Flue gas denitrification device used for coal-fired boiler

A technology for coal-fired boilers and flue gas, which is applied in gas treatment, membrane technology, and separation of dispersed particles, etc. It can solve the problems of expensive oxidant, easy decomposition by heat, and unstable properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

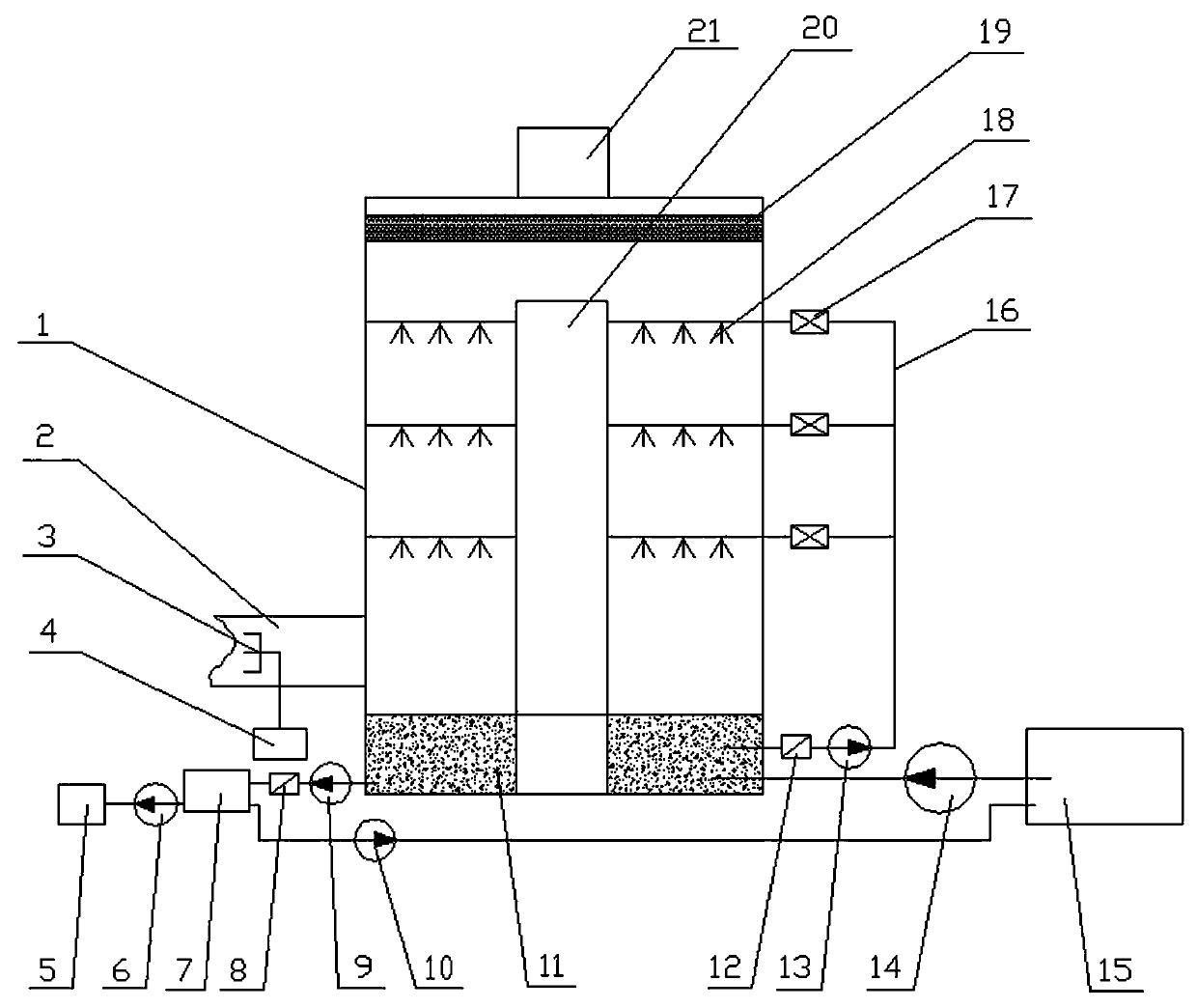

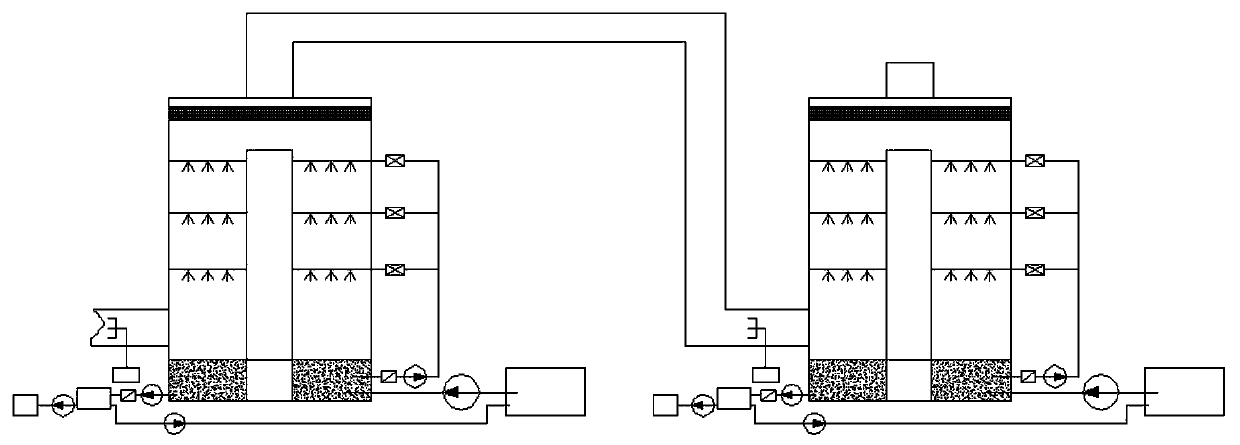

[0026] like figure 1 As shown, a flue gas denitration device for a coal-fired boiler of the present invention includes a spray tower, an oxidation system, a spray system and a circulation system. The flue gas is oxidized into water-soluble high-priced nitrogen oxides through the oxidation system in the spray tower, and