Patents

Literature

30results about How to "Fully quenched" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

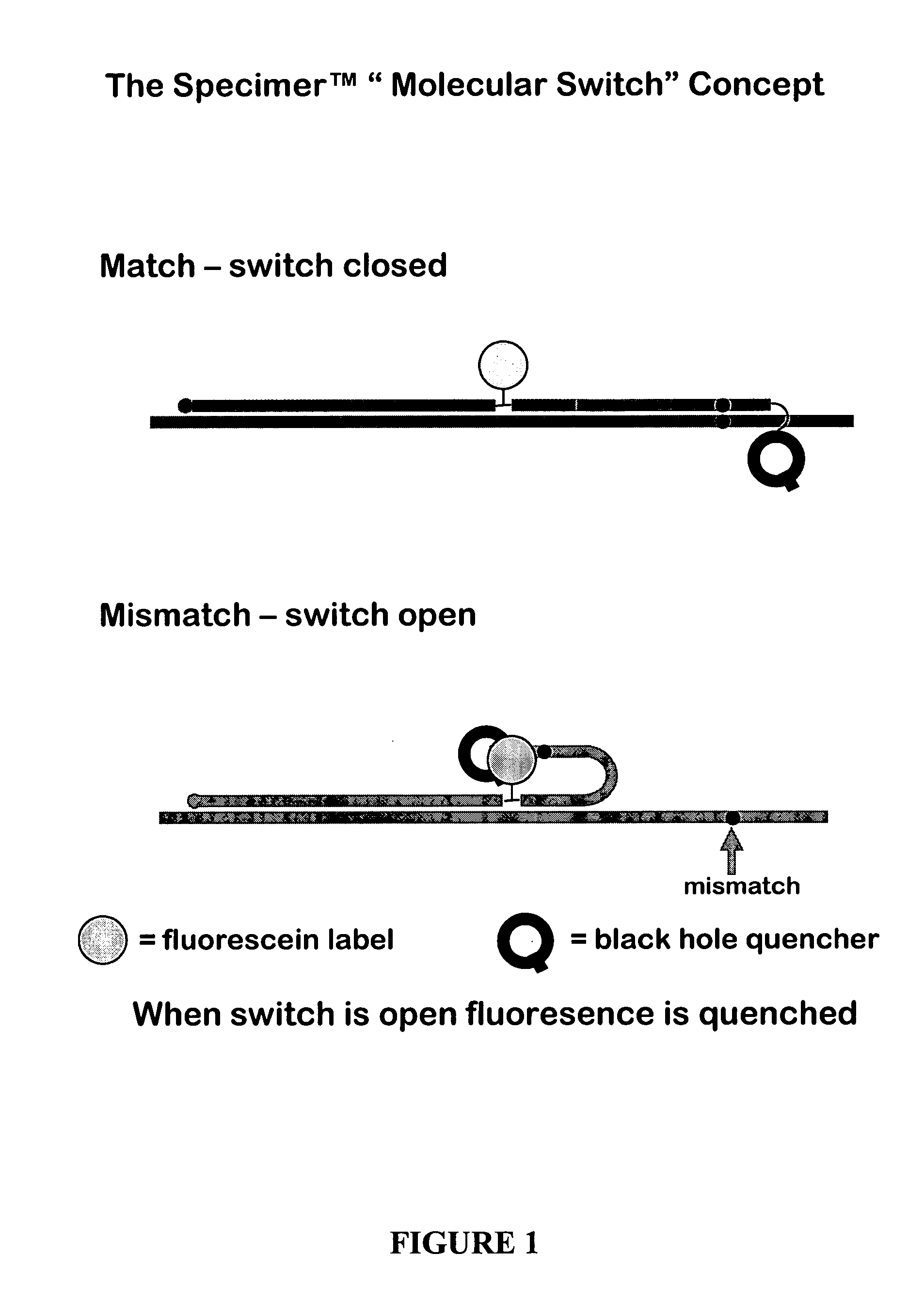

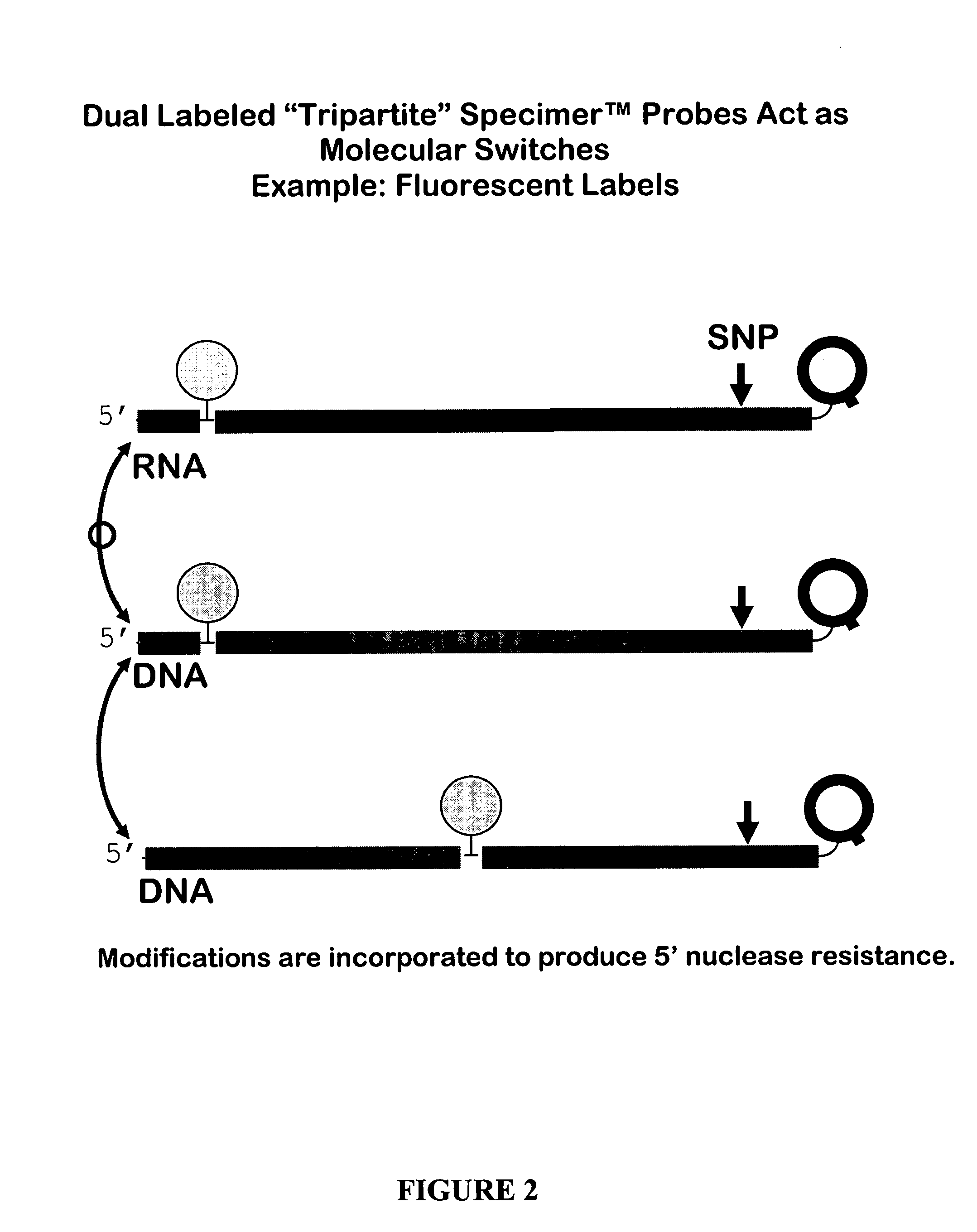

Oligonucleotides comprising a molecular switch

ActiveUS20050042638A1Strong specificityGuaranteed positioningSugar derivativesMicrobiological testing/measurementBinding domainMolecular switch

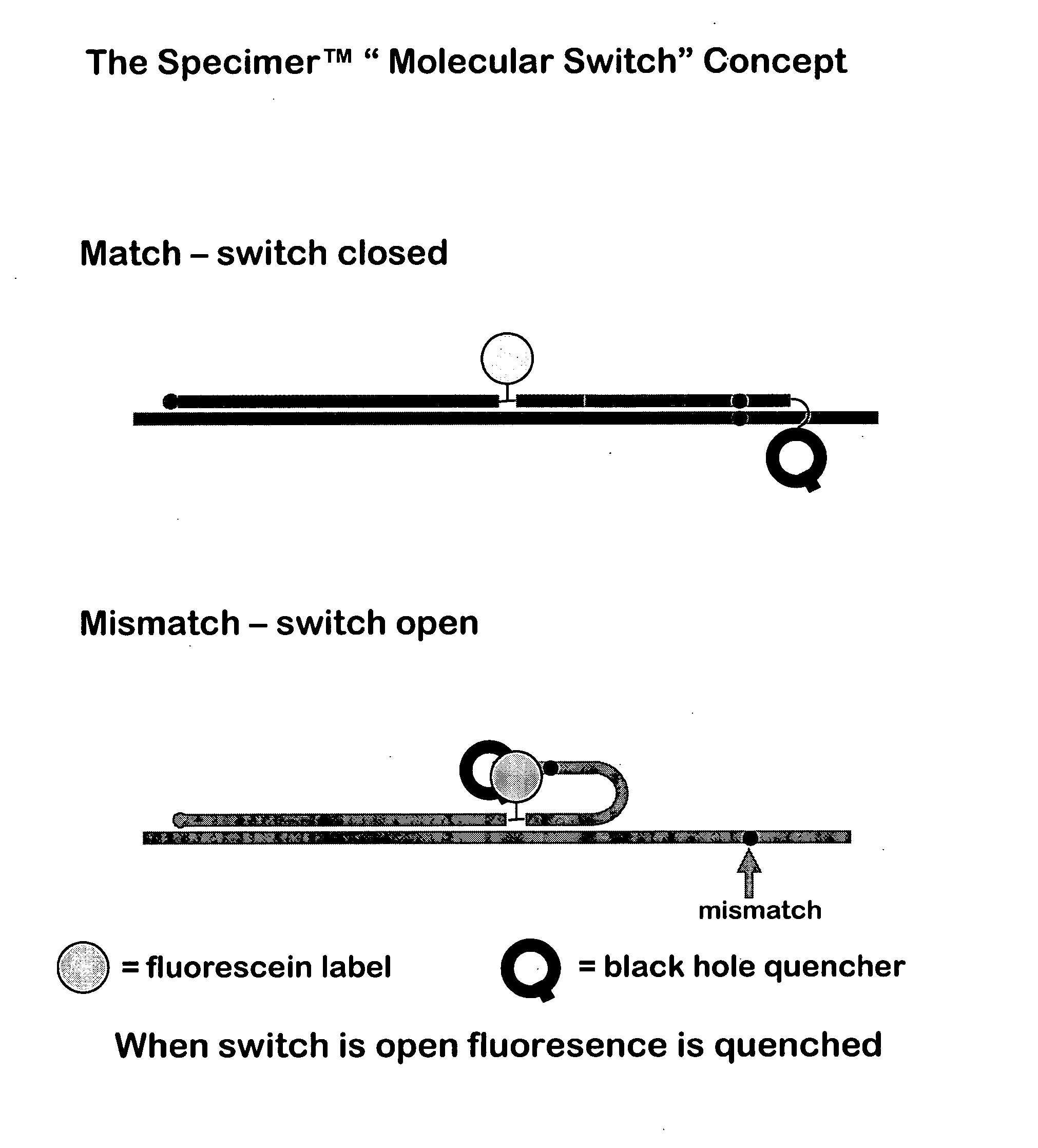

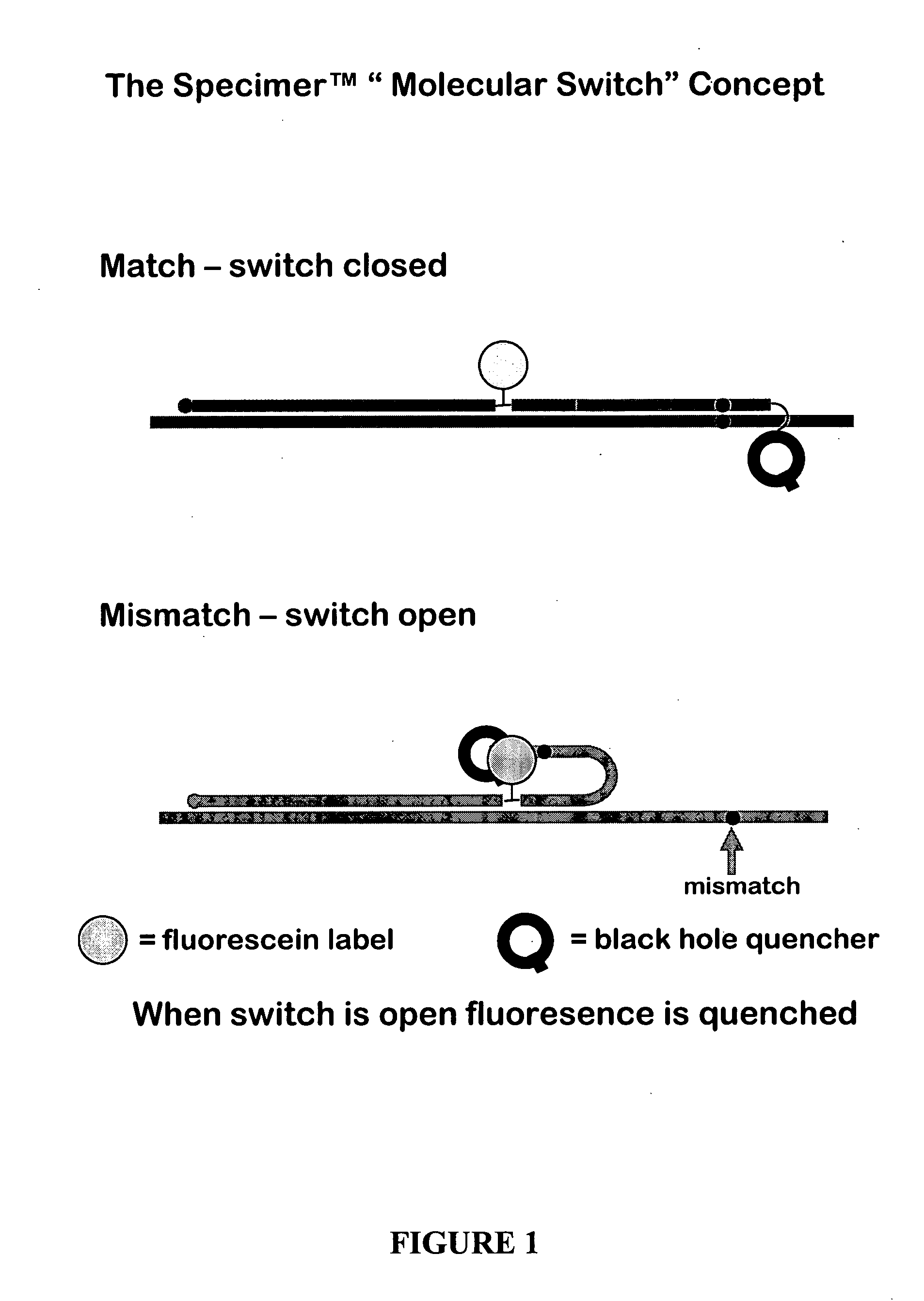

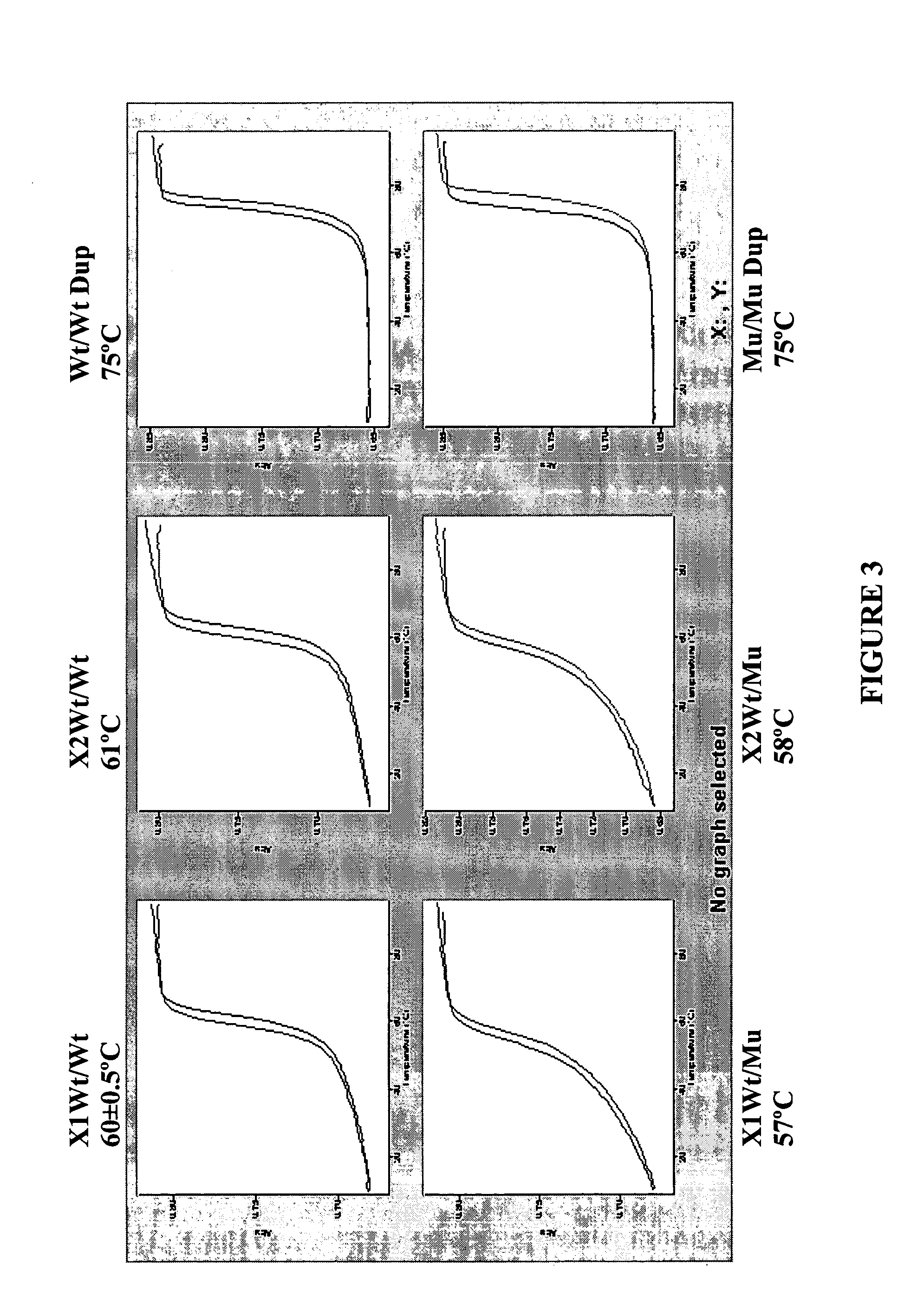

This invention relates to oligonucleotides comprising a molecular switch which may exist in an “open” or “closed” position. The molecular switch portion of the probe is particularly sensitive to the identity of sequences complementary to the molecular switch. Oligonucleotides containing a molecular switch are applicable to all kinds of hybridization processes. Due to the sensitivity of the switch domain of the oligonucleotide, probes containing a molecular switch are particularly useful in the identification of single point mismatches. More specifically, a portion, but not all, of the oligonucleotide becomes unbound from a mismatched target. The invention further relates to methods of using said oligonucleotides for research reagents, and clinical diagnostics. An exemplary oligonucleotide comprises a first hybridizable domain, a second bridging block domain, and a third binding domain.

