Food processing method of food processor and food processor

A food processing machine and food processing technology, applied in the food processing field of food processing machines and food processing machines, can solve the problems of not knowing the degree of air thinning in the mixing cup, easy to cause physical discomfort, and it is not easy for materials to be cooked, etc. The effect of shortening pulping time, improving user experience and reducing the loss of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

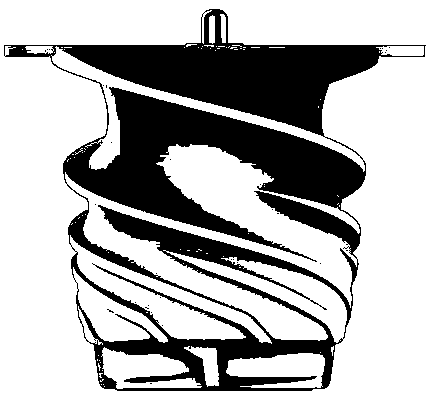

[0033] Such as figure 1 As shown, a food processor includes a machine base 1 with a motor 2, a circuit board 9 disposed inside the machine base 1, a stirring cup 3 disposed on the machine base 1, and a cup cover on the top of the stirring cup 3 , the crushing knife 4 located in the stirring cup 3, the heating device 5 for heating the material in the stirring cup 3, the vacuum pump 6 for extracting the air in the stirring cup 3, the air pressure for detecting the air pressure in the stirring cup 3 The sensor 7 and the pressure relief module for releasing the pressure of the stirring cup 3 and the sealing module for sealing the stirring cup 3, the motor 2 drives the pulverizer 4 to rotate and crush the materials in the stirring cup 3, wherein the circuit board 9 is provided with a pulping program, and the pulping program includes the food processing method described in this embodiment.

[0034] In this embodiment, the pressure relief module and the sealing module have the same ...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that the intermittent vacuuming step is located in the crushing step, that is to say, the vacuum is pumped while crushing. When the crushing knife 4 crushes the material, the vacuum pump 6 works intermittently, which is beneficial to the separation of the material. Collision between the material and the cup wall, the material and the pulverizing knife, the pulverizing effect is good, and the oxidation and nutrient loss are prevented, and the noise of the pulverizing process is reduced.

Embodiment 3

[0044] The difference between this embodiment and Embodiment 1 is that the intermittent vacuuming step is located after the crushing step, which has the advantage of eliminating the foam generated during the crushing process of the material, improving the taste and making the visual effect better, which is beneficial to the crushing process. Due to the centrifugal force, the pulverized material stuck to the side wall of the mixing cup 3 returns to the slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com