Patents

Literature

1146results about How to "Guaranteed positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oligonucleotides comprising a molecular switch

ActiveUS20050042638A1Strong specificityGuaranteed positioningSugar derivativesMicrobiological testing/measurementBinding domainMolecular switch

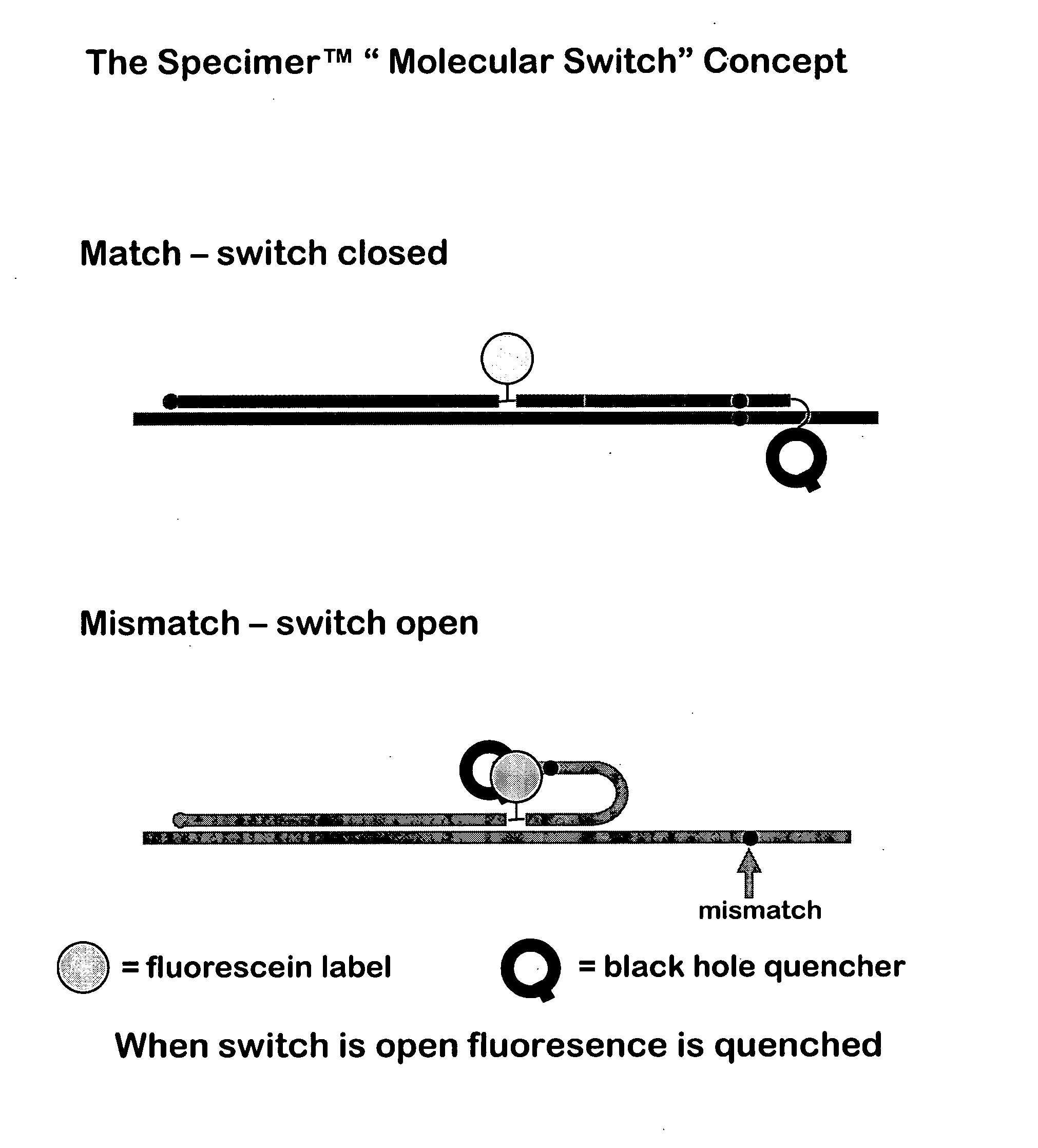

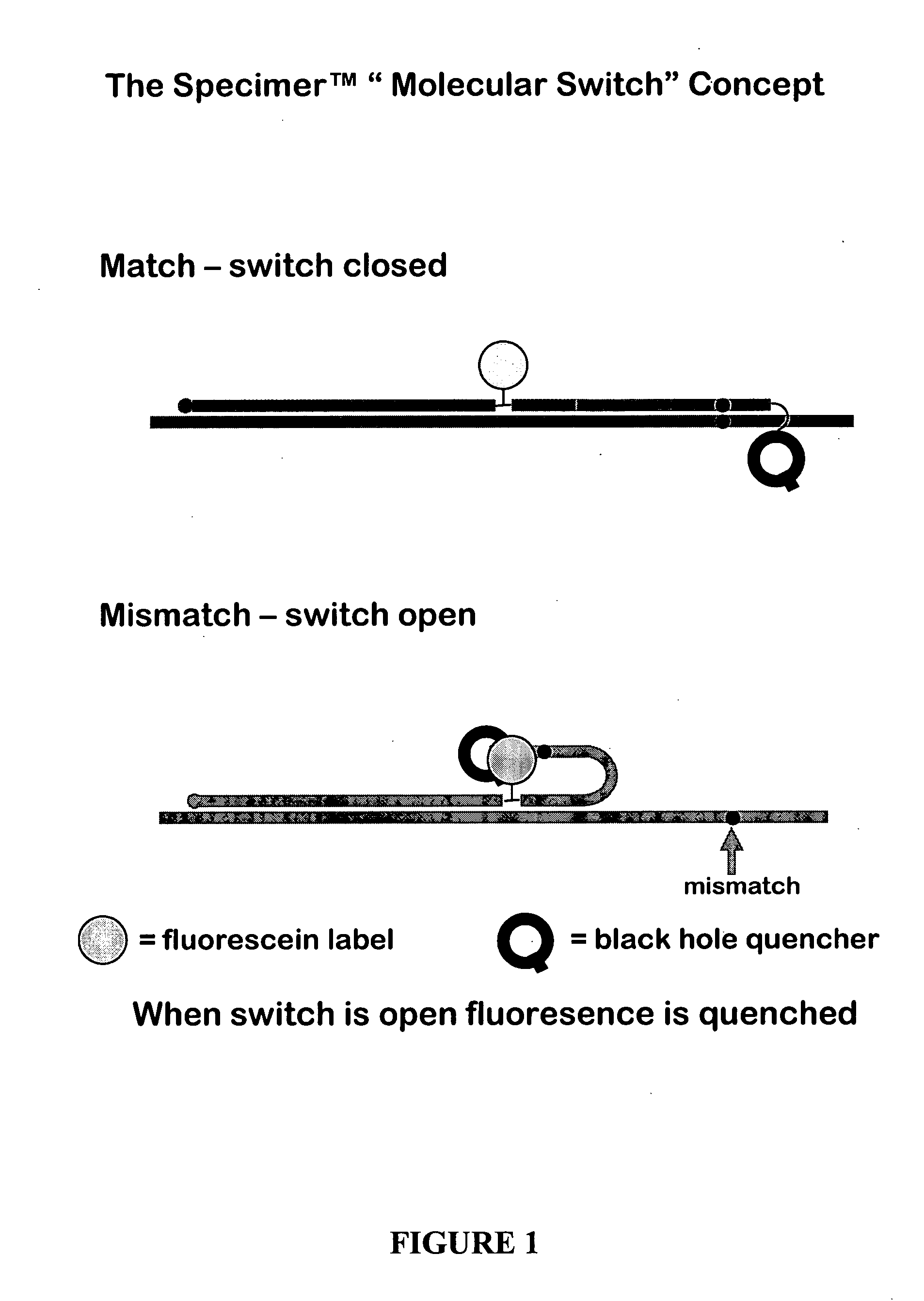

This invention relates to oligonucleotides comprising a molecular switch which may exist in an “open” or “closed” position. The molecular switch portion of the probe is particularly sensitive to the identity of sequences complementary to the molecular switch. Oligonucleotides containing a molecular switch are applicable to all kinds of hybridization processes. Due to the sensitivity of the switch domain of the oligonucleotide, probes containing a molecular switch are particularly useful in the identification of single point mismatches. More specifically, a portion, but not all, of the oligonucleotide becomes unbound from a mismatched target. The invention further relates to methods of using said oligonucleotides for research reagents, and clinical diagnostics. An exemplary oligonucleotide comprises a first hybridizable domain, a second bridging block domain, and a third binding domain.

Owner:GEN PROBE INC

Breast neoplasms ultrasonic image segmentation method based on improved level set algorithm

InactiveCN104599270AGuaranteed positioningReduce over-segmentationImage enhancementImage analysisSonificationAlgorithm

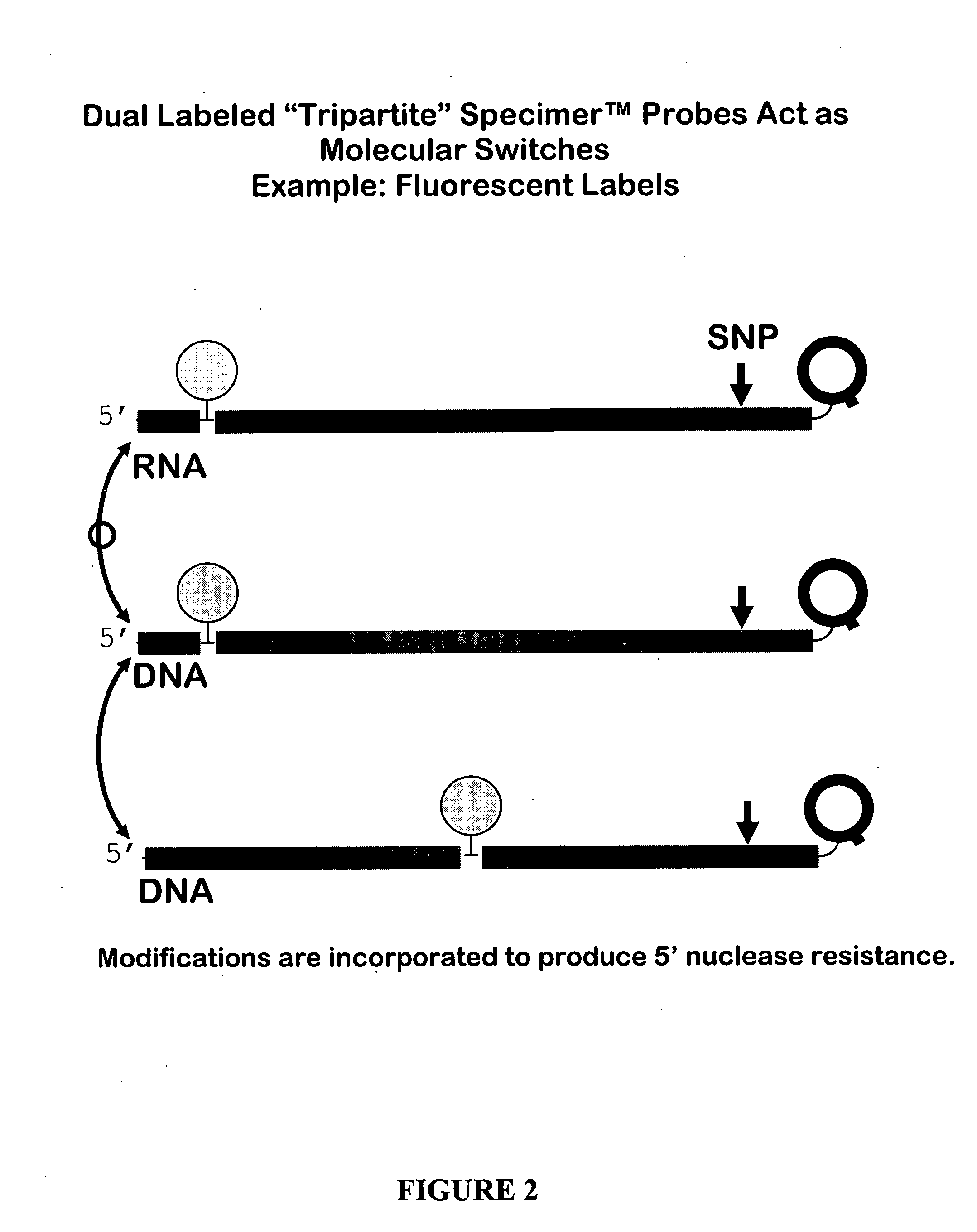

The invention belongs to the field of treatment of medical images, and relates to a breast neoplasms ultrasonic image segmentation method based on improved level set algorithm. The method is characterized in that the original image is pre-treated and remains the effective area, the speckle noise is removed, so as to achieve the purpose of protecting the boundary; the image is adaptively segmented according to the threshold. The method comprises the steps of (1) inversing color for the image; (2) determining the threshold; (3) screening candidate areas; (4) arranging the rest candidate areas; (5) determining seed points. With the adoption of the method, the seed points can be quickly found, the seed points can be kept in a neoplasms area, and the accurate determination of the seed points ensures the accuracy of area growth and level set; in addition, the seed points grow in the area, and the initial contour can be found; the classic Chan-Vese (CV) algorithm is improved; the global statistics information of the curved line of the contour in the development process is considered during calculating the global statistics information; the accuracy of the segmentation result is ensured, and moreover, the automation level of the segmentation method can be further improved.

Owner:BEIJING UNIV OF TECH

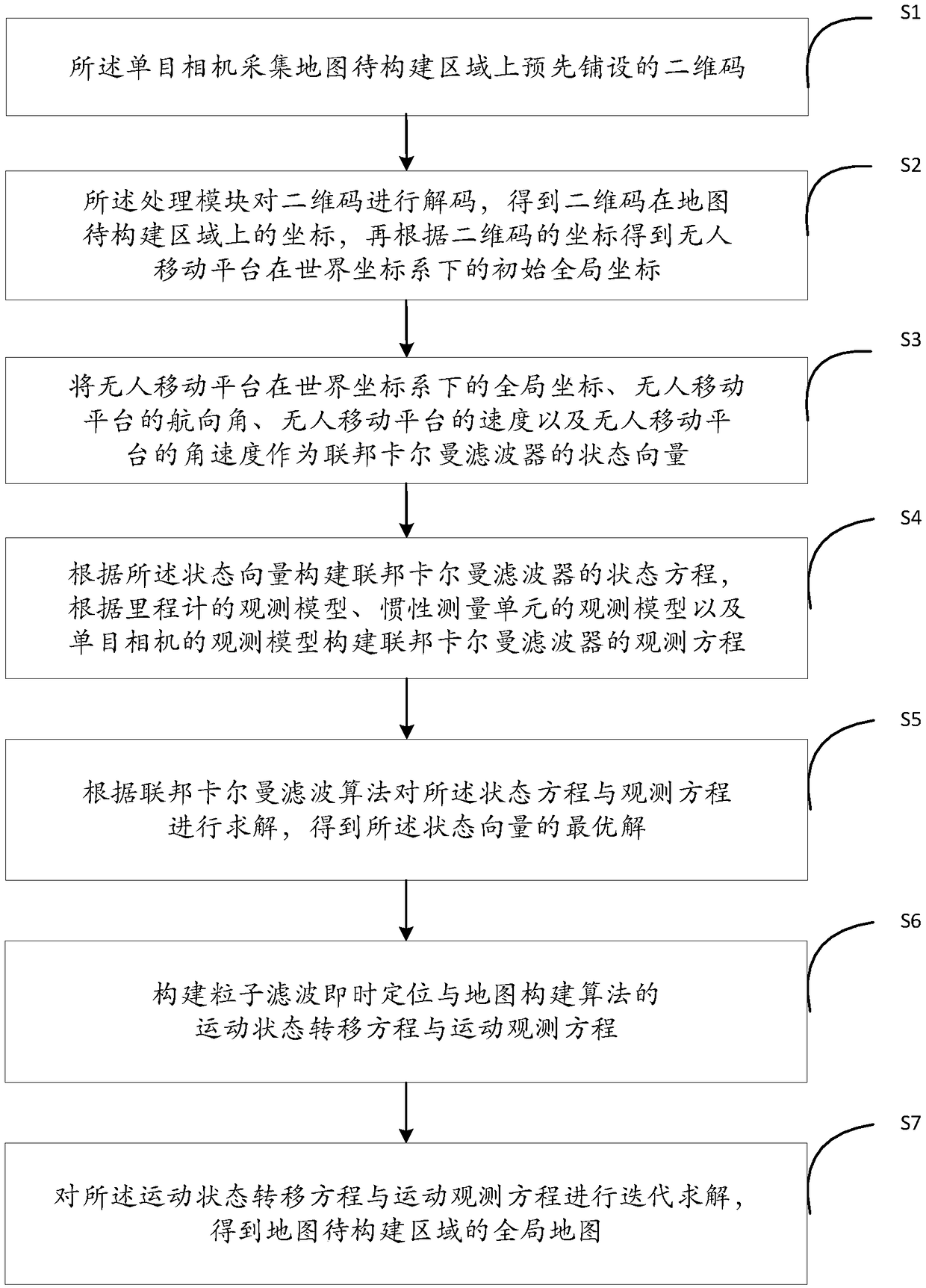

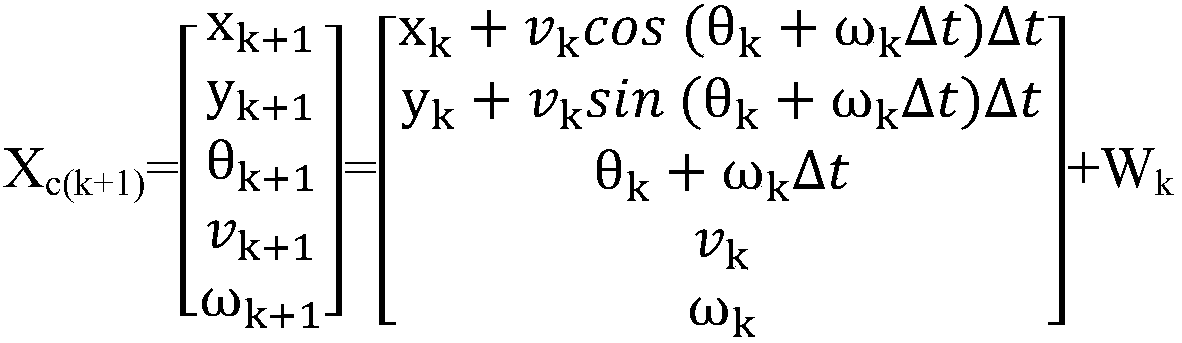

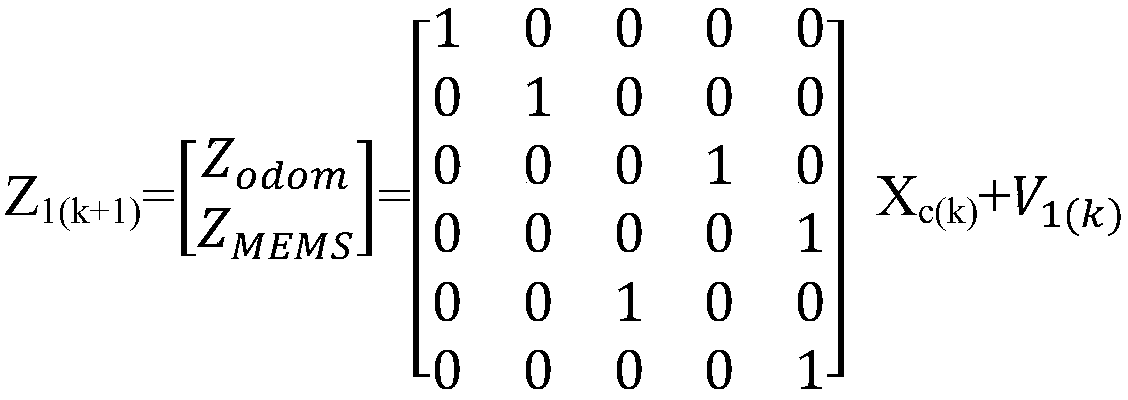

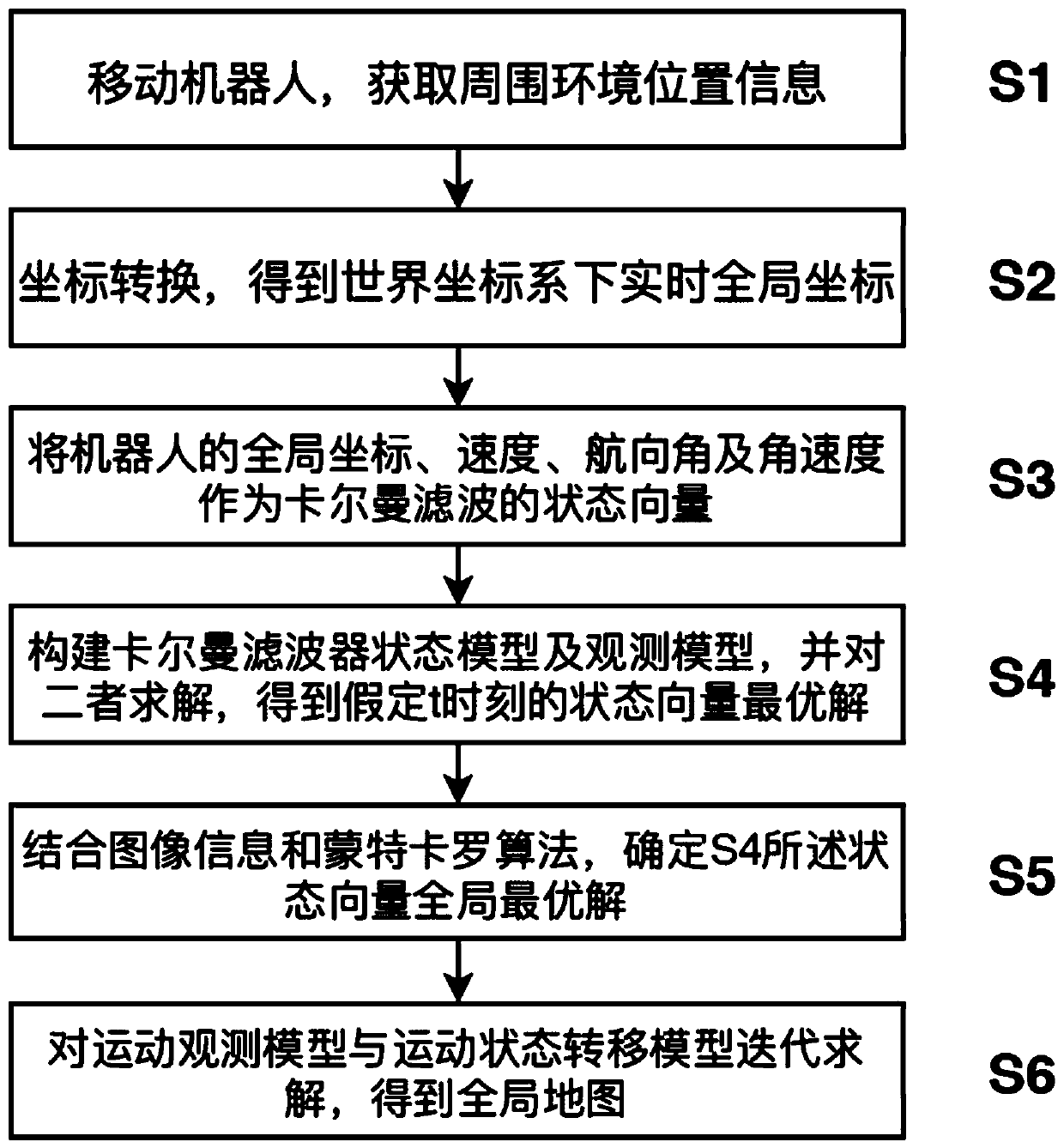

Method for instant positioning and map building based on fusion of laser and two-dimensional code

ActiveCN109211251AImprove robustnessHigh precisionInstruments for road network navigationSimultaneous localization and mappingInformation processing

The invention provides a method for the instant positioning and the map building based on the fusion of a laser and a two-dimensional code. The driving distance and the speed information of an odometer, a two-dimensional code acquired by a monocular camera, and the information of an inertial measurement unit are integrated into a state vector. An observation equation of the federated Kalman filteris constructed according to an observation model of the odometer, an observation model of the inertial measurement unit, and an observation model of the monocular camera. The two-dimensional code positioning information is added on the basis of a traditional odometer and the inertial measurement unit, thereby obtaining the optimal solution of the state vector of an unmanned mobile platform; the pose prediction information with higher accuracy is formed by using the characteristics of the fastness and the accuracy of the two-dimensional code information processing, thereby reducing the numberof particles in the method for particle filter instant positioning and map building, and improving the low-power processor, such as the positioning accuracy of the unmanned mobile platform. The positioning effect of the unmanned mobile platform in the complex environment is ensured, map building is completed, and the application need in the complex environment is met.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

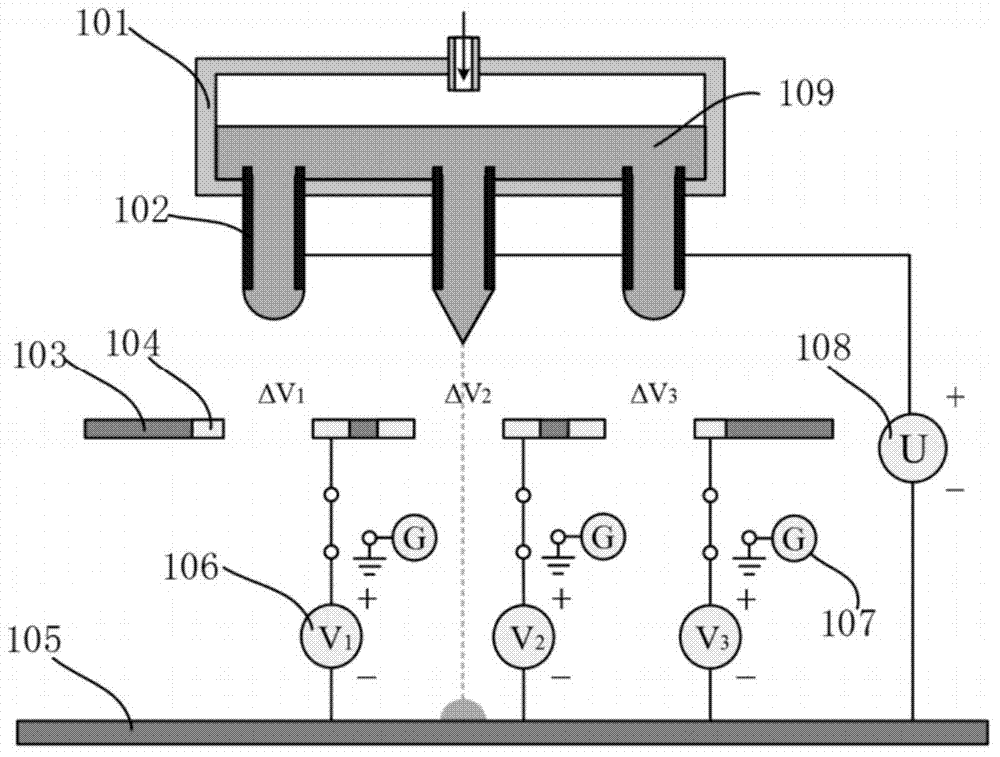

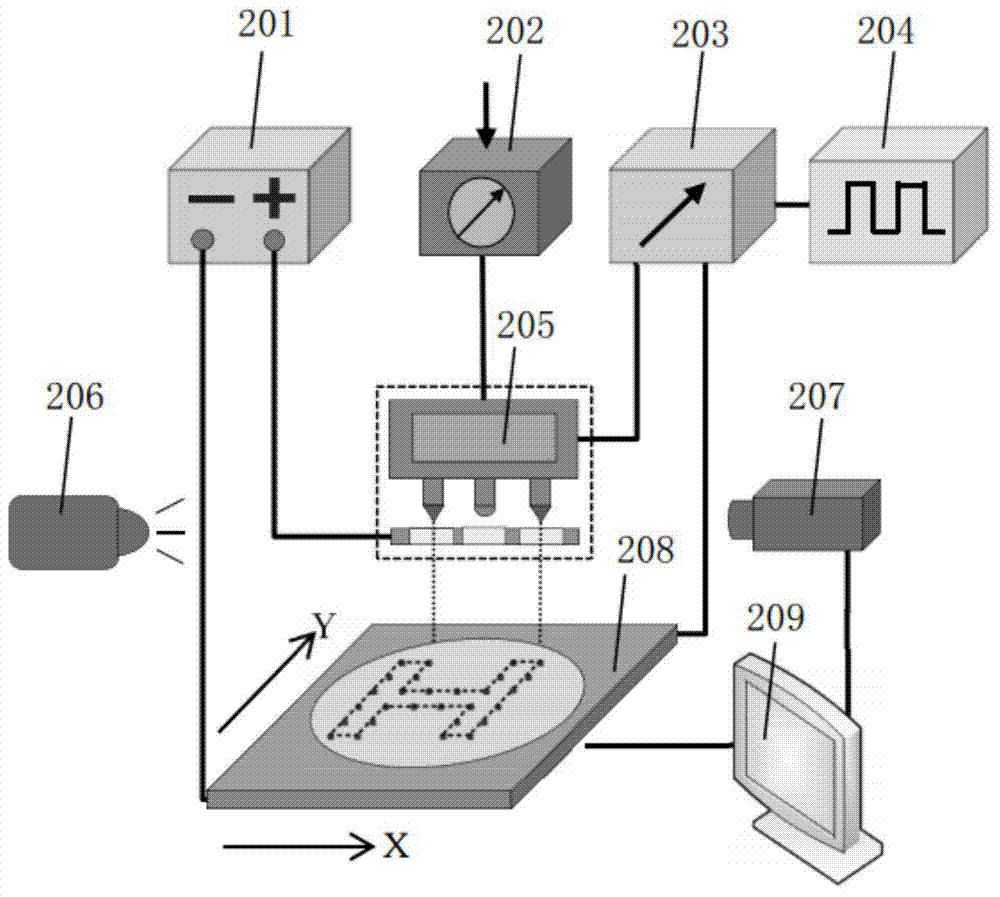

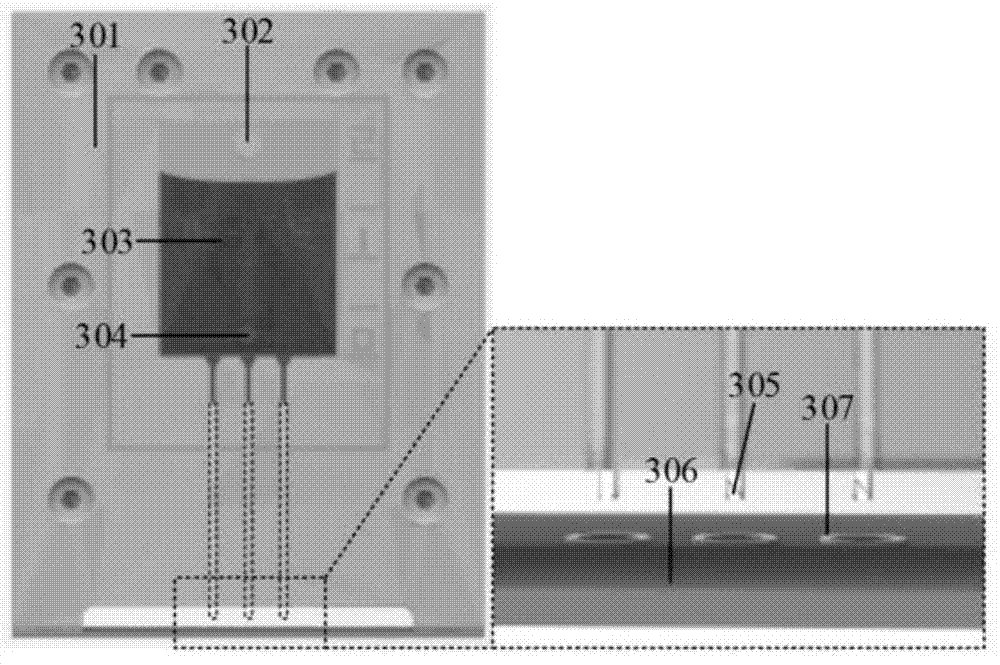

Array electric fluid jet printing head characterized by independently controllable nozzle jet and realization method of independent control of jet of nozzles

