Production method of germinated brown rice and application thereof

A technology of germinated brown rice and its production method, which is applied in the fields of application, seed immunization, edible seed preservation, etc., can solve the problems of germinated brown rice such as difficult cooking, low nutritional value, poor stability, etc., so as to improve storage stability, prolong shelf life, and inhibit growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

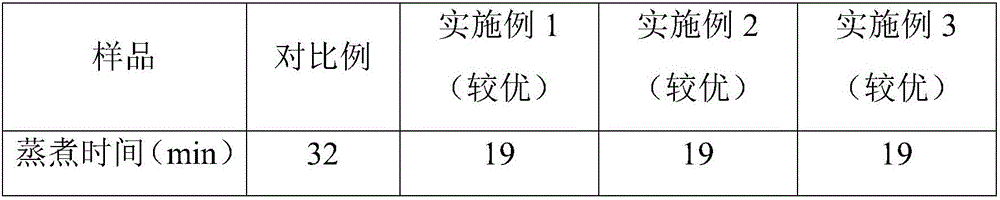

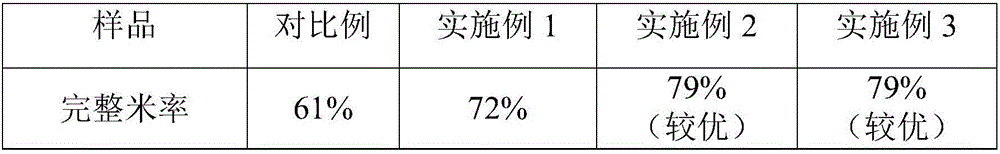

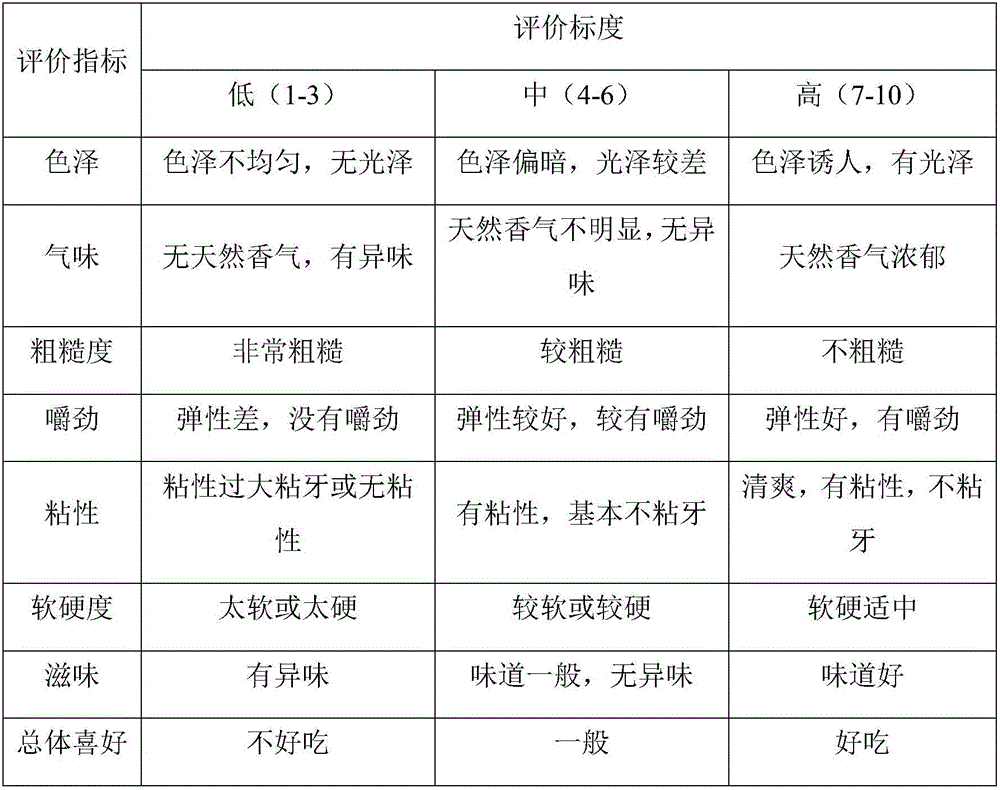

Examples

Embodiment 1

[0029] The japonica rice is dried in a drying tower and stored in a low-temperature constant temperature storage. Then, the rice is removed from impurities, cleaned, destoned, and shelled to be processed into brown rice as a raw material to produce germinated brown rice. The production method includes the following steps:

[0030] (1) Cleaning and disinfection: add water three times its weight to the brown rice, rinse twice, drain the water, irradiate under ultraviolet rays, and pass into ozone for disinfection for 20 minutes;

[0031] (2) Soaking and sterilizing: add 2.5 times its weight of water to the sterilized brown rice in step (1), after soaking for 4 hours at 24°C, pass through ozone for disinfection for 10 minutes, then let it stand for 10 minutes, and drain the water;

[0032] (3) Germination: put the sterilized brown rice in step (2) in water at 35°C, germinate for 24 hours under the condition of avoiding light, and change the water every 6 hours; wherein, the weight...

Embodiment 2

[0037] The japonica rice is dried in a drying tower and stored in a low-temperature constant temperature storage. Then, the rice is removed from impurities, cleaned, destoned, and shelled to be processed into brown rice as a raw material to produce germinated brown rice. The production method includes the following steps:

[0038] (1) Cleaning and disinfection: add water three times its weight to the brown rice, rinse twice, drain the water, irradiate under ultraviolet rays, and pass into ozone for disinfection for 20 minutes;

[0039] (2) Sterilization by soaking: add water 2.5 times its weight to the brown rice sterilized in step (1), soak it at 24°C for 4 hours, then pass it into ozone for disinfection for 10 minutes, let it stand for 10 minutes, and drain the water;

[0040] (3) heat treatment: the brown rice after the sterilization in step (2) is placed in the water of 50 ℃ and soaks 6min, drains;

[0041] (4) Germination: place the heat-treated brown rice in step (3) in ...

Embodiment 3

[0047] The japonica rice is dried in a drying tower and stored in a low-temperature constant temperature storage. Then, the rice is removed from impurities, cleaned, destoned, and shelled to be processed into brown rice as a raw material to produce germinated brown rice. The production method includes the following steps:

[0048] (1) Cleaning and disinfection: add water three times its weight to the brown rice, rinse twice, drain the water, irradiate under ultraviolet rays, and pass into ozone for disinfection for 20 minutes;

[0049] (2) Soaking and sterilizing: add 2.5 times its weight of water to the sterilized brown rice in step (1), after soaking for 4 hours at 24°C, pass through ozone for disinfection for 10 minutes, then let it stand for 10 minutes, and drain the water;

[0050] (3) heat treatment: the brown rice after the sterilization in step (2) is placed in the water of 50 ℃ and soaks 6min, drains;

[0051] (4) Germination: place the heat-treated brown rice in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com