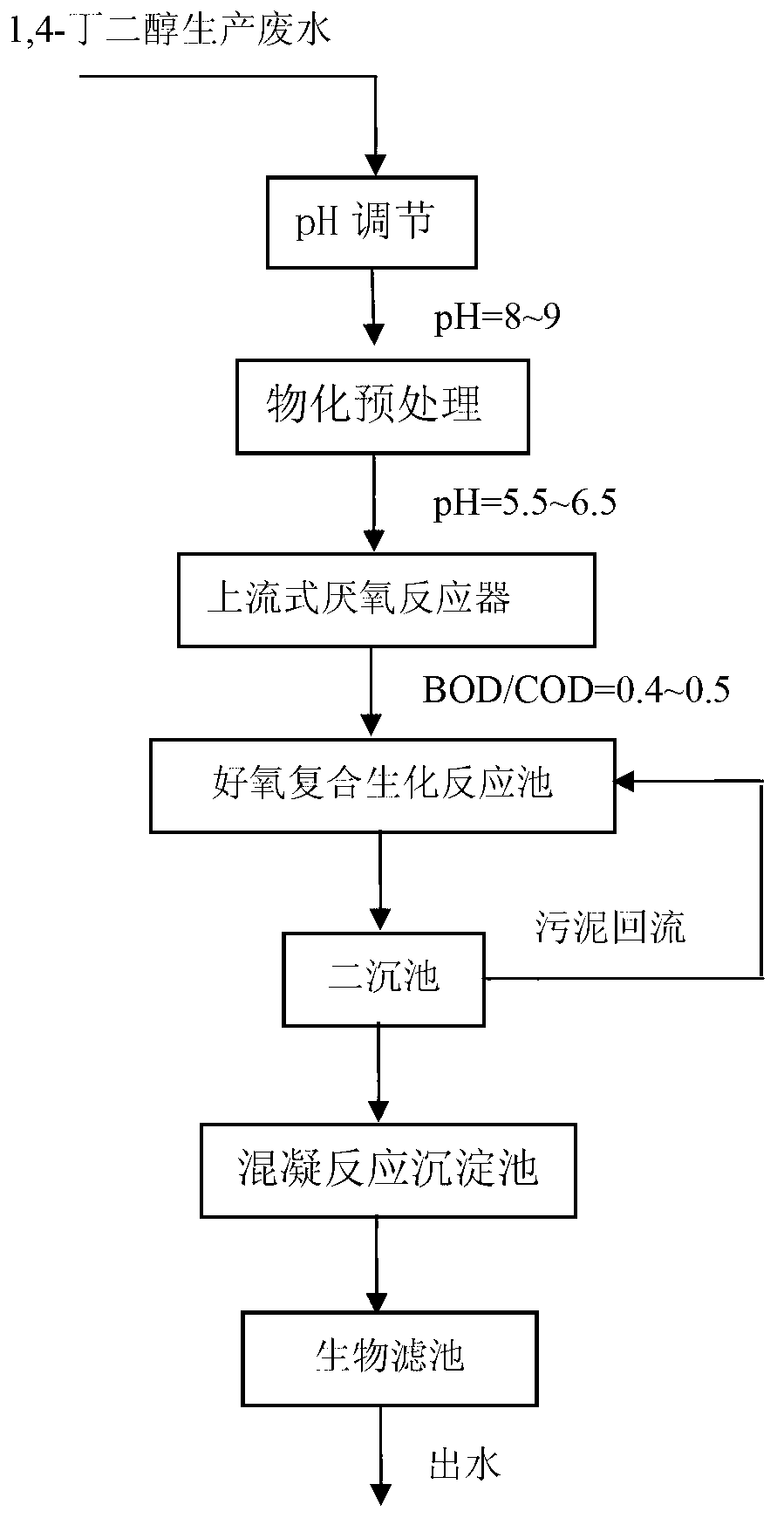

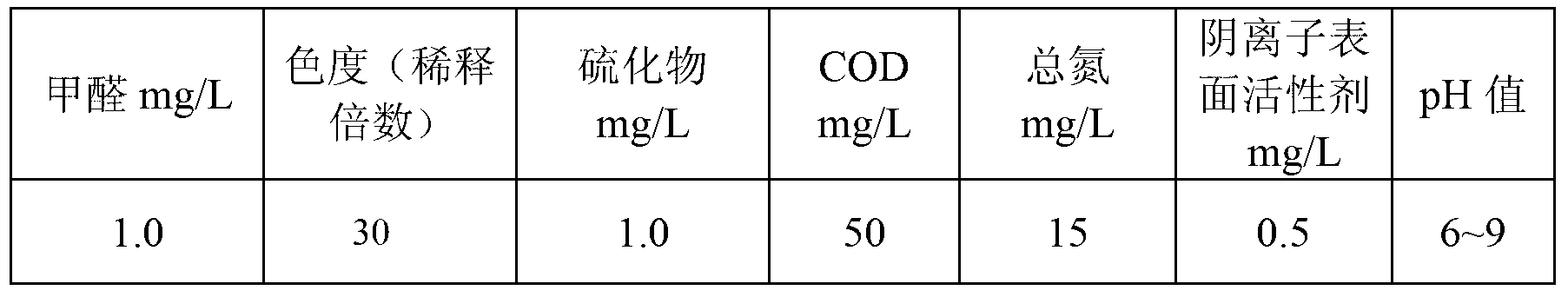

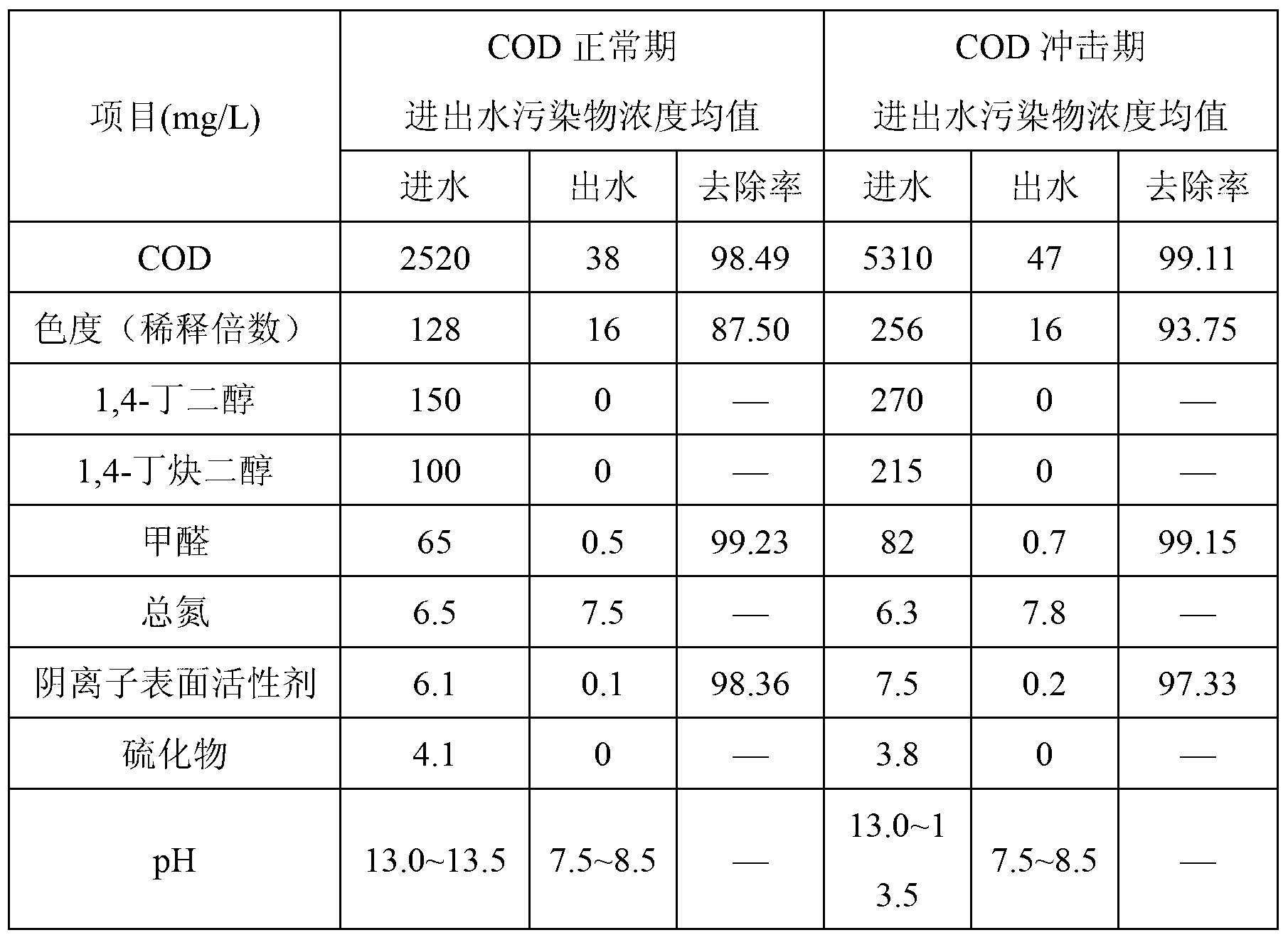

Combined treatment method of 1,4-butanediol production wastewater

InactiveCN103253827AReduce acidityWeak acidMultistage water/sewage treatmentNature of treatment waterHigh concentrationChemical oxygen demand

The invention relates to a combined treatment method of 1,4-butanediol production wastewater, which comprises the following steps: carrying out physical and chemical pretreatment on wastewater firstly so as to obtain pre-optimized wastewater; improving the biodegradability of the wastewater and further reducing the COD (chemical oxygen demand) concentration of the wastewater through an upflow anaerobic reactor and an aerobic combined biochemical reaction tank; and after the muddy water separation of the wastewater is realized through a secondary sedimentation tank, sequentially feeding the wastewater into a coagu-flocculation reaction settling pond and a biological filter, carrying out deep treatment on the wastewater, removing substances