Patents

Literature

260 results about "Fiber coil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

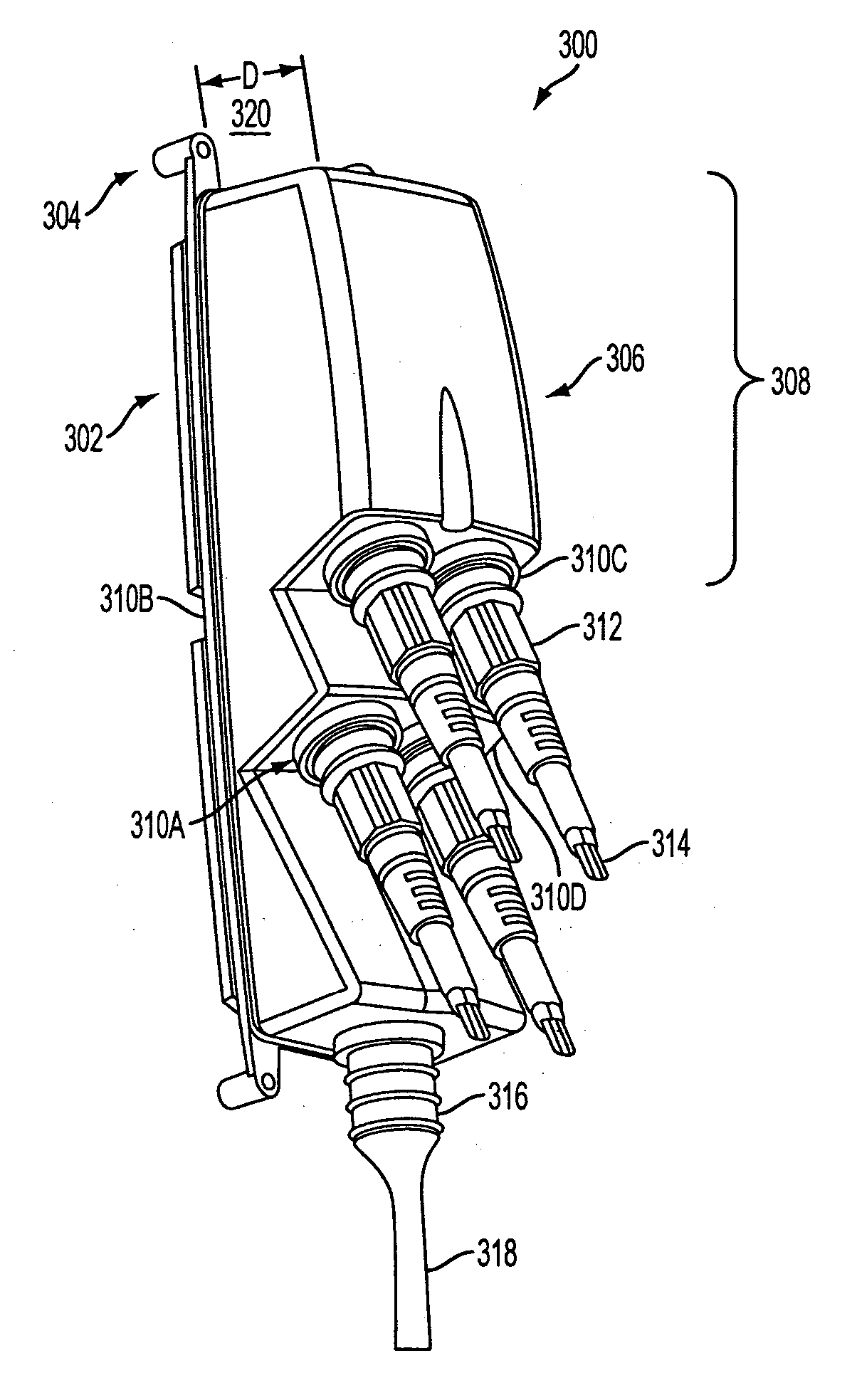

Fiber drop terminal

ActiveUS20060093303A1Easy accessCoupling light guidesTransmission monitoring/testing/fault-measurement systemsFiberEngineering

