Patents

Literature

218results about How to "Guaranteed measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

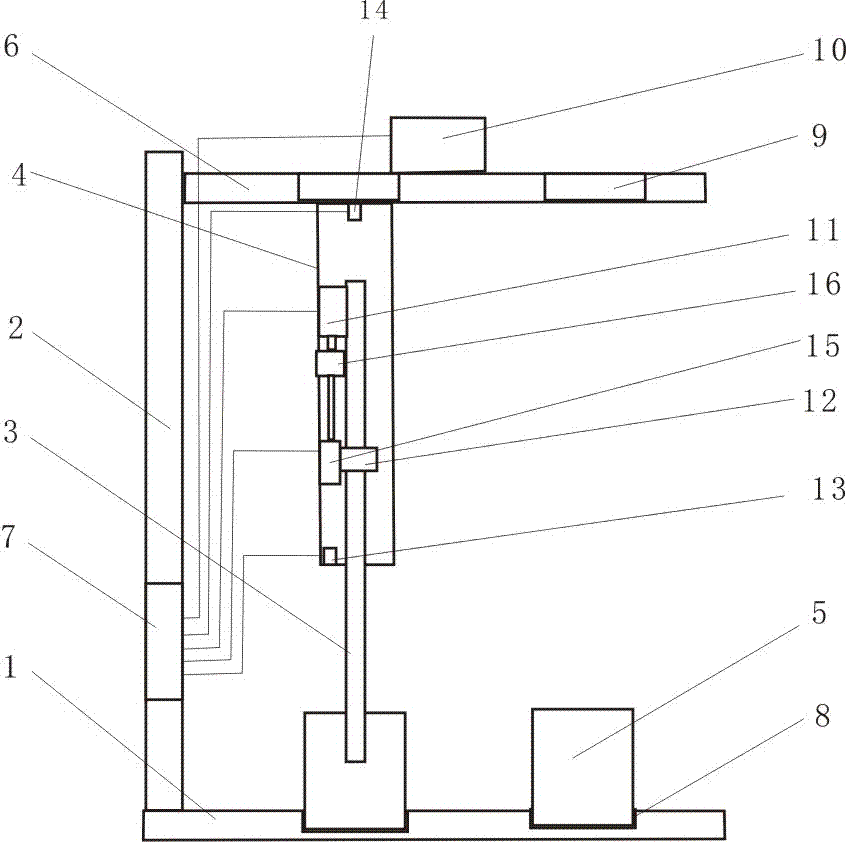

River channel two-dimensional flow velocity and flow measuring system and method

ActiveCN107632168AAdd measurement dataImprove accuracyVolume/mass flow measurementFluid speed measurementEngineeringStreamflow

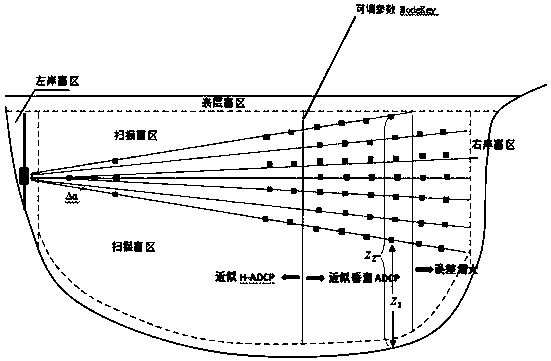

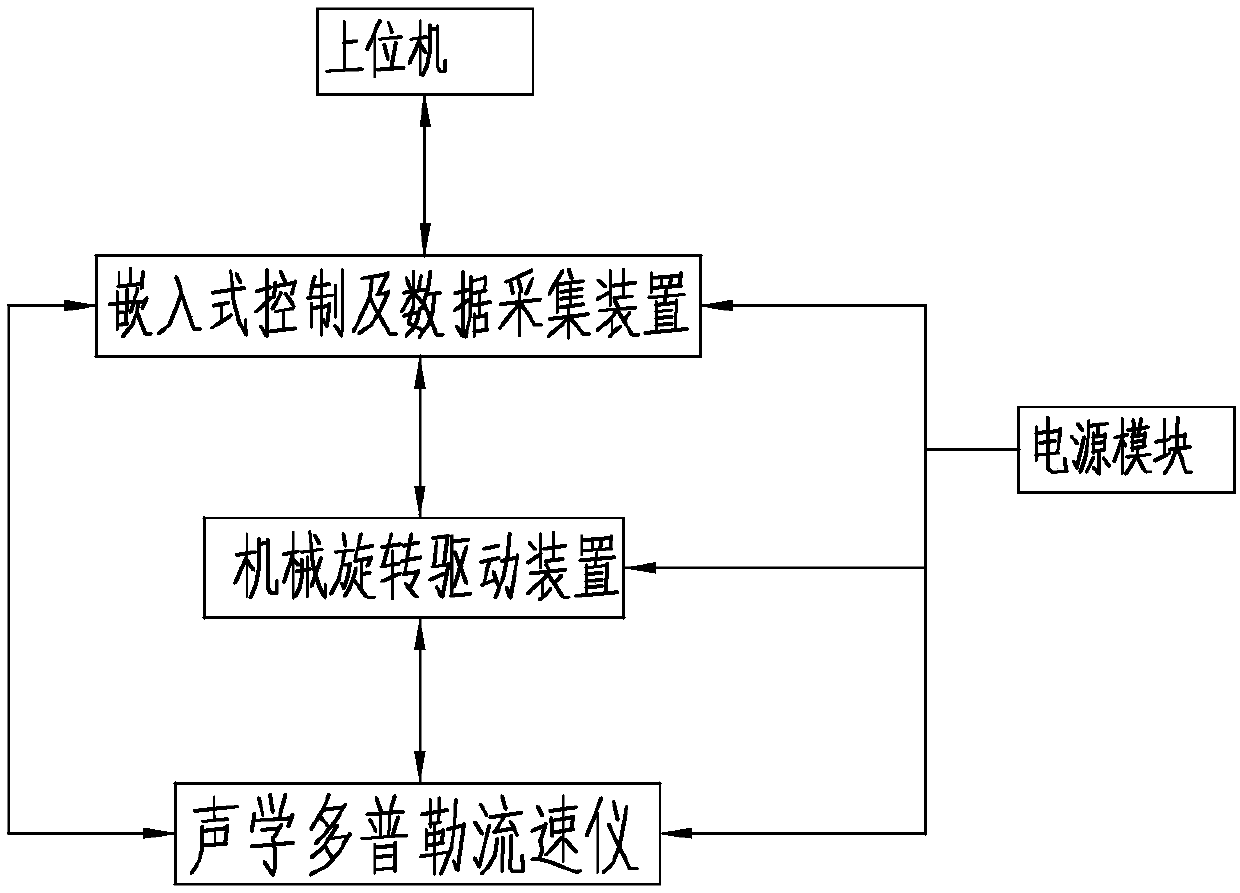

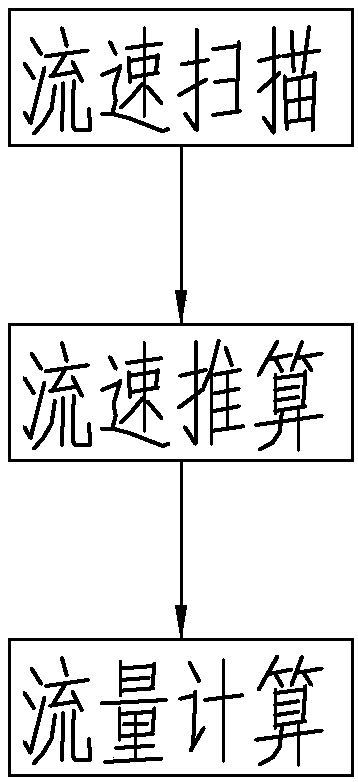

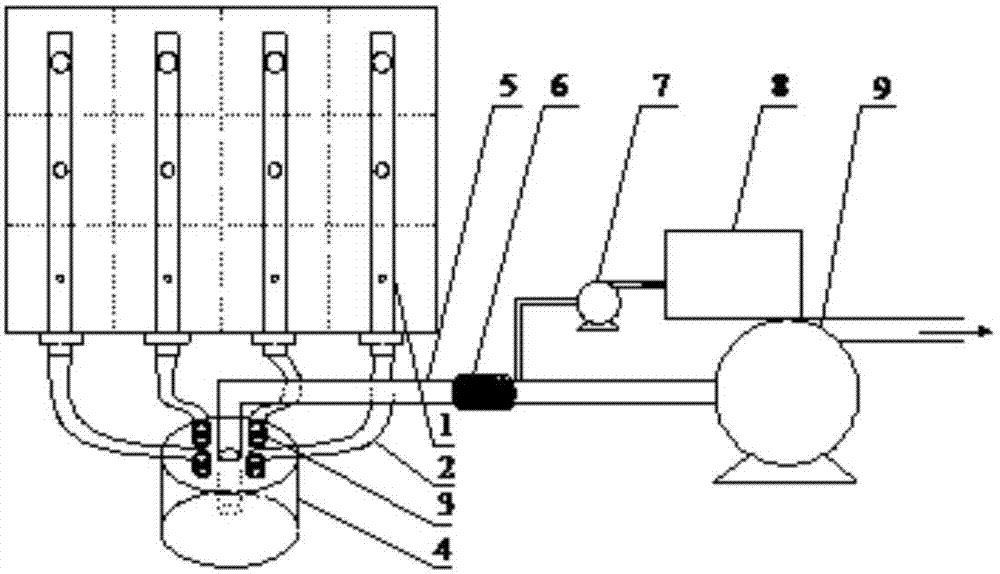

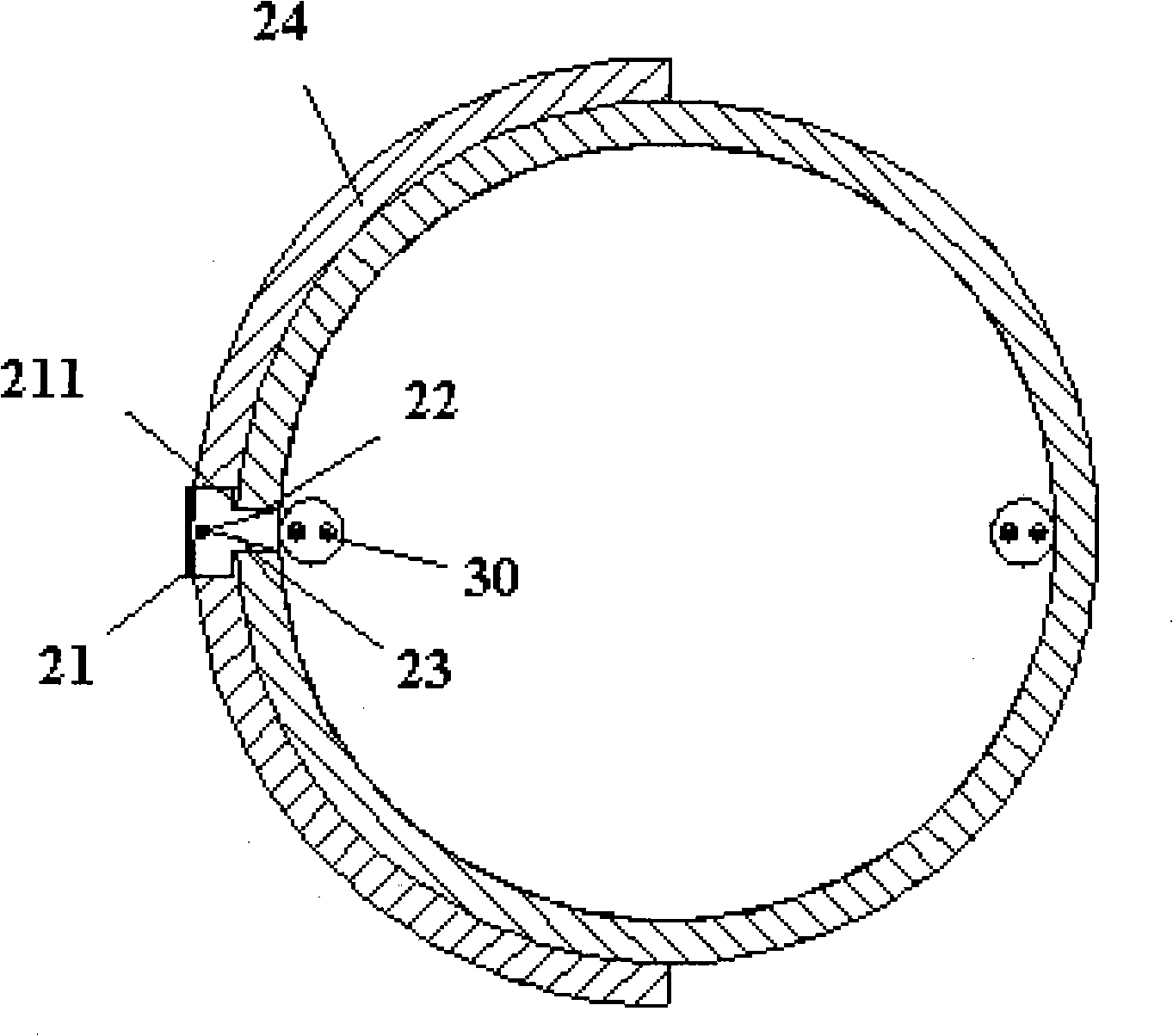

The invention discloses a river channel two-dimensional flow velocity and flow measuring system. The system comprises an acoustic Doppler current profiler, a mechanical rotation driving device, an embedded control and data acquisition device and a host computer, the host computer is connected with the embedded control and data acquisition device, the embedded control and data acquisition device isconnected with the mechanical rotation driving device, and the mechanical rotation driving device is connected with the acoustic Doppler current profiler. A river channel two-dimensional flow velocity and flow measuring method includes following steps: (a) flow velocity scanning; (b) flow velocity calculation; and (c) flow calculation. According to the system, the design of the combination of theunderwater mechanical rotation device and the acoustic Doppler current profiler is employed, conventional one-dimensional flow velocity profile data is extended to two-dimensional scanning flow velocity data, and the calculation fitting of the river channel flow is performed by employing a calculation model of fluid dynamics so that more accurate flow data is obtained, and the problem that the conventional measuring system cannot guarantee timeliness, accuracy and validity of measured flow data is solved.

Owner:HANGZHOU KAIHONG FLUID TECH CO LTD

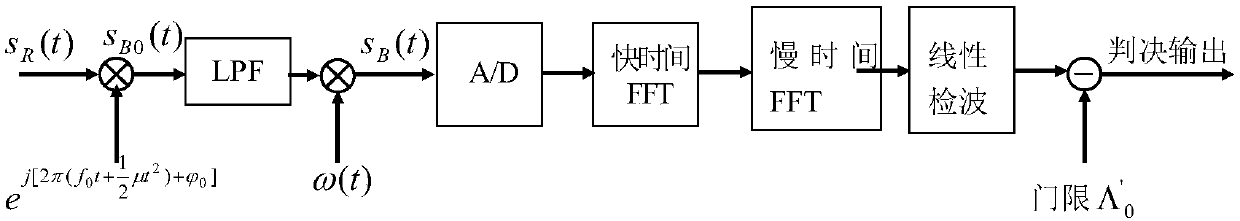

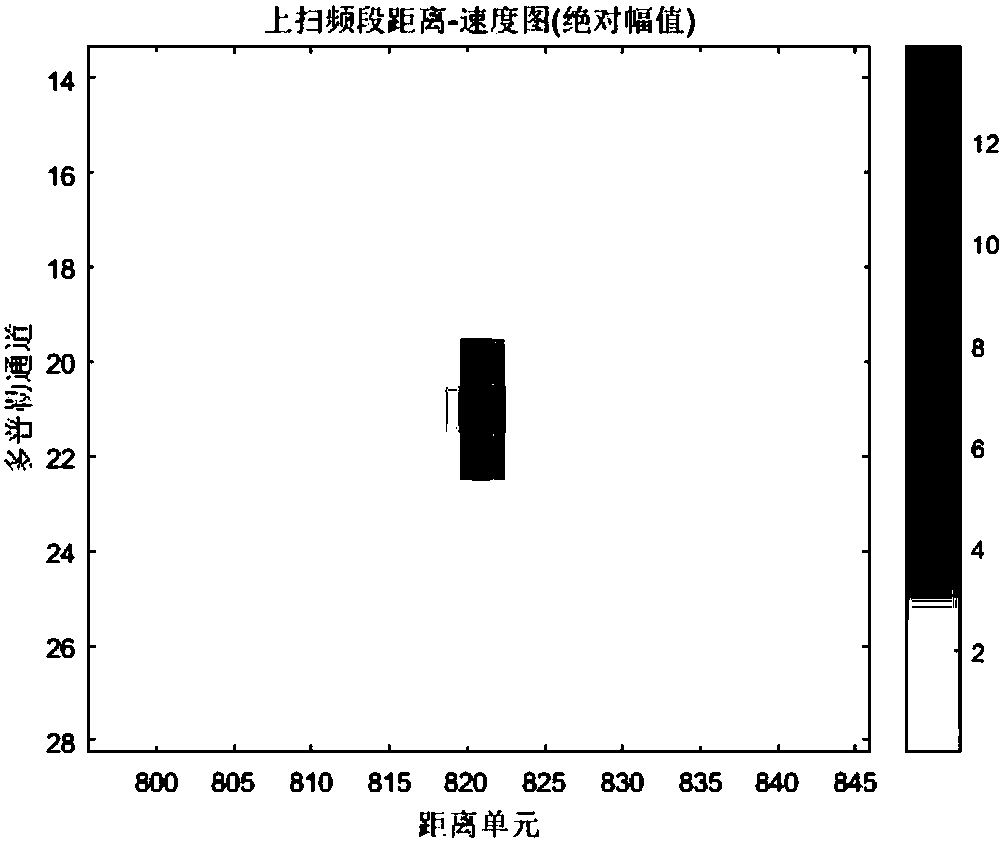

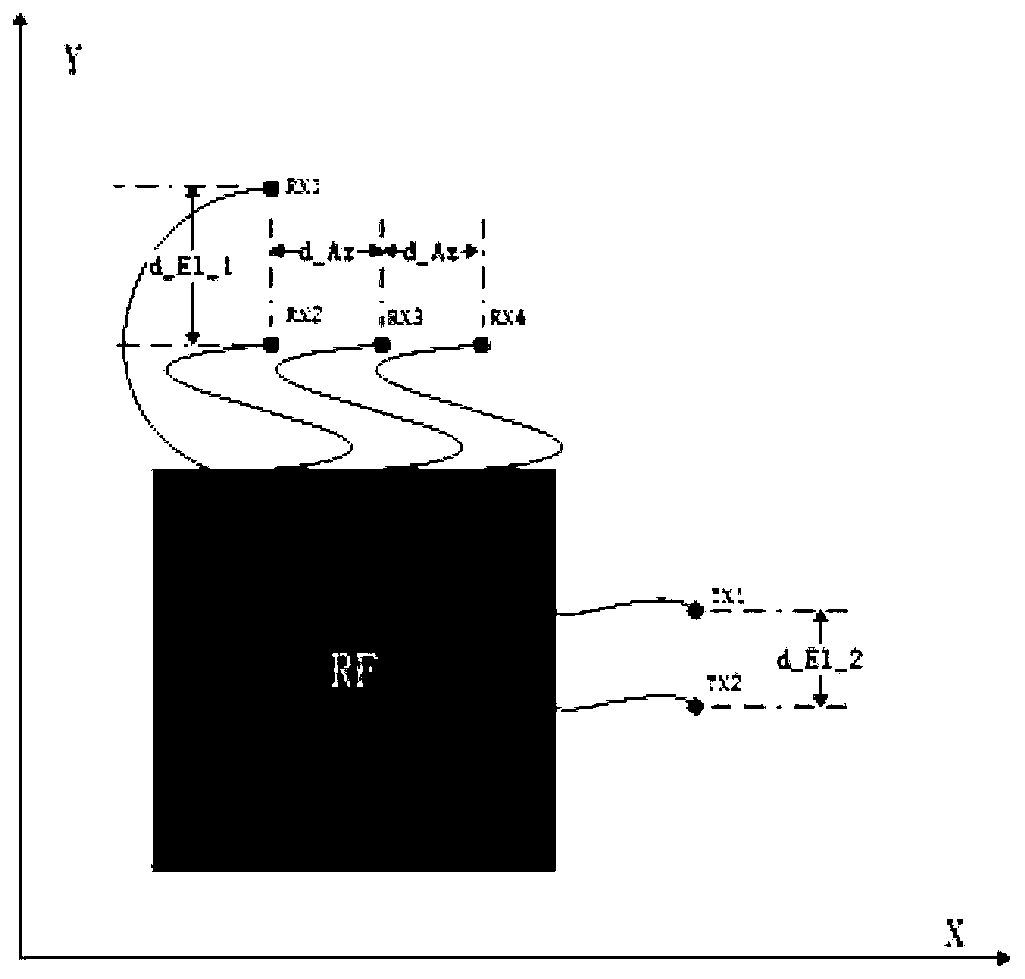

Double-threshold CFAR and trace point condensation method suitable for continuous wave radar

ActiveCN107861107AEnsure correct pairingReduce the number of statistical sortsRadio wave reradiation/reflectionGrazingDouble threshold

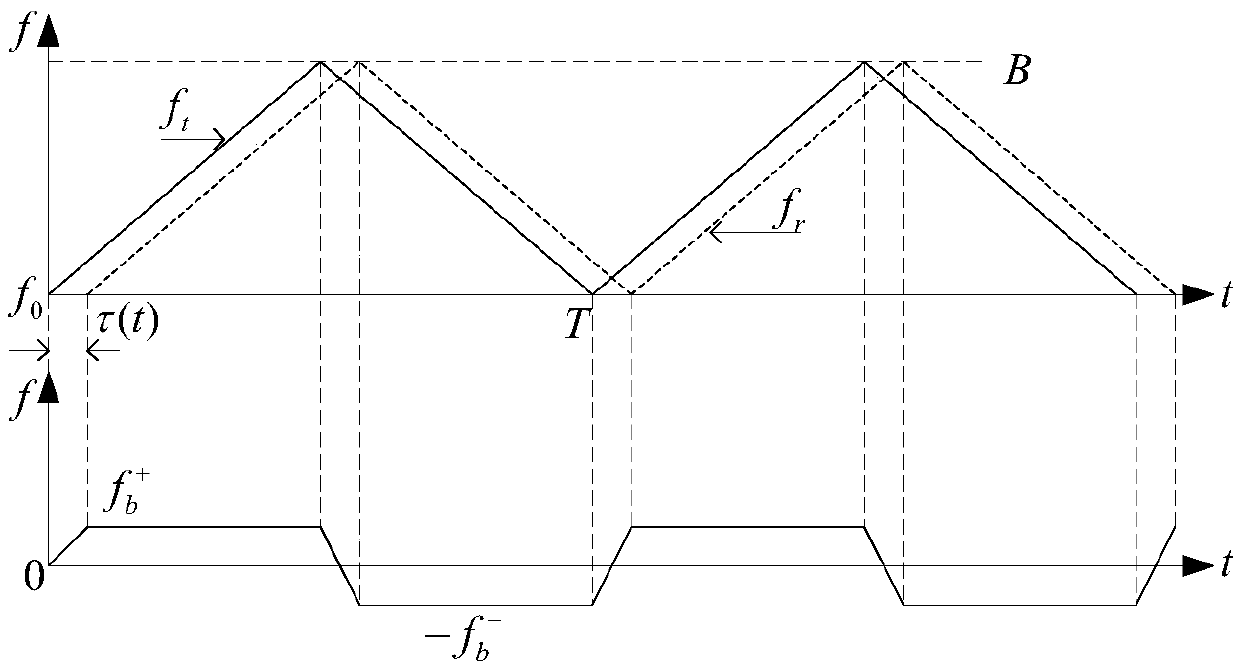

The invention discloses a double-threshold CRAR and trace point condensation method suitable for a continuous wave radar, belongs to a signal processing technology, and specifically relates to a continuous wave radar target constant false alarm detection and distance-speed two-dimensional trace point condensation method. Aiming at the characteristics of a relatively small wave beam grazing angle and relatively high resolution ratio of a continuous wave perimeter monitoring radar, a false alarm probability formula for ordered statistics of CRAR after Weibull clutter is subjected to linear detection and a corresponding clutter parameter estimation method are given; aiming at the problem that traditional OS-CRAR needs ranking operation and is relatively large in time consumption, a method fordouble-threshold CFAR is proposed, the number of times of statistical ranking is greatly reduced, and through addition of GO logic, running time is further reduced, and performance in clutter edges is improved; and joint realization of CRAR detection and trace point condensation is proposed, correct pairing of upper and lower frequency sweeping in subsequent processing of the continuous wave radar is guaranteed, and compared with traditional serial operation, computational complexity is greatly reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

