Patents

Literature

50results about How to "Realize the turning function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

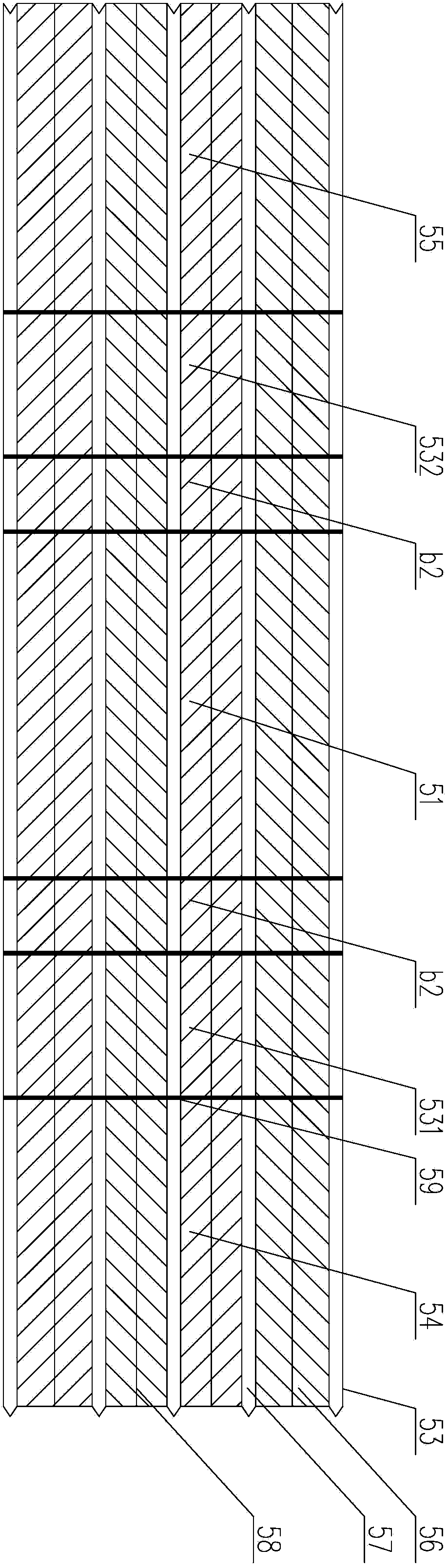

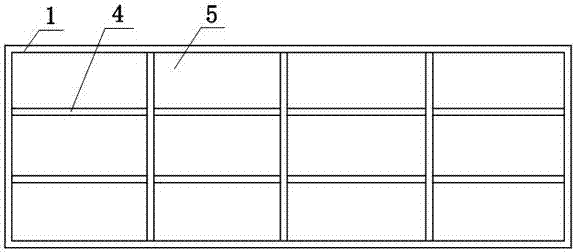

Cast-in-place hollow floor system using steel mesh and inflatable tube combination box for pore-forming

InactiveCN103967181AEnhanced resistance to construction loadsPrevent forward leakageFloorsForms/shuttering/falseworksRebarHollow core

The invention provides a cast-in-place hollow floor system using a steel mesh and inflatable tube combination box for pore-forming. The cast-in-place hollow floor system is composed of a main beam, a ribbed beam, an upper flange plate, a lower flange plate and the steel mesh and inflatable tube combination box. The main beam is a reinforced concrete combination beam or a fashioned iron beam. The steel mesh and inflatable tube combination box is formed by interacting a steel mesh and inflatable tubes. The steel mesh forms a box top, a box bottom and two side walls of the combination box. According to the inflatable tubes, plastic is made into air storage tubular bodies or polystyrene blocks to form the other two side walls of the steel mesh and inflatable tube combination box and the height of the inner space of the supporting box top and the box bottom. An existing full-sealed hollow filling body and solid filling body are replaced by an unsealed mesh-like box-shaped member for the pore-forming technology of the cast-in-place hollow floor system, and the combination of the steel mesh and the inflatable tubes is adopted. In this way, the problems of plugging of the other two side walls of the steel mesh box and the height of the inner space between the supporting box top and the box bottom are effectively solved, and construction of the cast-in-place hollow floor system is facilitated.

Owner:王本淼

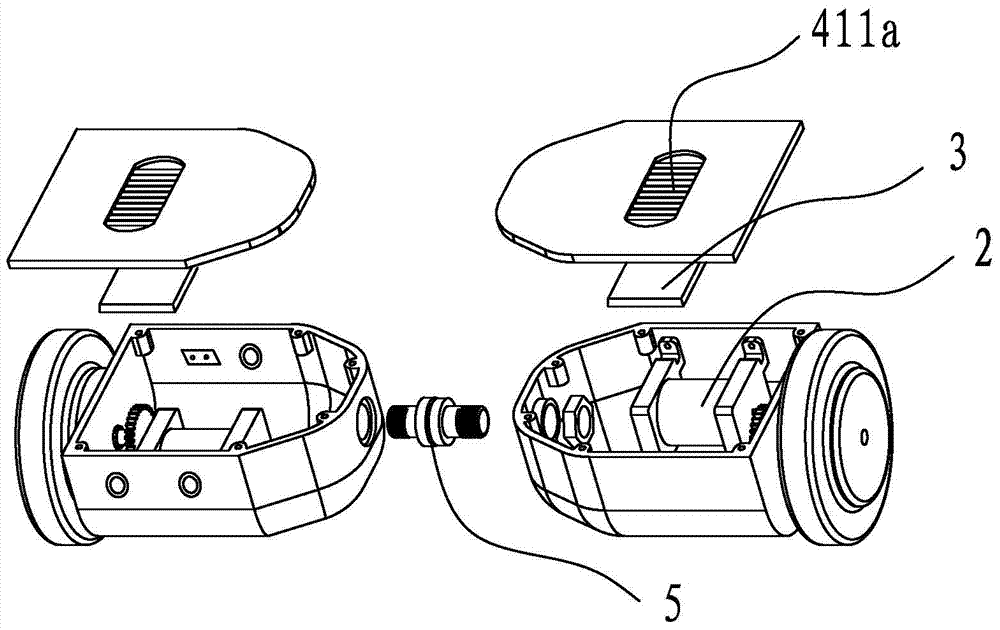

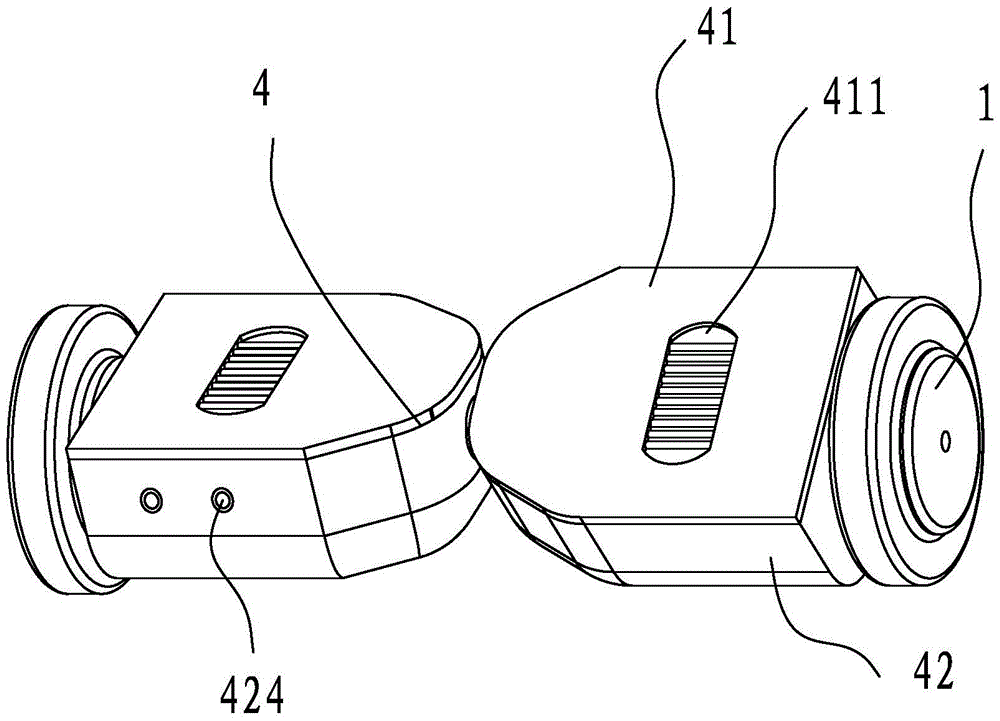

Steering control method for self-balancing two-wheeled vehicle

InactiveCN104163222ARealize the turning functionEasy to operateMotorcyclesRider propulsionVehicle frameGyroscope

The invention discloses a steering control method for a self-balancing two-wheeled vehicle. The two-wheeled vehicle comprises two separated split frames, a connecting shaft is arranged between the two split frames, and motors and gyroscopes capable of controlling the rotating speed of the motors are arranged in the split frames. The steering control method for the self-balancing two-wheeled vehicle comprises the following steps that firstly, the outer split frame needing to turn is treaded by the foot, and the inner split frame is kept horizontal. According to the split frame in the horizontal state, due to the fact that the gyroscope does not induct changes of the inclination angle, the motor does not rotate, the gyroscope at the bottom of an upper cover pedal inducts the changes of the inclination angle after inclination, signals are output to a circuit board to enable the motor to rotate, and therefore wheels are driven to rotate. Finally, one wheel does not rotate, the other wheel rotates, the two-wheeled vehicle turns and moves with the wheel which does not rotate as the center, the acceleration, speed reduction and turning functions can be achieved through foot treading, and the structure is simple.

Owner:重庆鹏得基业汽车部件有限公司

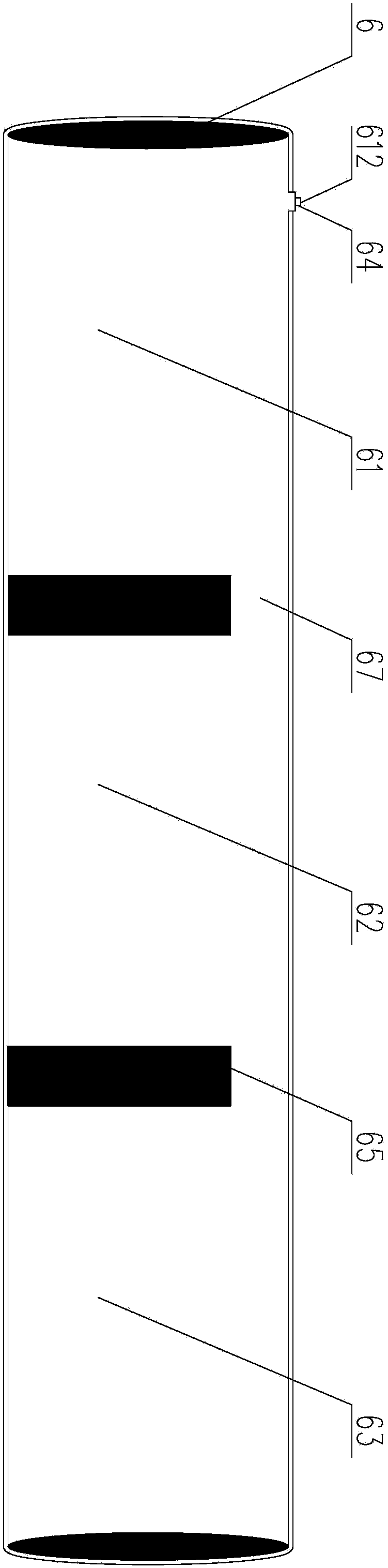

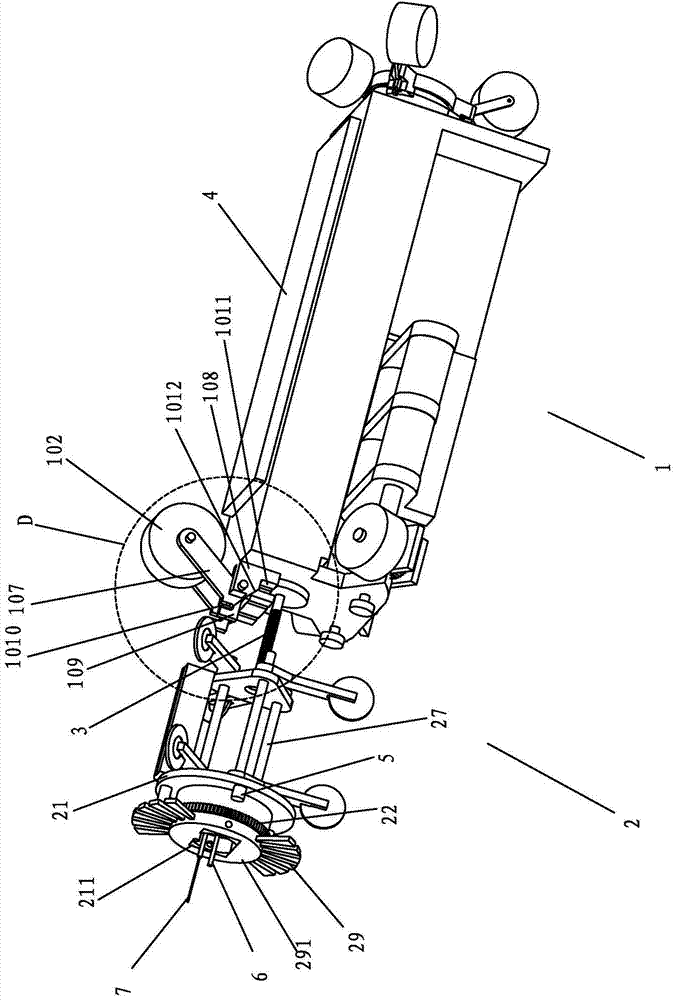

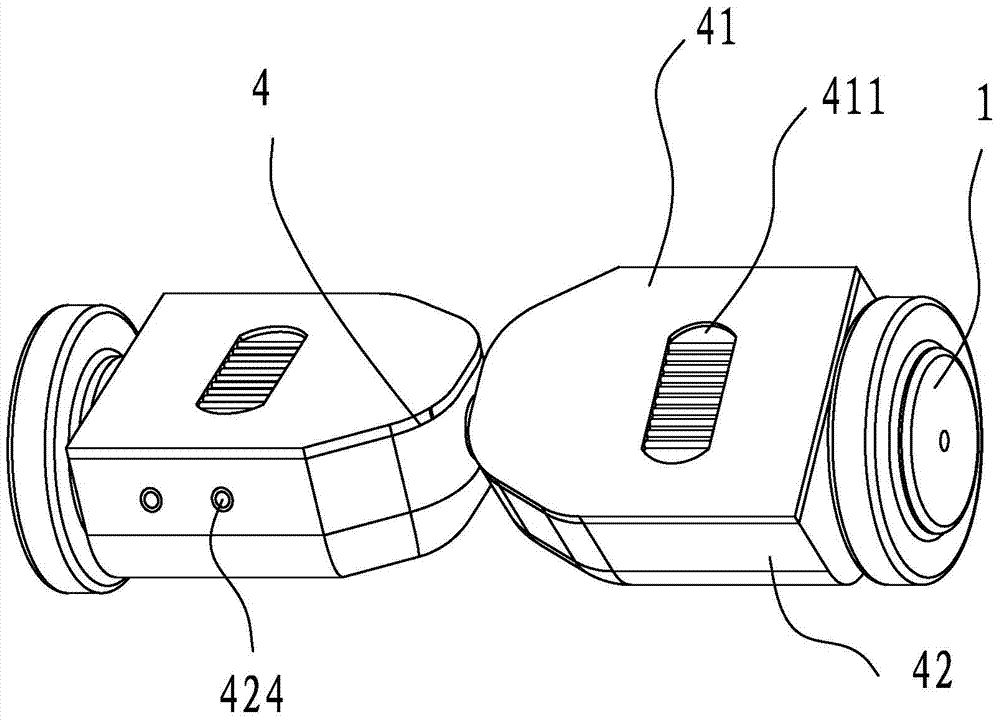

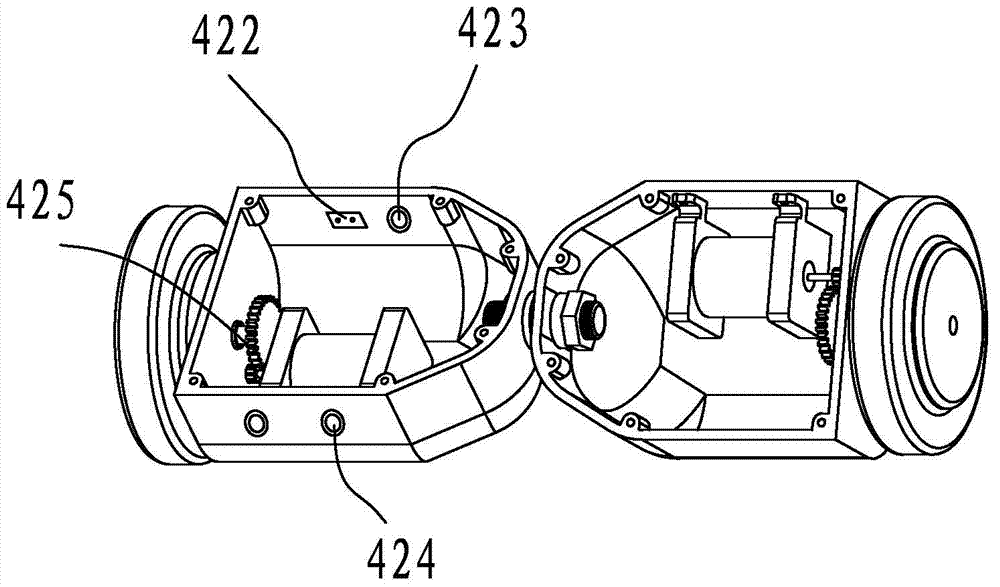

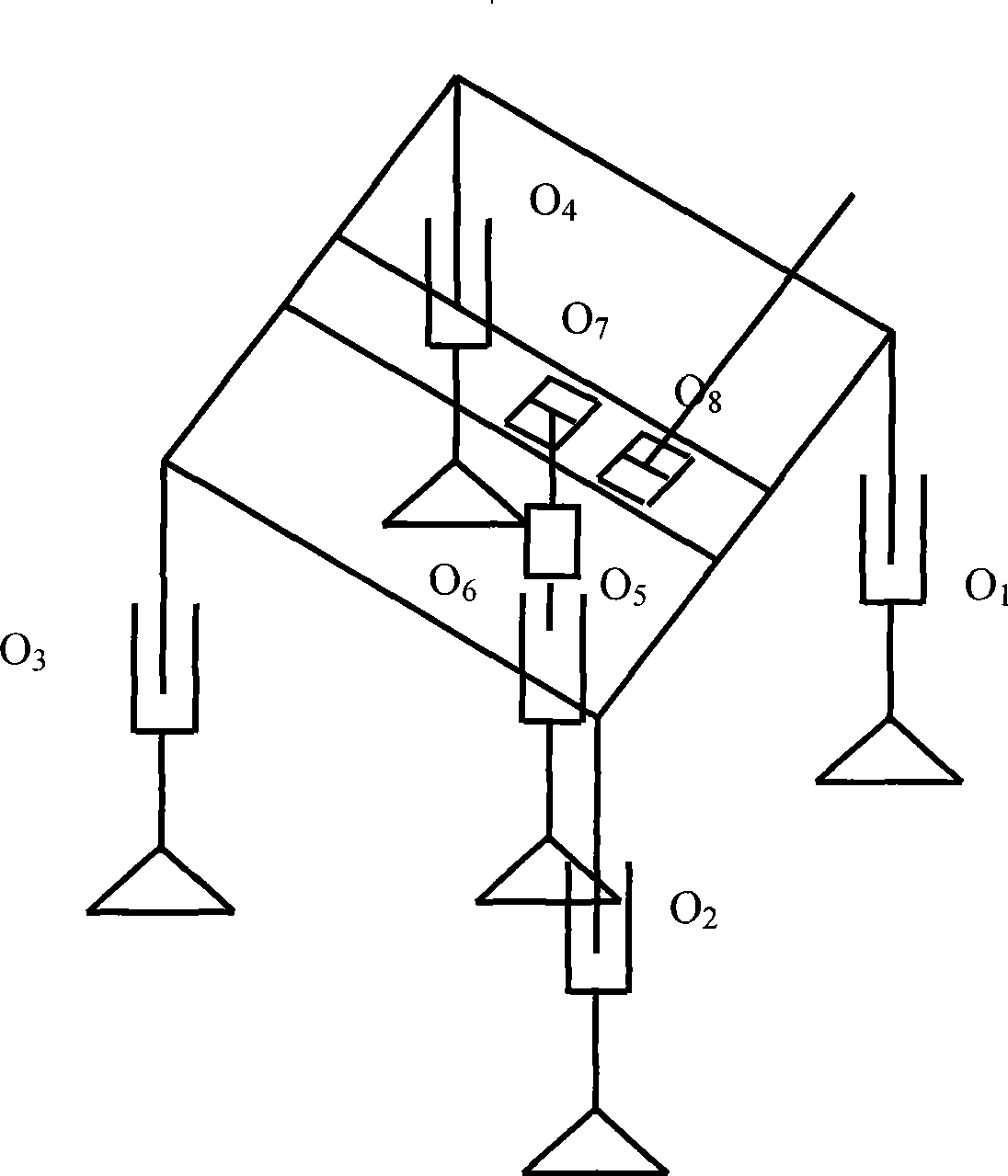

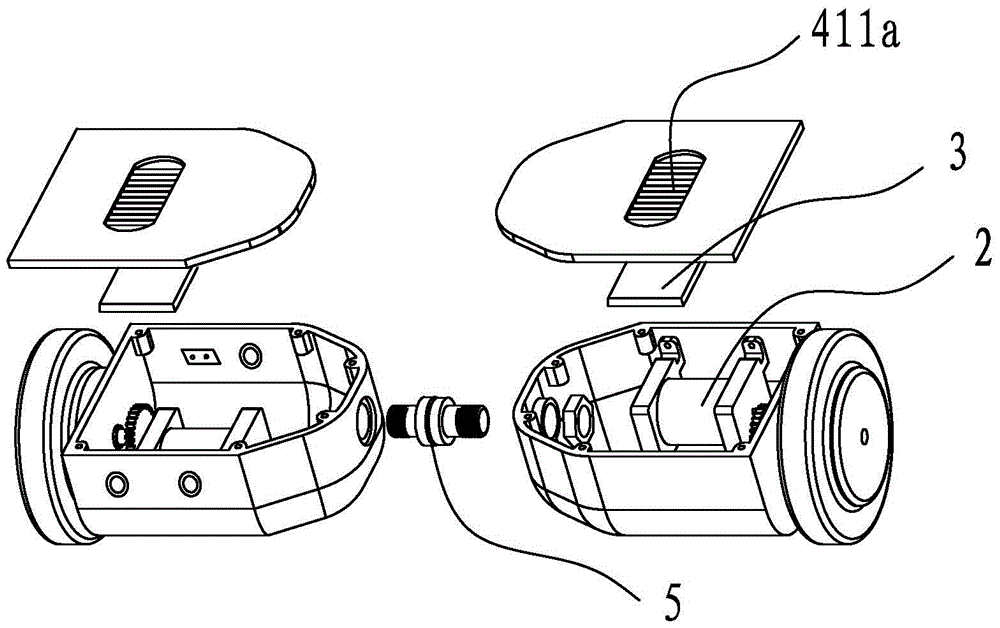

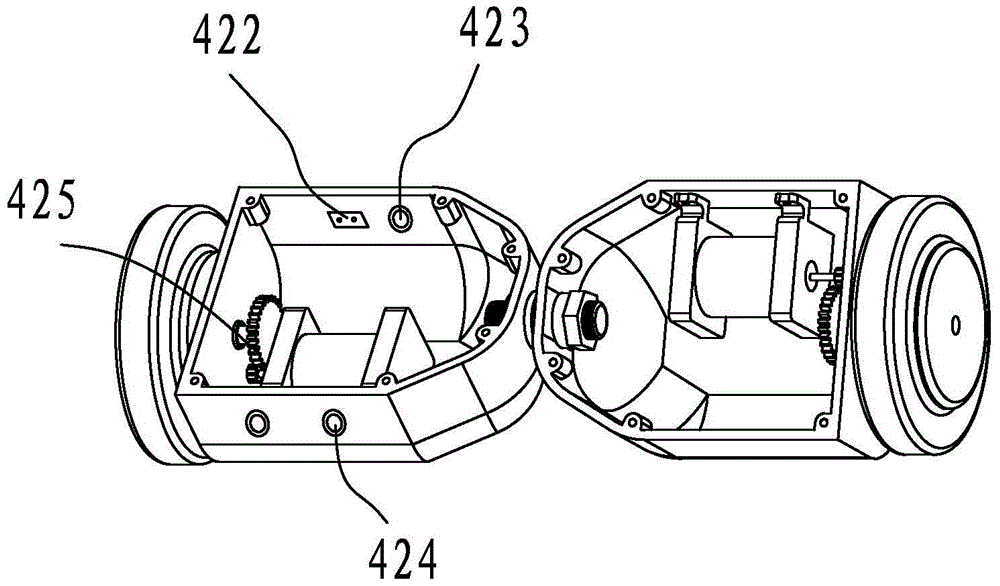

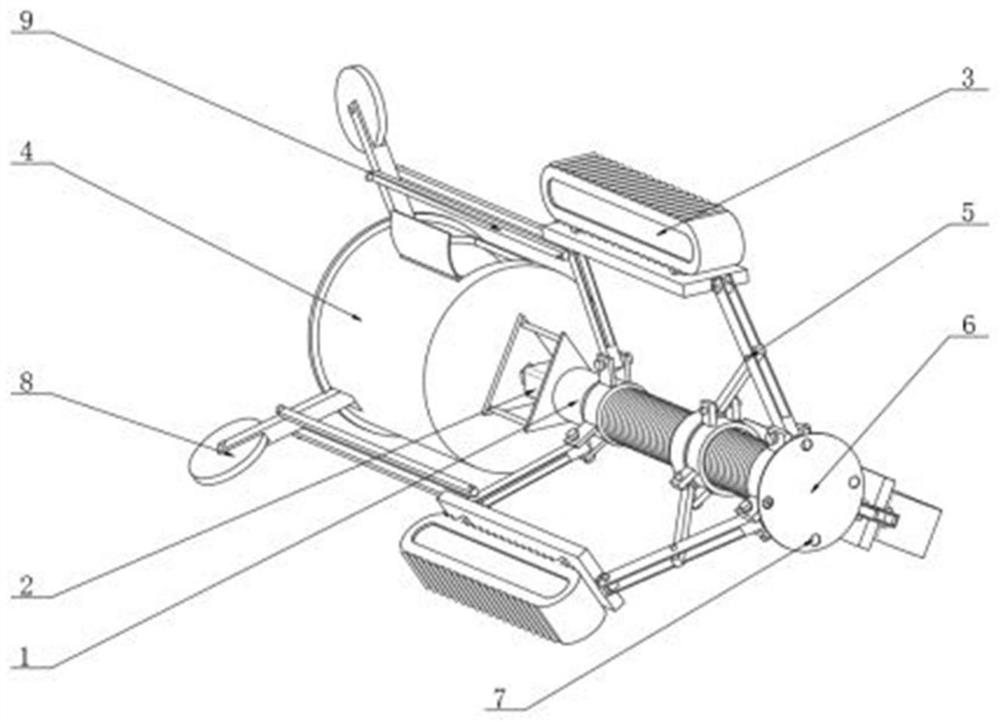

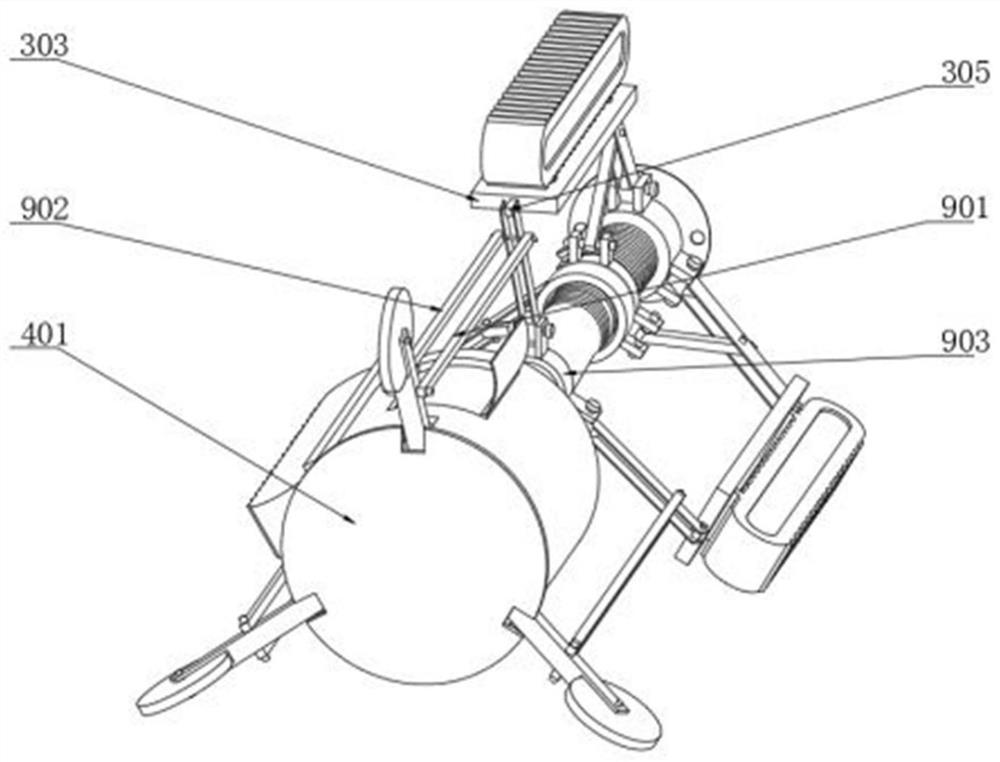

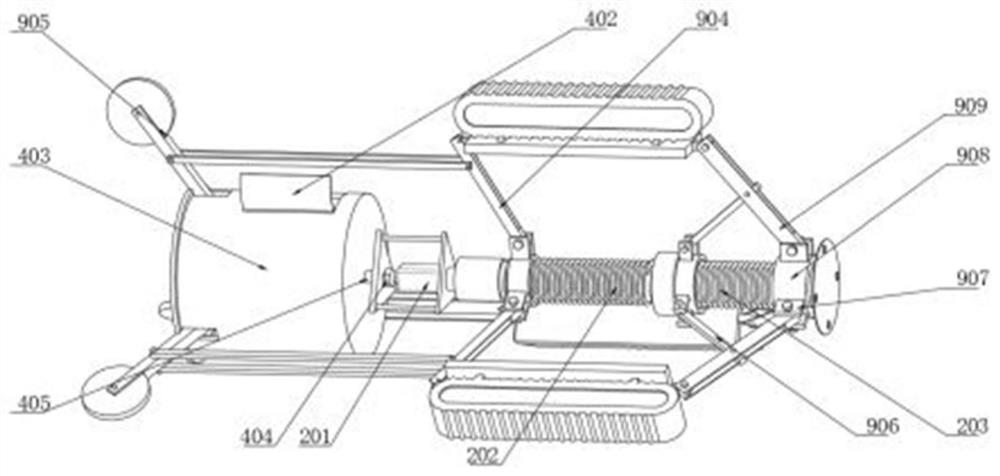

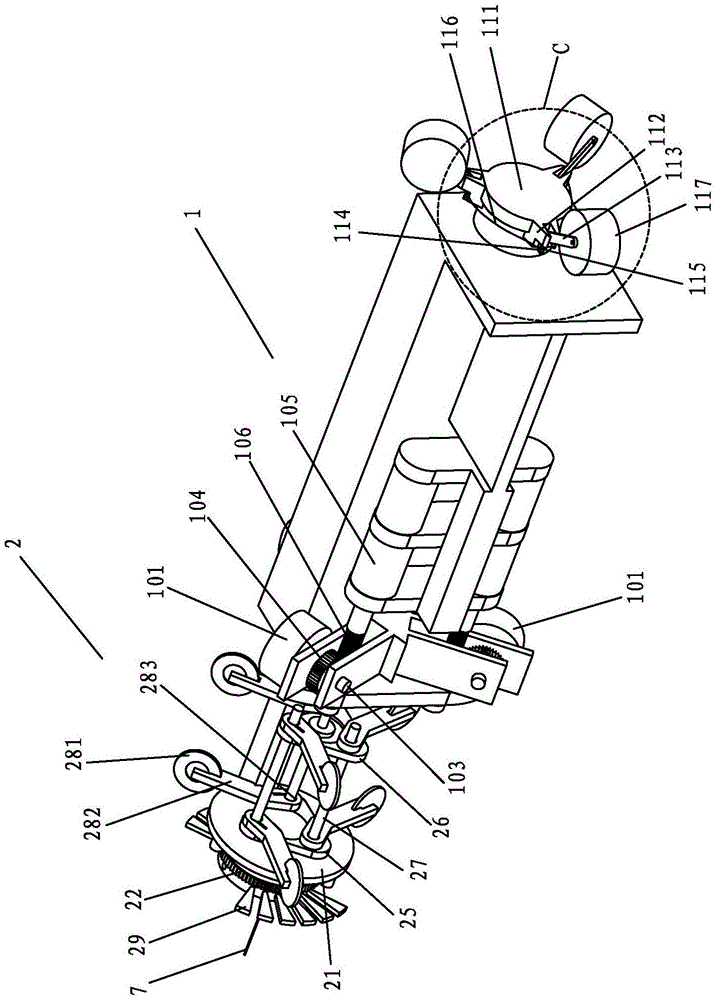

Multifunctional pipeline robot

ActiveCN104259158ARealize the turning functionWalking smoothlyHollow article cleaningDrive wheelEngineering

