Patents

Literature

1147 results about "Extrusion moulding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extrusion is a manufacturing process used to make pipes, hoses, drinking straws, curtain tracks, rods, and fibre. The granules melt into a liquid which is forced through a die, forming a long 'tube like' shape. The shape of the die determines the shape of the tube. The extrusion is then cooled and forms a solid shape. The tube may be printed upon, and cut at equal intervals. The pieces may be rolled for storage or packed together. Shapes that can result from extrusion include T-sections, U-sections, square sections, I-sections, L-sections and circular sections.

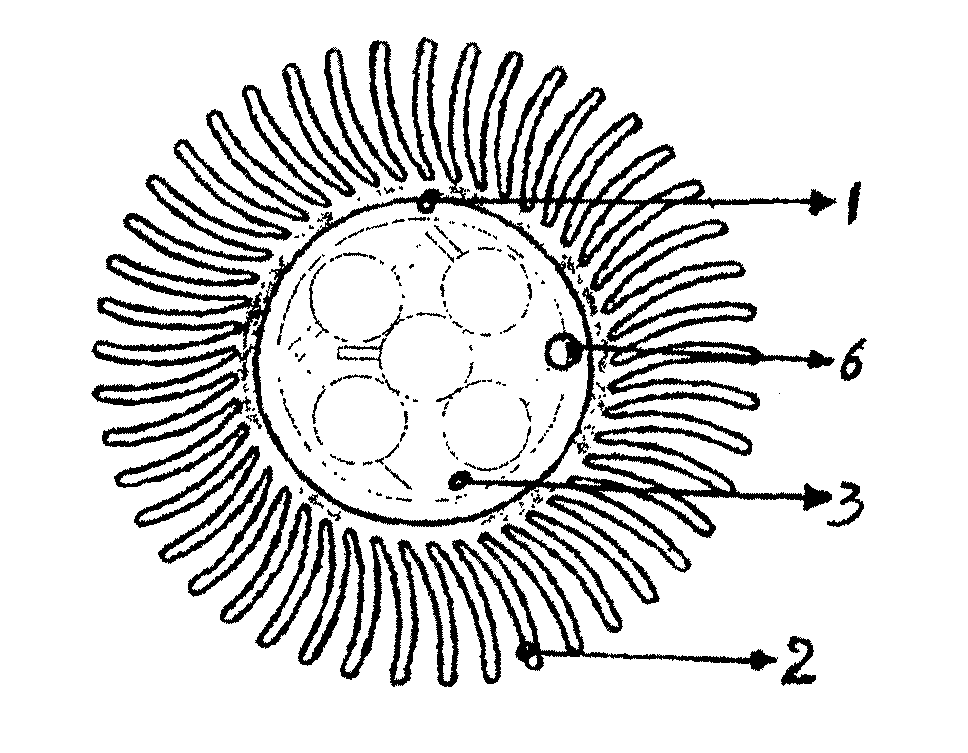

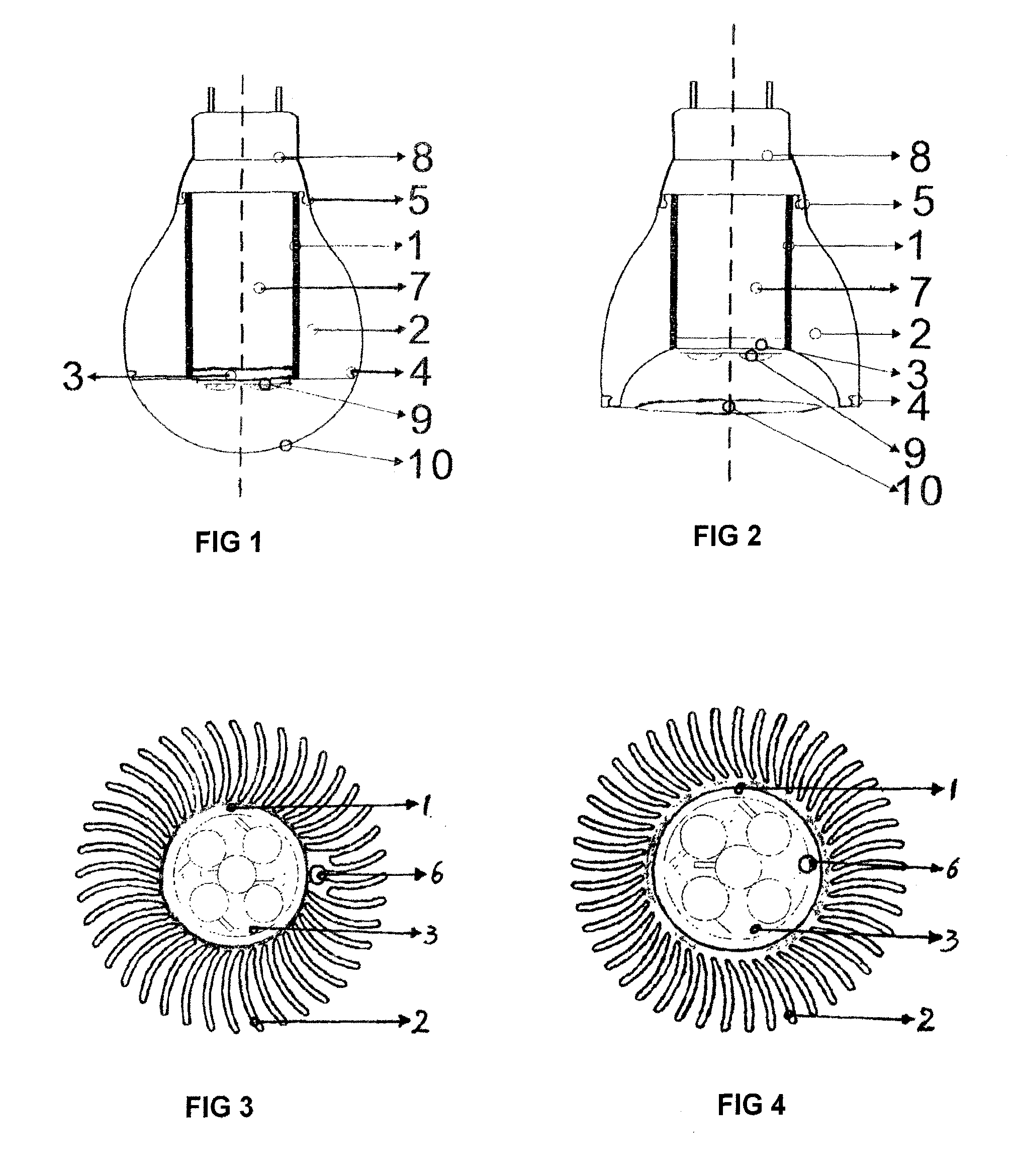

Built-in Heat Diffusion Lamp Body for LED Lamp

InactiveUS20090016063A1Simple materialSimple structurePoint-like light sourceElectric circuit arrangementsDiffusionInterference fit

A built in beat diffusion lamp body for LED lamp was invented. The purpose of the invention is to solve the difficulties of poor heat conduction and diffusion caused by the small heat diffusion surface of the material of a conventional LED lamp. The lamp body is made of a set of heat diffusion vanes encircling the heat diffusion complex. The vanes and heat diffusion complex are made from Aluminum alloy in a single process of extrusion moulding. The transverse section of the heat diffusion body is volute shaped. The bottom of the heat diffusion complex is fixed to an aluminum board or an aluminum circuit: board by interference fit. The heat generated by the LED elements can be absorbed and diffused by the board, the heat diffusion complex and the surrounding diffusion element. The outward appearance of the heat diffusion lamp body may be shaped into cup, ladder, or cylinder likeness to satisfy the application requirement. The advantages of current invention are: efficient heat absorption, conduction, and diffusion, low cost for manufacturing, and aesthetic appearance.

Owner:HU KAI

Method for preparing magnetic filling with biological affinity, hydrophilicity and activity for water treatment

InactiveCN1522972AEasy to grow and compactGood compatibilitySustainable biological treatmentBiological water/sewage treatmentInjection molding machineInjection moulding

The present invention relates to a preparation method of biological affinity hydrophilic active magnetic seed filling material for treating water. It is characterized by that said method includes the following steps: mixing biological affinity substance, hydrophilic substance, magnetic powder and active carbon or magnetic powder and calcium carbonate in the high-molecular base material, and adding dispersion lubricating agent, uniformly stirring them, placing them into injection moulding machine, utilizing filling mould to make extrusion moulding and magnetizing, so as to obtain the invented filling material. It has biological affinity and hydrophilicity, at the same time can induce microbial activity and enzyme activity, and can raise oxygen utilization rate in water and water treatment efficiency.

Owner:SOUTH CHINA UNIV OF TECH

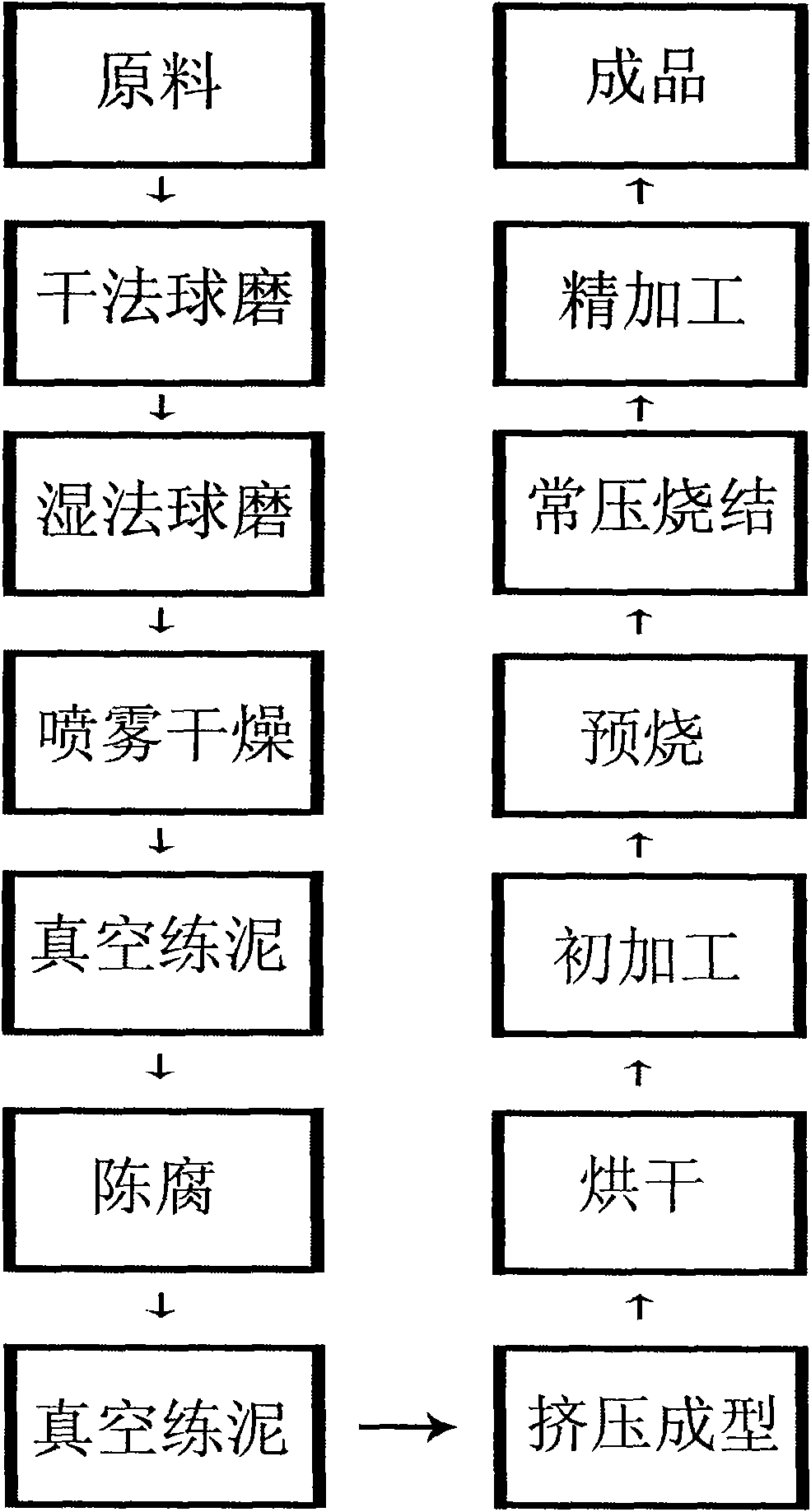

Preparation method for silicon carbide ceramic tube or rod

ActiveCN101560104AEvenly dispersedUniform moisture contentCeramic shaping apparatusClay processing apparatusShielding gasSlurry

The invention relates to a preparation method for a silicon carbide ceramic tube or rod. An extrusion moulding method is adopted to form a blank body; a normal pressure sintering method is adopted for sintering; and submicron level silicon carbide powder and additives are taken as main raw materials. The preparation method comprises the following steps: 1) carrying out ball milling on the main raw materials by a dry method, adding water, a dispersant, a plasticizer, a lubricant and a liquid state binder, and then carrying out ball milling by a wet method; 2) adopting a spray granulation process to granulate silicon carbide slurry; 3) extruding the blank body by a one-shot direct extrusion moulding method after vacuum pug, corrosion, and vacuum pug; 4) drying the molded blank body by a stage drying mechanism; and 5) placing the blank body of the silicon carbide ceramic tube or rod in a vacuum furnace and carrying out sintering for two times by taking argon gas as protective gas. The high temperature resisting strength and the corrosion resistance of the silicon carbide ceramic tube or rod prepared by the method are both better than those of a reactive sintered product. Compared with a hot press sintering method, the method has lower limit on the product shape and size, and lower cost. The method is suitable for the industrialized production.

Owner:宁波欧翔精细陶瓷技术有限公司

Special-purpose board for building and producing method thereof

ActiveCN101168610AProtect the environmentOvercome fear of waterBuilding constructionsSlagPolyvinyl chloride

The invention relates to a building product and the generating method thereof, in particular to a construction special-purpose plate and the manufacturing method thereof. The invention is made of the following raw material according to the parts by weight: 20 to 50 percent of thermoplastic resin comprising polyvinyl chloride, polyethylene and polypropylene, 50 to 80 percent of bulking agent comprising iron ore waste tailing sand, calcium carbonate and slag, and additive occupying 0.05 to 5 percent of the gross weight of the thermoplastic resin and the bulking agent and comprising plasticizer, heat stabilizer and lubricating agent. The product is made by adopting a stone molding and extrusion moulding way, no pollution is produced, no distortion exists, the product is moistureproof and fireproof, the processing waste and the disposed plate of the product can be recycled and newly processed to ensure zero waste, the damage to the environment cannot be caused, and the product is made into a hollow plate structure which has the advantages that the elasticity and the sound insulation effect are good and the heat transfer effect is good, therefore, the invention is very suitable for the heating of a geothermic pipeline, and the difficult problem that a wooden compound floor plate in the present market cannot be used for the heating of the northern geothermic building because of the distortion due to the heating or poor heat insulation heating effect is solved.

Owner:唐山金三顺装饰材料有限公司

Coarse cereals instant noodle and preparation method thereof

InactiveCN101449765AOvercoming the technical difficulty of gluten-free moldingRipe fullyDough treatmentFood preparationFood additiveMicrowave

The invention discloses coarse cereals instant pasta and a preparation method. The coarse cereals instant pasta includes 15%-40% of coarse cereals powder, 57%-84% of wheat flour and 1%-3% of food additives. The preparation method includes steps: mixing raw materials, adding proper amount of water according to need, extruding and slaking, secondary extruding and slaking, shaping, heating by microwave, drying by hot wind, and packaging into bag-type or cup-type or bowl-type instant pasta with flavoring packet. The method has advantages of secondary extrusion moulding, no need of frying process, low oil content, rich nutrition, good rehydration performance, tough and slippery taste, coarse cereals characteristic flavor, and long storage life.

