Patents

Literature

415results about How to "Guaranteed spraying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

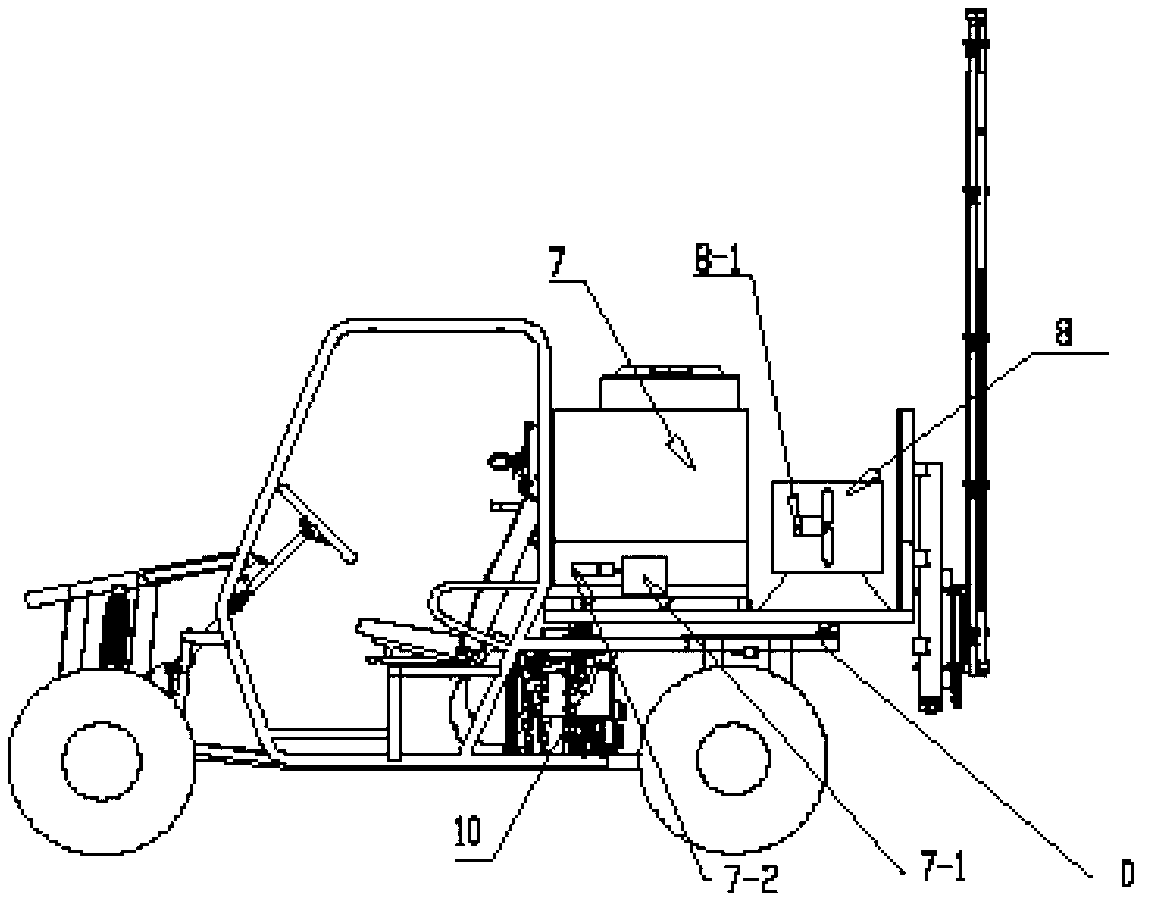

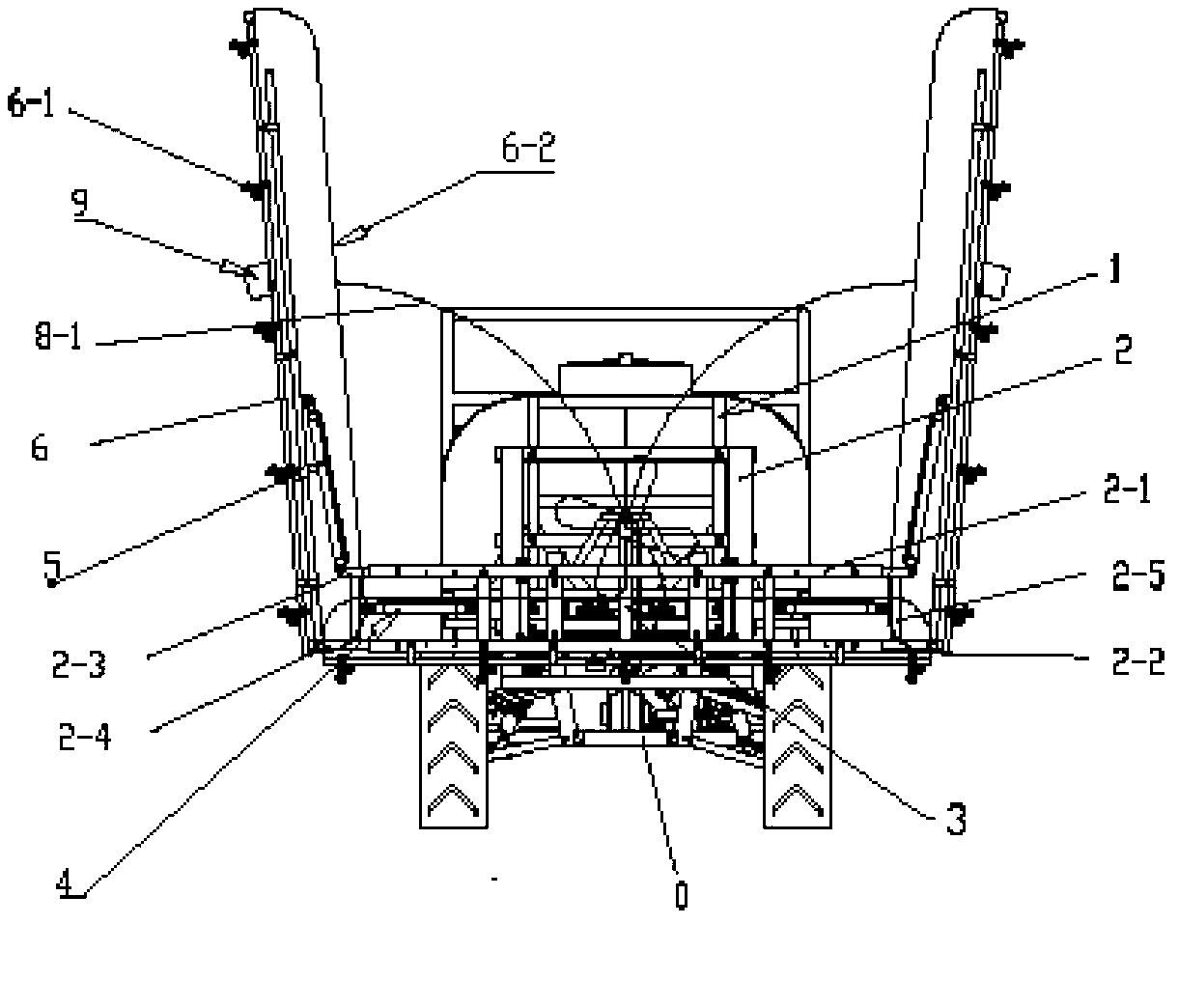

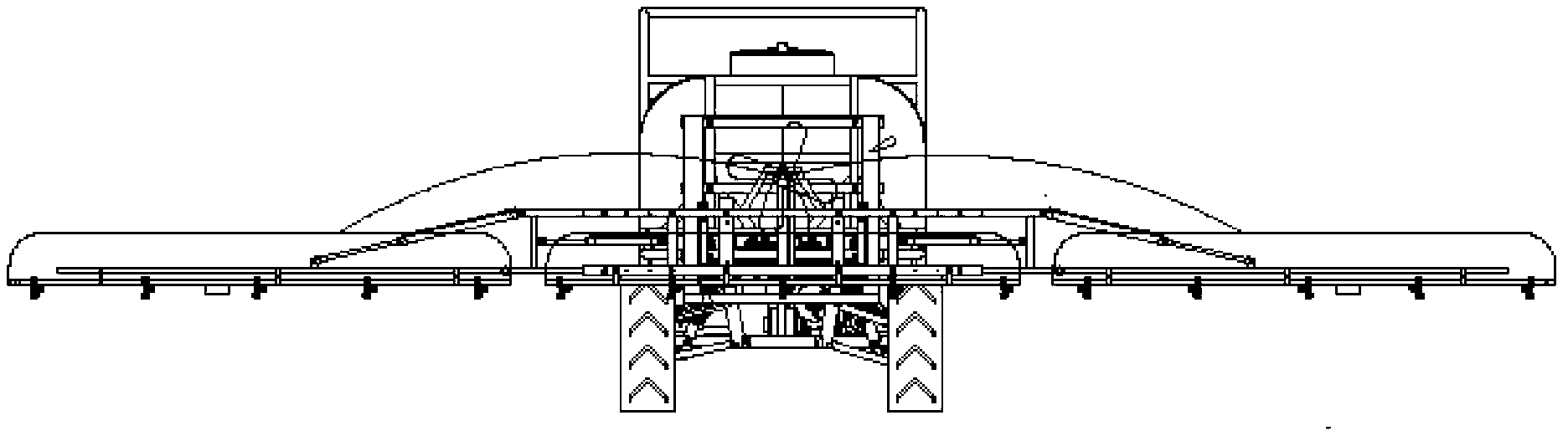

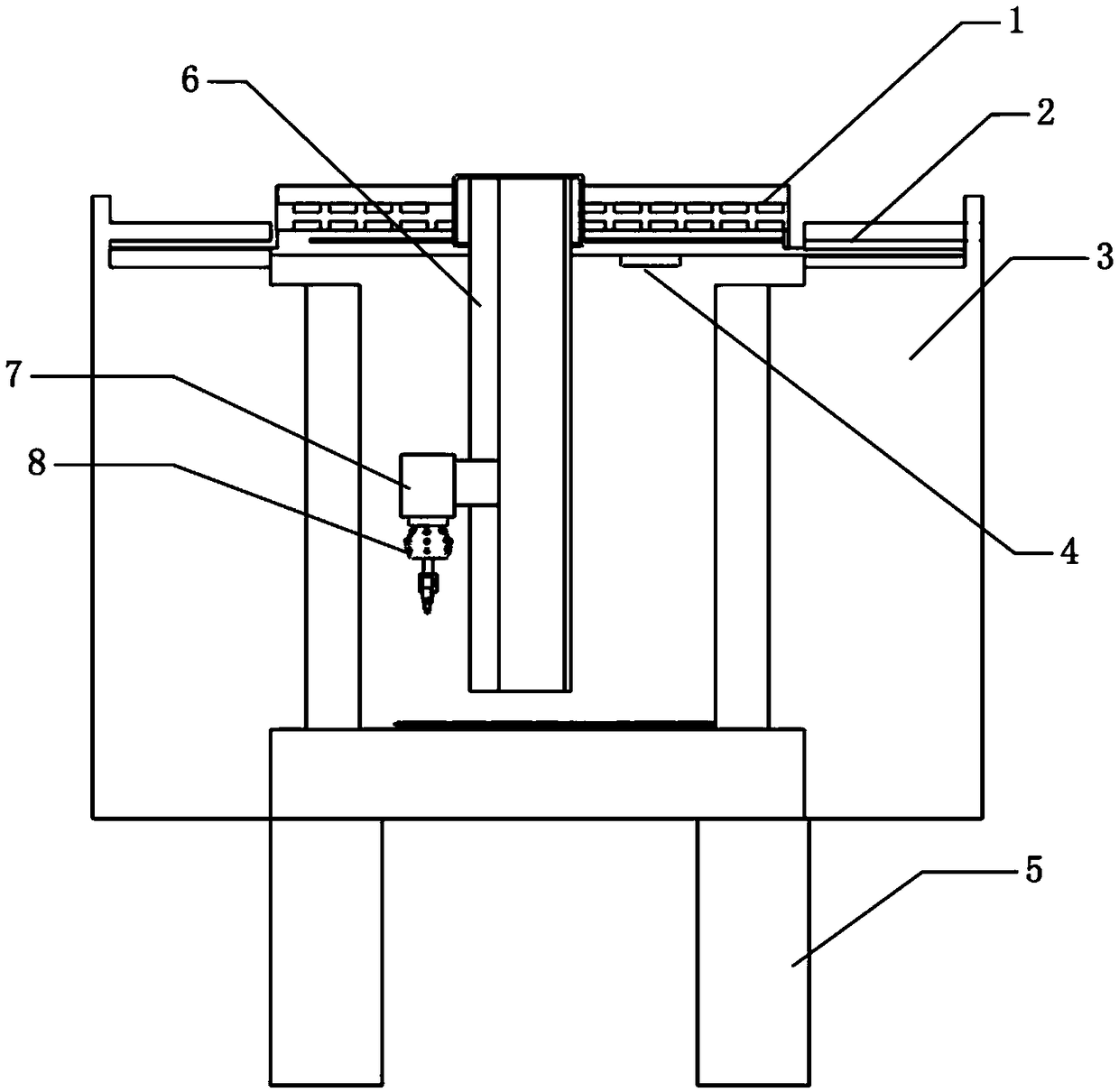

Self-propelled boom sprayer

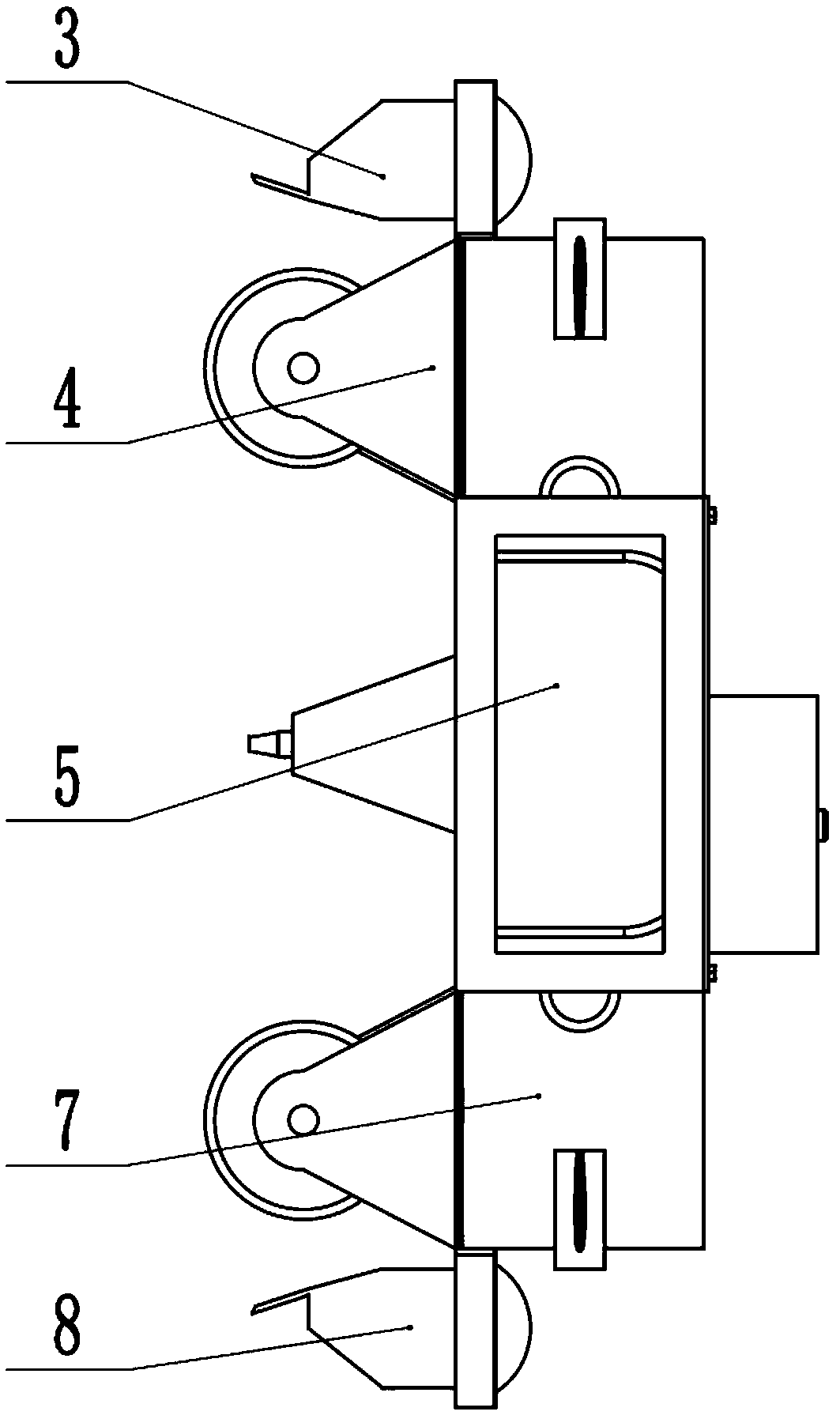

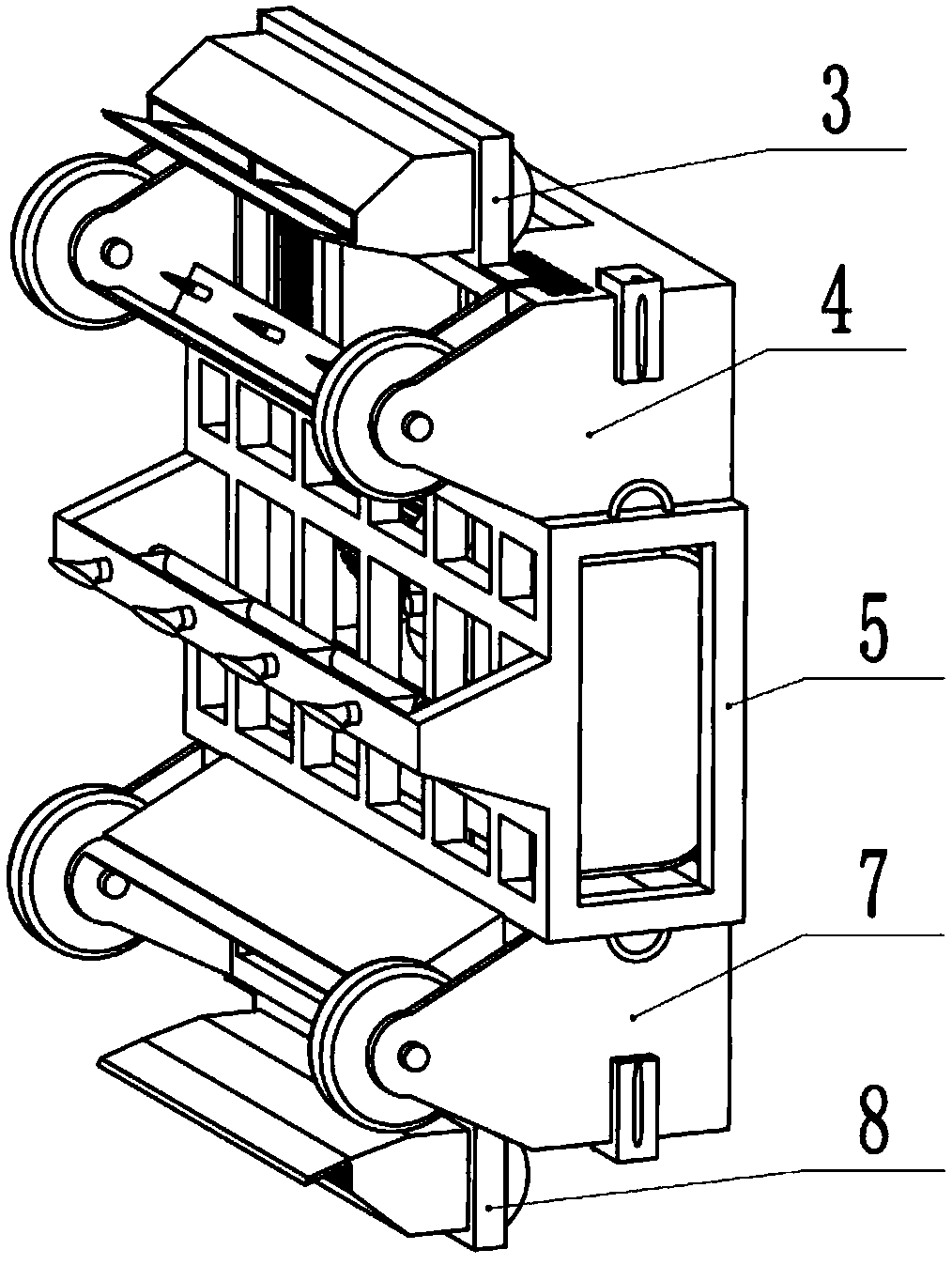

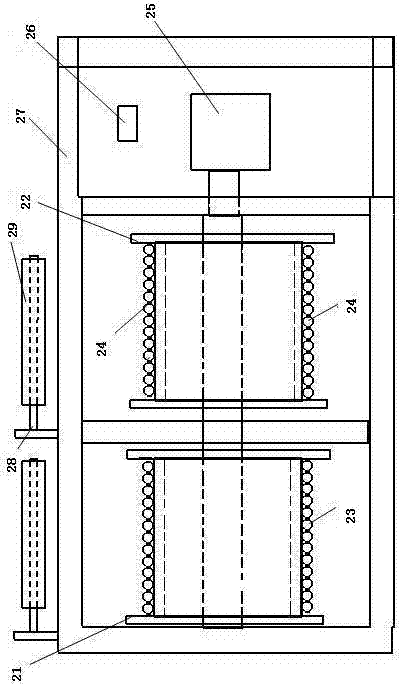

The invention relates to a self-propelled boom sprayer, which belongs to the technical field of plant protection machinery. A spraying device frame is mounted on a gantry of the sprayer; the spraying device frame is provided with an upper horizontal beam rail and a lower horizontal beam rail fixedly connected with each other; the middle part of the upper horizontal beam rail is connected with the upper end of a piston rod of a vertical oil cylinder; the two ends of the upper and the lower horizontal beam rails form horizontal moving pairs together with an upper and a lower sliding rods respectively; the upper and the lower sliding rods are fixedly connected through an upright rod, and the middle part of the upright rod is connected with the external end of a piston rod of a horizontal oil cylinder; the external end of the upper horizontal sliding rod is hinged with a cylinder body of one rototary oil cylinder; the external end of the lower horizontal sliding rod is hinged with the inner end of a deformation spraying rod; the external extending end of the piston rod of the rotary oil cylinder is hinged with the middle part of the deformation spraying rod; and nozzles distributed at intervals and gas-pockets which discharge gas towards the nozzles are mounted on the horizontal spraying rod and the transformation spraying rod below the lower horizontal beam rail. The self-propelled boom sprayer has the characteristics of good adaptability, wide application range, convenience in operation and good fog drop drifting effect.

