Patents

Literature

86results about How to "Ripe fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pre-cured alkali-activated inorganic coating material

The invention discloses a pre-cured alkali-activated inorganic coating material, which is applied to the repair and protection of outside surfaces of underground spaces and buildings, and particularly applicable to the surface repair and protection of exterior walls, basements, water conservancy projects, tunnels, bridges, highways, docks and pools. According to the invention, through a pre-curing process, the alkali-activated coating material is more convenient to use, and pre-cured more fully; and the pre-curing process refers to a step-by-step curing process, and in the first curing, an alkali-activator is not completely put, so that the pre-curing is performed at low alkalinity, therefore, the pre-curing can be gradually performed in two steps or multiple steps.

Owner:吕孟龙

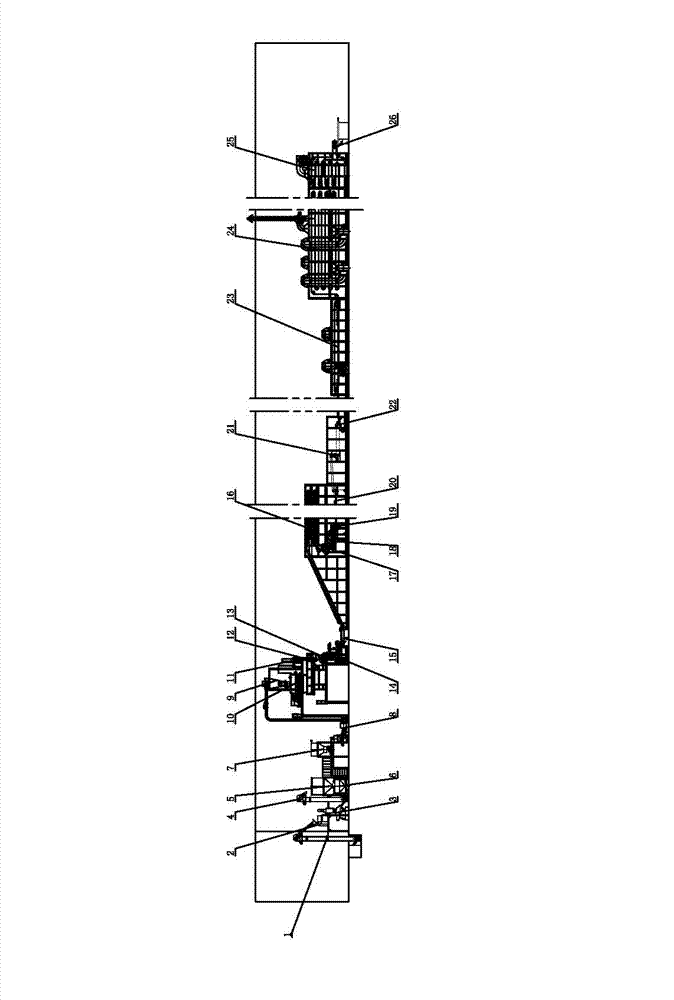

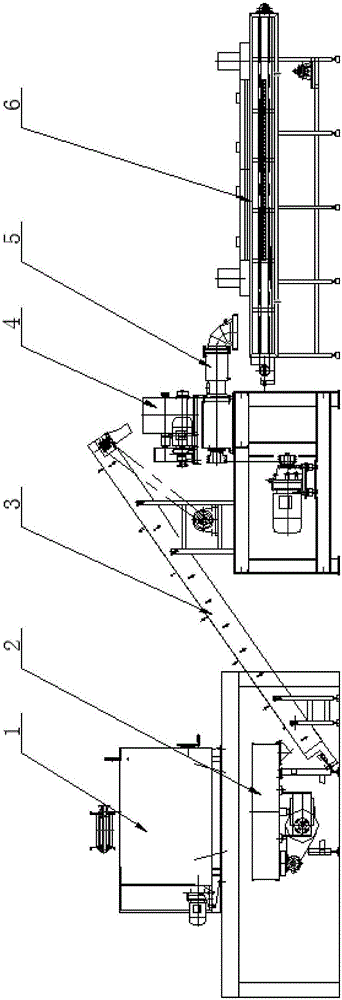

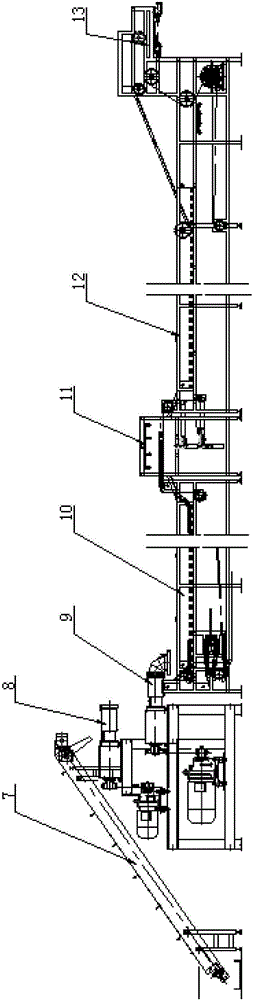

Rice noodle production line and rice noodle production process

The invention discloses a rice noodle production line and a rice noodle production process. The rice noodle production line comprises a first rice elevator, a rice polisher, a specific gravity sand remover, a second rice elevator, a rice storage tank, a jet rice washer, a water-rice separator, a rice grinder, a dry powder pneumatic conveyor, a powder mixer, a quantitative water adding barrel, a dough aging conveyor, a dough feeder, a continuous dough cooking device, a swing dough separator, a dough body aging machine, a dough body crumbler, an automatic curing machine, a noodle extruder, a noodle aging machine, a quantitative cutter, a folding forming machine, a predrying shaping machine, a drying machine, an air cooler and a packaging conveyor. The rice noodle production process comprises making rice into dough, curing, conveying, crumbling, feeding, curing, separating the dough by swinging, aging dough bodies, crumbling the dough bodies, automatically curing, extruding noodles, aging the noodles, quantitatively cutting, forming by folding, predrying, shaping, drying, air cooling and packaging. The rice noodle production line and the rice noodle production process are simple and low in cost. The rice noodles produced is fine in quality and taste and high in puffing degree.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

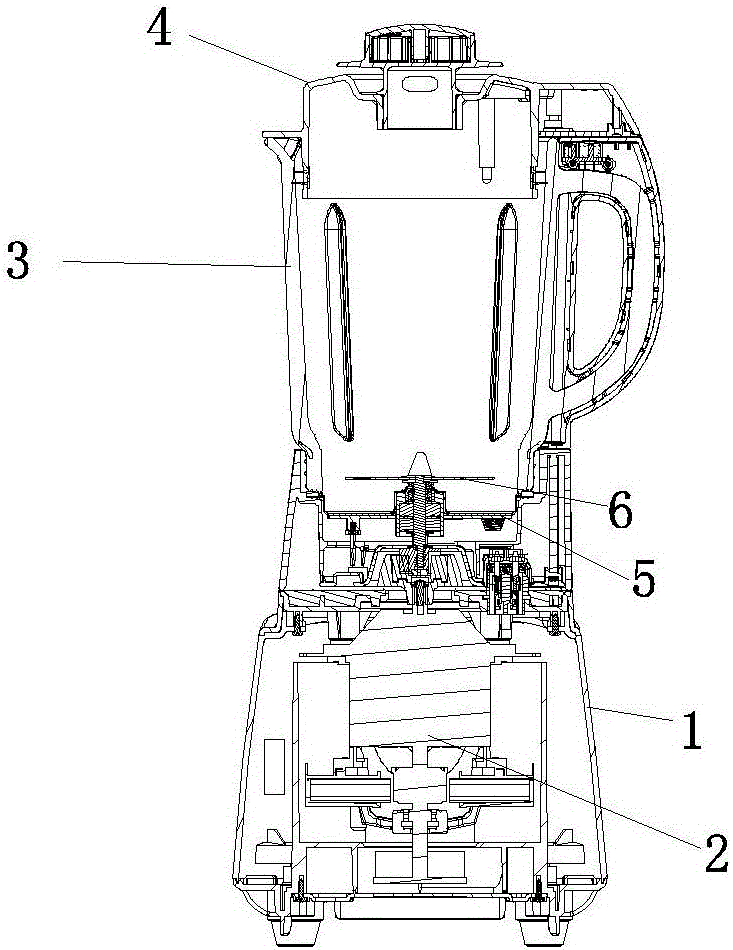

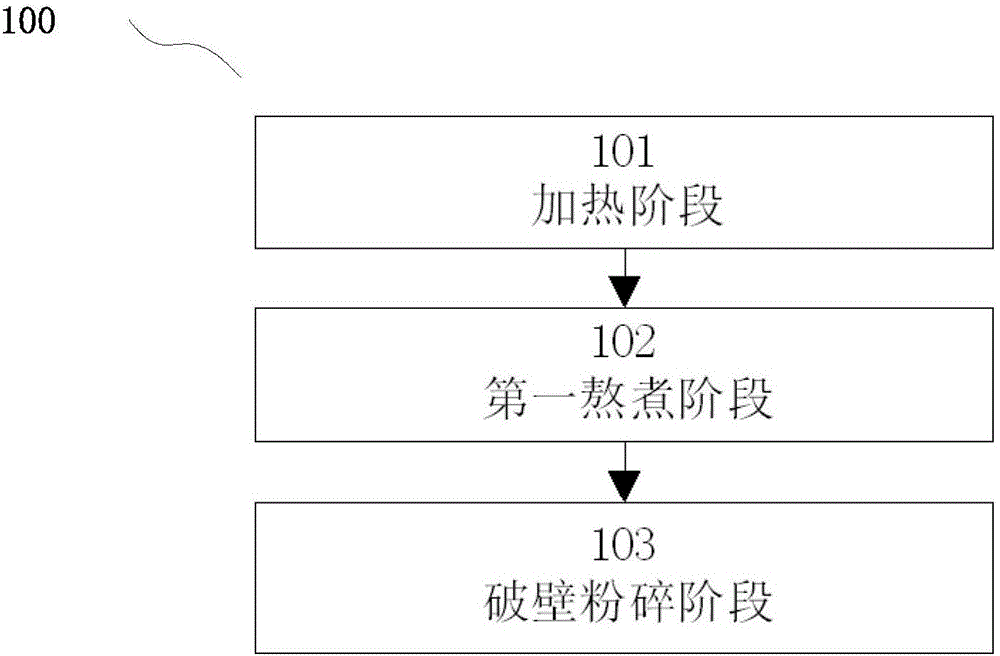

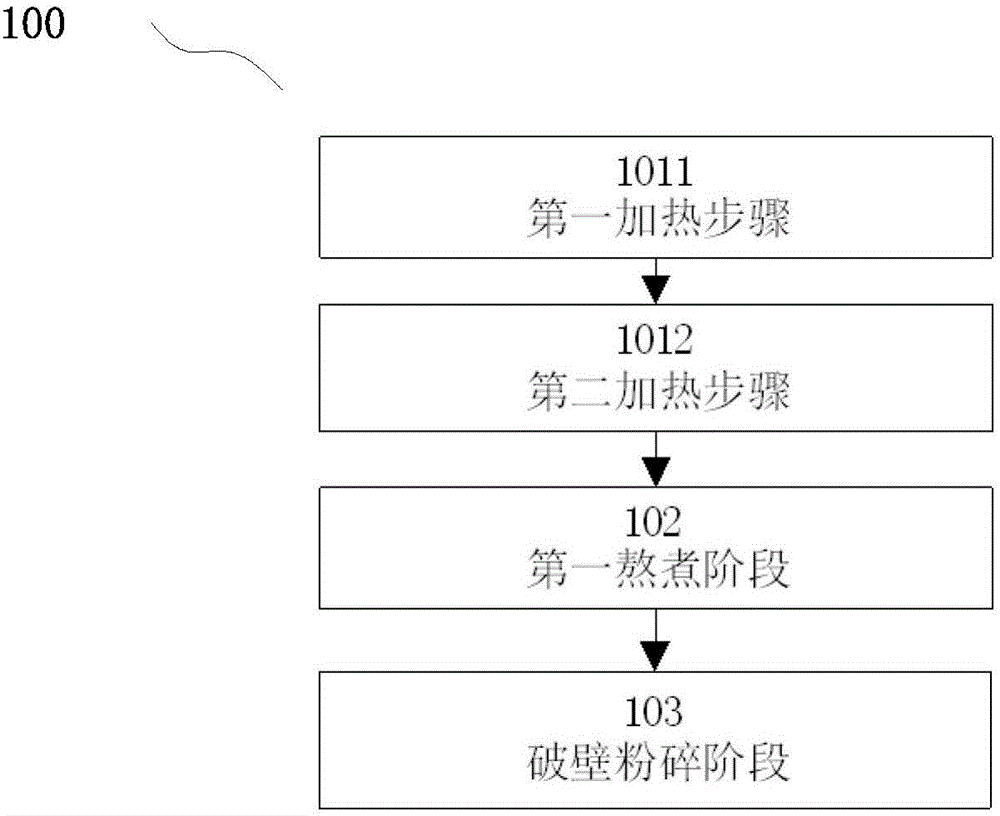

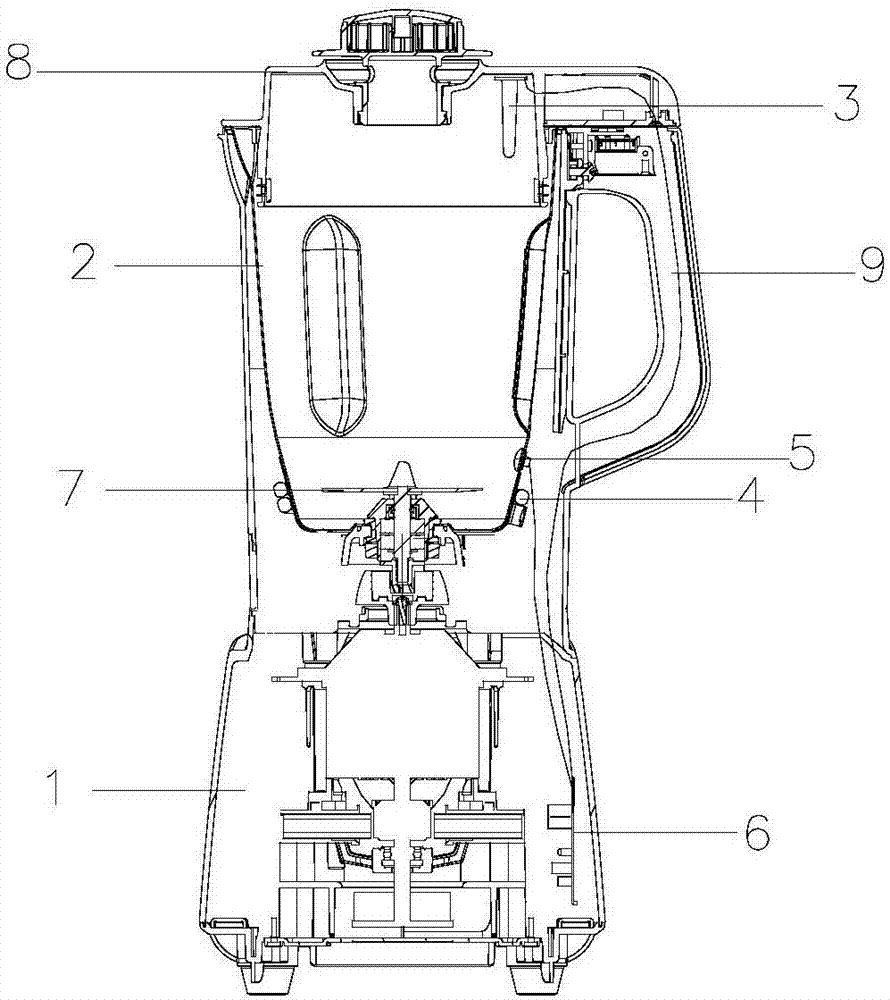

Food processing method of motor under-set-type food processing machine and food processing machine

The invention relates to a food processing method of a motor under-set-type food processing machine and the food processing machine, and belongs to the field of food processing. The food processing method at least comprises a heating stage, a first cooking stage and a wall-breaking and grinding stage, wherein in the heating stage, food in a stirring cup is heated to be boiling by virtue of a heating device; in the first cooking stage, the food in the stirring cup is cooked for a duration of t1 by virtue of the heating device until the food is completely cooked, and during cooking, a grinding cutter is driven to do intermittent rotation at a first rotating speed by virtue of a motor; and in the wall-breaking and grinding stage, the grinding cutter is driven to rotate at a second rotating speed by virtue of the motor so as to grind the cooked food in the stirring cup, and the second rotating speed, which ranges from 20000r / min to 40000r / min, is greater than the first rotating speed, wherein the power of the heating device in the first cooking stage is less than that in the heating stage. The food processing machine using the food processing method provided by the invention can uniformly heat the food, and the phenomenon of over-burnt bottom and spillover cannot occur easily.