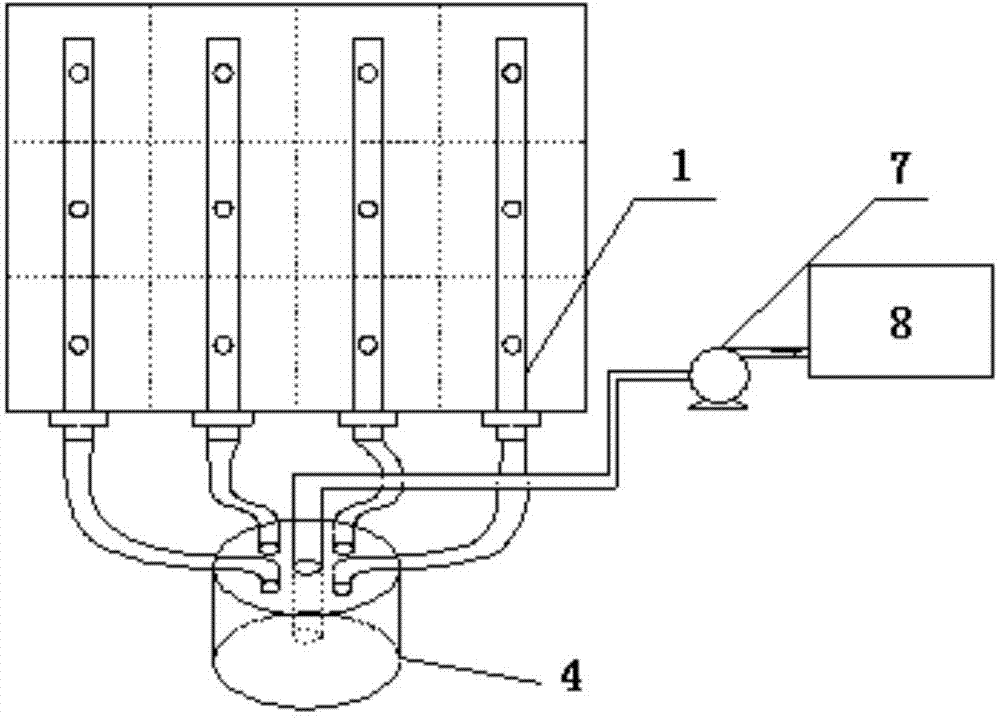

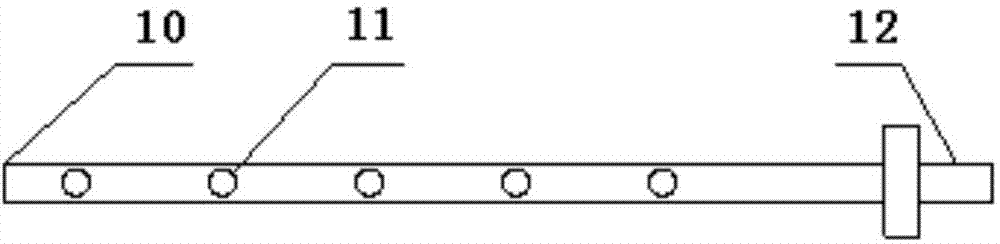

Dual-pump flow-equalizing flue sampling device and sampling method

ActiveCN103674631AImprove accuracyMeasurement equalizationWithdrawing sample devicesMixing tankStreamflow

The invention particularly discloses a dual-pump flow-equalizing flue sampling device and a sampling method. The dual-pump flow-equalizing flue sampling device comprises a flue mixing tank, wherein a flue sampling gun and a flue lead-out pipe are arranged on the flue mixing tank and communicated with the flue mixing tank; the outlet end of the flue lead-out pipe is connected with a pump I, and a branch connected with a flue analyzer is also led out from the flue lead-out pipe; one end, communicated with the flue mixing tank, of the flue sampling gun is provided with a throttling device, and a filter is also arranged on the flue lead-out pipe. With the adoption of the dual-pump flow-equalizing flue sampling device and the sampling method, the flue flow of each measurement hole in a single sampling gun is equalized, and the accuracy of flue oxygen measurement is improved.

Owner:STATE GRID CORP OF CHINA +1

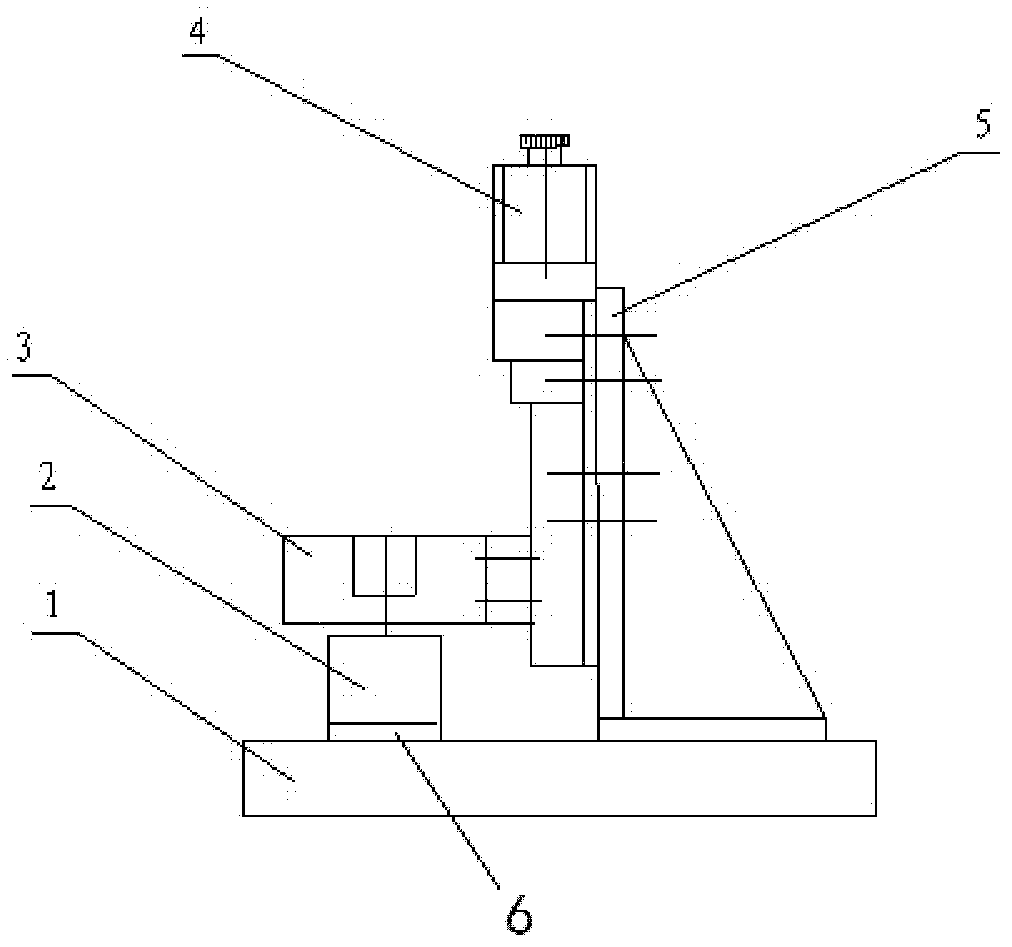

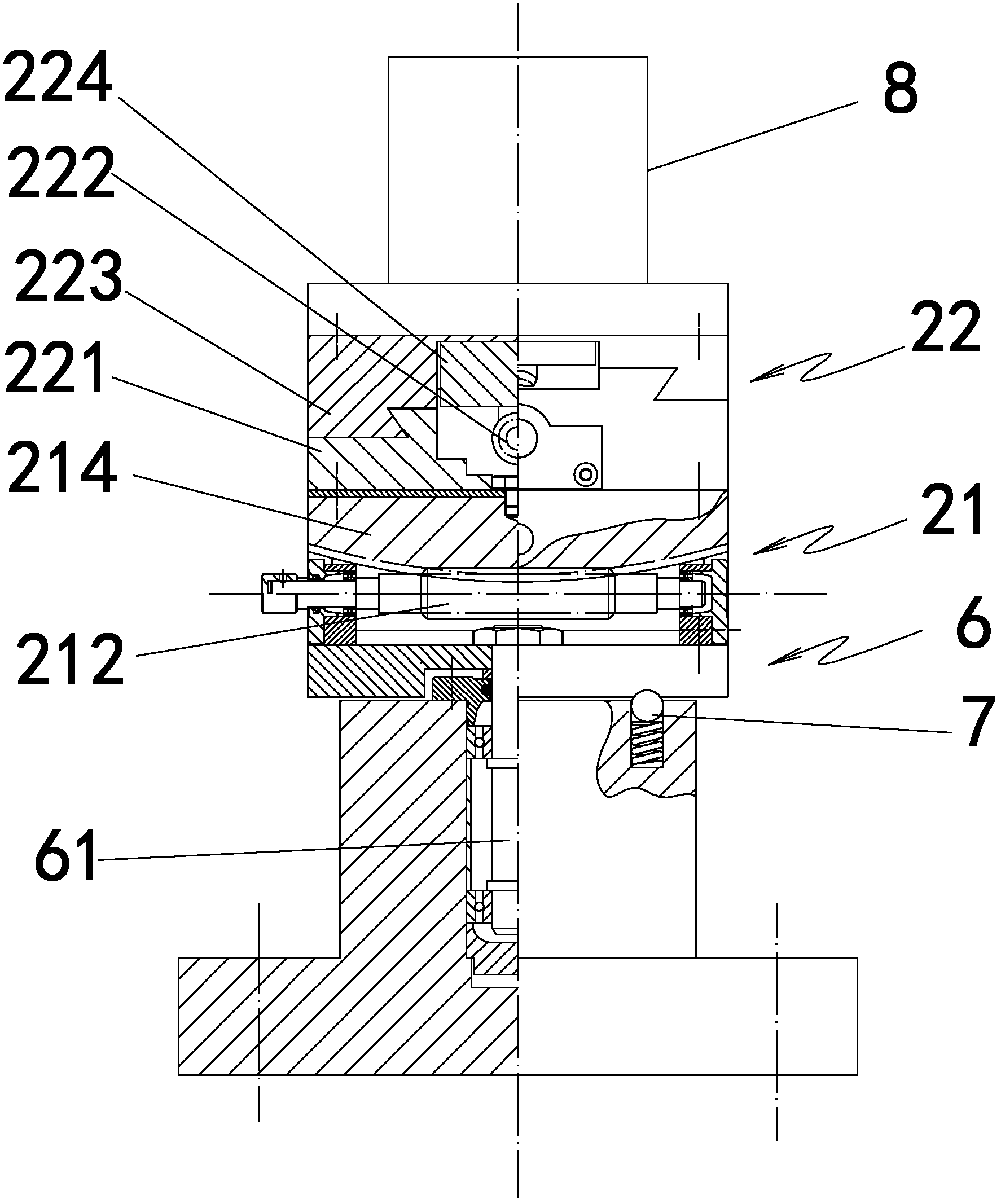

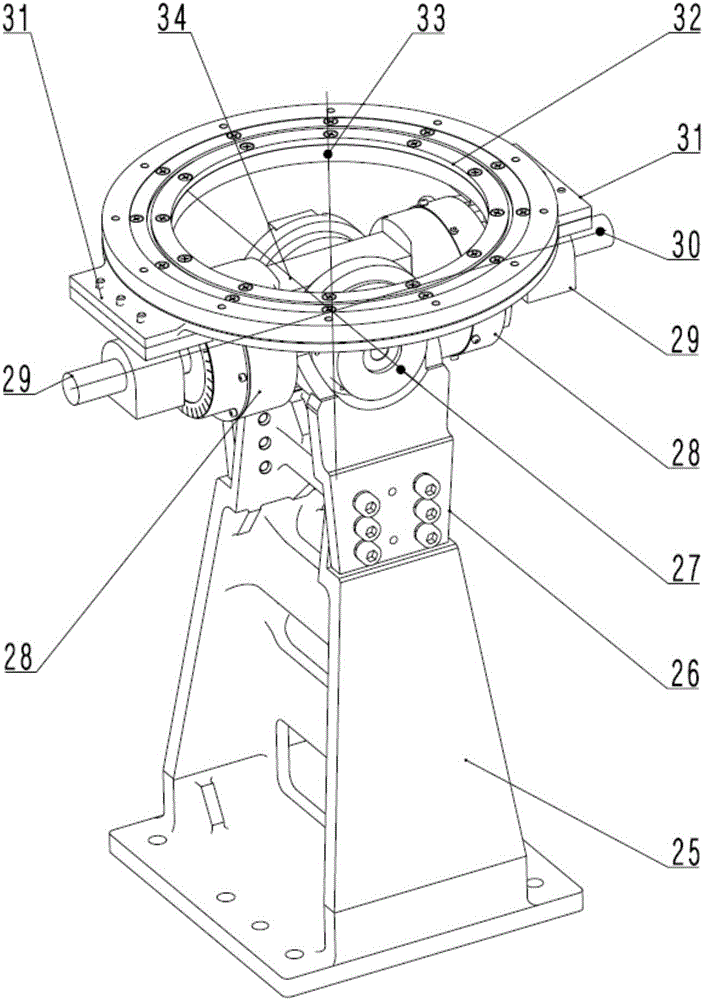

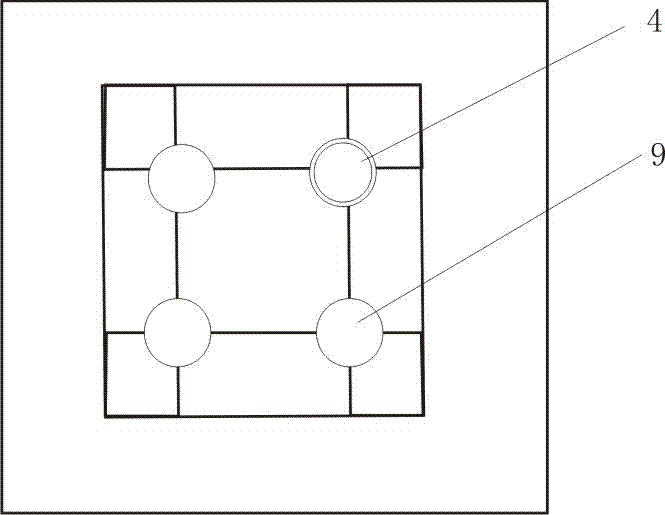

Measurement method and measurement instrument of revolution body part

InactiveCN102679904AAchieving Quadrature Coupling RegulationAccurately capture spatial poseUsing optical meansMarine engineeringOptical measurements

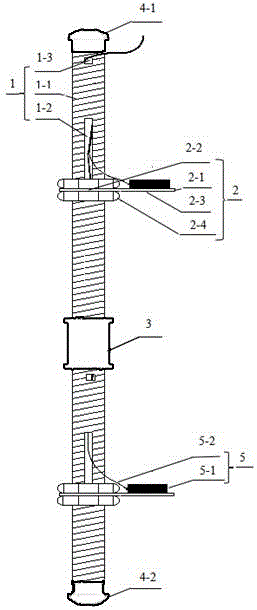

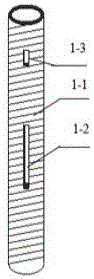

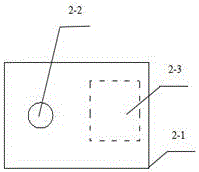

The invention discloses a measurement method and a measurement instrument of a revolution body part, wherein the measurement instrument comprises a base, a vertical post and an optical measurement head, wherein the vertical post is fixed on the base; the optical measurement head is movably assembled on the vertical post through a vertical orientation mode; a working platform which is used for placing and revolving a part is correspondingly arranged on the base below the optical measurement head; the working platform comprises a revolution platform and an angle displacement regulating platform which are arranged from bottom to top; the angle displacement regulating platform comprises a first angle displacement platform and a second angle displacement platform which respectively comprise a first deflection platform and a second deflection platform; and the deflection axes surrounded by the first deflection platform and the second deflection platform in rotation are vertical mutually and are both parallel to a plane of a light curtain of the optical measurement head. For the angle displacement regulating platform in the measurement instrument provided by the invention, by adopting the deflection surrounding the deflection axes parallel to the plane of the light curtain of a parallel light source through driving the two angle displacement platforms respectively by the revolution driving mechanism, the cross coupling regulation of the deflection angles of the working platform is realized, the space posture of a workpiece can be captured accurately, and the accurate positioning and measurement to the part are ensured.

