Single-screw low-temperature wet-process puffing machine

A single-screw, extruder technology, used in feed, food forming, food science and other directions, can solve the problems affecting the extensibility and plasticity of starch gluten, tailing, long conditioning time, etc., to improve water absorption and extensibility. , The feeding is uniform and stable, and the effect of insufficient penetration is avoided.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

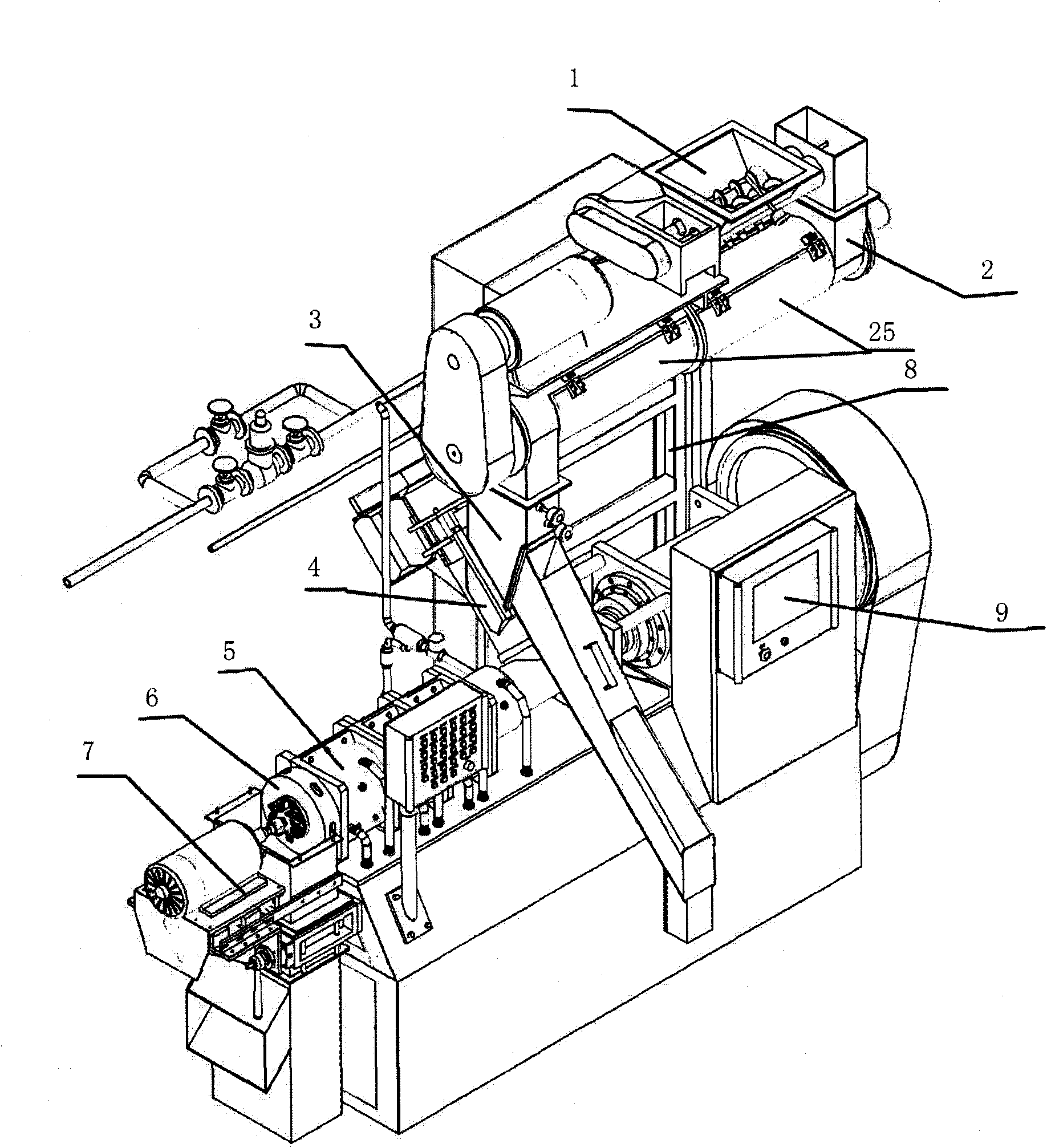

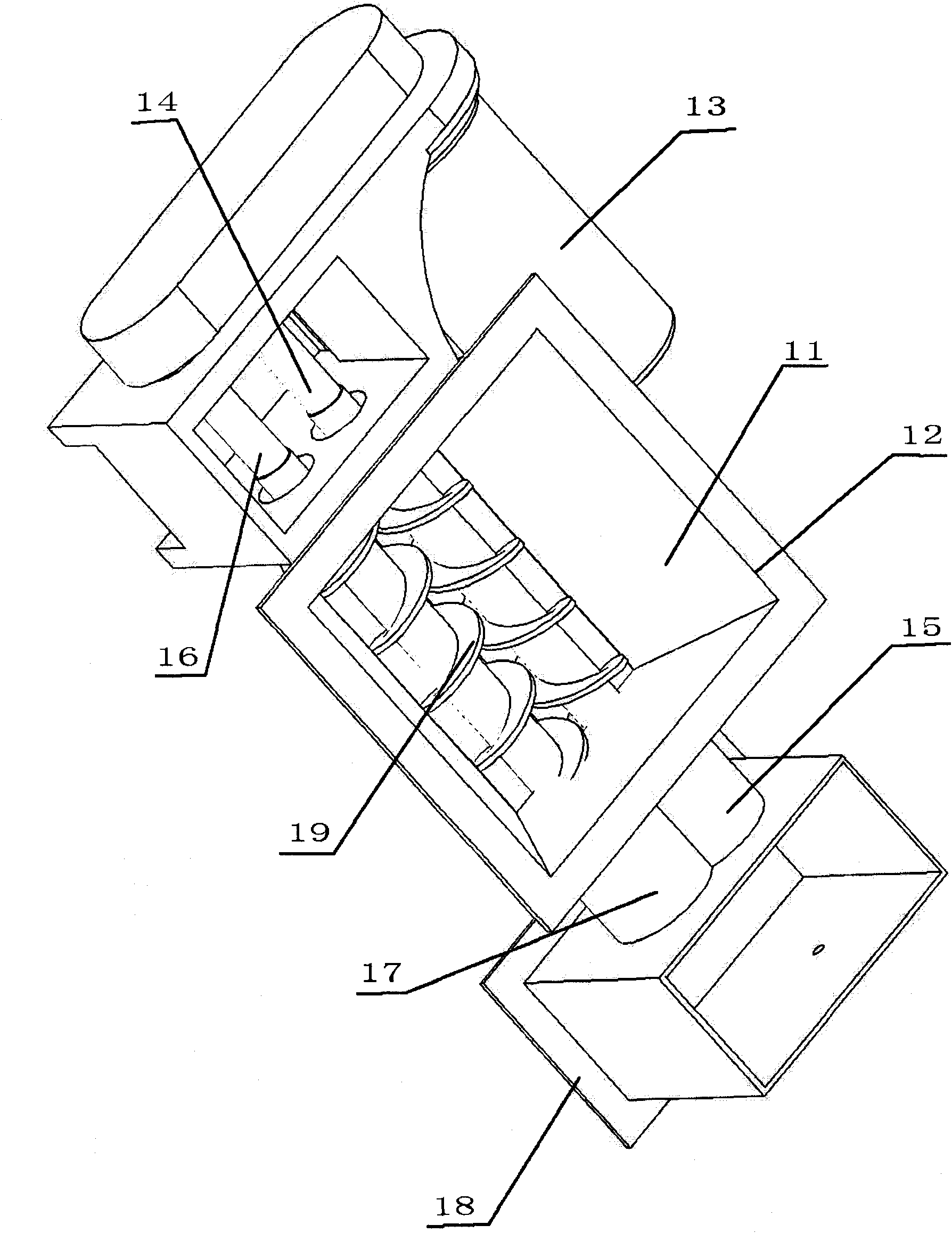