such as tiny suspended solids and colloids and the like in the wastewater through coagu-flocculation reaction and precipitation, and enabling discharged water to meet the requirements of one-class A standards in the Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB18918-2002) through the synergistic effect of adsorption and biodegradation of the biological filter. The method disclosed by the invention not only has a stable removal effect on COD in 1,4-butanediol production wastewater, but also can effectively resist violent water impacts; and the method has the characteristics of rapid system startup and the like. The method disclosed by the invention also can be applied to the treatment of other high-concentration toxic degradation-resistant organic wastewater with a water quality similar to that of 1,4-butanediol production wastewater.

Owner:TONGJI UNIV +1

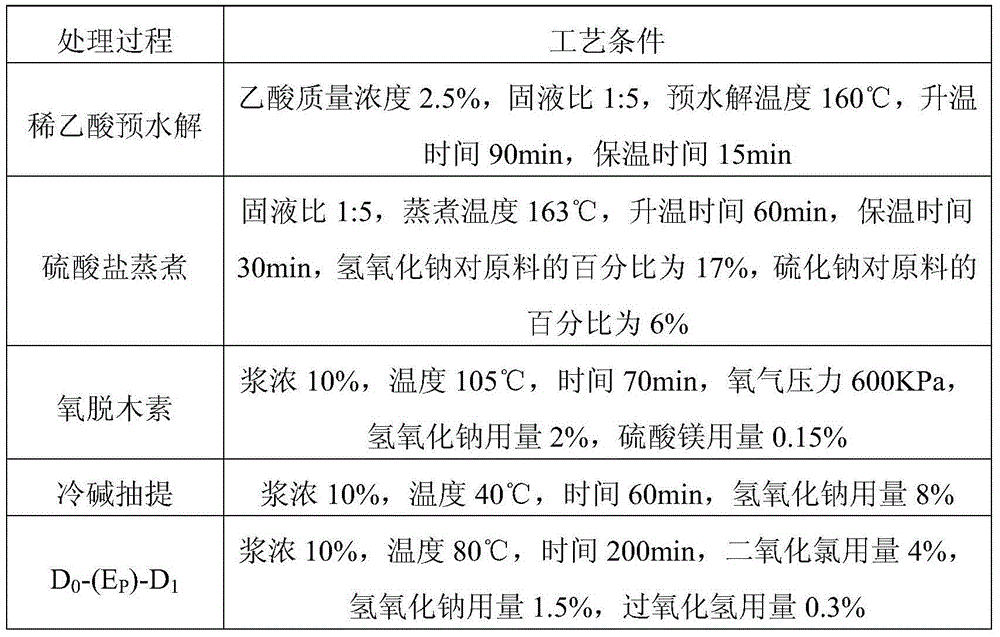

Preparation method of bamboo dissolving pulp

InactiveCN104153229AHigh yieldWeak acidPretreatment with acid reacting compoundsPulp bleachingAcetic acidSulfate