Owner:GEN PROBE INC

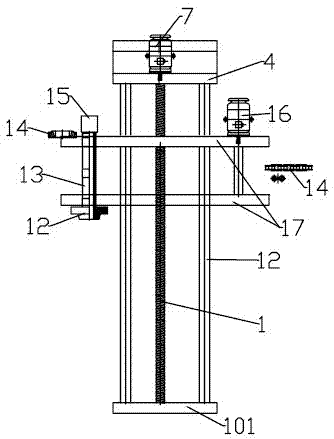

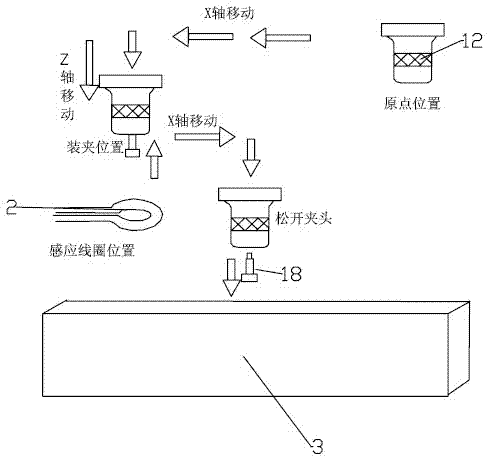

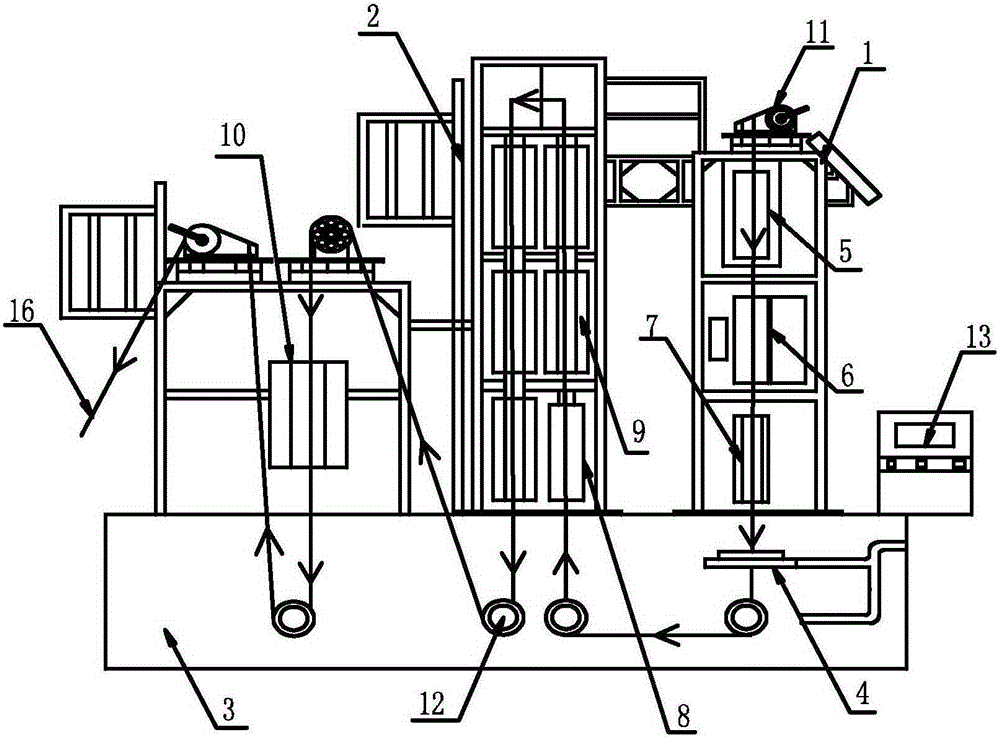

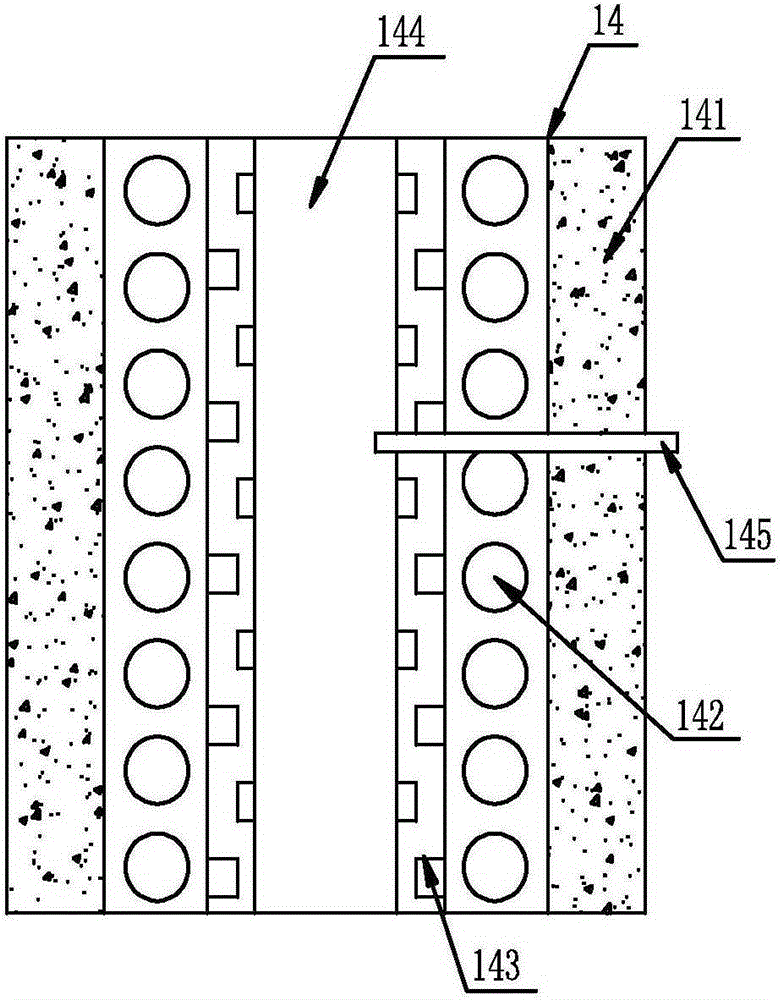

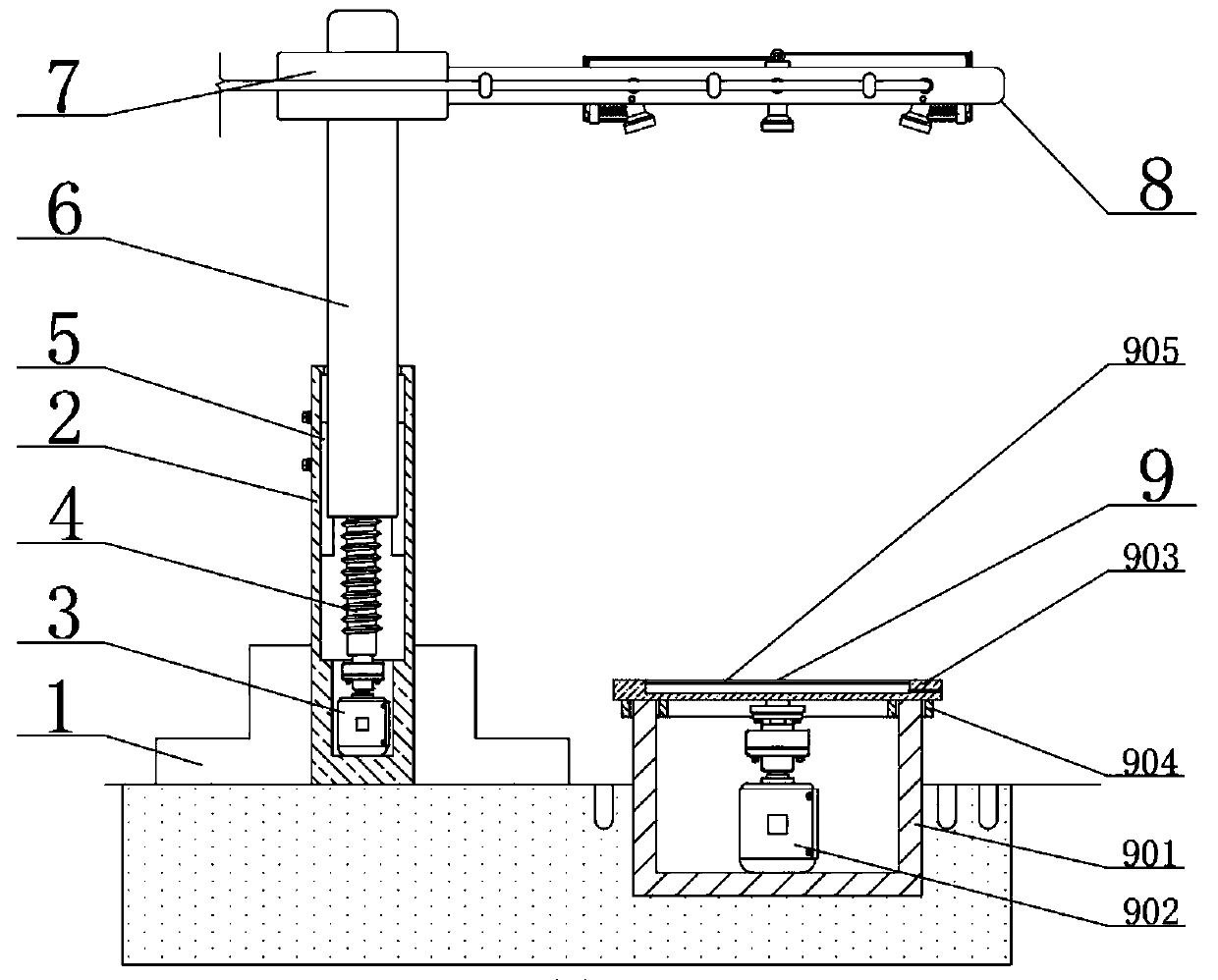

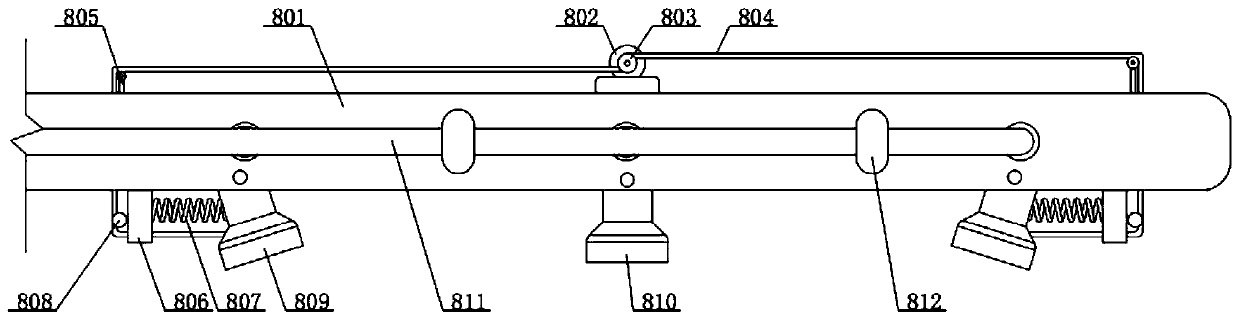

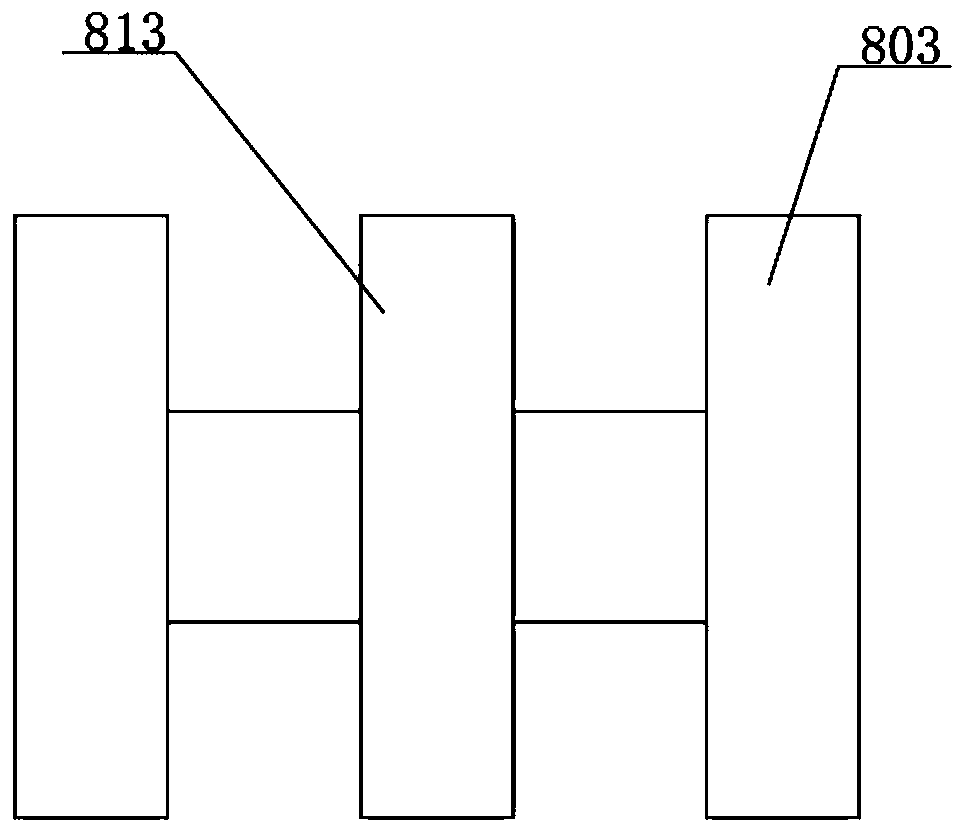

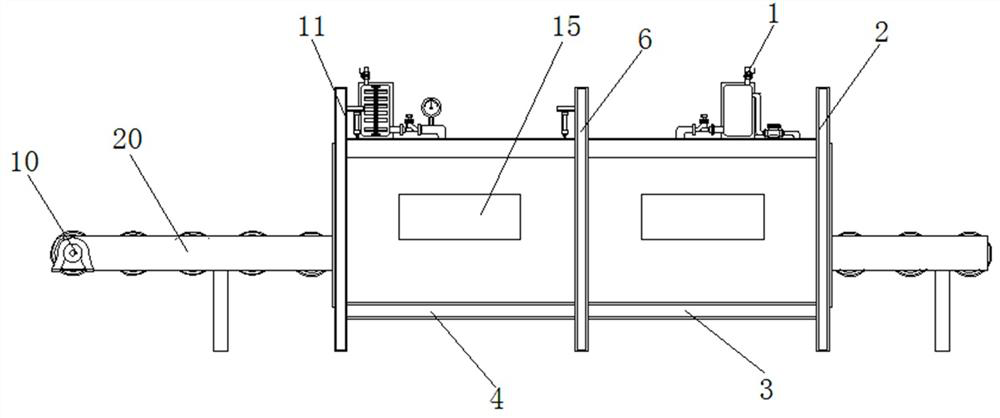

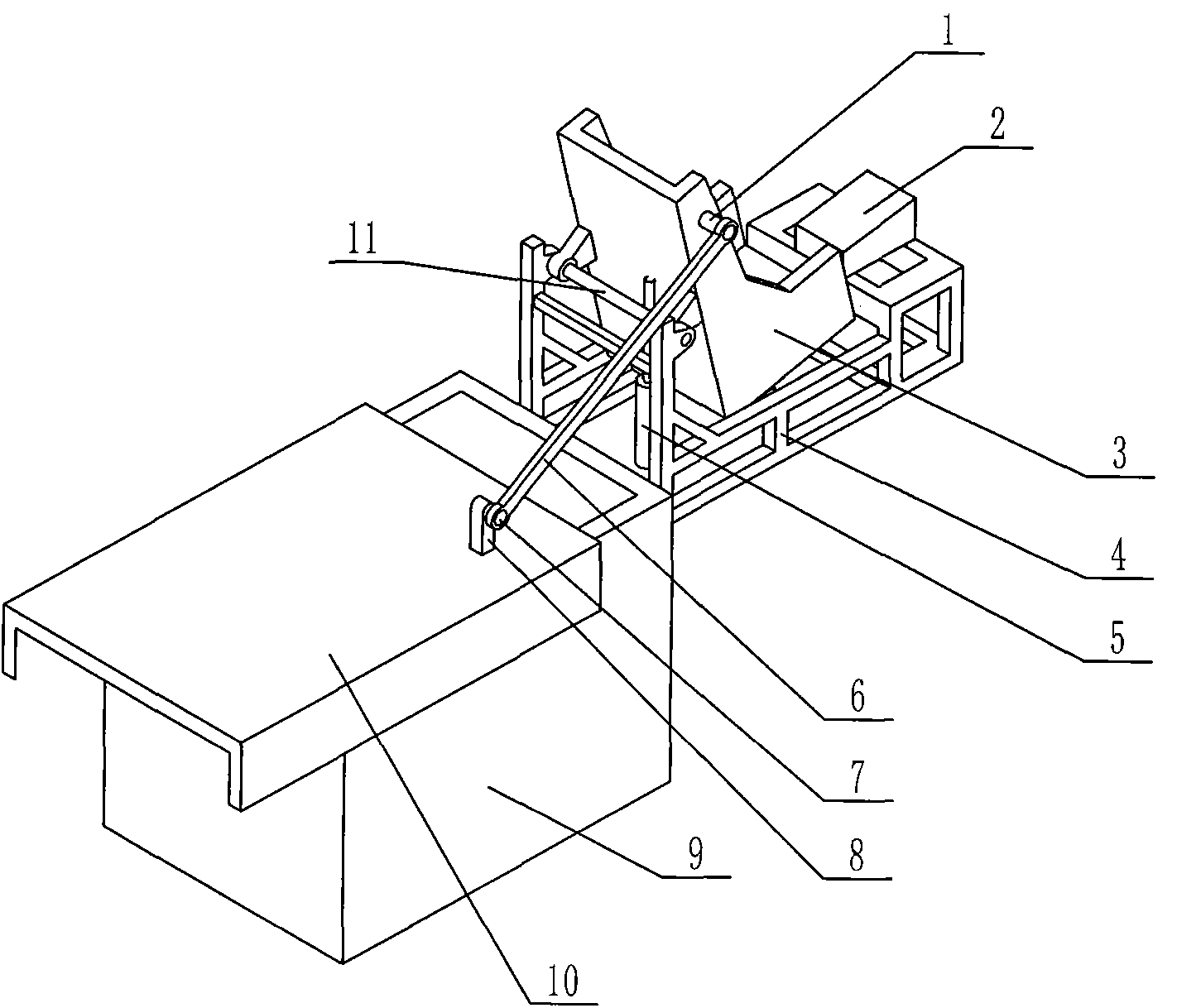

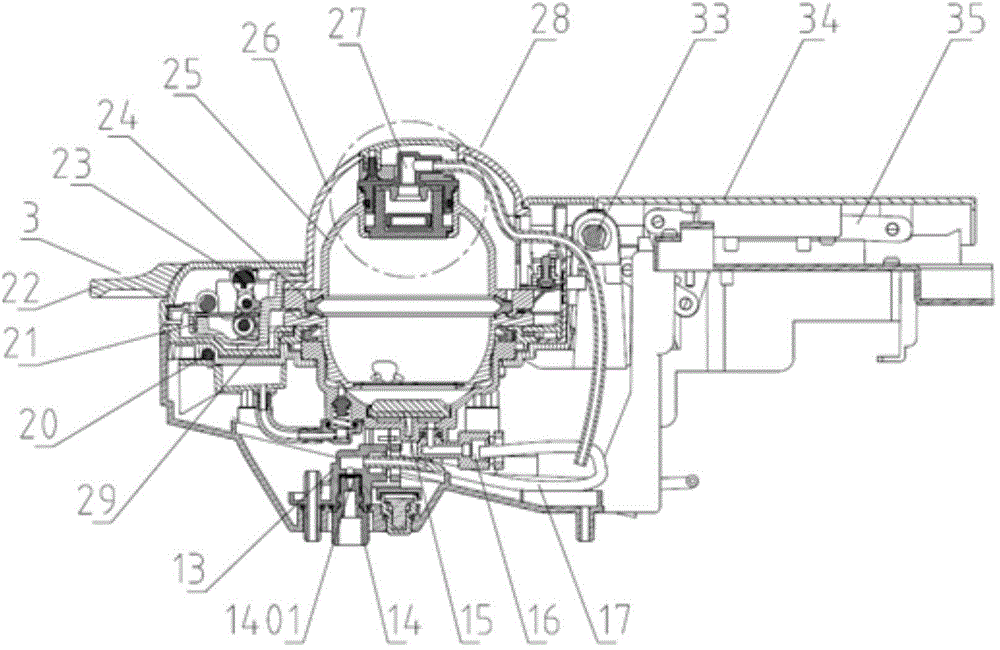

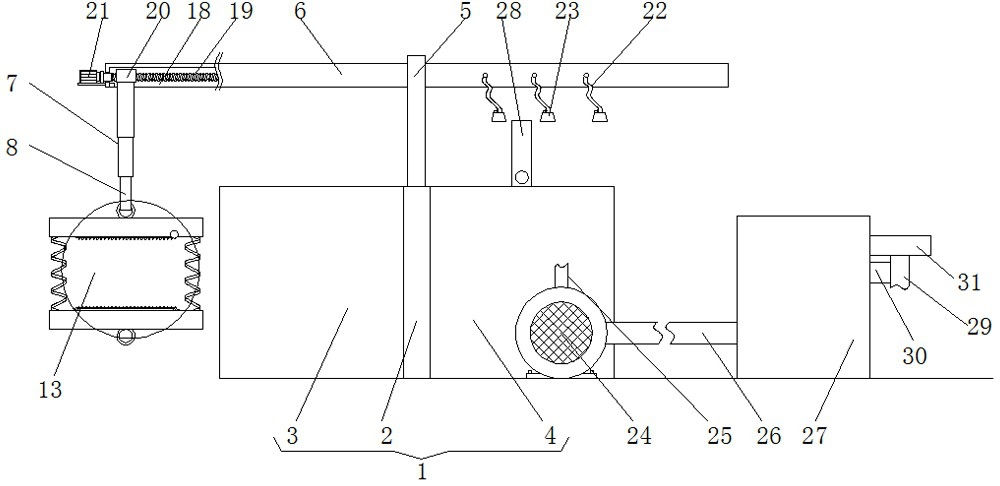

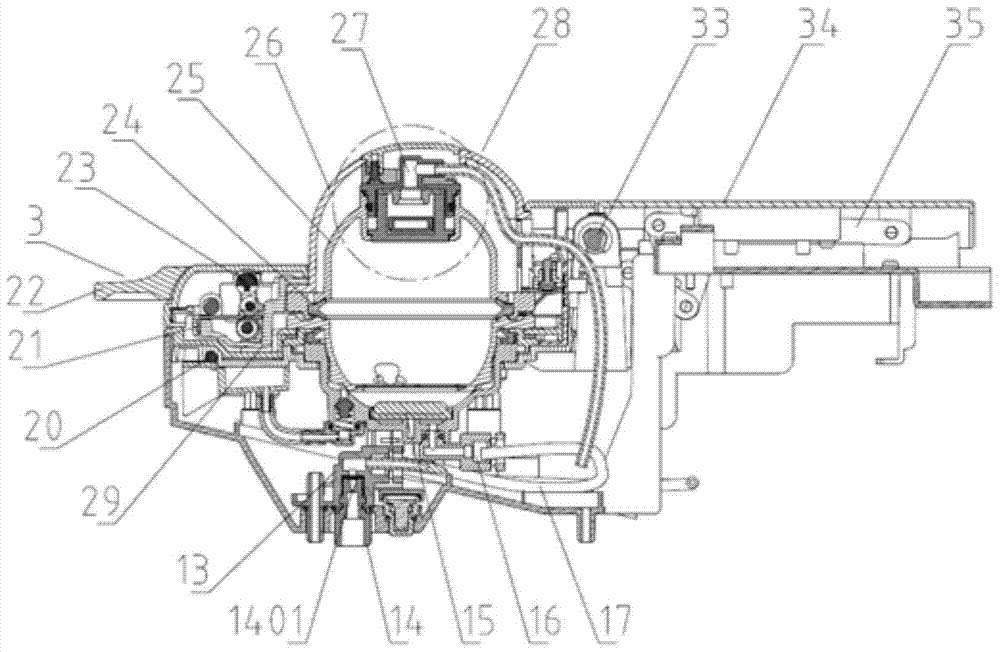

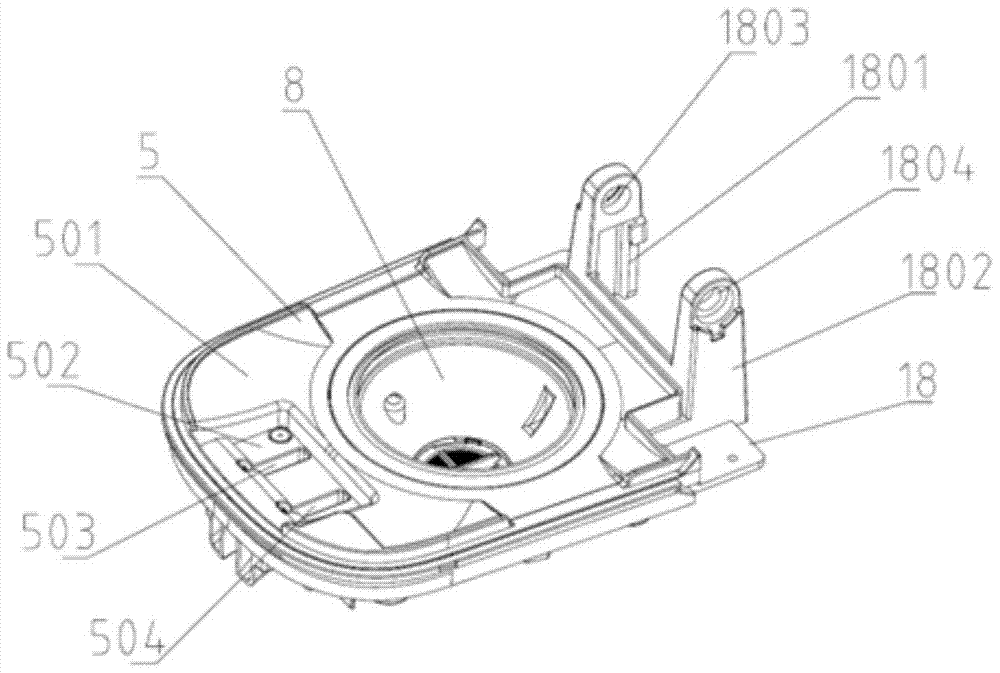

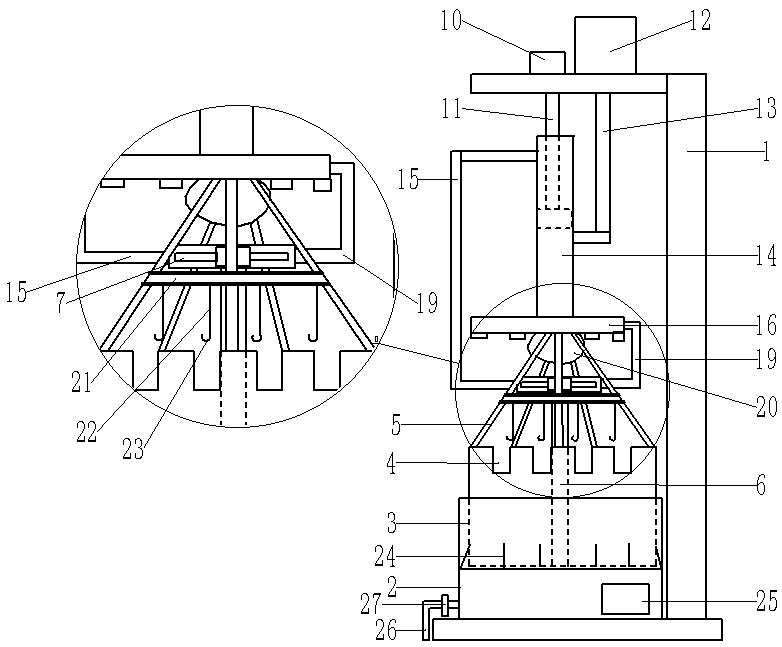

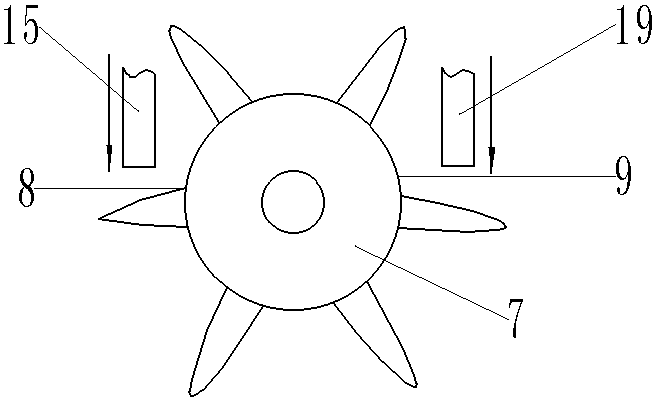

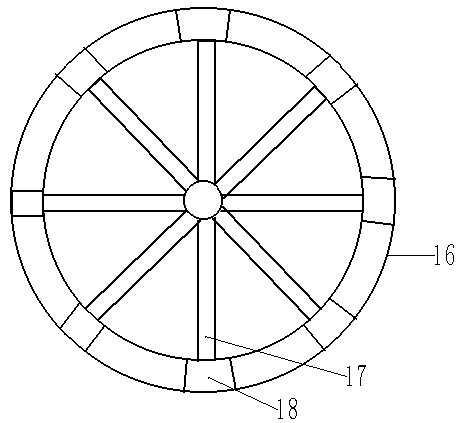

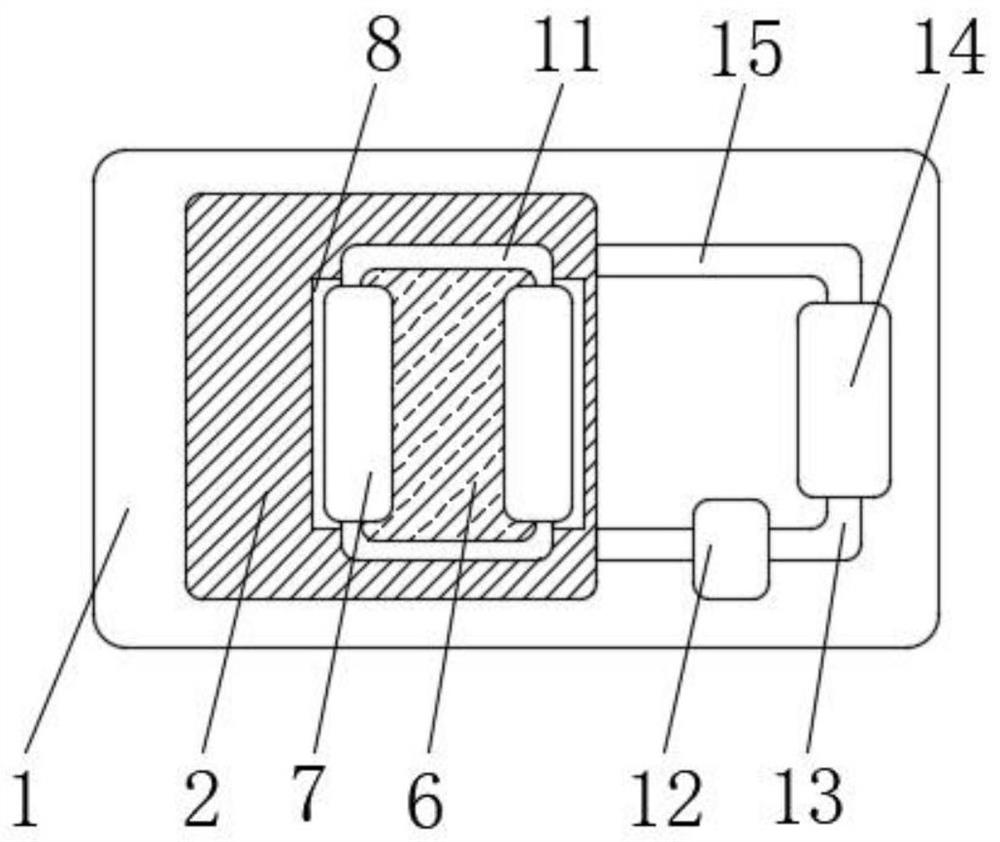

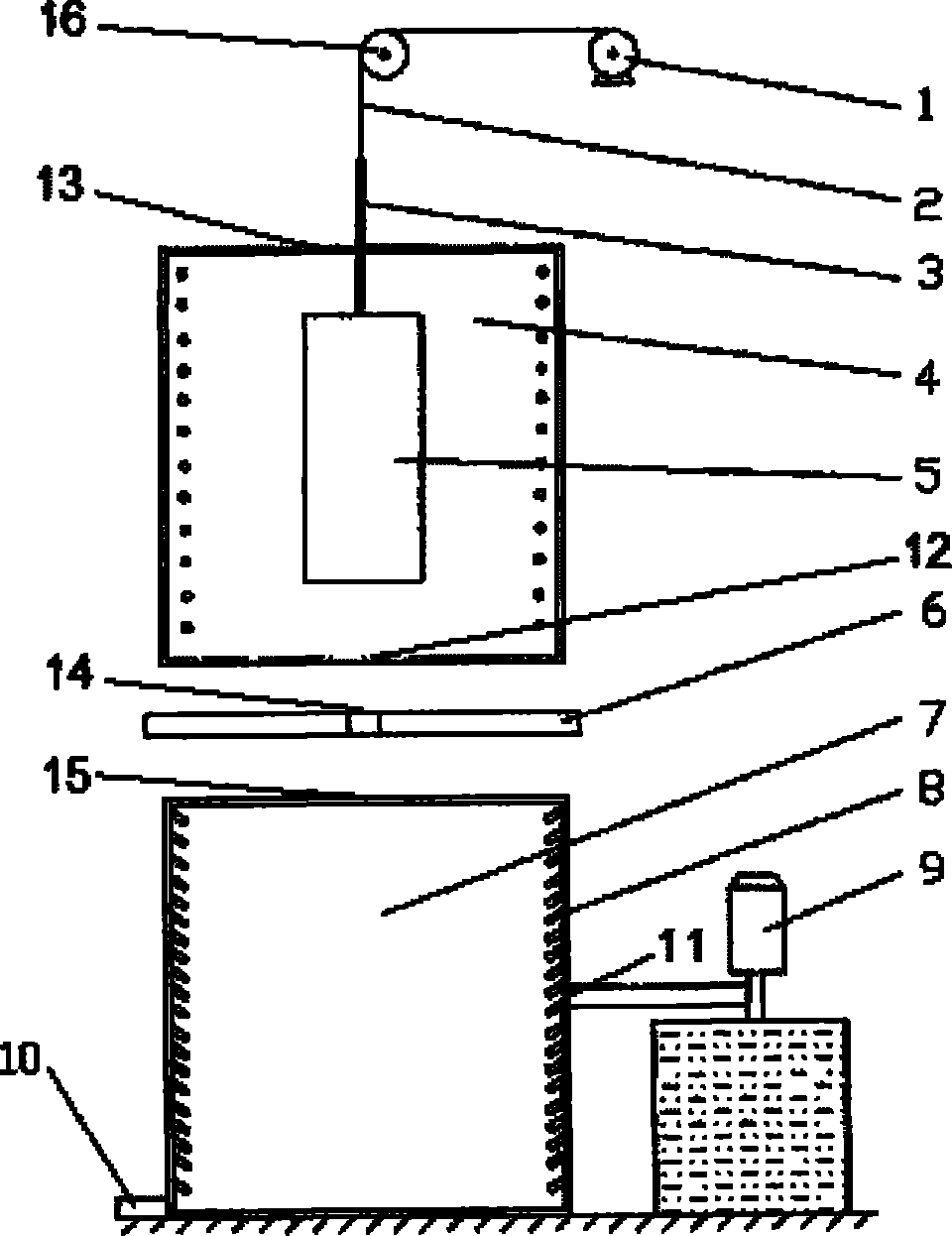

Vertical high-frequency quenching machine

ActiveCN102925632AFully QuenchedAchieve local quenchingIncreasing energy efficiencyQuenching devicesQuenchingProcessing accuracy

