Patents

Literature

91results about How to "Reduce attenuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

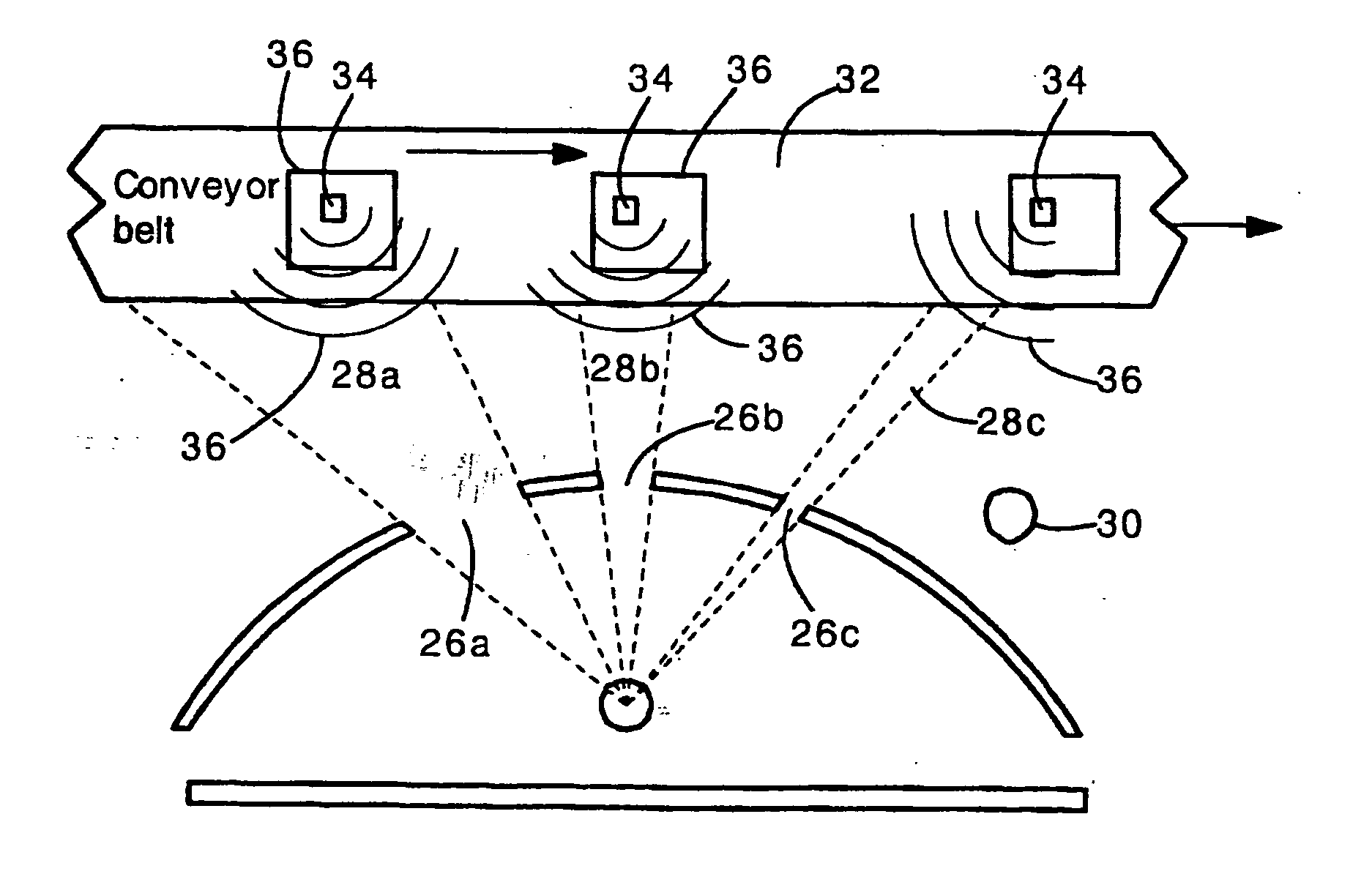

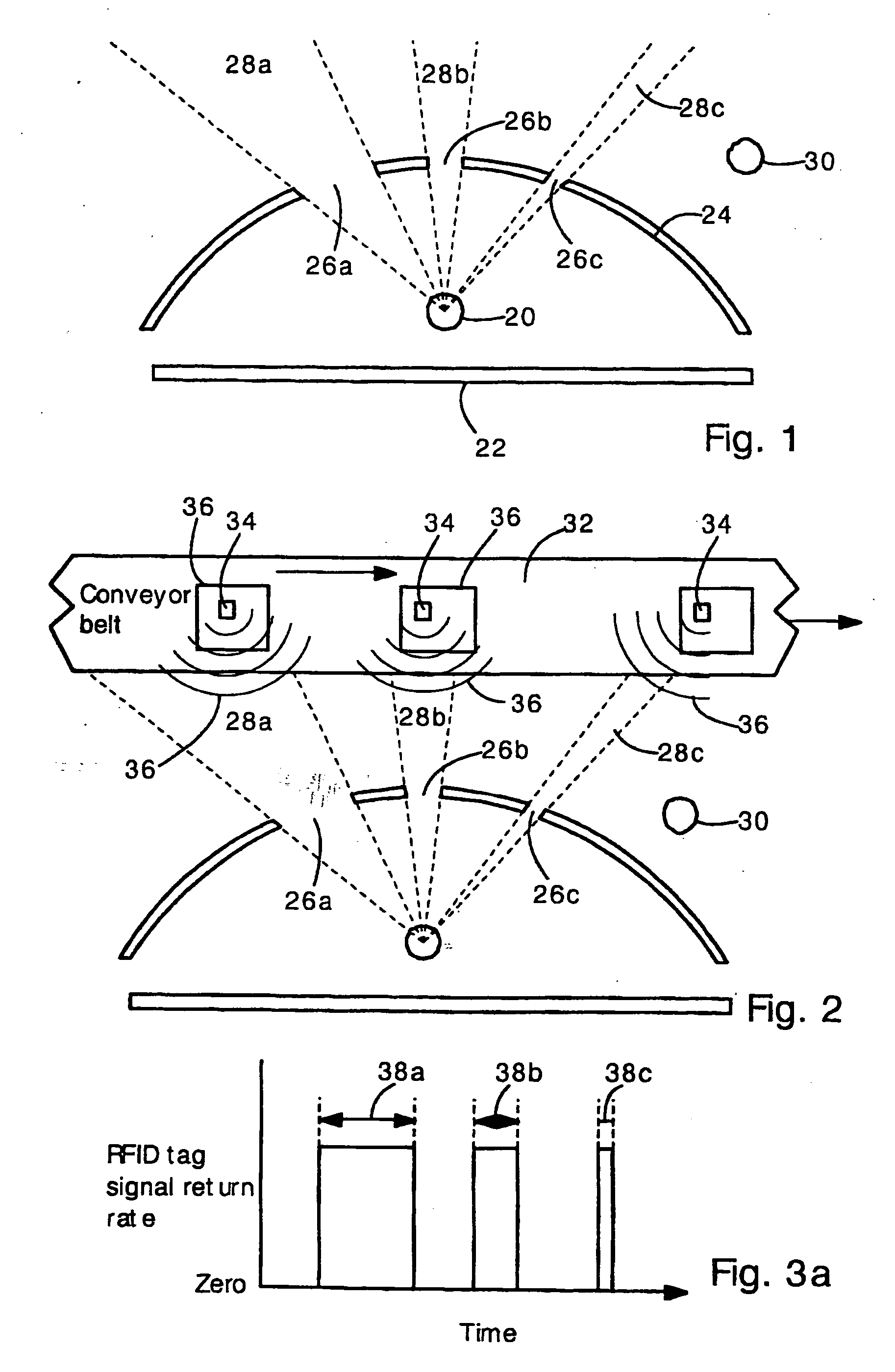

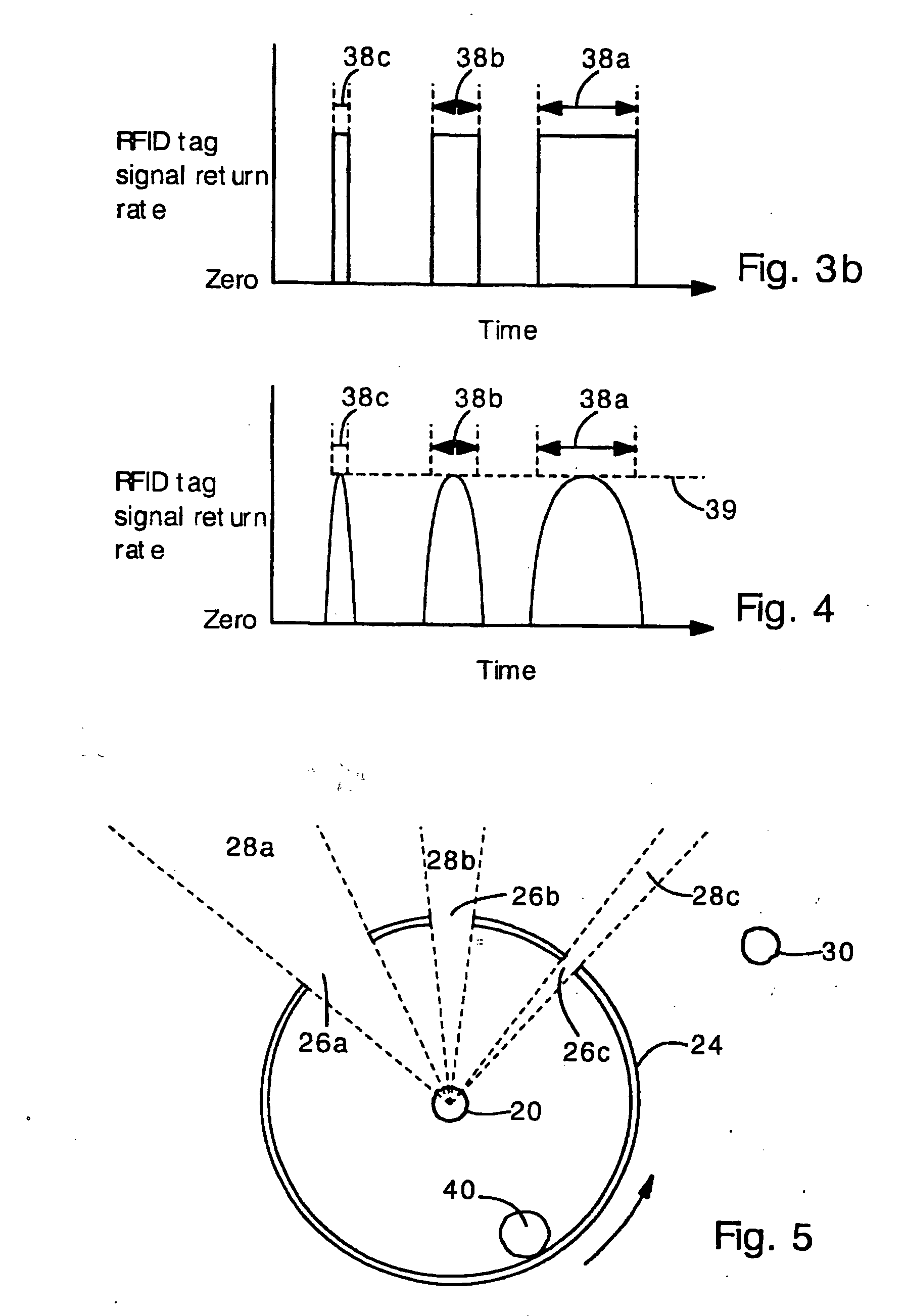

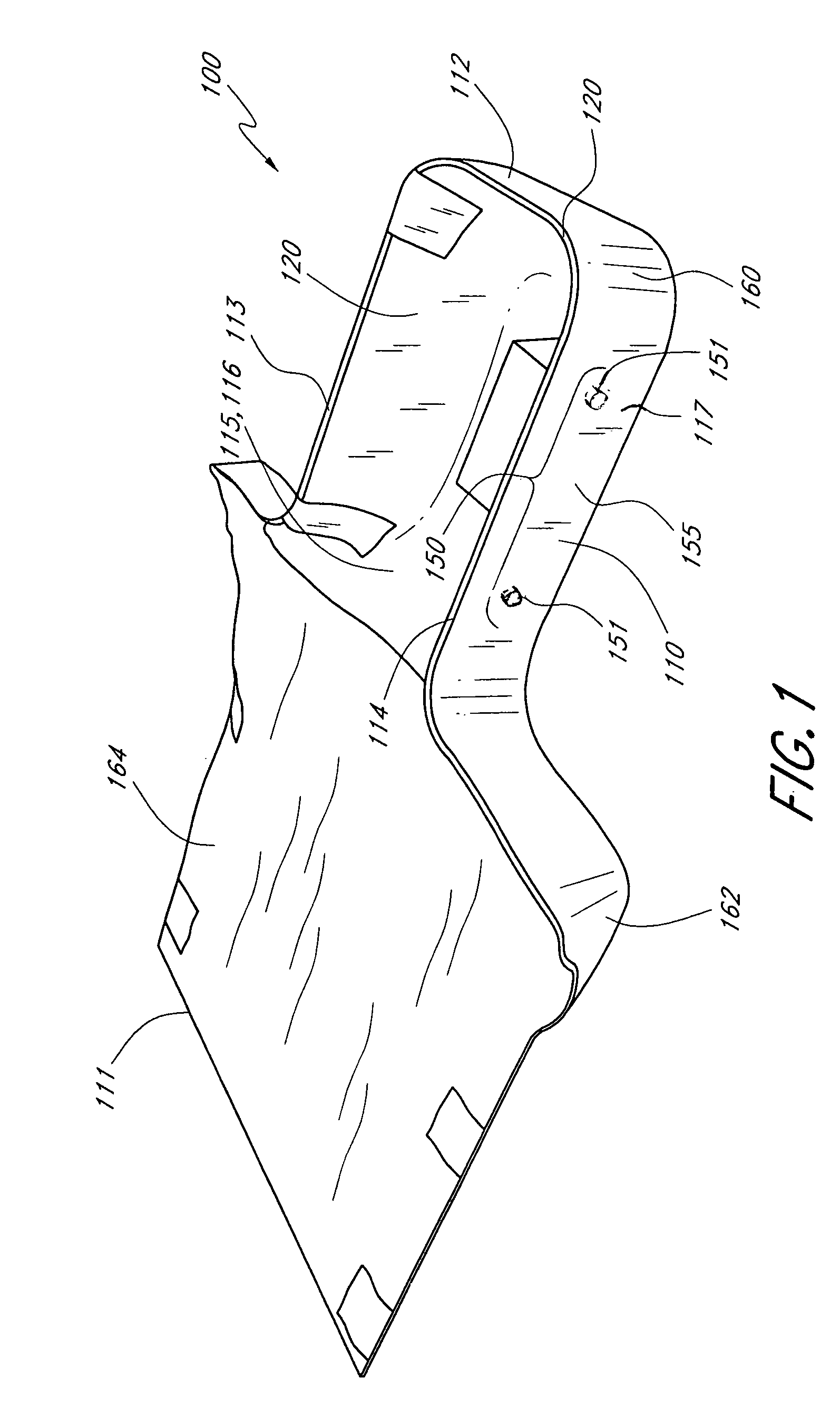

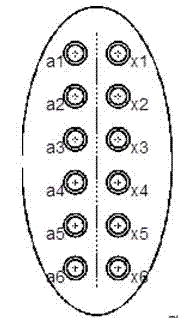

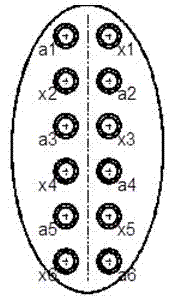

RFID reader having antenna with directional attenuation panels for determining RFID tag location

InactiveUS20070030150A1Reduce attenuationReduced to zeroAntenna supports/mountingsSensing record carriersUltrasound attenuationElectrical and Electronics engineering

An antenna structure capable of determining the direction of a radiofrequency identification (RFID) tag includes a wide-angle antenna disposed within an attenuator that has regions of low attenuation. The attenuator may include a metal plate with holes. In this case, the antenna only detects RFID tags that are aligned with a hole, and hence the direction of the RFID tag is detected. Multiple holes of different sizes can be provided. In this case, if the RFID tag is moving, the direction and speed of movement can be determined from the duration of received RFID signals. For example, a long period of RFID tag signal reception indicates that the tag passed in front of a large hole in the attenuator. The present invention is particularly well suited for use with conveyor belts and in applications where RFID tags move along known paths.

Owner:IBM CORP

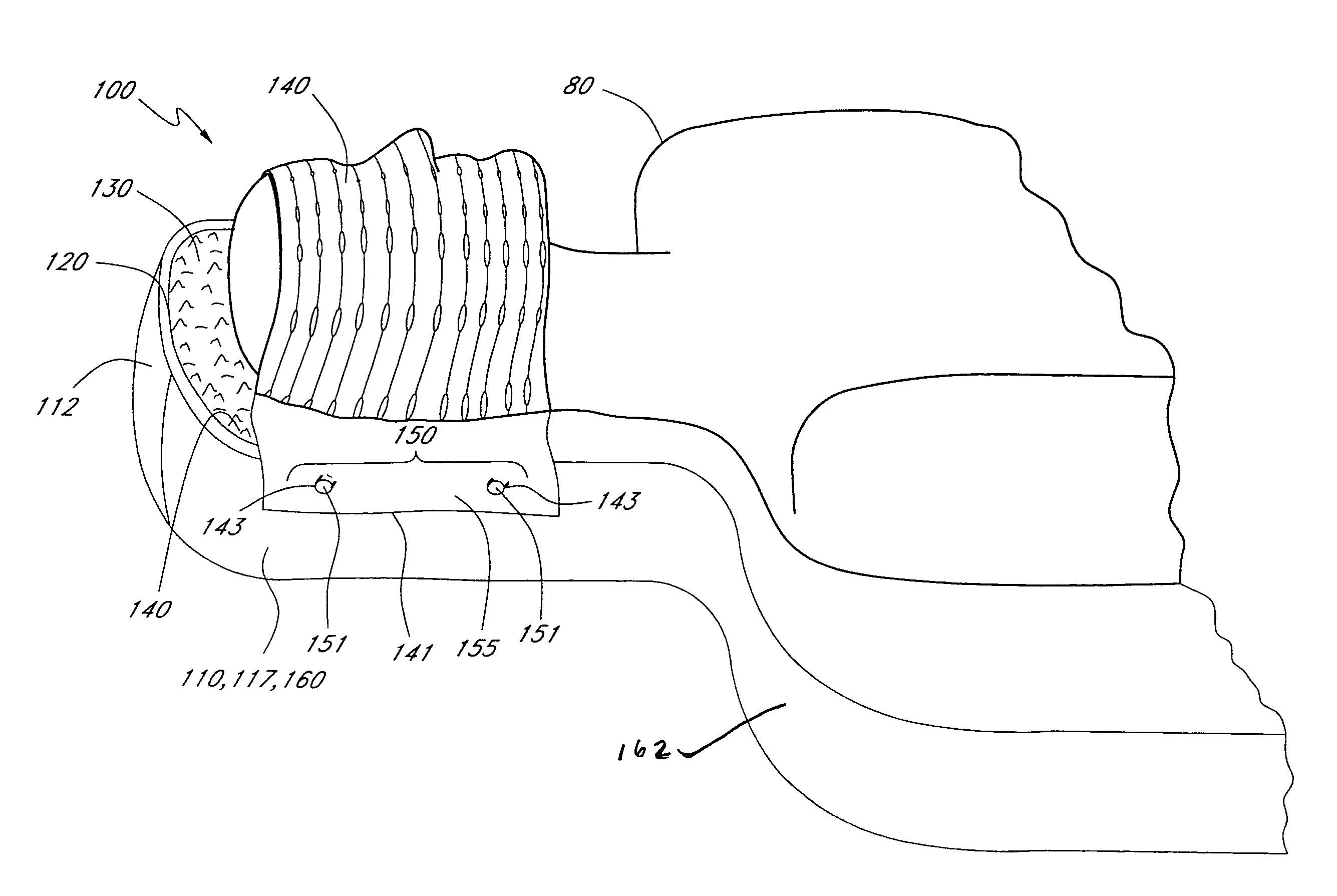

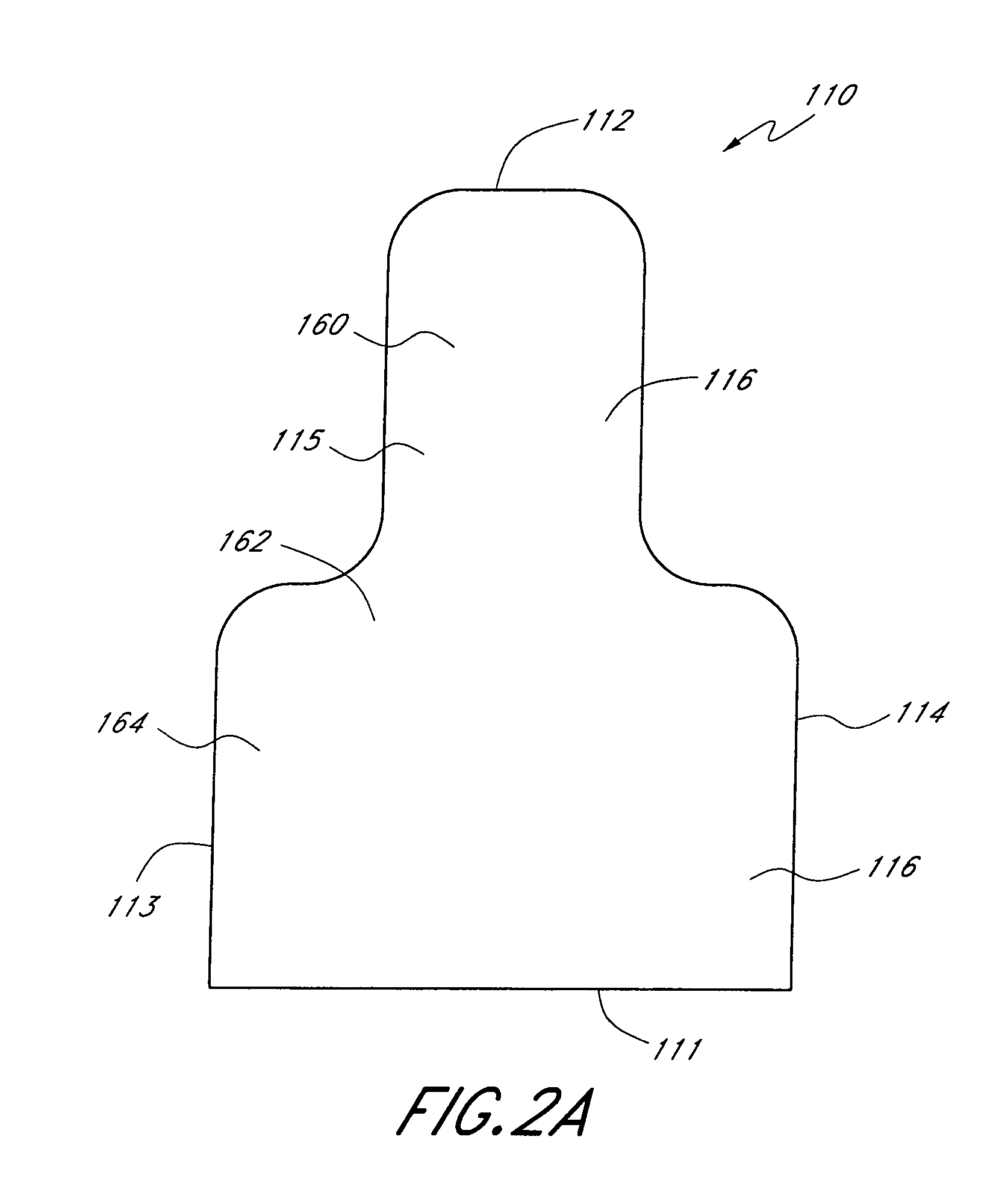

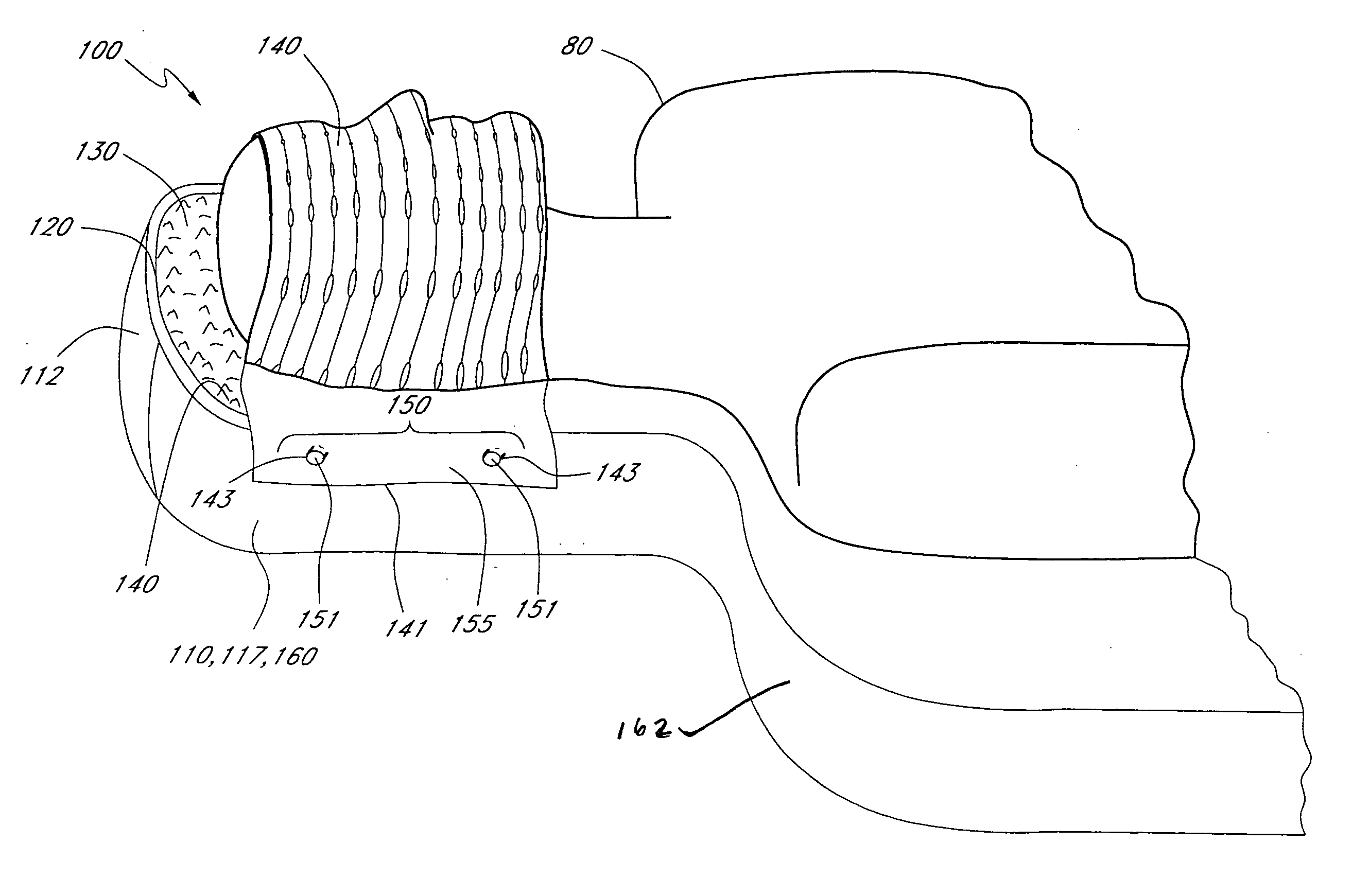

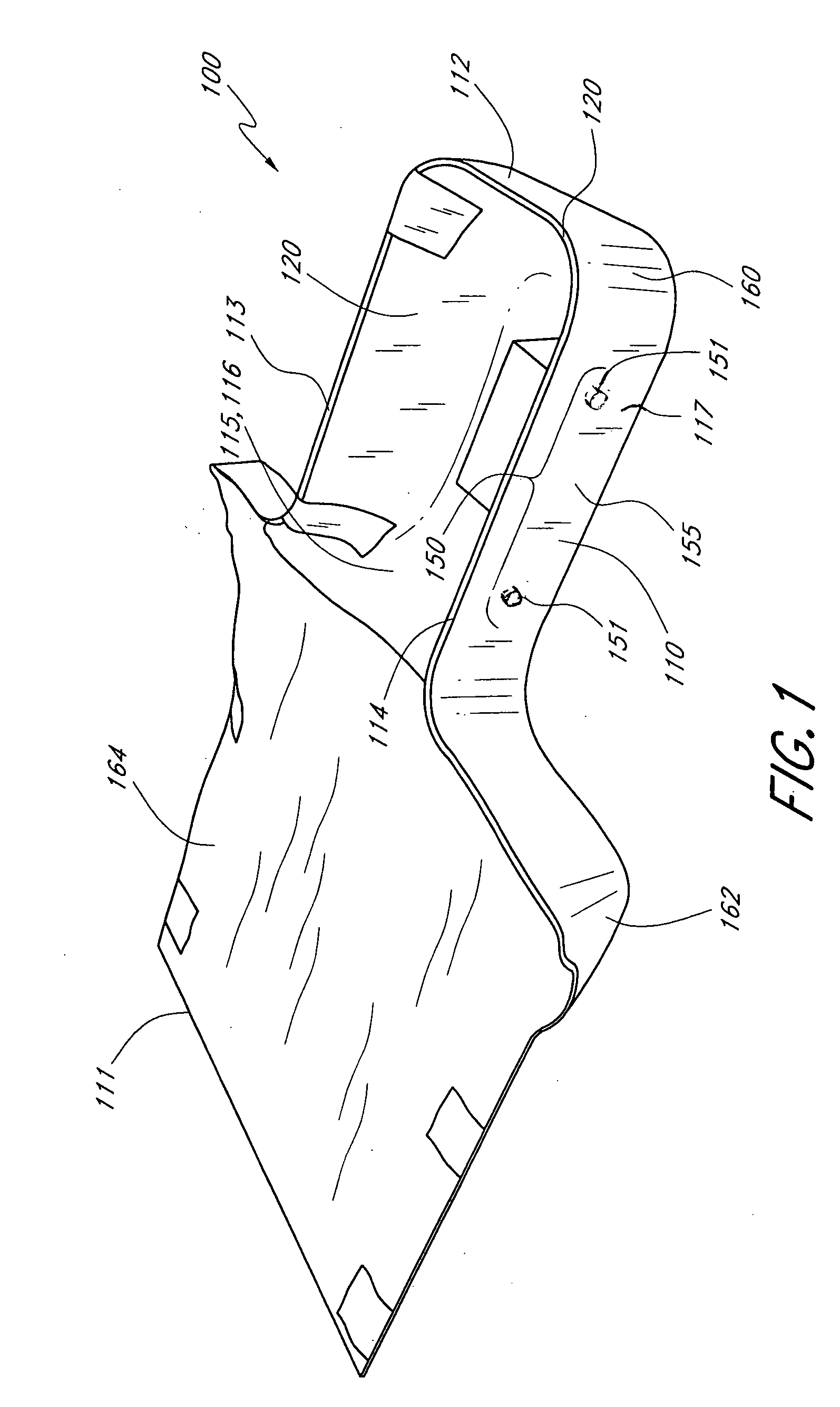

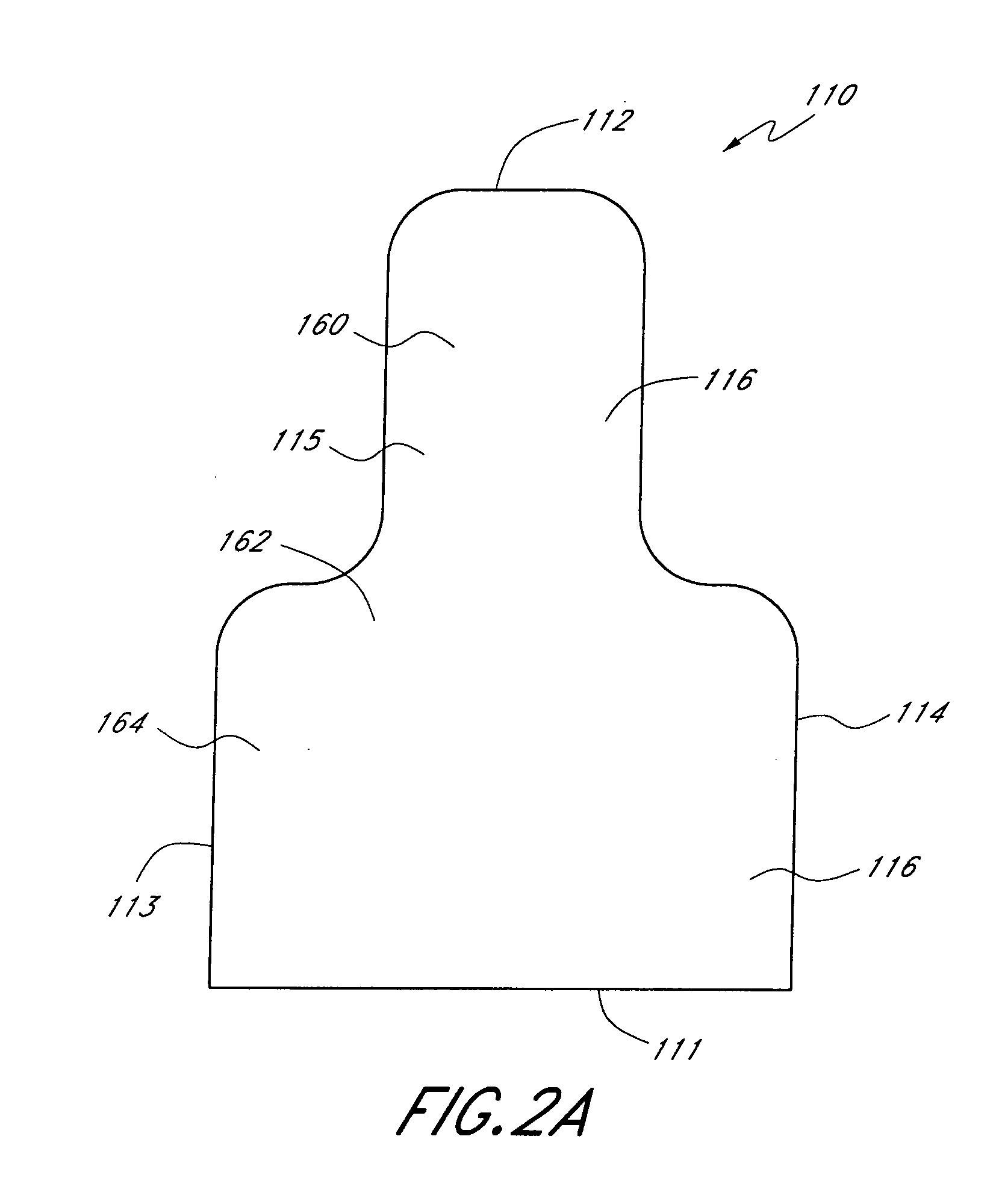

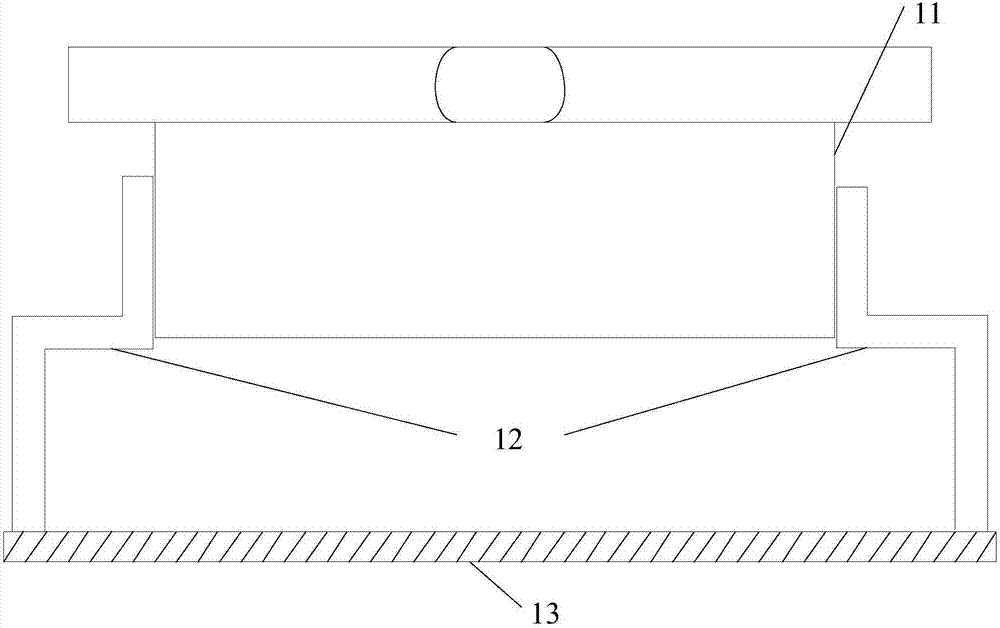

Method and device for registration and immobilization

InactiveUS7073508B2Reduce attenuation and distortionReduce deliveryEar treatmentRestraining devicesUltrasound attenuationPrescribed radiation dose

Support devices and pods for the head and neck region of patients undergoing radiation therapy are provided herein. The pod generally includes a support shell shaped to generally conform to the shape of the head and neck region of the patient, a foam insert that conforms to the head and neck region of the patient, and an immobilization facemask attached directly to the shell, thereby facilitating close placement of the radiation beam delivery device to the patient and reducing any attenuation and perturbation of radiation doses directed at the patient. The components of the pod are made from materials having properties that reduce any attenuation and perturbation of prescribed radiation doses.