Owner:NANJING NANJI INTELLIGENT AGRI MASCH TECH RES INST CO LTD

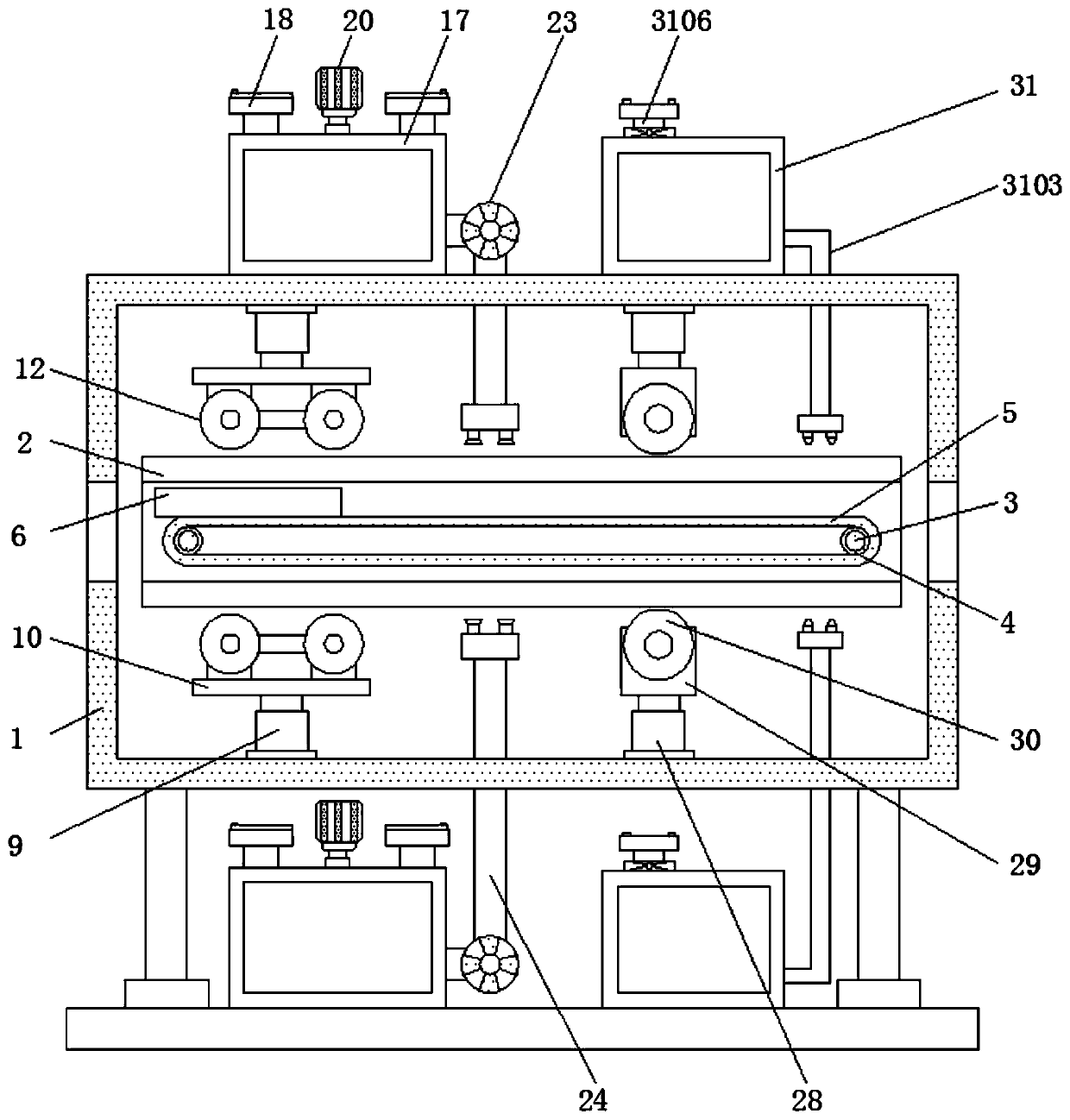

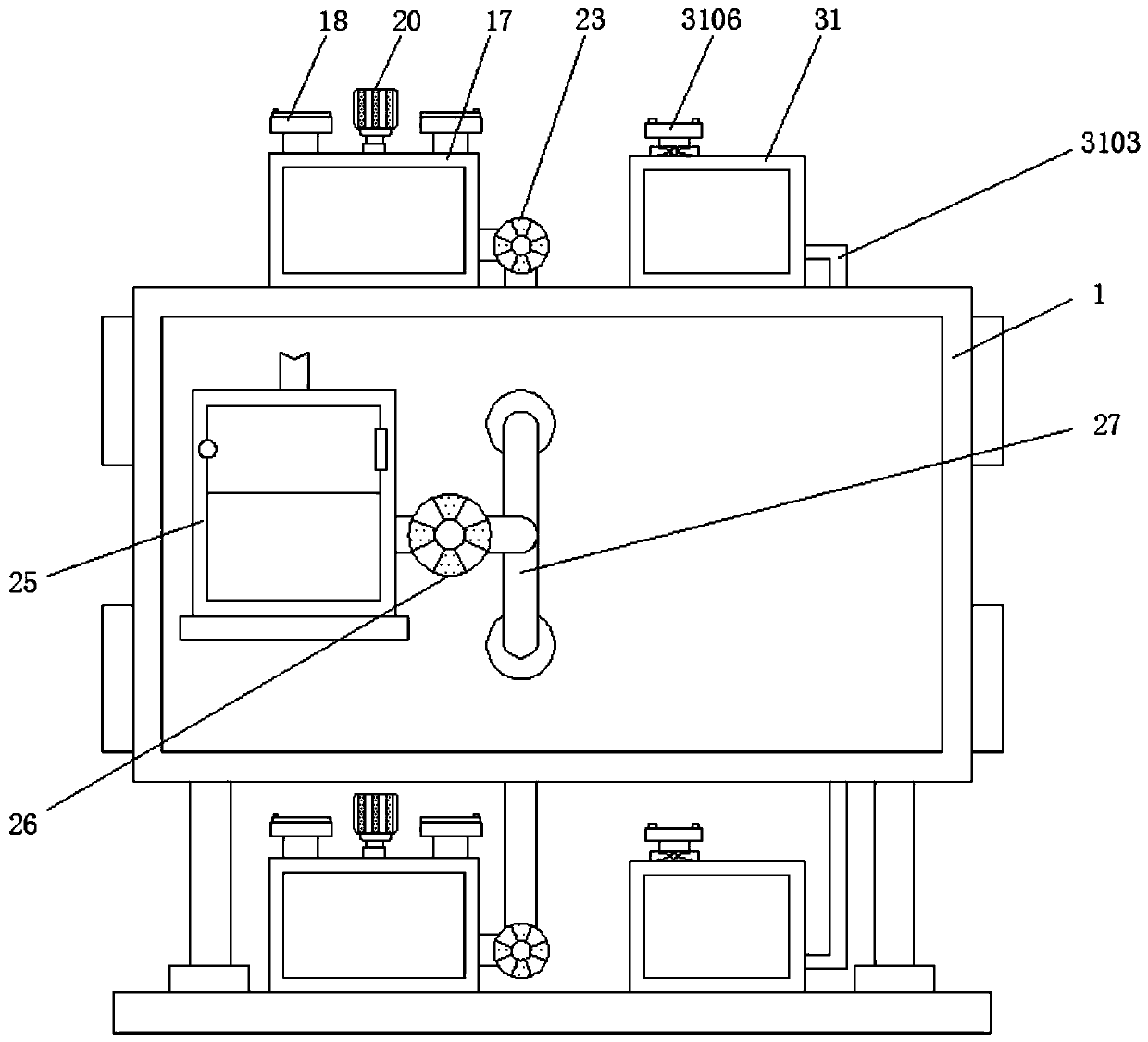

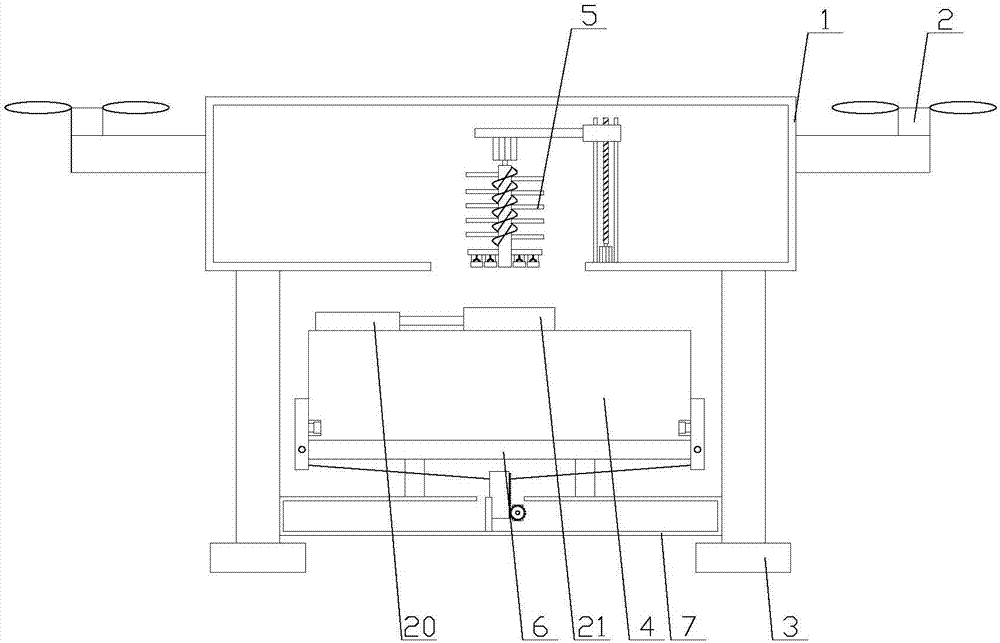

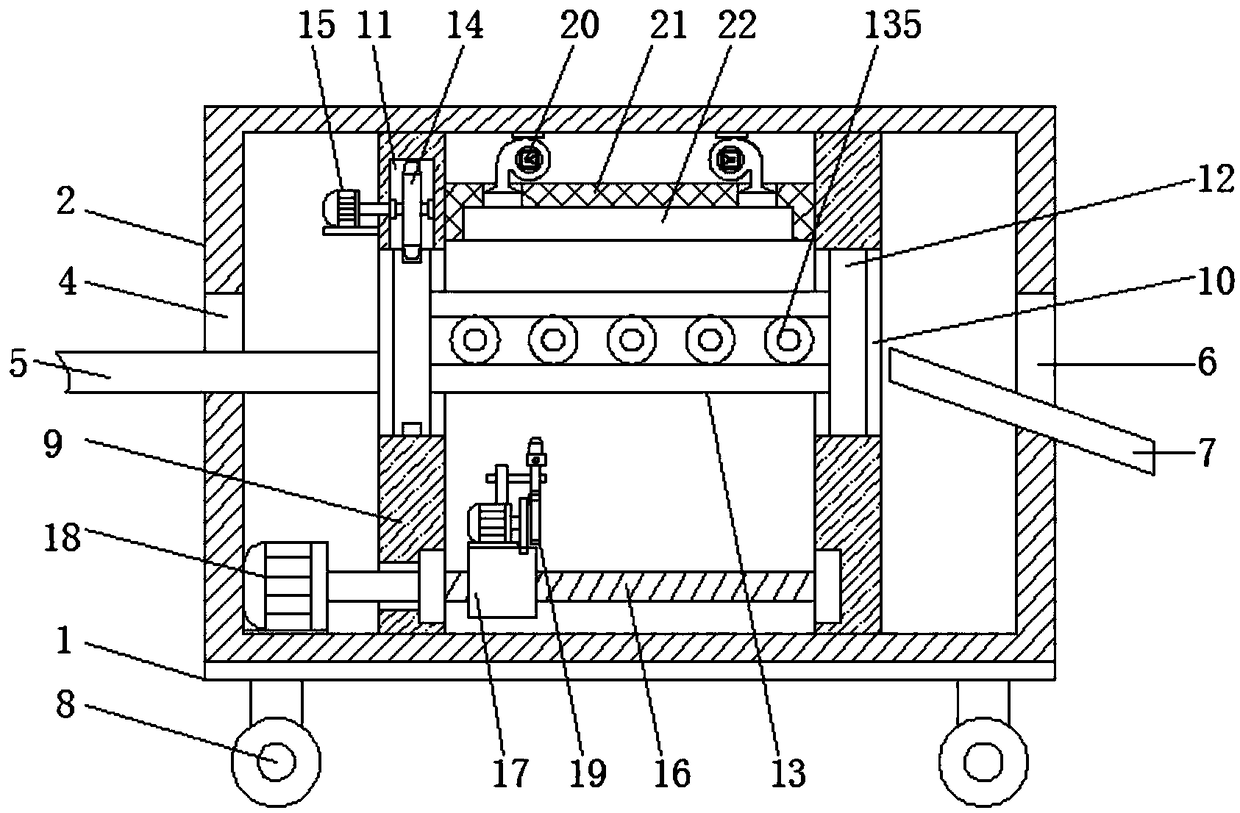

Spraying device for building material machining

ActiveCN110653110AAvoid occlusionPlay a limiting effectPretreated surfacesCleaning using toolsConstruction engineeringStructural engineering

The invention discloses a spraying device for building material machining. The spraying device for building material machining comprises a device body, material supplying boxes and treating boxes; connecting plates are arranged at the inner ends of first hydraulic telescopic rods; cleaning rolls are rotatably connected to the inner side walls of first U-shaped frames, second rotation shafts penetrate through the back side walls of the first U-shaped frames, and the second rotation shafts on the left sides are connected with second motors; the treating boxes are arranged on the front side faceand the back side face of the device body and arranged on the left sides of first motors; first fans are arranged on the right sides of the treating boxes and connected with suction pipes; and secondhydraulic telescopic rods are arranged on the upper side wall and the lower side wall of the device body, second U-shaped frames are arranged at the inner ends of the second hydraulic telescopic rods,and flattening rolls are rotatably connected to the inner side walls of the second U-shaped frames. According to the spraying device for building material machining, a coating in the material supplying boxes is sprayed to building plates through spraying pipes at the upper end and the lower end, and the two faces of the building plates can be simultaneously sprayed.

Owner:徐州思达新技术开发有限公司

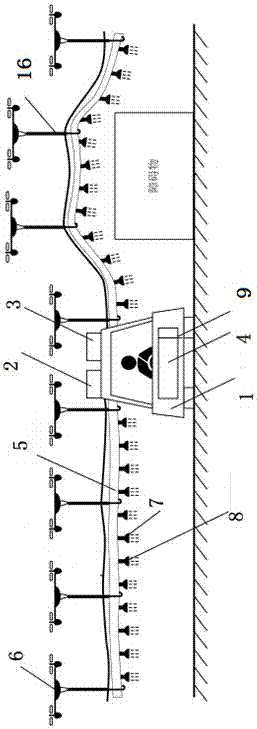

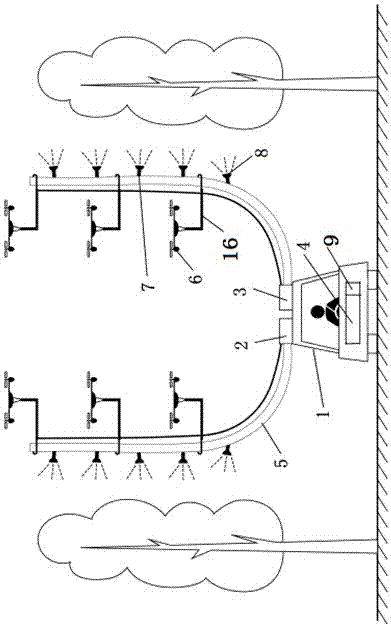

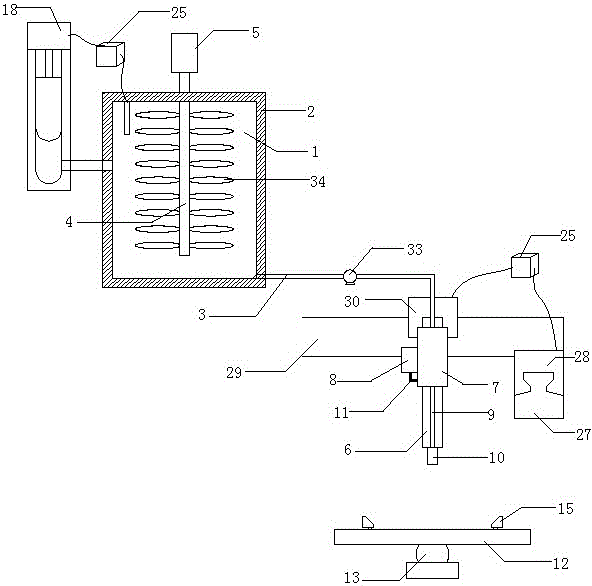

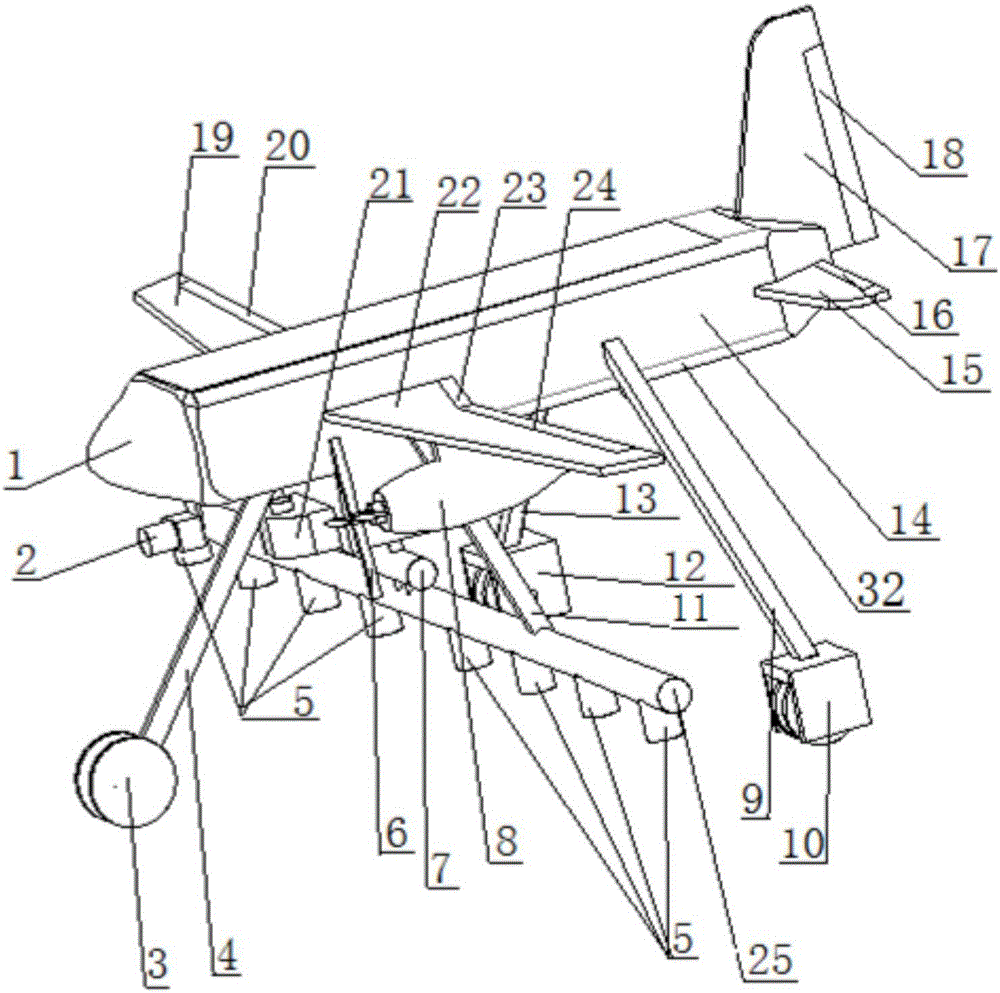

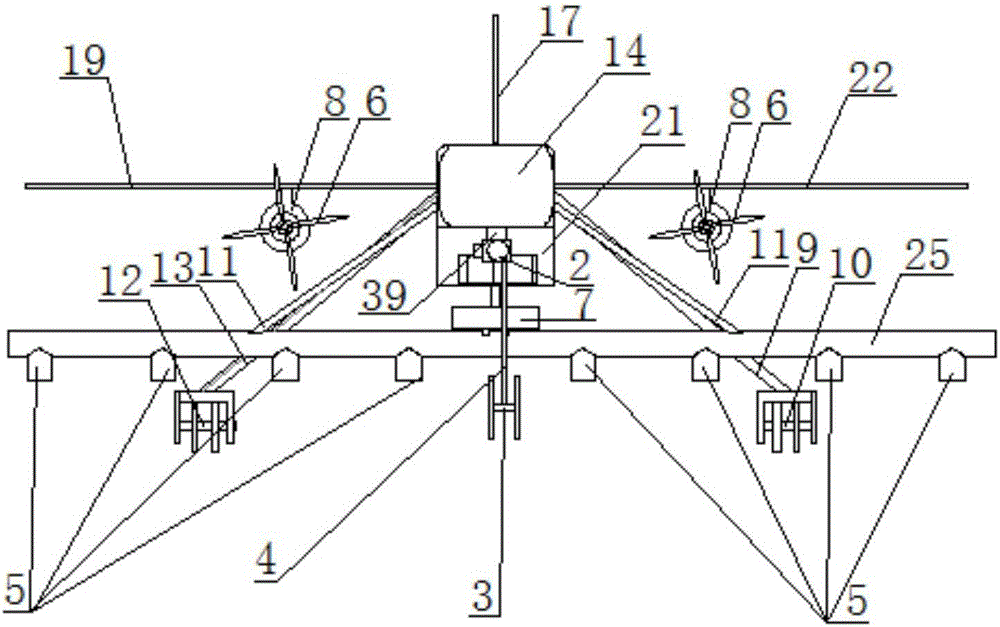

Air-ground integrated agricultural and forestry plant protection system device and use method

PendingCN106882380AAvoid rolling lossExpand the spraying rangeFor captive aircraftsPosition/course control in three dimensionsAgricultural scienceSprayer

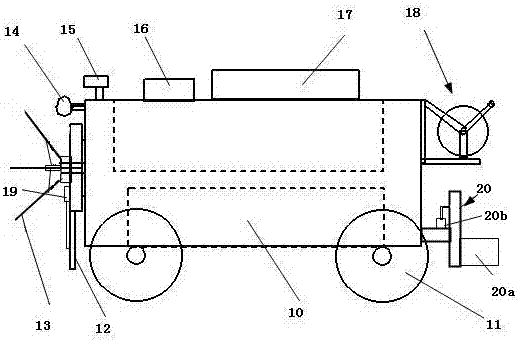

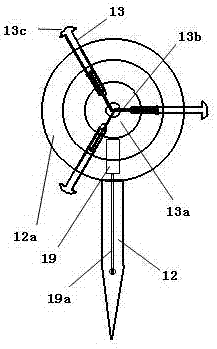

The invention discloses an air-ground integrated agricultural and forestry plant protection system device and a use method. The air-ground integrated agricultural and forestry plant protection system device comprises a ground vehicle, power supply equipment, a hydraulic pump, a liquid tank and a liquid delivery flexible pipe, wherein the power supply equipment, the hydraulic pump, the liquid tank and the liquid delivery flexible pipe are arranged on the ground vehicle. The liquid delivery flexible pipe is provided with unmanned aerial vehicles and sprayers, each sprayer is provided with an electronic obstacle detector, the electronic obstacle detectors are connected with a central controller, and the central controller is connected with the unmanned aerial vehicles and electronic signal locators. Support is provided for spraying operation through the power supply equipment, the hydraulic pump and liquid tank on the ground vehicle, and the unmanned aerial vehicles suspend the liquid delivery flexible pipe for spraying operation; the central controller receives signals from the electronic signal locators so as to control the synchronization of the unmanned aerial vehicles and the ground vehicle, and the central controller controls the unmanned aerial vehicles to automatically overcome obstacles by receiving the signals of the electronic obstacle detectors. The air-ground integrated agricultural and forestry plant protection system device and the use method have the advantages that the spraying width and the spraying height can be adjusted in real time, the spraying efficiency is improved, the unmanned aerial vehicles can automatically get over the obstacles and the operation is simple.

Owner:杭州杉林科技有限公司

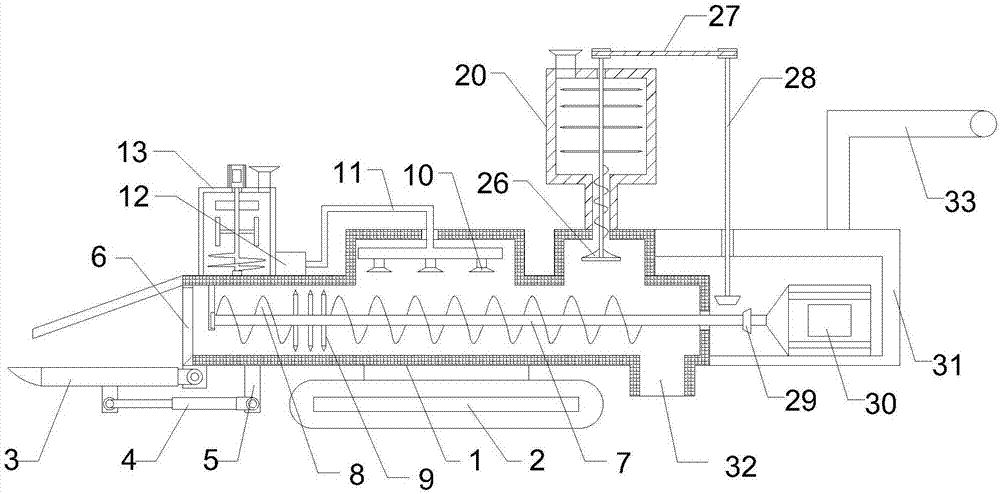

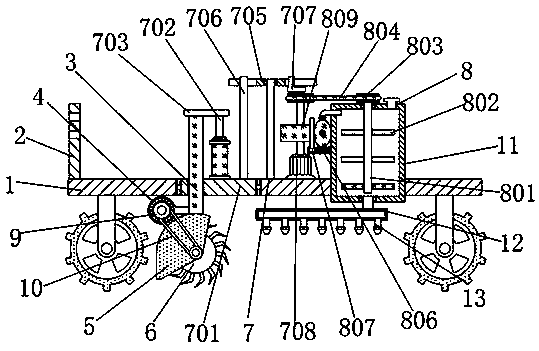

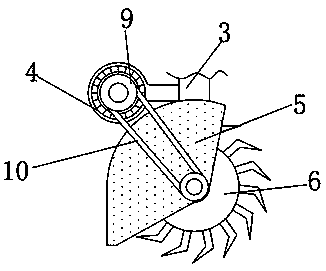

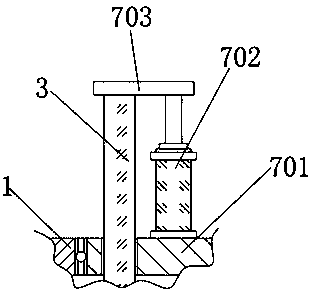

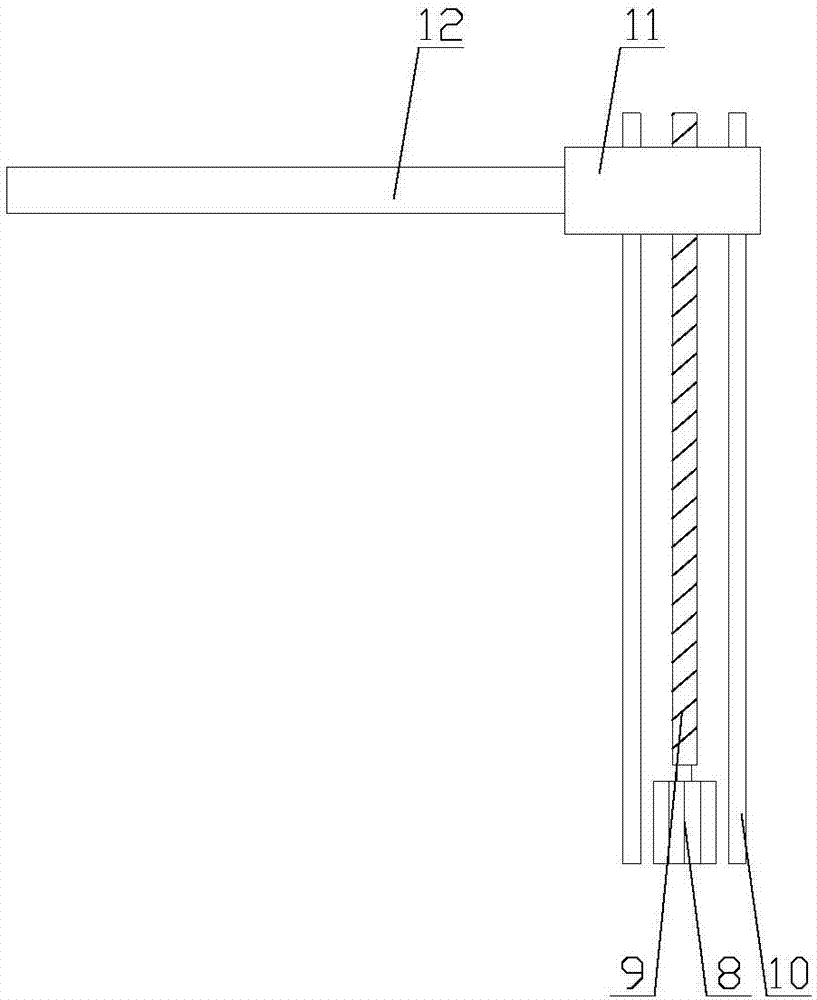

Mini-type hand-push soil governing device

InactiveCN107567733AGood uniformityGuaranteed spraying effectSoil lifting machinesSpadesEngineeringSprayer

The invention discloses a mini-type hand-push soil governing device, which comprises a shell body and a track travelling device; the left side of the shell body is hinged with a shovel plate; one sideof a main rotary shaft closing to a feeding opening is fixedly connected with a vertical smashing cutter blade; a sprayer is arranged at the place where the shell body is located at the upper part ofthe right side of the vertical smashing cutter blade. Through the shovel plate and the vertical smashing cutter blade, soil is efficiently collected and smashed to facilitate the subsequent mixing. The mini-type hand-push soil governing device is provided with a mixing tank, the soil disinfectant raw materials are efficiently mixed and blended, thus the disinfectant homogeneity is better; the spraying effect is guaranteed while the raw materials are saved. The horizontal smashing cutter blade can efficiently smash the solid soil improver so as to mix and contact with soil and improve the mixing effect. A first spiral blade is provided and used for fully and efficiently mixing the soil with the drug; moreover, the soil governing effect is improved, and the operation is continuous and high-efficient.

