Patents

Literature

82results about How to "Improve storage stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Assay devices

InactiveUS6187269B1Improve storage stabilityConveniently formedAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorAntibodyBiomedical engineering

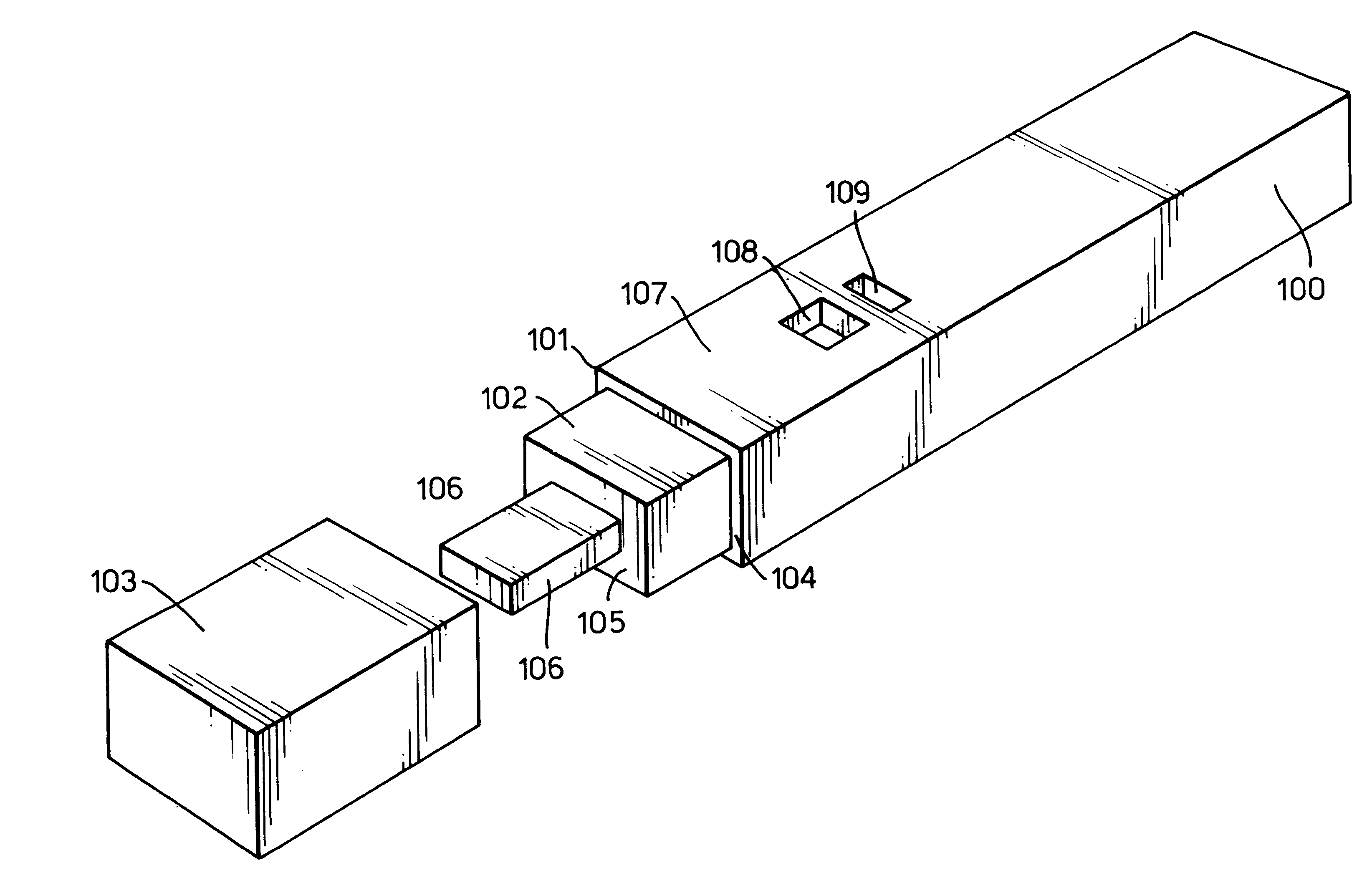

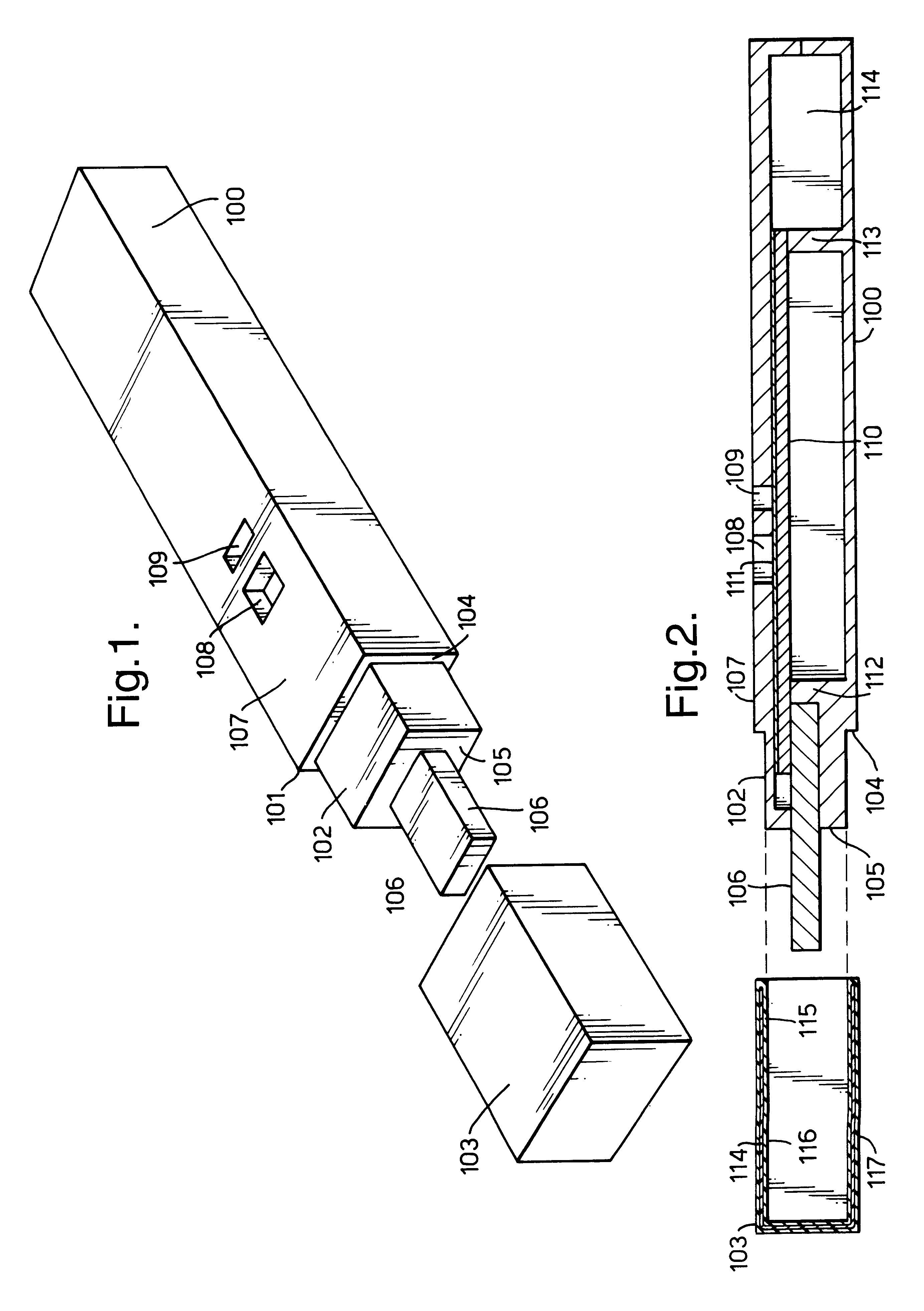

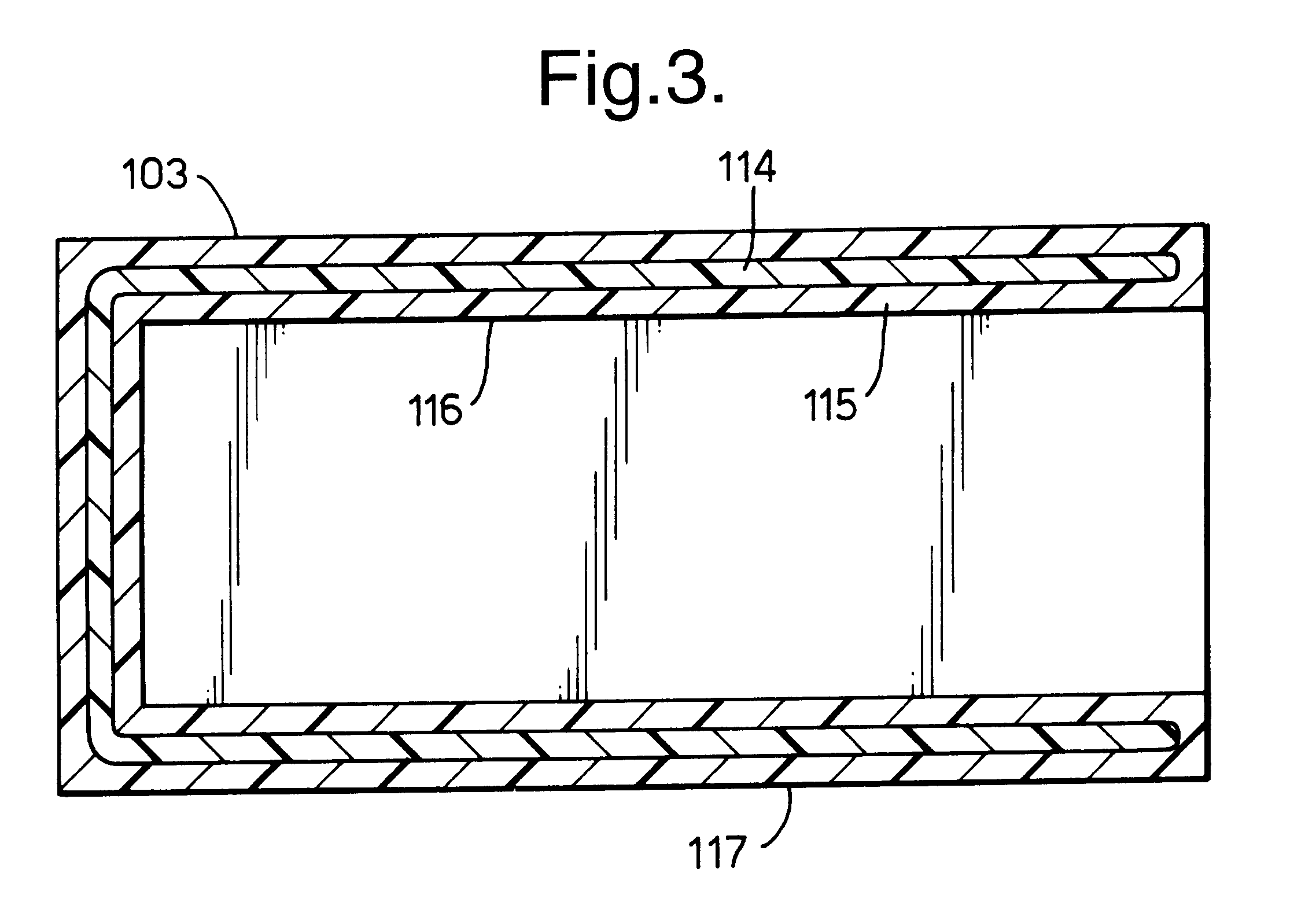

Storage stability of an assay device, comprising an assay strip and sensitive reagents such as antibodies within a plastics casing, is maintained by moulding some or all of the casing from dessicant-containing plastics material, especially a blend of about 60-65% polystyrene and about 30% silica dust. Ideally the desiccant-containing plastics material is used in the moulding of a removable cap for the device. The cap can be made by sandwich injection moulding, using the dessicant-containing polystyrene as a core, surrounded by conventional polystyrene.

Owner:INVERNESS MEDICAL SWITZERLAND GMBH

Starch-based wood adhesive and preparation method and application thereof

ActiveCN102031078AImprove storage stabilityHigh bond strengthGraft polymer adhesivesButyl acrylateBonding strength

The invention provides a starch-based wood adhesive and a preparation method and application thereof, and belongs to the technical field of adhesive. In the invention, a starch adhesive for woods with good property is prepared by performing acidolysis and gelatinization on starch serving as raw materials, grafting, copolymerizing and modifying the starch by using two monomers of vinylacetate and butyl acrylate under the condition of adding an emulsifier, and adding an accessory ingredient after lowering the temperature. The adhesive prepared by the preparation method has the advantages of good preservation stability, high bonding strength, milky white and glossy color and the like, and can be applied to decoration of woods and bonding of artificial plates and glued plates.

Owner:JIANGNAN UNIV

Nanometer modified ultraviolet curing coating for synthetic leather

InactiveCN101613942AImprove storage stabilityThere is no problem of volatilizationFibre treatmentPhotoinitiatorDefoaming Agents

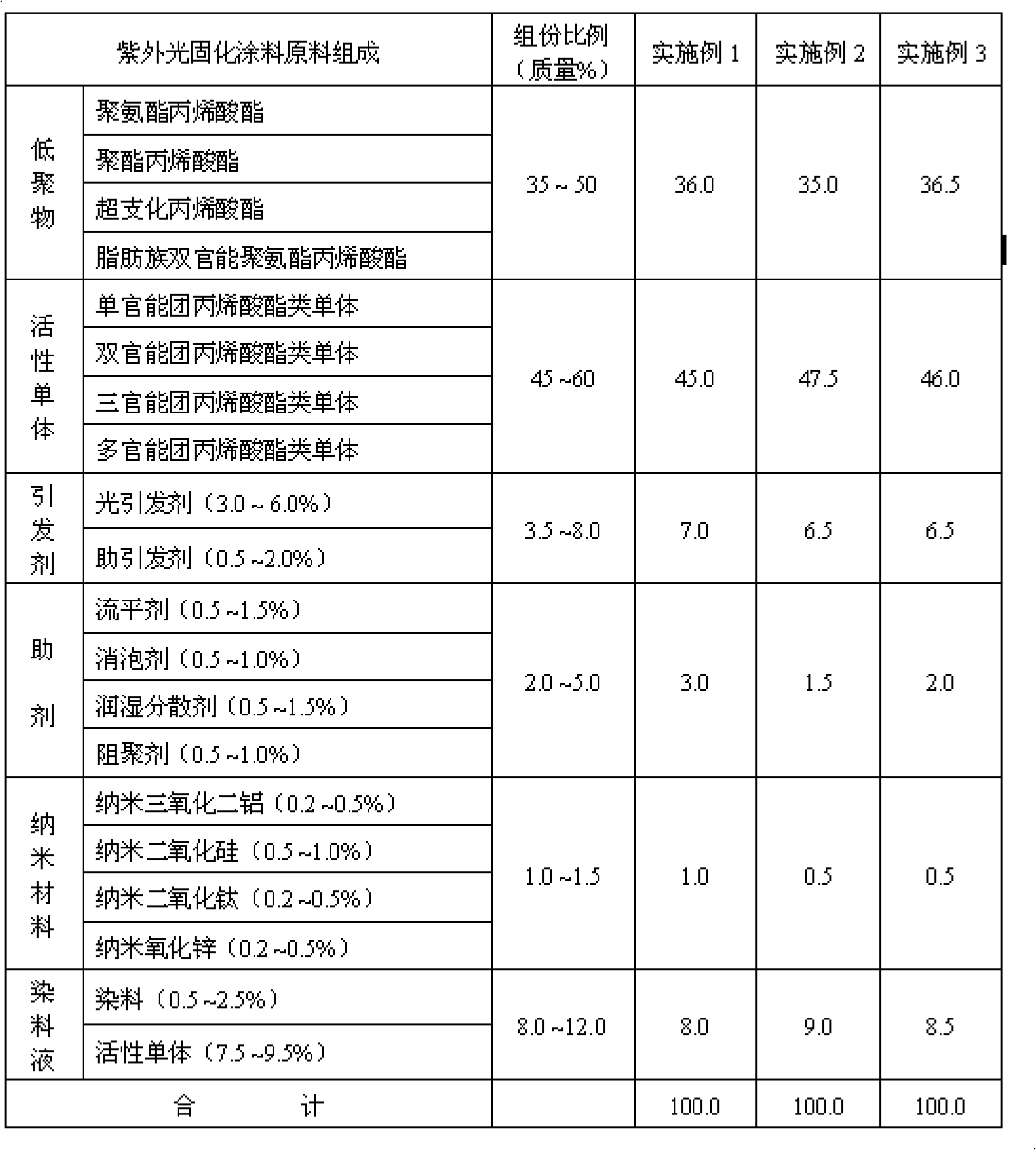

The invention relates to a nanometer modified ultraviolet curing coating for synthetic leather and a preparation method thereof. The coating comprises the following components in percentage by mass: 35 to 50 percent of acrylic ester oligomers, 45 to 60 percent of acrylic ester active monomers, 3.5 to 8.0 percent of photoinitiator and co-initiator, 0.5 to 1.5 percent of flattening agent, 0.5 to 1.0 percent of defoaming agent, 0.5 to 1.5 percent of wetting dispersant, 0.5 to 1.0 percent of polymerization retarder, 1.0 to 1.5 percent of nanometer material, and 8.0 to 12.0 percent of dye solution. The nanometer modified ultraviolet curing coating for the synthetic leather adopts more reasonable components and does not use organic solvent, so the problem of the volatilization of the organic solvent does not exist during the production, and the storage stability can also be improved to more than 18 months at the same time.