Owner:LOMA LINDA UNIV MEDICAL CENT

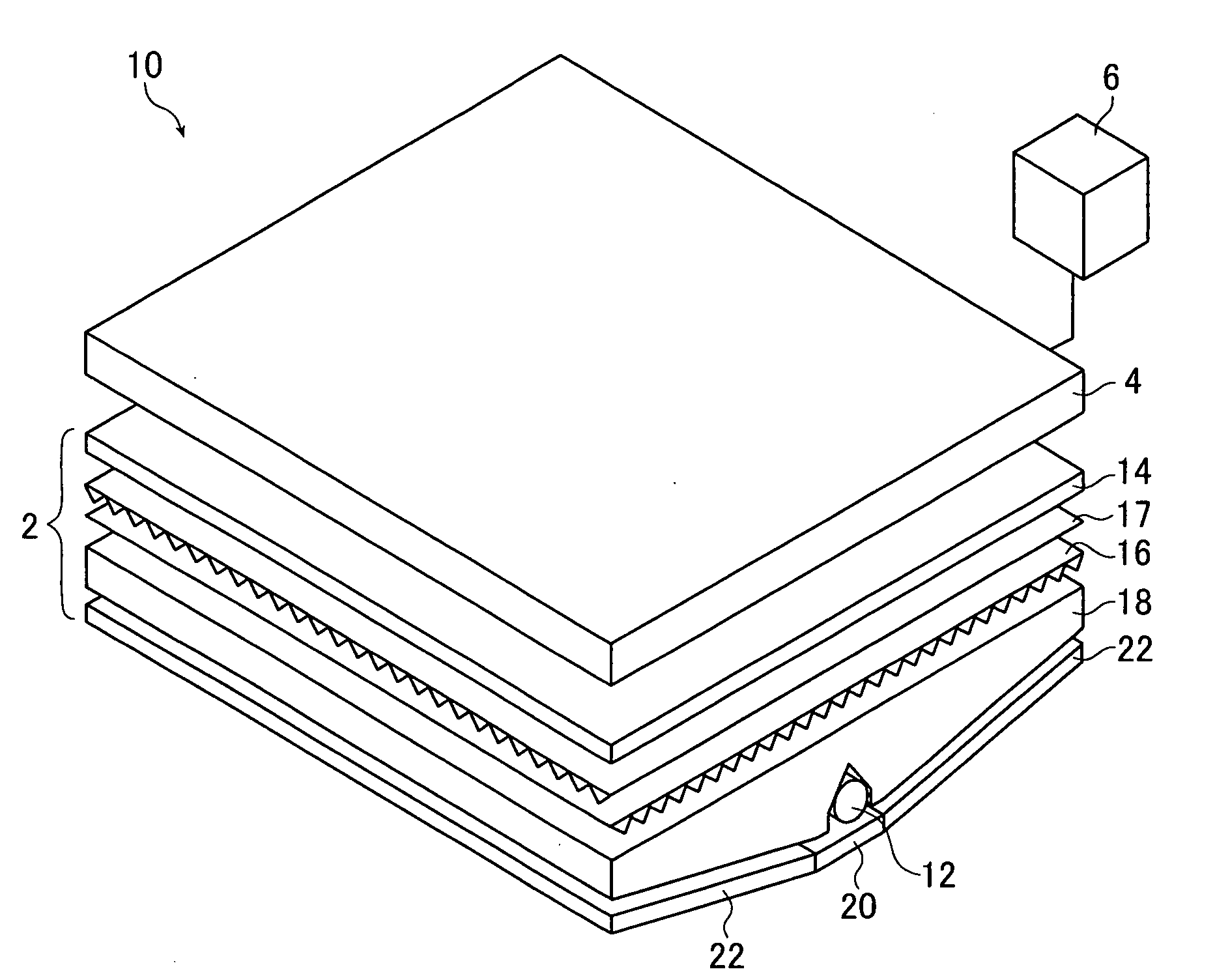

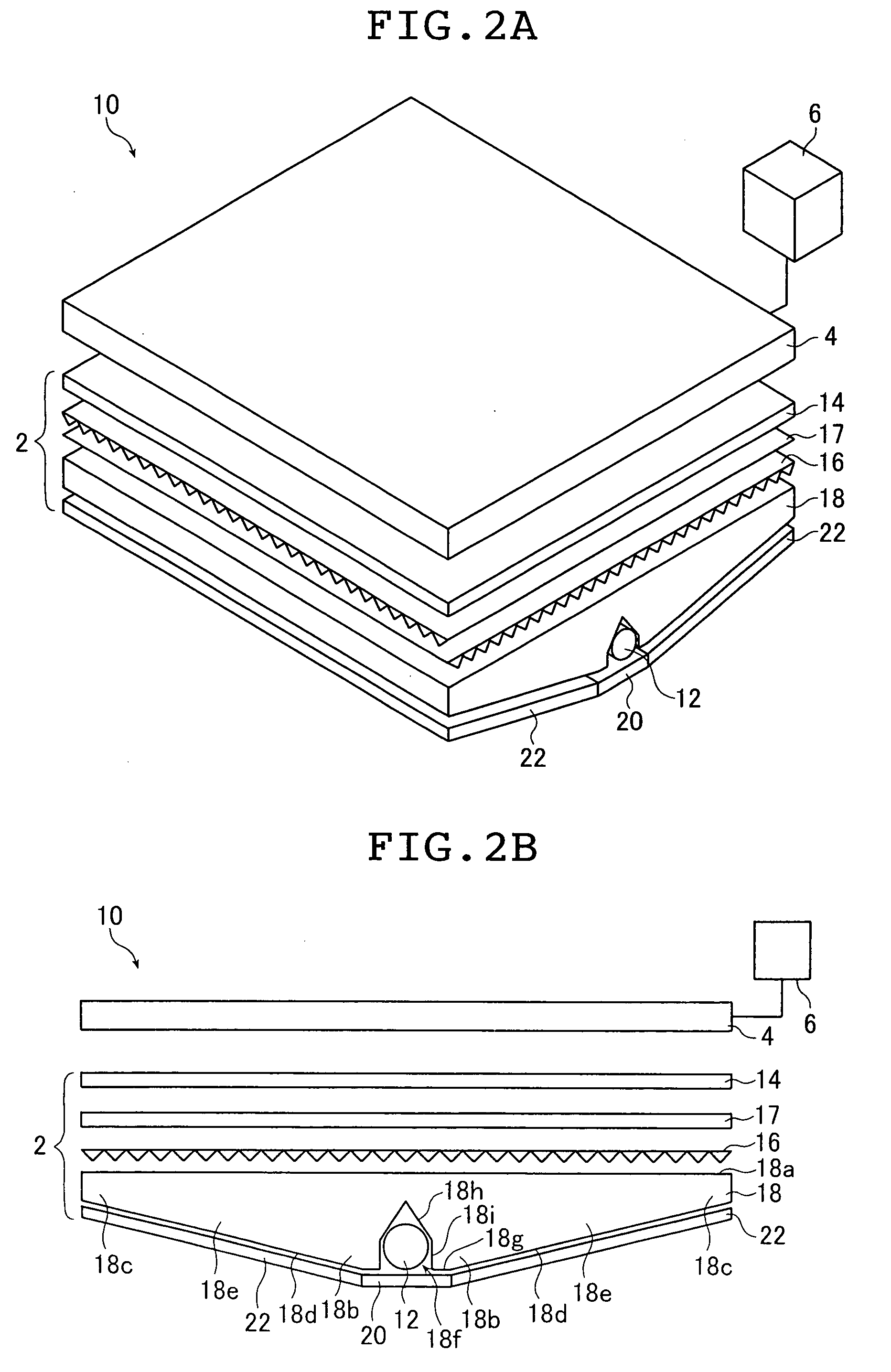

Light Guide Plate, and Planar Lighting Device and Liquid Crystal Display Device Using Such Light Guide Plate

InactiveUS20080137004A1Improve light utilization efficiencyReduce unevennessMechanical apparatusPlanar/plate-like light guidesLiquid-crystal displayLight guide

A parallel groove of a light guide place for accommodating a light source has, in a perpendicular cross section, a shape composed of a pair of contour lines that approach each other toward a light emitting plane, cross at a peak, and has a part where an inclination angle to a line vertical to the light emitting plane changes, and the inclination angle at a base end side far from the peak is sharper than that at a tip end side close to the peak. Thus, uniform and high brightness light can be emitted.

Owner:FUJIFILM CORP

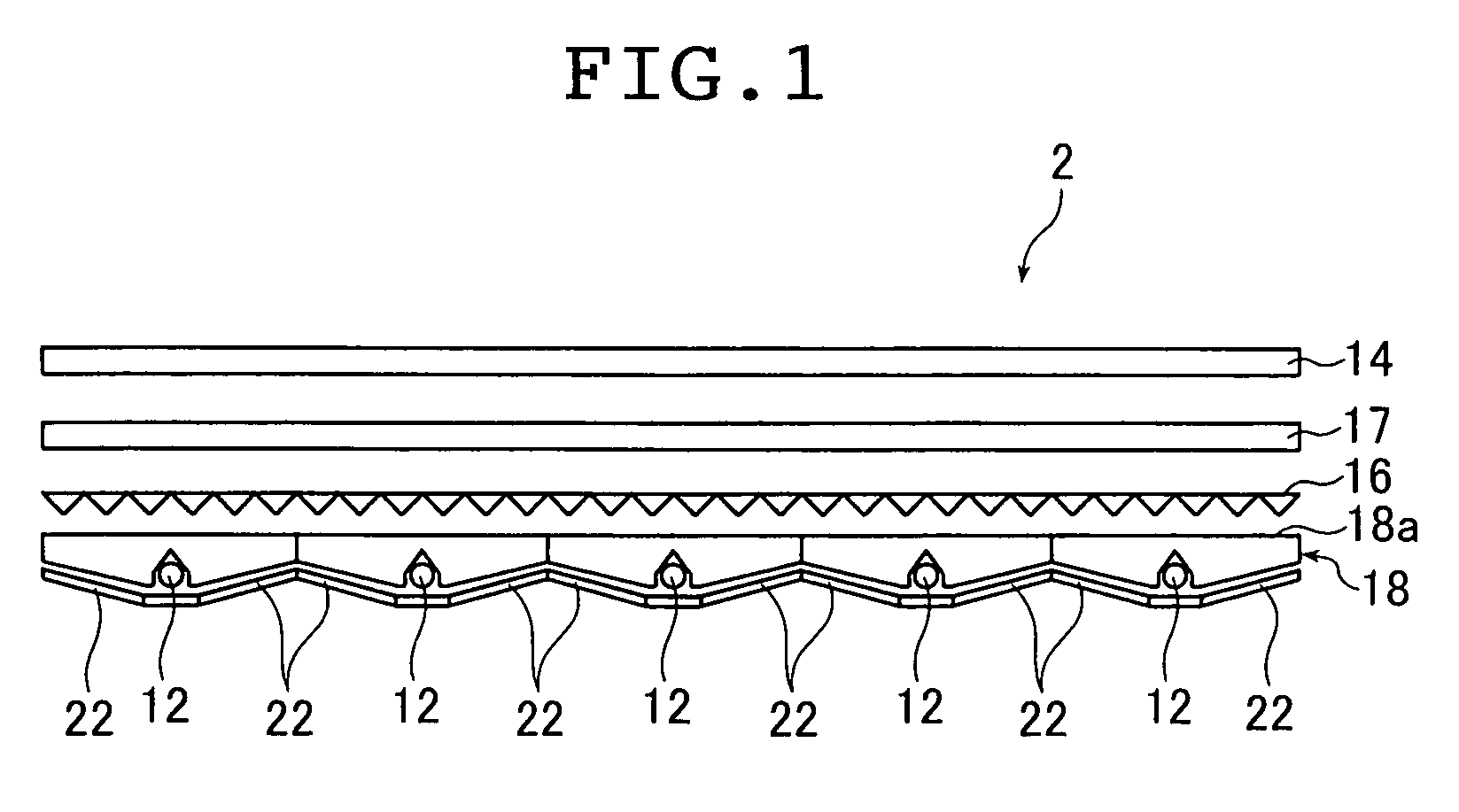

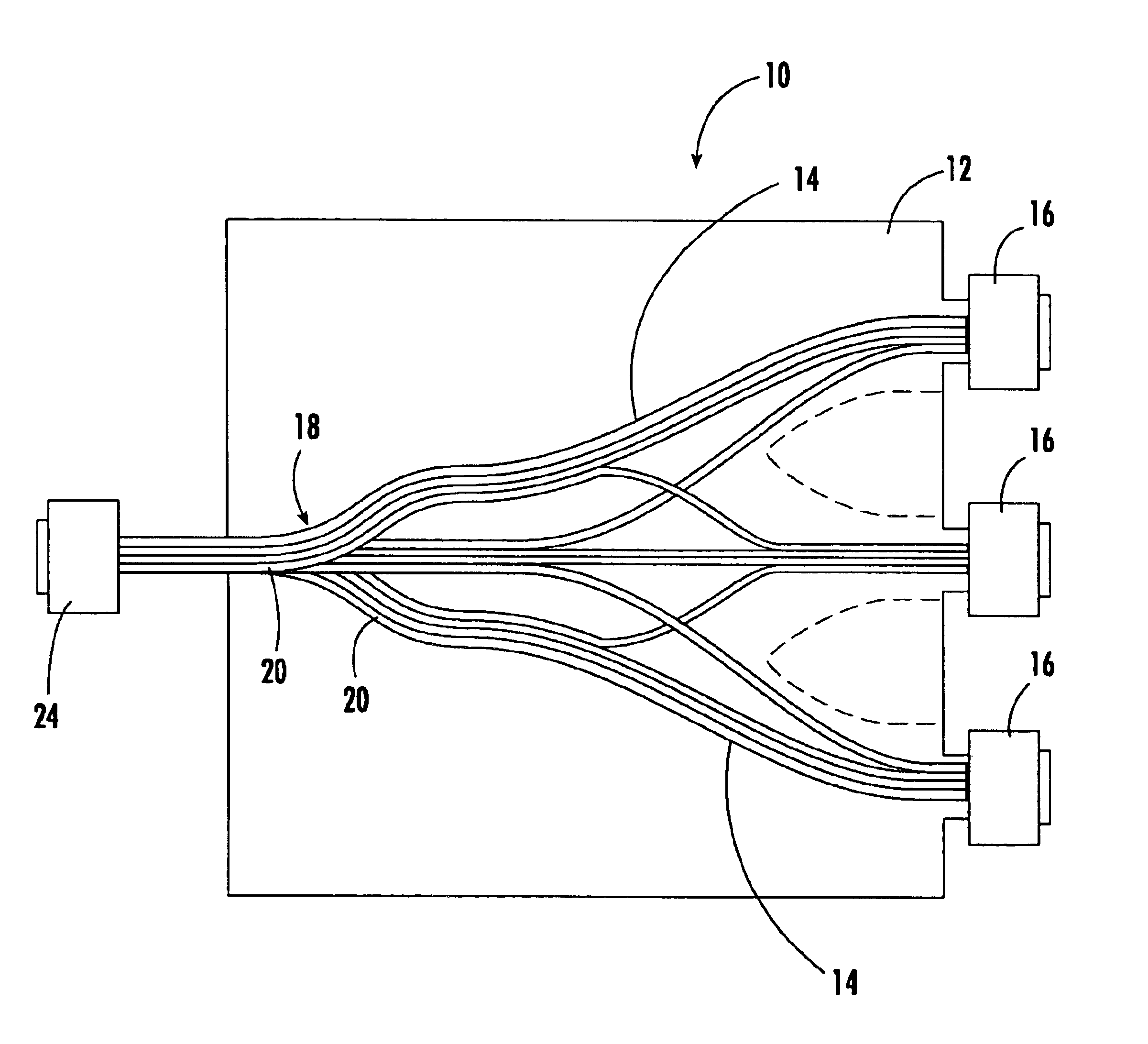

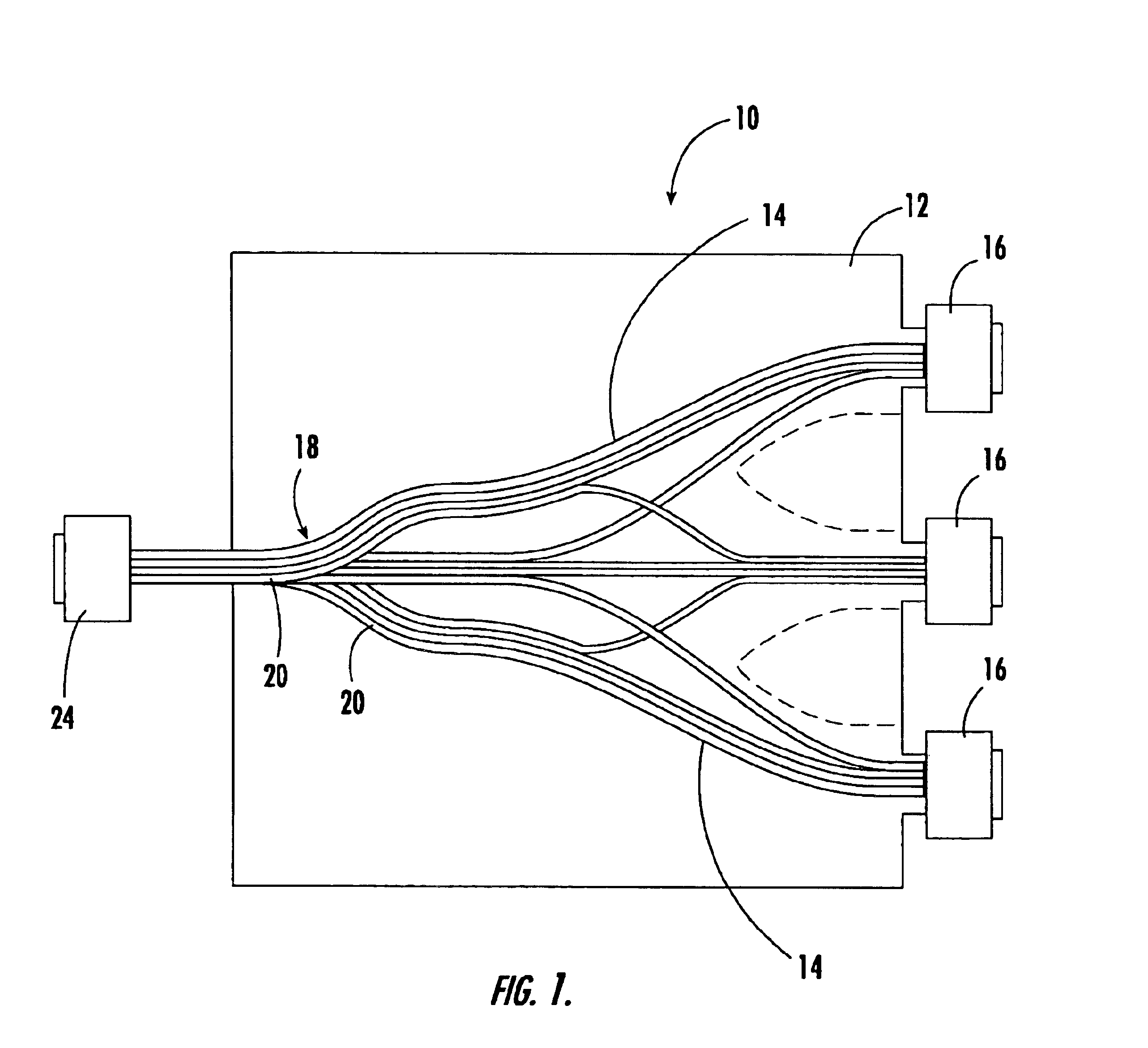

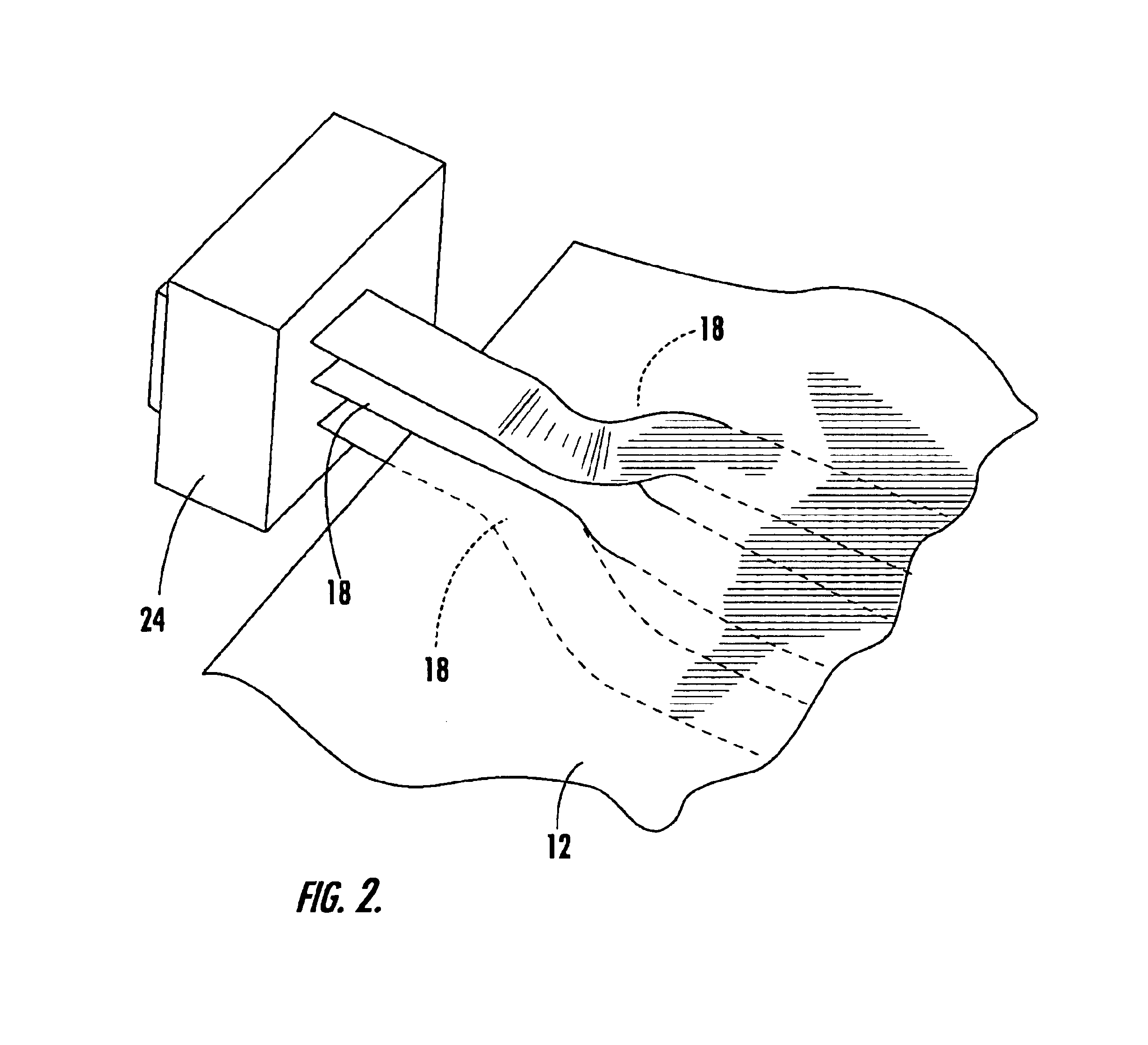

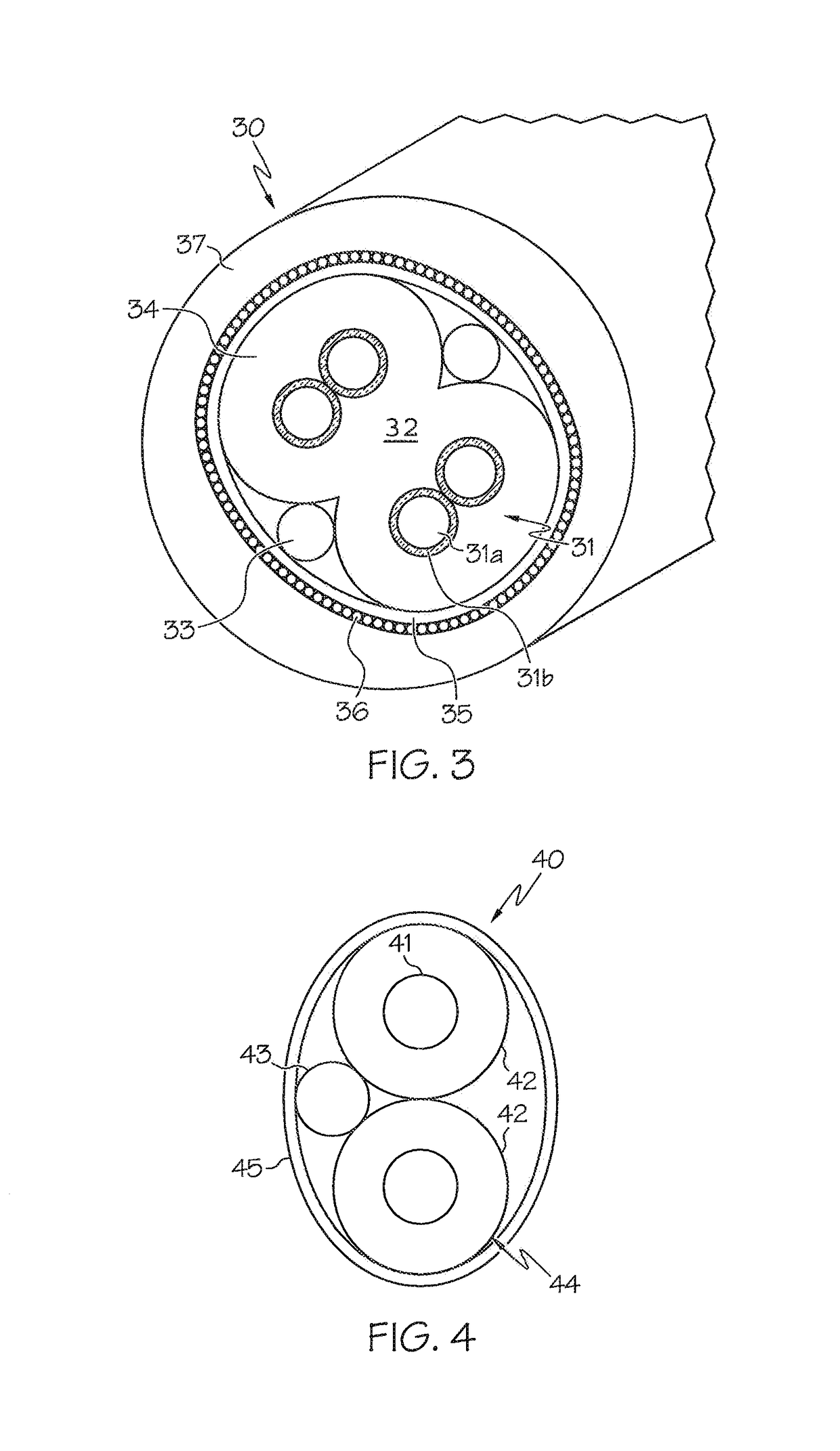

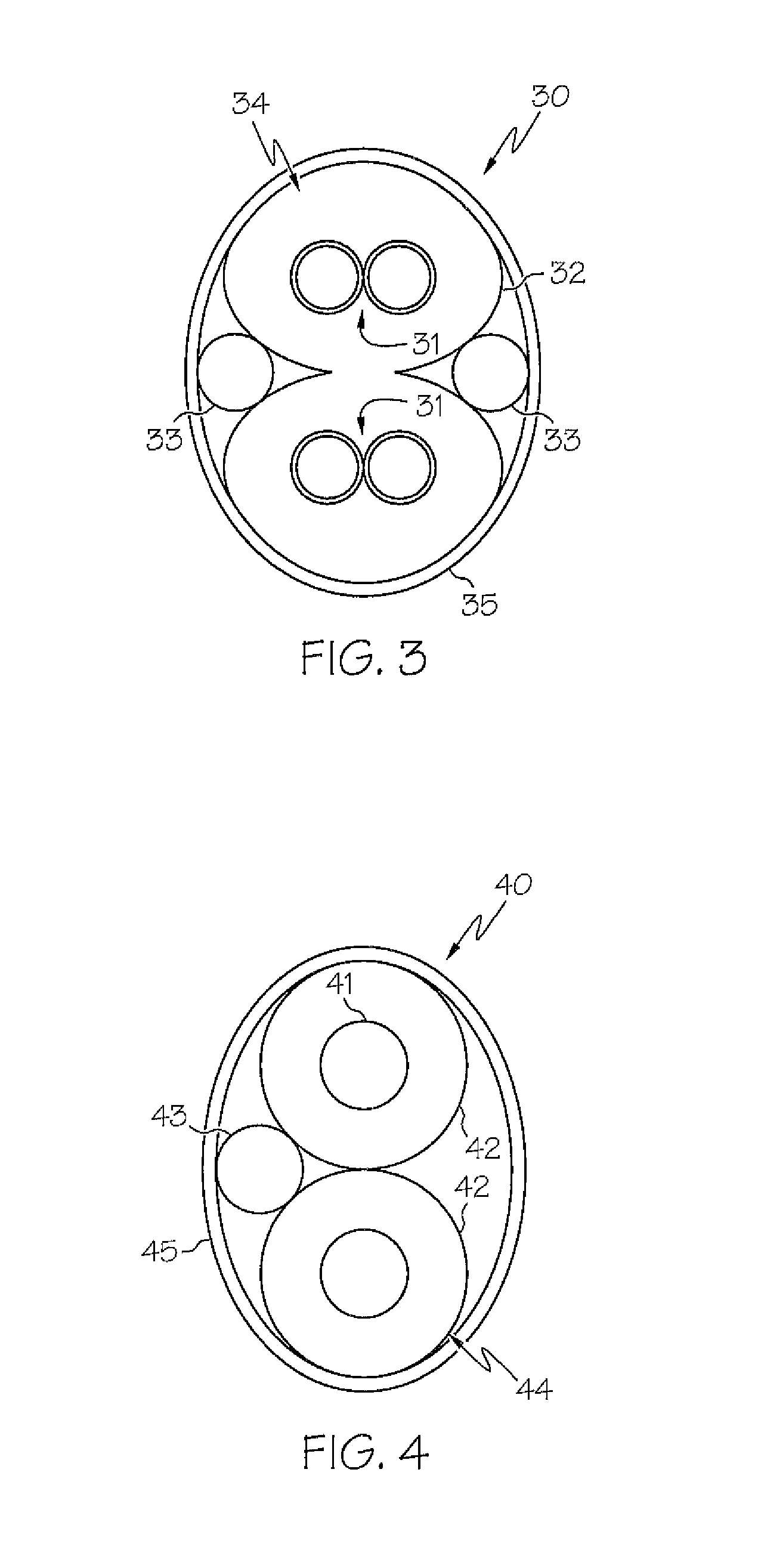

Optical circuit having legs in a stacked configuration and an associated fabrication method

InactiveUS6850671B2Improves fiber managementImprove organizationCoupling light guidesFibre mechanical structuresEngineeringOptical fiber

An optical circuit is provided having a plurality of legs, each of which may have one or more optical fibers bound together by a matrix material, arranged in a stacked configuration in such a manner as to reduce, if not eliminate, the stress to which the optical fibers are subjected. The optical circuit includes a main body having a flexible substrate and a plurality of optical fibers mounted upon the substrate and lying in a common plane. The plurality of legs extend outwardly from an edge of the main body. The legs are disposed in a stacked configuration in which at least one leg overlies another leg. As such, at least one leg lies at least partially outside of the common plane defined by the substrate. A method for fabricating the optical circuit is also provided.

