Patents

Literature

123 results about "Types of concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Concrete is produced in a variety of compositions, finishes and performance characteristics to meet a wide range of needs.

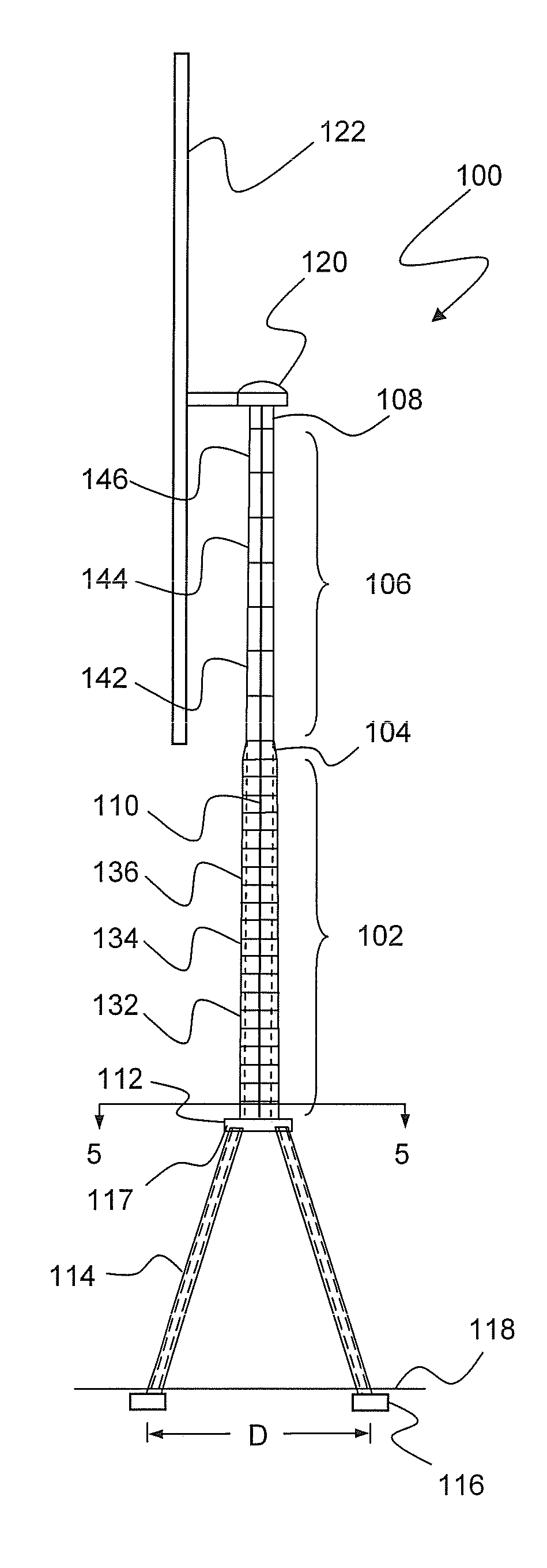

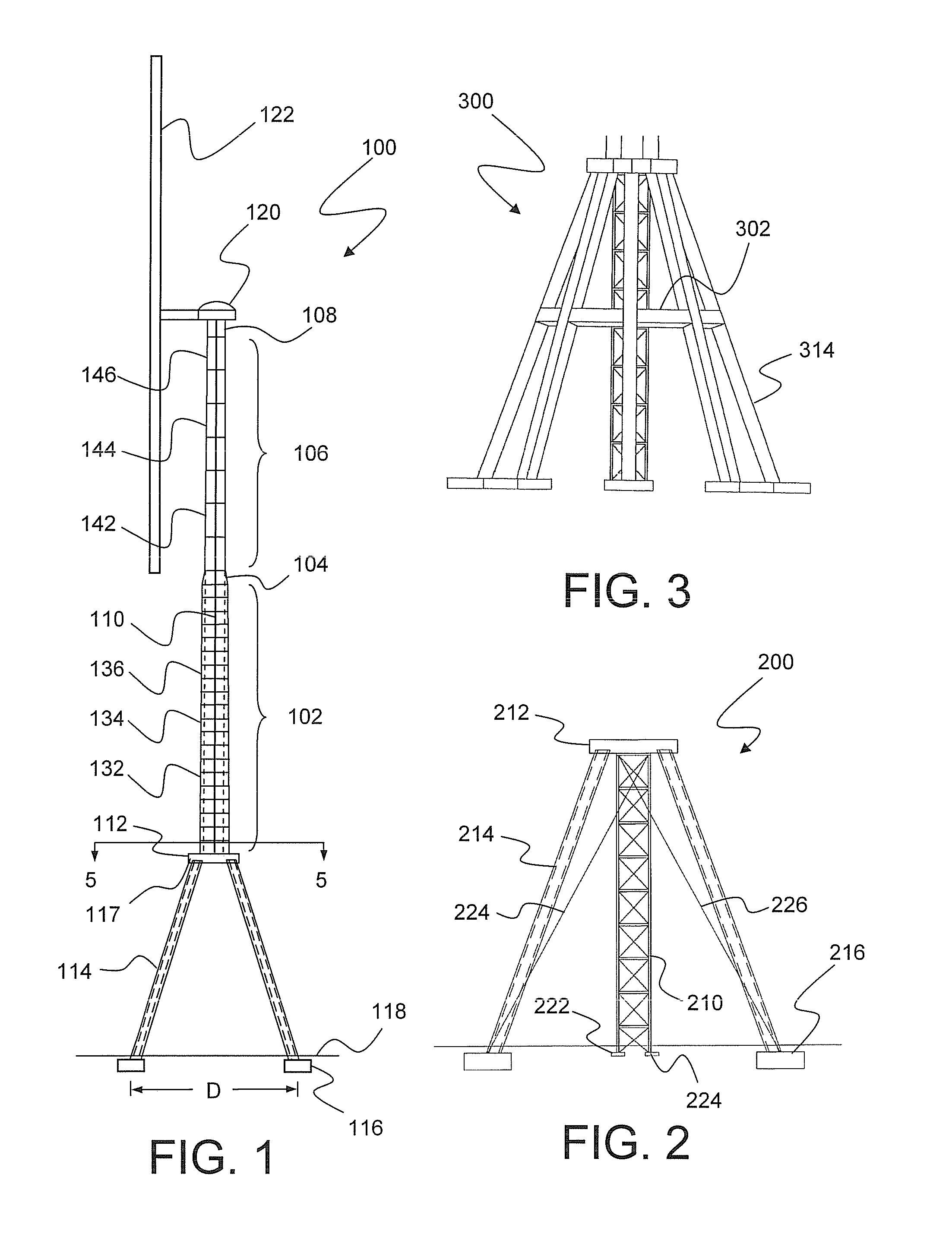

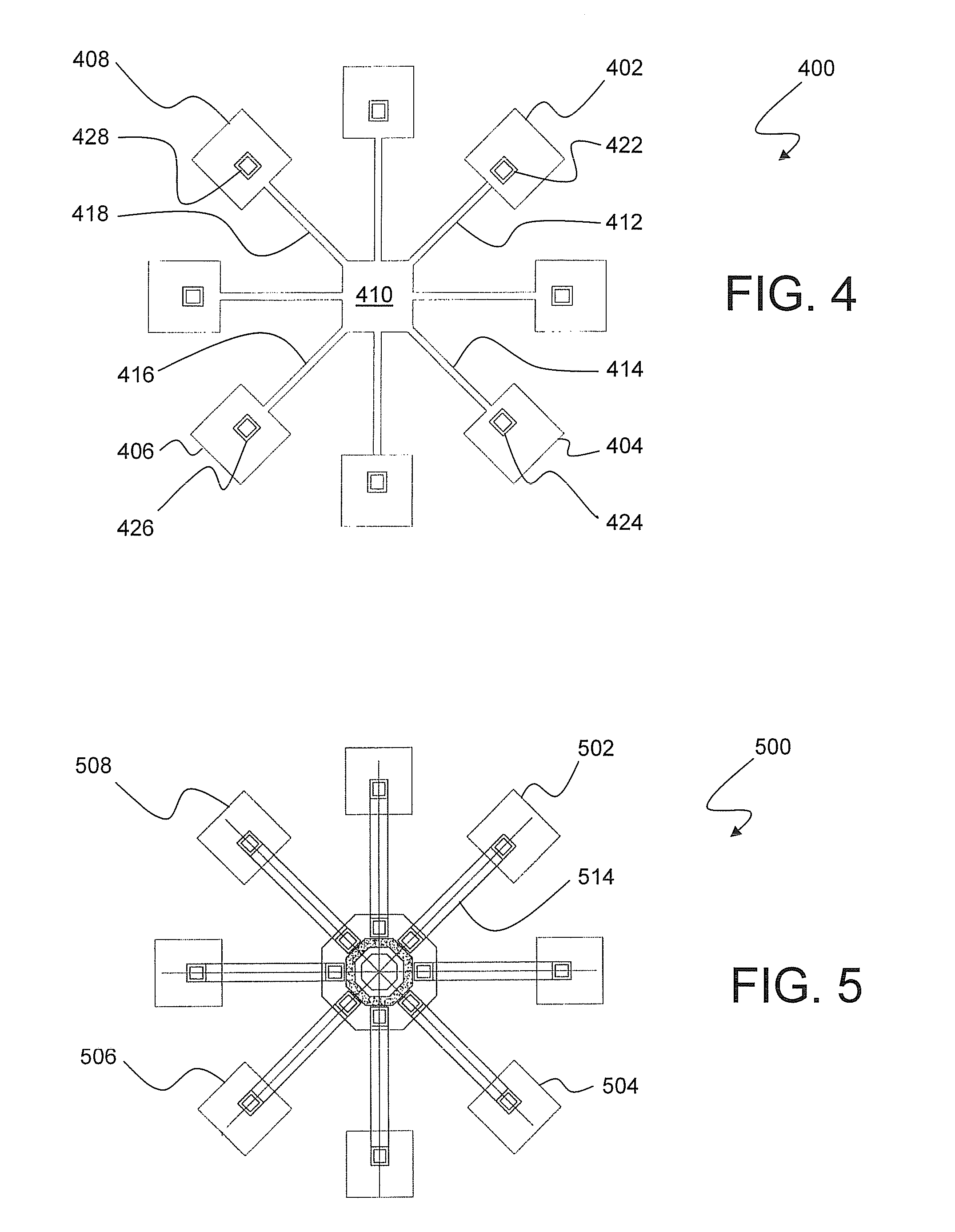

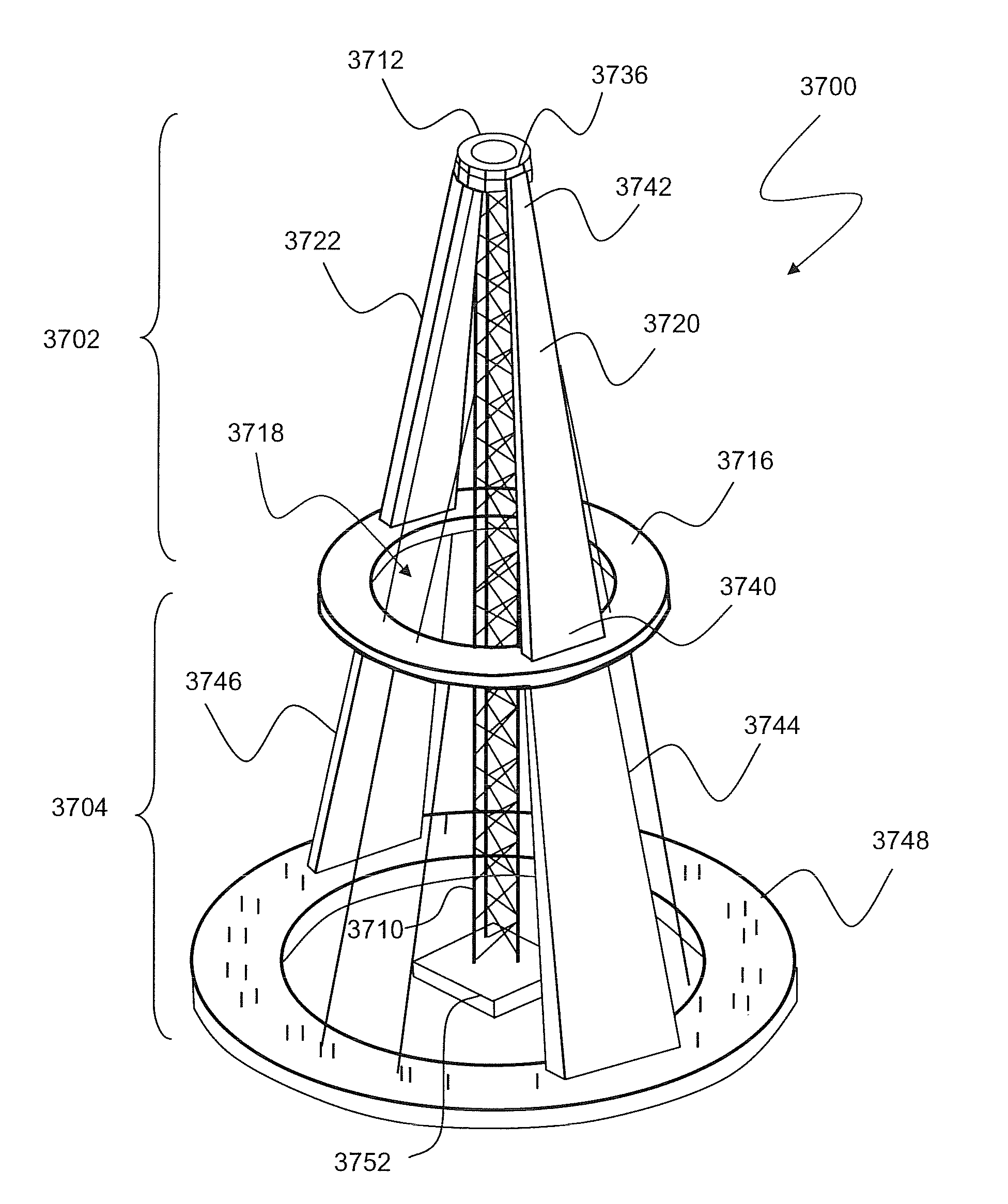

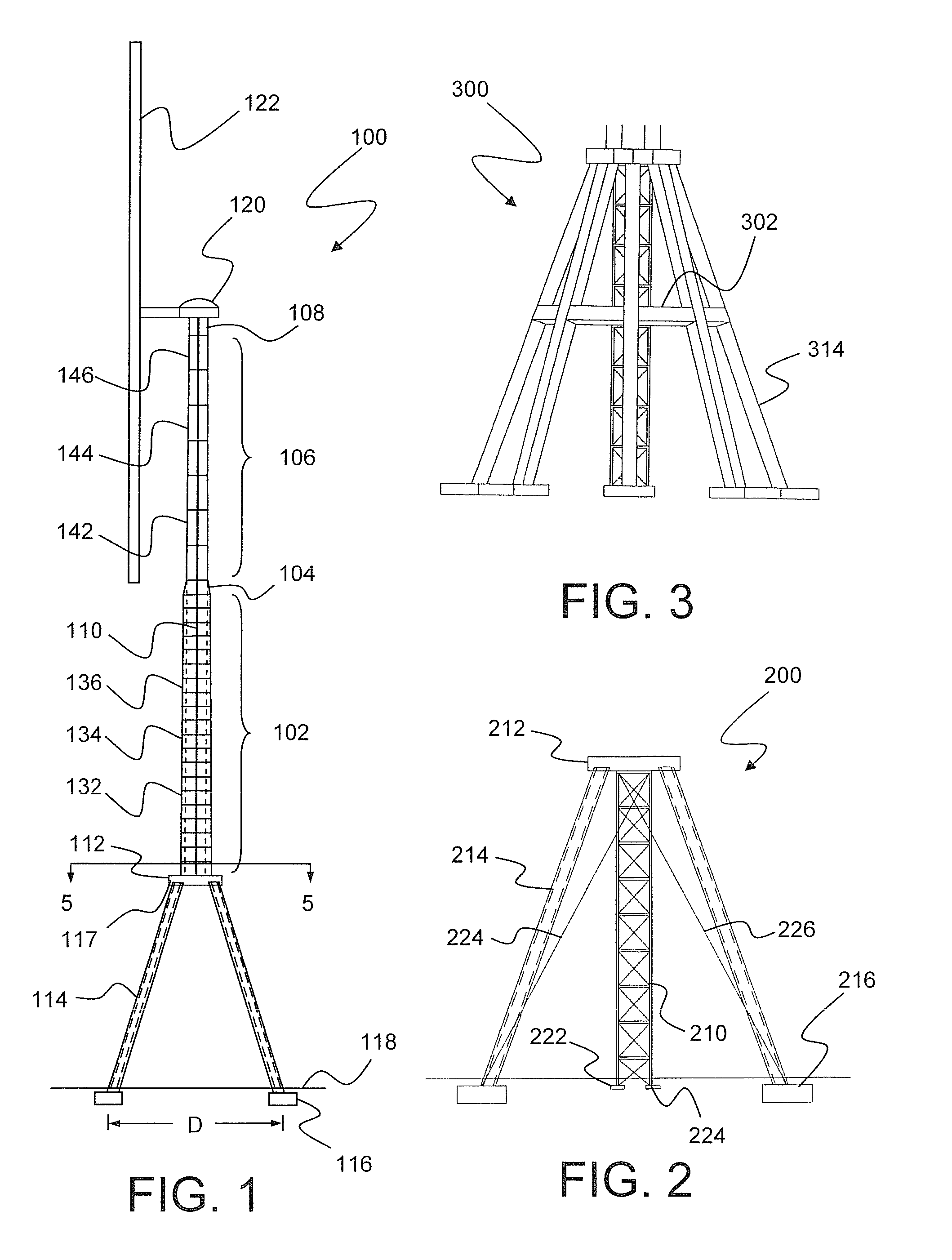

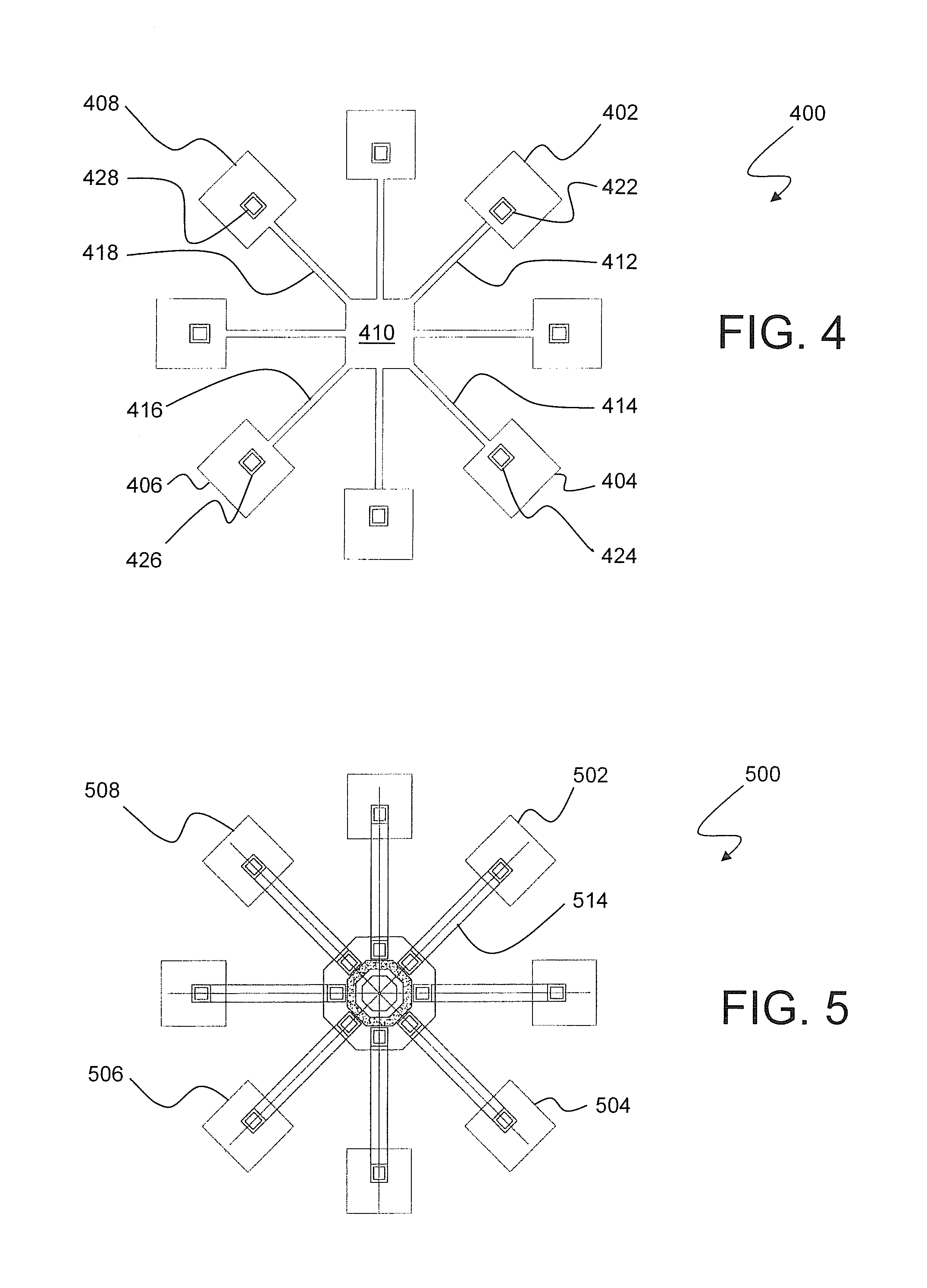

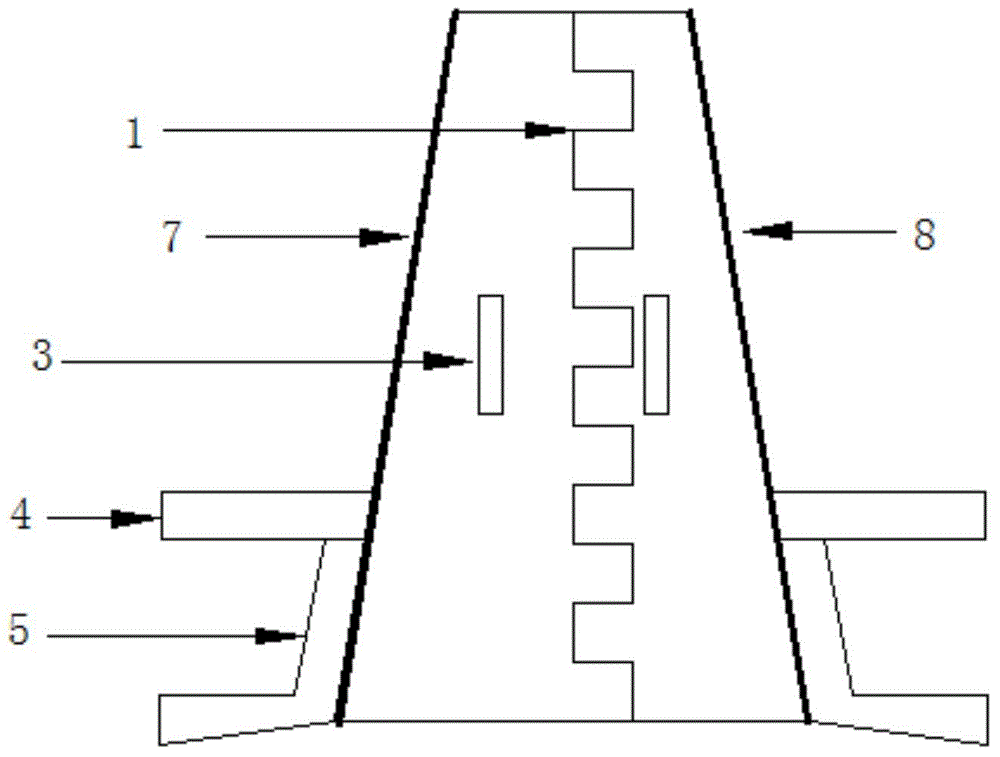

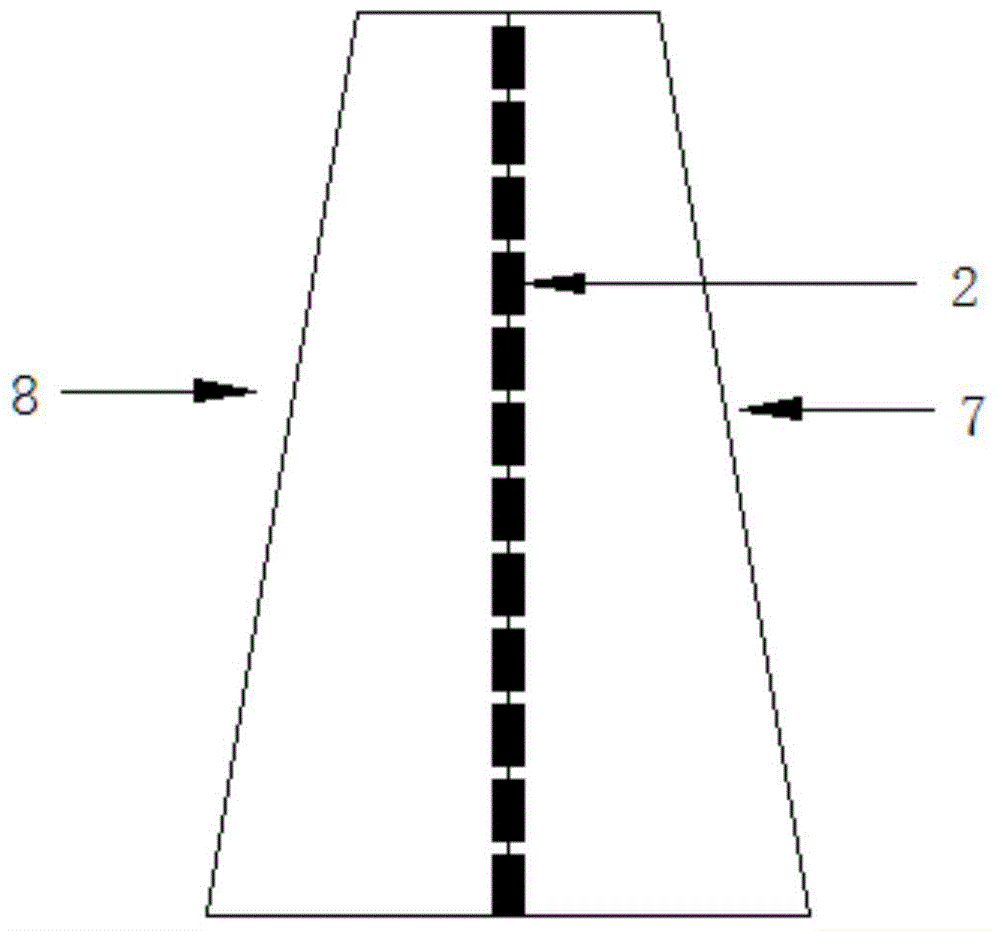

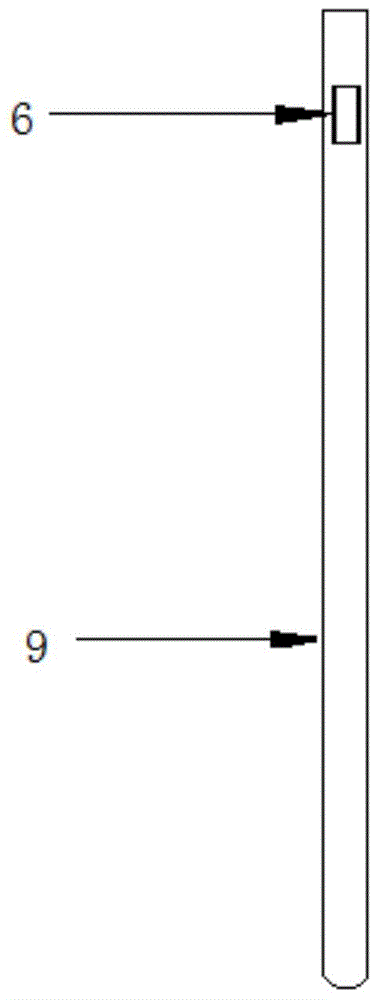

Base support for wind-driven power generators

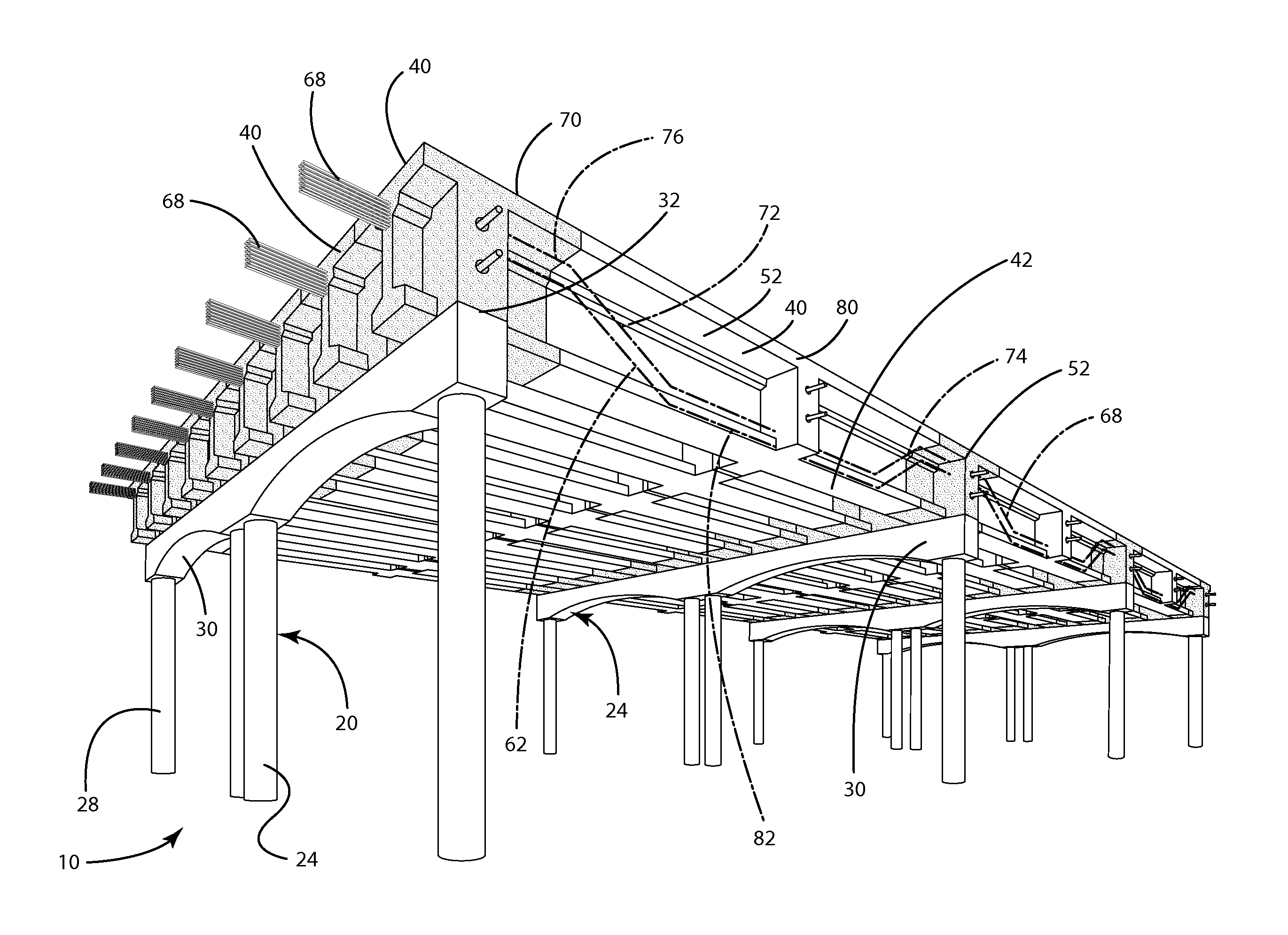

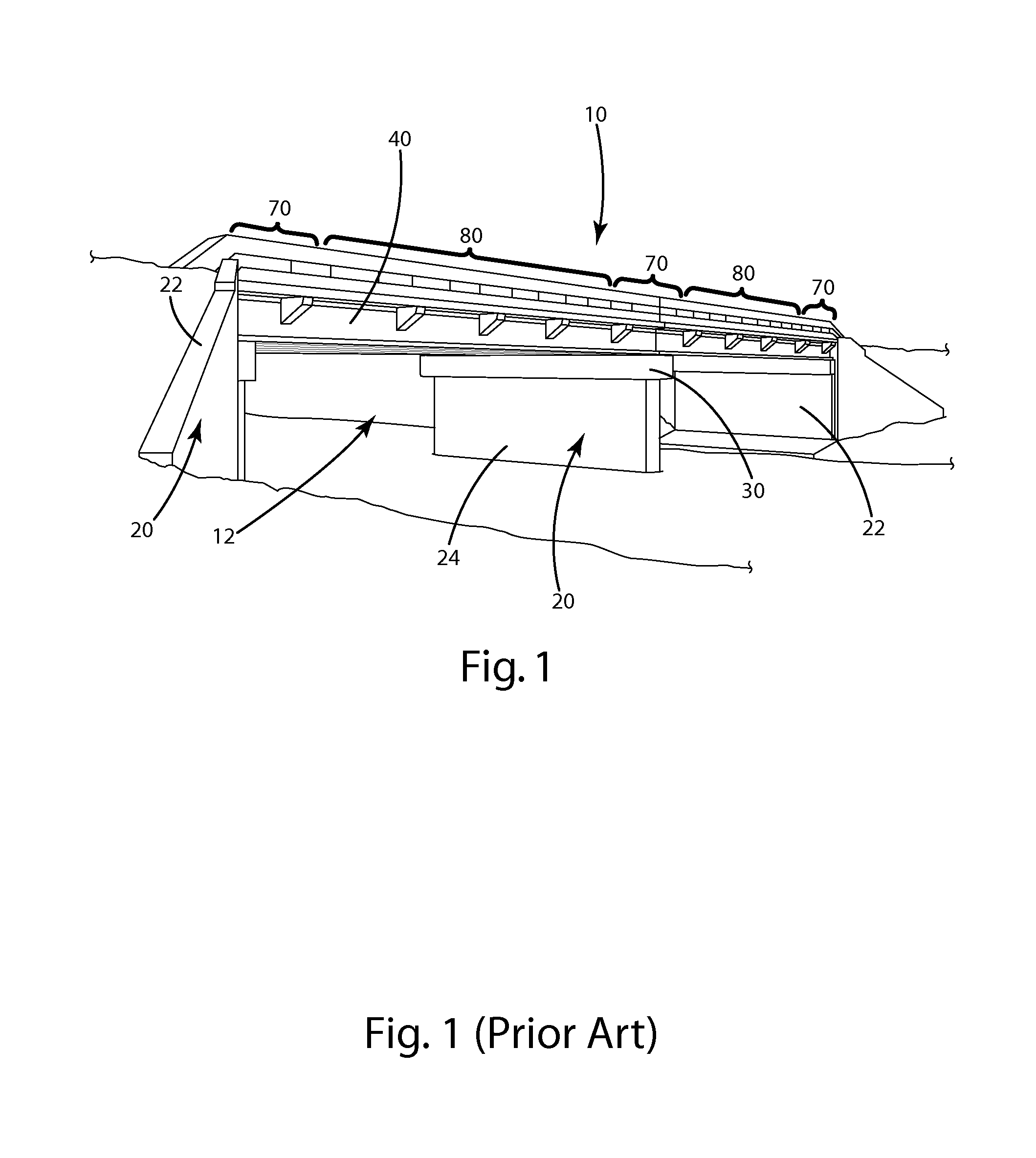

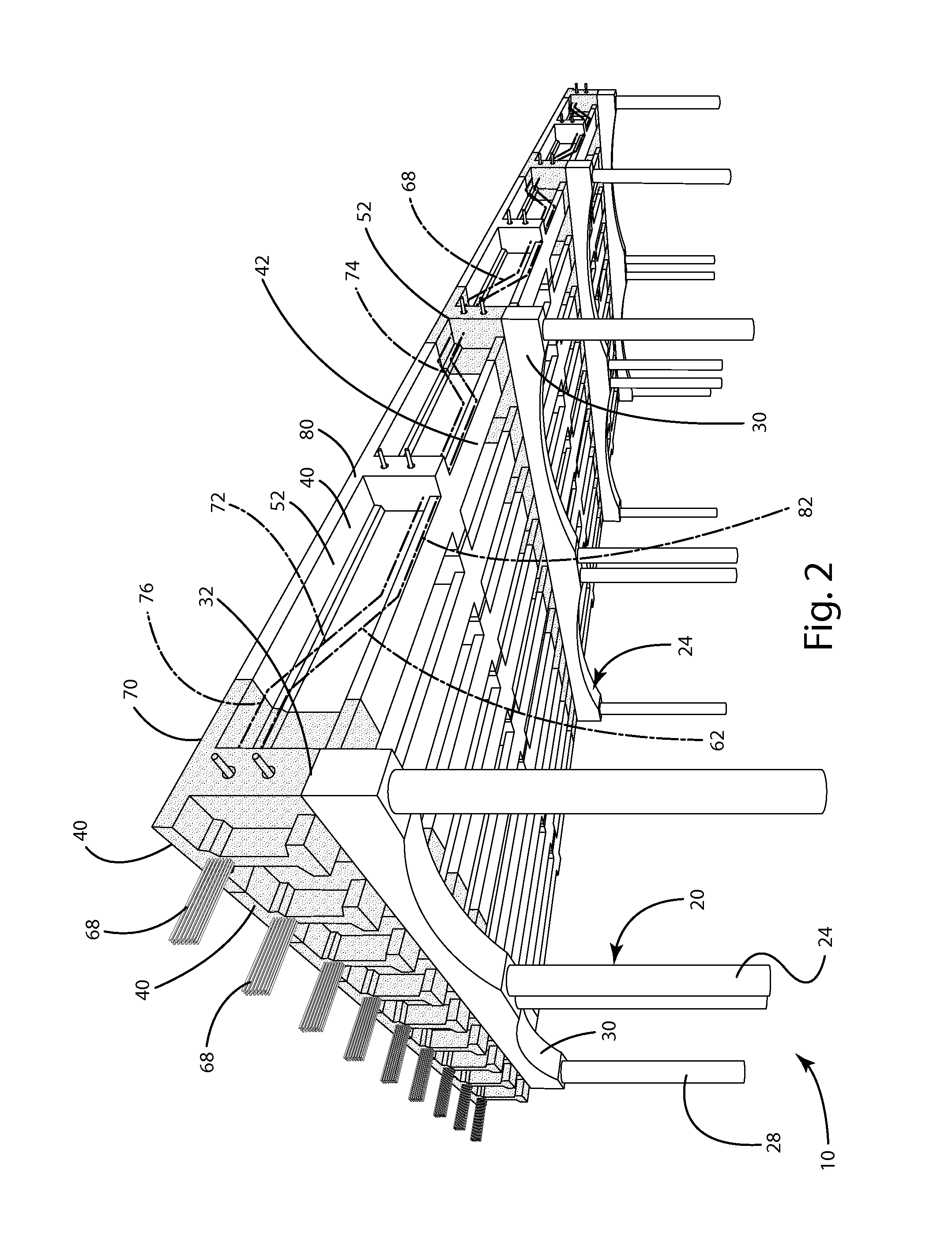

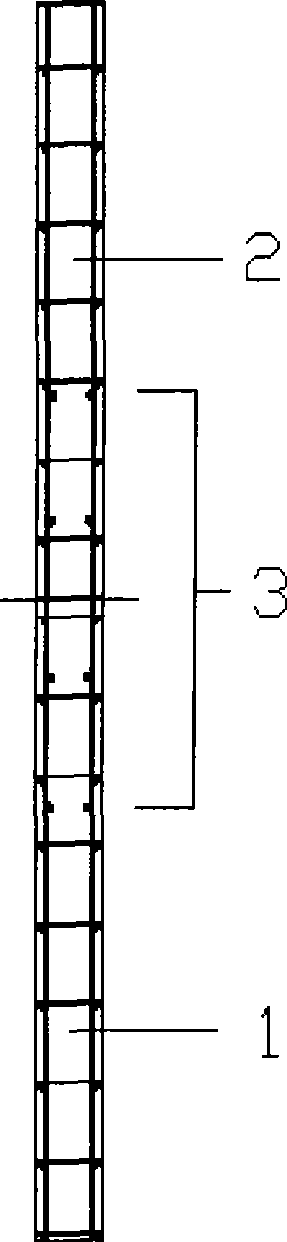

Disclosed are apparatus and corresponding methodology for providing a base support, such as including concrete, and used such as for a wind-driven generator. Precast concrete cylinders are stacked in place upon a platform that may be partially precast and partially cast in place during assembly and supported, in certain embodiments, by plural concrete legs, the other ends of which are supported on a unitary or subdivided concrete foundation. In other embodiments, the platform may be supported by ribbed concrete panels. The concrete cylinders are glued together using an epoxy and then secured by an internal vertical post tension system extending from the platform to the upper most cylinder. Different types of concrete are used between upper and lower sections of the stacked cylinders. The lower section uses reinforced concrete while the upper section used ultra high performance fiber reinforced concrete.