The invention discloses a preparation method of bamboo dissolving pulp. The preparation method disclosed by the invention comprises bamboos as the raw material and comprises the following steps: pre-hydrolyzing bamboo chips through diluted acetic acid, stewing the pre-hydrolyzed raw material with sulphate, processing pulp through oxygen delignification, extracting the pulp with cold caustic, bleaching with D0-(EP)-D1, and thus obtaining the bamboo dissolving pulp. The prepared bamboo dissolving pulp is more than 90% of ISO (International Standardization Organization) in whiteness, more than 92% in content of alpha-cellulose, 959 ml / g in intrinsic viscosity, 3.23% in content of pentosan, 0.11% in content of ash, and 38% in yield; compared with the yield of 30-35% in the common process currently, the yield of the bamboo dissolving pulp disclosed by the invention is at least increased by 3-8%, and therefore, the preparation method of the bamboo dissolving pulp disclosed by the invention has great economic benefit.

Owner:SOUTH CHINA UNIV OF TECH

Composite molecular sieve-based catalyst for methanol to gasoline and preparation method and application thereof

InactiveCN102861608AStrong mass transmission performanceLower Diffusion LimitsMolecular sieve catalystsLiquid hydrocarbon mixture productionIon exchangeGasoline

A composite molecular sieve-based catalyst for methanol to gasoline is prepared by the following method: (a) template and aluminium source are dissolved in deionized water and stirred until the deionized water is clear, silicon source and alkali source are then dripped in, and after crystallization under the hydrothermal conditions of self-generated pressure and crystallization temperature, ZSM-5 molecular sieve precursor is prepared; (b) the ZSM-5 molecular sieve precursor and the alkali solution of cetyl trimethyl ammonium bromide as template are mixed, and after crystallization under the hydrothermal conditions of self-generated pressure and crystallization temperature and roasting, ZSM-5 / MCM-48 composite molecular sieve is prepared; (c) the ZSM-5 / MCM-48 composite molecular sieve and acid solution are subjected to ion exchange and are roasted, so that acidic HZSM-5 / MCM-48 composite molecular sieve is prepared; (d) the HZSM-5 / MCM-48 composite molecular sieve and binder are uniformly mixed, kneaded with nitric acid solution with volume concentration less than 10 percent to shape and roasted, so that the catalyst is prepared. The invention also discloses the preparation method for the catalyst.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Acetophenone hydrogenation catalyst and preparation method thereof

ActiveCN109529870AIncrease the outer surface areaImprove active site utilizationOrganic compound preparationHeterogenous catalyst chemical elementsMicrospherePolymethyl methacrylate

The invention relates to an acetophenone hydrogenation catalyst and a preparation method thereof, which comprises the following steps: (1) hydrochloric acid, F127, KCl, 1,3,5-trimethylbenzene and polymethyl methacrylate microspheres are mixed evenly, then tetraethylorthosilicate is added to the mixture, and 4-12 hour later, a sol is obtained; (2) a mixed metal salt solution containing Cu, Mn, Bi and Pb is prepared, a solution of an alkaline precipitant is prepared, the two kinds of solutions are allowed to contact with the obtained sol for precipitation reaction, heating and aging to obtain aslurry; (3) the slurry is subjected to filtering, washing, drying and roasting to obtain composite compound powder; (4) the composite compound powder is mixed with a binder, an alkaline auxiliary agent and a forming auxiliary agent and extruded to obtain the catalyst. The catalyst active component copper prepared by the method has high dispersion, the acidity is weak and mass transfer performanceis good, side reactions such as hydrogenolysis and the like are effectively inhibited, and good activity and selectivity are obtained.

Owner:WANHUA CHEM GRP CO LTD +1

Halogen-free water-soluble flux with weak acidity and low corrosion

InactiveCN101992366ABroaden the field of applicationExpand scopeWelding/cutting media/materialsSoldering mediaOrganic acidHalogen

The invention discloses a halogen-free water-soluble flux with weak acidity and low corrosion, which comprises the following components in percentage by weight: 3 to 8 percent of organic acid and organic amine active agent, 0.5 to 2 percent of halogen-free surfactant, 1 to 15 percent of cosolvent, and the balance of deionized water. A preparation method comprises the following steps of: weighing the organic acid and organic amine active agent, the halogen-free surfactant and the cosolvent, putting the deionized water and the organic acid active agent into a stirring kettle, uniformly stirring, sequentially adding the cosolvent and the halogen-free surfactant in the stirring process, and uniformly stirring to obtain a finished product. Compared with the conventional water-soluble flux, the halogen-free water-soluble flux has the advantages that: 1, the flux has weak acidity and low corrosion, and small damage to welding equipment and appliances, improves production efficiency and reduces production cost; and 2, the flux does not contain halogens at all, so that a printed circuit board has high electric property, high reliability and long service life and meets the halogen-free requirement after being welded, and the application field and application range of the water-soluble flux are greatly expanded.

Owner:PERFECTION SCI & TECH DONGGUAN

Process for producing acid adduct salt of polyacidic base compound

InactiveUS20060079688A1Easy to prepareWeak acidOrganic active ingredientsOrganic chemistryPyridineAdduct

This invention relates to a method for preparing an acid addition salt of a polyacidic basic compound, or a water adduct having basic site(s) stronger than pyridine. The method comprises reacting the polyacidic basic compound with an acid salt of pyridine. By the present invention, the number of moles of an added acid in the acid addition salt of the polyacidic basic compound can be readily changed to a number suited for the polyacidic basic compound as needed.

Owner:KOWA CO LTD

Rust remover and preparation method thereof

The invention discloses a rust remover and a preparation method thereof. The rust remover is prepared from the following components in percentage by mass: 60 to 80 percent of organic acid, 19 to 39 percent of inorganic acid and 0.8 to 3 percent of corrosion inhibitor, wherein the organic acid is one or more than two kinds of tartaric acid, citric acid, oxalic acid and trichloroacetic acid; the inorganic acid is one or more than two kinds of sulfamic acid, phosphorous acid and ammonium acid fluoride; and the corrosion inhibitor is benzotrizaole or / and sodium dihydrogen phosphate. According to the rust remover disclosed by the invention, the use of hydrochloric acid or sulfuric acid is completely avoided; no acid mist during rust removal is generated, the corrosion to equipment in a workshop is avoided and the labor environment is improved; meanwhile, the corrosion inhibitor is weaker in acidity, the over corrosion to workpieces is avoided and the condition that the skin of an operator is severely corroded is prevented; in addition, after a certain amount of workpieces are treated, the rust removing efficiency is reduced; and by continuously adding the rust remover disclosed by the invention, the rust removing efficiency can be restored, i.e., a rust removing bath solution disclosed by the invention can be conveniently and repeatedly used.