Owner:李林

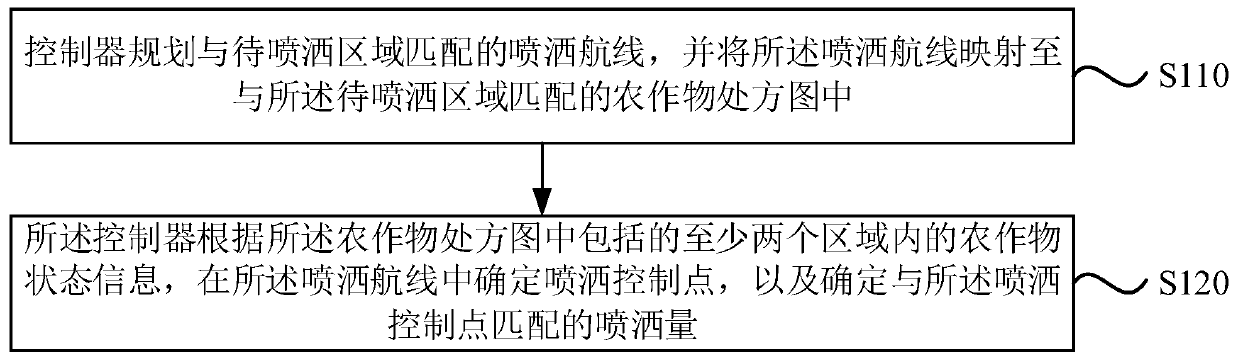

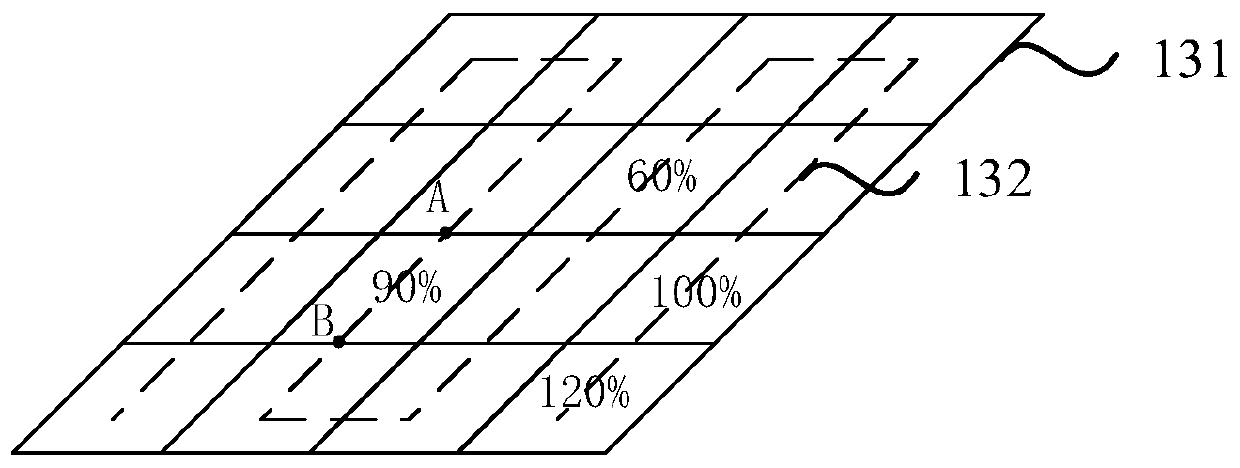

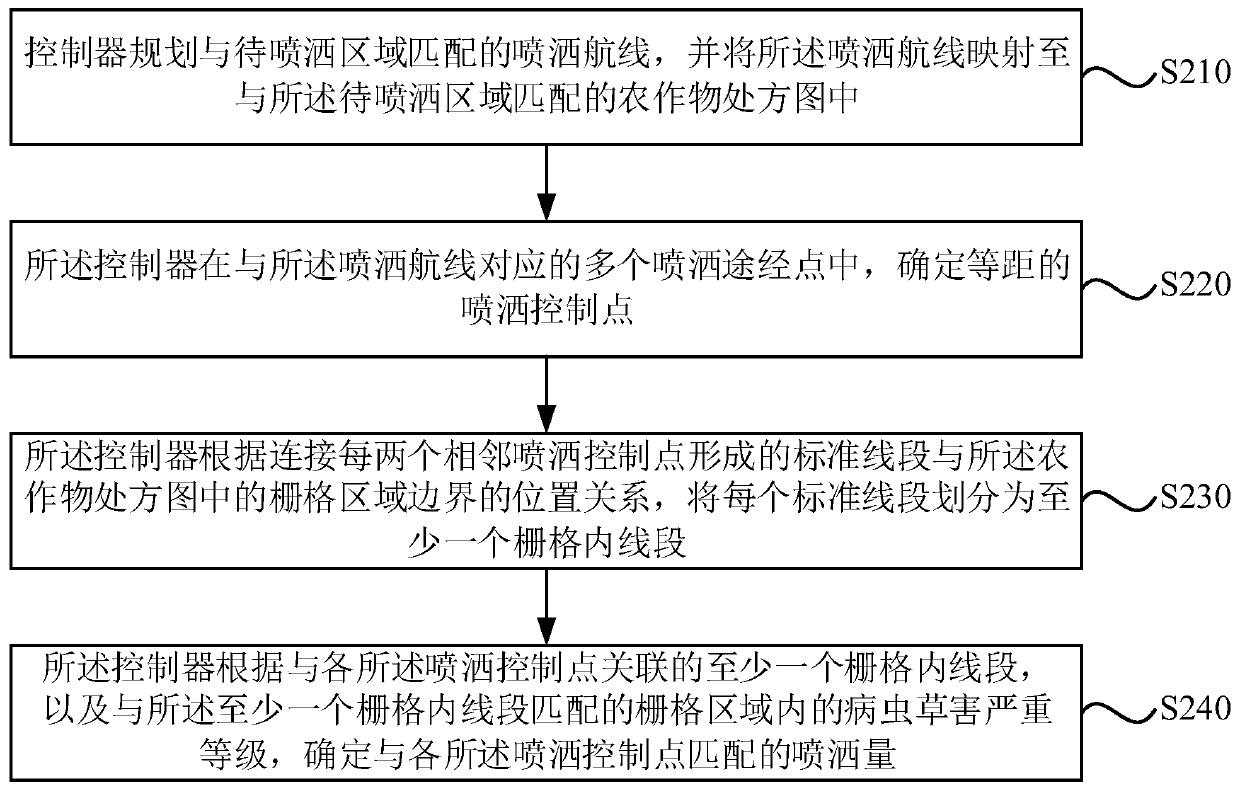

Pesticide spray control method, device, equipment and storage medium

ActiveCN109845715AGuaranteed spraying effectSolve problems not covered by pesticidesAircraft componentsData processing applicationsMedical prescriptionComputer science

The embodiment of the invention discloses a pesticide spray control method, device, equipment and storage medium. The method comprises that a controller plans a spray route matched with an area to besprayed and maps the spray route to a crop prescription map matched with the area to be sprayed; according to status information containing of crops in at least two areas in the crop prescription map,the controller determines spray control points in the spray route as well as spray mounted matched with the spray control points, wherein the spray control points are correlated with actual spray points of an operation unmanned aerial vehicle, the actual spray points are spaced at a set interval apart from the correlated spray control points on the spray route, and in the forward motion directionof the operation unmanned aerial vehicle, the actual spray points are arranged in front of the correlated spray control points. The pesticide spray control method, device, equipment and storage medium can optimize the existing pesticide spray technology and maximize the spray effects of an adaptive pesticide spray process.

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

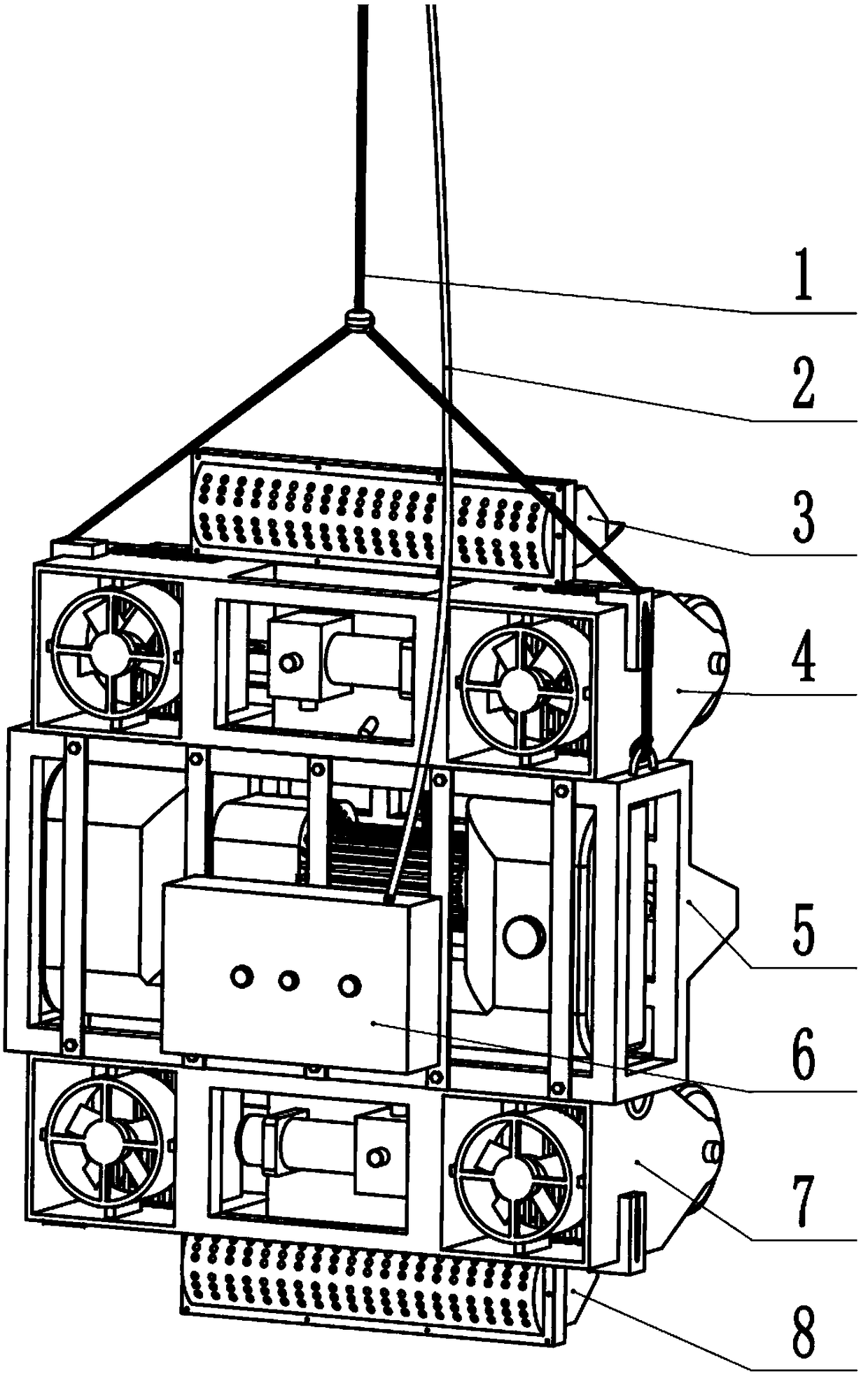

High-rise wall spraying robot

ActiveCN109162431AFully automatedGuaranteed uniformityBuilding constructionsRemote controlControl system

The invention discloses a high-rise wall spraying robot and relates to the technical field of high-rise wall surface spraying. The high-rise wall spraying robot comprises a hoist, an electric cable pay-off and take-up device, a roof moving crane, a panoramic camera, an anemometer, a remote control device, a steel wire rope and a cable line. The roof moving crane is parked on a side close to a wallto be painted. The high-rise wall spraying robot also includes a hot air drying device I, a dust cleaning device I, a spraying device, a control system device, a dust cleaning device II, and a hot air drying device II. The anemometer is also arranged on the mobile crane. The hoist is connected to the spraying device through the steel wire rope. The spraying device is provided with the control system device and the panoramic camera. An upper side of the spraying device is sequentially connected to the dust cleaning device I and the hot air drying device I, and a lower side of the spraying device is sequentially connected to the dust cleaning device II and the hot air drying device II. According to the invention, the automation of the wall surface spraying is realized, the spraying efficiency is improved, the uniformity of the spraying density is ensured, the labor cost is reduced, an artificial high-altitude operation is substituted, and the danger is reduced.

Owner:冠品机具(深圳)流体科技有限公司

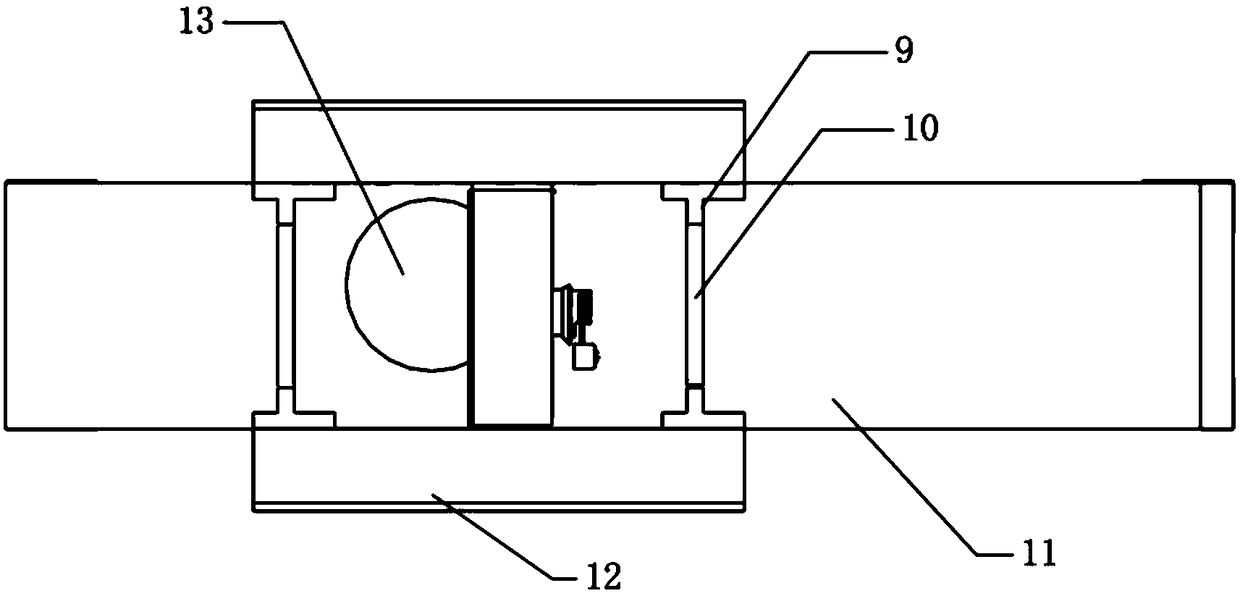

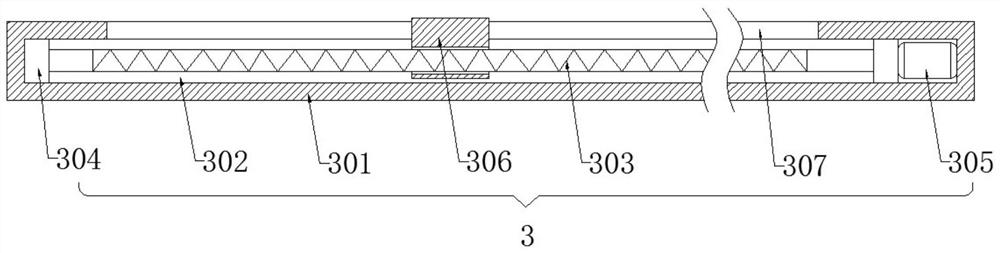

Pipeline inner wall coating machine

PendingCN107008606AWalking smoothlyWalk; through the spray evenlySpraying apparatusJackhammerIndustrial engineering

The invention discloses a pipeline inner wall coating machine and belongs to the field of pipeline equipment. Travelling wheels are connected to a driving device output shaft. Nozzles are at least arranged on the coating machine and are evenly distributed on the periphery of the inner wall of a pipeline. A jackhammer, an illuminating device and a camera device are arranged on the upper portion of the front portion of the pipeline. An automatic take-up wheel is arranged behind the pipeline. A coaxial compression air pipe roller is arranged beside the take-up wheel. A steel wire rope traction hole is further formed in the rear portion of the coating machine. The nozzles and the jackhammer are arranged on rotary plates correspondingly. Through the pipeline inner wall coating machine, obstacles in the pipeline can be cleared, smooth flowing of liquid in the pipeline can be ensured, the labor intensity of painters is relieved, physical discomfort of workers due to the harsh paint environment is avoided, automatic operation is achieved, the paint efficiency is improved, and the health of the workers is ensured.

Owner:ANYANG GUOLONG MACHINERY

Treating process before spraying aluminum profile

InactiveCN102527609AMeet the chrome-free requirementsImprove attachment conditionsAnodisationPretreated surfacesAnodic oxidationEnvironmental resistance

The invention discloses a treating process before spraying an aluminum profile. Before spraying, a blank is subjected to treatment of deoiling, alkaline degreasing, neutralizing, oxidizing a positive electrode and sealing half of a hole, so that a semi-closed oxidized film is formed on the surface of the blank; and the oxidization treatment is that: the blank is put into H2SO4 with the concentration of between 160 and 180 g / L, the oxidization temperature is of between 18 and 22 DEG C, and the current density is of between 140 and 160 A / dm<2>. By adoption of the oxidization treatment step, the formed semi-closed oxidized film has a pore structure, so that a good attachment condition is supplied to paints; furthermore, compared with a non-closed oxidized film, the semi-closed oxidized film has the advantages that: impurities, such as dust and the like, cannot be attached to the surface of the profile easily before the profile is sprayed, and a subsequent spraying effect can be guaranteed. Meanwhile, a chromizing treatment step is avoided, and the finally obtained aluminum profile product does not contain chromium; and therefore, the aluminum profile can meet a non-chromizing requirement, and is relatively safe and environment-friendly.

Owner:肇庆亚洲铝厂有限公司

Automatic oil spraying device and method

ActiveCN103657941ARealize automatic separationPrevent rustLiquid surface applicatorsLiquid spraying apparatusControl systemElectromagnetic valve

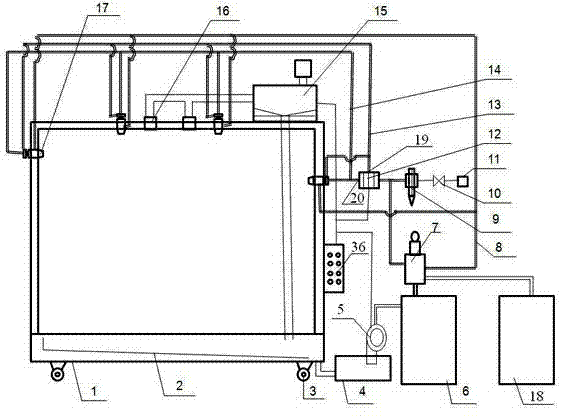

The invention discloses an automatic oil spraying device which comprises a closed oil spraying room, a fog spraying system, an oil recycling system and a control system. The fog spraying system comprises a main air source, a pressurizing mechanism, an oil drum, an electromagnetic valve and fog spraying valves, wherein the main air source is connected with the pressurizing mechanism, and the oil drum, the pressurizing mechanism and the fog spraying valves are sequentially connected through oil pipes. The electromagnetic valve comprises an air inlet, a first air outlet and a second air outlet, wherein the air inlet is connected with the main air source through a pipe, the first air outlet is connected with the fog spraying valves through a driving air source pipe, and the second air outlet is connected with the fog spraying valves through an atomization air source pipe. The driving air source pipe and the atomization air source pipe are provided with a first pressure adjustment mechanism and a second pressure adjustment mechanism respectively. The electromagnetic valve and the oil recycling system are respectively connected with the control system, and the oil recycling system is connected with the closed oil spraying room. The invention further discloses an automatic oil spraying method achieved through the automatic oil spraying device. By means of the automatic oil spraying device and the automatic oil spraying method, rapid and safe rust prevention processing on a large number of plates can be achieved, operation risks to persons are reduced, and waste oil can be recycled.

Owner:GUANGZHOU AUTOMIBILE GRP MOTOR

Inner wall spraying putty and using method thereof

The invention discloses an inner wall spraying putty which comprises the following materials: white cement, slaked lime, heavy calcium carbonate, cellulose ether, polymer powder, a thixotropic agent, a water reducer, a moisture repellent, a defoaming agent and wood fiber. The invention also discloses a method of using the inner wall spraying putty. The method comprises the following steps of: mixing the inner wall spraying putty with clean water, stirring the mixture to be at a uniform block-free state, standing for two minutes, and then stirring for 30 seconds. The inner wall spraying putty has a reasonable formula, and is green due to no using of 107 or 108 glue and containing no formaldehyde, the sprayed putty is flat and smooth, has a firm surface, is unlikely to dust and craze, has good water resisting property, is easily stirred uniformly, free from obvious blocks, less in spraying resistance and strong in constructability, is particularly suitable for mechanized construction, ensures the spraying effect, and also greatly improves the construction efficiency. The method provided by the invention has simple technique steps, and is easy to realize and high in efficiency.

