Method for preparing modified polymethyl methacrylate anticorrosive coating on magnesium alloy surface

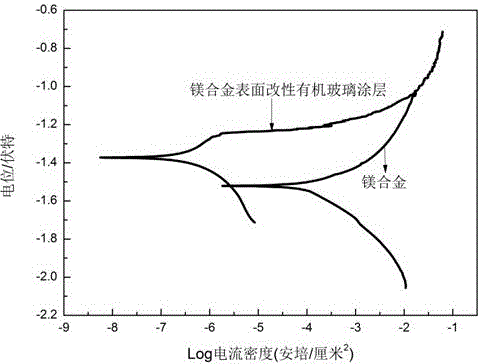

A plexiglass and surface modification technology, which is applied in metal material coating technology, coating, liquid chemical plating, etc., can solve the problem of unsustainable protection, poor protection effect of a single film layer, and excessive particle size of sol agglomeration and other issues to achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

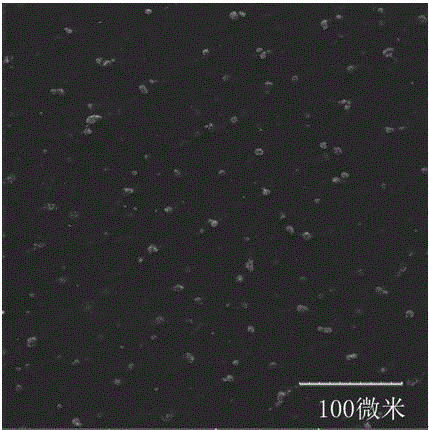

Image

Examples

Embodiment 1

[0034] (1) Use 360#, 600#, 800#, 1000#, 1200#, 1500#, 2000# sandpaper to polish in sequence until the surface of AZ91D magnesium alloy is bright. After mechanical polishing, wash it with running water, dry it with cold wind, deionized water, Acetone was used to ultrasonically remove surface impurities in sequence, and then ultrasonically cleaned in a NaOH solution with a pH of 10 in a water bath at 50°C for 10 minutes, and dried with cold air for later use.

[0035] (2) Weigh 5g of tetraethyl orthosilicate and 2.98g of KH-570 and mix evenly, add 1mL of dilute hydrochloric acid with a mass fraction of 5% to catalyze, 45 。 Heating at C for 2h, forming viscous liquid A, namely SiO 2 Sol.

[0036] (3) Fully dissolve 1.68g of zirconium oxychloride in 10mL of ethanol solution, add the above mixed solution A, continue to heat, add about 1mL of 5% NaOH lye solution dropwise in the middle to control the reaction hydrolysis polycondensation rate, and form SiO 2 -ZrO 2 hybrid sol.

...

Embodiment 2

[0040] (1) Grind the magnesium alloy with sandpaper, and mechanically polish it to a mirror surface, wash it with deionized water and acetone in sequence, and then ultrasonically wash it in NaOH solution with a pH value of 9 at 50°C for 5 minutes, and then ultrasonically wash it in deionized water for 3 minutes. Blow dry with cold air.

[0041] (2) Weigh 7g of tetraethyl orthosilicate solution and 4g of γ-methacryloxypropyltrimethoxysilane solution and mix evenly, and add 2mL of dilute hydrochloric acid with a mass fraction of 5% as a catalyst, and heat to form Viscous liquid is SiO 2 Sol.

[0042] (3) Fully dissolve 1g of zirconium oxychloride in 20mL ethanol solution, add the SiO 2 In the sol, continue heating, and add 5% sodium hydroxide alkali solution drop by drop during the heating process to control the reaction hydrolysis polycondensation rate to form SiO 2 -ZrO 2 hybrid sol.

[0043] (4) Add 10 g of methyl methacrylate dissolved in 0.03 g of azobutyronitrile, add...

Embodiment 3

[0046] (1) Grind the magnesium alloy with sandpaper, and mechanically polish it to a mirror surface, wash it with deionized water and acetone in sequence, and then ultrasonically wash it in NaOH solution with a pH value of 11 at 80°C for 15 minutes, and ultrasonically in deionized water for 5 minutes. Blow dry with cold air.

[0047] (2) Weigh 7g of tetraethyl orthosilicate solution and 4g of γ-methacryloxypropyltrimethoxysilane solution and mix evenly, and add 1mL of dilute hydrochloric acid with a mass fraction of 5% as a catalyst, and heat to form Viscous liquid is SiO 2 Sol.

[0048] (3) Fully dissolve 3g of zirconium oxychloride in 10mL ethanol solution, and add the SiO 2 In the sol, continue heating, and add 5% sodium hydroxide alkali solution drop by drop during the heating process to control the reaction hydrolysis polycondensation rate to form SiO 2 -ZrO 2 hybrid sol.

[0049] (4) Add 10 g of methyl methacrylate dissolved in 0.03 g of azobutyronitrile, add 1 mL o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com