Real-time distribution of actuator torque in a vehicle

A technology of actuators and actuator groups, which is applied to vehicle components, power devices, motion deposition, etc., and can solve problems such as complex control distribution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

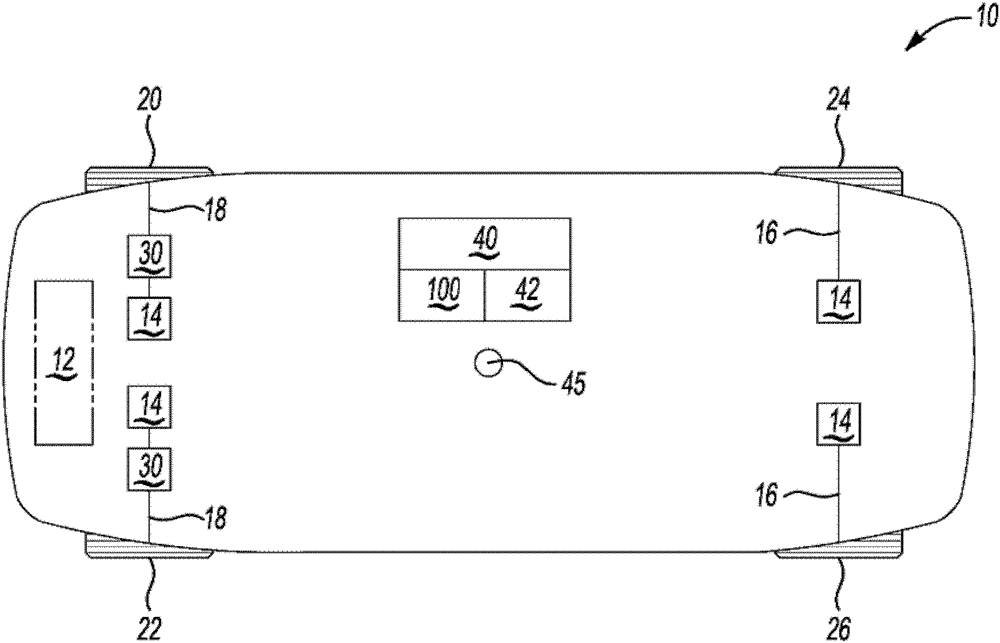

[0013] Referring to the drawings, a vehicle 10 having a center of gravity (point 45) is schematically shown at figure 1 shown in . According to two possible embodiments, the vehicle 10 may be configured as a hybrid electric vehicle (HEV) or a battery electric vehicle (BEV). If configured as an HEV, the vehicle 10 may include an internal combustion engine 12 , as shown in phantom. Vehicle 10 includes one or more electric motors 14 , one or more rear axles 16 , one or more front axles 18 , and wheels 20 , 22 , 24 and 26 , one at each corner of vehicle 10 . Other vehicle embodiments may have a different number of corners, such as a tricycle design with three corners.

[0014] In some embodiments, the vehicle 10 may also include a transmission (not shown) having one or more clutches, gear sets, etc., adapted to establish a desired speed or torque ratio. figure 1 The particular vehicle embodiment shown in has a different motor 14 positioned at each corner as a wheel motor, altho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com