Owner:JOYOUNG CO LTD

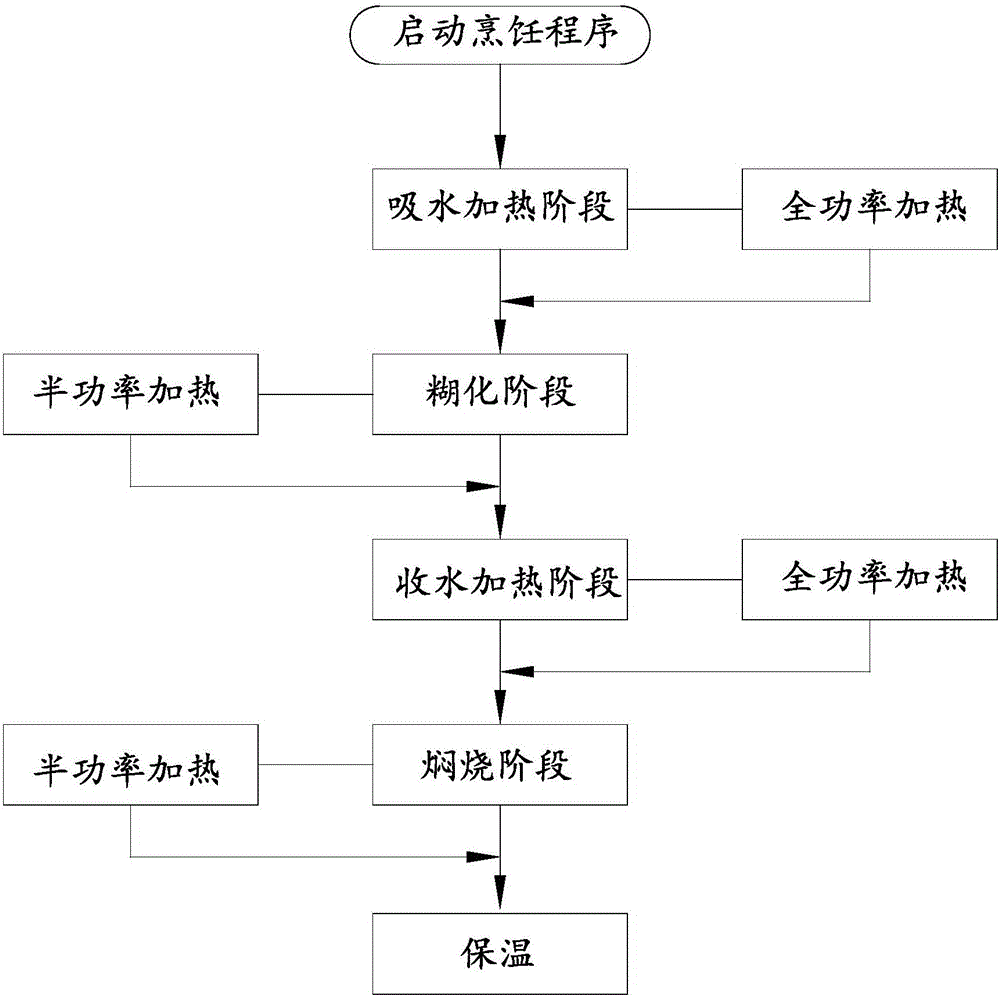

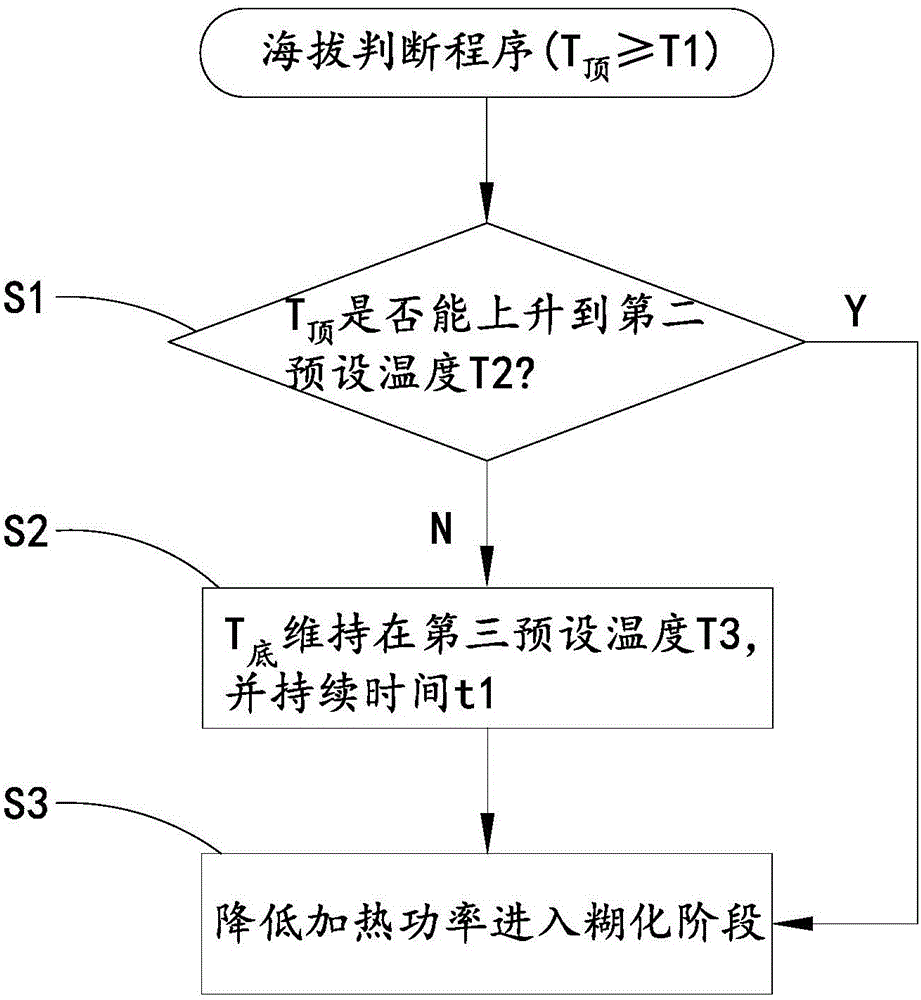

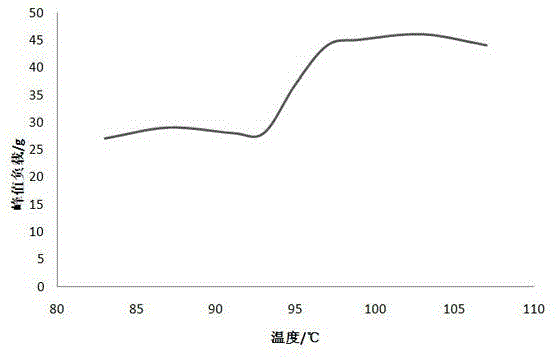

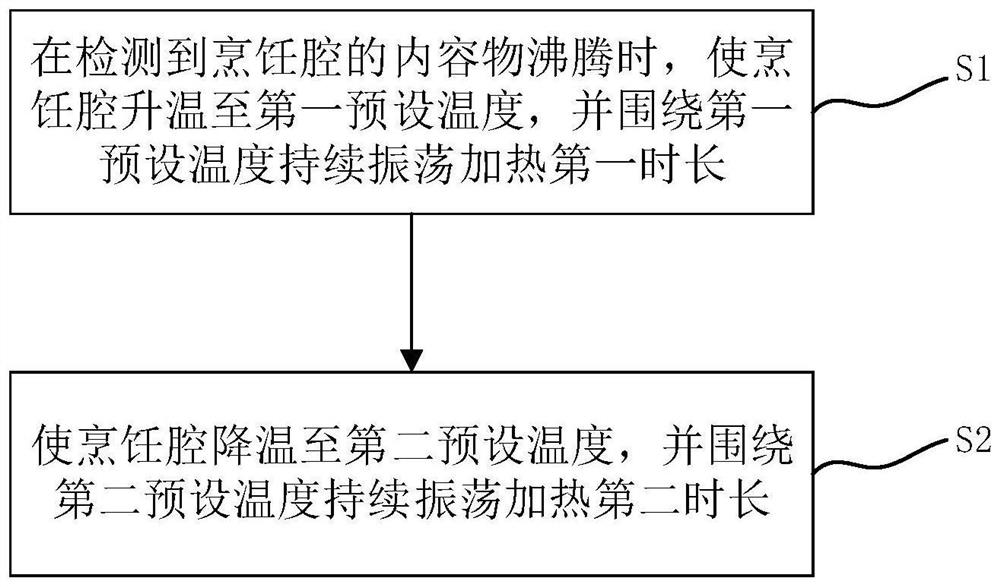

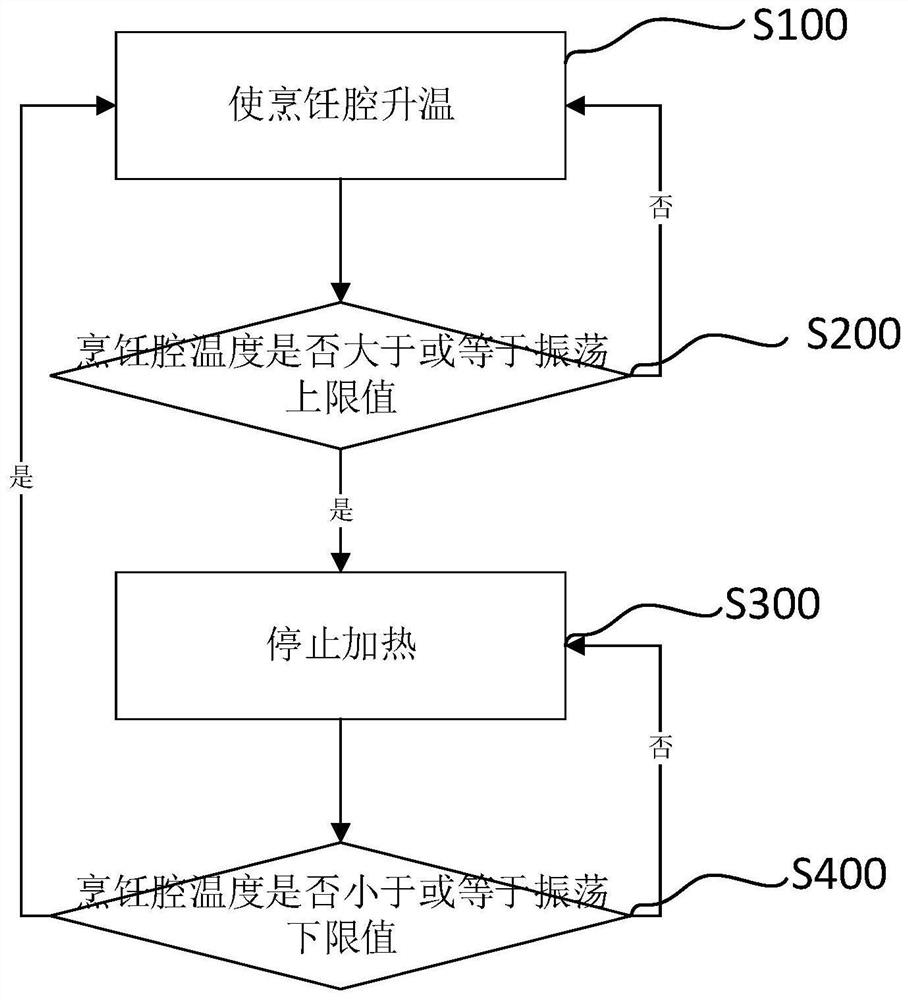

Cooking control method of electric cooker

ActiveCN105747835ALow reliabilityExtend cooking timeAuxillary controllers with auxillary heating devicesVessels with intergral heatingEngineeringCooker

The invention discloses a cooking control method of an electric cooker, and belongs to the technical field of kitchen cooking.The problem that an existing electric cooker can not meet the cooking requirements of different altitude regions is solved.The method includes the water absorption heating stage, the gelatinizing stage, the water drainage heating stage and the smoldering stage, and is characterized in that in the water absorption heating stage, when the temperature Ttop of the top of an inner pot reaches a first preset temperature T1 preset by a control unit, the electric cooker enters an altitude judging program, the control unit compares the temperature Ttop of the top of the inner pot with a second preset temperature T2 preset by the control unit in the altitude judging program and selects a cooking program according to the comparison result.The cooking control method is used when the electric cooker cooks food such as rice and porridge.

Owner:HONGYANG HOME APPLIANCES

Temilmyces fuiginosus noodle and processing method thereof

InactiveCN103380878AHigh nutritional valueHas the function of nourishing spleen and QiFood preparationAgaricSodium stearyl

The invention discloses a temilmyces fuiginosus noodle and a processing method thereof. The temilmyces fuiginosus noodle is composed of following components in parts by weight: 200 to 260 parts of temilmyces fuiginosus, 70 to 100 parts of flour, 10 to 30 parts of rice flour, 20 to 40 parts of soybean flour, 20 to 30 parts of peanut flour, 30 to 50 parts of oatmeal, 10 to 20 parts of eggs, 10 to 30 parts of milk powder, 20 to 40 parts of yam flour, 20 to 30 parts of bucket wheat flour, 40 to 70 parts of sweet potato flour, 10 to 20 parts of black fungus flour, 20 to 30 parts of corn flour, 1 to 4 parts of transglutaminase and 3 to 8 parts of sodium stearyl lactate. The prepared temilmyces fuiginosus noodles taste smooth and delicious after the noodles are thoroughly cooked, and the noodles will not gelatinize during the cooking.

Owner:安徽省凤宝粮油食品(集团)股份有限公司

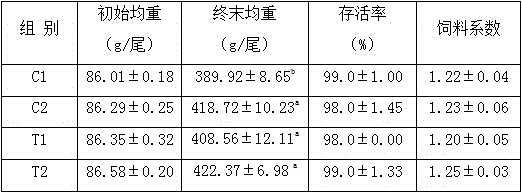

Slowly-sinking puffed compound feed for channel catfish and preparation method thereof

InactiveCN105815603AEasy feedingIncrease food intakeFood processingClimate change adaptationBiotechnologyVitamin C

The invention relates to a slowly-sinking puffed compound feed for channel catfish and a preparation method thereof and belongs to the technical field of production of puffed feeds for aquatic products. The feed contains fish meal, pork powder, rice protein powder, fermented soybean meal, rapeseed meal, soybean meal, rapeseed dregs, cottonseed meal, rice bran, flour, wheat, soybean oil, monocalcium phosphate, bentonite, 98.5% lysine hydrochloride, 99% DL-methionine, choline chloride, a compound vitamin premix, 35% vitamin C phosphate, vitamin A acetate, vitamin E, a composite mineral substance premix, a micro-ecological preparation, an antioxidant and a mildew preventive. The feed is conveniently eaten by the channel catfish, improves the feeding rate, has good water resistance and has not higher the technical requirement for feeding. In addition, intestinal health of the channel catfish can be improved, then the feed utilization efficiency of the channel catfish can be improved, eventually the growth speed and yield per unit volume of the channel catfish can be improved, and the breeding benefits of farmers can be improved.

Owner:TONGWEI

Food processing method of food processor and food processor

InactiveCN108652478ALower oxygen levelsReduce churnVessels with intergral heatingVacuum pumpingStopped work

The invention discloses a food processing method of a food processor and the food processor, and relates to the field of food processing. The food processor comprises a machine base provided with a motor and a circuit board, a vacuum pump, a mixing cup, a grinding cutter, a pressure relief module used for pressure relief of the mixing cup and a sealing module used for sealing the mixing cup. The circuit board is provided with a control circuit. The food processing method at least comprises the steps that a intermittent vacuum extraction step is performed, specifically, the sealing module sealsthe mixing cup, then the vacuum pump works to extract air in the mixing cup to enable the mixing cup to be in a negative pressure state and then the vacuum pump stops working, then the pressure relief module performs pressure relief on the mixing cup, and the intermittent vacuum pumping step is executed repeatedly; and a crushing step is performed, specifically, the motor drives the grinding cutter to rotate to crush materials in the mixing cup. According to the food processing method, no burnt bottom and less foam are achieved, and the noise is low.