Owner:COMMSCOPE TECH LLC

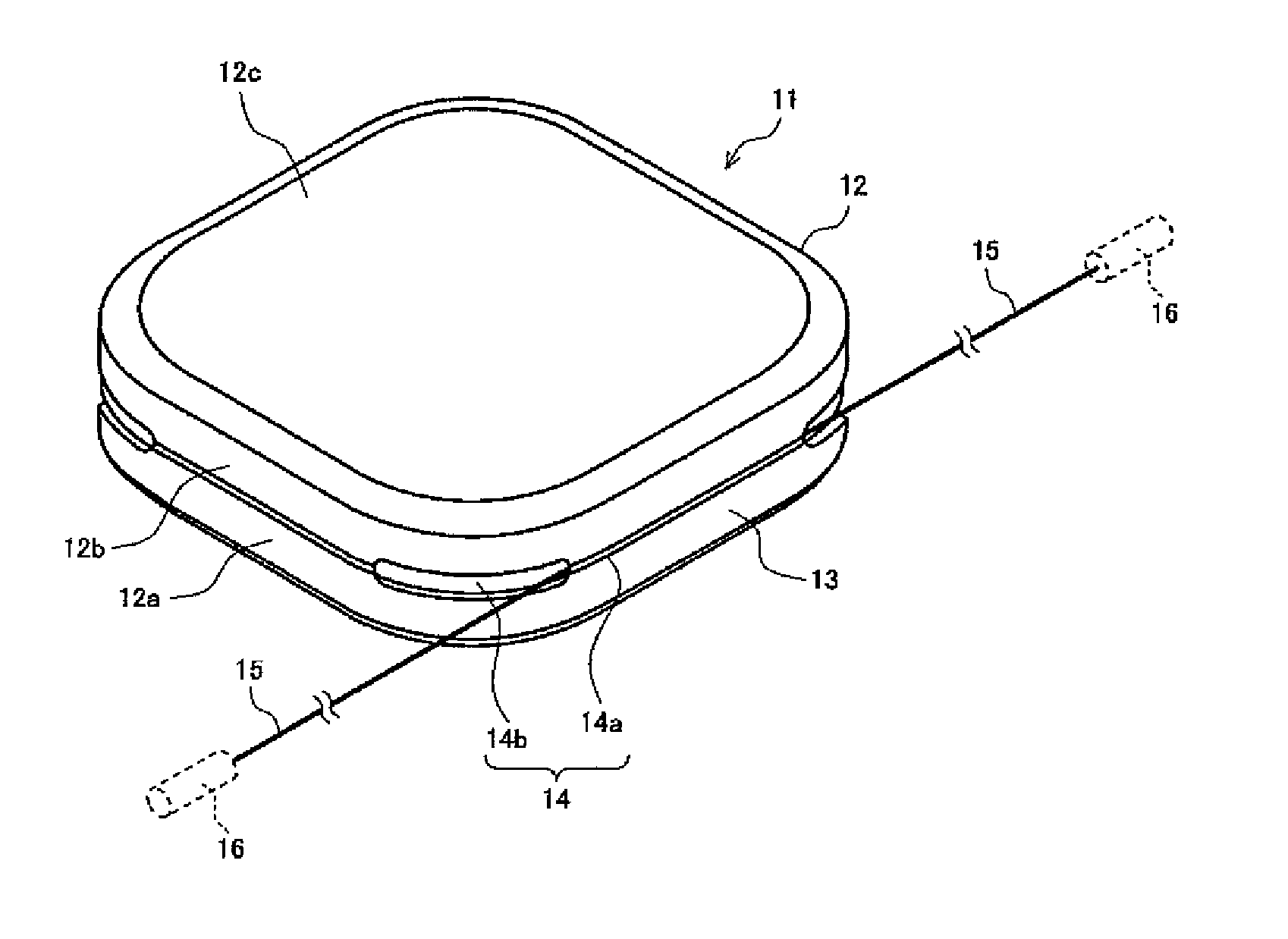

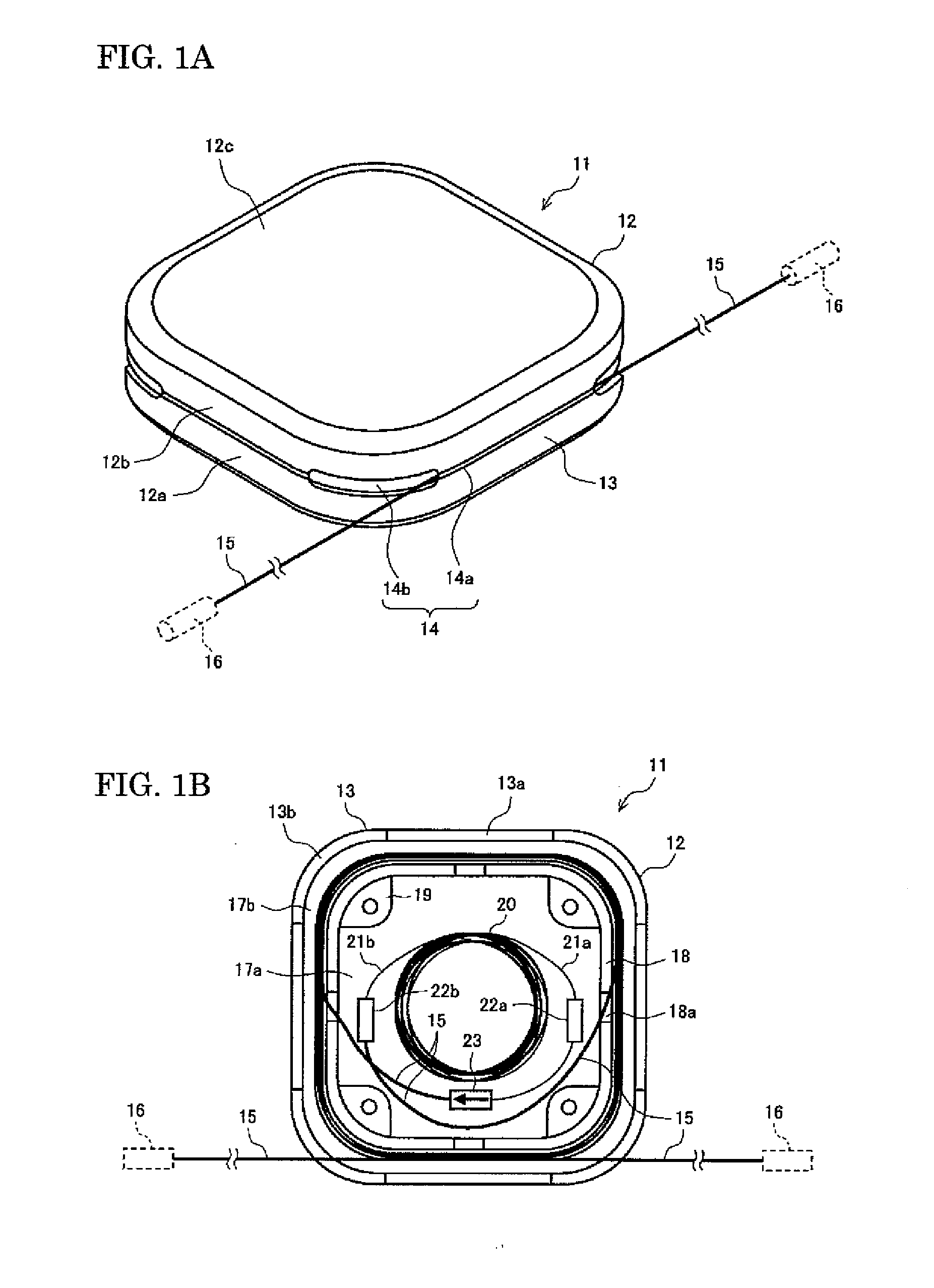

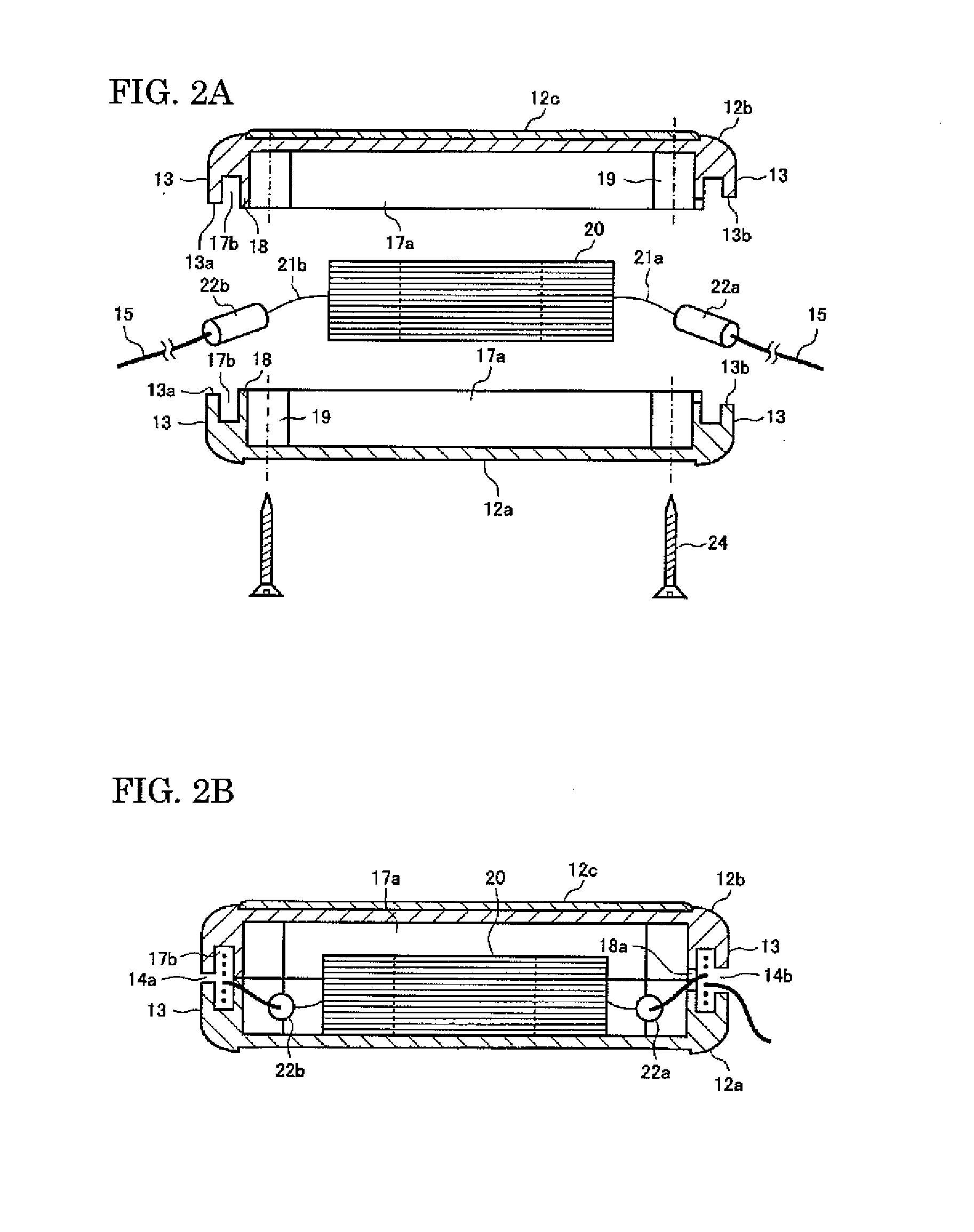

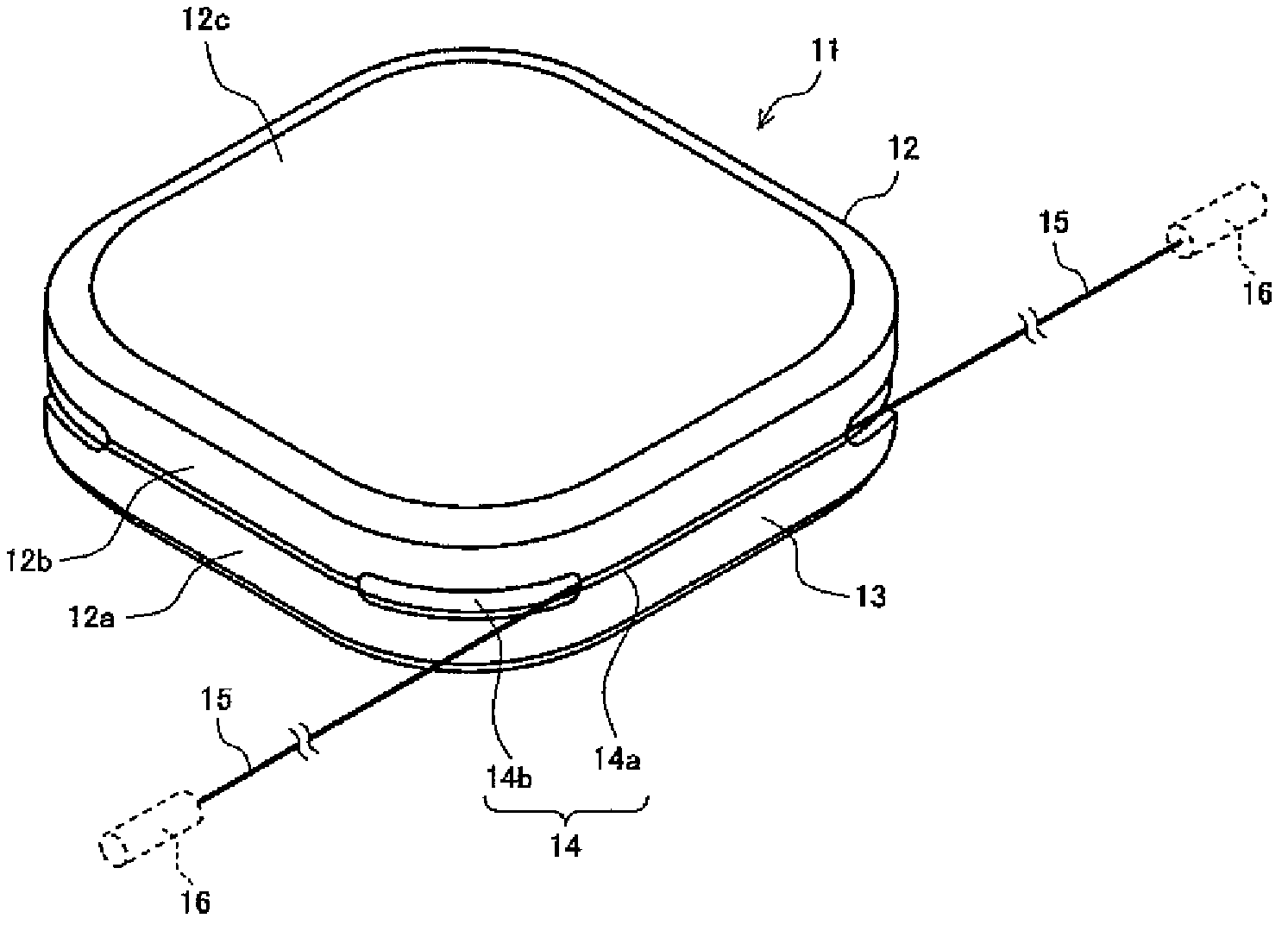

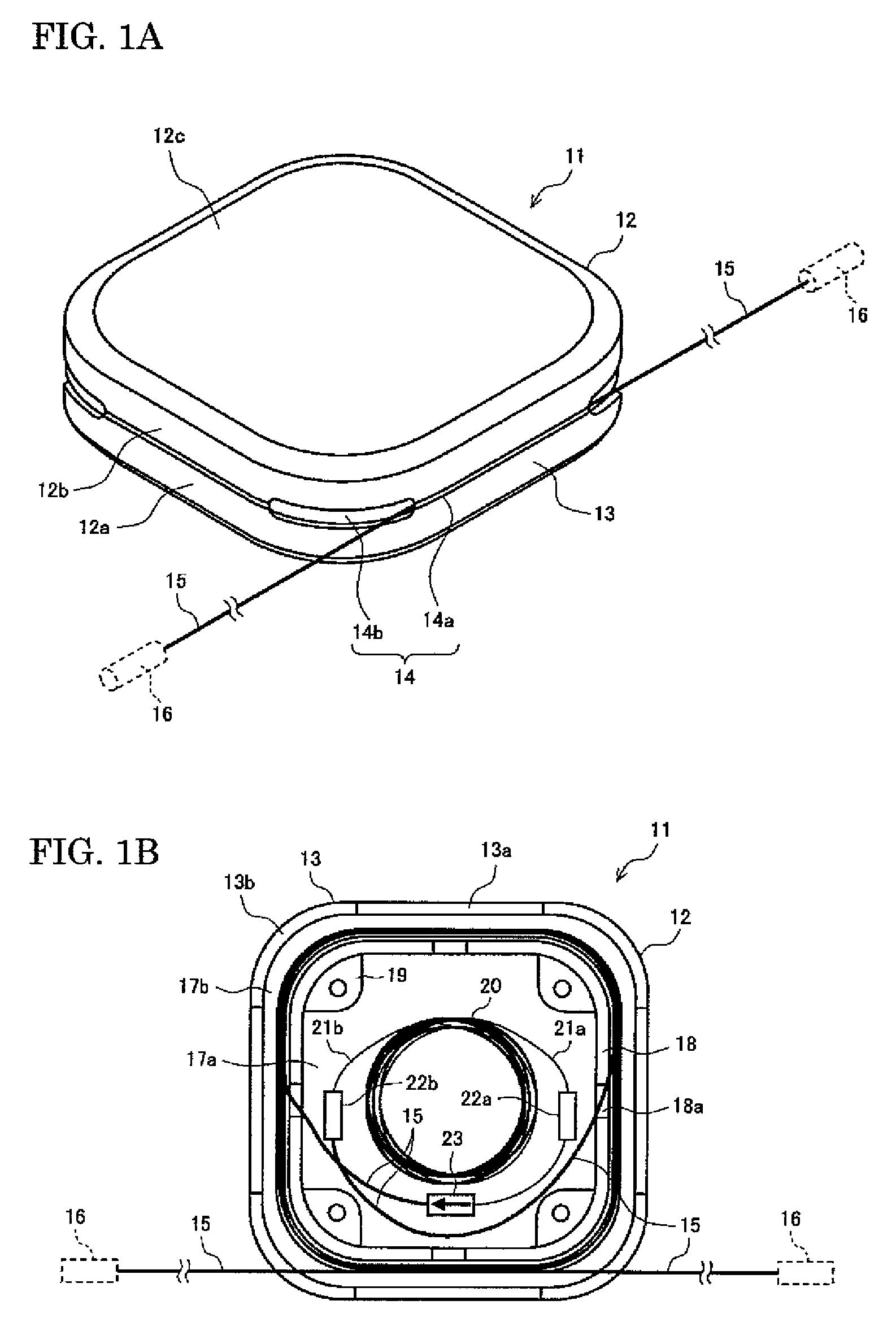

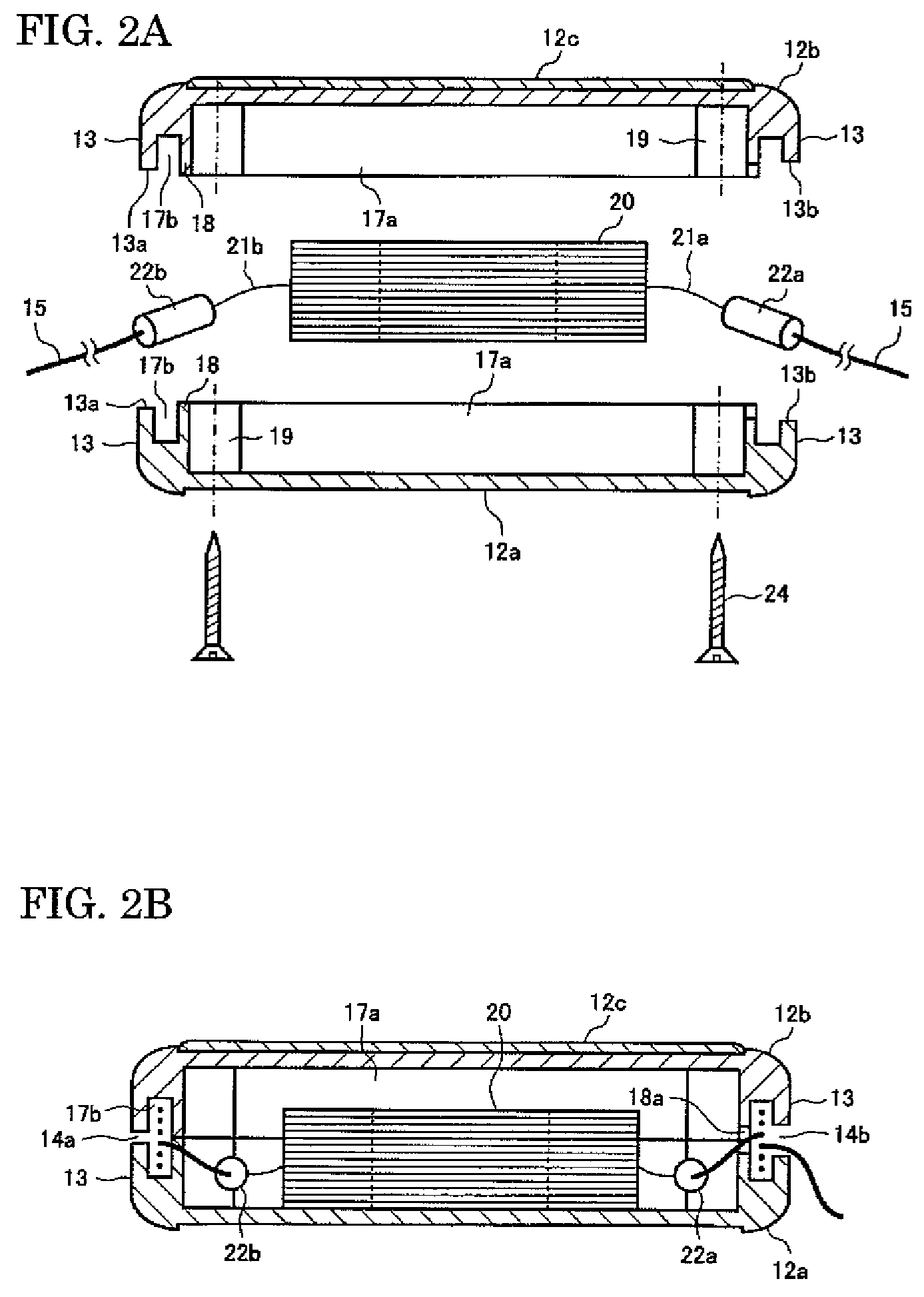

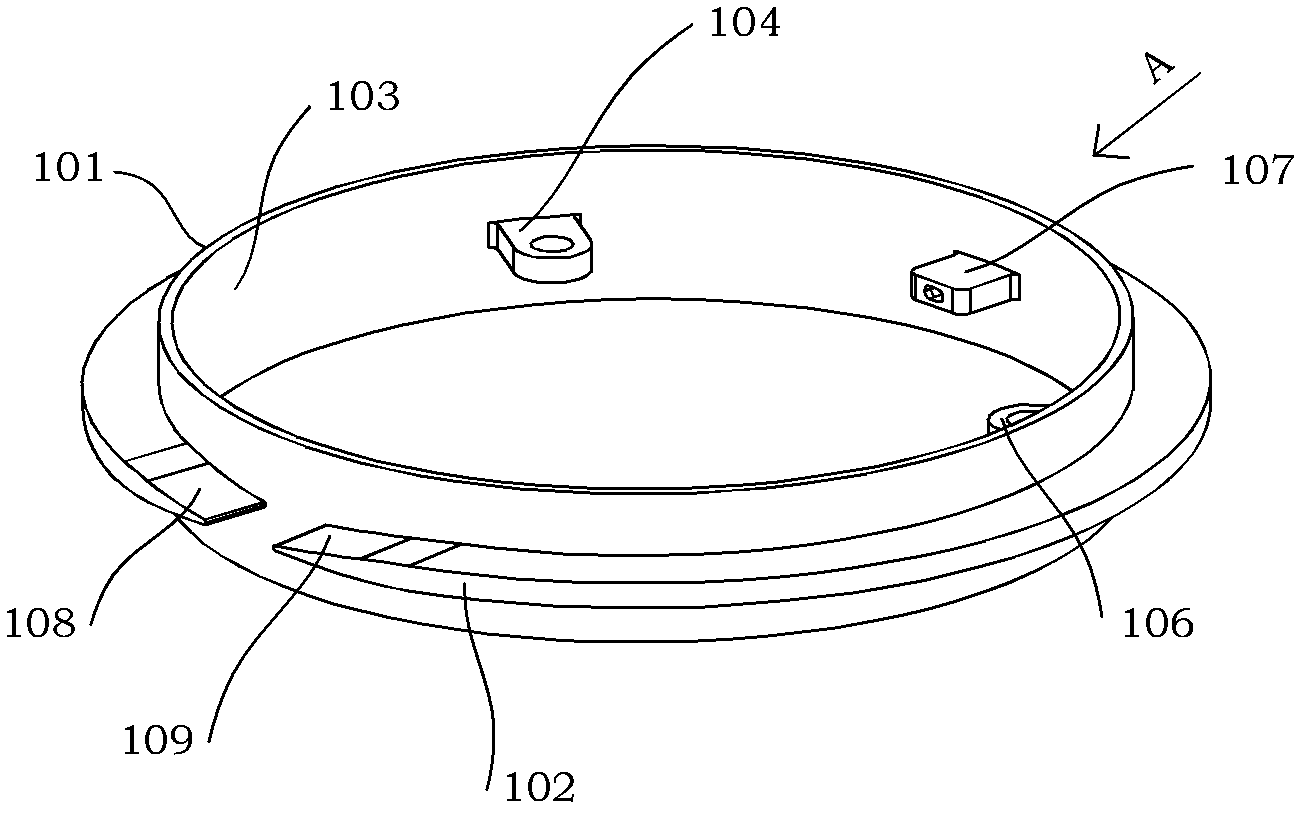

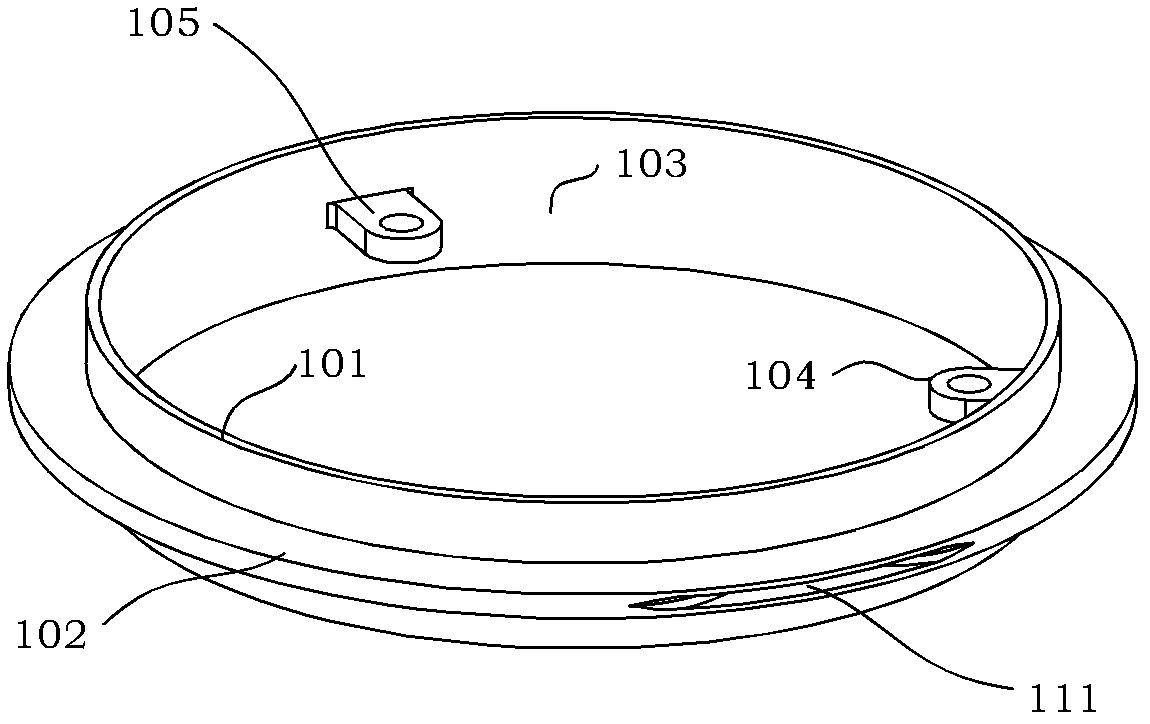

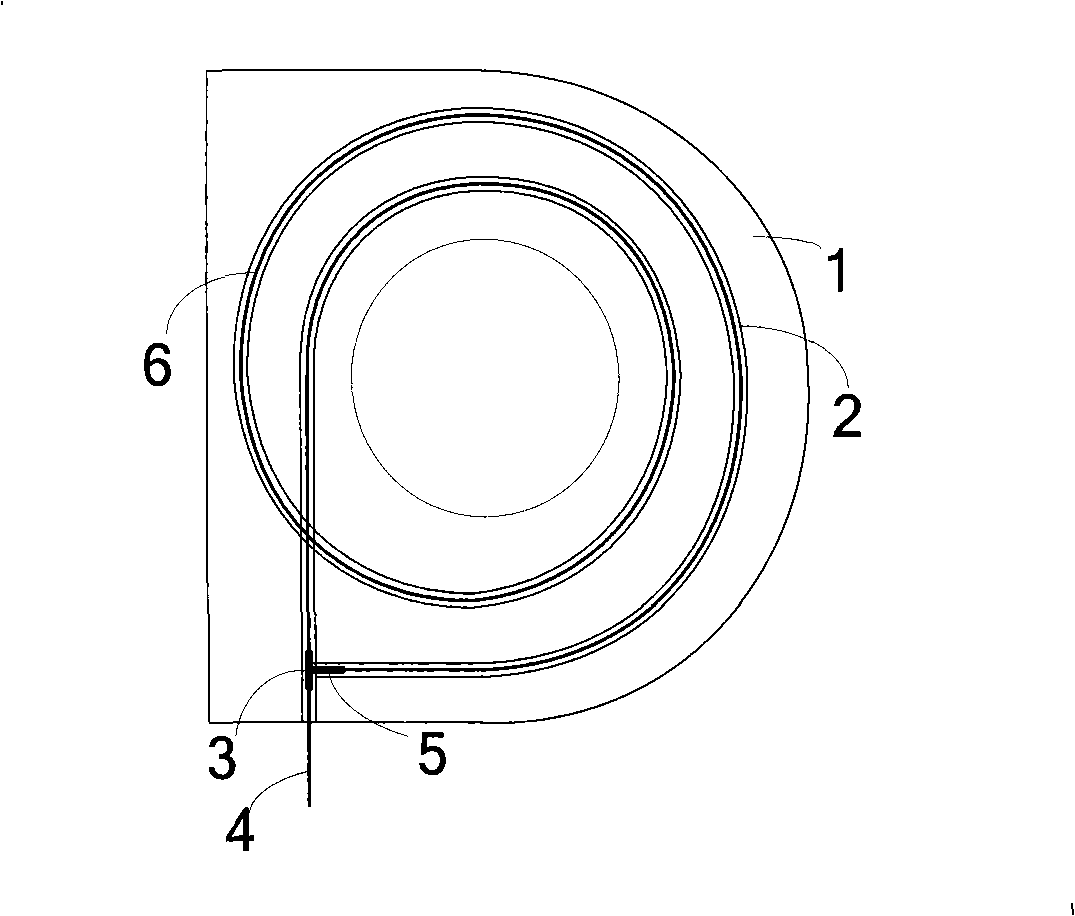

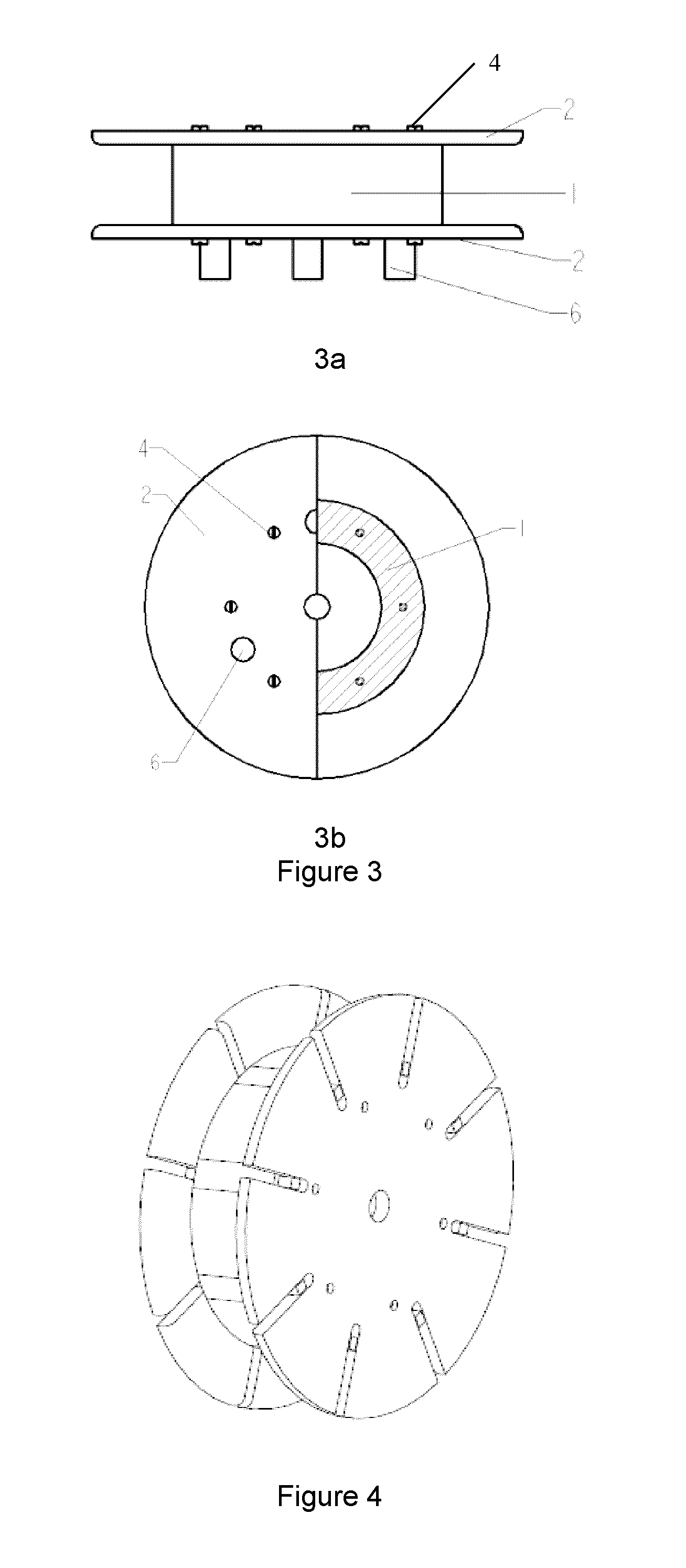

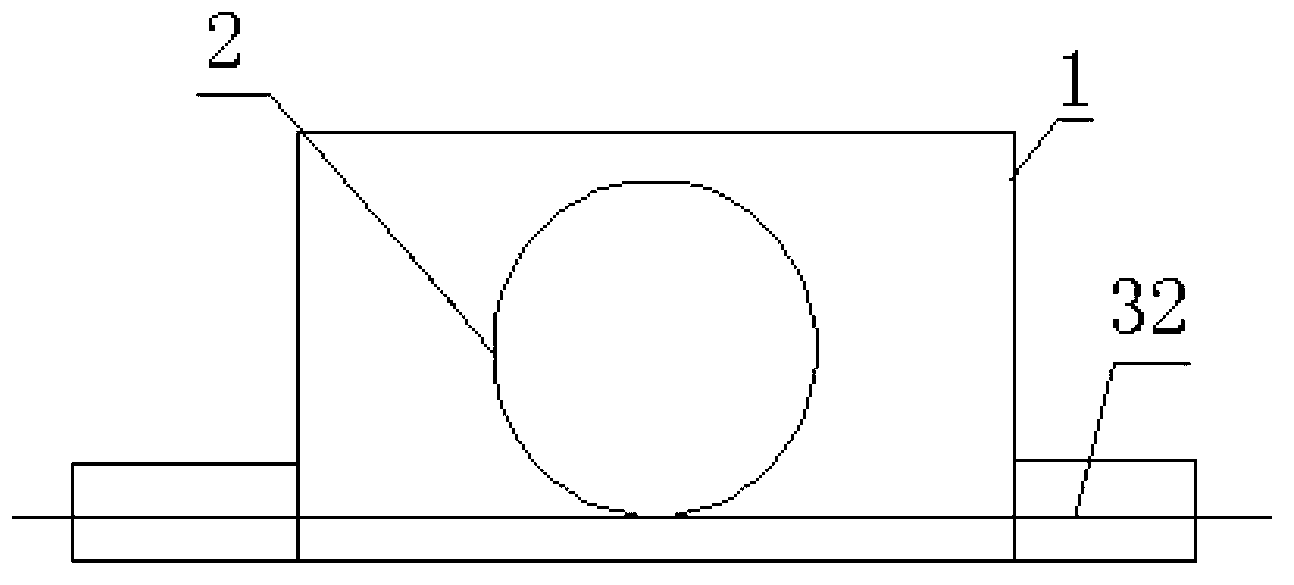

Container for accommodating optical fiber coil and optical fiber module having the container

InactiveUS20080152294A1Convenient to accommodateSimple configurationOptical light guidesFiberOptical Module

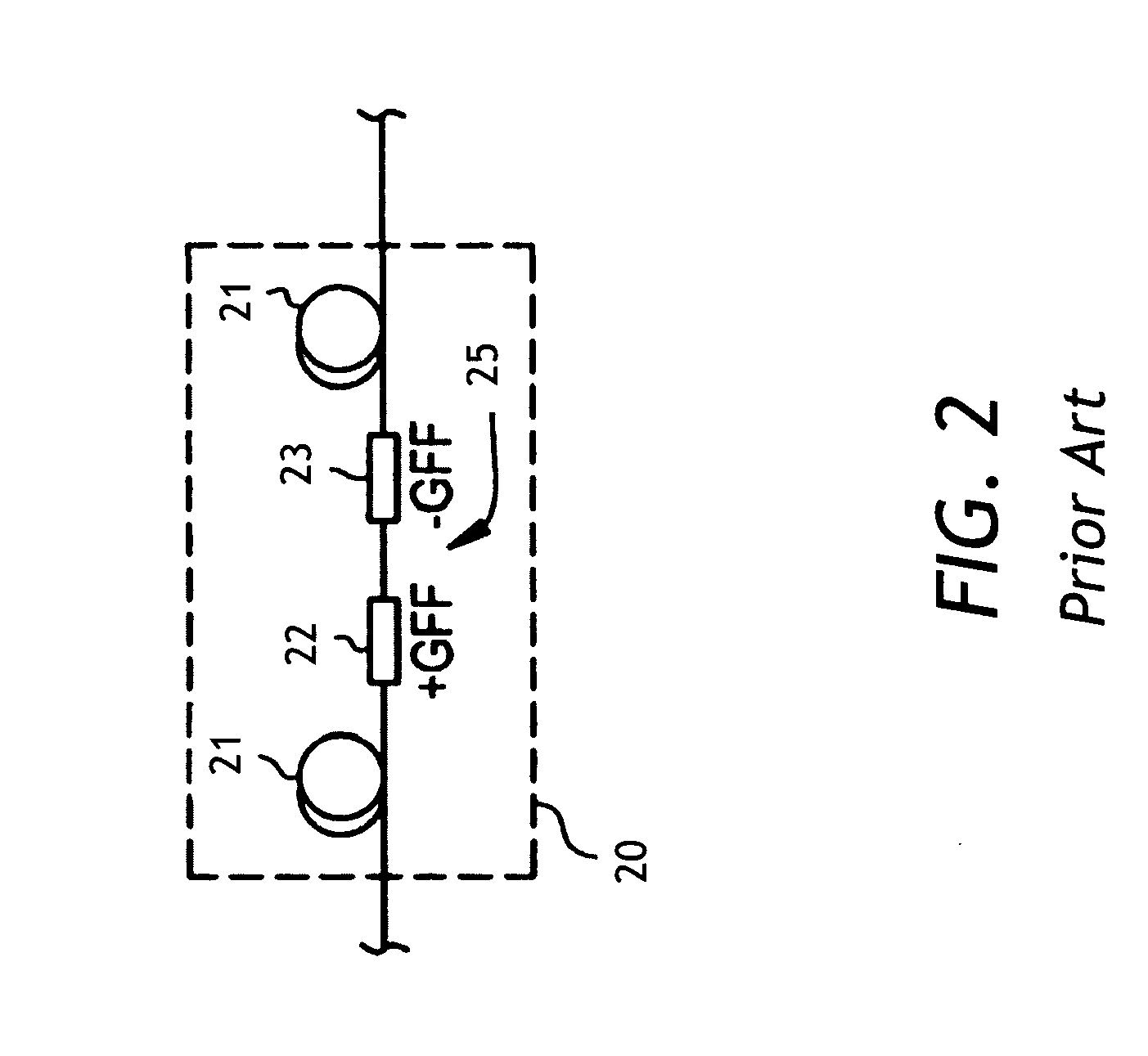

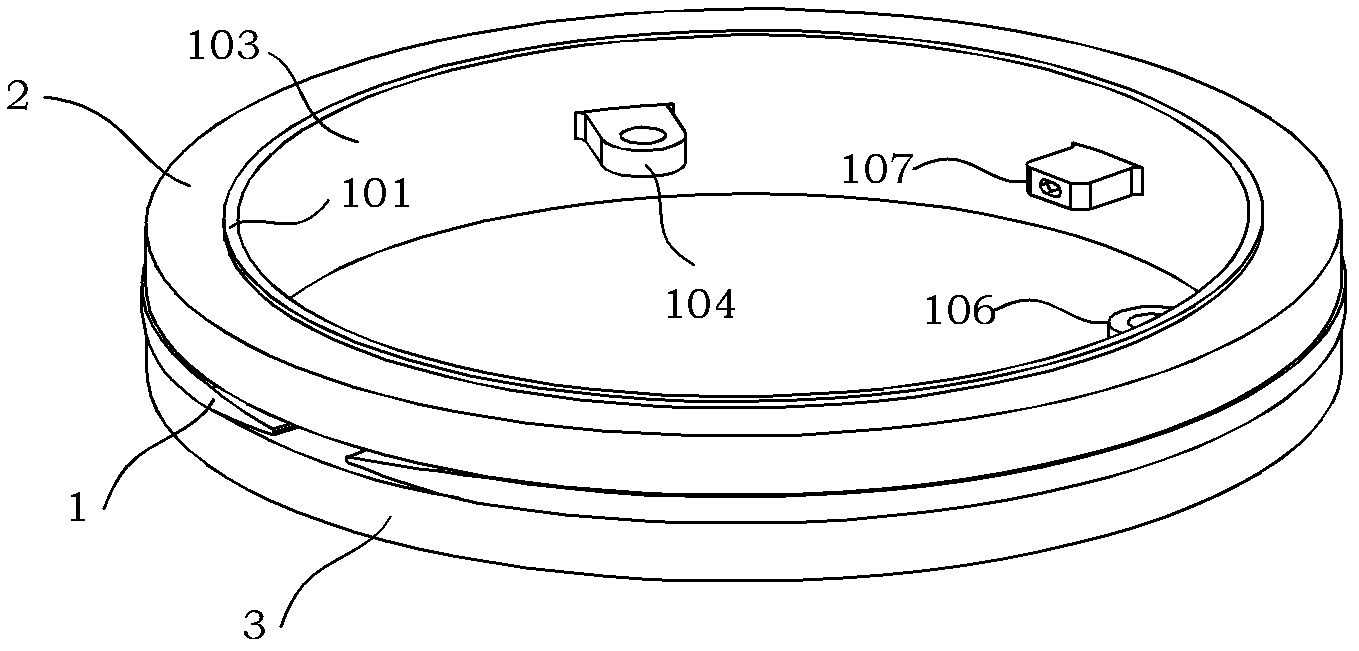

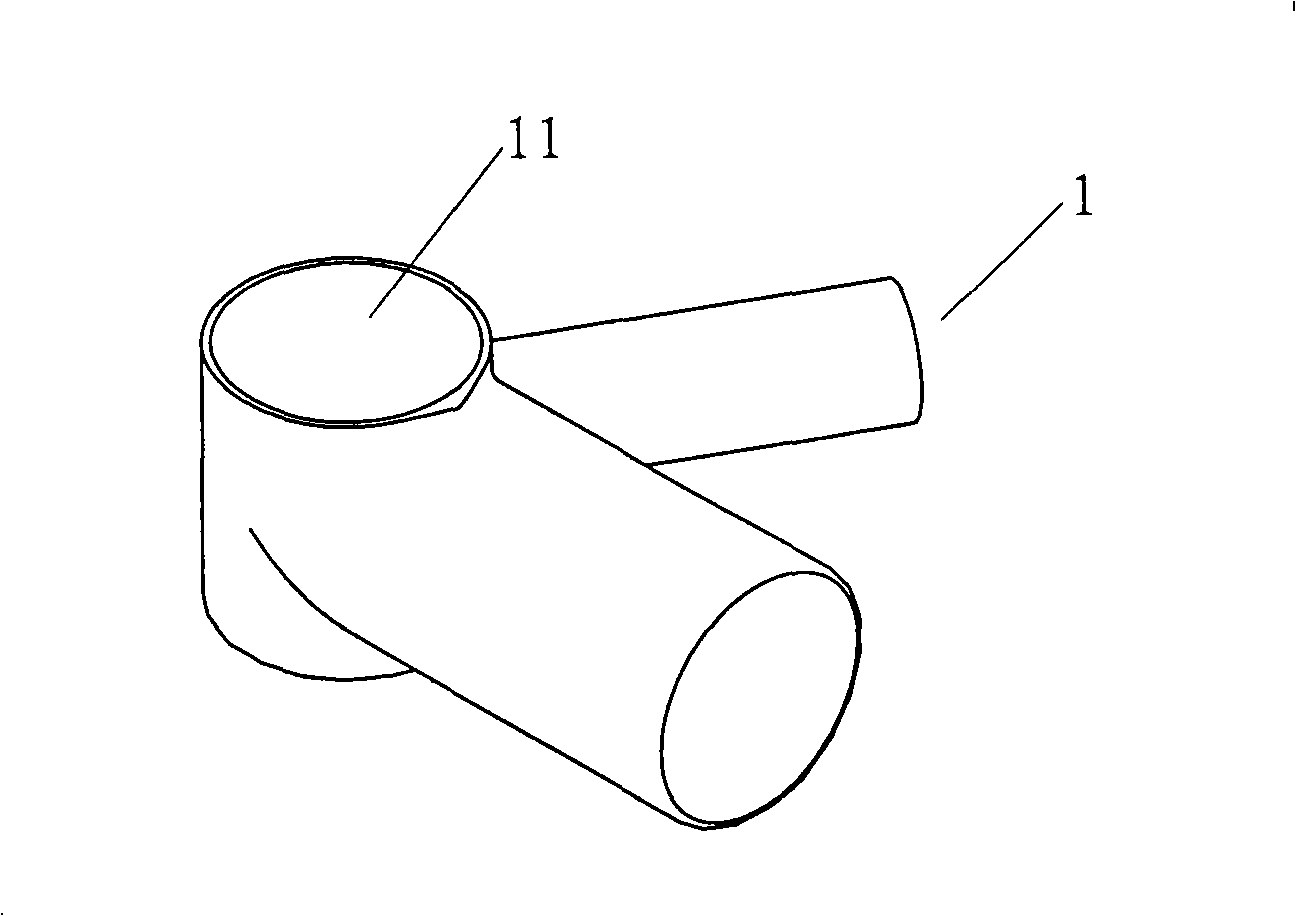

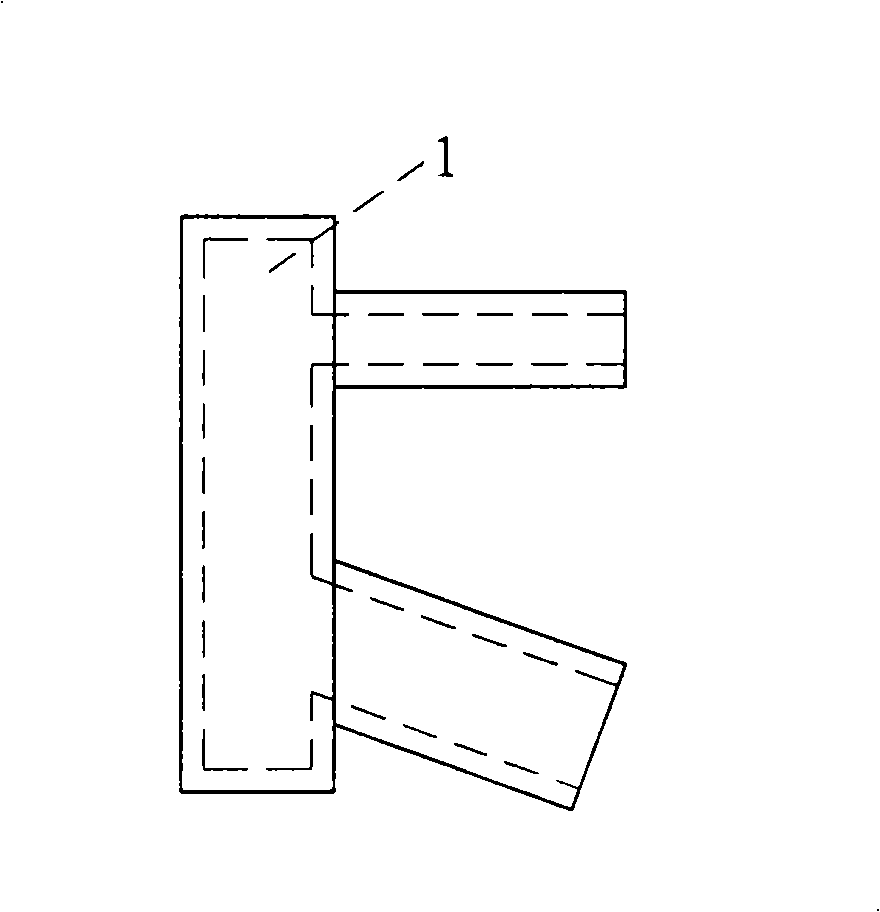

A container for an optical fiber coil and an optical fiber module including the container is provided, wherein an excess length portion of a pigtail fiber is accommodated in the container and the remaining portion can be drawn out from the container. The container includes a first part for accommodating a coil having a functional optical fiber, and a second part disposed on an outer periphery side of the first part and windingly accommodating a pigtail fiber that is optically connected to the functional optical fiber. The second part has a gap that extends over the entirety of the outer periphery, and communicates with the exterior. The optical fiber module includes the container, the coil having the functional optical fiber accommodated in the first part of the container, and the pigtail fiber that is optically connected to the functional fiber and that has a portion windingly accommodated in the second part.

Owner:SUMITOMO ELECTRIC IND LTD

Container for accommodating optical fiber coil and optical fiber module having the container

InactiveUS7548679B2Convenient to accommodateSimple configurationOptical light guidesFiberOptical Module

A container for an optical fiber coil and an optical fiber module including the container is provided, wherein an excess length portion of a pigtail fiber is accommodated in the container and the remaining portion can be drawn out from the container. The container includes a first part for accommodating a coil having a functional optical fiber, and a second part disposed on an outer periphery side of the first part and windingly accommodating a pigtail fiber that is optically connected to the functional optical fiber. The second part has a gap that extends over the entirety of the outer periphery, and communicates with the exterior. The optical fiber module includes the container, the coil having the functional optical fiber accommodated in the first part of the container, and the pigtail fiber that is optically connected to the functional fiber and that has a portion windingly accommodated in the second part.

Owner:SUMITOMO ELECTRIC IND LTD

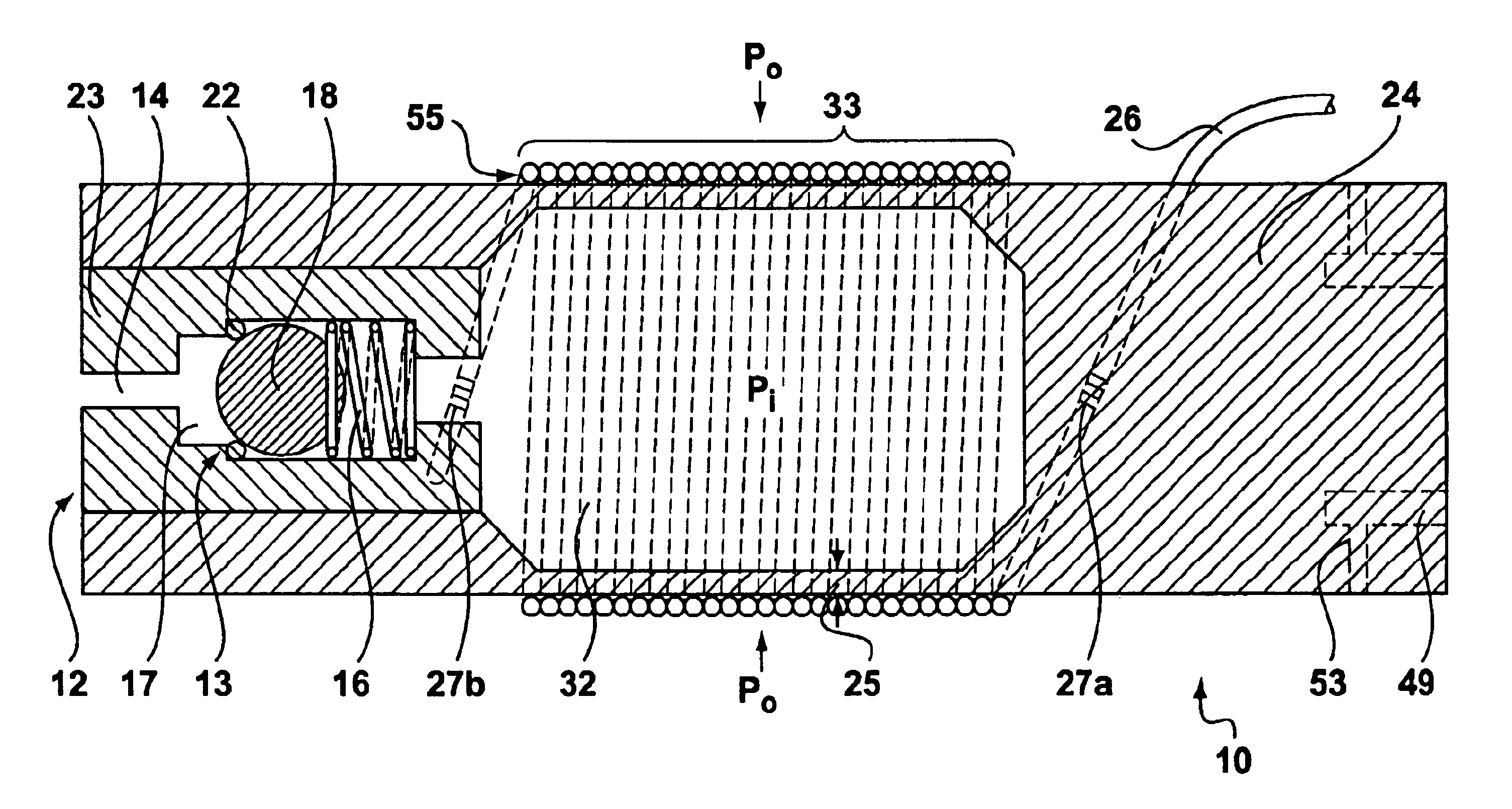

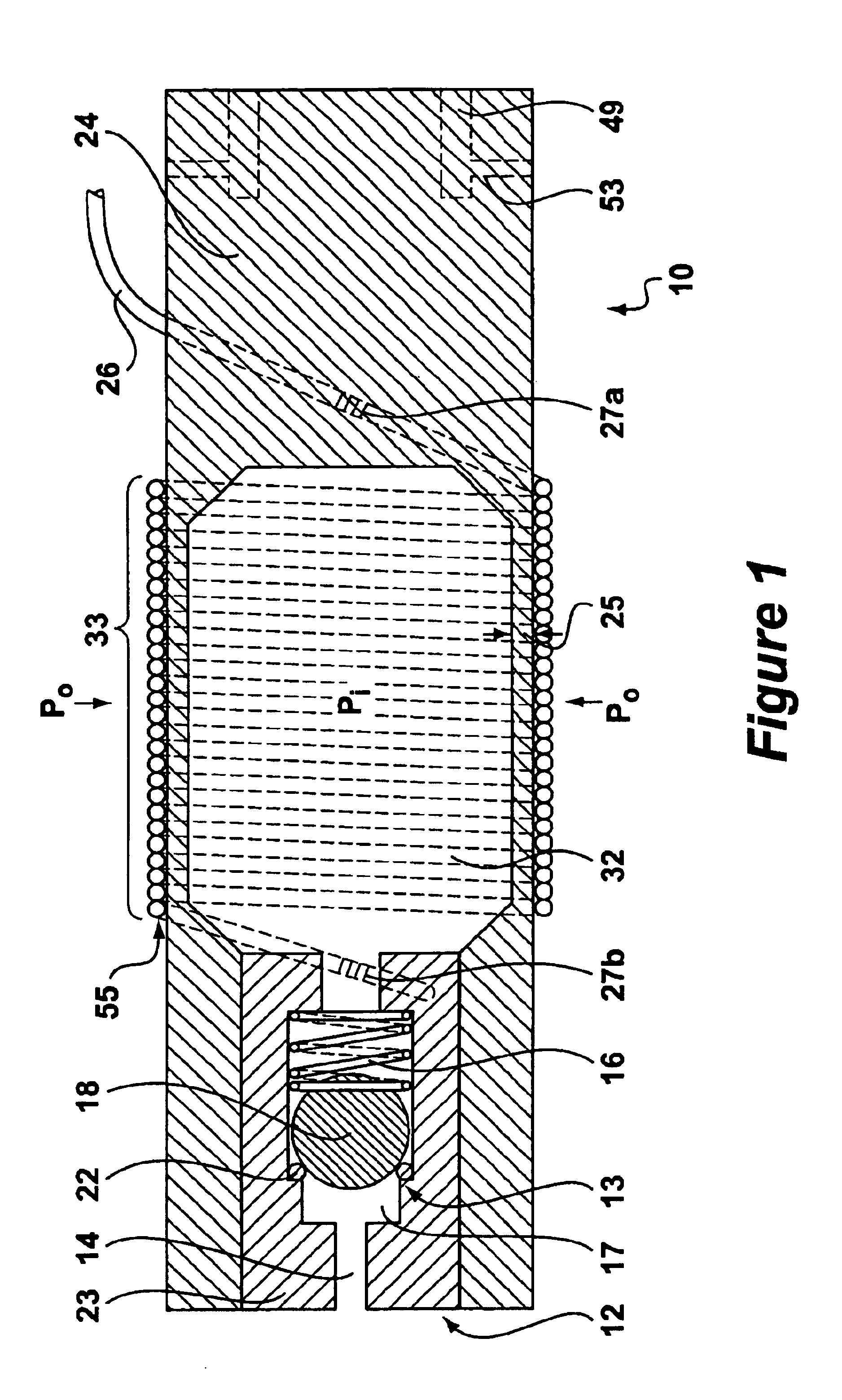

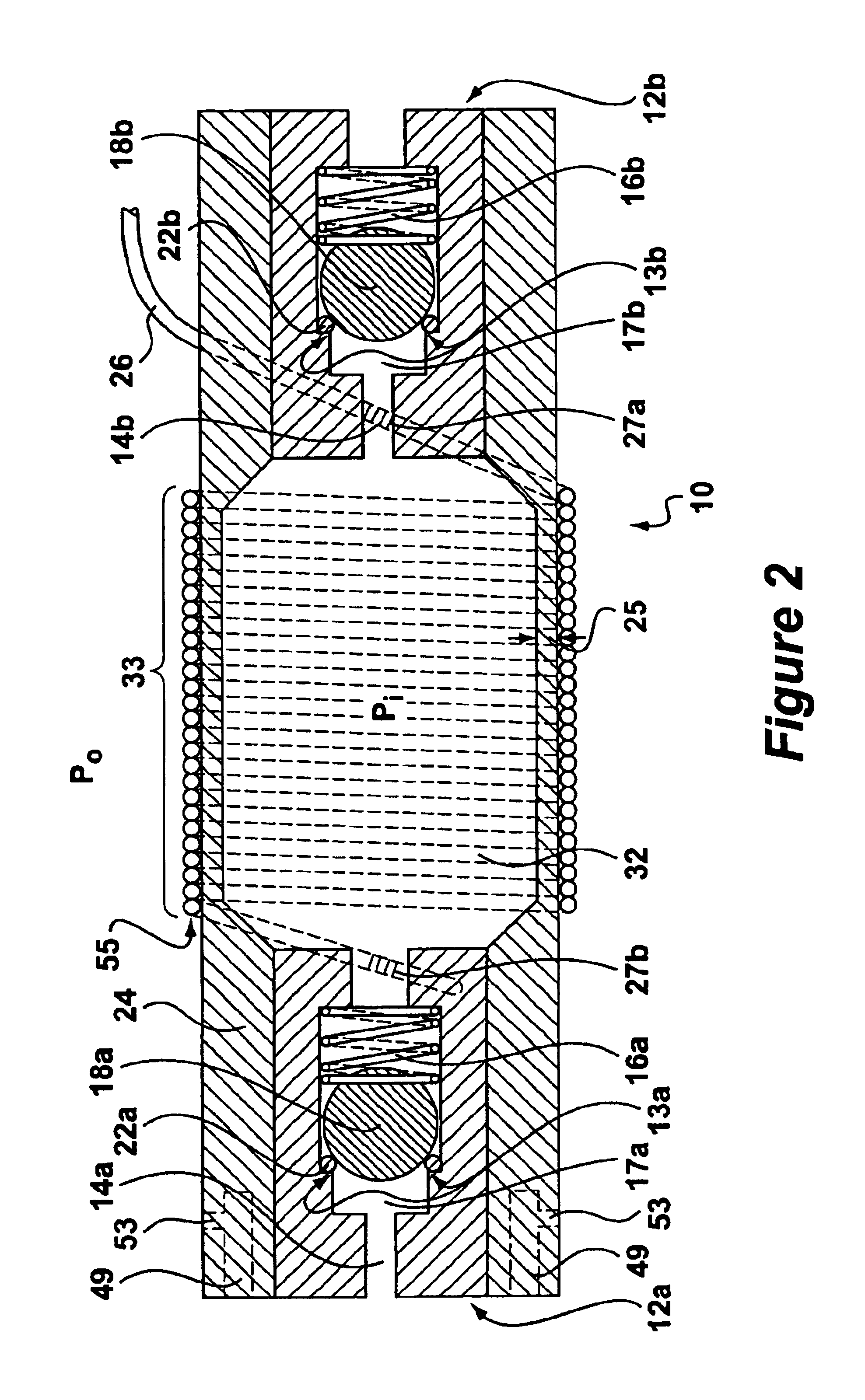

Pressure compensated hydrophone

InactiveUS6882595B2Subsonic/sonic/ultrasonic wave measurementSeismic signal receiversFiberHydrophone