Owner:WUHAN POLYTECHNIC UNIVERSITY

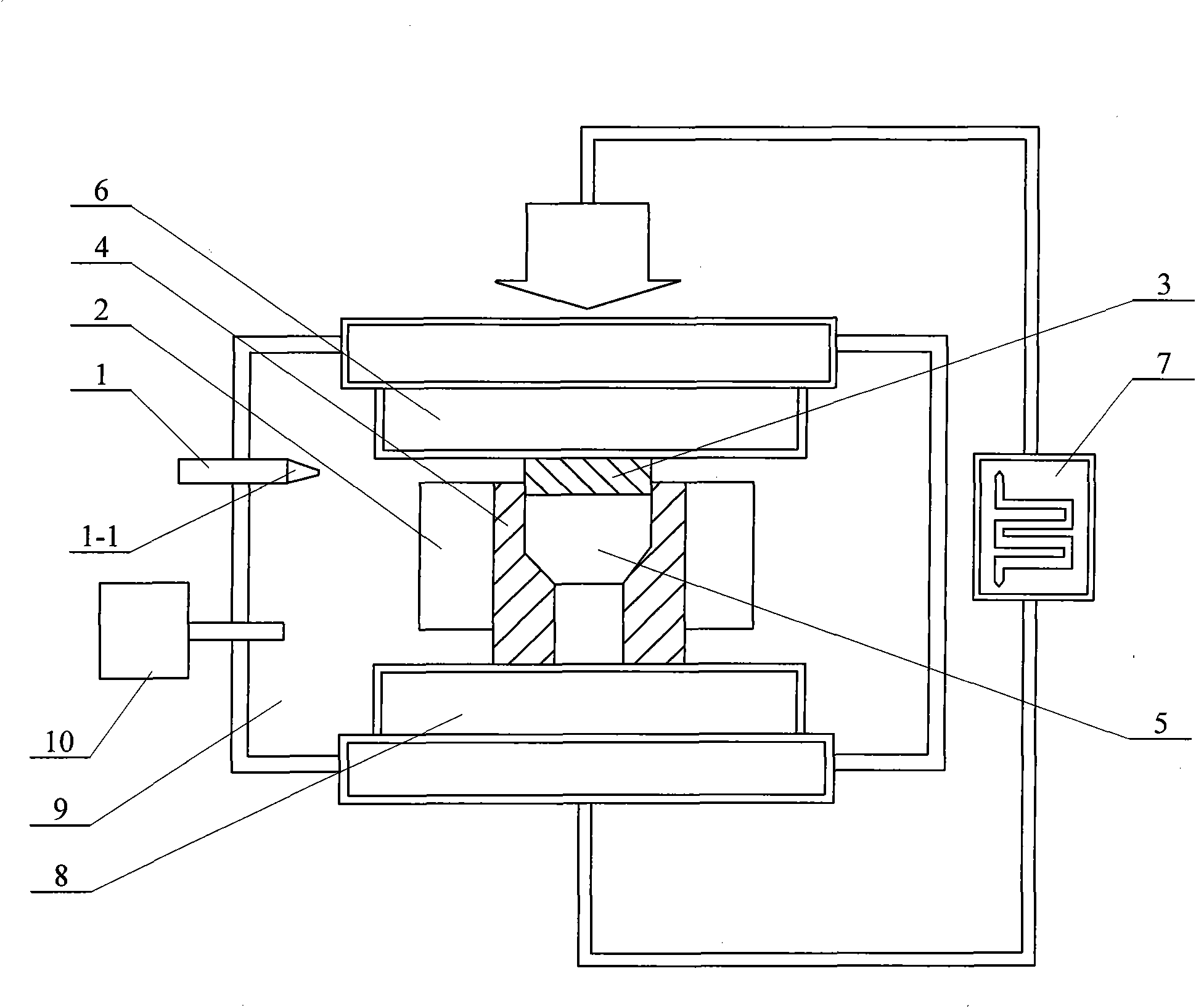

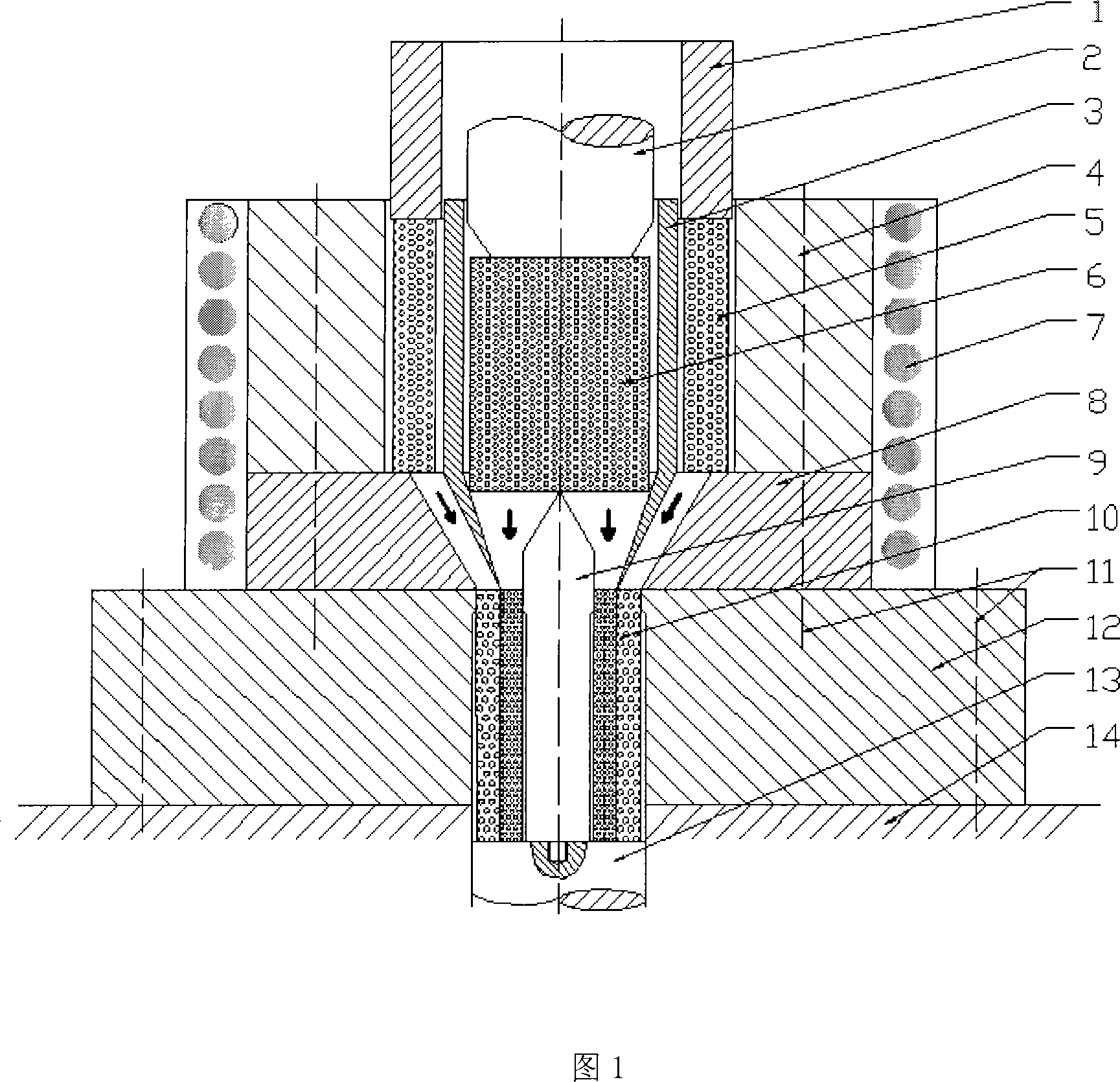

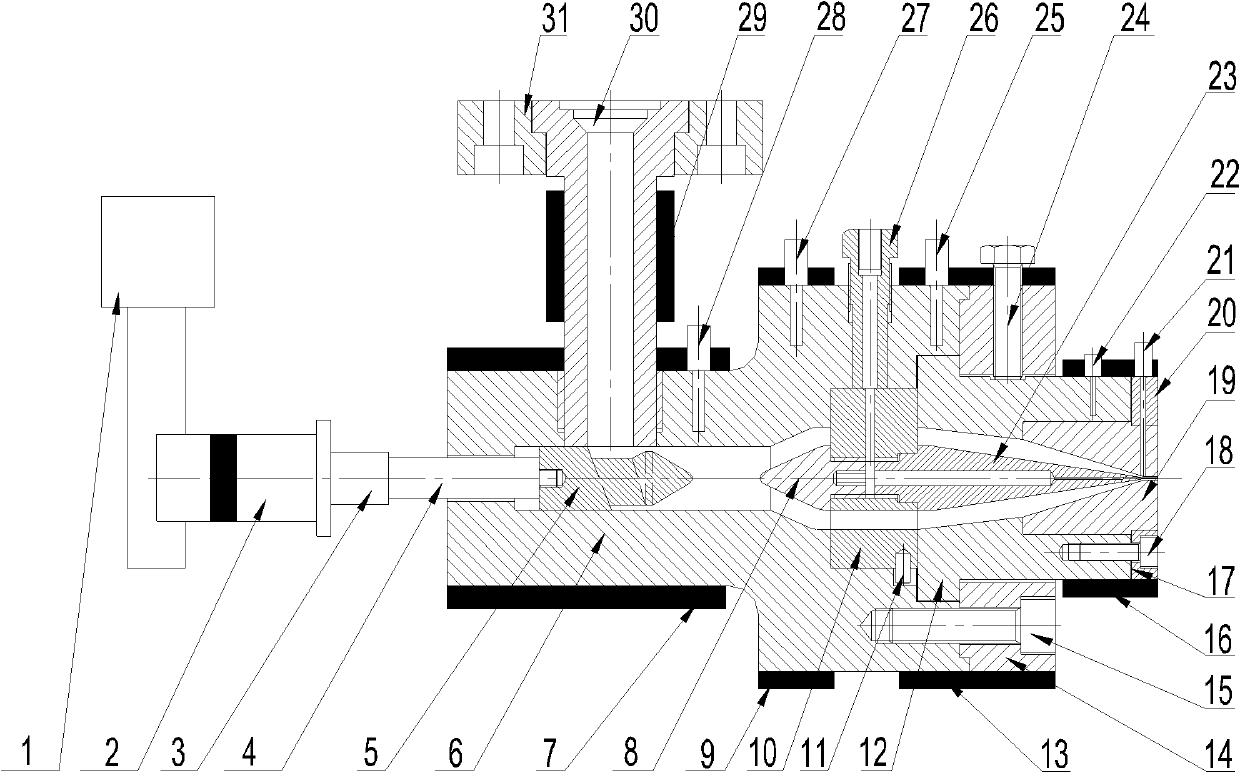

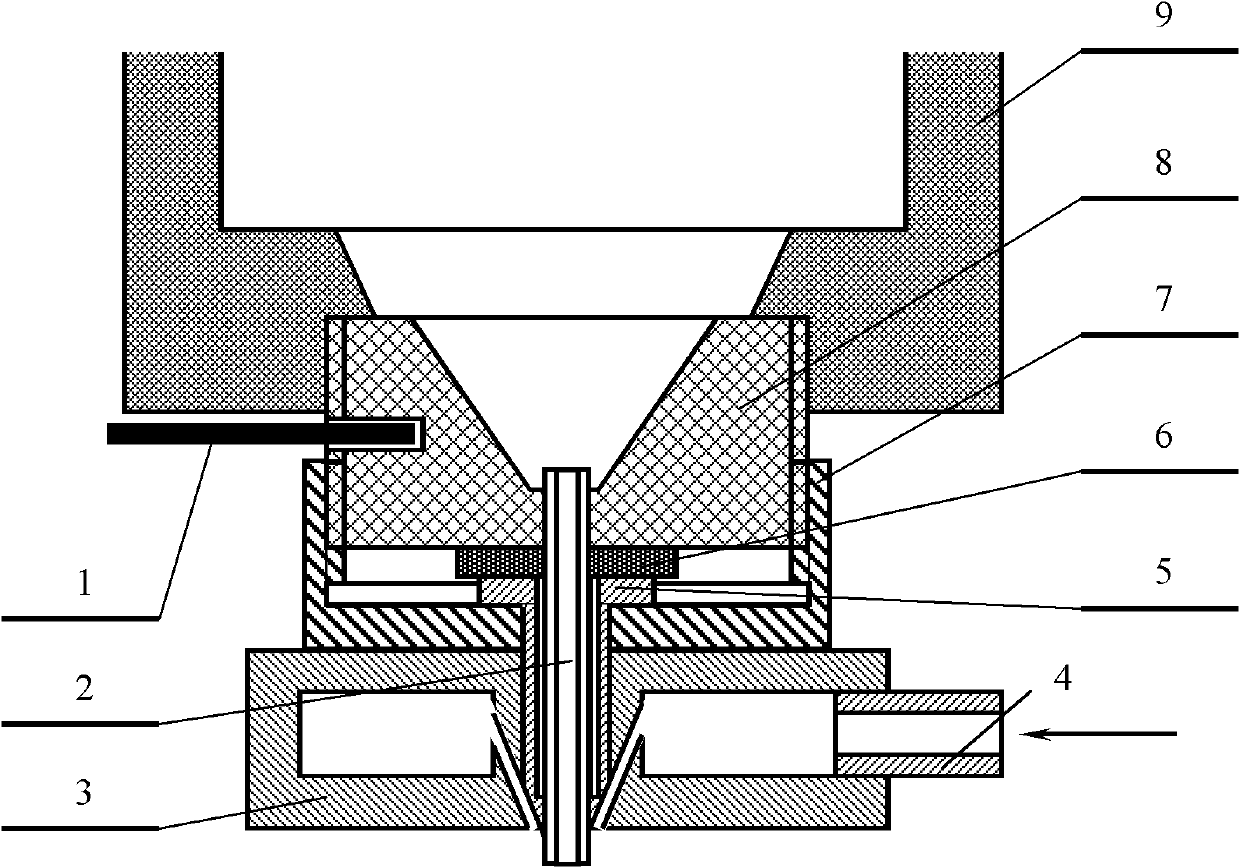

Pulse current assisted extrusion forming device and extrusion forming method

InactiveCN101670385AFast heatingImprove energy utilizationExtrusion diesExtrusion control devicesPressure rangePower flow

A pulse current assisted extrusion forming device and an extrusion forming method relate to an extrusion forming device and a method thereof. The invention solves the problems that the existing extrusion forming device is great in heat loss, and long in heating time, and the existing extrusion forming method is complicated in technical process flow, low in work efficiency and non-homogenous in distribution of density of the current produced inside the blank on the cross-section and easy to cause skin effect. A current-conducting female mold of the device is arranged in a mold cavity of an insulating outer film; a current-conducting male mold and the current-conducting female mold are used as electrodes and connected on a high frequency pulse power source; the pressure within the range of 5-200MPa is applied to the current-conducting male mold by an upper pressure head according to a yield strength value at the temperature selected by the blank to be formed so that the blank is extrudedto be a required shape by the mold after plastic extrusion deformation; the device has high heating speed and improves the work efficiency; and the method uses the heat effect of pulse current and the electro-plastic effect, thereby obviously improving the forming efficiency of the blank, increasing the material plasticity and saving the energy resource.

Owner:HARBIN INST OF TECH

Hot extrusion forming process of half-shaft casings and special device

InactiveCN101690965AShorten molding timeImprove efficiencyForging/hammering/pressing machinesPunchingForming processes

The invention discloses a hot extrusion forming process of half-shaft casings, comprising the following steps: 1) selecting proper round steel according to design products and heating the round steel to 1100-1250 DEG C, 2) carrying out forward extrusion and upsetting, 3) carrying out backward extrusion and positioning, 4) carrying out shallow punching and performing, and 5) carrying out deep punching, finish forging and forming. The invention also discloses a special device for implementing the hot extrusion forming process, comprising upsetting tools, positioning tools, tools for shallow punching and performing and tools for deep punching, finish forging and forming, which are arranged from left to right in sequence. The process has four stations. Each station has enough cooling and lubricating time. Not only can the special device not be deformed after long-term use and the workpieces can not have the problem that inner hole inclination leads to inner and outer coaxiality difference, but also the special device is protected to reduce damage while the capacity is increased.

Owner:济南中森机械制造有限公司

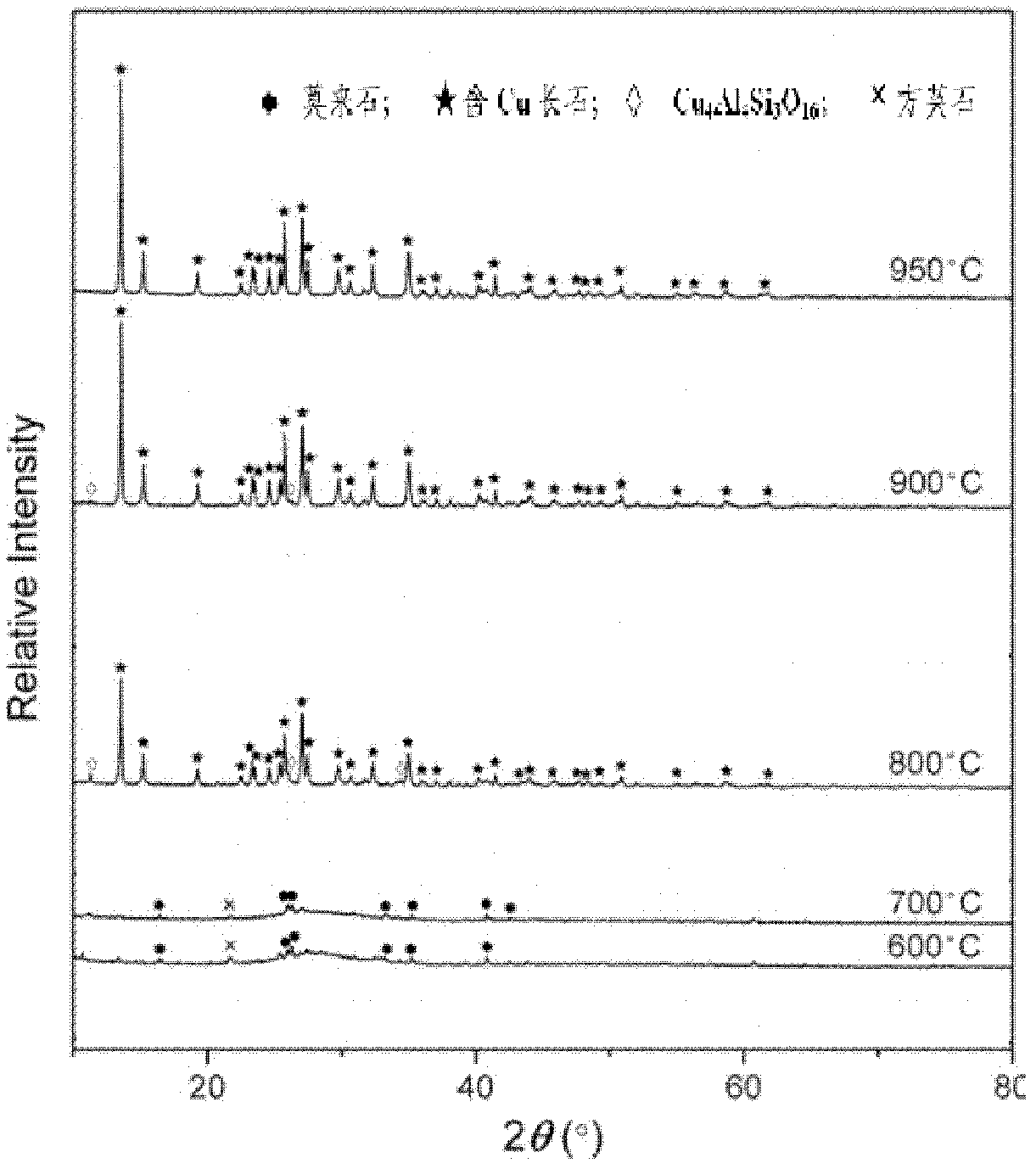

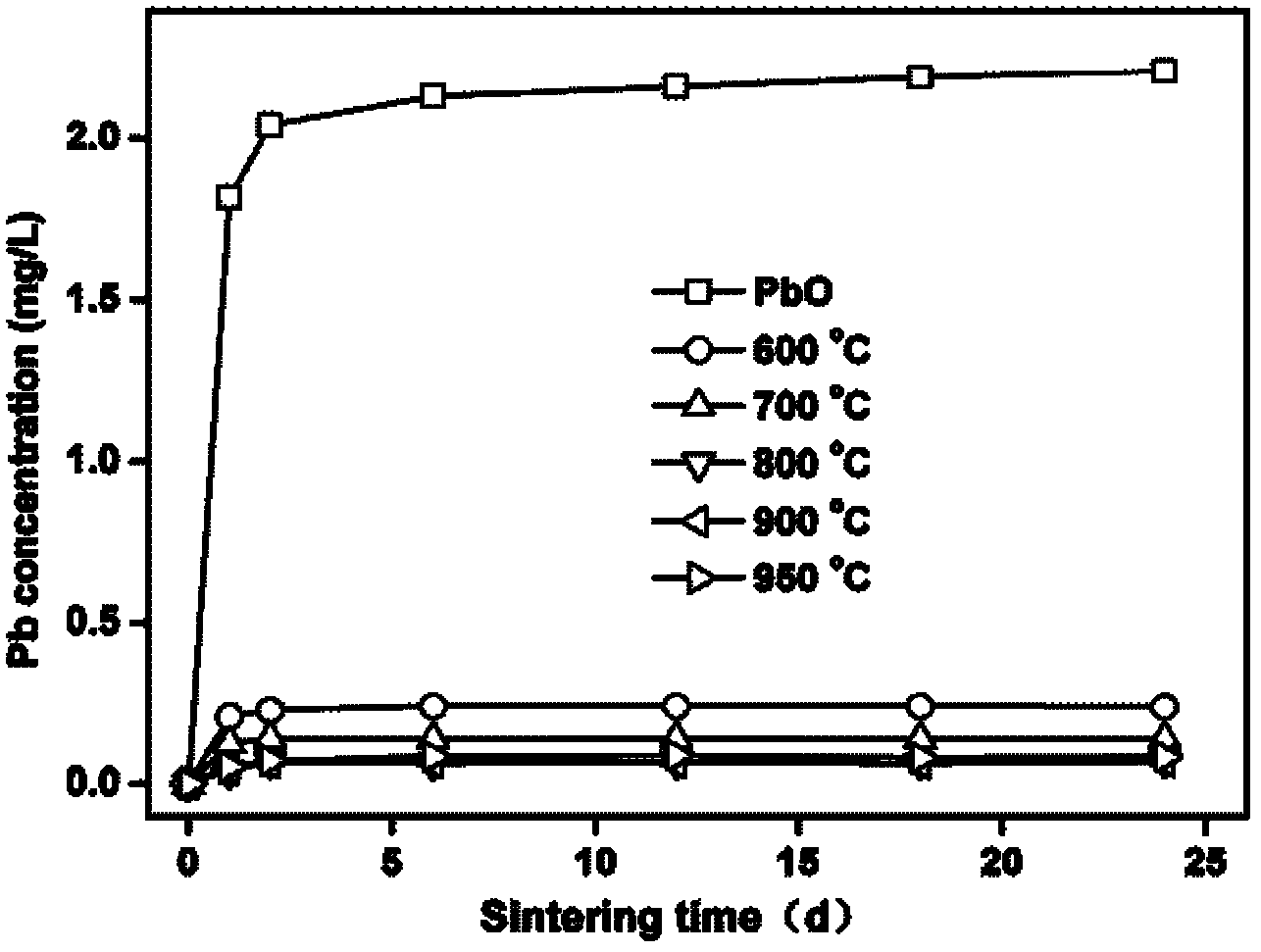

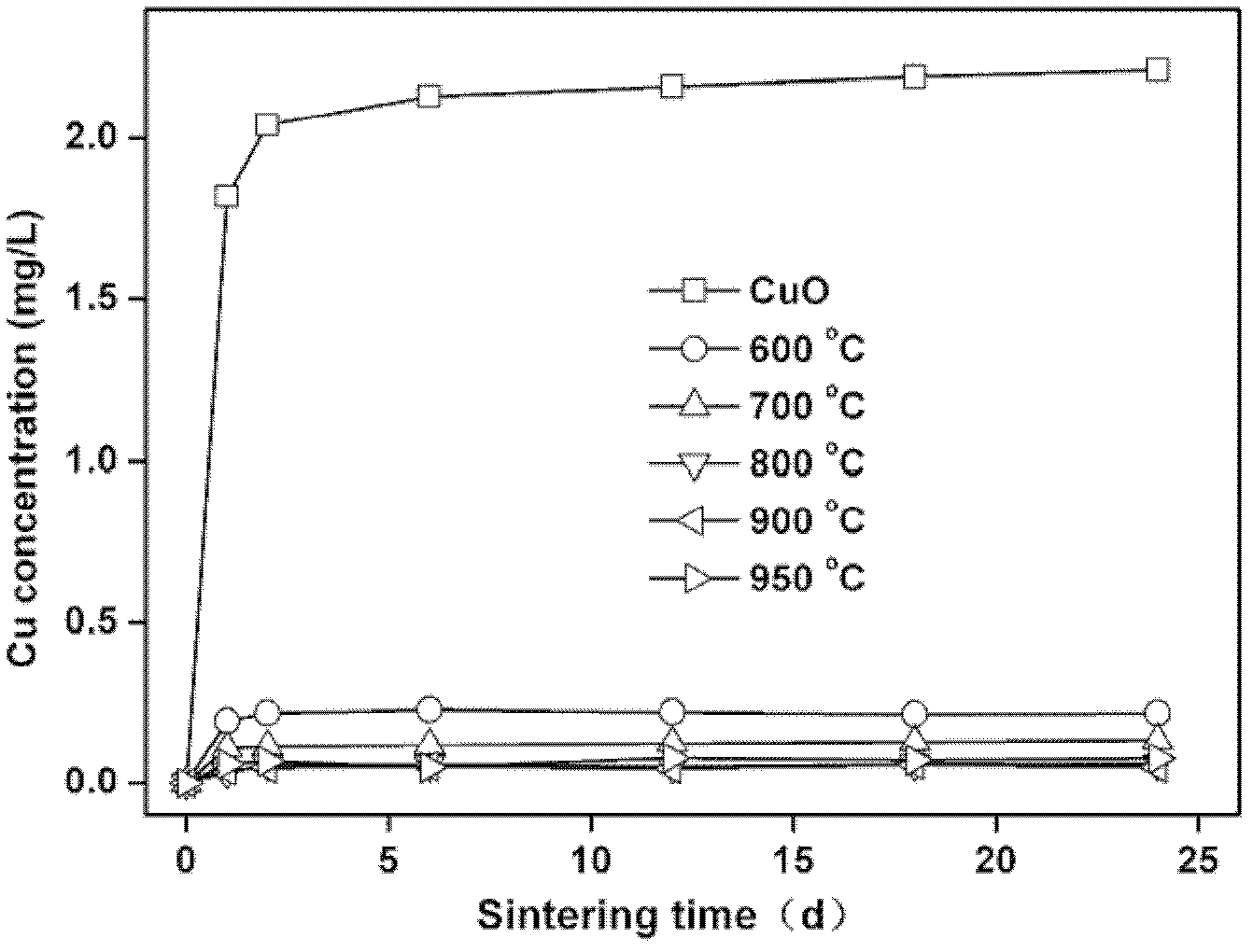

Clay-based heavy metal thermal curing agent and its method for curing heaving metal

ActiveCN102657925ANothing producedEasy to handleContaminated soil reclamationOrganic fertilisersMass ratioStone dust

The invention discloses a clay-based heavy metal thermal curing agent and its method for curing heavy metal. The clay-based heavy metal thermal curing agent comprises, by weight, 40-60% of clay, 5-15% of iron oxide, 20-30% of fly ash and 15-25% of stone flour. The method provided by the invention comprises the following steps of: uniformly mixing the clay-based heavy metal thermal curing agent and a heavy metal pollutant according to the mass ratio of 1: 5-10: 1, carrying out extrusion moulding on the mixed sample at the pressure of 300-1000Mpa, and sintering the molded sample at the temperature of more than 800 DEG C for 2-5 h to obtain a recycled material. According to the invention, heavy metal is coalesced by absorption of clay to heavy metal; fly ash and stone flour are used to fully mix heavy metal with the clay-based heavy metal thermal curing agent during the mixing process; iron oxide and alumina components in the clay-based heavy metal thermal curing agent react with heavy metal at the temperature of more than 800 DEG C for high-temperature fusion glass transition so as to form a spinel structure; and heavy metal in the form of spinel and feldspar crystal structural components is fixed in the heavy metal thermal curing agent to form the recycled material.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Coupling and capacity increasing technique for coblended interface of biodegradation polylactic acid/starch composite material

The invention relates to a fully biologically degradable poly lactic acid / starch composite material, the composite material is composed of PLA (poly lactic acid) and the polymer thereof, starch, surfactant and coupling agent or compatibilizer and processing agent. The contents of the components are: 10-80 percent of PLA, 10-80 percent of starch, 0-3 percent of coupling agent, 2-20 percent of compatibilizer and 0.05-5 percent of processing agent. The surfactant, coupling agent and compatibilizer which have feature structures can change the dispersion of starch in the PLA, adjust and enhance the interphase compatibility of the PLA-starch blend system, strengthen the interaction among the composing substances, enhance the stability of the structure of PLA-starch interface blend, improve the mechanical performance of the composite material and the processing performance. The fully biologically degradable poly lactic acid / starch composite material can be used to produce panels, vessels, blank sheets, film, bands, wires and other products in particular shapes by injection moulding, extrusion moulding, press moulding, blow moulding, hot moulding, and the like, and the material is extensively applied to the fields of packaging, agricultural film, domestic and medical products, and the like.