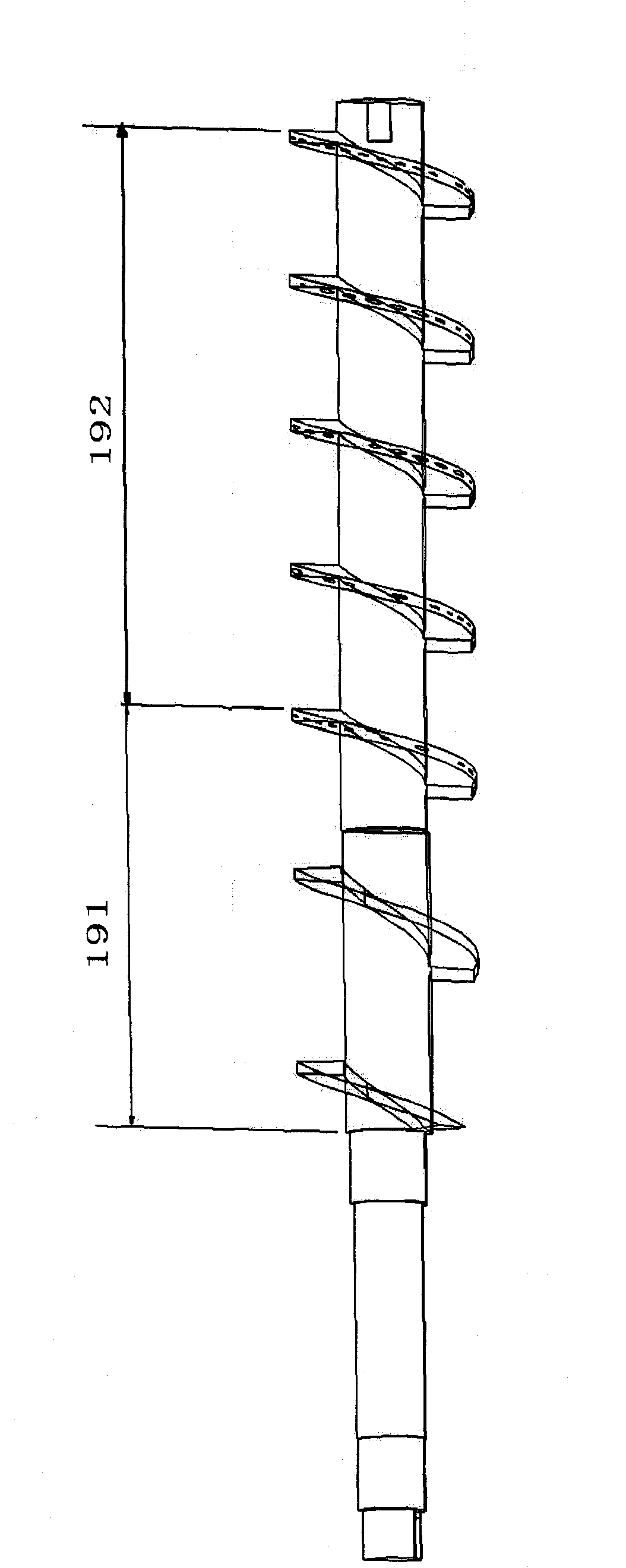

[0029] The present invention will be further described below in conjunction with accompanying drawing,

[0030] Such as Figures 1 to 11 The shown single-screw low-temperature wet-process extruder comprises a frame body 8 and a motor, the motor is connected to the bottom of the frame body 8, and the top of the frame body 8 is provided with a twin-screw feeder 1, and the frame The conditioner 2 connected to the twin-screw feeder 1 is arranged on the middle and upper part of the frame body 8, and the secondary feeder 4 connected to the conditioner 2 through the outlet tee 3 of the conditioner is arranged on the middle part of the frame body 8. The low-temperature extrusion device 5 driven by the motor is connected to the secondary feeder 4, and the end of the low-temperature extrusion device 5 is connected with an extrusion die 6, and the outer side of the extrusion die 6 is also provided with a Self-adjusting gap cutter device 7.

[0031] The twin-screw feeder 1 includes a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com