Owner:ZHONGSHAN HUAGUANG CHEM

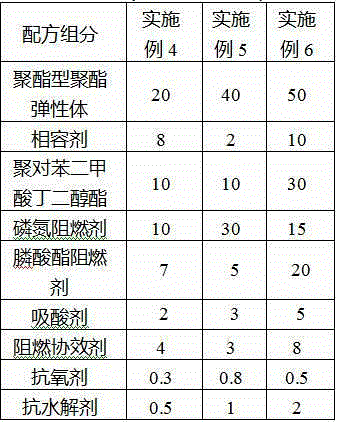

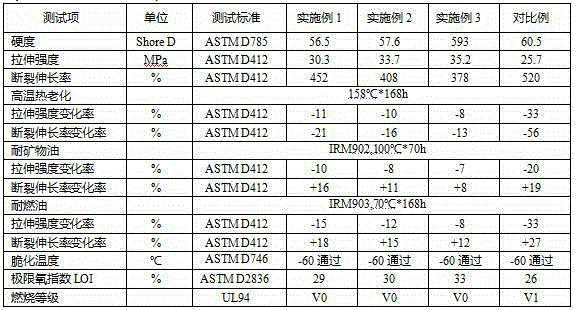

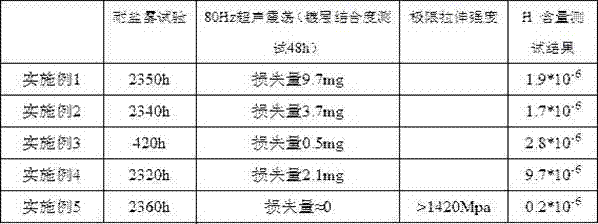

Halogen-free flame-retardant high-temperature-resistant polyester elastomers and a preparation method therefor

ActiveCN105400179AImprove heat resistanceImprove flame retardant performanceElastomerPolytetramethylene terephthalate

Provided are halogen-free flame-retardant high-temperature-resistant polyester elastomers and a preparation method therefor. The provided polyester elastomers comprise the following raw materials, by weight, 20-50 parts of polyester elastomers, 10-30 parts of polybutylene terephthalate, 2-10 parts of compatilizer, 10-30 parts of phosphor-nitrogen flame retardant, 5-20 parts of phosphonate flame retardant, 2-5 parts of acid absorbing agent, 3-8 parts of flame retardation synergistic agent, 0.3-0.8 part of anti-oxidant and 0.5-2 parts of anti-hydrolysis agent. The preparation method is as follows: polyester elastomers and polybutylene terephthalate are subjected to drying processing, and are mixed with other ingredients uniformly in a high-speed mixing machine; discharging is carried out, the mixture is subjected to bar drawing and granulation by a double screw extruder, and halogen-free flame-retardant high-temperature-resistant polyester elastomers are prepared. The defects of the prior art are overcome, on the premise that present device configuration and technological parameter setting are not changed, an optimal solution is provided that halogen-free flame-retardant high-temperature-resistant polyester elastomers can be produced stably, the high temperature resistance of the material is improved obviously, the flame resistance is raised greatly, and other performances are optimized.

Owner:中广核三角洲(江苏)塑化有限公司

Waste hydrogenation catalyst utilization method

ActiveCN106944137AIncrease profitImprove pore structureOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsHeteropoly acidFurfural

The present invention discloses a waste hydrogenation catalyst utilization method, which comprises: grinding a waste hydrogenation catalyst, soaking with ammonia water, adding alumina, a binder and an acid solution to the remaining solid, and carrying out mixing kneading molding; carrying out reducing treatment with hydrogen gas in a high pressure reaction kettle; adding a polyol and / or furfural solution to the high pressure reaction kettle, and carrying out a hydrogenation reaction; and drying the material obtained after the reaction until the surface is liquid-free, sequentially contacting an organic acid, ammonium or ammonia, and loading a heteropoly acid to produce the catalyst for ethylene preparation through ethanol dehydration. According to the present invention, with the method, the hydrogenation activity metal component and the carrier component in the waste hydrogenation catalyst are utilized, and the hydrogenation activity of the waste hydrogenation catalyst is completely utilized, such that the utilization rate of the waste catalyst is improved, the pollution problem of the waste catalyst is solved, and the obtained catalyst for ethylene preparation through ethanol dehydration has the excellent performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for electroplating high-strength corrosion-proof cadmium-tin-titanium alloy on 304 or 316 L stainless steel surface

The invention provides a method for electroplating a protective plating layer of high-strength corrosion-proof cadmium-tin-titanium alloy on a 304 or 316 L stainless steel surface. The corrosion resistance of a plating layer is 6 to 7 times higher than that of a cadmium-plated layer, and the plating layer is uniform and fine and can be matched with cadmium-plated cyanide; after surface pre-treatment and in advanced cadmium-plating, the binding force of a cadmium-tin-titanium alloy plating layer is far more than that of the same kind of cadmium-tin plated alloy and the cadmium-plated layer; the cadmium-tin-titanium plating layer is porous, so that the hydrogen is beneficial for escaping; the cadmium-tin-titanium plating layer has good paintability, weldability, formability and low-hydrogen embrittlement; the whole preparation process is simple, cyanogen-free electroplating is achieved, and the preparation process is safe and environmentally-friendly.