Owner:黄明杰

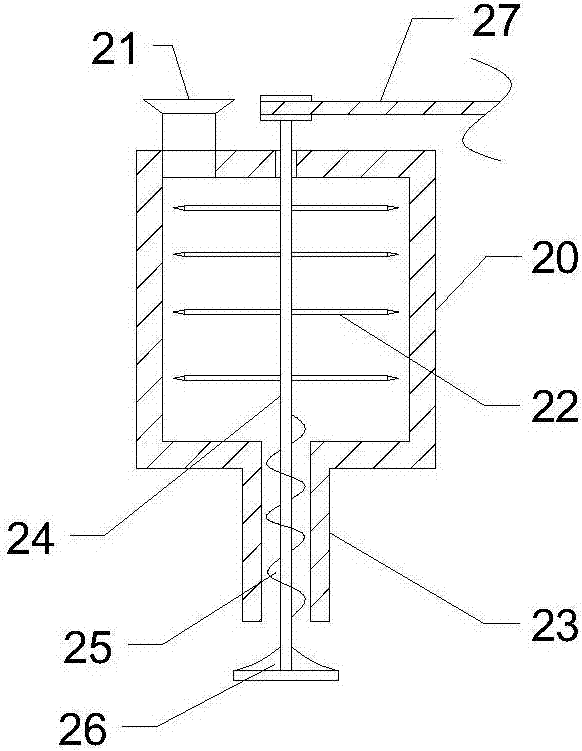

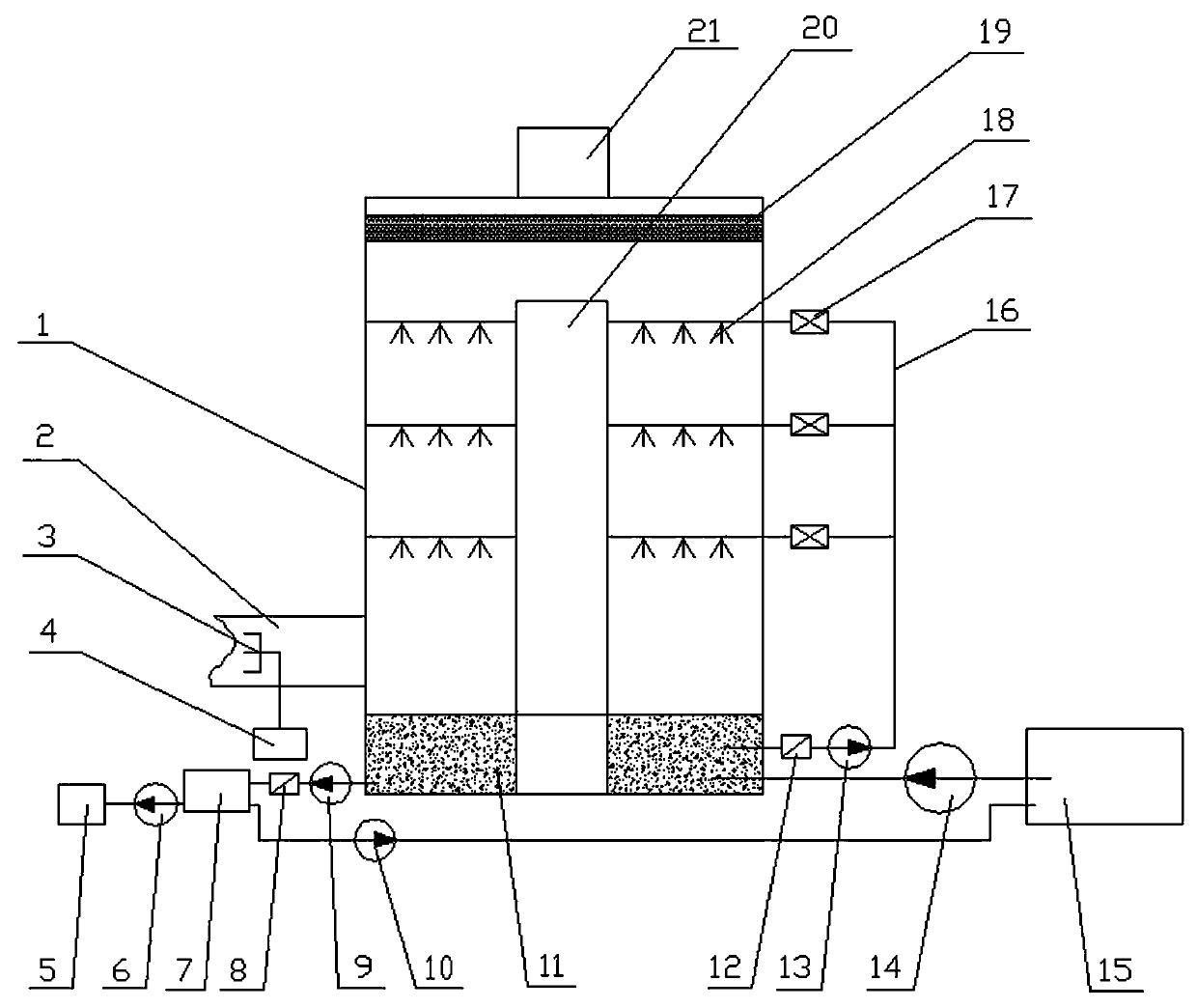

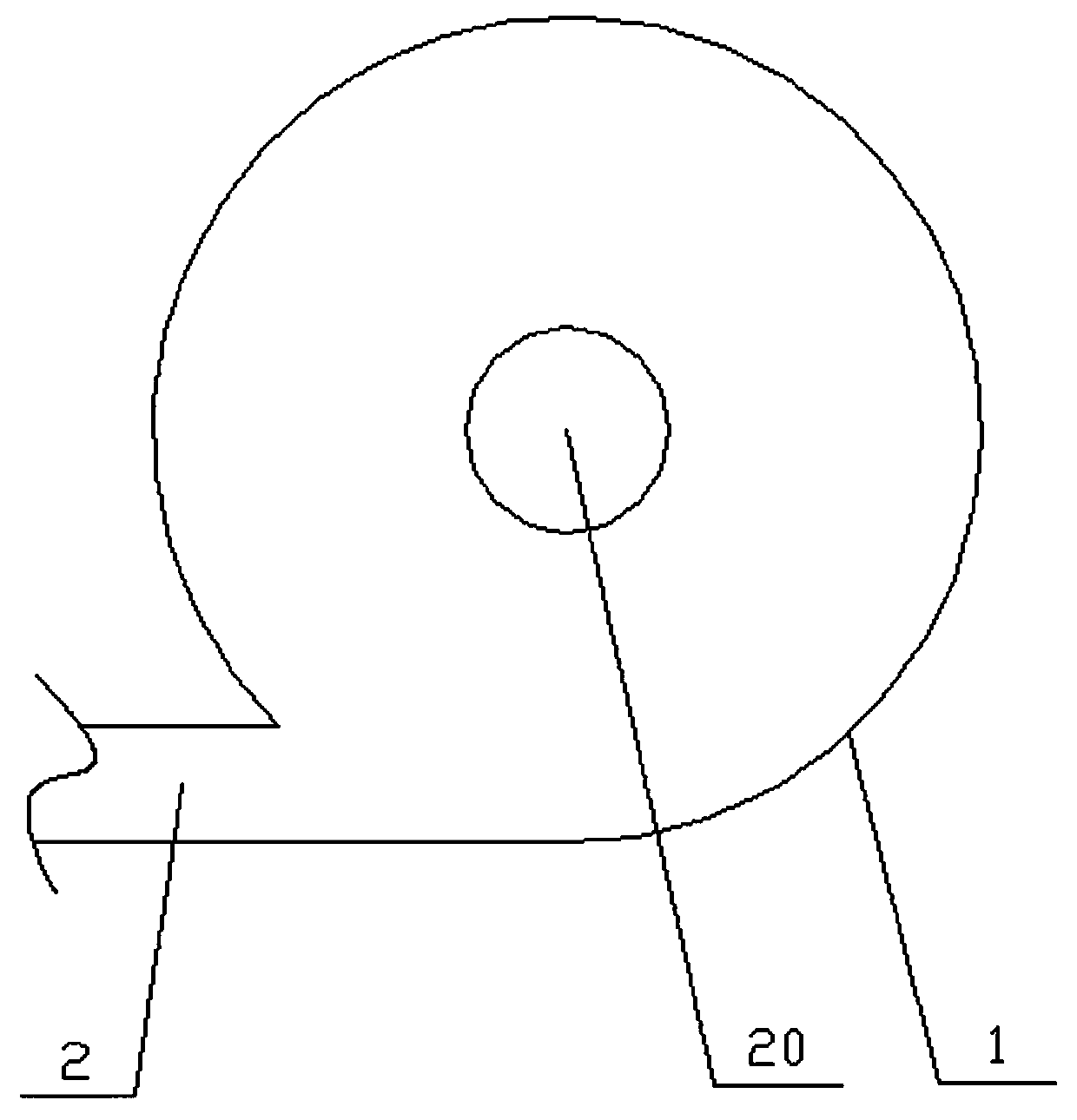

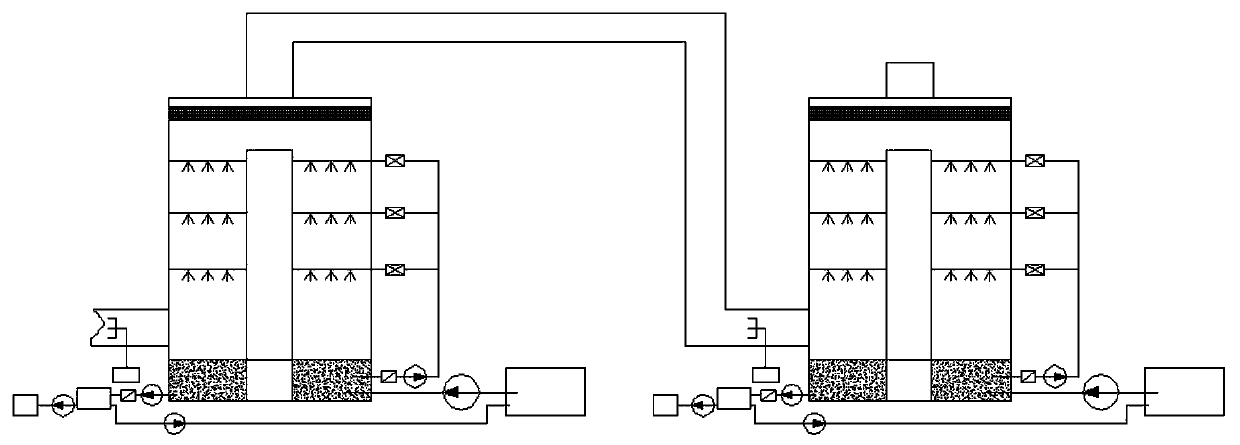

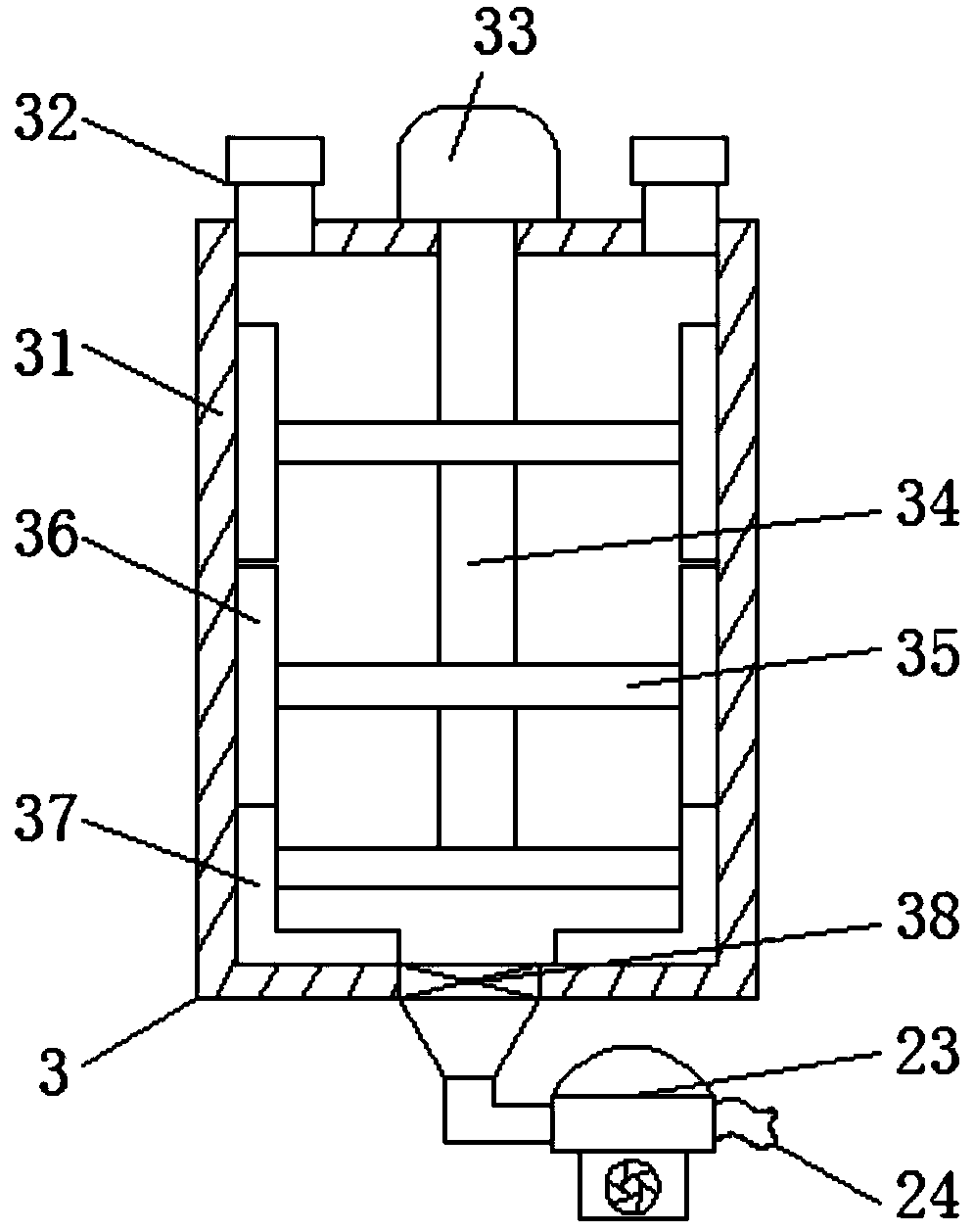

Flue gas denitrification device used for coal-fired boiler

InactiveCN109621662AStrong oxidation abilityImprove oxidation efficiencyGas treatmentDispersed particle separationLiquid wasteFluid cell

The invention relates to the field of environmental protection equipment, in particular to a flue gas denitrification device used for a coal-fired boiler. The flue gas denitrification device comprisesa spray tower, an oxidation system, a spraying system and a circulating system, wherein the spray tower comprises a tower body and an internal core, a flue gas inlet pipe is connected to the bottom of the tower body, and the top of the tower body is connected with a flue gas outlet pipe; the oxidation system comprises an ozone generator and an ozone ejector which is arranged in the flue gas inletpipe and connected with the ozone generator; the spraying system comprises a liquid tank, an absorption liquid, a spraying pipe and a plurality of nozzles, the liquid tank is distributed on the bottom of the tower body, the spraying pipe is communicated with the liquid tank through a circulating pump, and the nozzles are arranged on the spraying pipe; the circulating system comprises a separator,the inlet end of the separator is connected with the liquid tank through a first liquid conveying pump, the salt liquid outlet end is connected with a waste liquid treatment device through a second liquid conveying pump, the absorption liquid outlet end is connected with a liquid storage tank used for storing the absorption liquid through a third liquid conveying pump, and the liquid storage tankis further connected with the liquid tank through a fourth liquid conveying pump. The flue gas denitrification device is high in denitrification efficiency, low in cost and facilitating environment friendliness.

Owner:HENAN UNIV OF SCI & TECH

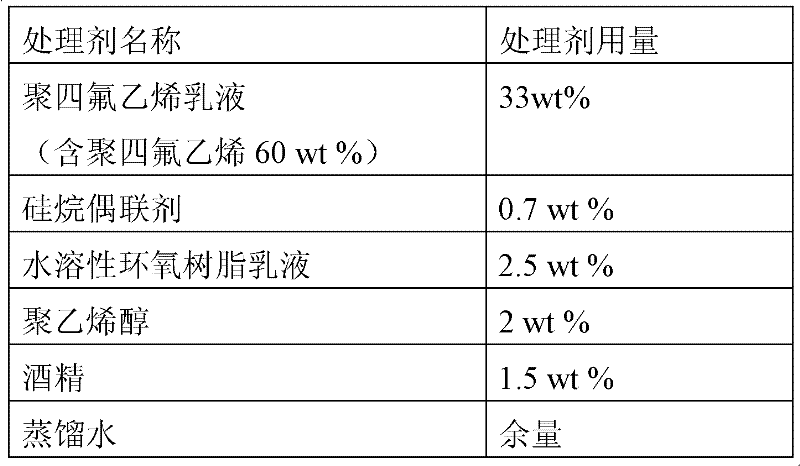

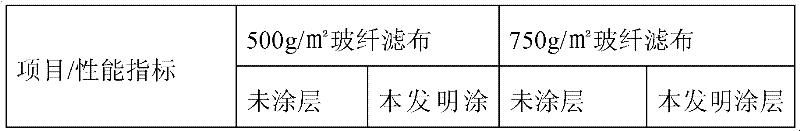

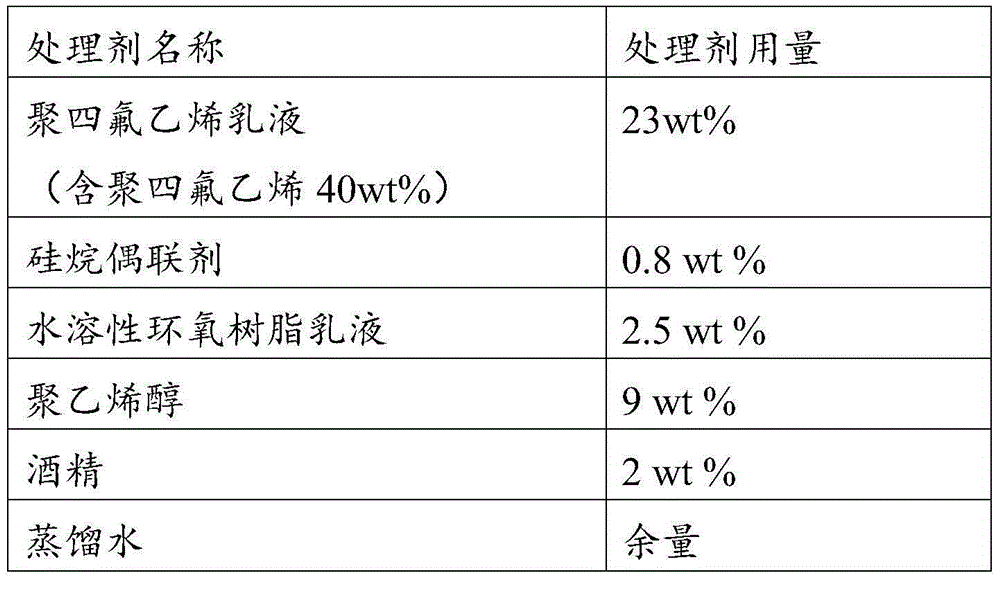

Manufacturing method for high-accuracy coating filter material

InactiveCN102512877AGood acid and alkali resistanceImprove water resistanceSynthetic resin layered productsGlass/slag layered productsFiberLoss strength

The invention provides a manufacturing method for a high-accuracy coating filter material, which has the advantages of good binding effect between the filter material and PTFE (Polytetrafluoroethylene) and capability of improving the performance of the filter material. The method comprises the following steps of: (1) thermal cleaning treatment, performing the thermal cleaning treatment on the filter material and removing various auxiliary agents on the surface of the filter material through high temperature; (2) dipping treatment, performing PTFE dipping treatment on the filter material which is subjected to the thermal cleaning treatment; (3) sequentially performing baking, drying and thermal forming treatment on the filter material which is subjected to the dipping treatment; (4) performing coating treatment on the filter material which is subjected to thermal forming; and (5) sequentially performing volatile treatment, baking treatment, sintering treatment and thermal forming treatment on the filter material which is subjected to the coating treatment. In the manufacturing method for the high-accuracy coating filter material, the thermal cleaning treatment is performed before the filter material is subjected to the dipping treatment, so that a wire drawing impregnating agent remained on the surfaces of fibers can be effectively removed, meanwhile, no loss strength of a textile is guaranteed; and the acid and alkali resistance, water resistance, oxidation resistance, wear resistance and folding resistance of the filter material are effectively improved, and the service life of the filter material is prolonged.