Owner:袁明龙

Process for forming medium-strength heat-resistant magnesium alloy thick plate

The invention discloses a process for forming a medium-strength heat-resistant magnesium alloy thick plate with the thickness of 50-80mm. The process route comprises the following steps: big furnace smelting, semi-continuous casting, homogenizing annealing, variable temperature multi-directional forging, extrusion forming and aging treatment, wherein the step of variable temperature multi-directional forging is performed on a hydraulic machine, the temperature of the ingot blank is kept at 380-410 DEG C for 3-5 hours before forging, and the pressing speed is 200-400mm / minute; the step of extrusion forming is performed on a horizontal extruder, the temperature of the ingot blank is kept at 340-350 DEG C for 3-5 hours before extrusion, and the thickness plate with the extrusion ratio of 13-15, the extruded thickness of 50-80mm, the width of 130-200mm and the length of more than or equal to 1000mm is extruded. After the aging treatment, the room-temperature yield strength of the thick plate along the extrusion direction is more than or equal to 260MPa, the tensile strength is more than or equal to 370MPa, and the elongation is more than or equal to 9 percent. The process is high in forming efficiency, and large-scale industrial production can be realized.

Owner:CENT SOUTH UNIV +1

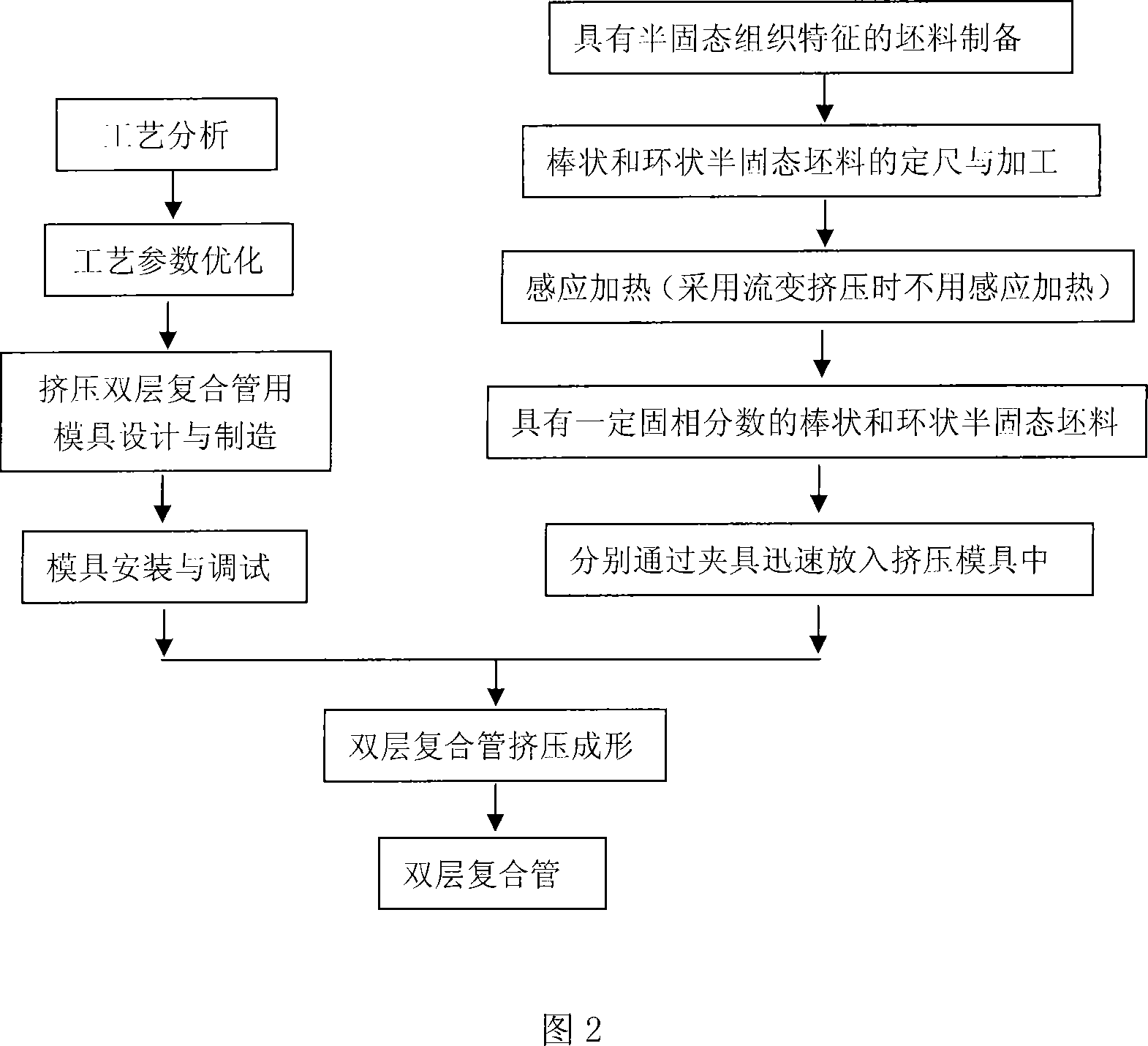

Semi-solid multi-blank extruding process and apparatus for forming double-layer composite pipe

InactiveCN101020201AReduce consumptionImprove product qualityExtrusion diesExtrusion control devicesTemperature controlControl system

The present invention relates to semi-solid forming technology, and is especially semi-solid multi-blank extruding process and apparatus for forming double-layer composite pipe. The technological process includes the following steps: pre-heating the mold to 200-300 deg.c and establishing temperature control system, setting the induction heated blank into the extruding mold, and extruding at regulated speed and stroke to obtain the required composite pipe. The new extruding process for making composite pipe has short procedure, low power consumption and high product quality.

Owner:TSINGHUA UNIV

Powder metallurgy production method of internal helical gear

The invention relates to a powder metallurgy production method of an internal helical gear. The powder metallurgy production method comprises the following steps: 1) preparing metal powder raw materials in proportion; 2) putting the prepared metal powder raw materials into a mould of a powder extrusion moulding machine for moulding by rotary extrusion to form a mould green compact; 3) putting the mould green compact into a high temperature mesh belt furnace for sintering treatment; and 4) putting a sintered product into a carburizing furnace for carburizing treatment. The powder metallurgy production method helps produce the internal helical gear with easy production and operation, less cost, high production efficiency, high material utilization rate and high product accuracy.

Owner:扬州保来得科技实业有限公司

Ultrahigh-molecular weight polyethylene composite material and preparation method thereof

The invention discloses an ultrahigh-molecular weight polyethylene composite material and a preparation method thereof. The ultrahigh-molecular weight polyethylene composite material comprises the following component in parts by weight: 100 parts of ultrahigh-molecular weight polyethylene, 0.1-10 parts of a lubricating agent, 10-60 parts of a filling material, 5-40 parts of reinforcing fiber and 0.1-10 parts of nanometer inorganic filler. The ultrahigh-molecular weight polyethylene composite material overcomes the difficulty that the ultrahigh-molecular weight polyethylene is very high in melt viscosity and is difficult to prepare; the ultrahigh-molecular weight polyethylene composite material can be prepared into different products through extrusion moulding of an extruder; the modified ultrahigh-molecular weight polyethylene composite material not only has high strength, impact resistance, wear resistance, high rigidity, high surface hardness, chemical corrosion resistance and other performance, but also has good self lubrication and dimensional stability.

Owner:GUANGDONG TAUGHNESS CONVEYOR BELTING

Preparation method of polylactic-acid hollow fiber dialysis membrane

ActiveCN102961977AGood biocompatibilityLess protein adsorptionSemi-permeable membranesDialysis membranesBiocompatibility Testing

The invention relates to a preparation method of a polylactic-acid hollow fiber dialysis membrane, which aims to overcome the defects that the conventional dialysis membrane material is poor in biocompatibility and easy to cause environmental pollution. The preparation method comprises the following steps of: adding polylactic acid, a pore-forming agent, a toughening agent and an inorganic filler to a solvent, stirring the components at 40-120 DEG C for 8-12 hours to obtain a spinning solution, and then deforming the spinning solution; carrying out extrusion moulding on the defoamed spinning solution and core liquid which respectively pass through an external channel and an inner channel of a spinning nozzle, thus obtaining nascent fibers; curing the nascent fibers in coagulating bath after the nascent fibers pass through air gaps of 0 to 50cm, thus forming a nascent polylactic-acid hollow fiber membrane; collecting the nascent polylactic-acid hollow fiber membrane by a coiler at a speed of 1-30 m / min, thus obtaining the polylactic-acid hollow fiber membrane; and finally soaking the membrane in circulating deionized water at 20-45 DEG C for 6 to 48 hours, and taking out and drying the membrane. The preparation method has the advantages of little pollution and energy conservation; and the prepared dialysis membrane is good in biocompatibility and low in adsorption capacity of proteins, has a good elimination effect on urotoxy matters, and is biodegradable.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

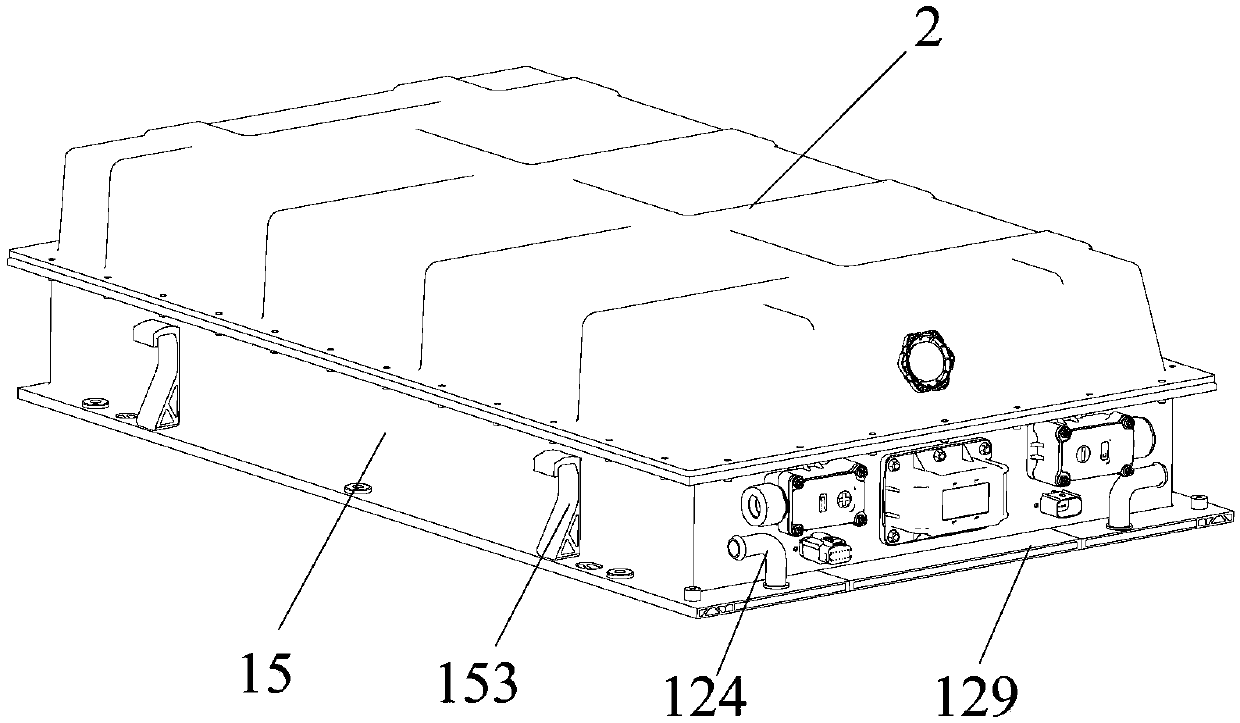

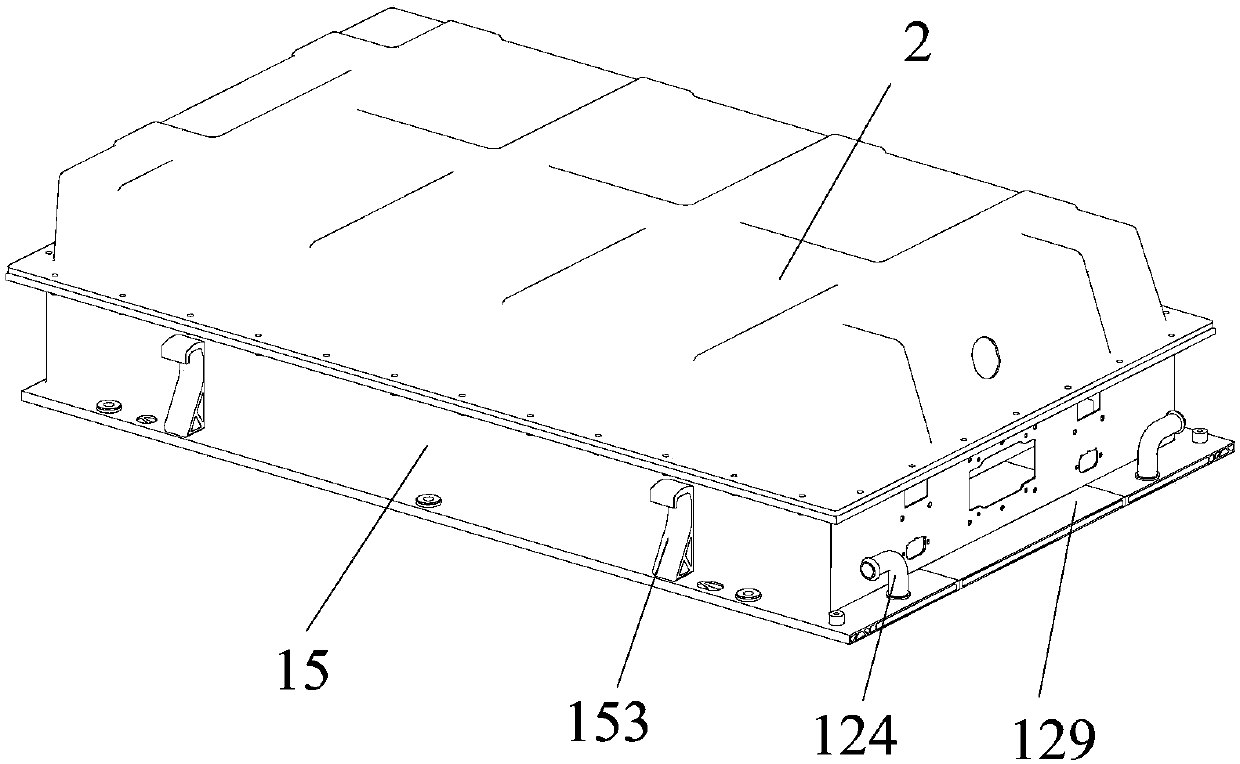

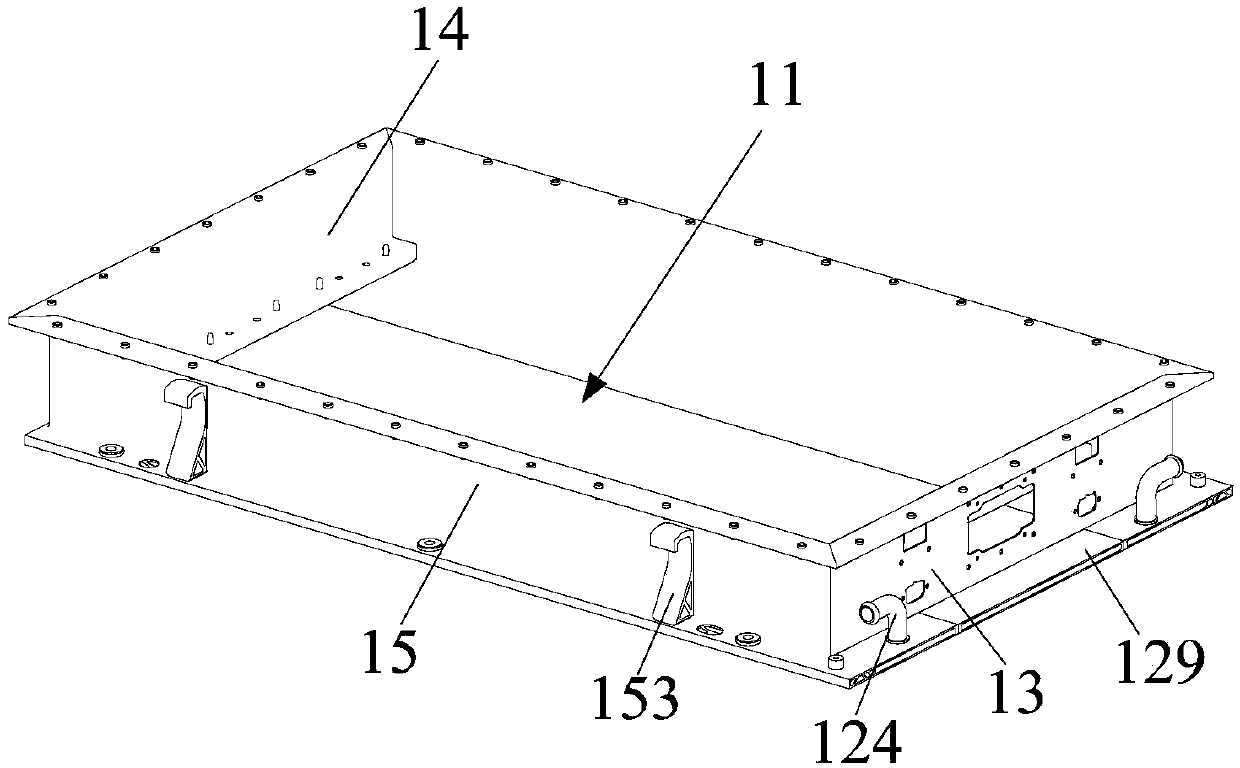

Integrated water-cooled power battery box

PendingCN108039434AMeet the intensityFulfil requirementsBattery isolationSecondary cellsPower batteryMechanical property

The invention relates to the technical field of electric cars, in particular to an integrated water-cooled power battery box. The integrated water-cooled power battery box provided by the invention comprises a box cover, a box body and a temperature regulating power system, wherein the box body is made of an aluminum alloy material and is manufactured by an extrusion moulding technology; a circulating flow passage is formed in the wall of the box body; a circulating loop for a temperature regulating medium to flow circularly is arranged inside the wall of the box body; and the temperature regulating power system can drive the temperature regulating medium to circularly flow in the circulating loop. In such a way, a water cooling board and a battery box are designed in an integrated manner,a hollow aluminum alloy section is adopted to achieve lightweight design, mechanical properties such as strength and rigidity are met, the integrated water-cooled power battery box is simpler in structure, better in technical performance and smaller in occupied space, and the comprehensive cost can be reduced; the heat-dissipating, cooling and temperature-raising and heating functions can be achieved by using one set of temperature regulating power system, the integrated water-cooled power battery box is simpler in structure, more convenient and fast to use and smaller in occupied space, themanufacturing cost and the using cost can be reduced, and the heat-dissipating efficiency and the heating efficiency can be improved.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