The invention relates to a multifunctional pipeline robot which comprises an advancing device, a sweeping device and a control circuit board. A driving device is arranged on the advancing device. The multifunctional pipeline robot further comprises a planetary wheel set A arranged on the advancing device and a planetary wheel set B arranged on the sweeping device, the advancing device is connected with the sweeping device through a spring, and a walking device pushes the sweeping device to advance in a pipeline. When the sweeping device encounters a curve, the spring can be net, and a steering function of the whole robot is achieved. Due to the fact that the walking device and the sweeping device are separately arranged, the length of the whole pipeline robot is quite decreased, and the phenomenon that the pipeline robot is clamped in the curve does not easily occur. The driving device adopts a worm wheel and worm structure, when the pipeline robot stops at a certain position in a vertically pipeline to perform sweeping or detection, a worm wheel does not drive a worm to rotate by utilizing the self-locking performance of the worm wheel and worm structure, and the phenomenon that driving wheel cannot reversely rotate and accordingly the pipeline robot slips down can be avoided.

Owner:FUJIAN QUANZHOU NO 7 MIDDLE SCHOOL

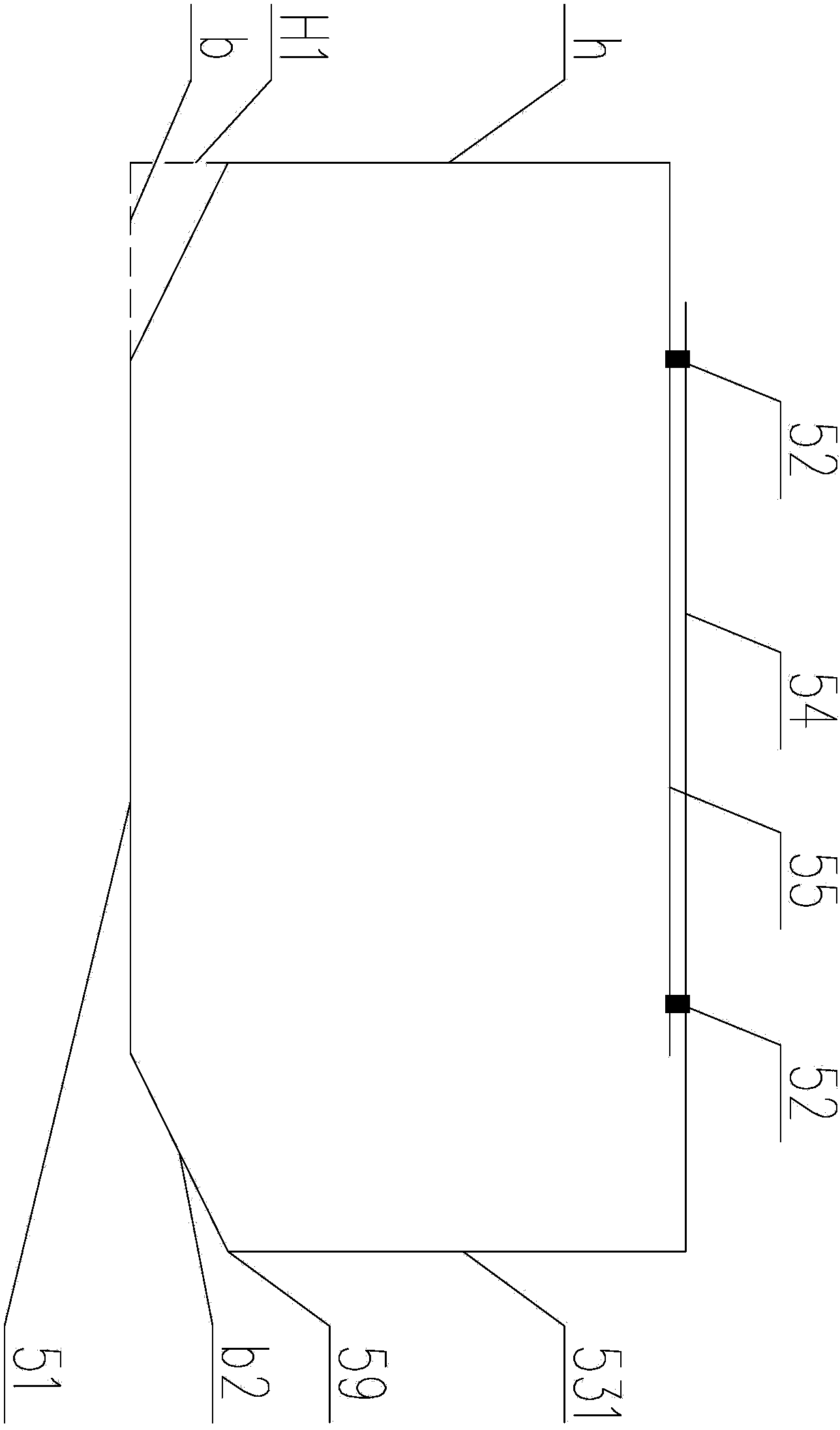

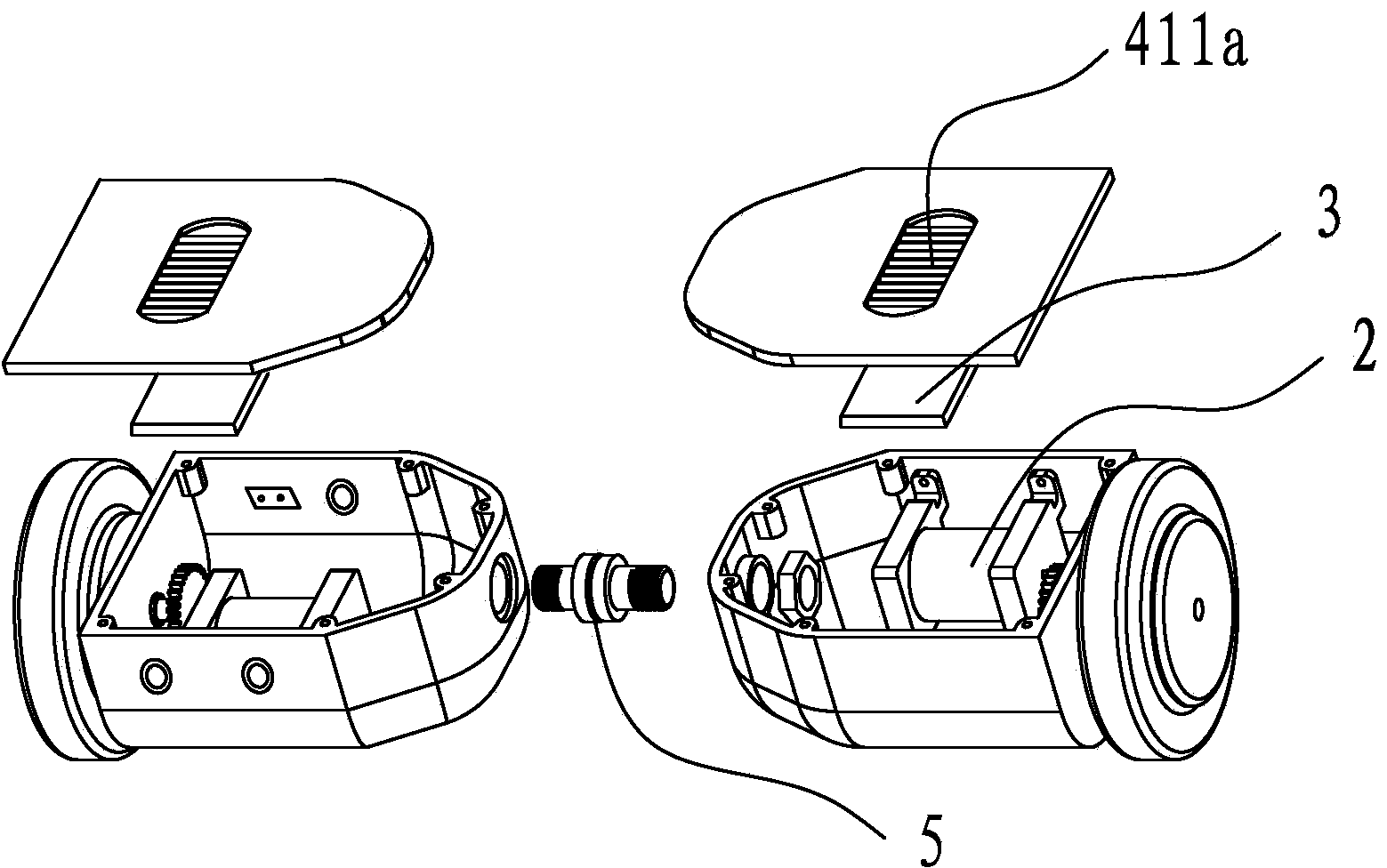

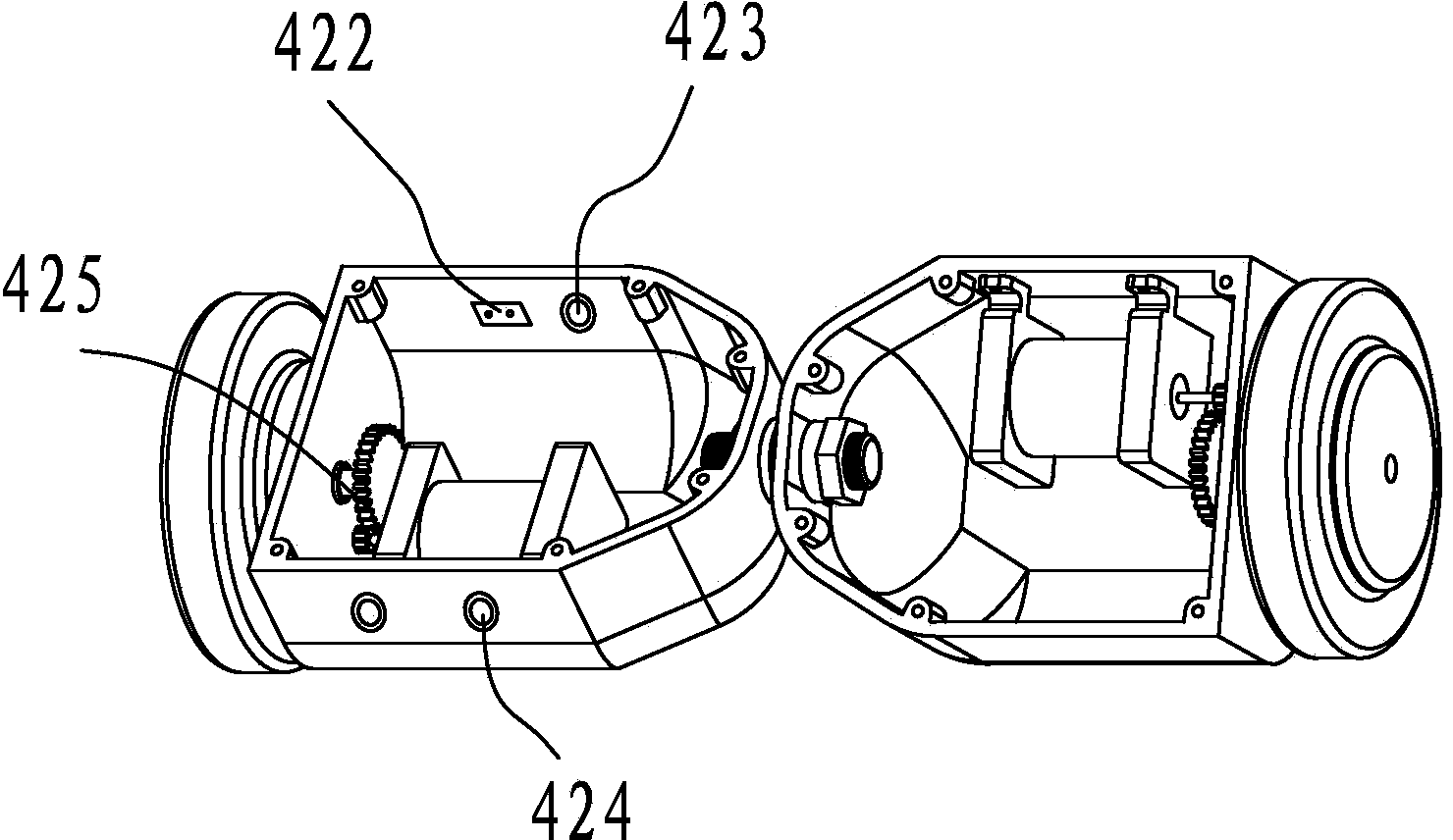

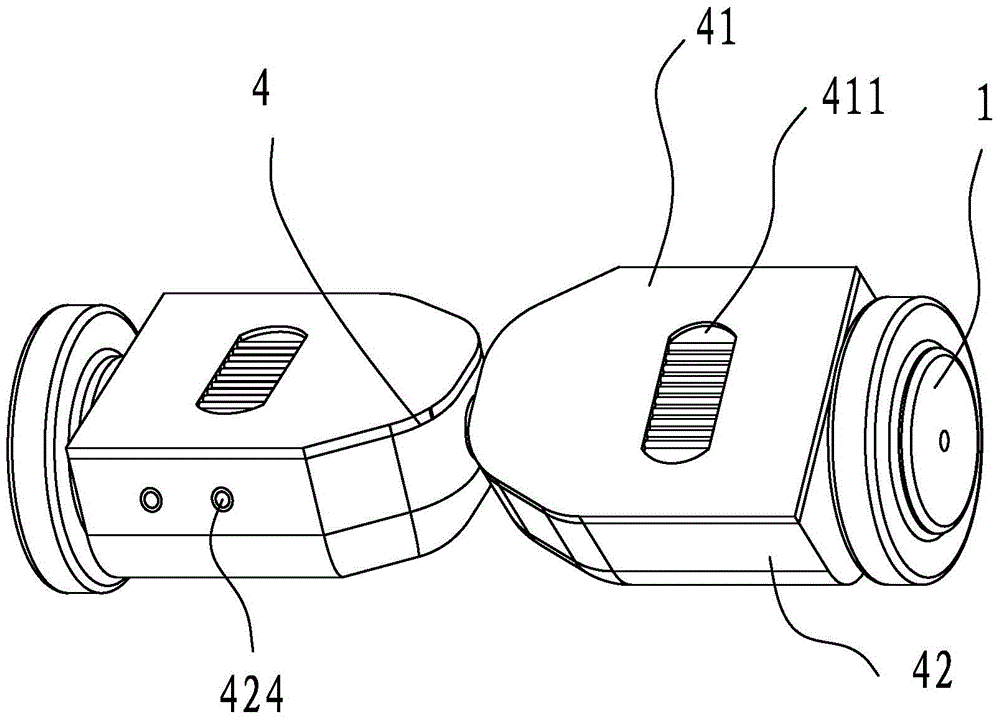

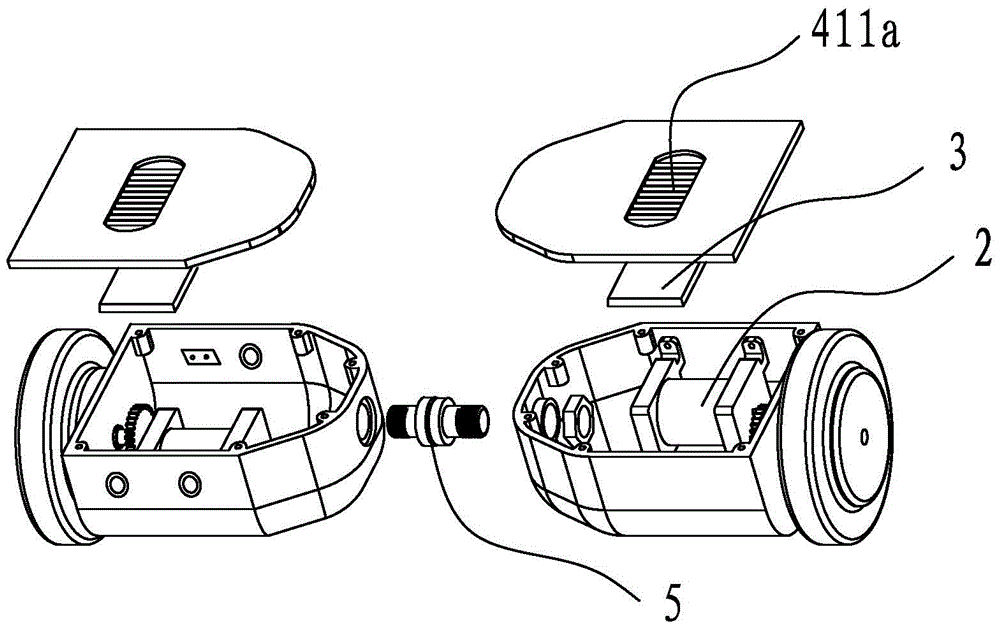

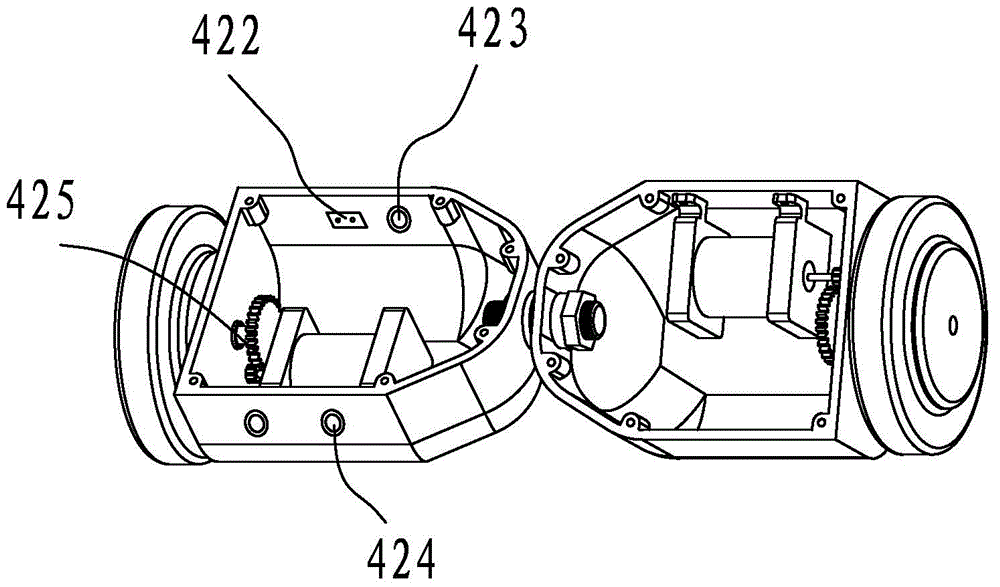

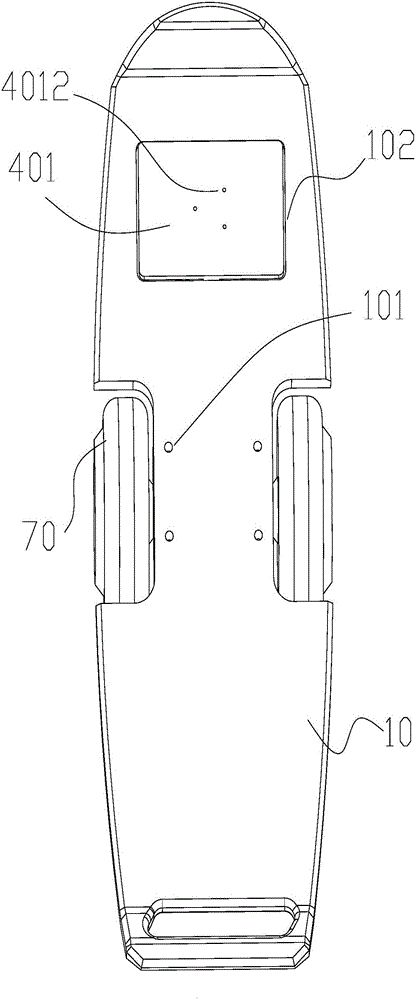

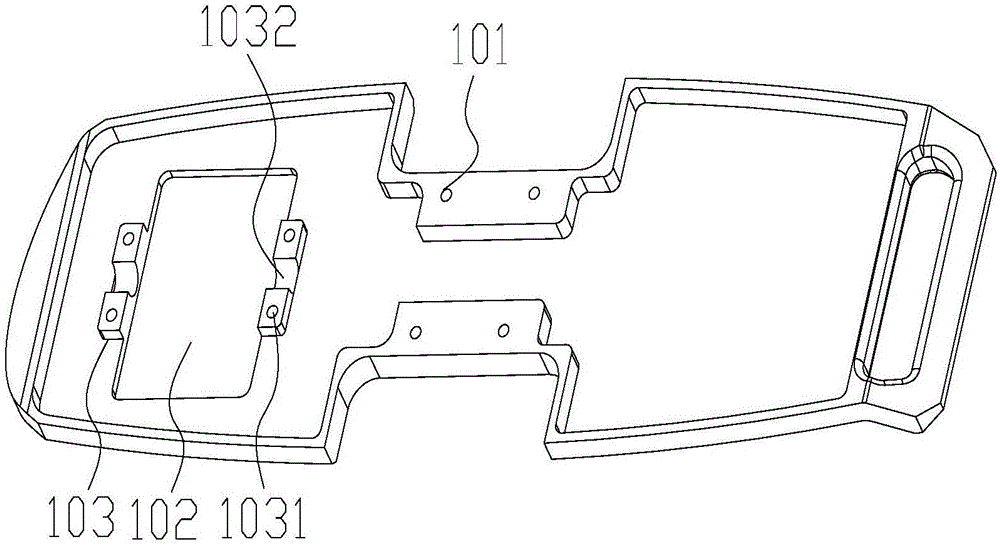

Split type vehicle frame structure of self-balance two-wheeled vehicle

The invention discloses a split type vehicle frame structure of a self-balance two-wheeled vehicle. The split type vehicle frame structure comprises a vehicle body main frame. Wheels are arranged on two sides of the vehicle body main frame, motors and gyroscopes capable of controlling the rotation speeds of the motors are arranged in the vehicle body main frame, the vehicle body main frame comprises two separate split type vehicle frames, a connecting shaft is arranged between the two split type vehicle frames, the two split type vehicle frames individually rotate around the connecting shaft which is used as rotation centers of the two split vehicle frames, the corresponding gyroscope and the corresponding motor are individually arranged in each split type vehicle frame, threads are arranged at two ends of the connecting shaft, two plane bearings are arranged in the middle of the connecting shaft, a bearing bush is arranged between the two plane bearings, through holes are formed in joints of the split type vehicle frames and the connecting shaft, bearing counter-bored holes are formed in the outer sides of the through holes, and the inner sides of the through holes are axially fixed to the ends of the connecting shaft by the aid of nuts. The split type vehicle frame structure has the advantages that acceleration, deceleration and corner turning functions can be implemented by the aid of the feet of a user, and the split type vehicle frame structure is simple.