Owner:无锡市恒利弘实业有限公司

Hydrocracking catalyst and preparation method therefor

ActiveCN107297224AHigh catalytic activityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingHeteropoly acidLiquid hydrocarbons

The invention discloses a hydrocracking catalyst and a preparation method therefor. The hydrocracking catalyst comprises an acidic component, hydrogenation metal components and a carrier, wherein the acidic component is an ammonium salt of heteropoly acid, the hydrogenation metal components comprise Mo and Ni, P serves as an assistant, and silicon oxide serves as the carrier. The invention further provides the preparation method for the hydrocracking catalyst. When the catalyst prepared by the method disclosed by the invention is applied to a hydrocracking reaction of long-chain alkanes, relatively high reaction activity and liquid hydrocarbon selectivity are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fischer-Tropsch synthesis wax hydrocracking catalyst, preparation method thereof, and Fischer-Tropsch synthesis wax hydrocracking method

PendingCN110433819AGood dispersionAvoid secondary crackingHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsWaxSorbent

The invention belongs to the field of Fischer-Tropsch synthesis catalytic hydrocracking, and discloses a Fischer-Tropsch synthesis wax hydrocracking catalyst, a preparation method thereof, and a Fischer-Tropsch synthesis wax hydrocracking method. The preparation method of the Fischer-Tropsch synthesis wax hydrocracking catalyst comprises following steps: 1, amorphous silicon aluminium and a binderare subjected to mixing kneading, strip extrusion moulding, primary drying, and primary roasting to obtain a catalyst carrier; and 2, the catalyst carrier is immersed in a dipping solution containinghydrogenation active metal elements and a competitive adsorbent, and secondary drying and secondary roasting are carried out to obtain the Fischer-Tropsch synthesis wax hydrocracking catalyst, wherein the hydrogenation active metal elements contain at least one metal element selected from VIII family in the periodic table of elements, and at least one metal element selected from VIB family in theperiodic table of elements at the same time, and the volume amount of the dipping solution containing hydrogenation active metal elements accounts for 65 to 85% of the pile volume of the catalyst carrier. The hydrogenation active metal components of the catalyst are excellent in dispersibility, and intermediate fraction oil selectivity is high.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

One-stage hydrogenation method for producing food-level white oil

ActiveCN101148606AHigh activityHigh selectivityTreatment with hydrotreatment processesEdible oils/fatsLiquid productMolecular sieve

The present invention provides one-section hydrogenation process for producing food level white oil. By using vacuum gas oil, deasphalted solvent oil and Fischer-Tropsch process oil as material, and hydrogenating catalyst containing modified beta-molecular sieve in 1-9 wt%, and through hydrocracking or hydrogenating, hot high pressure separating out gas and light distillate to obtain liquid product, mixing with newly formed hydrogen, and high pressure hydro-finishing in a reactor with loaded reduction type hydrogenating catalyst, food level white oil is produced. The process is simple and has high product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

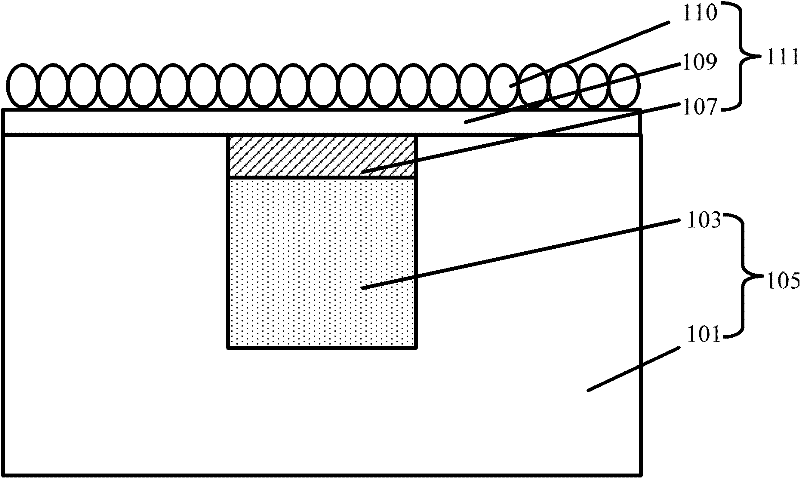

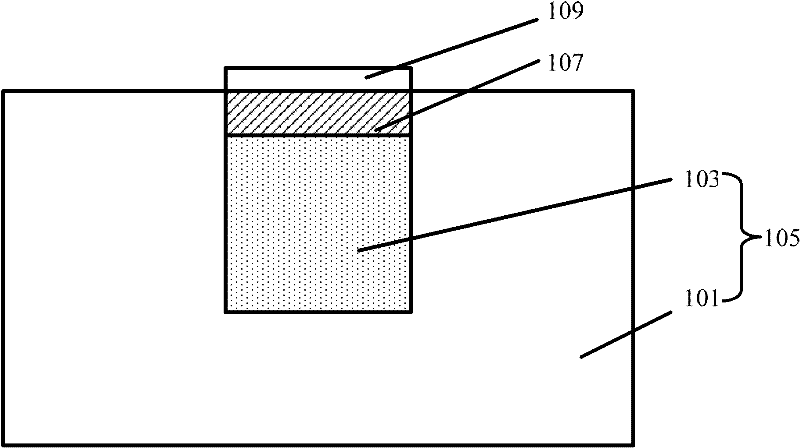

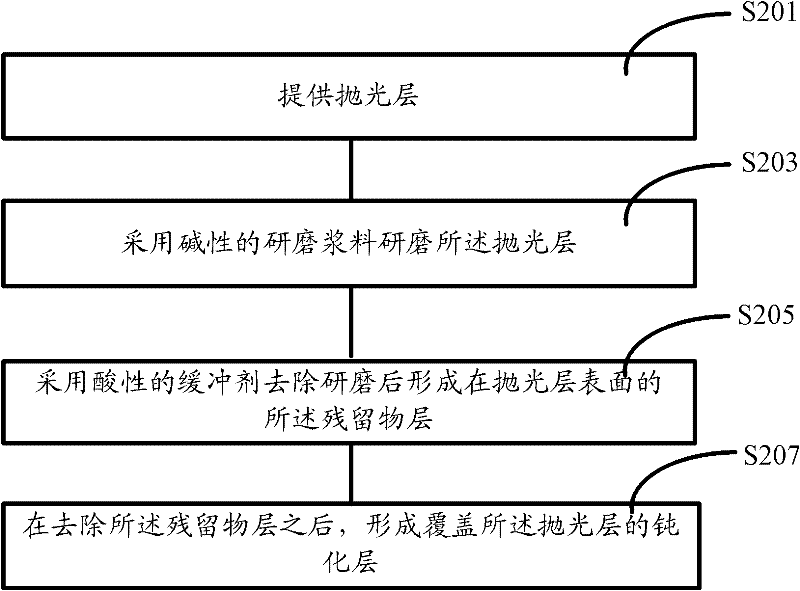

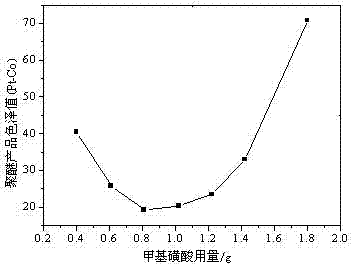

Chemical mechanical polishing method

ActiveCN102689265AEasy to removeImprove solubilitySemiconductor/solid-state device manufacturingLapping machinesMetallurgyCompound (substance)

Provided is a chemical mechanical polishing method, comprising: providing a polishing layer; adopting alkaline polishing slurry to polish the polishing layer; adopting an acidic buffering agent to remove a residual layer formed on a surface of the polishing layer after the polishing; and after the removal of the residual layer, forming a passivation layer that covers the polishing layer. With the chemical mechanical polishing method in an embodiment of the invention, flatness degree of the surface of the polishing layer is high, yield of semiconductor devices is high, and long-term stability of semiconductor devices is good.