ActiveCN104191819AAchieve independent controllable injectionSimple structurePrintingSpray nozzleEngineering

The invention discloses an array electric fluid jet printing head characterized by independently controllable nozzle jet. The array electric fluid jet printing head comprises a guide electrode layer arranged between a nozzle array and a receiving plate, and a plurality of round holes corresponding to nozzles in number are formed in the guide electrode layer; the centers of the round holes are collinear with the centers of the nozzles; a circle of conducting ring is coaxially disposed on the outer periphery of each round hole in the guide electrode layer, and is connected with one voltage source; and the nozzle array is connected with the jet voltage sources; and the voltage value of each voltage source is properly adjusted, so that the voltage differences of the nozzles required for jet printing and the corresponding conducting rings are greater than the voltage differences of the remaining nozzles, the field strength of the nozzles for jet is greater than the field strength needed to start the jetting, the field strength of the nozzles not required for jetting is lower than the field strength needed to start the jetting, and the independent control of all the nozzles can be realized. The invention further discloses a realization method of the independent control of the jet of the nozzles. The array electric fluid jet printing head and the realization method can solve the problems of complex structure and incapability of large-scale integrated use in the conventional independent jet control to printing heads.

Owner:HUAZHONG UNIV OF SCI & TECH

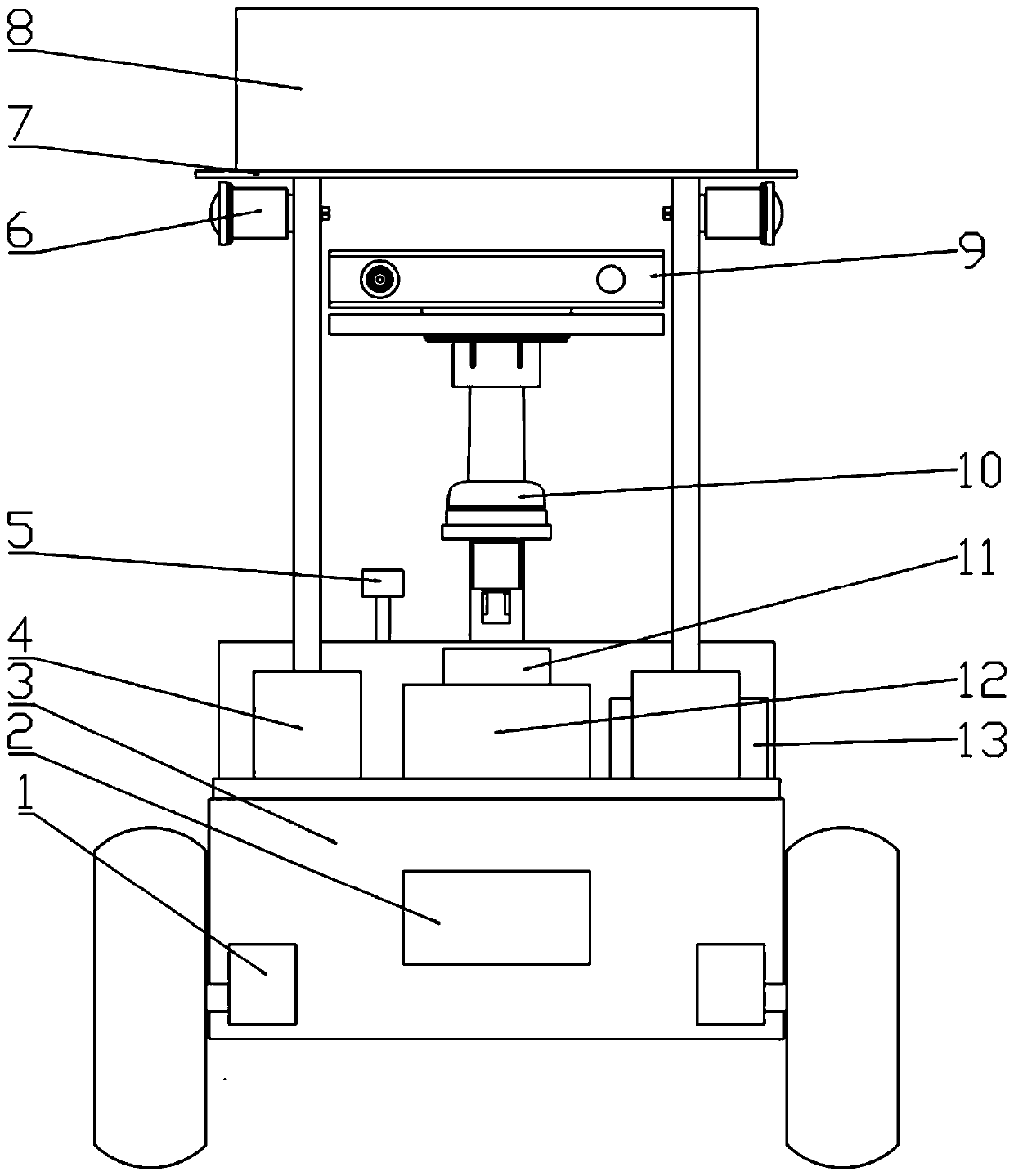

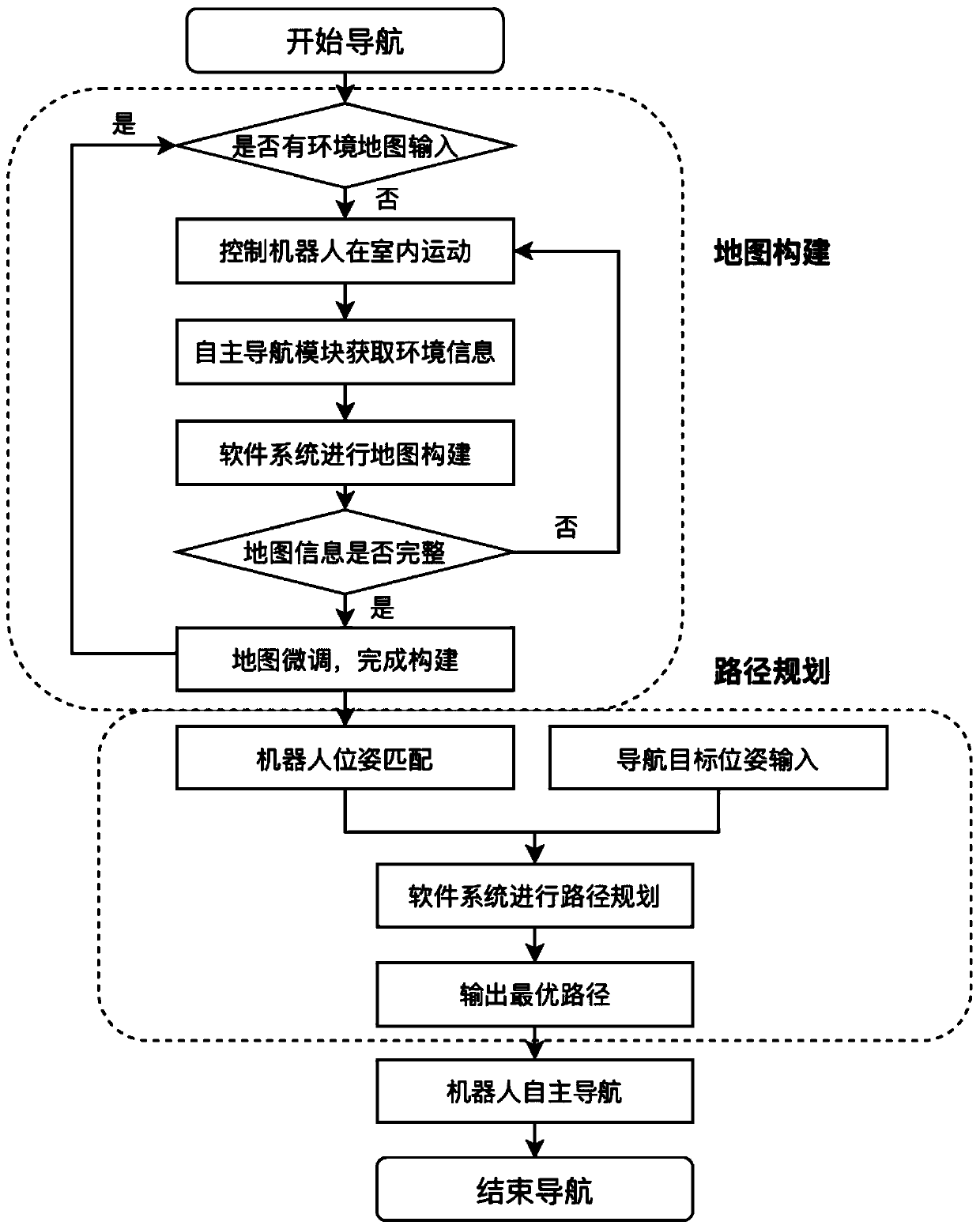

Livestock and poultry information sensing robot based on autonomous navigation and map construction method

ActiveCN109900280AImplement automatic detectionRealize automatic collectionImage enhancementInstruments for road network navigationMicrocontrollerLivestock

Owner:ZHEJIANG UNIV

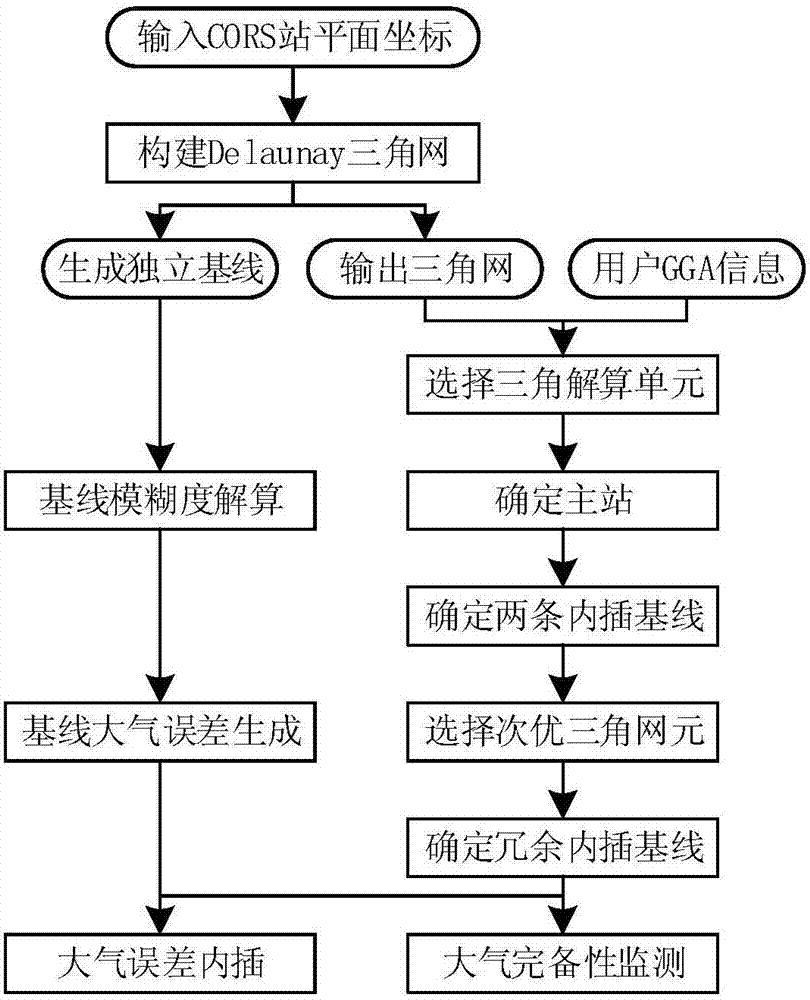

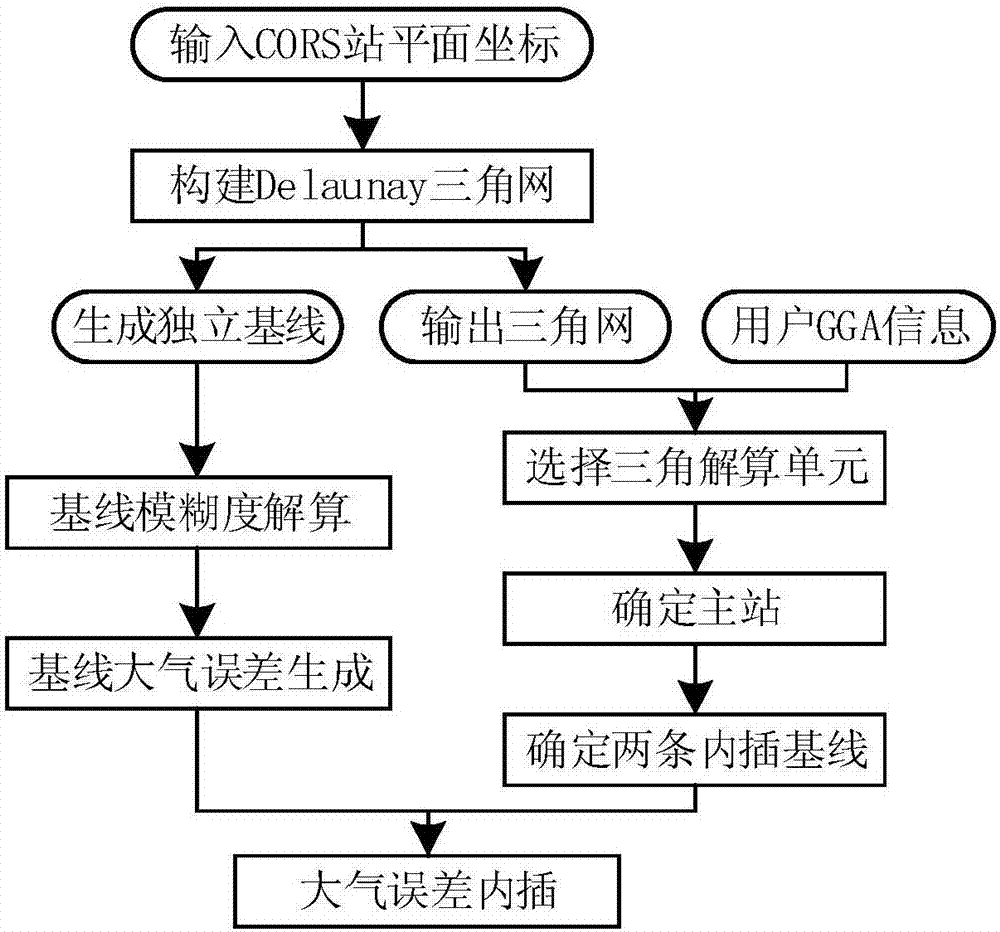

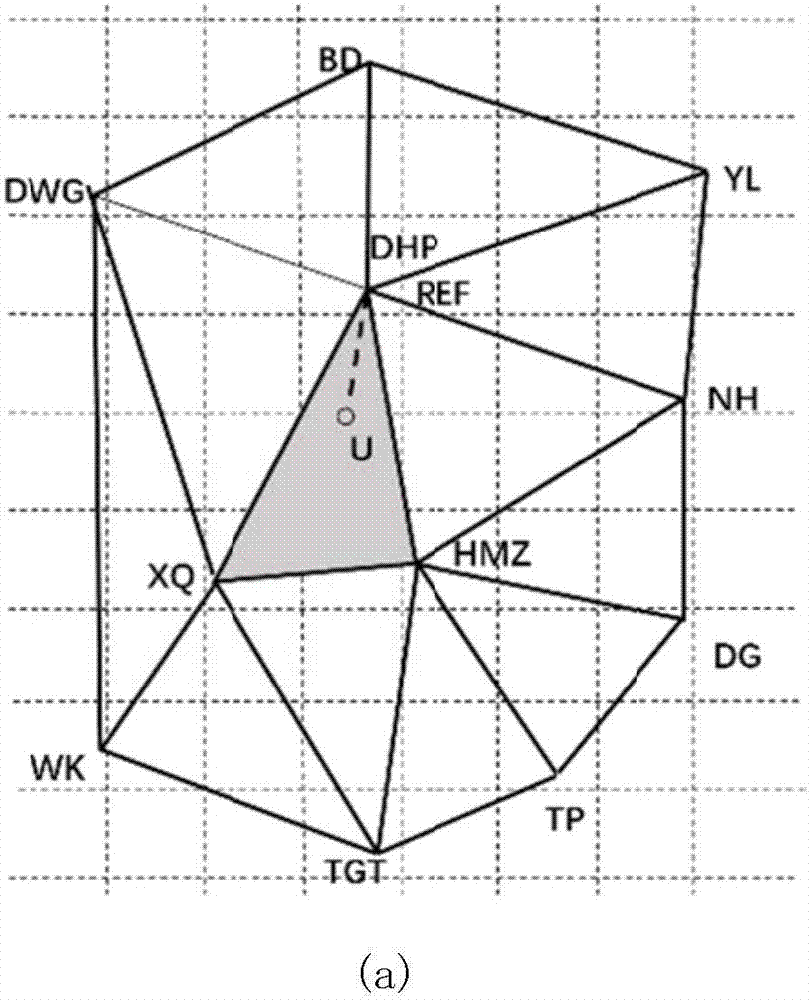

Delaunay-triangulation-network-based multi-redundancy network RTK atmospheric error interpolation method

ActiveCN106970404AIncrease the number ofSolve the problem of not being able to take advantage of redundant baselinesSatellite radio beaconingCentimeterBaselining

The invention discloses a delaunay-triangulation-network-based multi-redundancy network RTK atmospheric error interpolation method. A network RTK data processing center constructs a Delaunay triangulation network based on a correct coordinate of a CORS base station; after a user is accessed to a data processing center, an optimal triangular unit and a suboptimum triangular unit of the location of the user are selected; an atmospheric error interpolation base line number is extended; an MLIM ionized layer interpolation model and an RELIM tropospheric interpolation model are established; and an atmospheric interpolation completeness monitoring method of a moving station in a grid is provided. The interpolation precision of the MLIM ionized layer interpolation model is higher than that of the traditional model by three times and the interpolation precision of the RELIM tropospheric interpolation model is higher than that of the traditional model by 6 to 30 times; and the two models can still have high interpolation precision at an area with a large elevation difference at the base station. A regional CORS ionized layer and tropospheric completeness index can reach a centimetre-level interpolation precision, so that real-time positioning completeness monitoring of a network RTK user can be realized. With the method provided by the invention, a CORS base station around a user can be utilized fully; the atmospheric delay interpolation precision of the area can be improved; and the rapid and high-precision positioning of the user can be guaranteed.

Owner:SOUTHEAST UNIV

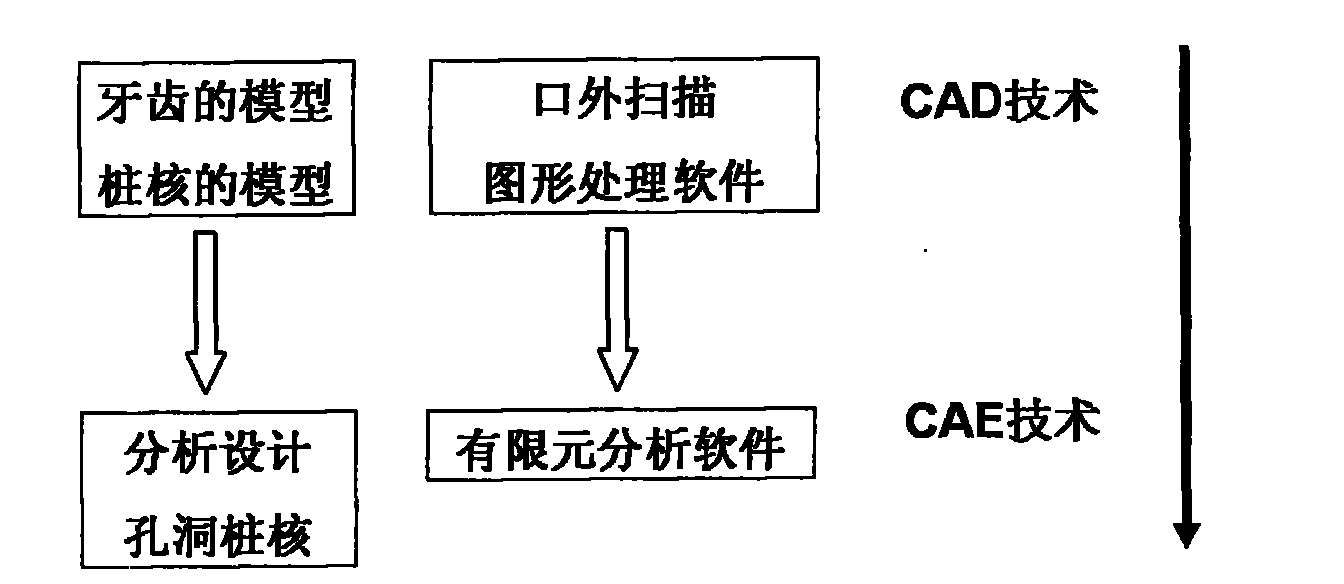

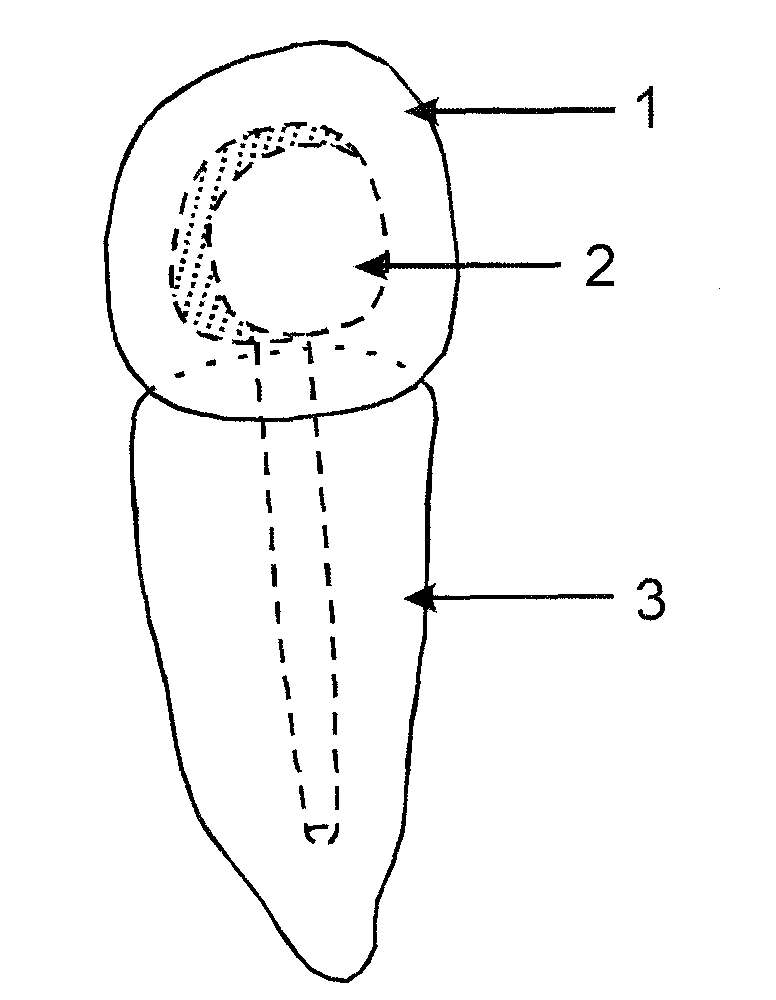

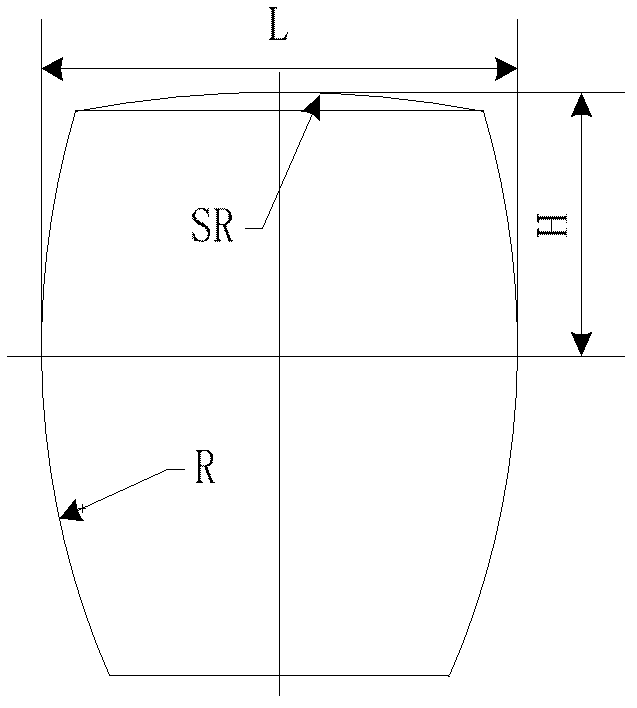

Integrated fiber post for dental restoration and preparation method thereof

ActiveCN101803958AHigh strengthImprove stress distributionImpression capsFastening prosthesisNumerical controlStress concentration

The invention discloses an integrated fiber post for dental restoration and a preparation method thereof. The integrated fiber post for dental restoration is characterized by integrating a post and a core and comprising a post and core tail part and a head core part; the conical structure of the post and core tail part is consistent with the conical structure of a dental drilling head; the head core part is in an umbrella cap structure; the lower edge of the umbrella cap structure is fully matched with the residual part of a defected tooth; the outline part of the umbrella cap structure is fully matched with a crown part; and a porcelain crown is directly sleeved on the head core part. The method for forming and machining the integrated fiber post comprises the following steps of: (1) acquiring CT (computed tomography) data of the defected tooth; (2) reconstructing the three-dimensional model of the tooth and a post and core crown through a computer; (3) building a CAD (computer-aideddesign) model of the integrated post and core; (4) transferring the information of the CAD model of the integrated fiber post and core into a CAM (computer-aided manufacturing) numerical control center; and (5) cutting and machining the integrated fiber post and core by a machining center of a numerical control machine. The fiber post of the invention has improved strength, reduced post and core abhesion in application, and avoidances of breakage of tooth posts and failure of restoration caused by stress concentration.