Owner:TINDALL CORP

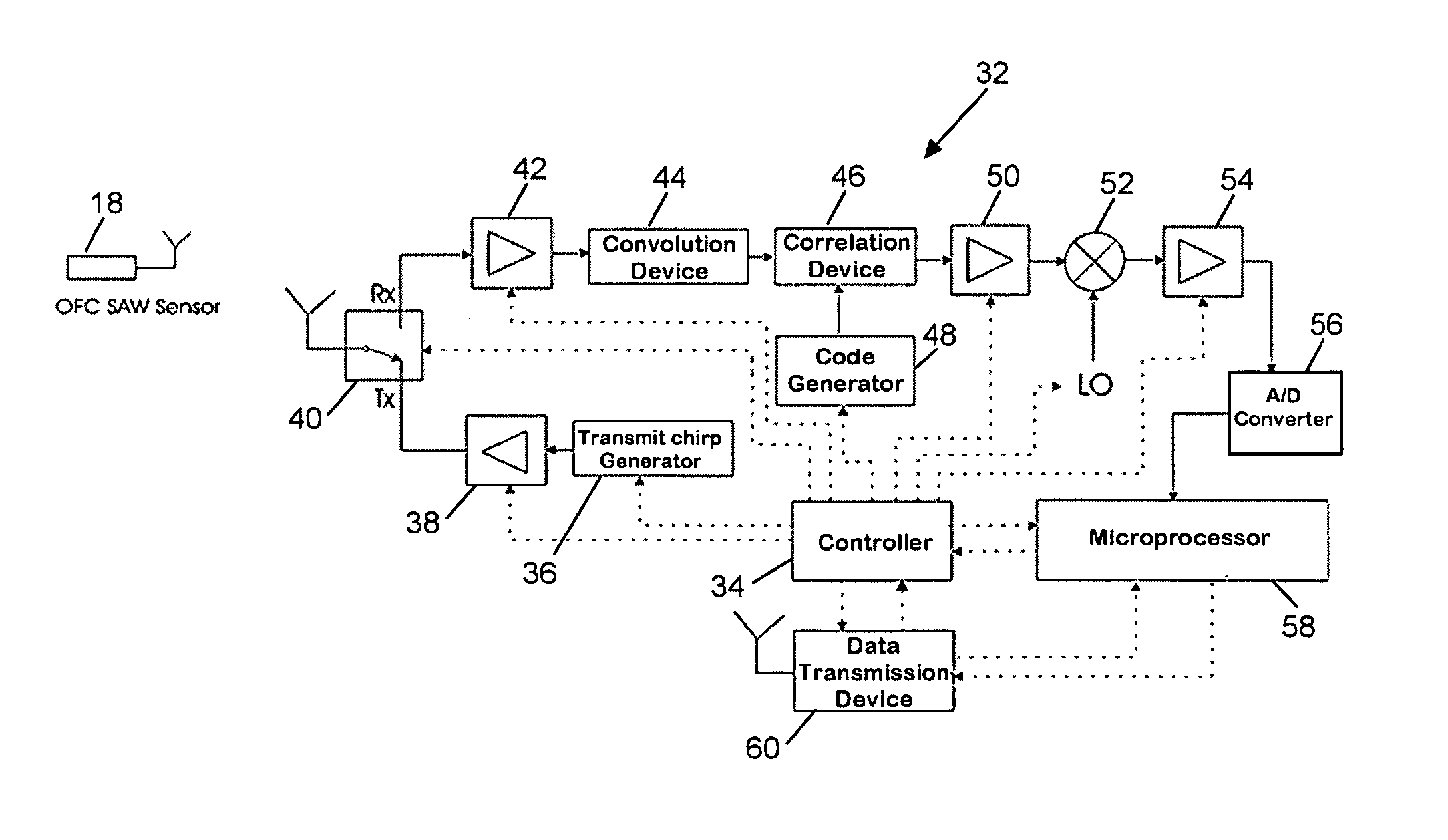

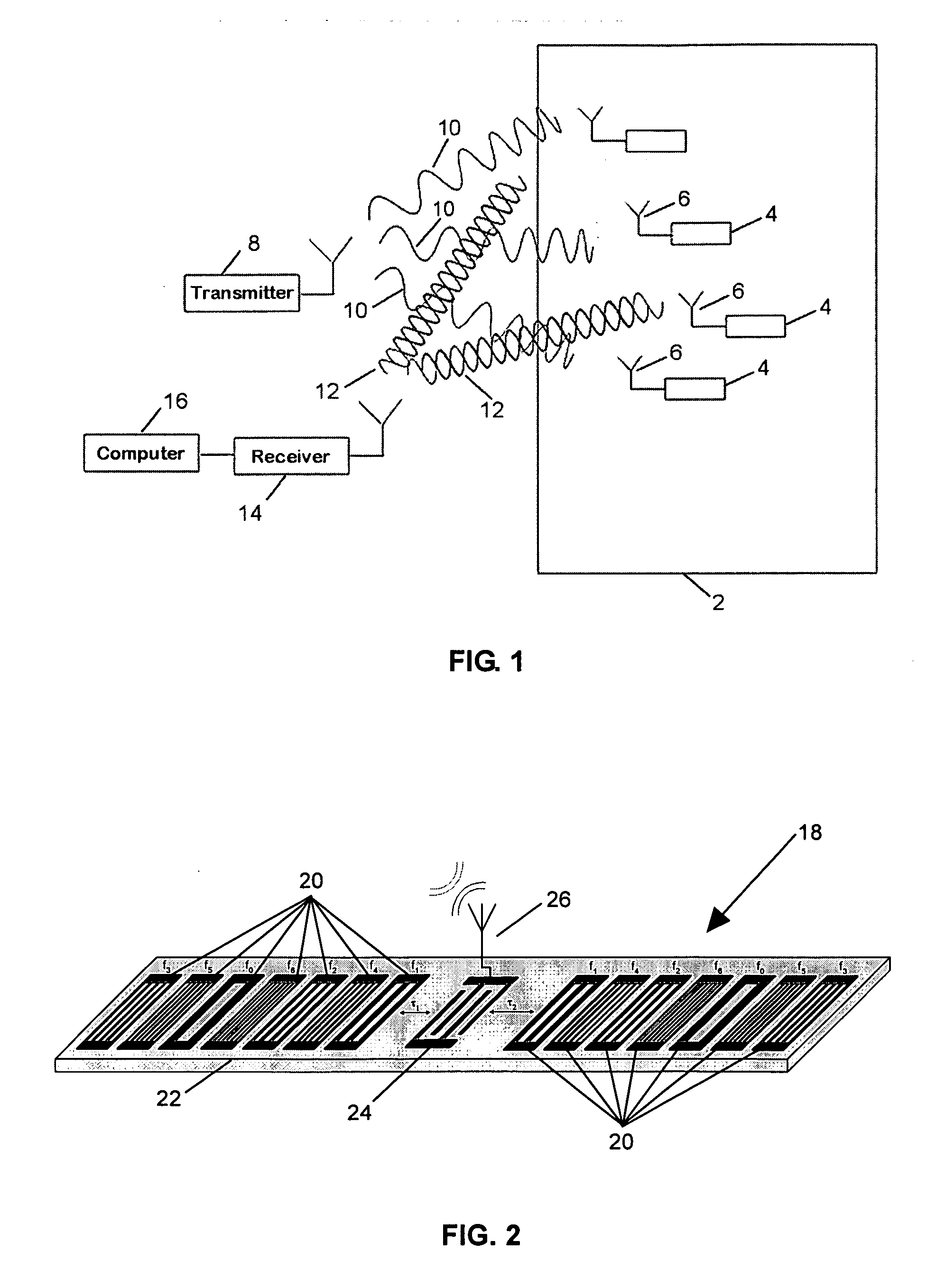

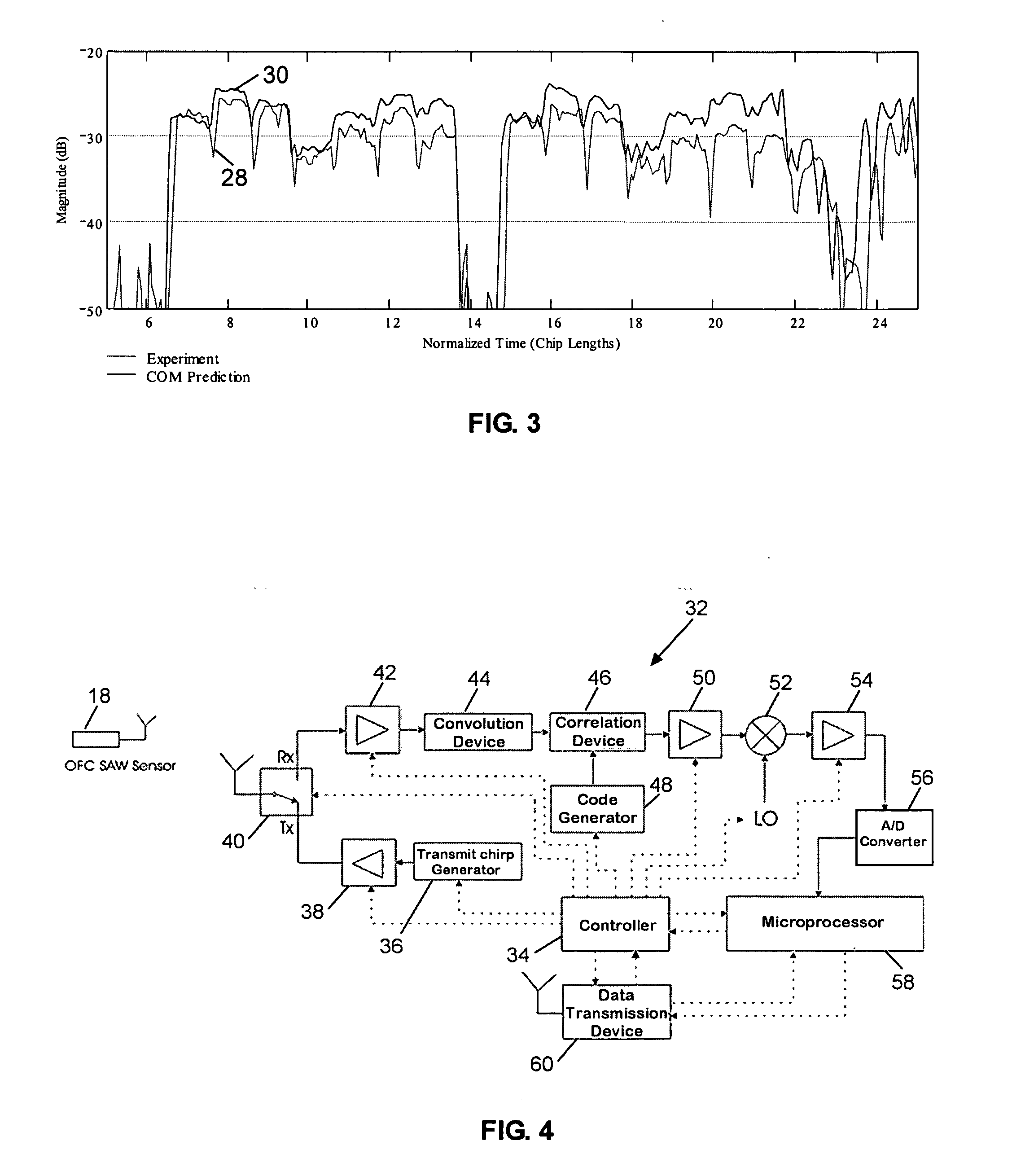

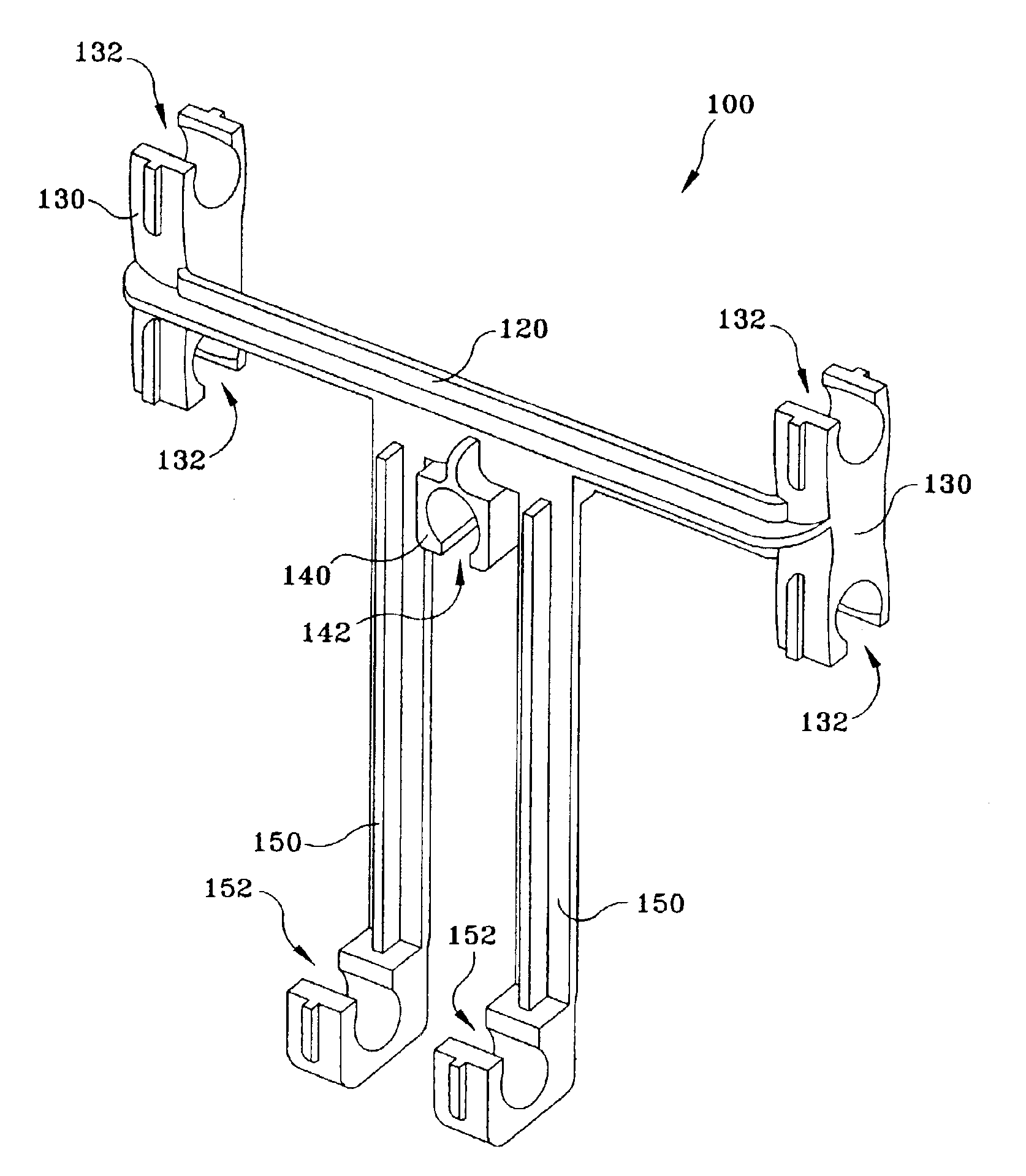

Concrete maturity monitoring system using passive wireless surface acoustic wave temperature sensors

InactiveUS20070046479A1Unlimited lifetimeOvercomes drawbackMaterial analysis using sonic/ultrasonic/infrasonic wavesFire alarmsTransceiverMonitoring system

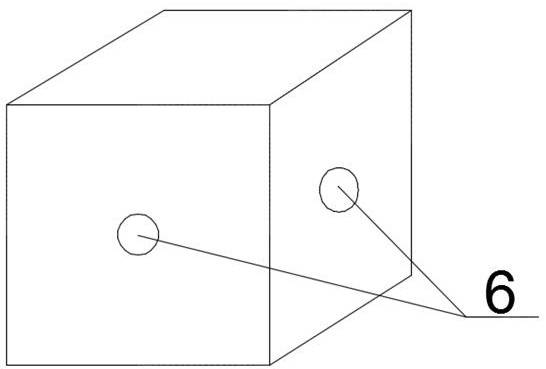

A method and apparatus for wireless measurement of the temperature in curing concrete is characterized by the use of a plurality of surface acoustic wave temperature sensors embedded in the concrete. An interrogation signal from an external transceiver system is modified by the sensors in accordance with the temperature of the concrete adjacent to the sensors. The return signals from the sensors are processed in a correlation device to identify each signal as originating from a specific sensor. A microprocessor calculates the maturity of the concrete based on the data received from the sensors as well as data input corresponding to the type of concrete. The maturity data is used to analyze the strength and integrity of the concrete structure being built.

Owner:APPLIED SENSOR RES & DEV

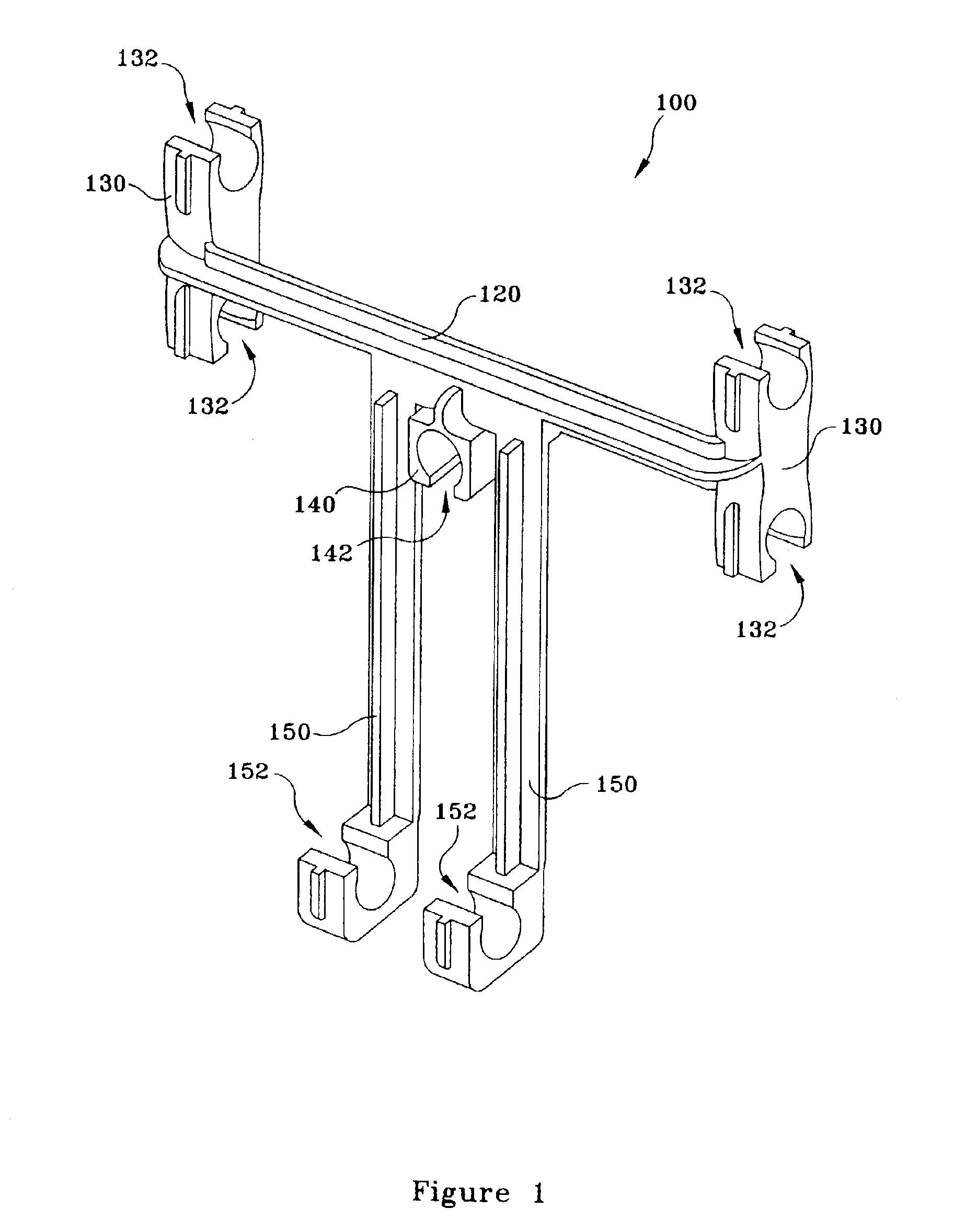

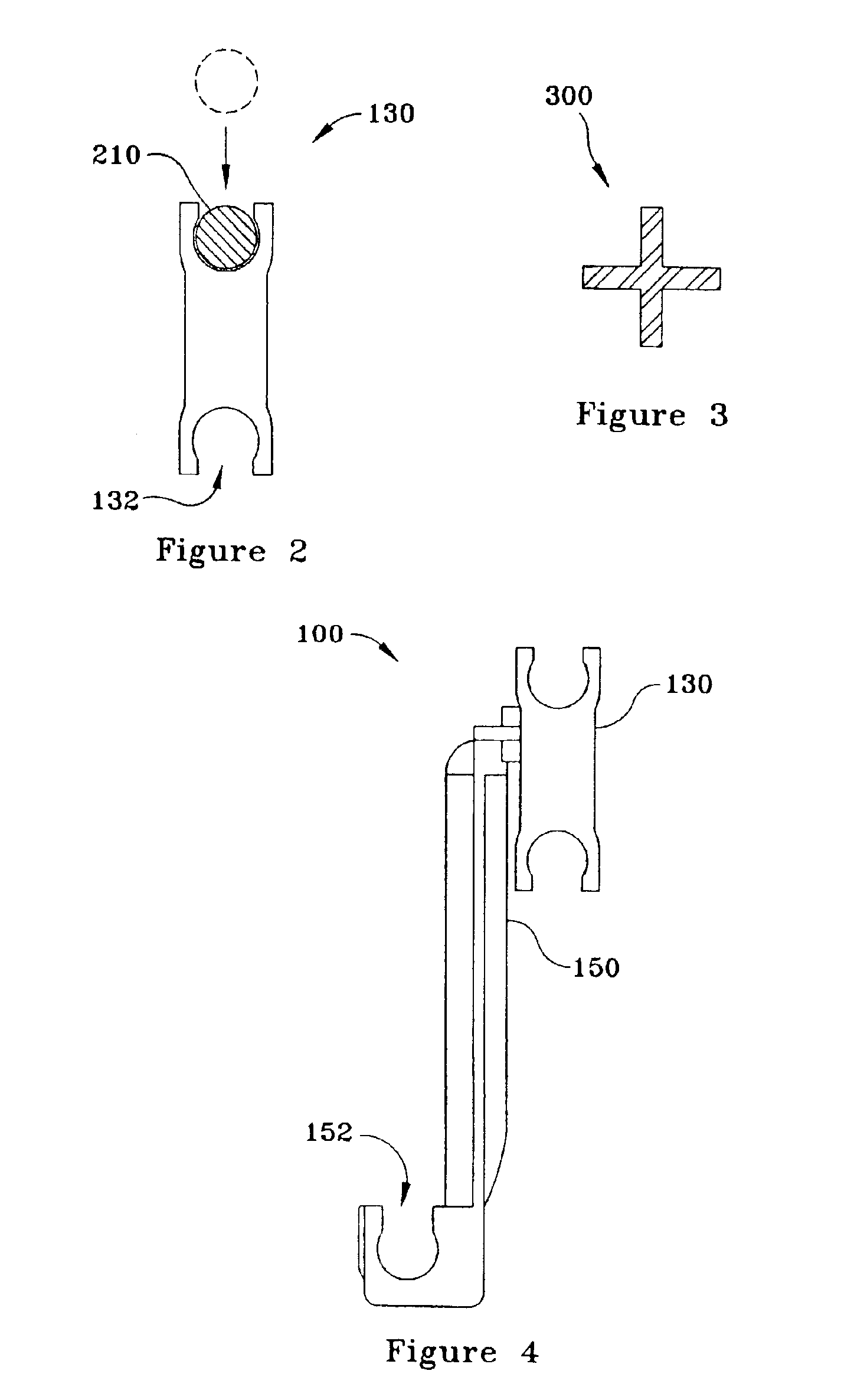

Apparatus and method for reinforcing concrete using rebar supports

The present invention provides an apparatus and method for suspending and positioning structural reinforcement elements such as rebar within a framework for a slab-on-grade foundation or other type of concrete structure. Each rebar support of the present invention comprises a plurality of rebar support arms that, in concert with the other components of the foundation or concrete structure, supports one or more pieces of rebar in a desired orientation.

Owner:JUEDES BRIAN M +2

Base support for wind-driven power generators

Disclosed are apparatus and corresponding methodology for providing a base support, such as including concrete, and used such as for a wind-driven generator. Precast concrete cylinders are stacked in place upon a platform that may be partially precast and partially cast in place during assembly and supported, in certain embodiments, by plural concrete legs, the other ends of which are supported on a unitary or subdivided concrete foundation. In other embodiments, the platform may be supported by ribbed concrete panels. The concrete cylinders are glued together using an epoxy and then secured by an internal vertical post tension system extending from the platform to the upper most cylinder. Different types of concrete are used between upper and lower sections of the stacked cylinders. The lower section uses reinforced concrete while the upper section used ultra high performance fiber reinforced concrete.

Owner:TINDALL CORP

Continuous CFRP Decked Bulb T Beam Bridges For Accelerated Bridge Construction

A pre-stressed concrete bridge using longitudinal load members of a single continuous beam including at least two types of concrete, one of which is ultra-high-performance concrete (UHPC) mix with a compressive strength exceeding 20 ksi and tensile strength exceeding 1.5 ksi in a region proximate to the support structure.