Owner:辽宁鸿顺环保新材料有限公司

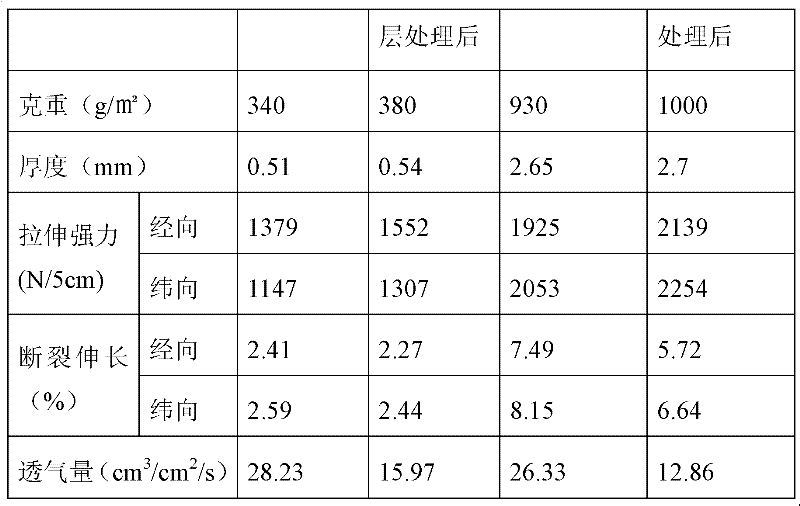

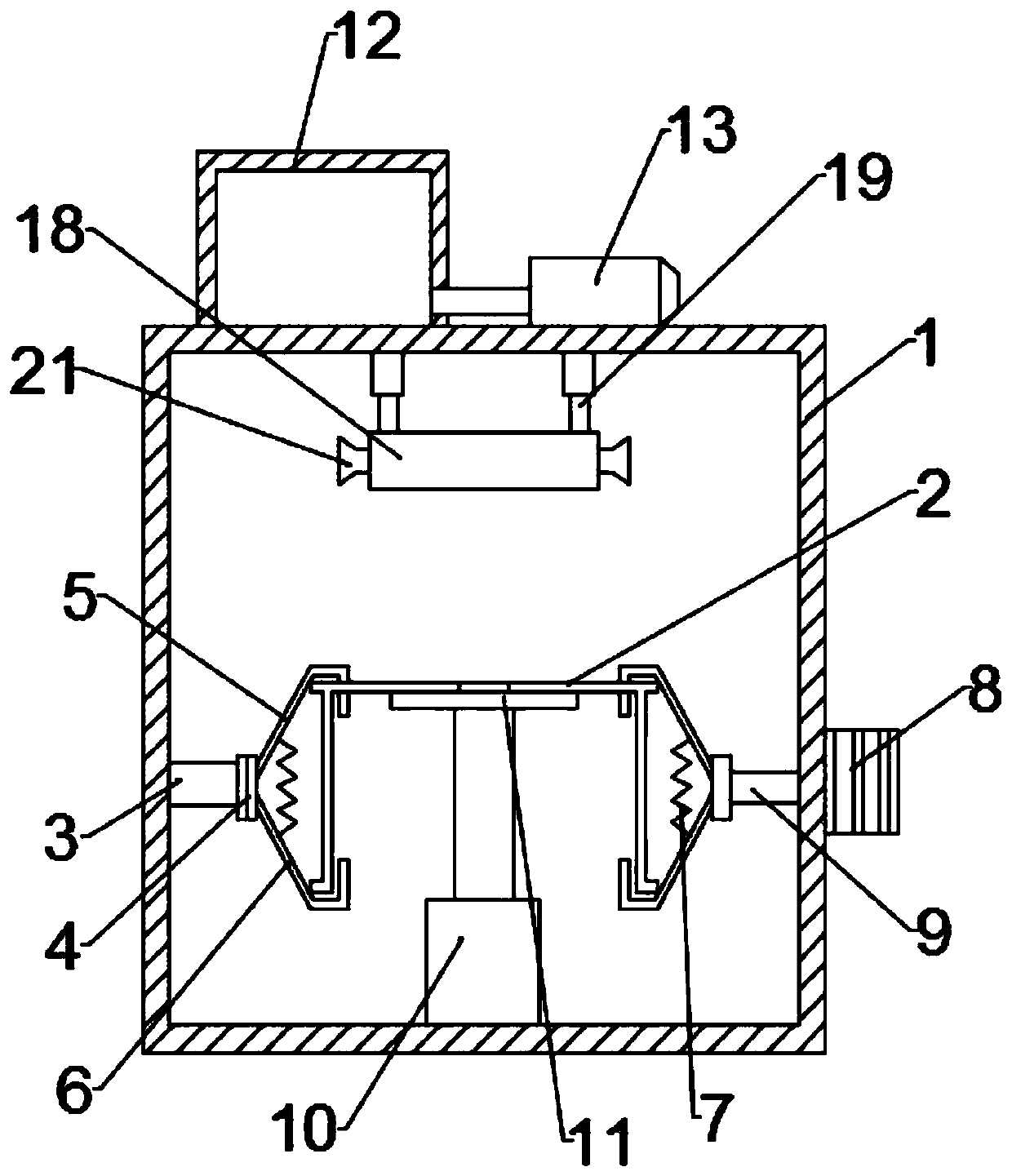

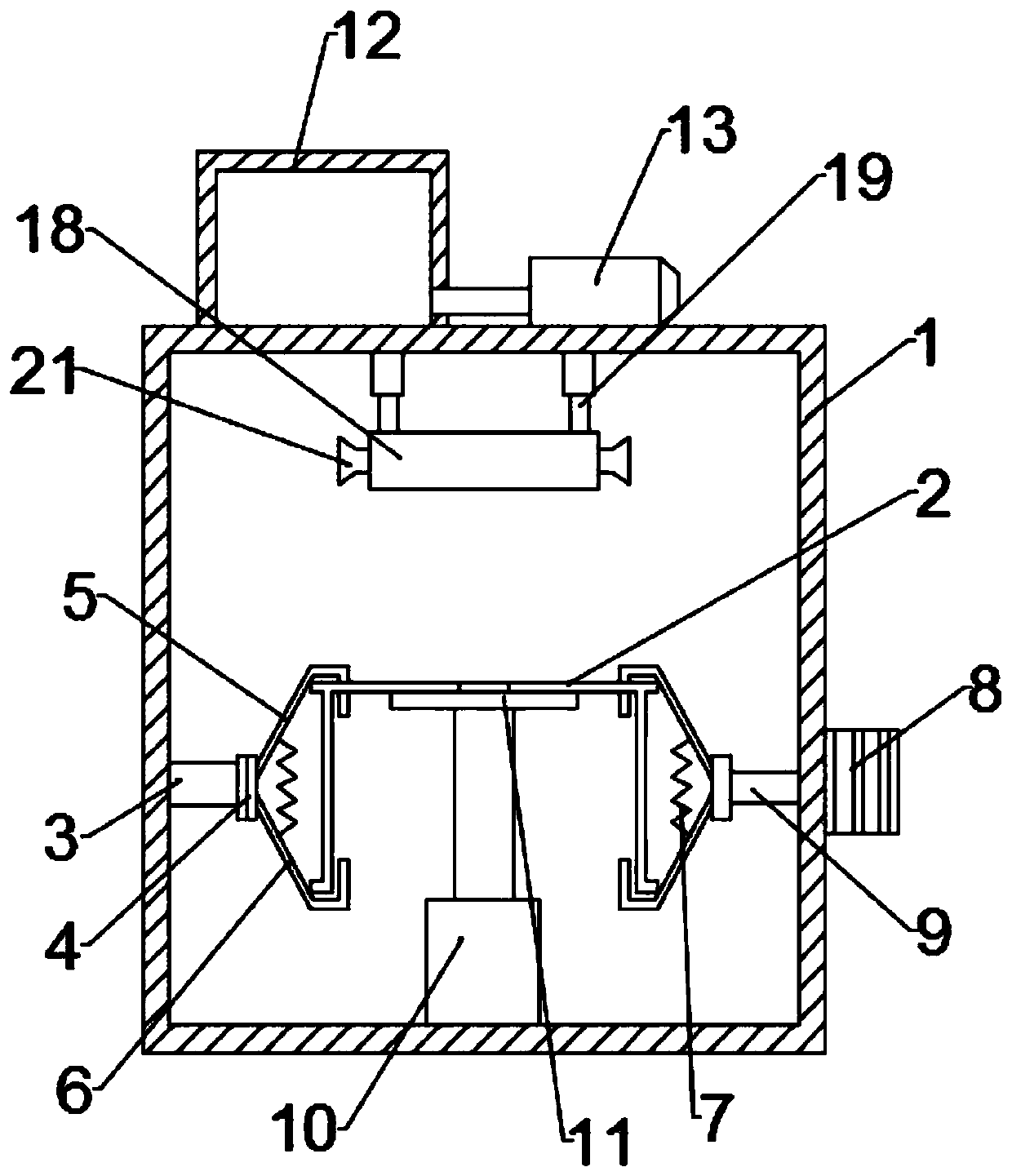

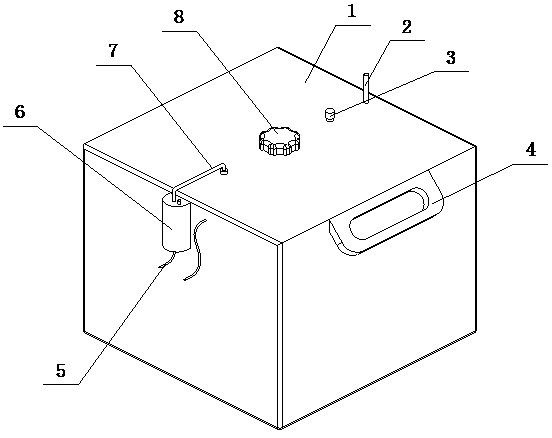

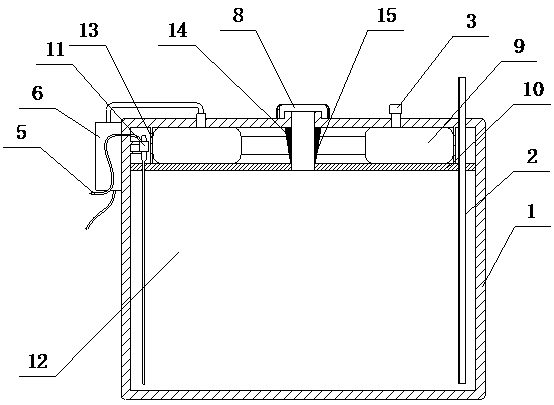

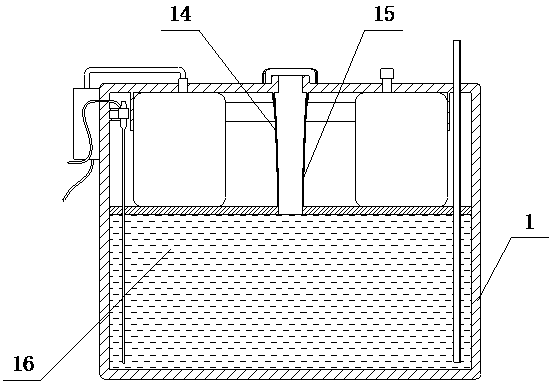

Automobile hub spraying device

InactiveCN110038756AImprove spraying effectGuaranteed spraying effectSpraying apparatusEngineeringIn degree

The invention relates to the technical field of automobile production, and specifically discloses an automobile hub spraying device. The automobile hub spraying device comprises a box body, wherein the inner part of the box body is provided with a turnover fixing mechanism for mounting an automobile hub and a multi-angle spraying mechanism for spraying the automobile hub; the multi-angle sprayingmechanism comprises a straight paint collecting tube and a ring-shaped paint collecting tube; the straight paint collecting tube is positioned inside the ring-shaped paint collecting tube; and the multi-angle spraying mechanism is positioned above the turnover fixing mechanism. The automobile hub spraying device is high in degree of automation, and is good in spraying effect; and an upper clampingblock is buckled in a seam in the top end of the automobile hub, a lower clamping block is buckled on the side wall of the bottom end of the automobile hub, a first automatic telescopic pole and a support plate guarantee mounting stability, and the straight paint collecting tube and the ring-shaped paint collecting tube can accomplish integral spraying of the automobile hub, so that a spraying dead angle is avoided to the greatest extent.

Owner:山东金马汽车装备科技有限公司

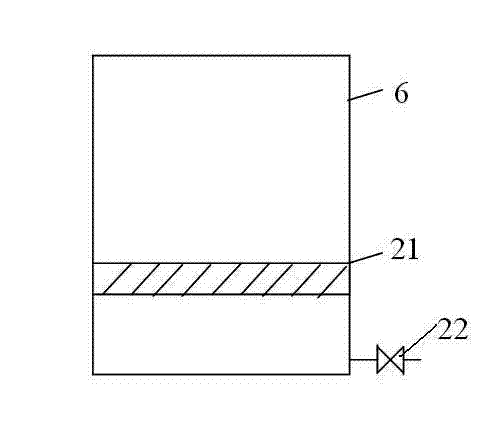

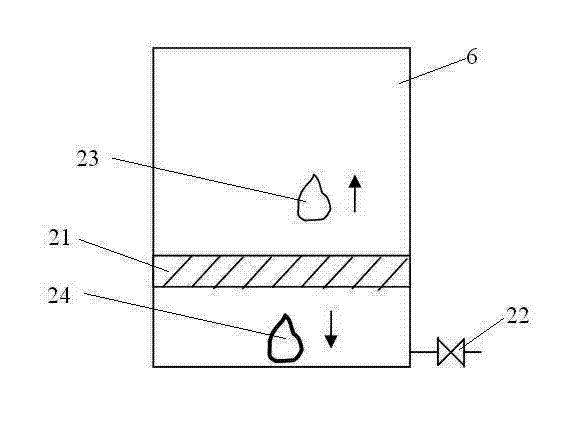

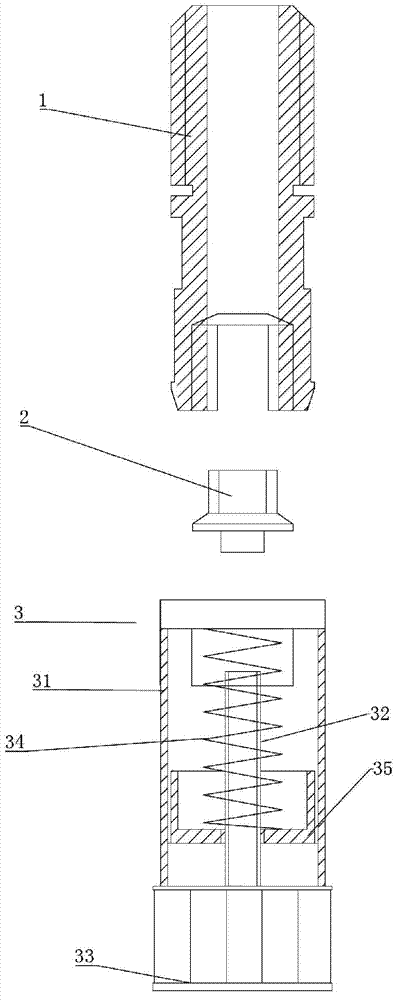

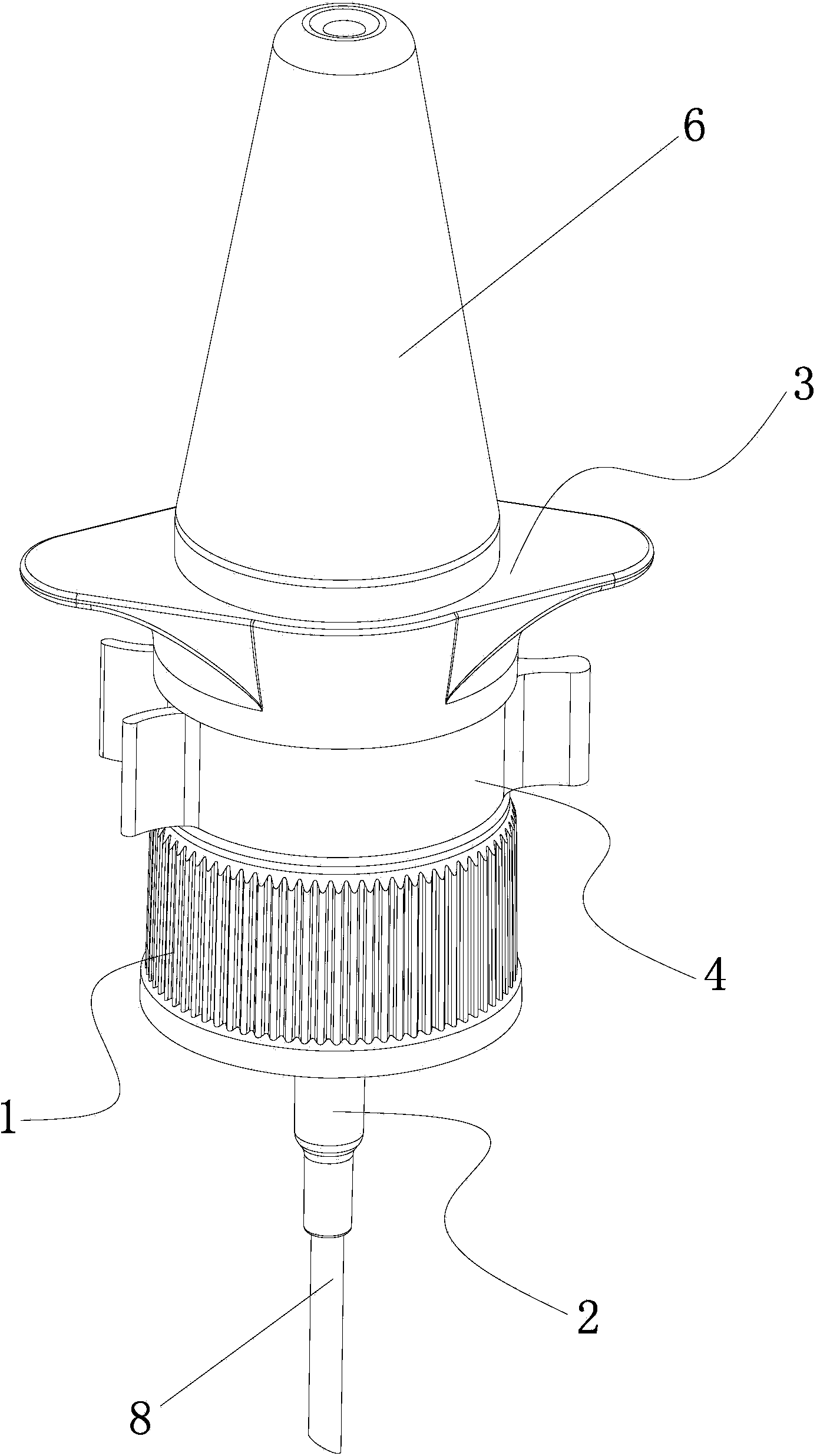

Self-regulation bifacial nozzle with random flow

The invention provides a self-regulation bifacial nozzle with random flow. The self-regulation bifacial nozzle with random flow comprises a nozzle body, a diversion piston and a water pressure regulator, wherein the nozzle body is of a round pipe shape; the diversion piston is arranged at the lower middle part of the nozzle body and can slide along the axial direction of the nozzle body; the water pressure regulator is arranged at the lower part of the nozzle body and is contacted with the diversion piston; the lower middle part of the inner hole of the nozzle body is provided with an axial locating slot; the diversion piston is arranged in the locating slot; the upper end of the diversion piston is provided with a diversion baffle; the water pressure regulator comprises a cylinder and a spring; the cylinder is connected with the nozzle body; the lower end of the spring is contacted with the cylinder; and the upper end of the spring is contacted with the bottom surface of the diversion piston. The nozzle body is provided with the water pressure regulator, the pressure balance of the diversion piston is regulated and controlled in real time by virtue of the spring, a better water spraying effect is achieved by automatically regulating the water flow according to the flow under a certain water pressure, and the dispersion angle and spraying angle of the sprayed water change slightly, so that the sprayed water is uniform, and the spraying effect is ensured.

Owner:SHANGHAI TIANBO ENERGY EQUIP +2

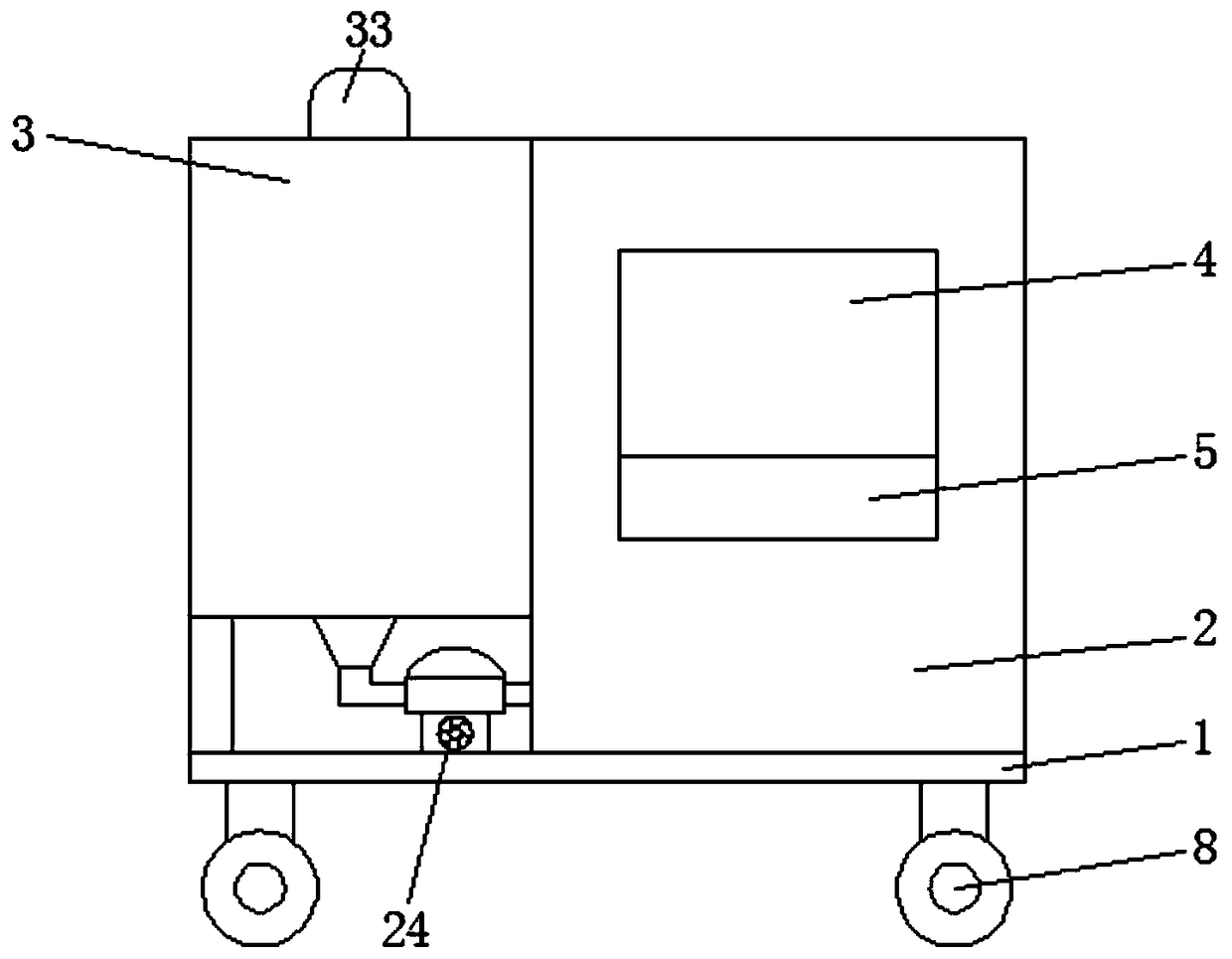

Environment-friendly soil remediation device

ActiveCN111389903APlay a mixing effectPrevent precipitationRotary stirring mixersTransportation and packagingSoil remediationLiquid storage tank

The device comprises an environment-friendly soil remediation device. The device includes a vehicle body, a connecting plate is fixedly connected to the left side of the top of the vehicle body, the bottom of a pesticide storage box is communicated with a diversion groove through a branch pipe, and a rotating assembly is arranged on the left side of the vehicle body. The invention discloses the environment-friendly soil remediation device, the vehicle body, the connecting plate, a first grooved wheel, a first belt and the rotating assembly are cooperated, in the rotating process of a hob, thehob can swing back and forth relative to the transmission of a fork-shaped sliding rail, then the soil breaking and turning capabilities and effects of the hob are further improved; through the cooperation of a second motor, a liquid storage tank, the diversion groove, spray heads and a turning assembly, a soil remediation liquid can be stirred by the device through the rotation of stirring rods,and then the soil remediation liquid can be uniformly mixed, the spraying effect is further guaranteed, a pressing plate can extrude an air bag in a reciprocating mode through extrusion of a cam on the pressing plate and springback of a compression spring, then the liquid storage tank is pressurized, and the spraying uniformity and the spraying continuity of the liquid medicine are greatly improved.

Owner:新昌县澄聚农业科技有限公司

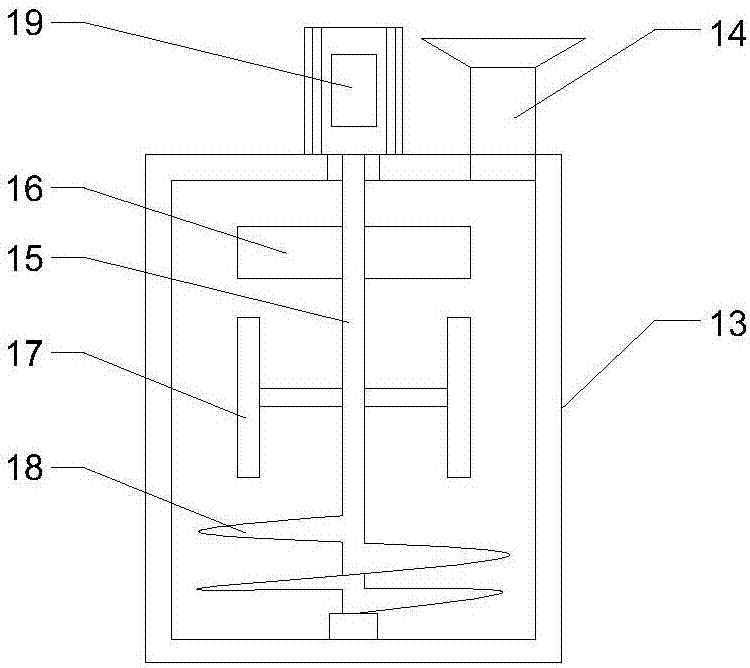

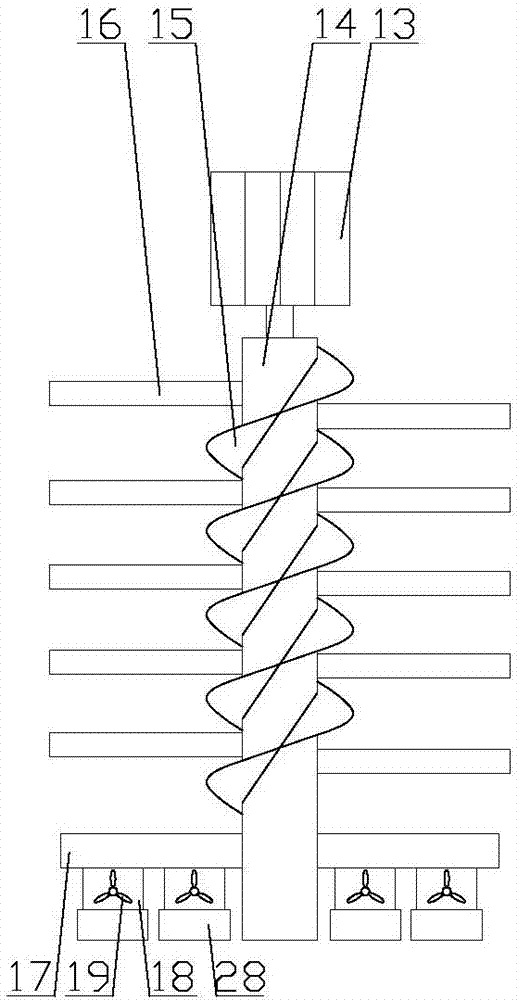

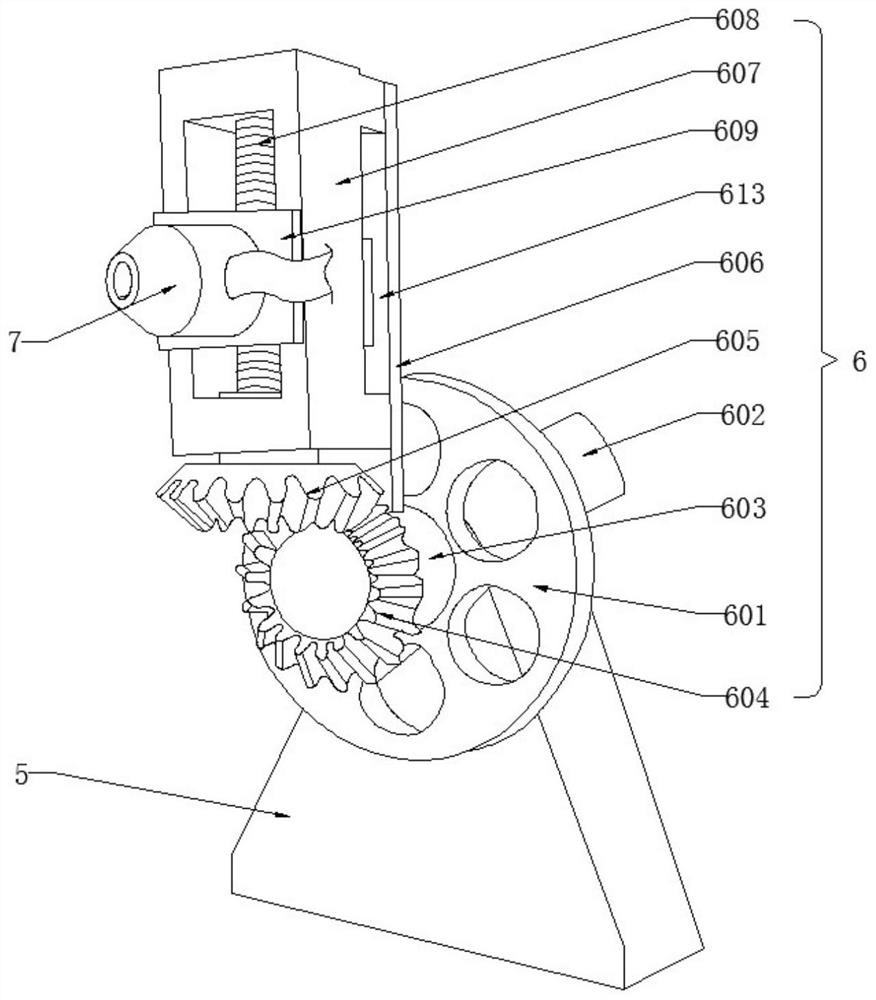

Agricultural plant protection unmanned aerial vehicle capable of guaranteeing pesticide spraying effect

ActiveCN107318810AGuaranteed spraying effectConcentration unchangedAircraft componentsInsect catchers and killersAgricultural engineeringPropeller

The invention relates to an agricultural plant protection unmanned aerial vehicle capable of guaranteeing a pesticide spraying effect. The agricultural plant protection unmanned aerial vehicle capable of guaranteeing the pesticide spraying effect comprises a body, a propeller, a support and a liquid storage box, wherein the body further comprises a stirring mechanism, a cover opening mechanism and a fixing mechanism; the stirring mechanism comprises a tightening and releasing assembly and a stirring assembly; a cover opening mechanism comprises a cylinder and a sealing cover; and the fixing mechanism comprises a third motor, a cylindrical gear, a rack, a fixing plate and a fixing assembly. According to the agricultural plant protection unmanned aerial vehicle capable of guaranteeing the pesticide spraying effect, the liquid storage box is opened by the cover opening mechanism; pesticide in the liquid storage box is stirred efficiently by the stirring mechanism, so that the pesticide cannot precipitate in a spraying process, the concentration of the pesticide is not changed, the pesticide spraying effect is guaranteed, and growth of crops is prevented from being affected; meanwhile, the liquid storage box is fixed on a support by the fixing mechanism, is fixed firmly, and is prevented from injuring people or crops; and when the liquid storage box needs to be taken down, parts do not need to be detached, the liquid storage box can be directly taken down from the support, and the time and labor are saved.