Owner:HENAN UNIV OF SCI & TECH

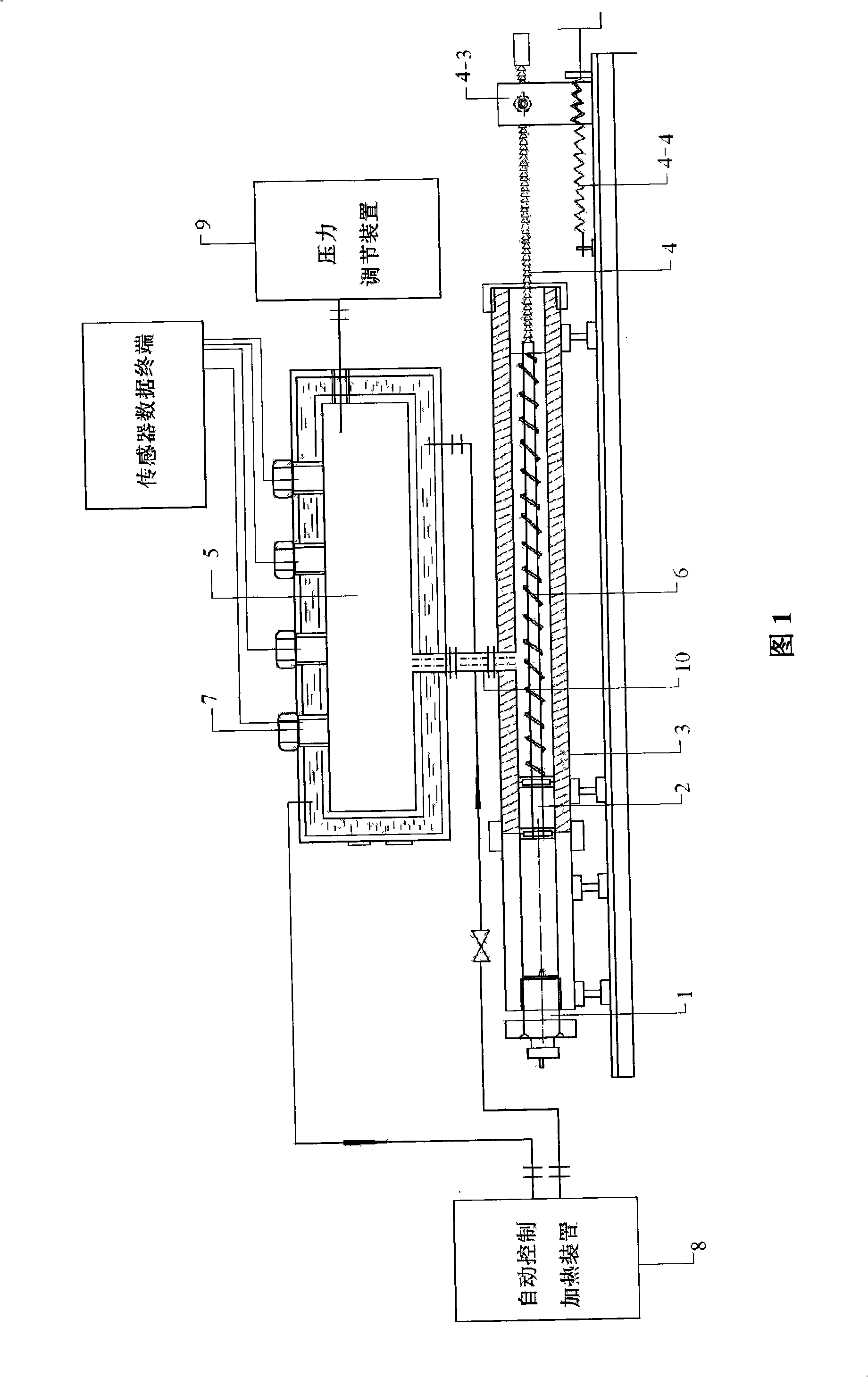

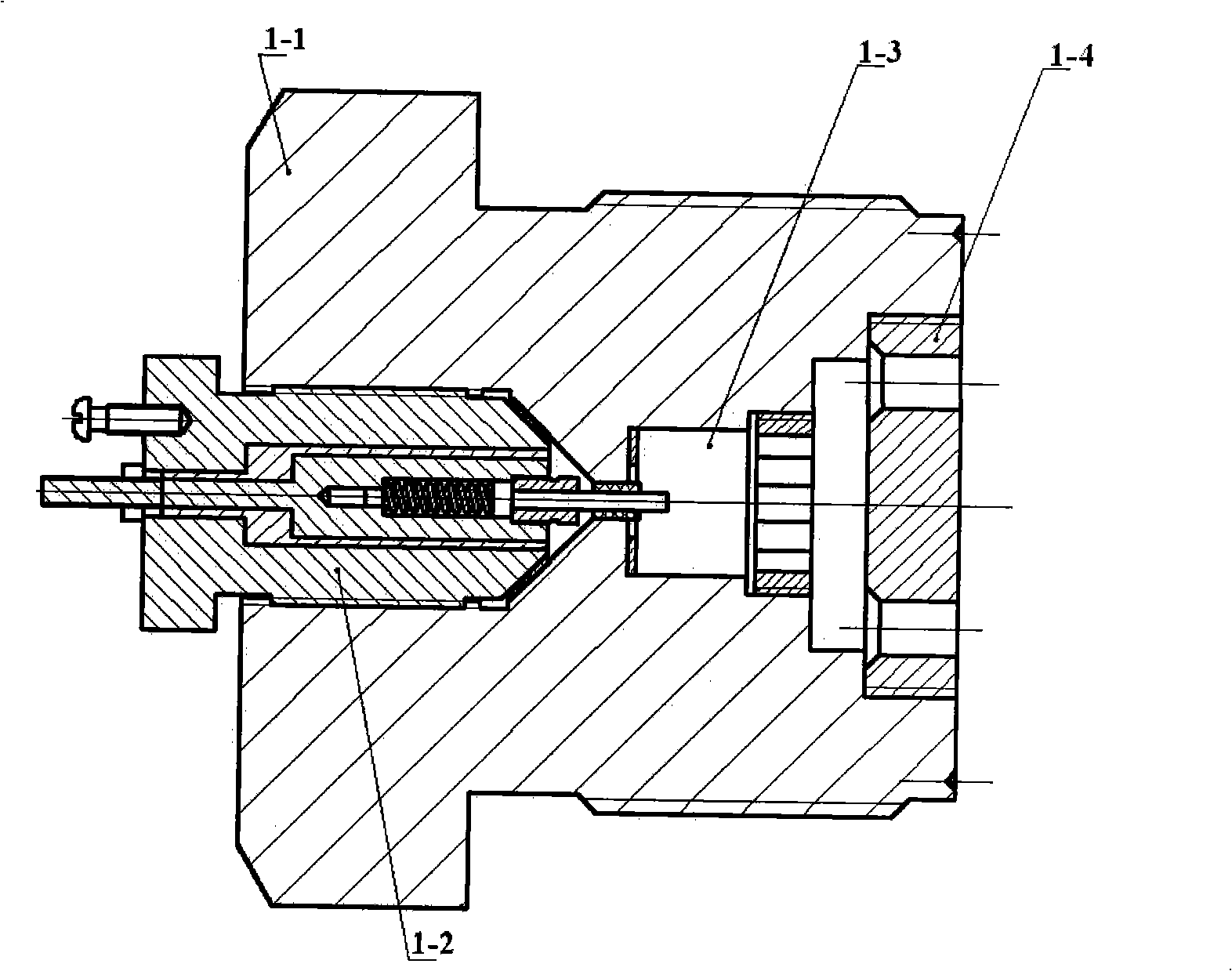

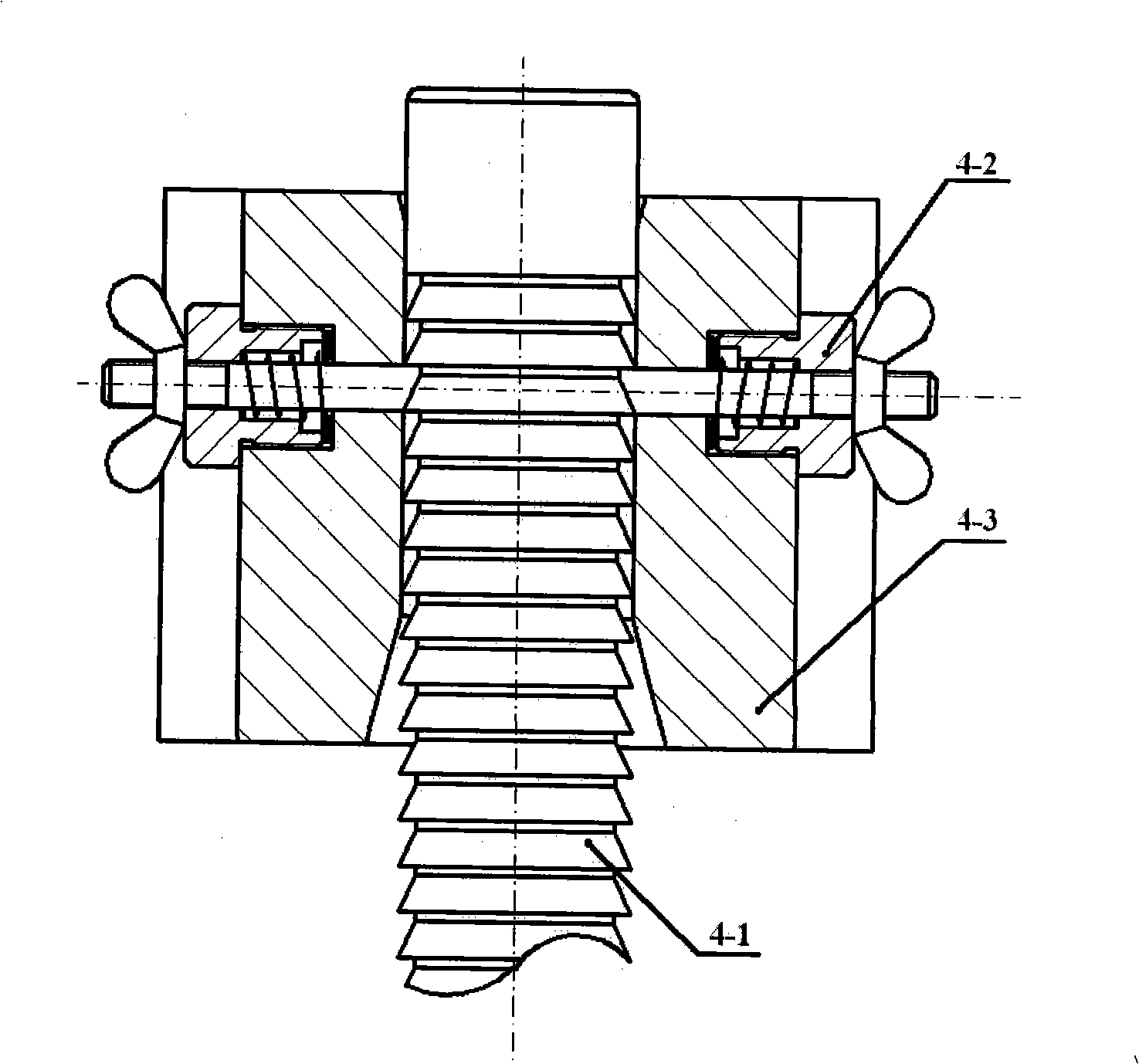

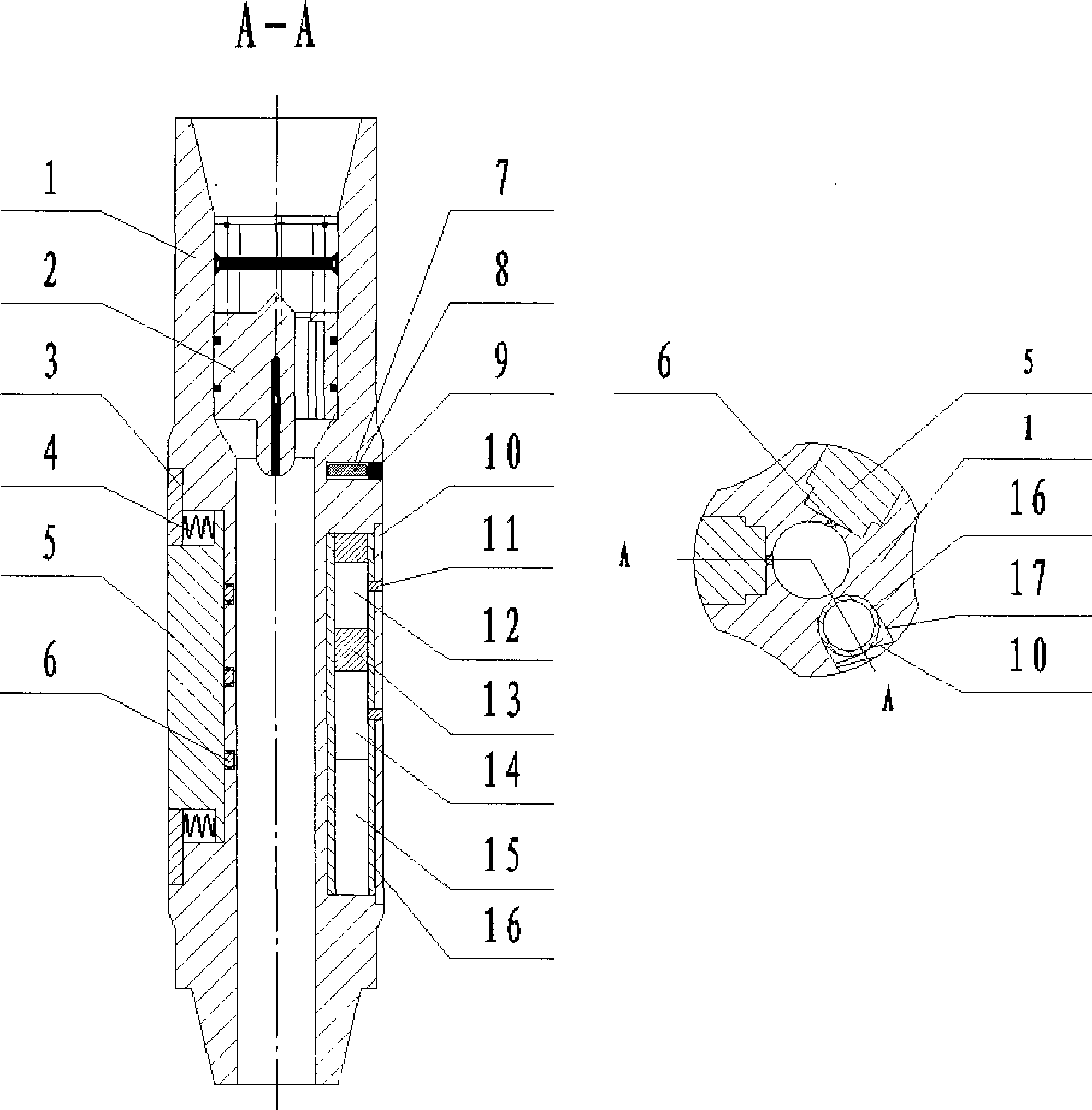

Propellant combustion tail gas quantitatively measuring device

ActiveCN101339182AGuaranteed measurementGuaranteed normal testFuel testingAutomatic controlMeasurement device

The invention discloses a quantitative measurement device of components of propellant powder burning tail gas, the device is characterized in that one end of a transmitting tube is connected with an electric ignition cable switch with an ignition groove; the big end of a piston is matched with the inner wall of the transmitting tube in a sliding way, while the small end of the piston is connected with a pawl arrester; an automatic control heating device and a pressure regulation device are adopted to ensure high constant temperature and stable air pressure of an air test chamber; an air outlet of the transmitting tube and an air inlet of the air test chamber are connected. When a measured propellant powder sample arranged on the ignition groove is burned, the burned gas of the propellant powder pushes the piston to move until the big end of the piston slides over the air outlet, the burned gas can enter the air test chamber; the above process truly simulates the whole process that a pill flies off a bouche from the ignition, when the piston moves to the position of maximum working stroke of the burned gas and then is locked. The burned gas entering the air test chamber is directly detected by a probe of a related sensor in real time; at last, each sensor gets the corresponding quantitative data of the components of the propellant powder burning tail gas. The quantitative measurement device has the advantages of accurate test result as well as good repeatability.

Owner:XIAN MODERN CHEM RES INST

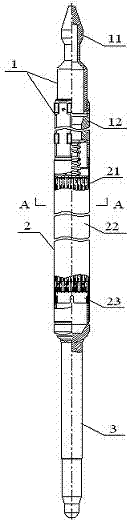

Wing rib telescopic while-drilling density logger

The invention relates to the rib-expansible density logging while drilling apparatus for use in the petroleum drilling industry. A density detector pup joint and a gamma radioactive source are sealed and arranged on a drill collar. An expandable rib is arranged on the surface of the drill collar at position of a groove, and the groove and the density detector pup joint are arranged at an interval of about 120 degrees in a circumferential direction. The expandable rib relies on a piston assembly to extend outward under the action of pressure drop (difference between inner pressure and outer pressure) generated due to instruments such as a drill bit (and a motor) arranged at the lower part of the apparatus and presses the detector pup joint against a well wall on a corresponding side by using counterforce of the well wall to realize density measurement by the well wall. And when a pump stops, the expandable rib retracts under the action of a return spring. The rib-expansible density logging while drilling apparatus is applicable to various wells, ensures measurement by the well wall, overcomes influence of slurry, mud cake or complex well structure on measurement precision, improves underground safety and is applicable to logging while drilling and geosteering drilling.

Owner:中石化石油工程技术服务有限公司 +3

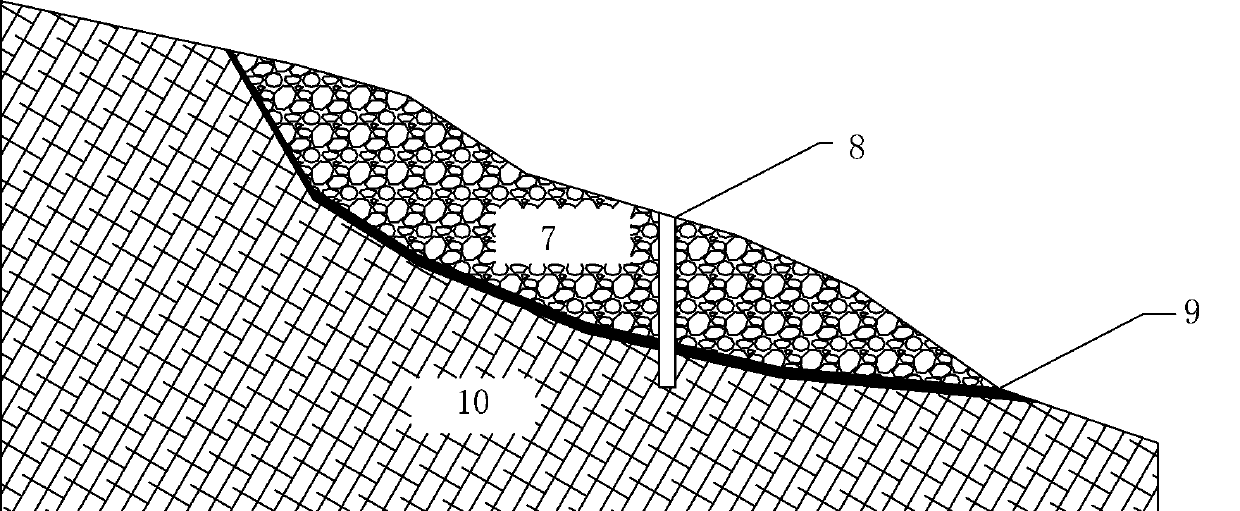

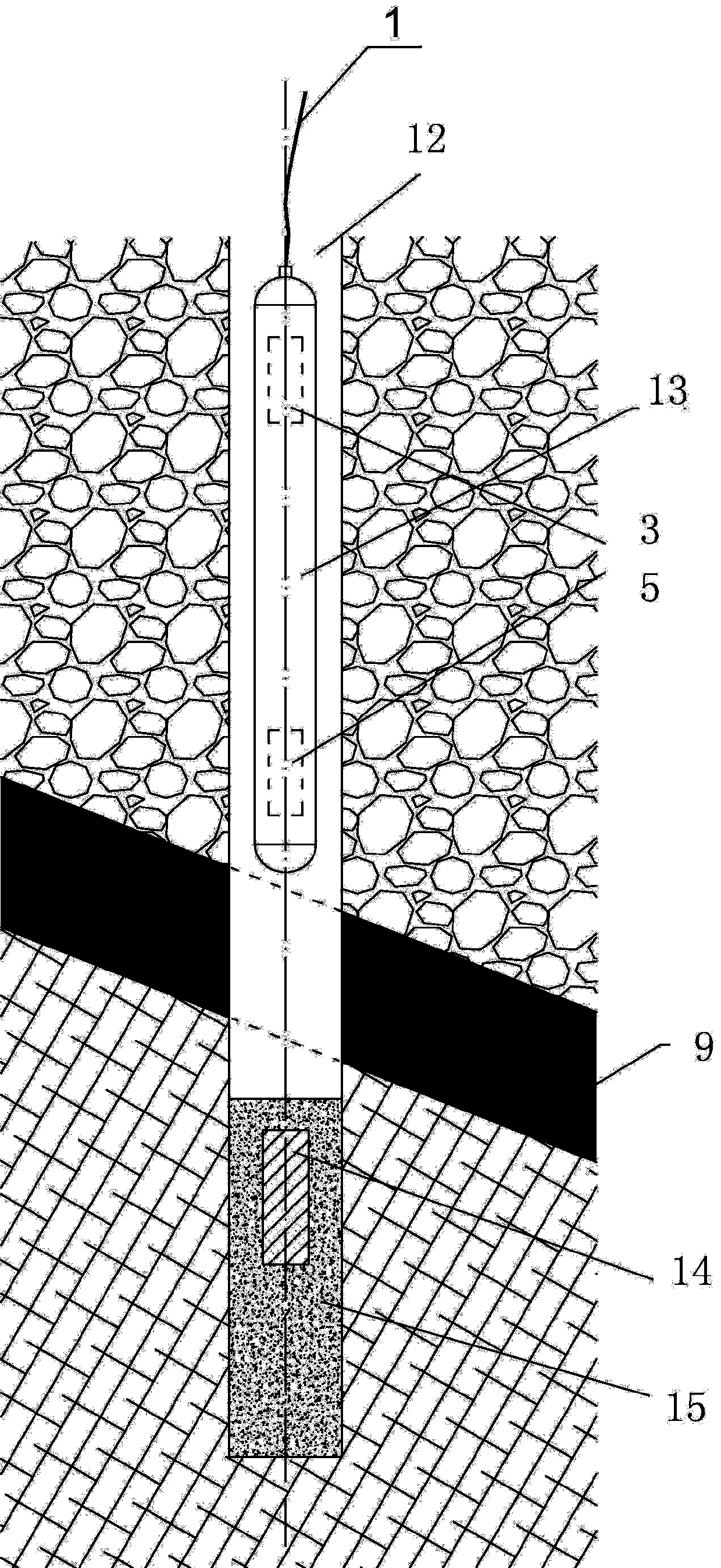

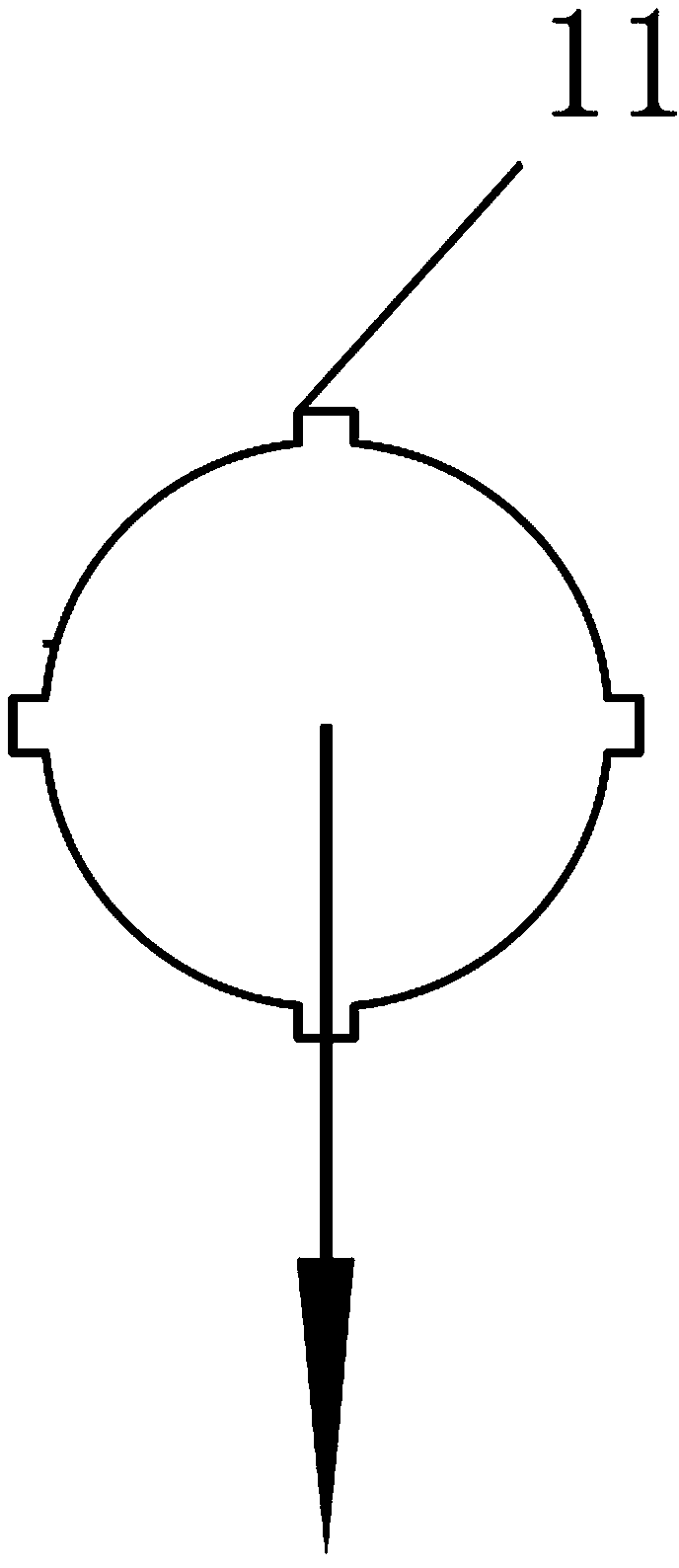

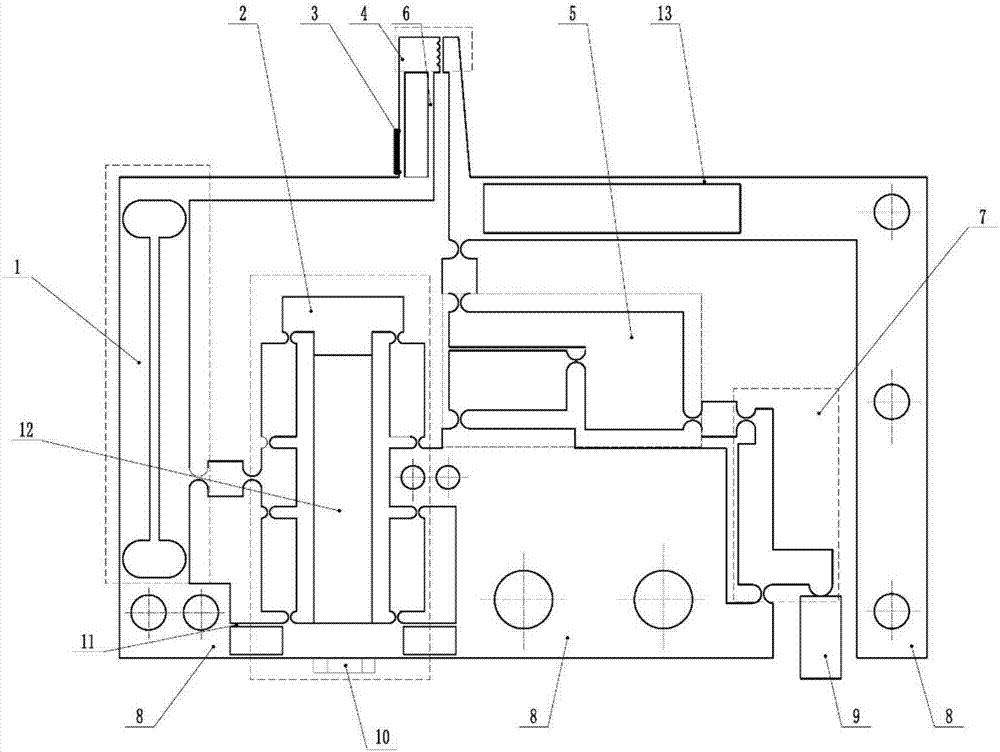

Magnetic measurement positioning device and method for monitoring slope deep displacement by utilizing magnetic measurement positioning device

InactiveCN105509628AGuaranteed measurementGuaranteed accuracyUsing electrical meansElectrical/magnetic solid deformation measurementMagnetic measurementsComputer module

The invention discloses a magnetic measurement positioning device, which comprises a packaging shell, wherein side guide wheels are respectively arranged on the upper portion and the lower portion of the packaging shell along the axial direction, a first three-dimensional fluxgate sensor is arranged on the upper portion of the packaging shell, a second three-dimensional fluxgate sensor is arranged on the lower portion of the packaging shell, the first and the second three-dimensional fluxgate sensors are respectively connected with signal collecting modules through wires, the signal collecting modules are connected with power supply and signal transmission cables which extend outside the packaging shell, and the distance between the first and the second three-dimensional fluxgate sensors is kept in constant. The invention provides the magnetic measurement positioning device and a method for monitoring slope deep displacement by utilizing the magnetic measurement positioning device can solve the problems that displacement values which meet monitoring accuracy requirement can not be calculated and more sensors are used, guarantee measurement accuracy of deep displacement, greatly reduce system cost, and is convenient in popularization and application.