Owner:US CONEC

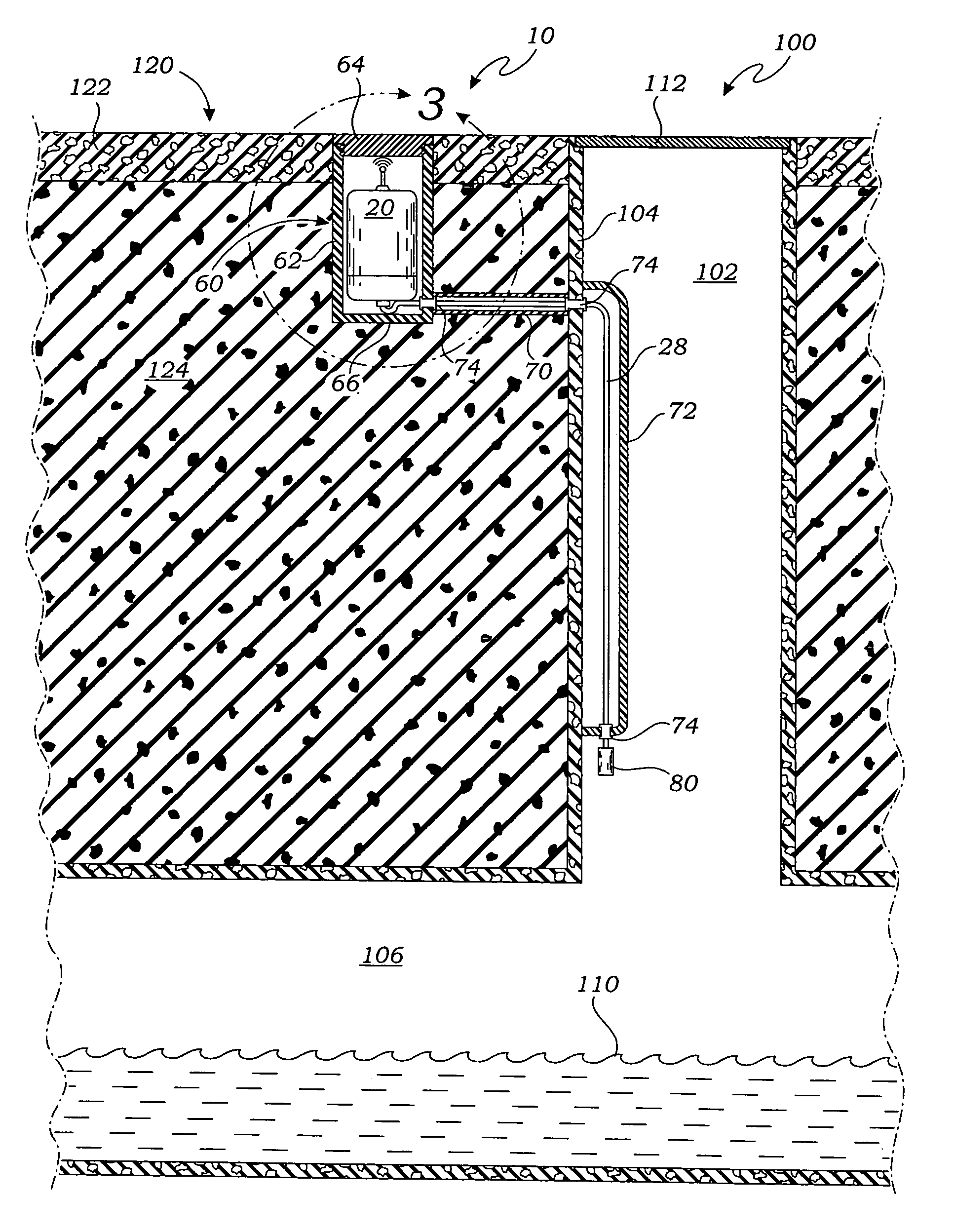

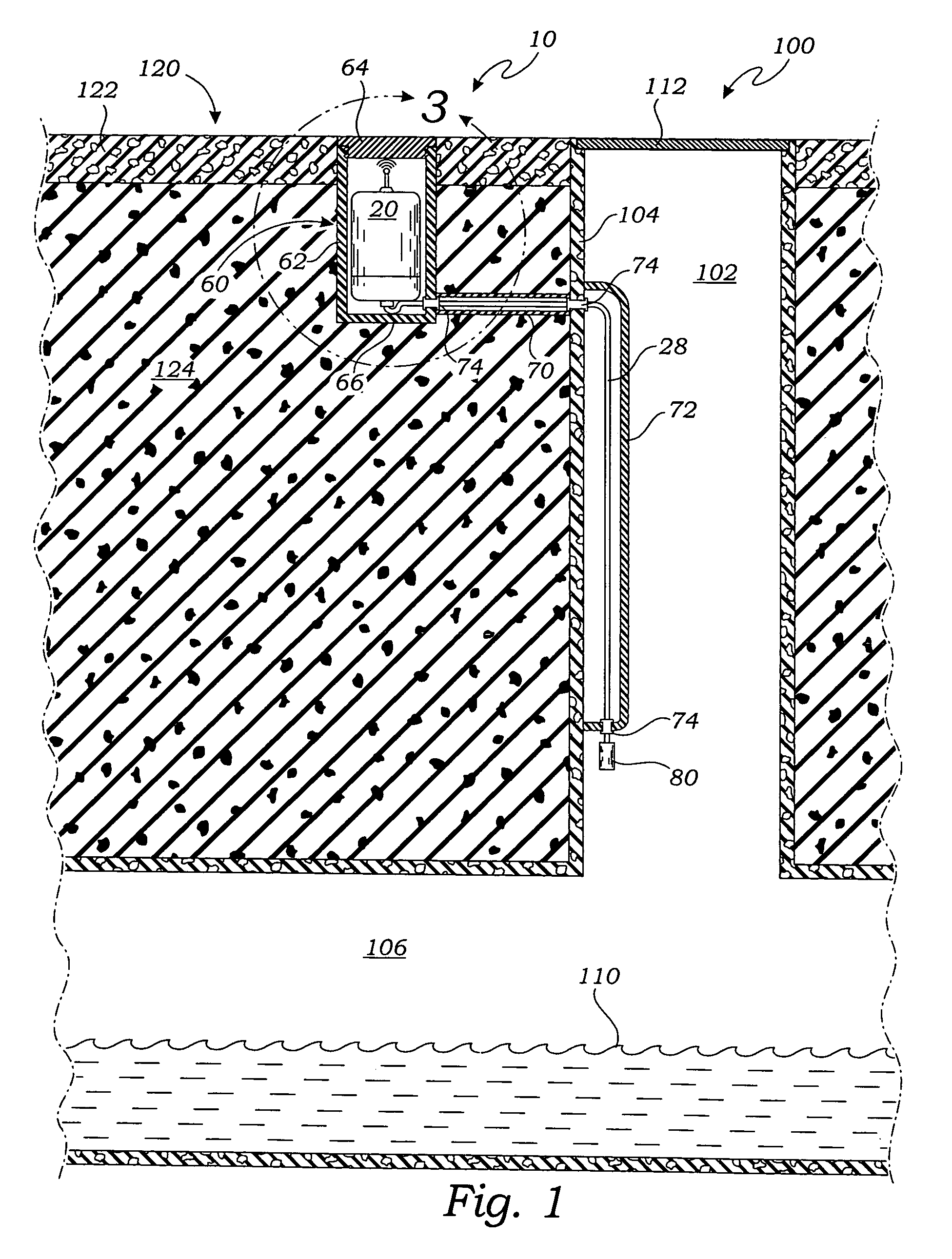

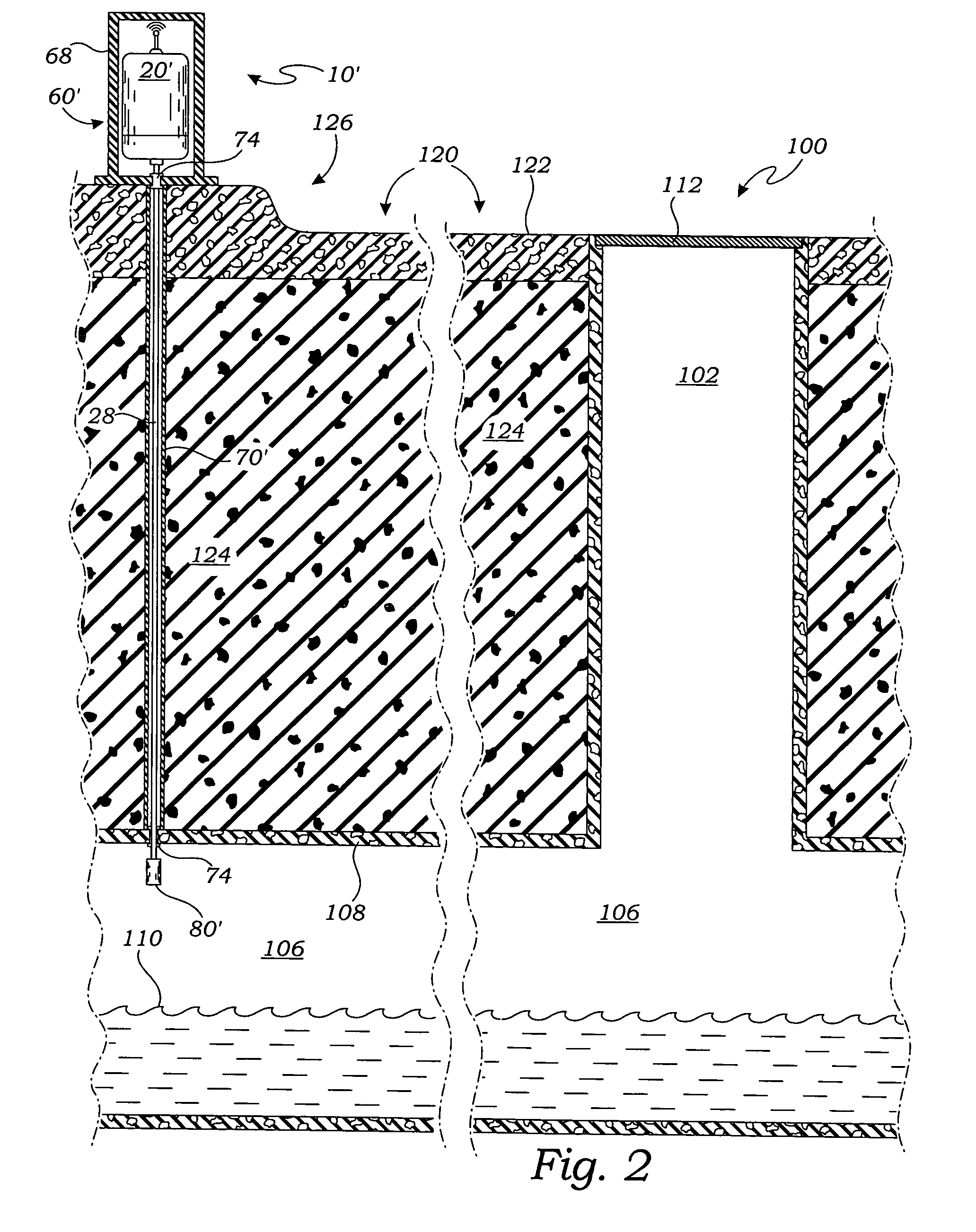

Wireless wastewater system monitoring apparatus and method of use

A wireless wastewater system monitoring apparatus generally comprising a processor / transceiver unit, housed within a synthetic protective enclosure formed outside of the wastewater system, and a fluid level sensor configured to send an overflow signal to the processor / transceiver unit when an overflow condition in the wastewater system is detected. The processor / transceiver unit is configured with at least one microprocessor wired between the sensor and a power supply and with a transceiver so as to detect the overflow signal from the sensor and, in response, transmit a wireless alarm signal. The processor / transceiver unit is further configured such that only a portion of its circuitry is constantly powered so as to continuously monitor the sensor, while the remainder of its circuitry, including the transceiver, is only powered and a wireless signal sent from the unit when an overflow condition is detected or a routine status-check is being conducted.

Owner:WIRELESS TELEMATICS

Method and device for registration and immobilization

InactiveUS20050284490A1Facilitate deliveryReduce attenuation and distortionEar treatmentRestraining devicesUltrasound attenuationMedical physics

Support devices and pods for the head and neck region of patients undergoing radiation therapy are provided herein. The pod generally includes a support shell shaped to generally conform to the shape of the head and neck region of the patient, a foam insert that conforms to the head and neck region of the patient, and an immobilization facemask attached directly to the shell, thereby facilitating close placement of the radiation beam delivery device to the patient and reducing any attenuation and perturbation of radiation doses directed at the patient. The components of the pod are made from materials having properties that reduce any attenuation and perturbation of prescribed radiation doses.

Owner:LOMA LINDA UNIV MEDICAL CENT

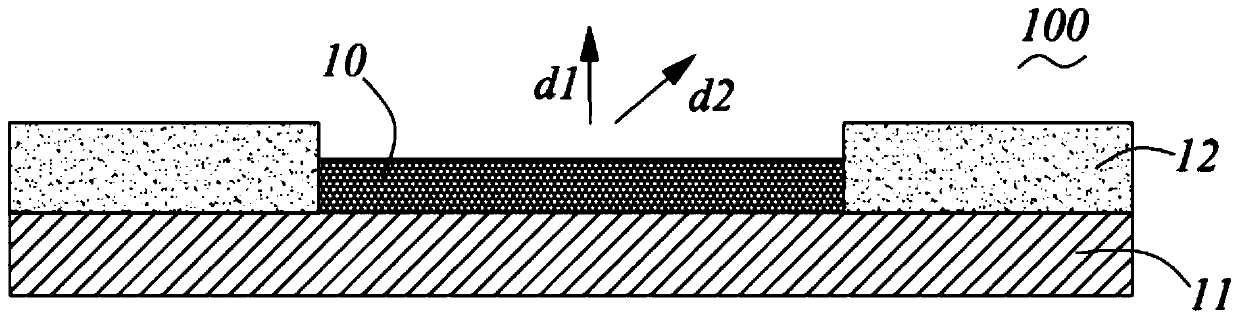

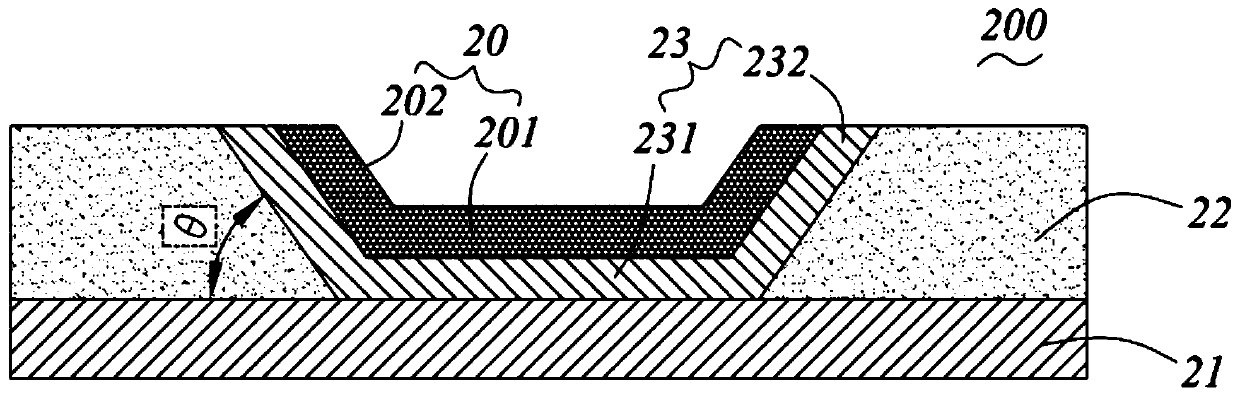

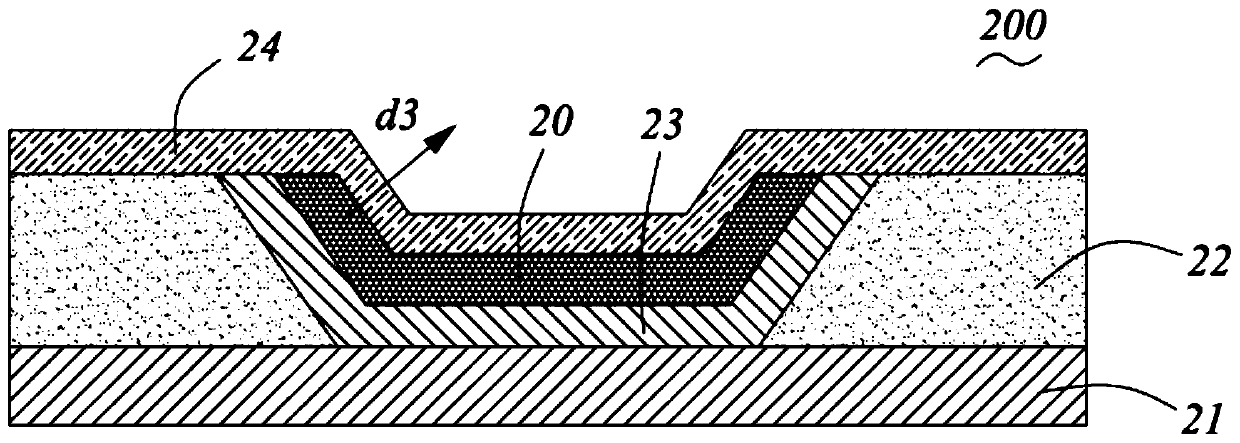

Electroluminescent device and manufacturing method thereof

ActiveCN105977393ABroadcast restrictionsShorten the propagation distanceSolid-state devicesSemiconductor/solid-state device manufacturingUltrasound attenuationRough surface

The invention discloses an electroluminescent device and a manufacturing method thereof. The electroluminescent device comprises a first electrode layer having transmissivity, a second electrode layer having reflectivity, a light-emitting layer arranged between the first electrode layer and the second electrode layer, and a second electrode layer contact layer adjacent to the second electrode layer; and the contact surface between the second electrode layer and the second electrode layer contact layer is a rough surface. According to the invention, the contact surface between the second electrode layer and the second electrode layer contact layer in the electroluminescent device is set to be a rough surface directly and lots of recessions and protrusions are distributed on the rough surface; and surface plasma waves are only be transmitted along the tangential directions of the contour lines of the recessions and the protrusions and thus the surface plasma wave propagation is limited and the surface plasma wave propagation distance is reduced substantially, so that the reflected light energy attenuation degree is reduced effectively.

Owner:NANJING TECH CORP LTD

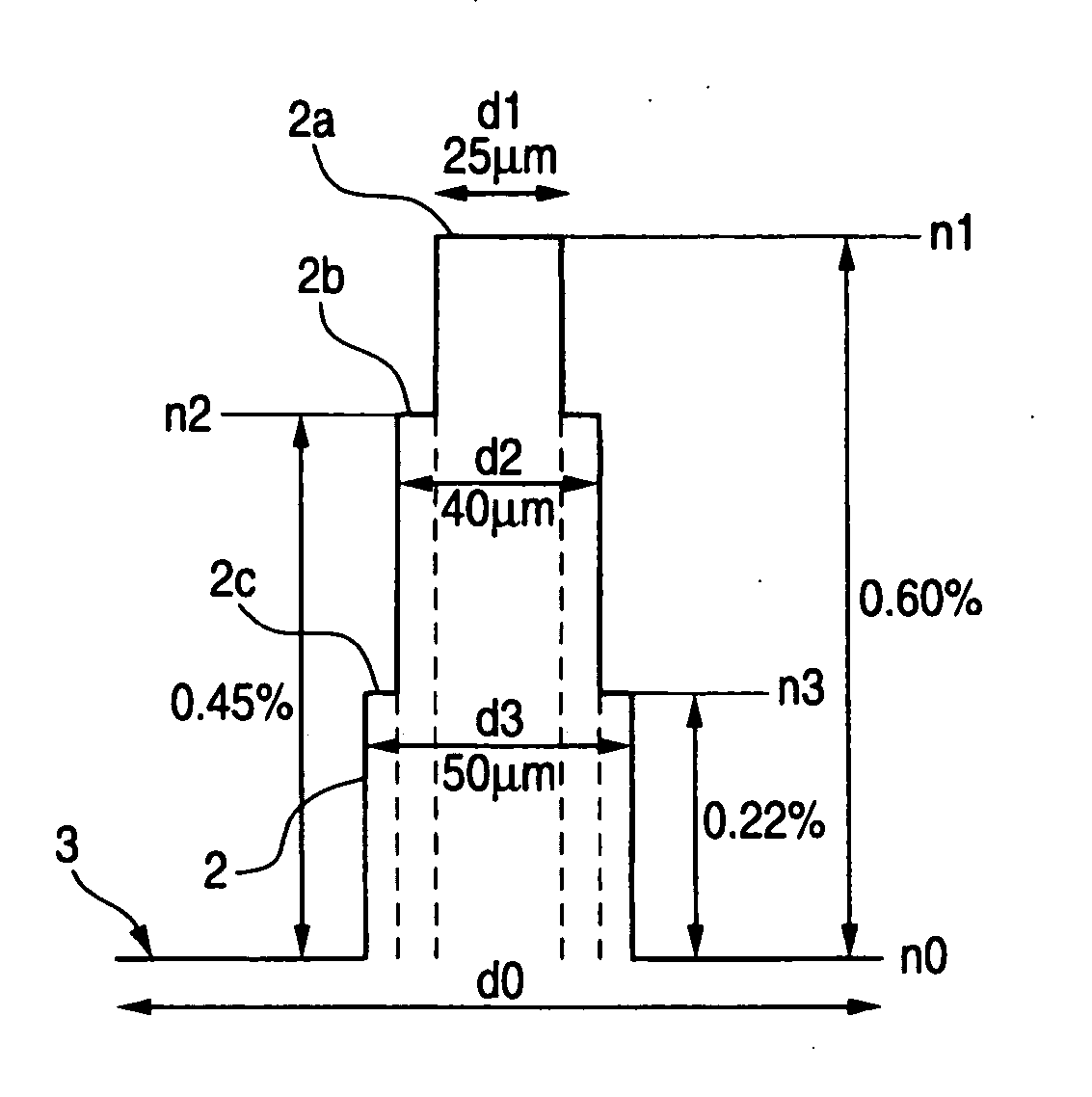

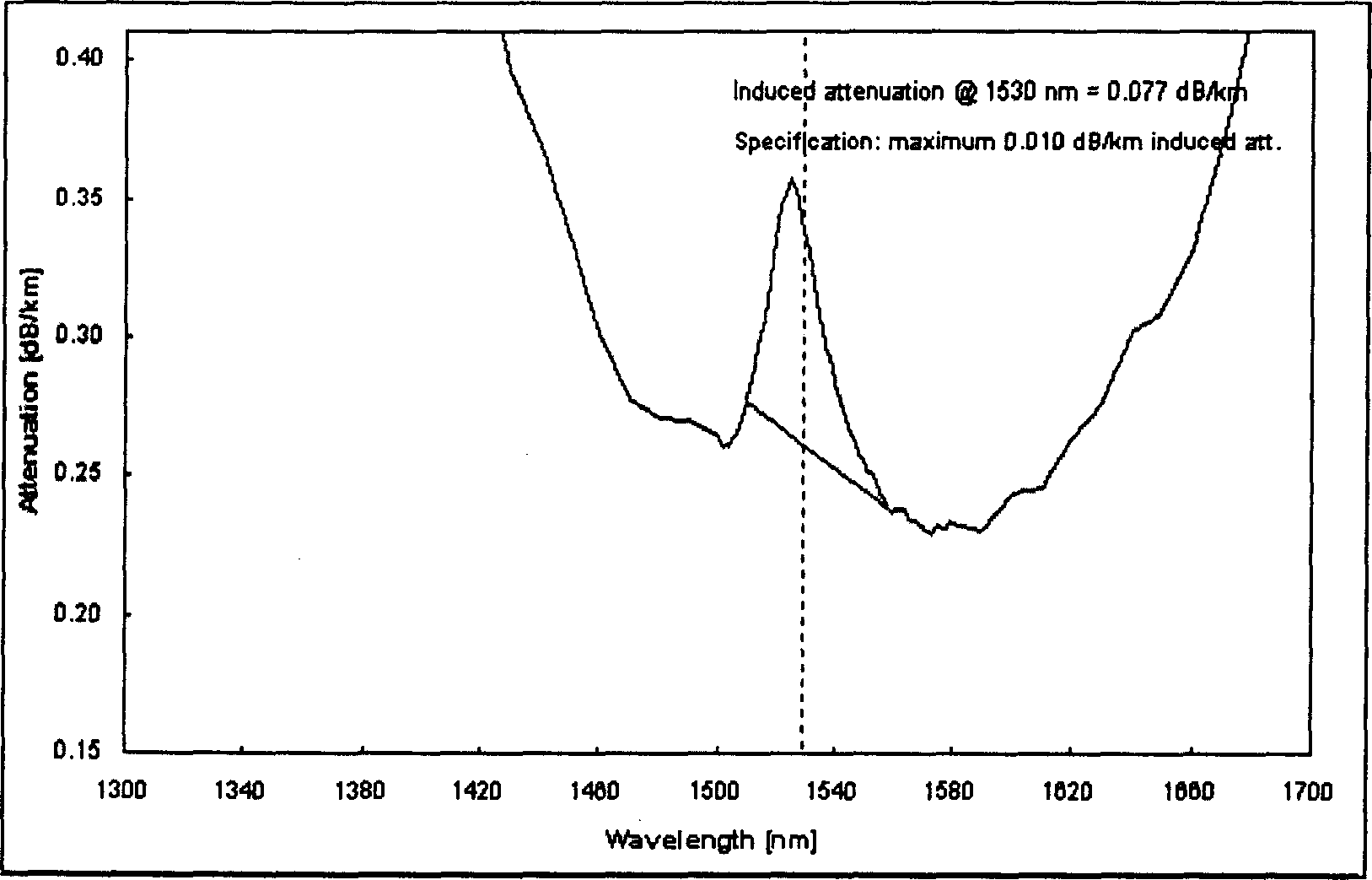

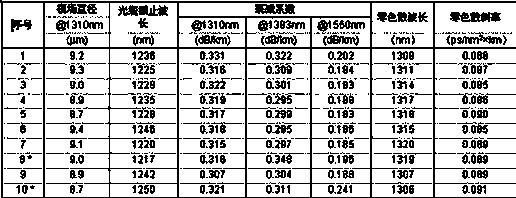

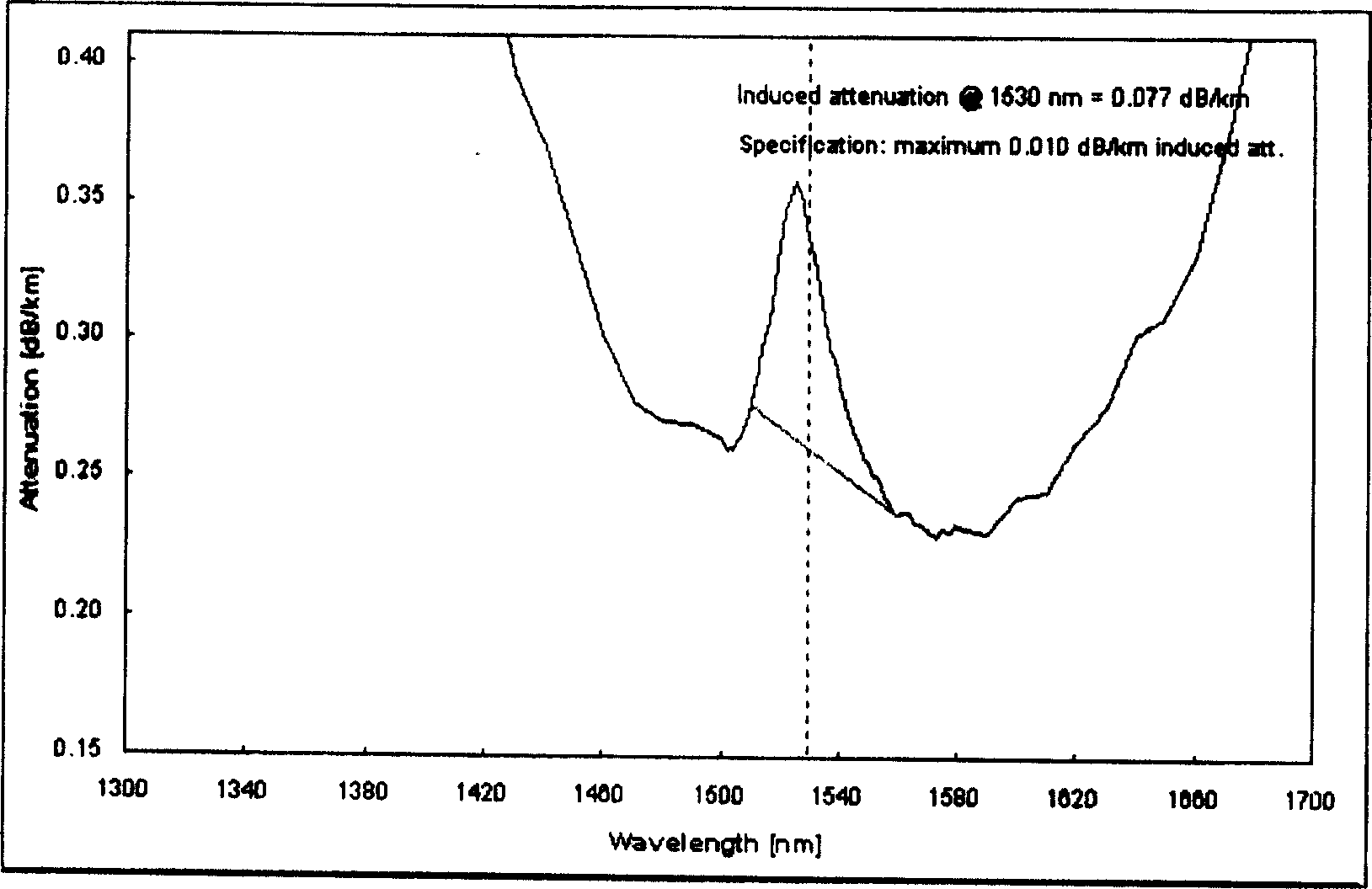

Method for manufacturing large-diameter optical fiber mandril through PCVD process