A pressure compensated hydrophone for measuring dynamic pressures is disclosed. The hydrophone includes a compliant hollow mandrel with a single optical fiber coiled around at least a portion of the mandrel. The mandrel further includes at least one pressure relief valve for compensating for changes in hydrostatic pressure. The pressure relief valve includes a micro-hole, which allows hydrostatic pressures or low frequency pressure events to couple into the interior of the mandrel to provide compensation against such pressure. Higher frequencies pressure events of interest do not couple through the micro-hole and therefore only act only on the exterior of the mandrel, allowing for their detection. Because (quasi) hydrostatic events are compensated for, the mandrel may be made particularly compliant, rendering the singular fiber optic coil particularly sensitive to the detection of the higher frequency signals of interest.

Owner:WEATHERFORD TECH HLDG LLC

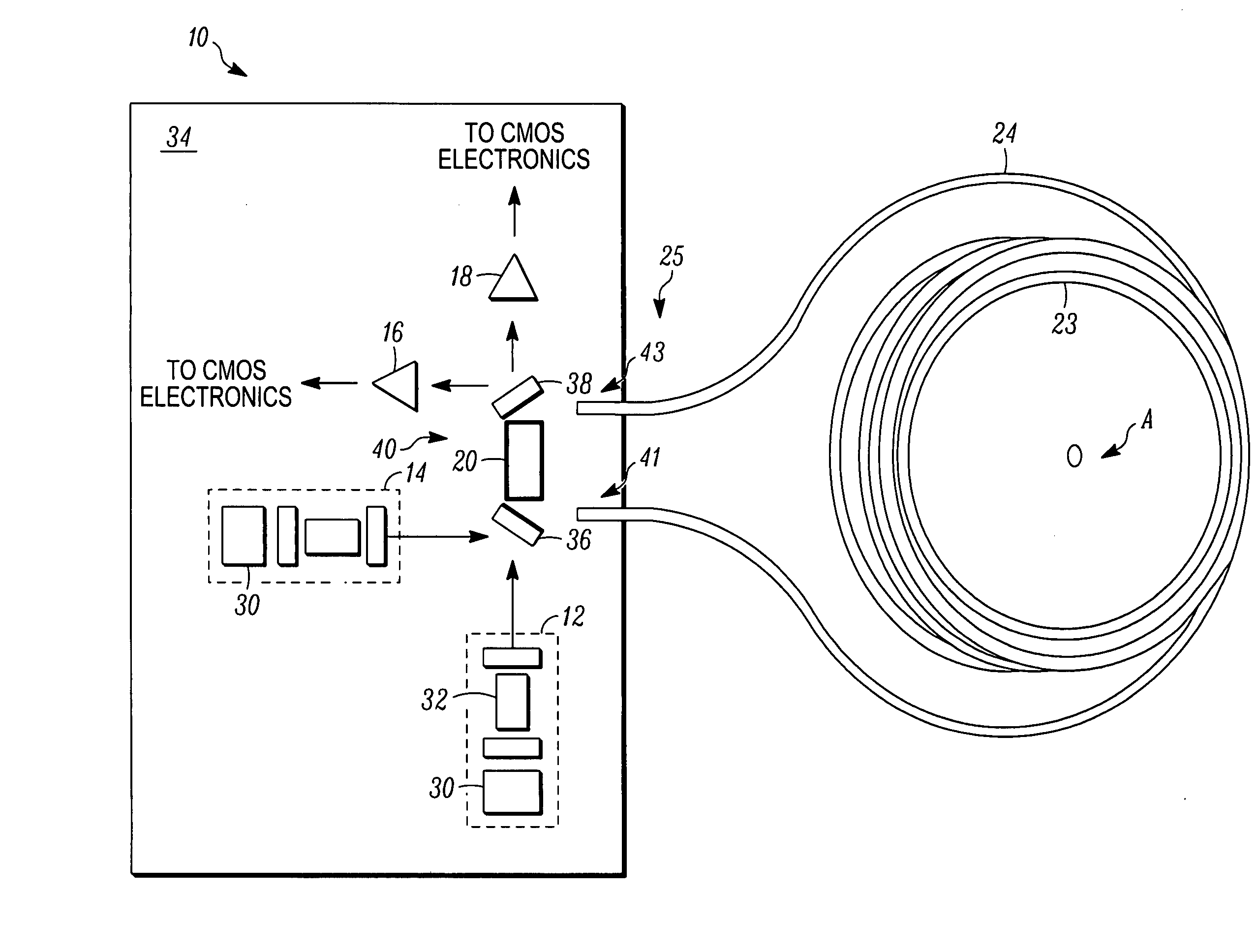

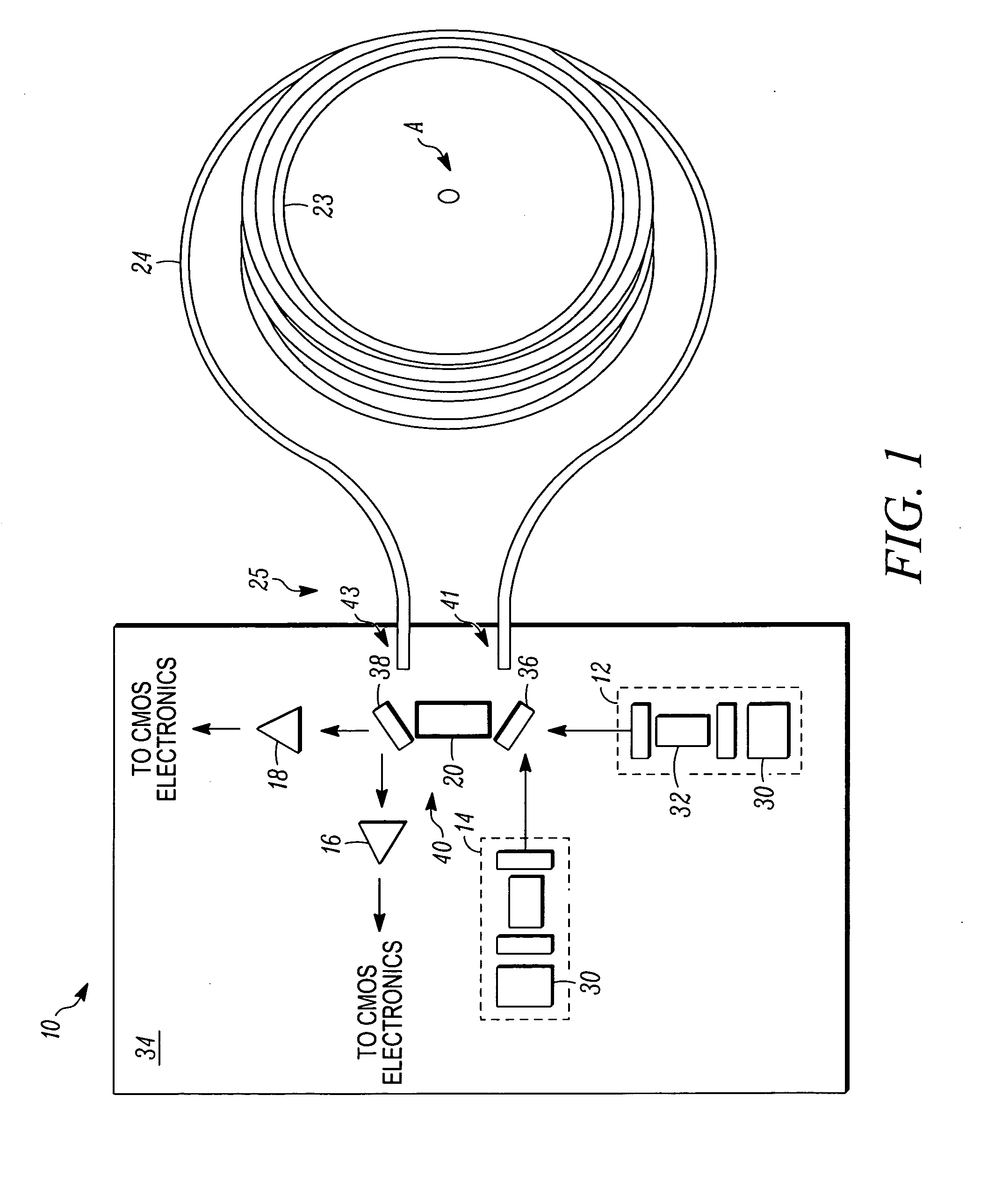

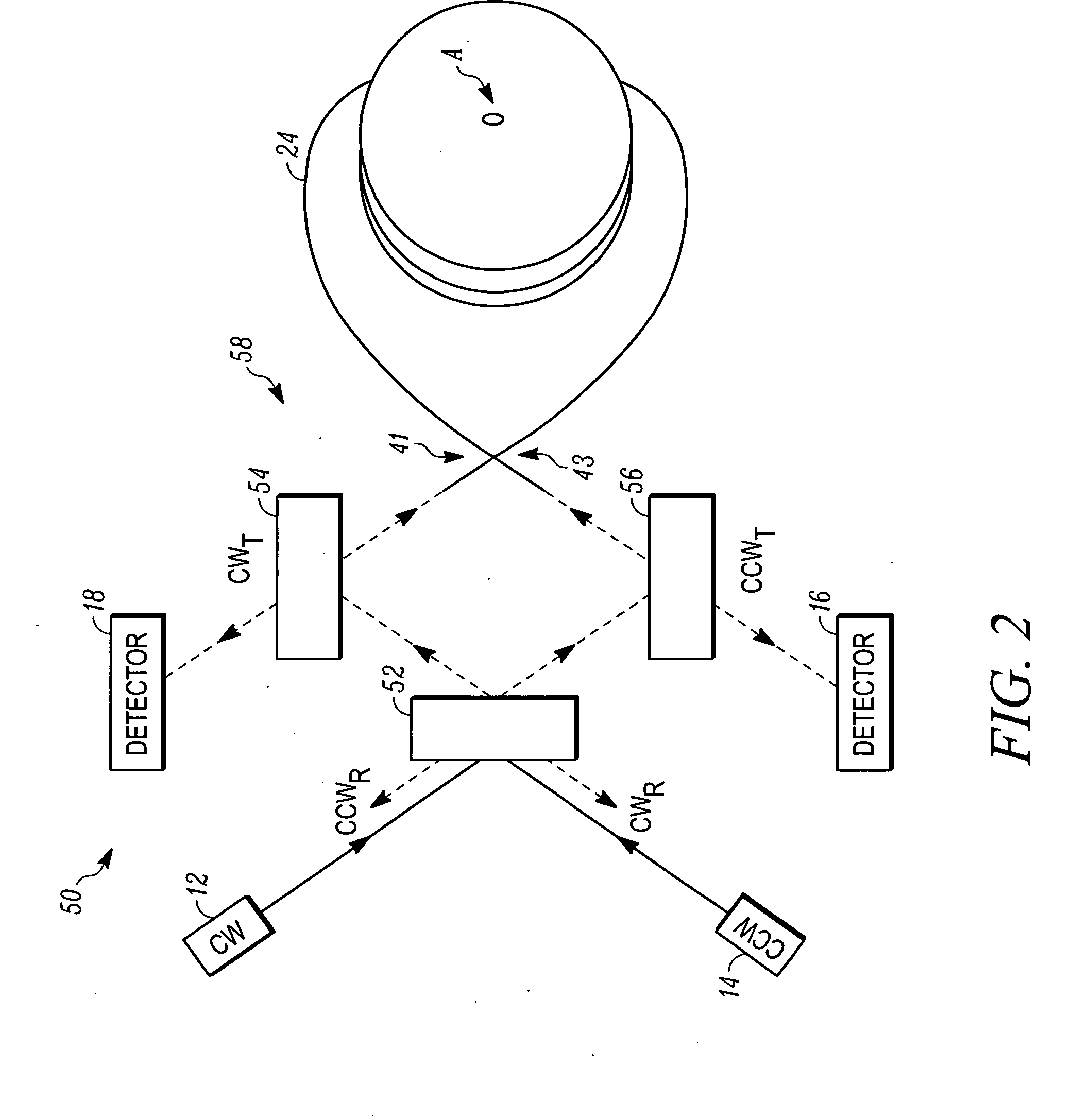

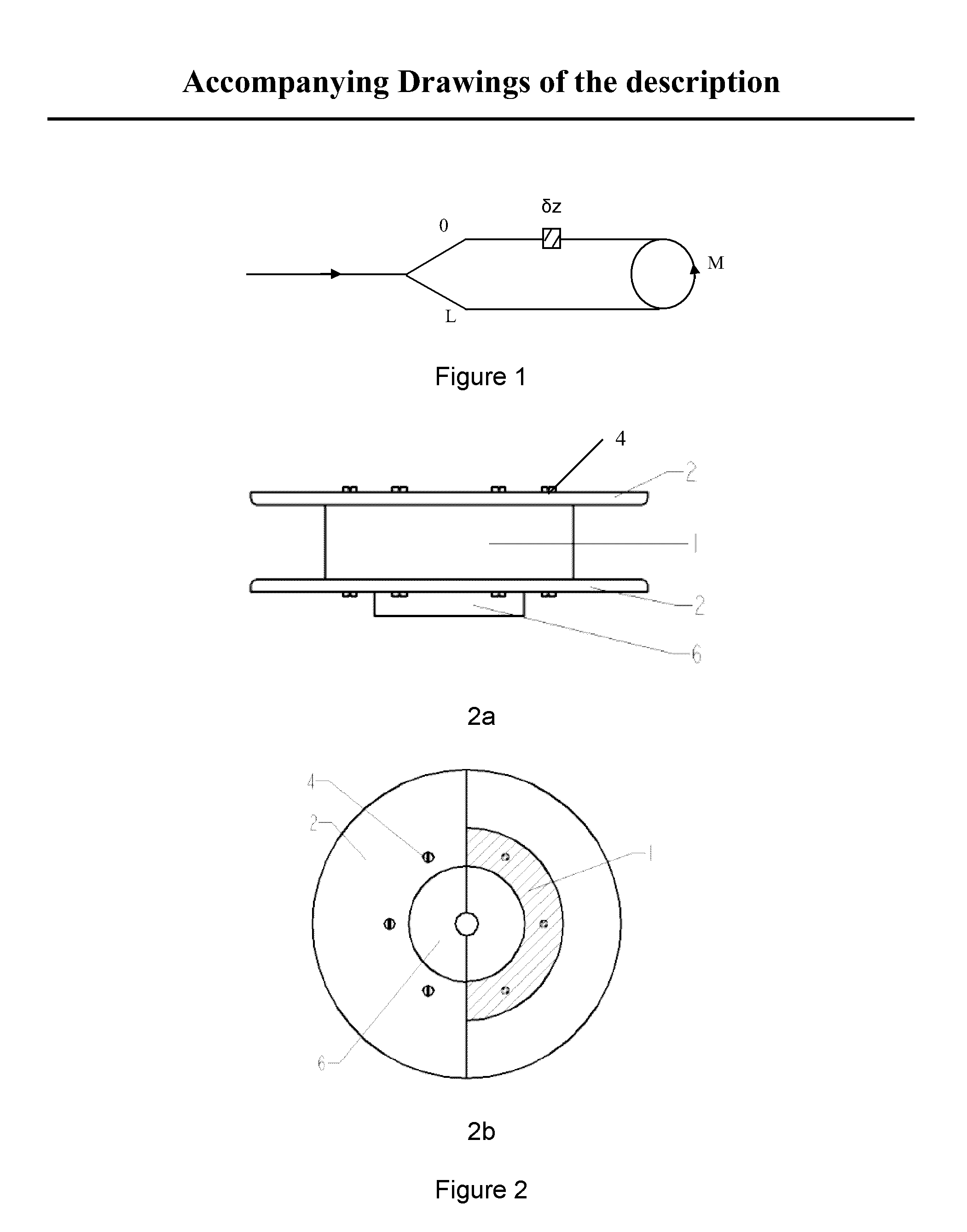

Optical resonator gyro and method for reducing resonance asymmetry errors

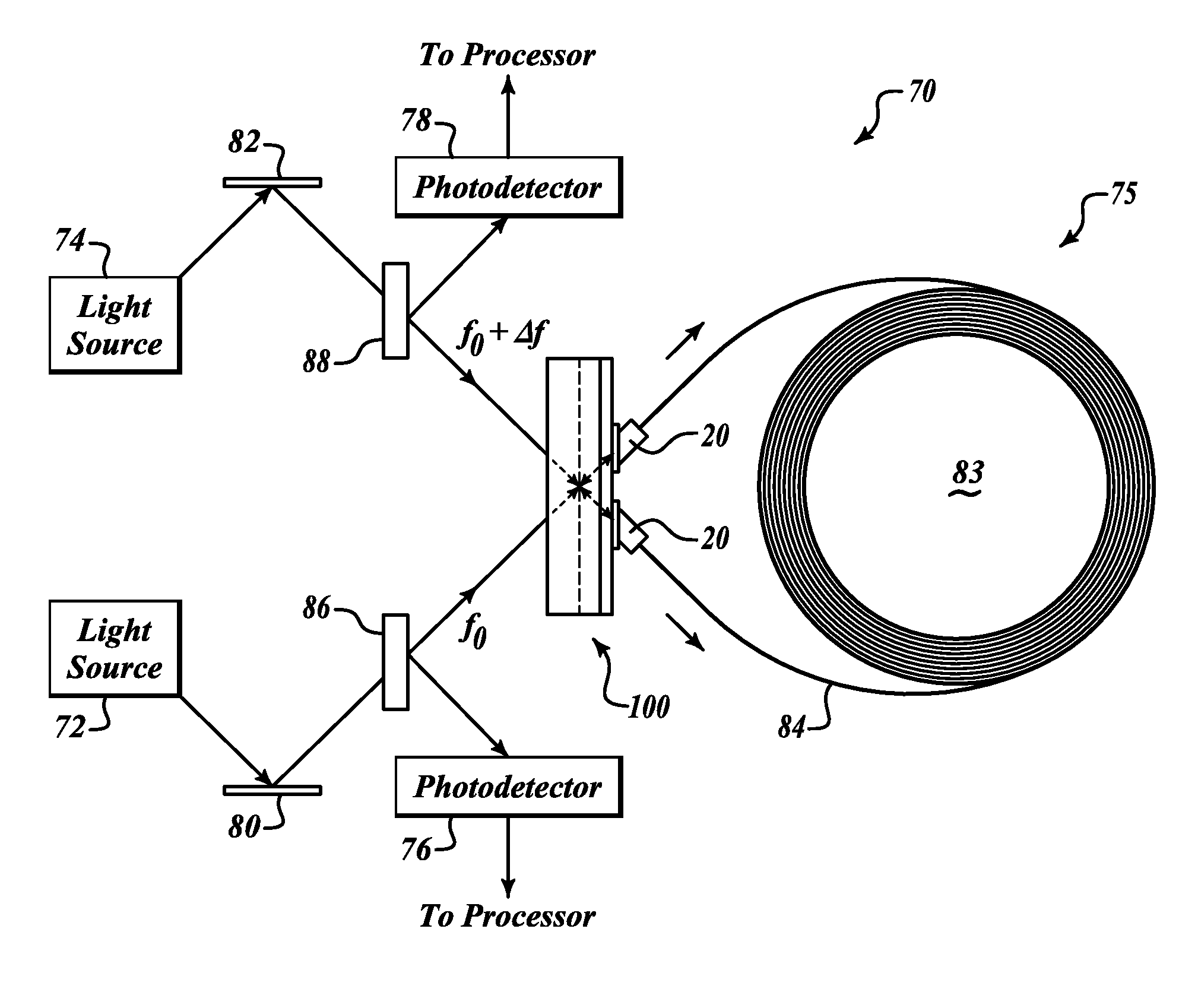

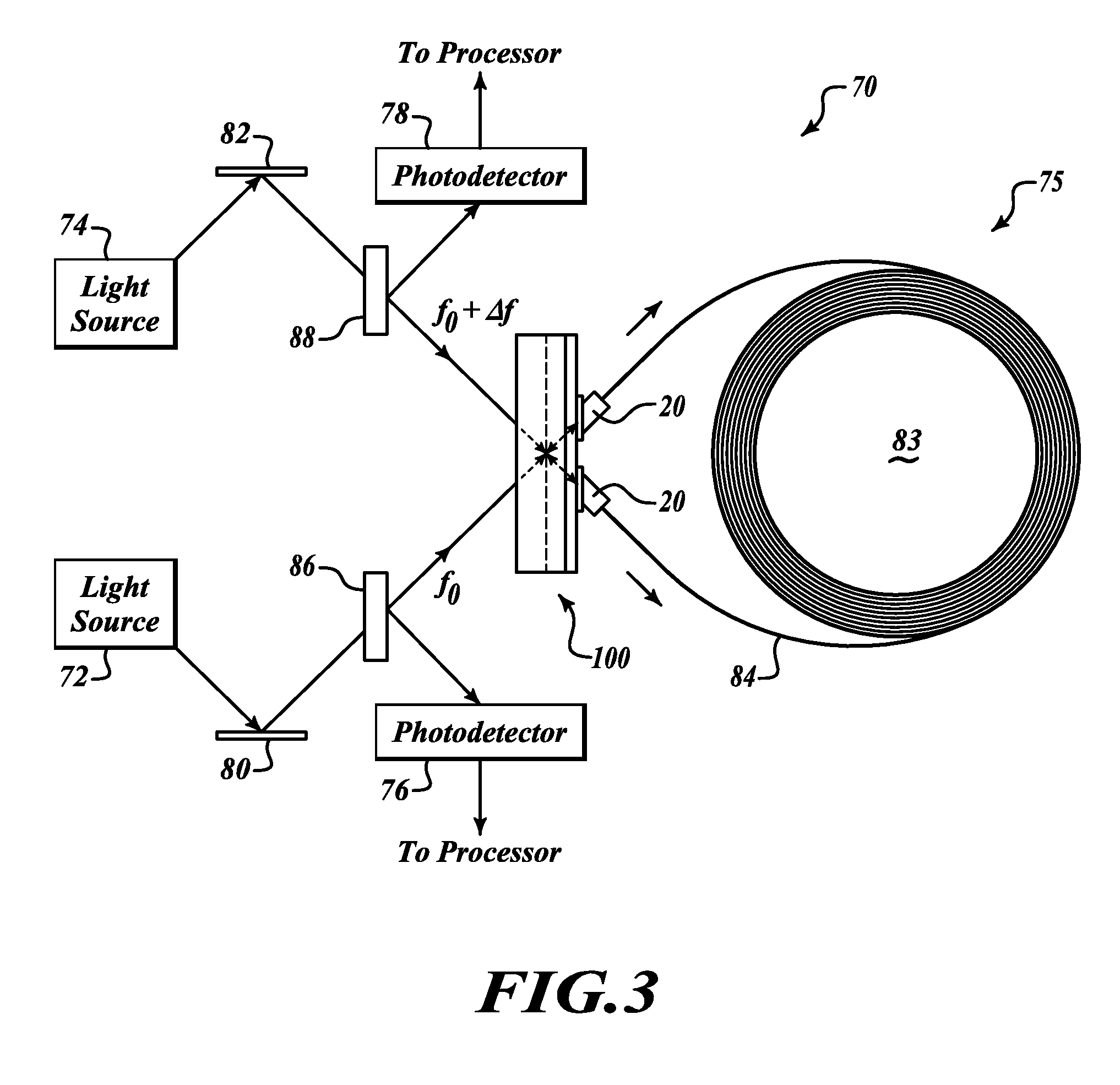

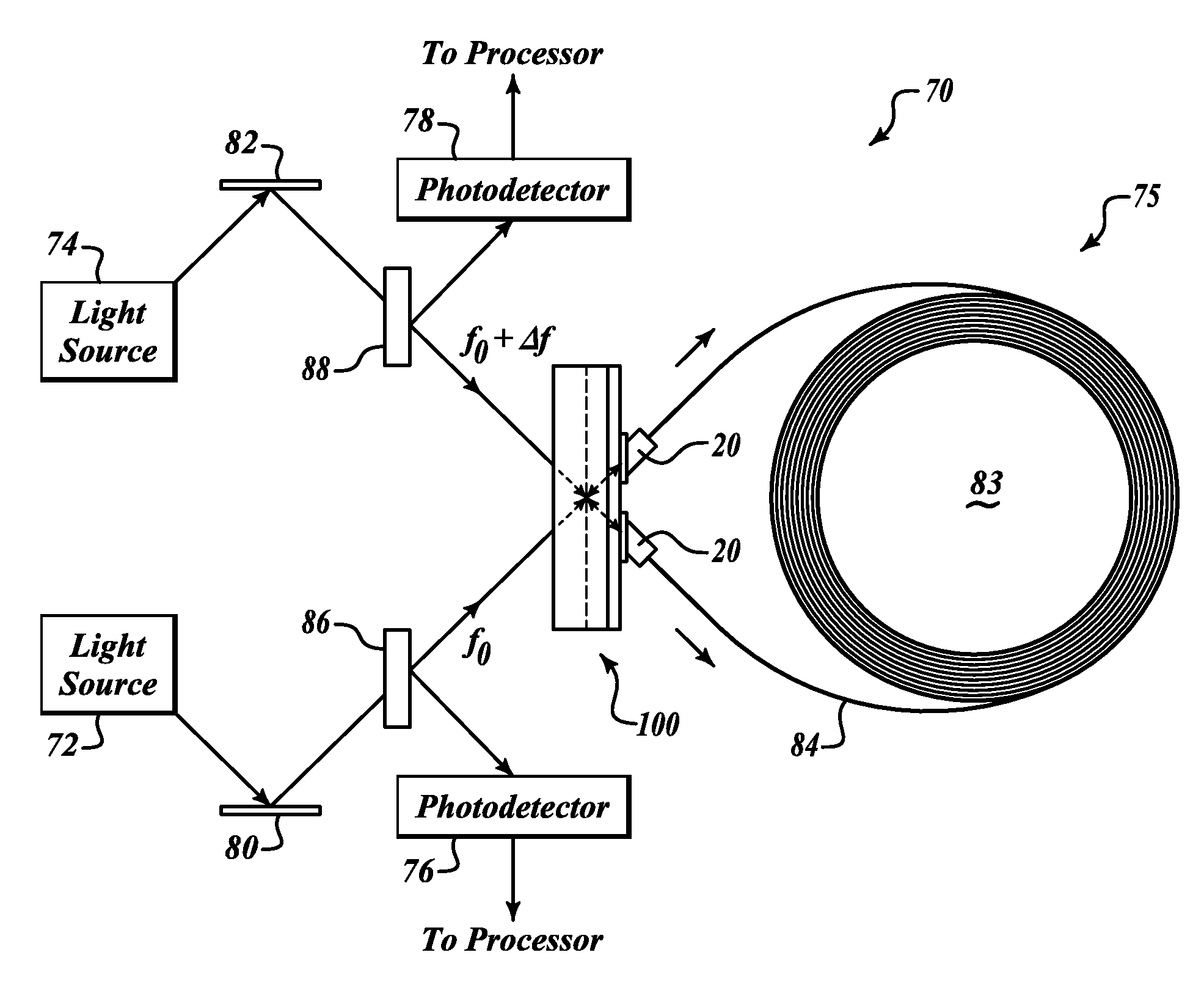

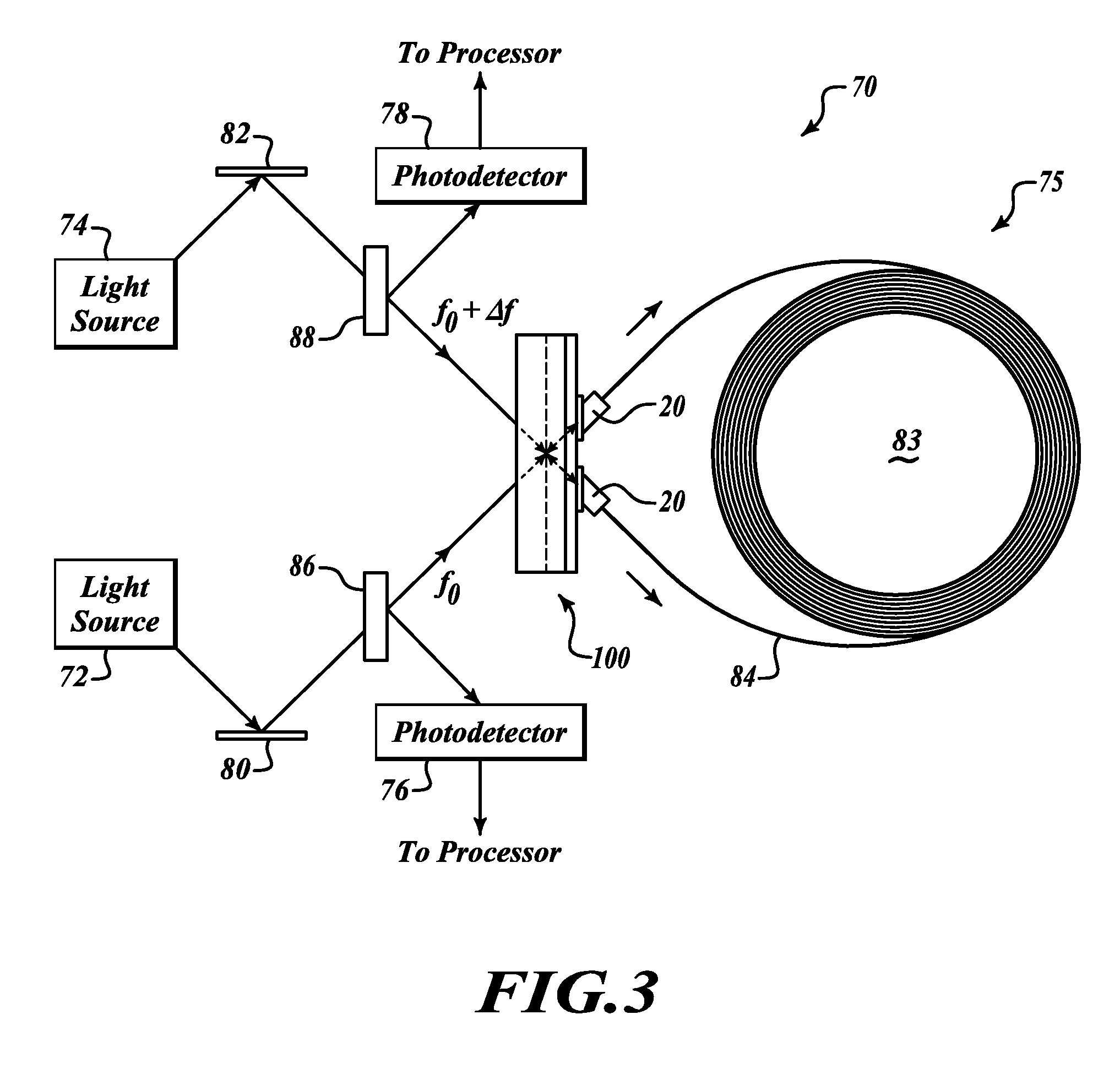

ActiveUS20080079947A1Reducing resonance asymmetry errorReduce errorsSpeed measurement using gyroscopic effectsSagnac effect gyrometersResonanceLight beam