Owner:北京欧亚瑞康新材料科技有限公司

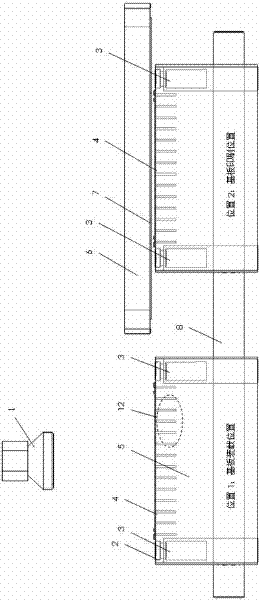

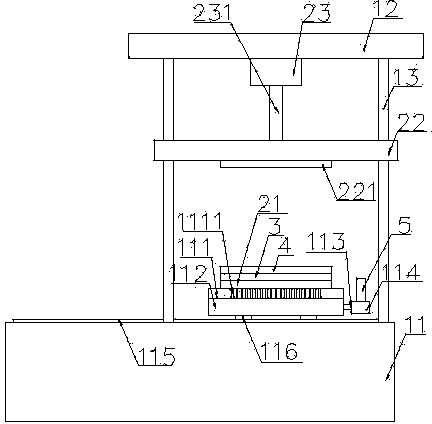

Substrate positioning method suitable for screen printing technology

The invention discloses a substrate positioning method suitable for a screen printing technology, which comprises the following steps of: adsorbing a substrate on the surface of a printing worktable; scanning by using an upper visual optical device to obtain the relative position of a reference mark of the substrate and a reference mark on the surface of the printing worktable; moving the substrate with the printing worktable until the substrate is below a printing screen frame, and scanning by using a lower visual optical device to obtain the relative position of the reference mark on the surface of the printing worktable and a reference mark of a screen; performing coordinate conversion to obtain a relative position relationship of the reference mark of the substrate and the reference mark of the screen because the reference mark on the surface of the printing worktable is scanned in two-time scanning, and performing fine adjustment on the screen frame; and printing when the substrate and the screen are completely aligned. The method is suitable for screen printing on a surface mount technology production line, electrode screen printing on a solar cell production line, and a similar production process for coating the surface of the substrate by using a scraper on the basis that the screen and the substrate are accurately aligned.

Owner:ZHEJIANG UNIV

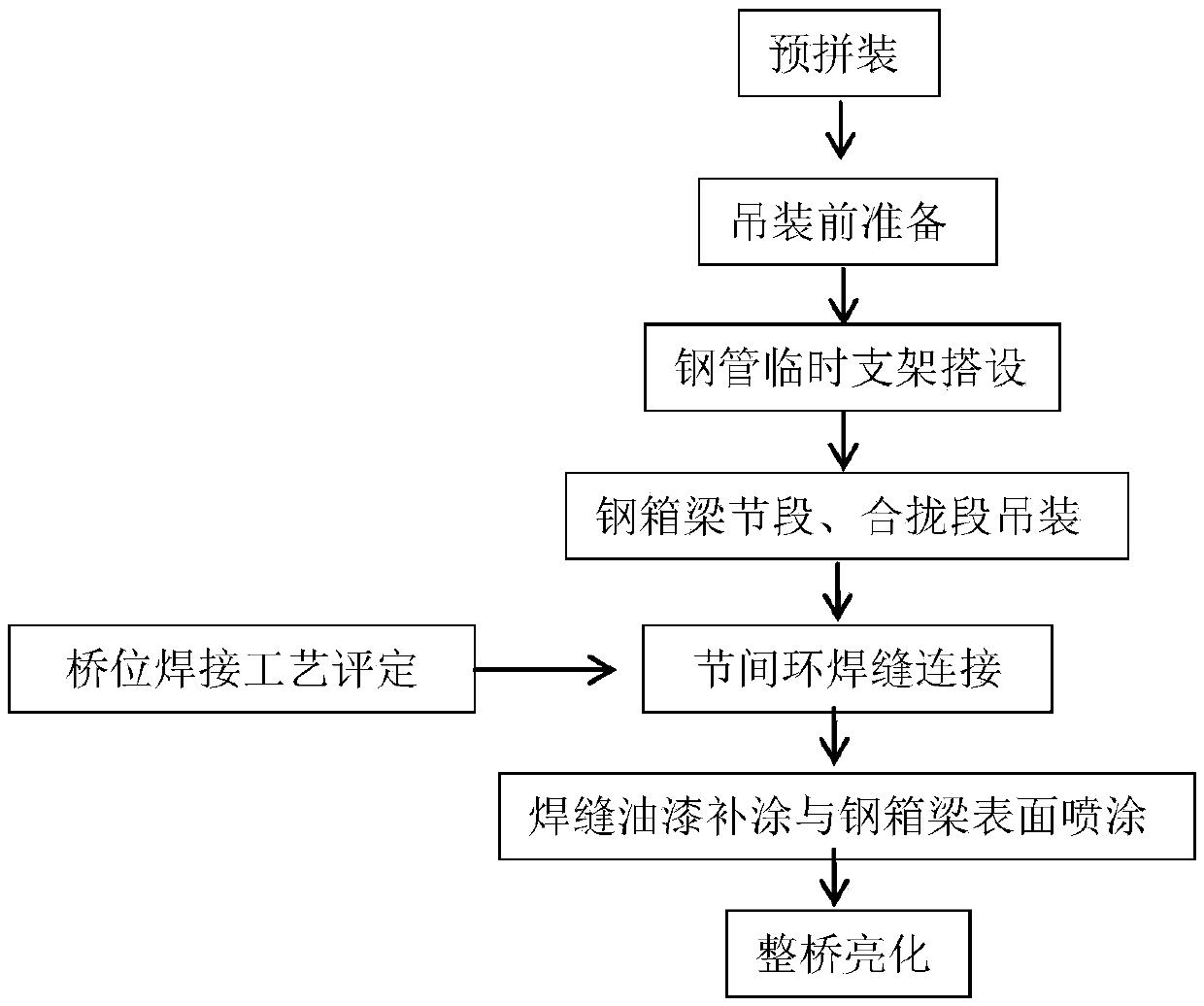

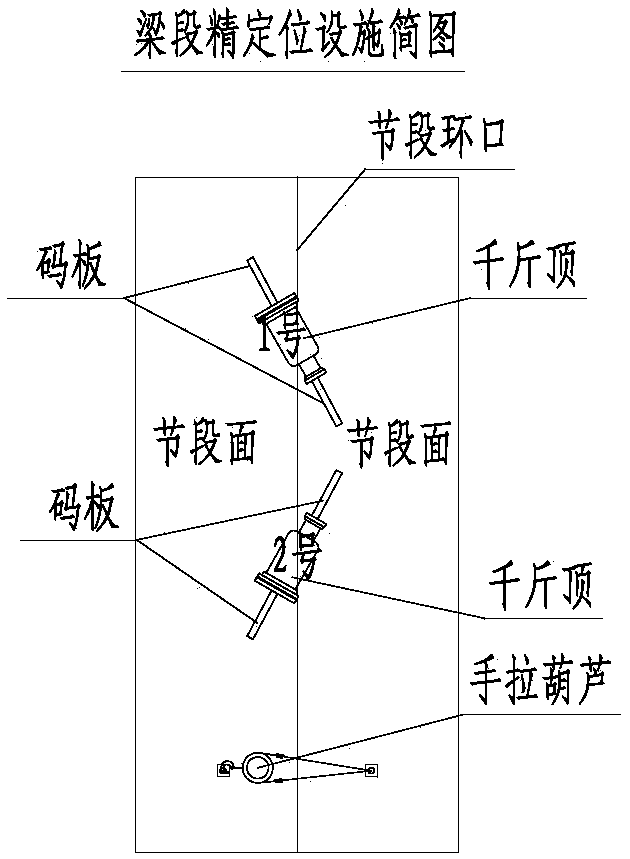

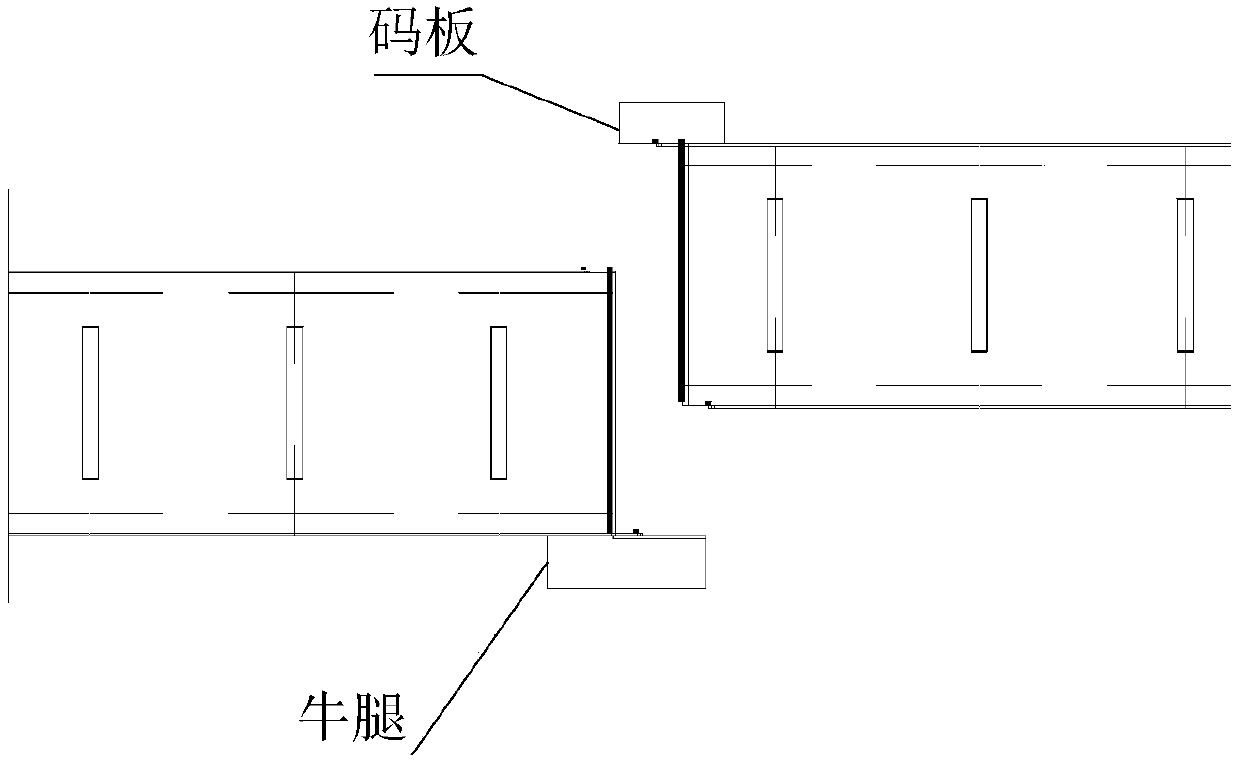

Limited bracket construction method of large-span S-shaped steel box girder

InactiveCN109594474ASmall footprintReduce the impactBridge erection/assemblyBridge materialsEngineeringSteel box girder

The invention discloses a limited bracket construction method of a large-span S-shaped steel box girder. The steel box girder comprises 14 small sections of prefabricated steel box girders; and the 14small sections of prefabricated steel box girders are assembled into seven large sections at a construction site, and then the seven large sections are hoisted and fixed. The construction method comprises the following specific steps of: prefabricating and assembling the steel box girders, constructing temporary brackets in water, hoisting and positioning steel box girder section blocks, connecting steel box girder interfaces, constructing closure sections and welding the collar extension of the steel box girders. According to the limited bracket construction method, a prefabricated assemblymode is used during construction; a floating crane is used for assembly, so that the occupation and pollution of a water area under a bridge are reduced; the parallel operation of multiple processes speeds up the construction progress and shortens the construction period; the temporary brackets are arranged only at circular seams of large-section girder joints; and the brackets occupy small space,thereby facilitating the navigation under the bridge in the construction state and reducing the influence on the navigation under the lake-across construction bridge and surrounding social environments.

Owner:合肥市公路桥梁工程有限责任公司

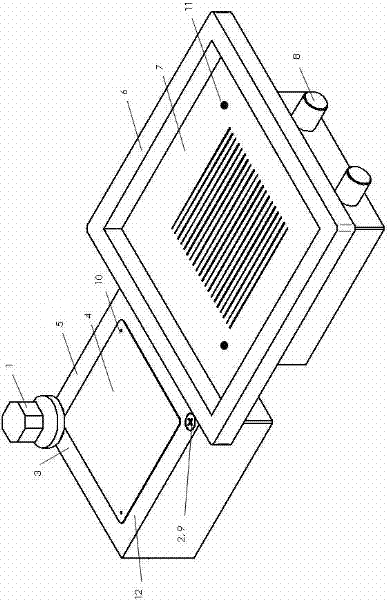

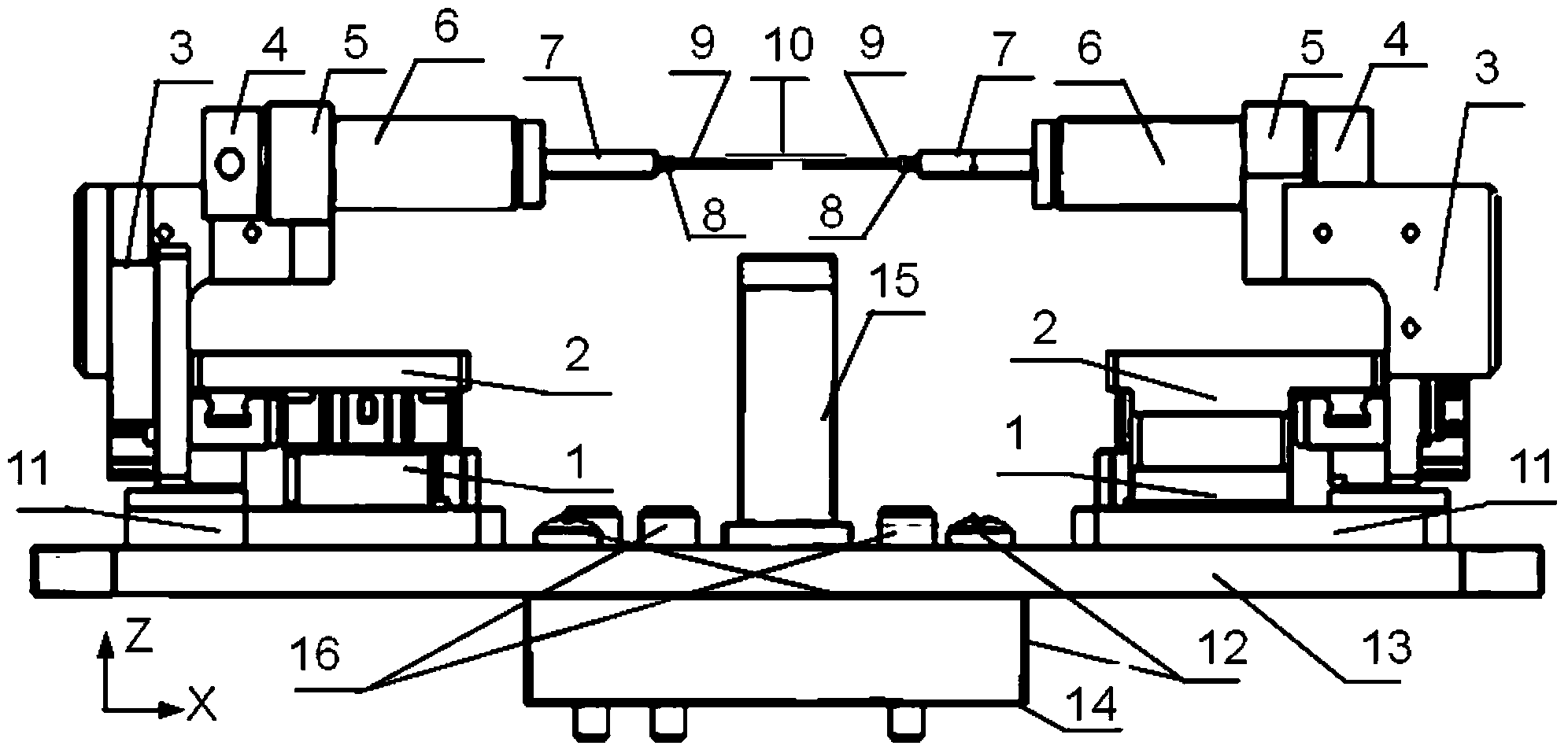

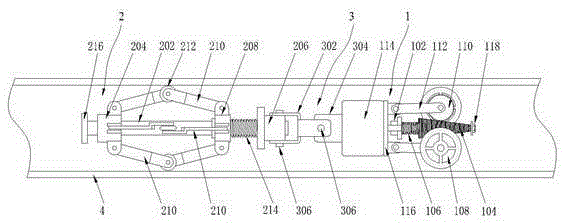

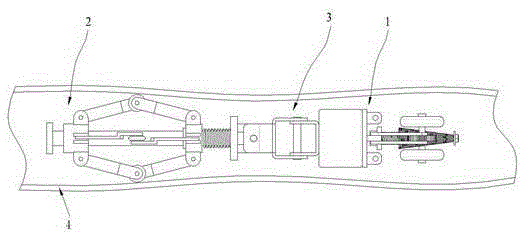

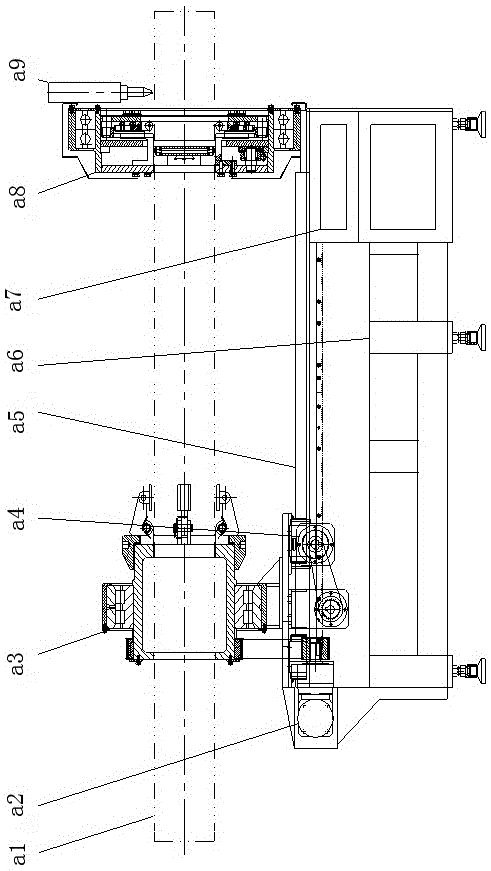

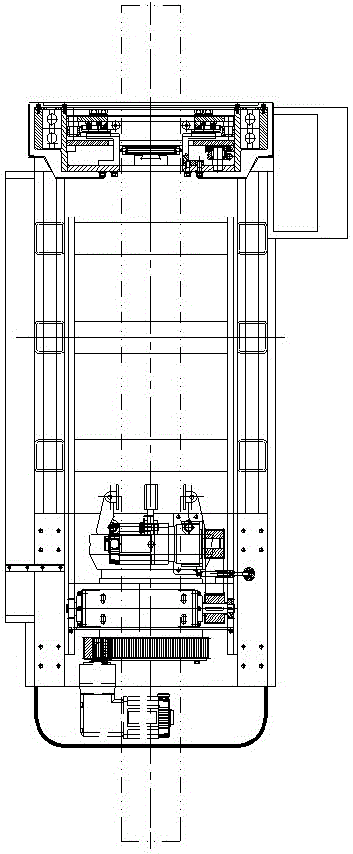

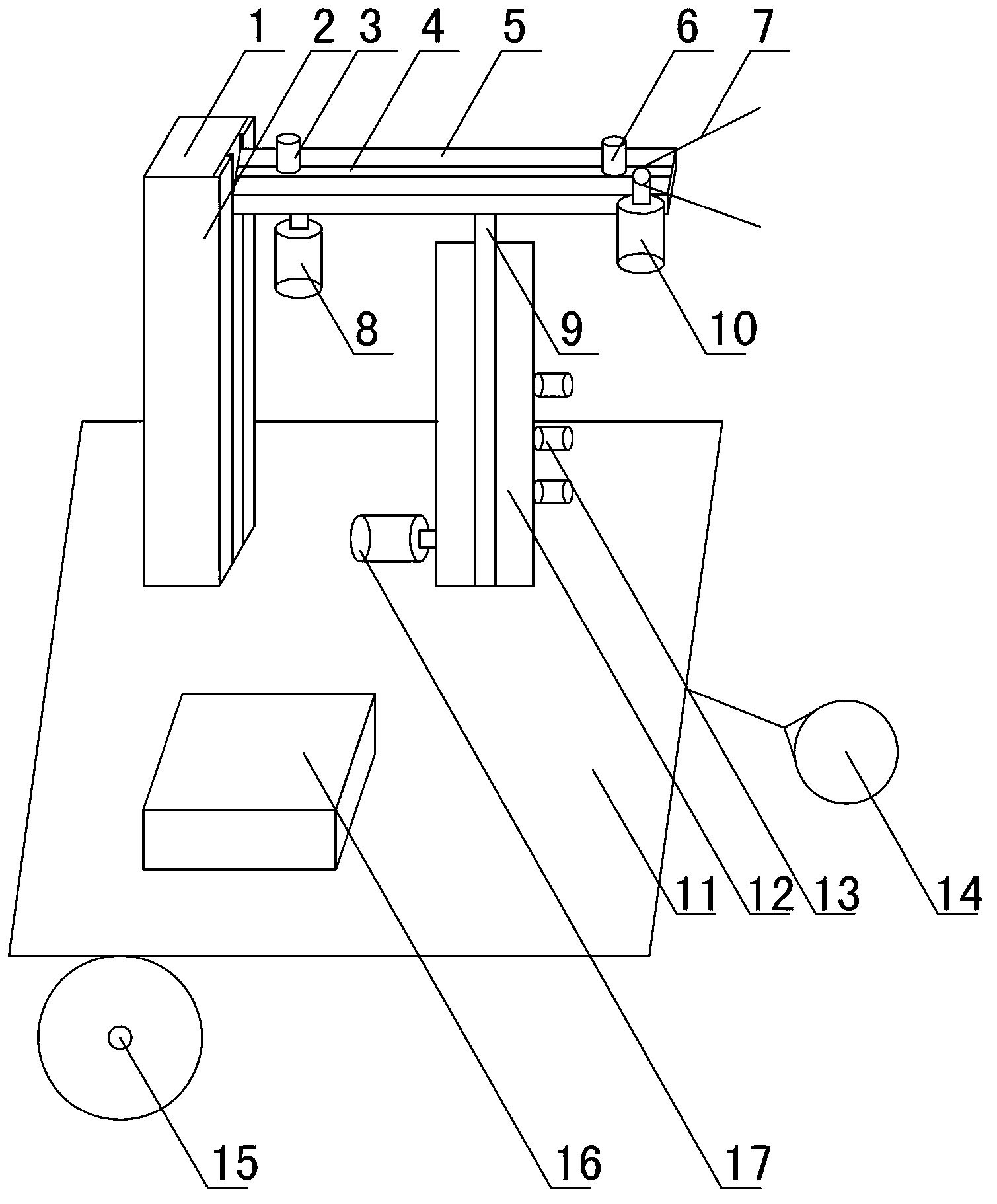

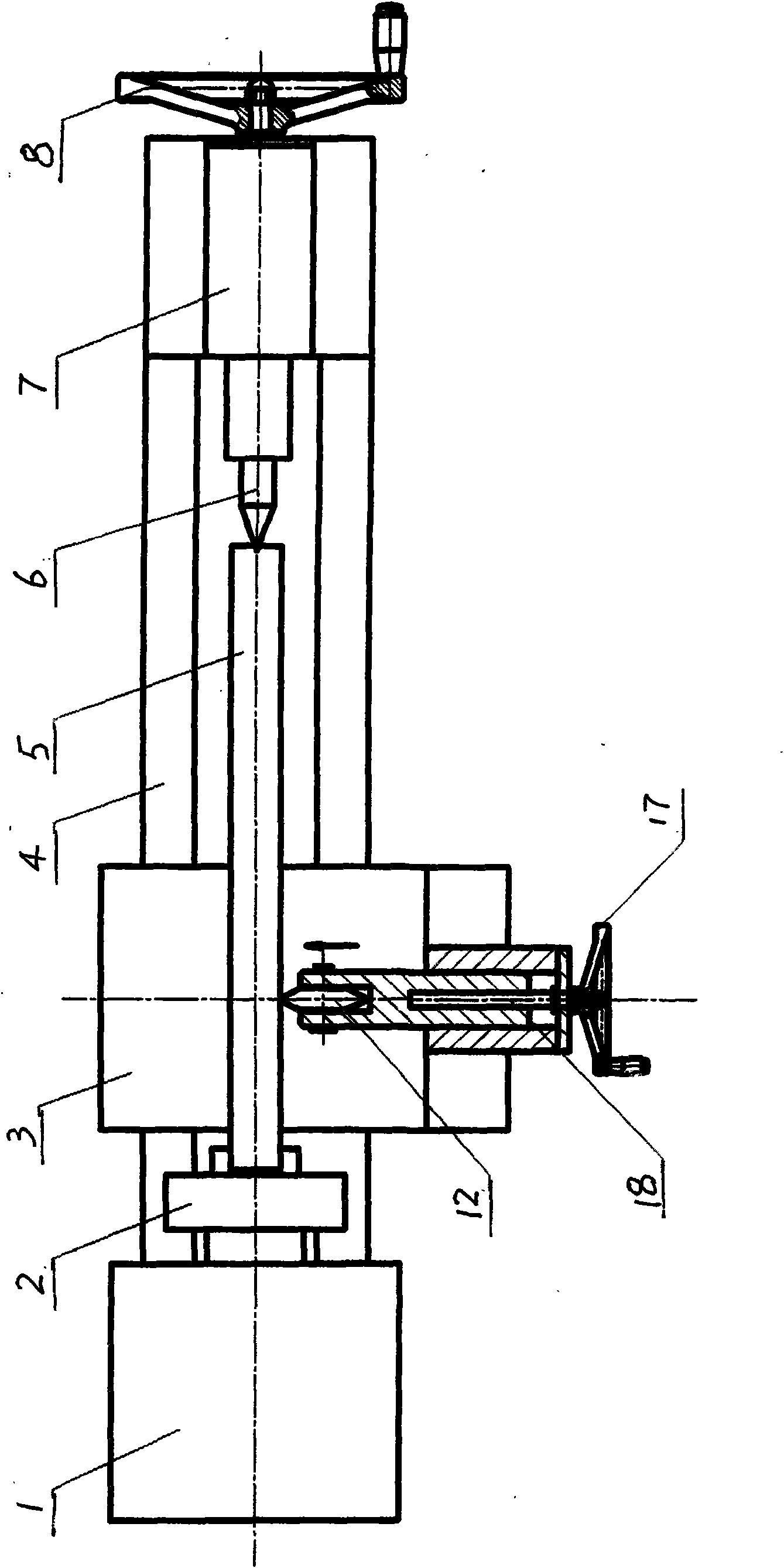

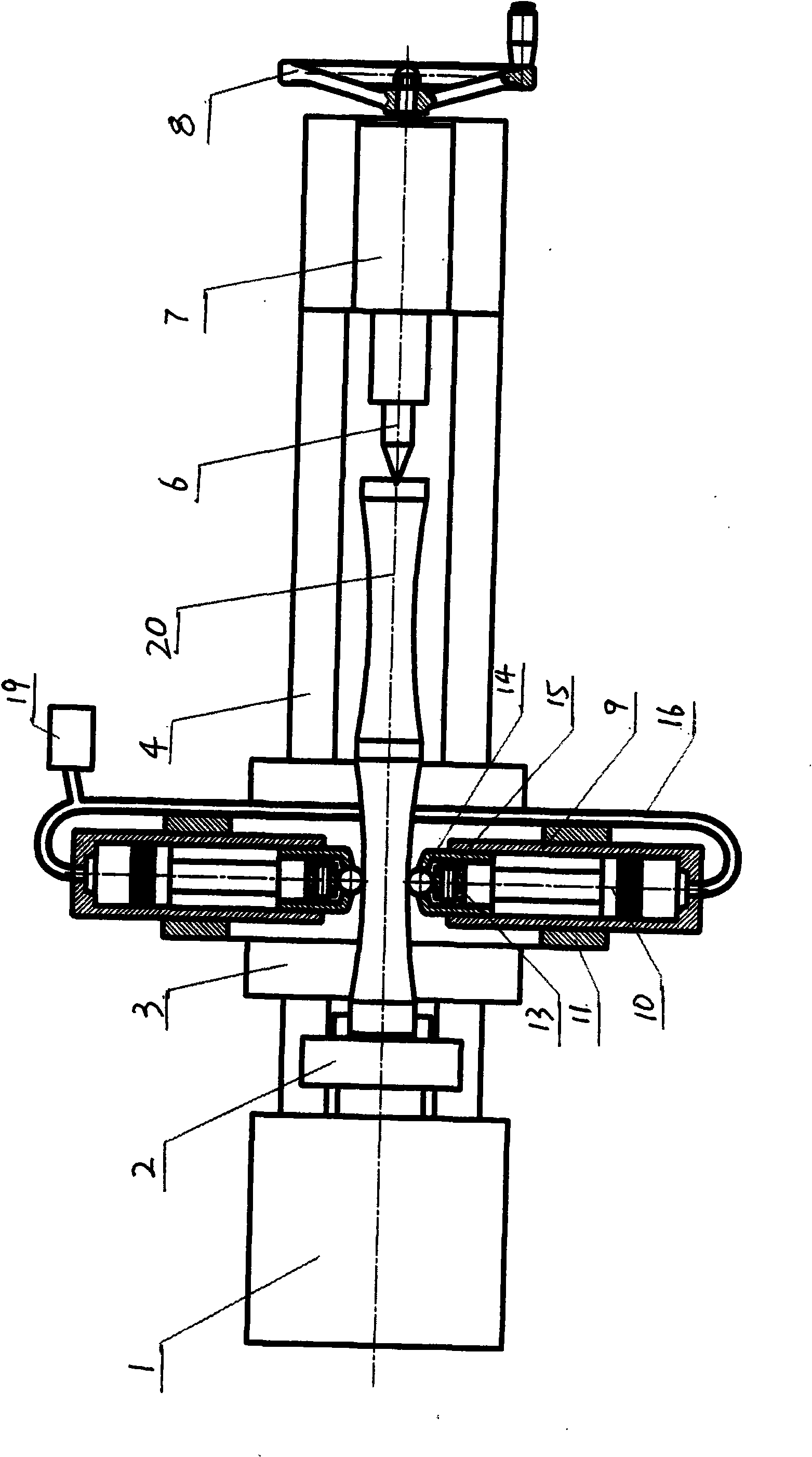

Uniaxial two-way micro mechanical measurement device and method for scanning micro environment

ActiveCN103471905ASchema Loading GuaranteeGuaranteed normal loadingMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesMeasurement deviceSpeckle correlation

The invention belongs to the fields of micro-nano mechanics and precision machinery, and in particular relates to a uniaxial two-way micro mechanical measurement device and method for a scanning micro environment. According to the device, symmetrical coordinate type three-dimensional coarse-tuning translation stages, symmetrical fine-tuning three-dimensional moving precision platforms and a sample platform are installed on a main support unit. Through the control operation of a control system and a manipulation unit, the device can be used for detecting micro-nano characteristic scale materials and a structural mechanical property, and can realize one-way centering stretch, compressing, bending and vibration measurement and micro-nano scale sample surface deformation and micro-structural evolution detection. The device can be repeatedly used and can combine a digital image / speckle correlation technique, an image processing technique or a micro-labeling technique to detect the in-situ deformation and mechanical property of samples in a high-spatial-discrimination scanning microscopic environment.