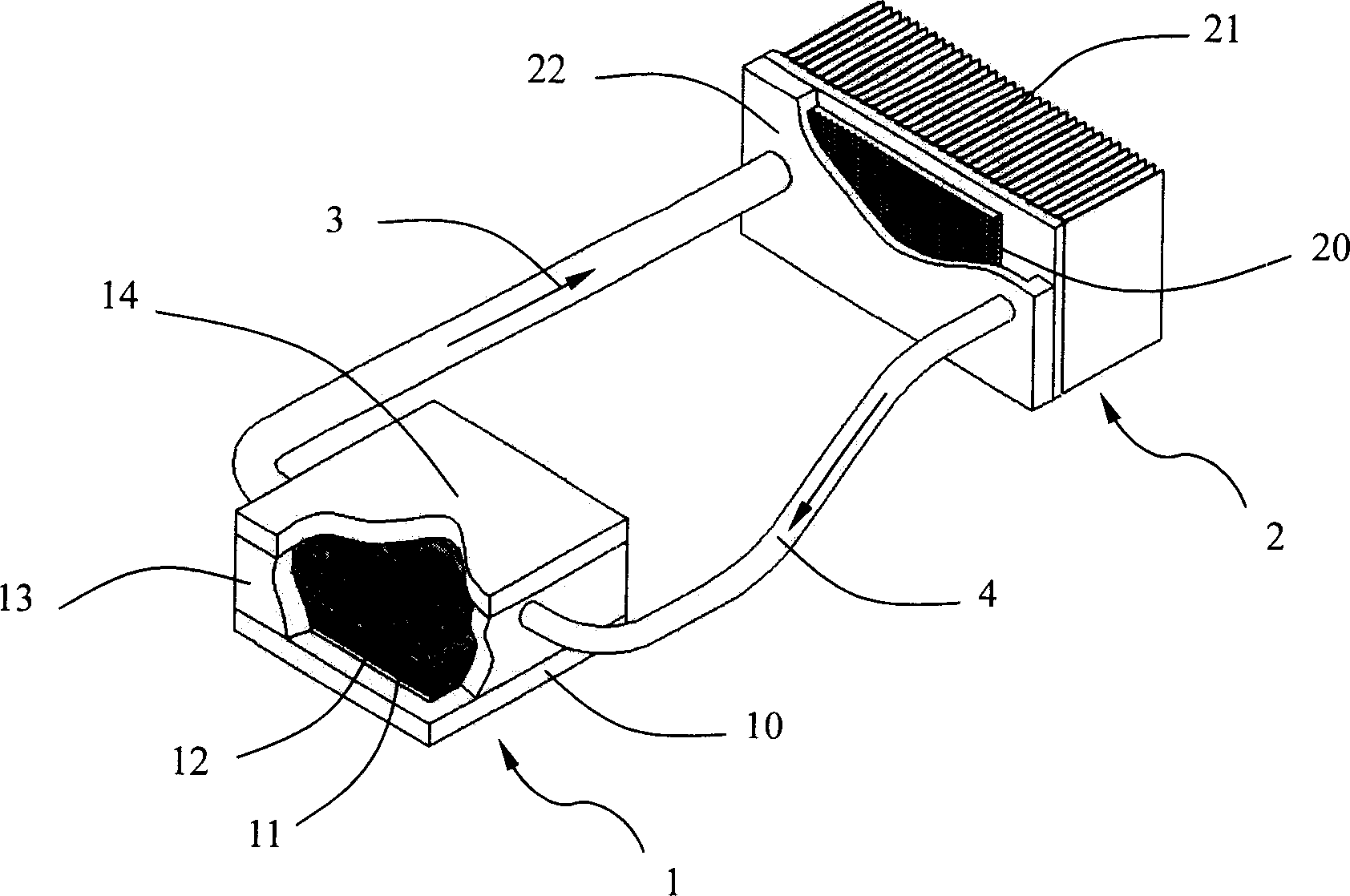

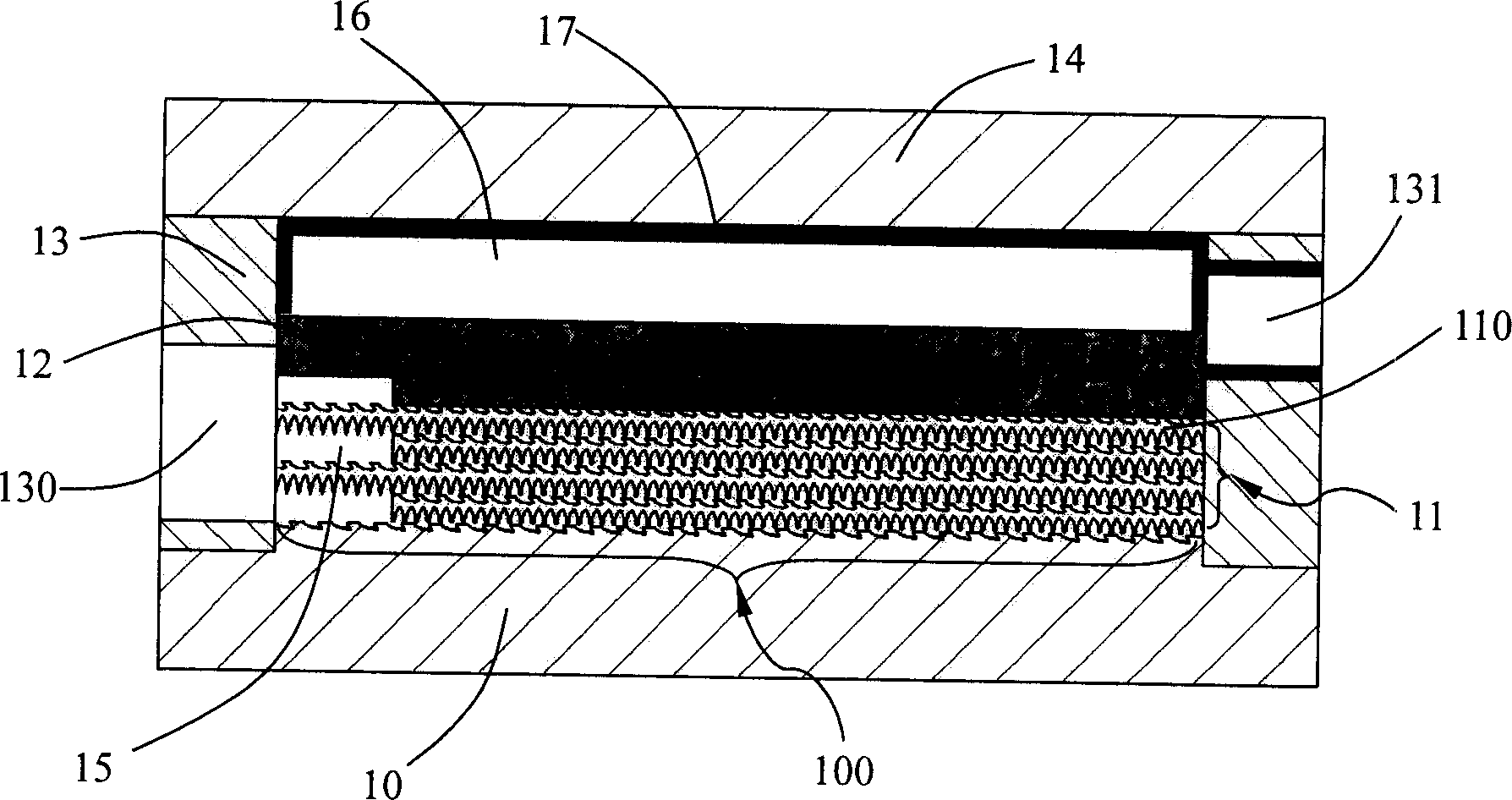

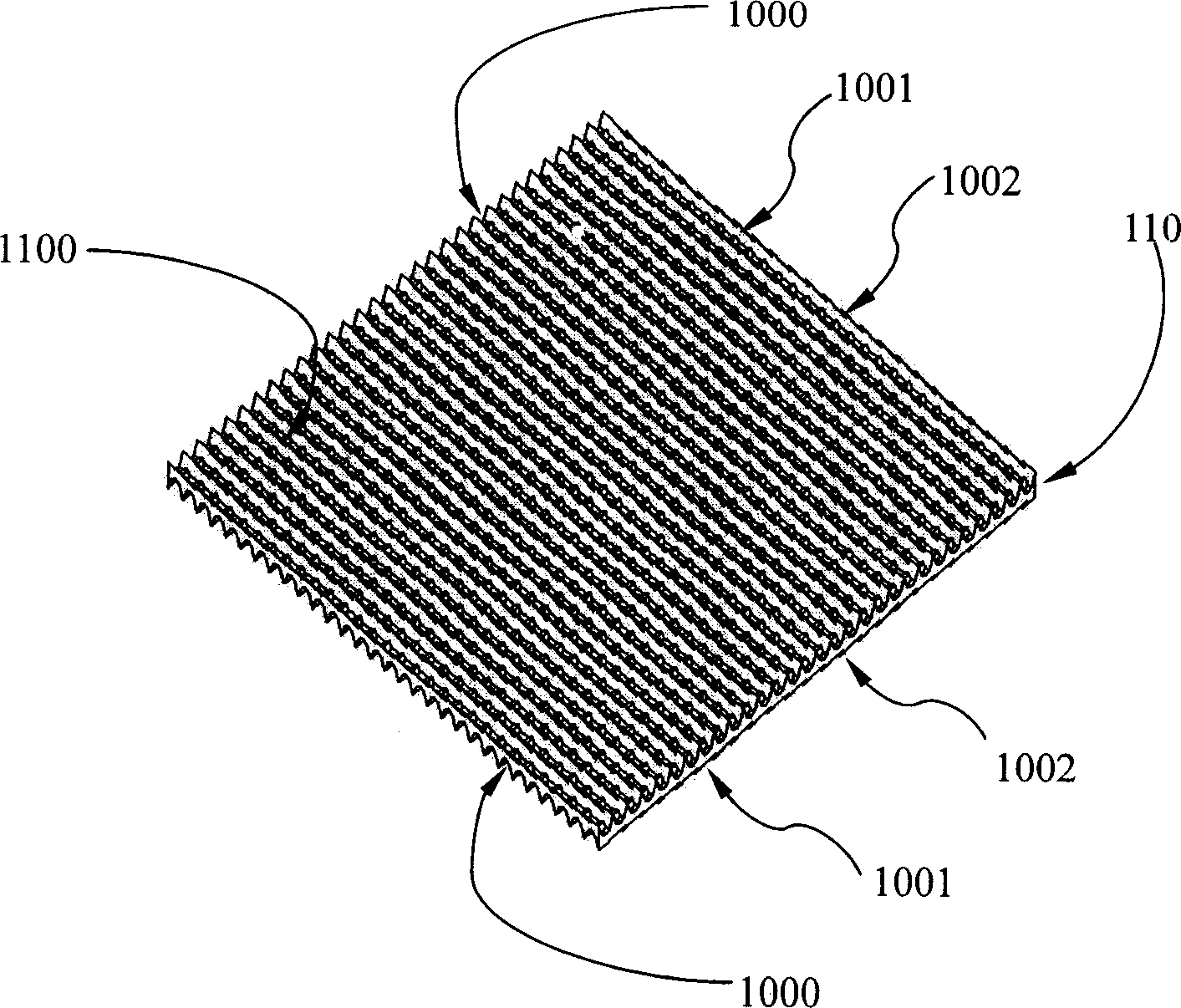

Capillary pump cooler with micro-groove wing structure and its manufacturing method

InactiveCN1801483ASimple structureFast heat conductionDigital data processing detailsSemiconductor/solid-state device detailsHeat flowInner loop

The invention relates to a capillary pumping cooling device with micro-groove wing structure, which comprises: an evaporator connected to a condensator by a steam union pipe and a liquid union pipe to form a system for operating means circulation; arranging a plurality of crossed-intercommunicating boiling strengthened plates with micro-groove wing structure on both sides. This invention is used mainly for heat dissipation of micro-electron chip. Wherein, this invention uses plough cutting-extrusion molding technology for micro-groove wing structure and planing forming technology for integrated wing cooling fin with low cost and high efficiency, which benefits to reinforce boiling, promote condensation and speed up convective dissipating heat.

Owner:SOUTH CHINA UNIV OF TECH

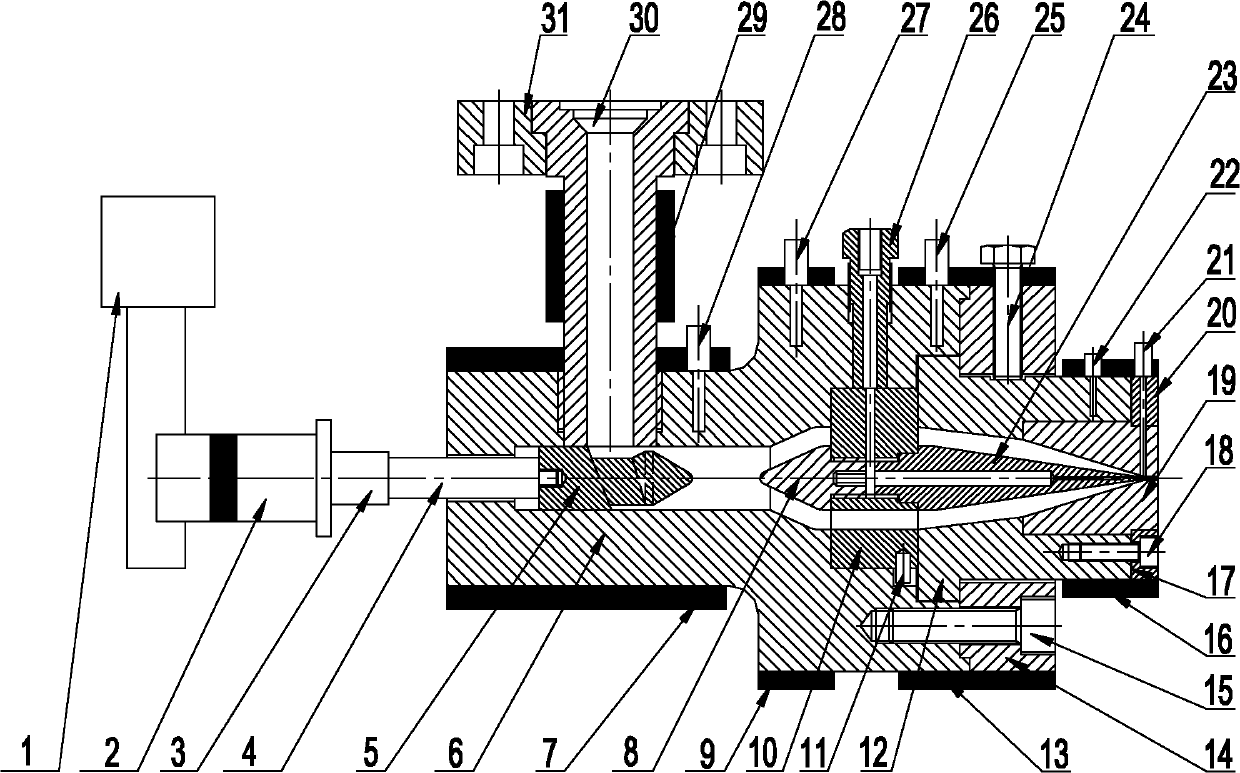

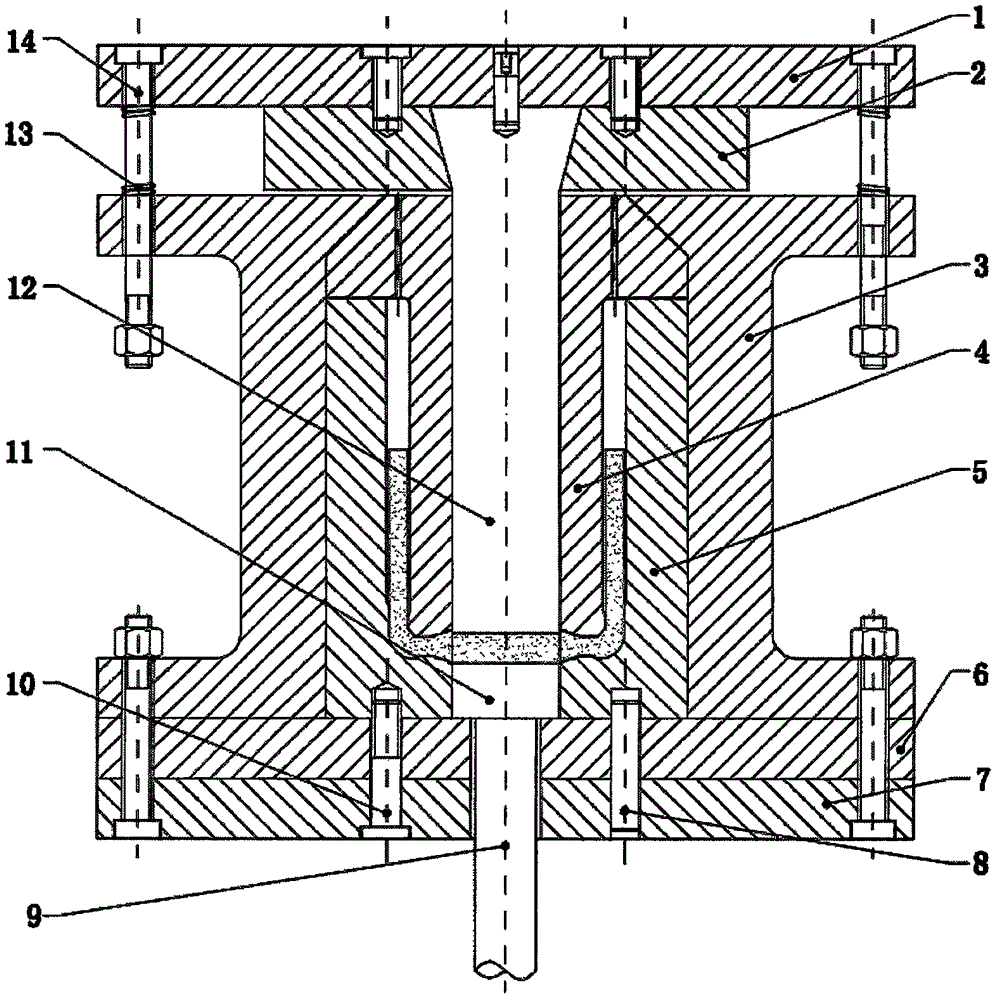

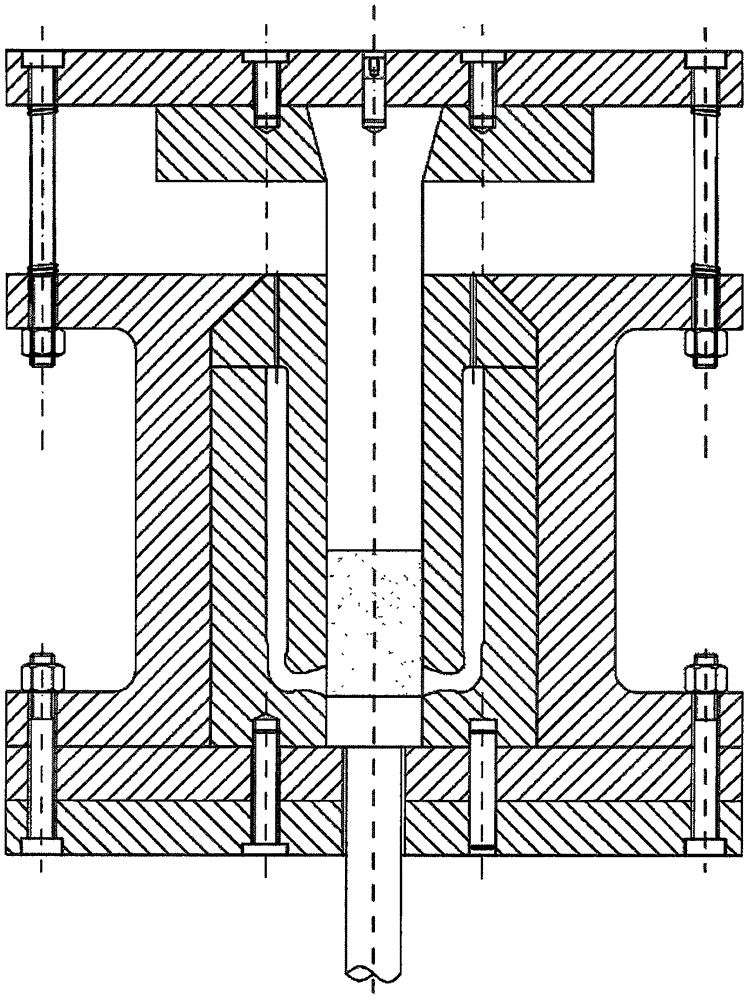

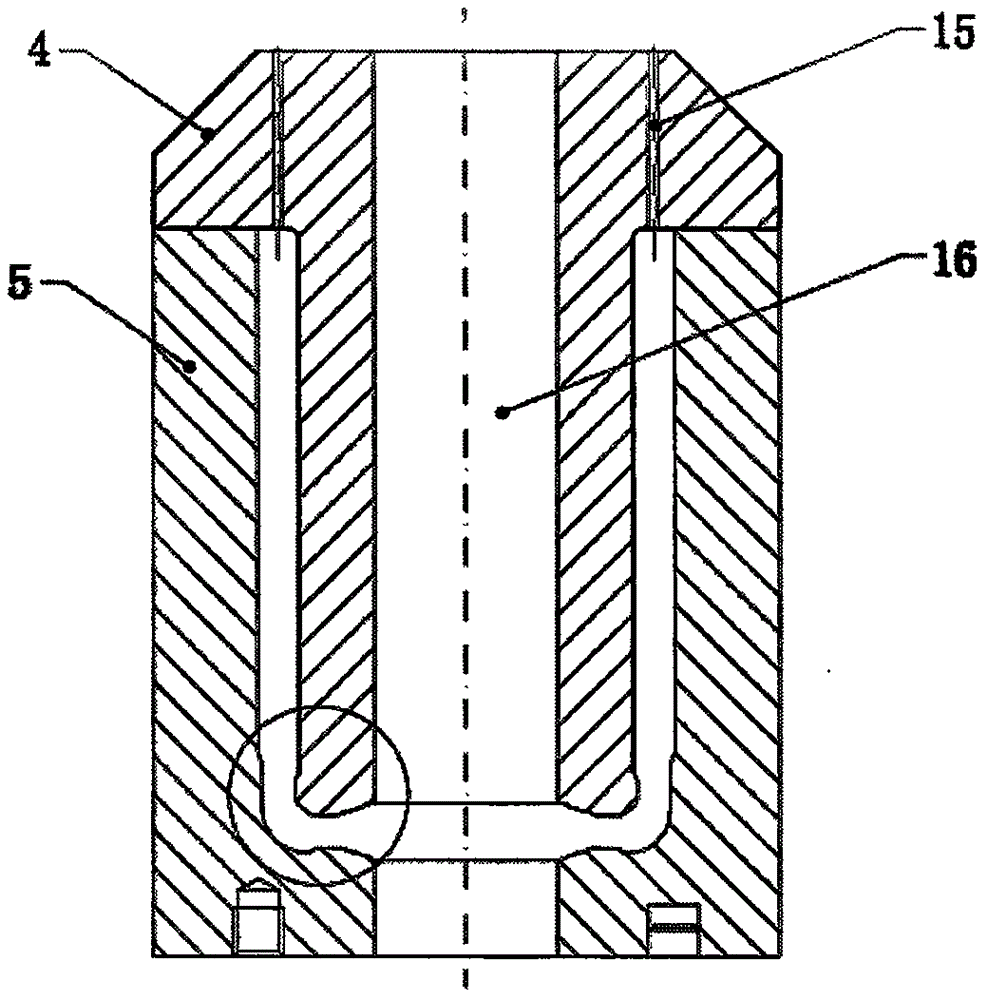

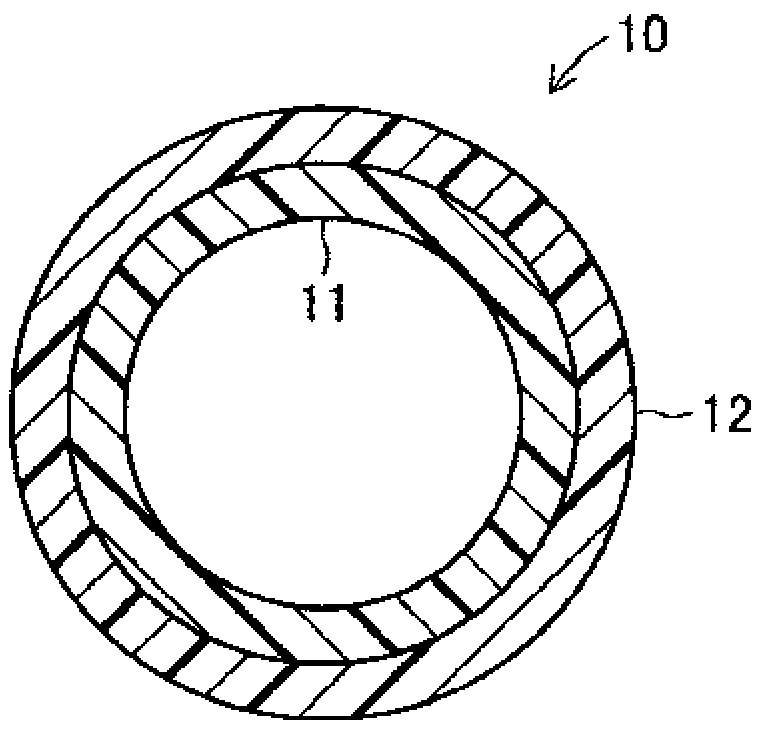

Ultrasonic vibration microtube extrusion mould

InactiveCN101947846AUniform distribution of melt flow fieldUniform distribution of flow fieldTubular articlesTransformerEngineering

The invention discloses an ultrasonic vibration microtube extrusion mould, belonging to the technical field of polymer extrusion moulding. The invention is characterized in that the mould comprises an ultrasonic-frequency power supply, an energy converter, a vibration rod, an amplitude transformer, a vibration head, a die head body, a spure sperader, a support plate, a positioning pin, a die supporting plate, a baffle plate, a fastening bolt, a washer, a die, a check ring, an integrated pressure / temperature sensor, a mandrel, an adjusting bolt, an air vent bolt, a heating ring, a temperature sensor, a connecting pipe and a flange plate. The mould adopts a feeding mode of which feeding direction is perpendicular to the extrusion direction; the vibration head adopts a spiral groove type structure and vibrates along the microtube extrusion direction; different spure speraders, mandrels and dies with different structural parameters can be changed according to demands; and the integrated pressure / temperature sensor is used to measure the changes of the pressure / temperature in the runner of the mould. By designing the ultrasonic vibration microtube extrusion mould capable of realizing vertical feeding, ultrasonic vibration is combined with the plastic microtube extrusion moulding, thus reducing flow resistance, increasing the production efficiency and obtaining the plastic microtube with high quality.