ActiveCN101811822AReduce manufacturing costReduced Rayleigh scatteringGlass making apparatusUltrasound attenuationResonant cavity

The invention relates to a method for manufacturing a large-diameter low-water peak optical fiber mandril through a high-deposition rate PCVD process, which comprises the following steps that: after a pure quartz liner with the outer diameter of 36 to 65mm is corroded and cleaned, PCVD processing is carried out; the pure quartz liner is arranged in a microwave resonant cavity heat insulation furnace, a microwave resonant cavity has axial reciprocating movement relative to the pure quartz liner, the movement speed is 15 to 30m / min, and the high-frequency power is 5.5 to 20.5kW; the deposition rate in the liner is 2.5 to 5.0g / min, and the single-layered deposition thickness is 1.0 to 3.0mu m; and after the deposition, an electric fusion shrink lathe shrinks to prepare the solid optical fiber mandril, the outer diameter of the mandril is 30 to 61mm, the diameter ratio of a cladding core layer b / a is more than or equal to 1.2 and less than 3.0, and the ratio of the outer diameter of the mandril to the diameter of the core layer c / a is more than or equal to 3.8 and less than 6.0. The method for manufacturing the large-diameter optical fiber mandril through the PCVD process not only has convenient manufacturing process and high deposition rate, but also can meet the design requirement on the diameter ratio of the cladding core layer in a wider scope and the optical fiber performance requirements on low water peak and low attenuation.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

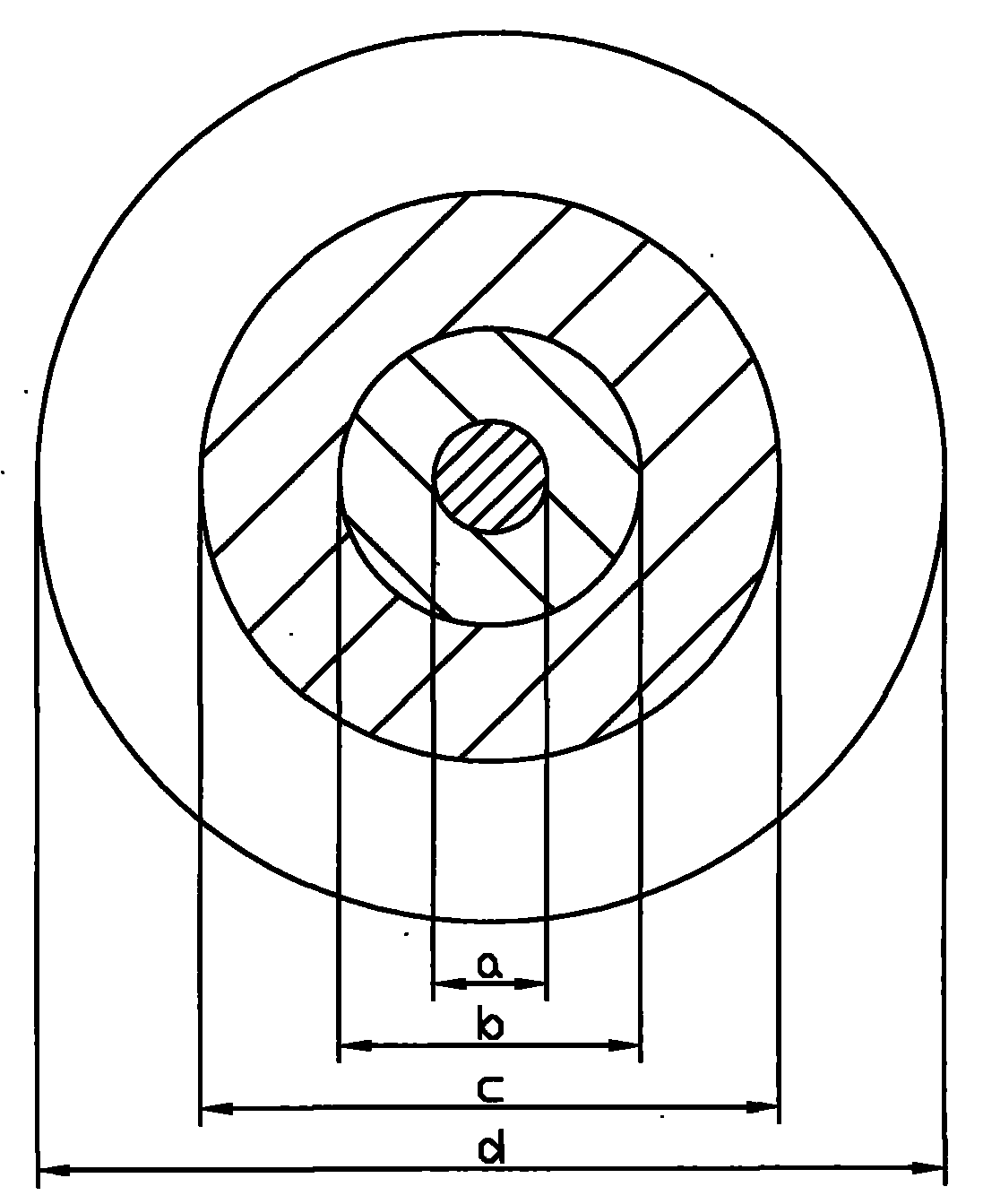

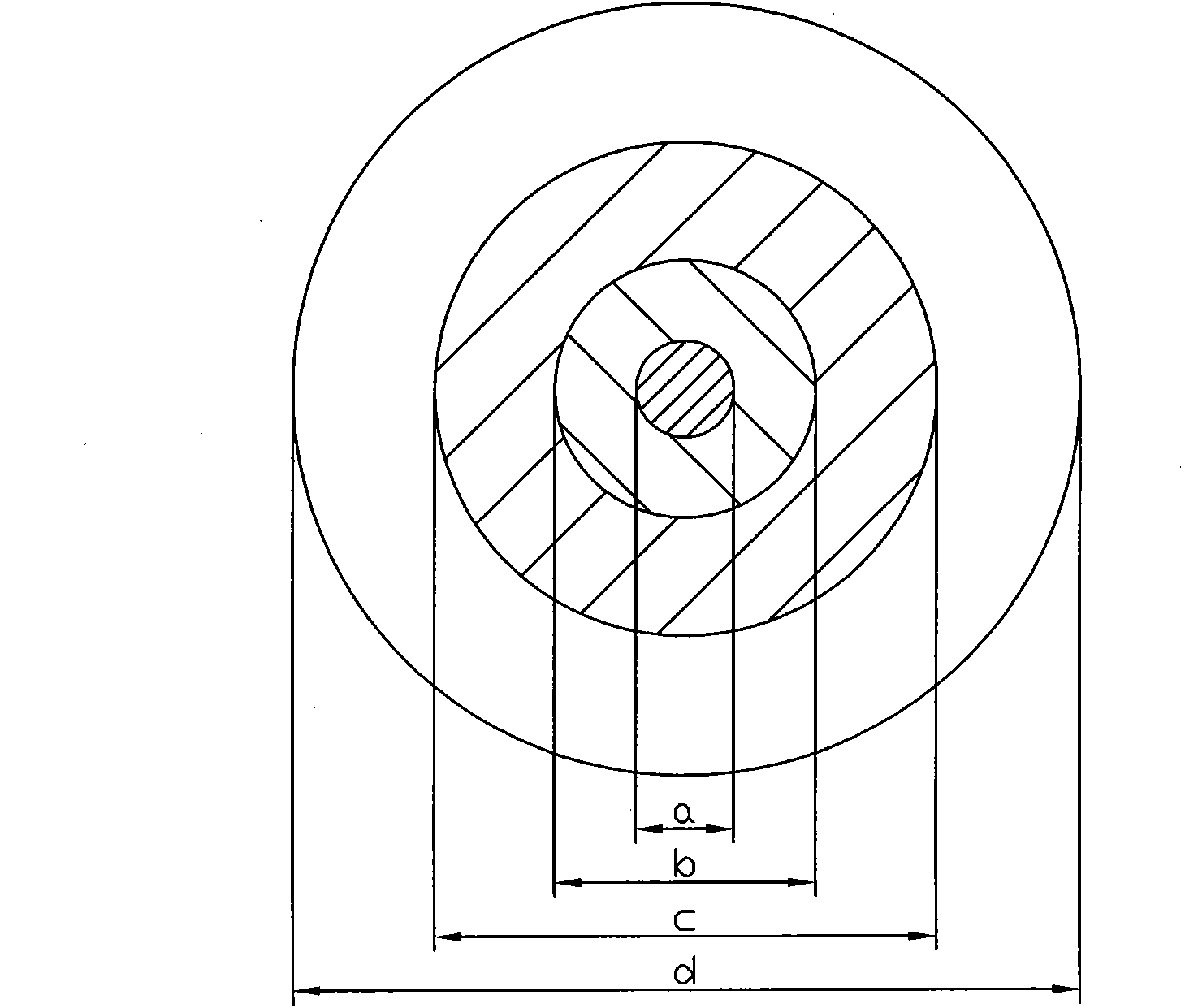

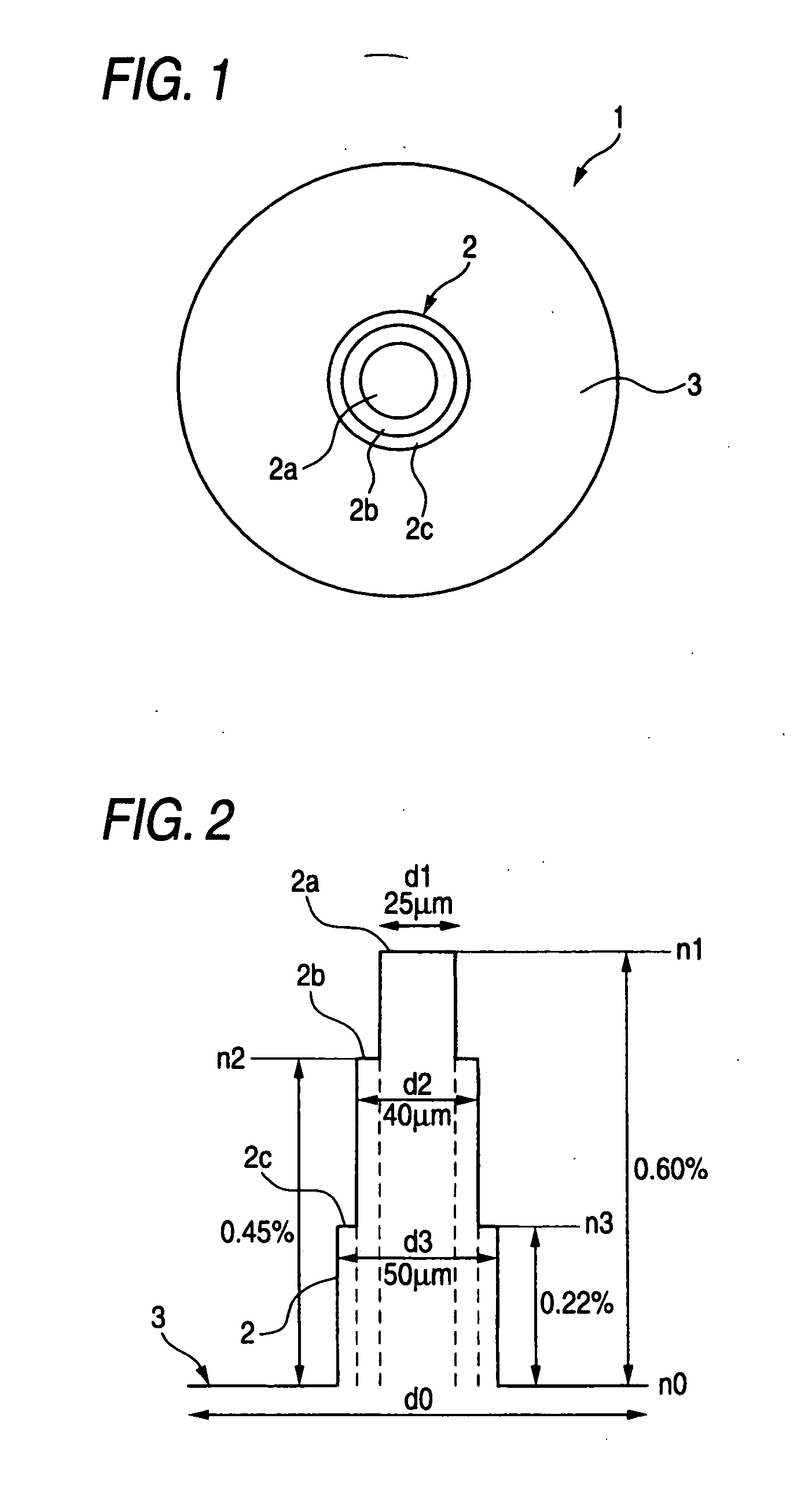

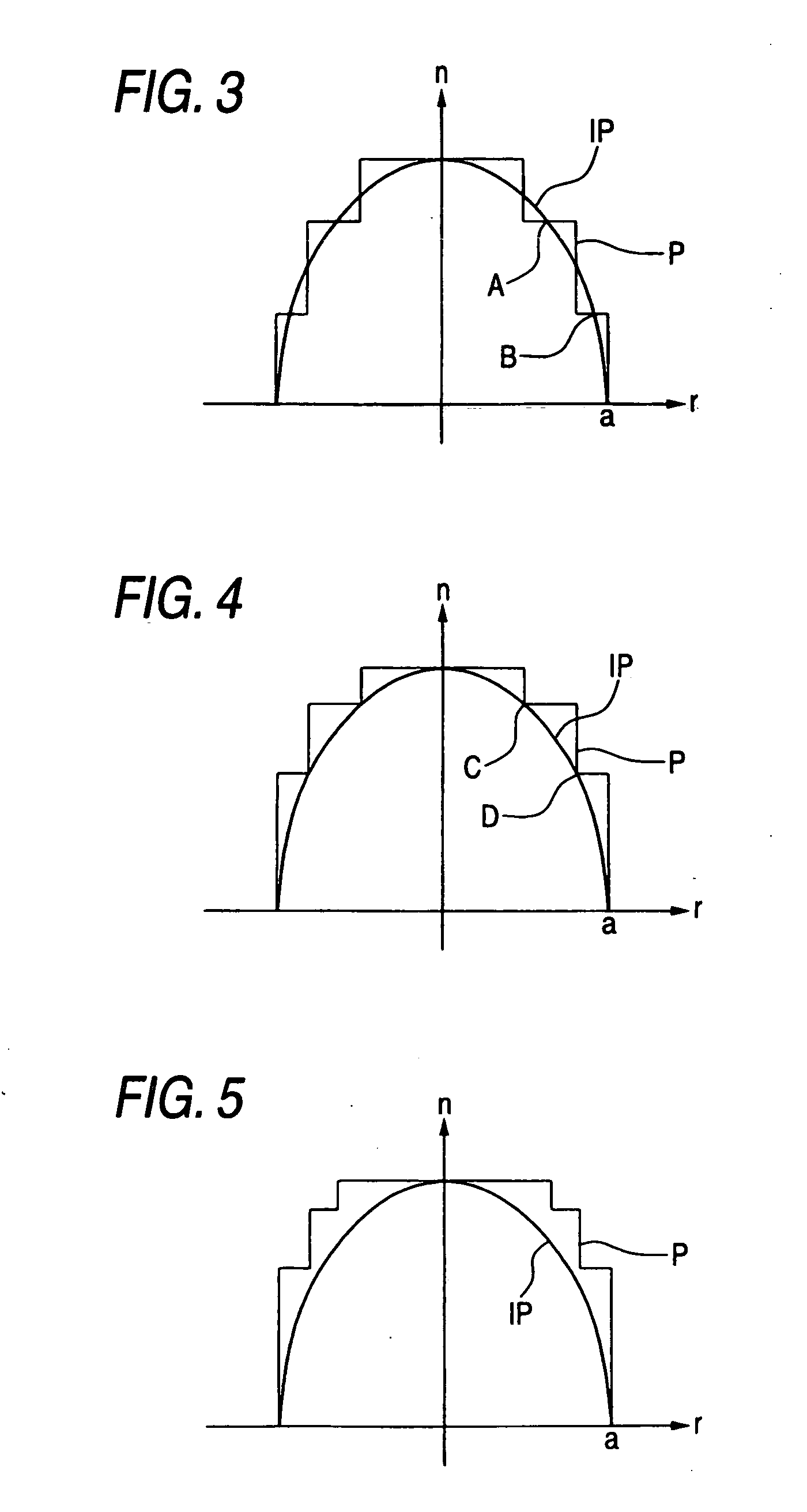

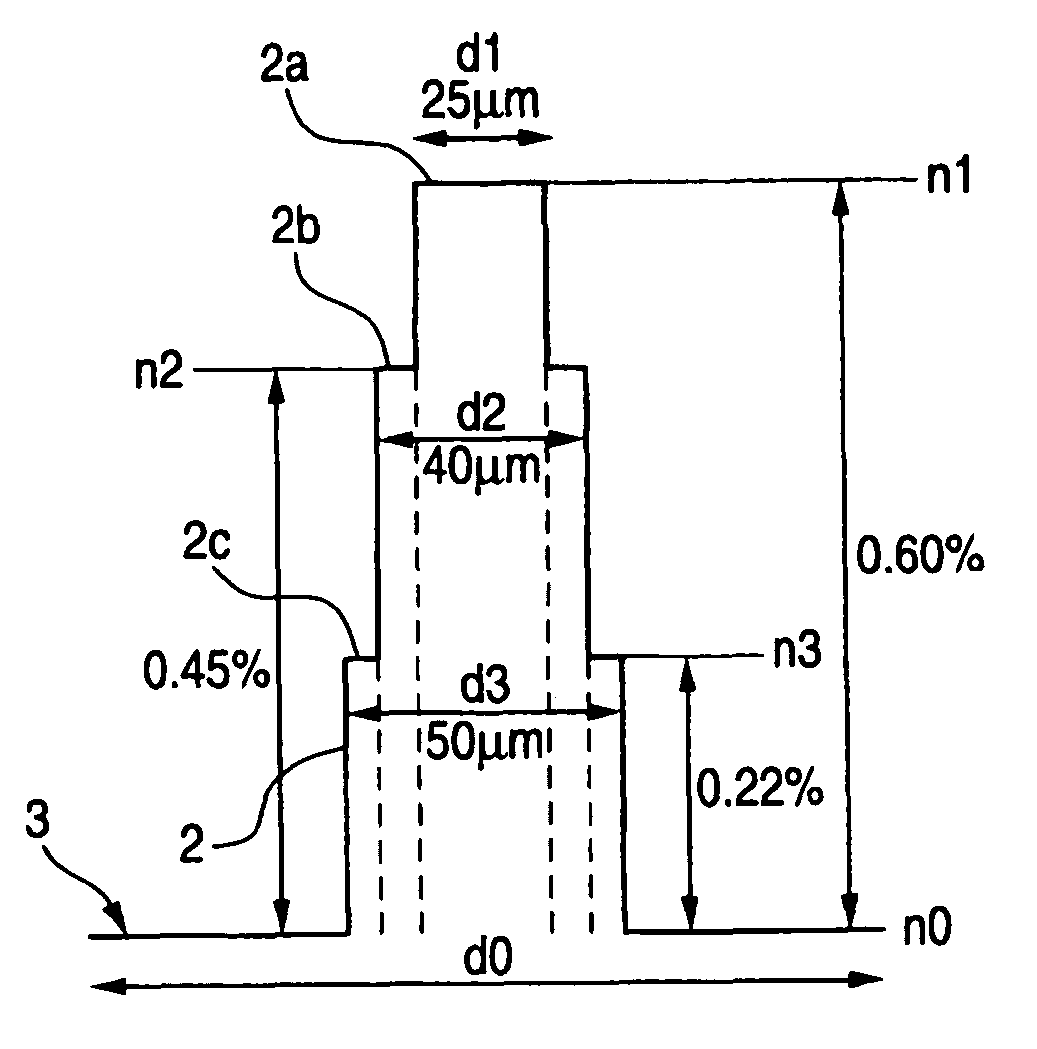

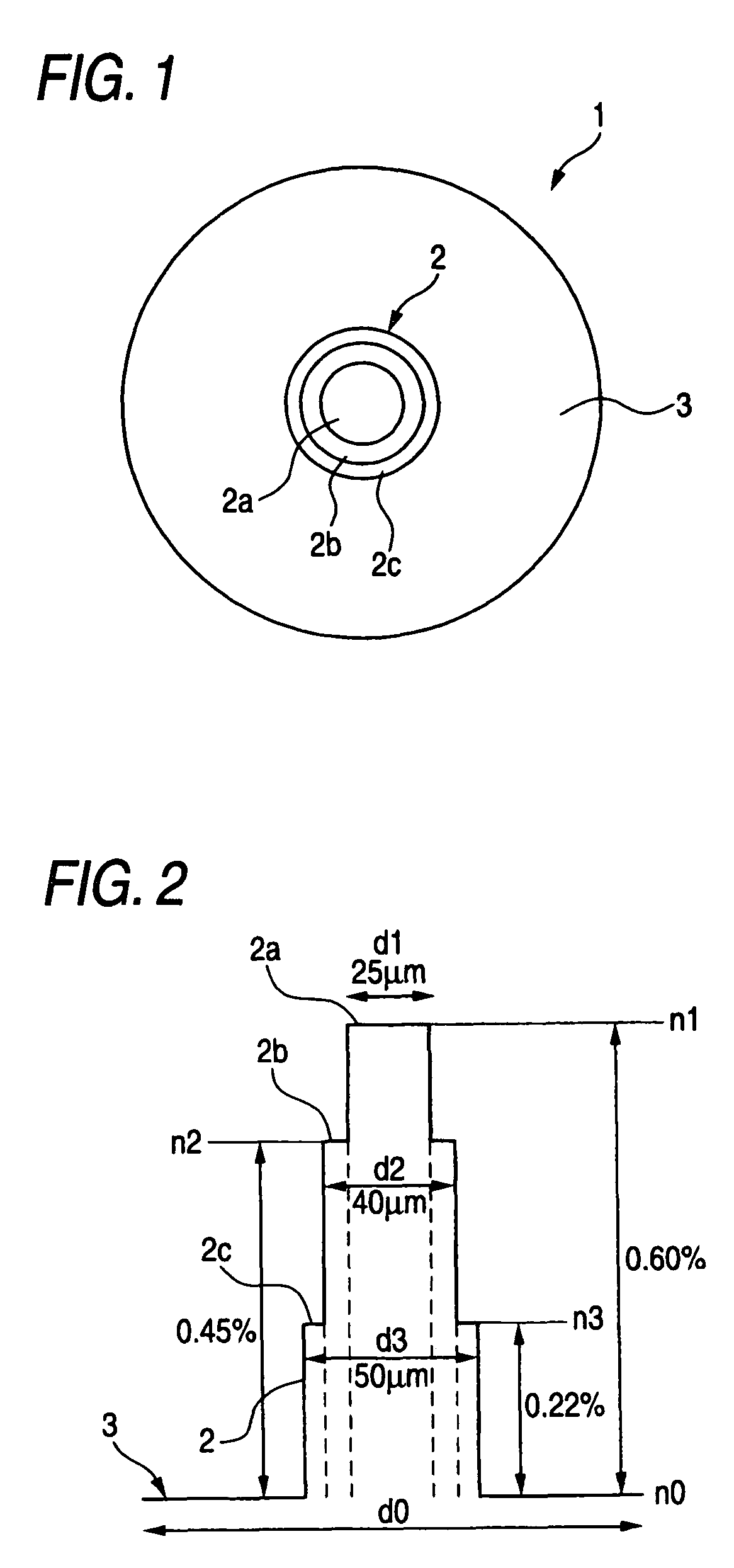

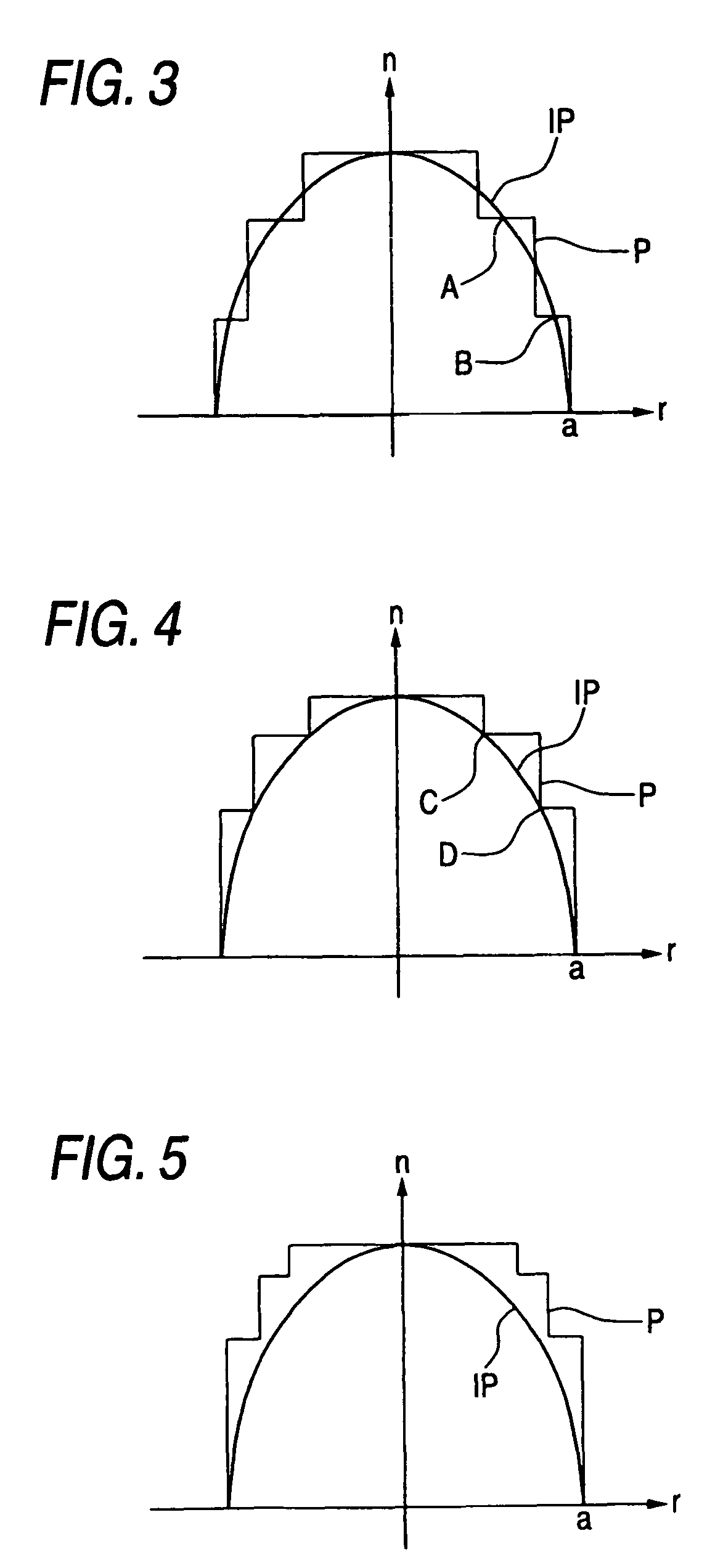

Multimode optical fiber

InactiveUS20060263019A1Easy to produceContinuous changeGlass making apparatusOptical fibre with multilayer core/claddingRefractive indexQuartz

A core part of a multimode optical fiber including the core part and a cladding part has a structure composed of a plurality of concentric layers in which a refractive index is decreased stepwise from a first core layer as an innermost layer to a third core layer as an outermost layer. The structure having the plurality of layers is formed by adjusting a quantity of addition of fluorine to silica glass. Fluorine is added to the cladding part so that a refractive index is lower than that of the third core layer as the outermost layer of the core part.