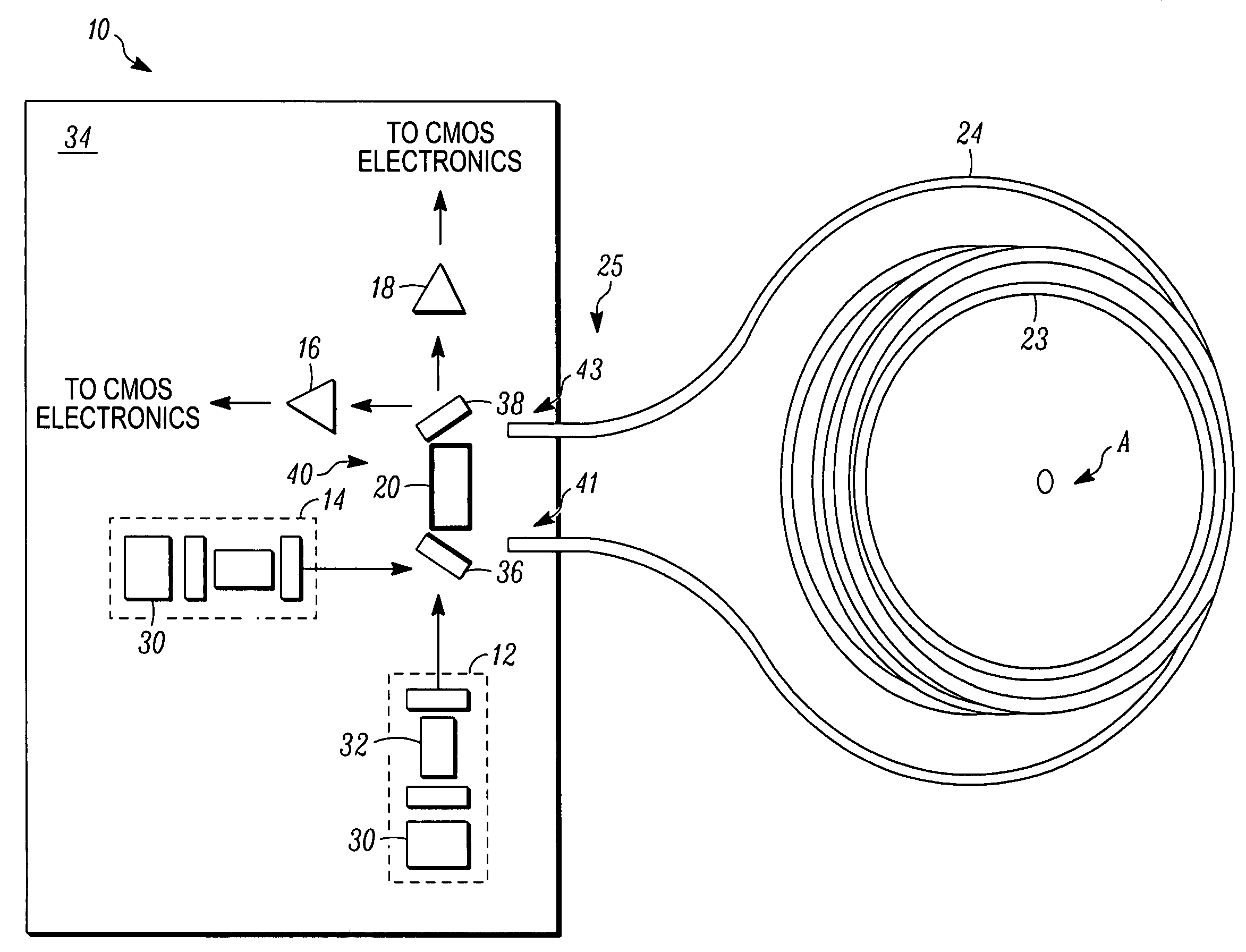

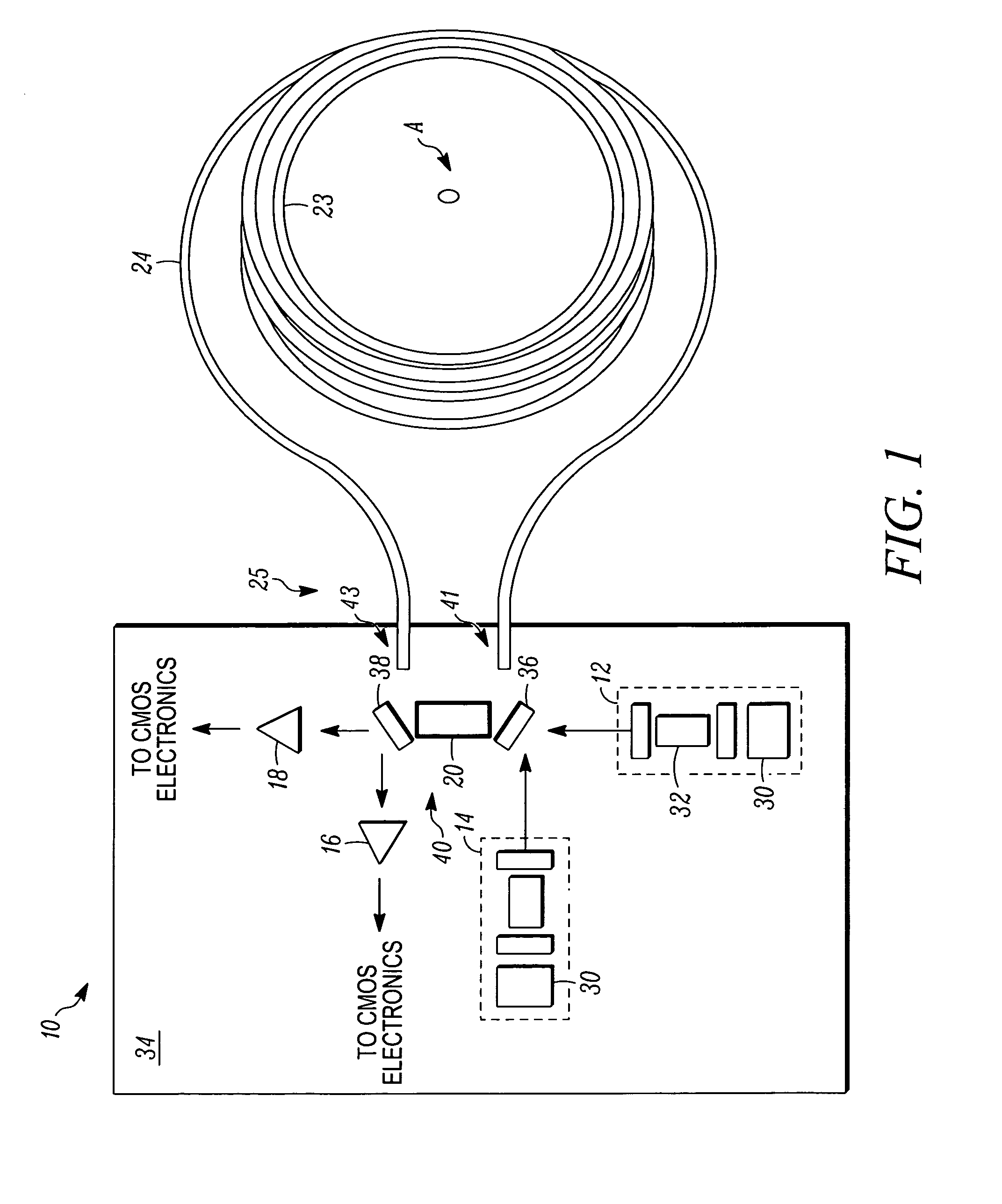

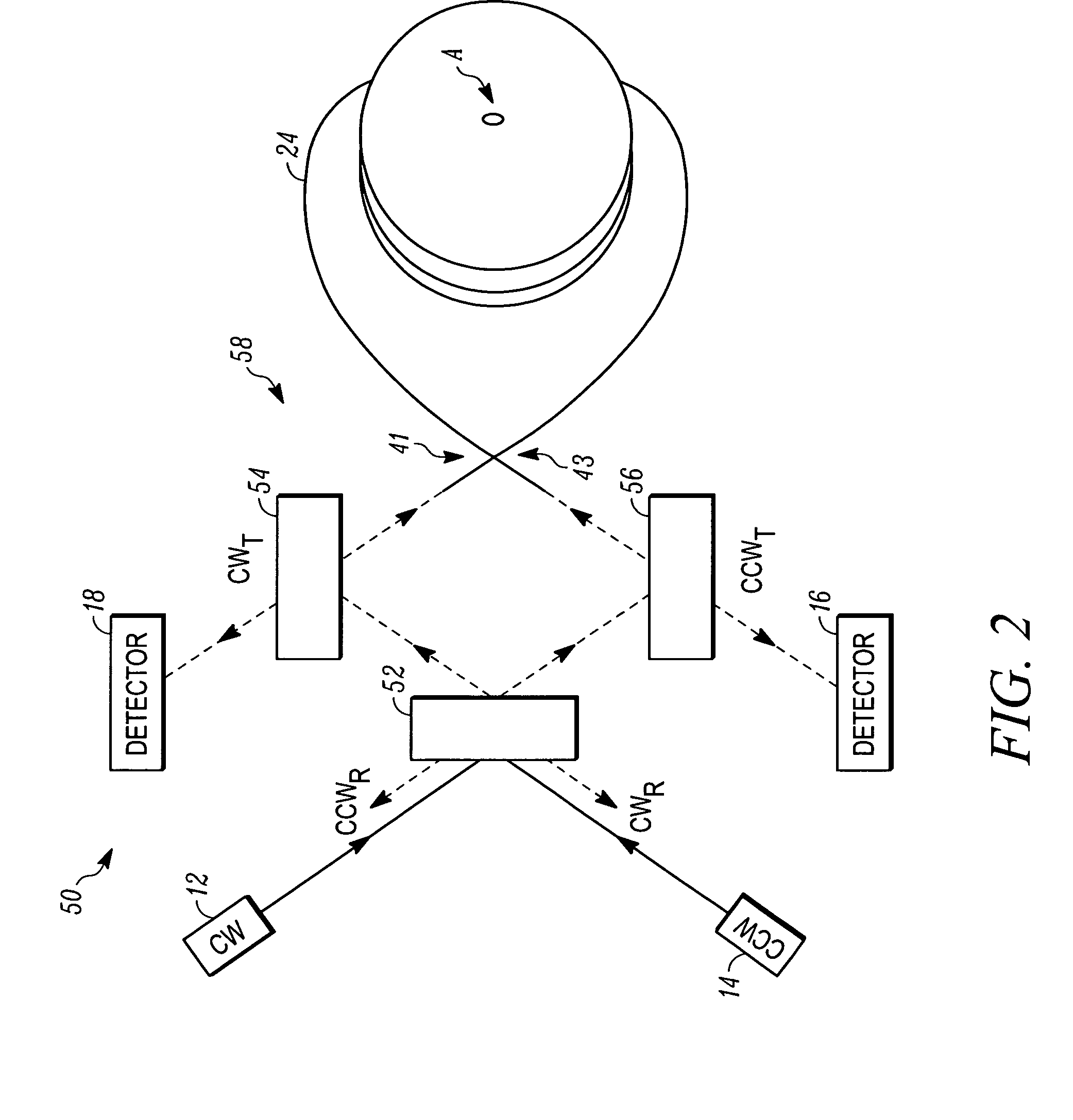

Methods and apparatus are provided for attenuating rotation rate errors in a resonator gyro. The gyro includes a ring resonator having a hollow core optical fiber coil and optical elements that are selected and / or oriented to reduce stray light that may be present in input light beams introduced to the ring resonator. The resonator has a predetermined mode. One of the optical elements partially transmits a portion of the input light beam to a first end of the fiber coil while partially transmitting a portion of the input light beam to a filter. Light having the predetermined mode is accepted into the first end of the fiber coil, and the filter accepts light of the input light beam having a corresponding mode. Transmission components of the circulating light beams indicates resonance peaks of the counter-propagating directions of the ring resonator.

Owner:HONEYWELL INT INC

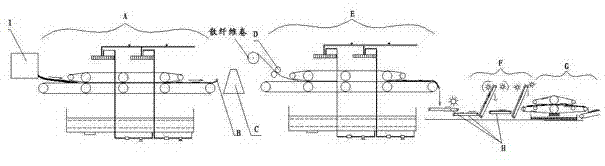

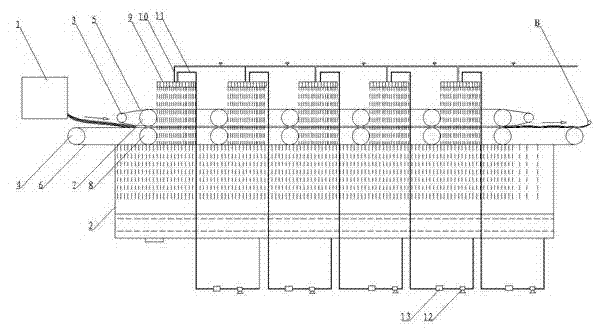

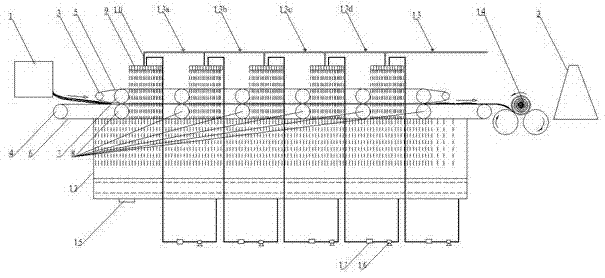

Continuous type colored loose fiber machining device

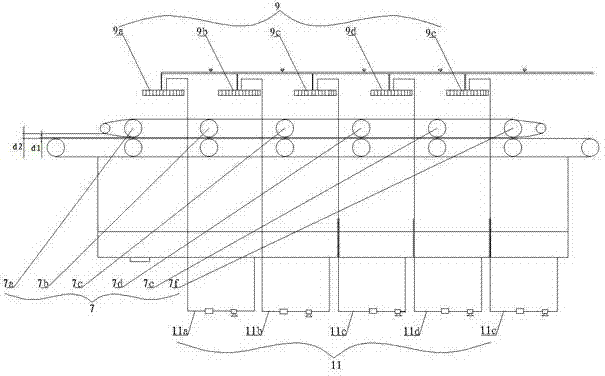

ActiveCN103774368ASolve uneven dyeingResolution cycleSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersFiberEngineering

The invention relates to a continuous type colored loose fiber machining device, and belongs to the technical field of loose fiber dyeing. The continuous type colored loose fiber machining device comprises a spray-rolling type drying machine, a coiling roller, a cold-batch fixation device, cotton conveying rollers, a spray-rolling type washing machine, a conveyor belt and a squeezing device in sequence. Loose fibers are subjected to spraying dyeing by being horizontally clamped by a transmission component of the spray-rolling type drying machine, the coiling roller is arranged on the rear portion of a lower guide belt of the spray-rolling type drying machine and coils the dyed loose fibers to be loose fiber coils, the loose fiber coils are transferred to the cold-batch fixation device for cold-batch fixation, the loose fiber coils are conveyed to the spray-rolling type washing machine through the cotton conveying rollers, spray washing is carried out on the cotton conveying rollers when the cotton conveying rollers are conveyed by being horizontally clamped through the transmission component of the spray-rolling type washing machine, the washed loose fibers fall down on the conveyor belt behind the spray-rolling type washing machine under the gravity of the loose fibers themselves, and the loose fibers are conveyed to the squeezing device for dewatering. The continuous type colored loose fiber machining device can continuously produce colored loose fibers, and greatly lower processing cost.

Owner:绍兴国周针织科技有限公司

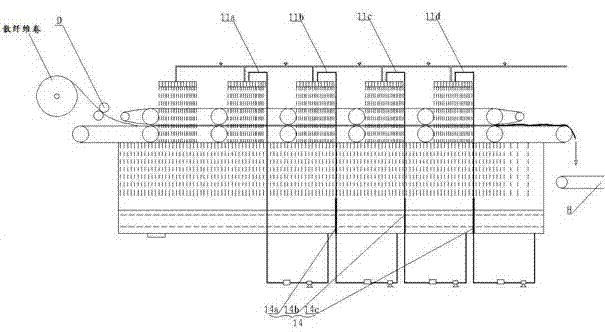

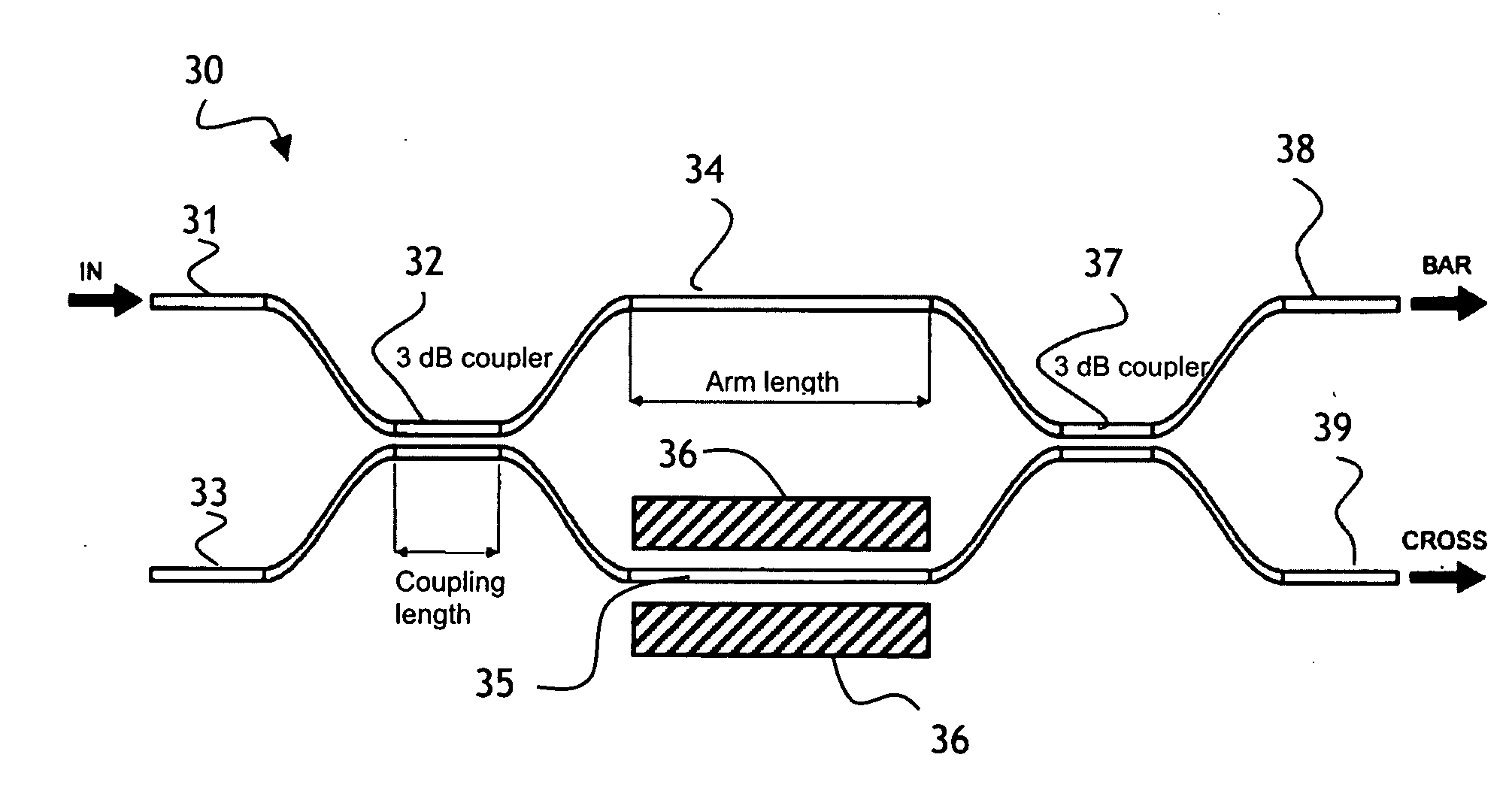

Optical fiber amplifier and a control method therefor

ActiveUS20090201576A1Improve performanceReduced footprintLaser detailsFibre transmissionFiberPhotodetector

A fiber amplifier having two erbium doped fiber coils and a pump laser diode optically coupled, through a fiber array, to a planar lightwave circuit, is described. A photodetector array, a multiport free-space optical isolator, and a strip of thin-film gain flattening filter are attached to a side surface of the planar lightwave circuit, which has a tunable optical power splitter for variably splitting the optical pump power for the laser diode between the two erbium doped fiber coils, and variable tilters for correcting the gain tilt of the amplifier. The variable splitter and the tilters are thermally tunable Mach-Zehnder interferometers.

Owner:LUMENTUM OPERATIONS LLC

Optical resonator gyro and method for reducing resonance asymmetry errors

ActiveUS7522284B2Reduce errorsSpeed measurement using gyroscopic effectsSagnac effect gyrometersResonanceLight beam

Methods and apparatus are provided for attenuating rotation rate errors in a resonator gyro. The gyro includes a ring resonator having a hollow core optical fiber coil and optical elements that are selected and / or oriented to reduce stray light that may be present in input light beams introduced to the ring resonator. The resonator has a predetermined mode. One of the optical elements partially transmits a portion of the input light beam to a first end of the fiber coil while partially transmitting a portion of the input light beam to a filter. Light having the predetermined mode is accepted into the first end of the fiber coil, and the filter accepts light of the input light beam having a corresponding mode. Transmission components of the circulating light beams indicates resonance peaks of the counter-propagating directions of the ring resonator.

Owner:HONEYWELL INT INC

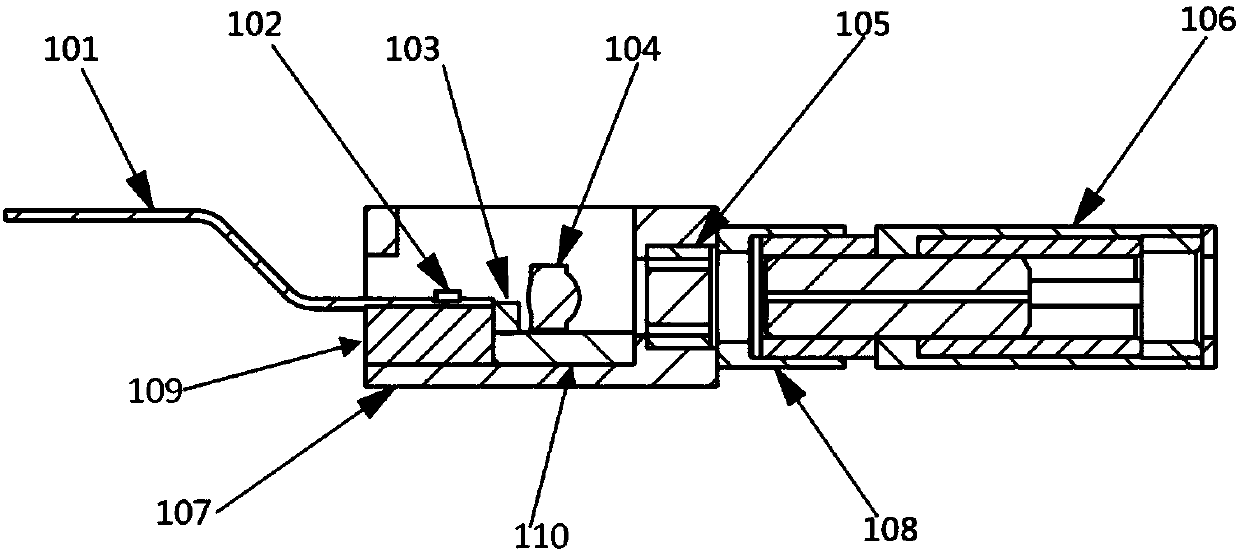

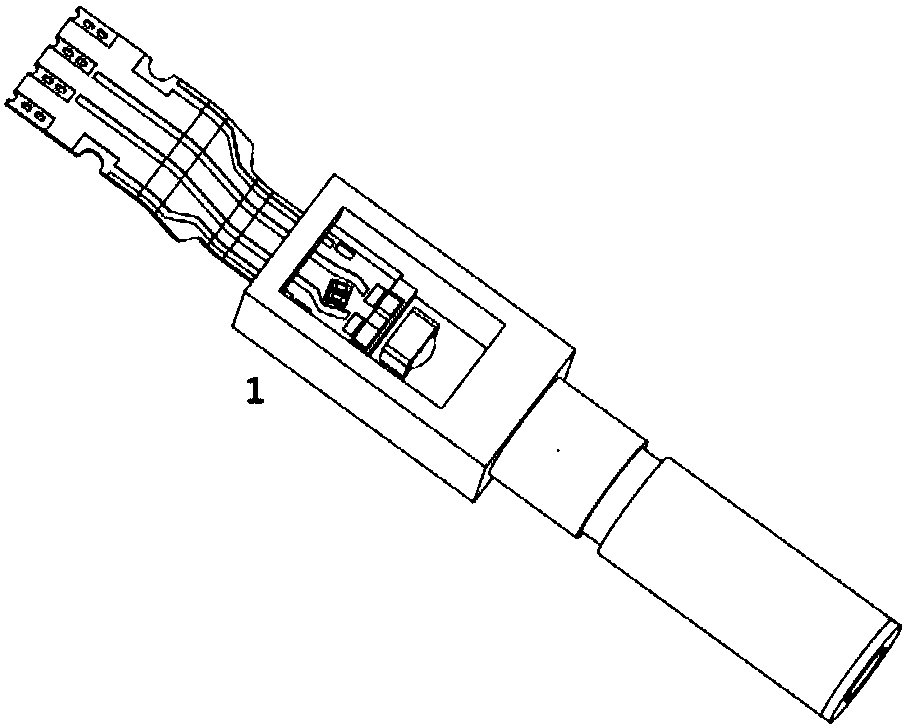

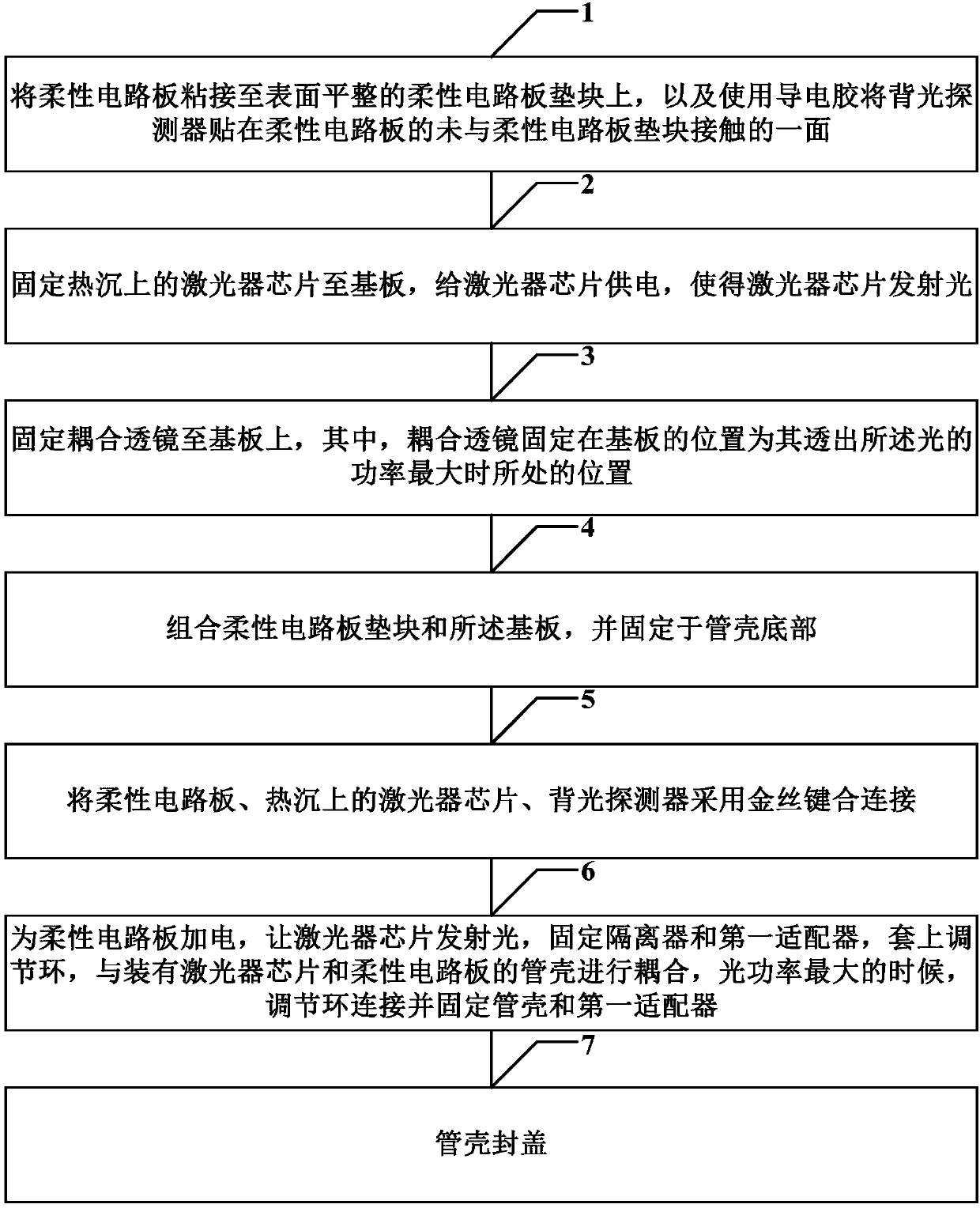

Light emitting assembly, packaging process and optical module

An embodiment of the invention provides a light emitting assembly, a packaging process and an optical module, wherein the light emitting assembly, the packaging process and the optical module are usedfor settling problems of high difficulty and no easy realization of a fiber coiling process in prior art. The light emitting assembly comprises the components of a flexible circuit board which is used for supplying electric energy to a laser chip and a backlight detector and transmitting an electric signal; the laser chip which is used for receiving the electric signal and converting the electricsignal to an optical signal; a coupling lens which is used for focusing the optical signal that is emitted from the laser chip, wherein the optical signal is transmitted to a single-mode fiber insertion core of a first adapter; and a substrate which is used for supplying an optical path coupling medium for the laser chip and the coupling lens. Because the new light emitting assembly which can beconnected with a multiplexing assembly in a non-welding manner is presented, the fiber coiling process is prevented, and the problems of high difficulty and no easy realization of the fiber coiling process in the existing light emitting assembly are prevented.

