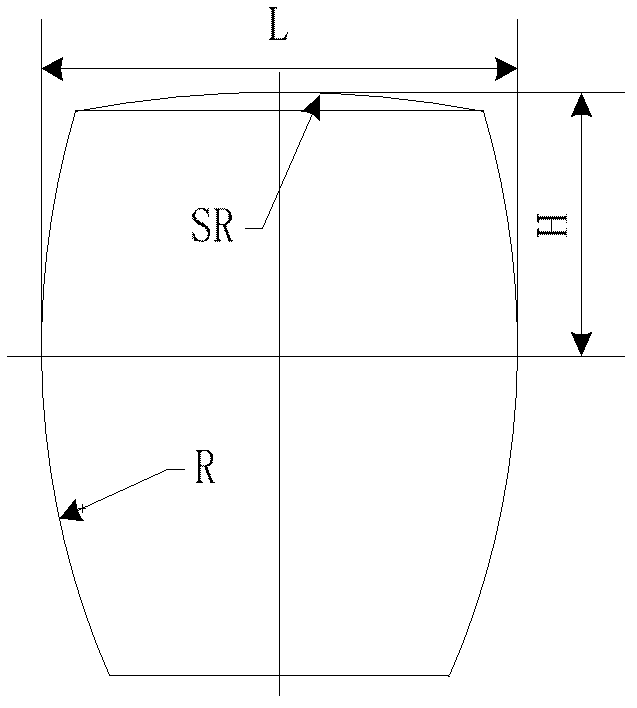

Measurement method and measurement instrument of revolution body part

A technology of measuring instrument and rotator, which is applied in the direction of measuring devices, instruments, optical devices, etc. It can solve the problems of unrealization, adjustment error, and inability to guarantee the overall level of the workbench, etc., and achieve the effect of fast speed and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