Owner:TSINGHUA UNIV +1

Universal mainframe case bracket device for operation of computer

The invention discloses a universal mainframe case bracket device for operation of a computer. The universal mainframe case bracket device comprises a device base; a brake axle is arranged on the device base in a penetrating mode; the brake axle is rotationally matched with the device base through a coil spring; a left brake rod and a right brake rod are disposed at the two ends of the brake axle correspondingly; the left brake rod is integrated with a rotary rod; a left side frame and a right side frame are disposed on the two sides of the device base correspondingly; a movable rod is connected to the right side frame in a threaded mode; a clamping plate is disposed at one end of the movable rod; a left lifting rod and a right lifting rod are disposed on the upper portions of the left side frame and the right side frame correspondingly; the top of the left lifting rod is connected with a left top frame; the top of the right lifting rod is connected with a right top frame; and the left top frame and the right top frame are matched with dust-proof cloth. The universal mainframe case bracket device for operation of the computer is quite convenient to move and position and easy to operate, can provide good fixing and shock absorption conditions for a mainframe case and prevent dust from falling on the top of the mainframe case and achieves humanized design.

Owner:孙丽君

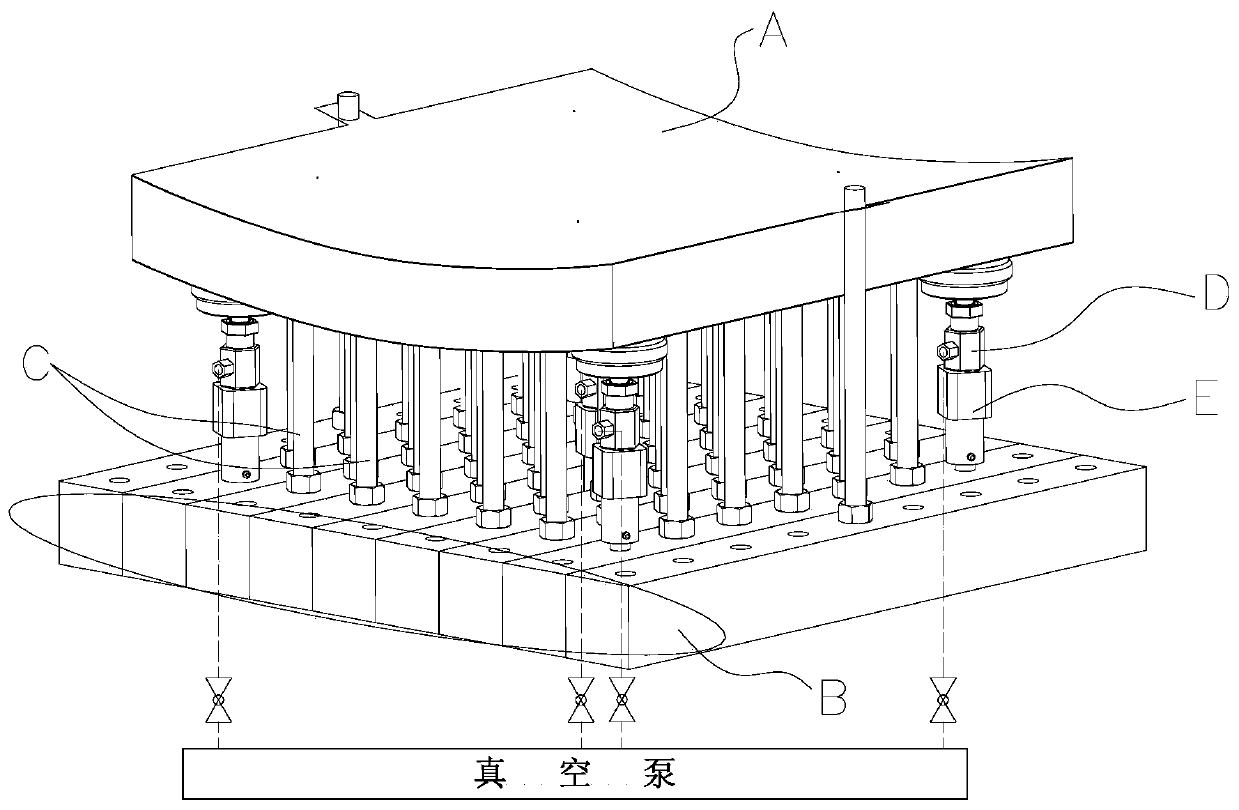

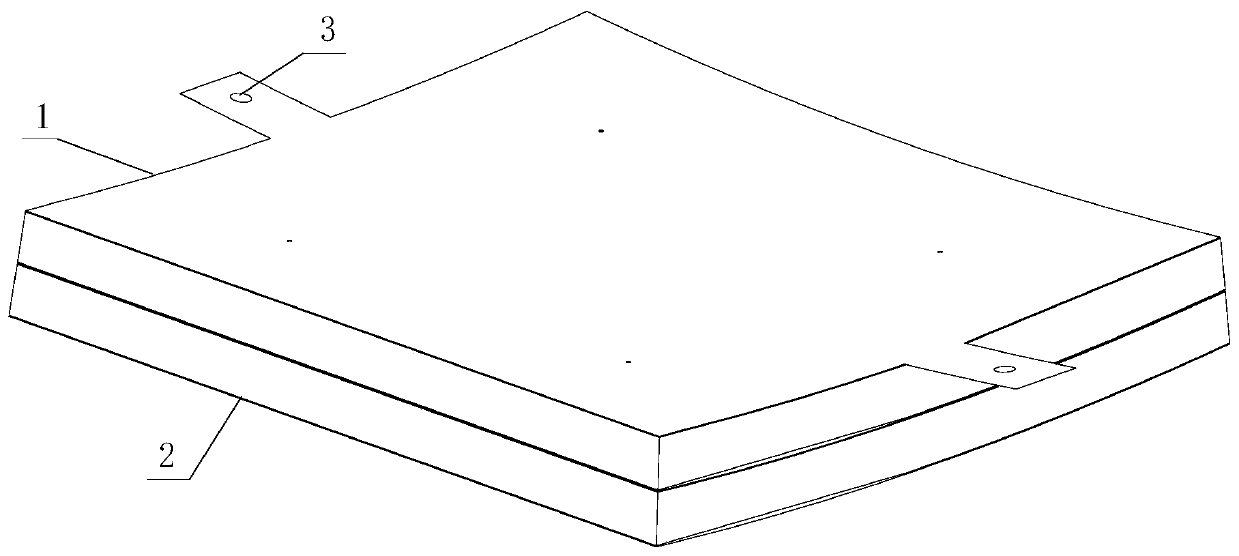

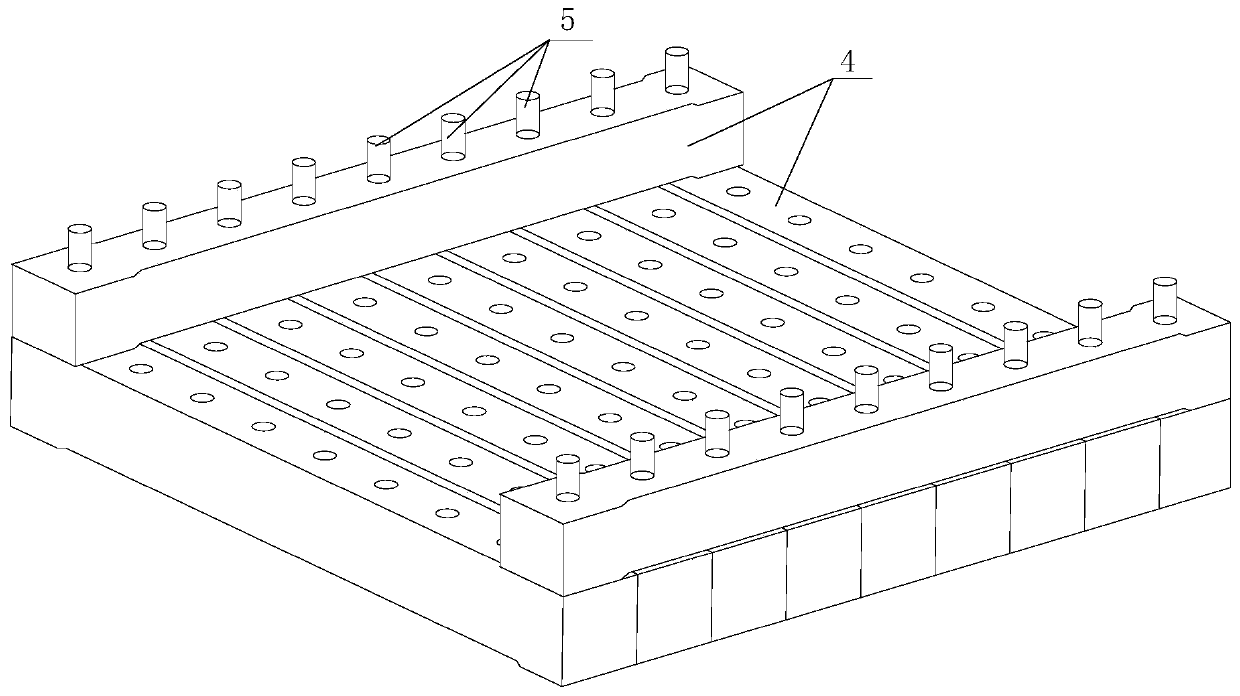

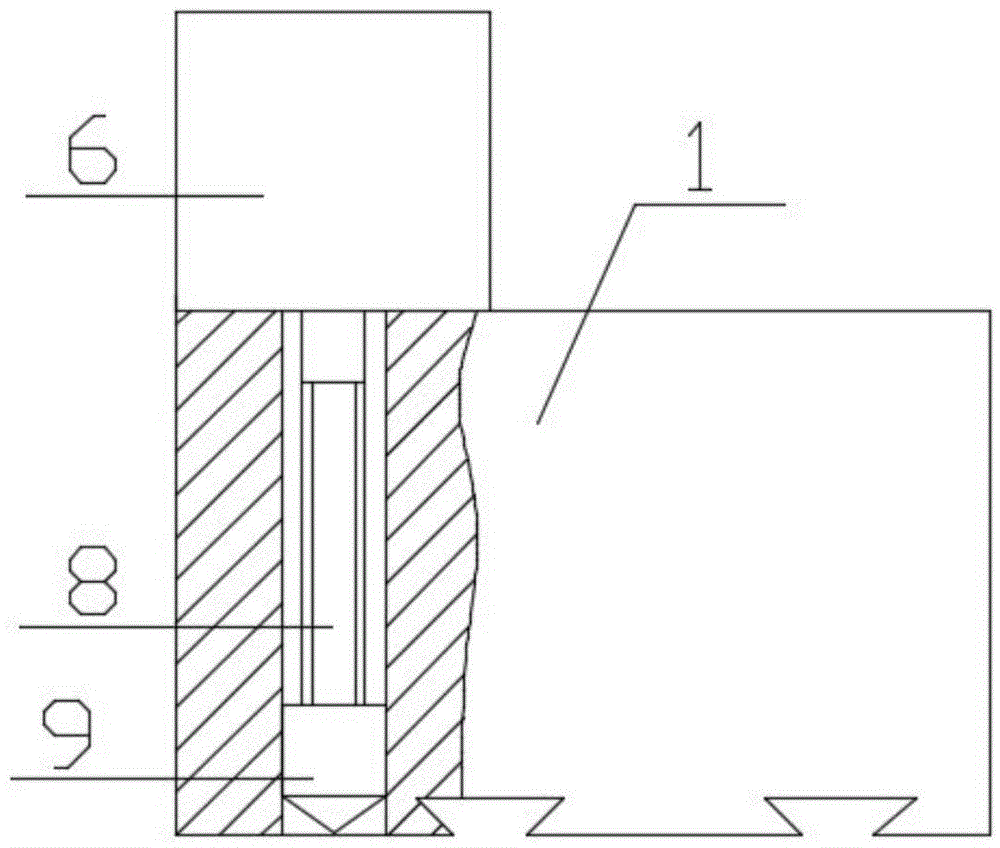

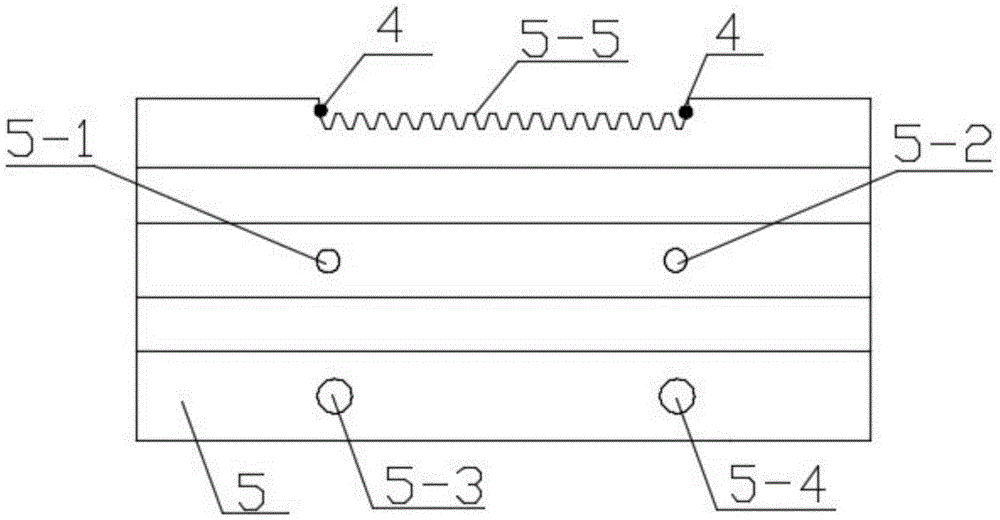

Multi-point-based large-curvature panel ultra-precision machining flexible clamping system

InactiveCN110142627AGuaranteed positioningDeformation stablePositioning apparatusMetal-working holdersEngineeringStability constraints

The invention discloses a multi-point-based large-curvature panel ultra-precision machining flexible clamping system. The system comprises a base, a height-adjustable nail column, a universal vacuum sucker and a transition connecting piece;the base takes stainless steel discrete spike strips with the same cross section and different lengths as a foundation, and the stainless steel discrete spike strips are reasonably combined and mechanical connected; the universal vacuum sucker can rotate in any direction within a 45-degree angle range; the bottom end of the height-adjustable nail column is provided with external threads so as to be installed in a nail hole of the base; and the transition connecting piece is composed of two parts, one part of the transition connecting piece is a sucker threaded sleeve, and the other part of the transition connecting piece is a nail column hole sleeve, and a hole which can be in clearance fit with the height-adjustable nail column is reserved in the center of the nail column hole sleeve. According to the flexible clamping system, concave discrete nail molds with different curvatures can be obtained by adjusting the height of the height-adjustable nail column and the vacuum sucker aiming at parts with different areas and panels with different curvatures, so that full positioning, stability constraint, micro deformation and flexible clamping of the parts with curved surfaces are realized.

Owner:BEIHANG UNIV

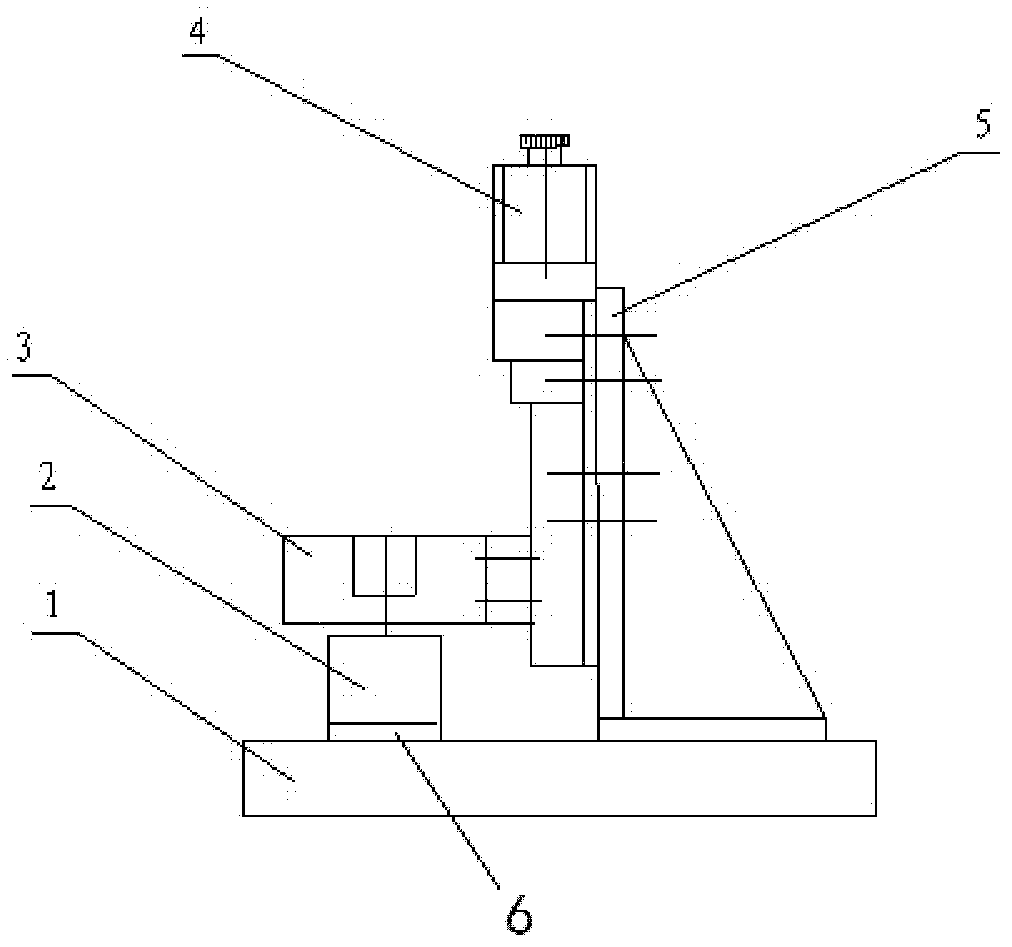

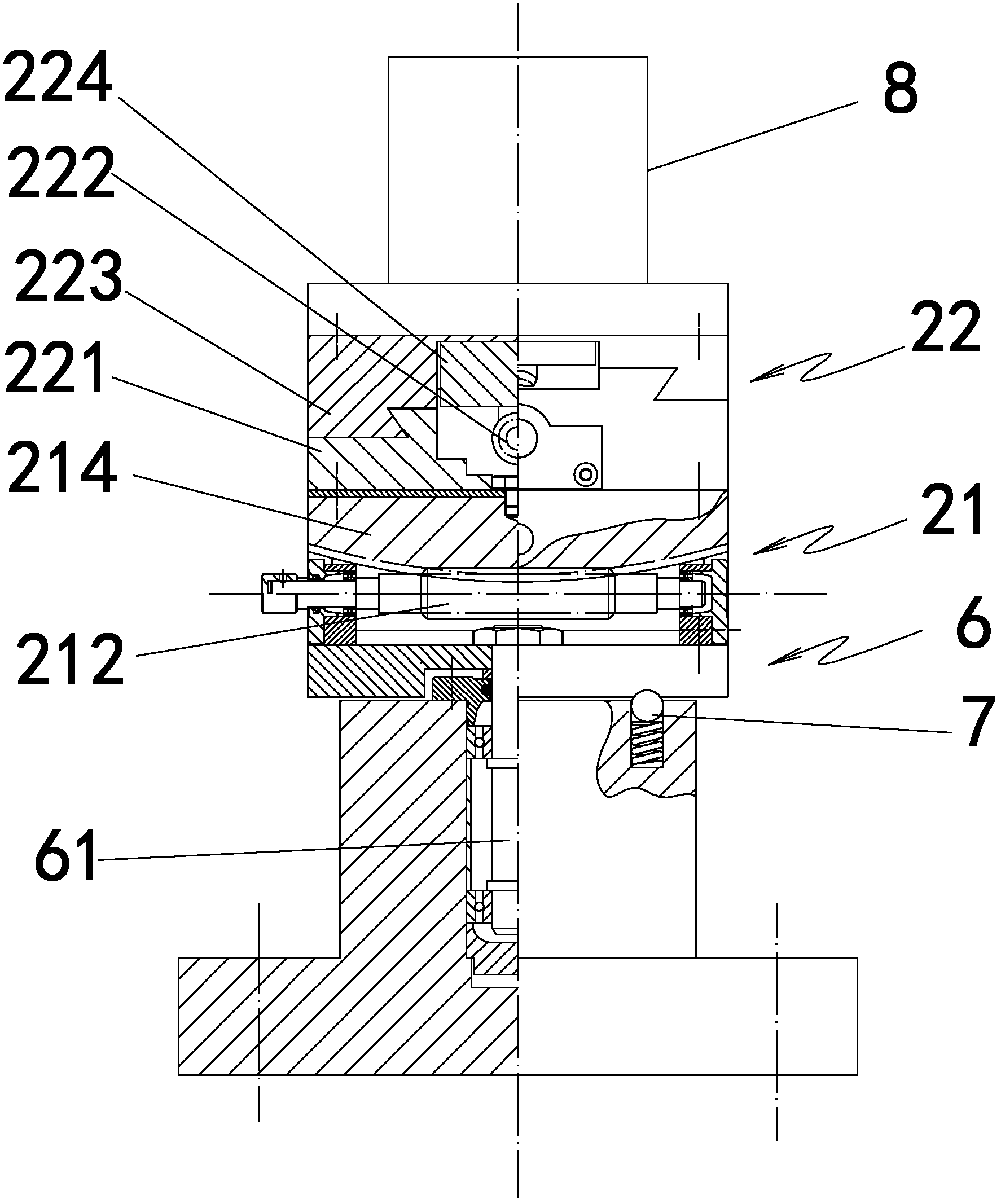

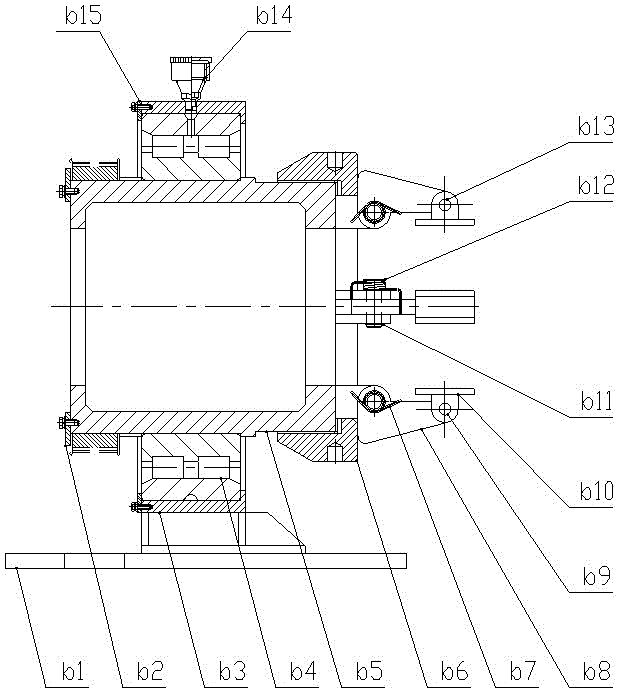

Measurement method and measurement instrument of revolution body part

InactiveCN102679904AAchieving Quadrature Coupling RegulationAccurately capture spatial poseUsing optical meansMarine engineeringOptical measurements

The invention discloses a measurement method and a measurement instrument of a revolution body part, wherein the measurement instrument comprises a base, a vertical post and an optical measurement head, wherein the vertical post is fixed on the base; the optical measurement head is movably assembled on the vertical post through a vertical orientation mode; a working platform which is used for placing and revolving a part is correspondingly arranged on the base below the optical measurement head; the working platform comprises a revolution platform and an angle displacement regulating platform which are arranged from bottom to top; the angle displacement regulating platform comprises a first angle displacement platform and a second angle displacement platform which respectively comprise a first deflection platform and a second deflection platform; and the deflection axes surrounded by the first deflection platform and the second deflection platform in rotation are vertical mutually and are both parallel to a plane of a light curtain of the optical measurement head. For the angle displacement regulating platform in the measurement instrument provided by the invention, by adopting the deflection surrounding the deflection axes parallel to the plane of the light curtain of a parallel light source through driving the two angle displacement platforms respectively by the revolution driving mechanism, the cross coupling regulation of the deflection angles of the working platform is realized, the space posture of a workpiece can be captured accurately, and the accurate positioning and measurement to the part are ensured.

