Tester of cement setting time

A time measurement and cement setting technology, which is applied in the field of cement setting time tester and cement performance quality measurement device, which can solve the problems of complicated operation and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

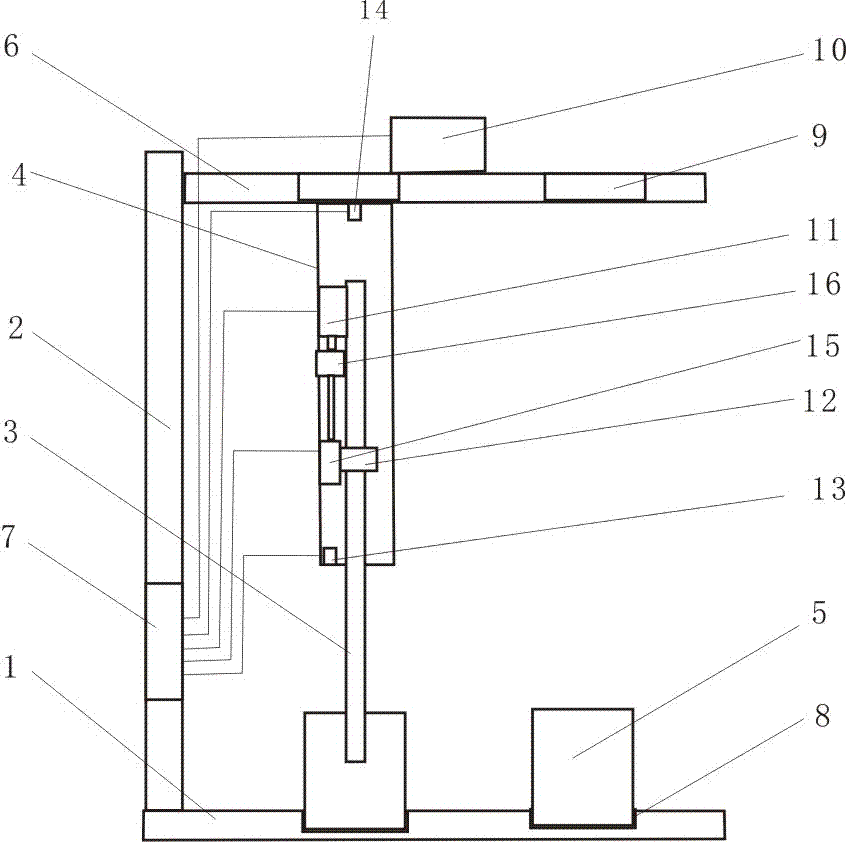

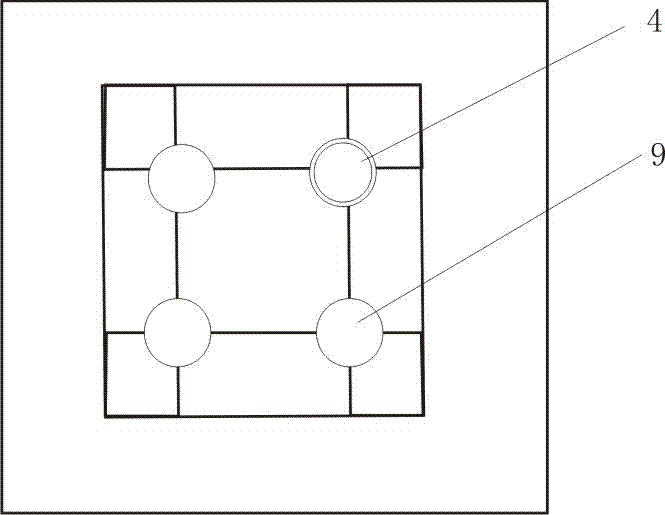

[0022] Embodiment 1: The test needle head position sensing device includes a distance sensor 13 in the vertical direction and a test needle displacement sensor 14 , and the distance sensor 13 and the test needle displacement sensor 14 are respectively connected to the controller 7 with signals. The distance sensor 13 in the vertical direction can measure the distance between the test needle control frame 4 and the cement sample surface on the test formwork frame 8 on the base 1, and the test needle displacement sensor 14 can measure the distance between the test needle control frame 4 and the test needle control frame. 4 position, the information of the position of the test needle head can also be obtained, and the signal when the test needle head touches the cement sample can be obtained by integrating the above information through the controller 7.

Embodiment 2

[0023] Embodiment 2: The test needle position sensing device is an electrification sensor. When the test needle 3 can be connected to a weak current, when the test needle touches the cement sample, the electrification sensor will sense the test needle control frame 4 The current, so as to obtain the signal when the test needle touches the cement sample. Since its structure is relatively simple, the accompanying drawings are omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com