Owner:DALIAN UNIV OF TECH

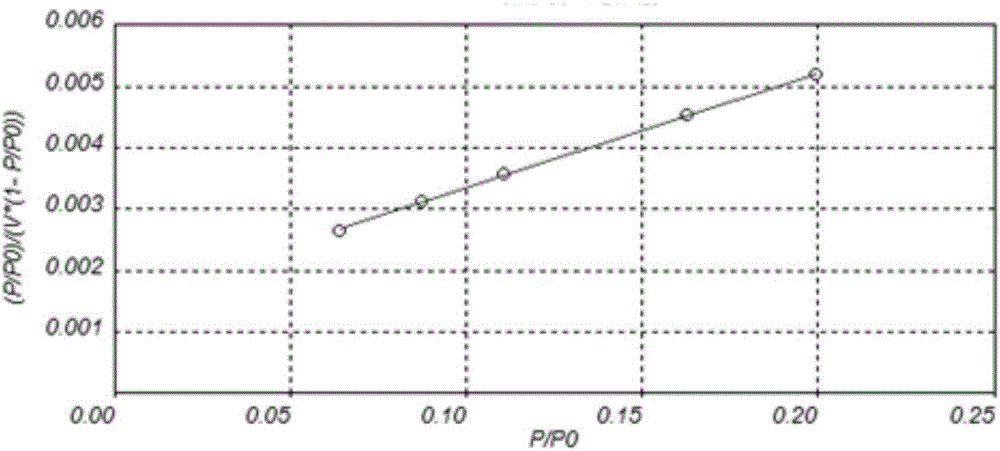

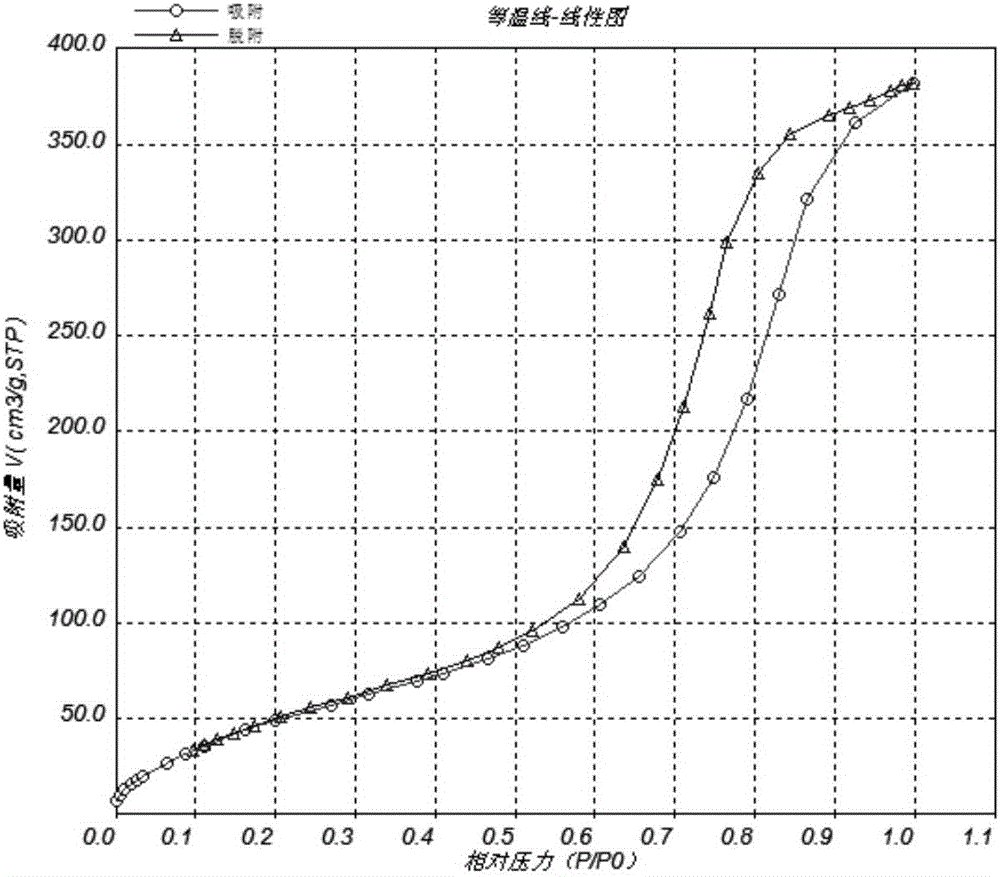

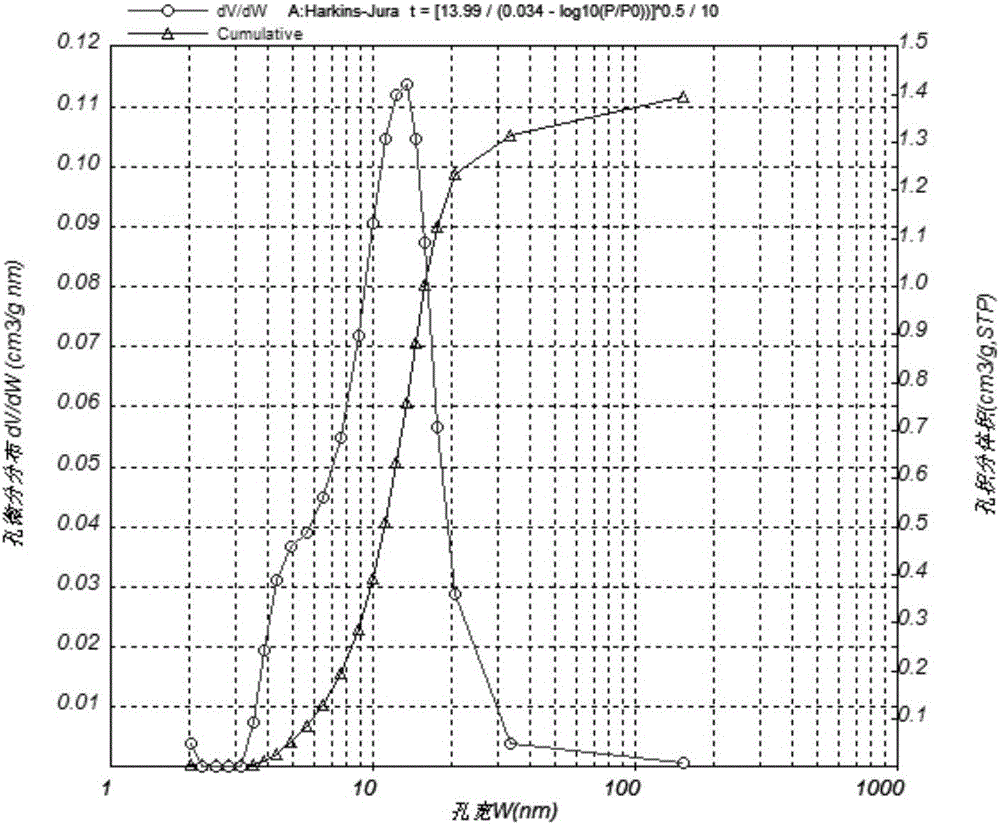

Catalyst for epoxidation of olefin and preparation method thereof

ActiveCN106582809ARaw materials are easy to getLow costMolecular sieve catalystsFiltrationThermal insulation

The present invention relates to a catalyst for epoxidation of an olefin. The catalyst is a modified titanium silica molecular sieve, the pore size is 10-30 nm, the content of TiO is 0.5-10 wt%, the pore volume is 1.0-1.5 mL / g, the aperture distribution rate is >=93.5%, and the specific surface area is 150-500 m<2> / g. A preparation method comprises the following steps: a template agent, a template modifier, water and a solvent are added into a reactor, heating under stirring is conducted, then a silicon source is added, and thermal insulation, suction filtration and drying are conducted to obtain a molecular sieve raw powder; the molecular sieve raw powder, an extrusion aid, an adhesive agent and a glue mixing agent are mixed evenly, an obtained mixture is subjected to extrusion molding, and then drying and roasting are conducted to obtain a molded molecular sieve; a titanium source is added into the molded molecular sieve to prepare the titanium silica molecular sieve, and finally a surface modifier is added for modificationto obtain the catalyst. The catalyst provided by the present invention is suitable for catalyzing the oxidation of propylene with cumyl hydroperoxide. The conversion rate of cumyl hydroperoxide is high, the selectivity of propylene oxide is high and the content of a byproduct, namely phenol is relatively little.

Owner:HONGBAOLI GRP CO LTD +1

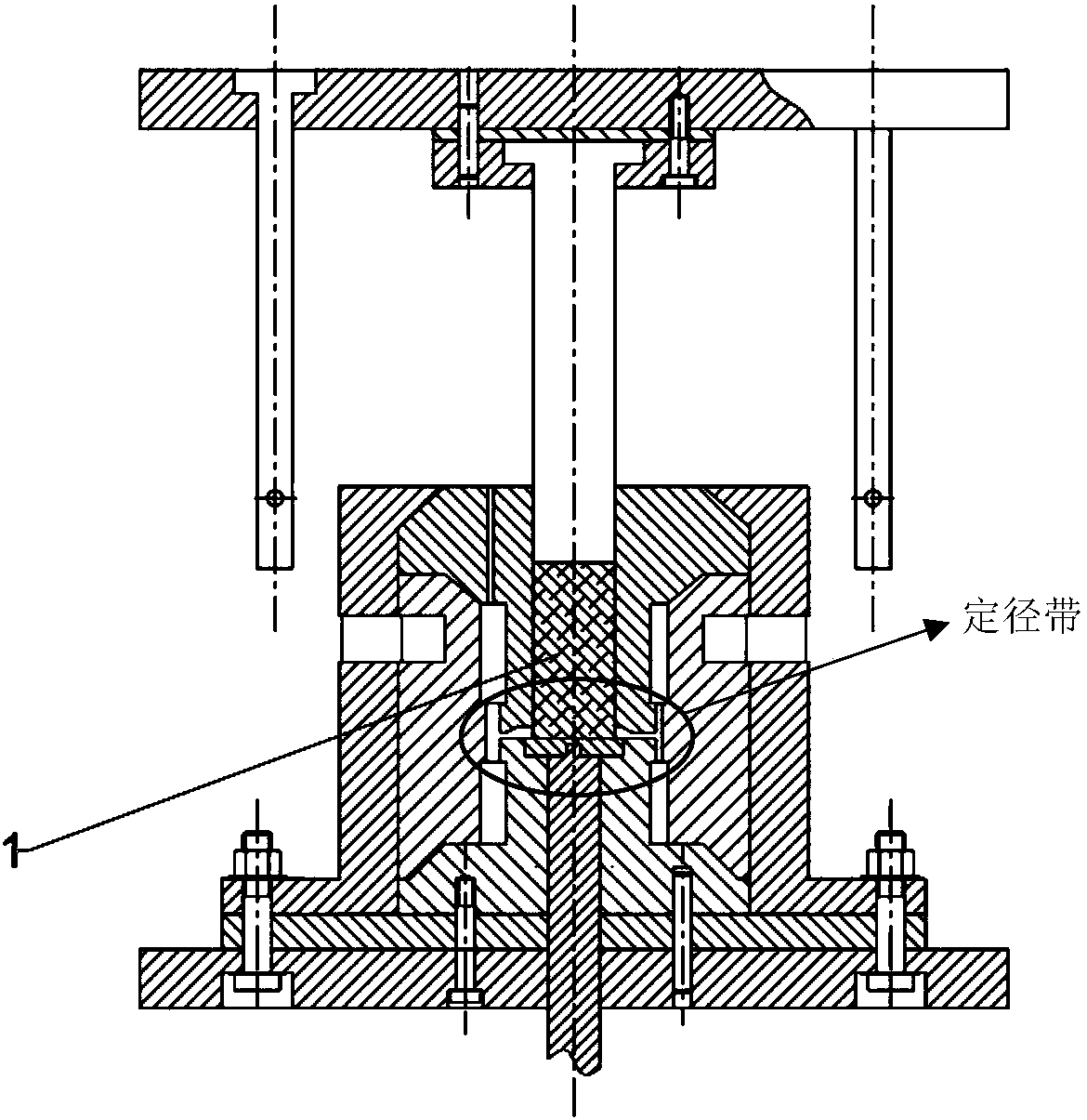

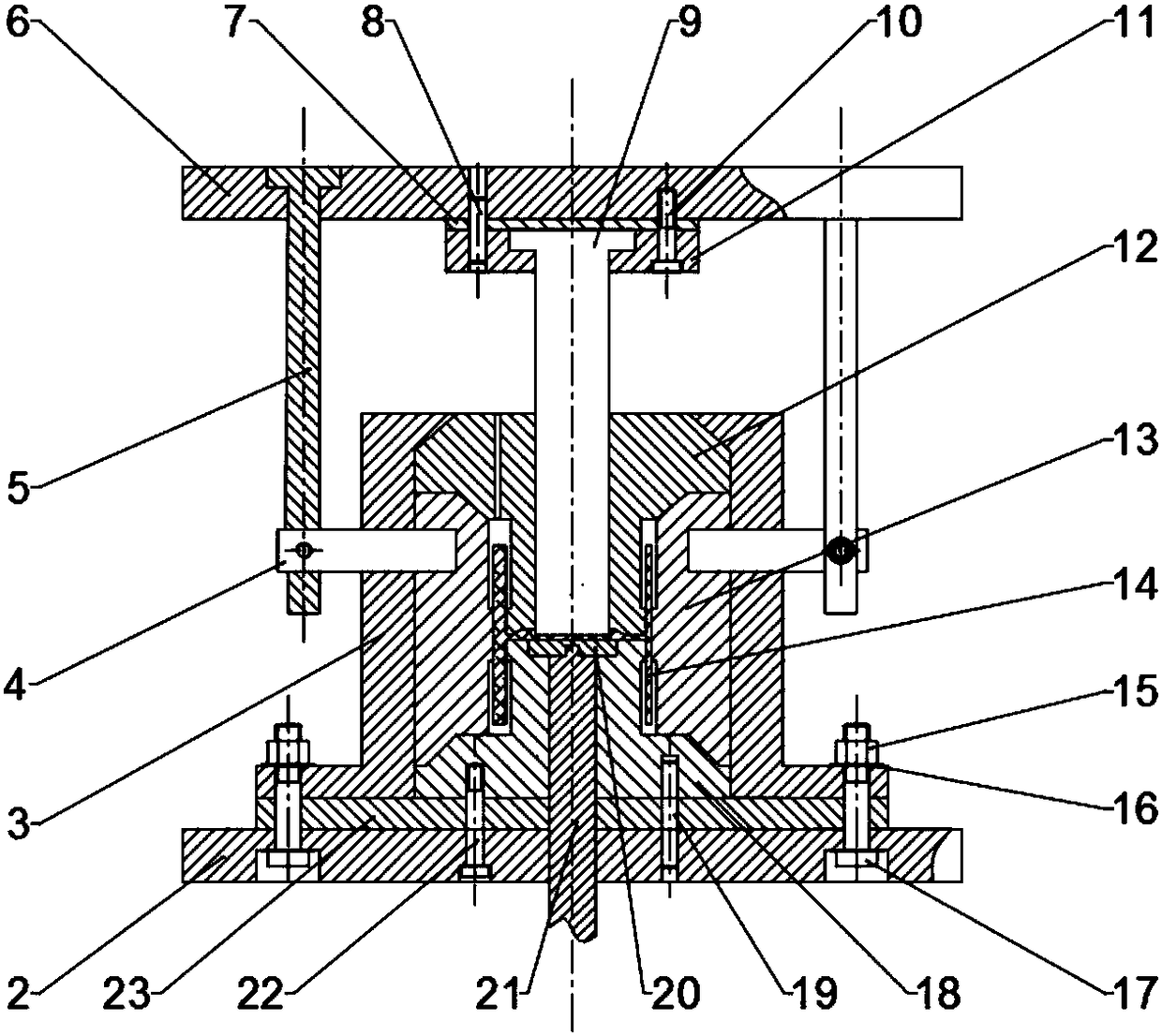

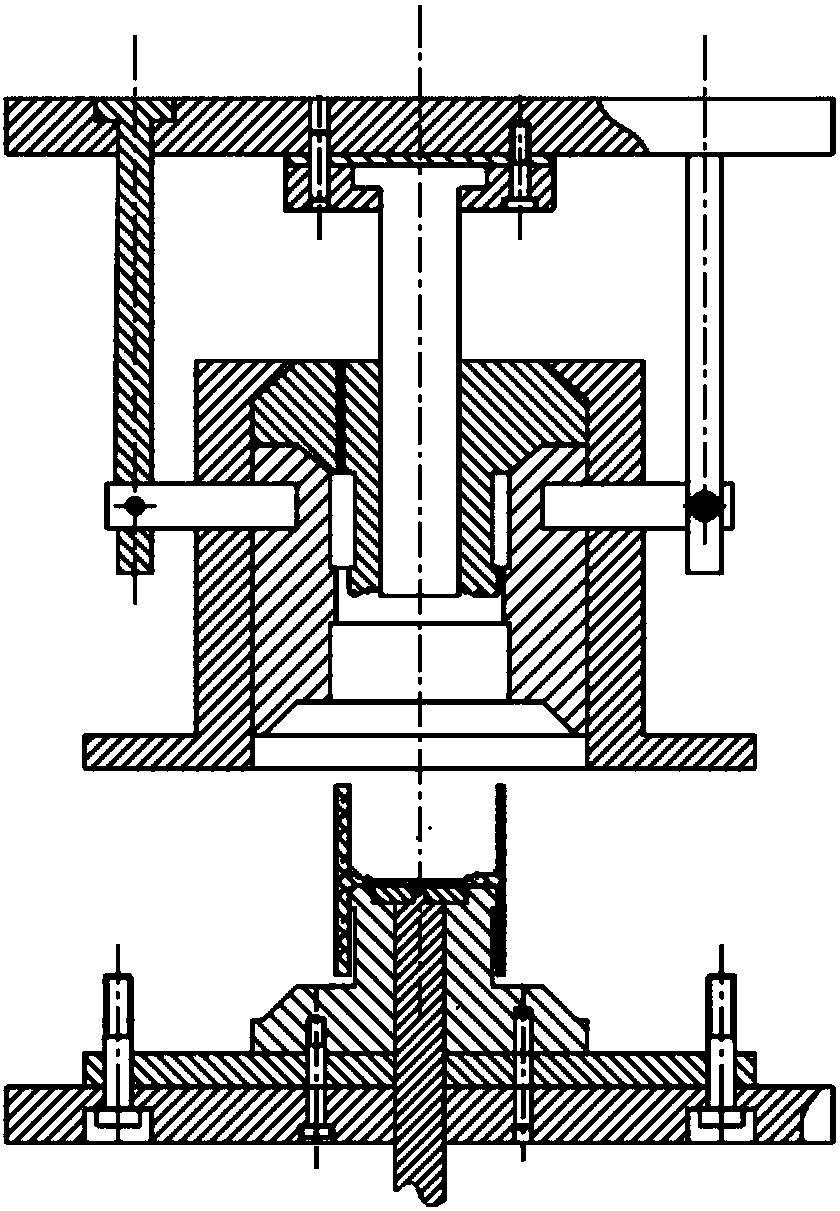

Strong plastic deformation extrusion molding device and method for magnesium alloy band rib barrel-type part

The invention provides a strong plastic deformation extrusion method and a molding device for magnesium alloy band rib barrel-type part, belonging to the technical field of plastic processing. A columnar billet is subjected to channel-changing corner extrusion for the first time to extend to a circumferential direction to form a circular rib and then subjected to the channel-changing corner extrusion for the second time to enter an up-down mold cavity to form a thin-walled cylinder provided with four longitudinal ribs. When a material is subjected to corner extrusion for multiple times, crystalline grains are constantly refined to generate strong plastic deformation to cooperate with the mold cavity to realize extrusion molding once and obtain the high-strength magnesium alloy band rib barrel-type part. The length of a diameter fixing band of an extrusion mold is shrunk so as to reduce friction between a formed part and a mold to decrease forming force. A longitudinal pull rod and a transverse shaft pin for special purpose are designed and cooperate with a mold structure, and after part molding is completed, the return stroke of a workbench on an extruder is utilized to disassemblethe mold and take out the formed part. A magnesium alloy barrel-type part, which has high strength, can be molded once, a circular rib and longitudinal bars therein can be used as support structures,and the designed part taking structure can be used for effectively solving the problem that a barrel-type extrusion part is difficult to take out.