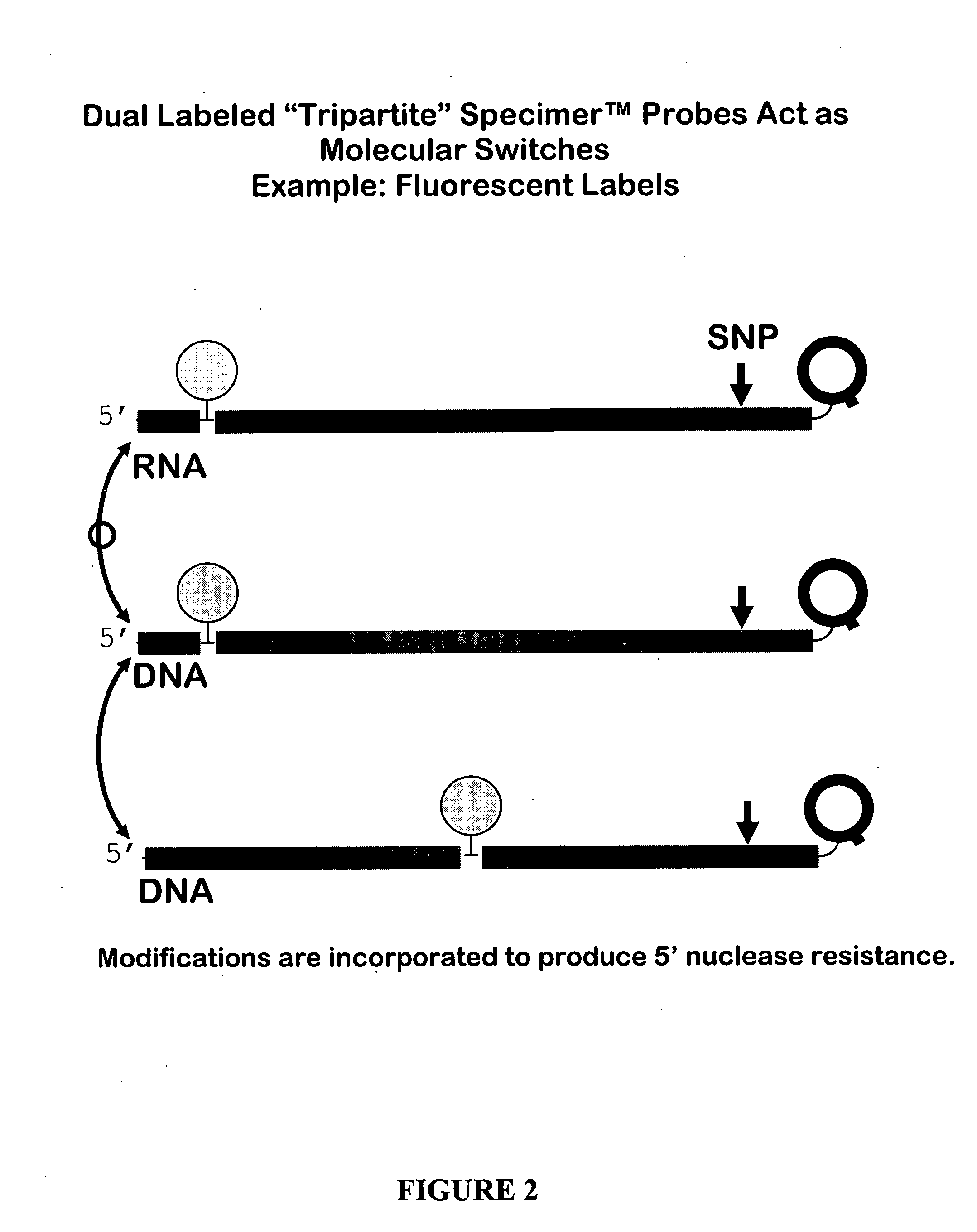

The invention discloses a vertical high-frequency quenching machine which comprises a high-frequency quenching heating device, cooling liquid, a cooling oil tank, a portal machine frame, a working sliding table and a control system. A straight track is arranged on the portal machine frame, the working sliding table is installed on the straight track and controlled to move horizontally through a translation mechanism, a lifting mechanism is arranged on the working sliding table, a clamping mechanism is installed on the lifting mechanism, the clamping mechanism is driven by the lifting mechanism and moves vertically under the control of a servo motor, a quenching workpiece is clamped by the clamping mechanism and arrives at an induction coil to be quenched under the control effect of a control system, and the control system controls the quenching workpiece through a numerical control programming control method. The vertical high-frequency quenching machine has the advantages of being high in automation degree, reducing labor intensity of workers, improving productivity, guaranteeing safety of the workers, and being capable of obtaining good processing accuracy, good in repeatability and capable of guaranteeing quenching quality of the workpiece.

Owner:广东利泰丰科技有限公司

Oligonucleotides comprising a molecular switch

ActiveUS8679789B2High sensitivityReduced stabilitySugar derivativesMicrobiological testing/measurementBinding domainMolecular switch

This invention relates to oligonucleotides comprising a molecular switch which may exist in an “open” or “closed” position. The molecular switch portion of the probe is particularly sensitive to the identity of sequences complementary to the molecular switch. Oligonucleotides containing a molecular switch are applicable to all kinds of hybridization processes. Due to the sensitivity of the switch domain of the oligonucleotide, probes containing a molecular switch are particularly useful in the identification of single point mismatches. More specifically, a portion, but not all, of the oligonucleotide becomes unbound from a mismatched target. The invention further relates to methods of using said oligonucleotides for research reagents, and clinical diagnostics. An exemplary oligonucleotide comprises a first hybridizable domain, a second bridging block domain, and a third binding domain.

Owner:GEN PROBE INC

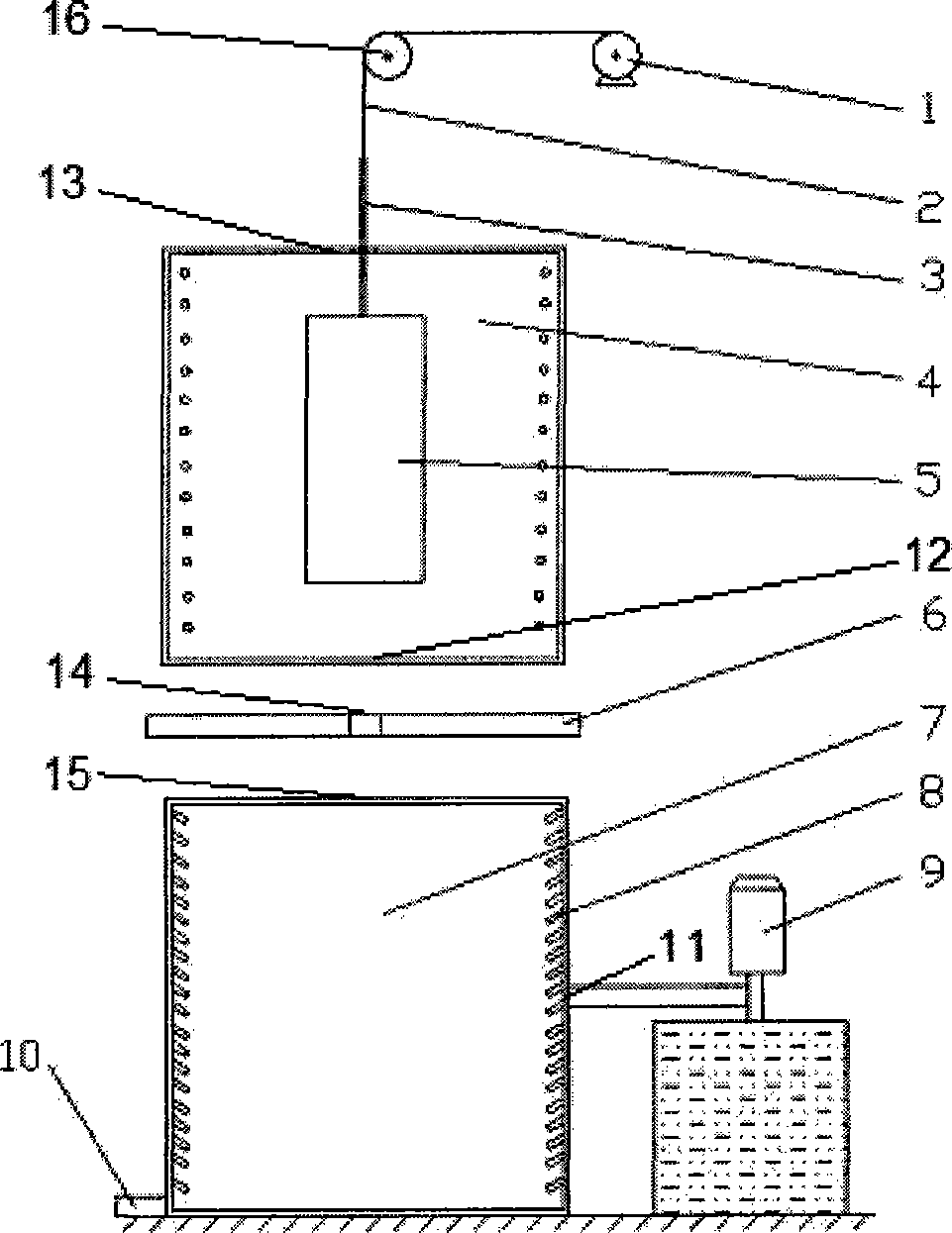

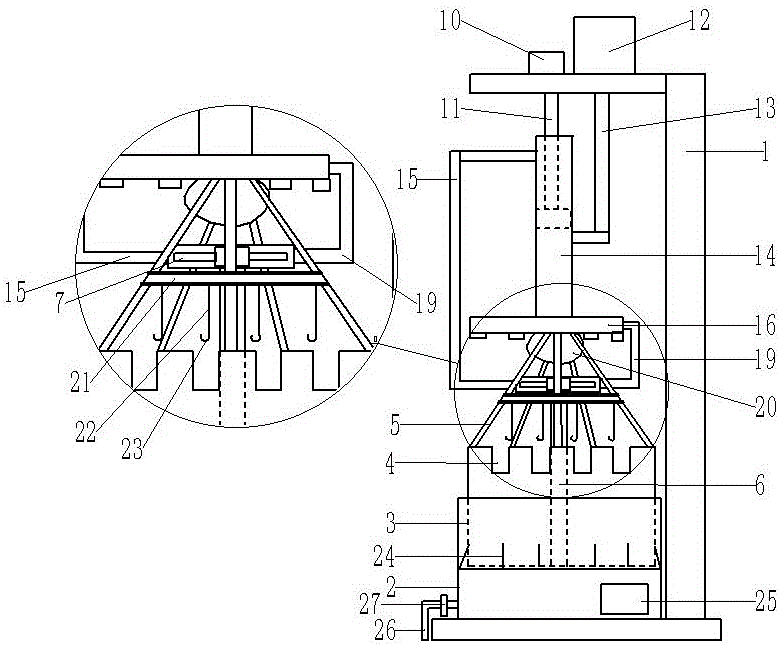

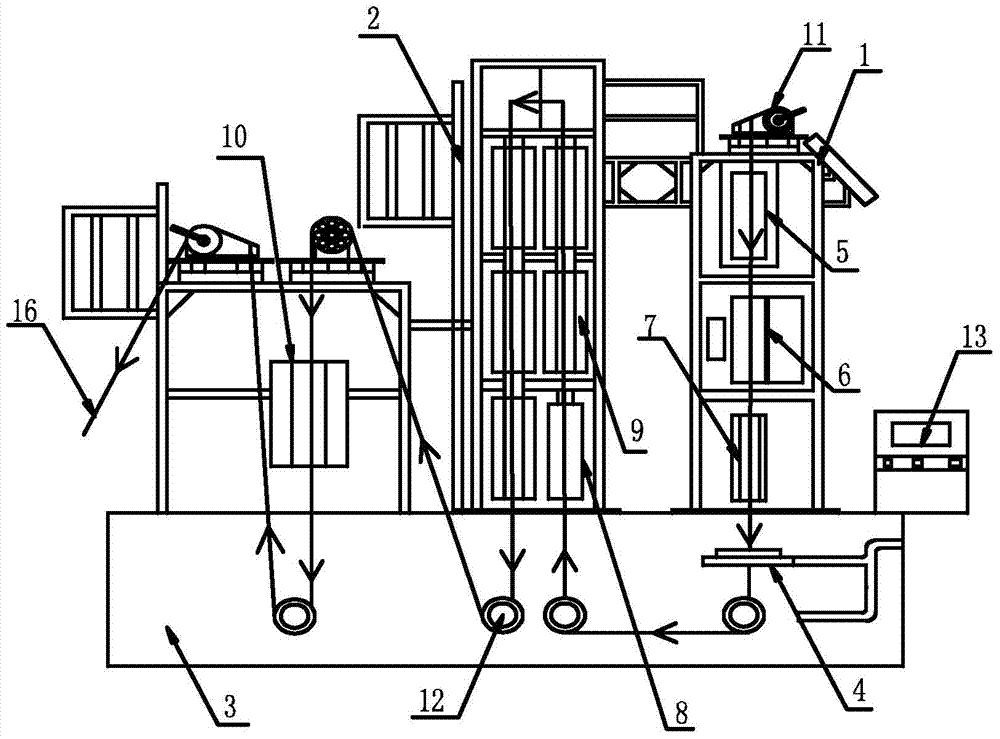

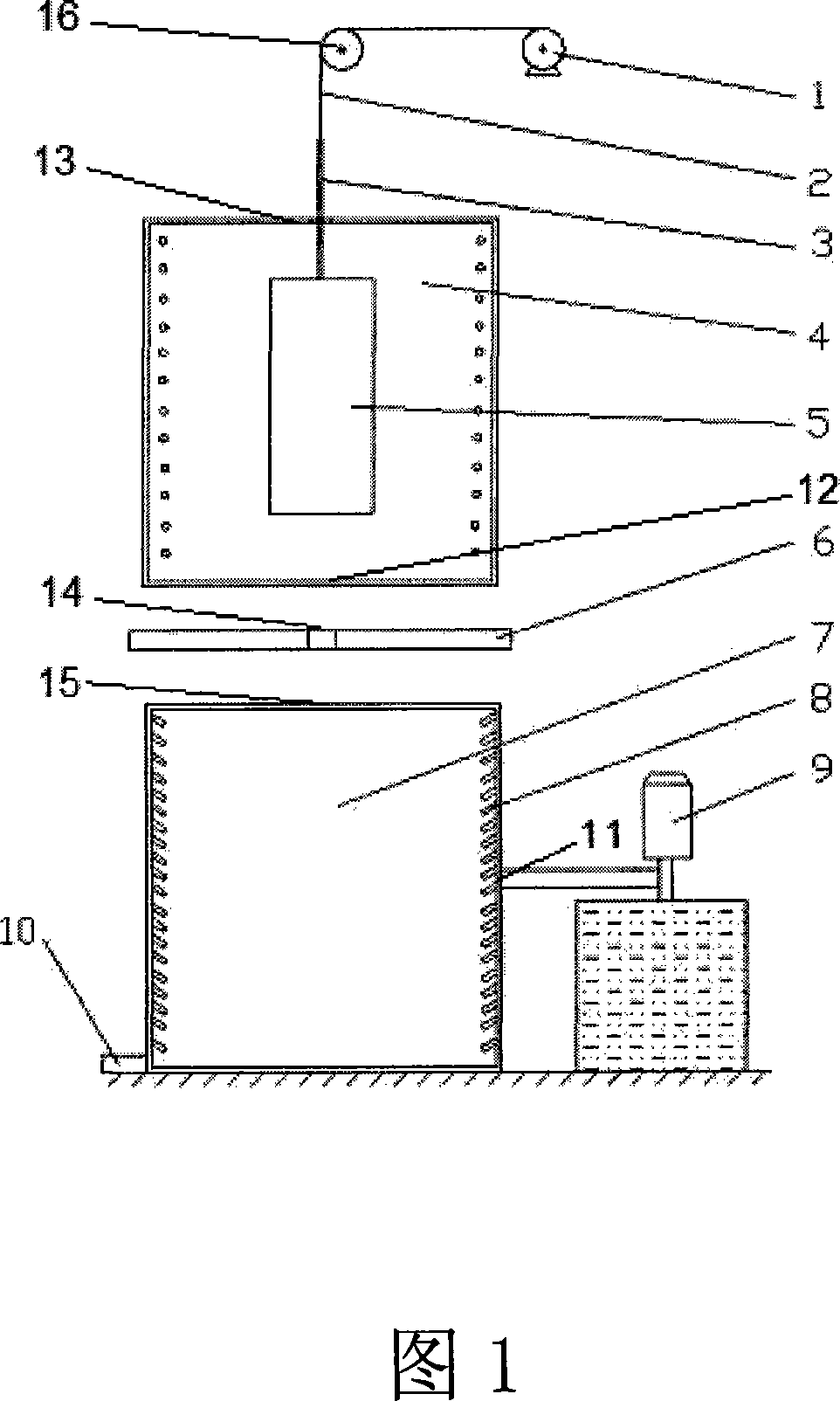

Vertical spray quenching apparatus and quenching technique

ActiveCN101469359AFully QuenchedFully consider convenienceFurnace typesHeat treatment furnacesWater vaporControl system

The invention relates to quenching equipment and a quenching process for applying the quenching equipment, in particular to vertical type spray quenching equipment and a quenching process for quenching a large diameter alloy bar. The equipment comprises a heating chamber, a vapor division board, a spray quenching chamber, a feed-and-discharge control system, and a booster pump, wherein the heating chamber, the vapor division board and the spray quenching chamber are arranged vertically in sequence; and the feed-and-discharge control system transports workpieces to the heating chamber and the spray quenching chamber in sequence for heating and quenching treatment. The quenching process comprises the following steps: placing an alloy workpiece at a proper position in the heating chamber; starting a heating program for heating treatment; opening a water inlet and a water outlet of the quenching chamber after heating treatment; then opening a bottom door of the heating chamber, and opening the vapor division board simultaneously; carrying out the quenching treatment after the alloy workpiece enters the proper position in the quenching chamber through the feed opening of the quenching chamber, and closing the vapor division board at the same time; and closing a water inlet valve after finishing the quenching treatment and taking out the alloy workpiece from the top of the heating chamber.