Owner:CHINA THREE GORGES UNIV +1

Piezoelectric drive type two-degree-of-freedom high-precision microoperation clamp

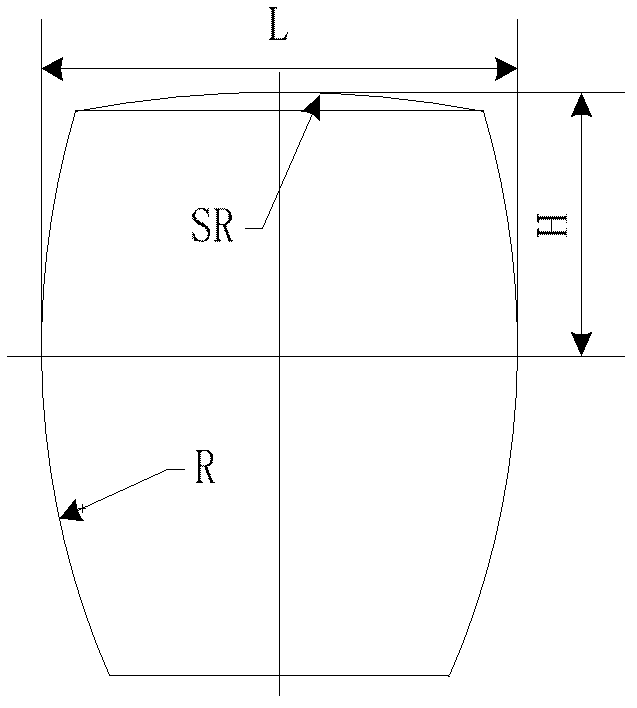

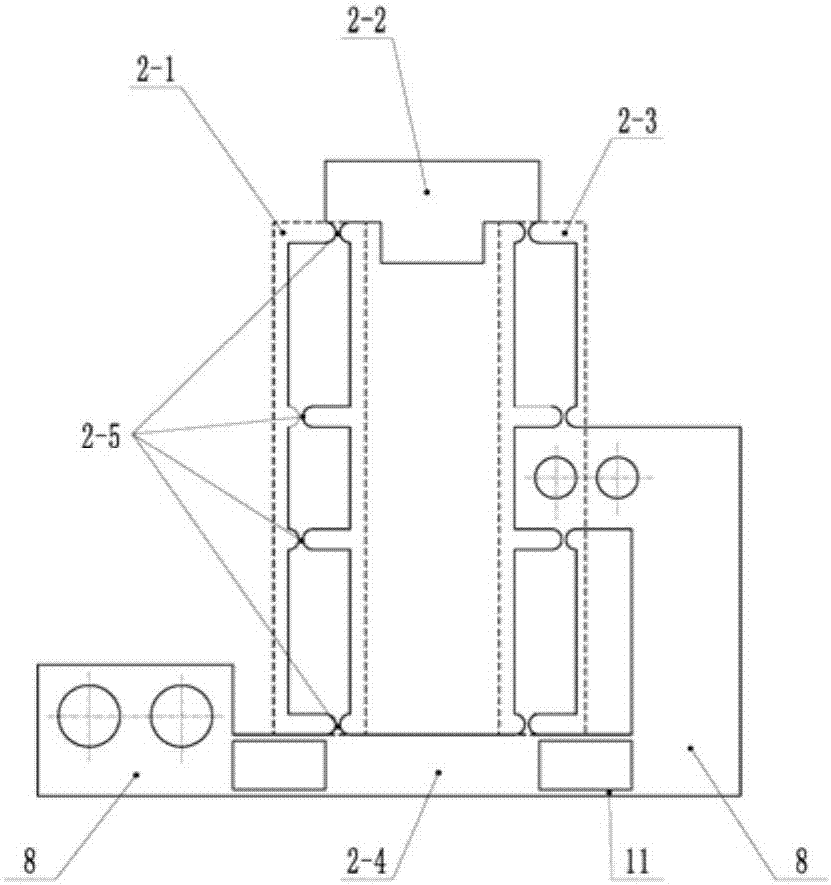

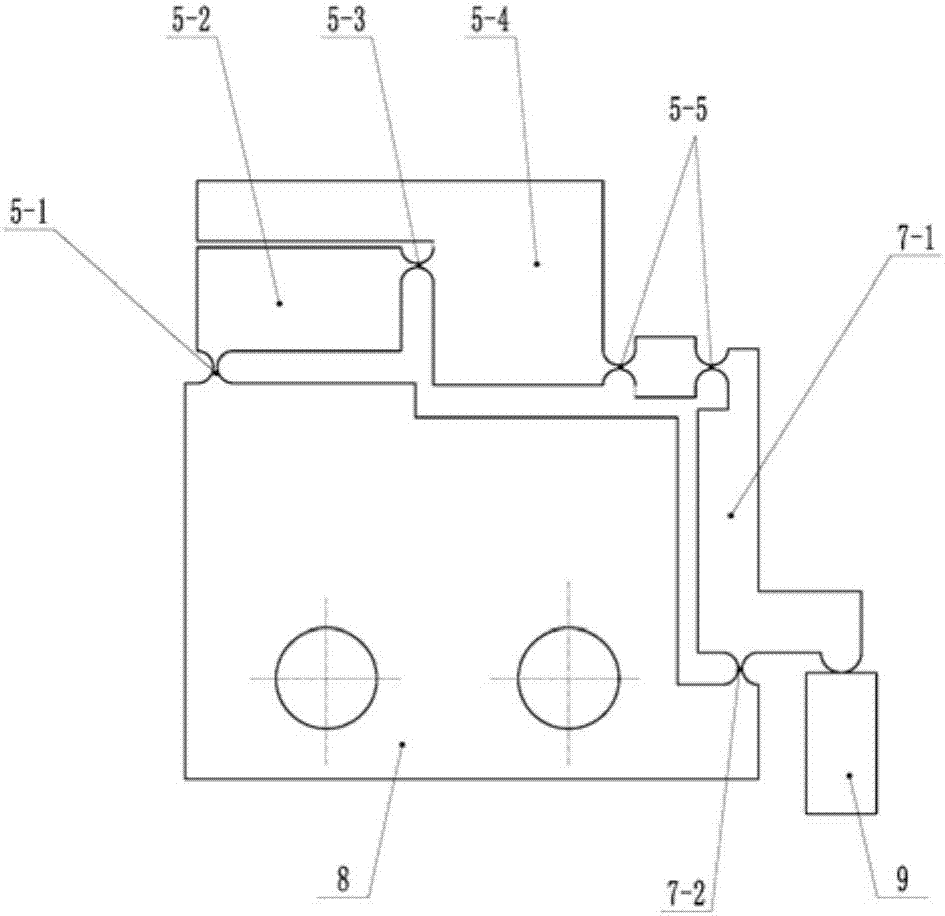

The invention discloses a piezoelectric drive type two-degree-of-freedom high-precision microoperation clamp. The piezoelectric drive type two-degree-of-freedom high-precision microoperation clamp comprises a bridge type displacement amplifying mechanism, a lever amplifying mechanism, an SR displacement amplifying mechanism and a base body. The bridge type displacement amplifying mechanism is provided with a movable upper cross beam and, a movable lower cross beam, a left four-connecting-rod mechanism and a right four-connecting-rod mechanism, wherein the upper cross beam and the lower cross beam are connected through the left four-connecting-rod mechanism and the right four-connecting-rod mechanism, the left four-connecting-rod mechanism and the right four-connecting-rod mechanism are each formed through connection by a flexible hinge I, and two flexible parallel double-plate mechanisms I which are connected with the base body are arranged at the two ends of the lower cross beam correspondingly; and a piezoelectric ceramic actuator I is arranged between the upper cross beam and the lower cross beam. A parallelogram mechanism formed through connection by a flexible hinge II is arranged on the left side of the bridge type displacement amplifying mechanism. A connecting beam perpendicular to the parallelogram mechanism is formed at the output end of the parallelogram mechanism, and a jaw is arranged on the connecting beam. The piezoelectric drive type two-degree-of-freedom high-precision microoperation clamp has the characteristics of being high in precision, high in response speed, low in manufacturing cost and the like.

Owner:TIANJIN UNIV

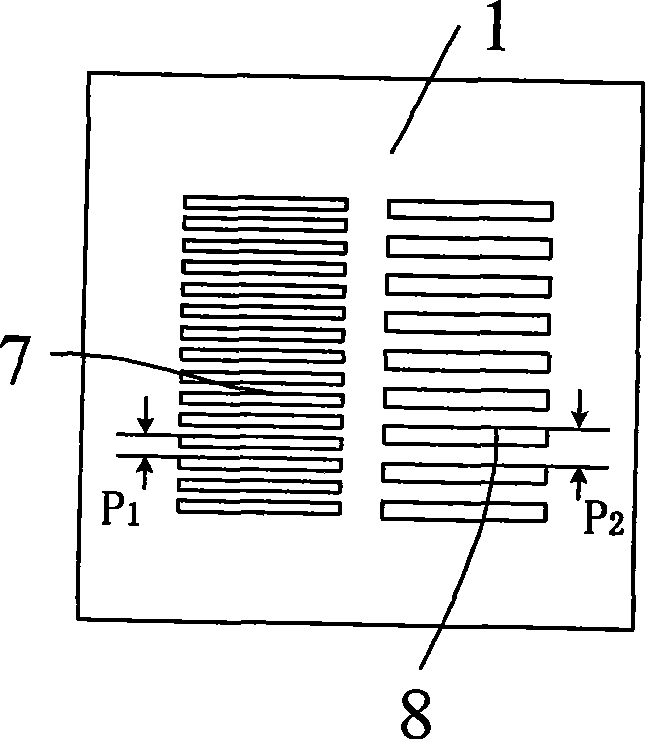

Small gapping place relatively rotating measuring and rotating positioning system and method

InactiveCN101419064AStrong process adaptabilityEasy to debugUsing optical meansPhotomechanical exposure apparatusPhysicsVertical orientation

The invention discloses a system and a method for the high-precision measurement direction sensing and rotary positioning of relative micro-rotation between two planes. Two gratings are arranged on the two planes to form two groups of measurement grating pairs. When the amount of relative rotation between the two planes is zero, grid lines of all gratings are in the same direction. Two groups of measurement grating pairs are opposite in the size relation of grating size but identical in period ratio. The number of fringes acquired by a measurement system is not less than 40. The method for measurement direction sensing and rotary positioning comprises the following steps of adopting the dimensions of fringe inclination angles obtained in the horizontal-vertical direction and two diagonal directions to obtain the directions of the fringe inclination angles. When two groups of interference fringes are identical in direction, rotary zero-point positioning is realized between the two planes, and when two groups of interference fringes are different in direction, relative rotation amount exists between the two planes.

Owner:XI AN JIAOTONG UNIV

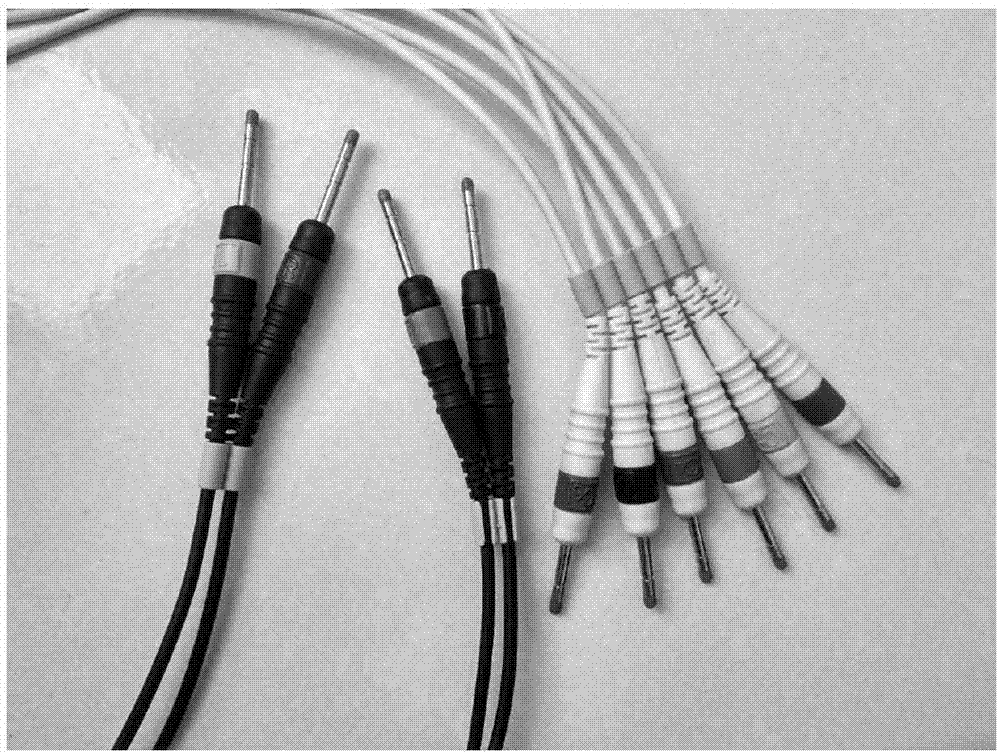

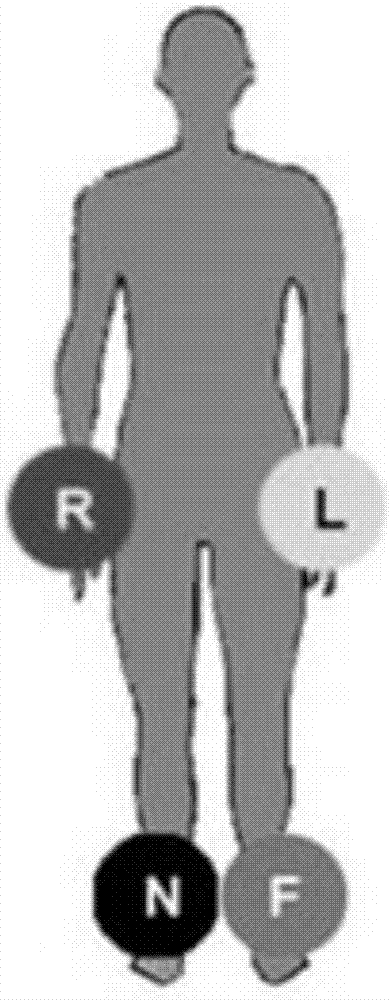

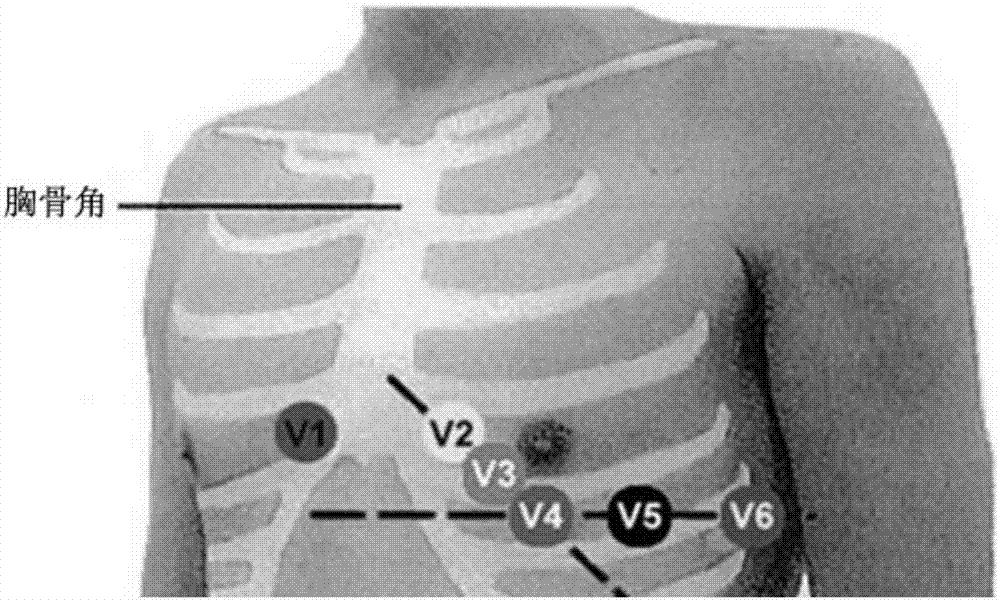

Automatic standardized electrocardiogram collecting system and method

ActiveCN107545149AAvoid mistakesPrevent deviationDiagnostic recording/measuringSensorsHuman bodyBroadcasting

The invention relates to an automatic standardized electrocardiogram collecting system and method. The system comprises electrodes, a mechanical arm, an examination table, a human body silhouette recognition subsystem, a pressure distribution testing subsystem, a skin treatment testing subsystem, an electronic voice subsystem and a main control computer. The human body silhouette recognition subsystem is used for obtaining human body silhouette information of an examinee and computing position information of four limbs and a chest wall; the pressure distribution testing subsystem is used for collecting pressure distribution information of the weight of the examinee and conducting pressure measurement on the chest wall to compute position information of an anatomic position of the chest wall; the skin treatment testing subsystem is used for executing skin treatment and measuring whether or not the resistance value reaches the standards under constant pressure; the electronic voice subsystem is used for broadcasting explanation or operation instructions. By means of the automatic standardized electrocardiogram collecting system and method, electrocardiogram collecting is more objective and scientific, so that the electrocardiogram recording quality can be improved, and direct contact between a doctor and a patient during electrocardiogram examination is avoided, and accordingly automation and standardization of electrocardiogram collecting are achieved.

Owner:青岛凯尔智能医疗设备有限公司

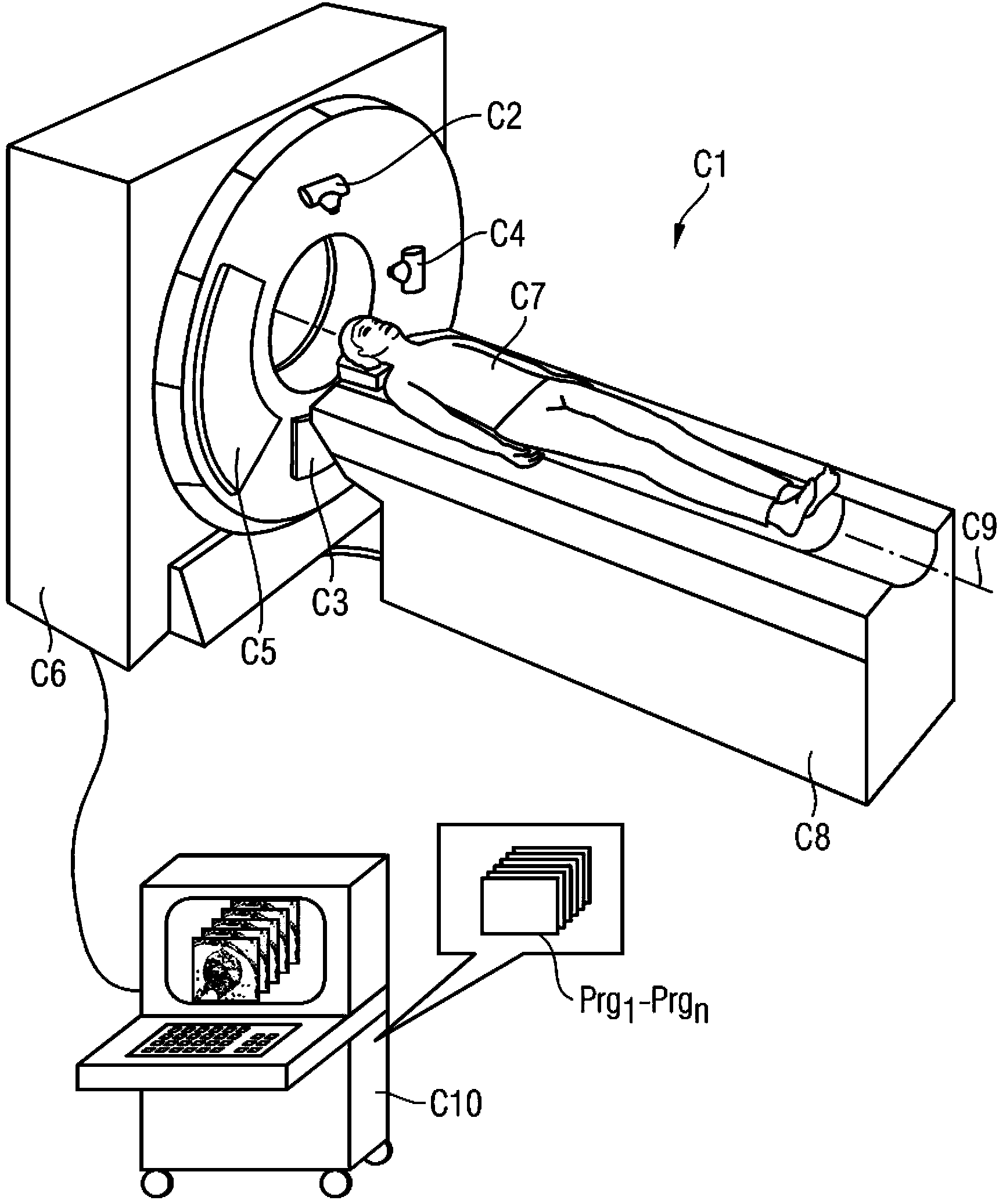

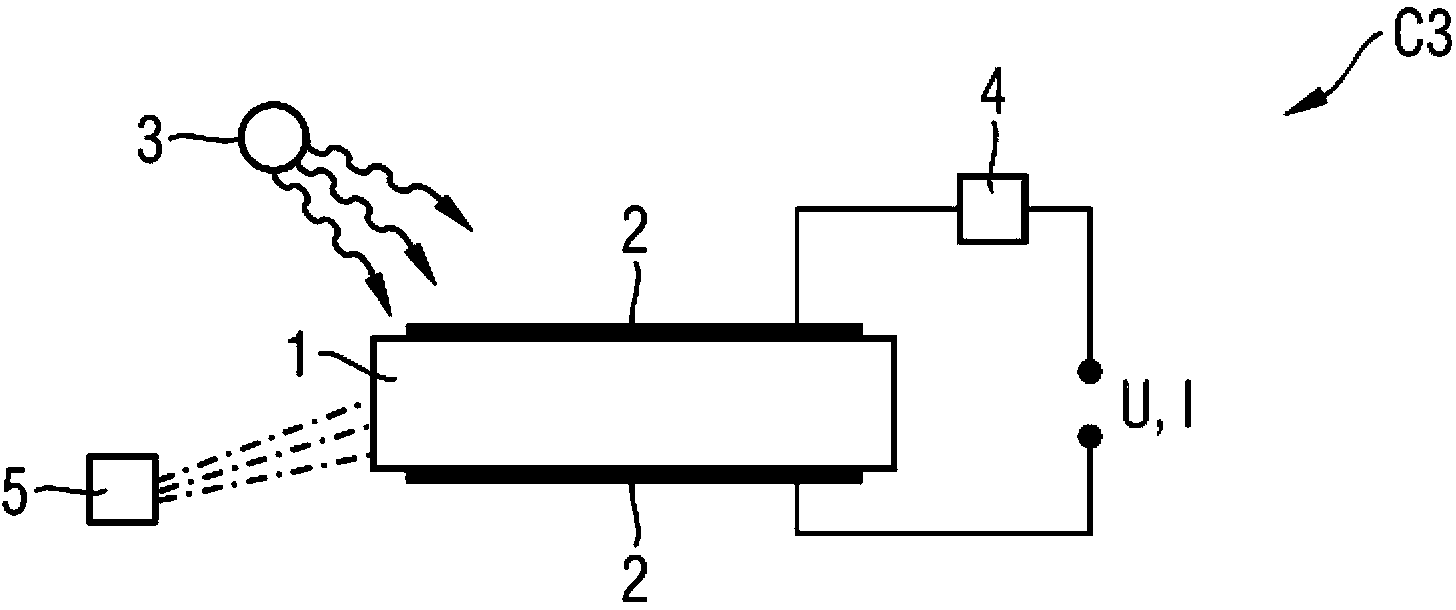

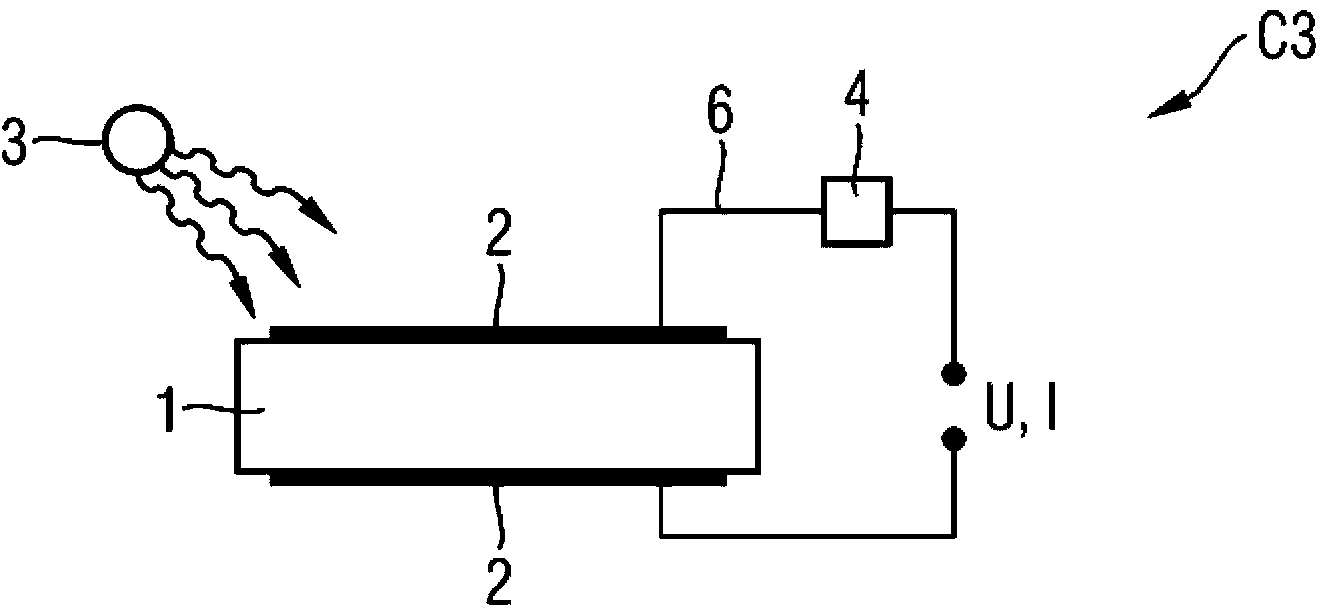

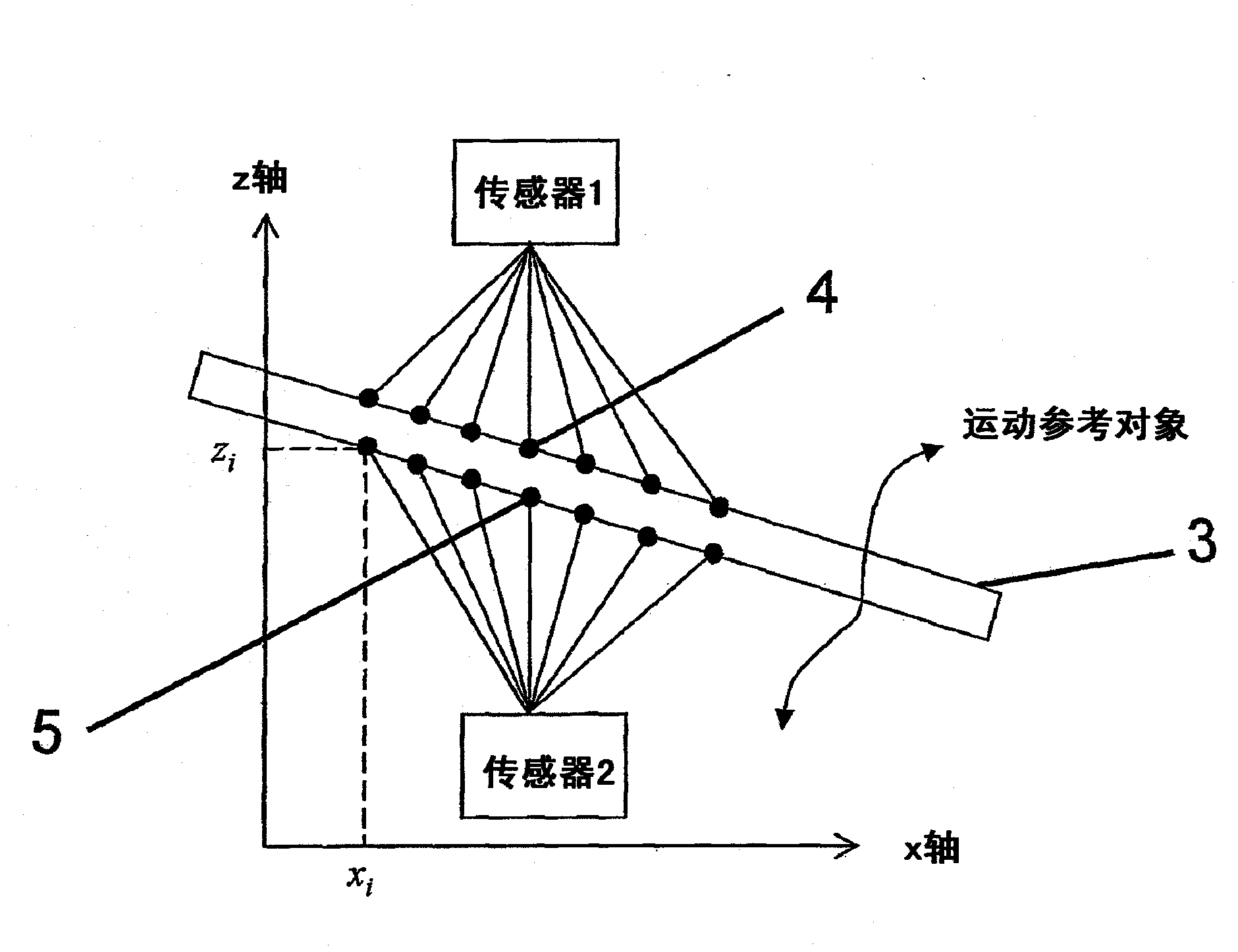

Method for temperature stabilization, X-ray detector and CT system

ActiveCN103576179ASimple structureSimplify your cooling solutionX-ray apparatusRadiation intensity measurementEnergy regulationX-ray