Owner:HENAN UNIV OF SCI & TECH

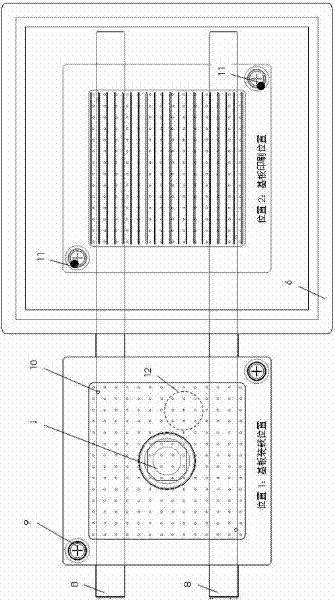

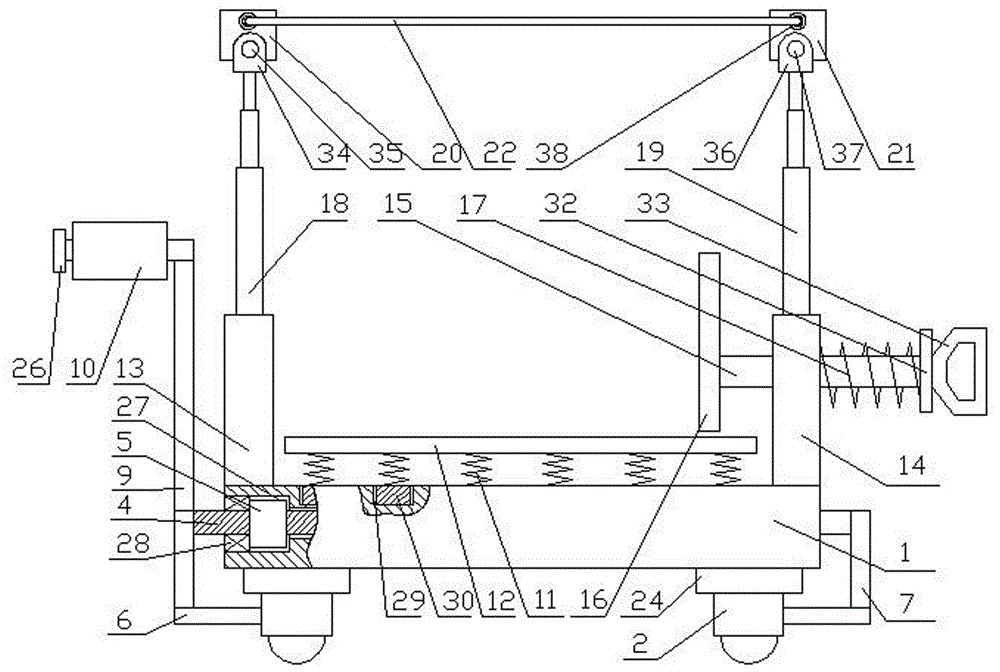

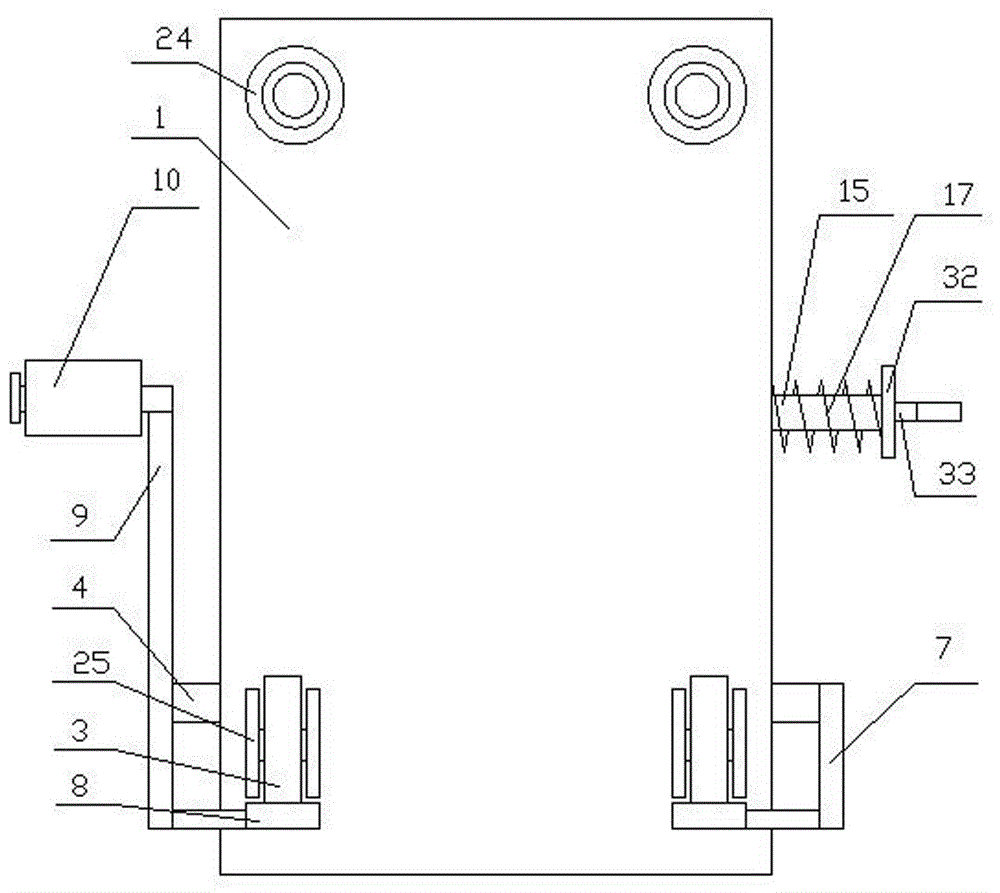

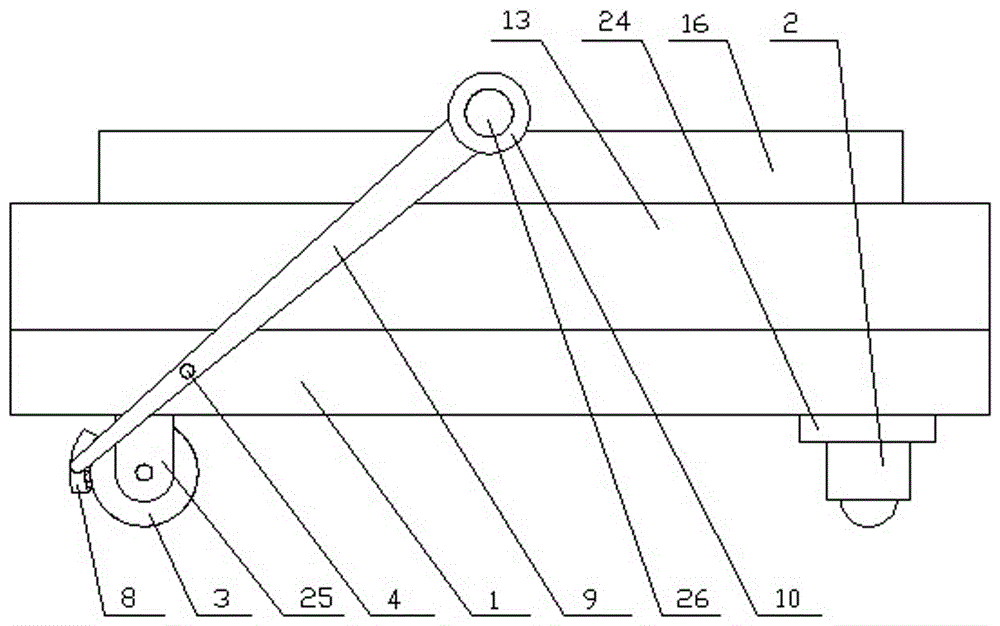

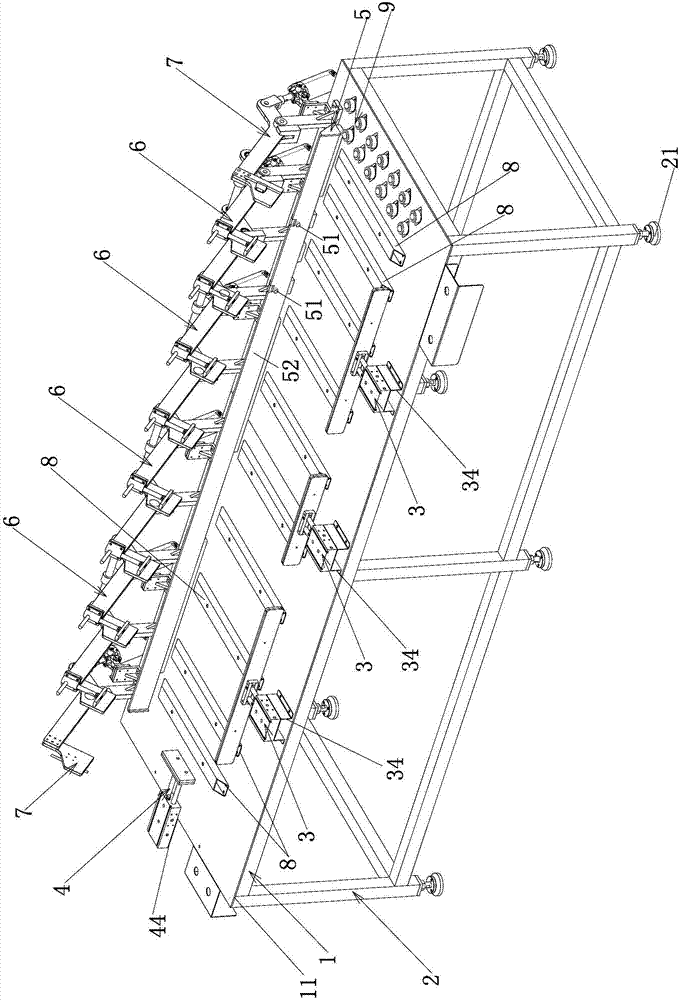

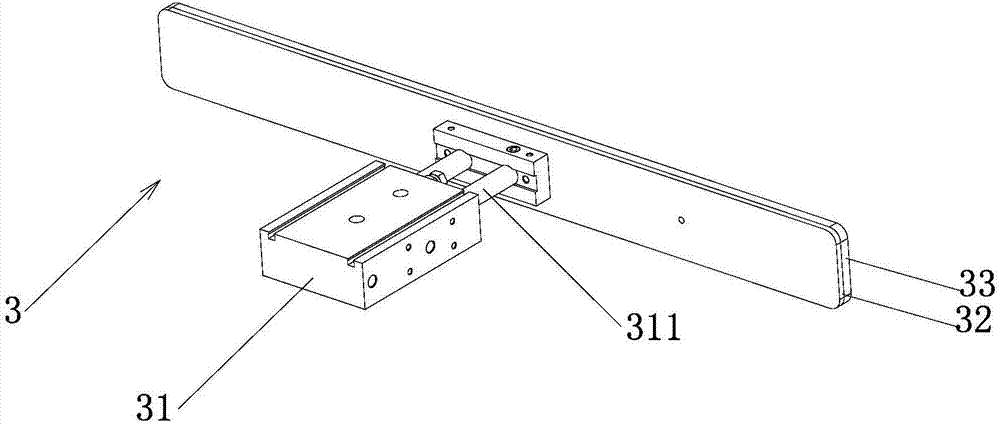

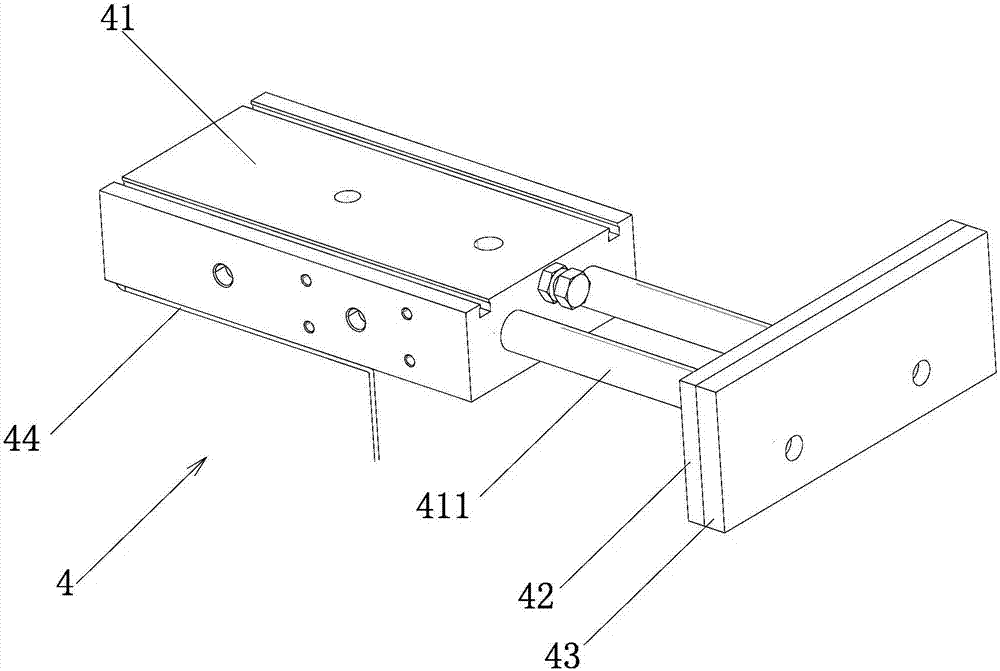

Welding and positioning tool platform for aluminium alloy template

PendingCN107138899AReduce labor intensitySimple and fast operationWelding/cutting auxillary devicesAuxillary welding devicesMetallurgyEngineering

A welding and positioning tool platform for an aluminium alloy template comprises a working platform supported on a frame body, at least one lateral positioning and pressing device arranged on the platform surface of the working platform, a longitudinal positioning and pressing device arranged at one end of the platform surface in the length direction, a positioning backing plate arranged in the length direction of the platform surface and located on one side of the platform surface, duplex overturning mechanisms close to the positioning backing plate as well as two single overturning mechanisms located at two ends of the platform surface in the length direction separately; multiple transverse supporting ribs are arranged on the platform surface at intervals in parallel; the positioning backing plate is used for positioning a to-be-welded aluminium alloy template main body; the at least one lateral positioning and pressing device presses the to-be-welded aluminium alloy template main body transversely; the longitudinal positioning and pressing device presses the to-be-welded aluminium alloy template main body in the length direction; the duplex overturning mechanisms are used for positioning and pressing to-be-welded transverse ribs; and the two single overturning mechanisms are used for positioning and pressing two to-be-welded gland plates separately. The platform is accurate in positioning, simple to operate and convenient in welding.

Owner:SHANDONG XINHUOXIN MATERIAL TECH CO LTD

In-pipe walking robot

The invention discloses an in-pipe walking robot. The in-pipe walking robot comprises a running mechanism, a connecting rod assembly and a universal connecting mechanism connected with the running mechanism and the connecting rod assembly. The running mechanism comprises a transmission mechanism, a first pressure spring, two road wheels and two rocker connecting rods. The connecting rod assembly comprises a center rod, a front locking block, a rear locking block, a sliding block, at least two pairs of connecting rod slices, at least two pulleys and a second pressure spring. According to the in-pipe walking robot, the synergistic effect of worm gears, a worm and the first pressure spring is adopted, the close fit of the worm gears and the worm is retained, and the road wheels are made to roll on the inner wall of a pipe in a tightly attached mode. When the worm is in a shape of a taper or a circular truncated cone, the running mechanism can automatically adjust the interval of the worm gears in pipes with different diameters, so that the road wheels are ensured to make contact with the inner wall of the pipe all the time and the adhesive force is retained; due to the second pressure spring, the symmetrical pulleys are always pushed by the sliding block to make contact with the inner wall of the pipe, so that a flange plate is ensured to be positioned on the central axis of the pipe all the time, and an operating mechanism externally connected with the flange plate can run with the flange plate steadily.

Owner:S Z VICTOR AUTOMATION TECH

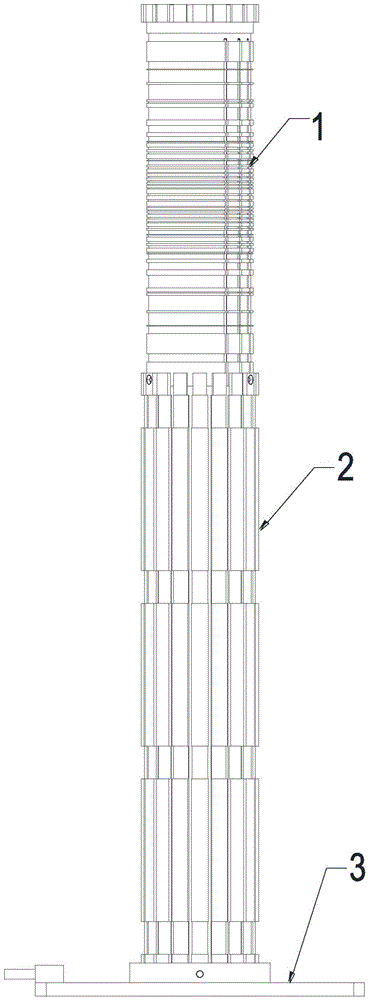

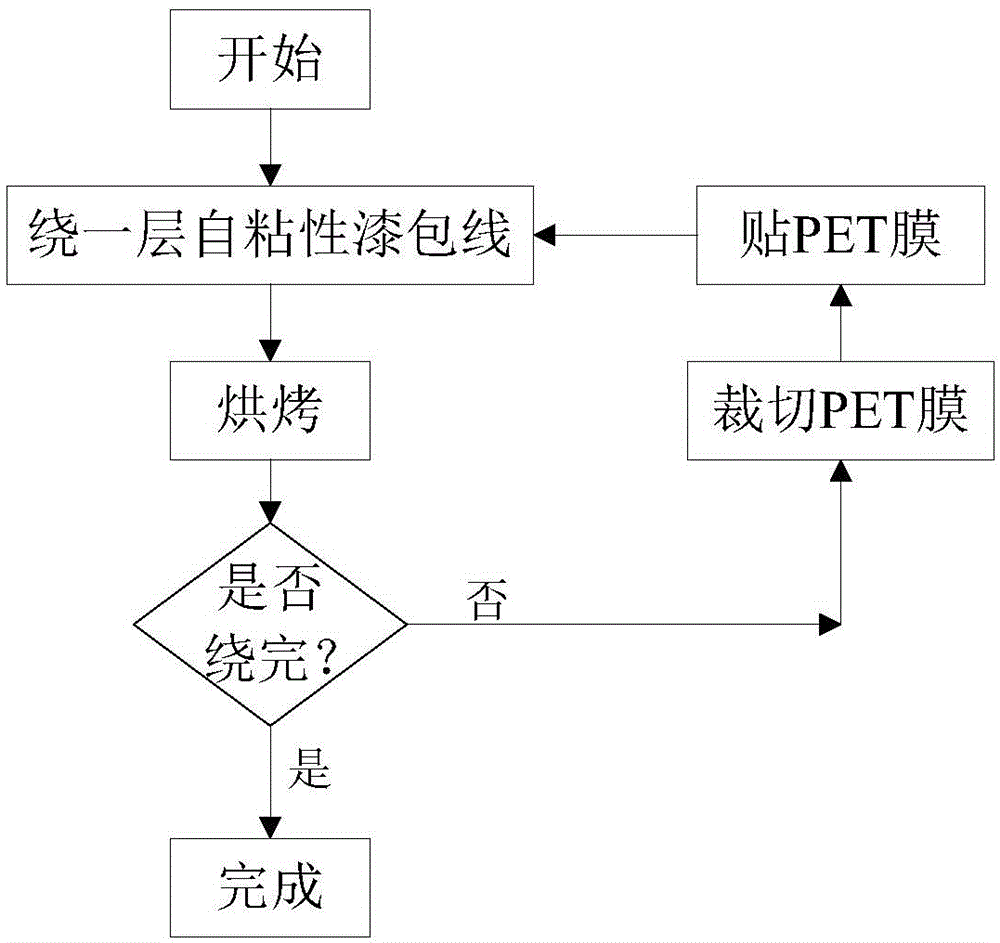

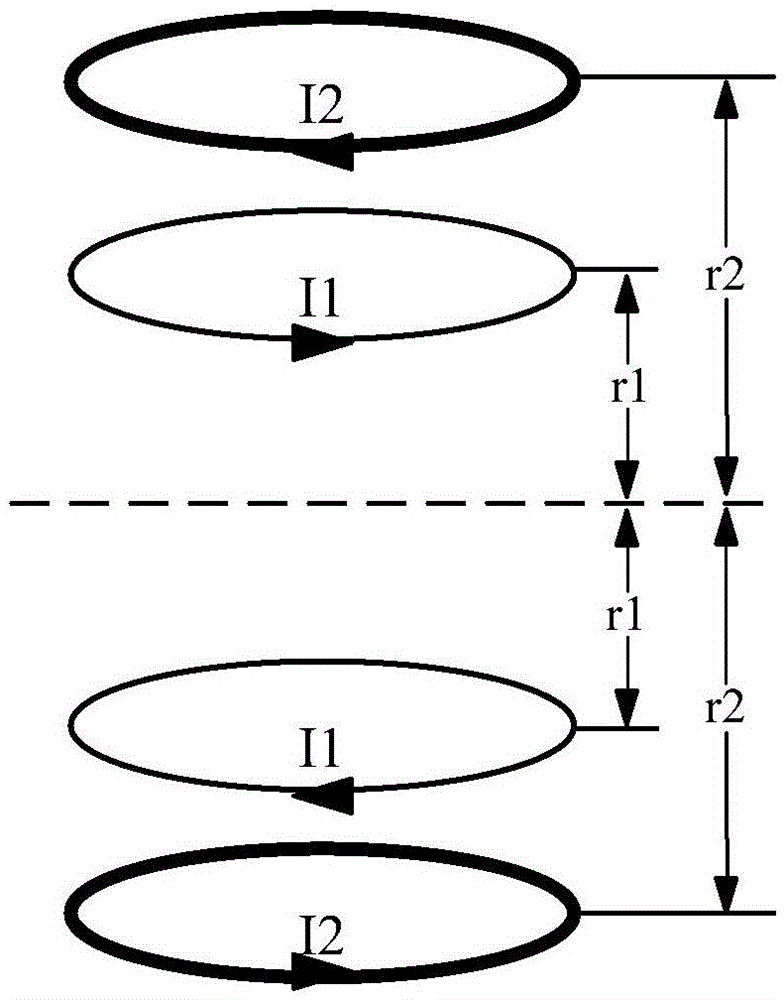

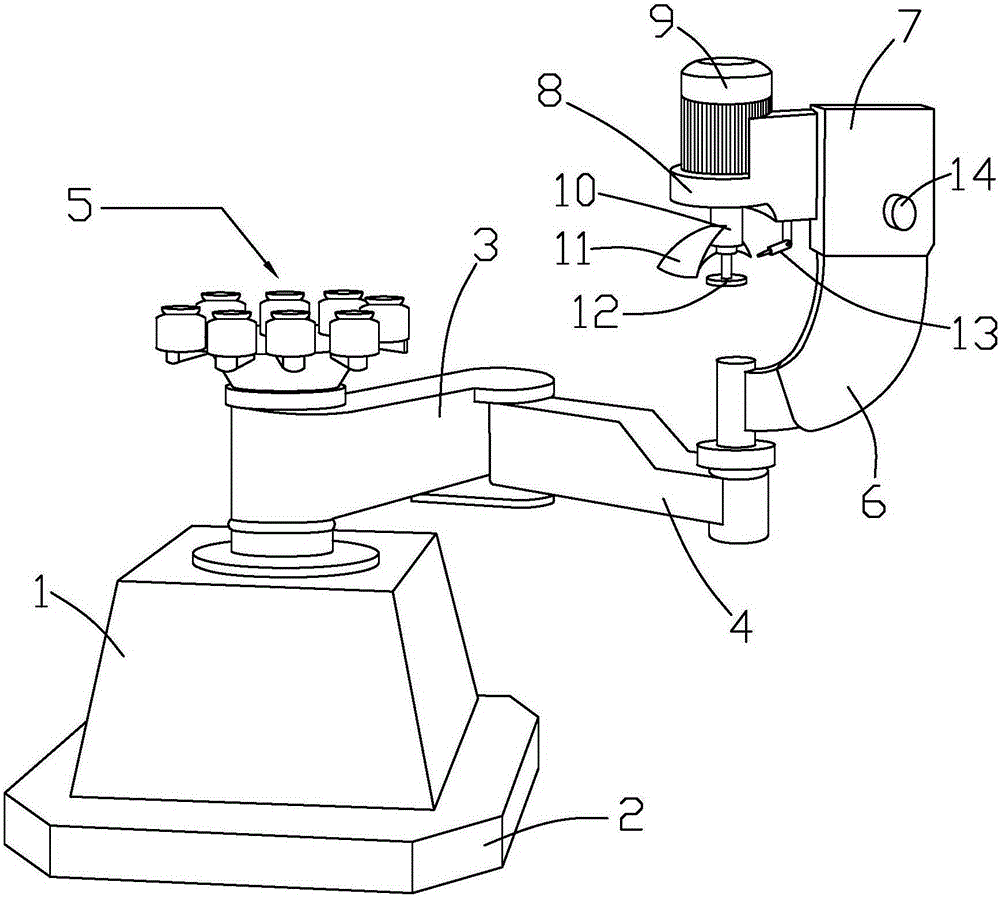

Room temperature shim coil of superconducting NMR spectrometer

The invention discloses a room temperature shim coil of a superconducting NMR spectrometer. The room temperature shim coil is formed by a winding region, a support frame, and a base from top to bottom in sequence. The inner layer of the winding region is axial coils, and the outer layer is radial coils. On the manufacturing method for a coil structure, the multiple order axial coils are compressed on a same cylinder to improve space utilization rate, and a winding method of self-bonding enamelled wires and PET films (also named as high-temperature polyester film) is used, so as to solve technical problems of wire positioning and fixing in a winding process of the room temperature shim coil. An optimization function is also designed and established aimed at an algorithm of the shim coil, and a problem of design of the room temperature shim coil is converted to a problem of solving the minimum value of the optimization function, and then through a particle swarm optimization, the functional equation is solved, and finally position distribution and number of turns of the coils can be calculated. According to the room temperature shim coil, reliability and adaptability of the shim coil can be obviously improved.