Owner:祝珍海

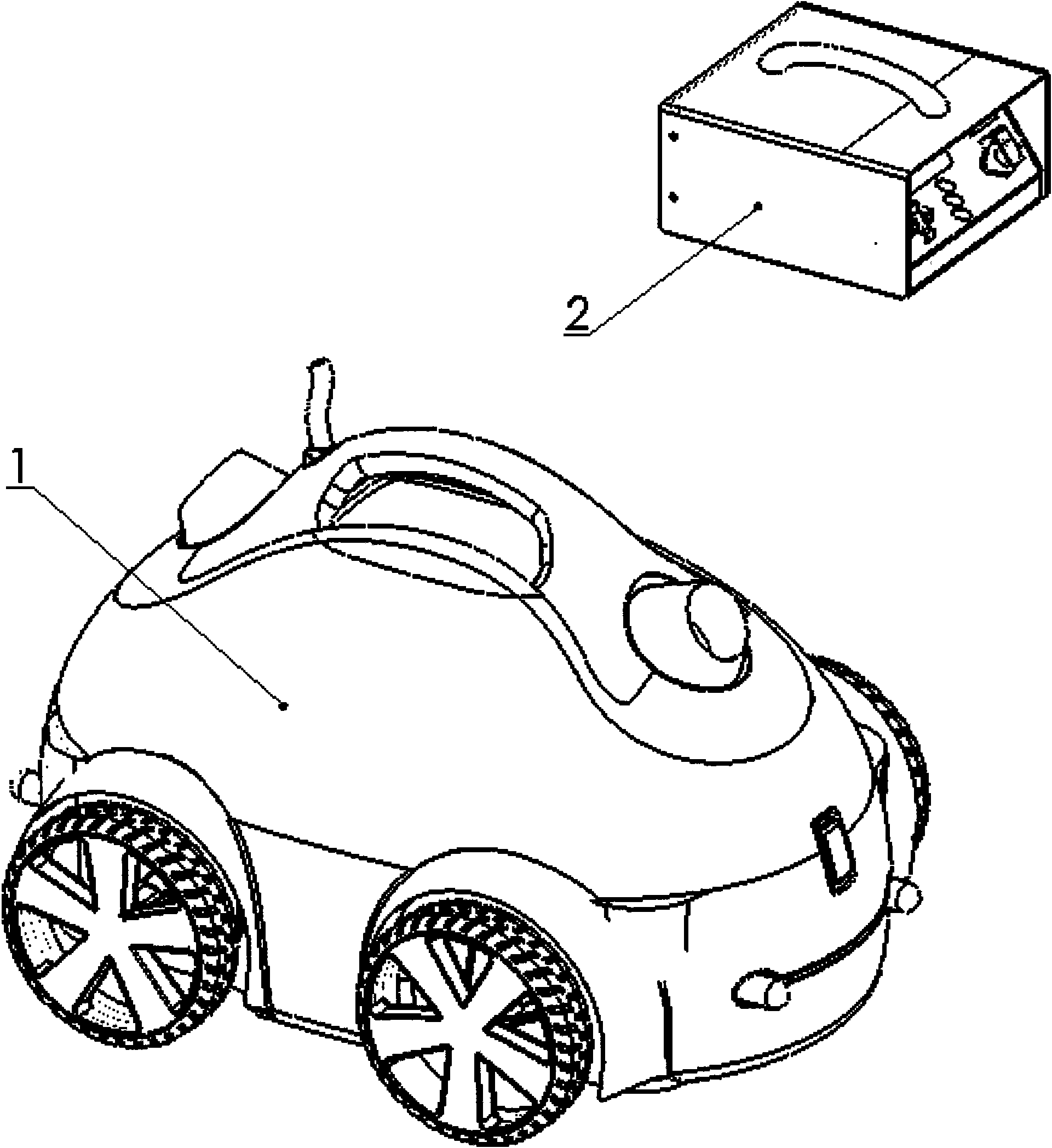

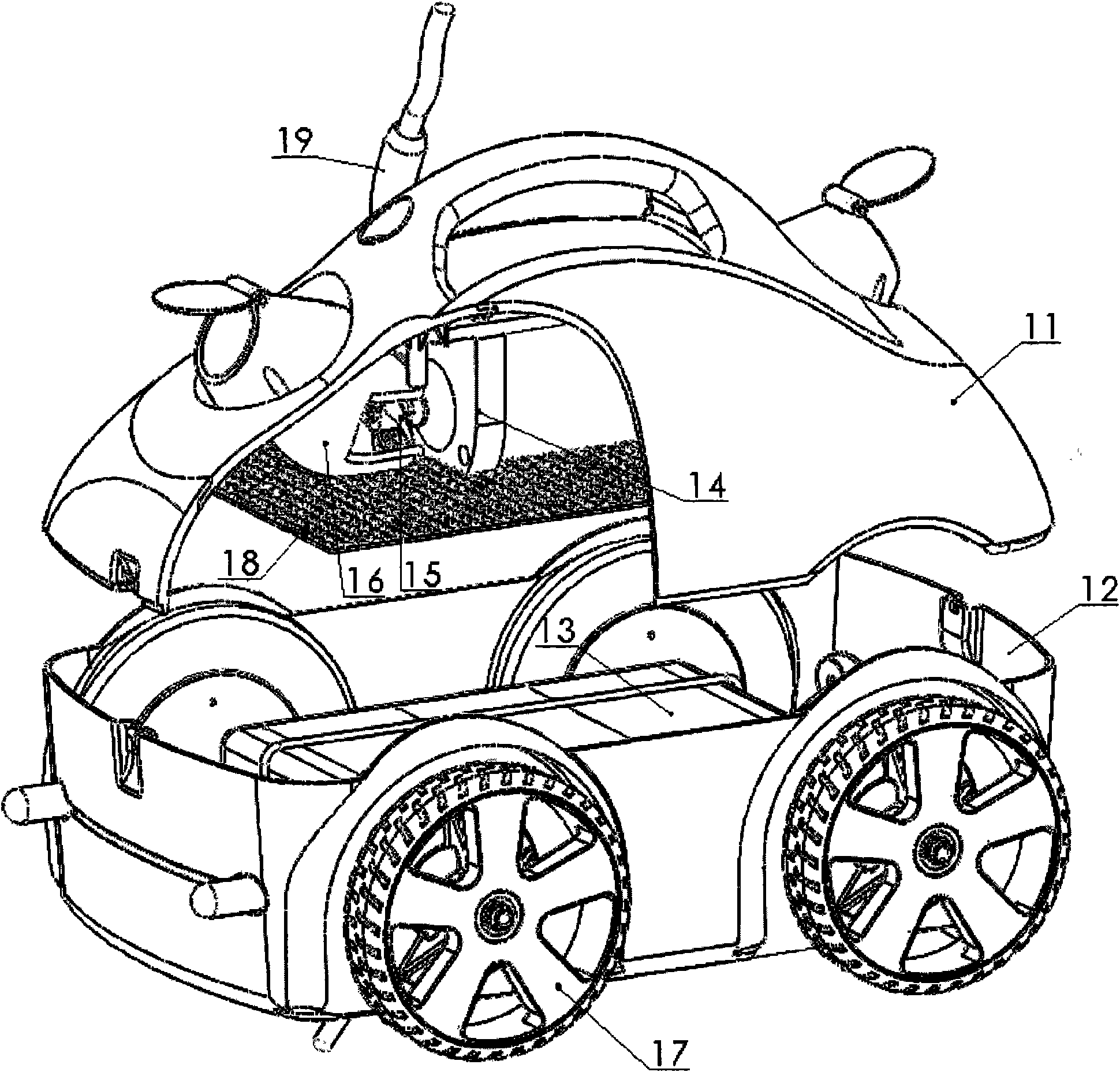

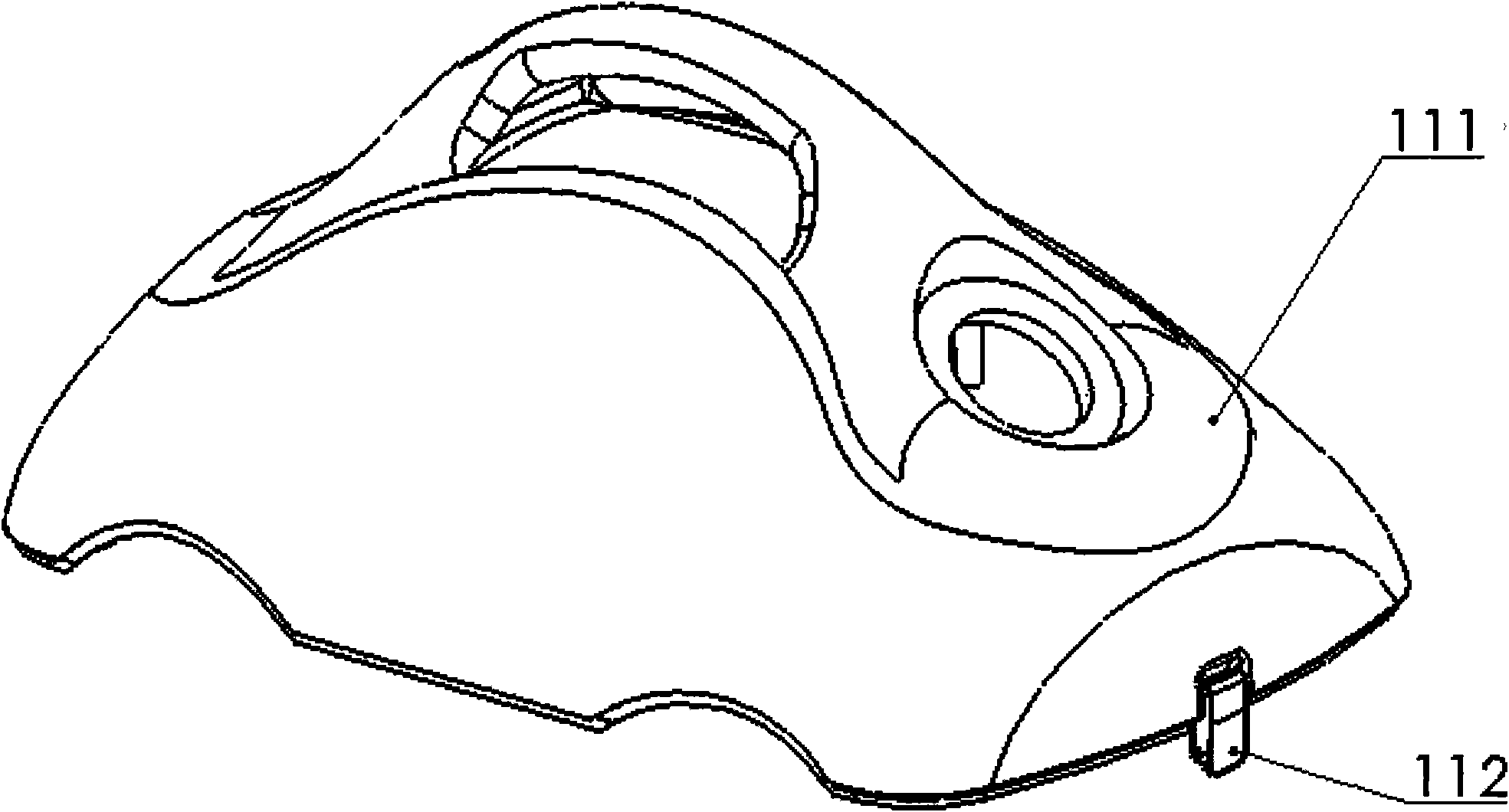

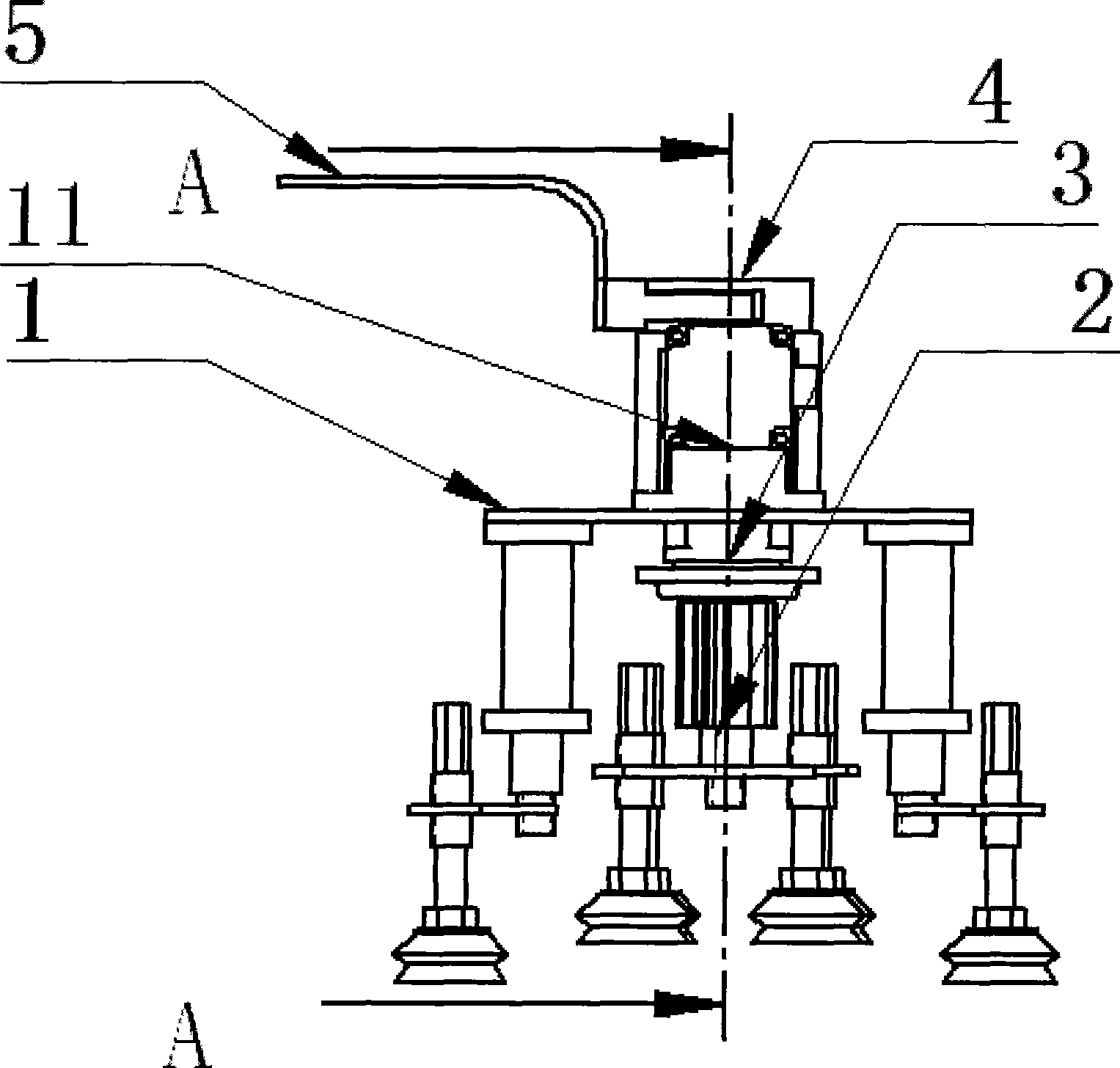

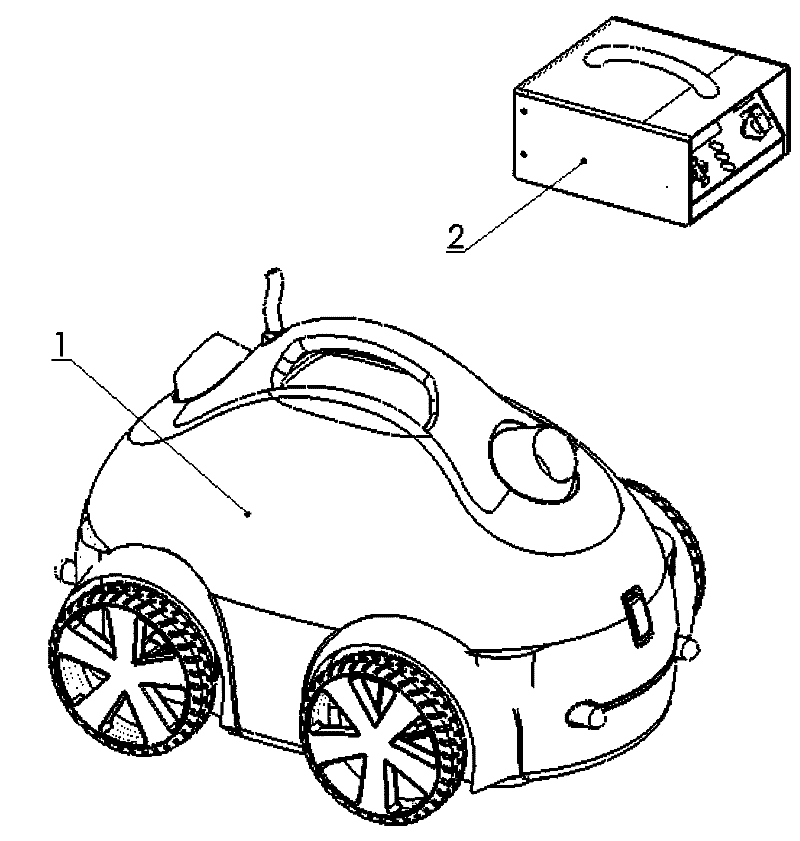

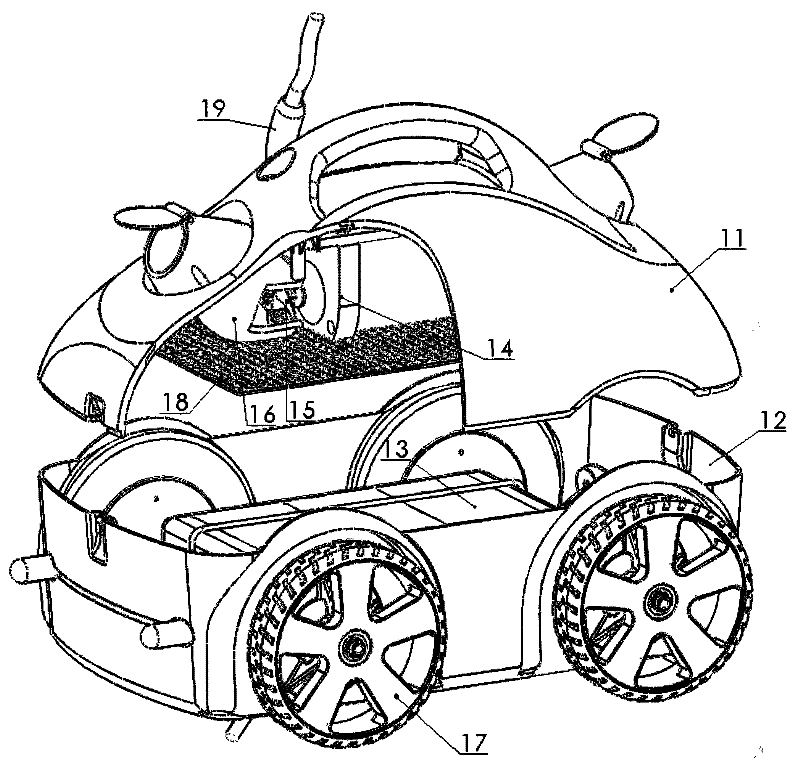

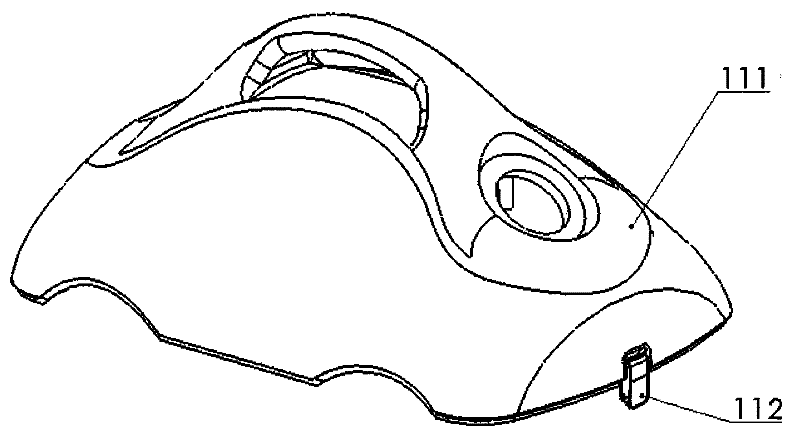

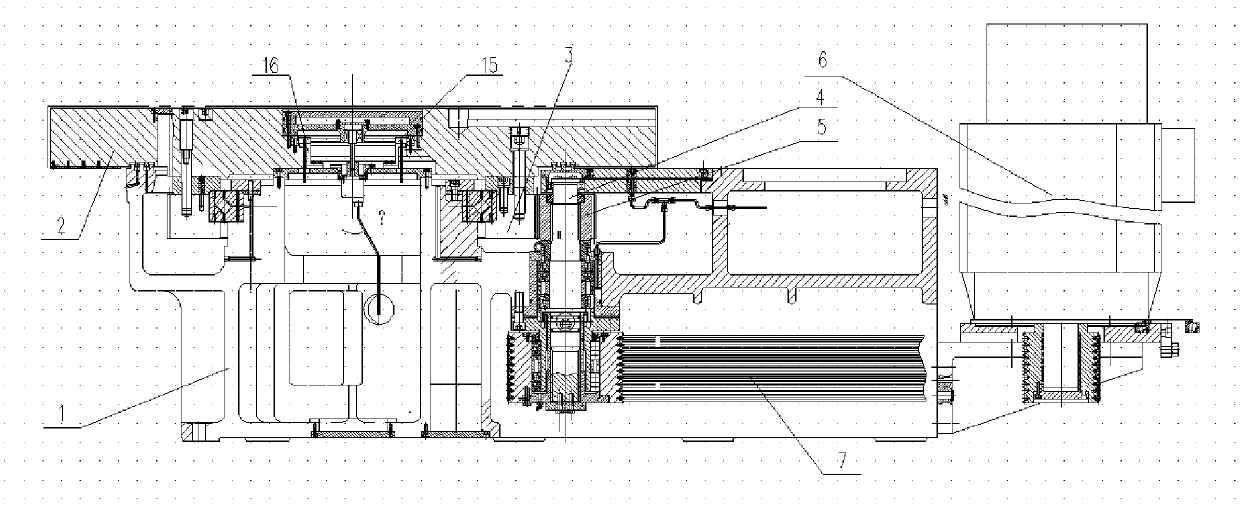

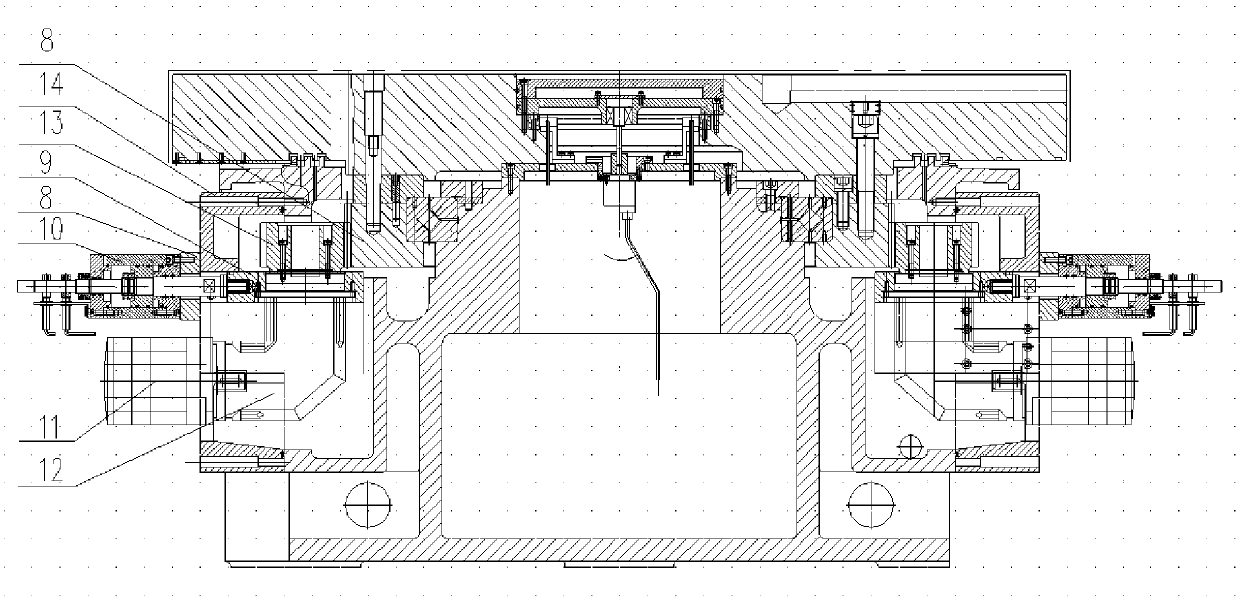

Swimming pool bottom hydro power pushed automatic cleaner

ActiveCN101666168ARealize work status changeChange water jetGymnasiumSwimming poolsAxial-flow pumpHydraulic action

The invention relates to a swimming pool bottom hydro power pushed automatic cleaner, comprising an underwater cleaner and a control power supply which are connected by a buoyancy cable; wherein the underwater cleaner comprises a shell cover part, a shell body part, a filter, a double extension motor assembly, a hydro power driven jaw clutch pulley assembly, a water flow channel, a wheel and support, an isolated hood and a cable with a buoy. Along with the rotating direction of the motor, the hydro power driven jaw clutch pulley assembly is reliably meshed or separated under the action of hydro power; the pulley changes working condition, so as to realize jet water to be flowed out and further change travel direction of the cleaner; the shell touches wall to cause the cleaner to automatically adjust direction after touching the wall, so as to change travel route after touching the wall; and an arranged suction tube and a unidirectional drainage valve avoid eddy diffusion of travel of the cleaner on sewage at the bottom and reduce the weight of the cleaner when being taken out from water. In addition, two or multiple axial-flow pumps are arranged horizontally, so that the cleaner has turning function and ordered full cover washing is realized.

Owner:TIANJIN WANGYUAN ENVIRONMENTAL PROTECTION & TECH CO LTD

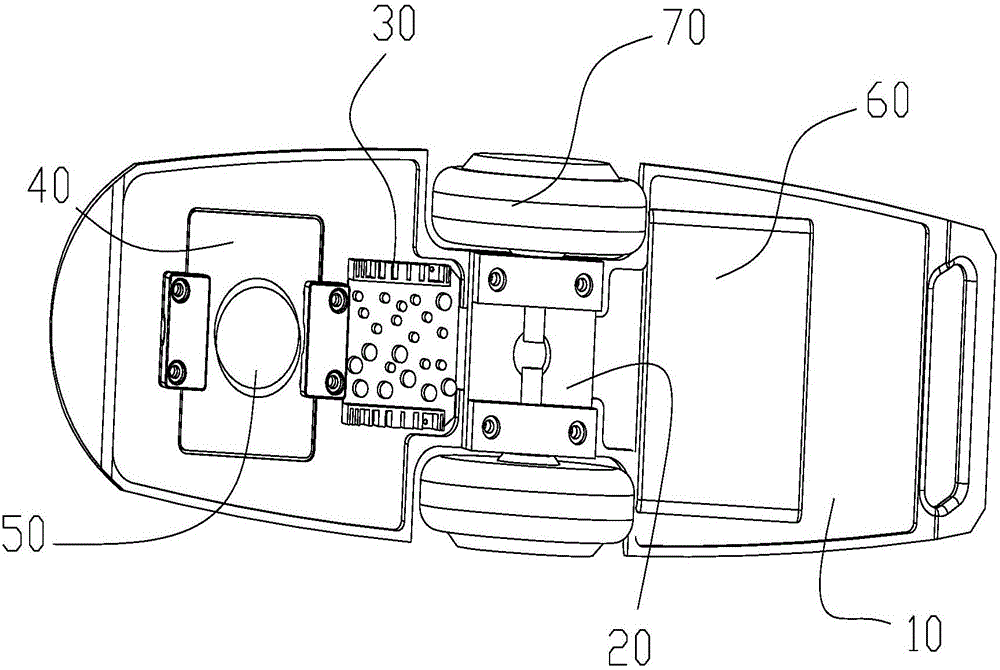

Split rotating type self-balancing two-wheeled car

InactiveCN104118507ARealize the turning functionEasy to operateMotorcyclesRider propulsionVehicle frameGyroscope

The invention discloses a split rotating type self-balancing two-wheeled car which comprises a car body frame. Wheels are arranged on the two sides of the car body frame, and motors and gyroscopes capable of controlling the rotation speed of the motors are arranged inside the car body frame. The car body frame comprises two split car frames separated from each other, a connecting shaft is arranged between the two split car frames, the two split car frames rotate with the connecting shaft as the rotation center separately, each split car frame is provided with one gyroscope and one motor independently, each split car frame comprises an upper cover pedal and a lower shell, each gyroscopes is fixed to the bottom of the corresponding upper cover pedal and connected with a circuit board, each circuit board is connected with the corresponding motor, and the motors drive the wheels. The functions of acceleration, deceleration and corner turning can be achieved through feet, and the structure is simple.