A method is disclosed for the temperature stabilization of a direct-converting X-ray detector, including a detector surface having a semiconductor and being divided into a plurality of partial detector surfaces. During the irradiation of the detector surface, heat is generated in the semiconductor by electric power. Electric power generated in the semiconductor is kept constant for each partial detector surface at least during a heterogeneous and / or temporally variable irradiation of the detector surface by feeding-in power-adjusted additional radiation for each partial detector surface. A direct-converting X-ray detector is disclosed for the detection of X-rays. At least one control loop with at least one reference variable is embodied for the energy regulation of the additional radiation, which keeps the temperature in the semiconductor constant for each partial detector surface by keeping the electric power in the semiconductor constant by changing the energy of the additional radiation. A CT system is disclosed.

Owner:SIEMENS HEALTHCARE GMBH

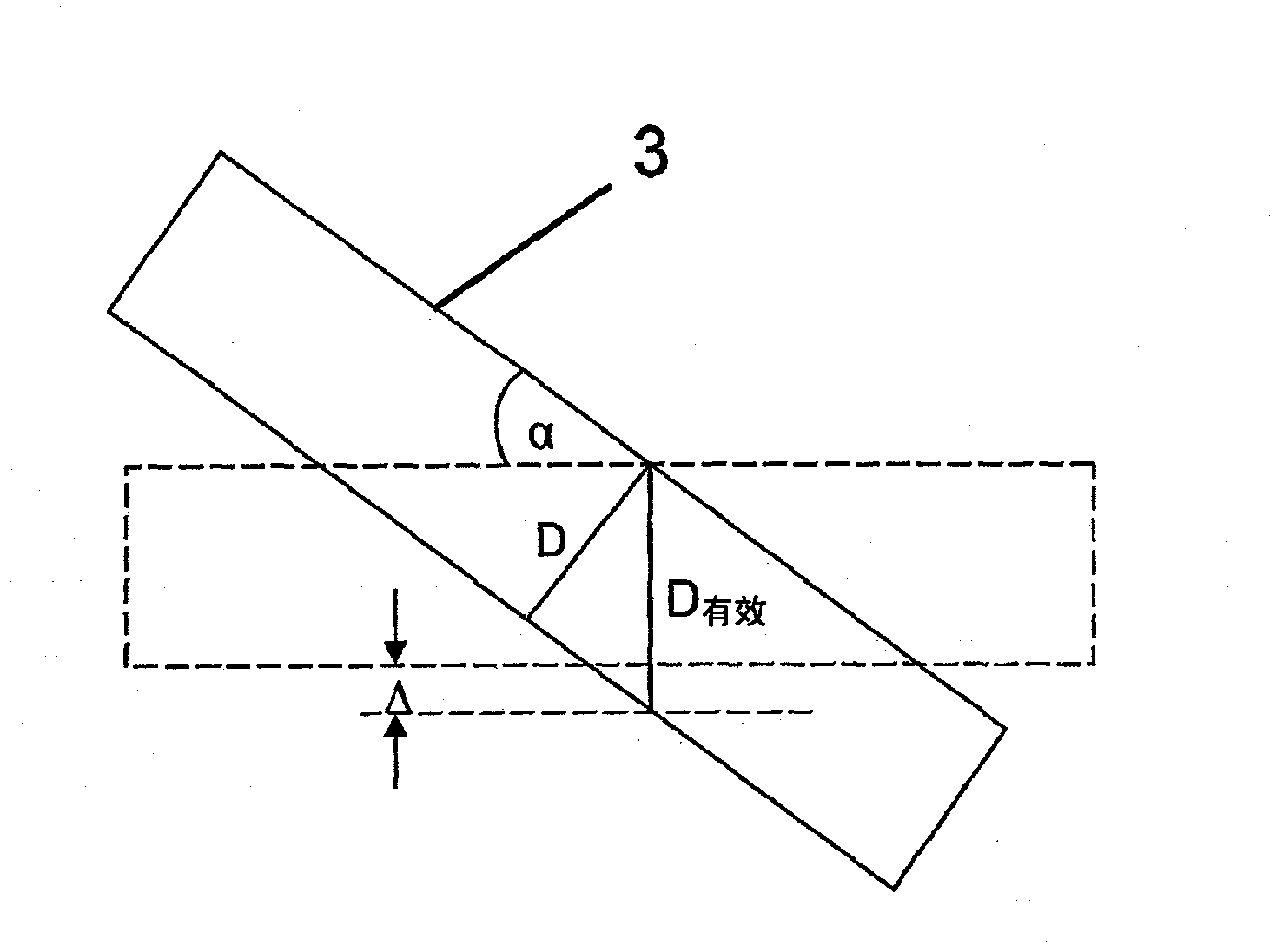

Method for calibrating a thickness gauge

InactiveCN102066872AGuaranteed measurementCaliper-like sensorsMeasurement devicesMeasurement deviceClassical mechanics

Owner:MICRO EPSILON MESSTECHNIK GMBH & CO KG

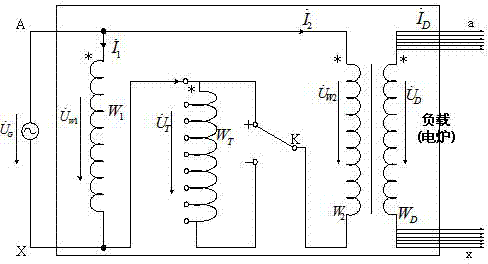

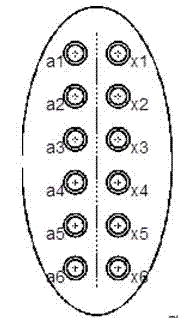

Method for collecting current on low-voltage side of electric furnace transformer and relay protection device

InactiveCN102435813AEasy to installGuaranteed measurementCurrent/voltage measurementEmergency protective circuit arrangementsShielded cableElectric arc furnace

The invention relates to a method for collecting current on the low-voltage side of an electric furnace transformer and a relay protection device. The relay protection device comprises electronic current sensors penetrating through corresponding terminals of lead conductors in parallel connection between the low-voltage side output terminal of the electric furnace transformer and an electric furnace electrode, wherein the signal output ends of each electronic current sensor are connected with each other in series, and are connected with a signal conditioning unit through a shielded cable. The technical scheme can be used for solving the difficult problems of measuring large current on the low-voltage side of the electric furnace transformer as well as the failing to achieve differential protection of the electric furnace transformer, and can meet the requirement on linearity and large-current unsaturation of differential protection.

Owner:XJ ELECTRIC +3

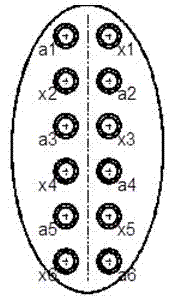

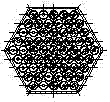

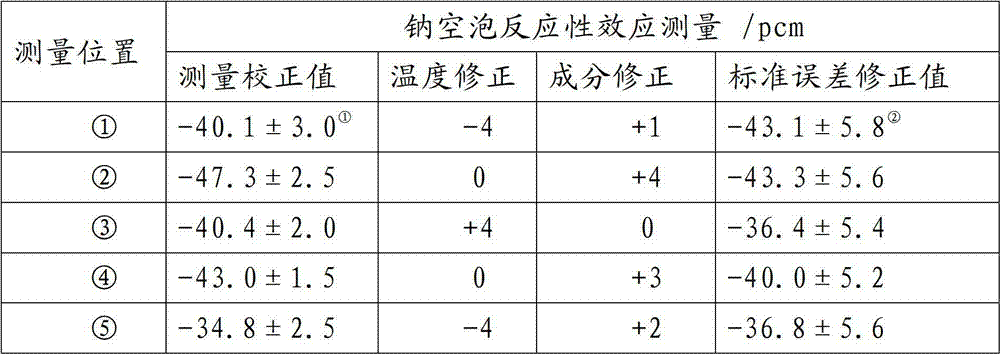

Sodium-void reactivity measurement method for sodium-cooled fast reactor and sodium-void experimental assembly

ActiveCN102810338AAccurate measurementGuaranteed measurementFuel elementsNuclear energy generationBand countsNuclear engineering

The invention relates to a sodium-void reactivity measurement method for a sodium-cooled fast reactor. The method comprises the following steps: (I), a measurement position is selected in a reactor core; (II) a sodium coolant for fuel components of the reactor core exists in the measurement position in the step (I) in a normal operation state, the reactor is adjusted to a tiny super-critical state, the state parameter of the reactor core, the rod positions of all control rods and counting and reactivity data of a neutron detector are recorded, and the super-critical reactivity Rho1 of a reference point is calculated in a fitting manner; (III) shutdown is performed, the sodium-void experimental assembly without the sodium coolant replaces fuel components in the step (II) when the counting drops to the background, and the super-critical reactivity Rho2 of a measurement point is obtained by adopting the method of the step (II); (IV) the measured value of the sodium-void reactivity is equal to (Rho1-Rho2); and (V) the measured value is subject to various modifications. The invention also provides a sodium-void experimental assembly used in the method. By adopting the method and the assembly which are provided by the invention, more accurate sodium-void reactivity value can be obtained.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

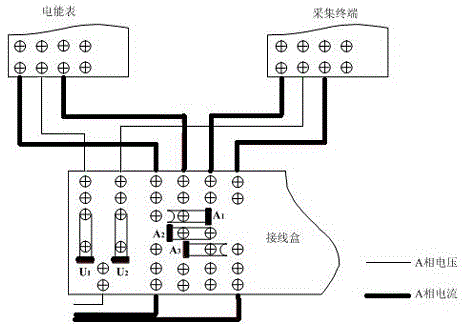

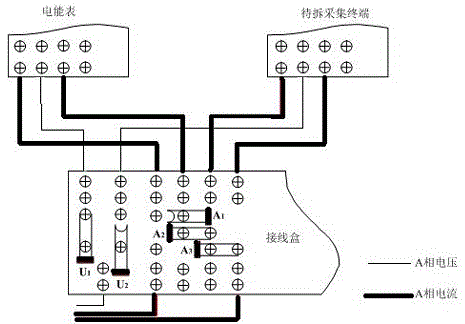

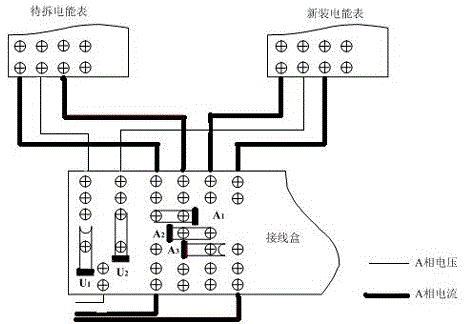

Conjunction box without power loss during replacement

InactiveCN105487039AGuaranteed measurementHigh precisionMeasurement instrument housingVoltage loopSecondary loop

The invention relates to a conjunction box without power loss during replacement, and belongs to high-supply high-metering and high-supply low-metering electric energy metering devices. Electricity is metered normally when the metering device as a collection terminal and an electric energy meter is replaced, and the conjunction box is prevented from power loss when a secondary loop is powered off transiently. The conjunction box is characterized in that a voltage loop connecting part is provided, four holes are formed in a T-shaped copper tube at the voltage wire inlet end at the bottom of the conjunction box, each of two linear copper tubes is provided with three holes at the wire outlet end in the upper portion of the conjunction box, the wire outlet end is connected with the T-shaped copper tube at the wire inlet end by cooperating two separate loops with two connection sheets respectively, and power supply of one voltage loop is not influenced when the connection sheet, cooperating with the other voltage loop, is disconnected. The conjunction box provided by the invention can be used to ensure that the electricity is metered normally in the wiring process of instruments during onsite examination.

Owner:STATE GRID CORP OF CHINA +1

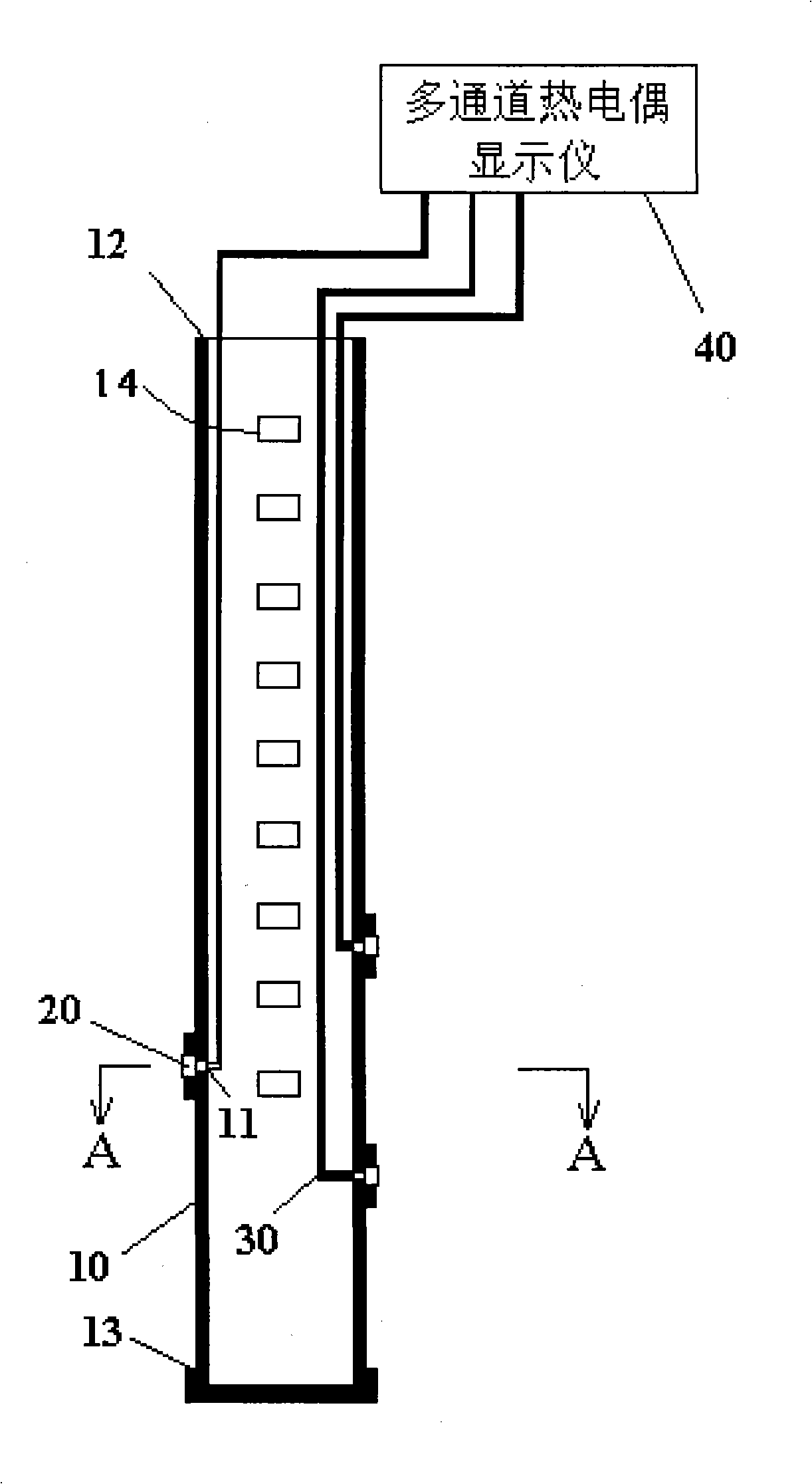

Multi-point temperature measurement method and temperature measurement equipment for down-hole formation

The invention provides an underground formation multipoint temperature measurement method which includes the following steps: setting a plurality of armored thermocouples, one end of which are connected with compensating wires; choosing one protection tube, the wall of which is provided with fixing holes formed at intervals along the axle direction according to the detecting points; penetrating the compensating wires connected with armored thermocouples in the protection tube and then out from the tube mouth, and limiting and fixing the protection lining of the armored thermocouples at the fixing holes; connecting the compensating wires out of the tub mouth with a multi-channel temperature measurement instrument display; extending the protection tube with the armored thermocouples into a well; and measuring the temperature. Formation temperatures at different depths can be measured by the method using only one pipeline; the armored thermocouples are fixed at the fixing holes of the tube wall that contacting outside directly, thus guarantee the high measurement precision; and the thermocouples with metal armor are not easy to be damaged during assembly, thus greatly prolonging the service time.

Owner:SHANGHAI UNIV OF ENG SCI

Method for detecting and solving anomaly of metering chips

ActiveCN104502883AGuaranteed measurementAvoid over-measured valuesElectrical measurementsAnomaly detectionPower grid

The invention discloses a method for detecting and solving anomaly of metering chips. The method includes steps of (1), powering up the metering chips and writing standard parameters into the metering chips; (2), keeping time periods N; (3), carrying out detection, to be more specific, a, detecting the frequencies of power grids, b, detecting voltages of the power grids, and c, detecting power; (4), enabling a chip managing MCU (micro-control unit) to read parameters of the metering chips when the time periods N are up, returning to the step (2) if the parameters are consistent with the standard parameters, enabling the chip managing MCU to initialize the metering chips if the parameters are not consistent with the standard parameters and returning to the step (2). The method has the advantages that the anomaly of the metering chips can be detected by the aid of the method, the metering chips can be recovered by the aid of the method, and accordingly the reliability and the stability of meters can be effectively improved.

Owner:NINGBO SANXING MEDICAL & ELECTRIC CO LTD

Earth pressure box burying device and method for fill engineering

ActiveCN106052916AGuaranteed accuracy requirementsAvoid destructionForce measurementThreaded rodGeotechnical engineering

The invention discloses an earth pressure box burying device and method for fill engineering. The device comprises connecting rods, a box accommodating disk, a bushing and seal covers. Each connecting rod is a hollow threaded rod, and the connecting rods of different lengths can be combined by the bushing to reach a design length; the box accommodating disk can adjust the measuring position of an earth pressure box via an adjusting nut; and the seal covers seal the top and bottom ends of the connecting rods. The method comprises that the box accommodating disk is fixed to the first connecting rod via the adjusting nut, and adjusted to a designed measuring position; the earth pressure box is fixed in a box accommodating area of the box accommodating disk in a welding manner; with increase of fill height, the second connecting rod is connected and fixed to the first connecting rod via the bushing, and the earth pressure box is mounted; and so on, all leads are led out of a bus hole and the top cover is mounted for sealing after the design fill height is reached. According to the device and method, the whole structure is simple, operation is convenient, the using effect is good, and the precision of earth pressure box burying is ensured effectively.