Owner:UNIV OF SCI & TECH BEIJING

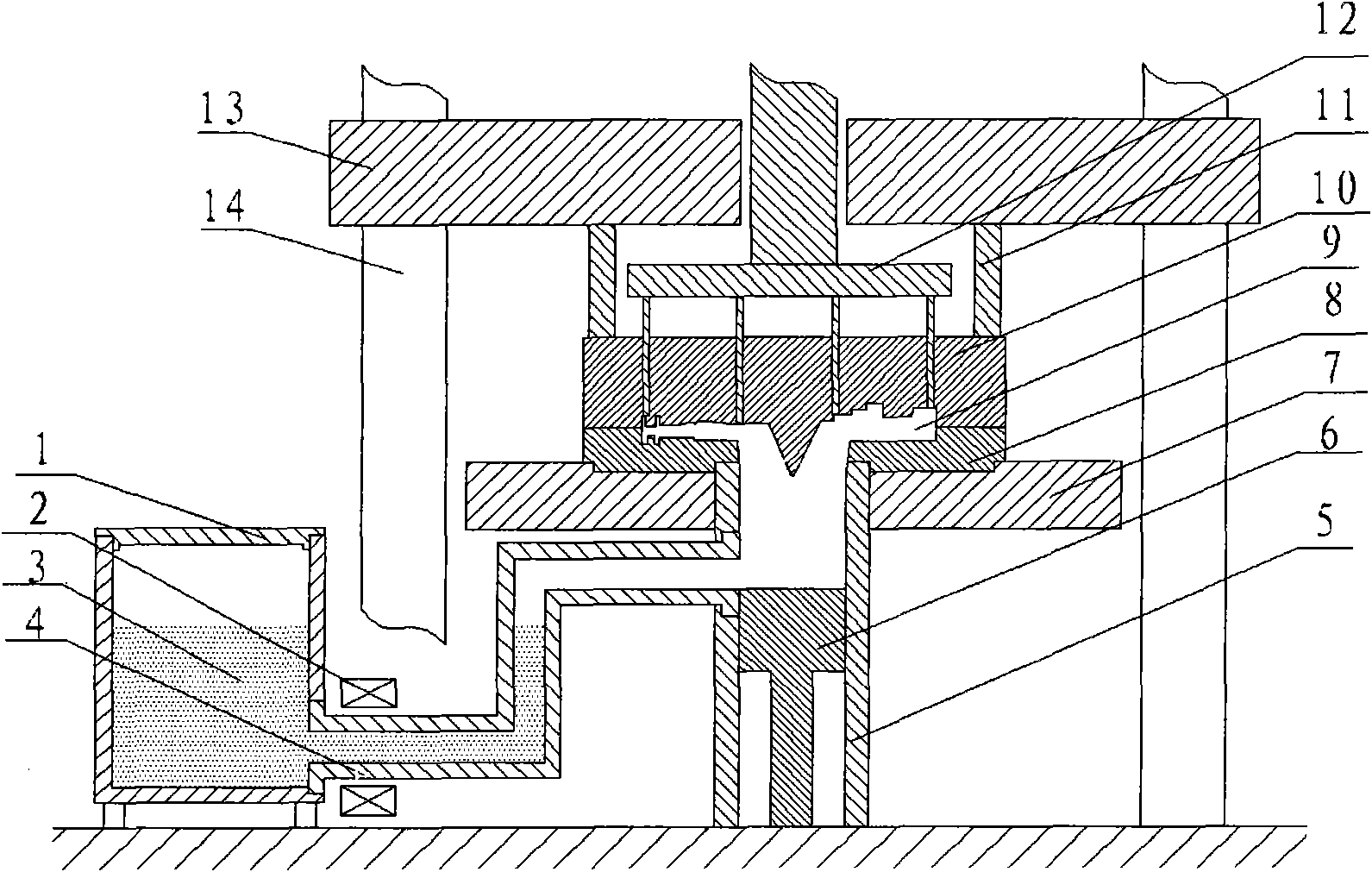

Method for indirect extrusion casting by utilizing filling of electromagnetic force and device thereof

The invention relates to a method for indirect extrusion casting by utilizing the filling of electromagnetic force and a device thereof. In the method, electromagnetic force is utilized to introduce liquid metal into an extrusion chamber to fill part of a mould cavity by a transmission pipeline; when the liquid metal in the mould cavity reaches a preset quantity, the transmission of the liquid metal is stopped; and an extrusion punching head ascends to push the liquid metal to fill the part which is not full in the mould cavity and continuously ascends to extrude and shape the liquid metal, and the liquid metal in the transmission pipeline flows back to a thermal insulation furnace under the function of reverse electromagnetic force. The invention has simple and convenient method, high automatization degree, good stability and skillful structural design of a special device. The liquid metal is transmitted and filled by a sealed transmission pipeline, and oxidation and air suction are reduced; the flow speed and the flow rate are controllable, and the quantification of extrusion casting is realized; at the time of extrusion shaping, the liquid metal in the transmission pipeline flows back, and the production efficiency is enhanced; and the friction and the abrasion of the extrusion punching head and the extrusion chamber are reduced, and the service lives of the extrusion punching head and the extrusion chamber are enhanced.

Owner:SOUTH CHINA UNIV OF TECH

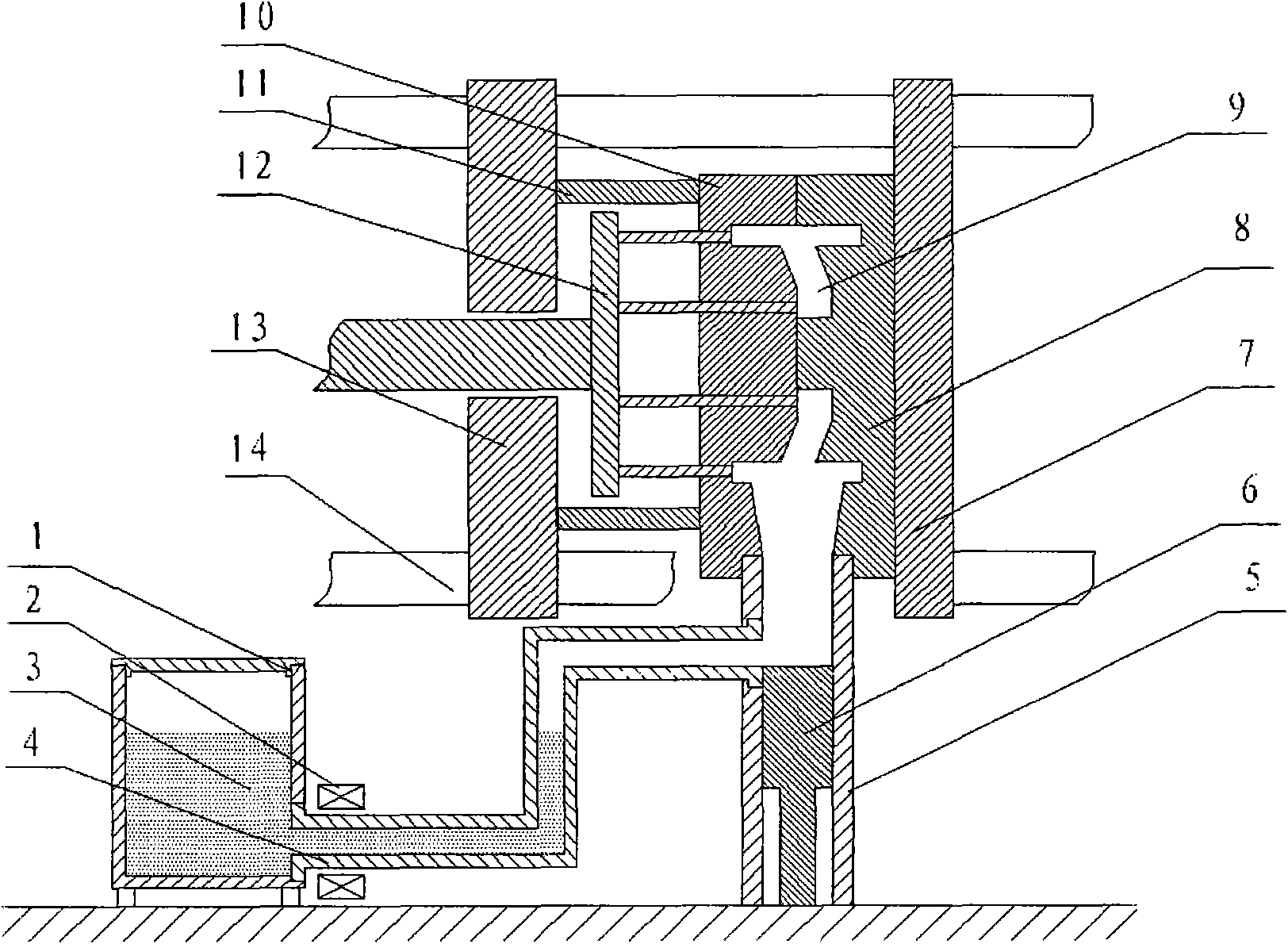

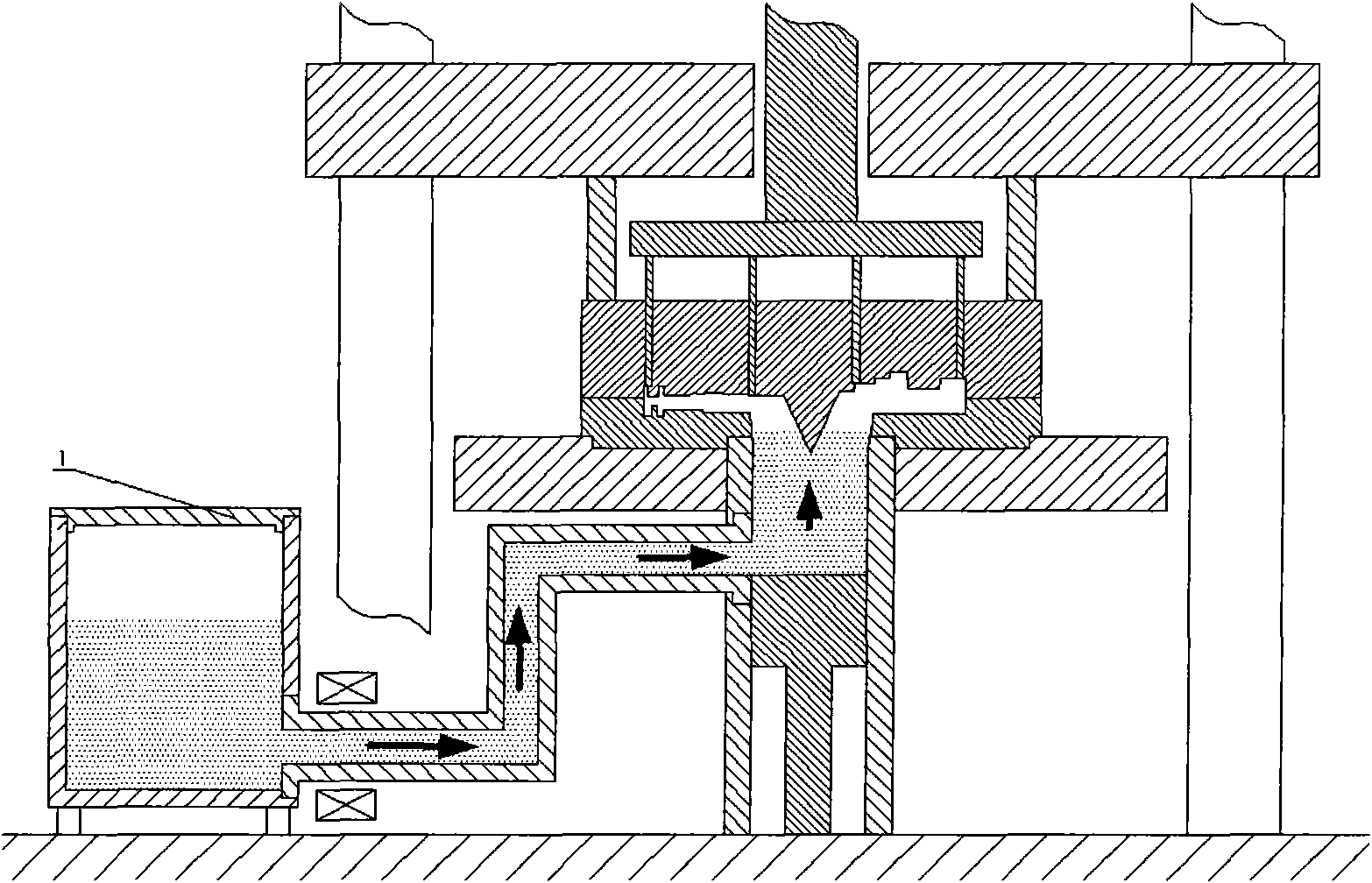

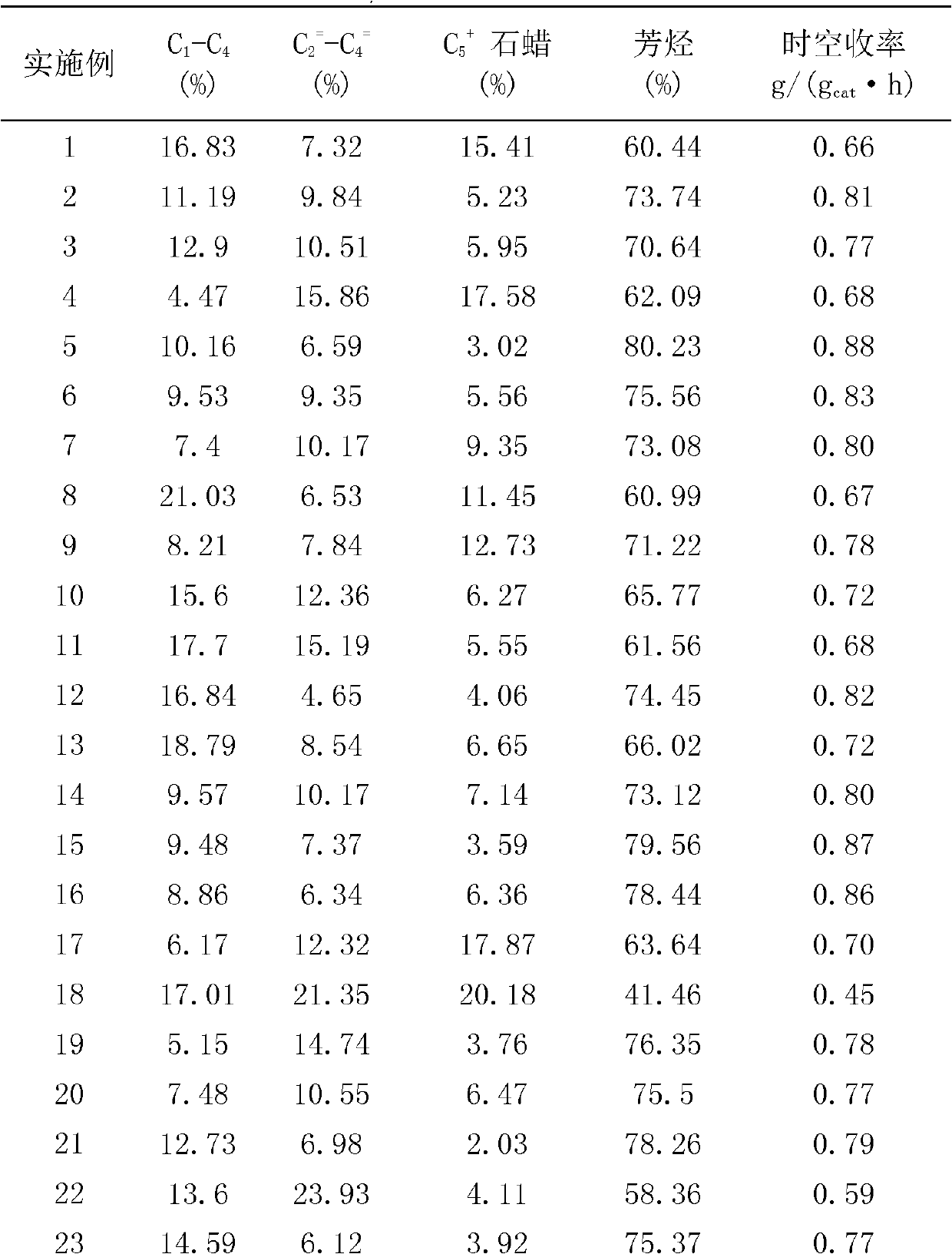

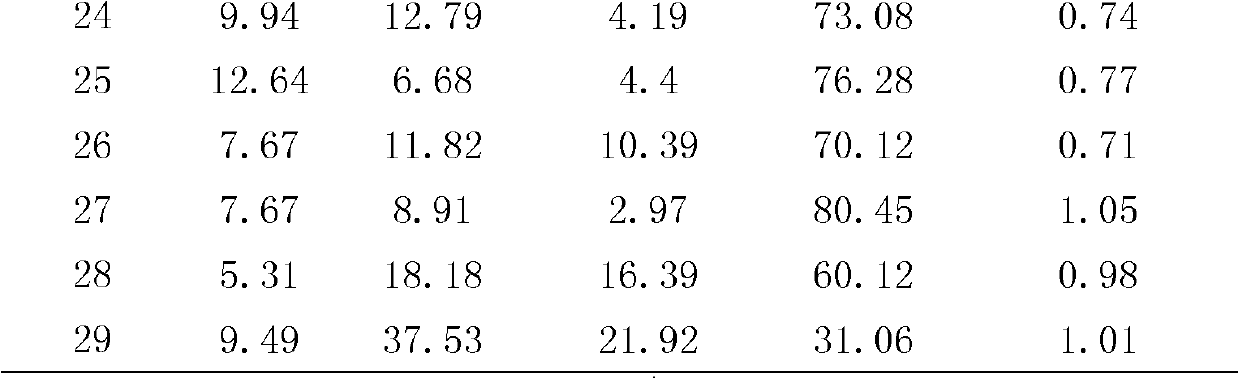

Molecular sieve based catalyst and preparation and application thereof

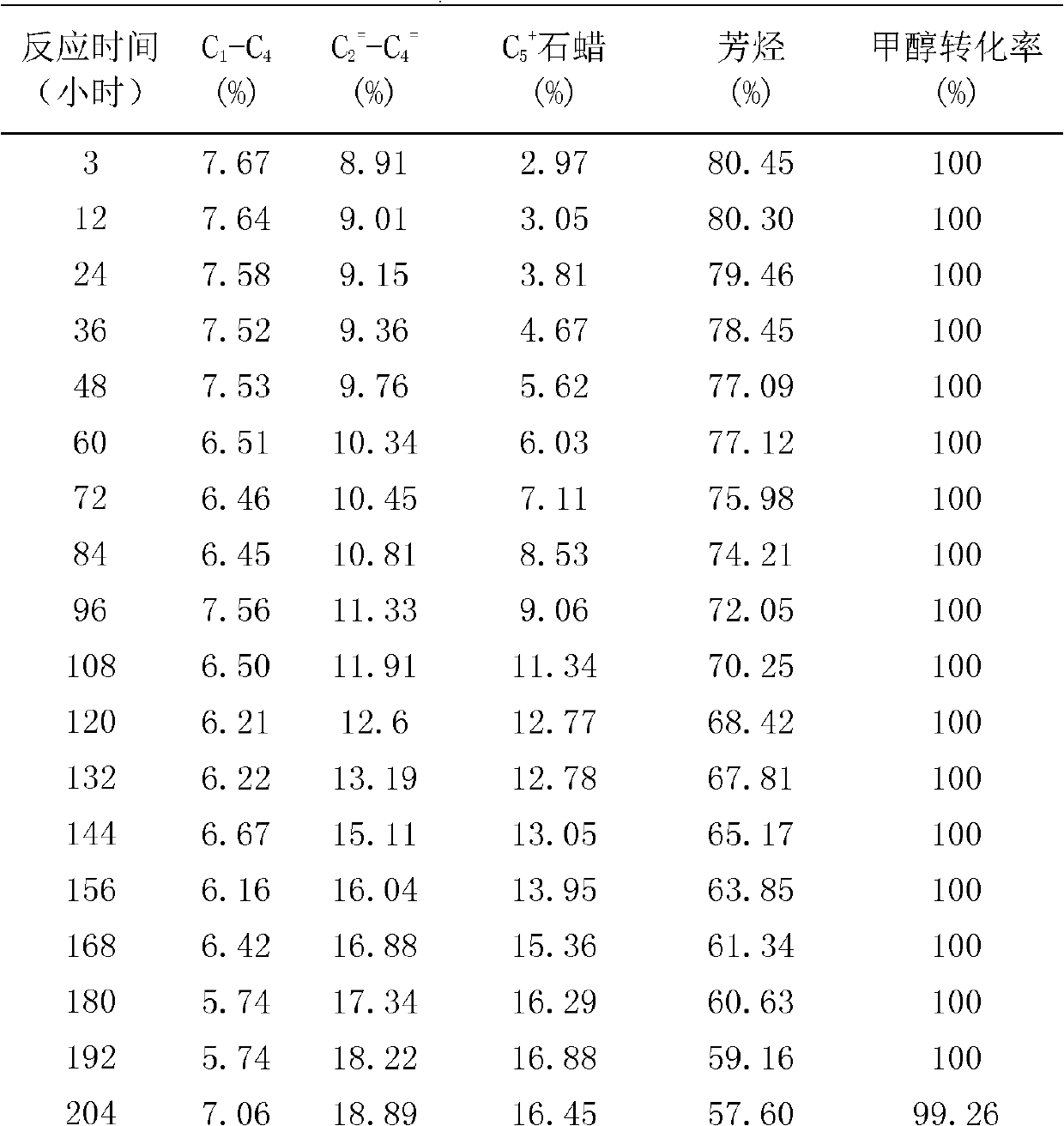

InactiveCN103372456AImprove stabilityExtend your lifeMolecular sieve catalystsHydrocarbon from oxygen organic compoundsFixed bedIon exchange

The invention discloses a molecular sieve based catalyst, which mainly comprises a Zn, Ag, Ga and La modified HZSM-5 molecular sieve and a binder, wherein the binder accounts for 5-50% of the total mass of the catalyst; the molar ratio of SiO2 to Al2O3 in the molecular sieve is 10-1000, and the molar ratio of SiO2 to metals is over 20. The invention also discloses preparation methods of the catalyst and the application of the catalyst in MTA (methanol to aromatics) reactions. The preparation method 1 comprises the following steps of: firstly carrying out extrusion moulding on the skeleton metal containing ZSM-5 molecular sieve; then treating by using alkali liquor; and finally carrying out ion exchange and high-temperature roasting to obtain the target product. The preparation method 2 comprises the following steps of: firstly carrying out extrusion moulding on the ZSM-5 molecular sieve; then, treating by using alkali liquor; and finally carrying out ion exchange, auxiliary soaking and high-temperature roasting to obtain the target product. According to the invention, through controlling the conditions such as the silica-alumina ratio of the molecular sieve and alkali treatment, the service life of the ZSM-5 molecular sieve on a fixed bed reactor is prolonged, and the activity of the catalyst and the selectivity of MTA reaction are improved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Preparation method of plastic starch-modified PBAT (poly(terephthalic acid-buthylene succinate)) biodegradable material

The invention relates to a preparation method of a plastic starch-modified PBAT (poly(terephthalic acid-buthylene succinate)) biodegradable material. The preparation method comprises the following three steps: preparing a plastic starch; performing melt blending on the plastic starch and PBAT; and processing the modified material. The plastic starch-modified PBAT biodegradable material can be applied through multiple processing measures of injection moulding, cast moulding, film casting, extrusion moulding and the like. In the modified material, the starch recycling rate is low, and the recycled starch has the particle diameter of 1-50 nm and is uniformly dispersed in a matrix; the tensile strength is 10-15 MPa, the elongation at break is 100-700%, and the melt index (150 DEG C, 2160g) is more than or equal to 1 g / 10 min; and under a composting condition, the plastic starch-modified PBAT biodegradable material is kept for 30 days at the temperature of 20-50 DEG C and the humidity of 30-60%, and 50-75% of the plastic starch-modified PBAT biodegradable material can be degraded. The plastic starch-modified PBAT biodegradable material integrates excellent mechanical properties and biodegradability and has a relatively large potential in industrial application.