Owner:广州天地林业有限公司

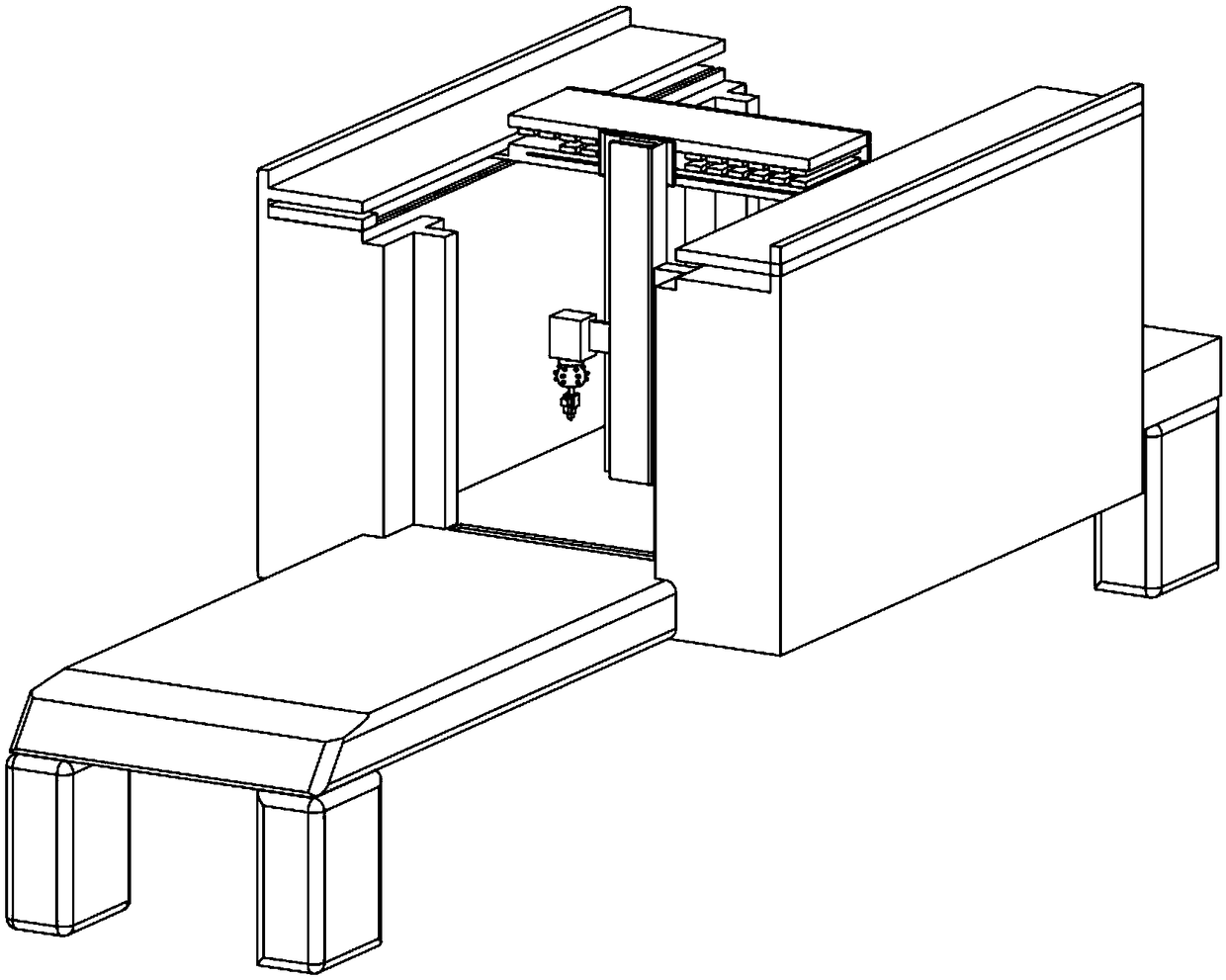

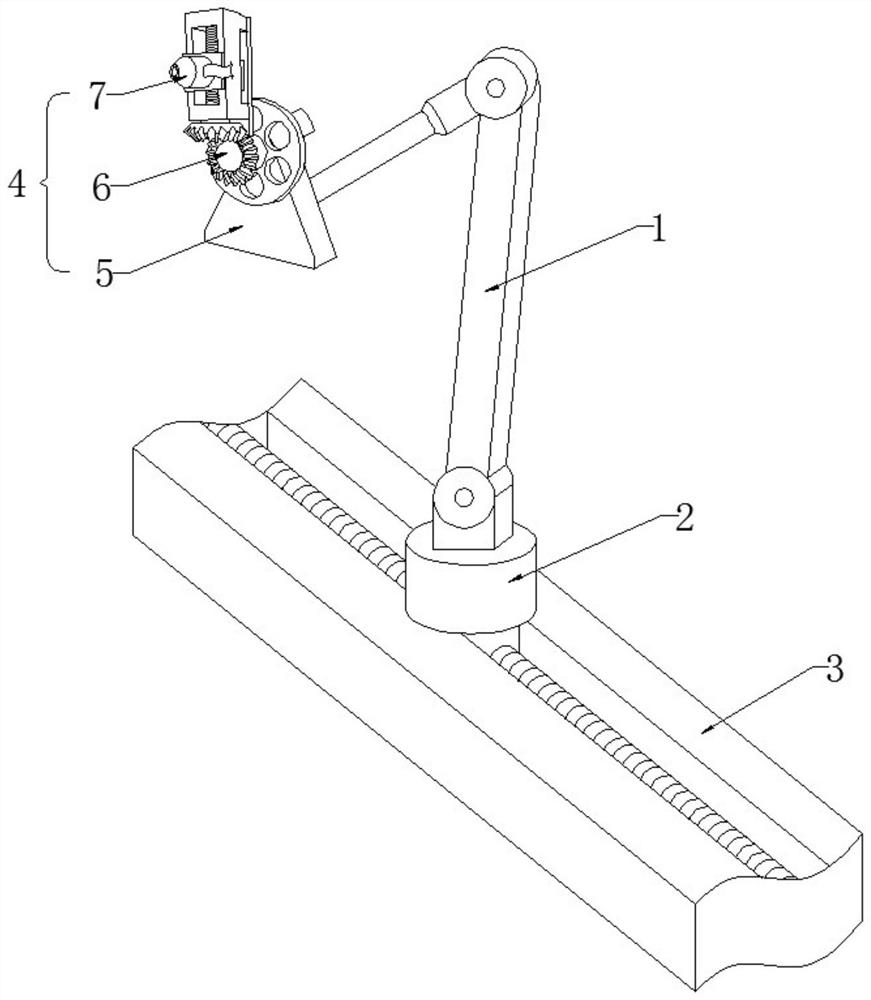

Spraying equipment based on multi-degree-of-freedom motor

InactiveCN109453928ASolve rough sprayingSolve the dead angle of sprayingSpraying apparatusMotor driveControl system

The invention provides spraying equipment based on a multi-degree-of-freedom motor, and relates to the technical field of spraying equipment. The spraying equipment based on the multi-degree-of-freedom motor mainly comprises a frame body, a three-dimensional movement mechanism, the multi-degree-of-freedom motor, a spray head, a rotary type working table and a control system, wherein the three-dimensional movement mechanism is connected with the multi-degree-of-freedom motor; the multi-degree-of-freedom motor is connected with the spray head; the controller comprises a camera; the three-dimensional movement mechanism drives the multi-degree-of-freedom motor; the multi-degree-of-freedom motor drives the spray head to spray multi-angularly in the space along a workpiece to be sprayed; a workpiece range is determined through image identification; and the angle of the spray head is adjusted according to the surface space radian of the workpiece so as to carry out spraying. The spraying equipment based on the multi-degree-of-freedom motor provided by the invention mainly solves the problems of spraying roughness, the existence of a spraying dead angle, material waste, a poor spraying effect, a big control error, low spraying accuracy and low spraying efficiency in the prior art, and has the characteristics of high spraying accuracy, good quality, high efficiency, saving in materialsand the like.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

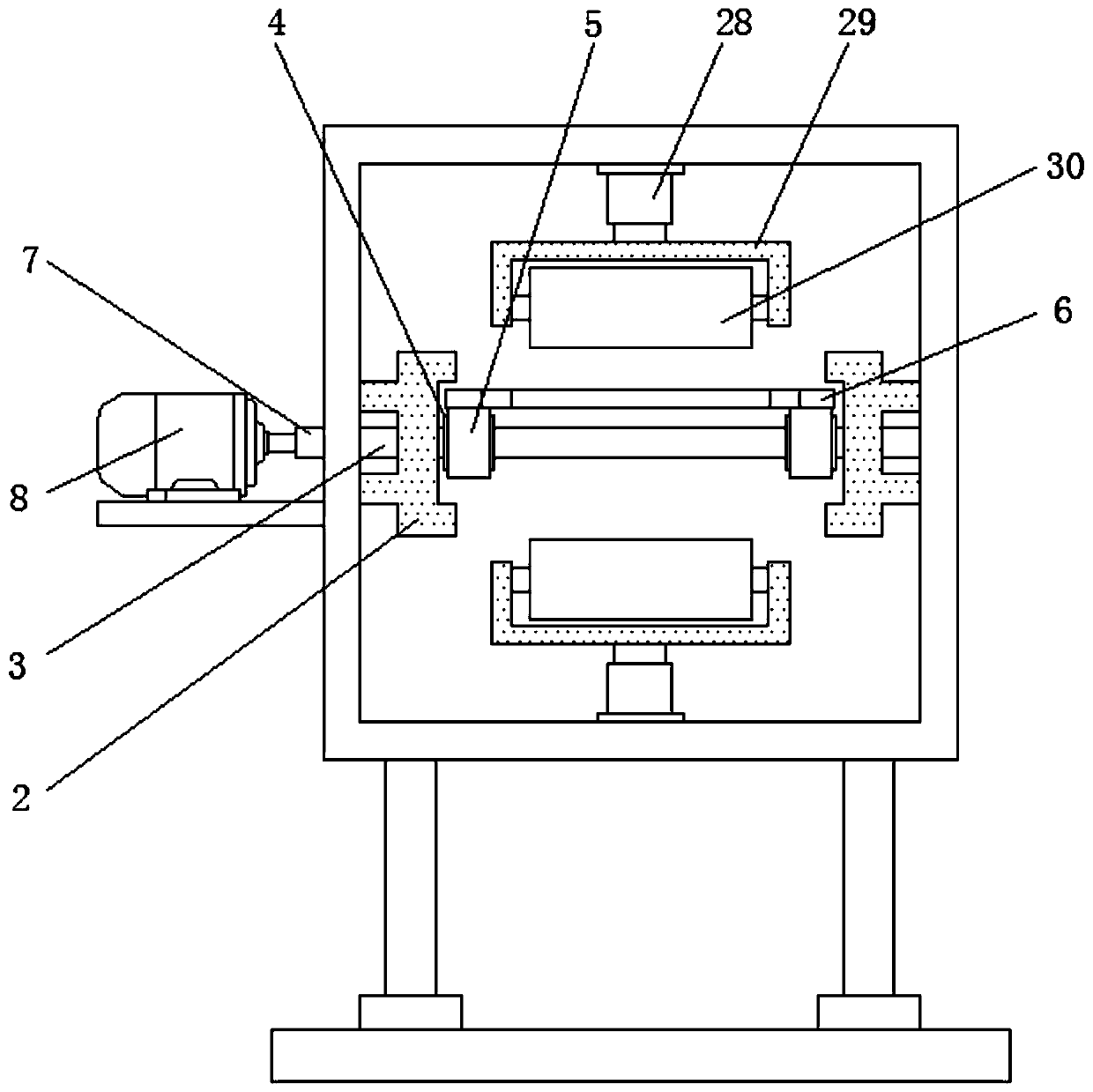

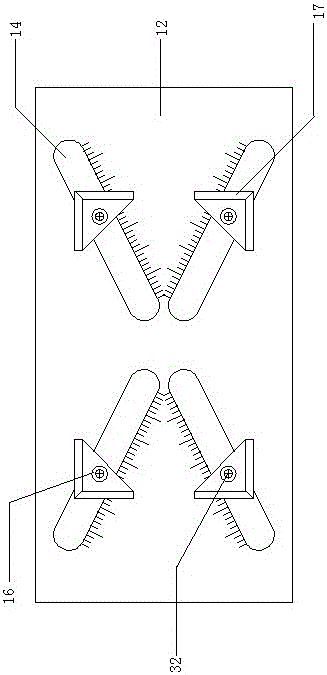

Polyurethane black material spraying equipment

ActiveCN105728236AAll-round sprayingSpray evenlySpray nozzlesLiquid spraying apparatusEngineeringPressurized spray

The invention provides polyurethane black material spraying equipment. The polyurethane black material spraying equipment comprises a black material extracting part, a black material spraying part and a plate clamping part, wherein the black material extracting part comprises a black material storage barrel and a black material stirring device; a cooling sandwich layer is arranged on the lateral wall of the black storage barrel, and a black material extracting pipe is connected to the bottom of the black material storage barrel; the black material stirring device comprises a stirring shaft and a stirring motor; the black material spraying part comprises a spraying gun, a to-be-sprayed black material storage tank and a pressurizing spraying device; the plate clamping device comprises a clamp plate and a universal ball. The polyurethane black material spraying equipment has the advantages that omnibearing and even spraying of the plate can be achieved, the storage quality of polyurethane black materials during storage and use can be guaranteed, and spraying quality and effect are further guaranteed; the polyurethane black material spraying equipment is efficient in spraying and capable of lowering spraying cost favorably.

Owner:上海林馨科技有限公司

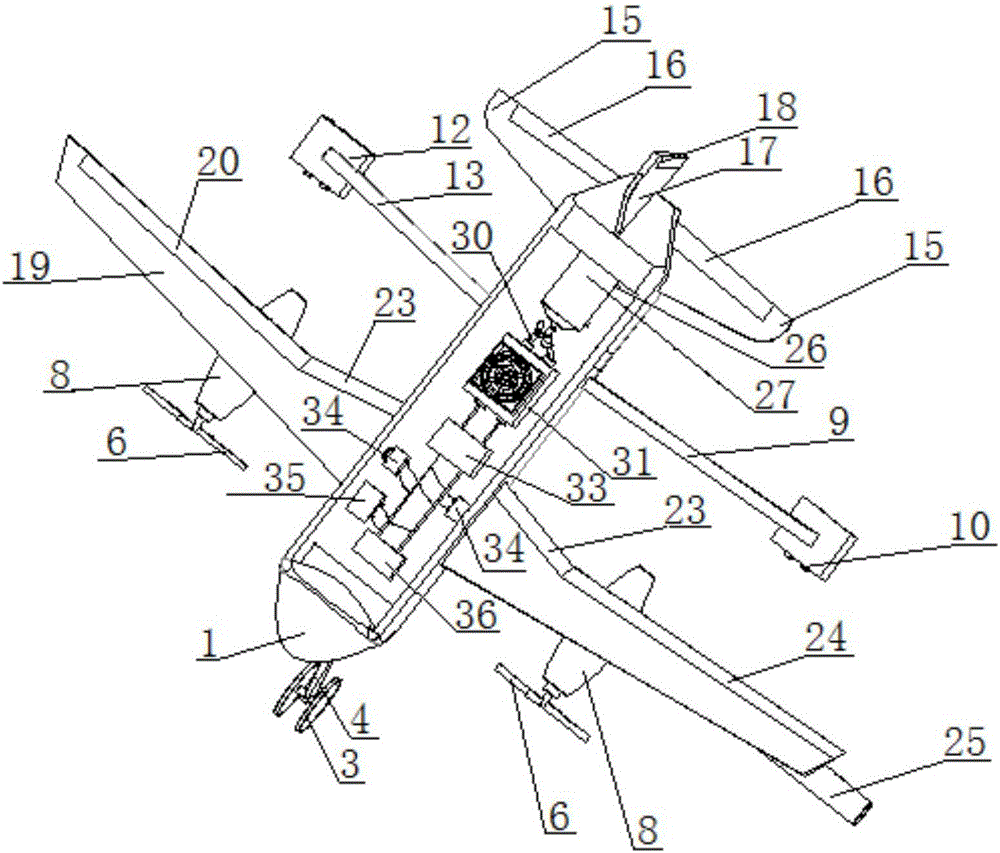

Fixed-wing fuel-cell unmanned aerial vehicle for plant protection

The present invention relates to the field of unmanned aerial vehicles, and discloses a fixed-wing fuel-cell unmanned aerial vehicle for plant protection. The fixed-wing fuel-cell unmanned aerial vehicle comprises a fuselage baseplate, a fuselage, a nose, a front frame, wings, a rear frame and empennages. A hydrogen cylinder, a fuel cell, a direct current converter, an electronic governor, an accumulator and a controller are sequentially mounted on the fuselage baseplate. The hydrogen cylinder is fixed to the fuselage baseplate through a hydrogen cylinder base; the fuel cell is connected with the hydrogen cylinder through a hydrogen pipeline, and the output end of the direct current converter is electrically connected with the accumulator, the controller and the electronic governor through a wire after being subjected to voltage conversion by the direct current converter; a pesticide box is arranged below the fuselage and connected with a water pump through a pipeline; and the outlet of the water pump communicates with multiple nozzles through a multi-pass joint and a pipeline. After the fixed-wing fuel-cell unmanned aerial vehicle for plant protection is started, the accumulator is cut off, the fuel cell supplies power for each piece of equipment of the system independently, the flight time is long, the spraying efficiency is high, and cleanness, environmental protection, safety and stability are realized.

Owner:HUBEI UNIV OF TECH

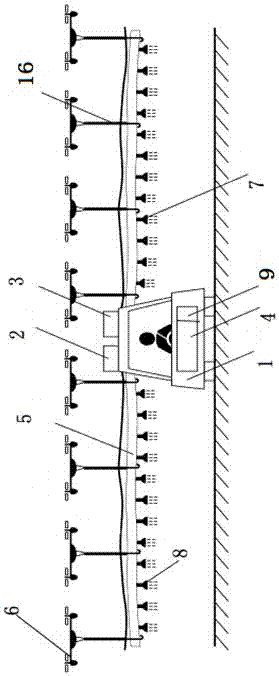

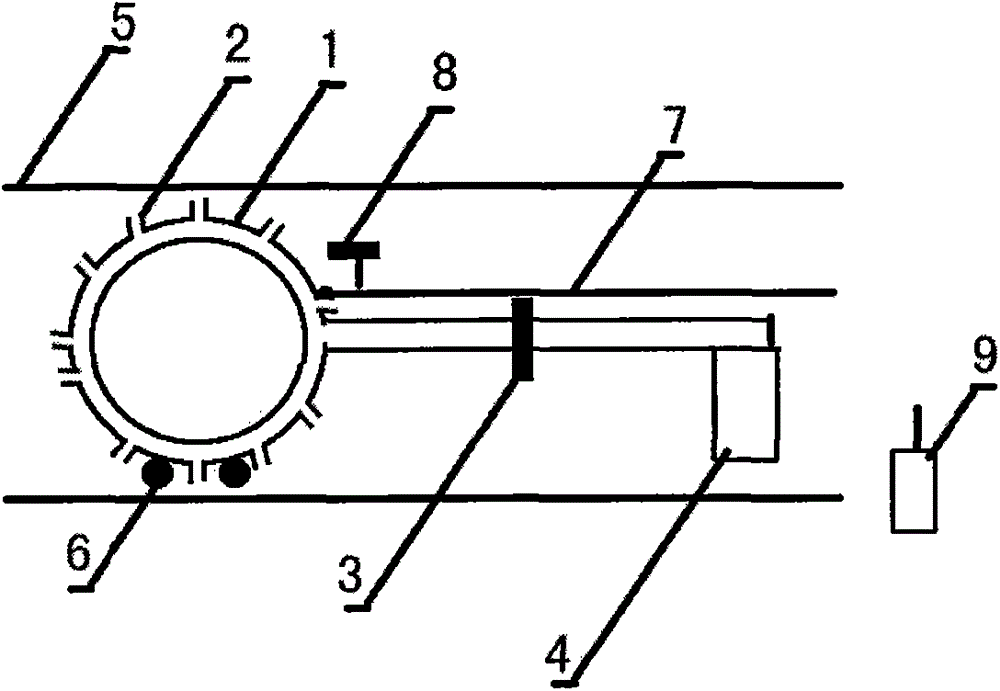

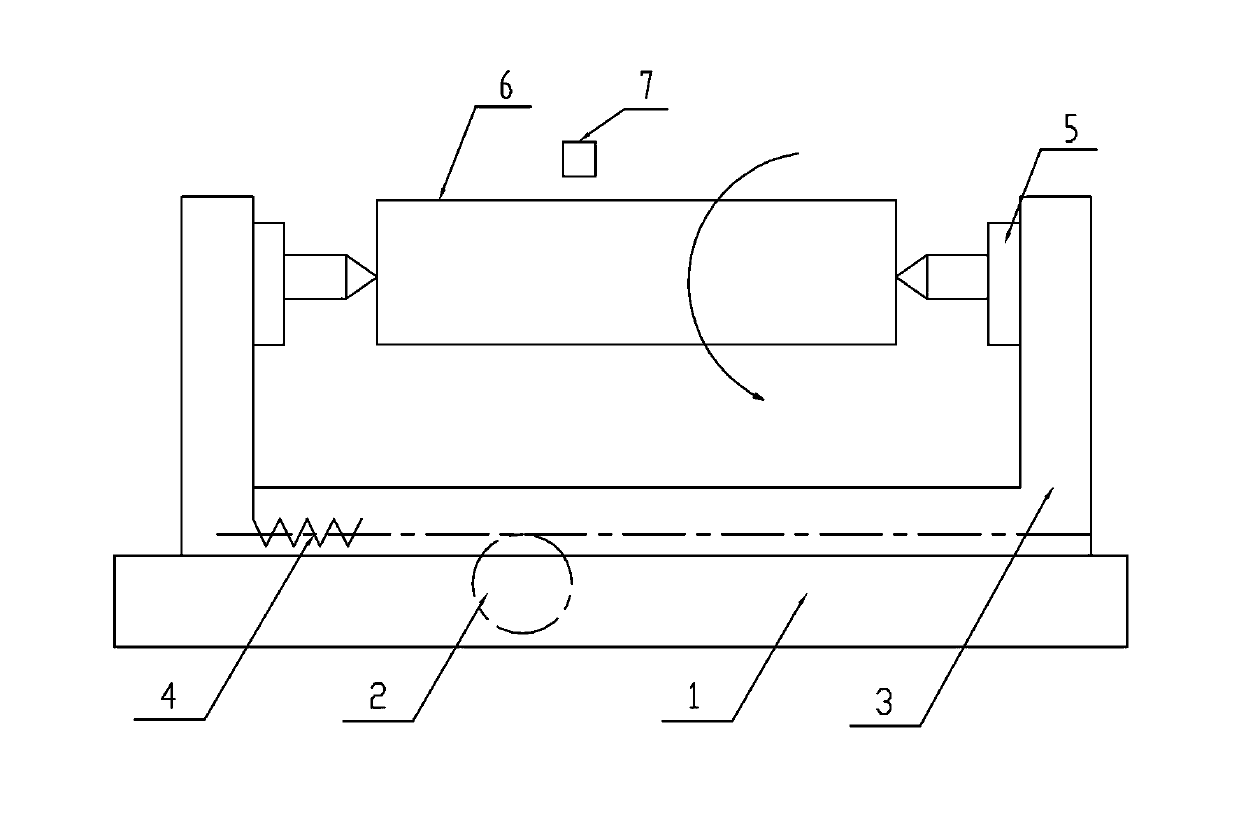

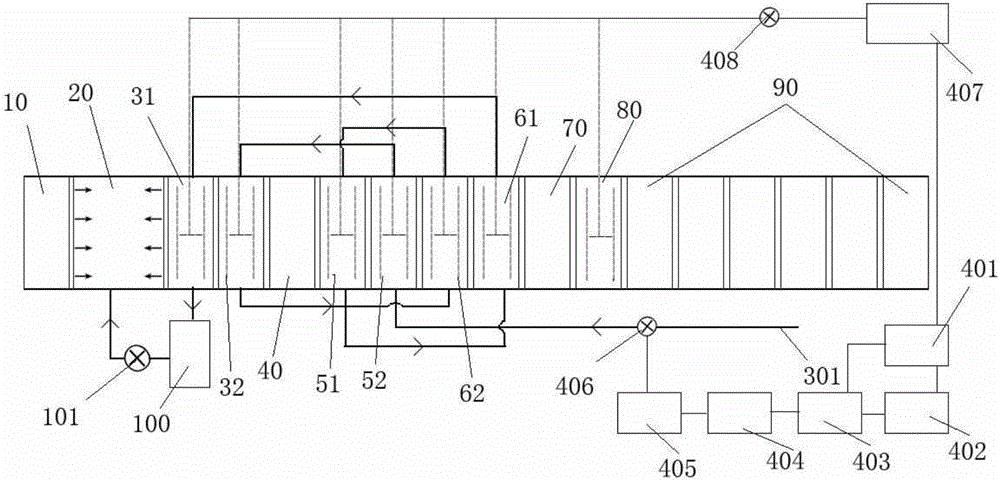

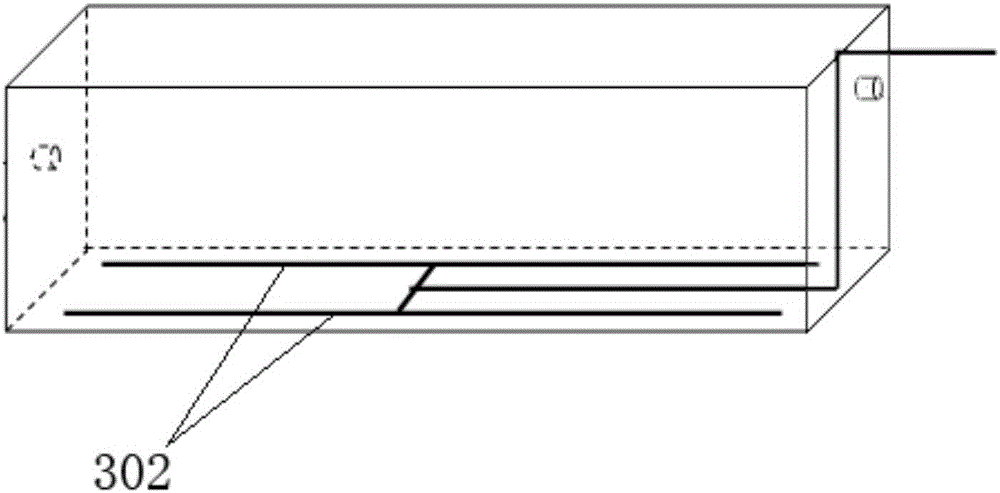

Pipeline inner-wall spraying device

InactiveCN105080792AAchieve sprayingGuaranteed spraying effectLiquid surface applicatorsCoatingsRemote controlEngineering

A pipeline inner-wall spraying device comprises a rack (1), and a circle of spraying pipes (2) are arranged on the ring edge of the rack and are connected with a negative pressure generator (3) and a paint tank body (4); in the use process, the negative pressure generator (3) is started, and paint is evenly sprayed to the inner wall of a pipeline (5); a stepping device (6) is arranged at the bottom of the rack, and easily moves in the pipeline (5); a traction rope (7) is arranged at the tail end of the rack (1), and an LED lighting assembly (8) is arranged, so that the pipe wall condition is observed; a remote control device (9) is arranged and controls various spraying process parameters; and the spraying pipes (2) are of an atomization spraying structure. Spraying to the interior of the pipeline can be rapidly and evenly achieved, and due to the fact that ring spraying is adopted, the spraying effect can be ensured.