Owner:SHIJIAZHUANG TIEDAO UNIV

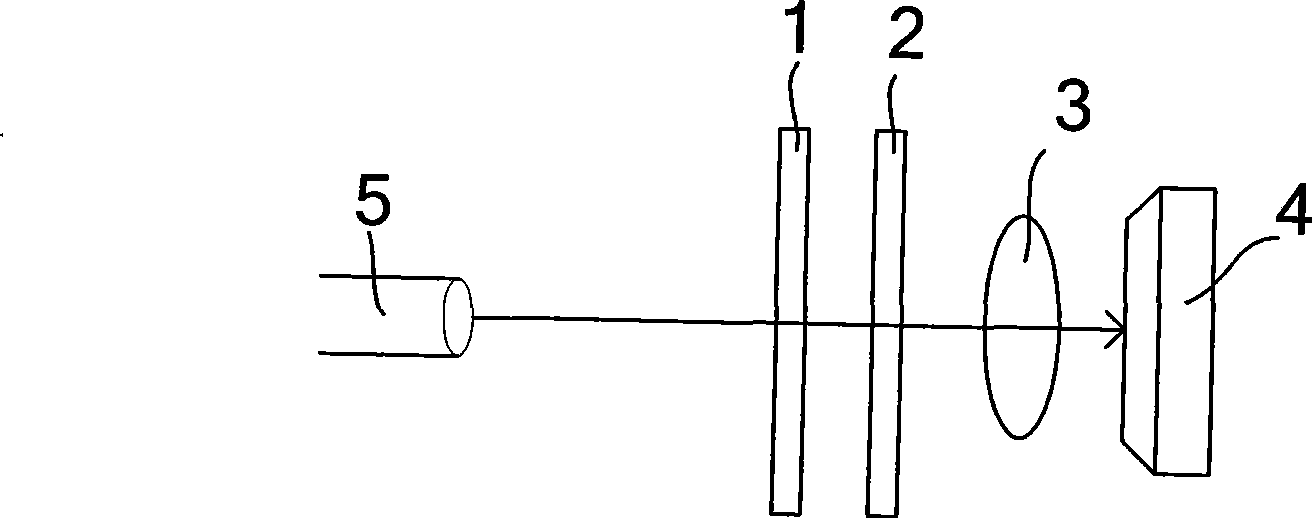

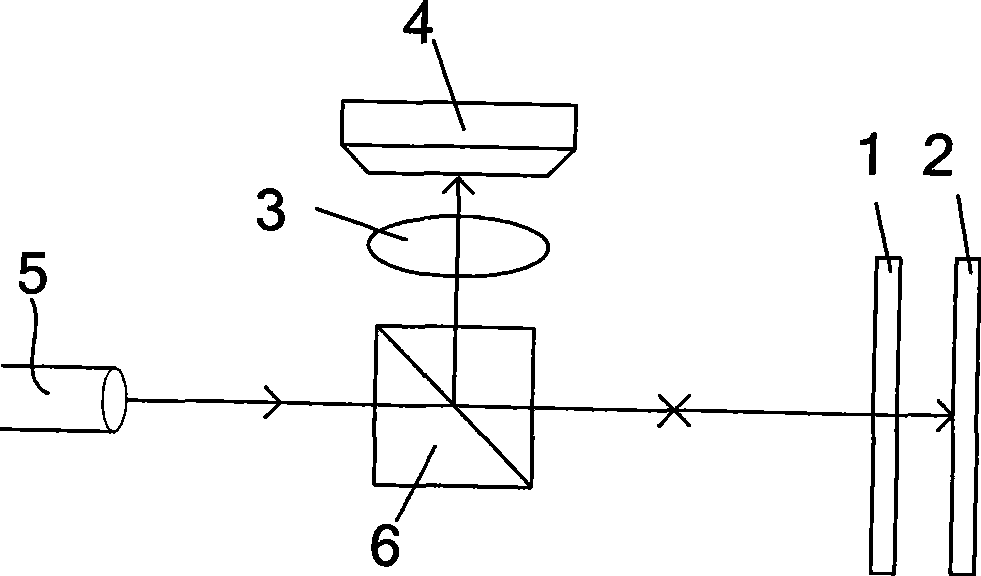

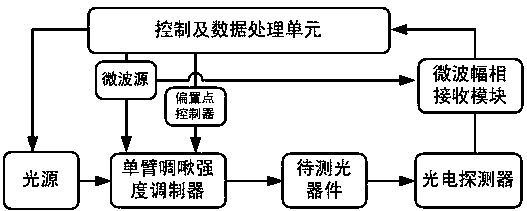

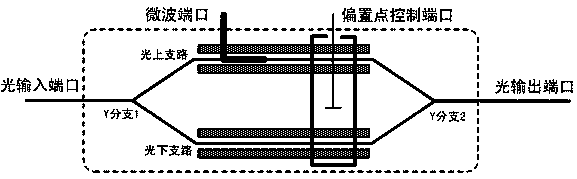

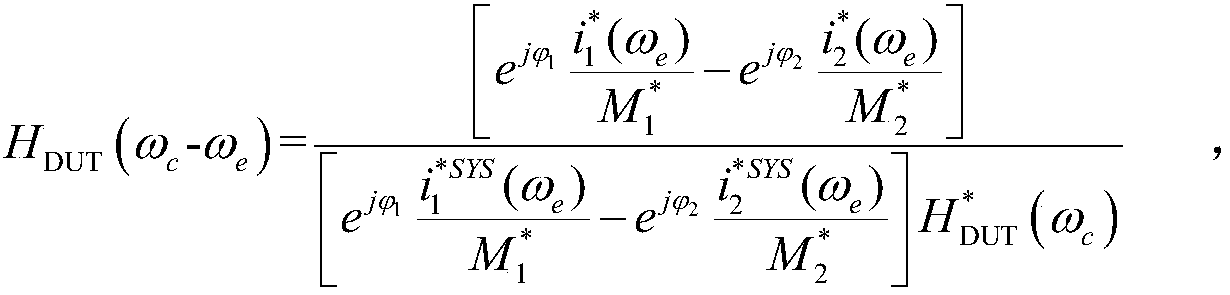

Optical vector analysis method and apparatus based on chirping intensity modulation

ActiveCN107634807AAvoid modulationAvoid carrier frequency shiftElectromagnetic receiversOptical apparatus testingObservational errorPhase difference

The invention discloses an optical vector analysis method based on chirping intensity modulation. The method comprises the following steps: using a chirping intensity modulation light double-sidebandsignal as detection light to irradiate a to-be-detected optical device, and converting an optical signal into an electric signal by photoelectric detection; changing the phase difference between the double-sideband signal and the optical carriers to obtain detection optical signals of different chirping intensity modulation states, then establishing an equation set by using the relationship between the amplitude information of the electric signals obtained by the detection optical signals of different chirping intensity modulation states and the detection optical signals, and solving to obtainamplitude response of the to-be-detected optical device. The invention further discloses an optical vector analysis apparatus based on chirping intensity modulation. By adoption of the optical vectoranalysis method and apparatus, complex and relatively narrowband single side band modulation or carrier frequency shift is avoided while realizing high precision measurement of the amplitude responseof the optical device, the measurement range is doubled, the measurement errors caused by vestigial sideband are eliminated, the filtering mechanism in the system is eliminated, and the cost and thecomplexity of the system are greatly reduced.

Owner:SUZHOU 614 INFORMATION TECH CO LTD +1

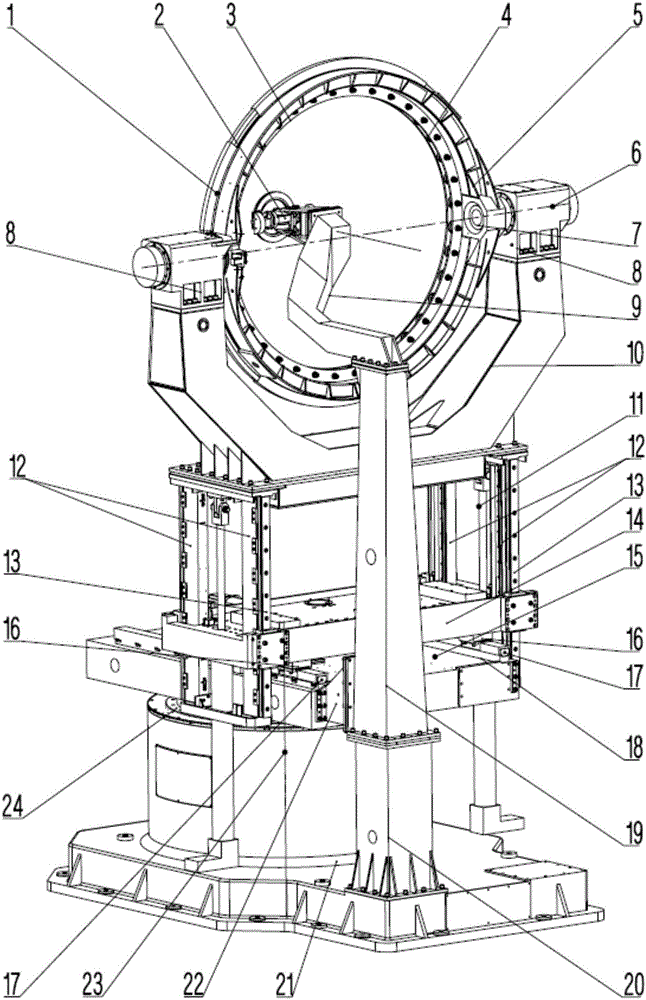

Eight-axis turntable for electromagnetic window testing

ActiveCN106771388ARealize electrical performance testGuaranteed measurementWave based measurement systemsMeasurement instrument housingPosition errorElectromagnetic testing

The invention belongs to the field of machinery technology, and relates to an eight-axis turntable for electromagnetic window testing. The turntable comprises a rolling ring assembly, a pitching assembly, an upward-and-downward linear assembly, a forward-and-backward linear assembly and a direction assembly. The turntable realizes transverse rolling rotary movement, pitching rotary movement, upward-and-downward elevating movement, frontward-and-backward translational movement and rotation movement of an electromagnetic window product, and realizes transverse rolling rotary movement, pitching rotary movement and rotation movement of a signal source. According to the eight-axis turntable, always perpendicularity between a tangential plane of a random point arm surface of the tested electromagnetic window product and the axis of the emitting surface of the signal source is ensured through eight-axis combined movement; and furthermore a fact that the emitting position of the signal source is always at the circle center of a fixed area arc surface on the tested electromagnetic window product is realized. The eight-axis turntable has advantages of performing real-time compensation on the angle and position error in measurement through eight-axis linkage, realizing accurate measurement and automatic measurement, and more accurately realizing electric performance testing on the electromagnetic window product with large eccentric moment and large dimension.

Owner:AVIC BEIJING CHANGCHENG AVIATION MEASUREMENT & CONTROL TECH INST +2

Tester of cement setting time

InactiveCN103163284AGuaranteed measurementEasy to operate manuallyMaterial testing goodsBiomedical engineeringClutch

The invention discloses a tester of cement setting time. The tester of the cement setting time comprises a base, a support, a test needle and a test needle control support, wherein the base and the support are perpendicularly fixed, and the test needle is fixed on the test needle control support. The tester of the cement setting time further comprises a control support working seat and a controller, wherein a plurality of test mould frames are arranged on the base, the control support working seat is provided with control support positions which are equal to the test mould frames in number, the control support working seat is further provided with a control support moving drive, and the control support moving drive is connected with the test needle control support in a transmission mode. The test needle control support is provided with a test needle drive, a test needle clamping block, a test needle clamping block drive and a test needle head position inductive device, wherein the test needle drive is connected with the test needle in a transmission mode, a clutch is arranged between the test needle drive and the test needle, and the test needle arranged on the test needle clamping block, and the test needle clamping block are connected with the test needle drive in a transmission mode. The controller is respectively connected with the control support moving drive, the test needle drive and the test needle head position inductive device in a signal mode. The tester of the cement setting time has the advantages of being high in working efficiency, simple in operation, and the like.

Owner:ZHEJIANG TUGONG INSTR

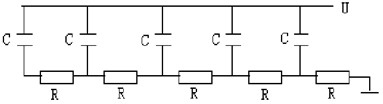

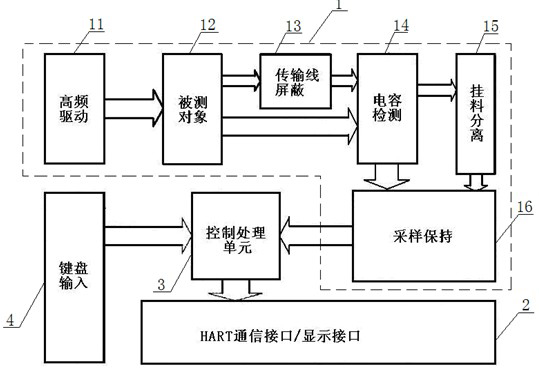

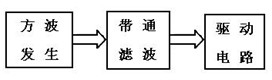

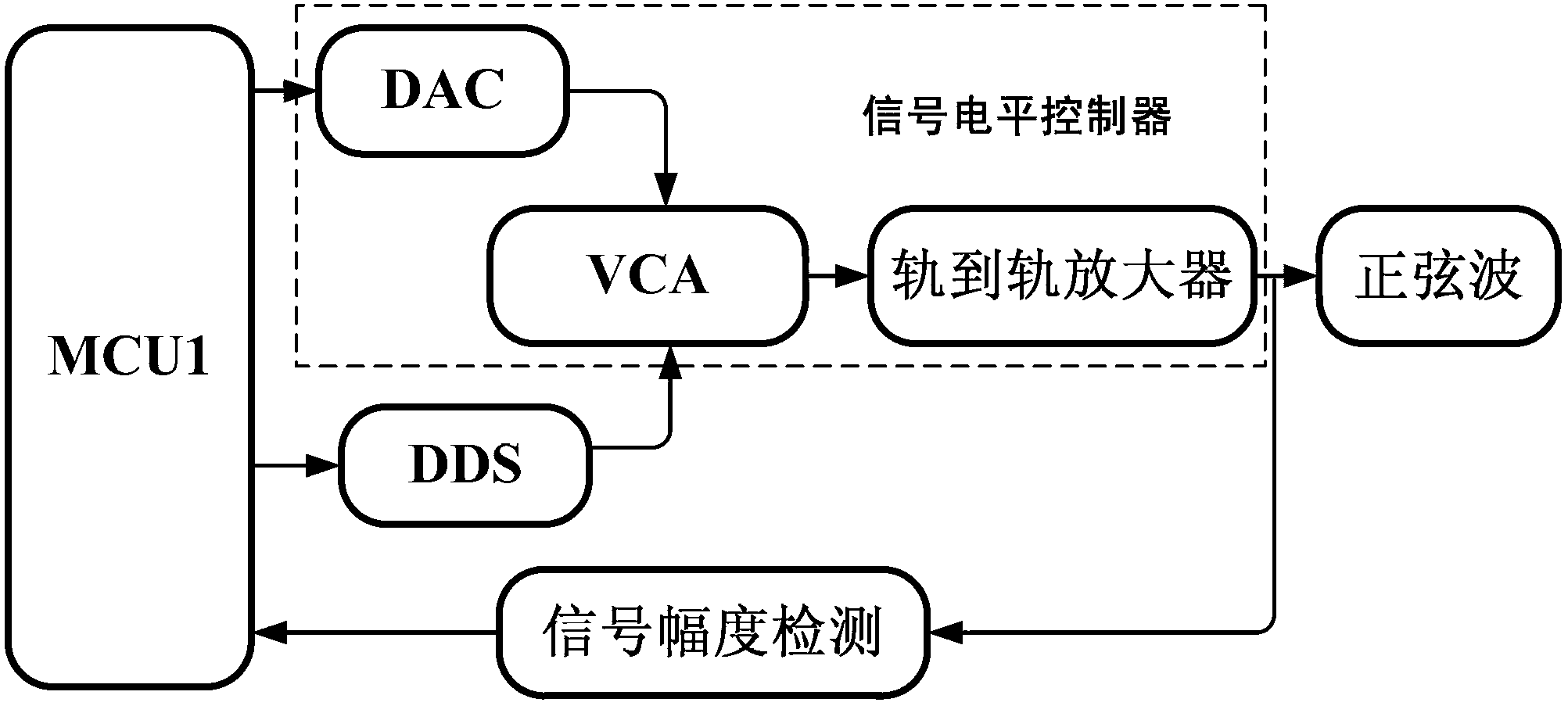

Capacitive radio-frequency admittance level transmitter and operating method thereof

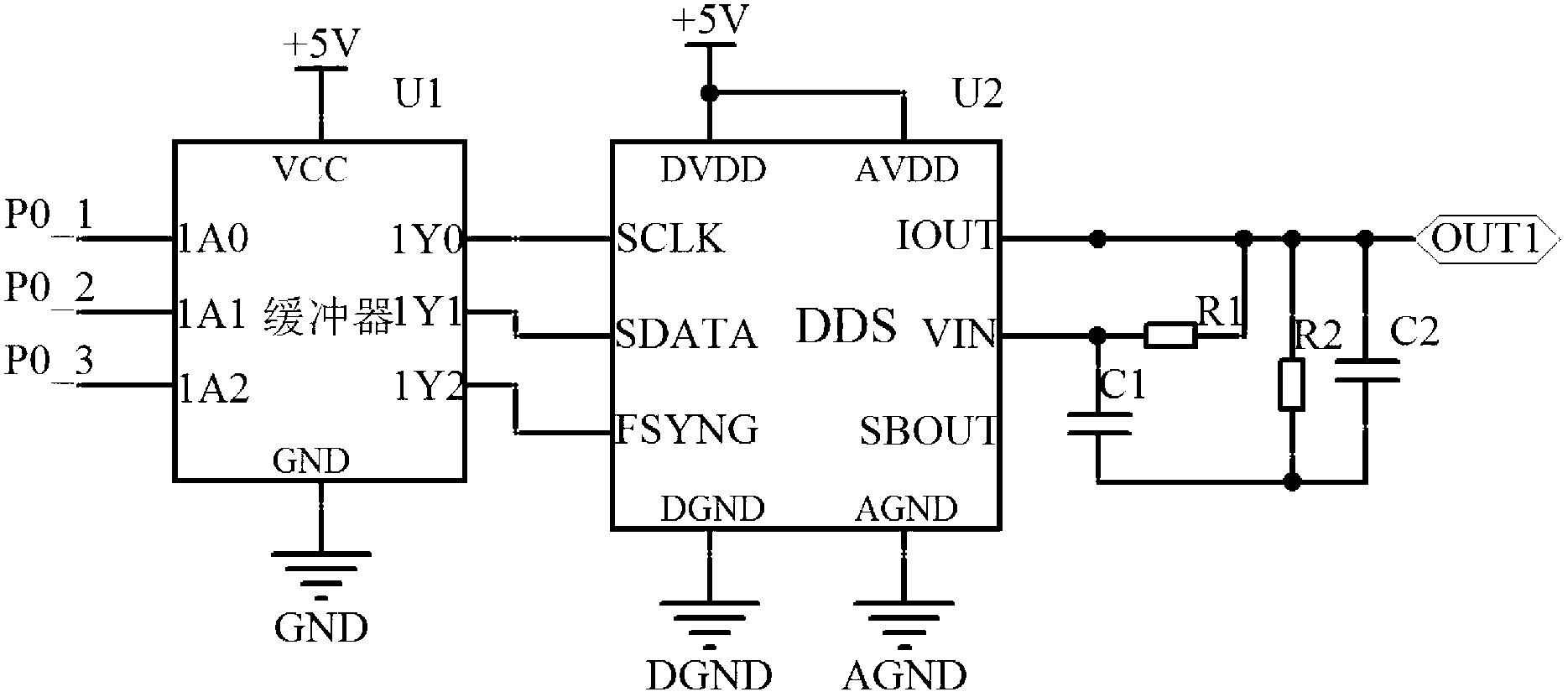

InactiveCN102538905AHigh precisionGuaranteed measurementLevel indicators by physical variable measurementRadio frequencyMeasurement precision

The invention relates to a capacitive radio-frequency admittance level transmitter and an operating method thereof. A high-frequency sinusoidal excitation signal output by a high-frequency driver is loaded into a capacitance sensor; through analyzing the sizes of an AC (alternating current) component and a DC (direct current) component of a response signal of the capacitance sensor, the impedance and condensance of the capacitance sensor are calculated through the operation of an MCU (micro-programmed control unit); and the condensance of an attachment is obtained through backstepping according to a conclusion that in a radio-frequency admittance theory, a real part and an imaginary part which are subjected to equivalent admittance by the attachment are numerically equal, so that the real capacitance is equal to a value obtained by subtracting the attachment capacitance from the measured capacitance, thereby eliminating the measurement errors of the attachment caused by that a measured medium is adhered to an electrode, solving the difficult problem that the measurement errors of viscous measured materials or solid powdered measured materials are large, improving the measurement precision, and guaranteeing the measurement stability.

Owner:NO 3 AUTOMATION INSTR & METERS FACTORY SHANGHAI AUTOMATION INSTR & METERS CO LTD

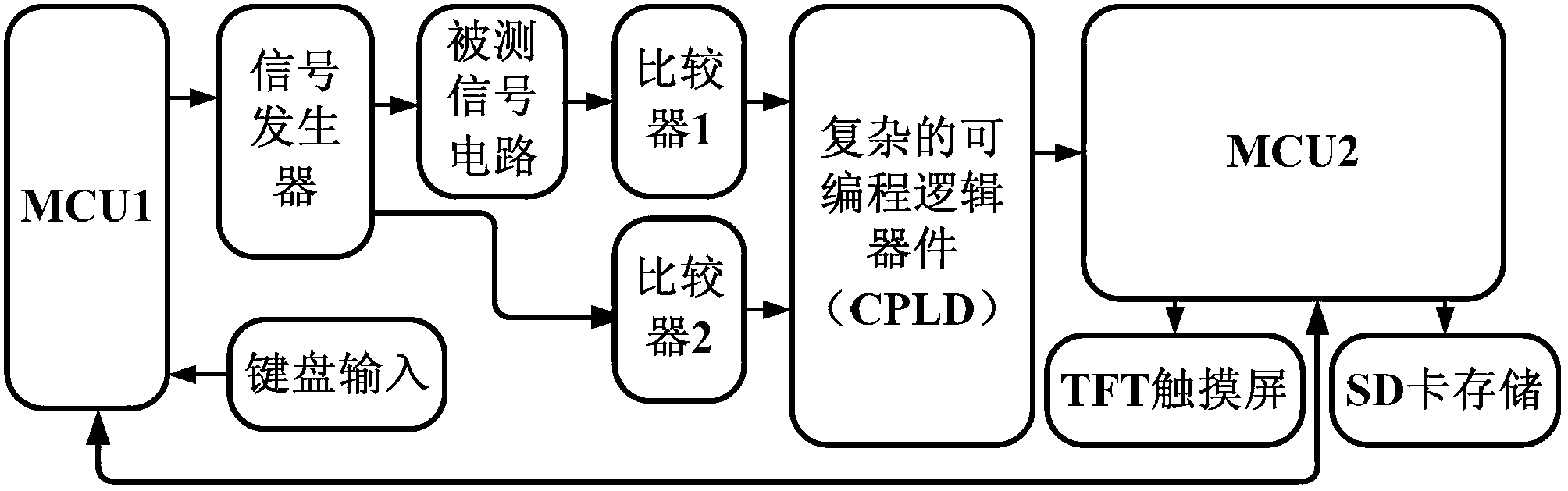

Time delay detection system for signal circuit

ActiveCN103163449AAccurate delay detectionGuaranteed measurementDigital circuit testingBroadbandVIT signals

The invention discloses a time delay detection system for a signal circuit. According to the time delay detection system, a first microprogrammed control unit controls a signal generator to generate two paths of signals; one path of signal is inputted to a second comparator directly, and the other path of signal passes through a measured signal circuit and is inputted to a first comparator; the two paths of signals which are outputted by the two comparators are inputted to a complex programmable logic device (CPLD); the output of the CPLD is connected to a second microprogrammed control unit; and the second microprogrammed control unit (MCU) 2 is connected with a thin film transistor (TFT) touch screen and a secure digital (SD) card for storing information. In a CPLD time delay detection unit, a dual-input time difference measuring method is adopted in the measured signal circuit, so that the measurement of a broadband signal can be ensured; the frequencies and amplitudes of the signals generated by the signal generator can be adjusted; and the signals with different frequencies can meet different measuring requirements, and the signal time delay characteristics of different signal unit circuits can be measured. According to the time delay detection system, time delay characteristic curves of different signal circuits within a certain frequency range can be measured, and can be stored to the SD card to be inquired historically and conveniently.

Owner:江苏正辉太阳能电力有限公司

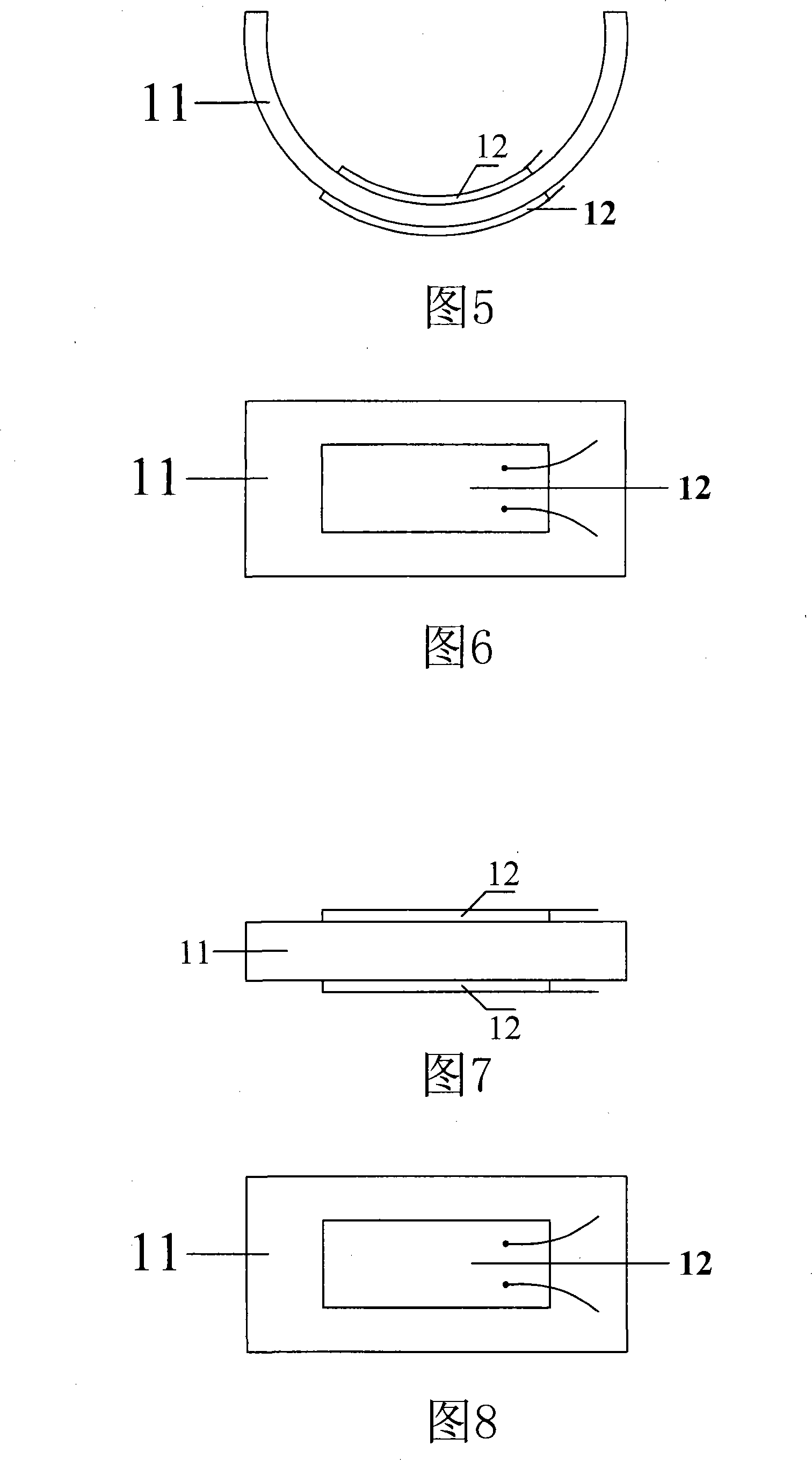

Soft rock large deformation three axis creep test transverse strain measuring extensometer and method

InactiveCN101221162AGuaranteed measurementAccurate measurementEarth material testingElectrical/magnetic solid deformation measurementEngineeringRock sample

An extensometer of the transverse strain measurement of a soft rock three-shaft creep test includes a slide ring, two pairs of supporters, two strips of extension arms, two sense elements and two springs. The inside diameter of the slide ring is larger than an outside diameter of an upper pressure head and a lower pressure head after a maximum deformation; the supporters are symmetrically arranged on two sides of the external ring surface of the slide ring; one ends of the two extension arms are hinged with one pair of supporters and the other end is provided with a contact terminal and a spring hook; one ends of the two sense elements are respectively fixed on two supporters and the other end is fixed at the end part of the hinged end of the extension arms hinged with the supporters; the two ends of the two springs are respectively connected with the spring hooks arranged on the two strips of extension arms; the hinged end between the two supporters and the two extension arms is provided with an extension arm locating hole and allocated with a locating pin. A method of the transverse strain measurement of a soft rock three-shaft creep test uses the extensometer of the structure for measuring and the quantity of the extensometer is equal to the quantity of the section to be detected of a soft rock sample.