Owner:JOYOUNG CO LTD

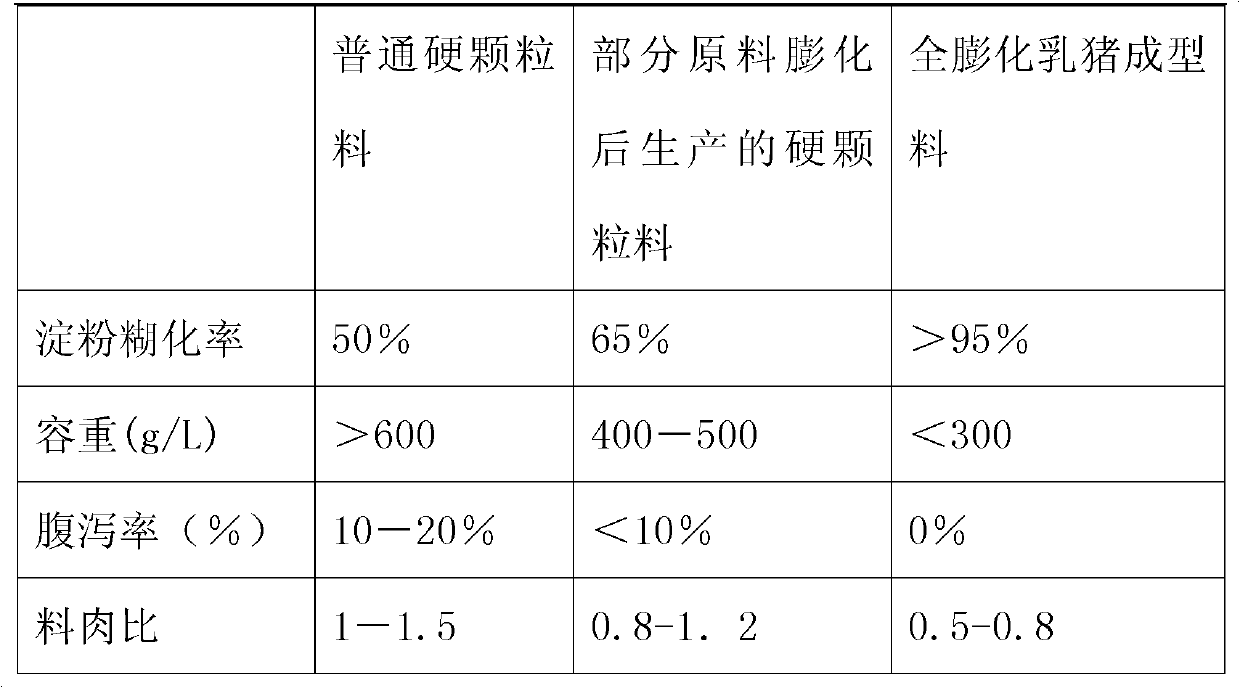

Fully puffed piglet formed feed and production process

The invention discloses a fully puffed piglet formed feed and a production process thereof. The feed comprises raw materials allowed to be added into the feed, wherein raw materials containing proteins in the raw materials are cured denatured protein raw materials subjected to precuring. According to the specific formula, the feed comprises the following raw materials in part by weight: 45 to 65 parts of corn, 0 to 20 parts of wheat, 5 to 10 parts of fish meal, 10 to 25 parts of puffed soybean, 5 to 10 parts of fermented soybean meal, 1 to 5 parts of soybean oil and 4 parts of premix. The production process comprises the following steps of mixing the raw materials containing the proteins, crushing the mixture for a first time, precuring the mixed raw materials containing the proteins, crushing the obtained product for a second time, mixing all the raw materials, performing puffed production and cooling and packaging the products to obtain the feed. The feed and the processing process overcome the defect that a high temperature, crispness and complete nutrition cannot coexist in the prior art by substituting the cured protein for a raw protein and by a new production process.

Owner:CHENGDU TONGWEI ANIMAL NUTRITION TECH

Standardization planting technology of cold-highland-area aconitum vilmorimianum kom

InactiveCN105532237ARipe fullyImprove fertilityPlant cultivationCultivating equipmentsDiseasePest control

The invention discloses a standardization planting technology of cold-highland-area aconitum vilmorimianum kom. The standardization planting technology includes the steps of 1, planting area selecting; 2, soil preparing; 3, seed selecting; 4, standardization cultivating; 5, field managing; 6, disease and pest preventing; 7, harvesting. By means of the planting technology of cold-highland-area aconitum vilmorimianum kom, a regular effect and a reasonable effect are achieved, the yield can be increased, quality can be guaranteed, and high-quality raw materials can be provided.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Method for processing 'plant milk' and 'plant milk powder' by pre-ripening plant seeds

The invention discloses a method for processing 'plant milk' and 'plant milk powder' by pre-ripening plant seeds, which belongs to the field of foods, and changes the process of an existing processing technology, does not ripen slurry by heating, and ripens whole raw materials plant seeds by heating before pulping process, thereby being capable of completely overcoming the defects in boiled pulp process that steam bubbles are produced, a pot overflows when bursting, heated ripening temperature is not enough or heating time is lack. The pre-ripening measure before pulping can lead trypsin inhibitors in 'soy milk' and 'soy milk powder' to completely inactivate, and thoroughly eliminates adverse impact of the trypsin inhibitors to human bodies. The method for processing the 'plant milk' and the 'plant milk powder' by pre-ripening the plant seeds comprises steps of raw material cleaning, pre-ripening processing, defibrinating, compounding, ultra high temperature flash pasteurizating, homogenizing, drying and finished product obtaining .

Owner:CHANGCHUN UNIV

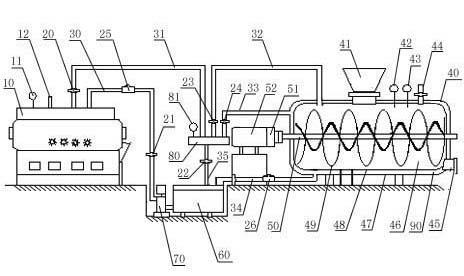

Feed maturation method and high-temperature maturation device

The invention discloses a feed maturation method and a high-temperature maturation device. The feed maturation method includes the following steps that: steam generated by a boiler is delivered to a maturation pot filled with materials; the materials are constantly stirred so that the materials can be fully matured; the matured materials are taken out and dried; and finally, fragmentation is carried out on the resulting materials to obtain a finished product. A novel feed processing technology and a device are provided in the present invention, being characterized in that the raw materials of feed after maturation, can make starch more easily digestible, protein content higher and protein more easily absorbed; and being advantaged in simple operation, energy conservation, low carbon, environmental protection and greatly reduced cost of feed processing.

Owner:明雷

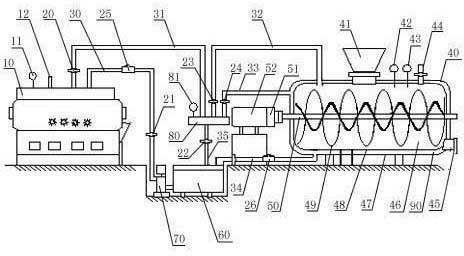

Three-cavity dosing device for sewage treatment and dosing method thereof

InactiveCN102327751AAchieve entryDoes not affect dosing workRotary stirring mixersMixer accessoriesMotor controlSewage treatment

The invention relates to a three-cavity dosing device for sewage treatment. The device comprises a chemical dissolving case and a control case, wherein the inside of the chemical dissolving case is divided into a dissolving cavity, a curing cavity and a storing cavity, a feed hopper is arranged on the dissolving cavity, a water supply system and a dry powder dosing system are arranged above the feed hopper, and a motor-controlled stirrer is arranged in the dissolving cavity; a stirrer and a curing cavity liquid level meter are arranged in the storage cavity; a metering pump is arranged at thebottom of the storage cavity, and is communicated with a chemical discharge tube which passes through a pipeline and penetrates out of the storage cavity; an air release valve is arranged at the bottom of the storage cavity; the dissolving cavity and the curing cavity are communicated at the bottom of the chemical dissolving case, while the curing cavity and the storage cavity are communicated onthe top of the chemical dissolving case; a horizontal pipeline communicated with the storage cavity from the dissolving cavity is arranged at the bottom of the chemical dissolving case, and an electromagnetic valve at one end, positioned in the dissolving cavity, of the horizontal pipeline; the middle part of the horizontal pipeline is connected with a vertical pipeline in the curing cavity through a tee-joint; and an electromagnetic valve is arranged on the vertical pipeline.