Owner:SUMITOMO ELECTRIC IND LTD

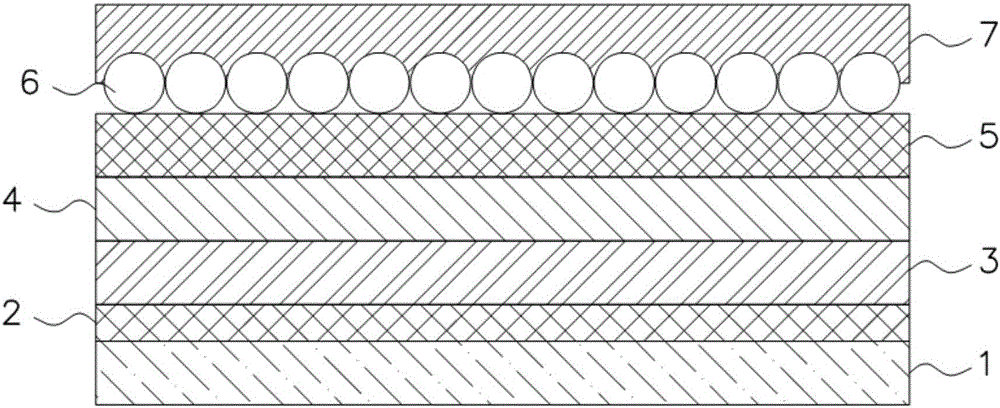

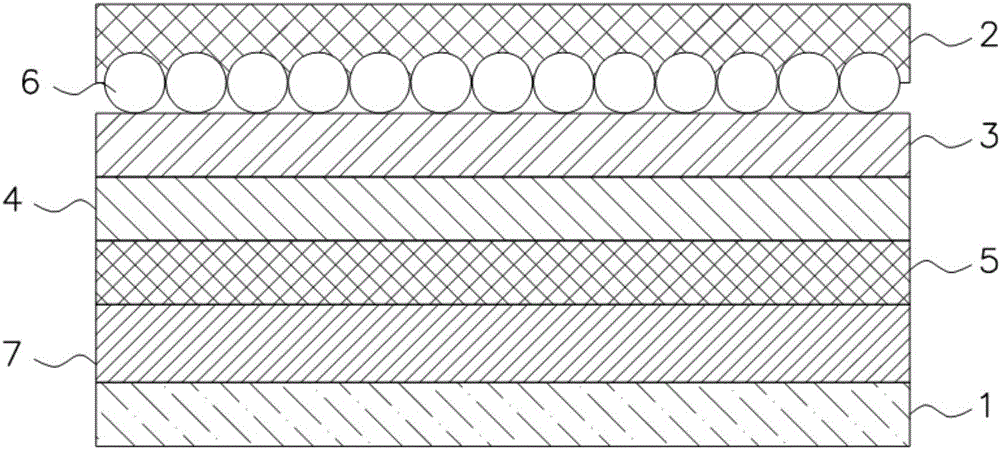

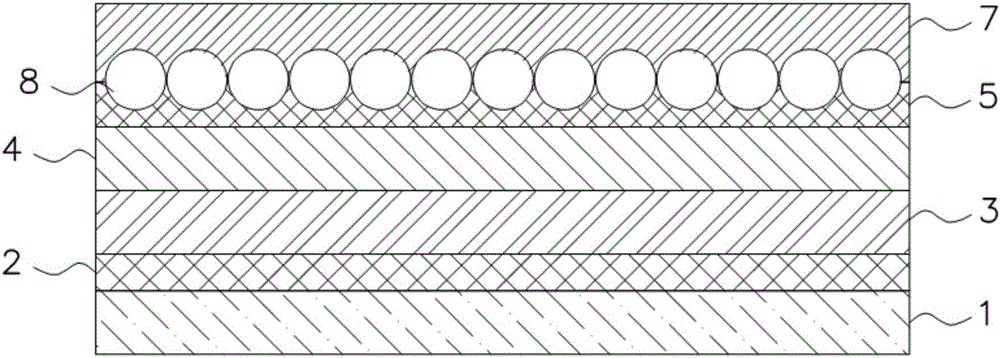

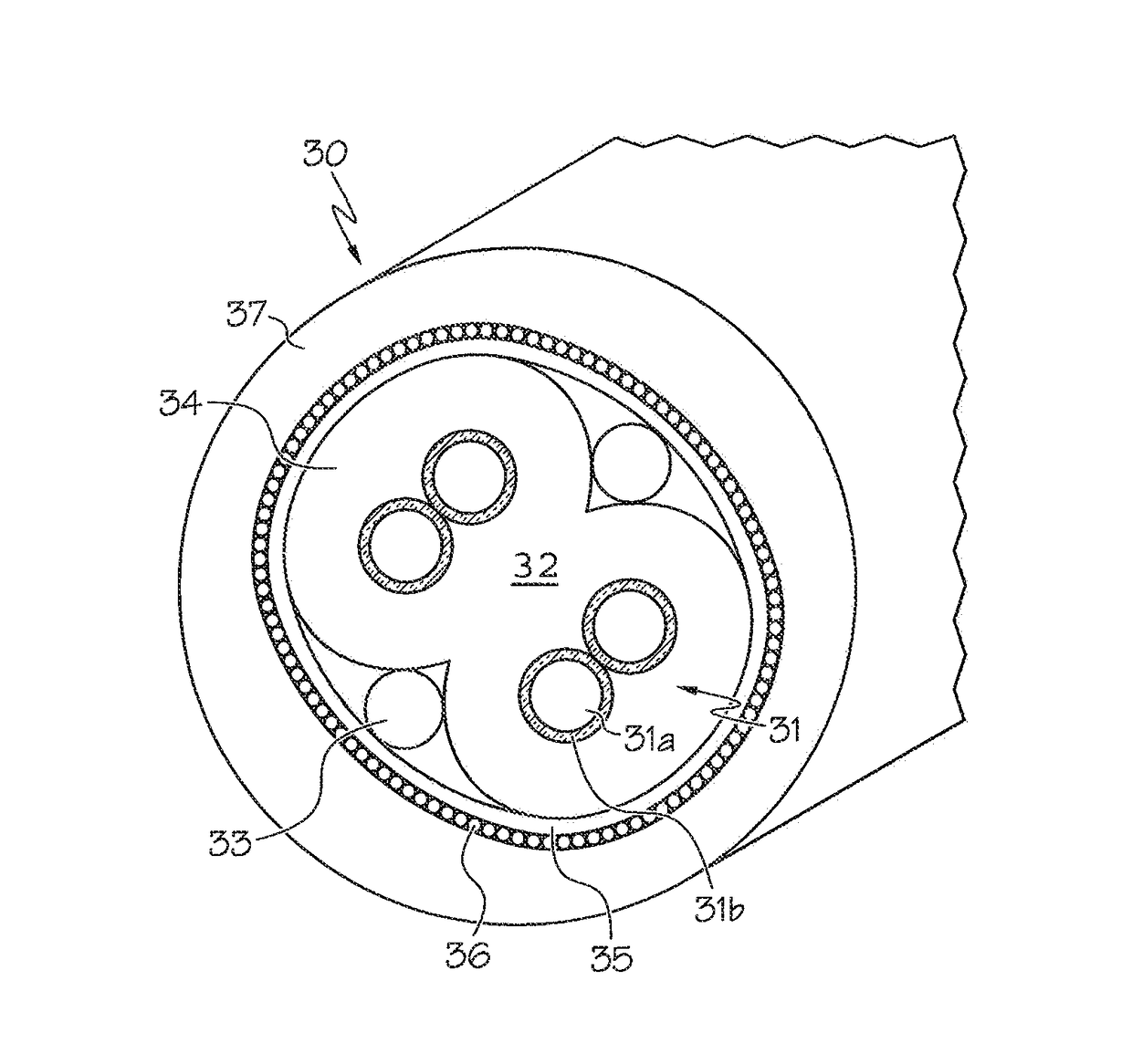

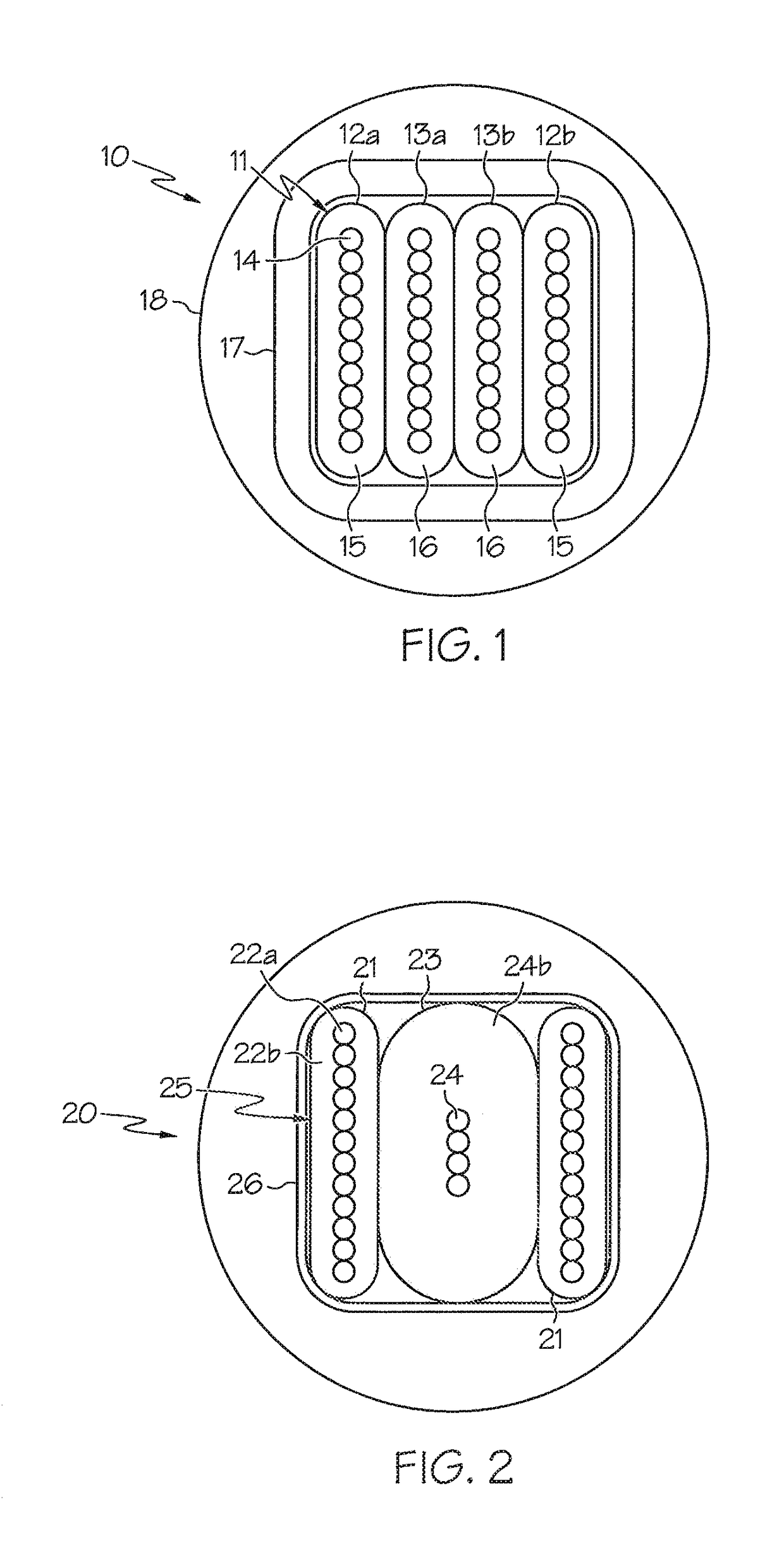

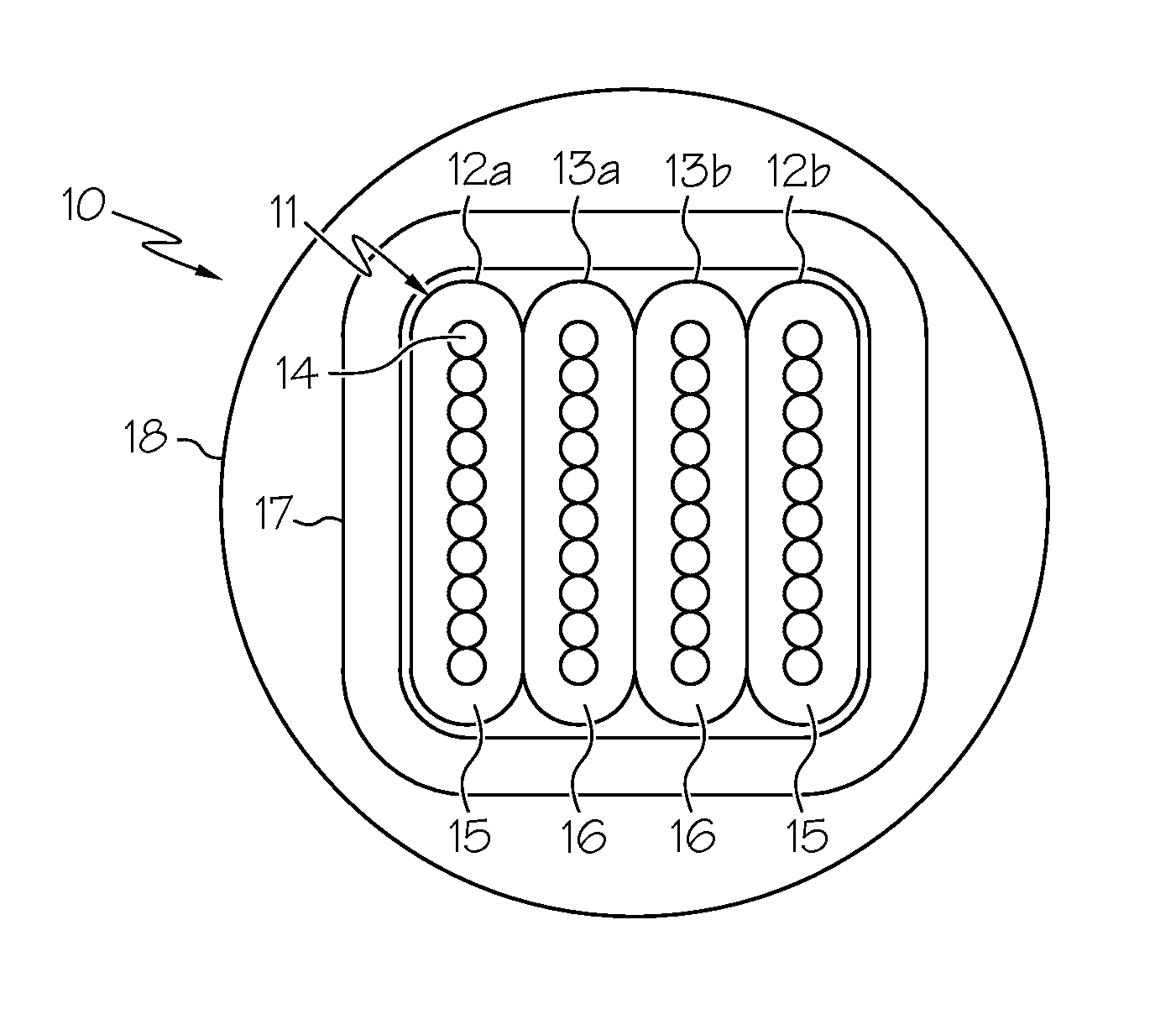

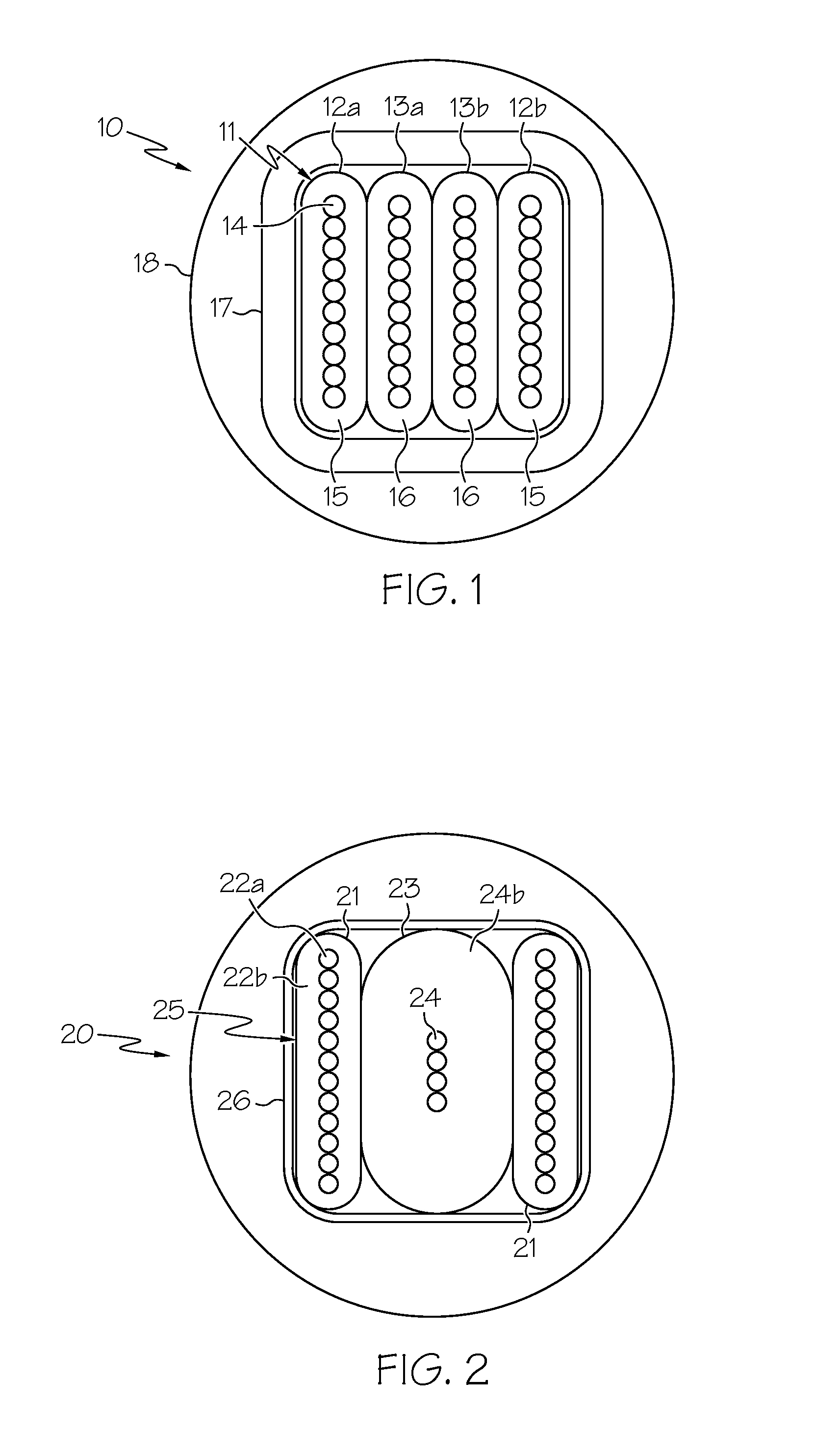

High speed, low noise, low inductance transmission line cable

ActiveUS9620262B1Reduce signal attenuationNoise generation is minimizedCoaxial cables/analogue cablesInsulated cablesLow noiseUltrasound attenuation

A transmission line cable that utilizes a plurality of substantially flat insulated conductors, each consisting of two or more solid metallic strands laid side by side in a parallel configuration within an extruded insulator. The plurality of insulated conductors are stacked into groups of two or more and may be utilized as signal conductors or shield conductors. Once the insulated conductors are stacked, the stack is twisted together, and either wrapped in a conductive insulator, placed in an extruded non-conductive insulator, or both, creating a cable that is stable, flexible, and has improved transmission characteristics, including reduced attenuation, noise and signal skew.

Owner:WIREWORLD BY DAVID SALZ

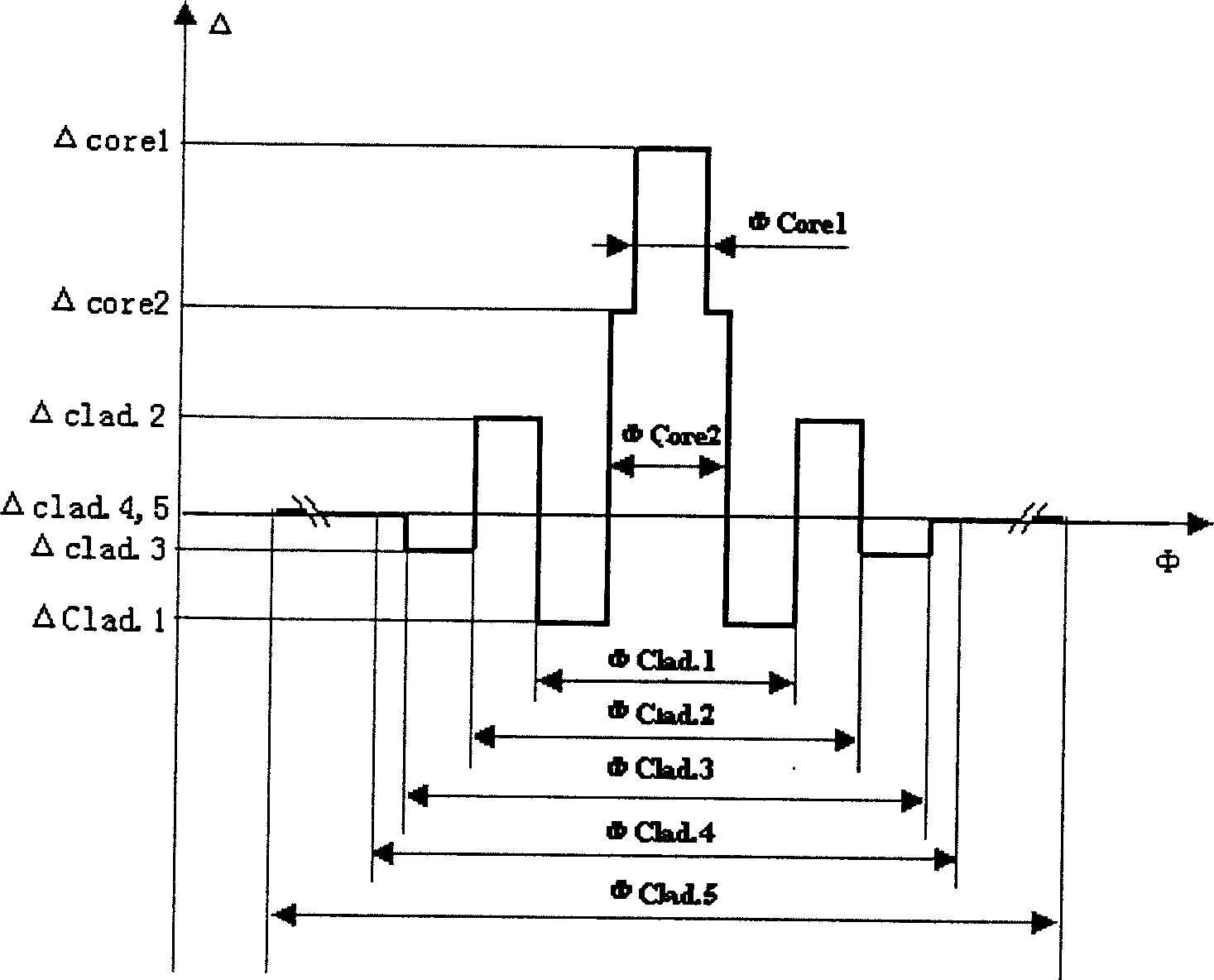

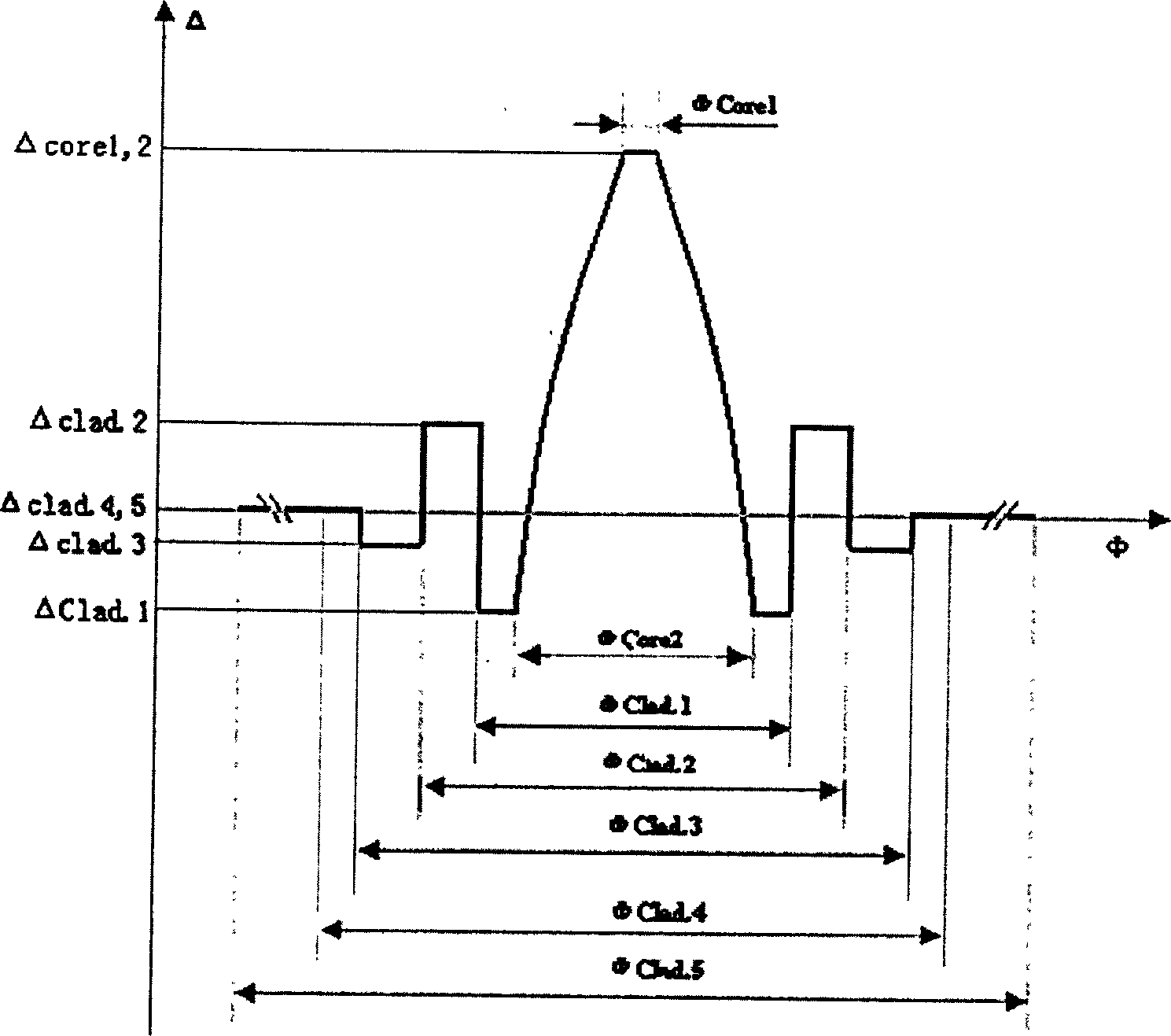

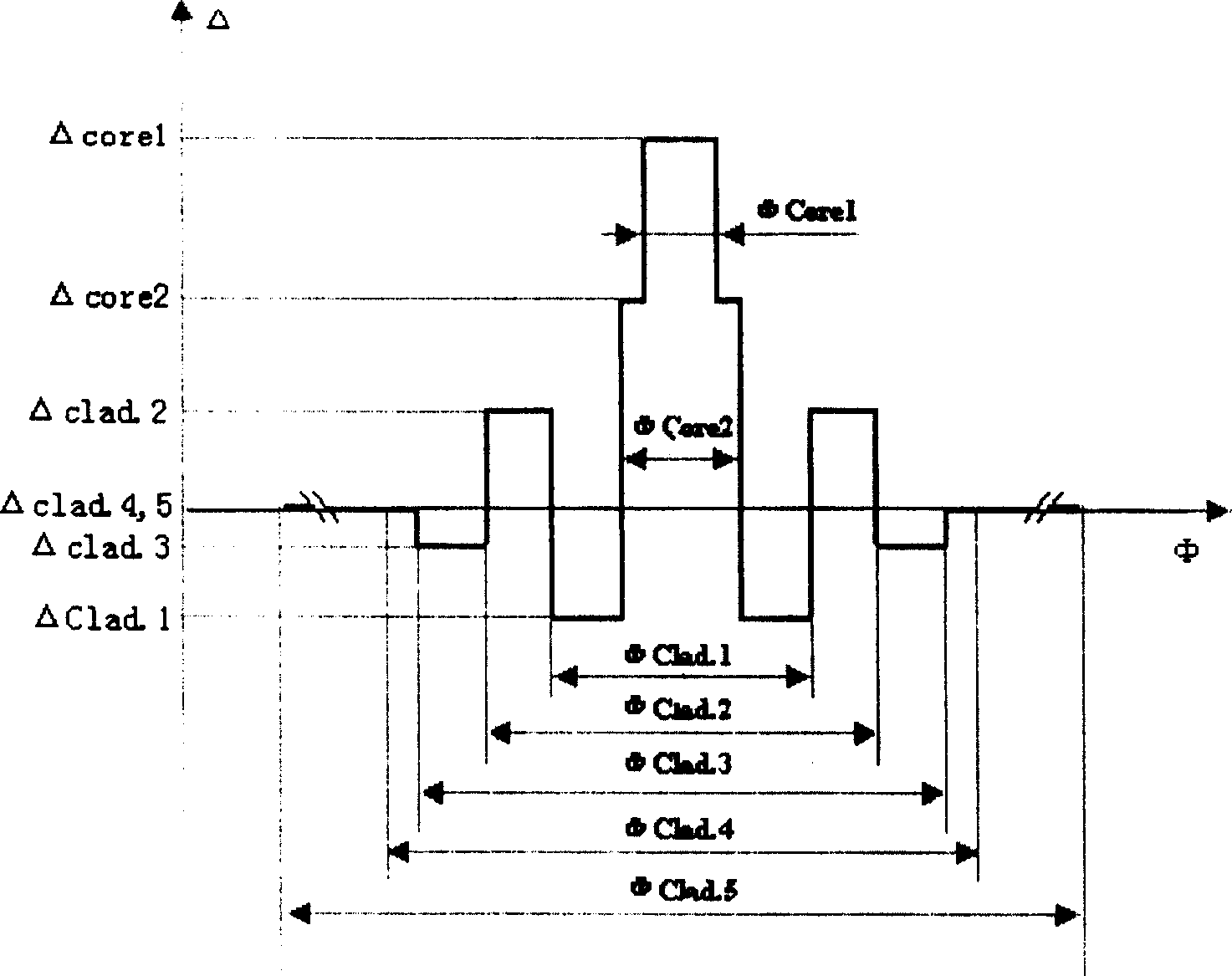

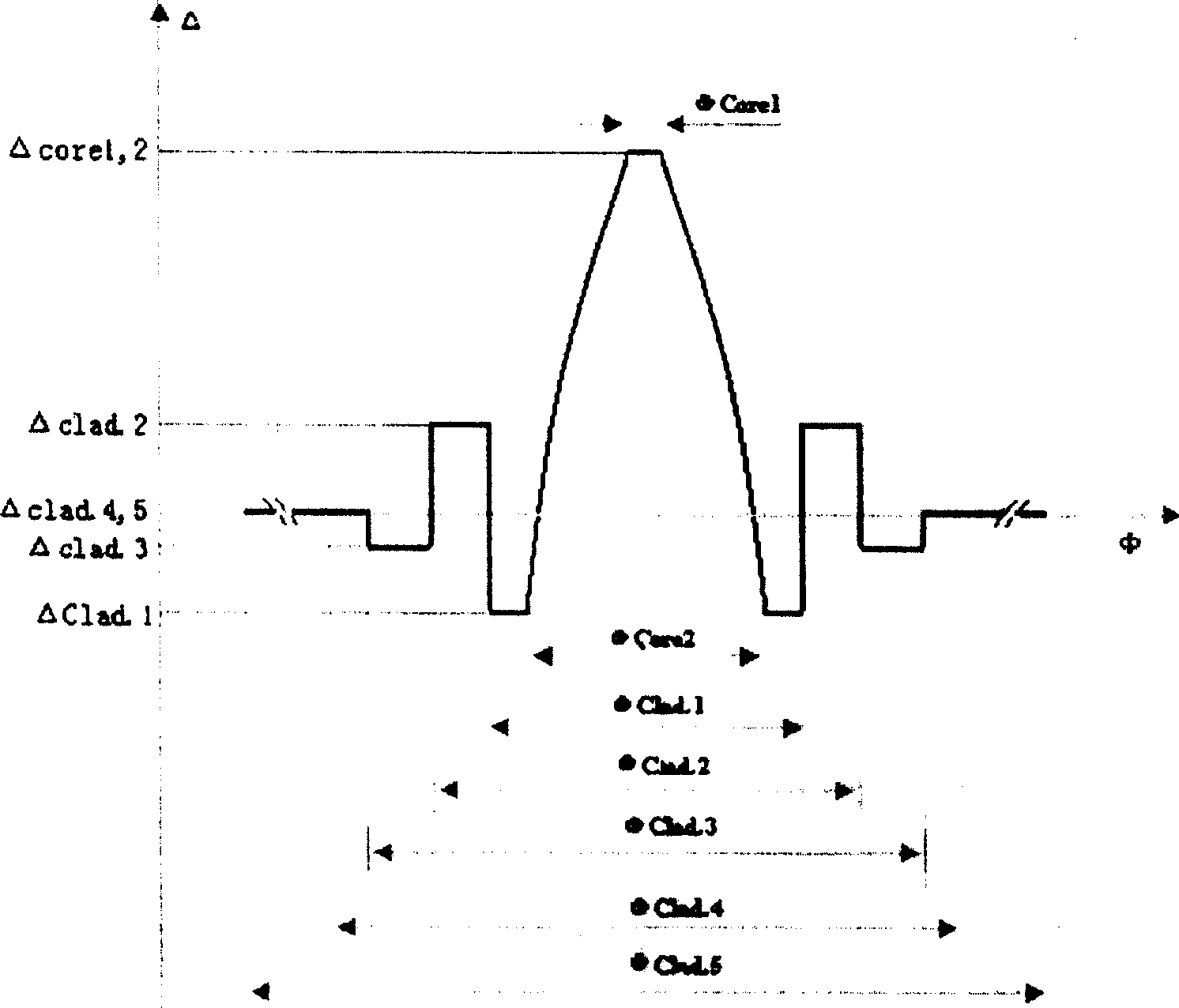

Dispersion compensating transmission optical fiber matched with orthochromatic dispersion and ortho chromatic dispersion slope unimodel optical fiber and use

ActiveCN1514262AReduce lossLow PCVWavelength-division multiplex systemsElectromagnetic transmissionWavelength-division multiplexingRefractive index profile

The waveguide structure of single-mode optical fibre comprises layered fibre core and layered clad. The fibre core is set with two core layers in different refractive indexed and layered clad consists of five layered clads. The codeposition of fluorine and germanium is applied by utilizing PCVD process to replace independent deposition of fluorine or germanium in deposition process for fibre core and clad so optical, mechanical and environmental performance of optical fibre is very much improved. The single-mode optical fibre produced in the present invention can be used in transmission of DWDM system.