Owner:ウーハン ジョンケ ニウジン マグネティック レゾナンス テクノロジー カンパニー リミテッド

Arc glass edge grinding machine

InactiveCN105171559APrevent splashImprove securityEdge grinding machinesGrinding work supportsFuel tankEngineering

The invention discloses an arc glass edge grinding machine. The arc glass edge grinding machine comprises a box body, positioning suction cups and a grinding mechanism. The positioning suction cups are connected with the box body through a first cantilever. The other end of the first cantilever is connected with a second cantilever in a rotating manner. The end of the second cantilever is connected with a grinding mechanism. The grinding mechanism comprises an arc-shaped supporting frame, a fixed box, a positioning buckle plate and a first motor. The top end of the arc-shaped supporting frame is connected with the fixed box. The positioning buckle plate is arranged on the side face of the fixed box. The first motor is limited by the positioning buckle plate. A second motor, a hydraulic oil tank and a draught fan are arranged in the box body. An air inlet pipe and an air outlet pipe are arranged on the draught fan. The arc glass edge grinding machine is simple in structure and high in practicability, can conduct edge grinding on arc-shaped edges of conventional glass and can conduct arc edge grinding on glass of different sizes as well, the stability of glass during edge grinding is improved, glass uniformly bears force, the service life of the edge grinding machine is prolonged, and economic benefits are remarkable.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

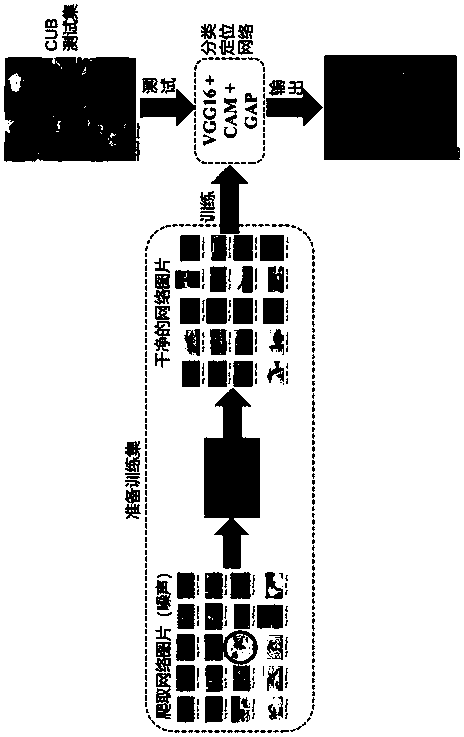

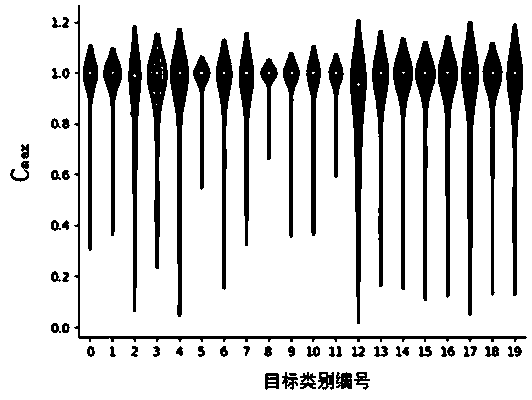

Target classification and positioning method based on network supervision

ActiveCN110717534AHigh feasibilityImprove practicalityCharacter and pattern recognitionNeural architecturesManual annotationClass activation mapping

The invention provides a target classification and positioning method based on network supervision. The target classification and positioning method comprises the following steps: automatically obtaining a large amount of network image data from a search engine according to the category of a to-be-tested target; filtering to remove noise images to form a training sample set; preliminarily constructing a classification and positioning network; and inputting samples in the training sample set into the preliminarily constructed classification and positioning network to perform feature extraction,classifying the features, obtaining position information of the target object, and training the classification and positioning network. According to the end-to-end fine classification and positioningmethod based on network supervision, massive network images easy to obtain are used as a training set, manual annotation is completely removed, only image-level labels are used, an efficient convolutional network is designed, and algorithms such as global average pooling and class activation mapping graphs are fused, so that the performance of the method exceeds that of a weak supervised learningmethod on fine classification tasks and positioning tasks.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

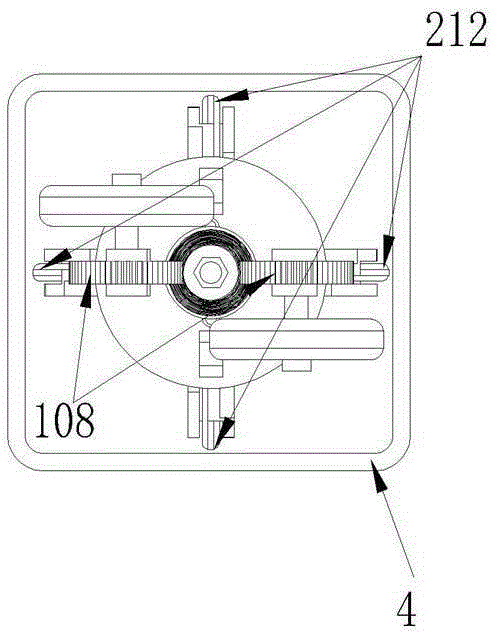

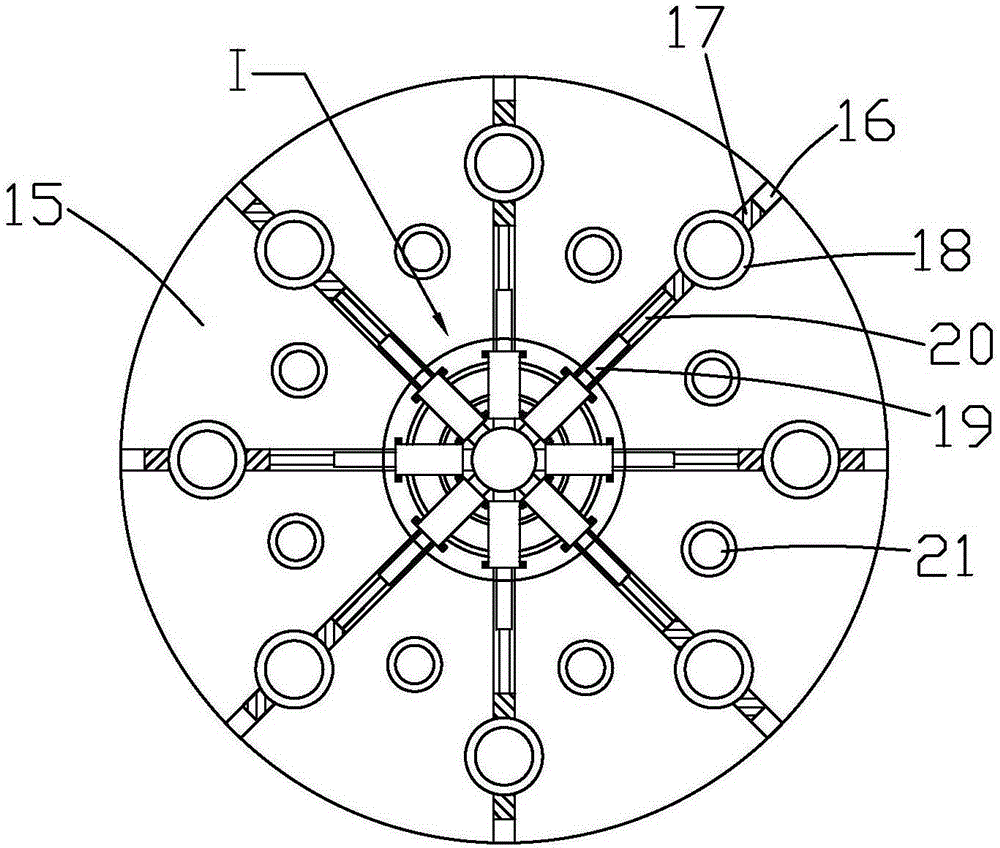

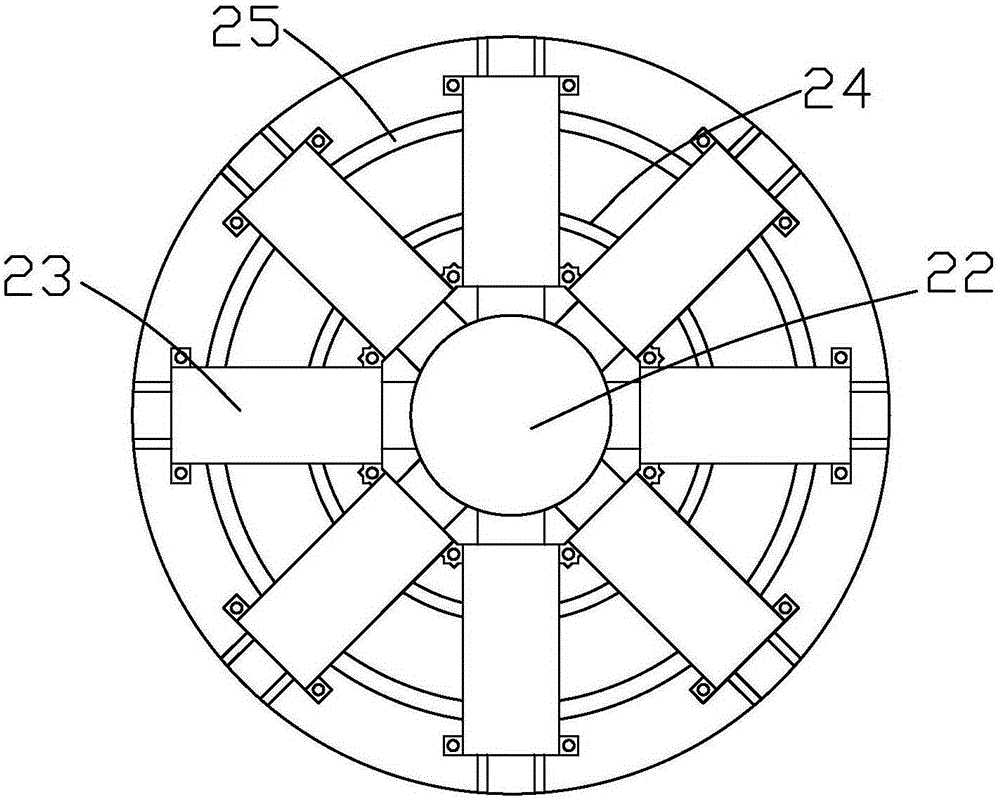

Rotary chuck and laser pipe cutting machine

ActiveCN105014295ARealize the function of rotating and walkingSmooth rotationWelding/cutting auxillary devicesAuxillary welding devicesCoil springEngineering

The invention discloses a rotary chuck which comprises bearing pedestals, a cylindrical roller bearing, a roller core, a lock disc, coil springs, clamping jaw blocks, first pin shafts, clamping jaw mats, a second pin shaft and a stopping lock. The roller core is fixed in the bearing pedestals through the cylindrical roller bearing, and a through hole allowing a workpiece to penetrate is formed in the roller core. The rear ends of the clamping jaw blocks are fixed to the front end of the roller core, and the clamping jaw blocks rotate with the second pin shaft as the axis. The second pin shaft is a hinge shaft of the roller core and the clamping jaw blocks, the coil springs for keeping the clamping jaw blocks expanding outwards are arranged on the second pin shaft, and the front ends of the clamping jaw blocks are hinged to the clamping jaw mats through the first pin shafts. The lock disc is in threaded connection with the roller core, and the clamping jaw blocks are driven to rotate around the second pin shaft through mutual movement of the lock disc and the roller core. The stopping lock capable of fixedly connecting the bearing pedestals and the roller core is arranged on the bearing pedestals. According to the rotary chuck, the pipe machining operating speed is greatly improved, and the rotary chuck is a great contribution to the social machining and manufacturing industry.

Owner:JINAN G WEIKE SCI & TECH

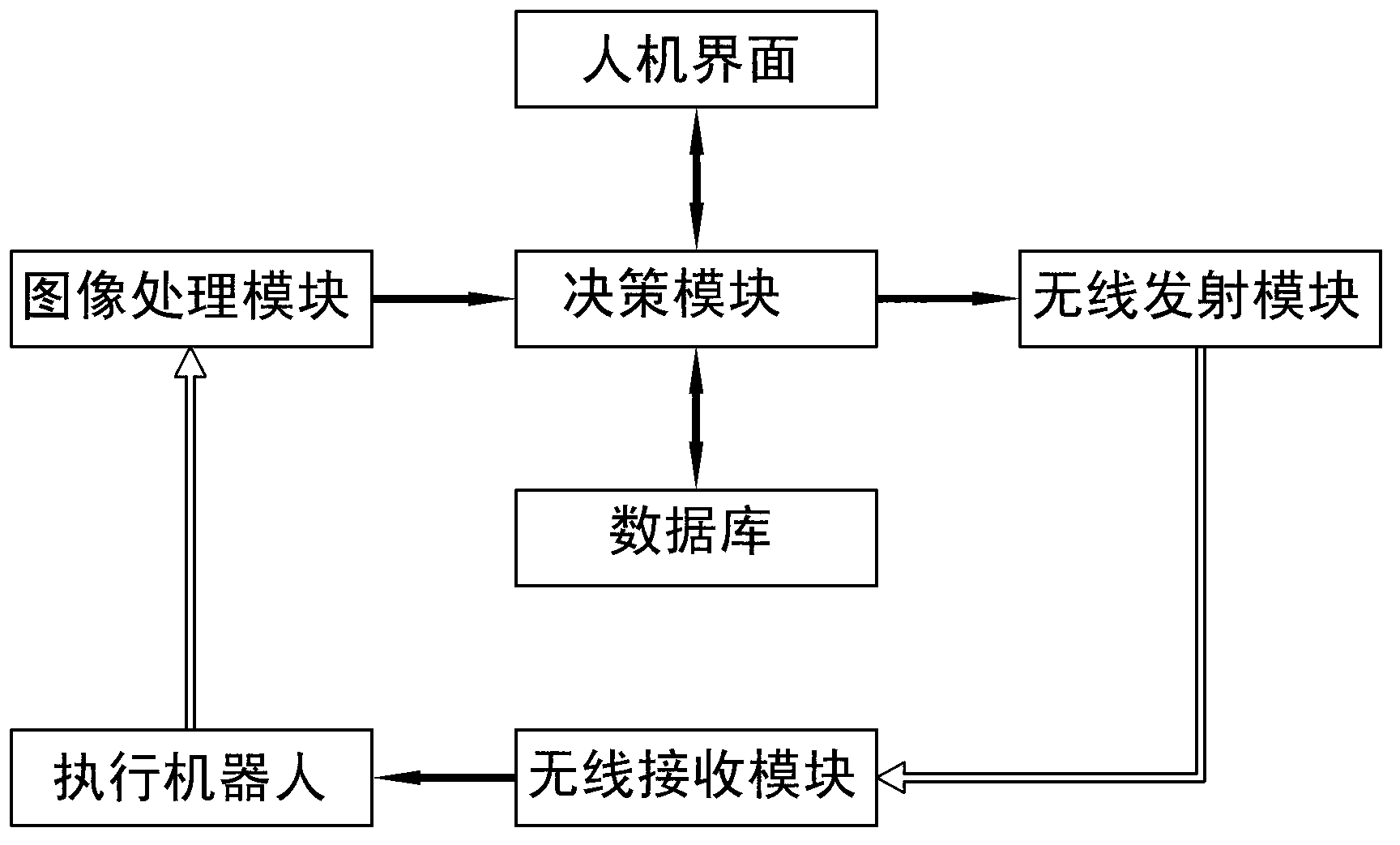

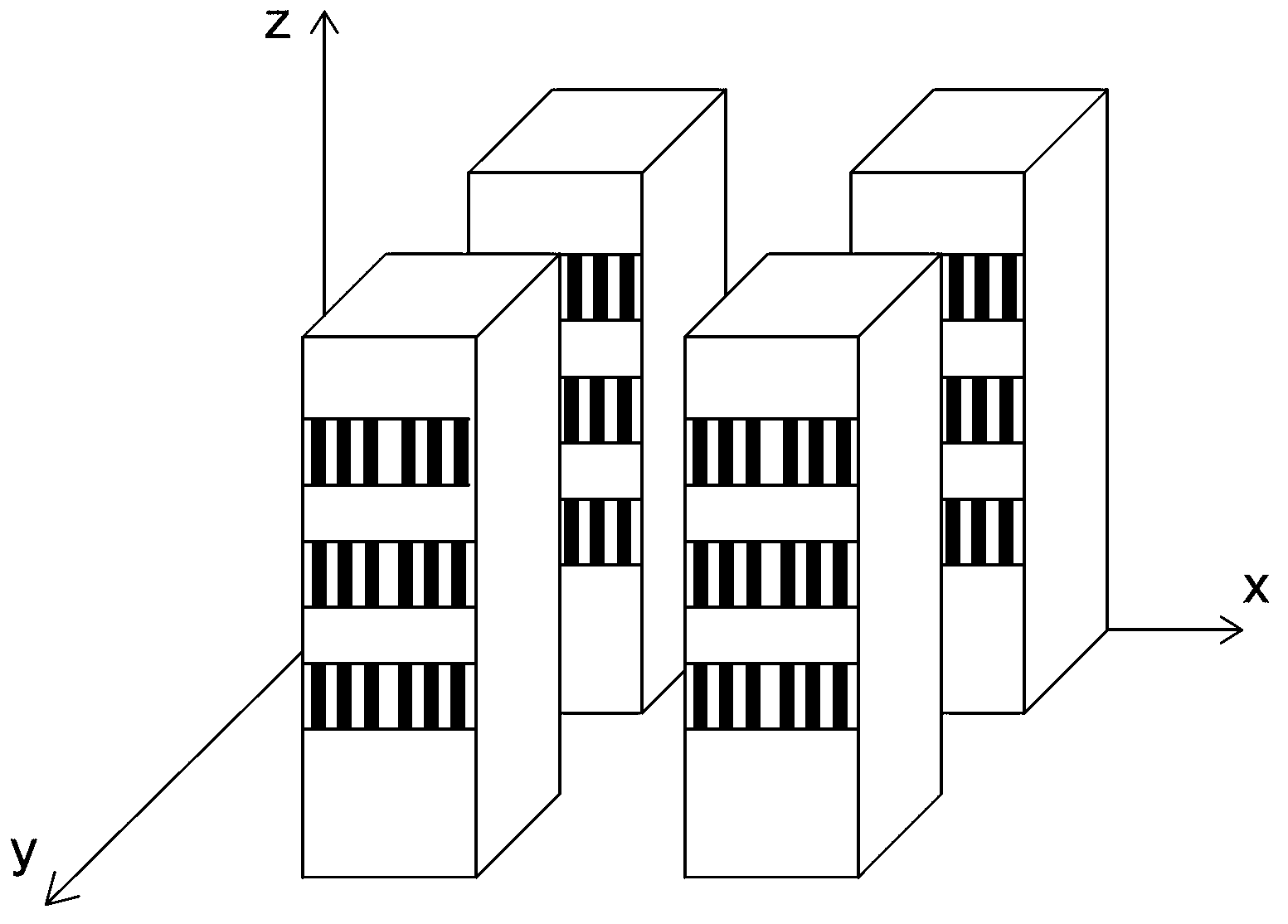

Books management method and books management system based on space coordinate positioning technology

InactiveCN103177332AAutomate managementIntelligent managementComputer controlResourcesHuman–machine interfaceImaging processing

The invention belongs to the field of automatic library management, and discloses a books management method and a books management system based on a space coordinate positioning technology. The system is characterized by comprising a control portion and an executing portion, the control portion comprises an image processing module, a wireless transmitting module, a human-computer interface, a decision-making module and a database, and the executing portion comprises a wireless receiving module and an executing robot. In the control portion, the image processing module is connected with the decision-making module, and the decision-making module is connected with the wireless transmitting module, and is simultaneously bi-directionally connected with the human-computer interface and the database. In the executing portion, the wireless receiving module is connected with the executing robot. The wireless transmitting module of the control portion is connected with the wireless receiving module through a wireless technology. By the system, library management automation and intelligentization are achieved, and library management reliability is improved.

Owner:SHANDONG UNIV OF TECH

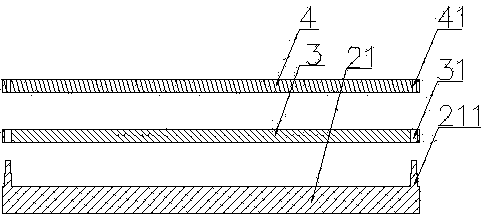

Assembling positioning jig

InactiveCN103419456AEasy to locatePrevent assembly deformationLaminationLamination apparatusEngineeringDisplay device

The invention discloses an assembling positioning jig which is used for installing a protection screen of a display on a display front frame and comprises a machine frame and a pressing device. The assembling positioning jig is high in positioning accuracy and accurate in installation and achieves mechanical automation.

