Connecting rod transmission type front wheel turning anti-swing mechanism

A technology of front wheel turning and connecting rod transmission, which is applied in the direction of wheels, aircraft parts, landing gear, etc., and can solve problems such as destroying aerodynamic shape, reducing aircraft range, and large dynamic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

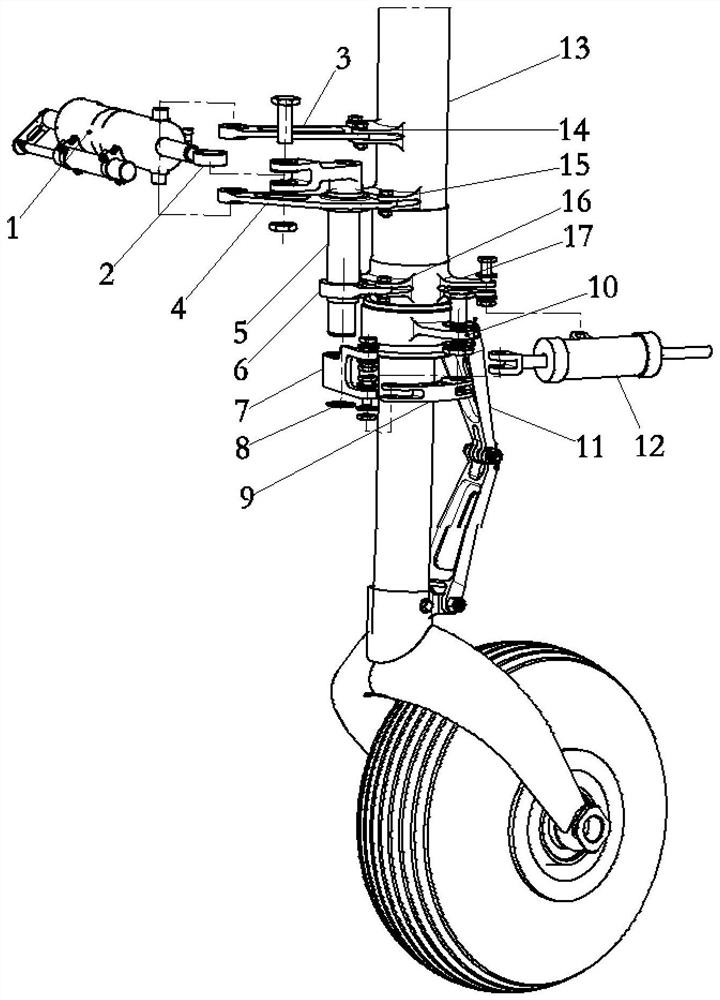

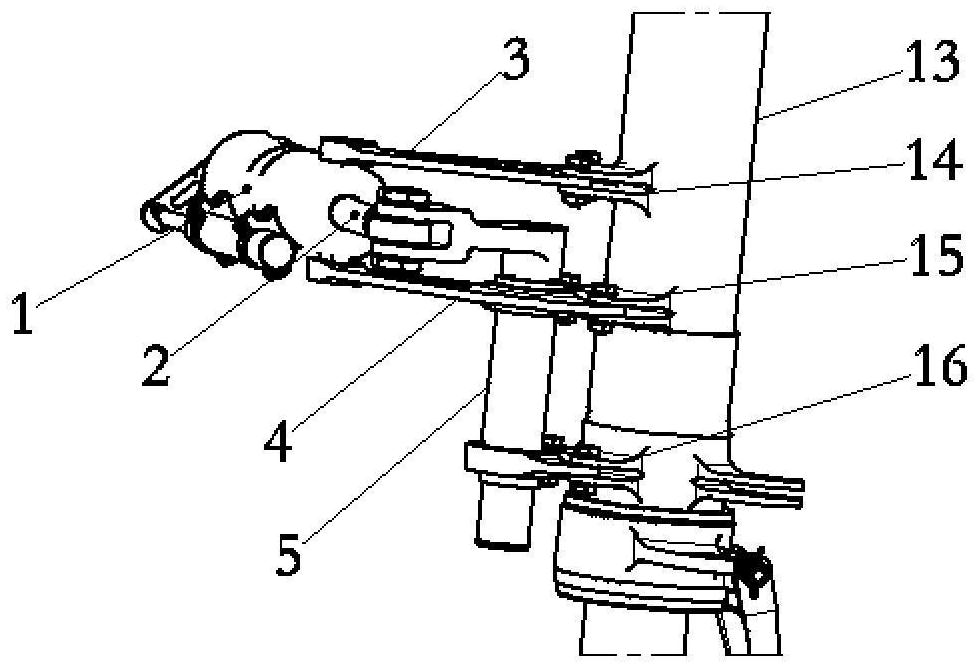

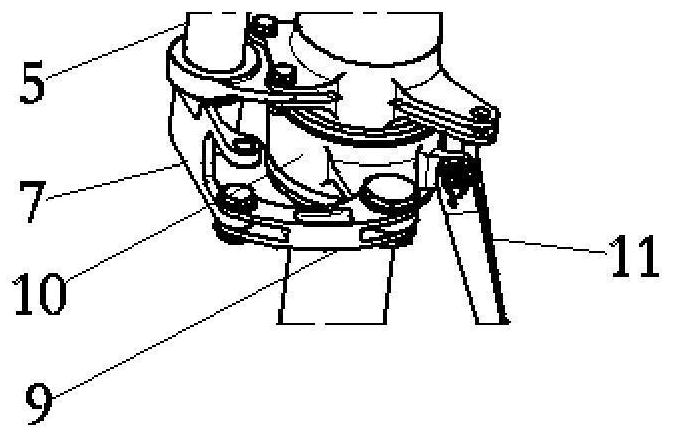

[0035] Such as Figure 5 Shown is an example of the use of the link transmission mechanism suitable for the front wheel turning anti-sway system. The landing gear of a certain type of aircraft is a non-retractable configuration, and the front landing gear is installed on the frame 3 of the fuselage. During the operation of the aircraft, the front wheel steering mechanism is added according to the user's needs, and the front wheel steering is realized by driving the front landing gear ring body through the steering actuator. According to calculations, the volume and length of the front wheel steering actuator 1 are relatively large, and if it is arranged outside the body structure, it will destroy the aerodynamic shape of the aircraft, generate greater aerodynamic resistance, and at the same time, seriously affect the aesthetics. Through the connecting rod transmission mechanism, the free arrangement of the turning actuator within a certain range can be realized, and the motio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com