Crack monitoring sensor and use method thereof based on OTDR (optical time domain reflectometry) technique

A technology for monitoring sensors and technologies, applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problems of insufficient operability, poor anti-interference ability, complicated operation, etc., and achieve simple structure, high safety, and high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

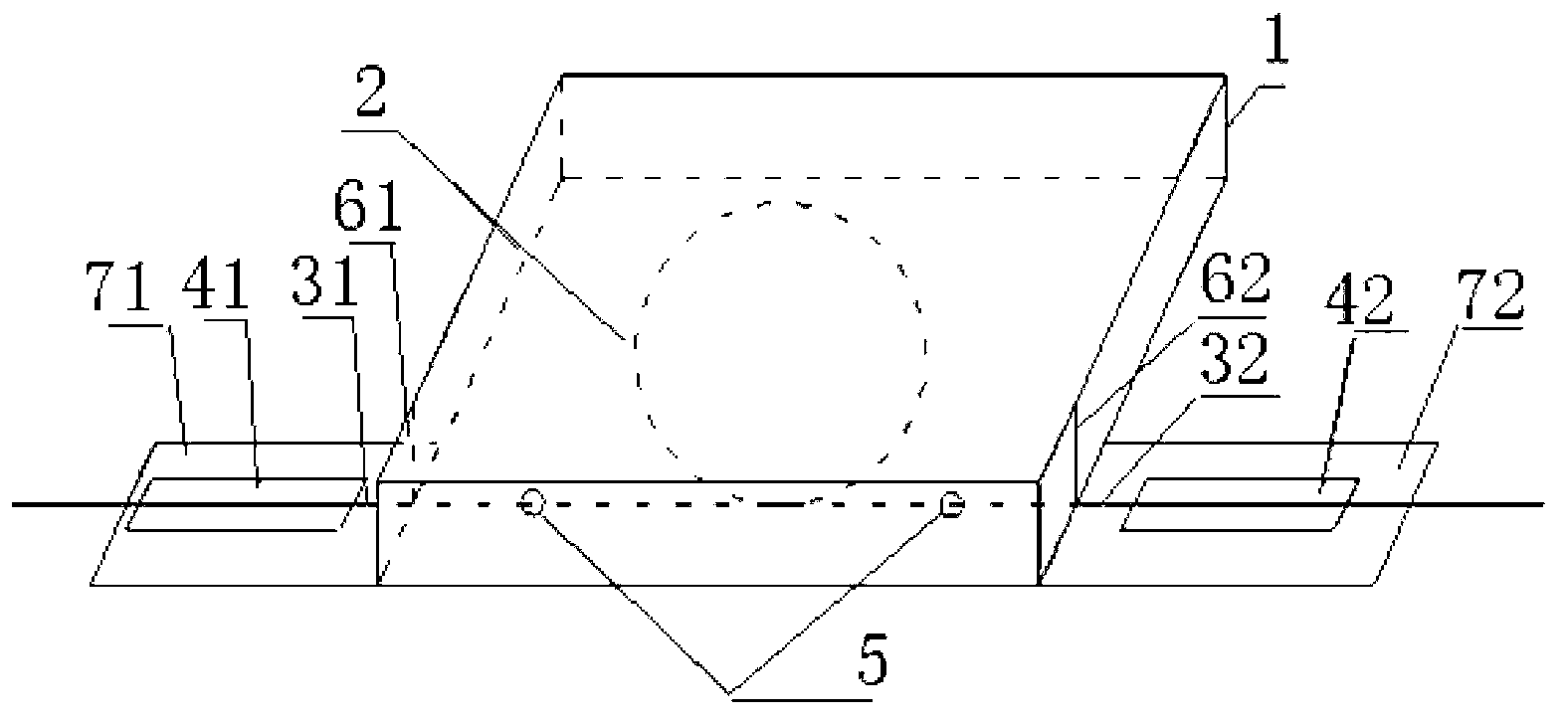

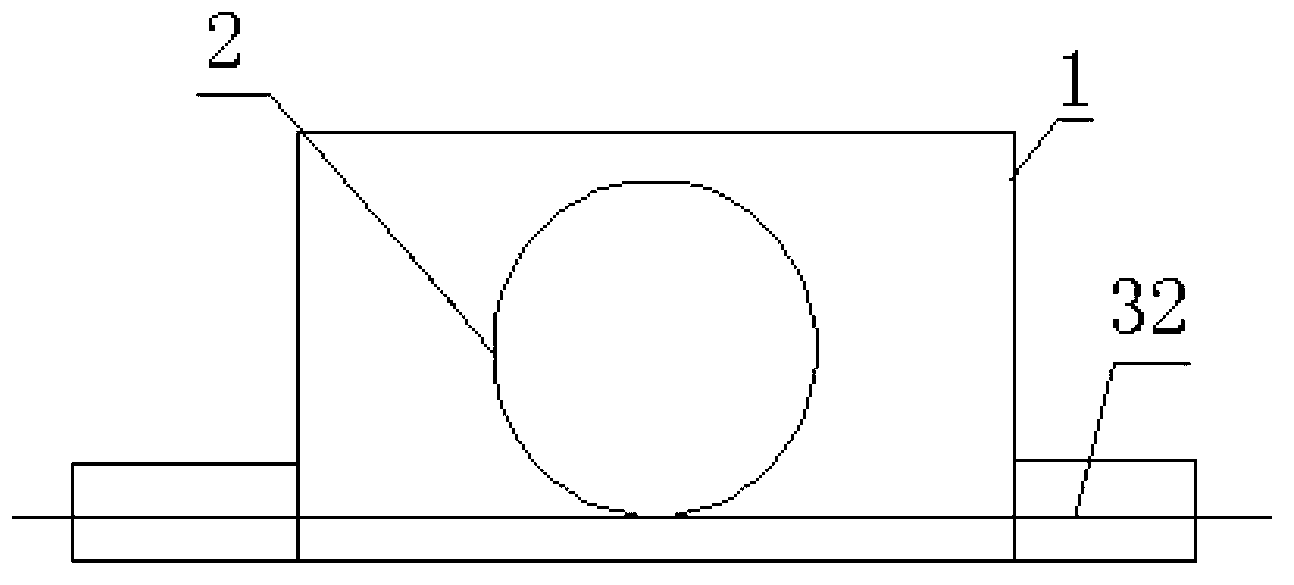

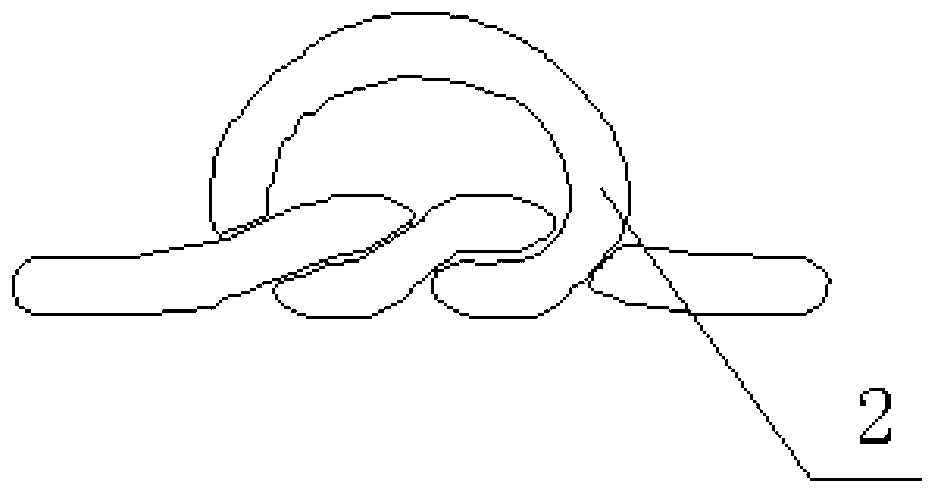

[0019] A crack monitoring sensor based on OTDR technology, such as figure 1 , 2 As shown, it includes a protective box, a bare fiber coil with two ends, and the first and second protected optical fibers. The bare fiber coil is arranged in the protective box, and the bare fiber coil is glued by epoxy resin Pasted in the protective box, the bottom two ends of the protective box are respectively provided with first and second outlets, the first and second outlets are used to lead out the first and second optical fibers with protective layers, and the second 1. The bottom of the protective box below the second outlet is respectively provided with the first and second optical fiber bonding platforms; since the bare optical fiber is easy to break, the bare optical fiber and the optical fiber with the protective layer are welded inside the protective box, and then the optical fiber with the protective layer is fused Lead out, not easy to break, that is, one end of the first protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com