Owner:SEMICON MFG INT (SHANGHAI) CORP

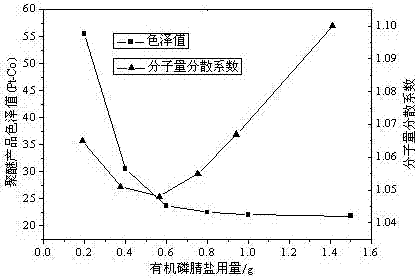

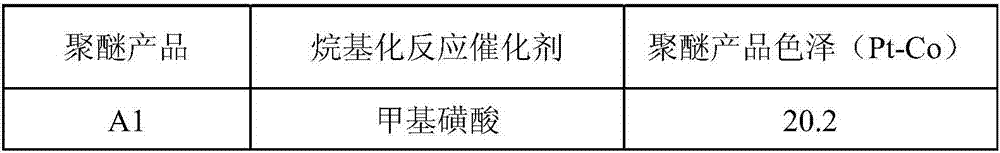

Styrylphenol polyoxyethylene ether and preparation method thereof

The invention relates to styrylphenol polyoxyethylene ether and a preparation method thereof, and belongs to the technical field of carbocyclic compounds. The method includes three steps of phenol alkylation reaction, ethylene oxide addition polymerization, polyether aftertreatment; to be more specific, feeding nitrogen in phenol and alkylation catalyst for heating up 80-100 DEG C, and dropwise adding styrene prior to heat reaction till the refractive index of the product reaches 1.5985-1.6020; heating up to 100-110 DEG C, performing vacuum dehydration prior to cooling and adding polymerization catalyst, heating to 80-120 DEG C under the atmosphere of nitrogen, and adding ethylene oxide for complete reaction at the temperature of 80-120 DEG C under the pressure of 0.01-0.04MPa; adding deionized water prior to heating to 60-70 DEG C, adding phosphoric acid and adsorbent with stirring prior to vacuum dehydration, and performing filtering to obtain the finished product. The preparation method can be applied to preparation of nonionic surfactants such as styrylphenol polyoxyethylene ether, and the product has the advantages of narrow distribution, light color, low content of K + / Na + ions and the like.

Owner:ZHEJIANG HUANGMA TECH

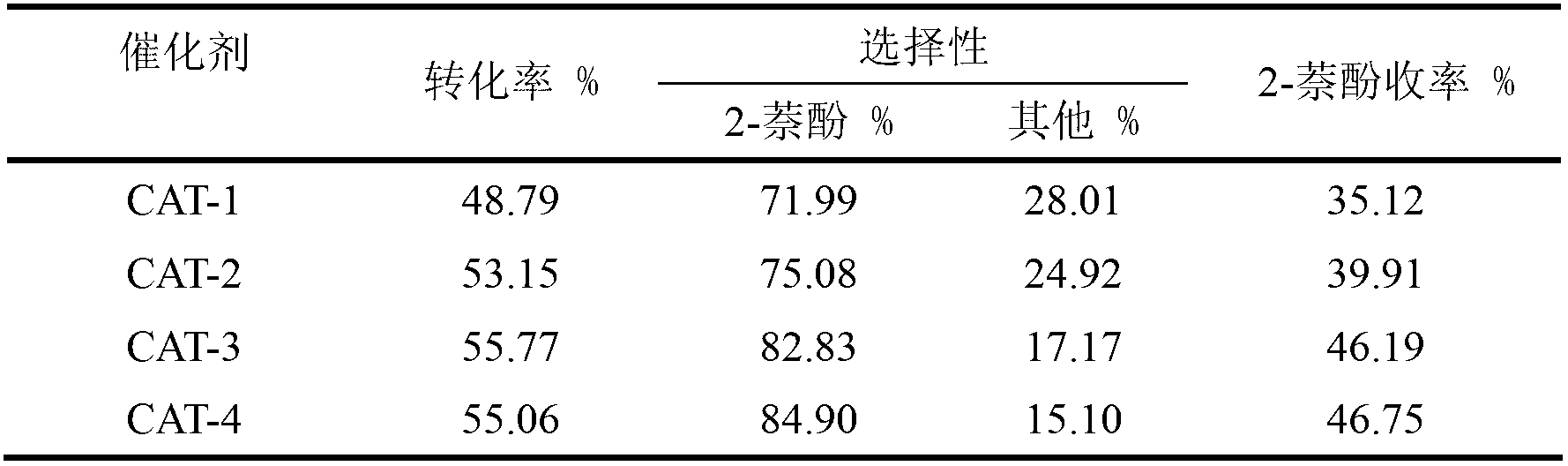

Preparation method for supported solid-acid catalyst for synthesising 2-isonaphthol via one-step hydroxylation of naphthalene

InactiveCN103055918AReduce acidityWeak catalytic activityOrganic chemistryMolecular sieve catalystsAirflowNaphthalene

The invention discloses a preparation method for a supported solid-acid catalyst for synthesising 2-isonaphthol via the one-step hydroxylation of naphthalene, belonging to the technical field of supported solid-acid catalysts, wherein via the technical scheme of soaking a supporter in a solution containing an auxiliary constituent precursor in a vacuum condition, vibrating and drying in a low-temperature water bath, and calcining for 1-3 hours at 400-600 DEG C at first, and then soaking the calcined powder in the solution containing an auxiliary constituent precursor in a vacuum condition, vibrating and drying in the low-temperature water bath, and baking in an airflow at 110-300 DEG C, a solid-acid catalyst which is adjustable in surface acidity and high in the dispersibility of active constituents is prepared. With the adoption of the method, the various problems existing in the prior art are effectively solved, the conversion rate of naphthalene and the selectivity of 2-isonaphthol are greatly increased, and good effects are obtained.