Owner:BAOSTEEL DEV CO LTD

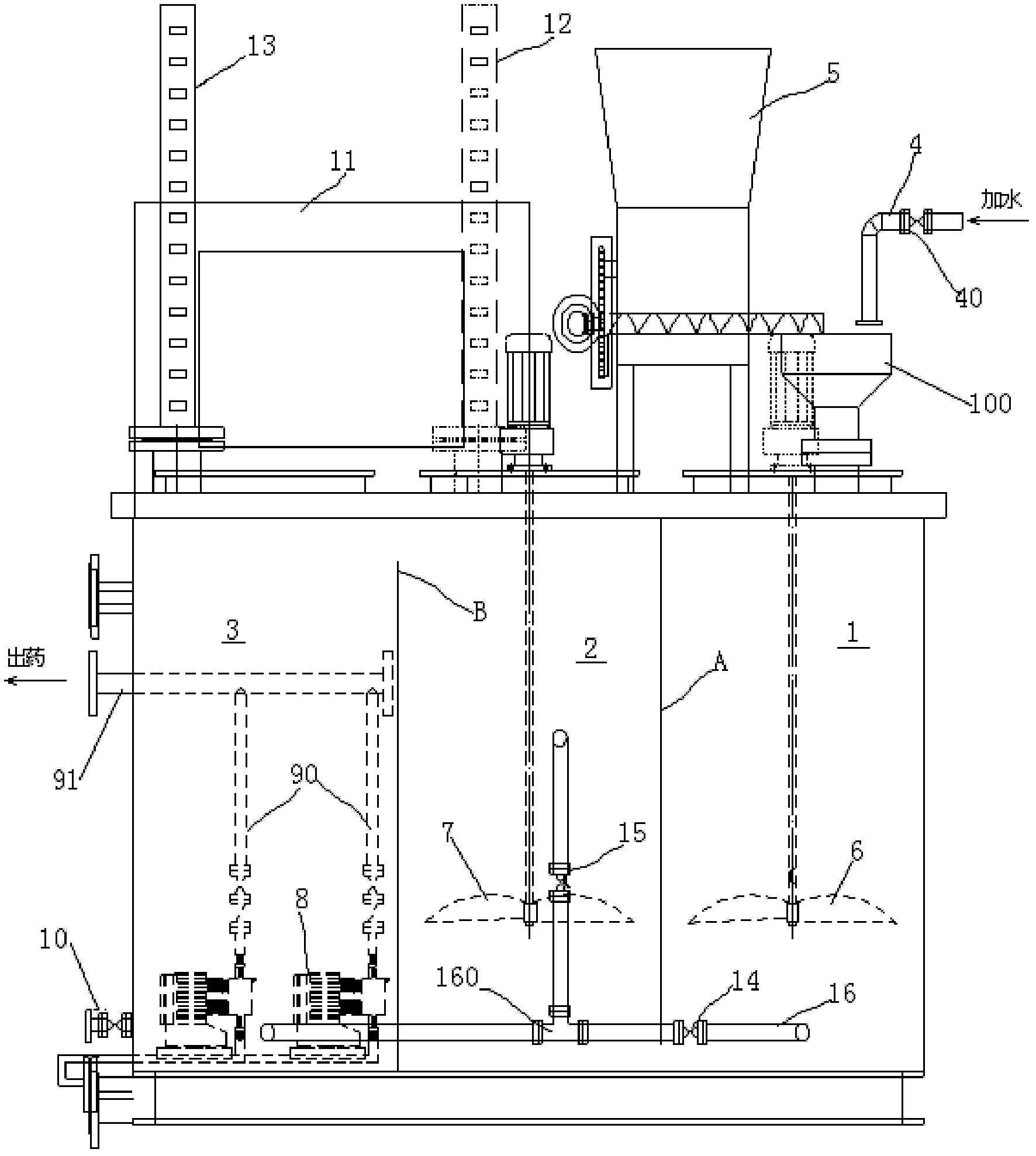

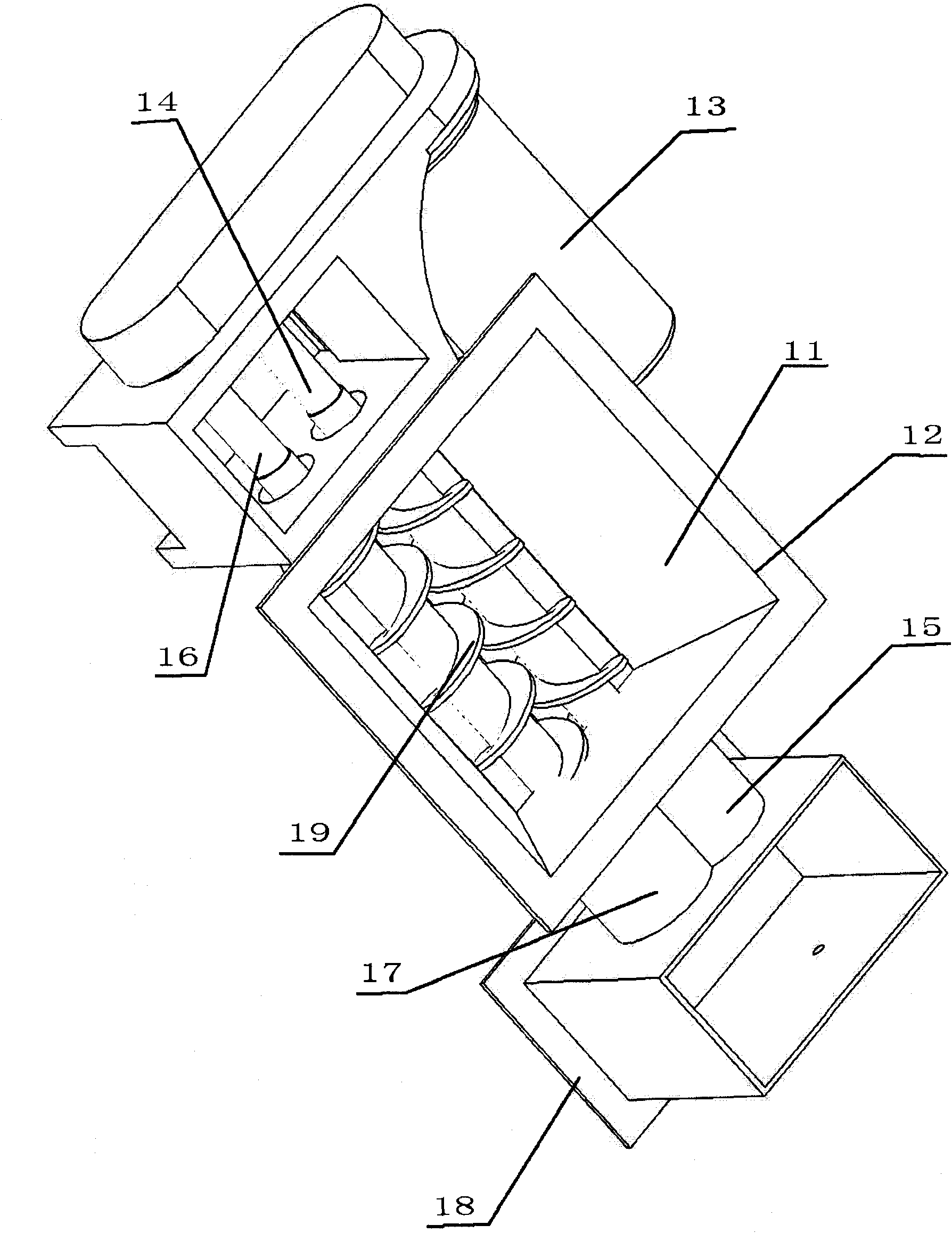

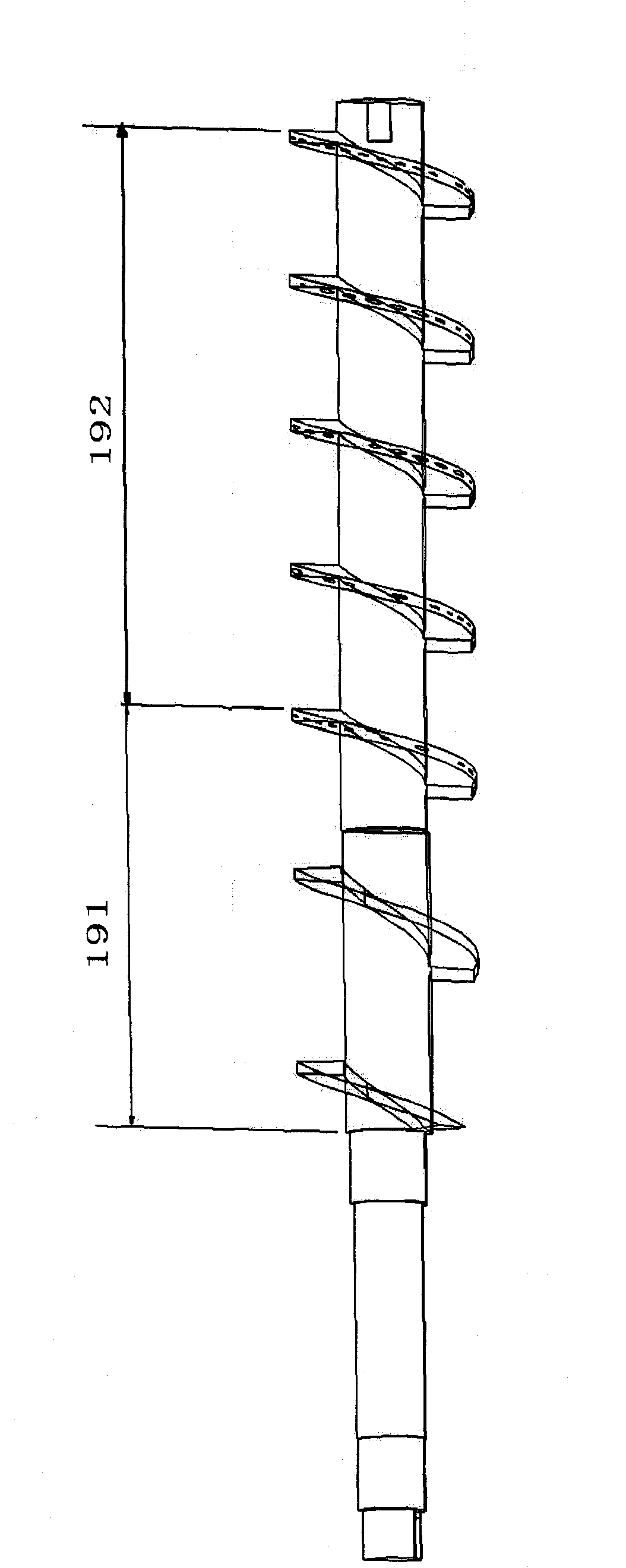

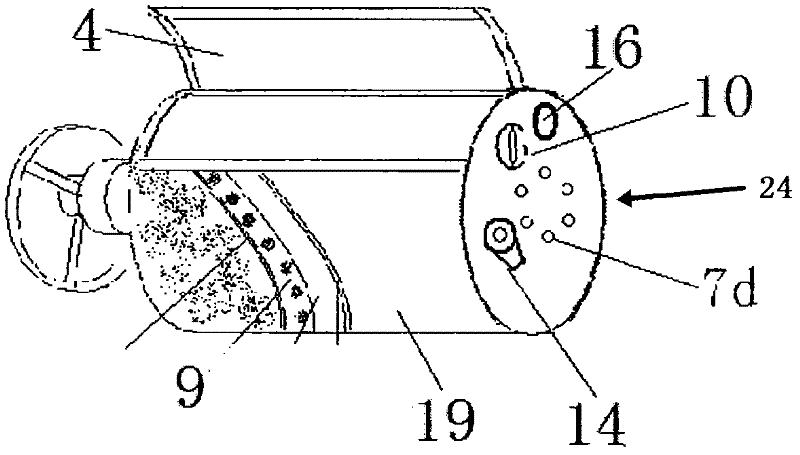

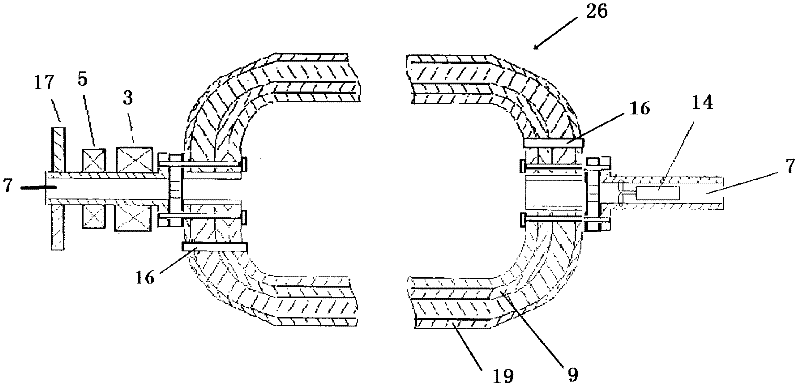

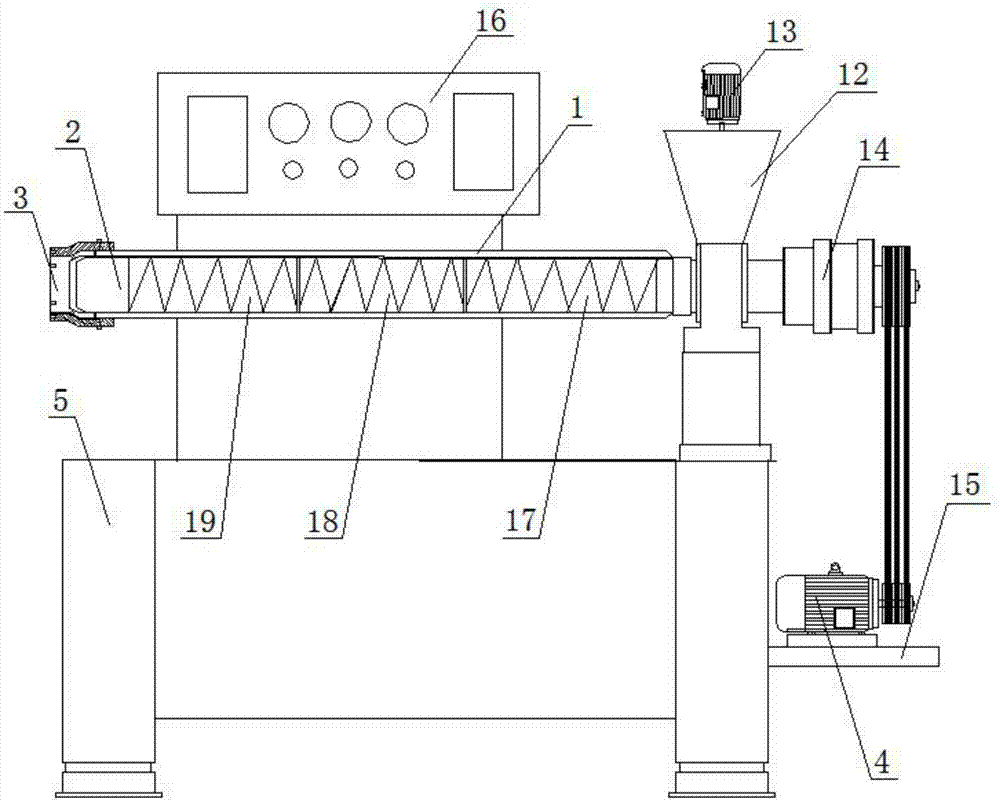

Single-screw low-temperature wet-process puffing machine

ActiveCN101773278AUniform and stable feedingReduce volumeFeeding-stuffFood shapingElectrical controlElectric machinery

The invention relates to a novel single-screw low-temperature wet-process puffing machine belonging to the field of puffing devices. The novel single-screw low-temperature wet-process puffing machine comprises a rack body and a motor, wherein the top of the rack body is provided with a double-screw feeder; the upper middle part of the rack body is provided with a conditioner connected with the double-screw feeder; the middle of the rack body is provided with a secondary feeder connected with the conditioner through a conditioner outlet tee joint; a low-temperature extrusion puffing device driven by the motor is connected with the secondary feeder; the tail end of the low-temperature extrusion puffing device is connected with an extrusion die device; and the outer side of the extrusion die device is also provided with a gap self-regulating cutter device connected with the rack body and an electrical control system. The invention is automatically controlled by a programmable logic controller (PLC) and realizes the production of puffed products, i.e. puffed foods, puffed pet foods, puffed aquatic feeds, puffed livestock and poultry feeds, puffed urea, and the like, under a low-temperature condition.

Owner:常州市宏寰机械有限公司 +1

Summer rice cake powder and edible method thereof

The invention provides summer rice cake powder and an edible method thereof. The summer rice cake powder comprises the following raw materials in percentage by weight: 40%-99.5% of starch, 0%-55% of rice flour and 0.5%-2.5% of alkaline. The summer rice cake powder is prepared by size mixing, boiling thoroughly and cooling for forming, then is eaten, retains the flavor of a conventional summer rice cake and is unique in taste and rich in nutrition.

Owner:CHENGDU SAFE BIO TECH

Electronic frying and baking dual-purpose stove

ActiveCN102327070AImprove business vitalityImprove qualityCooking vesselsRoasters/grillsElectricityMarket place

The invention discloses an electronic frying and baking dual-purpose stove which comprises a freight house assembly, a bracket, a heating part, an insulating part, a power supply control part, a conductive slip ring part, a speed reduction motor and a blower part, and also comprises a freight house assembly with an air blower, a dual-hollow shaft freight house assembly, a nose assembly, a heat-radiating air assembly, a support shaft assembly and a driven nose assembly, wherein the heat-radiating air assembly is of a heat-radiating air structure arranged on the nose assembly, the heat-radiating air structure introduces hot air of the speed reduction motor into a freight house; and the support shaft assembly is arranged at one side of the freight house assembly and respectively correspond to an equidirectional output speed reduction motor or vertical output speed reduction motor. The electronic frying and baking stove does not generate pollution, has small occupation area, and does not damage appearance of foods during working. The electronic frying and baking stove is suitable for site processing in a market place, can meet frying and baking two-purpose functions, ensures that processed foods are baked, and can realize the purposes of saving electricity and energy and protecting environment.