Owner:SICHUAN LEFEI OPTOELECTRONICS TECH CO LTD +1

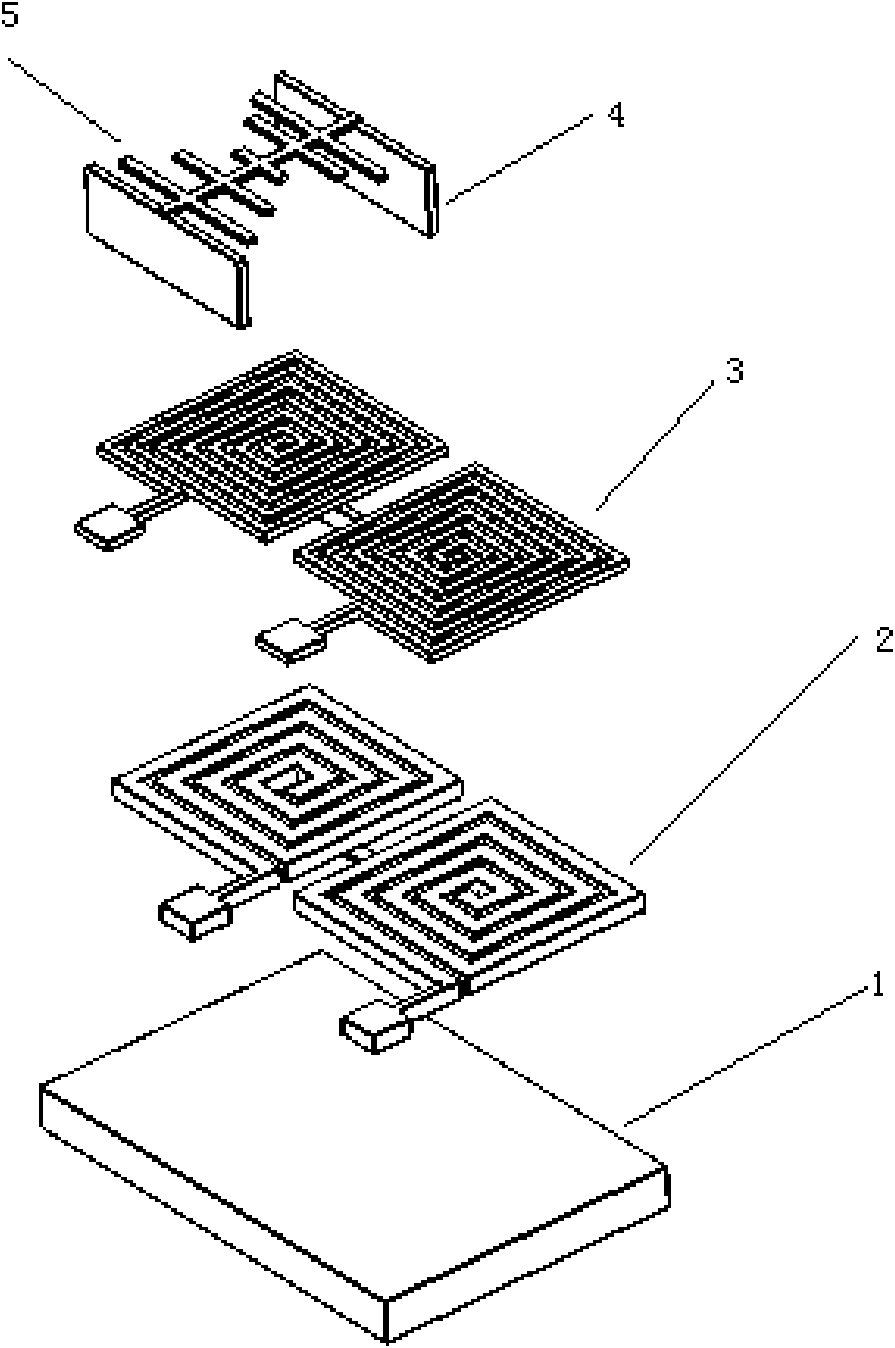

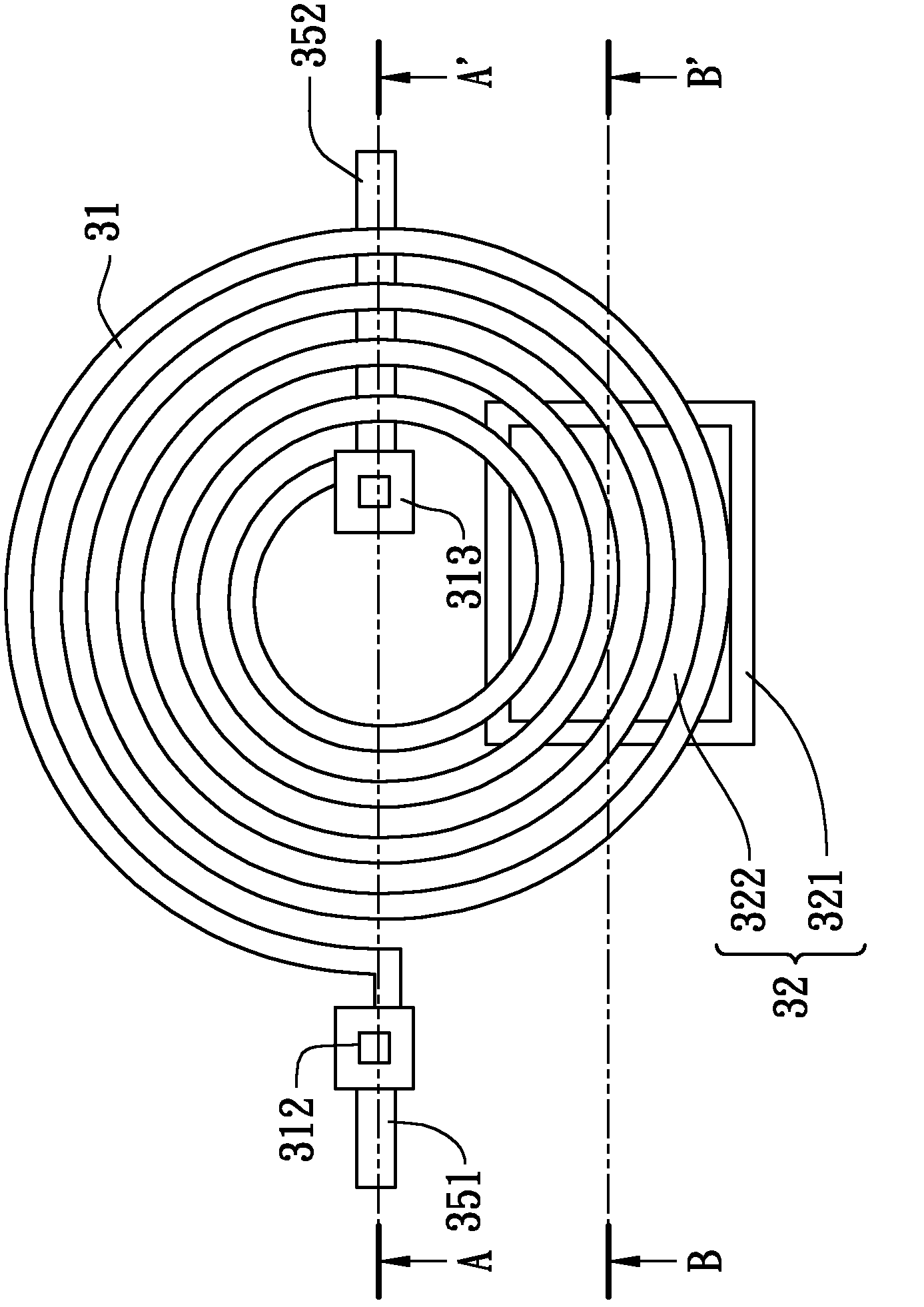

Integrated magnetic elasticity sensor

InactiveCN101975591AMiniaturizationPortableConverting sensor output electrically/magneticallyMicroelectromechanical systemsExcitation signal

The invention relates to an integrated magnetic elasticity sensor, belonging to the technical field of micro electro mechanical systems. The integrated magnetic elasticity sensor comprises a glass substrate, a magnetic field excitation offset coil, a signal reception coil, a sensor support, a magnetic belt material and insulation material layers. The magnetic field excitation offset coil is located on the glass substrate; the signal reception coil is located above the magnetic field excitation offset coil; the sensor support is located above the signal reception coil; the insulation material layers are respectively located among the magnetic field excitation offset coil, the signal reception coil and the sensor support; and both ends of the magnetic belt material are fixed on the sensor support. The invention has the advantages of high processing precision and small size of the device, can eliminate background signals of the excitation signal in the reception coil by adopting an 8-shaped collection coil, realizes real-time monitoring of vibration signals and can realize the portable characteristic.

Owner:SHANGHAI JIAO TONG UNIV

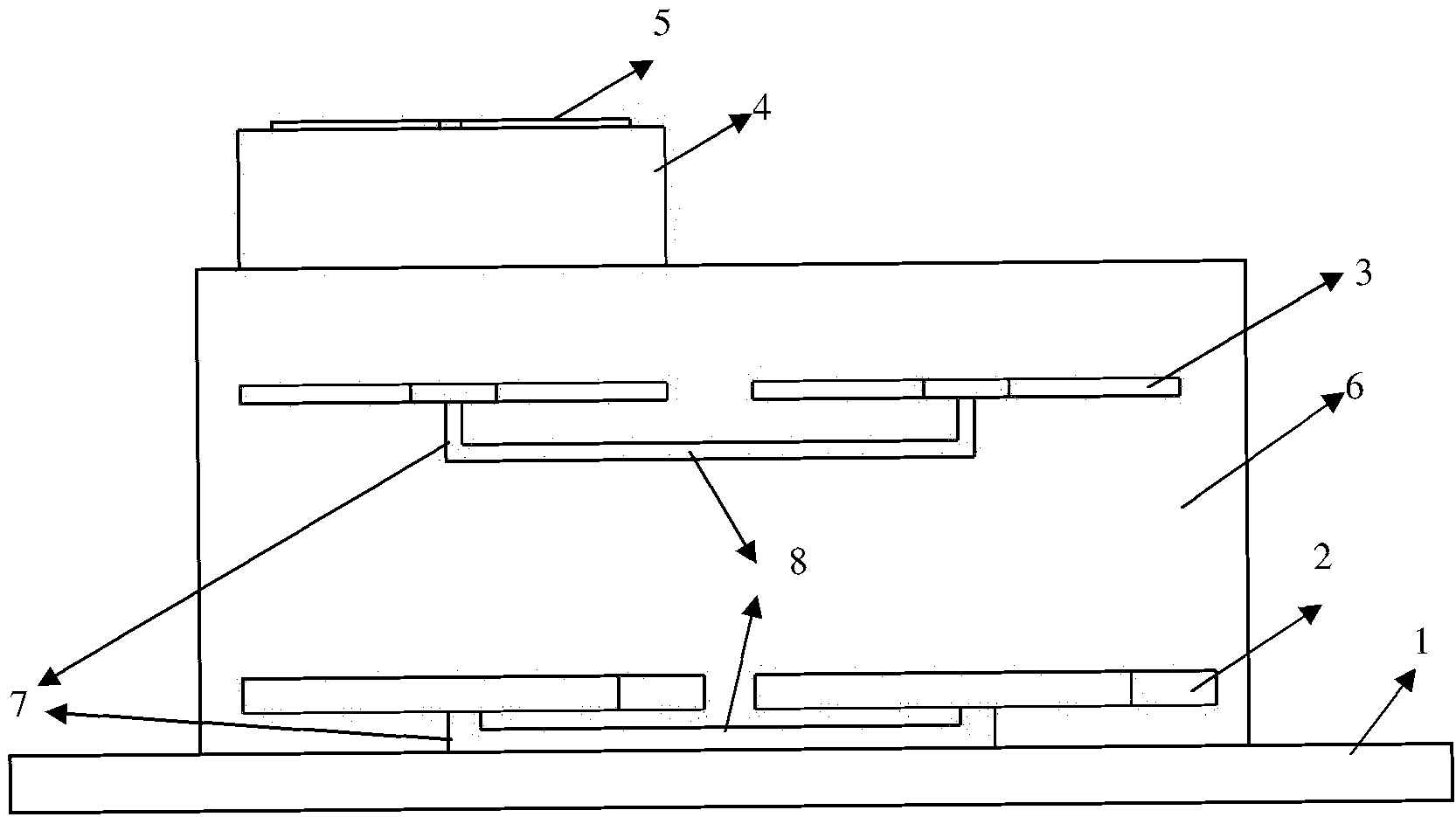

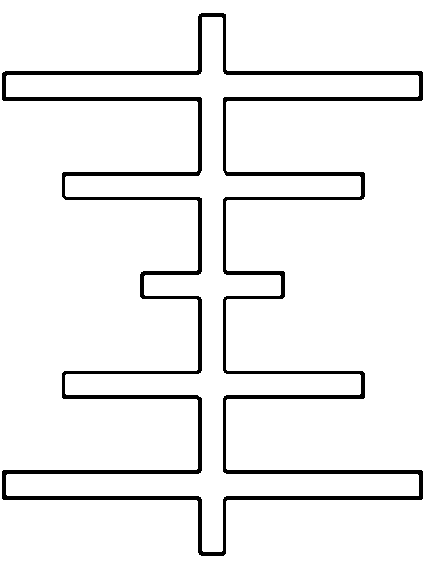

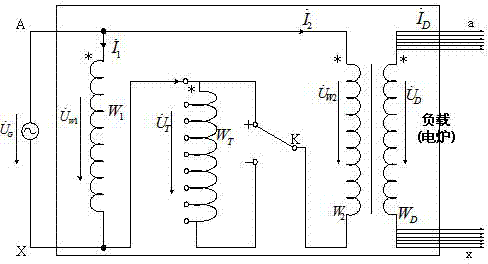

Method for collecting current on low-voltage side of electric furnace transformer and relay protection device

InactiveCN102435813AEasy to installGuaranteed measurementCurrent/voltage measurementEmergency protective circuit arrangementsShielded cableElectric arc furnace

The invention relates to a method for collecting current on the low-voltage side of an electric furnace transformer and a relay protection device. The relay protection device comprises electronic current sensors penetrating through corresponding terminals of lead conductors in parallel connection between the low-voltage side output terminal of the electric furnace transformer and an electric furnace electrode, wherein the signal output ends of each electronic current sensor are connected with each other in series, and are connected with a signal conditioning unit through a shielded cable. The technical scheme can be used for solving the difficult problems of measuring large current on the low-voltage side of the electric furnace transformer as well as the failing to achieve differential protection of the electric furnace transformer, and can meet the requirement on linearity and large-current unsaturation of differential protection.

Owner:XJ ELECTRIC +3

High speed, low noise, low inductance transmission line cable

ActiveUS8569627B1Increase mutual inductanceReduce signal attenuationPower cables with screens/conductive layersFlat/ribbon cablesUltrasound attenuationTransmission line

A transmission line cable that utilizes a plurality of substantially flat insulated conductors, each consisting of two or more solid metallic strands laid side by side in a parallel configuration within an extruded insulator. The plurality of insulated conductors are stacked into groups of two or more and may be utilized as signal conductors or shield conductors. Once the insulated conductors are stacked, the stack is twisted together, and either wrapped in a conductive insulator, placed in an extruded non-conductive insulator, or both, creating a cable that is stable, flexible, and has improved transmission characteristics, including reduced attenuation, noise and signal skew.

Owner:WIREWORLD BY DAVID SALZ

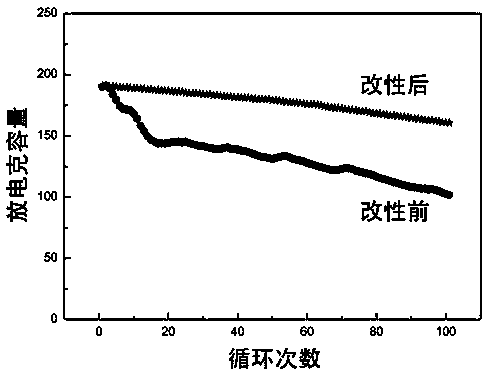

Preparation method of modified lithium ion battery positive electrode material

InactiveCN109585810AReduce corrosionInhibition of surface remodelingCell electrodesSecondary cellsCalcium hydroxideLithium electrode

The invention provides a preparation method of a modified lithium ion battery positive electrode material, and belongs to the technical field of lithium ion battery positive electrode materials. Firstly, a hydroxide composite precursor containing nickel, cobalt and manganese is prepared; Mixing the composite precursor with lithium hydroxide, and carrying out high-temperature sintering to obtain alithium ion battery positive electrode material; And finally, performing surface amorphous fast ion conductor coating modification on the obtained positive electrode material to obtain the lithium ionbattery positive electrode material with excellent performance. The surface of the modified lithium ion battery positive electrode material is coated with a layer of amorphous compound, so that the side reaction of an electrolyte and an active substance is favorably reduced, and the cycle performance of the positive electrode material is obviously improved. The process is simple and easy to implement, has low requirements on raw materials and equipment, has better product stability and meets the requirements of high-performance power battery materials. Good economic benefits and good market promotion values are achieved.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

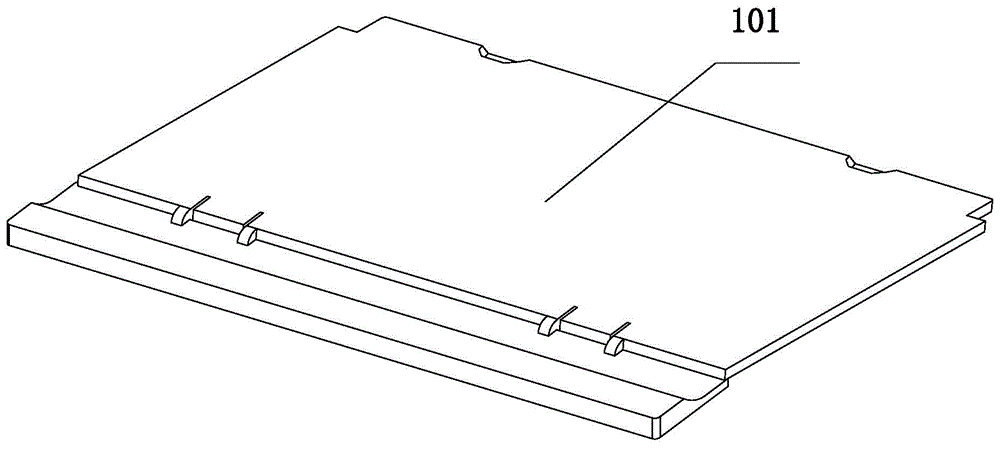

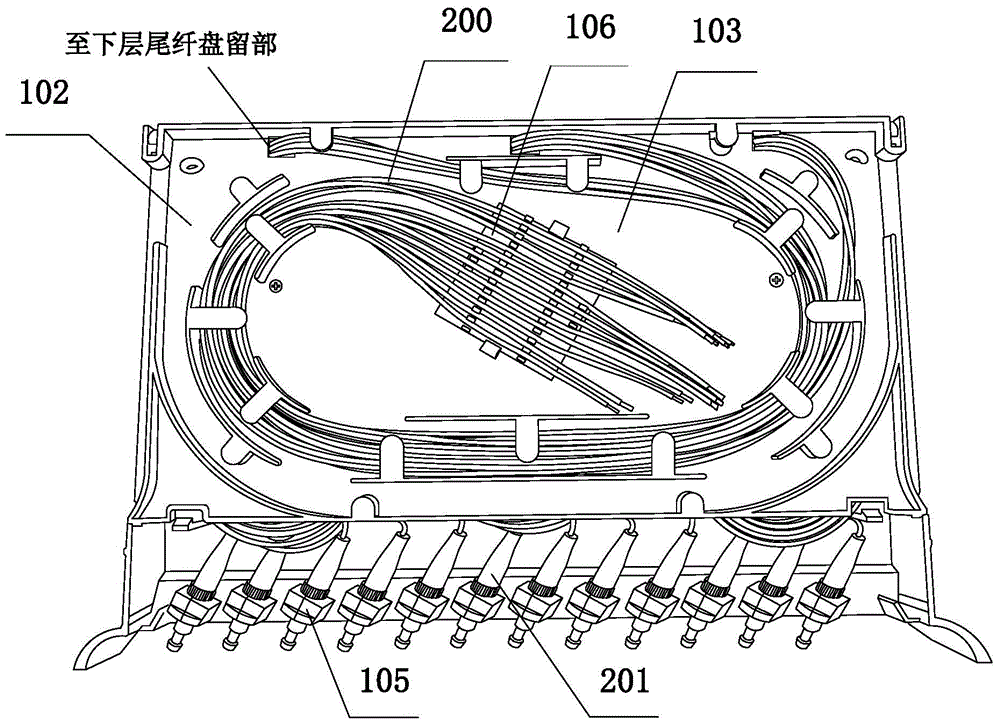

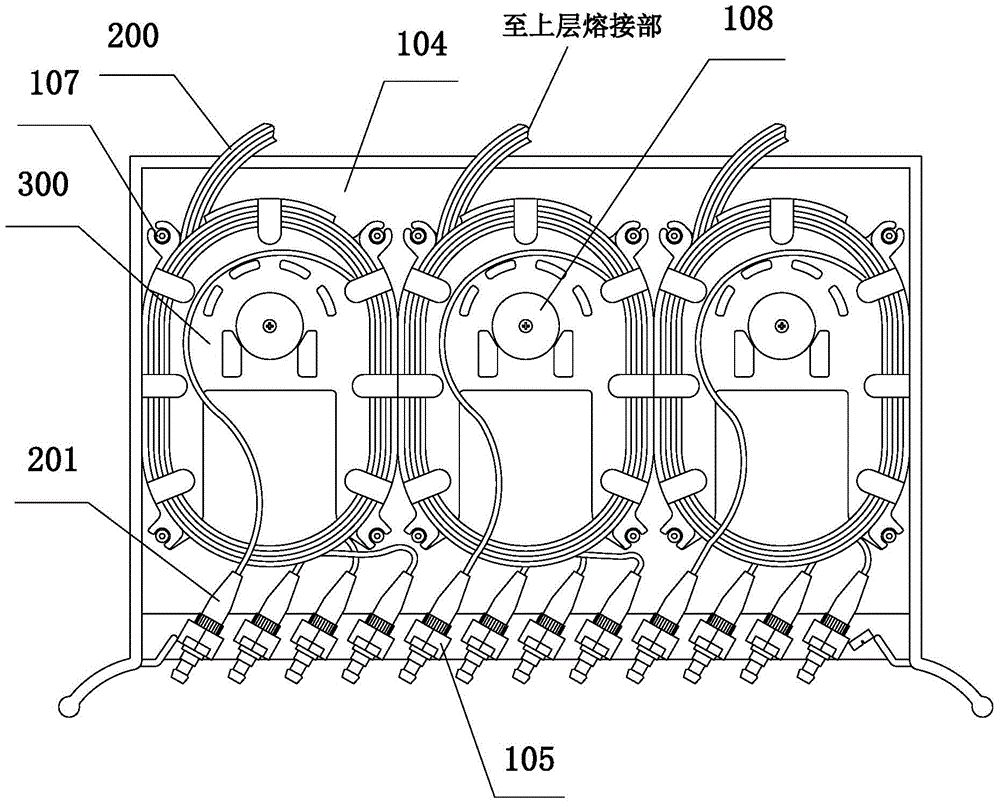

Optical fiber fusion and distribution integrated unit disc

InactiveCN104459920AEasy to processEasy to installCoupling light guidesFibre mechanical structuresFiberUltrasound attenuation

The invention provides an optical fiber fusion and distribution integrated unit disc, and belongs to an optical fiber fusion and distribution part. The optical fiber fusion and distribution integrated unit disc comprises a cover plate and a unit disc body. The unit disc body comprises a fusion part in the upper layer and a tail fiber coiling part in the lower layer. A plurality of fiber winding-unwinding structures used for coiling tail fibers are arranged in the tail fiber coiling part, each fiber winding-unwinding structure is formed by detachably connecting a plurality of fiber winding-unwinding discs, and the fiber winding-unwinding discs of each fiber winding-unwinding structure are stacked in the vertical direction. The optical fiber fusion and distribution integrated unit disc can be used as a distribution unit disc in an optical cable splice box, and in the optical cable splice box, the tail fibers can be directly connected with an adapter of a standard main unit disc through the tail fibers. Attenuation in the whole light path process is effectively reduced, the network quality is improved, and obstacle points caused by connecting the optical fibers with the adapter are reduced. In addition, the tail fibers in the optical fiber splice box can be orderly and tidily arranged, and disordering of the tail fibers can be avoided.

Owner:高文亭 +2

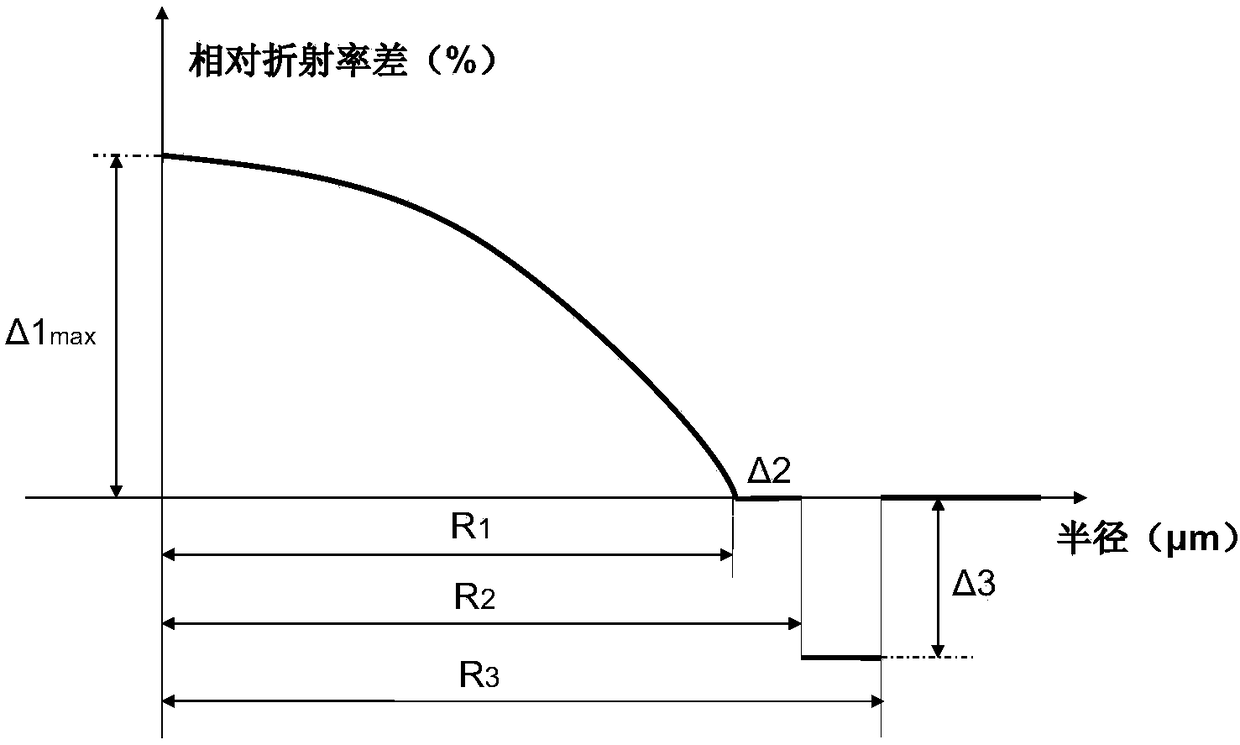

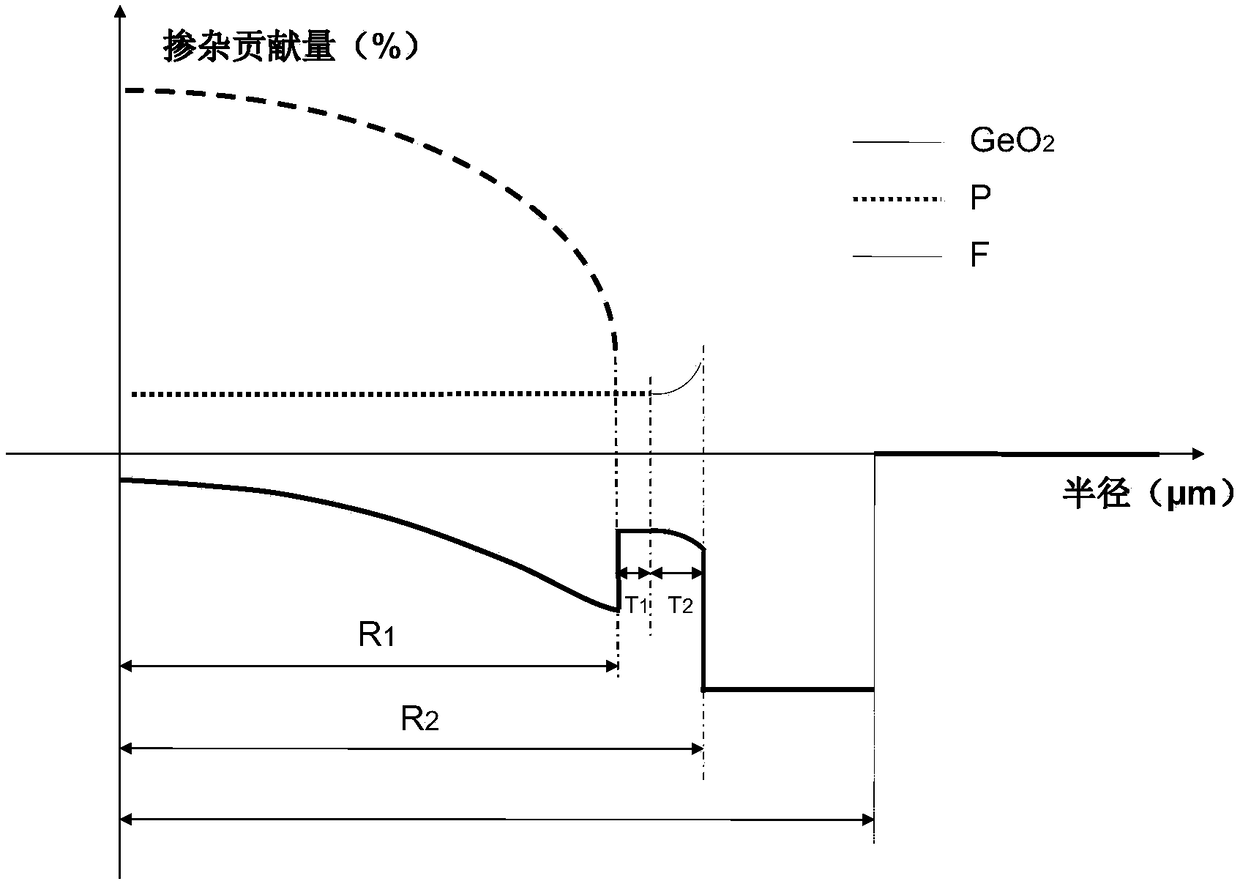

High-bandwidth bending-insensitive multimode optical fiber

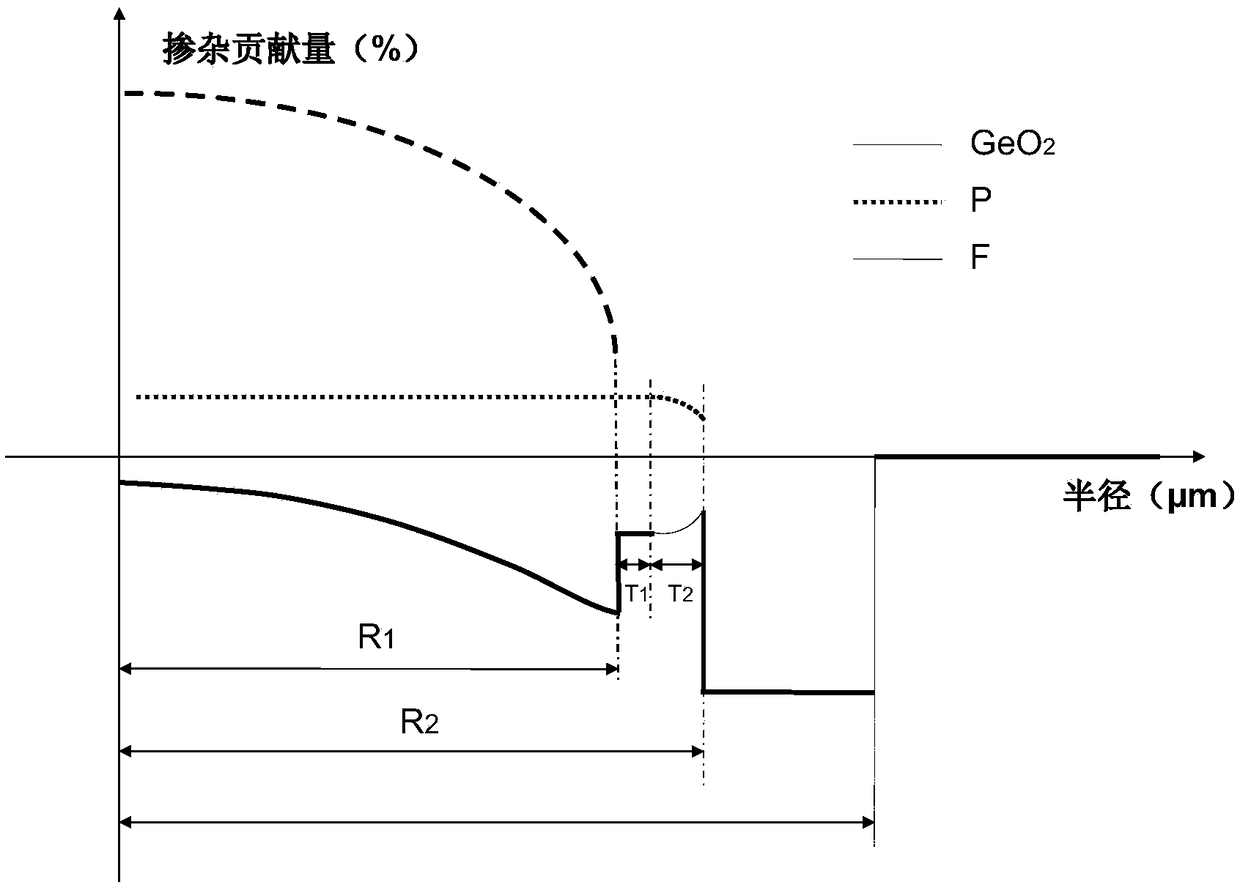

ActiveCN108375815AIncrease concentrationImproved material dispersionOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingRelative refractive indexSilicon dioxide

The present invention relates to a high-bandwidth bending-insensitive multimode optical fiber. The optical fiber comprises a core layer and a cladding layer, wherein the cladding layer includes an inner cladding layer, a depressed cladding layer and an outer cladding layer which are distributed from inside to outside. The optical fiber is characterized in that the refractive index profile of the core layer is of a parabola shape; the distribution index alpha of the core layer ranges from 2.0 to 2.3; the radius R1 of the core layer ranges from 23 to 27 micrometers; the maximal relative refractive index difference delta1max of the center of the core layer ranges from 0.9% to 1.2%; the core layer is a germanium (G), phosphorus (P) and fluorine (F) co-doped silica glass layer; the contributionamount deltaP0 of phosphorus (P) at the center of the core layer ranges from 0.01% to 0.30%; the contribution amount deltaP1 of phosphorus (P) at the interface of the core layer and the inner cladding layer ranges from 0.01% to 0.30%; the content of phosphorus (P) at the center of the cover layer is consistent with the content of phosphorus (P) at the edge of the core layer; the doping amount offluorine (F) is gradually increased from the center of the core layer to the edge of the core layer; the contribution amount deltaF0 of fluorine (F) at the center of the core layer ranges from 0.0% to-0.1%; and the contribution amount deltaF1 of fluorine (F) at the edge of the core layer ranges from -0.4% to -0.20%;. The material compositions of the high-bandwidth bending-insensitive multimode optical fiber and the structural design of the core layer and cladding layer of the high-bandwidth bending-insensitive multimode optical fiber are reasonable; the chromatic dispersion of the optical fiber is reduced; the bandwidth performance of the optical fiber is improved; and the attenuation of the optical fiber is reduced.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Single mode fiber