Owner:SHANGHAI JIAO TONG UNIV +1

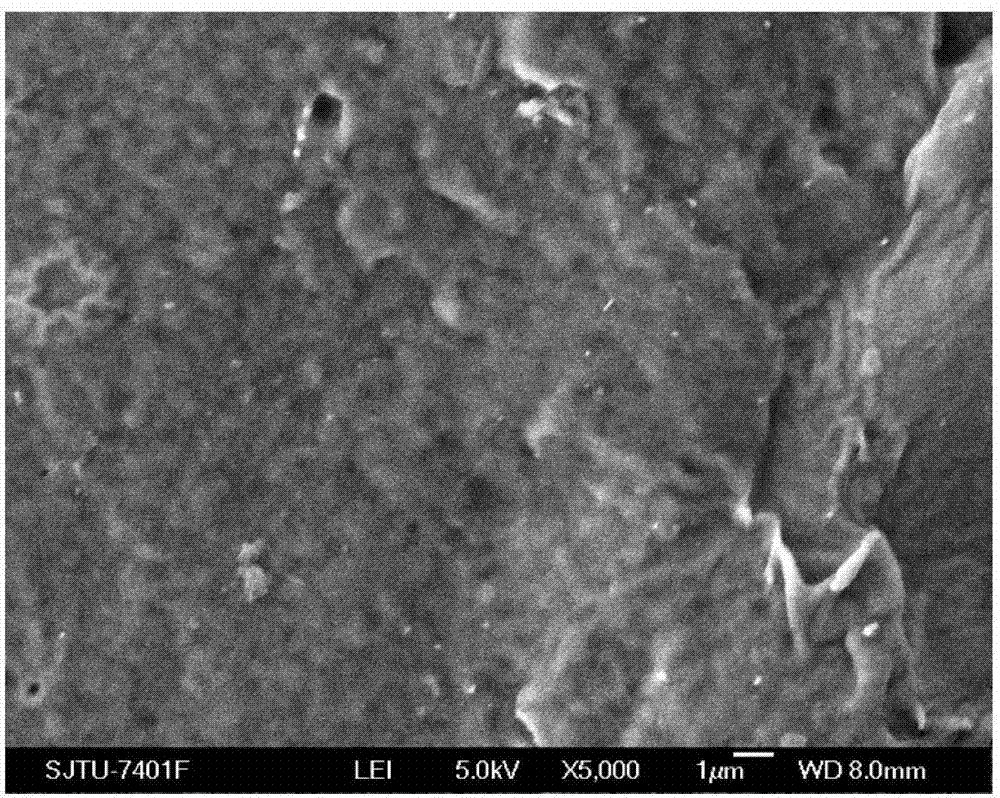

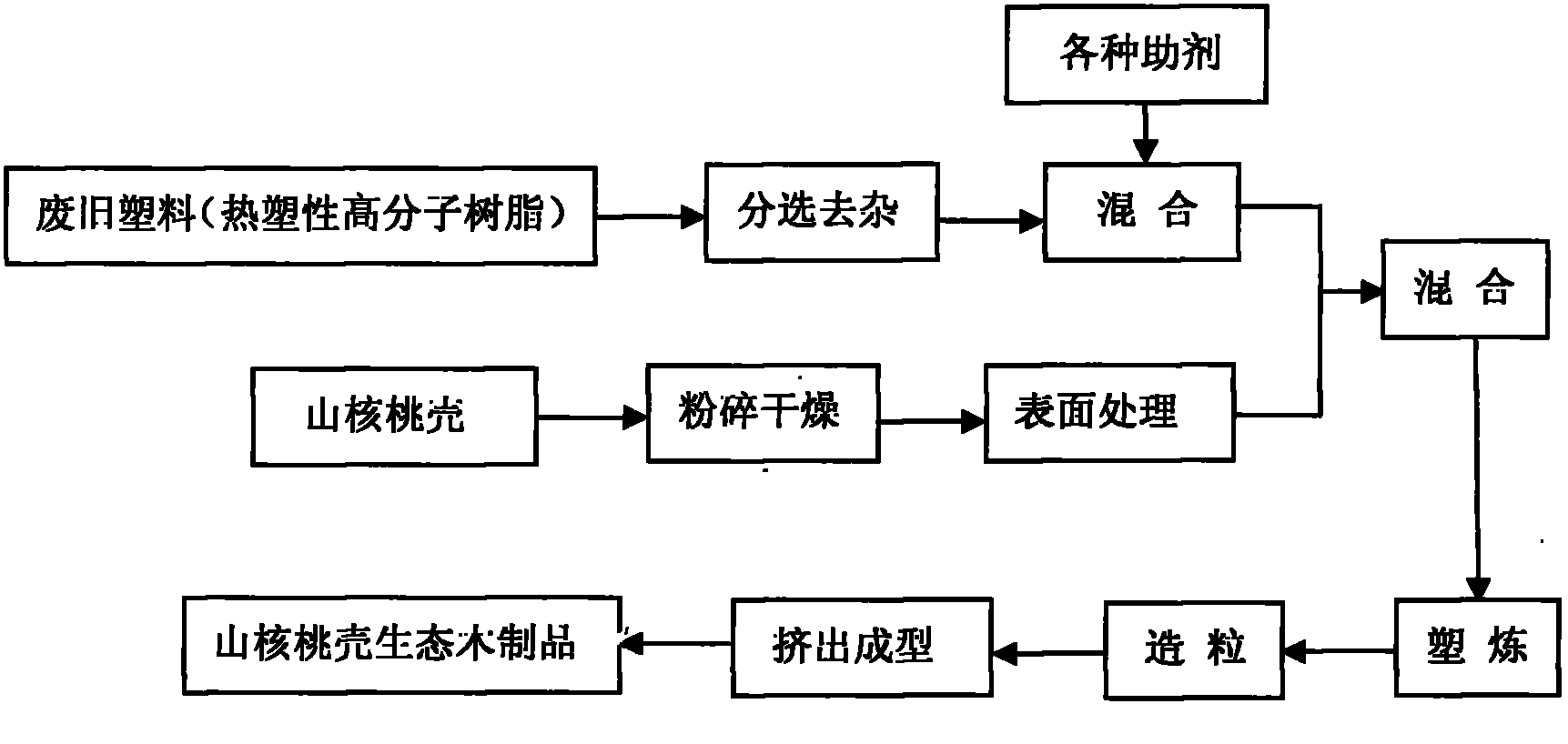

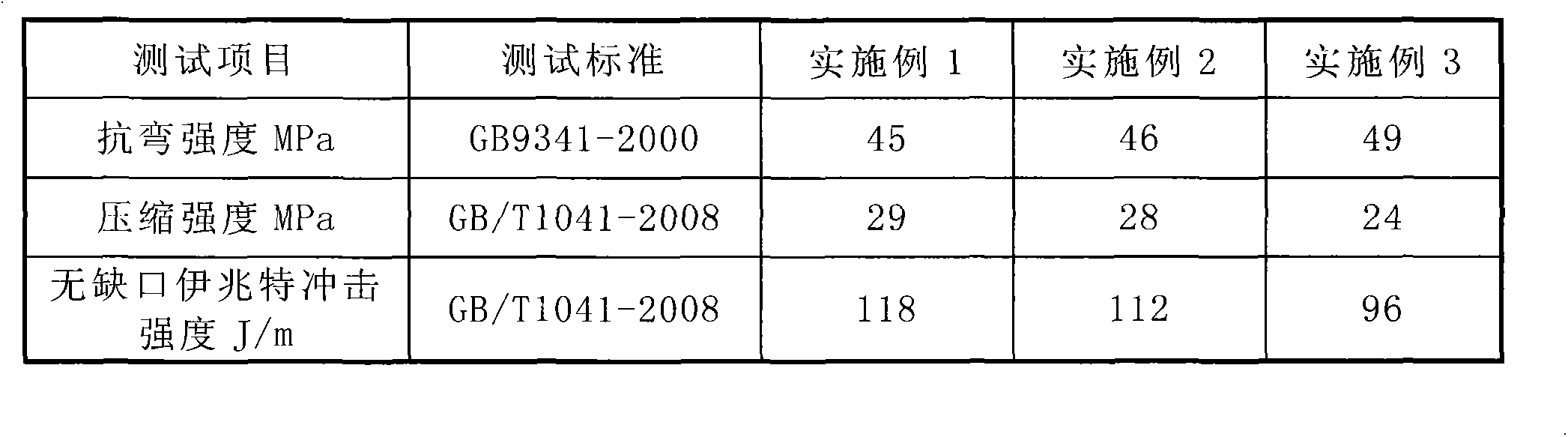

Hickory nut shell ecologic wood composite material and preparation method thereof

The invention relates to a plastic-wood composite material and provides a hickory nut shell ecologic wood composite material and a preparation method thereof. The hickory nut shell ecologic wood composite material is prepared from following components including, by weight, 50-60 parts of a thermoplastic high-molecular resin, 40-50 parts, or 30-40 parts, of hickory nut shell powder, 10-20 parts of wood powder, 8-10 parts of light calcium carbonate, 10-14 parts of a compatilizer, 2-4 parts of a thermal stabilizer, 2-4 parts of a lubricant, 2-3 parts of a plasticizer, and 1-3 parts of an antioxidant and an ultraviolet stabilizer. A comprehensive technology comprising deep process of raw materials and extrusion moulding and the like is employed. Deep process waste of wild hickories and waste plastic resources are employed. The composite material in the invention has dual-characteristics, which exist in common plastic-wood, of wood and plastic, is better in mechanical performances and is more rigid, durable, wear-resistant and weather-resistant. The method is simple and convenient, is low in manufacturing cost, can be recovered and recycled, can save energy resources and can protects environment.

Owner:LIAONING CHANGBAIXIANZI BIOTECH

Ultrahigh-strength aluminum alloy material and preparation method of pipe blank for preparing internal cylinder of separator

The invention relates to an ultrahigh-strength aluminum alloy material and a preparation method of a pipe blank for preparing an internal cylinder of a separator, belonging to the technical field of material processing and solving the problems that the traditional aluminum alloy material has lower tensile strength and the internal cylinder of the separator, which is prepared by using the traditional aluminum alloy material, can not meet the requirements on the separator for working for a long time at high rotating speed. The invention puts a technical emphasis on that the ultrahigh-strength aluminum alloy material comprises the following components in percentage by weight: 10.5-13.0wt% of Zn, 2.3-3.2wt% of Mg, 1.2-1.8wt% of Cu, 0.2-0.3wt% of Mn, 0.2-0.3wt% of Cr, 0.1-0.2wt% of Zr, 0.1-0.2wt% of Sc, less than 0.05wt% of Fe, less than 0.05wt% of Si and the balance of Al. The preparation method of the pipe blank comprises the following steps of: melting alloys, and casting into an alloy ingot; carrying out melting, casting transfer, atomized spray and deposition forming on the alloy ingot to prepare a flash set billet; carrying out isothermal forging performing; carrying out hot extrusion forming by adopting an extrusion mould; and carrying out twin-stage solid solution and aging treatment on a preformed pipe blank so as to prepare the pipe blank which can be used for preparing the internal cylinder of the separator. The invention is suitable for preparing the internal cylinder of a centrifugal separator which works for a long time at the rotating speed of 8000-10000 rpm.

Owner:HARBIN INST OF TECH

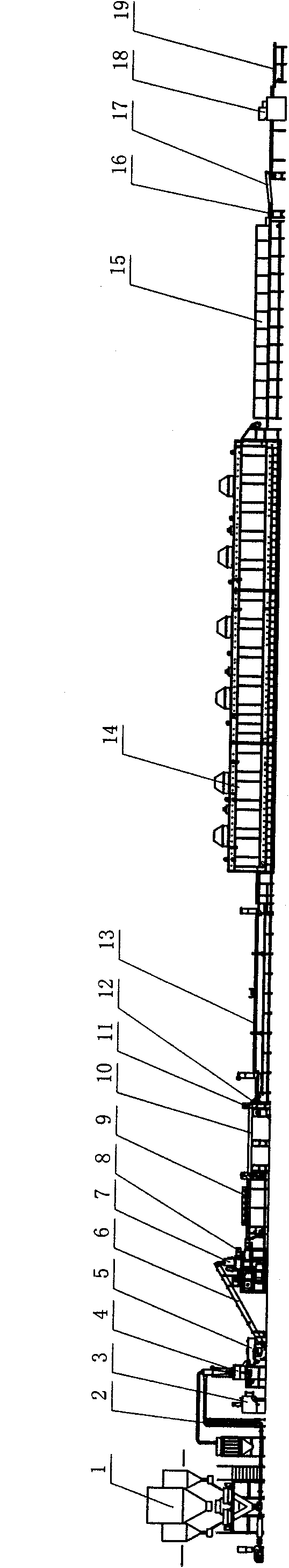

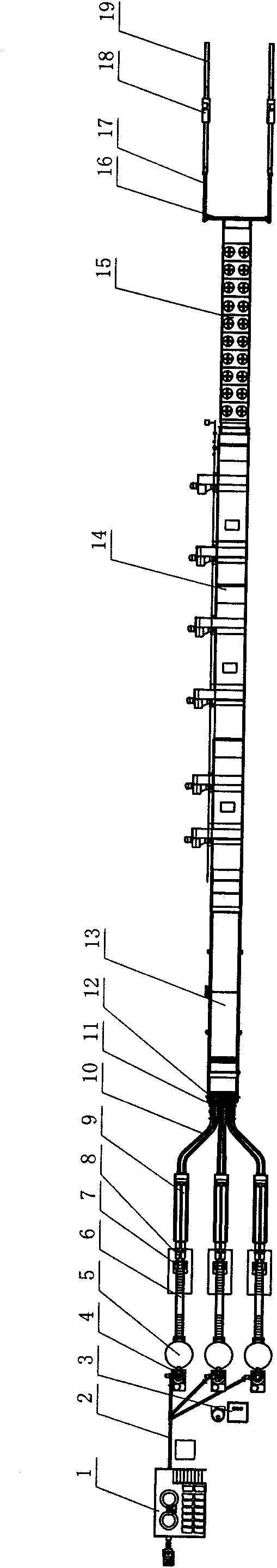

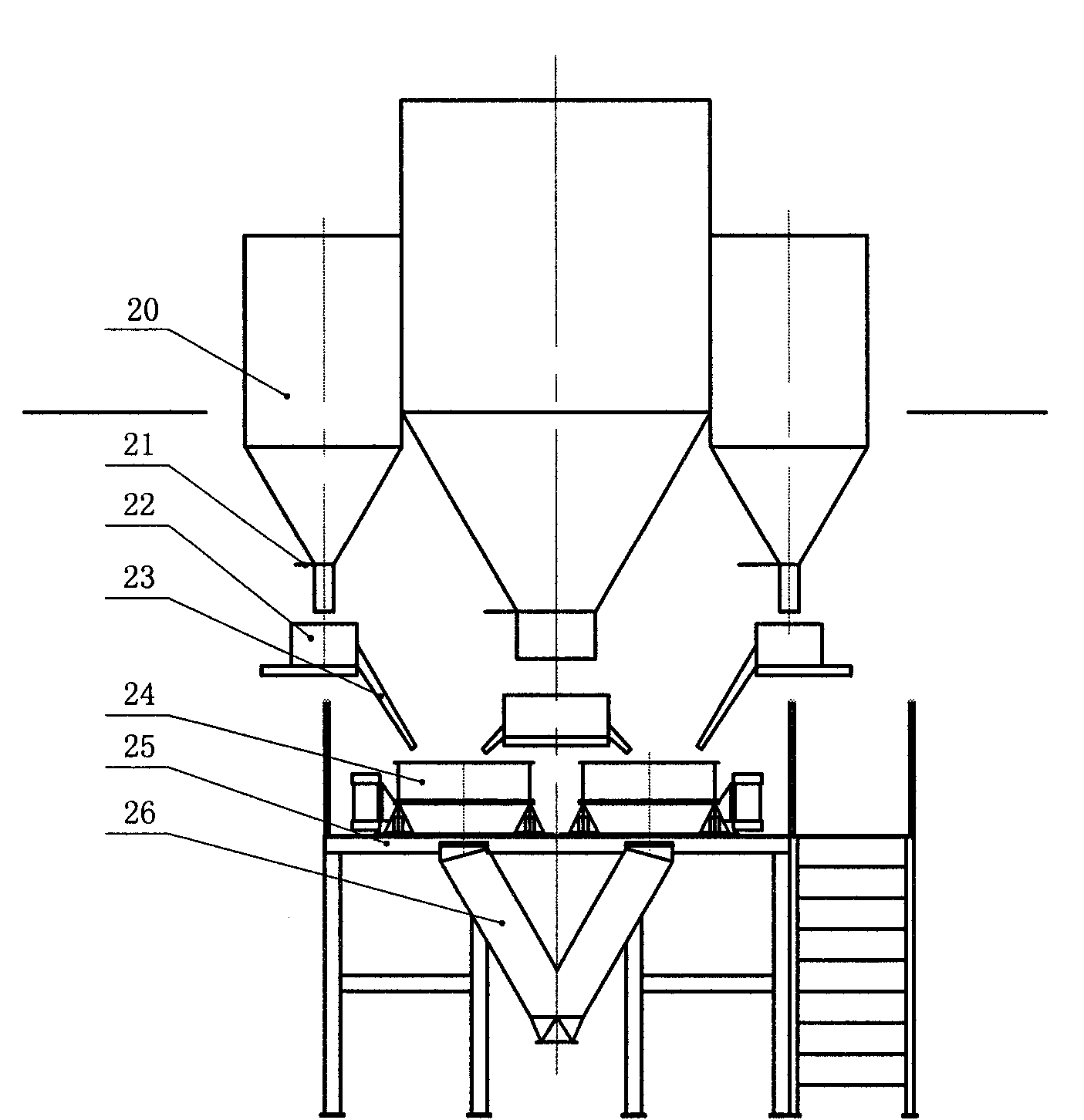

Cereal coarse grain instant noodle processing production line

InactiveCN102058056AGuaranteed uptimeReduce labor intensityDough shaping and cutting apparatusDough extruding machinesAutomatic controlPositive pressure

The invention relates to a cereal coarse grain instant noodle processing production line, comprising a mixing drum, a flour mixing machine, a hoisting machine, a flour feeding machine, an extrusion moulding machine, a quantitative cutting machine, a row combining machine, a pneumatic stopping device, a row separating device, a flour steaming machine, a drying machine, a cooling machine, an inspection conveyor, a packaging machine and a finished product conveyor which are sequentially connected, wherein an automatic weighing blanking device and a positive pressure conveying device are arranged in the procedure before the procedure of the flour mixing machine; a flour softening machine is arranged between the flour mixing machine and the hoisting machine; the extrusion moulding machine is one with automatically controlled temperature and curing degree; the quantitative cutting machine is of high accuracy type; the row separating device is of pneumatic type; the drying machine is a multi-section temperature and humidity controllable drying machine; and a transition conveyor is arranged between the cooling machine and the inspection conveyor. The invention can complete integration continuous production including burdening, conveying powder, mixing flour, softening flour, extruding and curing, high accuracy quantitative cutting, stewing and curing, multi-section drying, cooling and finished product packaging.