Owner:武雄

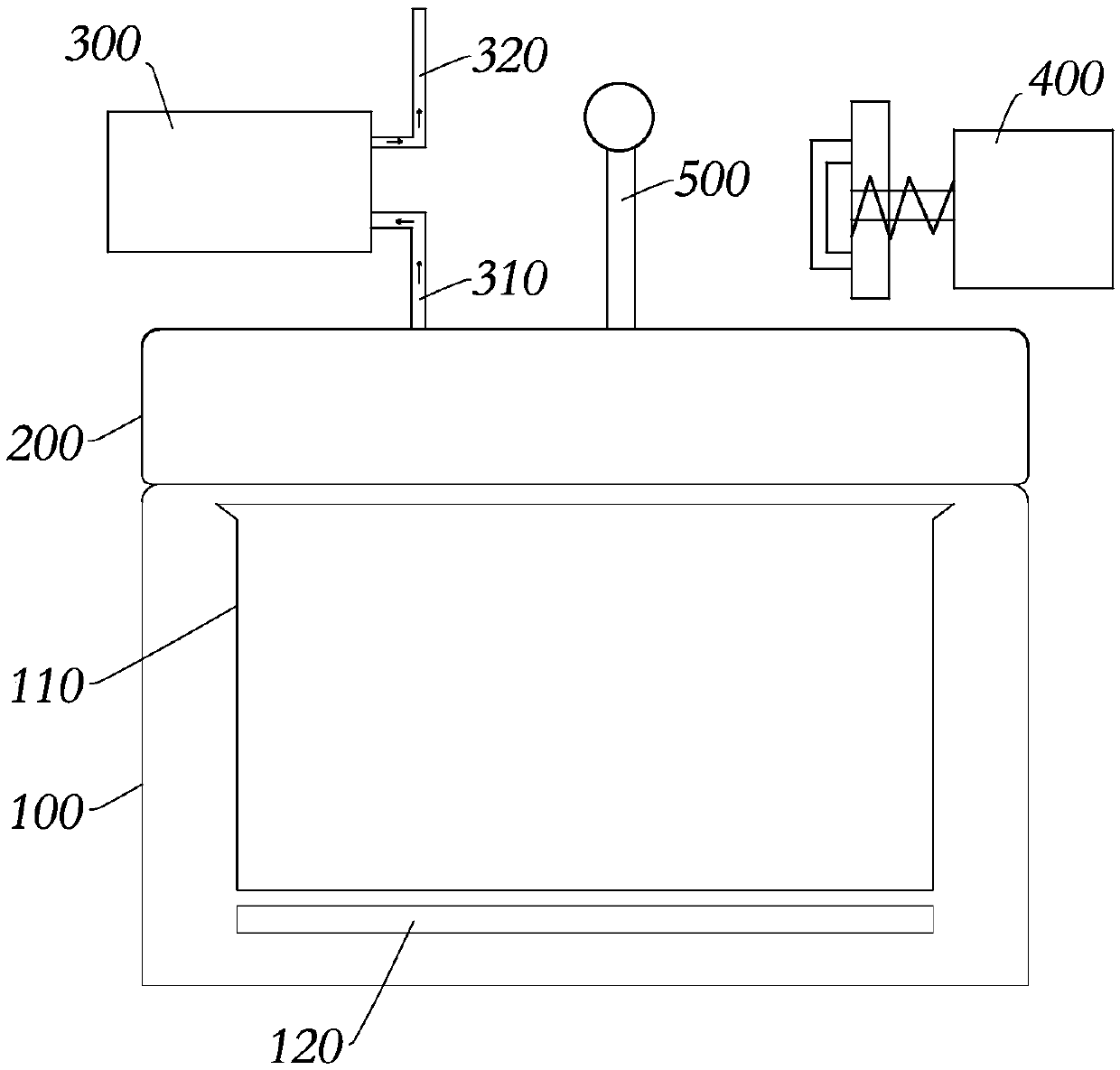

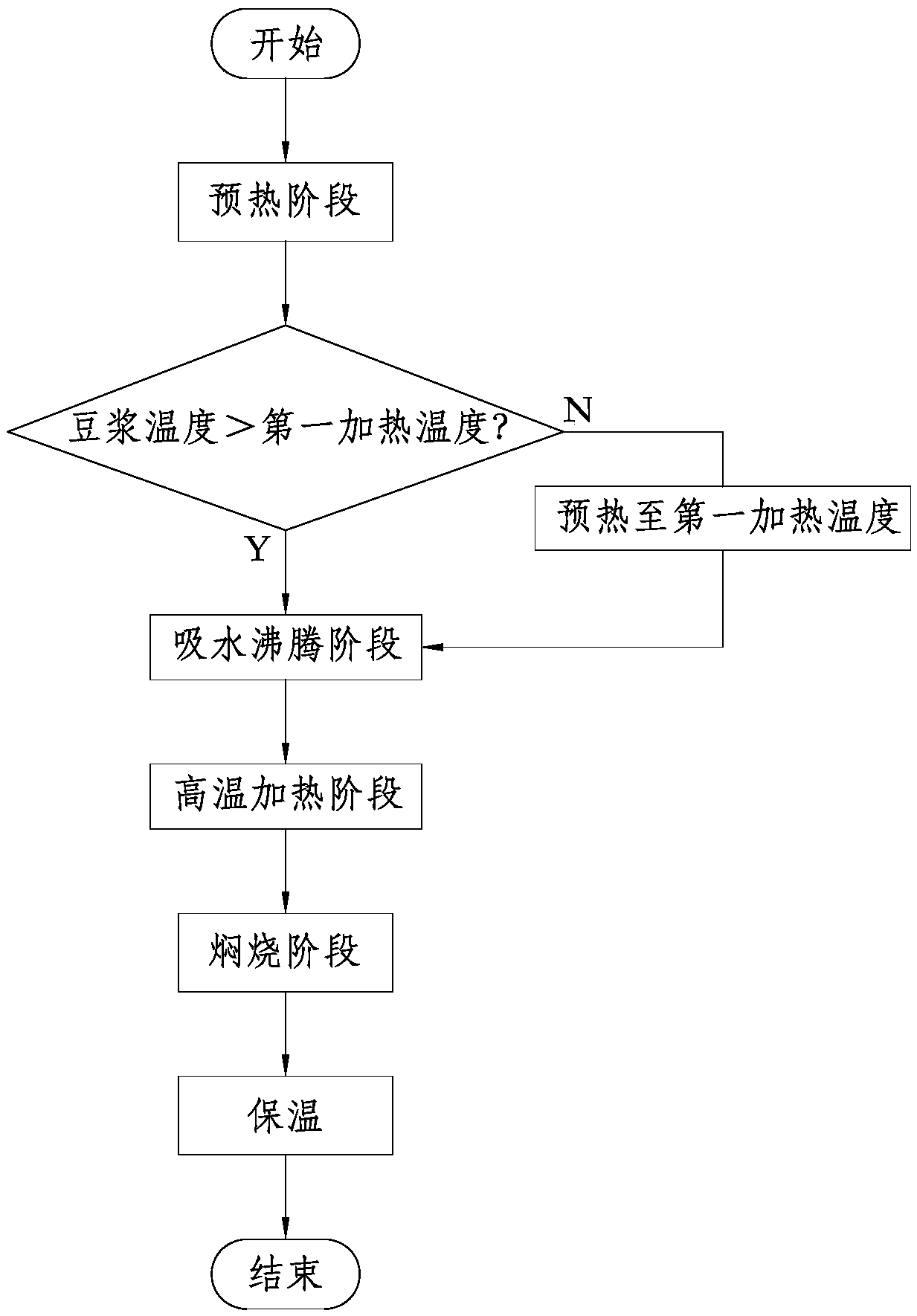

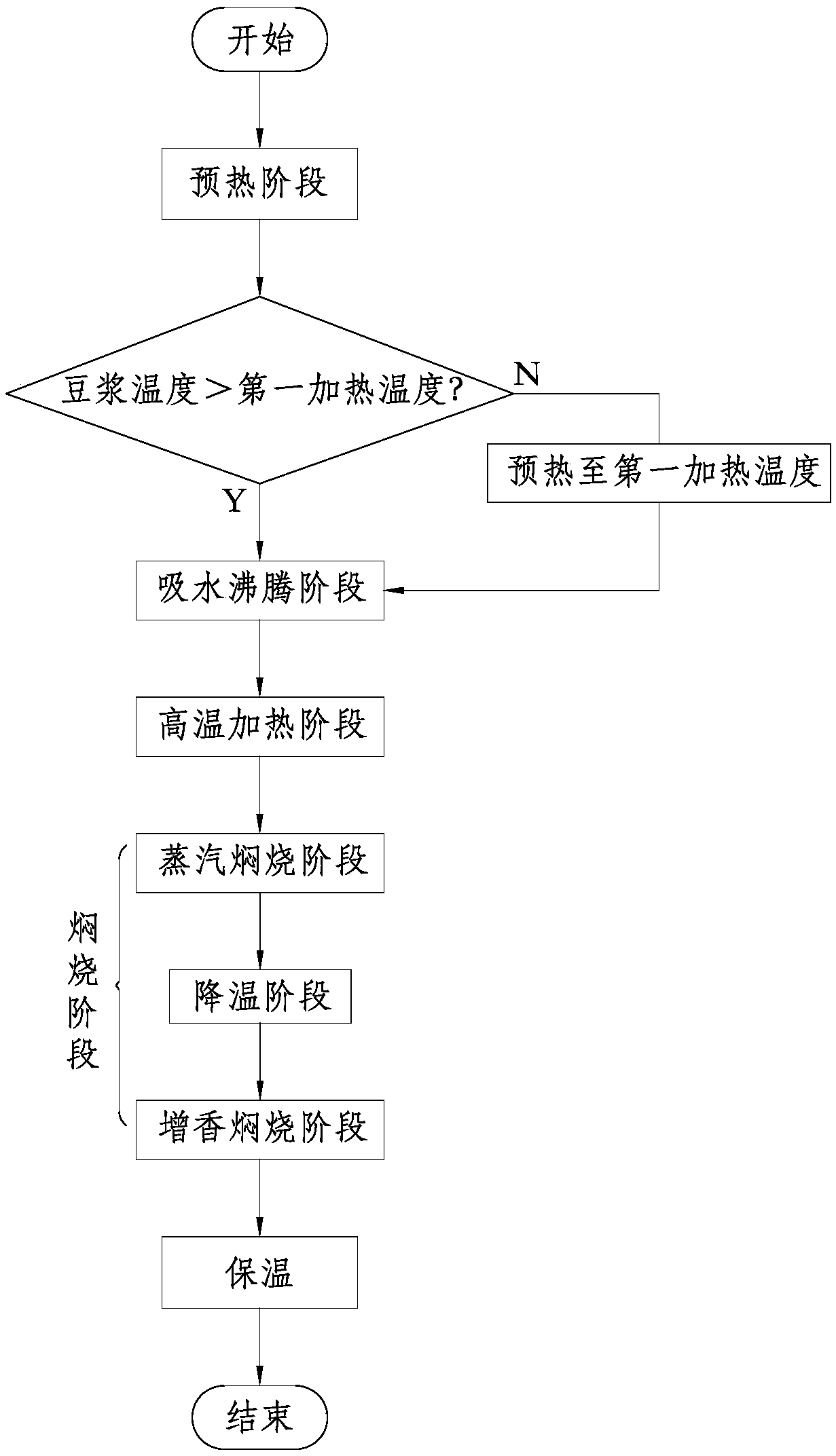

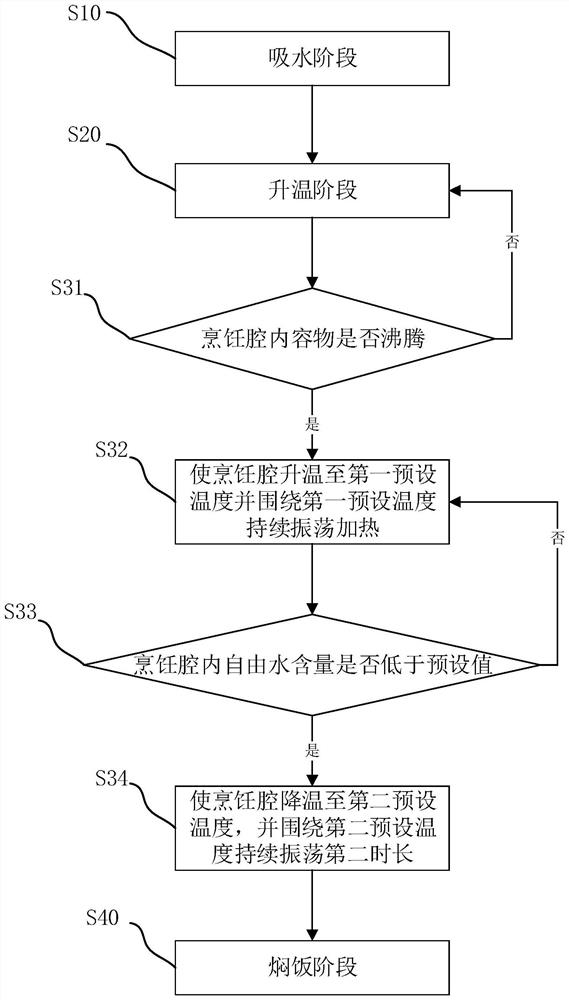

Method for making soybean milk rice

PendingCN111449488ARelieve pressureEasy to integrateVessels with intergral heatingRice dishesEngineering

The invention discloses a method for making soybean milk rice by using a cooking utensil, belongs to the technical field of kitchen appliances, and solves the technical problem that bean dregs precipitate and the like in the soybean milk rice producing method using the existing cooking method. The method for making soybean milk rice through the cooking utensil comprises the steps that in a water absorption boiling stage, an air sucking device works to keep a cooking cavity at a preset negative pressure, a mixture of soybean milk and rice can be kept at a first heating temperature, and the first heating temperature is the boiling point temperature under the preset negative pressure; and in a high-temperature heating stage, the air sucking device stops working, and a cooking utensil performshigh-power heating, so that the temperature of the mixture of the soybean milk and the rice is rapidly increased to a second heating temperature. According to the invention, by setting the water absorption boiling stage, rice and soybean milk are fused through the boiling effect while rice absorbs water, and due to the fact that the water absorption rate of the rice is increased under the negative pressure condition, so that the rice and the soybean milk which are boiled together are easy to combine so as to effectively reduce bean dreg precipitate and solves the problem that bean dregs precipitate at the top of rice in the prior art.

Owner:JOYOUNG CO LTD

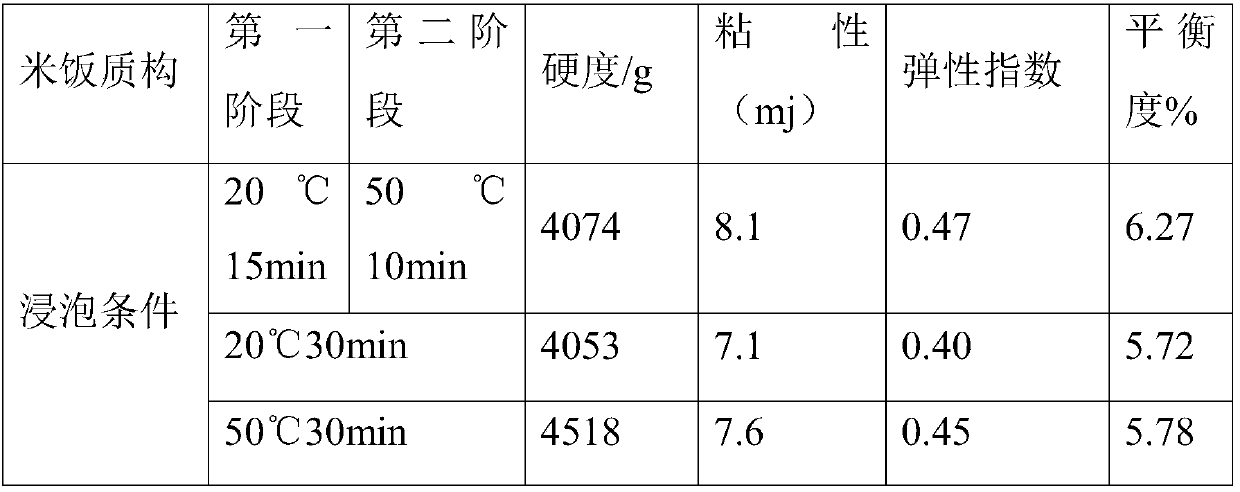

Preparation method of purely fragrant cooked rice

The invention relates to a preparation method of purely fragrant cooked rice. The preparation method at least comprises the following a plurality of stages: (a) a fragrance preparing stage: soaking rice at 10-25 DEG C for 10-15 minutes, then raising temperature to 50-60 DEG C and performing soaking for 5-10 minutes, and then performing heating at a heating rate of 8-15 DEG C / minute to 70 DEG C orhigher with the heating power P1; (b) a boiling stage: performing heating with the heating power P2 to boiling and maintaining the condition for a period of time; and (c) a fragrance stuffing stage: performing heating with the heating power P3 and maintaining the condition for a period of time, wherein P1 is greater than P2 and P2 is greater than P3. Compared with the prior art, the cooked rice prepared by the preparation method disclosed by the invention is more purely fragrant, moderate in hardness and viscosity and better in mouthfeel.

Owner:JOYOUNG CO LTD

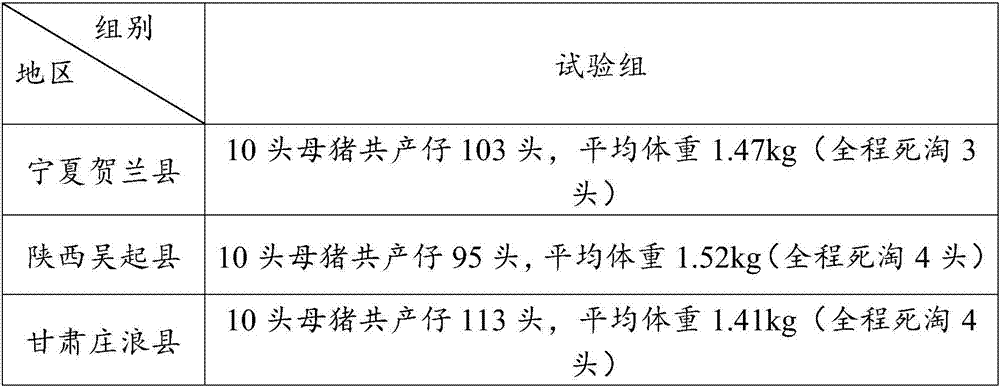

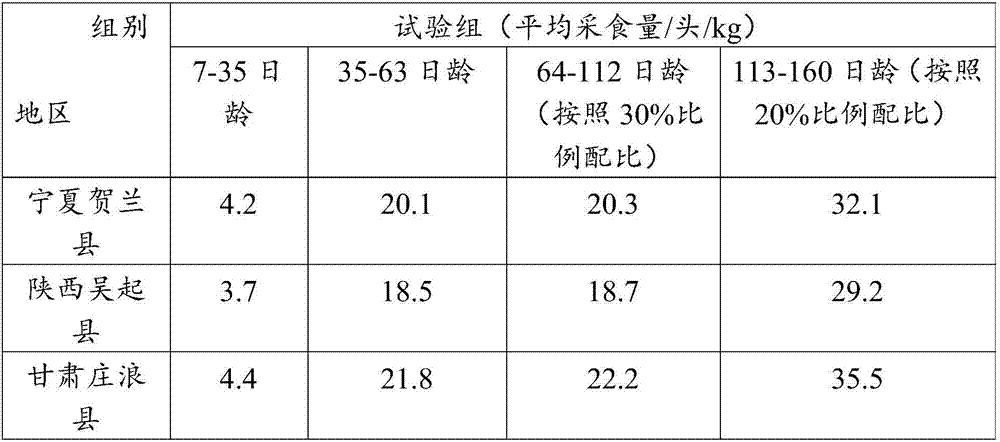

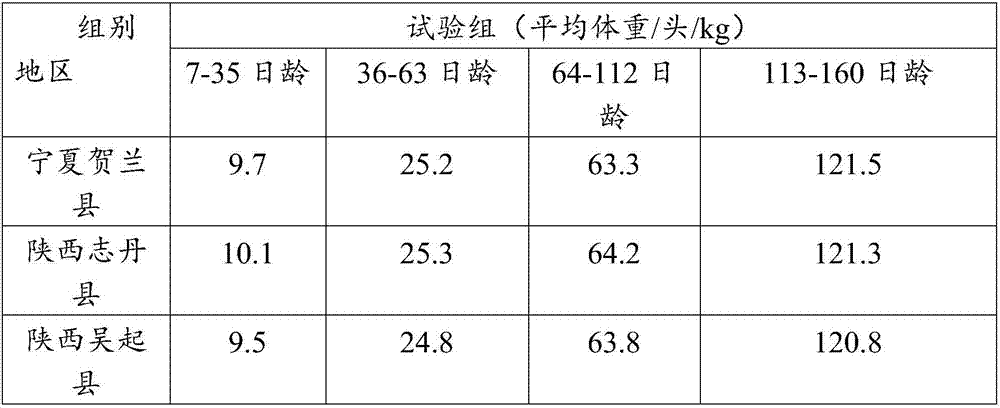

Pig concentrated efficient breeding feeding mode suitable for northwest regions and pig feeding system suitable for northwest regions

The invention provides a pig concentrated efficient breeding feeding mode suitable for northwest regions and a pig feeding system suitable for the northwest regions and relates to the technical field of feeding. The method includes that different concentrate products are fed at different stages: at a piglet stage, powdery feed and granular creep feed are combined, the powdery feed is high in palatability, and the piglets are quick in feed acquaintance, stress is small after weaning; the granular feed is high in intake, little in waste and high in subsequent growing speed; at a growing and fattening stage, according to pig growing characteristics, feeding is performed according to stages and varieties by studying pig nutrition needs. Low-protein daily ration is adopted, various amino acids are balanced, and concentrate nutrition index and preparation proportion are designed reasonably with reference to convenience in purchasing corn and bran raw materials in the northwest region, so that nutrition needs can be met better, waste of nutritional ingredients in the feed can be reduced, the nutritional ingredients of the feed are ensured to be fully digested and absorbed, environment pollution degree and feeding cost of farmers can be lowered, and economic benefit of pig farms can be increased.