is efficiently absorbed by the absorption liquid through the spray system. The circulation system is used to maintain the activity of the absorption liquid in the spray tower to absorb nitrogen oxides .

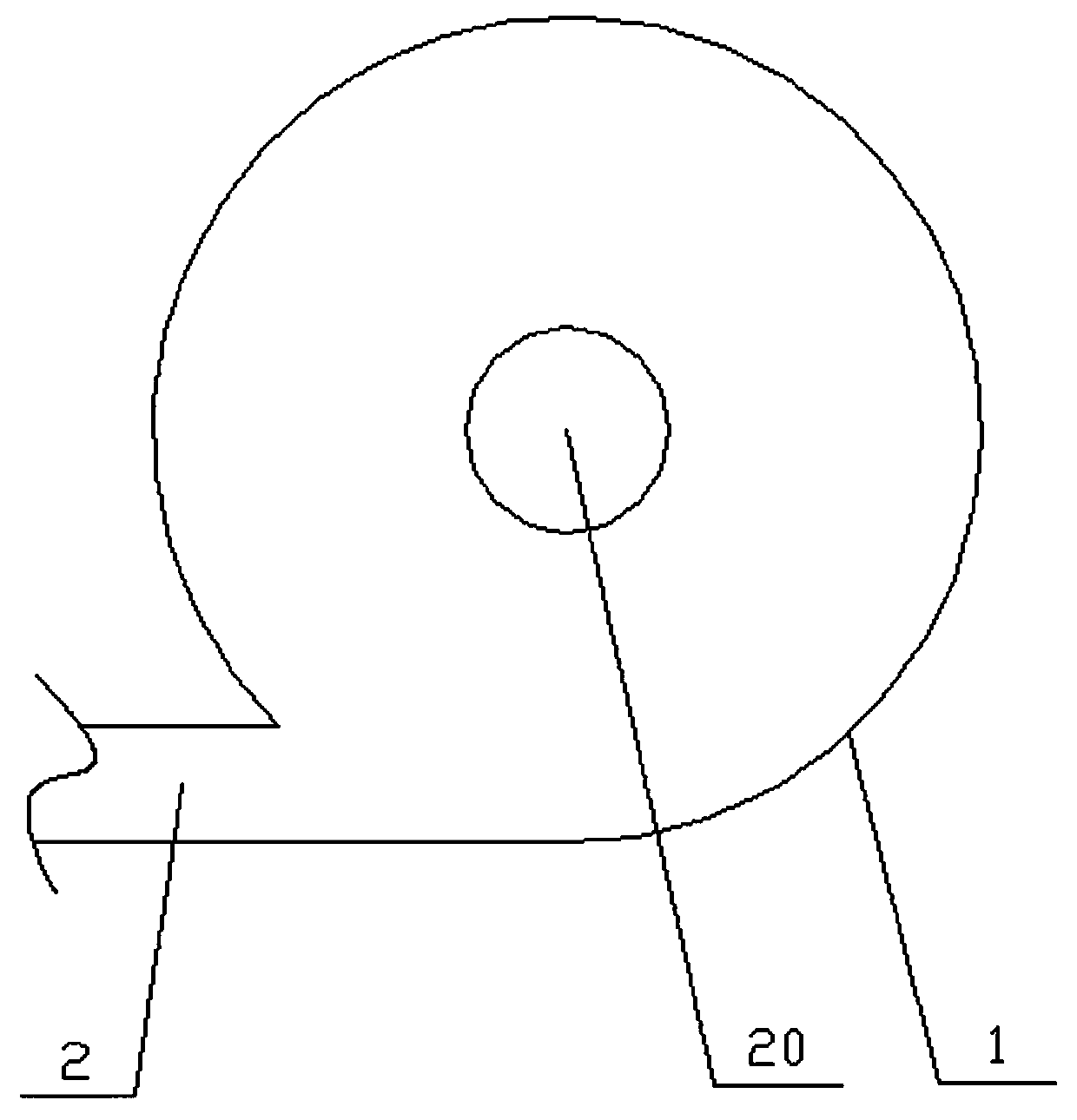

[0027] The spray tower includes a cylindrical tower body 1 and an inner core 20 concentrically arranged in the inner cavity of the tower body 1 along the height direction of the tower body 1 . A flue gas outlet pipe 21 is connected to the top of the tower body 1 . like figure 2 As shown, flue gas inlet pipes 2 distributed along the tangential direction of the tower body 1 are connected to the bottom of the tower body 1 . The flue gas inlet pipe 2 distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com