Owner:WENZHOU LUCHENG INK CHEM

Starch-based graft copolymer coal water slurry dispersant and preparation method thereof

InactiveCN102351995AImprove storage stabilityGood dispersion performanceLiquid carbonaceous fuelsCoal waterChemistry

The invention provides a starch-based graft copolymer coal water slurry dispersant and a preparation method thereof. The method comprises steps that: a 10% to 20% starch aqueous suspension is heated; an oxidizing agent which takes 0.1% to 5% of the mass of starch is added to the aqueous suspension of starch for carrying out an oxidization reaction for 10 to 60min; the mixture is heated to a temperature of 80 to 95 DEG C, and the mixture is gelatinized for 20 to 60min while maintaining the temperature; the temperature of the mixture is reduced to 40 to 70 DEG C, and meanwhile mixed monomer and an initiator are dropped into the mixture; the mixture is heated to a temperature of 80 to 95 DEG C, and is subject to a reaction while maintaining the temperature for 20 to 120min; the temperature is reduced to 20 to 40 DEG C, and the pH value of the mixture is regulated to 7-9 by using a sodium hydroxide solution. The dispersant is a viscous emulsion with a color of light yellow to off-white, a solid content of 25 to 35%, a pH value of 7 to 9, and a viscosity of 30 to 150mPa.s. According to the invention, strong dispersibility of styrene and carboxylic salt is fully utilized. Hydrogen bonding effect of polyhydroxy on starch straight chains upon hydrones is adopted, such that the storage stability of the coal water slurry is improved, the dispersibility of the coal water slurry is good, and the stationary phase of the coal water slurry is long-lasting.

Owner:SHAANXI UNIV OF SCI & TECH

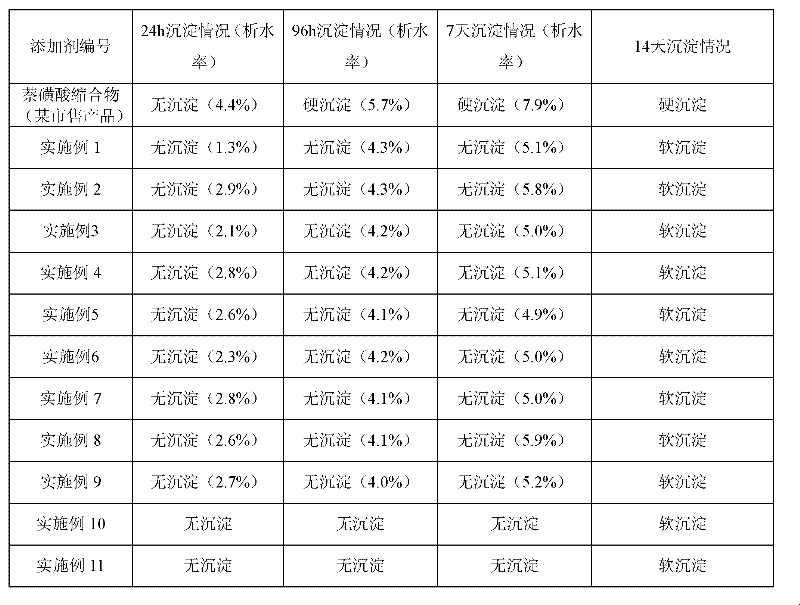

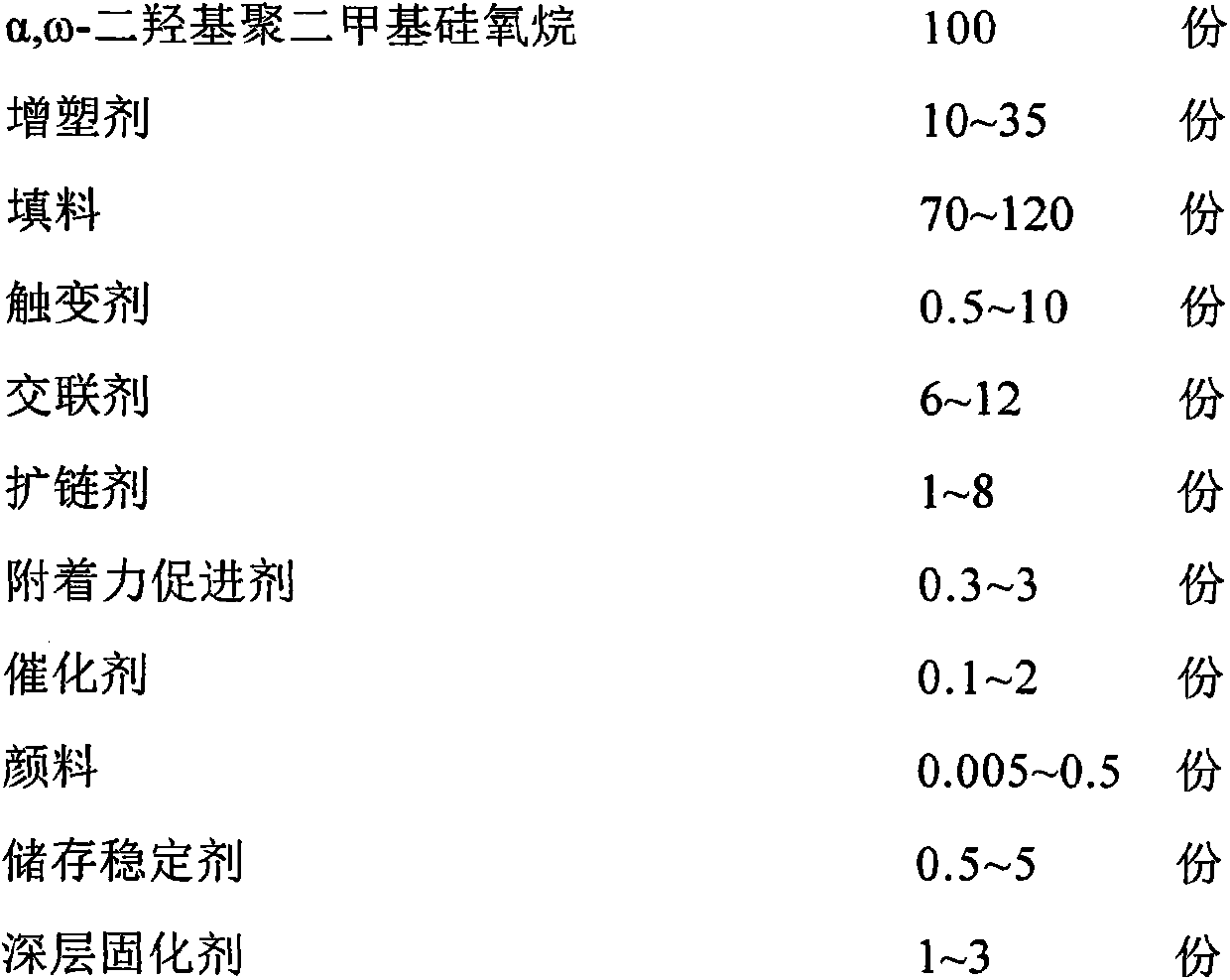

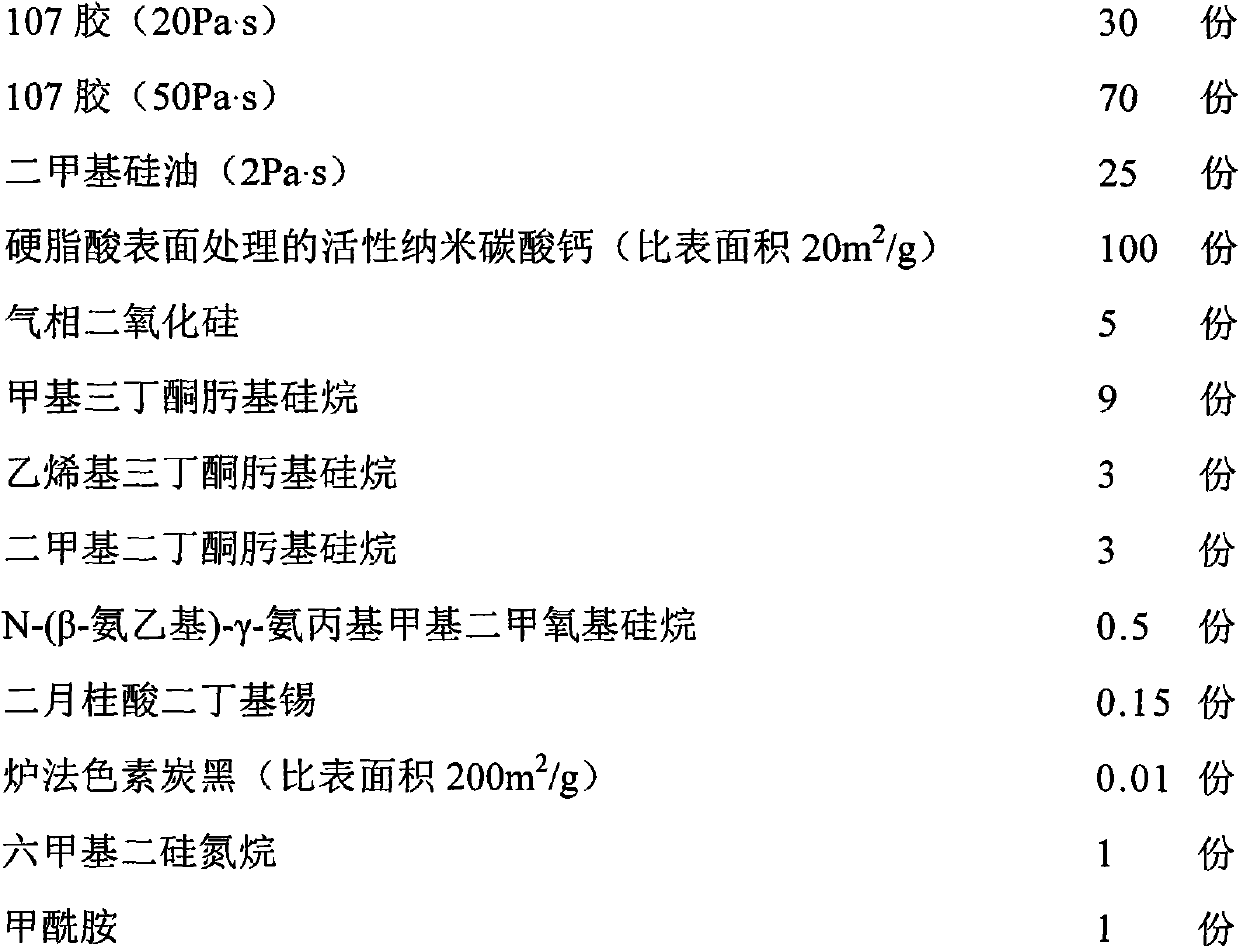

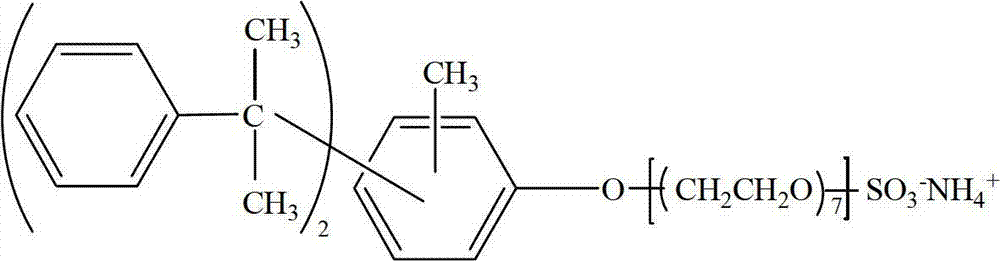

Silicone caulking material for concrete expansion joints of ballastless tracks and preparation method thereof

ActiveCN104004492AImprove storage stabilityFacilitate rapid progressNon-macromolecular adhesive additivesOther chemical processesPlasticizerAging resistance

The invention relates to a silicone caulking material for concrete expansion joints of ballastless tracks and a preparation method thereof. The caulking material is composed of the following raw materials in parts by mass: 100 parts of alpha, omega-dihydroxy polydimethylsiloxane, 10-35 parts of a plasticizer, 70-120 parts of filler, 0.5-10 parts of a thixotropic agent, 6-12 parts of a crosslinking agent, 1-8 parts of a chain extender, 0.3-3 parts of an adhesion promoter, 0.1-2 parts of a catalyst, 0.005-0.5 part of a pigment, 0.5-5 parts of a storage stabilizer, and 1-3 parts of a deep curing agent. The silicone caulking material is prepared by using the preparation method disclosed by the invention. The silicone caulking material has the characteristics of good construction performance, high displacement capacity, good interface adhesion, excellent aging resistance, long storage life, good deep-layer curing performance, and the like, is suitable for being applied to concrete expansion joints of ballastless tracks of high-speed rails, expansion joints of airport pavements and cement concrete pavements, and the like, and also can be applied to the failure repair of existing expansion caulking materials.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Emulsion carbon fiber sizing agent as well as preparation method and application of sizing agent

ActiveCN102828416AEnhanced storage and usage stabilityImprove storage stabilityFibre treatmentInterlaminar shearFiber size

The invention discloses an emulsion carbon fiber sizing agent and a preparation method and application of the sizing agent. The sizing agent comprises the following components by weight percent: 2-50% of epoxy resins, 35-97% of water, 0.5-15% of surfactants and 0.1-2.0% of inorganic ammonium salt. The emulsion carbon fiber sizing agent contains the stabilizing agent inorganic ammonium salt, so the storage stability of the sizing agent is greatly improved compared with the existing sizing agents; the emulsion can still maintain the stable property and layering and uneven concentration distribution can be avoided after the sizing agent is stored for more than three years under normal temperature; after the carbon fiber sized with the sizing agent has been stored for five years under normal temperature, the mass percentage of the sizing agent on the surface of the carbon fiber is not changed; when the sizing agent is used, stirring can be carried out at 200r / min to convey and dilute the sizing agent so that the sizing agent can not generate layering and demulsification; the interlaminar shear strength of carbon fiber composites made of the carbon fibers sized with the sizing agent is enhanced by more than 10% compared with the existing carbon fiber composites; and the mechanical properties of the carbon fiber composites are not obviously changed after the carbon fiber composites are stored for two years under normal temperature.

Owner:KINGFA SCI & TECH CO LTD +1

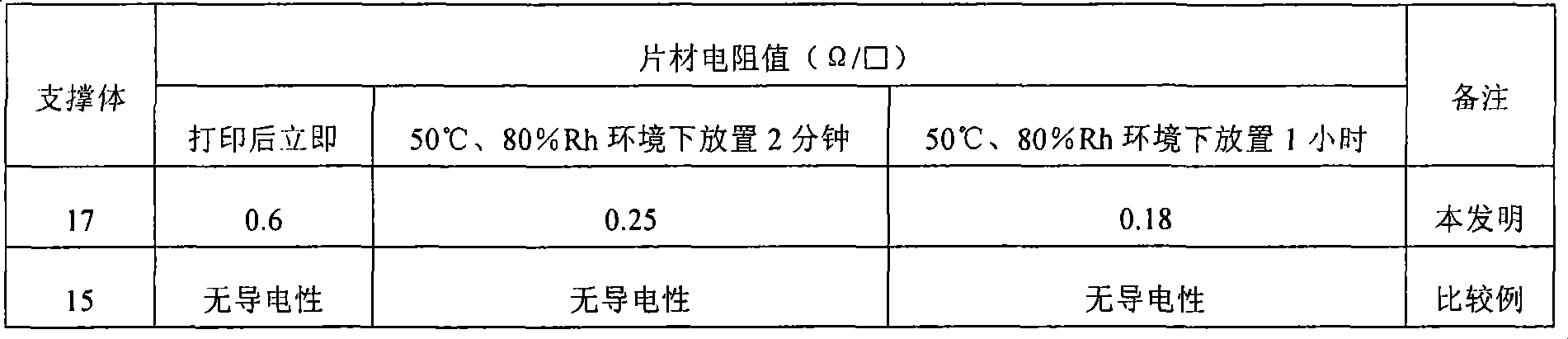

Method for producing conductive material

ActiveCN101473386AHigh conductivity and transparencyImprove storage stabilityConductive layers on insulating-supportsPrinted circuit manufactureHalogenWater soluble

Disclosed is a method for producing a conductive material which is high in transparency and conductivity, while having high storage stability. Also disclosed is a method for producing a conductive material by using ultrafine silver particles, which enables to obtain a conductive material having high conductivity without requiring a sintering step which has been necessary for conventional methods. Specifically disclosed is a method for producing a conductive material having a conductive pattern containing silver on a supporting body. This method for producing a conductive material is characterized in that one of the substances (I)-(IV) shown below is caused to act on the pattern portion containing silver which is formed on the supporting body. (I) a reducing substance (II) a water-soluble phosphorus oxo acid compound (III) a water-soluble halogen compound (IV) hot water at 55 DEG C or higher.

