Pipeline inner wall flaw detection crawling robot and application method thereof

A technology for crawling robots and pipelines, applied in the field of crawling robots, can solve the problems of inconvenient control, insufficient ability to overcome obstacles, and adapt to a single pipe diameter, and achieve the effects of easy upgrading, high cost performance, and wide practical fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

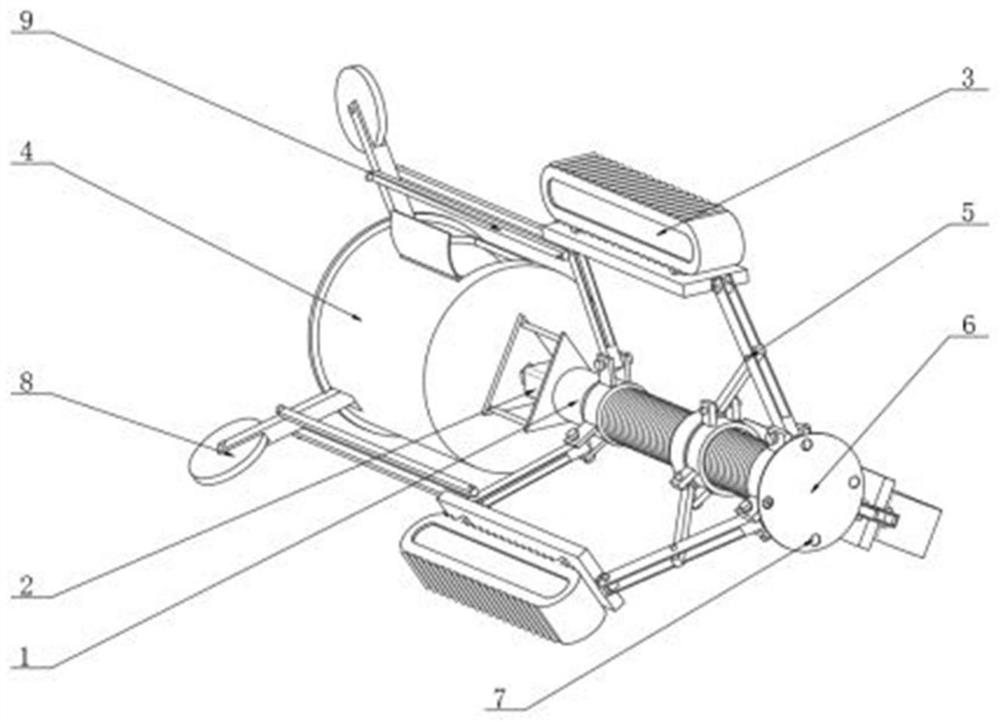

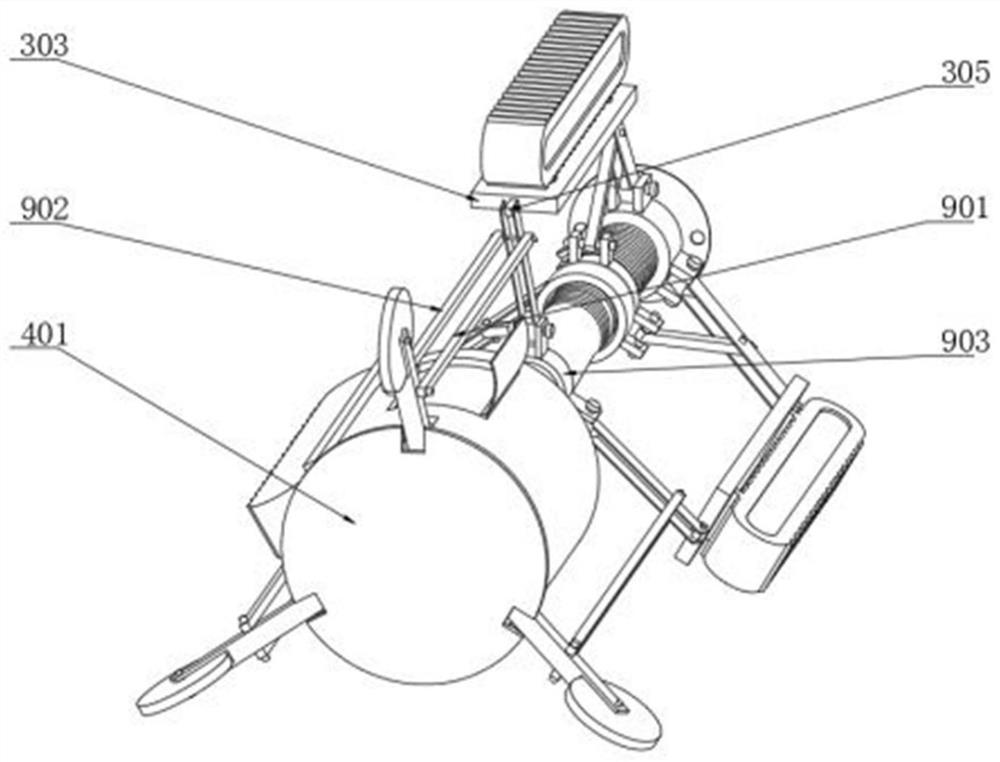

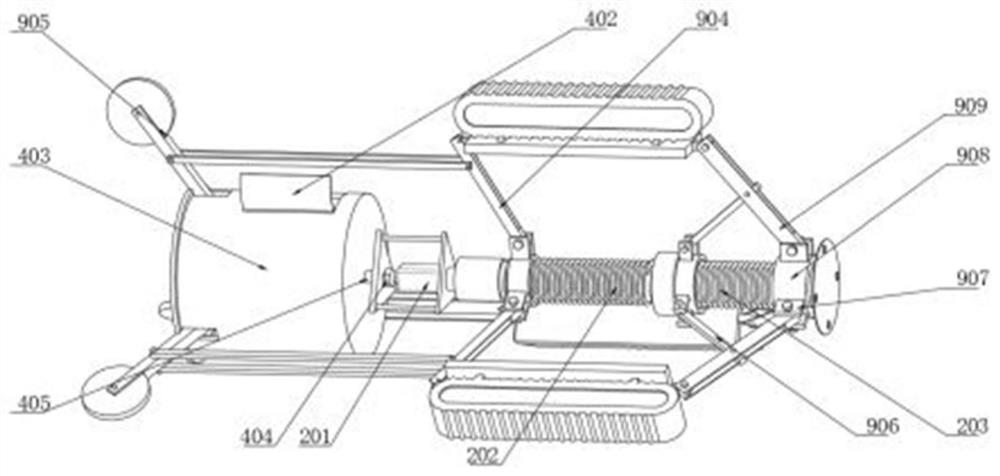

[0040] Such as Figure 1-6 As shown, a crawling robot for flaw detection on the inner wall of a pipeline includes

[0041] Mounting assembly 2, the interior of mounting assembly 2 includes first triangular mounting plate 204 and triangular plate docking rod 205, the front end surface of first triangular mounting plate 204 is fixedly installed with second triangular mounting plate 206 through several triangular plate docking rods 205, the second triangular mounting plate 206 is installed The plate 206 is fixedly installed with a support docking base 1 through the output end of the motor 201, and the front end of the support docking base 1 is fixedly equipped with a device main rod 10. With reverse thread 202;

[0042] Walking assembly 3, the inside of walking assembly 3 includes non-slip track 301 and assembly mounting plate 303, assembly mounting plate 303 is provided with three and each outer surface is fixedly installed with assembly baffle plate 307 by C-shaped mounting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com