Propellant combustion tail gas quantitatively measuring device

A quantitative measurement and propellant technology, applied in fuel oil testing, material inspection products, etc., can solve the problems of inconsistent exhaust gas components, poor repeatability of experimental data, interference with exhaust gas component testing, etc., to achieve accurate test results and prevent moisture condensation , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

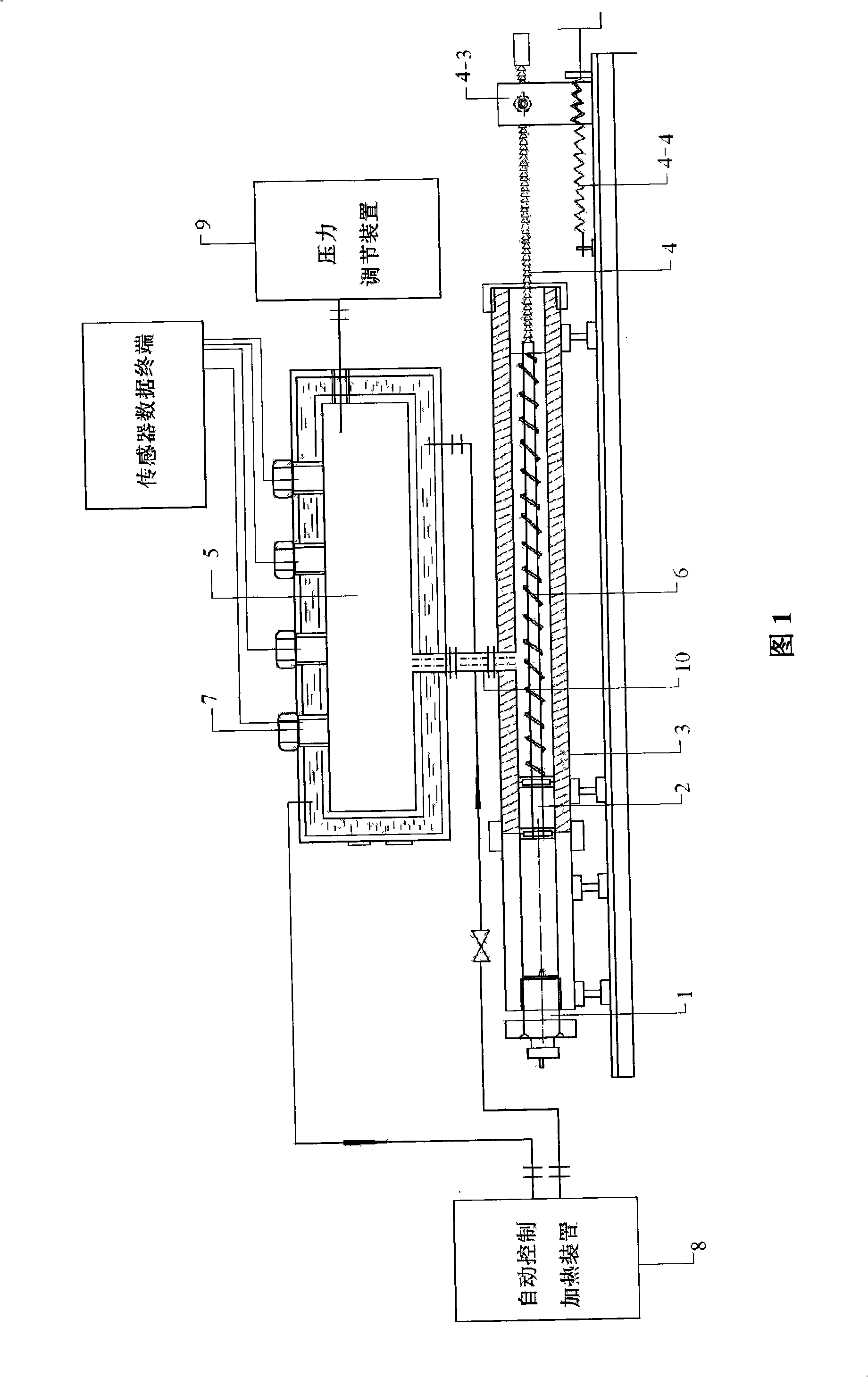