Owner:MITSUBISHI PAPER MILLS LTD

Anticorrosive bottom lacquer of water-soluble alcohol acid, and preparation method

ActiveCN101050272AImprove storage stabilityImprove water resistanceAnti-corrosive paintsPolyester coatingsChemistryWater soluble

This invention discloses formula and method for preparing high-performance water-soluble alkyd antirust primer. The method comprises: synthesizing water-soluble alkyd resin solution, mixing with antirust pigment, filler, water, drier and additives, dispersing, and grinding. The primer utilizes water as the diluting agent, and is noncombustible, thus is safe for the operators. The volatile organic compound (VOC) content is very low, and can meet the state standards of China. Besides, the primer also has such advantages as safe and convenient usage, high mechanical strength, high corrosion, acid, alkali, salt, oil, weathering and water resistance, and good antirust effect, and can be used as primer for transportation means, bridges, storage tanks, pipes and mechanical equipment.

Owner:NANJING CHANGJIANG PAINT

Poly(ethylene carbonate) type polyurethane water-based adhesive

ActiveCN102093836AGood bond strengthImprove storage stabilityPolyureas/polyurethane adhesivesChemistryCarbon dioxide

The invention discloses a poly(ethylene carbonate) type polyurethane water-based adhesive which is prepared through the following method: taking 100 parts of poly(ethylene carbonate) diol according to parts by weight, adding 2-10 parts of dimethylol propionic acid, stirring and slowly raising temperature to 100-120 DEG C under nitrogen protection, reducing the temperature to 50-70 DEG C after dissolution, dropping 20-60 parts of diisocyanate, raising the temperature to 70-80 DEG C, reacting for 2-3 hours, stopping heating when glue solution has viscosity and is transparent, naturally cooling to 40-50 DEG C, stopping introducing nitrogen, adding 100-700 parts of 5-30% of catalyst water solution while stirring intensely, neutralizing, emulsifying and preparing the adhesive. As a large number of carbonate bonds are contained in molecules of poly(ethylene carbonate) polyol, the bonding strength of a product is high; simultaneously, the carbonate bonds are less prone to hydrolysis, the storage stability of the product is high. In addition, the poly(ethylene carbonate) polyol is prepared by copolymerizing carbon dioxide and epoxy ethane, the cost is low, and the poly(ethylene carbonate)type polyurethane water-based adhesive has broad market application space.

Owner:HUIZHOU DAYAWAN DAZHI FINE CHEM

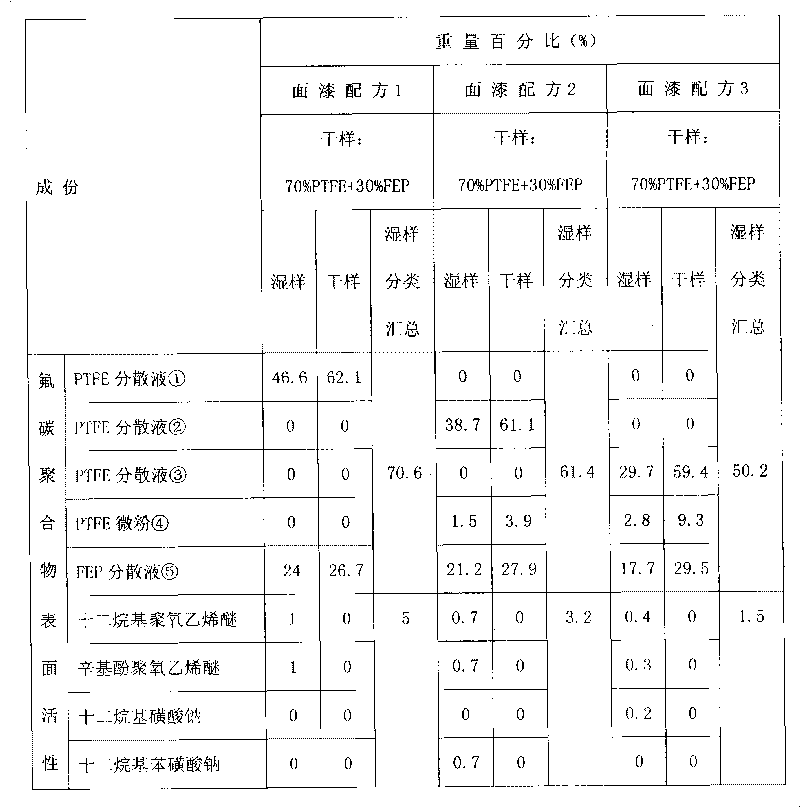

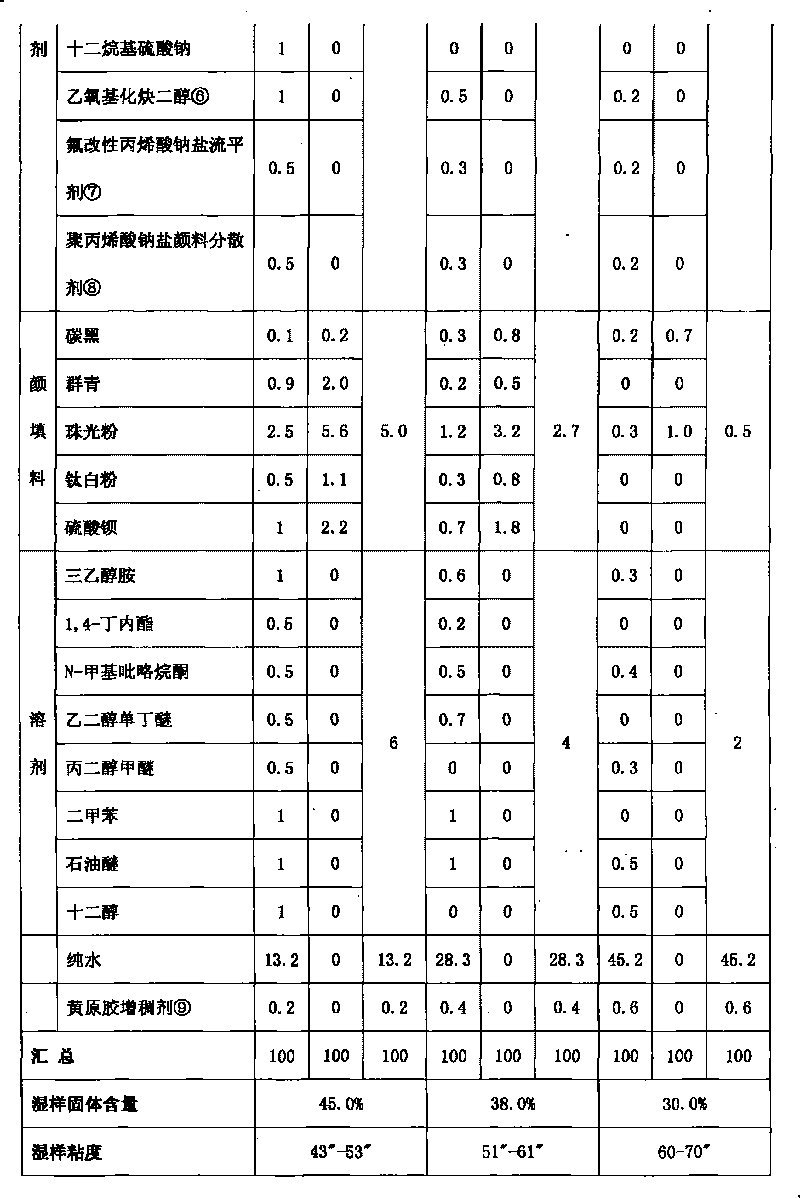

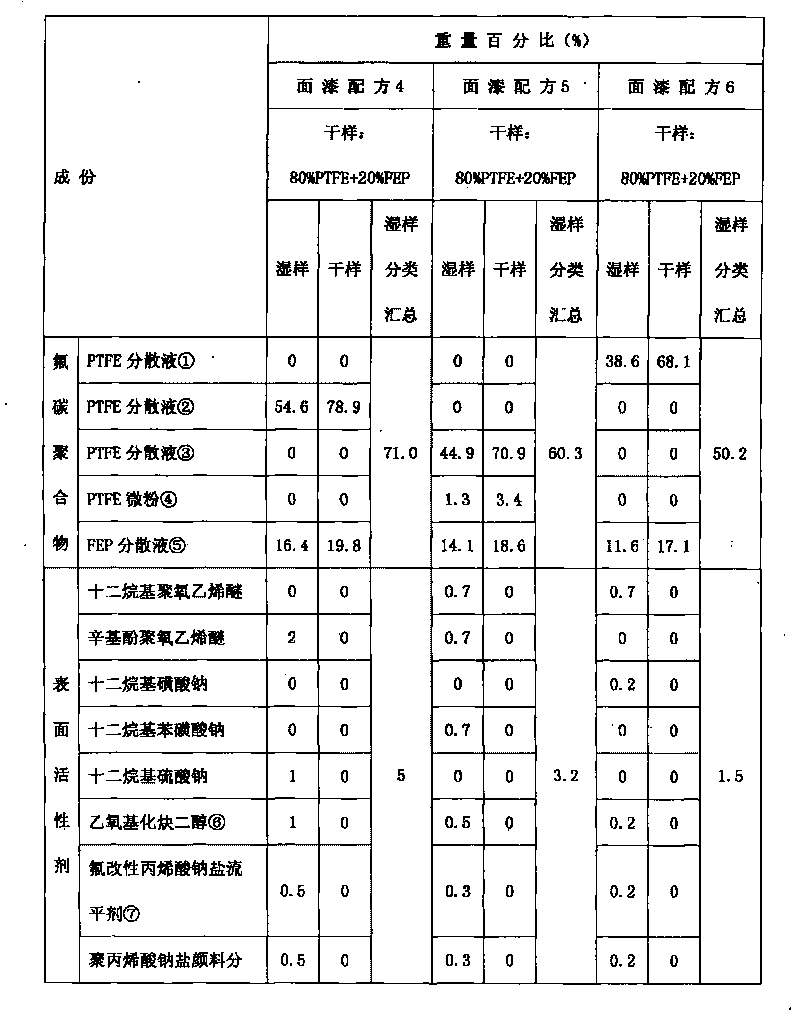

Finishing coat of aqueous non-viscous paint

The invention provides a finishing coat of aqueous non-viscous paint, which comprises the following raw materials in percentage by weight: (1) 50-71% of fluorine-carbon polymer, (2) 1.5-5% of surfactant, (3) 2-6% of solvent, (4) 0.2-0.6% of thickening agent, (5) 0.5-5% of colour filler and (6) the balance of purified water. The finishing coat of the aqueous non-viscous paint is hardly influenced by the performance fluctuation of the fluorine-carbon polymer, especially the finishing coat of the aqueous non-viscous paint, which uses the following fluorine-carbon polymers, can also obtain favorable paint storage stability and spraying application performance and enhances the chemical prevention performance, the durability, the spraying thickness and the filming compactness of a coating. The invention can adopt PFOA which is popularized at home and abroad now and a fluorine-carbon polymer of salt thereof as main resin and fluorine-carbon polymers with more economy.

Owner:SHENZHEN YITUMEI TECH

Unsaturated polyester resin with high cohesive force and high wettability and preparation method for unsaturated polyester resin

The invention discloses an unsaturated polyester resin with high cohesive force and high wettability and a preparation method for the unsaturated polyester resin, and belongs to the technical field of unsaturated polyester resins. The unsaturated polyester resin with high cohesive force and high wettability comprises the following components in percentage by weight: 28 to 33 percent of dibasic alcohol, 30 to 40 percent of dibasic acid or acid anhydride, 30 to 35 percent of diluent and 2 to 4 percent of glycerol. The unsaturated polyester resin obtained by the process according to the formula has high wettability and cohesive force, and has a good and quick effect of wetting glass fiber; and the cohesive force is subject to pressure and shear force tests, is increased by over 30 percent compared with an ordinary o-phthalate resin, and is over 20MPa. When quartz stone boards are produced, the average using amount of the resin of each board can be reduced from 25KG to 23KG; and the caking is difficult in the stirring process of the resin and quartz sand, so that the spreading and pressing are easier during production of manufacturers, the phenomena of deformation, cracking and the like which appear in the convention manufacturers can also be further improved, and the thixotropic property of the resin and gaseous silicon can be greatly improved additionally.

Owner:浙江天和树脂有限公司 +1

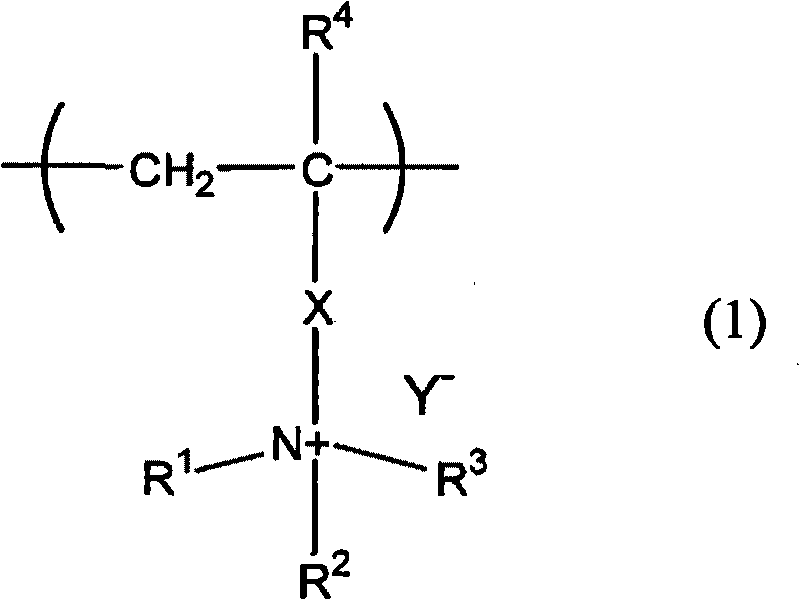

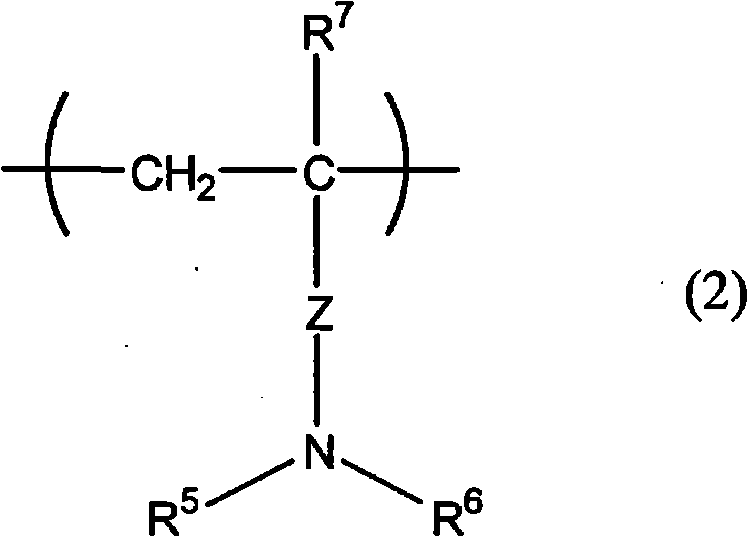

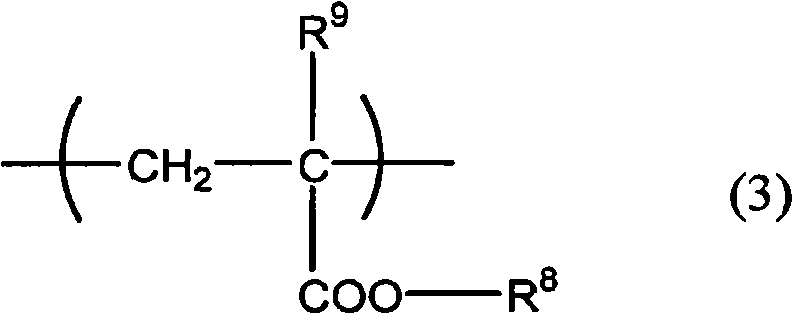

Coloring combination, color filter and color liquid crystal display element

ActiveCN101726999AImprove storage stabilityOptical filtersPhotosensitive materials for photomechanical apparatusHigh contrastSide chain

The invention relates to a coloring combination, color filter and color liquid crystal display element. The coloring combination is capable of forming pixels having relative high contrast with excellent storage stability. The coloring combination comprises (A) colorant, (B) dispersant, (C) resin for adhesive and (D) polyfunctionality monomer, characterized in that: the (B) dispersant comprises block copolymer comprising A block with quaternary ammonium salt and amino group at the side chain and B block without quaternary ammonium salt amino group at the side chain.

Owner:JSR CORPORATIOON

Preparation method for acrylic acid modified polyurethane water dispersion

InactiveCN101343341AImprove storage stabilityImprove poor hydrolytic stabilityCoatingsEmulsionDouble bond

The invention discloses a preparation method for acrylic acid modified polyurethane waterborne dispersion, which comprises three steps, namely polyesterglycol synthesis, polyurethane dispersion synthesis and acrylic acid modified polyurethane waterborne dispersion synthesis. In the preparation method of the invention, polyesterglycol is synthesized by adopting neopentylene glycol and isophthalic acid with the better hydrolytic stability, thus the storage stability of polyesterglycol is improved. A given mass of conjugated double bond is introduced in the trunk chain, the conjugated double bond can be copolymerized with acrylic monomers, thereby graft copolymer is formed. Because the product is the graft copolymer of polyurethane and acrylic acid, advantages of the two substances can be fully exerted, thus disadvantages of poor stability, poor water resistance and weatherability of single group modified water-based polyurethane hydrolization and poor adhesive force of acrylic acid emulsion, and the like, are ameliorated. By utilizing water as a dispersion medium in the acrylic acid modified polyurethane dispersion used for woodenware priming paint prepared through the invention, the capability of environment protecting without pollution is provided, therefore, the acrylic acid modified polyurethane waterborne dispersion is suitable for indoor decorating utilization, and has the advantages of being harmless and secure to human body.

