Method for collecting current on low-voltage side of electric furnace transformer and relay protection device

A technology for relay protection devices and electric furnace transformers, applied in emergency protection circuit devices, measuring current/voltage, measuring devices, etc., can solve problems such as inaccuracy and inconvenient current measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

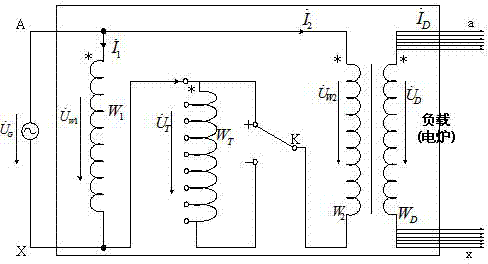

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] method embodiment

[0028] A method for collecting current at the low-voltage side of an electric furnace transformer, in which electronic current transformers are installed on the same-named ends of each lead wire conductor connected in parallel between the low-voltage side output end of the electric furnace transformer and the electrodes of the electric furnace, and the signal output ends of each electronic current transformer are connected to each other. After being connected in series, connect to the signal conditioning unit of the relay protection device.

[0029] Device embodiment

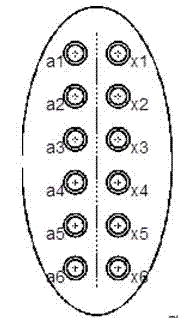

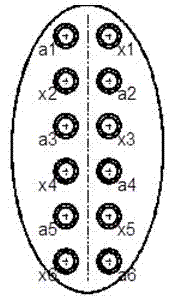

[0030] Such as Figure 7 The acquisition device in the system includes a Rogowski coil sensor, a conditioning unit and an acquisition unit. The lead wire copper bar between the low-voltage side of each phase of the transformer and the electric furnace electrode is determined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com