Owner:GRIMAT ENG INST CO LTD

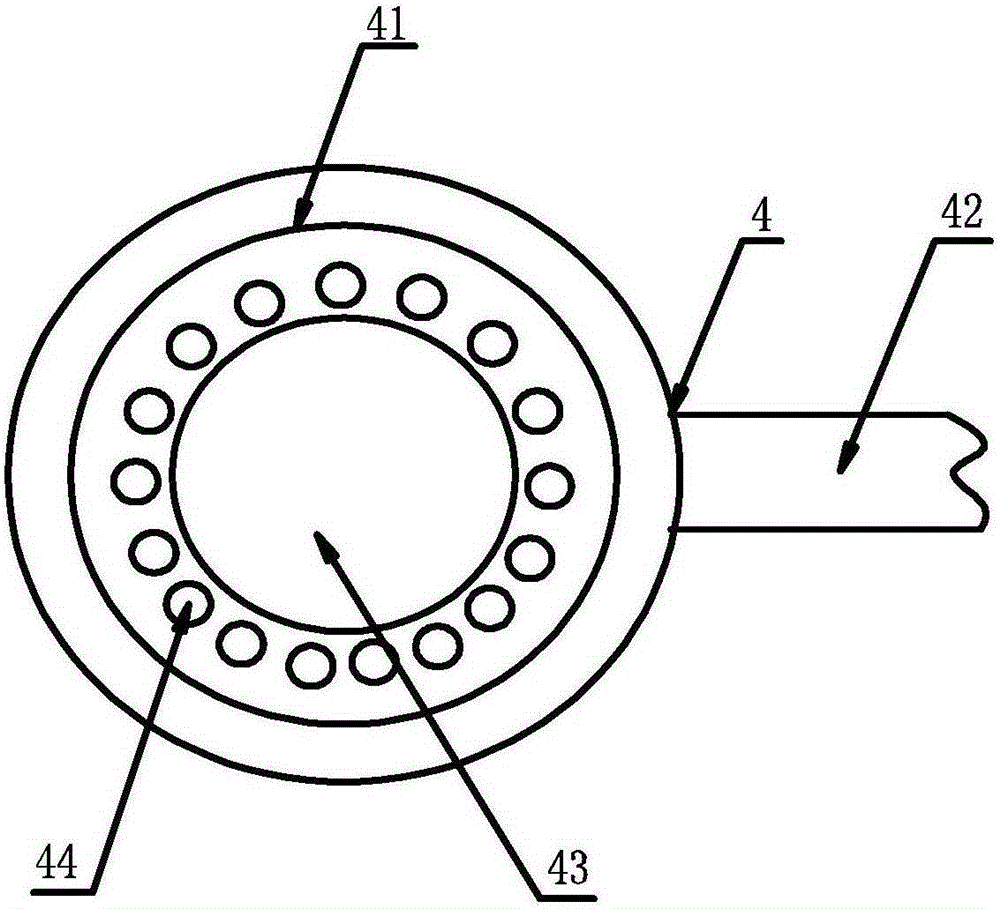

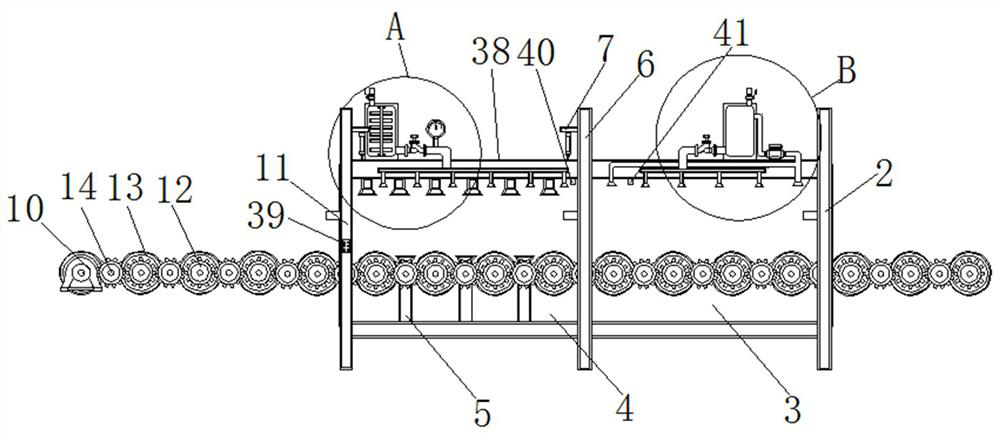

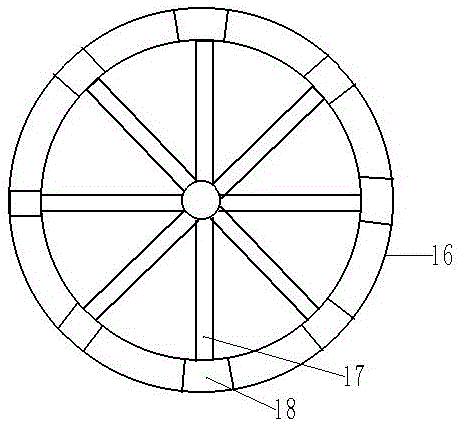

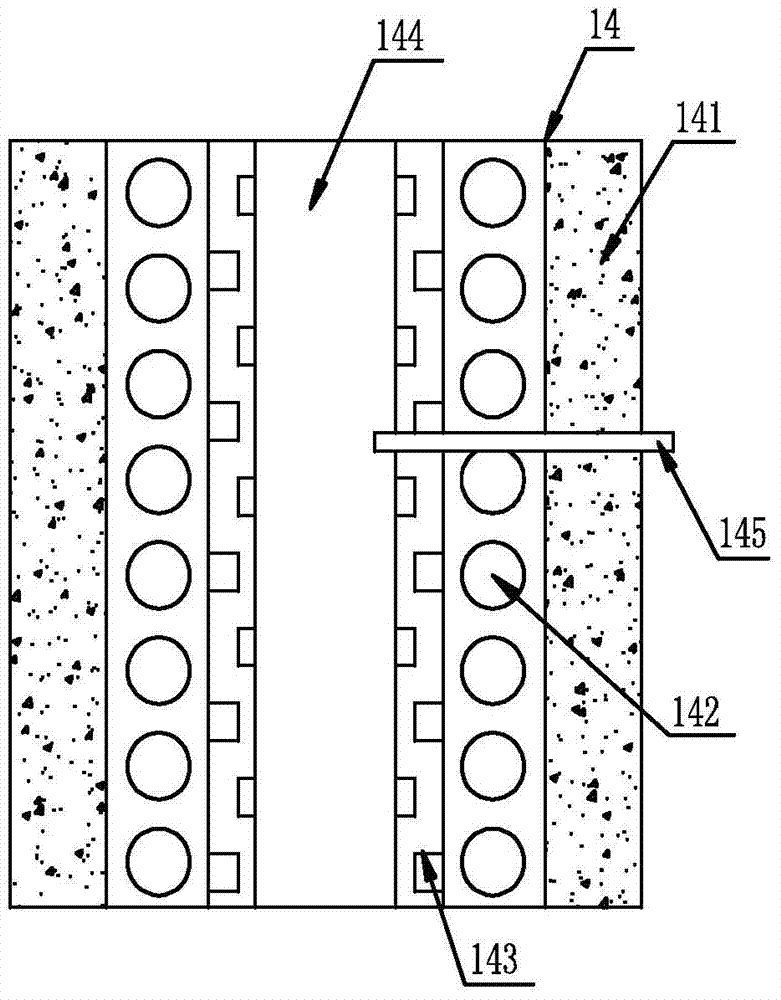

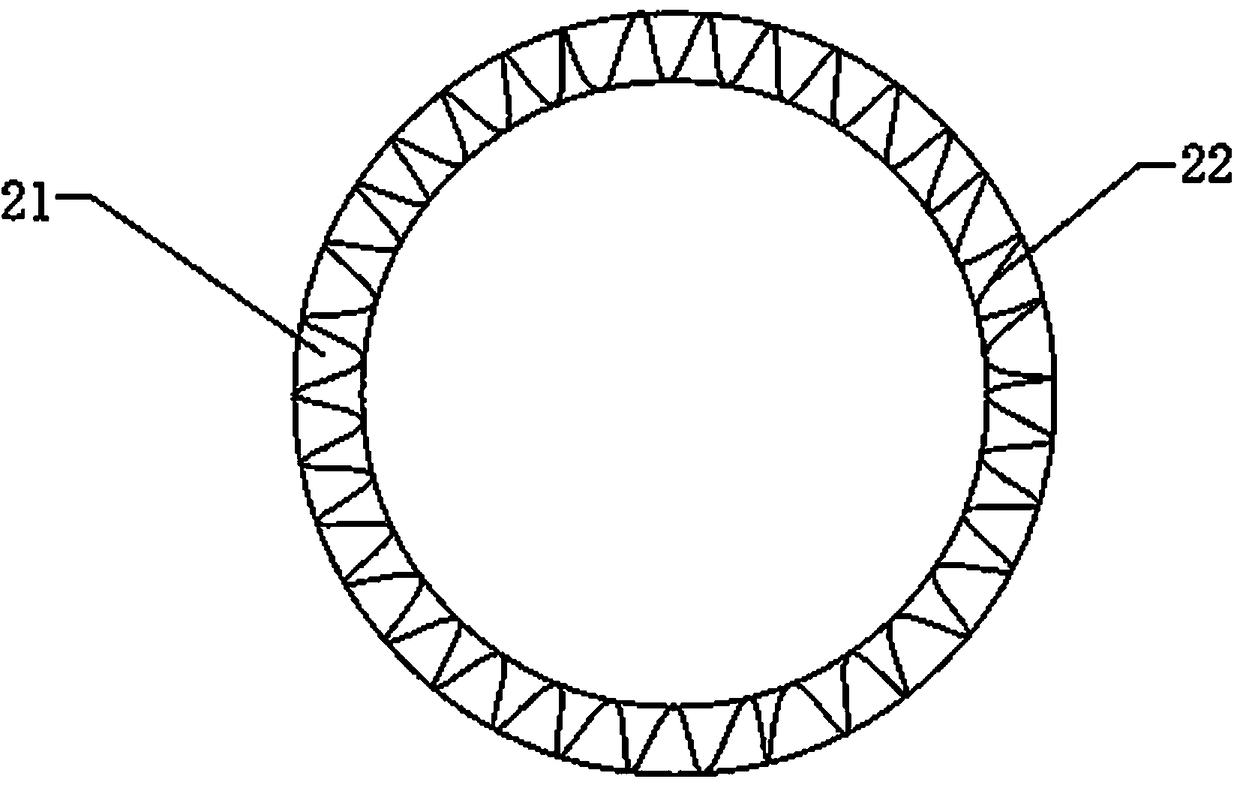

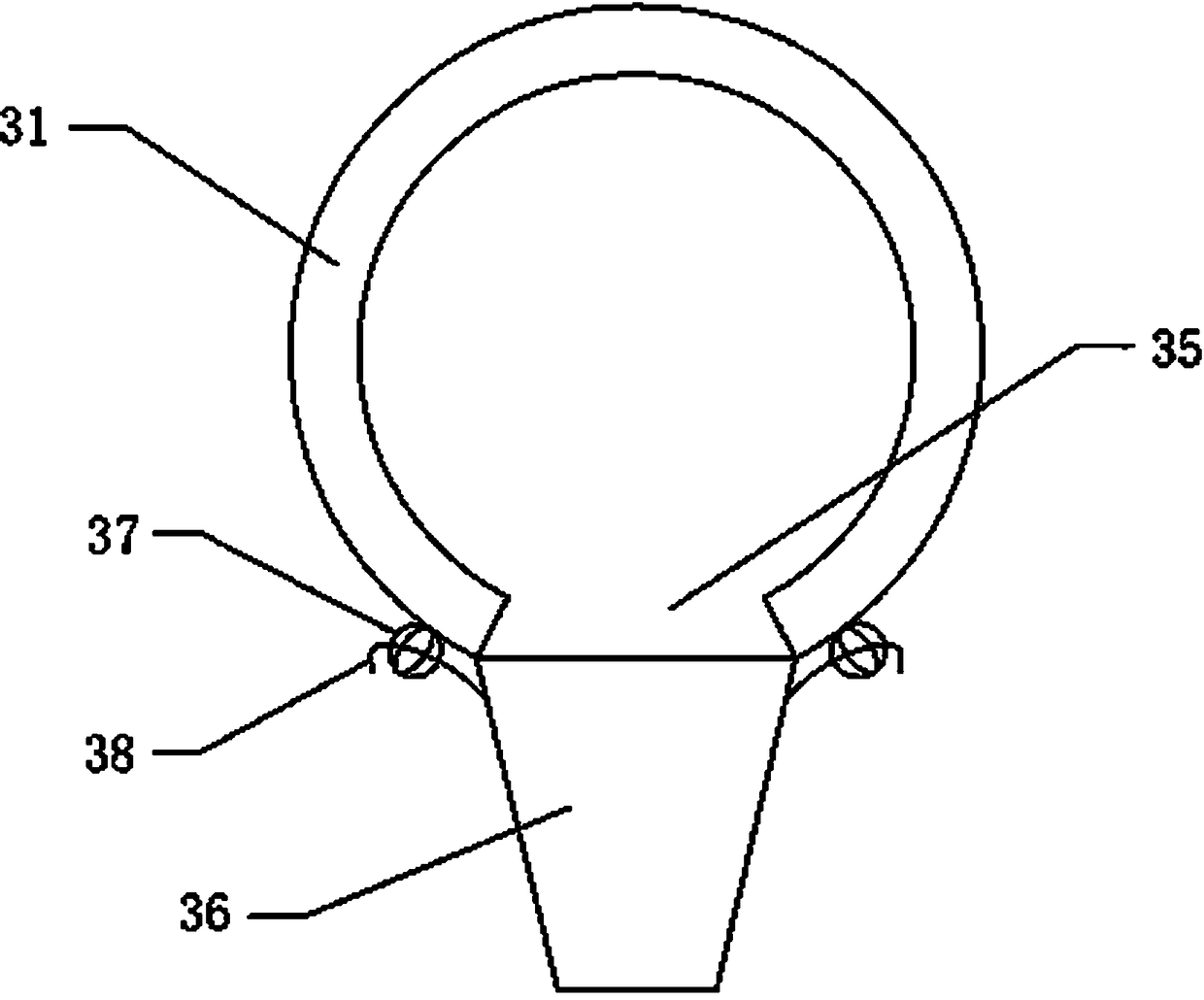

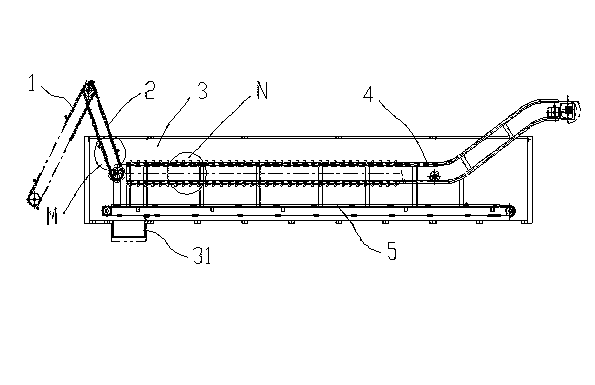

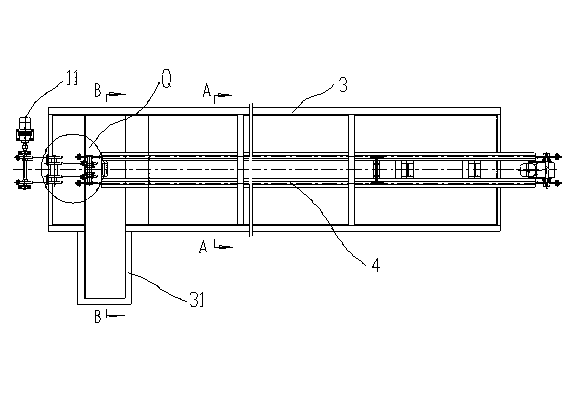

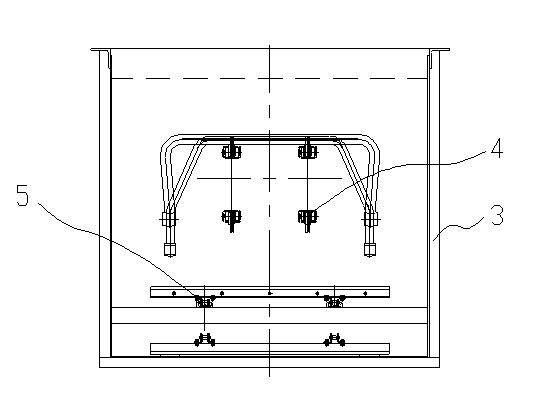

Heat treatment device for round-link chain and application method thereof

ActiveCN105349757AHigh degree of integrationImprove work efficiencyFurnace typesHeat treatment furnacesHardnessLath

The invention discloses a heat treatment device for a round-link chain and an application method thereof. The device comprises a quenching part and a tempering part which are sequentially arranged, wherein first cooling parts are arranged at the quenching part and the tempering part; the quenching part is provided with a quenching temperature regulating box; the tempering part is sequentially provided with an uniform-temperature tempering heating box, at least one tempering temperature regulating box and a differential-temperature tempering heating box; the quenching temperature regulating box is provided with a second cooling part. The device has the characteristics of being high in integration degree and high in working efficiency; after the round-link chain is quenched, an uniform and small low-carbon lath martensite structure can be obtained; the quenching quality is high; the second cooling part and the first cooling parts are correspondingly connected to a cooling source, so that the cooling quality can be improved, and the requirements of each part of the round-link chain on hardness and toughness can be met.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

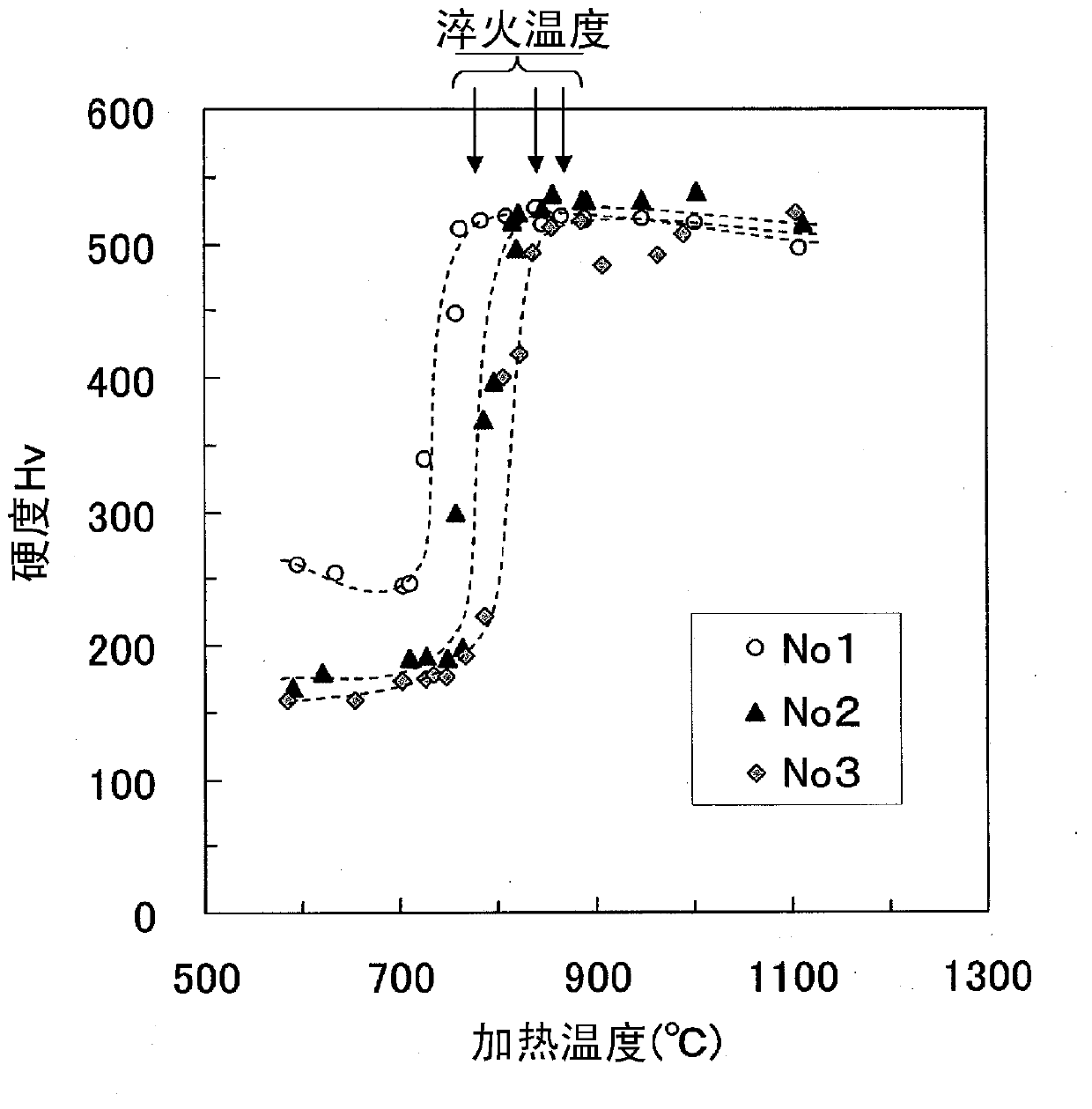

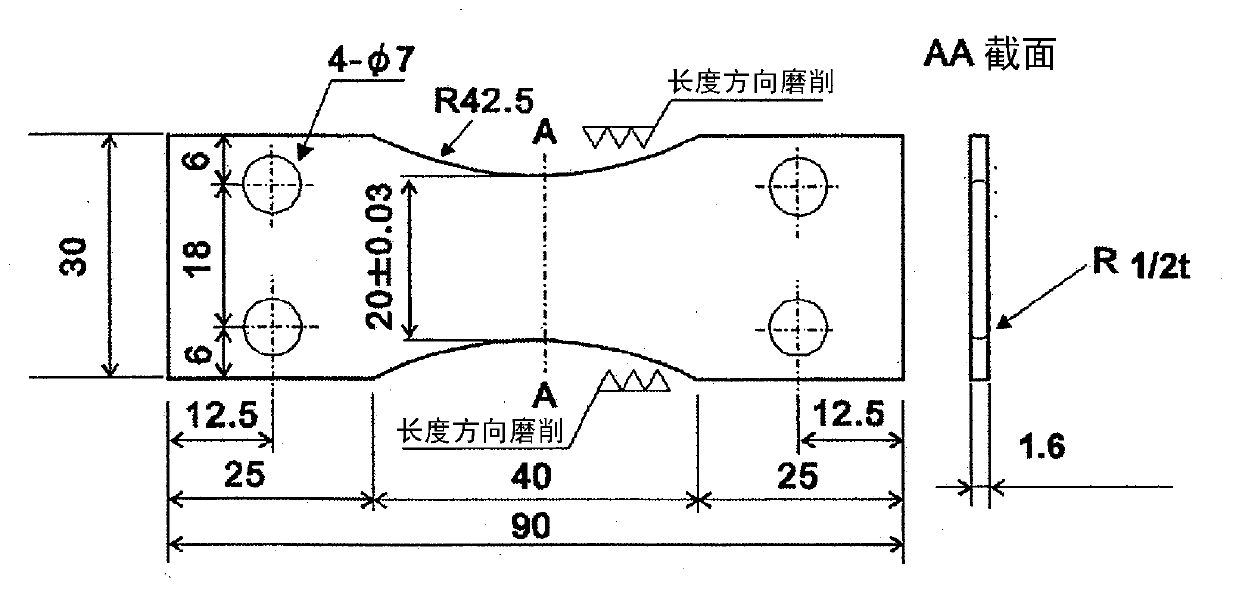

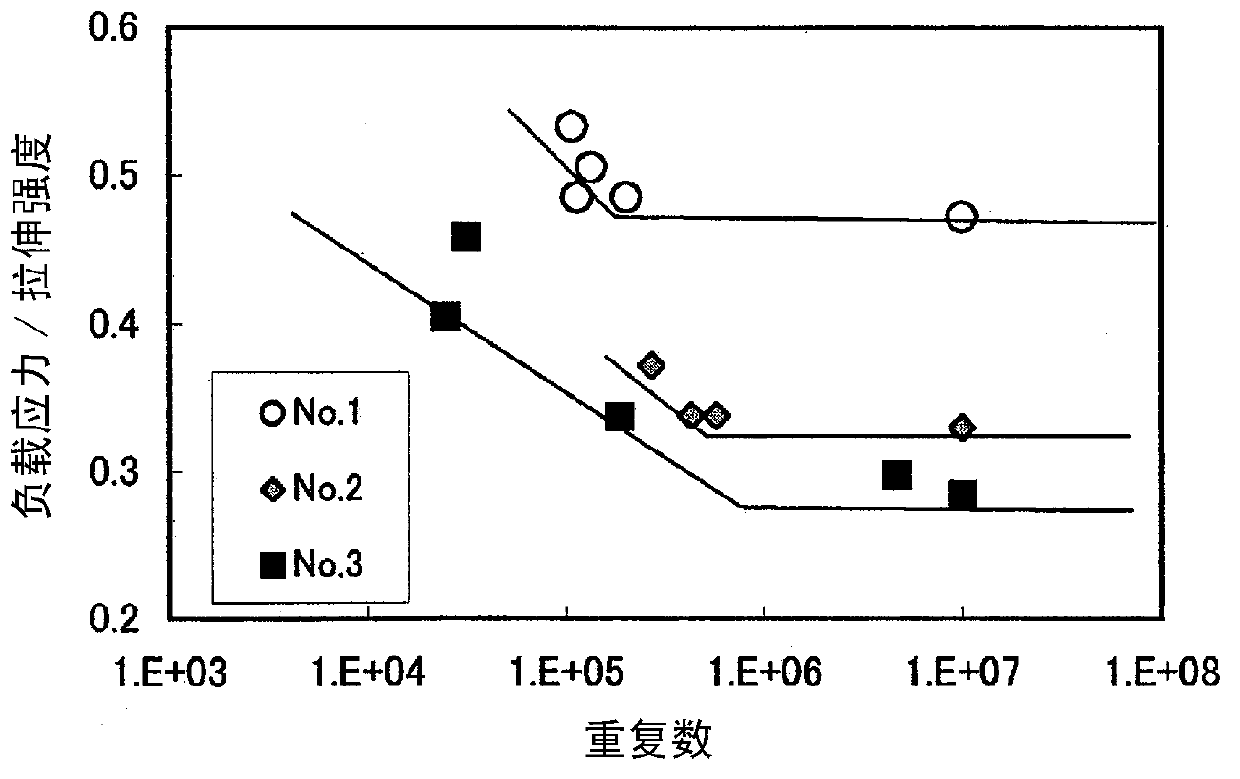

Heat-treated steel material, method for producing same, and base steel material for same

ActiveCN102859020AFully quenchedHigh strengthFurnace typesThin material handlingChemical compositionCarbide

Disclosed is a steel material which can be sufficiently quenched by short time heating at low temperatures and is capable of providing a high strength molded article. The steel material is suitable as a material for hot pressing or hot three-dimensional bending. Specifically, the steel material has a chemical composition that contains, in mass%, 0.05-0.35% of C, 0.5% or less of Si, 0.5-2.5% of Mn, 0.03% or less of P, 0.01% or less of S, 0.1% or less of sol. Al, 0.01% or less of N, and if necessary, one or more elements selected from the group consisting of 0.0001-0.005% of B, 0.01-0.1% of Ti, 0.18-0.5% of Cr, 0.03-0.1% of Nb, 0.18-1.0% of Ni and 0.03-0.5% of Mo, and has a steel structure wherein the spheroidization ratio of carbides is 0.60-0.90.

Owner:NIPPON STEEL CORP

Heat treatment process for powder metallurgical high-speed steel

InactiveCN103849738AImprove impact toughnessGuaranteed quenching process requirementsQuenchingHeat treated

The invention discloses a heat treatment process for powder metallurgical high-speed steel. The heat treatment process comprises the following steps: A, carrying out annealing treatment, heating the powder metallurgical high-speed steel to 850 DEG C, then carrying out heat preservation, cooling to 750 DEG C along with a furnace, carrying out heat preservation again for 3 h, then cooling to 500 DEG C along with the furnace, and discharging out of the furnace; B, carrying out quenching treatment with the quenching temperature of 1230-1260 DEG C and the austenitizing heat preservation time of 12-15 s / mm; and C, carrying out tempering treatment, tempering for 3-4 times with the tempering temperature of 540 DEG C. The invention discloses the heat treatment process for the powder metallurgical high-speed steel; in the quenching process, the quenching process requirements are ensured, and the impact toughness of the material is enhanced; and three times of tempering treatment are carried out, so that tempering is allowed to be more full.

Owner:DALIAN QIANBAO CAST IRON FOUNDRY

Plate shearing machine tool rest with locking mechanism and tool thereof

InactiveCN105880722AReduce frettingReduce distortionShearing machinesShearing machine accessoriesLocking mechanismEngineering

The invention discloses a plate shearing machine tool rest with a locking mechanism and a tool thereof. The plate shearing machine tool rest comprises an upper tool rest module and a lower tool rest module. The upper tool rest module and the lower tool rest module are fixed to a plate shearing machine platform. The upper tool rest module comprises an upper tool rest body, an upper tool body and tool guide rails, the tool guide rails are fixed to the two sides of the upper tool rest body, and the upper tool body is embedded into grooves of the tool guide rails and slides up and down in a fixed stroke. The lower tool rest module comprises a lower tool rest body and a lower tool body, and the lower tool body is fixed to one side of the lower tool rest body. The plate shearing machine tool rest has the beneficial effects that (1) final motion of an upper blade and a lower blade is reduced through the locking mechanism, the eccentric shearing phenomenon is eliminated, twisting of plates is reduced, and the quality of workpieces is improved; and (2) a step-shaped corrugated surface blade is adopted as the upper blade, the rigidity, hardness, abrasion resistance, fatigue strength, toughness and the like of blade steel are greatly improved, burrs and flangings of machined faces are effectively reduced, and the technical performance and production efficiency of a plate shearing machine are improved.