Owner:WUXI HUHUANG PAINT

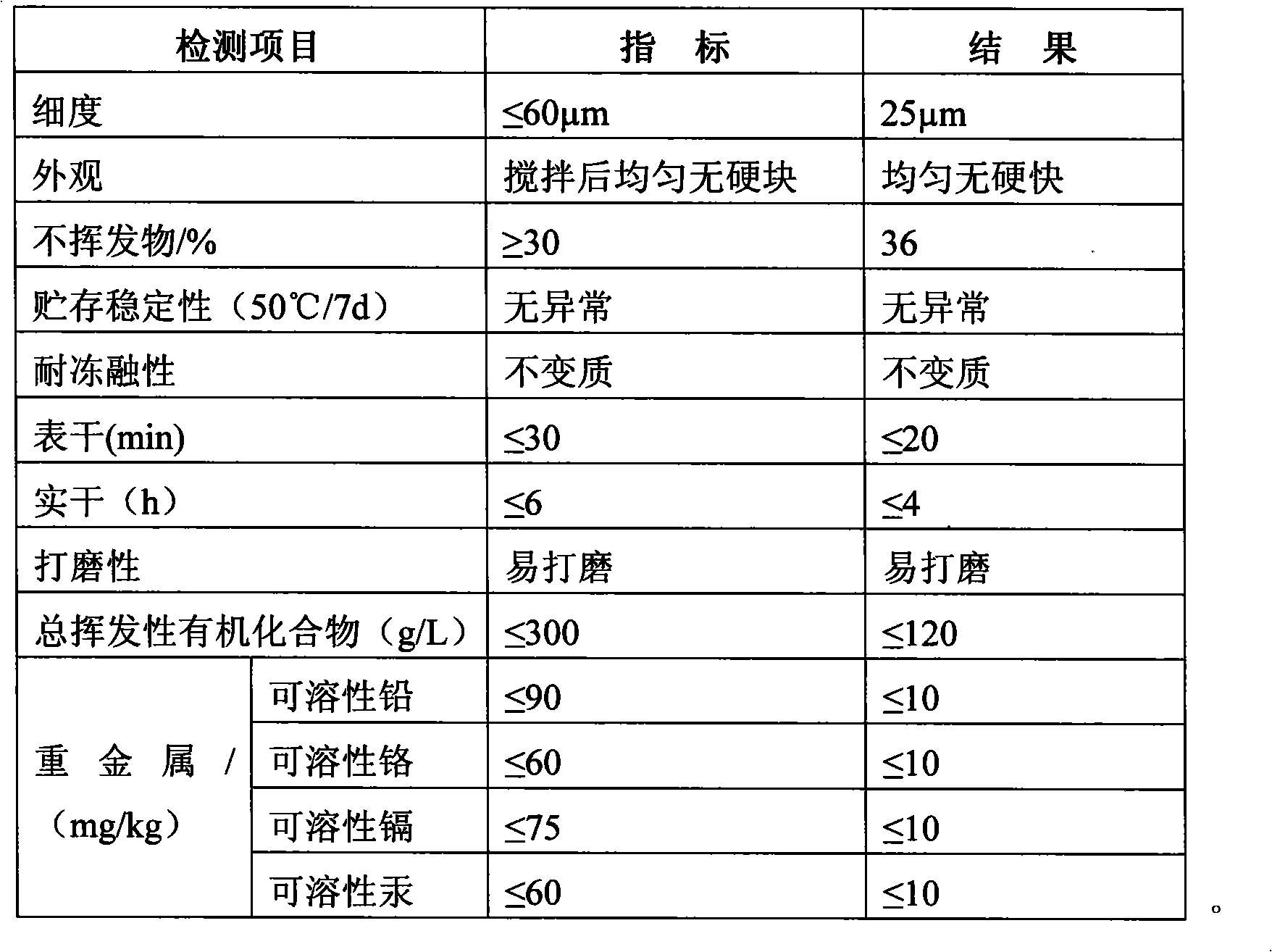

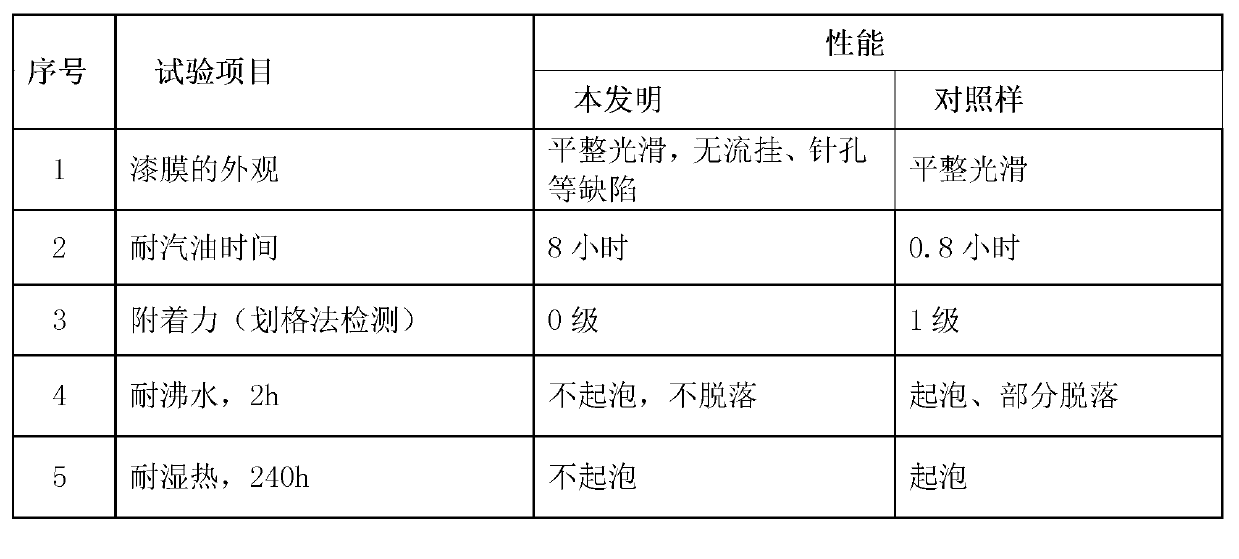

Middle coating paint for polypropylene plastic and preparation method thereof

InactiveCN103342933AImprove storage stabilityAbundant sources of raw materialsCoatingsChemistryPolypropylene

The invention provides a middle coating paint for a polypropylene plastic, which consists of chlorinated polypropylene modified acrylic resin, modified chlorinated polypropylene, a curing agent, pigment, filler, a dispersing agent, an auxiliary and the like. The invention also provides a preparation method of the middle coating paint, which comprises the following steps of: mixing the chlorinated polypropylene modified acrylic resin with the auxiliary, putting the mixture into a sand mill and uniformly dispersing; and adding the modified chlorinated polypropylene and the curing agent, and uniformly mixing to obtain the paint. The middle coating paint provided by the invention has the advantages of low cost, simple preparation technology, wide application and great market potential; when in use, the paint can be coated through special treatment on substrates, the coated paint does not need roasting and can be naturally dried, the construction is convenient, and the energy is saved; and the obtained composite paint film is resistant to ethanol gasoline for 8 hours.

Owner:TIANCHANG JULONG TRAVEL PAINT

Polyurethane microcapsule dispersing agent preparation method and product thereof

ActiveCN106582463AImprove dispersion performanceImprove storage stabilityMicroballoon preparationMicrocapsule preparationPrepolymerIsocyanate

The invention provides a polyurethane microcapsule dispersing agent preparation method and a product thereof. The preparation method comprises the following steps that excessive polyisocyanate and hydrophilic surfactant with a hydroxyl group is subjected to tetramethylethylenediamine catalytic reaction for 2-4 h at the temperature of 65-90 DEG C, and a polyurethane prepolymer is generated; the temperature of polyurethane prepolymer is lowered to be 25-40 DEG C, the polyurethane prepolymer is stirred and mixed with core materials to be uniform, and an oil phase is formed; the oil phase is added into a polyvinyl alcohol aqueous solution, homogeneous emulsification is conducted, and an O / W type emulsion is prepared; at the temperature ranging from 40 DEG C to 60 DEG C, a polyamine aqueous solution is slowly and dropwise added into the O / W type emulsion, after dripping is completed, heat preservation and curing are conducted for 1-2 h, and a polyurethane microcapsule dispersing agent is obtained. The polyurethane microcapsule dispersing agent has the excellent storage stability, dilution stability, centrifugal stability and acid and alkali resistant stability, harmful ingredients such as APEO, formaldehyde and aniline are not contained, and environmental protection is achieved; the polyurethane microcapsule dispersing agent preparation method and the product thereof have a wide application prospect and potential market value.

Owner:TAICANG BAONI IND CO LTD

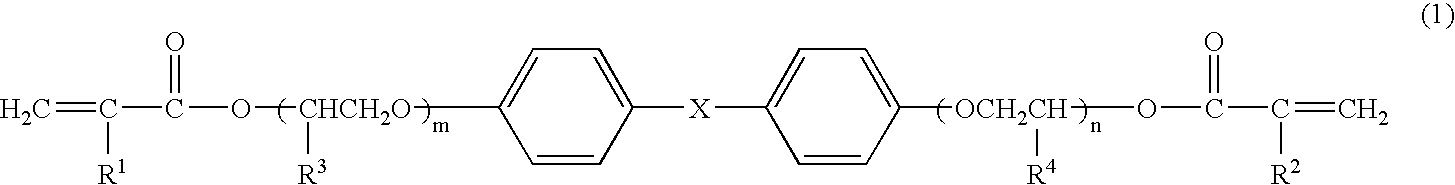

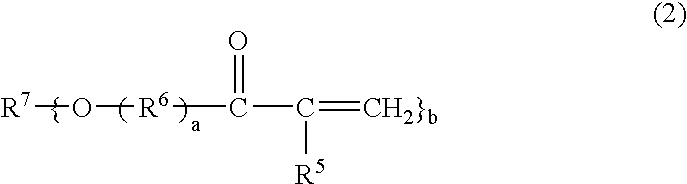

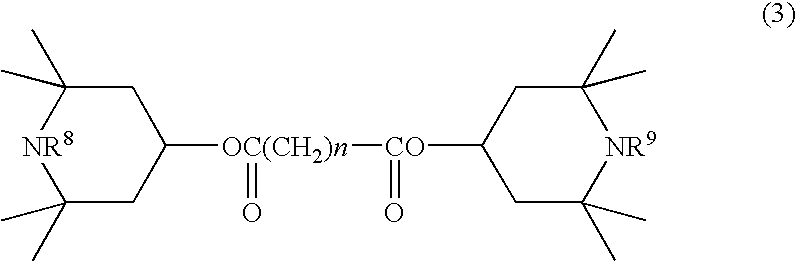

Polymerization Curable Composition

ActiveUS20080058444A1Improve storage stabilityDeterioration of qualityGreenhouse cultivationCultivating equipmentsPolymer chemistryPhotochromism

A polymerization curable composition prepared by blending specific amounts of a photochromic compound and a specific light stabilizer such as bis(1,2,2,6,6-pentamethyl-4-piperidyl)sebacate with monomer components including a specific bifunctional monomer having a structure that two phenylene groups are bonded together by a specific group, such as 2,2-bis(4-methacryloyloxypolyethoxyphenyl)propane, a polyfunctional polymerizable monomer having a functionality of 3 or more such as trimethylolpropane trimethacrylate, and a monomer other than these in a specific ratio. The polymerization curable composition provides a cured product having excellent photochromic properties such as fast fading rate and sufficiently high drilling strength that allows for its use in rimless spectacles and has high long-term storage stability.

Owner:TOKUYAMA CORP

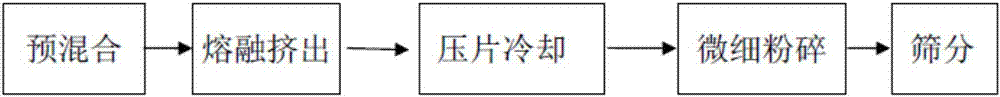

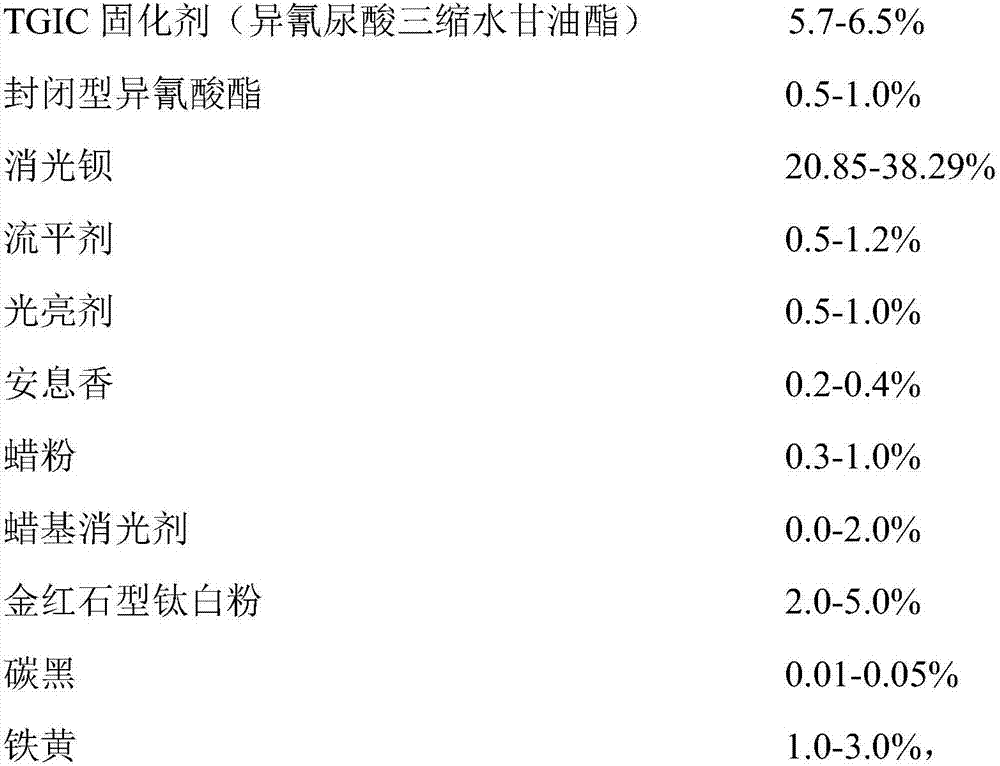

Low-gloss bending-resistant heat transfer printing powder coating used for section aluminum and a preparing method thereof

ActiveCN106867371AImprove storage stabilityReduce glossPowdery paintsPolyester coatingsWaxCarbon black

The invention relates to low-gloss bending-resistant heat transfer printing powder coating used for section aluminum and a preparing method thereof. The powder coating is prepared by mixing an A component and a B component. Raw materials of the A component include saturated carboxyl-ended polyester resin A, a TGIC curing agent, enclosed type isocyanate, extinction barium sulfate, a leveling agent, a brightening agent, benzoin, wax powder, a wax-based flatting agent, rutile type titanium dioxide, carbon black and iron oxide yellow. Raw materials of the B component include saturated carboxyl-ended polyester resin B, a TGIC curing agent, enclosed type isocyanate, extinction barium sulfate, a leveling agent, a brightening agent, benzoin, wax powder, rutile type titanium dioxide, carbon black and iron oxide yellow. Coating films of the powder coating have significant characteristics of extremely good storage stability, bending resistance and impact resistance, excellent whether resistance, high decoration performance, and the like.