Owner:SICHUAN UNIV

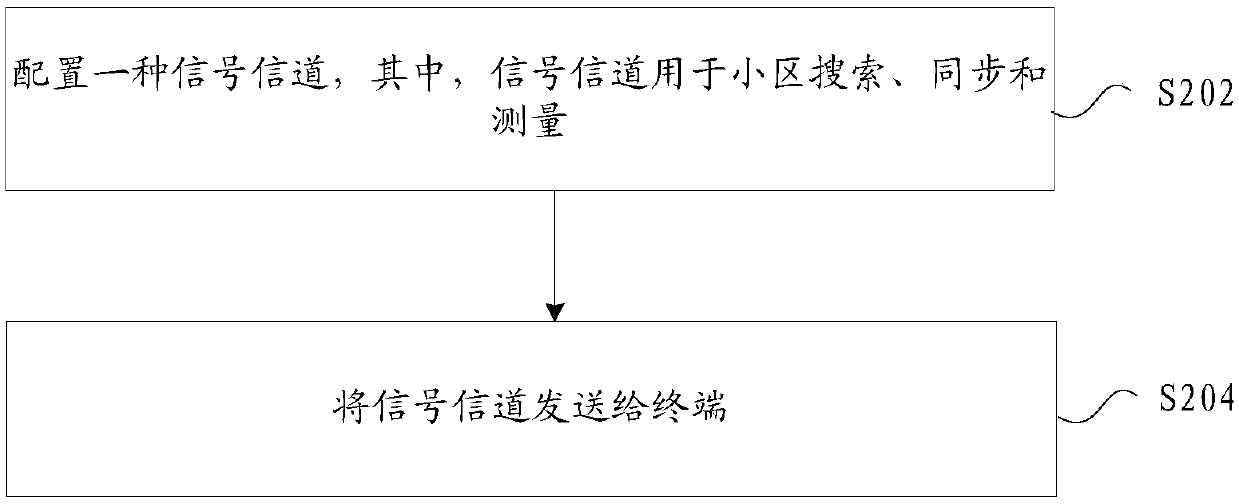

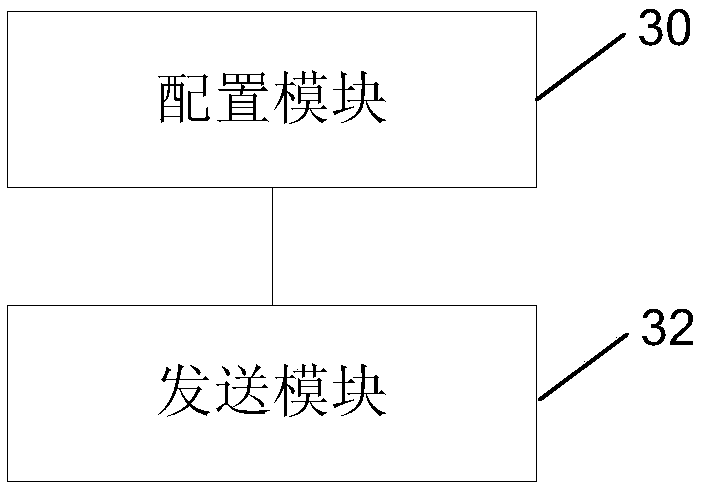

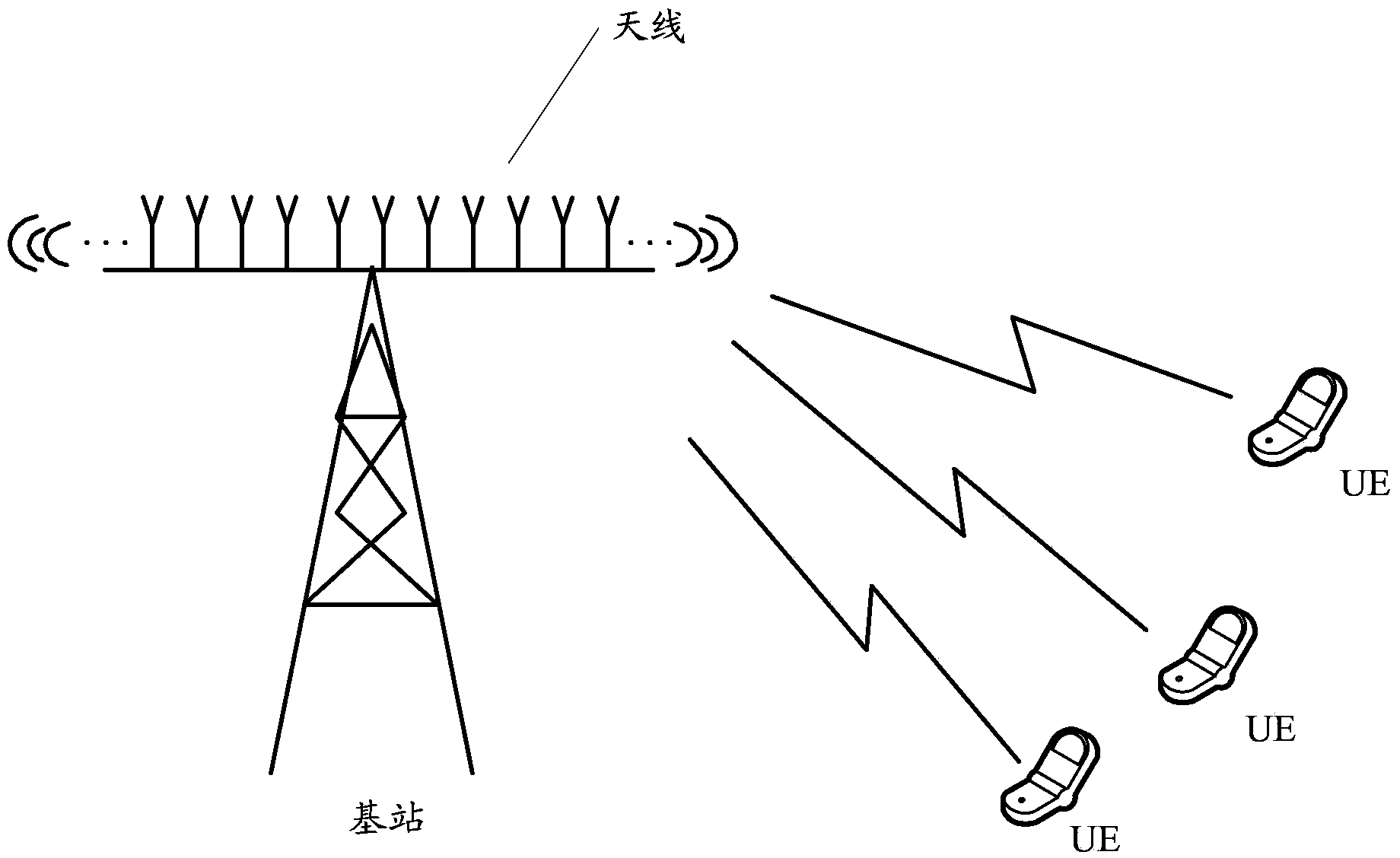

Signal channel sending method, base station, storage medium and electronic device

PendingCN110351740AImprove work efficiencyIncrease chances of sendingSynchronisation arrangementTransmission path divisionComputer scienceBase station

The invention provides a signal channel sending method, a base station, a storage medium and an electronic device, and the method comprises the steps: configuring a signal channel which is used for cell searching, synchronization and measurement; and sending the signal channel to a terminal. According to the invention, the technical problem that the discovery signal cannot be fairly sent in the prior art is solved.

Owner:ZTE CORP

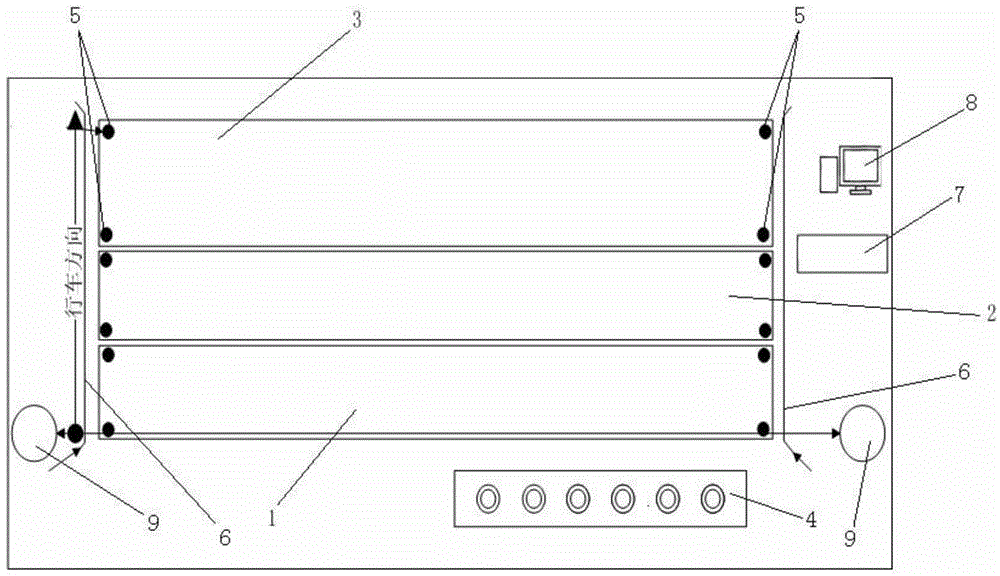

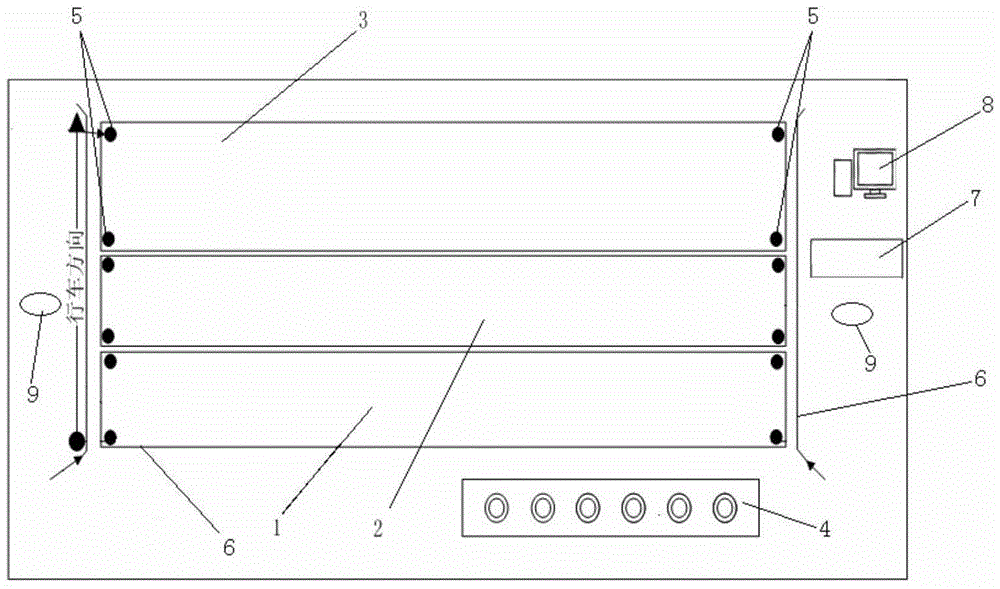

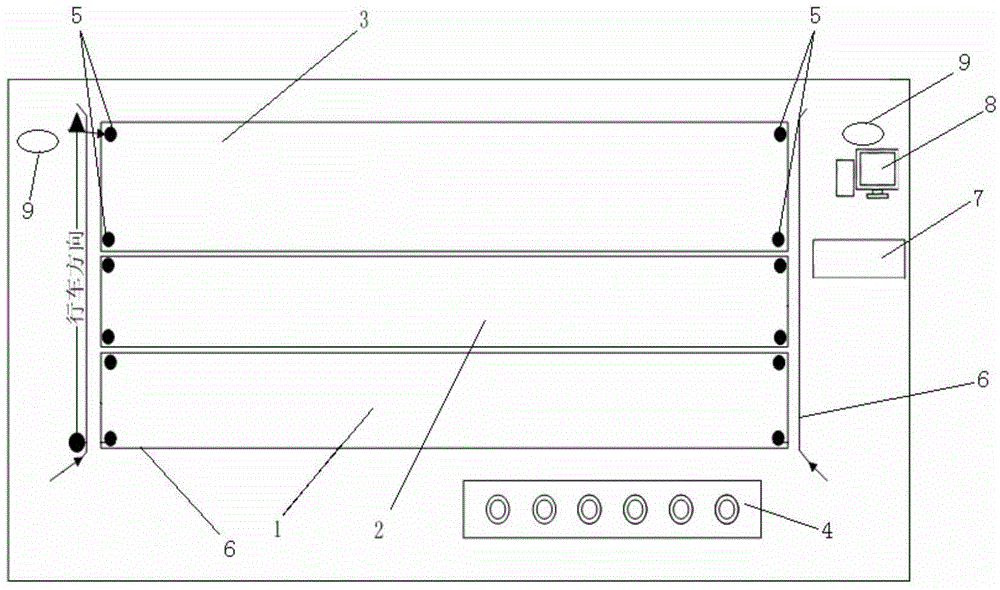

Novel multi-platform-surface dynamic weighing system

InactiveCN104359540AGuaranteed measurementIncrease widthSpecial purpose weighing apparatusMulti platformHigh velocity

The invention discloses a novel multi-platform-surface dynamic weighing system. The novel multi-platform-surface dynamic weighing system comprises a vehicle separator, a tire identifier, a scale body, signal acquisition equipment, signal processing equipment, a first scale platform, a second scale platform and a third scale platform, wherein the first scale platform, the second scale platform and the third scale platform are sequentially arranged abreast along the driving direction; the vehicle separator is used for separating vehicles; the tire identifier is arranged in front of the first scale platform or behind the third scale platform, and the vehicles pass through the tire identifier and the vehicle separator. Due to the adoption of the structure in which the three scale platforms are arranged abreast, the length of the three-scale-platform weighing system is increased compared with a single-scale-platform weighing system and a double-scale-platform weighing system, the staying time of the vehicles on the scale platforms is prolonged, and the influence on weighing errors caused by non-standard vehicle passing behaviors such as S-type passing of the vehicles, jumping of the vehicles over the scale platforms and high-speed passing of the vehicles through the scale platforms can be eliminated.

Owner:重庆市华驰交通科技有限公司

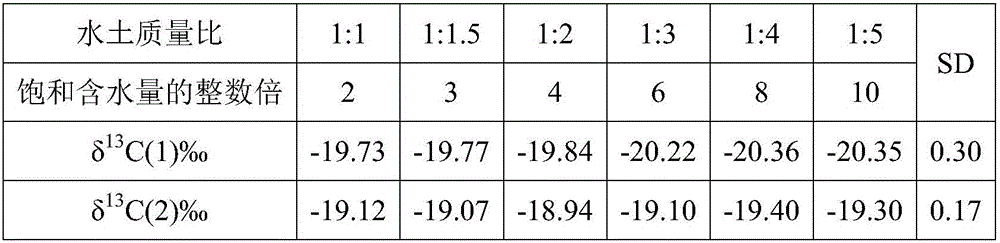

Method for measuring soil soluble organic carbon isotope

InactiveCN106770606AGuaranteed measurementAchieve homogenizationMaterial analysis by electric/magnetic meansSoil massFreeze-drying

The invention discloses a method for measuring a soil soluble organic carbon isotope. In the method, an EA-IRMS method is adopted. The method comprises the following steps: firstly, extracting soil water-soluble organic carbon through a multi-water to soil mass ratio method to obtain a solution containing the soil water-soluble organic carbon; then, concentrating the obtained solution through freeze drying; adding purified water into concentrated substances for re-dissolving, drying and measuring delta<13>C through EA-IRMS. The novel method for measuring the soil soluble organic carbon isotope provided by the invention is rapid and efficient, is easy and convenient to operate, and has high measuring accuracy.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

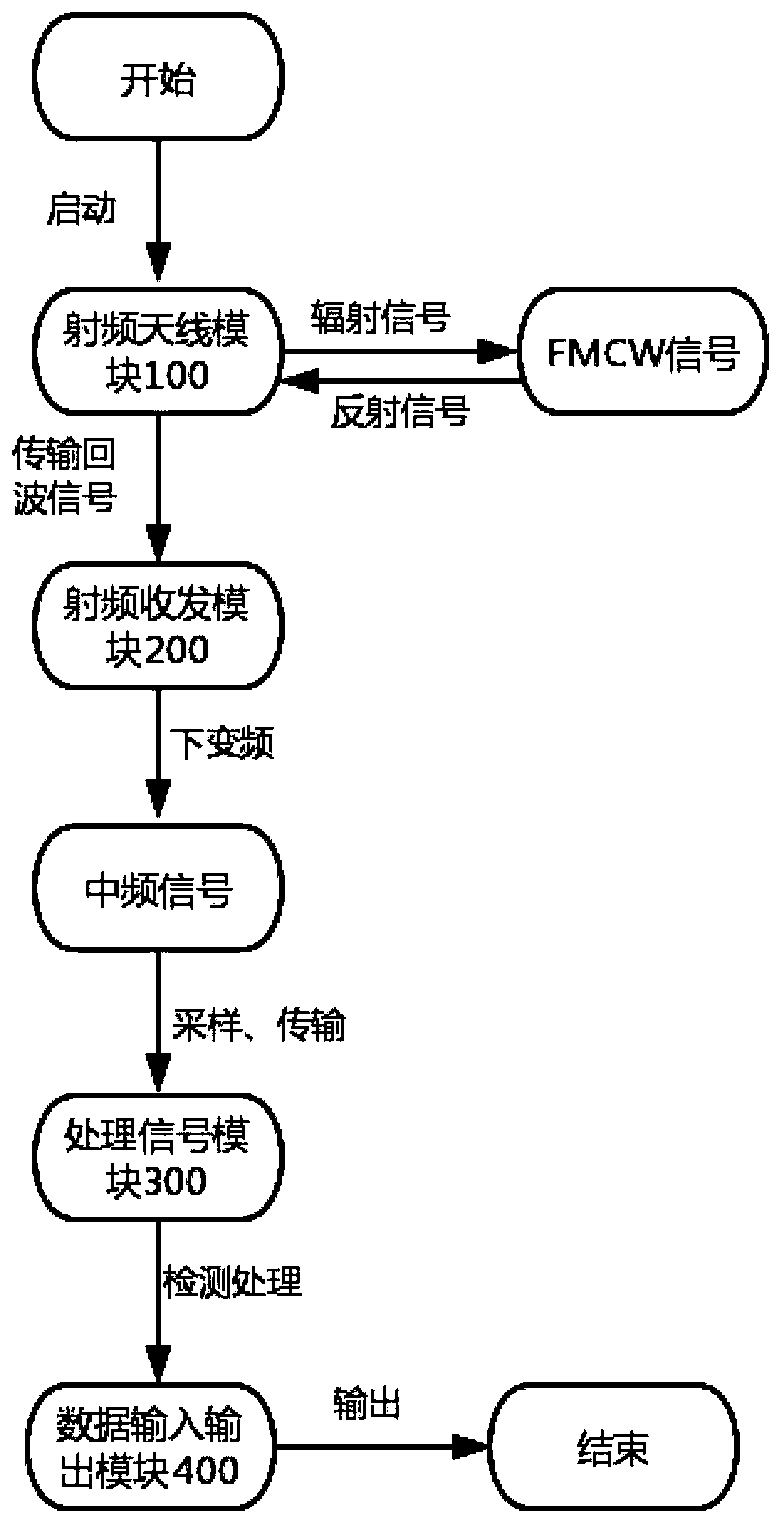

Radar sensing method and system based on extremely short distance millimeter waves

PendingCN110988862AGuaranteed measurementReduce the cost of detection and perceptionRadio wave reradiation/reflectionIntermediate frequencyRadar

The invention discloses a radar sensing method and system based on extremely short distance millimeter waves. The method comprises the following steps: radiating an FMCW signal to a target by using aradio frequency antenna module, receiving a radar echo signal reflected by the target, converting the signal into an intermediate frequency signal, sampling and processing the received signal by usingan ADC, outputting the detected target, measuring the distance, speed and angle of the target, and transmitting data. Environmental modeling and object classification can be perfected in an extremelyshort distance range, the method is very important for researching and developing an advanced driving assistance algorithm and an automatic driving function, a larger FOV ensures that fewer sensors are used for sensing the surrounding 360-degree environment, and the detection sensing cost is reduced; and the height measuring function is achieved, and measurement in the height direction is guaranteed.