Owner:NINGXIA DABEINONG TECH IND

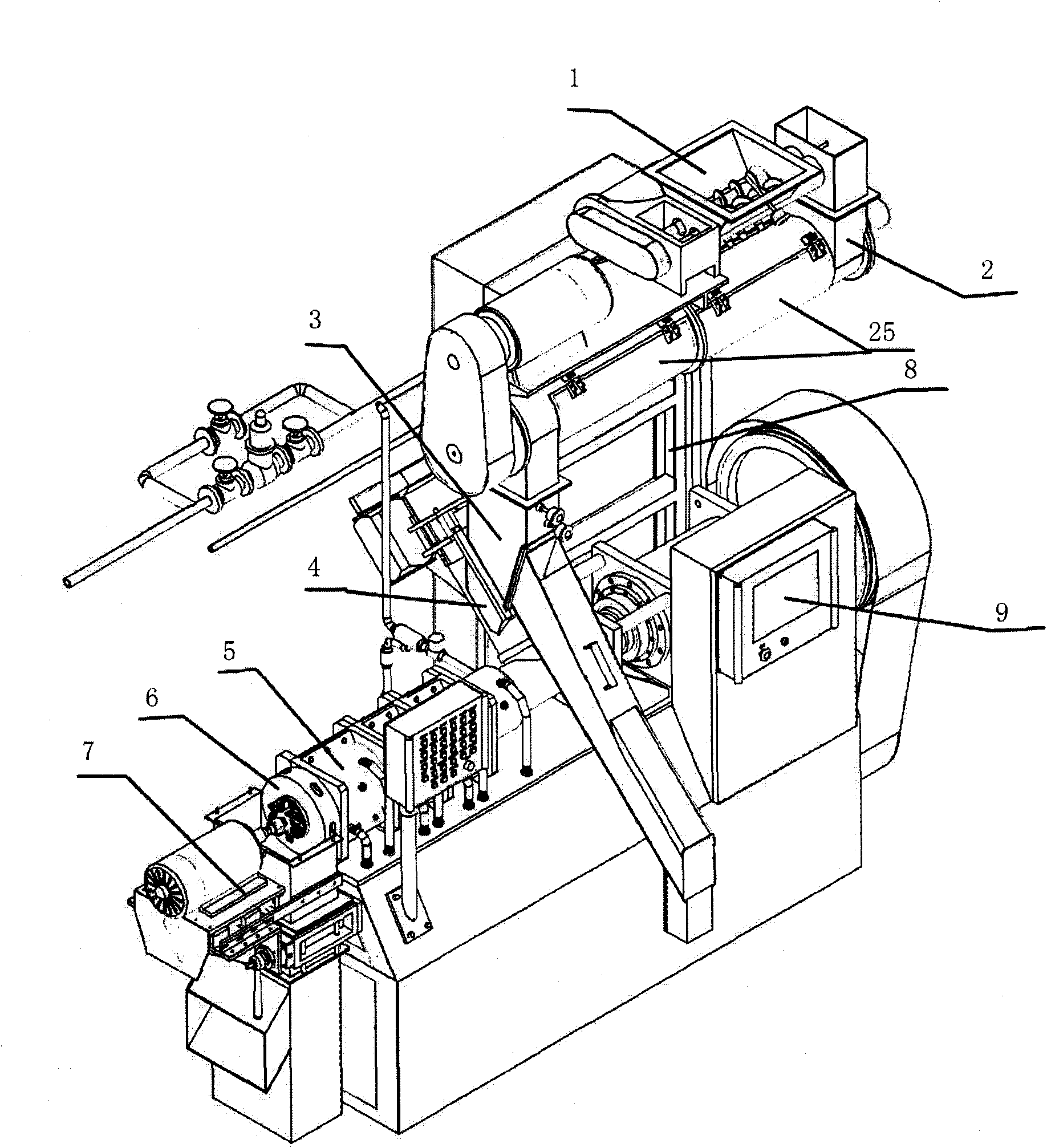

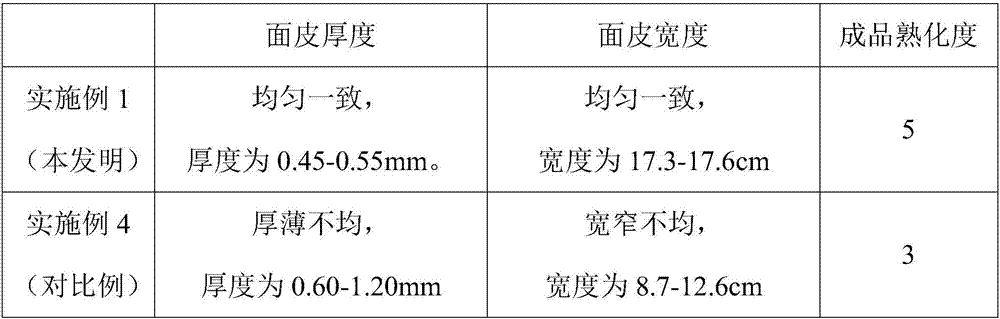

Preparation method of non deep-fried instant noodles and screw extrusion equipment

The invention discloses a preparation method of non deep-fried instant noodles and screw extrusion equipment, and solves the problems that in the prior art, a screw rod extrusion and curing production technology is used for non deep-fried instant noodles, cooking and curing need to be performed twice, else the curing degree is insufficient, and the production stability is poor. The preparation method comprises the following steps of uniformly mixing raw materials in proportion, adopting a three-stage heating and extruding manner for curing, then performing twisting, performing shaping twice so as to obtain uniform wrappers, cutting the wrappers into shreds, performing four-stage drying, and then performing packaging so as to obtain the non deep-fried instant noodles, wherein the curing, twisting and shaping twice are continuously performed. The method disclosed by the invention is simple, the operation is simple and convenient, the production technology stability of the non deep-fried instant noodles is improved, and the automatic and standardized production of the non deep-fried instant noodles is realized.

Owner:四川白家阿宽食品产业股份有限公司

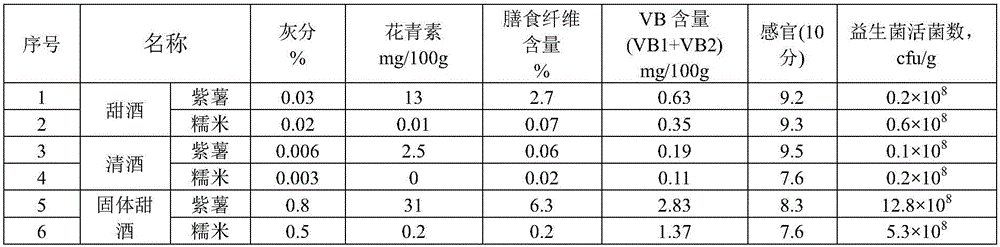

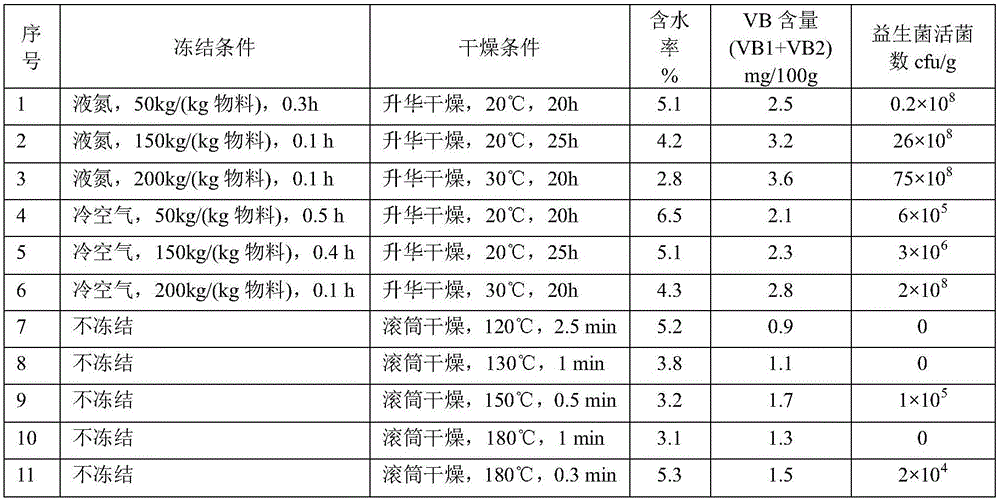

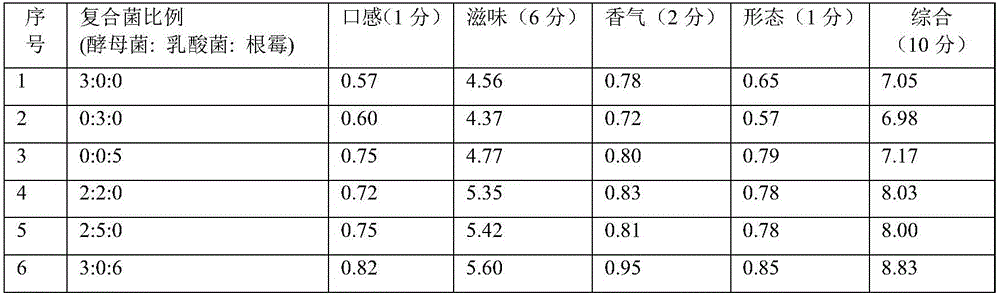

Cereal sweet wine, solid-state cereal sweet wine, cereal clear wine and preparation method thereof

InactiveCN105754789ARipe fullyRetain nutritionAlcoholic beverage preparationMicroorganism based processesSodium GlutamateSugar

The invention relates to the field of fermented food processing, in particular to cereal sweet wine, solid-state cereal sweet wine, cereal clear wine and a preparation method thereof. The sweet wine comprises the following components in parts by weight: 100 parts of sticky rice, 20-200 parts of cereal rice, 0.5-2 parts of compound bacteria as well as modulating matters comprising 1-15 parts of white sugar, 1-15 parts of proteins, 1-5 parts of dietary fiber powder, 0.0001-0.003 part of vitamin, 1-25 parts of fruit-vegetable powder, nutrient substances comprising 0.0001-0.0003 part of sodium glutamate and 0.0001-0.002 part of calcium salt. According to the cereal sweet wine and the preparation method thereof, cereal subjected to soaking and sprouting treatment as well as extrusion forming is heated and pasted, and the compound bacteria is added into the cereal for being fermented to prepare the cereal sweet wine. The cereal sweet wine, solid-state cereal sweet wine and cereal clear wine prepared by the preparation method contain live bacteria, are beneficial to improvement on functions of human intestinal tracts and promoting digestive absorption, are good in instant-food property, and are rich in nutrient.

Owner:WUHAN BOSIDE TECH

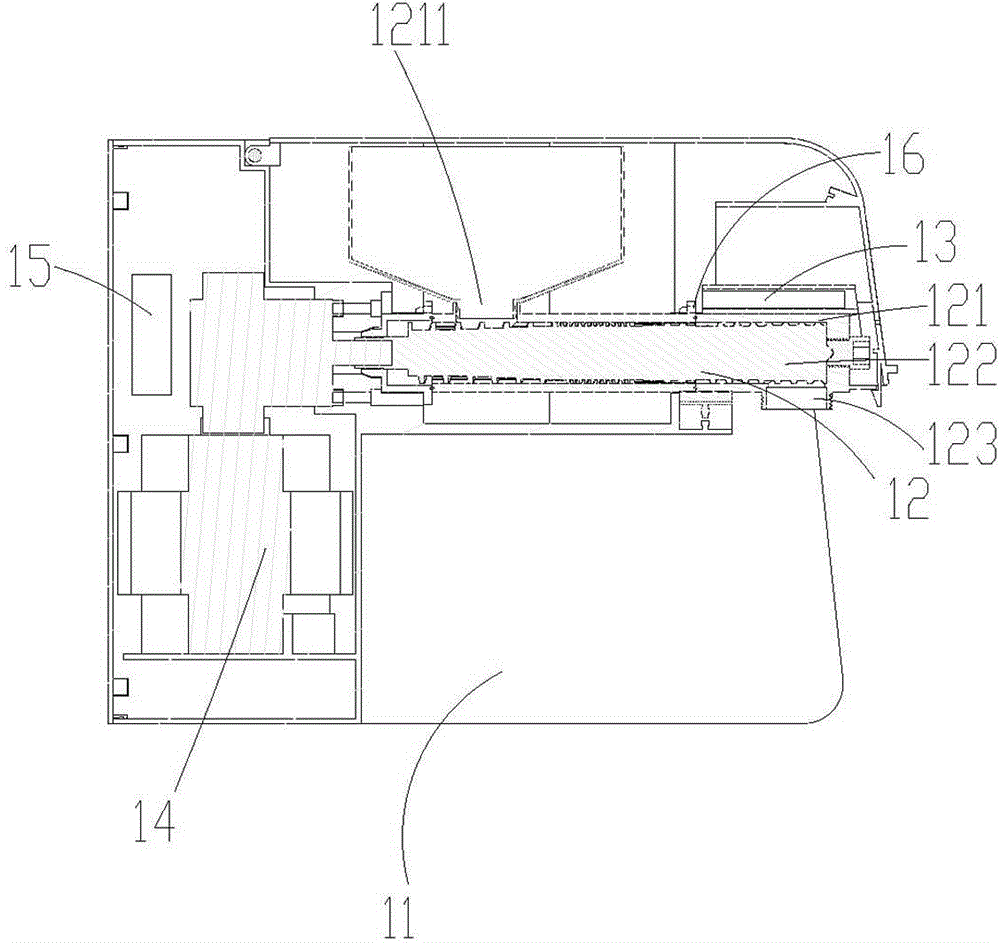

Rice noodle preparation method of household rice noodle machine and household rice noodle machine

ActiveCN104621443AHelp shapeImprove gelatinization efficiencyFood shapingFood preparationWarming processEngineering

The invention relates to a rice noodle preparation method of a household rice noodle machine and the household rice noodle machine. The rice noodles preparation method of the household rice noodle machine comprises the following steps: a feeding stage, namely driving a screw rod to rotate by a drive system and feeding raw materials into an extrusion grinding cavity by the screw rod; a curing and noodle-extruding stage, namely driving the screw rod to rotate by the drive system, grinding the raw materials by the screw rod, mixing, simultaneously curing the raw materials, and extruding into rice noodles from the ground, crushed, mixed and cured raw materials through a molding die head; and a once warming process, namely heating a extrusion crushing cavity by a heating device before the curing and noodle-extruding stage, so that the temperature of the extrusion crushing cavity ascends to T1, and the range of T1 is 80-110 DEG C, and feeding the rice material into the extrusion grinding cavity for curing after the once warming process is additionally added in the rice noodle preparation process, so that the hardness of the rice material is reduced, and the crushing of the rice material by virtue of a crushing, extruding and molding system in the curing and noodle-extruding stage is facilitated, and forming of the rice noodles are facilitated.

