Fischer-Tropsch synthesis wax hydrocracking catalyst, preparation method thereof, and Fischer-Tropsch synthesis wax hydrocracking method

A Fischer-Tropsch synthetic wax and hydrocracking technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical elements of heterogeneous catalysts, etc., can solve the problem of low selectivity of middle distillates , the need for post-treatment, the poor dispersion of hydrogenation active metals, etc., to achieve the effect of improving the dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

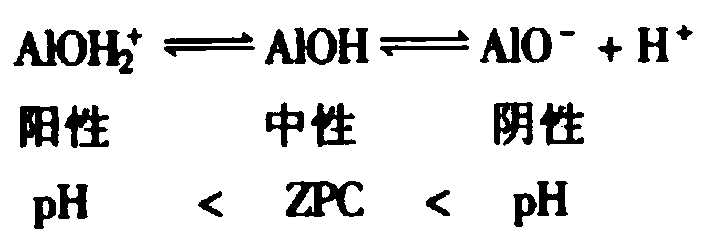

Method used

Image

Examples

preparation example Construction

[0048] The first aspect of the present invention provides a kind of preparation method of Fischer-Tropsch synthetic wax hydrocracking catalyst, the method comprises the following steps:

[0049] (1) Carrying out kneading, extruding, first drying and first roasting of amorphous silica-alumina and binder to obtain catalyst carrier;

[0050] (2) impregnating the catalyst carrier in an impregnation solution containing hydrogenation active metal elements and competing adsorbents, and then performing second drying and second roasting to obtain a Fischer-Tropsch synthetic wax hydrocracking catalyst, wherein the The hydrogenation active metal element is at least one metal element selected from Group VIII of the Periodic Table of Elements, and at the same time contains at least one metal element selected from Group VIB of the Periodic Table of Elements, wherein the hydrogenation active metal element contains The volume consumption of the impregnating liquid is 65%-85% of the bulk volum...

Embodiment 1

[0070] Get 129g amorphous silicon aluminum (specific surface area 500m 2 / g, pore volume 1.6mL / g, SiO 2 Content 40% by weight), 111g pseudo-boehmite (specific surface area 233m 2 / g, pore volume 0.52mL / g, not roasted), add 170g of nitric acid aqueous solution (concentration of nitric acid is 0.077% by weight) under the state of stirring, mix well, after mixer kneading into agglomerate, put into extrusion machine (purchase The S1 catalyst carrier was obtained by extruding a clover shape with a diameter of 2 mm from Guangzhou Huagong Opto-Mechanical Technology Co., Ltd. (model: CD4-1TS), drying at 120°C for 4 hours, and then calcining at 500°C for 4 hours.

[0071] Take 20 grams of ammonium metatungstate, 18 grams of nickel nitrate, and 0.77 grams of nitric acid, add water to make 75 mL of impregnating liquid, take 57 g of the obtained S1 catalyst carrier (the bulk volume is 2 mL / g), add it to the above impregnating liquid, and then Immerse in a rotary evaporator at 80°C for 2...

Embodiment 2

[0073] Get 129g amorphous silicon aluminum (specific surface area 500m 2 / g, pore volume 1.6mL / g, SiO 2 Content 40% by weight), 111g pseudo-boehmite (specific surface area 233m 2 / g, pore volume 0.52mL / g, not roasted), add 170g of nitric acid aqueous solution (the concentration of nitric acid is 0.077% by weight) under the state of stirring, mix evenly, after the mixer is kneaded into a ball, put it into the extruder Extrude the clover shape with a diameter of 2 mm, then dry it at 120°C for 4 hours, and then bake it at 500°C for 4 hours to obtain the S2 catalyst carrier.

[0074] Take 20 grams of ammonium metatungstate, 18 grams of nickel nitrate, and 1 gram of nitric acid, add water to make 97 mL of impregnating liquid, take 57 g of the obtained S2 catalyst carrier (the bulk volume is 2 mL / g), add it to the above impregnating liquid, and then It was impregnated in a rotary evaporator at 500°C for 2 hours, and then calcined at 500°C for 2 hours to prepare catalyst S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com