Owner:SHENZHEN GIGALIGHT TECH

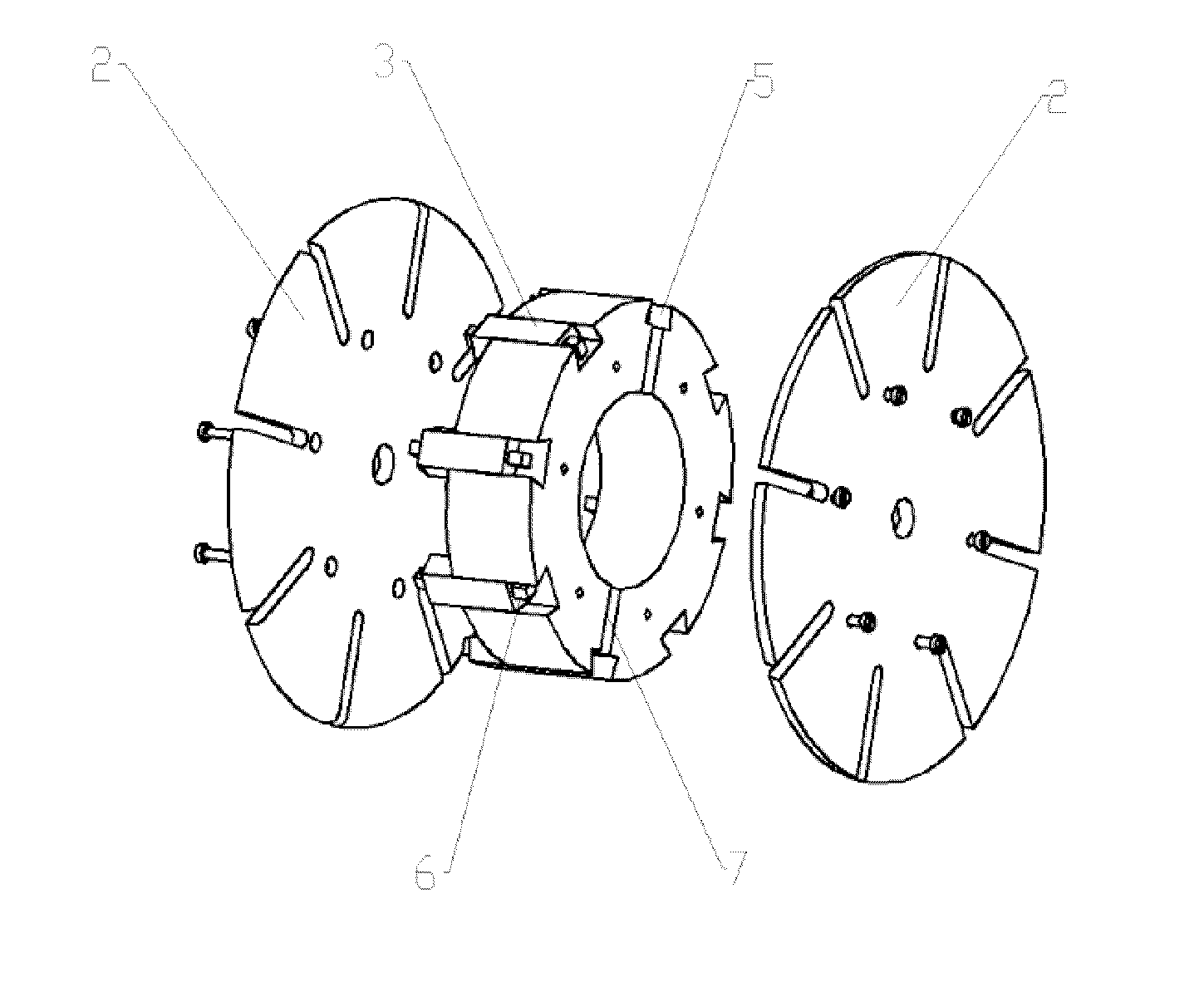

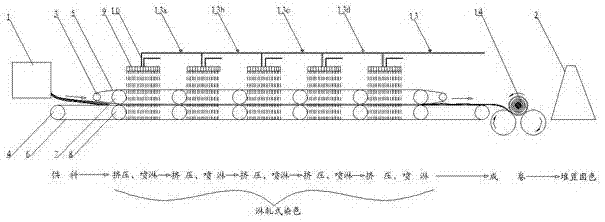

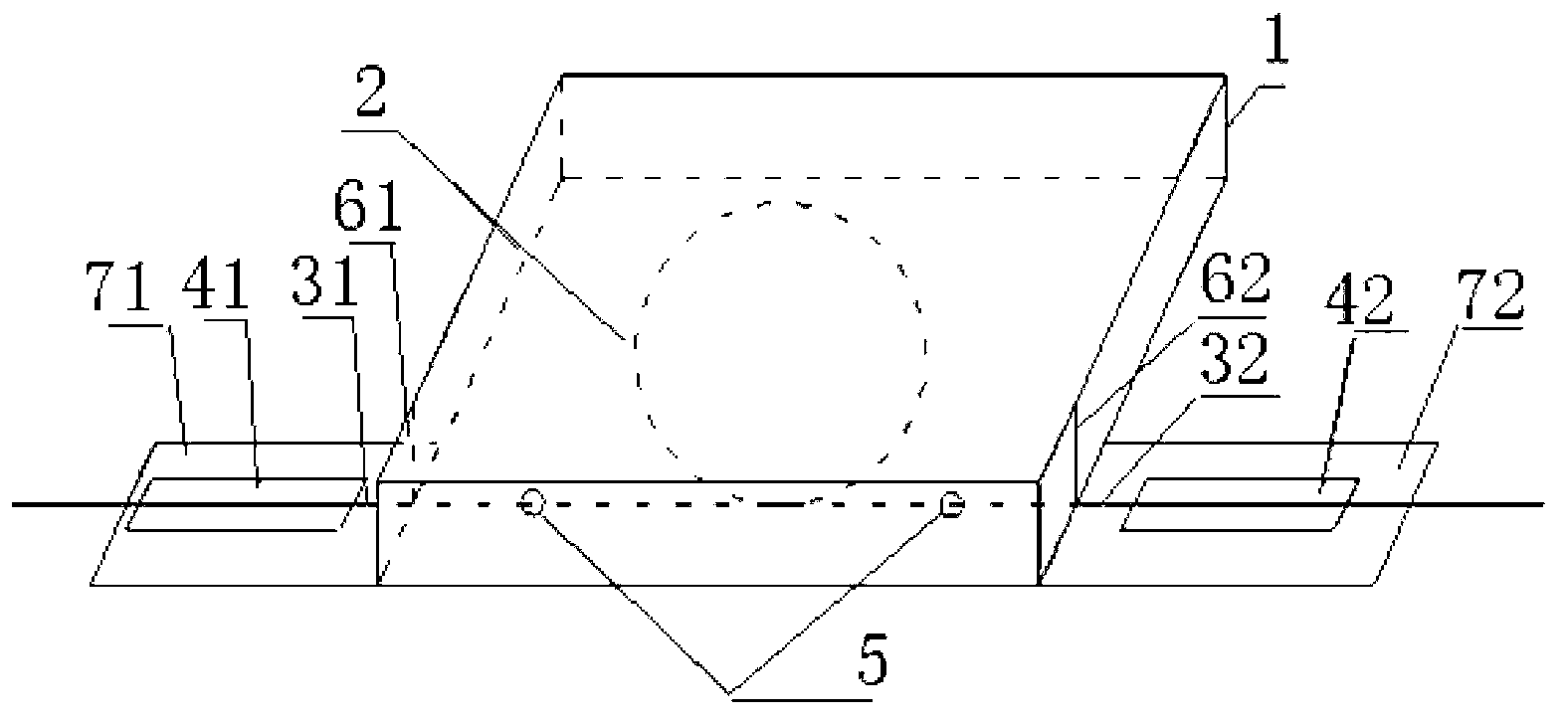

Fiber-optic loop structure wound in vertically symmetrical cross manner for fiber-optic gyroscope and winding method

The invention discloses a fiber-optic loop structure wound in a vertically symmetrical cross manner for a fiber-optic gyroscope. The fiber-optic loop structure comprises a fiber-optic loop skeleton which comprises a wrapping post and a middle flange, wherein the middle flange is arranged at the periphery of the wrapping post, the middle flange is provided with a fiber passing notch, horizontally run-though bellmouth orifices are arranged on the wrapping post and the middle flange and are located at the symmetrical positions of the fiber passing notch, and a fiber outlet is formed on the middle flange. A vertically symmetrical crosswise winding method for the fiber-optic gyroscope comprises the following steps: 1, setting the midpoint of an optical fiber at the position of the fiber passing notch of a fiber-optic loop; 2, winding the optical fiber; and 3, leading the optical fiber into the fiber outlet. According to the invention, a fiber-optic coil is divided into an upper part and a lower part, and each of the two parts has one side which is free of structural restriction and is not compressed in conditions of vibration and temperature variation; and through cross winding, the coils at two sides both have forward and reverse optical fibers which are the same in length, so that temperature gradients in axial and radial directions have the same temperature modulation effect on the optical fibers.

Owner:BEIHANG UNIV

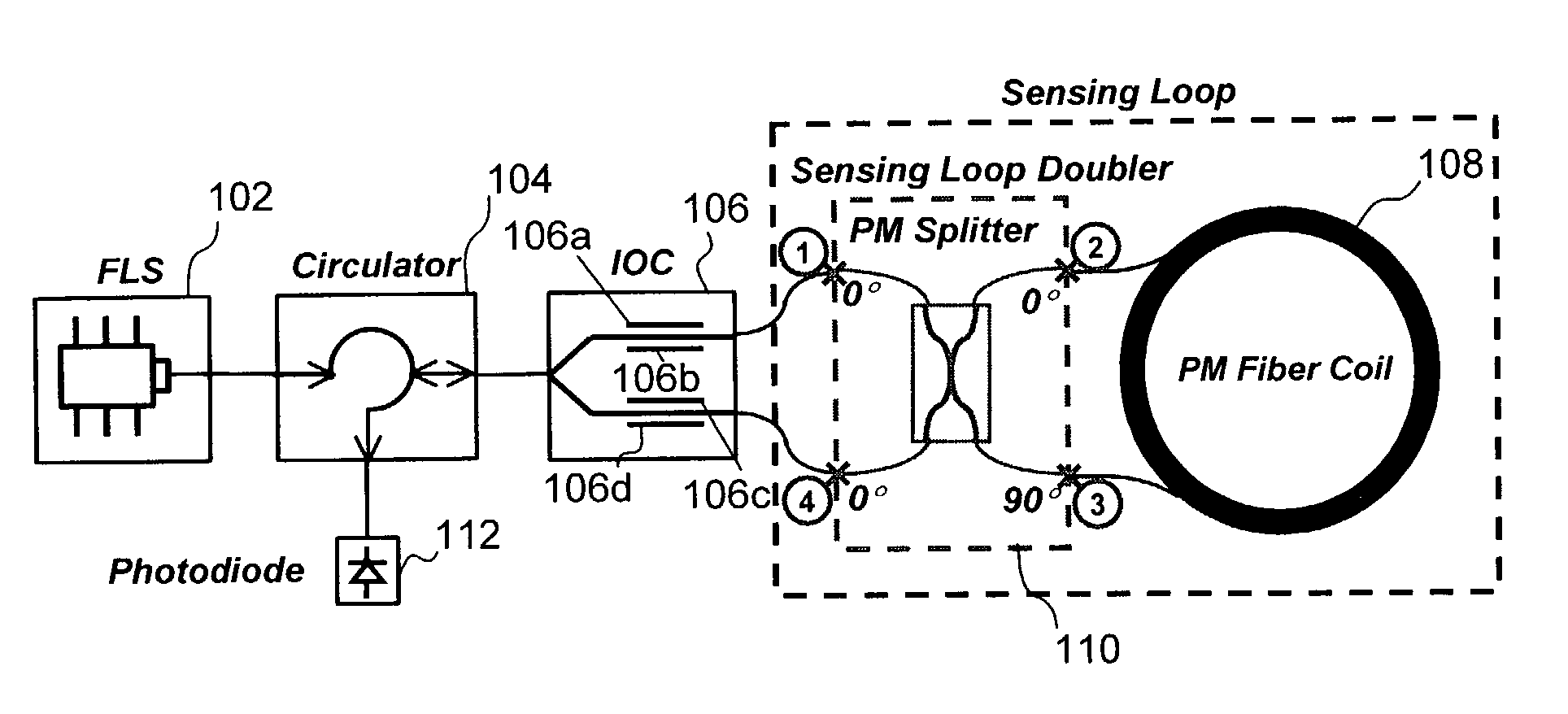

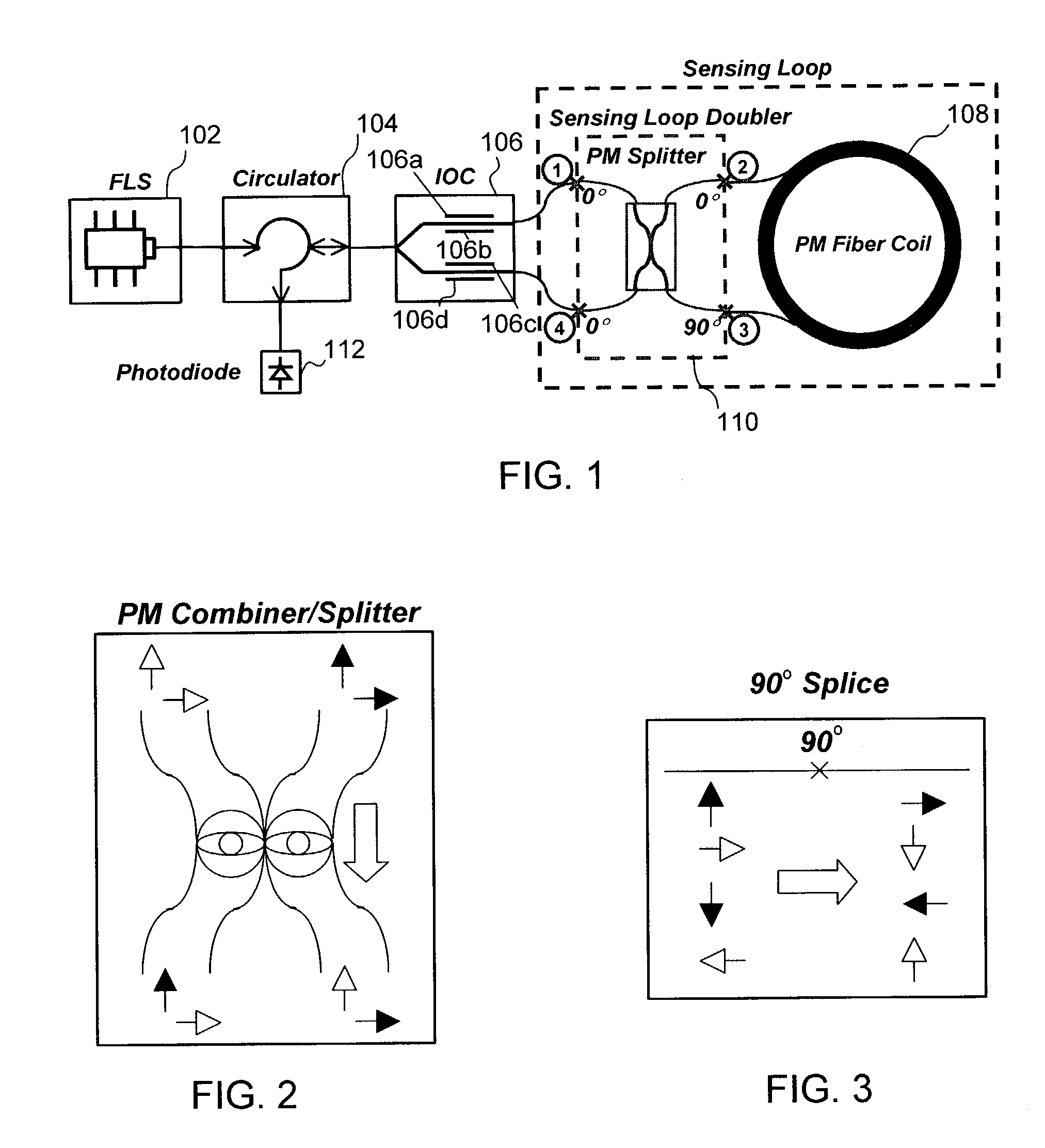

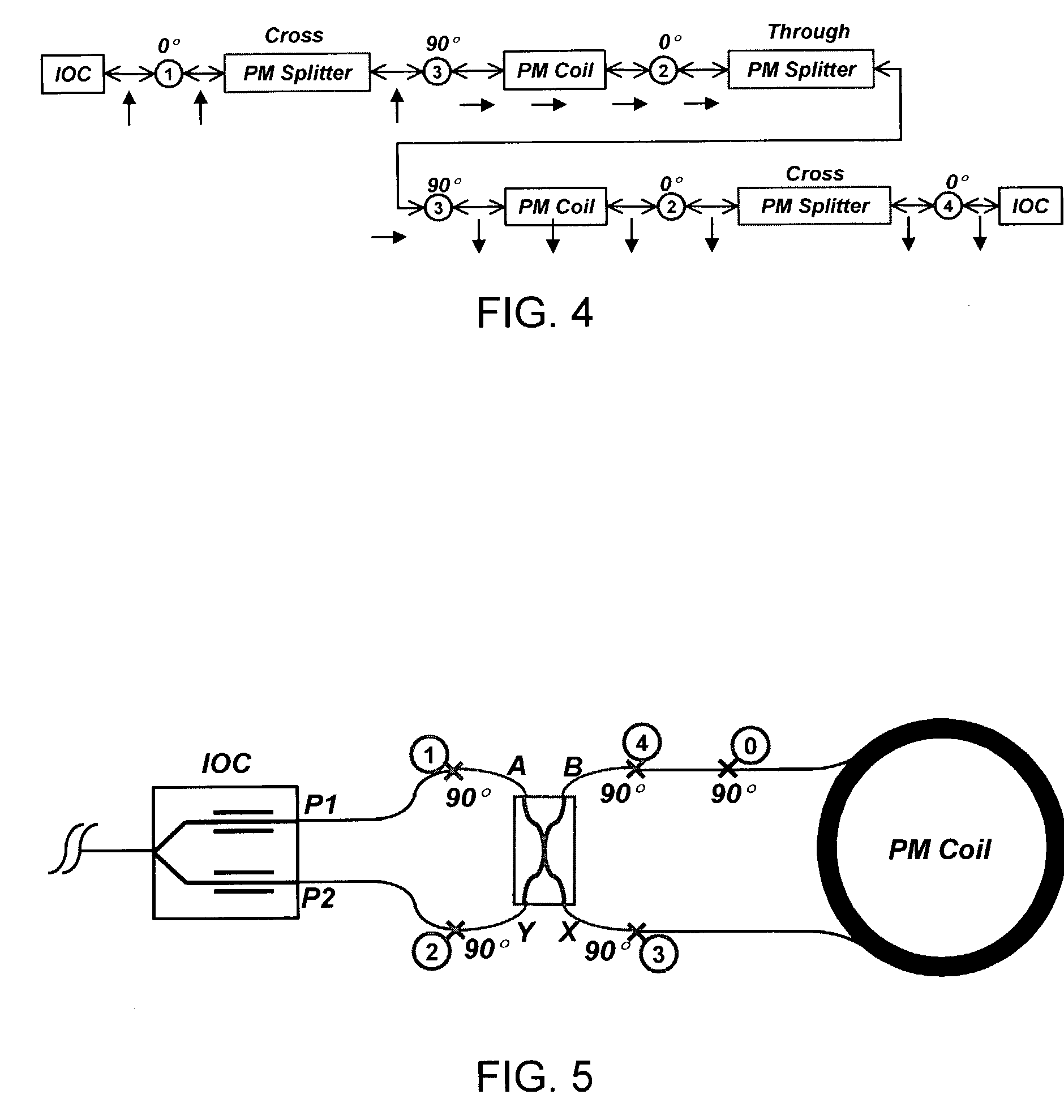

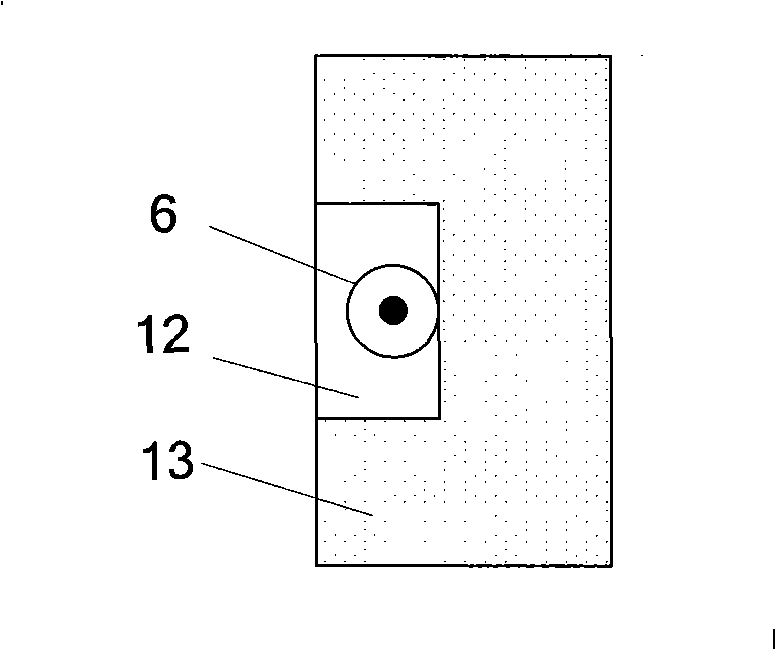

Fiber optic gyroscope sensing loop doubler

InactiveUS7034946B2Doubles sensitivityReduces bias instabilitySagnac effect gyrometersSpeed measurement using gyroscopic effectsEngineeringOptical communication

A fiber optic ring interferometer, such as an interferometric fiber optic gyro (IFOG), with a sensing loop doubler. The IFOG device includes a light source, a circulator in optical communication with the light source and a photo diode, an integrated optical chip (IOC) capable of splitting light emitted from the circulator into two paths each of which is capable of being modulated, the IOC further being capable of combining light from each of the two paths when light travels in a direction towards the circulator, a fiber coil, and a polarization maintaining (PM) combiner / splitter disposed in between the IOC and the fiber coil. The PM combiner / splitter operates to send light through the fiber coil a first time in a first polarization state and to subsequently send the same light a second time through the fiber coil in a second orthogonal polarization state, whereby light travels twice the distance compared to a single loop IFOG device and, as such, effectively doubles the LD product.

Owner:HONEYWELL INT INC

Method for preparing sensitive coil of reflection type optical fiber current sensor

ActiveCN101408559AImprove stabilityGood shock and vibration resistanceCurrent/voltage measurementVoltage/current isolationFiberCurrent sensor

The invention relates a method for making a sensor coil of a reflective optical fiber current sensor. A groove which takes the shape of the spiral of Archimedes is processed on a ring-shaped metallic framework, and sensitive fiber is wound in the groove; after filled with fiber paste and fixed, the groove is sealed; finally, the stress on the sensitive fiber is released by temperature ictus and vibration, thus causing the state of the sensitive fiber to be stable. The method of the invention can ensure that the sensitive fiber coil has good stability even under certain perturbation and can guarantee the ideal measuring precision; meanwhile, in the method of the invention, the metallic framework is adopted, so as to reduce the making difficulty and cost and realize the consistency of winding easily with respect to the technique.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

Reliable low loss hollow core fiber resonator

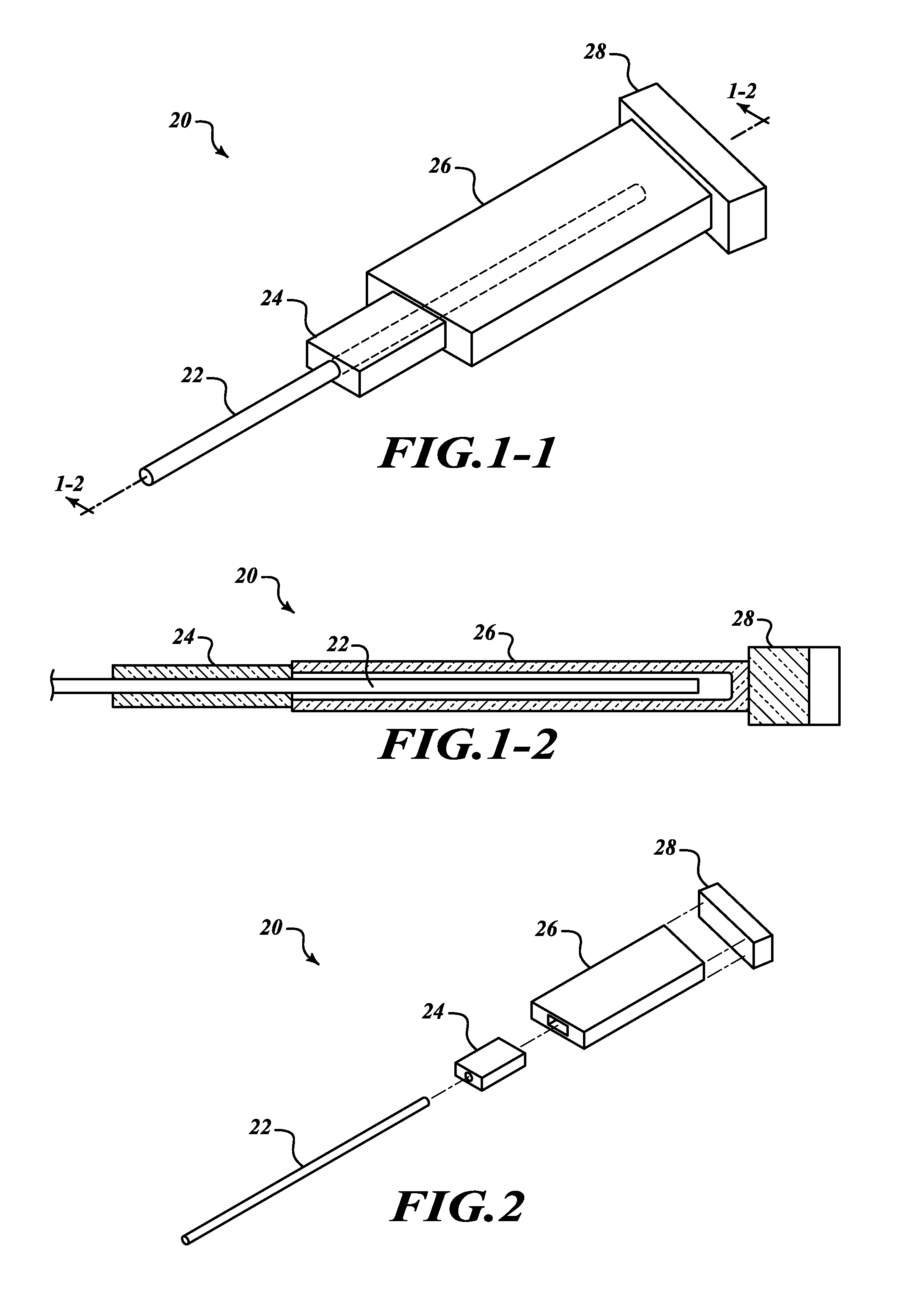

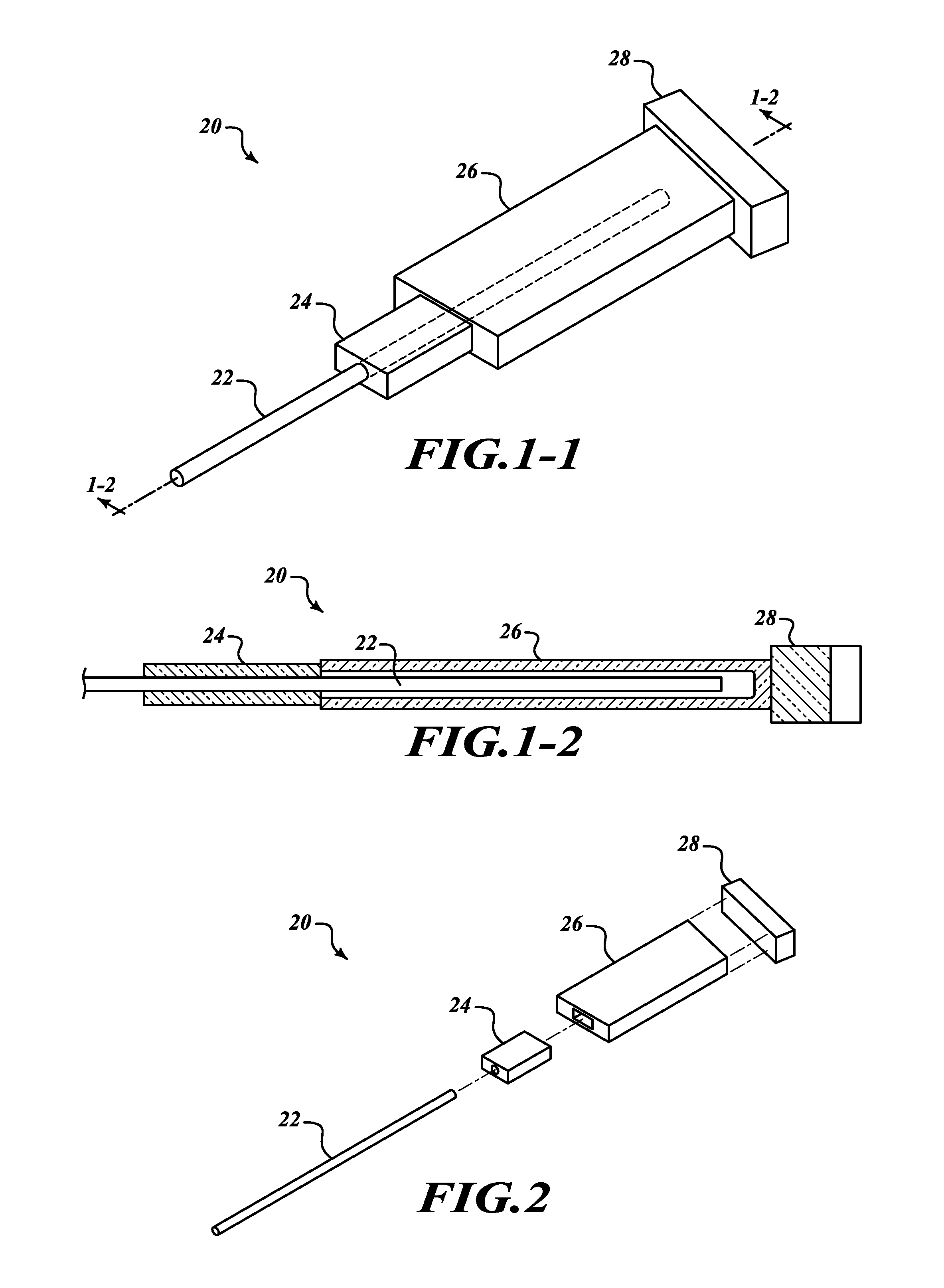

ActiveUS7697143B2Prevent backreflectionsSagnac effect gyrometersSpeed measurement using gyroscopic effectsFiberOptical coupling

An optical coupling device for connecting hollow core optical fiber coils in a fiber optic gyro system. An example fiber optic gyro system includes a recirculator or an integrated optics chip, a fiber coil of hollow core optical fiber with first and second ends, and a coupling device that holds an end of the hollow core optical fiber in an enclosed cavity at some predefined distance from the recirculator or integrated optics chip. The coupling device includes a housing for rigidly holding the fiber end in position. The housing includes a cavity that receives the fiber end.