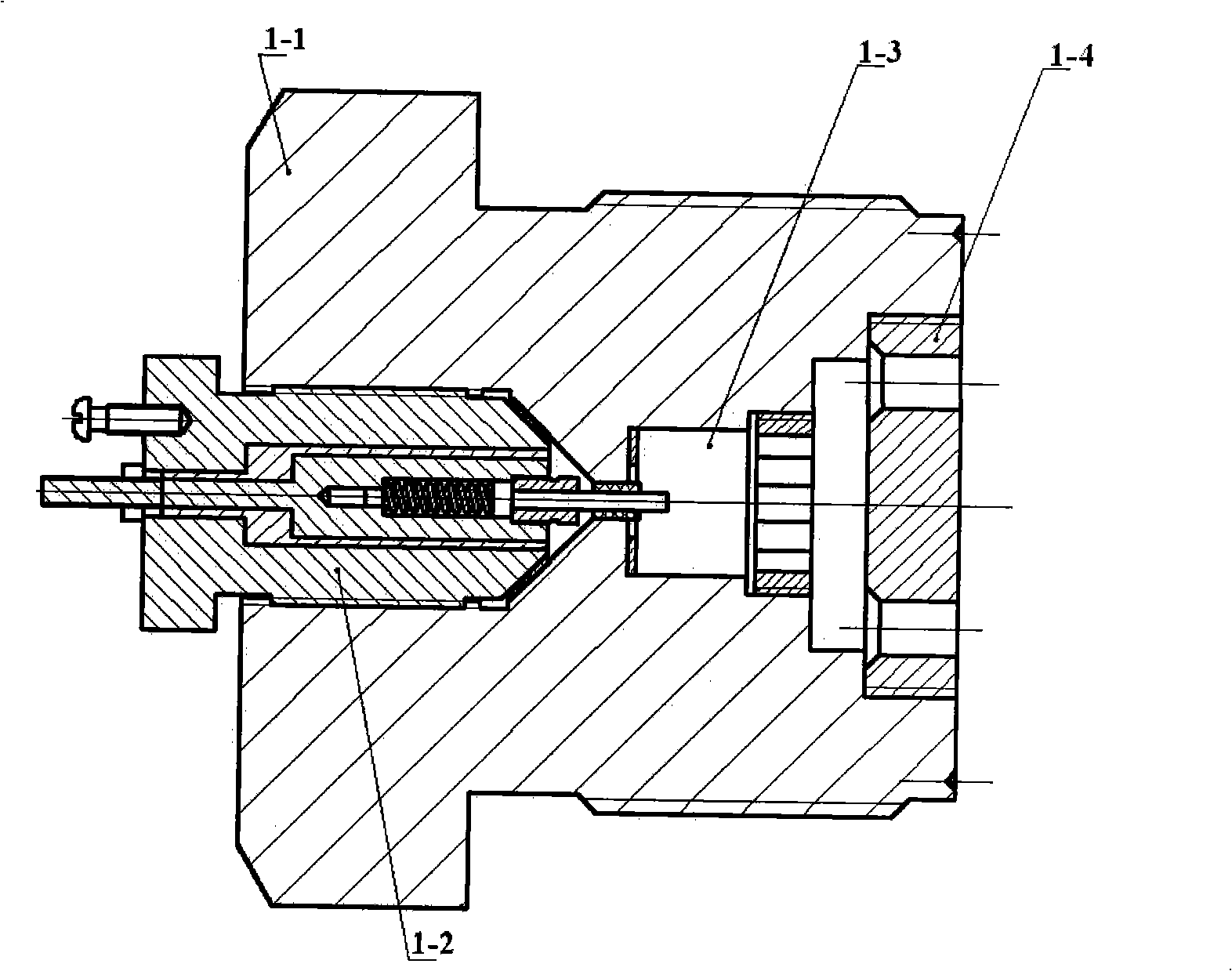

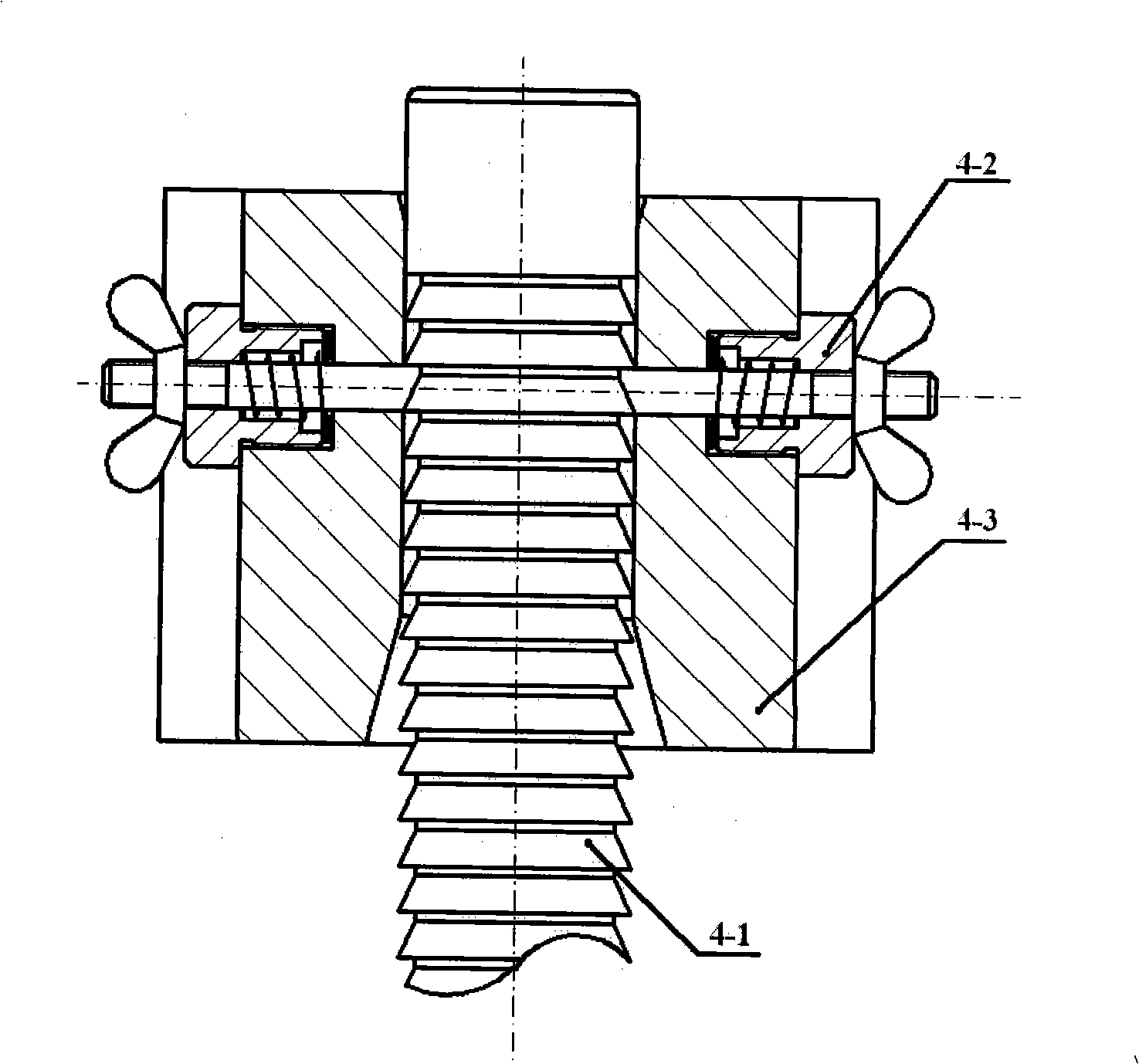

[0015] As shown in Figure 1, the preferred embodiment of the propellant combustion tail gas quantitative measurement device of the present invention comprises an electric ignition head 1, a piston 2, a launch tube 3, a tail cover with a central hole, a pawl brake 4, a gas test chamber 5, First compression spring 6, automatic control heating device 8, pressure regulating device 9, four measuring sensors (not shown in the figure). The design of the first compression spring 6 should be based on the internal ballistic principle of the gun and the law of energy conservation, and be designed and processed into various specifications according to the theoretical working ability and corresponding energy loss of different propellant samples to be tested. Stage clip 6 is made by the 30CrMnSi material of φ 5~10mm specification. During the use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com