Owner:NANTONG ZHIGAO HEAVY IND TECH CO LTD

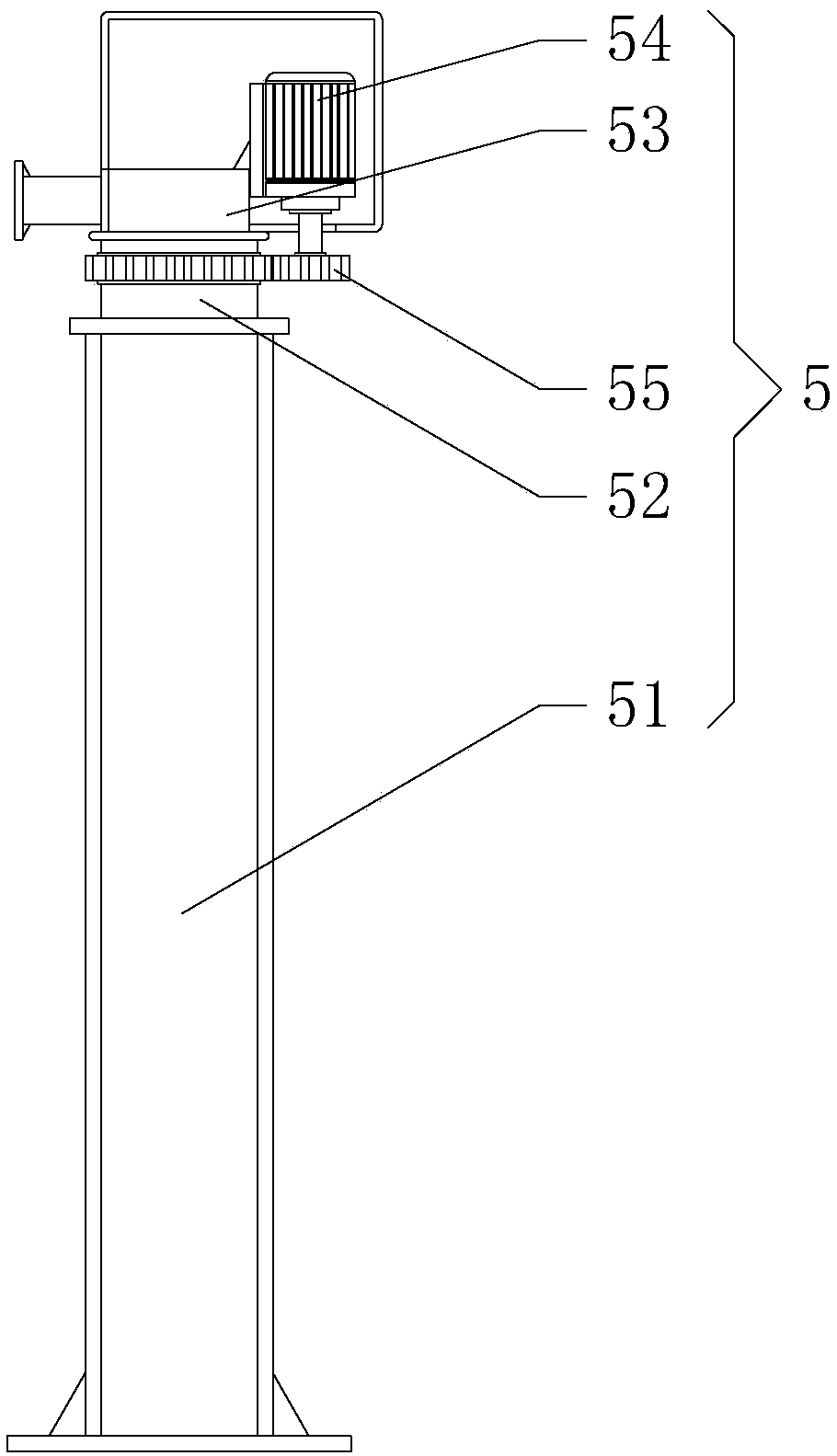

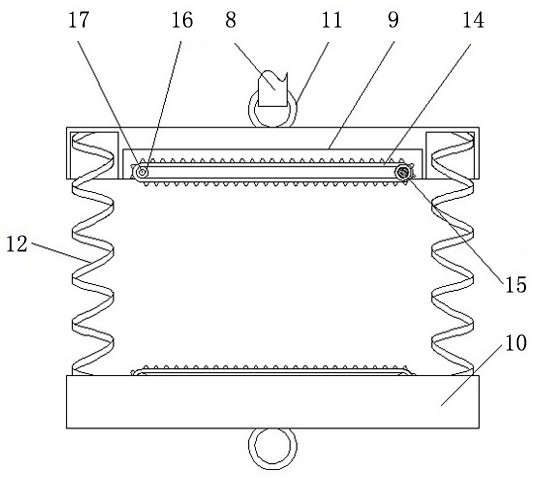

Spray quenching device with rotating effect and using method thereof

InactiveCN110804689ARapid coolingFully quenchedQuenching devicesElectric machineStructural engineering

The invention relates to the technical field of quenching, and particularly relates to a spray quenching device with a rotating effect and a using method thereof. The spray quenching device comprisesa fixed base and a fixed cylinder, wherein the fixed cylinder is fixedly connected to the interior of the fixed base; a rotating motor is fixedly connected to the interior of the lower end surface ofthe fixed cylinder; a threaded rod is fixedly connected to the tail end of a main shaft of the rotating motor; a lifting rod is spirally connected to the outer side of the threaded rod; a fixing ringis fixedly connected to the upper part of the outer side of the lifting rod; a spraying device is fixedly connected to the right end surface of the fixing ring; the spraying device comprises a fixingrod and a pay-off motor; and the left end surface of the fixing rod is fixedly connected with the fixing ring. According to the spray quenching device, the fixing rod, a side water mist spray head anda central water mist spray head are arranged, and a connecting line is driven to move through the rotation of the rotating motor, so that the angle of the side water mist spray head is adjusted, workpieces with different sizes can be rapidly cooled, the workpieces can be comprehensively quenched, the product quality is guaranteed, and the product percent of pass is improved.

Owner:HENGYANG HONGYU MACHINERY MANFUACTURING CO LTD

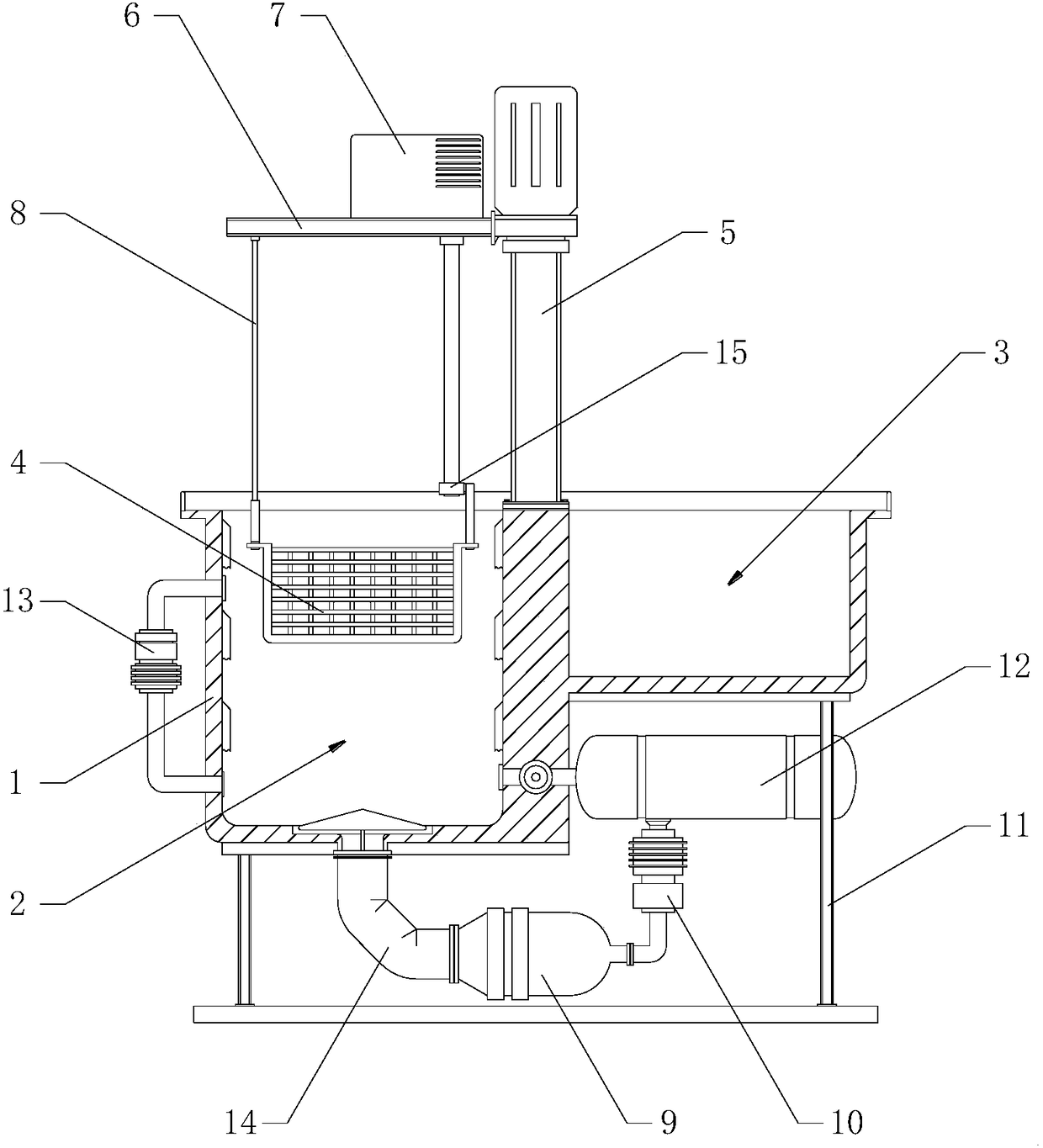

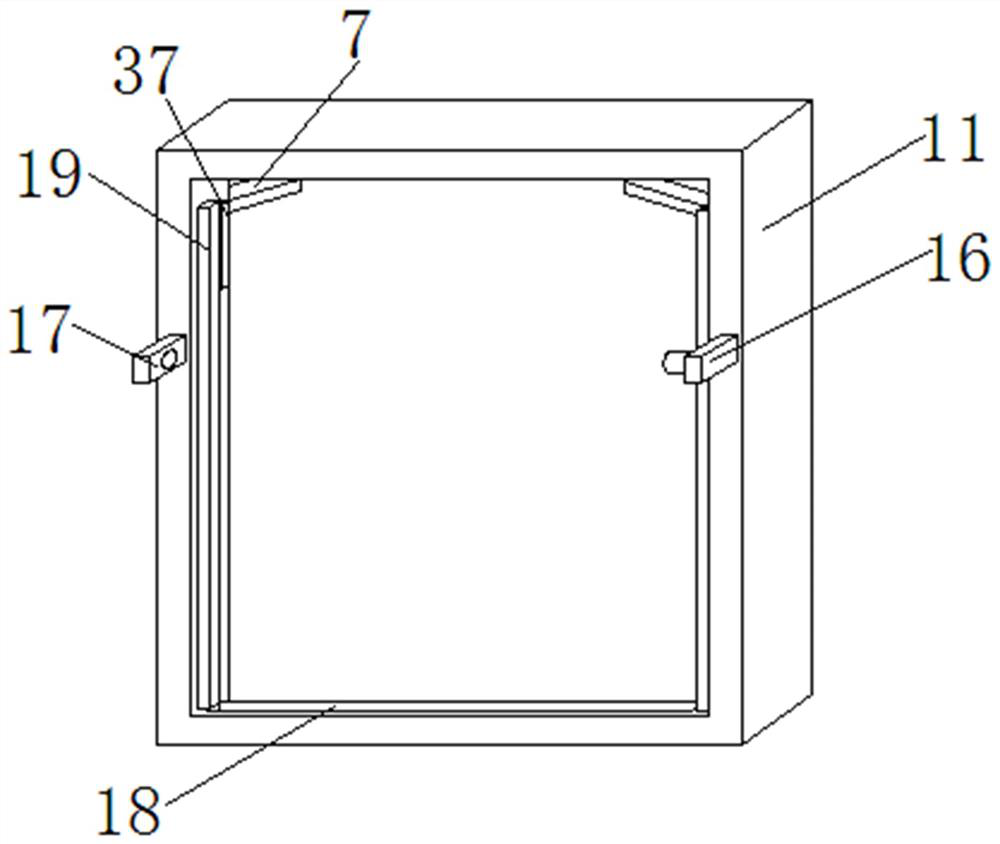

Agricultural machine casting quenching unit

InactiveCN108277332AUniform temperatureLow water consumptionFurnace typesHeat treatment furnacesQuenchingWater pipe

The invention discloses an agricultural machine casting quenching unit which comprises a water tank and a filter. A quenching chamber is arranged on one side of the interior of the water tank, an airdrying chamber is arranged on the other side of the interior of the water tank, an adjusting mechanism is vertically installed at the middle portion of the upper portion of the water tank, a top support is horizontally installed on one side of the upper portion of the adjusting mechanism, a lifting mechanism is installed on one side of the upper portion of the top support, one side of a straight rod is sleeved with an object containing basket in a sleeving manner, a circulation pump is arranged outside the side, close to the quenching chamber, of the water tank, a water inlet of the filter isconnected to the other end of a guide rail pipe, and a water outlet of the pressure water tank communicates with the quenching chamber through a guide pipe. According to the agricultural machine casting quenching unit, water is guided to the interior of the filter through a water guide pipe to be filtered and then conveyed into the pressure water tank for temporary storage, then the water is appropriately conveyed back to the interior of the quenching chamber for supplementing for internal water amount, water consumption is reduced, the water using efficiency is improved, and the environment is protected.