Owner:广东华江粉末科技有限公司

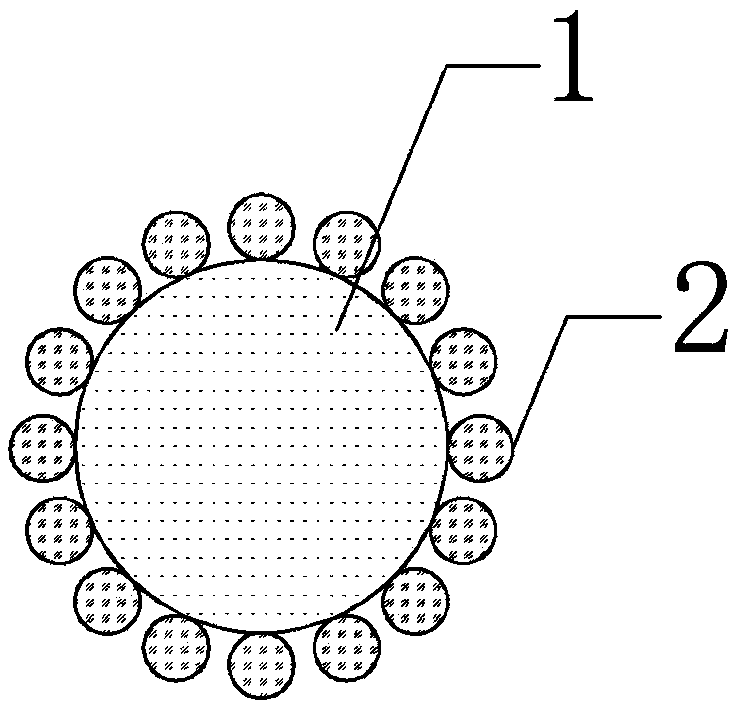

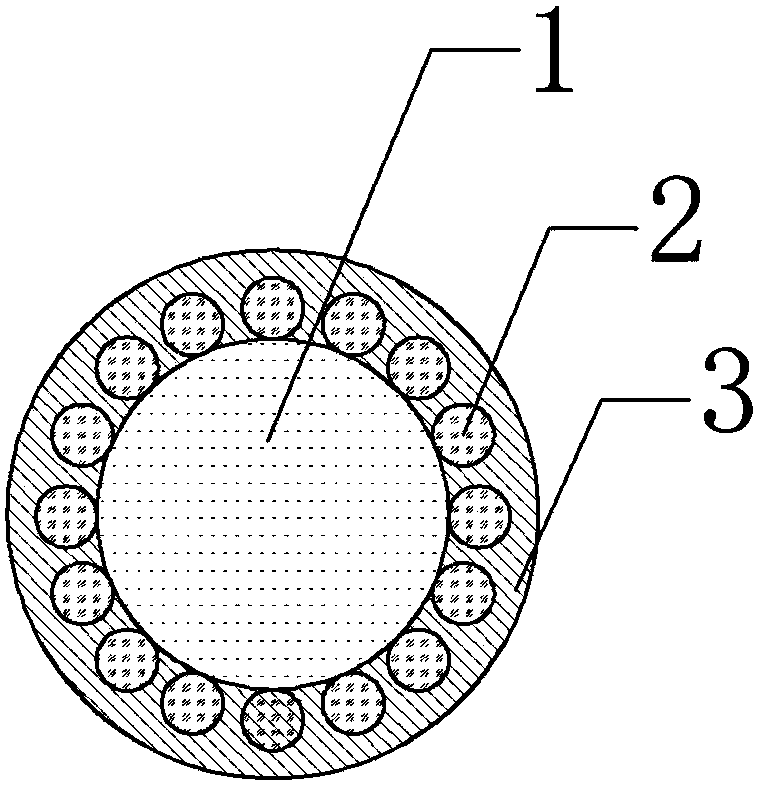

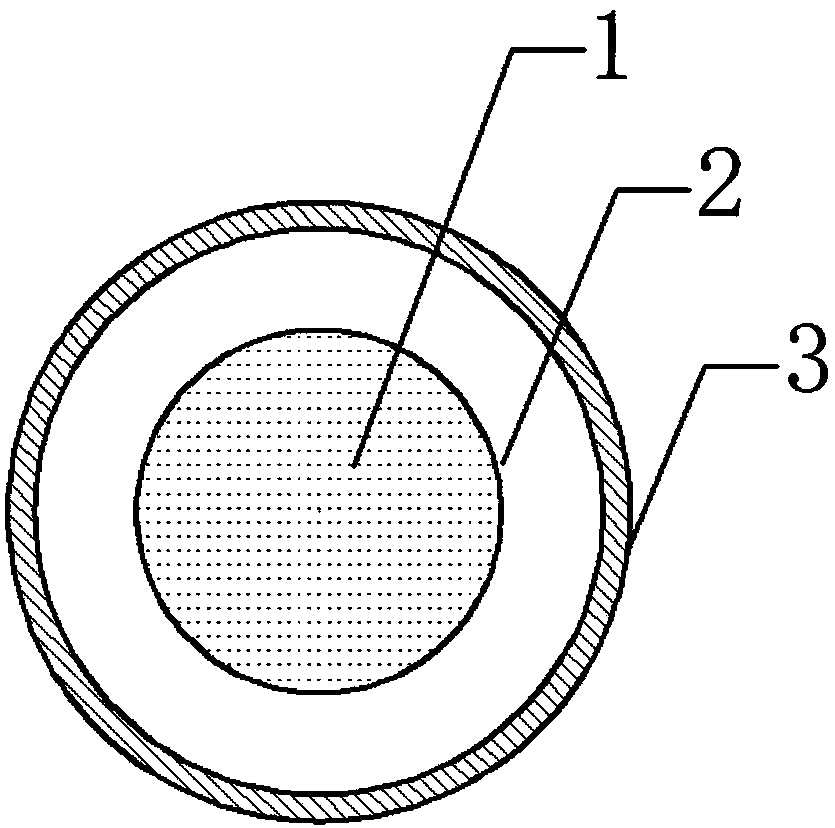

Method for coating thermal expansion hollow microspheres with energy-containing additive

ActiveCN108358733AImprove storage stabilityPrevent oxidationNon-explosive stabilisersGrinding millBall mill

The invention relates to an energy-containing sensitizing agent and in particular relates to thermal expansion hollow microspheres with an energy-containing additive and a production method thereof. The energy-containing sensitizing agent is prepared from the following components: 1 to 10 parts of expanding agent, 60 to 95 parts of energy-containing additive and 10 to 30 parts of polymer monomer.The production method comprises the following steps: firstly, adding the expanding gent and the energy-containing additive into a ball grinding mill according to a certain ratio and mixing to form scattered expanding agent particle coating on the outer surface of the energy-containing additive; finally, adding an oil-soluble initiator into the polymer monomer and carrying out body pre-polymerization at certain temperature to obtain a cross-linked pre-polymer with proper viscosity; adding the coated energy-containing additive into the cross-linked pre-polymer; after uniformly mixing, dispersing, suspending and polymerizing in a water phase; then raising the temperature and curing to obtain compound type energy-containing microspheres; finally, carrying out heating, foaming and expansion andcooling treatment to obtain the energy-containing additive coated with the hollow microspheres.

Owner:ANHUI UNIV OF SCI & TECH

Method of Stabilizing Fluorine-Containing Acid Amplifier

ActiveUS20140065541A1Improve storage stabilityImprove stabilityOrganic chemistryOther chemical processesOrganic solventPhotochemistry

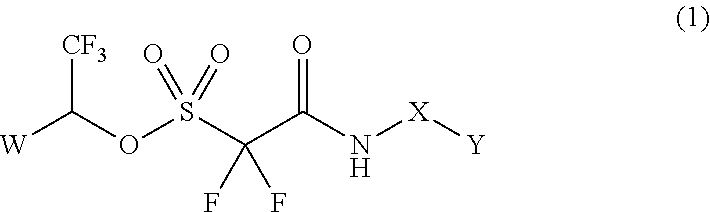

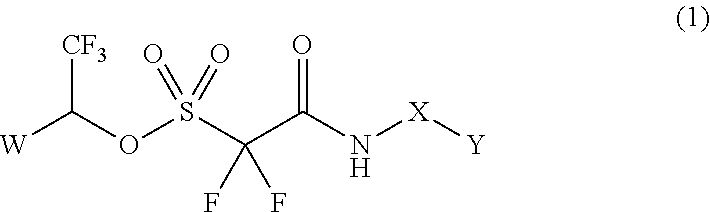

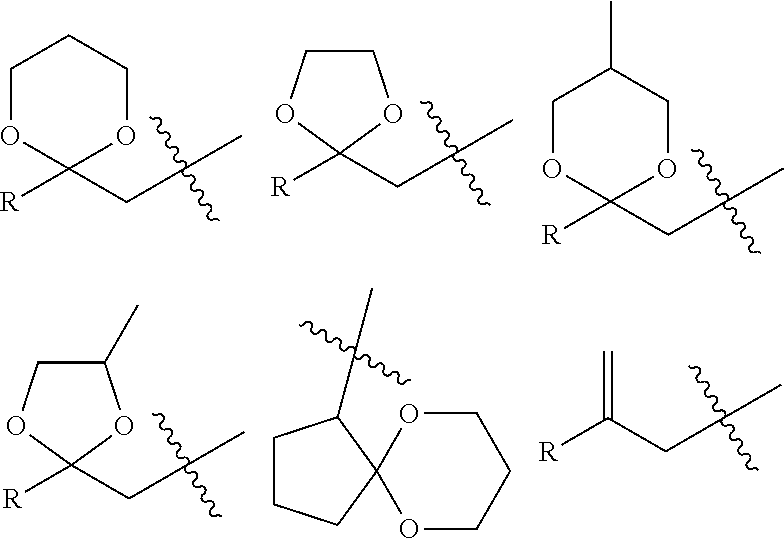

A method of stabilizing a fluorine-containing acid amplifier. The method is provided to include the step of dissolving a fluorine-containing acid amplifier in an organic solvent thereby producing a solution of the fluorine-containing acid amplifier, the fluorine-containing acid amplifier being represented by general formula (1):

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK +1

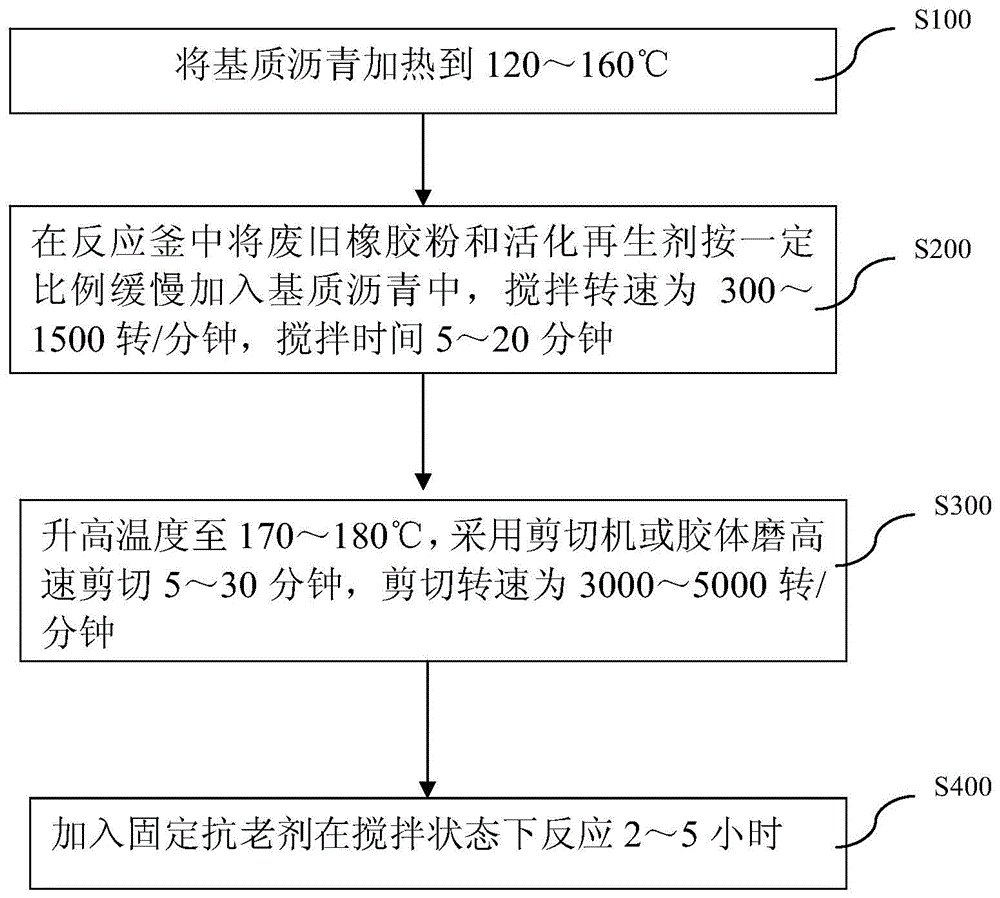

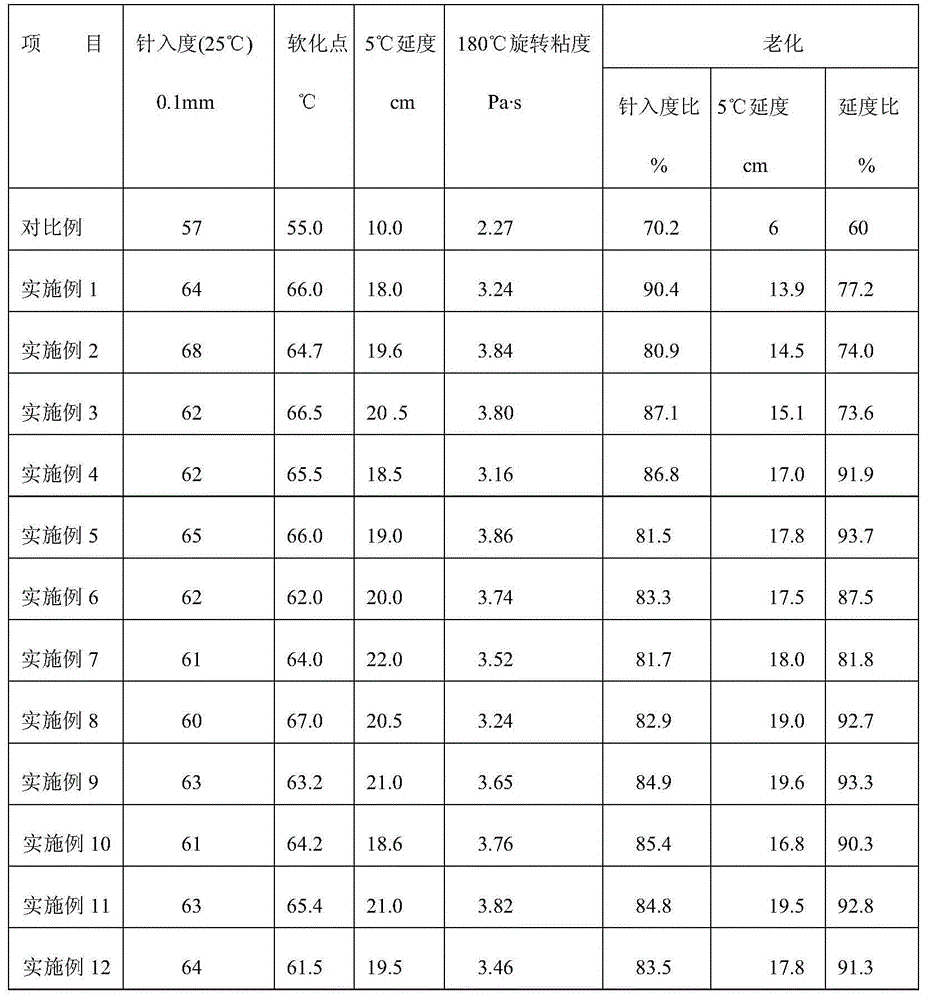

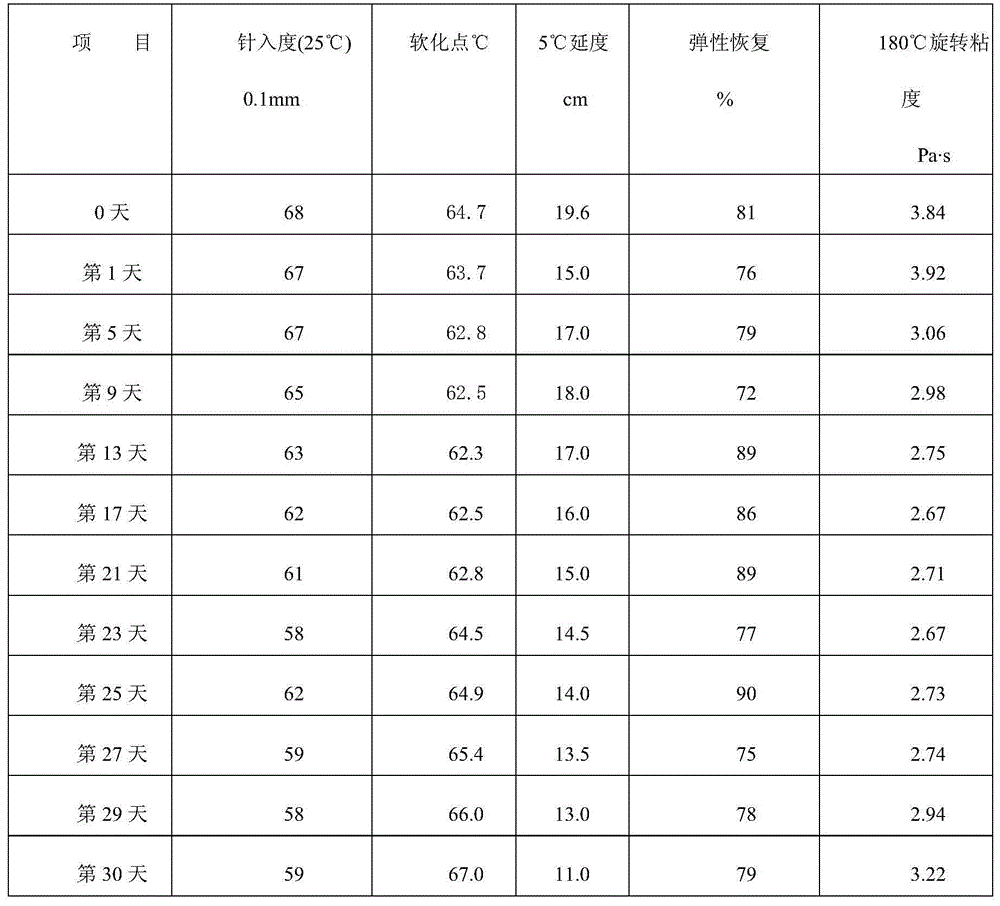

Rubber asphalt and preparation method thereof

ActiveCN105733275AThe colloidal system is chemically stableImprove storage stabilityPlastic recyclingBuilding insulationsRubberized asphaltColloid mill

The invention relates to rubber asphalt. The rubber asphalt is compounded from the following ingredients: base asphalt, waste rubber powder, an activating and recycling agent and a fixing and anti-aging agent. Accounted by total weight of the rubber asphalt, per 100% of the rubber asphalt comprises the ingredients in the following percentage: 70-89.4% of the base asphalt, 10-29.4% of the waste rubber powder, 0.1-1% of the activating and recycling agent and 0.5-1.5% of the fixing and anti-aging agent. A preparation method of the rubber asphalt comprises the following steps: heating the base asphalt to 120-160 DEG C; slowly adding the waste rubber powder and the activating and recycling agent into the heated base asphalt according to a certain proportion in a reaction kettle while stirring, wherein stirring speed is 300-1500 round / minute and stirring time is 5-20 minutes; raising temperature of the mixture to 170-180 DEG C, and performing high-speed shearing on the heated mixture by a shearing machine or a colloid mill for 5-30 minutes, wherein the shearing speed is 3000-5000 round / minute; and adding the fixing and anti-aging agent into the mixture and reacting the mixture while stirring for 2-5 hours. Compatibilities of the rubber powder and the asphalt are improved by the preparation method, so that the problem of instabilities of rubber asphalts in high-temperature storage is solved.