Owner:LAWRENCE TECHNOLOGICAL UNIV

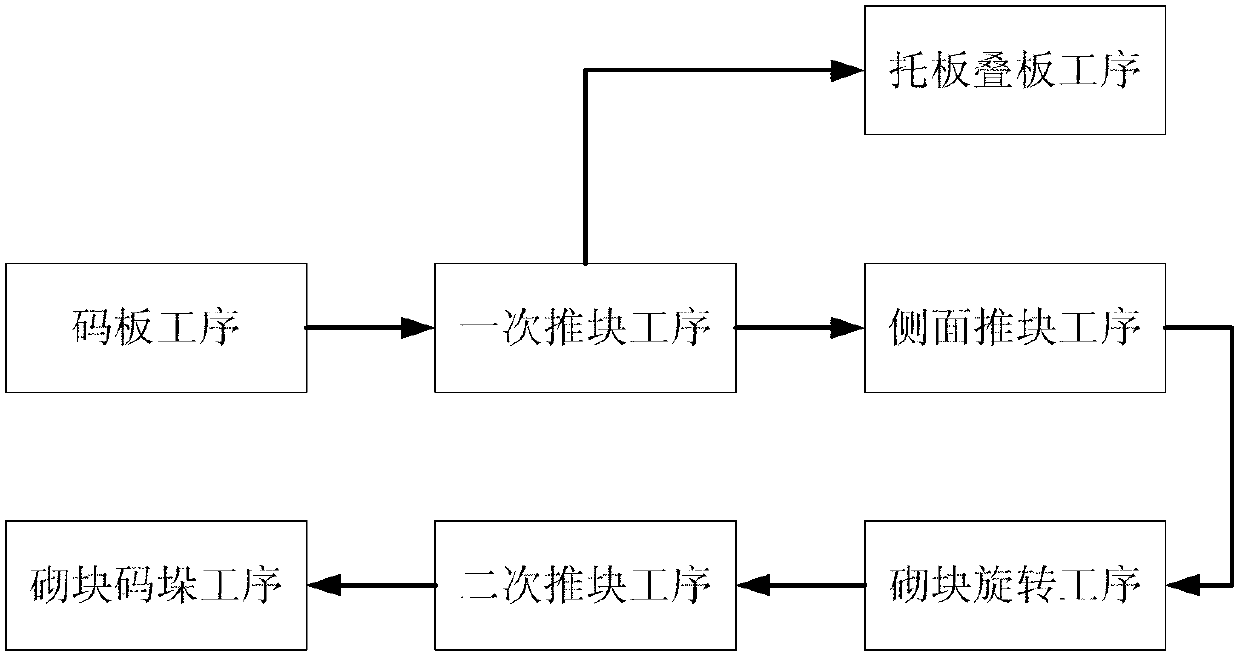

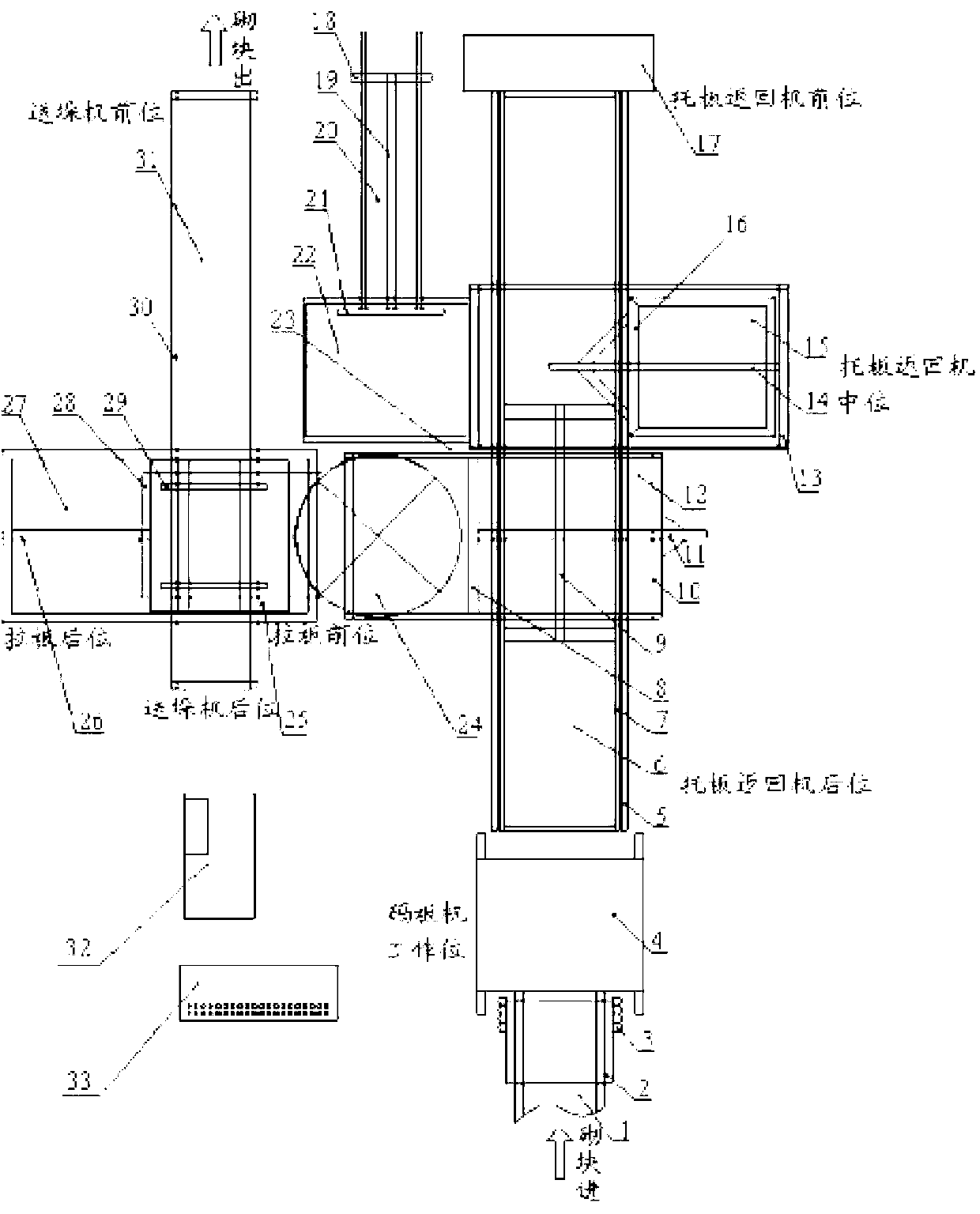

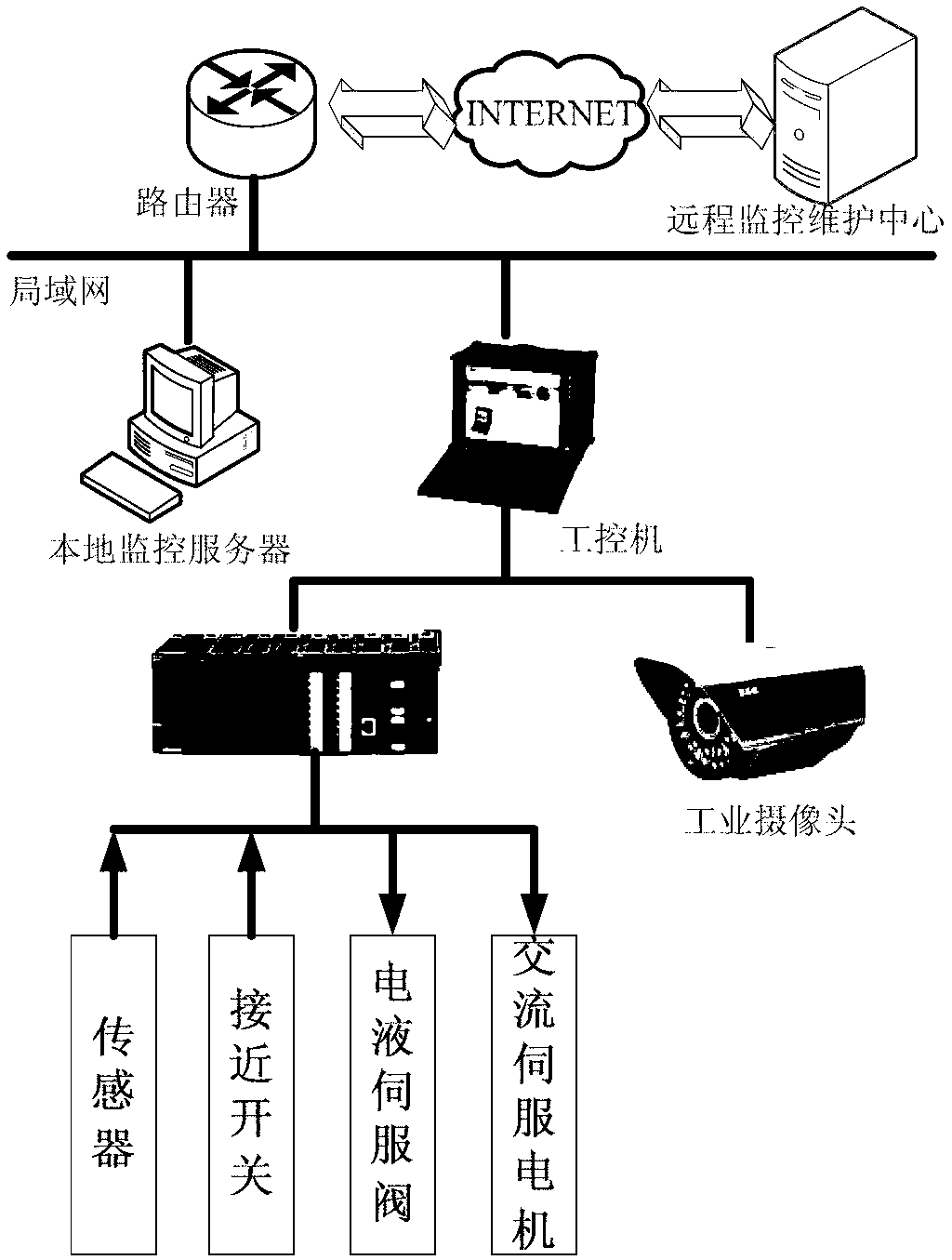

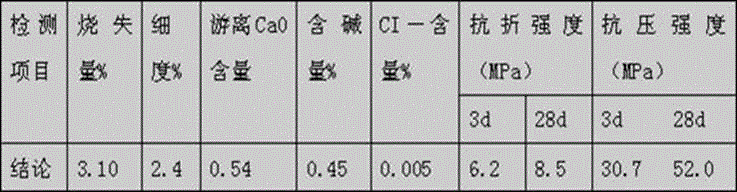

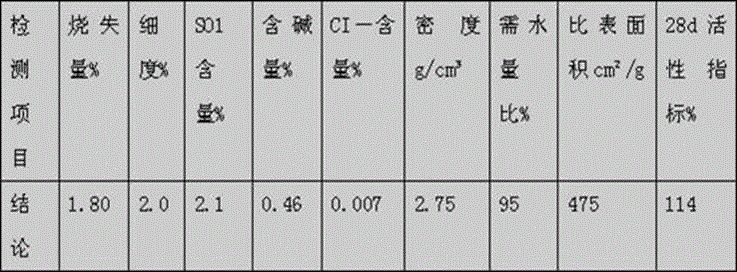

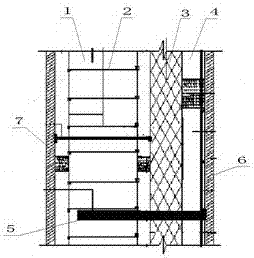

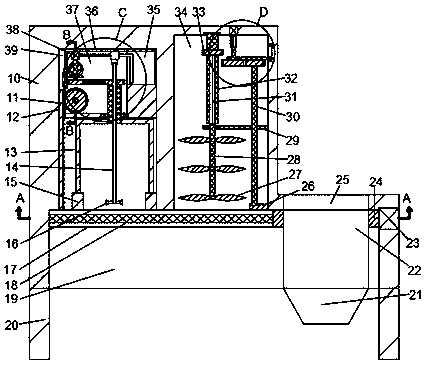

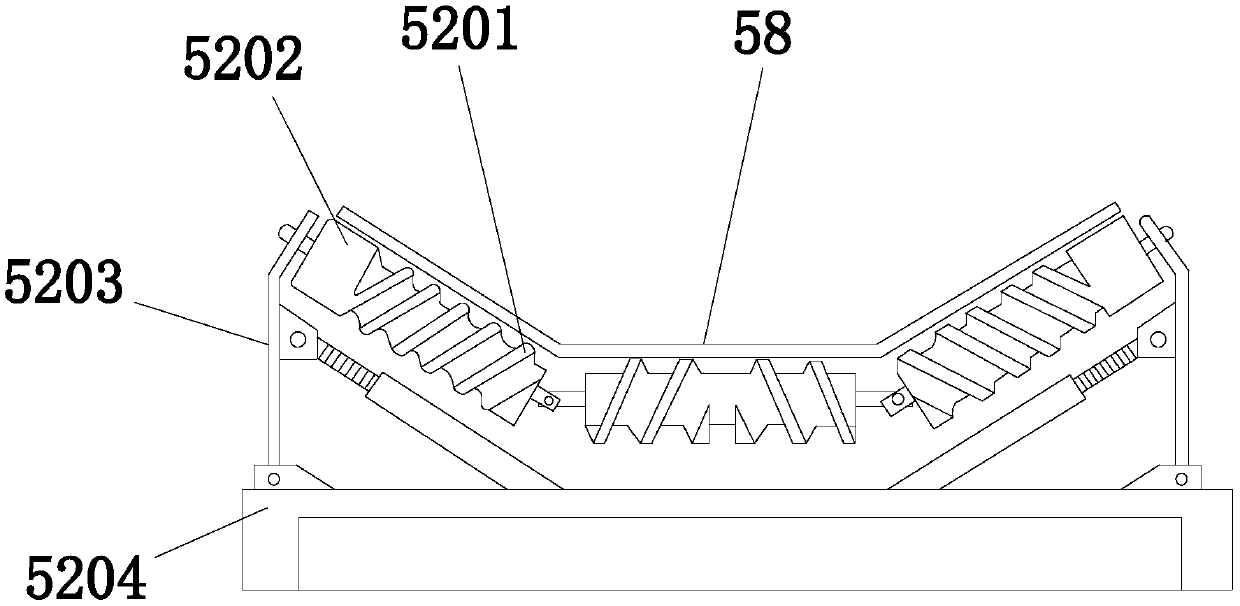

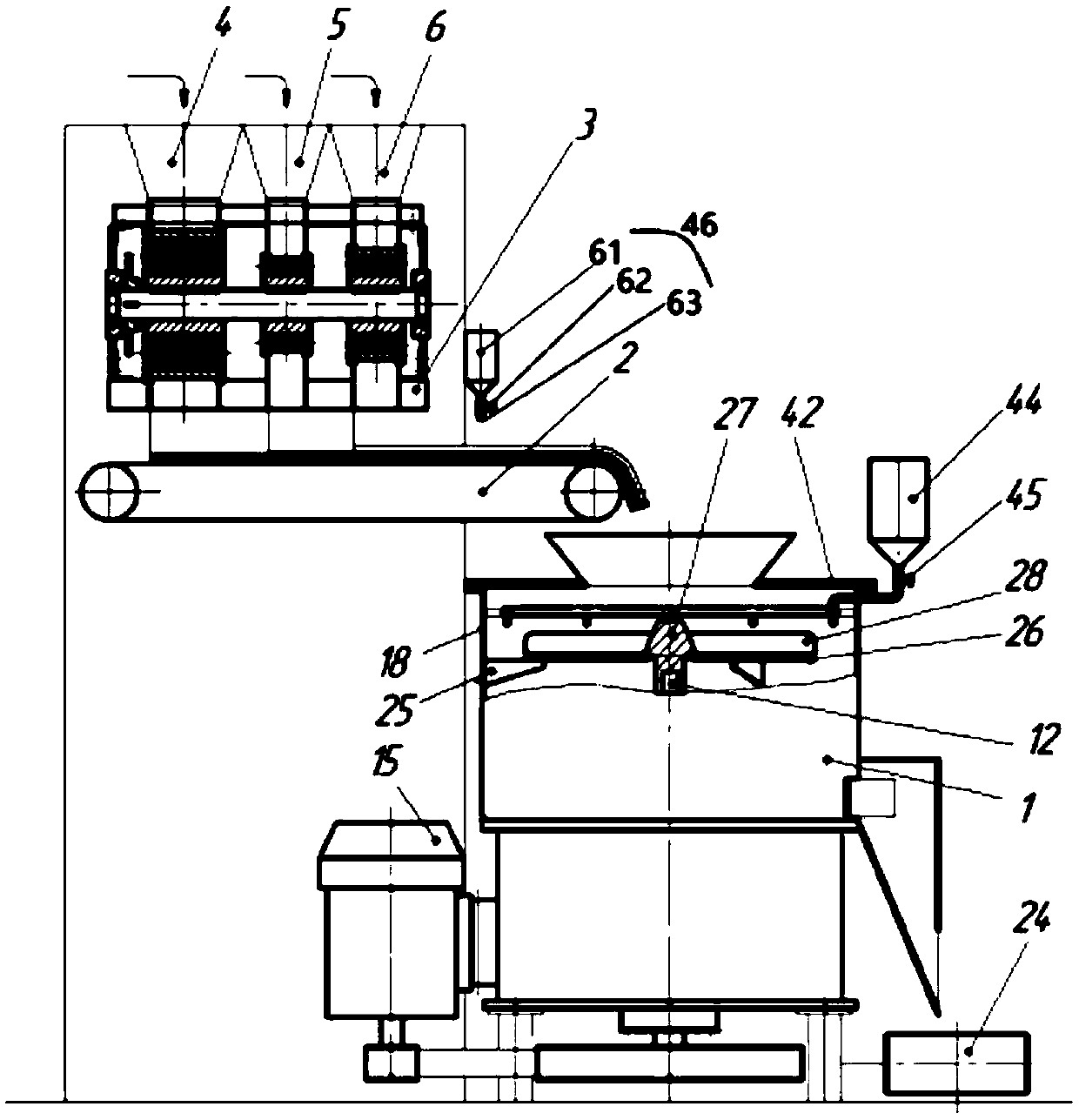

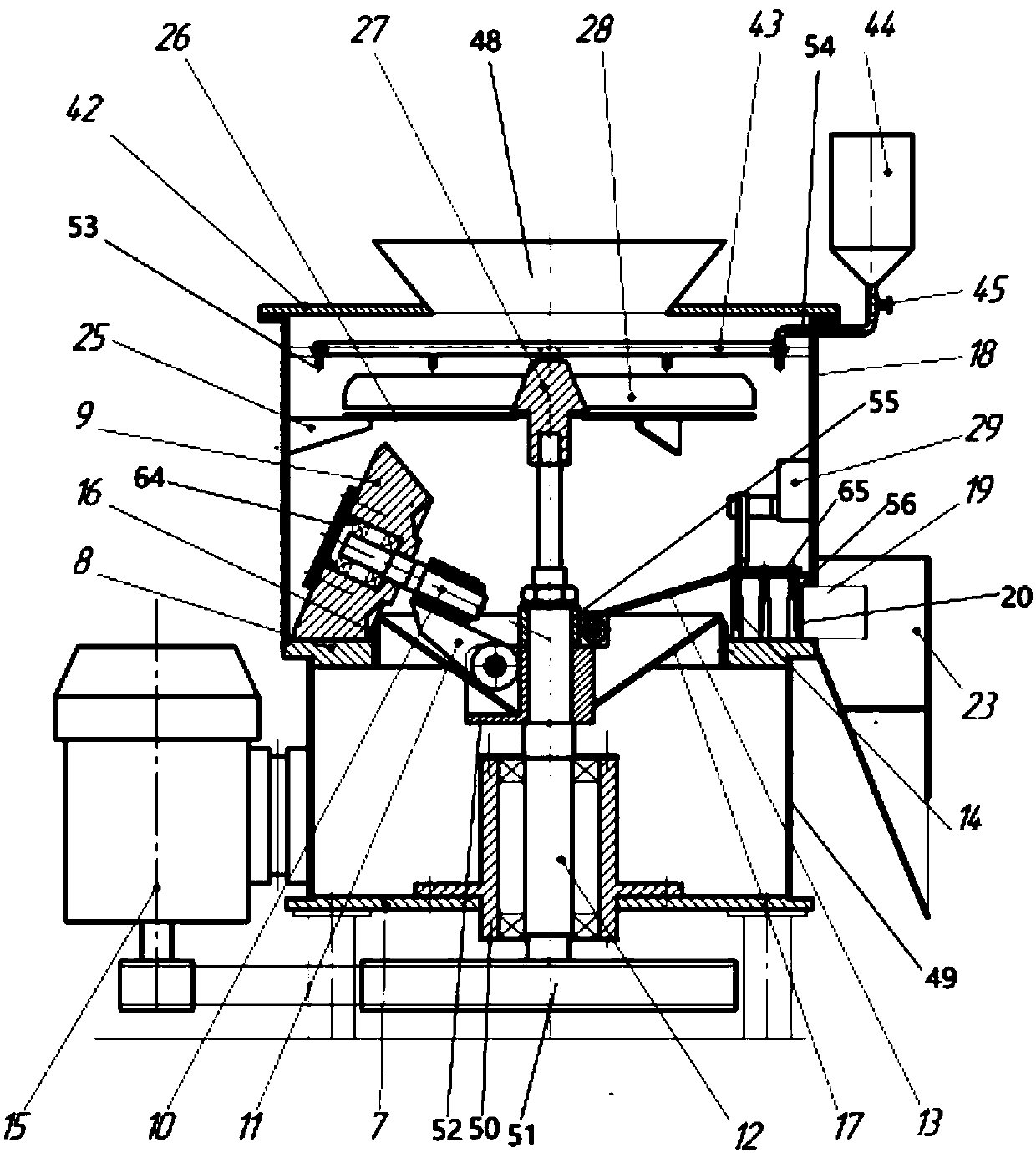

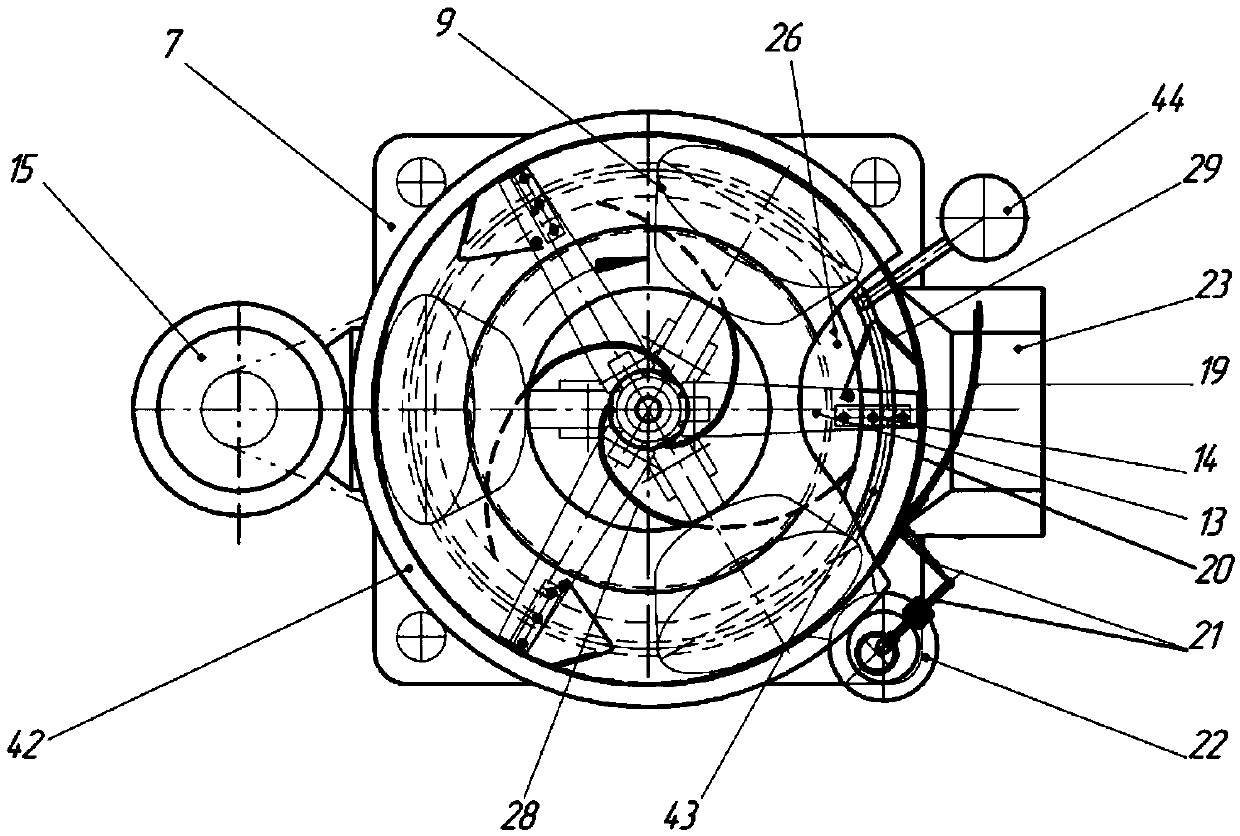

Automatic stacking device of concrete blocks and stacking process thereof

InactiveCN103213849ALow technical requirementsRealize automatic staggered palletizingStacking articlesMechanical conveyorsStack machineProgrammable logic controller

The invention discloses an automatic stacking device of concrete blocks and a stacking process thereof. The device mainly comprises a layer board returner which separates the layer boards and the concrete blocks, a primary block stacking machine, a side stacking machine which transfers the concrete blocks to a on a rotary table, the rotary table which rotates the concrete blocks at 90 degrees, a secondary block stacking machine which transfers the concrete blocks from the rotary table to the inner side of a hydraulic clamp, a stacking platform which stacks the concrete blocks and a palletizing machine which recovers the layer boards. According to the invention, an industrial personal computer and a PLC (Programmable Logic Controller) are used as a core of a control system, and an industrial camera and the Ethernet are used for site and remote monitoring, so that high automation of the concrete block stacking process is realized. The device is of strong adaptability to different types of concrete blocks and production sites, and the labor intensity of workers is remarkably reduced, and the efficiency and quality of concrete block production are improved.