Owner:天津市中云慧德科技有限公司 +1

Method for extracting persimmon leaf tartaric acid by combining microwave-assisted extraction and membrane separation

InactiveCN102846518AEasy to recycleReduce extraction timeCosmetic preparationsToilet preparationsSeparation technologyBULK ACTIVE INGREDIENT

The invention relates to a method for extracting persimmon leaf tartaric acid which is an active ingredient in a persimmon leaf by the coupling technique of microwave-assisted extraction and membrane separation. The method comprises the following steps of: after the dried persimmon leaf is smashed, adding ethanol, and extracting at constant pressure and under the microwave environment; removing organic acid substances, such as chlorophyll, tannin, resin, reducing sugar and polysaccharide by the membrane separation technology; after the mixture is condensed, successively adding alkali and acid to process; and finally recrystallizing to obtain the persimmon leaf tartaric acid. The raw material adopted by the method disclosed by the invention is the natural persimmon leaf, no three wastes are generated, and the technology is simple and environment friendly. The method has the advantages of short extraction time, high yield, small impurity content and stable quality, and the obtained product persimmon leaf tartaric acid achieves the requirement for serving as the raw material of cosmetics, and the economic benefit is obvious.

Owner:NANNING JIAOYANG PHARM

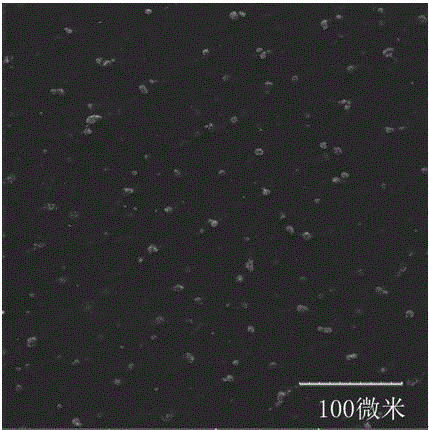

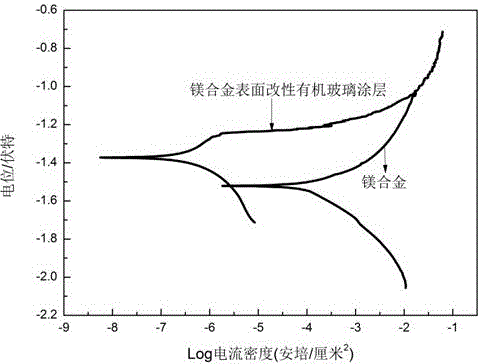

Method for preparing modified polymethyl methacrylate anticorrosive coating on magnesium alloy surface

InactiveCN105862014AImprove corrosion resistanceImprove bindingLiquid/solution decomposition chemical coatingWater bathsN dimethylformamide

The invention discloses a method for preparing a modified polymethyl methacrylate anticorrosive coating on a magnesium alloy surface. The method comprises the steps of treating the magnesium alloy surface; mixing a tetraethyl orthosilicate solution with a gamma-methacryloxy propyl trimethoxyl silane solution, adding a catalyst, and heating to form sol; adding an ethanol solution in which zirconium oxychloride is dissolved into the sol, continuously heating, dropwise adding a sodium hydroxide alkaline solution, and controlling the reaction rate to form SiO2-ZrO2 hybrid sol; adding methyl methacrylate in which AIBN is dissolved, N-N-dimethylformamide and a cerous nitrate aqueous solution, and heating in the water bath environment to prepare modified PMMA-SiO2-ZrO2 hybrid sol; and smearing the PMMA-SiO2-ZrO2 hybrid sol on the surface of a magnesium alloy surface base material through rotation, drying, keeping the temperature, and cooling to prepare the modified polymethyl methacrylate anticorrosive coating on the magnesium alloy surface. According to the method, different catalysts and chemical additives are added, so that the corrosion resistance of a sol gel film on the magnesium alloy surface is improved.

Owner:TAIYUAN UNIV OF TECH

Method for hydrogenating naphthenic base distillate to produce lubricating oil basic oil

ActiveCN102311785BImprove comprehensive hydroprocessing capacityImprove stabilityTreatment with hydrotreatment processesLubricant compositionHydrogenation processBase oil

The invention relates to a method for hydrogenating naphthenic base distillate to produce lubricating oil basic oil. The naphthenic distillate is used as raw material and a one-stage in series hydrogenation process of hydrotreating-hydrodewaxing-hydrofinishing is adopted to produce the lubricating oil basic oil. Ordinary hydrotreating catalysts are filled in the upper part of a hydrotreating reaction area, and hydrotreating catalysts containing modified zeolites are filled in the lower part of the hydrotreating reaction area. The hydrodewaxing and hydrofinishing reaction areas are the same as those of the prior art, and are filled with hydrodewaxing catalysts and hydrofinishing catalysts. Compared with the prior art, the method disclosed by the invention has the advantages that system energy consumption is reduced, the pour point of a product is properly reduced, and the stability of the product is effectively improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