Owner:郑伟杰

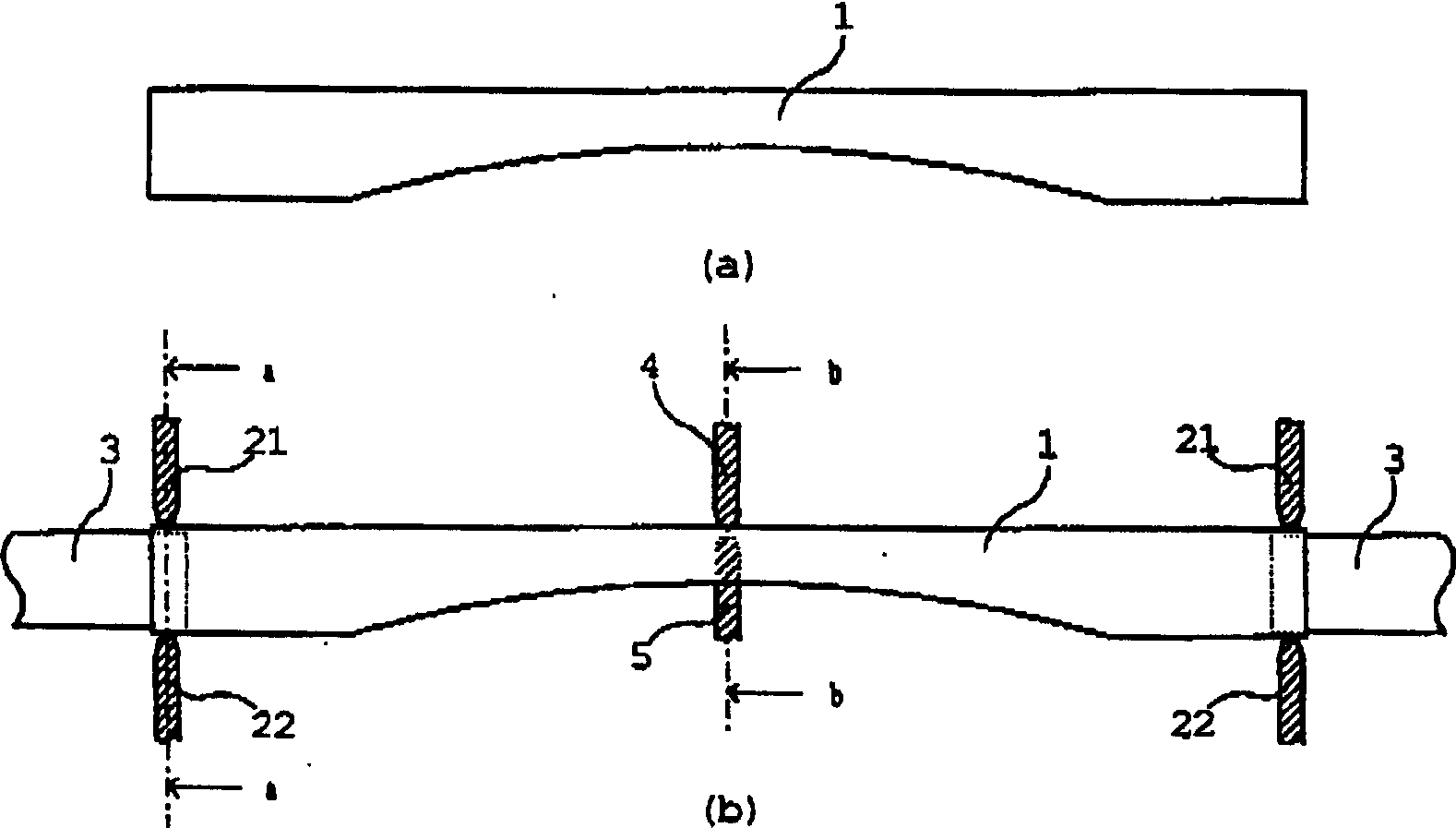

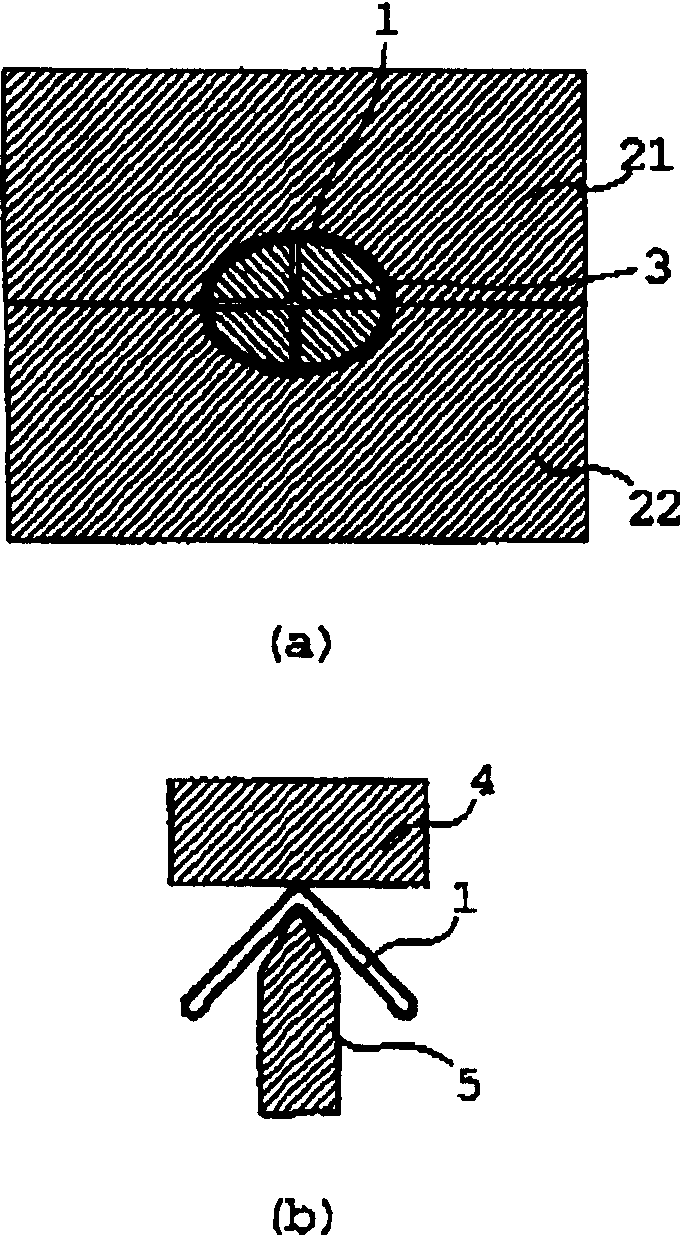

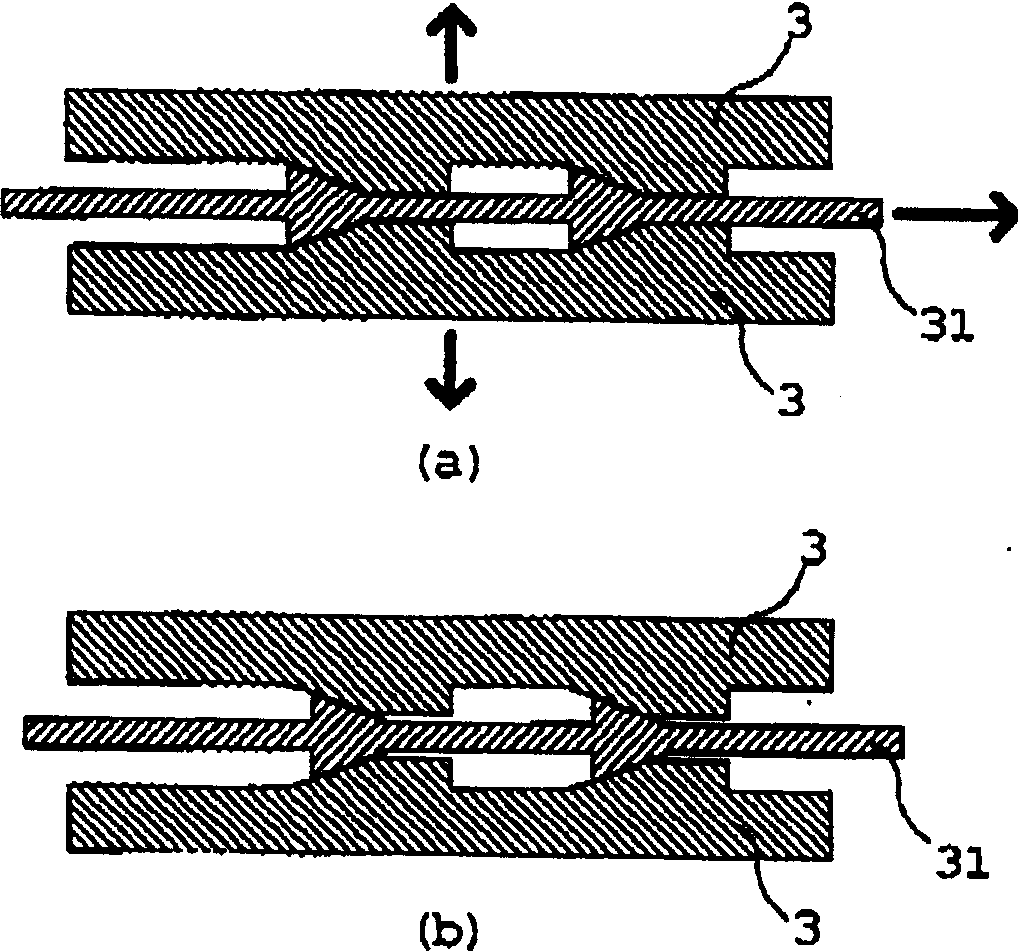

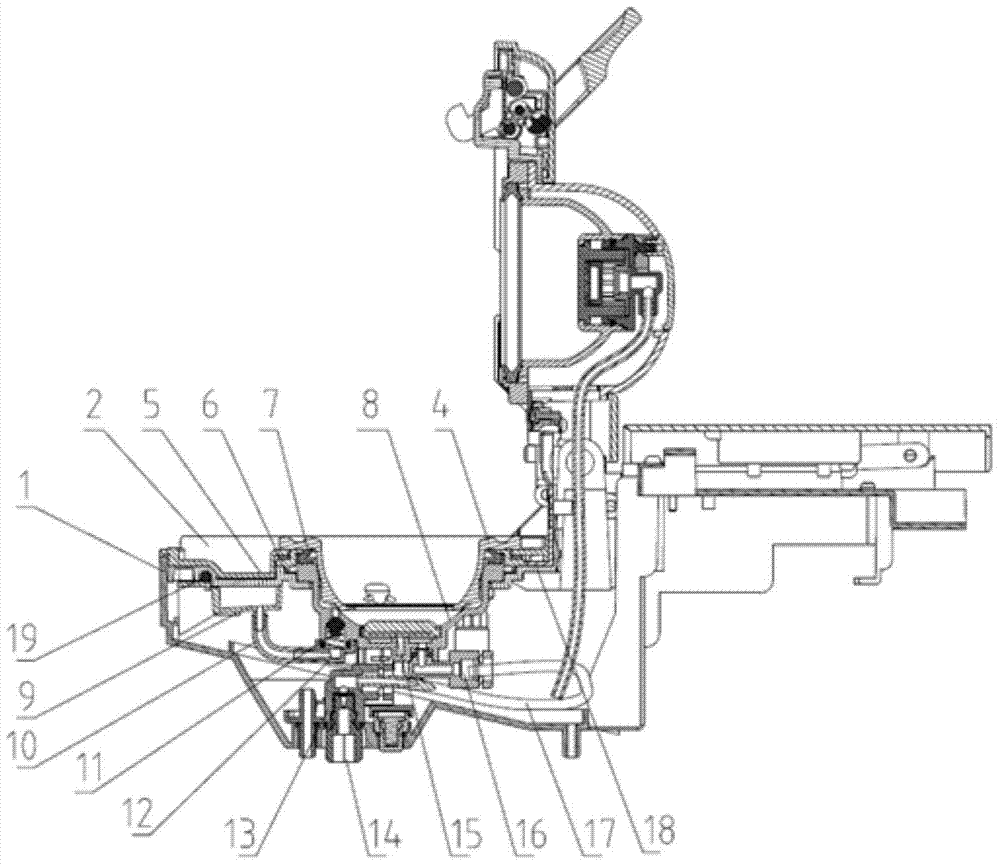

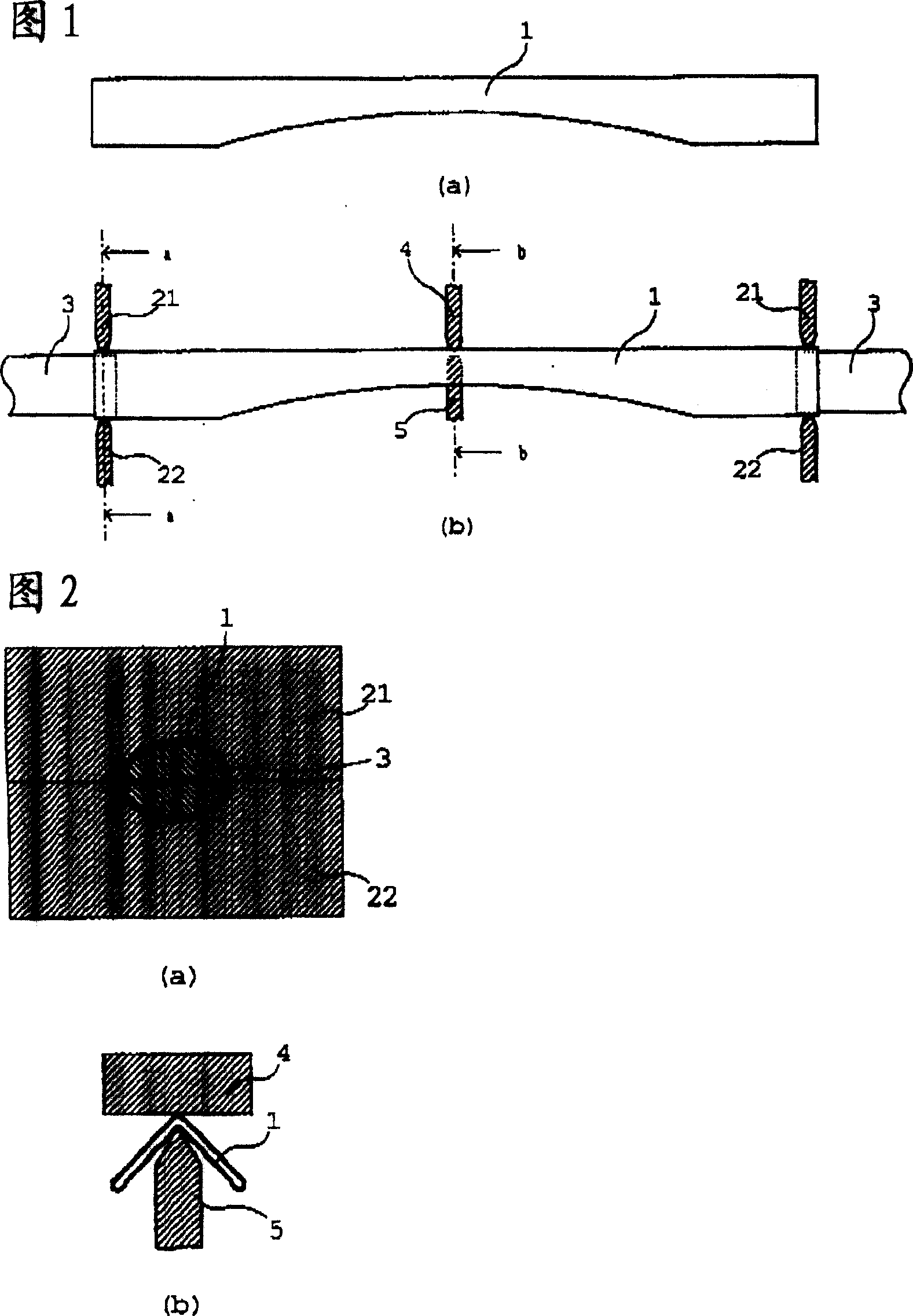

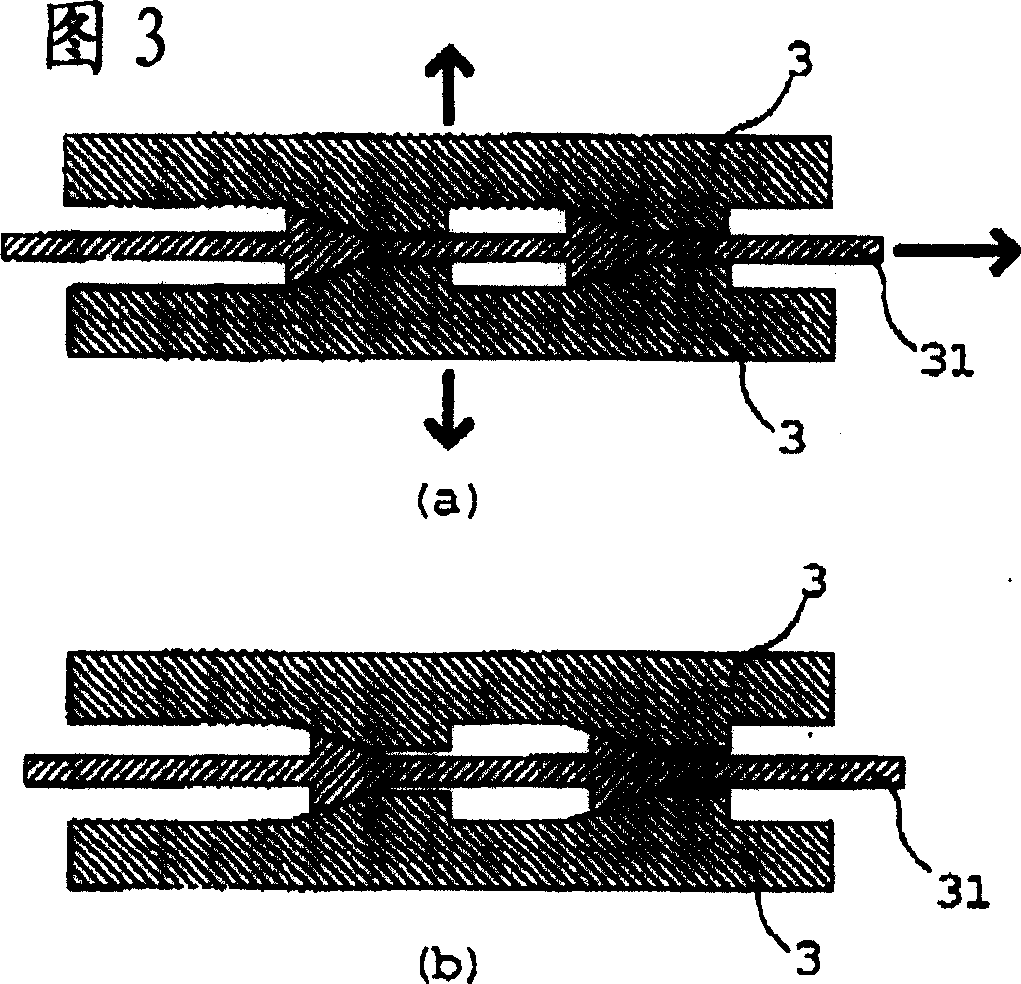

Quenching apparatus for hollow structural component and quenching method

InactiveCN1772928ASuppress uneven coolingFully quenchedFurnace typesHeat treatment furnacesCooling fluidQuenching

Provided is a quenching device that can reliably perform quenching with less uneven quenching and less deformation in a hollow member. It is characterized by comprising: an end having a set of internal restraint jigs 3 and a set of external restraint jigs 2 having external shapes approximately corresponding to the shapes of the inner peripheries of the respective ends of the cylindrical hollow member 1 that are open at both ends. part of the hollow member 1, thereby holding its contact jigs 4 and 5; inserting the internal restraint jig 3 into both ends of the heated hollow member and bringing the contact jigs 4 and 5 into contact A device that sprays coolant to cool the device while it is in a predetermined position. That is, by inserting the internal restraining jigs into both ends of the hollow member, cooling fluid is prevented from entering the hollow member, thereby suppressing uneven cooling, and at the same time suppressing occurrence of distortion by the end restraining jigs and contact jigs.

Owner:TOYOTA JIDOSHA KK

Surface heat treatment device suitable for large-sized metallic object

InactiveCN111690792AImprove wear resistanceImprove fatigue resistanceQuenching devicesGear driveGear wheel

The invention discloses a surface heat treatment device suitable for a large-sized metallic object. The surface heat treatment device suitable for the large-sized metallic object comprises a heat treatment cavity. A first gate frame is installed on one side of the heat treatment cavity. A second gate frame is installed on the other side of the heat treatment cavity. Fixing plates are installed onthe top of the side, close to the heat treatment cavity, of the first gate frame and the top of the side, close to the heat treatment cavity, of the second gate frame. The bottoms of the fixing platesare provided with second electric lifting rods. A lifting plate is installed at the bottoms of the second electric lifting rods. A chemical liquid box is installed on one side of the top of the lifting plate. The motor can be started through a control panel, by means of mutual cooperation between first round gears and second round gears, conveying rollers are driven to rotate, and then the large-sized metallic object is driven to move; and compared with chain conveyance which is prone to causing the phenomenon that a chain falls off or breaks up, the surface heat treatment device adopts geartransmission and does not need frequent chain replacement, so that the possibility of chain fall is avoided, in this way, the manpower and material resources can be saved, and the work efficiency is improved.

Owner:萧县华恒静电科技有限公司

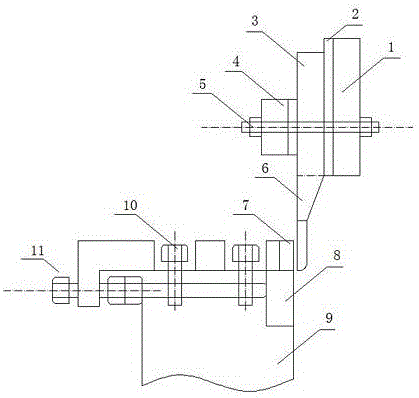

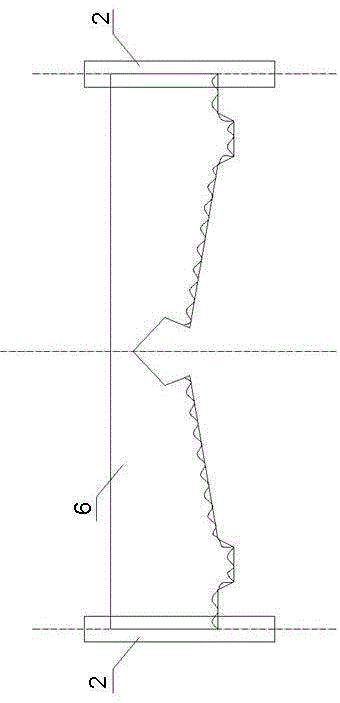

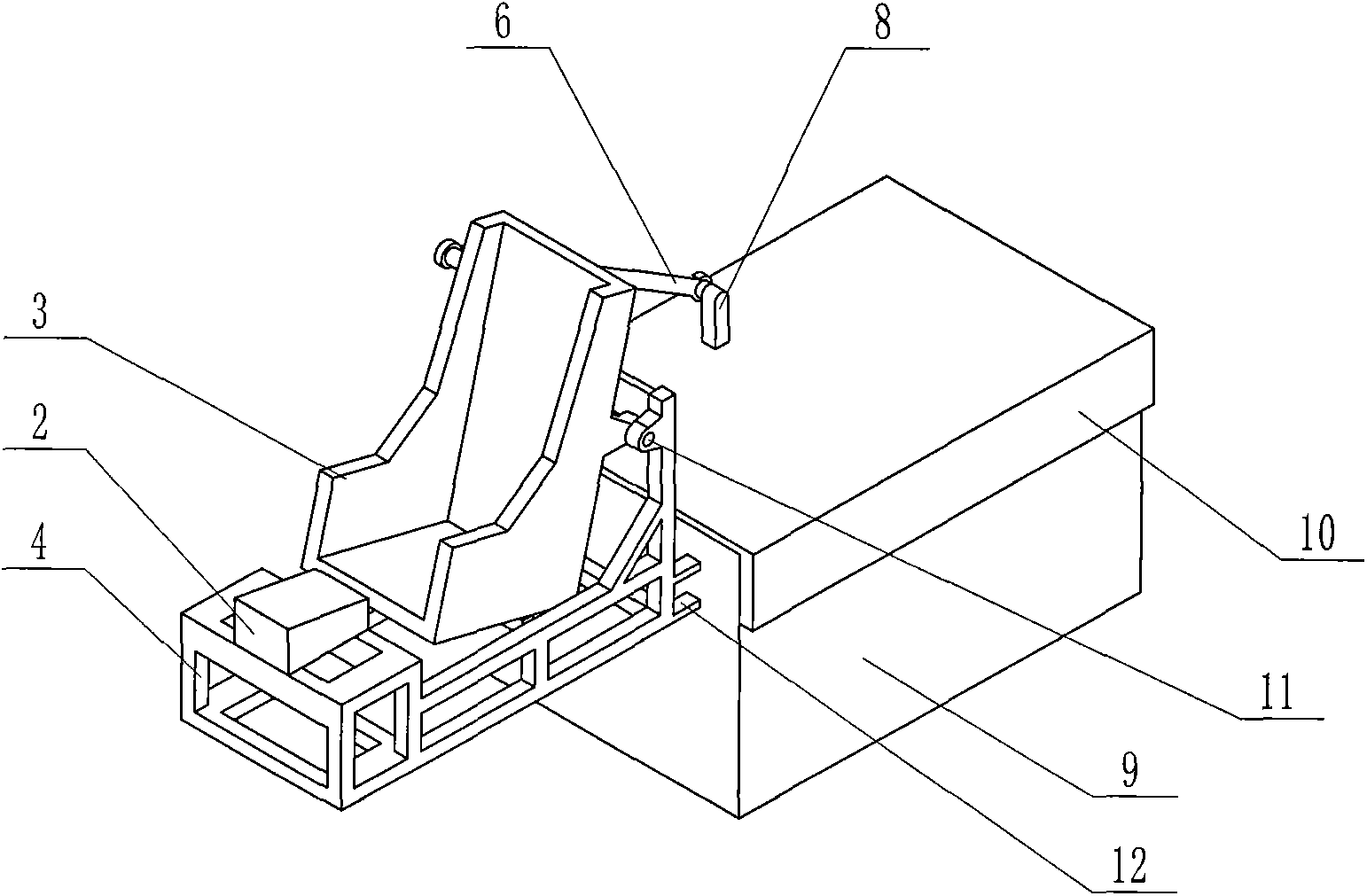

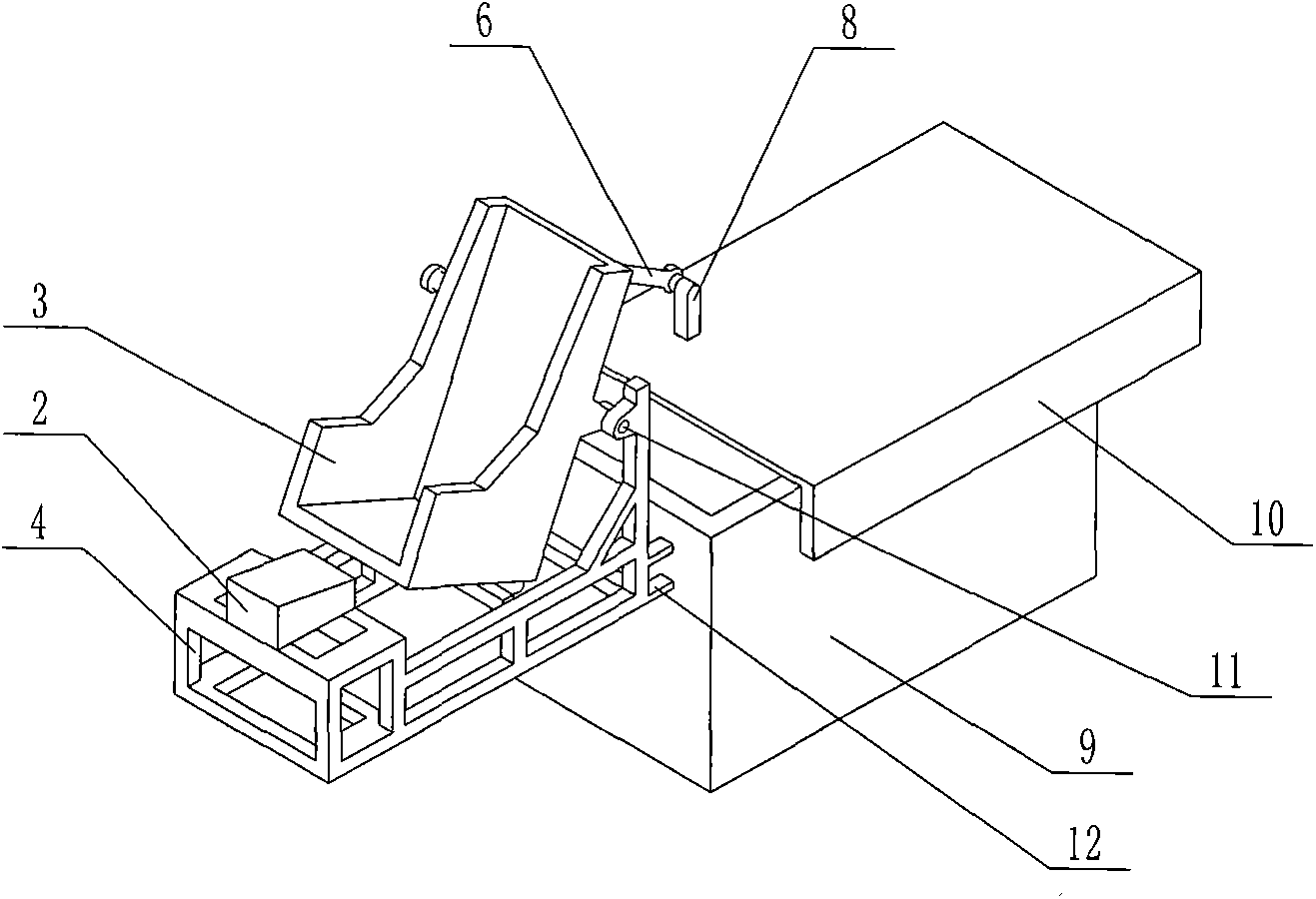

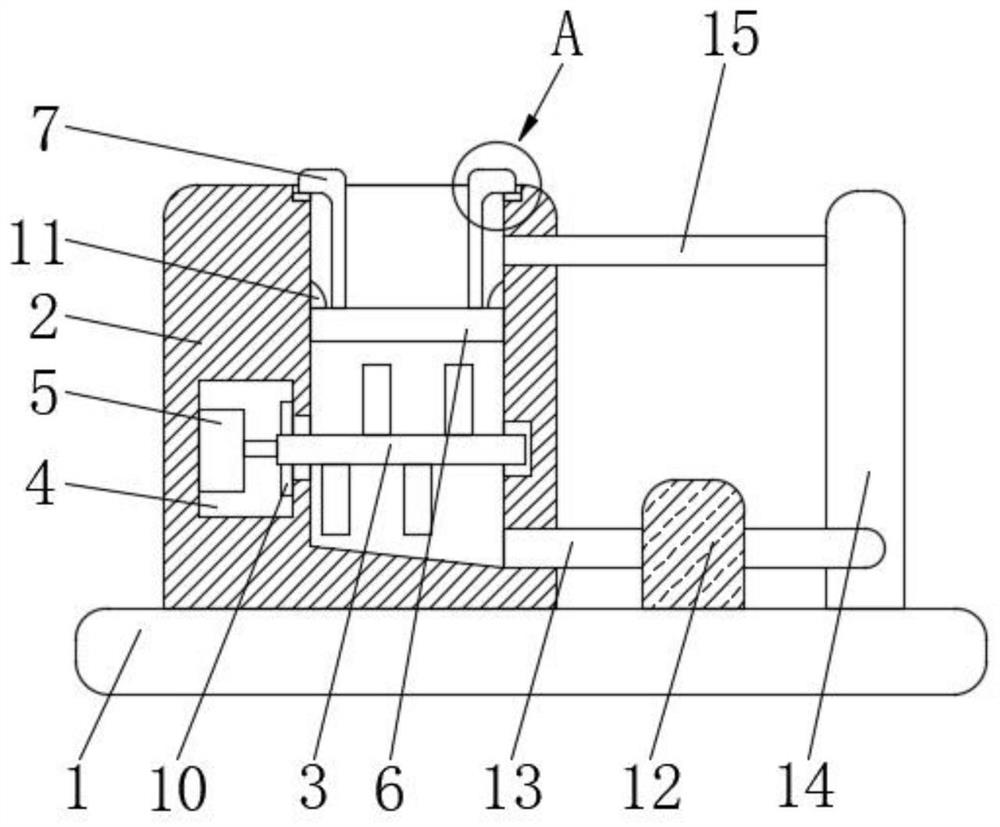

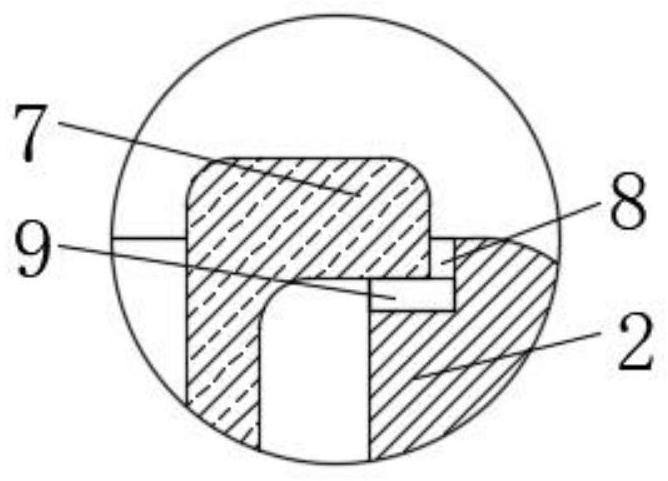

Quenching device

InactiveCN103849730AFully quenchedDifficult to distributeQuenching devicesHydraulic cylinderQuenching

The invention discloses a quenching device. The quenching device comprises a sliding table (2), a hopper (3), a bracket (4), a hydraulic cylinder (5), a long pin shaft (11), a quenching box (9) and a slip cover device. During quenching of workpieces after the adoption of the structure, a guide rod (6) can be driven to move through overturning of the hopper (3), the slip cover (10) is driven to slide in a reciprocating manner along the quenching box (9), and opening and closing of the quenching box (9) are realized. Heat of water in the quenching box (9) is prevented from dissipating, so that workpieces are quenched fully. Meanwhile, water in the quenching box (9) is prevented from being sputtered out of the box (9), so that the personal safety is ensured.

Owner:ANHUI NINGGUO HUADA WEAR RESISTANT MATERIALS

Gear quenching treatment device

ActiveCN106636597AAchieve salvageFully cleanedFurnace typesProcess efficiency improvementImpellerEngineering

The invention relates to the technical field of machining of gears and discloses a gear quenching treatment device. The gear quenching treatment device comprises a rack which is provided with a quenching cylinder and an oil cylinder; the oil cylinder is provided with clamping grooves and supporting rods; a center shaft is arranged in the oil cylinder and is provided with an impeller which is provided with a first side portion and a second side portion, and the first side portion and the second side portion are symmetrical; a first cylinder and a second cylinder are arranged above the impeller; the first cylinder is provided with a first piston rod; a pipeline is arranged below the first cylinder; the second cylinder is provided with a second piston rod which is connected with the pipeline; the first piston rod and the pipeline are in clearance fit with each other; a reverse-direction gas blowing pipe is arranged on the pipeline; the other end of the reverse-direction gas blowing pipe faces the first side portion; a rotating disk is arranged at the lower end of the pipeline and is connected with a forward-direction gas blowing pipe; the other end of the forward-direction gas blowing pipe faces the second side portion; the rotating disk is provided with a slide groove; the supporting rods are connected in the slide groove in a sliding manner; an elastic gas bag is arranged below the rotating disk and is located in the middles of the supporting rods; and the exteriors of the supporting rods are provided with elastic rings which are provided with hooks. By means of the gear quenching treatment device, the problem that a gear is difficult to salvage after being quenched can be solved.