Owner:PETROCHINA CO LTD

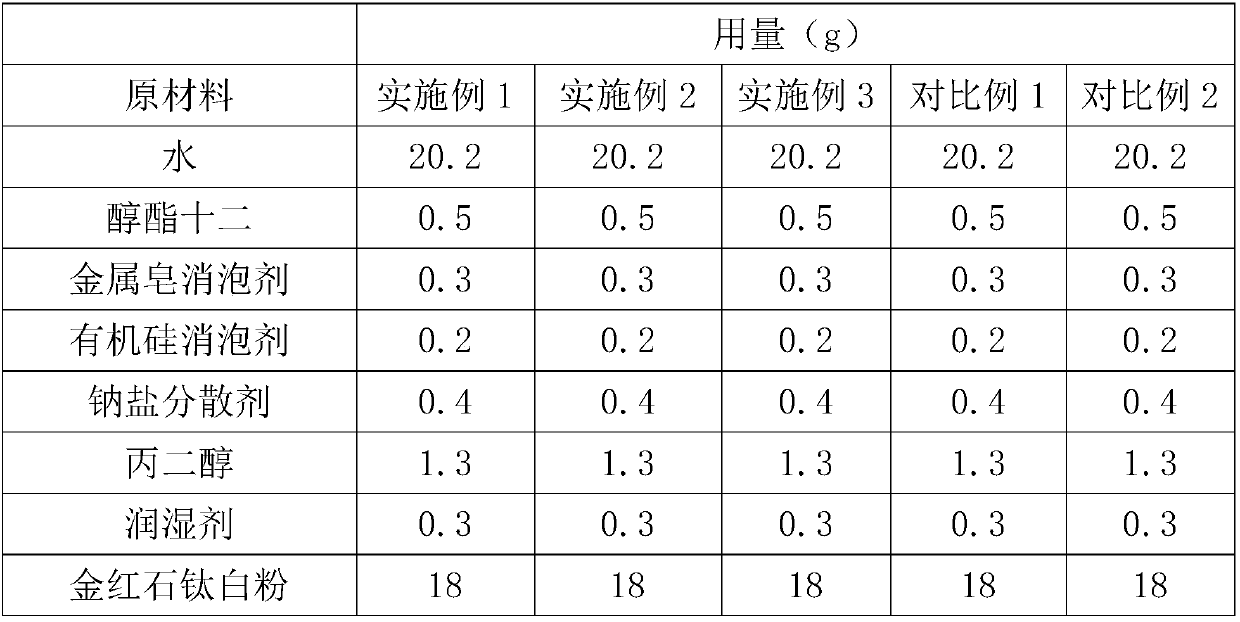

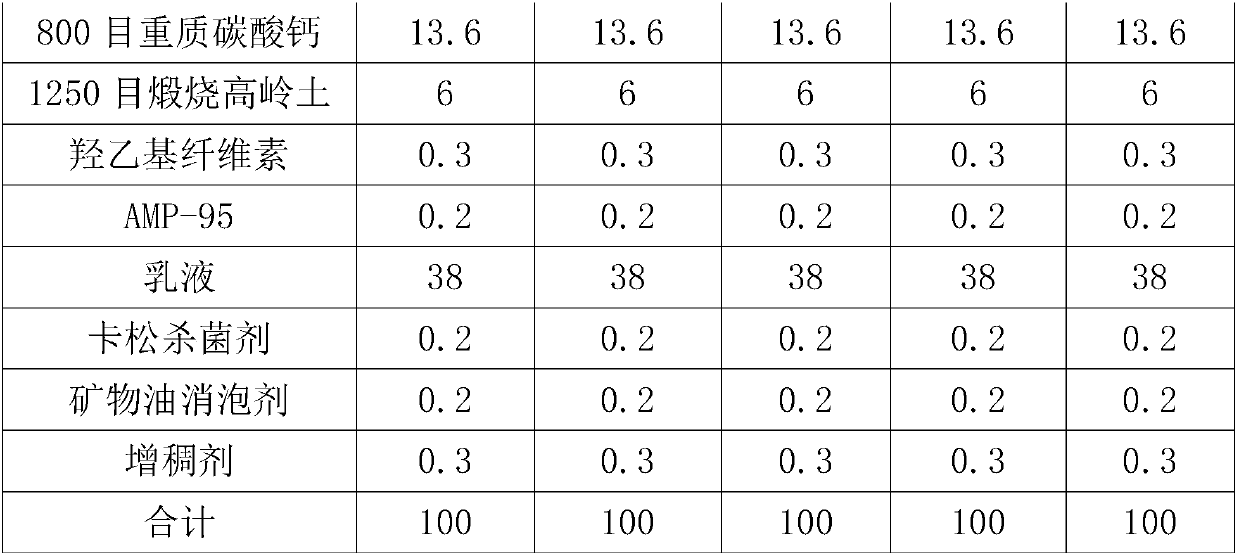

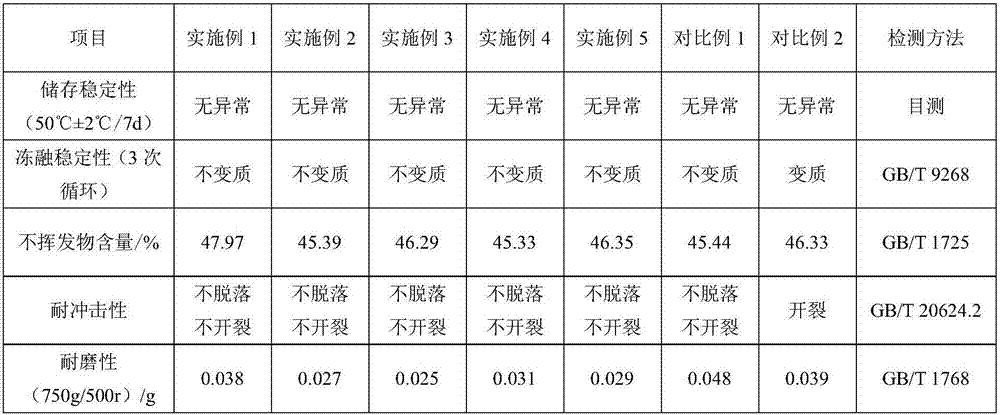

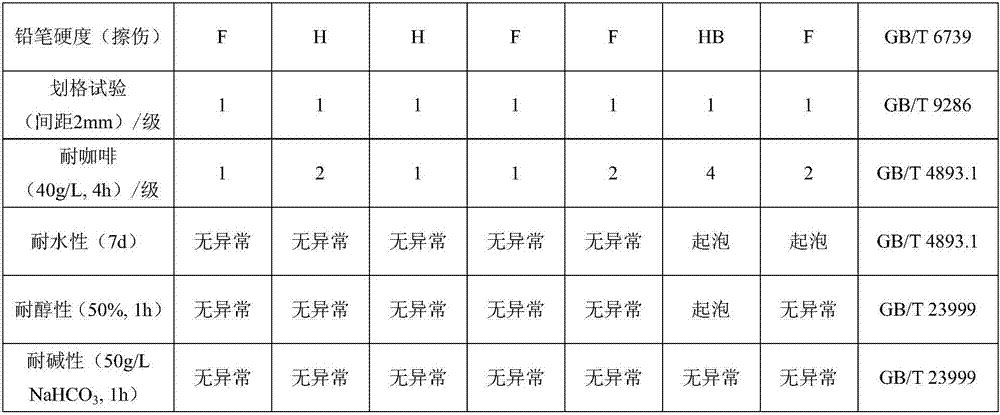

Multi-crosslinking high-elastic outer-wall emulsion as well as preparation method and application thereof

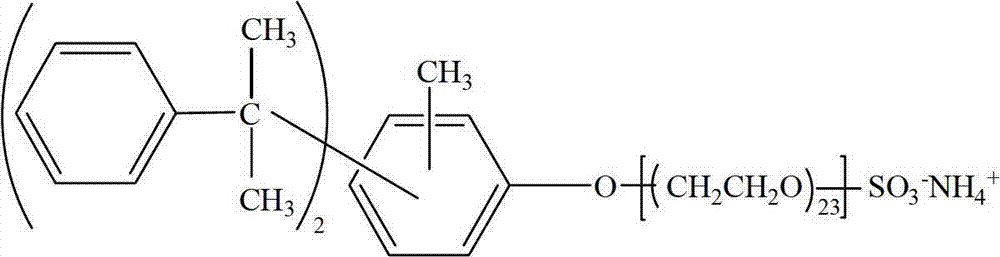

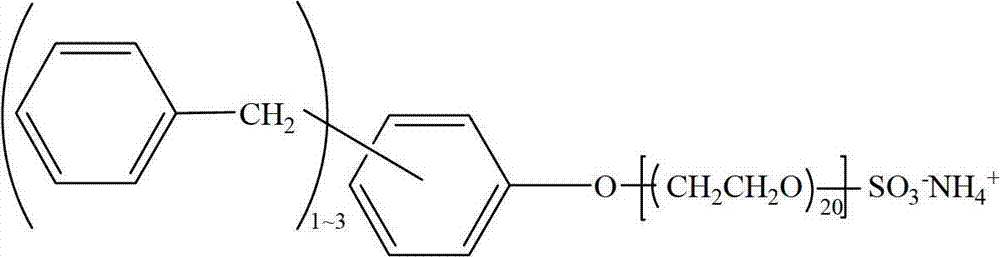

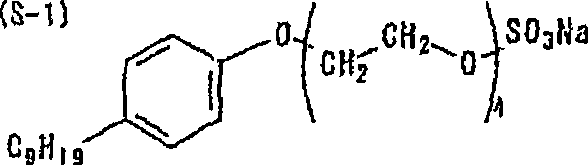

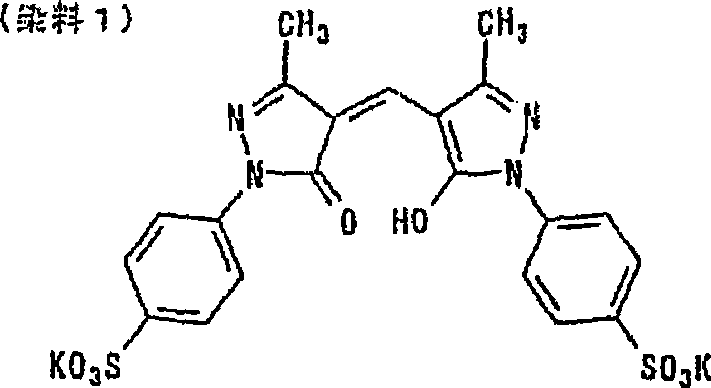

PendingCN107828302AGuaranteed stabilityImprove storage stabilityAntifouling/underwater paintsPaints with biocidesIonEmulsion

The invention relates to the technical field of outer wall coatings, and particularly discloses multi-crosslinking high-elastic outer wall emulsion as well as a preparation method and application thereof. The emulsion is prepared from the following components in parts by weight: 40 to 50 parts of deionized water, 0.1 to 5 parts of emulsifier, 0.02 to 10 parts of outer crosslinking monomer, 0.01 to5 parts of metal crosslinking agent, 0.1 to 2 parts of ultraviolet crosslinking agent, 0.05 to 40 parts of hydrophilic monomer, 0.05 to 40 parts of crosslinking monomer of carboxyl, 0.05 to 40 partsof main monomer, 0.05 to 20 parts of polymerization stabilizer, 0.02 to 5 parts of silane coupling agent, 0.02 to 5 parts of initiator, 0.02 to 5 parts of pH value buffering agent, 0.02 to 5 parts ofdefoaming agent, 0.02 to 5 parts of anticorrosion agent and 0.2 to 10 parts of pH conditioning agent. By adopting the multi-crosslinking high-elastic outer-wall emulsion, the preparation method and application thereof, the relationship between tension strength and breaking elongation of the elastic coating is balanced, and the tension strength and the breaking elongation are outstanding.

Owner:GUANGDONG HENGGUANG CHEM CO LTD

Storage-stable compositions of organosilicon compounds

ActiveUS20050137362A1Improve storage stabilityGood storage stabilityGroup 4/14 element organic compoundsOrganosiliconSilanes

Owner:WACKER CHEM GMBH

Thermosetting solvent-free single-component substances and use thereof

ActiveCN101253249AOvercoming slow curingImprove storage stabilityPolyureas/polyurethane adhesivesSolventChemical compound

Disclosed is a thermosetting, solvent-free single-component substance that has a minimum shelf life of 2 weeks at ambient temperature and is composed of (A) 5 to 90 parts by weight of an at least bifunctional (iso)cyanate component, (B) 5 to 50 parts by weight of a latent hardener which is solid up to a temperature of at least 40 DEG C and is based on nitrogen compounds suitable for addition-crosslinking, (C) 0 to 50 parts by weight of an epoxy-containing compound, D) 0 to 50 parts by weight of modifiers, the sum of all parts by weight amounting to 100. Also disclosed is the use of said substance for gluing, pouring, sealing, and coating substrates, particularly of electronic components. The inventive substance is cured within seconds at 120 to 150 DEG C.

Owner:DELO工业胶粘剂有限及两合公司

Compound undecylenic nanoemulsion and preparation method thereof

InactiveCN102526010AHigh thermodynamic stabilityImprove storage stabilityAntimycoticsAldehyde active ingredientsEugenolSolubility

The invention discloses a compound undecylenic nanoemulsion, which is formed by the following raw materials in mass percent: 18.05%-38.62% of surfactant, 0-9.15% of cosurfactant, 0-3.50% of oil, 0.50%-5.18% of undecylenic acid, 0.50%-3.00% of cinnamyl aldehyde, 0.50%-3.00% of eugenol and the balance of distilled water, wherein the sum of the mass percents of the raw materials is 100%. According to the compound undecylenic nanoemulsion disclosed by the invention, the solubility of the undecylenic acid is enhanced, the drug stability and the bioavailability of the undecylenic acid are improved, and the metabolic time of the undecylenic acid in vivo is retarded; and the undecylenic acid is in compatible with the cinnamyl aldehyde and the eugenol, the antimicrobial spectrum is enlarged, the drug consumption is reduced, and the cost for drug consumption is lowered, so that the compound undecylenic nanoemulsion has broad market prospects in the medicine field.