Owner:昆山濡鑫光电科技有限公司

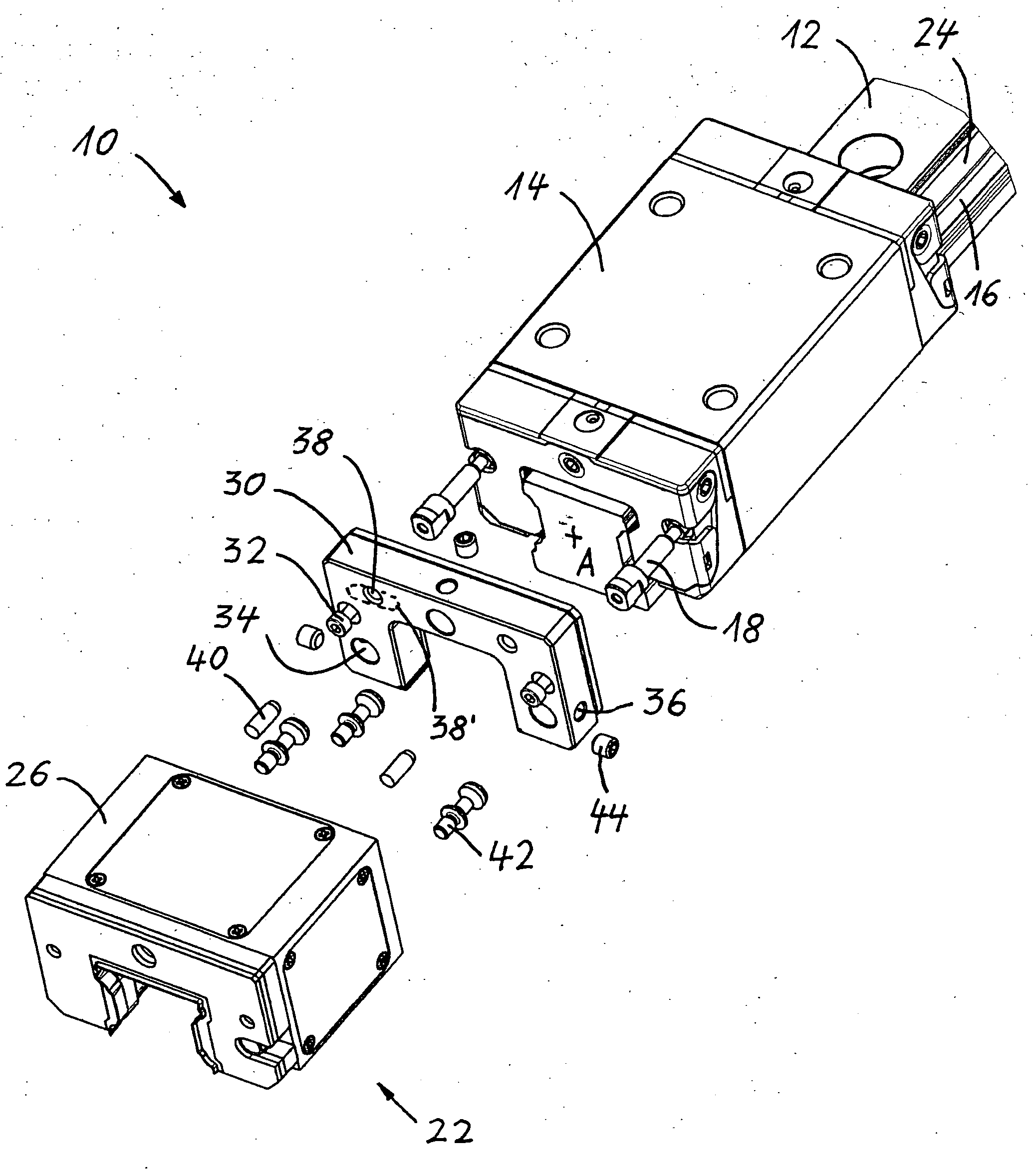

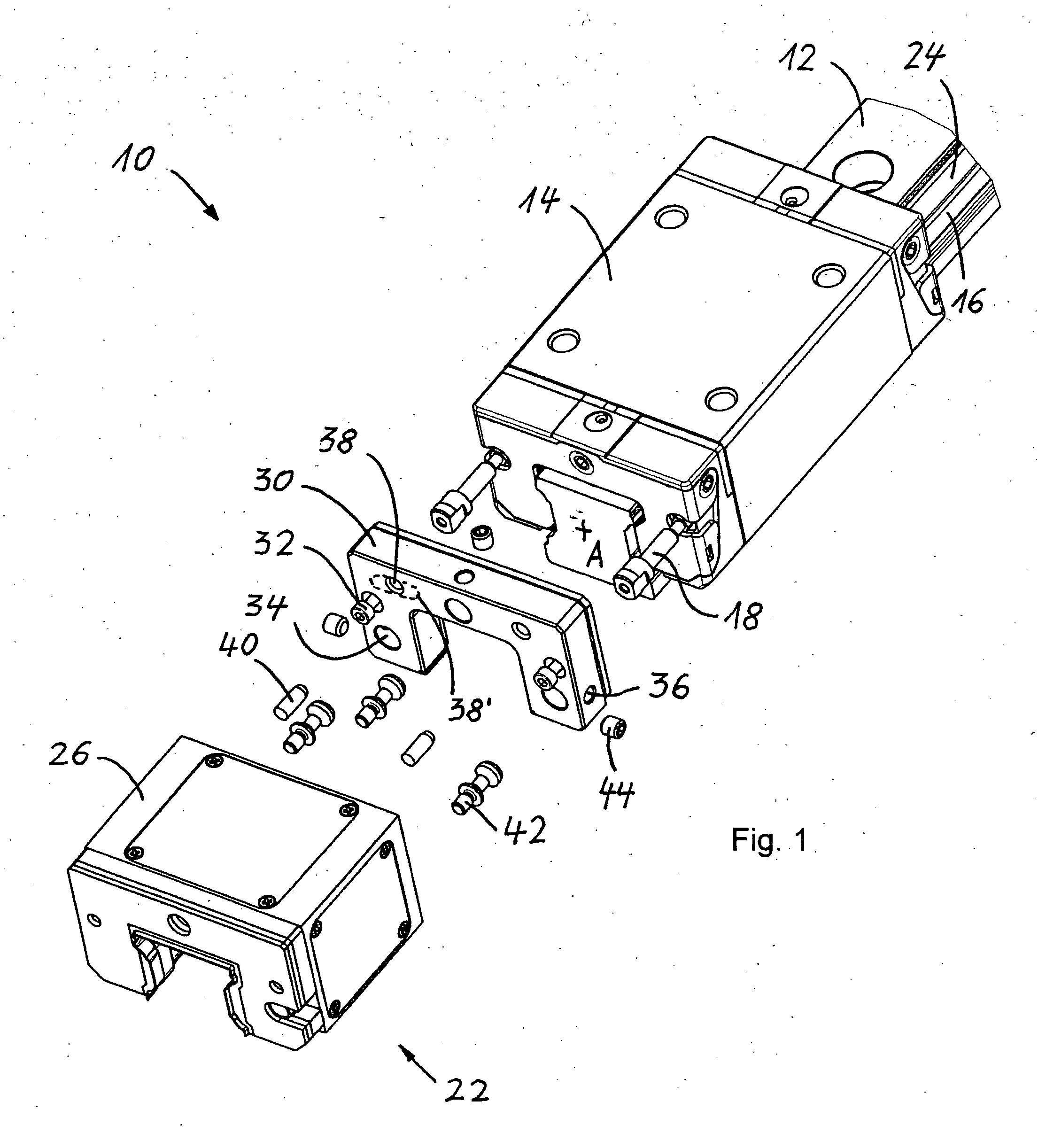

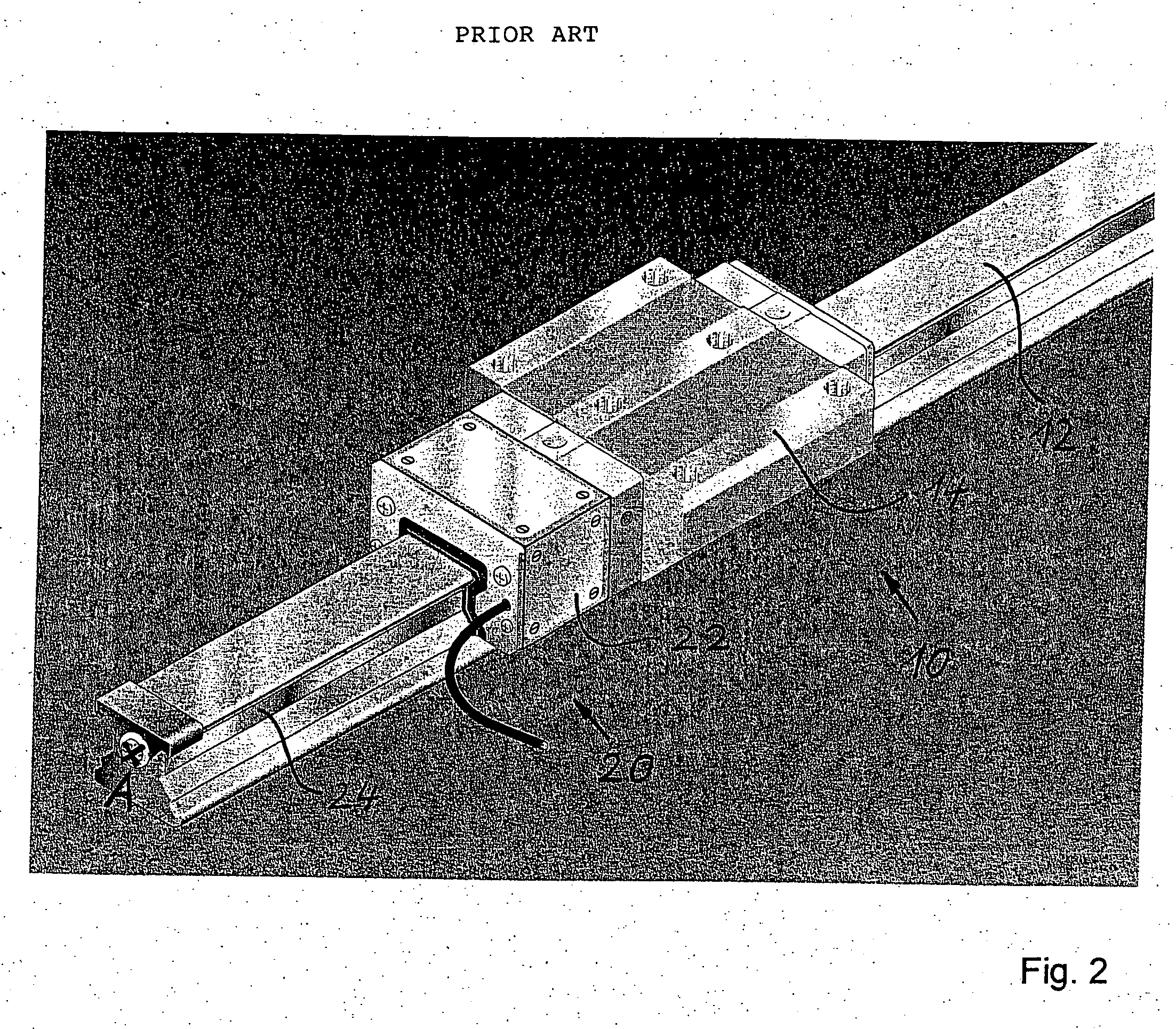

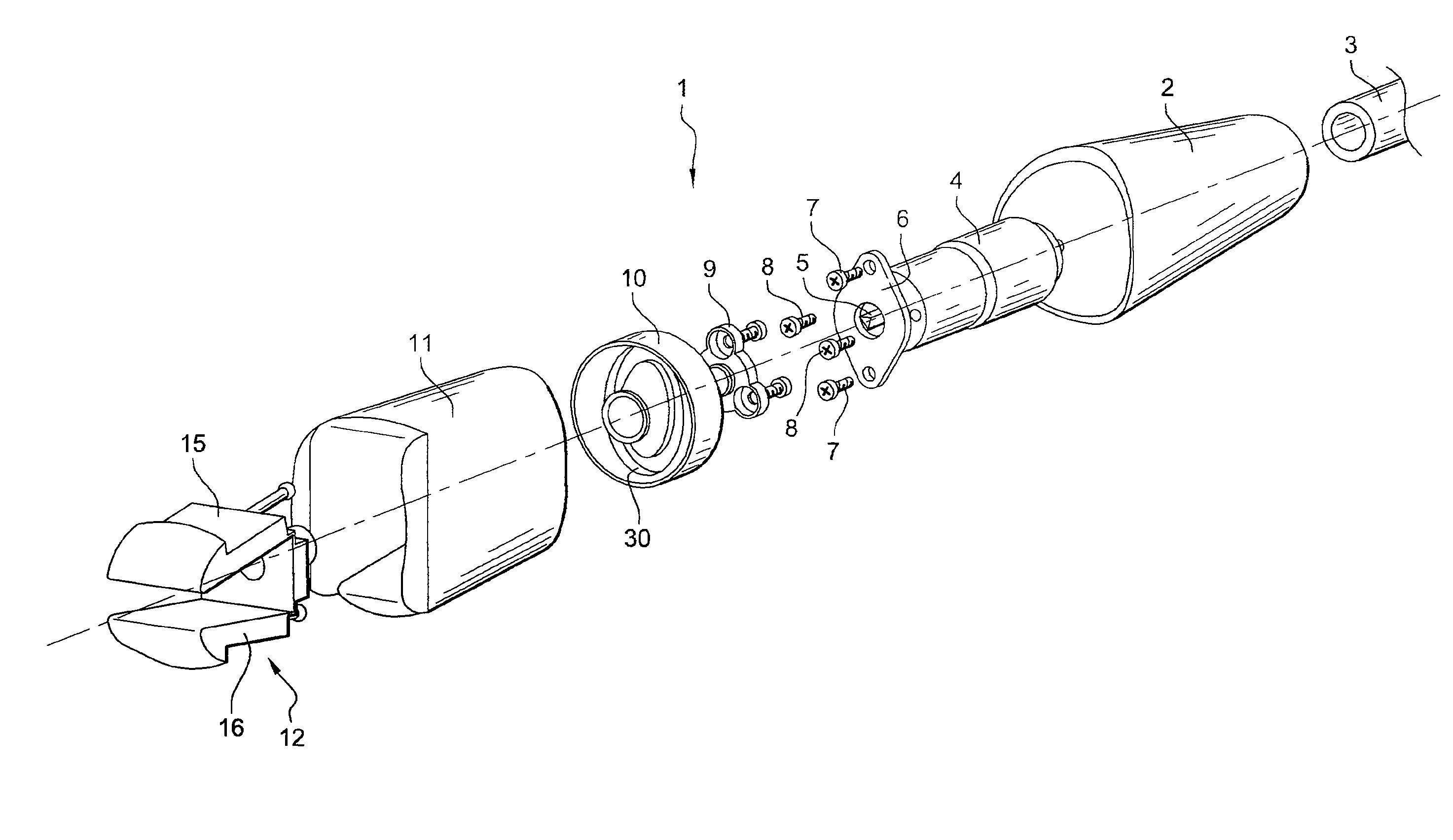

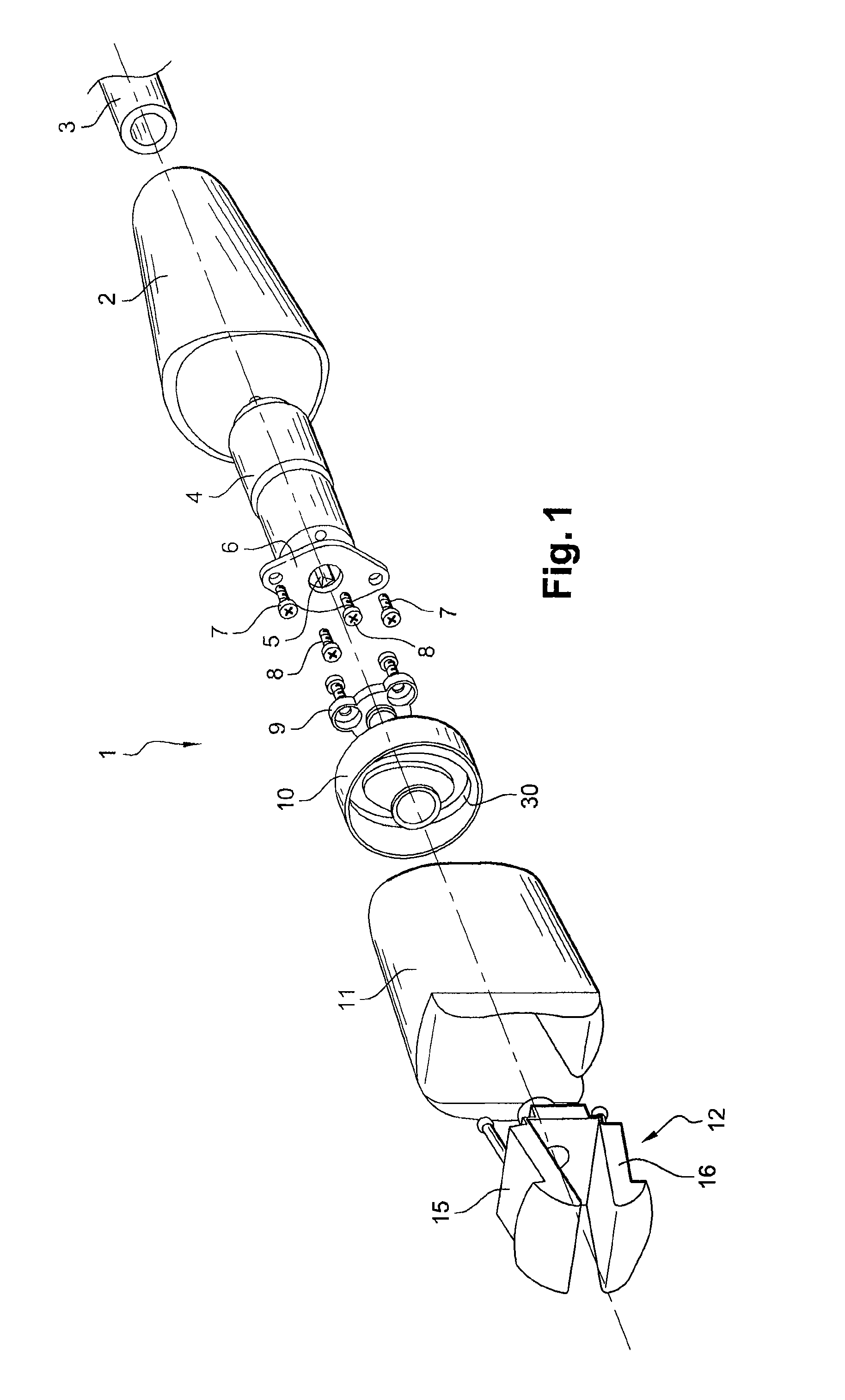

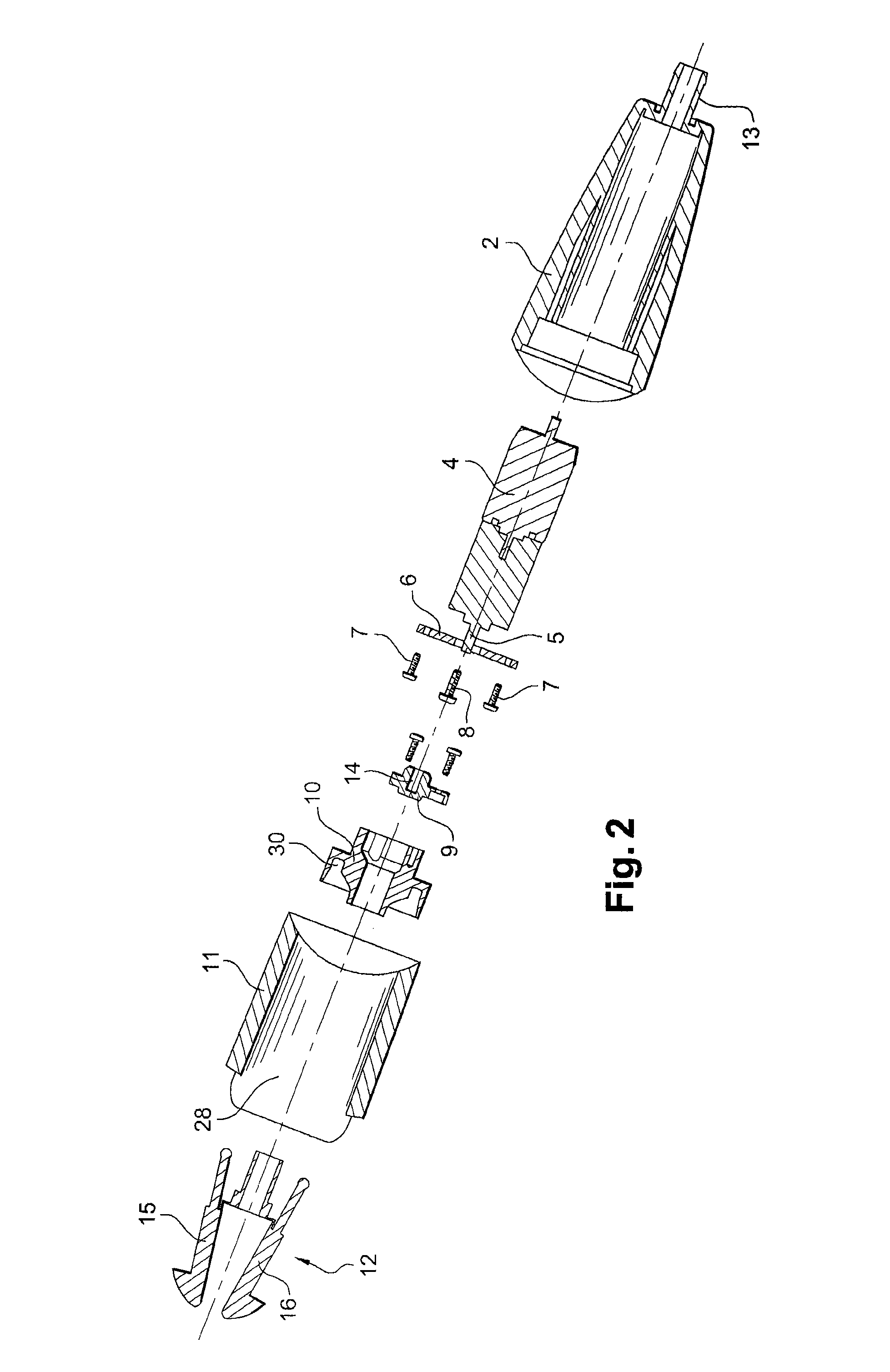

Guide with measuring device, and method with producing such a guide

ActiveUS20050076526A1Simple and position-accurate mountingGuaranteed positioningWalking sticksLinear bearingsMeasurement deviceEngineering

Owner:REXROTH STAR

Method and system for monitoring local integrity of train satellite positioning

ActiveCN108761497AAvoid difficultiesImprove tracking adaptabilitySatellite radio beaconingObservation dataFault detection and identification

The invention discloses a method and system for monitoring the local integrity of train satellite positioning. The method comprises the steps of collecting track line geospatial information and trainrunning plan information of a target train; dividing the running process of the target train to obtain spatial-temporal local area grids; collecting satellite positioning observation performance information in real time in the running process of the target train, and calculating a satellite positioning local area observation model of each spatial-temporal local area grid; integrating parameters ofthe models to construct a satellite positioning observation model parameter set; extracting model parameters of the located spatial-temporal local area grid by using the satellite positioning observation data received by the train in the running process, and calculating on-line and off-line positioning error level protection grades; judging the availability state of integrity monitoring, carryingout fault detection and identification on the satellite positioning observation set under an available condition, performing reconstruction on the train satellite positioning observation set in realtime, and implementing positioning calculation. The method can realize effective adaptation to the uncertainty of satellite signal observation conditions in the actual running of the train.

Owner:BEIJING JIAOTONG UNIV

Massage head and massage apparatus employing said head

ActiveUS20100036298A1Optimize bloodOptimize lymphatic circulation processGenitals massageSuction-kneading massageRelative displacementMassage

This massage head is fitted with a case defining an internal chamber in which a skinfold is formed when it is applied to the skin of a patient. The fold presses against the lower edges of the chamber, which is defined by two lateral walls and by two transverse walls The transverse walls each include a clack valve able to be driven in a pivoting motion, so as to cause the lower edges of the clack valves in contact with the skinfold to come closer together or move further apart. The relative displacement of the clack valves is ensured by of a motorized rotary cam provided in the massage head. The cam defines a cam path engaging with a component associated with the clack valves, and able to cause the swivelling motion thereof.

Owner:LPG SYSTEMS

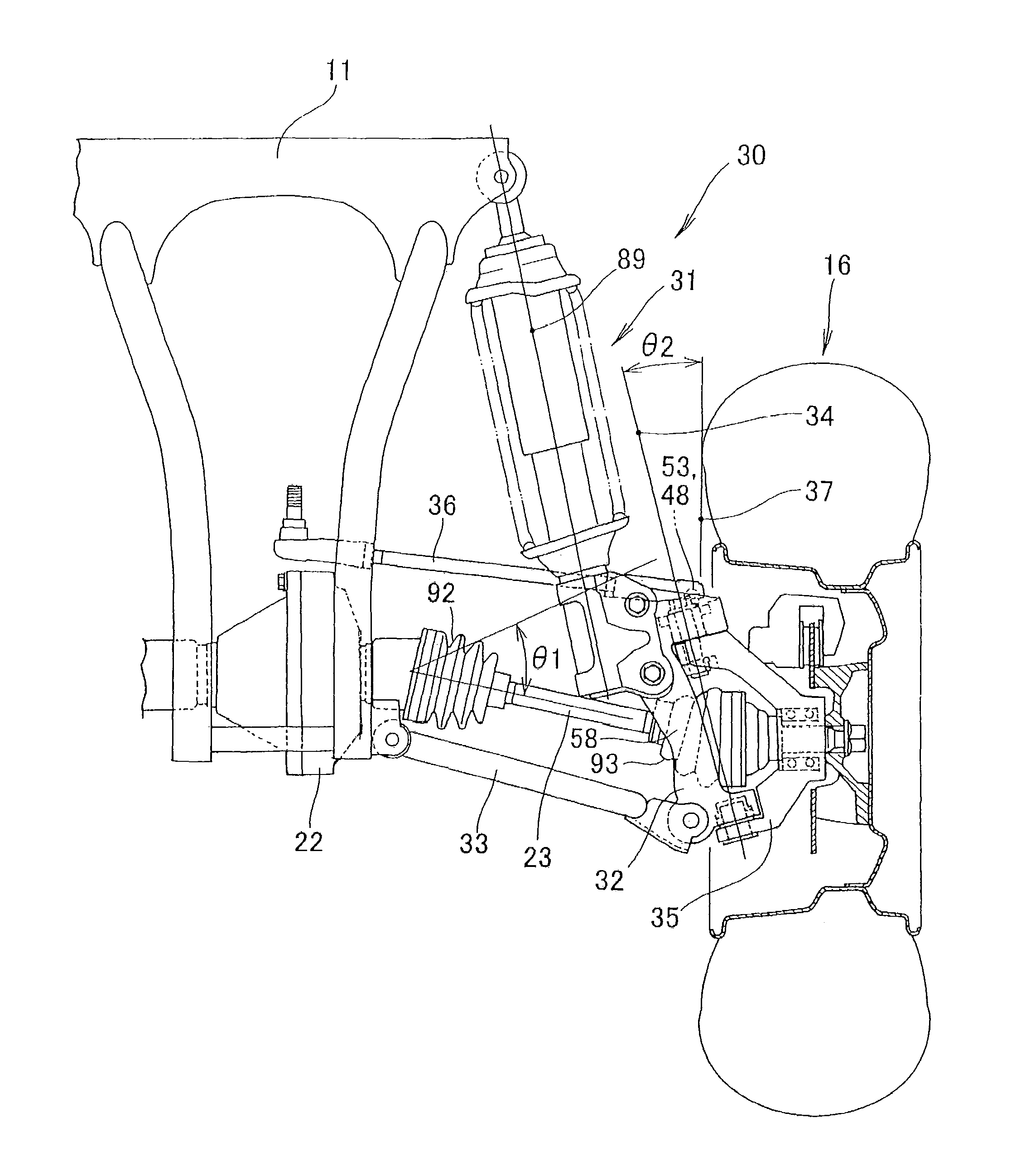

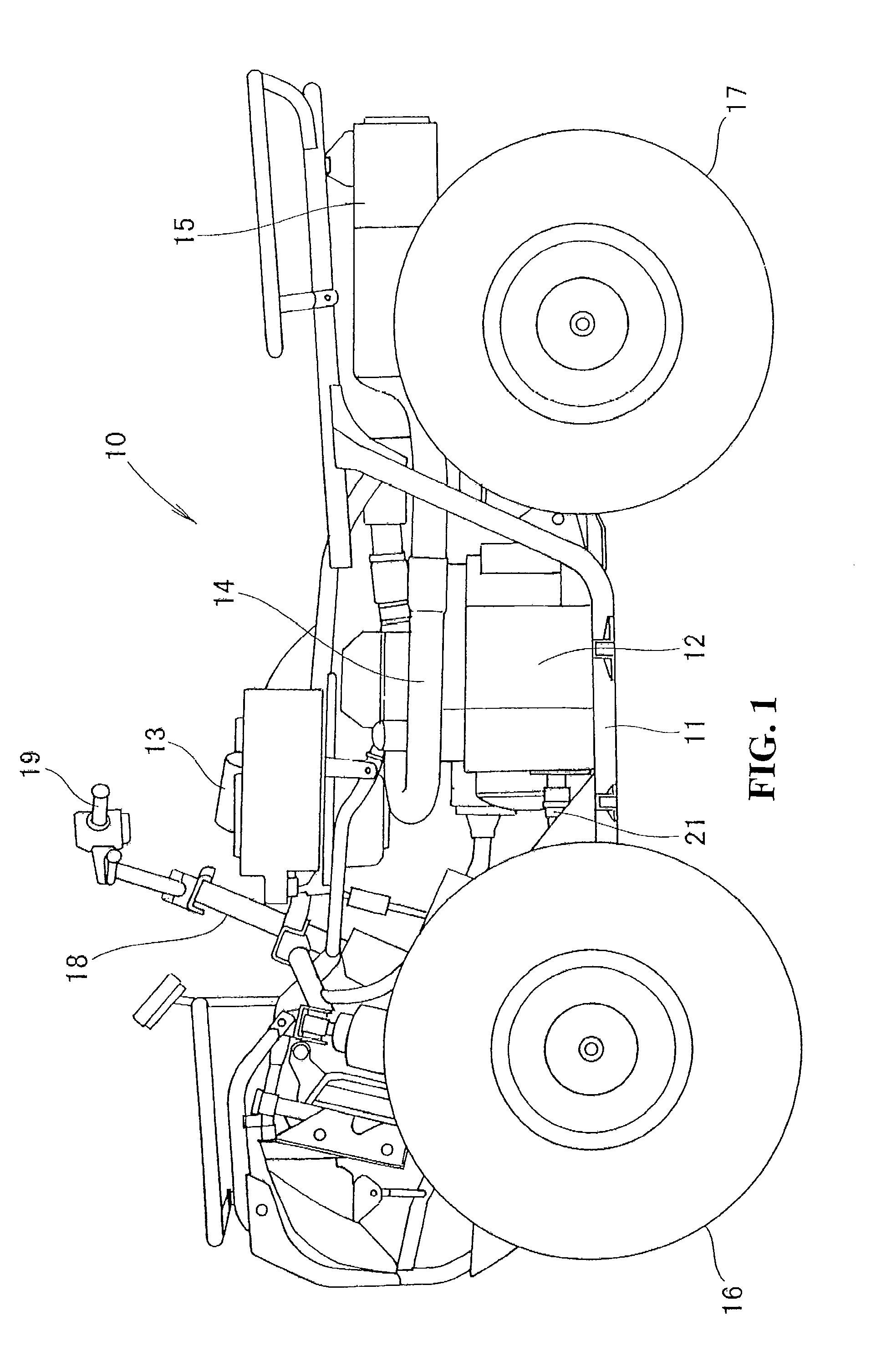

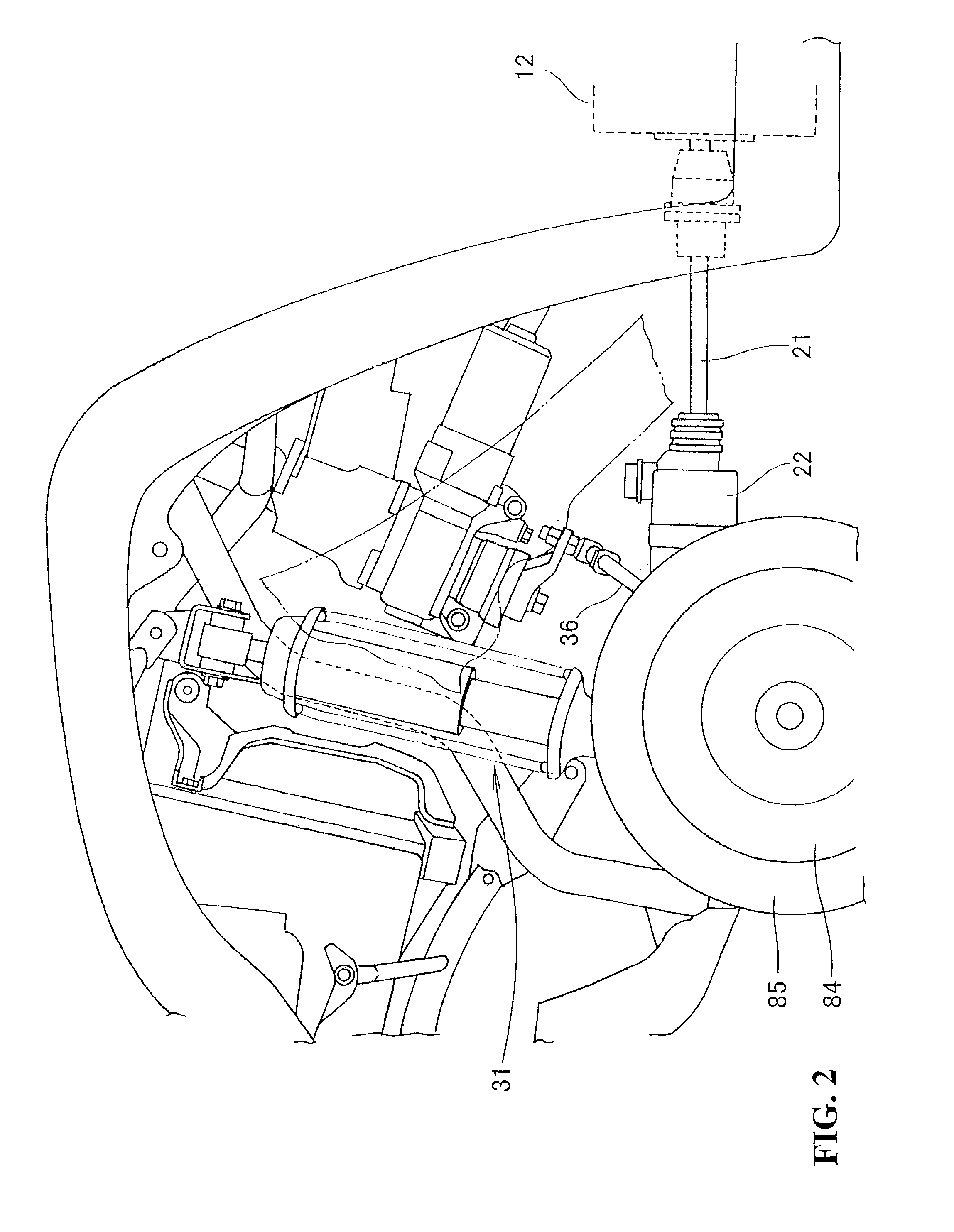

Suspension system for vehicle

ActiveUS8573615B2Guaranteed positioningReduce the overall heightCyclesSteering linkagesDrive shaftControl theory

A suspension system suitable for a small-sized vehicle such as an all terrain vehicle. A strut damper is arranged wherein a downwardly extending line of an axis of the strut damper is located in front of a drive shaft extending to the depth of a drawing from the rotational center of a front wheel. As interference between the strut damper and the drive shaft is not a concern, a mounting position of the strut damper can be fully lowered. In addition, the length of the axis of the strut damper can be fully secured. Therefore, the height of the vehicle can be lowered. In addition, the design of a vehicle body is facilitated.

Owner:HONDA MOTOR CO LTD

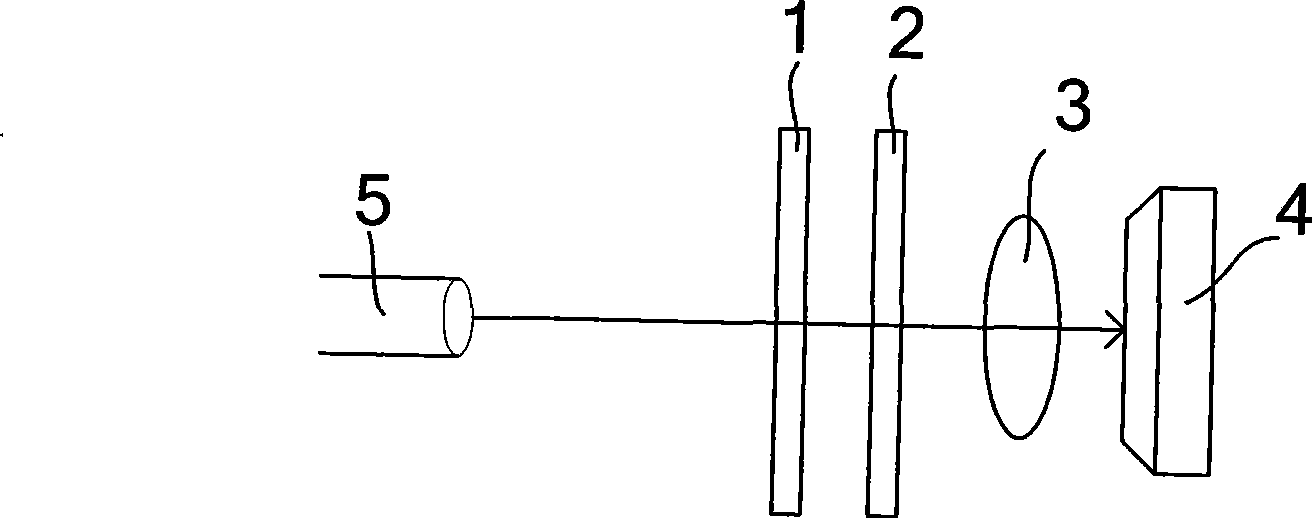

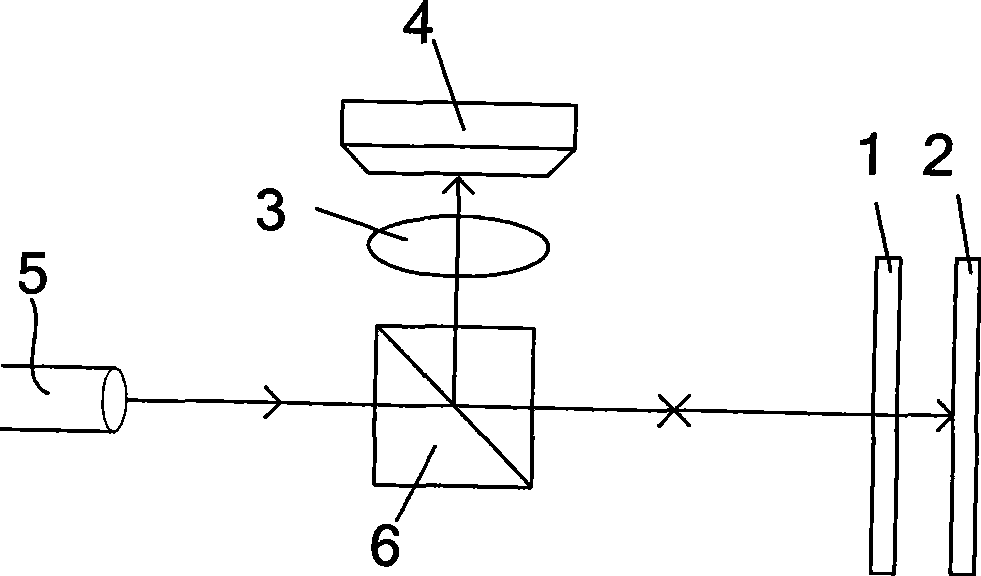

Small gapping place relatively rotating measuring and rotating positioning system and method

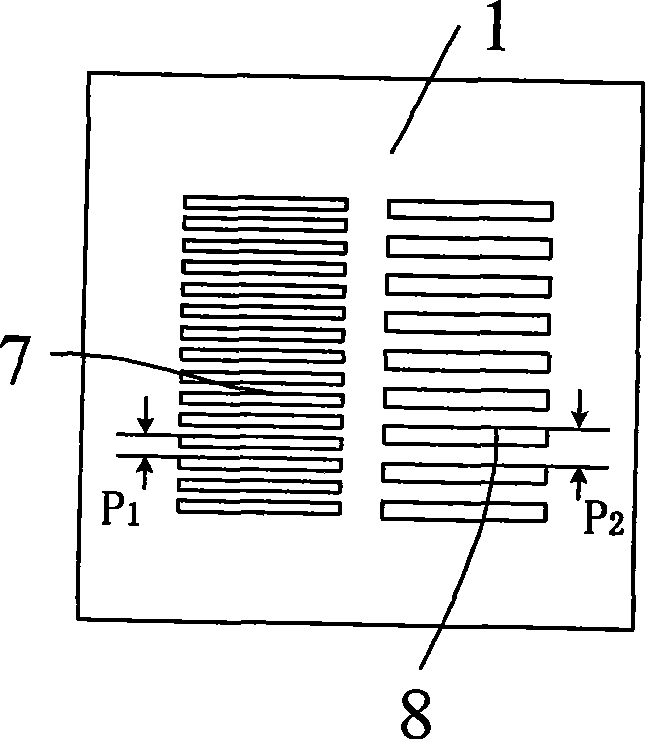

InactiveCN101419064AStrong process adaptabilityEasy to debugUsing optical meansPhotomechanical exposure apparatusPhysicsVertical orientation

The invention discloses a system and a method for the high-precision measurement direction sensing and rotary positioning of relative micro-rotation between two planes. Two gratings are arranged on the two planes to form two groups of measurement grating pairs. When the amount of relative rotation between the two planes is zero, grid lines of all gratings are in the same direction. Two groups of measurement grating pairs are opposite in the size relation of grating size but identical in period ratio. The number of fringes acquired by a measurement system is not less than 40. The method for measurement direction sensing and rotary positioning comprises the following steps of adopting the dimensions of fringe inclination angles obtained in the horizontal-vertical direction and two diagonal directions to obtain the directions of the fringe inclination angles. When two groups of interference fringes are identical in direction, rotary zero-point positioning is realized between the two planes, and when two groups of interference fringes are different in direction, relative rotation amount exists between the two planes.