Owner:祝珍海

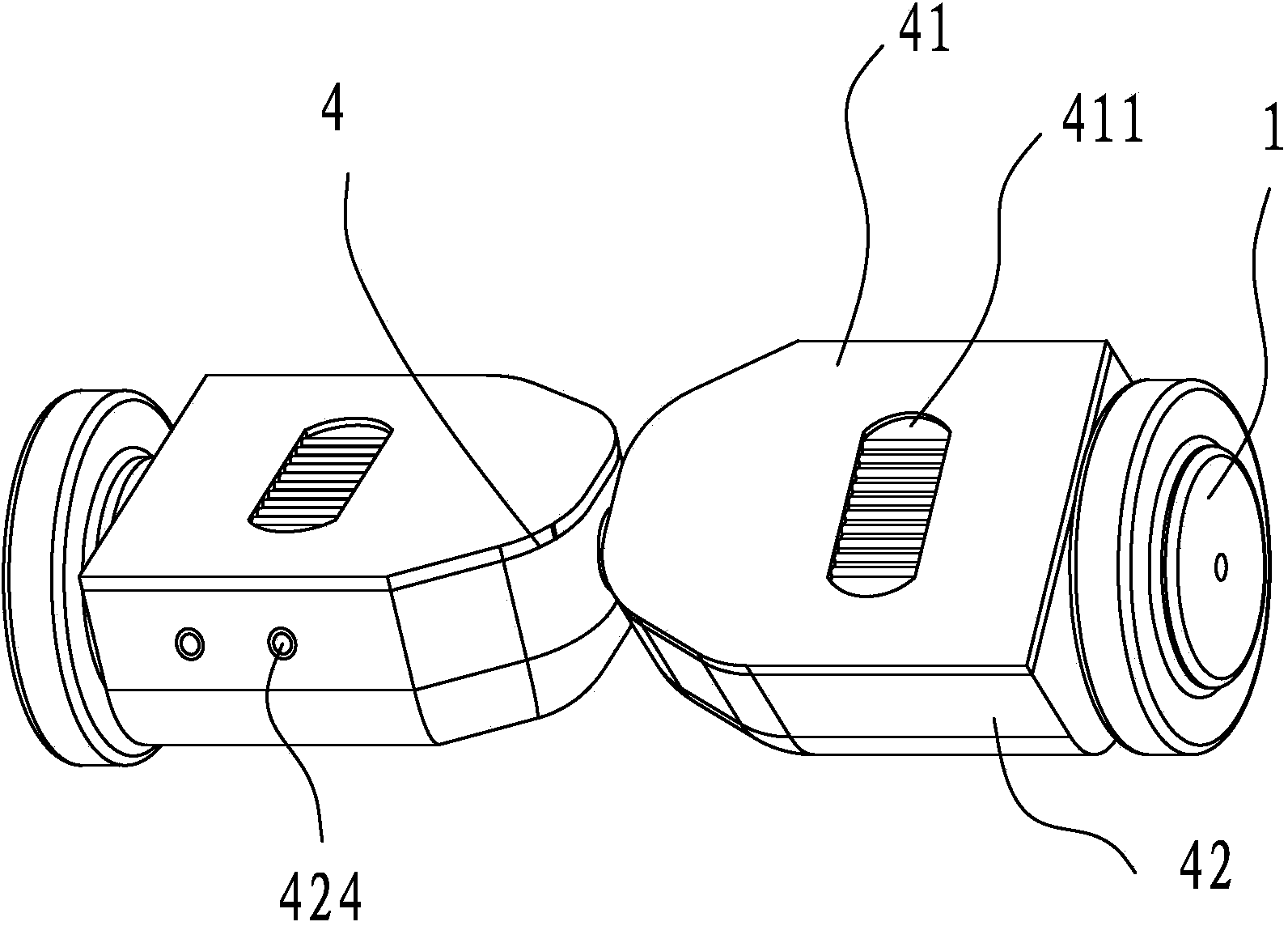

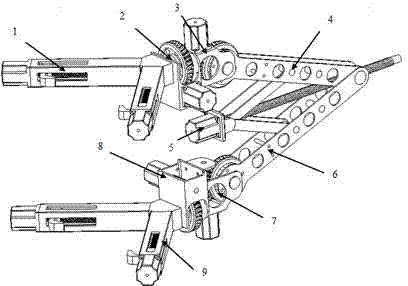

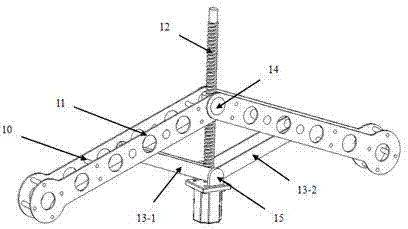

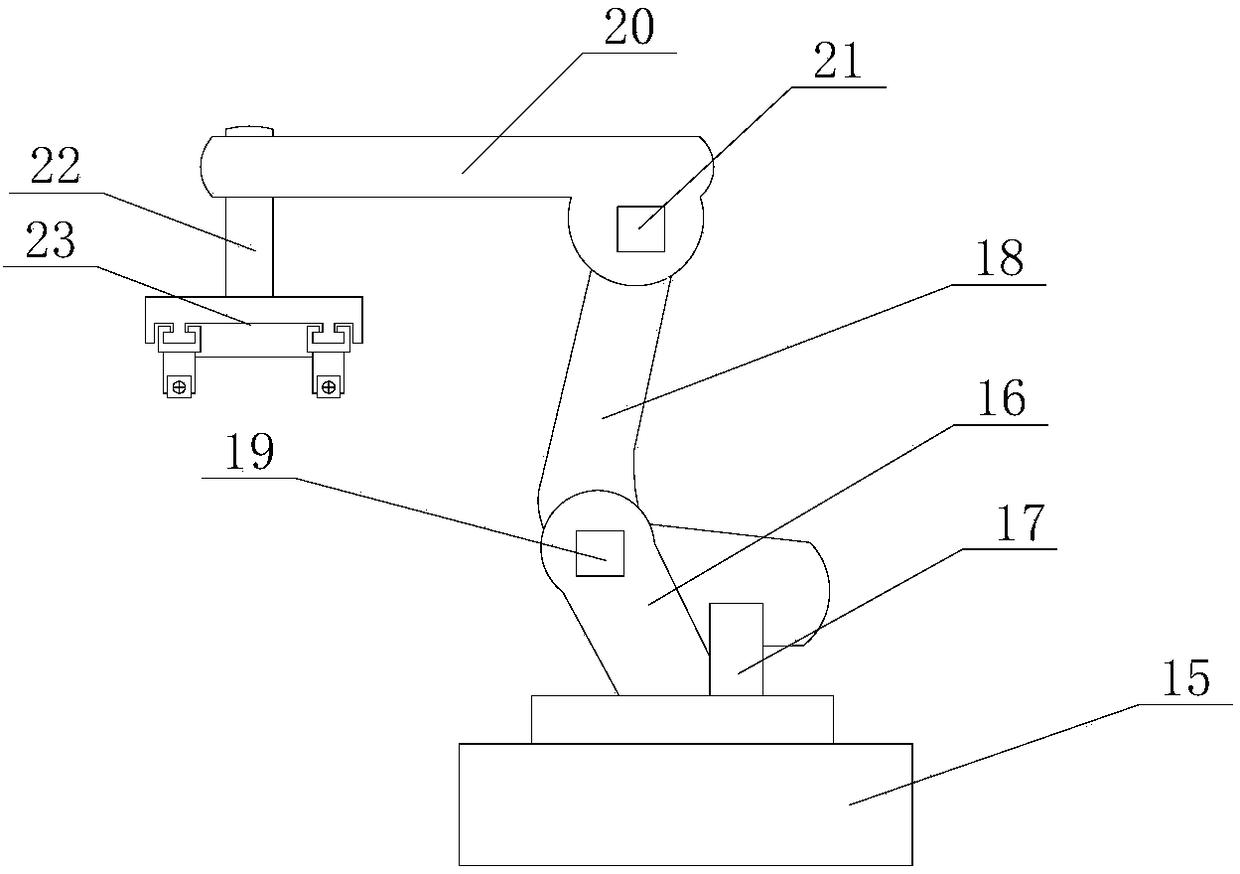

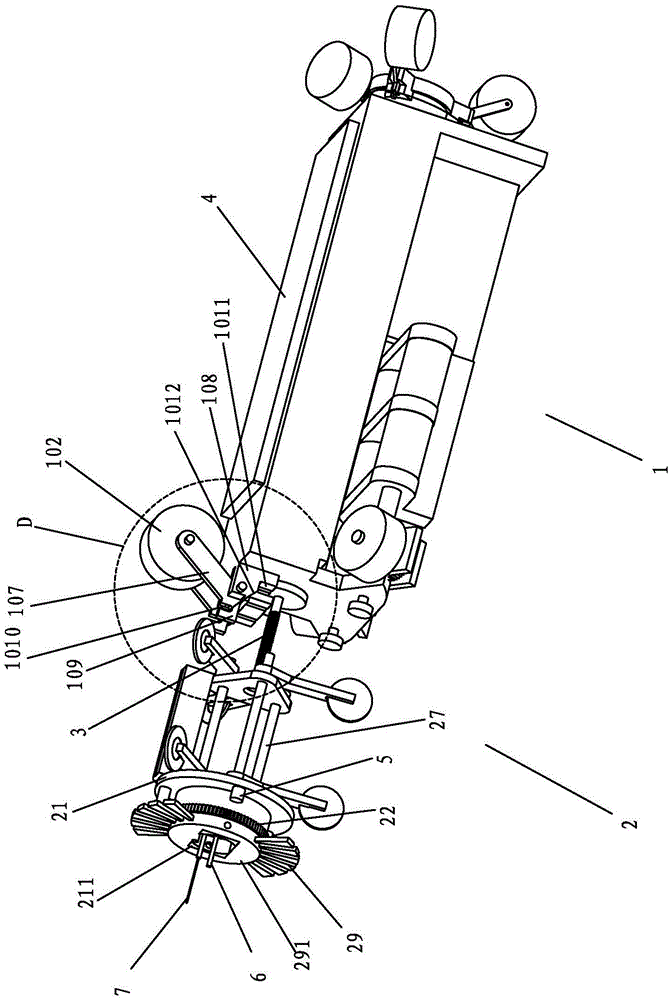

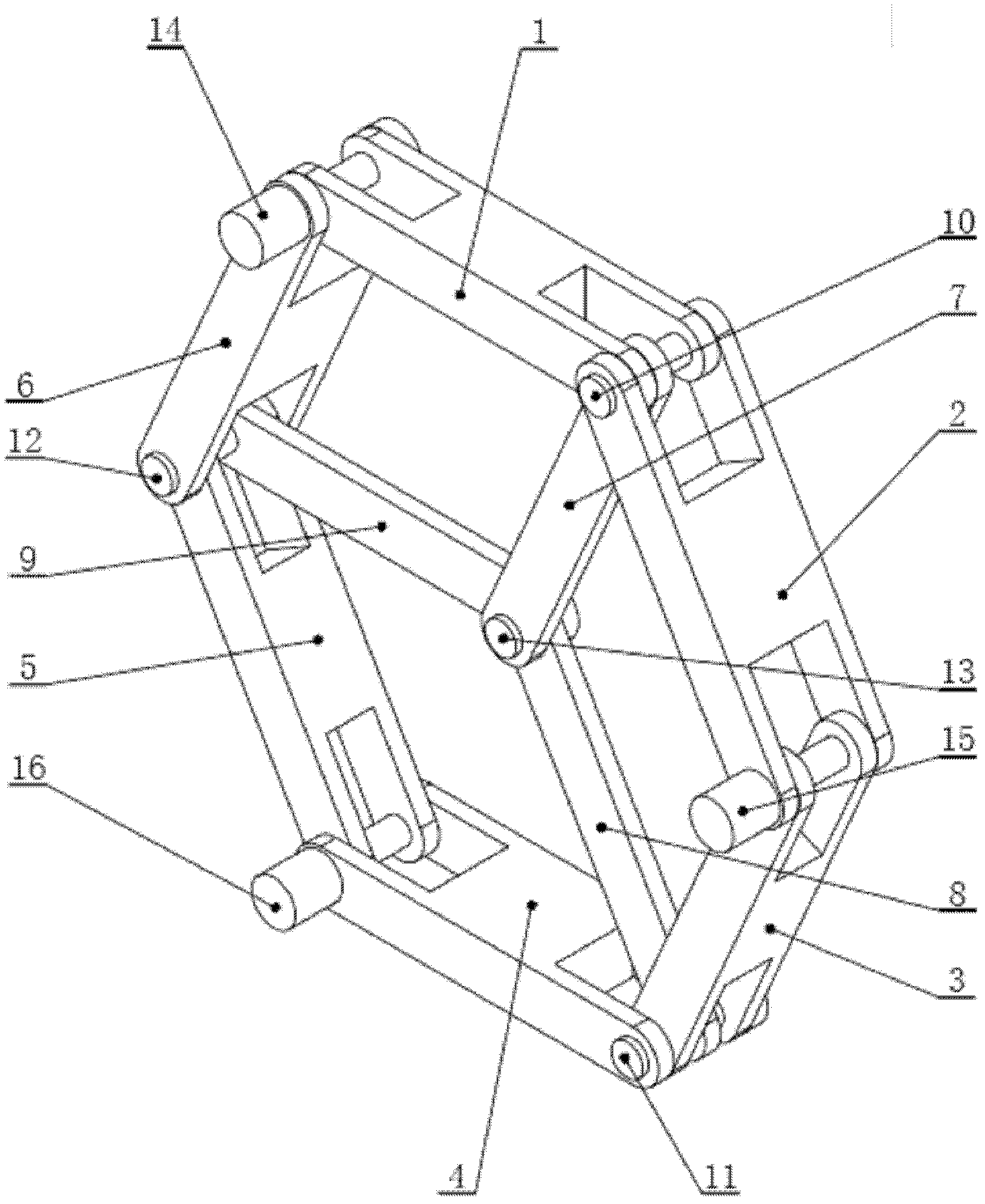

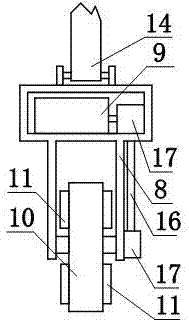

Tower climbing robot

InactiveCN103692432ARealize the turning functionImprove securityProgramme-controlled manipulatorJointsTowerLoad capacity

The invention relates to a tower climbing robot and belongs to the technical field of a robot. The tower climbing robot comprises a robot main body structure, an upper manipulator and a lower manipulator, wherein the robot main body structure consists of an upper mechanical arm (4), a lower mechanical arm (6), an arm opening and closing electric motor (5), an arm opening and closing driving motor support (15), an arm opening and closing screw rod (12), a pin nut (14), an upper connecting plate (13-1) and a lower connecting plate (13-2); the upper manipulator and the lower manipulator are respectively arranged at the second end of the upper mechanical arm (4) and at the second end of the lower mechanical arm (6); and each manipulator consists of a pitching joint, a wrist joint and a gripper jaw. The tower climbing robot has a compact structure, can complete complex actions of surmounting obstacles, turning and the like by linkage of a plurality of joints, can climb different structure types of towers, has a wide application range, has a certain load capacity, can carry about necessary overhaul equipment, and replaces a worker to climb the power tower to complete corresponding overhaul tasks.

Owner:NANJING INST OF TECH

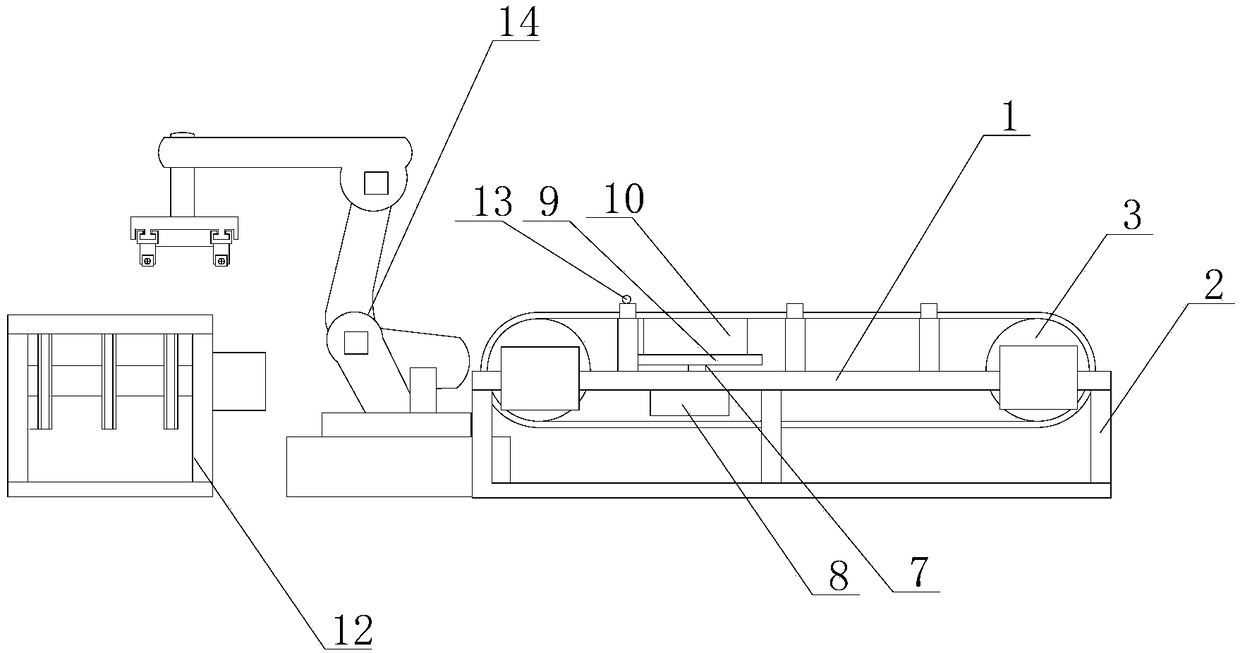

Automatic stacking system

InactiveCN108082891AAchieve clampingAchieve releaseConveyorsControl devices for conveyorsIdle timeIngot casting

The invention discloses an automatic stacking system, and belongs to the technical field of zinc ingot casting. The automatic stacking system comprises a conveying mechanism, a photosensitive sensor,a mechanical arm and a control system. The conveying mechanism comprises a first conveying device and a second conveying device. The photosensitive sensor is arranged on the first conveying device. Aclamping device of the mechanical arm comprises a stress frame, a plurality of claws and a plurality of telescopic air cylinders. Each claw comprises a sliding plate, a clamping plate and a second rotary motor. The sliding plates slide on the stress frame under the action of the telescopic air cylinders, and clamping and releasing of zinc ingots are achieved. The clamping plates are used for clamping zinc ingots, the second rotary motors are used for driving the clamping plates to rotate, and an ingot turnover function is achieved. The control system is used for coordinating the work of the first conveying device and the mechanical arm according to the induction condition of the photosensitive sensor. According to the automatic stacking system, the problems that an existing stacking systemis high in ingot turnover noise, long in equipment shutdown idle time, high in maintenance cost and large in occupied area of a ingot turnover device.

Owner:南丹县南方有色金属有限责任公司

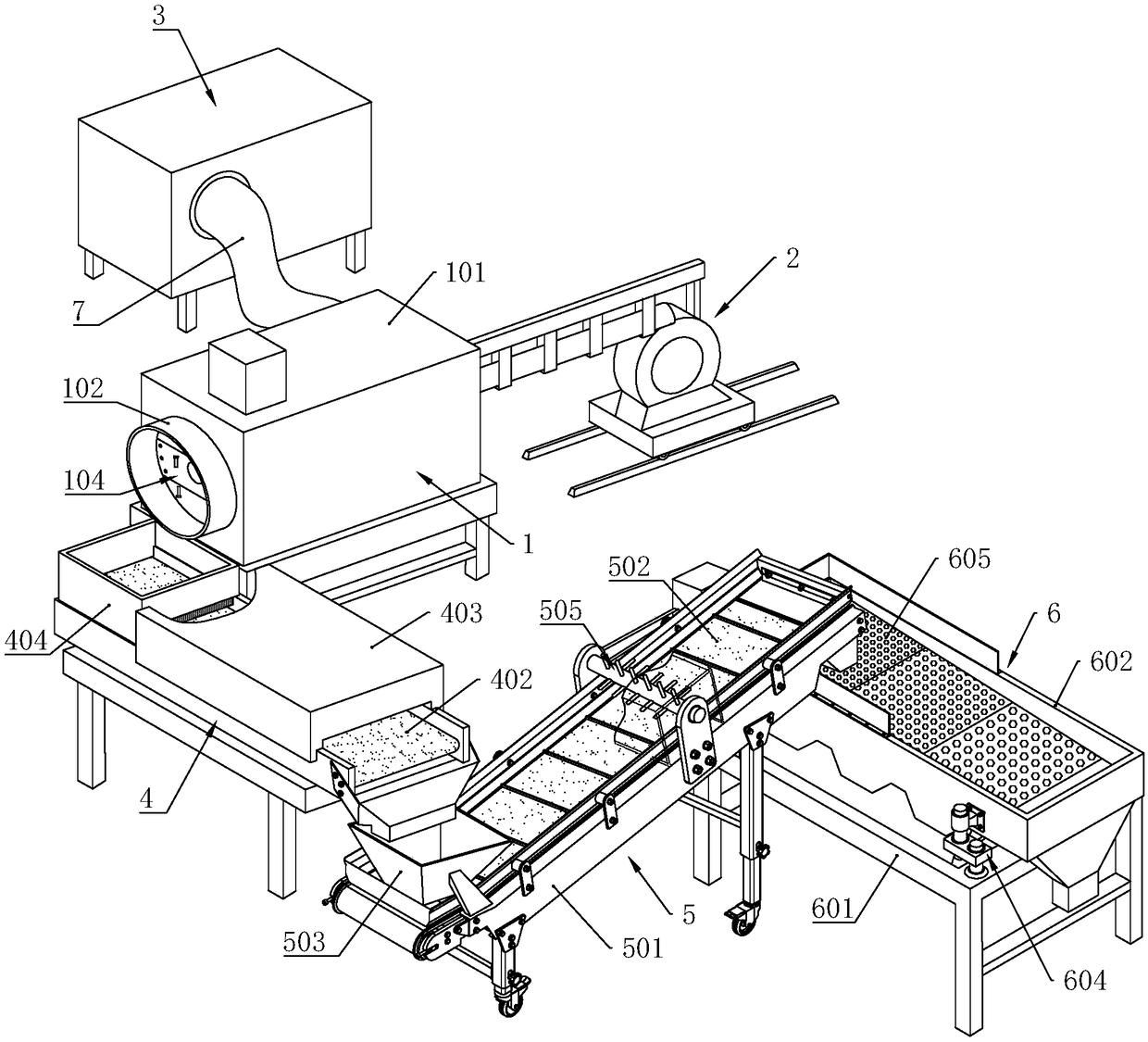

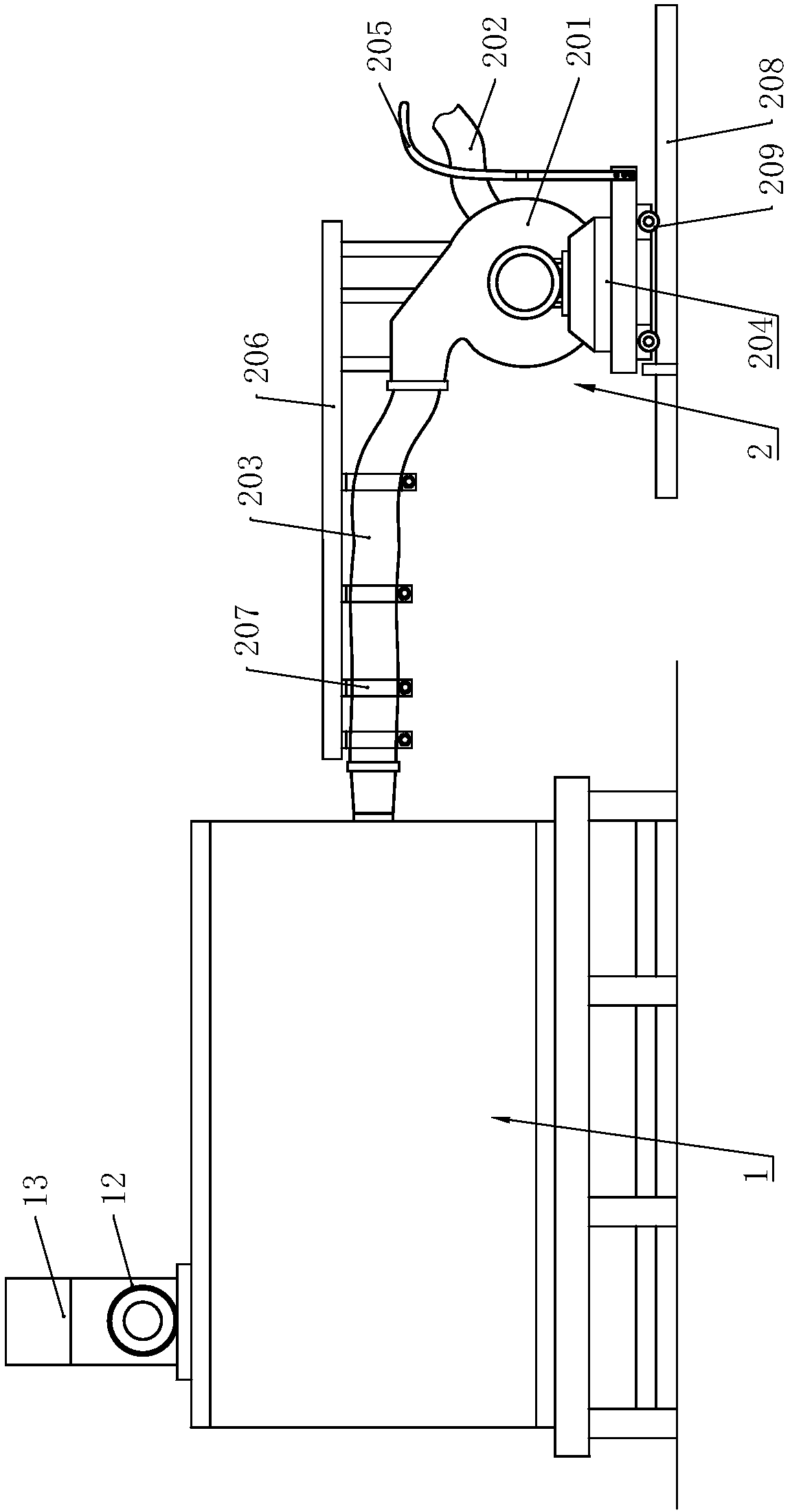

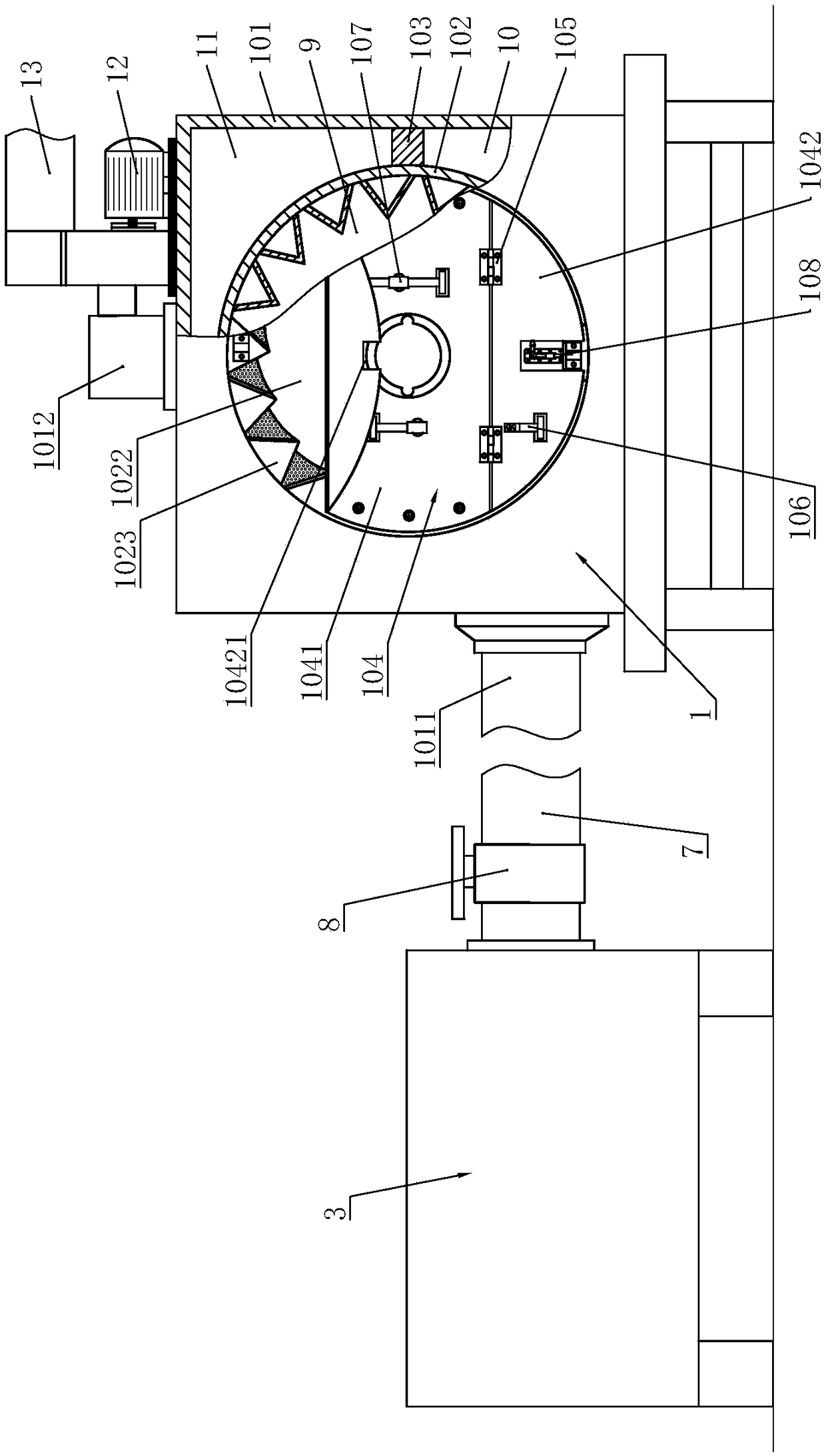

Drying and screening integrated production line

PendingCN108518967AImplement the sieving operationRealize automatic processingSievingScreeningProcess efficiencyEngineering

The invention belongs to the technical field of automated production and provides a drying and screening integrated production line. The drying and screening integrated production line comprises a feeding mechanism, a first dryer, a hot-blast stove, a second dryer, a material conveying machine and a material screening machine. The feeding mechanism and a feeding port of the first dryer are arranged in a corresponding manner. A temperature sensor is arranged in the first dryer. The hot-blast stove communicates with the first dryer through a hot air pipe. Additionally, the hot air pipe is equipped with an electromagnetic valve electrically connected with the temperature sensor. The downstream of the first dryer is provided with a second dryer. A feeding end of the second dryer and a discharge port of the first dryer are arranged in a corresponding manner. The downstream of the second dryer is provided with the material conveying machine. A feeding end of the material conveying machine and a discharge end of the material conveying machine are arranged in a corresponding manner. Integral automated processing such as material drying, conveying and screening is achieved. Therefore, processing efficiency and processing quality of material are increased.

