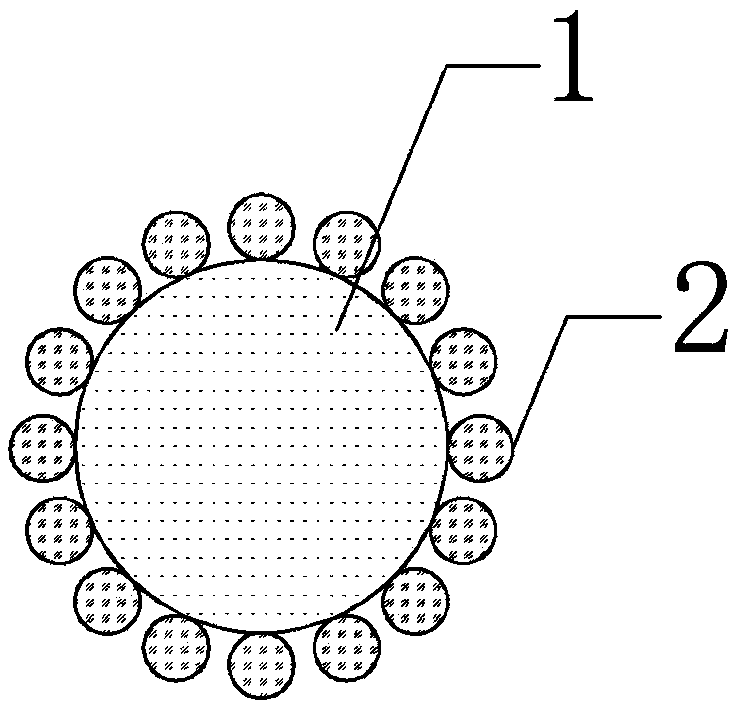

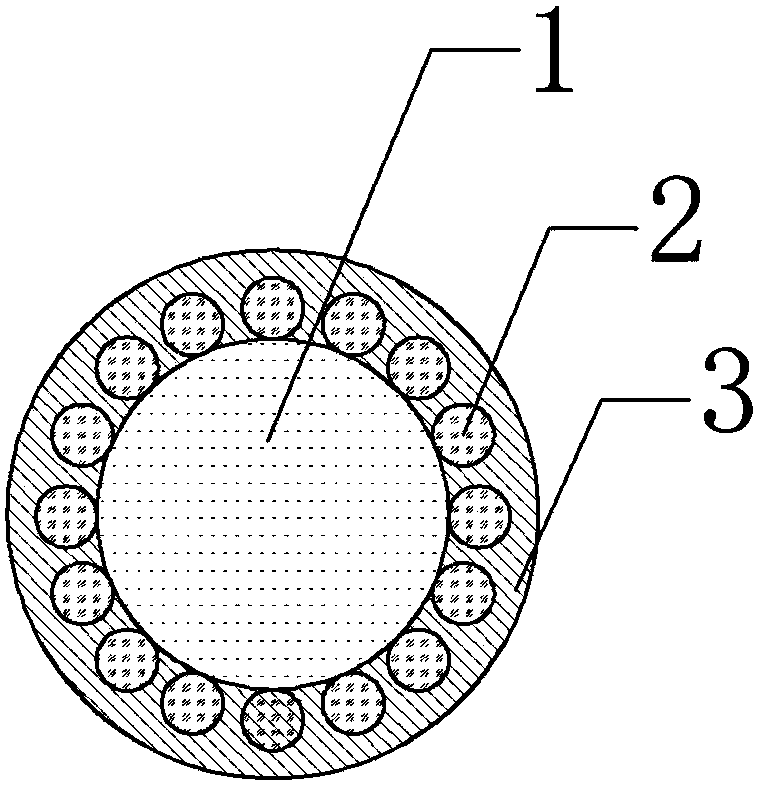

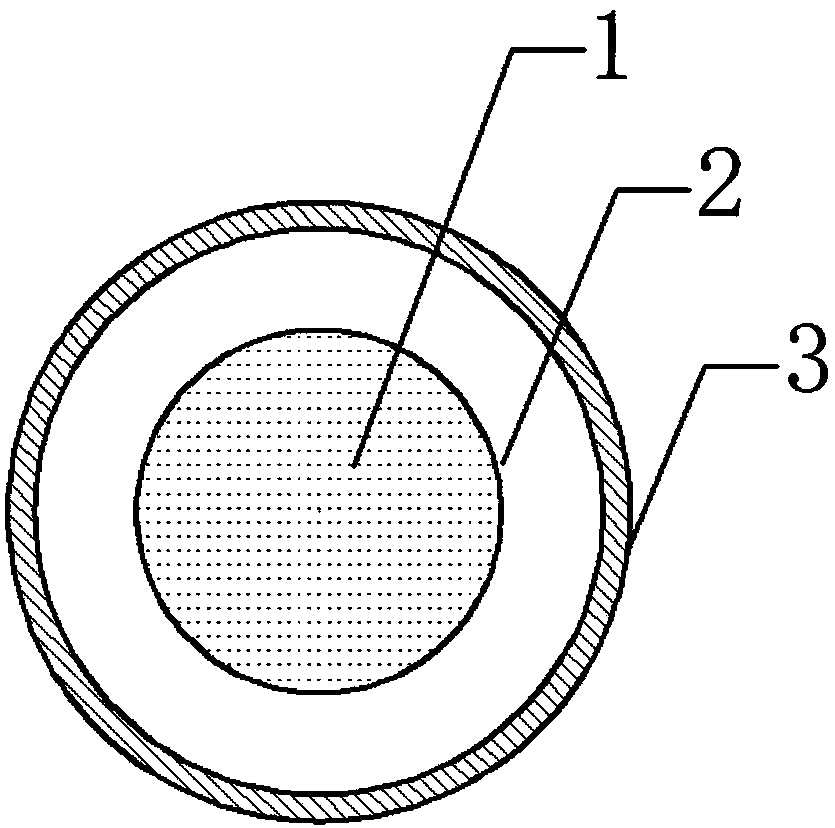

Method for coating thermal expansion hollow microspheres with energy-containing additive

An additive and thermal expansion technology, applied in non-explosive/non-thermal agent components, non-explosive stabilizers, offensive equipment, etc., can solve the problems of hydrogen bubbles of different sizes, hidden safety hazards, and difficult to control, so as to improve the working ability , reduce sensitivity and prevent demulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Polymer hollow microspheres encapsulated hydrogen storage material TiH 2 The preparation method:

[0031] St1: mix 0.2g sodium bicarbonate with 20g TiH 2 Add it to the ball mill, the speed of the ball mill is 30rpm / min, and the ball mill is 2h. After the ball mill is completed, the sodium bicarbonate particles are dispersed and coated with TiH 2 particle surface.

[0032] St2: Add 3g of acrylonitrile, 1g of methyl acrylate, and 1g of vinyl acetate to a stirrer with a heating function. After stirring and mixing evenly, add oil-soluble initiator azobisisobutyronitrile and 0.3 % cross-linking agent polyethylene glycol 200 dimethacrylate, after stirring and mixing evenly, the temperature was raised to 62°C for bulk polymerization, and after pre-polymerization for 30 minutes, the system temperature was quickly lowered to 20°C with an ice bath. Add the energetic additive coated in St1, and stir well, so that the coated energetic additive and the prepolymer are evenly mixed...

Embodiment 2

[0036] The preparation method of Al powder coated with polymer hollow microspheres:

[0037] St1: Add 0.5g of modified azodicarbonamide and 30g of Al powder into a ball mill, the speed of the ball mill is 60rpm / min, and ball mill for 2h to complete the coating of the expansion agent on the aluminum powder.