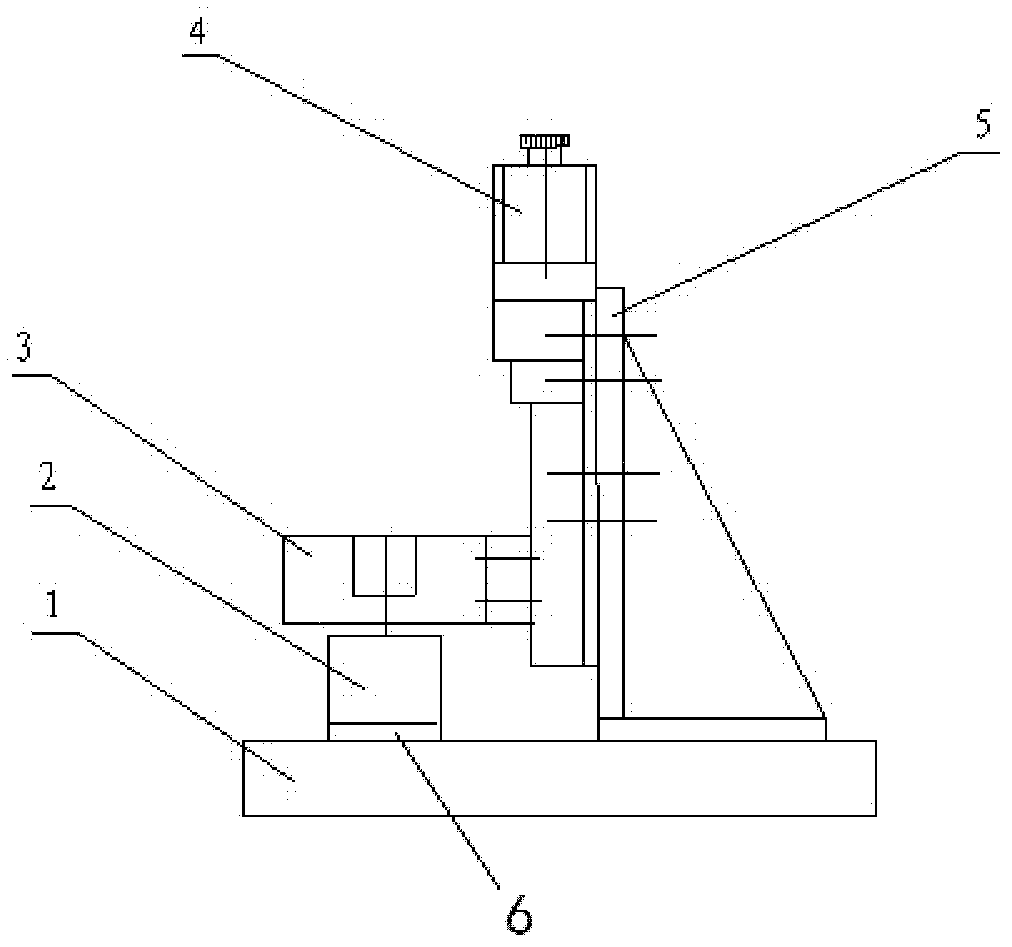

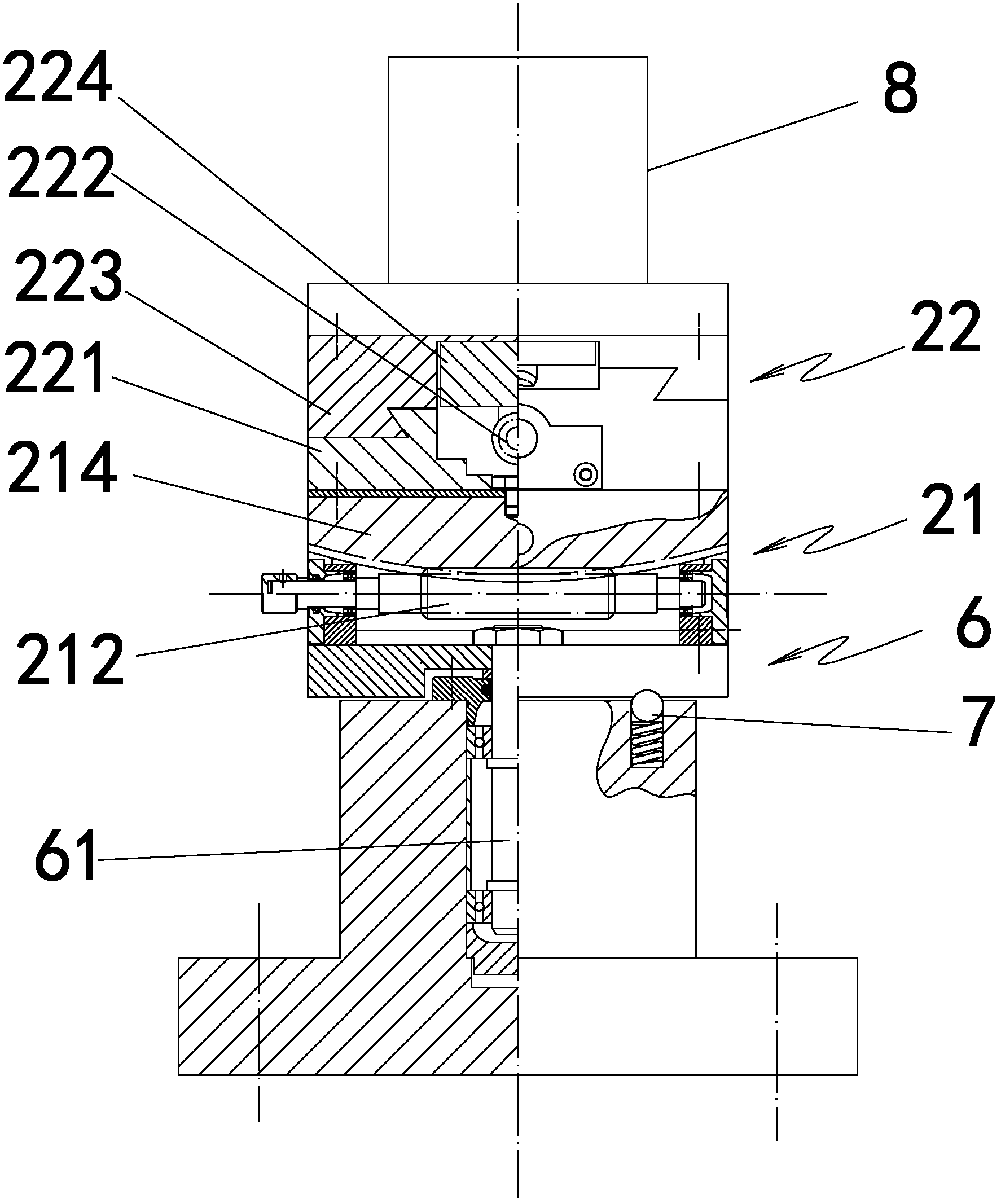

[0024] An embodiment of the measuring instrument of the present invention is Figure 2-Figure 4 As shown, it includes a base 1 and a column 5 fixed on the base 1. An optical probe 3 is installed on the column 5 to move along the vertical direction, and an electric translation platform that drives the optical probe 3 to reciprocate vertically is installed on the top of the column 5. 4. A workbench for placing and rotating parts is correspondingly provided on the base 1 under the optical probe 3 . The workbench includes a turntable 6 and an angular displacement adjustment table 2 set up from bottom to top. The turntable on the top of the turntable 6 rotates around the axis of its vertical shaft 61. The shaft 61 is supported by a precision B-grade bearing and is lifted by a spring. The positioning mechanism 7 formed by the cooperation of the steel ball and the corresponding positioning pit is indexed at 90°. In addition, the base 1 is also equipped with a grating ruler for measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com