Alkali-free liquid accelerator

A technology of quick-setting agent and liquid, which is applied in the field of non-alkali liquid accelerator, which can solve the impact of concrete type and batch, unfavorable liquid non-alkali accelerator is widely used, and the matching items of liquid non-alkali accelerator are not very good and other problems, to overcome the obvious decline in strength in the later period, good storage stability, and improve storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

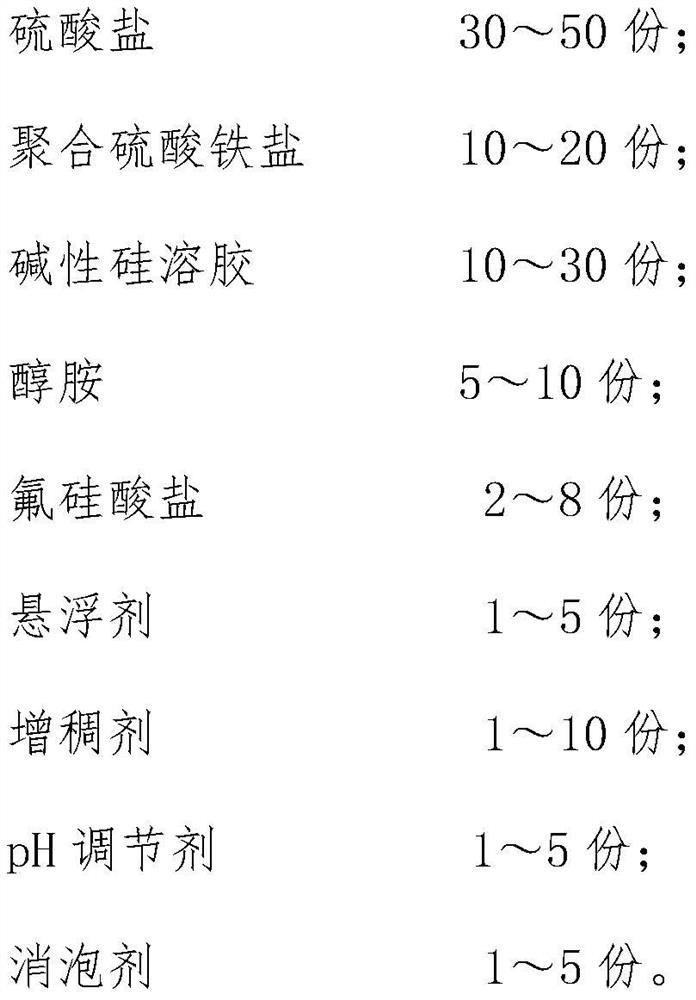

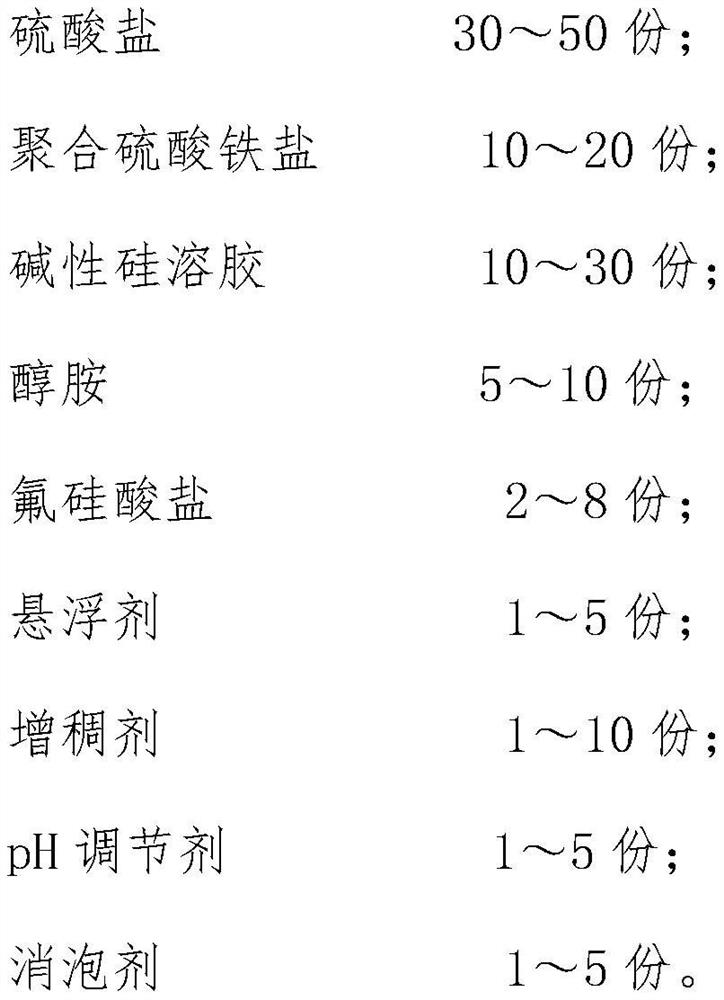

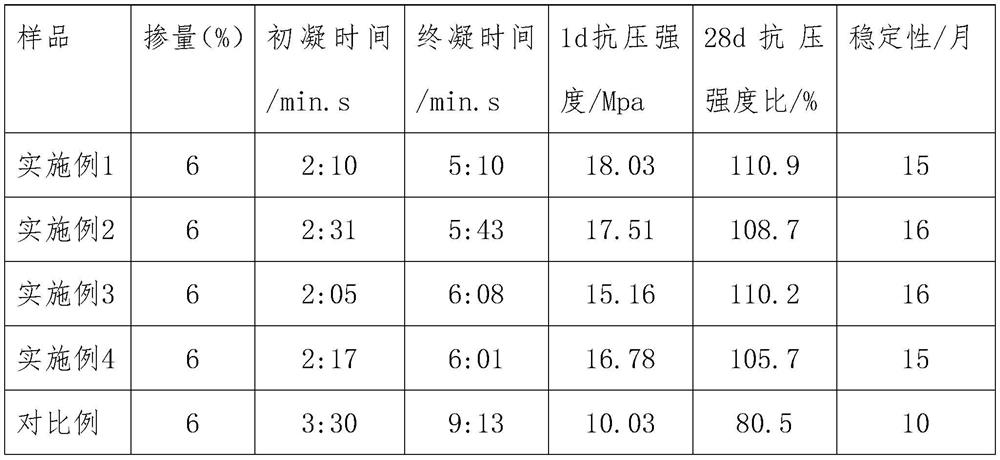

[0024] An alkali-free liquid quick-setting agent, comprising the following raw materials in parts by weight: 30 parts of sulfate; 10 parts of polyferric sulfate; 10 parts of alkaline silica sol; 5 parts of alcohol amine; 2 parts of fluorosilicate; suspending agent 1 part; thickener 1 part; pH regulator 1 part; defoamer 1 part.

[0025] The sulfate is polyaluminum sulfate; the alcohol amine is diethanolamine; the suspending agent is hydroxypropyl starch ether; the thickener is modified aluminum magnesium silicate; the pH regulator is ethylenediamine; the defoamer is silicone defoaming agent; fluorosilicate is magnesium fluorosilicate;

[0026] Alkali-free liquid quick-setting agent, the preparation method comprises the following steps:

[0027] (1) Mix the sulfate and fluorosilicate in parts by weight, add water with 0.6 times the parts by weight of sulfate, and fully dissolve in a constant temperature water bath at 60°C to obtain solution A;

[0028] (2) Mix the polyferric s...

Embodiment 2