Owner:JOYOUNG CO LTD

Potato dough curing method

The invention discloses a potato dough curing method. Potato dough consists of the following raw materials in parts by weight: 35-50 parts of full potato powder, 50-65 parts of wheat flour and 35-38 parts of water; curing duration is 40-120min, curing temperature is 20-30 DEG C and curing humidity is 80-90%. According to the potato dough curing method disclosed by the invention, the potato dough is cured at special curing temperature and curing humidity, so that the potato dough is fully cured.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

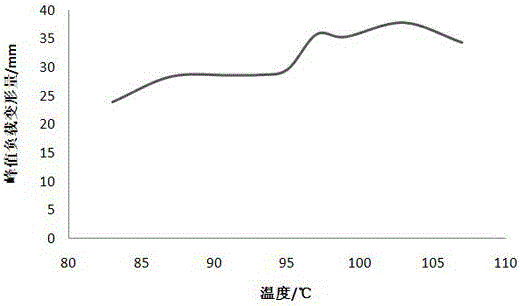

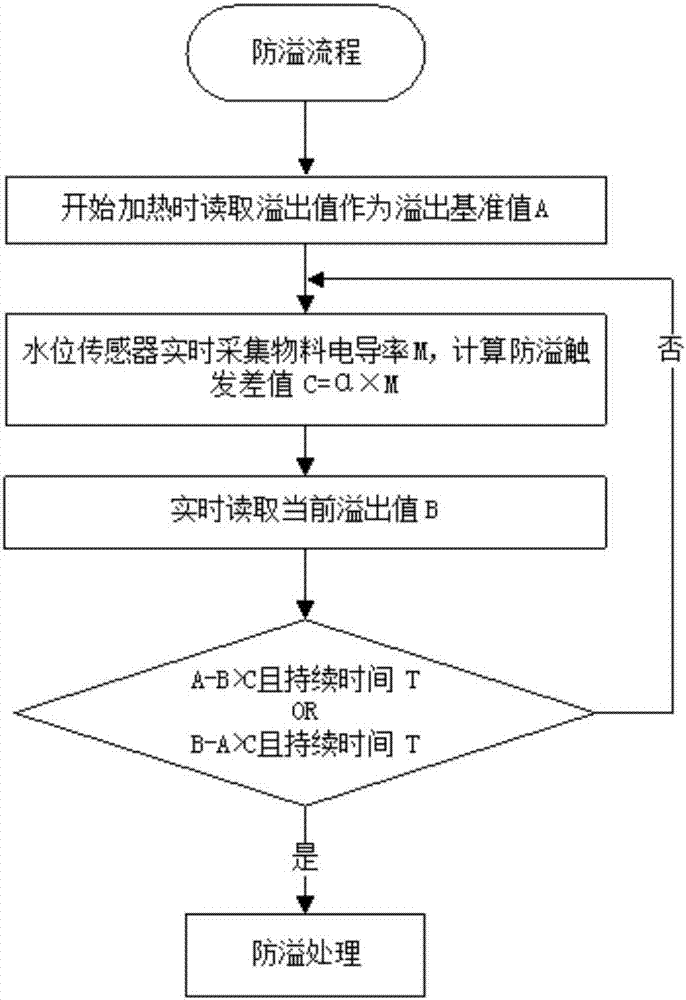

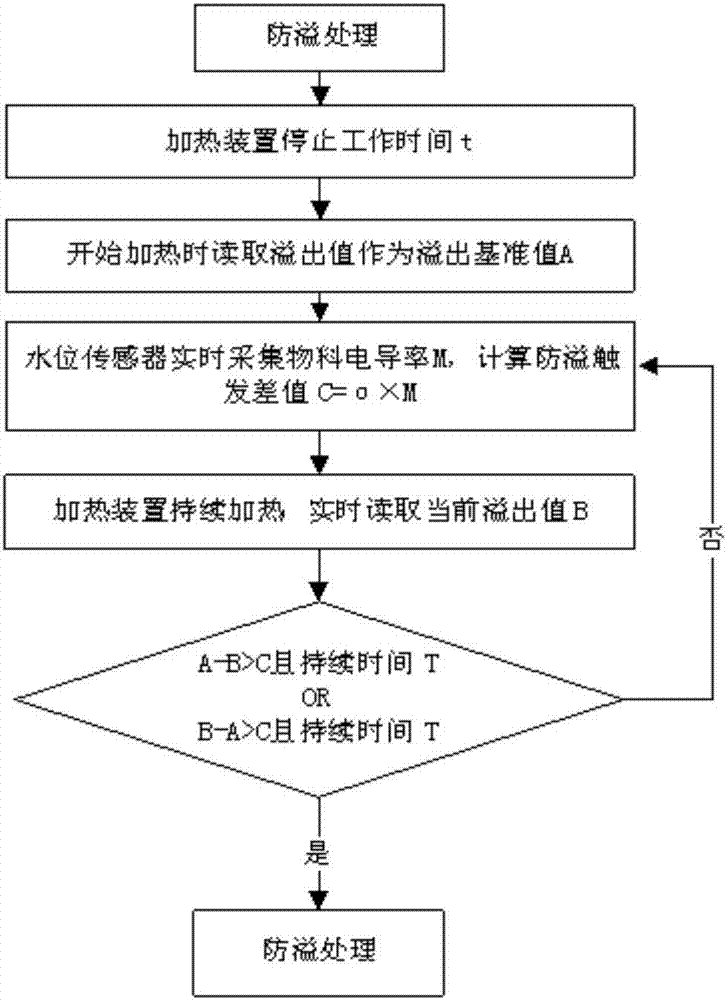

Overflow preventing control method of wall-breaking food processer and wall-breaking food processer

Owner:JOYOUNG CO LTD

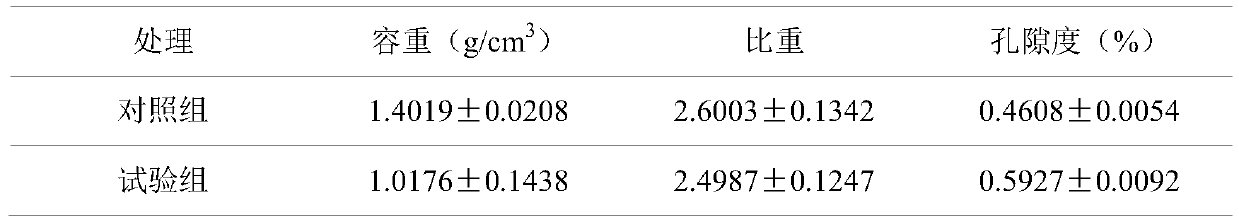

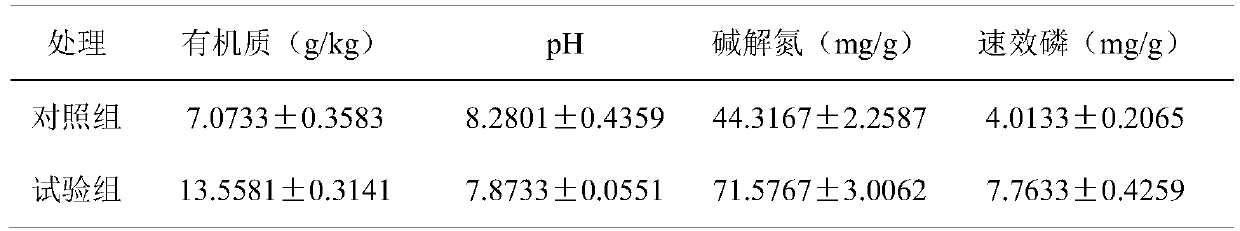

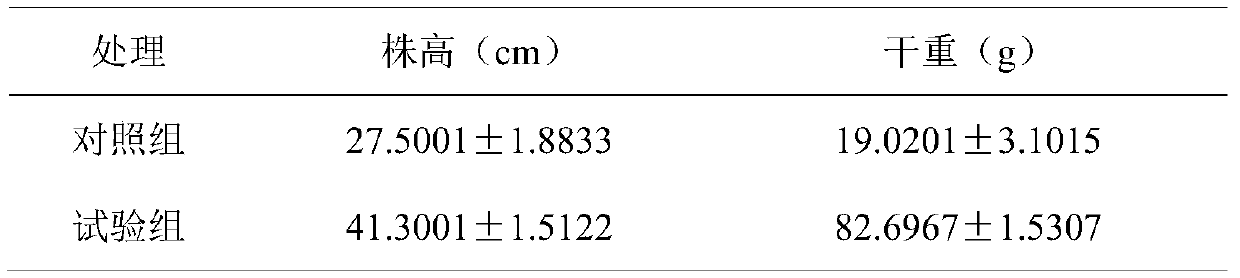

Soil conditioner for quickly ripening semi-mature soil and method for quickly ripening semi-mature soil

ActiveCN110041941ARipe fullyAvoid wastingAgriculture tools and machinesOrganic fertilisersGrowth plantSoil conditioner

The invention relates to a soil conditioner for quickly ripening semi-mature soil and a method for quickly ripening semi-mature soil and belongs to the technical field of soil conditioners. The soil conditioner provided by the invention is mainly composed of the following components in parts by weight: 5-10 parts of ammoniated humic acid, 10-15 parts of charcoal and 1-5 parts of water-retaining agent. The soil conditioner for quickly ripening semi-mature soil has a simple formula and is capable of improving physical and chemical properties of soil, promoting water-preserving and fertilizing level of soil, regulating soil environment, boosting plant growth and reducing volume weight of the semi-mature soil.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Mixed rice flour for clearing away heat and toxic materials and lowering blood pressure and preparation method thereof

InactiveCN106578869AUniform energyMore energyNatural extract food ingredientsFood ingredient functionsToxic materialNutrients substances

The invention discloses mixed rice flour for clearing away heat and toxic materials and lowering blood pressure; the mixed rice flour comprises the raw materials: a nutritional additive, honey powder, glutinous rice flour, brown rice flour, buckwheat flour, black sesame flour, pumpkin flour, mung bean flour, soybean flour, maltodextrin and xylitol. The invention provides a preparation method of the mixed rice flour for clearing away heat and toxic materials and lowering blood pressure. The obtained mixed rice flour for clearing away heat and toxic materials and lowering blood pressure has the advantages of sweet and fragrant taste, rich nutrition and high processing precision, allows the nutrient substances to be more easily absorbed by a human body, is convenient to eat, and has the efficacies of clearing away heat and toxic materials and lowering blood pressure.

Owner:桑文凡

Mixed rice flour having efficacy of reducing blood lipid and preparation method of mixed rice flour

InactiveCN106690008AFull of nutritionUniform energyFood ingredient functionsNutrientShiitake mushrooms

The invention discloses mixed rice flour having the efficacy of reducing blood lipid. The mixed rice flour comprises the following raw materials of a nutritive additive, garlic, wheat flour, coarse rice powder, shiitake mushroom powder, black sesame seed powder, soybean flour, corn flour, pumpkin powder, kelp powder, black fungus powder, a composite sweetening agent and a vitamin compound. The invention provides a preparation method of the mixed rice flour having the efficacy of reducing blood lipid. The mixed rice flour having the efficacy of reducing blood lipid, prepared by the method disclosed by the invention, is fragrant and sweet in mouth feel, rich in nutrition, high in processing precision and convenient to eat, and nutrient substances are easy to absorb by human bodies.