Owner:XINCHANG KANGHONG MACHINERY TECH

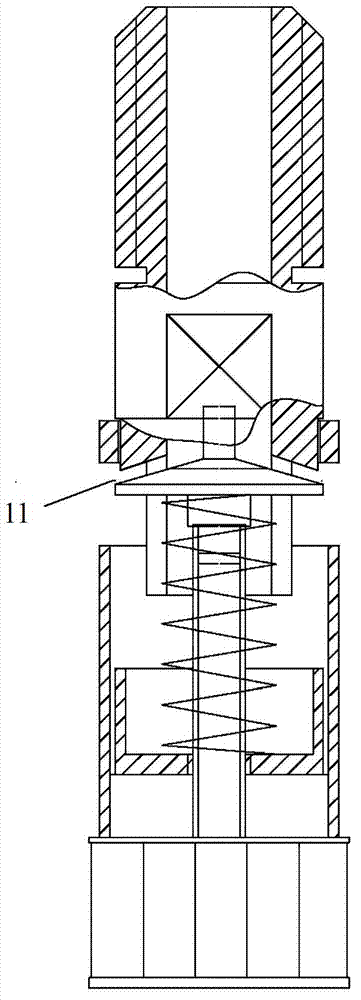

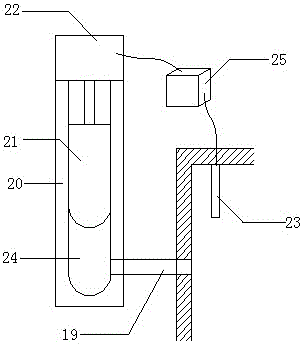

Anti-shaking pesticide box for plant protection unmanned aerial vehicle

PendingCN111532432AAvoid shaking and bumpingGuaranteed uniformityAircraft componentsInsect catchers and killersAgricultural scienceAgricultural engineering

The invention discloses an anti-shaking pesticide box for a plant protection unmanned aerial vehicle. An air bag extrudes a floating plate, a cavity of a liquid storage cavity is avoided, shaking is prevented and uniform pesticide spraying is ensured. One end of a telescopic pipe is connected with the middle of a top plate of a pesticide box main body; a connecting pipe is arranged in the middle of the top plate of the pesticide box main body; the telescopic pipe is connected with the connecting pipe; the other end of the telescopic pipe extends downwards; one end of a pesticide inlet pipe isarranged in the telescopic pipe; the floating plate is arranged in the pesticide box main body; the floating plate is connected with the other end of the pesticide inlet pipe; a pesticide storage cavity is formed between the floating plate and the bottom of the pesticide box main body; and the pesticide storage cavity is connected with the pesticide inlet pipe, the air bag is arranged in the pesticide box main body and located between the floating plate and the top plate of the pesticide box, an air release valve is arranged on the air bag, the air release valve extends out of the pesticide box main body, an inflation box is arranged on the pesticide box main body, one end of an inflation pipe is connected with the inflation box, and the other end of the inflation pipe penetrates through the pesticide box main body to be connected with the air bag.

Owner:徐州徐薯食品研究院有限公司

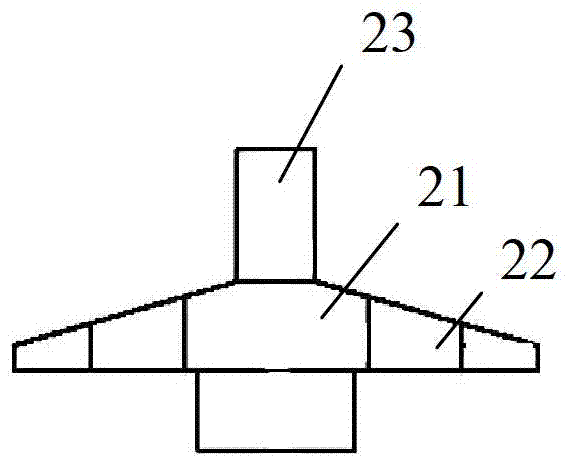

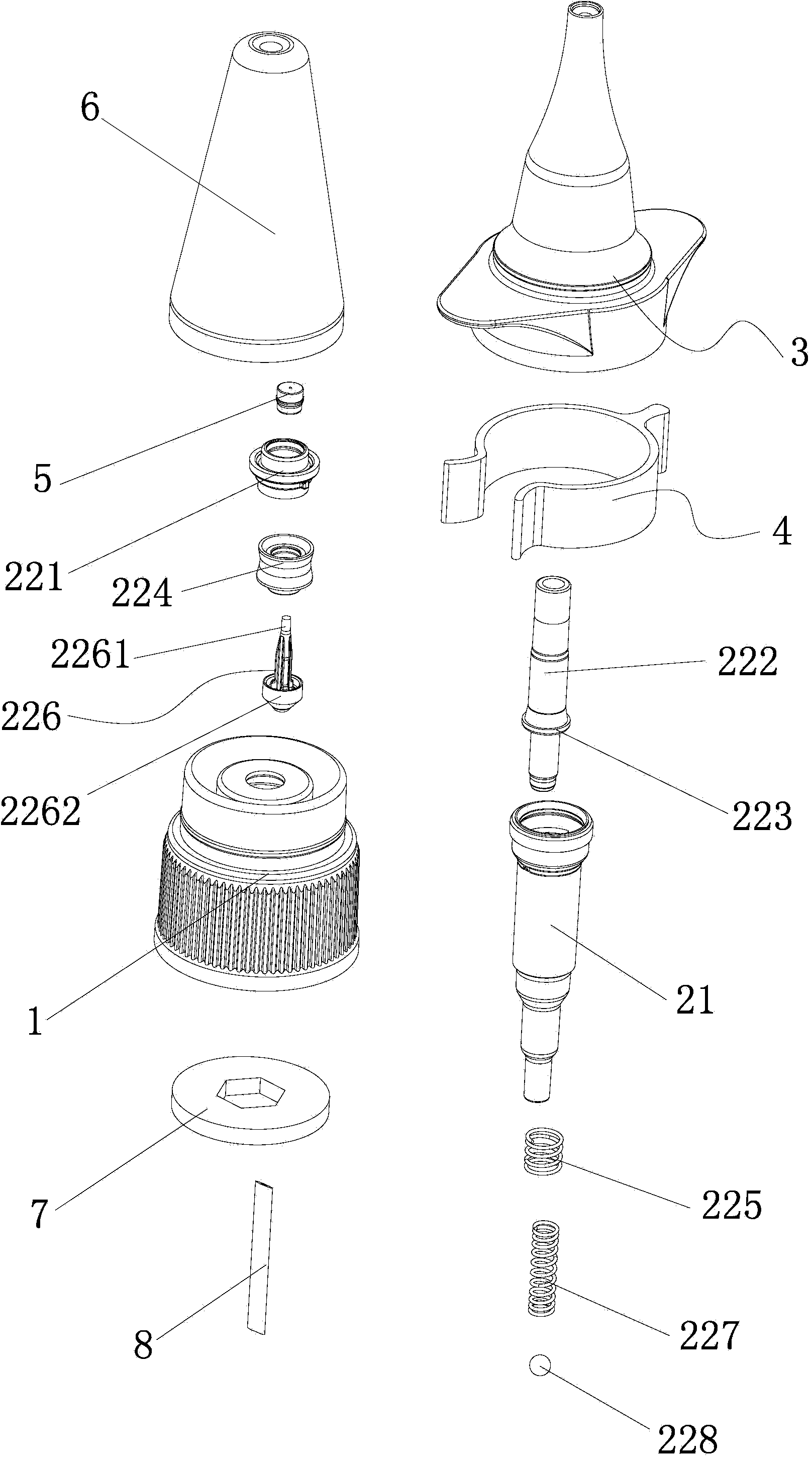

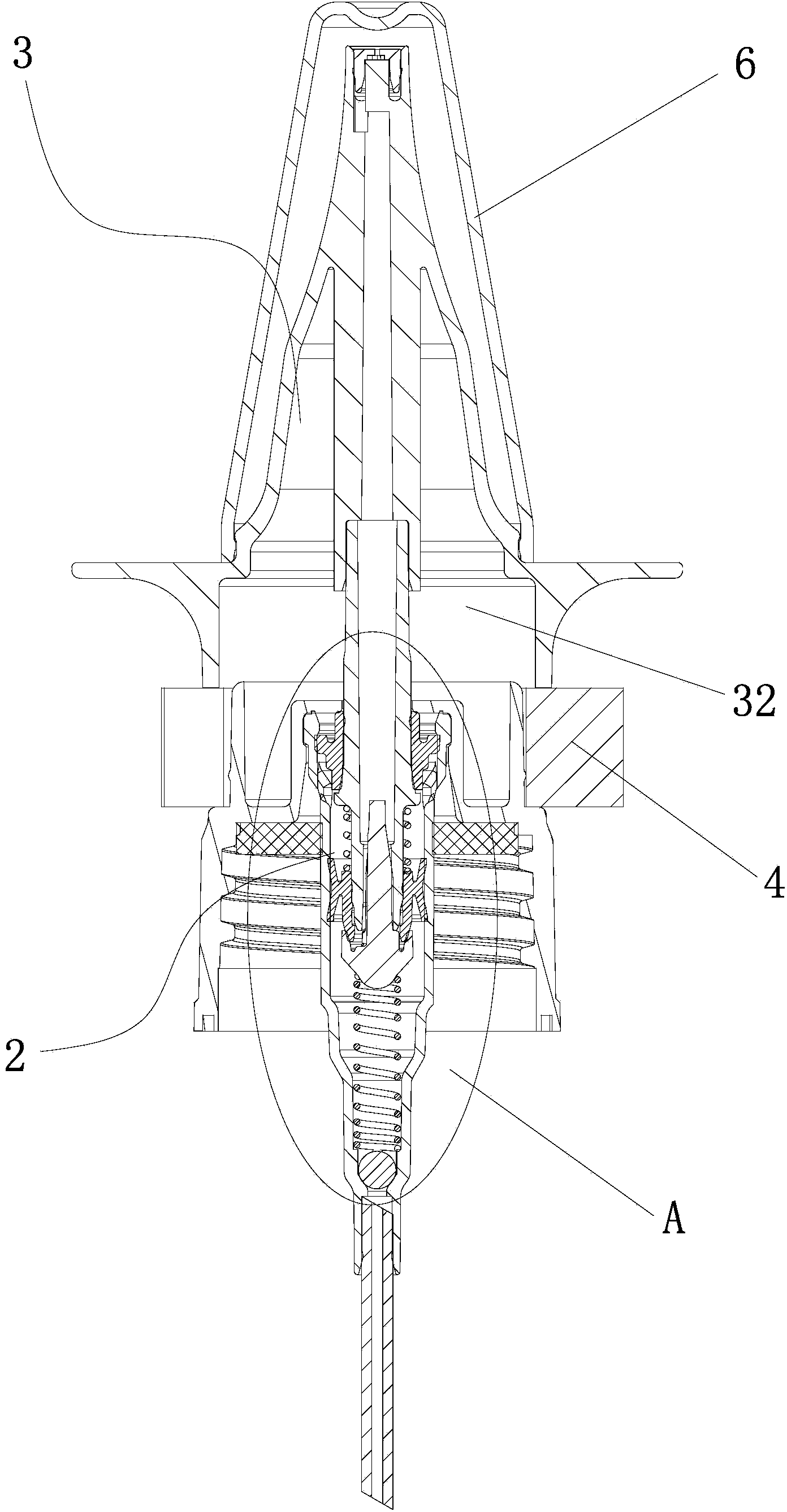

Sprayer for medical purpose

The invention discloses a sprayer for medical purpose. The sprayer for the medical purpose comprises a combination cover, and is characterized in that a connecting protruding ring is arranged on the upper end face of the combination cover, a pump component is arranged in the combination cover, a press head nozzle capable of driving the pump component to work when pressed is arranged above the combination cover, the press head nozzle is connected above the pump body component and communicated with the same, and a protective cover capable of blocking the press head nozzle for moving down under stress is arranged between the press head nozzle and the combination cover. In order to overcome shortcomings in the prior art, the sprayer for the medical purpose is simple in structure, capable of being effectively prevented from being pressed by mistake, fast in pump starting, and relatively stable in spray amount.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

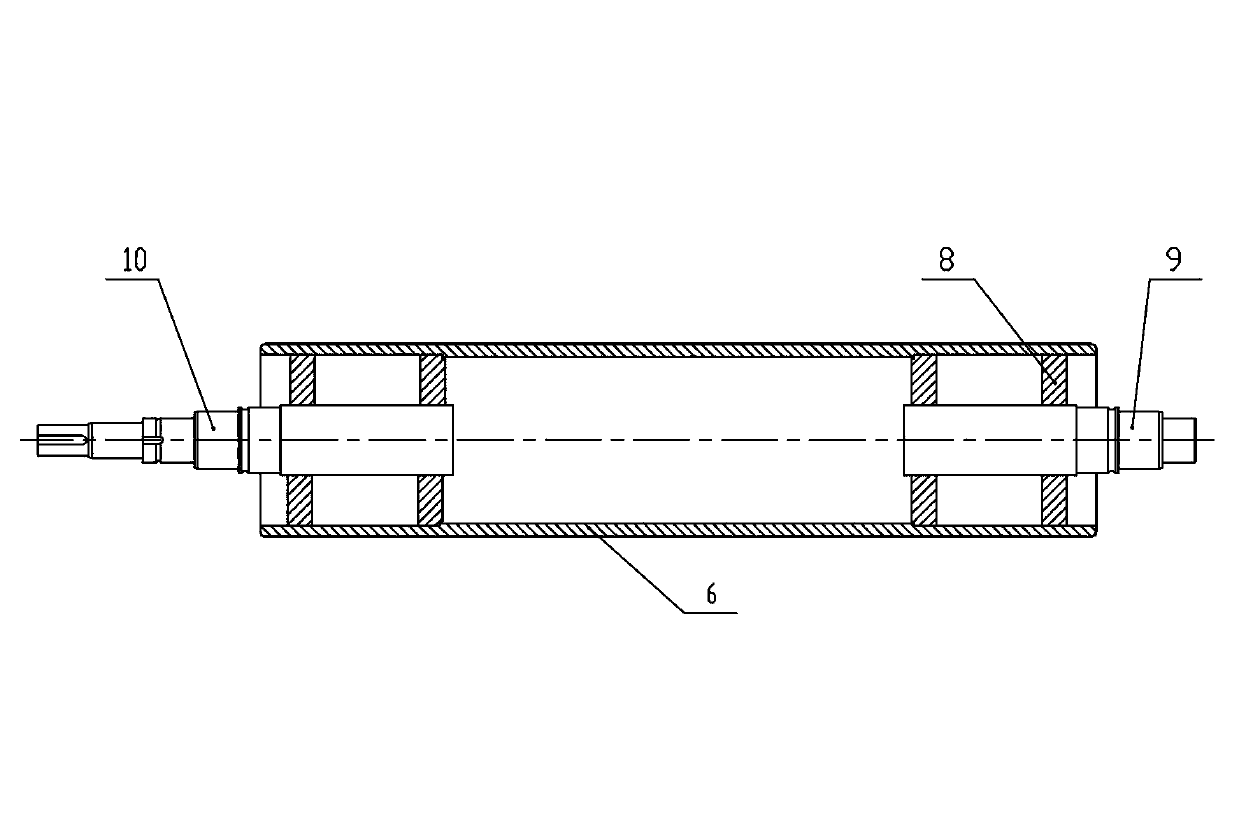

Spray-welding coating technology for hot-rolling laminar cooling roller and use fixture for technology

ActiveCN103695831AGuaranteed to be heatedGuaranteed spraying effectMolten spray coatingCarbide coatingLaminar cooling

The invention relates to a spray-welding coating technology for a hot-rolling laminar cooling roller. The spray-welding coating technology comprises the following steps: 1) blanking a roller and processing before spraying; 2) preheating a workpiece; 3) conducting spray-welding coating: adjusting the velocity of the roller to be 15-20 revolutions per minute, adjusting the position of a spray gun and opening the spray gun, adjusting the powder delivery volume and flame, and meanwhile, moving the roller forwards at a constant speed of 280 mm / min, so as to ensure that the hard alloy in the spray gun is uniformly sprayed on the outer circumference of the roller; 4) auto-rotating the sprayed roller in the environment at the temperature of 370 DEG C to enable the hard alloy on the roller to remelt, and after the hard alloy coating is molten, placing the roller to be subjected to air cooling to obtain the roller with the hard alloy coating. The cooling roller sprayed and welded by adopting the technology and the fixture for spray-welding coating has the functions of abrasion resistance, thermal barrier, antioxidation, corrosion protection, scaffolding resistance, caking inhibition and the like, as well as the service life longer than that of a roller bed in market application.

Owner:ANSHAN ZHENGFA SURFACE TECHN & ENG CO LTD

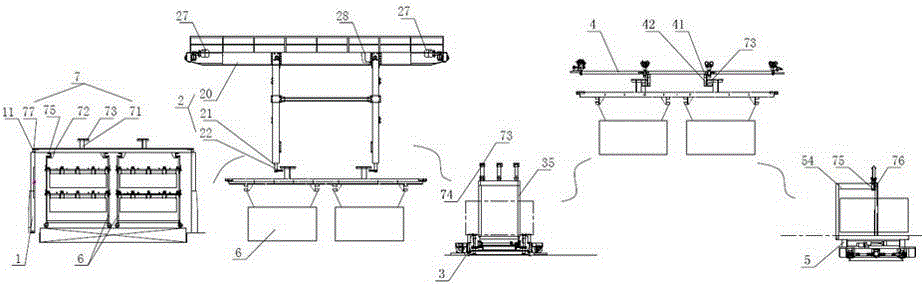

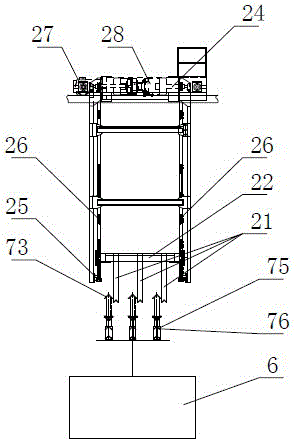

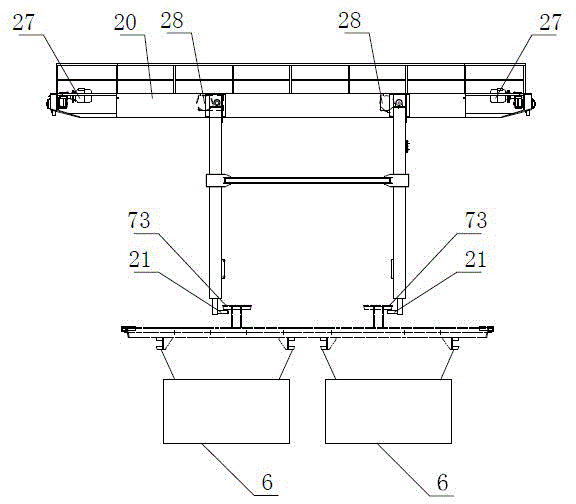

Automatic conveying system of large equipment coating line

ActiveCN104528313AImprove transport efficiencySmall footprintMechanical conveyorsElectrophoresisSmall footprint

The invention discloses an automatic conveying system of a large equipment coating line. The automatic conveying system comprises a workpiece storage rack, a stored program control conveying machine, a roller machine conveying machine and a friction power and free chain conveying line. A sling transport rack is connected to the workpiece storage rack and connected with a workpiece bracket. The top of the sling transport rack is provided with an upward-extending hoisting branch arm, and the lower portion of the sling transport rack is provided with a suspension rack. The hoisting branch arm is provided with an outward-extending hoisting arm. A limiting groove is formed in the hoisting arm. Two suspension arms are arranged on one side of the suspension rack and provided with opposite suspension grooves. A workpiece suspension arm is arranged on the workpiece bracket. A stored program control suspension arm is arranged on the stored program control conveying machine and provided with a stored program control bracketing arm. The friction power and free chain conveying line is provided with a friction conveying base. The bottom of the friction conveying base is provided with a power and free chain suspension arm. The automatic conveying system can continuously transport large workpieces from electrophoresis to coating, and has the advantages of being high in transport efficiency, small in occupied area and accurate in reaching position.

Owner:MH ROBOT & AUTOMATION

Automatic spraying industrial robot and method

InactiveCN112170066AGuaranteed spraying effectRealize wrap around spraying jobSpraying apparatusSprayerEngineering

The invention discloses an automatic spraying industrial robot and method. The automatic spraying industrial robot comprises an industrial robot body, a base is arranged at the bottom of the industrial robot body, a moving platform is arranged at the bottom of the base, and a spraying mechanism is arranged at one end of the top of the industrial robot body, wherein the spraying mechanism comprisesa mounting base, the back face of the mounting base is fixedly connected with one end of the top of the industrial robot body; and a rotating assembly is arranged on the surface of the mounting base,and a sprayer assembly is arranged on the surface of the rotating assembly. The automatic spraying industrial robot has the beneficial effects that surrounding spraying operation on the end face of apipeline can be achieved, compared with a traditional spraying mode, waste of paint is effectively reduced, the phenomenon that subsequent pipeline surface spraying is uneven is effectively avoided,and therefore the overall spraying effect of the pipeline is effectively guaranteed.

Owner:NANJING YUSHENG ROBOT CO LTD

Automatic casting coating spraying device

ActiveCN108816612ASpeed up the mixingPrevent adhesionSpray boothsEngineeringUltimate tensile strength

The invention relates to the technical field of spraying devices, in particular to an automatic casting coating spraying device which comprises a base, wherein a mixing device is arranged on one sideof a work box; a feeding device is arranged in a feeding hole; a guide plate is obliquely arranged in a discharging hole; two fluted discs are rotatably connected with the interior of a through groove; fixed devices are symmetrically arranged between the two fluted discs; a lead screw is rotatably connected between the lower parts of two partition boards through a bearing pedestal; a sliding seatis in screw joint with the outer side of the lead screw; a spraying mechanism is arranged at the upper end of the sliding seat; and the output shaft of a second motor penetrates through the partitionboards to be fixedly connected with the lead screw. The automatic casting coating spraying device is reasonable in structural design and convenient and fast to use, can mix coating uniformly and avoids sedimentation, ensures the casting spraying effect and also carries out air drying treatment on the castings to greatly improve the working efficiency and lower the labor intensity of a worker, hashigh practicality and deserves popularization.