Owner:青岛创高世纪信息科技有限公司

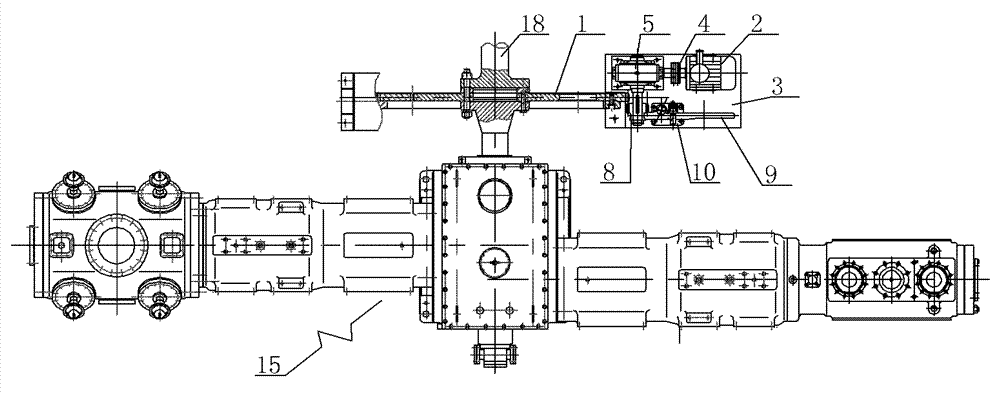

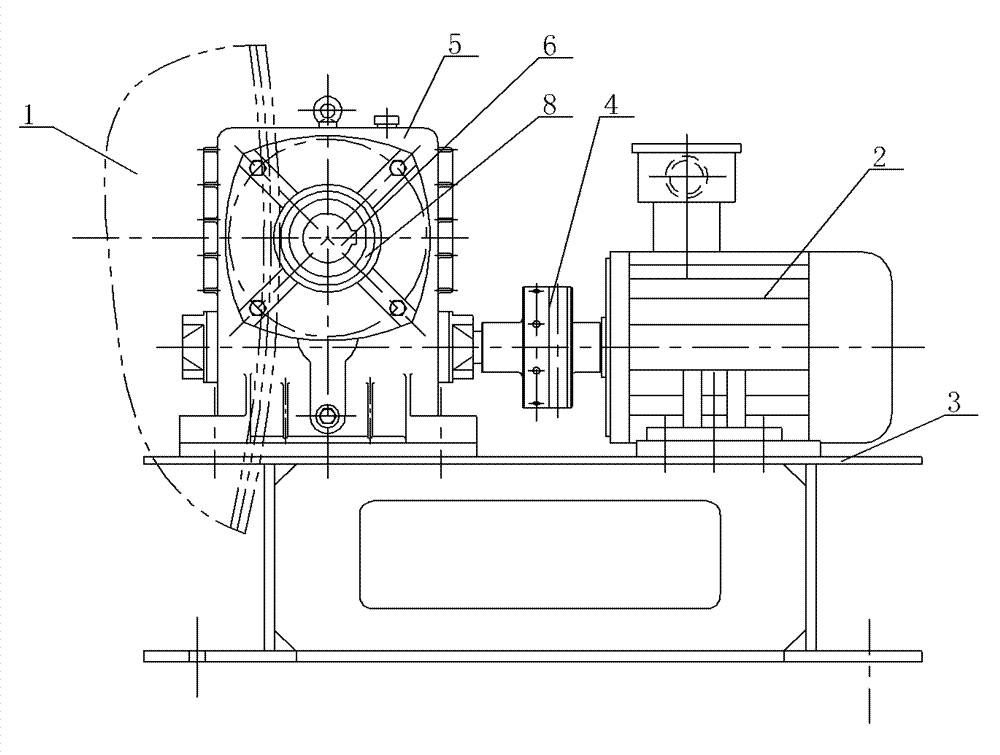

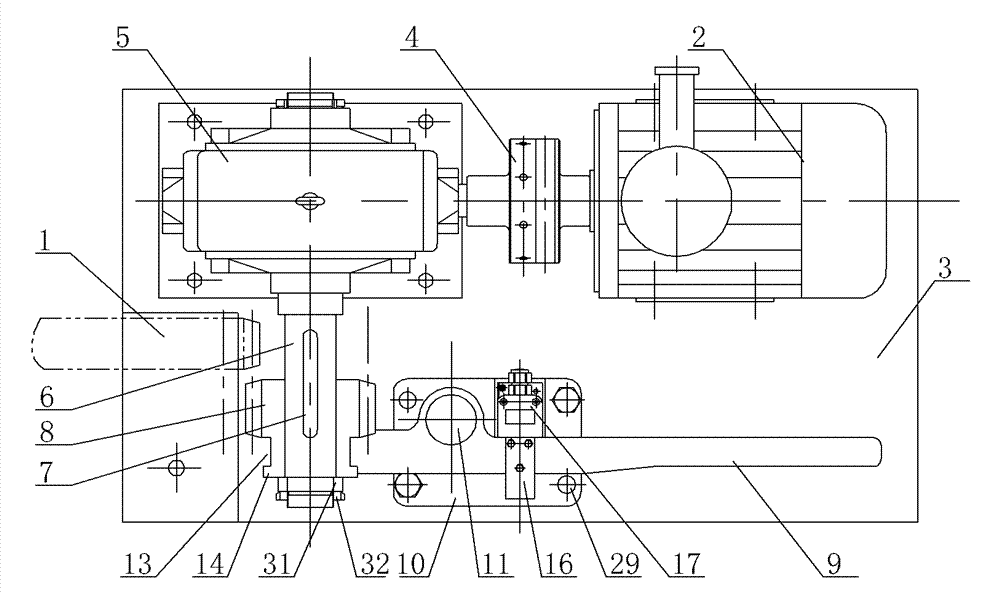

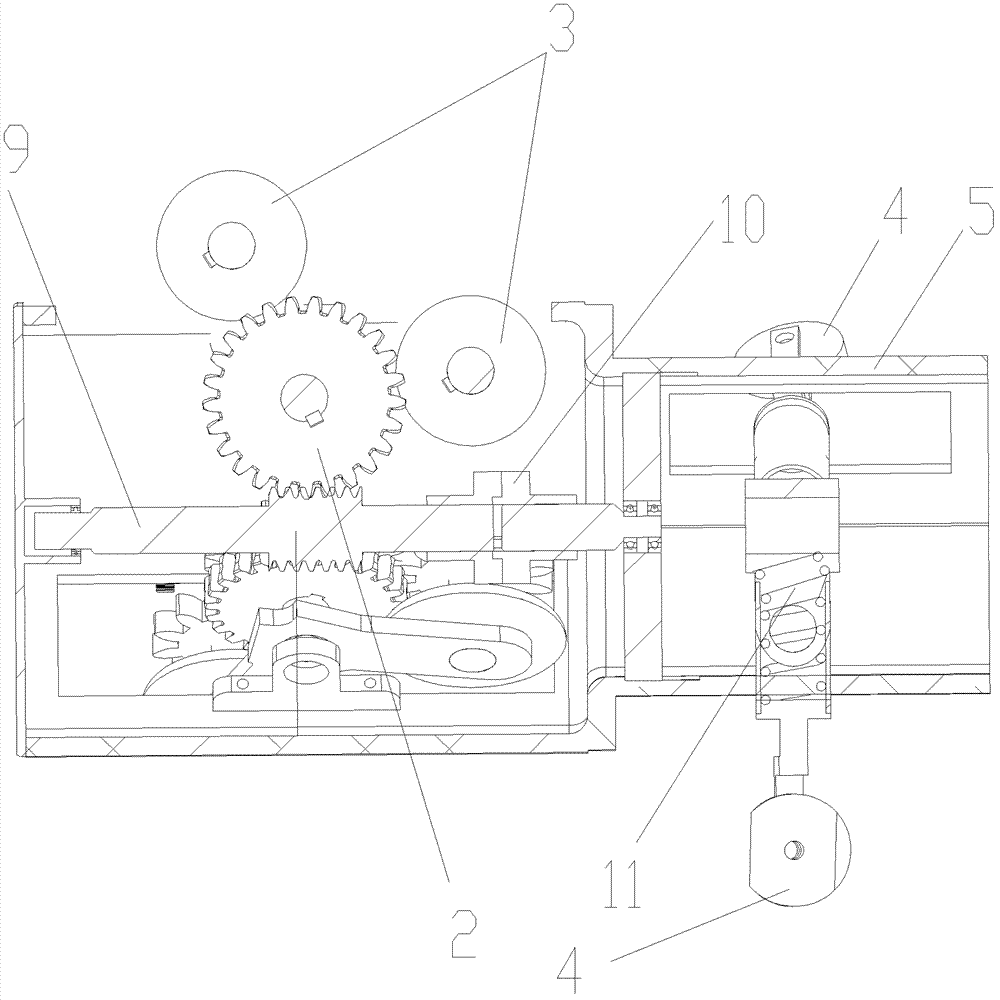

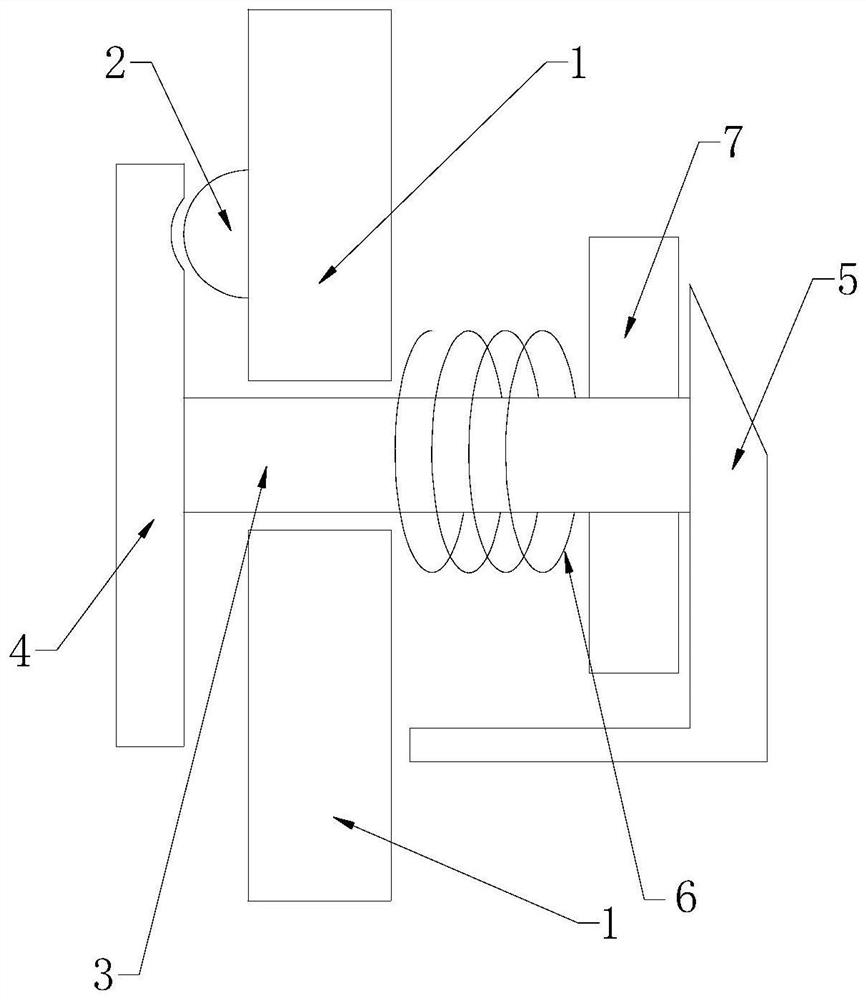

Electric turning device for piston compressor

ActiveCN104265602AImprove securitySuitable operating heightPositive displacement pump componentsMechanical energy handlingReducerEngineering

The invention provides an electric turning device for a piston compressor. The electric turning device is compact in structure and safe and reliable, allows damage caused by overloading to be effectively avoided, is applicable to an explosion-proof area and allows higher overall safety for a unit. The electric turning device comprises a large turning gear, a turning motor and a base; the turning motor is supported on the base; the electric turning device is characterized in that the turning motor is an explosion-proof motor, the output end of the turning motor is connected with one end of an overrun clutch, the other end of the overrun clutch is connected with the input end of a worm-gear reducer supported on the base, an exposed output portion of the worm-gear reducer is specifically a sliding shaft, the front end of the exposed portion of the sliding shaft is connected with a small gear through flat keys in a sleeved manner, the small gear can slide axially along the flat keys, a stirring rod is arranged on one side of the small gear, and the inner end of the stirring rod drives the small gear to axially slide.

Owner:WUXI COMPRESSOR CO LTD

Barrier-free constant speed creeping robot

The invention provides a barrier-free constant-speed crawling robot and belongs to the technical field of robots. The robot comprises an outer frame, an inner frame, a rotating mechanism, a linear-motion mechanism fixed on the upper surface of the outer frame and a linear motor for fixing an actuating mechanism. The rotating mechanism is connected with the linear-motion mechanism and is capable of performing linear motion along the outer frame under the drive of the linear-motion mechanism. The inner frame is connected with the output shaft of the rotating mechanism and is capable of rotating relative to the outer frame under the drive of the rotating mechanism. The linear motor is arranged on the upper surface of the outer frame. The robot can go across barriers with a certain height, the rotating mechanism between the inner and outer frames can realize the turning of the robot, and the constant-speed motion of the actuating mechanism during operation can be realized through the resultant of the dynamic speed vectors of the motions of the linear motor relative to the inner and outer frames.

Owner:BEIJING UNIV OF TECH

Robot turnover control method based on energy optimization

ActiveCN109159123ARealize the turning functionWide adaptabilityProgramme-controlled manipulatorGravity centerControl theory

The invention discloses a robot turnover control method based on energy optimization. The robot turnover control method based on energy optimization comprises the following steps that one turnover strategy is chosen on the basis of the energy optimization principle according to the environmental condition of the outside world; a robot prepares for turnover, and poses according to the chosen turnover strategy; turnover is conducted according to the step of the chosen turnover strategy; and finally, the turnover motion is accomplished, and the robot recovers to be in the normal working posture.The turnover strategies of the robot include the gravity center turnover strategy, the supporting turnover strategy and the torque turnover strategy. The robot can choose one turnover mode to accomplish turnover according to the environment on the basis of the energy optimization principle. The method effectively overcomes the limitation of the environment and the space, and only one tail needs tobe additionally arranged on the robot so that the robot can utilize the multiple strategies to accomplish turnover under the extreme condition that the body is completely inverted. A new method is provided for posture adjustment of the land robot.

Owner:THE 28TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Two-wheel scooter

The invention discloses a two-wheel scooter which comprises a scooter plate, a roller component, a rotation device fixedly connected with the scooter plate and capable of positioning the around-axle roller component, a battery fixedly connected with the scooter plate, a gyro sensor and a controller. The two-wheel scooter also comprises a pedal device connected with the scooter plate and the gyro sensor, wherein the pedal device is controlled to link the rotation of the gyro sensor, and then a signal is output to the controller to control one roller in the roller component to accelerate and generate centripetal force relative to the other roller so as to realize a turning function; and the control is convenient while the turning speed can be controlled, and thus the user feels easy when playing the scooter.

Owner:朱剑青 +2

Steering control method for a self-balancing two-wheeled vehicle

InactiveCN104163222BRealize the turning functionEasy to operateMotorcyclesBicyclesGyroscopeVehicle frame

The invention discloses a steering control method for a self-balancing two-wheeled vehicle. The two-wheeled vehicle comprises two separated split frames, a connecting shaft is arranged between the two split frames, and motors and gyroscopes capable of controlling the rotating speed of the motors are arranged in the split frames. The steering control method for the self-balancing two-wheeled vehicle comprises the following steps that firstly, the outer split frame needing to turn is treaded by the foot, and the inner split frame is kept horizontal. According to the split frame in the horizontal state, due to the fact that the gyroscope does not induct changes of the inclination angle, the motor does not rotate, the gyroscope at the bottom of an upper cover pedal inducts the changes of the inclination angle after inclination, signals are output to a circuit board to enable the motor to rotate, and therefore wheels are driven to rotate. Finally, one wheel does not rotate, the other wheel rotates, the two-wheeled vehicle turns and moves with the wheel which does not rotate as the center, the acceleration, speed reduction and turning functions can be achieved through foot treading, and the structure is simple.

Owner:重庆鹏得基业汽车部件有限公司

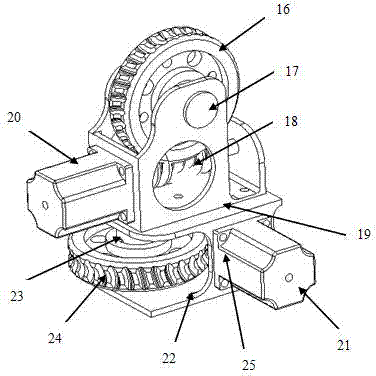

Travelling mechanism of pipeline robot

The invention provides a travelling mechanism of a pipeline robot. The travelling mechanism of the pipeline robot comprises a worm, a motor and three planetary gear sets, wherein the motor is used for driving the worm, and the axis of the worm is superposed with that of a pipeline; the three planetary gear sets are respectively positioned in three planes; each planetary gear set comprises a worm gear engaged with the worm, a sun gear coaxially connected to the worm gear, and two planetary gears which are mutually separated and respectively engaged with the sun gear; each planetary gear is coaxially connected with a travelling wheel, and the diameter of the travelling wheel is greater than that of the planetary gear; and one of the two travelling wheels is hinged on a rotating shaft of thesun gear through a first connecting rod arm, and the included angle formed between the first connecting rod arm and a second connecting rod arm is 0 to 180 degrees. According to the travelling mechanism, a closed force system is not required to be formed by an external spring force in the robot, and the worm drives the planetary gears to rotate, so that a transmission mechanism is integrated withan adjusting mechanism and the structure is simpler.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

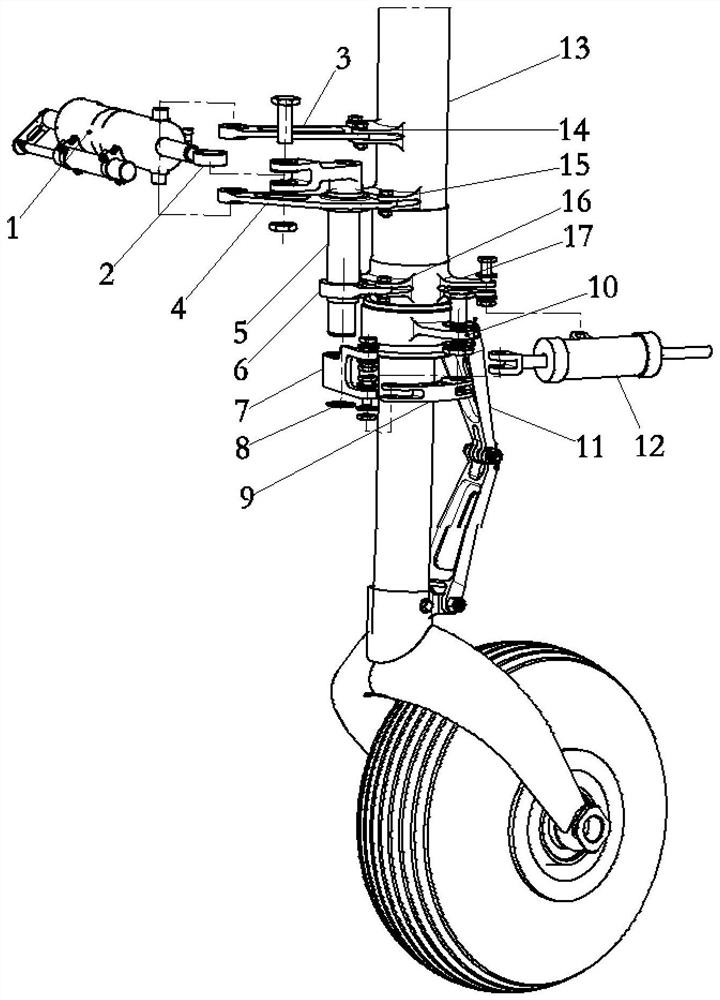

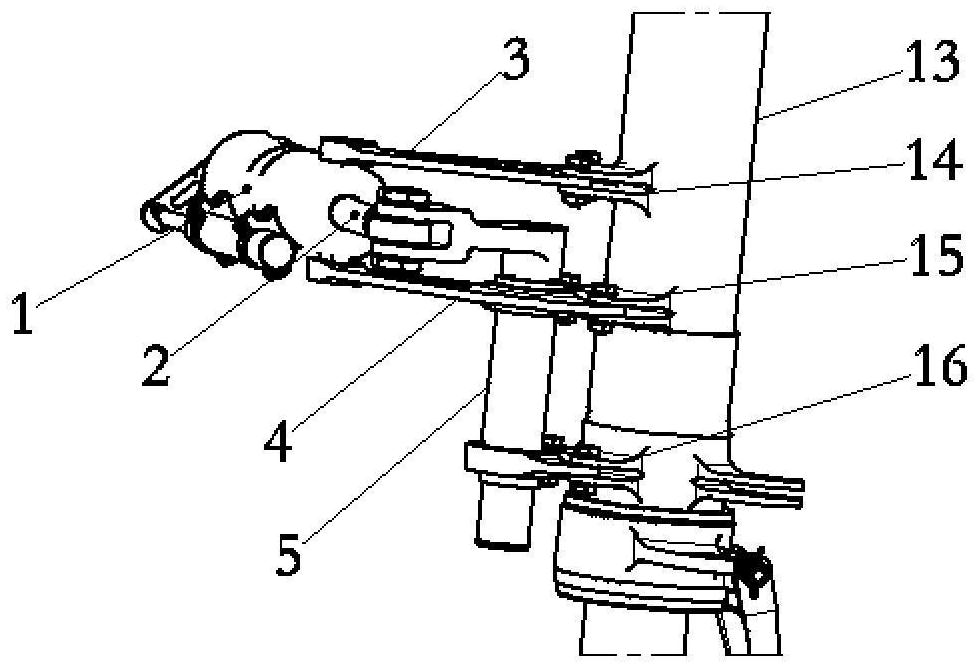

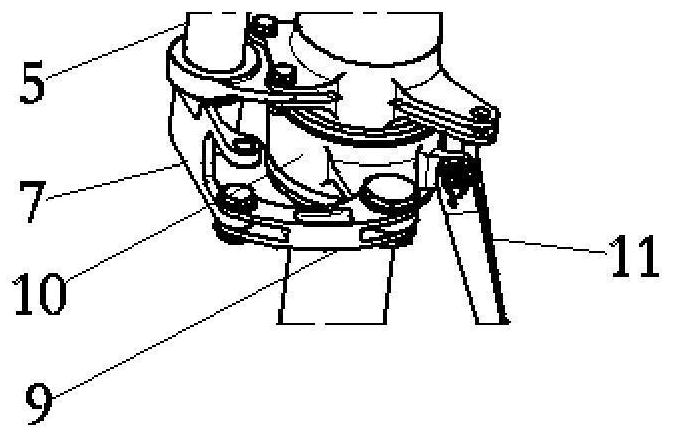

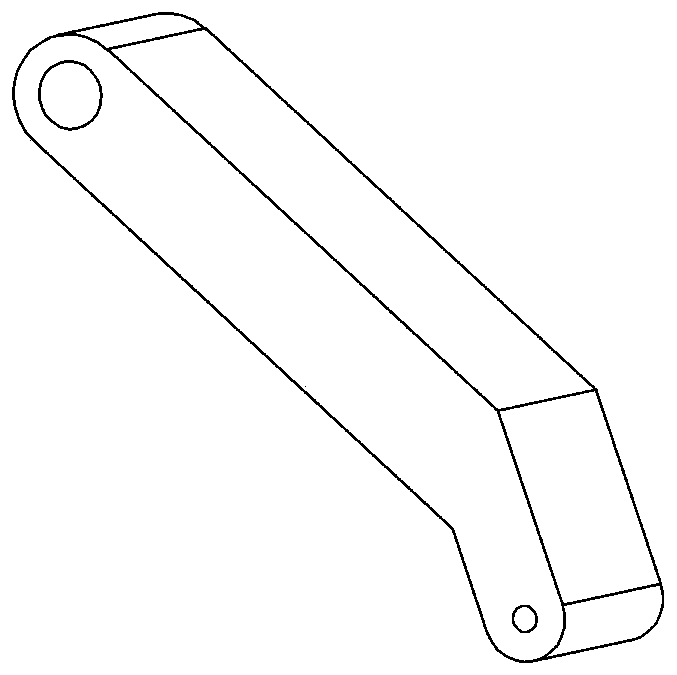

Connecting rod transmission type front wheel turning anti-swing mechanism

PendingCN112389641AChange the transmission ratioMeet the needs of use layoutWheel arrangementsActuator torqueReducer

The invention discloses a connecting rod transmission type front wheel turning anti-swing mechanism which comprises a turning actuator torque transmission mechanism, a planar connecting rod mechanismand a swing reducer. The turning actuator torque transmission mechanism comprises a turning actuator, a torsion bar, a second support and a first support, the turning actuator is connected with the front undercarriage outer cylinder through the second support and the first support, the piston rod of the turning actuator is movably connected with the rocker arm end of a torsion bar, and the bar body of the torsion bar is partially hinged to the second support and a third mounting connecting lug of the front undercarriage outer cylinder, and can rotate around the axis. The planar connecting rodmechanism comprises a double-lug connecting rod, a middle connecting rod, a front undercarriage ring body and a torsion arm, the double-lug connecting rod is connected with the bottom end of the torsion rod body part, an upper connecting lug of the double-lug connecting rod is hinged to the swing reducer, the lower connecting lug of the double-lug connecting rod is connected with one end of the middle connecting rod, and the other end of the middle connecting rod is connected with the front undercarriage ring body; the nfront undercarriage ring body is arranged on the front undercarriage outercylinder and can rotate around the outer cylinder, and one end of the torque arm is connected with the outer portion of the front undercarriage ring body.