Owner:的卢技术有限公司

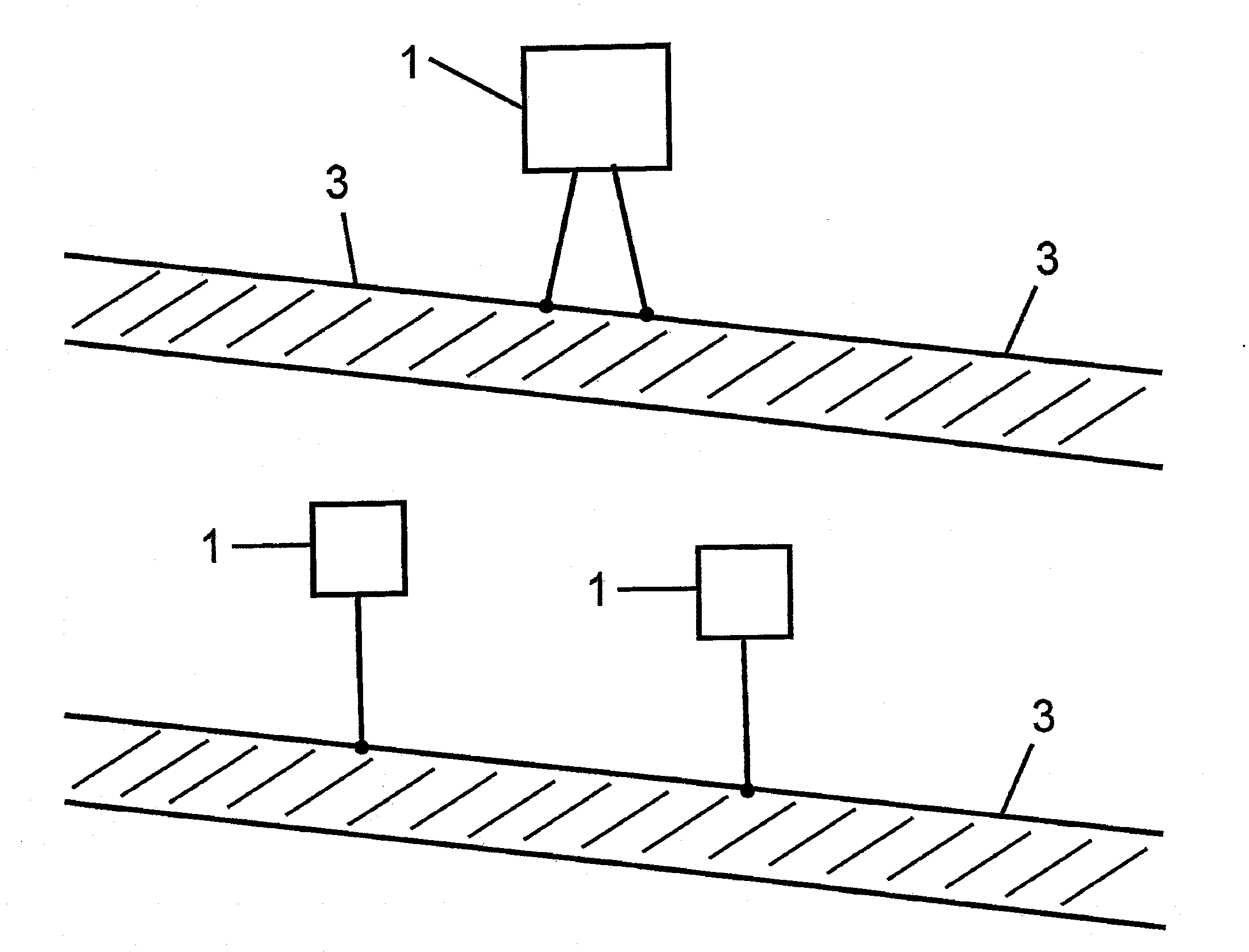

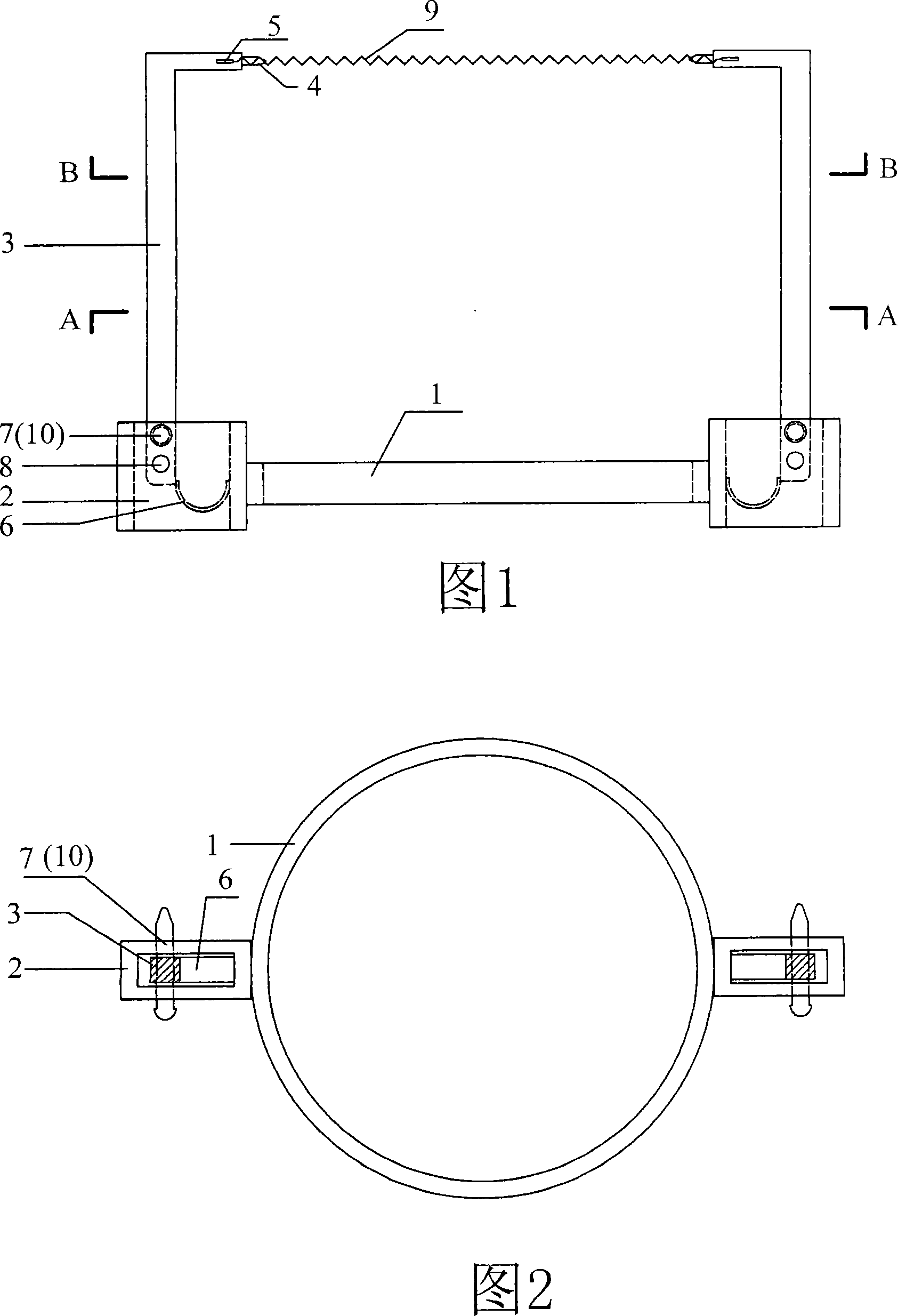

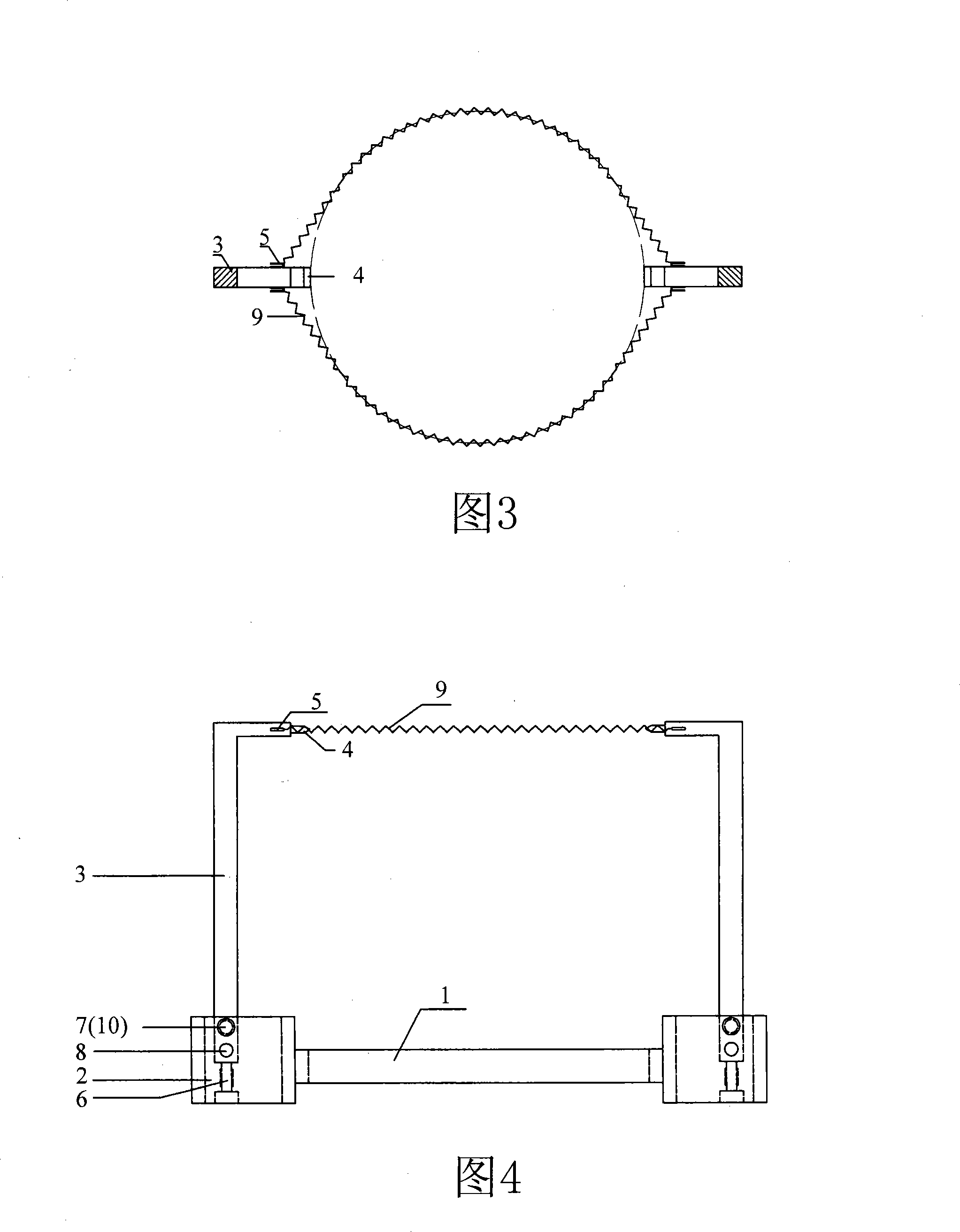

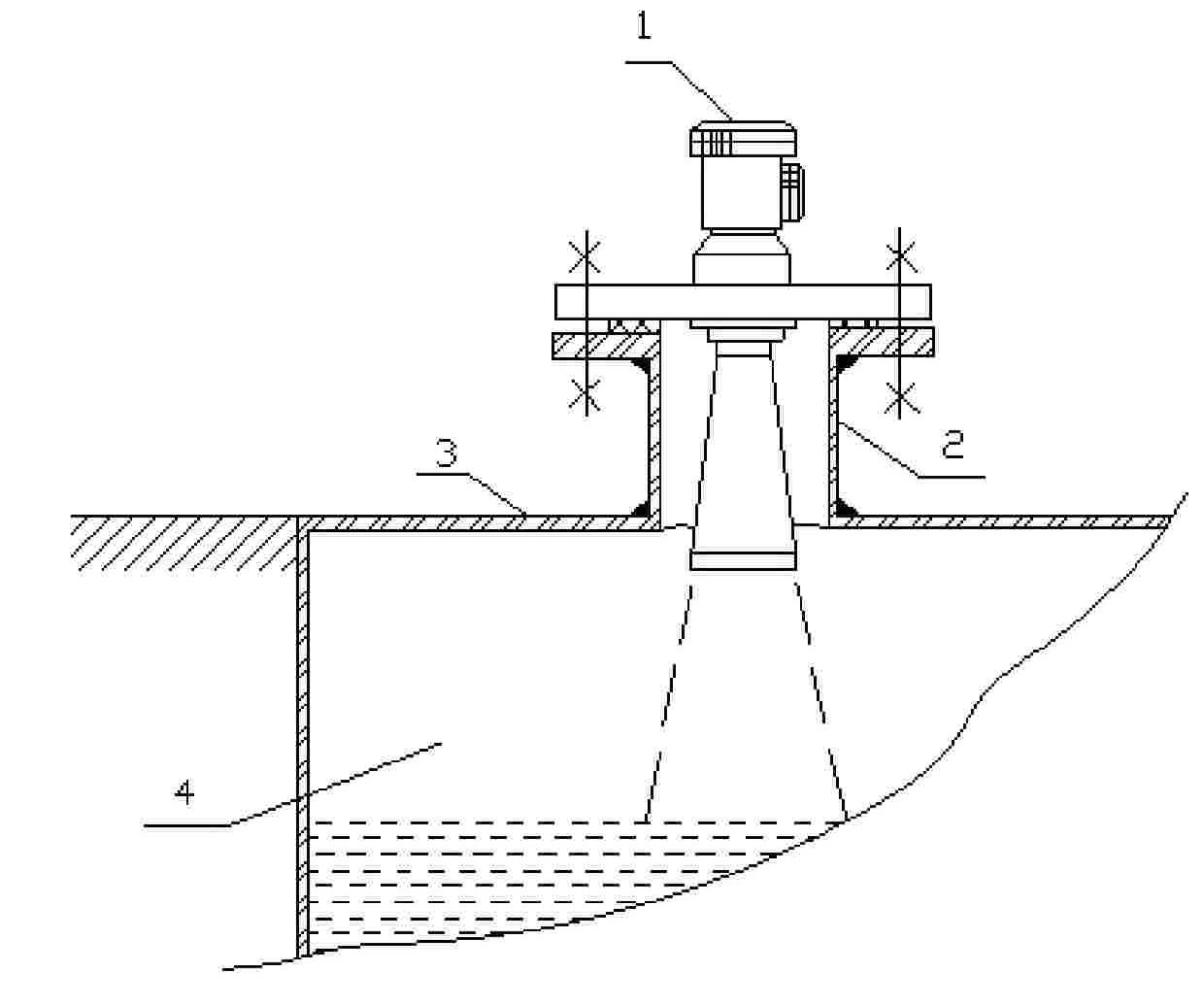

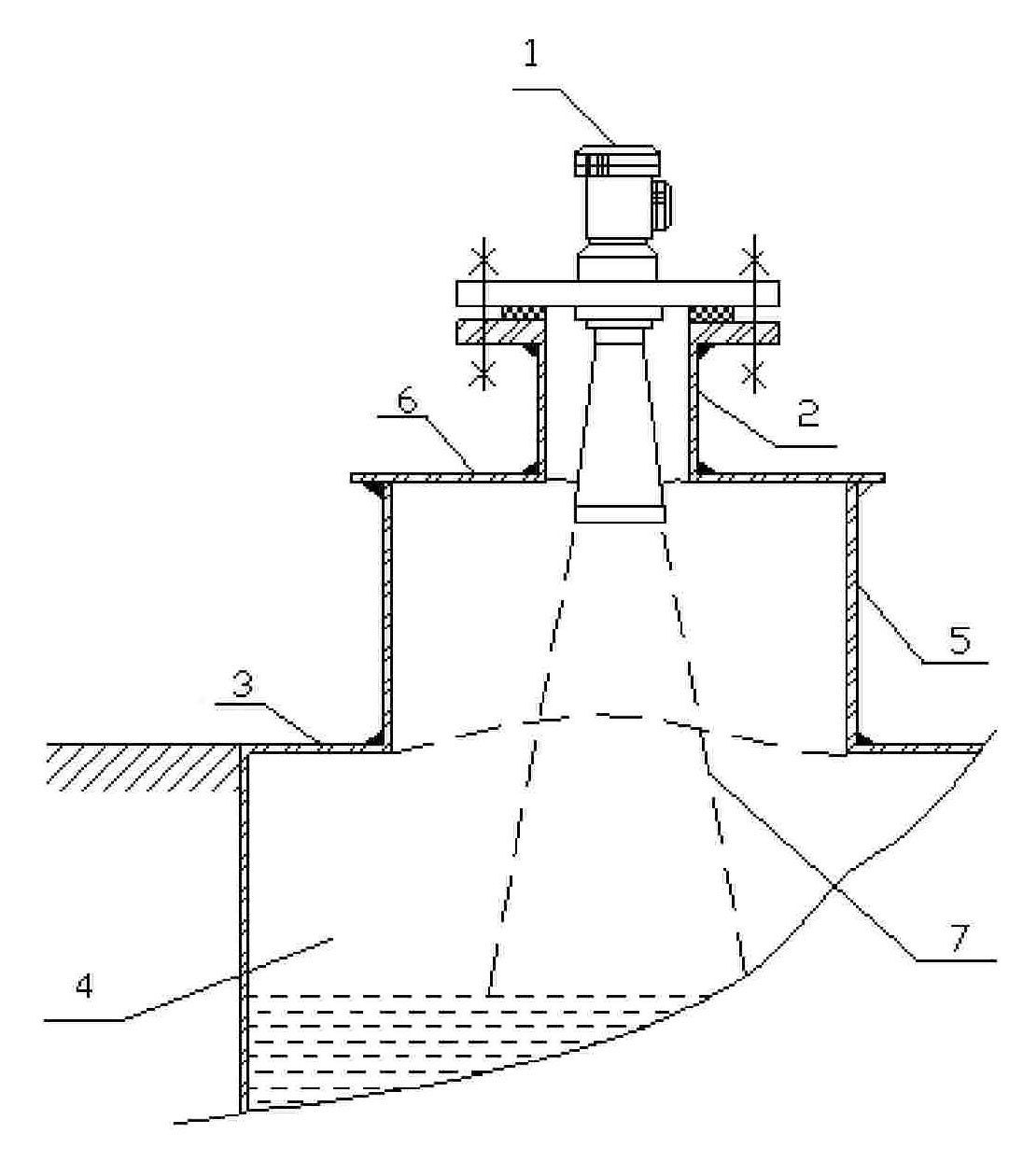

Installation structure of radar level meter on sewage tank of alumina plant

InactiveCN102095468AIncrease the installation heightAvoid soakingWater/sewage treatmentMachines/enginesRadarSewage

The invention discloses an installation structure of a radar level meter on a sewage tank of an alumina plant, which comprises the radar level meter (1), wherein the radar level meter (1) is installed on a tank cover (3) of the sewage tank (4) through an installation joint pipe (2), a connecting joint pipe (5) is additionally arranged between the installation joint pipe (2) and the tank cover (3), and a ring-shaped steel plate (6) is arranged between the installation joint pipe (2) and the connecting joint pipe (5). The installation structure avoids that the radar level meter is immersed in rainwater, prevents the sewage in the sewage tank from splashing owing to stirring to corrode a bell mouth of the radar level meter, and simultaneously guarantees the effective measurement for the liquid level of the sewage tank by the radar level meter. The installation structure is outstanding in effect, simple in structure, convenient in installation, easy in implementation and worthy of popularization and application.

Owner:GUIYANG AL-MG DESIGN & RES INST

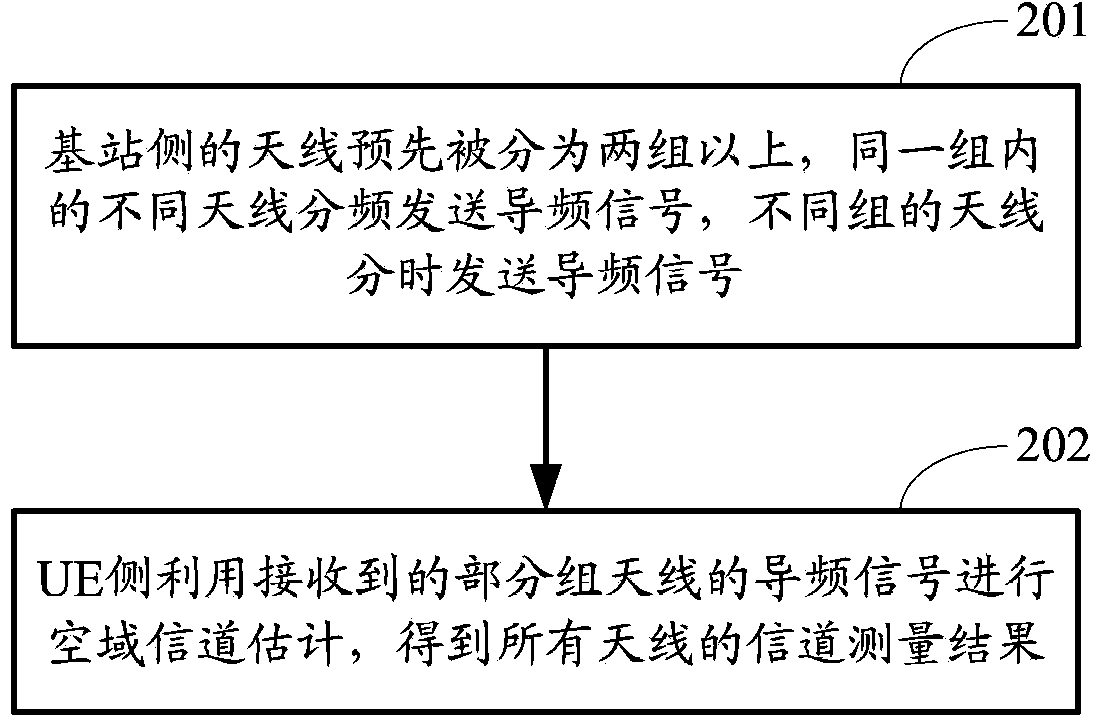

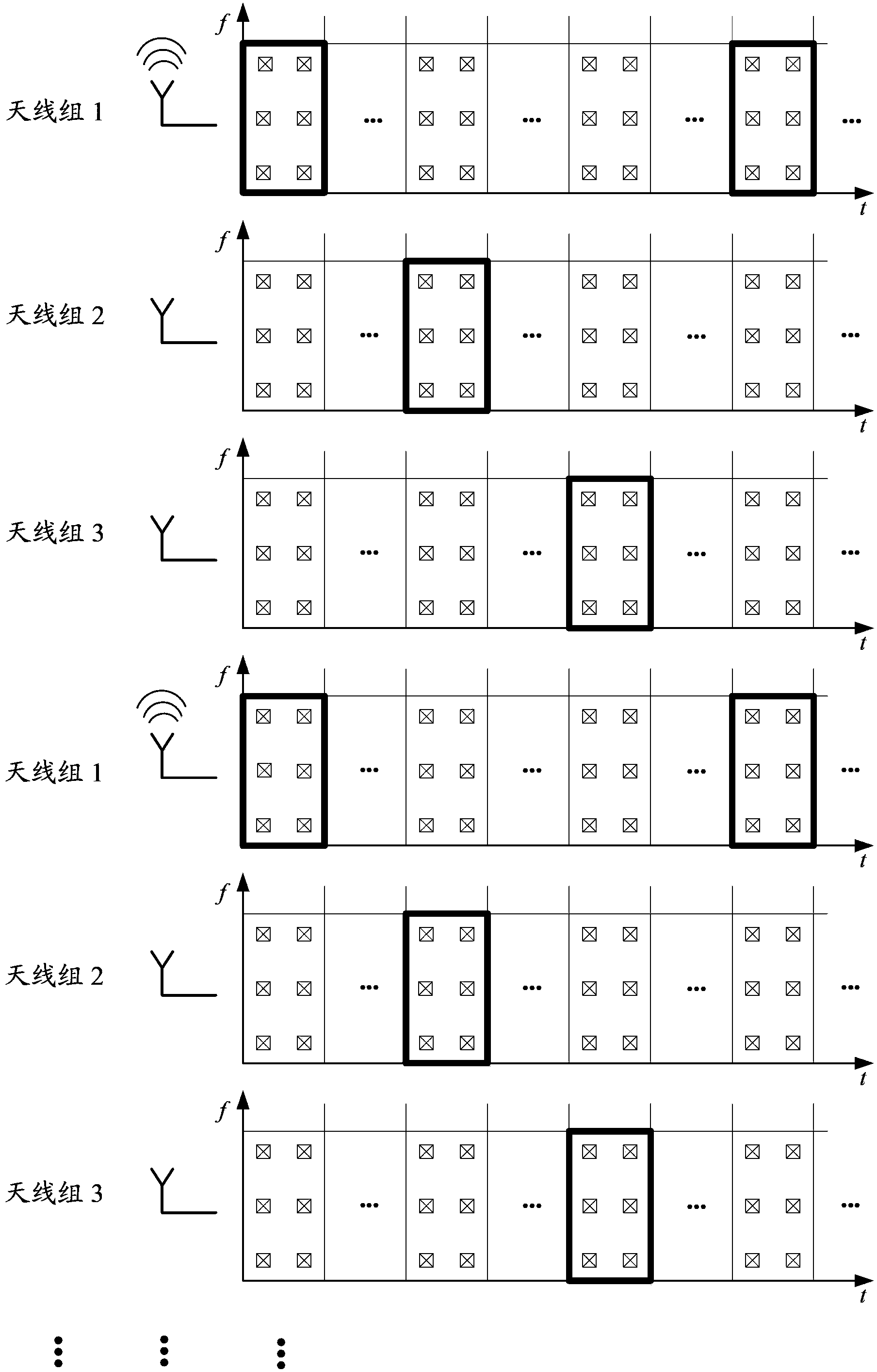

Channel measuring method for large-scale antennas, and user terminal

ActiveCN104348763AReduce overheadGuaranteed measurementSpatial transmit diversityChannel estimationChannel parameterTime delays

Provided are a channel measurement method for large-scale antennas, and a user terminal. The method comprises: pre-dividing antennas at a base station side into more than two groups, and a user terminal receiving pilot signals which are sent by different antennas in the same group at the base station side by adopting a frequency division manner and antennas in different groups by adopting a time division manner; and using the received pilot signals of some groups of antennas to conduct airspace channel estimation, so as to obtain channel measurement results of all the antennas. The present invention can ensure the integrity of channel measurement while reducing the pilot overhead. In addition, the user terminal has no need to conduct airspace channel estimation after waiting to receive the pilot signals of all groups of antennas, thereby reducing the time delay of channel parameter feedback.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com