Owner:SHENGCHANGDA MACHINERY TIANJIN

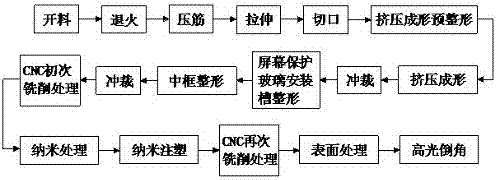

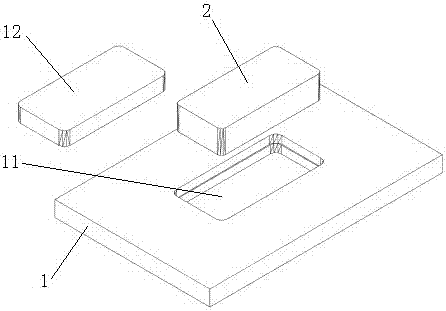

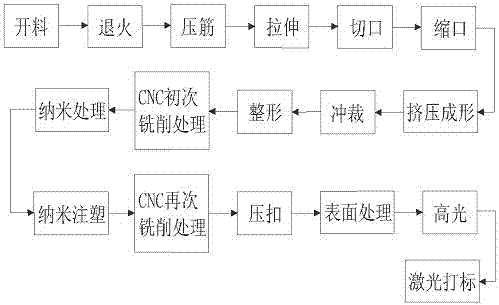

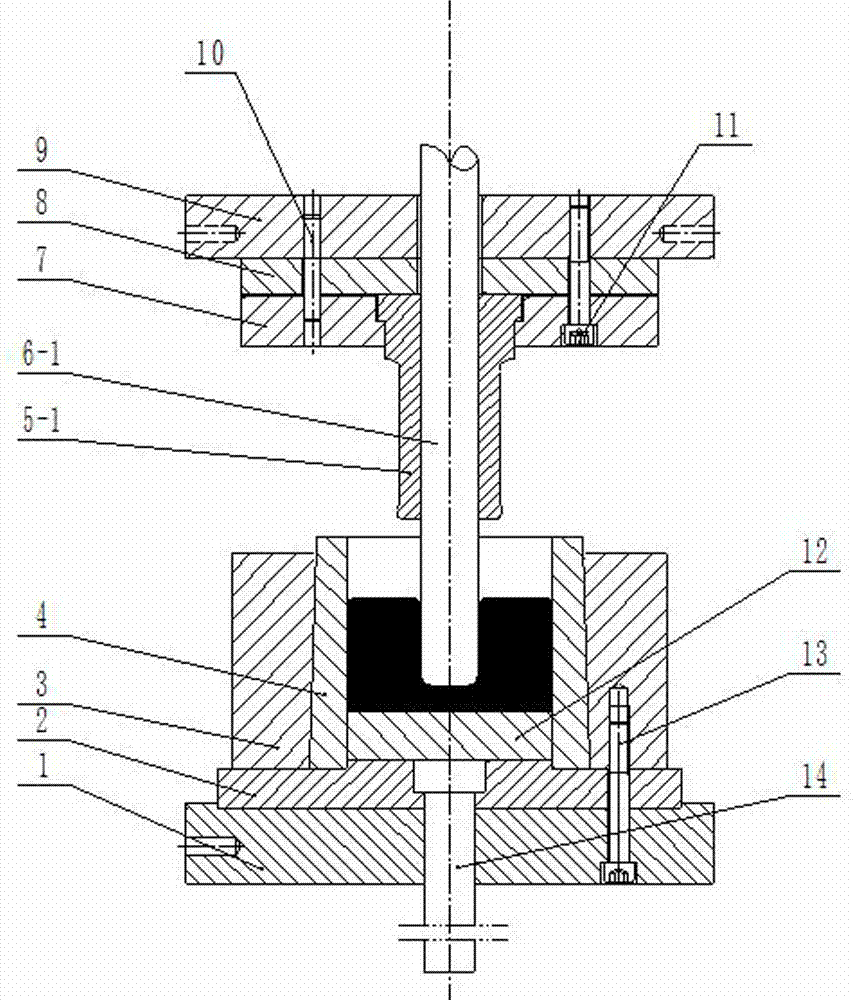

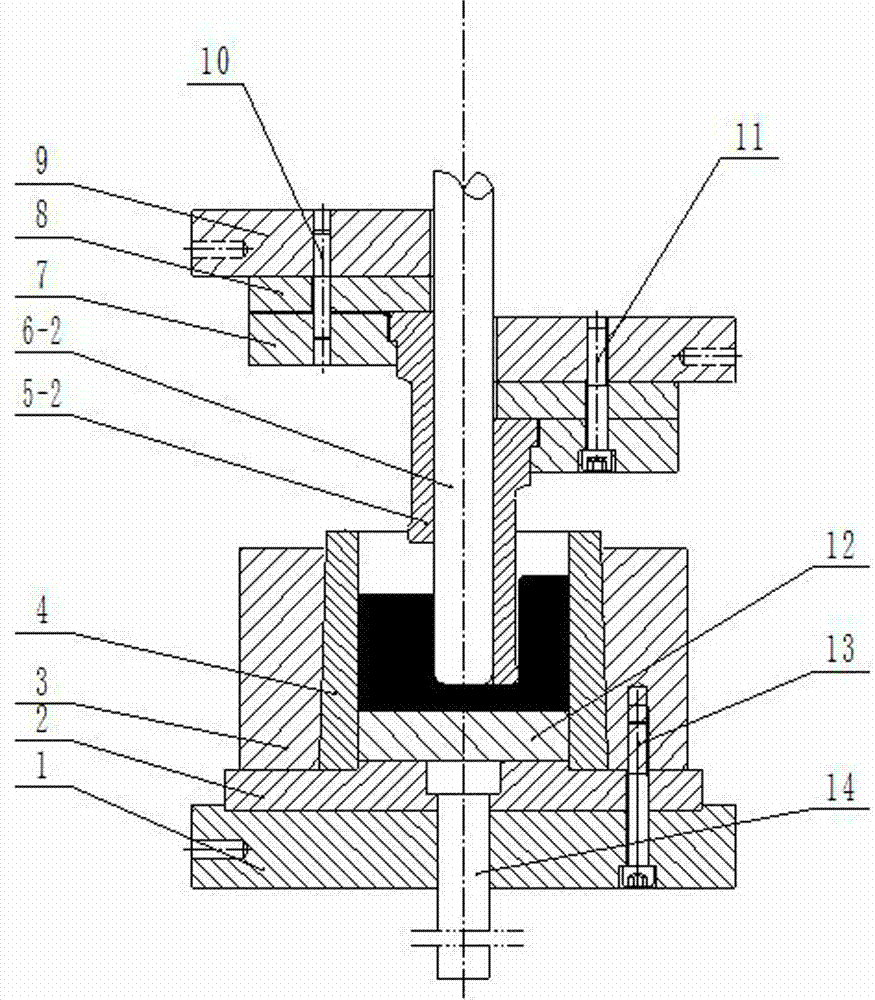

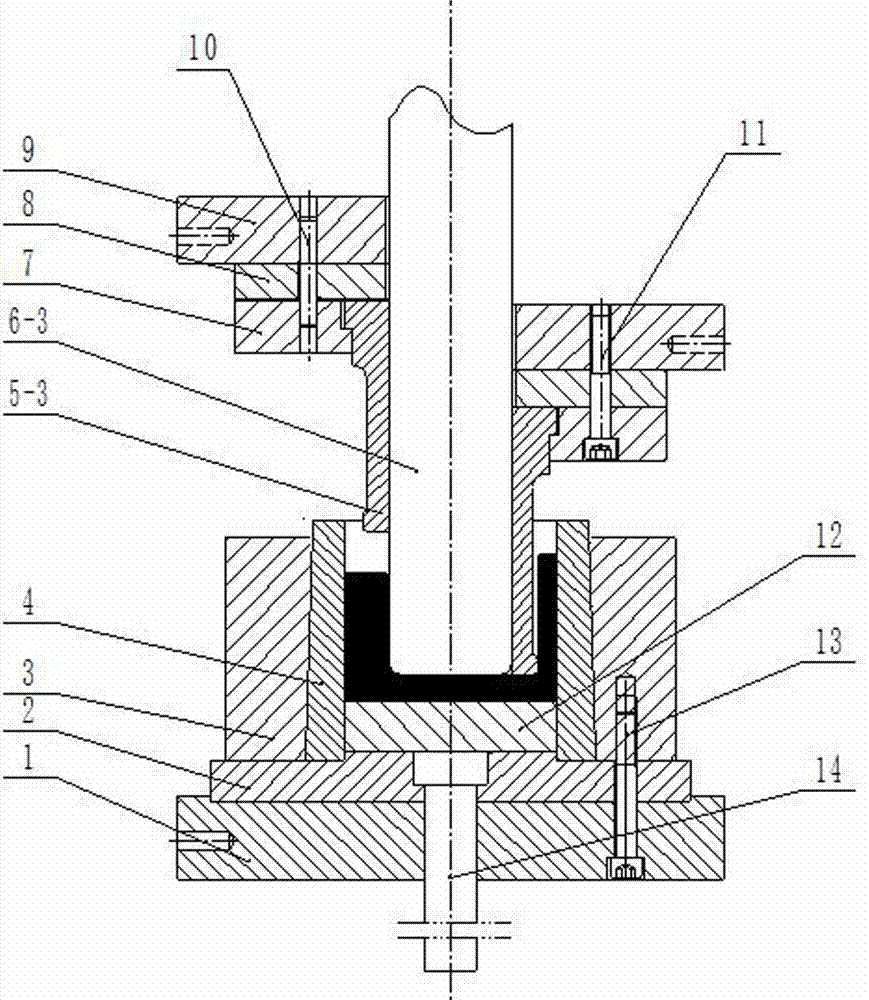

Manufacturing method of mobile phone shell and special die

ActiveCN107199287AMany structural stylesHigh strengthShaping toolsExtrusion diesNumerical controlMetal sheet

The invention relates to a manufacturing method of a mobile phone shell and a special die. The method is used for manufacturing a front shell or a back shell of a mobile phone and specifically comprises the following steps of cutting sheet metal into metal sheets first, drawing the metal sheets into concave hollow pieces, shaping notches of the concave hollow pieces, then putting in a die for extrusion forming, performing nanometer treatment and nanometer injection molding after extrusion forming, milling and trimming a workpiece through CNC (Computer Numerical Control), and then performing surface treatment on the workpiece. The die for manufacturing the front shell or the back shell of the mobile phone comprises a lower die and an upper die, wherein the upper die is matched with the lower die. The manufacturing method has the advantages of reasonable concept, simple operating process, good manufacturing quality and high efficiency and is suitable for popularization and application.

Owner:蔡振豪

Elastic body material for refrigerator sealing strips and preparation method thereof

ActiveCN101983984AReduce weightIncrease elasticityDomestic cooling apparatusLighting and heating apparatusElastomerPolymer science

The invention discloses an elastic body material for refrigerator sealing strips and preparation method thereof. The elastic body material for refrigerator sealing strips consists of hydrogenation styrene resin, rubber filling oil, polypropylene, mineral filler, weather resistant agent, compatibilizer and processing aids. The elastic body material for refrigerator sealing strips is manufactured by extrusion graining with counter-rotating twin-screw extruder after the raw material is mixed in high-speed mixer. Halogen material and o-benzene plasticizer which is harmful to human health will not be introduced in practical production process of the elastic body material for refrigerator sealing strips. The thermoplastic elastomer material produced in the invention has the advantages of light weight, high resilience, high welding strength, easy colorizing and good low-temperature resistance. There is no need for the treatment of high temperature sulfidation when extrusion moulding is operated with the above material. Decomposion of toxic gas and corrosion of production equipments will not happen during the process of extrusion moulding, and scraps can be recovered and re-used.

Owner:KINGFA SCI & TECH CO LTD +1

Extrusion and molding method for cup-shaped part and special extrusion die

The invention relates to an extrusion and molding method for a cup-shaped part and a special extrusion die. The extrusion and molding method comprises the following steps that (1) a blank to be extruded is put into a concave die, wherein the extrusion die comprises an inner convex die; an outer convex die is sleeved outside the inner convex die; the outer convex die is in guided sliding fit with the inner convex die; a pressure machine is provided with a power output shaft which is correspondingly connected with the outer convex die and the inner convex die; a corresponding output shaft of the pressure machine drives the inner convex die which is in transmission connection with the pressure machine to downwards extrude the blank; the inner convex die is moved downwards to the thickness of the needed part; (2) the lower end of the inner convex die is ejected against the blank to keep still; the output shaft on which the pressure machine and the outer convex die are in the transmission connection drives the outer convex die to slide downwards along the outer periphery of the inner convex die to extrude the blank to form the needed cup-shaped part; (3) after the extrusion is finished, the pressure machine drives the inner convex die and the outer convex die to return so as to eject the molded part. According to the extrusion and molding method for the cup-shaped part and the special extrusion die, the inner convex die and the outer convex die are extruded in sequence; the single-time extrusion area is small and the tonnage of extrusion equipment can be reduced so that the production cost is reduced.

Owner:HENAN UNIV OF SCI & TECH

Differential extrusion forming die of high-performance magnesium alloy cup-shaped part

ActiveCN106825098AIncrease the number of deformationsIncrease the amount of plastic deformationExtrusion diesExtrusion mandrelsChinese charactersMachining process

The invention discloses a differential extrusion forming die of a high-performance magnesium alloy cup-shaped part and relates to the technical field of metal plastic machining processes and forming. A combined type female die comprising a T-shaped upper female die body and a U-shaped lower female die body is adopted. A cylindrical cavity is formed inside the T-shaped upper concave die body mounted on the U-shaped lower concave die body, and the cross section of a formed revolution body cavity is shaped like the Chinese character 'shan'. Staggered ladder type differential extrusion steps are arranged at the bottom of the extrusion cavity shaped like the Chinese character 'shan'. The magnesium alloy cup-shaped part is extruded through the extrusion cavity shaped like the Chinese character 'shan' and the staggered ladder type differential extrusion steps at the bottom of the cavity, so that the forming capacity of a magnesium alloy material is improved greatly, a high compact structure and large plastic deformation are obtained, the grain refining effect is significant, the effect of removing grain dual modality distribution of the cylinder wall of the cup-shaped part is obvious, and the manufacturing process of the high-performance magnesium alloy cup-shaped part is accelerated.

Owner:ZHONGBEI UNIV

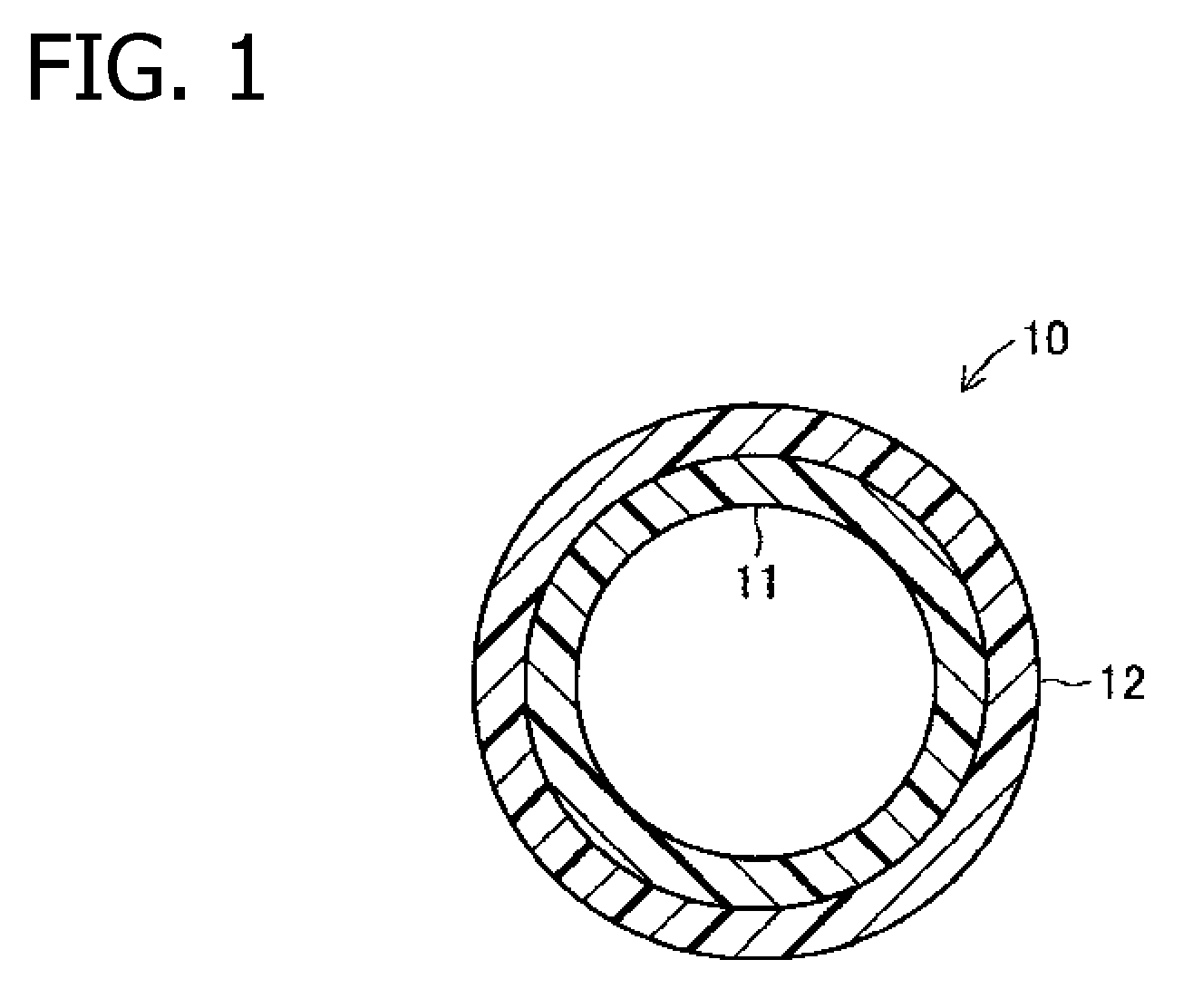

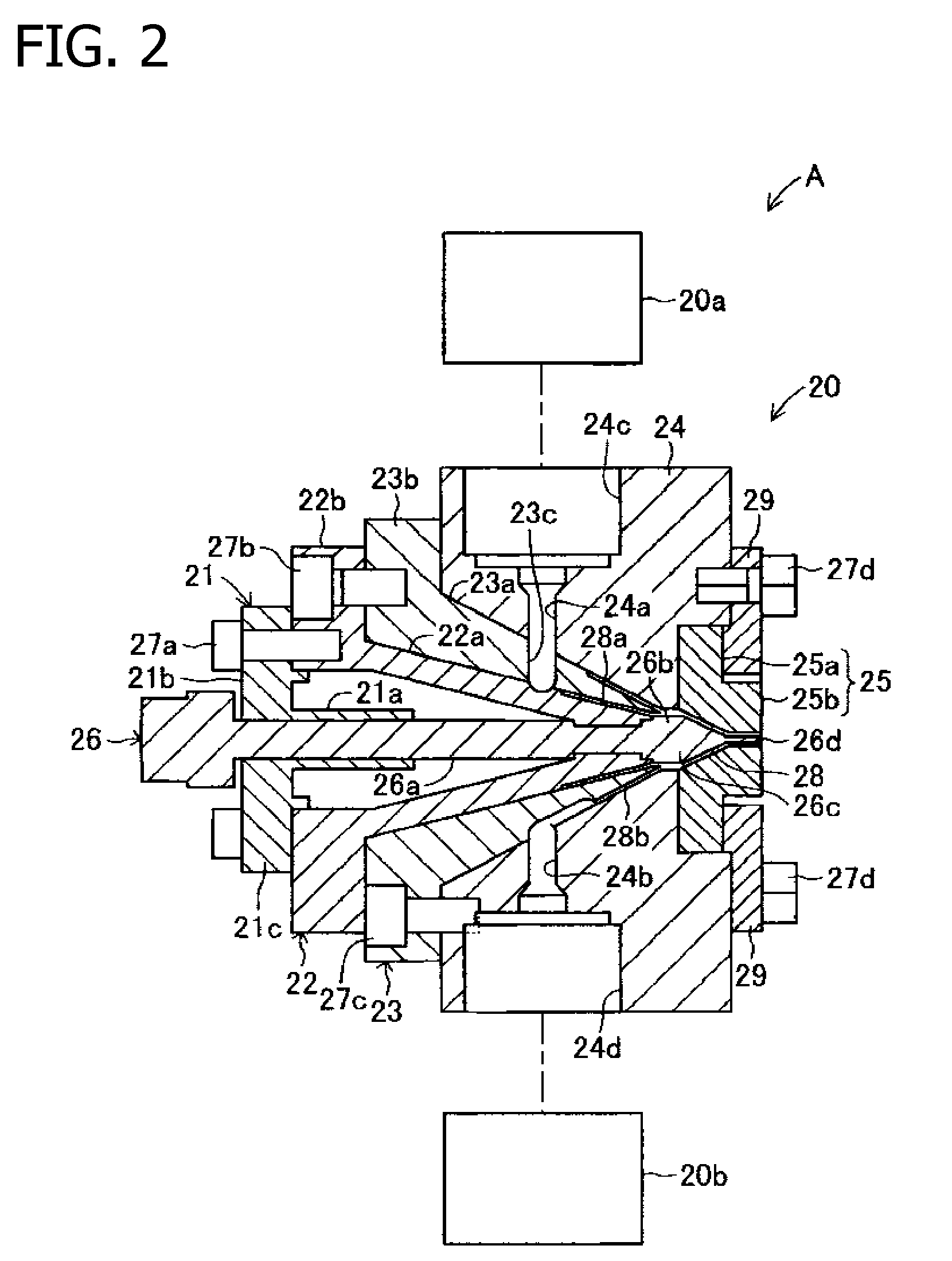

Multilayer Tube for Medical Use

InactiveUS20100055367A1Hollow filament manufactureSynthetic resin layered productsPolypropyleneMaterials science

A multi-layer tube for medical purposes formed by simultaneous extrusion moulding at least a moulding material mixture comprising styrene / ethylene / butylene / styrene block copolymer, polypropylene, polyurethane and mineral oil, and a moulding material comprising polyurethane.

Owner:TYCO HEALTHCARE GRP LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com