Owner:HARBIN

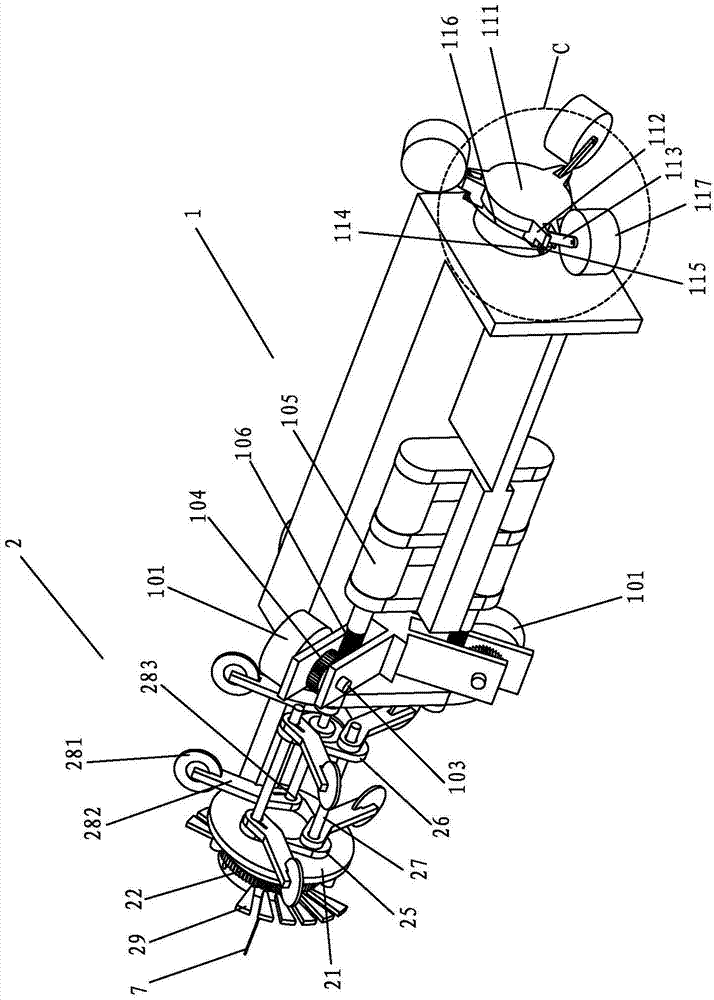

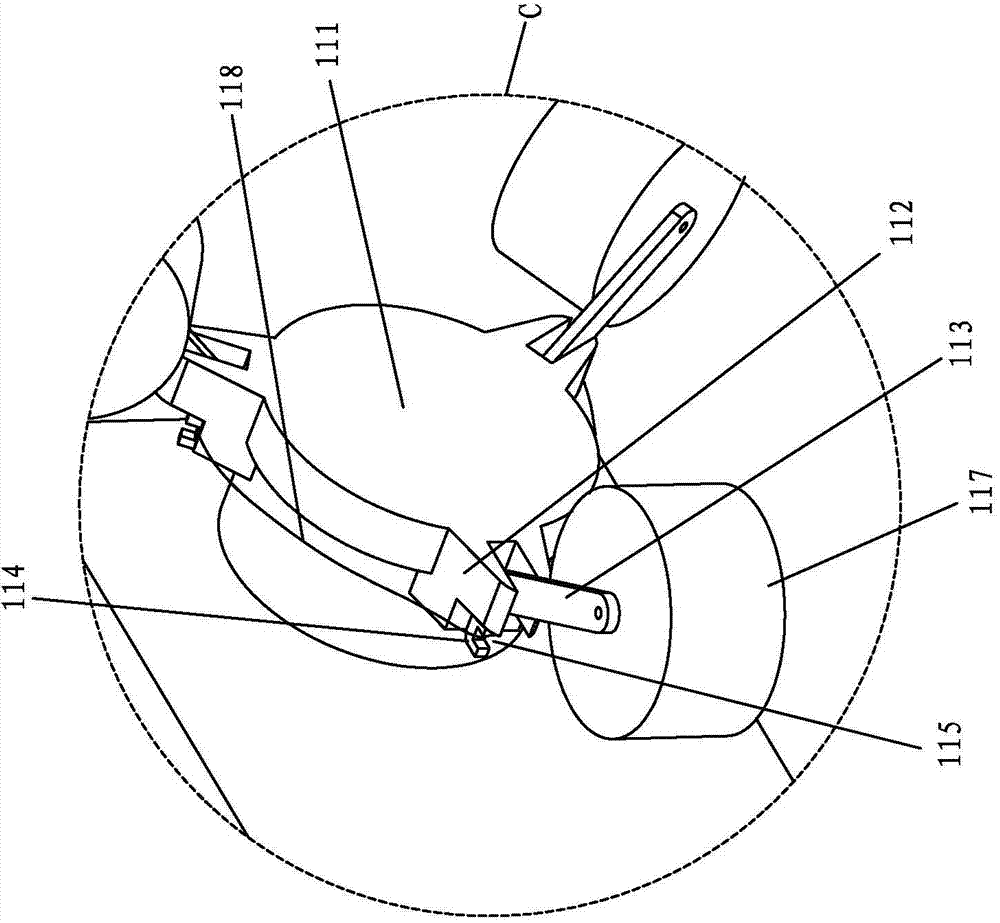

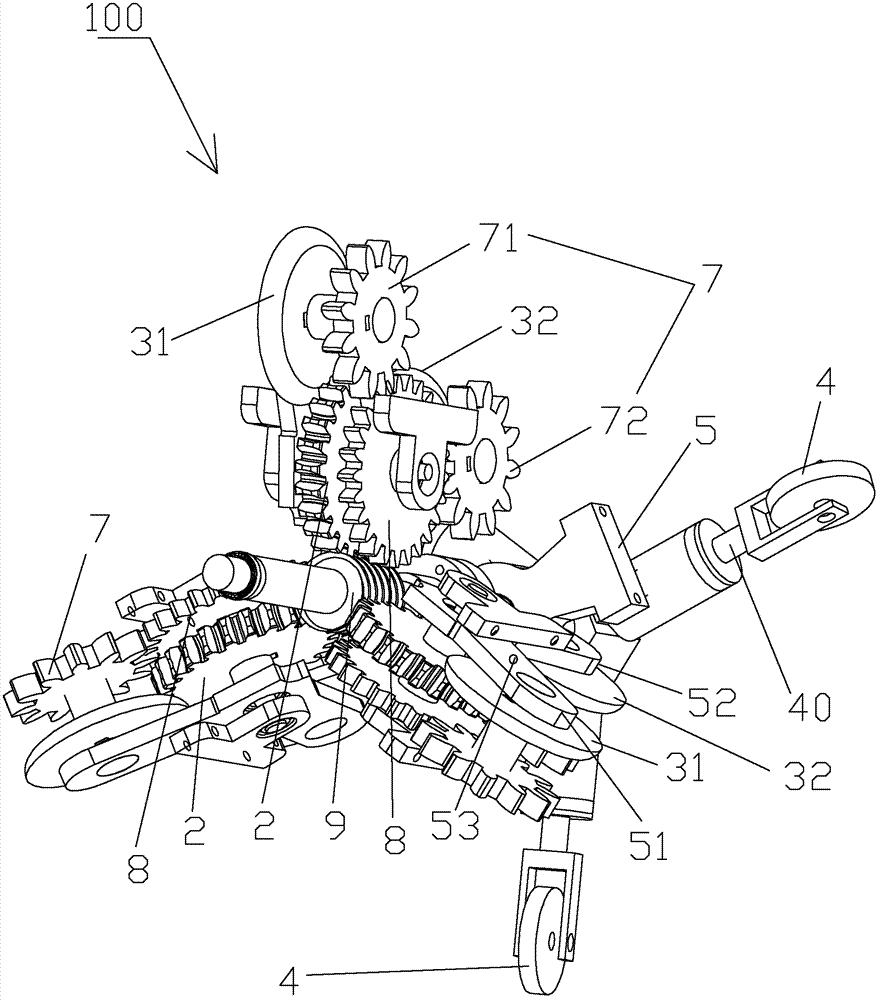

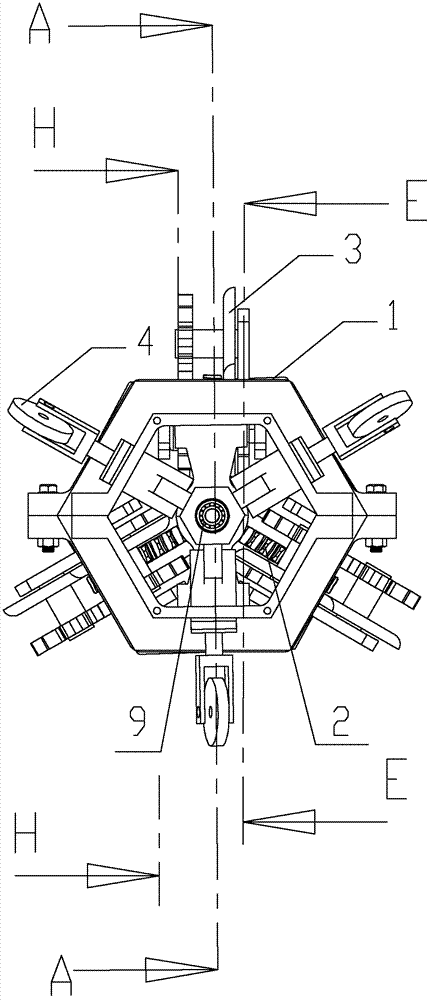

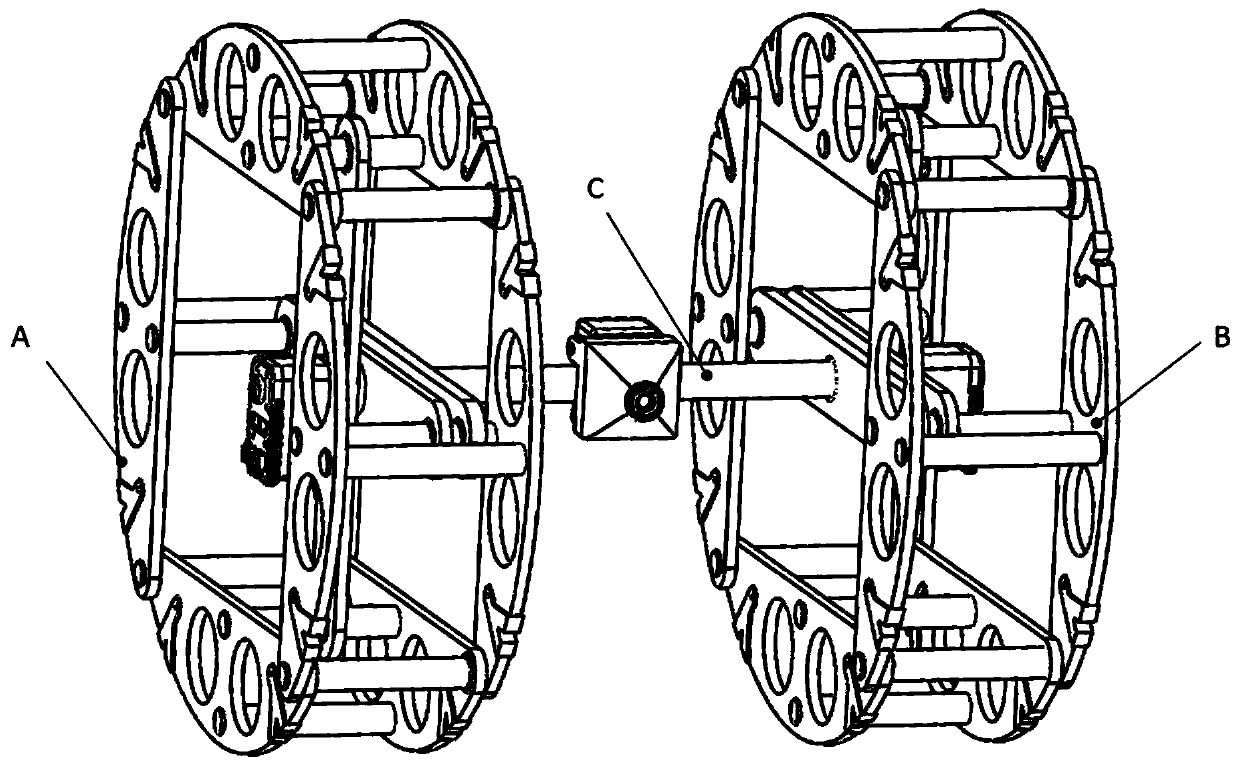

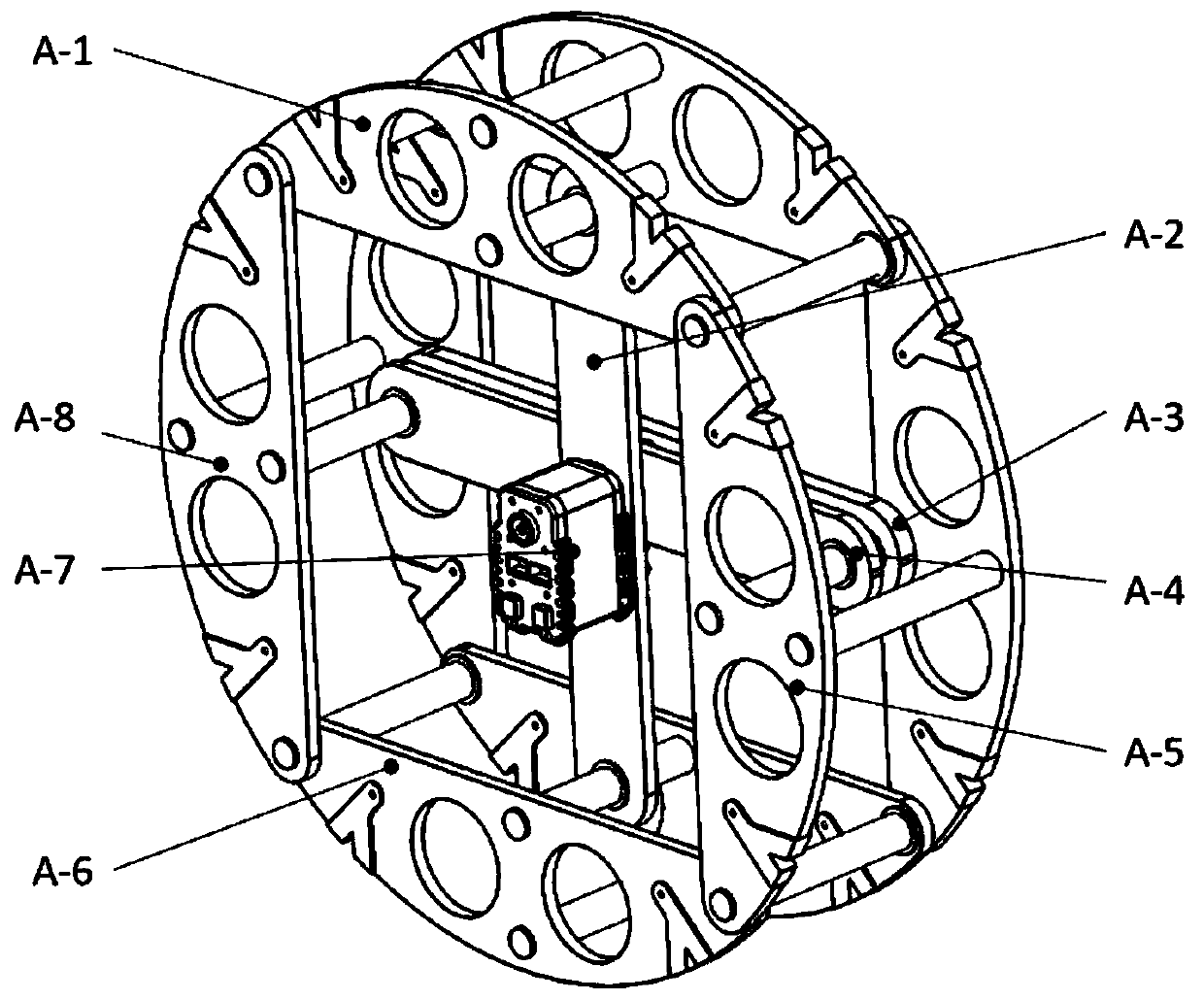

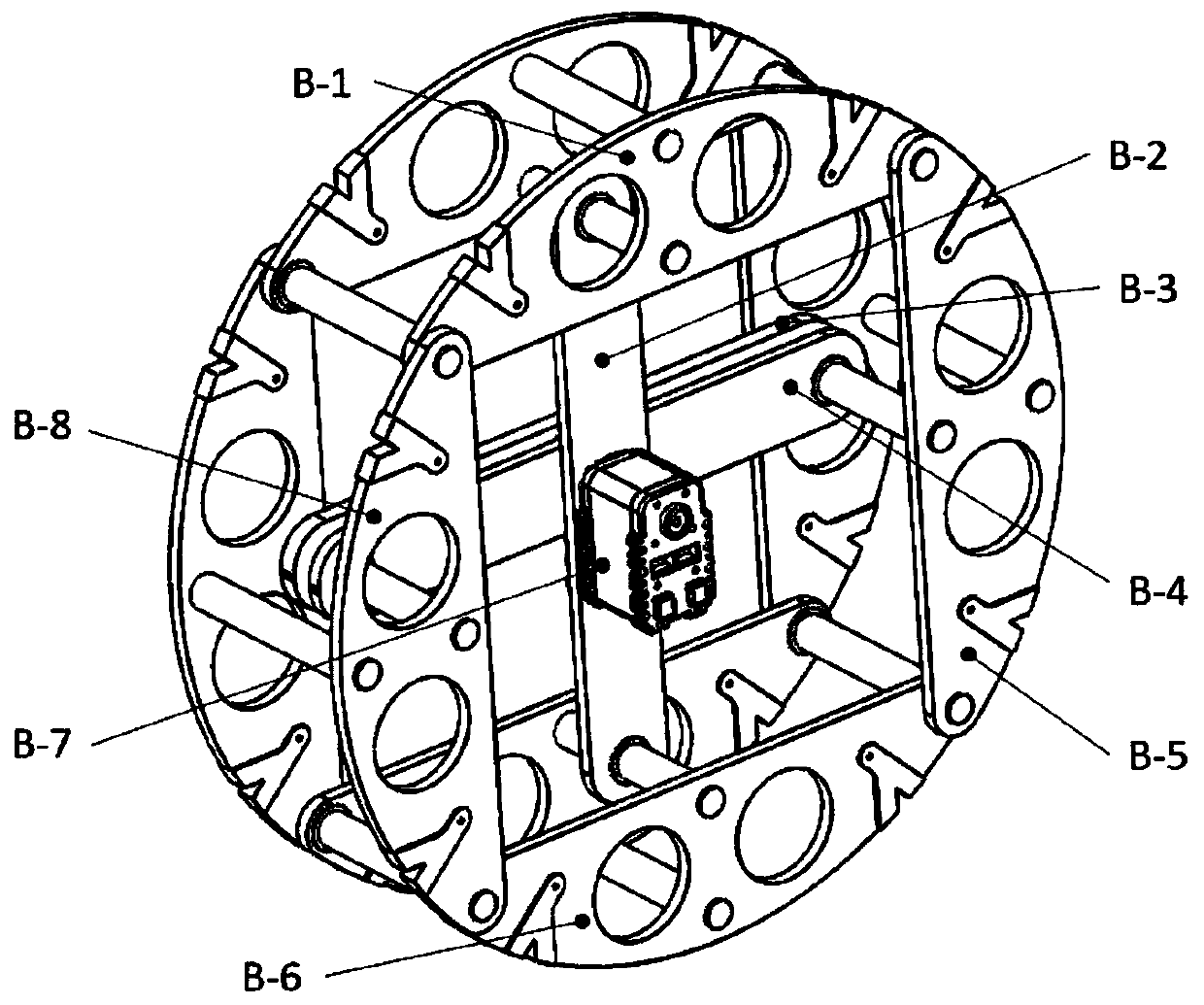

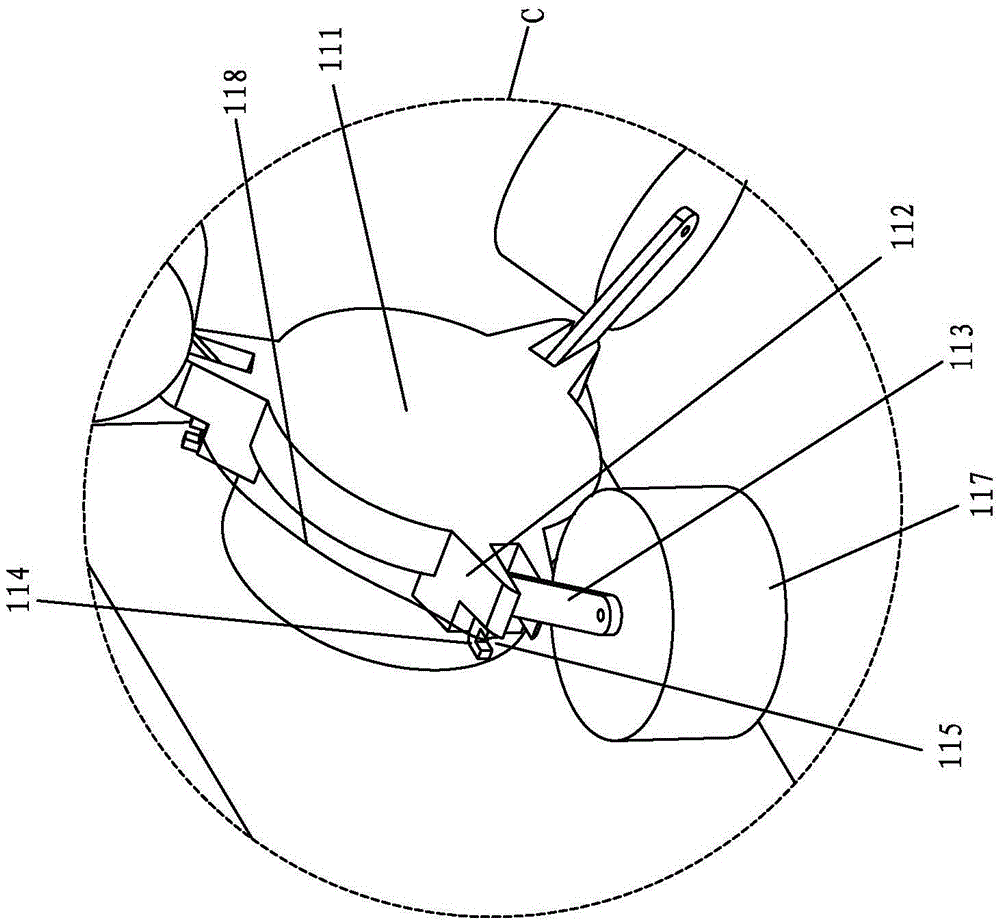

Wheel-like rolling reconnaissance robot

ActiveCN110091933AAchieve scrolling straightSimple structureVehiclesMechanical engineeringFixed angle

The invention belongs to the field of ground mobile robots, and particularly relates to a wheel-like rolling reconnaissance robot which comprises a left wheel mechanism (A), a right wheel mechanism (B) and a holder (C), and the robot is characterized in that the left wheel mechanism (A) and the right wheel mechanism (B) are connected in parallel through the holder (C); the holder is composed of aconnecting rod (C-1) and a camera device (C-2), and the camera device (C-2) is fixed on the connecting rod (C-1). According to the wheel-like rolling reconnaissance robot provided by the invention, the left wheel mechanism (A) and the right wheel mechanism (B) are respectively driven and controlled through two steering engines, so that the rolling motions of the mechanisms are realized; zero-radius turning and fixed-angle turning can be achieved, the obstacle climbing function can be achieved through deformation of the left wheel mechanism and the right wheel mechanism, the application range is wide, and carrying and transportation are convenient after contraction and folding of the robot.

Owner:BEIJING JIAOTONG UNIV

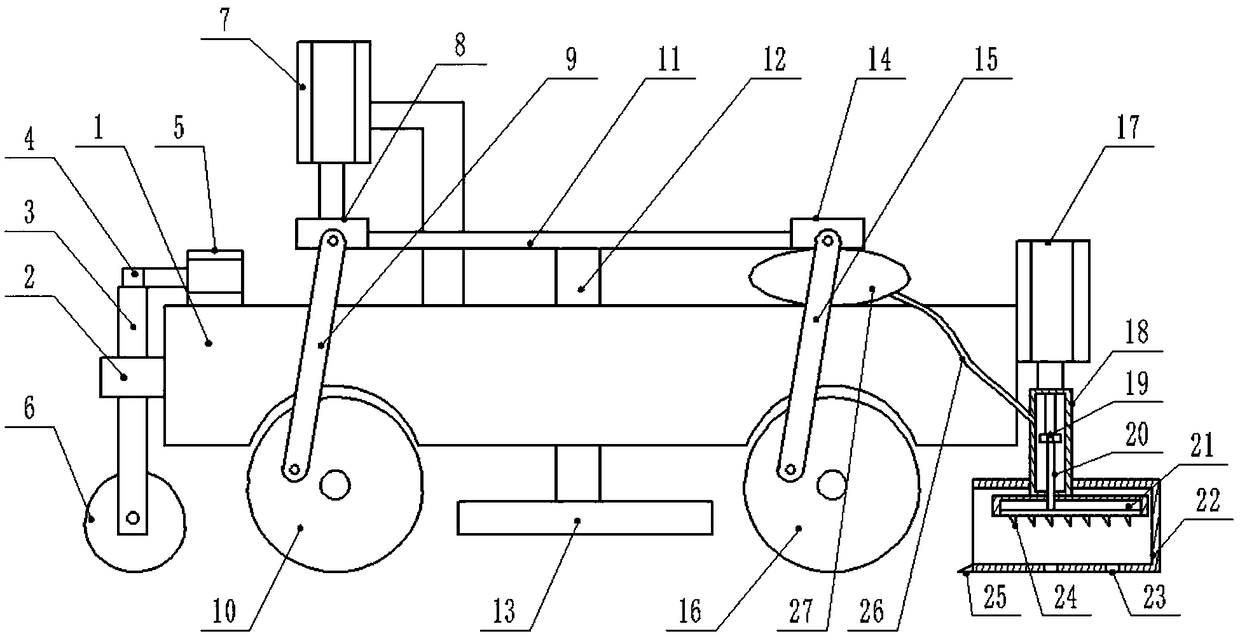

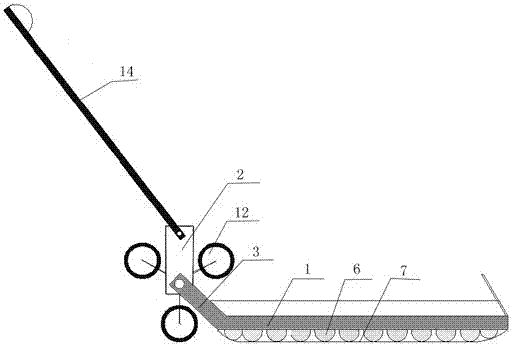

Hydraulic transmission paddy field flattening machine

ActiveCN109479408ARealize the turning functionAchieve rotationSpadesPloughsHydraulic cylinderSteering wheel

The invention belongs to the technical field of agricultural machinery, and discloses a hydraulic transmission paddy field flattening machine. The hydraulic transmission paddy field flattening machinecomprises a supporting plate, and further comprises a remote controller, wherein a bearing is mounted on the head of the supporting plate; a support is fixed on the bearing; a steering wheel is arranged at the lower end of the support; the upper end of the support is fixedly connected with a push rod; an end of the push rod is connected with a first hydraulic cylinder; the supporting plate is provided with a front wheel and a rear wheel; the supporting plate is provided with a second hydraulic cylinder; the second hydraulic cylinder is connected with a first cross rod; the first cross rod iseccentrically hinged to the front wheel through a first rocker rod; the first cross rod is connected with a second cross rod through a horizontal rod; the second cross rod is eccentrically hinged to the rear wheel through a second rocker rod; and the remote controller is used for remotely controlling operation of the first hydraulic cylinder and the second hydraulic cylinder. A tractor driving mode is not required, the hydraulic transmission paddy field flattening machine can be self-driven by remote control, the hydraulic transmission paddy field flattening machine is suitable for flatteninga small paddy field, and the flattening effect is improved.