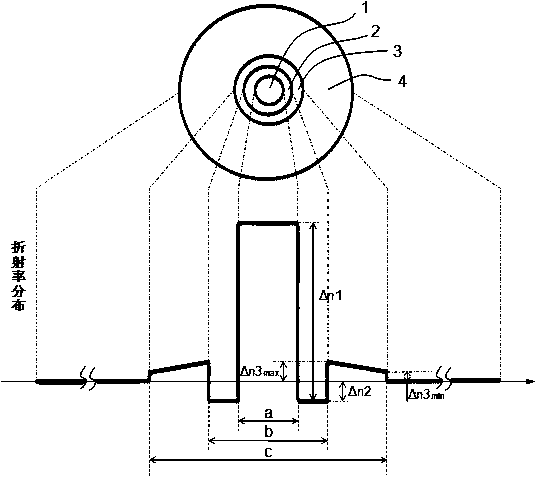

ActiveCN103760634AReduce manufacturing costSmall attenuationOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingAttenuation coefficientUltrasound attenuation

The invention relates to a single mode fiber with the lower manufacturing cost. The single mode fiber comprises a core layer, wherein a first inner wrapping layer, a second inner wrapping layer and an outer wrapping layer wrap the core layer in sequence. The single mode fiber is characterized in that the outer wrapping layer is made of natural siliceous sand, the absolute refraction index of the outer wrapping layer ranges from 1.4572 to 1.4574, the diameter alpha of the core layer is 8-10 micrometers, the refraction index difference delta n1 of the core layer and the outer wrapping layer ranges from 4.1*10<-3> to 6.4*10<-3>, the ratio b / a of the diameter b of the first inner wrapping layer to the diameter a of the core layer is greater than or equal to 1.6, the refraction index difference delta n2 of the first inner wrapping layer and the outer wrapping layer ranges from -2.4*10<-3> to -0.7*10<-3>, and the ratio c / a of the diameter c of the second inner wrapping layer to the diameter a of the core layer is greater than or equal to 3.6. The outer wrapping layer of an optical fiber prefabricated bar is made of the natural siliceous sand with the lower cost, so that the manufacturing cost of the optical fiber is lowered greatly; the structure of the inner wrapping layers and the outer wrapping layer is adopted, the ratio of the inner wrapping layers to the core layer is selected reasonably, and the fluorine mixing amount and the chloride ion concentration in the second inner wrapping layer are controlled, so that influence on optical attenuation from the impurities of the outer wrapping layer made of the natural siliceous land is reduced, and the water peak performance and the attenuation coefficient of the single mode fiber are reduced effectively.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

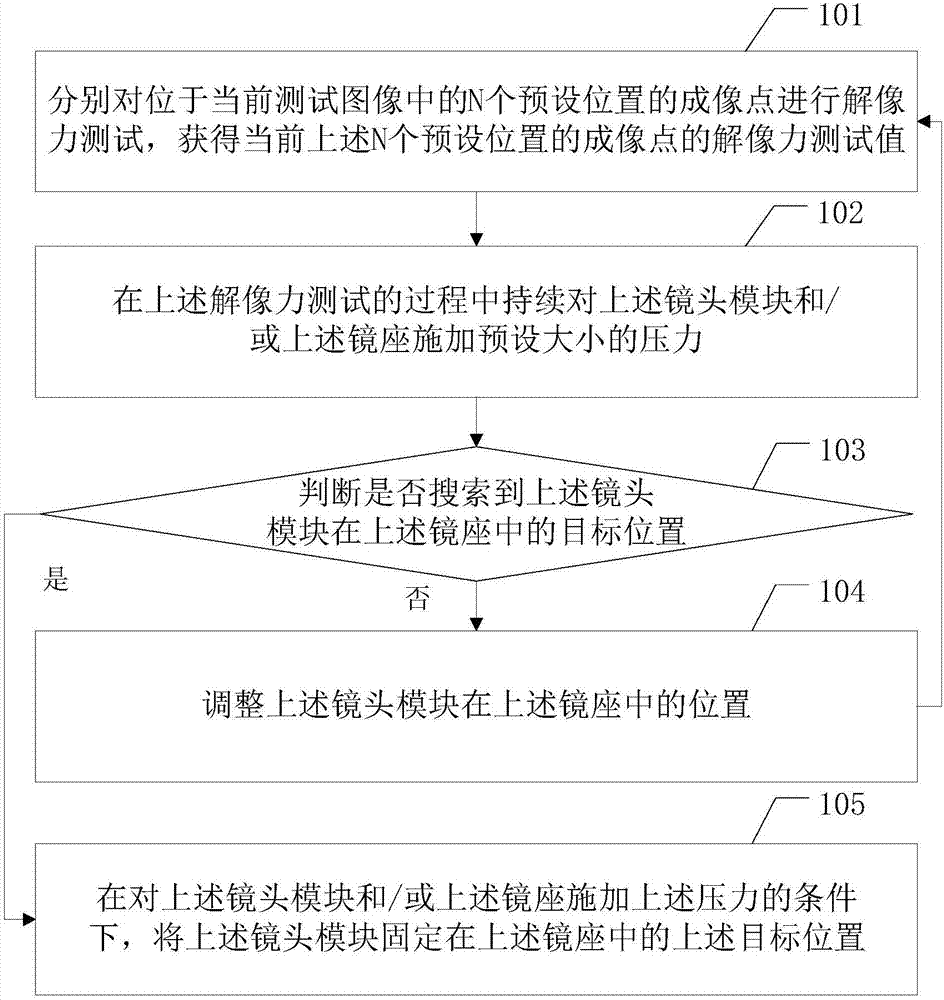

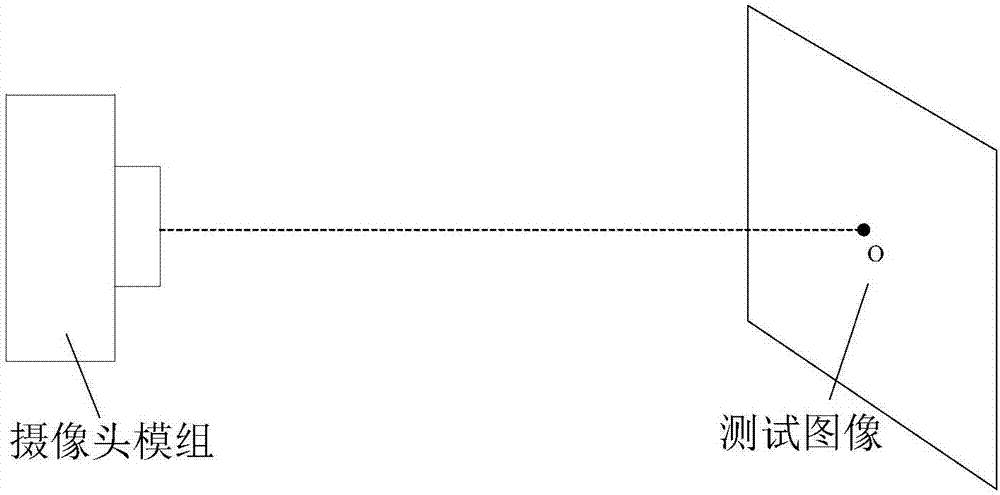

Camera module testing method, camera module testing device and computer readable storage medium

ActiveCN107147904AReduce attenuationReduce offsetTelevision systemsCamera lensUltrasound attenuation

The invention discloses a camera module testing method, a camera module testing device and a computer readable storage medium, wherein the camera module testing method comprises the steps of: respectively performing resolution power testing of imaging points of N pre-set positions in a current test image; continuously applying pre-set pressure on the lens and / or the holder of a camera assembly in a resolution power testing process; adjusting the position of the lens in the holder, and returning to the resolution power testing step and the subsequent step till the target position of the lens in the holder is searched, wherein when the lens is at the target position in the holder, the resolution power testing value of the imaging point at the pre-set position in the N pre-set positions is maximum; and fixing the lens at the target position in the holder when the target position is searched. By means of the technical scheme provided by the invention, the resolution power attenuation degree of a camera module after being assembled on electronic equipment can be effectively reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Multimode optical fiber

InactiveUS7773847B2Easy to produceReduce attenuationGlass making apparatusOptical fibre with multilayer core/claddingRefractive indexQuartz

A core part of a multimode optical fiber including the core part and a cladding part has a structure composed of a plurality of concentric layers in which a refractive index is decreased stepwise from a first core layer as an innermost layer to a third core layer as an outermost layer. The structure having the plurality of layers is formed by adjusting a quantity of addition of fluorine to silica glass. Fluorine is added to the cladding part so that a refractive index is lower than that of the third core layer as the outermost layer of the core part.

Owner:SUMITOMO ELECTRIC IND LTD

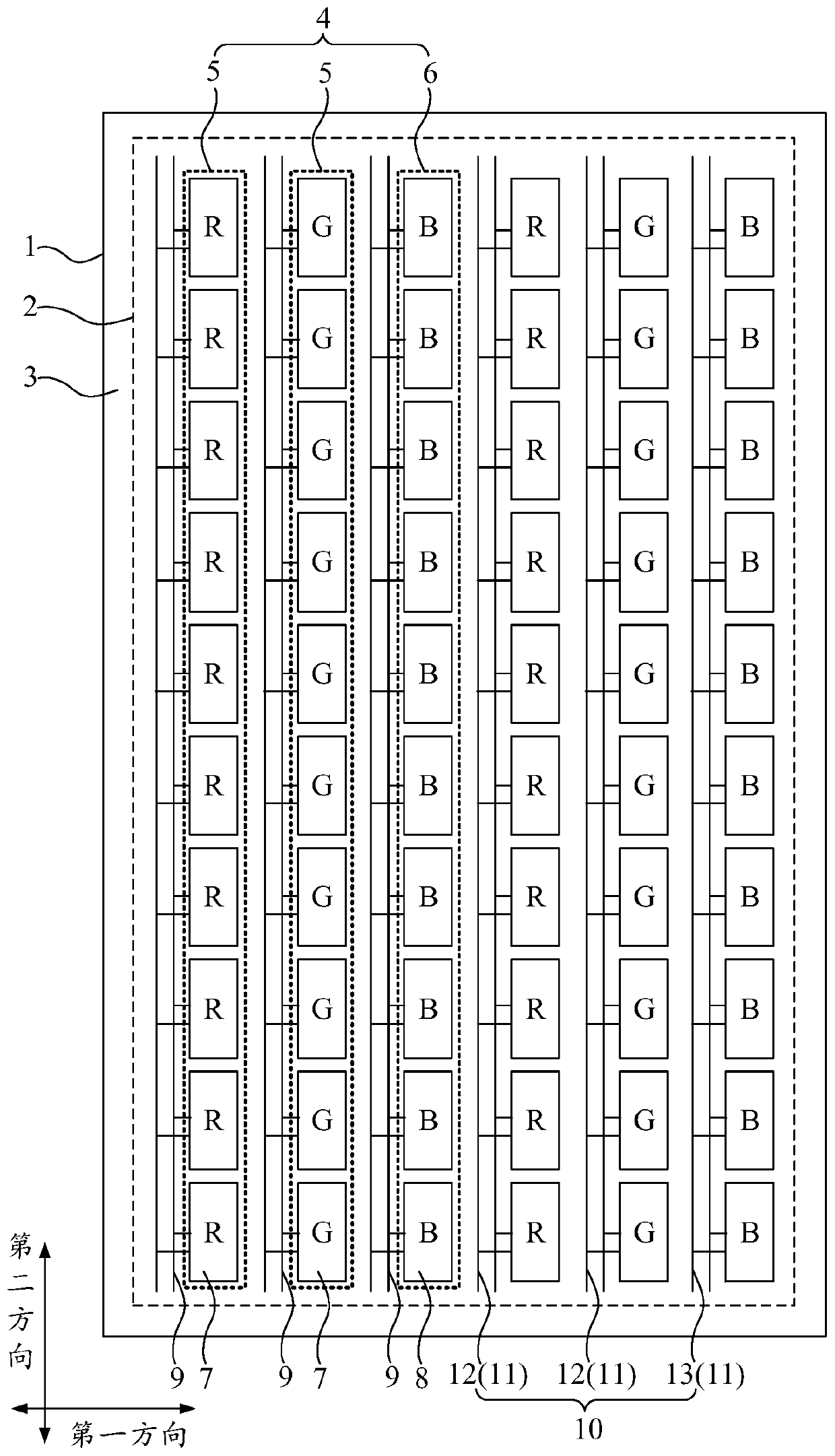

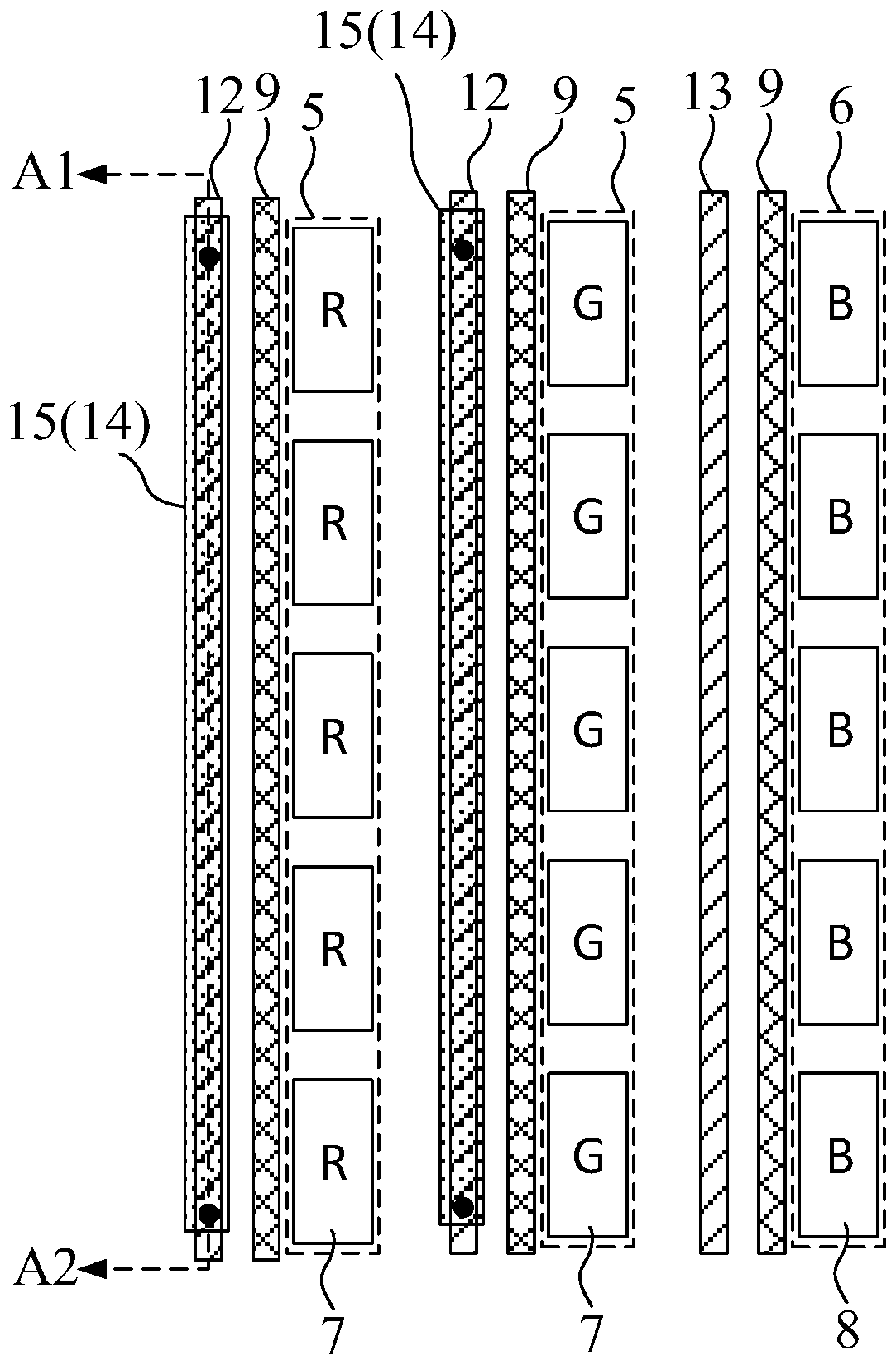

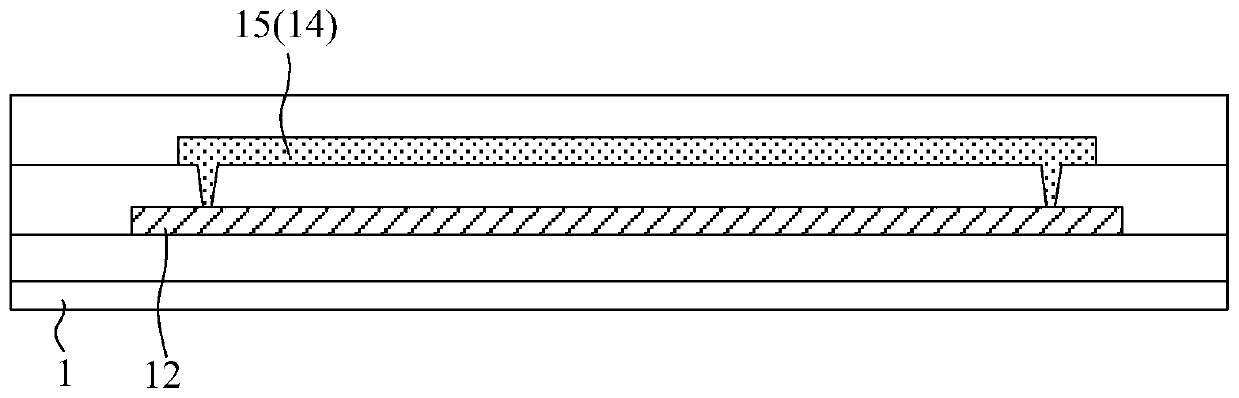

Display panel and display device

ActiveCN110751922AIncrease the cross-sectional areaLower resistanceStatic indicating devicesComputer hardwareDisplay device

The embodiment of the invention provides a display panel and a display device, and relates to the technical field of display, which can effectively improve the color cast phenomenon. The display panelcomprises a substrate base plate; a display area and a non-display area; pixel columns which comprise a first pixel column and a second pixel column, wherein the first pixel column comprises first sub-pixels, the second pixel column comprises second sub-pixels, and the luminous efficiency of the first sub-pixels is higher than that of the second sub-pixels; data lines connected with the pixel columns; power supply signal lines which comprise longitudinal power supply signal lines, wherein the longitudinal power supply signal lines comprise a first longitudinal power line and a second longitudinal power line, the first longitudinal power line is connected with the first pixel column, and the second longitudinal power line is connected with the second pixel column; compensation signal lines which comprise first compensation signal lines, wherein the first compensation signal lines are connected with the first longitudinal power lines, and the first compensation signal lines are overlapped with the first longitudinal power lines connected with the first compensation signal lines in the direction perpendicular to the plane where the substrate is located.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Seed treatment compositions & methods

ActiveUS20140336049A1Promote growthIncrease nutritionBiocideMagnesium fertilisersNatural organic matterCold resistance

A seed composition comprising a seed and a first component comprising an agriculturally acceptable complex mixture of dissolved organic material characterized by natural organic matter that is partially humified and methods of seed treating. A method comprising contacting a seed with a first component comprising an agriculturally acceptable complex mixture of dissolved organic material characterized by natural organic matter that is partially humified, where the first component enhances at least one of germination, emergence, root development, seedling vigor, seedling growth, mortality resistance, chlorophyll production, cold resistance, water log resistance, and nutrient uptake compared to similar seed not contacted with the first component.

Owner:FBSCI HLDG

Pixel structure and OLED display panel with same

ActiveCN109860416AReduce attenuationLarge viewing angleSolid-state devicesSemiconductor/solid-state device manufacturingUltrasound attenuationComputer science

The invention provides a pixel structure and an OLED display panel with the same. The involved pixel structure comprises a pixel defining layer with an opening, a first electrode and a color error adjusting layer arranged in the opening, wherein the first electrode is arranged below the pixel defining layer and at least part of the surface of the first electrode passes through the opening to be exposed; the color error adjusting layer has a side edge part attached to the inner wall of the opening of the pixel defining layer and an organic light emitting layer covering the color error adjustinglayer; and the inner surface of the side edge part is configured to be inclined outwardly from bottom to top and is electrically connected with the first electrode. Based on the specific design of the pixel structure, the part of the organic light emitting layer located on the side edge part of the color error adjusting layer forms compensation for brightness attenuation of light under a large viewing angle, the light brightness attenuation degree under the large viewing angle is further reduced, and the color error problems involved in the prior art can be weakened or completely avoided.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