[0031] An alkali-free liquid quick-setting agent, comprising the following raw materials in parts by weight: 50 parts of sulfate; 20 parts of polyferric sulfate; 30 parts of alkaline silica sol; 10 parts of alcohol amine; 8 parts of fluorosilicate; suspending agent 5 parts; 10 parts of thickener; 5 parts of pH regulator; 5 parts of defoamer.

[0032] Sulfate is polyaluminum sulfate, polymagnesium sulfate; alcohol amine is diethanolamine, triethanolamine; suspending agent is hydroxypropyl starch ether, graphene oxide; thickener is modified aluminum magnesium silicate, bentonite; pH regulator is Ammonia; defoamer is polyether defoamer; fluorosilicate is magnesium fluorosilicate, zinc fluorosilicate;

[0033] Alkali-free liquid quick-setting agent, the preparation method comprises the following steps:

[0034] (1) Mix the sulfate and fluorosilicate in parts by weight, add water with 0.8 times the parts by weight of sulfate, and fully dissolve in a constant temperature water bath...

Embodiment 3

[0038] An alkali-free liquid quick-setting agent, comprising the following raw materials in parts by weight: 40 parts of sulfate; 15 parts of polyferric sulfate; 20 parts of alkaline silica sol; 7 parts of alcohol amine; 5 parts of fluorosilicate; suspending agent 3 parts; 5 parts of thickener; 3 parts of pH regulator; 3 parts of defoamer.

[0039] The sulfate is polyaluminum sulfate, polymagnesium sulfate, iron sulfate; the alcohol amine is diethanolamine; the suspending agent is sodium polyacrylate; the thickener is modified aluminum magnesium silicate, aluminum silicate; the pH regulator is ethylenediamine; The defoamer is a silicone defoamer; the fluorosilicate is magnesium fluorosilicate;

[0040] The preparation method of alkali-free liquid quick-setting agent is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com