Flap stopper for a rotatable flap

A technology of stopper and damper, used in engine components, vehicle components, lift valves, etc., can solve problems such as high cost and achieve the effect of high heat resistance and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

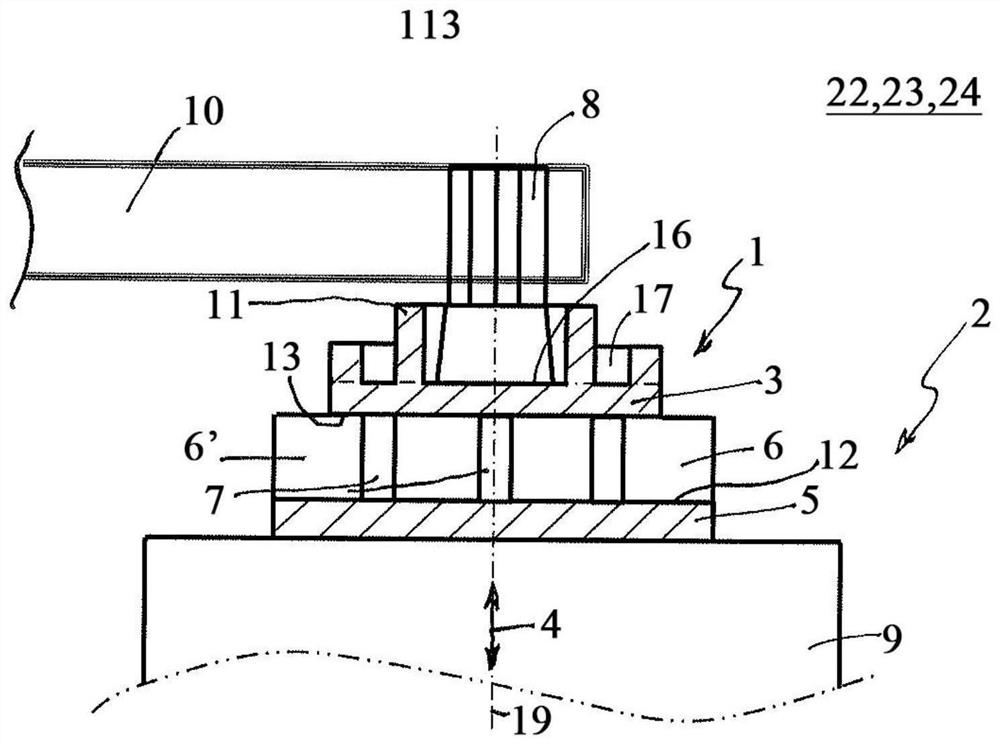

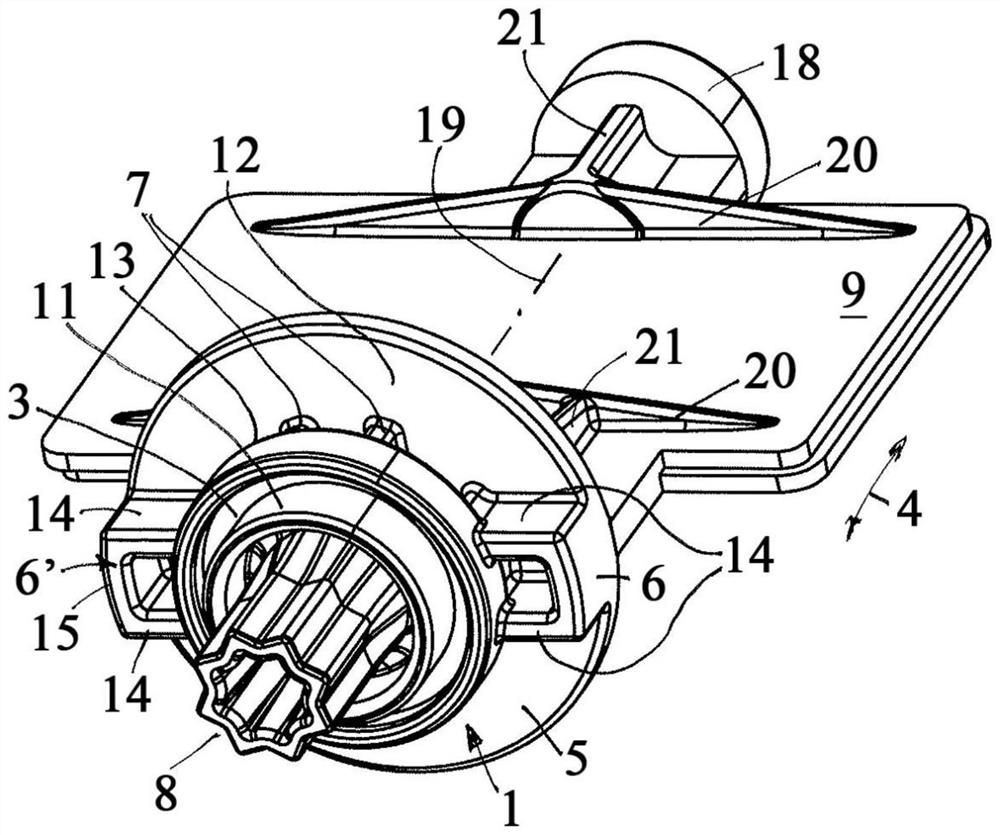

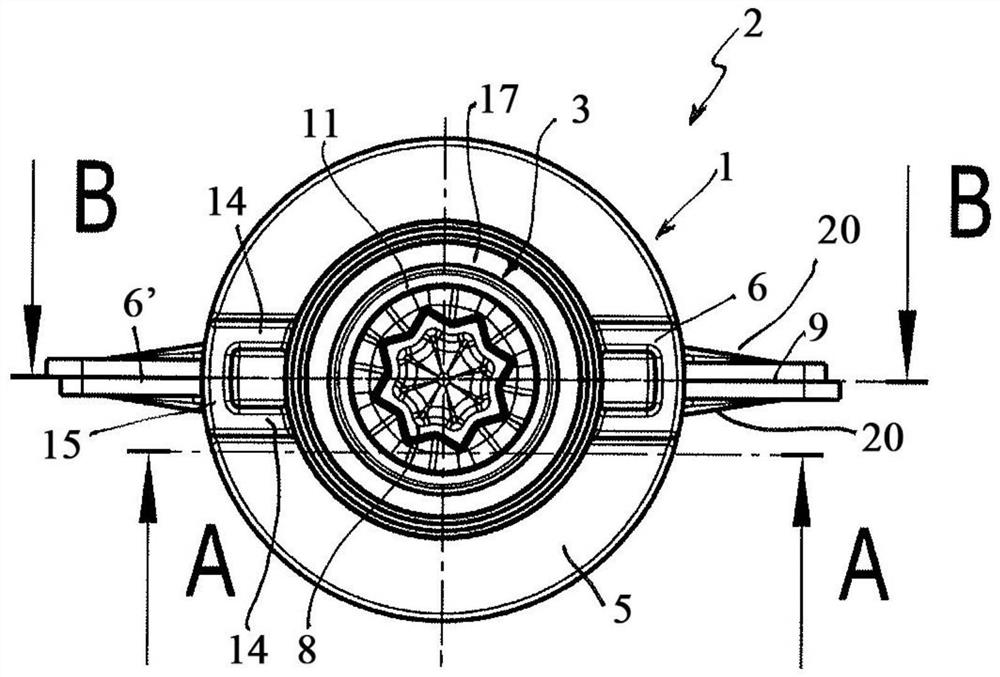

[0026] according to Figure 1 to Figure 5A damper stop 1 of a rotatable damper 2 for controlling an air flow according to the invention has a disc-shaped support support plate 3 and a disc-shaped stop support plate 5 spaced therefrom in the axial direction 4 . The two stop elements 6 , 6 ′ are thus arranged on the stop support plate 5 , wherein a connecting rib 7 is additionally arranged or extends between the carrier support plate 3 and the stop support plate 5 . According to the invention, the carrier support plate 3 , the stop support plate 5 , the stop elements 6 , 6 ′ and the connection rib 7 are now formed as a one-piece plastic injection molded part, in particular even from the same plastic. By means of the bearing support plate 3 and the stop support plate 5 , due to their disk-shaped design, relatively high torques can be introduced into the axial extension 8 via the stop elements 6 , 6 ′ and thus simultaneously provided by The stop elements 6, 6' are formed from a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com