Spray quenching device with rotating effect and using method thereof

A technology of quenching device and spraying device, which is applied in the field of quenching, can solve the problems of uneven quenching and many unqualified workpieces, achieve uniform quenching, improve product qualification rate, and ensure the effect of product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

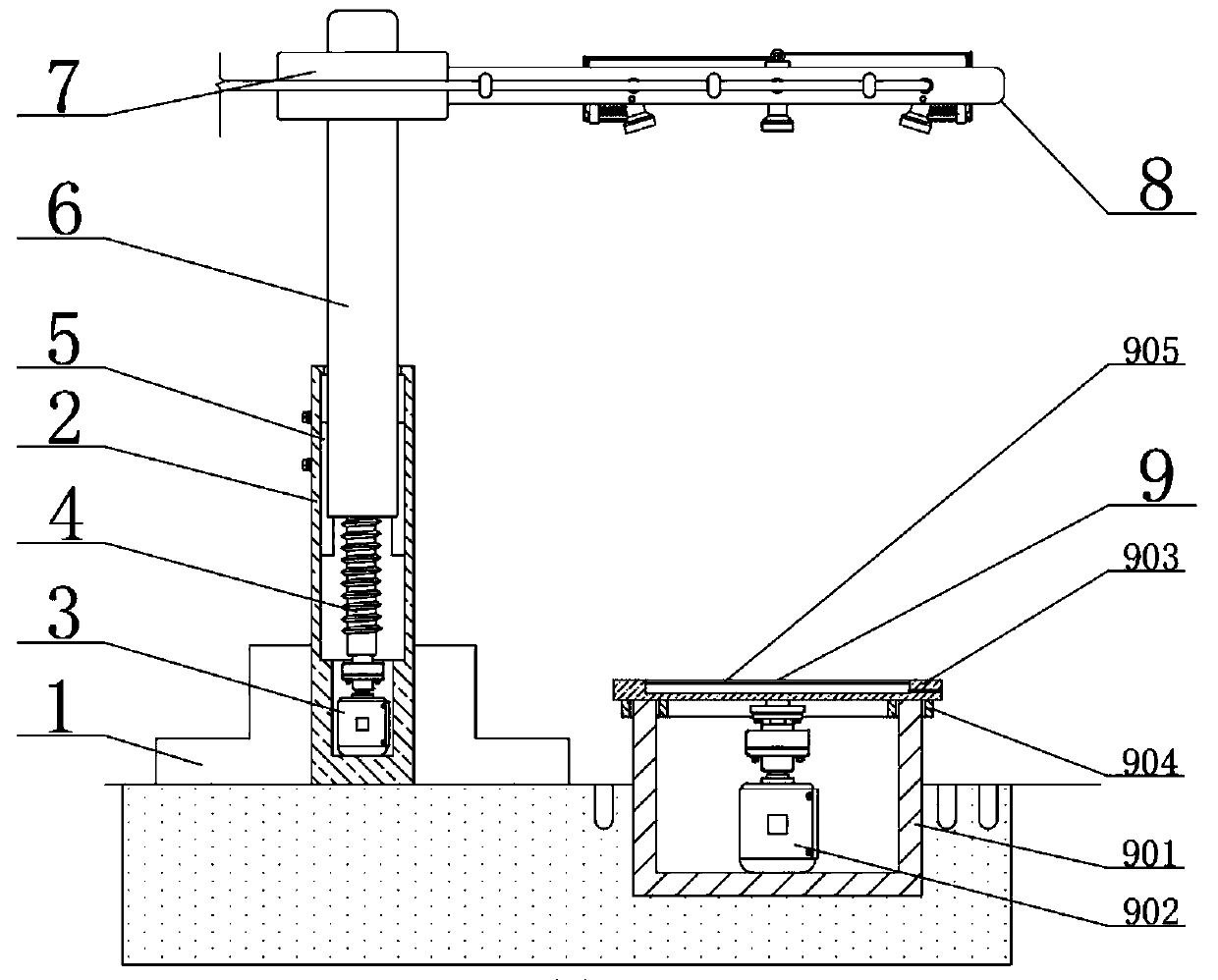

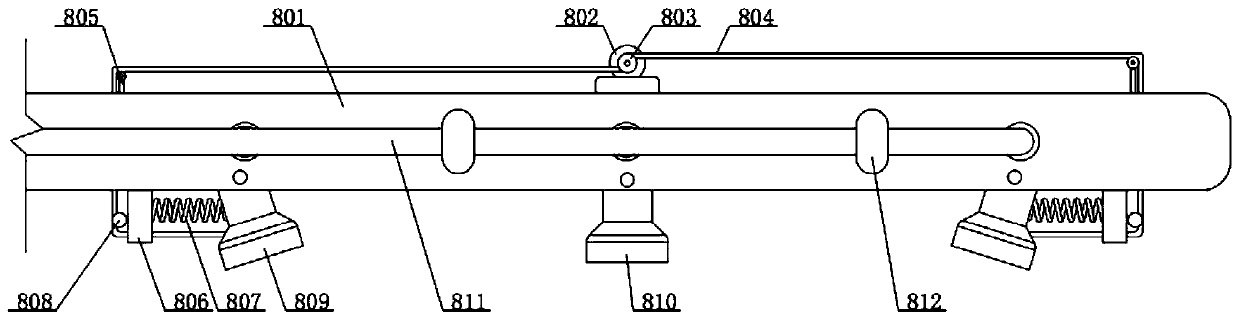

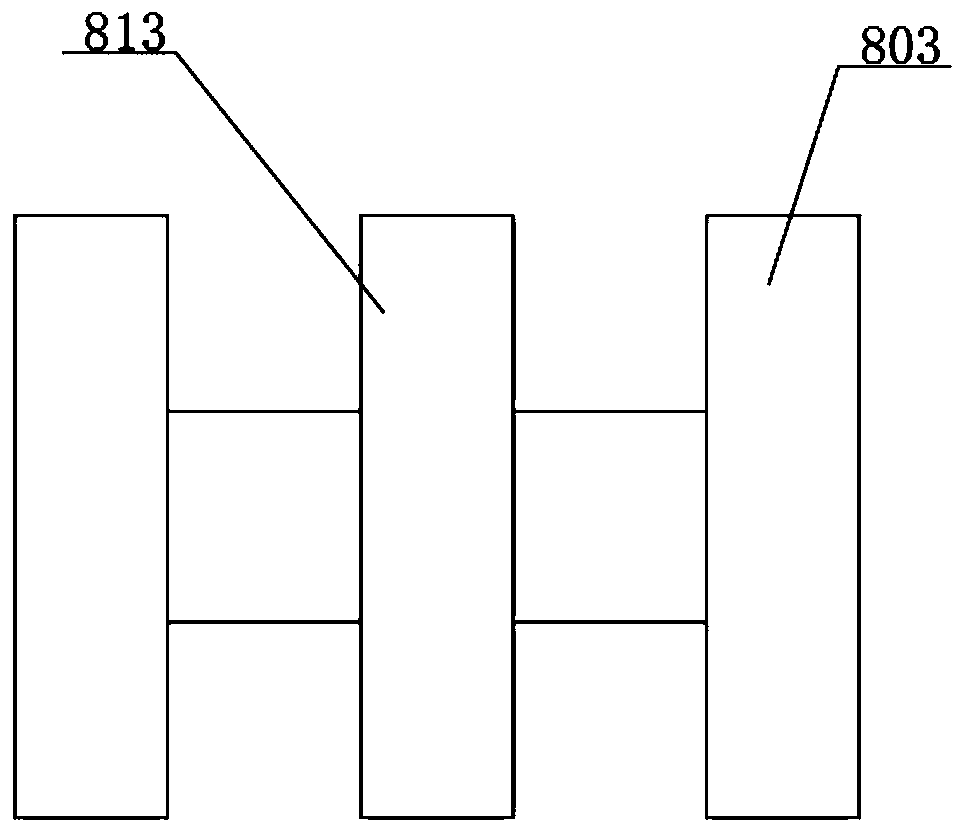

[0029] see Figure 1-Figure 4 , the present invention provides a technical solution:

[0030]A spray quenching device with rotation effect and its use method, comprising a fixed base 1 and a fixed cylinder 2, the fixed base 1 is fixedly connected with the fixed cylinder 2 inside, the lower end surface of the fixed cylinder 2 is fixedly connected with the rotating motor 3 inside, and the rotating motor 3 The end of the main shaft is fixedly connected with the threaded rod 4, and the outer side of the threaded rod 4 is spirally connected with the lifting rod 6, and the left and right sides of the lifting rod 6 are provided with grooves, and the lifting rod 6 is slidingly connected with the limit plate 5 through the groove, and the lifting rod The outer side of 6 is slidingly connected with the fixed cylinder 2. This setting ensures that the lifting rod 6 can only move up and down, avoids its own rotation, and ensures the normal spraying work of the spraying device 8. The upper s...

Embodiment 2

[0040] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a technical solution:

[0041] A spray quenching device with rotation effect and its use method, comprising a fixed base 1 and a fixed cylinder 2, the fixed base 1 is fixedly connected with the fixed cylinder 2 inside, the lower end surface of the fixed cylinder 2 is fixedly connected with the rotating motor 3 inside, and the rotating motor 3 The end of the main shaft is fixedly connected with the threaded rod 4, and the outer side of the threaded rod 4 is spirally connected with the lifting rod 6, and the left and right sides of the lifting rod 6 are provided with grooves, and the lifting rod 6 is slidingly connected with the limit plate 5 through the groove, and the lifting rod The outer side of 6 is slidingly connected with the fixed cylinder 2. This setting ensures that the lifting rod 6 can only move up and down, avoids its own rotation, and ensures the normal spraying work of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com