Pipeline inner wall coating machine

A technology of spraying machine and pipeline, applied in the field of spraying machine and pipeline inner wall spraying machine, can solve the problems of unsuitable temperature and strong paint smell.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings. In the following description, the side in the forward direction of the sprayer is referred to as the front or the front, and the side opposite to the forward direction of the sprayer is described as the rear or the rear.

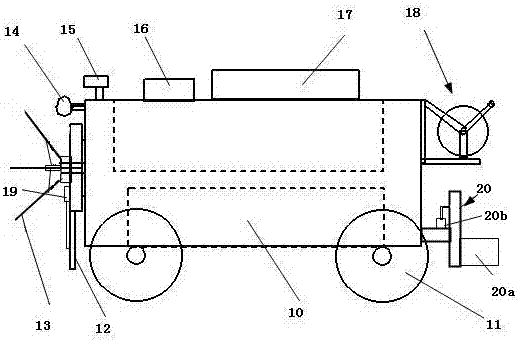

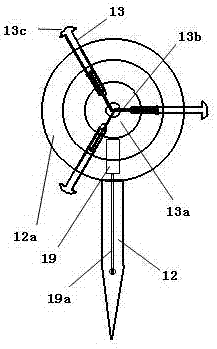

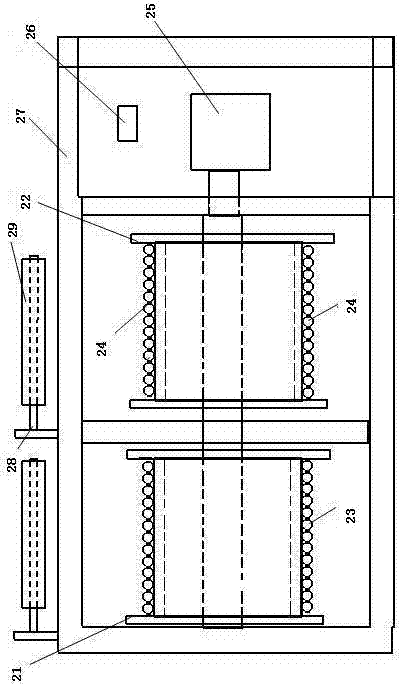

[0022] A pipeline inner wall spraying machine, figure 1 It is a schematic diagram of the appearance structure of the present invention. 10 is the main body of the spraying machine. The spraying machine on the inner wall of the pipeline includes a driving device and an information transmission device. The two semi-shafts of the output shaft of the driving device are respectively connected with running wheels 11. A plurality of nozzles 13c and wind guns 12 are arranged in front of the spraying machine. The wind gun 12 and a plurality of nozzles 13c are arranged on the nozzle rotating disk 13a by the spray bar 13, and the wind g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com