Owner:NAN COUNTY WEIYE MACHINERY MFG

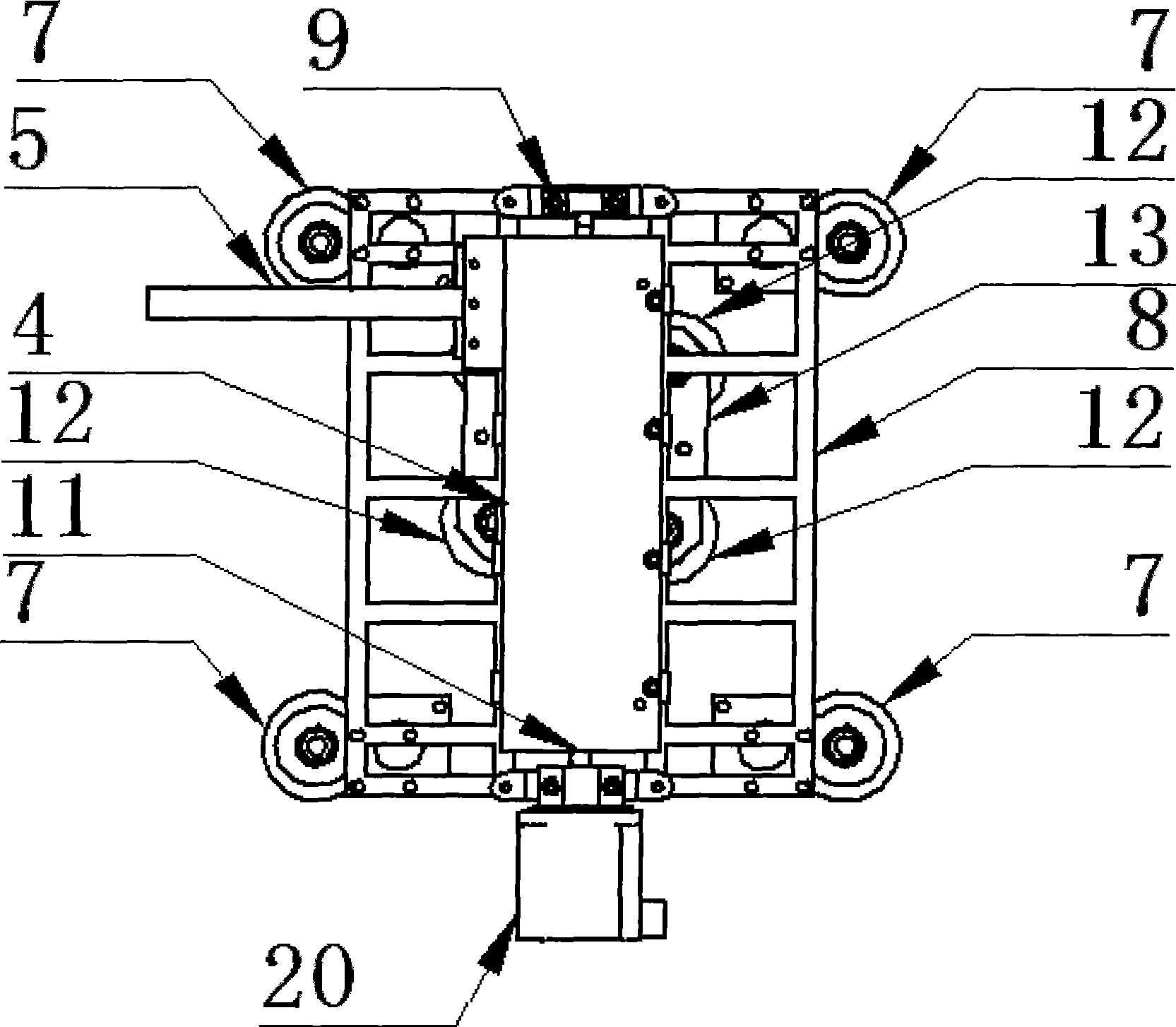

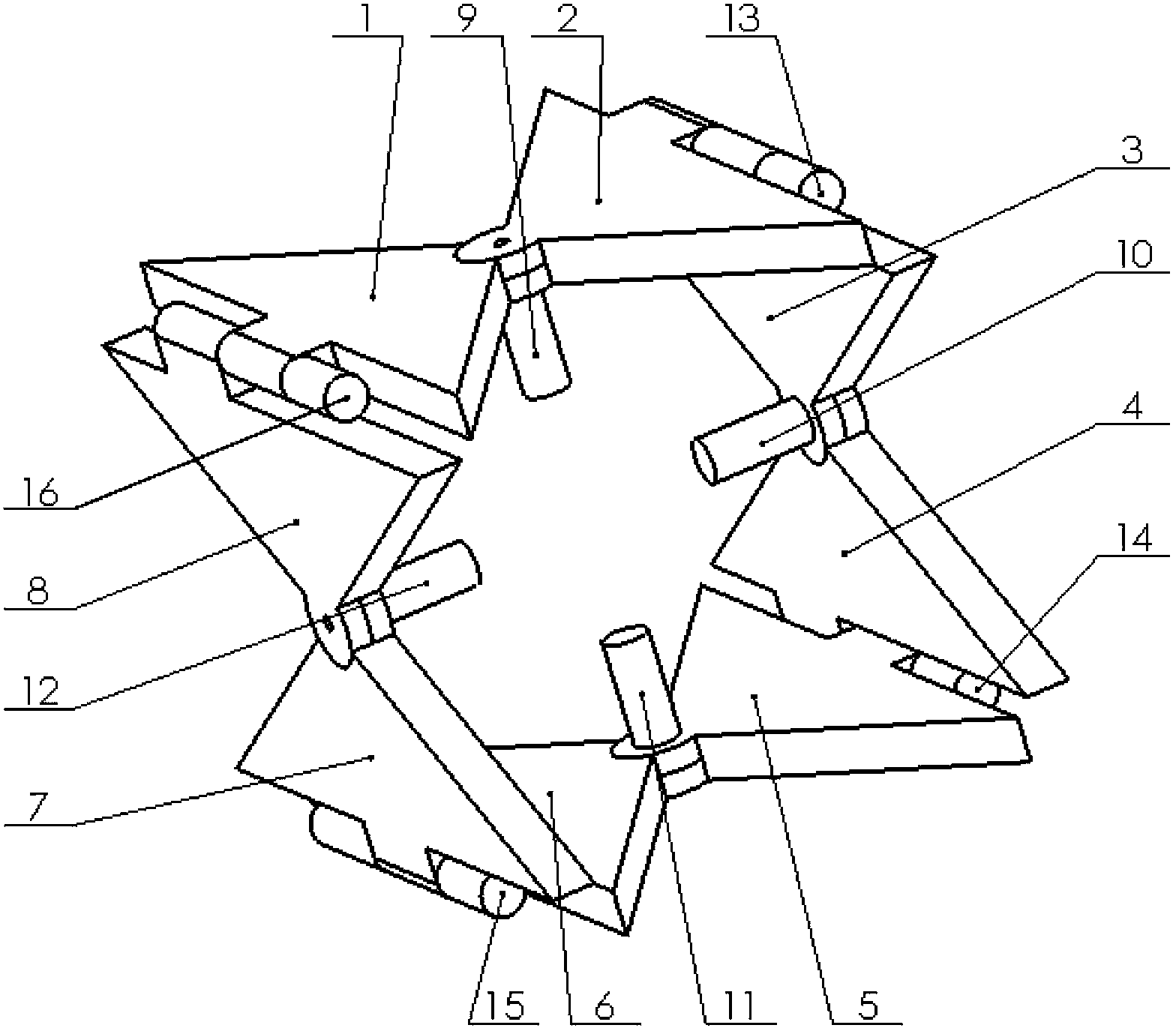

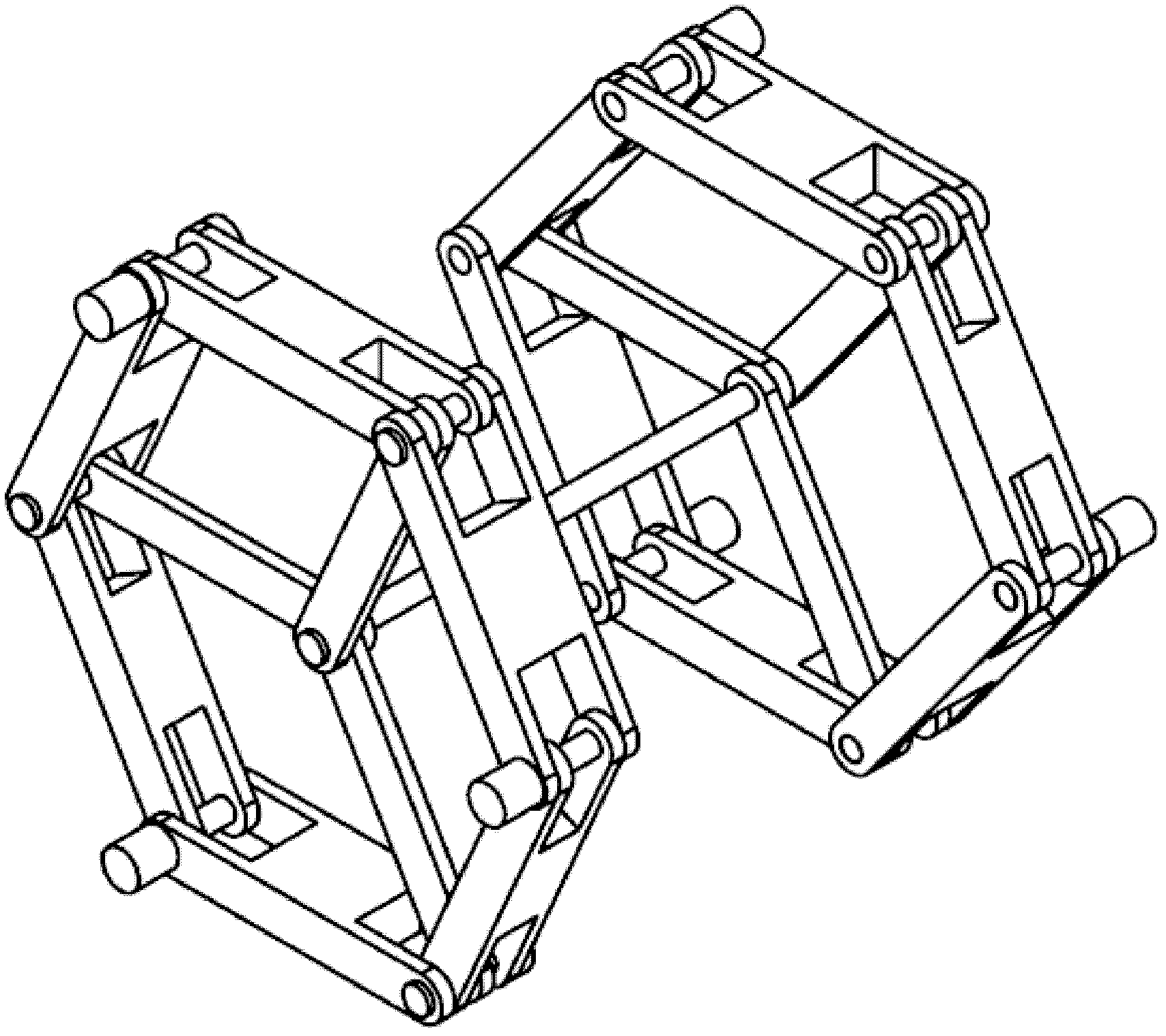

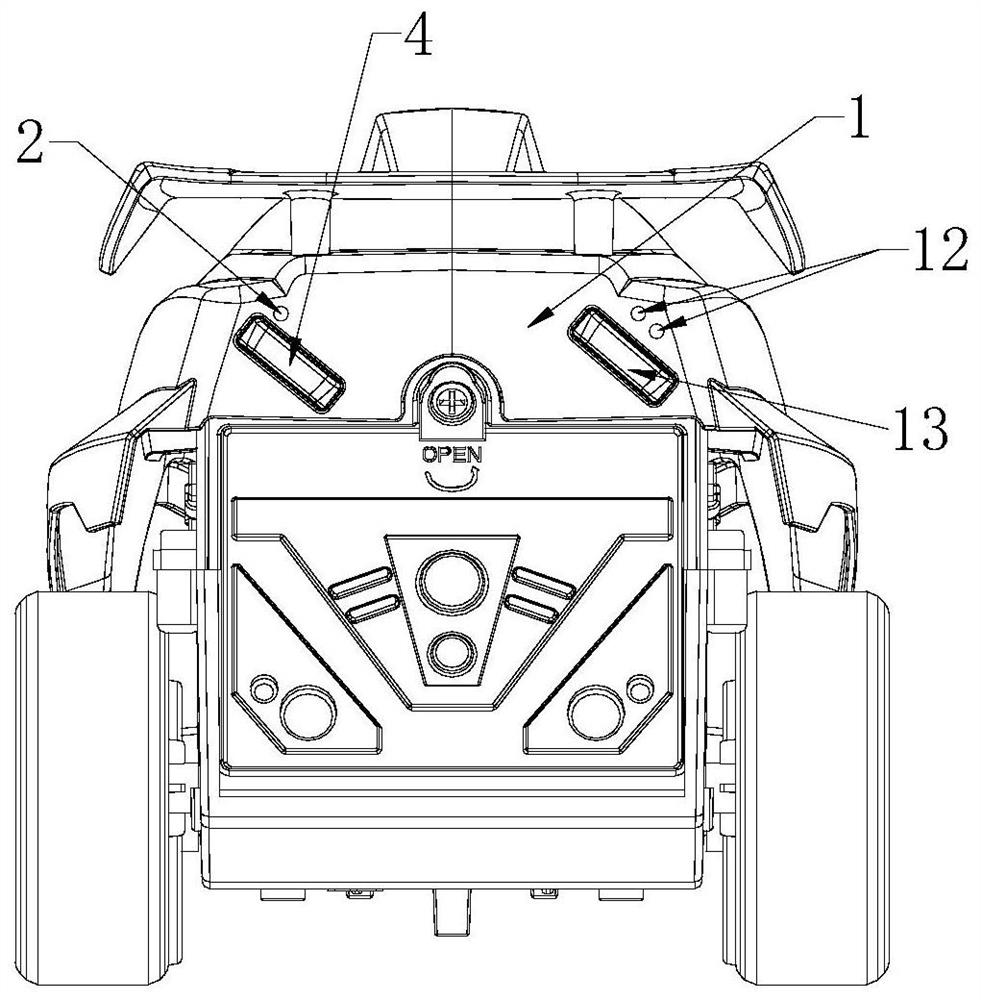

Quadrilateral rolling mechanism capable of steering

The invention discloses a quadrilateral rolling mechanism capable of steering. The quadrilateral rolling mechanism capable of steering comprises eight connection plates and connection structures thereof. Each connection plate is provided with two shaft holes; according to each connection plate, the perpendicular distances of axes between two shaft holes are equal; the eight connection plates form a quadrilateral, wherein the plates (1) and (2), the plates (3) and (4), the plates (5) and (6), and the plates (7) and (8) form four sides of the quadrilateral respectively; any adjacent connection plates are connected by a rotation pair; when the interior angles of the quadrilateral are 90 degrees, and the axes of the rotation pairs of the four corners of a square are parallel to each other, the mechanism has a square appearance; and the movement of the mechanism is controlled by motors (9), (10) and (15); and counter weights (11), (12), (13), (14) and (16) have the same weight as the motors to ensure that the structure of the mechanism is symmetrical. The motor (13) is controlled, so that the mechanism is deformed and rolls due to inertia; and the motors (9) and (10) are controlled, the mechanism is formed so as to swerve.

Owner:BEIJING JIAOTONG UNIV

Pipeline inner wall flaw detection crawling robot and application method thereof

PendingCN112728291ASimple structureWide range of applicationsPigs/molesNuclear energy generationElectric machineryControl mode

The invention provides a pipeline inner wall flaw detection crawling robot and an application method thereof. The pipeline inner wall flaw detection crawling robot comprises a mounting assembly, wherein the interior of the mounting assembly comprises a first triangular mounting plate and triangular plate butt joint rods, a second triangular mounting plate is fixedly mounted on the surface of the front end of the first triangular mounting plate through a plurality of triangular plate butt joint rods, a supporting butt joint base is fixedly mounted on the second triangular mounting plate through an output end of a motor, a device main rod is fixedly mounted at the front end of the supporting butt joint base, forward rotation threads are arranged at the front end of a rod body of the device main rod, and reverse rotation threads are arranged at the rear end of the rod body of the device main rod. Compared with a traditional pipeline detection scheme, the robot adopts the modular structural design and has the advantages of being simple in structure, wide in practical field, safe, reliable, high in cost performance, capable of achieving a certain turning function, applicable to variable-diameter pipeline detection, flexible in control mode and the like.

Owner:SHENGLI COLLEGE CHINA UNIV OF PETROLEUM

Swimming pool bottom hydro power pushed automatic cleaner

ActiveCN101666168BRealize work status changeChange water jetGymnasiumSwimming poolsAxial-flow pumpHydraulic action

Owner:TIANJIN WANGYUAN ENVIRONMENTAL PROTECTION & TECH CO LTD

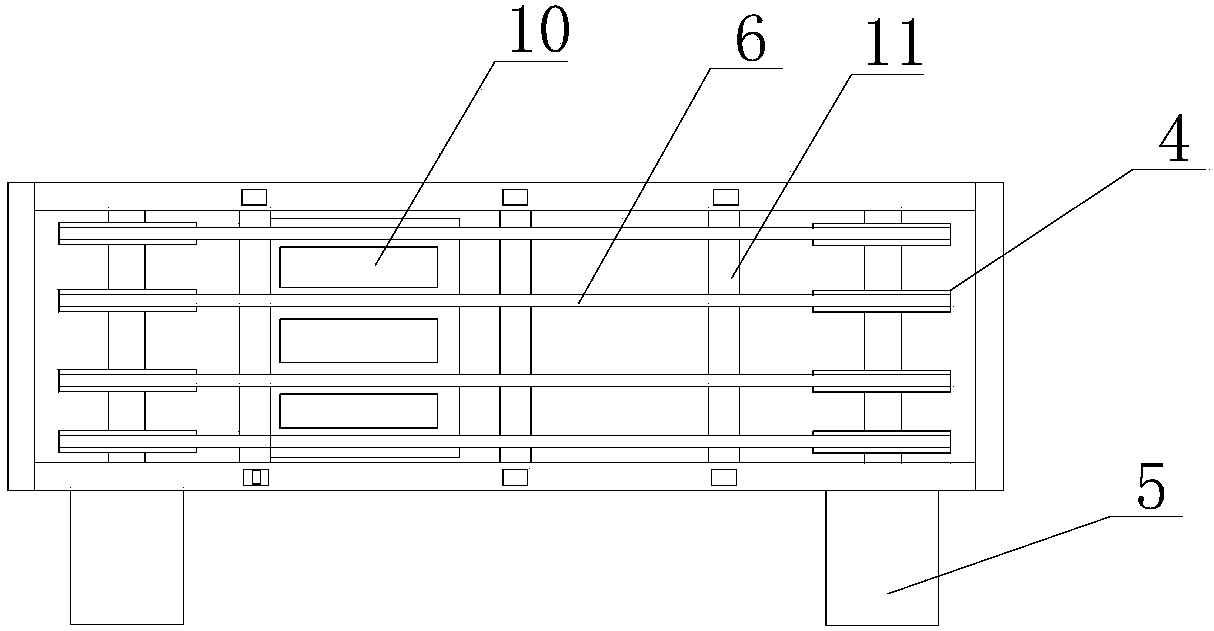

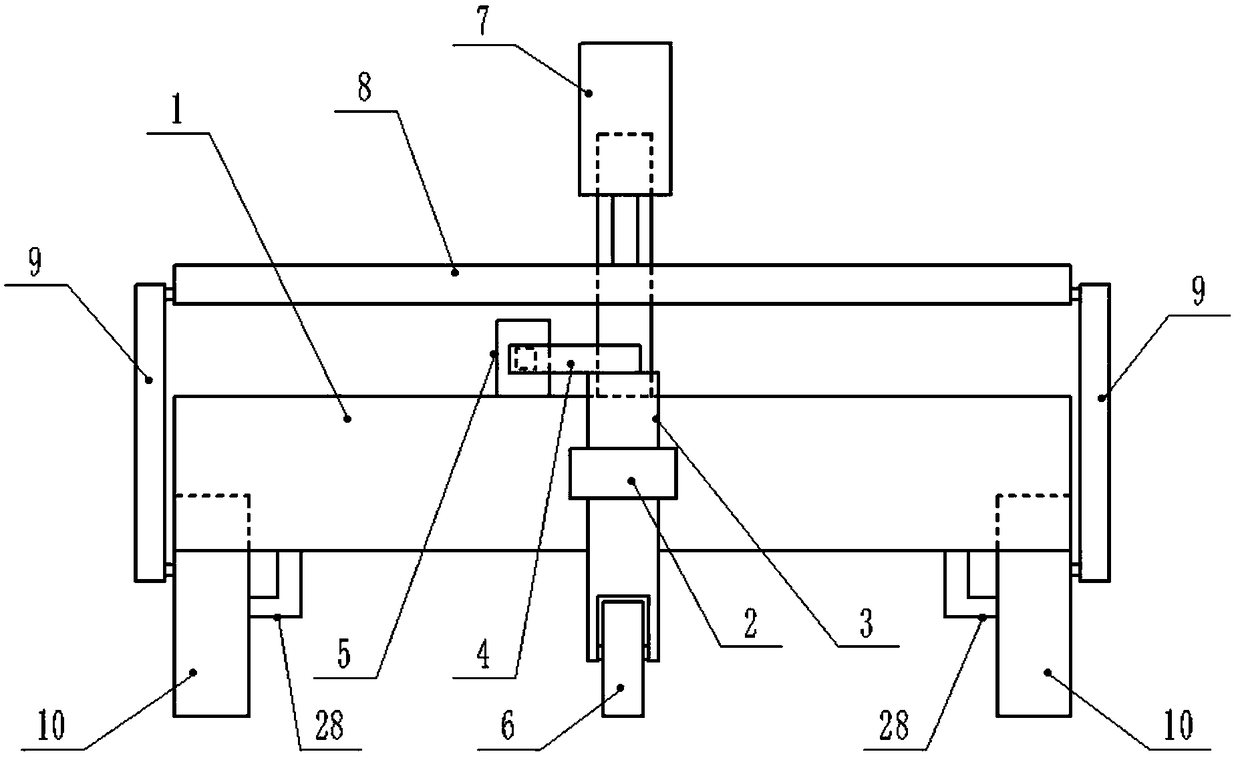

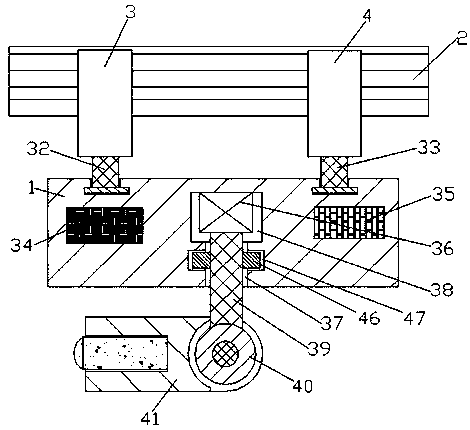

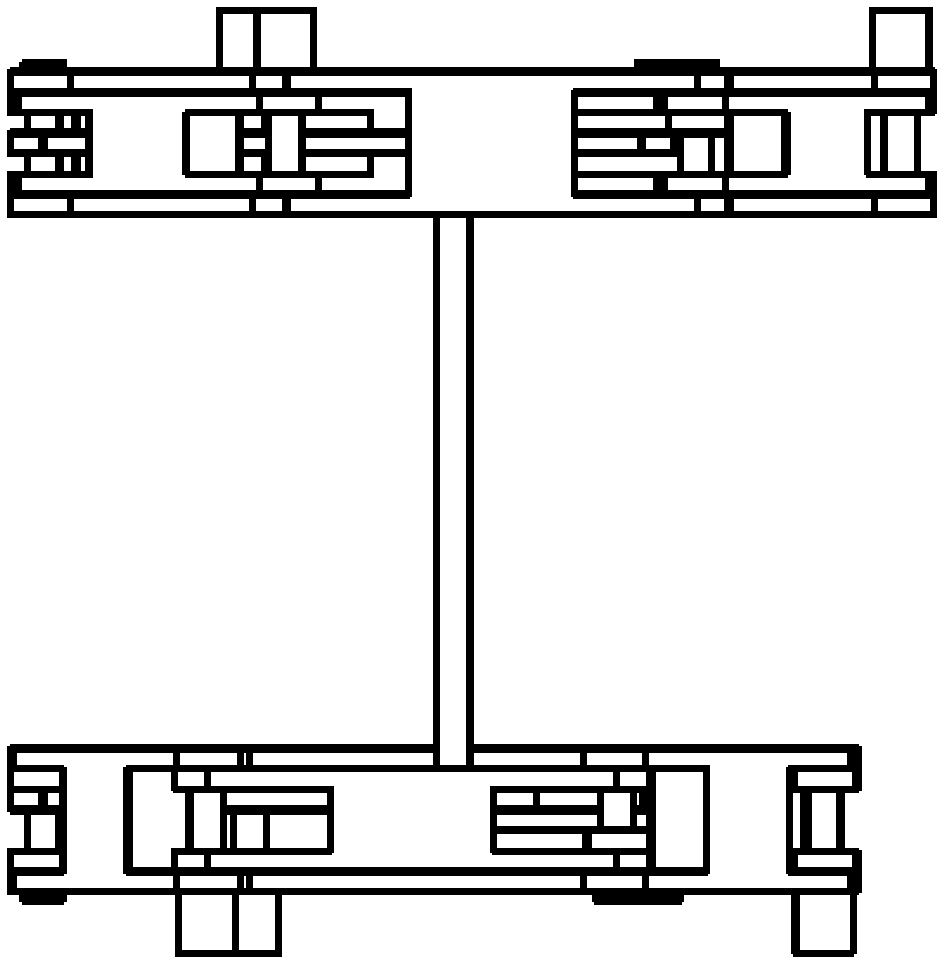

Numerically-controlled vertical turning and milling combined processing center working platform

InactiveCN109571051AHigh positioning accuracyRealize the turning functionLarge fixed membersControl engineeringSlide plate

The invention relates to the technical field of vertical turning and milling combined processing equipment for vertical lathes, and discloses a numerically-controlled vertical turning and milling combined processing center working platform. The numerically-controlled vertical turning and milling combined processing center working platform comprises a working platform base, wherein a working platform body for turning is rotatably connected to the upper end of the working platform base; a working platform gearwheel is fixedly connected to the lower end of the working platform body; two shafts are rotatably connected into the working platform base, and the upper ends of the two shafts are fixedly connected to two shaft gears which are engaged with the working platform gearwheel; a double-speed high-power servo main shaft motor is arranged at one side of the working platform body; an output shaft at the lower end of the double-speed high-power servo main shaft motor is in transmission connection with the surfaces of the two shafts through a tight-up V belt; C-shaped driving mechanisms are arranged on two reverse sides of the working platform base, and each C shaft driving mechanism comprises a supporting seat which is fixedly connected to the sidewall of the working platform base; and a sliding plate is glidingly connected to each supporting seat. The numerically-controlled vertical turning and milling combined processing center working platform has the advantages of being high in C-shaft indexing accuracy, and sensitive and reliable in turning and milling switching.

Owner:DALIAN YIMEI MACHINERY

A multifunctional pipeline robot

ActiveCN104259158BRealize the turning functionWalking smoothlyHollow article cleaningDrive wheelEngineering

The invention relates to a multifunctional pipeline robot which comprises an advancing device, a sweeping device and a control circuit board. A driving device is arranged on the advancing device. The multifunctional pipeline robot further comprises a planetary wheel set A arranged on the advancing device and a planetary wheel set B arranged on the sweeping device, the advancing device is connected with the sweeping device through a spring, and a walking device pushes the sweeping device to advance in a pipeline. When the sweeping device encounters a curve, the spring can be net, and a steering function of the whole robot is achieved. Due to the fact that the walking device and the sweeping device are separately arranged, the length of the whole pipeline robot is quite decreased, and the phenomenon that the pipeline robot is clamped in the curve does not easily occur. The driving device adopts a worm wheel and worm structure, when the pipeline robot stops at a certain position in a vertically pipeline to perform sweeping or detection, a worm wheel does not drive a worm to rotate by utilizing the self-locking performance of the worm wheel and worm structure, and the phenomenon that driving wheel cannot reversely rotate and accordingly the pipeline robot slips down can be avoided.

Owner:FUJIAN QUANZHOU NO 7 MIDDLE SCHOOL

Intelligent information acquisition equipment

The invention discloses intelligent information acquisition equipment. The equipment comprises a mainframe box and moving guide rails fixed on a roof, the left and right sides of the upper portion ofthe mainframe box are respectively provided with a driven device and a driving device, the left and right sides of the inner portion of the mainframe box are respectively provided with a power supplymodule and an information positioning module, the lower portion of the mainframe box is provided with a swing block, the right end face of the swing block is provided with a vertically through swing groove with a rightward opening, an annular fixing block is located in the swing groove, and the left end face of the swing block is fixedly provided with an image acquisition module. The intelligent information acquisition equipment has the advantages that a power supply module provides power source for the running of the equipment, the information positioning module provides positioning information for the equipment and feeds back the parking situation to a mainframe chamber, so that workers can know the on-site parking situation in time, the situation of occupying multiple parking spaces canbe controlled, empty parking spaces are fed back to a parking person, thereby reducing a large amount of time for finding a parking space.

Owner:何丽进

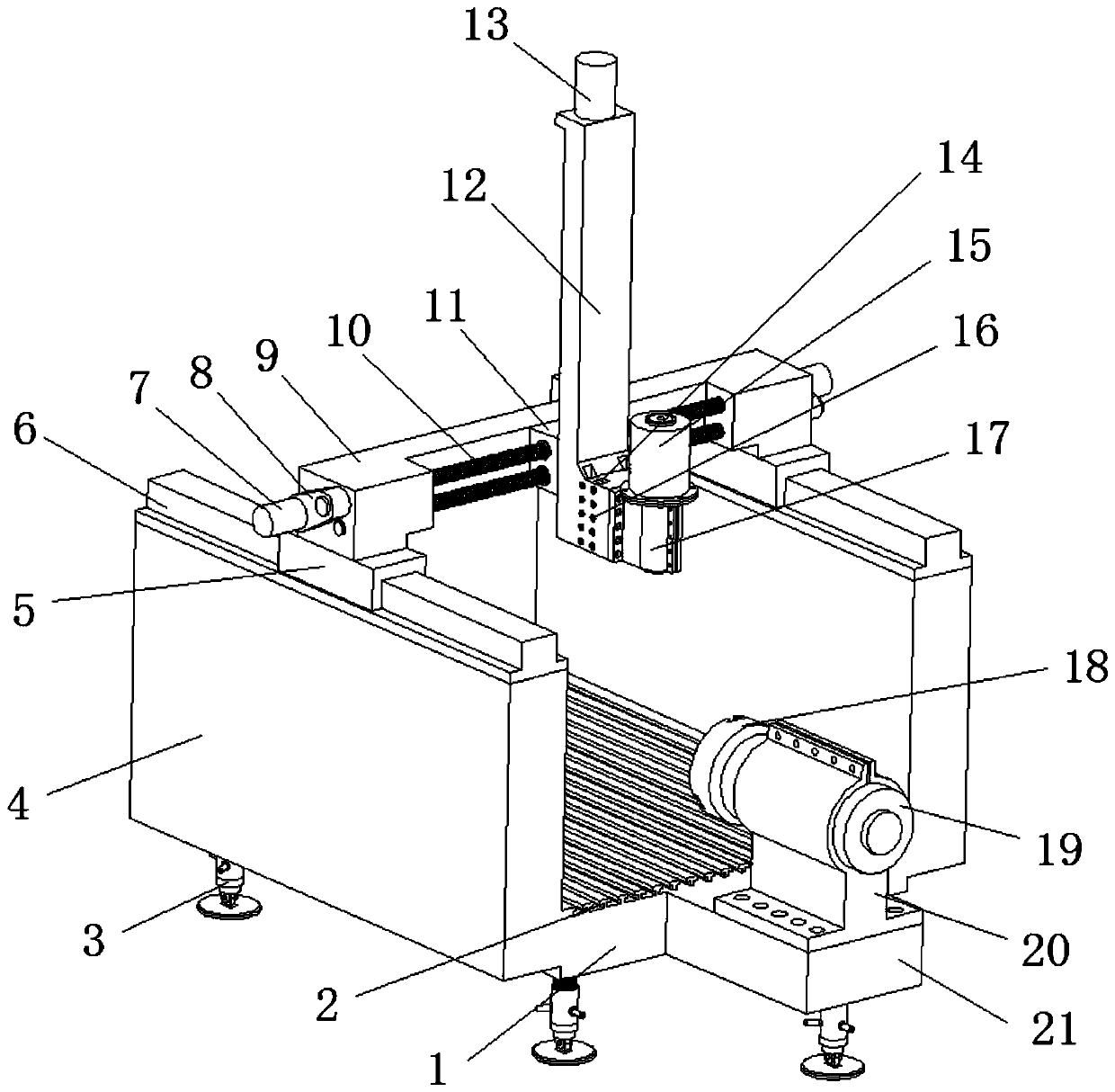

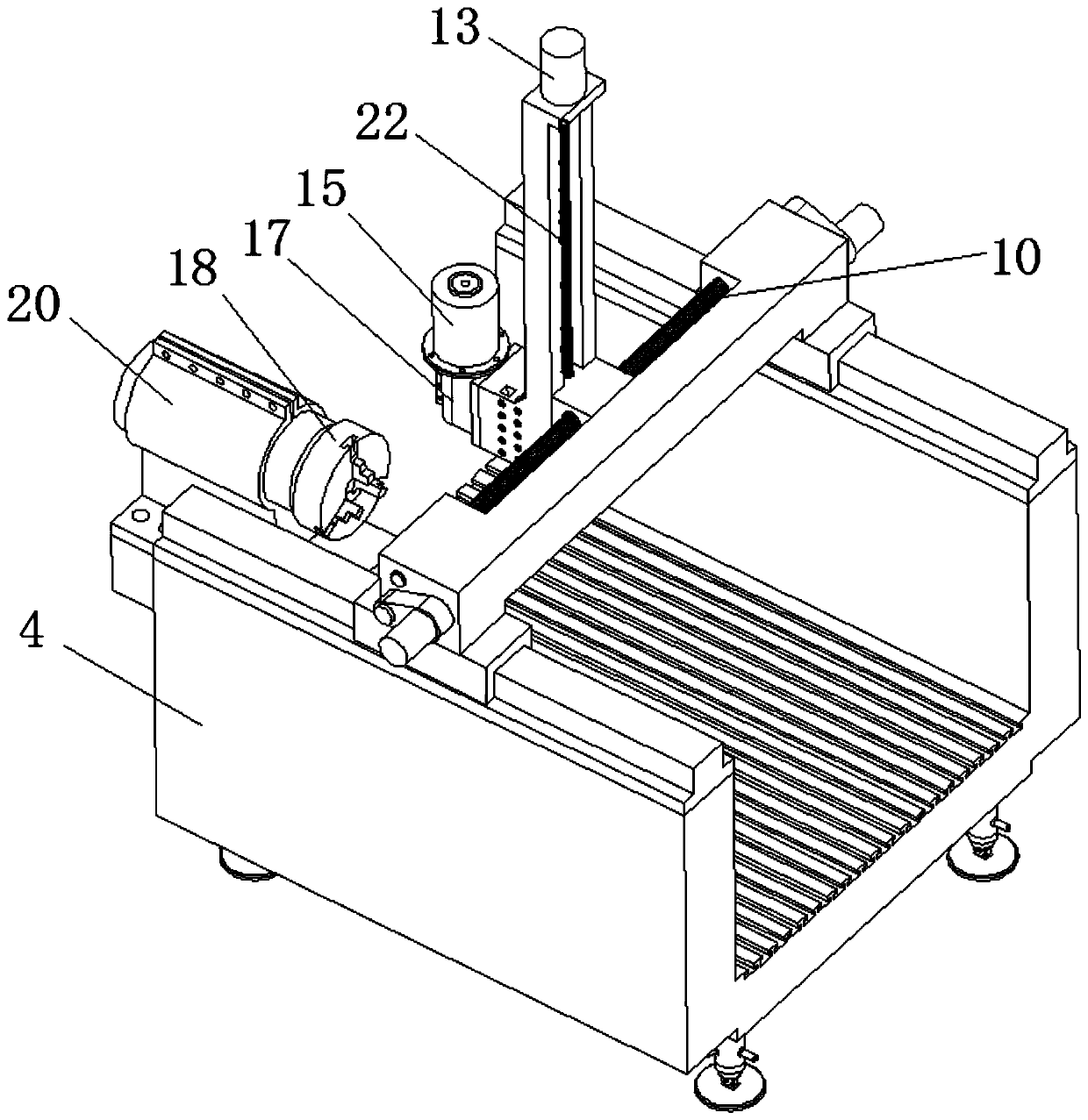

Moving column type gantry turning, milling, grinding and drilling integrated machining device

InactiveCN110315343ARealize the turning functionCapable of processingOther manufacturing equipments/toolsEngineeringMachining

The invention discloses a moving column type gantry turning, milling, grinding and drilling integrated machining device. The moving column type gantry turning, milling, grinding and drilling integrated machining device comprises a bottom plate which is in the horizontal state, the outer contour of the bottom plate is of a rectangular plate-shaped structure, multiple parallel T grooves are formed in the upper portion of the bottom plate, vertical plates perpendicular to the upper surface of the bottom plate are arranged on the two sides of the bottom plate, first sliding rails with the outlinesbeing in strip shapes are arranged on the tops of the vertical plates, first sliding blocks are arranged on the two sets of first sliding rails, a gantry frame with the outline being of the strip-shaped rectangular structure is fixed above the first sliding blocks through screws, an opening is formed in one side of the gantry frame, two first screws with the axis lines parallel are arranged in the opening of the gantry frame, the two ends of the first screws are located in the structures of the two ends of the gantry frame, and the two first screw rods in the opening of the gantry frame are sleeved with second sliding blocks. The moving column type gantry turning, milling, grinding and drilling integrated machining device can bear workpieces with the large weight, has multiple machining functions and is suitable for being used and popularized greatly.