Owner:HONEYWELL INT INC

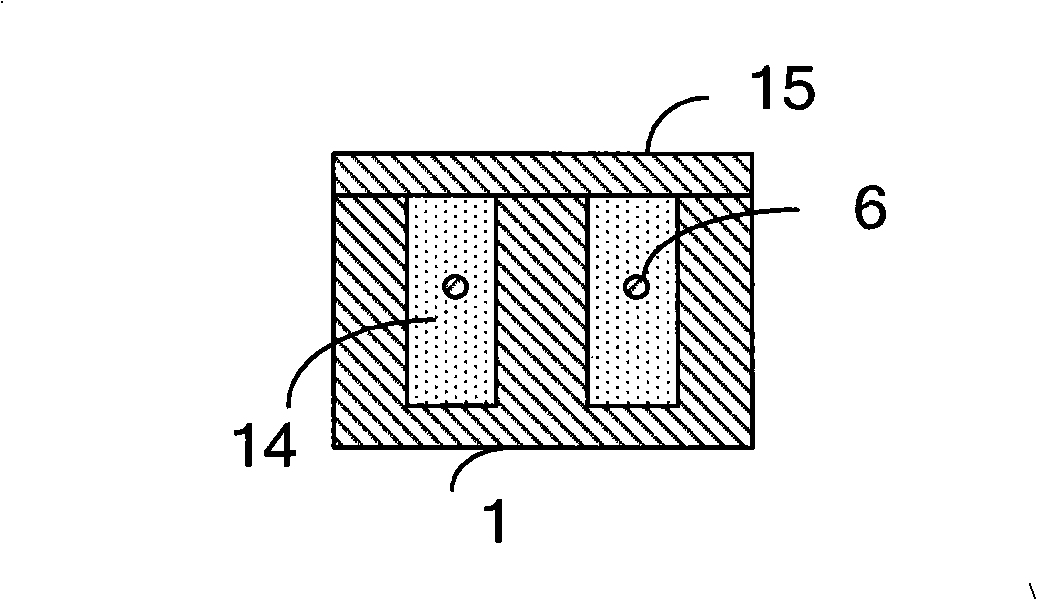

Detachable framework used for winding optical fiber coil and a method of producing optical fiber coil

ActiveUS20100260930A1Improve temperature characteristic and vibration characteristicCladded optical fibreFilament handlingVacuum pressureAdhesive

A detachable framework used for winding optical fiber coils and a method of producing optical fiber coils with this framework. A framework with a suitable structure is designed considering comprehensively three factors, i.e., the window ratio of an optical fiber coil, the precision of an optical fiber gyro and the easy detachment of the framework from the optical fiber coil. A surface treatment with the framework is performed by coating a layer of thermosol on the surface of the framework so the optical fiber coil can be easily detached from the framework after curing. The required length of optical fiber is winded around the optical fiber coil framework, accompanying with vacuum pressure impregnating with curing adhesive after winding and optical fiber coil curing subsequently. The framework is taken off from the optical fiber coil under the heating circumstances, thereby completing production of the non-framework optical fiber coil.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

Spray-rolling type loose fiber cold-batch dyeing process

ActiveCN103774361AFast absorptionFacilitated DiffusionLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsFiberRoom temperature

The invention relates to a spray-rolling type loose fiber cold-batch dyeing process, and belongs to the technical field of loose fiber dyeing. The spray-rolling type loose fiber cold-batch dyeing process comprises the steps of spray-rolling type dyeing, coiling and batching fixation, cotton blanket type loose fibers are conveyed to a spray-rolling type dyeing device and horizontally conveyed by a guide belt, after a plurality of groups of spray-rolling dye with alternative squeezing and spraying, the loose fibers are coiled to be loose fiber coils, the loose fiber coils are subjected to the batching fixation at the room temperature for 10-12 hours to complete loose fiber dyeing, the spray-rolling type dyeing process comprises the steps of squeezing, spraying, squeezing, spraying, squeezing, spraying, squeezing, spraying, squeezing and spraying, in the squeezing process, the squeezing force on the loose fibers is 3-15 kg per square centimeters, and in the spraying process, the spraying amount of dyeing liquid is 1.5-2 times the conveying amount of the loose fibers. The spray-rolling type loose fiber cold-batch dyeing process can be used for continuous production, dyeing is even, and cost can be lowered to 1 / 3-1 / 5 of the original cost.

Owner:SHAOXING JINYU TEXITLE NEW TECH CO LTD

Reliable low loss hollow core fiber resonator

ActiveUS20090296098A1Prevent backreflectionsSpeed measurement using gyroscopic effectsSagnac effect gyrometersFiberOptical coupling

An optical coupling device for connecting hollow core optical fiber coils in a fiber optic gyro system. An example fiber optic gyro system includes a recirculator or an integrated optics chip, a fiber coil of hollow core optical fiber with first and second ends, and a coupling device that holds an end of the hollow core optical fiber in an enclosed cavity at some predefined distance from the recirculator or integrated optics chip. The coupling device includes a housing for rigidly holding the fiber end in position. The housing includes a cavity that receives the fiber end.

Owner:HONEYWELL INT INC

Aerogel material reinforced by fiber reinforcement and preparation method of aerogel material

InactiveCN106866093ADiffusion is easy to completeEasy to complete distributionSupercritical dryingPolymer science

The invention relates to an airgel material reinforced by fiber reinforcement and its preparation method. The width of the material is 0.5-1.5 meters, and the length is 5-30 meters. Its composition includes silicon dioxide airgel and reinforced continuous fiber, and its weight ratio is 1:0.5-2.5. The present invention also relates to (1), limiting and winding the continuous reinforcing fiber into a winding unit while keeping a certain gap between the continuous fibers; (2), disposing silicon alkoxide, alcohol solvent and basic catalyst according to a certain ratio (3) Immerse the silica sol into the continuous reinforcing fiber winding unit through the impregnation process; (4) After the silica gel is aged for a certain period of time, the surface is treated with a hydrophobizing agent; (5) The silica gel containing silica gel The continuous fiber winding unit of glue is supercritically dried. The material prepared by the invention has large specific surface area and low thermal conductivity, and can be applied in many fields such as fire retardation, sound insulation, gas adsorption and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Novel fiber hydrophone sound-sensitive structure and realization method thereof

InactiveCN107367321AAvoid the problem of poor voltage resistanceResolve SensitivitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansElastomerHydrophone

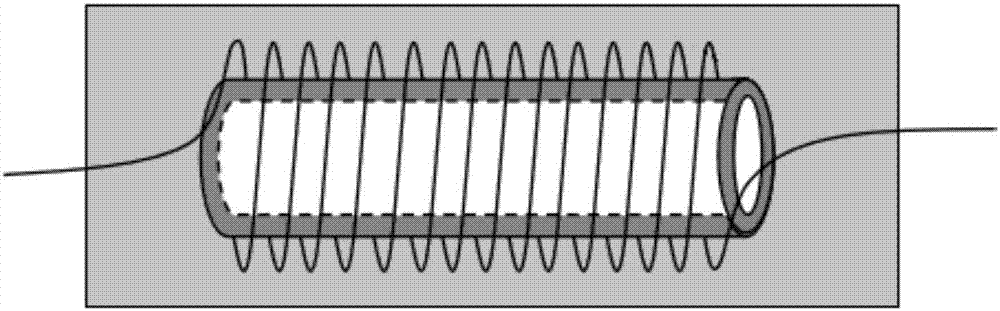

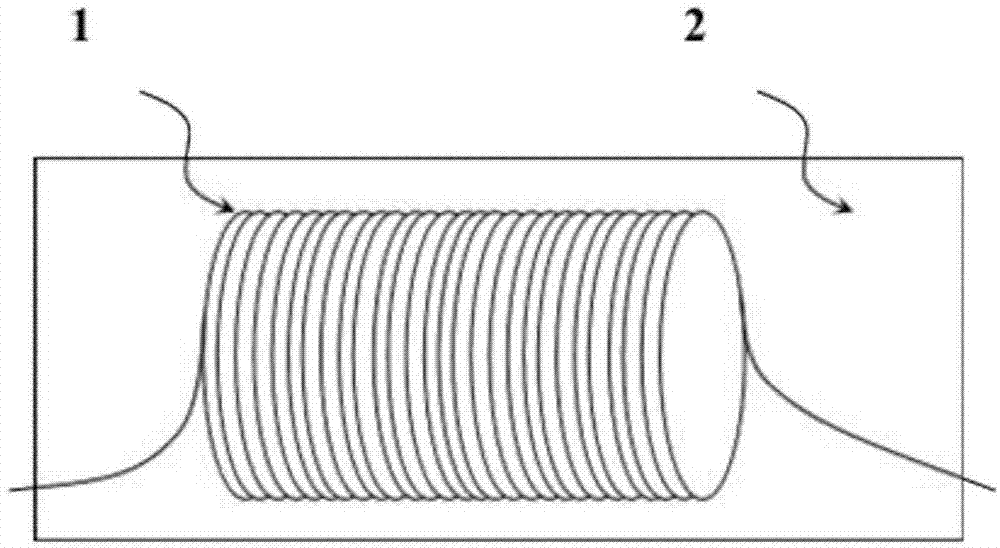

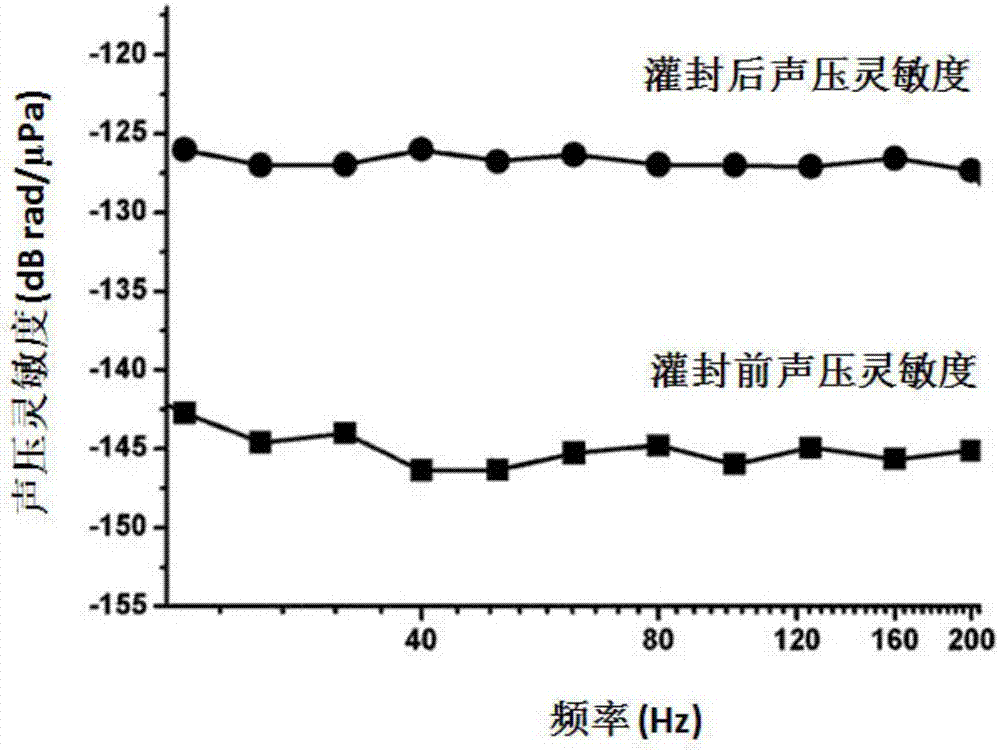

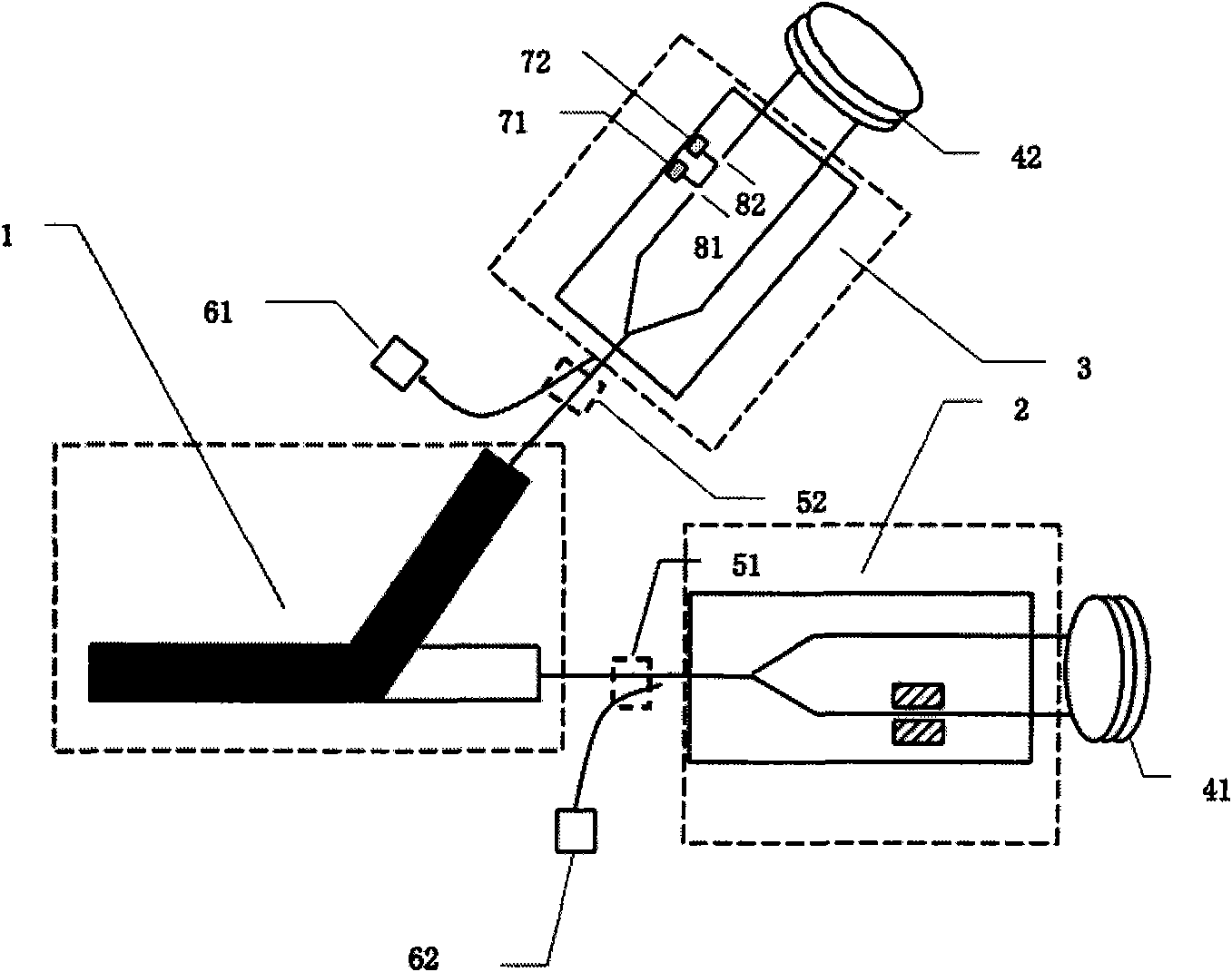

A novel fiber hydrophone sound-sensitive structure is characterized in that the sound-sensitive structure is made of a fiber coil and a polymeric material; the fiber coil is a cylindrical form coiling fiber, and embedded in the polymeric material; the sound-sensitive structure is a solid elastomer structure in an axisymmetric shape; the whole structure is formed by the fiber and the same polymeric material, is simple in structure, easy to make, and low in cost; on one hand, the problems that a conventional hollow sound-sensitive structure is poor in overpressure resistant performance can be solved; on the other hand, the fiber coiling structure is innovatively improved, the integral solid elastomer structure is combined, and the polyurethane embedding material with the smaller young modulus than a hard elastomeric material is employed, thus greatly improving the sound pressure sensitivity, and solving the contradictions between the interference type hydrophone sound-sensitive structure sound pressure sensitivity and overpressure resistant capability; the novel fiber hydrophone sound-sensitive structure is suitable for deep sea applications.

Owner:上海传输线研究所

Biaxial optical gyroscope

ActiveCN101566475AAchieve polarizationIncrease profitNanoopticsSagnac effect gyrometersOptical gyroscopePolarization-maintaining optical fiber

The invention relates to a biaxial optical gyroscope, which consists of a surface plasma excimer Y-type mode separator, a Y waveguide integrated optical device, a Y waveguide integrated optical chip, a first polarization-preserving fiber coil, a second polarization-preserving fiber coil, a directional coupler and a detector. The invention belongs to the technical field of integrated optics and inertial sensor, and provides the biaxial optical gyroscope. The biaxial optical gyroscope with a separation mode is realized by adopting waveguide devices made of different materials, and has the advantages of improvement on the utilization rate of light sources, high integrity and the like.

Owner:SOUTHEAST UNIV

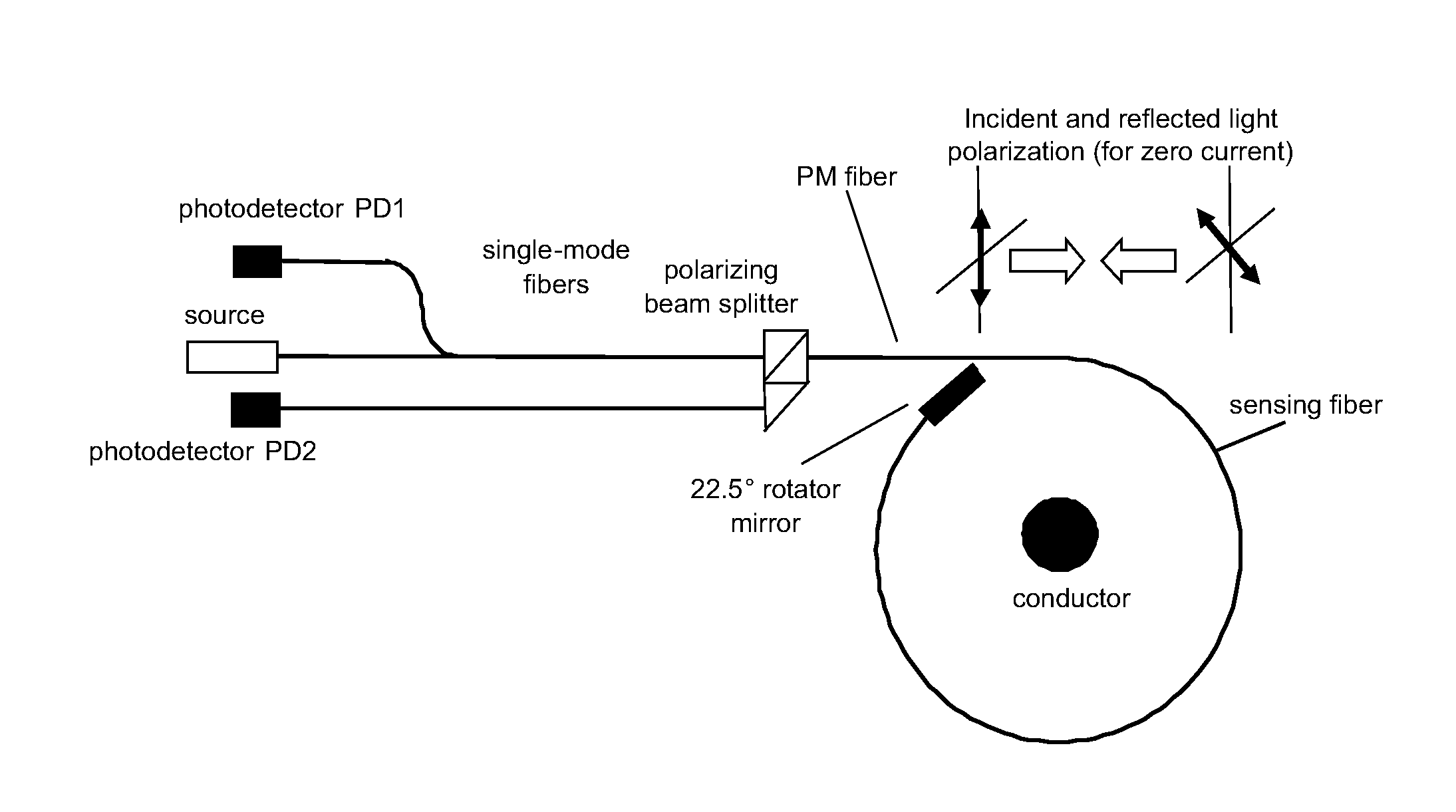

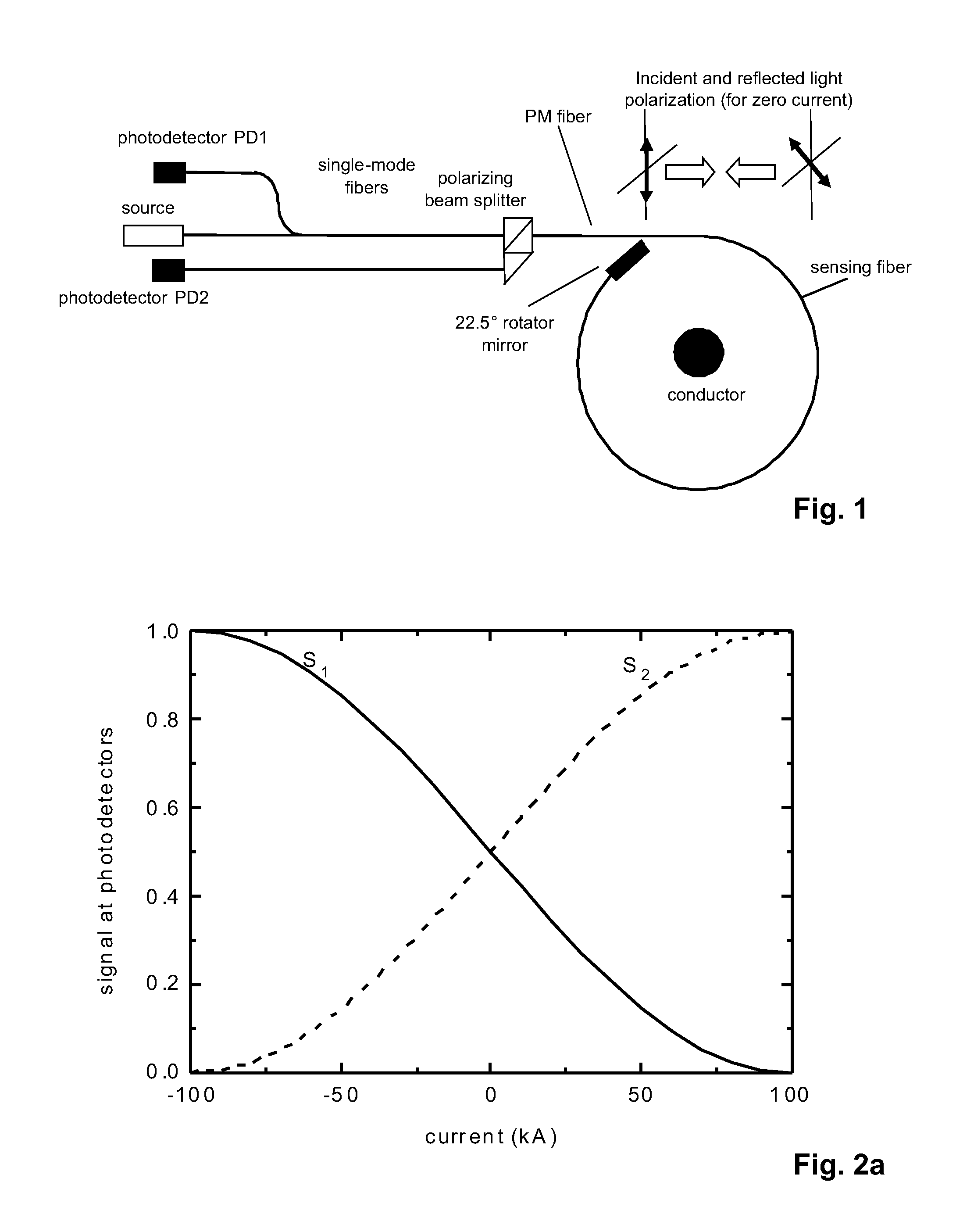

Temperature Compensated Fiber-Optic Current Sensor

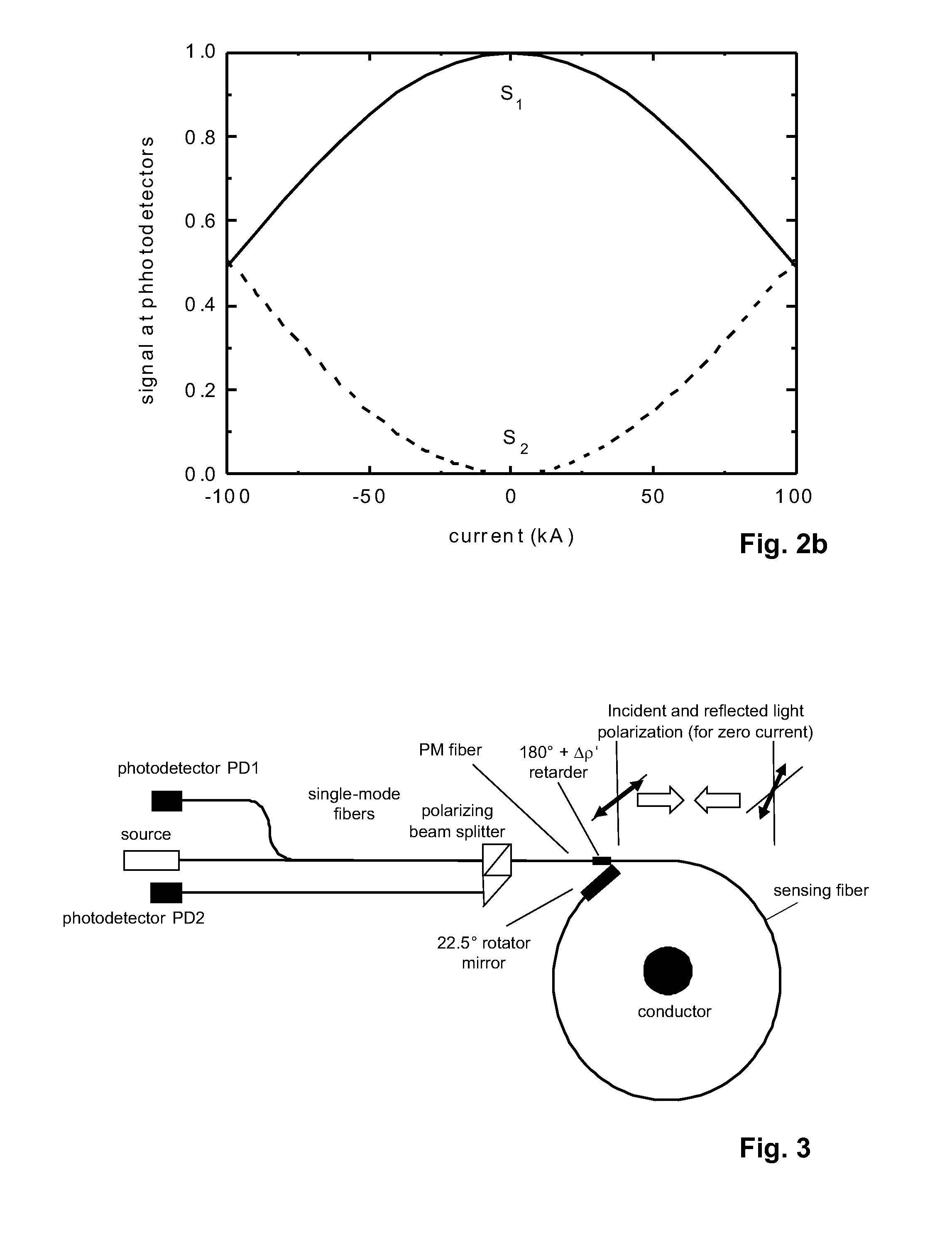

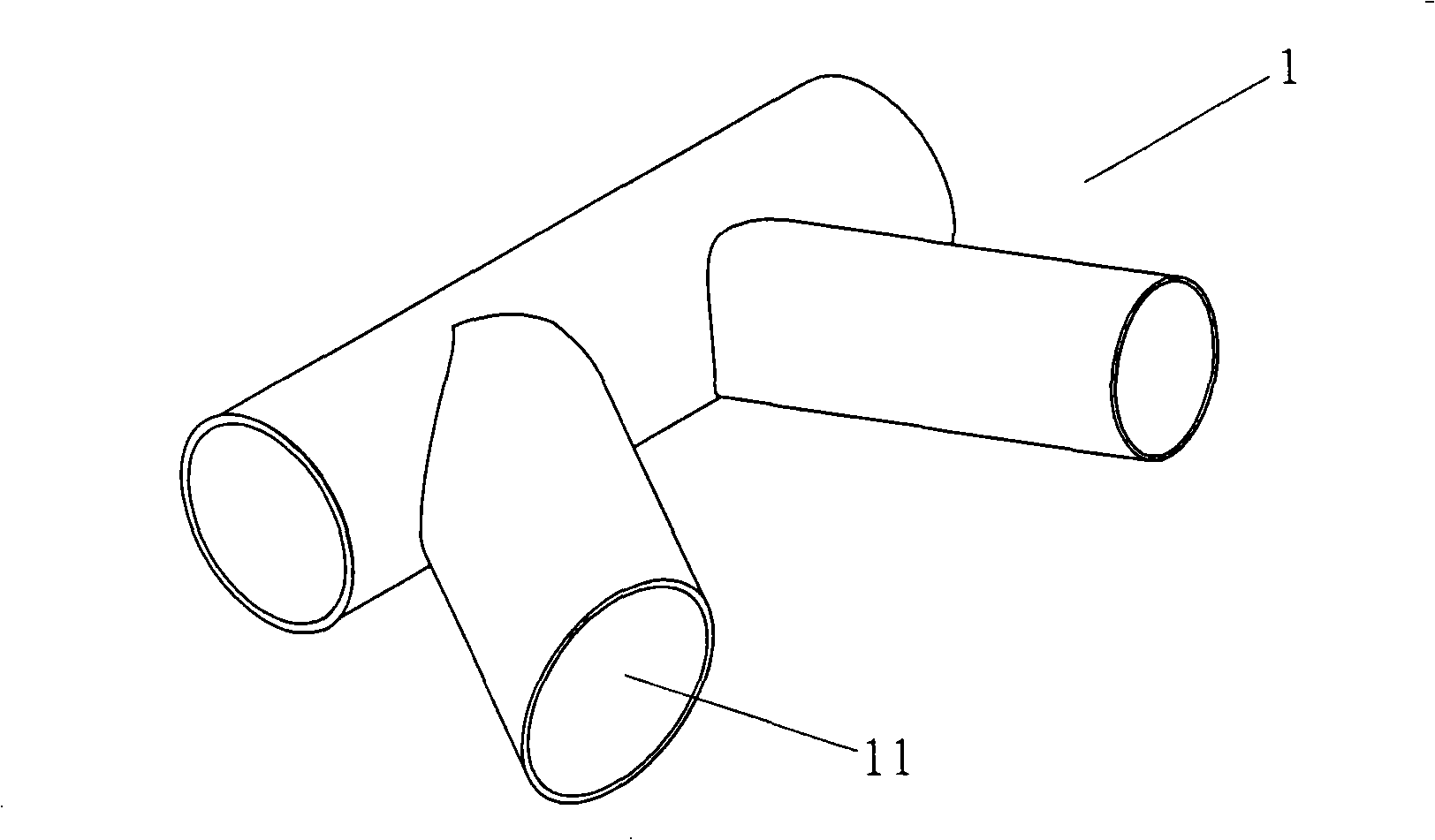

ActiveUS20150115934A1Reduce the impactReduce impactCurrent/voltage measurementElectrical testingFiberCurrent sensor

In a fiber-optic current sensor, a 22.5° Faraday rotator, which is part of the sensing fiber coil, determines the working point of the sensor. The coil is operated with substantially linearly polarized light or incoherent substantially left and right circularly polarized light waves. In one arrangement, a polarization beam splitter generates two optical signals that vary in anti-phase with changing current. A signal processor determines the current from the two anti-phase signals. Appropriately detuned and oriented fiber-optic half-wave or quarter-wave retarders before the fiber coil are used to reduce or cancel the adverse effects of temperature and bend-induced birefringence on the measurement signal. Moreover, the temperature may be derived from the difference in the bias of the anti-phase signals and may be used to cancel temperature effects in the signal processor.