Owner:盐城伟一汽车配件有限公司

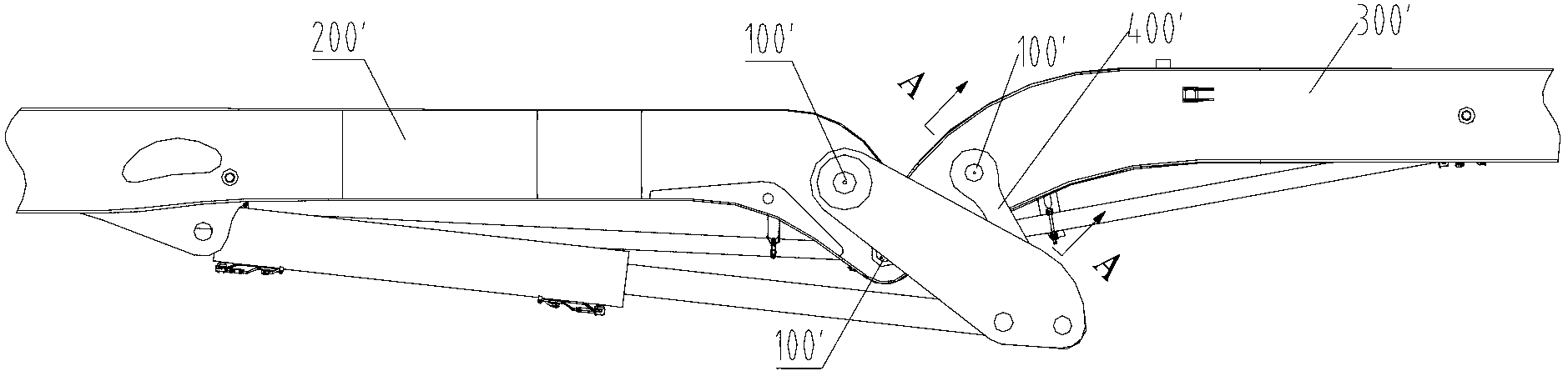

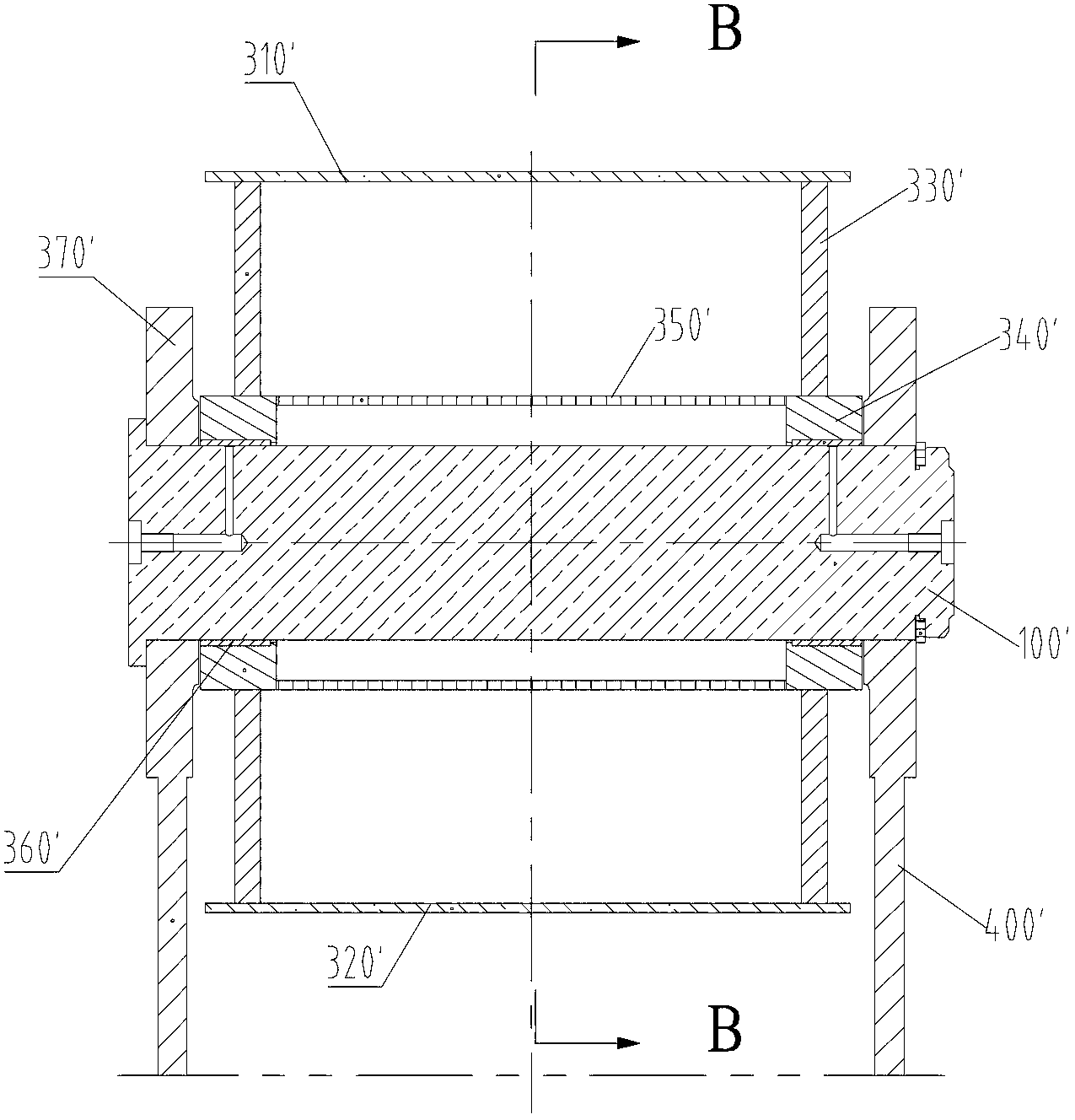

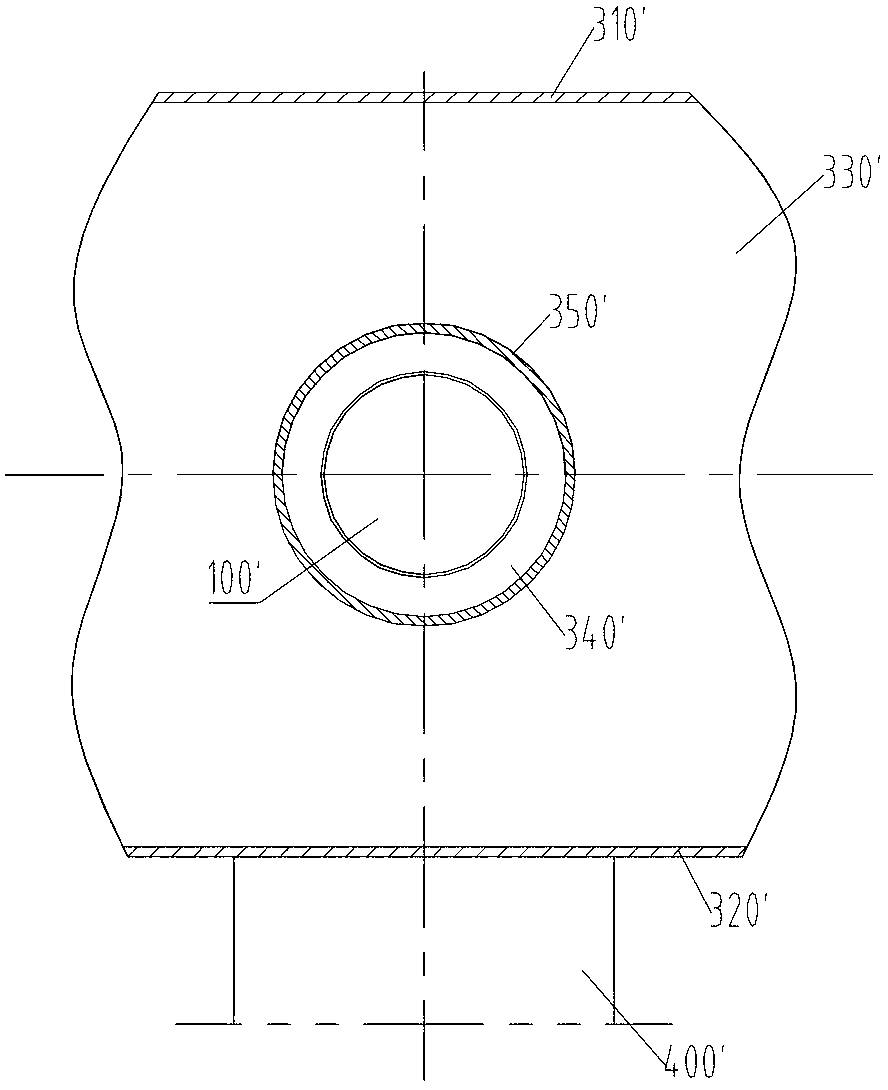

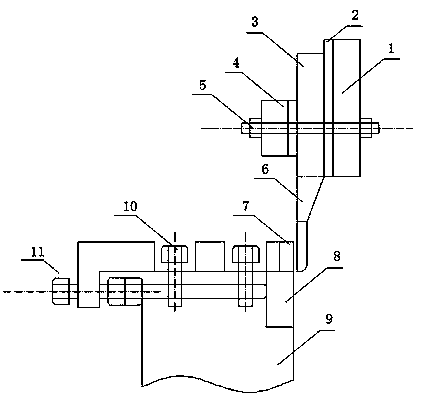

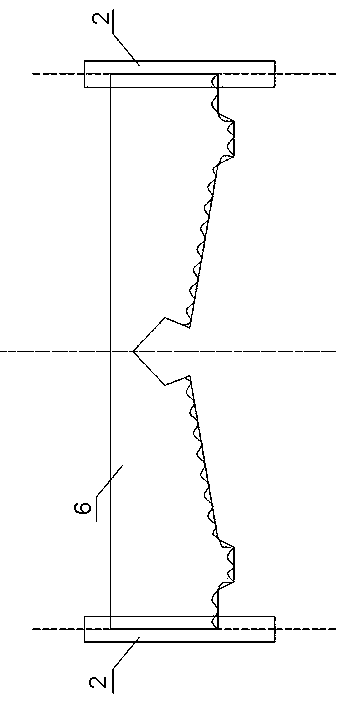

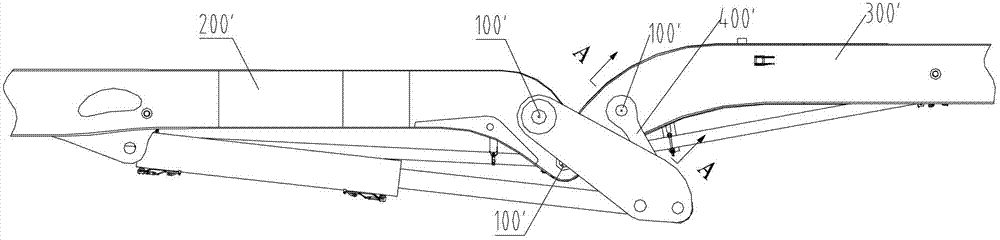

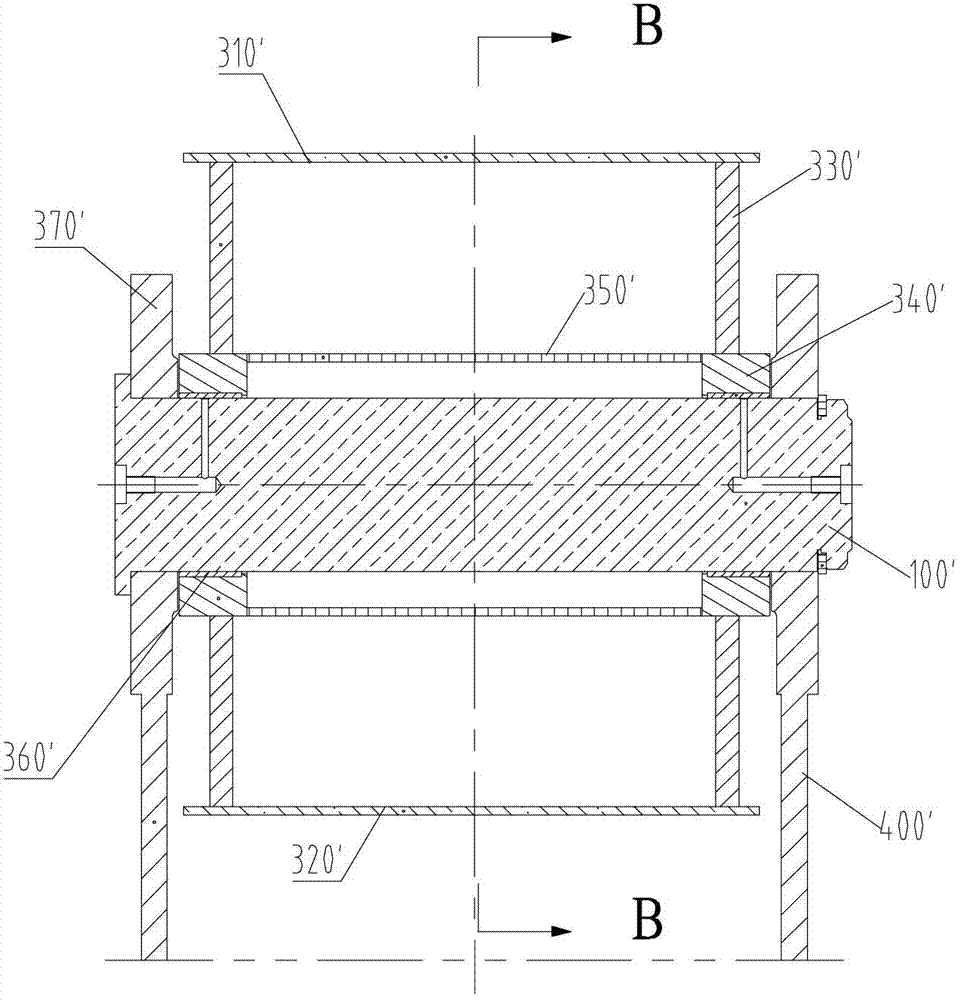

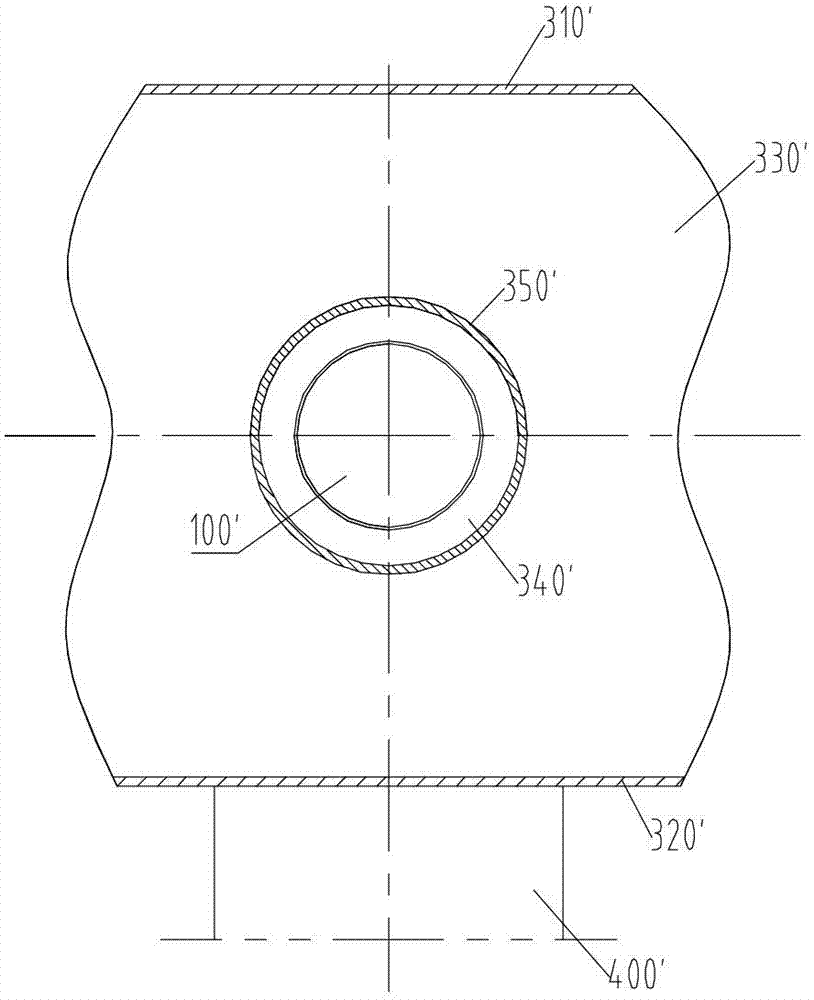

Pin shaft, mounting structure for pin shaft, and concrete pumping equipment

ActiveCN102705330AReduce weightHigh strengthBoltsBuilding material handlingUltimate tensile strengthMechanical engineering

The invention provides a pin shaft, a mounting structure for the pin shaft, and concrete pumping equipment. The pin shaft comprises a body and shaft center parts, wherein the body comprises a cavity body; the cavity body is extended along the axial direction of the pin shaft, and comprises at least one end part which is arranged along the axial direction of the pin shaft; and the shaft center parts are arranged on the end parts. The shaft center parts of the pin shaft are used for resisting a shear load, and a part opposite to the cavity body is used for resisting a bending moment load, so that materials of the pin shaft are optimally distributed, and the aim of reducing the weight of the pin shaft is fulfilled. In addition, the pin shaft is hollow, so that the inner and outer surfaces of the pin shaft are fully hardened and tempered to strengthen the strength of the shaft center parts and the whole strength of the pin shaft.

Owner:ZOOMLION HEAVY IND CO LTD

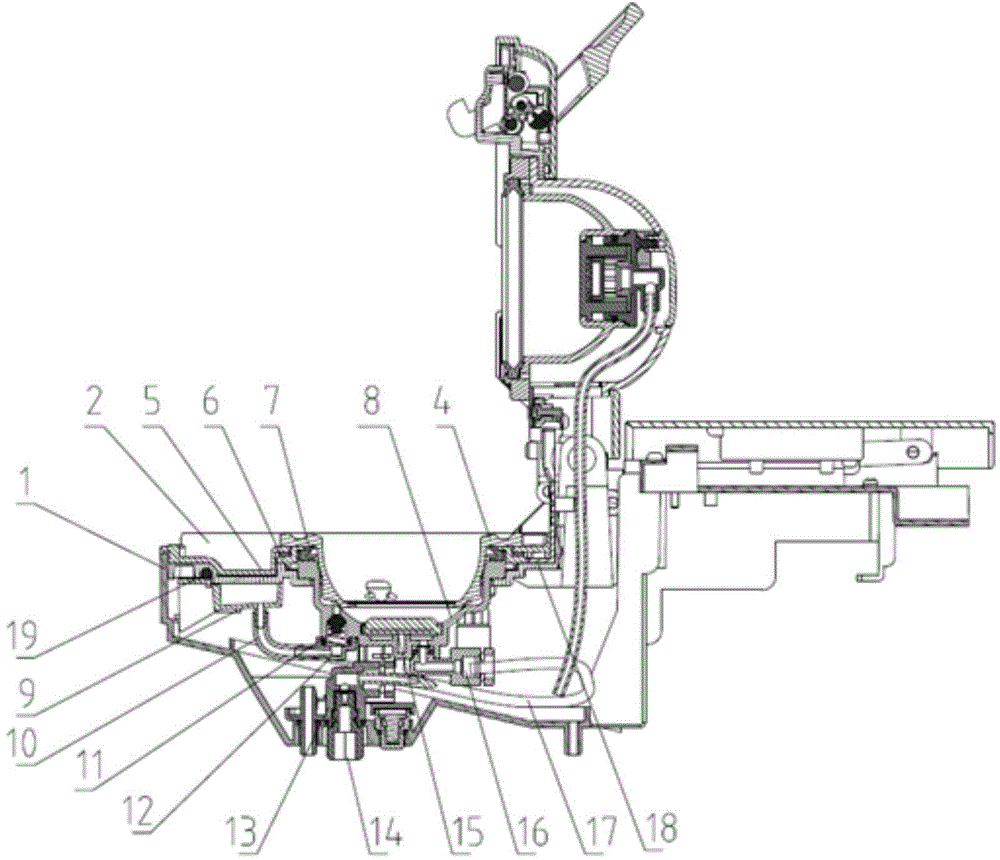

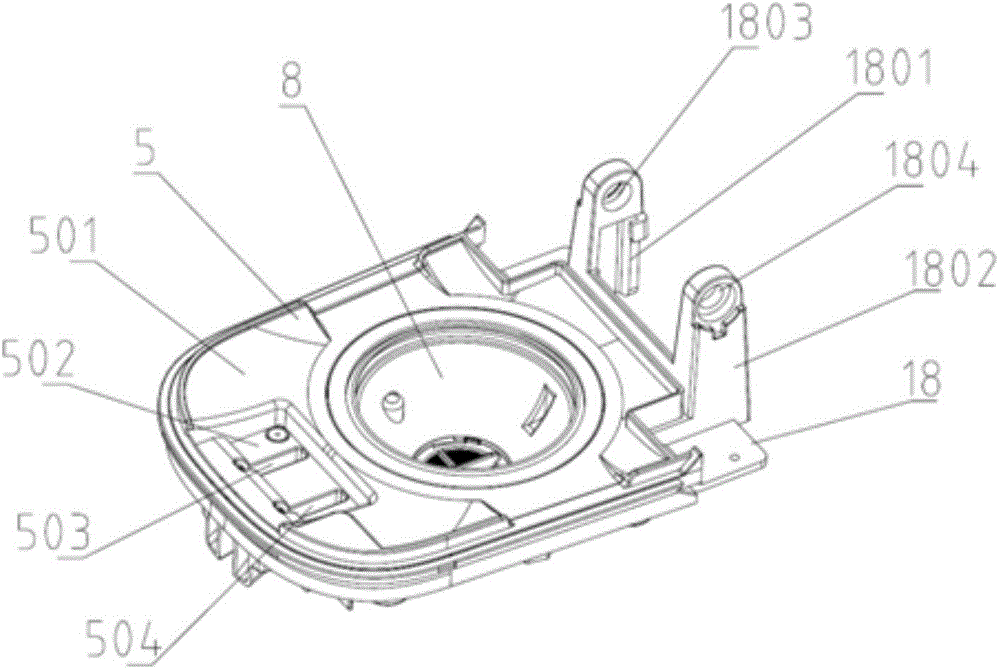

Pressure type beverage brewing machine

ActiveCN104905685AFast brewing speedImprove brewing resultsBeverage vesselsBrewingMechanical engineering

The invention discloses a pressure type beverage brewing machine which comprises a body. The body is provided with an upper support assembly, a lower support assembly and a brewing spoon. The upper support assembly comprises an upper support and an upper brewing chamber arranged on the upper support, the lower support assembly comprises a lower support and a lower brewing chamber arranged on the lower support, the brewing spoon is arranged in the lower brewing chamber, and a lock cover mechanism used for locking the upper support assembly and the lower support assembly is arranged between the upper support assembly and the lower support assembly. When the upper support assembly and the lower support assembly are in a locking state, a brewing chamber is formed between the upper brewing chamber and the lower brewing chamber and provided with a water inlet device to supply water, the body is provided with a water outlet device communicated with the brewing chamber, the brewing chamber is provided with a pressure generating structure, and when the brewing machine brews a beverage, steeping pressure for carrying out pressure steeping on the beverage is generated in the brewing chamber by the pressure generating structure. By means of the pressure type beverage brewing machine, the beverage is steeped under pressure so that the needed beverage can be quickly brewed, and the nutrition of the beverage can be fully extracted.

Owner:宁波亚特电器有限公司

A shearing machine tool holder with a locking mechanism and its tool

InactiveCN105880722BImprove rigidityHigh hardnessShearing machinesShearing machine accessoriesLocking mechanismEngineering

The invention discloses a plate shearing machine tool rest with a locking mechanism and a tool thereof. The plate shearing machine tool rest comprises an upper tool rest module and a lower tool rest module. The upper tool rest module and the lower tool rest module are fixed to a plate shearing machine platform. The upper tool rest module comprises an upper tool rest body, an upper tool body and tool guide rails, the tool guide rails are fixed to the two sides of the upper tool rest body, and the upper tool body is embedded into grooves of the tool guide rails and slides up and down in a fixed stroke. The lower tool rest module comprises a lower tool rest body and a lower tool body, and the lower tool body is fixed to one side of the lower tool rest body. The plate shearing machine tool rest has the beneficial effects that (1) final motion of an upper blade and a lower blade is reduced through the locking mechanism, the eccentric shearing phenomenon is eliminated, twisting of plates is reduced, and the quality of workpieces is improved; and (2) a step-shaped corrugated surface blade is adopted as the upper blade, the rigidity, hardness, abrasion resistance, fatigue strength, toughness and the like of blade steel are greatly improved, burrs and flangings of machined faces are effectively reduced, and the technical performance and production efficiency of a plate shearing machine are improved.

Owner:NANTONG ZHIGAO HEAVY IND TECH CO LTD

Quenching equipment for gear production and machining

InactiveCN114058826AFully QuenchedImprove the quality of the working environmentFurnace typesHeat treatment furnacesSuction forceAir purifiers

The invention relates to the technical field of gear production, and discloses quenching equipment for gear production and machining. The quenching equipment comprises a quenching equipment body and a gear fixing device, a partition plate is fixedly connected to the middle of an inner cavity of the quenching equipment body, the partition plate divides the inner cavity of the quenching equipment body into a heating cavity and a cooling cavity, the top of the partition plate is fixedly connected with a supporting frame, and the middle of the top of the supporting frame is fixedly connected with a supporting pipe. According to the quenching equipment for gear production and machining, due to the arrangement of an exhaust fan, the exhaust fan works to enable an air suction head connected with the exhaust fan to generate suction force, and the air suction head sucks air above the cooling cavity and smoke generated in the gear cooling process into the exhaust fan; and the sucked air is moved into an air purifier through an air outlet pipe under the action of the exhaust fan to be purified, and the purified air is discharged into the air, so that the environment around the device can be improved, and the working environment quality of workers is improved.

Owner:湖南飞阳齿轮制造有限责任公司

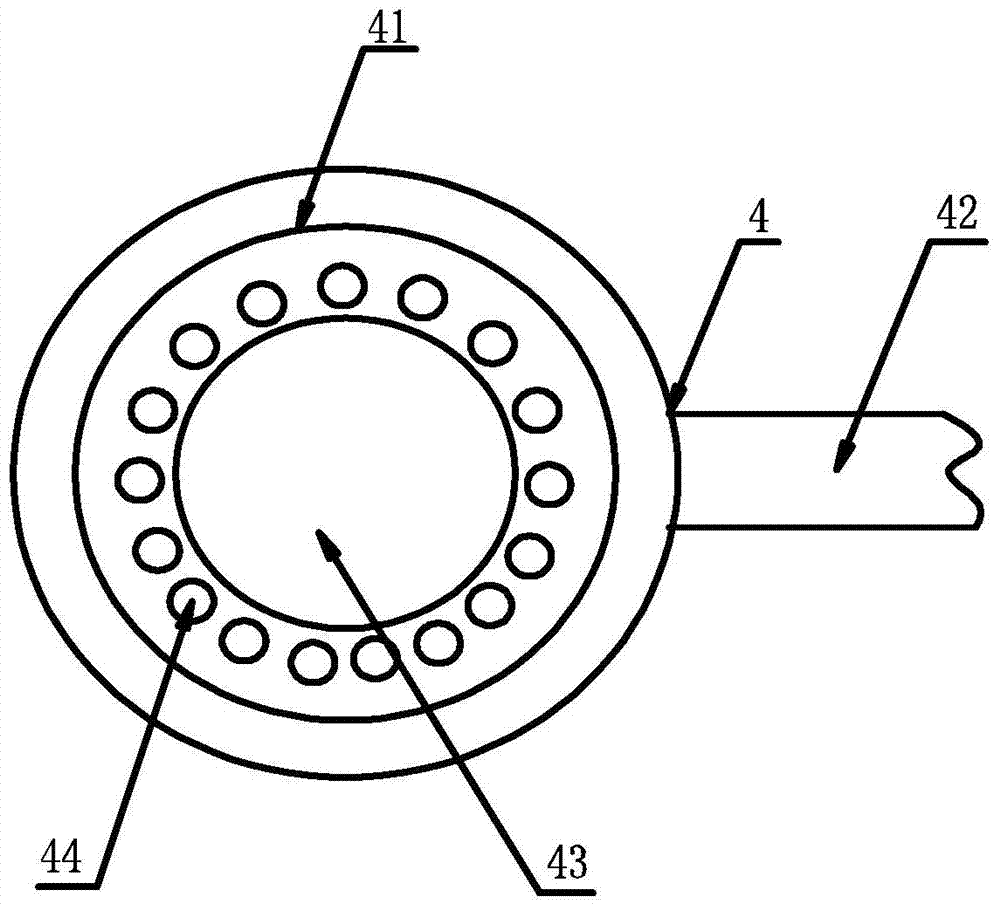

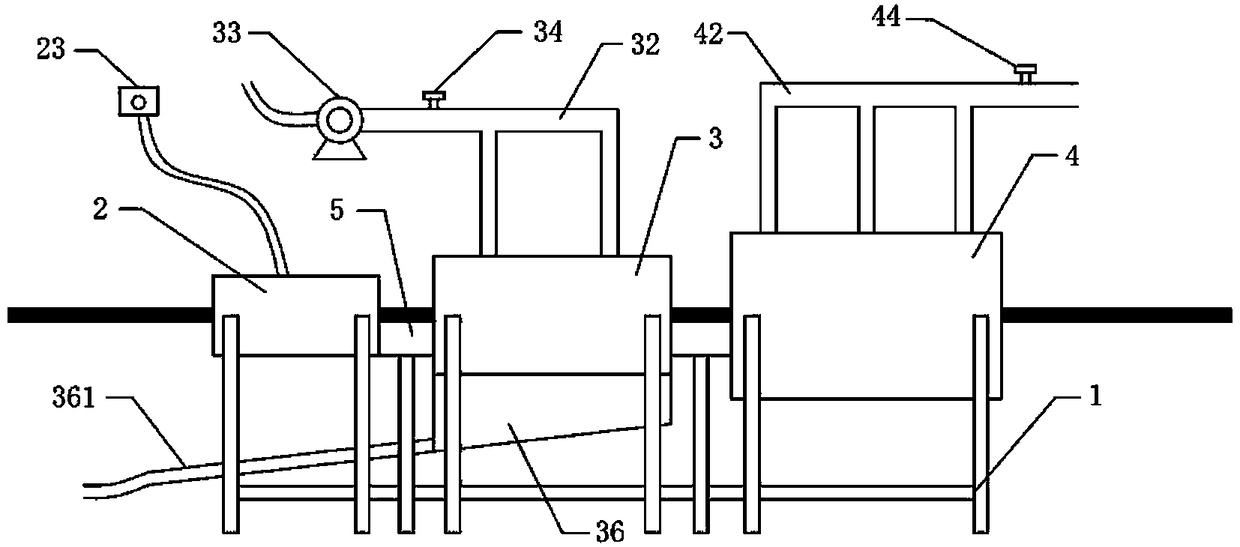

A quenching medium stirring cooling device

ActiveCN103924048BFully quenchedGuarantee the quality of quenchingQuenching devicesPropellerWater circulation

Owner:HULUDAO WEILI MACHINE MFG

A pressure beverage brewing machine

The invention discloses a pressure type beverage brewing machine, comprising a main body, an upper bracket assembly, a lower bracket assembly and a brewing spoon are arranged on the main body, the upper bracket assembly includes an upper bracket and an upper brewing chamber arranged on the upper bracket, and a lower bracket assembly It includes a lower bracket and a lower brewing chamber arranged on the lower bracket. The brewing spoon is placed in the lower brewing chamber. A locking mechanism for locking the upper bracket assembly and the lower bracket assembly is arranged between the upper bracket assembly and the lower bracket assembly. When the combination is in a locked state, a brewing chamber is formed between the upper brewing chamber and the lower brewing chamber, the brewing chamber is provided with a water inlet device for water supply, the main body is provided with a water outlet device that communicates with the brewing chamber, and the brewing chamber is provided with a pressure generating structure. When the brewing machine brews the beverage, the pressure generating structure generates the brewing pressure inside the brewing chamber to brew the beverage under pressure. In the present invention, the beverage is soaked under pressure, so the desired beverage can be quickly brewed, and the nutrition of the beverage can be fully extracted.