Owner:桑文凡

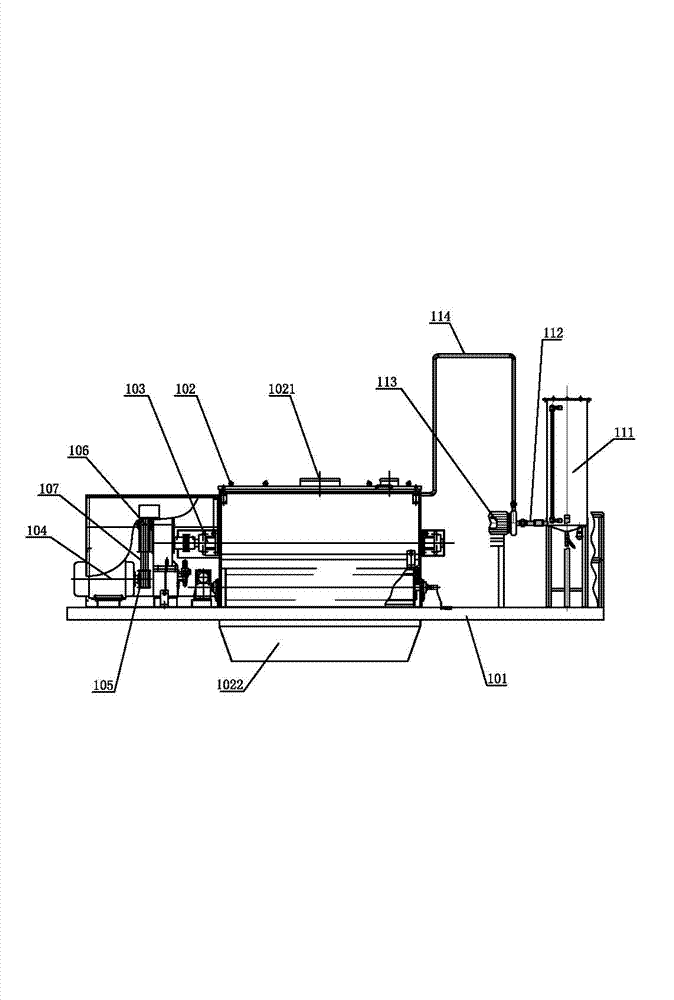

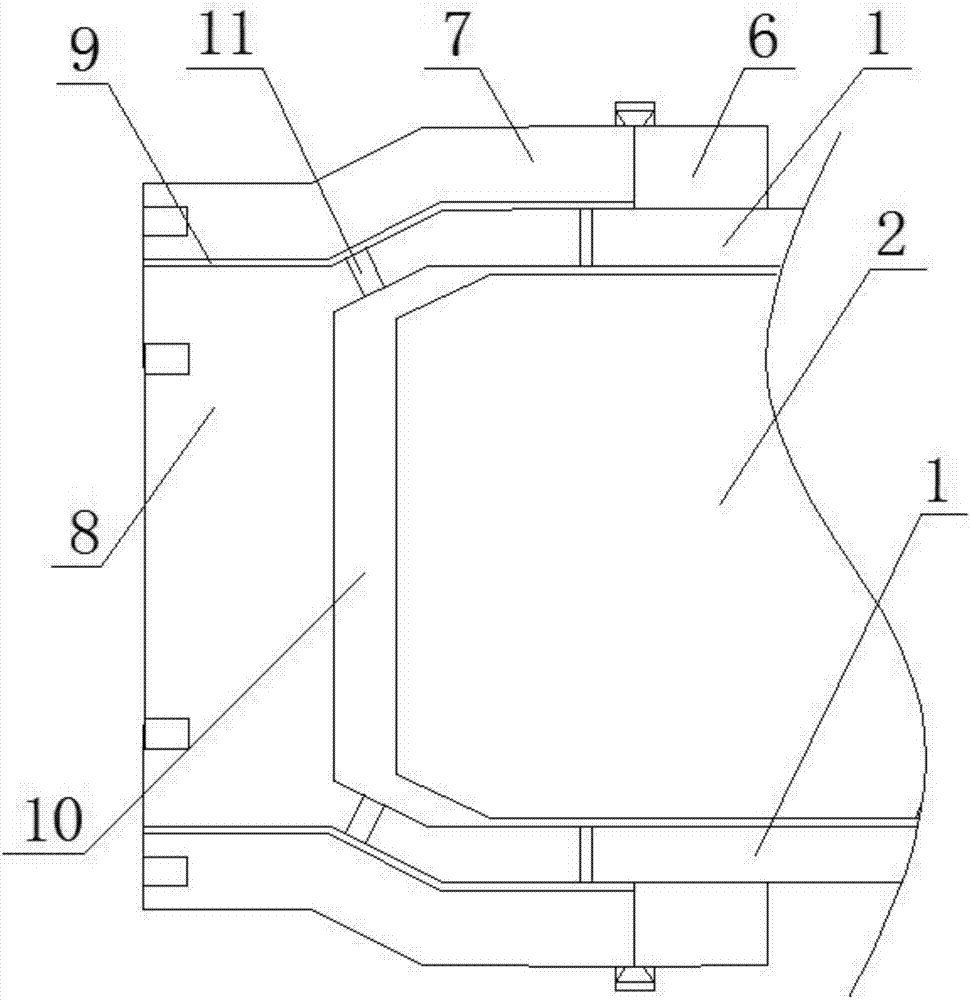

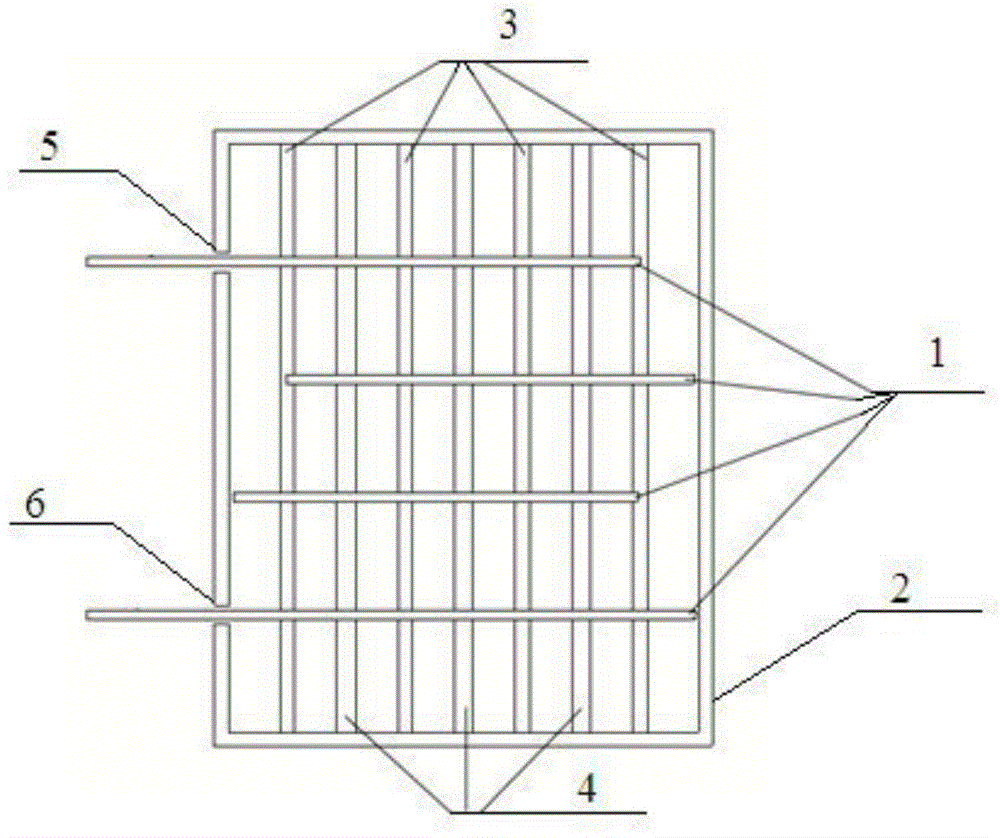

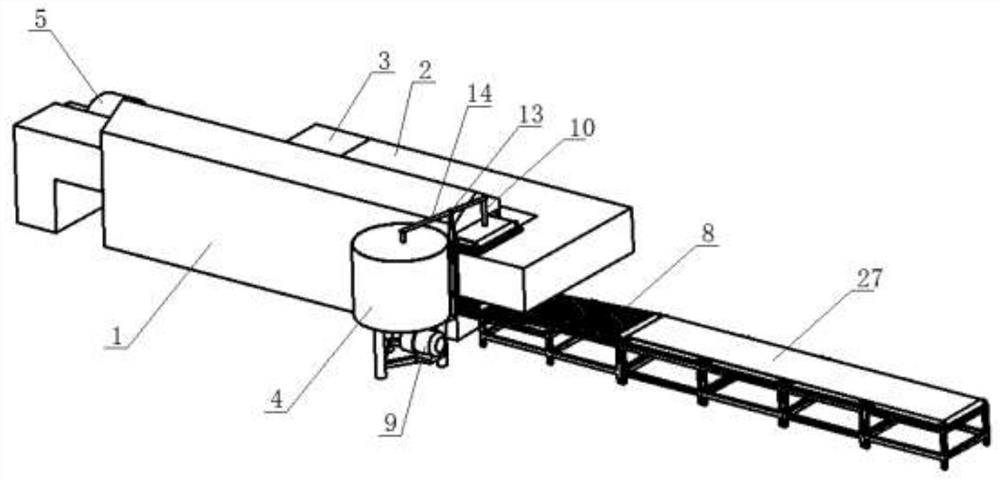

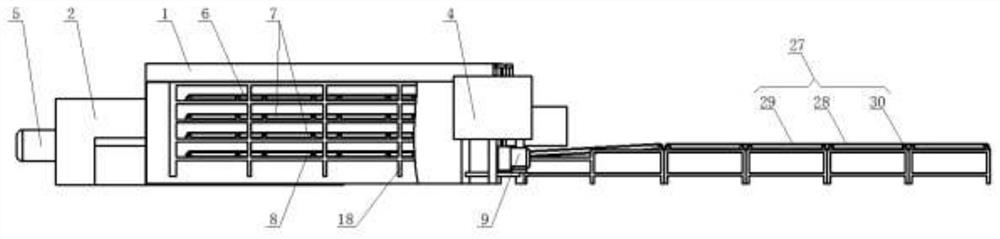

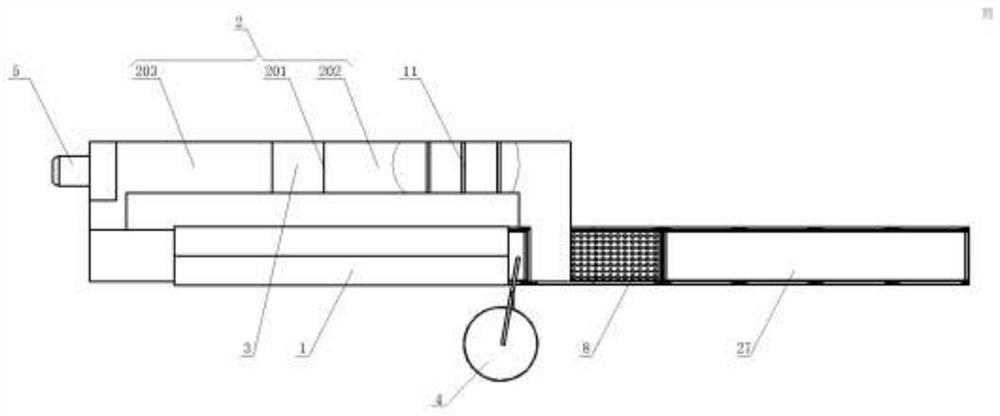

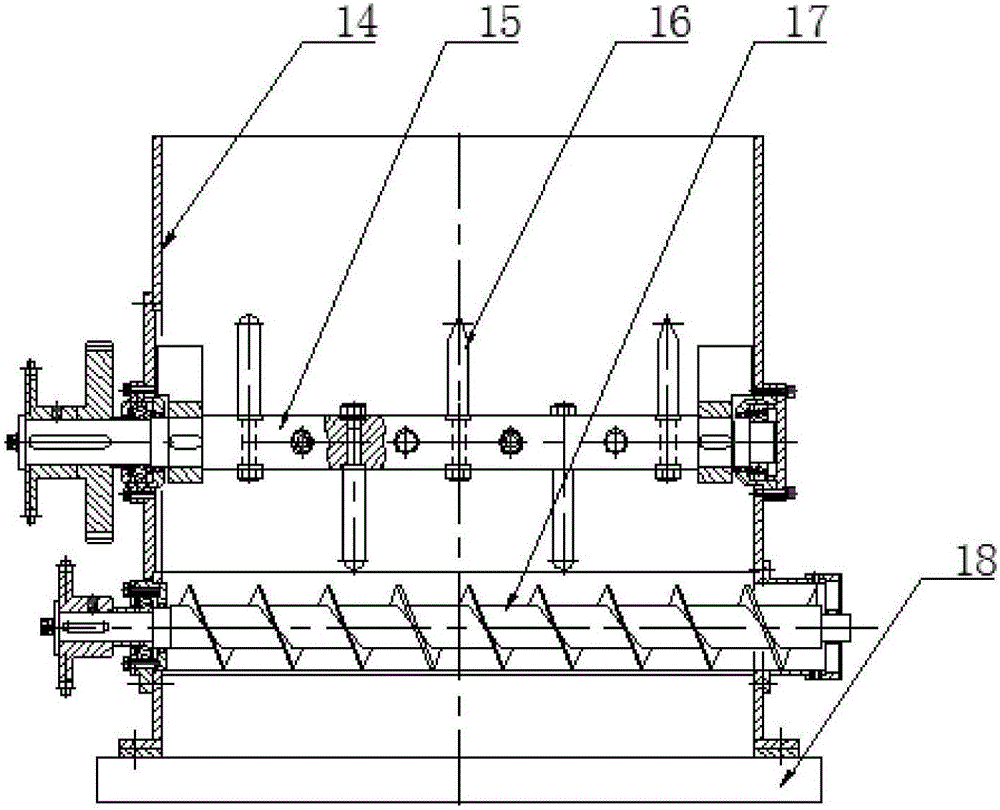

A rice flour ripening and loosening integrated equipment

ActiveCN110787695BImprove product qualityAvoid accumulationTransportation and packagingRotary stirring mixersAgricultural engineeringRipening

The invention discloses a kind of rice flour ripening and loose integration equipment, which comprises a constant temperature oven and a mixing cylinder with an opening at one end. A rack is arranged inside the constant temperature oven, and a feeder, a conveyor and a discharger are installed in sequence from top to bottom of the rack. , the feeding machine includes feeding cloth and several rollers A, the two ends of the roller A are installed on the frame through the bearing seat, the feeding cloth is wound on the outer peripheral surface of the roller A, the conveyor or the discharging machine includes a machine installed on the There are several rollers B on the frame, and the two ends of the rollers B are equipped with sprockets, and the sprockets are driven by chain meshing. There are several steel wires fixedly connected between the two chains. The slurry pipe sends the rice flour slurry to the upper surface of the feeding cloth. Adopting the technical scheme of the present invention, the vibration of the sprocket during the transmission process is used to vibrate the load-carrying steel wire in a small range at the same time, so that the rice noodle slurry in the process of cooking is continuously loosened, which lays a foundation for reasonable packaging of the finished rice noodle in the later stage.

Owner:贵州金晨农产品开发有限责任公司

Cooking utensil, control method and device thereof, and storage medium

InactiveCN111938410AFully boiledPromote boilingTemperatue controlWarming devicesThermodynamicsProcess engineering

Owner:GREE ELECTRIC APPLIANCES INC

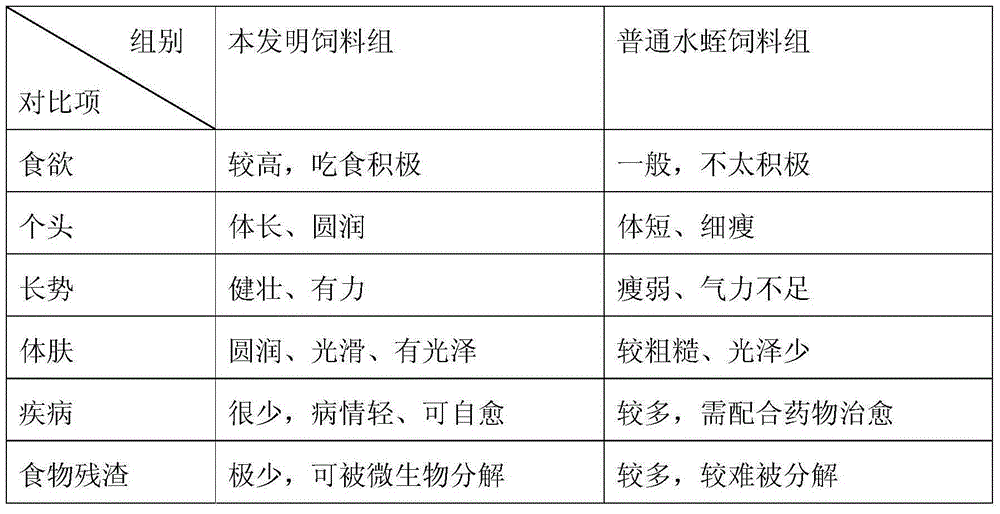

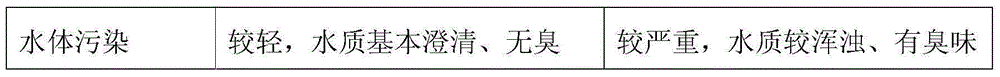

Bacterium and disease preventing leech culturing feed and preparation method thereof

InactiveCN104996775AReduce fecal odorPrevent constipationAnimal feeding stuffDiseaseGlucose-Fructose Syrup

The present invention discloses a bacterium and disease preventing leech culturing feed and a preparation method thereof. The feed comprises the following raw materials in parts by weight: corn flour 70-80 parts, sesame seed meal 20-30 parts, pig hair powder 50-70 parts, soybean dregs 20-50 parts, duck oil 7-9 parts, soy peptides 20-30 parts, shii-take extract 0.3-0.5 part, dried banana powder 1-2 parts, fructose-glucose syrup 0.4-0.6 part, yucca smalliana 2-3 parts, ophiopogon japonicus 1-2 parts, dilute milk 20-30 parts, EM zymophyte 0.1-0.2 part and liquid protein concentrate 0.7-0.8 part. The finished products of the bacterium and disease preventing leech culturing feed are in micro powder states, are easily dissolved or suspended in water, can adsorb onto sponges to conduct feeding, are easier to be taken and digested than the feed of ordinary big grain sizes, and are easy in storage, and long in shelf life.

Owner:MAANSHAN CHUANGYUAN LEECH FARMING PROFESSIONAL COOP

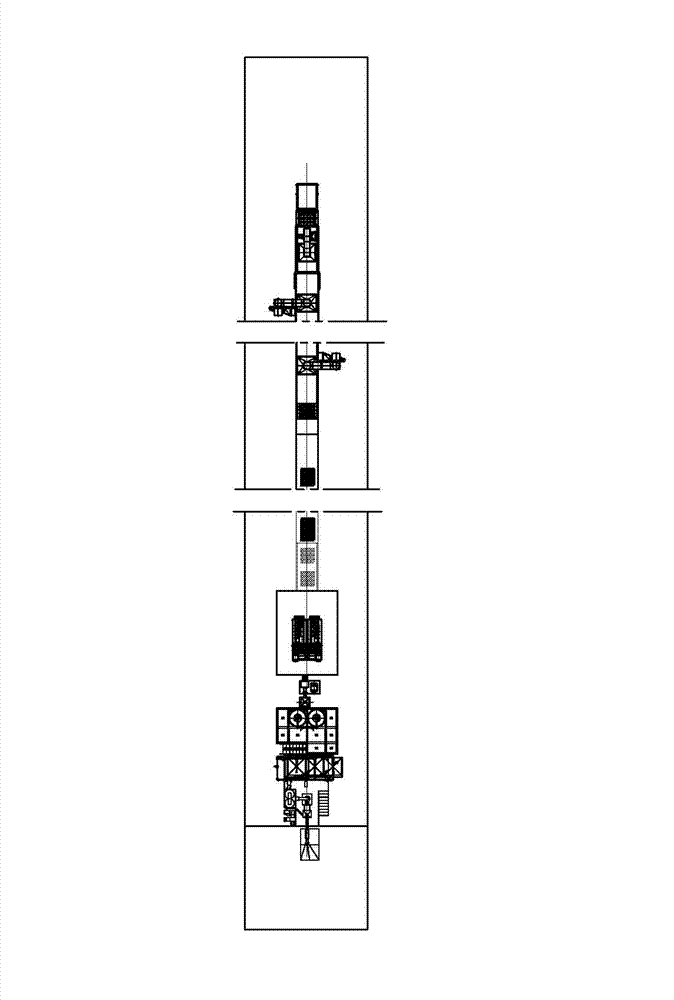

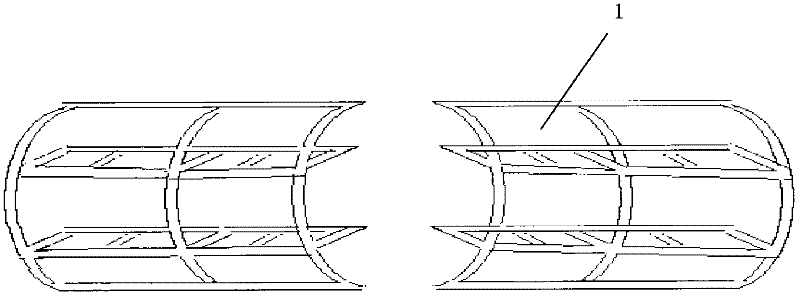

Three-stage extrusion fresh wet bean vermicelli production line

InactiveCN105010936AReasonable configurationSimple processFood shapingFood preparationAutomatic processingManufacturing engineering

The invention relates to a three-stage extrusion fresh wet bean vermicelli production line. The production line is characterized by comprising a dough batch, a dough fermenting machine, a first lifting machine, a dough feeding machine, a first-stage granule extruder, a continuous steaming machine, a second lifting machine, a second-stage sheet extruder, a third-stage vermicelli extruder, a bean vermicelli cooking machine, a sprayer, a cooler and a cutting mechanism which are connected sequentially. The production line has the advantages of high production efficiency, small labor intensity and high product quality. The whole production line is reasonable in configuration and concise in process, is safe and clean, and can be used for completing automatic processing of fresh wet bean vermicelli.

Owner:SHENGCHANGDA MACHINERY TIANJIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com