Owner:HITACHI ENERGY SWITZERLAND AG

Compound material special piece molding method and molding central spindle

The invention provides a moulding method for composite material irregular pipe fitting and a moulded pivot thereof. The support pivot made of the materials with low softening temperature and high melting point is arranged at the irregular position of a pipe, which is matched with the irregular position in shape. Macromolecule composite carbon fiber is coated on the support pivot so that the thickness of the support pivot reaches the required thickness of the shell of the pipe before the coated support pivot is arranged in a forming die; the support pivot is arranged in a blast pipe for heating and extrusion forming; after the pivot is cooled, the melted and deformed support pivot is taken out from the pipe, thus completing the forming process of the irregular pipe fitting. By adopting the support pivot, flexible macromolecule composite carbon fiber can be braided and preformed according to the shape, and the fiber grain direction when the macromolecule composite carbon fiber coils yarn is ensured. While hot air is fed to the blast pipe and the blast pipe is pressurized so that the macromolecule composite material is melted and shaped, the support pivot with low softening temperature and high melting point is melted and deformed; after the formed irregular pipe fitting is cooled, the support pivot is deformed and broken; subsequently, a tool is used for taking out the broken support pivot from the irregular pipe. The disposable support pivot brings convenience to moulding of irregular pipe fittings.

Owner:XIAMEN KEENTECH COMPOSITE TECH CO LTD

Optical fiber splicing method

InactiveCN102736179AImprove connection qualityImprove work efficiencyCoupling light guidesFiberAdhesive

The invention discloses an optical fiber splicing method, comprising the following steps of: preparing an optical fiber end face, including stripping an optical fiber coating, cleaning naked fiber and cutting the naked fiber; melting the optical fiber; and coiling the fiber, wherein during the fiber coiling operation, the coiling of the optical fiber on a reservation disc is positioned at the bottom and is close to a side and an adhesive is applied for pasting and reinforcement; testing, namely monitoring performed by a monitor; and sealing a box. The optical fiber splicing method has the beneficial effects that splicing quality is high, working efficiency is improved and cost is saved.

Owner:成都亨通光通信有限公司

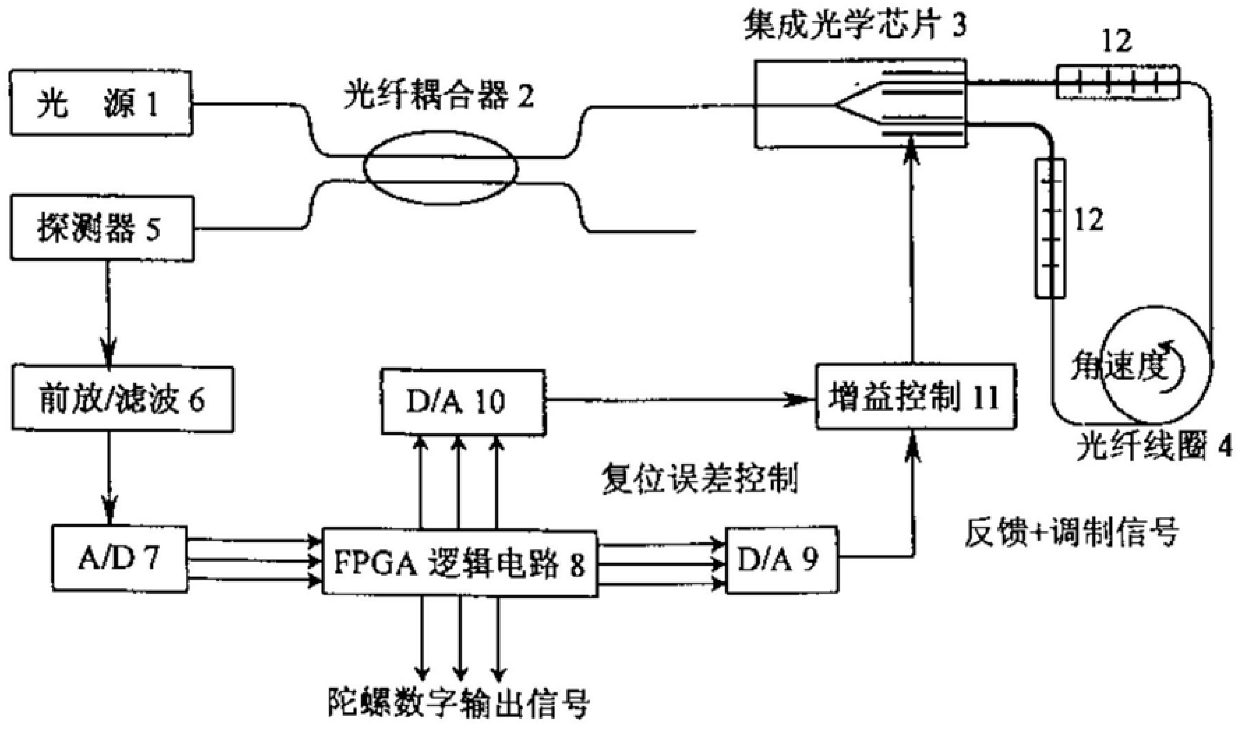

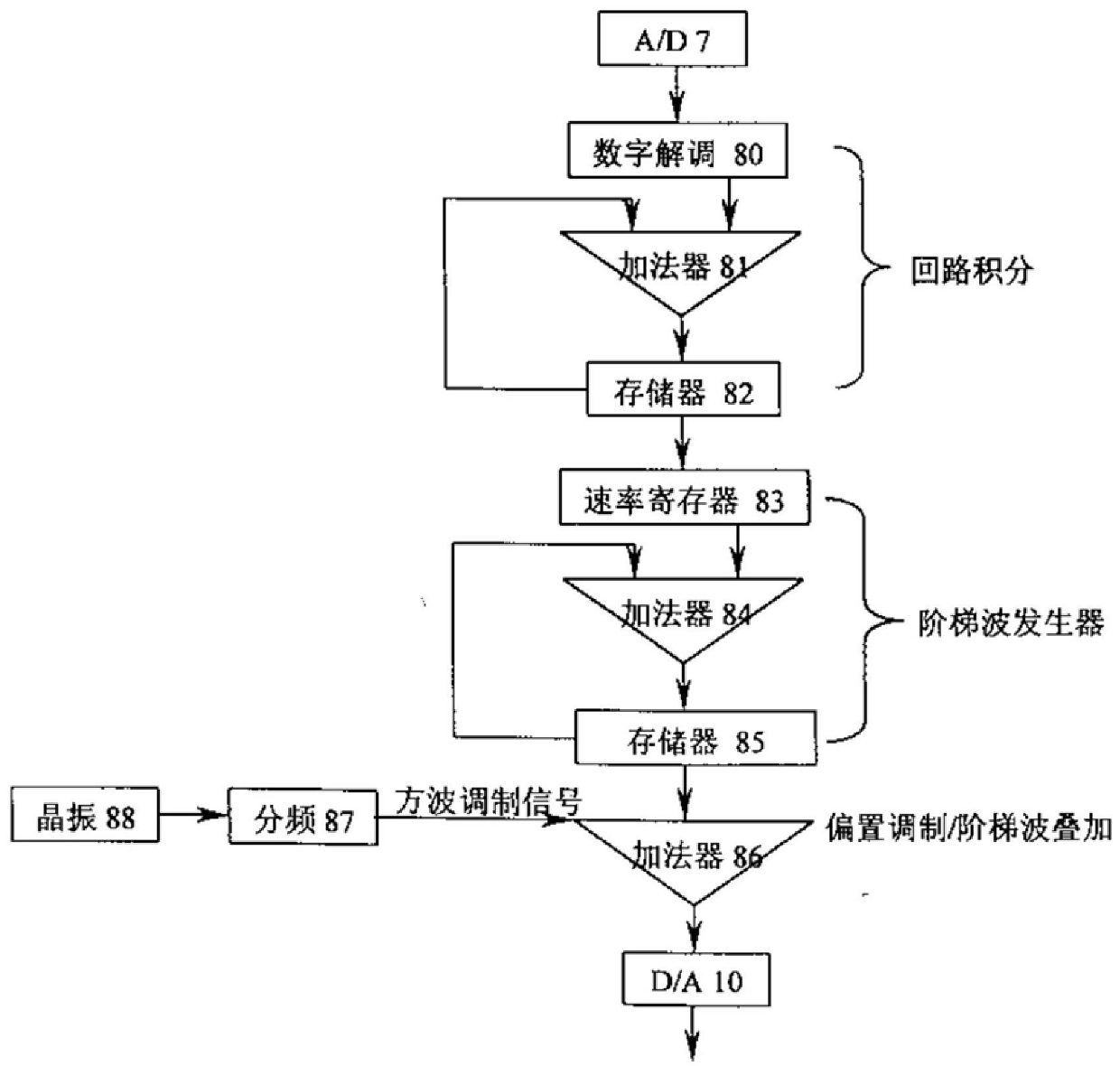

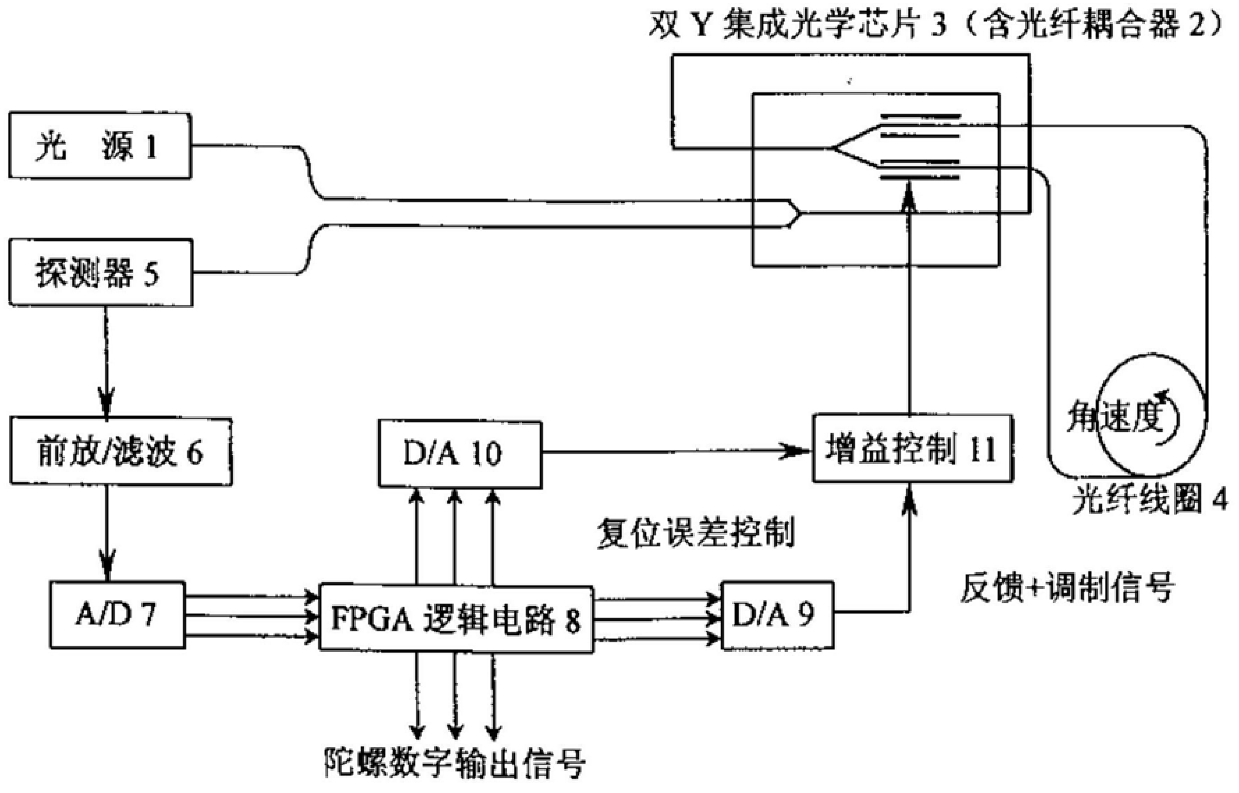

Full digital processing closed-loop fiber optic gyroscope based on fpga

InactiveCN106507910BReduce weightReduce power consumptionSagnac effect gyrometersDigital signal processingGyroscope

FPGA-based full-digital processing closed-loop fiber optic gyro is composed of an optical path part and a circuit part. The optical path part is composed of a broadband light source, a fiber optic coupler, a multifunctional integrated optical chip and a fiber optic coil. The circuit part is composed of an amplification filter circuit, A / D conversion, Composed of FPGA logic circuit, D / A converter, etc., the FPGA logic circuit completes the processing of digital signals, and the sum of the square wave modulation and digital ladder wave feedback signal generated by it is added to the multifunctional integrated optical chip after passing through the D / A converter. On one arm, the fiber coil is a single-mode fiber with lyot depolarizers added at one or both ends. Because the present invention adopts the addition of a lyot depolarizer on the basis of the single-mode fiber coil, the polarization evolution along the single-mode fiber will no longer affect the output of the gyroscope, which improves the zero-bias stability of the fiber-optic gyroscope, and then makes the gyroscope The accuracy is greatly improved; in addition, the modulation and demodulation method of the single-mode fiber coil with depolarizer is the same as that of the polarization-maintaining fiber, but its cost is only one tenth of the price of the polarization-maintaining fiber.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

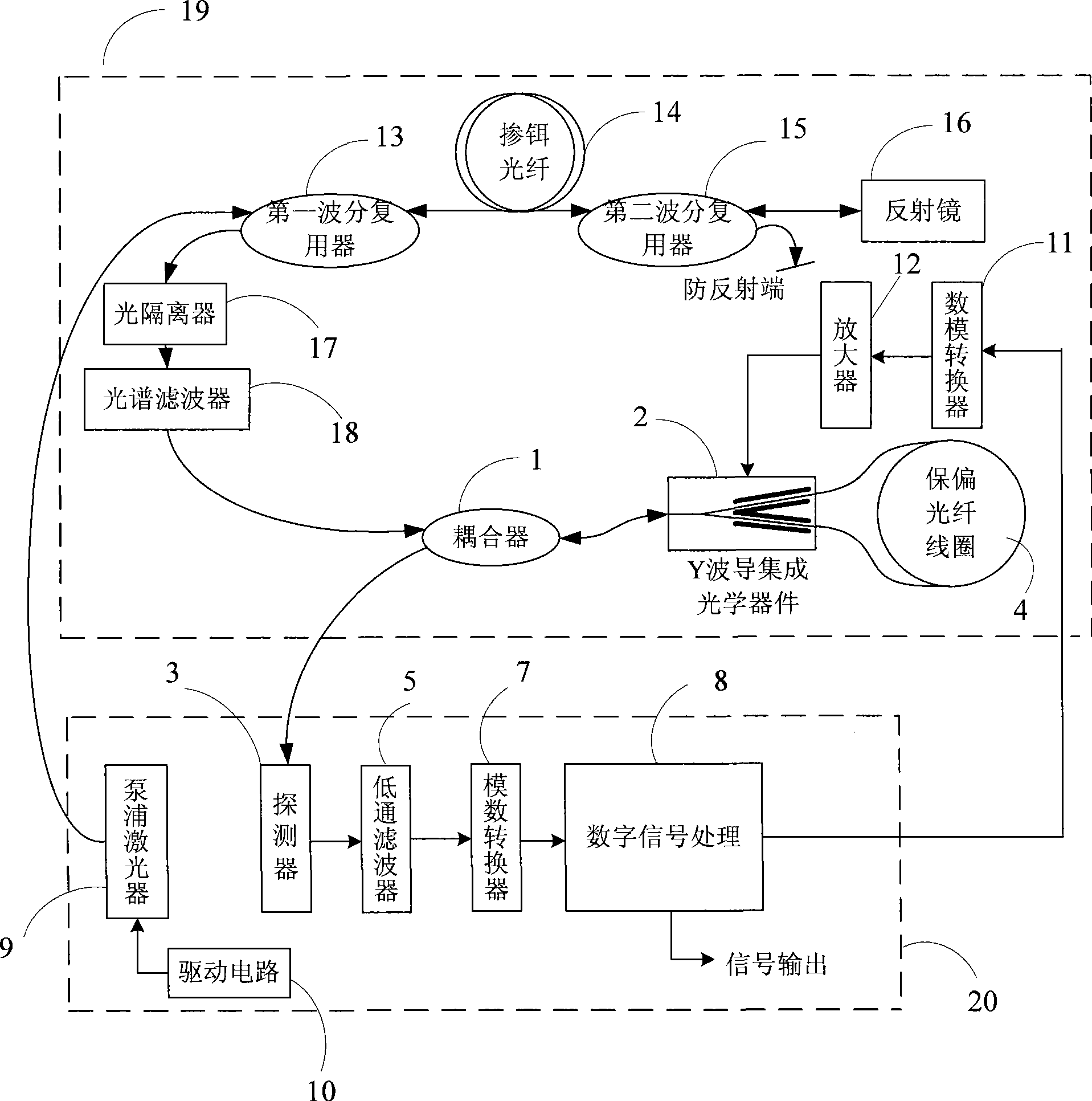

1.55 mum wavelength high precision fiber gyroscope for eliminating dead zone

A high-precision optical gyroscope with 1.55 um wavelength for eliminating dead area, comprising a light path unit and a circuit unit; wherein the circuit unit comprises a laser, a laser driving circuit, a detector, a low pass filter, a analog-to-digital converter and a digital signal processing circuit; the light path unit comprises a spectral filter, an optoisolator, a first wavelength division multiplexer, an Er-doped fiber, a second wavelength division multiplexer, a reflector, a coupler, a Y-waveguide integrated optical device and a fiber coil; the spectral filter outputs superfluorescence with 1.55 um wave band; the light path unit further comprises a digital-analog converter and an amplifier; the digital-analog converter, amplifier and Y-waveguide integrated optical device are packed together by a metal box to form electromagnetic shielding. The invention interferes with the electron between driving signal of the Y-waveguide integrated optical device and the signal received by the detector on the structure to isolate, thereby eliminating the dead area caused by interference.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

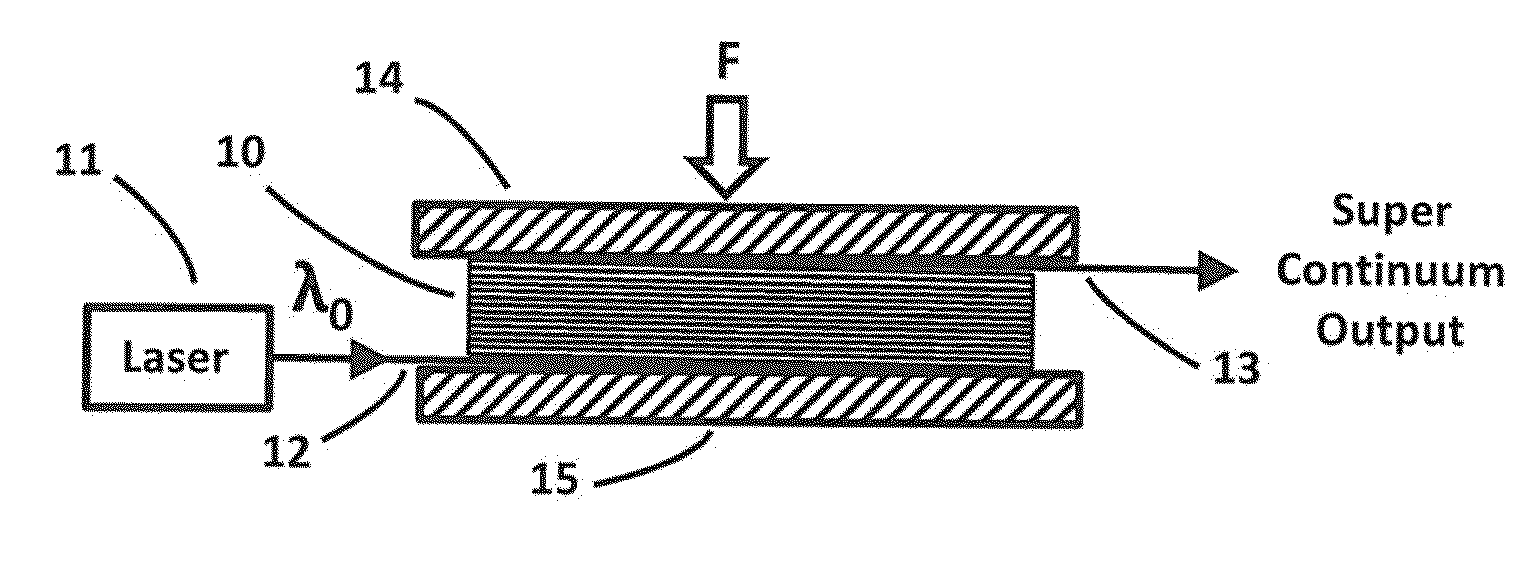

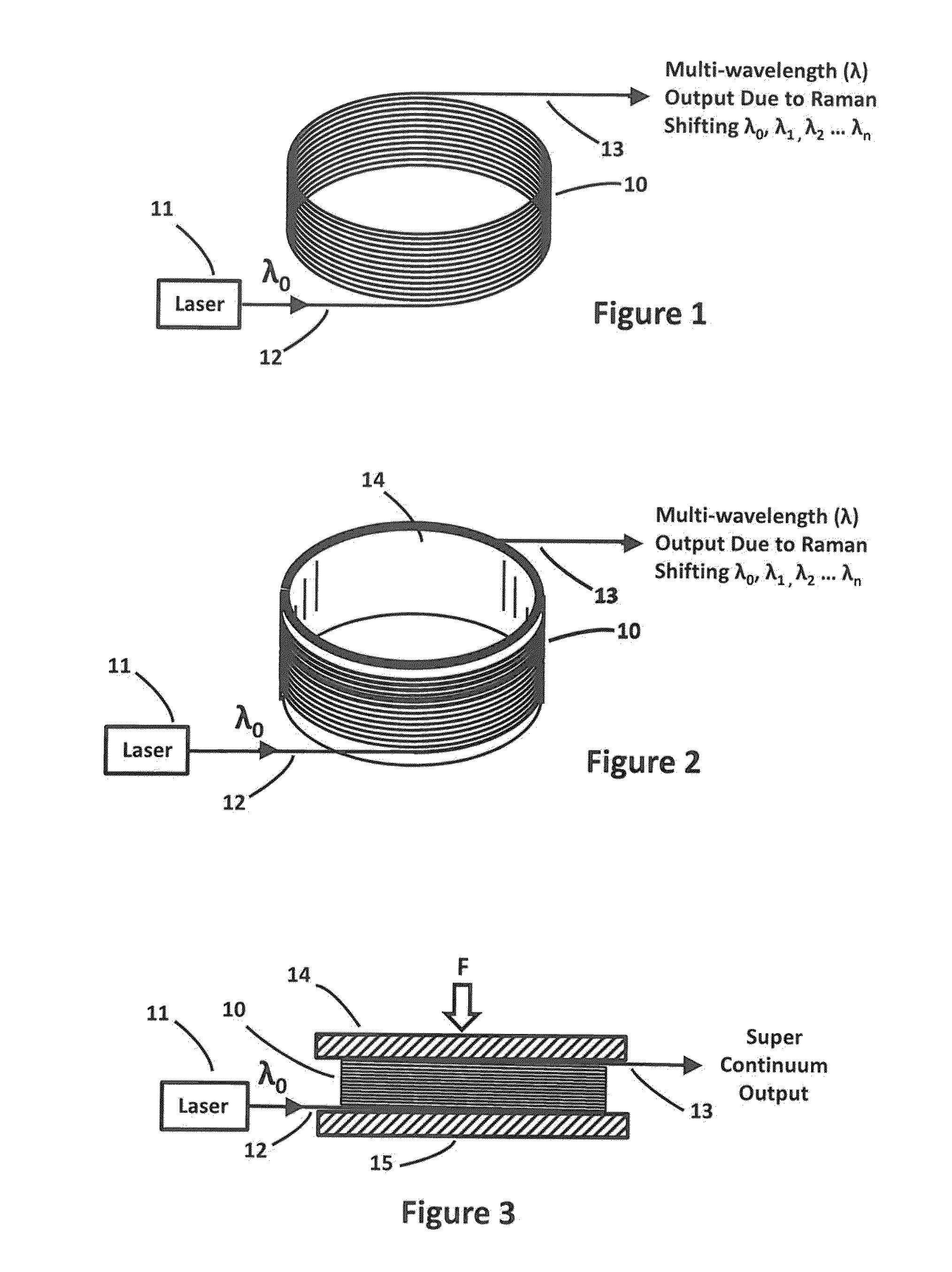

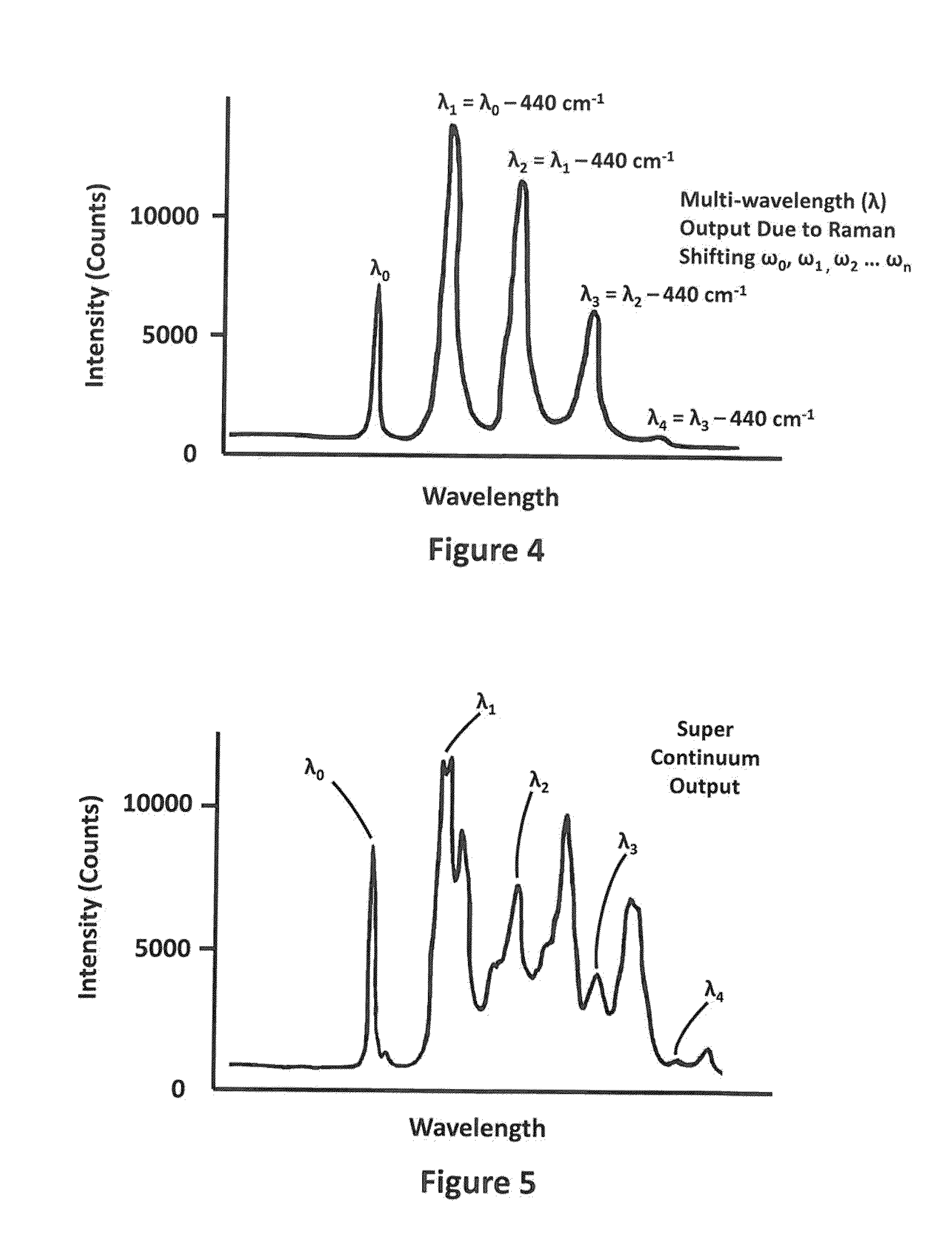

Generating Broadband Spectral Power In Multimode Optical Fibers

A broadband spectral power generator in a multimode optical fiber utilizes a standard multimode fiber that is coiled. A plate is placed on the coiled fiber and a force is applied to compresses the coiled fiber and thereby increase the interactions between the compressed windings and induce modal mixing and birefringence in the fiber. In addition, the compression causes additional non-linear processes to be excited and occur in the compressed fiber coil to generate more broadband light. This allows for better “mixing” of the spatial beam in the multimode fiber coil and allows for the various modes to overlap. The multimode fiber coil is made of silica, silicate, germinate, phosphate, fluoride, chalcogenide, or telluride. The compressed coiled fiber may be driven by a laser providing more than one wavelength output and this greatly increases the amount of nonlinear mixing in the fiber for a greatly enhanced spectral coverage.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

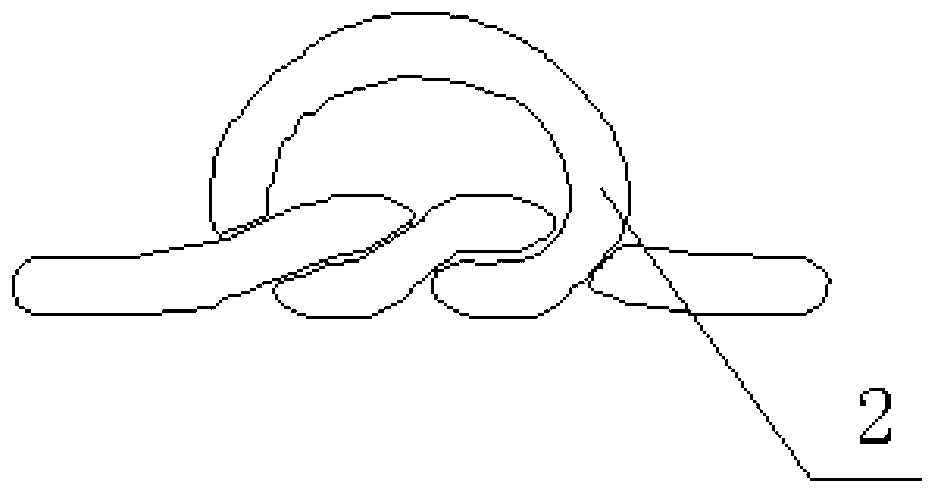

Crack monitoring sensor and use method thereof based on OTDR (optical time domain reflectometry) technique

InactiveCN103217109ARealize dynamic monitoringRealize distributed monitoringOptically investigating flaws/contaminationUsing optical meansEpoxyBare fiber

The invention relates to a crack monitoring sensor and use method thereof based on an OTDR (optical time domain reflectometry) technique, and belongs to the technical field of monitoring of optical fibers. The crack monitoring sensor comprises a protection box, a bare optical fiber coil, a first optical fiber with a protecting layer, and a second optical fiber with a protecting layer, wherein the bare optical fiber coil is provided with two end joints, the bare optical fiber coil is an optical fiber coil which is formed by winding and knotting a bare optical fiber, and the diameter of the bare optical fiber coil is 14mm to 16mm. When the crack monitoring sensor is used, firstly, the outer optical fiber of the sensor is welded with the first optical fiber with the protecting layer and the second optical fiber with the protecting layer through the end joints, secondly, the adhering function of epoxy resin adhesive is released by an adhesive release agent, so that the inner optical of the sensor is ensured to be freely stretched along with the extension of the crack, and then the concrete is cast. The crack monitoring sensor and the use method have the advantages that the construction is convenient, the manufacturing is simple, the cost is low, the crack monitoring sensor and the use method are suitable for monitoring the cracks of various types of concrete inner structures, meanwhile, the operability is high, and the real-time monitoring and the distributed monitoring on the concrete inner structures are realized.