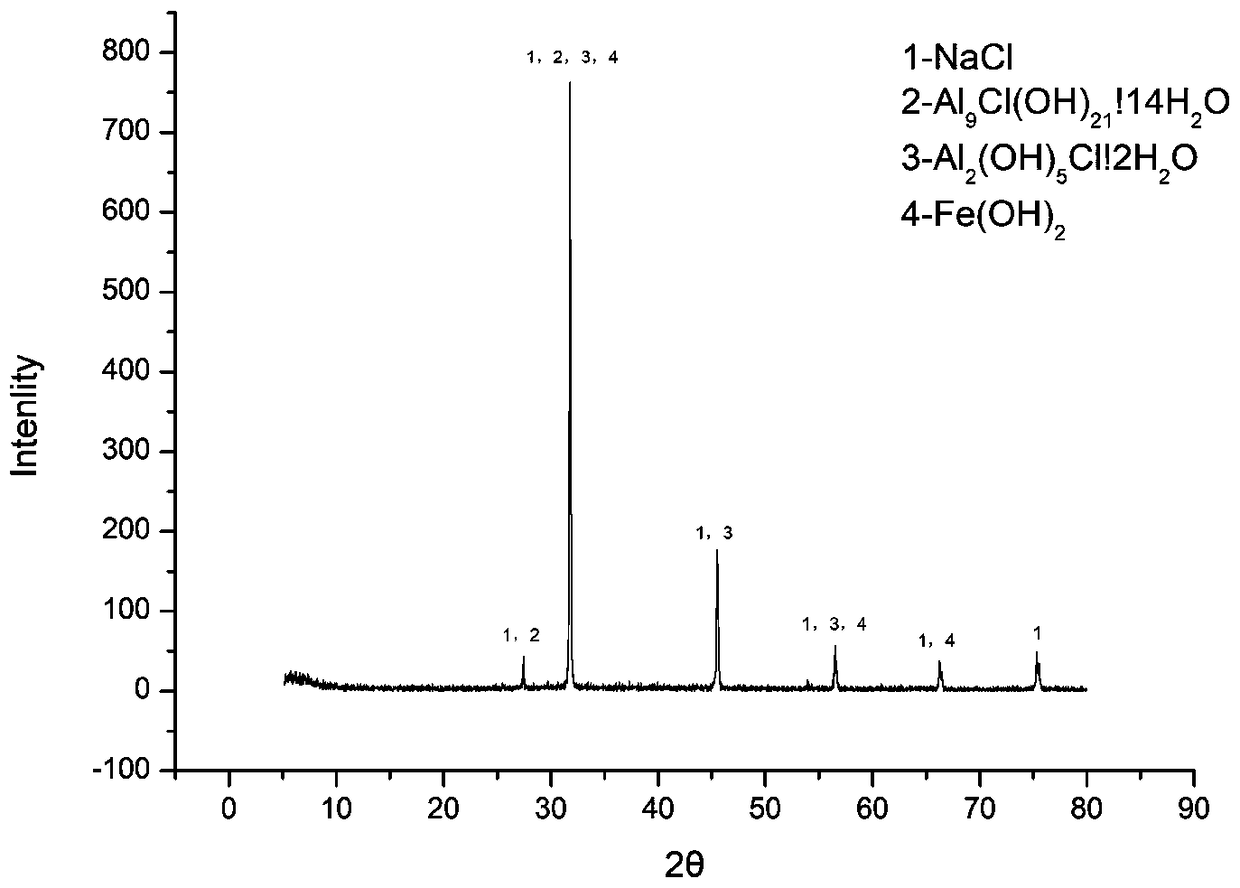

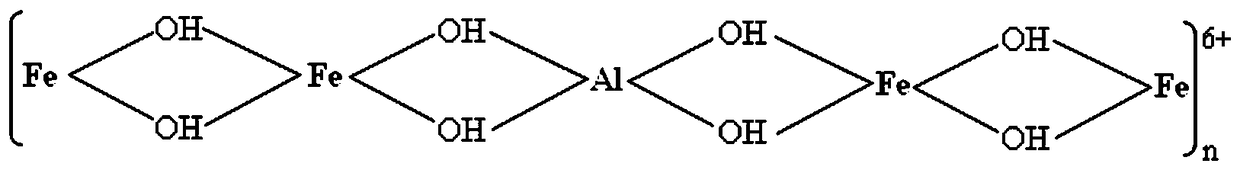

Method for preparing aluminum-iron flocculant by red mud

ActiveCN109336236AStrong sourEfficient leachingIron compoundsWater/sewage treatment by flocculation/precipitationRed mudPhytic acid

The invention discloses a method for preparing an aluminum-iron flocculant by red mud. According to the method, red mud is firstly washed to obtain washing liquid and a washing residue, the washing residue is mixed and stirred with a mixed leaching solvent of citric acid, tannic acid and malic acid at a mass ratio of 1: 3-7, a reaction temperature of 80-100 DEG C and a stirring intensity of 250-400r / min for 30-90min, after the end of the stirring, solid-liquid separation is carried out to obtain a titanium-rich material and acid leaching solution, the washing liquid is utilized to adjust the pH value of the acid leaching liquid to 7-9, a mixed polymeric medicament of triglycollamic acid and phytic acid in a liquid-solid mass ratio of 5-10: 1 is added for stirring and dissolution, after thestirring is completed, the mixture is aged at 50-80 DEG C for 5 to 10 hours, standing and ageing are carried out at room temperature for 24 to 48 hours, the aged upper liquid is discharged to obtaina milky polymeric aluminum-iron flocculant, and finally drying is carried out at 100-110 DEG C for 8 to 16 hours to obtain the aluminum-iron flocculant product with less than 0.2% of water-soluble impurities.

Owner:HENAN POLYTECHNIC UNIV

Heteropolyacid ammonium salt catalyst and preparation method thereof

ActiveCN106944152AIncrease acidityLarge specific surface areaMolecular sieve catalystsMolecular sieve catalystHigh selectivityEthanol

The present invention discloses a heteropolyacid ammonium salt catalyst and a preparation method thereof. The catalyst comprises an active component, auxiliary agents and a carrier, wherein the active component is a heteropolyacid ammonium salt, the auxiliary agents are nickel, phosphorus and vanadium, the carrier is an amorphous silicon-aluminum coated molecular sieve, the auxiliary agents comprise (calculated as the oxide) 3.0-10.0% of P2O5, 0.2-4.0% of V2O5 and 8-20% of NiO by adopting the weight of the carrier as the reference, the heteropolyacid ammonium salt content is 8-30% by adopting the weight of the catalyst as the reference, and the total content of the auxiliary agents and the carrier is 70-92% (calculated as the oxide). According to the present invention, the catalyst has advantages of high low-temperature activity, high selectivity, high carbon deposition resistance and improved stability, and is particularly suitable for the ethylene preparation reaction through dehydration by using the low-concentration ethanol aqueous solution as the raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation catalyst and preparation method and application thereof

ActiveCN111715238AUnobstructed channelWeak acidOrganic compound preparationHeterogenous catalyst chemical elementsAlkaline earth metalPtru catalyst

The invention discloses a catalyst for preparing trimethylolpropane through hydrogenation of 2,2-dimethylolbutyraldehyde and a preparation method of the catalyst. The catalyst comprises 35 to 70 wt% of copper oxide, 5 to 25 wt% of zinc oxide, 5 to 35 wt% of aluminum oxide, 10 to 30 wt% of silicon dioxide, 0.5 to 5 wt% of alkaline earth metal oxide, 0.05 to 1.0 wt% of palladium oxide, 0.01 to 1.0 wt% of iridium oxide and 0.01 to 1.0 wt% of tin oxide. When the catalyst is used for preparing trimethylolpropane by a hydrogenation method, the catalyst not only has good activity and selectivity, butalso has strong formate conversion capability and high mechanical stability.

Owner:WANHUA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com