Owner:XI AN JIAOTONG UNIV

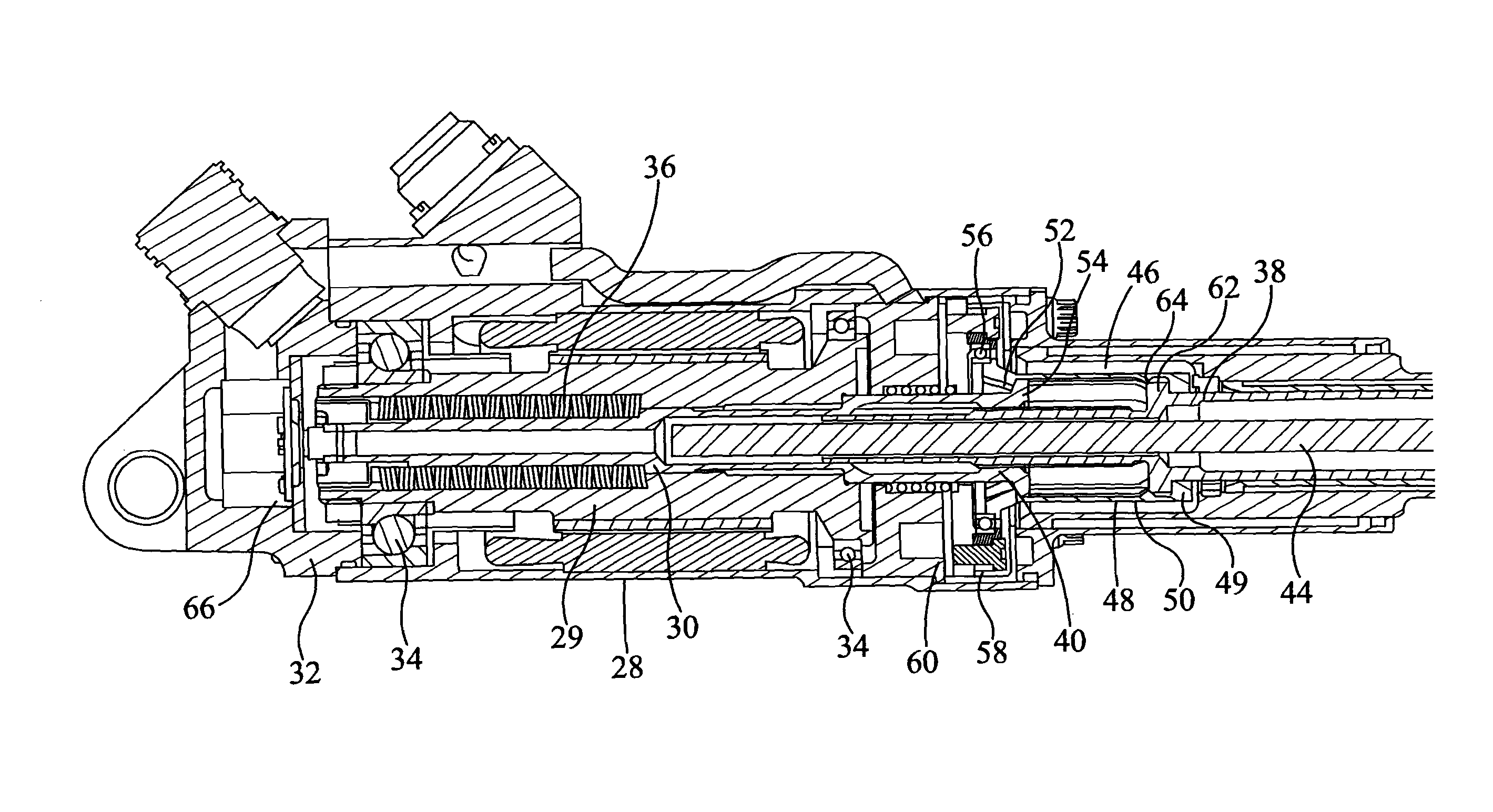

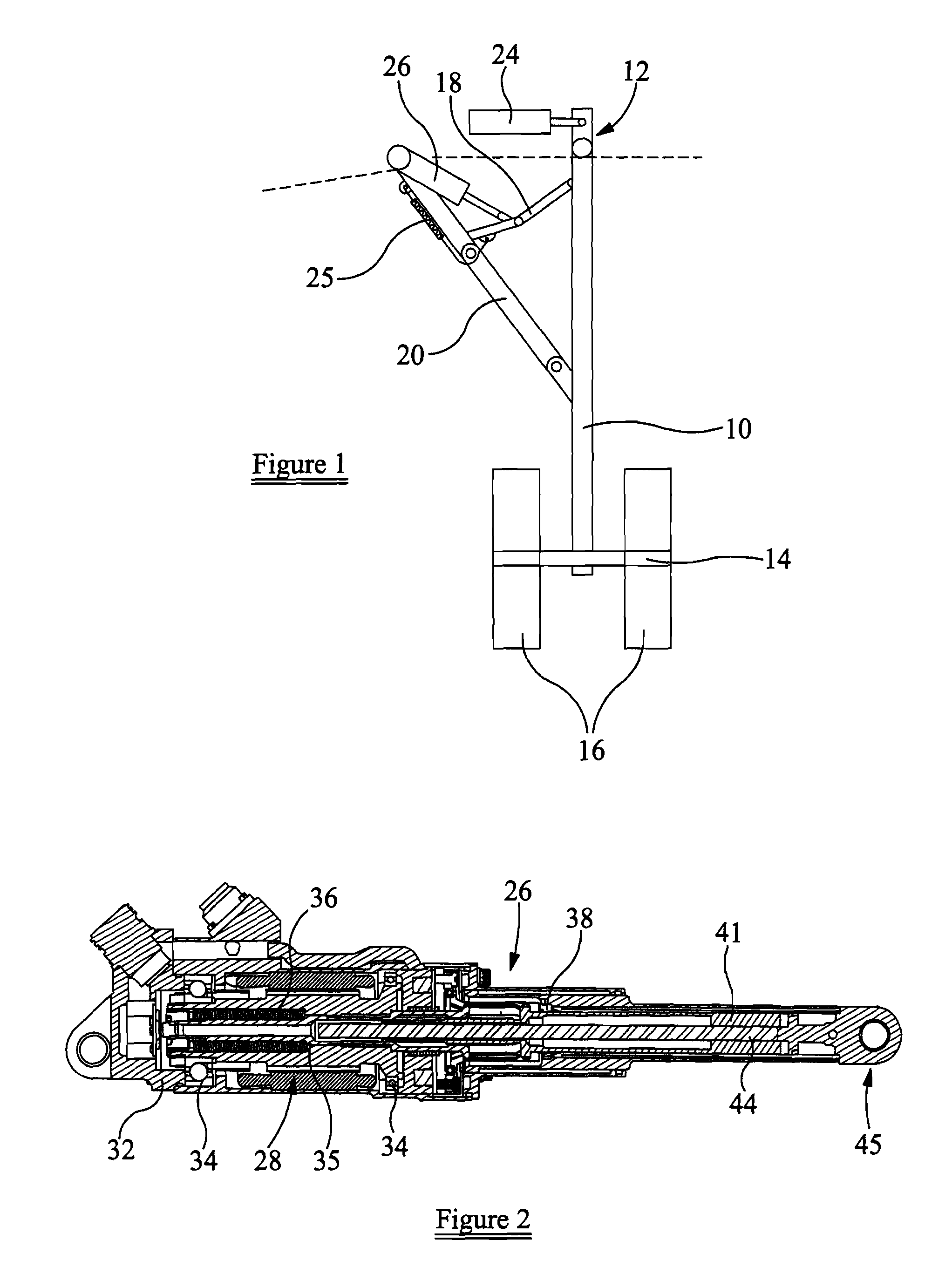

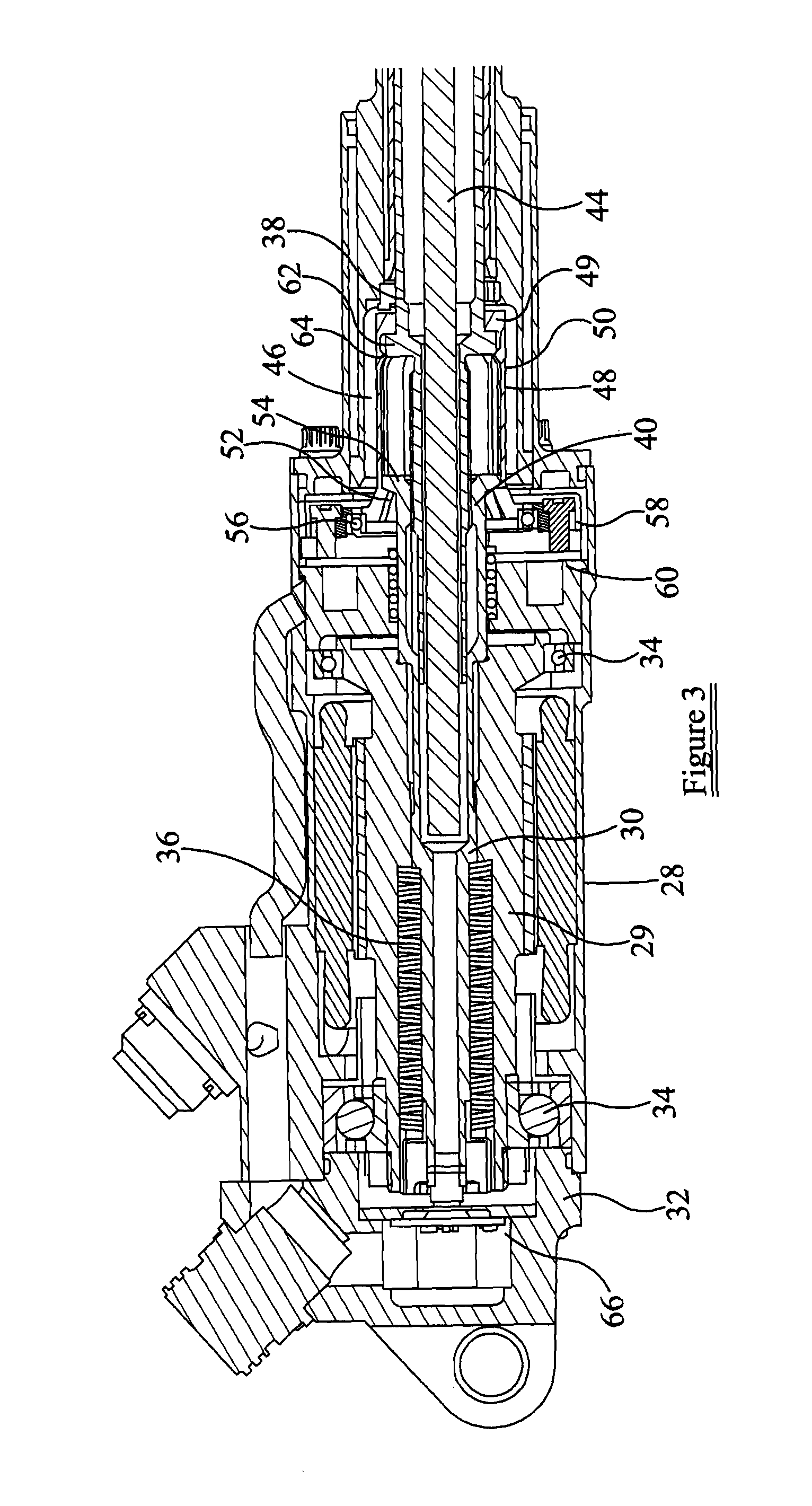

Failsafe actuator

An actuator comprises an actuator shaft mounted for rotation by a drive shaft, releasable lock means operable to restrict axial movement of the actuator shaft relative to the drive shaft, and an output member co-operating with the actuator shaft such that rotation of the actuator shaft drives the output member for translating movement relative to the actuator shaft.

Owner:GOODRICH ACTUATION SYST

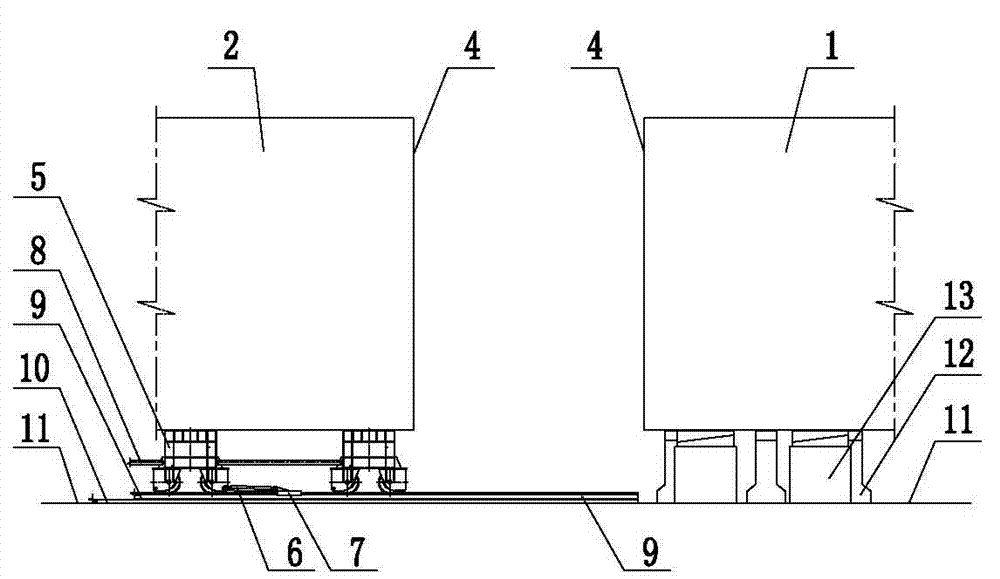

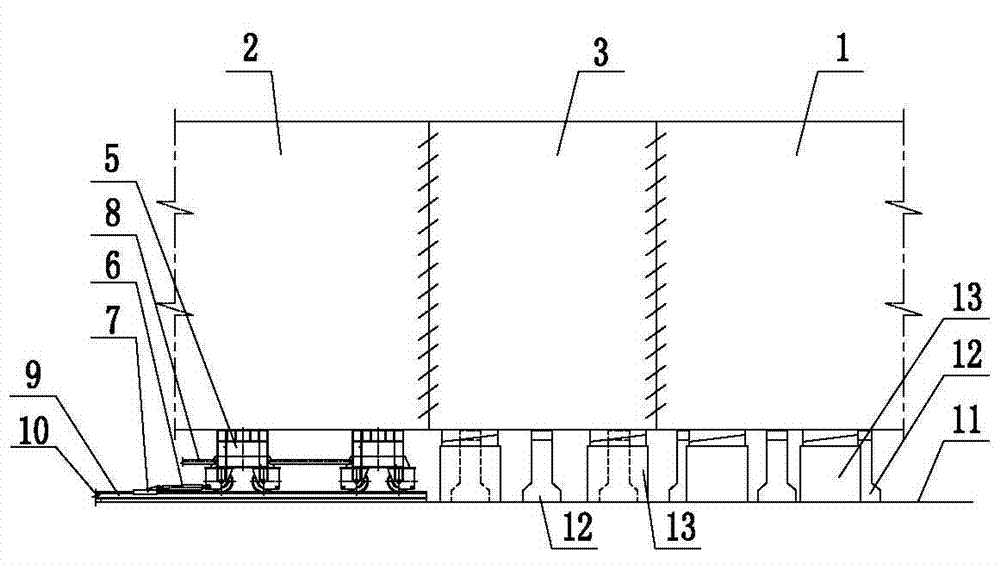

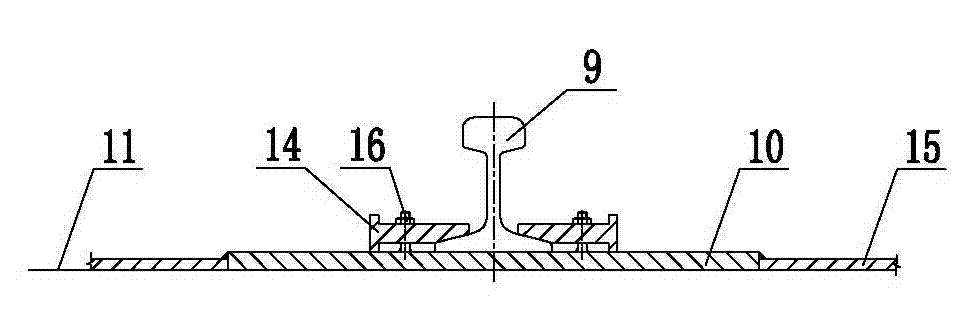

Retrofit technology for cutting and lengthening ships via dry-type trolley method

ActiveCN102923254AImprove securityEasy to fixVessel partsRecycling waterborne vesselsKeelMarine engineering

The invention discloses a retrofit technology for cutting and lengthening ships via a dry-type trolley method. The technology is carried out by prefabricating newly-added sections by sectioning, arranging docking blocks, drawing lines on a ship body, strengthening the structure of the ship body, and cutting by sectioning. The technology comprises the following main steps of: controlling the docking precision of the ship; paving a combined-type rail, connecting and putting a combined trolley; precisely lying the ship on a keel block after the ship docks; arranging a thrust device; adding supports at the front end of a bow section and the rear end of a stern section of the ship; displacing the bow section; assembling the newly-added sections and folding the newly-added sections with the stern section; and precisely aligning, locating and folding the bow section with the newly-added sections. The technology is suitable for cutting and lengthening ships in any mold lines and tonnages and has the advantages of rapid folding speed, high firmness safety, simple and reliable process operation, short retrofit period and low cost. The folding and locating precisions are high, so that the precise displacement and aligned location of the bow section are effectively guaranteed and the folding precision reaches the level of a newly-constructed ship. On the other hand, the technology is less affected by the change of exterior environment factors such as weather, which is beneficial to the control of the docking period in enterprises.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

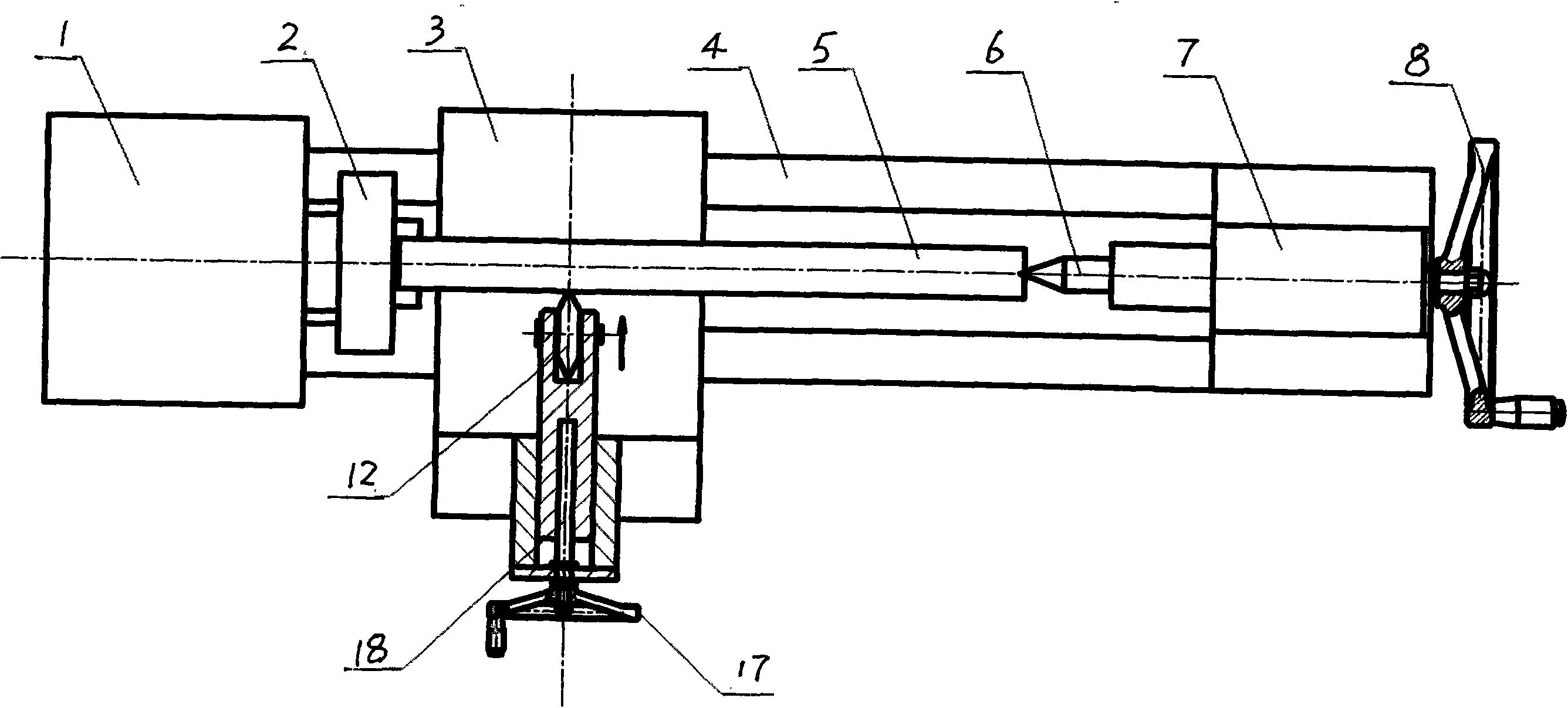

Curve shaft rolling machine

The invention relates to a curve shaft rolling machine belonging to the technical field of processing of shaft rolling machinery. The invention mainly solves the problems that single rolling head and rolling wheel of the traditional rolling machine only can rotate in one direction, so that in the shaft rolling and processing procedure, the rolling head and the rolling wheel are pushed and bent, the rolling quality is poor, the shaft range capable of rolling is small, and the like. The curve shaft rolling machine is mainly characterized by comprising a rotary power mechanism, a horizontal movement mechanism, a workpiece proping mechanism and a stand, wherein the rotary power mechanism comprises a power box and a chuck; the horizontal movement mechanism comprises a sliding table and a guide rail; the workpiece propping mechanism comprises a tip, a tailstock and a hand wheel; a group of rolling heads which are symmetrically distributed by a rotary shaft axis are fixed on the sliding table through a bracket, and each rolling head comprises a cylinder body, a piston, a rolling wheel, steel balls, a retaining sleeve and an oil pipe; the cylinder body is fixed on the bracket; the retaining sleeve is fixed on the piston, and the steel balls are arranged at the end part of the retaining sleeve; the rolling wheel is arranged in the retaining sleeve, and the rolling wheel is in contact with the steel balls; and the oil pipe is connected with a hydraulic station. The invention is mainly used for rolling and processing of various curve shafts.

Owner:南车襄樊机车有限公司

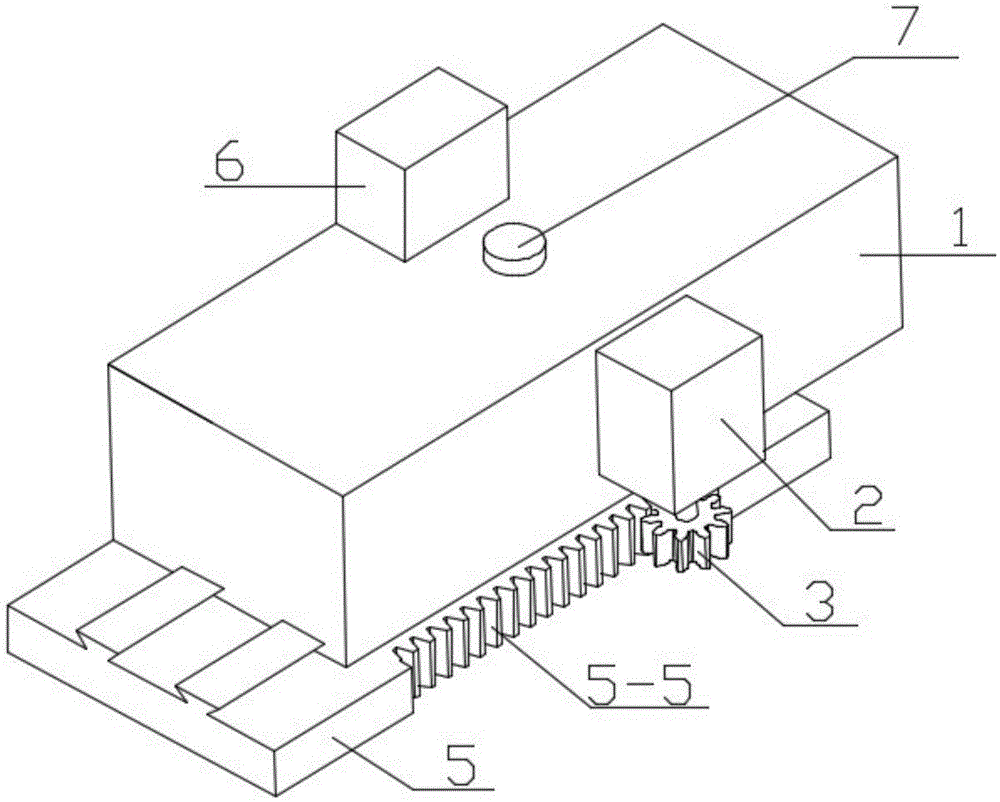

3D (Three Dimensional) printer capable of changing spraying heads for printing

ActiveCN105109041AReduce printing timeImprove processing efficiencyAdditive manufacturing apparatusDrive motorEngineering

The invention discloses a 3D (Three Dimensional) printer capable of changing spraying heads for printing. The 3D printer comprises a material feeding device, a heating and clamping device (1), a driving device, a positioning device, a base (5), spraying heads (10) and a control system, wherein the heating and clamping device comprises a heating device and an electromagnet; a material inlet (7) is formed in the top part of the heating and clamping device; the driving device comprises a driving motor (2) and a driving gear (3); the positioning device comprises a positioning motor (6) and a positioning pin (9); the base is provided with material outlets, positioning holes and a rack of which the two ends are provided with position switches (4); the base is connected with the heating and clamping device; the spraying heads comprise a spraying head I and a spraying head II; and the control system is connected with the material feeding device, the driving device, the positioning device and the spraying heads. According to the 3D printer disclosed by the invention, the free change of the spraying heads is realized; processing materials with different diameters are sprayed at different working conditions; the processing efficiency is improved; the raw materials are saved; the production cost is lowered; meanwhile high-precision change of the spraying heads is realized through the positioning device; and the processing precision of parts is improved.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com