Owner:HOHAI UNIV

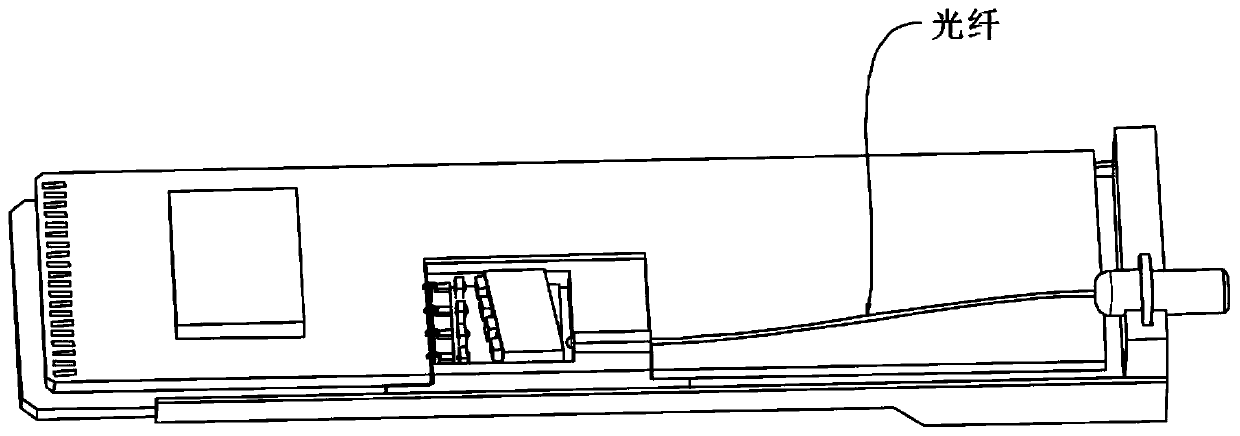

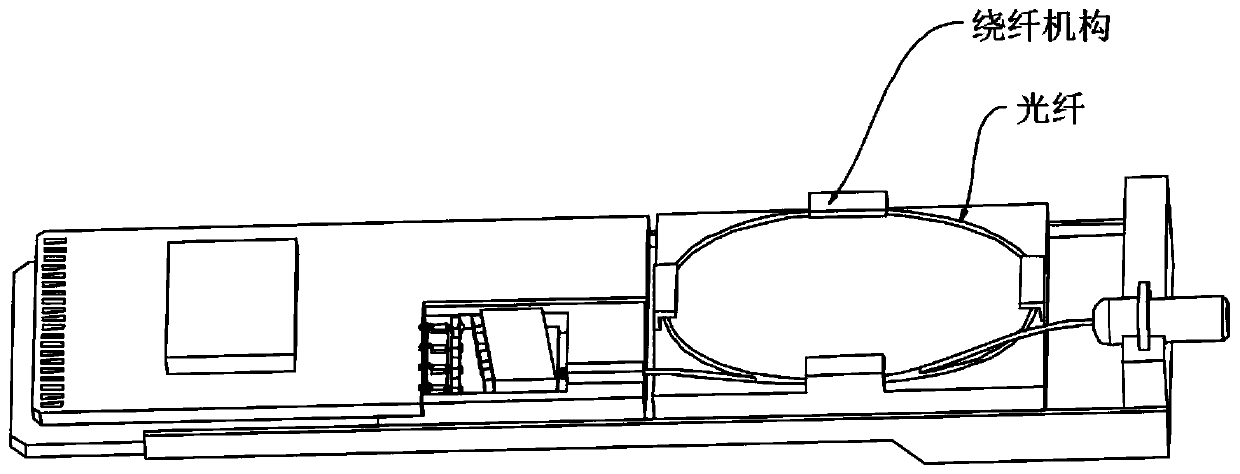

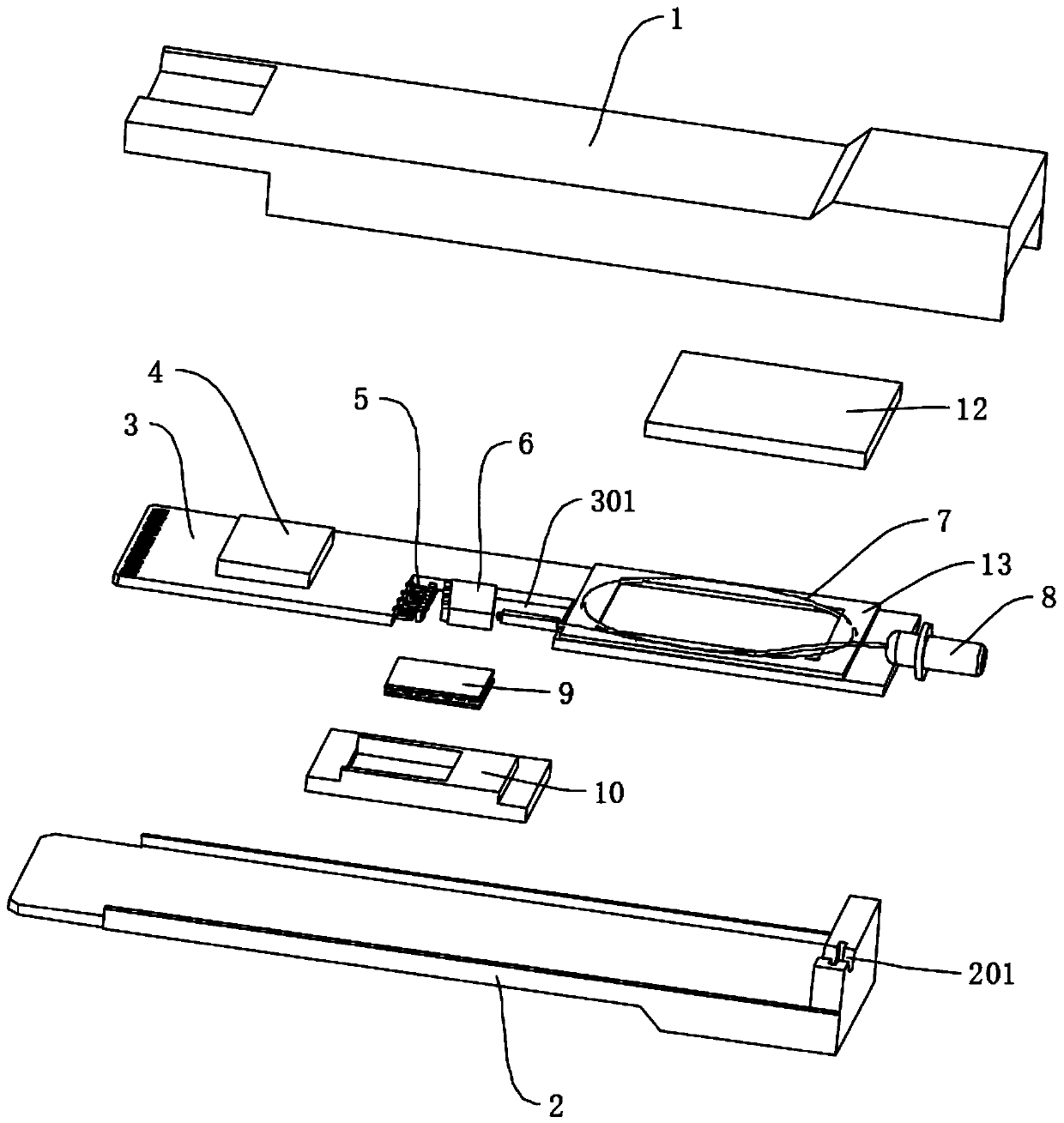

Optical module with fiber winding mechanism

PendingCN110888208APlay a protective effectLow costCoupling light guidesFibre mechanical structuresFiberOptical Module

The invention provides an optical module with a fiber winding mechanism. The fiber winding mechanism is simple in structure and extremely simple and convenient to operate so that the fiber coiling process becomes simple and feasible, high subsequent reliability can also be ensured and the internal space occupation of the optical module is greatly reduced. The optical module comprises an upper heatdissipation shell and a lower heat dissipation shell which can be spliced into a whole and a PCB which is arranged in the upper heat dissipation shell and the lower heat dissipation shell. A controlchip is arranged on the PCB, a laser device is connected on the PCB, and an optical device is arranged on the front side of the laser. The optical device is connected with an optical fiber, the otherend of the optical fiber is connected with an optical head, the laser and the optical device are respectively arranged on a TEC refrigerator, the TEC refrigerator is installed in a metal heat sink, and an optical fiber adhesion device is correspondingly arranged on the PCB and located on the rear side of the optical device and used for fixing the coiled optical fiber.

Owner:HENGTONG ROCKLEY TECHNOLOGY CO LTD +1

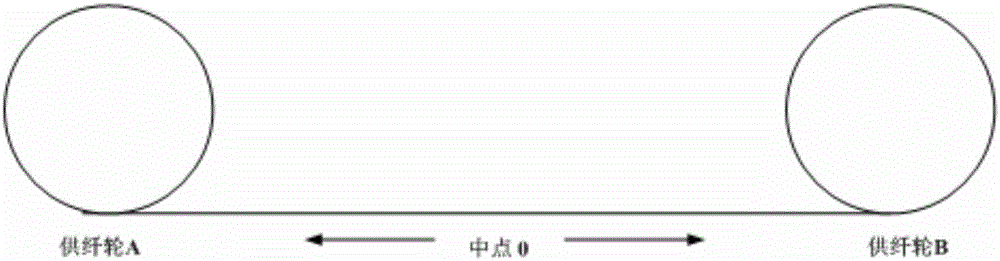

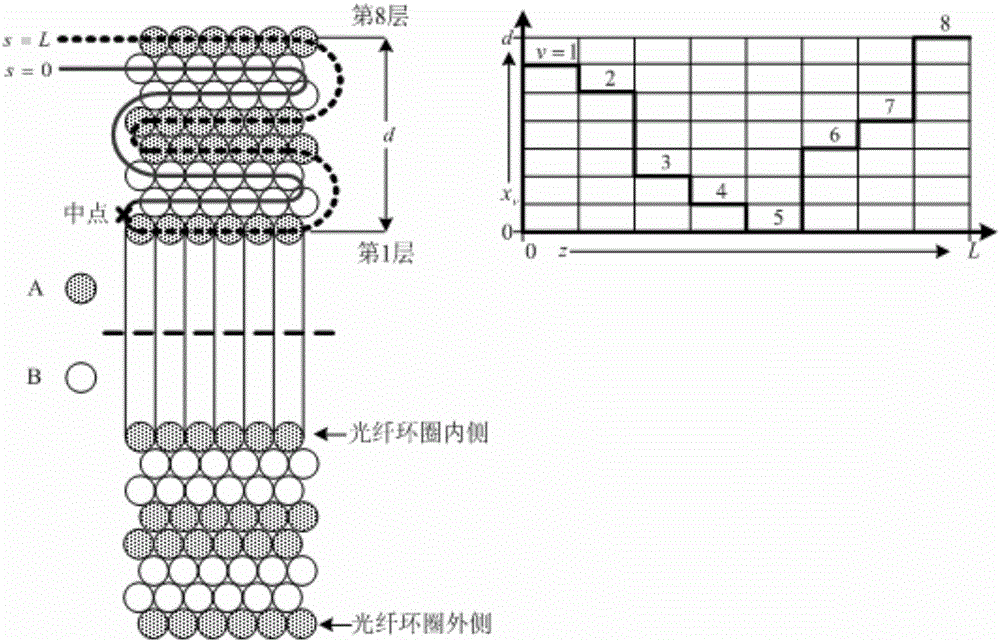

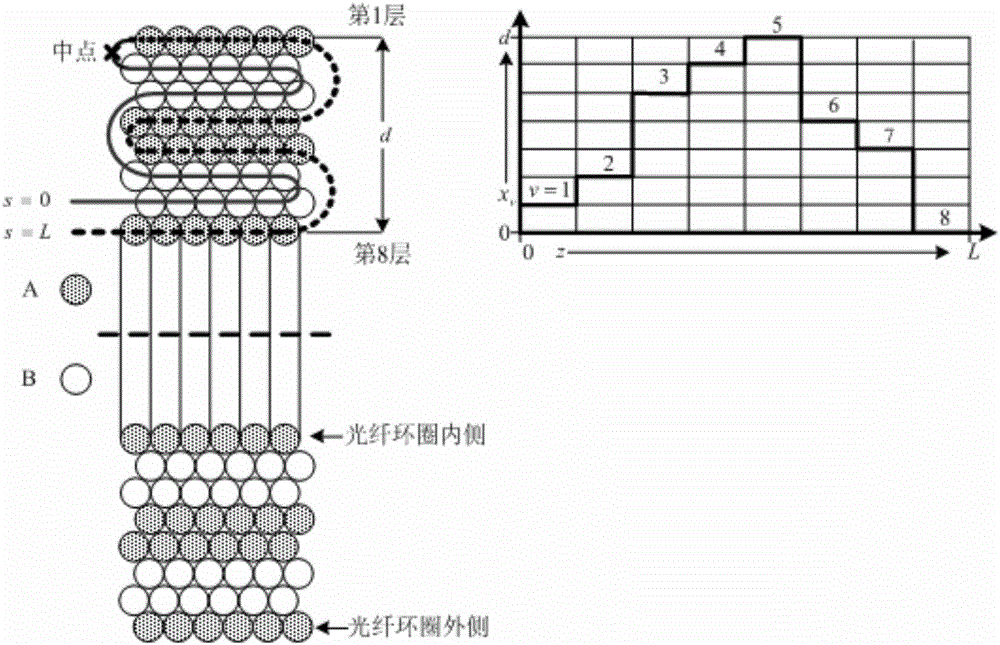

High-efficiency winding method for inhibiting temperature error of fiber gyro coil

The invention relates to a high-efficiency winding method for inhibiting temperature error of fiber gyro coil. According to the invention, fiber is divided into a segment A and a segment B from a central point, the segment A and the segment B are respectively wound on two fiber supplying wheels, the middle point of the fiber is fixed on a connection part of the wheel shaft used for winding a frame and a wheel rim, the fiber A is vertically wound on a first layer of a fiber ring along the wheel shaft, the fiber B is vertically wound on a second layer of the fiber ring along the wheel shaft, then the fiber B is rewound to form a third layer, then the fiber A is rewound to form a fourth layer, according to an outer to inner mode, four layers alternatively wind the all fibers, and a quadrupolar symmetrical winding structure is completed. Based on symmetrical winding, a concept of the outer to inner symmetrical winding mode is introduced, the concept and a traditional symmetrical winding method are combined, and the outer to inner symmetrical winding mode is formed, the method can be used for any traditional symmetrical winding mode, the temperature characteristic of the fiber coil is greatly increased, such as the outer to inner quadrupolar winding mode, the outer to inner octupole-winding mode and the outer to inner hexadecapole winding mode.

Owner:中国船舶重工集团公司第七〇七研究所

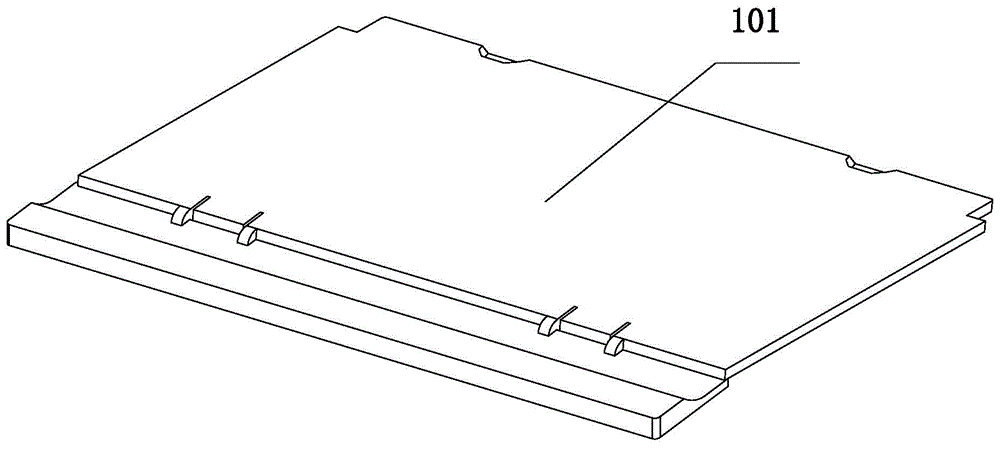

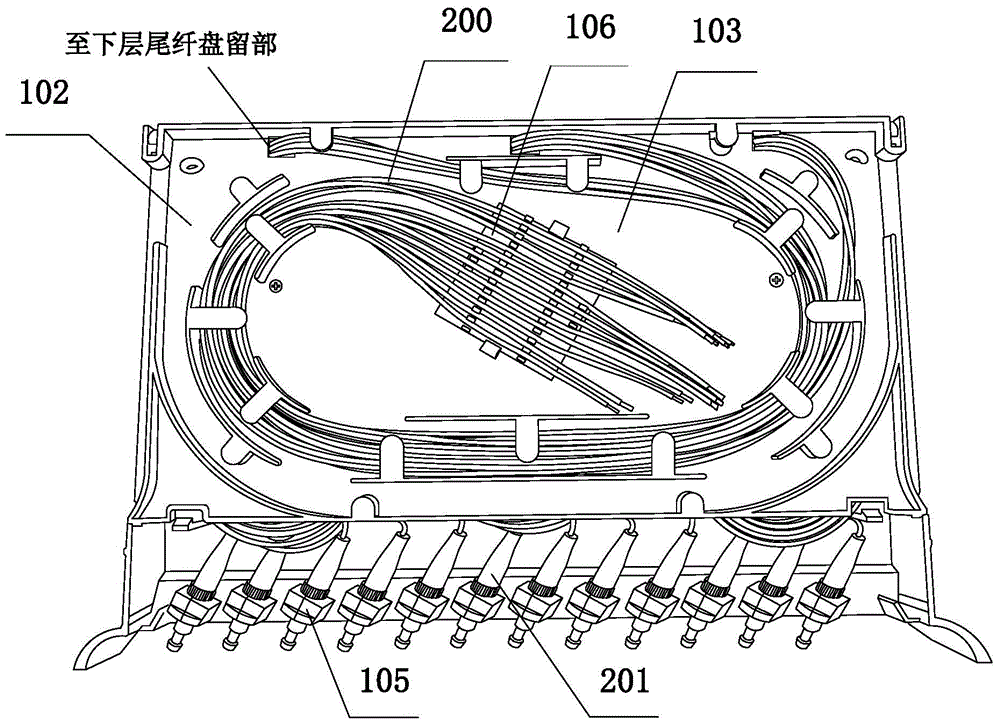

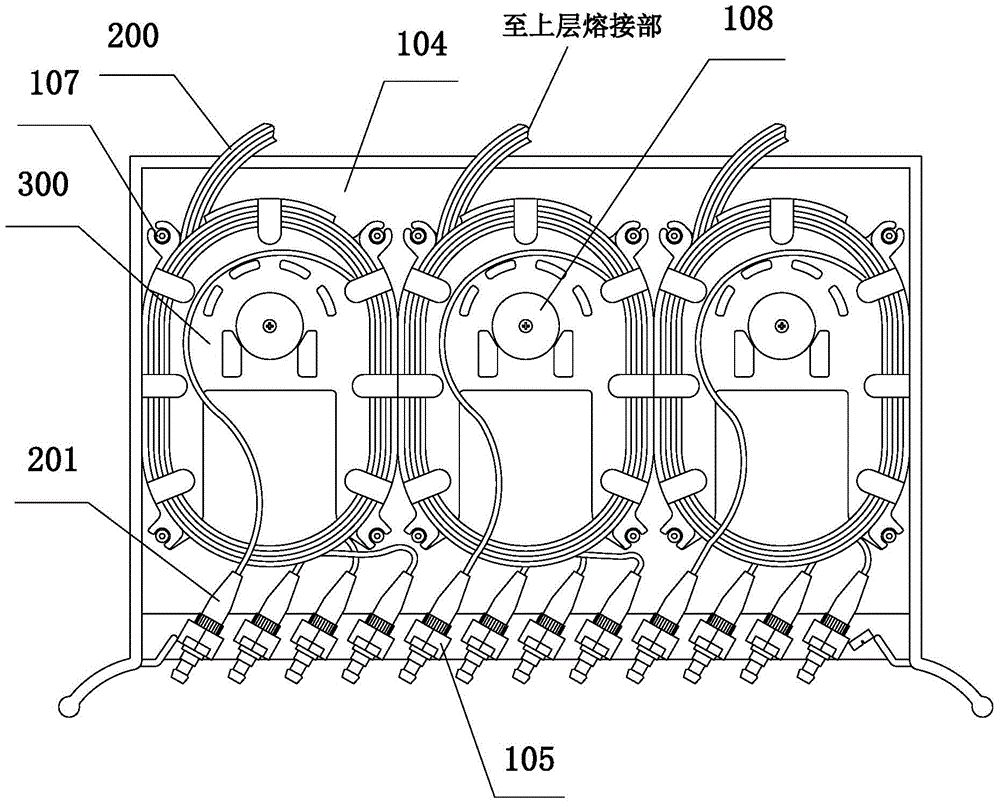

Optical fiber fusion and distribution integrated unit disc

InactiveCN104459920AEasy to processEasy to installCoupling light guidesFibre mechanical structuresFiberUltrasound attenuation

The invention provides an optical fiber fusion and distribution integrated unit disc, and belongs to an optical fiber fusion and distribution part. The optical fiber fusion and distribution integrated unit disc comprises a cover plate and a unit disc body. The unit disc body comprises a fusion part in the upper layer and a tail fiber coiling part in the lower layer. A plurality of fiber winding-unwinding structures used for coiling tail fibers are arranged in the tail fiber coiling part, each fiber winding-unwinding structure is formed by detachably connecting a plurality of fiber winding-unwinding discs, and the fiber winding-unwinding discs of each fiber winding-unwinding structure are stacked in the vertical direction. The optical fiber fusion and distribution integrated unit disc can be used as a distribution unit disc in an optical cable splice box, and in the optical cable splice box, the tail fibers can be directly connected with an adapter of a standard main unit disc through the tail fibers. Attenuation in the whole light path process is effectively reduced, the network quality is improved, and obstacle points caused by connecting the optical fibers with the adapter are reduced. In addition, the tail fibers in the optical fiber splice box can be orderly and tidily arranged, and disordering of the tail fibers can be avoided.

Owner:高文亭 +2

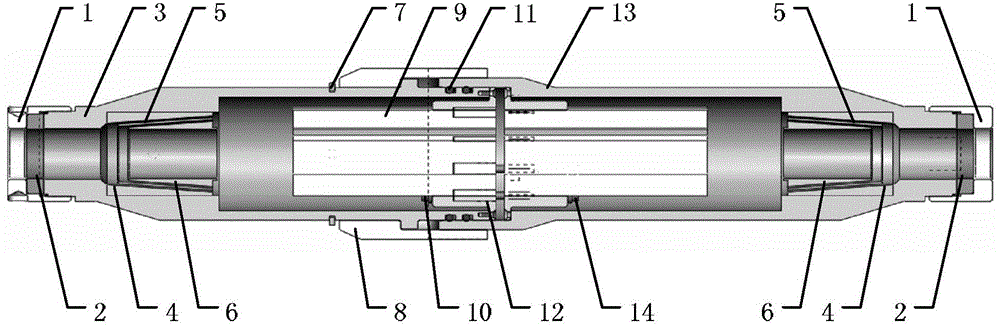

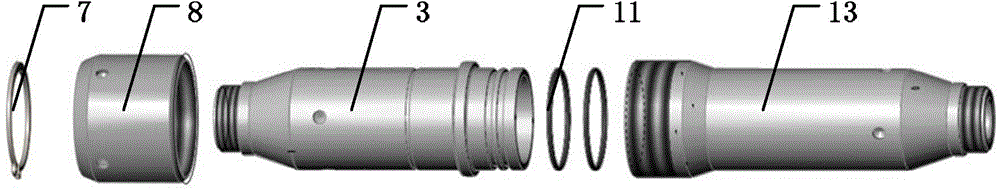

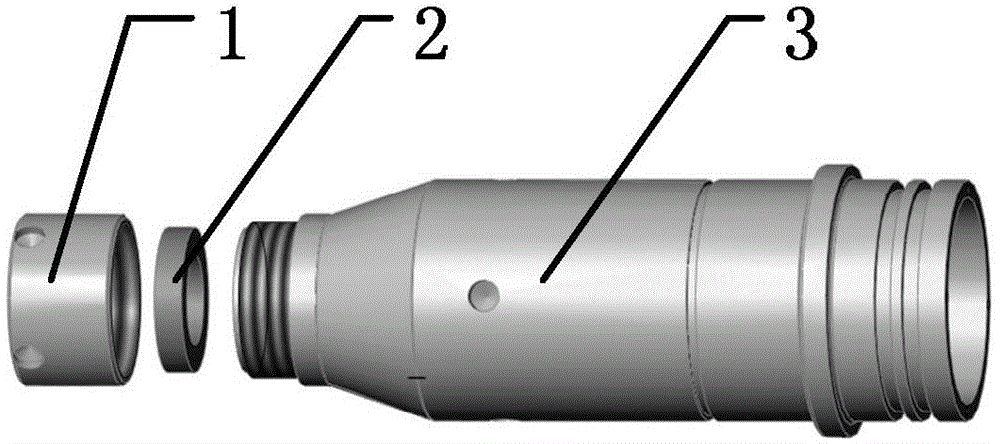

Rapid connection apparatus of photoelectric composite cable of fiber-optic hydrophone array

ActiveCN104538788ASolve the problem of fast and reliable connectionReduce volumeCoupling device detailsTwo-part coupling devicesCopper conductorFiber

The invention relates to a rapid connection apparatus of a photoelectric composite cable of a fiber-optic hydrophone array. The rapid connection apparatus comprises an upper sealing cylinder, a lower sealing cylinder, a fastening screw ring, sealing O-shaped rings, two composite cable sealing nuts, two sealing washers, two sets of composite cable clamping assemblies, two fiber coiling boxes, a copper conductor electrical connector assembly, and composite cables. The fiber coiling boxes are respectively installed in the upper sealing cylinder and the lower sealing cylinder; and the upper sealing cylinder and the lower sealing cylinder are connected into a sealing cylinder by the fastening screw ring and the two sealing O-shaped rings and the copper conductor electrical connector assembly is installed in the sealing cylinder. The composite cables in the upper sealing cylinder and the lower sealing cylinder are fixed by the composite cable clamping assemblies and are connected with the copper conductor electrical connector assembly. The end portions of the upper sealing cylinder and the lower sealing cylinder enable the composite cables and the sealing cylinder to be sealed and fixed by the composite cable sealing nuts and the sealing washers. The apparatus has advantages of small size, good quick and convenient properties, high confined water tightness, and good photoelectric composite connection and the like and is absolutely necessary for marine resource exploration and underwater target detection array.

Owner:BEIJING SHENZHOU PUHUI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com