Owner:NANJING UNIV OF SCI & TECH +1

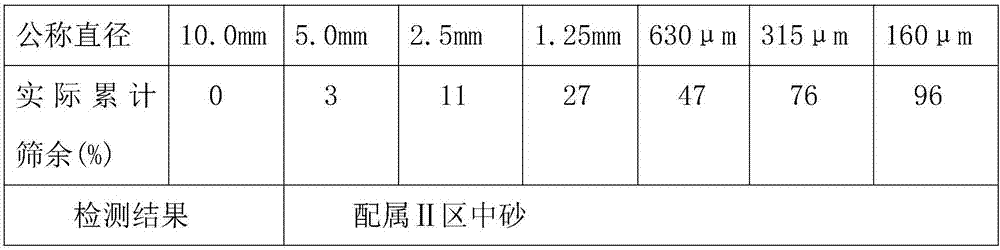

Sulfate-resistant concrete

The invention belongs to the technical field of concrete of constructional engineering, and provides a sulfate-resistant concrete for solving the problems that, in the sulfate ion severely corroded environment, concrete structure is easy to destroy, service life of the concrete is reduced, but mixing amount of the existing compound concrete antiseptic is 4% of usage amount of cementitious material, proportion is too low, antiseptic effect is difficult to realize, or various types of concretes are used in actual application, under the condition of improper control on the antiseptic, technical effects cannot be satisfactory if adding proportion is inappropriate. The sulfate-resistant concrete is prepared from the cementitious material, sand, broken stones, cement, pelletized blast furnace mineral powder 95#, silica fume, fly ash, antiseptic, water-reducing agent, corrosion inhibitor and air entraining agent according to certain proportion. The sulfate-resistant concrete has the strength of C35 standard, effectively prevents damage caused by external force and inner stress, resists corrosion of sulfate ions, and has good compactness and anti-penetrability performance, thus, durability of the concrete is increased and service life of the concrete is prolonged. The sulfate-resistant concrete is safe and reliable, and completely overcomes corrosion of sulfate ions.

Owner:CHINA SHANXI SIJIAN GRP

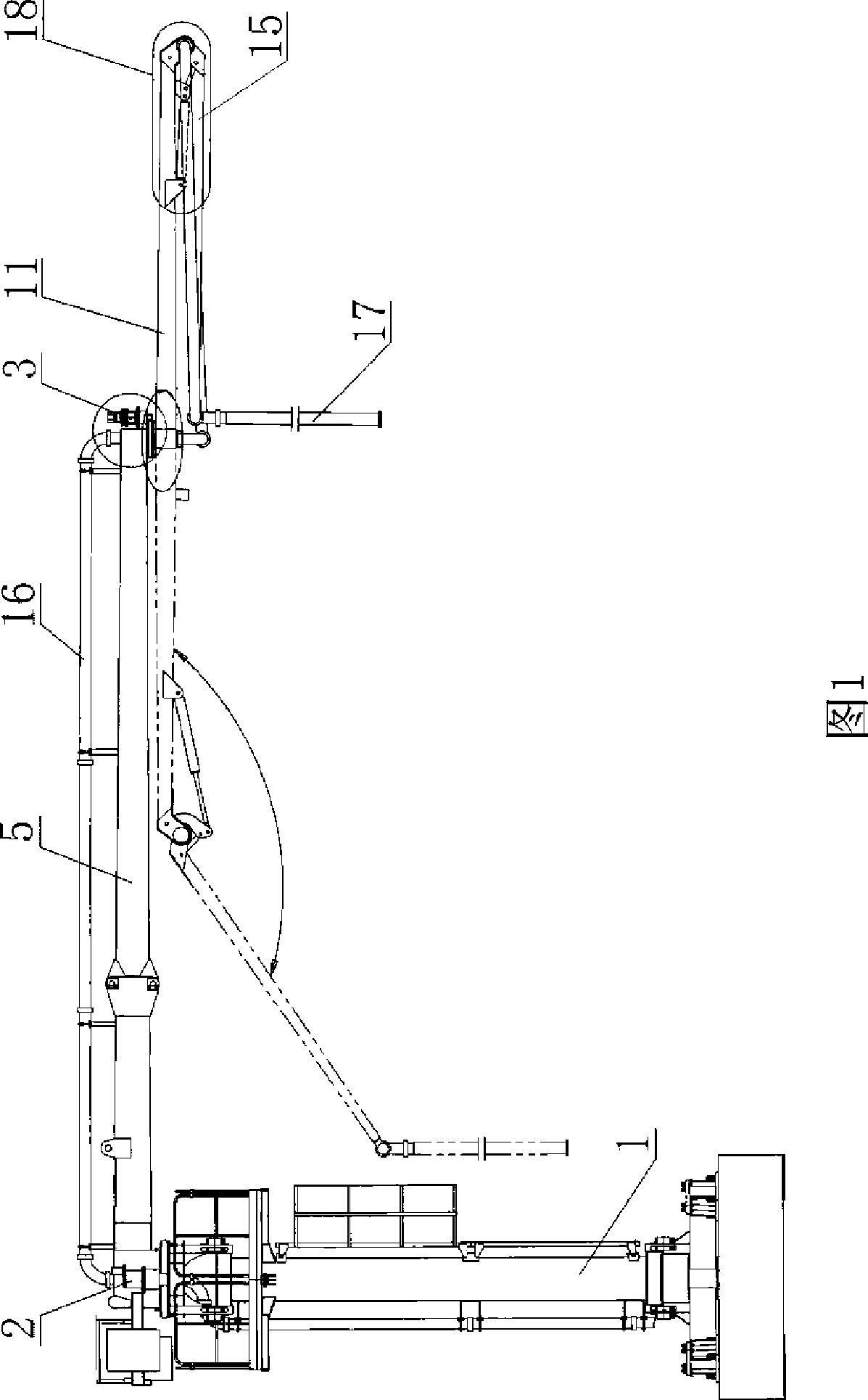

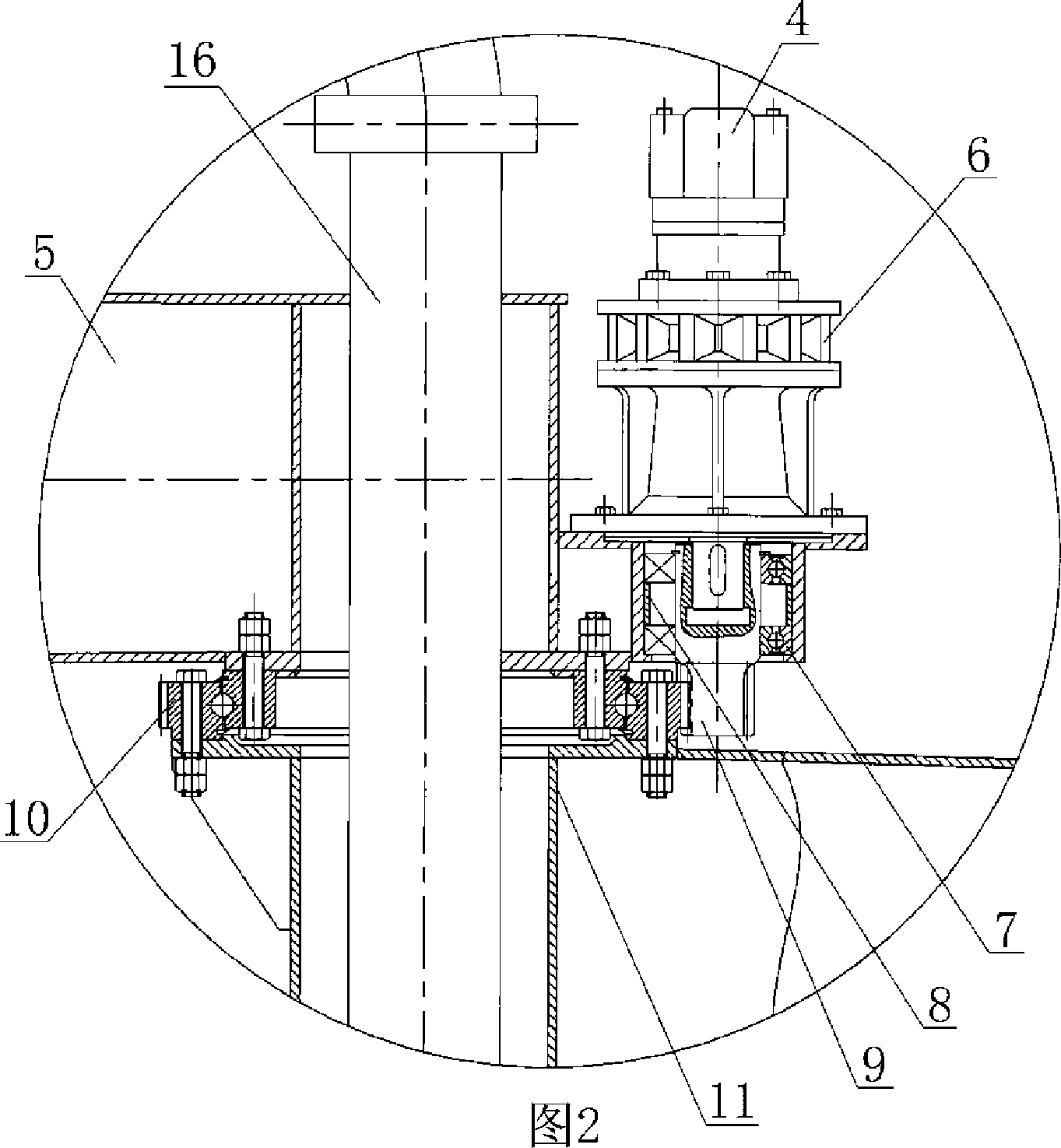

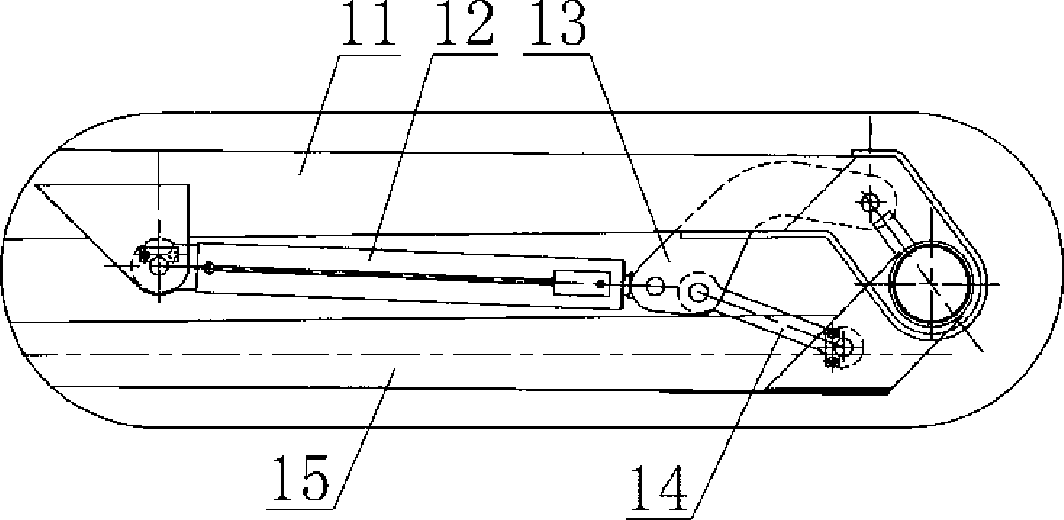

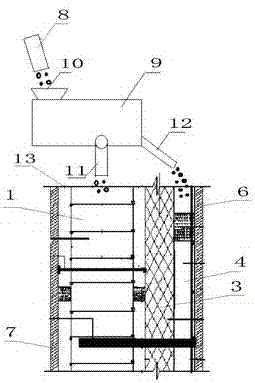

Concrete distributor with arm support capable of both horizontal rotation and pitching movement

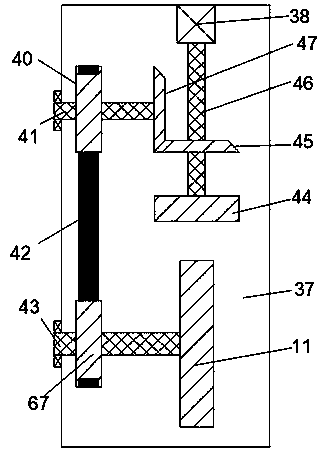

InactiveCN101446134AImproved single job formImprove the form of workBuilding material handlingSupporting systemOperation mode

The invention provides a concrete distributor with an arm support capable of both horizontal rotation and pitching movement. The concrete distributor comprises a tower body support and an arm support system connected in parallel with a concrete pumping pipeline. The head end of the arm support system is rotationally connected with the tower body support in horizontal rotation manner via a first horizontal rotation mechanism. The concrete pumping pipeline comprises a feeding pipe and a discharge nozzle. The arm support system is formed by the tail-to-head connection of a large arm, a middle arm and a small arm, which are in relative movement to one another. The tail end of the large arm is rotationally connected with the head end of the middle arm in horizontal rotation manner via a second horizontal rotation mechanism. The tail end of the middle arm is rotationally connected with the head end of the small arm via a pitching mechanism. The tail end of the small arm is connected with the discharge nozzle. Since the arm support system is capable of both horizontal rotation and pitching movement, the concrete distributor incorporates the horizontal operation and the vertical operation, integrates the advantages of the prior two types of concrete distributors, improves the single operation mode of the prior concrete distributor, and substantially overcomes the problems of the prior two types of concrete distributors.

Owner:CABR CONSTR MACHINERY TECH +1

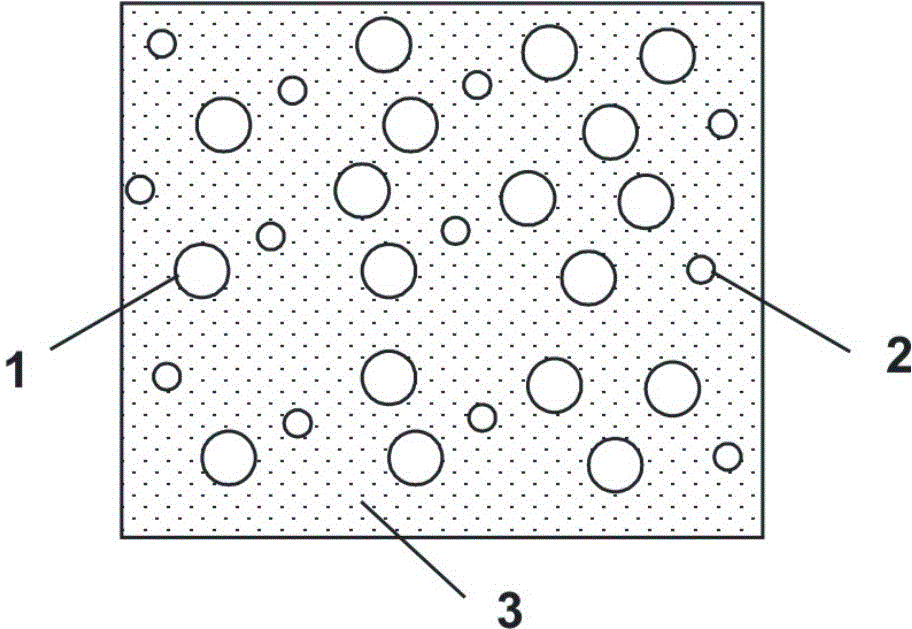

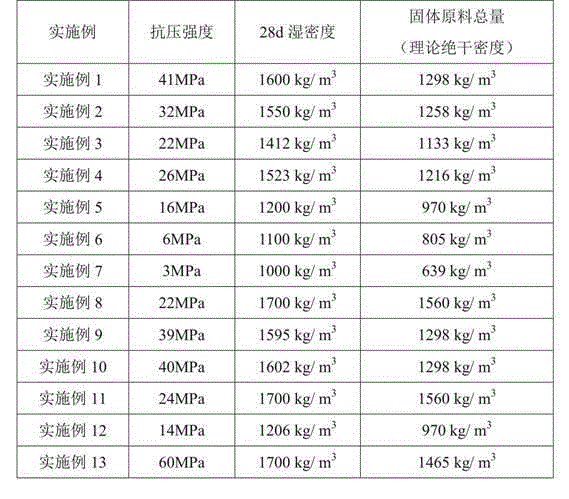

Water absorbent swelling resin aggregate concrete and preparation method thereof

The invention relates to a water absorbent swelling resin aggregate concrete and a preparation method thereof. The water absorbent swelling resin aggregate concrete is prepared by blending the following raw materials by weight through a certain preparation process: 300-420 portions of cement, 186-306 portions of an admixture, 0-624 portions of a water absorbent swelling aggregate, 0-954 portions of a fine aggregates, 87-131 portions of mixing water, 11-14 portions of a water reducing agent and 1.8-2.2 portions of a fiber. The invention employs spherical polymer water absorbent resin particles as the water absorbent swelling resin aggregate; a type of concrete with controllable internal pore structure is prepared by controlling the size of the water absorbent swelling aggregate; the inside of the concrete comprises closed spherical pores with regular shape and in uniform distribution, and has the advantages of low density, strength high, good performance and saving of concrete solid material; besides, the water absorbent swelling aggregate before absorption has small volume, light weight, and is convenient for transportation.

Owner:WUHAN UNIV OF TECH

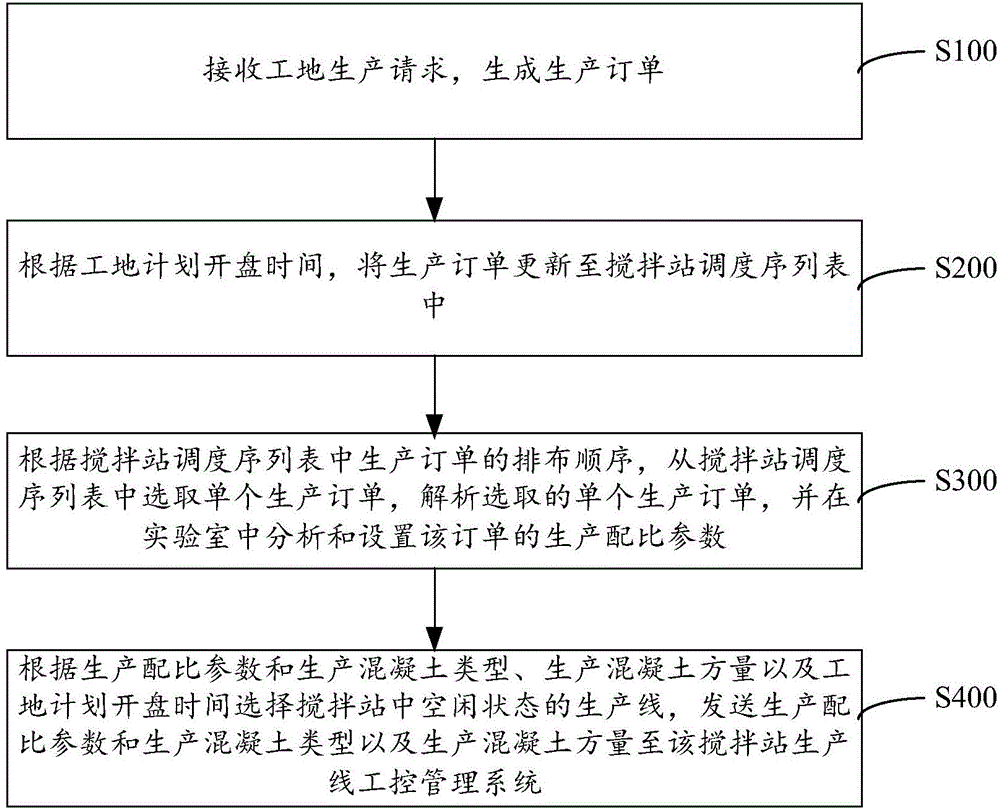

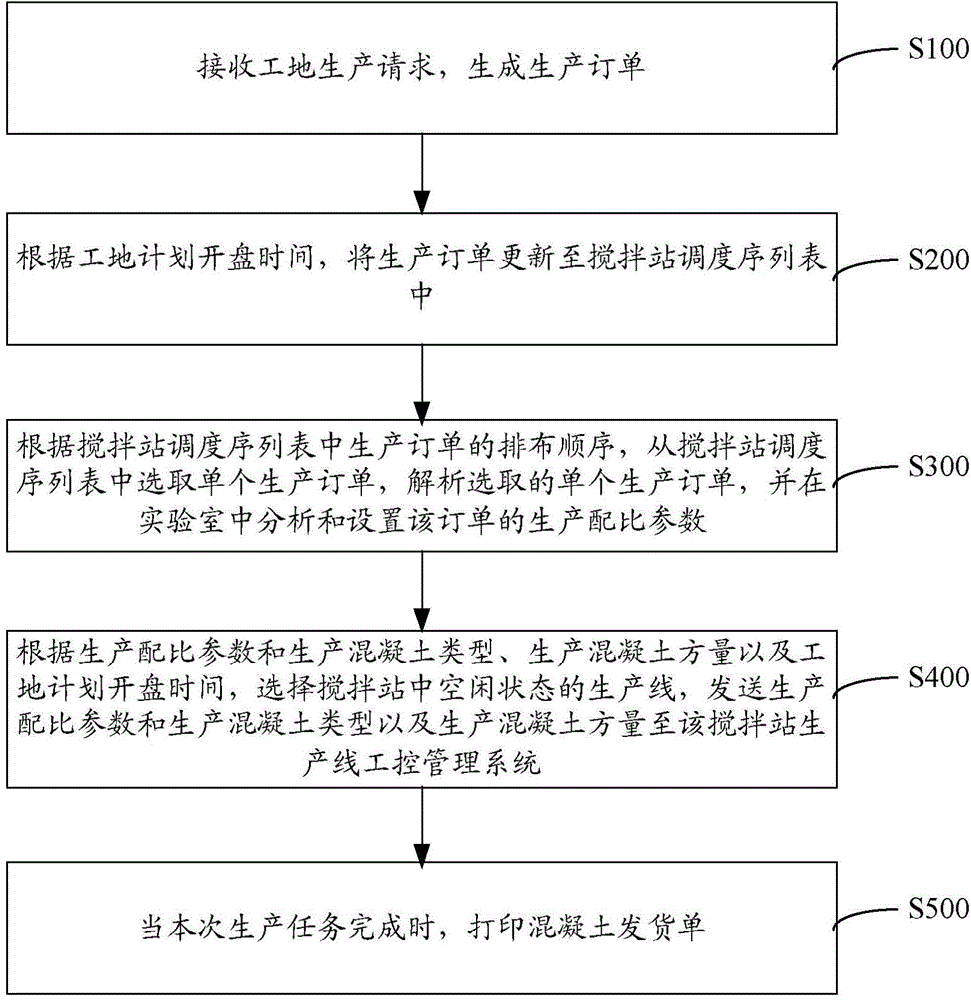

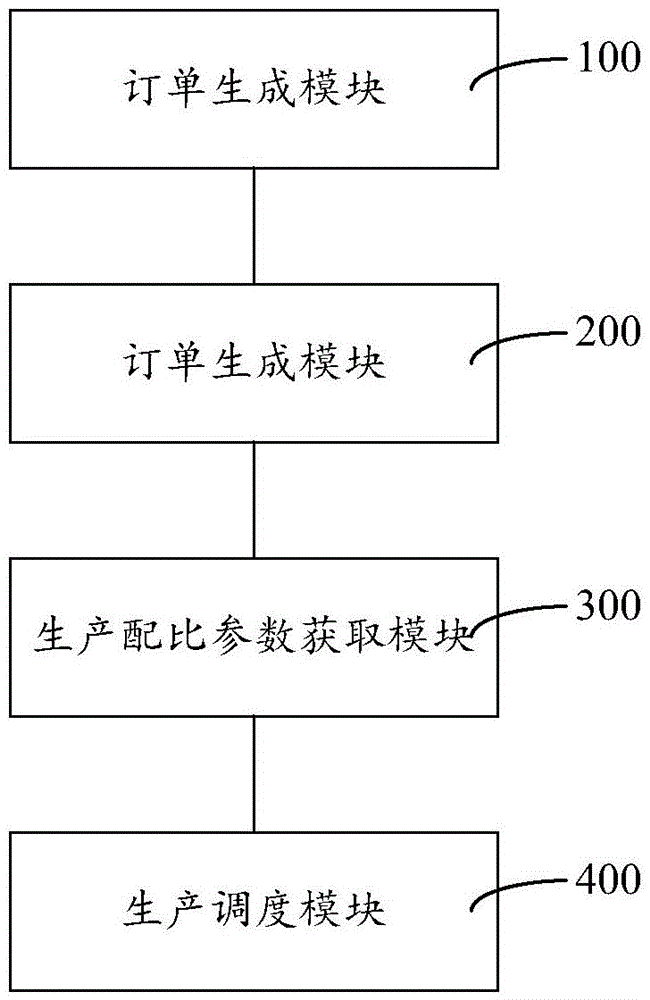

Production scheduling method and system for mixing plant

InactiveCN104573943ANormal productionProduction scheduling is normalResourcesTypes of concreteManagement system

The invention provides a production scheduling method and system for a mixing plant. According to the production scheduling method, production requests of construction sites are received, production orders are generated, and the production orders are updated in a scheduling list of the mixing plant according to planned opening time of the construction sites; a single production order is selected and analyzed, the production proportional parameters of the order are analyzed and set in a laboratory, the production proportional parameters, produced concrete type and produced concrete cubic meters are sent to a mixing plant industrial control management system, and a mixing plant production line for executing the production task is selected. In the production scheduling process in the whole mixing plant, the production orders can be received automatically without too many operators for control, coordination work with mixing plant industrial control management can be realized, the production line meeting the production task requirements is selected in the mixing plant for concrete production, good production scheduling of the mixing plant is realized, and normal and efficient production of the mixing plant is guaranteed.