Owner:NORTHWEST A & F UNIV

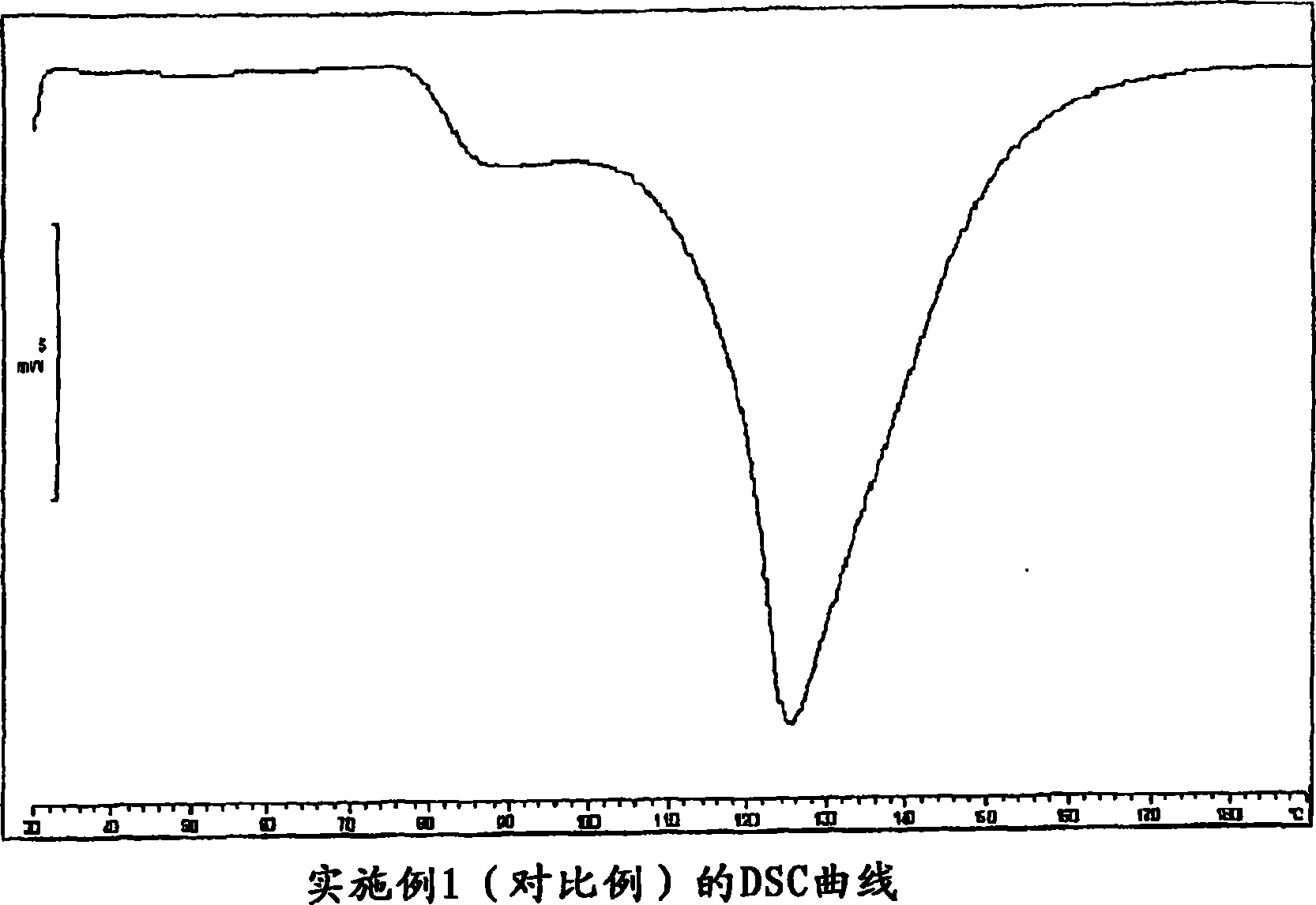

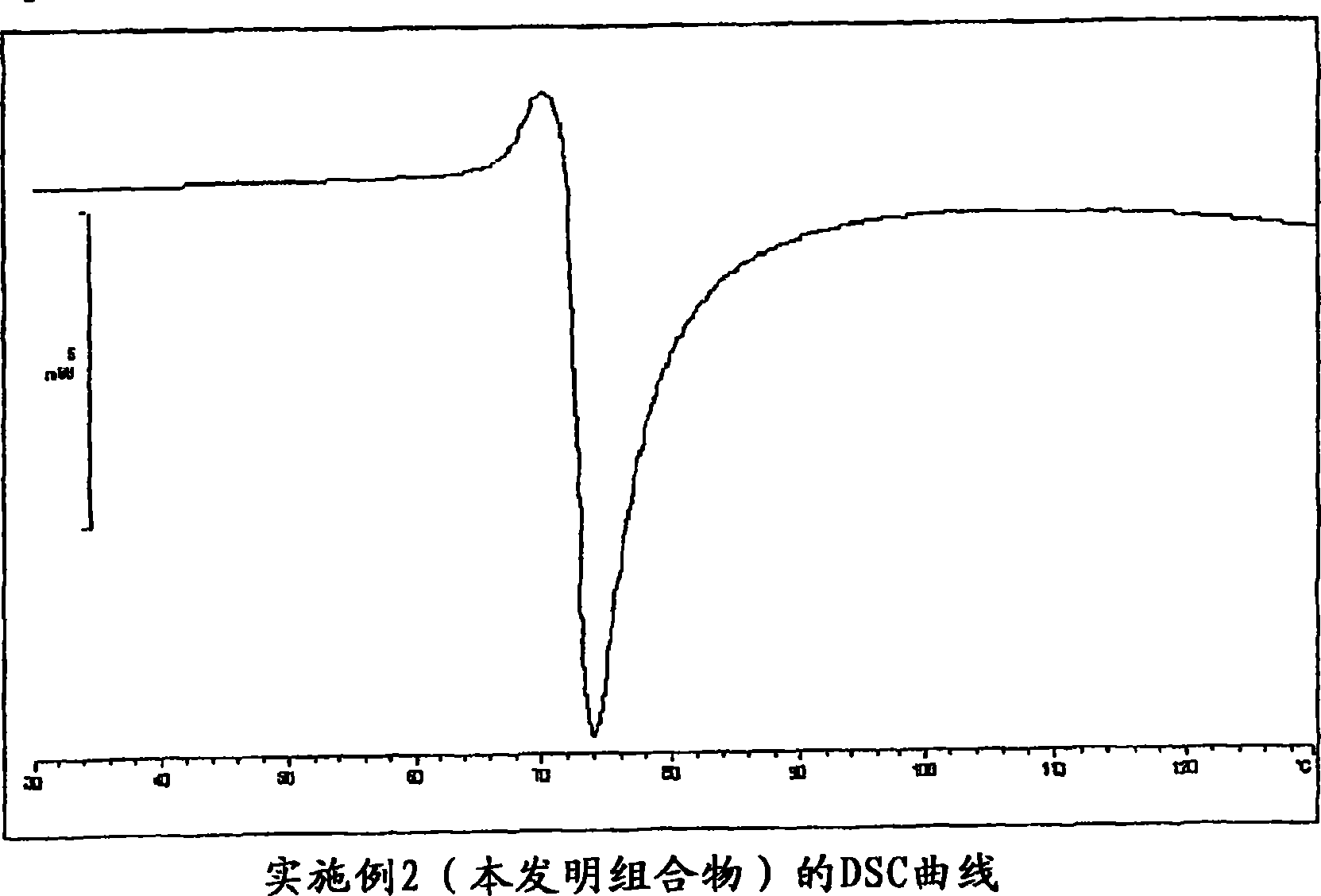

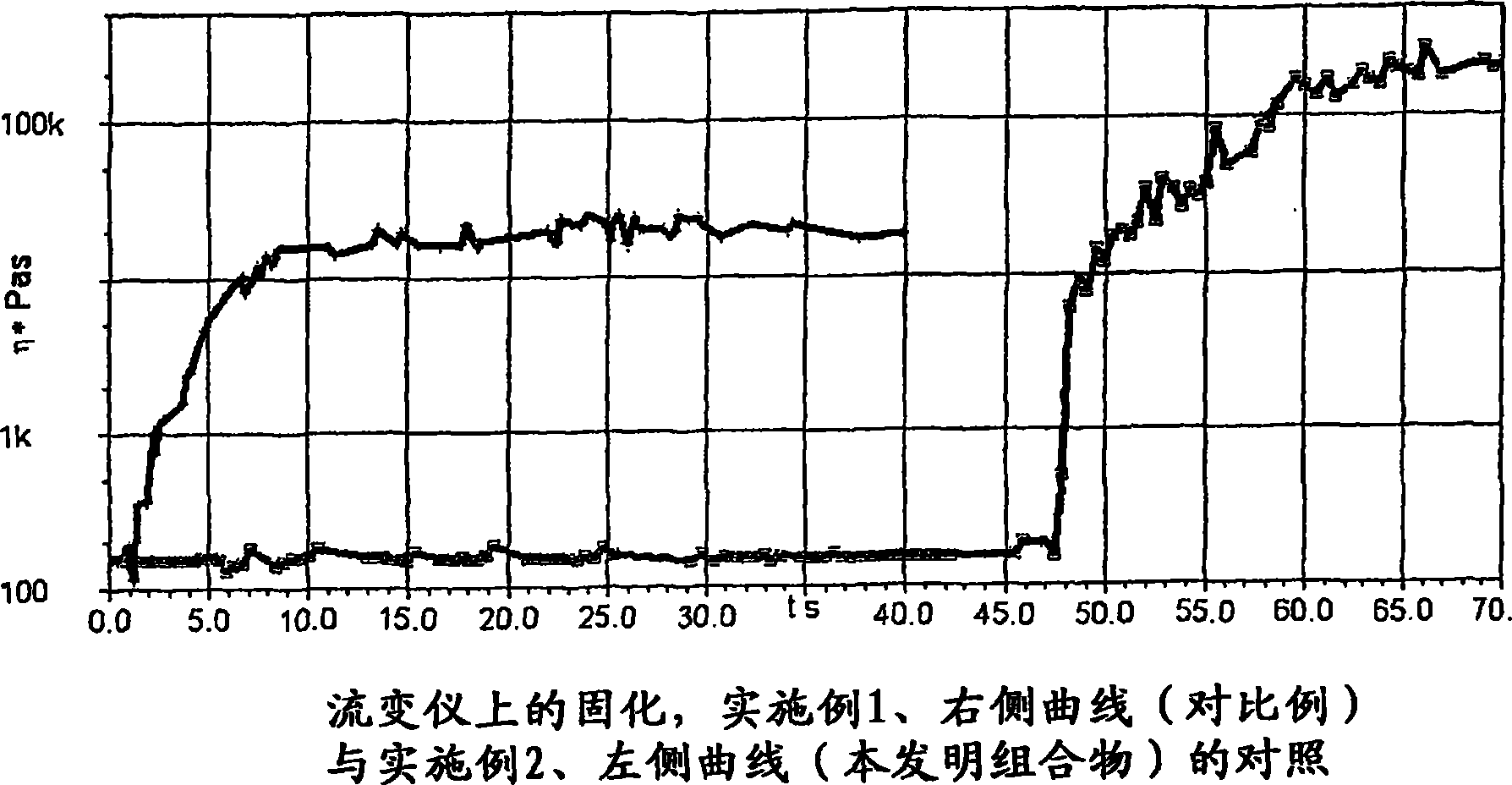

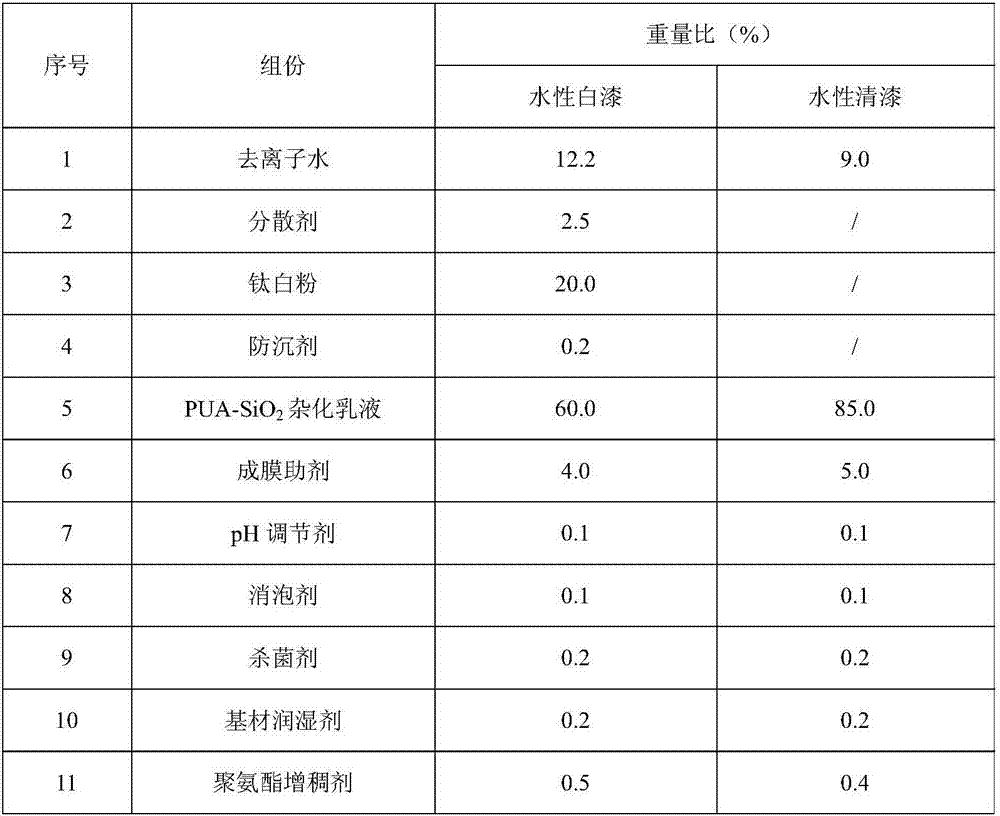

Room temperature self-crosslinking type PUA-SiO2 hybrid emulsion and preparation method thereof

The invention discloses a room temperature self-crosslinking type PUA-SiO2 hybrid emulsion and a preparation method thereof. The hybrid emulsion consists of a core-shell type waterborne polyurethane-polyacrylate copolymer, functional nanosilicon dioxide and water. Different from traditional blend doping, the PUA-SiO2 hybrid emulsion disclosed by the invention realizes filler reinforcing through chemical bonding generated by self-crosslinking. In the film-forming stage of the hybrid emulsion, a firm organic-inorganic hybrid network is formed among organic and inorganic components through coupled reactions of acetylacetic ester units and primary amines, so that the hybrid emulsion has the excellent characteristics of high film hardness, scratch resistance, water resistance, chemical product resistance, heat resistance and the like. The hybrid emulsion is applicable for high-performance water-based coatings, and is particularly applicable for product preparation of water-based wood coatings.