Owner:宁波亚特电器有限公司

A circular chain heat treatment device and its application method

ActiveCN105349757BHigh degree of integrationImprove work efficiencyFurnace typesHeat treatment furnacesHardnessLath

The invention discloses a heat treatment device for a round-link chain and an application method thereof. The device comprises a quenching part and a tempering part which are sequentially arranged, wherein first cooling parts are arranged at the quenching part and the tempering part; the quenching part is provided with a quenching temperature regulating box; the tempering part is sequentially provided with an uniform-temperature tempering heating box, at least one tempering temperature regulating box and a differential-temperature tempering heating box; the quenching temperature regulating box is provided with a second cooling part. The device has the characteristics of being high in integration degree and high in working efficiency; after the round-link chain is quenched, an uniform and small low-carbon lath martensite structure can be obtained; the quenching quality is high; the second cooling part and the first cooling parts are correspondingly connected to a cooling source, so that the cooling quality can be improved, and the requirements of each part of the round-link chain on hardness and toughness can be met.

Owner:SHANDONG LUNAN GRP ENERGY EQUIP MFG

Quenching apparatus for hollow structural component and quenching method

InactiveCN100363512CSuppress uneven coolingFully quenchedFurnace typesHeat treatment furnacesQuenchingMaterials science

To provide a quenching apparatus capable of surely quenching with less fear of uneven quenching and deformation with respect to a hollow member. This quenching apparatus has: a set of inner part restraining tools having the outer shapes almost corresponding to the shapes of the respective inner peripheries at both end parts of the cylindrical hollow member opened at both end parts; end part restraining tools provided with a set of outer part restraining tools; abutting tools holding by abutting a part in the hollow member; and a means for performing cooling by inserting the inner restraining tools at both end parts of the heated hollow member under abutting state of the abutting tools at a prescribed position. That is, the intrusion of cooling liquid into the inner part of the hollow member is restrained by inserting the inner part restraining tools at both end parts of the hollow member and thus, the cooling unevenness is restrained and also, the strain caused by the end part restraining tools and the abutting tools, is restrained.

Owner:TOYOTA JIDOSHA KK

Gear Quenching Treatment Device

ActiveCN106636597BAchieve salvageFully cleanedFurnace typesProcess efficiency improvementImpellerEngineering

Owner:盐城伟一汽车配件有限公司

Heat treatment quenching device for high chrome alloy wear-resistant steel forging

PendingCN112746154AWork without interruptionFully quenchedQuenching devicesElectric machineEngineering

The invention discloses a heat treatment quenching device for a high chrome alloy wear-resistant steel forging, and belongs to the field of quenching. The heat treatment quenching device comprises a base, wherein a quenching box is fixedly arranged at one side of the upper end face of the base; a stirring shaft is fixedly arranged at the two sides of the lower end in the quenching box through bearings; the side face of the stirring shaft is located in a cavity arranged in one side in the quenching box; a motor is fixedly arranged on the side face of the cavity; the shaft end of the motor is fixedly arranged at the end of the stirring shaft; a sealing block is fixedly arranged on the side face of the cavity and located on the periphery of the stirring shaft; the sealing block is rotationally connected to the side face of the stirring shaft in a sleeving mode; a filter screen is slidably connected to the inner side face of the quenching box; and connecting plates are fixedly arranged at the two sides of the upper end face of the filter screen. According to the heat treatment quenching device for the high chrome alloy wear-resistant steel forging, the stirring shaft can be driven to rotate through the motor, so that when materials are quenched, quenching oil flows on the surfaces of the materials, workpieces can be sufficiently quenched, and the quenching effect is improved.

Owner:济南厚德耐磨材料有限公司

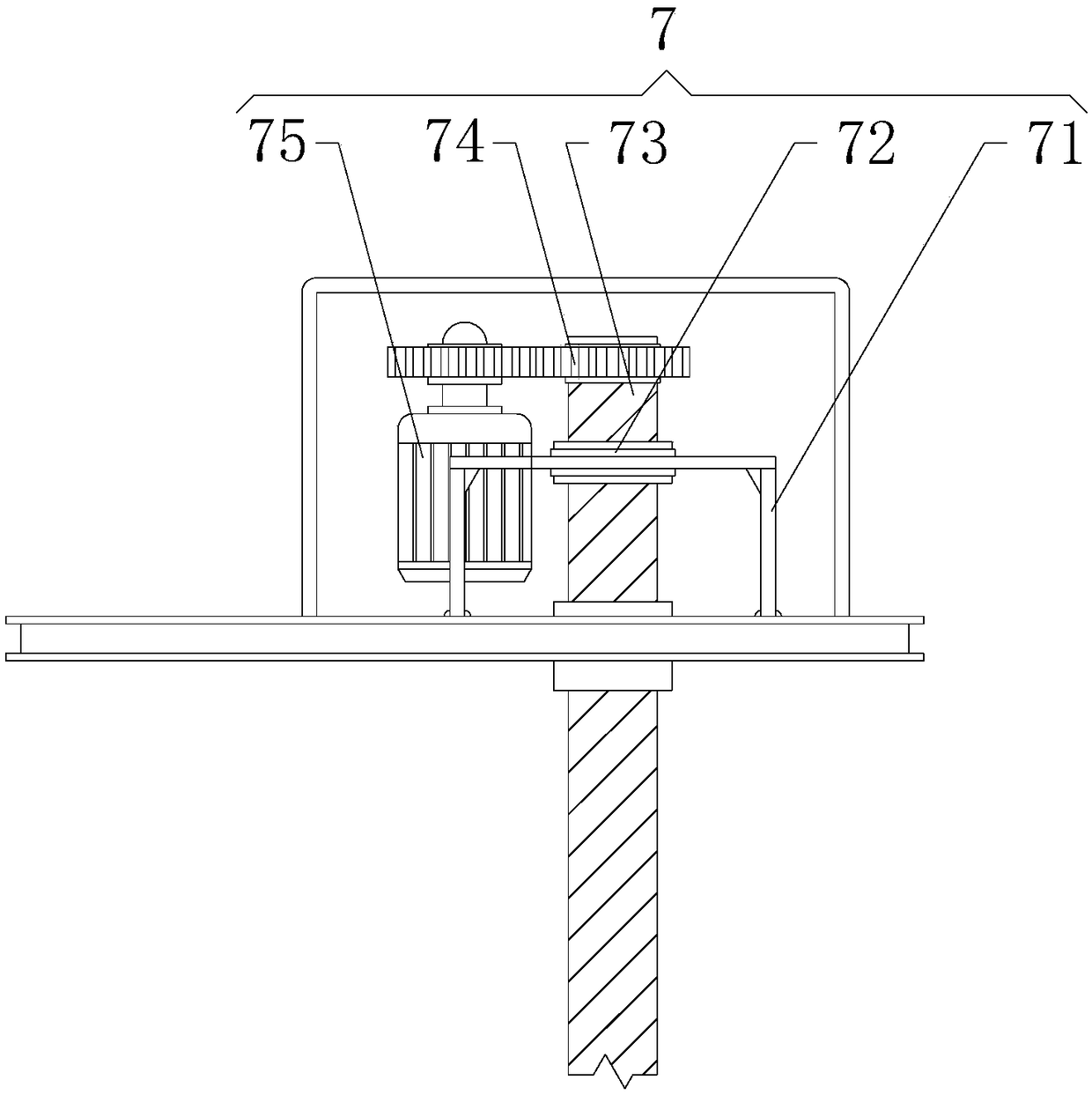

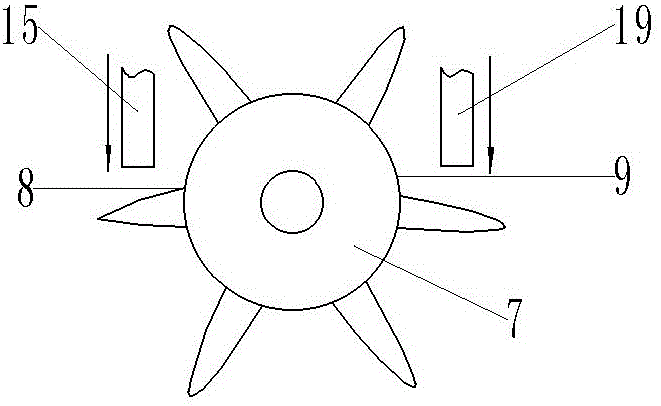

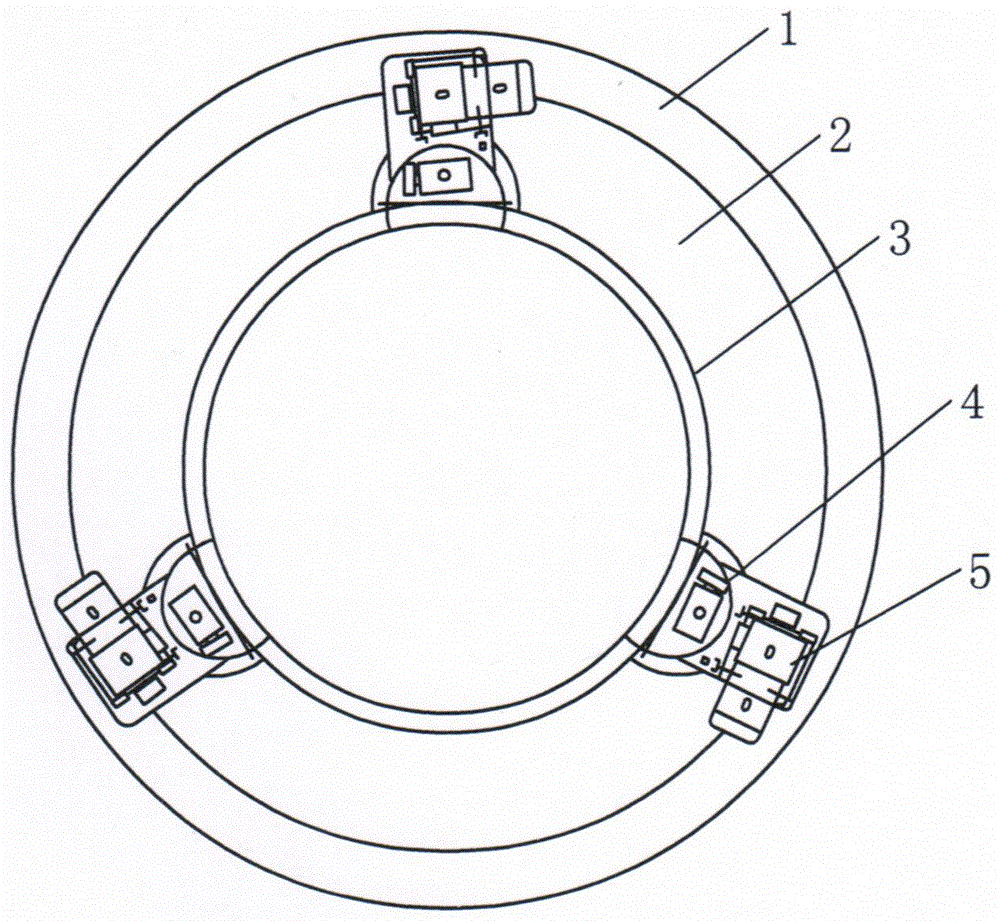

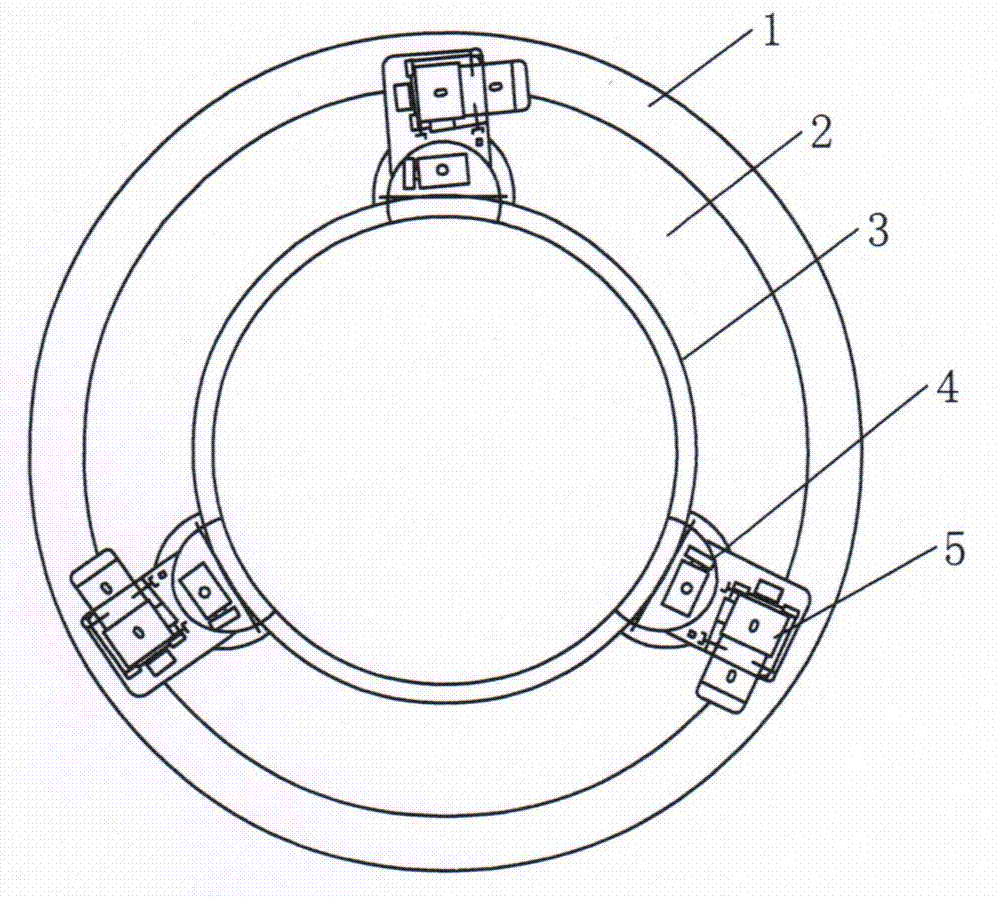

Quenching medium stirring cooling device

ActiveCN103924048AFully quenchedGuarantee the quality of quenchingQuenching devicesPropellerQuenching

The invention discloses a quenching medium stirring cooling device. Propeller stirrers are arranged on the outer edge of a quenching liquid tank, the propeller stirrers are in 120 degree angle with each other and are driven by propeller speed regulation motors, and a cooling water circulation system is arranged between the periphery of the outer edge of the quenching liquid tank and a concrete waterproof wall. The propeller stirring direction and the quenching liquid tank center form a 5 degree angle, and the rotation direction of a quenching workpiece is opposite to that of a quenching medium. The quenching medium stirring cooling device can fully quench the workpiece to ensure the quenching quality by quenching liquid stirring, cooling water cooling and workpiece rotation manners, and is suitable for using as a workpiece quenching device.

Owner:HULUDAO WEILI MACHINE MFG

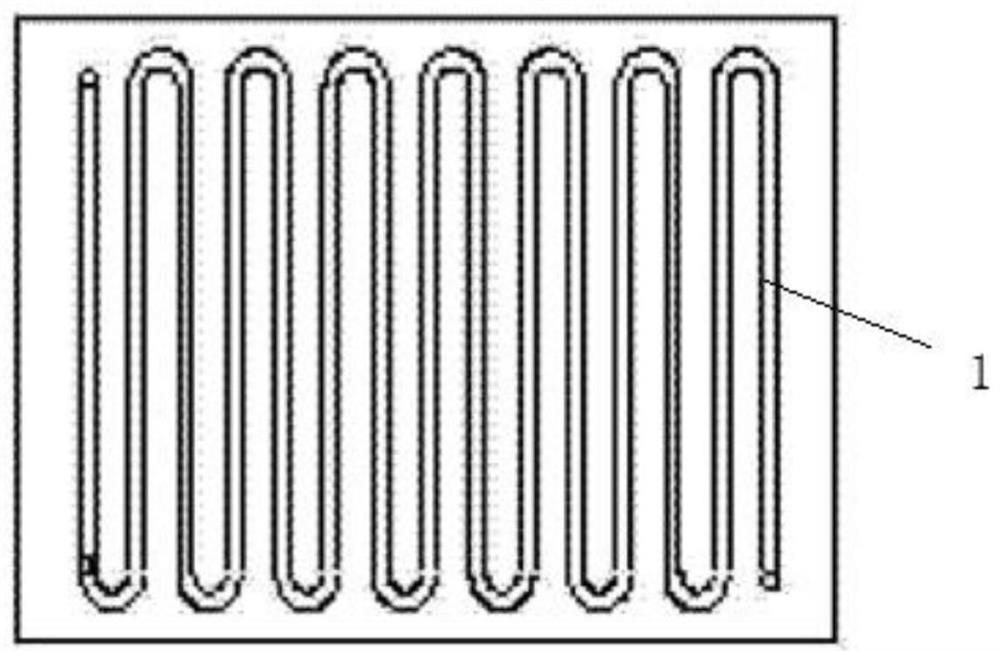

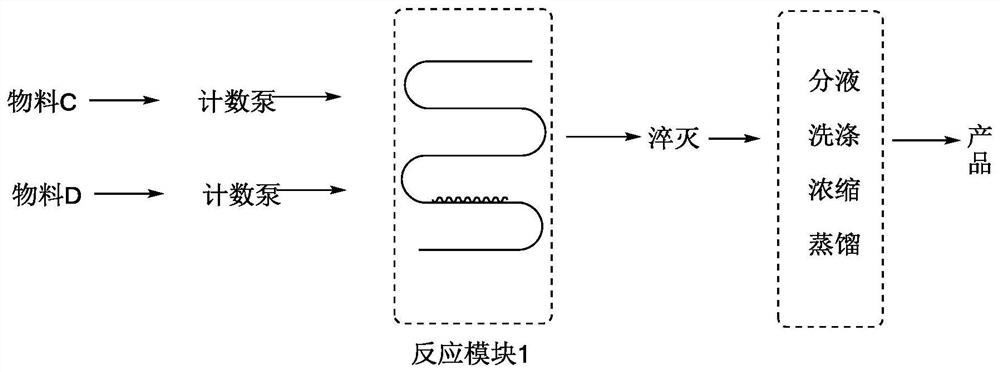

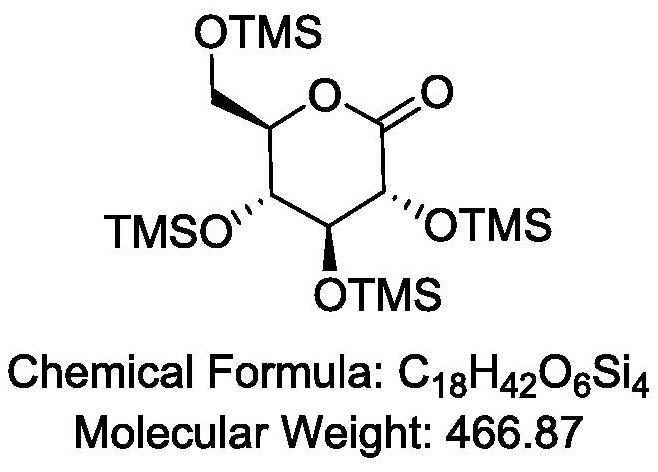

Method for preparing 2, 3, 4, 6-tetra-O-trimethylsilyl-D-glucolactone by using continuous flow micro-channel reactor

PendingCN113372379AShort reaction timePrecise feed ratioGroup 4/14 element organic compoundsPtru catalystBis(trimethylsilyl)amine

The invention relates to the technical field of synthesis of medical intermediates, in particular to a method for preparing 2, 3, 4, 6-tetra-O-trimethylsilyl-D-glucolactone by using a continuous flow micro-channel reactor. In a continuous flow micro-channel reactor, 1, 5-glucolactone and hexamethyldisilazane are used as raw materials, iodine is used as a catalyst, and a target product is prepared within the reaction time of dozens of seconds. The method is simple and safe to operate, high in yield, short in reaction time and capable of realizing continuous production, the product yield is 80% or above, and the purity reaches 98% or above.

Owner:JIANGSU ALPHA PHARM CO LTD

Pin shaft, mounting structure for pin shaft, and concrete pumping equipment

ActiveCN102705330BReduce weightHigh strengthBoltsBuilding material handlingUltimate tensile strengthConcrete pump

A pin shaft, a pin shaft mounting structure, and a concrete pumping apparatus. The pin shaft (100) comprises a main body (110). The main body (110) comprises a cavity (120) extending along the axial direction of the pin shaft. The pin shaft (100) also comprises an axis part (130). The cavity (120) comprises at least one end part provided along the axial direction of the pin shaft. The axis part (130) is provided at the at least one end part. The pin shaft utilizes the axis part thereof to withstand a shear load, and utilizes a part corresponding to the cavity to withstand a bending moment load, thus allowing the material of the pin shaft to achieve optimum distribution, and implementing the goal of reducing the weight of the pin shaft. The pin shaft is hollow, therefore the inner and outer surfaces of the pin shaft are allowed to be fully tempered and quenched, thus increasing the strength of the axis part, thereby increasing the overall strength of the pin shaft.

Owner:ZOOMLION HEAVY IND CO LTD

Vertical spray quenching apparatus and quenching technique

ActiveCN101469359BFully consider convenienceFully quenchedFurnace typesHeat treatment furnacesWater vaporControl system

The invention relates to quenching equipment and a quenching process for applying the quenching equipment, in particular to vertical type spray quenching equipment and a quenching process for quenching a large diameter alloy bar. The equipment comprises a heating chamber, a vapor division board, a spray quenching chamber, a feed-and-discharge control system, and a booster pump, wherein the heating chamber, the vapor division board and the spray quenching chamber are arranged vertically in sequence; and the feed-and-discharge control system transports workpieces to the heating chamber and the spray quenching chamber in sequence for heating and quenching treatment. The quenching process comprises the following steps: placing an alloy workpiece at a proper position in the heating chamber; starting a heating program for heating treatment; opening a water inlet and a water outlet of the quenching chamber after heating treatment; then opening a bottom door of the heating chamber, and opening the vapor division board simultaneously; carrying out the quenching treatment after the alloy workpiece enters the proper position in the quenching chamber through the feed opening of the quenching chamber, and closing the vapor division board at the same time; and closing a water inlet valve after finishing the quenching treatment and taking out the alloy workpiece from the top of the heating chamber.

Owner:GRIMAT ENG INST CO LTD

Quenching cooling conveying line for aluminum profiles

InactiveCN108149170AQuenching is normalFully quenchedQuenching devicesResource utilizationEngineering

A quenching cooling conveying line for aluminum profiles comprises a conveying support and a quenching cooling system arranged on the conveying support. The quenching cooling system comprises a heat-insulating mechanism arranged at the front end of the conveying support and used for preventing the aluminum profiles subjected to extruding discharging just now from radiating excessively, a liquid cooling mechanism arranged in the middle of the conveying support, and an air cooling mechanism arranged at the tail end of the conveying support. The quenching cooling conveying line is compact is structure and convenient to use; a quenching processing line of the aluminum profiles is systematically arranged to ensure that quenching of the aluminum profiles is normal, sufficient and even, an idealcrystal phase structure is obtained, and the disadvantages, such as cracking, caused by improper control over the temperature before quenching or the cooling efficiency, the cooling area and the likeduring quenching are avoided; and the property reaches the standard, and resource utilization is reasonable.

Owner:汤长翠

Quenching device of stabilizer bar

ActiveCN102703661BSimple structureStable quenching processFurnace typesHeat treatment furnacesManufacturing technologySlag

Owner:QIANJIANG SPRING HANGZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com