Optical fiber fusion and distribution integrated unit disc

A fusion and optical fiber technology, applied in the field of optical fiber fusion integrated unit disk, can solve the problems of affecting the speed of fiber finding, reducing network quality, increasing optical path attenuation, etc., achieving convenient installation and disassembly, improving network quality, reducing Effects of Pigtail Redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

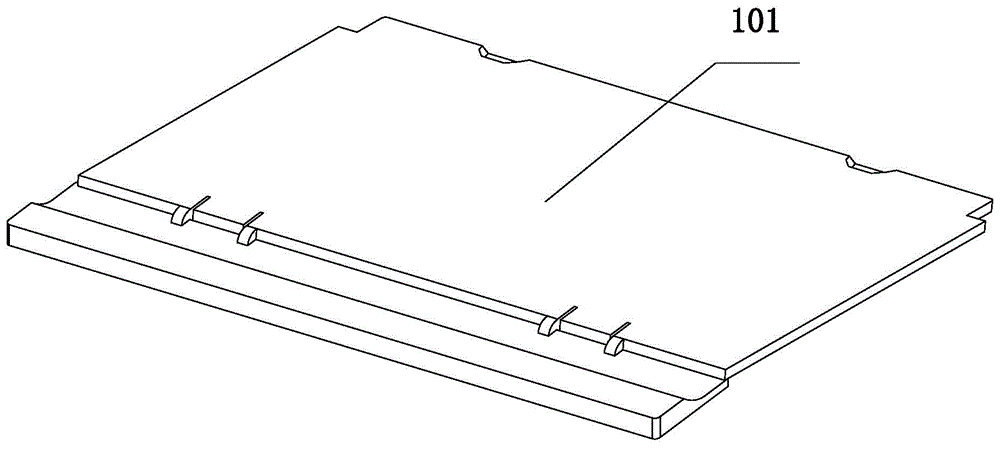

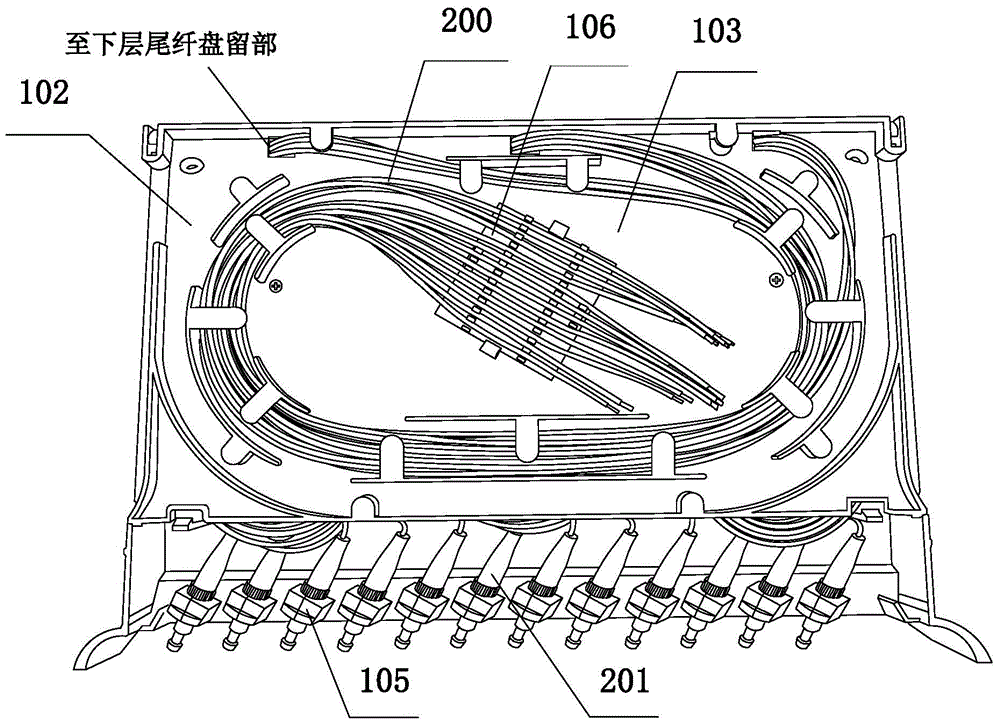

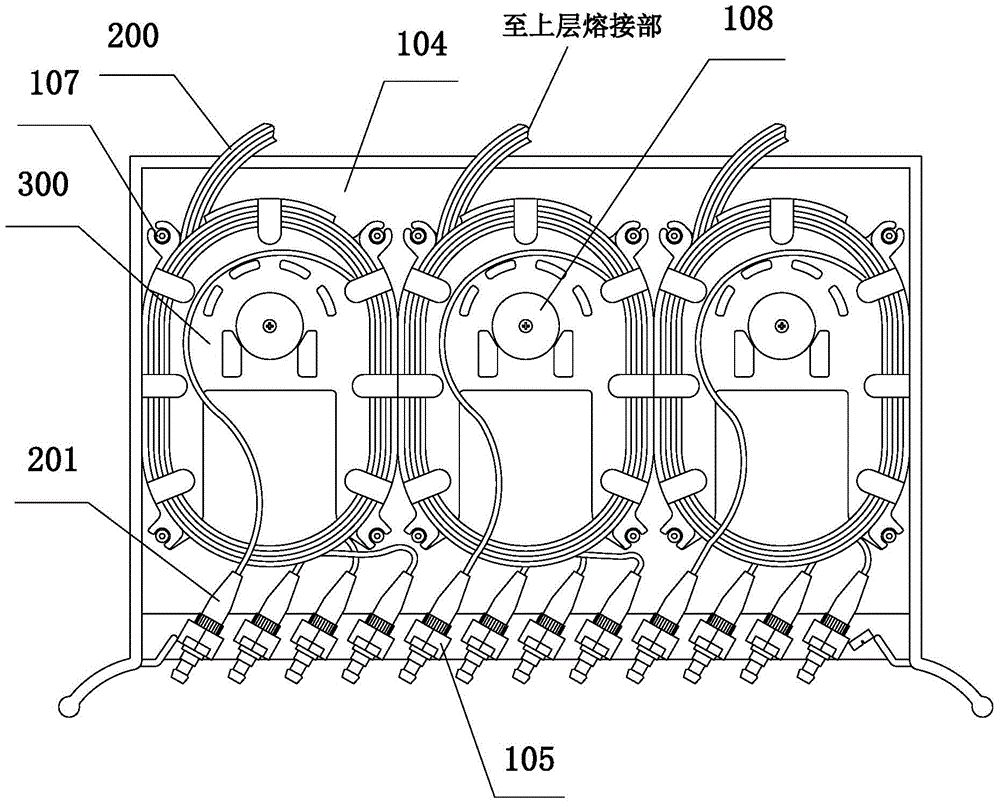

[0042] Embodiment 1, with reference to Figure 1 to Figure 8 , an integrated unit tray for optical fiber fusion, including a cover plate 101 and a unit tray body 102, the unit tray body 102 includes an upper layer of welding portion 103 and a lower layer of pigtail tray remaining portion 104, the cover plate 101 of the present invention and the unit tray body 102 The existing optical fiber fusion integrated unit tray is the same, including the first plate body connected to the unit tray body 102, and the second plate body hinged with the first plate body, the second plate body and the tail fiber tray remaining part 104 The positions of the fiber outlets correspond to each other. The first board is hinged or clipped to the unit tray body 102 , which is easy to open. When connecting the pigtail 200 , it is only necessary to turn the second board upward relative to the first board.

[0043] The fusion splicing part 103 is also the same as the existing optical fiber fusion integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com