Owner:湖北省丹江口丹传汽车传动轴有限公司

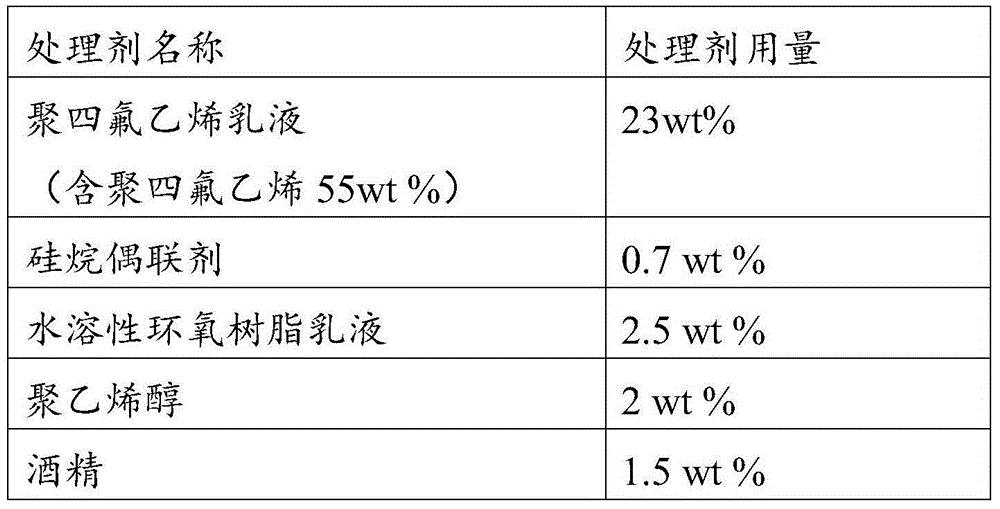

Preparation method of high-precision coating filter material

ActiveCN104436861AImprove acid and alkali resistanceExtended service lifeSynthetic resin layered productsGlass/slag layered productsPolytetrafluoroethyleneFilter material

The invention provides a preparation method of a high-precision coating filter material. According to the preparation method, the filter material can be well combined with PTFE (Polytetrafluoroethylene), and the performances of the filter material can be improved. The method comprises the following steps: (1) carrying out heat cleaning treatment, namely, performing the heat cleaning treatment on the filter material and removing various assistants on the surface of the filter material at high temperature; (2) performing immersion treatment, that is, performing PTFE immersion treatment on the filter material after heat cleaning treatment; (3) baking, drying, and carrying out heat setting on the filter material after immersion treatment sequentially; (4) coating the filter material after heat setting; and (5) performing volatilization, drying, sintering and heat setting on the filter material after coating treatment sequentially. According to the preparation method of the high-precision coating filter material, the filter material is subjected to heat cleaning treatment before immersion treatment, thus, wiredrawing impregnating compound remained on the surface of the fiber can be effectively removed, and the fabric strength can be ensured not to be lost; the acidic and alkali resistances, the water resistance, the oxidation resistance and the abrasion and folding resistances of the filter material can be effectively improved, and the service life of the filter material can be prolonged.

Owner:辽宁新洪源环保材料有限公司

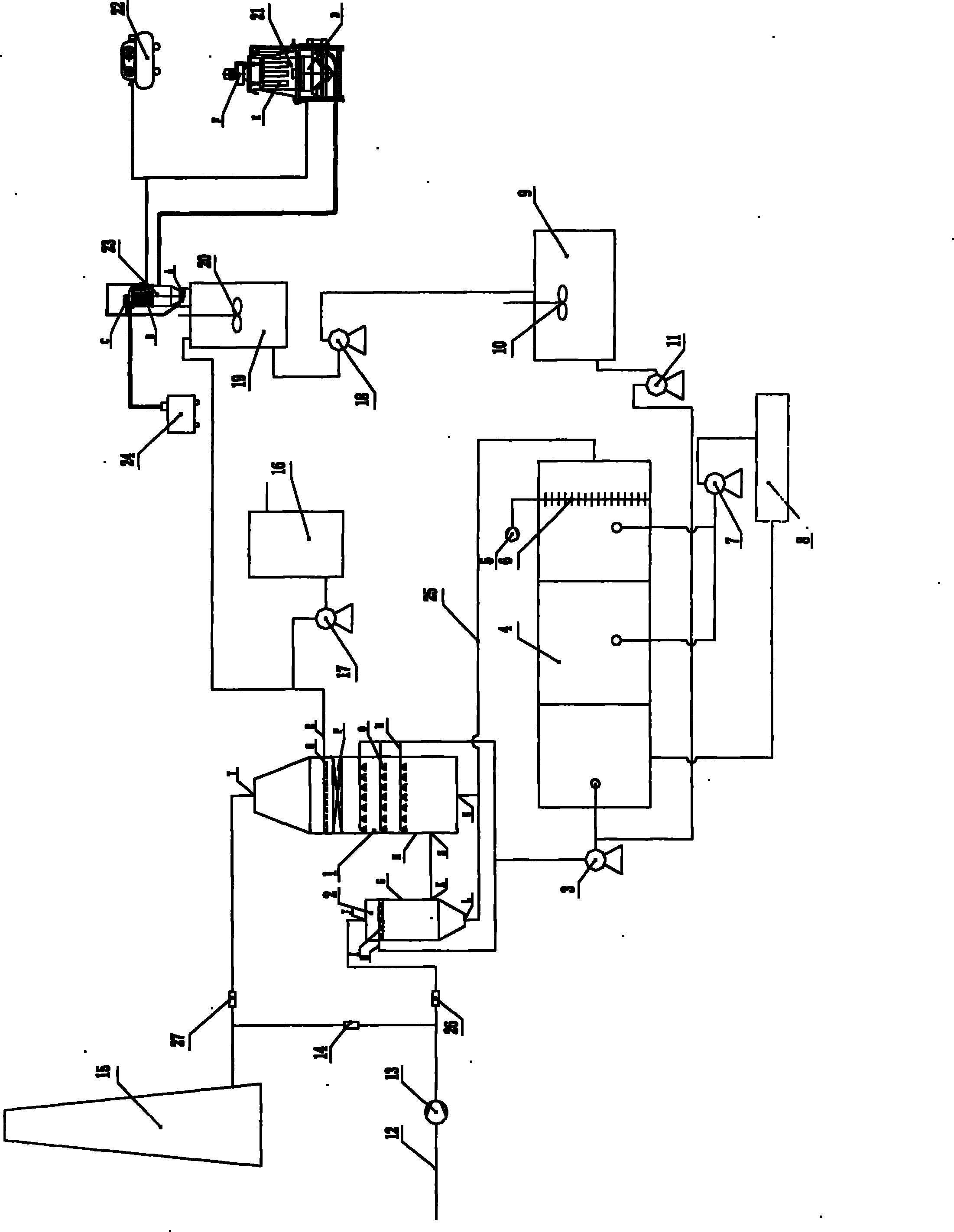

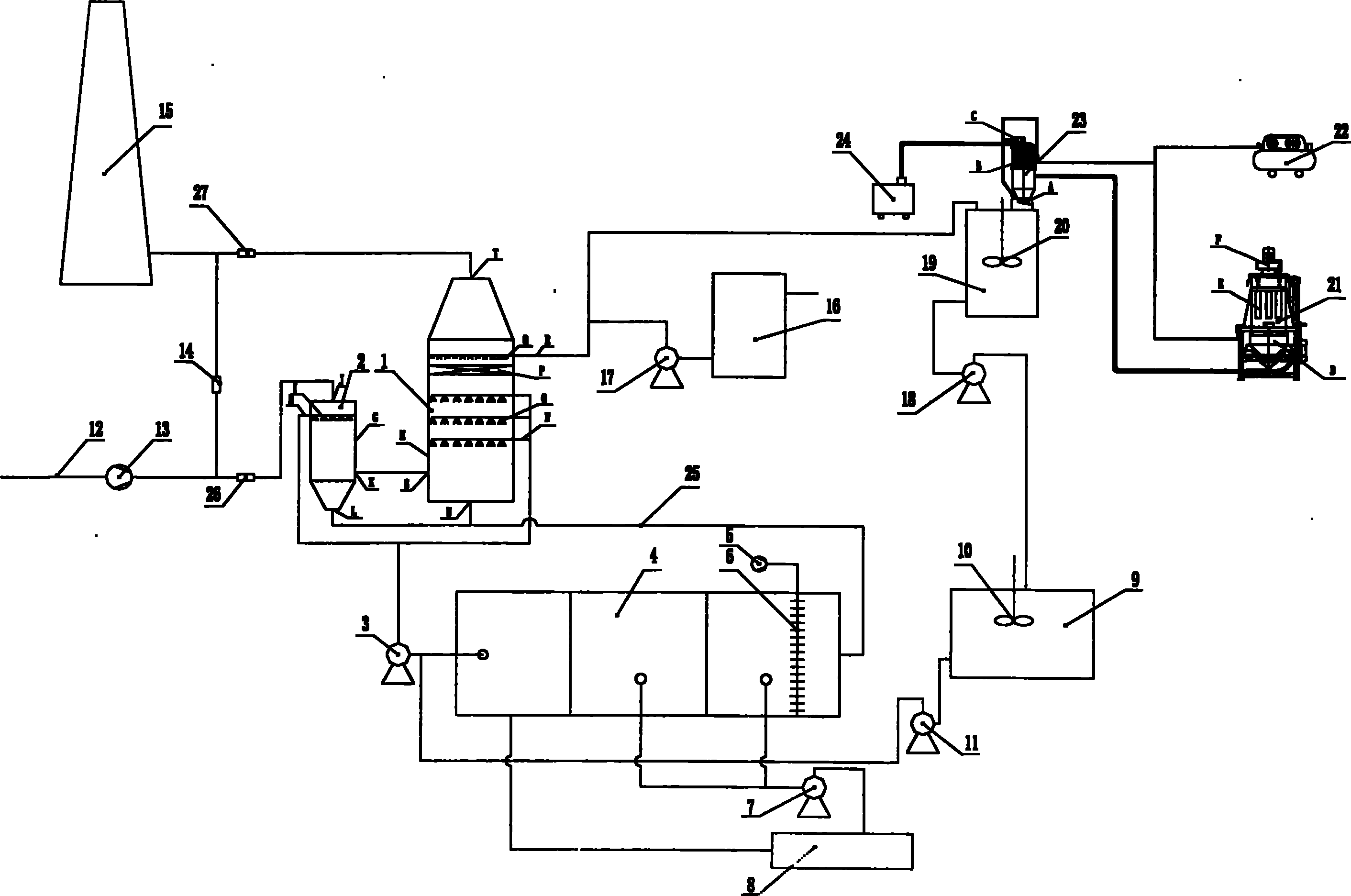

Flue gas desulfurization method of heating boiler and device thereof

InactiveCN101804293AAvoid pollutionCause secondary pollutionLighting and heating apparatusAluminium oxide preparationEngineeringDigestion

The invention relates to a flue gas desulfurization method of a heating boiler and a device thereof, belonging to the technical field of heating boilers. The flue gas desulfurization method of the heating boiler comprises the following steps of: precooling, desulfurizing, magnesium oxide pulping, absorption liquid aeration and crystallizing dehydration. In the precooling step, glue gas enters a precooling tower through a flue gas inlet channel for precooling, and absorption liquid is atomized and sprayed; in the desulfurizing step, the flue gas enters a desulfurizing tower for desulfurizing, and the absorption liquid is atomized and sprayed; the flue gas is discharged through a chimney; in the step of magnesium oxide pulping, magnesium oxide powder is pulped in a digestion tank; in the step of absorption liquid aeration, an air blower carries out aeration on the absorption liquid by a gas distribution pipe; and in the step of crystallizing dehydration, magnesium sulfate crystal size is crystallized and dehydrated. The flue gas desulfurization device of the heating boiler is characterized in that the flue gas inlet channel is communicated with the precooling tower by a draught fan; the precooling tower is communicated with the desulfurizing tower through a flue; the desulfurizing tower is communicated with the chimney; an absorption liquid atomization spray mechanism is respectively arranged in the precooling tower and the desulfurizing tower; the air blower is communicated with an aeration gas distribution pipe; a circulating water pool is communicated with a dehydrator; and a spray circulating pump is communicated with the digestion tank. The invention has the advantages of good desulfurizing effect, high desulfurizing efficiency, little water along with flue gas discharge, convenient operation, environmental protection and the like.

Owner:TIANJIN XIAOWO ENVIRONMENTAL PROTECTION ENG CO LTD

Vertical electroplating production equipment

The invention relates to vertical electroplating production equipment, and belongs to the technical field of electroplating. The vertical electroplating production equipment comprises a micro etching cylinder, an electroplating cylinder, at least two first water washing cylinders, at least one second water washing cylinder and at least one third water washing cylinder, wherein the second water washing cylinder, one of the at least two first water washing cylinders, the third water washing cylinder and the other one of the at least two first water washing cylinders are communicated in sequence through pipelines; and the second water washing cylinder is also communicated with a clear water pipe. Water of all the water washing cylinders is from one clear water source; the flowing direction of the water is reasonably arranged according to the achieved cleaning effect and the workpiece polluted degree in each water washing procedure; the water is recycled in all the water washing procedures; and when sewage is treated, the total use level of clear water is decreased under the condition of equal cleaning effect, the use cost of the clear water is reduced, the sewage treatment amount is correspondingly reduced, and the sewage treatment pressure is reduced.

Owner:NEW FOUNDER HLDG DEV LLC +1

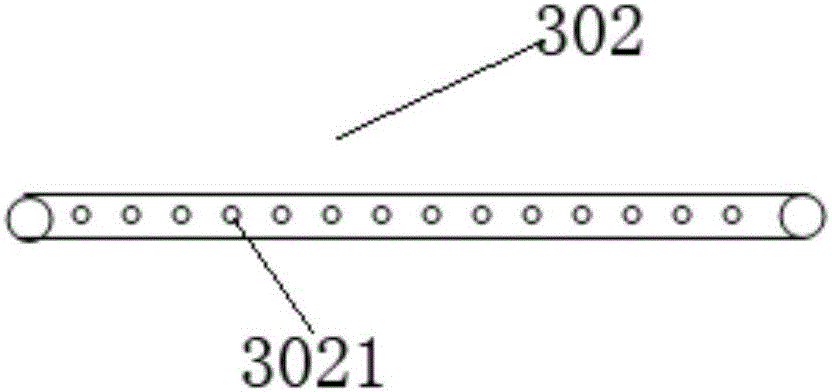

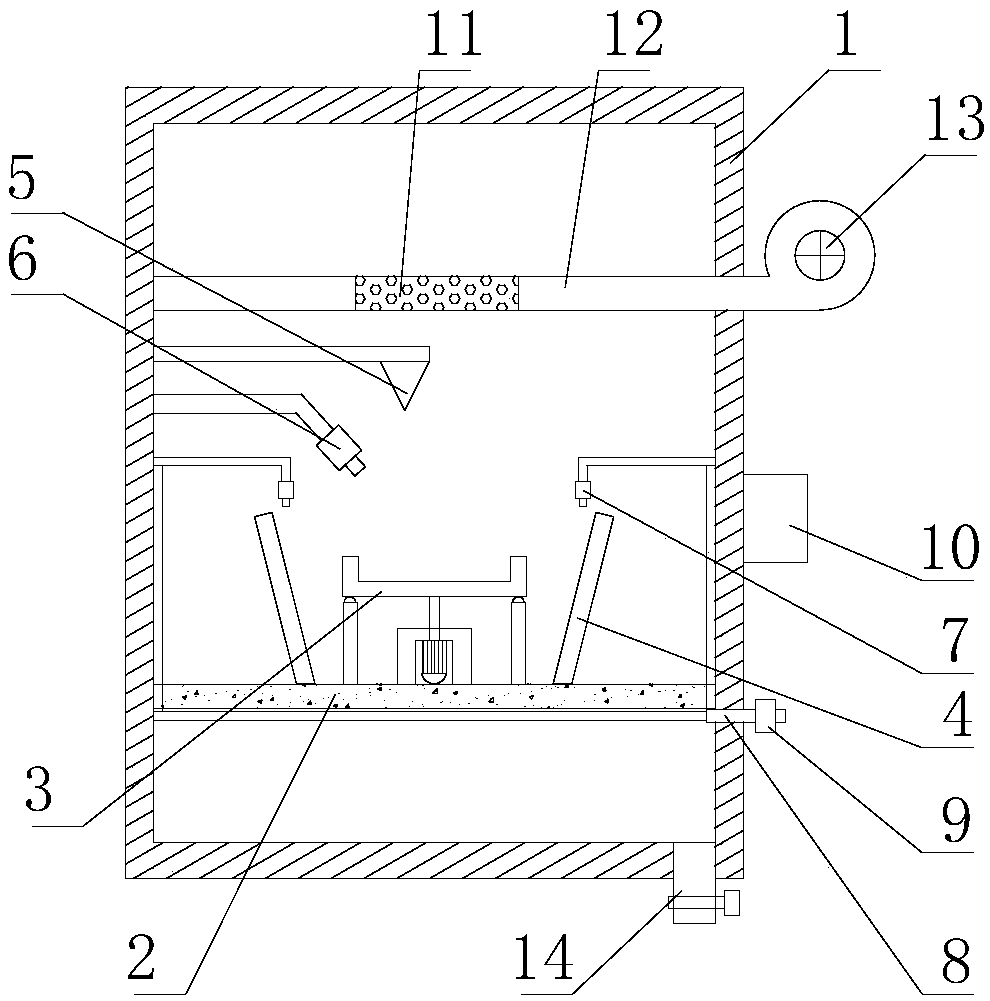

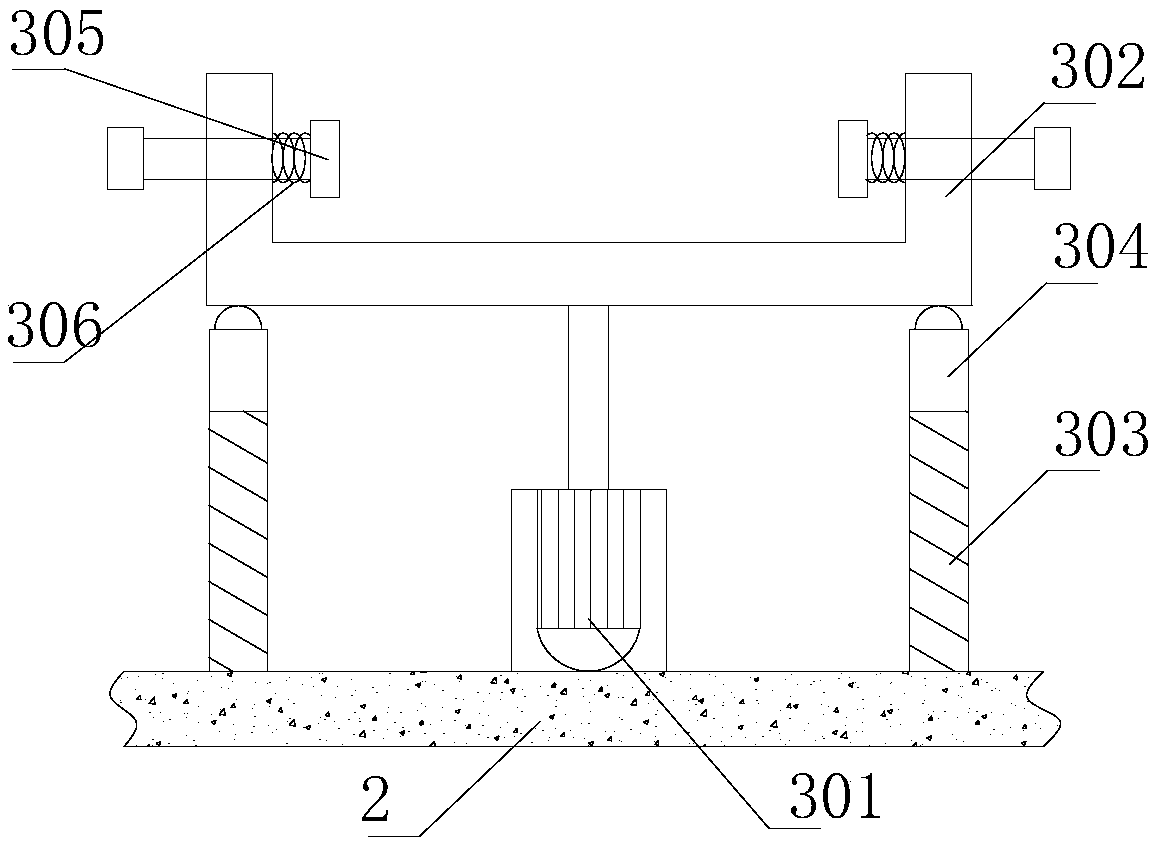

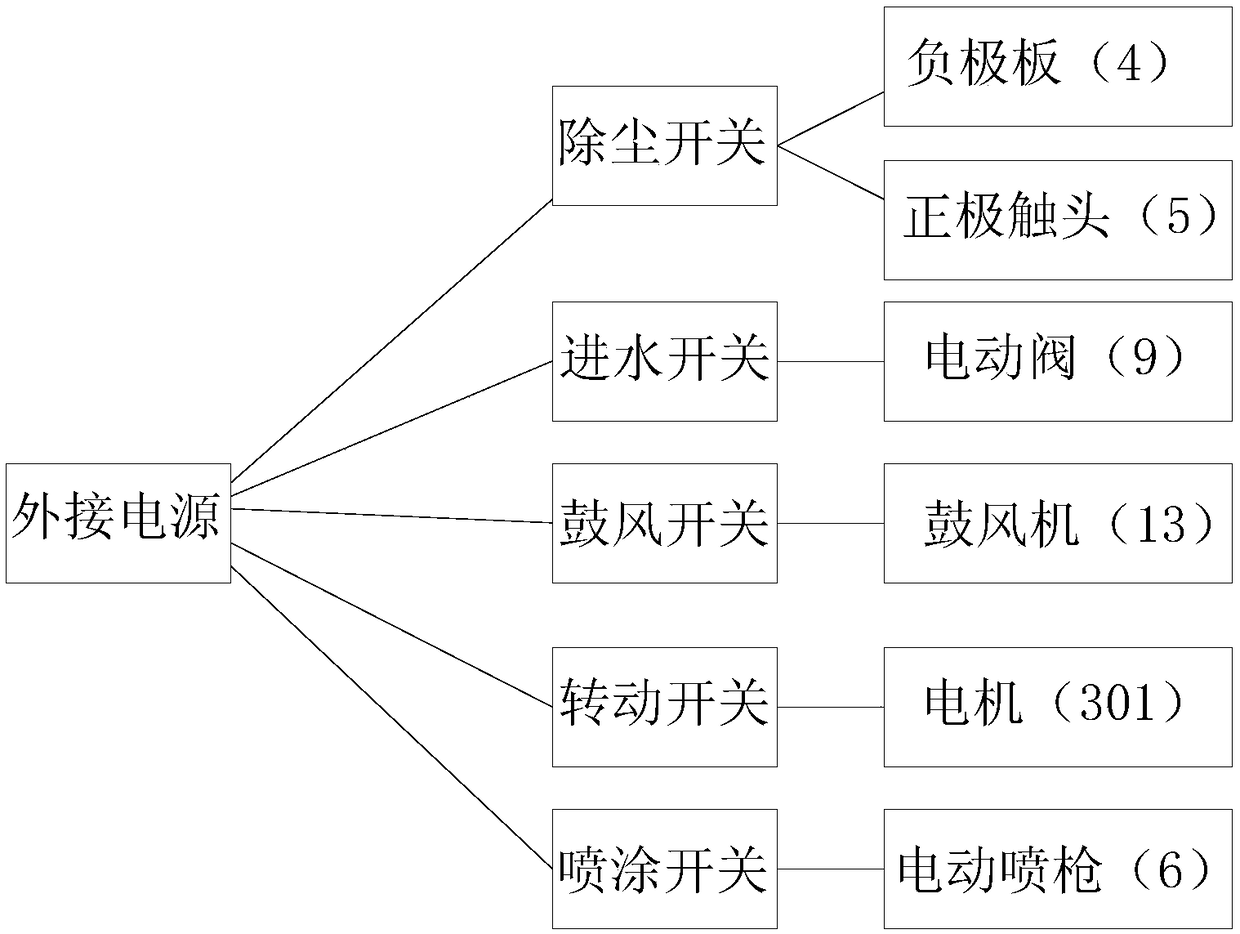

Spraying device used for metal furniture

The invention discloses a spraying device used for metal furniture. The spraying device comprises a cabinet and a water permeable plate arranged inside the cabinet. A holding plate is arranged in themiddle of the top end of the water permeable plate. An electric spray gun is arranged at one side of the top of the holding plate. Negative plates are arranged at the two sides of the holding plate symmetrically. Water spraying nozzles are arranged at the top ends of the two negative plates correspondingly. The two water spraying nozzles communicate with a water inlet pipe through pipelines correspondingly. An electrically operated valve is arranged on the water inlet pipe. An air blower is arranged at the top of the outer wall of one side of the cabinet. An air outlet pipe of the air blower communicates with an air inlet pipeline. Air spraying pipes are arranged in the middle of the air inlet pipeline. A positive contact is arranged at the bottoms of the air spraying pipes and fixedly connected with the inner wall of one side of the cabinet through a support. According to the spraying device used for the metal furniture, by arranging the negative plates, the positive contact and the water spraying nozzles, dust in the cabinet can be removed before spraying, and the spraying reliability is guaranteed; through the arranged holding plate, the furniture can be clamped during spraying;and during spraying, the furniture rotates, spraying is more uniform, and the spraying effect is guaranteed.

Owner:四川风格家家居有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com