[0038] St2: Add 4g of styrene, 3g of acrylonitrile, and 3g of vinylidene chloride monomer into a reactor with a stirrer and a heating device. After stirring and mixing evenly, add 1% of the total mass of the monomers as an oil-soluble initiator azo Diisobutyronitrile and 0.75% cross-linking agent trimethylolpropane triacrylate, stir and mix evenly, then heat up to 65°C for bulk polymerization, pre-polymerize for 1 hour, quickly lower the system temperature to 25°C with an ice bath, Add the energetic additive coated in St1, and stir well to make the Al powder of the energetic additive and the prepolymer evenly mixed;

[0039] St3: configure 150ml Mg(OH) 2 solution, and th...

Embodiment 3

[0042] The preparation method of polymer hollow microspheres encapsulating boron powder:

[0043] St1: Put 0.6g of azodicarbonamide and 30g of boron powder into a ball mill, the ball mill rotates at a speed of 45m / min, and mill for 2 hours, and the expansion agent-modified azodicarbonamide is dispersed and coated on the surface of the boron powder particles.

[0044] St2: Add 7g of acrylonitrile, 2g of methyl methacrylate, and 1g of glycidyl methacrylate into a reactor with a stirrer and a heating device. Agent benzoyl peroxide and 1% cross-linking agent polyethylene glycol 400 dimethacrylate, stir and mix evenly, then raise the temperature to 90°C for bulk polymerization, pre-polymerize for 45min, and quickly lower the system temperature to 30°C , add the energetic additive coated in St1, stir well, so that the energetic additive and the prepolymer are evenly mixed;

[0045] St3: configure 150ml Mg(OH) 2 solution, then add the St2 mixture, stir and disperse at 350rpm / min fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com