Owner:NANJING CHANGJIANG PAINT

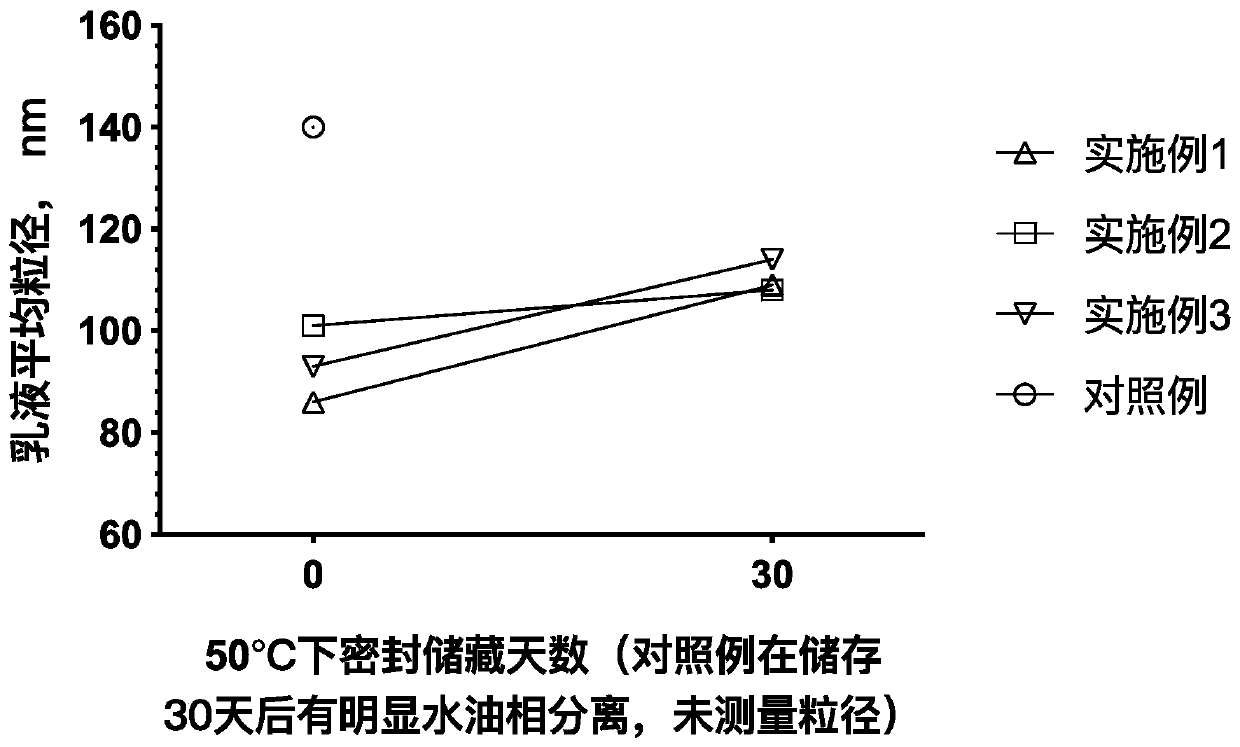

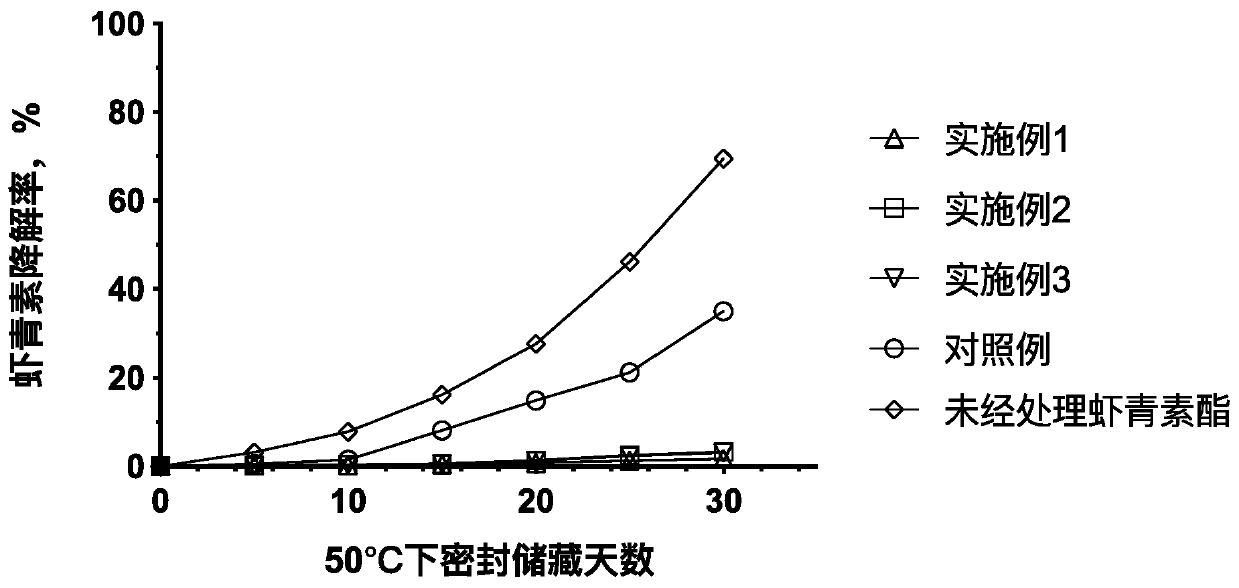

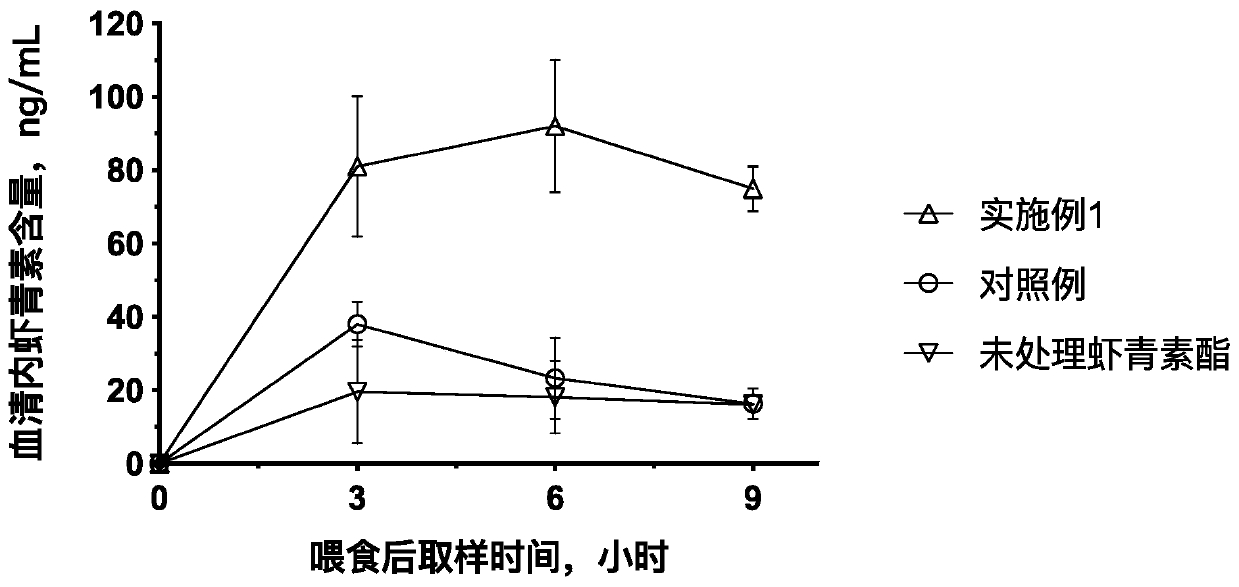

Lotion containing natural astaxanthin ester and preparation method thereof

ActiveCN109820746AReduce moisture contentImprove storage stabilityOrganic active ingredientsCosmetic preparationsAbsorption rateAstaxanthin

The invention discloses a lotion containing natural astaxanthin ester. The lotion is prepared from natural astaxanthin ester, fat, oil, phospholipid, polyalcohols, sucrose ester, polyalcohol aliphaticester, a stabilizer and water. The lotion is low in water content. Under the condition that no chemical processing is performed on the natural astaxanthin ester, the storage stability of the naturalastaxanthin ester is remarkably improved, meanwhile, liquid drops with the average grain size being 100 nanometers are dispersed into water to form a transparent water solution, and meanwhile the natural astaxanthin ester living body absorption rate is remarkably increased. The lotion can be applied to food, beverages, cosmetics, skincare products, medicine and other products.

Owner:睿藻生物科技(苏州)有限公司

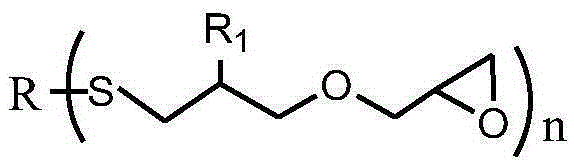

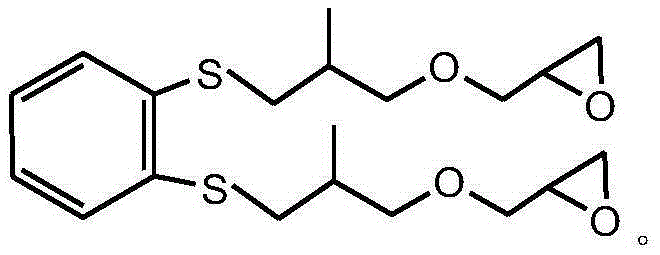

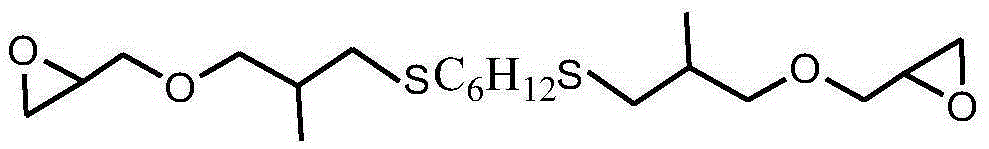

Sulfur-containing glycidyl ether epoxy resin and preparation method thereof

The invention relates to the technical field of preparation of epoxy resin and particularly relates to sulfur-containing glycidyl ether epoxy resin and preparation method thereof. The preparation method comprises the steps of carrying out ultraviolet irradiation reaction on a sulfydryl compound and (2-methyl)allyl glycidyl ether in the presence of a photoinitiator and an organic solvent for 2-10 minutes, so as to obtain the sulfur-containing glycidyl ether epoxy resin. According to the preparation method, the epoxy resin can be synthesized from monofunctional, bifunctional and multifunctional sulfydryl compounds through one-step irradiation reaction, the reaction efficiency is high, the reaction time is short, and the yield reaches above 98%; the prepared sulfur-containing epoxy resin does not contain hydroxy, has relatively low viscosity and relatively high storage stability, is expected to be applied to the fields of environment-friendly low-volatility coatings, low-volatility resin, solvent-free epoxy resin insulating paints and the like and can be directly applied without being added with an organic solvent or an active diluent. Besides, the preparation method is simple, low in cost and easy for industrial production, and the pollution of waste water and water gas is avoided.

Owner:WUHAN HYPERBRANCHED POLYMER RESINS SCI& TECH CO LTD

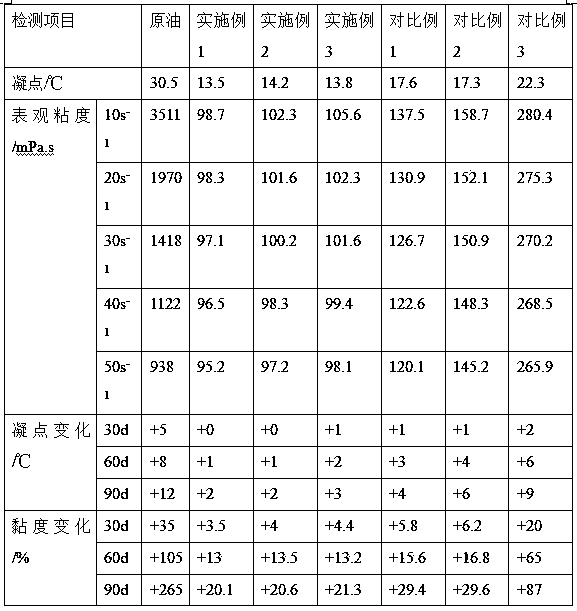

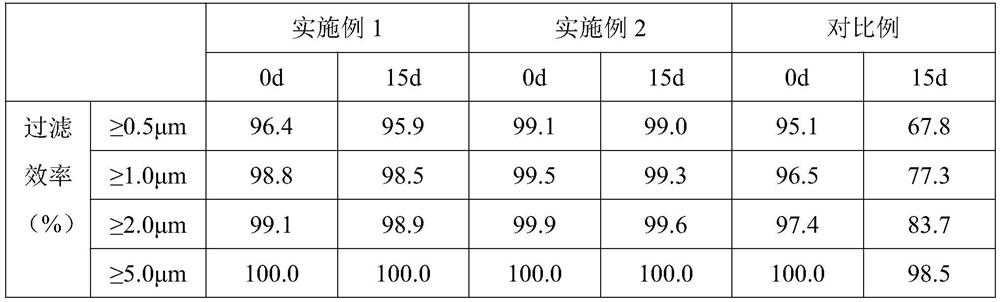

Low-temperature high-efficiency crude oil pour point depressant

PendingCN109897620AAlleviate condensation and sedimentationImprove storage stabilityDrilling compositionIon exchangeIon

The invention relates to a low-temperature high-efficiency crude oil pour point depressant, and belongs to the field of petroleum industry. Sepiolite is subjected to secondary roasting after drying, an ion diffusion channel in the sepiolite is widened, in combination with ion exchange and charge effects, the sepiolite is retarded and prevented from settling, the storage stability is improved, acrylic acid and maleic anhydride are used as raw materials, an dispersion effect is improved through steric hindrance and charge effects, and agglomeration and coagulation of heavy components in crude oil are slowed down; and chitosan, stearic acid, sodium bentonite and the like are used as raw materials, larger steric hindrance is generated, stable dispersion performance is provided, phospholipid isadded when a paraffin treating material is prepared, a single phospholipid molecule has more negative charges and can be adsorbed and wrapped on the surface of colloid, microgels have the same charges and repel each other, so that the pour point depression effect is improved, agglutination deposition of components of the crude oil is slowed down, and the storage stability of the crude oil is further improved. The problems of poor viscosity reduction effect and poor storage stability of the conventional pour point depressant at a low temperature are solved.

Owner:广州市天河区车陂亚贝思烘焙店

Environment-friendly air filtration non-woven fabric as well as production process and application thereof

ActiveCN112853619AImprove electret effectImprove storage stabilityUltrasonic/sonic fibre treatmentGrip property fibresPolypropyleneWoven fabric

The invention provides a production process of an environment-friendly air filtration non-woven fabric, and belongs to the technical field of air filtration. Polypropylene, electret master batch and high-molecular electret are uniformly mixed, the prepared mixture is fed into a screw extruder, melt extrusion is performed through the screw extruder to form a melt, the melt is sprayed out through a spinneret plate to form fibers, the fibers are subjected to constant-temperature and constant-pressure hot air drafting, melt-blown cloth is formed on a web curtain, then infrared radiation heat treatment, high-pressure electret treatment and cooling treatment are sequentially conducted, then rolling is conducted, and the air filtration non-woven fabric is obtained, wherein electret master batches are composed of polypropylene, few-layer graphene nanosheets, an antioxidant, a compatilizer and a nucleating agent; the few-layer graphene nanosheet is prepared by taking magnesium oxide microcrystals with a face-centered cubic structure as a substrate and a template through a chemical vapor deposition method; and the electret master batch improves the electret degree of fibers, improves the storage stability of charges and further improves the filtering performance.

Owner:DONGGUAN CHUNXIA IND CO LTD

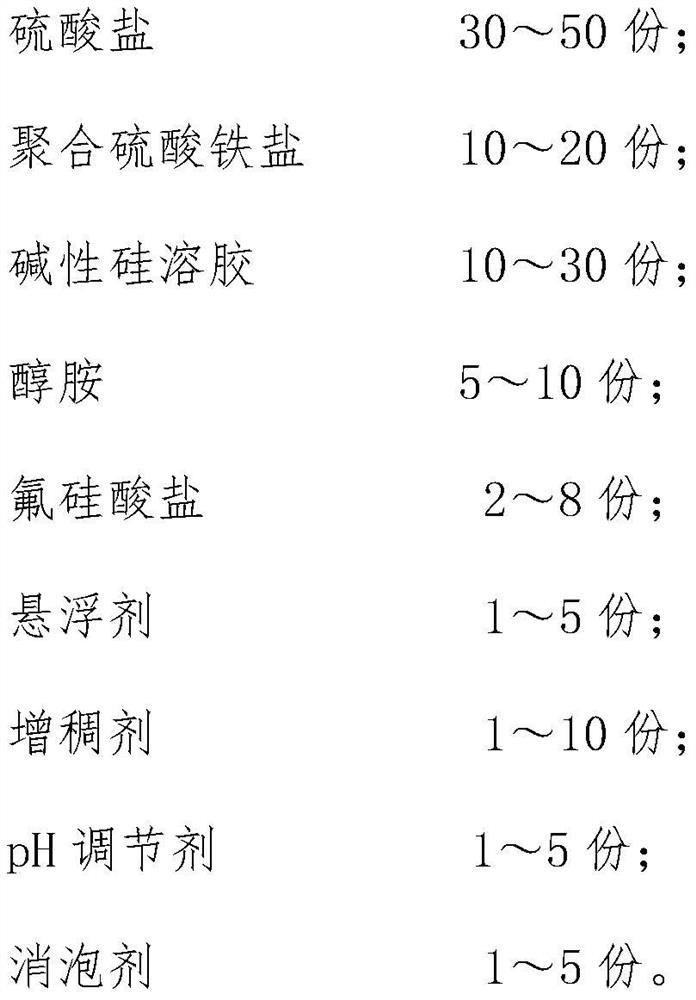

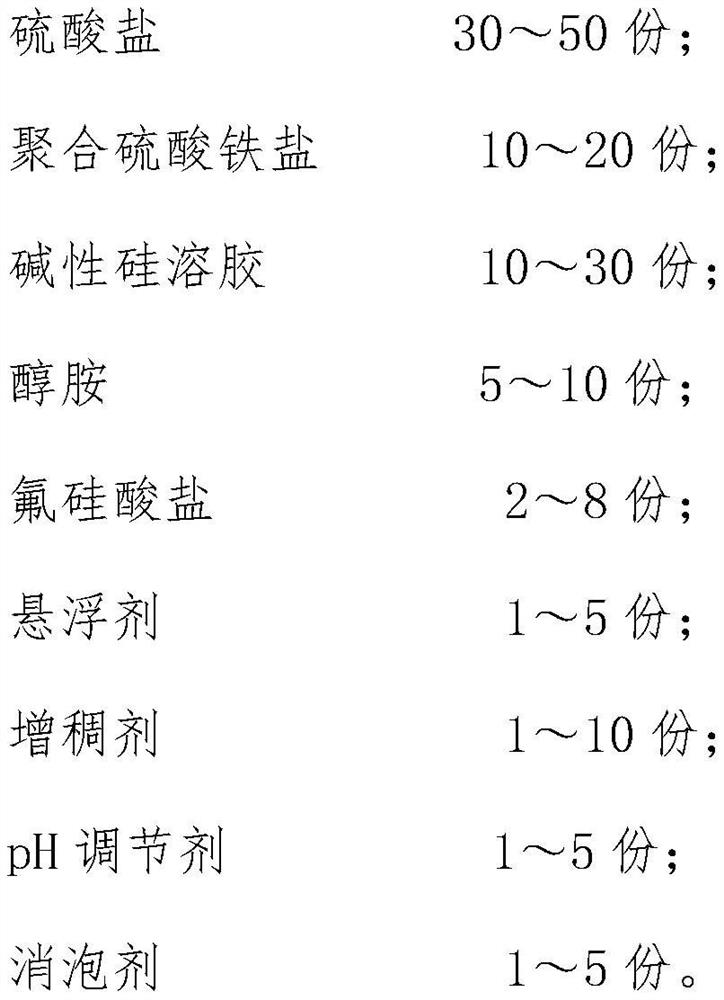

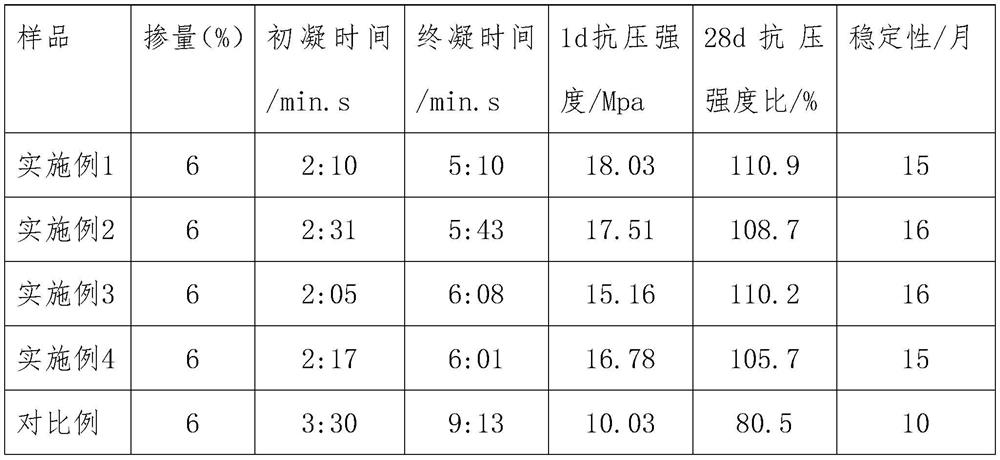

Alkali-free liquid accelerator

The invention relates to the technical field of building materials, in particular to an alkali-free liquid accelerator. The accelerator comprises the following raw materials in parts: 30-50 parts of sulfate, 5-10 parts of alcohol amine, 1-5 parts of a suspending agent, 1-10 parts of a thickening agent, 1-5 parts of a pH regulator, 1-5 parts of a defoaming agent, 2-8 parts of fluosilicate, 10-20 parts of polymeric ferric sulfate salt, and 10-30 parts of alkaline silica sol. The invention aims to provide the alkali-free liquid accelerator, and the accelerator is good in compatibility with various types of concrete, wide in adaptability, capable of effectively inhibiting precipitation, good in storage stability and free of influence on the uniformity of sprayed concrete; and the accelerator has no corrosion and special smell, and has no adverse effect on constructors.

Owner:陳森章

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com