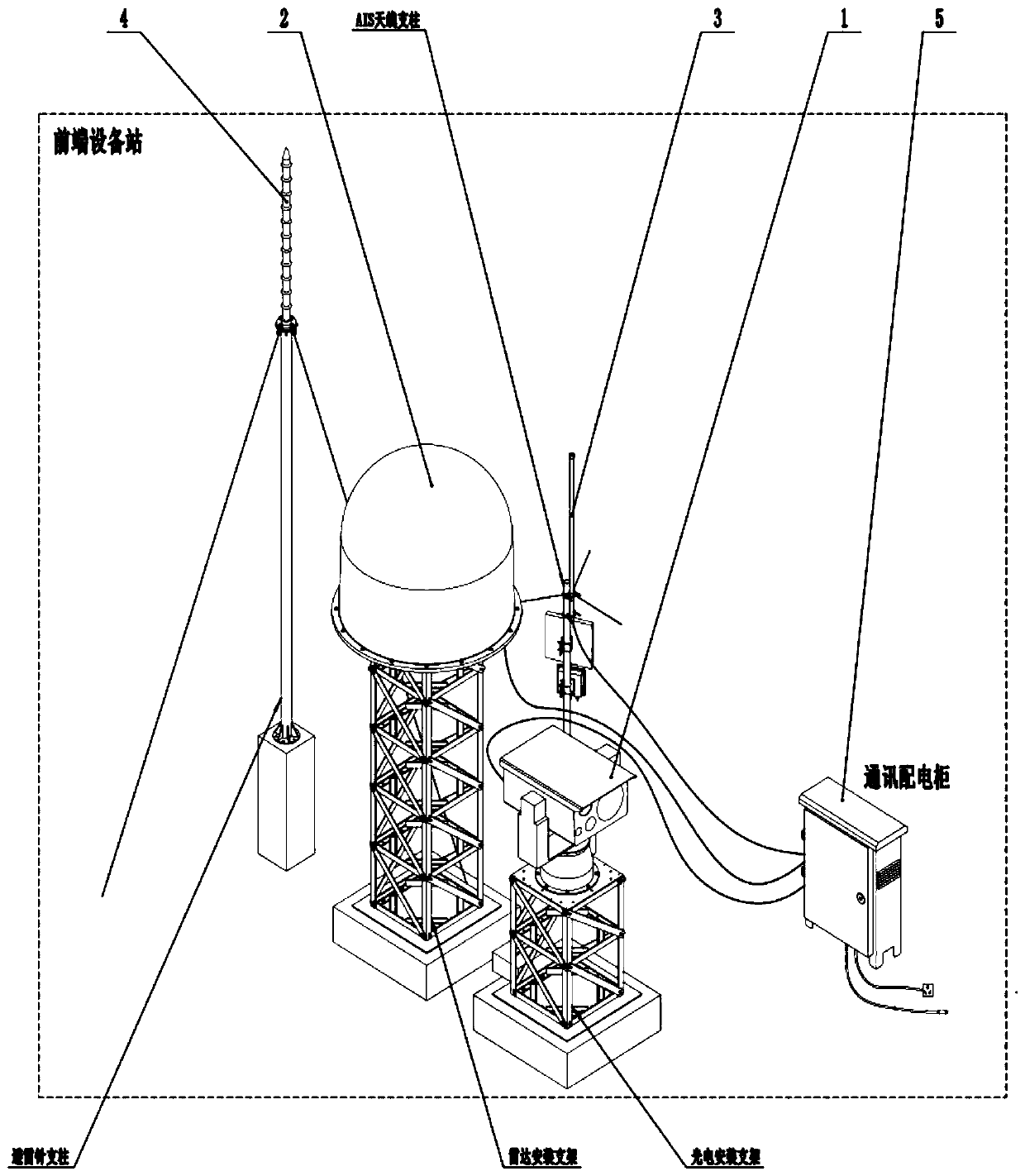

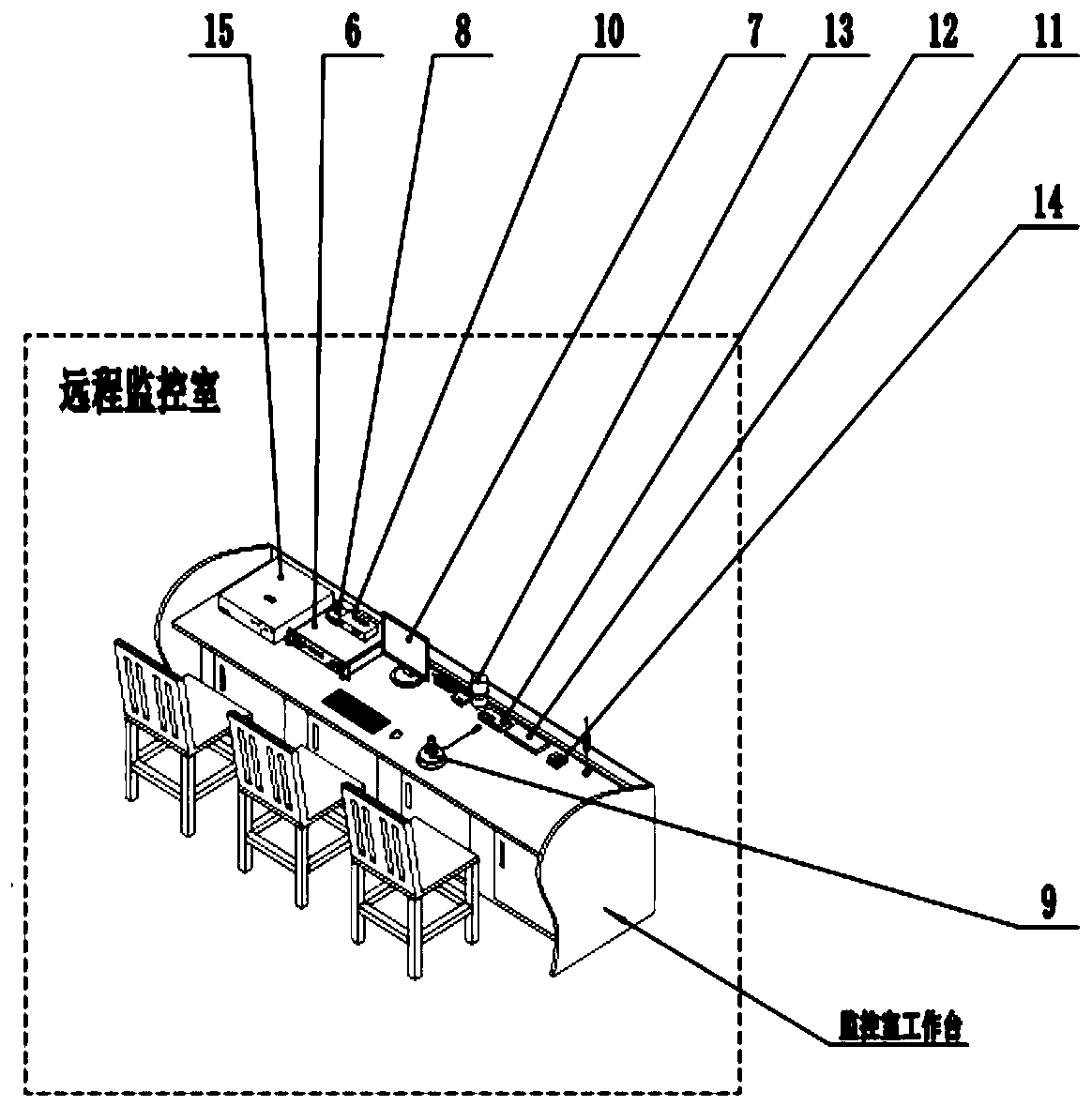

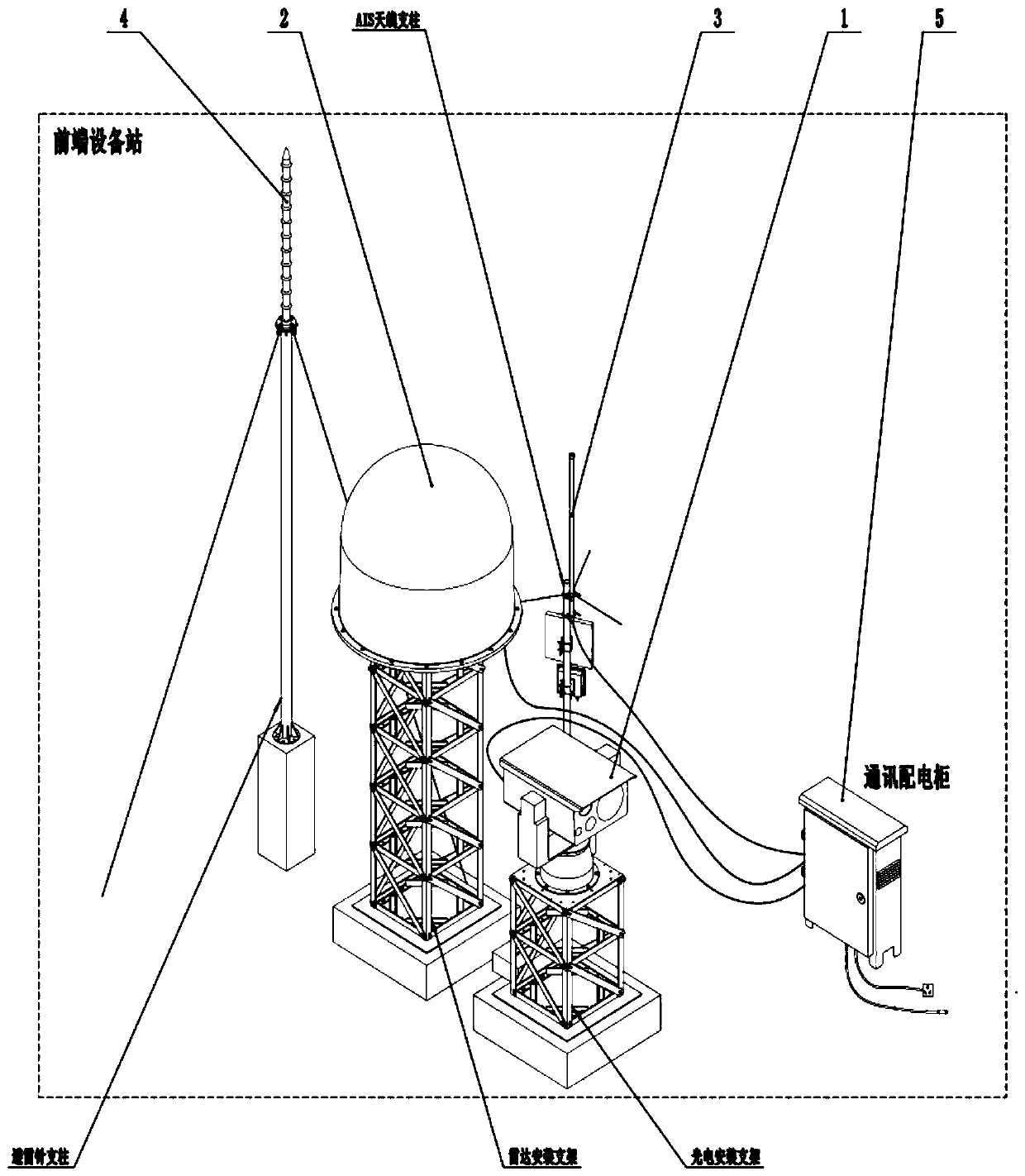

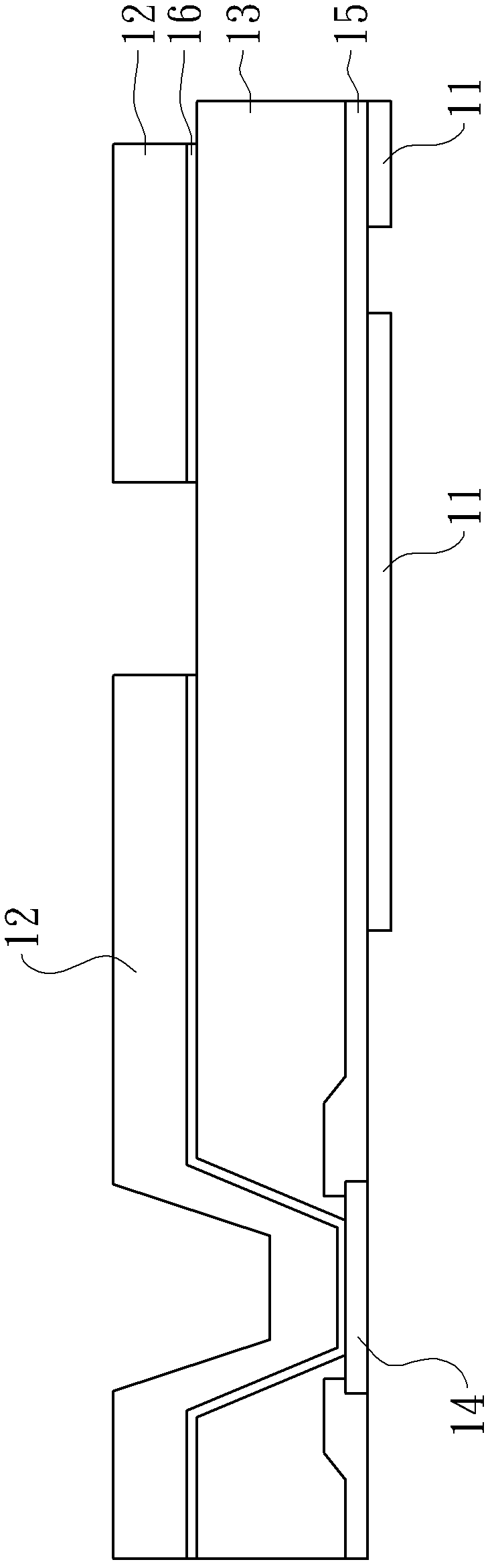

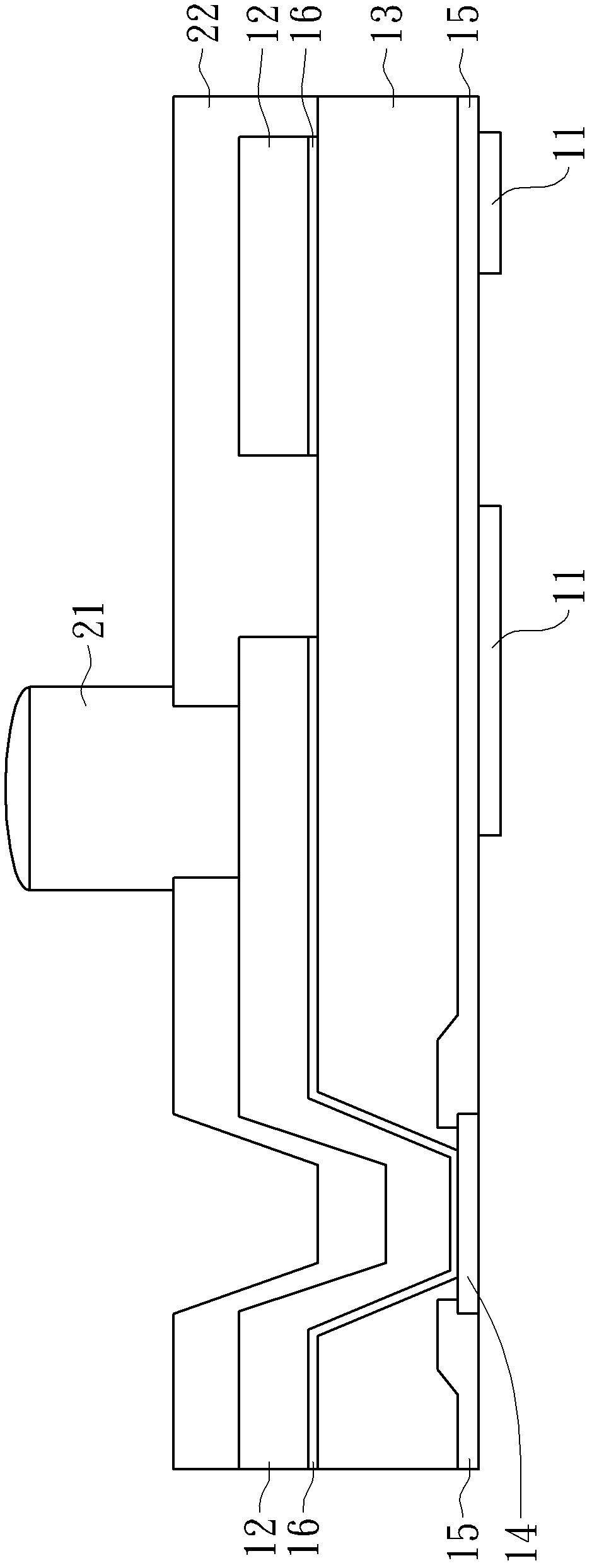

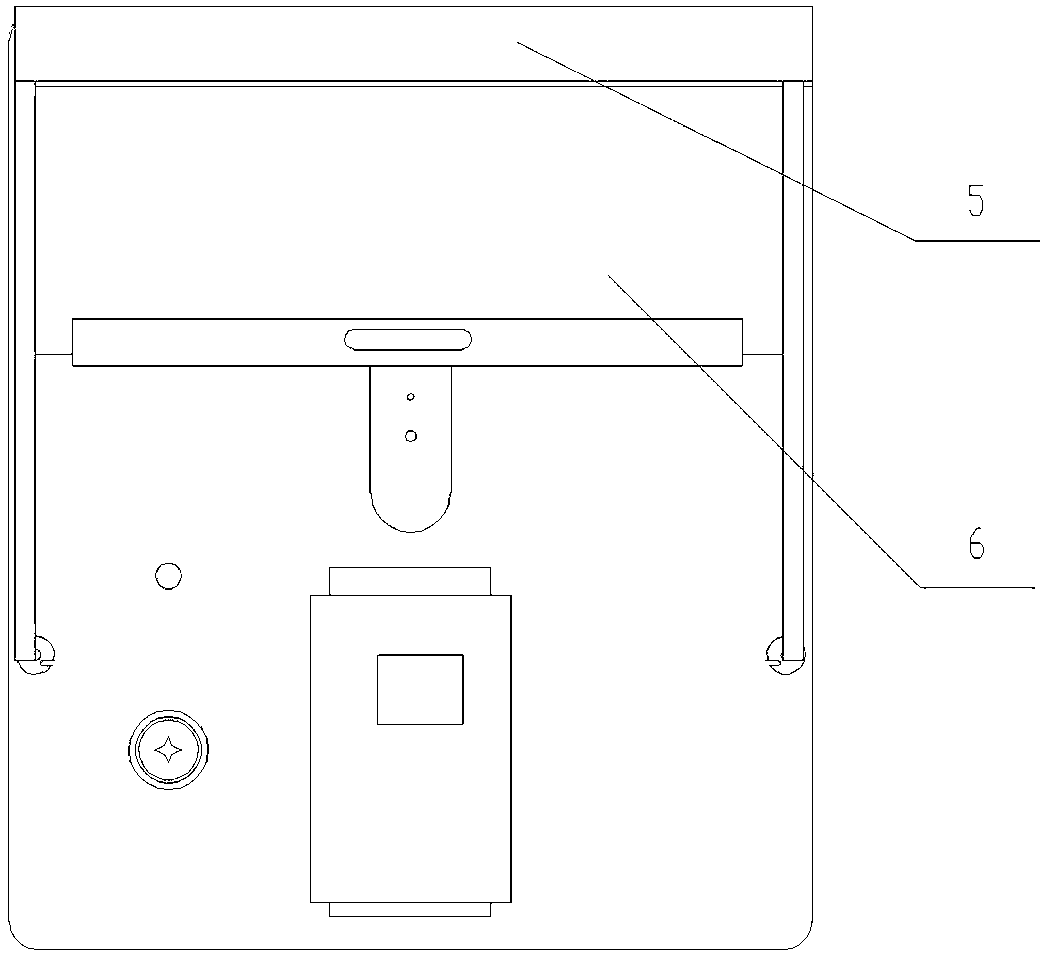

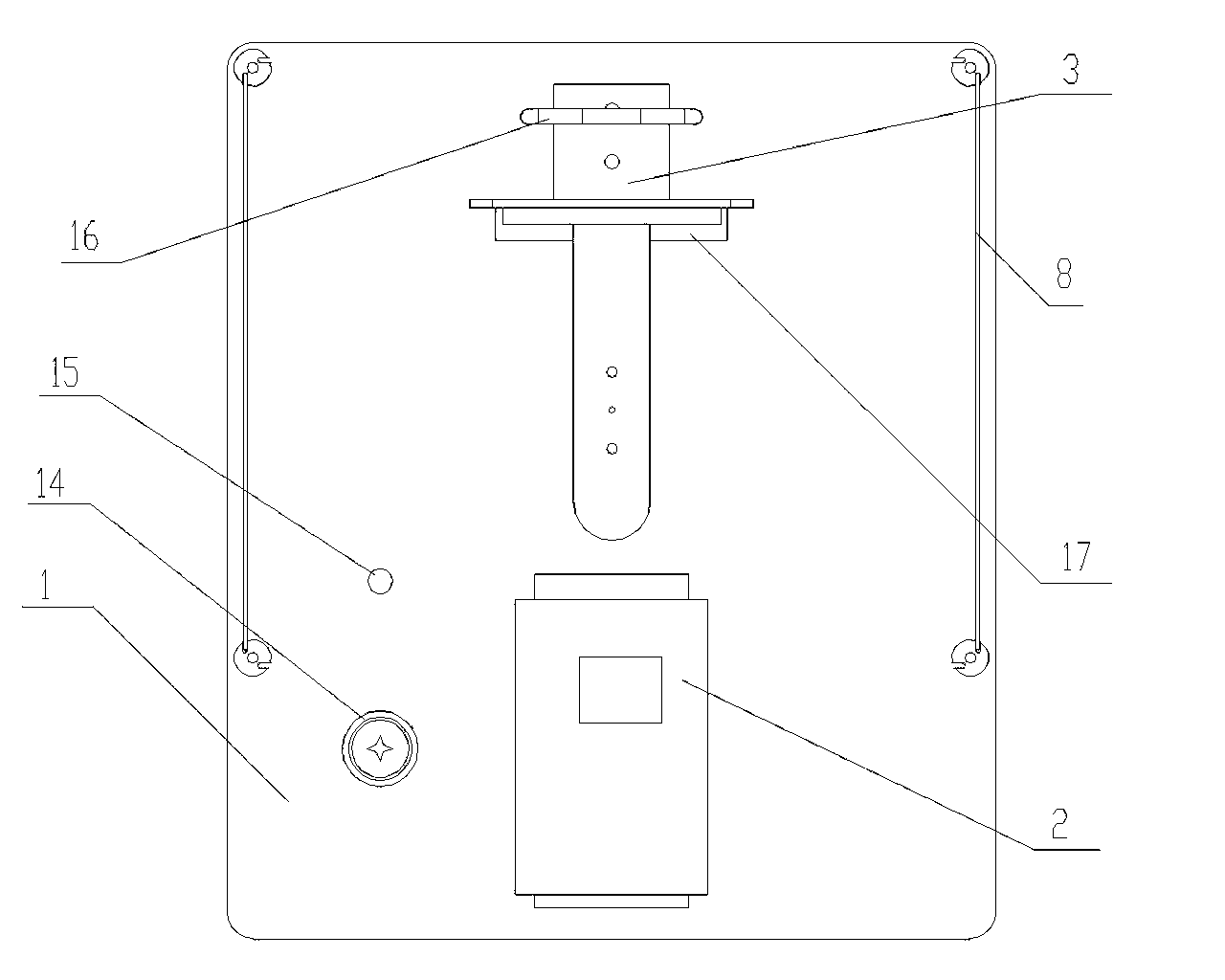

Warning system integrating radar guidance and photoelectric tracking functions

PendingCN109917364AEasy to observeEasy to monitorMarine craft traffic controlClosed circuit television systemsRadarDisplay device

The invention provides a warning system integrating radar guidance and photoelectric tracking functions, can monitor specific areas in real time, discover abnormal activities of various ships, vehicles and personnel in time so as to achieve early warning and alarm purposes to realize the warning function, and can remotely control front-end devices through utilizing networked equipment and corresponding transmission means. The warning system includes a front-end equipment station, a remote monitoring station and a communication link, wherein the front-end equipment station includes a photoelectric subsystem (1), a radar subsystem (2), an AIS subsystem (3) and a communication distribution cabinet (5), and the remote monitoring station includes a workstation host (6), a workstation display(7), a video tracking module (8), a rocker(9), a video switcher (10) and a sound and light alarm device(13).

Owner:ZNPL OCEAN DETECTION SYST ENG

Composite semi-conductor integrated circuit with three-dimensional element

InactiveCN103208472ASmall sizeReduce attenuationSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuitWire bonding

The invention relates to a composite semi-conductor integrated circuit with a three-dimensional element. In the composite semi-conductor integrated circuit, a welding pad or an inductor is arranged above an electronic element in a three-dimensional mode. The thickness of a dielectric layer inserted between the welding pad or the inductor and the electronic element ranges from 10 microns to 30 microns, so that influence on the performance of the element caused by the structure is effectively reduced. A protective layer can be coated on the electronic element to prevent pollution from metal materials making the welding pad or the inductor, and therefore, relatively cheap copper can be used for making the welding pad and the inductor. The three-dimensional welding pad can be applied to a wire bonding technology or a lug bonding technology.

Owner:WIN SEMICON

Cable splicing operation platform

InactiveCN103293601AEnsure cutover safetyImproved cutover securityCoupling light guidesTerrainCircular disc

The invention discloses a cable splicing operation platform comprising a platform body with support legs. Two ends, in the horizontal direction, of the top of the platform body are provided with a groove for accommodating a splicer and a U-shaped clamping board for fixing a cable joint box. A rectangular fixing groove is formed at the inner top of the U-shaped clamping board and matches with a disc part of the cable joint box. Wind boards are arranged at a cable inlet of the platform body and on adjacent two sides. By the aid of the cable splicing operation platform, splicing workers can set up and place splicing equipment conveniently under various conditions, the cable splicer, an OPGW (optical fiber composite overhead ground wire) cable and the joint box can be fixed, cable breakage or core breakage due being mistakenly hit by external forces can be avoided, safe cutting and splicing of the cables can be guaranteed, the reliability rate, quality and efficiency of cable splicing can be increased, and quality and efficiency of cable splicing can be improved. The cable splicing operation platform can be assembled rapidly, and is adaptable to terrains, convenient to operate and carry, reasonable in structure, light in weight, durable and consistent to splicing specifications.

Owner:STATE GRID CORP OF CHINA +1

Dispersion compensating transmission optical fiber matched with orthochromatic dispersion and ortho chromatic dispersion slope unimodel optical fiber and use

InactiveCN1252498CReduce lossLow PCVOptical fibre with multilayer core/claddingWavelength-division multiplex systemsDispersion compensationMaterials science

The waveguide structure of single-mode optical fibre comprises layered fibre core and layered clad. The fibre core is set with two core layers in different refractive indexed and layered clad consists of five layered clads. The codeposition of fluorine and germanium is applied by utilizing PCVD process to replace independent deposition of fluorine or germanium in deposition process for fibre core and clad so optical, mechanical and environmental performance of optical fibre is very much improved. The single-mode optical fibre produced in the present invention can be used in transmission of DWDM system.

Owner:SICHUAN LEFEI OPTOELECTRONICS TECH CO LTD +1

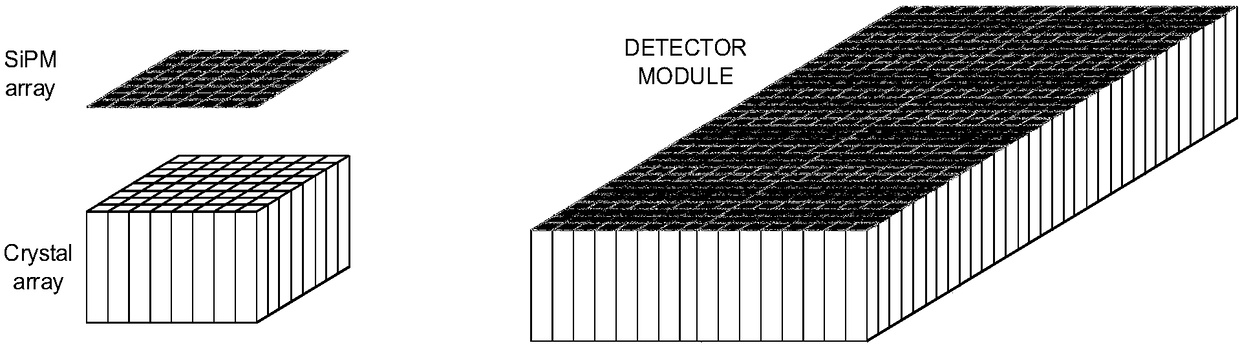

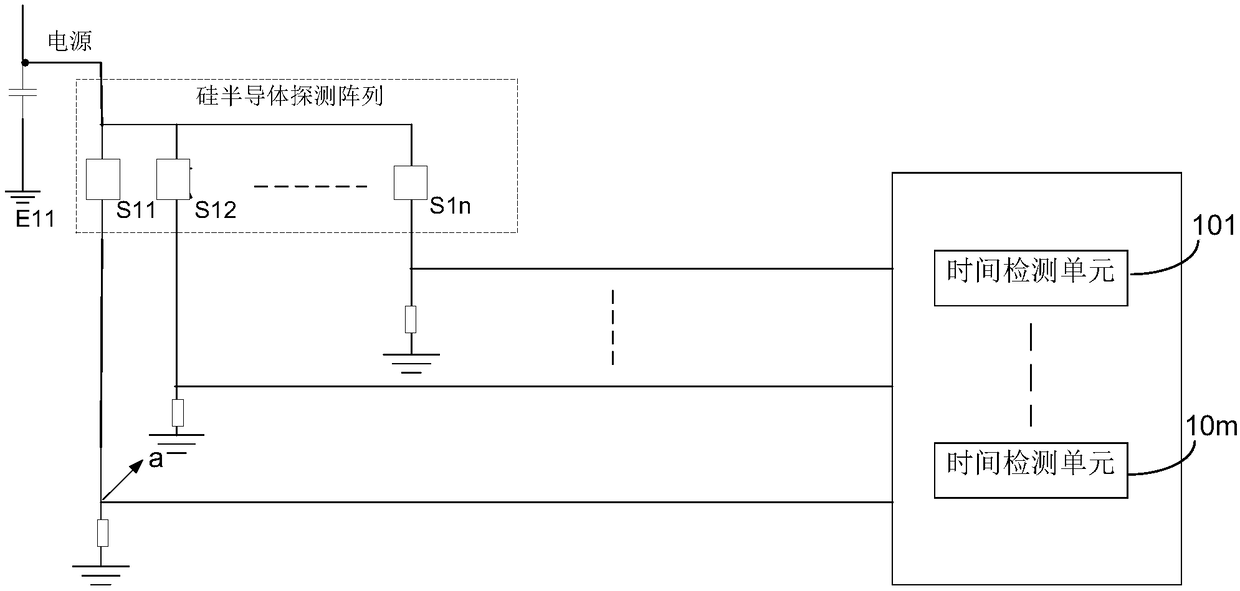

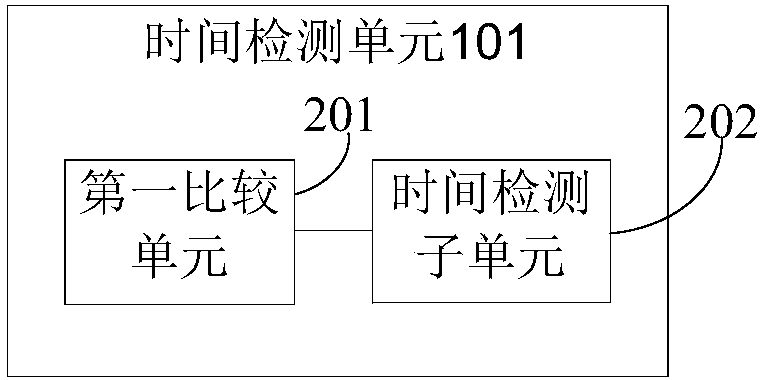

Positron emission computer tomography detector device

ActiveCN108294771AReduce capacitive effectReduce attenuationRadiation detection arrangementsCapacitanceCapacitive effect

The embodiment of the invention discloses a positron emission computer tomography detector device. The device comprises a silicon semiconductor detection array, wherein the silicon semiconductor detection array comprises a plurality of silicon semiconductor detection units; the cathodes of the plurality of silicon semiconductor detection units are connected with a power supply; the anodes or the cathodes of the plurality of silicon semiconductor detection units are taken as first signal output ends which are connected with corresponding time detection circuits; the number of the time detectioncircuits is more than 1 and is smaller than or equal to the number of the first signal output ends, by reducing the number of the silicon semiconductor detection units connected to the same time detection circuit, the capacitance effect of the silicon semiconductor detection units for collecting pulse signals is weakened, thus the attenuation degree of the high-frequency part in the pulse signalsis reduced, and the detection accuracy for gamma photon receiving time is improved.

Owner:SHENYANG INTELLIGENT NEUCLEAR MEDICAL TECH CO LTD

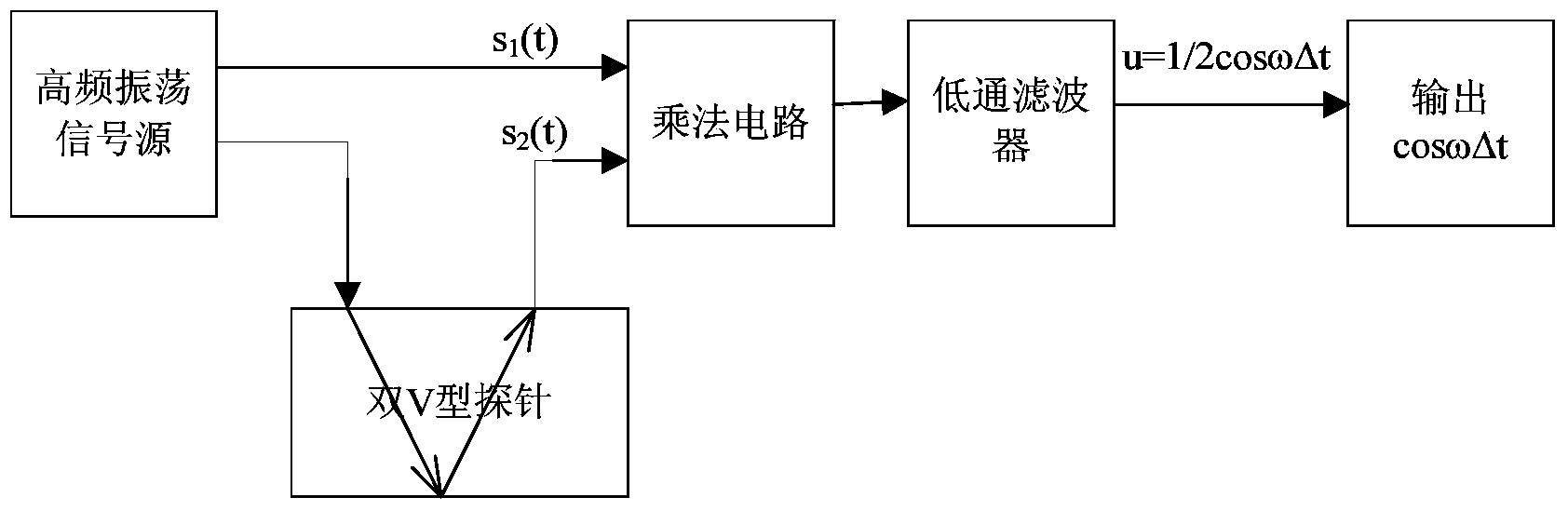

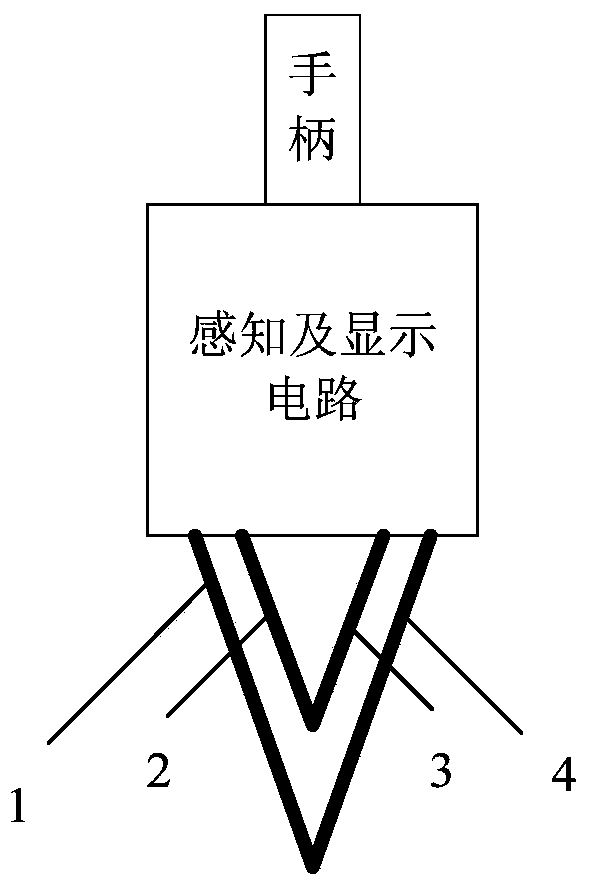

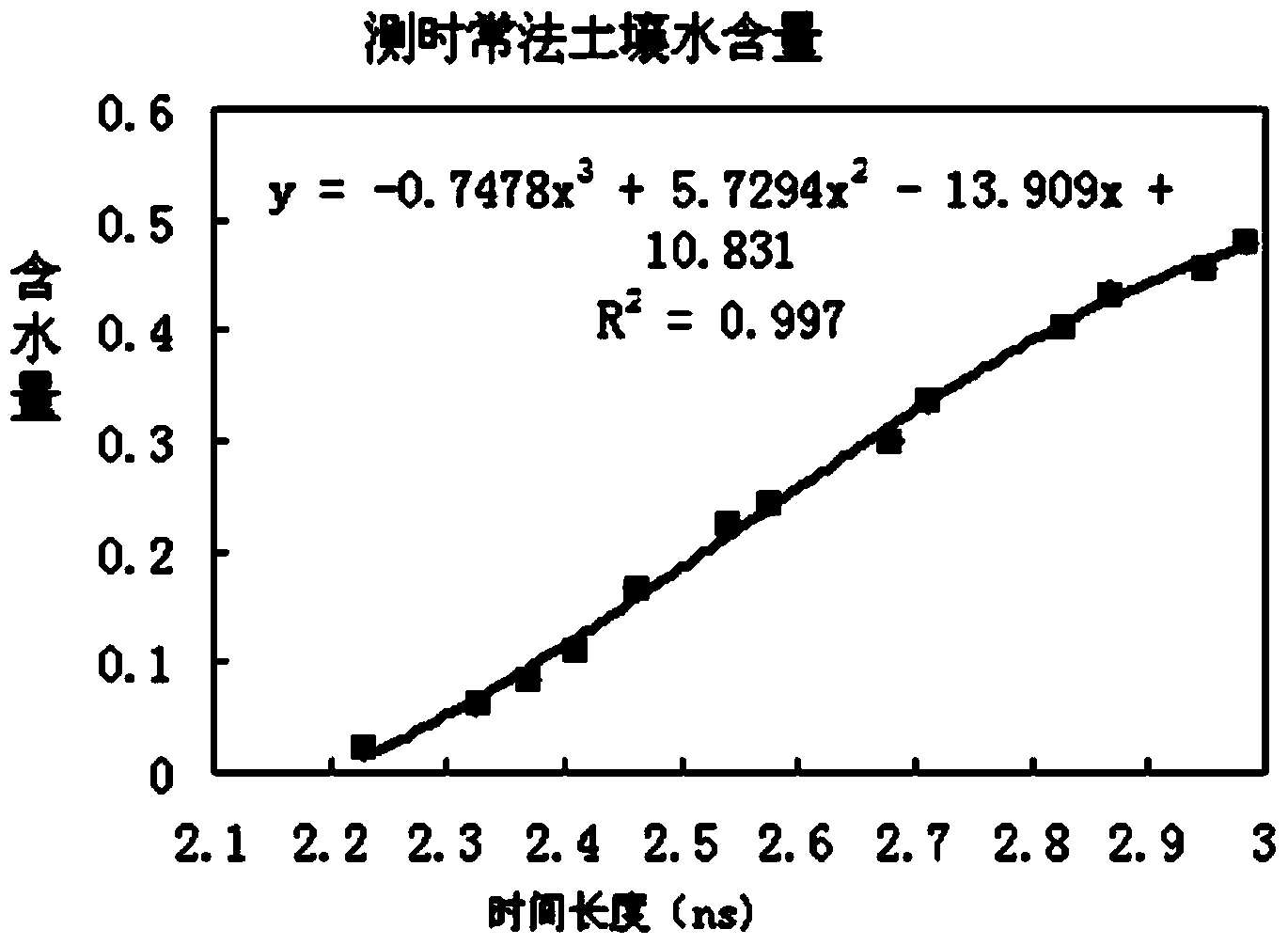

Method for measuring water content of soil by adopting time length measurement technology

InactiveCN104007128AMeasurement results are stableUndisturbedMaterial analysis using wave/particle radiationPhase differenceLength measurement

The invention discloses a method for measuring the water content of soil by adopting a time length measurement technology in the field of measurement for the water content of soil, which aims at solving the problems of conventional researches in the field of measurement for the water content of soil. The method comprises the following steps of firstly, inserting a double-V soil probe into prepared soil to be measured; secondly, transmitting a high-frequency electromagnetic wave to the soil probe; thirdly, comparing the phase difference of the electromagnetic waves at a transmitting end and a receiving end to accurately calculate the transmission time of the electromagnetic waves in the probe, and finally calculating the water content of the soil according to a fitting formula of a relationship between the transmission time and the water content of the soil. According to the method, the limits of complexity, low accuracy, difficulty in the implementation of a hardware circuit and the like of a conventional soil water content measurement method in practical application are broken, and the method for measuring the water content of the soil by adopting the time length measurement technology is effectively implemented.

Owner:CHINA AGRI UNIV

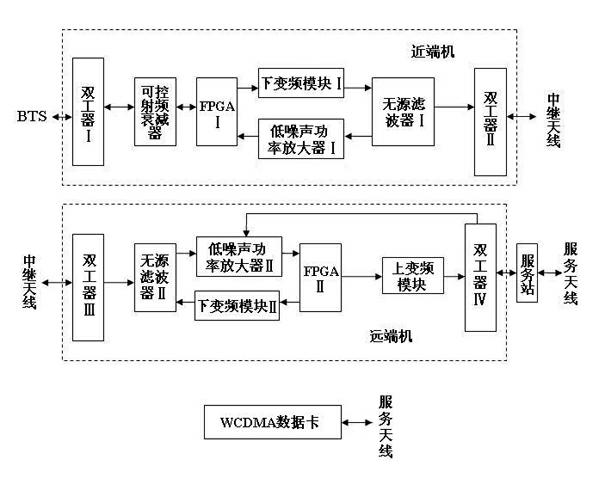

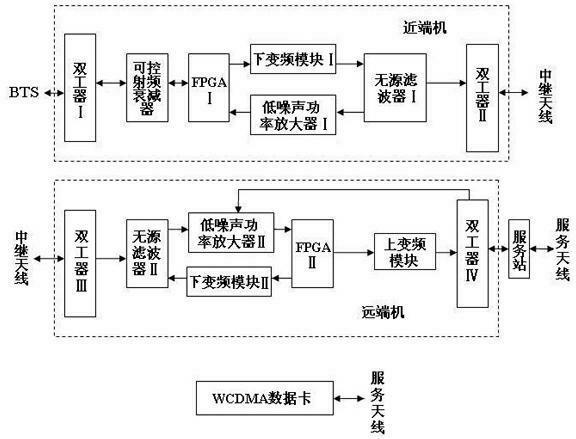

3G (third-generation) broadband digitalized super-remote wireless transmission system

InactiveCN102625477ARealize ultra-long-distance transmissionIncrease coverageNetwork topologiesCode division multiple accessIntermediate frequency

The invention discloses a 3G (third-generation) broadband digitalized super-remote wireless transmission system, which comprises a near terminal, a remote terminal and a WCDMA (wideband code division multiple access) data card. The near terminal is communicated with the remote terminal through a relay antenna, the transmission frequency of the relay antenna adopts an intermediate frequency bandwidth, and the information transmission between the WCDMA data card and a service station is performed through a service antenna. Based on the WCDMA interface standard, the near terminal is installed on the existing base station, and the remote terminal is installed on a service tower in remote areas, so that the super-remote transmission of wireless communication is realized, the problem of 3G broadband access in the remote areas can be solved without cable laying, and the coverage rate of wireless network signals in hilly, mountainous and woodsy areas is increased.

Owner:河北人天通信技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com