Owner:HUNAN WANWU IND SOFTWARE

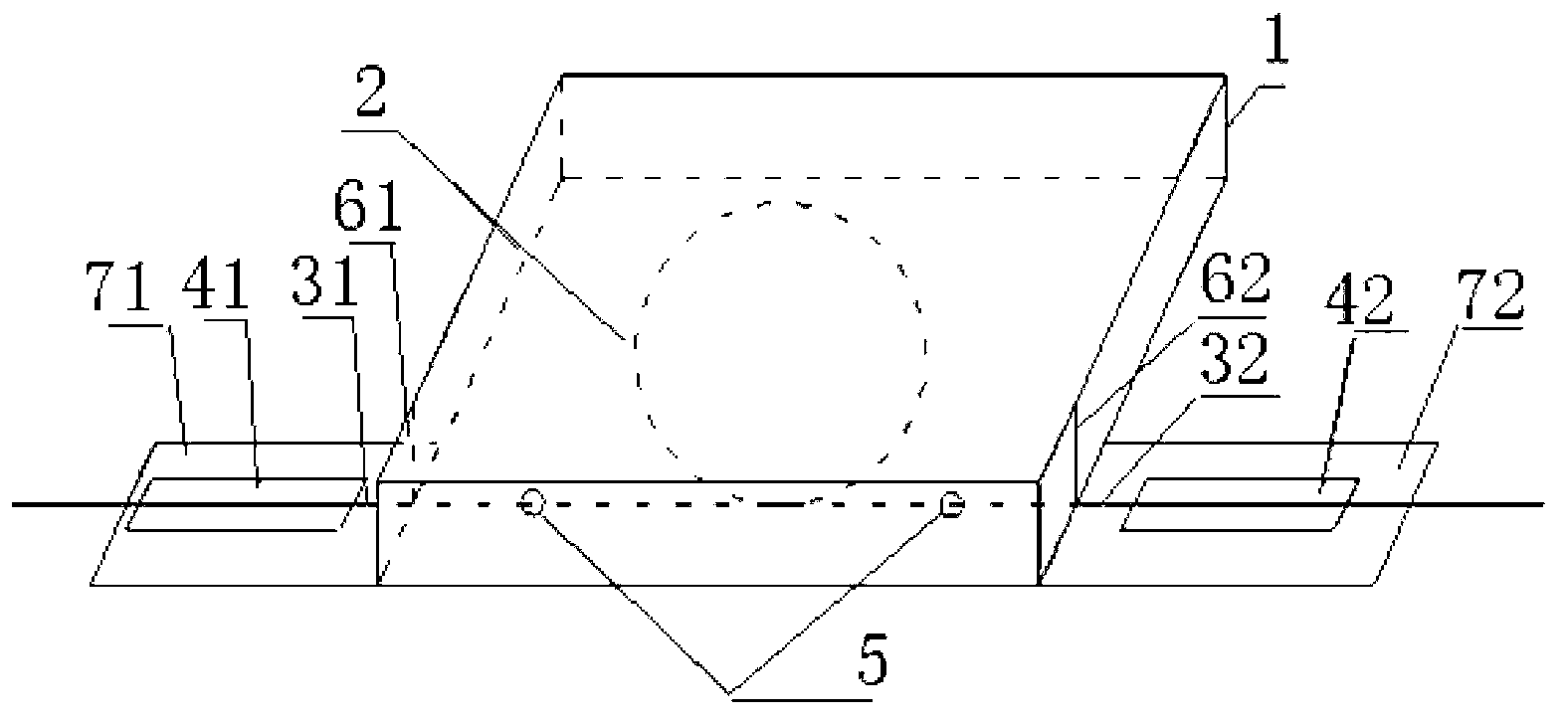

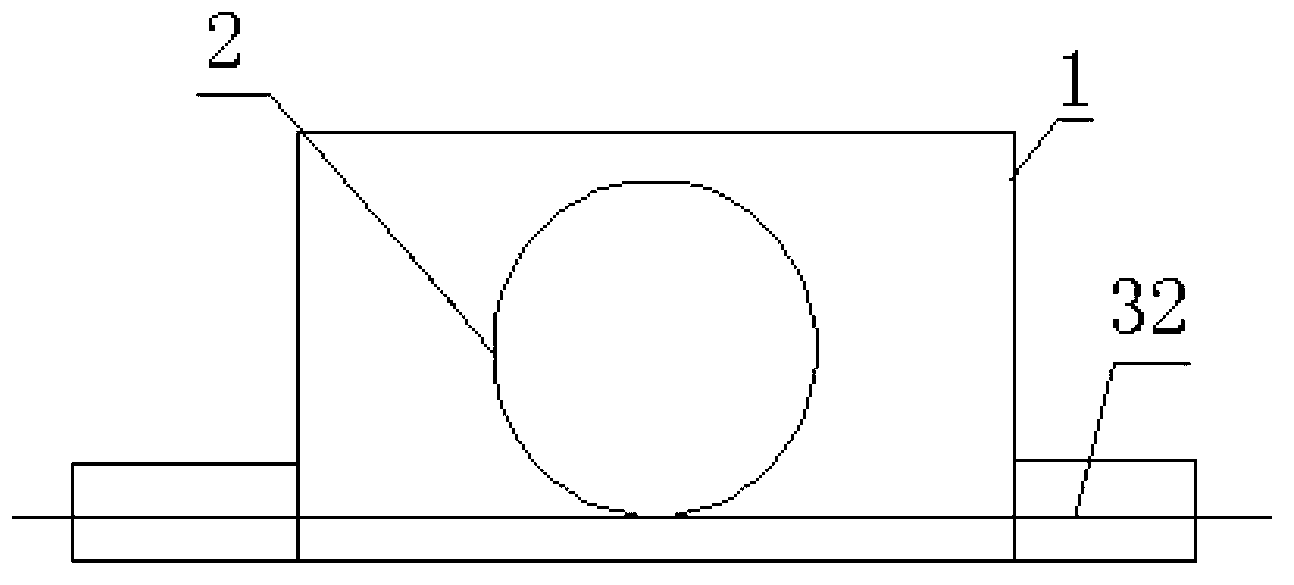

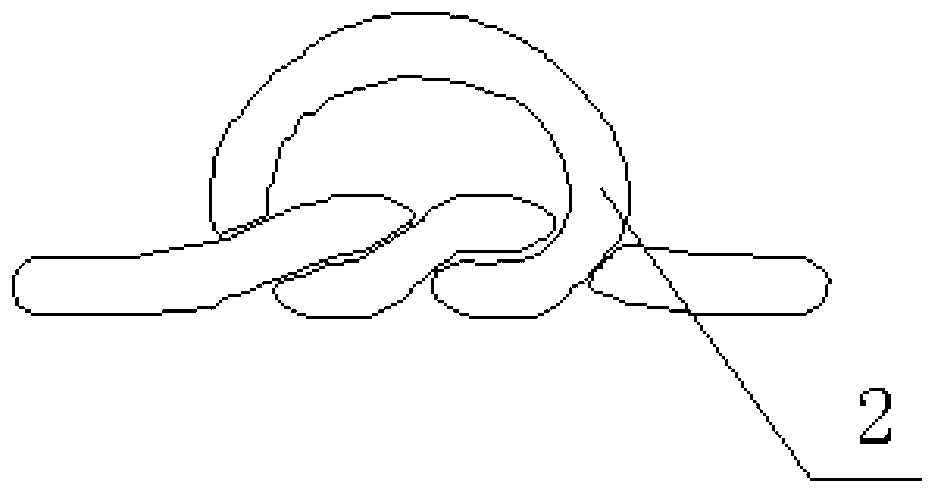

Crack monitoring sensor and use method thereof based on OTDR (optical time domain reflectometry) technique

InactiveCN103217109ARealize dynamic monitoringRealize distributed monitoringOptically investigating flaws/contaminationUsing optical meansEpoxyBare fiber

The invention relates to a crack monitoring sensor and use method thereof based on an OTDR (optical time domain reflectometry) technique, and belongs to the technical field of monitoring of optical fibers. The crack monitoring sensor comprises a protection box, a bare optical fiber coil, a first optical fiber with a protecting layer, and a second optical fiber with a protecting layer, wherein the bare optical fiber coil is provided with two end joints, the bare optical fiber coil is an optical fiber coil which is formed by winding and knotting a bare optical fiber, and the diameter of the bare optical fiber coil is 14mm to 16mm. When the crack monitoring sensor is used, firstly, the outer optical fiber of the sensor is welded with the first optical fiber with the protecting layer and the second optical fiber with the protecting layer through the end joints, secondly, the adhering function of epoxy resin adhesive is released by an adhesive release agent, so that the inner optical of the sensor is ensured to be freely stretched along with the extension of the crack, and then the concrete is cast. The crack monitoring sensor and the use method have the advantages that the construction is convenient, the manufacturing is simple, the cost is low, the crack monitoring sensor and the use method are suitable for monitoring the cracks of various types of concrete inner structures, meanwhile, the operability is high, and the real-time monitoring and the distributed monitoring on the concrete inner structures are realized.

Owner:HOHAI UNIV

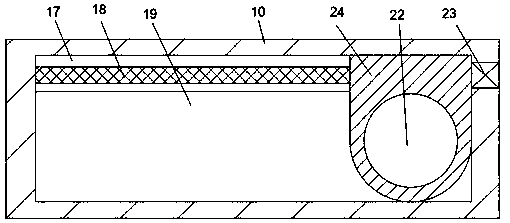

Concrete pouring method of concrete heat insulating curtain wall

InactiveCN106869503AAvoid displacementMeet the design requirementsBuilding material handlingSurface layerHeight difference

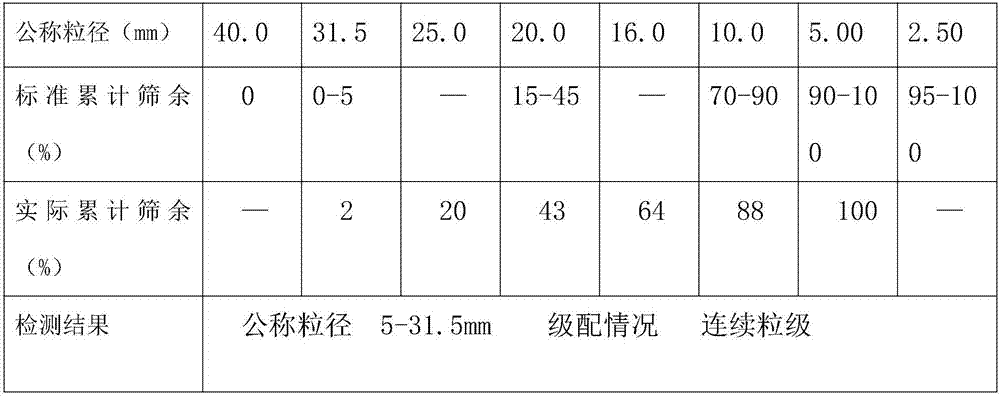

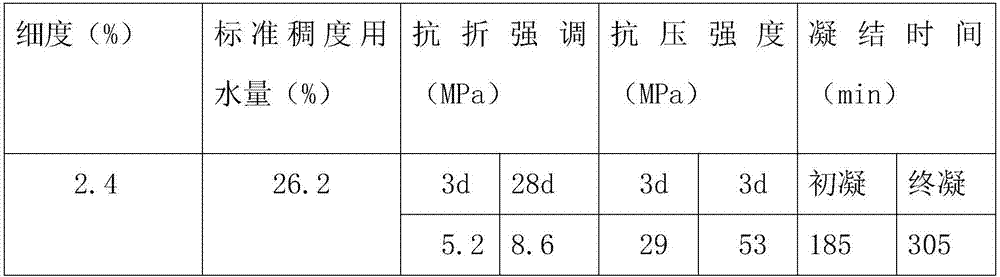

The invention relates to a building construction method, in particular to a concrete pouring method of a concrete heat insulating curtain wall. The method comprises the following steps that (1) concrete is prepared, specifically, according to the thickness of structural concrete and surface layer concrete, the aggregate particle size of the concrete adopts segmentation continuous grading, the amount of stones with the particle size of 5-10 mm accounts for 15-20% of the total amount of stones, the amount of stones with the particle size of 10-30 mm accounts for 80-85% of the total amount of stones, and the slump of concrete stirring material is 160-180 mm; and (2) concrete is poured, specifically, the prepared concrete is injected into concrete separation equipment through a concrete pump pipe, the concrete separation equipment produces two types of concrete of large and small different particle sizes, the stone concrete of with the particle size of 5-10mm enters a template of one side of the surface layer concrete through a fine aggregate outlet, the stone concrete of the particle size of 10-30mm enters the template of one side of the structural concrete through coarse aggregate outlet, and the height difference of the concrete on the two sides is observed and is not more than 200 mm during pouring. According to the concrete pouring method of concrete heat insulating curtain wall, a set of concrete pouring equipment is adopted, simultaneous casting of two types of concrete in a working face is achieved, and the effect that the concrete strength and the structural size met the design requirements is ensured.

Owner:河南省华亿绿色建材有限公司

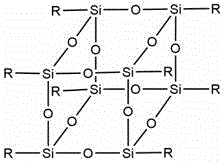

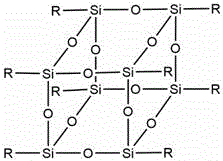

POSS (Posspolyhedral Oligomeric Silsesquioxane) containing construction engineering waterproof coating and preparation method thereof

The invention belongs to the technical field of macromolecule fine chemical engineering, and discloses a POSS (Posspolyhedral Oligomeric Silsesquioxane) containing construction engineering waterproof coating and a preparation method thereof. The preparation method comprises the following step: polymerizing vinyl-containing POSS and fluorine-containing metacrylic acid ester, thereby obtaining a POSS-containing fluorine-containing metacrylic acid ester polymer, wherein the vinyl-containing POSS is vinyl-containing polyhedron polysilsesquioxane. The polymer disclosed by the invention is good in weather resistance, very good in adhesion property and permeability on building materials such as concrete, good in waterproof effect and applicable to waterproof operation of various types of concrete construction engineering.

Owner:UNIT 61489 OF PLA

Alkali-activated industrial waste residue marine coral aggregate concrete and preparation method thereof

ActiveCN110451853ARealize resource reuseSolve processing problemsBULK ACTIVE INGREDIENTTypes of concrete

The invention discloses an alkali-activated industrial waste residue marine coral aggregate concrete and a preparation method thereof. The concrete is is prepared from mixing industrial waste residue,coral sand, coral reef stone, seawater and alkali activator. The ratio of active ingredient of alkali activator to industrial waste residue, that is, the amount of alkali added is 12%-16%. The alkali-activated industrial waste residue marine coral aggregate concrete not only realizes the resource reuse of the industrial waste residue, solves that problem of industrial waste residue treatment andat that same time, utilizes island-specific material such as coral reef sand and solves the problem of scarcity of traditional building materials in island areas, and realizes the complete substitution of Portland cement in concrete processing, the use of cement is greatly reduced and the carbon emission is correspondingly reduced, and the slump degree of the prepared alkali-activated industrial waste residue seawater coral concrete is up to 210 mm, the compressive strength is over 50 MPa in 28 days and the tensile-compressive ratio is up to 0.086, the strength of the concrete is better than that of the same type of concrete on the market at present, which is in line with the actual engineering application.

Owner:OCEAN UNIV OF CHINA

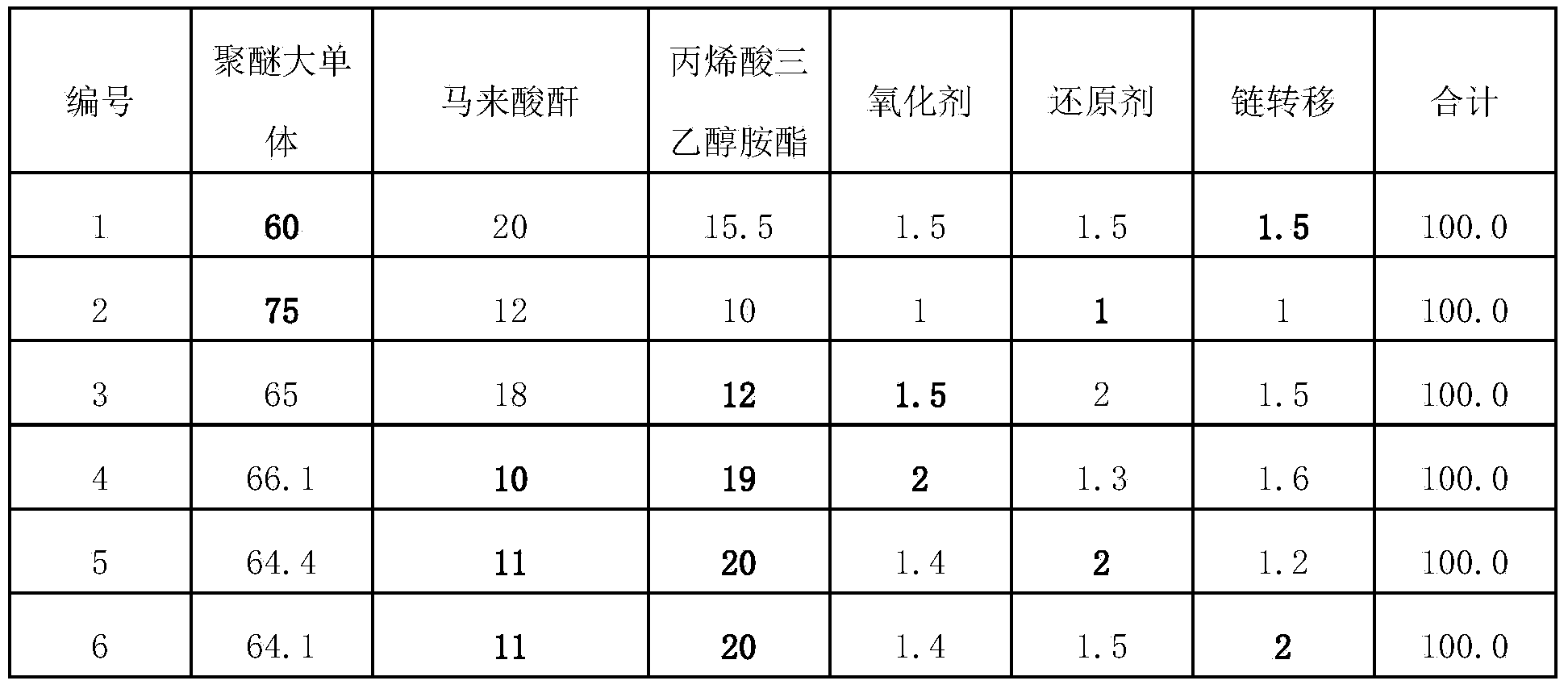

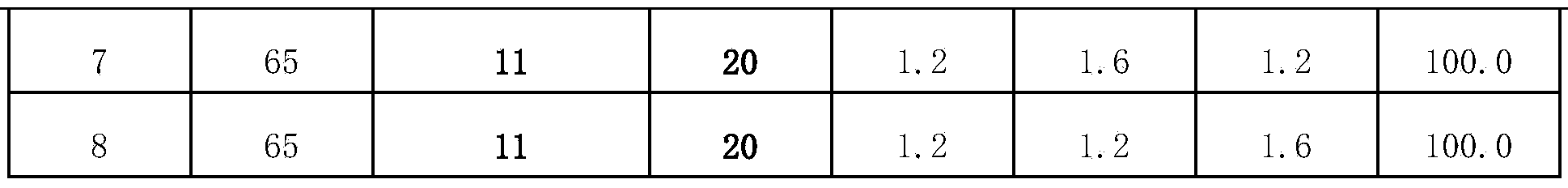

Preparation method of triethanolamine modified early-strength polylactic acid water-reducing agent

The invention relates to a preparation method of a triethanolamine modified early-strength polylactic acid water-reducing agent. The preparation method comprises the following steps: 1) selecting raw materials: selecting the raw materials; 2) stirring and dissolving polyether macromonomer, maleic anhydride and acrylic acid triethanolamine ester to obtain a uniform solution, further adding an oxidizer, and stirring to obtain the uniform solution; 3) adding a mixture of a reducer and a chain transfer agent into the uniform solution obtained in the step 2) once, and continuously stirring to obtain the early-strength polylactic acid water-reducing agent. The preparation method provided by the invention mainly has the following advantages: 1) the water-reducing rate is high, cement particles can be effectively dispersed, and the degree of hydration is improved; 2) triethanolamine can be released slowly so as to further promote hydration, improve early strength and prevent affecting the initial fluidity of slurry; 3) one-step method and one-time feeding are adopted, the process is simple, the reaction period is short, and the triethanolamine modified early-strength polylactic acid water-reducing agent can be used as an auxiliary material for being widely applied to various types of concrete.

Owner:WUHAN UNIV OF TECH

Method for researching measured value of concrete slump cone based on critical value comparison method

InactiveCN104614286AImprove bindingDoes not bother cleaningFlow propertiesInvalid DataConversion coefficients

The invention provides a method for researching a measured value of a concrete slump cone based on a critical value comparison method. The method comprises the following steps: measuring concrete with different slumps by using an opening and closing slump cone to obtain each group of measured data, and taking an arithmetic mean value of each group of measured data after excluding invalid data to obtain the slump t measured by the slump cone; repeating the above step to obtain slumps t1, t2, t3... measured by each type of concrete; and combining the slumps t1, t2, t3... measured with a conversion coefficient to obtain a converted slump. The critical value comparison method measures the slump by adopting a precise measuring opening and closing slump cone, so that the measured valve of the slump cone is reliably combined with a code value in the industry.