Owner:泉州市科恩智能装备技术研究院有限公司

Rollingly-marching robot with two wheel-like hexagonal mechanisms

The invention relates to a rollingly-marching robot with two wheel-like hexagonal mechanisms, comprising a connecting bar, the two independent wheel-like hexagonal mechanisms and connections, wherein each wheel-like hexagonal mechanism comprises three parallelograms consisting of nine connecting rods: two adjacent parallelogram share one side, the three parallelograms share one vertex and any adjacent sides are connected by using a revolute pair; two parallelograms are respectively formed by rods (1), (6), (7) and (9) and rods (2), (3), (7) and (8) and shapes of the parallelograms are respectively controlled by motors (14) and (15); and a servo parallelogram is formed by rods (4), (5), (8) and (9) and a counterweight (16) is of the same weight as the motors to ensure that the structure issymmetrical. The change of interior angles of the parallelograms is controlled to ensure that the mechanisms are deformed and rolled and the cornering of the robot is realized through the different rolling speed of the two parallel wheel-like hexagonal mechanisms.

Owner:BEIJING JIAOTONG UNIV

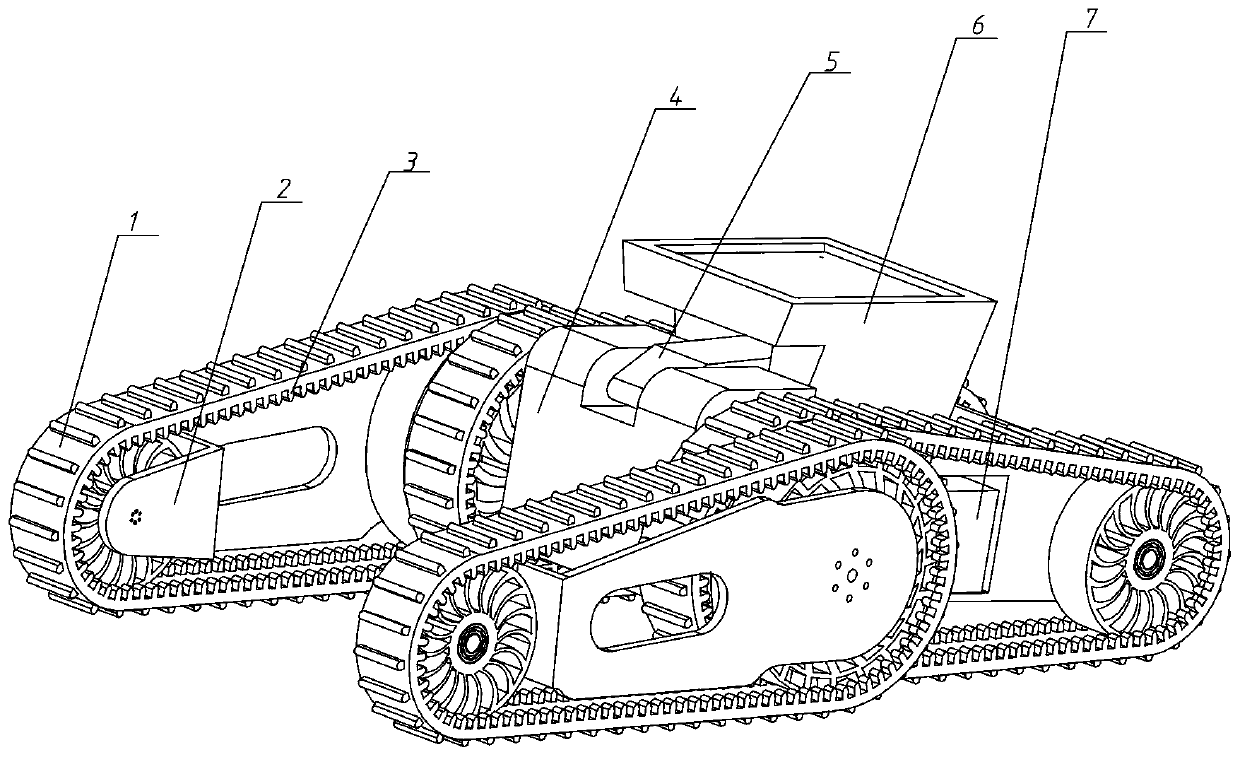

Novel tracked robot

InactiveCN111055937AAchieve climbingRealize the turning functionEndless track vehiclesNon-deflectable wheel steeringStair climbingBevel gear

The invention discloses a novel tracked robot. The tracked robot comprises a transmission case, and a battery box is mounted on the transmission box; a worm and gear reduction box and two arc bevel gear reduction boxes are mounted at one end of the transmission box; hollow spindles are installed on the outer sides of the two arc-shaped bevel gear reduction boxes through arc-shaped bevel gears respectively, driving wheels are installed at the other ends of the hollow spindles, swing arm wheels are installed on the outer sides of the driving wheels through long screws, driven shafts are installed at the other ends of the transmission boxes, and first driven wheels are installed at the two ends of each driven shaft. The novel tracked robot, the four crawler belts are connected with the wheelsin a matched mode, the vehicle can walk at a certain angle with the ground, the functions of climbing, stair climbing, sinking and the like of the crawler vehicle can be achieved through cooperationof the swing arm plate, the swing arm wheels and the worm and gear reduction box, and rotation of the multifunctional cradle head is achieved through a first-level gear and is not affected by the motion state of the vehicle.

Owner:HEFEI UNIV OF TECH

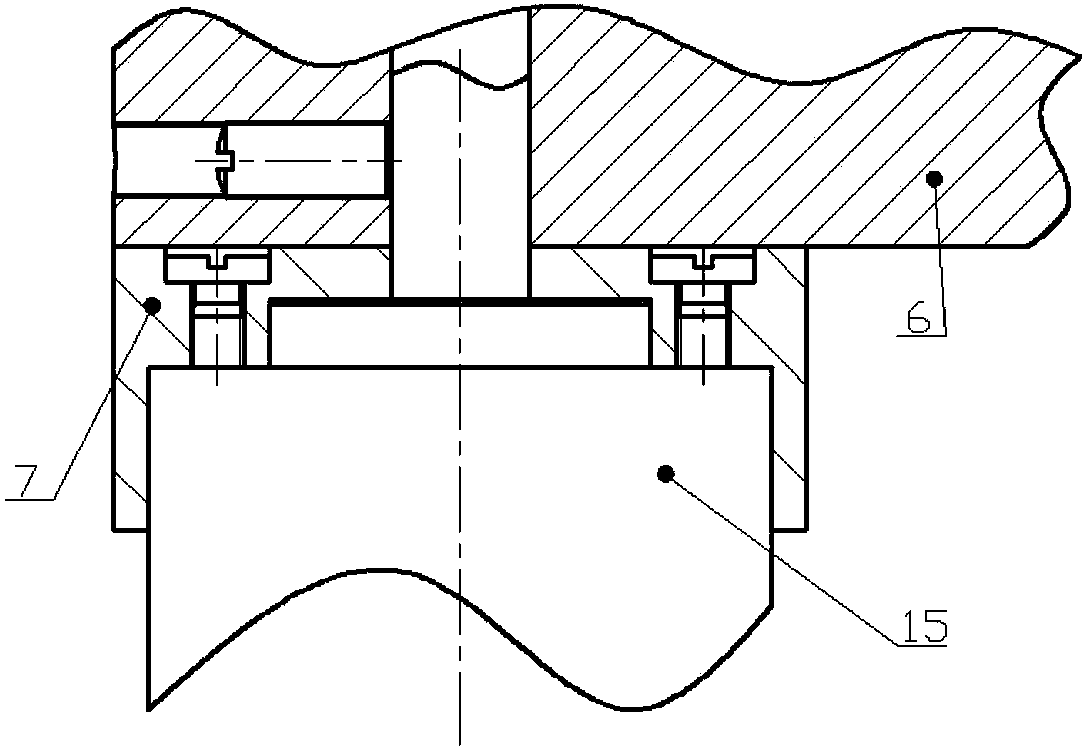

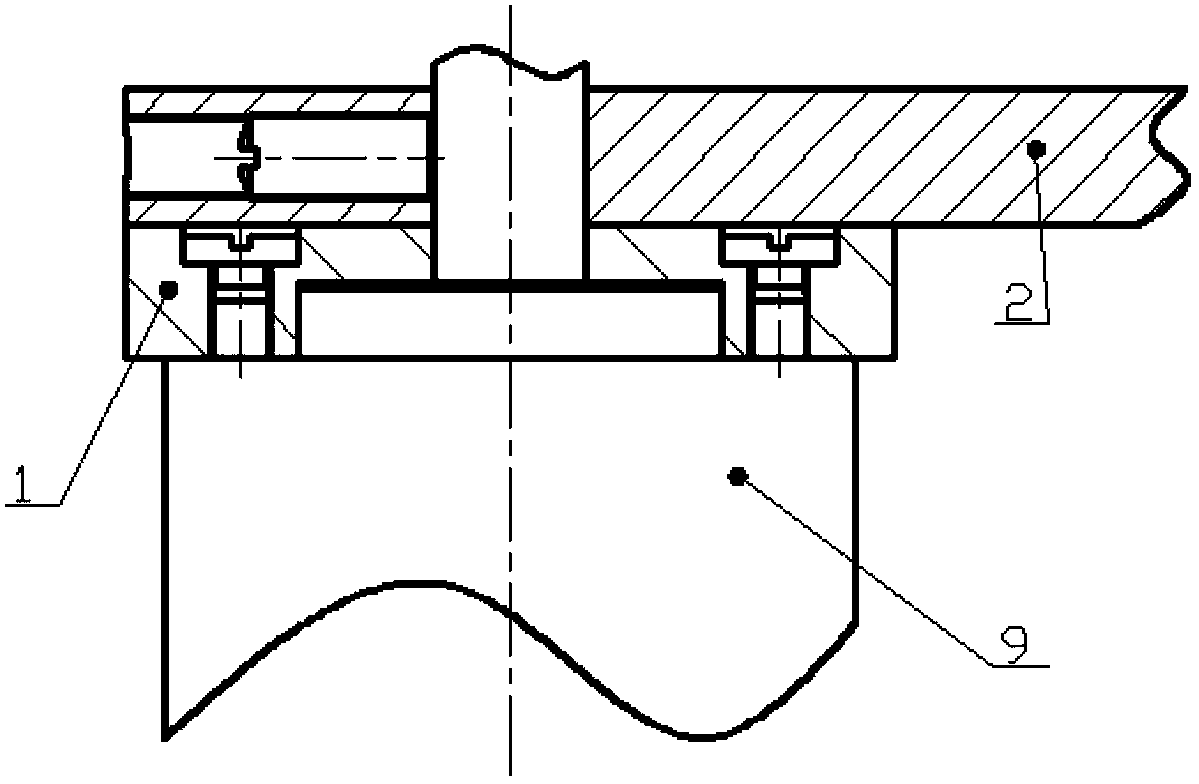

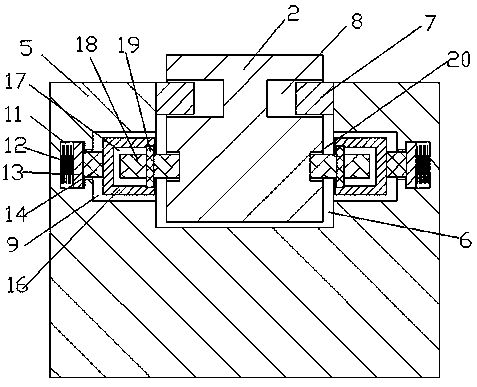

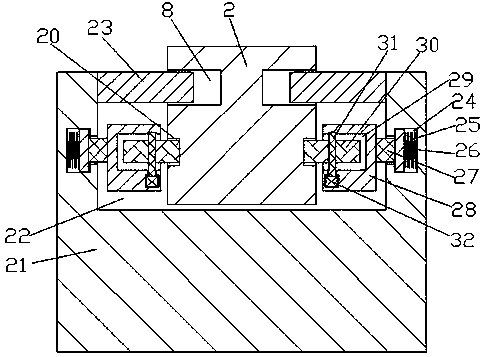

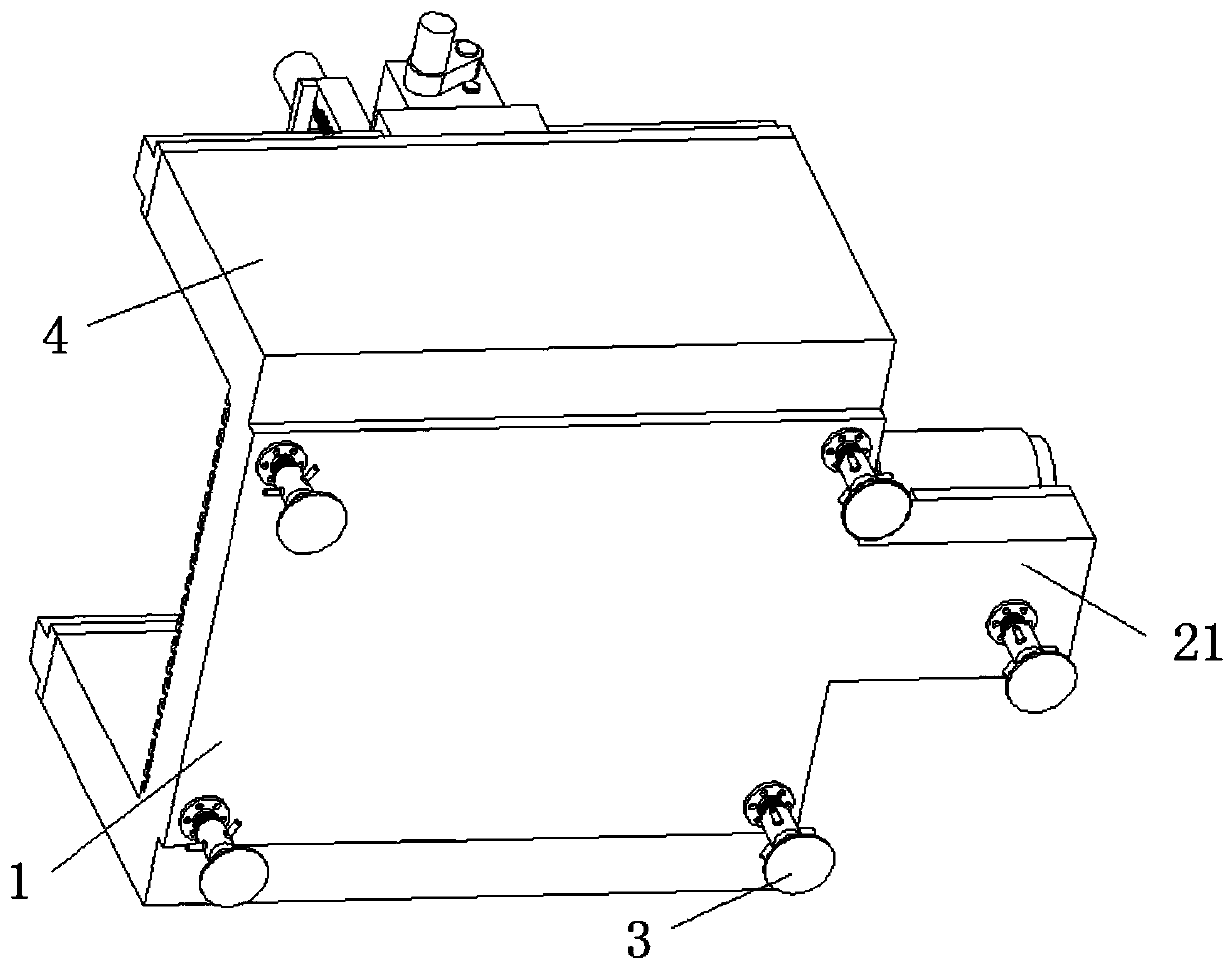

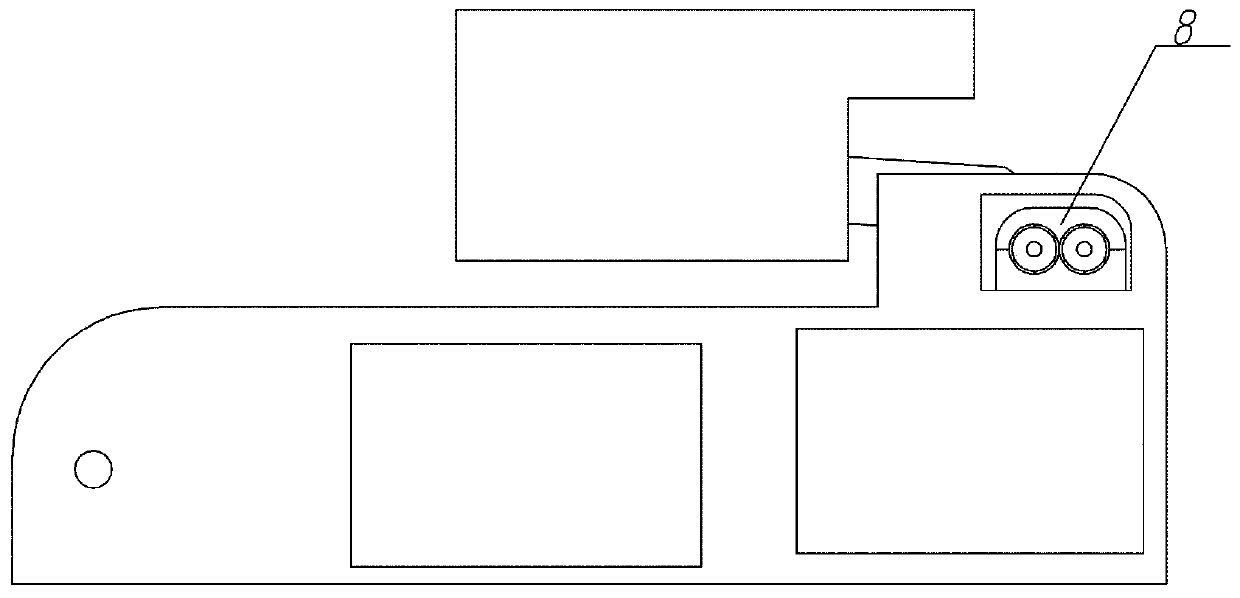

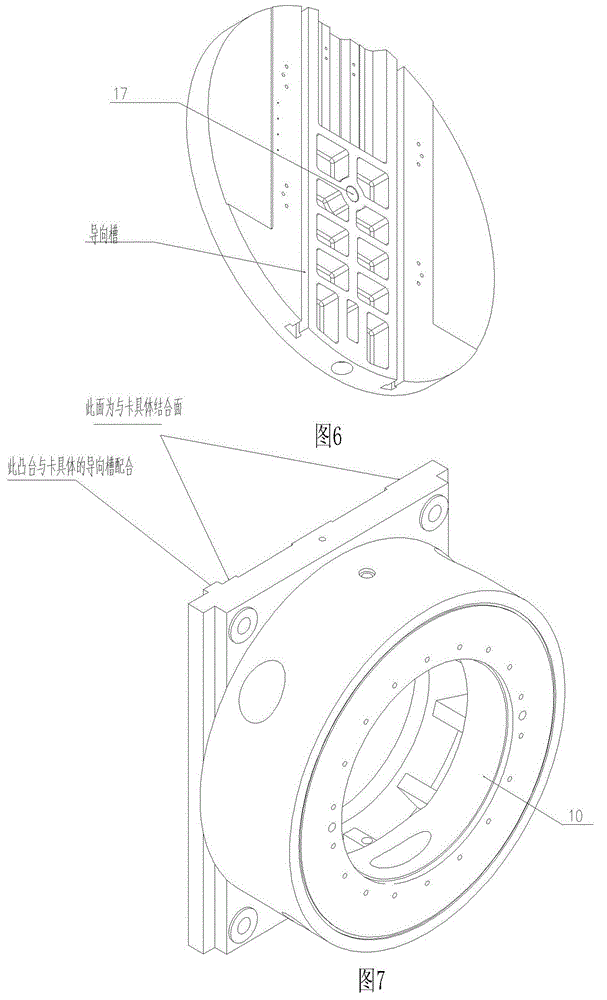

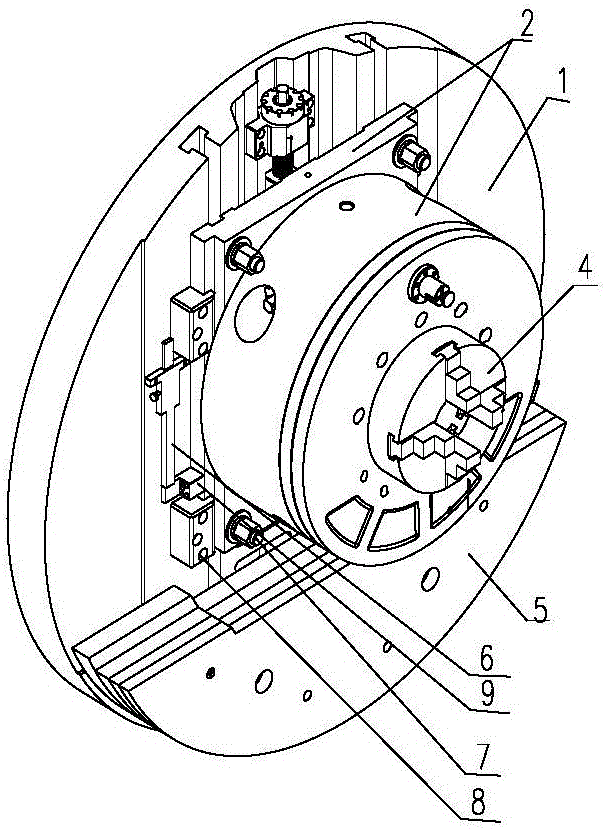

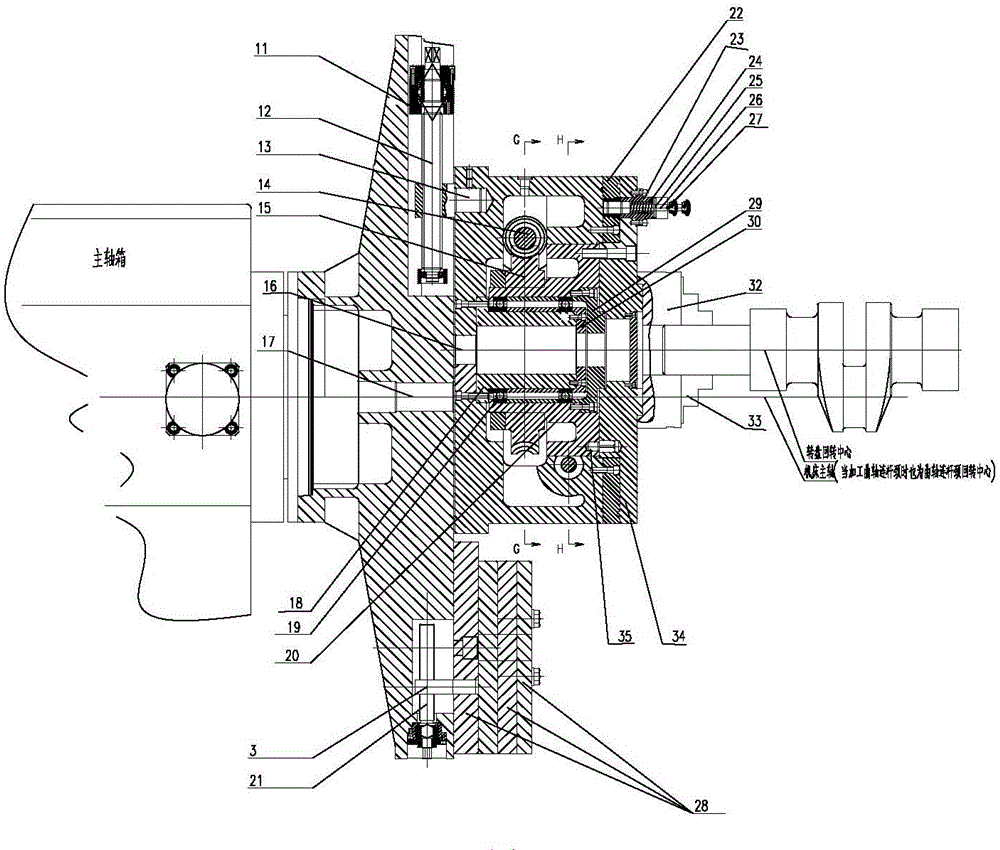

Turning jig device and manufacturing method dedicated to crankshaft

ActiveCN103612147BAchieve eccentric rotationRealize the turning functionPrecision positioning equipmentWork clamping meansLocking mechanismEngineering

The invention discloses a turning clamp device special for a bent axle and a manufacturing method. A left clamp and a right clamp are basically identical in structure. The turning clamp device special for the bent axle is characterized in that an eccentric distance moving and positioning mechanism of each clamp is installed on a clamp body through a lead screw supporting mechanism, and pressing plates, a position-measuring mechanism and a screw-locking mechanism carry out locking and positioning on a sliding plate; a connecting rod neck indexing positioning and locking mechanism is installed in a conical frustum of the sliding plate, a worm gear is fixed to a drum wheel, a rotary disc is fixed to the drum wheel through a positioning pin, a worm drives the worm gear to rotate around a rotation central hole, and therefore rotation, positioning and fixing locking of a workpiece are achieved; a bent axle clamping mechanism can rotate around the rotation central hole in an indexing mode while clamping the workpiece; an eccentric balance weight mechanism achieves rotary balance of a whole rotary system. By means of the eccentric clamp on a main shaft of a lathe, bent axles of multiple series, different eccentric distances and different main shaft neck diameters can be machined on one device, only one time of clamping is needed in the machining process of each bent axle, and then a connecting rod neck, the main shaft neck and web plates at two sides of the bent axle are turned.

Owner:沈阳机床中捷友谊厂有限公司

Stairs-climbing carrier for batteries

PendingCN107399346AWith steering functionEasy to operateHand carts with multiple axesHand cart accessoriesRatchetElectrical battery

The invention discloses a stairs-climbing carrier for batteries. The carrier comprises a body and a coupling device, the body and the coupling device are hinged through a connecting mechanism enabling the coupling device to rotate on the body up and down as well as leftwards and rightwards, the body is of a cuboid structure formed by welding angle steel, the body is provided with grooves which are partitioned with at least two retaining plates and used for holding batteries, two rows of rollers composed of at least two single rollers are arranged on the body, the outer sides of the two rows of rollers are wrapped with rubber tracks, the rollers are arranged on the body through ratchet mechanisms, the coupling device comprises a coupling device bracket and a three-phase alternating-current motor arranged on the coupling device bracket, and the three-phase alternating-current motor is connected with a power wheel through a rotary mechanism. The body is hinged to the coupling device multi-directionally, the body moves on stairs and the ground with the coupling device through power of the coupling device, and the carrier has a steering function and is convenient for people to operate.

Owner:ZHUMADIAN POWER SUPPLY ELECTRIC POWER OFHENAN +1

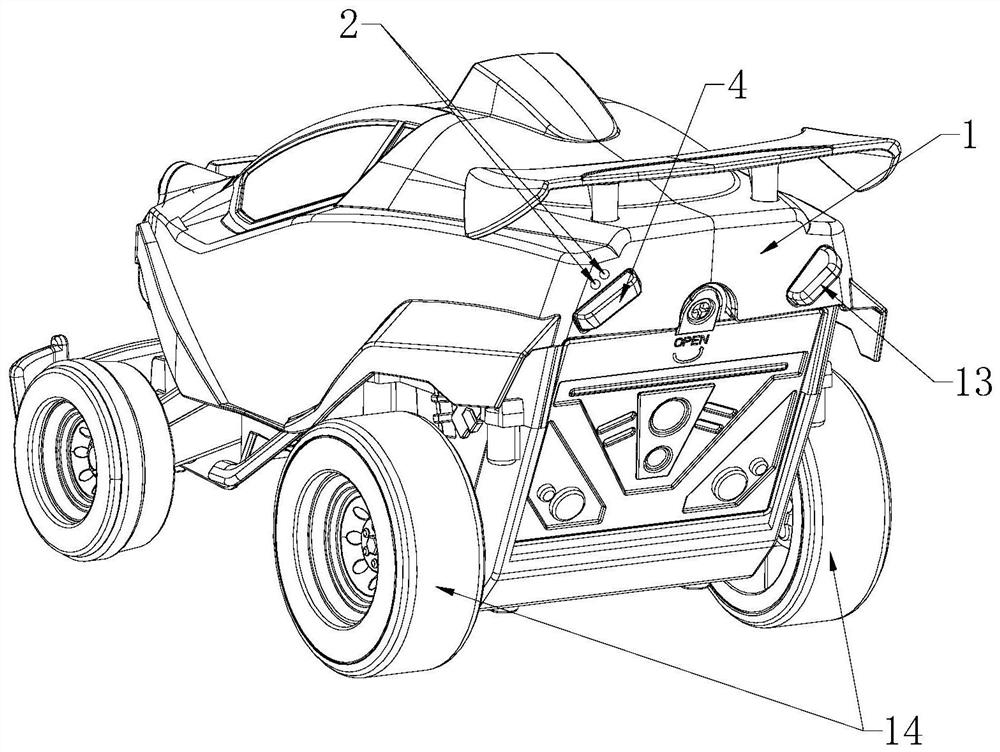

Stunt car upright track adjustment device

Owner:DONGGUAN MEICHITU IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com