Owner:NANJING INST OF TECH

High-strength anti-crack concrete and preparation method thereof

InactiveCN107337396AHigh compressive strengthImprove carrying capacityHigh intensityTypes of concrete

The invention discloses high-strength anti-crack concrete and a preparation method thereof. The high-strength anti-crack concrete comprises cement, sand, pebble, water, additives, a cement expansive material and coal ash, wherein the ratios of the raw materials are as follows: 900-1050kg / m<3> of pebble, 250-350kg / m<3> of cement, 630-700kg / m<3> of sand, 150-180kg / m<3> of water, 10-16kg / m<3> of the additives, 8-15kg / m<3> of the cement expansive material and 60-80kg / m<3> of coal ash. The materials are fed and stirred according to formulae, and then different types of concrete are prepared. Due to addition of the concrete expansive material and t he coal ash, the compressive strength and the internal bonding strength of concrete are improved, the crack rate of the concrete is reduced, furthermore the bearing capacity of the concrete is increased, and the service life of the concrete is prolonged.

Owner:宿松县尚鼎建材有限公司

Formulation for Obtaining a Translucent Concrete Mixture

A formulation for obtaining a translucent concrete mixture comprising a mixture of polycarbonate and epoxy matrices, as well as glass fibres, optical fibres, colloidal silica, silica and Portland cement. The invention has greater mechanical strength properties than those of a standard concrete, with lower density and mechanical characteristics that enable same to be used in both a structural and architectonic manner. The formulation used to obtain the translucent concrete mixture comprises a type of concrete that is different from those currently available, which combines the advantages of existing concretes with translucency.

Owner:CONCRETOS TRANSLUCIDOS S DE R L DE C V

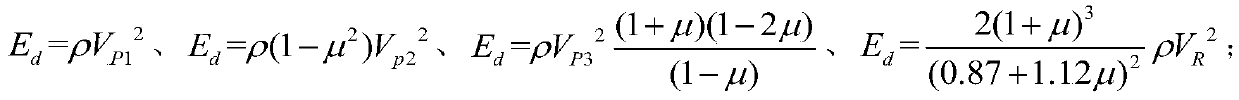

Concrete strength nondestructive test method based on elastic wave

ActiveCN109932423AAccurate testing of compressive strengthIncreased intensityAnalysing solids using sonic/ultrasonic/infrasonic wavesTypes of concreteUltimate tensile strength

The invention discloses a concrete strength nondestructive test method based on an elastic wave. The method successively comprises the following steps of S1, obtaining the elastic modulus of a concrete member to be tested by the elastic wave; S2, introducing the elastic modulus obtained in the step S1 into a relationship between the known elastic modulus and the compressive strength to obtain thecompressive strength corresponding to the elastic modulus obtained in the step S1, wherein the relationship between the known elastic modulus and the compressive strength is a relationship between theknown elastic modulus of a concrete member having the same type as the tested concrete member and the compressive strength. The method can quickly obtain the concrete strength in the concrete structure.

Owner:四川升拓检测技术股份有限公司

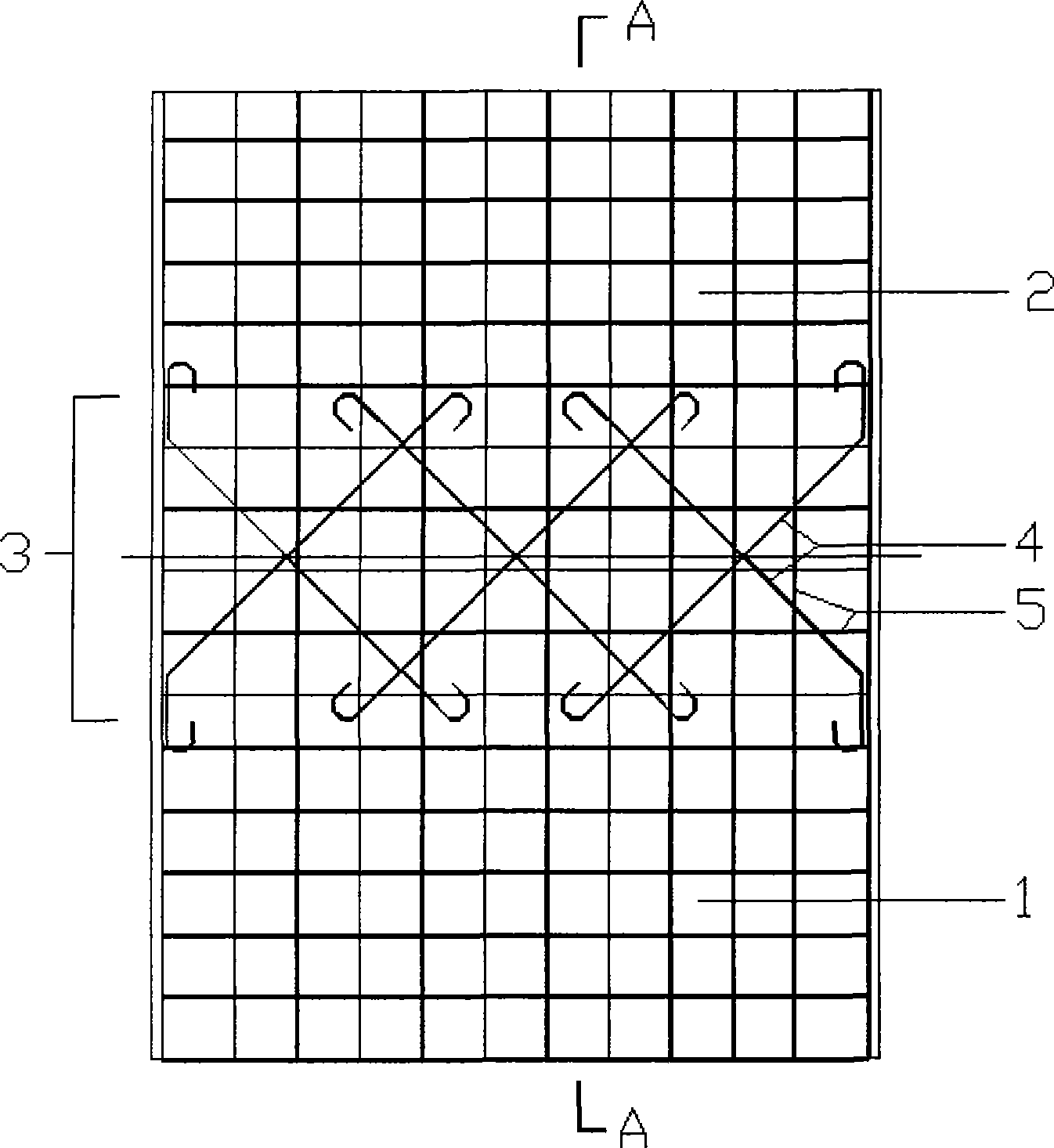

Recycled concrete shear wall with cross reinforcement conversion layer

InactiveCN101451381APrevents shear slippageSimple structural designConstruction materialWallsTypes of concreteRebar

The invention relates to a regenerated concrete shear wall provided with a cross reinforcement conversion layer, which belongs to shear wall structure, wherein the lower part of the shear wall adopts common concrete, and the upper part of the shear wall adopts regenerated concrete; the thickness of the intermediate conversion layer is 3 times that of the shear wall, and an X-shaped reinforced sway brace is arranged inside the intermediate conversion layer; and the reinforced sway brace is connected with a reinforcement mat of the shear wall, and a hidden brace is formed inside the concrete shear wall. The regenerated concrete shear wall provided with the cross reinforcement conversion layer gives full play to the advantages of two types of concrete, and utilizes a regenerated concrete structure to optimize the structural design and guarantee the structural performance. The lower part of the shear wall with larger shearing force adopts the common concrete with stable performance, and the upper part of the shear wall with smaller shearing force adopts the regenerated concrete with slightly poor performance. A cross reinforcement is arranged on the conversion layer of which the stiffness is suddenly changed, so that shearing resistant slippage between different concrete layers can be prevented, and simultaneously variation of the shearing resistant bearing capacity of the shear wall has a transitional process.

Owner:沧州市建筑设计研究院有限公司 +1

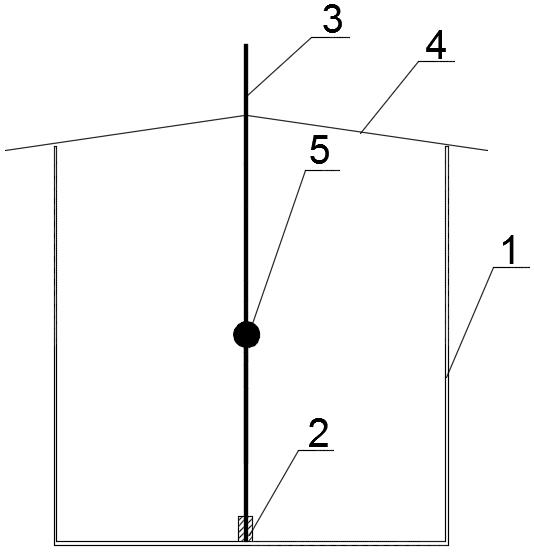

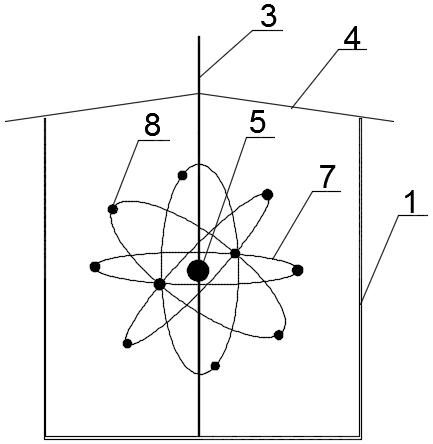

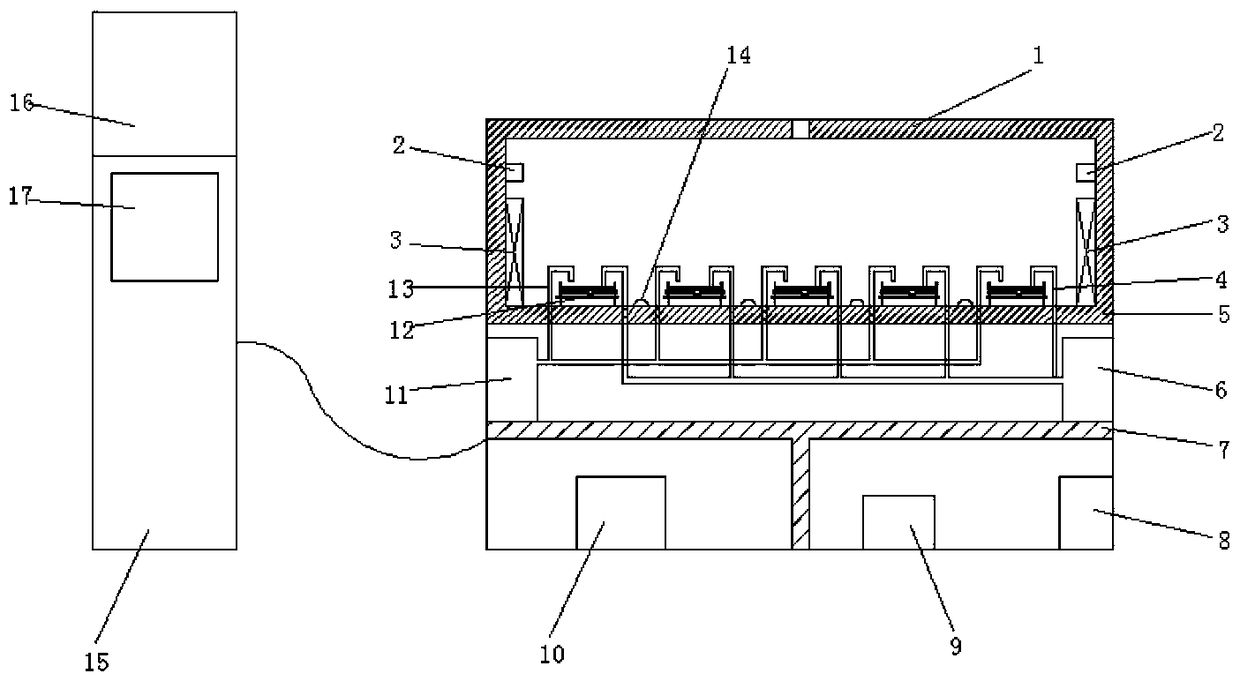

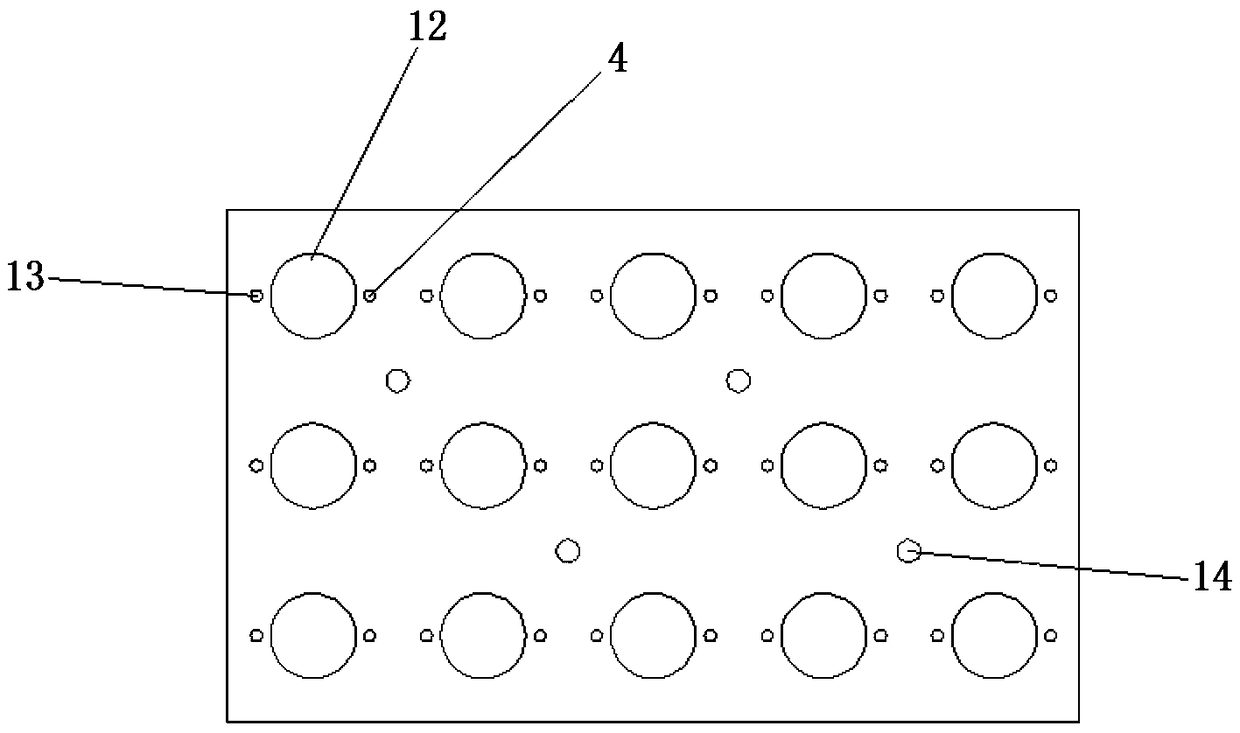

Piezoelectric ultrasonic device for online monitoring of cement concrete hydration process

ActiveCN112305074ANo launch dead angleSensitively measuredAnalysing solids using sonic/ultrasonic/infrasonic wavesClassical mechanicsEngineering

Disclosed is a piezoelectric ultrasonic device for online monitoring of a cement concrete hydration process. The piezoelectric ultrasonic device comprises a container used for containing cement concrete, wherein an opening is formed in the upper portion of the container, and a limiting groove is formed in the bottom wall of the container; and a supporting rod, wherein the upper portion of the supporting rod is provided with a support, the bottom of the supporting rod is located in the limiting groove, the supporting rod is erected in the container through the limiting groove and the support, aspherical piezoelectric ultrasonic sensor is fixed to the supporting rod, and the spherical piezoelectric ultrasonic sensor is located in the center of the container. By utilizing the excellent characteristics of ultrasonic waves and designing sensors for transmitting and receiving ultrasonic signals, the device can be suitable for concrete structures of various different conditions, is wide in application range, and can realize good online monitoring on hydration of different types of concrete.

Owner:UNIV OF JINAN

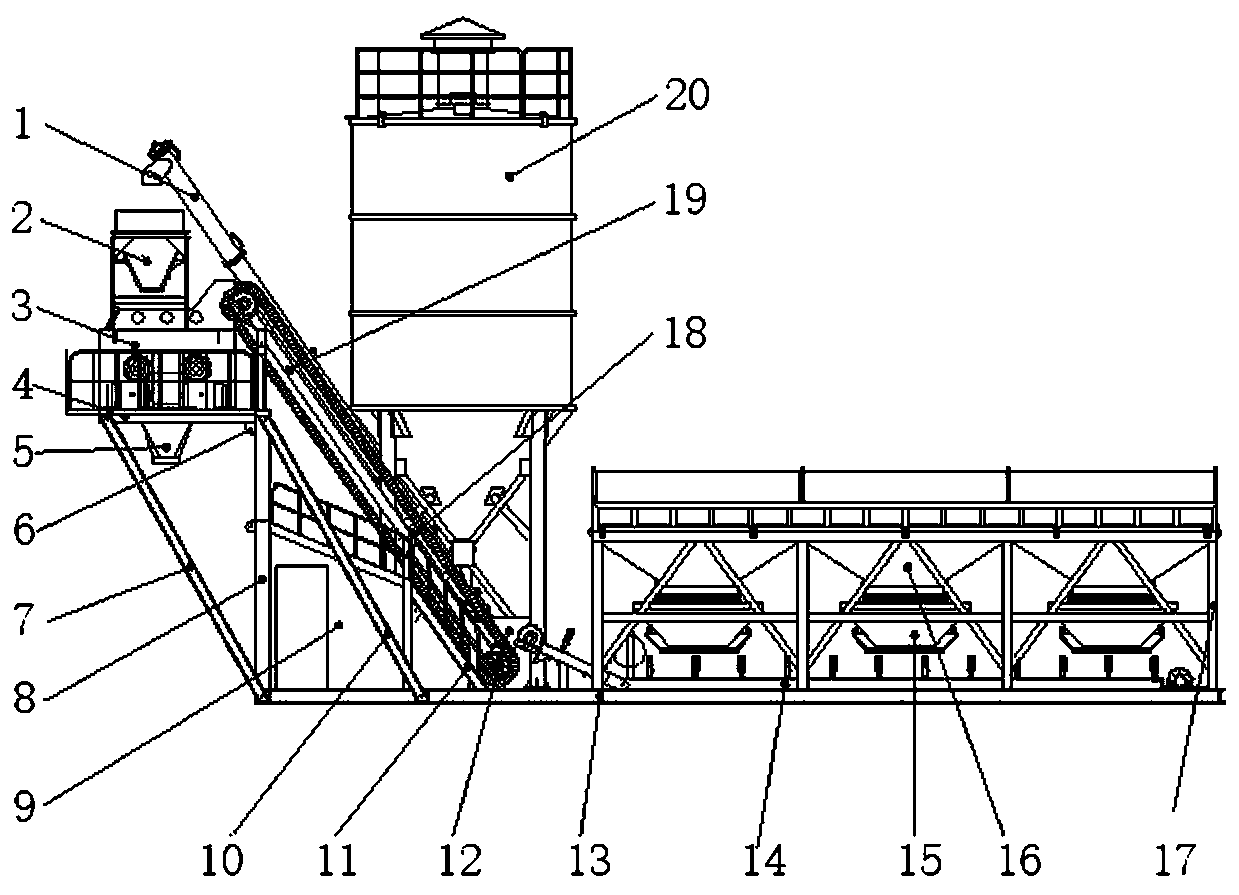

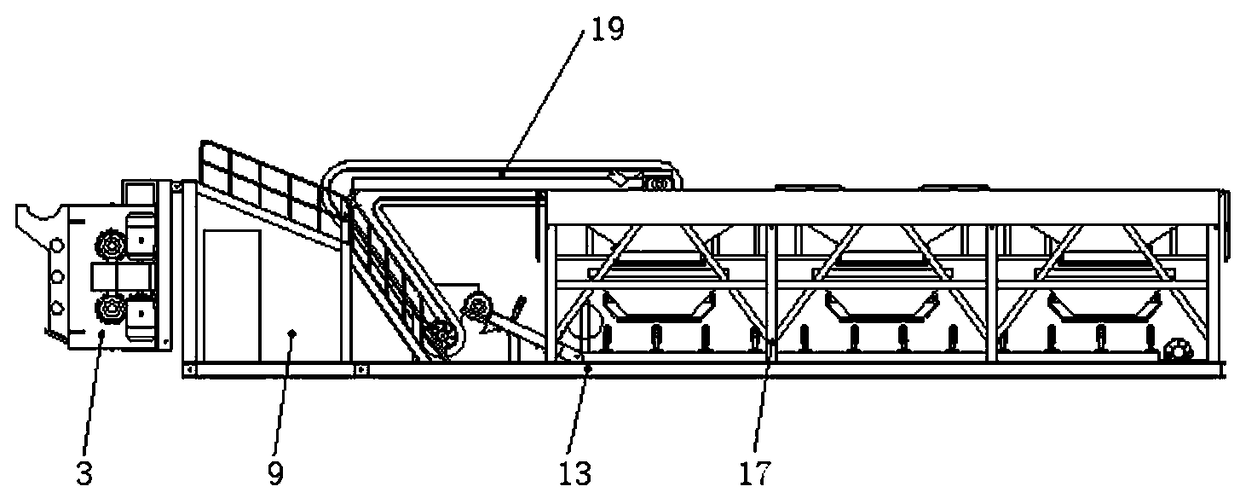

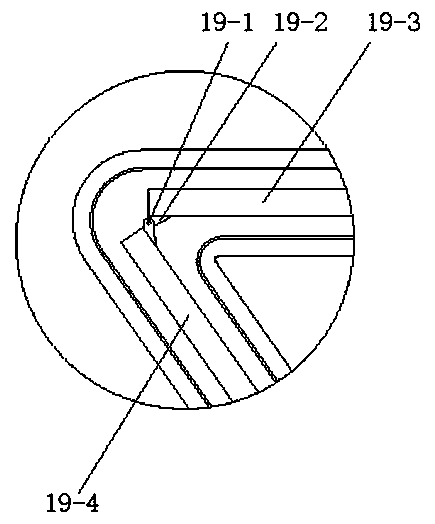

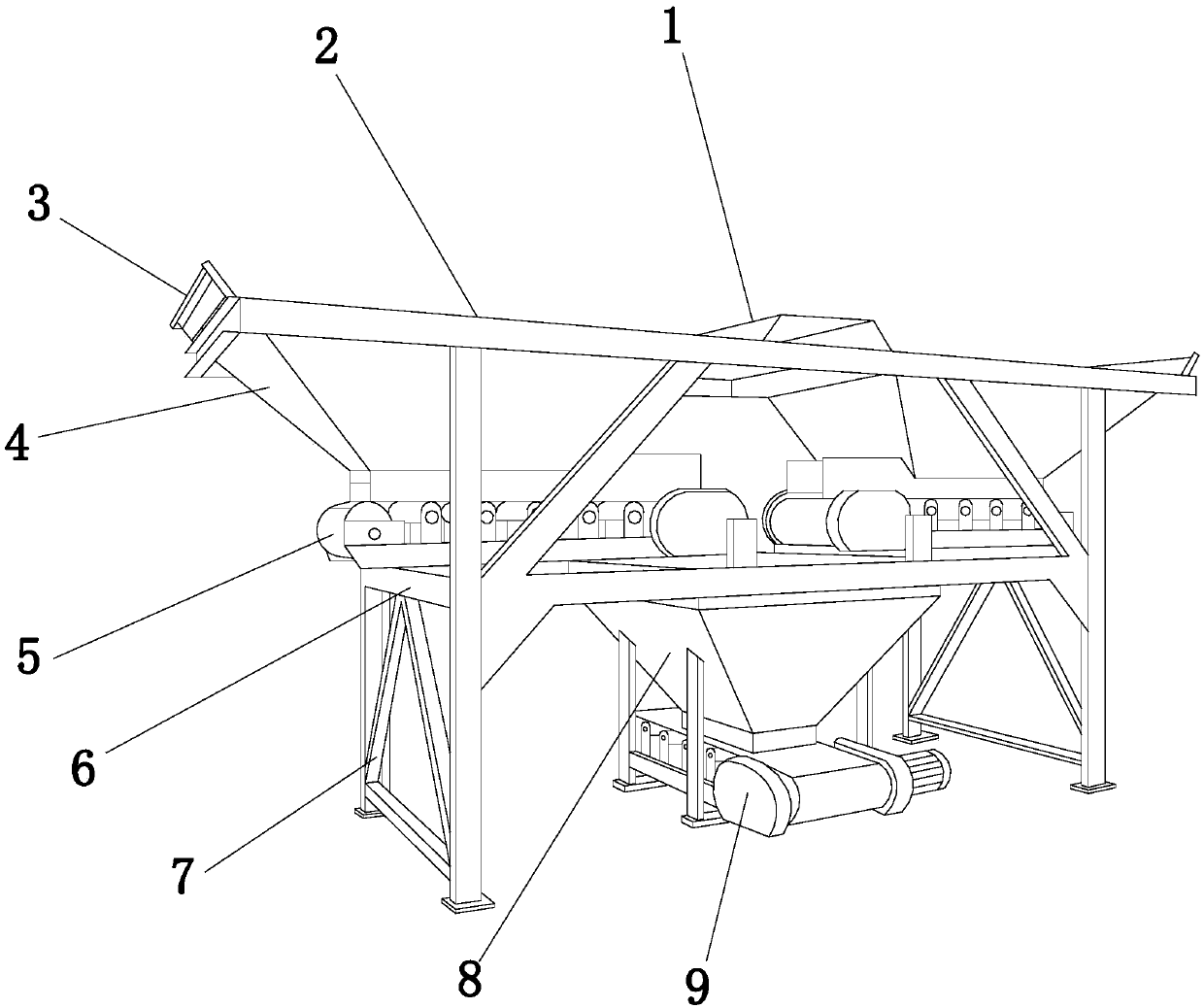

Integrated foldable foundation-free concrete mixing plant

InactiveCN109397547AMeet the qualitySatisfy productionSold ingredients supply apparatusMixing operation plantEngineeringTypes of concrete

The invention relates to an integrated foldable foundation-free concrete mixing plant which comprises a bottom frame of a frame structure. One side of the bottom frame is provided with a proportioningmachine support for bearing a proportioning machine, and a horizontal conveyer is arranged at the bottom of the proportioning machine support. The other side of the bottom frame is provided with a main supporting frame, the upper end of the main supporting frame is provided with an upper hinge point, a main machine platform is hinged to the upper end, a mixing main machine is arranged on the mainmachine platform, and a material gathering hopper is arranged at a discharging port of the mixing main machine. A belt conveyer is arranged between the mixing main machine and the discharging end ofthe horizontal conveyer, and the discharging end of the belt conveyer is communicated with a feeding port of the stirring main machine. The integrated foldable foundation-free concrete mixing plant can meet the demands for quality and yield of various specification and types of concrete, foldable structures of a mixing main machine frame and a conveying frame are designed during use, dismounting and transportation, and transportation can be achieved through one truck in a folded state.

Owner:新疆胜达机械设备制造有限公司

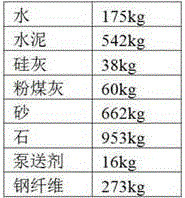

Steel fiber concrete with high fracture resistance and preparation method thereof

InactiveCN105859213AImprove flexural strengthIt is not suitable to form a groupSolid waste managementFiberHigh fracture

The invention discloses steel fiber concrete with high fracture resistance and a preparation method thereof. The steel fiber concrete comprises matrix concrete and steel fiber, and is characterized in that: the volume percent content of the steel fiber is 3.5%; and the used raw materials comprise the following materials by weight: 125-175Kg of water, 500-542Kg of cement, 25-38Kg of silica fume, 40-60Kg of fly ash, 500-662Kg of sand, 800-953Kg of stone, 10-16Kg of a pumping agent, and 250-273Kg of steel fiber. During stirring of concrete production, the steel fiber in the steel fiber concrete disclosed by the invention cannot agglomerate easily, so that the steel fiber concrete has good construction workability and can meet pouring construction requirements; the breaking strength of the concrete is greatly improved, high-performance concrete with the breaking strength of 20MPa is successfully prepared, and under an equal strength condition, the thickness of a concrete pavement is reduced, and the construction cost is reduced. This special type of concrete can be applied to construction parts with high requirements on crack control, toughening and shock resistance, and can be widely applied to road, bridge and pavement constructions.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

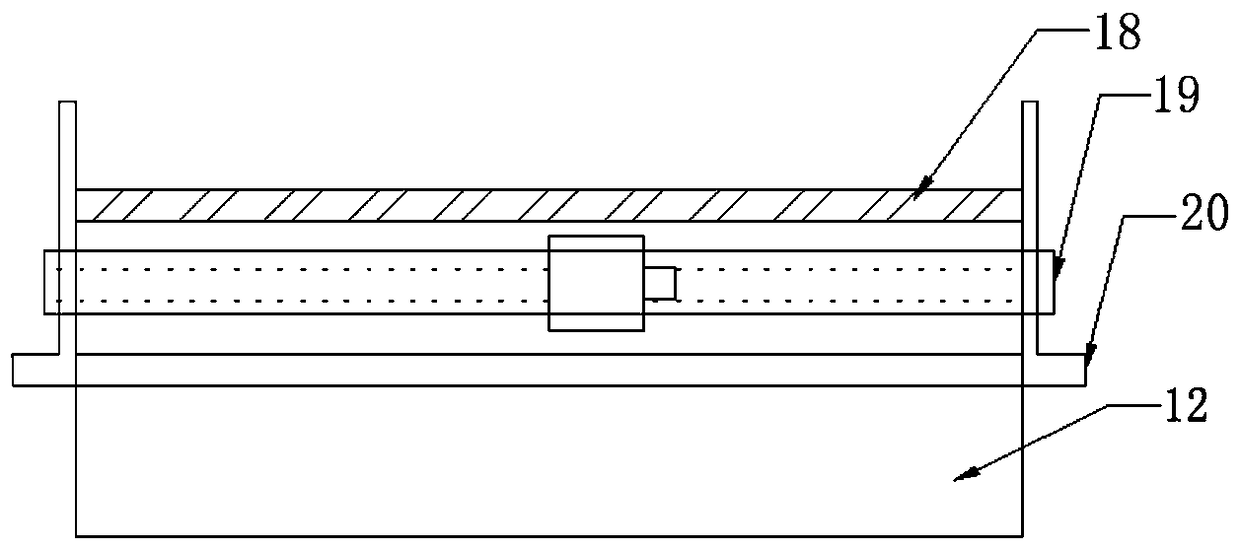

Salt freezing-dry and wet cycle coupling test device and method for cement-based materials

PendingCN108426823ASimulation is accurateComply with the anti-salt freezing performance indexWeather/light/corrosion resistanceFreeze-dryingThermal insulation

The invention relates to a salt freezing-dry and wet cycle coupling test device and method for cement-based materials. The test device comprises a test chamber provided with a thermal insulation board, wherein a humidifier and an air outlet are arranged on each of two sides of the test box from top to bottom sequentially, a plurality of test pieces and temperature and humidity sensors are arrangedin the test chamber, the left side of each test piece is connected with a liquid injection pipe, the right side of each test piece is connected with a liquid drainage pipe, and an automatic liquid injection device and an automatic liquid drainage device are arranged below the test chamber. The test method comprises steps of two-time salt freezing and one-time dry and wet cycle which form a test cycle system of salt freezing-dry and wet cycle. The device and the method have the advantages that through multiple single-sided salt freezing-dry and wet cycle tests, key performance indexes of concrete can be obtained, the durability of concrete is reflected, and a basis is provided for durability design of a concrete structure in the seasonally frozen region. Through evaluation of different types of concrete, the concrete material applicable to the seasonally frozen region can be selected preferably through comparison and analysis.

Owner:LIAONING PROVINCIAL TRANSPORTATION PLANNING & DESIGN INST

Concrete mixing device with cleaning function

ActiveCN111168850ASimple structureEasy to operateHollow article cleaningCement mixing apparatusSpray nozzleStructural engineering

The invention relates to the field of concrete mixing, in particular to a concrete mixing device with a cleaning function. The concrete mixing device comprises a main body. The lower end of the main body is provided with four supports. The main body is internally provided with a first sliding cavity. A cleaning assembly is arranged in the first sliding cavity. The main body is internally providedwith a second sliding cavity located on the right side of the first sliding cavity. A mixing assembly is arranged in the second sliding cavity. A third sliding cavity of which the upper end communicates with the first sliding cavity and the second sliding cavity is arranged on the lower side of the first sliding cavity and the second sliding cavity. A sliding assembly is arranged in the third sliding cavity. A first sliding block is slidably arranged in the first sliding cavity. The first sliding block is internally provided with a first transmission cavity. When the concrete mixing device with the cleaning function needs to mix concrete, the mixing assembly slides downwards to mix the concrete. When the concrete mixing device with the cleaning function needs to mix different types of concrete, a mixing tank needs to be cleaned, and a cleaning block and spray nozzles slide downwards to rotate simultaneously to clean the mixing tank.

Owner:景德镇市黑猫资源综合利用有限责任公司

Self-compensating shrinkage and slump-retaining copolymer and preparation method thereof

The invention relates to the technical field of building materials, in particular to a self-compensating shrinkage and slump-retaining copolymer and a preparation method thereof. The copolymer is prepared from 2-3 parts of acrylic acid, 1-2 parts of sodium allylsulfonate, 2.5-4 parts of methoxy polyethylene glycol monomaleate with mass concentration of 60%, 30-35 parts of alkylene alkenyl polyoxyethylene ether, 1.5-2.5 parts of ammonium persulfate, 3-5 parts of a NaOH solution with mass concentration of 30% and 50-60 parts of water by reaction in accordance with a certain technological process. Slow-release slump retaining and self-compensation shrinkage are realized by conversion of a methoxy polyethylene glycol monomaleate-cement calcium aluminate intercalation hydration product into mono-sulfur hydrated calcium sulfoaluminate; 0.2%-0.5% by mass of a cementing material is mixed with concrete or a concrete product, the slump loss of the concrete in one hour is lower than 10%, the compressive strength ratio in one to three days is higher than 160%, the compressive strength ratio in 28 d is 140%-150%, and the shrinkage ratio in 28 d is lower than 80%, workability and volume stability of the concrete are remarkably improved, and the copolymer is applicable to various types of concrete and products.

Owner:江苏昆腾新材料科技有限公司 +1

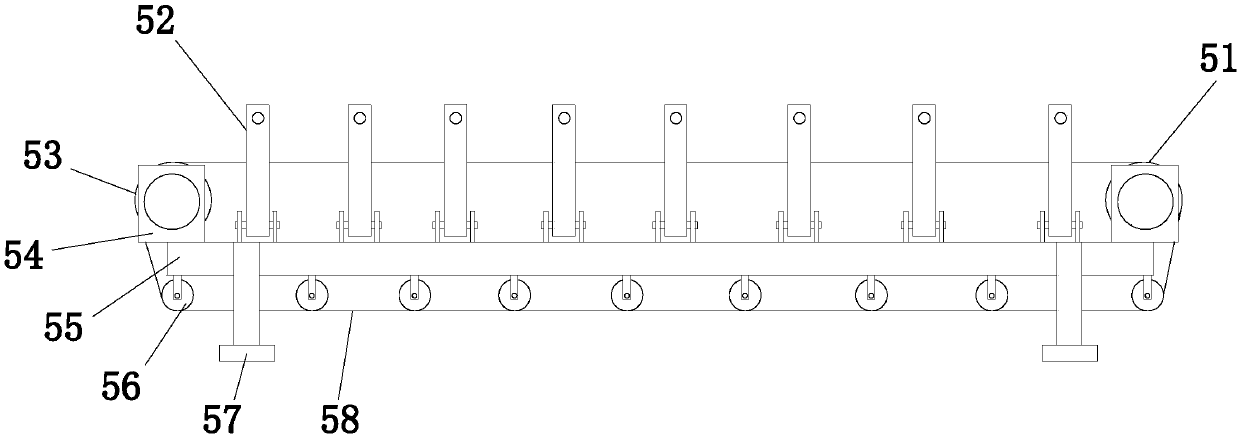

A new type of concrete batching machine

The invention discloses a novel concrete batching machine which structurally comprises a separating plate, a frame, an adjustable material guiding plate, a storage bin, a belt conveyor, a support frame, a triangular reinforcement frame, a mixed weighting hopper and a belt weigher; the belt conveyor is composed of a bend pulley, an adjustable roller, a front roller, a gear motor, a machine body, aguiding roller, a supporting leg and a belt; the adjustable roller is composed of slip-resistant lines, a roller, a movable support, a base and a tension bar; the belt conveyor is arranged at the bottom of the storage bin of the novel concrete batching machine; the adjustable roller is arranged on the belt conveyor; the adjustable roller drives the movable support to carry out angle adjustment byadjusting the tensile elongation of the tension bar, thereby enabling the roller to be capable of carrying out corresponding angle adjustment. Therefore, the adjusting function of the guiding chute ofthe belt conveyor is achieved.

Owner:浙江永坚新材料科技股份有限公司

Concrete mixer unit

PendingCN109514738AShorten mixing timeReduce processing efficiencyMixing operation control apparatusIngredients weighing apparatusTypes of concreteConveyor belt

The invention provides a concrete mixer unit. The concrete mixer unit comprises a raw material stirring processor, a belt feeder, a separation feeder, a hopper I, a hopper II, a hopper III and a conveyor belt I. The hopper I, the hopper II and the hopper III are used for storing various types of concrete materials. The separation feeder is located above the belt feeder and below the hopper I, thehopper II and the hopper III. The separation feeder is parallel to a conveyor belt shaft of the belt feeder. The raw material stirring processor is located below the belt feeder. A feed port of the raw material stirring processor is connected with a discharge port of the belt feeder. The conveyor belt I is located below the raw material stirring processor and used for receiving and conveying processed raw materials. A feeding device of the separation feeder of the concrete mixer unit is provided with a moving part. The volume of a feeding unit of the feeding device can be effectively adjustedby adjusting the position of the moving part, and then quantitative feeding is realized. The concrete mixer unit is wider in application range and more convenient to use.

Owner:厦门市南昇机械设备有限公司

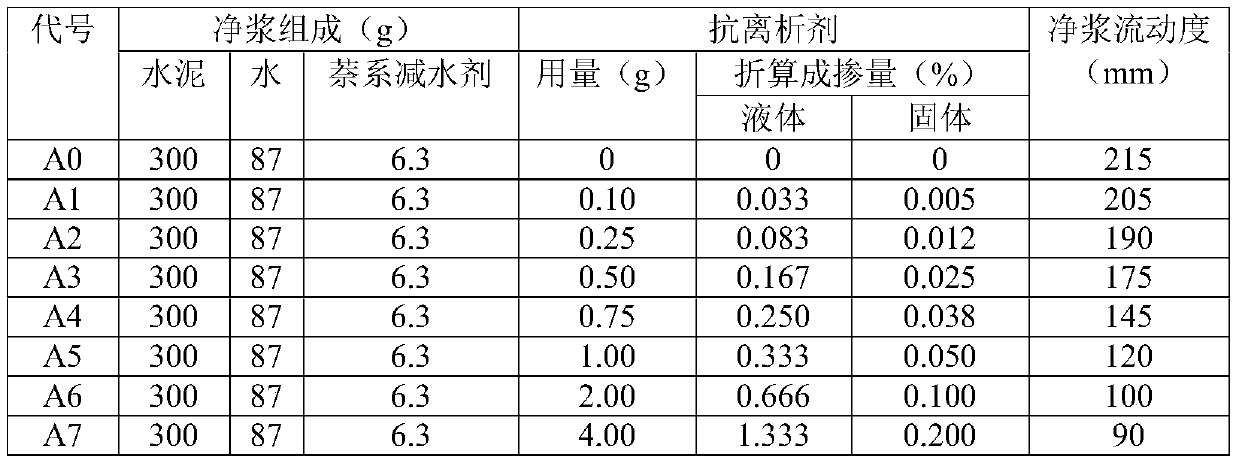

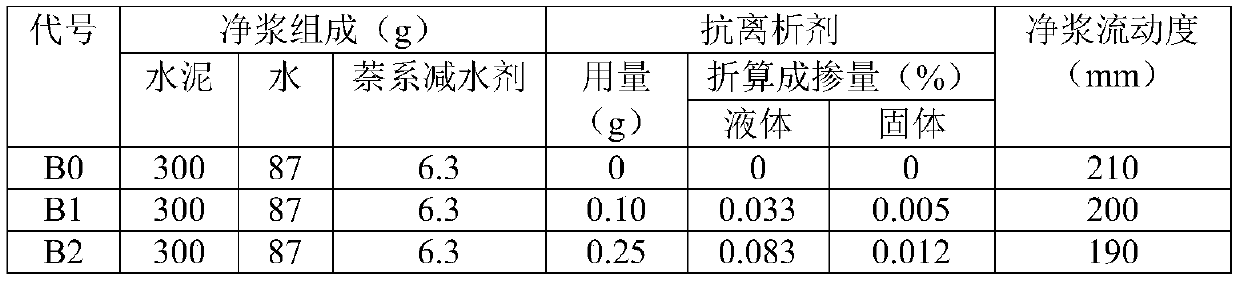

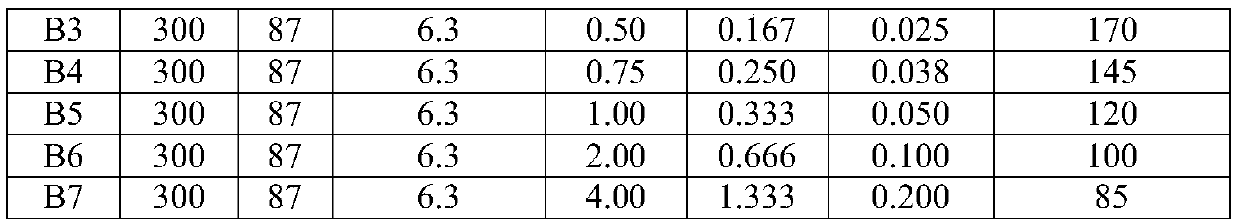

Segregation resistant agent for concrete adding naphthalene water reducer and pumping aid of naphthalene water reducer, and preparation method and application thereof

The invention discloses a segregation resistant agent for a concrete adding naphthalene water reducer and a pumping aid of the naphthalene water reducer. The segregation resistant agent is prepared from a polycarboxylate superplasticizer and water; and the solid content of the polycarboxylate superplasticizer is 2%-50%, and an additive can further be added. The invention discloses application of the segregation resistant agent in segregation of the concrete prepared from mixing of the naphthalene water reducer and the pumping aid of the naphthalene water reducer. The segregation resistant agent can decrease the water-reducing rate of an original naphthalene water reducer, thus mobility lowering and segregation phenomenon disappearing are achieved, and the compressive strength of the concrete is hardly decreased. The concrete segregation phenomenon further occurs when the water using amount in not controlled to be increased in production, the segregation phenomenon can disappear by adding the segregation resistant agent, but for the type of concrete, the compressive strength grade should be reduced as appropriate.

Owner:绍兴市华冠新型建材有限公司

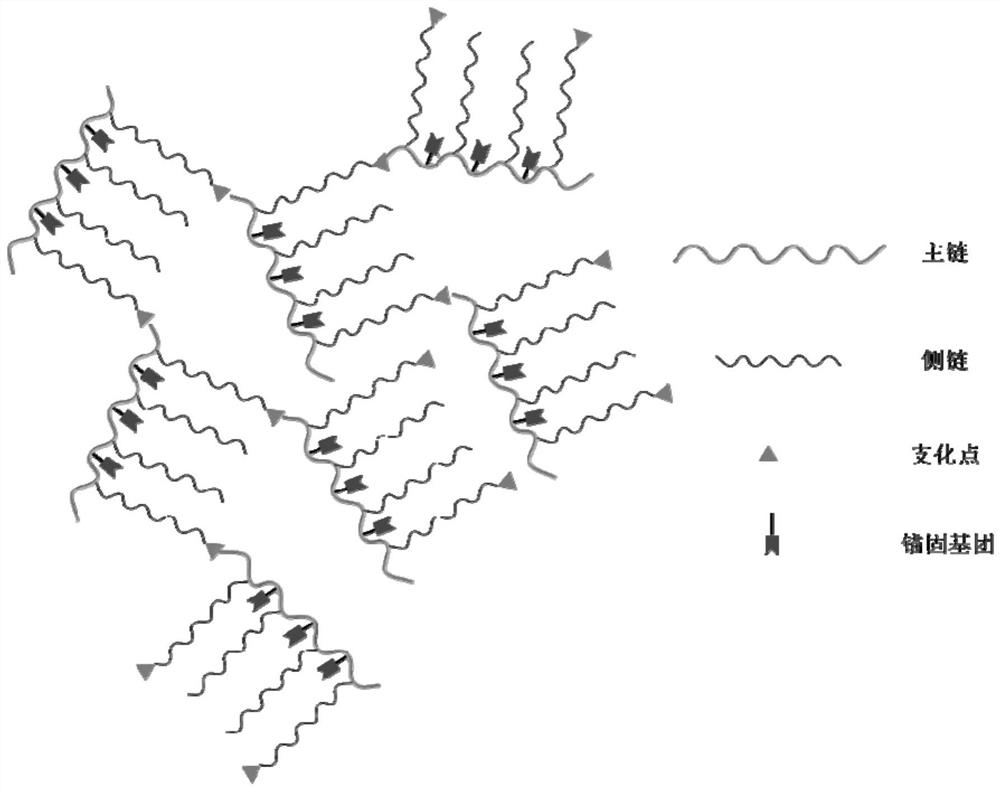

Hyperbranched water-reducing and viscosity-reducing concrete admixture, preparation method and application thereof

The invention discloses a hyperbranched water-reducing and viscosity-reducing type concrete admixture, a preparation method and application thereof. The preparation method of the hyperbranched water-reducing and viscosity-reducing type concrete admixture comprises the steps: through chemical reaction of a monomer A and a monomer B, introducing another double bond to the tail end of the monomer A to prepare a double-end-group alkylene macromonomer; and carrying out addition polymerization reaction on the double-end-group alkylene macromonomer, the monomer A and the monomer C to prepare the hyperbranched water-reducing viscosity-reducing concrete admixture. According to the invention, the hyperbranched water-reducing and viscosity-reducing concrete admixture prepared by the invention contains a plurality of comb-shaped structure PCE, so that a large number of anchoring groups can be exposed, the fluidity of concrete can be greatly improved, and the viscosity of concrete can be greatly reduced; the preparation method is mild in synthesis condition, the monomer source is wide, the yield is high, the mixing amount is low, the water-reducing rate is high, and the viscosity reduction is good; and the admixture can be widely applied to various types of concrete.

Owner:CENT SOUTH UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com